Laser metal direct forming method of liquid argon jet cooling directional solidification

A directional solidification, liquid argon technology, applied in metal material coating process, coating and other directions, can solve the problems of reducing temperature gradient, affecting the microstructure and mechanical properties of formed parts, and unable to maintain the complete directional growth of columnar crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

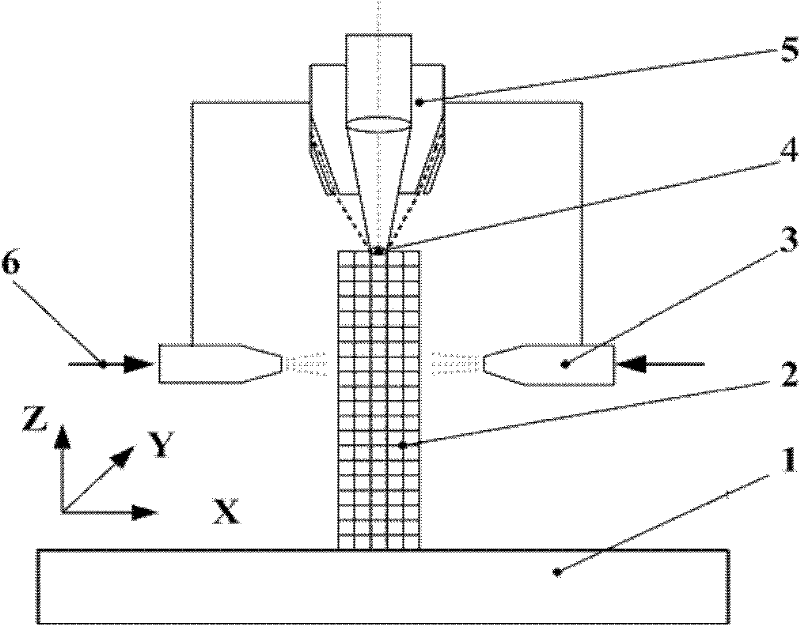

[0017] like figure 1 As shown, a laser metal direct forming method for liquid argon spray cooling and directional solidification adopts the following steps:

[0018] (1) Firstly, the solid wall is formed on the base plate by the method of multi-pass jointing to between 20 and 30 layers, and the thickness of each layer is 0.10 to 0.20 mm;

[0019] (2) Suspend the direct forming of laser metal, and spray liquid argon onto the two side walls of the formed solid wall through the liquid argon nozzle to make it cool rapidly, so as to ensure that the molten pool has a positive temperature gradient from bottom to top, so as to facilitate directional solidification Continuous epitaxial growth of columnar crystals, the structure is both fine and dense;

[0020] (3) Continue laser metal direct forming on the top layer of the cooled solid wall;

[0021] (4) After reshaping 10 to 20 layers, adopt step (2) to continue cooling the formed solid wall by spraying liquid argon;

[0022] (5) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com