Patents

Literature

1273 results about "Liquid oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid oxygen—abbreviated LOx, LOX or Lox in the aerospace, submarine and gas industries—is the liquid form of elemental oxygen. It was used as the oxidizer in the first liquid-fueled rocket invented in 1926 by Robert H. Goddard an application which has continued to the present.

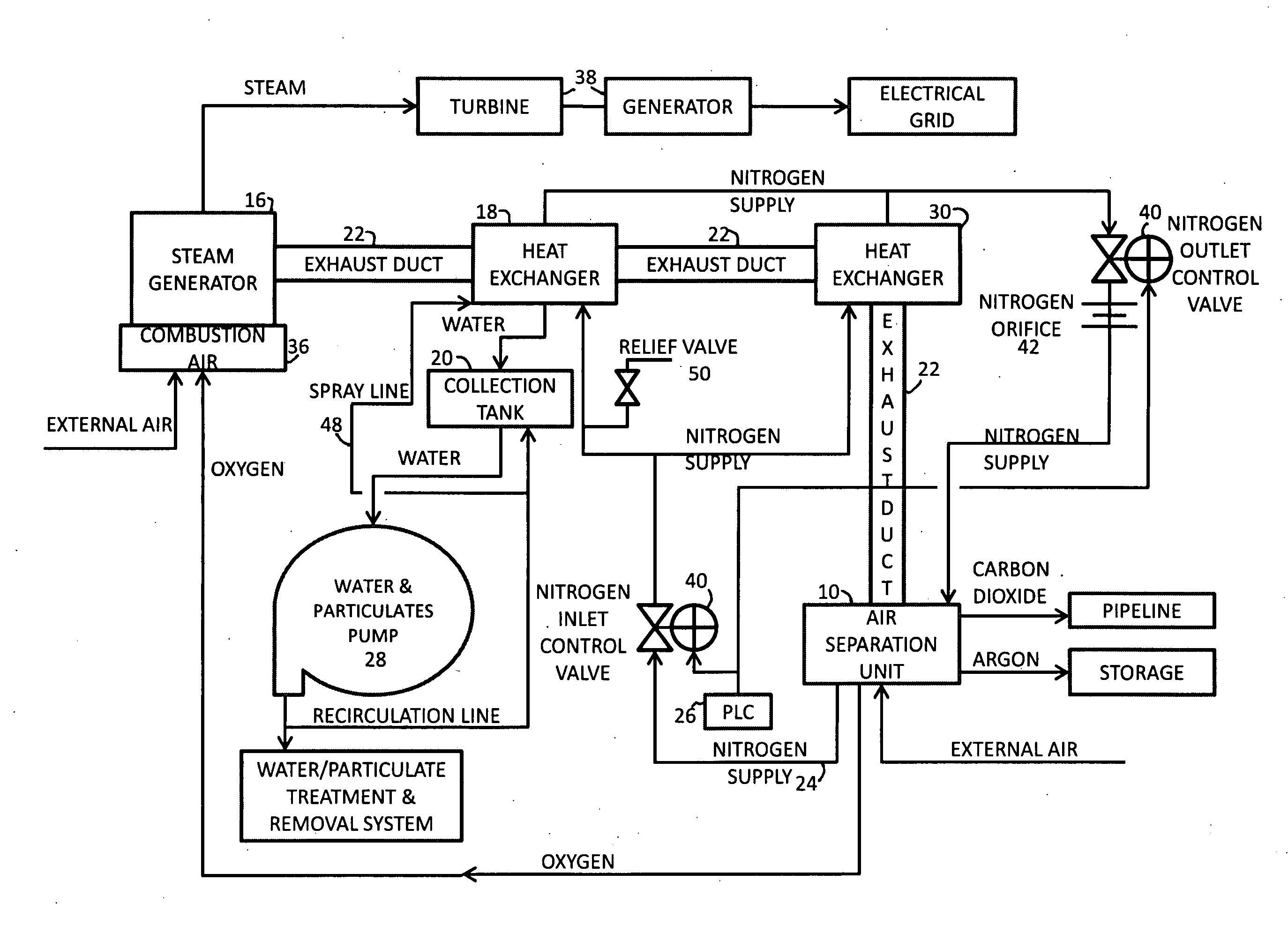

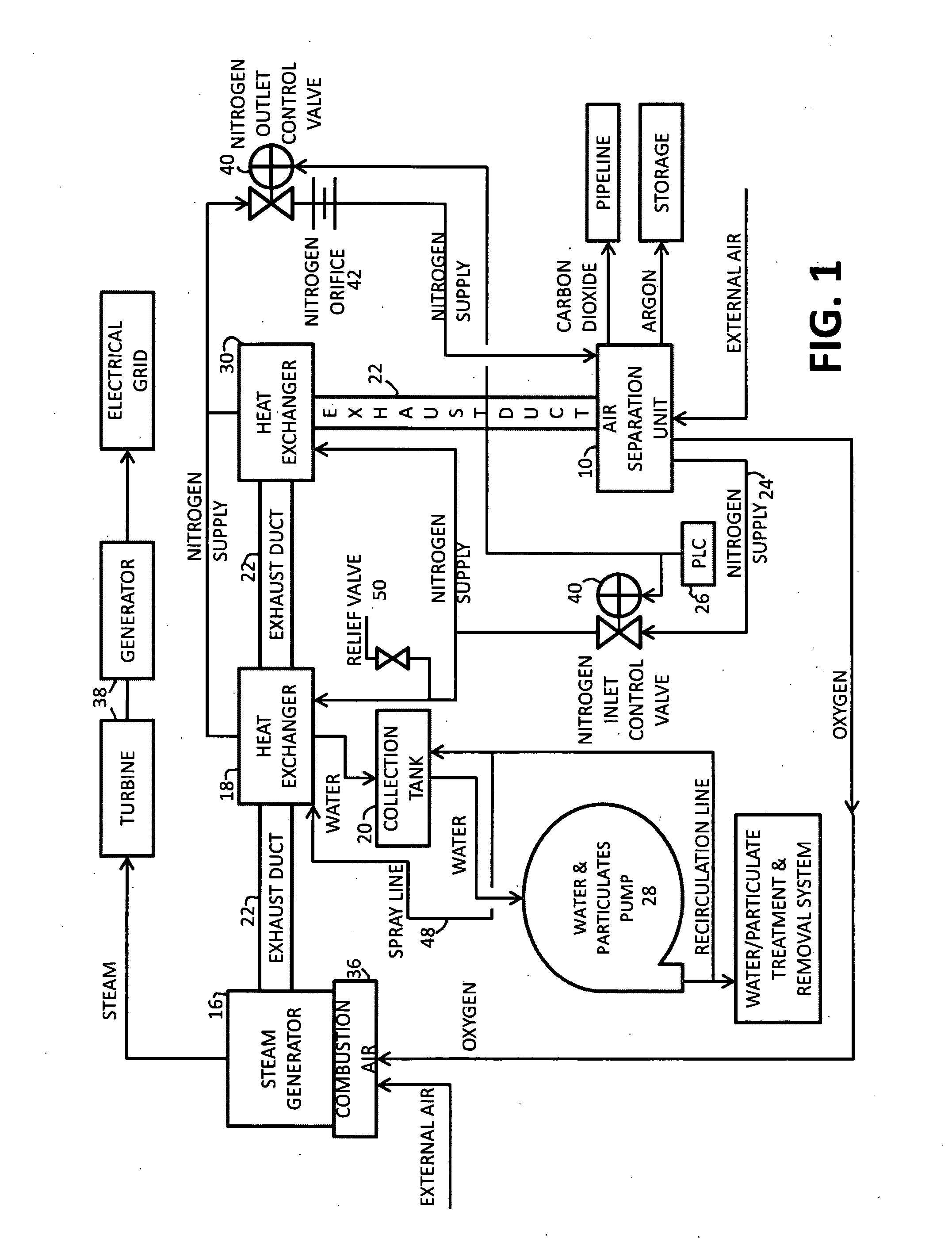

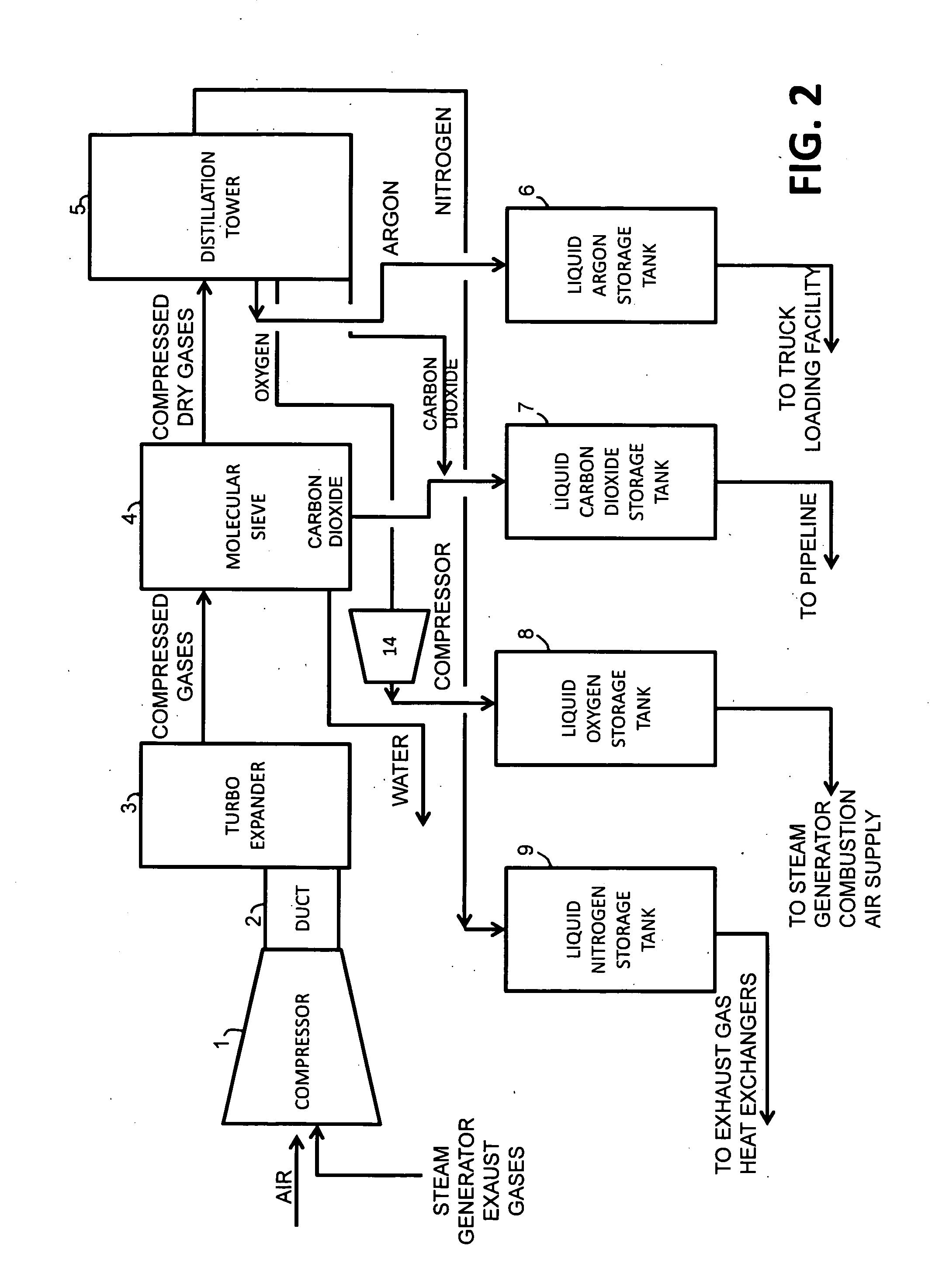

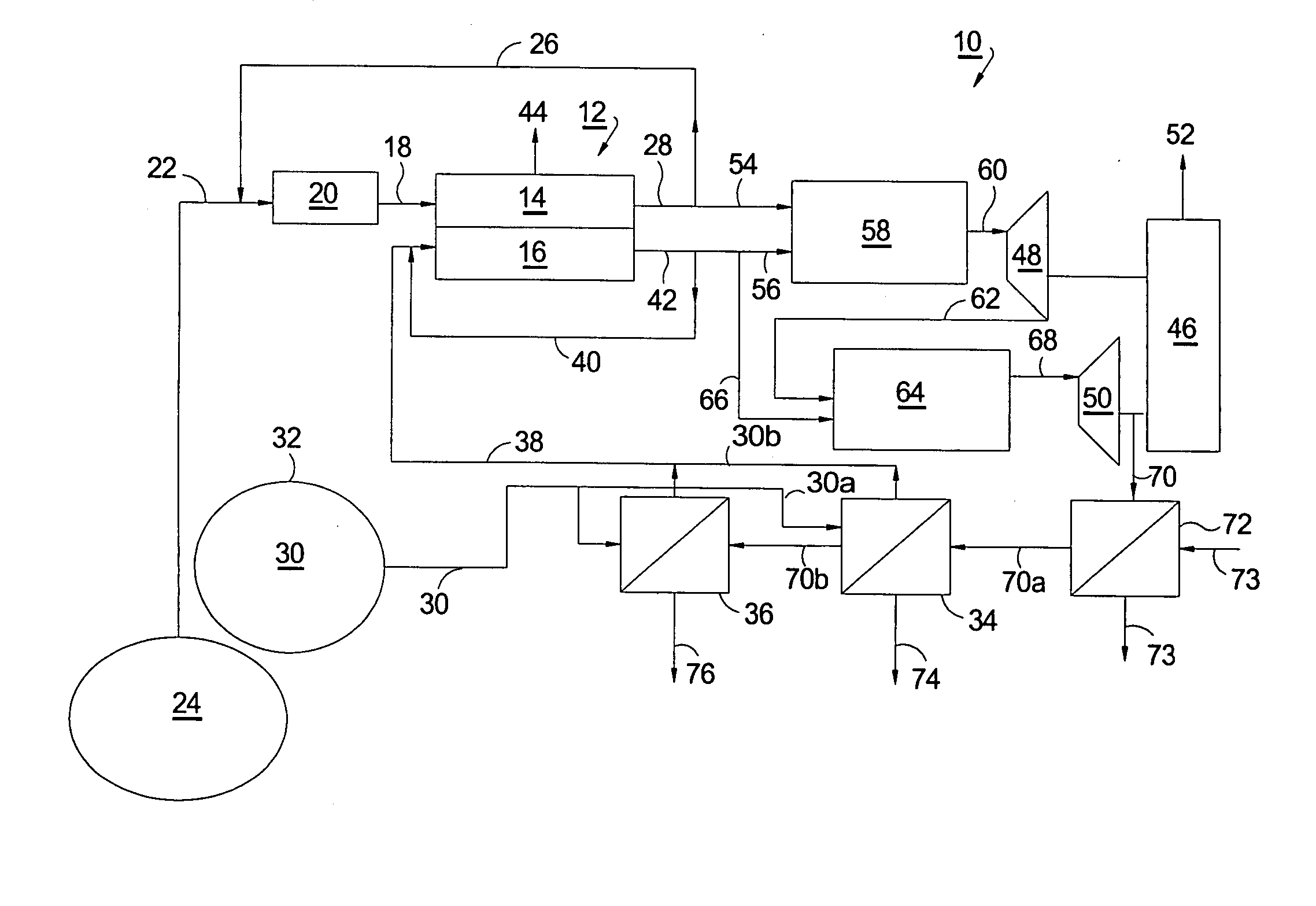

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

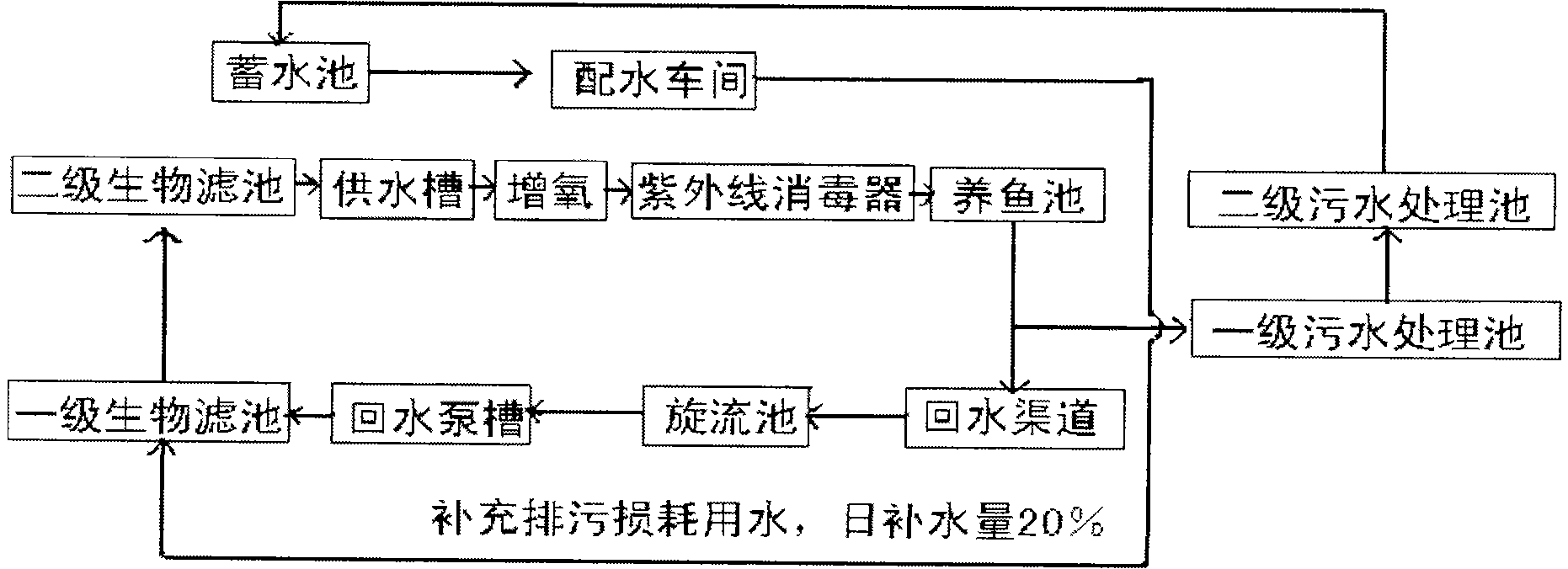

Ecological closed cycle water fish-cultivating method

InactiveCN101548655AClean up sediment pollutionWater/sewage treatment by irradiationClimate change adaptationDiseaseParticulates

The present invention belongs to an industrialization aquiculture field, particularly relates to a closed cycle water industrialized fish cultivating system. The system separates solid and liquid in a storage sedimentation basin and a backwater channel sedimentation and rotational flow pool sedimentation, the tiny particulate matter is separated and purified by a sandrock filtering bed of a one level biological filter based on the water particulate matter separation, the water purified by the one level biological filter is feed into a two stage biological filter, the biological film of biologic filling material in the one level and the two stage biological filters is degraded with ammonia nitrogen and azote nitrous acid, the total purifying rate of the water particulate matter reaches more than 99%, the culturing water is added with oxygen mechanically or by liquid oxygen, finally the water is disinfected and sterilized through a ultraviolet ray sterilizer, and the clean ecological water is feed into a fish pool, thus the waste water of the fish pool may be purified and used in repeat. The fish-cultivating system implements completely closed cycle water industrialized fish cultivation, the fish is out of a disease or less, and the fish survival is more than 80%.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Multi-mode multi-propellant liquid rocket engine

InactiveUS6619031B1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberLiquid fluorine

A multi-mode multi-propellant rocket engine capable of operating in a plurality of selected modes.Propellant components may include liquid hydrogen, liquid hydrocarbon, liquid oxygen, liquid fluorine, and liquid air. The liquid oxygen and the liquid air are stored in separate tanks are mixed in a dedicated mixer prior to their injection into the combustion chamber.

Owner:MSE TECH APPL

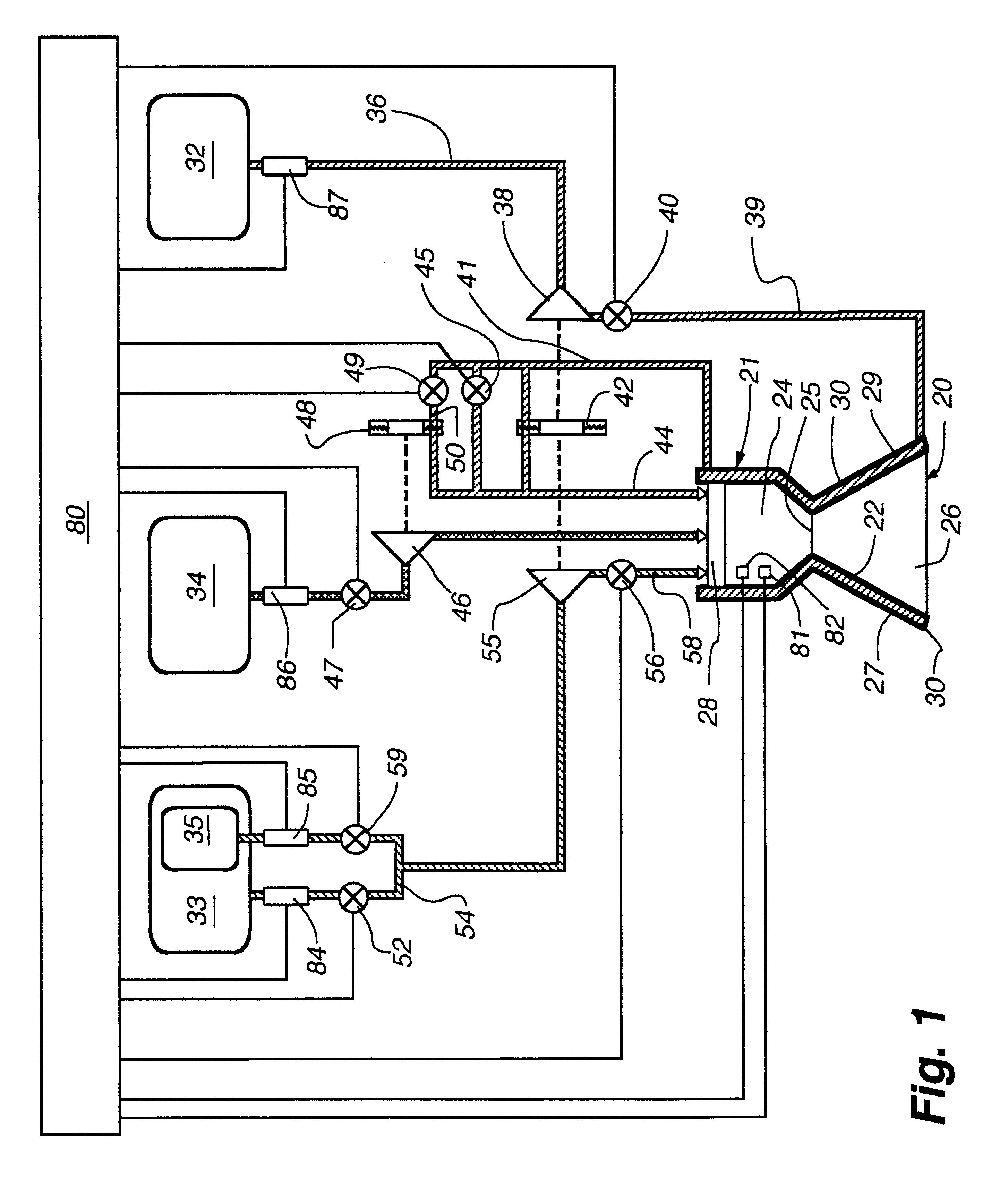

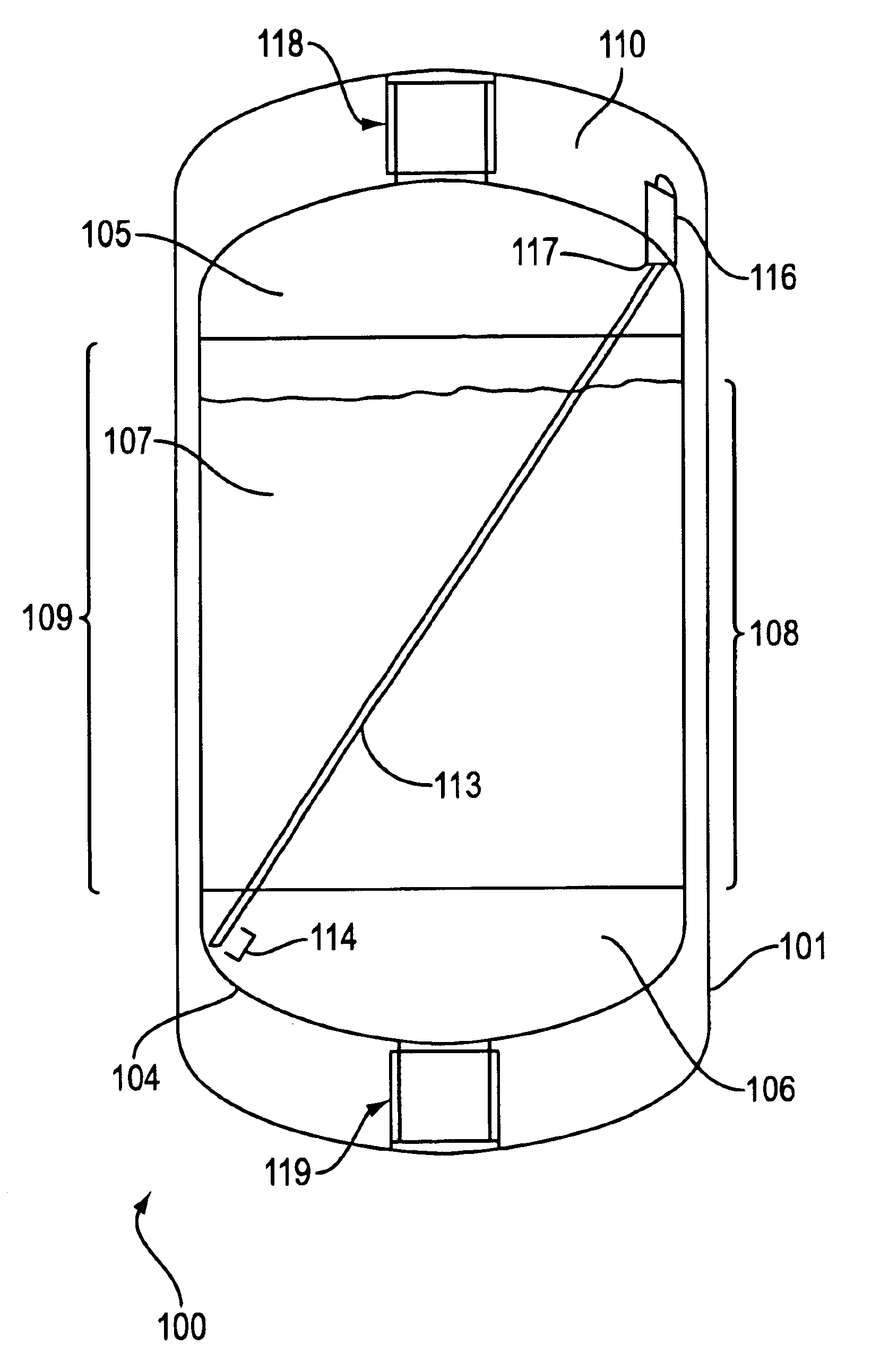

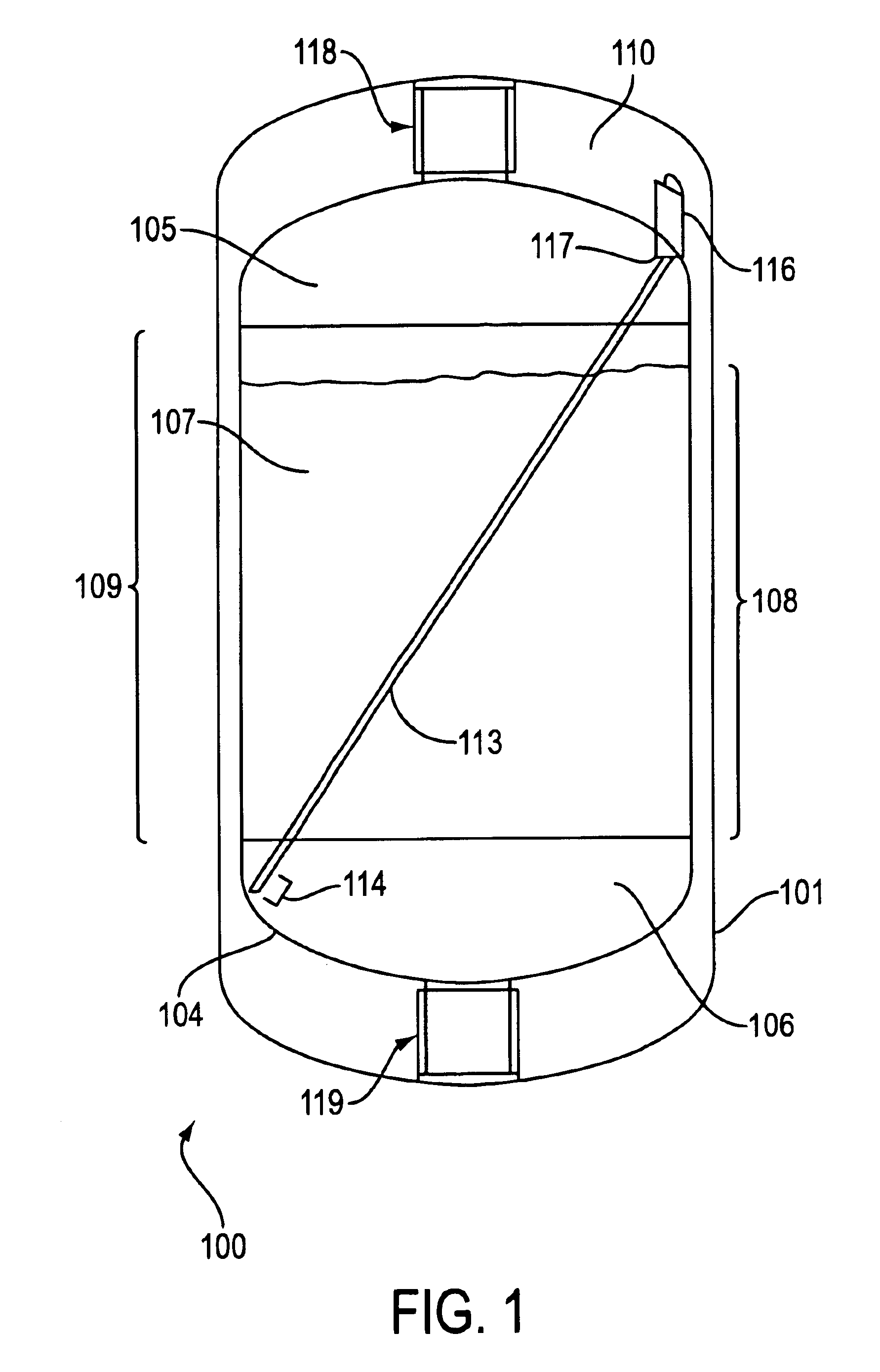

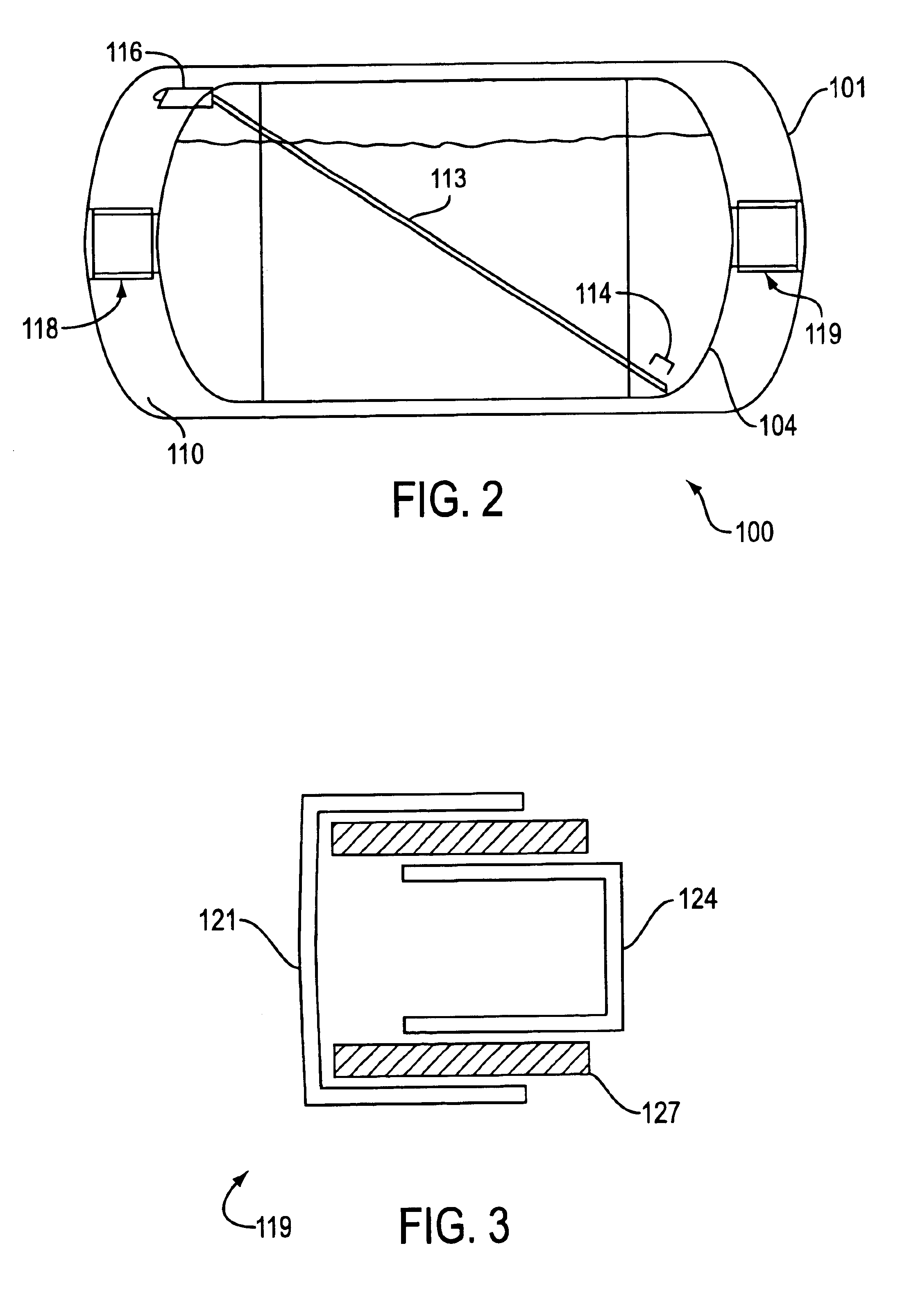

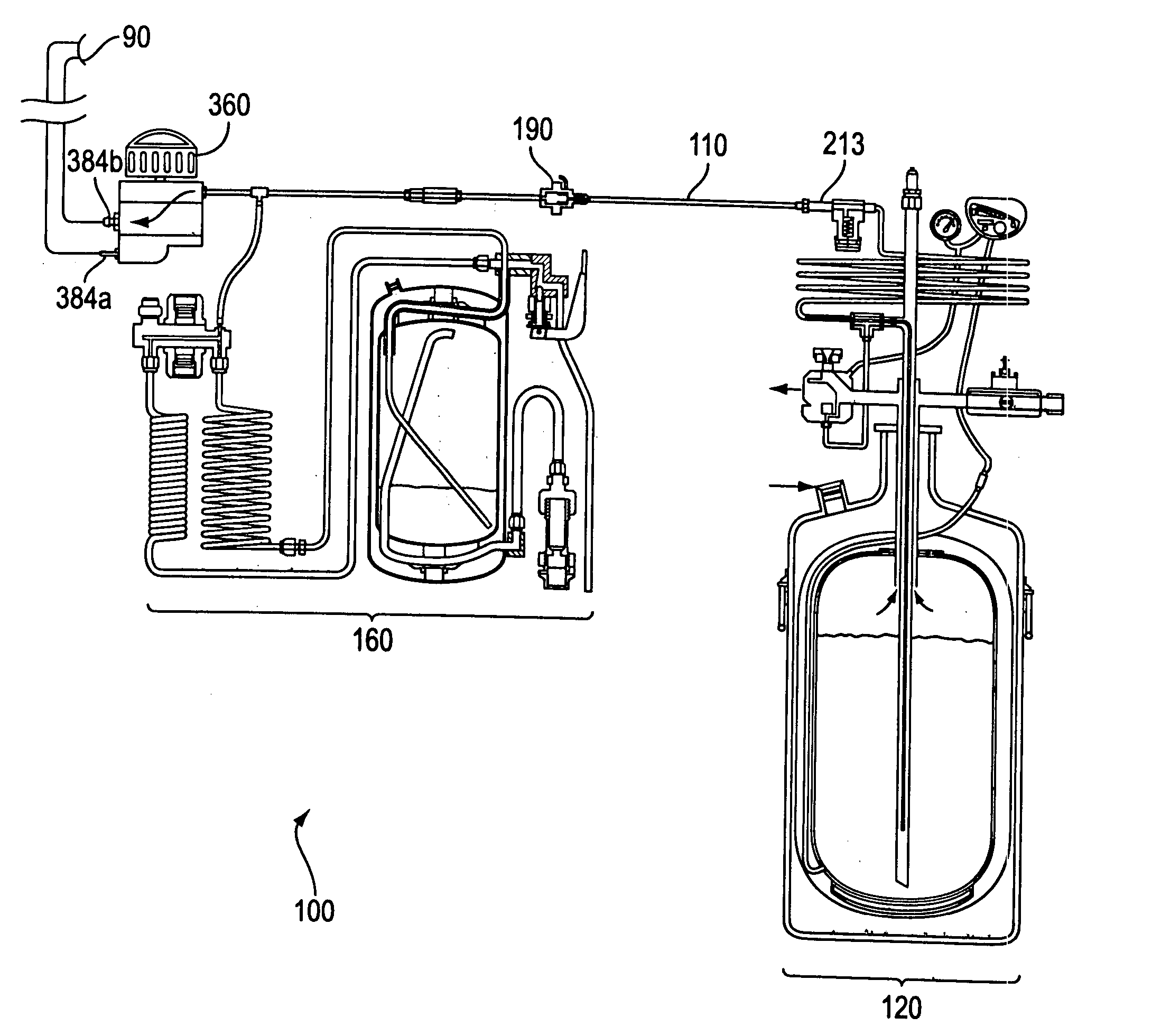

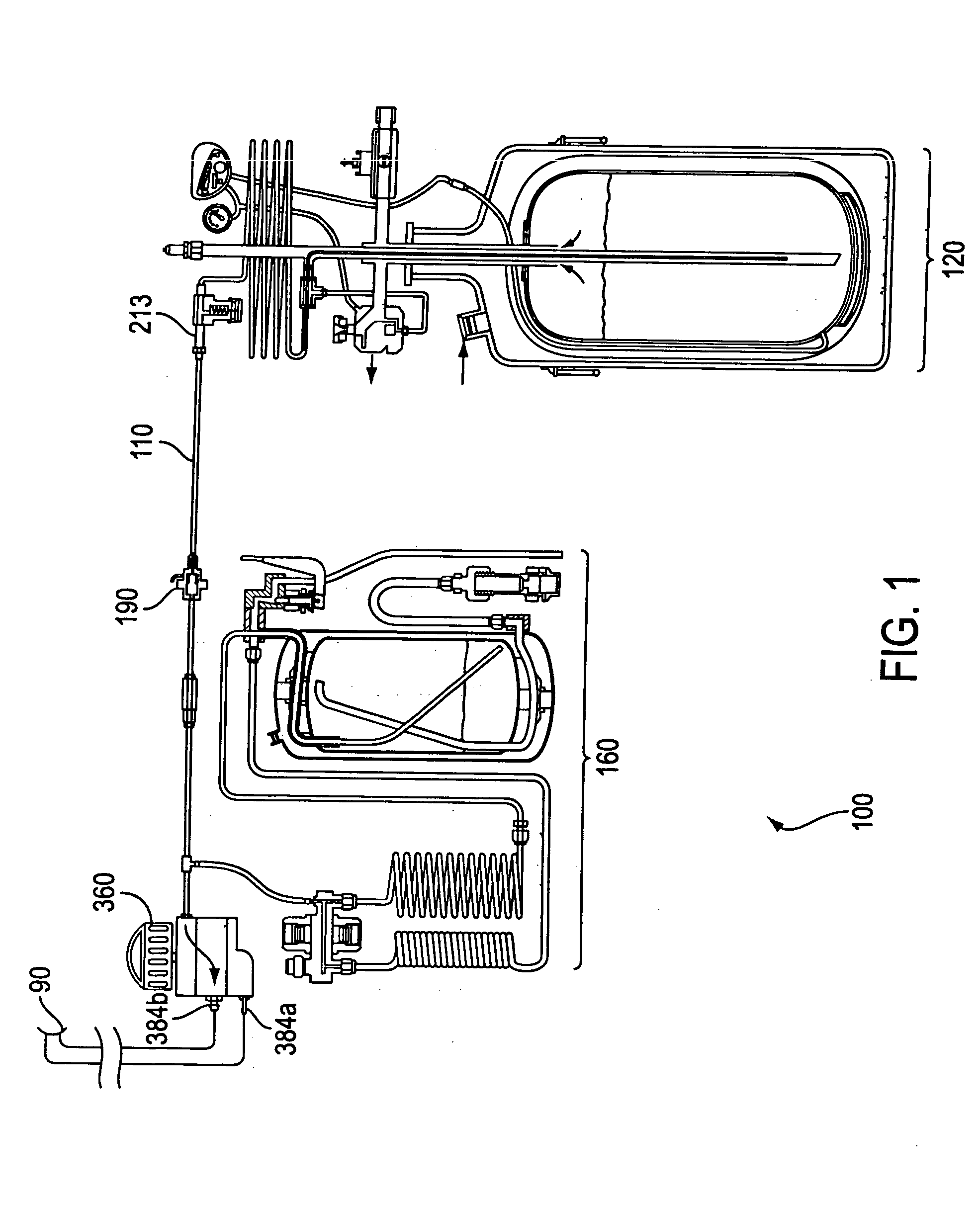

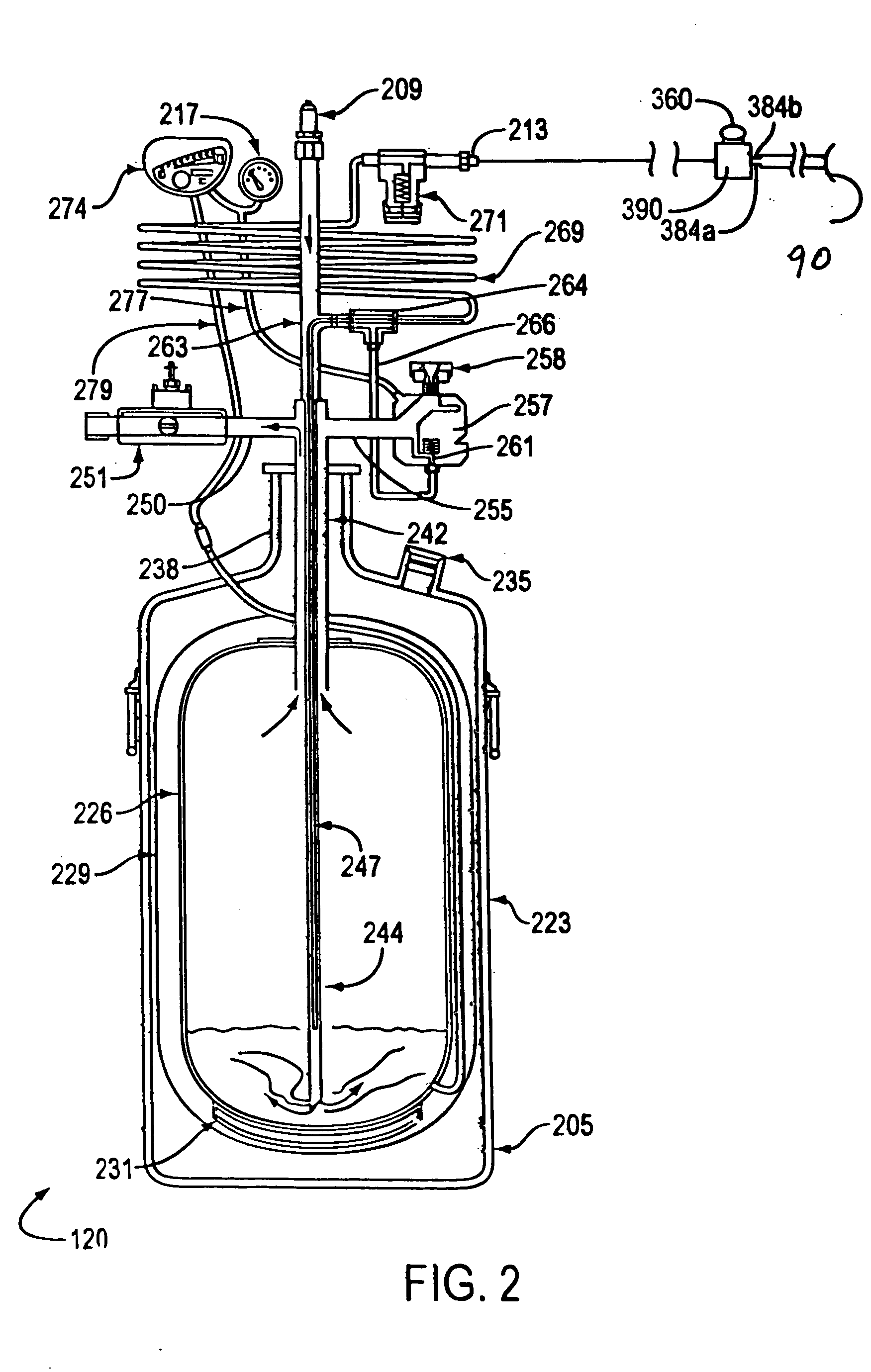

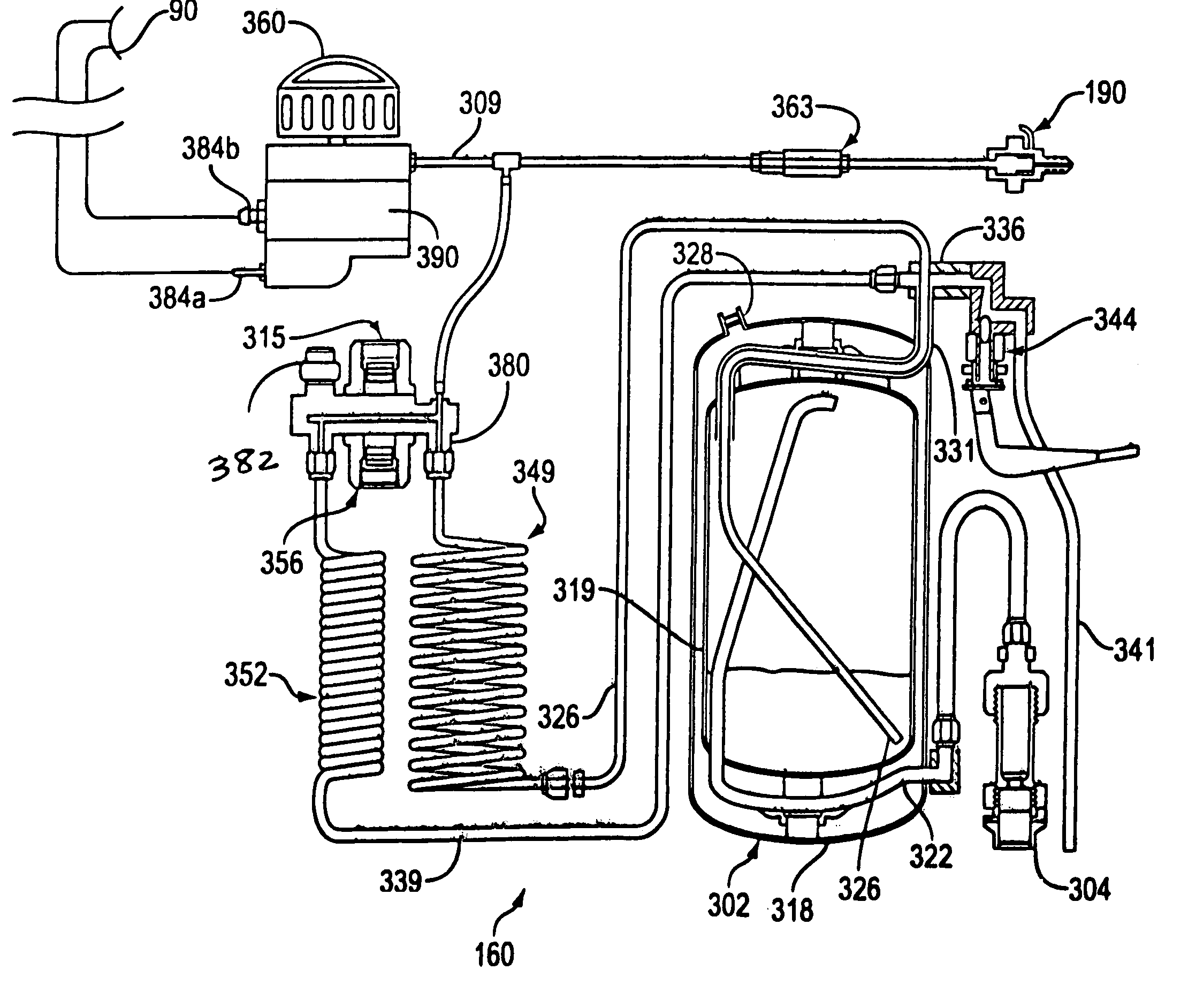

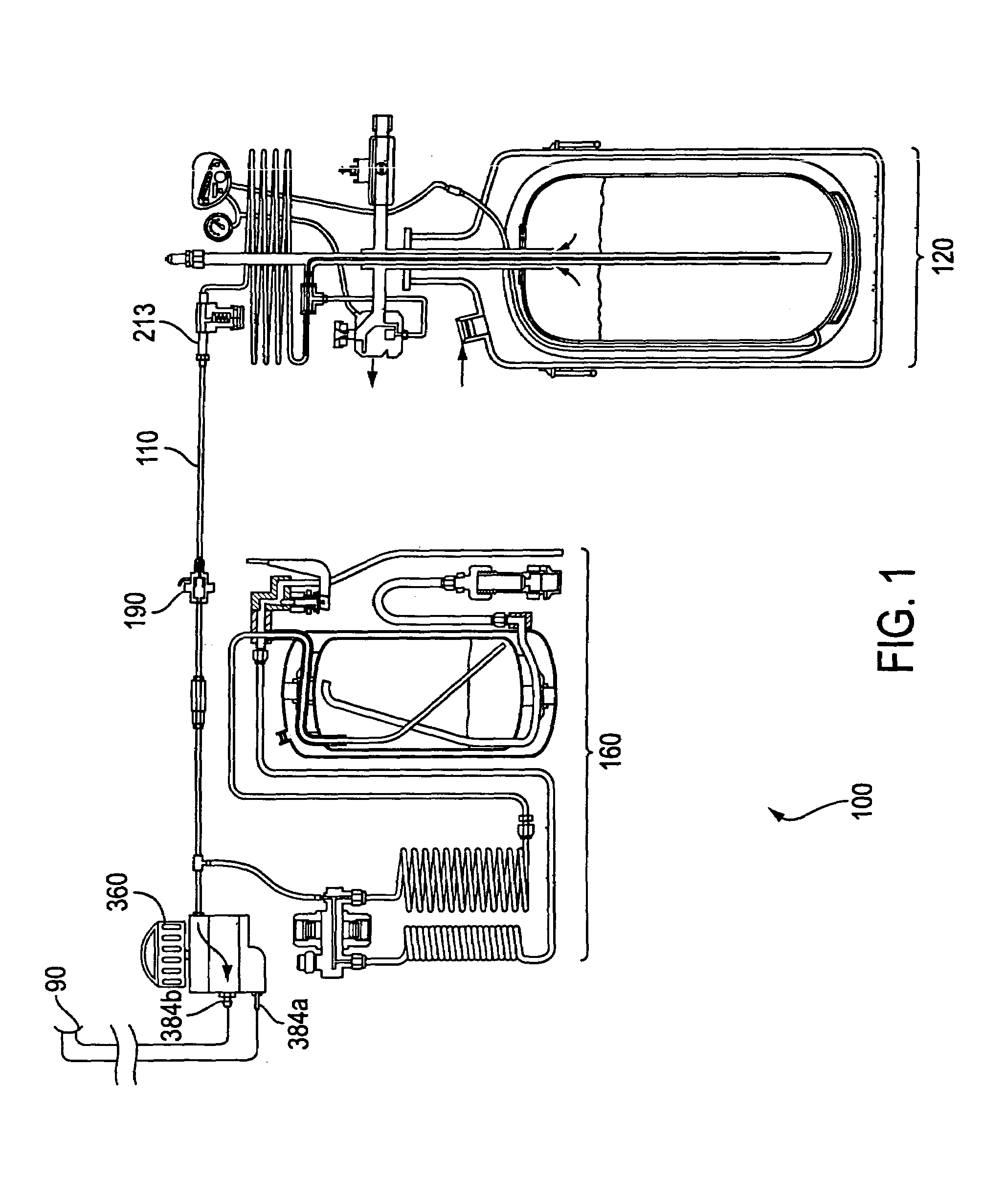

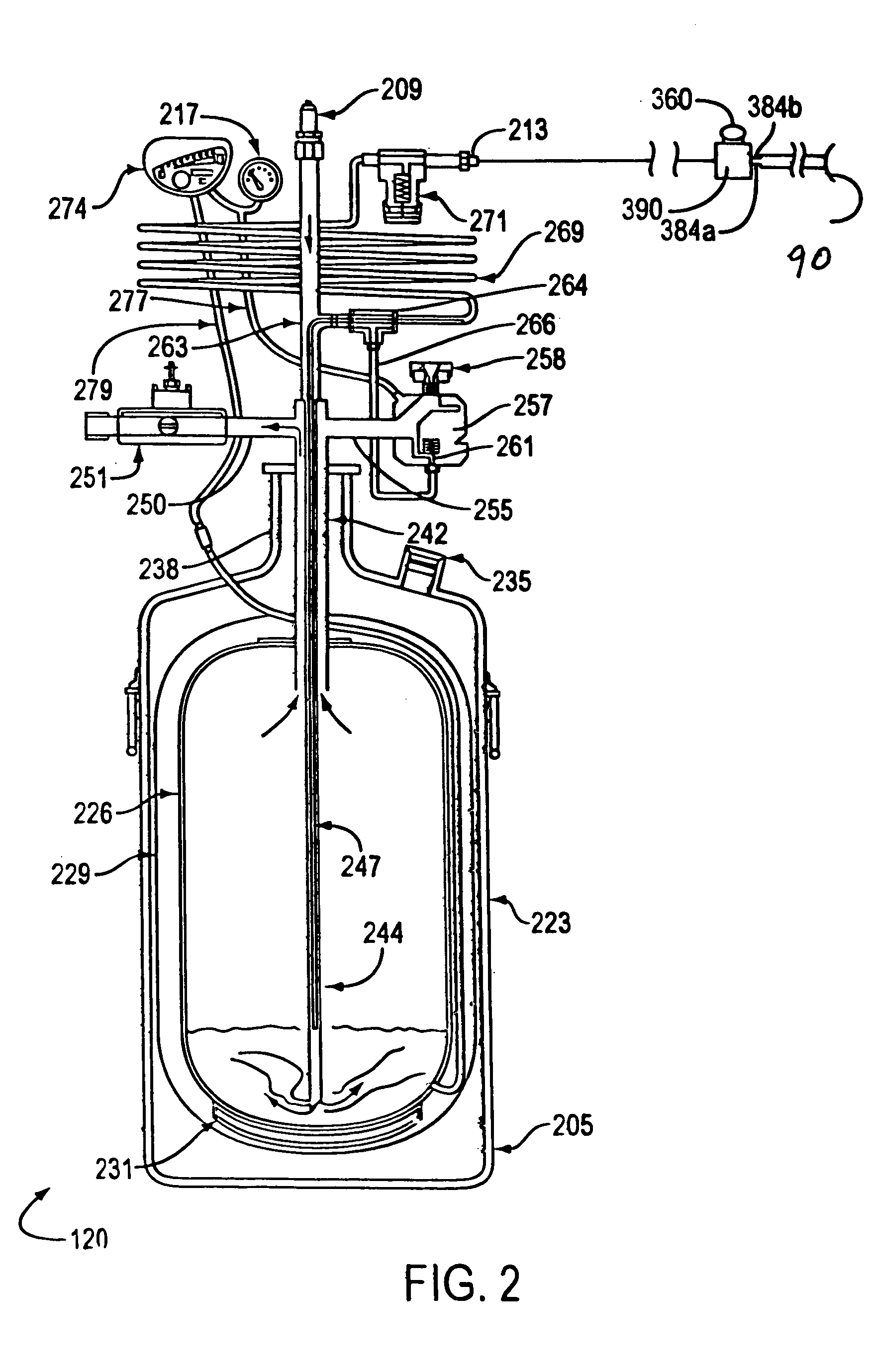

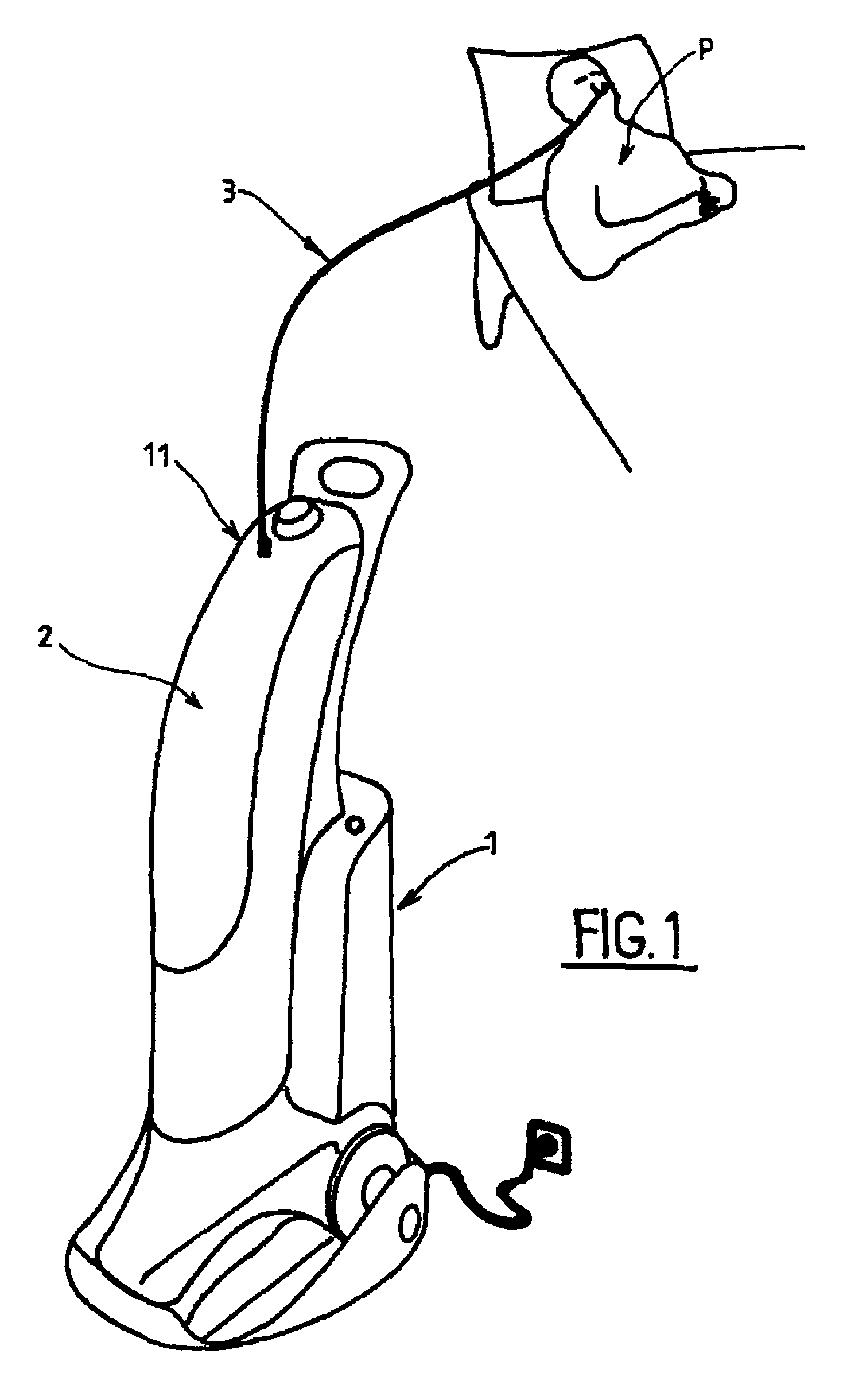

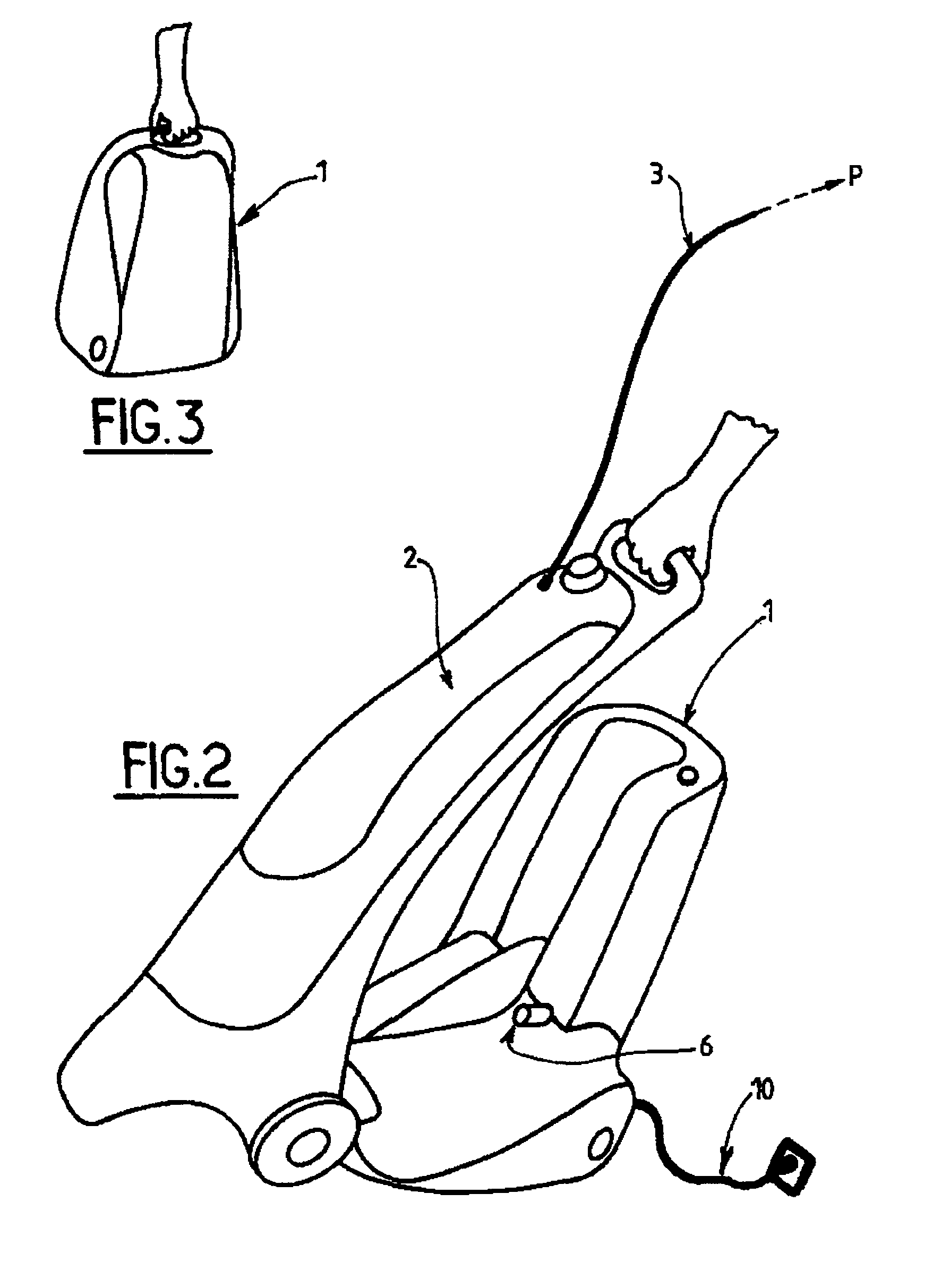

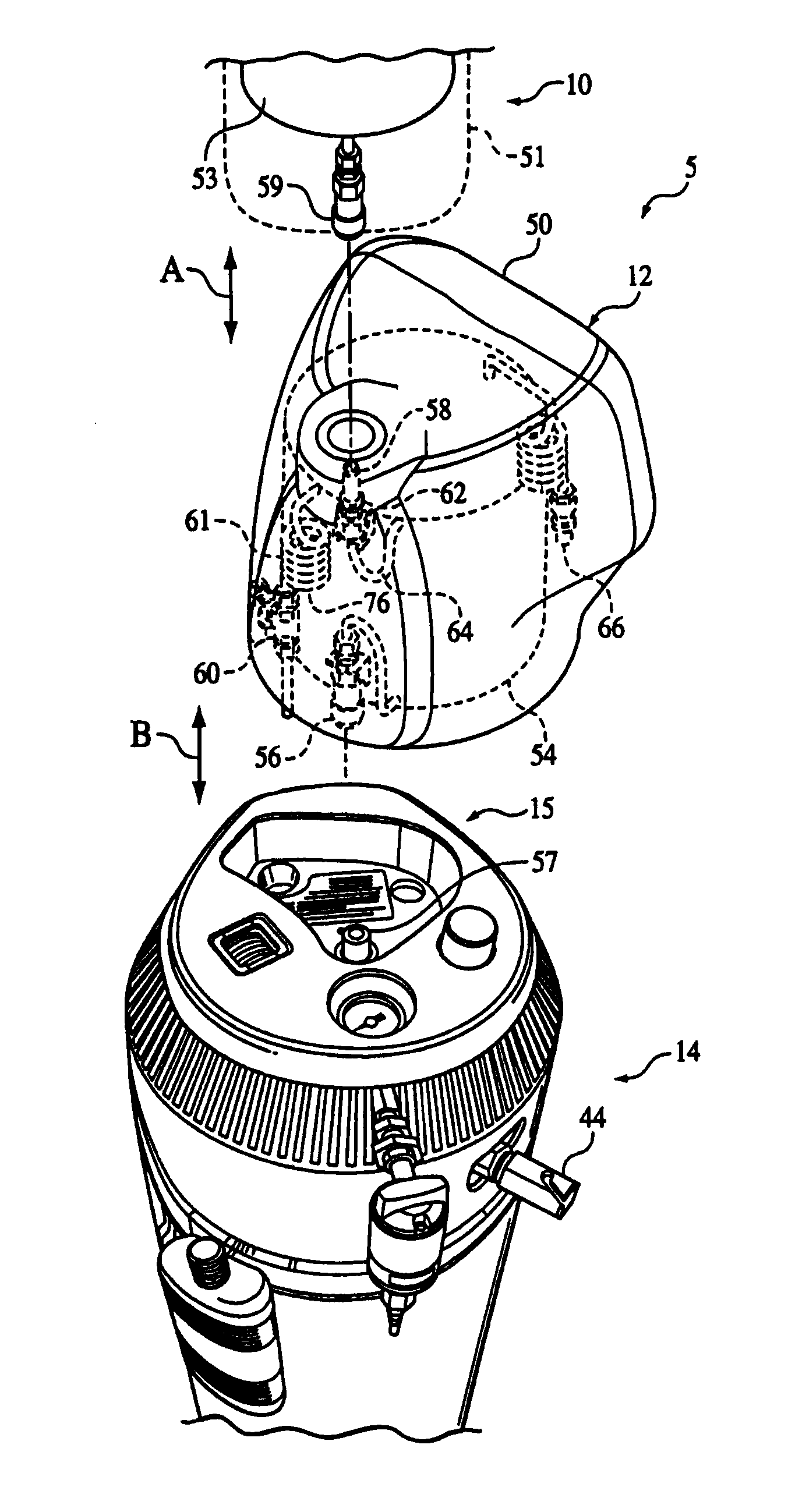

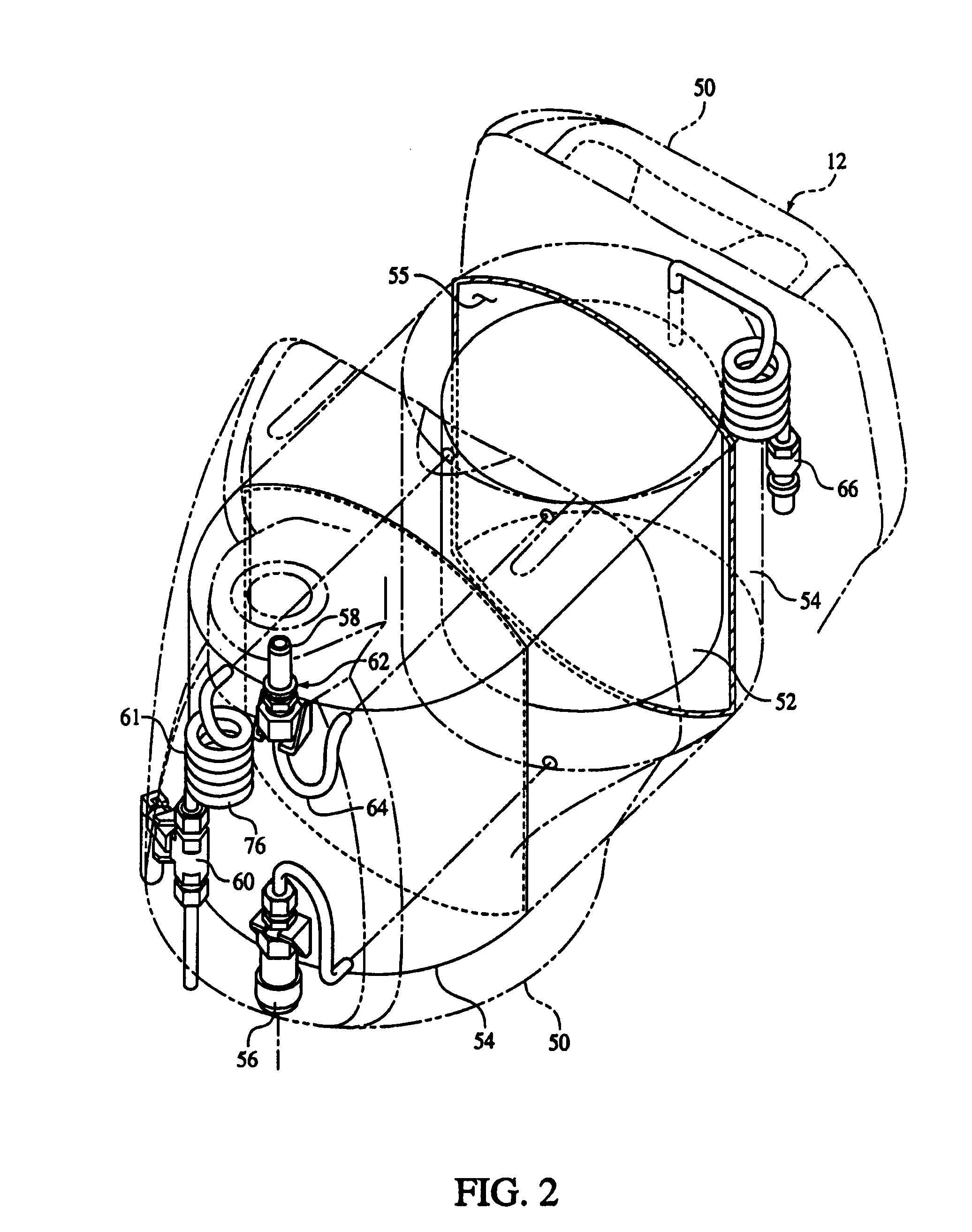

Portable liquid oxygen unit with multiple operational orientations

A portable liquid oxygen (LOX) storage / delivery apparatus is provided, including an insulated LOX container having an interior, a top portion, bottom portion, and sidewall, the sidewall including a first and second side portion, both extending between the top and bottom portion, and a port system in communication with the interior for charging the container and for withdrawing LOX and gaseous oxygen. The gaseous oxygen is withdrawn from the container through a first outlet and LOX is withdrawn from the container through a second outlet when the container is positioned in a first orientation with the sidewall vertically oriented, as well as when the container is positioned in a second orientation with the second side portion oriented downwardly and with the first side portion upwardly and overlying the second side portion, and any position in between.

Owner:CAIRE

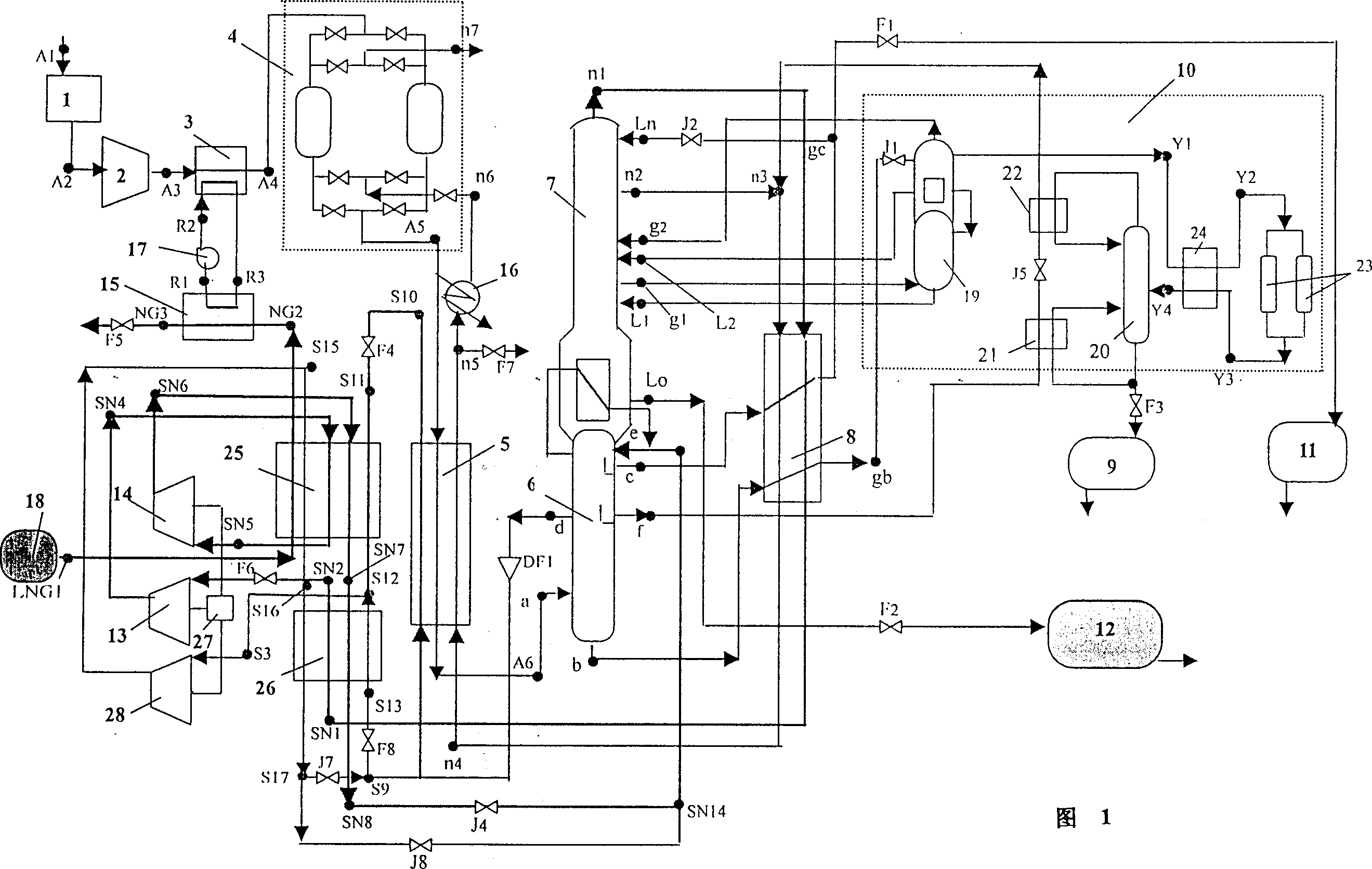

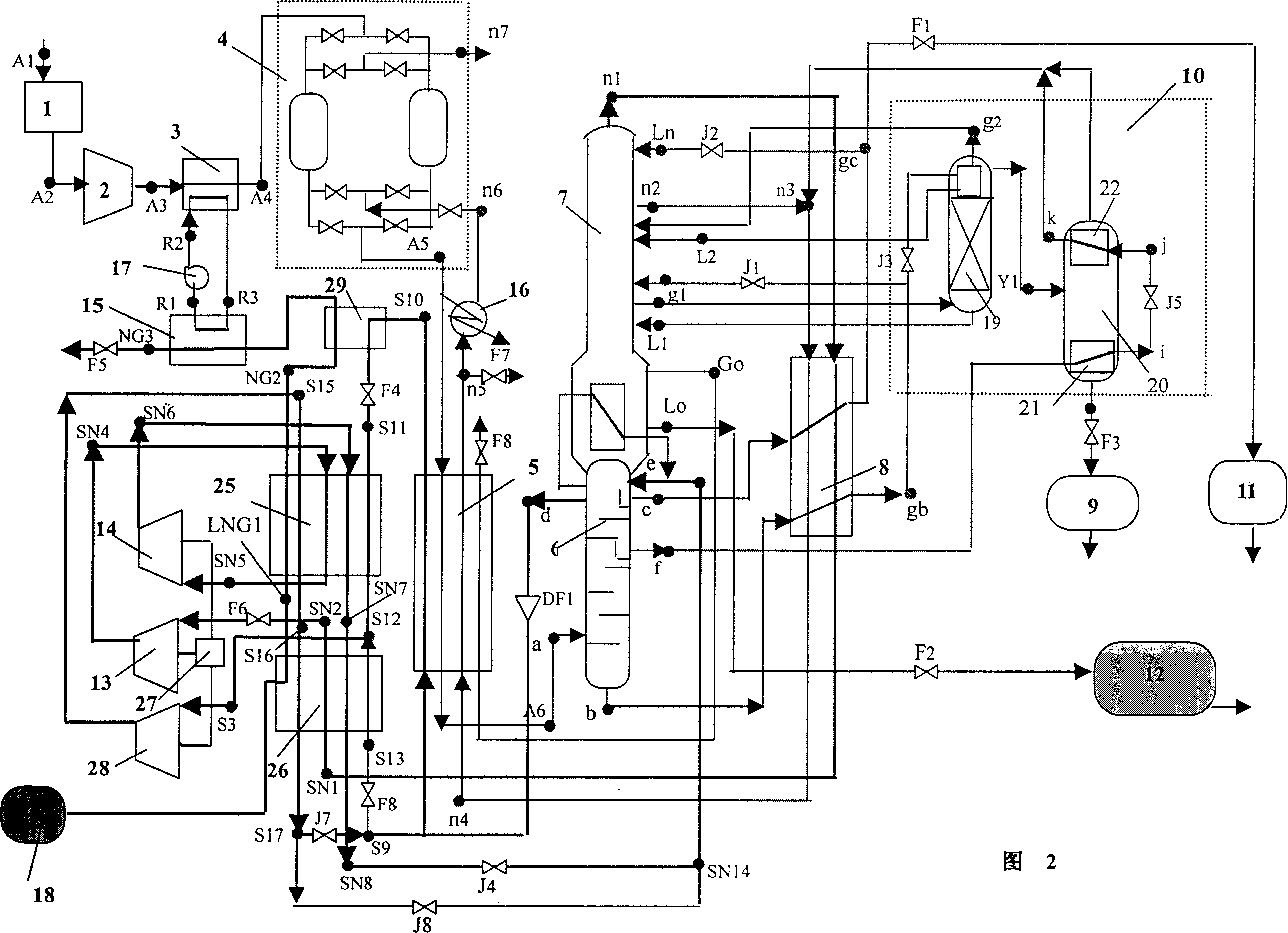

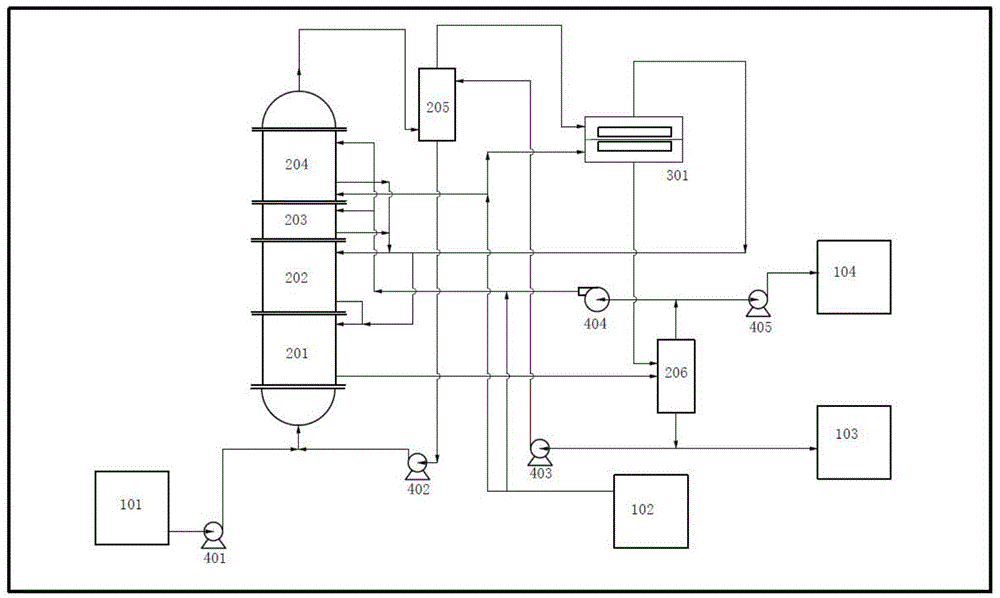

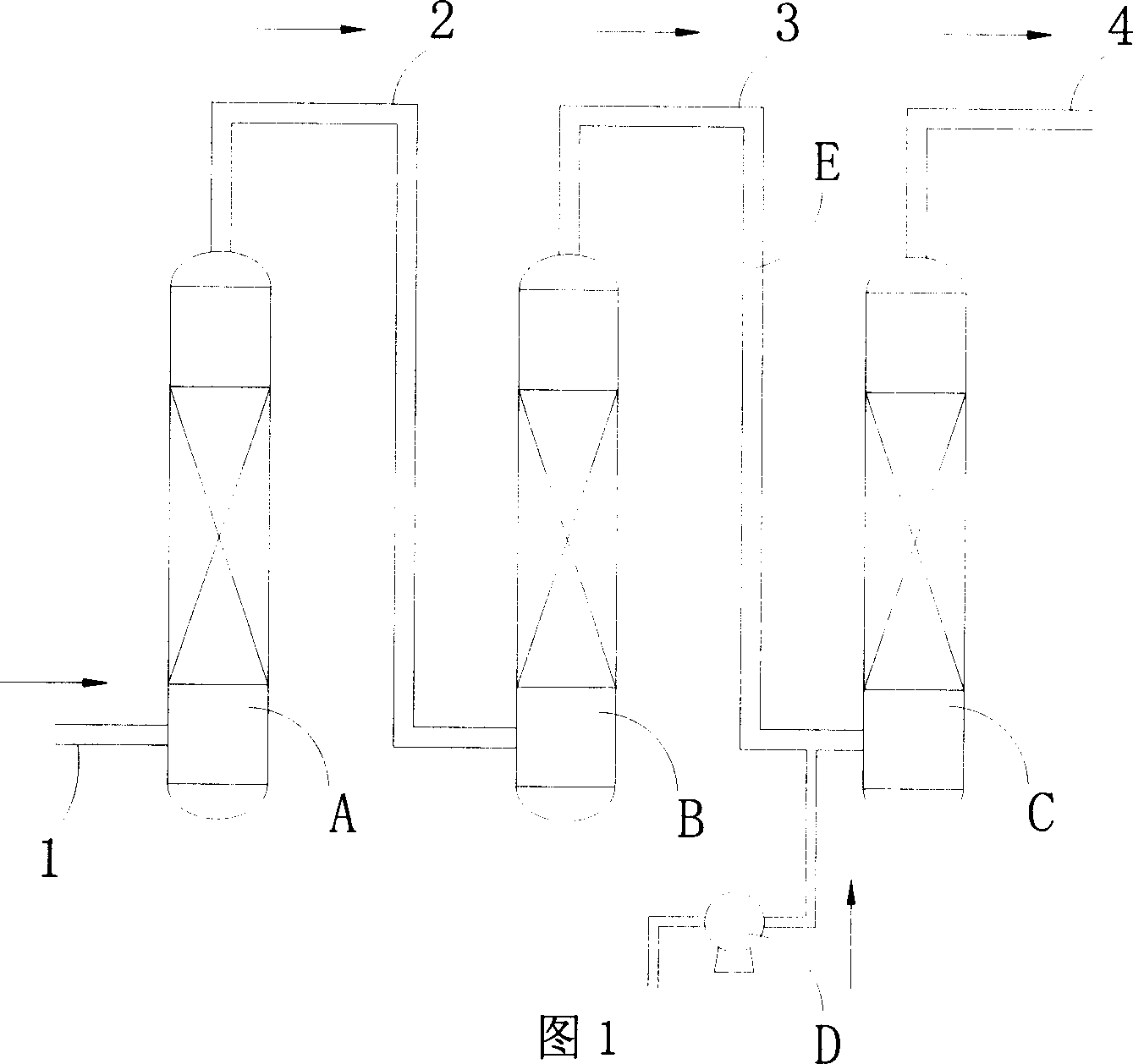

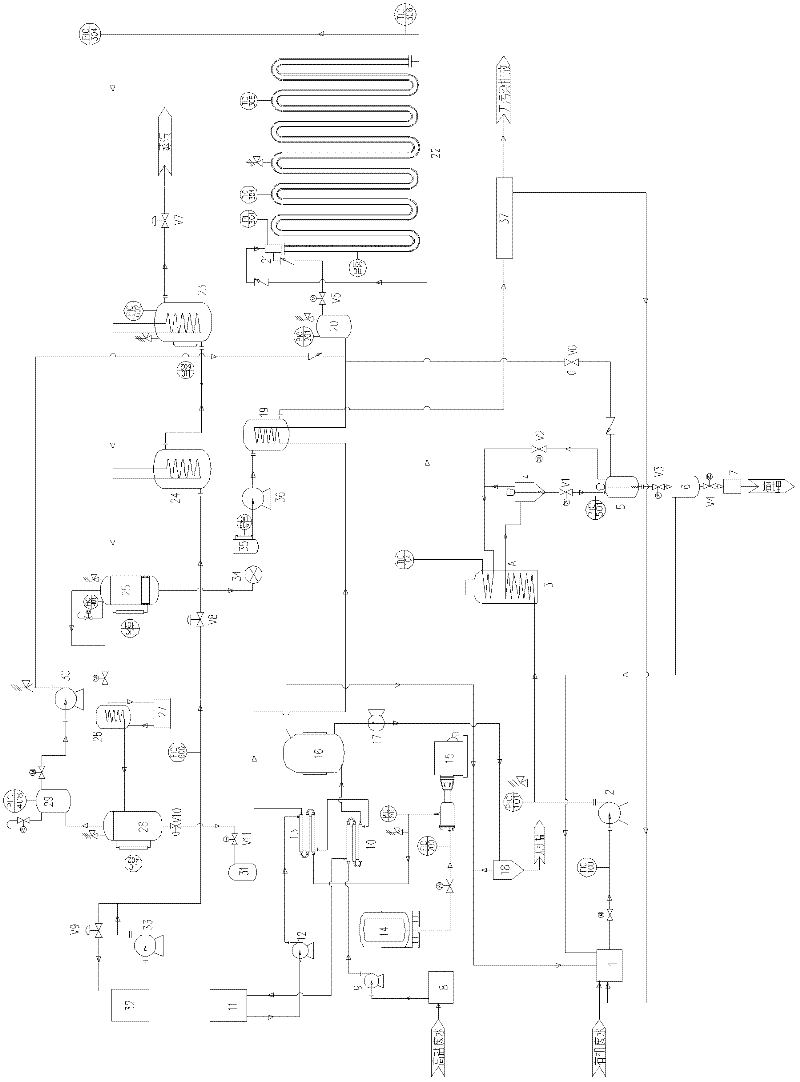

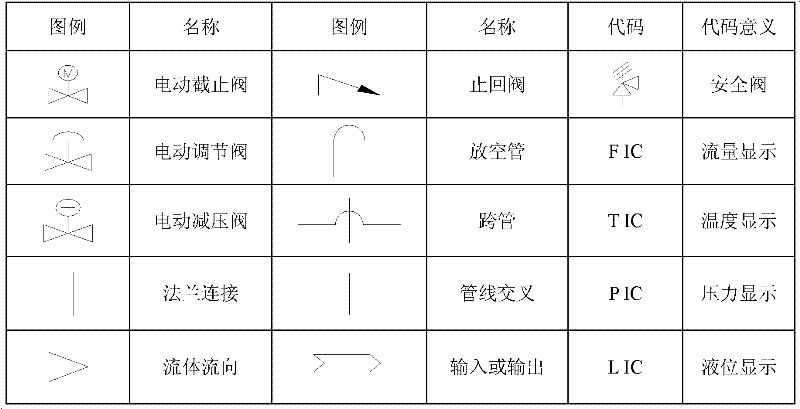

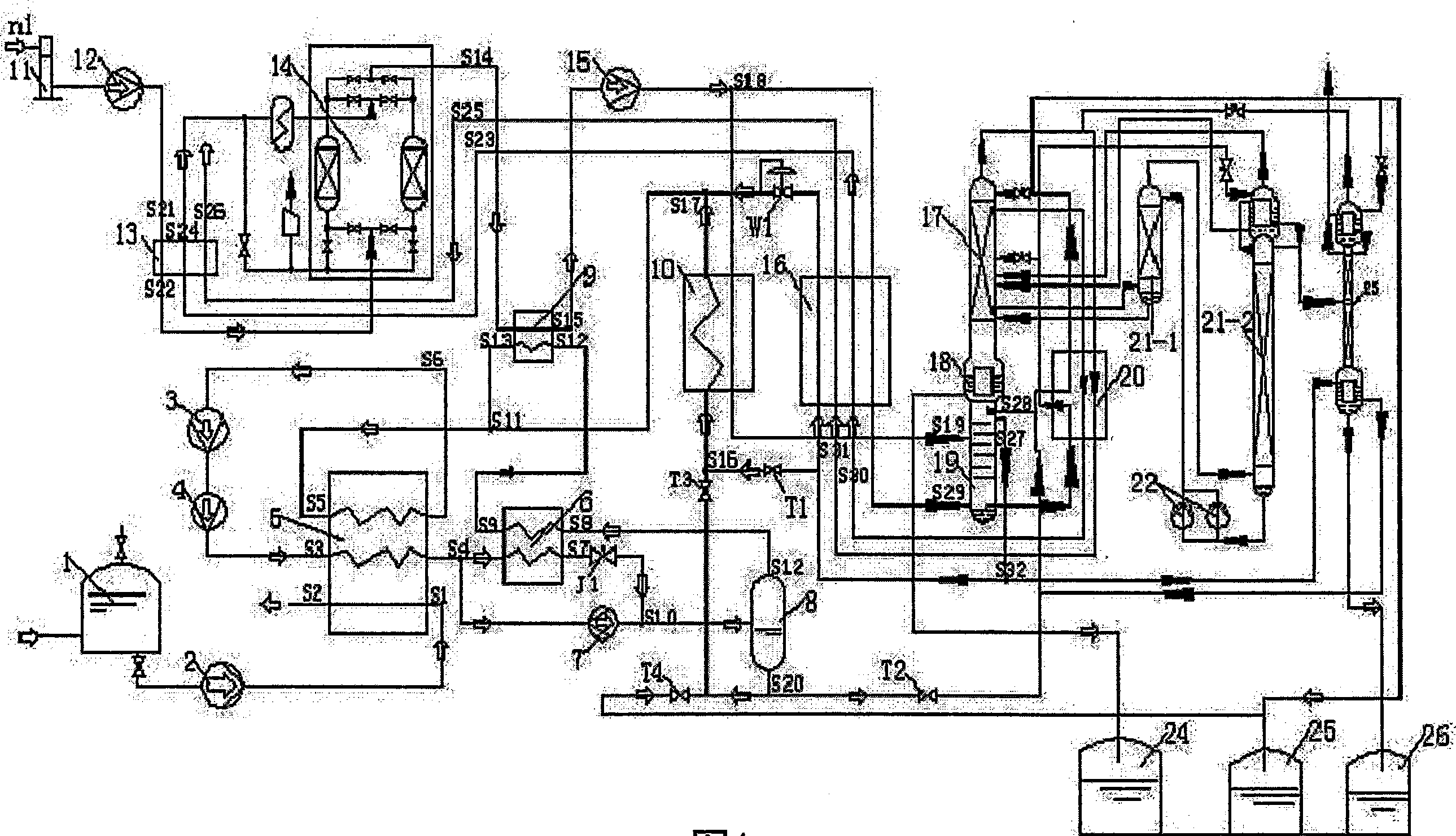

Air separation system for generating liquid oxygen and liquid nitrogen

This kind of air separation system obtaining liquid oxygen and liquid nitrogen at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; oxygen is drawn out from the underpart of the upper column on the fractionating tower, and cools and liquefied in the liquid-oxygen heat exchanger as the liquid oxygen products; after nitrogen from the top of the upper column passes through a liquid-nitrogen liquid air subcooler and is reheated by main heat exchanger, some nitrogen enters into liquefied-natural-gas heat exchanger to recool and exchange heat to become high pressure nitrogen through primary compression and pressurization at least. And through throttling expansion and air-liquid separator, nitrogen and liquid nitrogen participate in recycling and other nitrogen as liquid-nitrogen products; energy consumption is reduced notably after using actually, power consumption which produces liquid oxygen of 1kg is 0.39kwh, while the power consumption of the traditional equal air separator is 1.0 to 1.25kwh, which is 2.4 to 3 times than the separator. And it is easy to popularize and apply.

Owner:HANGZHOU HANGYANG

High efficiency liquid oxygen system

A high-efficiency liquid oxygen (LOX) storage / delivery system utilizes a portable LOX / delivery apparatus with a portable LOX container. A portable-unit LOX transfer connector is connected to the portable LOX container and is connectable to a main source of LOX in a primary reservoir LOX container. A portable-unit oxygen gas transfer connector is provided for transferring oxygen gas from the portable LOX container to an oxygen gas delivery device for delivering oxygen gas to a patient. An inter-unit oxygen gas transfer connector also is provided for connecting the portable apparatus to a stationary source of oxygen gas in the primary reservoir container, for transferring oxygen gas to the portable apparatus. A portable-unit primary relief valve is connected to the portable LOX container for venting oxygen gas out of the portable LOX container when pressure in the portable LOX container reaches a predetermined level. When the inter-unit oxygen gas transfer connector of the portable container is connected to the stationary source of oxygen in the primary reservoir container, oxygen gas can be transferred to the oxygen gas delivery device for delivery to the patient from the portable LOX container while oxygen gas is transferred to the portable container from the stationary source of gas in the primary reservoir LOX container.

Owner:CAIRE

Stabilized and Lyophilized Radiopharmaceutical Agents For Destroying Tumors

InactiveUS20070248533A1Easy to refactorReduces predictabilityPowder deliveryNervous disorderAbnormal tissue growthDiagnostic radiopharmaceuticals

A novel method is set out of preparation of radioactive diagnostic radiopharmaceutical in a stable, shippable, lyophilized form by an apparatus designed to rapidly flash freeze and dehydrate a radiopharmaceutical composition to minimize auto radiolysis. The method proposes rapid cooling and removal of ambient vapor, and then ultra cold removal when the potential of explosive liquid oxygen is eliminated. The radioactive diagnostic radiopharmaceutical requires no further cold or refrigerated storage, including with respect to shipping, subsequent to stabilization. The preferred composition can be reconstituted “on site” by the addition of a suitable diluent to bring the radiopharmaceutical complex into solution at a desired concentration.

Owner:KUPERUS JOHN H +2

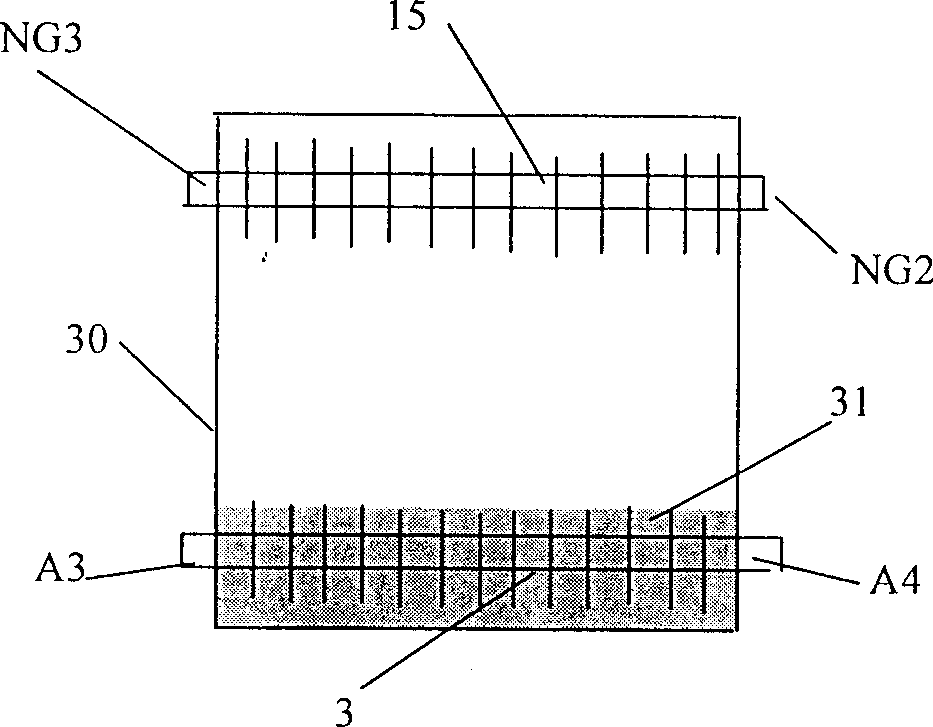

Air separator by utilizing cold energy of liquefied natural gas

InactiveCN1407303AReduce power consumptionRetrofit smallSolidificationLiquefactionEngineeringNitrogen gas

An air separator using the cold energy generated by liquefying natural gas to prepare liquefied oxygen, liquefied nitrogen and liquefied argon is based on existing air separator, and features that the multi-stage circulating nitrogen compressors, LNG heat exchanger and circulated nitrogen heat exchanger are additionally used to form a combined refrigerating system, and an air cooling system is also used.

Owner:UNIV OF SCI & TECH OF CHINA

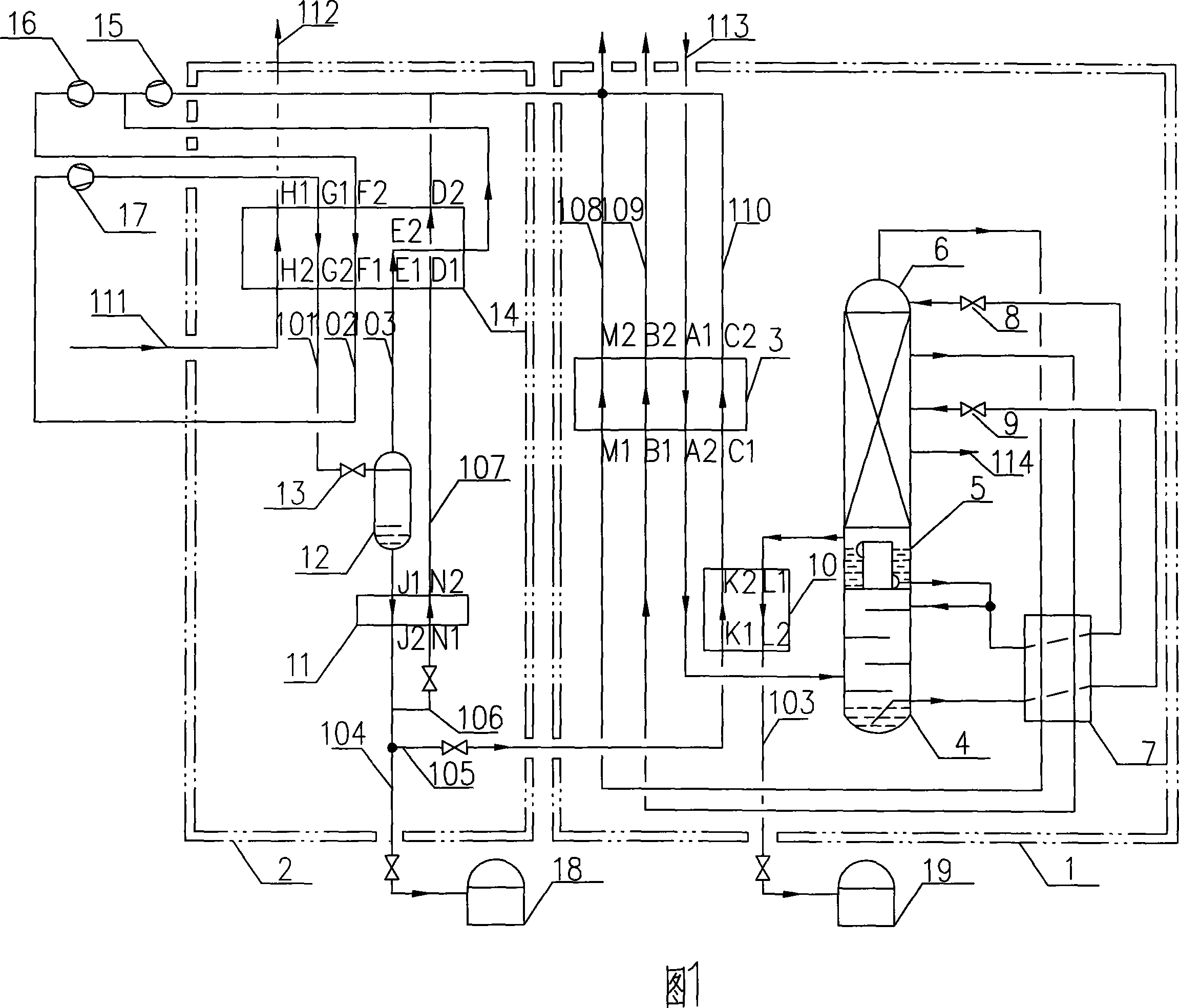

System integrating air separation with cool capacity recovery of liquefied natural gas

ActiveCN101033910AReduce energy consumptionGuaranteed safe operationSolidificationLiquefactionNitrogen gasCooling capacity

This kind of system separating air and recovering cold energy of liquefied natural gas at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; nitrogen drawing out from the underpart of the upper column on the fractionating tower passes through liquid-nitrogen liquid air subcooler and reheated by main heat exchanger, and enters into liquefied-natural-gas heat exchanger to precool and exchange heat; the equipment recovering cold energy of liquefied natural gas at least includes air-liquid separator and liquid nitrogen subcooler, which is placed in a single ice chest II; while main heat exchanger, liquid-oxygen heat exchanger, liquid-nitrogen liquid air subcooler and fractionator consisting of the lower column, the upper column and main evaporator are placed in an ice chest I; it fully utilizes high-grade cooling capacity of liquefied natural gas, and makes energy consumption of air separator reduce notably and ensures it operate safely, and can get the great society and economy benefits.

Owner:HANGZHOU HANGYANG

Liquid oxygen and liquid nitrogen preparation device and method

InactiveCN104061757AIncrease subcoolingReduce gasification lossSolidificationLiquefactionAir filterEngineering

The invention relates to a liquid oxygen and liquid nitrogen preparation device and method. The device comprises a self-cleaning air filter, an air compressor, a cold air unit, a separator, a molecular sieve adsorber, a main heat exchanger, a lower tower, an upper tower, a subcooler and an expander. The raw material of the device is air. The air passes through the self-cleaning air filter, the air compressor, the supercharging end of the expander, the cold air unit and the molecular sieve adsorber in sequence and then enters a cold box; after passing through the main heat exchanger, a part of the air is pumped out of the lower middle portion of the main heat exchanger and enters the expanding end of the turbo expander for adiabatic expansion; expanded air is reheated by the main heat exchanger and then sent out of the cold box; the remaining air is cooled to a liquefaction point, goes out of the main heat exchanger and enters the lower tower for rectification. A liquid oxygen product is pumped out of the bottom of the lower tower and then conveyed to a liquid oxygen storage tank; a liquid nitrogen product is pumped out of the main cold liquid nitrogen side and then conveyed to a liquid nitrogen storage tank. According to the liquid oxygen and liquid nitrogen preparation device and method, operation is simple in the technological process, the extraction rate is high, energy consumption is low, and meanwhile equipment investment cost is low.

Owner:KAIFENG AIR SEPARATION GROUP

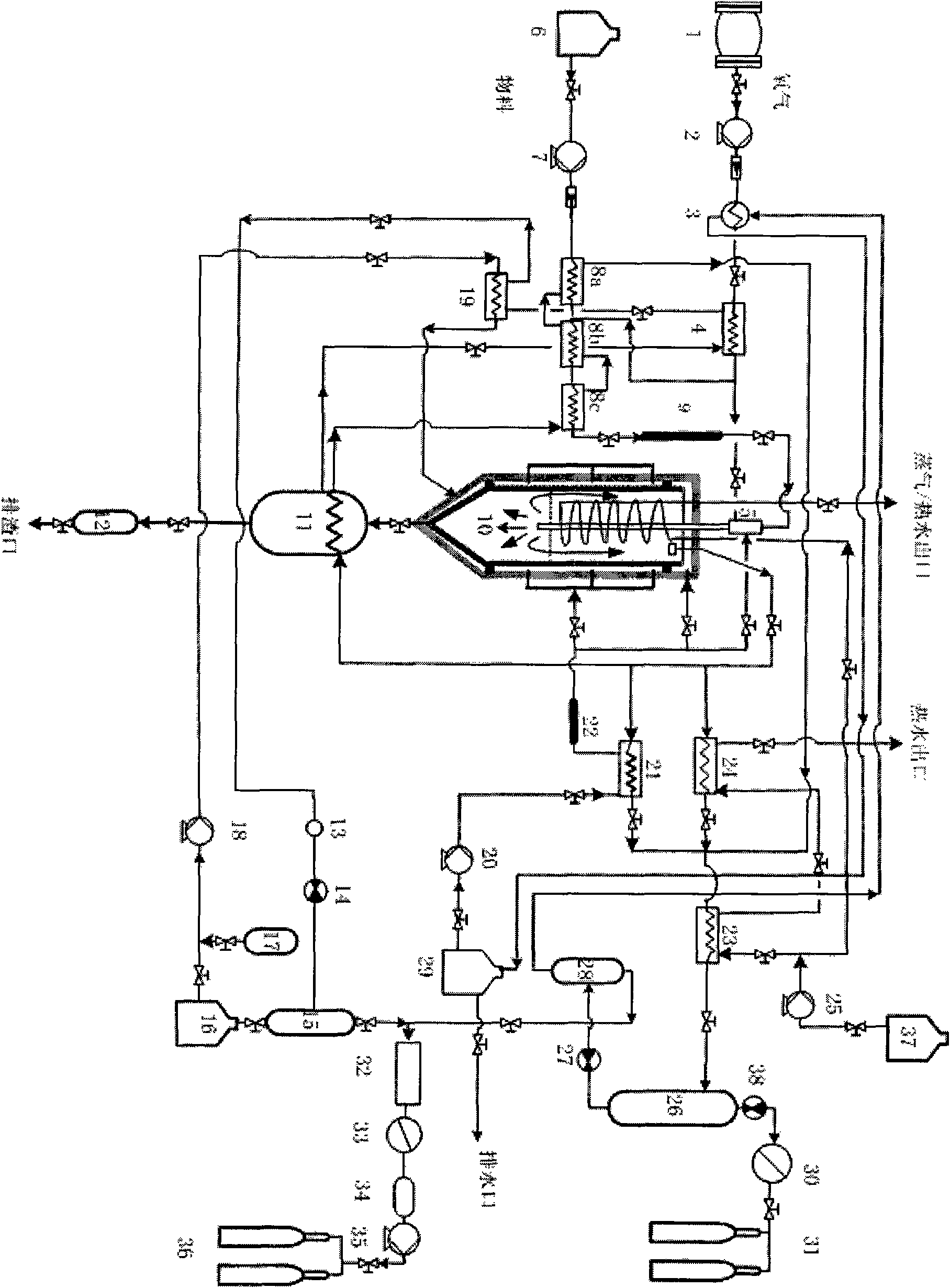

Method for recovery and cascade utilization of waste heat of supercritical water treatment system of waste organic substances

InactiveCN101570375AReasonable distributionReasonable useSolid waste disposalMultistage water/sewage treatmentVapor liquidWater treatment system

The invention belongs to the field of supercritical water treatment, and discloses a method for recovery and cascade utilization of waste heat of a supercritical water treatment system of waste organic substances. The method comprises the following steps that: for fluid overflowing out of the reaction outlet end of a reactor, one part of the fluid flows through a heating coil pipe in a desalting and deslagging device first, and then flows through a heat exchanger group to preheat materials after strong brine in the desalting and deslagging device is heated; another part of the fluid is used for preheating a first path of evaporation wall water; then two parts of the fluids are mixed together, and after vapor-liquid separation, the liquid flows through a hot bath type liquid oxygen vaporizer to vaporize liquid oxygen, and finally flows back into a first liquid collection box; and the fluid overflowing out of the upper outlet end of the desalting and deslagging device flows through a first heat exchanger to preheat oxygen first and then preheat a second path of the evaporation wall water, and after the vapor-liquid separation, the liquid flows back into a second liquid collection box. Thus, the sufficient recovery and the cascade utilization of the waste heat are achieved.

Owner:XI AN JIAOTONG UNIV +1

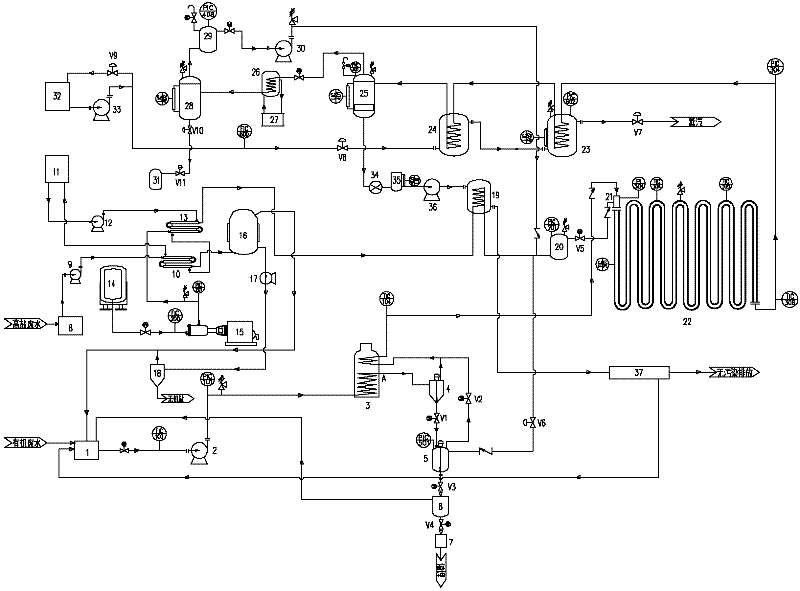

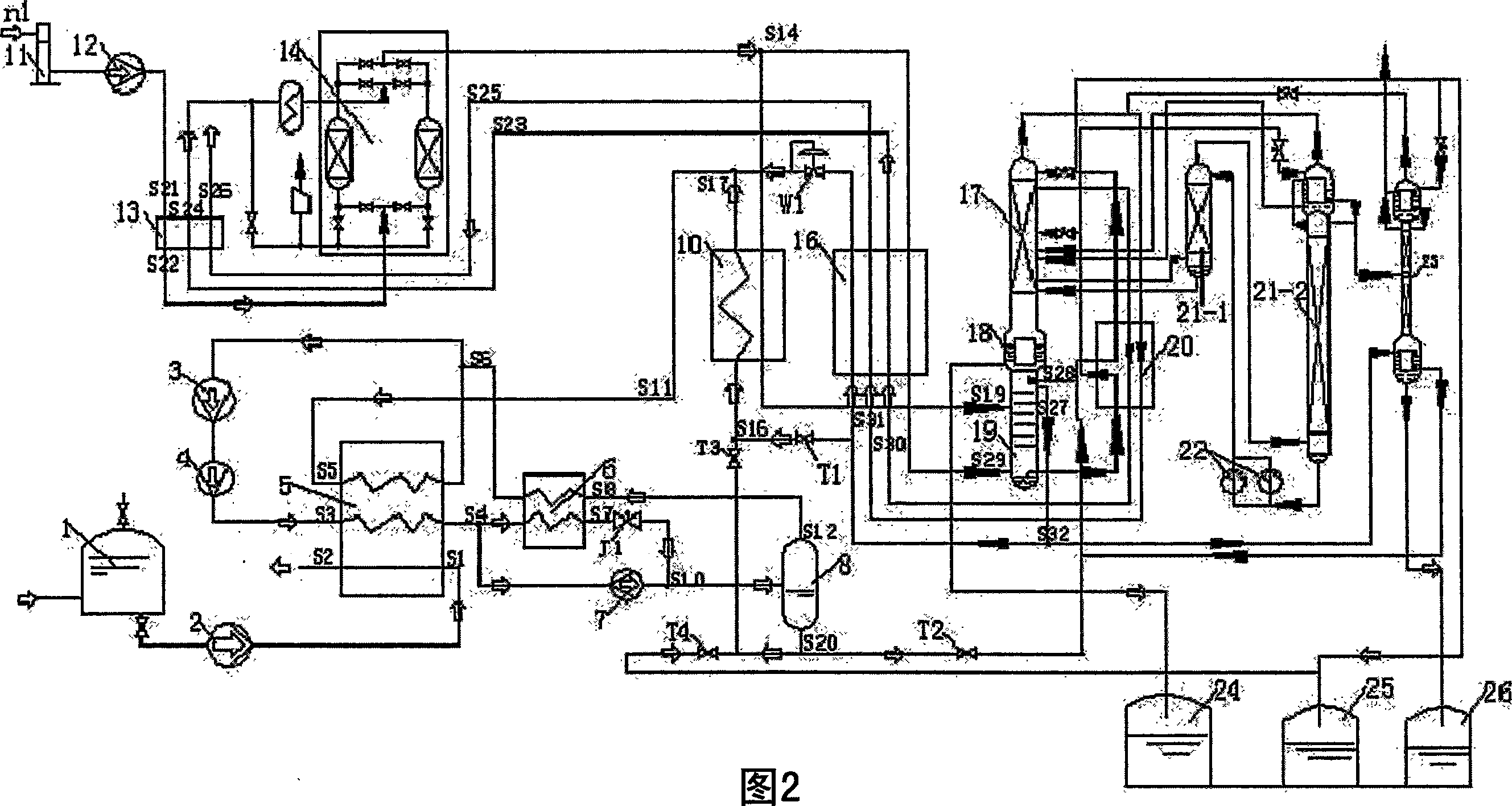

Supercritical water oxidation treatment system for printing and dyeing wastewater and sludge

InactiveCN104030427AReduce volumeReduce secondary pollutionSludge treatment by oxidationWaste water treatment from textile industryLiquid wasteHigh concentration

The invention discloses a supercritical water oxidation treatment system for printing and dyeing wastewater and sludge. The system comprises a concentration pretreatment device, a supercritical water oxidation device, an oxidizing agent supply device and a wastewater recycling system, wherein the concentration pretreatment device comprises a waste liquid storage tank, a nanofiltration membrane concentration module and a printing and dyeing sludge storage pool, the oxidizing agent supply device comprises a liquid oxygen storage tank, a liquid oxygen gasifier and a buffer tank, and the supercritical water oxidization device comprises an auxiliary heating supercritical water oxidization reactor, a methyl alcohol starting preheater, a methyl alcohol preheater and a waste liquid preheater. The system can be used for realizing efficient, clean and harmless treatment of high-concentration printing and dyeing wastewater and sludge at low cost.

Owner:山川丽(苏州)环保科技有限公司

Enclosed methanol-water steam reforming fuel cell hydrogen source system and hydrogen production method

ActiveCN105655612AReduce CO2 concentrationGuaranteed uptimeHydrogenFuel cell auxillariesElectrochemical responseSteam reforming

The invention discloses an enclosed methanol-water steam reforming fuel cell hydrogen source system, which comprises a methanol supplying device, a liquid oxygen device, a carbon dioxide storage device, a water storage device, and a methanol hydrogen producing device; wherein the methanol hydrogen producing device comprises an evaporation device, a reforming device, a combustion device, a carbon monoxide selective oxidation reactor, and other auxiliary systems; and the combustion device, reforming device, evaporation device, and carbon monoxide selective oxidation reactor are integrated into a module. According to the hydrogen production method, methanol and water are gasified by the evaporation device and then react in the reforming device to obtain reformed gas; then the reformed gas is processed by the monoxide selective oxidation reactor, the concentration of carbon monoxide in reformed gas is further reduced, and finally the reformed gas is introduced into the fuel cell system to carry out electrochemical reactions. The provided system has the advantages that the system operates in an enclosed space, the operability and safety of the system are both improved; the heat exchange and reactions are well matched, and the whole reforming hydrogen production system is high efficient and compact.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

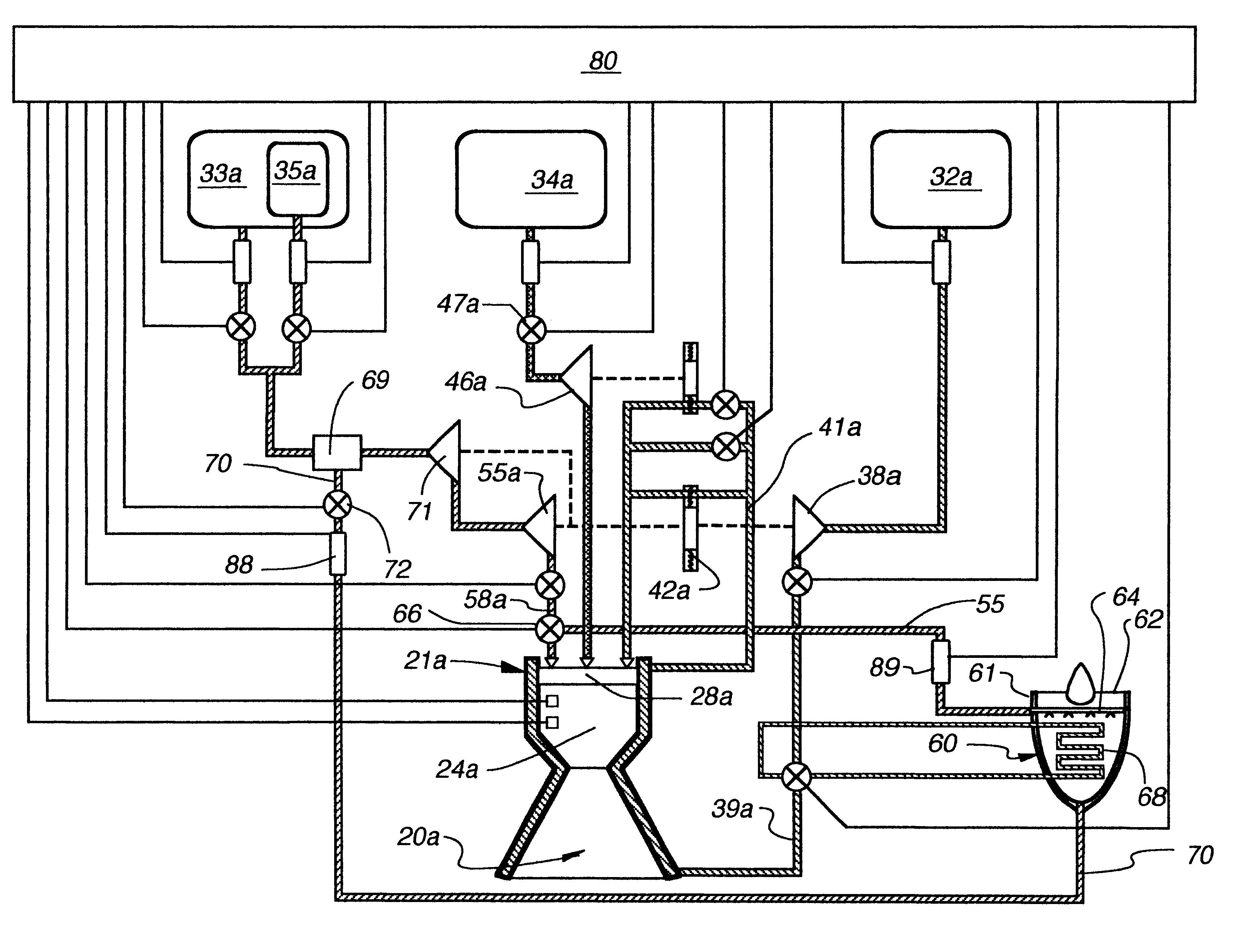

High efficiency liquid oxygen system

A high-efficiency liquid oxygen (LOX) storage / delivery system utilizes a portable LOX / delivery apparatus with a portable LOX container. A portable-unit LOX transfer connector is connected to the portable LOX container and is connectable to a main source of LOX in a primary reservoir LOX container. A portable-unit oxygen gas transfer connector is provided for transferring oxygen gas from the portable LOX container to an oxygen gas delivery device for delivering oxygen gas to a patient. An inter-unit oxygen gas transfer connector also is provided for connecting the portable apparatus to a stationary source of oxygen gas in the primary reservoir container, for transferring oxygen gas to the portable apparatus. A portable-unit primary relief valve is connected to the portable LOX container for venting oxygen gas out of the portable LOX container when pressure in the portable LOX container reaches a predetermined level.

Owner:CAIRE

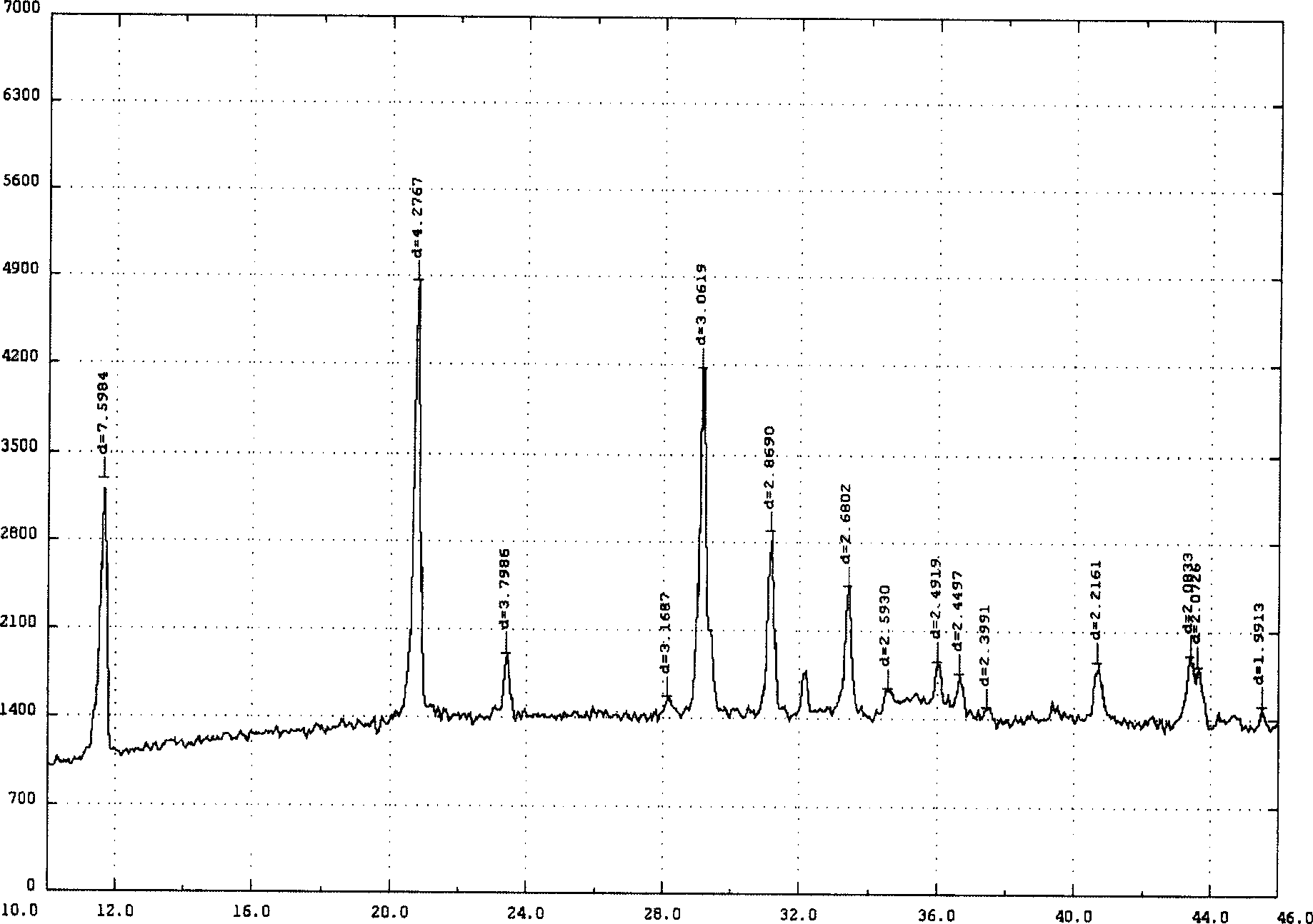

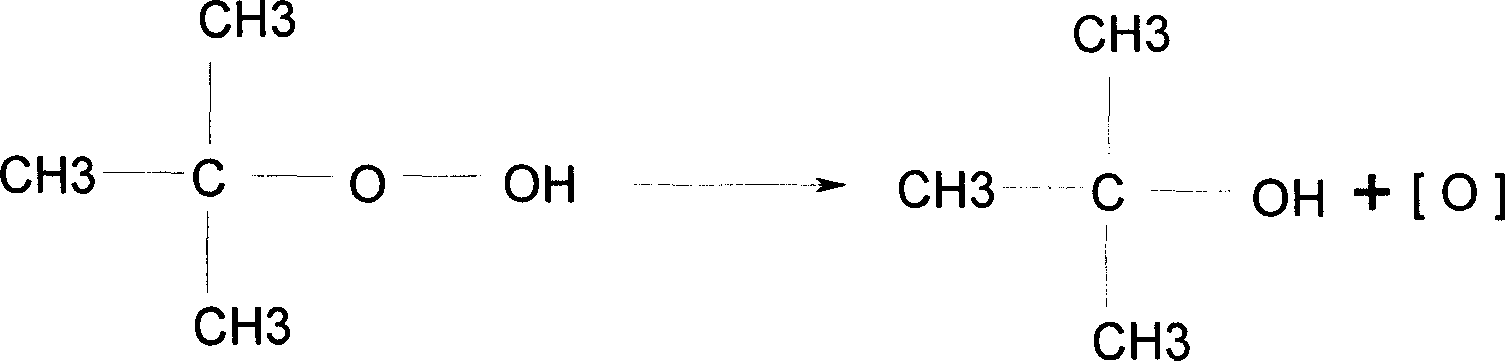

Method for refining catalytic liquefied petroleum gas

The present invention relates to a method for refining catalytic liquefied petroleum gas, in which catalyzed liquefied petroleum gas by alconol-amine method removing hydrogen sulfide process is operated by hydrolysis carbonyl sulfur process by passing through carbonyl sulfur hydrolysis activator bed layer, such that carbonyl sulfur hydrolysis generates sulfureted hydrogen and carbon dioxide; then it passes through the desulfurizer bed layer to operate hydrogen sulfide removing process, the preparation of reaction of the hydrogen sulfide and the desulfurizer is chemically absorbed on the desulfurizer; at last, liquid oxygen supplying agent having effective component of tert-butyl hydroperoxide is applied into the catalyzed liquefied petroleum gas, then it is processed by transformation mercaptan by passing through the double effects activator bed layer, under the effect of the double effects activator, the tert-butyl hydroperoxide is hydrogen peroxide decomposed to release fresh state oxygen, and the mercaptan is oxygenated to bisulfide; the activate component of the double effects activator is compound of manganic.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

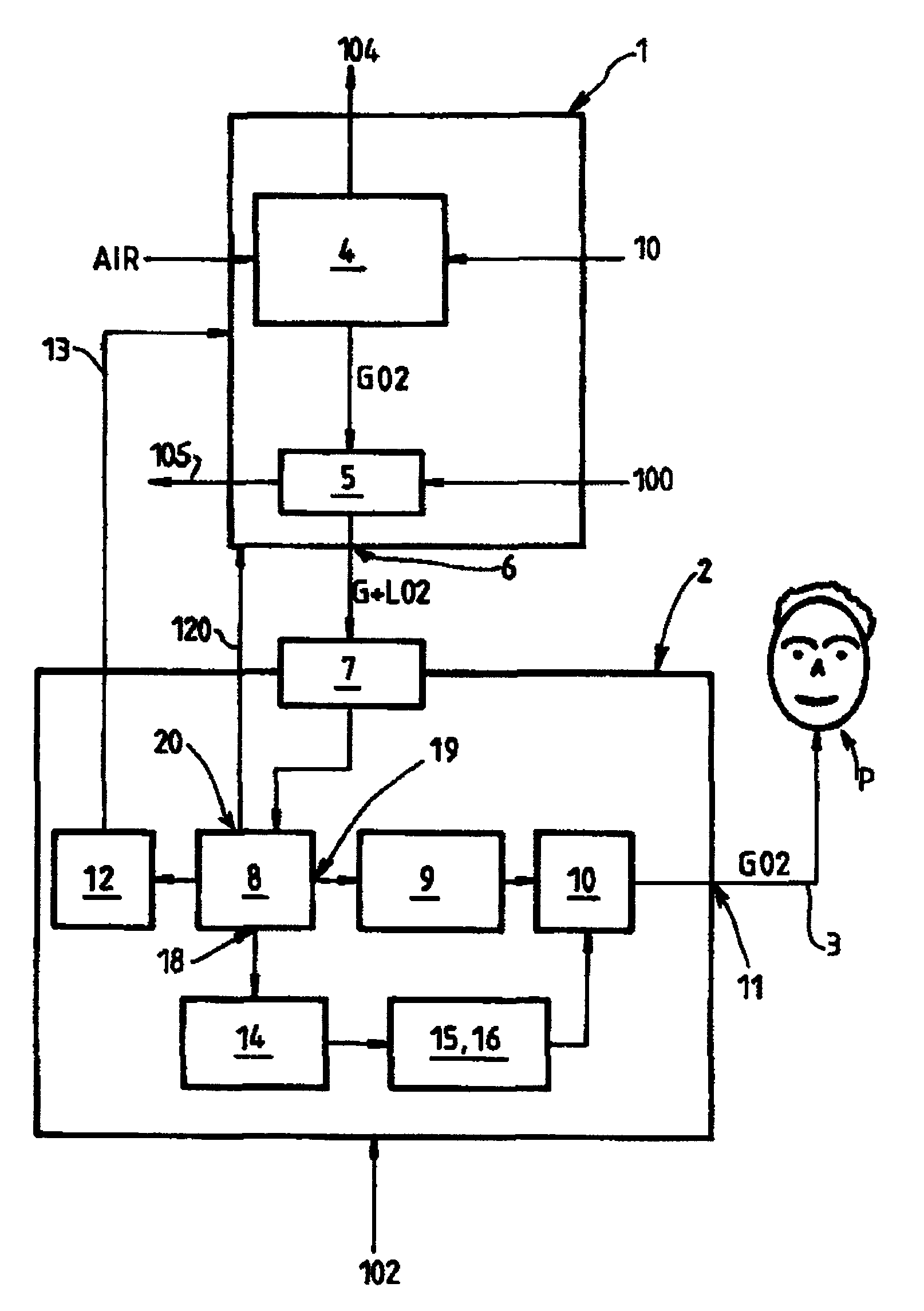

Device for supplying domiciliary and ambulatory oxygen

Device for supplying domiciliary and ambulatory oxygen, comprising an oxygen filling station and a portable oxygen reserve that can be selectively connected to the filling station, the filling station comprising an oxygen concentrator intended to isolate gaseous oxygen from the air, a liquefier connected to one outlet of the concentrator to receive the isolated gaseous oxygen so that it can be liquefied, a transfer connector connected to one outlet of the liquefier and intended to be connected to an inlet connector of the reserve, the reserve comprising a tank connected to the inlet connector so that liquid oxygen can be transferred from the filling station to the tank, a delivery system comprising members for tapping off, heating and regulating the flow of the oxygen from the tank so as to deliver gaseous oxygen to a patient.

Owner:CRYOPAL

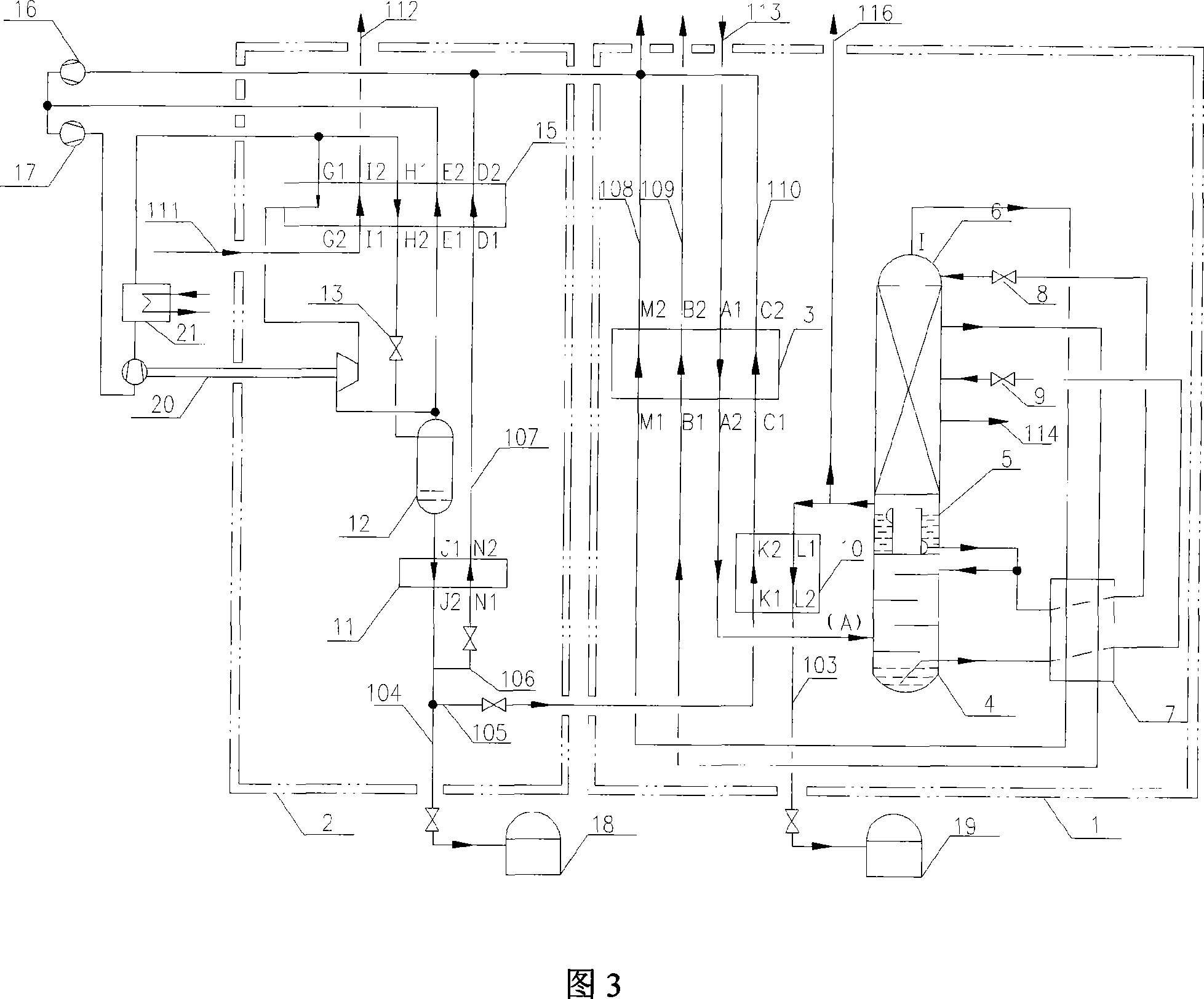

Supercritical water oxidization treatment system for high-salinity organic waste water

InactiveCN102642947AGuaranteed heat transfer coefficientAvoid cloggingSolidificationLiquefactionCycloneReaction temperature

The invention discloses a supercritical water oxidization treatment system for high-salinity organic waste water. The high-salinity waste water is subjected to cooling crystallization through cold energy of liquid oxygen to reduce mass concentration of inorganic salt in the waste water; a large amount of solid salt grains separated out from the waste water are removed by using a hydraulic cyclone device under a supercritical water condition to effectively prevent a subsequent pipeline and a reactor of the hydraulic cyclone device from plugging; and a desalting device is arranged at the lower part of the hydraulic cyclone device to continuously remove the inorganic salt from the system. In addition, excessive oxygen and CO2 product gas are recovered through a separation recovery part; the reaction time and the reaction temperature of supercritical water oxidization are reduced through arranging a simple subsequent treatment unit; and the system recovers heat energy of the reacted high-temperature fluid in a steam mode through the arrangement of a water softening device, so that the operation cost of the system is reduced. The system can be widely applied to the innocent treatment process of the high-salinity organic waste water.

Owner:XI AN JIAOTONG UNIV +1

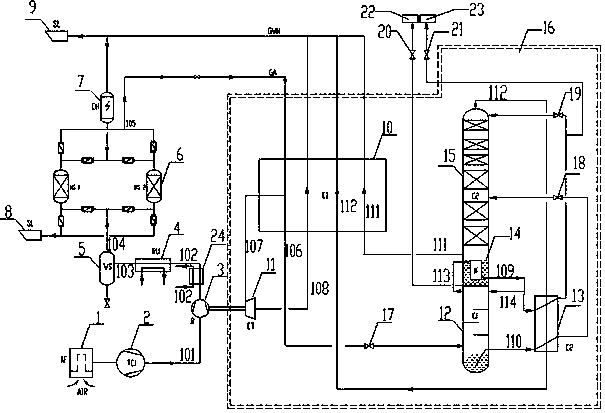

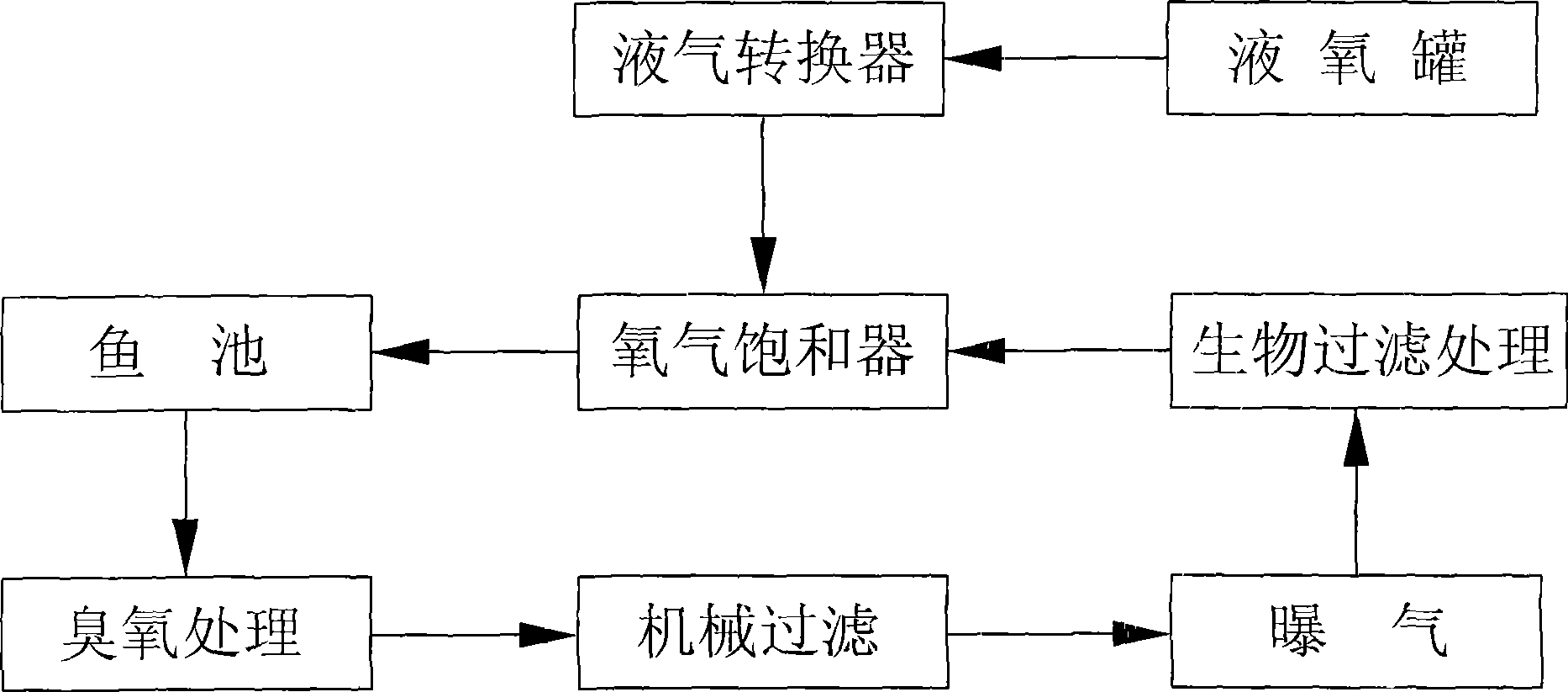

Water circulation filtering system for aquiculture

InactiveCN101475288AConstant water temperatureImprove water qualityWater aerationMultistage water/sewage treatmentFiltrationWater quality

The invention relates to a water cycle filtering system for aquiculture, which comprises an ozone treatment system, a mechanical filtration system, a biological filtration system, a liquid-oxygen conversion system and an oxygen saturation system, wherein all systems are communicated through gas pipelines or liquid transport pipelines. In the overall system, the aquaculture water is circularly treated in 24 hours, the aquaculture waste water is treated and then fed into an aquaculture pond again to be used, and the water changing ratio every day is only 3 percent; and the system has the advantages of constant water temperature, good water quality in dynamic water aquaculture, low water consumption in static water aquaculture, and the like. Equipment generates basically enough heat to insulate a fishery so as to save energy; the aquaculture waste is reclaimed for producing organic fertilizer so as to change waste into valuable; the system can achieve zero discharge of the aquiculture, and a water environment achieves pathogen free, waste residue free and pollution free and keeps enough oxygen content of the water body; and the system does not use fishery drugs to cultivate, and is a green, environment-friendly, energy-saving and low-cost aquiculture water treatment system.

Owner:韶关市力冉农业科技有限公司

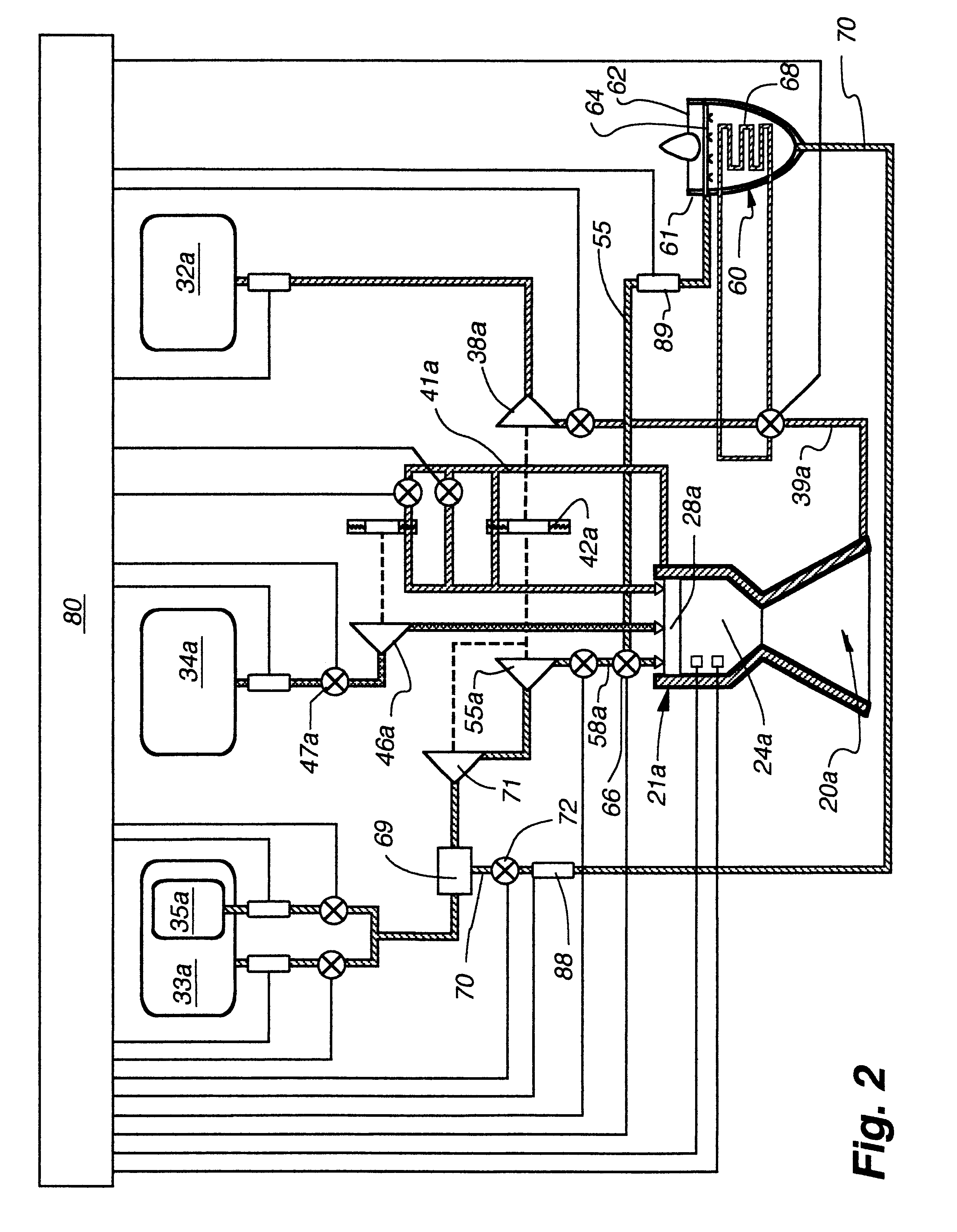

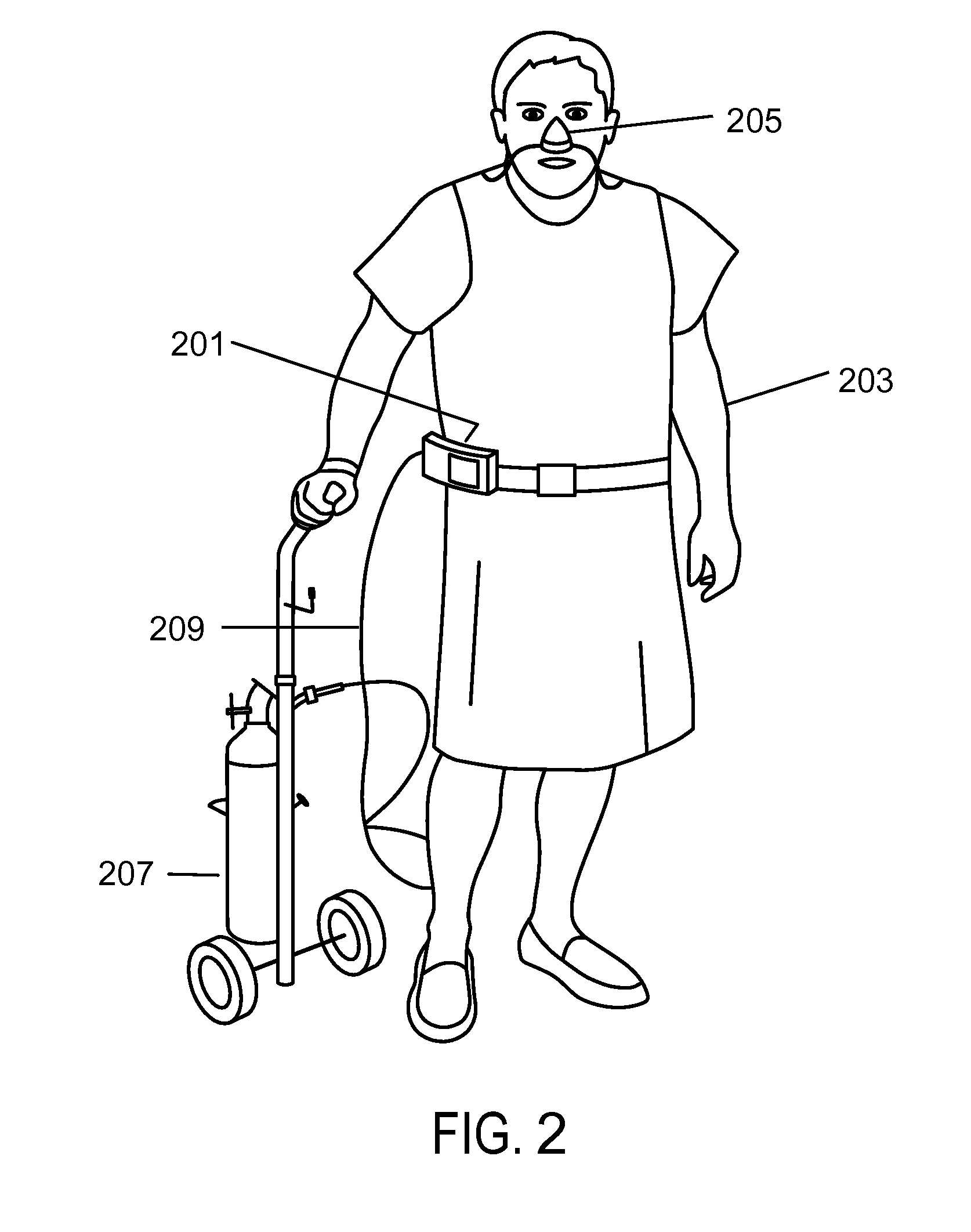

Portable liquid oxygen delivery system

InactiveUS7721733B2Sufficiently lightweight for portabilitySufficiently lightweightSurgeryMedical devicesEngineeringLiquid oxygen

A portable liquid oxygen medical delivery system including a portable liquid oxygen delivery apparatus and a portable liquid oxygen recharger. The portable liquid oxygen delivery apparatus contains an initial quantity of liquid oxygen. The liquid oxygen delivery apparatus is sufficiently lightweight for portability by an ambulatory patient and has a fill port for receiving liquid oxygen. The liquid oxygen recharger stores a supplemental quantity of liquid oxygen and is also sufficiently lightweight for portability by an ambulatory individual. The liquid oxygen recharger has an interface for interfacing the liquid oxygen recharger with the portable liquid oxygen delivery apparatus for delivering the supplemental quantity of liquid oxygen to the portable liquid oxygen delivery apparatus.

Owner:RIC INVESTMENTS LLC

Air separation system for recycling cold energy of liquified natural gas

ActiveCN1873357AGuaranteed uptimePrevent intrusionSolidificationLiquefactionNitrogen gasRaw material

The present invention provides an air separation system capable of recovering cold energy of liquefied natural gas and using it to produce liquid oxygen, liquid nitrogen and liquid argon. Said system includes nitrogen gas refrigeration circulation device, air cooling device and air separation device, in which the nitrogen gas refrigeration circulation device includes liquefied natural gas beat exchanger and gas-liquid separator, the liquefied natural gas heat exchanger can be used for isolating the cold energy of liquefied natural gas and exchanging it to the nitrogen gas in nitrogen gas refrigeration circulation device, the gas-liquid separator can be used for separating the nitrogen gas undergone the process of heat exchange by means of liquefied natural gas heat exchanger into gas nitrogen gas and liquid nitrogen gas, said liquid nitrogen gas after which is undergone the process of cold energy exchange with raw material air is combined with gas nitrogen gas and can be again fed into the liquefied natural gas heat exchanger.

Owner:福建智舟技术有限公司

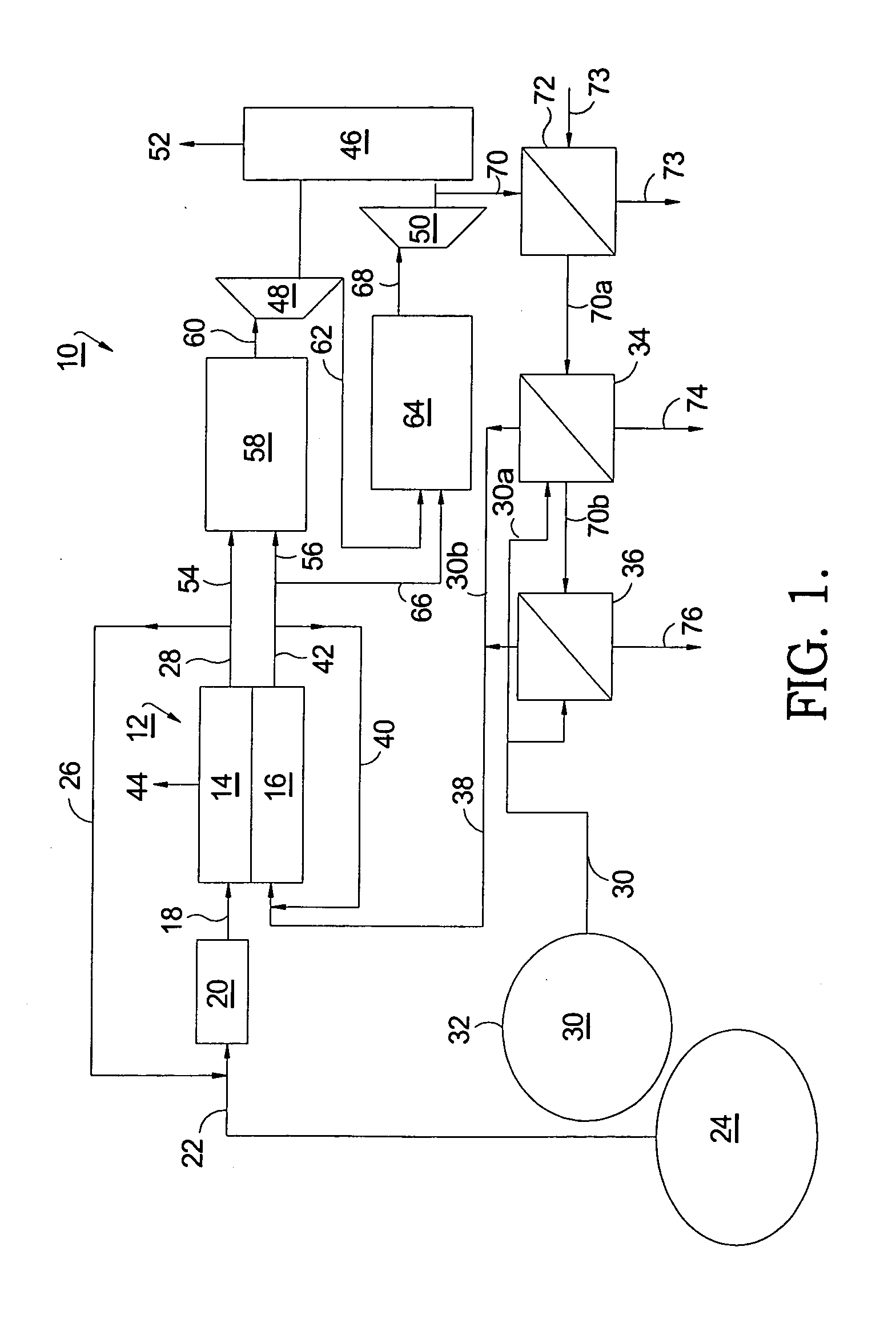

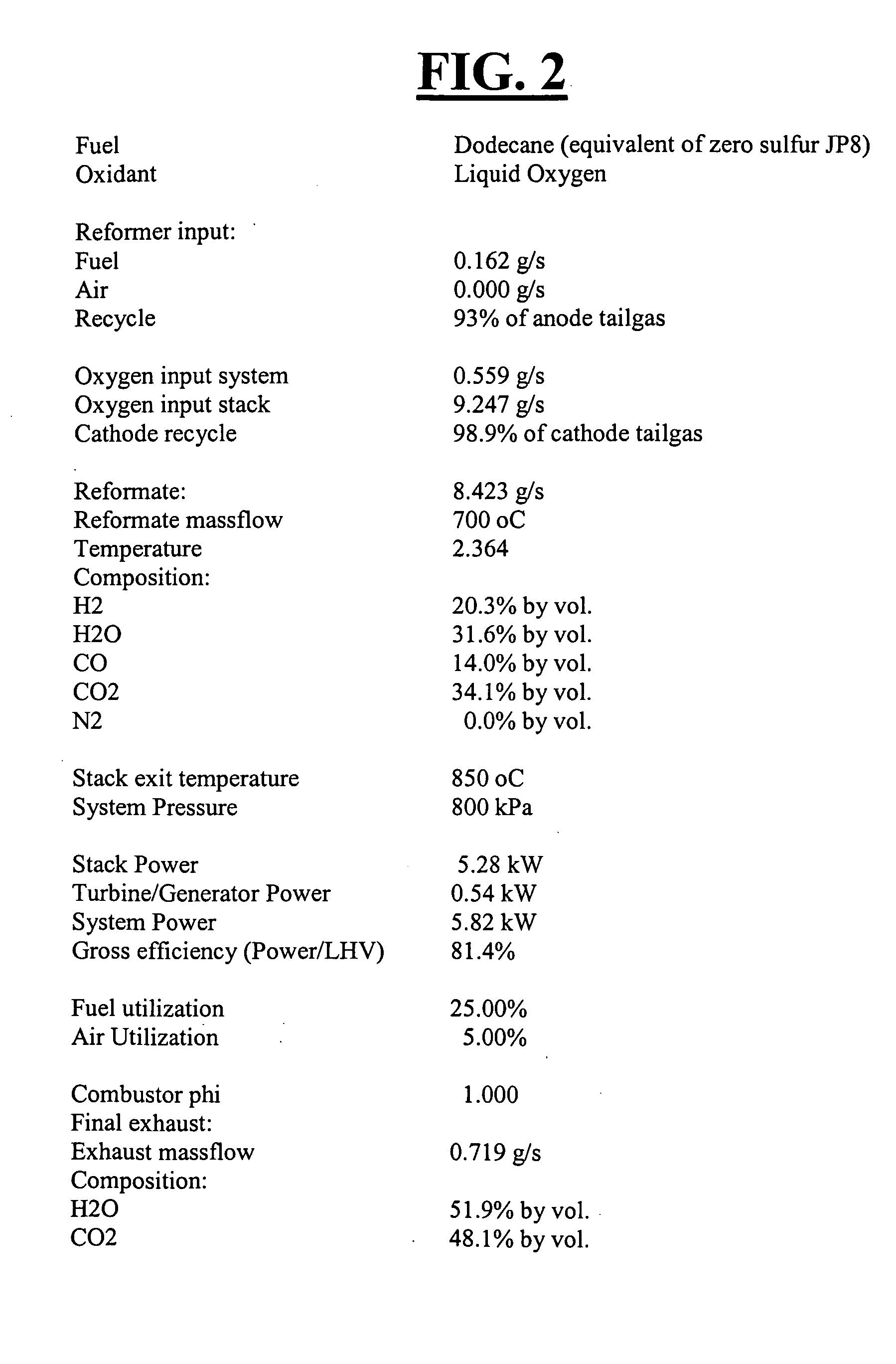

Hybrid solid oxide fuel cell and gas turbine electric generating system using liquid oxygen

InactiveUS20070163822A1Increasing oxygen pressureImprove efficiencyHybrid vehiclesAuxillary drivesHydrocotyle bowlesioidesElectric generator

A hybrid SOFC / gas turbine electric generating system comprising an SOFC stack, a hydrocarbon reformer, a first anode tailgas hydrogen-rich combustor to drive a first gas turbine stage, and a second stoichiometric combustor to drive a second gas turbine stage to drive a generator. Anode tailgas is also recycled into the reformer for substantially endothermic reforming of hydrocarbon fuel. Oxidant is provided as pure oxygen—which may be stored as liquid oxygen. All nitrogen may be excluded. Cathode exhaust is passed to the first combustor, to the second combustor, and is recycled into the cathodes. The turbine exhaust is passed through successive heat exchangers cooled by liquid oxygen being vaporized, precipitating water and solid CO2. The system is operated at about 800 kPa (about 8 atmospheres), thereby increasing the power output of the stack. The system may be operated with no gaseous exhaust or with by-products of water and CO2.

Owner:DELPHI TECH INC

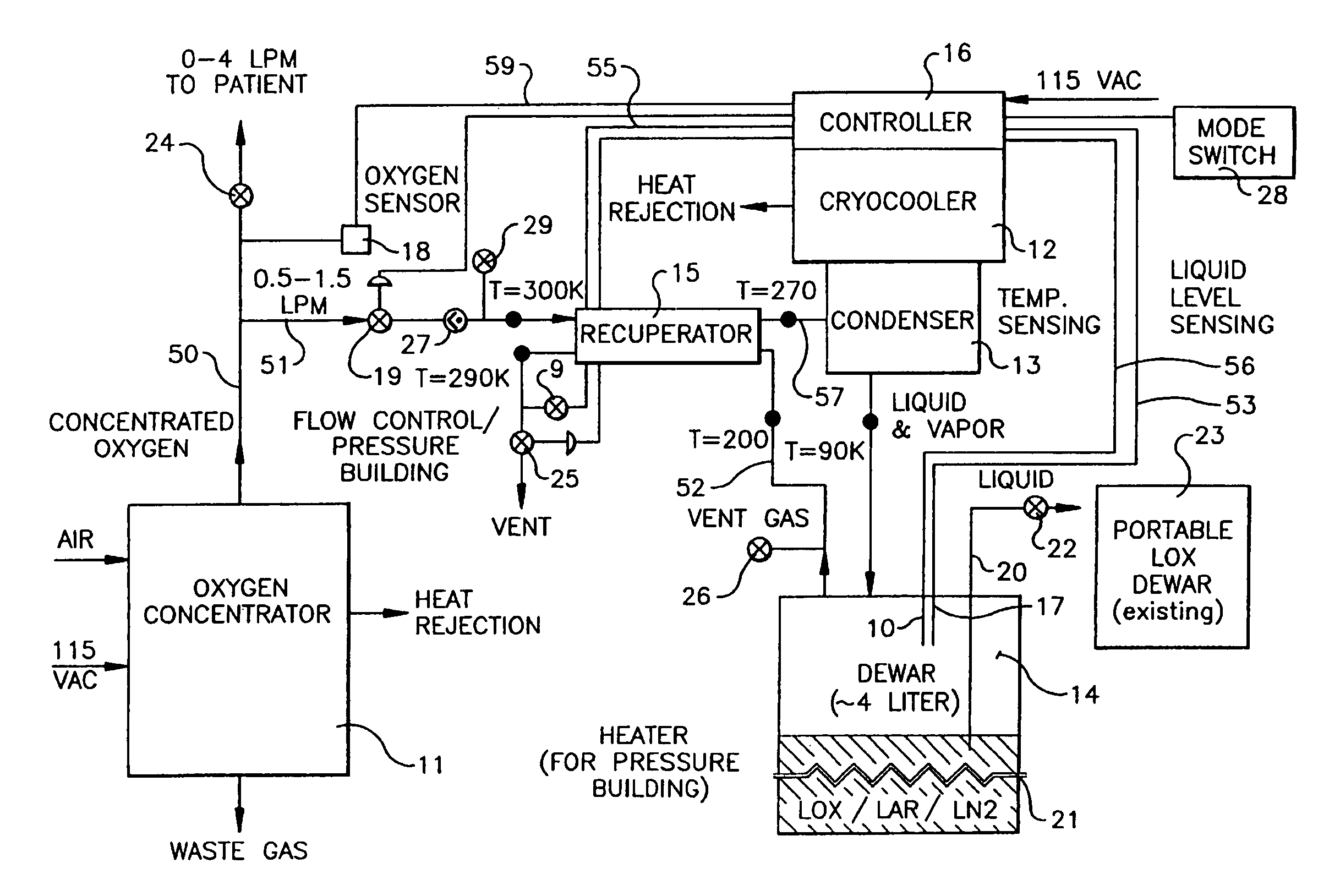

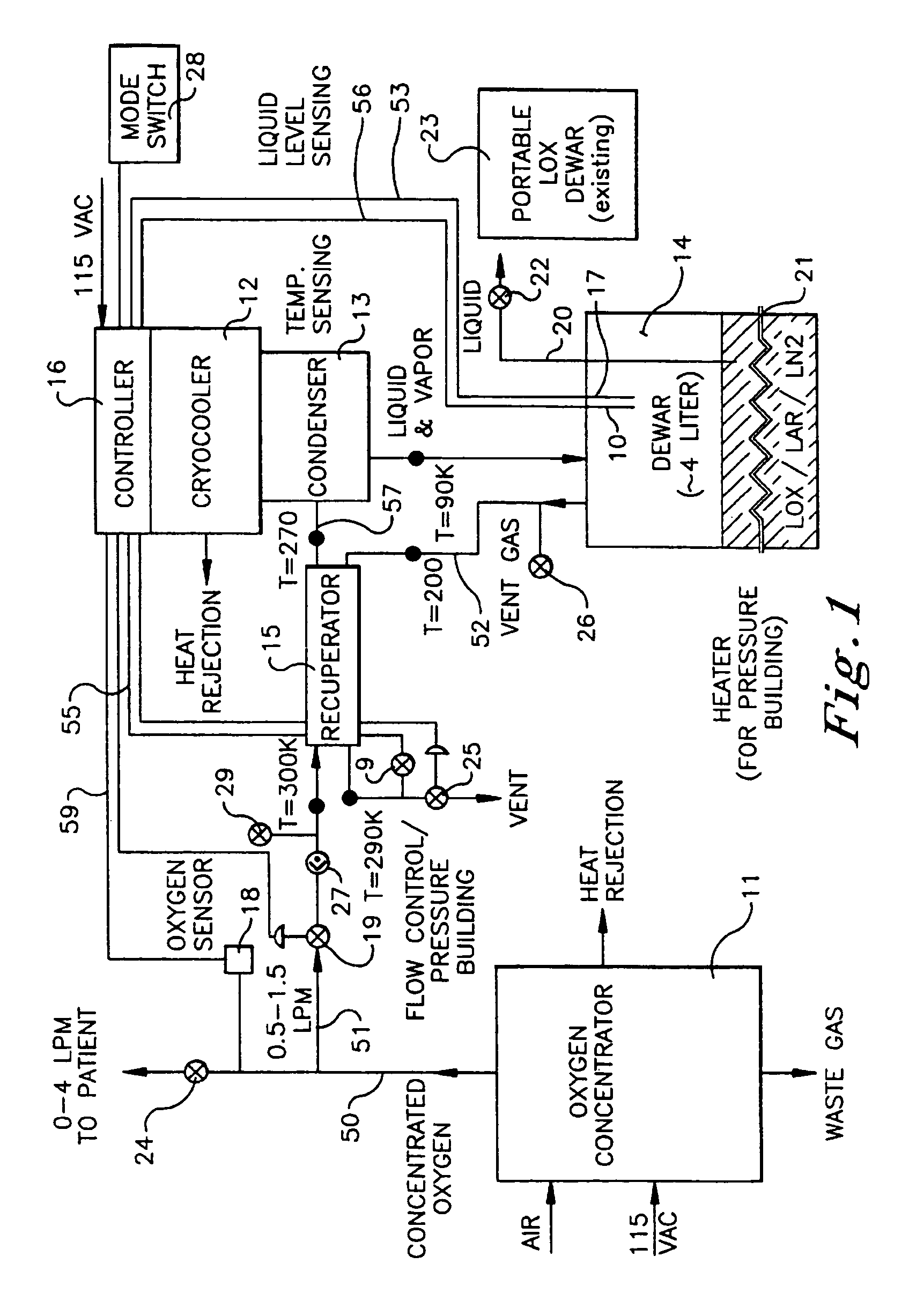

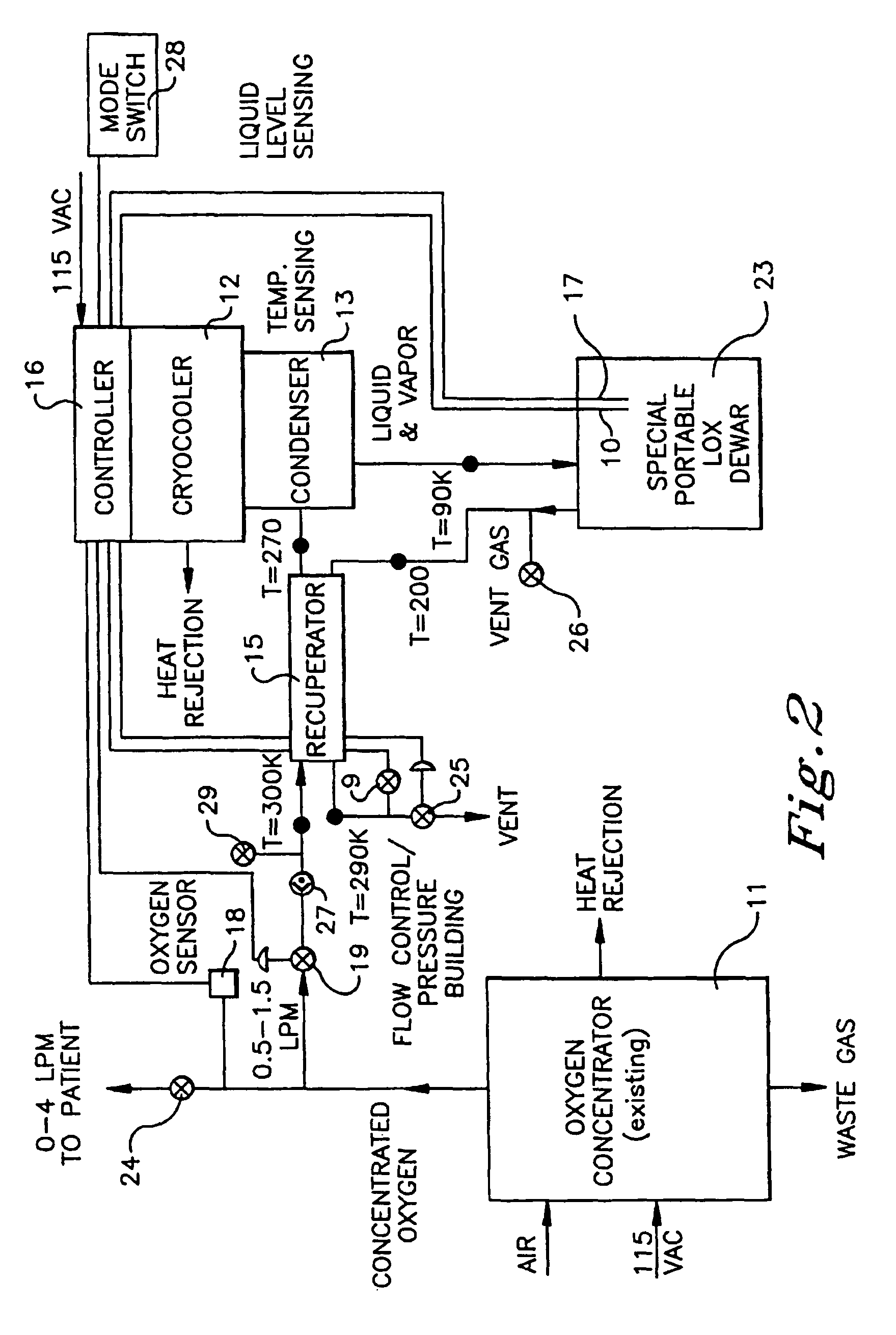

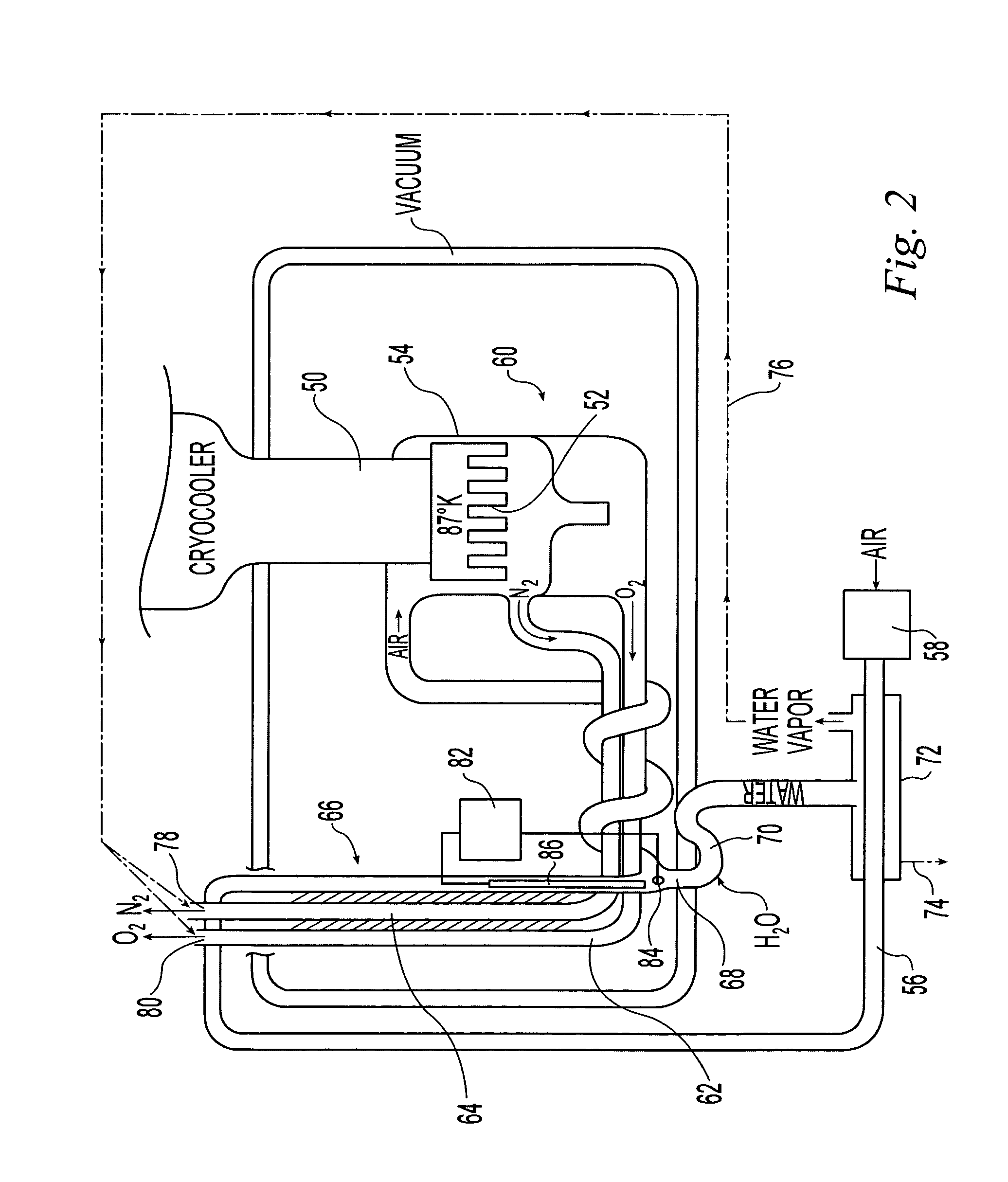

Methods and apparatus to generate liquid ambulatory oxygen from an oxygen concentrator

InactiveUSRE43398E1Increase condensation rateIncrease the areaLiquefactionOther heat production devicesAmbulatory systemCryocooler

Owner:RESPIRONICS

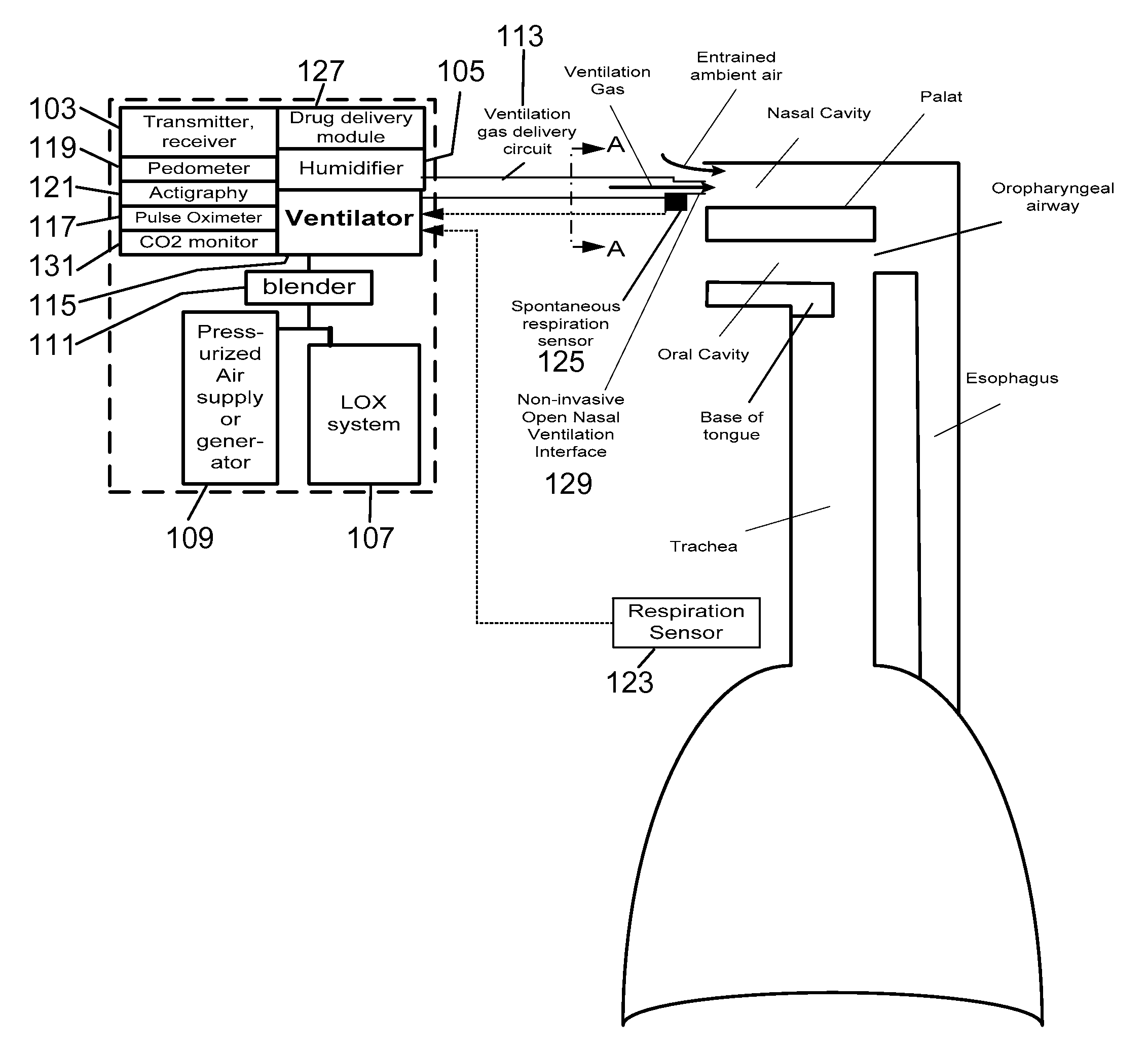

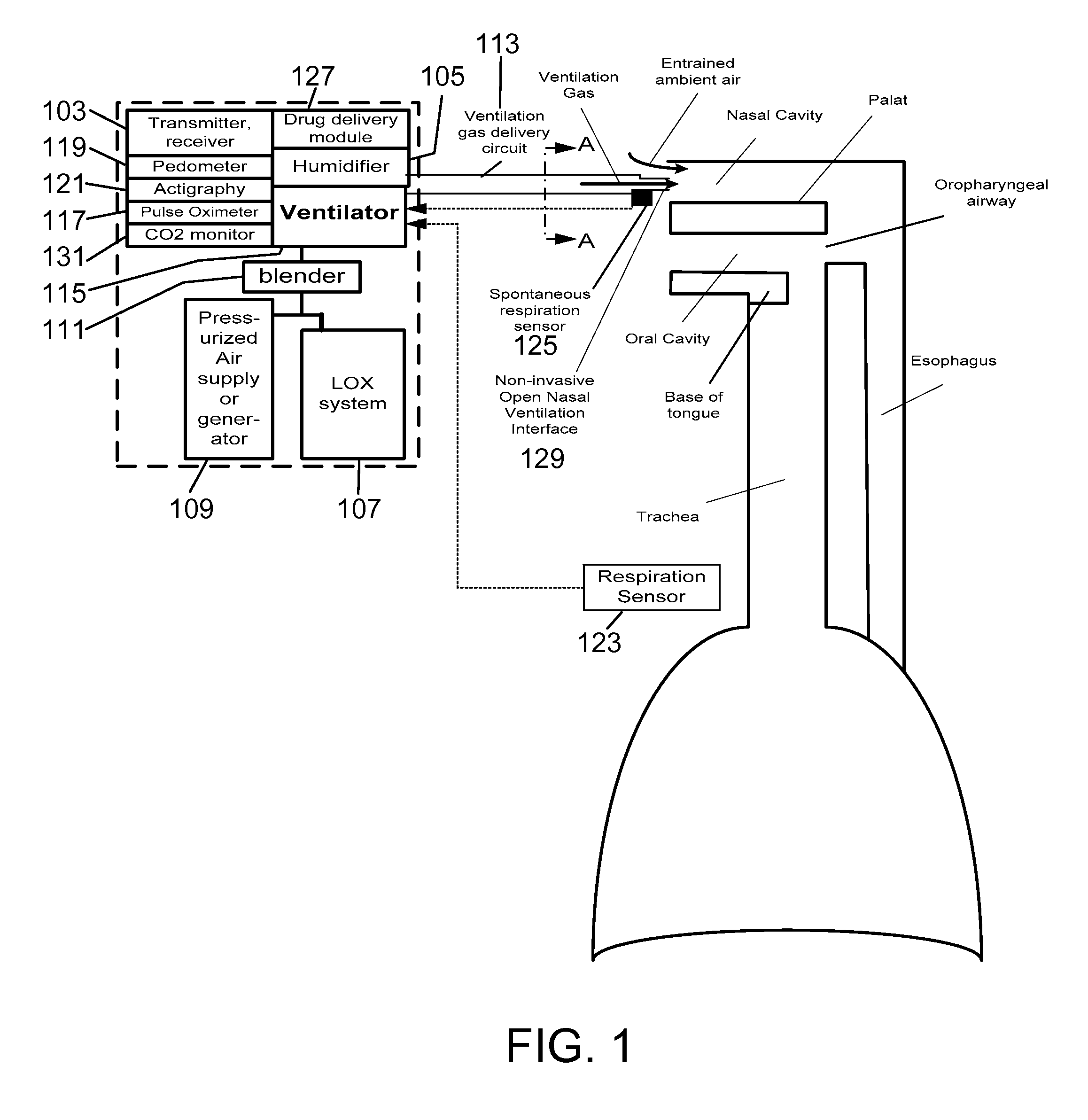

Methods, systems and devices using lox to provide ventilatory support

A portable liquid oxygen system may provide an average flow rate of oxygen gas at approximately 6-approximately 20 lpm using a rapid gas conversion mode.

Owner:BREATHE TECHNOLOGIES INC

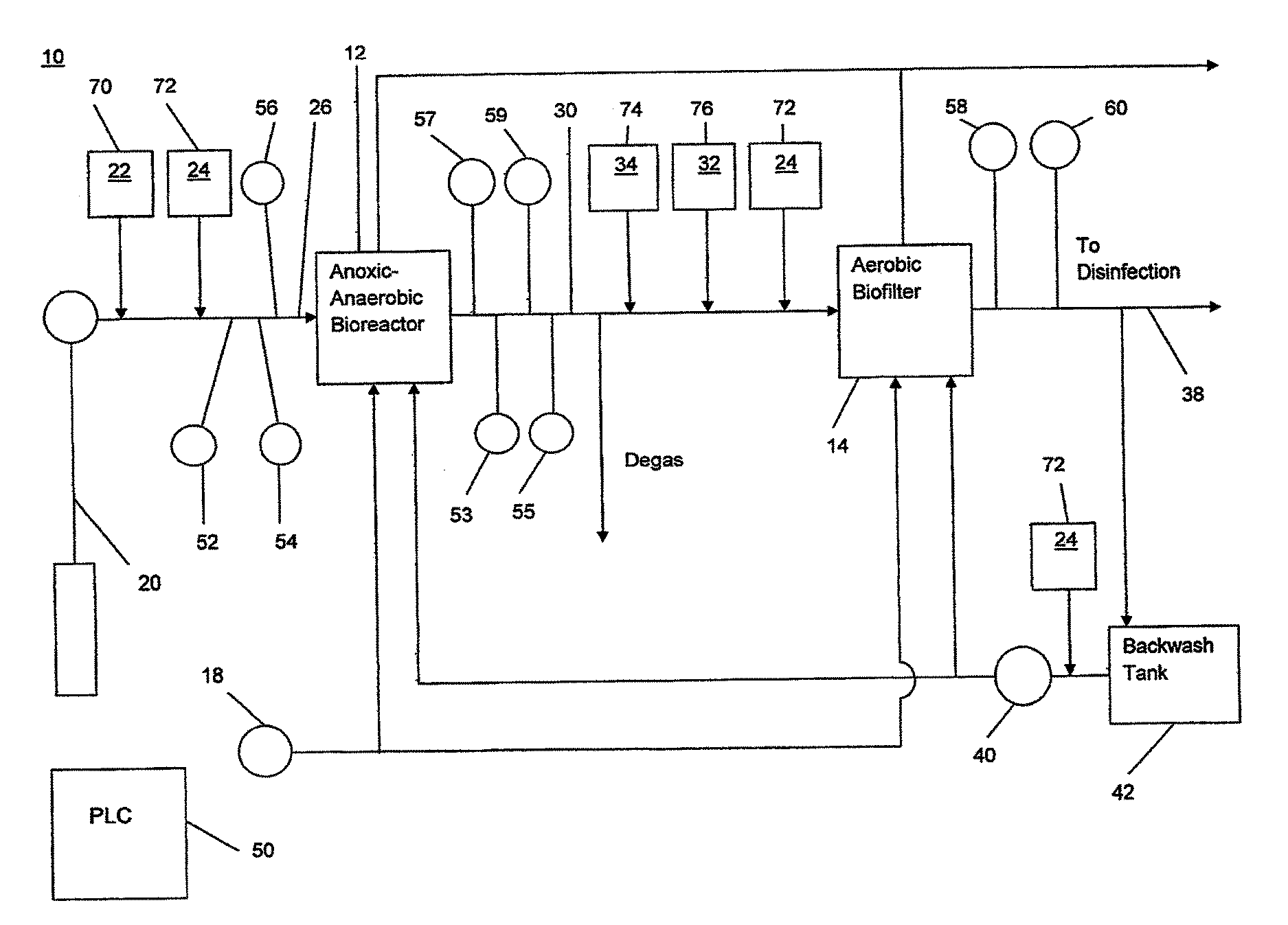

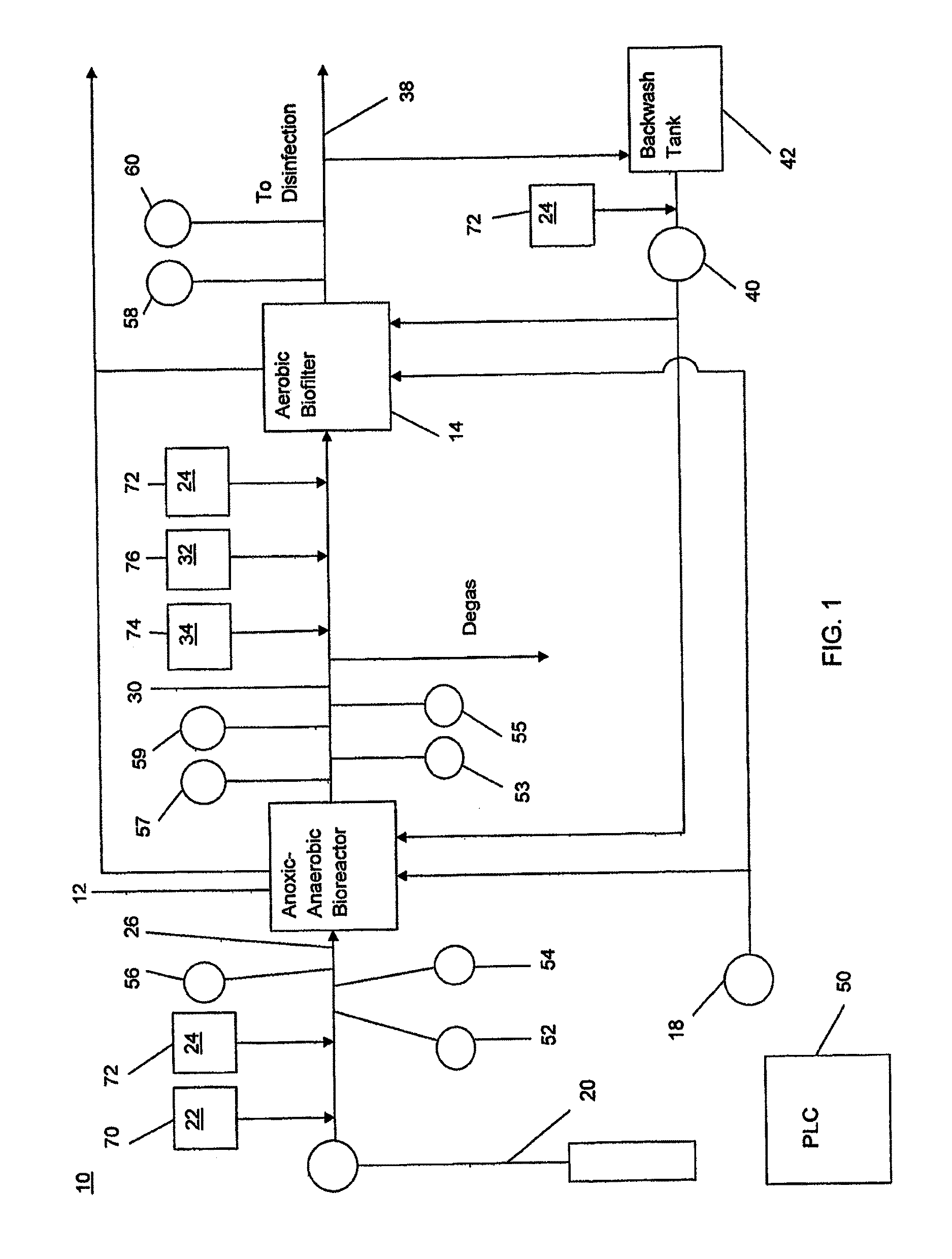

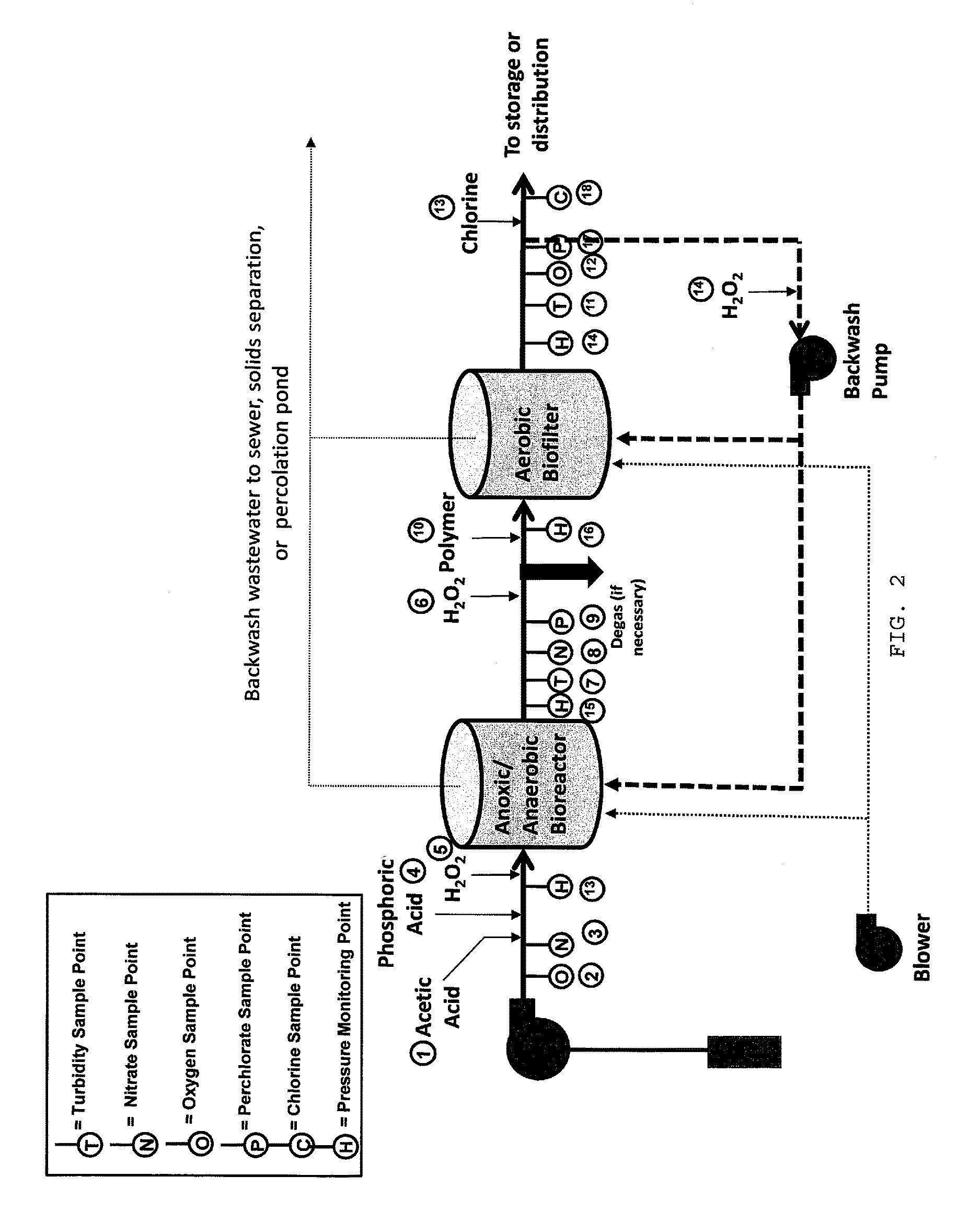

Biological two-stage contaminated water treatment system and process

ActiveUS9580341B1Water treatment parameter controlWater treatment compoundsBiological filterTreated water

The systems and methods may be used for treatment of water that contains contaminants. Water containing at least one of a nitrate, percholate, chromate, selenite, and a volatile organic chemical is combined with nutrients and then is processed in an anoxic-anaerobic bioreactor. The combined effluent may also be oxygenated by dosing with hydrogen peroxide or liquid oxygen. The combined effluent of the bioreactor is dosed with a particle conditioning agent. The combined effluent treated water of the bioreactor is then filtered in a biofilter to produce a treated effluent stream. The influent water and combined effluent of the anoxic-anaerobic bioreactor may also be dosed with hydrogen peroxide to control biomass content in the system.

Owner:BIOTTTA

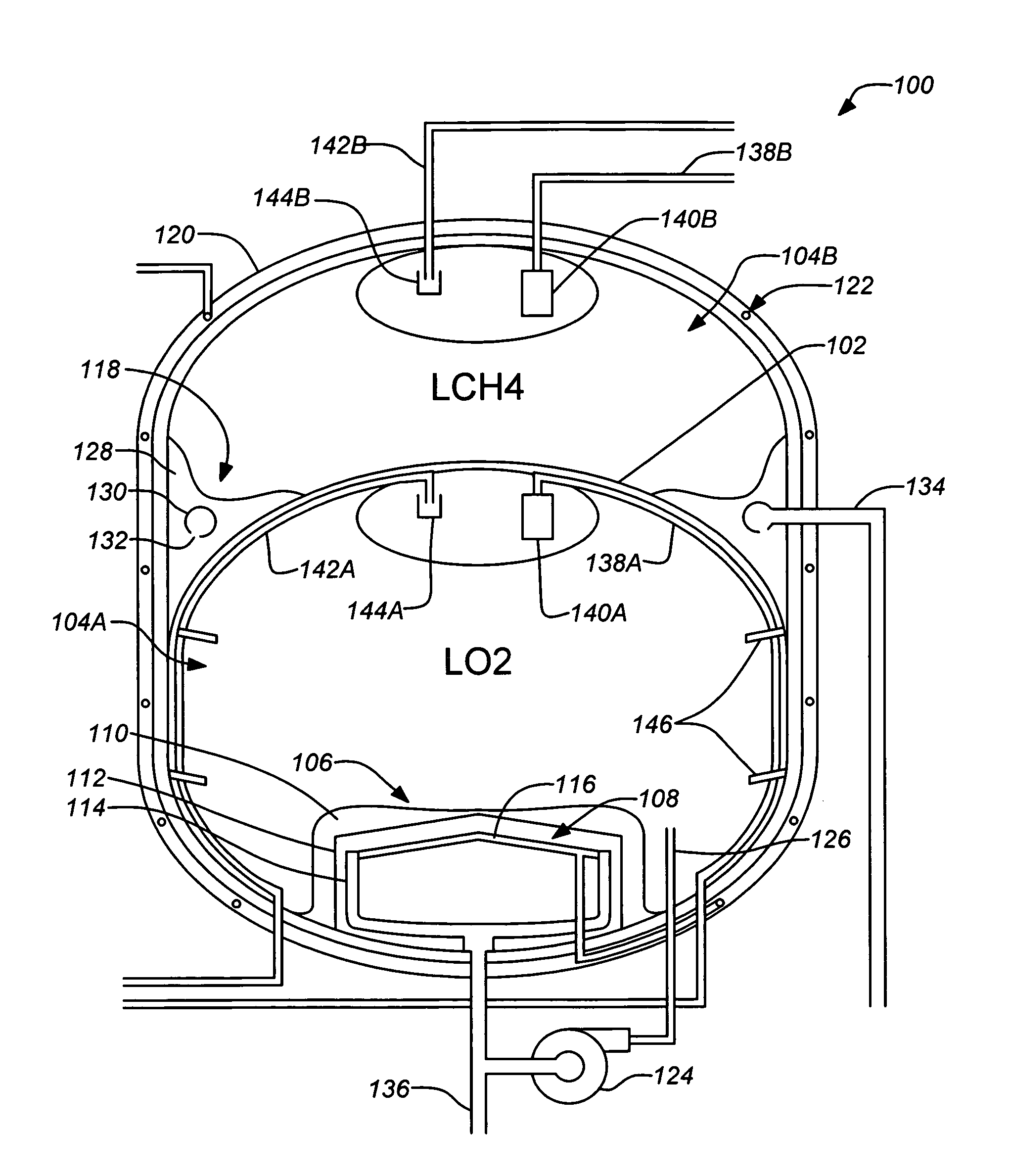

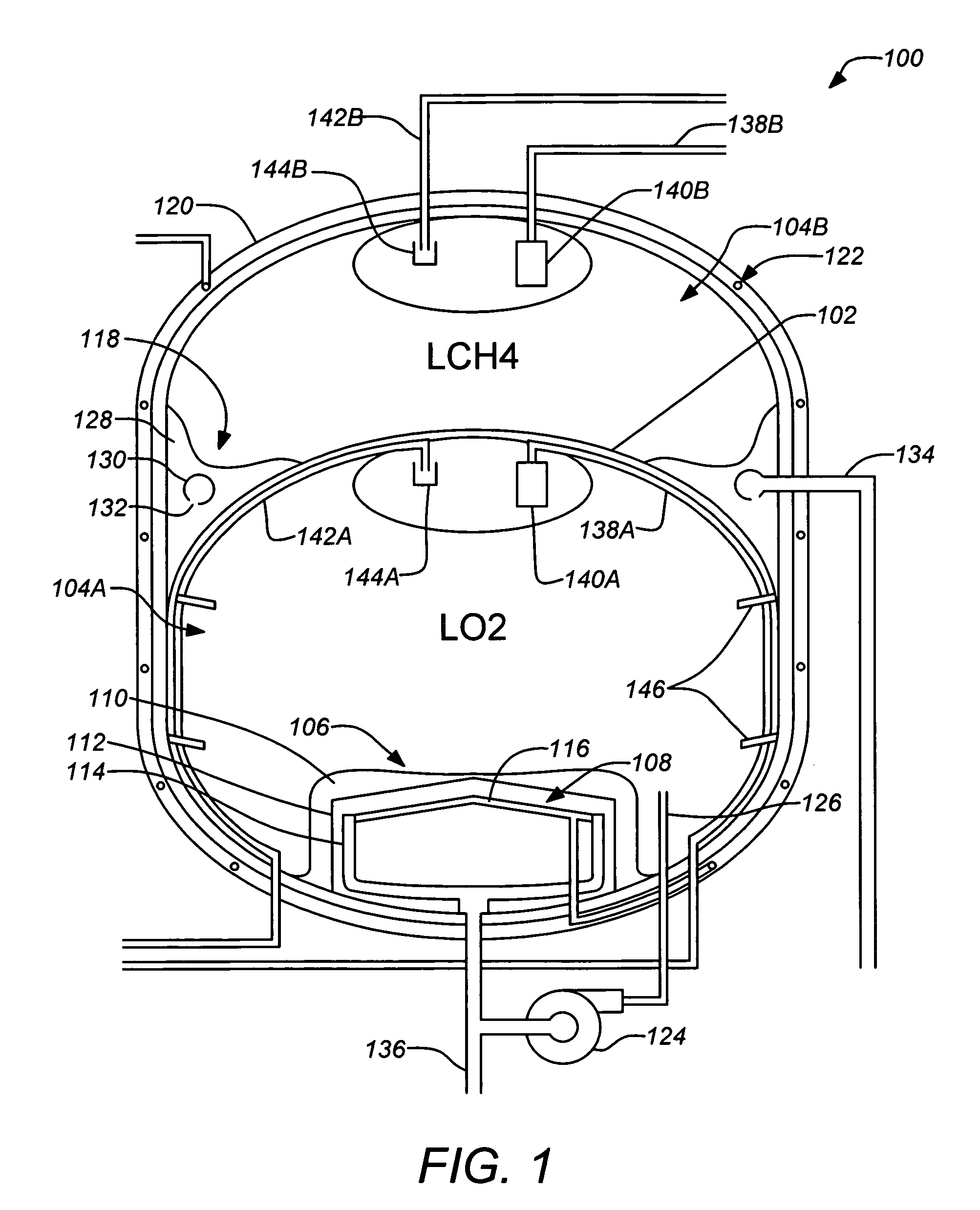

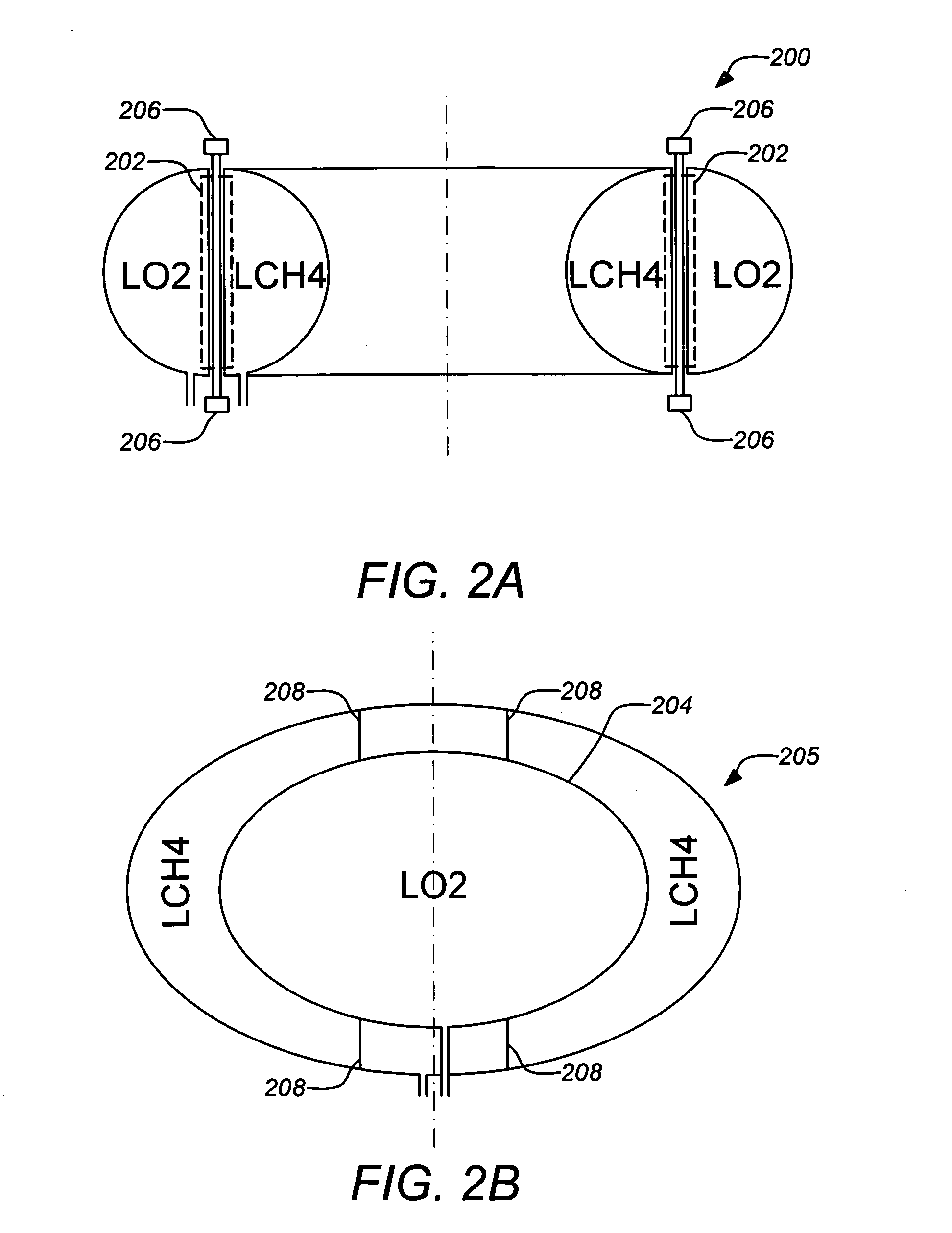

Thermally coupled liquid oxygen and liquid methane storage vessel

InactiveUS20070193282A1Elimination reductionVessel mounting detailsVessel geometry/arrangement/sizeThermal conductivityLiquid oxygen

A cryogenic propellant storage tank system and method are disclosed that thermally couple LO2 and LCH4 tanks together by using either a single tank compartmentalized by a common tank wall or two separate tanks that are coupled together with one or more thermal couplers having high thermal conductivity. Cryogenic cooling equipment may be located only in the LO2 tank while the LCH4 is cooled by the LO2 tank interface. Embodiments of the invention may employ both LO2 and LCH4 liquid acquisition devices (LADs) for low-gravity use. In further embodiments, only the LO2 LADs may be integrated with thermal cooling equipment.

Owner:THE BOEING CO

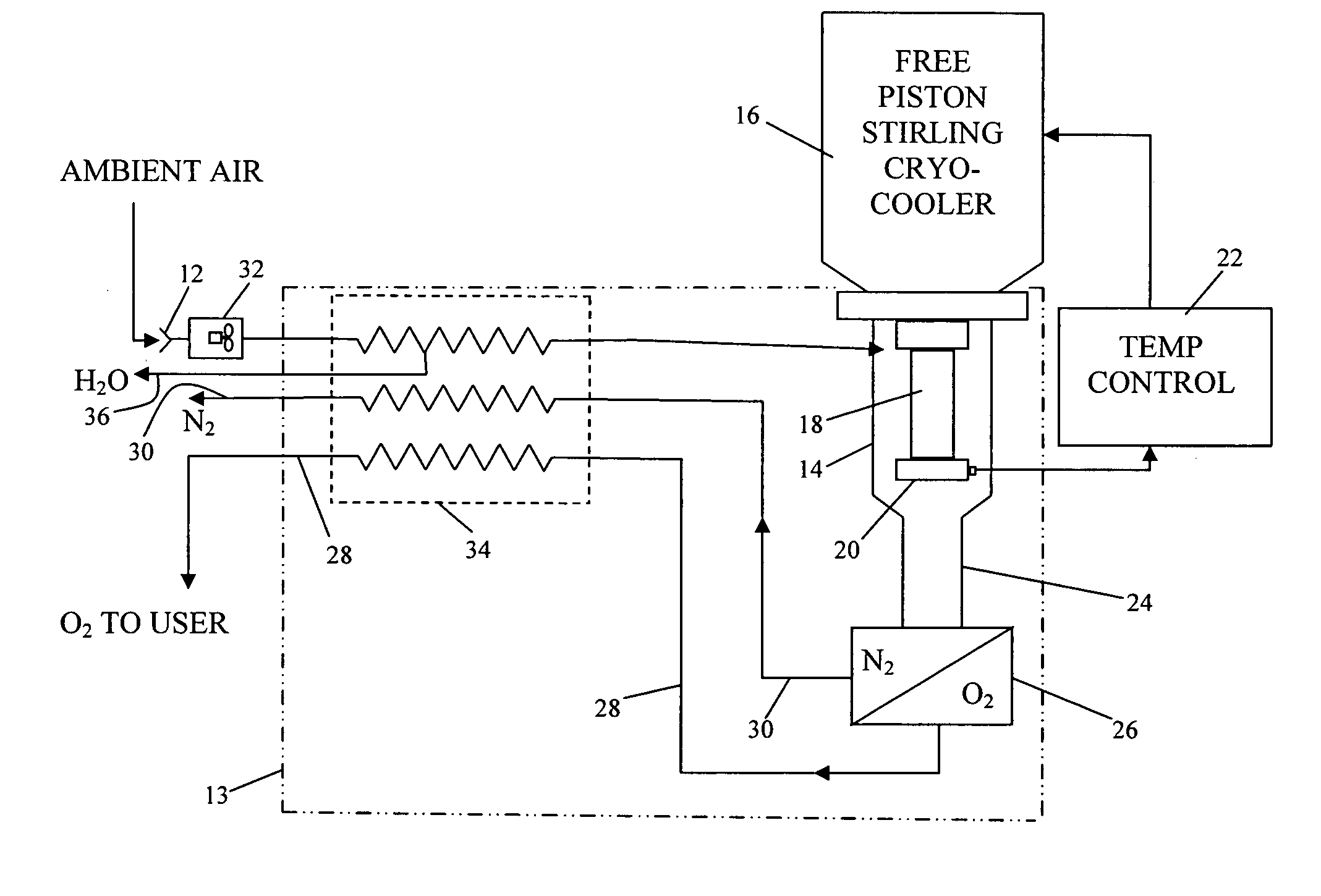

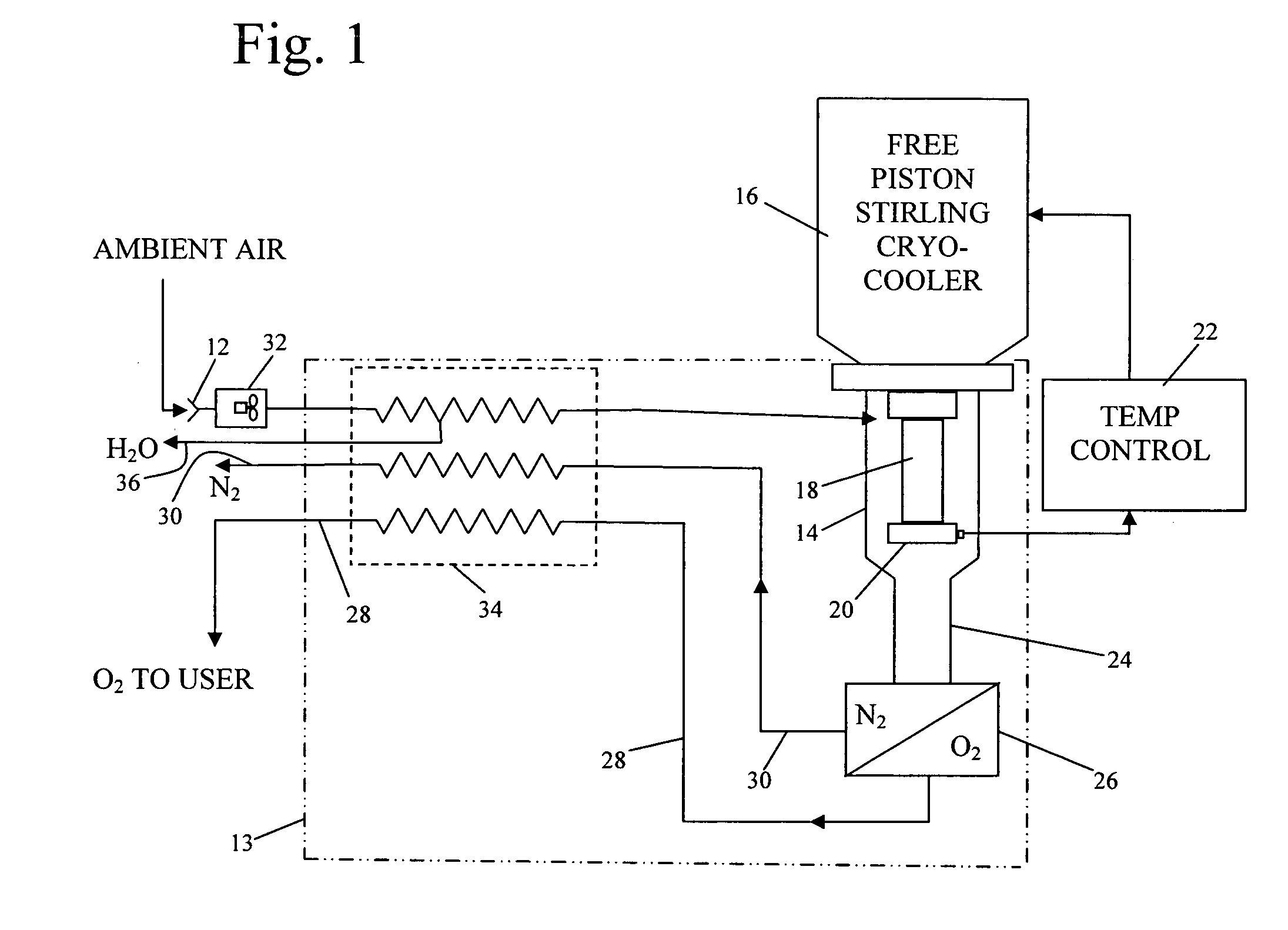

Energy efficient, inexpensive extraction of oxygen from ambient air for portable and home use

Apparatus and method for separating oxygen directly from air, operating at substantially atmospheric pressure and recuperating energy used for cooling incoming air. An ambient air input leads from the atmosphere to a vessel for confining gases. A cryocooler has a cooled surface in the vessel for directly condensing oxygen from the air at substantially atmospheric pressure. The cryocooler cools the cold surface to a temperature greater than the boiling point temperature of nitrogen and not greater than the boiling point temperature of oxygen for condensing oxygen. A liquid / gas separator separates the liquid oxygen from residual gases which both flow out through separate outputs. Air is propelled through the system at substantially atmospheric pressure by an air impeller. A heat exchanger recovers cooling energy and dehumidifies incoming air by transferring heat from the incoming air to outgoing gases.

Owner:SUNPOWER

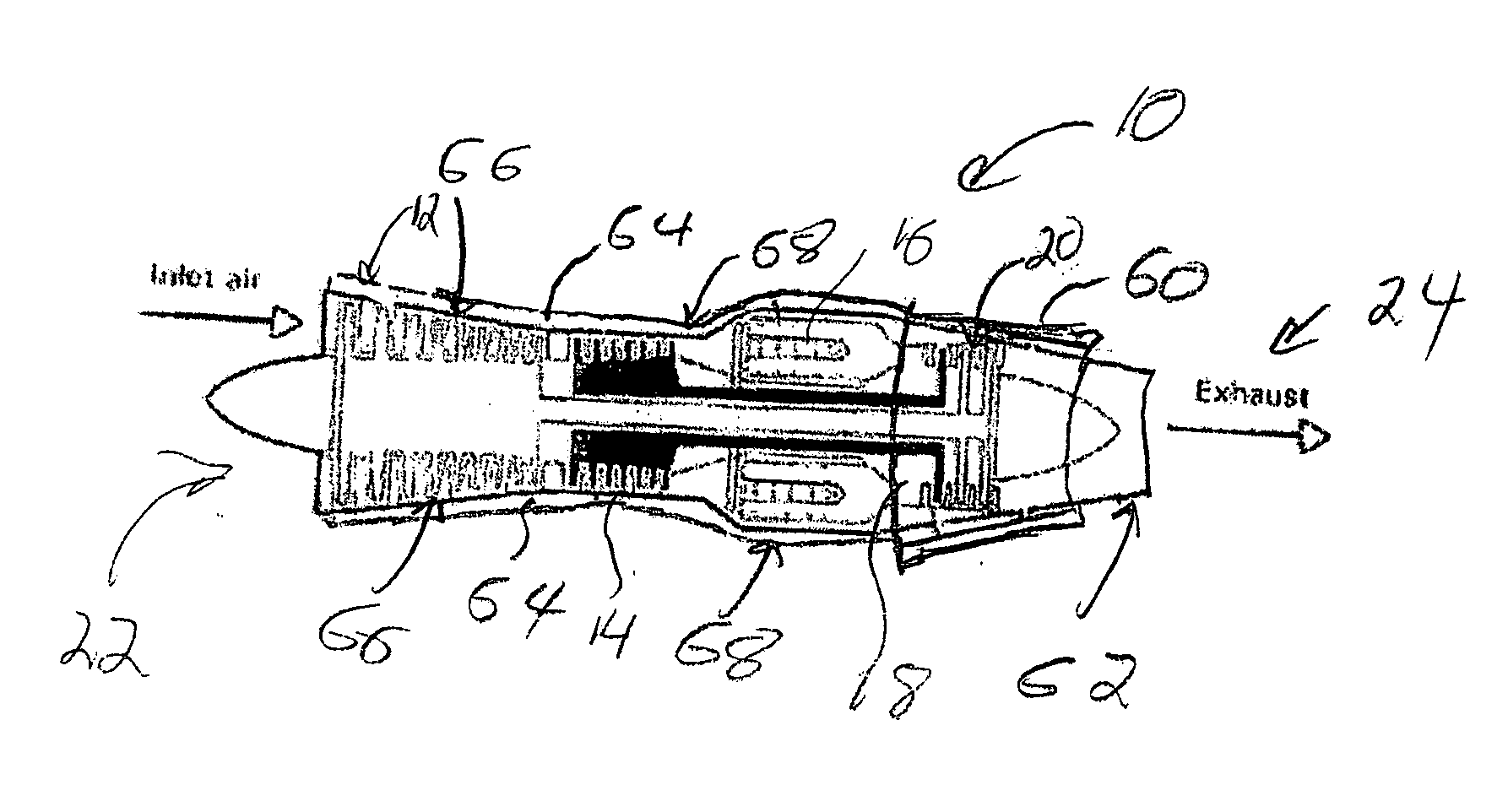

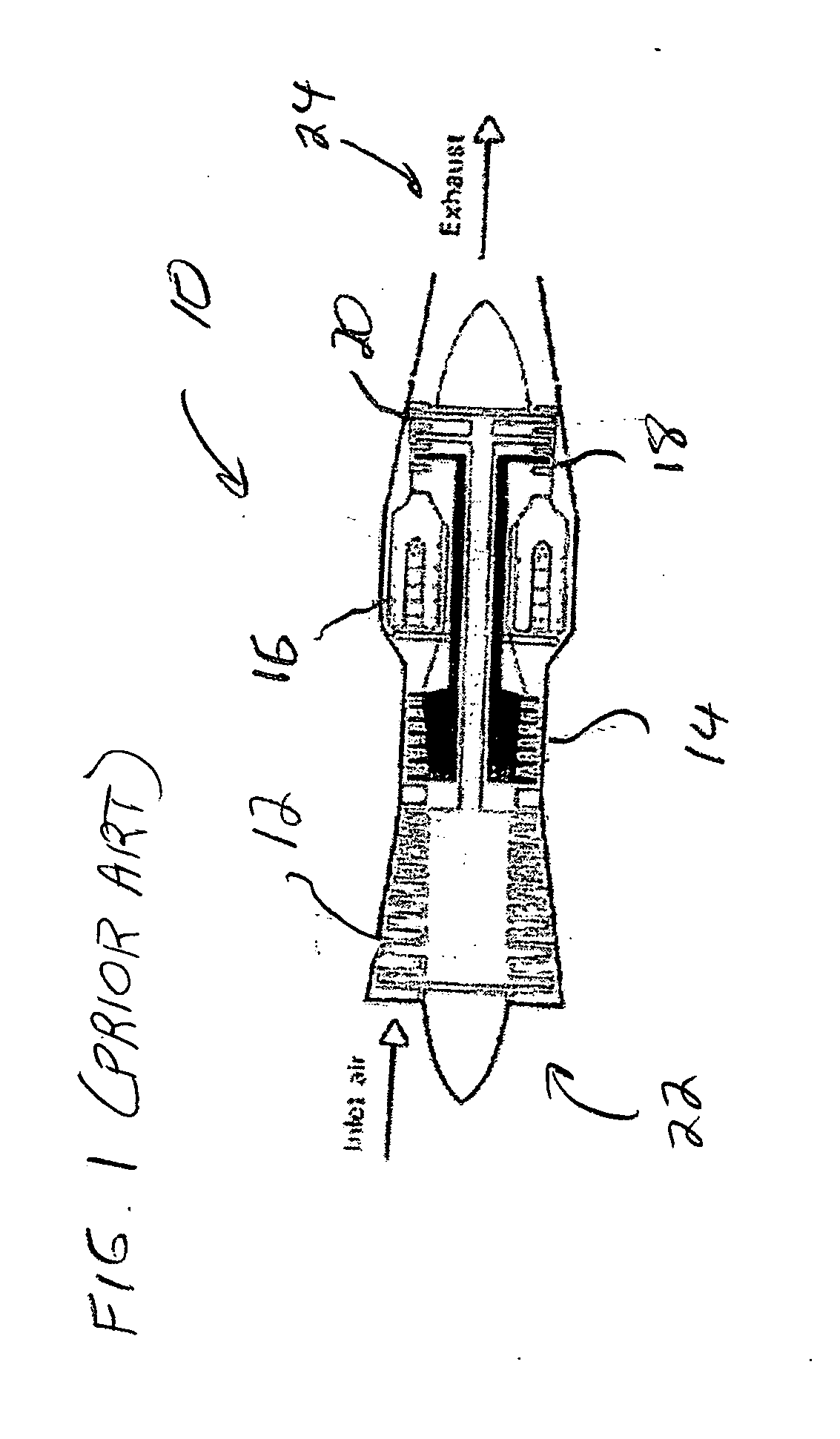

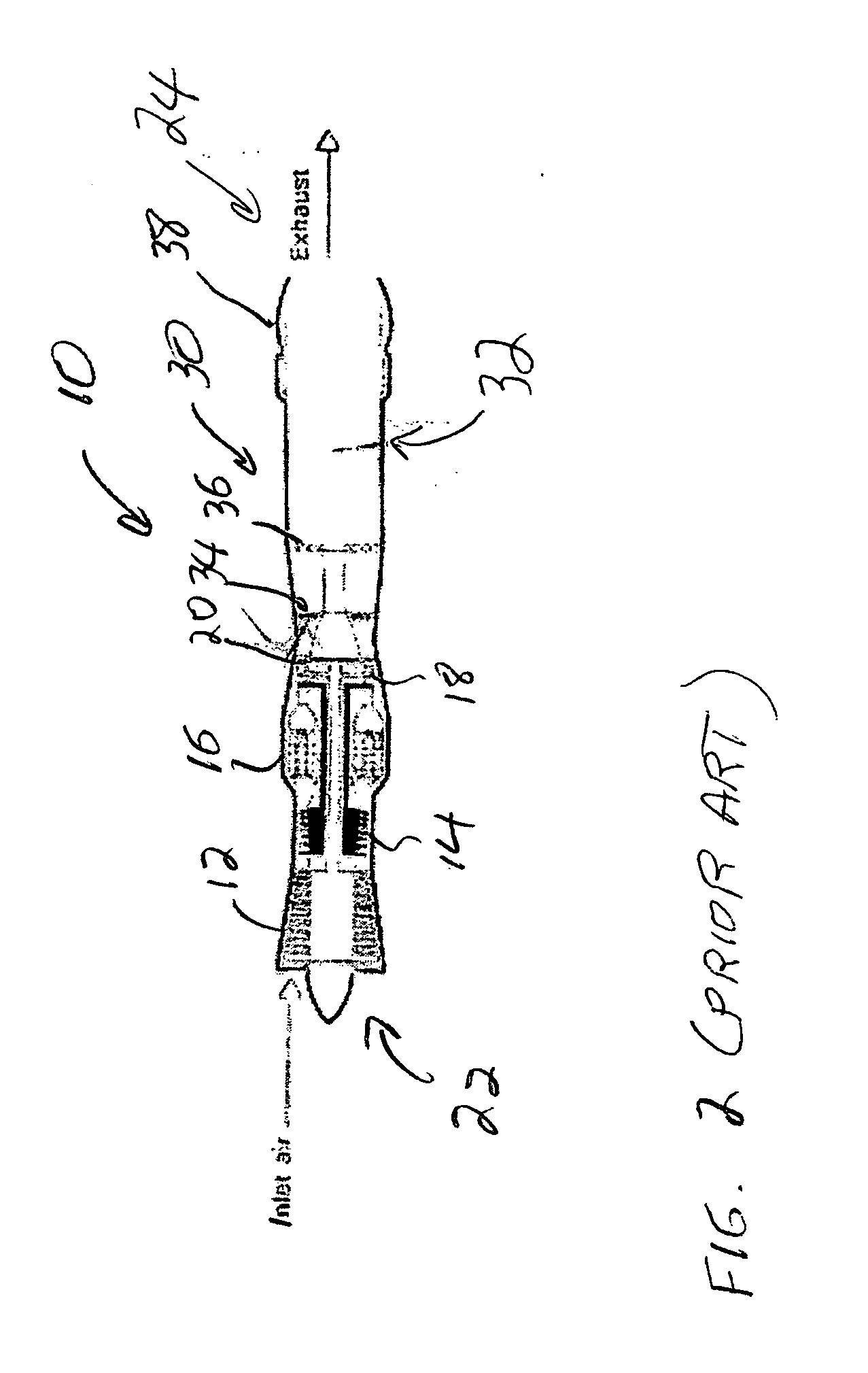

Retractable afterburner for jet engine

The present invention is a retractable afterburner shroud for use upon a jet engine. The retractable shroud conforms to an outer surface of a jet engine. The afterburner shroud is affixed by a plurality of moveable support arms. The afterburner shroud is retractable. During operation of the afterburner shroud, the afterburner shroud is extended rearward toward the exhaust of the jet engine. A storage tank provides liquid oxygen through the support arms to a mixing ring located within the afterburner shroud. The mixing ring mixes the liquid oxygen and fuel to form a combustible mixture. The combustible mixture is injected into the exhaust wherein the mixture is ignited. The ignited mixture provides additional thrust for the jet engine.

Owner:ADTECH

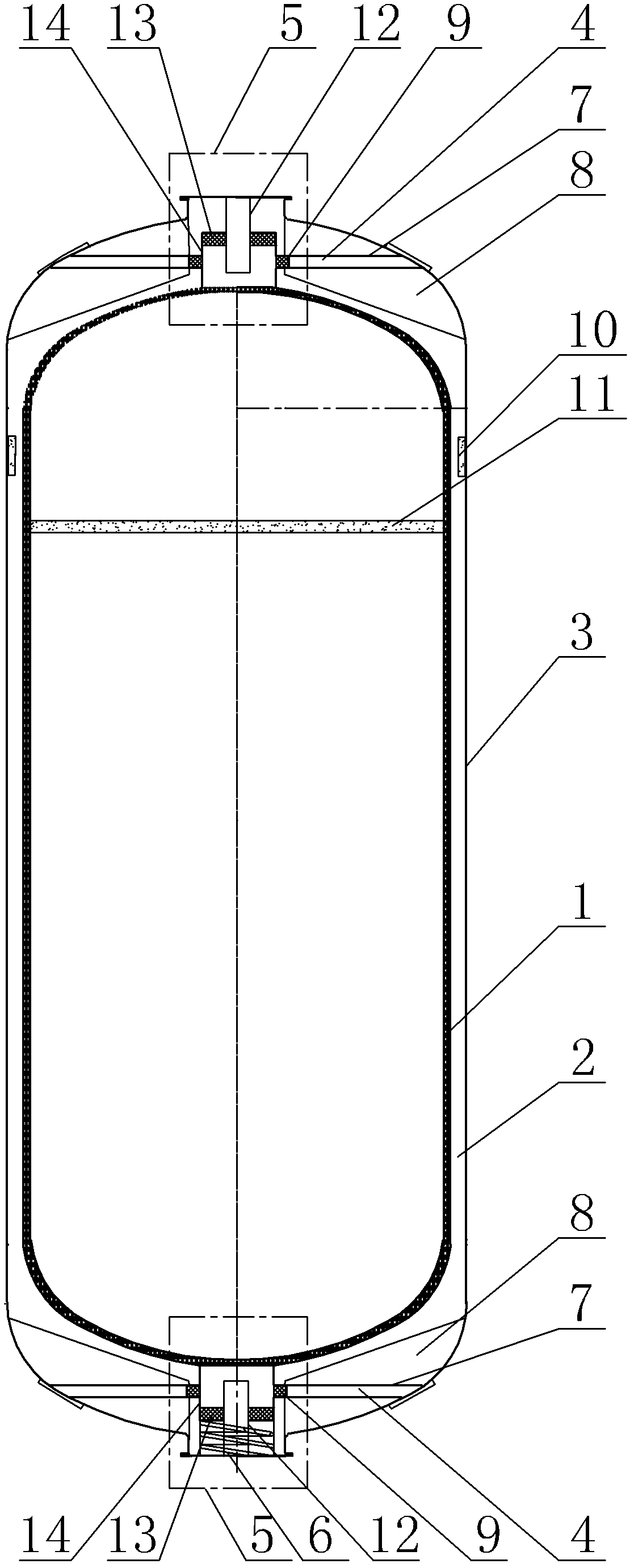

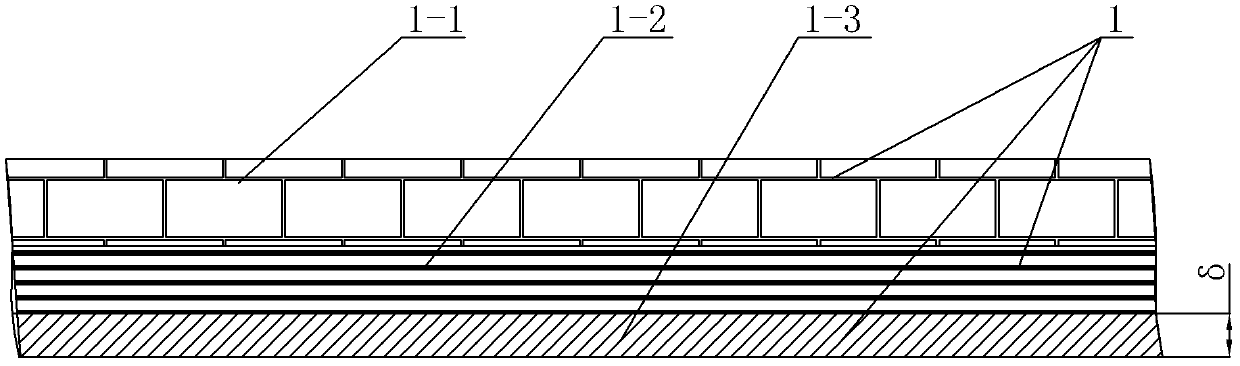

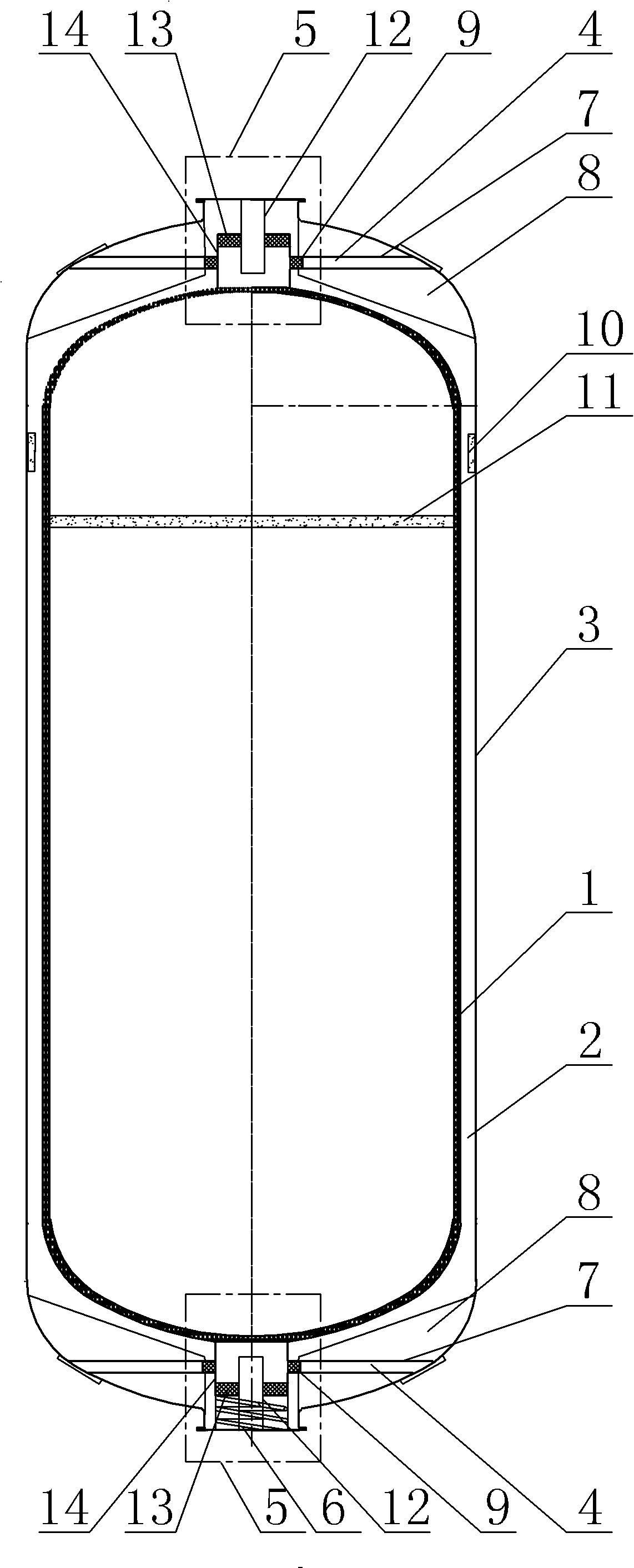

Liquid oxygen container with multi-layer vacuum thermal insulation layer and fiber reinforced composite material layer

InactiveCN102606874AResist damageIncrease pressurePressure vesselsThermal insulationFiber-reinforced composite

The invention discloses a liquid oxygen container with a multi-layer vacuum thermal insulation layer and a fiber reinforced composite material layer, relates to a liquid oxygen container and solves the problems that the conventional liquid oxygen container is in a stainless steel structure and has the defects of high weight, low storage and transportation efficiency and high storage and transportation cost. A second supporting disc is fixedly sleeved on each supporting cylinder; a third supporting disc is fixedly sleeved on each second supporting disc; each third supporting disc is fixedly connected with the inner wall of a shell of the container in the circumferential direction; a liner consists of a metal liner layer, the fiber reinforced composite material layer and the multi-layer vacuum thermal insulation layer sequentially from interior to exterior; the fiber reinforced composite material layer is wound on the outer wall of the metal liner layer; and multi-layer vacuum thermal insulation layer is coated on the outer surface of the fiber reinforced composite material layer. The liquid oxygen container with the multi-layer vacuum thermal insulation layer and the fiber reinforced composite material layer is used for storing and transporting liquid oxygen.

Owner:HARBIN INST OF TECH

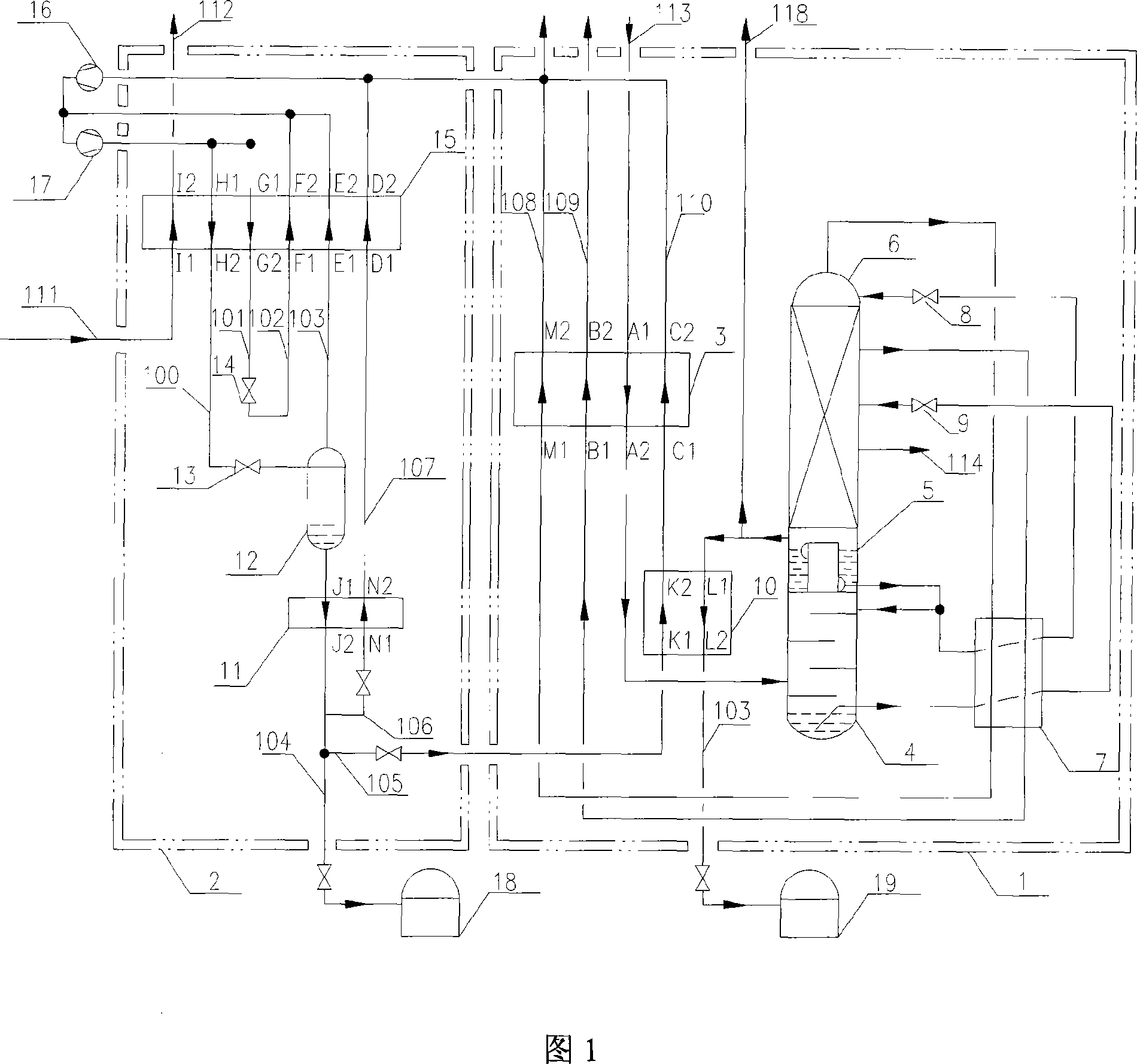

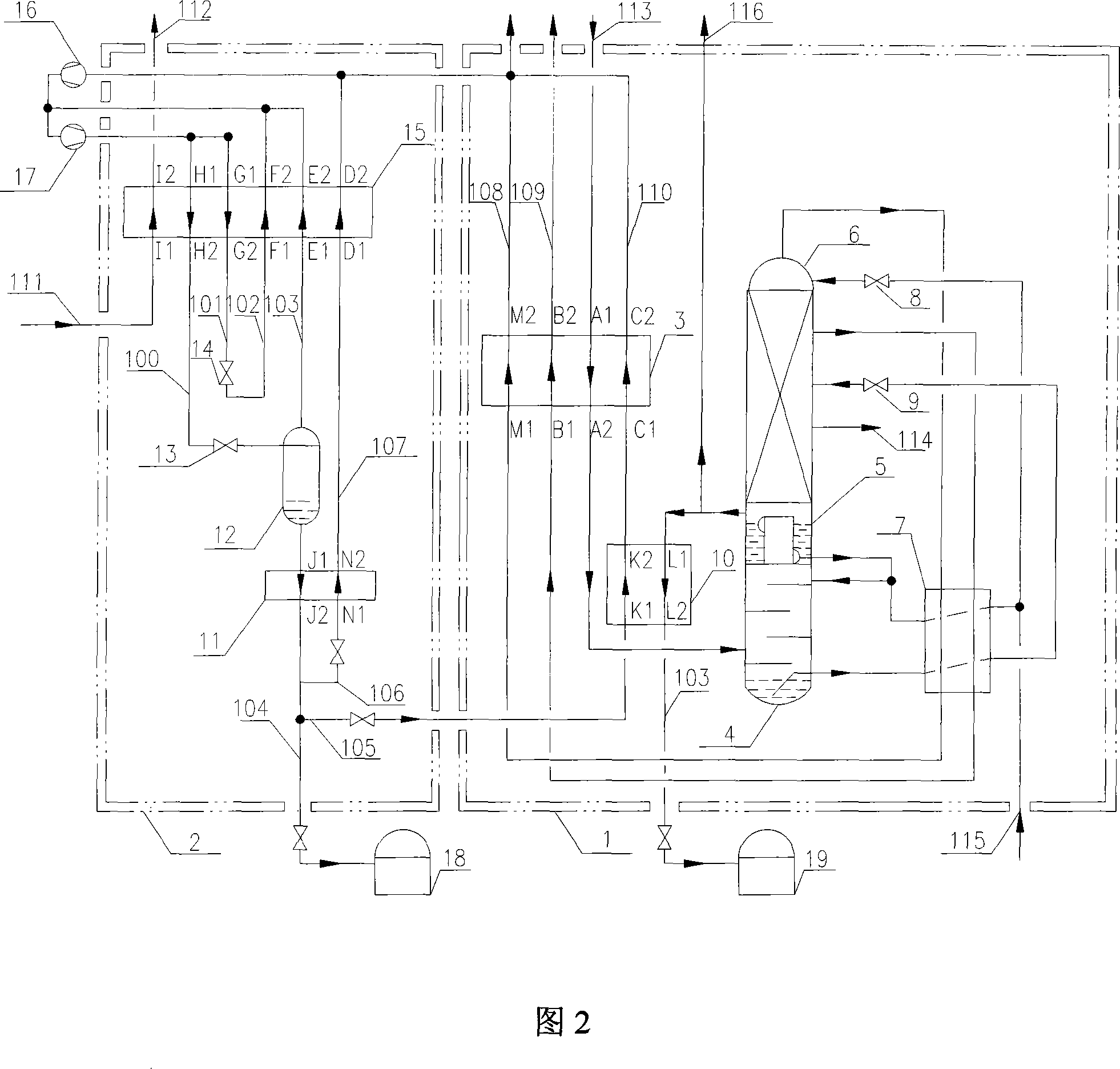

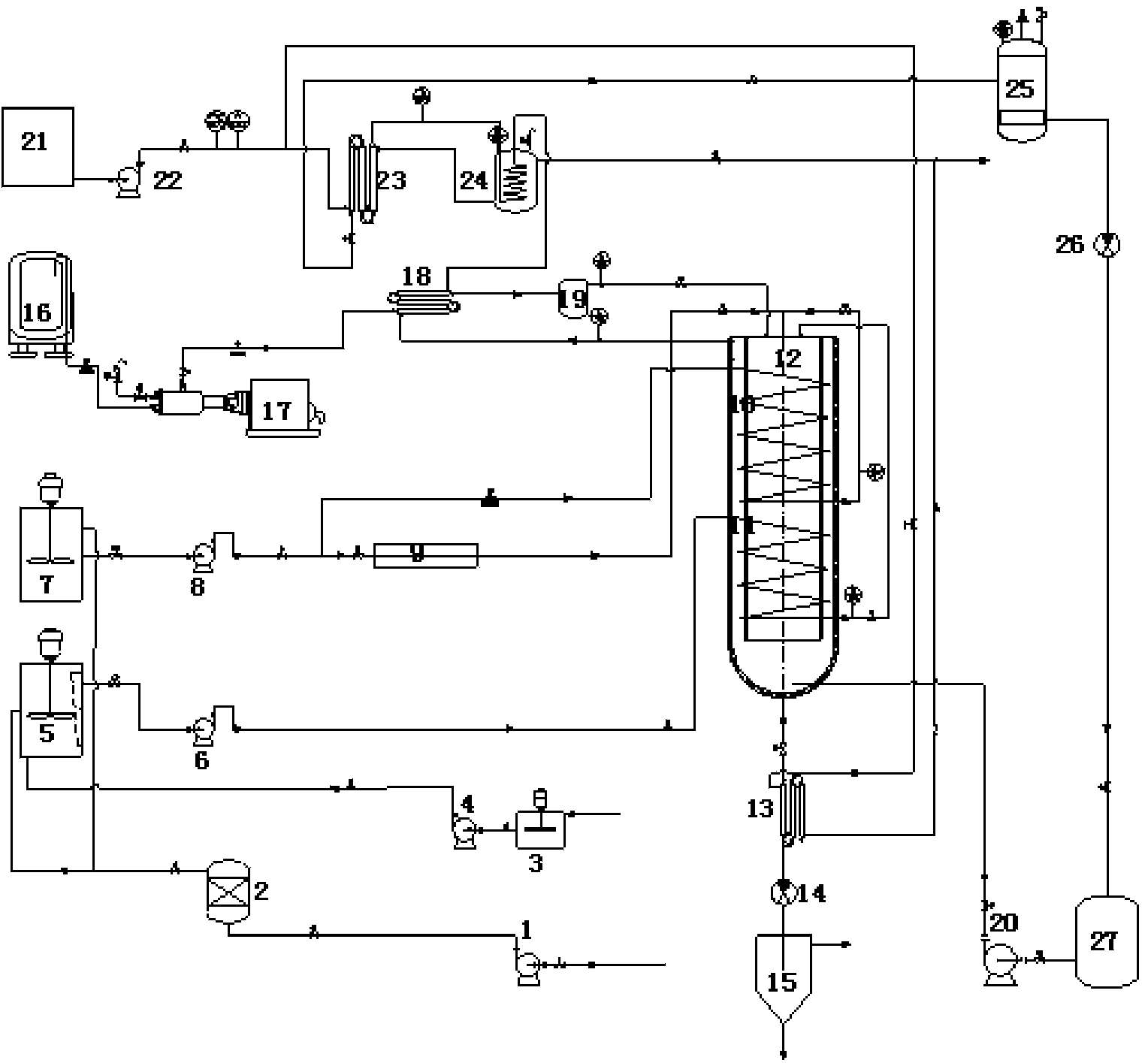

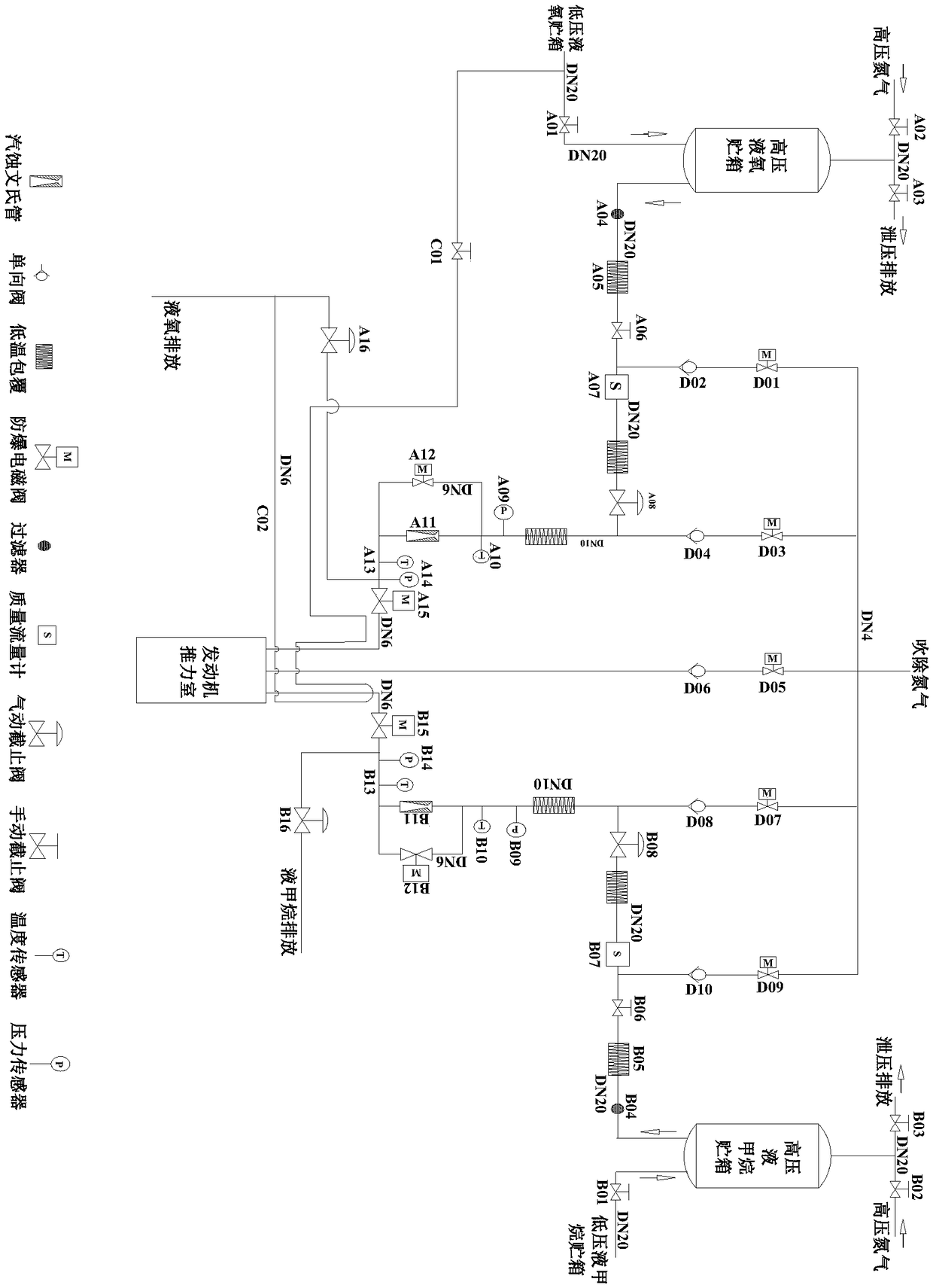

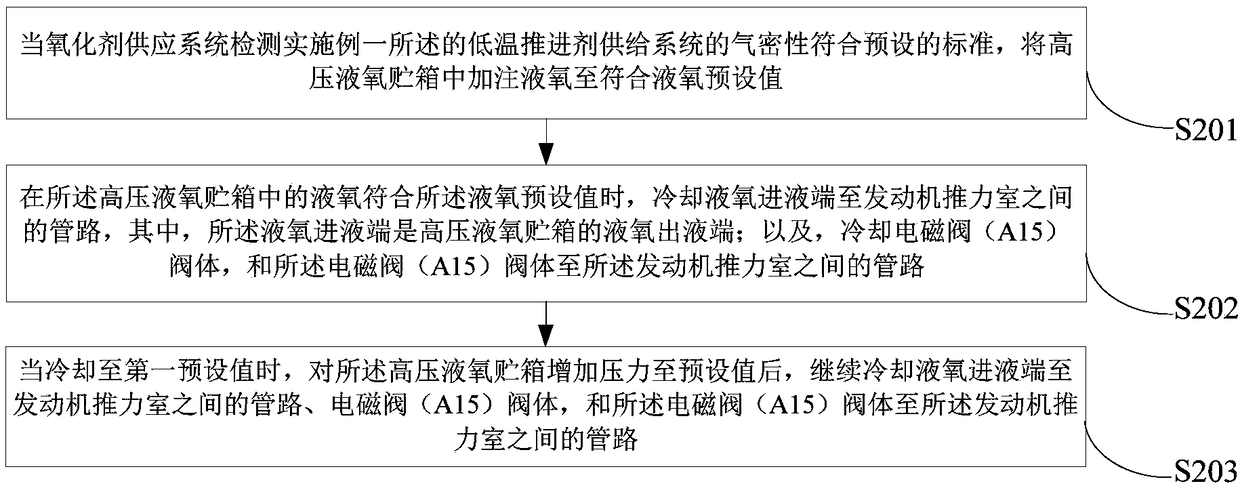

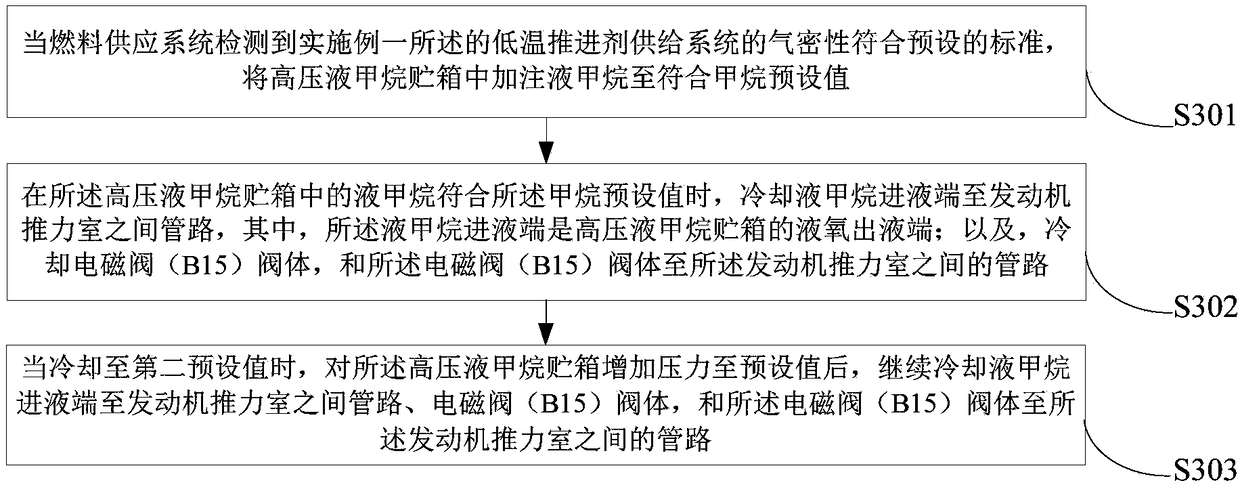

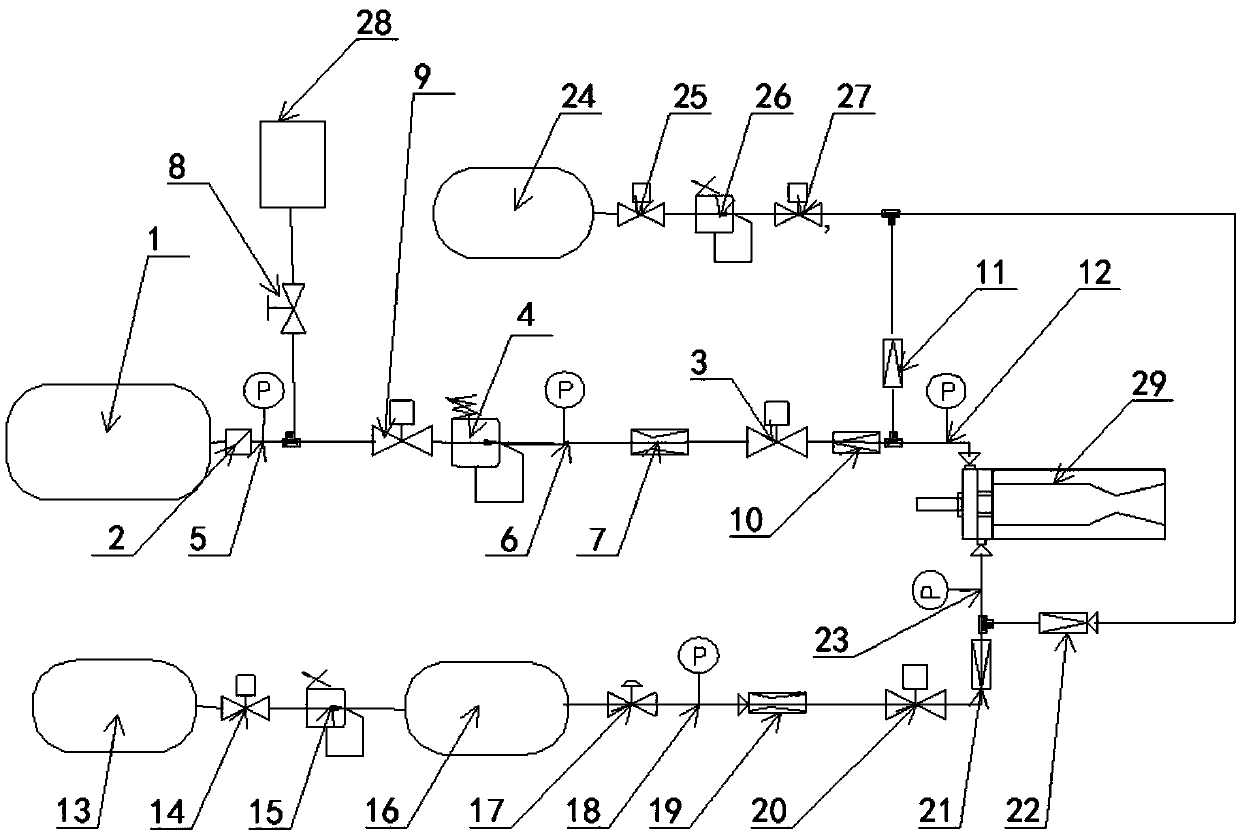

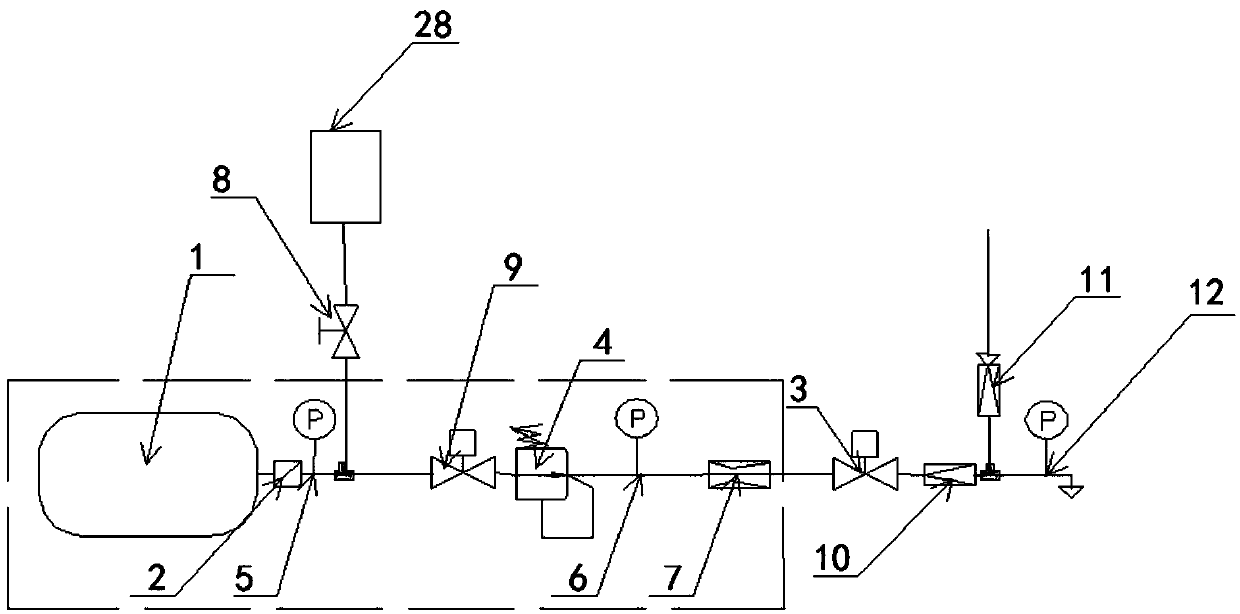

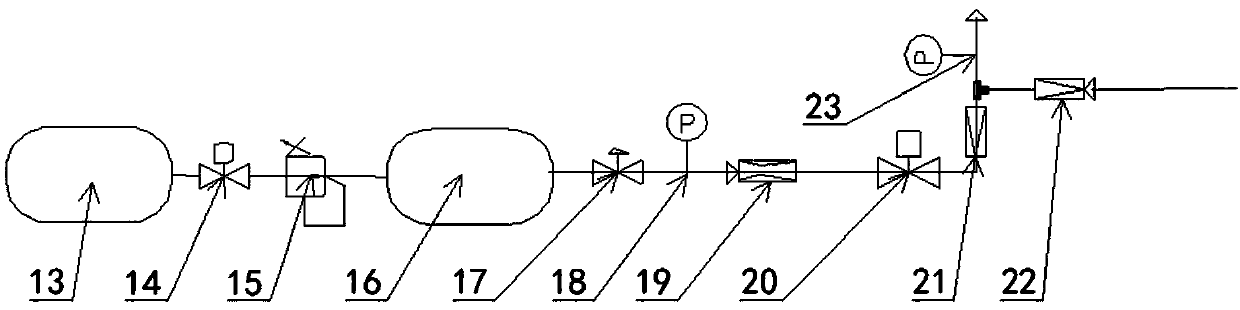

Low-temperature propellant supplying system, method and device

ActiveCN109469558AStable adjustment of delivery volumeControl flowGas-turbine engine testingRocket engine plantsThrust chamberNitrogen

The invention provides a low-temperature propellant supplying system, a method and a device. The low-temperature propellant supplying system comprises a nitrogen blowing away system, an oxidant supplying system, a fuel supplying system and a low-pressure liquid oxygen cooling system; the nitrogen blowing away system is used for carrying out purging operation on a system pipeline before and after an experiment and detecting the air tightness of the low-temperature propellant supplying system; under the condition that the air tightness of the low-temperature propellant supplying system is qualified, the oxidant supplying system is used for conveying liquid oxygen to an engine thrust chamber; the fuel supplying system is used for conveying liquid methane to the engine thrust chamber; the low-pressure liquid oxygen cooling system is used for cooling a pipeline, wherein partial pipeline is located between an electromagnetic valve (A15) and the engine thrust chamber and partial pipeline is located between an electromagnetic valve (B15) and the engine thrust chamber. According to the embodiment of the supplying system, the method and the device, the required preset temperature can be achieved before the test, the low-pressure liquid oxygen cooling system adopts low-pressure liquid oxygen to cool the environment so as to ensure the safety, the propellant conveying amount can be stablyadjusted, and simplicity and reliability are achieved.

Owner:BEIHANG UNIV

Gas-oxygen-kerosene rocket-engine pressurizing delivery system and small-rocket-engine propellant supplying system

The invention relates to the field of rocket-engine propellant delivery systems, in particular to a gas-oxygen-kerosene rocket-engine pressurizing delivery system and a small-rocket-engine propellantsupplying system. The pressurizing delivery system comprises an oxygen supplying system, a fuel oil supplying system and a blowing-off system; the oxygen supplying system comprises an oxygen storage tank valve assembly, a first stop valve, a first one-way valve and a second one-way valve; the oxygen storage tank valve assembly, the first stop valve and the first one-way valve are sequentially communicated through a pipe, the second one-way valve is communicated with the blowing-off system, and an outlet of the first one-way valve and an outlet of the second one-way valve are connected with a thrust chamber through the same pipe; the fuel oil supplying system is connected with the blowing-off system to enter the thrust chamber through the pipe. The gas-oxygen-kerosene rocket-engine pressurizing delivery system in the technical scheme is compared with a liquid-oxygen-kerosene rocket propellant delivery system, complex design such as pressurization-system gas-liquid phase transition, delivery-system low-temperature two-phase flow and engine pre-cooling are not required to be considered, and the complex degree and the quality of the system structure are also greatly reduced.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com