Strain-induced semi-solid forming process and die for magnalium mobile phone shells

A technology for semi-solid forming and mobile phone casings, applied in metal extrusion dies, etc., can solve the problems of short service life, poor wear resistance, corrosion resistance, high maintenance costs, etc., and achieve good surface quality, high material utilization, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

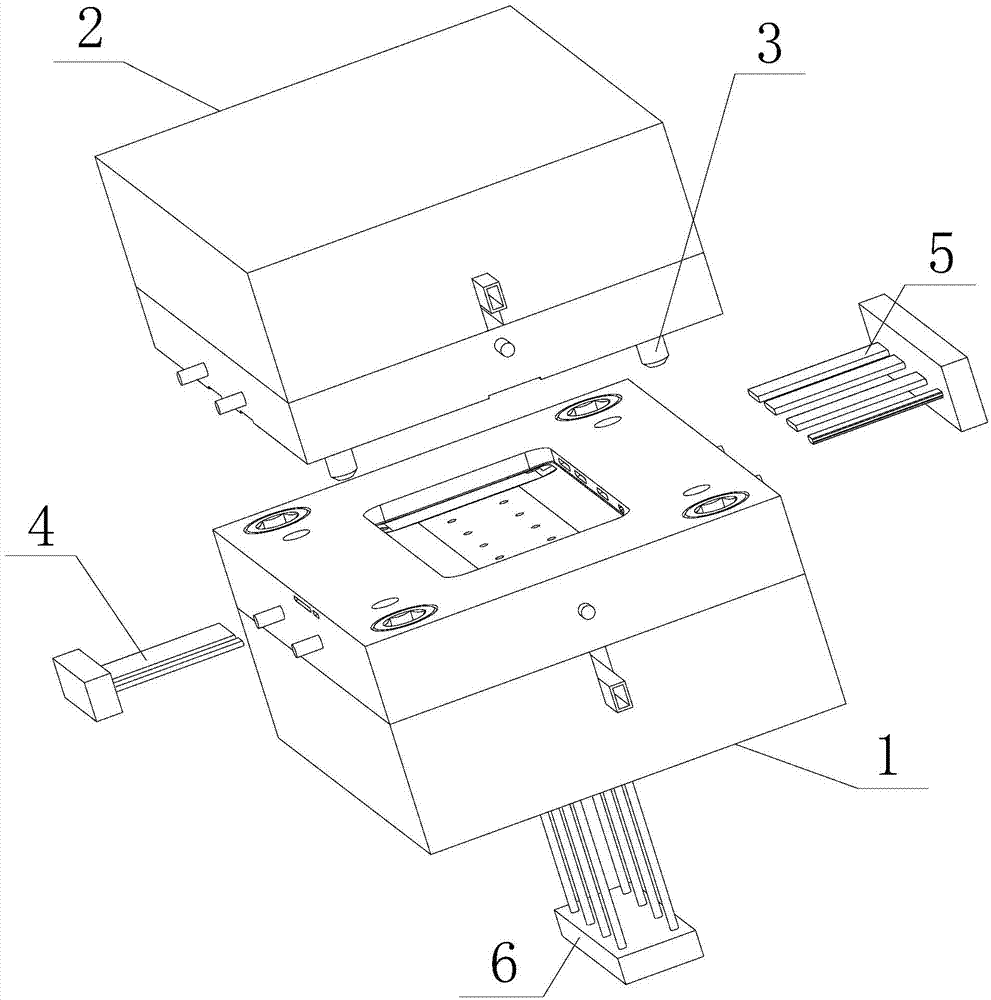

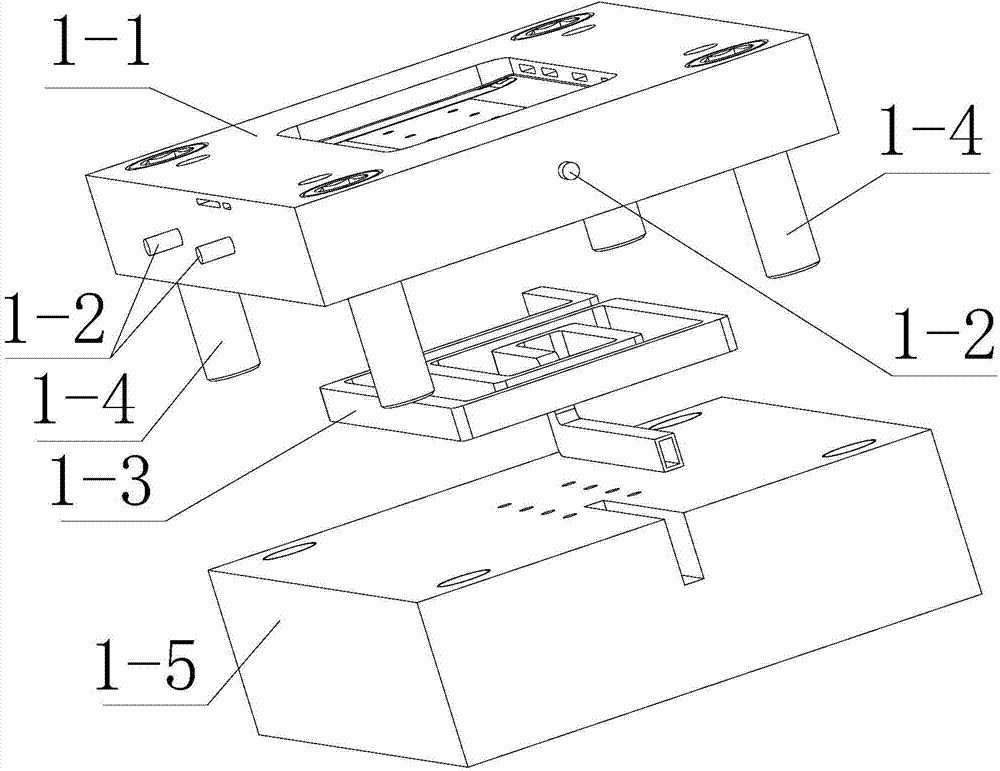

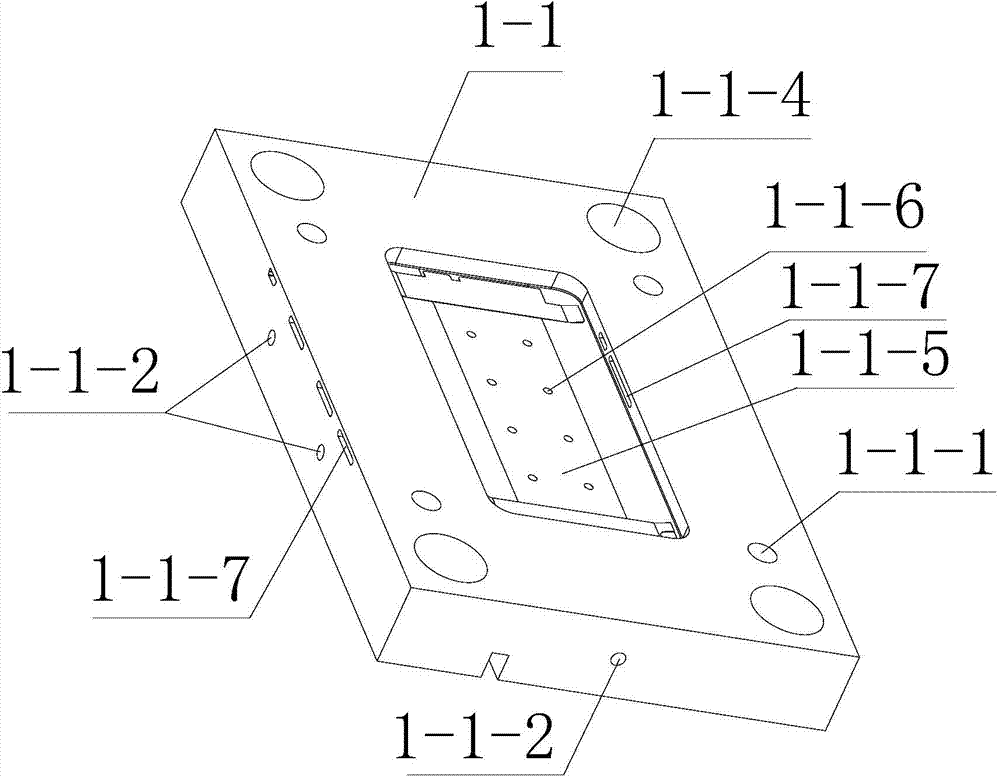

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] A strain-induced semi-solid forming process for a magnesium-aluminum alloy mobile phone casing, including the following steps:

[0036] 1) Compression deformation: the prepared 5mm thick magnesium-aluminum alloy sheet is rolled on a rolling mill, extruded on a press or forged at a high speed to produce 20-40% compression deformation;

[0037] 2) Cutting: cutting the compressed magnesium-aluminum alloy plate obtained in step 1) into a suitable size to meet the requirements of forming the mobile phone shell;

[0038] 3) Semi-solid heat preservation: put the magnesium-aluminum alloy plate obtained in step 2) into a resistance furnace or an intermediate frequency induction furnace for semi-solid heat preservation, wherein the heat preservation temperature is set within the semi-solid temperature range of the magnesium-aluminum alloy, and the heat preservation time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com