Patents

Literature

224 results about "Polychlorotrifluoroethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

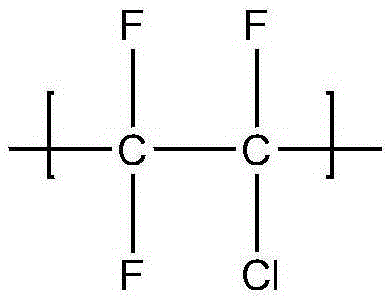

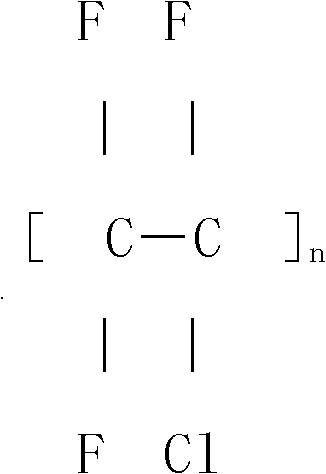

Polychlorotrifluoroethylene (PCTFE or PTFCE) is a thermoplastic chlorofluoropolymer with the molecular formula (CF₂CClF)ₙ, where n is the number of monomer units in the polymer molecule. It is similar to polytetrafluoroethene (PTFE), except that it is a homopolymer of the monomer chlorotrifluoroethylene (CTFE) instead of tetrafluoroethene. It has the lowest water vapor transmission rate of any plastic.

Compositions of ethylene/vinyl acetate copolymers for heat-sealable easy opening packaging

Disclosed are compositions comprising ethylene / vinyl acetate copolymers, tackifying resins and optionally polyolefins (for example, polyethylene and polypropylene) that provide strong, tight hermetic heat seals with an easily peelable opening feature to fluoropolymers such as polychlorotrifluoroethylene. Also disclosed are multilayer structures and packages comprising these compositions.

Owner:DOW GLOBAL TECH LLC

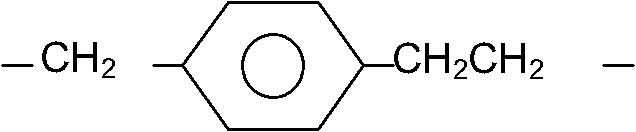

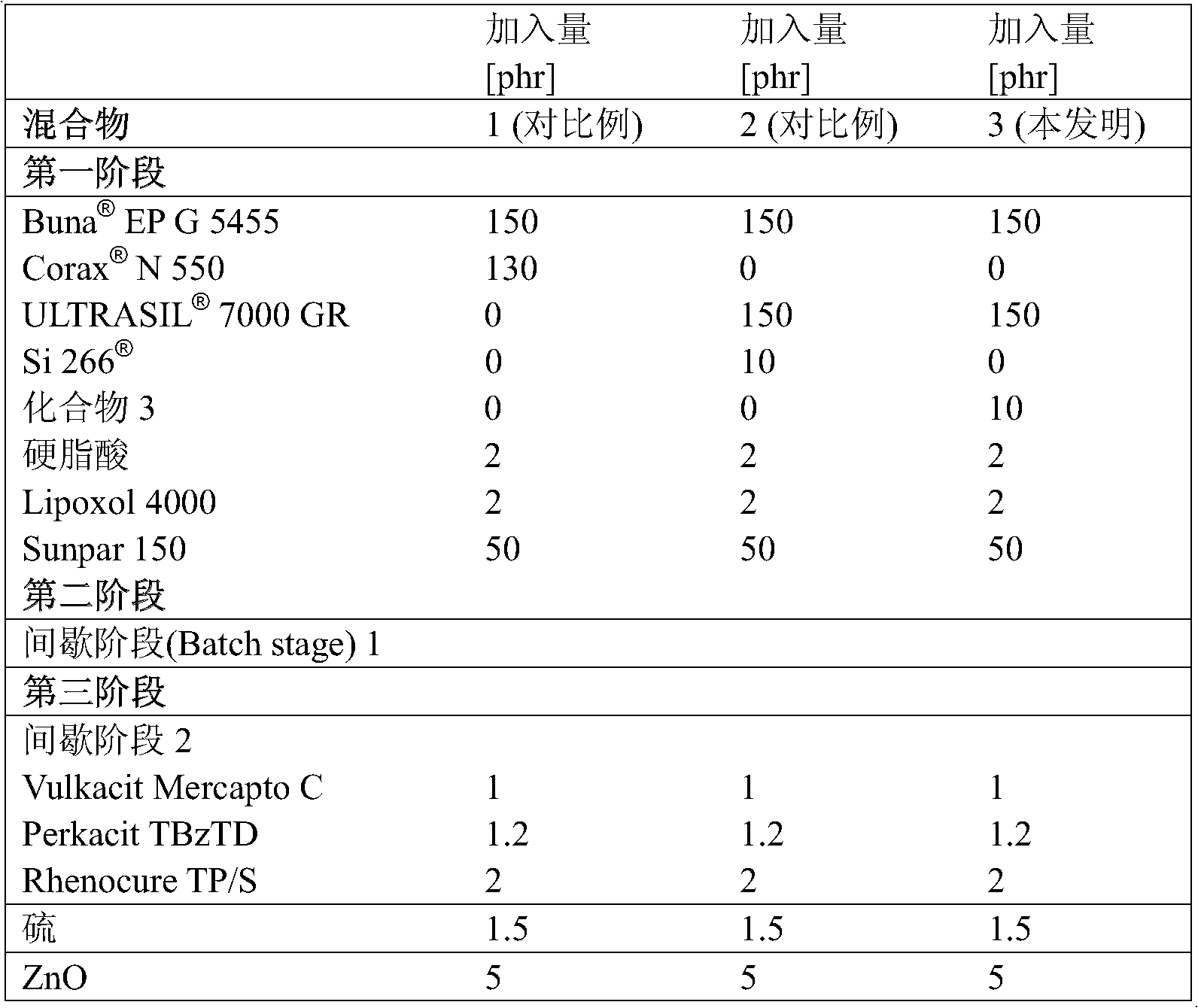

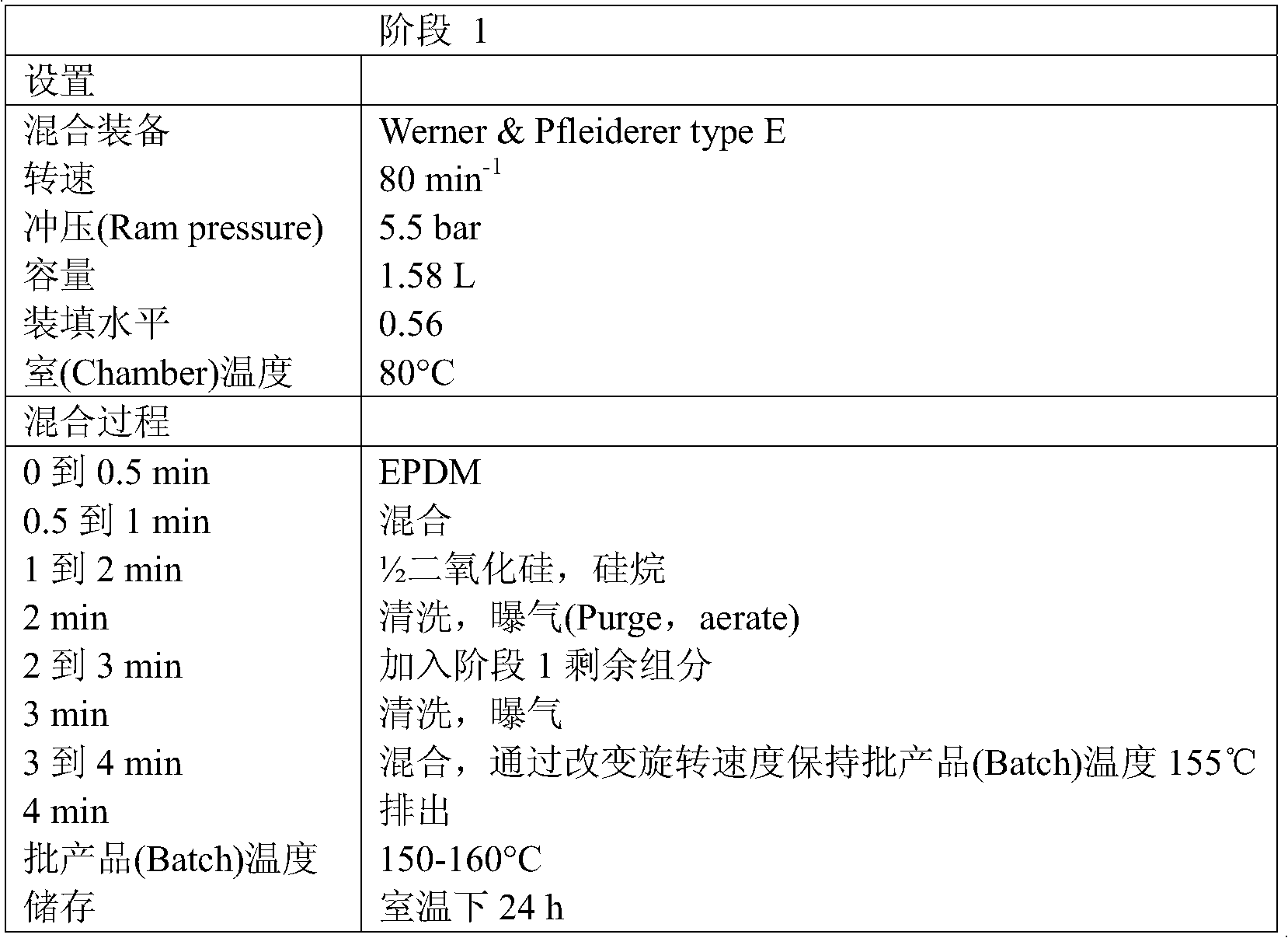

Rubber mixtures

ActiveCN102731915AHysteresis loss is smallImproved Dynamic BehaviorThin material handlingPolyesterPolymer science

A rubber mixture, comprising (A) at least one rubber selected from the group of ethylene-propylene-diene copolymer (EPDM), ethylene-propylene copolymer (EPM), chloroprene rubber (CR), chloropolyethylene (CM), chloro-isobutene-isoprene (chlorobutyl) rubber (CIIR), chlorosulfonyl polyethylene (CSM), etylene-vinyl acetate copolymer (EAM), alkyl acrylate copolymer (ACM), polyester polyurethan (AU), polyether polyurethane (EU), bromo-isobutene-isoprene (bromobutyl)rubber (BIIR), polychlorotrifluoroethylene (CFM), isobutene-isoprene rubber (butyl rubber, IIR), isobutene rubber (IM), polyisoprene (IR), thermoplastic polyester polyurethane (YAU), thermoplastic polyether polyurethane (YEU), silicone rubber with methyl groups on the polymer chain (MQ), hydrogenated acrylonitrile-butadiene rubber (HNBR), acrylonitrile-butadiene rubber (NBR) or carboxylated acrylonitrile-butadiene rubber (XNBR), (B) at least one oxidic filler, and (C) at least one silicon containing azodicarbamide of the general formula I (R 1 ) 3-a (R 2 ) a Si-R I -NH-C(O) -N=N-C (O)-NH-R I -Si(R 1 ) 3-a (R 2 ) a (I) . The rubber mixture is produced by mixing at least one rubber, at least one oxidic filler, and at least one silicon containing azodicarbamide of the general formula I. It may be used for moldings.

Owner:EVONIK OPERATIONS GMBH

Catalyst for tert-butyl alcohol cleavage reaction and preparation method thereof

ActiveCN103611572AIncreased intermolecular attractionNot easy to fall offOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsChlorinated polyvinyl chloridePolystyrene

The invention provides a catalyst for tert-butyl alcohol cleavage reaction, which is prepared by the following steps: by using a melt granulation process, blending and melting polystyrene, chlorinated polyvinyl chloride, polytrifluorochloroethylene and polyvinylidene fluoride, and granulating; and carrying out sulfonation reaction on the granulation product in the fixed bed and sulfur trioxide to obtain the catalyst. When being used for tert-butyl alcohol cleavage reaction, the catalyst has the advantages of high selectivity for technique reaction, fewer side reactions and low shedding tendency of sulfo-group under high-temperature conditions. The invention also provides a preparation method of the catalyst.

Owner:南通灵润医用新材料有限公司

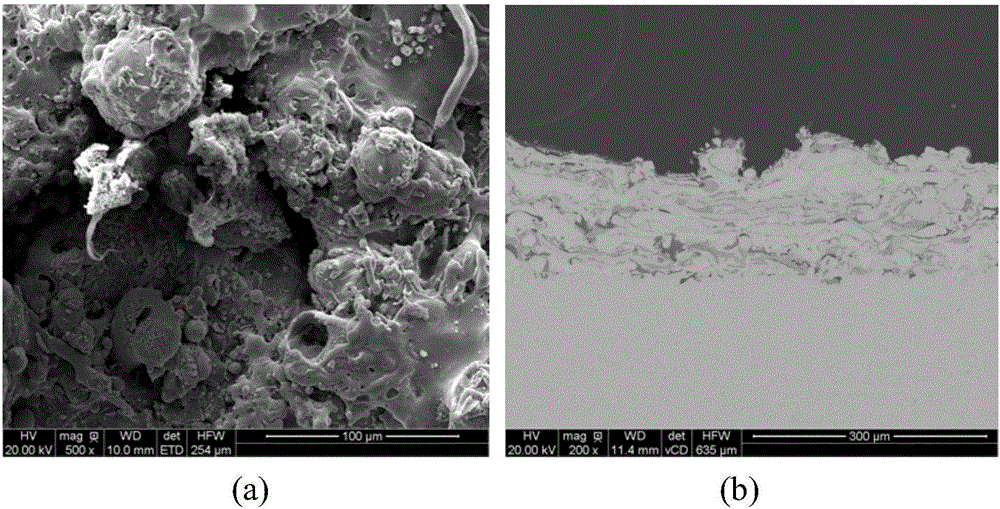

Dust removal and waste gas decomposition double-effect filter material and preparation method thereof

ActiveCN102512878AHigh catalytic activityImprove permeabilitySynthetic resin layered productsDispersed particle separationFiberDecomposition

The invention discloses a dust removal and waste gas decomposition double-effect filter material and a preparation method thereof. The filter material comprises a raw felt, catalyst powder and a coating. The filter material utilizes the raw felt as a carrier, the catalyst powder is adhered to the inside of the raw felt, and the coating is coated on the surface of the raw felt and is of a polytrifluorochloroethylene microporous film structure. The catalyst powder is in a grade of nanometer or micron and is selected from one or more of vanadium pentoxide, vanadium trioxide, tungsten trioxide, titanium dioxide and manganese dioxide. By utilizing the preparation method to prepare the filter material, the process is simple and easy to implement, and processing costs of preparation of catalyticfibers, film covering and the like are reduced. In addition, compared with a polytetrafluoroethylene microporous film, running resistance is low, and difficulties in follow-up sewing, transportation,installation and the like of the filter material are reduced simultaneously.

Owner:南京际华三五二一环保科技有限公司

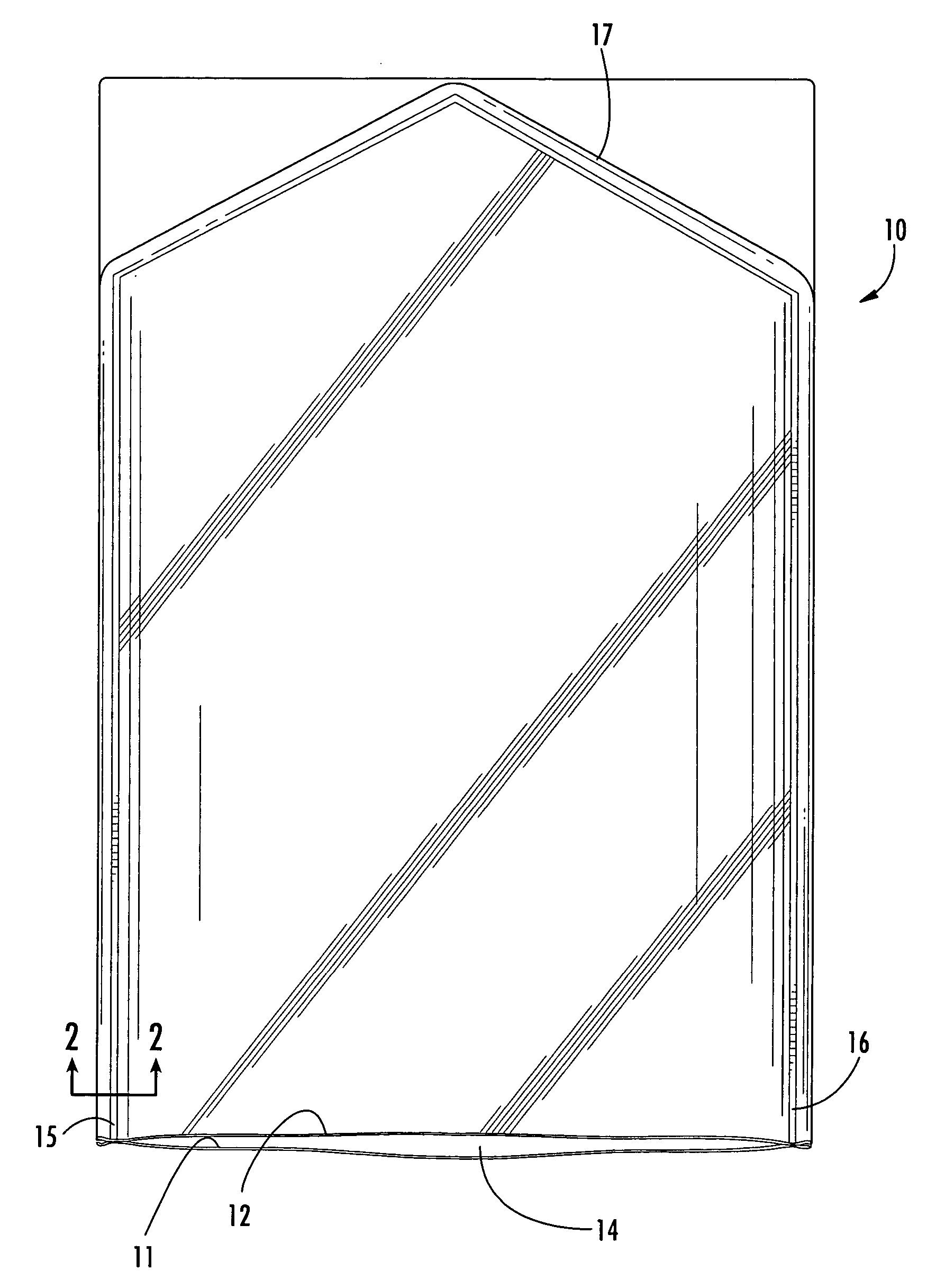

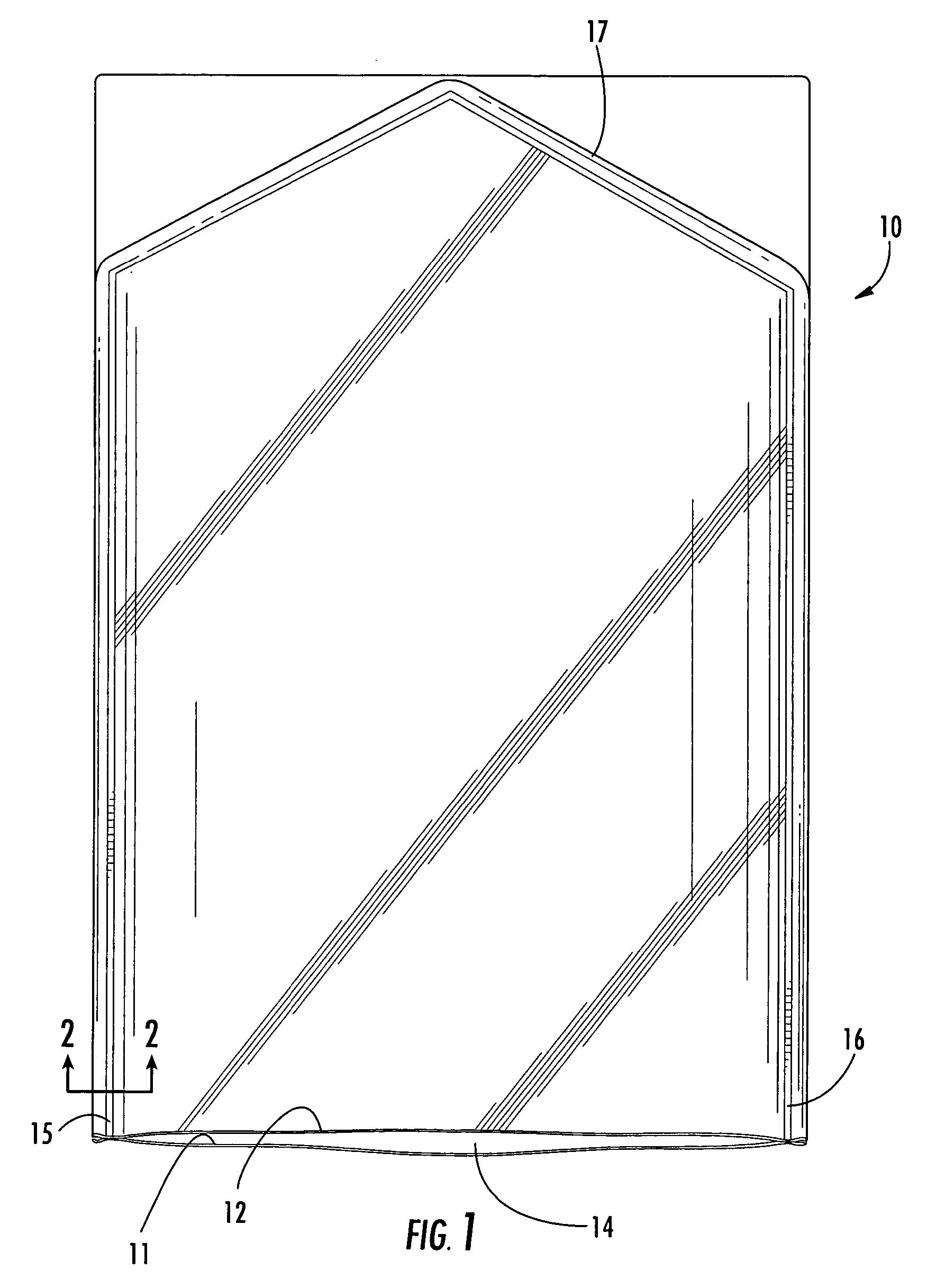

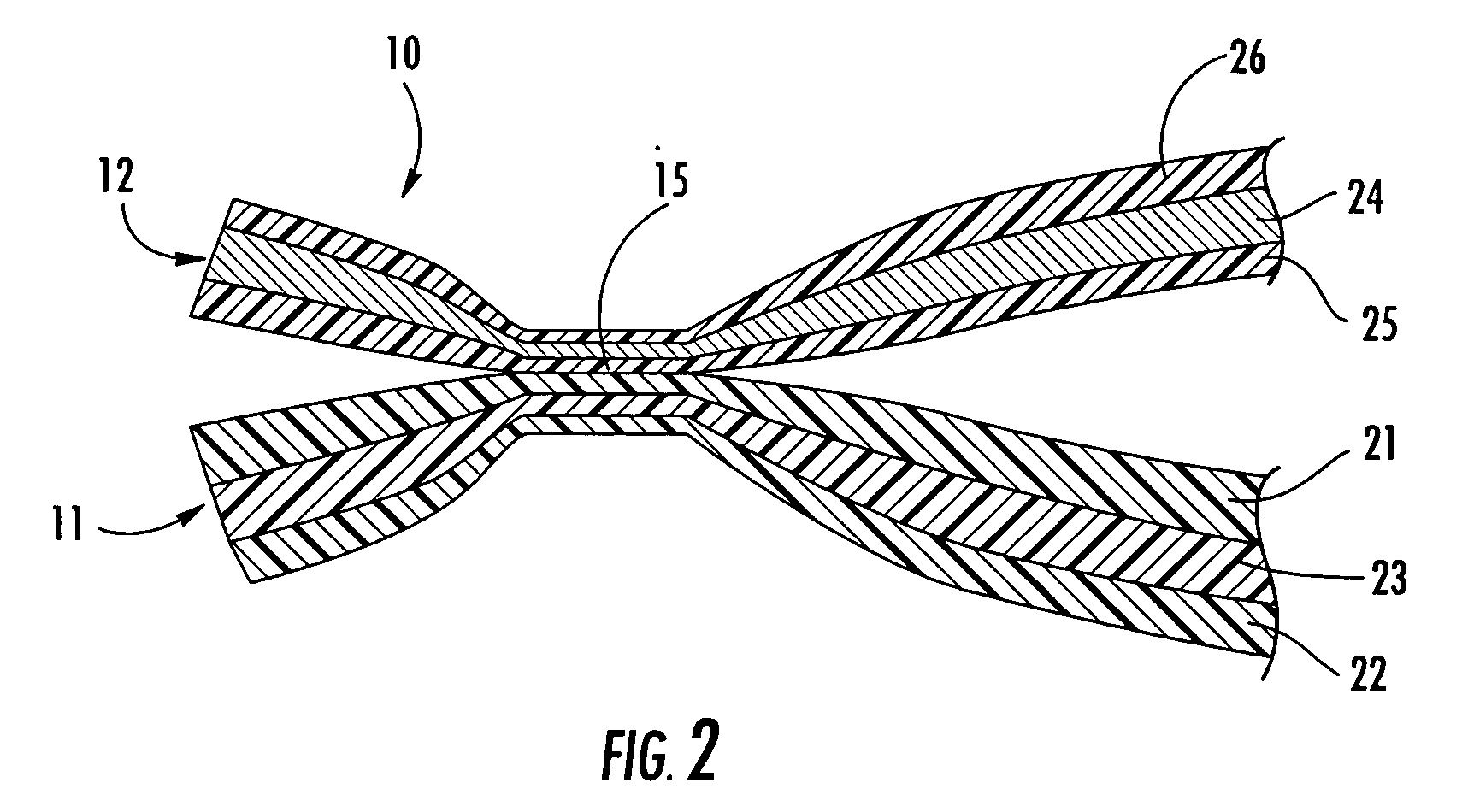

Transparent autoclavable bag

InactiveUS20060016708A1Improve barrier propertiesSufficient barrier propertySurgical furnitureDiagnosticsPolyethylene terephthalatePolyolefin

An autoclavable sterilization bag is provided having first and second composite film laminates positioned in opposing relation and sealed to one another to form a pouch. At least the first laminate comprises a heat sealable transparent thermoplastic polymer inner layer forming an inner surface of the laminate and a transparent polymer film outer layer. A transparent barrier layer is located between the inner and outer layers and formed of molecularly oriented polychlorotrifluoroethylene (PCTFE). In advantageous specific embodiments of the invention, the heat sealable transparent thermoplastic polymer inner layer is a polyolefin film, and the transparent polymer outer layer is a film selected from the group consisting of polyethylene terephthalate, nylon, polypropylene, polyethylene and cellophane.

Owner:AMCOR FLEXIBLES INC

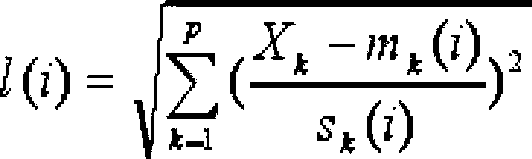

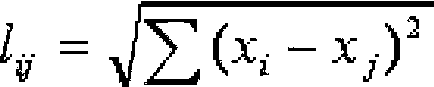

Method for determination of PCTFE content in PBX explosive by near infrared spectrum

ActiveCN103018195AImprove robustnessImprove accuracyColor/spectral properties measurementsPolymer-bonded explosiveRoot mean square

The invention discloses a method for determination of the polychlorotrifluoroethylene (PCTFE) content in a polymer-bonded explosive (PBX) by near infrared spectroscopy. The method includes the steps of: preparing and collecting 260 PBX samples, taking 180 samples of them as a calibration set for establishing a calibration model, taking the remaining 80 samples as a validation set for model validation, and acquiring the near infrared spectrum data of all the samples; using a standard method to determine the PCTFE content in the samples; subjecting the spectrum data of the validation set samples in the wave bands of 6102.0cm<-1>-5697.0cm<-1> and 4680.2cm<-1>-4242.9cm<-1> to a first order derivative treatment, correlating the treated spectrum data with the PCTFE content by a partial least squares method, and establishing the calibration model by cross validation; employing the calibration model to predetermine the PCTFE content of the validation set samples, and selecting an optimal model according to a minimum root mean squared error of prediction (RMSEP) of the validation set; and acquiring the near infrared spectrum data of the samples to be determined, and making use of the optimal model to obtain the PCTFE content directly. Being suitable for determination of the PCTFE content in a PBX explosive, the method has the characteristics of convenient operation, and rapid and accurate analysis.

Owner:XIAN MODERN CHEM RES INST

Compositions of ethylene/vinyl acetate copolymers for heat-sealable easy opening packaging

Disclosed are compositions comprising ethylene / vinyl acetate copolymers, tackifying resins and optionally polyolefins (for example, polyethylene and polypropylene) that provide strong, tight hermetic heat seals with an easily peelable opening feature to fluoropolymers such as polychlorotrifluoroethylene. Also disclosed are multilayer structures and packages comprising these compositions.

Owner:DOW GLOBAL TECH LLC

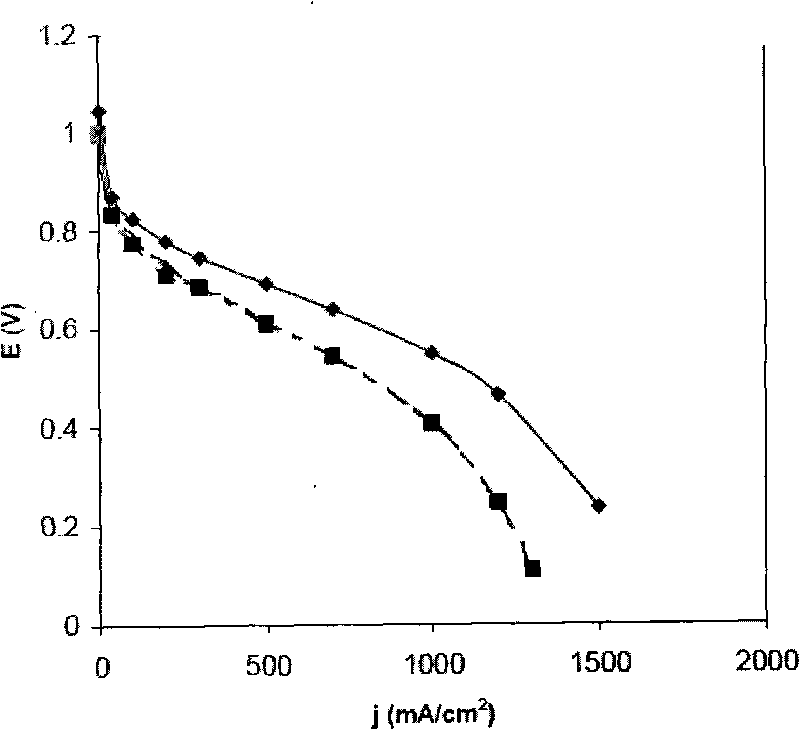

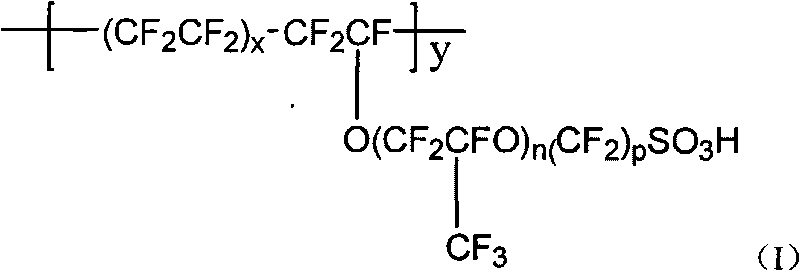

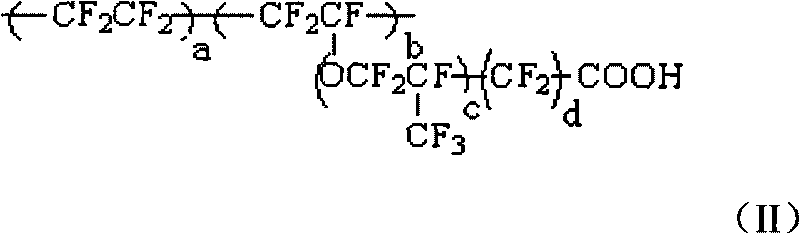

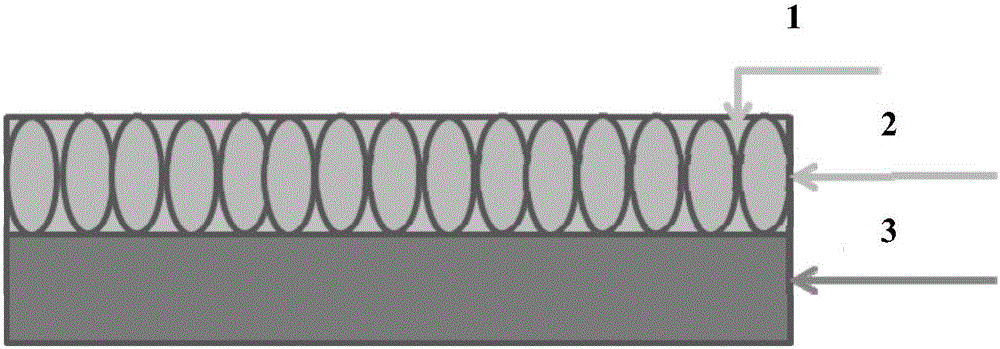

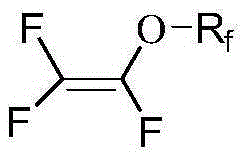

High-temperature proton exchange compound film

ActiveCN101728549ALower internal resistanceIncrease output powerCell component detailsFuel cell detailsFuel cellsInternal resistance

The invention relates to a high-temperature proton exchange compound film. The film is formed by using a fluorine-containing thin polymer film having a cellular structure as a carrier, filling a perfluor resin having a function of ion exchange into the micro-pores of a micro-porous film and covering the surface of the micro-porous film, wherein the compound film is 5 to 15 microns thick. The fluorine-containing thin polymer film having a cellular structure is a polyfluortetraethylene porous film, a polyvinylidene fluoride porous film, a polytrifluorochloroethylene porous film or a polyfluortetraethylene ethylene porous film. The perfluor resin having a function of ion exchange is a perfluor sulfo resin, a perfluor carboxylic resin or a perfluor phosphoric resin. The compound film of the invention is thin and can be applied to a fuel cell having a decreased internal resistance in order to promote the output power of the cell.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

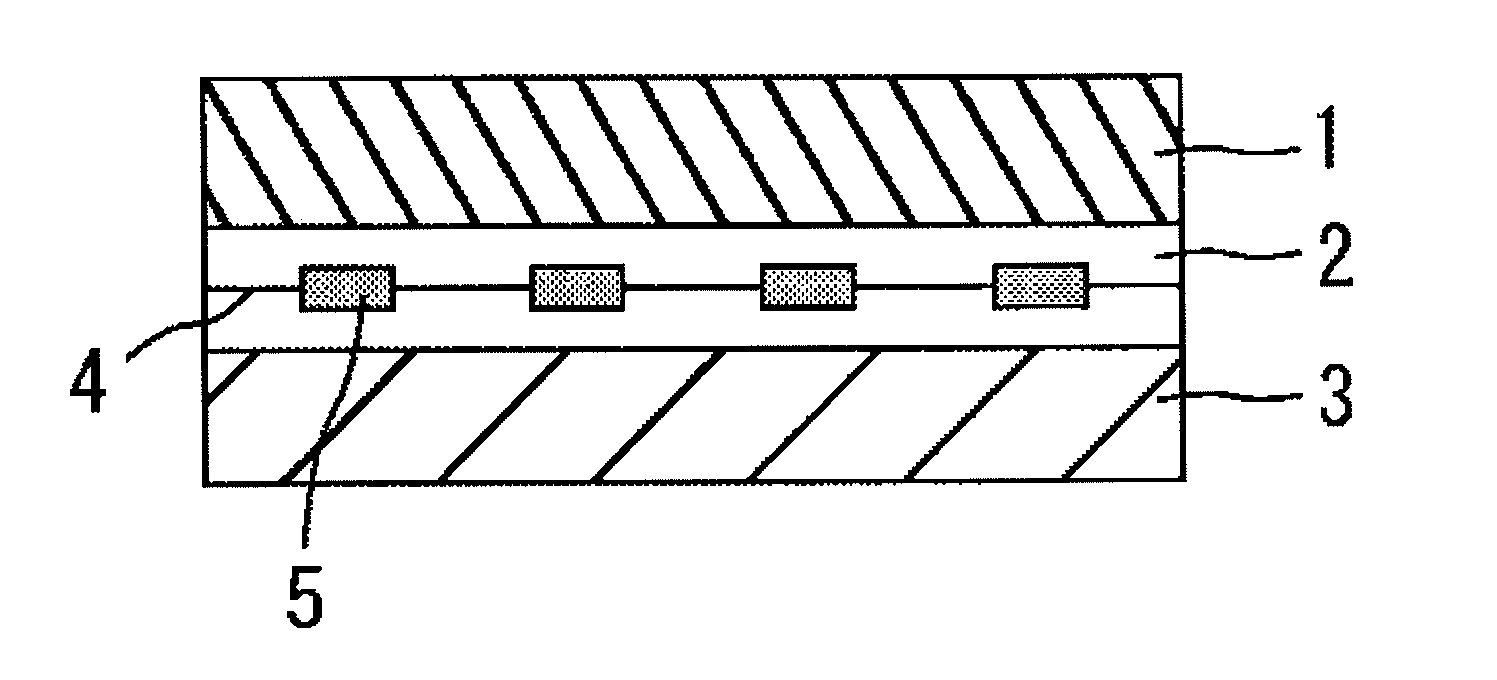

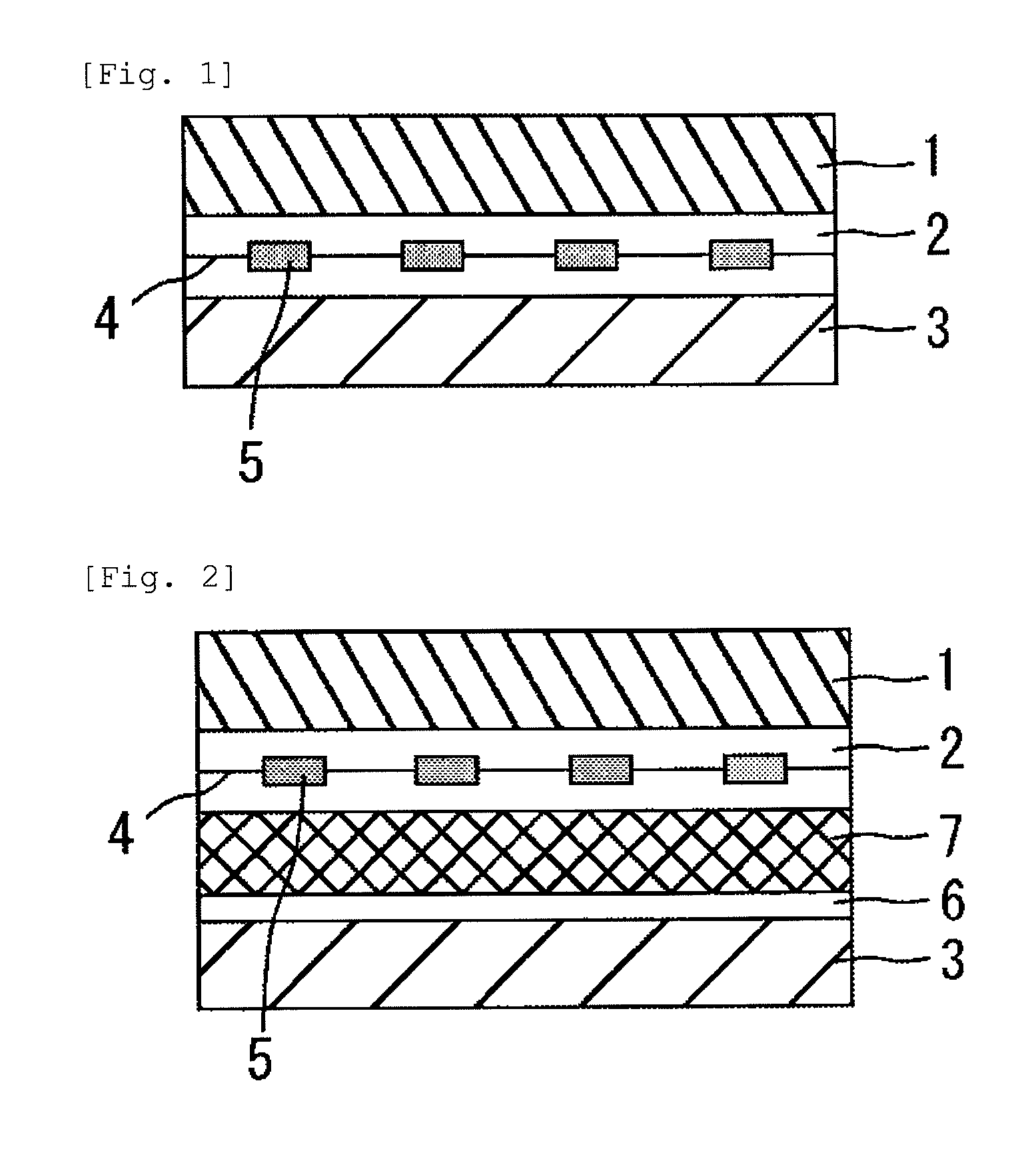

Solar cell module, laminate, and method for production of solar cell module

InactiveUS20100313946A1Improve interlayer adhesionGood weather resistanceSpark gapsSynthetic resin layered productsElectric dischargeSurface layer

Provided is a solar cell module which has a PCTFE film as the light-transmitting surface layer and / or back side protective sheet and is excellent in interlayer adhesion. The invention consists in a solar cell module comprising a light-transmitting surface layer, a solar cell element embedded in a filler and a back side protective sheet, wherein at least one of the light-transmitting surface layer and back side protective sheet is a polychlorotrifluoroethylene film (A) having a treated surface layer obtained by electric discharge treatment in an inert gas containing a reactive organic compound and the treated surface layer is disposed on the solar cell element side.

Owner:DAIKIN IND LTD

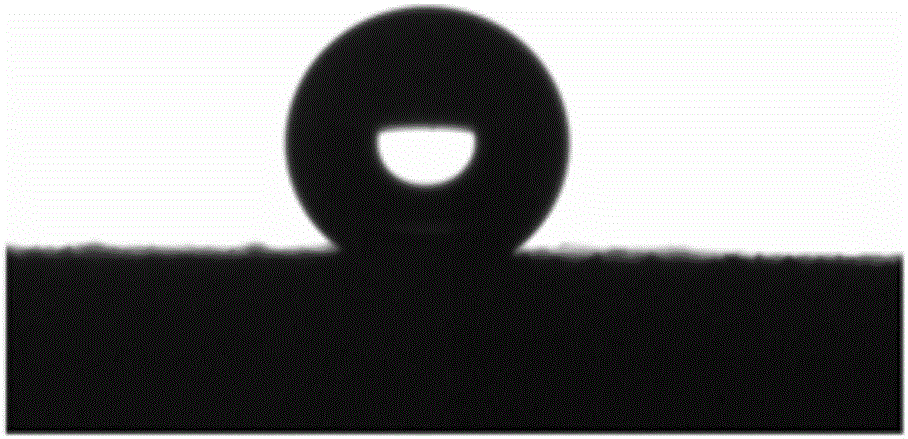

Cored wire with super-hydrophobic function and application of cored wire with super-hydrophobic function to preparation of coating with super-hydrophobic function

ActiveCN106676451AImprove self-cleaning effectImprove corrosion resistanceMolten spray coatingThermal sprayingAlloy

The invention provides a cored wire with a super-hydrophobic function. The cored wire with the super-hydrophobic function comprises a cored material and a metal wire coat, wherein the metal wire coat is used for coating the cored material. The cored material is formed by a metal cored material and a high molecular cored material through mixing. The metal cored material is selected from metal aluminum, copper, nickel and chromium or is any one kind of alloy formed by two kinds of the metal. The high molecular cored material is at least one of teflon, fluorinated ethylene-propylene, polytrifluorochloroethylene, polyvinylidene fluoride, ethylene-tetrafluoroethylene copolymer, ethylene-chlorotrifluoroethylene copolymer, polyvinyl fluoride, fluorocarbon resin and polyurethane. The invention further provides a coating with a super-hydrophobic function. The coating with the super-hydrophobic function is made of cored wires with the super-hydrophobic function and prepared through a thermal spraying technology. The coating has excellent super-hydrophobic performance and corrosion resistance, and has the good application prospect in the fields of self-cleaning, marine pollutant prevention, contamination resistance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

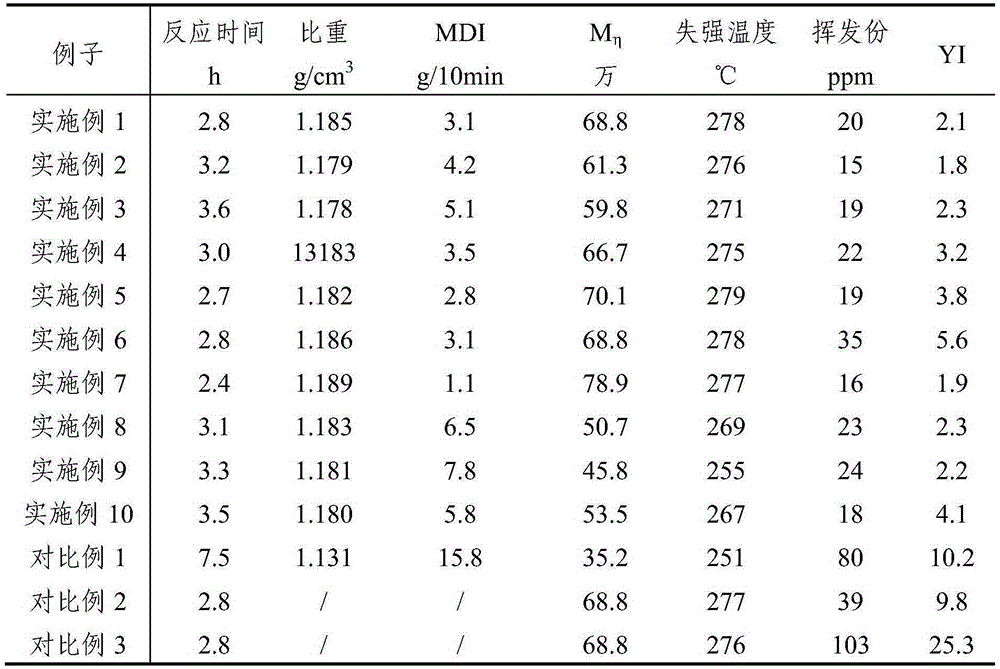

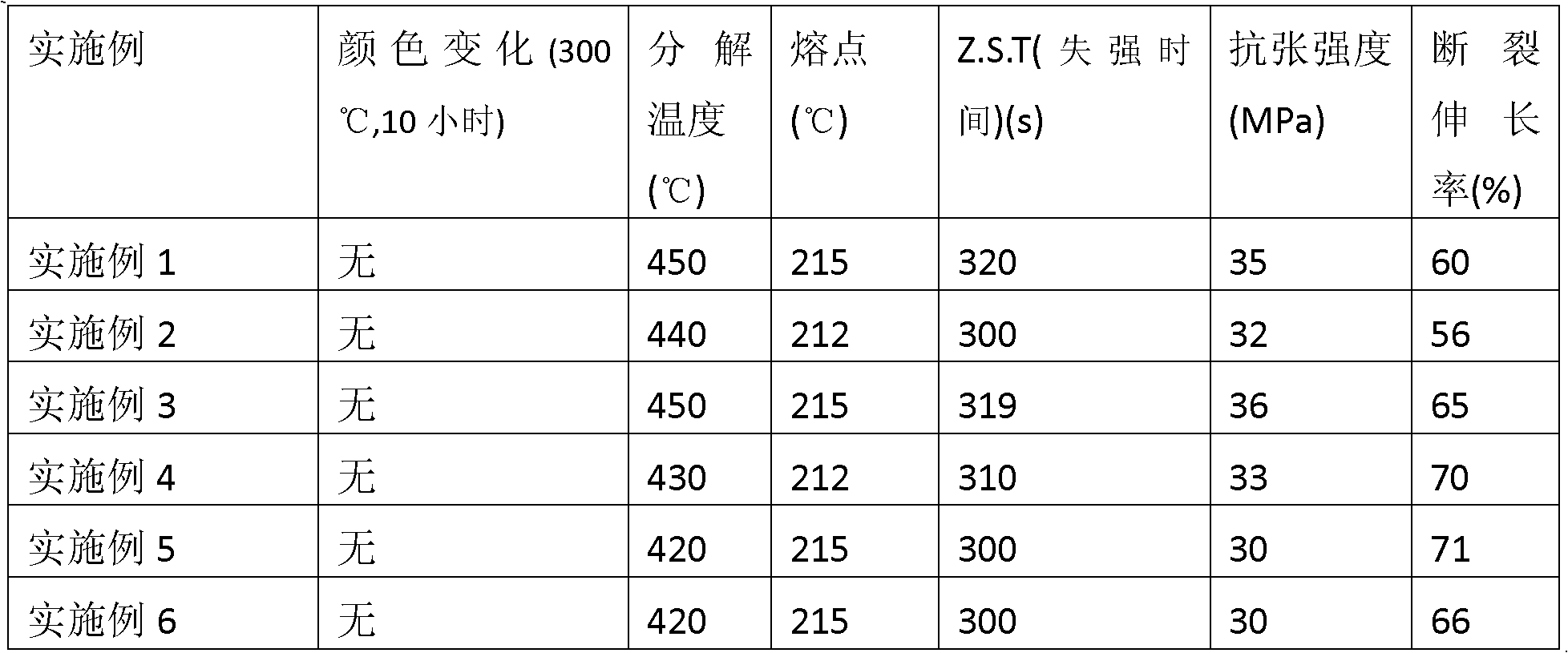

Polychlorotrifluoroethylene resin and preparation method thereof

ActiveCN106832072ALarge mass transfer areaQuick responseAnti-corrosive paintsPolymer scienceEmulsion

The invention relates to a preparation method of polychlorotrifluoroethylene resin, which adopts a horizontal reactor with an aspect ratio ≥ 1.0 as polymerization equipment; uses chlorotrifluoroethylene monomer or chlorotrifluoroethylene monomer and other comonomers The polymerization reaction occurs under constant pressure conditions, which improves the reaction speed and polymerization efficiency; the semi-mechanical and semi-chemical coagulation method is used to effectively separate the impurities in the emulsion, and the residual unstable groups are removed through wet heat treatment, effectively reducing the volatilization of the product parts, greatly improving the appearance of the product. M can be obtained by the method of the present invention η PCTFE and its copolymerization products exceeding 500,000, volatile matter less than 0.01%, strength loss temperature higher than 260°C, yellowness index (YI) less than 10.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

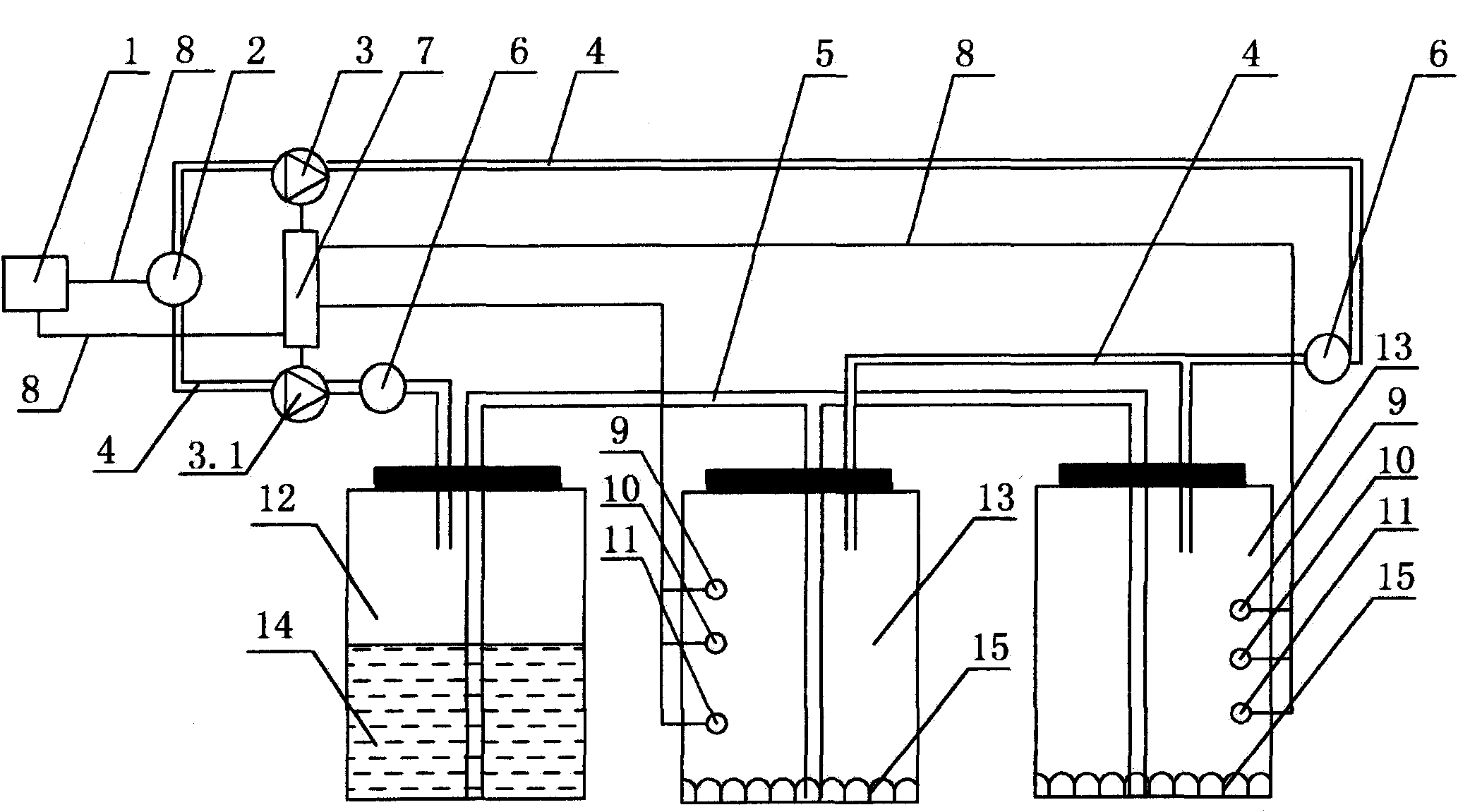

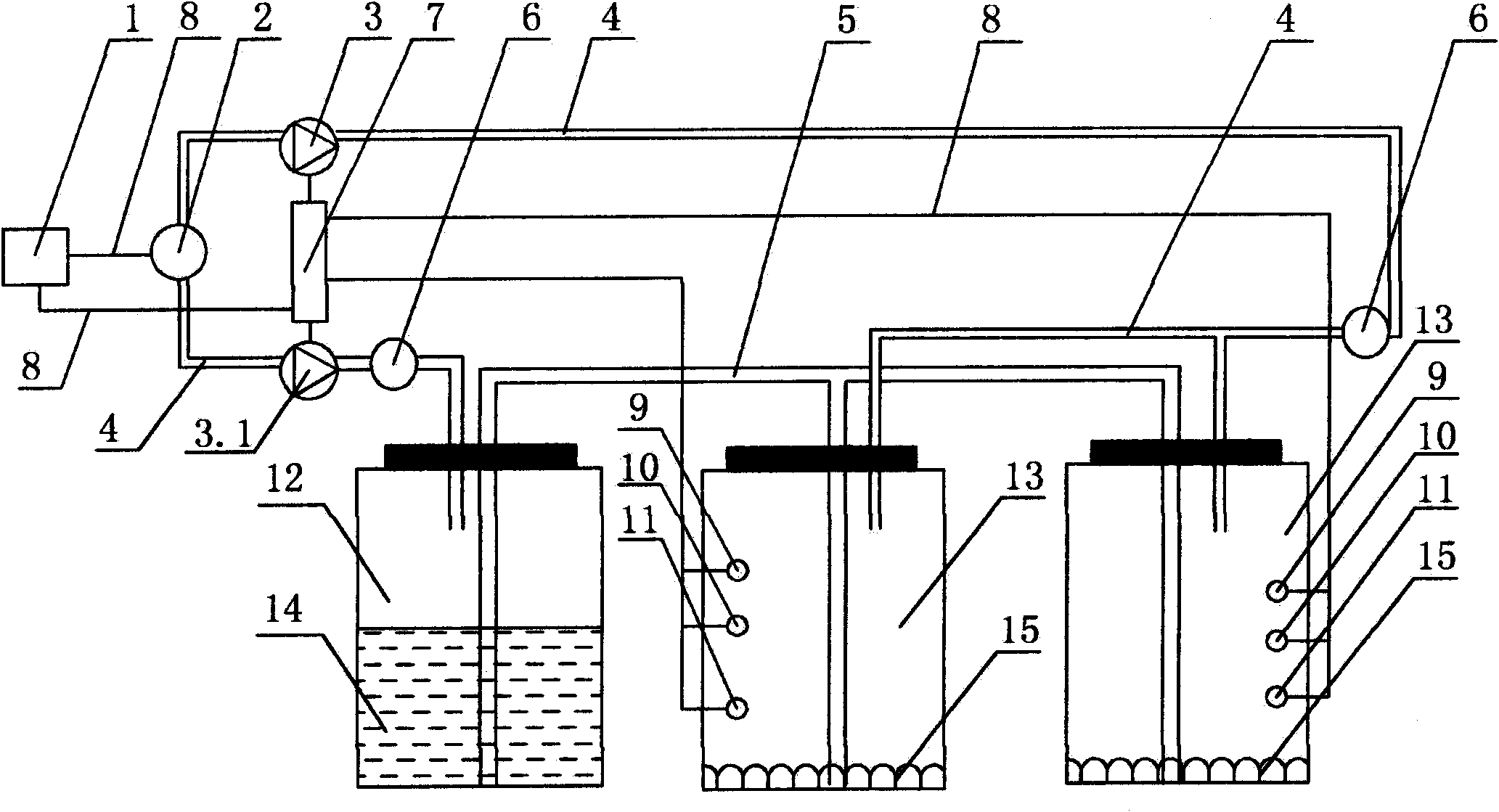

Plant tissue liquid automatic intermittent immersion circulation culture device

InactiveCN102286374ARealize automated trainingReduce dependenceBioreactor/fermenter combinationsBiological substance pretreatmentsAir filterSolenoid valve

The invention relates to a plant tissue liquid automatic intermittent immersion circulation cultivation device, which is characterized in that at least two groups of cultivation tanks are arranged around the nutrient solution tank, and the nutrient solution tank communicates with the cultivation tank through a high-temperature and high-pressure sterilized diversion tube to cultivate Gas concentration sensors, temperature sensors and humidity sensors are installed on the side wall of the tank, solenoid valve A and solenoid valve B are arranged on the upper and lower sides of the programmable integrated circuit board, and the reinforced polychloride on the left side of the programmable integrated circuit board A pressure regulator is set on the vinyl tube, the right side of the air pump is connected to the pressure regulator through a line, the lower end of the air pump is connected to the programmable integrated circuit board through a line, and an air filter is set on the reinforced polyvinyl chloride tube near the nutrient solution tank The front end of the branch pipe on the right side of the reinforced polyvinyl chloride pipe is provided with an air filter. The invention realizes liquid automatic culture, reduces dependence on agar in plant tissue culture, and reduces labor intensity.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

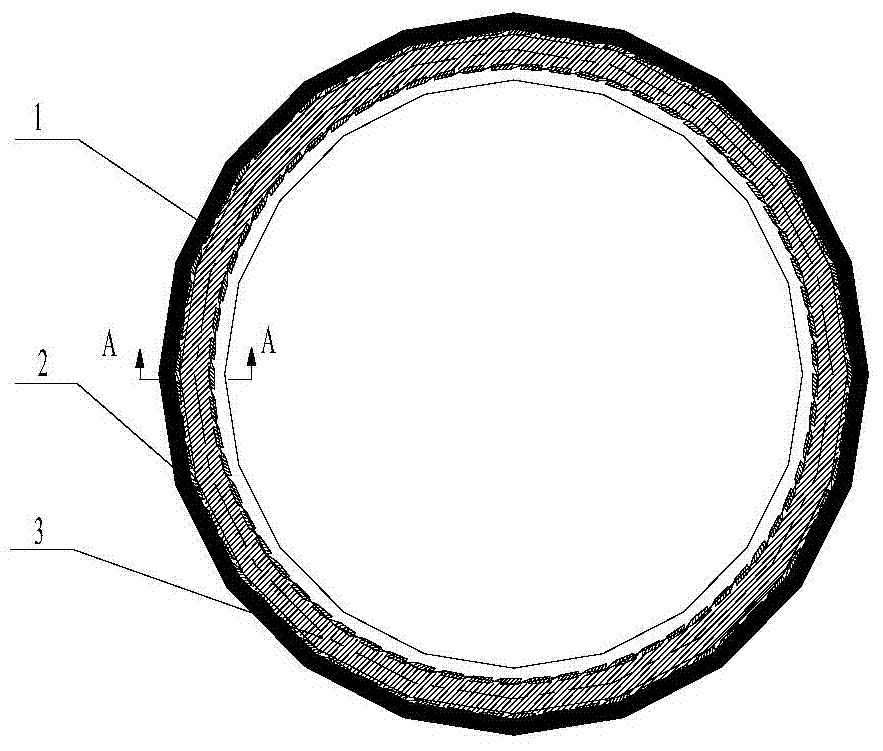

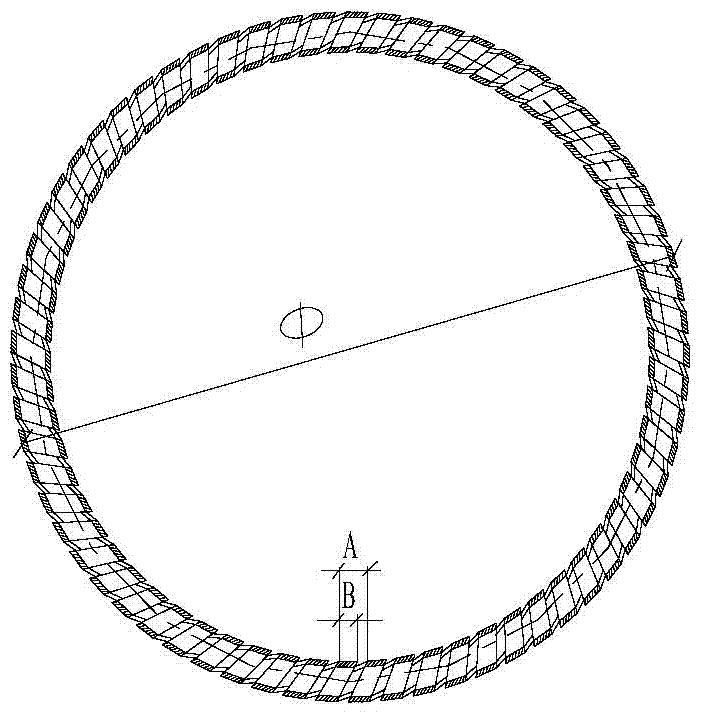

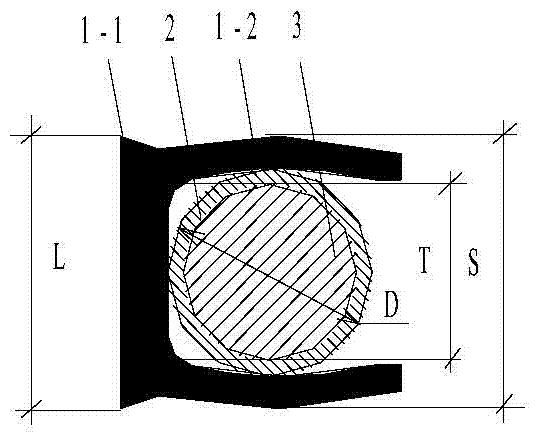

Composite sealing ring for low-temperature valve

The invention relates to a composite sealing ring for a low-temperature valve, and belongs to the technical field of fluid control valves. The sealing ring comprises a sealing ring jacket made of modified polytrifluorochloroethylene, a hollow metal energy storage spring with a circular section is clamped in an annular groove with a C-shaped section formed by the section of the sealing ring jacket and comprises a spring strap wound outside a metal rubber ring with the circular section, the ratio of the inner distance between two surrounding edges in a natural state to the diameter of the metal energy storage spring is 0.7-0.9, the ratio of the maximum outer distance formed by unfolding the two surrounding edges after clamping the metal energy storage spring and the length of a base edge to the depth of a sealing groove to be embedded is 1.1-1.3, and metal materials in the metal rubber ring are as same as those of the metal energy storage spring. The sealing ring appropriately solves the problem of serious reduction of sealing specific pressure caused by the expansion coefficient difference between a nonmetal material and a metal material at a low temperature and solves the problem that the materials are hard and brittle at a deep-cold temperature, and reliable sealing of the valve in a -196 DEG C to -269 DEG C ultra-low temperature environment can be practically achieved.

Owner:JIANGSU EVALVE GRP

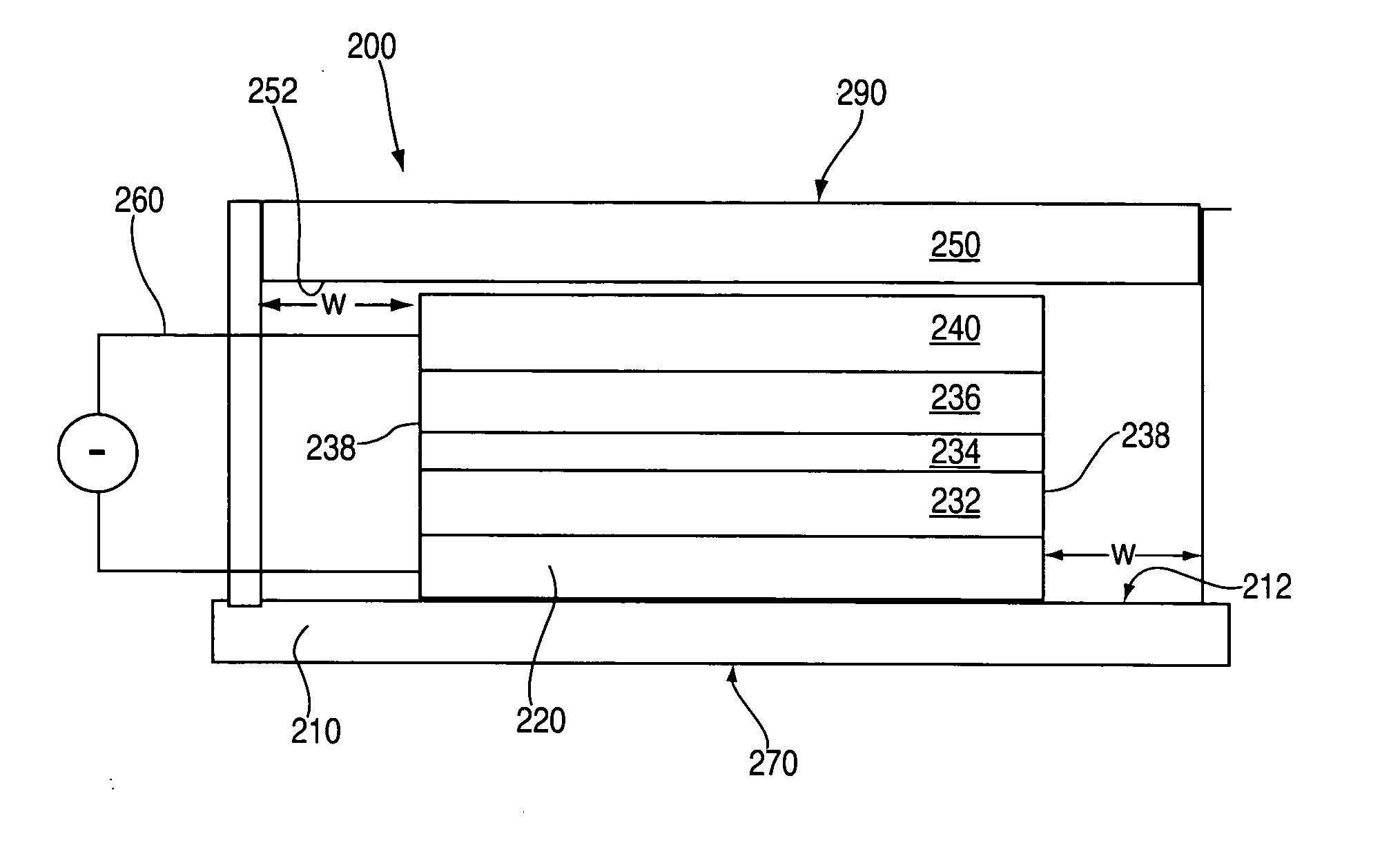

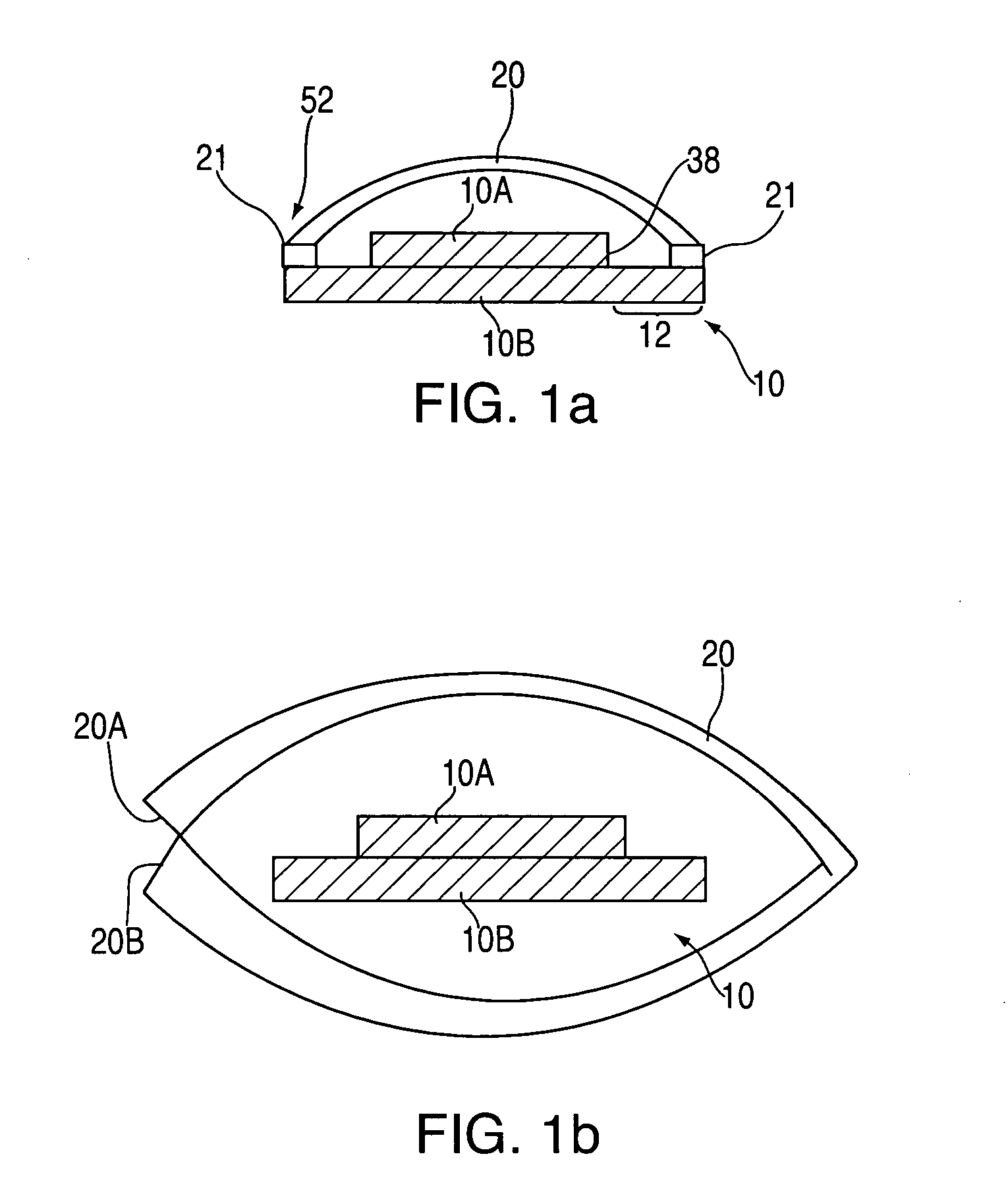

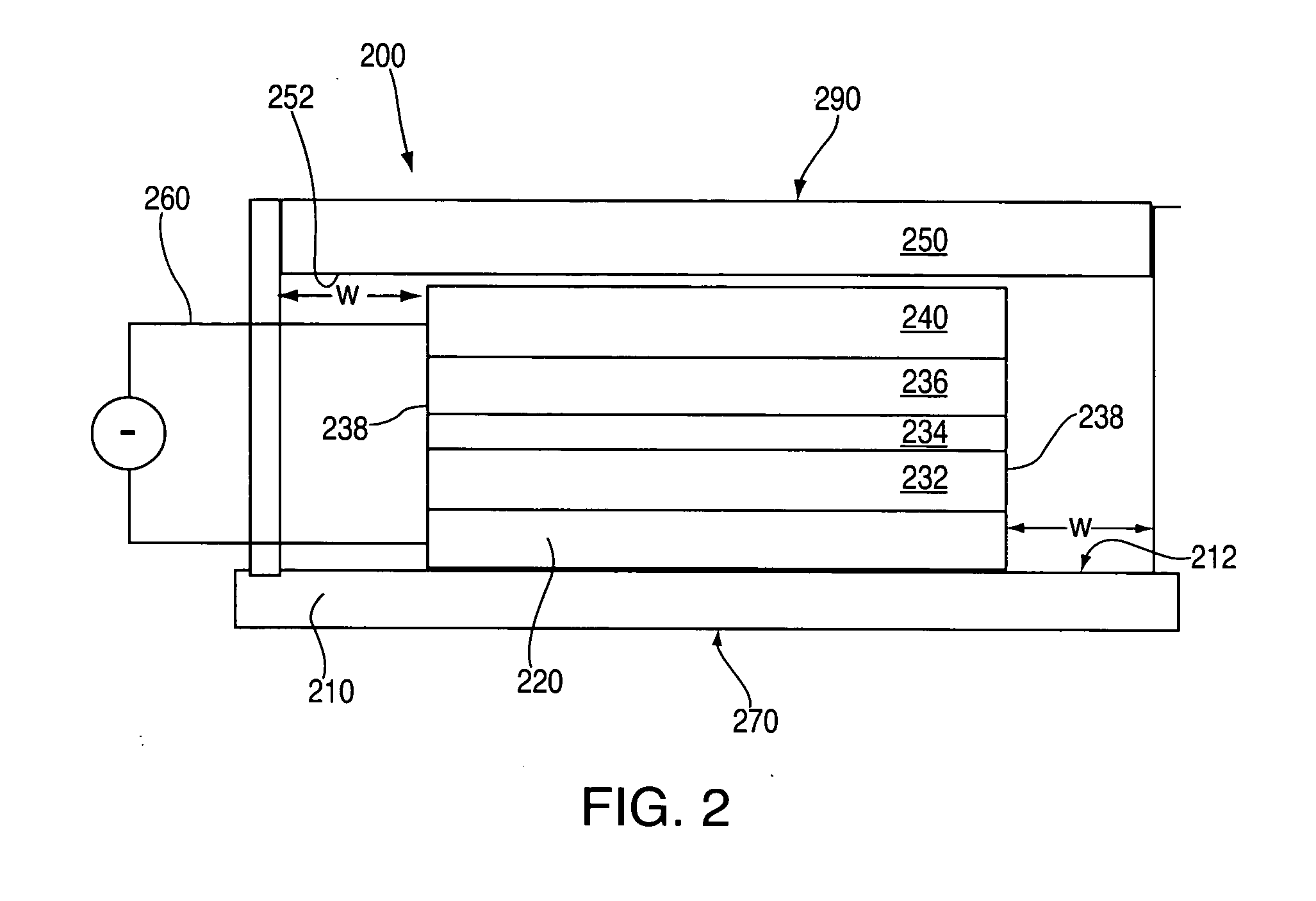

Protecting electro-optical devices with a fluoropolymer

InactiveUS20050070196A1Discharge tube luminescnet screensElectroluminescent light sourcesEngineeringFluoropolymer

A method for protecting an electro-optical device includes the steps of providing an electro-optical device including a first electrode, a second electrode, and an emitting layer disposed between the first electrode and the second electrode, where at least one of the electrodes is optically transparent; and sealing at least a portion of the electro-optical device within a casing formed of a fluoropolymer, preferably a polychlorotrifluoroethylene film. Where the electro-optical device is provided with at least one wire lead extending from a peripheral portion of the electro-optical device, the method includes the step of protecting the wire lead from detrimental environmental conditions using a fluoropolymer. An environmentally sealed electro-optical device is also provided, including an electro-optical device and a fluoropolymer, preferably a polychlorotrifluoroethylene film, protecting at least a portion of the electro-optical device.

Owner:COLOMBO FR J +2

Modified polytrifluorochloroethylene and molding process thereof

The invention relates to a modified polytrifluorochloroethylene and a molding process thereof. The modified polytrifluorochloroethylene is prepared from polytrifluorochloroethylene and a modifier, wherein the modifier is a mixture of more than one, in an arbitrary ratio, selected from the group consisting of p-polyphenylene, graphite, carbon fiber, glass fiber, ceramic powder, polybenzoate, pigment, molybdenum disulfide and aluminum powder. The molding process for the modified polytrifluorochloroethylene is to subject polytrifluorochloroethylene and the modifier to drying, mixing, molding and cooling. The invention has the following beneficial effects: after addition of the modifier, the prepared modified polytrifluorochloroethylene has improved hardness, dimensional stability, high temperature resistance, wear resistance, thermal conductivity and creep resistance and altered friction coefficient; meanwhile, cost of polytrifluorochloroethylene is reduced, and the application scope of the modified polytrifluorochloroethylene is widened.

Owner:WENZHOU OUKE FLUORINE GASKETS CO LTD

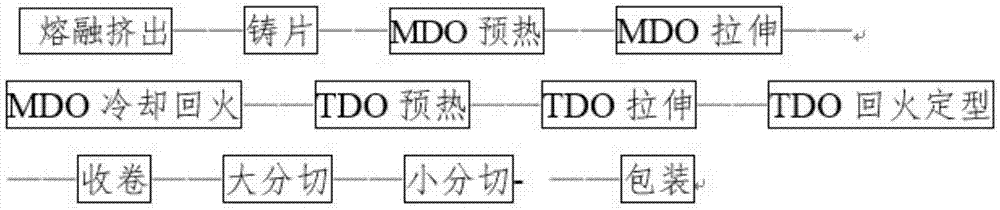

A dry double-pulling lithium battery diaphragm production process

ActiveCN105017546BFast crystallizationOvercoming lateral shrinkage issuesCell component detailsFiberPolyethylene terephthalate glycol

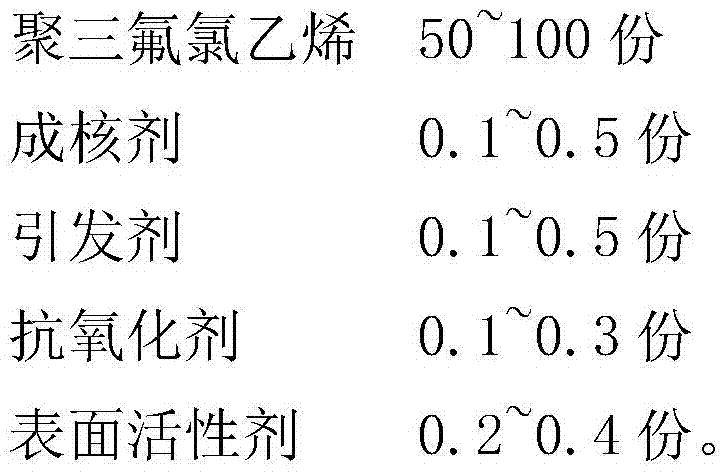

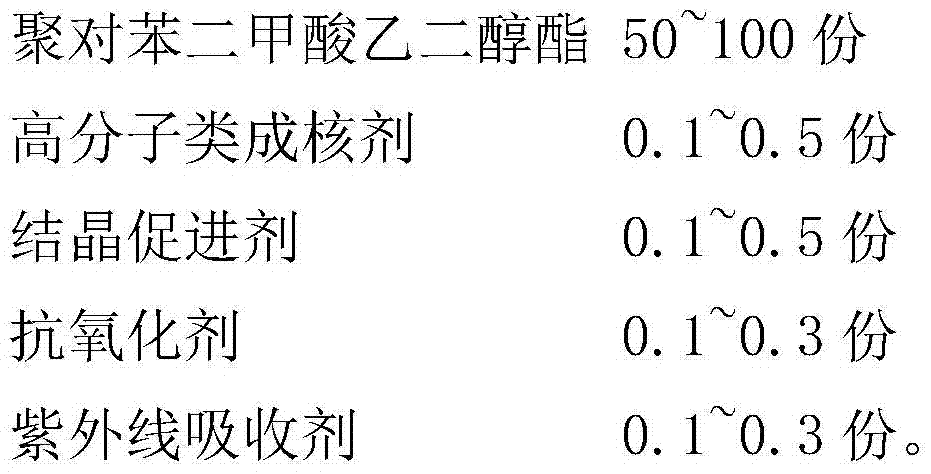

A dry-process double-pulling lithium battery diaphragm production process, characterized in that the process steps are as follows: 1) Weigh 100 parts of PP / PE, 10 parts of modified poly-paratrifluorochloroethylene, modified poly-para-polyethylene 10 parts of ethylene glycol phthalate, 0.5 part of cyclohexane, 2 parts of toluene, 5 parts of nano silicon carbide, 0.5 part of carbon fiber, 2 parts of polyethylene wax; 2) mixing the raw materials in step 1), heating, Send it to the extruder for melting and extrusion, and then cool and cast it into a thick sheet on the casting roll; 3) Preheat and stretch the thick sheet in step 2) using MDO technology, cool and temper after completion, and make a film Stretching the film along the machine direction can improve the performance of the film, such as stiffness, flatness, tensile strength and porosity etc.; 4) the film in step 3) is preheated and stretched using TDO technology, and returned to the film after completion Fire setting; 5) the film after setting in step 4) is rewound, big cut, small cut, then pack and form lithium battery diaphragm.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

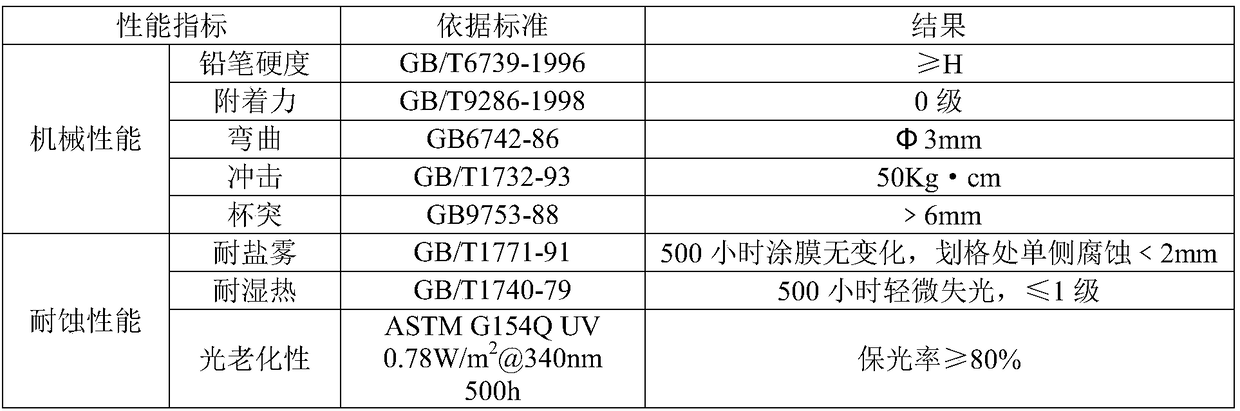

Environmental stress-resistant epoxy resin powder coating and preparation method thereof

InactiveCN108250908AImprove heat resistanceImprove toughnessAnti-corrosive paintsPowdery paintsEpoxyMonomer composition

The invention relates to the technical field of epoxy resin powder coating, in particular to environment stress-resistant epoxy resin powder coating and a preparation method thereof. The environmentalstress-resistant epoxy resin powder coating is prepared from components such as epoxy resin, high-density polyethylene resin, polybismaleimide resin, hydroxyl silicone oil, a silane cross-linking agent, salicylic acid, an organic solvent, polyvinylidene fluoride, polyhexafluoropropylene or polytrifluorochloroethylene, a ABS monomer composition, an initiator, water, an antioxidant, a light shielding agent, filler and a curing agent. The epoxy resin is mixed with the hydroxyl silicone oil and the silane coupling agent to form organic silicone modified epoxy resin which is then mixed with a mixture of the polyvinylidene fluoride, the polyhexafluoropropylene or the polytrifluorochloroethylene, and the ABS monomer composition to be extruded and molded to obtain the epoxy resin powder coating.The environmental stress-resistant epoxy resin powder coating is high in damp and heat resistance and corrosion resistance, high in weather resistance, good in mechanical performance, convenient to produce with a simple process, safe and nontoxic.

Owner:ZHEJIANG HUACAI NEW MATERIAL CO LTD

Shock resistance fluoroplastic for protection shell of mobile phone

The invention discloses a shock resistance fluoroplastic for a protection shell of a mobile phone. The shock resistance fluoroplastic is prepared from, by weight, 20-40 parts of polytrifluorochloroethylene, 5-15 parts of an ethylene-vinyl acetate copolymer, 10-20 parts of polystyrene, 20-40 parts of modified fish skin collagen, 10-20 parts of polyacrylonitrile-based carbon fibers, 5-12 parts of graphene, 3-10 parts of nano-kaolin, 8-16 parts of hollow glass microspheres, 0.5-1.5 parts of diethylenetriamine, 0.5-1.2 parts of dicumyl peroxide, 1-2 parts of p-phenylenediamine, 0.5-1.5 parts of chlorinated polyethylene wax, 0.5-1.5 parts of microcrystalline wax, 0.2-0.6 part of lanthanum oxide, 0.2-0.6 part of cerium oxide, 1-2 parts of a polyphenol antioxidant 1076 and 1-2 parts of polyphenol antioxidant 1010. The shock resistance fluoroplastic is not likely to bend when subjected to shock, capable of well protecting components inside the mobile phone and high in heat resistance and aging resistance.

Owner:安徽酷米智能科技股份有限公司

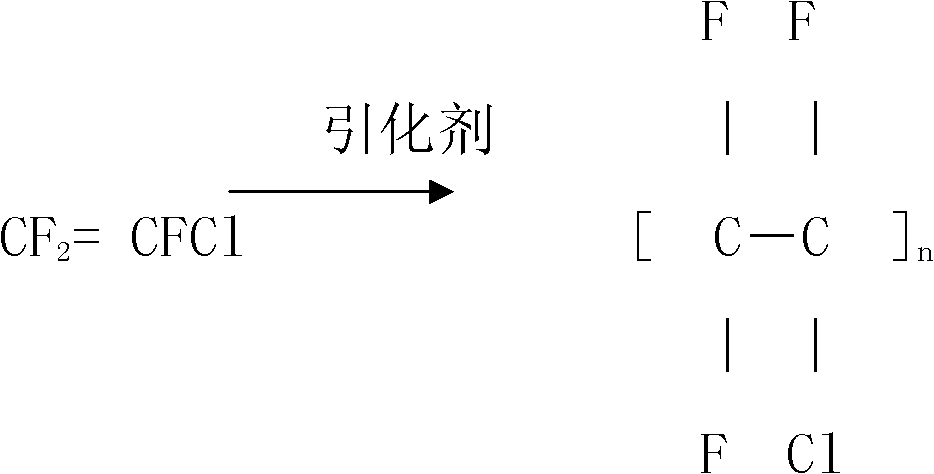

Preparation method of high-temperature resistant and high-transparent polychlorotrifluoroethylene

The invention relates to a preparation method of high-temperature resistant and high-transparent polychlorotrifluoroethylene, which comprises the steps of firstly preparing polychlorotrifluoroethylene resin in deionized water from chlorotrifluoroethylene under the action of an azo type initiator, and then using cobalt fluoride to terminate the polychlorotrifluoroethylene. The polychlorotrifluoroethylene prepared by the method has excellent mechanical properties and can be resistant to the temperature of 400 DEG C, and the color can not be changed within 10 hours at the temperature of 300 DEG C.

Owner:司林旭 +1

Production method of polychlorotrifluoroethylene for electrostatic spraying

InactiveCN101113186AImprove wettabilityGood dispersionLiquid surface applicatorsCoatingsAqueous solutionMechanical property

A production method of fluorothene for electrostatic spray relates to a synthetic method of fluorothene for electrostatic spray. The fluorothene for electrostatic spray is obtained by aqueous solution suspension radical polymerization: first pH buffer: initiator equaling to 1:0.01-100 molar ratio is weighted; then water is added in the pH buffer and initiator, 0.1-1 percent of aqueous solution is produced and the aqueous solution is evenly stirred at 0-20 DEG C to produce initiator aqueous solution, pH value of which is 5-8; chlorotrifluoroethylene is added in the initiator aqueous solution to practice polymerization, the ratio of the chlorotrifluoroethylene and initiator aqueous solution is 1:0.01-1 molar, the temperature is raised to 20-80 DEG C, the stirring rate is 100-300rpm, the reaction pressure is 0.5-1.5MPa, the reaction time is 4-15 hours, and powder fluorothene for electrostatic spray is obtained after filtering, washing and drying. The invention has high raw material conversion rate, small polymer particle size, good physical and mechanical properties and simple process and is suitable for industrial production.

Owner:青岛宏丰氟硅科技有限公司

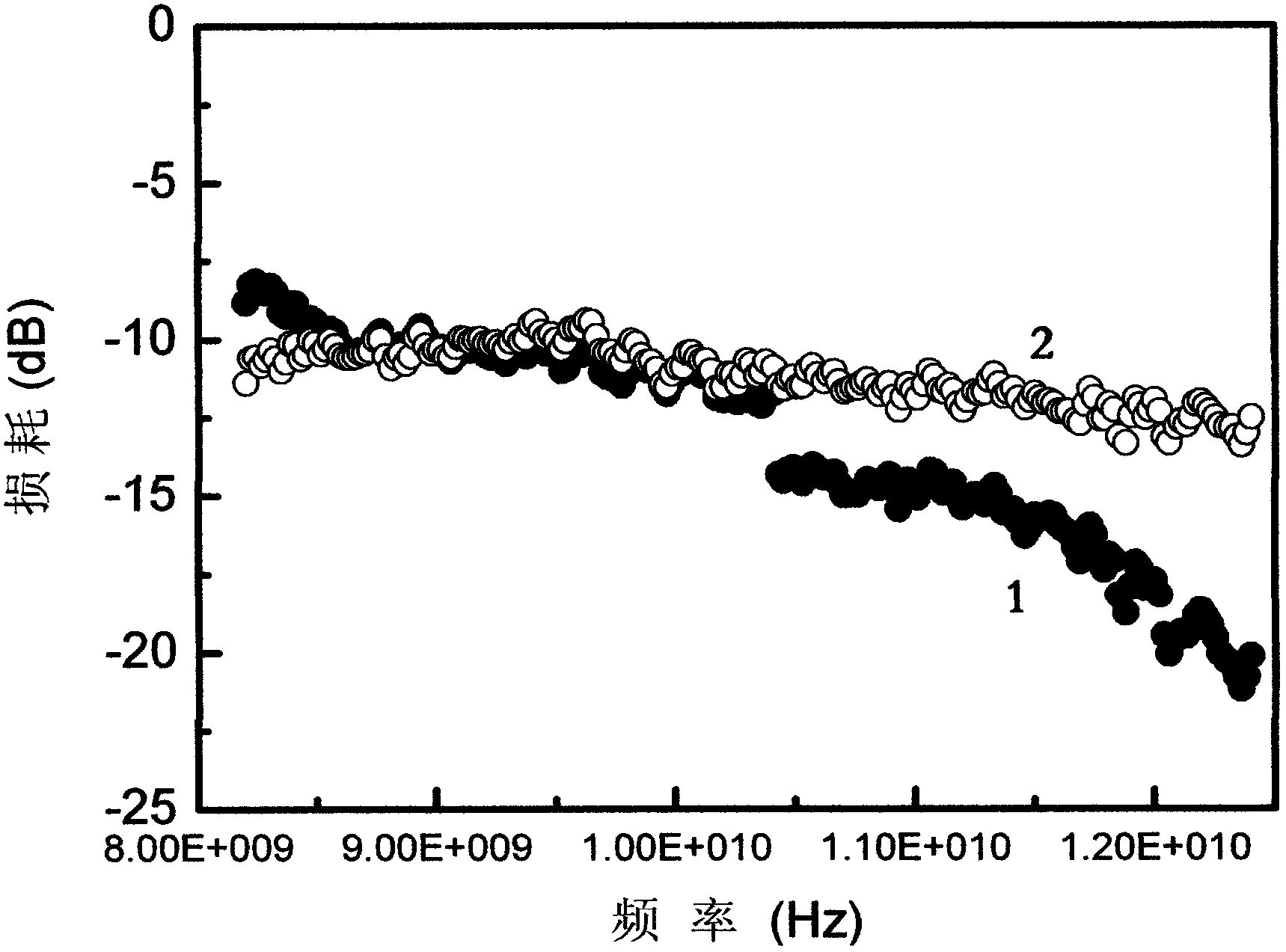

Fluoroplastic-based micro-nano composite wave-absorbing material and preparation method thereof

ActiveCN103509298AGood chemical resistanceImprove oxidation resistanceOther chemical processesMicro nanoCarbon nanotube

The invention discloses a fluoroplastic-based micro-nano composite wave-absorbing material and a preparation method thereof. The material comprises fluoroplastic, a carbon nanotube and a basalt fiber in a weight ratio of 100: 0.5-20: 0.5-20, wherein the fluoroplastic is one selected from the group consisting of polytetrafluoroethylene, a perfluoro (ethylene-propylene) copolymer, a poly(perfluoroalkyloxy) resin, polytrifluorochloroethylene, an ethylene-trifluorochloroethylene copolymer, an ethylene-tetrafluoroethylene copolymer, polyvinylidene fluoride and polyvinyl fluoride, the carbon nanotube has a diameter of 20 to 30 nm and length of 10 to 30 mu m, and the basalt fiber has a diameter of 13 to 18 mu m and length of 6 to 25 mm. The preparation method adopts melt blending and comprises the following steps: uniformly mixing the fluoroplastic, the carbon nanotube and the basalt fiber so as to obtain a mixture; and placing the mixture in a torque rheometer and carrying out mixing at a temperature of 200 to 350 DEG C for 5 to 25 min so as to prepare the fluoroplastic-based micro-nano composite wave-absorbing material. The fluoroplastic-based micro-nano composite wave-absorbing material has the characteristics of a wide shielding frequency range and good wave-absorbing performance and can be used as a material for prevention of electromagnetic wave pollution.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for preparing polychlorotrifluoroethylene resin

InactiveCN102603944AImprove conversion rateThe polymerization reaction is fastPolymer scienceMethyl group

The invention discloses a method for preparing polychlorotrifluoroethylene resin. The method includes: using CTFE (chlorotrifluor ethylene) as monomer, using mixture of deionized water with perfluor-4-methyl-2-pentane as media, and using perfluor-amyl-butyl peroxide initiator for polymerization of chlorotrifluoroethylene at the temperature of 0-70 DEG C in the existence of fluorine-contained decyl-acrylic acid dibutyl ester surfactant, wherein the feeding amount of the CTFE is 10-40 of the weight of the mixed media, the mass ratio of the deionized water to the perfluor-4-methyl-2-pentane is 2-5:1, usage of the perfluor-amyl-butyl peroxide initiator is 0.1-2% of the weight of CTFE, and usage of the fluorine-contained decyl-acrylic acid dibutyl ester surfactant is normally 0.02-2% of the weight of CTFE. The method is short in polymerization time and high in conversion rate, the obtained polymer is not easy to degrade, deteriorate in performance and discolor at high temperature.

Owner:CHANGSHU XINHUA CHEM

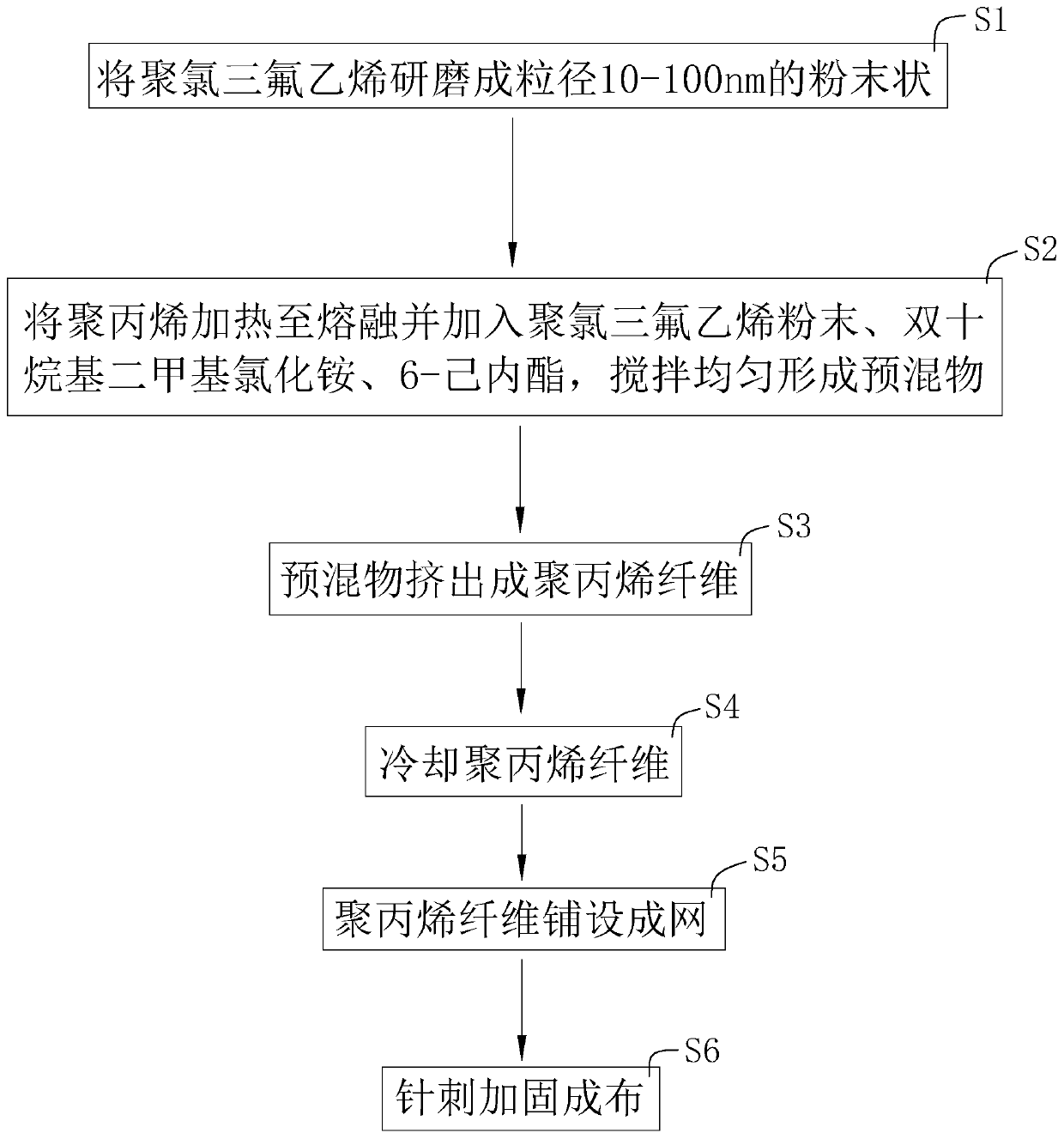

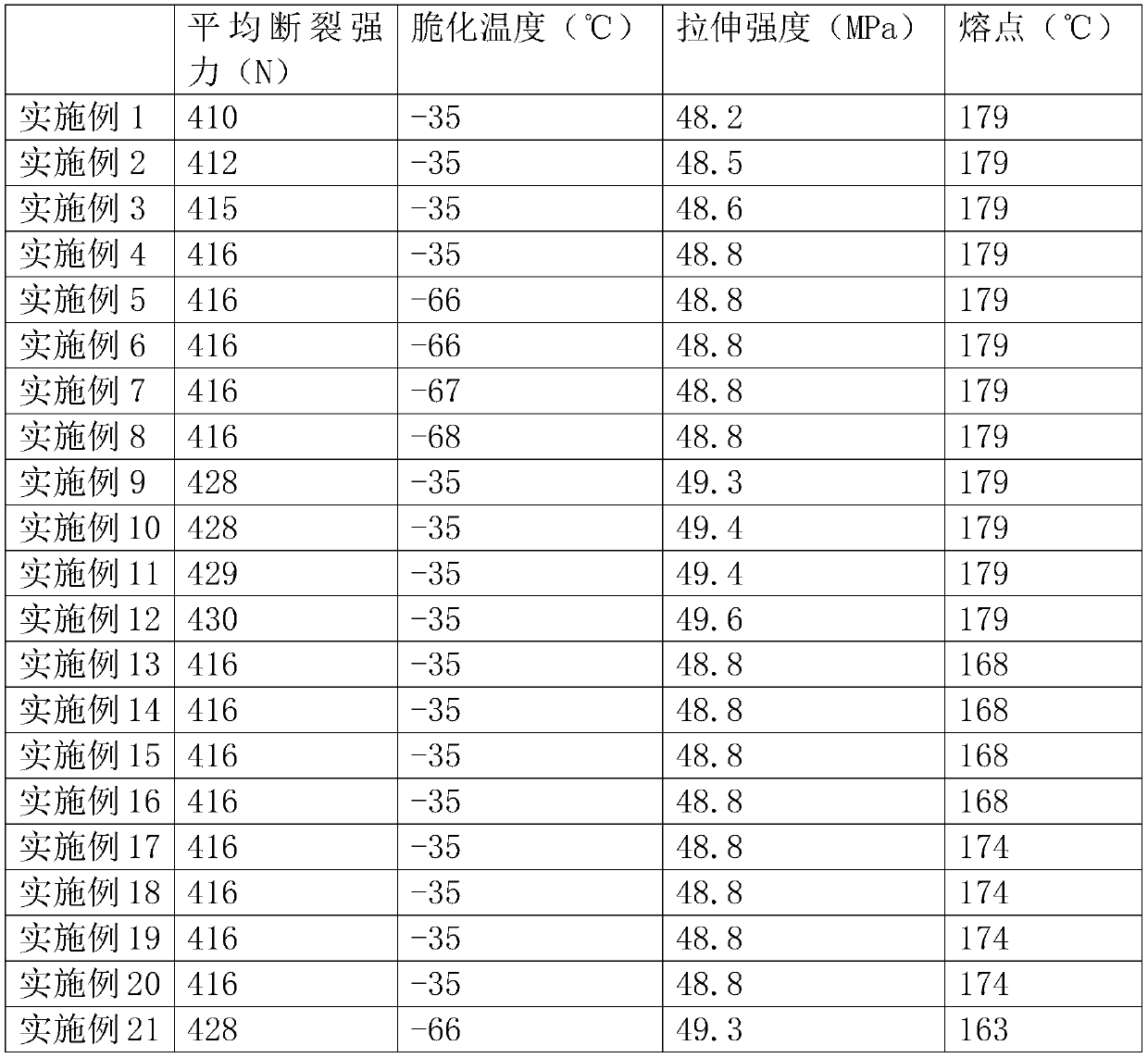

Non-woven fabric

InactiveCN110938891AHigh tensile strengthHigh strengthConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer scienceNonwoven fabric

The invention relates to the technical field of non-woven fabrics, and aiming at the problem that the application prospect of the non-woven fabrics is greatly limited by the sufficient strength of thenon-woven fabrics, provides a non-woven fabric. The technical scheme is as follows: the non-woven fabric comprises the following components in parts by mass: 100 parts of polypropylene, 30-45 parts of polychlorotrifluoroethylene, 10-15 parts of didecyldimethylammonium chloride and 3-5 parts of 6-caprolactone. By adding the polychlorotrifluoroethylene into the polypropylene, the tensile strength of the polypropylene is effectively improved, so that the prepared non-woven fabric is relatively high in strength and not easy to crack, is better applicable to various industrial fields and is relatively wide in applicability.

Owner:广东骏钱实业有限公司

Energy-saving thermal insulation material for building walls and preparation method thereof

InactiveCN105060837AImprove insulation effectImprove flexural strengthSolid waste managementThermal insulationPolystyrene

The invention discloses an energy-saving thermal insulation material for building walls and a preparation method thereof. The energy-saving thermal insulation material comprises 15-30 parts of polystyrene, 5-15 parts of glass wool, 4-10 parts of rape stalk, 3-7 parts of cassava stalk, 6-14 parts of phenolic foam, 3-8 parts of magnesium chloride, 4-7 parts of poly(chlorotrifluoroethylene), 3-6 parts of calcium fluoride and 4-9 parts of diatom ooze. The preparation method comprises the steps of crushing, stirring for mixing, die forming, cooling and the like. The prepared energy-saving thermal insulation material has the characteristics of high rupture strength, low heat conductivity and high oxygen index.

Owner:苏州凯欧曼新材料科技有限公司

Low-temperature-resistant packaging material and preparation method therefor

The invention discloses a low-temperature-resistant packaging material. The packaging material contains the following raw materials in parts by weight: 15-30 parts of polyimide, 10-15 parts of polytetrafluoroethylene, 10-15 parts of polytrifluorochloroethylene, 5-10 parts of butyronitrile, 2-5 parts of polysulfone, 2-5 parts of silicon rubber, 5-10 parts of methylphenylvinyl silicone, 10-20 parts of organic silicone gel, 5-15 parts of asbestos, 5-10 parts of polyester, 5-10 parts of epoxy resin, 5-15 parts of polycarbonate, 5-10 parts of cycloheptene, 2-5 parts of aziridine, 5-10 parts of an emulsifier and 5-10 parts of an accelerant. Meanwhile, the invention discloses a preparation method for the low-temperature-resistant packaging material.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

Modified polytrifluorochloroethylene plastic

The invention discloses a modified polytrifluorochloroethylene plastic. The modified polytrifluorochloroethylene plastic is prepared from the polytrifluorochloroethylene plastic and additives, including an anti-wear agent, an impact modifier, a weather-proof agent, an anticorrosion agent and a coupling agent; the anti-wear agent is a polyethylene having an ultra-high molecular weight, the impact modifier is a methyl methacrylate- butadiene-styrene copolymer, the weather-proof agent is a 2-hydroxyl-4-n-octanoylbiphenyl ketone, the anticorrosion agent is a polytetrafluoroethylene resin, and the coupling agent is glycidyloxypropyltrimethoxysilane. Since a plurality of additives are added to the polytrifluorochloroethylene plastic, the prepared modified polytrifluorochloroethylene plastic is good in quality, and also has excellent abrasive resistance, mechanical strength, weather fastness and corrosion resistance.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Production method for heat-insulation noise-insulation water-proofing material

InactiveCN101314709AGood heat collectionEasy to installOther chemical processesMetal layered productsPolyesterPolymer science

The invention provides a method for manufacturing thermal-insulation, sound-insulation and waterproof material, which comprises the following steps: preparing a frame with a rectangular shape, a shape in Chinese character 'tian' or other shapes from materials such as steel materials, aluminum materials or composite straw materials for supporting the atmospheric pressure formed by a vacuum layer; and secondarily, processing polymer materials such as thermoplastic polyester, poly(chlorotrifluoroethylene), poly(vinyl fluoride) and chlorinated polyether into polymer film or other materials, preparing sheets, wrapping the frame, sealing, pumping the air by a vacuum machine to obtain vacuum or sub-vacuum board, or processing in vacuum or sub-vacuum state to obtain the vacuum or sub-vacuum board, or making into sealed hollow board if the board has no need to be pumped to vacuum or sub-vacuum state after sealing. The polymer film is processed to a shape like to pingpong ball rubber with particles, and the two surfaces with particles are opposite to each other to form a space and can be made into vacuum or sub-vacuum or hollow clothing fabrics by adhesion. Compared with the prior art, the thermal-insulation, sound-insulation and waterproof material has the advantages of simple process, low cost, extremely light weight, and high efficiency in insulating heat and sound and resisting water, and has good generalization and use value.

Owner:郝迎华

Modified polytrifluorochloroethylene plastic for junction box of SF6 density relay

The invention discloses modified polytrifluorochloroethylene plastic for a junction box of an SF6 density relay. Raw materials of the modified polytrifluorochloroethylene plastic in parts by weight are as follows: 20-40 parts of ethylene-vinyl acetate copolymer, 30-40 parts of polytrifluorochloroethylene, 5-15 parts polyacrylic acid, 5-20 parts of bisphenol A type polyarylester, 1-2 parts of dicumyl peroxide, 1-2 parts of diethylenetriamine, 1-2 parts of N,N-diethylethanolamine, 1-2 parts of cerium oxide, 0.5-1 part of lanthanum oxide, 1-3 parts of stearic acid, 1-2 parts of liquid coumarone, 10-20 parts of glass fibers, 20-40 parts of superfine modified kaolin, 5-15 parts of clay, 10-20 parts of glass beads, 10-20 parts of nanosilicon dioxide, 1-2 parts of an anti-ageing agent 264, 1-2 parts of an anti-ageing agent DPPD and 1-2 parts of p-phenylenediamine. The modified polytrifluorochloroethylene plastic disclosed by the invention has excellent heat resistance, ageing resistance and mechanical properties.

Owner:ANHUI RUIXIN AUTOMATION INSTR

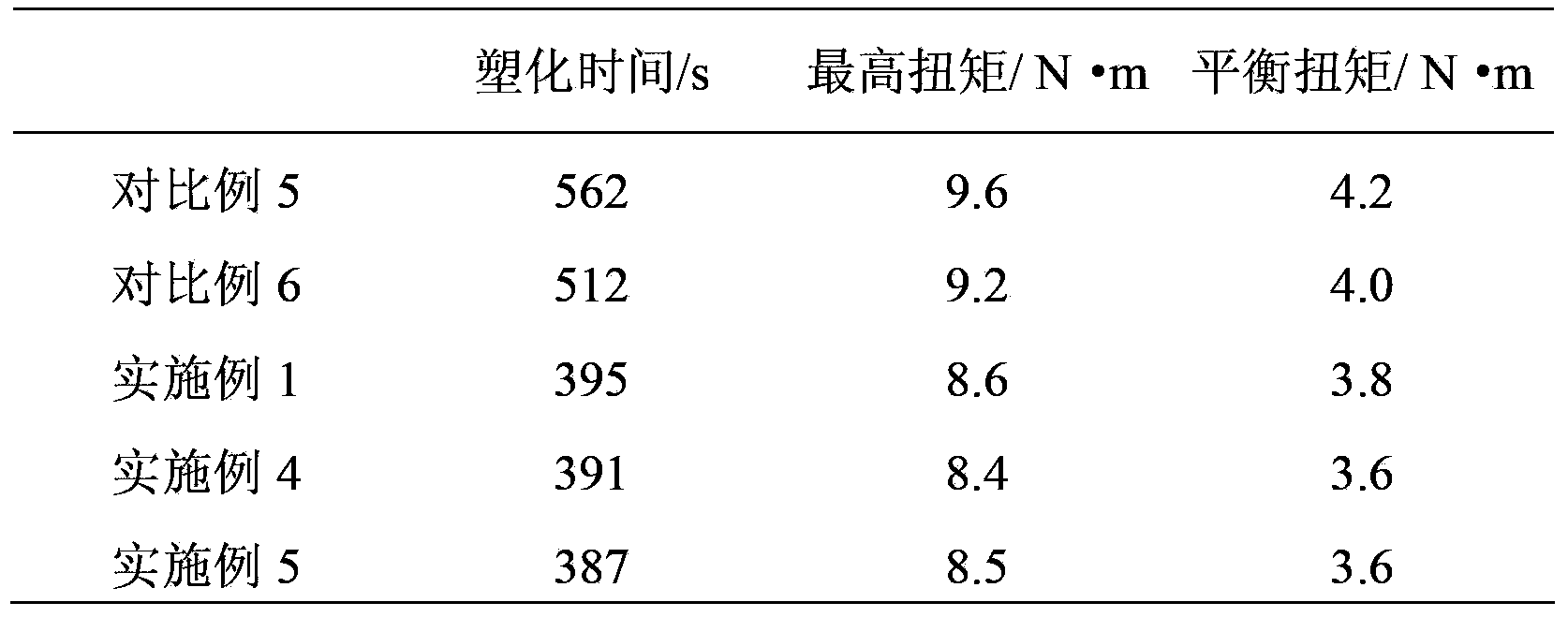

Preparation method of modified polytrifluorochloroethylene material

InactiveCN103450605AShorten melting and plasticizing timeSlows down the reaction rate of free radicalsWaxRare earth

The invention relates to a preparation method of a modified polytrifluorochloroethylene material. The method comprises the following steps of: mixing PCTFE (polychlorotrifluoroethylene), a rare earth complex stabilizer, N,N'-bi[Beta-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl] hydrazine, acrylic ester, stearic acid and PE wax together according to the mass ratio of 100:6-8:0.5-1:1-2:0.5-1:1-2, and adding the mixture into a mixing mill for melting and plasticizing, wherein the mixing processing temperature is 250-280 DEG C, and the revolving speed is 20-50r / min. The preparation method effectively broadens the processing window of PCTFE, makes the PCTFE material be subjected to injection molding while keeping better performance, plays an important role in expansion of application range of PCTFE products, and provides research basis and practical guiding significance to industrial production of the PCTFE products.

Owner:DALIAN POLYTECHNIC UNIVERSITY

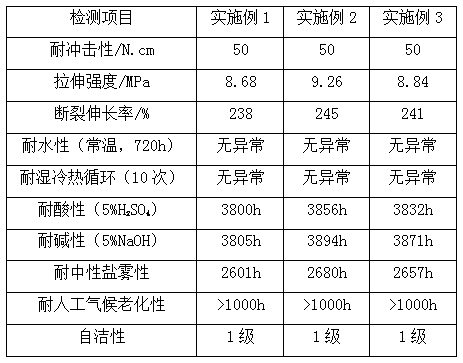

Anticorrosive tough coating material for outdoor communication tower, and preparation method thereof

InactiveCN110684440AGood dispersionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsXylyleneFiber

The invention discloses an anticorrosive tough coating material for an outdoor communication tower, and a preparation method thereof, wherein the anticorrosive tough coating material is prepared fromthe following raw materials by weight: 12-18 parts of a polytrifluorochloroethylene resin, 35-45 parts of a bisphenol A type epoxy resin, 8-12 parts of polyphenylmethylsiloxane, 2-6 parts of alpha,omega-dihydroxy polydimethylsiloxane, 2-6 parts of amino-modified polysiloxane, 2-6 parts of hexamethyldisilazane, 2-6 parts of gas-phase nanometer silicon dioxide, 7-11 parts of silicon carbide short fibers, 12-16 parts of mica iron oxide powder, 2-8 parts of xylene, 10-20 parts of an acetone aqueous solution and 1-3 parts of a polyamine mixed curing agent. According to the invention, the prepared anticorrosive tough coating material has excellent anticorrosive performance, weather resistance and good elasticity; and by coating the communication tower with the anticorrosive tough coating material, the coating is compact, has excellent anticorrosive, anti-aging, hydrophobic, stain-resistant and impact-resistant effects, can well adapt to severe environments, and effectively prolongs the service life of the communication tower.

Owner:广西凯威铁塔有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com