Jet flow cooling method and device in narrow slit water jacket passage of steel plate

A technology of jet cooling and water jacket, which is applied to the cooling of hot-rolled steel sheets and the field of jet cooling in narrow water jacket channels, can solve the problems of large power consumption, large water consumption, large water demand, etc., and achieves convenient adjustment of cooling capacity, Small cooling rate, good uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred modes of the invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

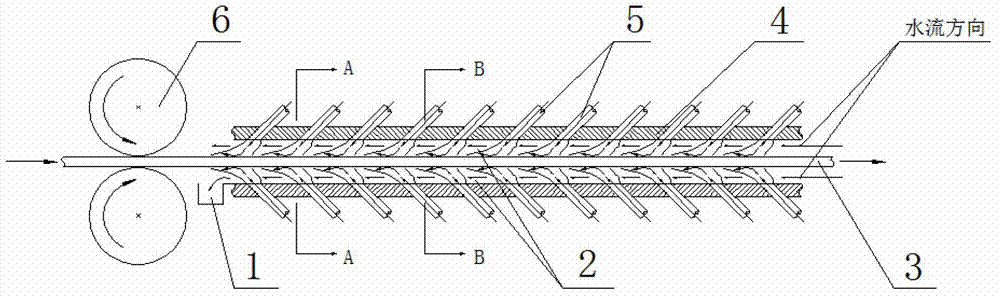

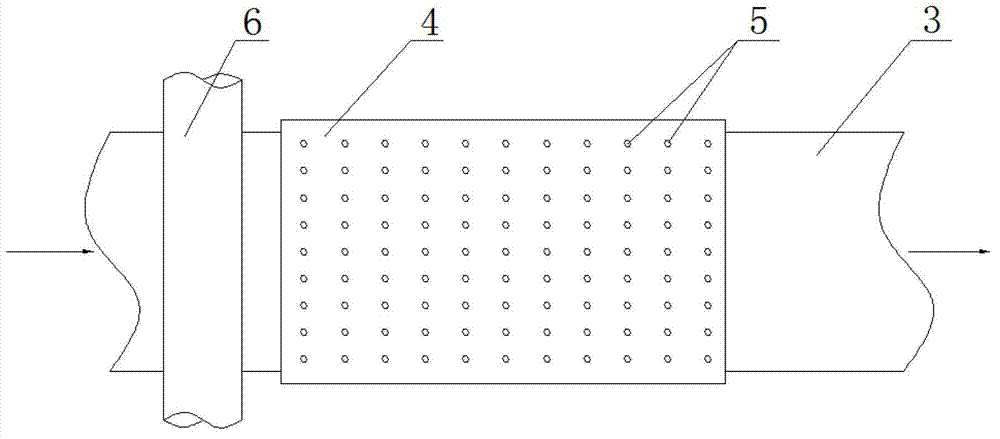

[0026] like figure 1 , figure 2 In the shown embodiment, the jet cooling device in the channel of the steel plate narrow slit water jacket includes a high-pressure water tank, a regulating valve, a plurality of jet nozzles 5, a water jacket 4 and a water storage tank 1.

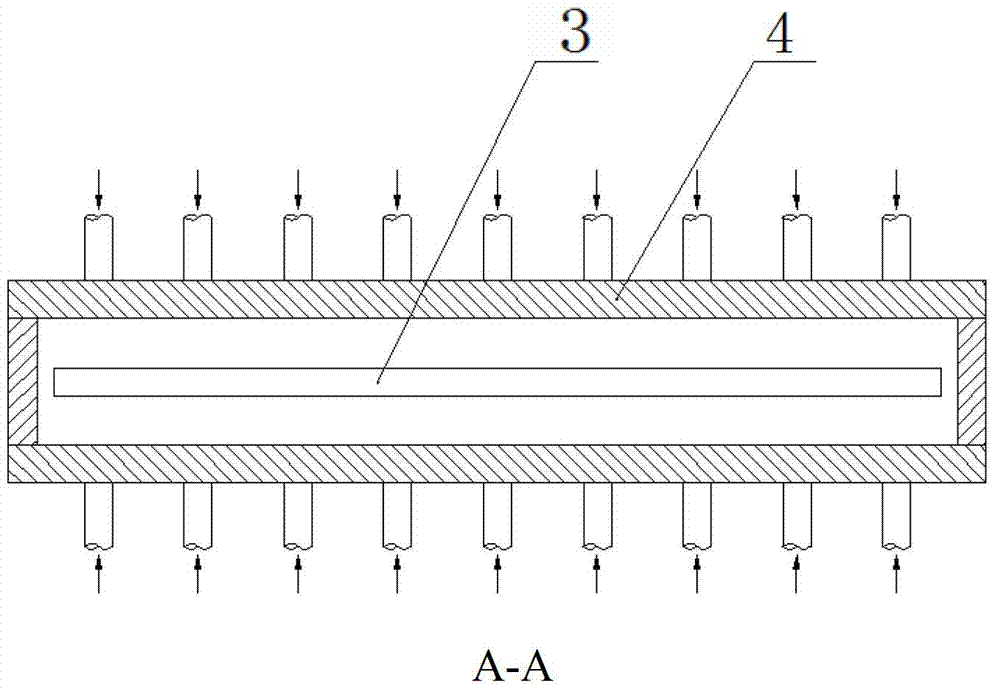

[0027] The water jacket 4 is a flat rectangular hollow tubular member (like a matchbox jacket), and is placed around the hot-rolled steel plate 3. The upper and lower walls of the water jacket 4 form a narrow gap between the upper and lower walls of the hot-rolled steel plate 3. slot channel 2, the height of the space between the upper wall and the lower wall of the water jacket 4 is not more than 2.5 times the thickness of the hot-rolled steel plate 3; the water jacket 4 is made of variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com