Patents

Literature

47results about How to "Good Machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

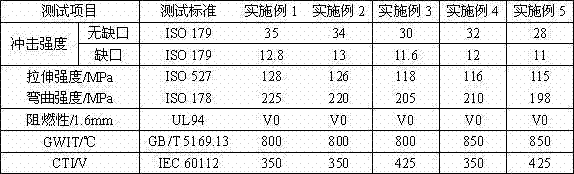

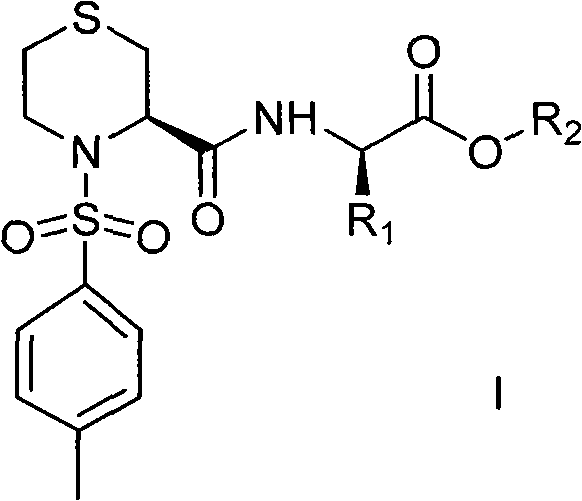

High CTI reinforced and flame-retarded PA6 composite material with high glowing filament and preparation method

InactiveCN104744931AGood machinabilityGood mechanical propertiesManufacturing engineeringTemperature control

The invention discloses a high CTI reinforced and flame-retarded PA6 composite material with a high glowing filament and a preparation method. The high CTI reinforced and flame-retarded PA6 composite material comprises the components in parts by weight: 30-50 parts of PA630, 25-35 parts of compounded fire retardant, 3-6 parts of compounded antimonous oxide, 20-30 parts of a glass fiber, 0-10 parts of a filler, 2-8 parts of a flexibilizer, 0.1-1 part of antioxidant, 0.1-1 part of a lubricating agent and 0.1-1 part of other auxiliary. According to the PA6 composite material prepared by the invention, GWIT can reach 850 DEG C, and CTI can reach 425V at most; the PA6 composite material is high in processing performance, high in mechanical performance, and can meet the requirements of the field of electric products such as shutdown switches, temperature control switches, wiring terminals and the like.

Owner:NANTONG DONGFANG PLASTIC CO LTD

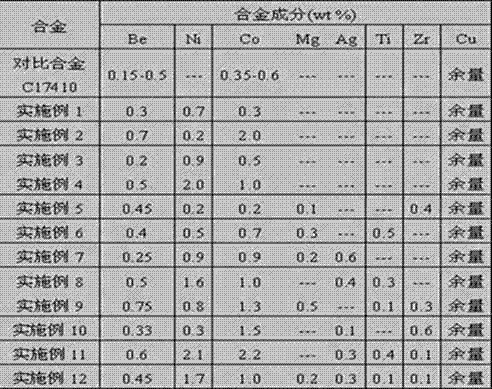

High-elasticity stress relaxation-resistant beryllium-copper alloy and its preparation and processing method

The invention relates to a high-elasticity stress relaxation-resistant beryllium-copper alloy and its preparation and processing method. The alloy comprises the following basic components by mass: 0.2-0.7% of Be, 0.5-2.0% of Co, 0.2-2.0% of Ni, and the balance Cu. The components of the copper alloy need to satisfy that: (a) the total content of Ni and Co is greater than or equal to 0.7% and less than or equal to 4%; and (b) the ratio of the sum of Ni and Co to Be is greater than or equal to 2 and less than or equal to 7. The preparation and processing method consists of: a. batching according to the mass percentage, charging, smelting and casting; b. surface milling; c. hot rolling; d. solid solution treatment; e. first cold rolling; f. first aging; g. second cold rolling; and h. second aging. The copper alloy provided in the invention has tensile strength sigmaB of 600-800MPa, plastic elongation delta of 4-10%, and electric conductivity of 35-50%IACS, and can be widely used in various elastic reeds, electrical contacts, spot welding poles, explosion-proof tools, electrical contact components, plug-in components and other occasions.

Owner:有研科技集团有限公司

Bismuth-contained lead-free easy-to-cut zinc-white copper alloy

The invention discloses a Bi-containing, Pb-free, easy-to-cut zinc-whit copper alloy, belonging to the field of metal material making technique, comprising: Cu 60.0-63.0wt%, Ni+Co 17.0-19.0wt%, Bi 0.6- 1.0wt%, Mn =<0.5wt%, Fe =<0.3wt%, Ce 0.03-0.1wt%, and the rest Zn and inescapable impurities, where the lead content of the impurities is less than 0.03wt%. And it has excellent synthetic mechanical property, corrosion resistance, easy to cut, able to be made into rods, lines, and widely applied to precision parts, glasses fittings, slide fasteners, keys, optical and clocks and watches industries, etc.

Owner:厦门火炬特种金属材料有限公司

Production method of thin steel strip hot galvanizing

ActiveCN102776460AStrong corrosion resistanceGood machinabilityHot-dipping/immersion processesCorrosionAir drying

The invention relates to a production method of thin steel strip hot galvanizing. The production method comprises the following steps of uncoiling, welding, chemical desorption, electrolysis, cleaning, air drying, annealing, galvanizing, air cooling, straightening, chemical coating and coiling. A steel strip subjected to galvanizing has good corrosion resistance and better machining performance, the plating layer is firm and uniform, the color is bright, the service life is long, the environment pollution is avoided, and the continuous large-scale production can be realized.

Owner:江苏大力神科技股份有限公司

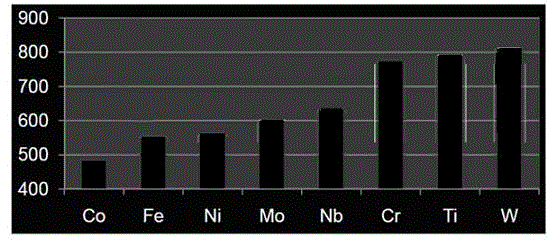

High temperature alloy material for engine turbine and preparation method thereof

The invention relates to a high temperature alloy material for an engine turbine. The high temperature alloy material comprises components according to weight percentage: 0.22-0.28% of C, 2.1-2.2% of Mn, 0.45-0.61% of Si, 18.3-19.2% of Cr, 8.25-10.4% of Mo, 3.50-3.80% of W, 0.05-0.35% of Al, 0.18-0.27% of Cu, 5.0-9.2% of Fe, 1.0-1.1% of B, 3.15-3.45% of Ti, 6.7-8.2% of Co, 0.12-0.18% of Zr, 1.12-1.38% of Nb, and the balance of Ni and inevitable impurities, and a preparation method which is matched with the material is provided. The prepared blank is reasonable in component design, and is matched with characteristics of reasonable thermal processing technology, convenient production organization, strong field operability and strong apparatus universality, so that the quality of the produced high temperature alloy large-sized turbine disk product is high, the structure property meets the standard requirements, the production efficiency is high, and the economic benefit and the social benefit are obvious.

Owner:北京金恒博远科技股份有限公司

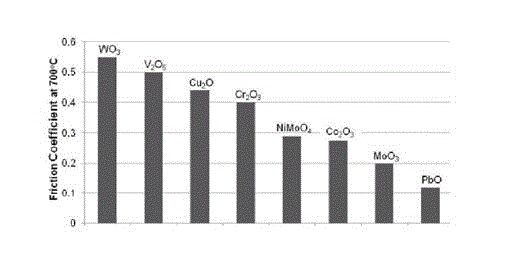

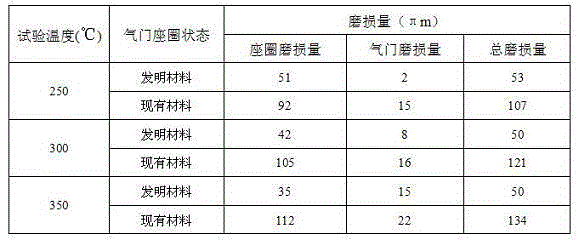

Valve seat ring for alternative fuel engine

ActiveCN104630659ALow initial oxidation temperatureLower coefficient of dynamic frictionTurbinesOther manufacturing equipments/toolsAlternative fuelsWear resistance

The invention relates to a valve seat ring for an alternative fuel engine. The valve seat ring comprises the following chemical components (weight percent): 0.8% -1.2% of C, 0.8% -1.2% of Si, 0. 4% -0.7% of Mn, 0.6% -0.9% of S, 5% -7% of Ni, 4% -6% of Cr, 10% -15% of Mo, 22%-27 % of Co, and the balance of Fe. The valve seat ring is machined by a powder metallurgy method in a vacuum environment, and the production process of two-time pressing and two-time sintering is adopted in the machining process. The valve seat ring has high abrasion resistance, high heat resistance and high corrosion resistance, the good matching of the valve seat ring and a valve is also ensured, and the high-strength valve seat ring material has good machinability, and the excessive machining cost cannot be caused. The content of hard particles reaches about 45%, and the high-strength valve seat ring can meet the requirements of various alternative fuels.

Owner:CHERY AUTOMOBILE CO LTD

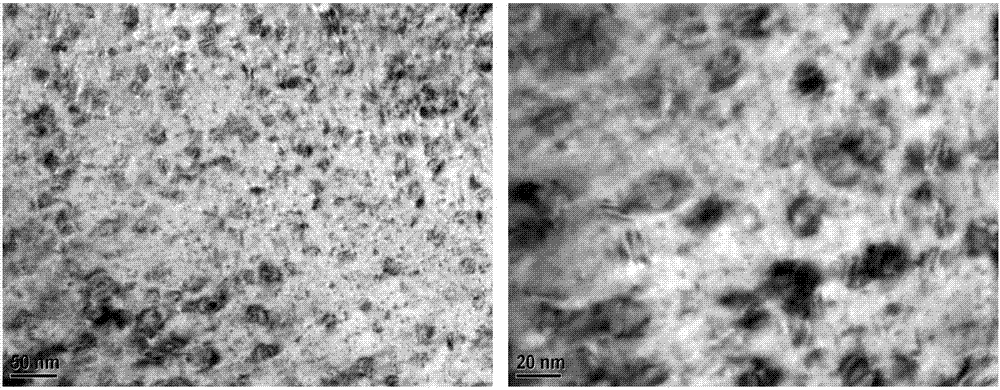

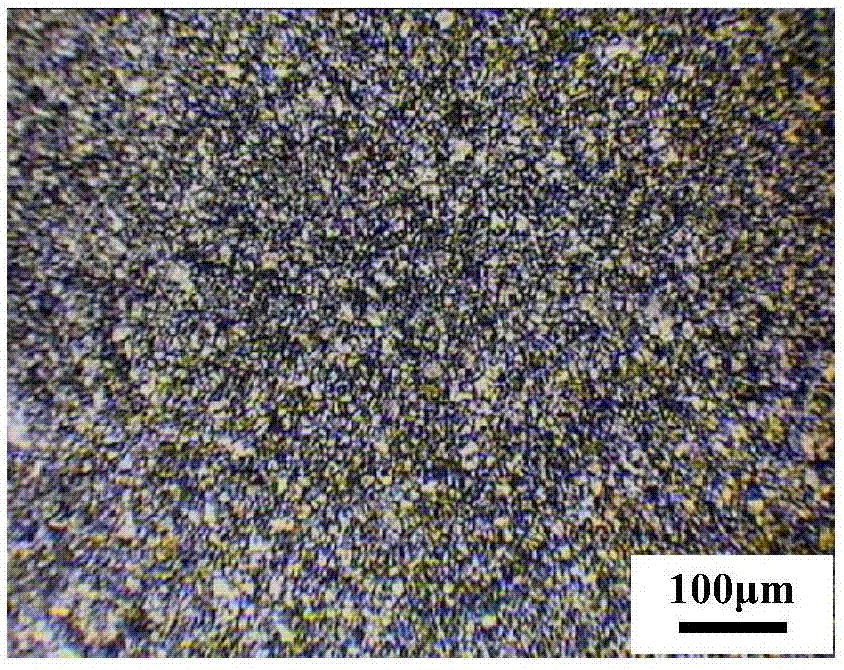

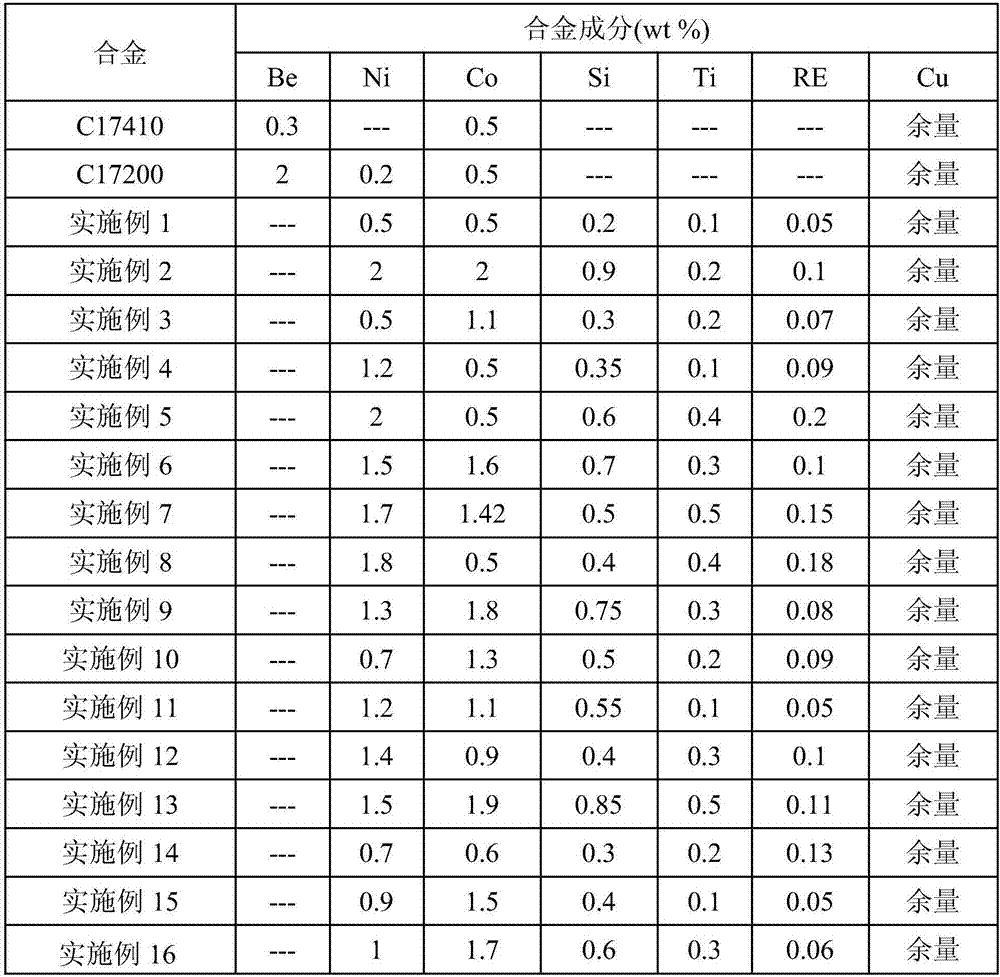

Cu-Ni-Si-Co-Ti-RE copper alloy and preparation method thereof

The invention discloses a Cu-Ni-Si-Co-Ti-Re copper alloy. The Cu-Ni-Si-Co-Ti-Re copper alloy comprises the following components in percentage by weight: 0.5%-2.0% of Ni, 0.2%-0.9% of Si, 0.5%-2.0% of Co, 0.1%-0.5% of Ti, 0.05%-0.2% of RE and the balance Cu, wherein RE is one or more of Ce, La and Y. The Cu-Ni-Si-Co-Ti-Re copper alloy has tensile strength sigma b which can reach 800-1000 MPa, plastic ductility sigma of 3-10%, electrical conductivity of 45%-55% of IACS, anti-stress-relaxation property greater than or equal to 80% (working for 1000 hours at a temperature of 200 DEG C). The invention further discloses a preparation method for the Cu-Ni-Si-Co-Ti-Re copper alloy.

Owner:JIANGXI UNIV OF SCI & TECH +1

Polychlorotrifluoroethylene resin preparation method

The invention provides a polychlorotrifluoroethylene resin preparation method, belonging to the technical field of the preparation of fluoropolymer material. The method comprises the following steps:firstly purifying polytrifluorochloroethylene, then adopting deionized water as medium and using initiator to performing chlorotrifluoroethylene polymerization in the presence of surfactant and obtaining polychlorotrifluoroethylene resin. The invention has the advantage that the polymerization reaction time is shortened to less than 10h, the conversion rate of chlorotrifluoroethylene reach above 90%, the obtained polychlorotrifluoroethylene resin has good heat resistance and processability and degradation and metachromatism can not appear under the processing temperature of 240-280 DEG C. Therefore, the method can meet the demand of industrialized production.

Owner:CHANGSHU XINHUA CHEM

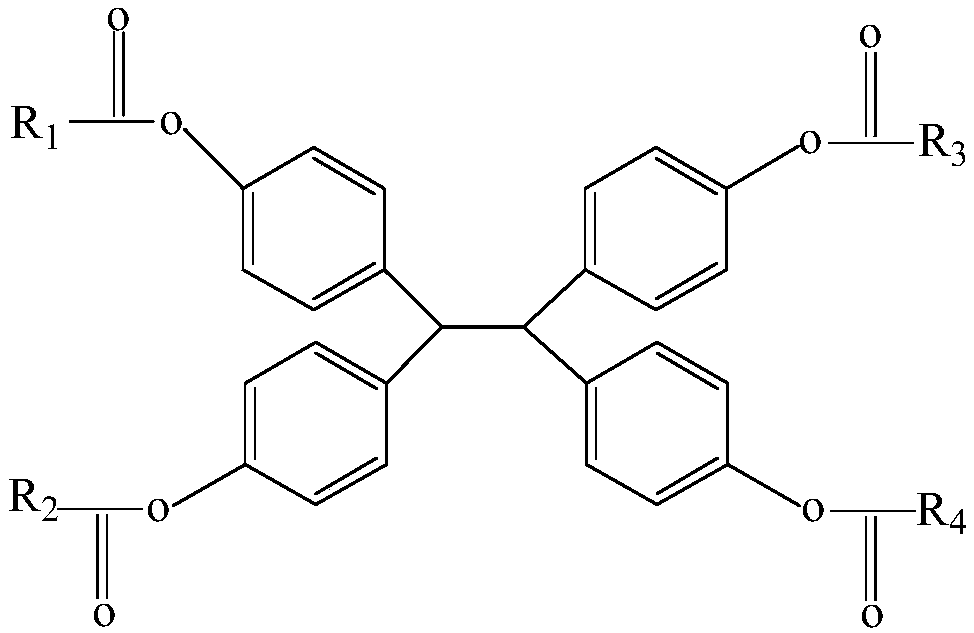

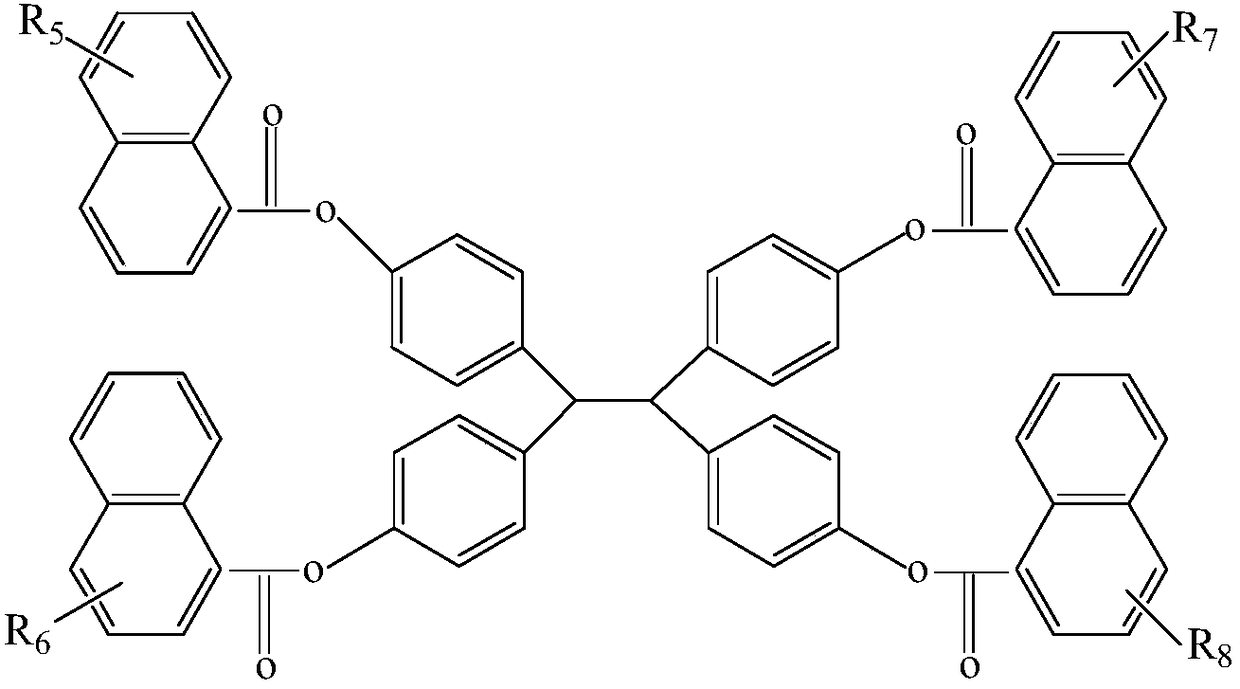

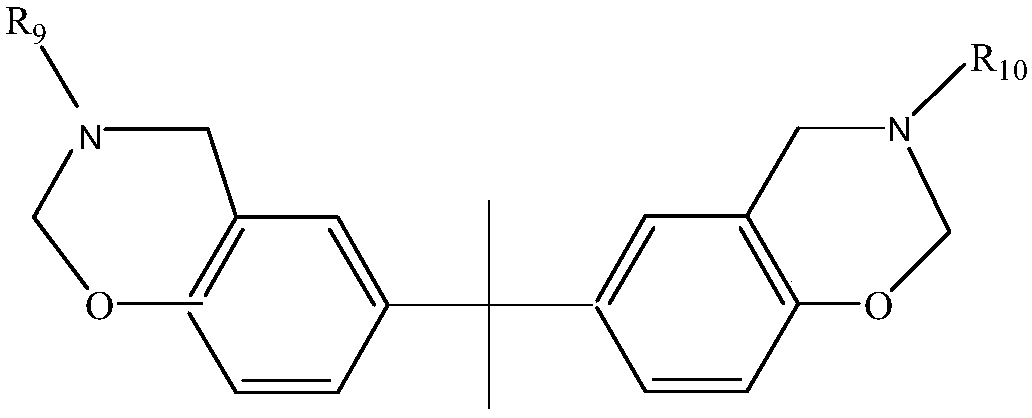

Resin composition and prepared prepreg thereof, laminated board

ActiveCN109265654AGood machinabilityLow dielectric lossSynthetic resin layered productsElectrical equipmentDielectric lossUv blocking

The invention provides a resin composition and a prepared prepreg thereof, a laminated board, and relates to the technical field of high molecular materials. The resin composition is prepared from 10-90 parts of epoxy resin and 1-50 parts of an active ester curing agent. A technical problem that current resin cannot meet high-frequency high-speed requirements of an electronic circuit base materialis relieved. The provided resin composition is capable of using the epoxy resin as main body resin, so the resin composition has a good machining property. A micromolecular substance with a naphthalene ring and a polyfunctionality ester bond structure is used as the active ester curing agent, so the cured resin composition is low in dielectric loss, high in vitrification transfer temperature, andhas a UV-blocking function at the same time, is capable of meeting high-speed and high-frequency using requirements of a base board material for a PCB.

Owner:同宇新材料(广东)股份有限公司

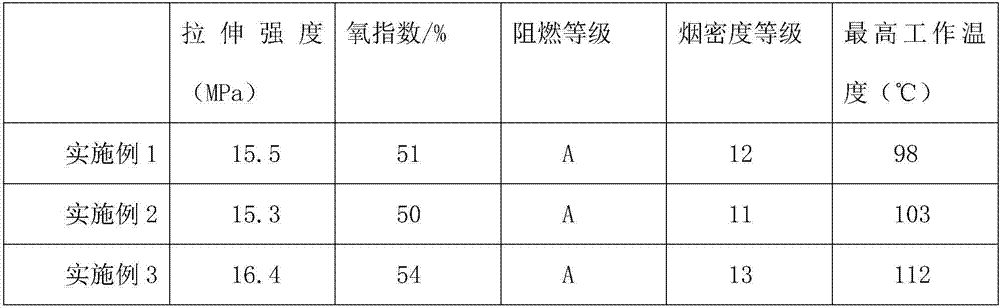

High wear resistant ultra-high carbon steel and preparation method for same

The invention relates to high wear resistant ultra-high carbon steel, which mainly contains alloy element chromium and comprises the chemical components: (according to weight percentage): 1.25-1.35% of C (carbon), 3.2-4.2% of Cr (chromium), 0.5-1.2% of Si+Al (silicon and aluminum), 0.85-1.25% of Mn (manganese), 0.08-0.15% of V (vanadium), 0.3% of Mo (molybdenum) or less than 0.3% of Mo, 0.025% of S (sulphur) or less than 0.025% of S, 0.025% of P (phosphorus) or less than 0.025% of P and the rest of Fe (ferrum) and inevitable impurities. The preparation method for the high wear resistant ultra-high carbon steel includes that after being refined, the components are heated at the temperature of 900-920 DEG C and are in salt bath at the constant temperature of 300-320 DEG C for 30min, and then the components are placed into a 320-340 DEG C box-type resistance furnace and insulated for 120-240min prior to air cooling. The high wear resistant ultra-high carbon steel can be produced by the aid of a medium frequency induction furnace, a vacuum induction furnace and an arc furnace with LF (low frequency) refining process. Compared with high manganese steel and high-chromium iron wear-resistant materials, the high wear resistant ultra-high carbon steel is remarkably lower in production cost. The high wear resistant ultra-high carbon steel with high hardness (55-57HRC (Rockwell hardness)) and fine impact flexibility (higher than or equal to 40J / cm2) can be used for manufacturing wear resistant parts such as hammerheads of crushers, liners for ball mills and the like requiring high wear resistance.

Owner:天津职业大学

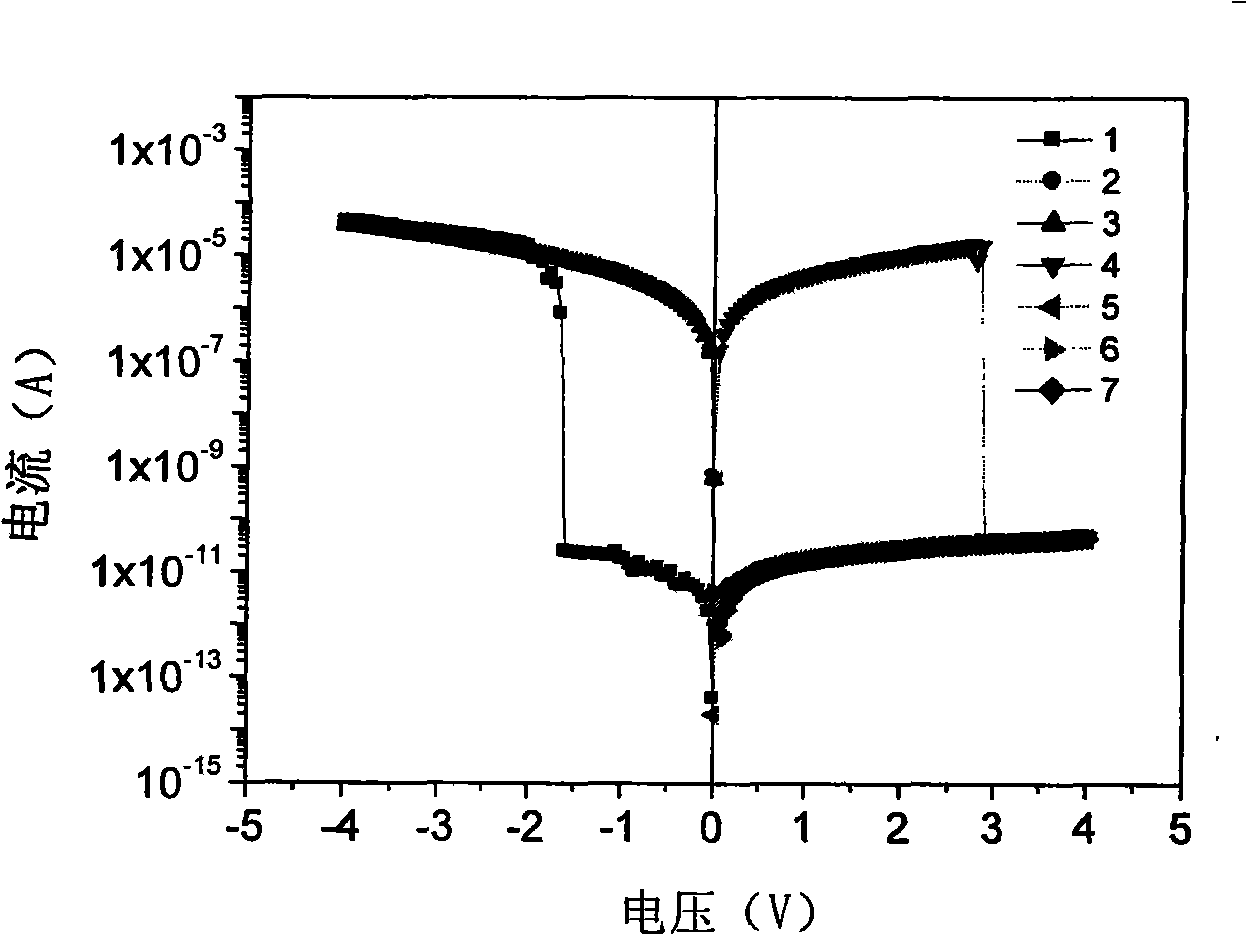

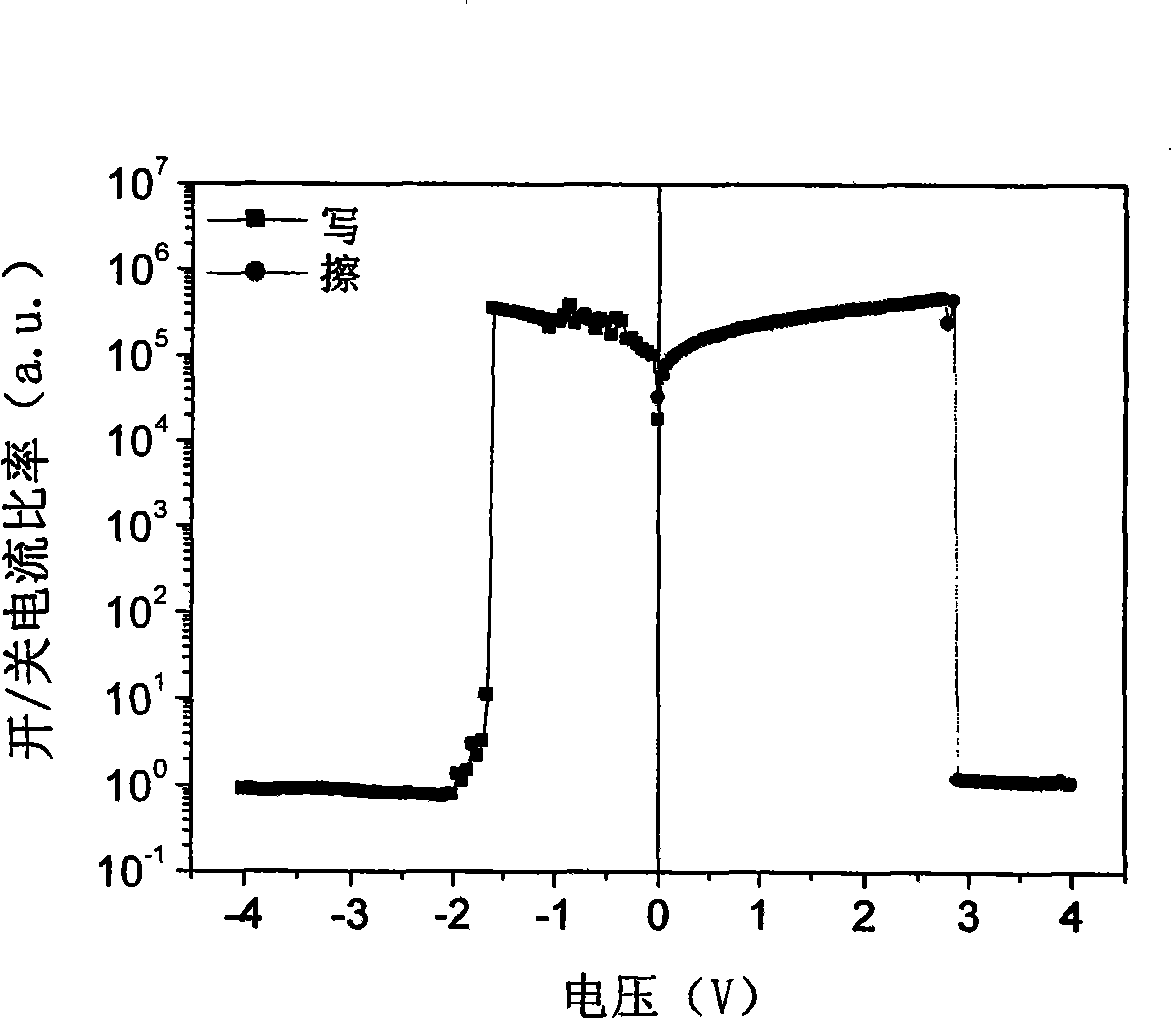

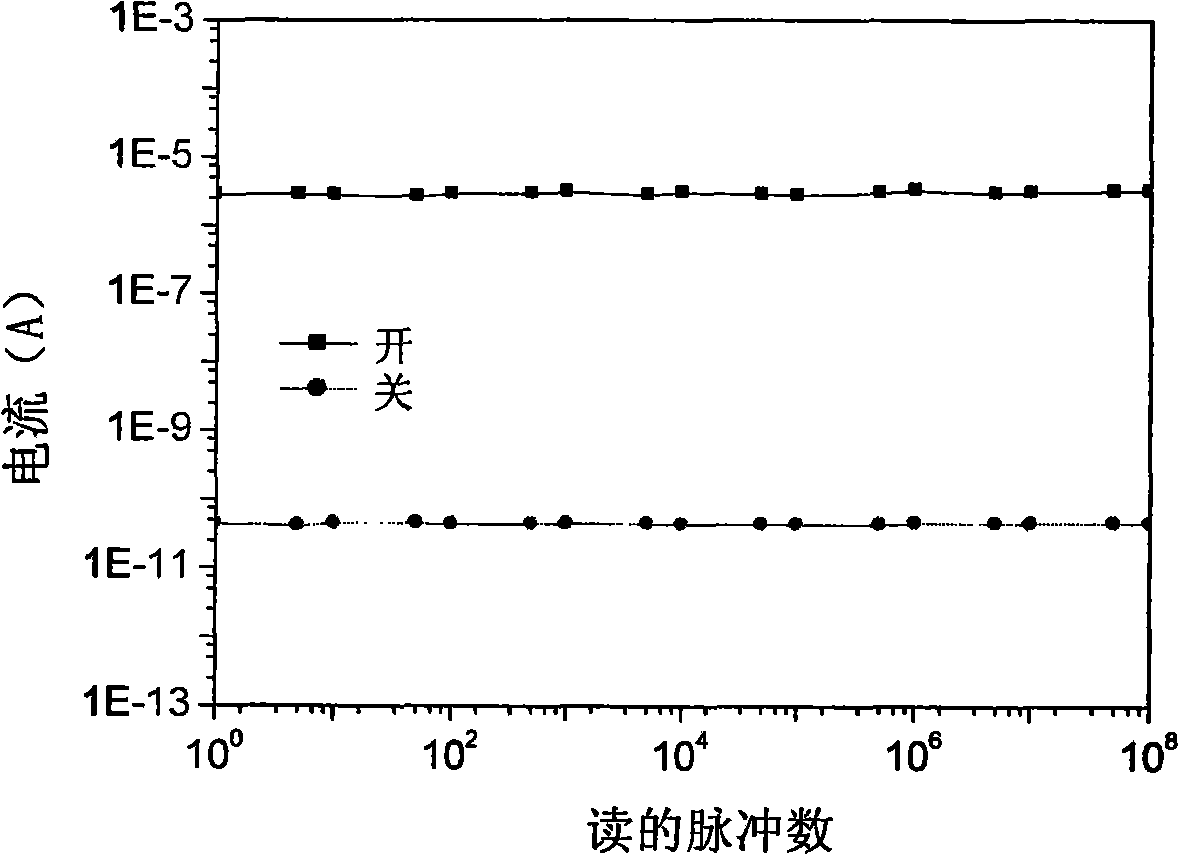

Conjugated polymer containing iridium complex and preparation of electrical storage device thereof

InactiveCN101280054AGood machinabilityReduce processing costsDigital storageLuminescent compositionsSolventPropanol

The preparation methods for conjugated polymer containing iridium complexes and the related electrical memory component of conjugated polymer comprise the following steps: ITO conductive glass is washed by water, acetone and 2-propanol respectively in ultrasonic wave; the conjugated polymer containing iridium complexes in the patent claim 1 is used as memory material to prepare polymer solution with concentration of 0.1-500mg / mL; the polymer solution is then spin-coated on the ITO conductive glass; the solvent is removed under vacuum to obtain the polymer membrane. Gold, aluminum, copper and other metal are used as the upper electrode after vapor plating, while the ITO conductive glass is used as the lower electrode; the polymer material is used as memory medium to prepare and obtain the monolayer polymer memory component. Such polymer contains donating electron units (fluorine unit and others) and withdrawing electron units (iridium complexes) at the same time. The materials presented in the invention can form membrane through spin-coating, without the problem of uneven disperse of heavy metal complexes; based on needs, other functional groups can be introduced into the polymer molecular chain to be expected to prepare highly-efficient and stable memory components.

Owner:NANJING UNIV OF POSTS & TELECOMM

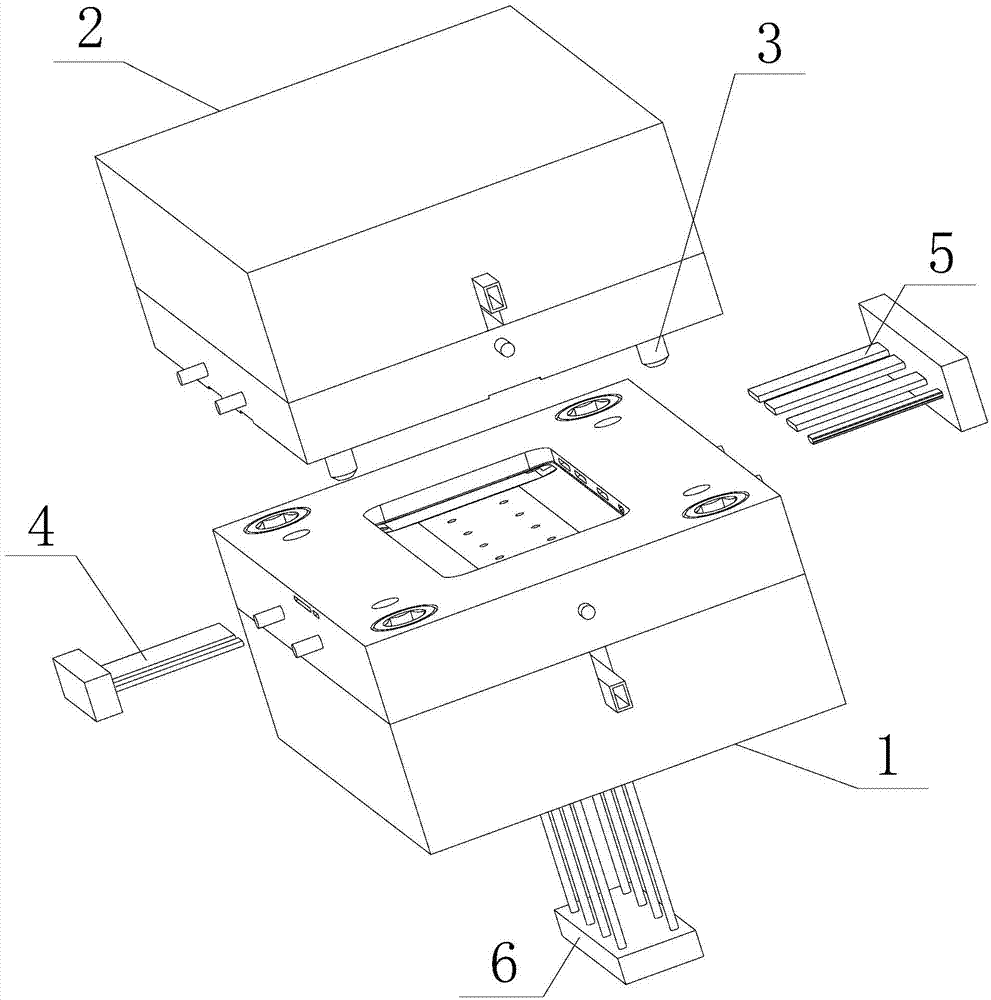

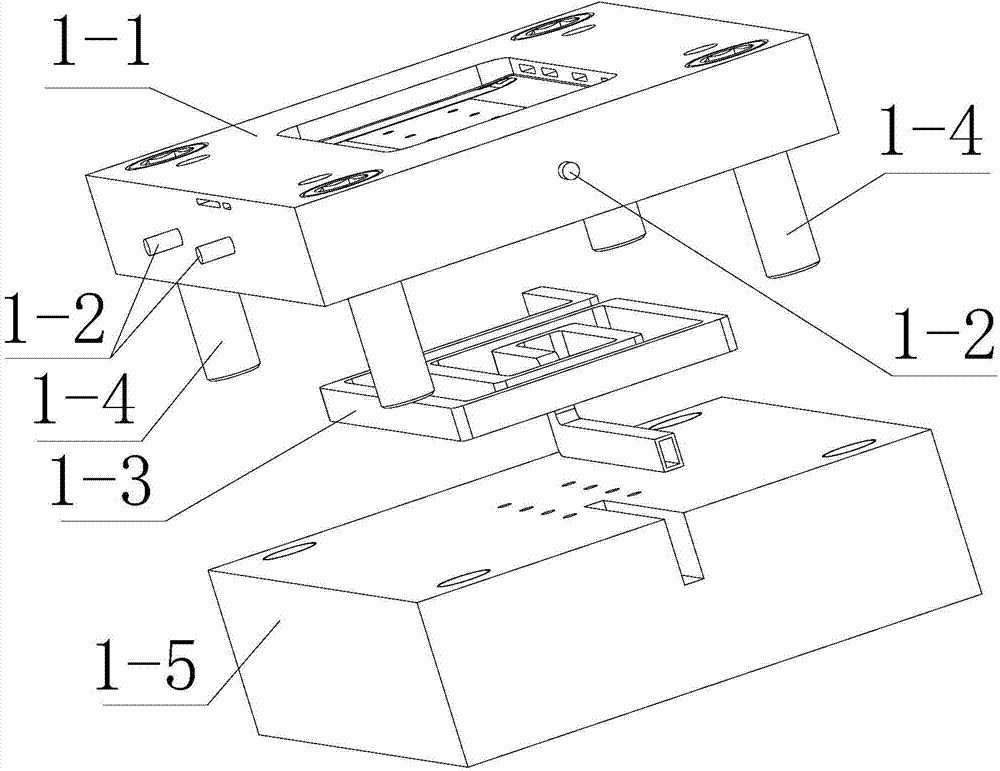

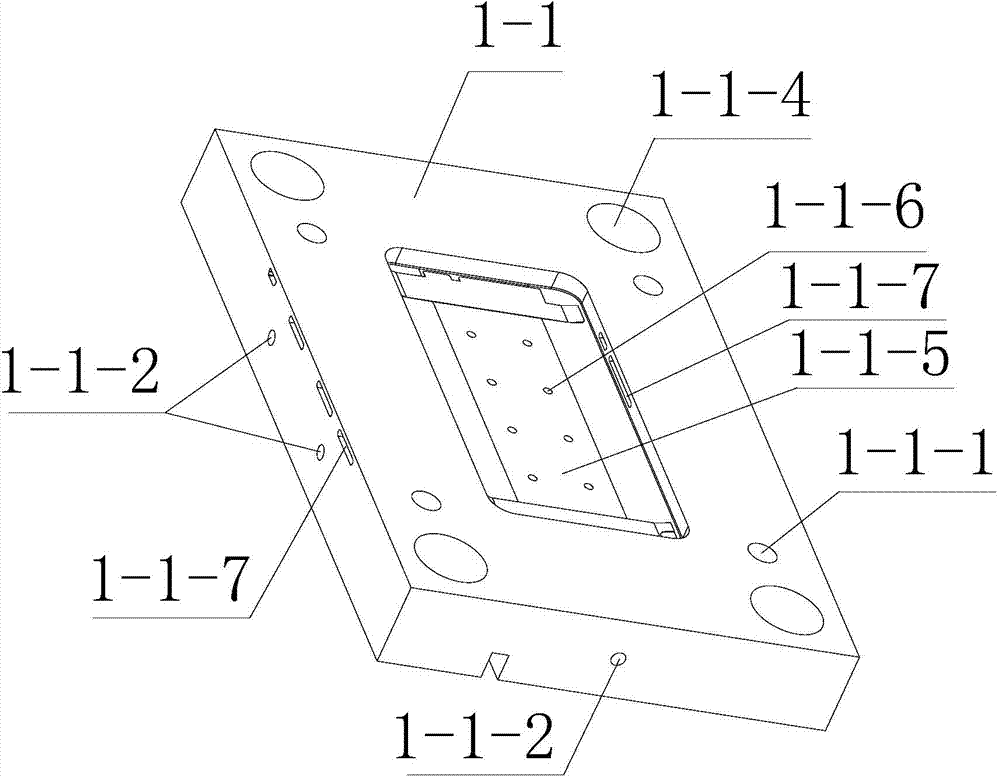

Strain-induced semi-solid forming process and die for magnalium mobile phone shells

InactiveCN104493429AHigh specific strengthGood machinabilityExtrusion diesAgricultural engineeringSemi solid

Disclosed is a strain-induced semi-solid forming process and die for magnalium mobile phone shells. The process includes cutting a magnalium plate with certain compressive deformation into the suitable size, performing semi-solid heat preservation on the cut magnalium plate, and then putting the obtained magnalium plate with semi-solid characteristics into the preheated die for extrusion forming. The die comprises a mobile phone shell bottom cavity die device, the upper side of the mobile phone shell bottom cavity die device is connected with a mobile phone shell top terrace die device, die guide rods are assembled on the mobile phone shell top terrace die device, a left mobile phone shell core-pulling slider is connected to the left of the mobile phone shell bottom cavity die device, a right mobile phone shell core-pulling slider is connected to the right of the mobile phone shell bottom cavity die device, and mobile phone shell ejection mechanism is connected to the lower side of the same. The magnalium mobile phone shells with superior performance can be produced, and the process and the die have the advantages of simple process, high forming speed, low cost and the like.

Owner:XI AN JIAOTONG UNIV

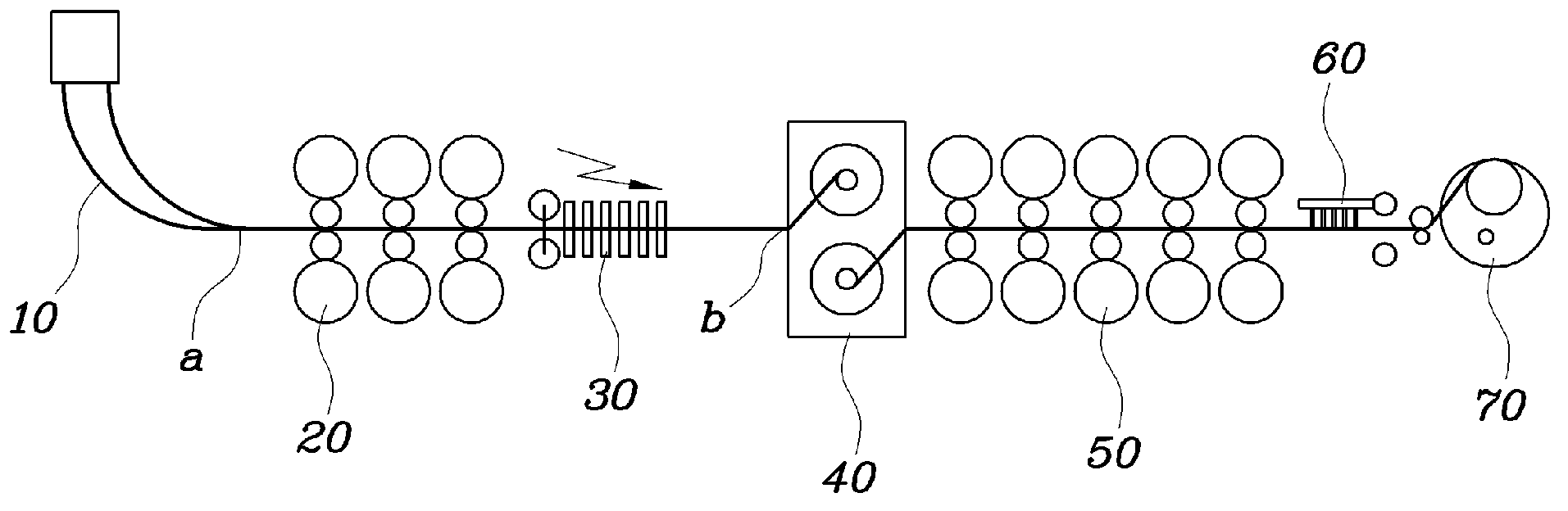

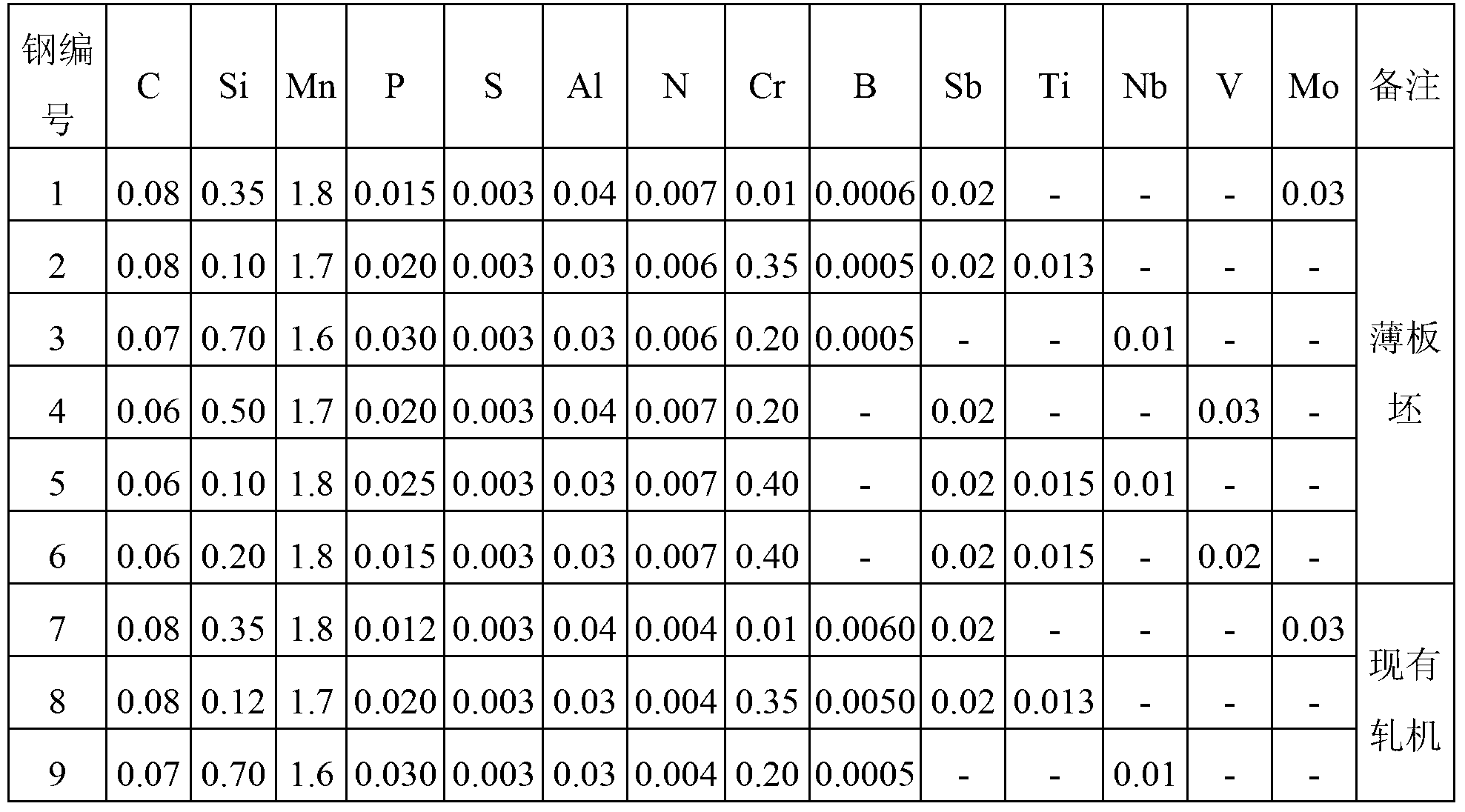

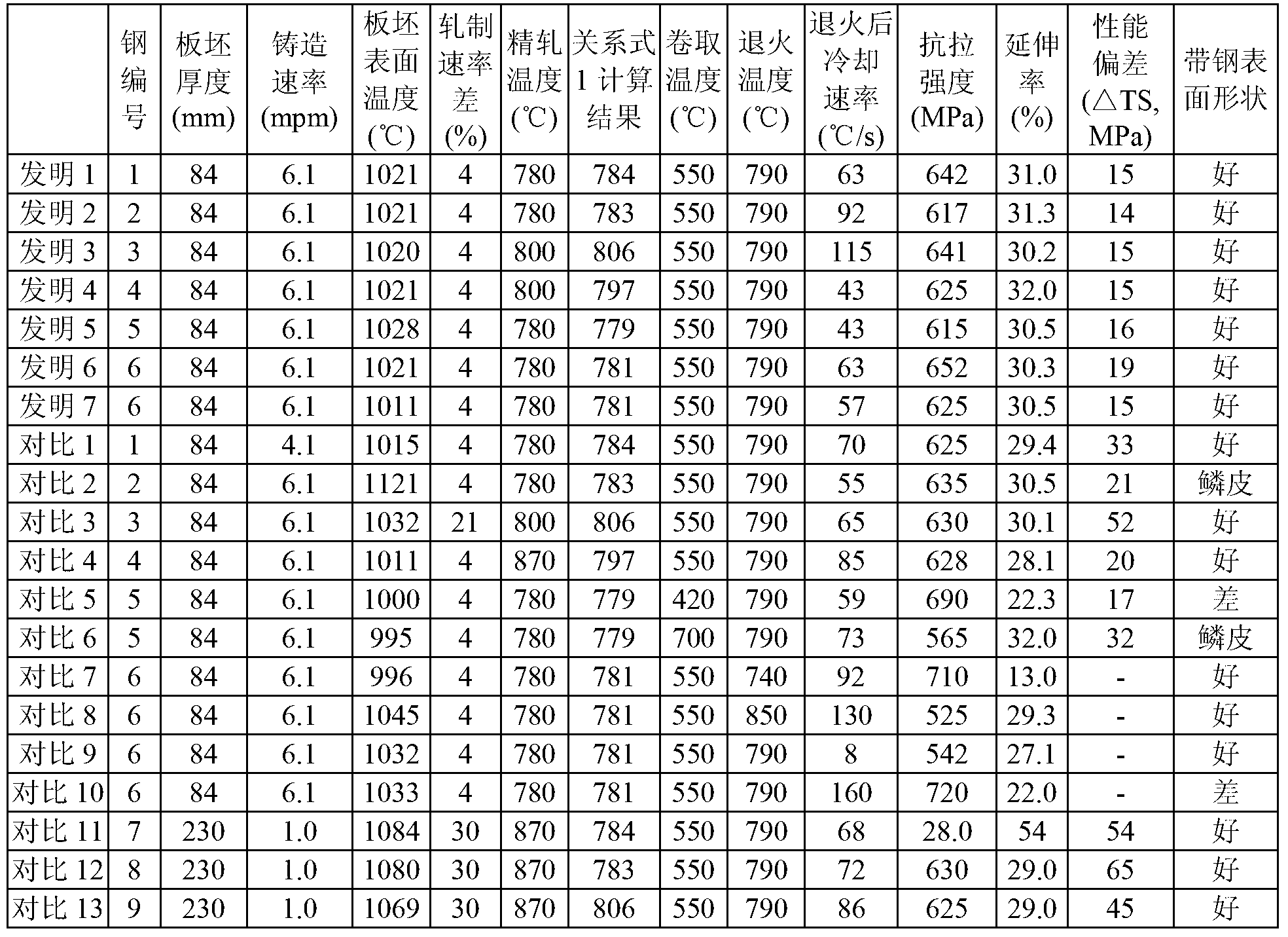

Method for manufacturing high-strength cold-rolled/hot-rolled DP steel having a tensile strength grade of 590 MPa and excellent workability, as well as little deviation in the material properties thereof

InactiveCN103237906AGood machinabilityReduce biasFurnace typesMetal rolling arrangementsThin sheetHigh intensity

An object of the present invention is to provide a method for manufacturing high-strength cold-rolled / hot-rolled DP steel having a tensile strength grade of 590 MPa and excellent workability, as well as little deviation in the material properties thereof, wherein said excellent workability can be achieved using thin-slab continuous casting, and deviations in the material properties in the widthwise and lengthwise directions of a strip can be significantly reduced.

Owner:POHANG IRON & STEEL CO LTD

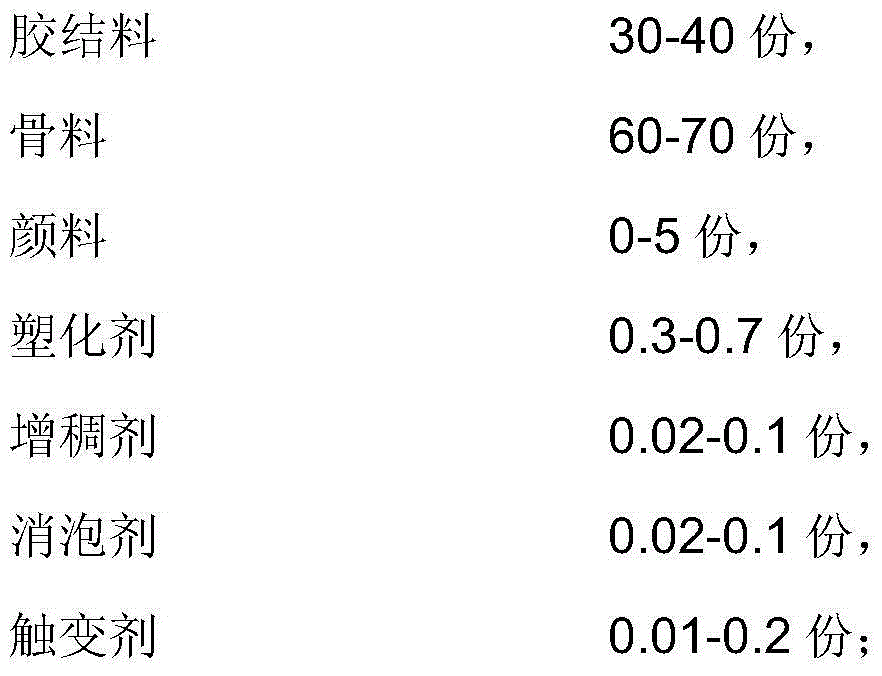

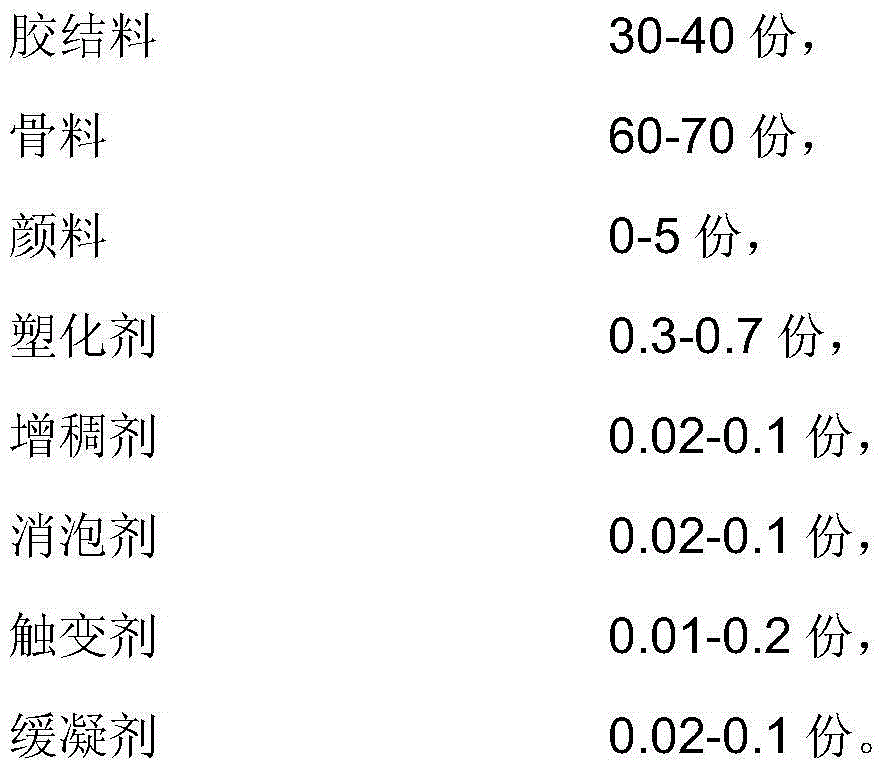

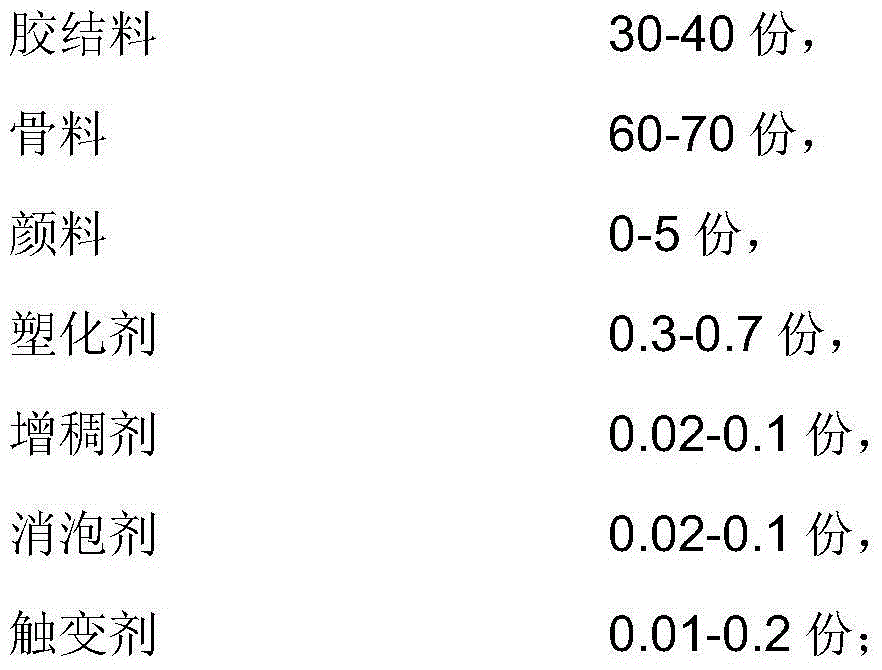

Nature-imitated travertine as well as composition and manufacture method thereof

The invention provides a nature-imitated travertine composition. The nature-imitated travertine composition comprises amphoteric metal, main color paste, and one or more auxiliary pastes, and comprises the following constituents: cementing material, aggregate, pigment, water and a chemical additive. The invention further provides a nature-imitated travertine prepared by the composition through the following preparation method. The invention further provides the preparation method of the nature-imitated travertine. The preparation method comprises the following steps: firstly, preparing the main color paste, secondly, preparing the auxiliary pastes, adding the amphoteric metal, and stirring, so as to obtain a mixture, thirdly, adding the main color paste to the mixture, and stirring, so as to obtain a paste body, fourthly, casting the paste body into a die, leveling the paste body, so as to obtain artificial travertine square stock, and fifthly, performing maintenance and secondary processing on the artificial travertine square stock, so as to obtain the nature-imitated travertine. Compared with the prior art, the nature-imitated travertine obtained has the characteristics of unique method, easy availability of materials, low cost, lifelike textures and good decorative effect, and is a high-grade external wall decoration material.

Owner:SHANGHAI APE STONE

White noble metal alloy

The present invention relates to a white noble metal alloy combination, which comprises at least one of platinum and palladium which alloying with gold, siller and one or more choice additive alloy elements. Specifically speaking, in a specific way of implementing, the present invention discloses a white noble metal alloy combination which can be used to manufacture headgear and other products. In addition, the present invention also relates to a method for manufacturing finished products with such white noble metal alloy combination.

Owner:何文金

Microcrystalline jade and preparation method thereof

The invention provides a microcrystalline jade and a preparation method thereof, wherein the microcrystalline jade comprises main components, auxiliary components and coloring agent, wherein the main components comprise SiO2, CaO, R2O, F<-> and Al2O3 and account for 80.0-95.0 percent of the total weight; the auxiliary components comprise ZnO, MgO, TiO2, B2O3, P2O5 and Cl<->, and account for 5.0-15.0 percent of the total weight; and the coloring agent accounts for 0-5.0 percent of the total weight. The preparation method of the microcrystalline jade comprises the following steps of: first, evenly mixing raw materials of the chemical composition of the microcrystalline jade; then, putting the raw materials into a high temperature smelting furnace to be molten into glass liquid, and molding the glass liquid into a basic glass plate or a special section block by a molding technique; and finally, carrying out crystallization or annealing heat treatment on the basic glass plate or the special section block, and forming the microcrystalline jade. The microcrystalline jade is in a semi-transparent wax-lipid shape, is fine and smooth in texture as well as crystal clear, can be widely used as a decorating plate, and can be also processed into artware, tableware or sanitary ware.

Owner:香港福山实业有限公司

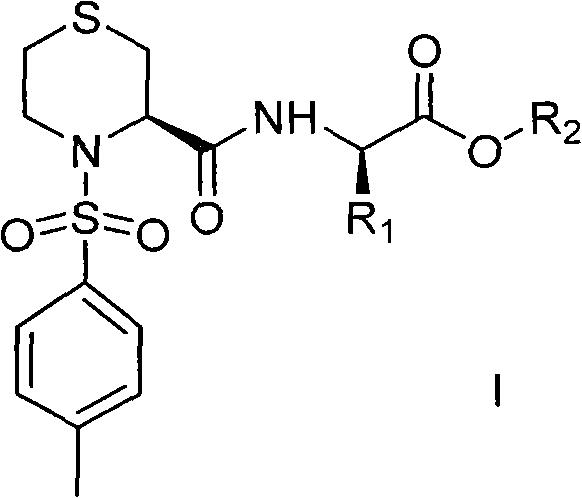

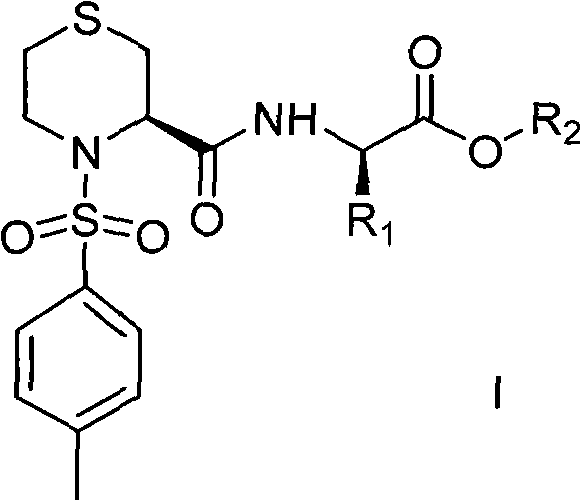

Thiazine amide derivative and application thereof in preparation of medicines for preventing and controlling neurodegenerative diseases

ActiveCN102675244AImprove bioavailabilityGood machinabilityNervous disorderOrganic chemistrySolventDisease

The invention relates to a compound shown as the formula I, pharmaceutically acceptable salts of the compound, and / or solvates and / or hydrates of the compound. The invention also relates to a preparation method of the compound, a medicinal composition containing the compound, and application of the compound in preparation of medicines for preventing and controlling neurodegenerative diseases. In the formula I, R1 is hydrogen or linear-chain or branched paraffin containing 1-4 carbon atoms, and R2 is linear-chain or branched paraffin containing 1-4 carbon atoms, or linear-chain or branched paraffin which contain 1-4 carbon atoms and is substituted by benzene ring.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

PVC cable sheath material and preparation method thereof

InactiveCN107383706AGood machinabilityEasy and effortless cuttingPlastic/resin/waxes insulatorsPerliteHexavalent chromium

The invention discloses a PVC cable sheath material which is prepared from the following raw materials in parts by weight: 50-60 parts of PVC resin, 5-10 parts of natural rubber, 5-10 parts of butadiene rubber, 5-10 parts of polyethylene, 1-4 parts of fumed silica, 1-2 parts of glass fiber, 2-5 parts of graphene, 1.5-3 parts of anti-impact modifier, 5-10 parts of nano titanium dioxide powder, 1-4 parts of thermal stabilizer, 4-8 parts of plasticizer, 4-6 parts of accelerator, 2-5 parts of barium oxide, 3-5 parts of coupling agent, 4-8 parts of calcium oxide, 5-15 parts of perlite, 5-10 parts of lubricant, 3-6 parts of diammonium phosphate and 3-6 parts of zinc borate. According to the cable material disclosed by the invention, PVC resin is adopted as the main ingredient which is accompanied by other accessories; the cable sheath material does not contain such heavy metals harmful to human and environment as lead, cadmium, hexavalent chromium and mercury, meets the standard requirements on environmental protection and is safe and environmentally friendly and thus has high wear resistance and mechanical processing property and is convenient and easy to cut; moreover, the diamagnetic property, the waterproof property, the high-temperature resistance and the chemical corrosion resistance are improved over common cable material; the biodegradation cycle is short, the production cost is low, the economic value is high, and the prospect is very broad.

Owner:安徽天大铜业有限公司

Low specific resistance glass and preparation thereof

The invention relates to a method for preparing low-resistivity glass, belongs to special glass technology and in particular relates to the technical field of detector glass. The method is characterized in that the low-resistivity glass is silicate-type low-resistivity glass mainly with SiO2 and phosphate-type low-resistivity glass mainly with P2O5; and the other compositions are Fe2O3, Al2O3, Na2O, MnO2 or BaO, Bi2O3 and CaO. The invention also provides a corresponding preparation method. At room temperature, the invention is the low-resistivity glass with volume resistivity of 10 omega.cm in order of magnitude. The particle counting rate of an MRPC detector made from the glass can reach 20kHz / cm; and the detector is widely applied to certain large-scale physical experiments.

Owner:TSINGHUA UNIV +1

Preparation method of cylinder body of oil feed pump

The invention discloses a preparation method of a cylinder body of an oil feed pump. The method comprises steps of producing metal melt which comprises the following chemical components by weight percent: 0.086 % <= C <= 0.150 %, trace <= Si <= 1.40 %, trace <= Mn <= 1.30 % trace <= P <= 0.033 %, trace <= S <= 0.0260 %, 0.11-0.22 % of Li, 11.50 % <= Cr <= 13.50 %, trace <= B <= 0.0018 %, and the balance being iron and unavoidable impurities. The preparation method of the cylinder body and cover of the oil feed pump provided by the invention is simple in molding technology, low in manufacture cost and high in product strength.

Owner:安徽蓝博旺机械集团精密液压件有限责任公司

Completely biodegradable bamboo microstructure unit and polylactic acid biomass composite and preparation method thereof

The invention relates to a completely biodegradable bamboo microstructure unit and polylactic acid biomass composite which is a biomass composite with high content of bamboo material which is prepared by using bamboo material and biodegradable polylactic acid as raw materials and adopting high-speed mixing method. The preparation method comprises the following steps: chipping or cutting bamboo material or bamboo material processing residues in other modes to prepare bamboo chips or bamboo sections; performing flaking separation, fiber pulping or other technologies to bamboo chips or bamboo sections to prepare bamboo microstructure units; weighting bamboo microstructure units and polylactic acid in a weight ratio of 60:40 to 90:10; then performing high-speed mixing in a high-speed mixer to heat materials through friction heating and external heating, mixing with bamboo microstructure units evenly; and using the prepared mixture of bamboo microstructure units and polylactic acid to prepare various high-intensity board or moulded products under the hot pressing technological conditions that the temperature is 150-200 DEG C, the pressure is 1-6MPa and the time is 5-30min.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

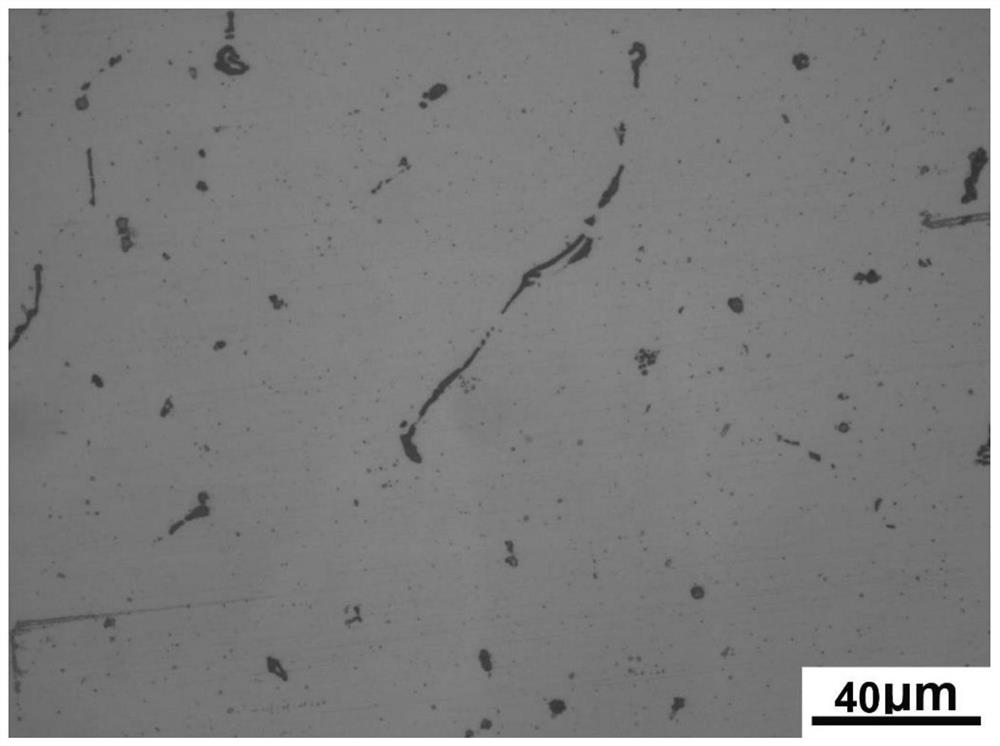

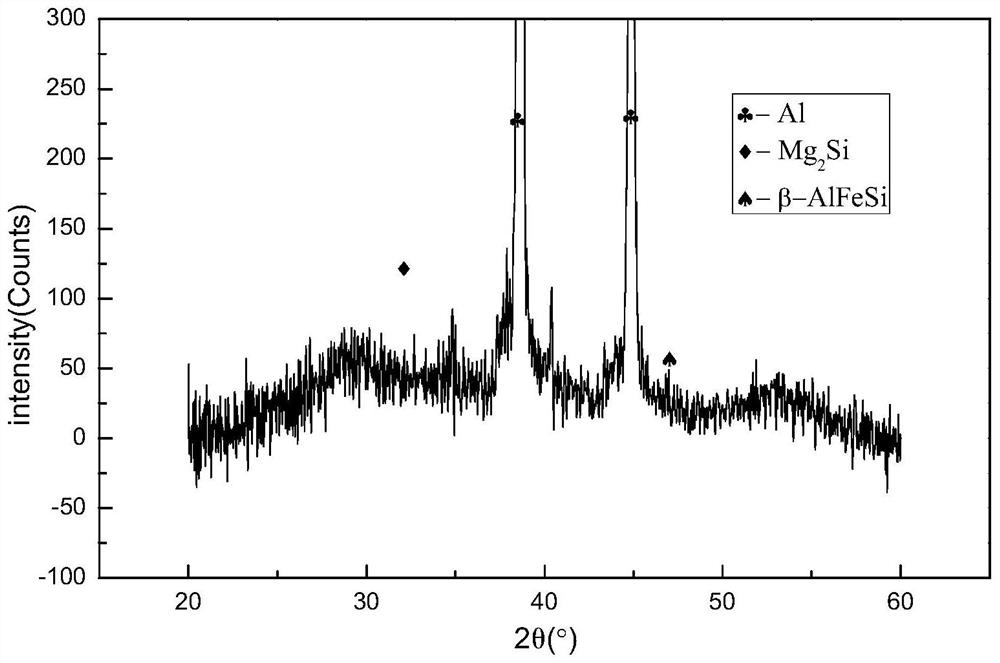

High-strength and high-conductivity wrought aluminum alloy and preparation method thereof

ActiveCN113528902AGood machinabilityImproved morphology and distributionTemperature control deviceMetal rolling arrangementsAlloy elementElectrically conductive

The invention discloses a high-strength and high-conductivity wrought aluminum alloy. The wrought aluminum alloy comprises the following alloy elements: 0.3 to 0.8% of Mg; 0.2 to 0.6% of Si; 0.1 to 0.3% of Fe; 0.2 to 0.5% of Ni; 0.05 to 0.3% of Cu; 0.05 to 0.2% of B; and the balance of Al. The invention further discloses a preparation method of the high-strength and high-conductivity wrought aluminum alloy. The preparation method comprises the specific steps of pure aluminum melting, basic alloying treatment, melt modification treatment, sub-rapid solidification, rolling plastic forming and solid solution-ageing heat treatment, the preparation process is simple, the cost is low, and the comprehensive performance is excellent. According to the method, the Ni element is adopted to improve the morphology and distribution of an iron-rich phase, precipitation of an Mg2Si phase is promoted, and the strengthening effect of the Mg2Si phase is achieved. According to the high-strength and high-conductivity wrought aluminum alloy, the defects are eliminated and the structure is improved by adopting sub-rapid solidification, rolling treatment and solid solution-ageing treatment, the mechanical property and the conductivity of the alloy are improved, the problem that the conductivity and the mechanical property in the alloy are mutually impeded is solved, and the high-strength and high-conductivity wrought aluminum alloy is obtained.

Owner:广东华昌集团有限公司 +1

Heat-resistant, cast ferritic steel having excellent machinability and exhaust member made thereof

ActiveUS20150275344A1Good machinabilityExcellent heat resistance characteristicExhaust apparatusSilencing apparatusMachinabilityMaterials science

Owner:HITACHI METALS LTD

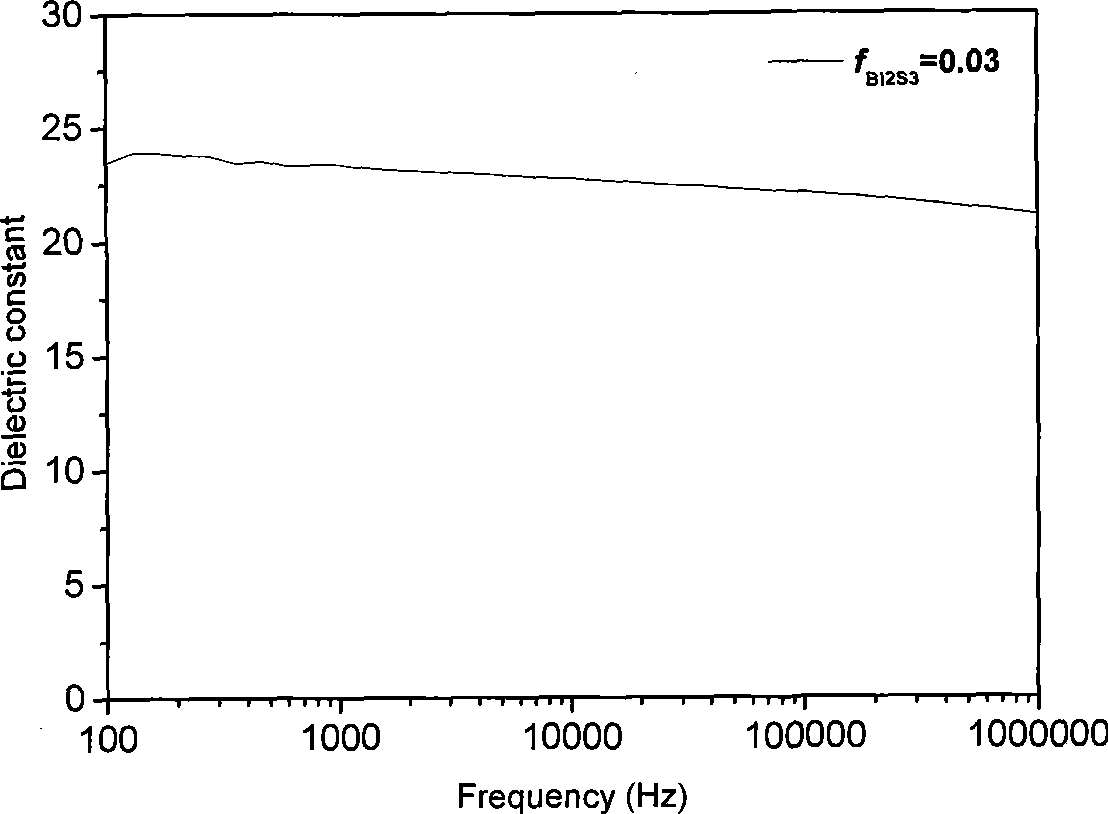

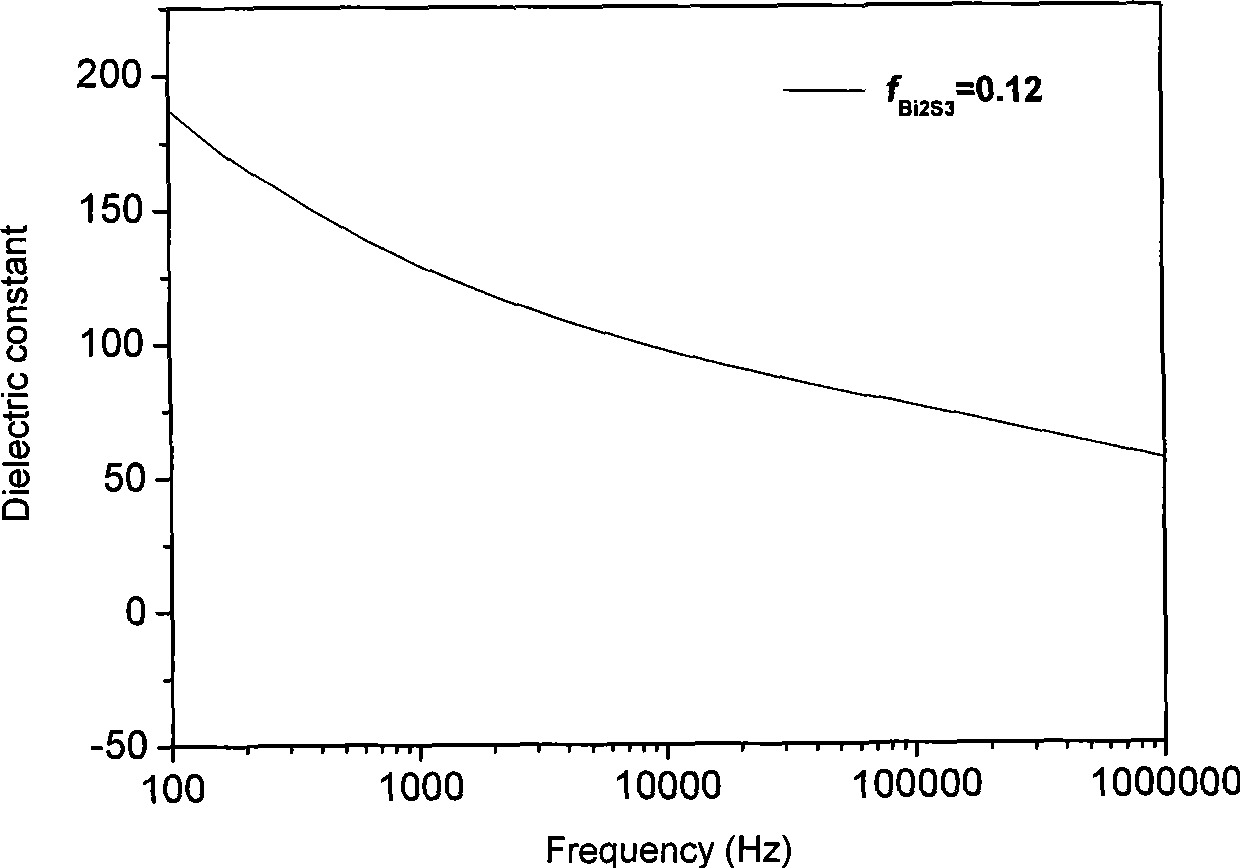

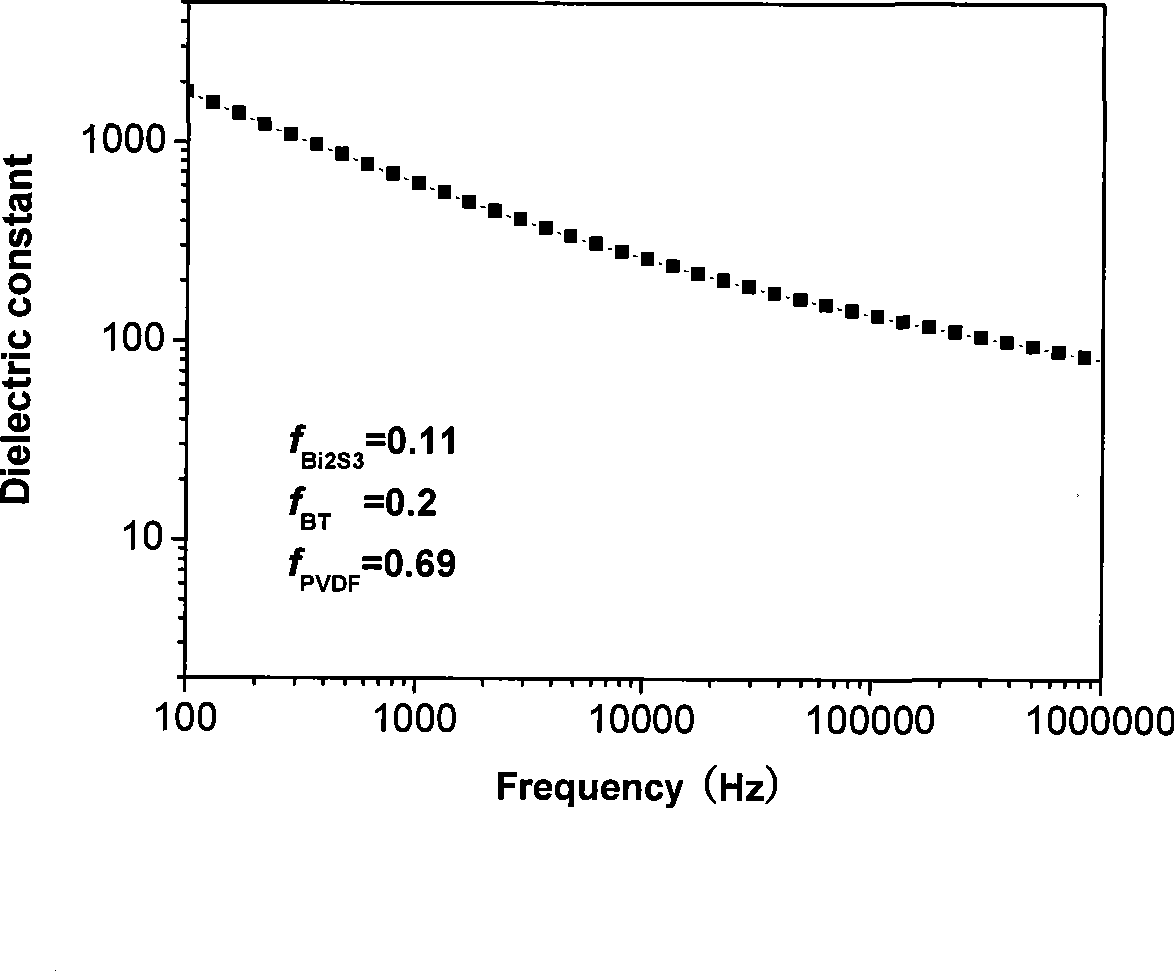

Bi2S3-BaTiO3/PVDF composite material and preparation method thereof

InactiveCN101423644ALow inorganic contentGood machinabilityFixed capacitor dielectricDimethyl formamideThree-phase

The invention provides a Bi2S3-BaTiO3 / PVDF composite material and a preparation method thereof. The material consists of Bi2S3 nano rod, BaTiO3 and PVDF, wherein the volume fraction of the BaTiO3 is 20 percent, the volume fraction of the Bi2S3 is between 3 and 12 percent, and the balance is the PVDF. The preparation method for the material comprises the following steps: raw materials are weighed according to the volume percentage; the weighed PVDF is added into 30 to 40 milliliters of N, N-dimethyl formamide (DMF), and fully dissolved to form a transparent solution; the weighed BaTiO3 and weighed Bi2S3 powder are added into the solution and uniformly dispersed in the solution through supersonic vibration, so as to prepare stable suspension; the suspension is poured into a surface vessel which is then placed into an oven for drying the suspension, and a dielectric film is obtained; and hot pressing is performed, and the dielectric performance is tested. The preparation method prepares the three-phase Bi2S3-BaTiO3 / PVDF composite material with superhigh dielectric performance by the simple mixing method, and has the characteristics of simple operation, low cost, good mechanical properties, suitability for industrial production, etc.

Owner:BEIHANG UNIV

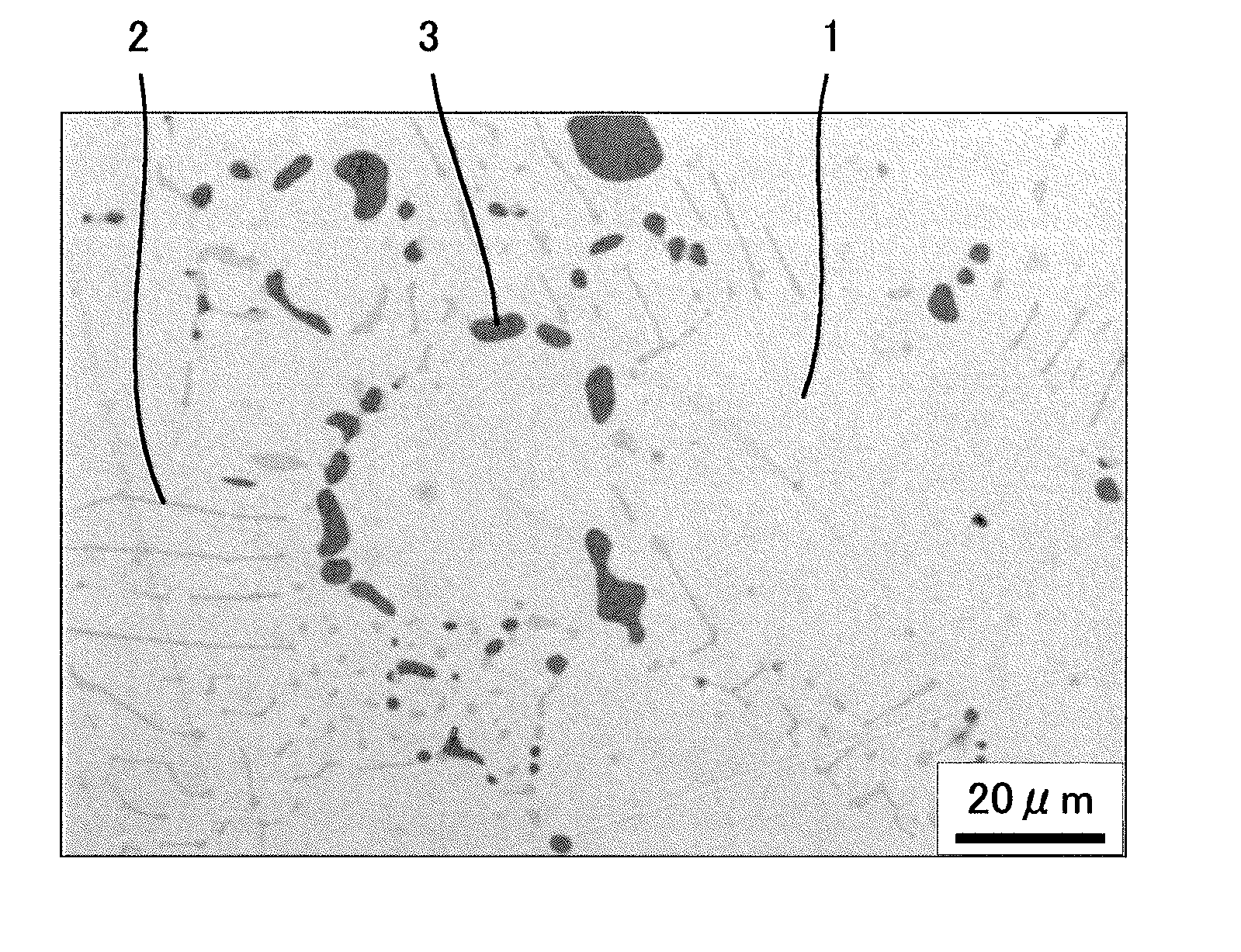

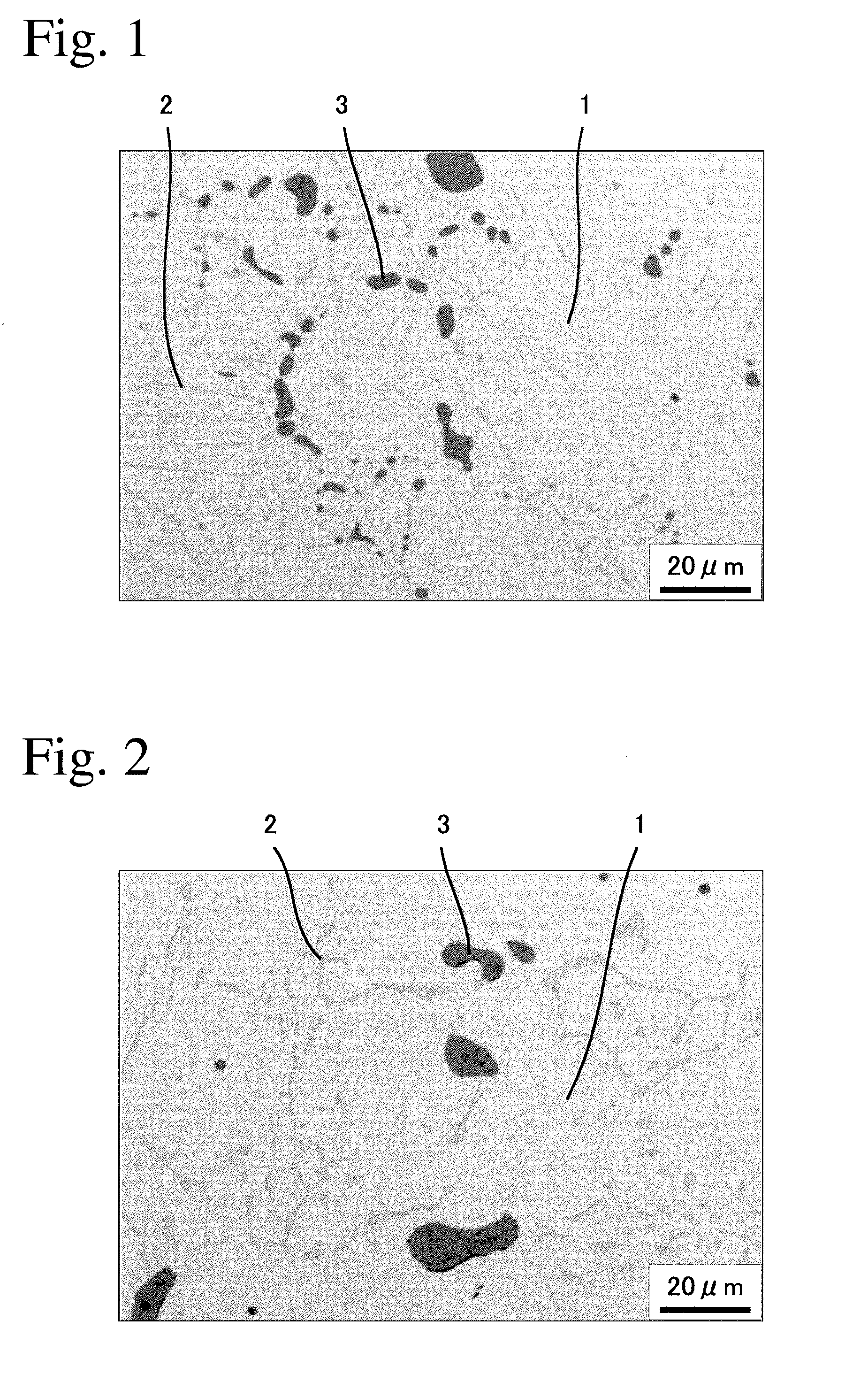

Material for dental prosthesis, block body for making dental prosthesis, and dental prosthesis

PendingUS20180133113A1Good machinabilityNecessary strengthImpression capsArtificial teethDental prosthesisDentures

In order to provide a material for forming a dental prosthesis which does not require further heat treatment after machining and can improve cutting ability even after obtaining necessary strength, the material for a dental prosthesis comprises 60.0 mass % or more and 80.0 mass % or less of SiO2, 10.0 mass % or more and 20.0 mass % or less of Li2O, and 5.1 mass % or more and 10.0 mass % or less of Al2O3.

Owner:GC CORP

Waterproof fabric material and preparation method thereof

ActiveCN104674379AGood machinabilityImprove mechanical strengthConjugated cellulose/protein artificial filamentsMelt spinning methodsDiethyl phthalateNatural fiber

The invention discloses a waterproof fabric material and a preparation method thereof. The waterproof fabric material is prepared from components in parts by weight as follows: 65-80 parts of polylactic acid, 28-38 parts of natural fiber, 2-4 parts of polyethylene wax, 1-2 parts of diethyl phthalate, 0.2-1.8 parts of sodium sulfate, 0.5-1.2 parts of octadecyl bis-quaternary ammonium salt and 0.5-1 part of polyvinylpyrrolidone. The invention further provides a preparation method of the waterproof fabric material. The method comprises steps as follows: the components are added to a shearing machine to be mixed, an acidity regulator is added to adjust the pH, the mixture is uniformly mixed, melt at the temperature of 195-220 DEG C under the airtight condition, subjected to spinning at the spinning speed of 1,500-2,000 m / min and subjected to drawing treatment, and the waterproof fabric material is prepared.

Owner:SUZHOU AILIFANG CLOTHES CO LTD

Low-nickel leadless free-cutting cupronickel and preparation method thereof

The invention discloses low-nickel leadless free-cutting cupronickel which comprises the following components by weight percentage: 72.0-77.35% of cuprum, 1-5% of nickel, 12% of manganese, 8% of zinc, 1% of aluminum, 0.65-2.0% of magnesium and calcium, and the balance of unavoidable impurities. According to the cupronickel, alloy elements such as the calcium and magnesium substitute lead, so that the cutting properties of the cupronickel can be improved, a content of the nickel in the cupronickel is reduced, the production cost of the cupronickel is lowered, and requirements on the mechanical cutting properties of the cupronickel, safety and environmental protection are met.

Owner:JIANGXI UNIV OF SCI & TECH

Floor adhesive and preparation method thereof

InactiveCN106085297AExcellent adhesive strength and nail holding powerGood machinabilityNon-macromolecular adhesive additivesAdhesiveMachinability

The present invention discloses a floor adhesive, comprising dimethylol propionic acid, N-methylmorpholine, PVC (polyvinyl chloride) and n-butanol having a weight ratio of (3-7):(1-2):(1-2):(1-2). The invention has the advantages that natural biological materials are used to completely replace traditional aldehydic adhesives, no formaldehyde is released, and the adhesive is adapted to the manufacturing process of particle boards and has excellent adhesive strength and nail-holding power and good machinability.

Owner:柳州市五源科技有限公司

Diopside reinforced mica-based machinable microcrystalline glass and preparation method thereof

The invention relates to machinable mica microcrystalline glass with high hardness and high toughness and a preparation method thereof. The mica microcrystalline glass is composed of the following ingredients by the mass percentage: 45% to 65% of SiO2, 16% to 26% of MgO, 4% to 10% of CaF2, 8% to 14% of Na2O and K2O and 2% to 9% of Li2O and BaO. The complex-phase reinforced mica microcrystalline glass is prepared by an integral crystallization method, and is characterized in that compared with glass prepared by a sintering method, the mica microcrystalline glass prepared by the integral crystallization method is compact in structure, high in crystallinity and suitable for large-scale continuous production. The hardness of the prepared microcrystalline glass can reach 5.51-6.94 GPa, and thefracture toughness of the prepared microcrystalline glass can reach 1.4-2.5 MPa*m<1 / 2>. By controlling the precipitation of mica and diopside crystals, the hardness and toughness of the microcrystalline glass can be practically improved on the premise of not influencing the processability of the mica microcrystalline glass, and the mica microcrystalline glass has wide application prospects in thefields of dental materials, building and ornament materials, mobile terminal equipment materials and the like.

Owner:UNIV OF JINAN

Method for preparing flaky AlON/ZrC composite material

InactiveCN103664176AGood machinabilityGood antioxidant propertiesMechanical properties of carbon nanotubesMachinability

A method for preparing a flaky AlON / ZrC composite material is characterized in that flaky AlON powder and ZrC ceramic powder are uniformly mixed with the weight ratio of (10-50):100 and fired in argon gas atmosphere in a hot-pressing manner for 30-180 min at 1,600-2,000 DEG C to manufacture the flaky AlON / ZrC composite material. The flaky AlON / ZrC composite material prepared by the method has machinability, the flaky AlON and ZrC are uniform in phase distribution and controllable in content, and the machinability, the mechanical property and the thermal property are favorable.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com