Patents

Literature

217 results about "Jet cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

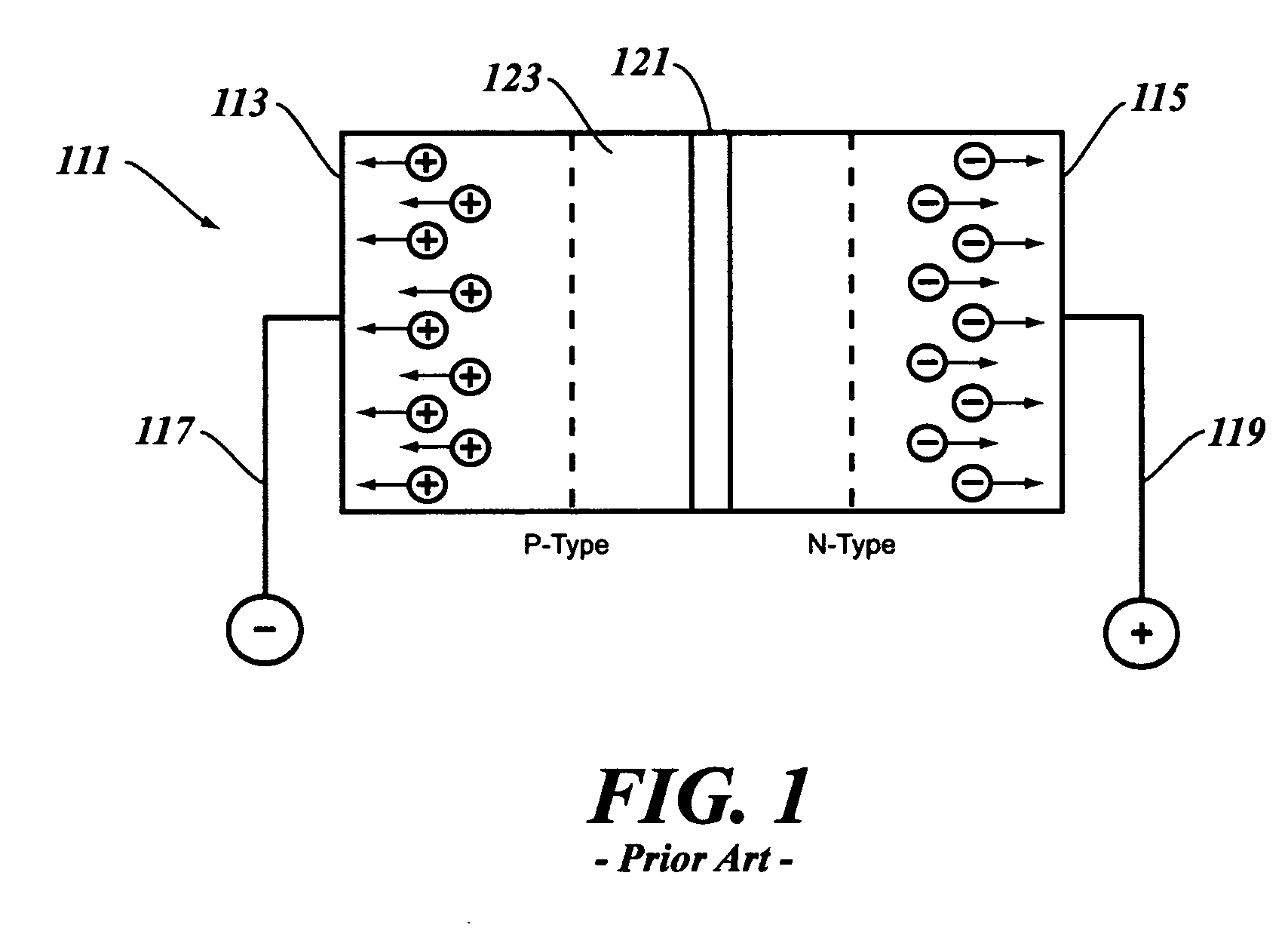

Synthetic jet cooling system for LED module

ActiveUS20070096118A1Point-like light sourceSemiconductor/solid-state device detailsEngineeringActuator

An LED assembly is provided herein. The assembly comprises a thermally conductive housing (201), wherein a portion of said housing is equipped with a plurality of fins (203); an LED (205) disposed in said housing; and a synthetic jet actuator (207) adapted to direct a synthetic jet onto said portion of the housing.

Owner:NUVENTIX

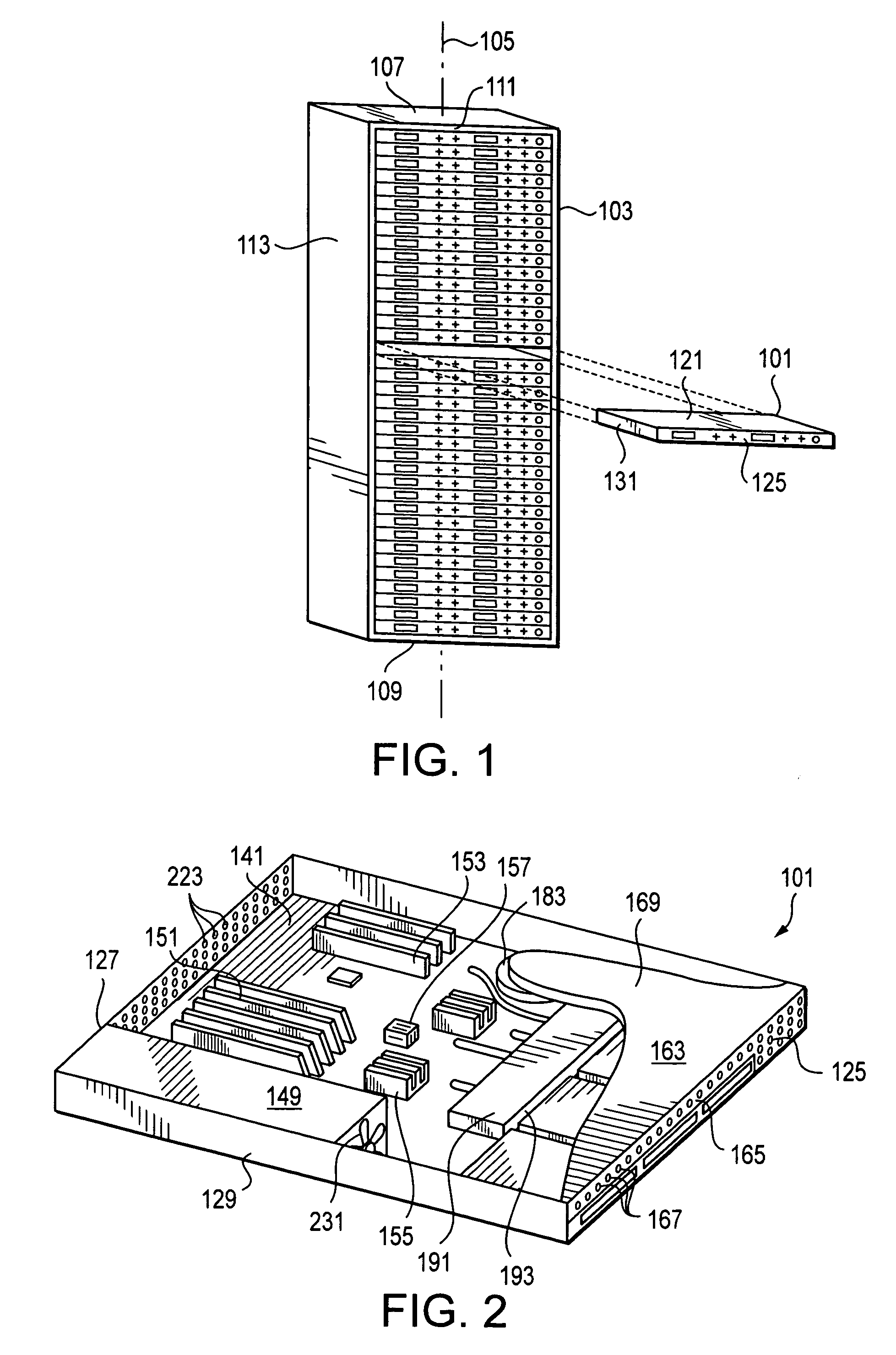

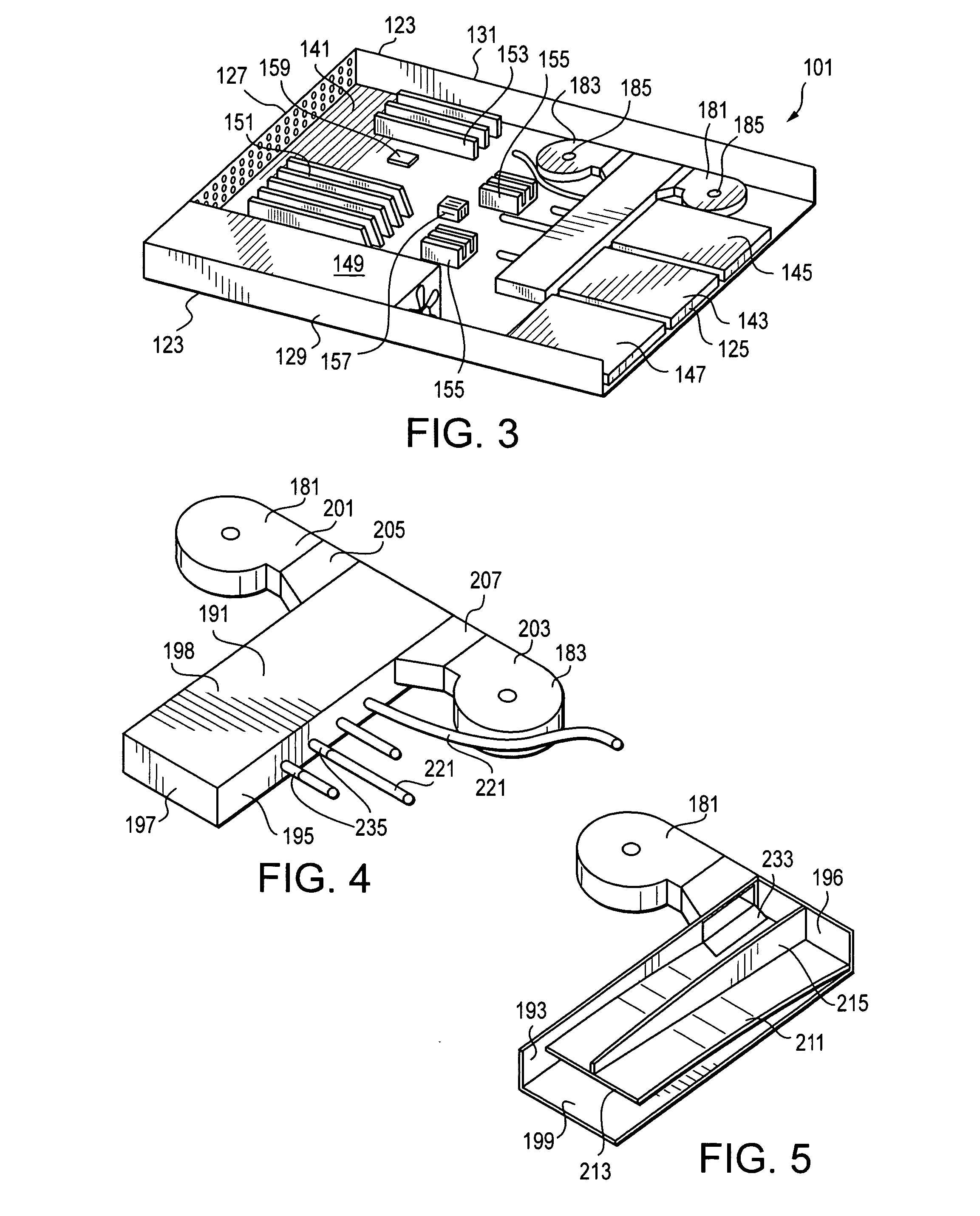

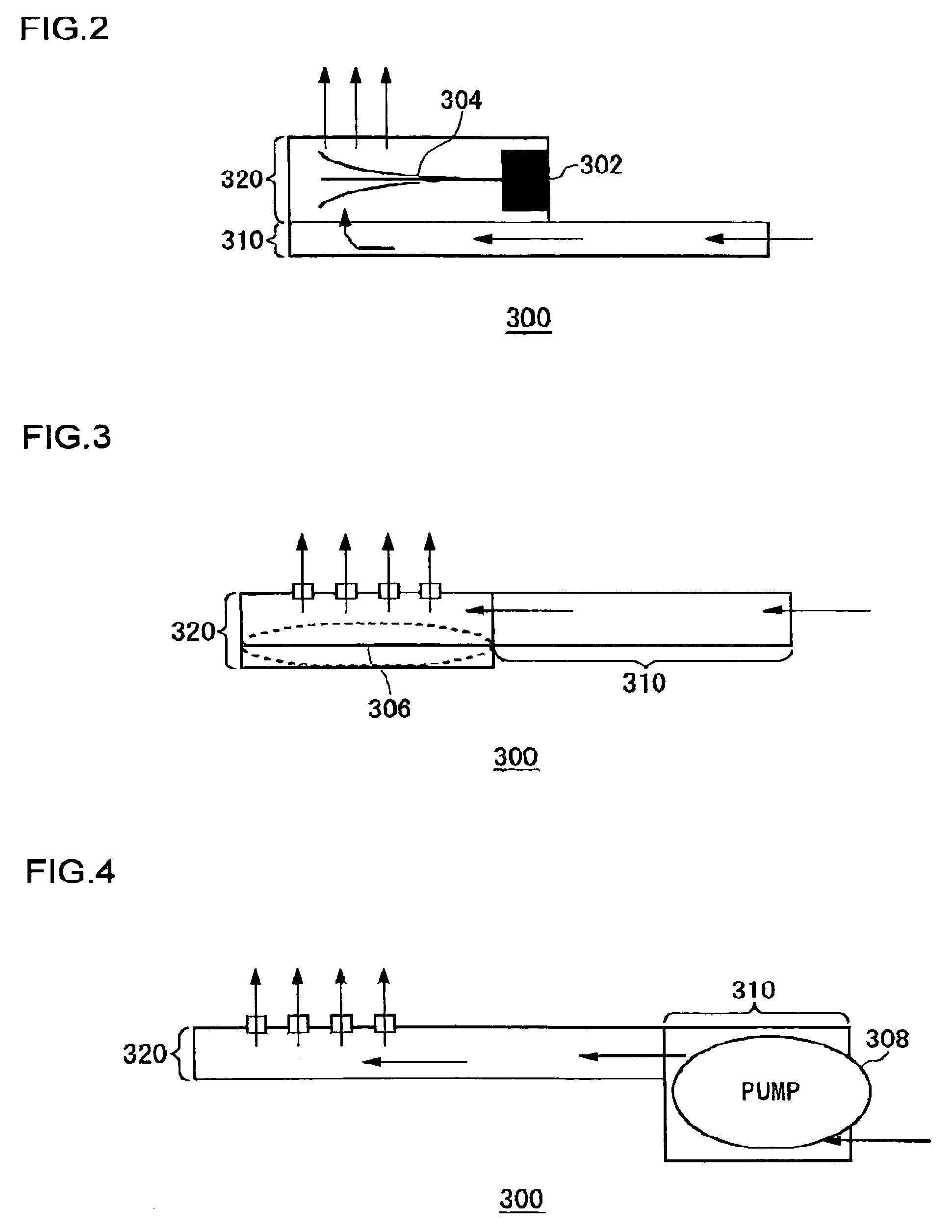

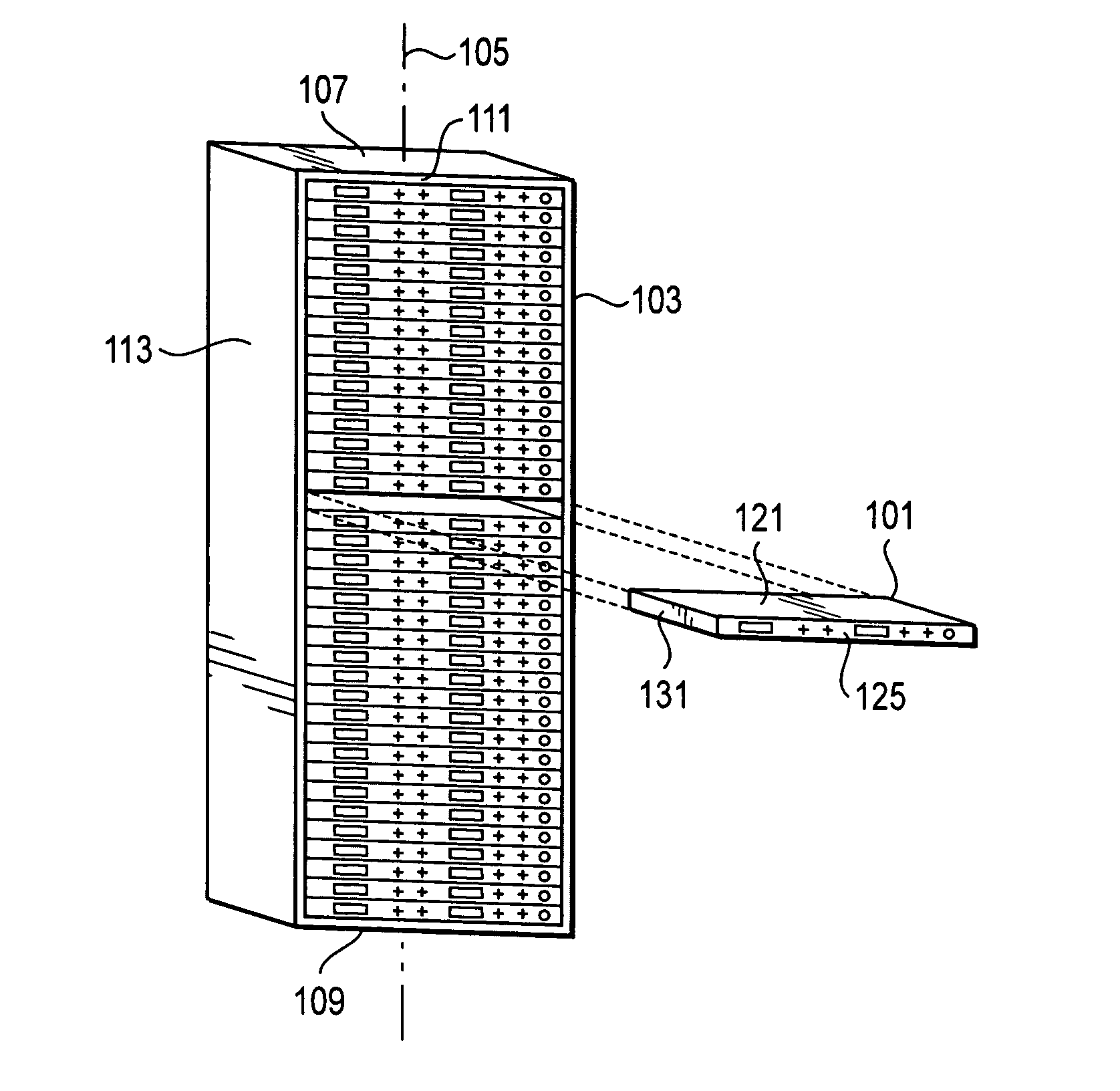

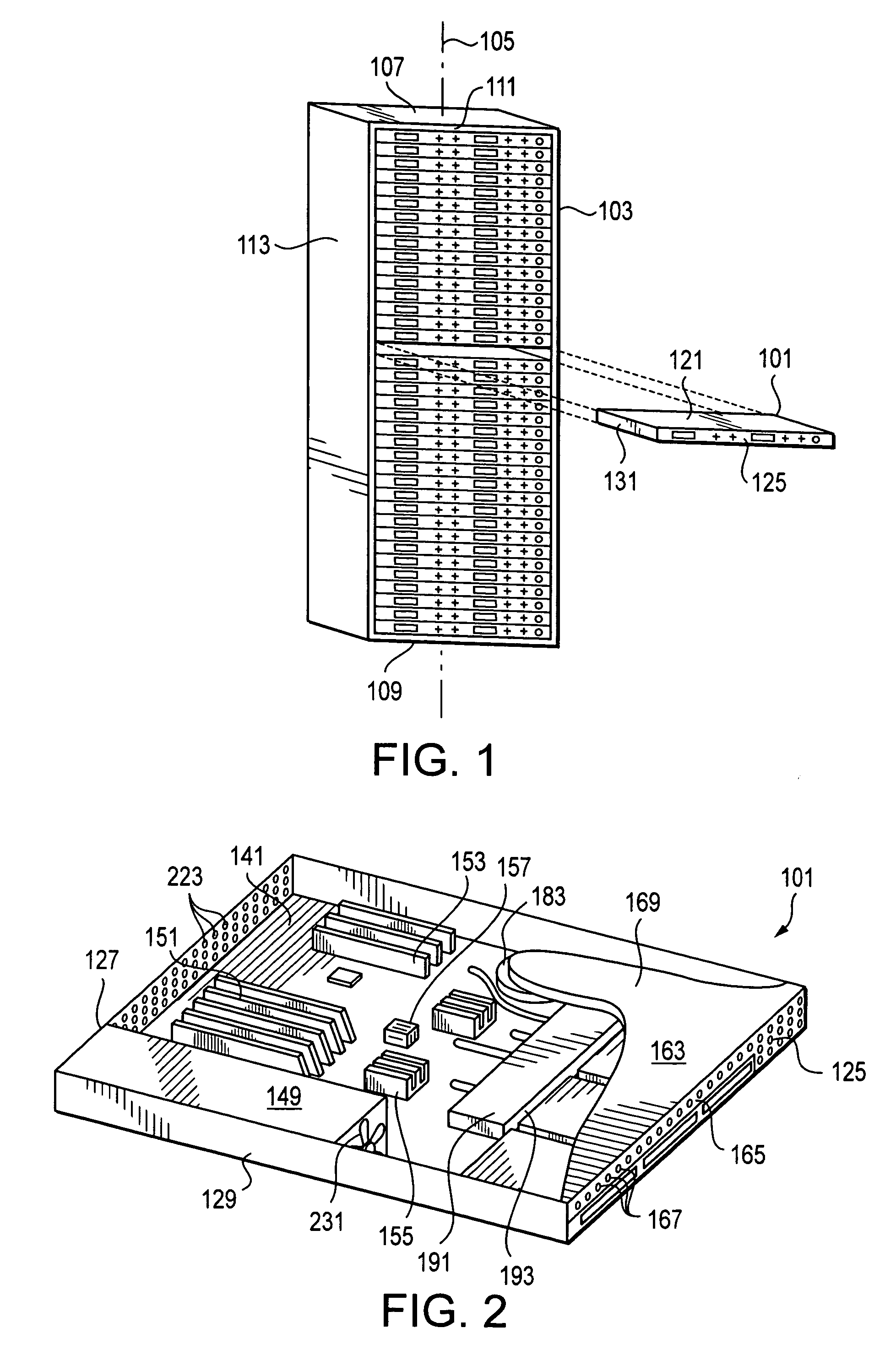

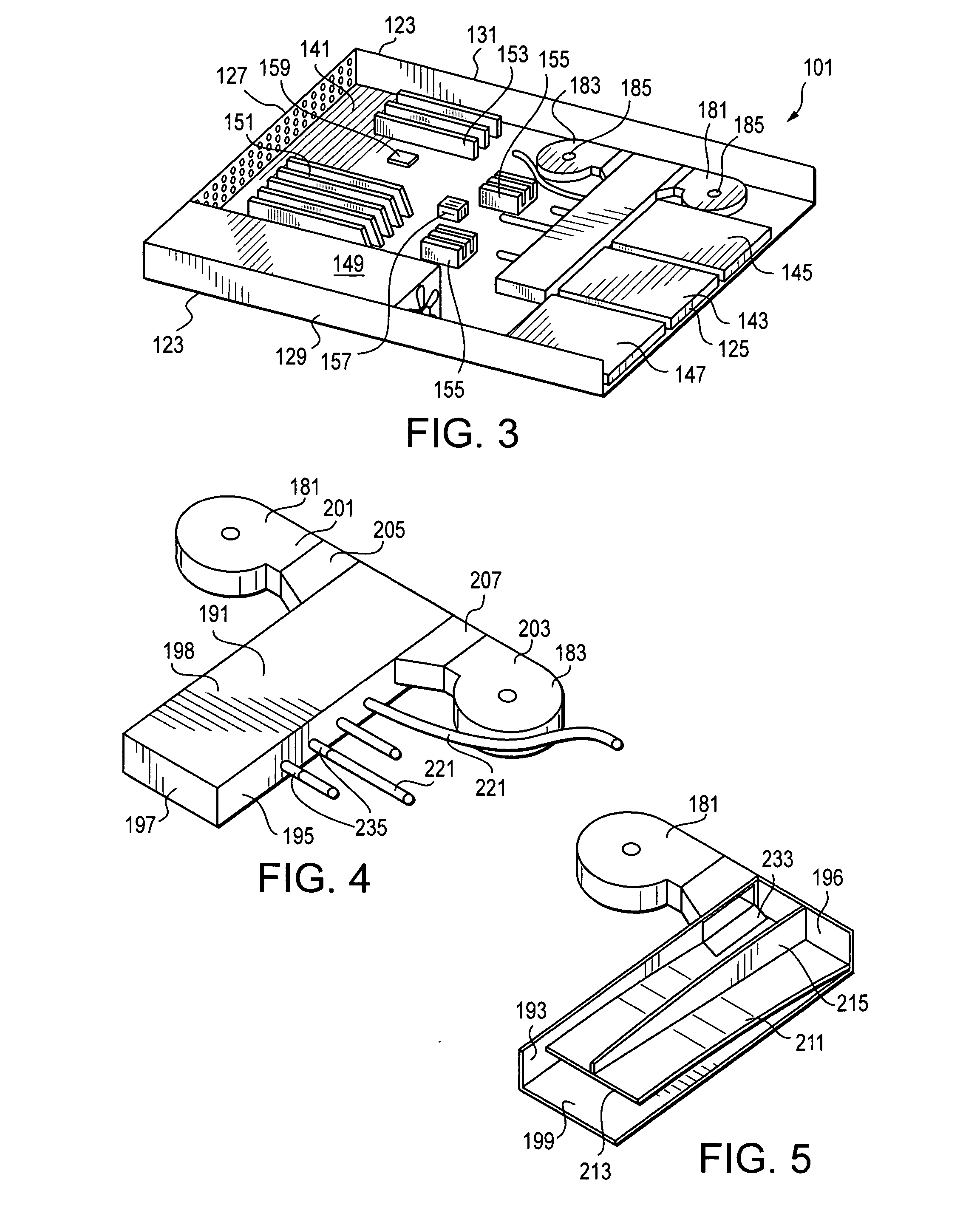

Small form factor air jet cooling system

ActiveUS7361081B2Casings/cabinets/drawers detailsCooling/ventilation/heating modificationsSmall form factorComputerized system

An enclosure forms a plurality of tiers vertically stacked in a longitudinal dimension. Each tier is a 1U modular computer system having a computer chassis configured for mounting in the multi-tiered support, and computer components that need cooling within the computer chassis. A cooling system is formed by a plenum pressurized by a blower. The plenum defines a plurality of configurable orifices in the chassis, each directing pressurized air toward a component. The plenum includes adjustable valves to controllably limit airflow through the orifices, and a controller to control the air pressure within the plenum and the orifice flow rates through the valves.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

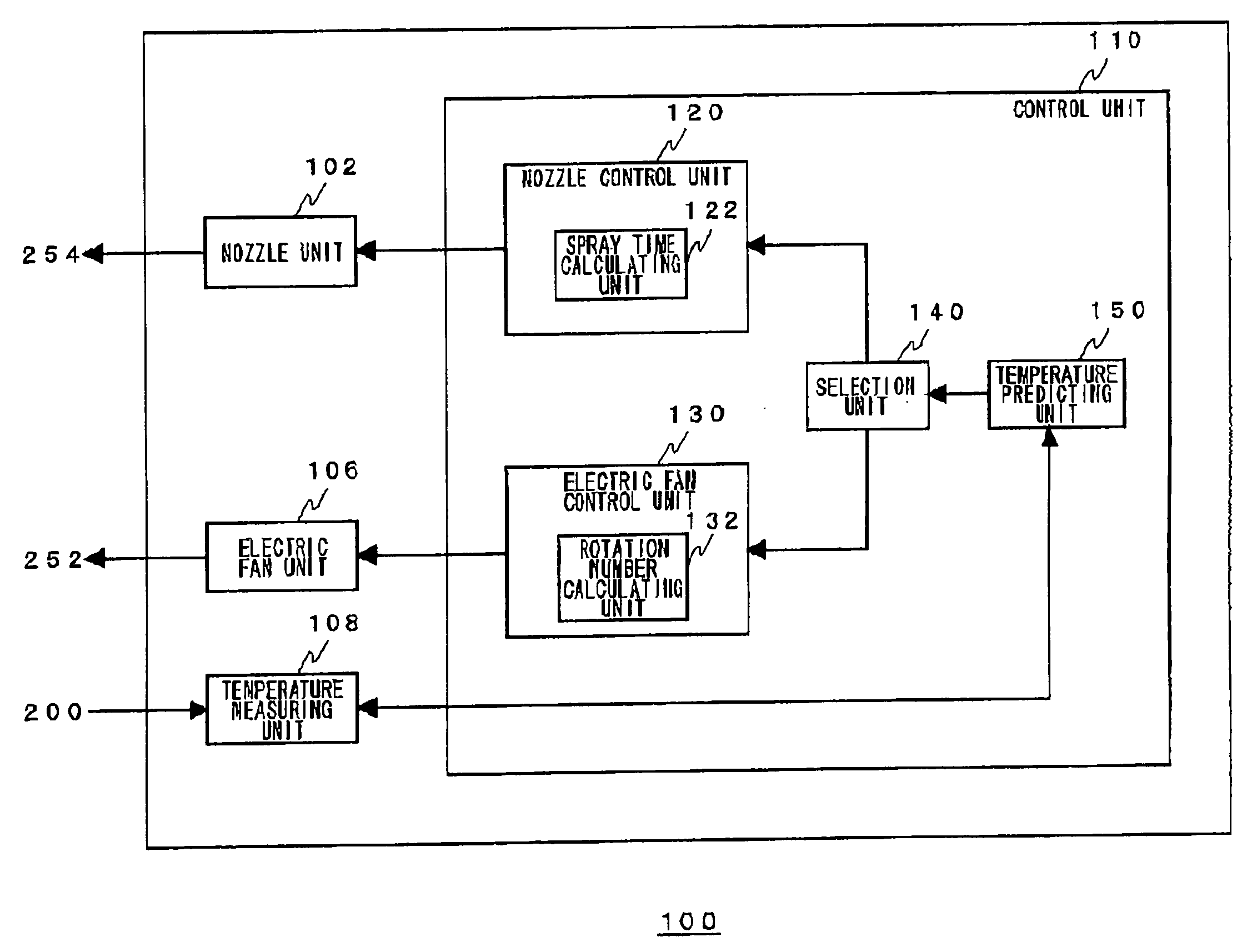

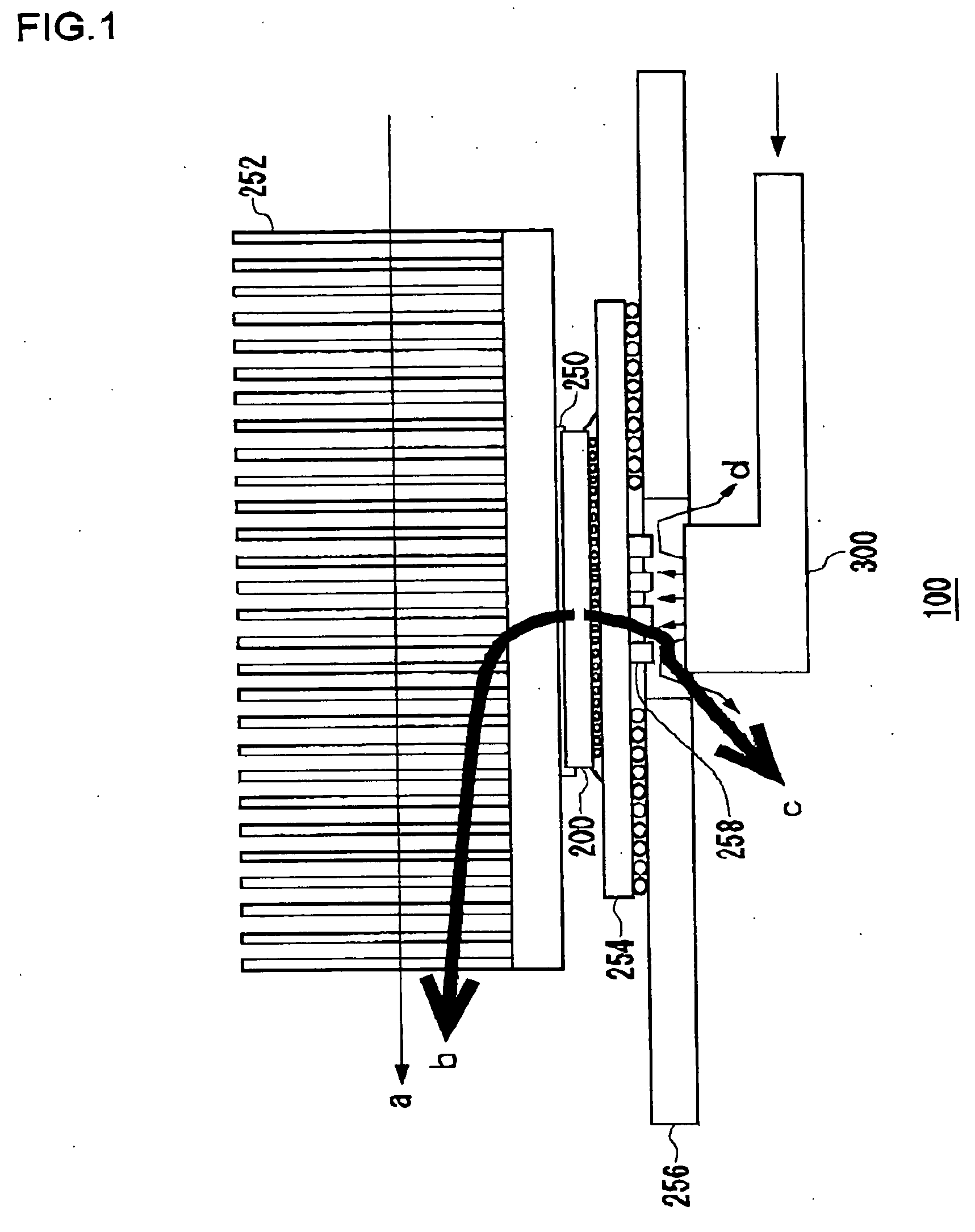

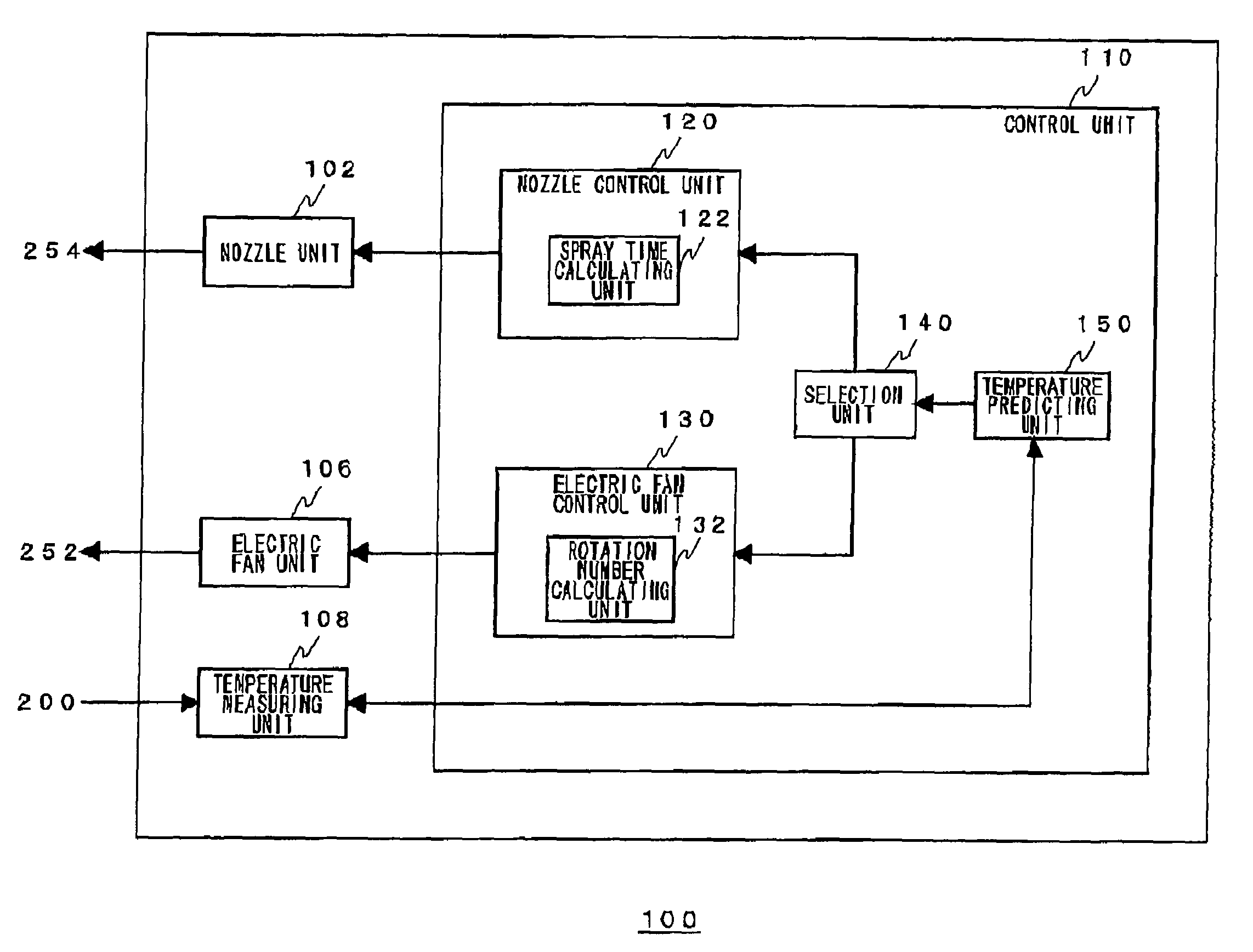

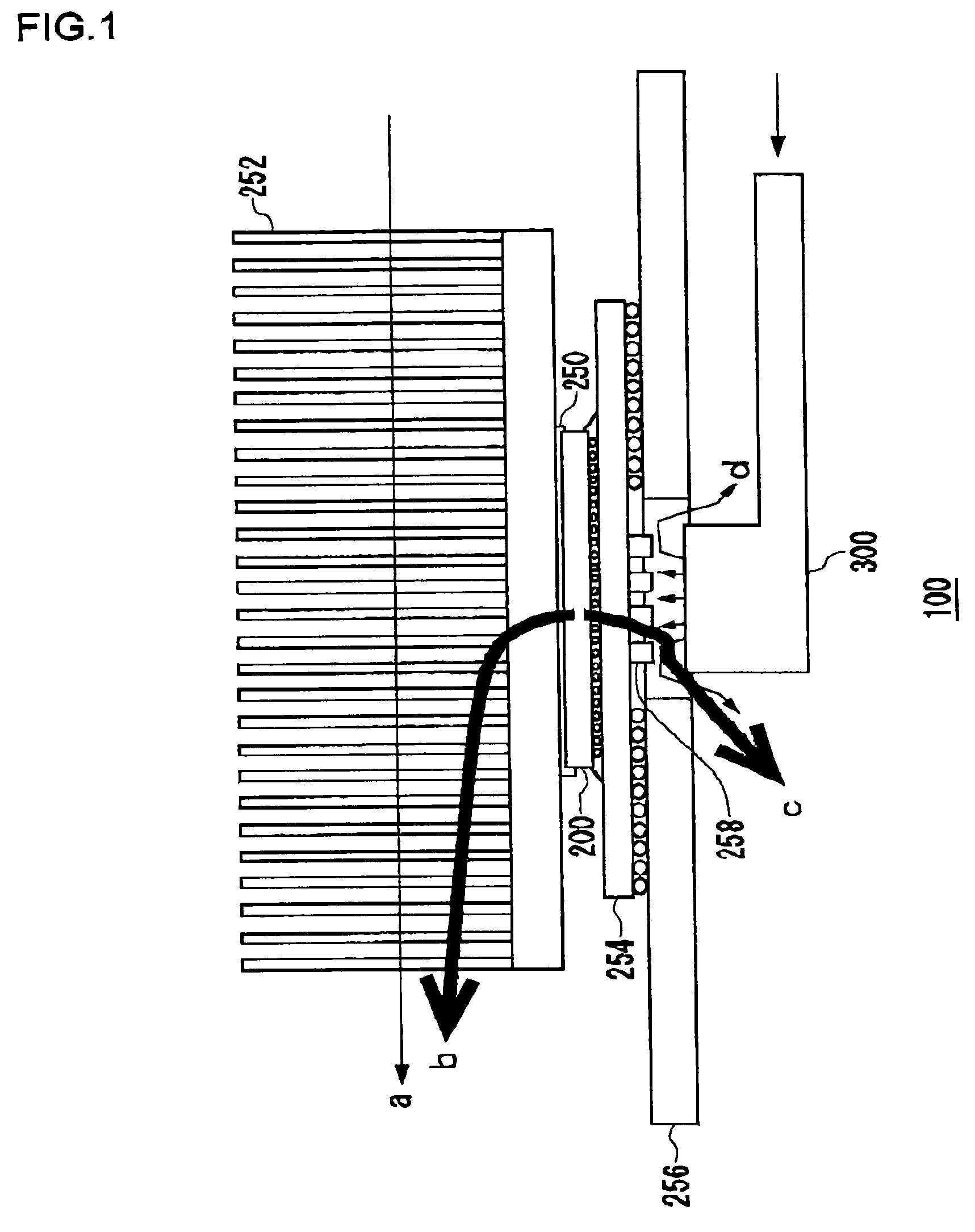

Electronic device cooling apparatus and method for cooling electronic device with temperature prediction

ActiveUS20050273208A1Improve cooling effectCooling an electronic device effectivelyTemperature control using digital meansDomestic cooling apparatusControl signalEngineering

A temperature predicting unit predicts the temperature of an electronic device after a predetermined period, and the speed of temperature variation from the operating state of the load. Based on the results of prediction by the temperature predicting unit, a selection unit instructs either one or both of a nozzle control unit and an electric fan control unit to exercise control. According to a control signal from the selection unit, the nozzle control unit transmits a control signal to a nozzle unit to drive a jet cooling apparatus. According to a control signal from the selection unit, the electric fan control unit transmits a control signal to an electric fan unit to drive an electric fan. The selection unit selects the electric fan when the predicted speed of temperature variation exceeds a predetermined threshold, and selects the jet cooling apparatus when the predetermined thresholds is not exceeded.

Owner:SONY COMPUTER ENTERTAINMENT INC

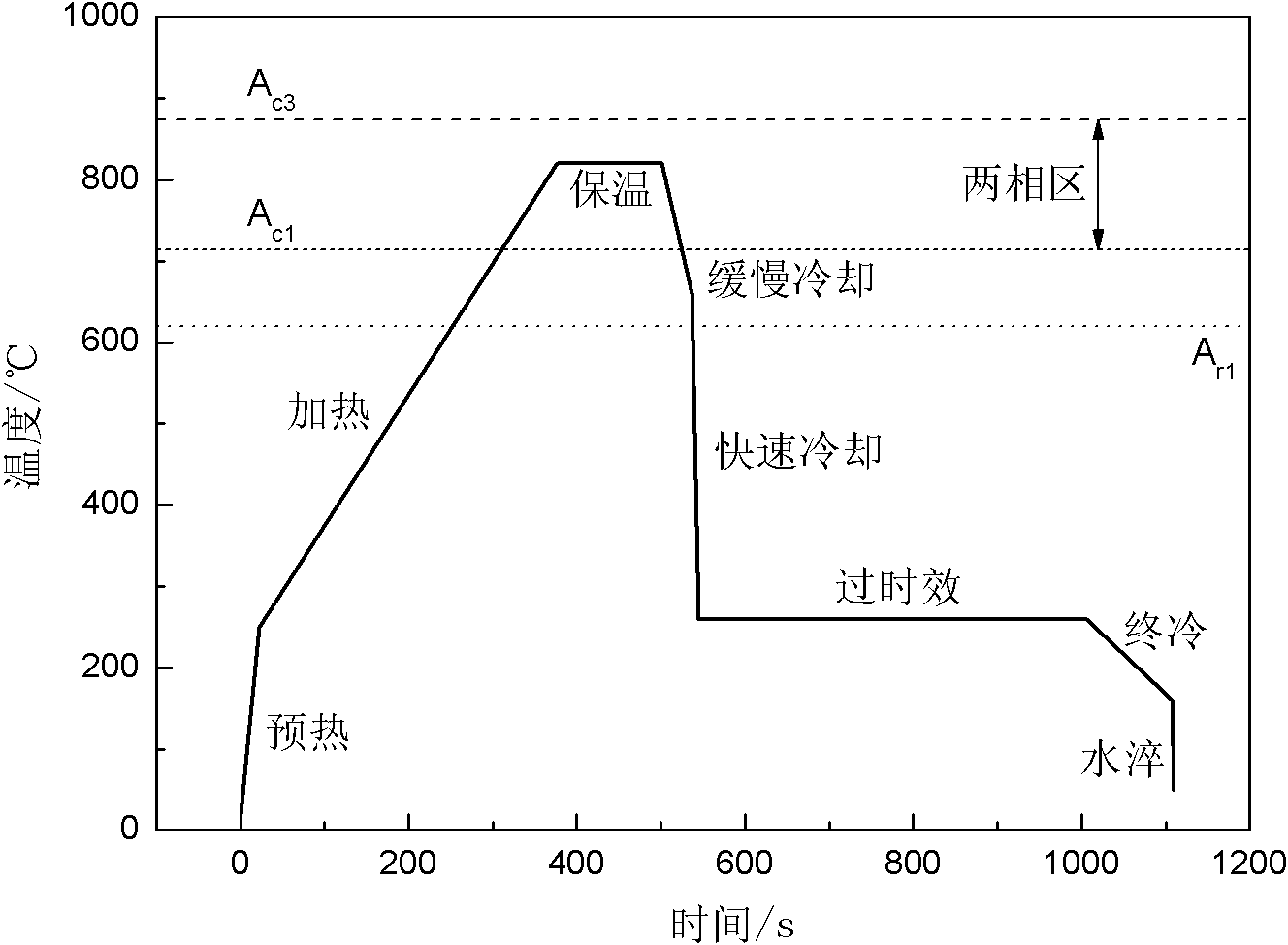

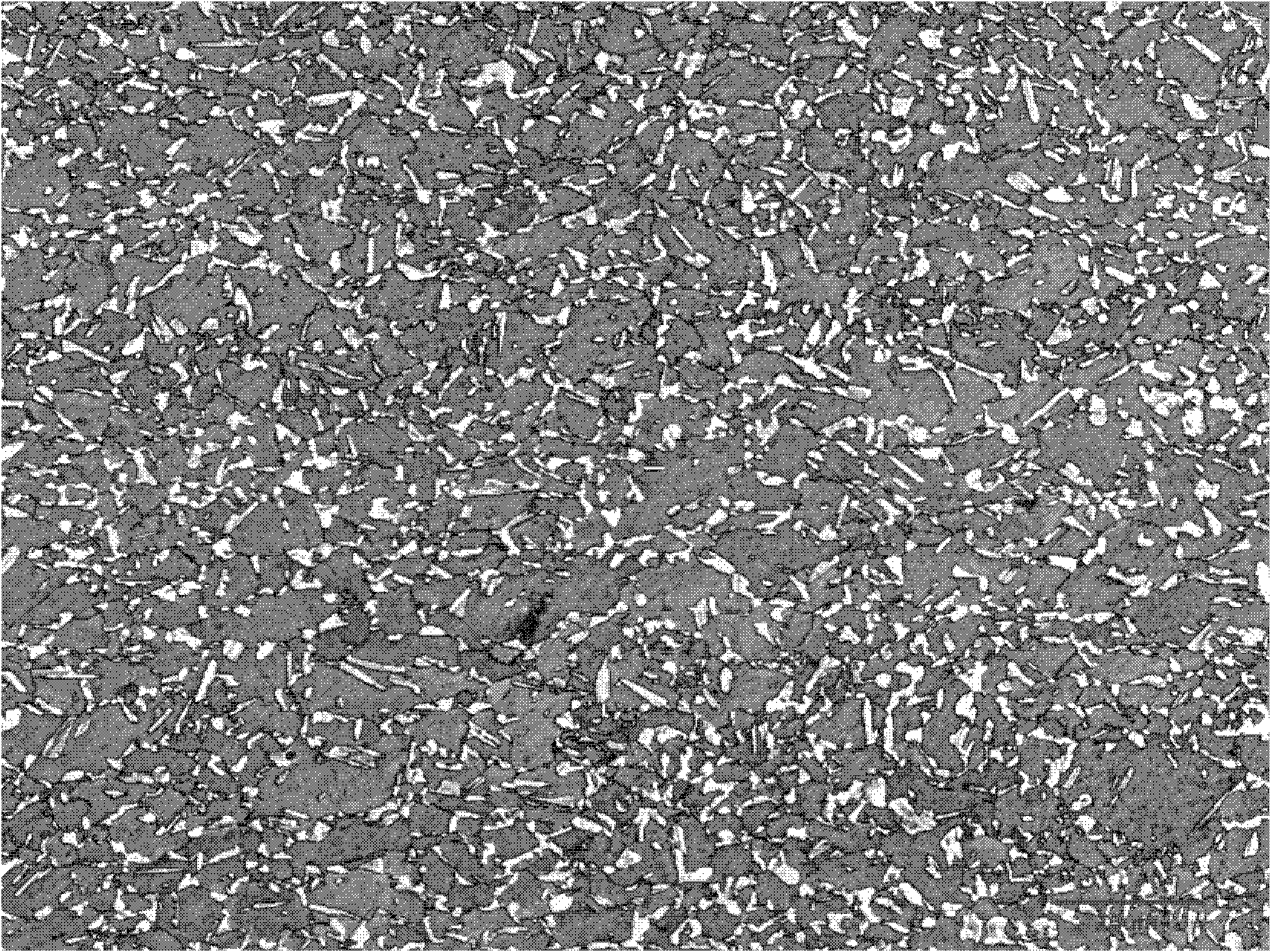

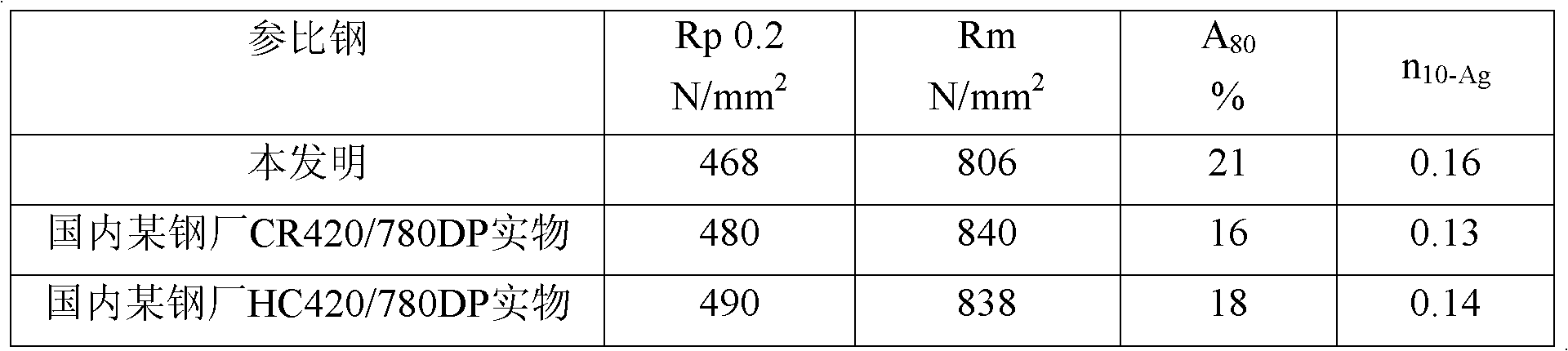

High-plasticity 780MPa-level cold rolled dual-phase steel and preparation method thereof

InactiveCN102212745ANominal C content decreasedGood welding performanceRoll mill control devicesHeat treatment process controlChemical compositionEconomic benefits

The invention discloses a high-plasticity 780MPa-level cold rolled dual-phase steel and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.06 to 0.08 percent of C, 1.0 to 1.3 percent of Si, 2.1 to 2.3 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.01 percent of S, 0.02 to 0.07 percent of Alt, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. According to the hot rolling process parameters, the heating temperature of a continuously cast bloom is 1,250+ / -30 DEG C, the final rolling temperature is 890+ / -30 DEG C, the coiling temperature is 670+ / -30 DEG C, the cold rolling press-down rate is 50 to 70 percent, and the continuous annealing process is controlled. The invention has the advantages that: the C equivalent weight of the steel is effectively reduced by regulating the components of the alloy based on a conventional gas jet cooling and continuous annealing mode, the elongation of the steel is improved, and considerable economic benefit can be brought.

Owner:SHOUGANG CORPORATION

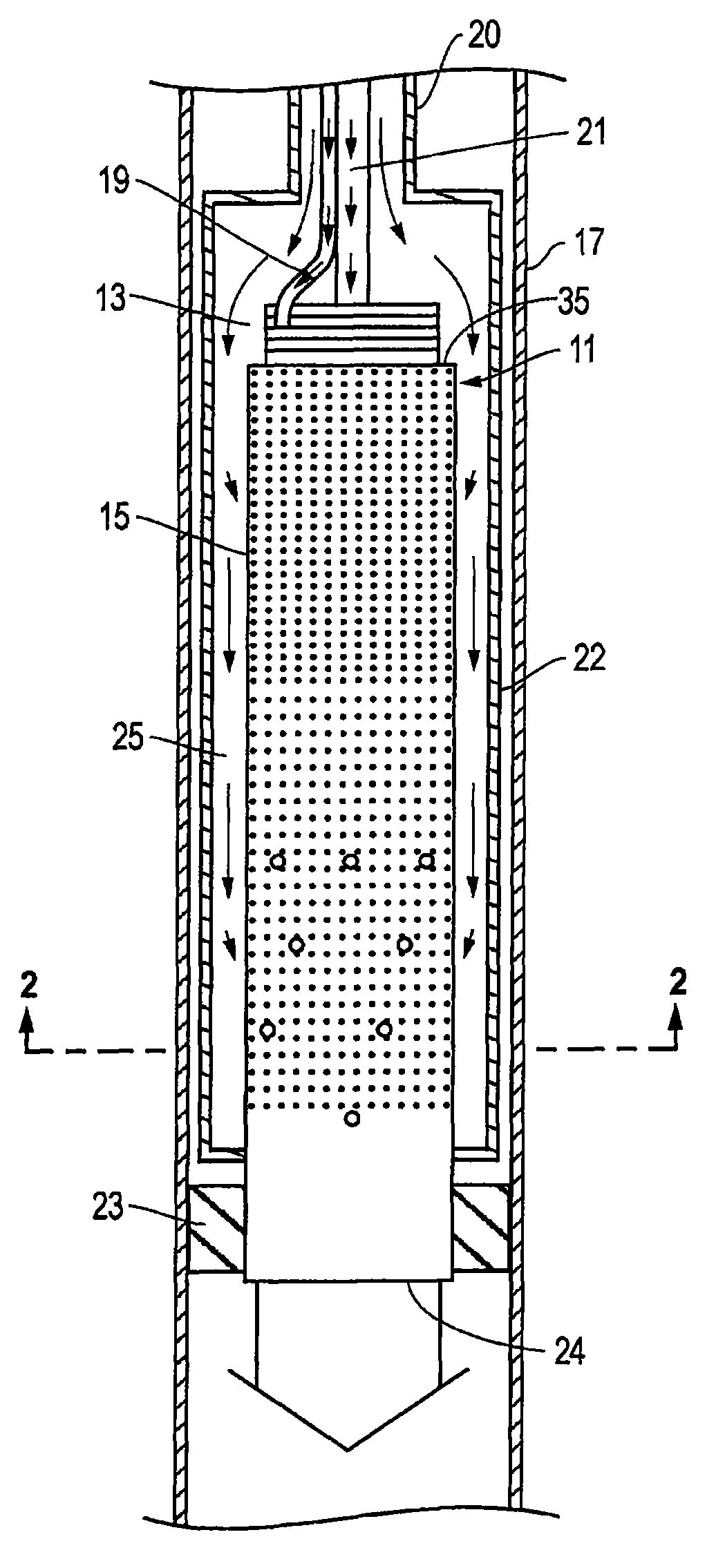

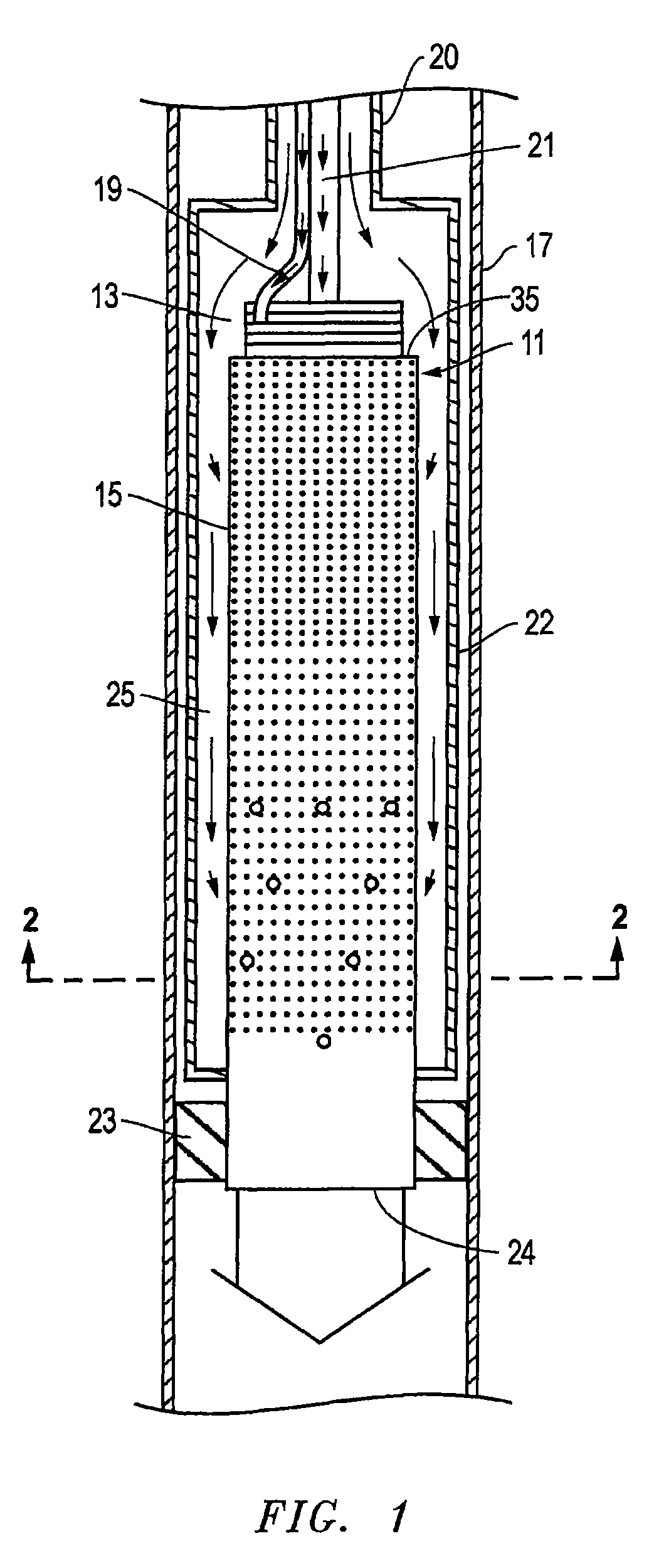

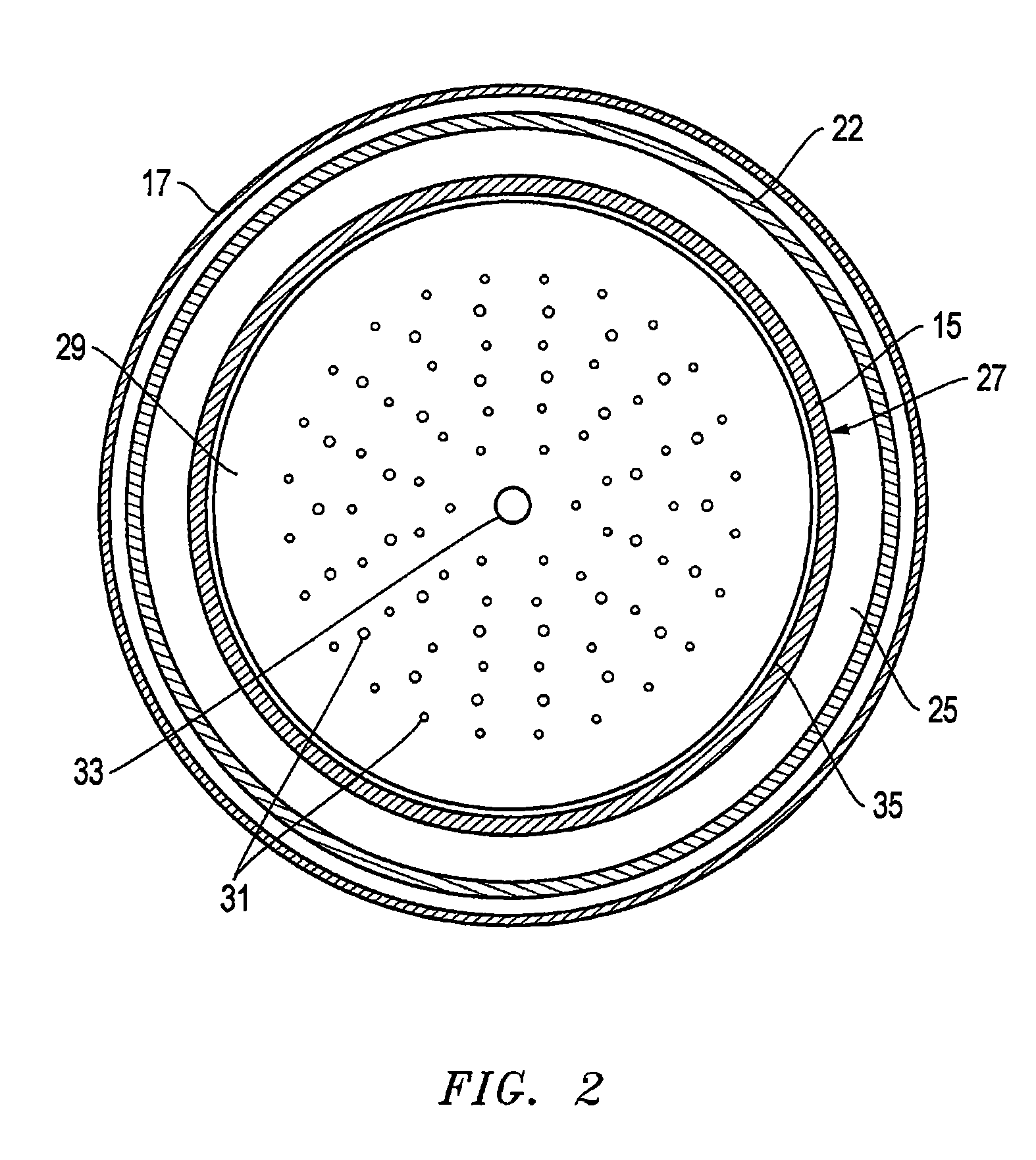

System, method and apparatus for hydrogen-oxygen burner in downhole steam generator

A downhole burner for a steam generator includes an injector and a cooling liner. Steam enters the burner through holes in the cooling liner. Combustion occurring within the cooling liner heats the steam and increases its quality and may superheat it. The heated, high-quality steam and combustion products exit the burner and enter an oil-bearing formation to upgrade and improve the mobility of heavy crude oils held in the formation. The injector includes a face plate, a cover plate, an oxidizer distribution manifold plate, and a fuel distribution manifold plate. The cooling liner has an effusion cooling section and effusion cooling and jet mixing section. The effusion cooling section includes effusion holes for injecting steam along the cooling liner surface to protect the liner. The effusion cooling and jet mixing section has both effusion holes and mixing holes for injecting steam further toward central portions of the burner.

Owner:WORLD ENERGY SYST

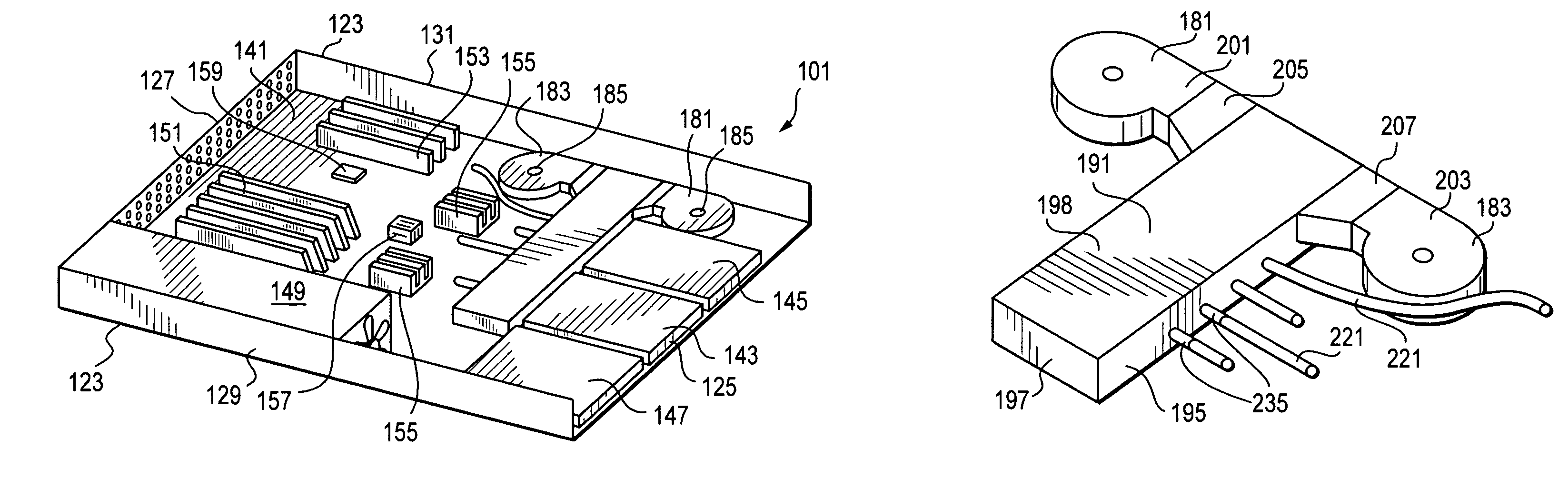

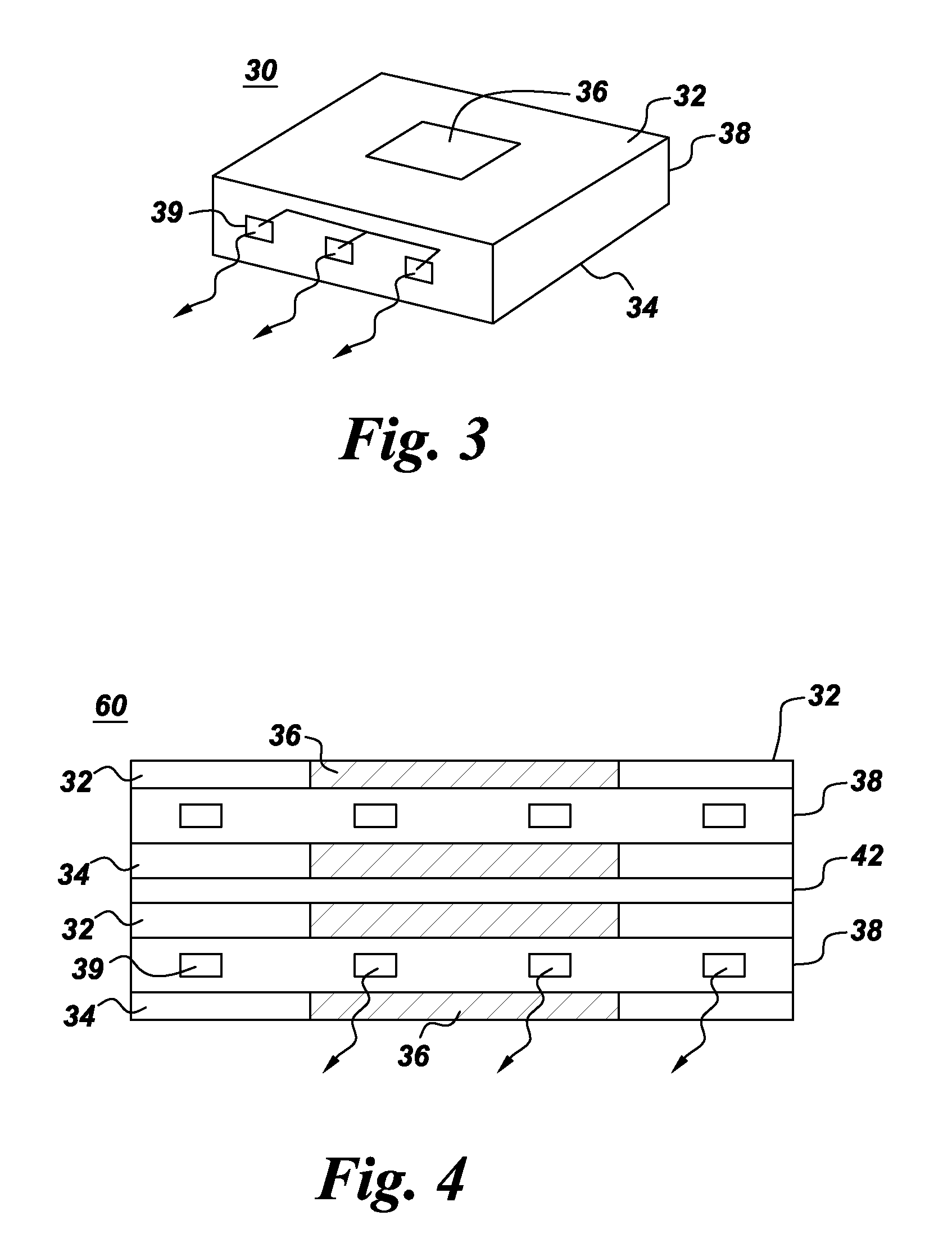

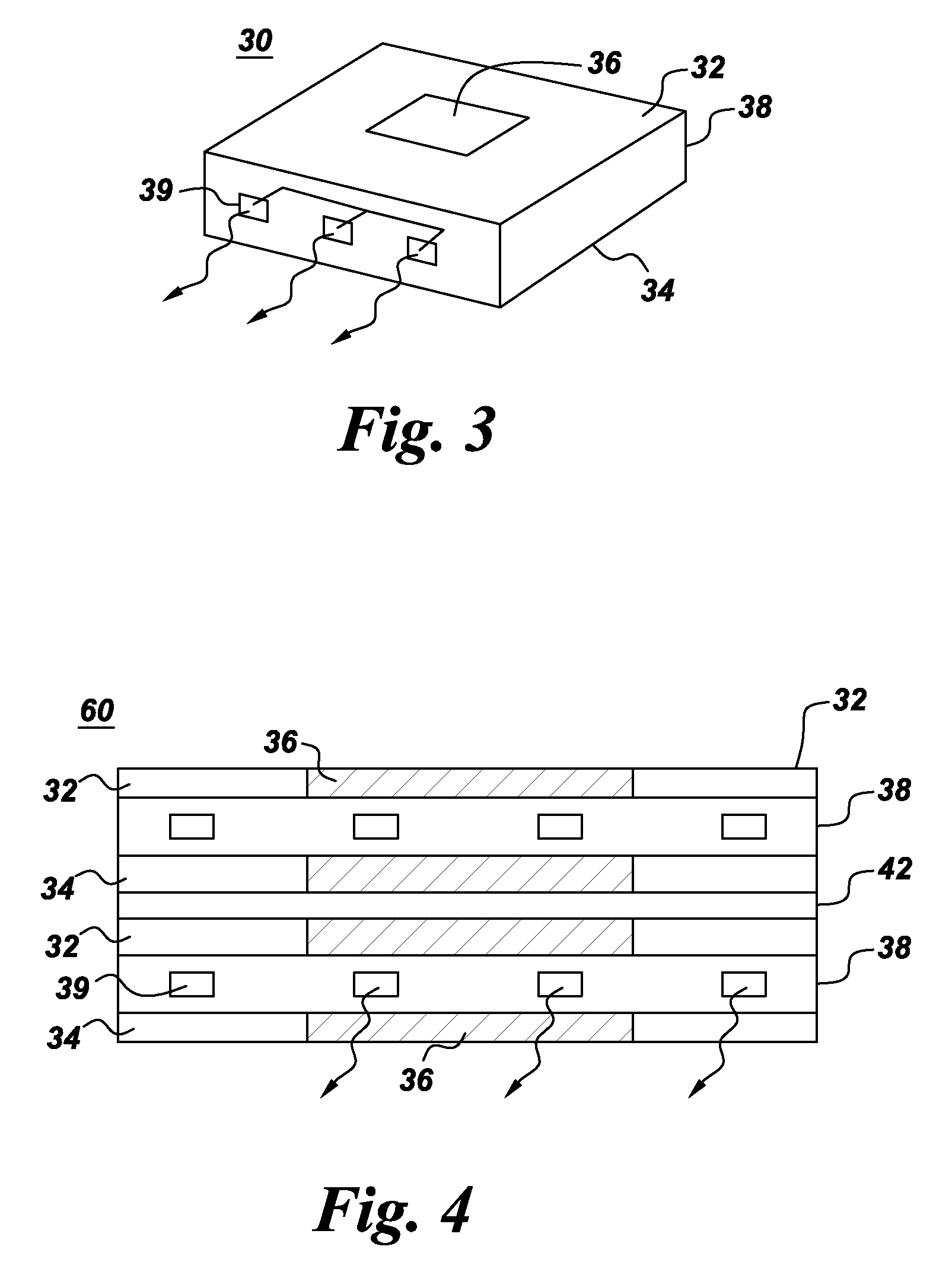

Heat sinks with distributed and integrated jet cooling

InactiveUS20100258270A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A heat sink with distributed jet cooling is provided. The heat sink includes a base for thermal connection to at least one heated object, an array of fins thermally coupled to the base, and at least one multi-orifice synthetic jet or multiple single orifice jets disposed on a side of the array of fins. A heat sink with distributed and integrated jet cooling is also provided and includes a base and an array of fins. Respective ones of at least a subset of the fins comprise a synthetic jet configured to eject an ambient fluid into an ambient environment of the fins and base. Another heat sink with distributed and integrated jet cooling is provided and includes a base, an array of fins and multiple synthetic jets coupled to respective ones of the fins. The synthetic jets are provided for at least a subset of the fins.

Owner:GENERAL ELECTRIC CO

Electronic device cooling apparatus and method for cooling electronic device with temperature prediction

ActiveUS7167778B2Cooling an electronic device effectivelyImprove cooling effectTemperature control using digital meansDomestic cooling apparatusState predictionControl signal

A temperature predicting unit predicts the temperature of an electronic device after a predetermined period, and the speed of temperature variation from the operating state of the load. Based on the results of prediction by the temperature predicting unit, a selection unit instructs either one or both of a nozzle control unit and an electric fan control unit to exercise control. According to a control signal from the selection unit, the nozzle control unit transmits a control signal to a nozzle unit to drive a jet cooling apparatus. According to a control signal from the selection unit, the electric fan control unit transmits a control signal to an electric fan unit to drive an electric fan. The selection unit selects the electric fan when the predicted speed of temperature variation exceeds a predetermined threshold, and selects the jet cooling apparatus when the predetermined thresholds is not exceeded.

Owner:SONY COMPUTER ENTERTAINMENT INC

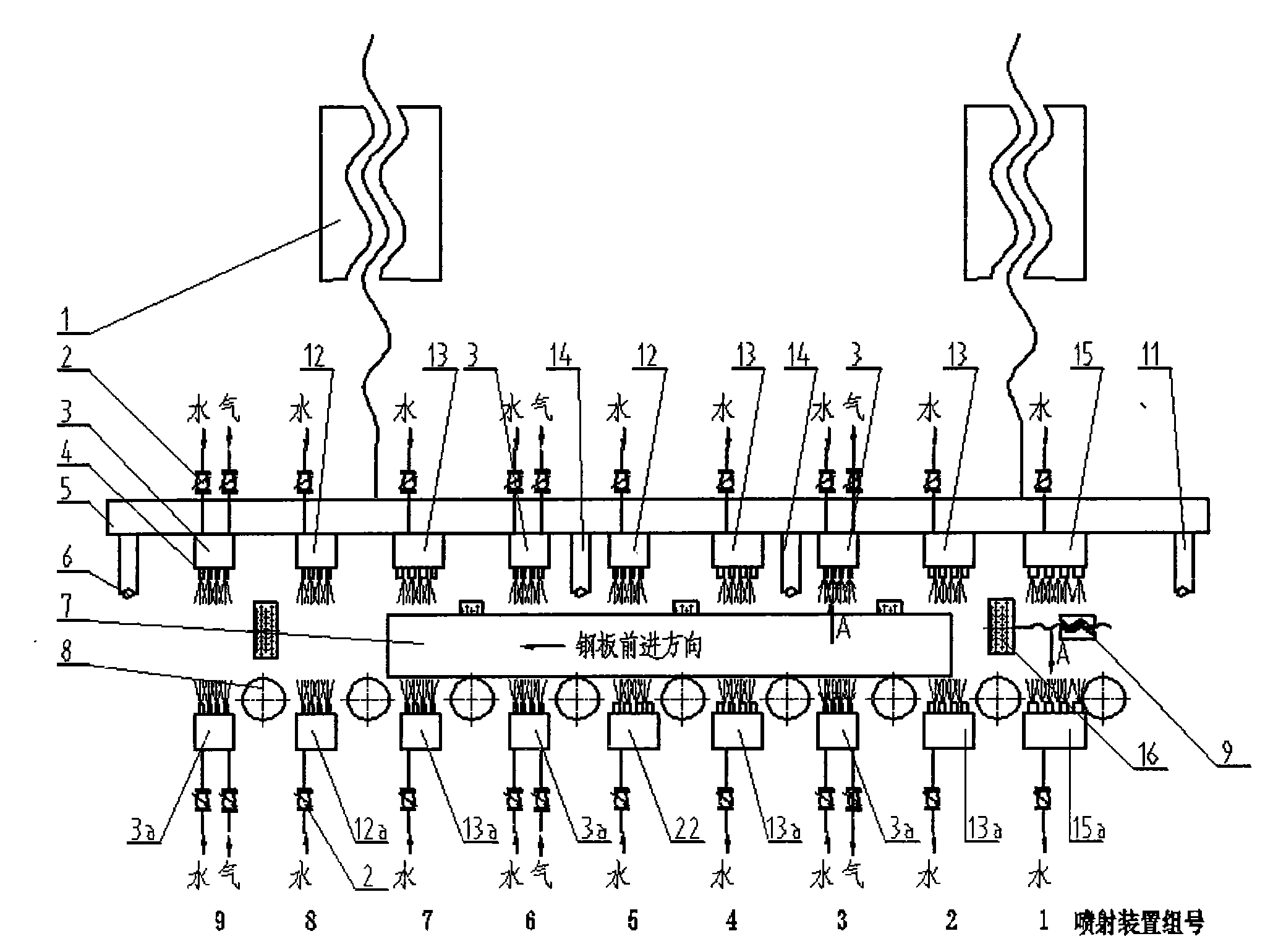

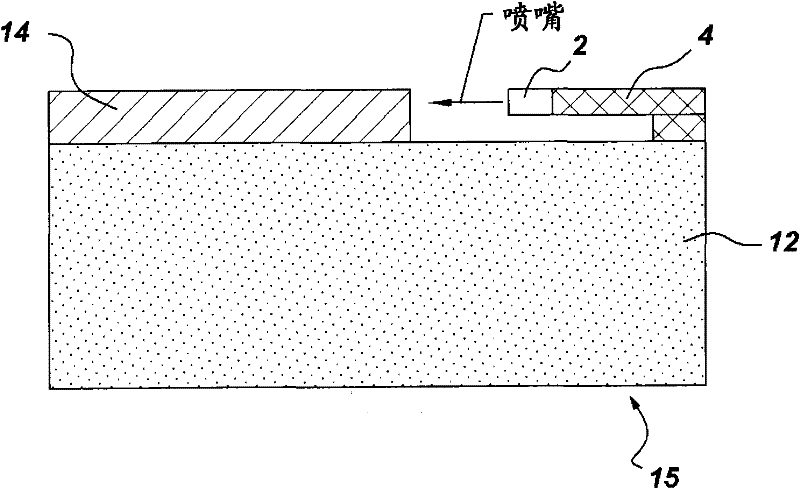

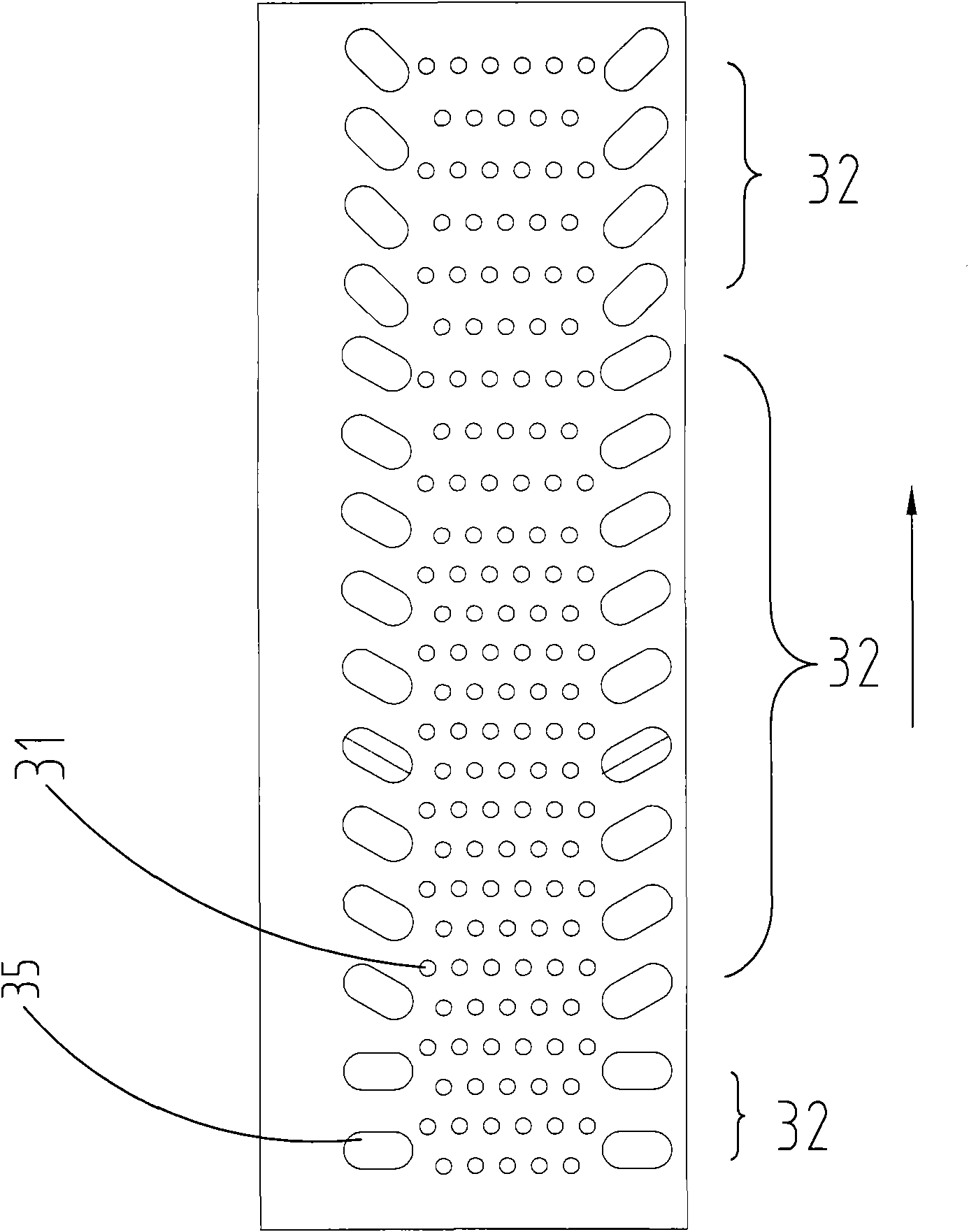

Square or flat material production line jet cooling system

ActiveCN102121063AFulfil requirementsImprove shape qualityFurnace typesHeat treatment furnacesProduction lineSpray nozzle

The invention relates to square or flat material production line jet cooling thermal treatment equipment, which mainly consists of upper and lower strong cold jet devices (15 and 15a), upper and lower medium cold jet devices (13 and 13a), upper and lower weak cold jet devices (12 and 12a), upper and lower aerosol jet devices (3 and 3a), side cold jet devices (16), front, middle and rear blowing devices (11, 14 and 6), a flow control device (2) and an upper jet device lifting device (1), wherein the upper strong, medium and weak jet devices (15, 13 and 12), the upper aerosol jet devices (3) and the front, middle and rear blowing devices (11, 14 and 6) can lift up and down together with the lifting device (1) so as to adapt to the requirements of square or flat materials of different thicknesses. The side cold jet devices (16) are arranged on two sides of a rail (8), and can quickly cool the thick square or flat materials. The cooling capacity of the cooling system can be regulated by opening the jet cooling devices of different groups and regulating the flow control device (2). Front and rear staggered nozzles dense in the middle and sparse on two sides are arranged so that the jet cooling system is uniform and the quenched square or flat materials have low deformation, unique texture and no cracking.

Owner:UNIV OF SCI & TECH BEIJING

Small form factor air jet cooling system

ActiveUS20060019597A1Improve cooling efficiencyCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersSmall form factorModularity

An enclosure forms a plurality of tiers vertically stacked in a longitudinal dimension. Each tier is a 1U modular computer system having a computer chassis configured for mounting in the multi-tiered support, and computer components that need cooling within the computer chassis. A cooling system is formed by a plenum pressurized by a blower. The plenum defines a plurality of configurable orifices in the chassis, each directing pressurized air toward a component. The plenum includes adjustable valves to controllably limit airflow through the orifices, and a controller to control the air pressure within the plenum and the orifice flow rates through the valves.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

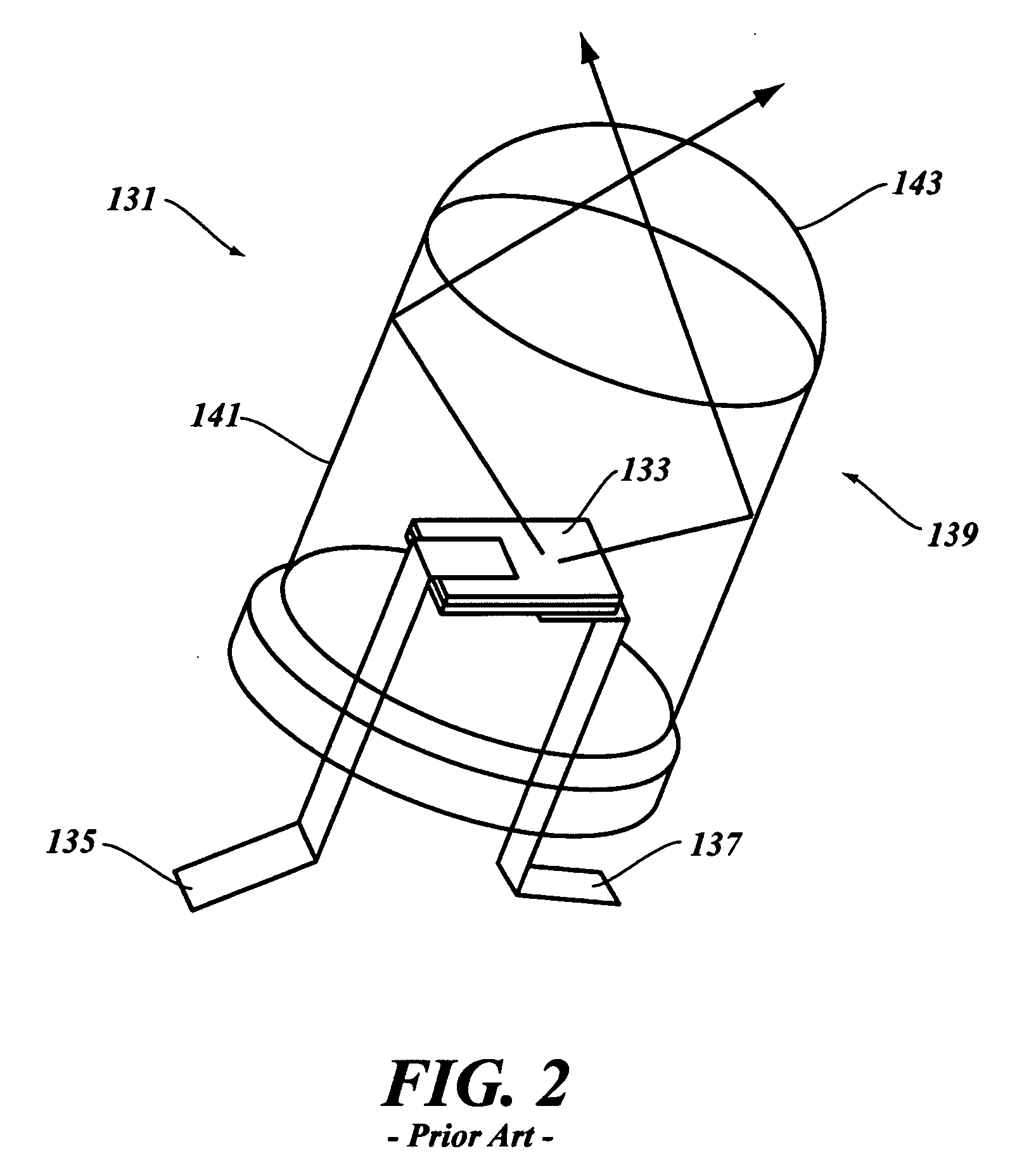

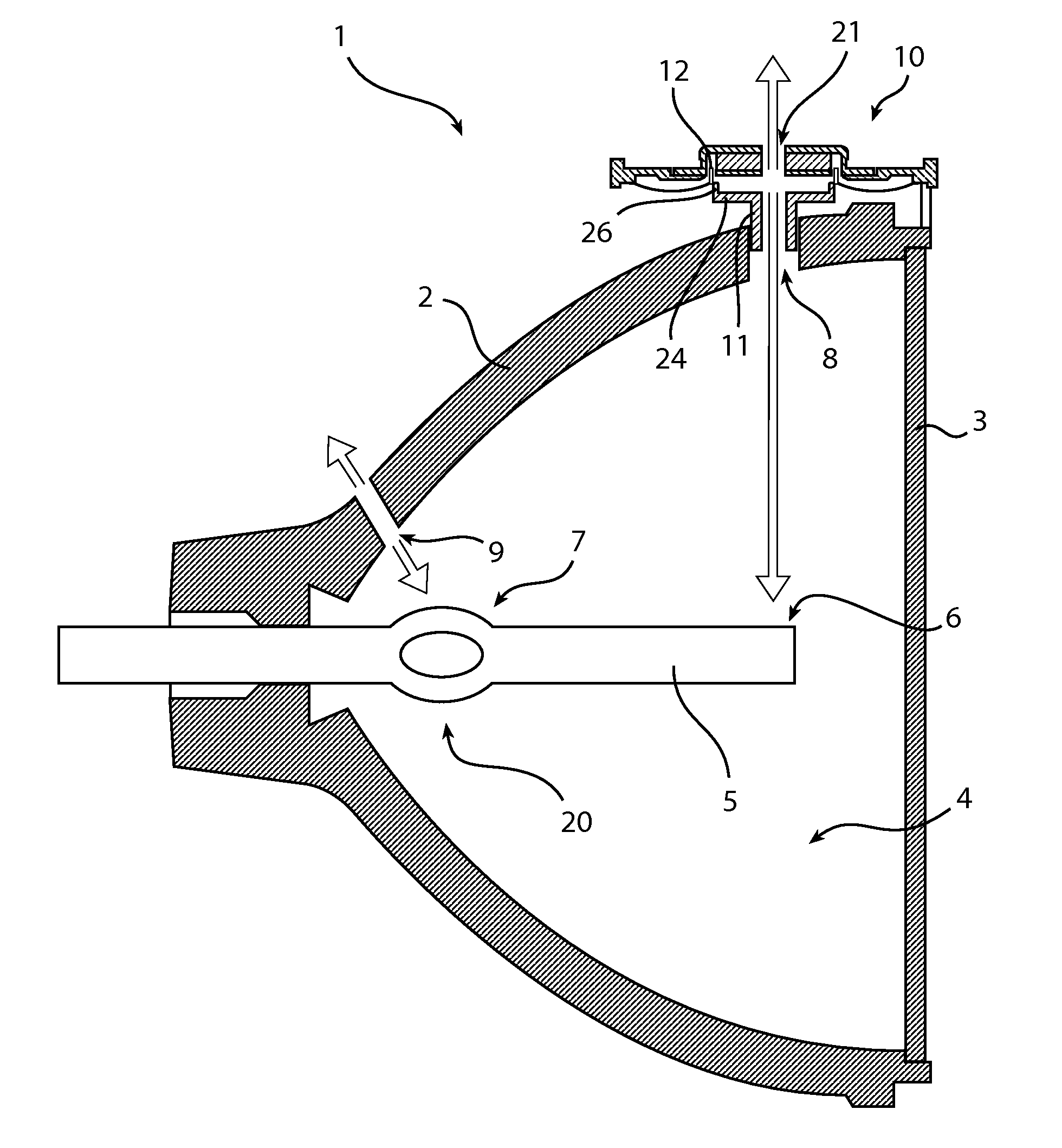

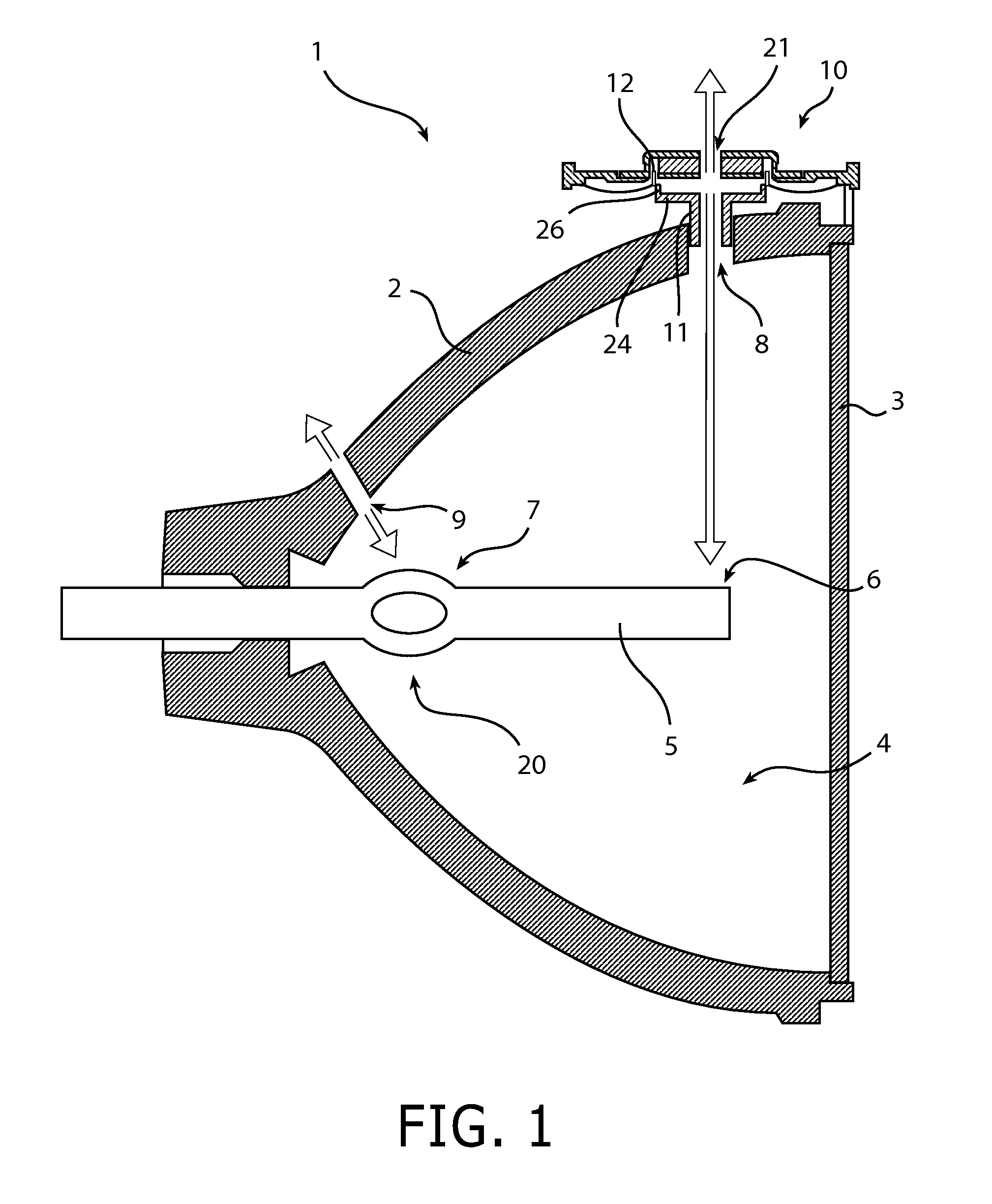

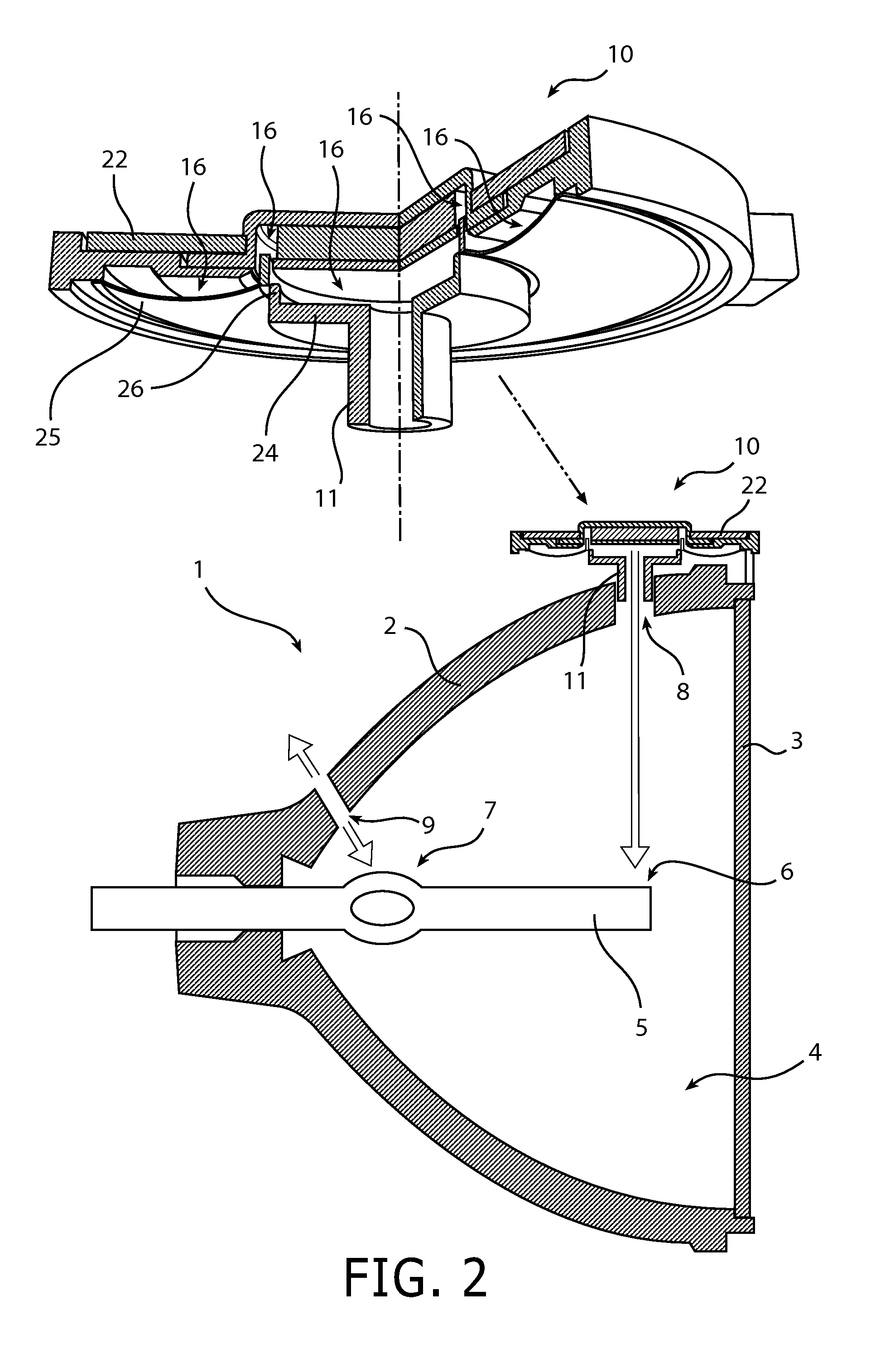

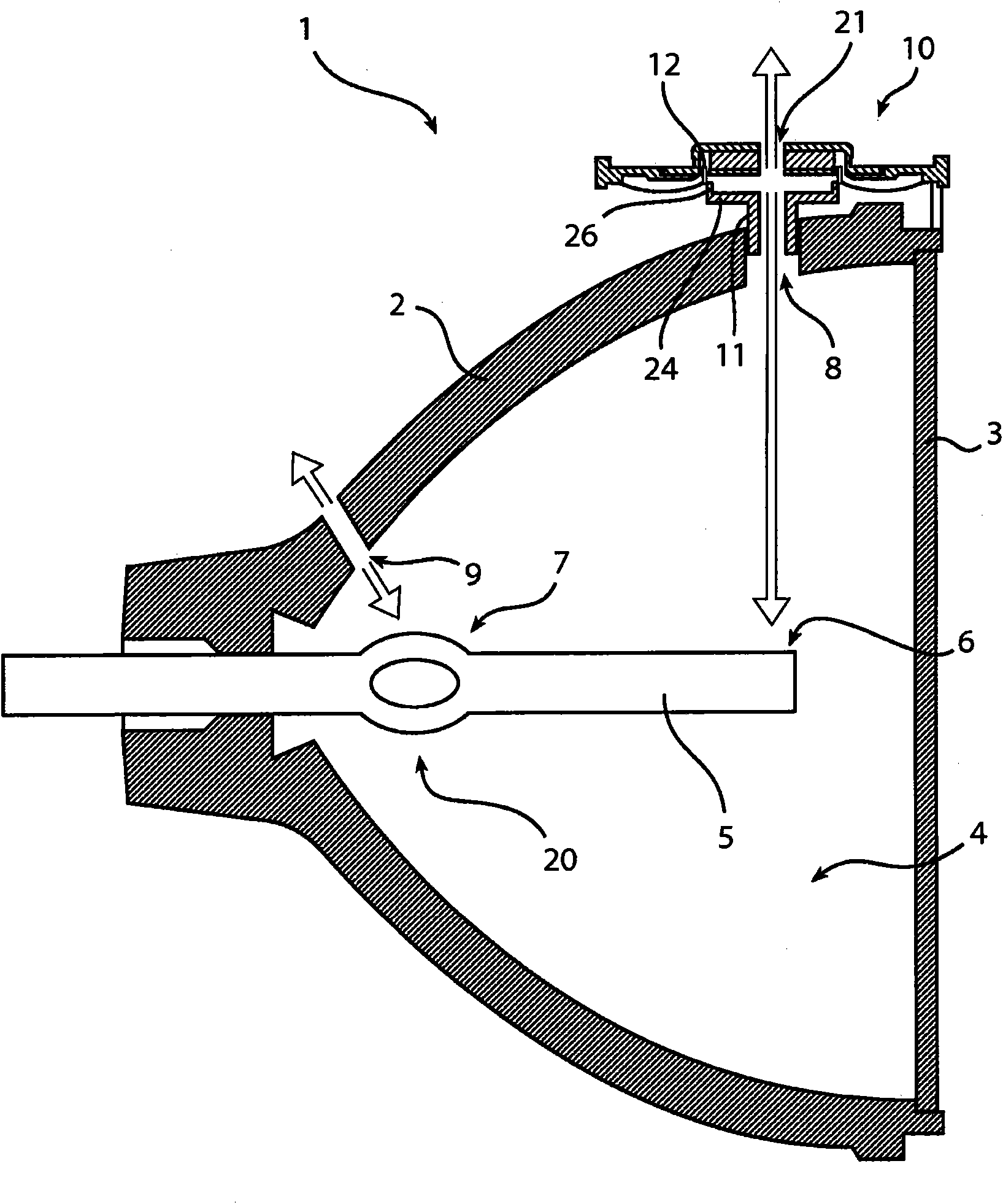

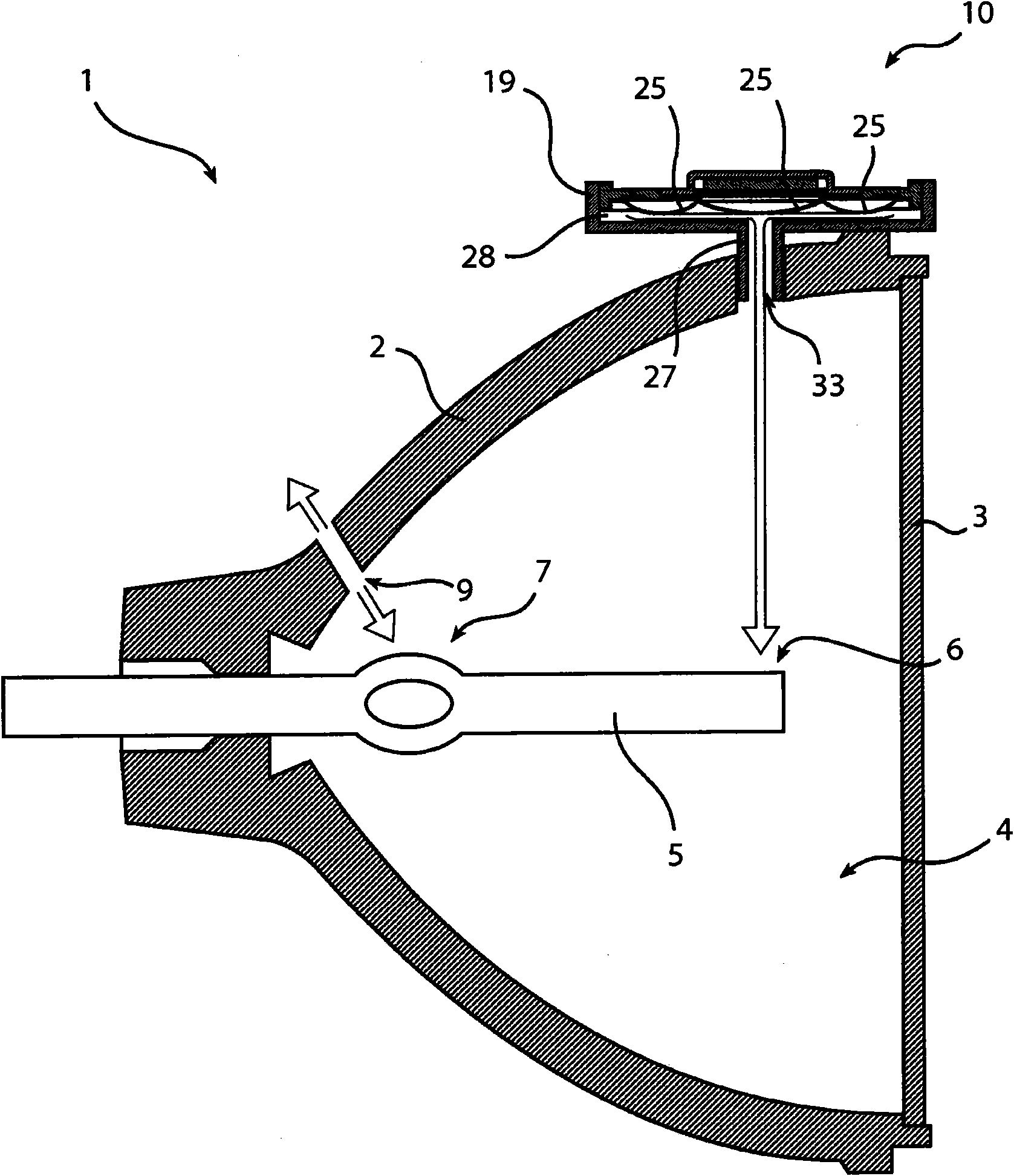

Cooling device utilizing internal synthetic jets

InactiveUS20100258274A1Boost vortex sheddingImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsTransducerEngineering

A synthetic jet cooling device (1) for cooling an object (5), comprising: a transducer (10) adapted to generate velocity waves, and an enclosure (4) arranged to receive the velocity waves via an actuated aperture (8). The enclosure (4) is sufficiently large to generate, at the actuated aperture (8), an internal synthetic jet inside the enclosure (4). Furthermore, the enclosure (4) is arranged to contain the object (5), thereby enabling cooling of the object (5) by the internal synthetic jet. The arrangement typically permits multifunctional use of an existing enclosure, containing the object to be cooled, both for its original purpose (e.g. a reflector in a lamp, or a LED backlight module) and as an enclosure generating internal synthetic jets, why the cooling device typically requires virtually no extra space and weight, and can be provided at a low cost.

Owner:SIGNIFY HLDG BV

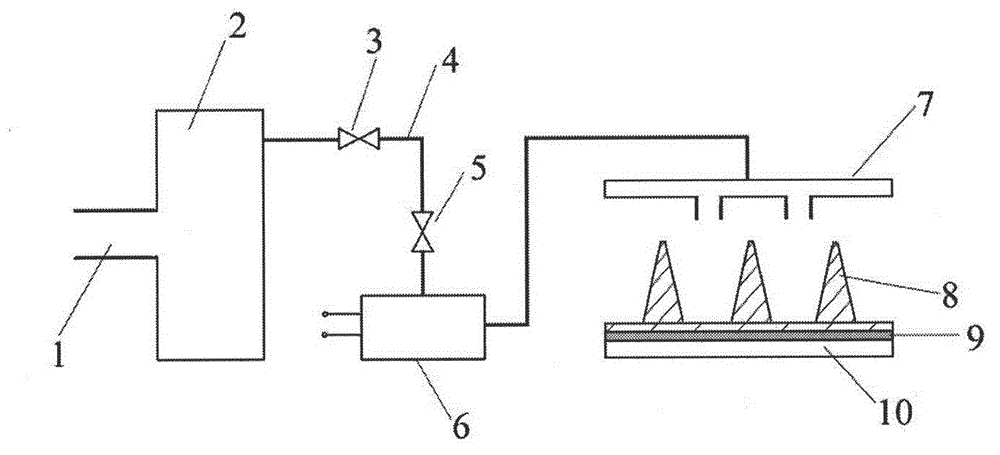

Jet type evaporation cooler with low water outlet temperature

InactiveCN102778144ALower the water temperatureReduce the temperatureStationary conduit assembliesEvaporative coolerEvaporation

The invention relates to a jet type evaporation cooler with low water outlet temperature. The jet type evaporation cooler comprises a filler, a cooling water coil pipe and a fan, wherein the filler is arranged below the cooling water coil pipe; the lower side of the filler is connected with a jet cooling device through a water baffle plate; the jet cooling device comprises a water tank, a water pump, a water segregator, spraying pipes, nozzles and a water receiver; the spraying pipes are respectively arranged on two sides on the upper side of the water tank and connected with the water tank through the water segregator and the water pump; a plurality of nozzles are arranged on the spraying pipes; and the water receiver is arranged in the middle of the jet cooling device. By the jet type evaporation cooler with low water outlet temperature, air is cooled and depressurized by water jetted by the nozzles and then enters the coil pipe region on the upper part; the temperature of circulating water is greatly reduced by increasing the ventilating amount through the high-power fan; therefore, scaling is avoided, and the water outlet temperature is relatively low; and furthermore, the cooler can adapt to different running modes in different seasons.

Owner:SHANGHAI TYACHT COOLING SYST

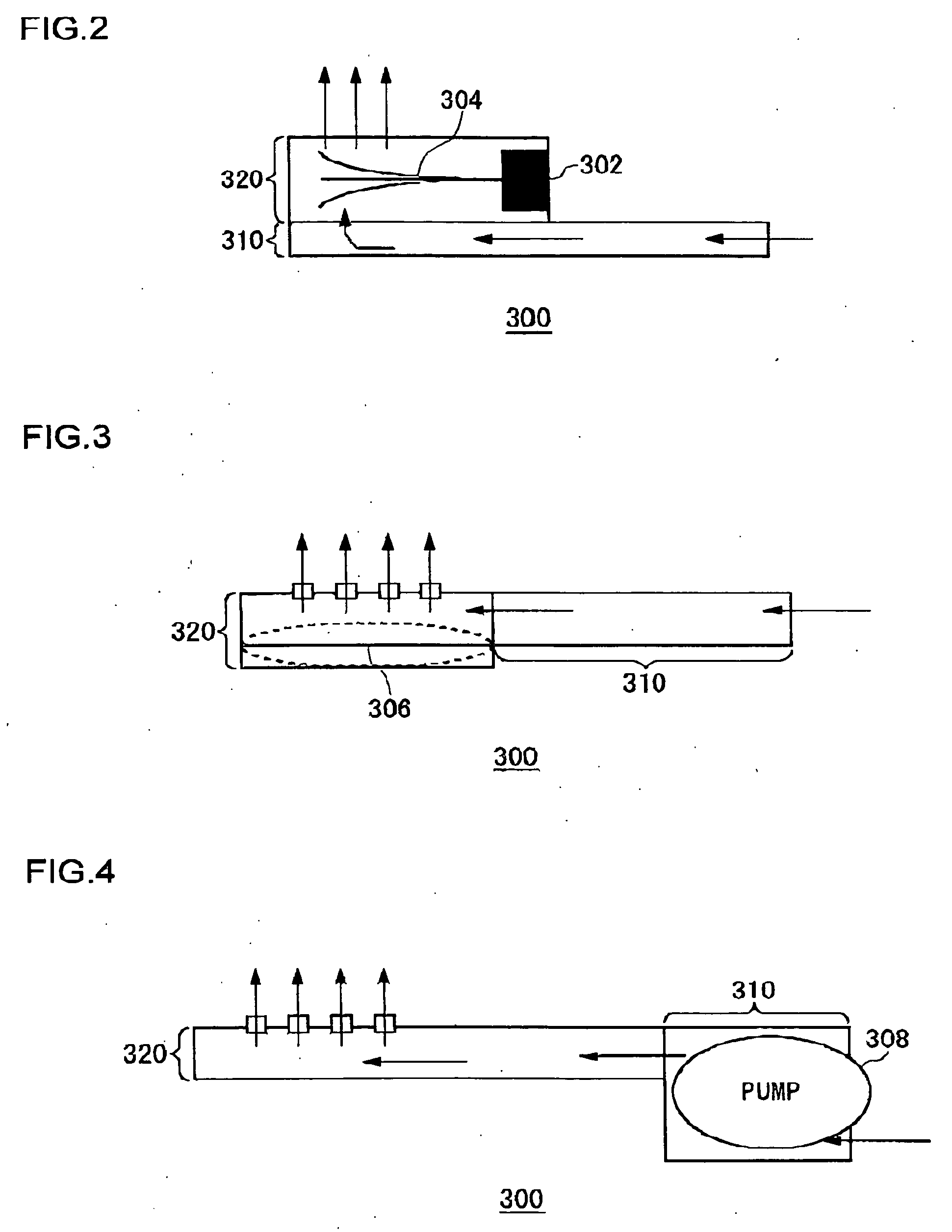

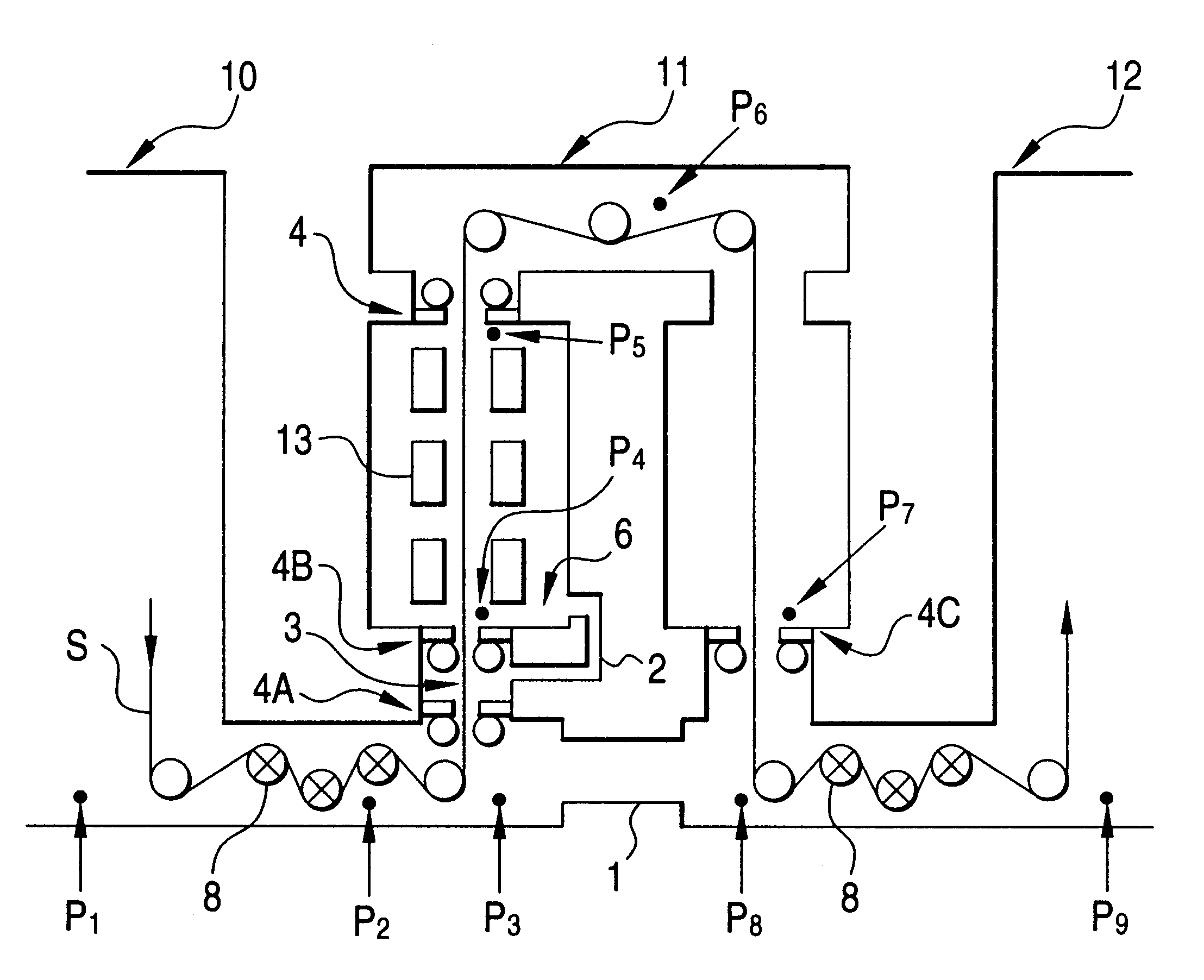

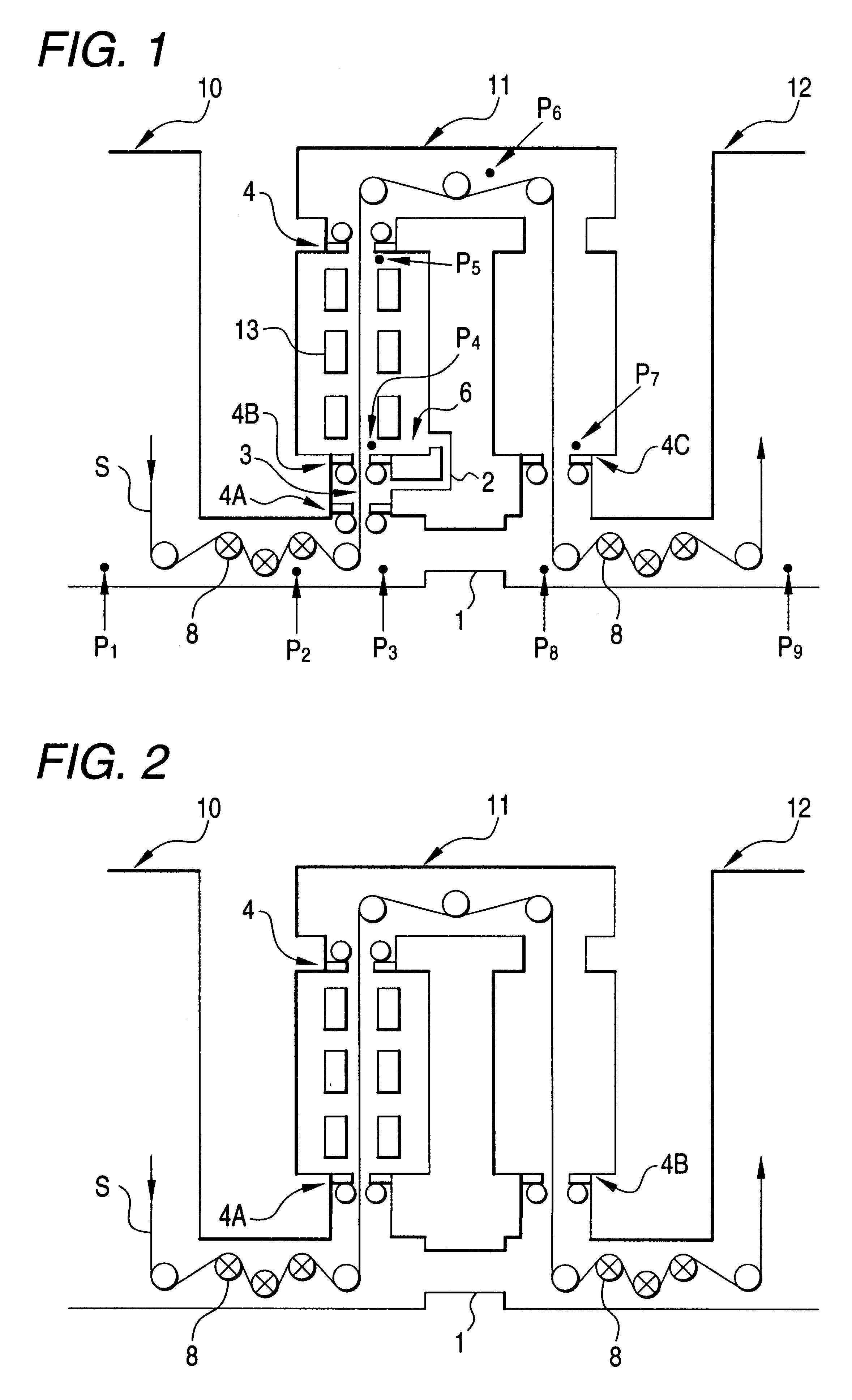

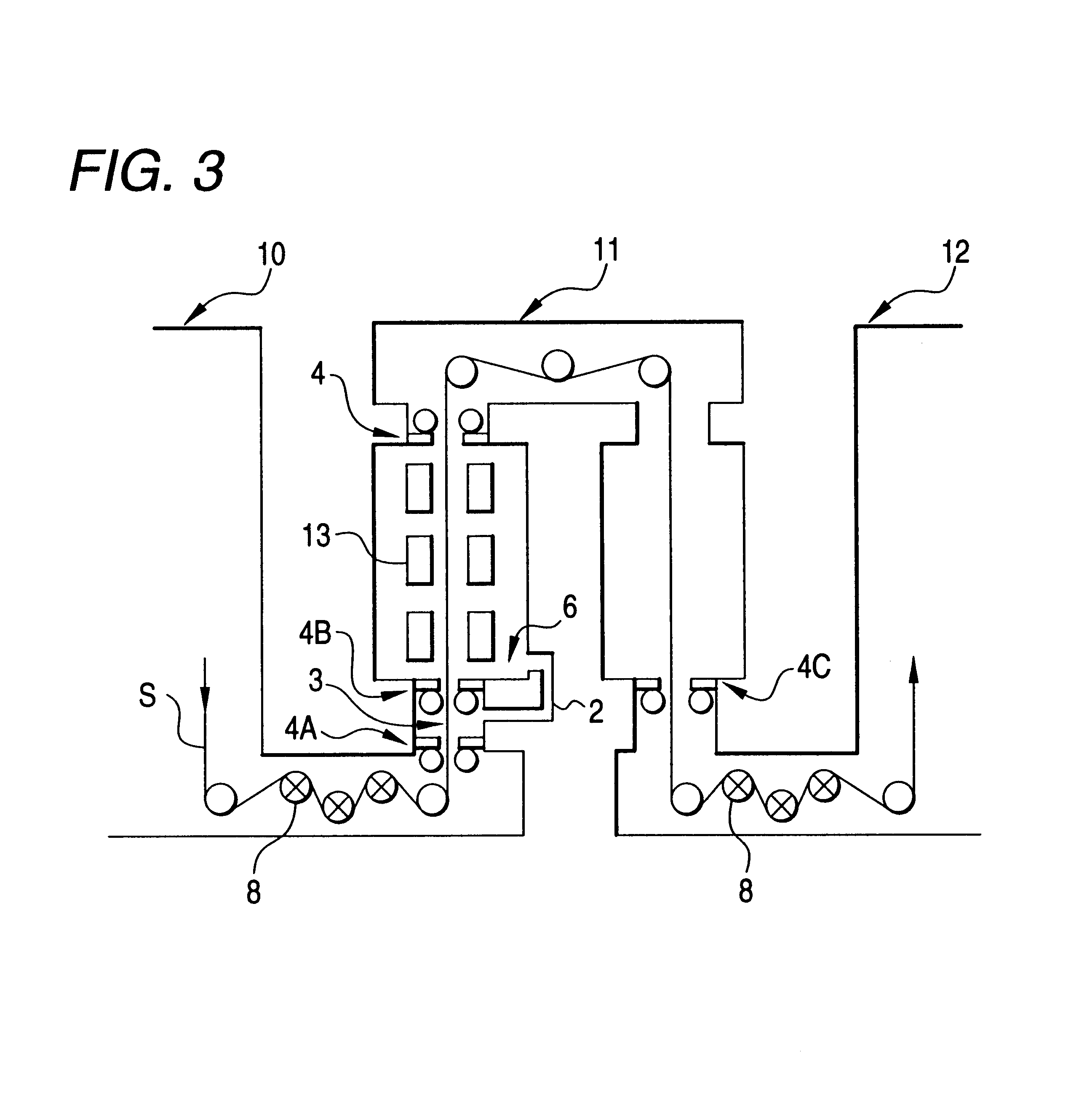

Continuous heat treating furnace and atmosphere control method and cooling method in continuous heat treating furnace

A continuous heat treatment furnace having one of a plurality of furnace zones except for first and last zones as a rapid cooling zone 11 for rapidly cooling a material by blowing an atmospheric gas, which comprises a roll-sealed chamber 3 partitioned at the inlet by first and second roll sealing devices 4A and 4B from the upstream and a third roll sealing device 4C at the outlet as sealing means for atmospheric gas, and in which the inlet of the first roll sealing device and the outlet of the third roll sealing device are connected, and / or the roll-sealed chamber and an uppermost stream portion 6 in the rapid cooling zone are connected, and in which the hydrogen concentration in the furnace is controlled to 10% or higher in the rapid cooling zone and is controlled to 10% or lower in the furnace zone at the inlet of the rapid cooling zone. A continuous heat treatment furnace capable of simply preventing mixing of atmospheric gases in the rapid cooling zone and the atmospheric gas in the zone (heating zone, cooling zone or the like) adjacent with the rapid cooling zone of a gas jet cooling system, and a method of controlling the atmospheric gas in the furnace capable of preventing nitridation are provided.

Owner:JFEENG CORP

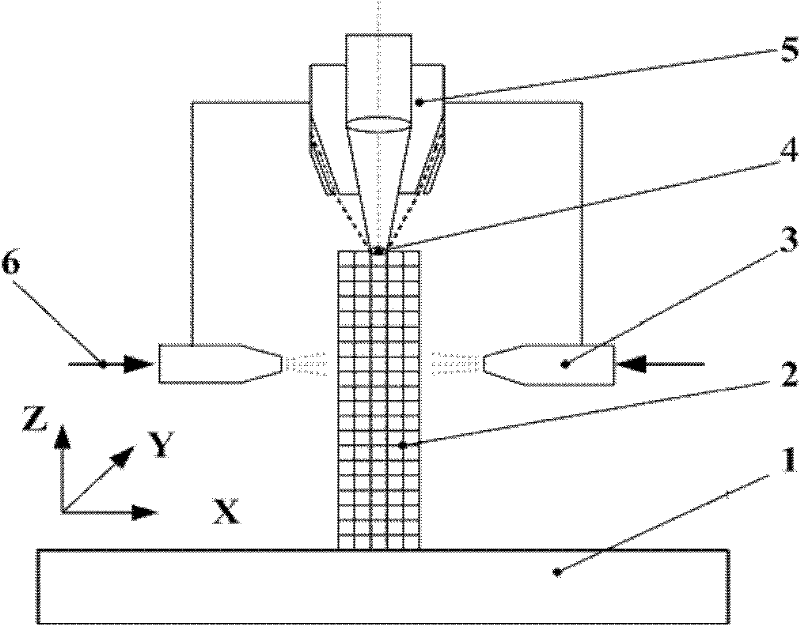

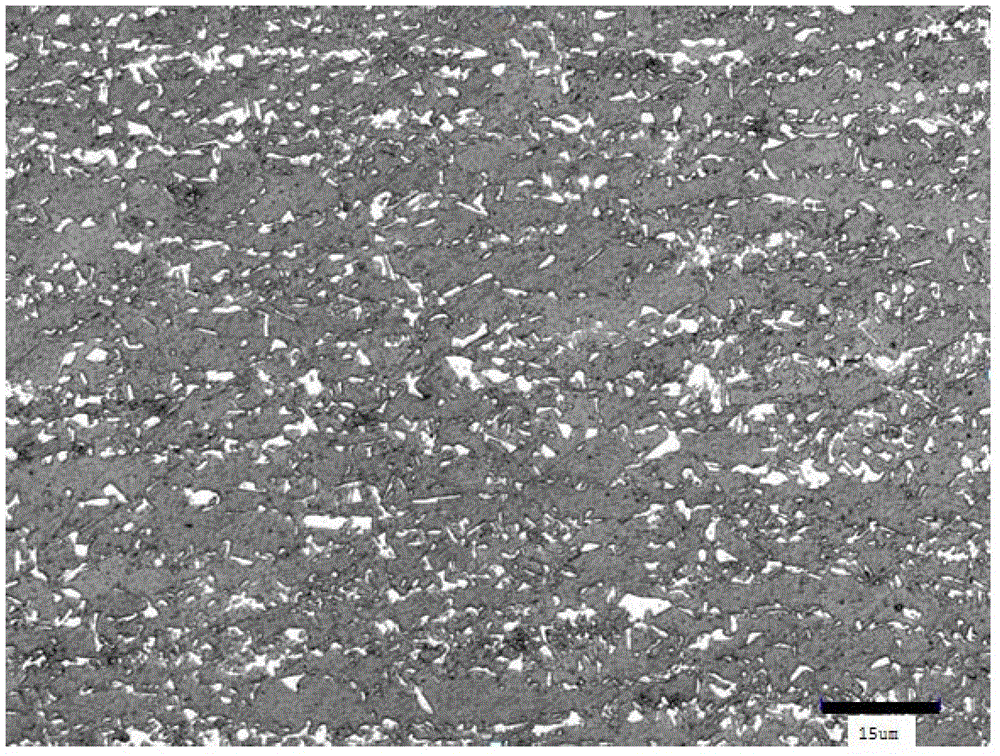

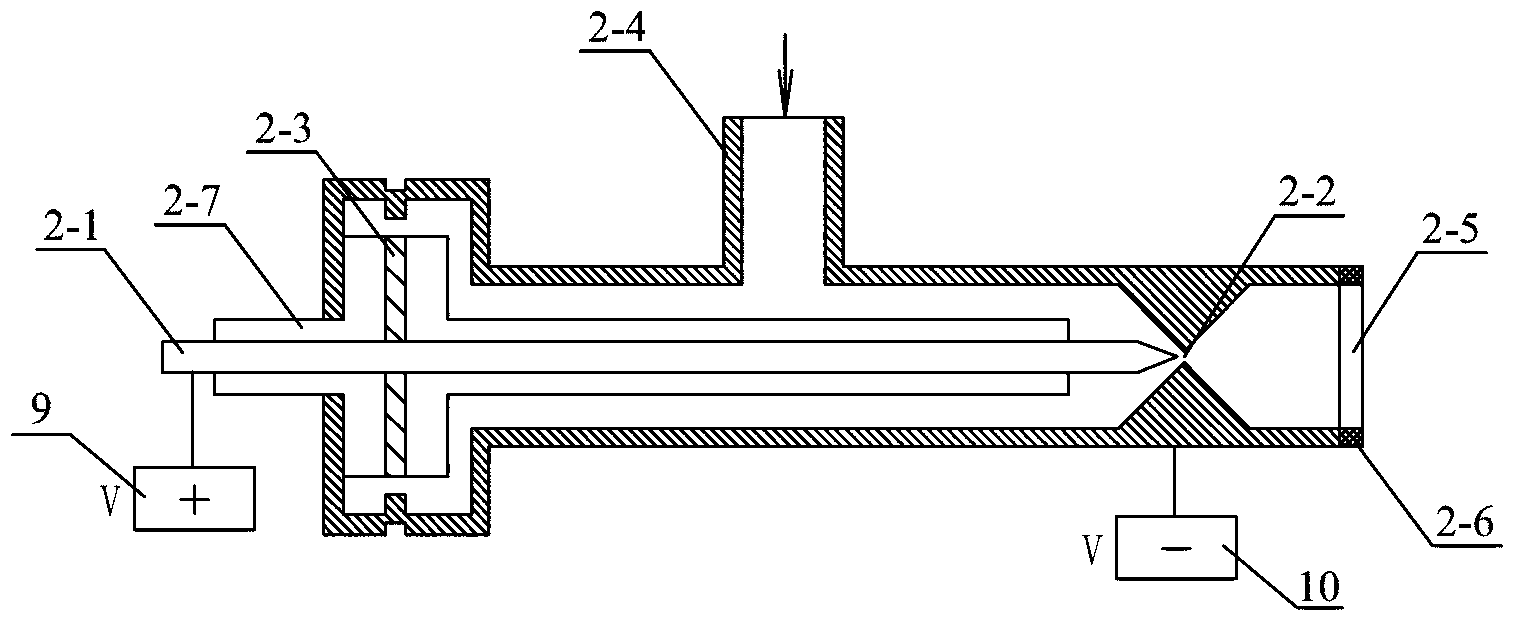

Laser metal direct forming method of liquid argon jet cooling directional solidification

InactiveCN102162096ANo heat accumulation problemReduce the temperatureMetallic material coating processesLiquid argonDirectional solidification

The invention discloses a laser metal direct forming method of liquid argon jet cooling directional solidification. The method is characterized in that: positive temperature gradient is kept all the time along the Z-axis direction in a molten pool in the subsequent forming process by adopting a method of liquid argon jet and quick cooling performed below the formed layer once a certain layer number is stacked. Meanwhile, the liquid argon for cooling is converted into argon gas and can also be used for reducing oxygen content in an argon protection box. Therefore, the columnar crystal tissue in a formed piece is continuously grown from a substrate along the Z-axis forming direction, and the formed piece obtains complete directional solidification columnar crystal tissue.

Owner:XI AN JIAOTONG UNIV +1

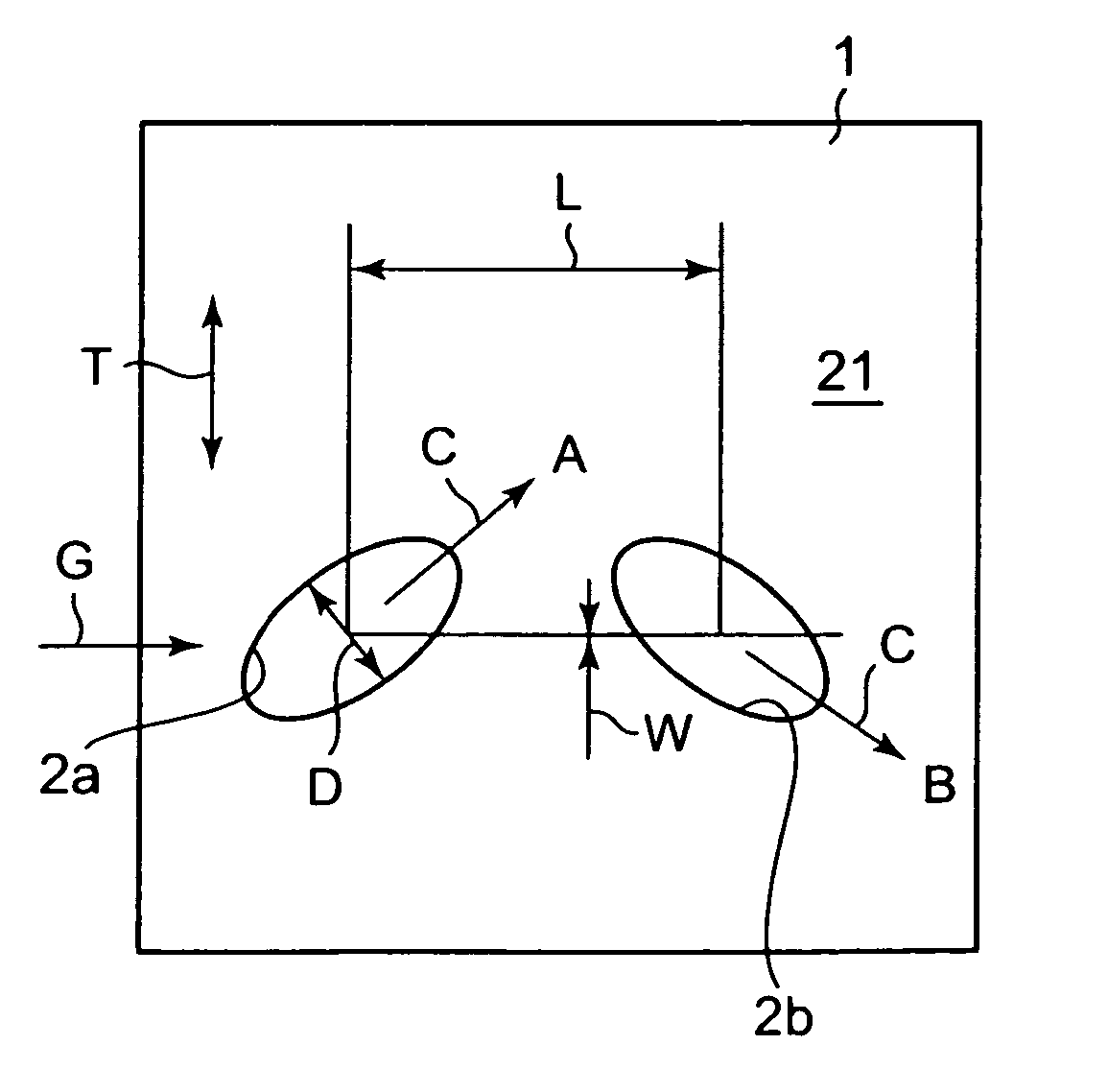

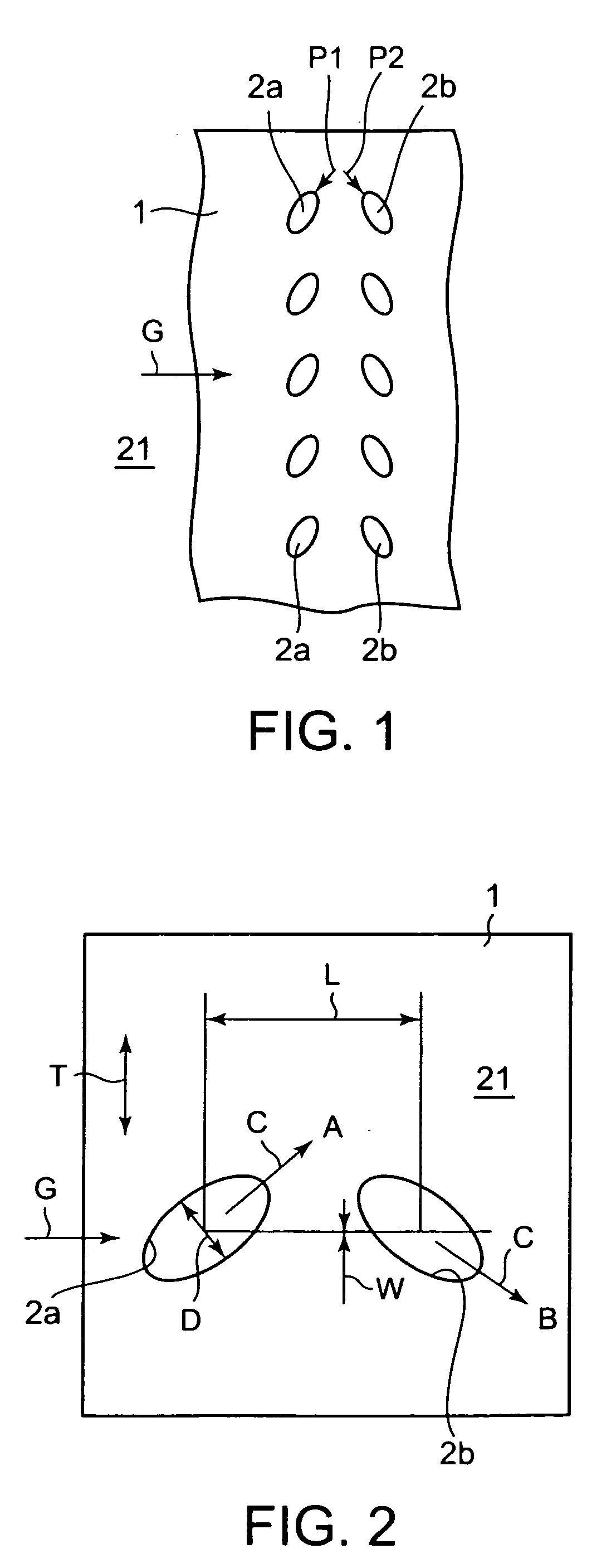

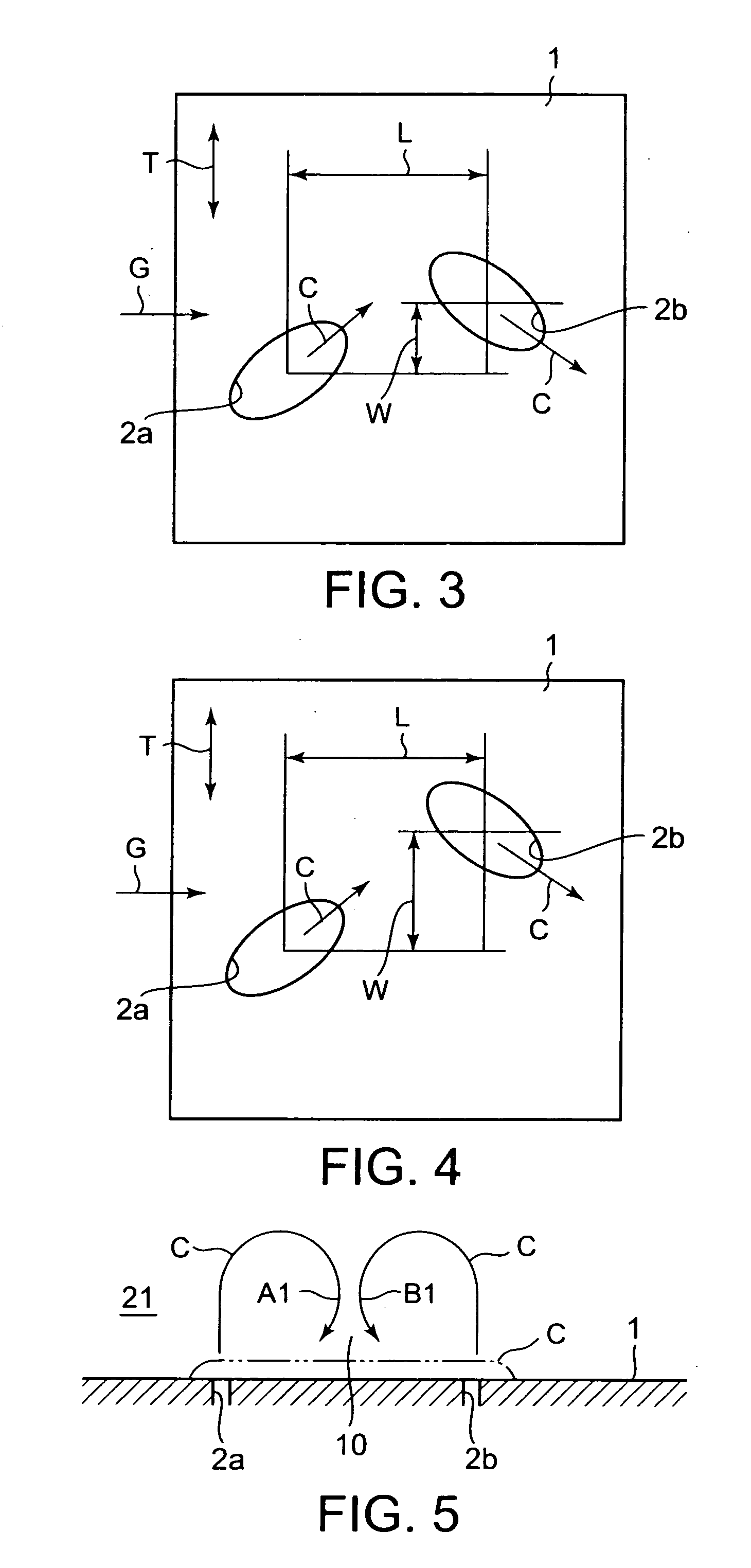

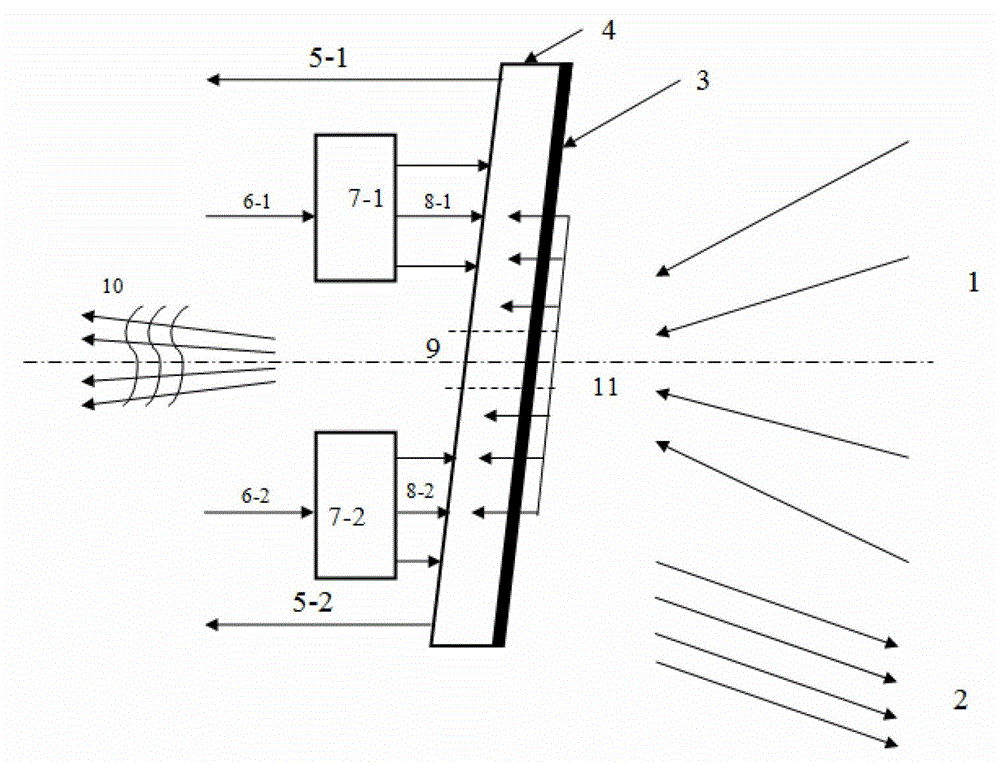

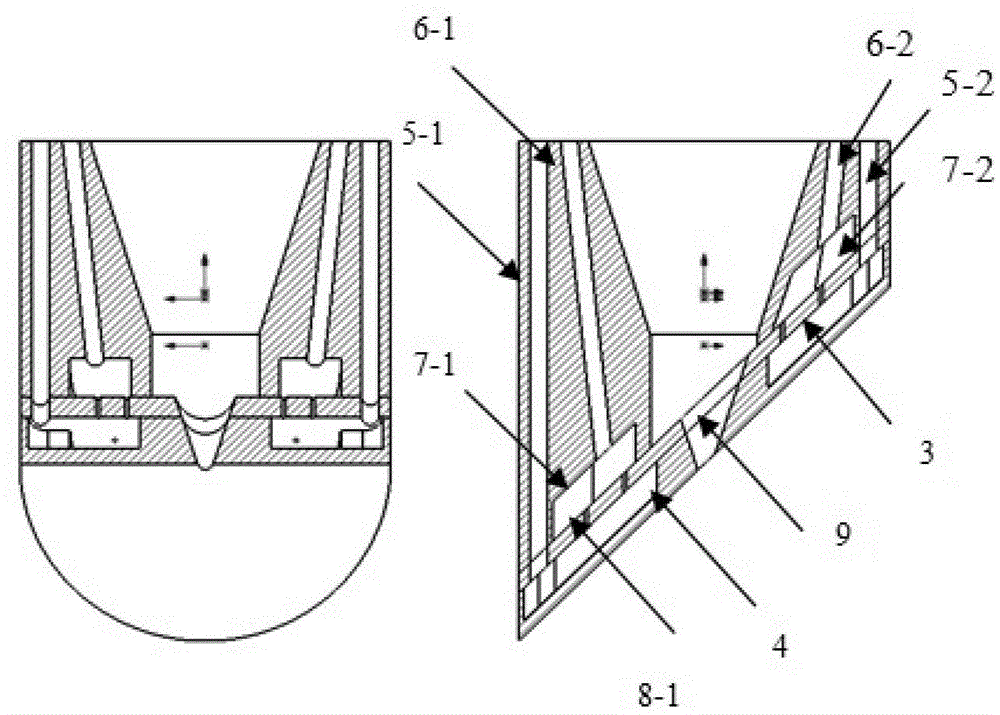

Double jet film cooling structure

ActiveUS20070109743A1Improve efficiencyImprove cooling effectEngine fuctionsBlade accessoriesHigh heatCooling medium

A film cooling structure includes a wall surface which faces a gas-flow passage for high-temperature gas. One or more than one pair of jetting holes are formed on the wall surface so as to respectively jet cooling media into the gas-flow passage. The pair of jetting holes respectively have jetting directions in which the cooling media are jetted from the pair of jetting holes into the gas-flow passage. The jetting directions of the pair of jetting holes are respectively set so as to respectively form swirls in directions in which the cooling media are mutually pressed against the wall surface.

Owner:KAWASAKI HEAVY IND LTD

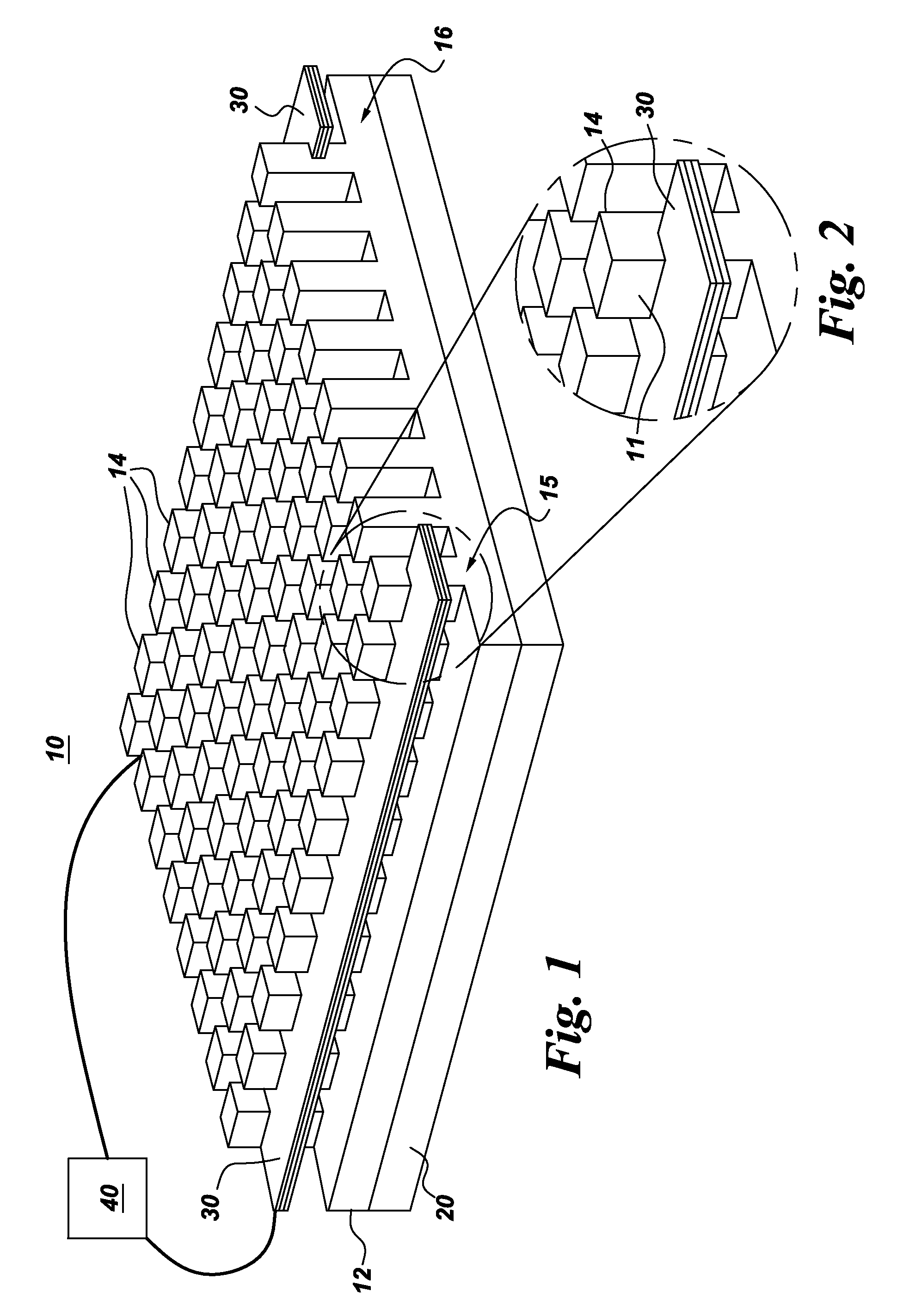

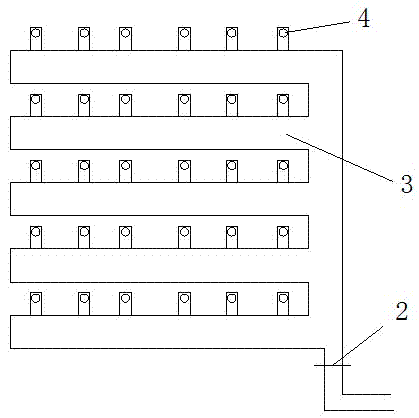

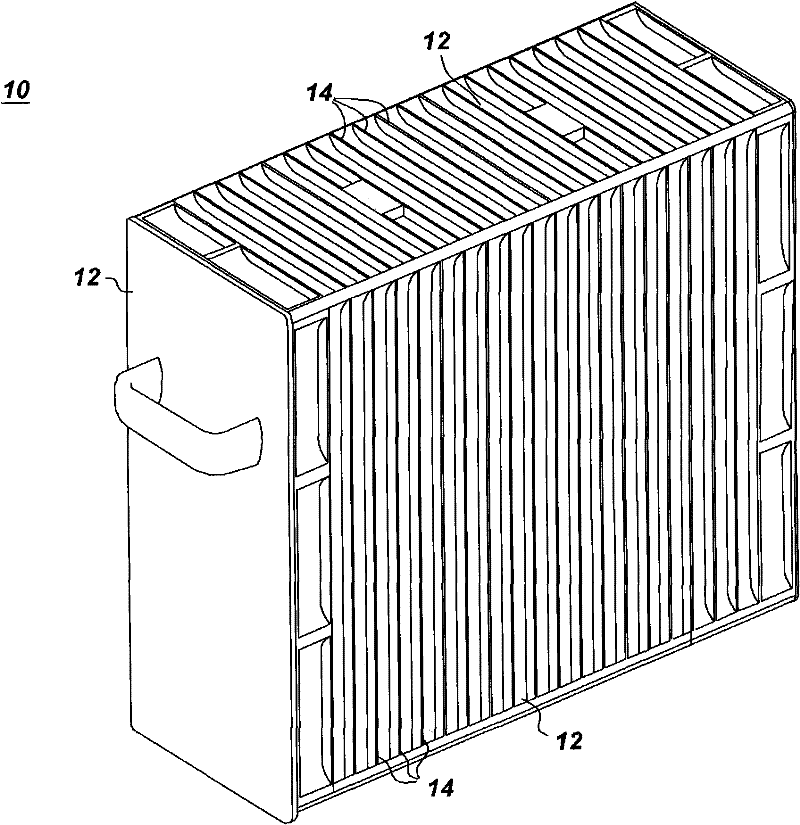

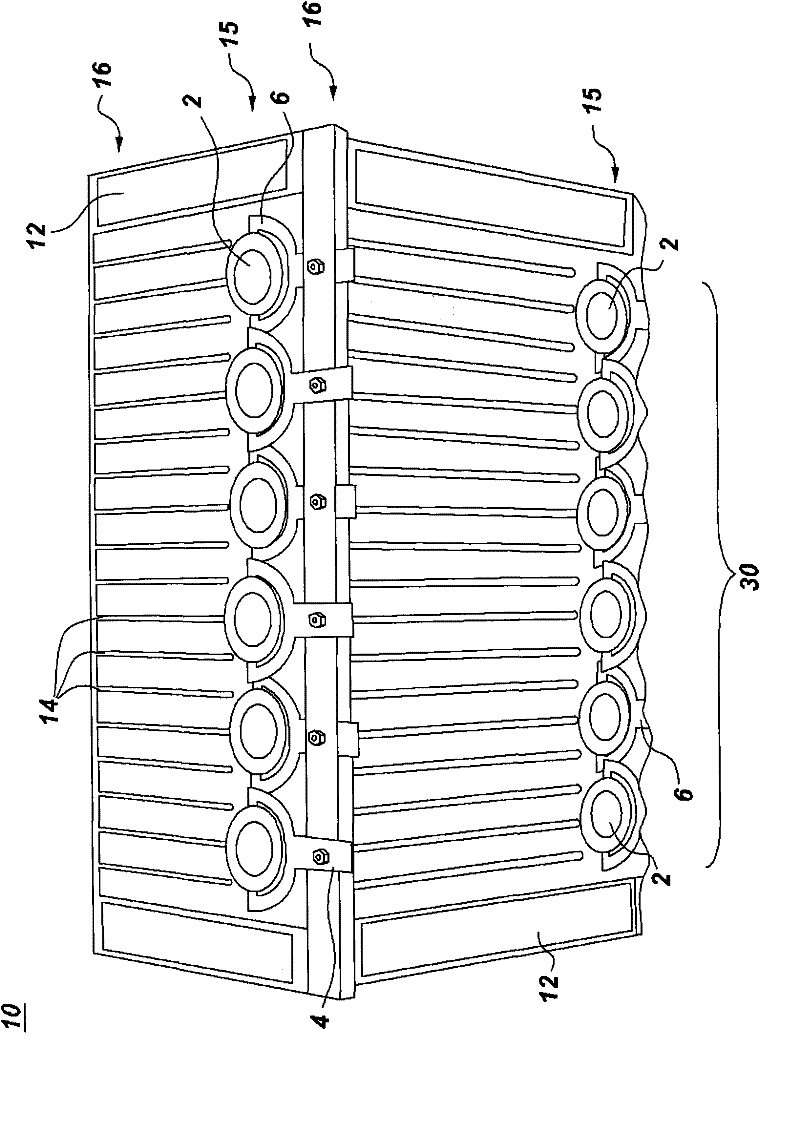

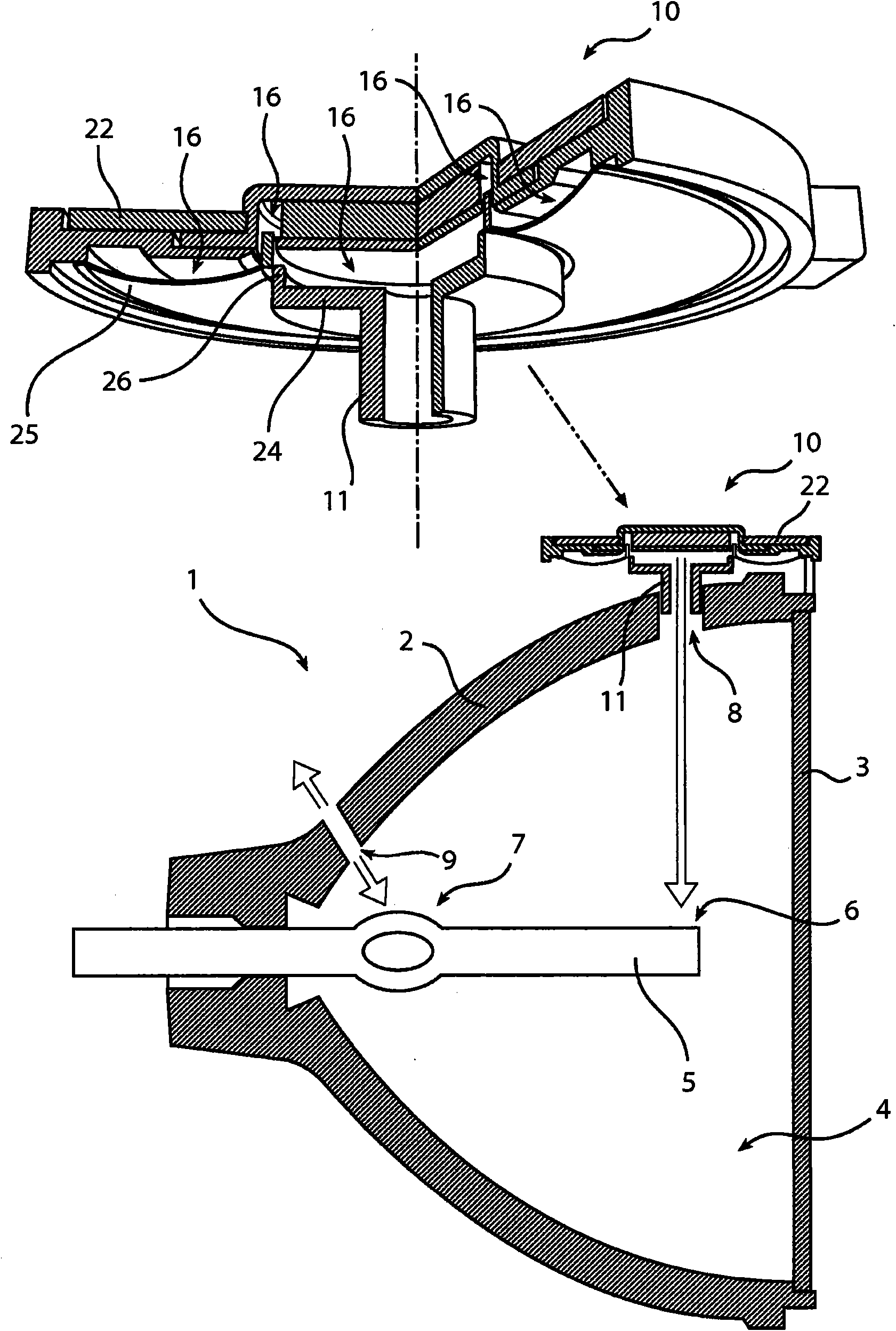

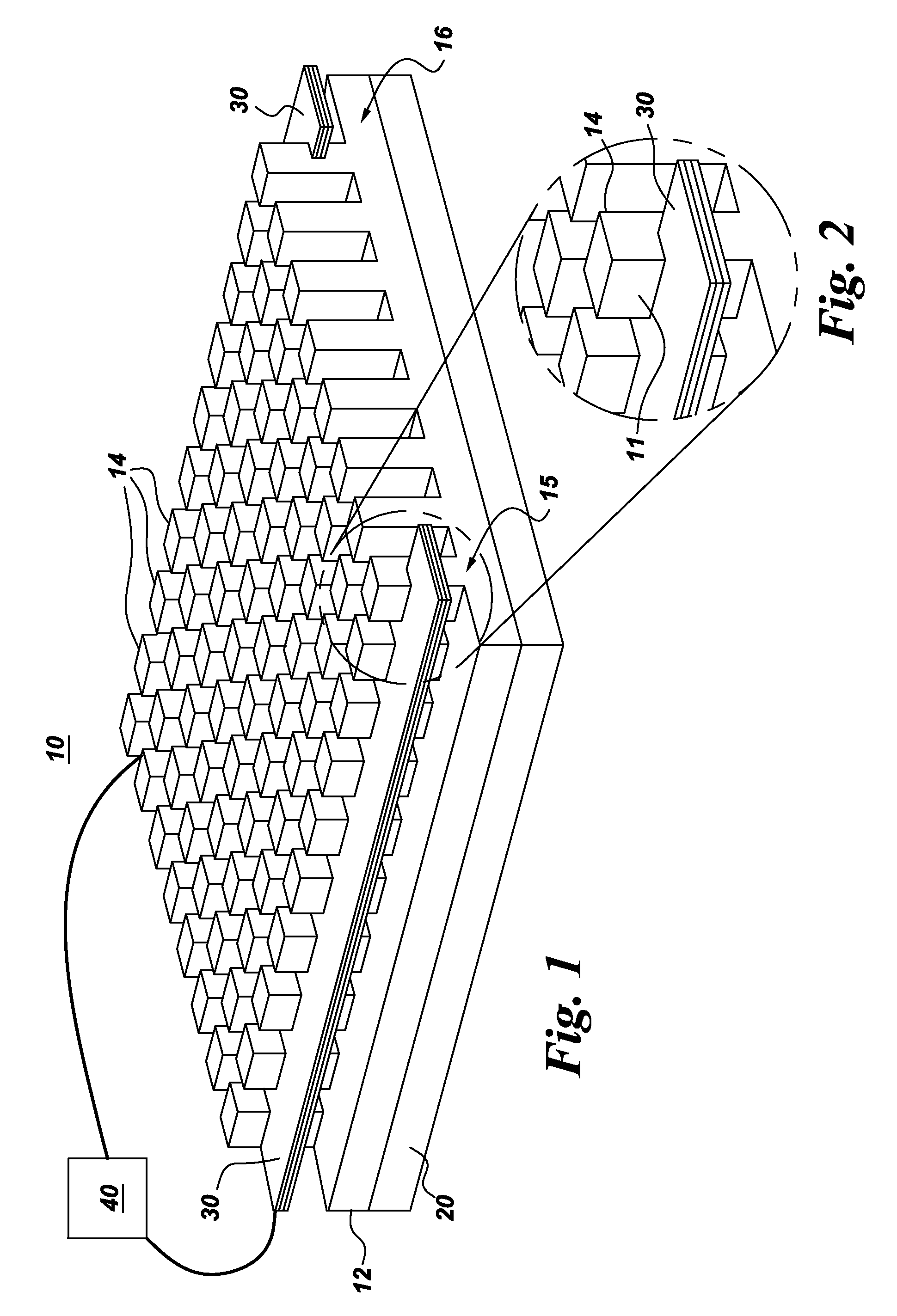

Chassis with distributed jet cooling

A chassis (10) with distributed jet cooling is provided. The chassis includes one or more sidewalls (12) defining a volume configured to substantially surround one or more heat generating components positioned within the volume. The chassis further includes at least one array of fins (14) thermally coupled to a respective one of the one or more sidewalls and at least one synthetic jet assembly (30) comprising a multi-orifice synthetic jet (30) or a number of single orifice synthetic jets (2) disposed on a side (15, 16) of a respective one of the array(s) of fins. The chassis further includes at least one attachment means (4, 6, 9, 11, 20, 44) for attaching a respective one of the at least one synthetic jet assemblies to a respective one of the one or more sidewalls.

Owner:GENERAL ELECTRIC CO

Transformation induced plasticity steel and preparation method thereof

InactiveCN102747276AGood welding performanceImprove plasticityHot-dipping/immersion processesChemical compositionNiobium

The invention discloses transformation induced plasticity steel and a preparation method thereof and belongs to the technical field of cold rolling hot galvanizing. The transformation induced plasticity steel comprises by mass, 0.18%-0.21% of carbon, 0.6%-10.5% of silicon, 1.8%-2.0% of manganese, 0.03%-0.04% of niobium, no more than 0.01% of phosphorus, no more than 0.01% of sulphur, 0.8%-1.0% of all aluminum, no more than 0.005% of nitrogen and the balance ferrum. Based on a producing method of conventional jet cooling hot galvanizing, the transformation induced plasticity steel and the preparation method are used in 780 MPa automobile cold rolling hot galvanizing, and the transformation induced plasticity steel not only can meet design strength and has good welding and plastic performances.

Owner:SHOUGANG CORPORATION

Supersonic combustion method actuated by combination plasma

InactiveCN103216317AAvoid layoutAvoid technical requirements for placing ionization electrodesInternal combustion piston enginesCombustion-air/fuel-air treatmentDiffusion flameCombustion chamber

The invention discloses a supersonic combustion method actuated by combination plasma, relates to the supersonic combustion method for an engine combustion chamber, and solves the problems that by using an existing concave chamber type combustion method, the concave chamber dimensions are large, the flow loss is large, and the supersonic combustion performance is poor. The method comprises the steps that 1) a ceramic membrane is plated on the inner surface of each through hole; 2) the first through hole is connected with a fuel oil outlet pipe, the second through hole and the fourth through hole are connected with a thermal equilibrium plasma generator respectively, and the third through hole and the fifth through hole are connected with a non-thermal equilibrium plasma generator respectively; 3) fuel oil is injected into the combustion chamber through the first through hole; 4) a working medium is ejected from the thermal equilibrium plasma generator, is injected into a combustion area of the engine combustion chamber and ignites the fuel oil at the combustion area to form diffusion flame and realize ignition; and 5) jet cooling plasma is ejected from the non-thermal equilibrium plasma generator, and is injected into different positions of the combustion chamber through the third through hole and the fifth through hole for forming reliable combustion. The method provided by the invention is used for organizing supersonic combustion.

Owner:HARBIN INST OF TECH

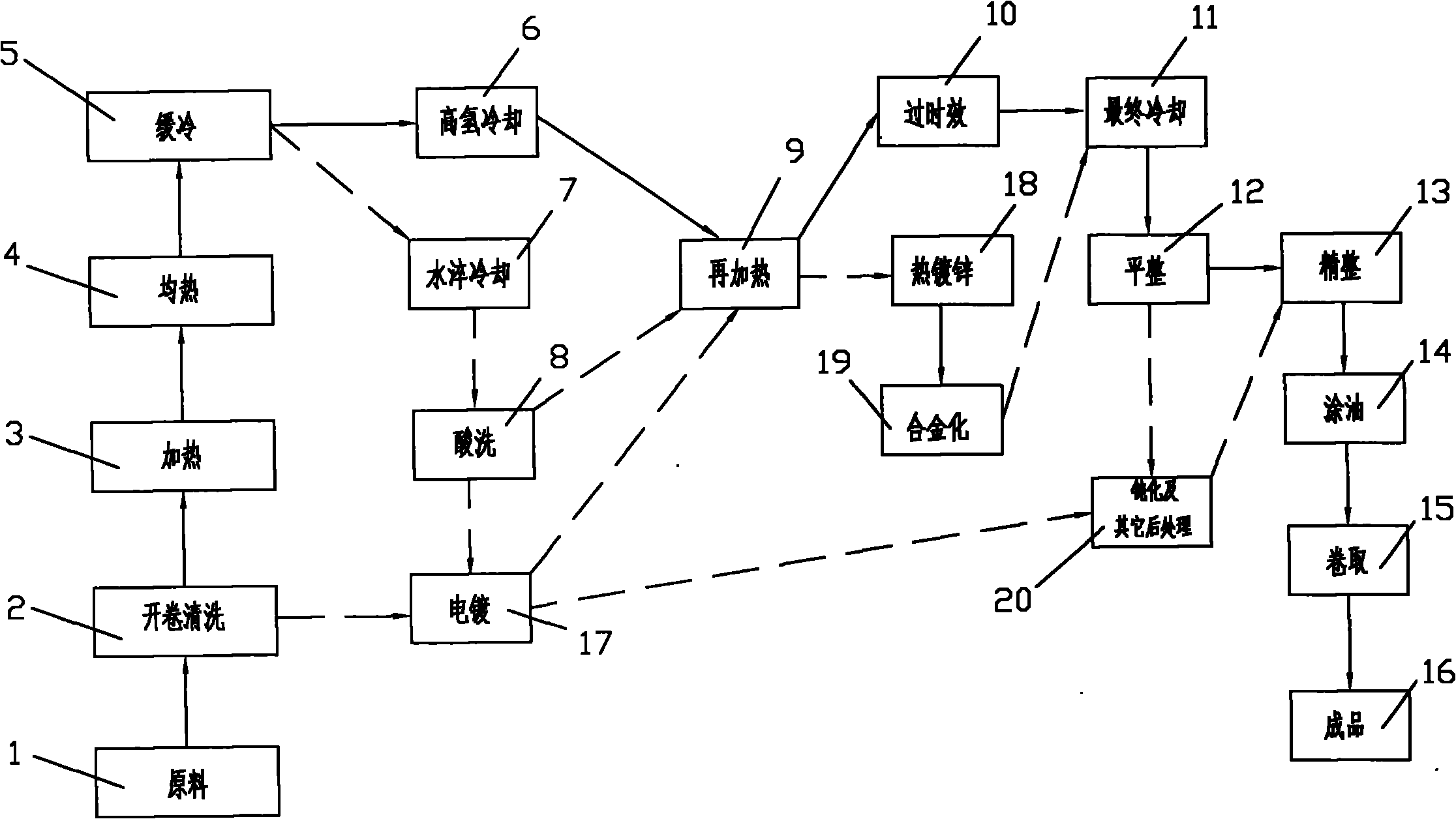

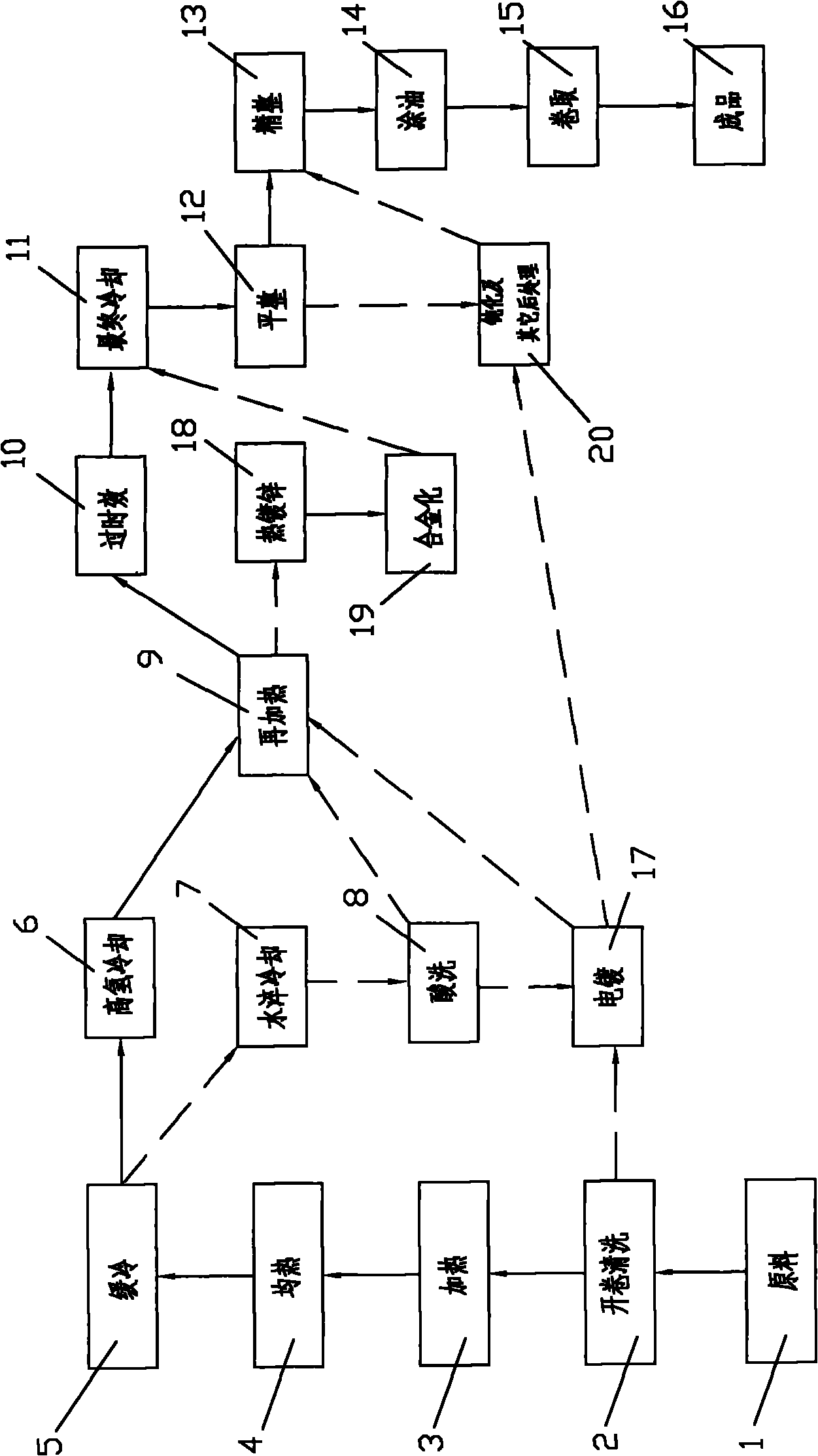

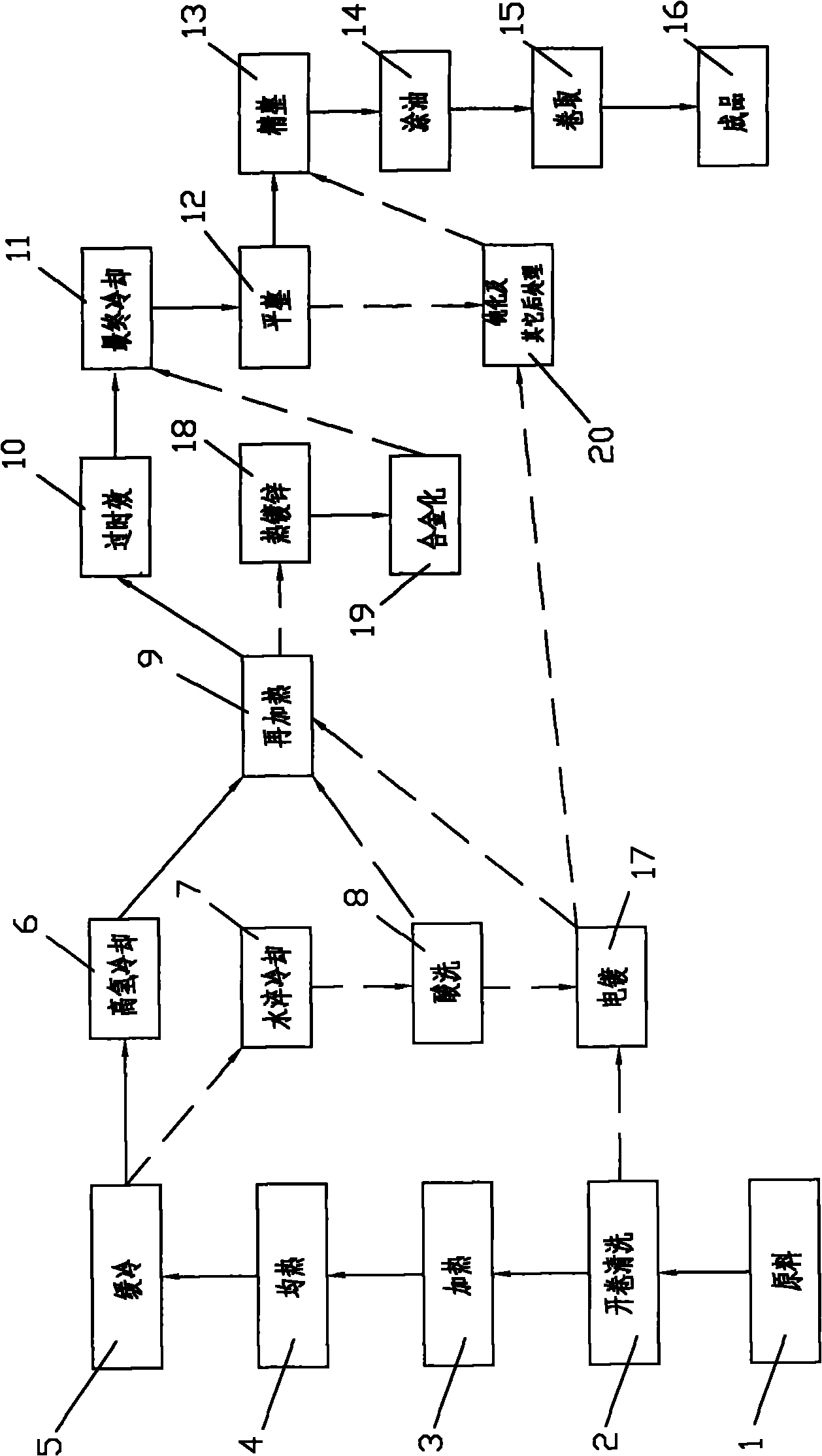

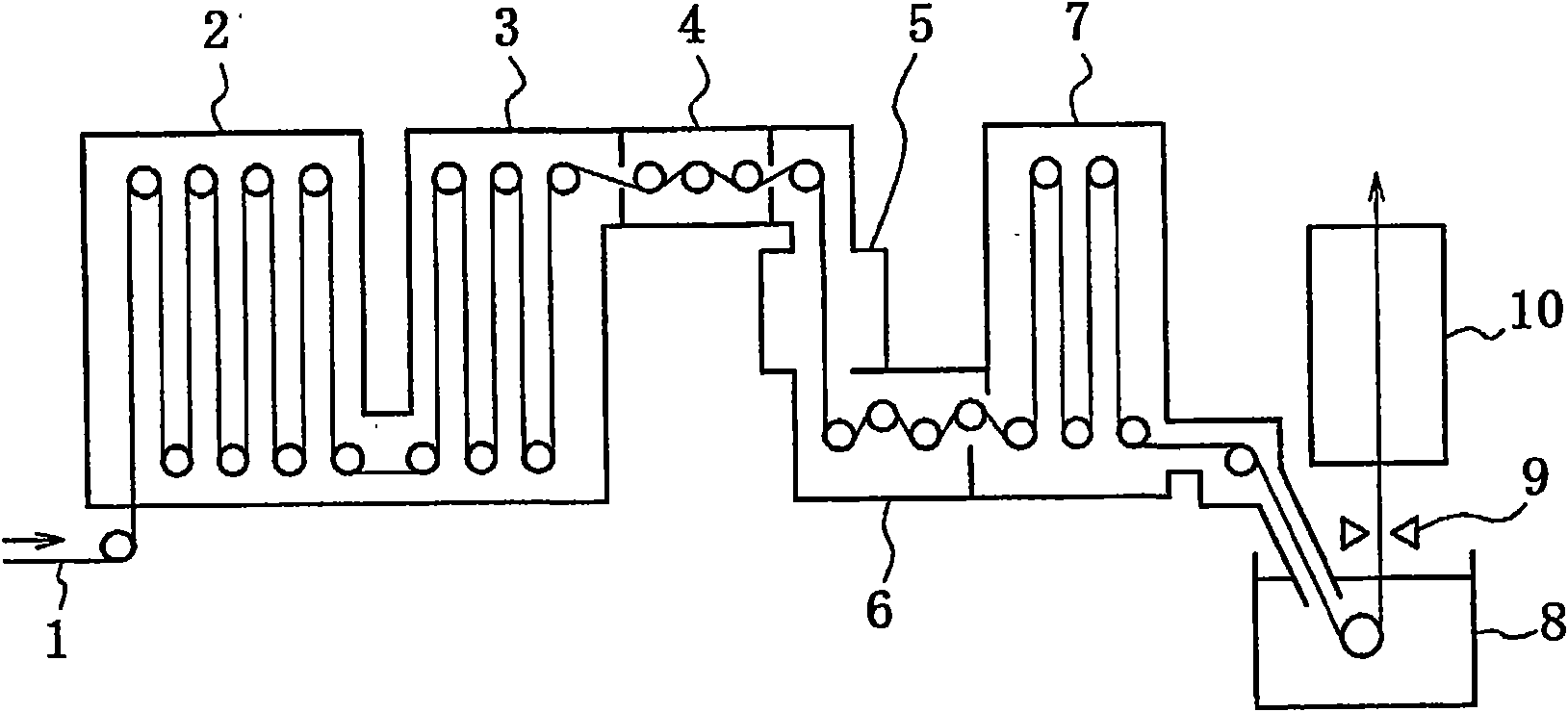

Flexible strip steel treating line suitable for producing various high-strength steel

ActiveCN101812579ARich varietyMeet actual needsHot-dipping/immersion processesElectrolysis componentsStrip steelSlow cooling

The invention discloses a flexible strip steel treating line suitable for producing various high-strength steel. The flexible strip steel treating line comprises an uncoiling working position, a washing working position, a heating working position, a soaking working position and a slow cooling working position, a jet cooling working position or a water quenching cooling working position in turn, wherein a reheating working position and then an overaging working position or a hot galvanizing working position and a cladding alloying and annealing working position are arranged after the jet cooling working position; a moveable bypass channel is arranged to connect the reheating working position and the overaging working position respectively; a final cooling working position and a flatting working position are connected after the overaging working position and the hot galvanizing working position; then, a finishing working position and an oil coating working position, or a passivating working position and other post-treatment working positions are connected; the finishing working position and the oil coating working position are connected to a coiling working position to finish a finished product; an acid cleaning working position and an electroplating working position are arranged corresponding to the water quenching and cooling working position; the reheating working position can be connected after the acid cleaning working position directly; an uncoiling and washing working position can be directly connected before the electroplating working position; and the bypass channel or a switching device is arranged after the electroplating working position to respectively and correspondingly connect the reheating working position or directly connect the passivating working position and the other post-treatment working positions.

Owner:BAOSHAN IRON & STEEL CO LTD

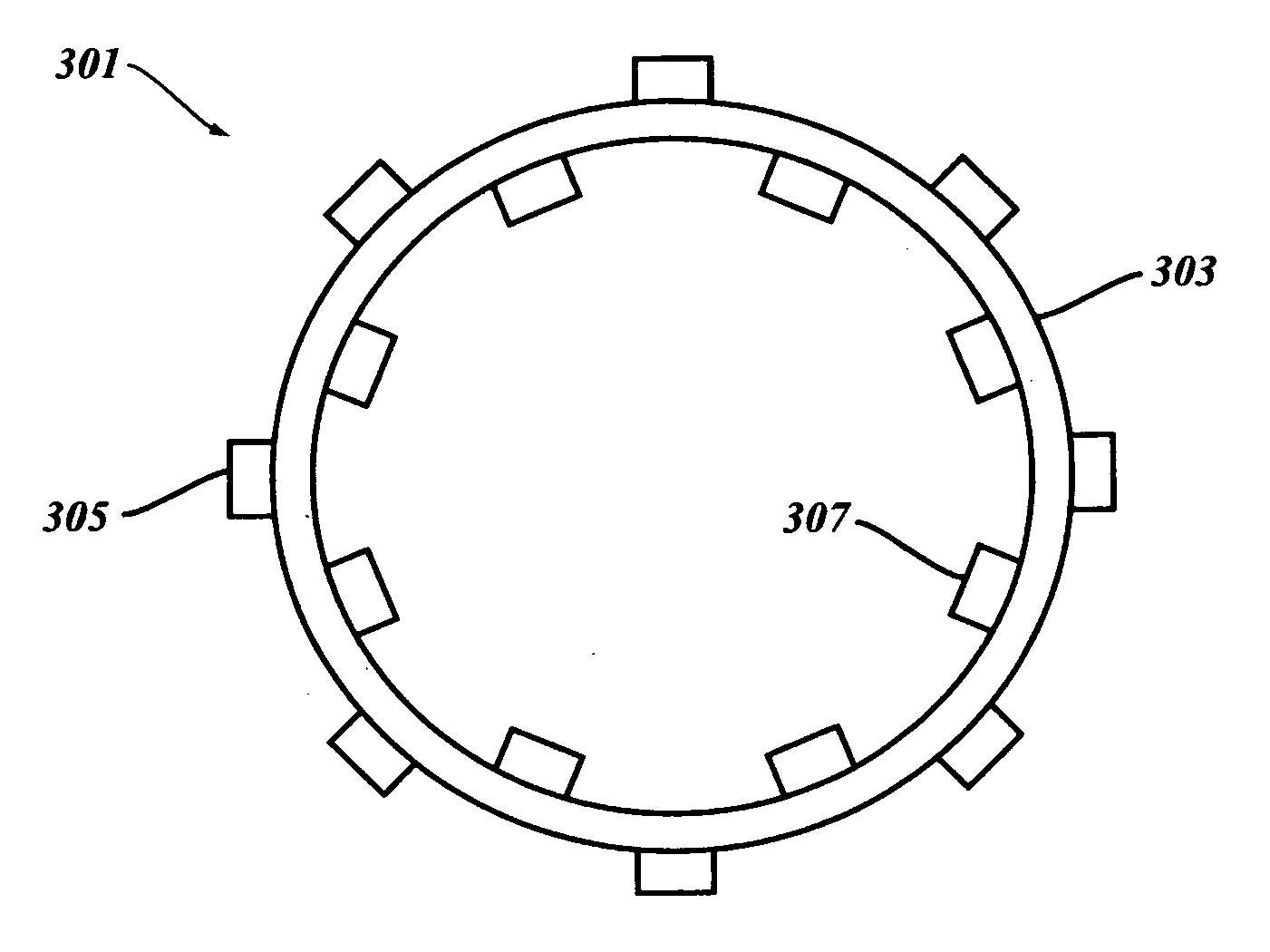

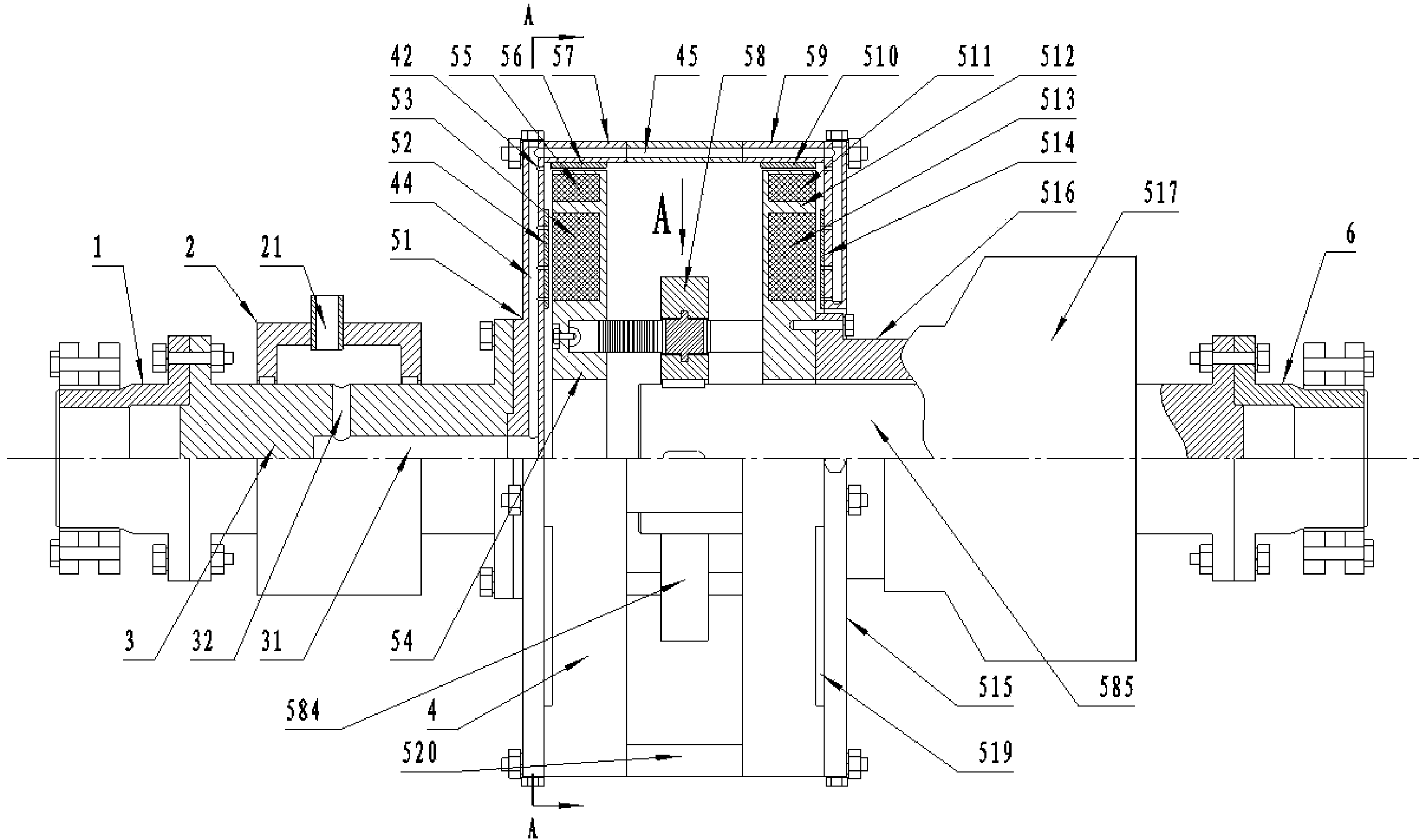

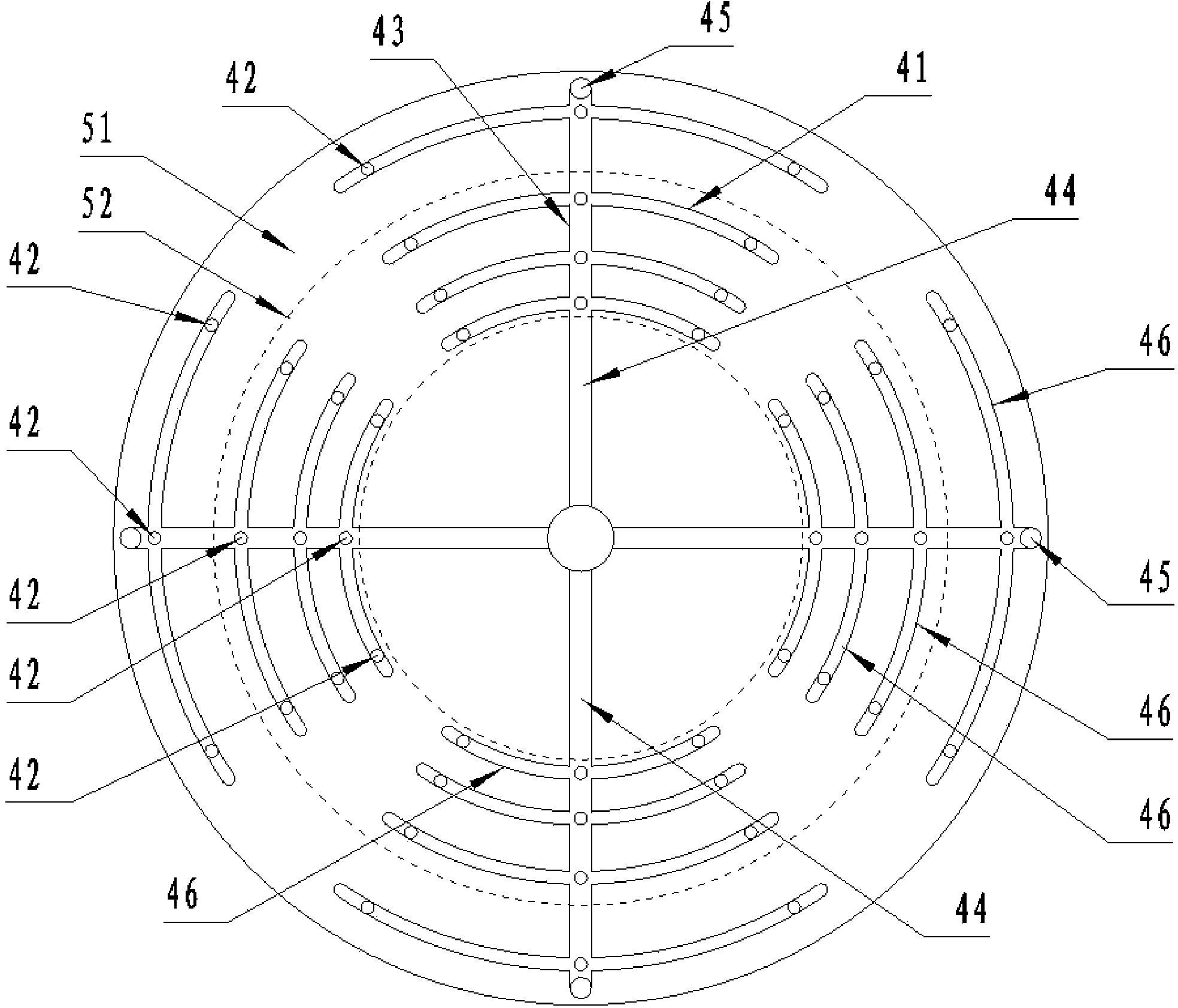

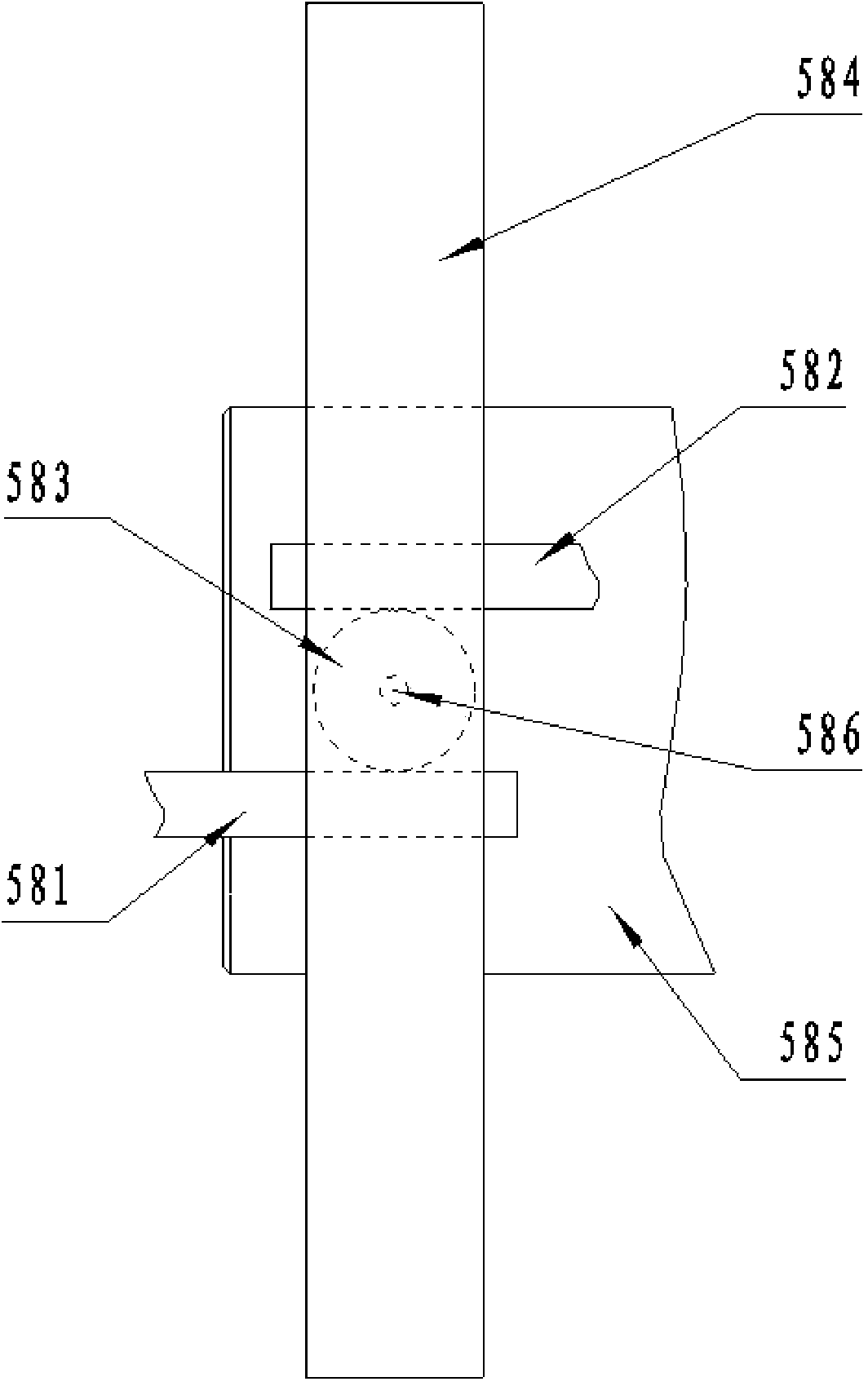

Water-cooling conductor rotor, permanent magnet eddy-current speed controller and permanent magnet eddy-current coupler

ActiveCN104283399AAvoid insufficient coolingGuaranteed cooling effectAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesElectrical conductorCooling effect

The invention provides a water-cooling conductor rotor, a permanent magnet eddy-current speed controller and a permanent magnet eddy-current coupler. The water-cooling conductor rotor comprises a shell (4) and a hollow shaft (3). The shell (4) and the hollow shaft (3) are coaxial, and the shell (4) is fixedly connected with one end of the hollow shaft (3). A cooling water main pipeline (31) is arranged in the hollow shaft (3). A water inlet (32) is formed in the hollow shaft (3). A cooling water branch pipeline (41) is arranged inside the side wall of the shell (4). A plurality of water jetting orifices (42) are sequentially formed in the shell (4) in the radial direction of the conductor rotor. The water inlet (32) is communicated with the water jetting orifices (42) through the cooling water main pipeline (31) and the cooling water branch pipeline (41) in sequence. The permanent magnet eddy-current speed controller with the water-cooling conductor rotor and the permanent magnet eddy-current coupler can jet cooling water to air gaps and the center of a permanent magnet, the whole permanent magnet can be cooled, and the cooling effect is good.

Owner:国能宁夏灵武发电有限公司 +1

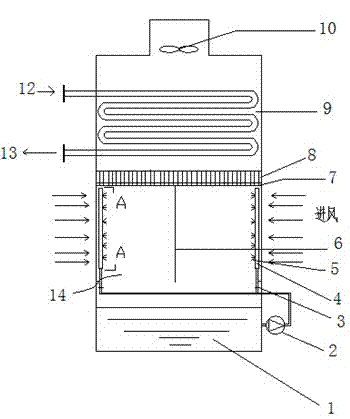

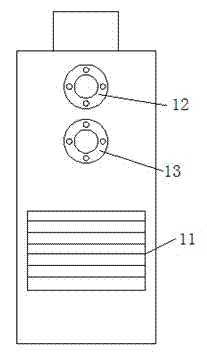

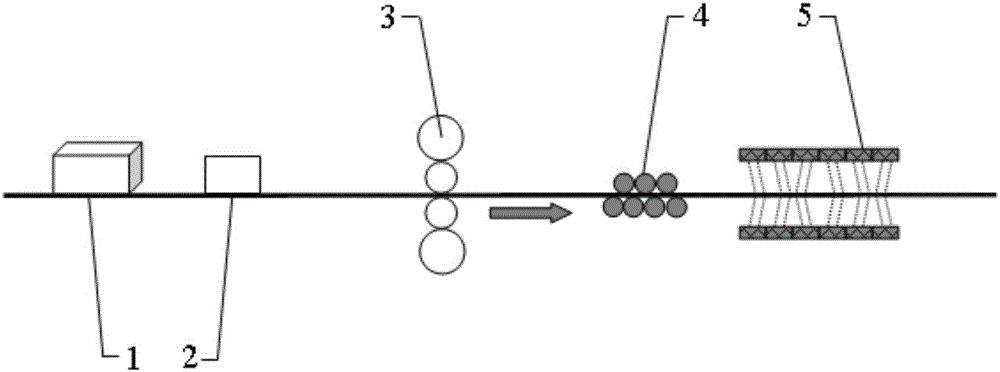

Pulse jet flow finned cooling device

InactiveCN103153023AImprove heat transfer performanceImprove heat transfer coefficientCooling/ventilation/heating modificationsJet flowHeat flow

The invention relates to a cooling device of an electron device, in particular to a pulse jet flow finned cooling device which is a high-efficiency cooling device with a pulse jet flow cooling technology and a finned radiator combined. The pulse jet flow finned cooling device mainly comprises a pulsating flow generating device, a jet flow matrix and the finned radiator. The pulse jet flow finned cooling device is characterized in that an electronic signal drives an acoustic excitation device to generate an unsteady pulsating flow which is jetted onto the finned radiator through the pulse jet flow matrix. Due to the fact that cooling media directly impact the finned surface, and a heat transfer process is strengthened through the unsteady pulsating flow, cooling efficiency is improved, energy consumption is reduced, the electronic device with high heat flux density can be effectively and fast cooled, and jet flow parameters can be set according to requirements to adapt working condition changes.

Owner:CHINA JILIANG UNIV

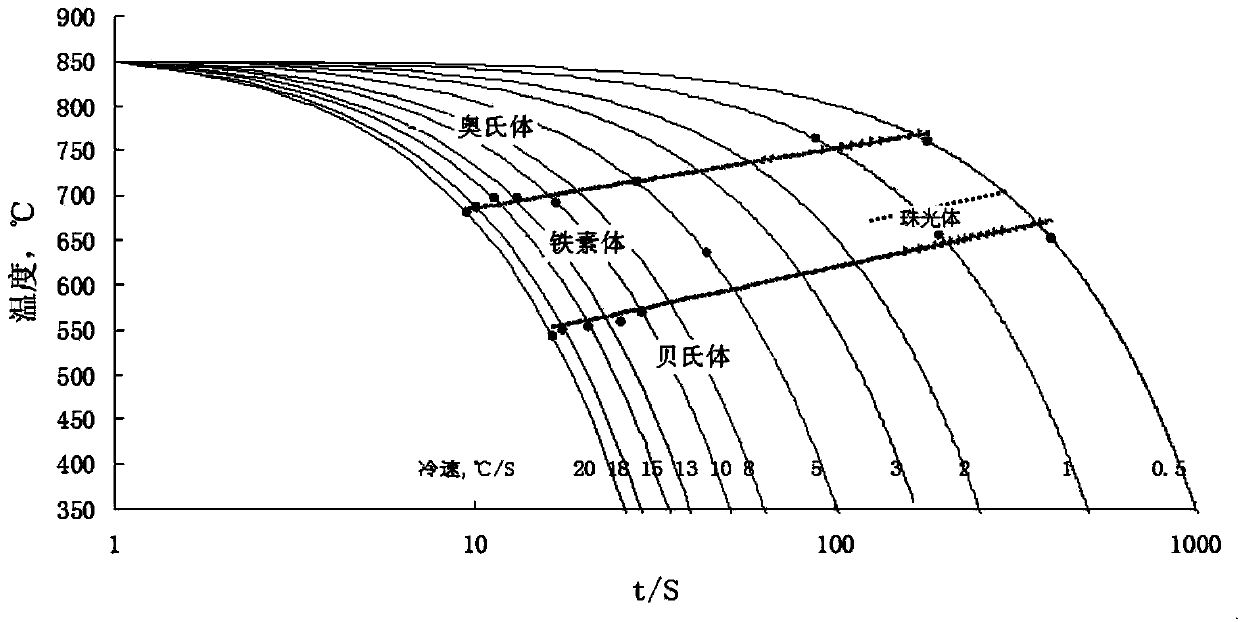

Method for linkage production of high-toughness pipeline steel by adopting jetting and laminar cooling

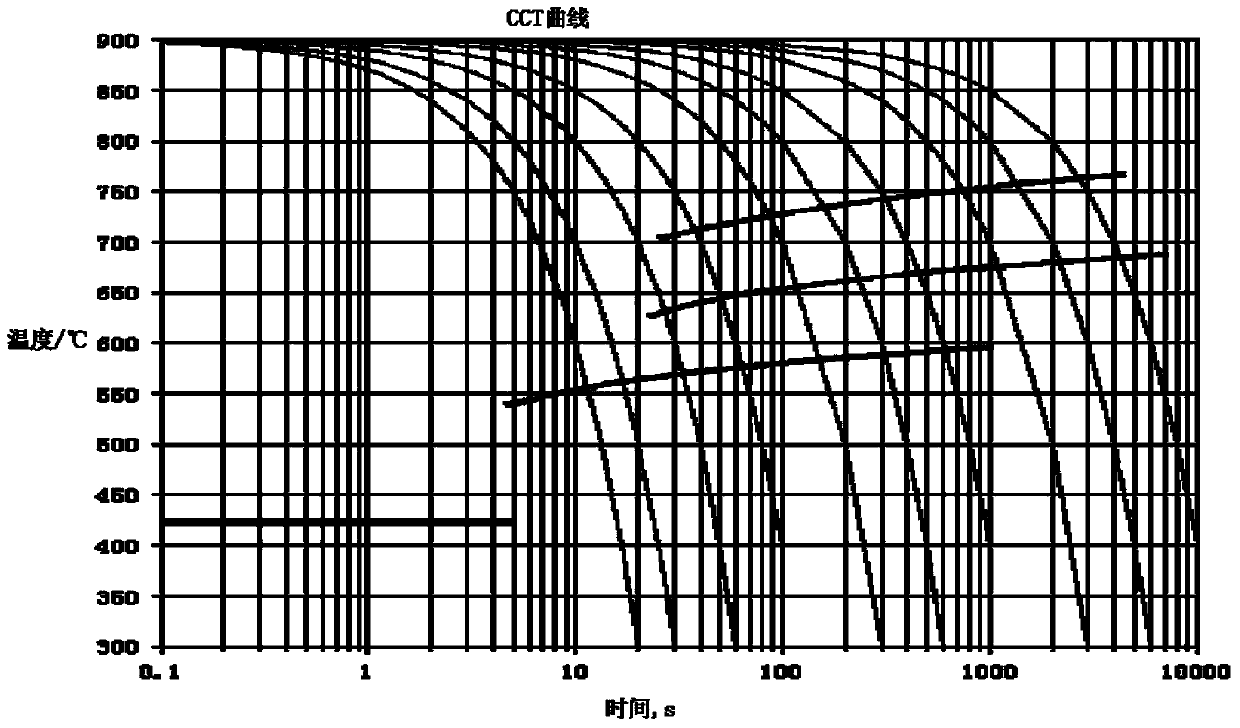

ActiveCN103740925AStable mechanical propertiesEasy to shapeFurnace typesHeat treatment process controlChemical compositionLine tubing

The invention discloses a method for linkage production of high-toughness pipeline steel by adopting jetting and laminar cooling, belonging to the technical field of production of medium-thickness plates. The super-cooled austenite continuous cooling transformation (CCT) curve of a steel plate is measured according to the chemical constituents of the steel plate. The steel plate comprises the following chemical ingredients in percentage by weight: 0.045-0.075 percent of C, 0.1-0.3 percent of Si, 1.55-1.85 percent of Mn, 0.045-0.085 percent of Nb, 0.1-0.2 percent of Mo, 0.1-0.3 percent of Ni, 0.01-0.02 percent of Ti and the balance of Fe and inevitable impurities. The method has the advantages that the problems of low toughness of pipeline steel plates of over grade X80 produced by jet cooling and low strength of pipeline steel plates of over grade X80 produced by laminar cooling are solved, and the high-toughness pipeline steel is produced.

Owner:SHOUGANG CORPORATION

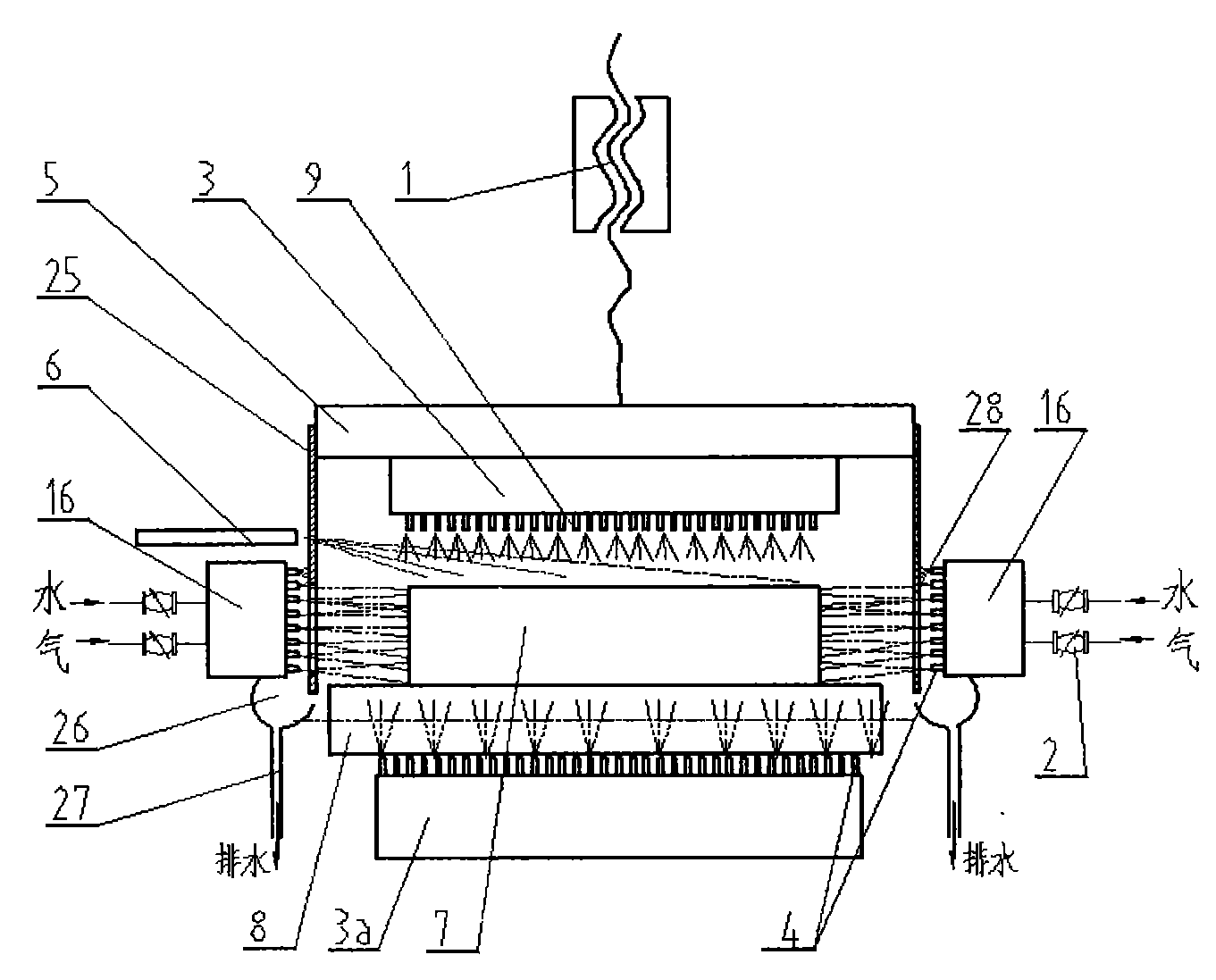

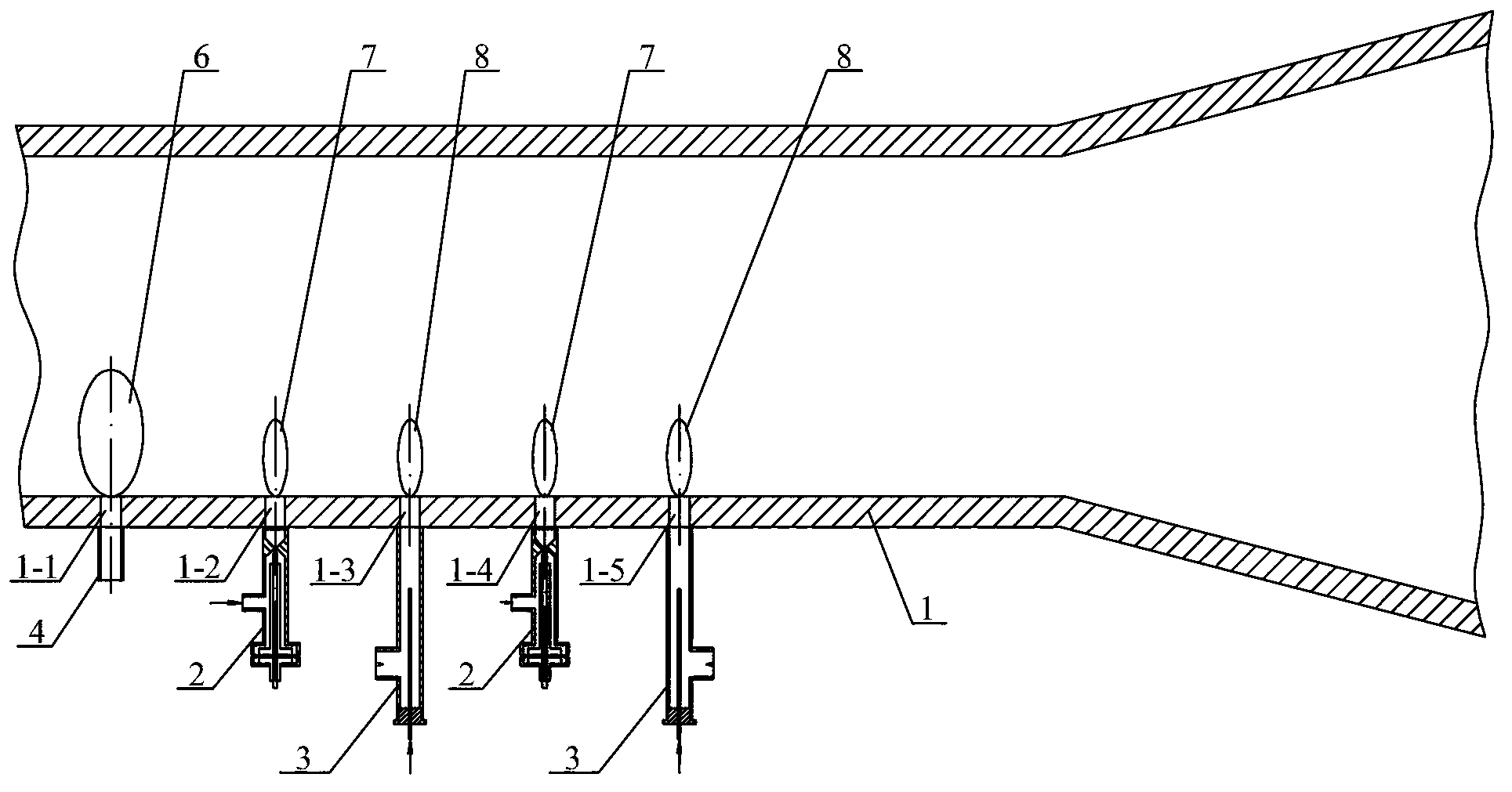

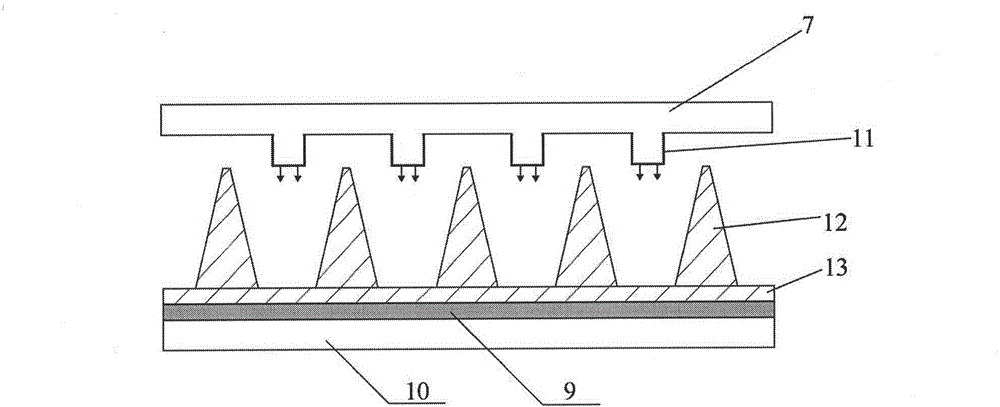

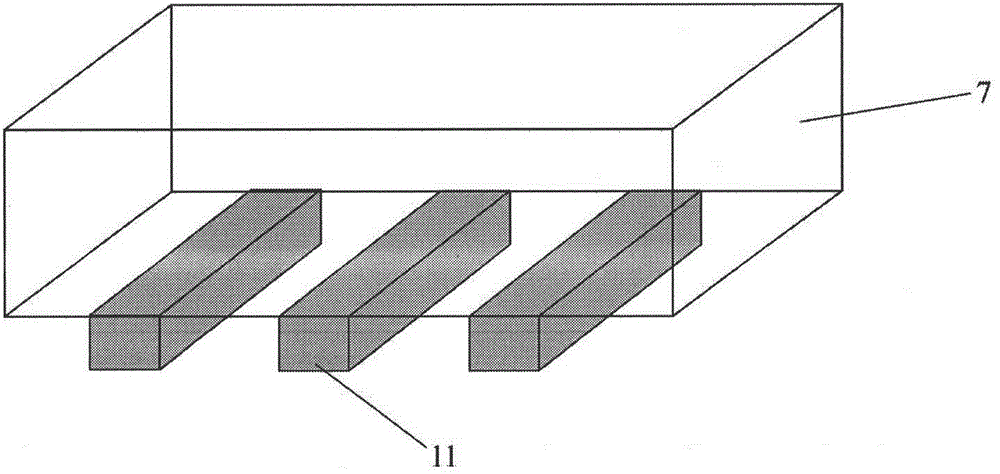

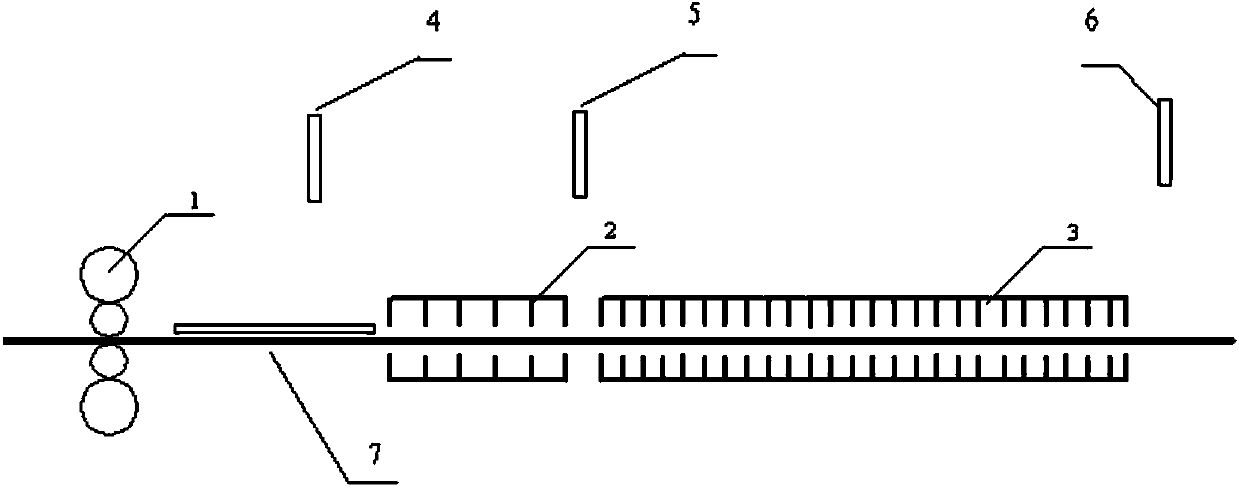

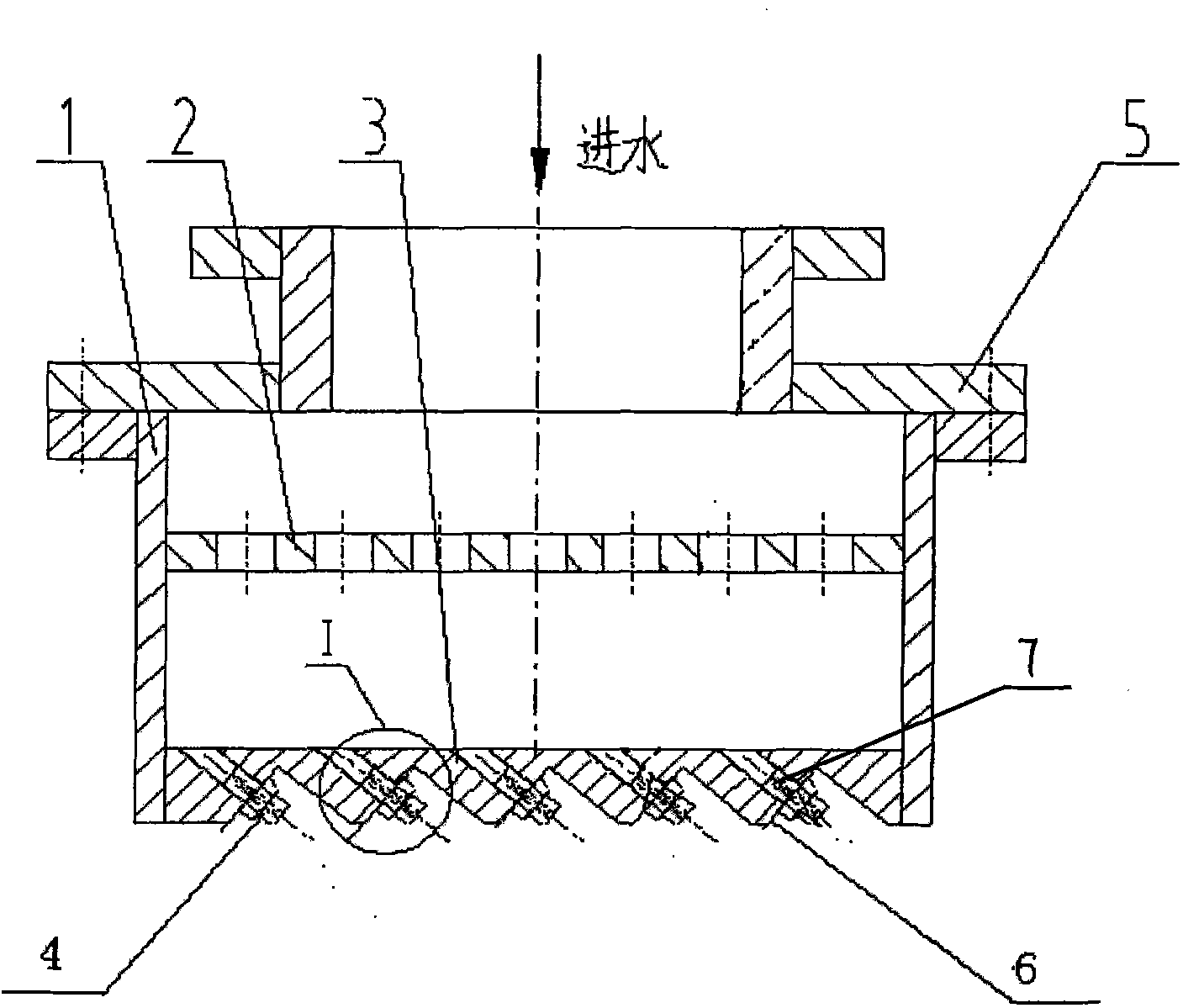

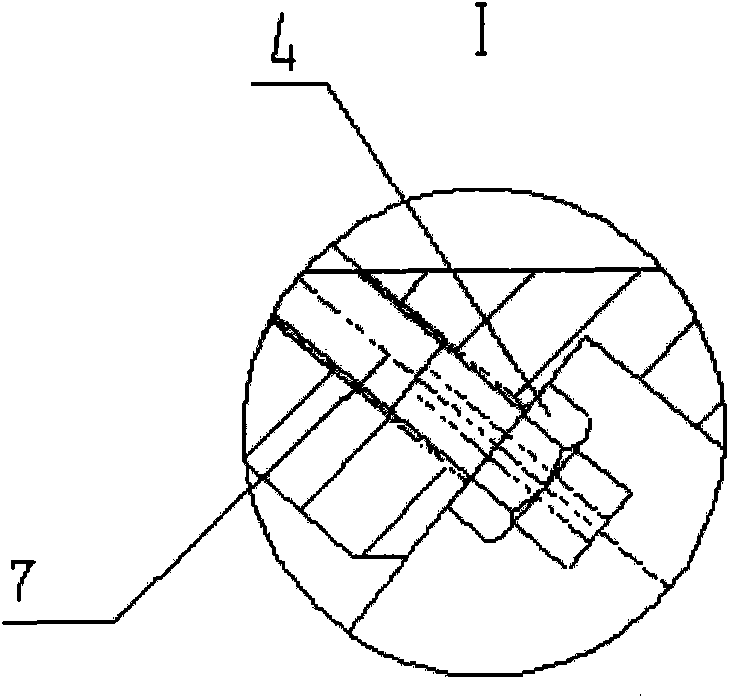

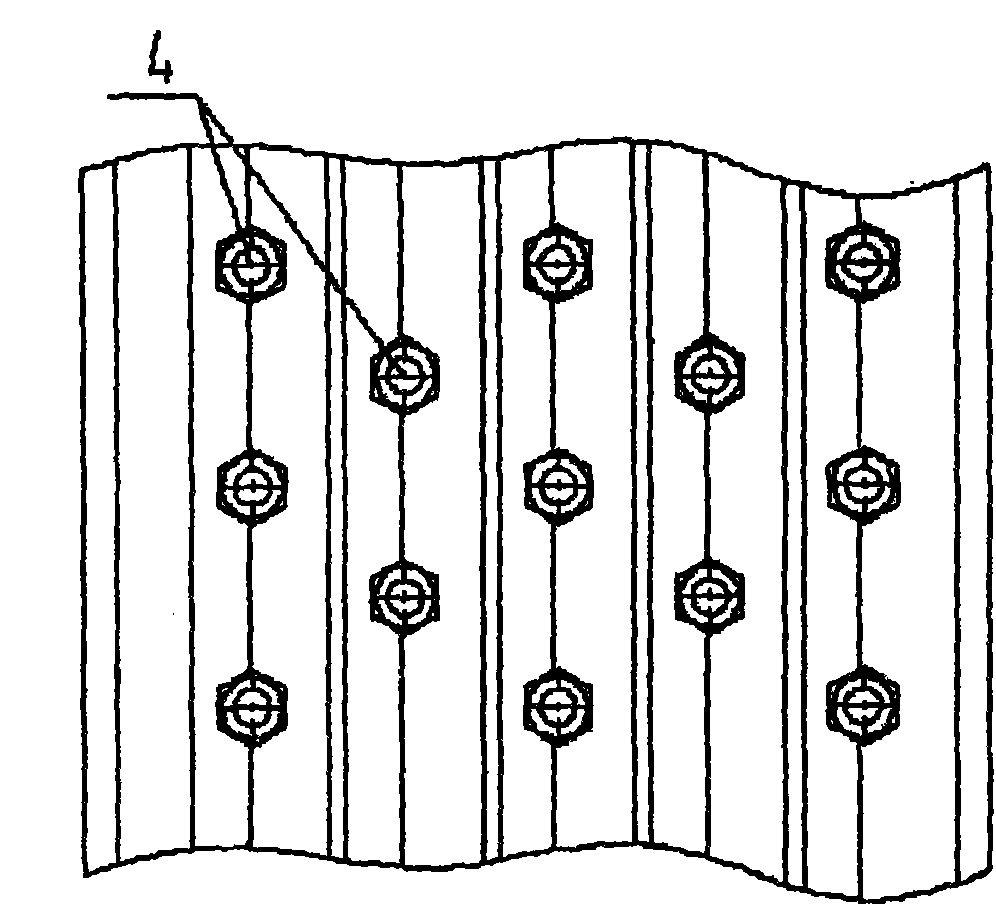

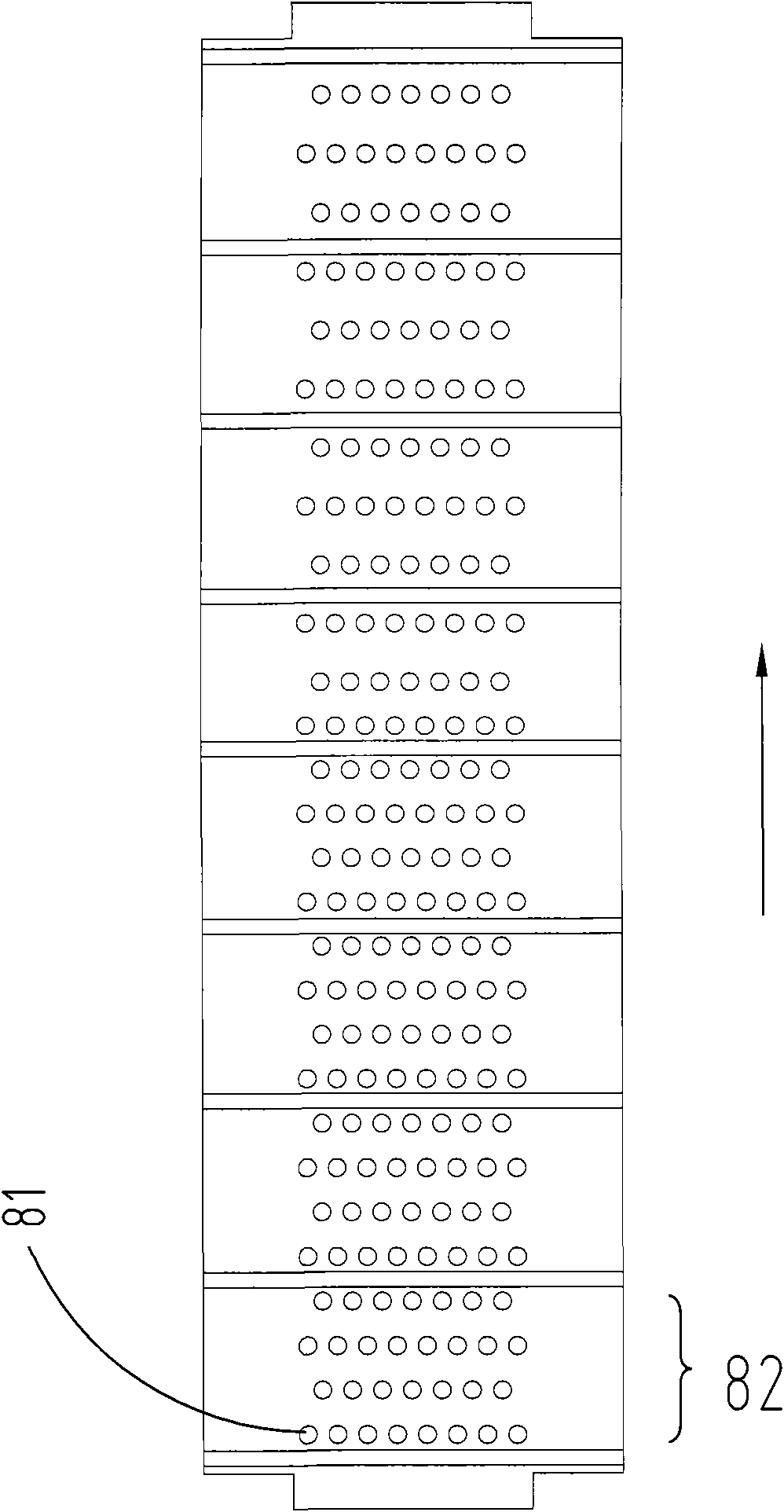

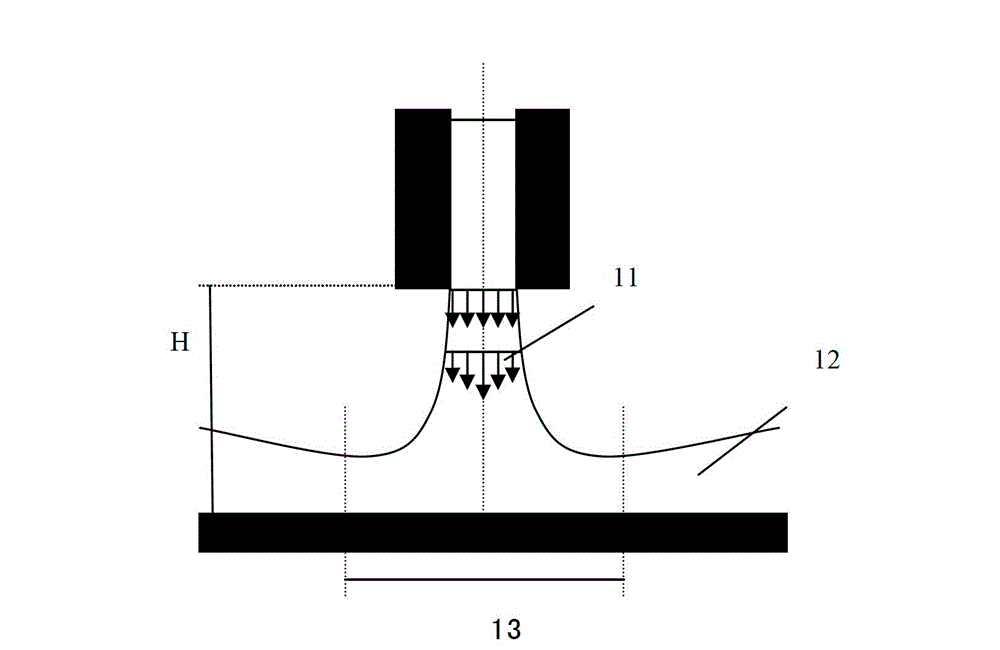

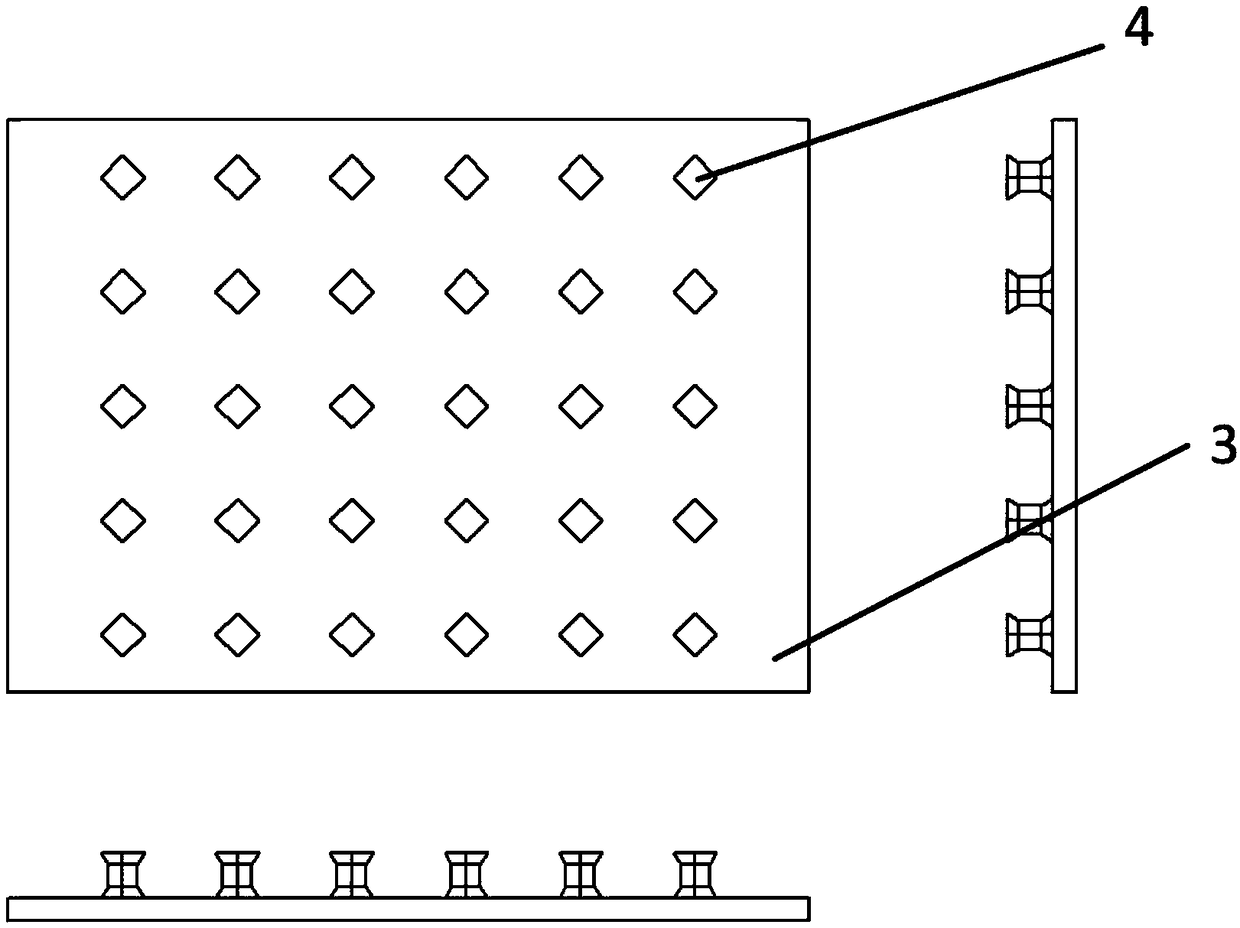

Medium plate on-line quenching inclined jet flow cooler

ActiveCN101935743AAvoid "stuck head" phenomenonLarge water flowFurnace typesHeat treatment furnacesProduction lineCooling effect

The invention relates to cooling technology after the steel rolling production line in the metal processing field, in particular to a medium plate on-line quenching inclined jet flow cooler. The cooler consists of a box body, a damping plate, a cooling panel, nozzles and a water inlet flange; the coolers are arranged in a high-pressure quenching area before a controlled cooling process and between post-rolling conveying roller ways, and the coolers are also up and down symmetrically arranged and vertical to steel plates to be cooled; a plurality of rows of nozzles are obliquely distributed and staggered; and the height between the upper cooler and the steel plates are adjustable. The cooler has the characteristics that: the cooling range is large, the space between roller ways is not required, the width of the box body and the number of rows of nozzles of the cooler can be adjusted according to the space between roller ways and the cooling speed, the phenomenon that the warped steel plates are stuck between the gaps between the coolers and the roller ways is eliminated, and the steel plates are quickly and uniformly cooled so as to achieve the expected cooling effect.

Owner:UNIV OF SCI & TECH BEIJING

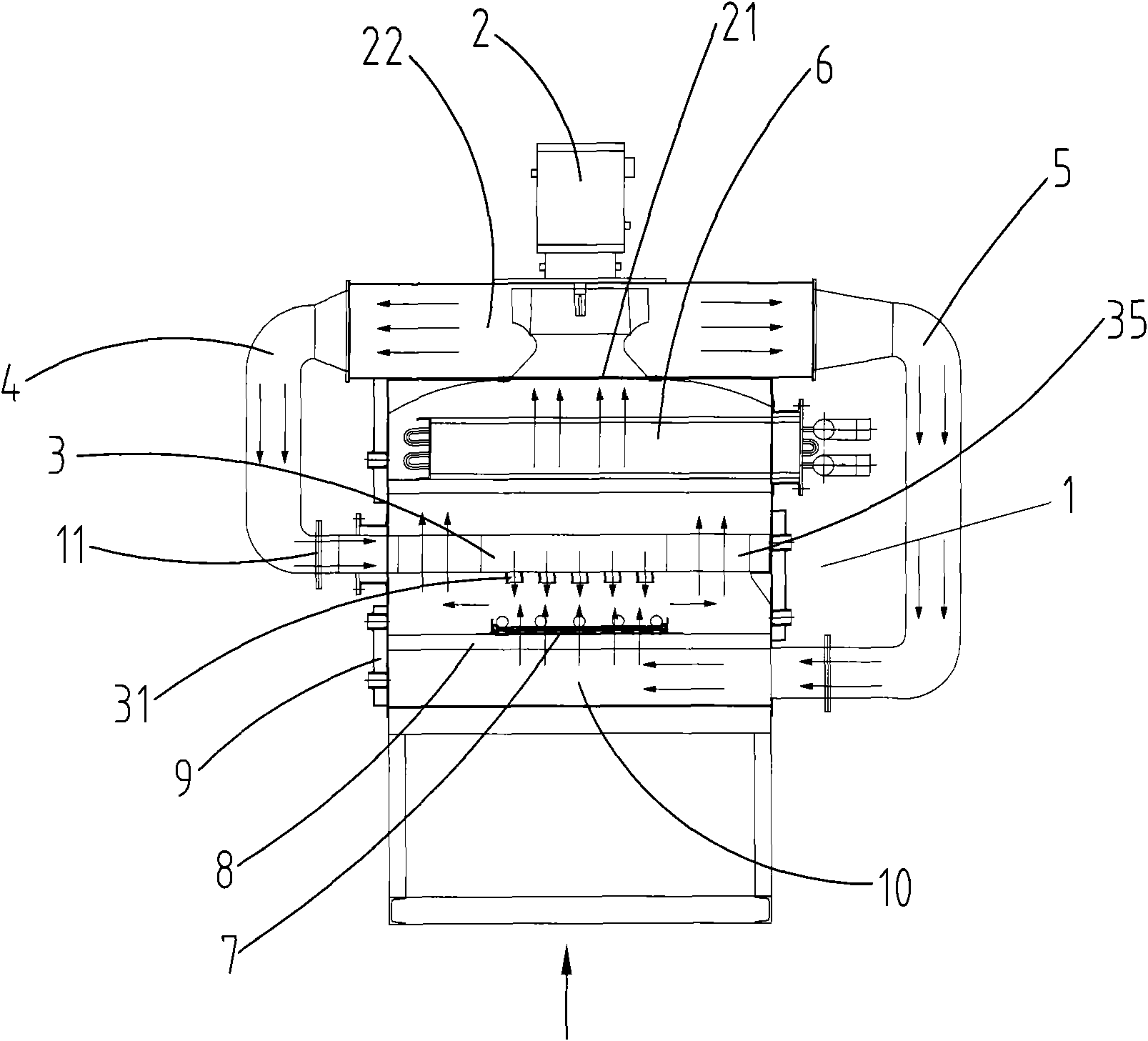

Jet cooling device for heat treatment furnace

ActiveCN101979675AImprove cooling effectCooling suitable forQuenching agentsQuenching devicesCooling chamberHeat exchanger

The invention discloses a jet cooling device for a heat treatment furnace. The jet cooling device comprises a circulating fan, an air-cooling chamber, a bearing table, a heat exchanger, an air jet body and a first passage, wherein the circulating fan is provided with an air inlet and an air outlet; the upper part of the air-cooling chamber is communicated with the air inlet of the circulating fan; the bearing table is arranged inside the air-cooling chamber and is used for bearing a workpiece; the heat exchanger is arranged inside the air-cooling chamber and is positioned above the bearing table; the air jet body is arranged inside the air-cooling chamber; two ends of the first passage are respectively communicated with the air outlet of the circulating fan and the air jet body; a plurality of air jet holes facing the bearing table are formed on the air jet body; and the distribution density of the air jet holes is gradually reduced from a feeding end to a discharging end. The jet cooling device has large air jet quantity at the feeding end and can improve the cooling speed of a front section of the workpiece.

Owner:SUZHOU ZHONGMENZI TECH

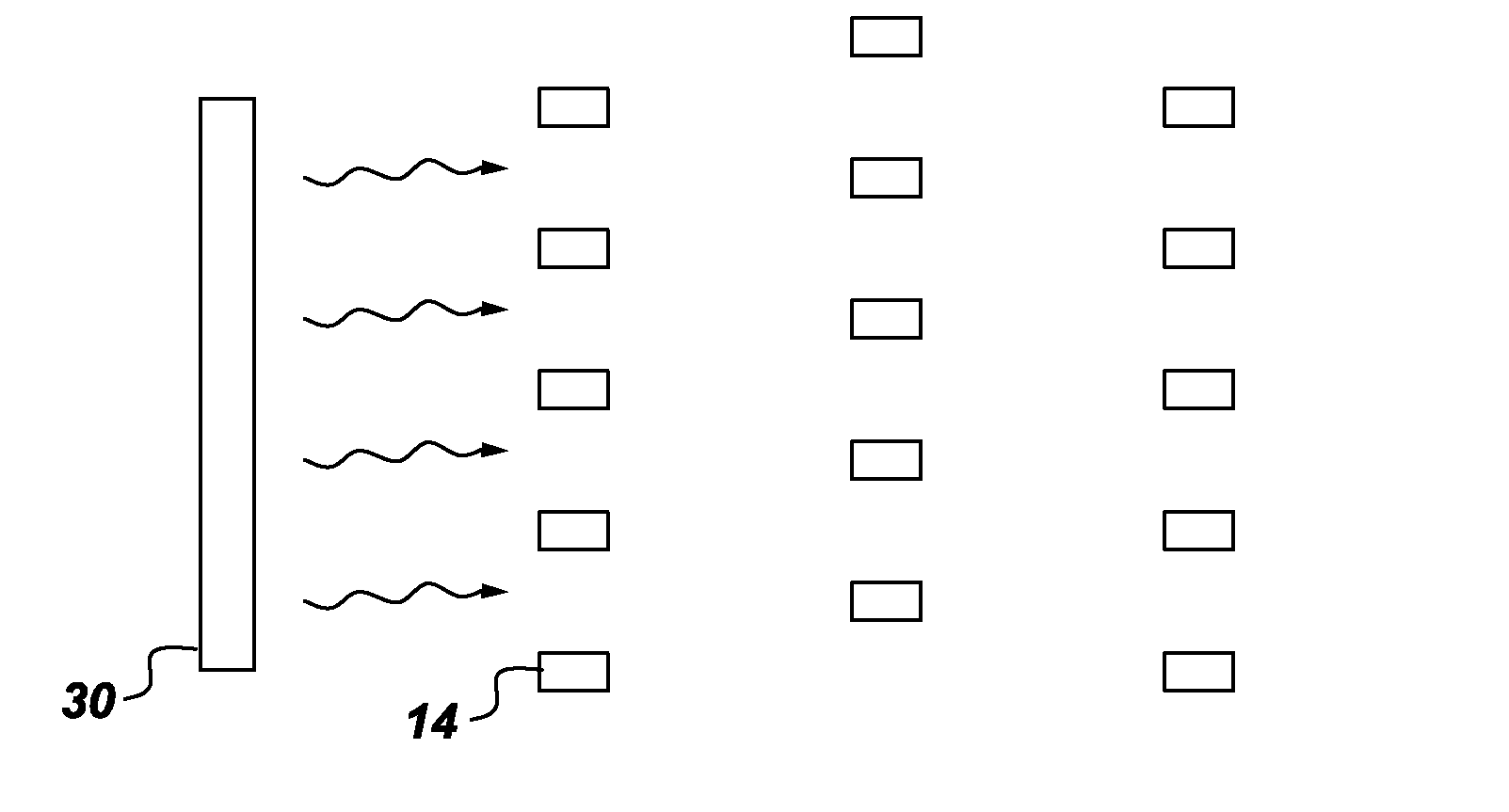

Cooling device utilizing internal synthetic jets

InactiveCN101889485ALow costSmall optical perturbationPoint-like light sourceSemiconductor/solid-state device detailsJet flowTransducer

A synthetic jet cooling device (1) for cooling an object (5), comprising: a transducer (10) adapted to generate velocity waves, and an enclosure (4) arranged to receive the velocity waves via an actuated aperture (8). The enclosure (4) is sufficiently large to generate, at the actuated aperture (8), an internal synthetic jet inside the enclosure (4). Furthermore, the enclosure (4) is arranged to contain the object (5), thereby enabling cooling ofthe object (5) bythe internal synthetic jet. The arrangement typically permits multifunctional use ofan existing enclosure, containing the object to be cooled, both for its original purpose (e.g. a reflector in a lamp, or a LED backlight module) and as an enclosure generating internal synthetic jets, why the cooling device typically requires virtually noextra space and weight, and can be provided at a low cost.

Owner:SIGNIFY HLDG BV

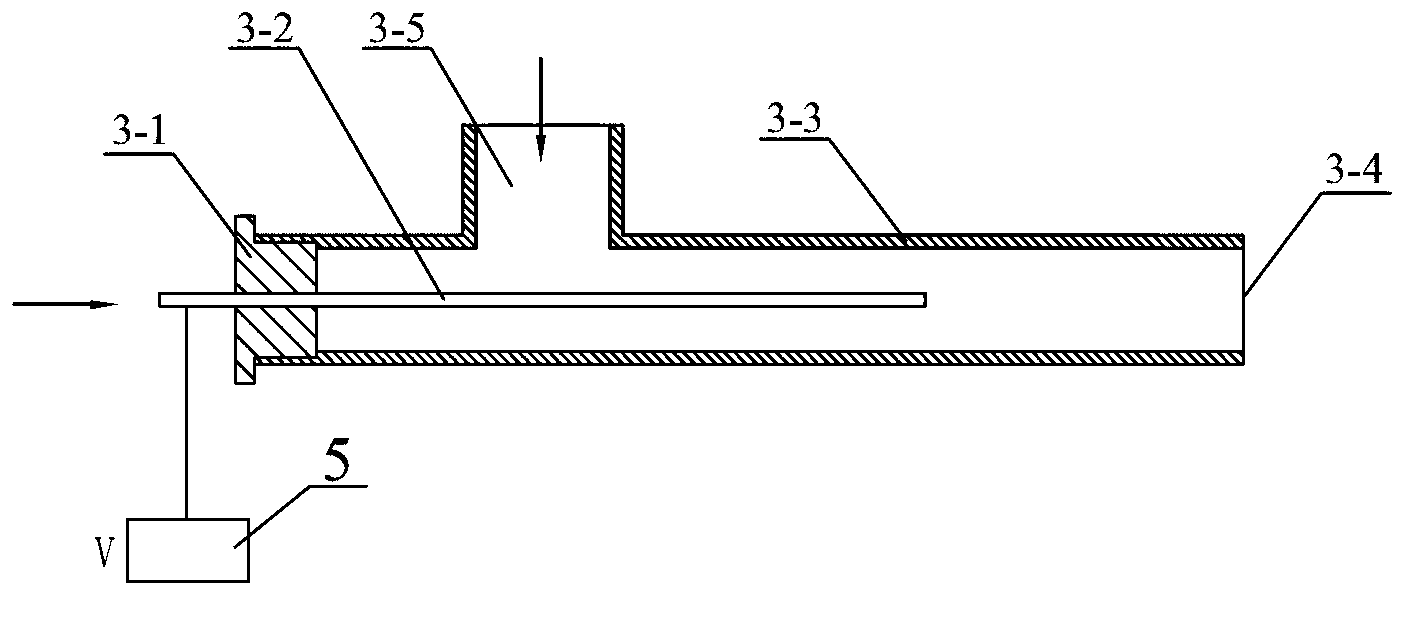

Big-caliber foundation solar telescope hot field diaphragm cooling device based on jet cooling principle

The invention provides a big-caliber foundation solar telescope hot field diaphragm cooling device based on a jet cooling principle. The device comprises a liquid inlet channel, a pressure cavity, a spraying pipe, a jet flow cavity, a reflection panel and a liquid outlet channel. According to fluid continuity and a jet flow cooling principle, the big-caliber foundation solar telescope hot field diaphragm cooling device greatly improves cooling efficiency, and overcomes the defects that a traditional hot field diaphragm cooling device using forced water cooling needs large amounts of cooling liquid and is not uniform in temperature distribution after cooling, and the like. The hot field diaphragm cooling device has high cooling efficiency and can achieve good cooling effects with small cooling liquid flow. Meanwhile, a surface temperature of a diaphragm is low after cooling, temperature distribution is uniform, damage to air seeing in the working process of the diaphragm of a hot field is further reduced, and telescope imaging quality is effectively improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

On-line quenching and plate shape control process of wide and thick plate for water and electricity

ActiveCN106350645ASave resourcesShorten the development cycleFurnace typesHeat treatment process controlElectricityProduction line

The invention relates to an on-line quenching and plate shape control process of wide and thick plate for water and electricity. According to the process, jet cooling on-line quenching is performed by using positive jetting, positive jetting and reverse jetting as one unit; in a jet impact region, cooling water and the surface of a steel plate perform heat exchange; meanwhile, most of cooling water is limited in the jet impact region using the positive jetting, positive jetting and reverse jetting as the unit. According to the thickness specification classification of the (wide) thick plate for water and electricity; the passing type cooling or swinging type cooling on-line quenching is selected; the maximum heat exchange efficiency of cooling water and the steel plate is realized; a good cooling plate shape is obtained. The process has the advantages that the temperature uniformity of an on-line quenching steel plate through plate is ensured; the off-line quenching of the (wide) thick plate for water and electricity is transplanted to on-line production; the production flow is simplified; the production cost is reduced; meanwhile, heat treatment production line resources are saved; the cargo supply period is shortened.

Owner:NANJING IRON & STEEL CO LTD

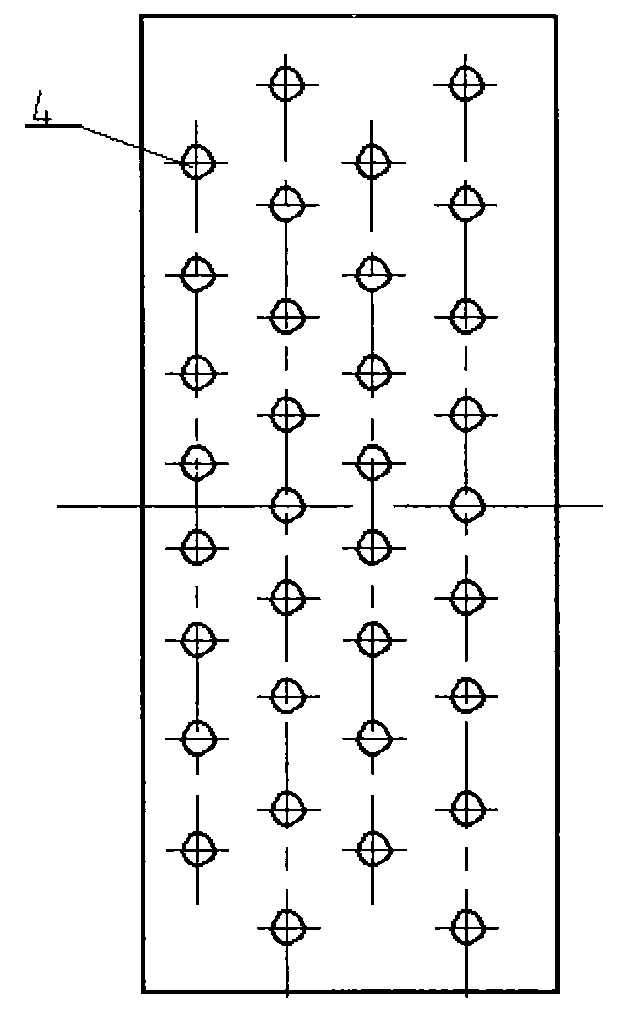

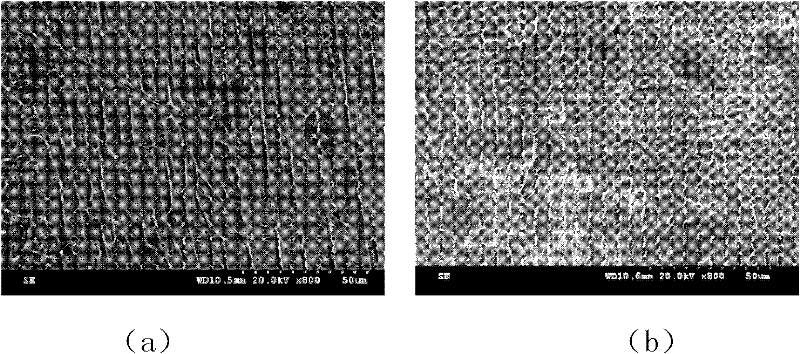

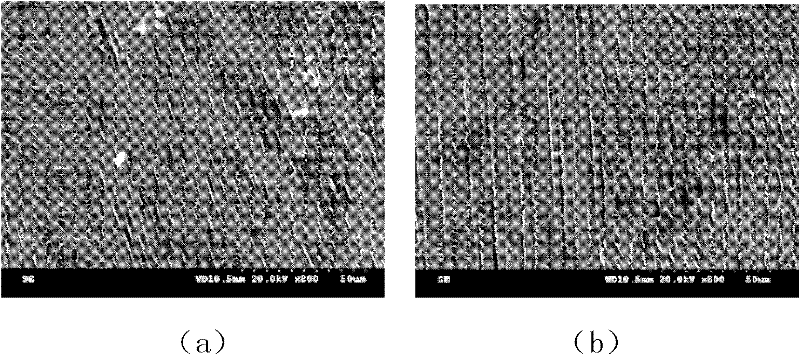

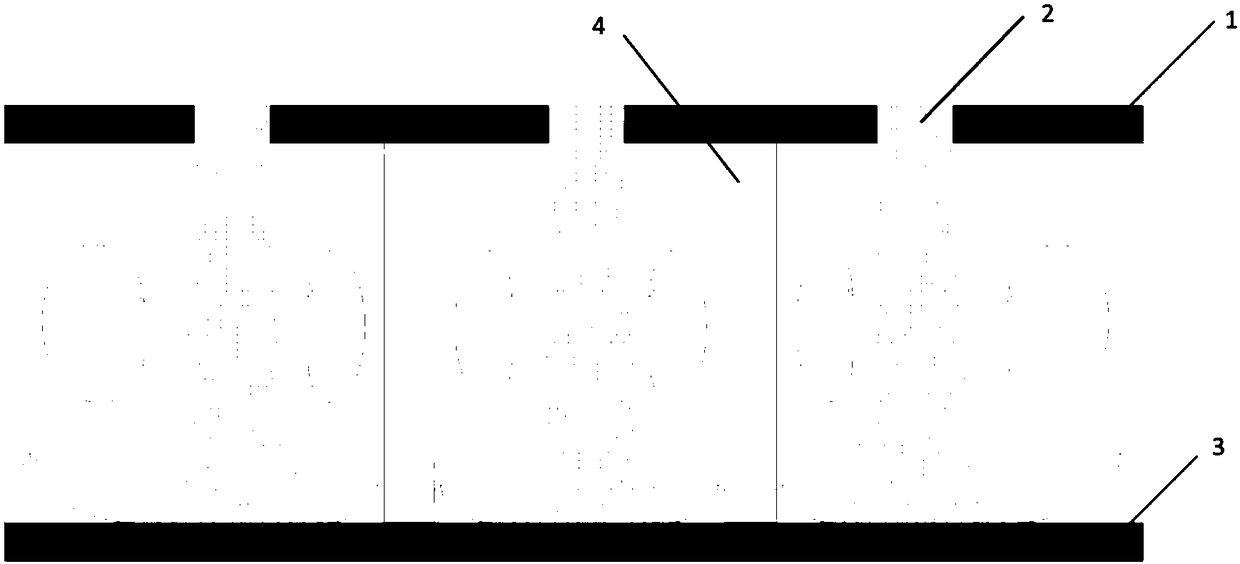

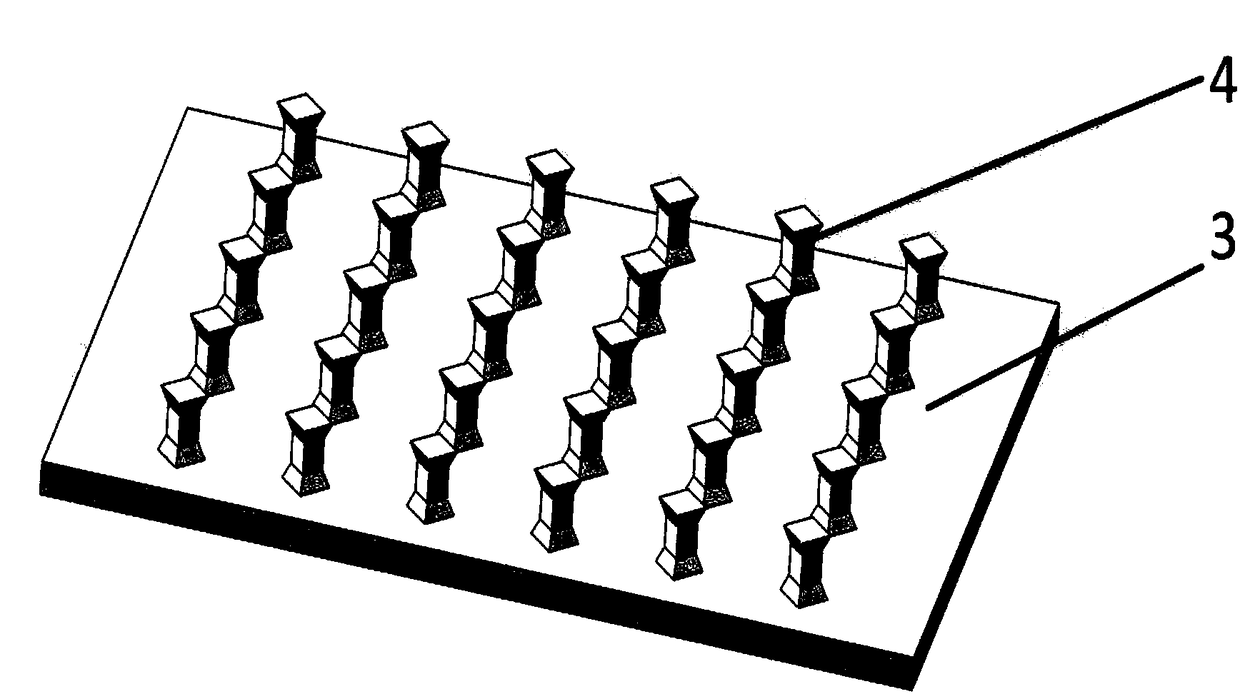

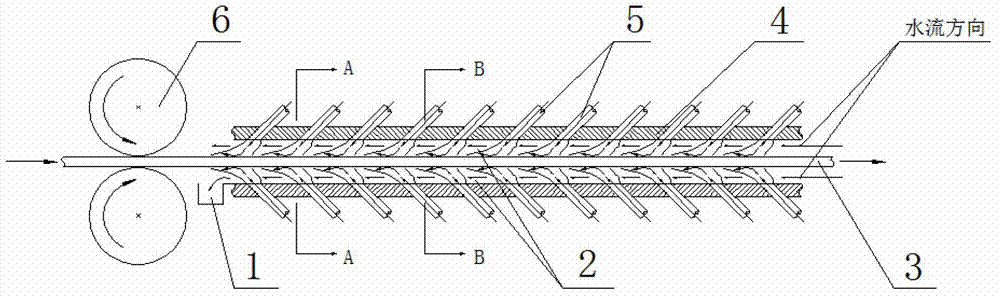

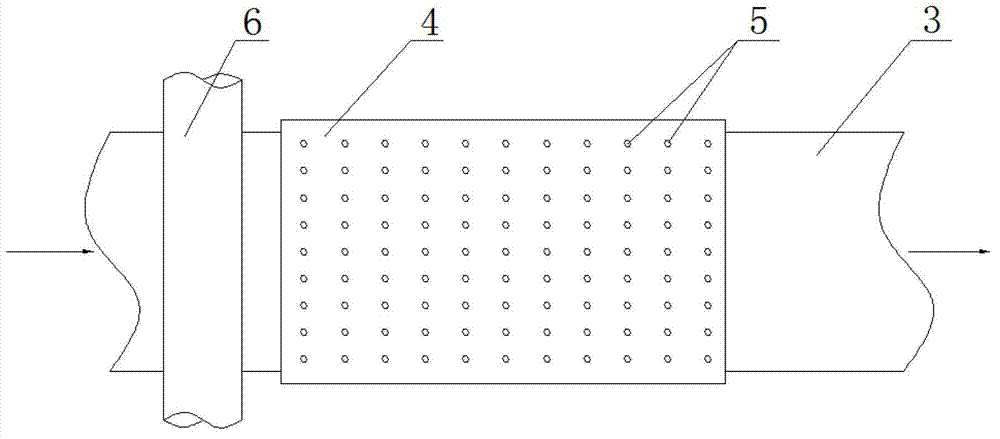

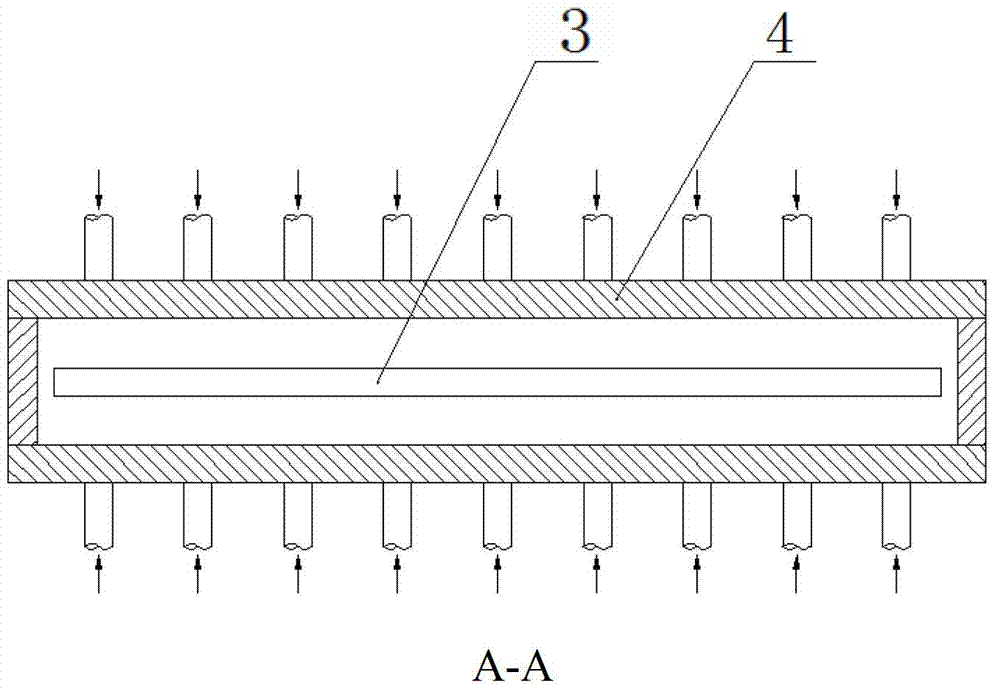

Turbulence structure in array jet cooling

ActiveCN108223022AUniform temperatureImprove heat transfer efficiencyEngine fuctionsBlade accessoriesJet flowPrism

The invention belongs to the field of cooling of high-temperature parts of gas turbines and aero-engines and some other fields involving array impact jet cooling, in particular to an efficient turbulence column structure in array jet cooling. According to the technical scheme, three turbulence column structure designs are provided, a jet flow target plate with four-prism-shaped turbulence column arranged in an array mode, a jet flow target plate with crescent arc-shaped columnar turbulence columns arranged in an array mode, and a jet flow target plate with dumbbell-shaped turbulence columns arranged in an array mode are comprised. The design has the advantages that the minimum amount of cooling air is used, the cooling efficiency is improved to the maximum degree, the overall temperature gradient of the cooling wall surface is reduced, so that the heat transfer is more uniform and stable.

Owner:SHENYANG AEROSPACE UNIVERSITY

Jet flow cooling method and device in narrow slit water jacket passage of steel plate

InactiveCN102756000AReduce cooling rateGood even coolingWork treatment devicesMetal rolling arrangementsSteel platesSpray nozzle

The invention discloses a jet flow cooling method in a narrow slit water jacket passage of a steel plate, wherein a flat rectangular hollow tubular water jacket is sleeved on the periphery of a hot rolled steel plate in a cooling region, narrow slit passages are formed between the upper and lower walls of the water jacket and the hot rolled steel plate, inclined jet flow nozzles with inward openings are installed on the upper wall and the lower wall of the water jacket, cooling water is injected into the narrow slit passages through the jet flow nozzles in an inclination manner to form vapor-liquid two-phase flow with the vapor generated on the surface of the hot rolled steel plate, the cooling water flows out from the ports of the narrow slit passages and flows into a circulating water storage tank arranged at the port of the water jacket; and the invention further provides a cooling device of executing the method. The method disclosed by the invention achieves the two technical effects of quick cooling and uniform cooling at the same time, and the method has the advantages of low water consumption and convenience in cooling capability adjustment, and the device is simple and convenient in installation.

Owner:SHANGHAI JIAO TONG UNIV

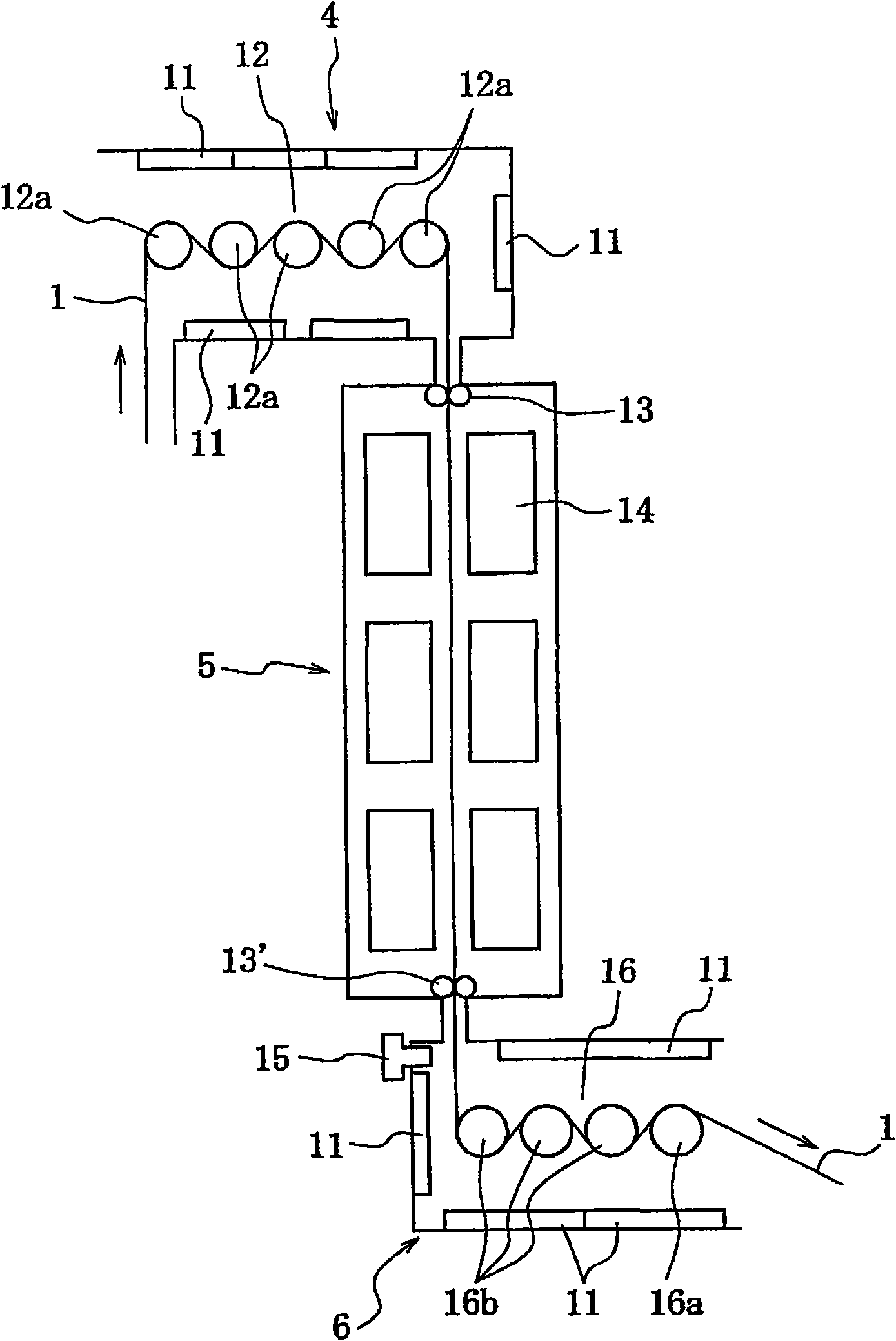

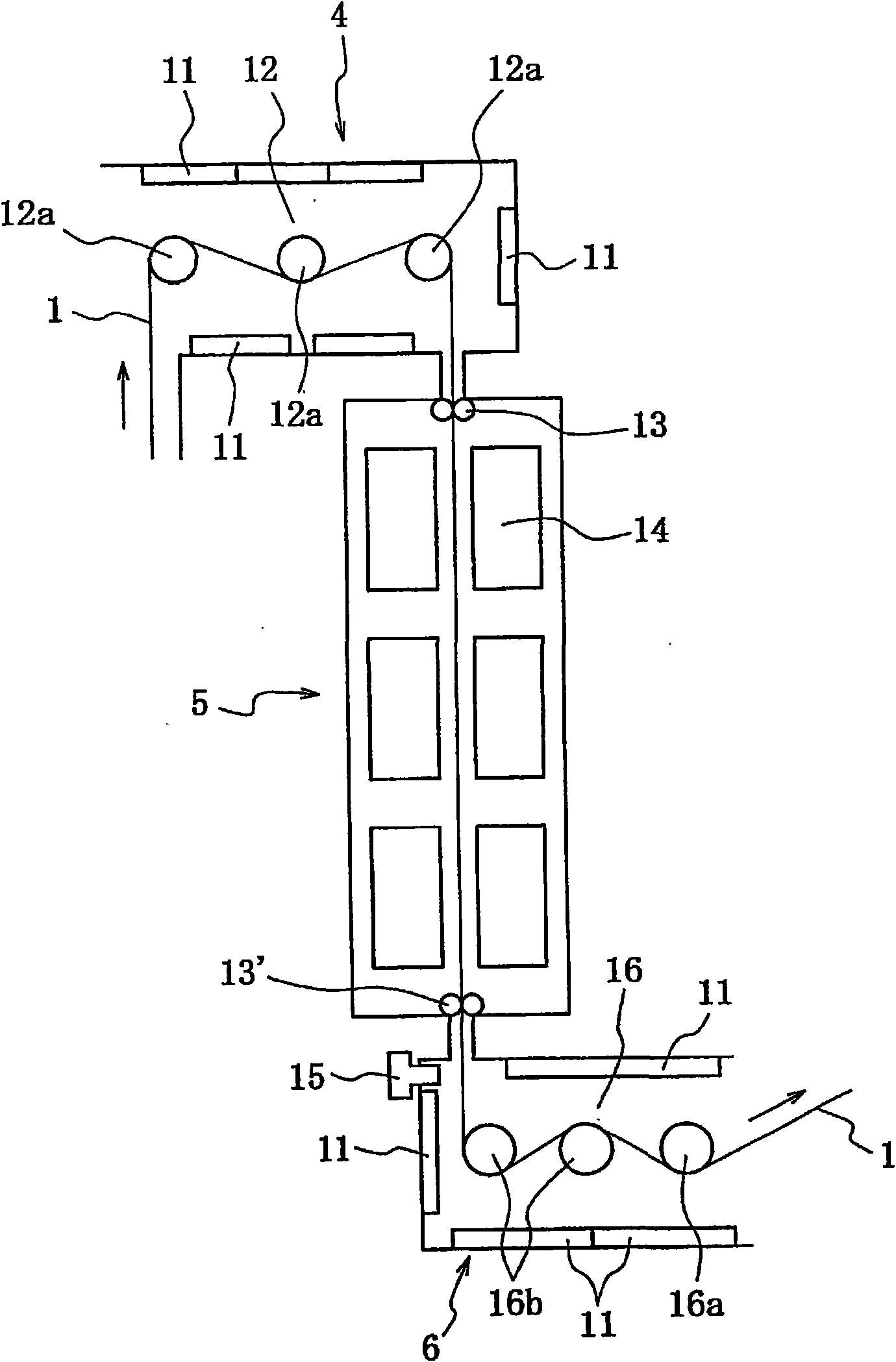

Continuous annealing equipment

InactiveCN101611159AQuality improvementImprove yieldFurnace componentsIncreasing energy efficiencyInduction heaterStrip steel

This invention provides continuous annealing equipment which can eliminate temperature non-uniformity along the widthwise or transverse direction of a steel strip at an exit side of a rapid cooling zone having gas jet cooling equipment and prevent the development of a stretcher strain or a wrinkle pattern of a bake-hardening steel sheet. The continuous annealing equipment is a continuous annealing equipment for a steel sheet, at least containing: a heating zone, a soaking zone, and a rapid cooling zone, the rapid cooling zone having gas jet cooling equipment and being provided with at least one pair of seal rolls at each of an inlet and an outlet thereof and bridle roll units each composed of two or more bridle rolls in front of and behind itself; the bridle roll unit behind the rapid cooling zone having two or more heating rolls each having an induction heater thereinside; and the heating roll having a winding angle of 100 DEG or more per heating roll and 380 DEG or more in total of all the heating rolls.

Owner:JFE STEEL CORP

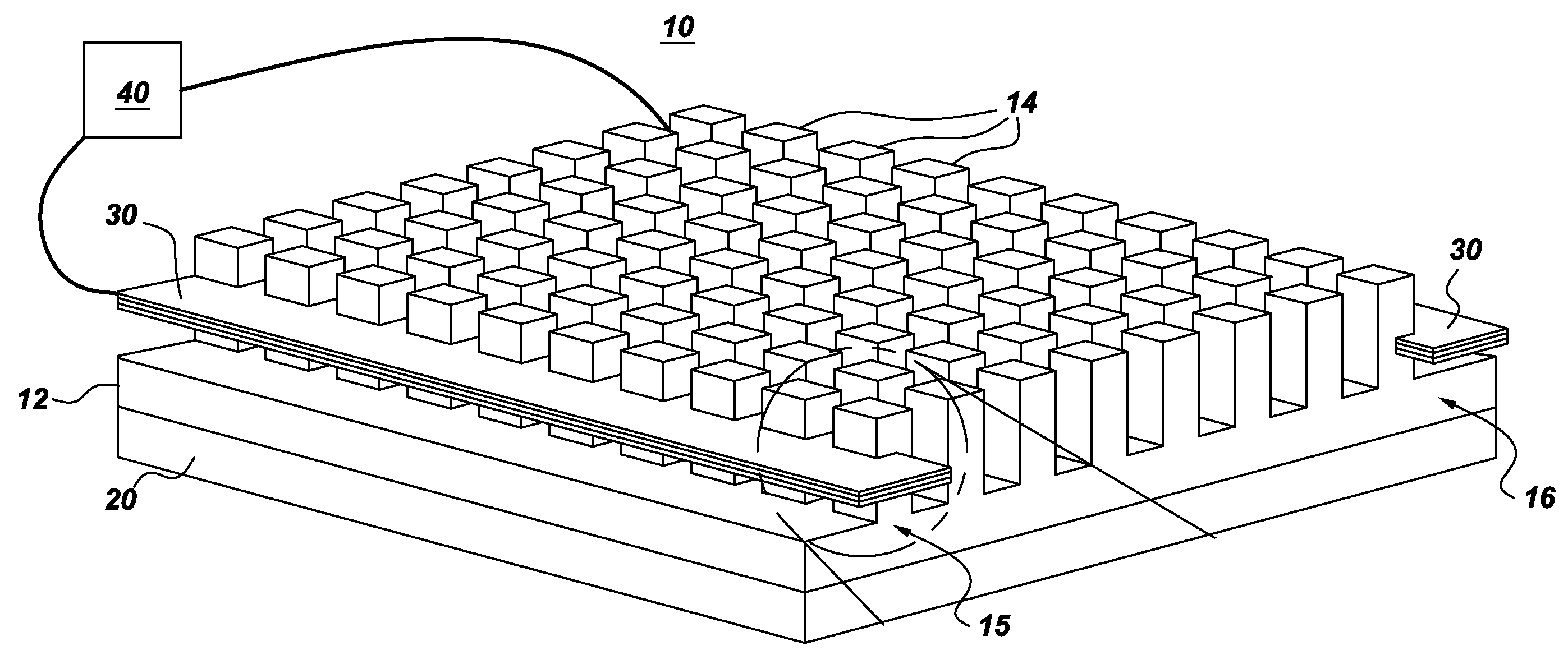

Heat sinks with distributed and integrated jet cooling

InactiveUS8496049B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A heat sink with distributed jet cooling is provided. The heat sink includes a base for thermal connection to at least one heated object, an array of fins thermally coupled to the base, and at least one multi-orifice synthetic jet or multiple single orifice jets disposed on a side of the array of fins. A heat sink with distributed and integrated jet cooling is also provided and includes a base and an array of fins. Respective ones of at least a subset of the fins comprise a synthetic jet configured to eject an ambient fluid into an ambient environment of the fins and base. Another heat sink with distributed and integrated jet cooling is provided and includes a base, an array of fins and multiple synthetic jets coupled to respective ones of the fins. The synthetic jets are provided for at least a subset of the fins.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com