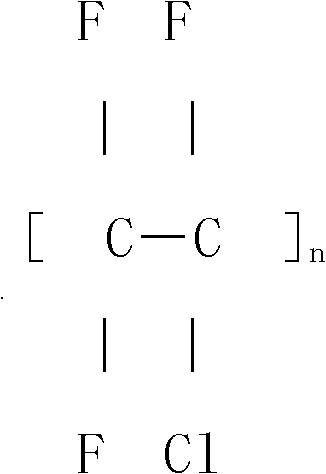

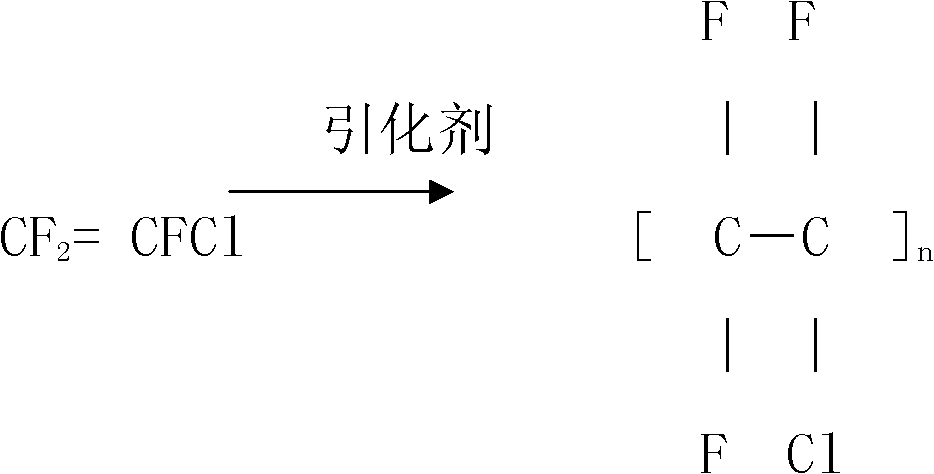

Method for preparing polychlorotrifluoroethylene resin

A polychlorotrifluoroethylene and resin technology, which is applied in the field of preparation of fluorine-containing polymer materials, can solve the problems of easy degradation, unstable end groups, low conversion rate of chlorotrifluoroethylene, etc., so as to improve the conversion rate and improve polymerization. The effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a 10-liter vertical SUS316L stainless steel polymerization reactor, add 5 kg of deionized water, 2 kg of perfluoro-4-methyl-2-pentane, 0.3 g of fluorine-containing decyl acrylate butanediol, 1.5 g of perfluoropentyl Butyl peroxide, control the stirring speed to 350 rpm, after deoxidation treatment, control the internal temperature of the polymerization tank to 40°C, add CTFE gas to make the internal pressure of the tank reach the gauge pressure of 0.9 MPa. When the pressure in the kettle drops to 0.8MPa, add CTFE gas to the kettle to maintain the pressure in the kettle at 0.85-0.9MPa. During the polymerization reaction, the internal temperature of the polymerization kettle was controlled at 40°C. When accumulatively 1.5 kilograms of CTFE monomers were added in the polymerization kettle, stop the feeding of CTFE, finish reaction after 1 hour. The total polymerization time was 8 hours. Recover the residual CTFE gas in the kettle, reduce the pressure of the kettle to ...

Embodiment 2

[0036] In a 10-liter vertical SUS316L stainless steel polymerization reactor, add 5.7 kg of deionized water, 1.3 kg of perfluoro-4-methyl-2-pentane, 0.35 g of fluorine-containing decanyl acrylate butanediol, and 1.4 g of perfluoropentyl Butyl peroxide, control the stirring speed to 350 rpm, after deoxidation treatment, control the internal temperature of the polymerization tank to 50°C, add CTFE gas to make the internal pressure of the tank reach the gauge pressure of 0.9 MPa. When the pressure in the kettle drops to 0.8MPa, add CTFE gas to the kettle to maintain the pressure in the kettle at 0.85-0.9MPa. During the polymerization reaction, the internal temperature of the polymerization kettle was controlled to 50°C. When accumulative 0.7 kilograms of CTFE monomers were added in the polymerization kettle, stop feeding of CTFE, finish reaction after 1 hour. The total polymerization time was 7 hours. The remaining CTFE gas in the kettle is recovered, the pressure of the kettle...

Embodiment 3

[0039] In a 10-liter vertical SUS316L stainless steel polymerization reactor, add 5 kg of deionized water, 2.5 kg of perfluoro-4-methyl-2-pentane, 5.625 g of fluorine-containing decanyl acrylate butanediol 9 g of perfluoropentyl Butyl peroxide, control the stirring speed to 350 rpm, after deoxidation treatment, control the inner temperature of the polymerization tank to 20°C, add CTFE gas to make the inner pressure of the tank reach the gauge pressure of 0.9 MPa. When the pressure in the kettle drops to 0.8MPa, add CTFE gas to the kettle to maintain the pressure in the kettle at 0.85-0.9MPa. During the polymerization reaction, the internal temperature of the polymerization kettle was controlled at 20°C. When accumulative 1.125 kilograms of CTFE monomers were added in the polymerization kettle, stop the feeding of CTFE, finish reaction after 1 hour. The total polymerization time was 6 hours. The remaining CTFE gas in the kettle is recovered, the pressure of the kettle is lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com