Patents

Literature

185 results about "Liquid argon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid argon is tasteless, colorless, odorless, non-corrosive, nonflammable, and extremely cold. Belonging to the family of rare inert gases, argon is the most plentiful of the rare gases, making up approximately 1% of the earth’s atmosphere.

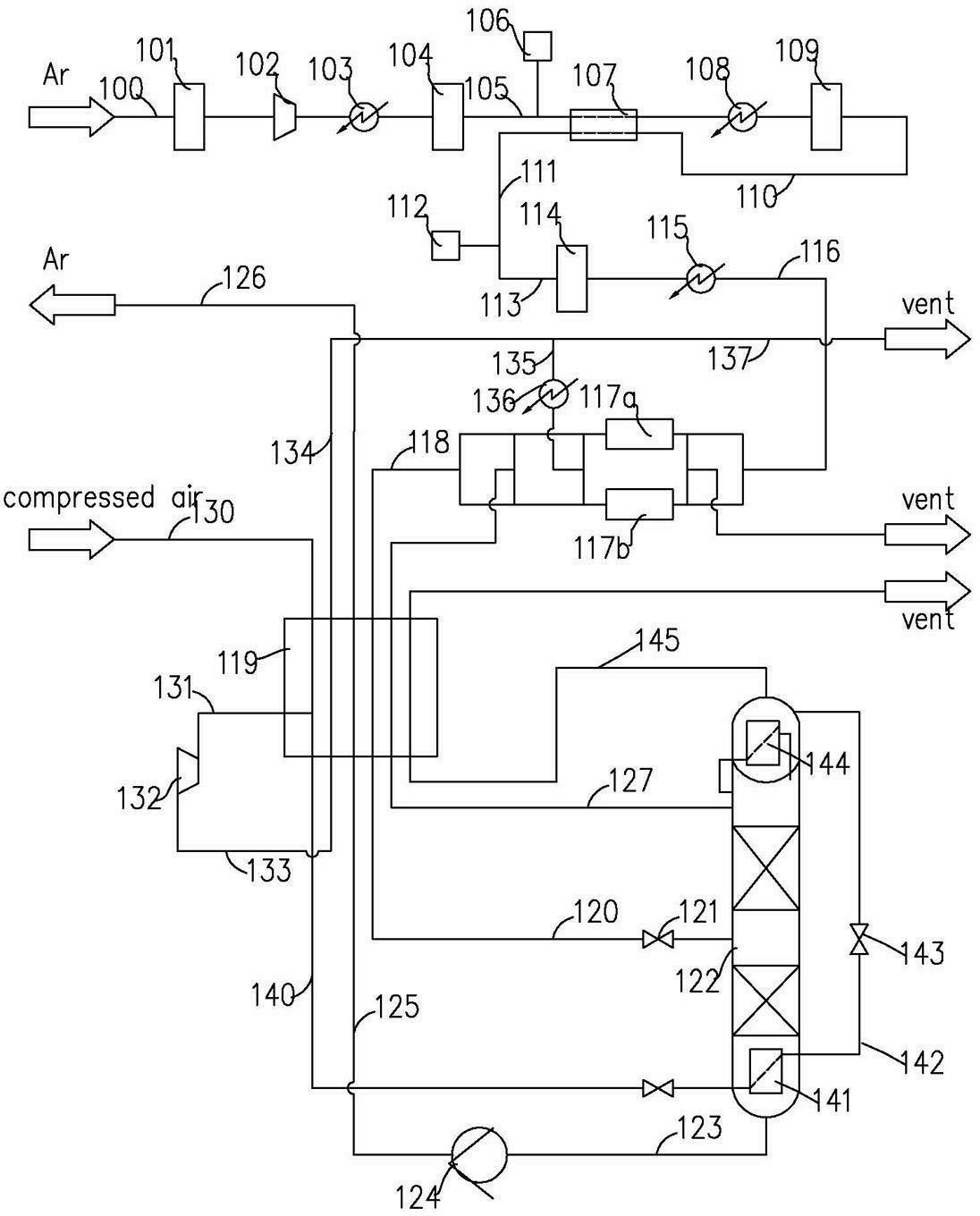

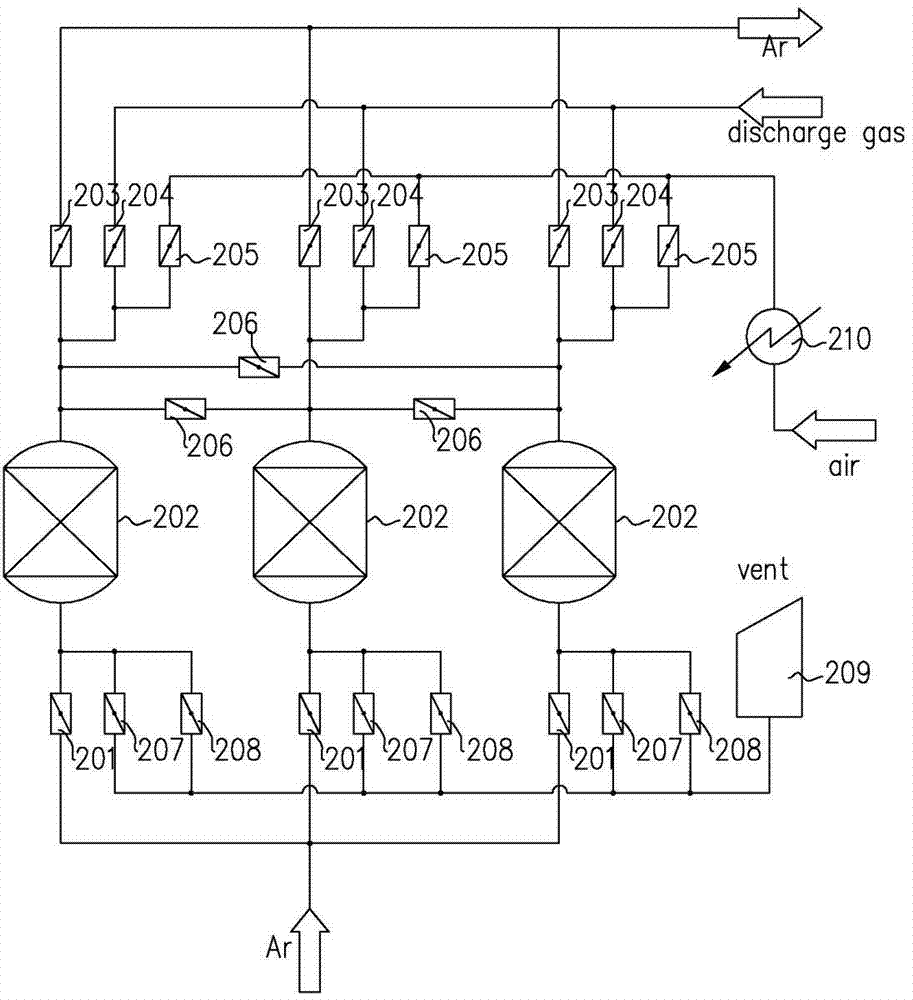

Argon production method and apparatus

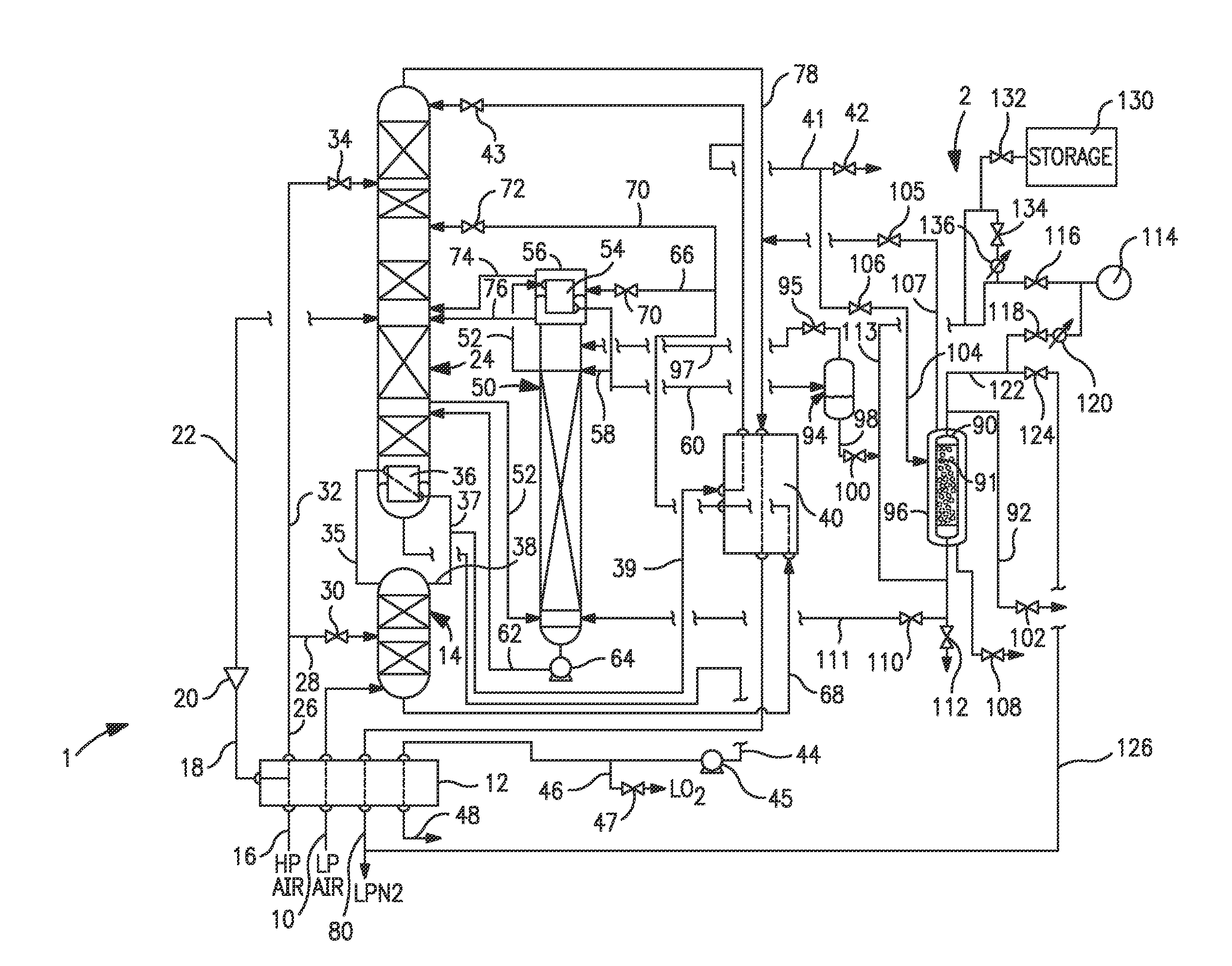

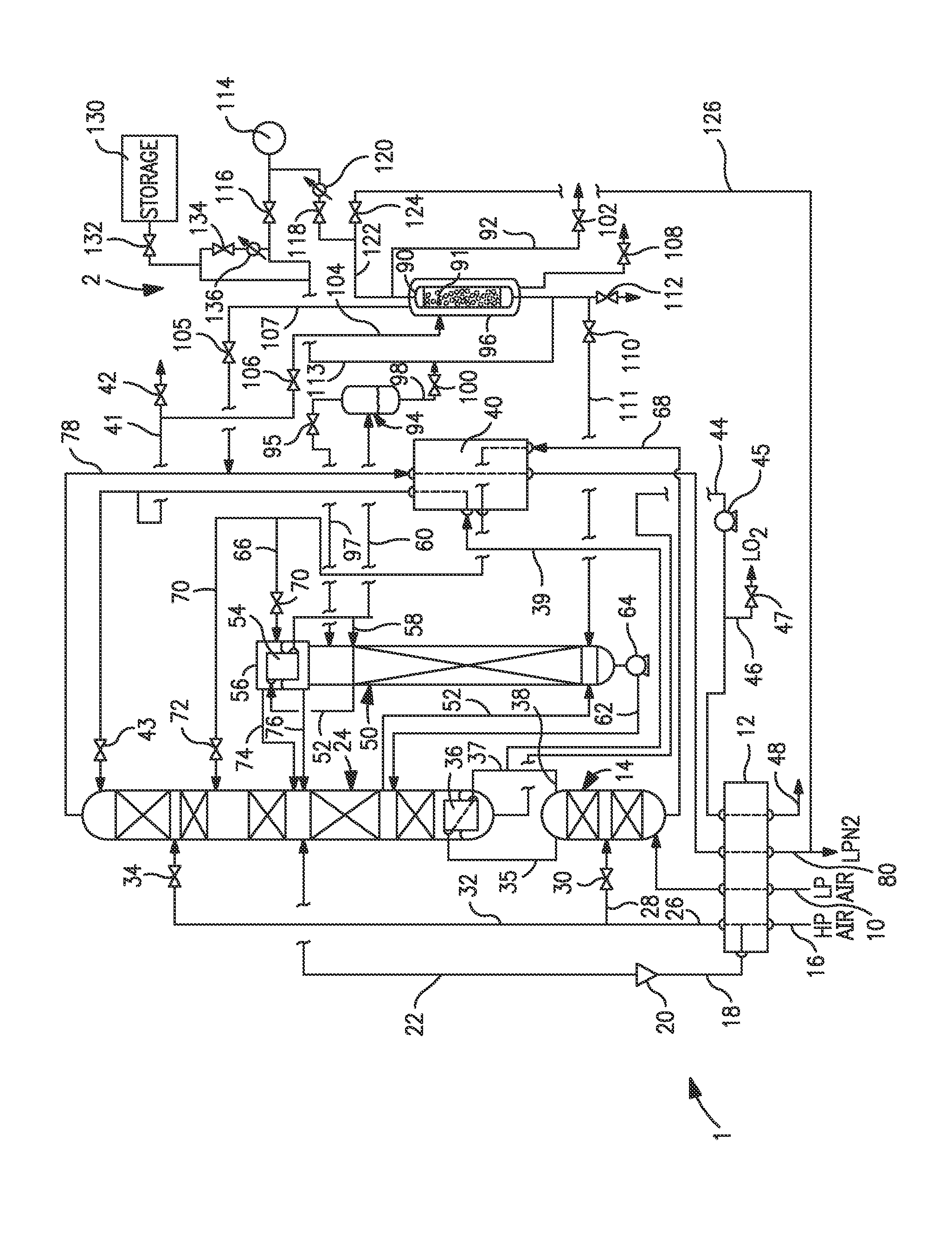

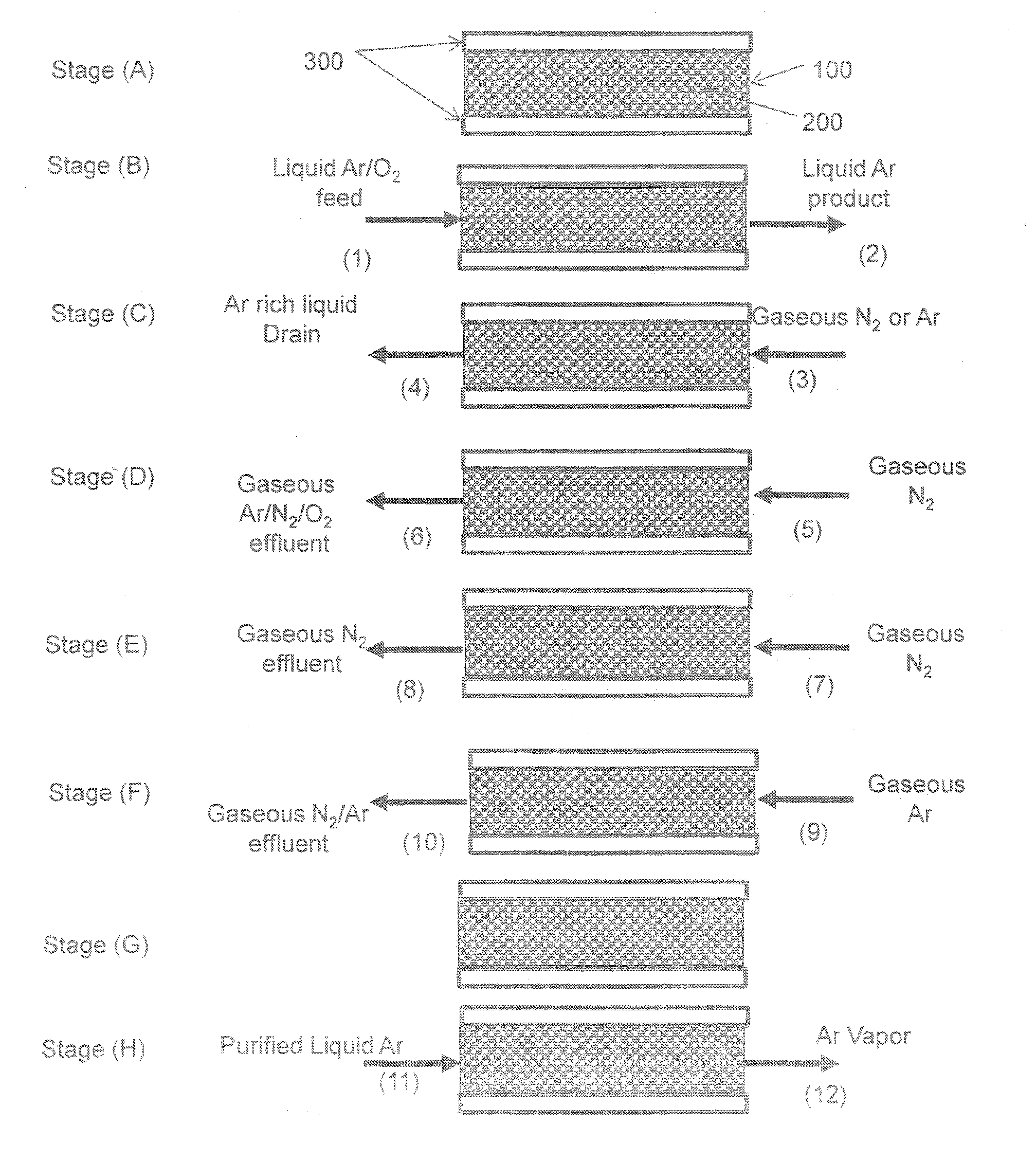

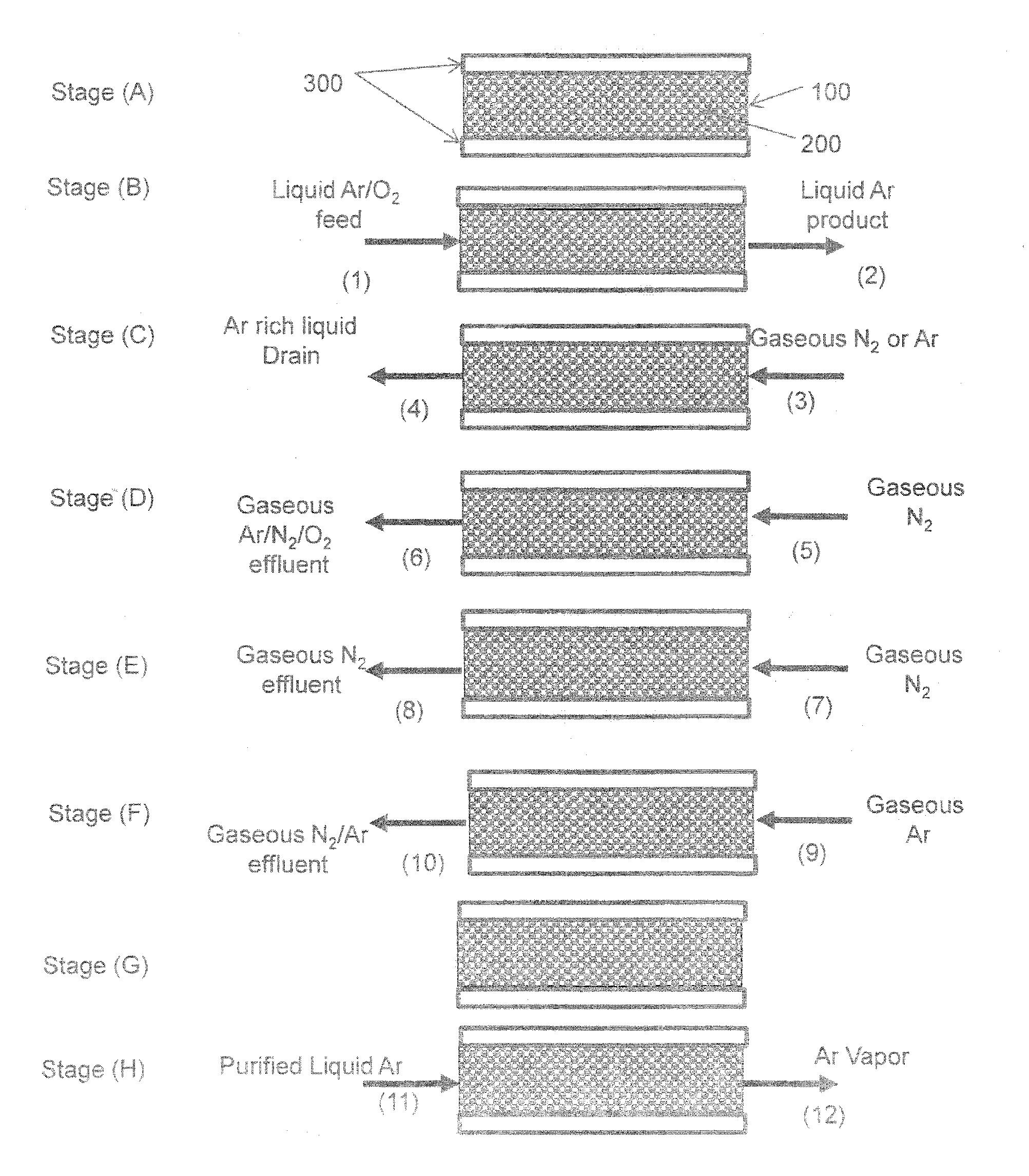

ActiveUS20140245782A1Reduce overall coldbox spaceSmall sizeSolidificationGas treatmentLiquid argonSorbent

A method and apparatus for producing a purified liquid argon product in which liquid argon having oxygen impurities is produced in a cryogenic air separation plant by separating argon from oxygen within an argon column. An impure liquid argon stream, composed of part of the liquid argon, is purified in an adsorbent bed by adsorbing the oxygen impurities in an adsorbent to produce a purified liquid argon stream that constitutes the purified liquid argon product. During adsorption, the adsorbent bed is maintained at a reduced temperature with a coolant to prevent vaporization of the liquid argon. The bed is then regenerated by draining residual liquid argon from the adsorbent bed, introducing the residual liquid argon back into the air separation plant and then desorbing the oxygen impurities with a regeneration gas. After regeneration, the adsorbent bed is refilled with purified liquid argon prior to being brought back on-line.

Owner:PRAXAIR TECH INC

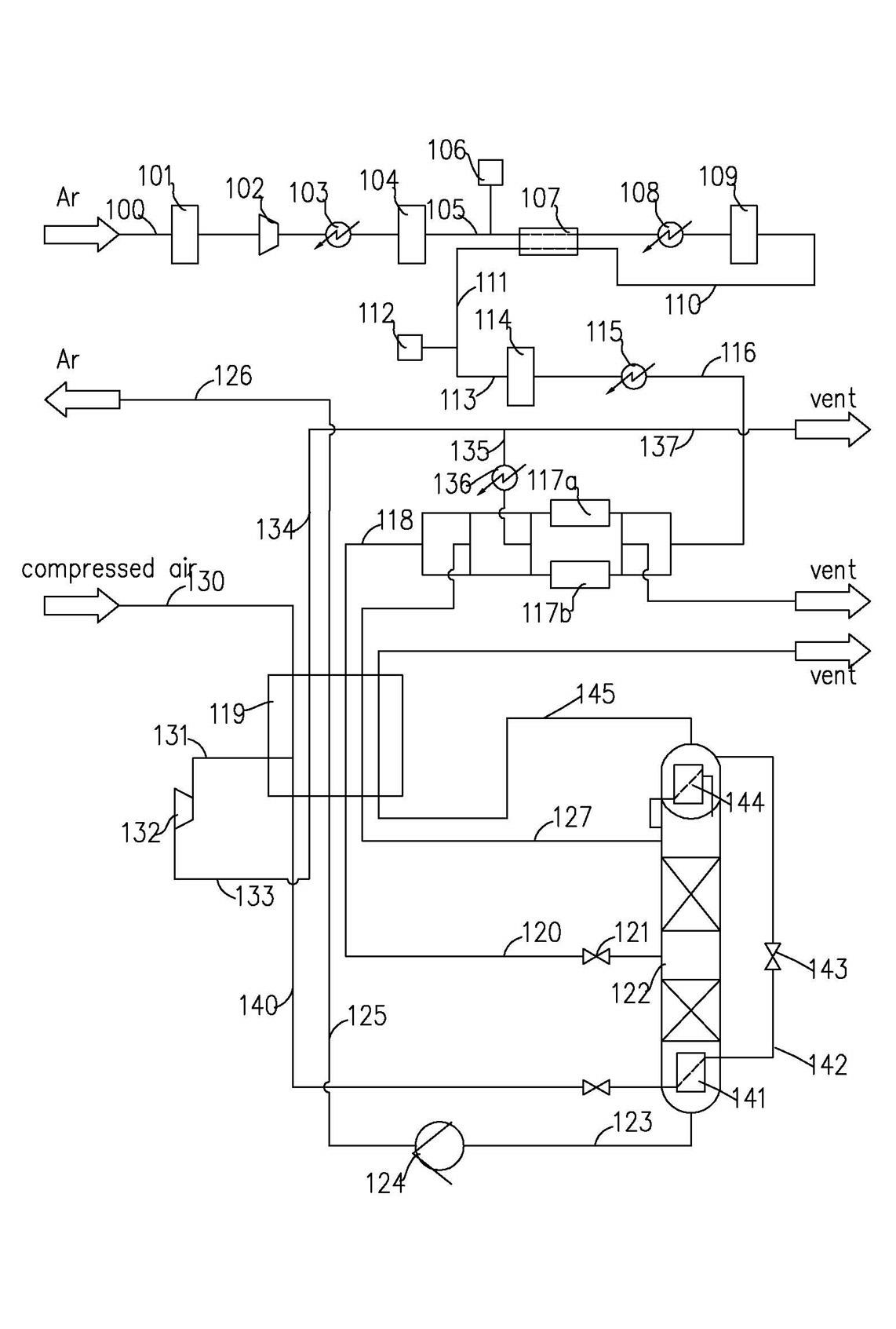

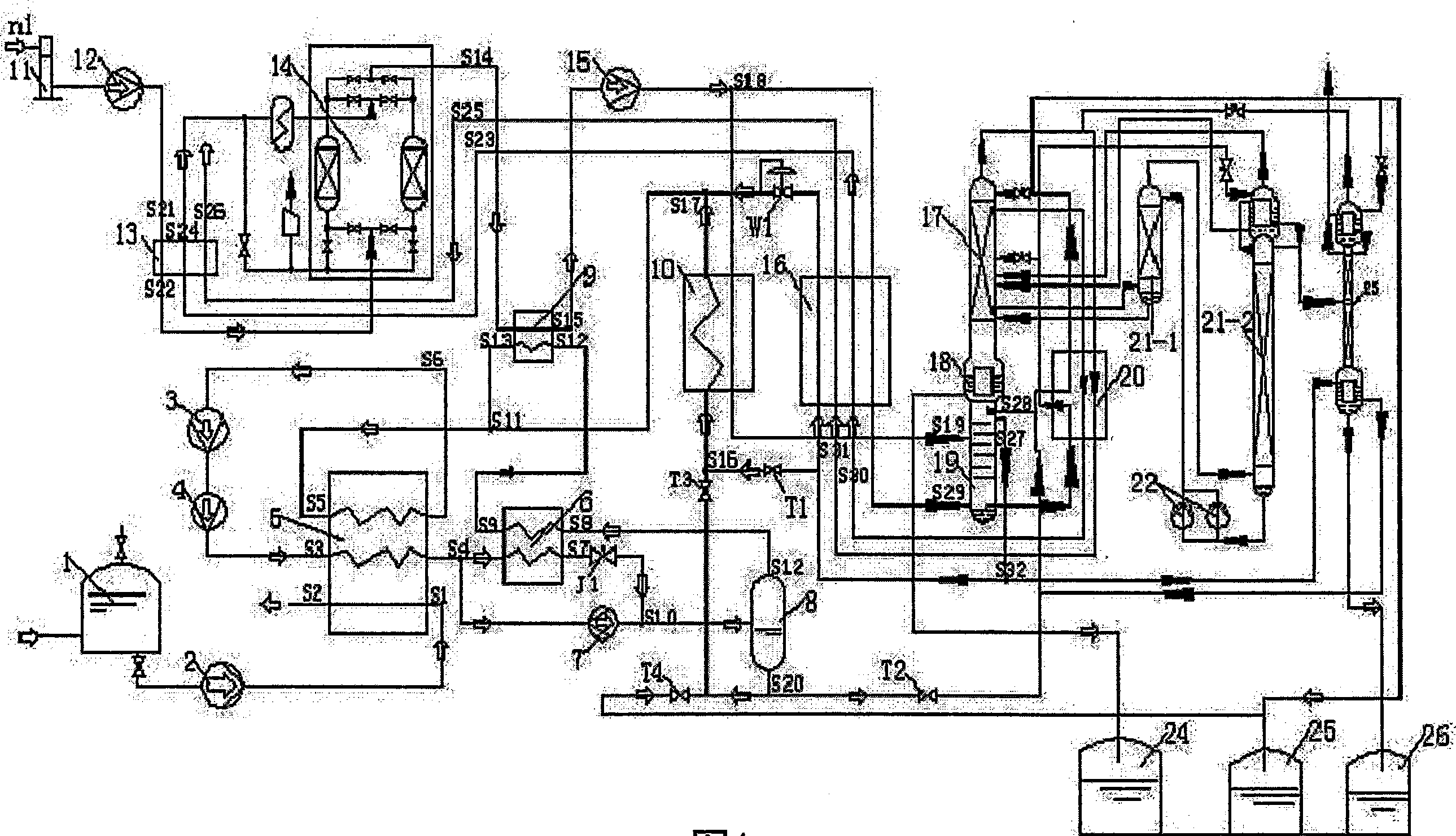

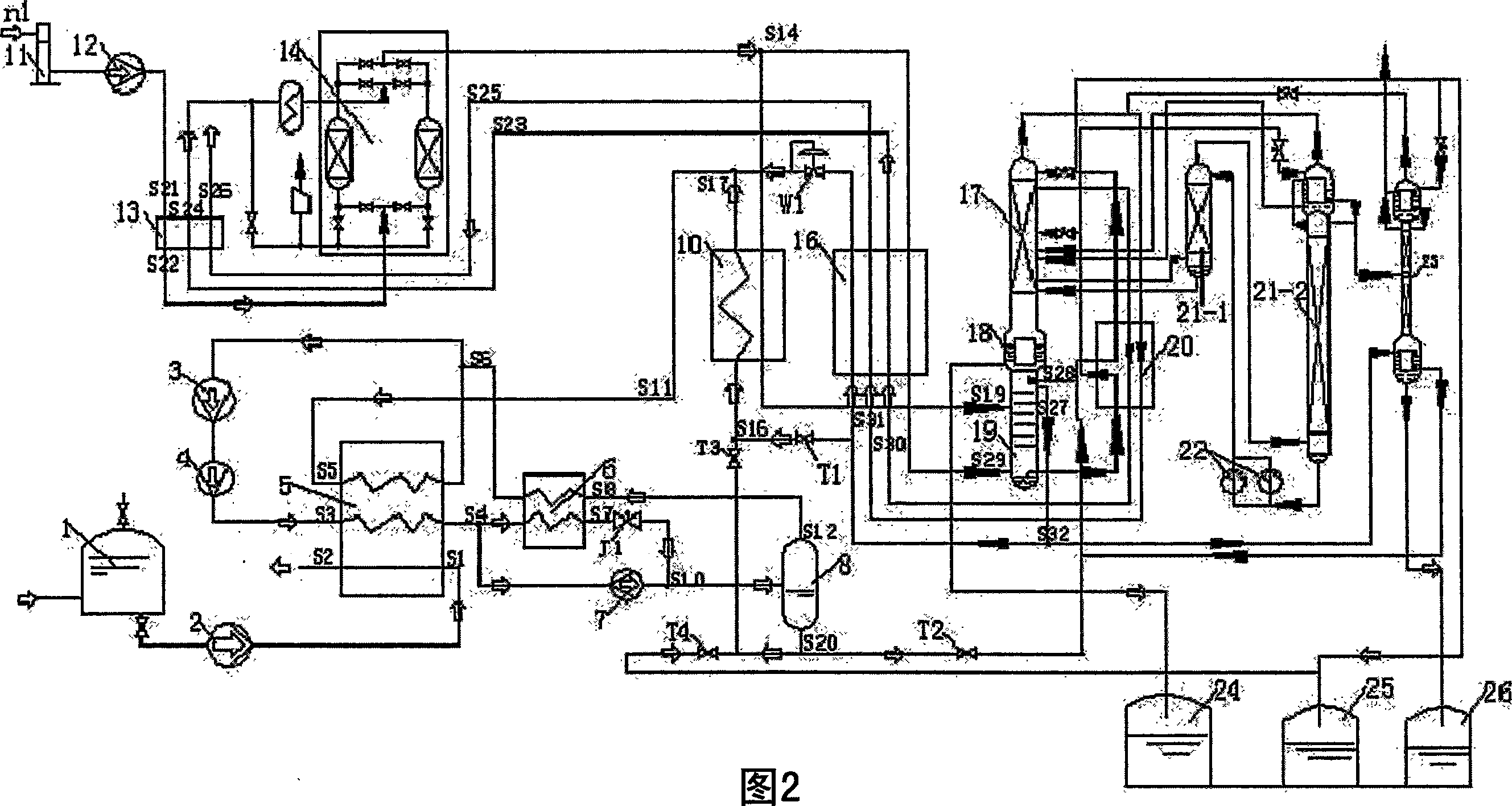

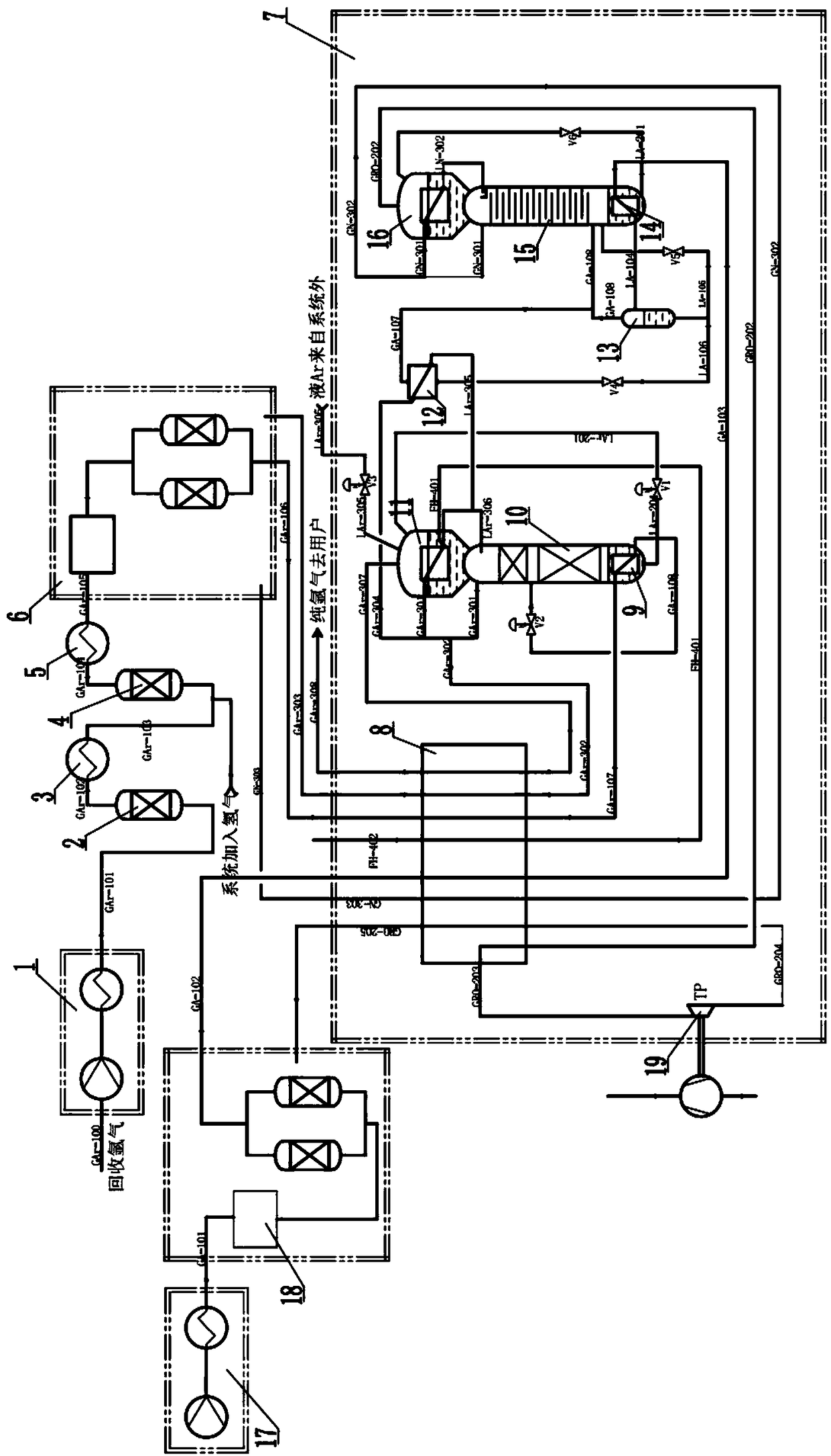

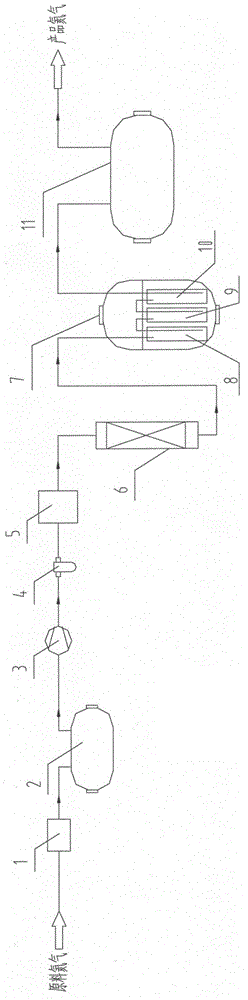

Method and device for recovering and purifying argon in monocrystalline silicon production

ActiveCN102583281AThorough responseHigh recovery rateNoble gas compoundsPtru catalystCatalytic oxidation

Provided is a method and a device for recovering and purifying argon in monocrystalline silicon production. The method comprises firstly conducting coarse oil removal on argon recovered from a single crystal furnace, compressing, cooling and conducting high-precision oil removal and dedusting; secondly enabling hydrocarbon such as methane and carbon monoxide to be reacted with oxygen to generate water and carbon dioxide through a high temperature catalytic reaction and guaranteeing the oxygen to be excessive in the catalytic reaction; thirdly enabling excessive oxygen to be reacted with added hydrogen to generate the water under effects of a catalytic agent after cooling and enabling argon after two catalytic reactions to penetrate through a normal temperature adsorption unit to absorb the water and the carbon dioxide; cooling the argon, sending a low temperature rectifying tower, enabling the argon, the nitrogen and the hydrogen to produce rectification separation, obtaining pure liquid argon, and conducting repeated heating to obtain pure argon products. The device mainly comprises an oil filter, a catalytic reactor of the hydrocarbon of high temperature catalytic oxidation carbon monoxide and methane and the like, a normal temperature hydrogenation deoxygenization catalytic reactor, a normal temperature adsorption unit for absorbing the carbon dioxide and the water at the normal temperature and the low temperature rectifying tower for rectifying and separating the hydrogen and the nitrogen at the low temperature. The device has the advantages of being high in argon recovery rate, high in purity of recovered argon, low in oxygen content, low in energy consumption for recovery and purification and the like.

Owner:HANGZHOU HANGYANG

Air separation system for recycling cold energy of liquified natural gas

ActiveCN1873357AGuaranteed uptimePrevent intrusionSolidificationLiquefactionNitrogen gasRaw material

The present invention provides an air separation system capable of recovering cold energy of liquefied natural gas and using it to produce liquid oxygen, liquid nitrogen and liquid argon. Said system includes nitrogen gas refrigeration circulation device, air cooling device and air separation device, in which the nitrogen gas refrigeration circulation device includes liquefied natural gas beat exchanger and gas-liquid separator, the liquefied natural gas heat exchanger can be used for isolating the cold energy of liquefied natural gas and exchanging it to the nitrogen gas in nitrogen gas refrigeration circulation device, the gas-liquid separator can be used for separating the nitrogen gas undergone the process of heat exchange by means of liquefied natural gas heat exchanger into gas nitrogen gas and liquid nitrogen gas, said liquid nitrogen gas after which is undergone the process of cold energy exchange with raw material air is combined with gas nitrogen gas and can be again fed into the liquefied natural gas heat exchanger.

Owner:福建智舟技术有限公司

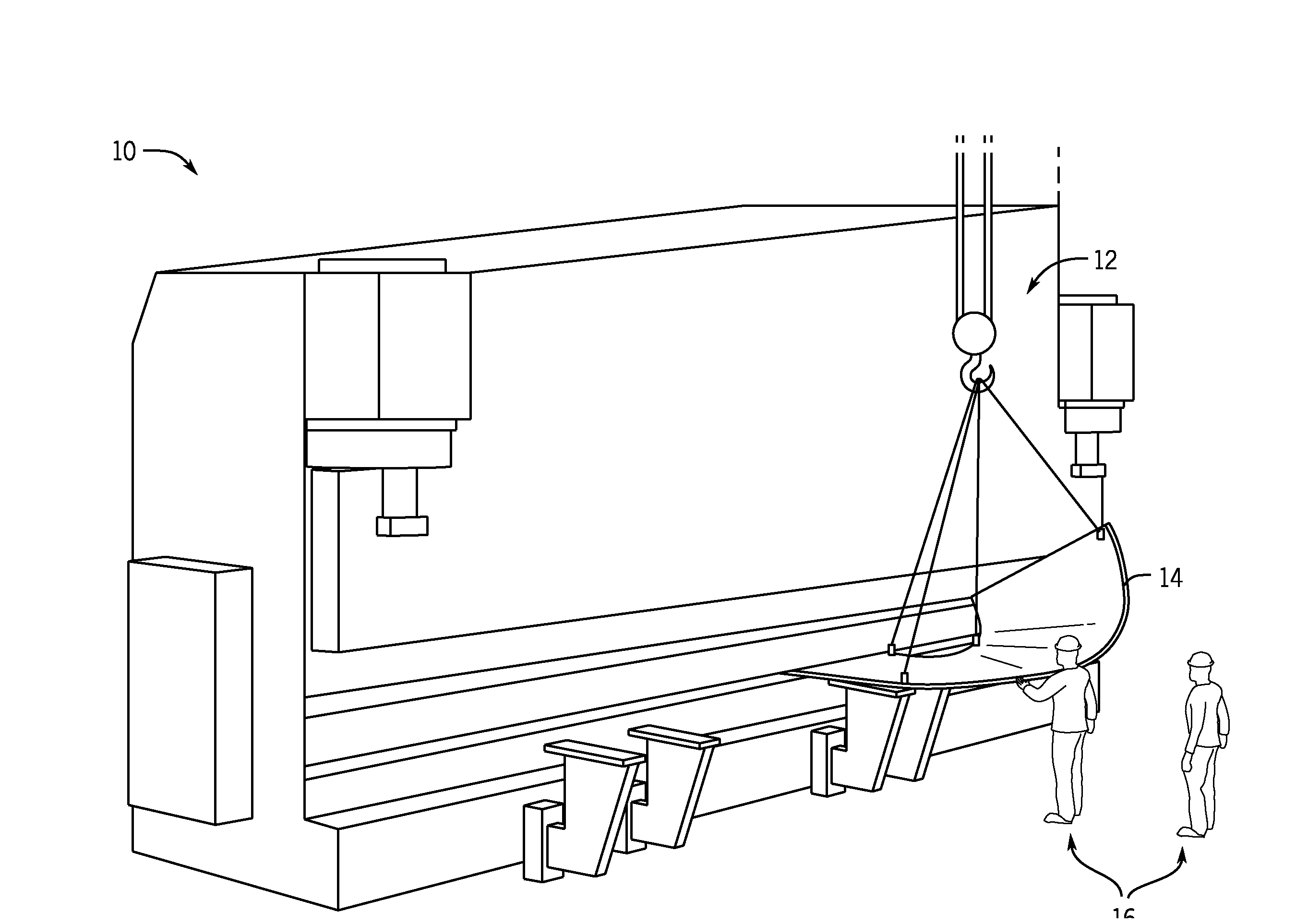

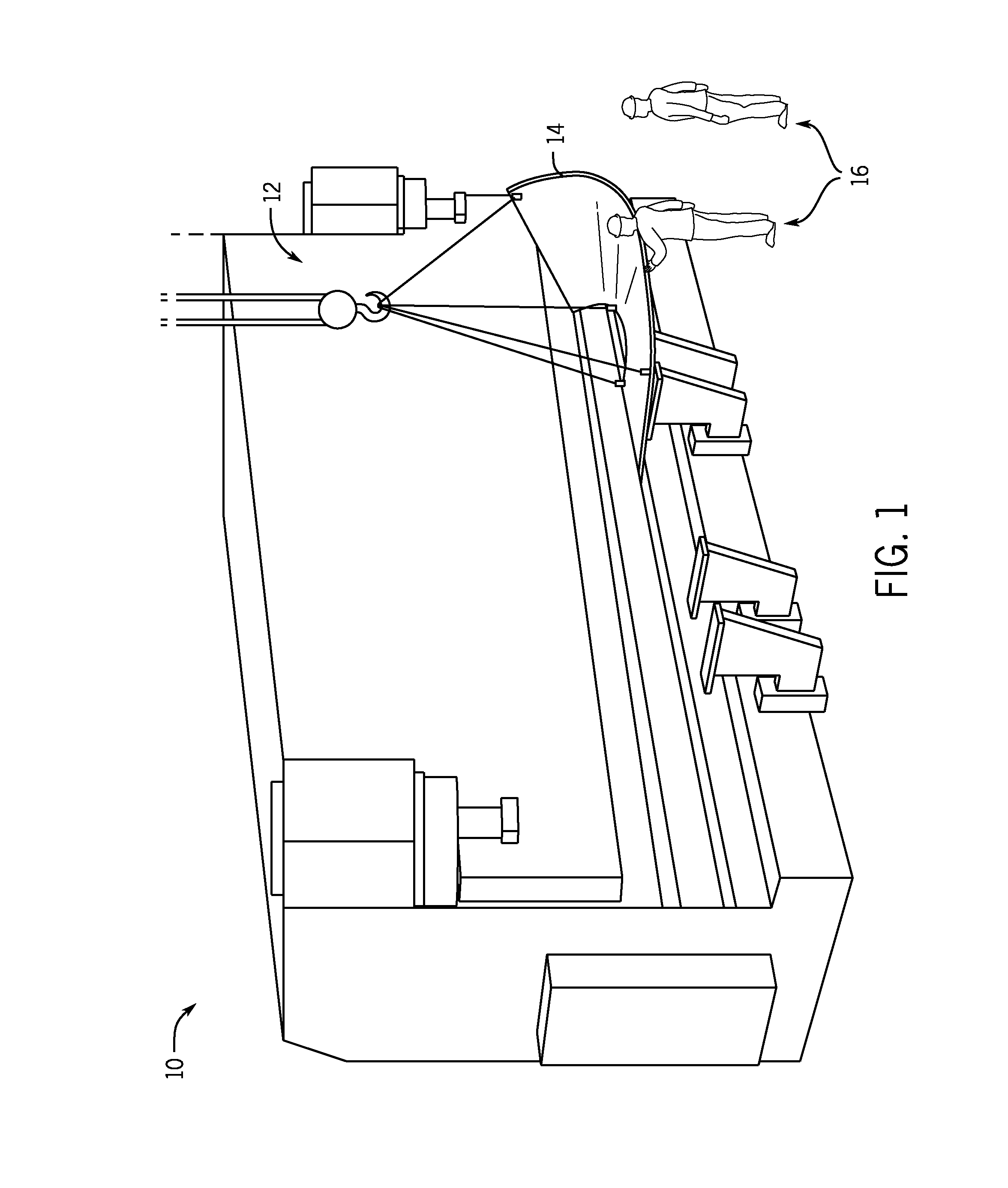

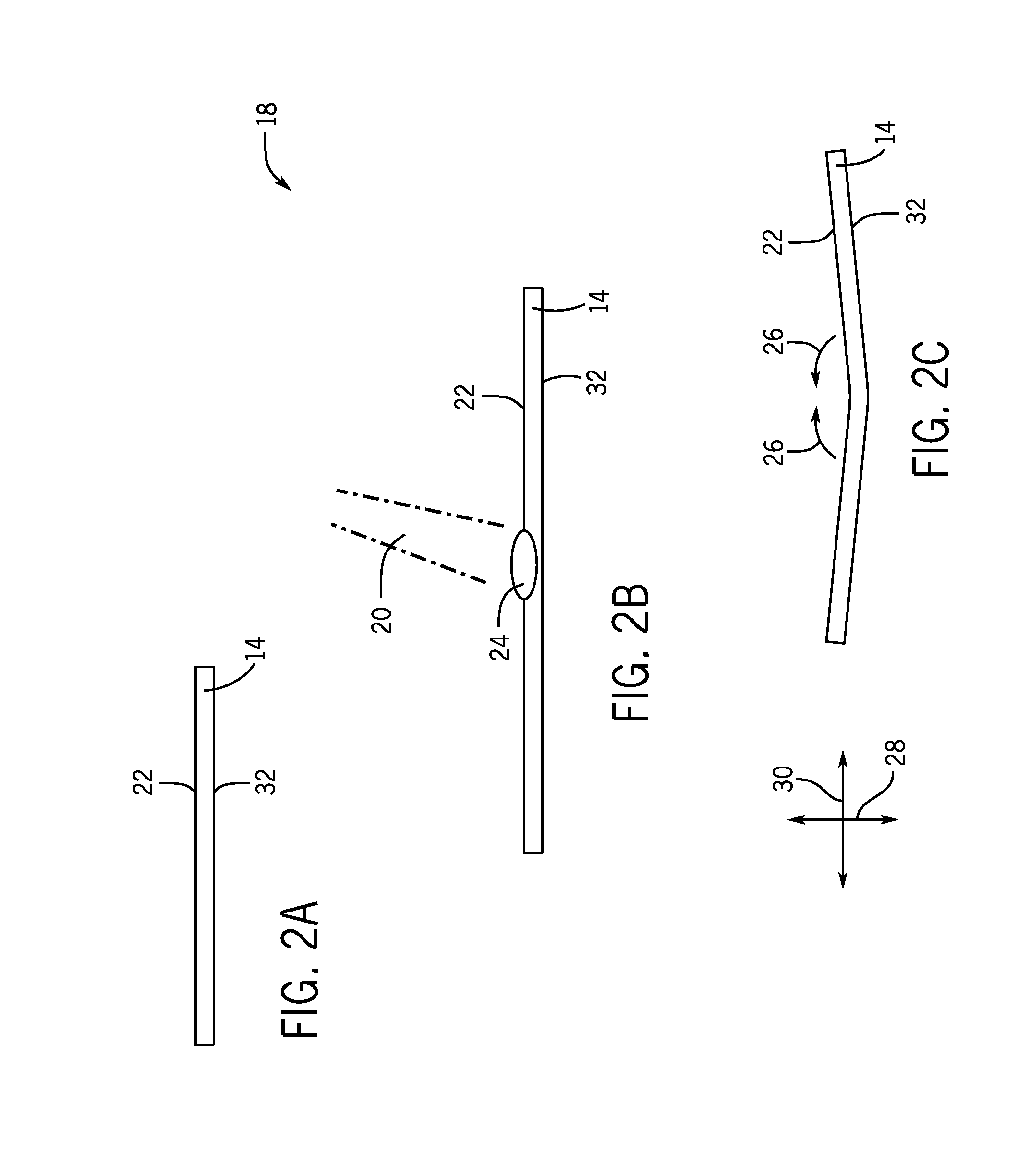

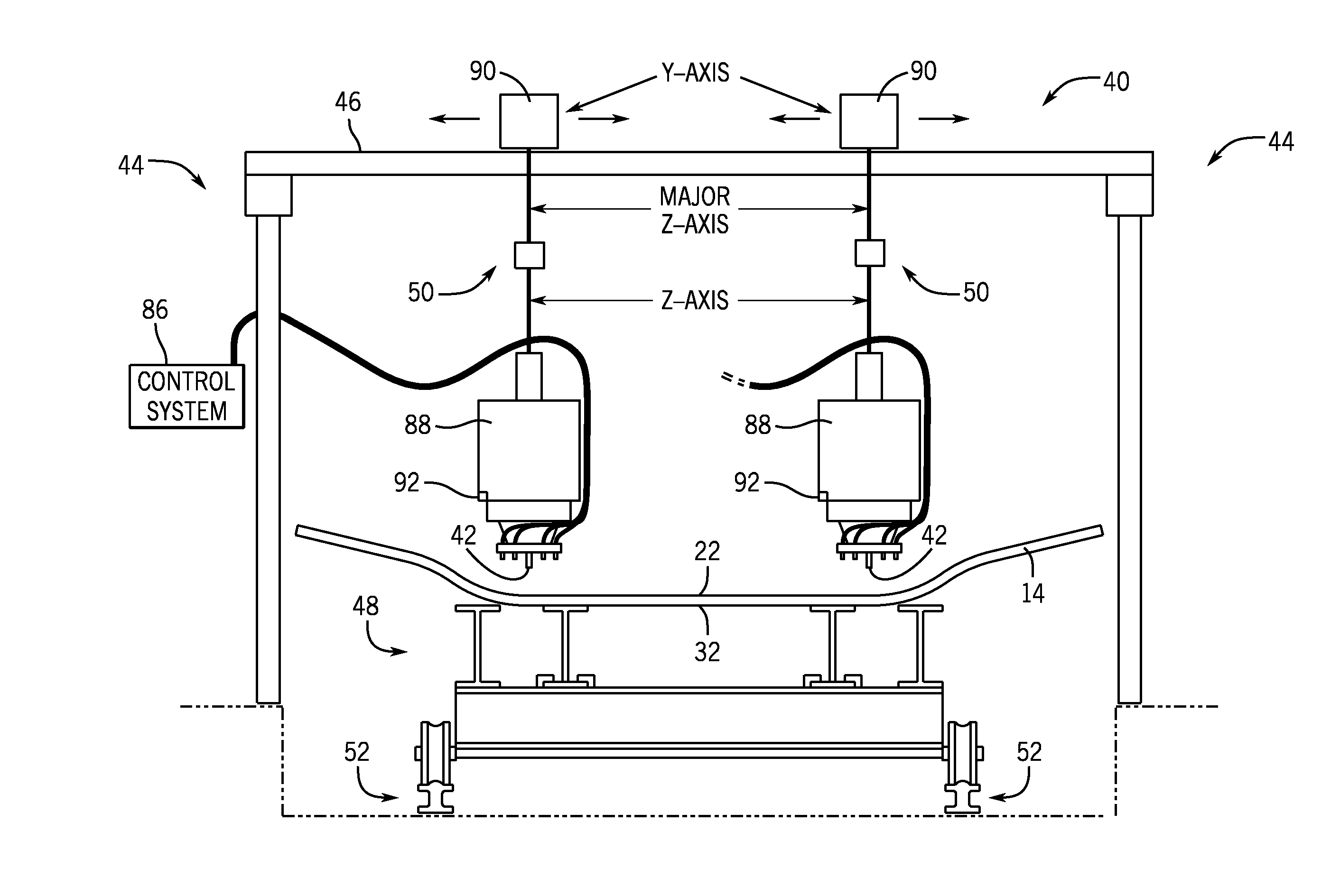

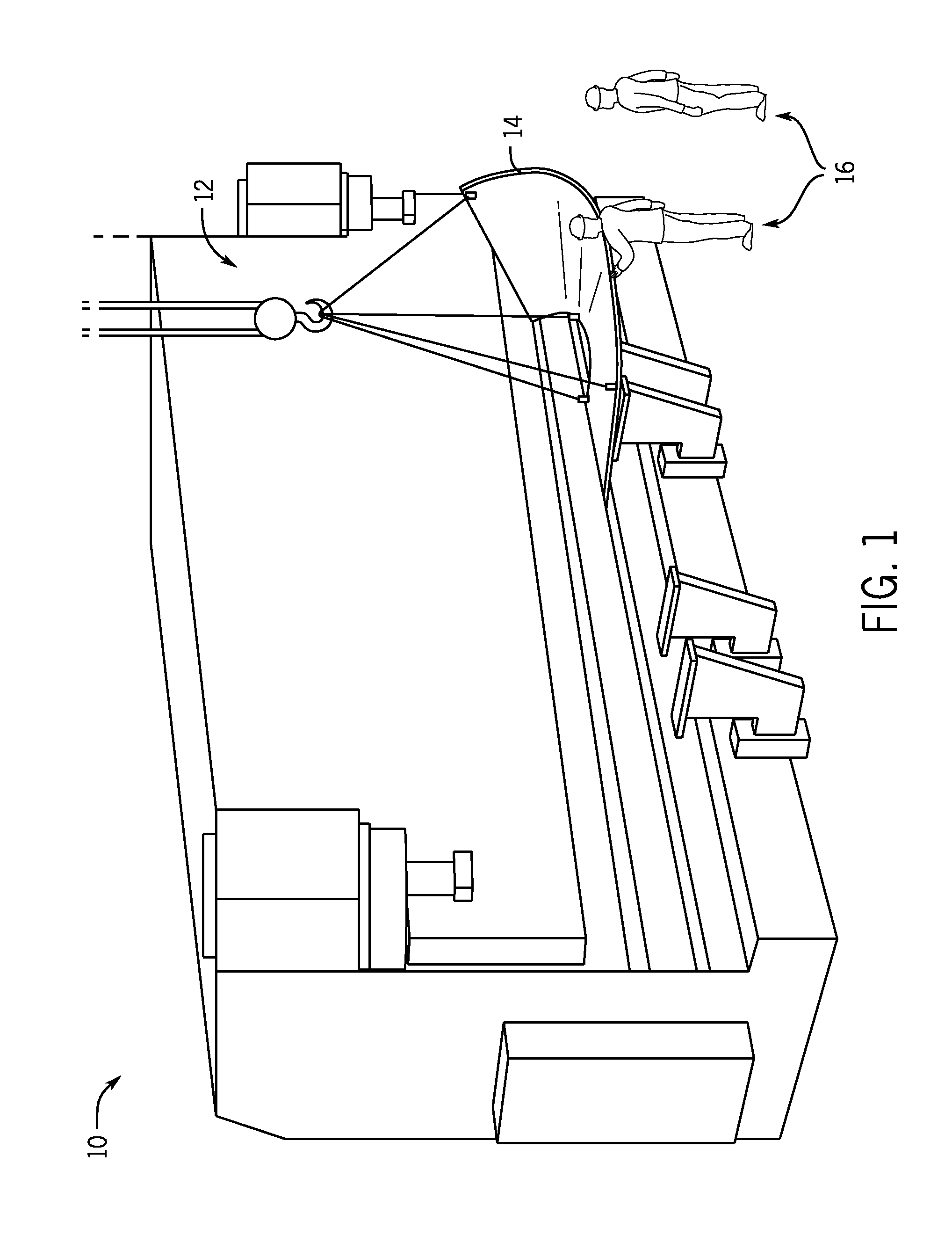

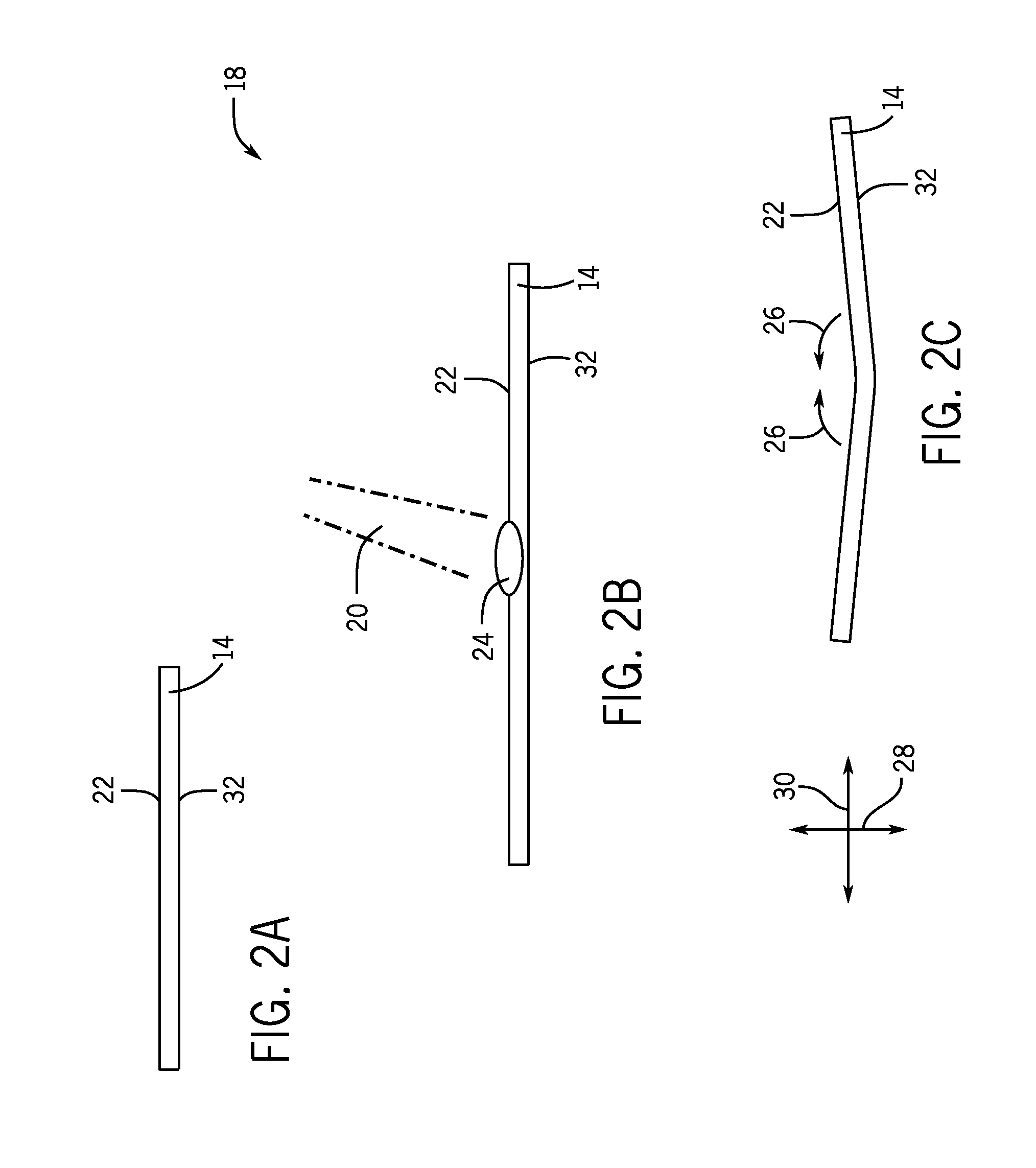

Large scale metal forming control system and method

In certain embodiments described herein, a heated line forming system includes a heating coil system configured to produce a heated line on a surface of a metal part. The heated line forming system also includes an air knife cooling system configured to maintain a dry area for the heated line, and to direct a coolant (e.g., cooling water, liquified gases such as liquid argon, solidified gases such as carbon dioxide snow, and so forth) around the heated line via a spray mechanism such that the coolant does not flow or splash into the heated line on the metal part. In certain embodiments, the heated line forming system includes multiple induction coils arranged along a line and spaced a short distance apart, but which, when operated simultaneously together, form a heated line on a surface of a metal part.

Owner:ILLINOIS TOOL WORKS INC

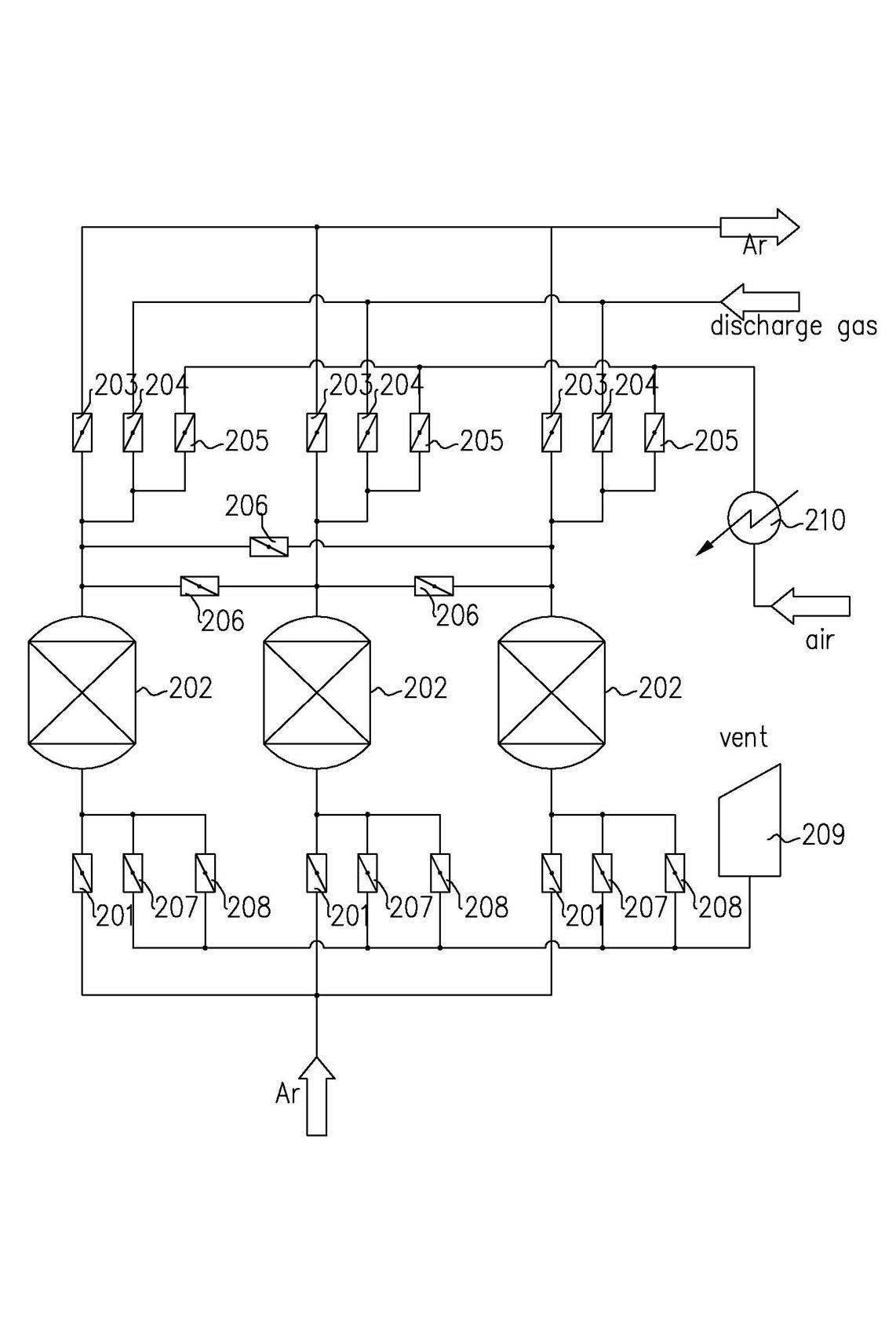

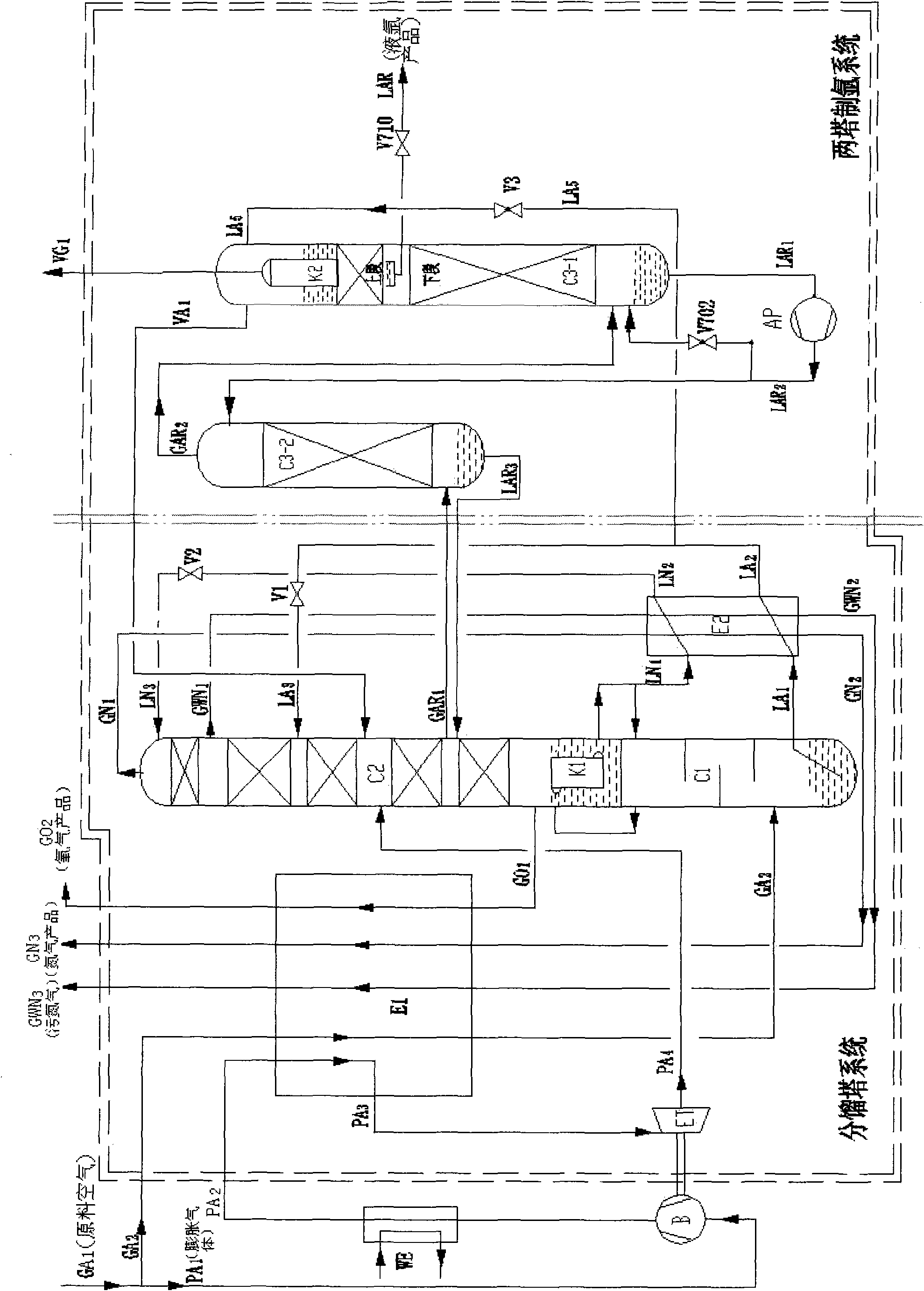

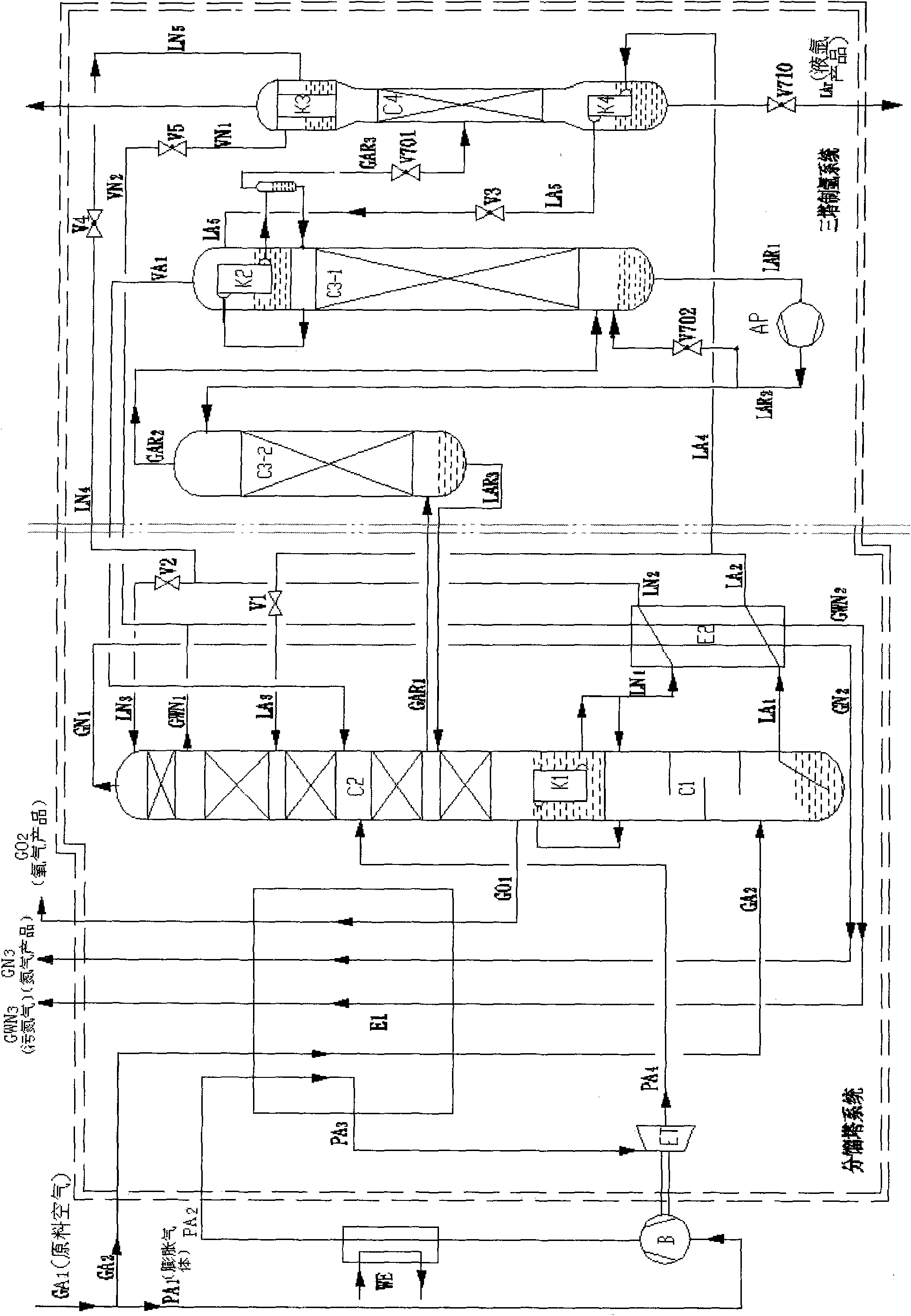

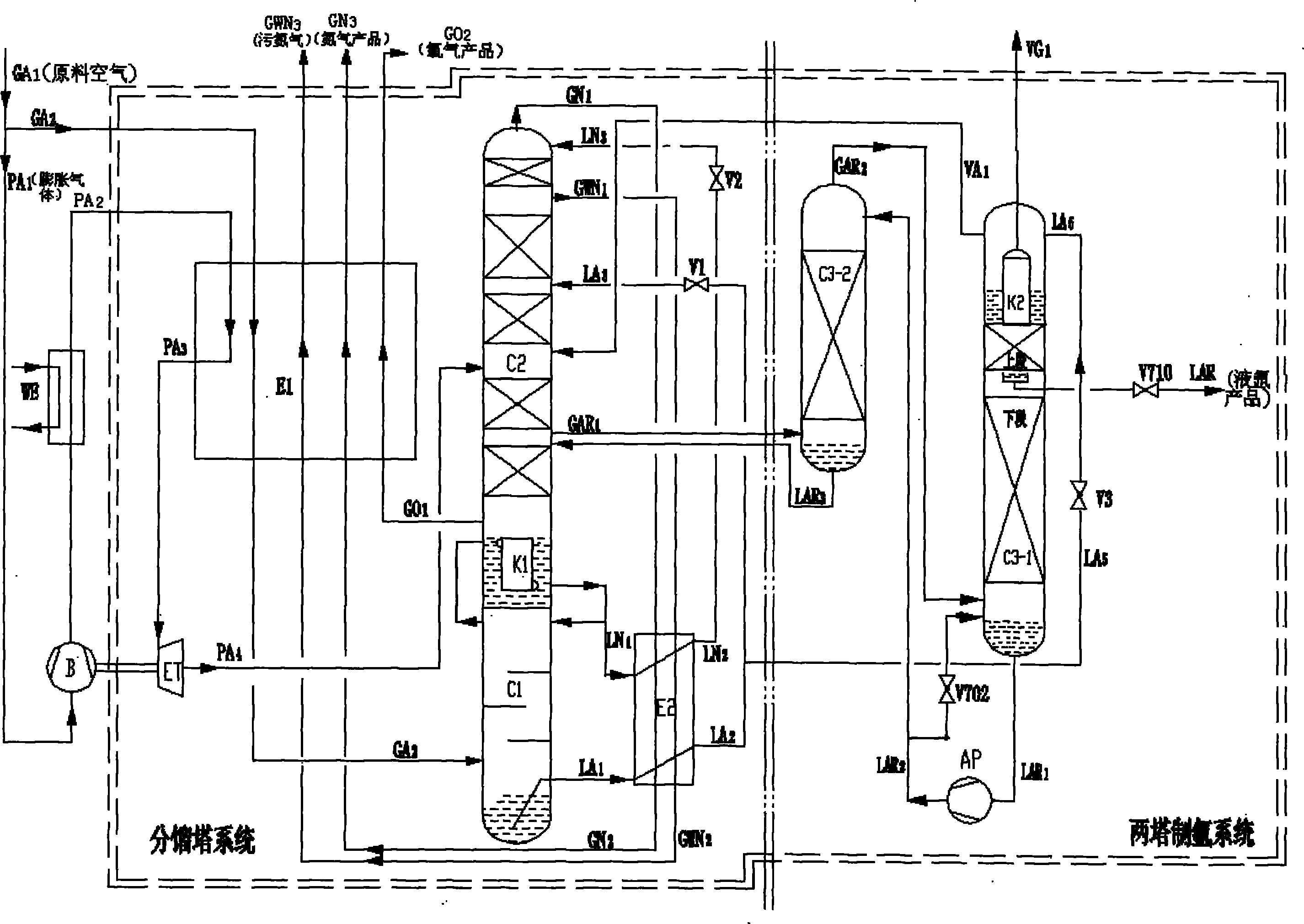

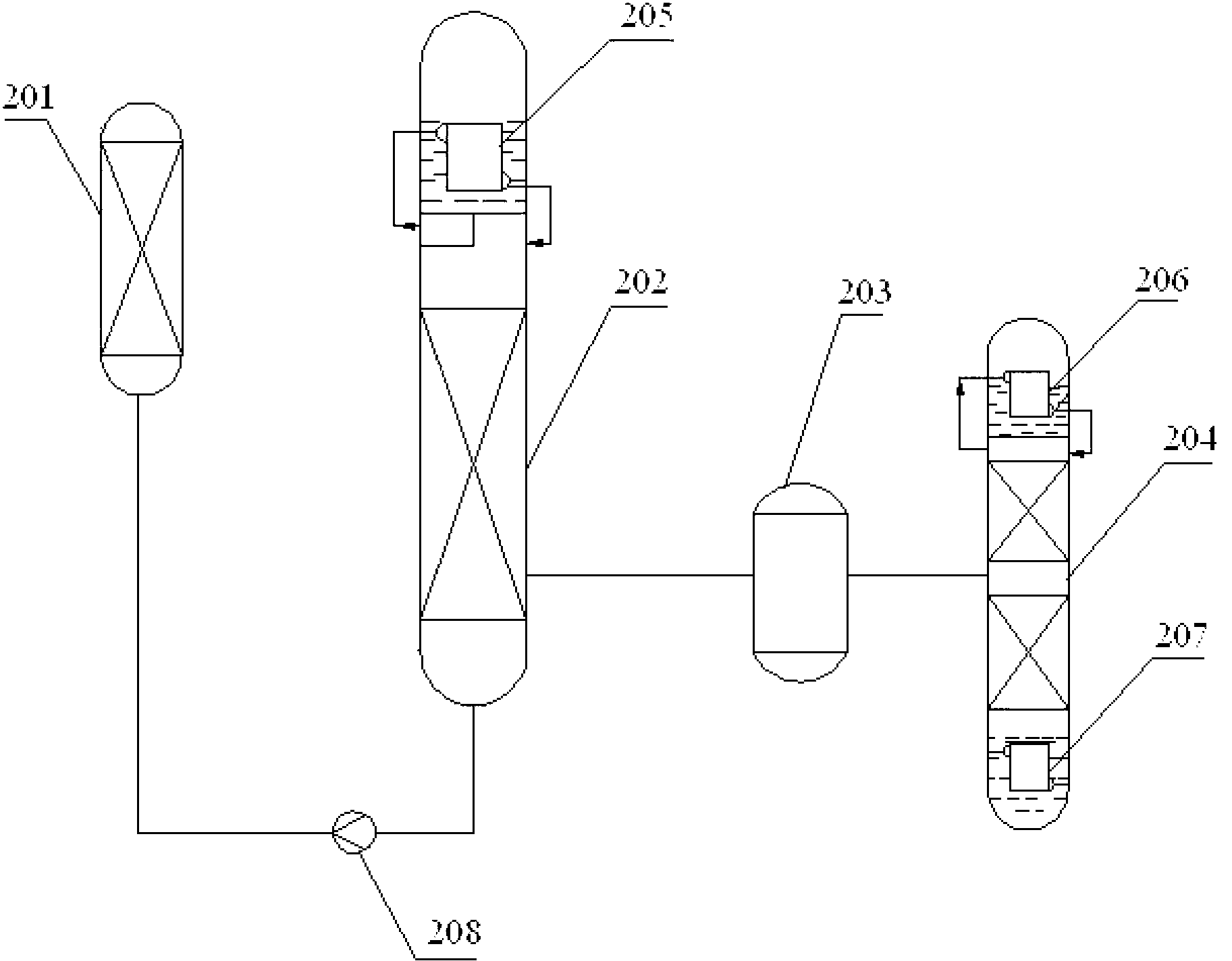

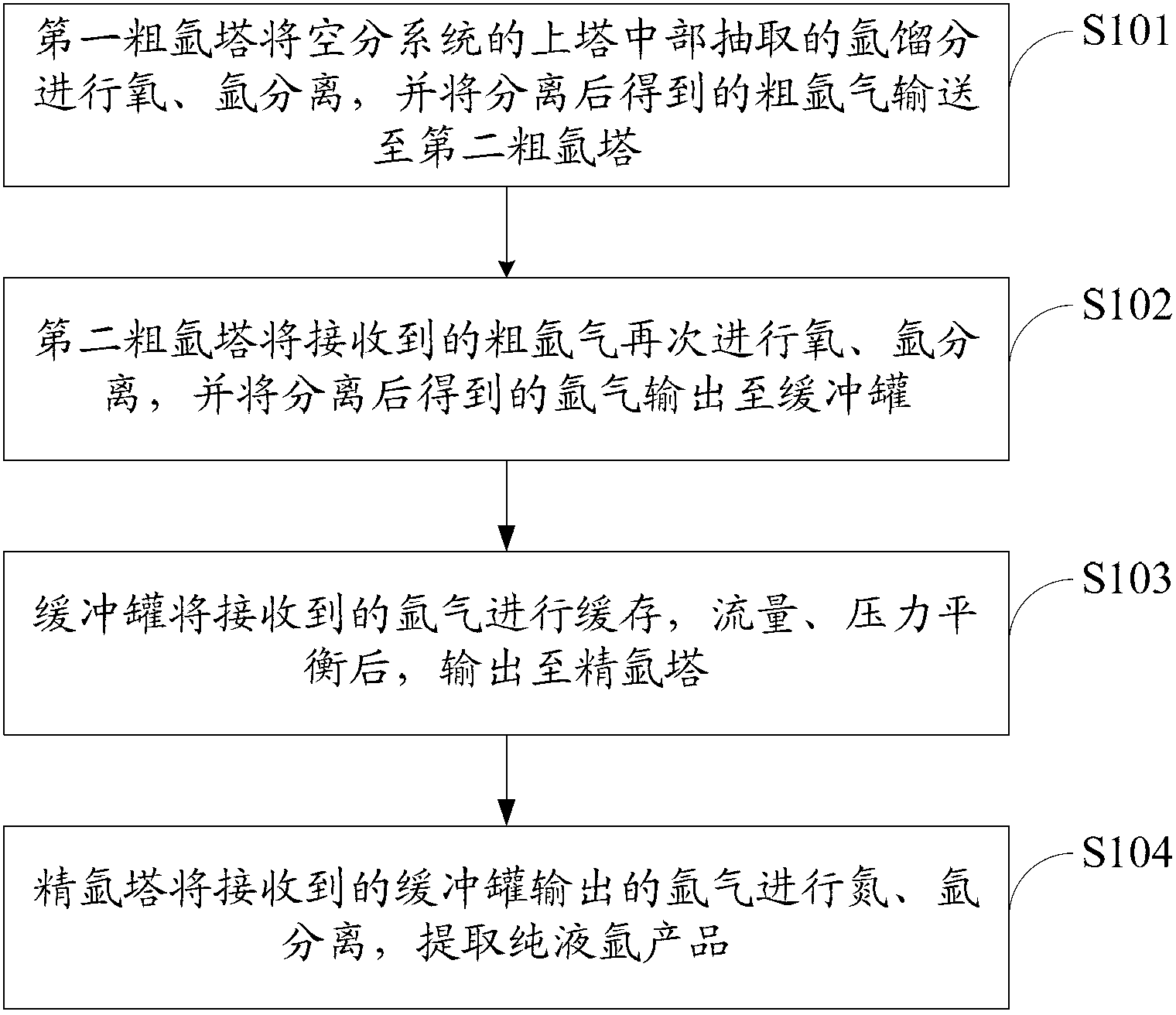

Dual-tower argon producing system and process thereof

InactiveCN101782309ASimple processEasy to controlSolidificationLiquefactionLiquid argonFractionation

The invention belongs to the technical field of space division, and in particular relates to a dual-tower argon producing system and a process thereof for producing argon by low temperature fractionation. The process comprises that: an air fractionating tower produces argon fraction containing 6 to 10 percent of argon GAR1; the argon fraction containing 6 to 10 percent of argon GAR1 is introduced into an argon roughening tower II (C3-2) to form argon fraction GAR2; the argon fraction GAR2 is introduced into an argon roughening tower I (C3-1); in the argon roughening tower I (C3-1), oxygen and nitrogen are removed through the rectification of an argon refining tower, and pure liquid argon is formed between the upper section and the lower section of the argon roughening tower I (C3-1), and is extracted to serve as a product. The system and the process have the advantages of simple process flow, low difficulty in controlling each part, investment conservation and high safety.

Owner:KAIFENG AIR SEPARATION GROUP

Thermal-state starting method of air separation equipment

InactiveCN101684982AReduce startup timeReduce consumptionSolidificationLiquefactionStart timeEvaporation

The invention relates to a thermal-state starting method of air separation equipment; and the technical scheme of the method is achieved by the following steps: according to the process which is carried out by the air separation equipment , adjusting the pressure of an upper rectifying column and increasing high pressure air quantity; according to the temperature of waste nitrogen from a subcooler, adjusting the opening degree and the opening speed of a pressure adjustment valve of a lower rectifying column; sending liquid argon out to a main heat exchanger to recycle the refrigeration of theliquid argon; starting liquid nitrogen and liquid oxygen process pumps in advance, and adjusting purification and increasing the evaporation capacity of liquid air of a primary argon tower in advance;increasing the refrigeration capacity and improving the cooling speed and liquid accumulation speed of the air separation equipment, thereby realizing the rapid starting in a thermal state. The method can shorten the starting time of the air separation equipment in a thermal state remarkably, not only can save electrical energy, but also can send products out significantly in advance of time. Bythe method, the product oxygen and nitrogen of 35000m<3> air separation equipment can be sent out 14 hours in advance, and the produce liquid argon can be sent out 11 hours in advance. The method hassignificant energy saving effect, remarkable economic benefits as well as wide promotion and application values.

Owner:ANGANG STEEL CO LTD

Large scale metal forming

In certain embodiments described herein, a heated line forming system includes a heating coil system configured to produce a heated line on a surface of a metal part. The heated line forming system also includes an air knife cooling system configured to maintain a dry area for the heated line, and to direct a coolant (e.g., cooling water, liquified gases such as liquid argon, solidified gases such as carbon dioxide snow, and so forth) around the heated line via a spray mechanism such that the coolant does not flow or splash into the heated line on the metal part. In certain embodiments, the heated line forming system includes multiple induction coils arranged along a line and spaced a short distance apart, but which, when operated simultaneously together, form a heated line on a surface of a metal part.

Owner:ILLINOIS TOOL WORKS INC

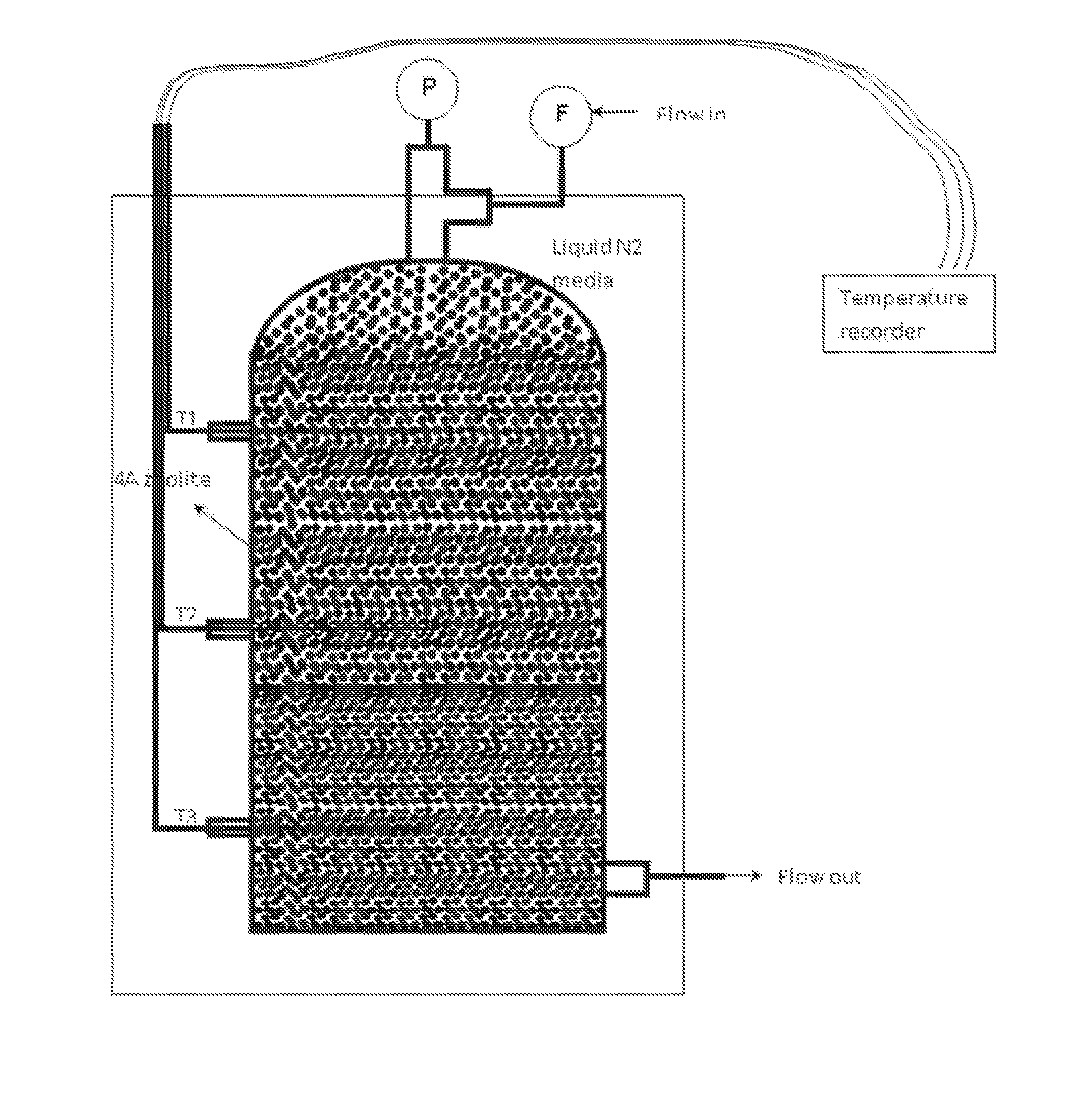

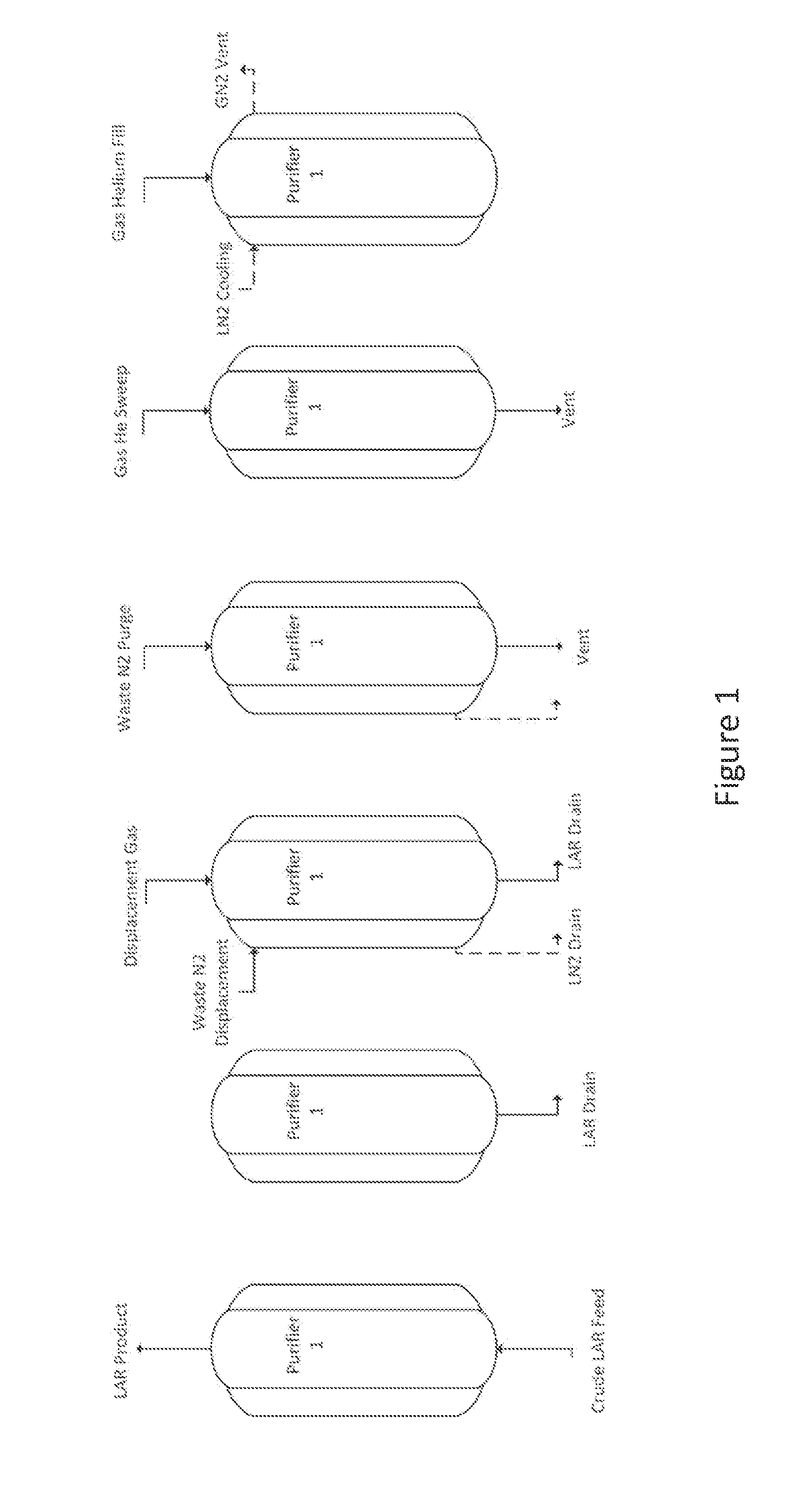

Purification of argon through liquid phase cryogenic adsorption

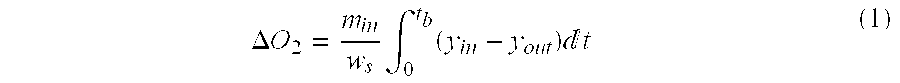

ActiveUS20140245781A1Lower cost of capitalEfficient regenerationSolidificationLiquefactionLiquid argonOxygen contamination

The invention relates to a process for removing oxygen from liquid argon using a TSA (temperature swing adsorption) cyclical process that includes cooling an adsorbent bed to sustain argon in a liquid phase; supplying the adsorbent bed with a liquid argon feed that is contaminated with oxygen and purifying the liquid argon thereby producing an argon product with less oxygen contaminant than is in the initial liquid argon feed; draining the purified residual liquid argon product and sending purified argon out of the adsorbent bed. Regeneration of specially prepared adsorbent allows the adsorbent bed to warm up to temperatures that preclude the use of requiring either vacuum or evacuation of adsorbent from the bed.

Owner:PRAXAIR TECH INC

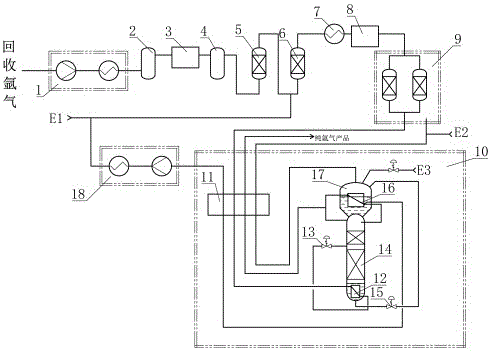

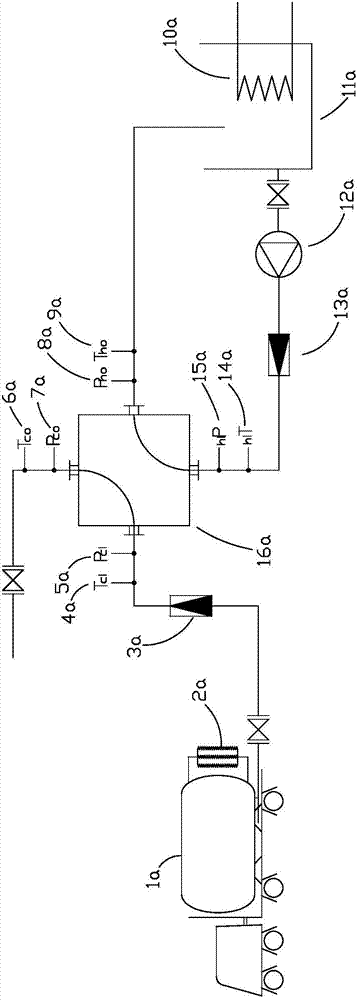

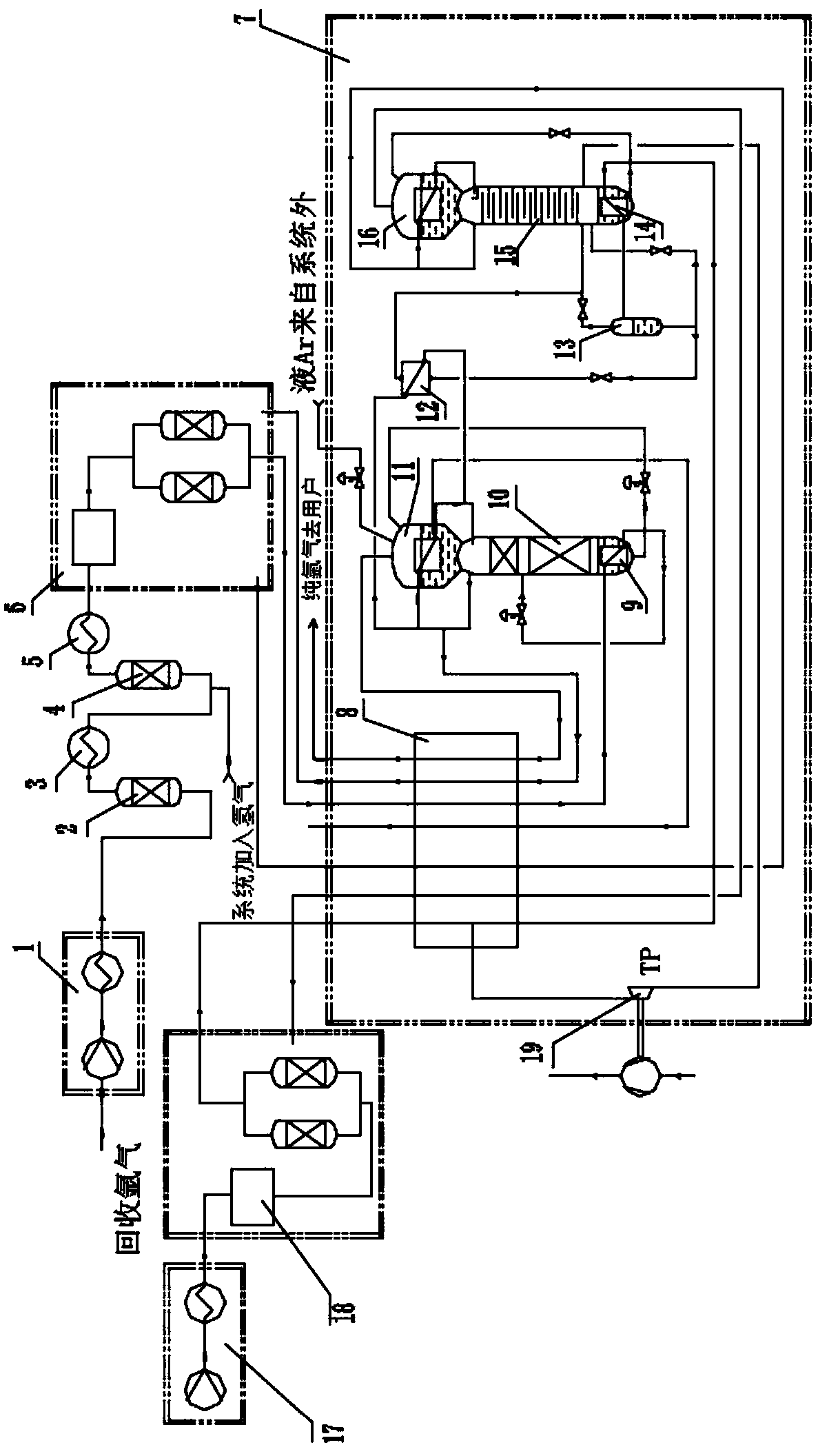

Device for recycling argon through single-tower low-temperature rectification and method for purifying and recycling argon

The invention provides a device for recycling argon through single-tower low-temperature rectification. The device comprises the following equipment: an argon recycling compressor, a first crude argon pre-cooling machine (3), an oil filter (4), an active carbon adsorber (5), an oxygen remover (6), a cooler (7), a second crude argon pre-cooling machine (8), a purifier (9) and a rectification cold box (10), wherein a heat exchanger (11), a reboiler (12), a rectification tower (14), a condensation evaporator (16) and a condensation evaporator shell (17) are arranged in the rectification cold box (10). The invention also provides a method for purifying and recycling the argon. According to the device and the method, which are provided by the invention, the convenience that a liquid argon providing system exists in a recovery scene is effectively utilized, loss of cooling capacity is supplemented by liquid argon and an expansion machine does not need to be provided singly; the recovery rate of the argon and the utilization rate of hydrogen are increased, operation is simplified, and operation energy consumption is reduced; thereby, the device and the method have good market prospects.

Owner:上海跃绅能源科技有限公司

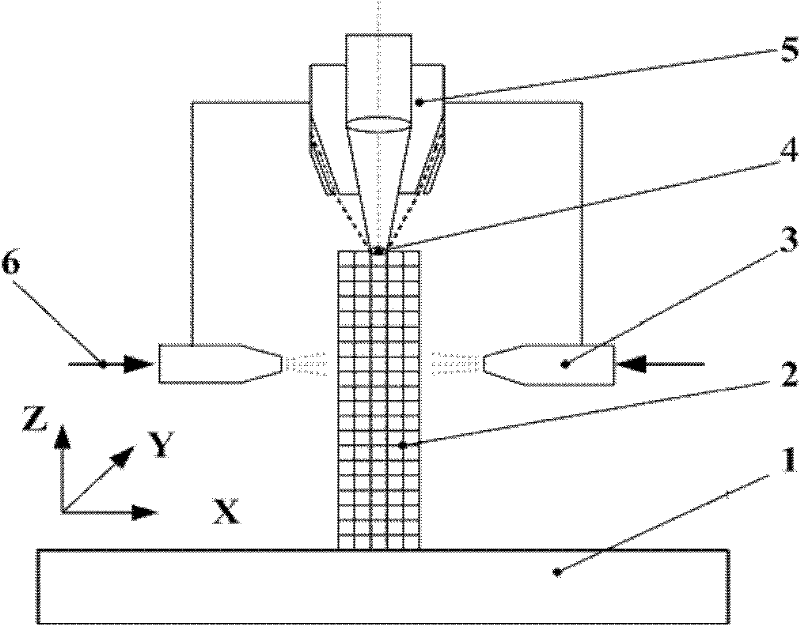

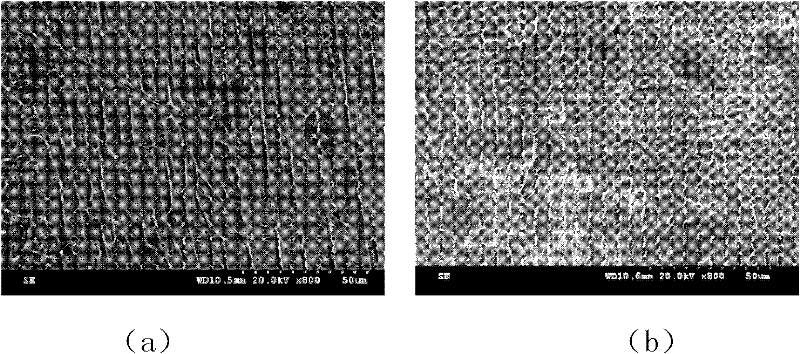

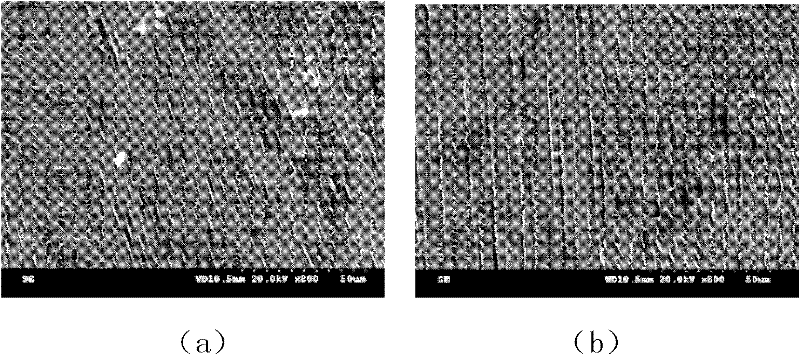

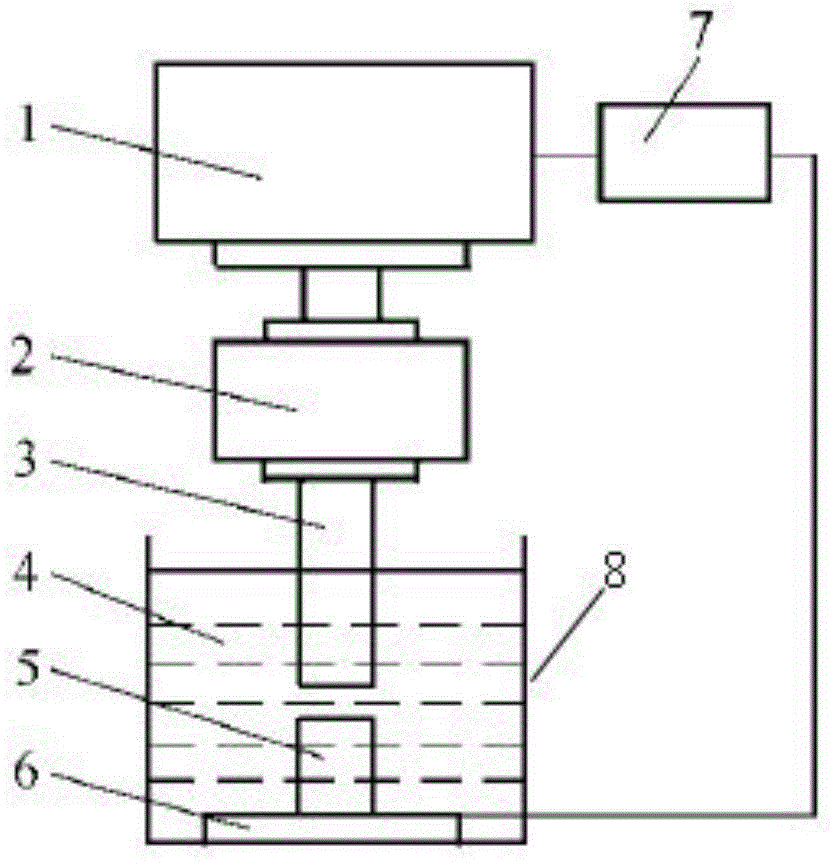

Laser metal direct forming method of liquid argon jet cooling directional solidification

InactiveCN102162096ANo heat accumulation problemReduce the temperatureMetallic material coating processesLiquid argonDirectional solidification

The invention discloses a laser metal direct forming method of liquid argon jet cooling directional solidification. The method is characterized in that: positive temperature gradient is kept all the time along the Z-axis direction in a molten pool in the subsequent forming process by adopting a method of liquid argon jet and quick cooling performed below the formed layer once a certain layer number is stacked. Meanwhile, the liquid argon for cooling is converted into argon gas and can also be used for reducing oxygen content in an argon protection box. Therefore, the columnar crystal tissue in a formed piece is continuously grown from a substrate along the Z-axis forming direction, and the formed piece obtains complete directional solidification columnar crystal tissue.

Owner:XI AN JIAOTONG UNIV +1

All-rectification argon extraction oxygen-enriched air separation device and process

ActiveCN109186179AReduce power consumptionFacilitate continuous productionSolidificationLiquefactionLiquid argonEconomic benefits

The invention provides an all-rectification argon extraction oxygen-enriched air separation device, and relates to the field of air separation equipment. The device comprises an air pretreatment section, a rectification section and a finished argon section; the rectification section comprises a lower tower, an upper tower, a condensation evaporator, a main heat exchanger, a supercharger / expander,a supercharged cooler and a subcooler; an oxygen-enriched liquid air outlet at the bottom of the lower tower is connected with an oxygen-enriched liquid air runner of the subcooler to divided into twoways, which are connected with an oxygen-enriched liquid air inlet of the upper tower and a liquid inlet of a rough argon condenser; liquid oxygen at the bottom of the upper tower enters the condensation evaporator, and is divided into two ways from an outlet of the condensation evaporator; one way is used as product liquid oxygen to connect with a pure liquid oxygen product conveying pipe, and the other way is connected with a liquid pump and the oxygen-enriched liquid air outlet at the bottom of the lower tower in sequence; argon distillates at the lower part of the upper tower pass througha first rough argon tower, a second rough argon tower and a finish argon tower in sequence to obtain pure liquid argon. The device has the beneficial effects of argon extraction by the oxygen-enriched air separation device, increment of the device product types and improvement of the economic benefit.

Owner:苏州制氧机股份有限公司

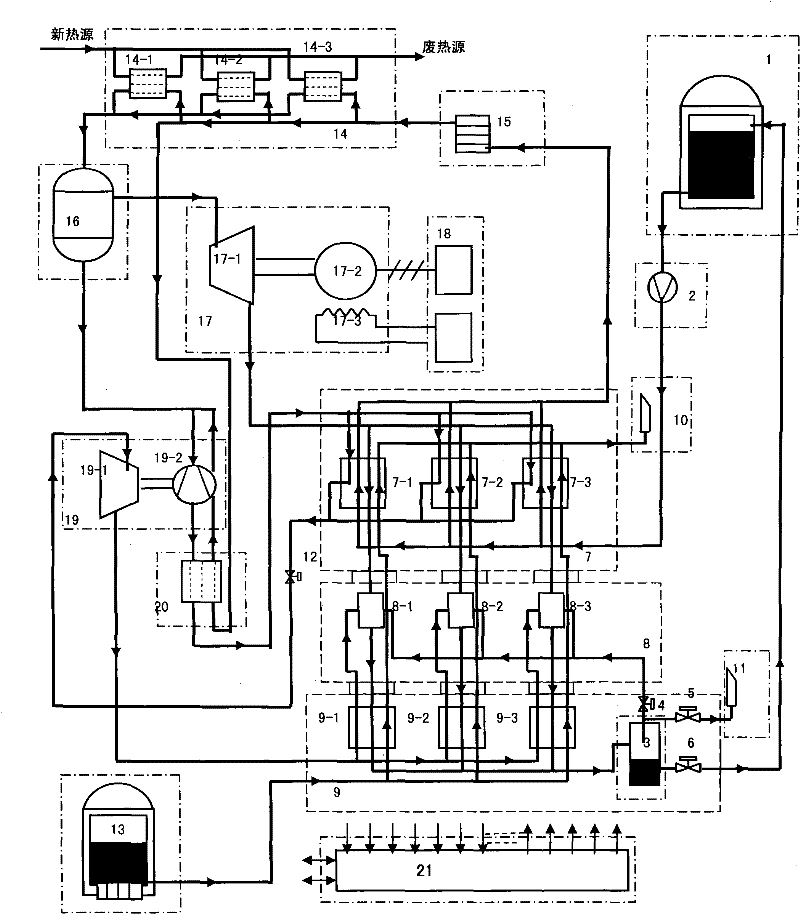

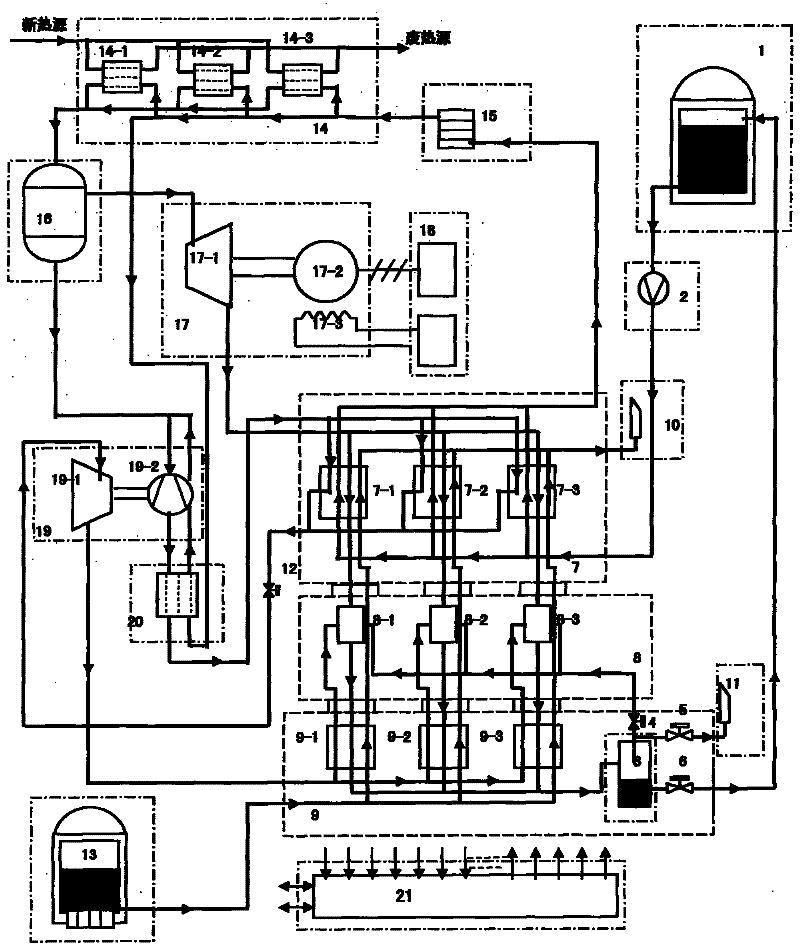

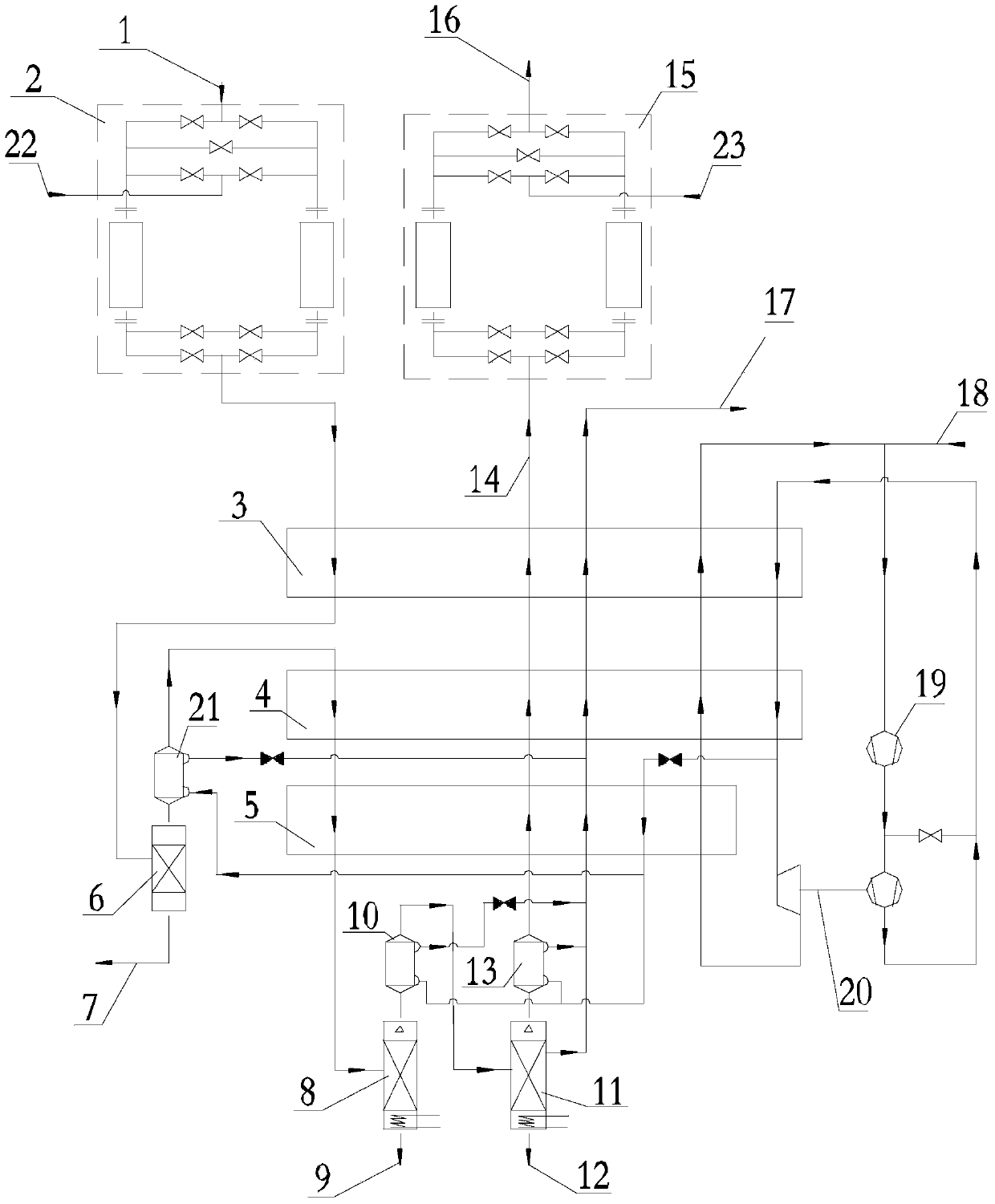

Method and equipment for realizing low-temperature thermal power generation by cryogenic technology

Low-temperature thermal power generation is realized in a new circulating mode. Natural substances such as liquid air, liquid nitrogen, liquid argon (1) and the like which exist in the atmosphere are taken as refrigeration working substances; the liquid nitrogen and the liquid argon are taken as assistant cold sources (13); the working substances are conveyed by a low-temperature liquid pump (2) in a pressure boosting mode; the working substances are cooled and cold is recovered by a low-temperature heat exchanging device (7); an intermediately-cold working substance performs heat exchange (15 and 14) with a low-grade heat source to generate intermediate-and-high pressure gas; one part of gas working substance of which the enthalpy value is increased is inflated to do work to generate electricity (17); and electric energy is merged into a local power grid (18). The other part of working substance is inflated in the pressure boosting mode (19) to generate the cold; the working substance is cooled, condensed, mixed and recovered by a low-temperature heat exchanging device (9) and an ejector (8); the working substance is supercooled in a liquefying mode (5) and recycled; and parameter detection, control and the like are realized by a computer control system (21).

Owner:墙新奇

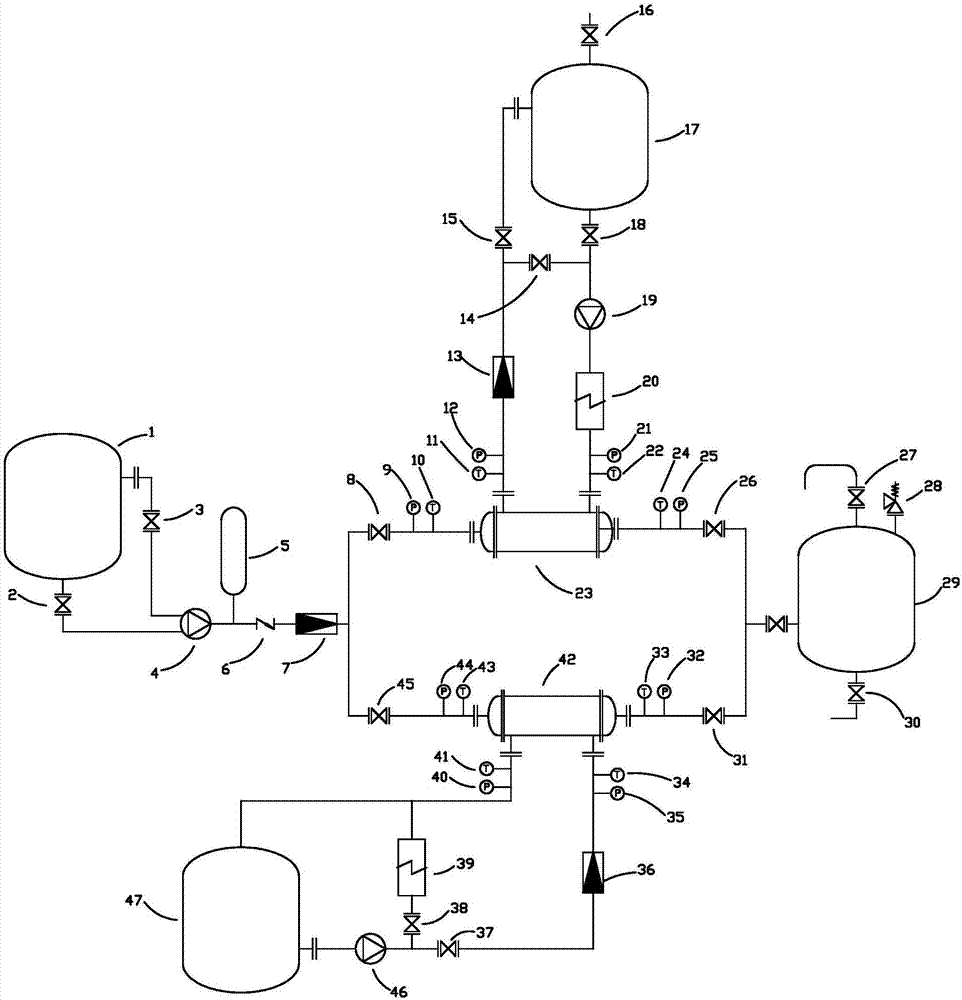

Dual-medium supercritical low-temperature thermal performance test platform

ActiveCN106896134AExpand the scope of testingRealize continuous adjustmentMaterial heat developmentLiquid argonTest sample

The invention relates to a dual-medium supercritical low-temperature thermal performance test platform. The test platform comprises the following components: a low-temperature loop, a high-temperature loop and an ethylene glycol loop, wherein a first test sample machine and a second test sample machine are arranged in parallel in the low-temperature loop; in the high-temperature loop, a high-temperature medium circulation pump, a high-temperature loop flow meter and a valve for cutting off an opening and closing pipe connected in series by a high-temperature medium circulation pipe are arranged between a high-temperature loop storage tank and a hot-side medium channel of the first test sample machine; in the ethylene glycol loop, an ethylene glycol circulation pump, an ethylene glycol loop flow meter and a valve for cutting off an opening and closing pipe connected by an ethylene glycol circulation pipeline are arranged between an ethylene glycol storage tank and a hot-side medium channel of the second test sample machine. With the adoption of a technical scheme provided by the invention, the thermal performance test for heat exchange between a low-temperature medium and each of two media including high-temperature water and ethylene glycol can be realized, thereby greatly expanding a test range of the supercritical low-temperature medium. The low-temperature medium in the invention comprises, but is not limited to, liquid nitrogen, liquid oxygen, liquid argon, liquefied natural gas and the like.

Owner:HEFEI GENERAL MACHINERY RES INST

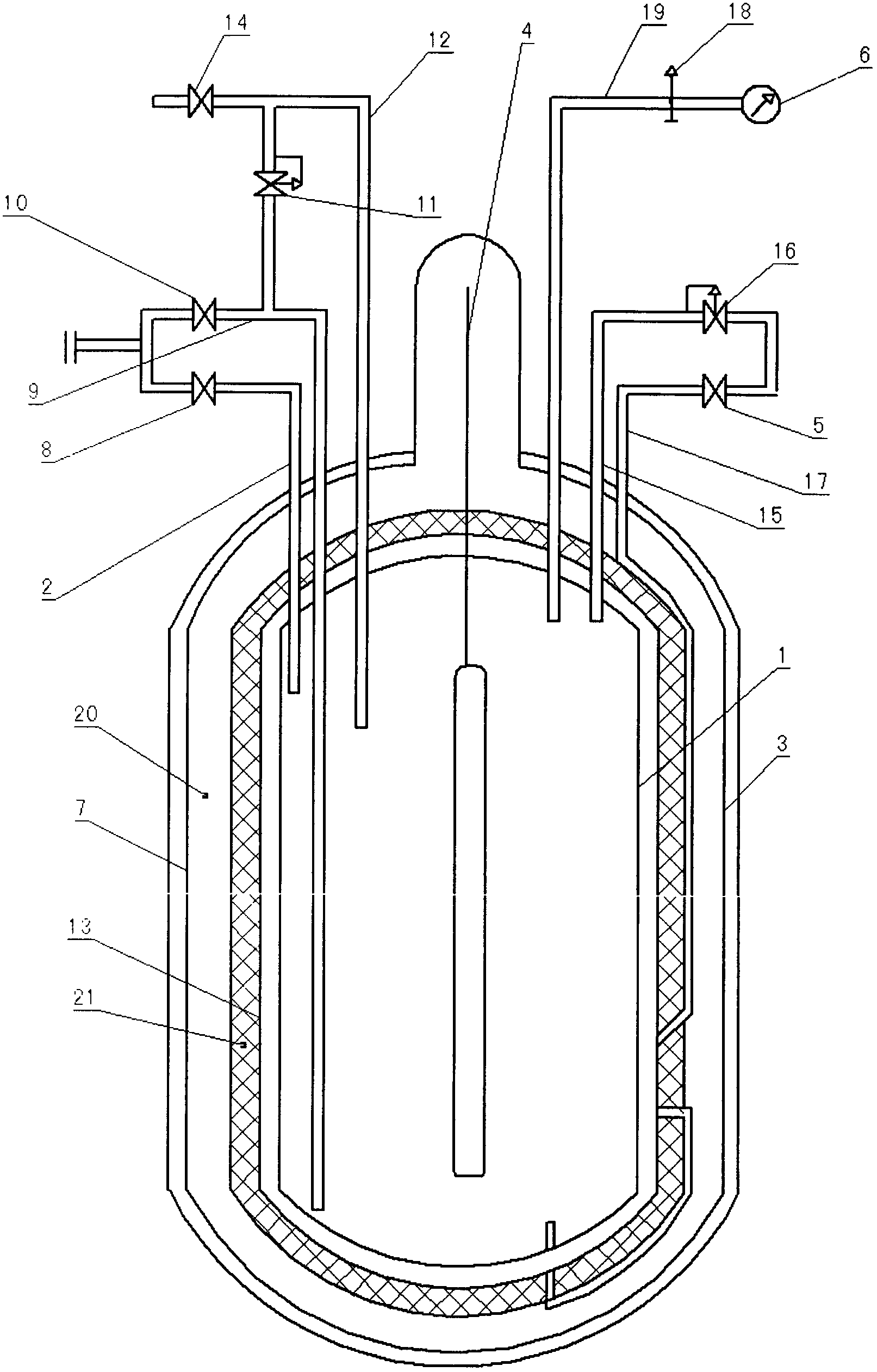

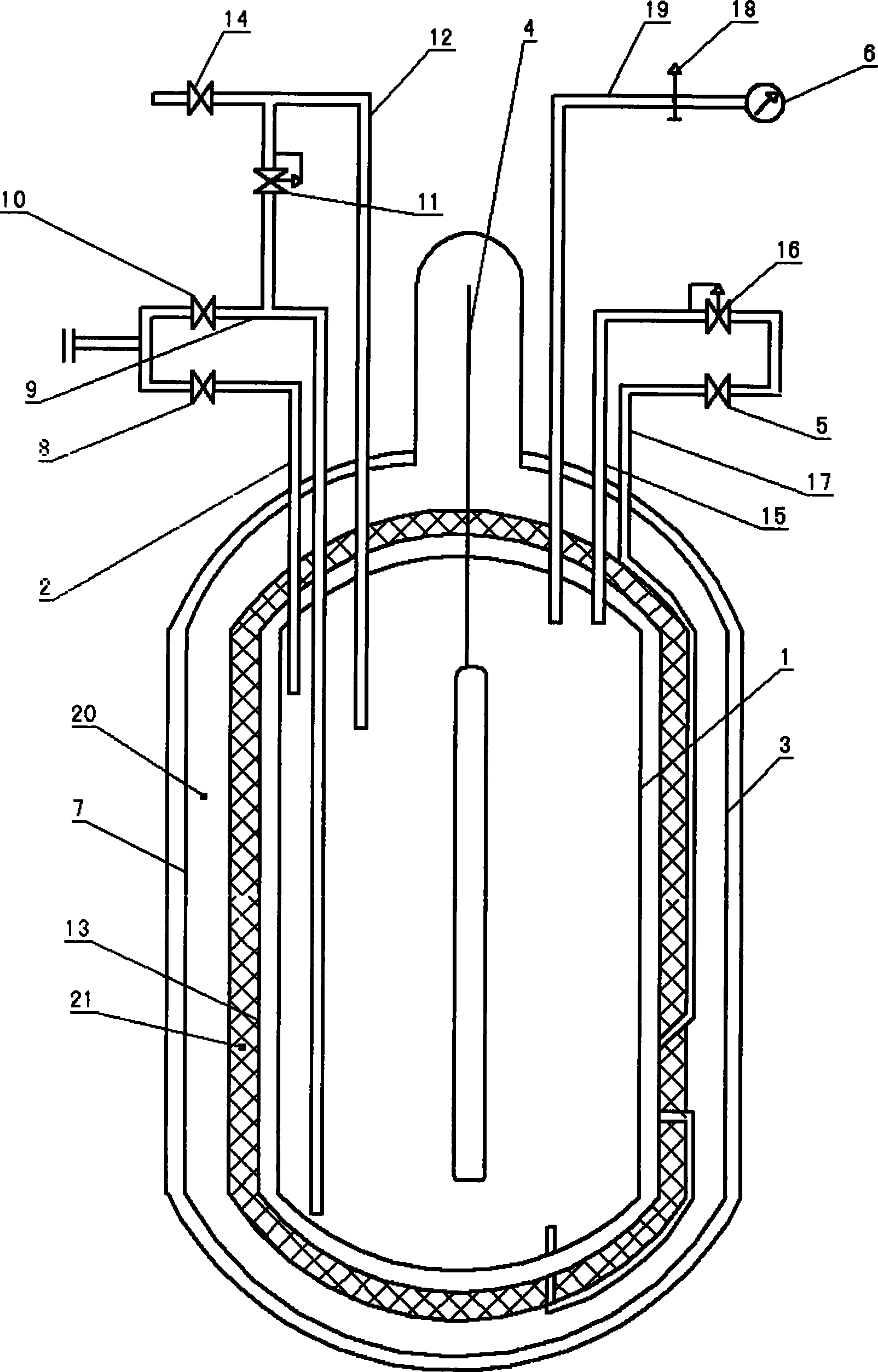

Welded adiabatic gas cylinder

InactiveCN102691881AHigh purityOvercome large heat leakageContainer filling methodsPressure vesselsGas cylinderEngineering

The invention relates to a pressure container with heat insulation measures, in particular to a welded adiabatic gas cylinder which comprises a cylinder body, a valve base, a safety valve, a rupture disk, a pressure gauge, a liquidometer and a connection pipe. The cylinder body consists of an inner tank and a housing; a vacuum interlayer is formed between the inner tank and the housing; an insulating layer is arranged in the vacuum interlayer; a supporting system and an inner evaporator are also arranged on the welded adiabatic gas cylinder; the supporting system is arranged in the vacuum interlayer and connected with the inner tank; the insulating layer is a structure of more than two layers of insulated packing layers, and the inner evaporator is arranged in the vacuum interlayer and provided with a degasser layer attached on the inner tank or attached on the housing. The welded adiabatic gas cylinder has the advantages of low heat leakage, good low-temperature insulating effect, excellent supporting strength, convenience for use, high loading rate, security and reliability, high purity of stored gas, high vacuum degree, long vacuum service life and the like and is mainly applied to low-temperature liquid such as liquid oxygen, liquid nitrogen and liquid argon.

Owner:ZHANGJIAGANG KEHUA CHEM EQUIP MFG

Method and device for recycling integrated high-purity nitrogen and argon

InactiveCN109631495AHigh recovery rateReduce restrictionsSolidificationLiquefactionOperational costsNitrogen gas

The invention discloses a method and device for recycling integrated high-purity nitrogen and argon. According to the method, a connection effect of an auxiliary condensing evaporator is utilized; cold energy exchange is performed between an argon recycling flow path and an air and nitrogen flow path; excessive cold energy generated by an expander is conveyed to the argon recycling flow path, so that the amount of liquid argon added externally can be obviously lowered, and operation cost of the equipment is lowered; meanwhile, convenience that liquid argon is provided on site is utilized, andcold energy is provided by liquid argon; then nitrogen and hydrogen are removed with a low-temperature distillation method; the recycling rate of argon and the utilization rate of hydrogen are improved; the procedure and operation of low-temperature distillation are simplified; operation energy consumption is lowered; furthermore, the integrated air and nitrogen flow path is utilized, and cold energy is generated by the expander, so that nitrogen is generated in a cold box; limitation of regenerated air can be lowered; and the extraction rate of recycled argon is improved.

Owner:上海联风能源科技有限公司

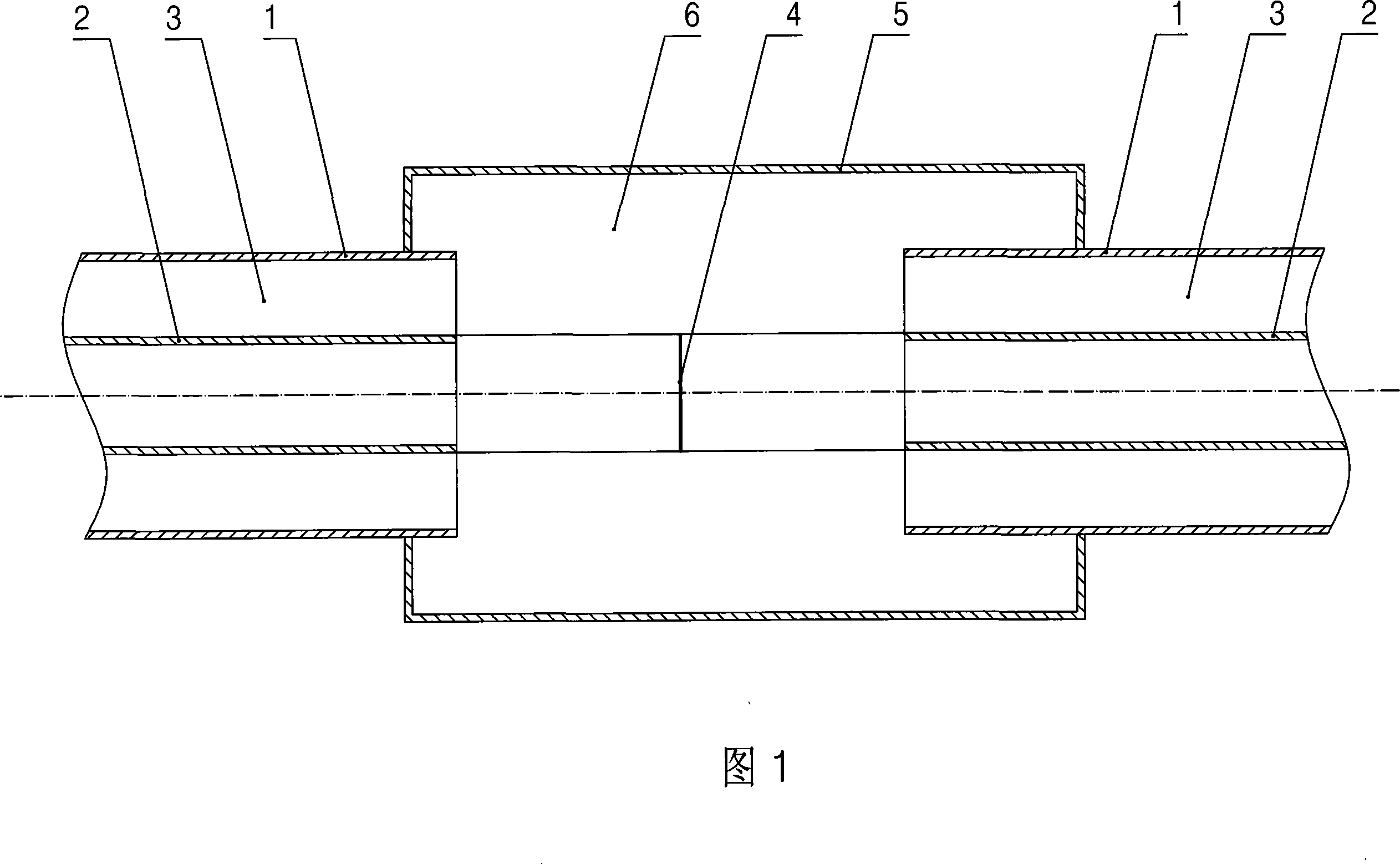

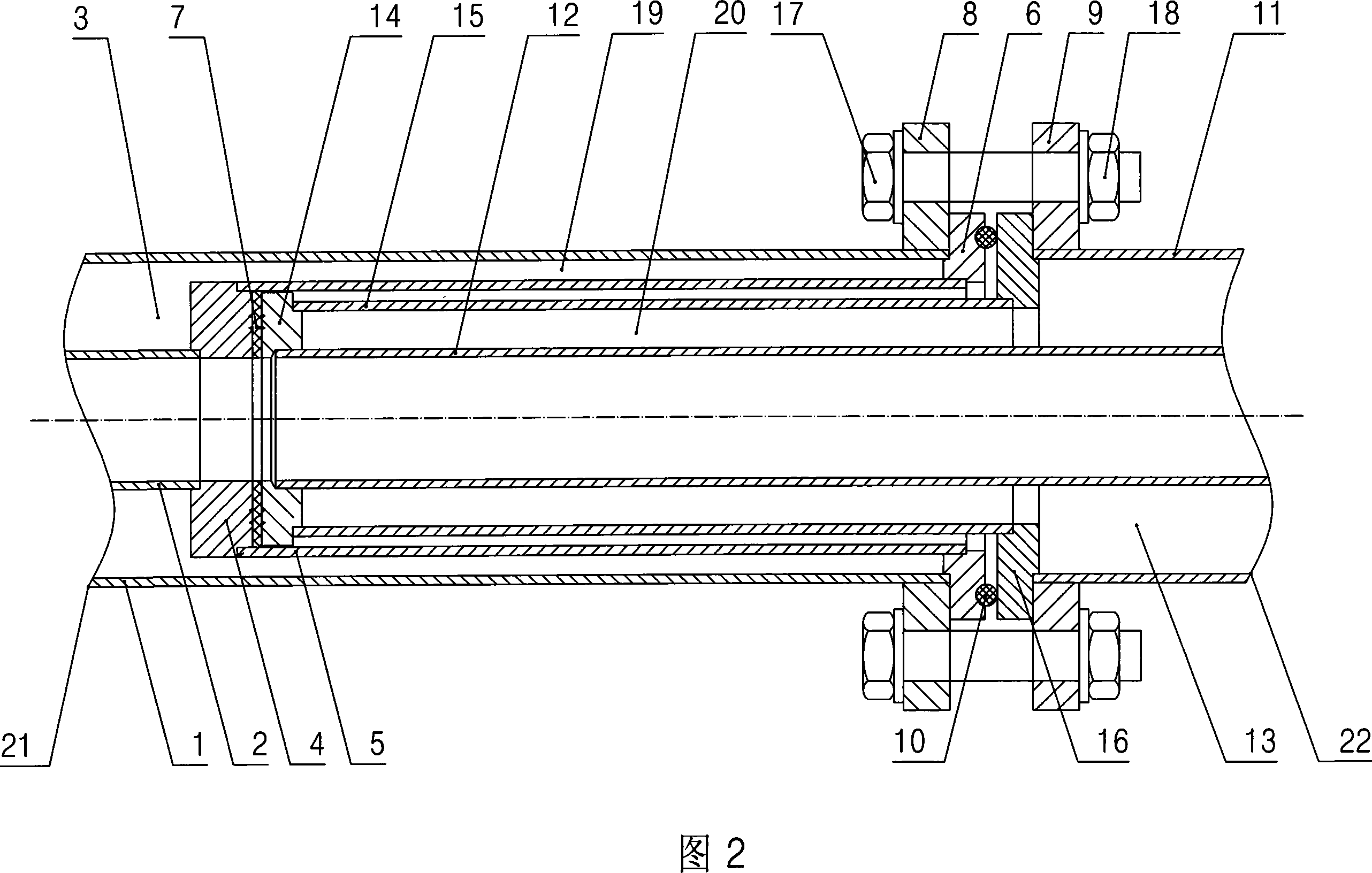

Vacuum pipe butting structure

InactiveCN101169202AEasy dockingAvoid WeldingSleeve/socket jointsFlanged jointsLiquid argonButt joint

The invention discloses a vacuum pipeline butt joint structure which can make butt joint of vacuum pipelines to be exceedingly convenient. The butt joint structure comprises a pair of vacuum pipelines each of which contains an outer sleeve and an inner pipe with a thermal-insulation vacuum cavity between; the butt joint end of the inner pipe of one vacuum pipeline is provided with a socket; a socket vacuum cavity communicating with the thermal-insulation vacuum cavity in the vacuum pipeline is arranged between the socket and the outer sleeve; the butt joint end of the inner pipe of the other vacuum pipeline is provided with a plug matching with the socket; a plug vacuum cavity communicating with the thermal-insulation vacuum cavity in the vacuum pipeline is arranged between the plug and the outer sleeve; a seal ring is arranged between the top of the plug and the bottom of the socket; the pair of vacuum pipelines is fixed together via a pair of flanges on the outer sleeves of the pipelines. The invention is mainly used for butt joint of vacuum pipelines for transmitting low-temperature liquids such as liquid nitrogen, liquid argon, liquid oxygen, liquefied natural gas, etc.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

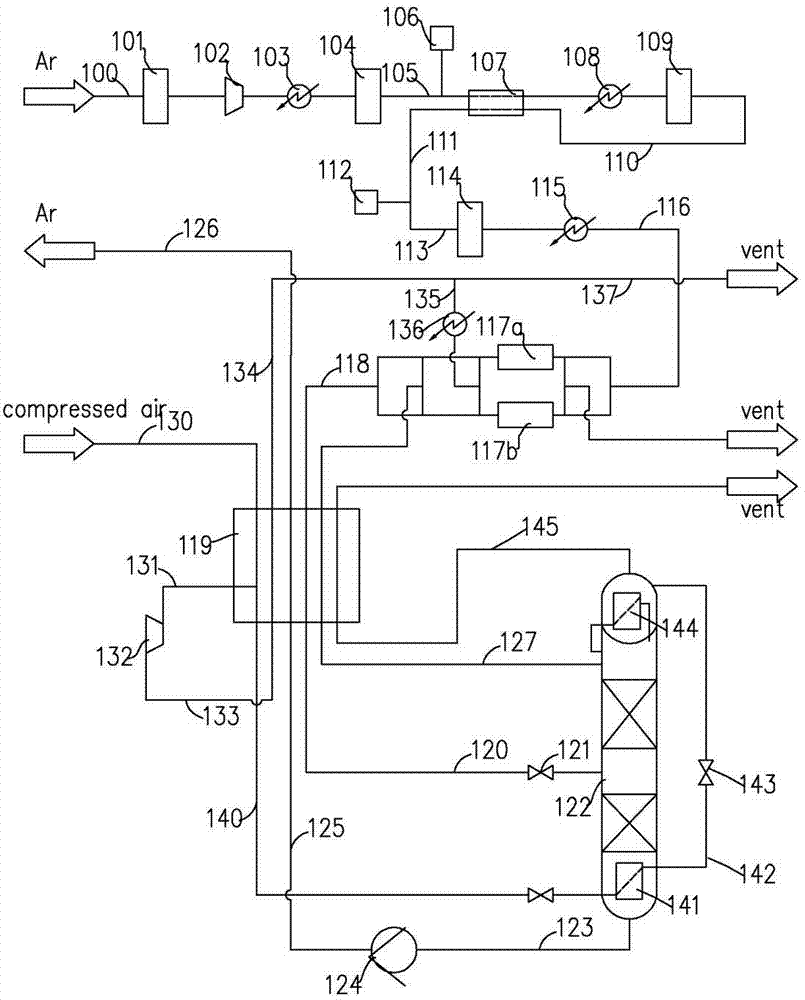

Device and method for improving argon recycling rate

PendingCN108645118AHigh recovery rateIncrease profitSolidificationLiquefactionLiquid argonOperational costs

The invention discloses a device and method for improving the argon recycling rate. The convenience that in the recycling site, liquid argon exists and is used for providing is used, liquid argon is used for providing cold amount, a low-temperature distillation method is used for removing nitrogen and hydrogen, the argon recycling rate and the hydrogen utilization rate are improved, the flow and the operation of low-temperature distillation are simplified, and running energy consumption is reduced; an integrated air and nitrogen flow path is used, cold amount is generated through an expansionmachine, nitrogen is generated from the interior of a cold box, limitation of regeneration air flow is reduced, the extraction rate of argon recycling is improved, in addition, the connection effect of an auxiliary condensation evaporator is used, an argon recycling flow path and an air and nitrogen flow path are subject to cold exchange, redundant cold amount generated by an expanding machine isconveyed to the argon recycling flow path, the liquid argon amount added from the exterior can be reduced, and the running cost of the device can be reduced.

Owner:上海联风能源科技有限公司

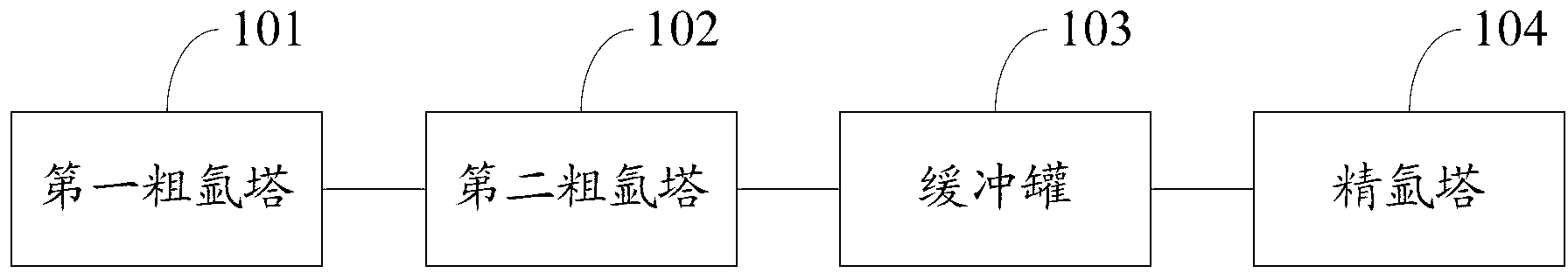

Method and system for increasing yield of liquid argon

The invention discloses a system for increasing the yield of liquid argon. The system comprises a first crude argon column, a second crude argon column, a buffer tank and a pure argon column. The first crude argon column is connected with the second crude argon column; the second crude argon column is connected with the buffer tank; and the buffer tank is connected with the pure argon column. The first crude argon column performs oxygen and argon separation on argon fractions with the oxygen content ranging from 88% to 92%, which are extracted in the middle of an upper column of an air separation system, and transmits crude argon with the oxygen content smaller than 3%, which is obtained after separation, to the second crude argon column. The second crude argon column performs oxygen and argon separation on the received crude argon with the oxygen content smaller than 3% again and outputs argon obtained after separation, of which the oxygen content is smaller than 3ppm, to the buffer tank. The buffer tank stores the received argon with the oxygen content smaller than 3ppm and outputs the argon to the pure argon column after the flow and the pressure are balanced. The pure argon column performs oxygen and argon separation on the received crude argon with the oxygen content smaller than 3%, which is output by the buffer tank, to extract pure liquid argon products. By means of the system, the yield of liquid argon can be improved.

Owner:YANKUANG GRP CO LTD +1

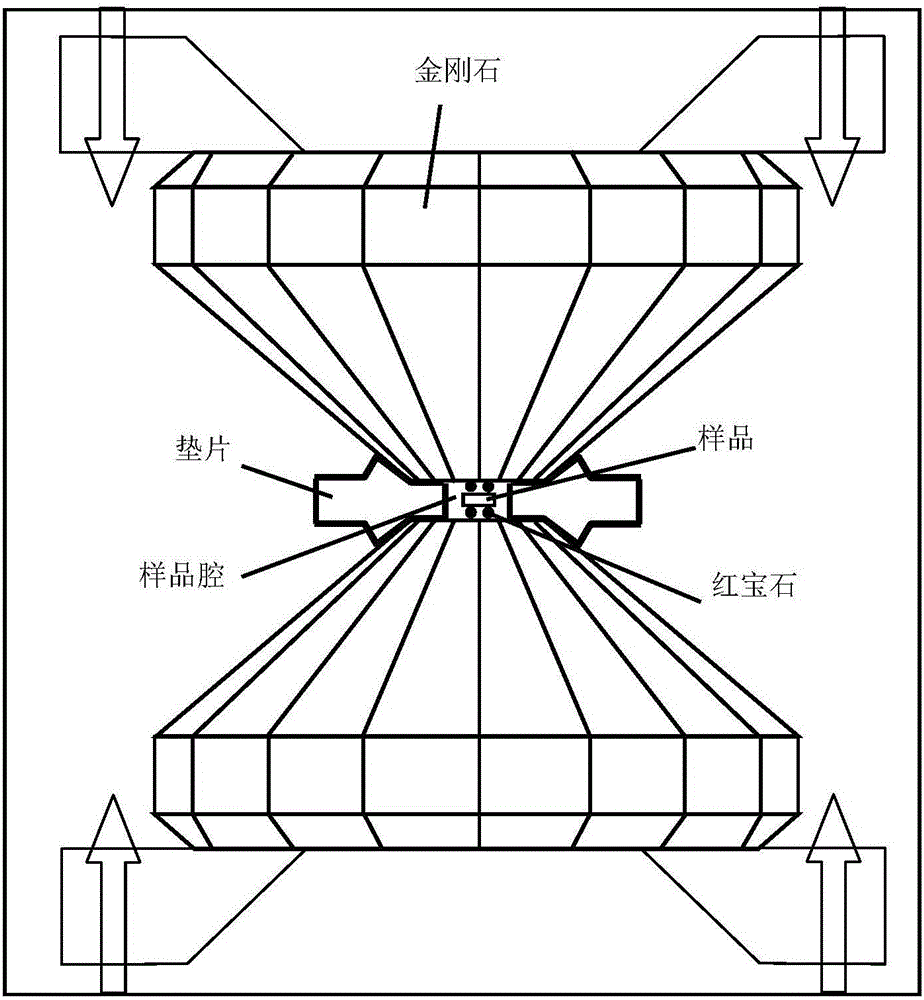

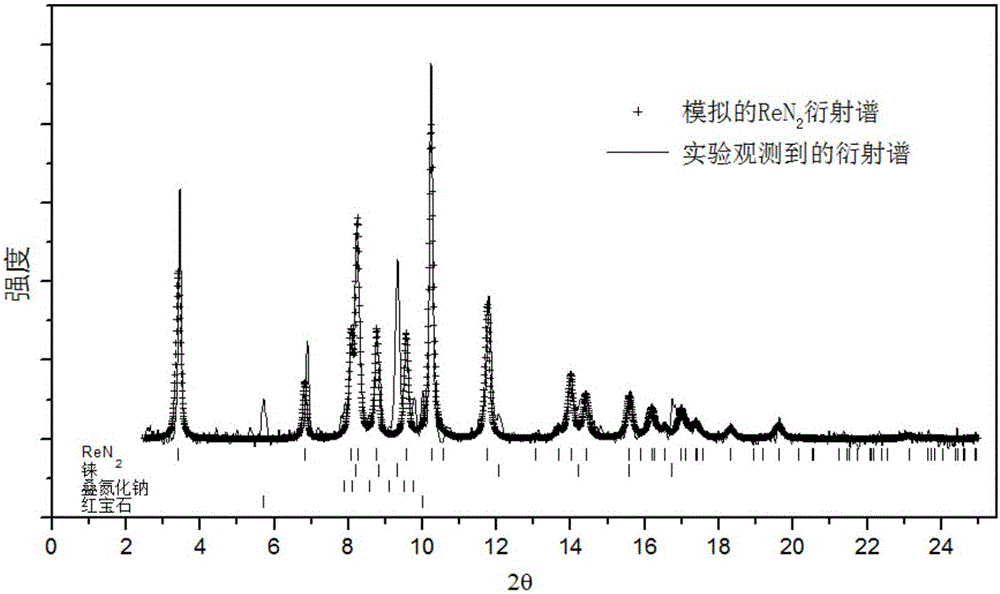

Synthesis method of layered rhenium-nitrogen compound ReN2

InactiveCN105752949ARaw material stabilitySimple experiment preparationNitrogen-metal/silicon/boron binary compoundsRheniumLiquid argon

The invention provides a synthesis method of a layered rhenium-nitrogen compound ReN2 and belongs to the technical field of synthesis methods of transition metal compounds. The method comprises the following steps: mixing rhenium powder and sodium azide at a mass ratio of 1:2 so as to serve as raw materials, placing the mixture in a mortar, fully grinding, feeding the ground mixture into a DAC device, introducing liquid argon into the DAC device, then pressurizing the raw materials to 30 GPa, and performing laser heating for 8-12 minutes at a power of 20W, so as to obtain ReN2 with a layered structure. The raw materials used in the method are stable in air; the experimental preparation process is simple, the synthesis safety is good, and the repeatability is high.

Owner:JILIN UNIV

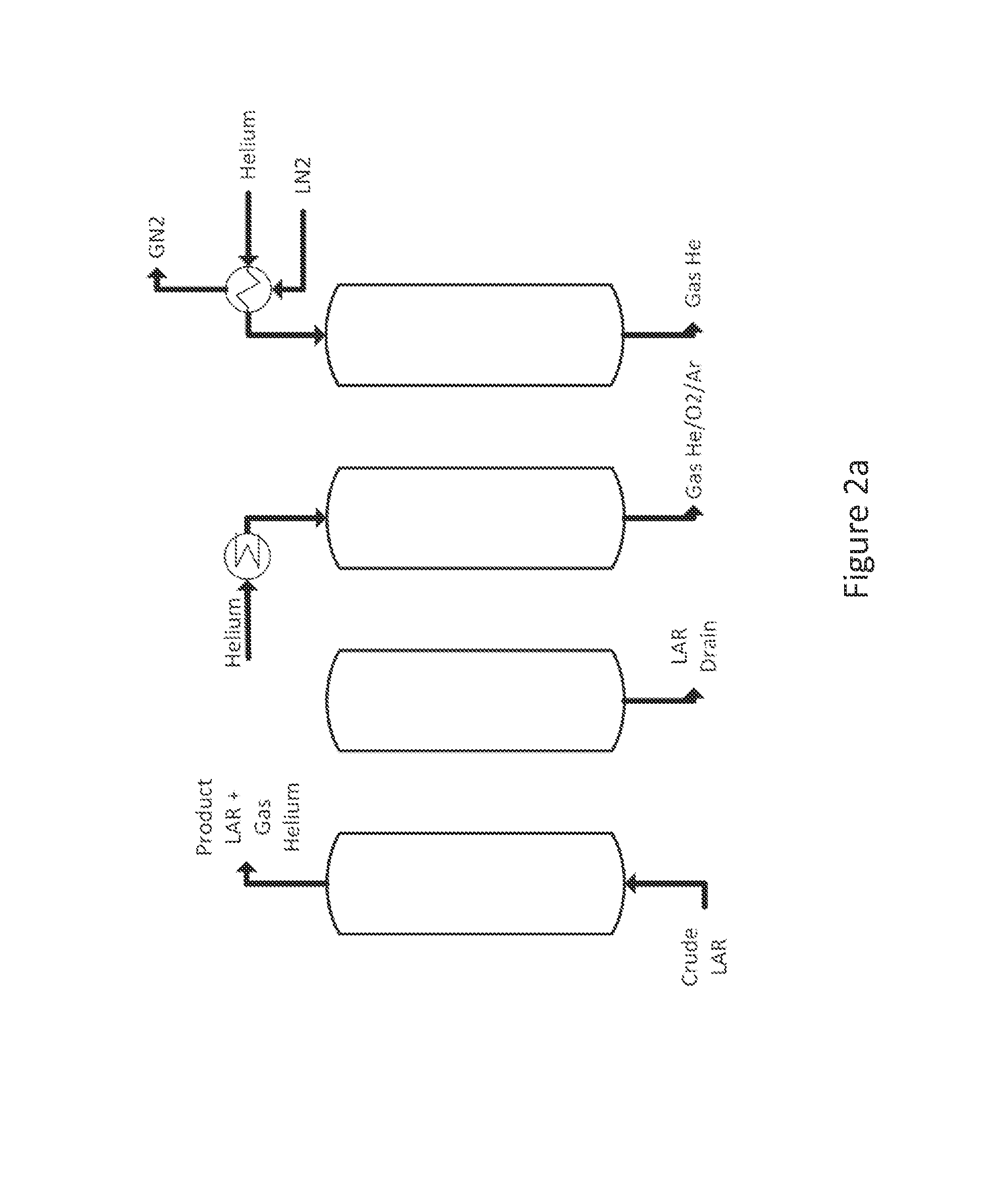

Helium enhanced heat transfer in adsorptive liquid argon purification process

ActiveUS20160362298A1Improve heat transfer performanceImprove thermal conductivitySolidificationLiquefactionLiquid argonHeat carrier

The present invention generally relates to a method to enhance heat transfer in the temperature swing adsorption process (TSA) and to an intensified TSA process for gas / liquid purification or bulk separation. Helium is designed as the heat carrier media to directly bring heat / cool to the adsorbent bed during the TSA cycling process. With helium's superior heat conductivity, the time consuming regeneration steps (warming, regeneration and precooling) of TSA process can be significantly reduced and allowing for the TSA process to be intensified.

Owner:PRAXAIR TECH INC

High-chromium nickel-based high-temperature alloy and preparation method and application thereof

ActiveCN110747377AImprove performanceImprove antioxidant capacityAdditive manufacturing apparatusIncreasing energy efficiencyLiquid argonChromium nickel

The invention relates to the field of advanced manufacturing and high-temperature alloys, in particular to a high-chromium nickel-based high-temperature alloy and a preparation method and an application thereof. The high-chromium nickel-based high-temperature alloy is prepared from the following components in percent by mass: 30-35% of Cr, 1-2% of Ti, 1-2% of Al, 2-3% of Ta, 1-2% of Nb, 2.5-3.5% of Mo, 4-5% of W, 0.2-0.5% of Fe, 0.005-0.03% of C, 0.003-0.01% of B, 0.003-0.01% of Y and the balance Ni. According to the high-chromium nickel-based high-temperature alloy prepared by a laser additive manufacturing method, thermal stress is reduced to reduce deformation and cracks of a workpiece in the laser additive manufacturing process by optimizing parameters of the laser additive manufacturing process and carrying out cooling by way of liquid argon synchronous chilling in the laser additive manufacturing process, and net shaping of the high performance high-chromium nickel-based high-temperature alloy is achieved, so that the high-chromium nickel-based high-temperature alloy which is excellent in comprehensive performance is obtained. The high-chromium nickel-based high-temperature alloy is suitable for the fields of aerospace, petrochemical engineering, nuclear power industry and the like.

Owner:TSINGHUA UNIV

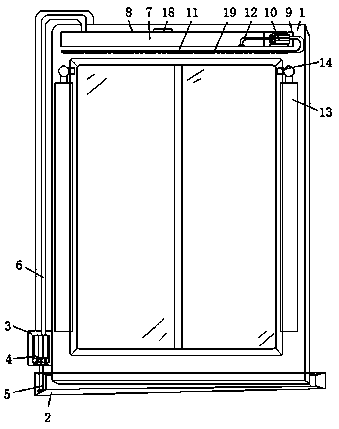

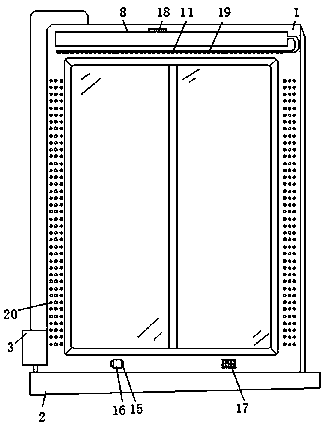

Wood-plastic aluminum alloy door and window with fire-extinguishing function

InactiveCN108179963AImprove cooling effectEffectively extinguish the fireFireproof doorsFire rescueSolenoid valveEngineering

The invention discloses a wood-plastic aluminum alloy door and window with a fire-extinguishing function. The wood-plastic aluminum alloy door and window with the fire-extinguishing function comprisesa frame body, a header tank and a first mounting box. The header tank is formed in the bottom of the frame body. The first mounting box is arranged at the bottom of one end of the frame body, and a first water pump is arranged at the middle position of the inner bottom end of the first mounting box. A first suction pipe extending to the header tank is arranged in the input end of the first waterpump. The output end of the first water pump communicates with the storage tank through a conveying water pipe, and the middle position on the top of the front face of the frame body is provided witha fireproof water tank. By the installation of liquid inert gas storage tanks and solenoid valves, liquid nitrogen, liquid carbon dioxide or liquid argon gas can be sprayed when flames reach the doorand window to effectively extinguish fires. By the installation of the storage tank and a water injection nozzle, the door and window which is on fire can be cooled to prevent survivors from being scalded through the hyperthermal door and window.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

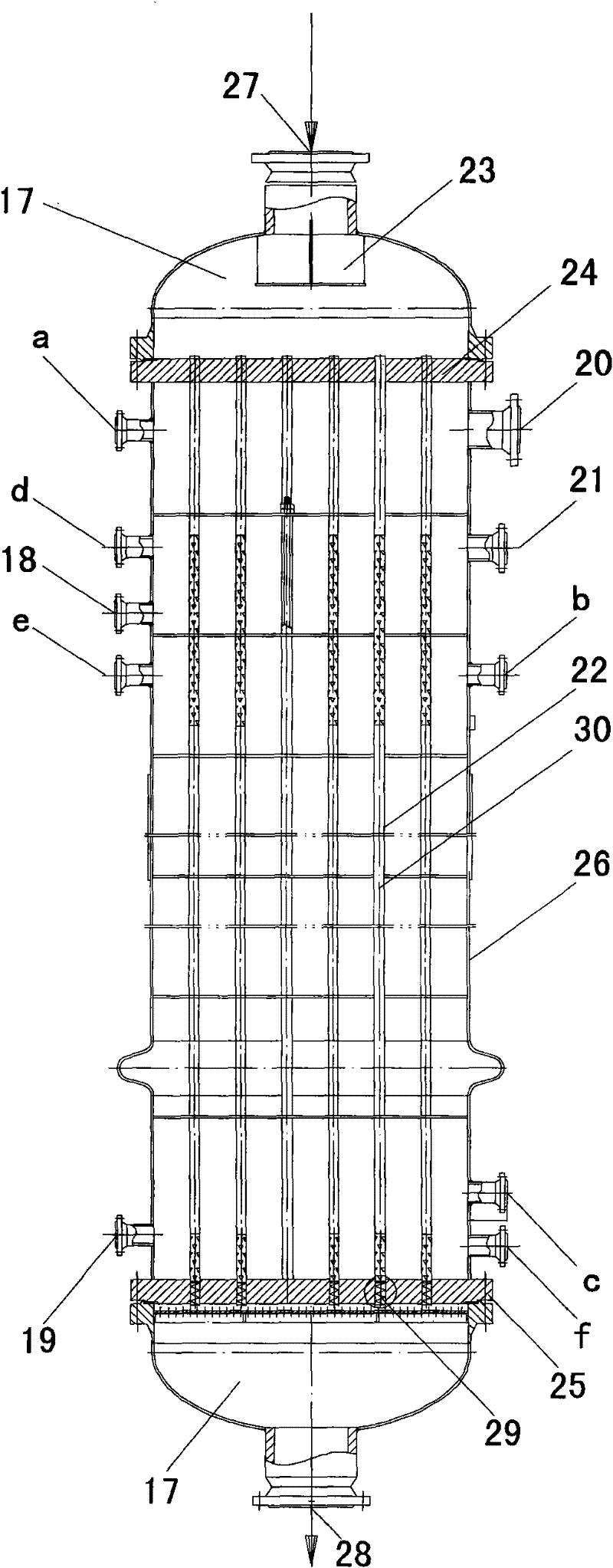

Ammonia synthesis waste gas recycling device

ActiveCN104190200AIncrease profitHigh economic valueHydrogen separationDispersed particle separationLiquid argonHydrogen

The invention discloses an ammonia synthesis waste gas recycling device. The device comprises a decarbonization adsorber, a first heat exchanger, a second heat exchanger, a third heat exchanger, a liquid ammonia rectifying tower, a liquid ammonia rectifying tower condenser, a methane rectifying tower, a methane rectifying tower condenser, an argon rectifying tower and an argon rectifying tower condenser, wherein the decarbonization adsorber is provided with a gas inlet and a first regenerated gas inlet, the liquid ammonia rectifying tower is provided with a liquid ammonia outlet, the methane rectifying tower is provided with a liquid methane outlet, the argon rectifying tower is provided with a liquid argon outlet and a waste gas outlet; the ammonia synthesis waste gas separating device further comprises a hydrogen pipeline with one end connected with the argon rectifying tower, a hydrogen purifying device connected with the hydrogen pipeline, a nitrogen circulating compressor, a nitrogen expander and a nitrogen supplementing port connected with the nitrogen circulating compressor; the hydrogen purifying device is provided with a hydrogen outlet and a second regenerated gas inlet; the recycling device can be used for extracting liquid ammonia, liquid methane, liquid argon, and high-pure hydrogen with relatively high purity from the waste gas.

Owner:SUZHOU XINGLU AIR SEPARATION PLANT SCI & TECH DEV CO LTD

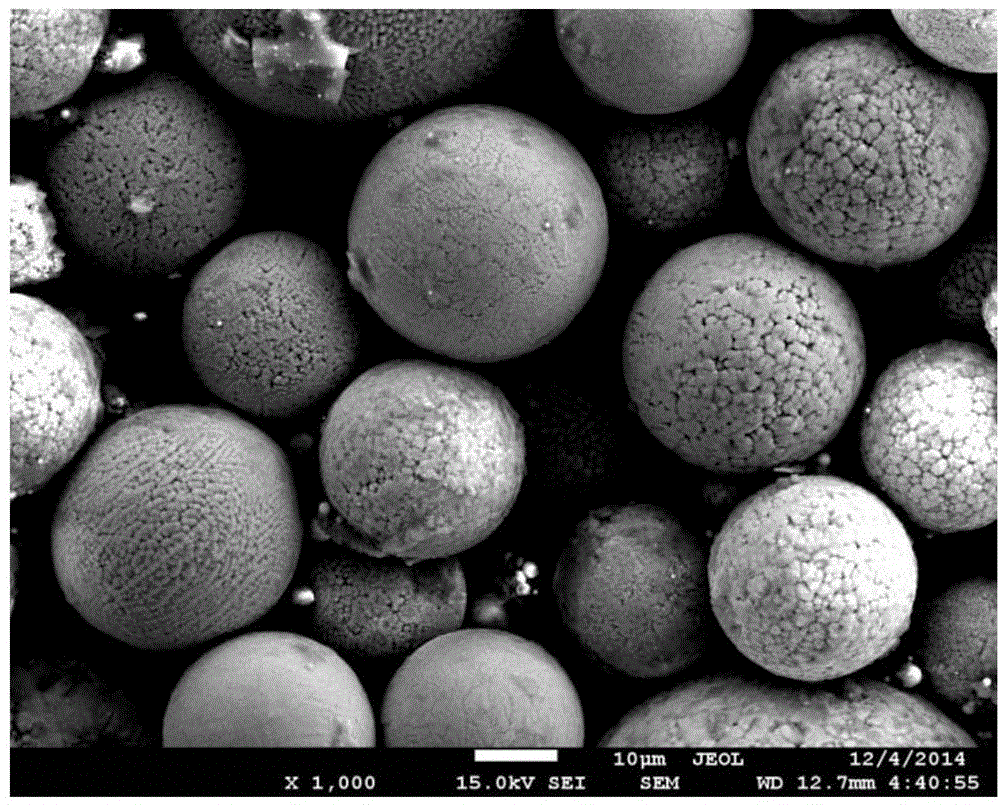

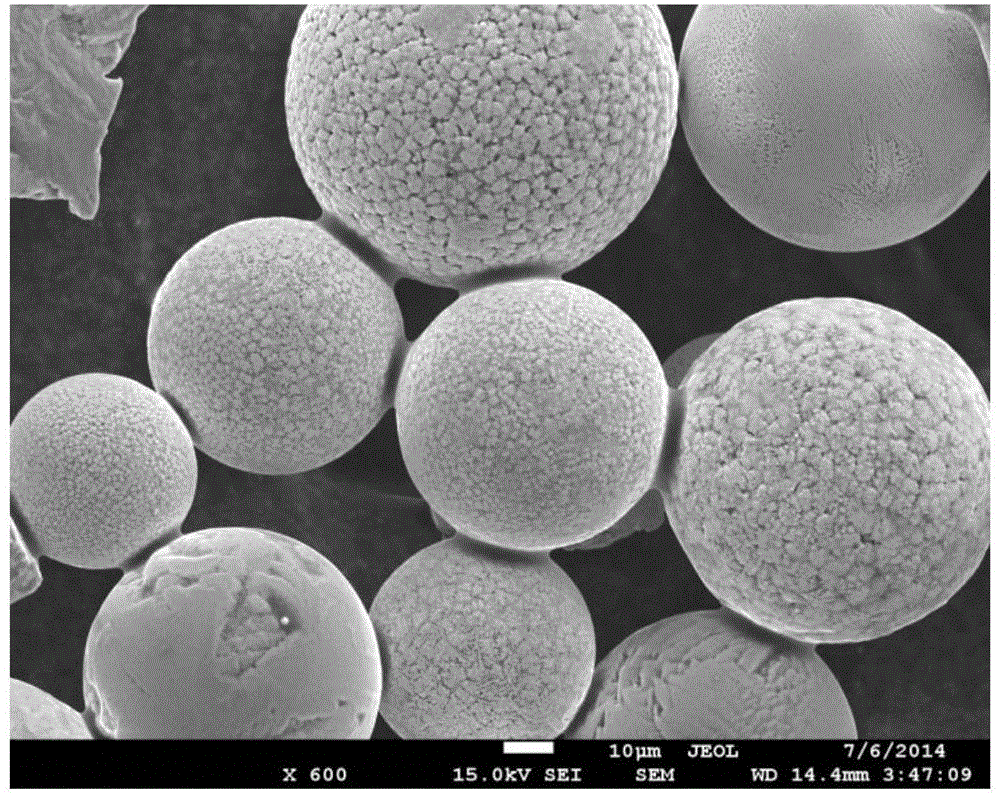

Preparation method for titanium-aluminum alloy superfine powder

The invention discloses a preparation method for titanium-aluminum alloy superfine powder. According to the technical scheme adopted by the invention, the preparation method comprises the following steps: selecting a titanium-aluminum alloy rod which is up-to-standard in component and 3mm and 6mm in diameter as a raw material, adopting a pulse electric spark processor to perform once processing on the titanium-aluminum alloy rod in liquid argon under proper pulse width and pulse interval parameter to obtain titanium-aluminum alloy superfine powder; and then, adopting vacuum low-temperature drying to obtain pure titanium-aluminum alloy superfine powder. The titanium-aluminum alloy superfine powder is widely applied to the titanium-aluminum alloy powder metallurgical preparation industry; the titanium-aluminum alloy material is widely applied to aviation, spaceflight, cars, metallurgy and the like.

Owner:SOUTHWEST JIAOTONG UNIV

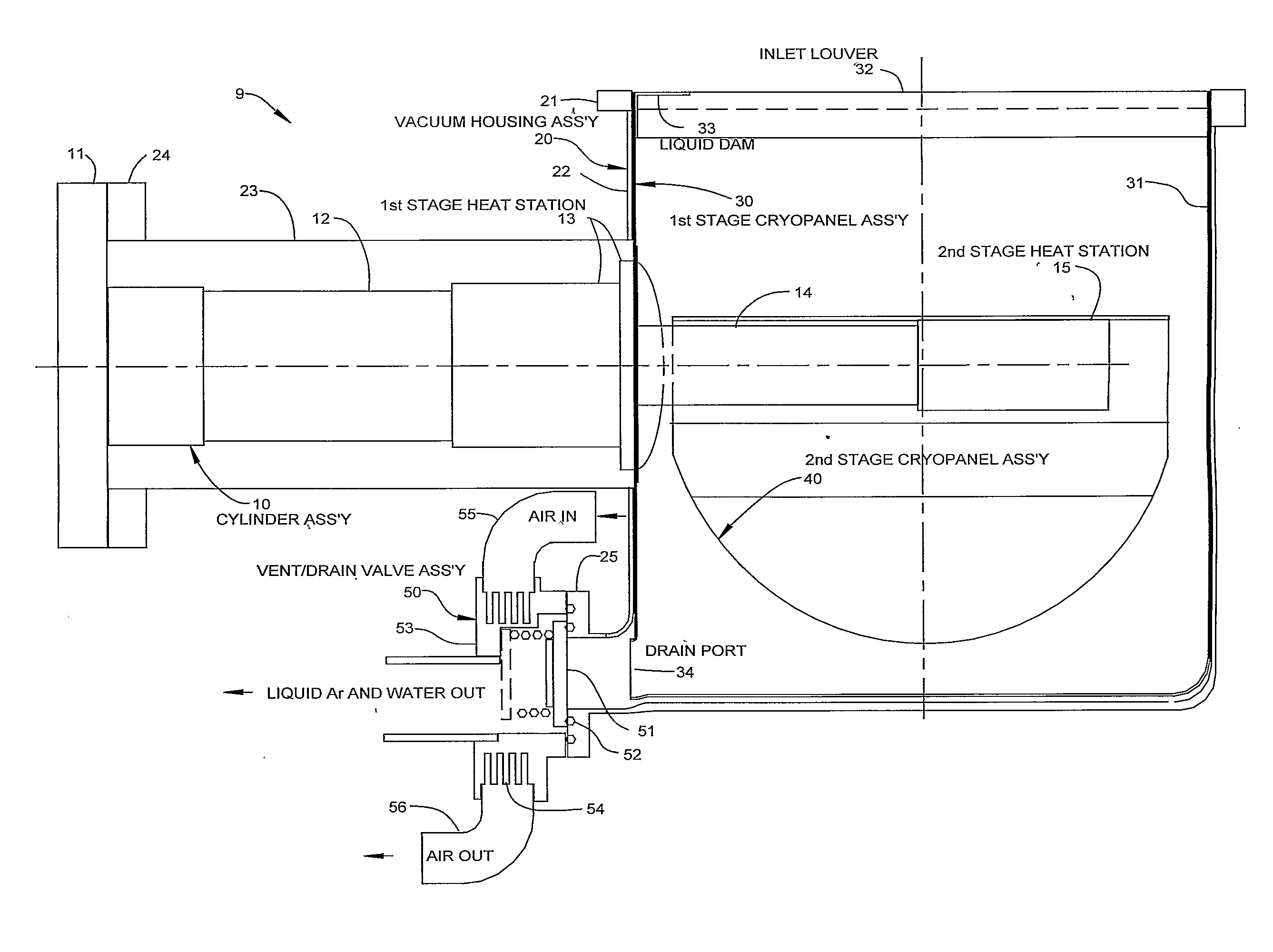

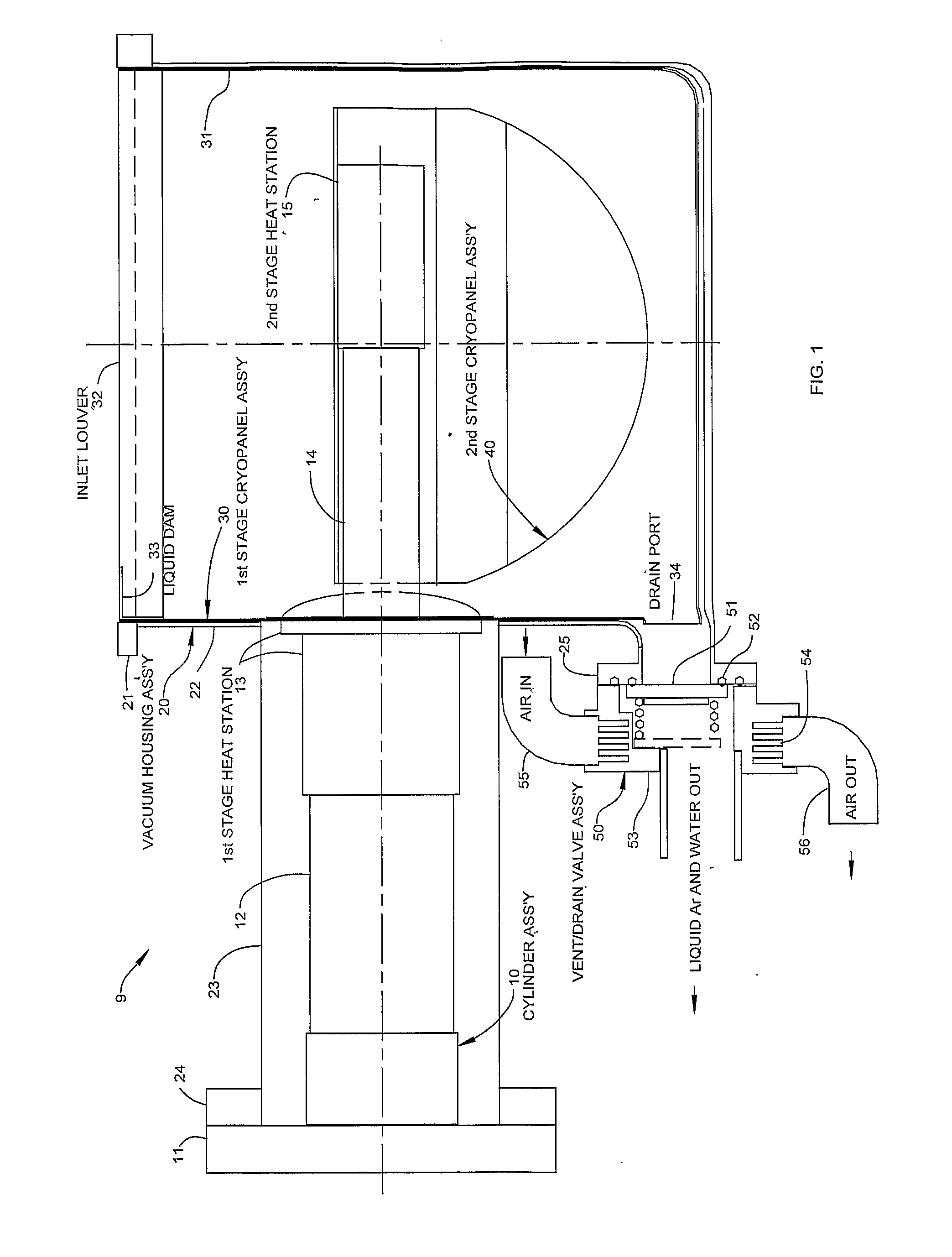

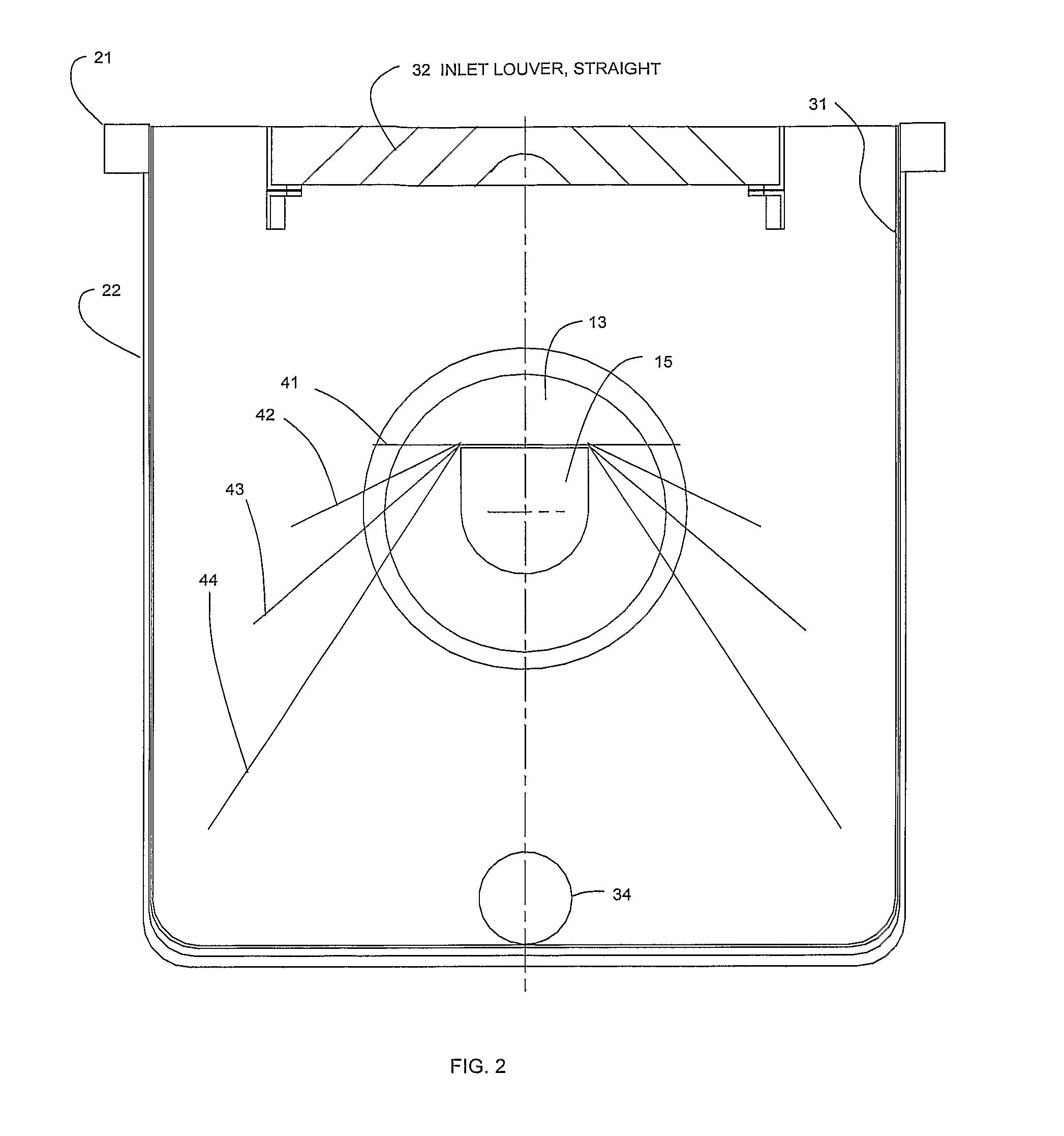

Cryopump

InactiveUS20080184712A1Reduce weightIncrease surface areaSolidificationLiquefactionIn planeLiquid argon

A cryopump cooled by a GM type refrigerator is disclosed in which the cold (second stage) cryopanel(s) are in planes that are pitched parallel to the axis of the expander cylinder; the cold end of the first stage expansion space is close to the point where the expander cylinder enters the vacuum housing that contains the cryopanels; and a drain system removes all the liquid argon and water flowing out through a vent port for two orientations of the cryopump.

Owner:SUMITOMO HEAVY IND LTD +1

Device and method for obtaining high-purity helium gas through concentration and purification

The invention provides a device and method for obtaining high-purity helium gas through concentration and purification. The device for obtaining high-purity helium gas through concentration and purification is characterized by comprising a dechlorination device, a buffer tank, a compressor, a filter, a drying machine, a drying tower, a liquid argon tank, a solid argon tank, an adsorption tank and a gas storage tank which are connected in sequence. According to the device and method for obtaining high-purity helium gas through concentration and purification, provided by the invention, the helium gas can be purified to achieve a concentration of 99.999% or above, the recovery rate of helium gas can reach 95% or above, the recovered helium gas can be resupplied to the user side for continual use, and the cycle use of helium gas is realized.

Owner:江苏正帆半导体设备有限公司 +1

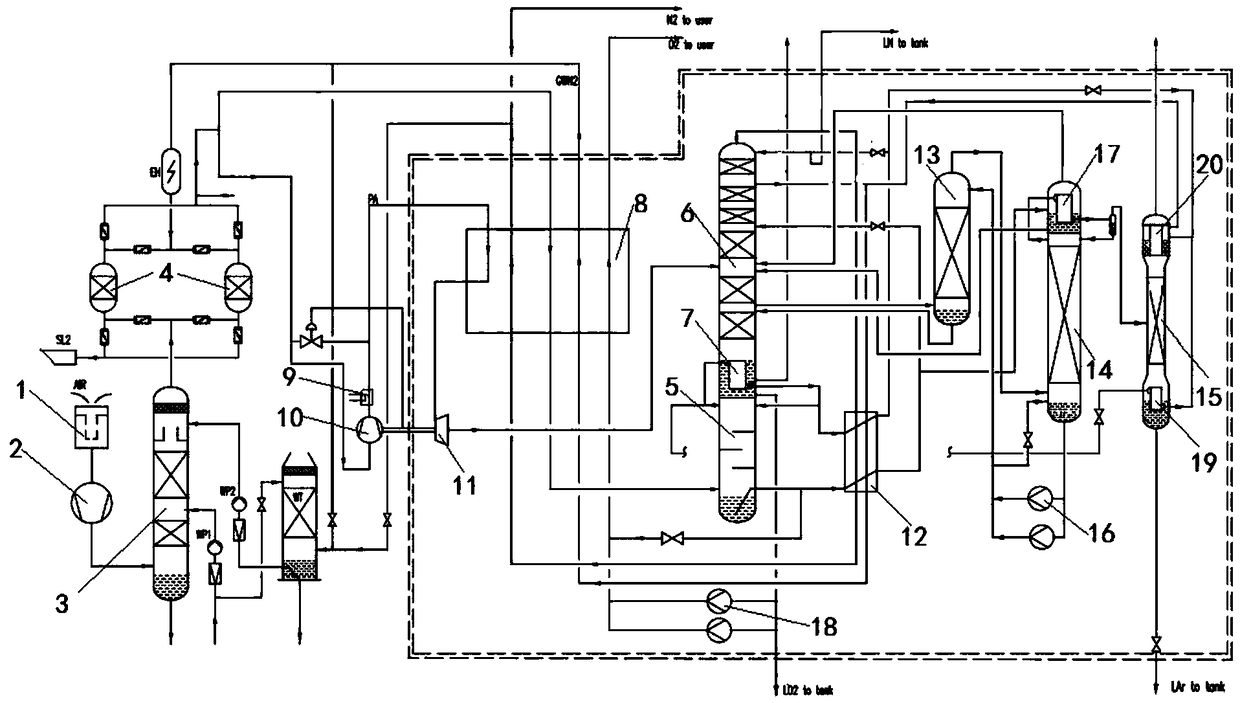

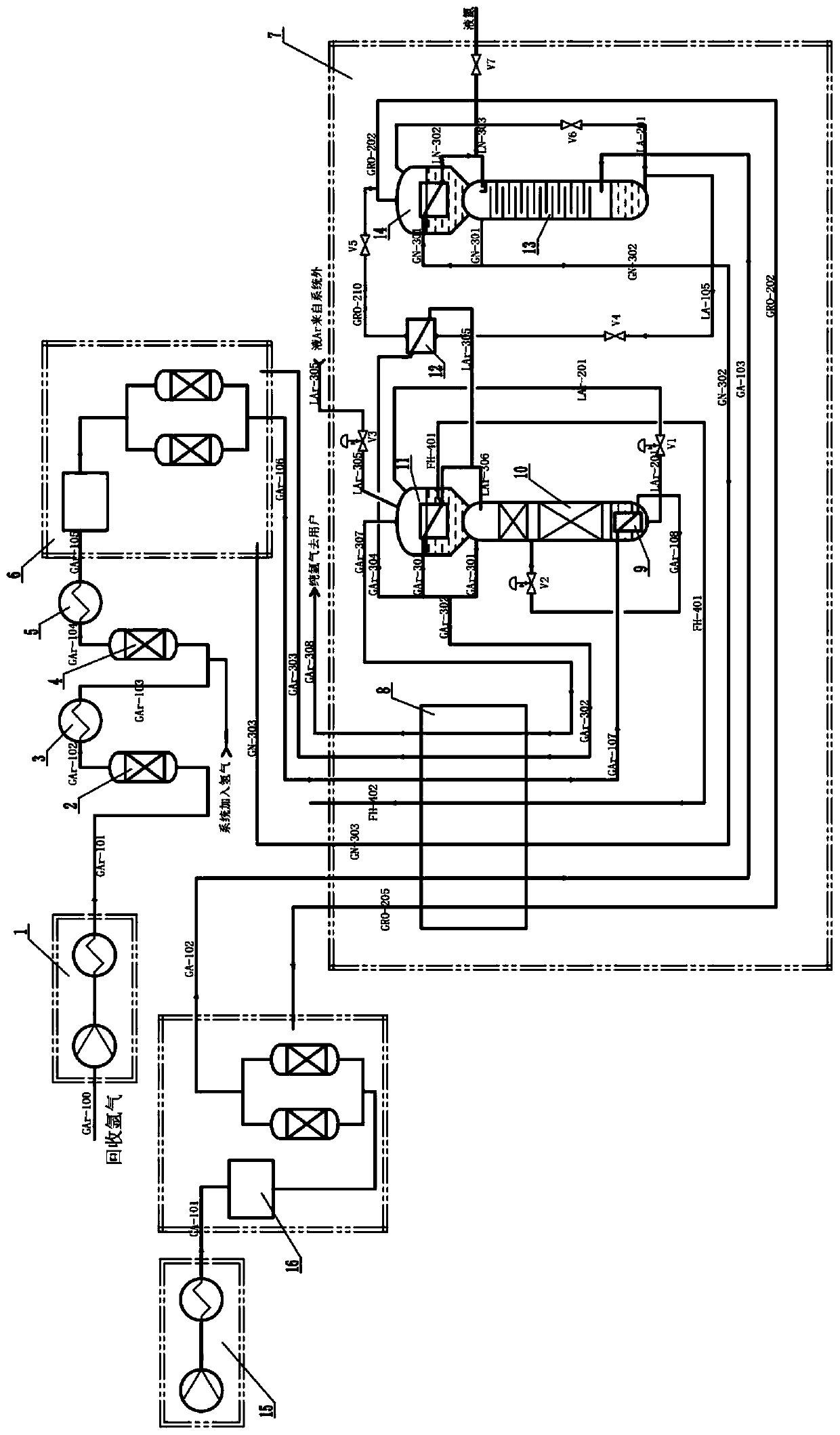

Method and device for recovering and purifying argon in monocrystalline silicon production

ActiveCN102583281BLow recovery and purification energy consumptionNoble gas compoundsPtru catalystCatalytic oxidation

Provided is a method and a device for recovering and purifying argon in monocrystalline silicon production. The method comprises firstly conducting coarse oil removal on argon recovered from a single crystal furnace, compressing, cooling and conducting high-precision oil removal and dedusting; secondly enabling hydrocarbon such as methane and carbon monoxide to be reacted with oxygen to generate water and carbon dioxide through a high temperature catalytic reaction and guaranteeing the oxygen to be excessive in the catalytic reaction; thirdly enabling excessive oxygen to be reacted with added hydrogen to generate the water under effects of a catalytic agent after cooling and enabling argon after two catalytic reactions to penetrate through a normal temperature adsorption unit to absorb the water and the carbon dioxide; cooling the argon, sending a low temperature rectifying tower, enabling the argon, the nitrogen and the hydrogen to produce rectification separation, obtaining pure liquid argon, and conducting repeated heating to obtain pure argon products. The device mainly comprises an oil filter, a catalytic reactor of the hydrocarbon of high temperature catalytic oxidation carbon monoxide and methane and the like, a normal temperature hydrogenation deoxygenization catalytic reactor, a normal temperature adsorption unit for absorbing the carbon dioxide and the water at the normal temperature and the low temperature rectifying tower for rectifying and separating the hydrogen and the nitrogen at the low temperature. The device has the advantages of being high in argon recovery rate, high in purity of recovered argon, low in oxygen content, low in energy consumption for recovery and purification and the like.

Owner:HANGZHOU HANGYANG

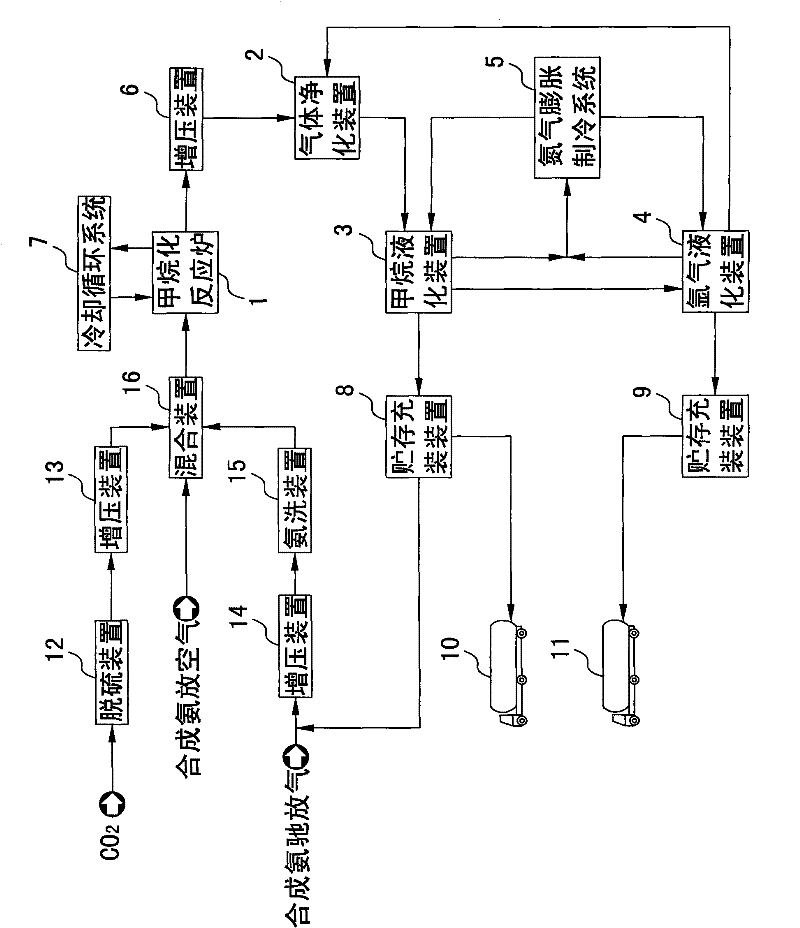

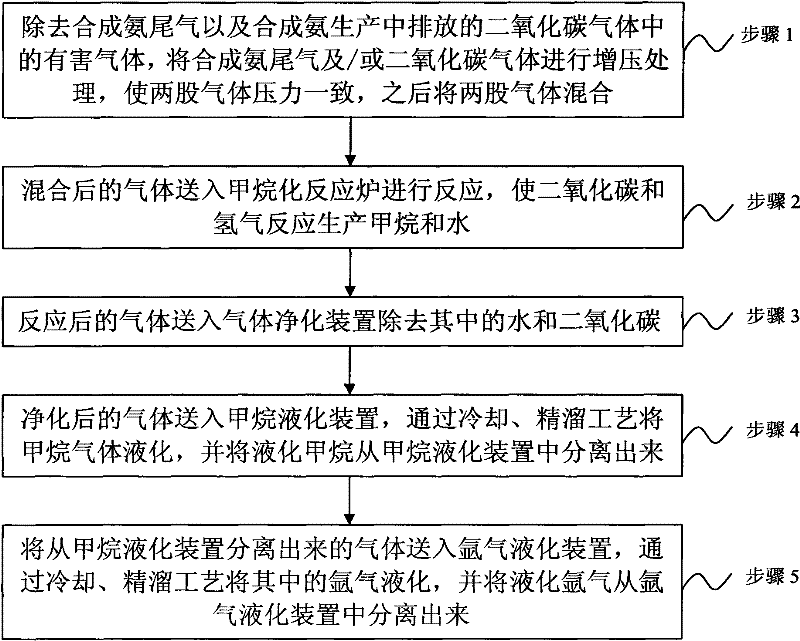

Method and device for preparing liquefied methane by using synthesis ammonia tail gas

ActiveCN102126905AHigh methane contentGuaranteed uptimeHydrocarbon from carbon oxidesLiquid argonMethanation

The invention discloses a method and a device for preparing liquefied methane by using synthesis ammonia tail gas. The method comprises the following steps of: 1, removing the synthesis ammonia tail gas and harmful gas which is exhausted during the production of synthesis ammonia in carbon dioxide gas, pressurizing the synthesis ammonia tail gas and / or the carbon dioxide gas to ensure that the pressure of the two kinds of gas is consistent, and mixing; 2, introducing the mixed gas into a methanation reaction furnace for reaction to ensure that carbon dioxide is reacted with hydrogen to produce methane and water; 3, introducing the reacted gas into a gas purifying device to remove the water and the carbon dioxide in the gas; and 4, introducing the purified gas into a methane liquefaction device, liquefying methane gas by cooling and rectification processes, separating the liquefied methane out of the methane liquefaction device, storing and packaging. In addition, the gas separated out of the methane liquefaction device can be introduced into an argon liquefaction device to prepare liquid argon. By the method, energy in the emptied tail gas is recycled, and the exhaust amount of greenhouse gas is reduced.

Owner:北京长征天民高科技有限公司

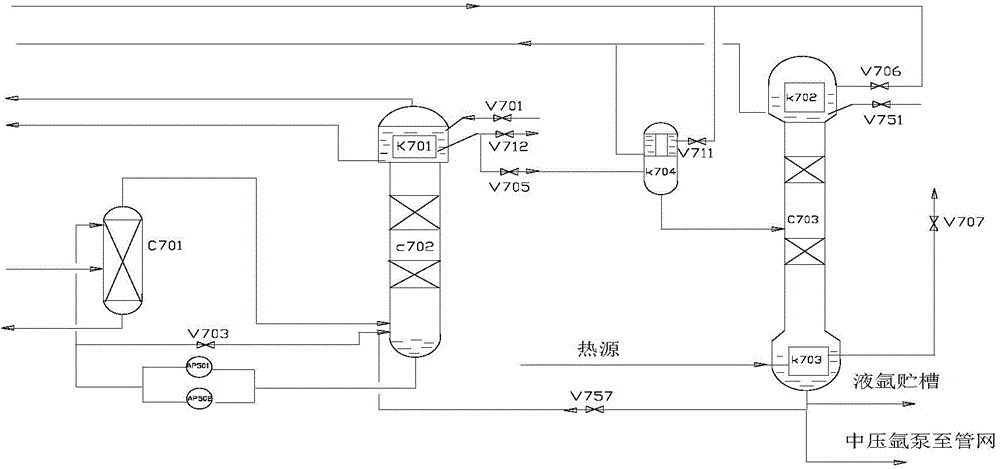

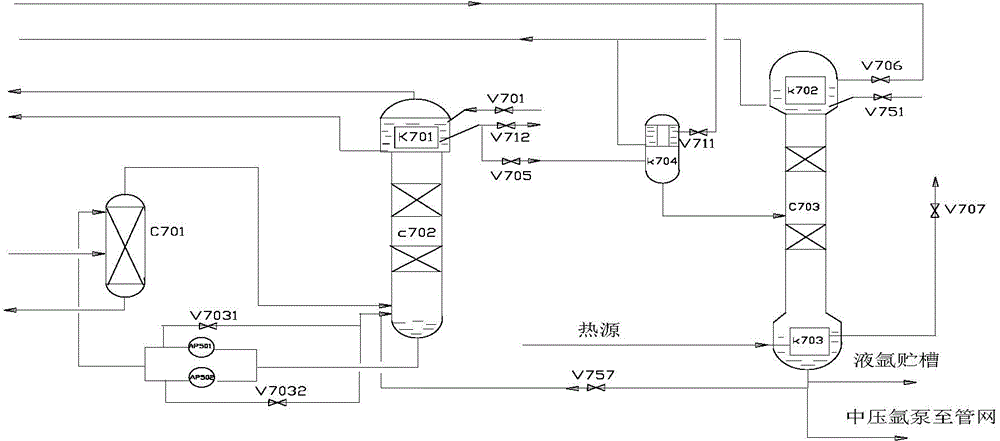

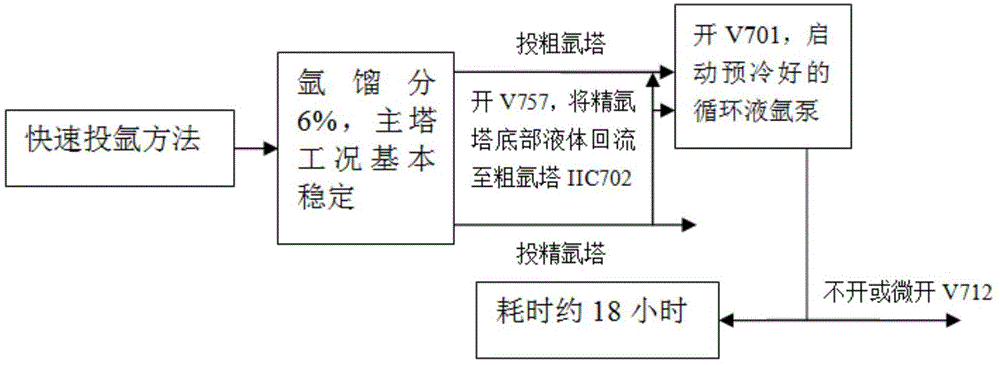

Quick argon feeding method for air separation device

ActiveCN104019631AIncrease the reflux ratioImprove utilization efficiencySolidificationLiquefactionLiquid argonAir separation

The invention belongs to the technical field of air separation. A quick argon feeding method for an air separation device comprises the following steps: 1) closing a coarse argon emptying valve (V712) after the air separation device stops for a short period, and quickly stopping a circulating liquid argon pump; 2) starting the air separation device, and opening a coarse argon condenser throttling valve (V701) of after an argon fraction of a main tower reaches 6 percent; 3) starting the circulating liquid argon pump to enable liquid argon at the bottom of a coarse argon tower II (702) to enter a coarse argon tower I (C701); 4) respectively opening a coarse argon liquefier adjustment valve (V711), a fine argon condenser adjustment valve (V706) and a technical argon adjustment valve (V705), and fully opening a fine argon emptying valve (V751) to enable a fine argon tower to work; 5) opening a backflow valve (V757) to enable liquid argon at the bottom of the fine argon tower (C703) and liquid condensed by a fine argon condenser (K702) to re-participate in rectification. The quick argon feeding method is conductive to improving the backflow ratio of the coarse argon tower II, shortening the argon tower adjustment time and accelerating concentration of argon.

Owner:LAIWU IRON & STEEL GRP

Recovery device and recovery method for integrated high-purity nitrogen and argon

PendingCN110207460AReduce the amount of liquid argonReduce operating costsSolidificationLiquefactionRecovery methodOperational costs

The invention discloses a recovery device and recovery method for integrated high-purity nitrogen and argon. The recovery device comprises an argon compressor, a carbon monoxide removal device, a deaerator, an argon pre-cooling purification system, an air compressor, an air pre-cooling purification system, a heat exchanger, an argon column reboiler, a pure argon column, an argon column condensation evaporator, an auxiliary condensation evaporator, a nitrogen column and a nitrogen column condensation evaporator. According to the recovery method, the liquid argon cooling capacity is transferredto an air pipeline through a main heat exchanger by mainly utilizing the connection effect of the auxiliary condensation evaporator, the cooling capacity entering the nitrogen column is partially recycled, the amount of liquid argon added from the outside can be reduced, the operation cost of equipment is reduced; convenience from the liquid argon on a recovery site is utilized, the cooling capacity is supplied through liquid argon, nitrogen and hydrogen are removed by using a low-temperature distillation method, the recovery rate of the argon and the utilization rate of the hydrogen are improved, the process and operation of low-temperature distillation are simplified, and the operation energy consumption is reduced.

Owner:上海联风能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com