Patents

Literature

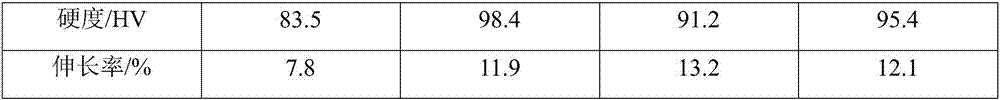

83results about How to "Good comprehensive mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-based powder metallurgy friction material for high-speed train braking and preparation method thereof

ActiveCN105063459AGood comprehensive mechanical propertiesStable friction and wear performancePowder metallurgyChromium

The invention provides a copper-based powder metallurgy friction material for high-speed train braking. The copper-based powder metallurgy friction material comprises, by weight percentage, 40%-60% of copper, 7%-20% of iron, 3%-5% of chromium, 5%-10% of zirconite, 3%-6% of aluminum oxide, 2%-5% of tin, 2%-4% of manganese, 5%-10% of graphite, 2%-5% of molybdenum disulfide and 1%-5% of ferrochromium. A preparation method of the copper-based powder metallurgy friction material comprises the steps of proportioning, mixing, pressing, sintering and the like. The copper-based powder metallurgy friction material has excellent friction performance and stable and safe braking performance, and can meet the braking requirement of a 380 km / h high-speed train. The preparation method is simple and environmentally friendly, and has a good market prospect.

Owner:GUANGXI UNIV FOR NATITIES

LPG boat storage tank steel plate and production method thereof

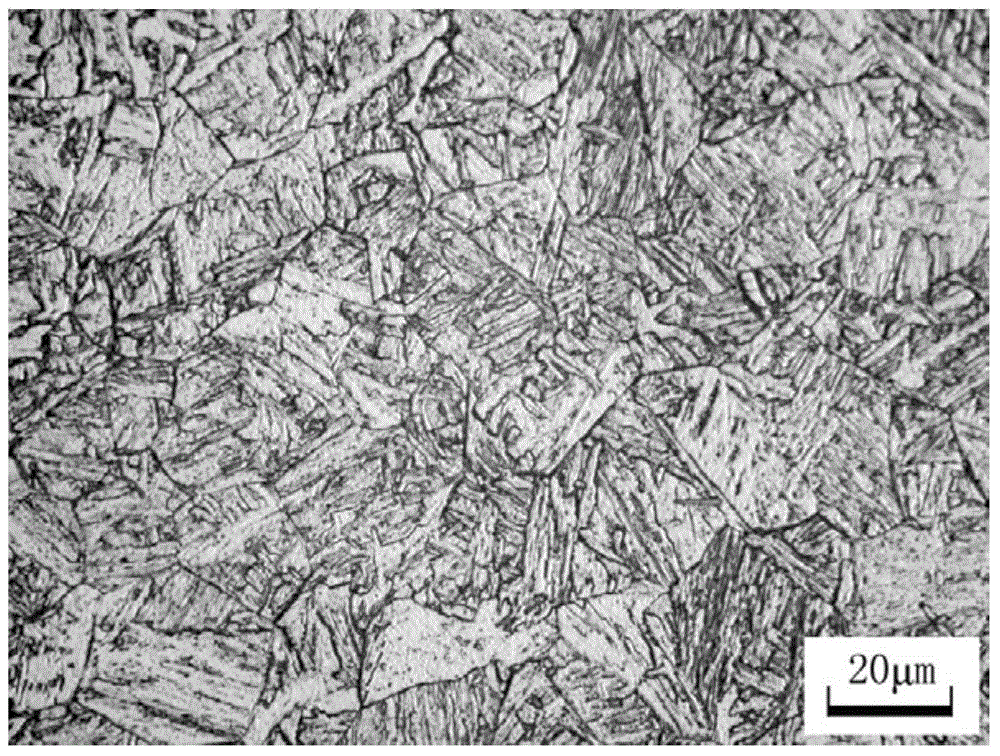

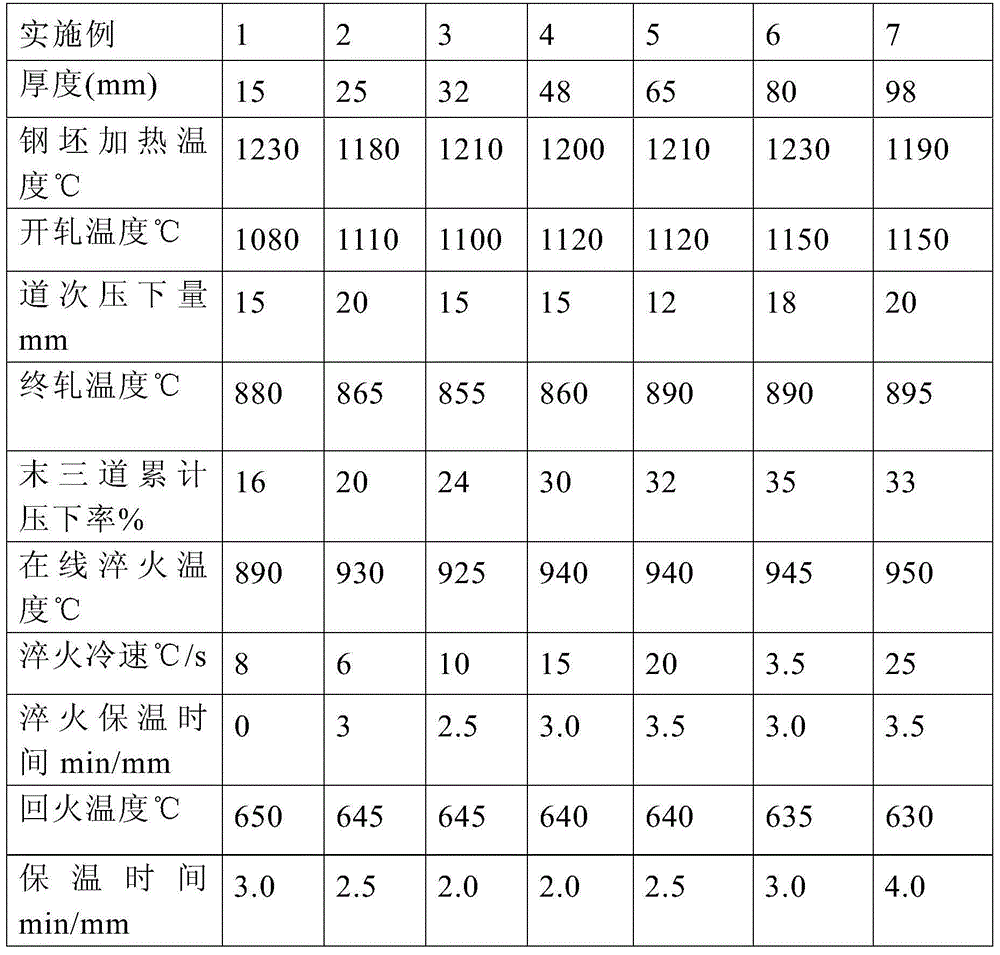

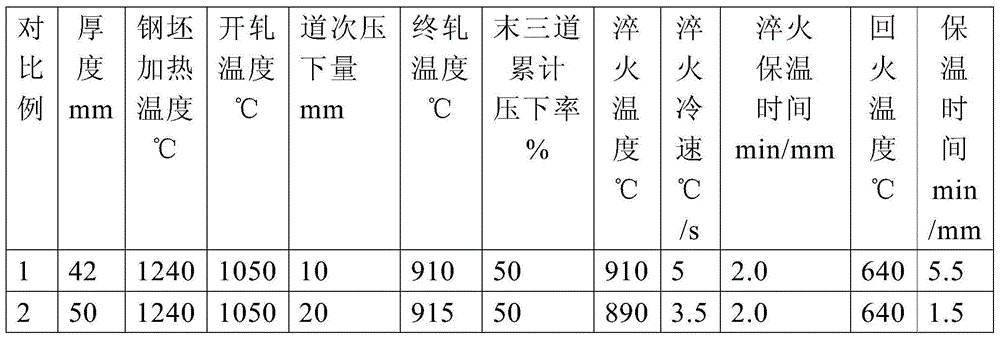

ActiveCN104131235AGood comprehensive mechanical propertiesGood cold and hot processing performanceQuenchingSteel plates

The invention discloses an LPG boat storage tank steel plate and a production method thereof. The steel plate comprises 0.05-0.12wt% of C, 0.30wt% or less of Si, 0.50-1.30wt% of Mn, 0.015wt% or less of P, 0.008wt% or less of S, 0.020-0.060wt% of Al, 0.15-1.20wt% of Cu, 0.20-1.50wt% of Ni, 0.35-1.00wt% of Cr, 0.20-0.60wt% of Mo, 0.008-0.020wt% of Ti, one or more of 0.0020-0.10wt% of Nb, 0.030-0.060wt% of V and 0.0005-0.0020wt% of B, and the balance Fe and inevitable impurities. The method comprises the steps of molten iron advanced desulphurization, converter top and bottom blowing, vacuum treatment, continuous casting, casting blank heating, rolling and heat treatment, the heating temperature of a casting blank is 1170-1250DEG C, and the heating rate of the casting blank is not less than 8min / cm; the blooming temperature is 1050-1150DEG C, the finishing temperature is 850-940DEG C, and the accumulated reduction rate of last three passes is not less than 16%; and heat treatment adopts online quenching and tempering treatment, or adopts offline quenching and tempering treatment. The steel plate obtained in the invention has the advantages of excellent mechanical properties, good hot and cold processing performance, excellent weldability and low sensitivity of weld cracks.

Owner:武汉钢铁有限公司

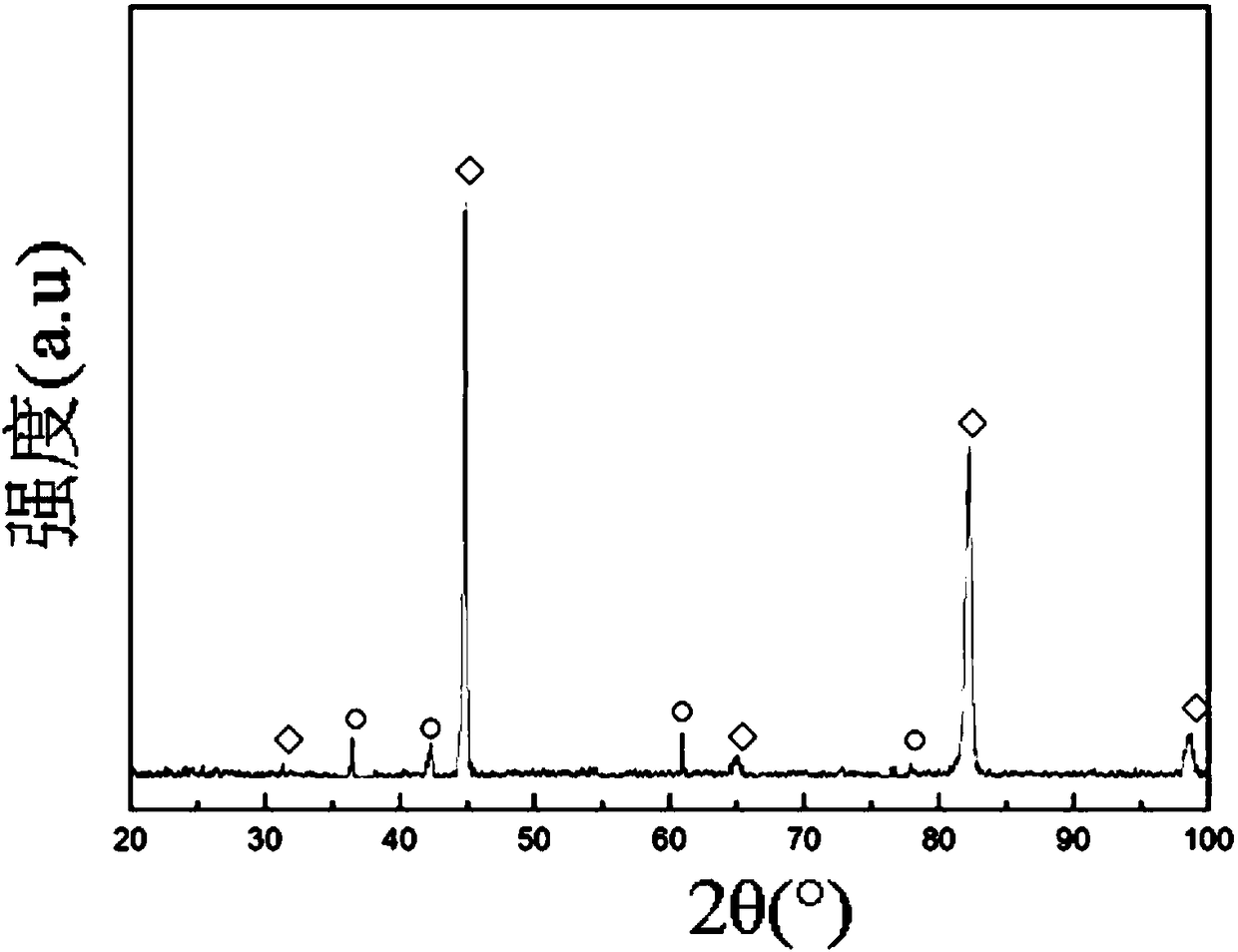

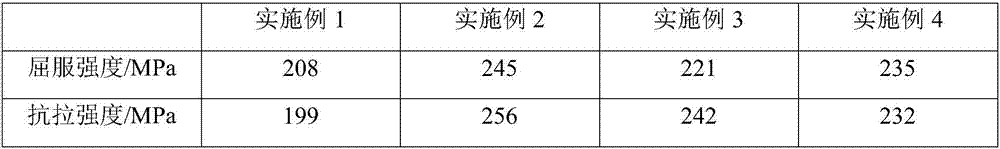

Base-containing high-entropy alloy composite and preparation method thereof

ActiveCN108504890AGood comprehensive mechanical propertiesBroad application prospectsHigh entropy alloysLimit strain

The invention discloses a base-containing high-entropy alloy composite and a preparation method thereof, and relates to a high-entropy alloy and a preparation method. The base-containing high-entropyalloy composite and the preparation method aim at solving the problems that the mechanical strength and the plasticity of an existing high-entropy alloy can not be improved, and the fragility is high.The base-containing high-entropy alloy composite is formed by preparing the following components of, by mass percentage, 1-20% of reinforced phase and 80-99% of base-containing high-entropy alloy matrix. The preparation method comprises the following steps that one, a raw base-containing high-entropy alloy composite is weighed; and two, the raw base-containing high-entropy alloy composite weighedin the Step one is smelted by an electric arc smelting method or an induction smelting method, and a base-containing high-entropy alloy is obtained. The yield strength of the prepared base-containinghigh-entropy alloy composite is 1200-2100 Mpa, the breaking strength is 2300-4000 MPa, and the limiting strain epsilon p (%) is 20-50%. The base-containing high-entropy alloy composite can be obtained.

Owner:HARBIN INST OF TECH

Preparation of seamless special-shaped steel pipe for low temperature resistance oil derrick electric transmission pole tower

InactiveCN101259582AGood comprehensive mechanical propertiesGood low temperature performanceFurnace typesHeat treatment furnacesSteel tubeQuenching

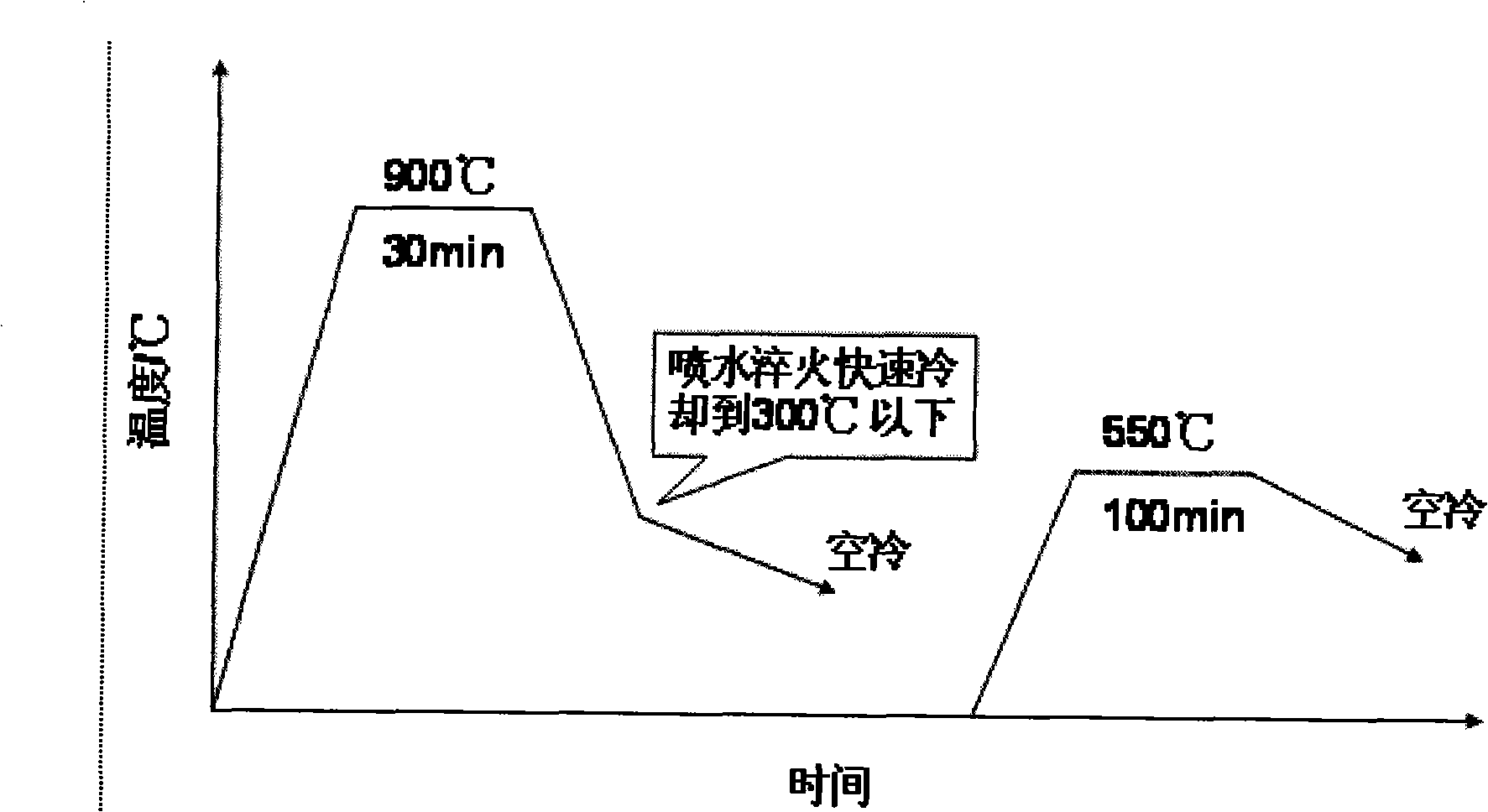

The invention relates to a manufacturing method of a seamless special steel pipe used in a low temperature tolerant petroleum derrick power transmission tower and is made of integral seamless steel pipe round pipe billet by adopting annealing heat treatment, process of setting and cold drawing and process of heat treatment of products; wherein, weight ratios of each chemical element of materials are as follows: C accounts for 0.15 to 0.18 percent, Mn accounts for 1.4 to 1.6 percent, Si accounts for 0.2 to 0.5 percent and trace elements of V accounts for 0.02 to 0.06 percent, Nb accounts for 0.015 to 0.06 percent, Ti accounts for 0.02 to 0.06 percent and Al accounts for 0.02 to 0.05 percent and the left is Fe and unavoidable impurities. The specific processing steps are as follows: annealing heat treatment and air cooling with the temperature of 850 to 880 DEG C for 30 minutes; setting and cold drawing; the heat treatment of the products adopts quenching, injection water cooling and tempering and hardening heat treatment process with the quenching temperature of 900 to 930 DEG C for 20 to 30 minutes, and air cooling is adopted after the fast injection water cooling is done under 300 DEG C with the tempering temperature of 550 DEG C for 100 minutes. The seamless special shaped steel pipe prepared by the method is characterized by good low temperature performance, high strength and comprehensive mechanical properties and lower cost, etc.

Owner:江苏界达特异新材料股份有限公司

TMCP-state low-cost high-strength ship plate steel for high-heat input welding and manufacturing method of TMCP-state low-cost high-strength ship plate steel

ActiveCN106756543AReasonable ingredientsGood comprehensive mechanical propertiesSteel platesHeat treated

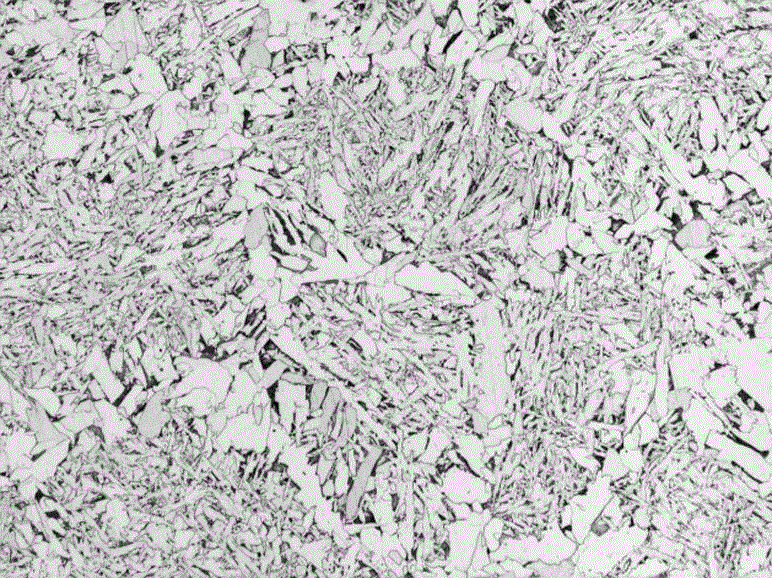

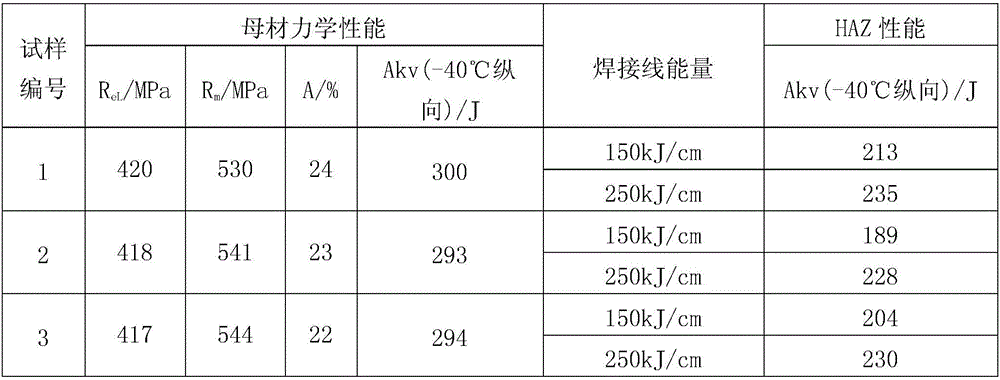

The invention discloses TMCP-state low-cost high-strength ship plate steel for high-heat input welding. The TMCP-state low-cost high-strength ship plate steel comprises the chemical components in percentage by weight: 0.04-0.12% of C, 0.15-0.35% of Si, 1.10-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030-0.060% of V, 0.005-0.060% of Alt, 0.32-0.41% of Ceq, 0.005-0.030% of Ti, 0.0005-0.0040% of Ca, 0.05-0.40% of Ni and the balance of Fe and unavoidable impurities. The steel plate disclosed by the invention has the yield strength of larger than or equal to 400MPa and the tensile strength of larger than or equal to 510MPa, is suitable for high-strength ship plate steel with welding heat input being within the range of 150-250kJ / cm, the average impact power of HAZ of the steel plate under 40 DEG C is higher than 150J under the high-heat input welding conditions of 150kJ / cm and 250kJ / cm, heat treatment is not needed, and the production cost is low.

Owner:NANJING IRON & STEEL CO LTD

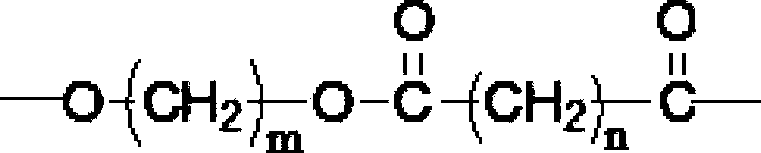

Polylactic acid composition and polylactic acid product

InactiveCN102618003AGood comprehensive mechanical propertiesImprove blow molding processabilityPlasticizerPolylactic acid

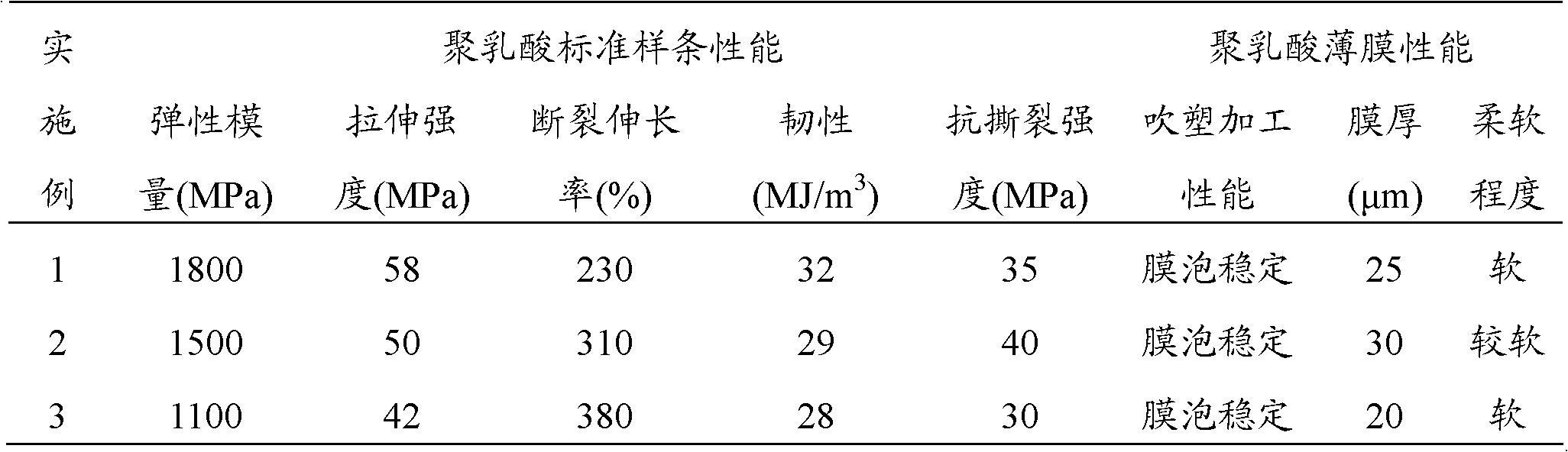

The invention provides a polylactic acid composition and a polylactic acid product. The polylactic acid composition comprises the following components by weight percent: 50 to 80 percent of polylactic acid, 0 to 35 percent of adipic acid-polybutylene terephthalate, 0 to 35 percent of poly(butylene succinate), 0.05 to 0.5 percent of peroxide, 0.05 to 0.5 percent of chain extendor and 3 to 15 percent of plasticizer, wherein the content of the adipic acid-polybutylene terephthalate and the content of the poly(butylene succinate) are not 0 percent. The mechanical properties such as melt strength, elongation at break, tenacity and anti-tear strength of the polylactic acid composition provided by the invention are improved, so that the polylactic acid composition with better comprehensive mechanical properties can be obtained, and the polylactic acid composition has more stable processability and better film forming stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

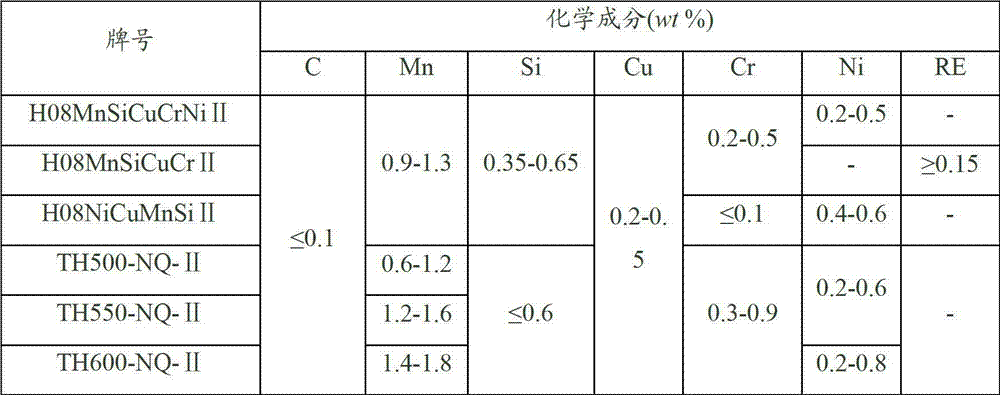

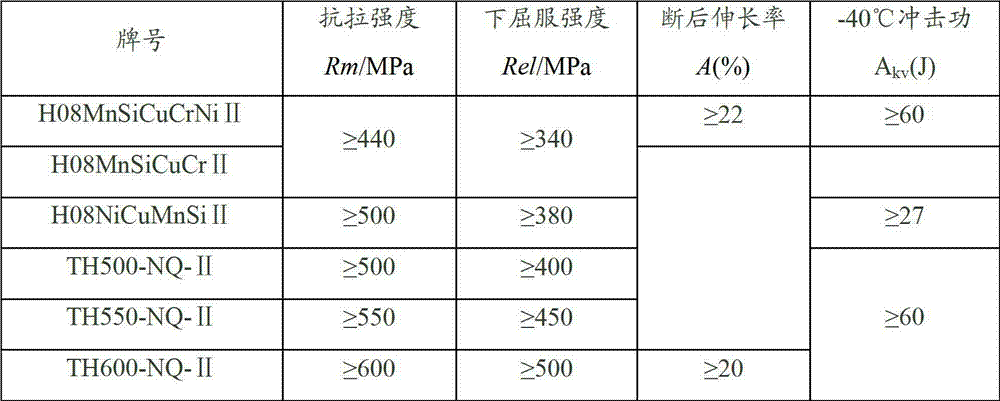

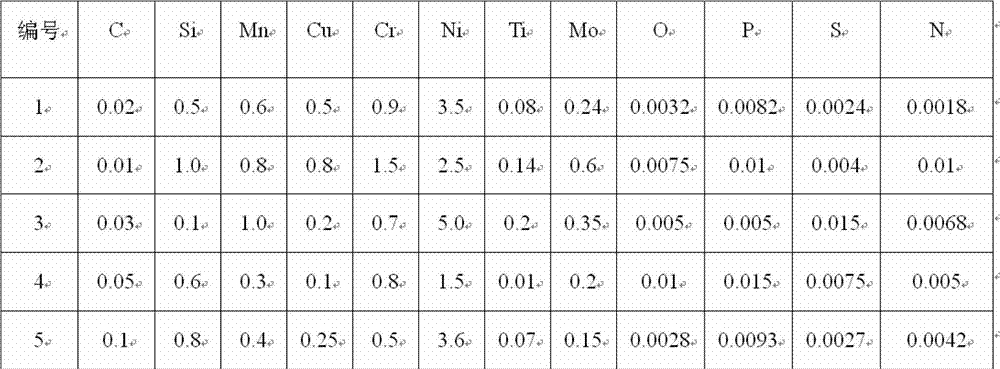

High-corrosion-resistance gas protection welding wire

ActiveCN103028865AGood atmospheric corrosion resistanceGood comprehensive mechanical propertiesWelding/cutting media/materialsSoldering mediaCorrosionGas protection

The invention belongs to the field of welding materials, and relates to a high-corrosion-resistance gas protection welding wire. The welding wire comprises the following chemical compositions in percentage by mass: 0.01-0.1 percent of C, 0.1-1.0 percent of Si, 0.3-1.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, 1.5-5 percent of Ni, 0.5-1.5 percent of Cr, 0.1-0.8 percent of Cu, 0.01-0.2 percent of Ti, 0.15-0.6 percent of Mo, less than or equal to 0.01 percent of O, less than or equal to 0.01 percent of N and the balance of ferrum. The welding wire has stable welding performance, and obtained deposited metal is matched with the corrosion resistance of parent metal; and meanwhile, the welding wire has high comprehensive mechanical performance, and is particularly suitable for novel high-weather-proof steel.

Owner:CENT IRON & STEEL RES INST

Preparations of bicomponent PSU type liquid rubber-based sealant and PSU liquid rubber thereof

InactiveCN101434826AGood comprehensive mechanical propertiesEasy to prepareOther chemical processesPolyureas/polyurethane adhesivesPrepolymerIsocyanate

The invention discloses a dual-component PSU-typed liquid rubber-based sealant and a preparation method of the PSU-typed liquid rubber, wherein, the sealant comprises a component A and a component B; the component A comprises PSU-typed liquid rubber, plasticizer, filling material, tackifier, antioxidant and vulcanization retarder; the component B comprises vulcanizing agent, vulcanization accelerator, plasticizer and filling material; and the component A and the component B are mixed together by normal method so as to prepare the finished product. The PSU-typed liquid rubber uses the mixture of polyether glycol and polyether-tribasic alcohol and polyisocyanate as raw materials to generate isocyanate-terminated polyurethane prepolymer under the action of acidic catalyst; furthermore, the isocyanate-terminated polyurethane prepolymer is terminated by sulfhydryl compounds to synthesize the sulfhydryl-terminated liquid rubber which takes the polyurethanes as main chain and has local crosslinking structure characteristic; the liquid rubber is taken as the basic rubber to prepare the sealant which has excellent mechanic performances and can be widely applied to the fields such as the construction of housing, plazas, roads, airports, bridges, hydraulic engineering, water conveyance project, sewage disposal engineering, and the like, the manufacture of automobiles, trains, containers, and the like, and the electric apparatuses, power, aeronautics and astronautics, and the like.

Owner:HENAN YONGLI CHEM

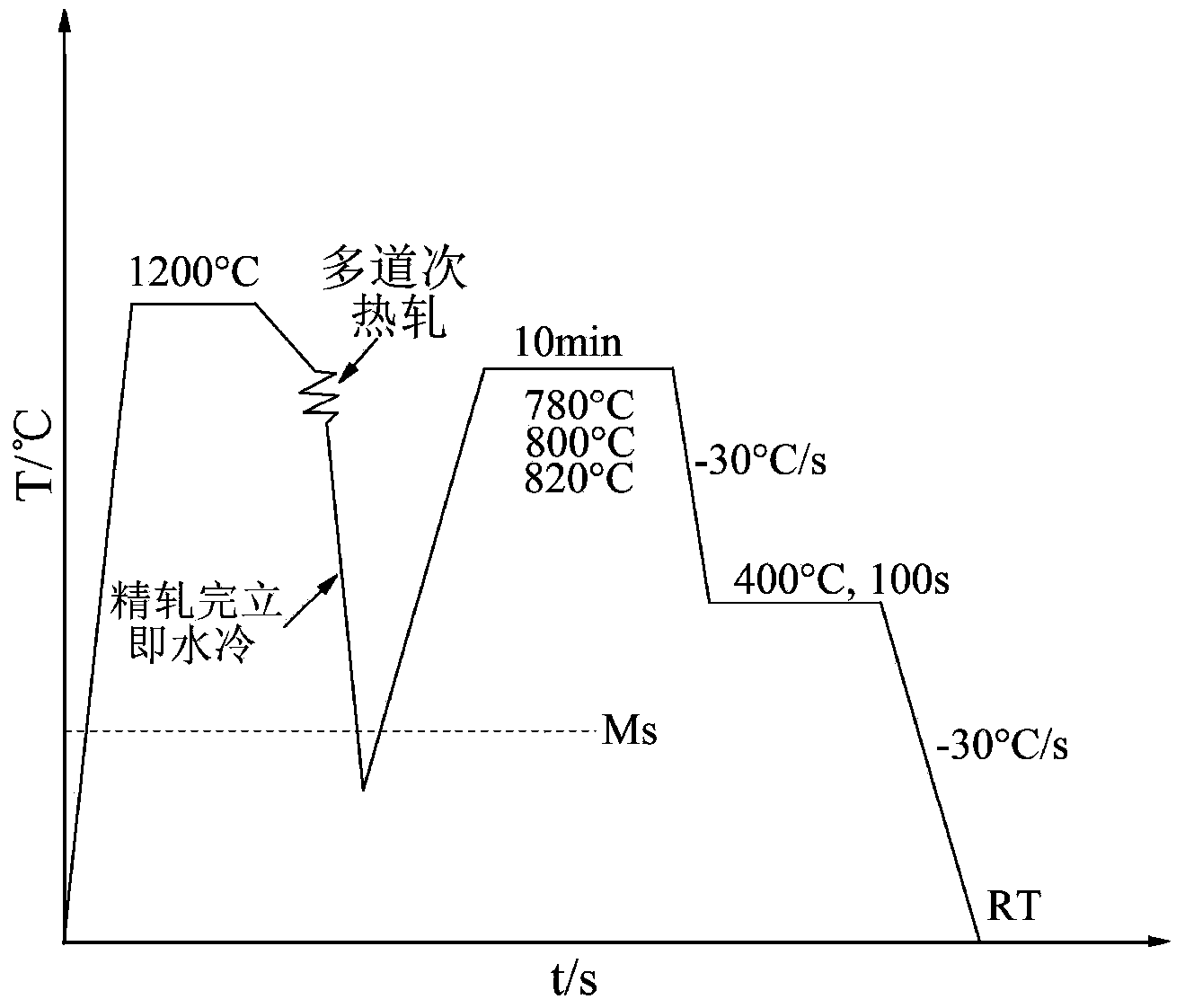

Method for manufacturing high-strength steel through hot rolling and on-line thermal treatment

ActiveCN104032109AGood comprehensive mechanical propertiesAlloy composition is simpleCarbon steelDuctility

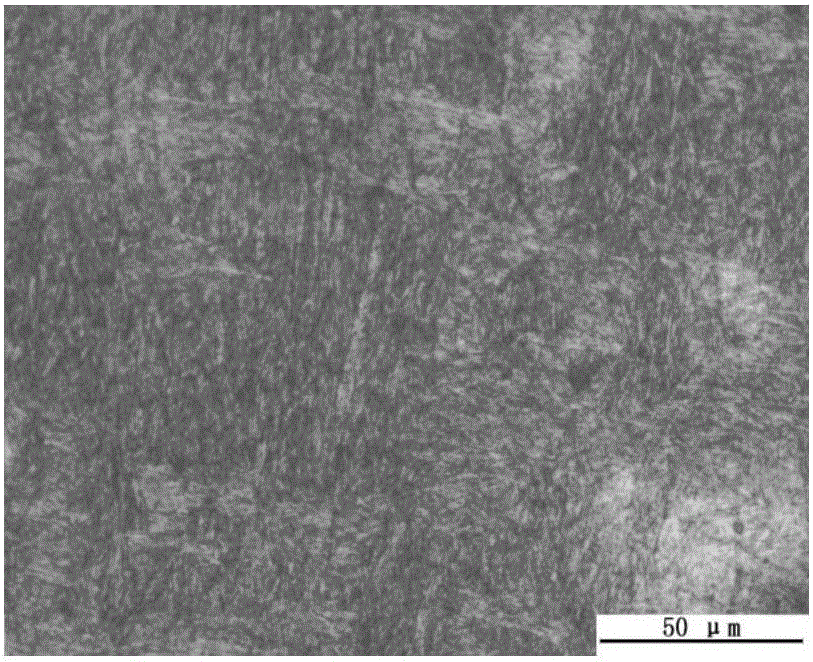

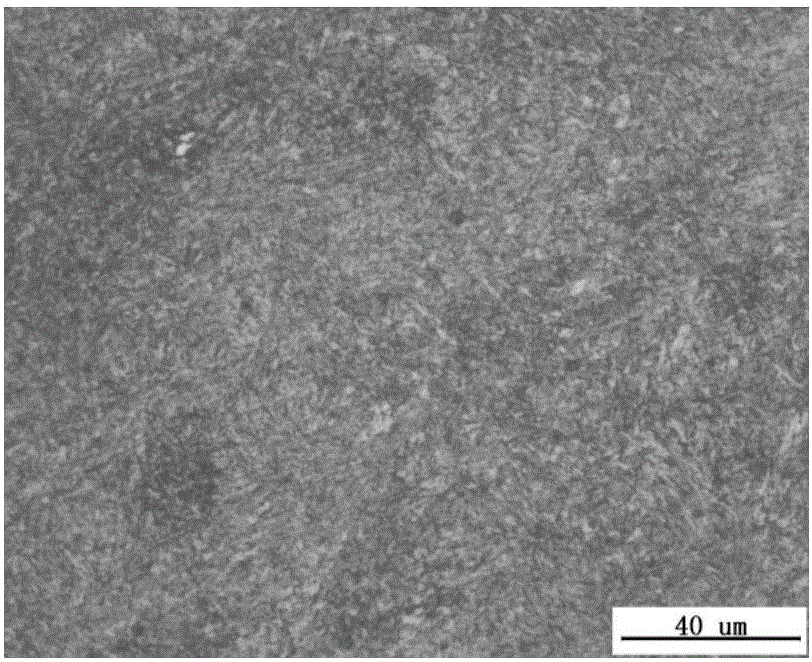

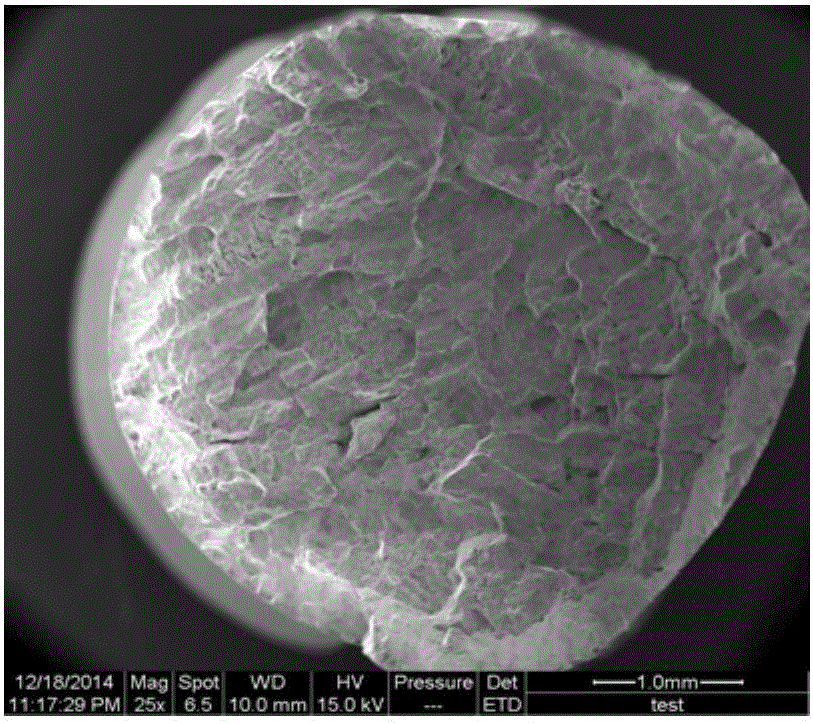

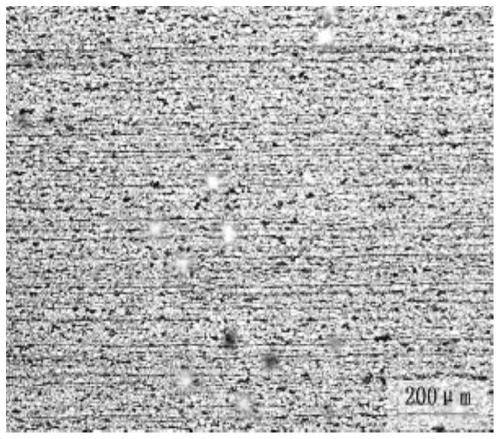

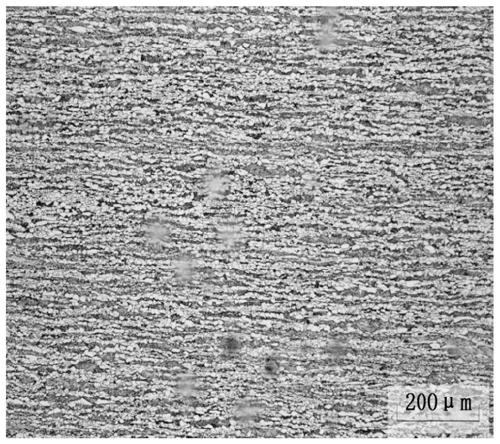

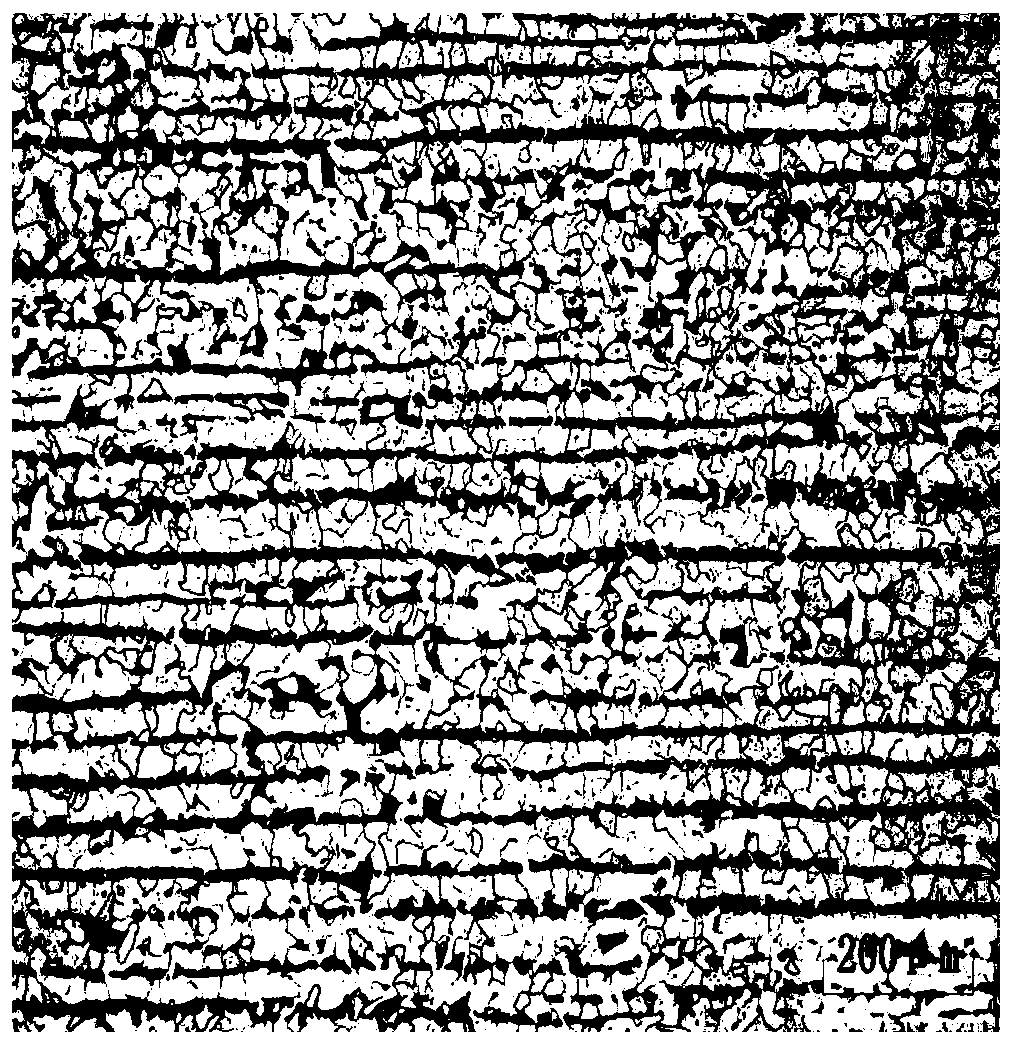

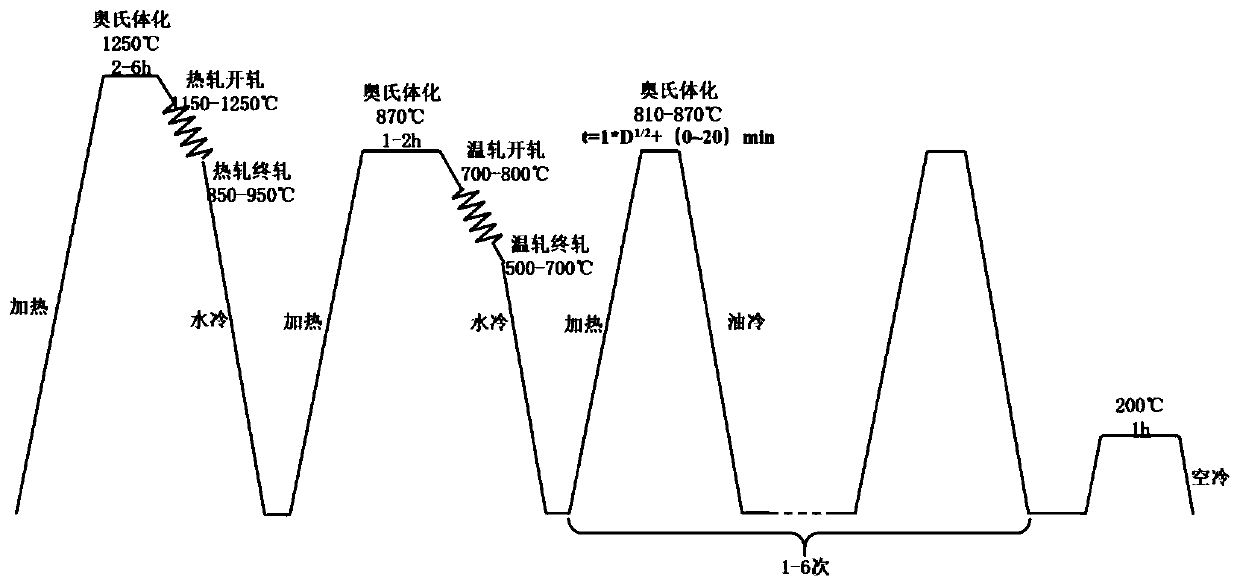

The invention relates to a method for manufacturing high-strength steel through hot rolling and on-line thermal treatment and belongs to the field of thermal treatment of metal materials. The method is characterized by comprising the following steps: immediately carrying out online waste heat quenching treatment on a hot rolled plate after hot rolling finishing by using low- and medium-carbon steel containing 0.5-3.5wt% of Mn to obtain a complete martensite or a part of ferrite+martensite organization structure; then carrying out online heating to a two-phase region and preserving heat to obtain a great deal of austenite among battens; then, quickly cooling to a partition region and partitioning so as to stabilize the austenite; and finally, quickly cooling to room temperature. The room-temperature tissues of the hot rolled plate produced by the process comprise an alpha phase with a quenching martensite form, retained austenite among battens, lath martensite / retained austenite island tissues and a ferritic structure formed before quenching. The tensile strength of the complex structure containing the retained austenite among battens can reach 800-1350MPa, the ductility reaches 20-35% and the product of strength and elongation can reach over 30GPa.%.

Owner:UNIV OF SCI & TECH BEIJING

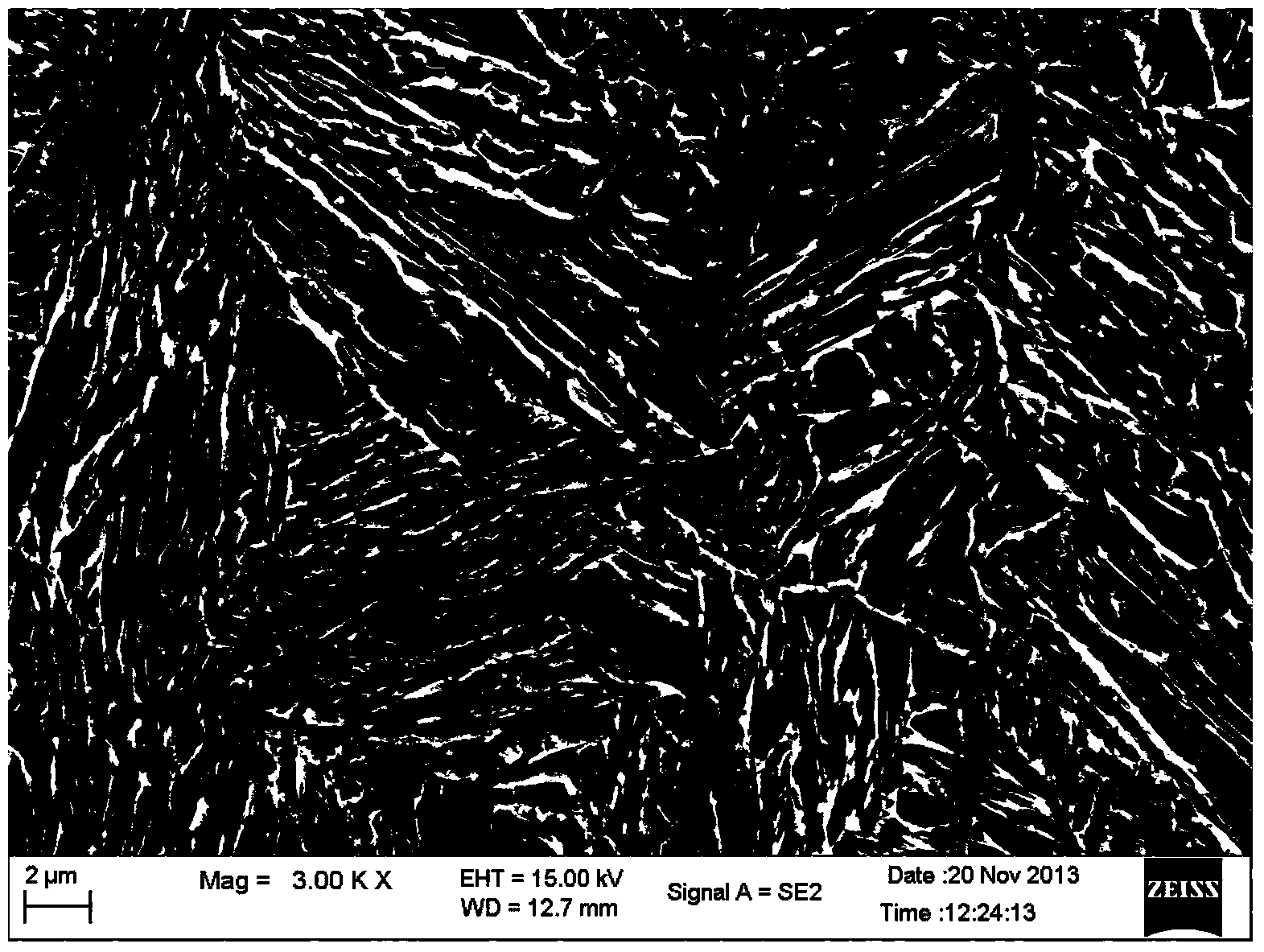

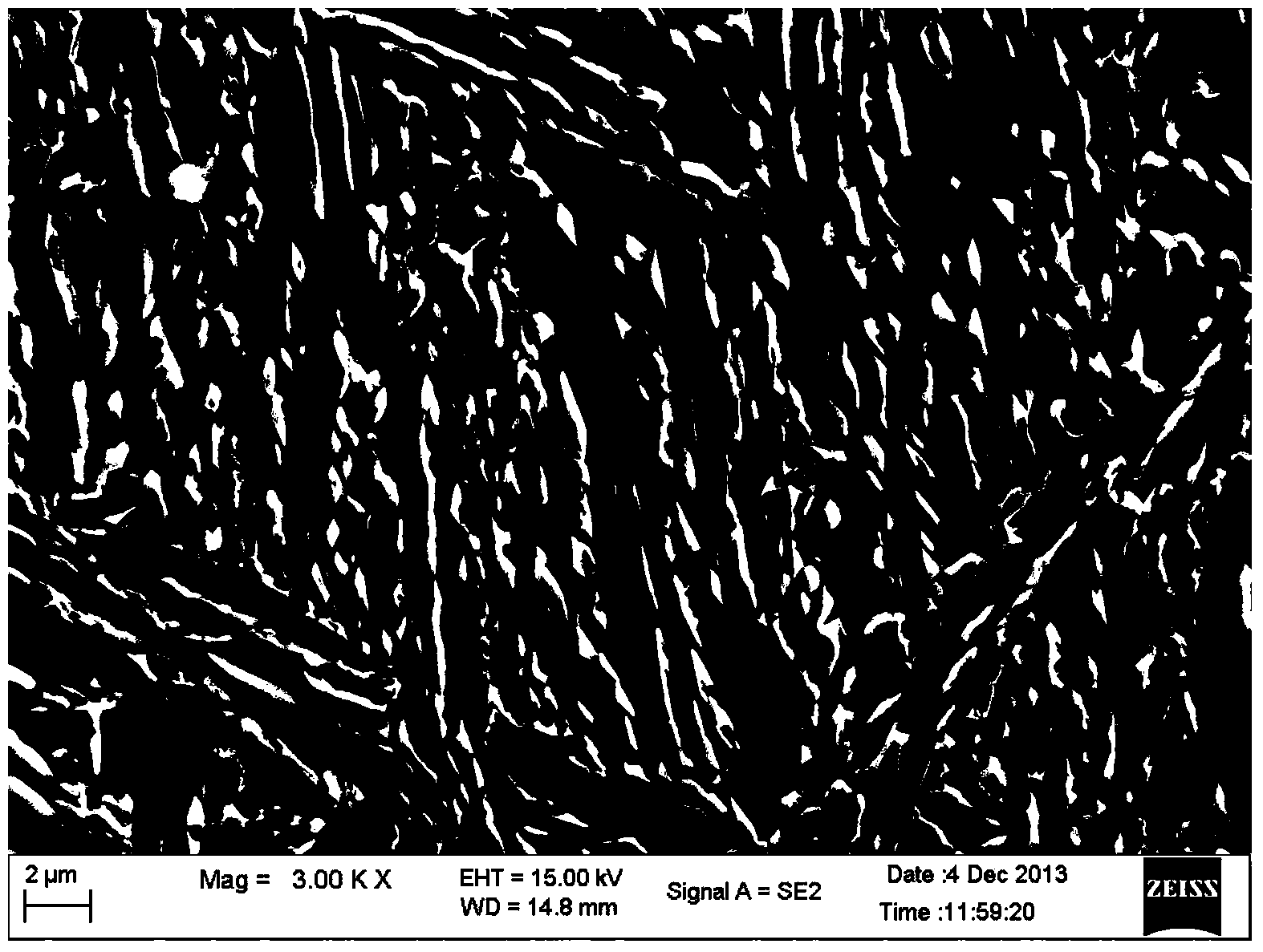

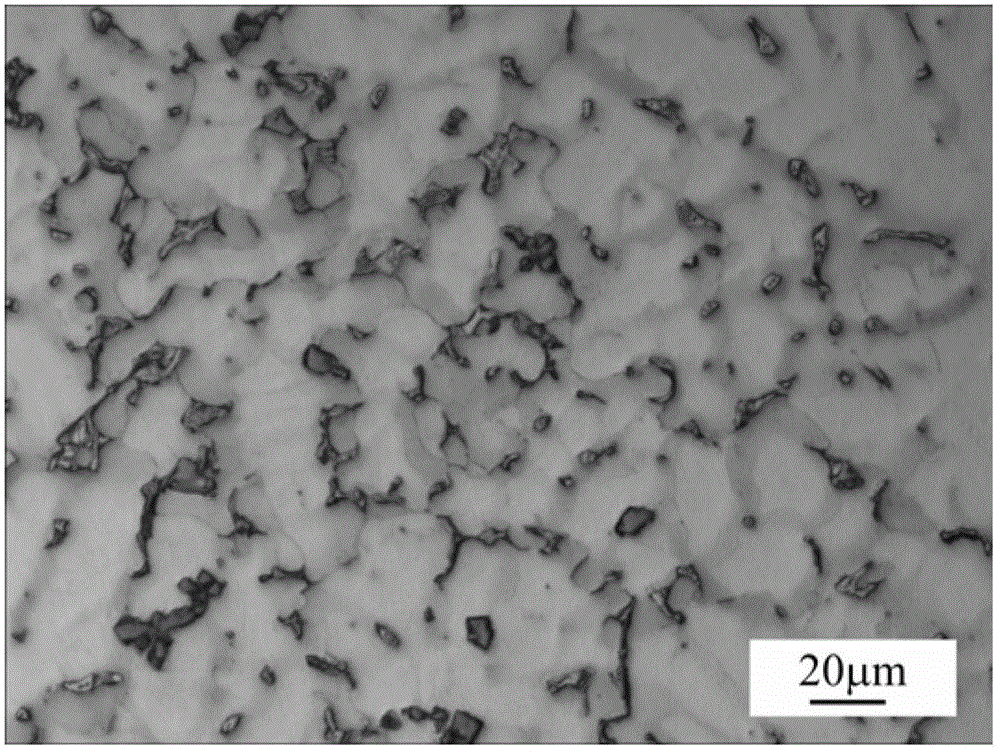

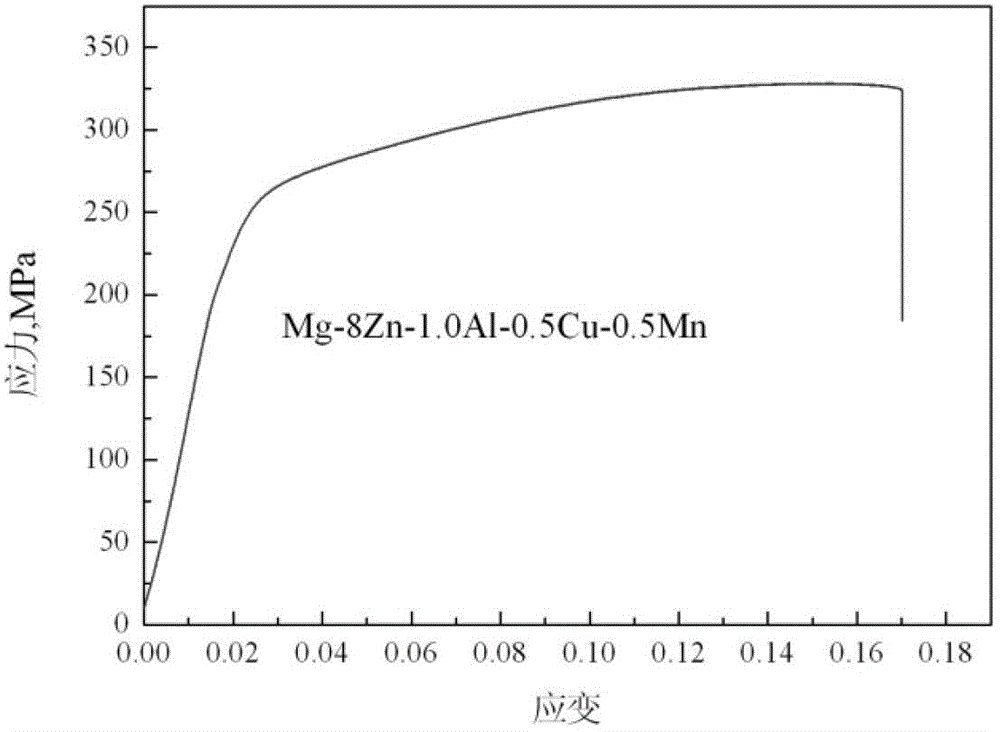

Casting magnesium alloy with high strength and toughness and preparation method thereof

ActiveCN102978497AGood comprehensive mechanical propertiesExcellent aging strengthening abilitySolution treatmentCrucible

The invention relates to the field of magnesium alloy of metal materials, and concretely relates to a casting magnesium alloy containing Zn, Al, Cu and Mn with high strength and toughness. The casting magnesium alloy comprises the following components in percentage by weight: 6.0-8.0% of Zn, 0.5-1.5% of Al, 0.5-1.0% of Cu, 0.3-0.7% of Mn and the balance of Mg and inevitable impurity elements, wherein the content of the impurity elements is less than 0.01%. A preparation method of the casting magnesium alloy comprises the steps of: smelting Mg at the temperature of 740-760 DEG C by using an iron crucible; after pure magnesium is completely smelted, sequentially adding preheated pure metal Zn, Al, Cu and Mg-10wt.% and Mg intermediate alloy for alloying, wherein mixed CO2 and SF6 are used as protective gases in the pure magnesium smelting and alloying processes; stirring, slagging off, standing for 15-20 minutes, adjusting the temperature of an alloy fusant to 700-720 DEG C, and casting into an ingot; and carrying out solution treatment on the alloy for 24-64 hours at 350-400 DEG C, quenching by warm water at 40-60 DEG C, then preageing for 8-24 hours at 50-70 DEG C, and finally preageing for 2-6 hours at 150-200 DEG C to obtain the casting magnesium alloy with high strength and toughness. In room temperature extension tests of the casting magnesium alloy, the yield strength is not less than 205MPa, the tensile strength is not less than 305MPa, the elongation rate is not less than 10%, and the casting magnesium alloy has excellent comprehensive mechanical property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Alloy forged steel and its heat treatment method and use

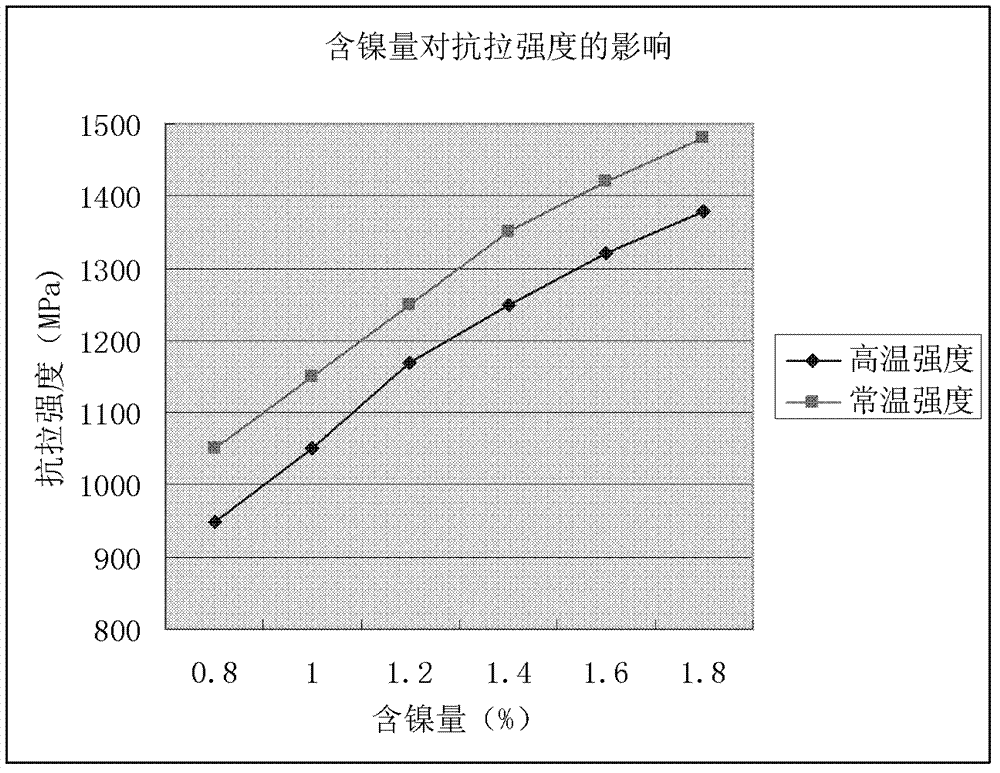

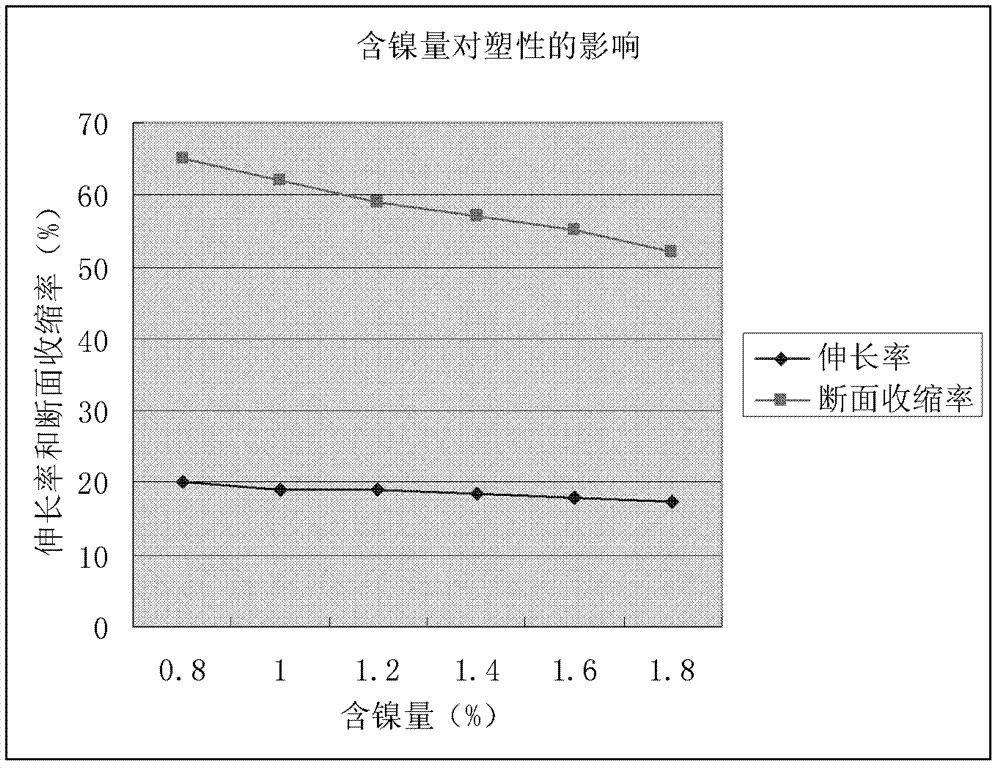

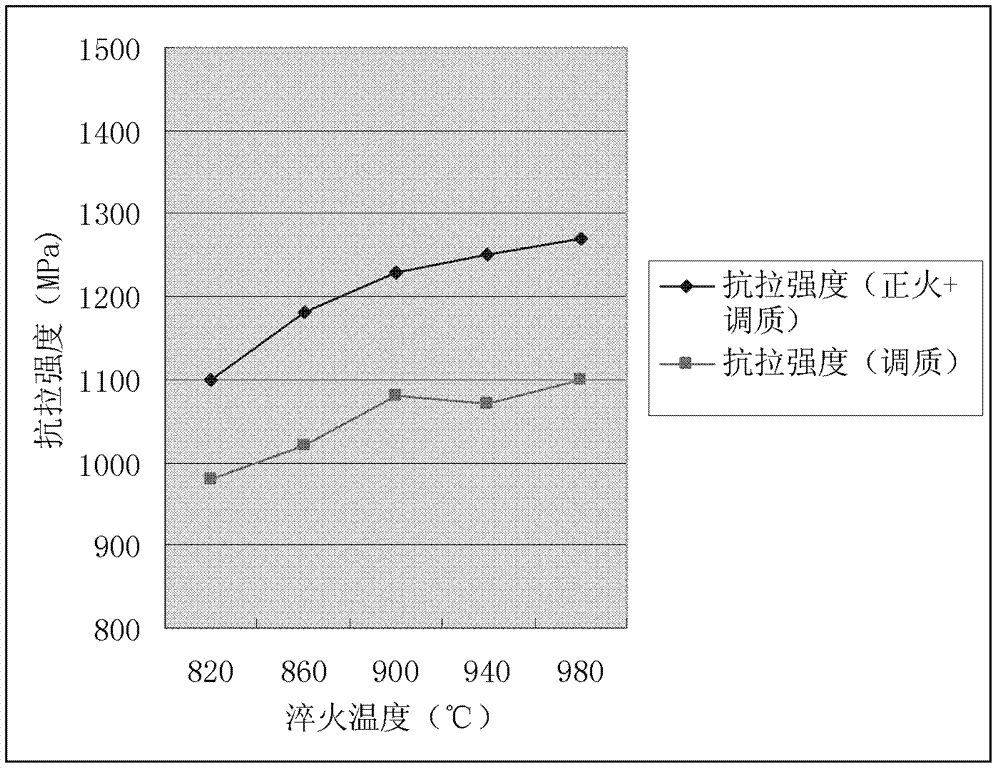

ActiveCN102953008AGood comprehensive mechanical propertiesImprove hardenability and heat strength propertiesBraking membersAlloy elementCompound (substance)

The invention provides an alloy forged steel and its heat treatment method and use. The alloy forged steel comprises: by mass, 0.26 to 0.35% of C, 0.15 to 0.39% of Si, 0.85 to 1.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.80 to 2.00% of Cr, 0.70 to 2.00% of Ni, 0.35 to 1.00% of Mo, and the balance Fe and other elements. Through reasonable proportioning of alloy elements such as Mn, Ni, Cr and Mo, and main chemical components such as C and Si in forged steel materials, through appropriate heat treatment processes, grains are refined; hardenability and heat intensity properties of the alloy forged steel are improved; normal temperature strength and high temperature strength of the alloy forged steel are greatly improved; and excellent comprehensive mechanical properties of the alloy forged steel are obtained.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

2xxx series aluminum alloy with high strength and high plasticity and manufacturing method thereof

The invention provides a 2xxx series aluminum alloy with high strength and high plasticity and a manufacturing method thereof. The aluminum alloy of the invention comprises the following components: 3.8-4.6wt% of Cu, 1.32-1.56wt% of Mg, 0.5-0.7wt% of Mn, less than or equal to 0.15wt% of Ti, less than or equal to 0.25wt% of Zn, less than or equal to 0.10wt% of Cr, less than or equal to 0.2wt% of Si and less than or equal to 0.2wt% of Fe. The manufacturing method of the aluminum alloy of the invention comprises the following steps: firstly, adding an aluminum ingot into a resistance furnace; when the melt temperature is 740-760 DEG C, adding AlCu50, AlMn10 and AlCr5 intermediate alloys, and stirring; after the temperature falls to 720-730 DEG C, adding Mg and Zn, removing slag and refining; when the temperature is 730-740 DEG C, adding Al-5Ti-B, stirring and standing for 10-25 minutes and then casting and forming; homogenizing and annealing the cast ingot at 500 DEG C for 24h, and then, extruding the cast ingot at 400-490 DEG C; carrying out solid solution on the extruded material at 490-500 DEG C for 1-2 hours; and carrying out water quenching, and putting the material at room temperature to T4 state to obtain a board. By reasonably adjusting the contents of Cu and Mg in the aluminum alloy, the material has better comprehensive mechanical properties and is an ideal material for manufacturing aviation components.

Owner:苏州有色金属研究院有限公司

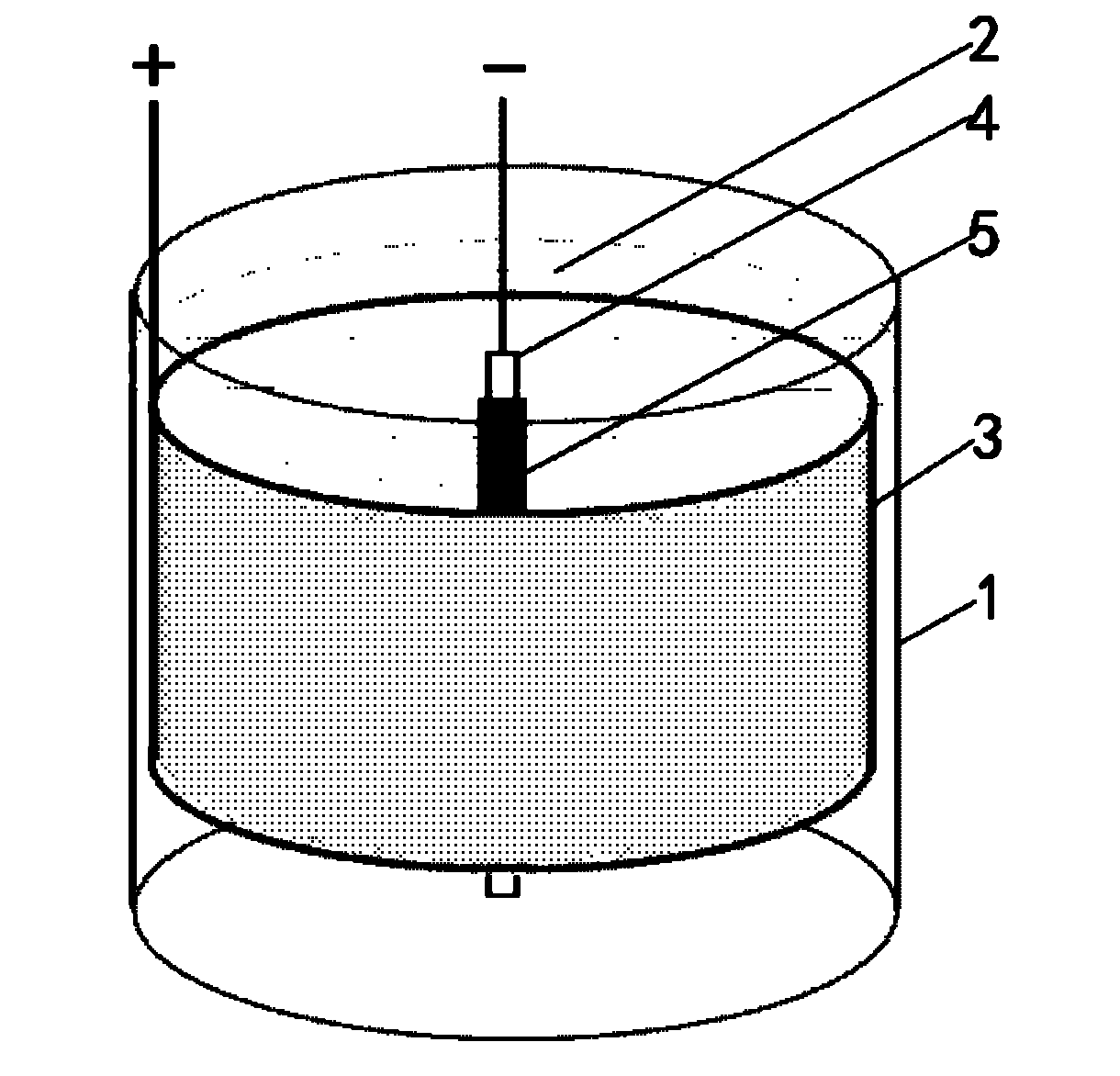

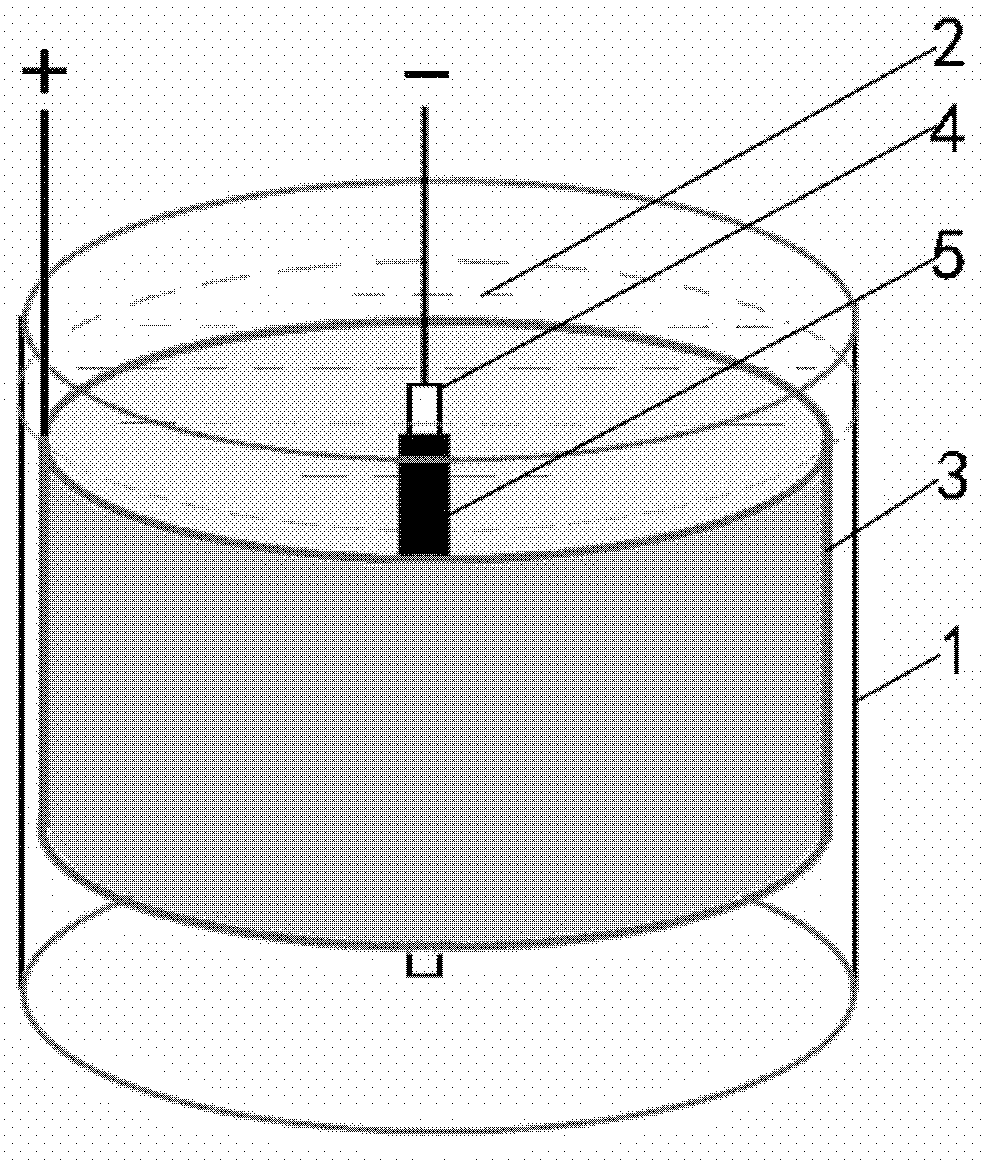

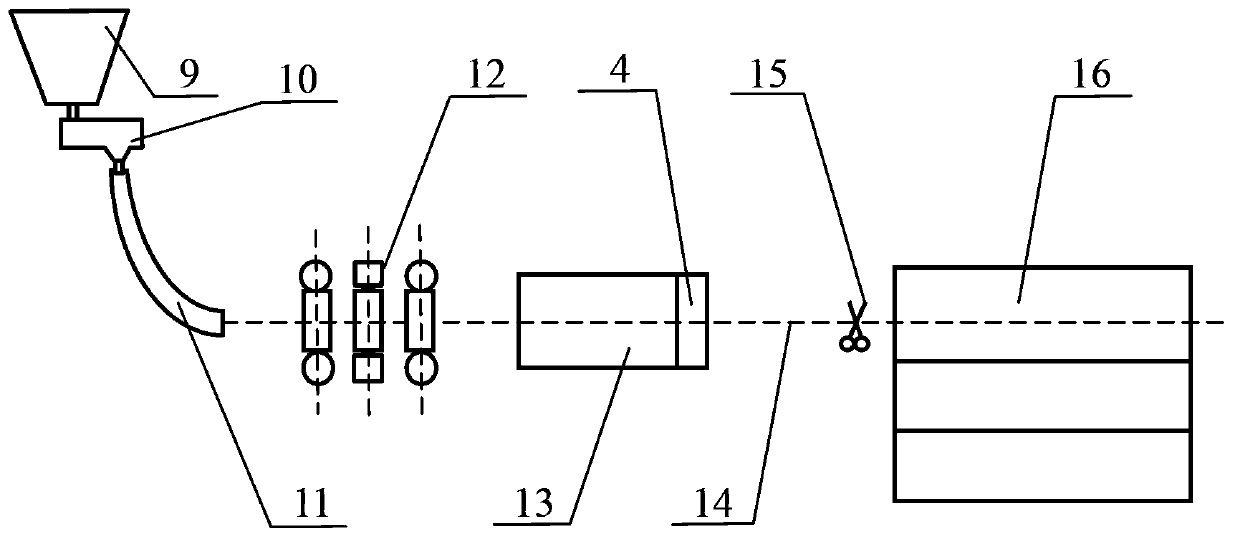

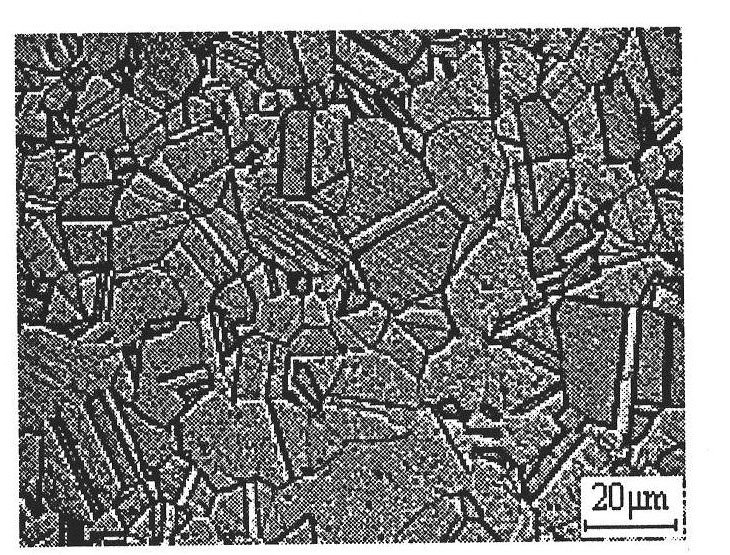

Method of preparing degradable Fe-Zn alloy pipe for intravascular stent by electroforming

ActiveCN102605390AGood comprehensive mechanical propertiesAvoid conventional pressure forming processStentsSurgeryIonMicrostructure

The invention discloses a method of preparing a degradable Fe-Zn alloy pipe for an intravascular stent by electroforming, belonging to the field of biological materials and electrochemical processing. The method is characterized in that a Fe-Zn alloy material is prepared by mutual-competition and codeposition processes of Fe ions and Zn ions, and the obtained alloy is fine in crystal grain and good in comprehensive mechanical performance; the thickness of an electroforming layer can be up to 7-150 microns, and the electroforming layer is served as an individual to be used independently after separating from a substrate, so that a seamless microcapillary pipe for a stent is directly obtained, and a regular pressure shaping procedure of a metal superfine pipe for laser-cutting of the stent is avoided; and a component ratio of a Fe-Zn alloy is changed by regulation of electroforming parameters, thermal treatment changes a microstructure of the Fe-Zn alloy, and the synergistic effect of both sides can regulate the degrading speed of the Fe-Zn alloy material in human body fluid or blood and improve the mechanical performance of the Fe-Zn alloy material. Therefore, according to the method provided by the invention, the Fe-Zn alloy pipe for the intravascular stent, with good biocompatibility, biological corrosion degradation performance and comprehensive mechanical performance is prepared.

Owner:DALIAN UNIV OF TECH

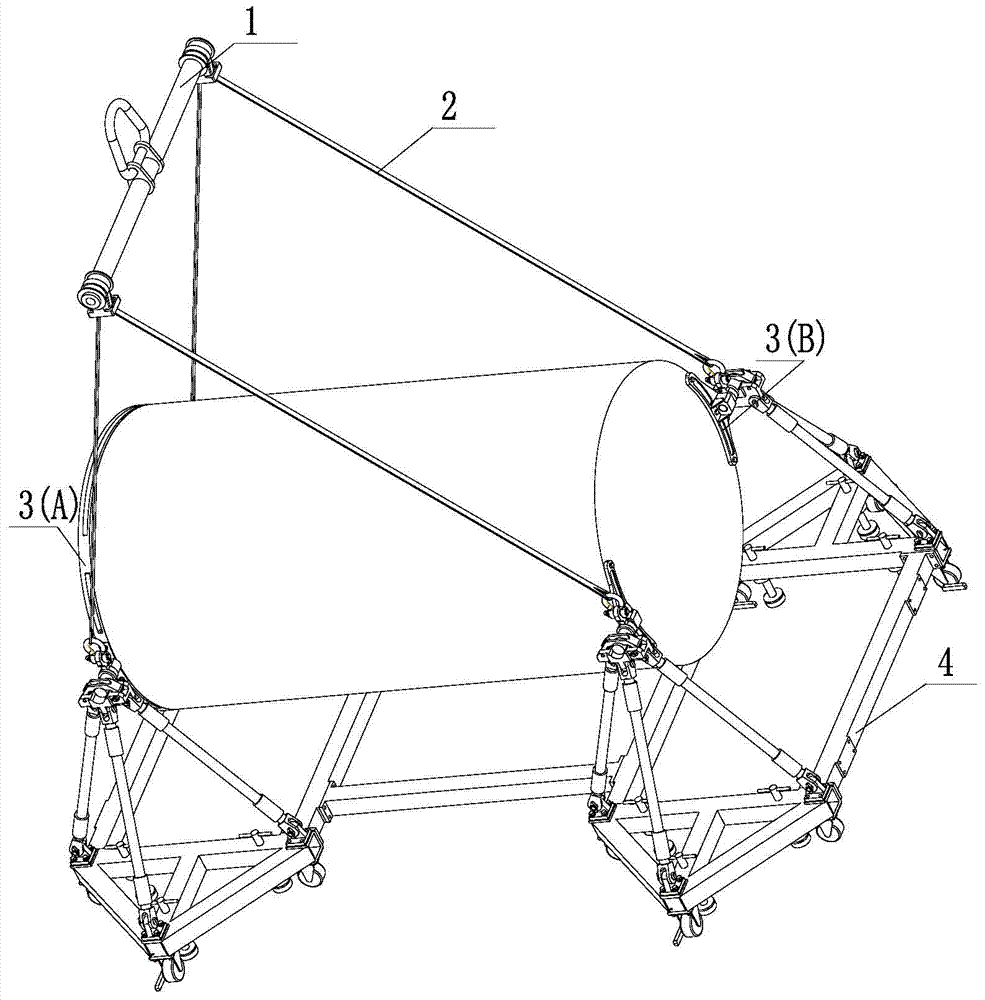

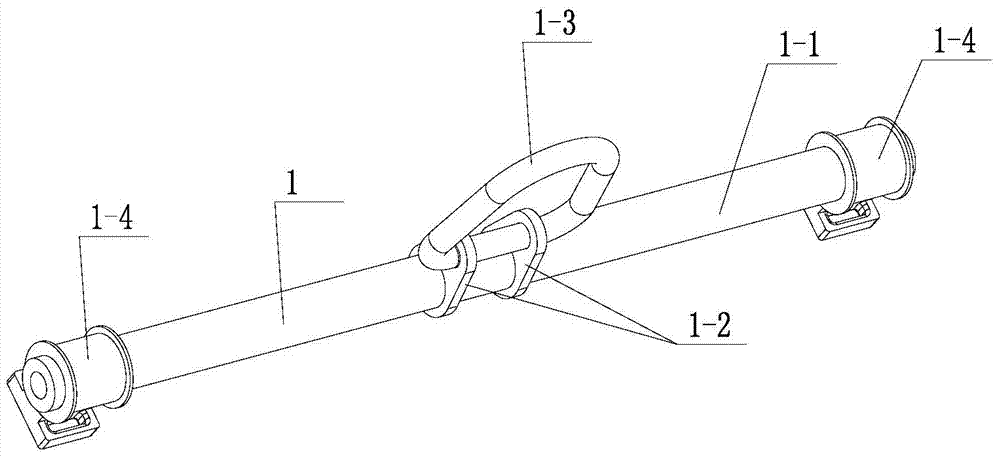

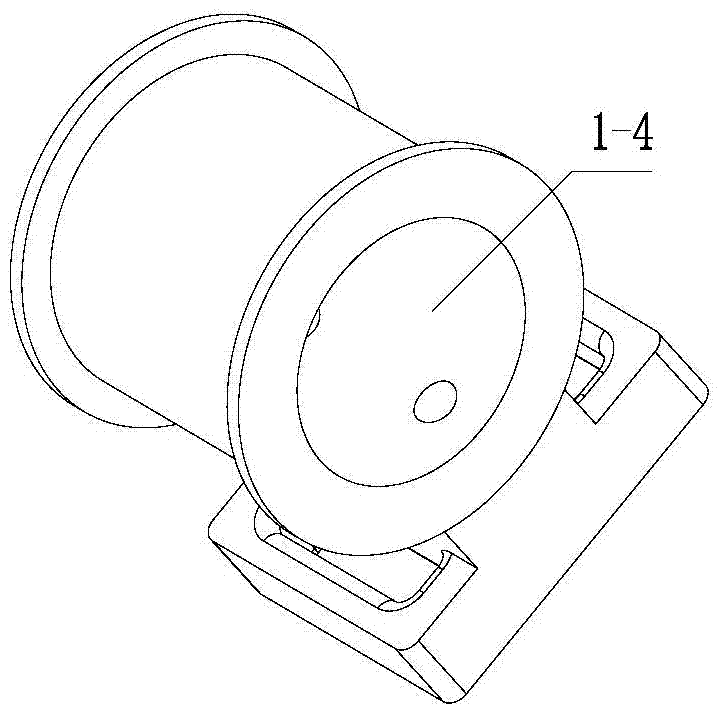

Lifting belt-type suspender for horizontal hoisting

ActiveCN104261242AHigh-strength comprehensive mechanical propertiesGood comprehensive mechanical propertiesLoad-engaging elementsMechanical engineeringCentroid

The invention discloses a lifting belt-type suspender for horizontal hoisting and belongs to mechanical hoisting equipment. The lifting belt-type suspender solves the problem that the existing horizontal hoisting suspender has a limited adjustment or use range, low efficiency and poor universality. The lifting belt-type suspender comprises a hanging beam, lifting belts, front and rear rotating shaft assemblies and an overturn support. The two lifting belts are hung under left and right ends of the hanging beam. One end of each one of the two lifting belts is connected to the front rotating shaft assembly and the other end of each one of the two lifting belts is connected to the rear rotating shaft assembly. The front rotating shaft assemblies and the two rear rotating shaft assemblies are connected to the overturn support. The overturn support comprises four tripods. The lifting belt-type suspender has a simple structure, good versatility, high strength and good integrated mechanical properties. All the parts of the lifting belt-type suspender can be detachably connected so that manufacture and maintenance are simple and manufacturability is good. The lifting belt-type suspender can be used for horizontal hoisting of cabins having different quality, centroids and sizes and realize change of a static displacement state of the cabins under support action of the overturn support.

Owner:航天科工火箭技术有限公司

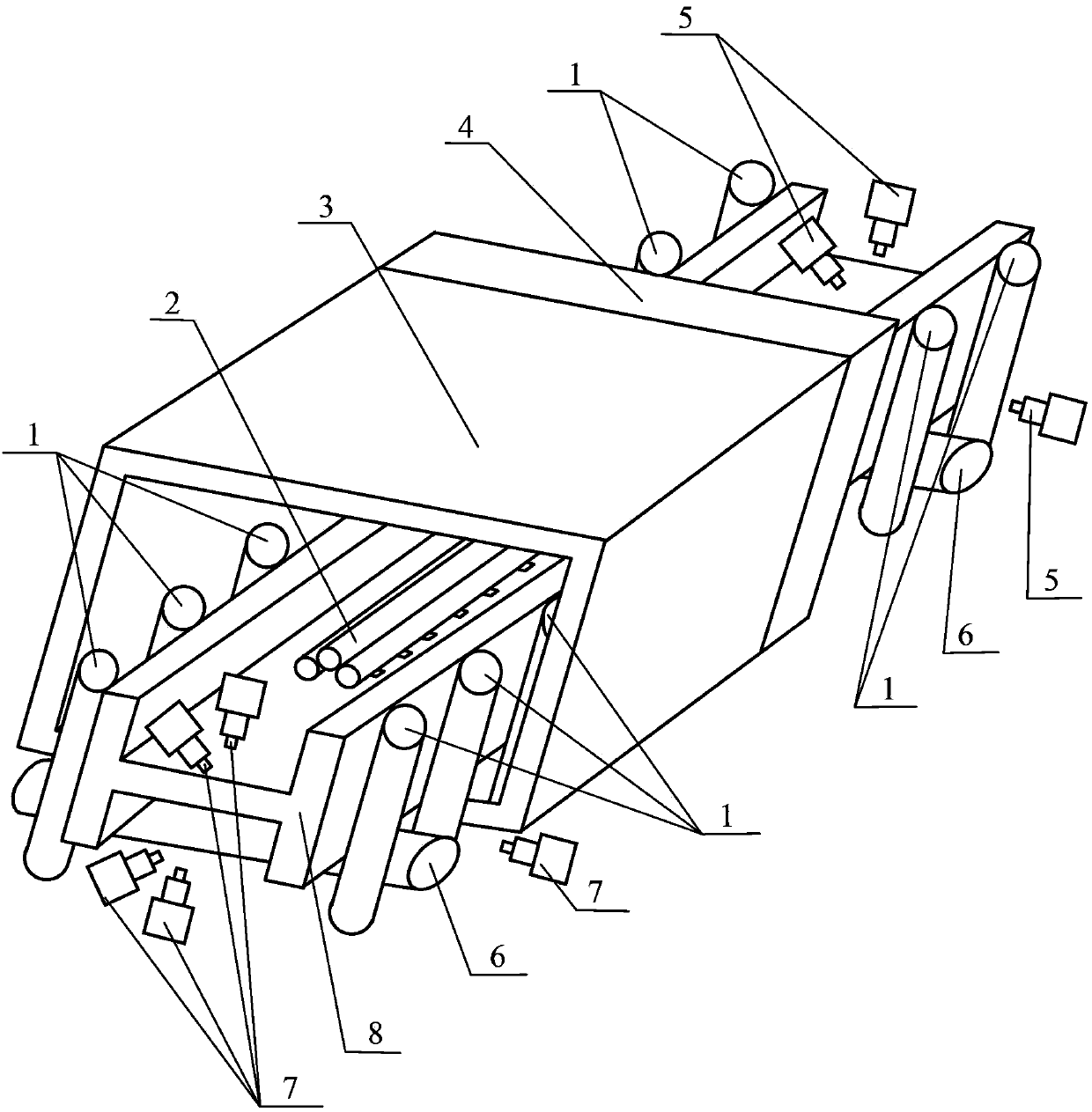

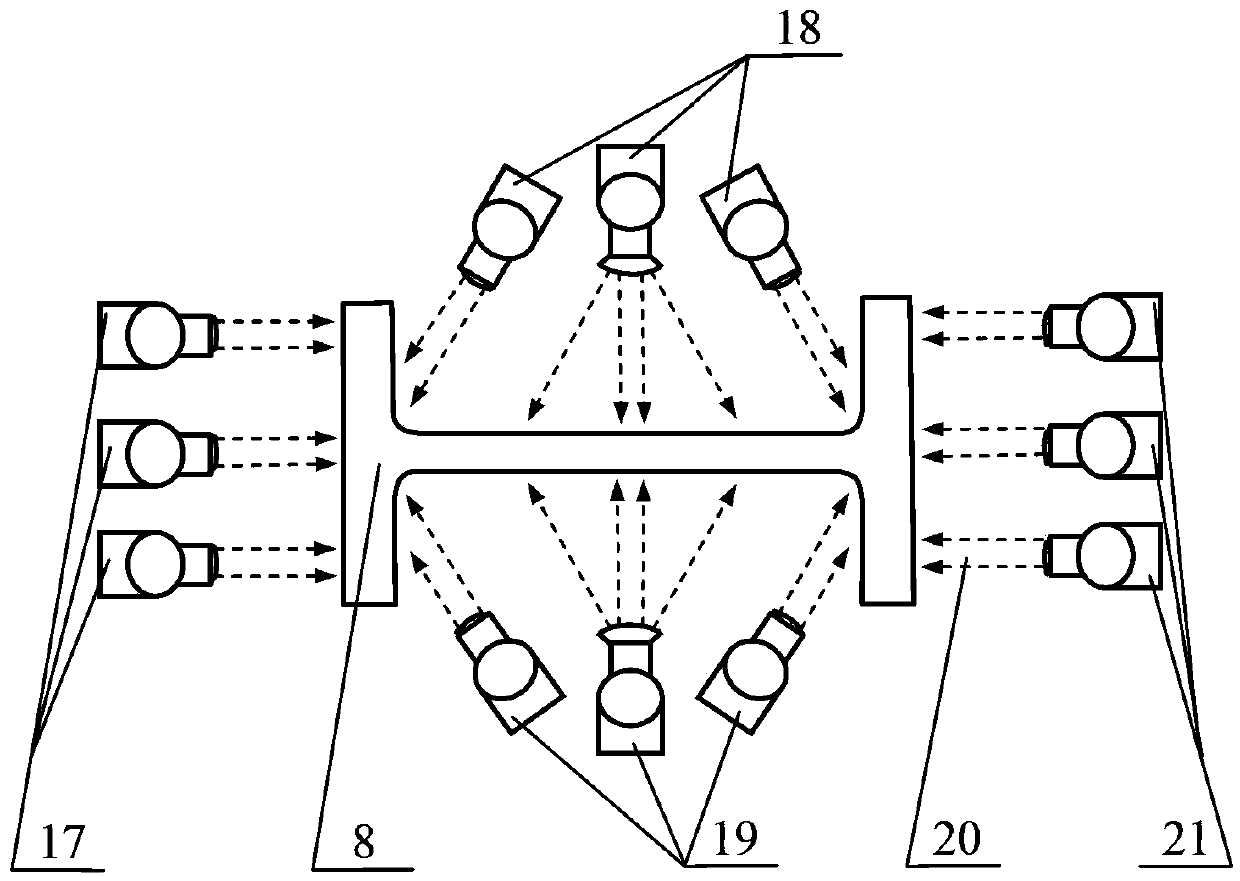

Cast rolling H-shaped steel cooling device

ActiveCN103357678AGood comprehensive mechanical propertiesWell organizedWork treatment devicesMetal rolling arrangementsSpray nozzleMechanical property

The invention provides a cast rolling H-shaped steel section cooling device. The cast rolling H-shaped steel section cooling device comprises a shell, three sets of upper spraying nozzles, an upper spraying pipe, three sets of lower spraying nozzles, a lower spraying pipe, three sets of left spraying nozzles, a left spraying pipe, three sets of right spraying nozzles and a right spraying pipe. The shell is of a box-shaped structure, the three sets of upper spraying nozzles are arranged in the shell and are used for being respectively aligned with two R portions of the upper side of the H-shaped steel section and the center of a web perpendicularly, the upper spraying pipe is arranged in the shell and is connected with the three sets of the upper spraying nozzle, the lower spraying pipe is arranged in the shell and is connected with the three sets of the lower spraying nozzles, the three sets of the left spraying nozzles are arranged in the shell and are sequentially arranged from top to bottom and are used for being aligned to the left side face of the H steel section to enable cooling water to be evenly sprayed to the left side face of the H steel section, the left spraying pipe is arranged in the shell and is connected with the three sets of left spraying nozzles, and the right spraying pipe is arranged in the shell and is connected with the three sets of right spraying nozzles. Cooling water sprayed by each set of spraying nozzles does not interfere with each other. The cast rolling H steel section cooling device enables the H steel section to be good in organization state, and therefore better comprehensive mechanical property is obtained.

Owner:LAIWU IRON & STEEL GRP

Twin induced plastic steel with high elongation percentage and high hole expansion rate and manufacture method thereof

The invention provided twin induced plastic steel with a high elongation percentage and a high hole expansion rate and a manufacture method thereof, the steel consists of 0.30 to 0.70 % of carbon, less than or equal to 1.0 % of silicon, 10 to 20% of manganese, less than or equal to 1.0 % of aluminum, 0.005 to 0.20% of polonium, 0.005 to 0.30% of Ra, 0.004 to 0.05% of nitrogen, less than or equal to 0.2% of niobium, less than or equal to 0.3 % of vanadium, less than or equal to 1 of copper and the balance of Fe. The method comprises the following steps of: (1) smelting: smelting by a vacuum furnace, allowing the molten steel to stand for 3-5 min, casting at a casting temperature of 1450-1550 DEG C; (2) hot rolling: heating the casting blank at a temperature of 1150 to 1200 DEG C, with a heating rate of 10-15 DEG C / min, performing heat preservation for 20 to 40 minutes, rolling at an initial rolling temperature of 1150-850 DEG C, stopping rolling at a finishing rolling temperature of 900-600 DEG C, rapidly cooling to room temperature at a rate of more than or equal to 20 DEG C / second after rolling; (3) cold rolling: performing cold rolling with a reduction ratio of the hot rolled plate being 40%-80% ; (4) heat treatment: performing heat treatment at a temperature of 600 to 1000 DEG C, rapidly cooling to room temperature at a rate of more than or equal to 20 DEG C / second after heat preservation for 3 to 10 minutes. The steel of the invention has low cost, a simple method, good quality of the product surface, an excellent processing property and an integrated mechanical property.

Owner:ANGANG STEEL CO LTD

Normalized extra-thick plate with high strength and toughness and thickness of 150mm and method for manufacturing normalized extra-thick plate

ActiveCN104962814AGood comprehensive mechanical propertiesLittle difference in mechanical propertiesSteel platesImpact toughness

The invention discloses a normalized extra-thick plate with high strength and toughness and the thickness of 150mm and a method for manufacturing the normalized extra-thick plate, and belongs to the field of technologies for manufacturing extra-thick plates. The method mainly includes controlling technological parameters in steps of molten steel smelting, plate slab casting, steel plate rolling, steel plate normalizing treatment, cooling and the like. The normalized extra-thick plate and the method have the advantages that reasonable composition systems and optimized 'control-rolling, normalizing and weak water cooling' technologies are designed, accordingly, the steel plate is excellent in comprehensive mechanical property and good in impact toughness at the temperatures of minus 40 DEG C and minus 60 DEG C, different positions of the steel plate in the thickness direction are low and stable in mechanical property difference, requirements of Q460-level extra-thick steel plates with the thicknesses of 150mm on the strength and the impact toughness can be completely met, and the normalized extra-thick plate and the method have excellent application prospects in the field of steel for engineering structures.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

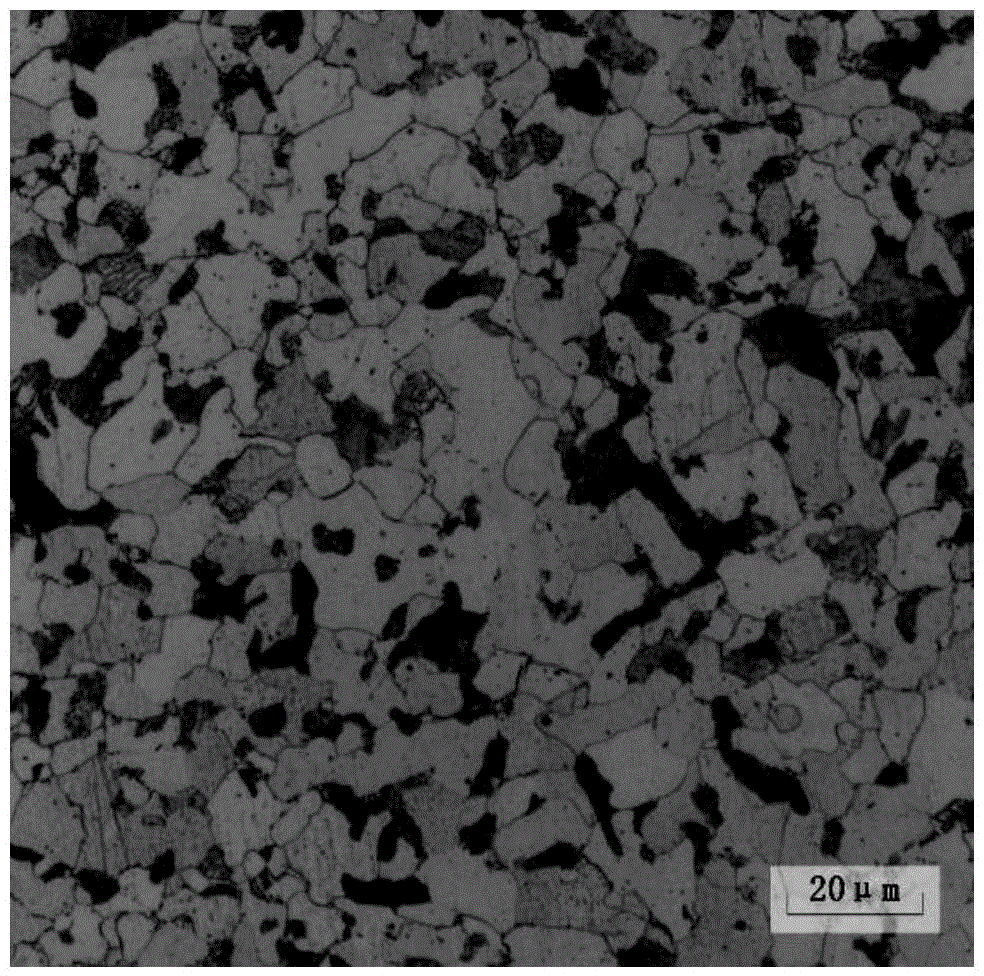

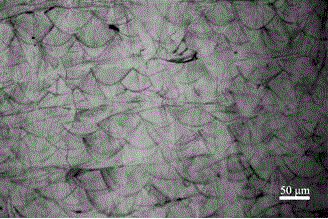

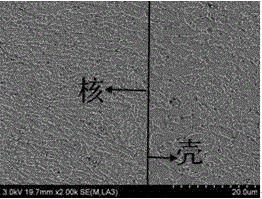

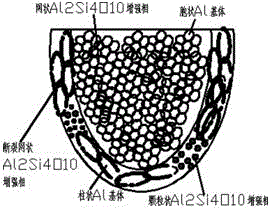

Aluminum-based in-situ composite material formed based on laser 3D printing and preparation method of aluminum-based in-situ composite material

ActiveCN105328186AGood comprehensive mechanical propertiesImprove the overall mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyLaser printingAluminium

The invention belongs to the technical field of particle-reinforced aluminum-based in-situ composite materials and discloses an aluminum-based in-situ composite material formed based on laser 3D printing and a preparation method of the aluminum-based in-situ composite material. The preparation method includes the steps that a mixture of Al-Si-Mg alloy powder and Al2O3 powder is prepared; the mixture is ball-milled through an intermittent ball-milling process; a three-dimensional CAD model established through a workpiece is subjected to layered slicing treatment; laser beams are adopted for scanning the laid powder line by line to form a two-dimensional section of the workpiece; and the steps are repeated till the workpiece is machined, and the aluminum-based in-situ composite material with an Al2Si4O10 reinforced element scattered on an Al matrix is formed. The operation method is easy and convenient to carry out, Al-Si-Mg alloy and Al2O3 generate the Al2Si4O10 reinforced phase in situ under the effect of high-energy lasers in the laser forming process, the interface wettability is improved, and then the interface strength of the composite material is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

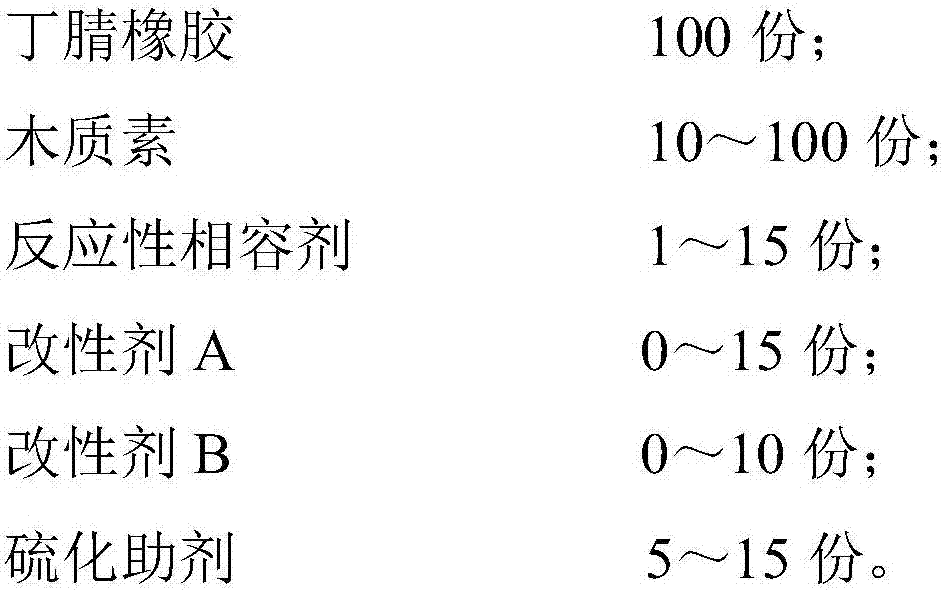

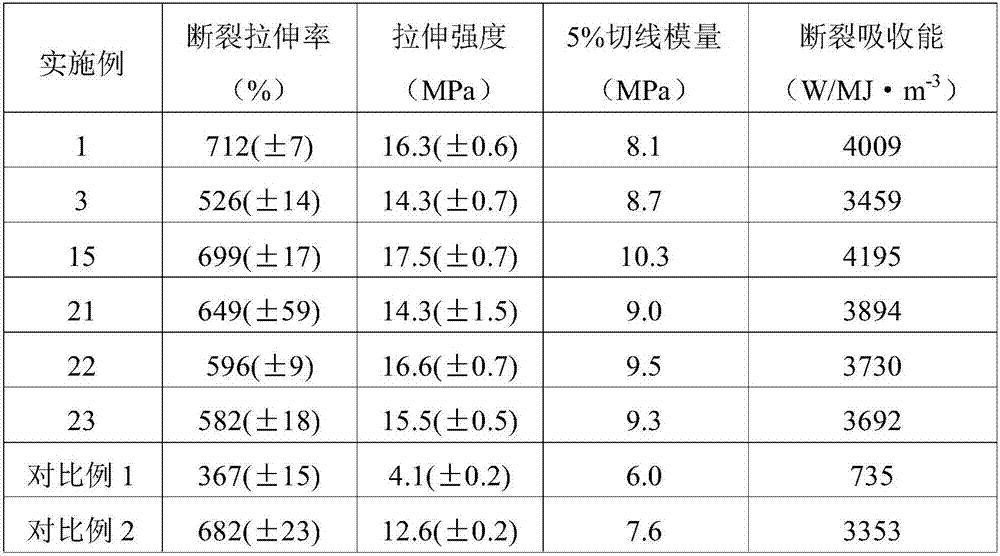

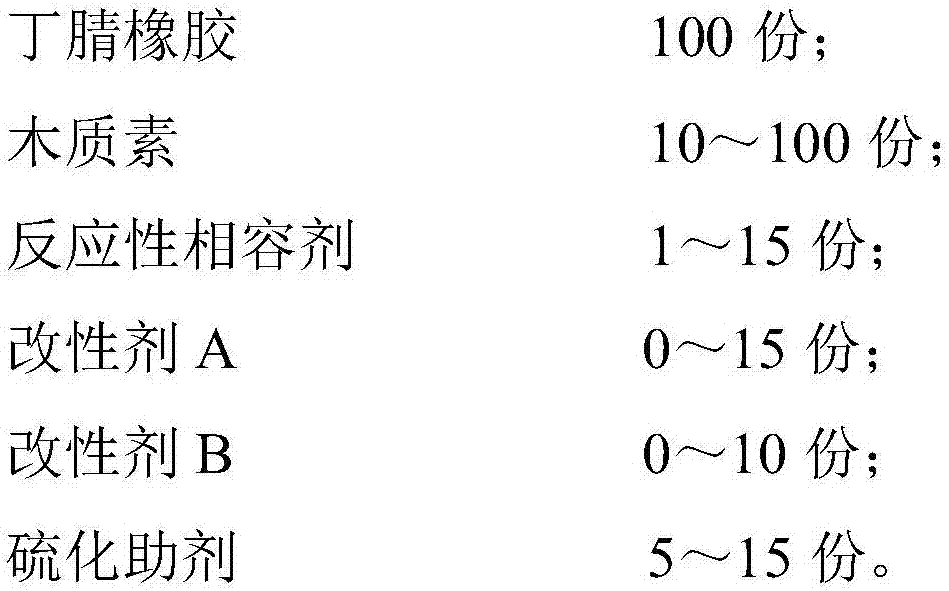

Lignin/nitrile butadiene rubber composite and preparation method thereof

ActiveCN107383475AGood comprehensive mechanical propertiesExtensive sources of raw materialsBond energyMechanical properties of carbon nanotubes

The invention belongs to the technical field of rubber materials and discloses a lignin / nitrile butadiene rubber composite and a preparation method thereof. The composite is prepared from components in parts by mass as follows: 100 parts of nitrile butadiene rubber, 10-100 parts of lignin, 1-15 parts of a reactive compatilizer, 0-15 parts of a modifier A, 0-10 parts of a modifier B and 5-15 parts of a vulcanizing agent through reactions. The composite with different mechanical performance is obtained by adjusting the use amounts of the lignin, the reactive compatilizer, the modifier A and the modifier B and has the tensile strength of 10-30 MPa and the elongation at break of 250%-800%. The non-covalent bonded energy sacrifice bond function is constructed between lignin and nitrile butadiene rubber phase interfaces under the effects of the reactive compatilizer and modifiers, the excellent comprehensive mechanical performance is obtained, the lignin can enhance and toughen rubber, and the problem of poor physical performance of composites due to poor compatibility is solved.

Owner:SOUTH CHINA UNIV OF TECH

Modified graphene enhanced aluminum-based composite material and preparation method thereof

InactiveCN107299257AGood comprehensive mechanical propertiesIncreased strength and hardnessAluminum matrix compositesCarbide silicon

The invention discloses a modified graphene enhanced aluminum-based composite material and a preparation method thereof. The modified graphene enhanced aluminum-based composite material comprises the following components in percentage by weight: 0.01 to 0.3 percent of modified graphene, 0.3 to 2.4 percent of copper, 0.2 to 1.3 percent of carbon, 1.2 to 4.6 percent of iron, 0.8 to 1.9 percent of silicon carbide, 0.1 to 1.5 percent of lanthanum oxide, 1.9 to 4.5 percent of a surfactant and the balance of aluminum. The modified graphene enhanced aluminum-based composite material provided by the invention has high comprehensive mechanical property, and the strength and the hardness are improved; the composite material maintains the original plasticity of the aluminum-based composite material; by using the method, the wettability of the graphene and a metal melt is guaranteed, compact structure and good interfacial bonding force of the composite material are guaranteed, and the graphene is distributed into the aluminum base uniformly in a sheet shape.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Bismuth-contained lead-free easy-to-cut zinc-white copper alloy

The invention discloses a Bi-containing, Pb-free, easy-to-cut zinc-whit copper alloy, belonging to the field of metal material making technique, comprising: Cu 60.0-63.0wt%, Ni+Co 17.0-19.0wt%, Bi 0.6- 1.0wt%, Mn =<0.5wt%, Fe =<0.3wt%, Ce 0.03-0.1wt%, and the rest Zn and inescapable impurities, where the lead content of the impurities is less than 0.03wt%. And it has excellent synthetic mechanical property, corrosion resistance, easy to cut, able to be made into rods, lines, and widely applied to precision parts, glasses fittings, slide fasteners, keys, optical and clocks and watches industries, etc.

Owner:厦门火炬特种金属材料有限公司

High-heat-resistance hot work die steel and preparation method

ActiveCN105018854AGood comprehensive mechanical propertiesImprove thermal fatigue resistanceAlloy elementCompound (substance)

The invention provides high-heat-resistance hot work die steel and a preparation method. The high-heat-resistance hot work die steel comprises the following chemical components in percentage by mass: 0.38-0.44% of C, 3.8-4.4% of Cr, 1.8-2.4% of Mo, 0.2-0.6% of Si, 0.5-0.8% of Mn, 0.5-0.7% of V, 0.8-1.2% of Ni, 0.02-0.05% of Cu, 0.08-0.12% of Ta, 0.01-0.03% of Nb, 0.008-0.016% of W, 0.008-0.016% of Co, P and S both less than 0.030%, and the balance of Fe. The steel is tapped until the chemical components are accordant with the requirements through the steps of alloying, burdening, smelting and analysis of stokehole chemical components; and then, the treatments of annealing, quenching and tempering are performed. The steel is excellent in comprehensive mechanical performance, high in heat fatigue resistance and excellent in heat stability and high-temperature strength; meanwhile, the steel carbon and the alloy element are lower in content; the production cost is low; the preparation procedures are simple; and the application value is excellent.

Owner:HARBIN ENG UNIV

Thin-specification high-strength steel plate with good low-temperature-resistant toughness and production method thereof

InactiveCN109722597AGood comprehensive mechanical propertiesAlloy addition is lessSteel platesImpact energy

The invention relates to a thin-specification high-strength steel plate with good low-temperature-resistant toughness and a low-cost production method thereof. The steel plate comprises the followingchemical components of, by weight, 0.11%-0.17% of C, 0.20-0.50% of Si, 1.00-1.50% of Mn, less than or equal to 0.010% of S, less than or equal to 0.020% of P, 0.010-0.030% of Nb, 0.010-0.020% of Ti, 0.015-0.050% of Als, and the balance Fe and trace impurities. The preparation method of the steel plate comprises molten iron pretreatment, converter smelting, LF refining, slab continuous casting, slab heating, controlled rolling, hot straightening and air cooling. According to the steel plate and the production method thereof, the yield strength of the obtained steel plate with the thickness of 8-10 mm can reach 380-490 MPa, the tensile strength reaches 510-630 MPa, and the Charpy impact energy of a V-shaped notch under minus 47 DEG C is larger than or equal to 110 J.

Owner:SHANDONG IRON & STEEL CO LTD

Quasi-crystal reinforced multi-element magnesium alloy and preparation method thereof

InactiveCN104372224AImprove comprehensive mechanical propertiesGood comprehensive mechanical propertiesMulti elementMagnesium alloy

The invention discloses a quasi-crystal reinforced multi-element magnesium alloy and a preparation method thereof, belonging to the field of industrial magnesium alloys and manufacturing thereof. The quasi-crystal reinforced multi-element magnesium alloy comprises the following components in percentage by mass: 6.0-16% of Zn, 1.4-3.6% of Y, 0.1-0.5% of Ho, 0.1-0.5% of Er, 0.05-1.2% of Mn, 0.02-1.6% of Ti, 0.05-1.8% of Zr, and the balance of Mg. The quasi-crystal reinforced multi-element magnesium alloy disclosed by the invention has relatively good comprehensive mechanical properties namely relatively high tensile strength and relatively high elongation percentage, and particularly has relatively high yield strength.

Owner:SOUTHWEST JIAOTONG UNIV

Superstrength high-toughness alloy steel and preparing method thereof

The invention discloses superstrength high-toughness alloy steel, and relates to the technical field of metal material and machining. The alloy steel comprises following components, by mass percent, 0.35 to 0.45% of C, 0.60 to 1.00% of Mn, 1.50 to 1.80% of Si, 0.60 to 1.00% of Cr, 1.60 to 2.00% of Ni, 0.30 to 0.50% of Mo, 0.025 to 0.045% of Nb, 0.05 to 0.10% of V, not larger than 0.010% of P, notlarger than 0.005% of S, 0.015 to 0.025% of La and the balance Fe and inevitable impurities. The weight percentage of (Cr+Ni) / Mo ranges from 6.0 to 8.0. The invention further discloses a preparing method of the superstrength high-toughness alloy steel. The production process is simple, the production equipment need is low, production efficiency is high, and industrial and production application isfacilitated.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of high intensity Ti6Al4V diphase reinforced composite material

InactiveCN101306501ASimple processGood comprehensive mechanical propertiesMetal-working apparatusTitanium carbideAluminium

The invention discloses a method for preparing a titanium-base high-strength composite material with two-phase of TiC and TiB as the particulate reinforcements, and Ti6A14V as the matrix. The method includes the following steps: titanium powder, aluminum-vanadium alloy powder, titanium diboride powder and titanium carbide powder are adopted as the raw materials, mixed in a certain proportion, dwelled by the mechanical pressure or the pressure at the fine pressure of 280-300MPa, pressed into a certain shape, sintered at the temperature of 1200 DEG C and reacted; then the sintered material is forged in different forging manners according to the purpose of the material and the condition of the product to be prepared; finally, the high-strength Ti6A14V two-phase reinforcement composite material can be obtained after heat treatment. The two-phase reinforcement composite material prepared by the method allows the tensile strength to be larger than 1200Mpa at the normal temperature and the percentage elongation after fracture to be above 4%, so as to be widely applied to titanium alloy parts on space air vehicles, seafaring ships, motorcars or sports equipment.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

Polylactic acid-polyester composite material and preparation method thereof

The invention relates to a polylactic acid-polyester composite material. The composite material contains polylactic acid, aliphatic aromatic copolyester, triblock copolyester and an organic peroxide. The invention also relates to a preparation method of the polylactic acid-polyester composite material. The method comprises the following steps: mixing polylactic acid, the aliphatic aromatic copolyester, the triblock copolyester and the organic peroxide, and carrying out extruding granulation of the above obtained mixture. The polylactic acid-polyester composite material has excellent comprehensive mechanical performances and an excellent biological degradability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special steel for knife tool

A cutter dedicated steels, is characterized in that: the chemical compositions and mass percent of each composition are: C 0.85%- 0.95%, Si 0.4%-0.5%, Mn 0.4%-0.5%, P <= 0.03%, S <= 0.02%, Cr 14.5%-15.5%, Mo 0.4%-0.6%, V 0.2%-0.3%, the residuel of Fe and inevitable micro impurity. The combination of the content of C and Cr in the inventive steels is the best combination suitable for producing cutter, the structure of steels is finer by adding Mo and V. The inventive steels have excellent integrated mechanical property, higher strength and rigidity, good toughness and excellent anti-rust property. The inventive steels have higher rigidity and better anti-rust property than the existing 3Cr13 steel, 4Cr13, 5Cr15MoVsteel, in particular the rididity HRC reach 57-58 HRC, and it is a cutter dedicated steels with excellent integrated mechanical property.

Owner:王泽红

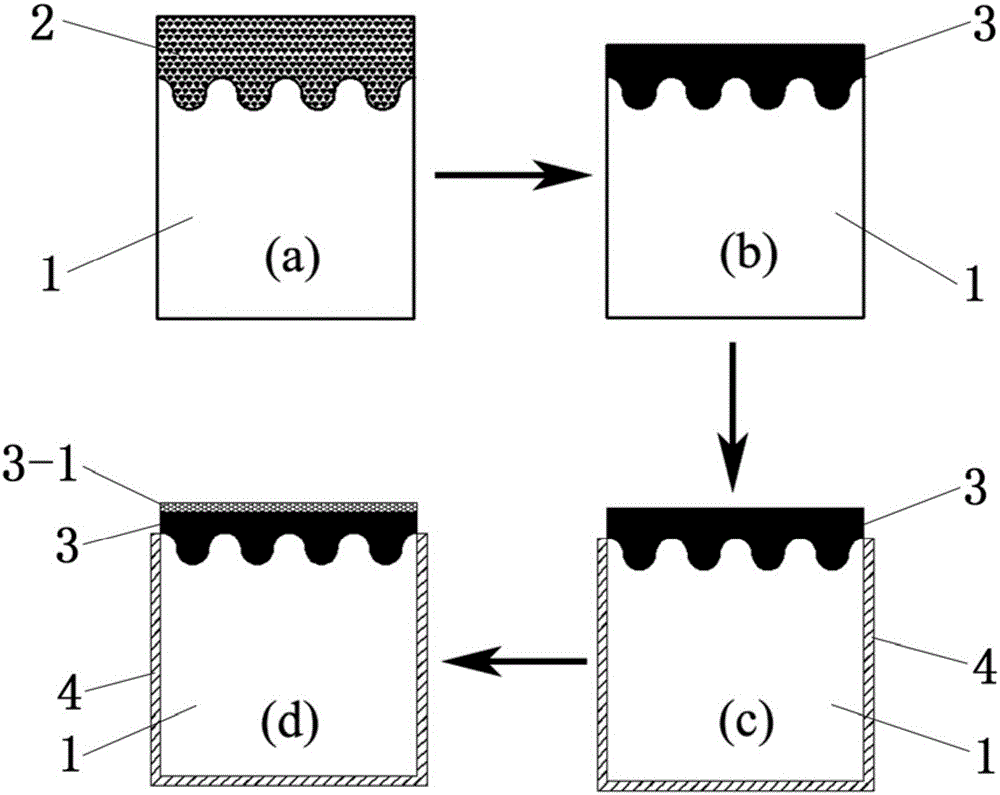

Thermostable polycrystalline diamond composite piece and preparation method thereof

InactiveCN105156037AGood comprehensive mechanical propertiesHigh wear resistance and thermal stabilityDrill bitsCoal miningCemented carbide

The invention discloses a thermostable polycrystalline diamond composite piece and a preparation method thereof. The thermostable polycrystalline diamond composite piece is prepared through the following steps of: coating a plastic layer on the surface of a hard alloy matrix of a polycrystalline diamond composite body compounded through high temperature and high pressure; and then immersing the coated polycrystalline diamond composite body into acid liquor so as to perform acid cooking. According to the thermostable polycrystalline diamond composite piece disclosed by the invention, the plastic layer is coated on the surface of the hard alloy matrix of the polycrystalline diamond composite body during preparing the thermostable polycrystalline diamond composite piece, and only the surface of a polycrystalline diamond layer is exposed into the acid liquor when the acid cooking is performed so as to prevent the hard alloy matrix and joints between the polycrystalline diamond layer and the hard alloy matrix from being damaged by the acid liquor. Compared with a conventional polycrystalline diamond composite piece, the thermostable polycrystalline diamond composite piece disclosed by the invention has excellent synthesized mechanical properties, particularly has high heat stability and a good abrasion resistant property, is suitable for the application fields of oil drilling, geological drilling, coal mining and the like, and has a high social value and high economic benefits.

Owner:FUNIK ULTRAHARD MATERIAL

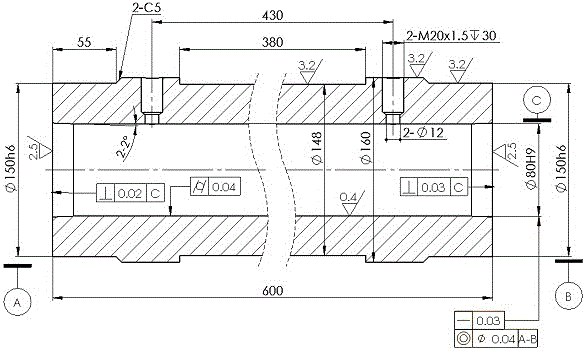

Hydraulic cylinder block machining process

InactiveCN107175469AGood comprehensive mechanical propertiesImprove wear resistanceFluid-pressure actuatorsSteel tubeCylinder block

The invention discloses a process for processing a cylinder block of a hydraulic cylinder. The method comprises the following steps: A: selecting seamless steel pipe as the material of the hydraulic cylinder; B: cutting and blanking the seamless steel pipe by a sawing machine; C: cutting and blanking the seamless steel pipe Quenching and carburizing treatment, after quenching and carburizing, check the hardness of the seamless steel pipe; D: lathe the outer circle of the seamless steel pipe, process thread, end face and chamfer; E: first rough the seamless steel pipe Boring, followed by semi-finish boring, then fine boring of seamless steel pipes, and finally fine reaming of seamless steel pipes; F: use rolling head to roll the holes obtained after deep hole push boring; G: Turning process thread, turning outer circle steps; H: taper hole and turning end face; I: drilling and tapping; J: checking the dimensional accuracy and surface roughness of the hydraulic cylinder; in general, the present invention has reliable quality , Long service life and good wear resistance.

Owner:卢晓鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com