Polyamide composition suitable for extrusion molding, blow molding and foaming multi uses and preparation method thereof

A technology of polyamide composition and thermoplastic polyamide, applied in the field of polyamide composition and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

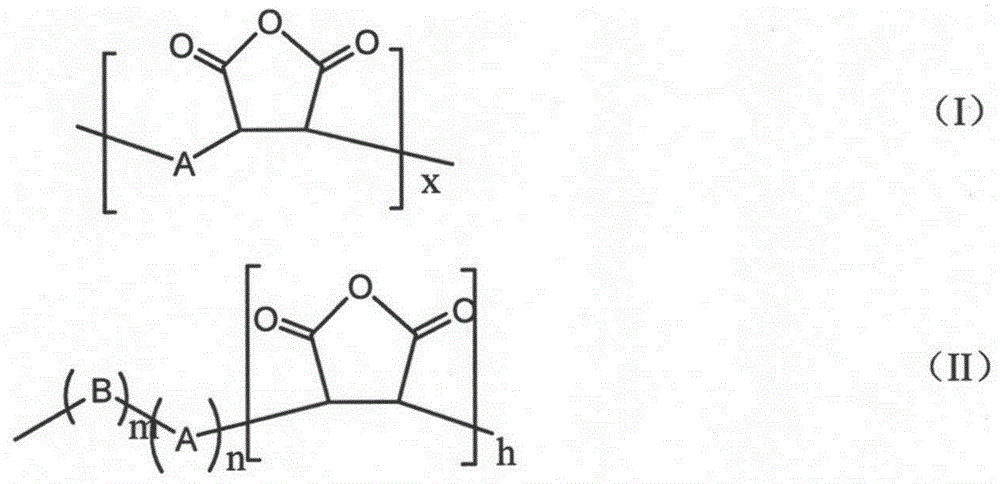

Method used

Image

Examples

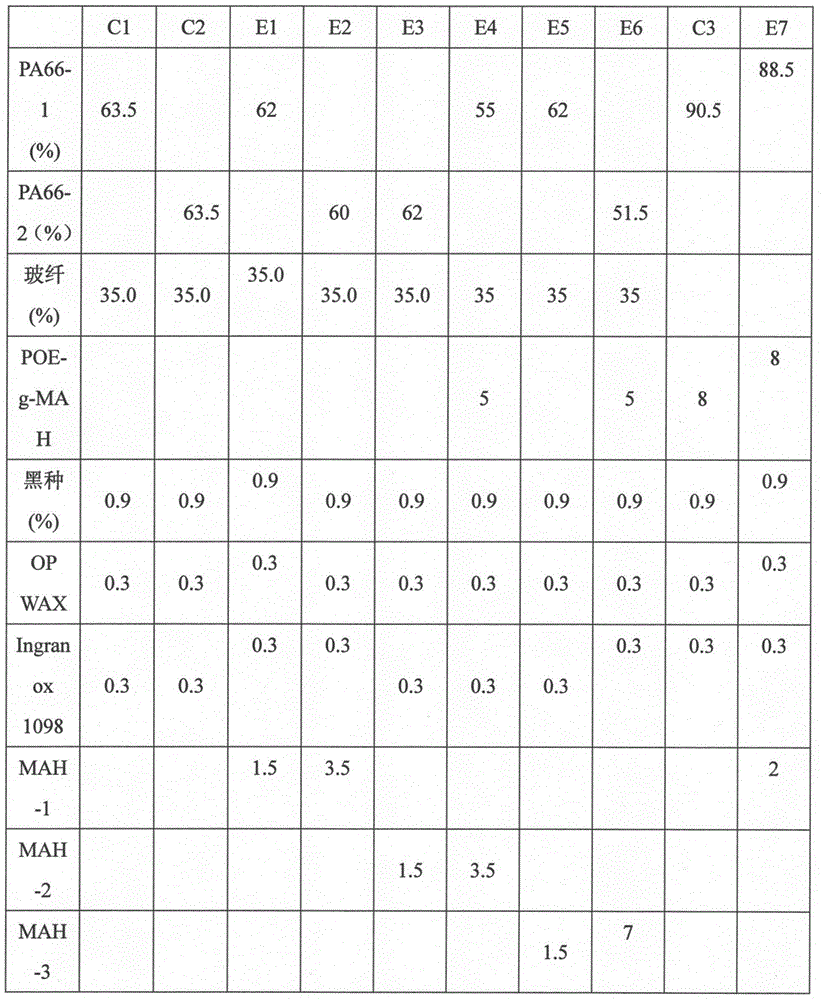

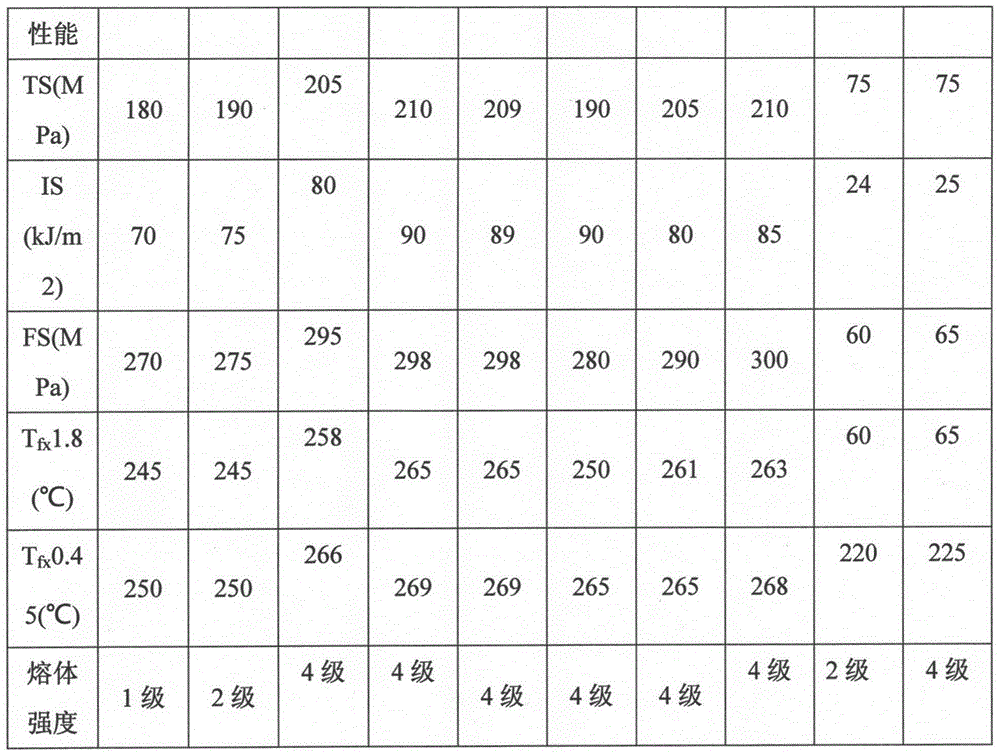

Embodiment 1-14

[0061] The polyamide compositions of Examples 1-14, which are suitable for extrusion blow molding and foaming multi-component applications, consist of the components listed in columns E1-E14 in Tables 1-2, respectively.

[0062] The preparation method of above-mentioned polyamide composition is:

[0063] Before extrusion, the thermoplastic polyamide resin pellets are dried to a moisture content of less than 1500 ppm, and then the ingredients are blended in proportion and put into the main feeder of the twin-screw extruder, and then extruded and pelletized by twin-screw. The processing conditions are: the temperature of the first zone is 240°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 270°C, the temperature of the seventh zone is 270°C, and the temperature of the eight zone is 275°C. ℃, the temperature of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com