Patents

Literature

48results about How to "Low water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and equipment for suppressing dust with dry mist

InactiveCN101757825ASimple system structureLow water consumptionUsing liquid separation agentDirt cleaningElectrical controlSystem structure

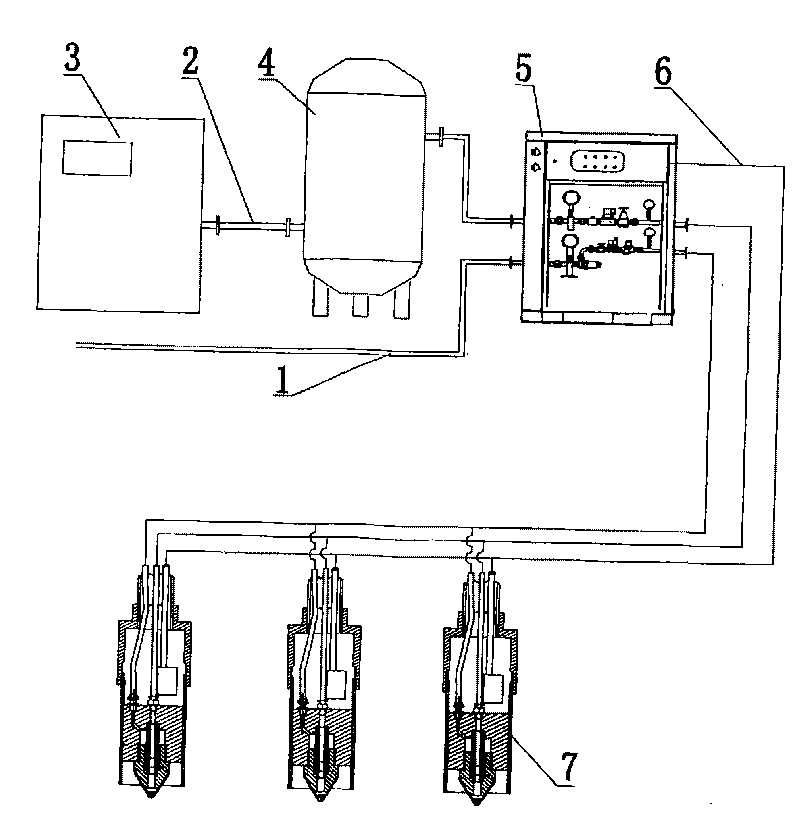

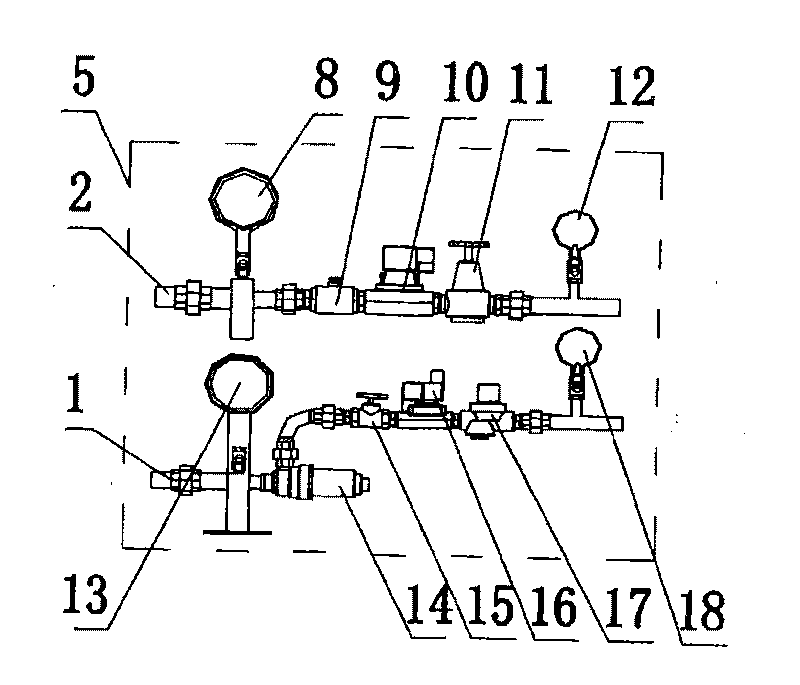

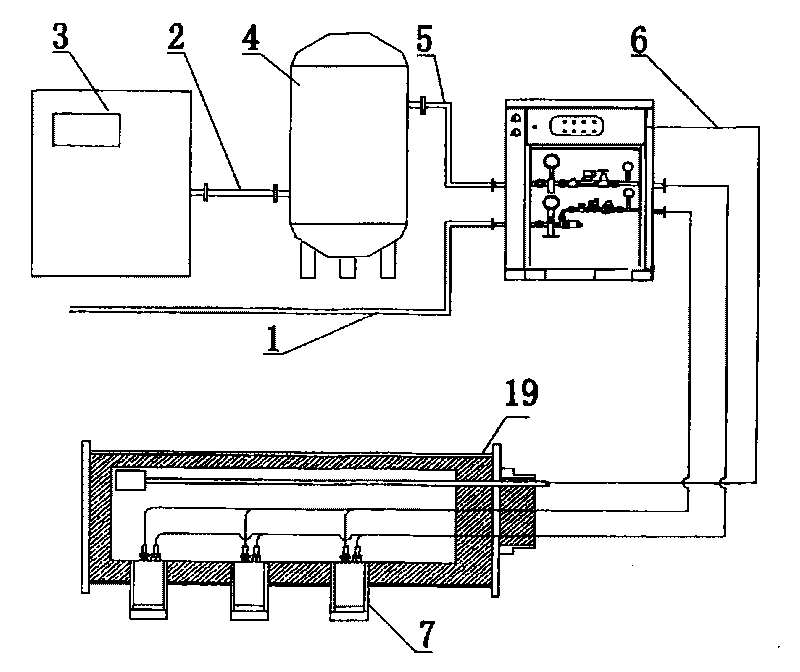

The invention relates to a method and equipment for suppressing dust with dry mist. The method for suppressing dust with dry mist is characterized in that a plurality of atomizing nozzles are arranged in parallel on a disorderly discharged dust drift outlet of a dust generation point and are used for spraying the dry mist having the particle size of less than 10 Mum and making the sprayed dry mist form into a dry mist curtain to prevent the dust generated in the dust generation point from diffusing outwards to pollute the environment. The equipment for suppressing dust comprises a water supplying pipeline, an air supplying pipeline, an air compressor, an air storage tank and a control box. The air supplying pipeline, the water supplying pipeline and an electrical control pipeline which are led out of the control box are respectively connected with the air inlets, the water inlets and tracing band inlets of the atomizing nozzles which are arranged in parallel. The micro-size dry mist is sprayed to form a dry mist curtain to suppress dust. The micro-size dry mist spraying system equipment adopts the air compressor to supply compressed air, and the water and the air enter the atomizing nozzles in two branches. The micro-size dry mist spraying system equipment has simple structure, low running cost, wide application range and good dust suppression effect, consumes less water and works stably and reliably.

Owner:QINHUANGDAO CAPITAL STARLIGHT ENVIRONMENTAL TECH CO LTD

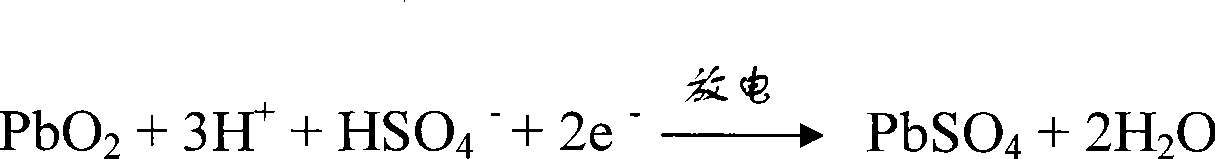

Non-water washing treatment method for formed plate of lead acid battery

ActiveCN101388456ALow water consumptionZero emissionFinal product manufactureLead-acid accumulator electrodesZero emissionTreatment effect

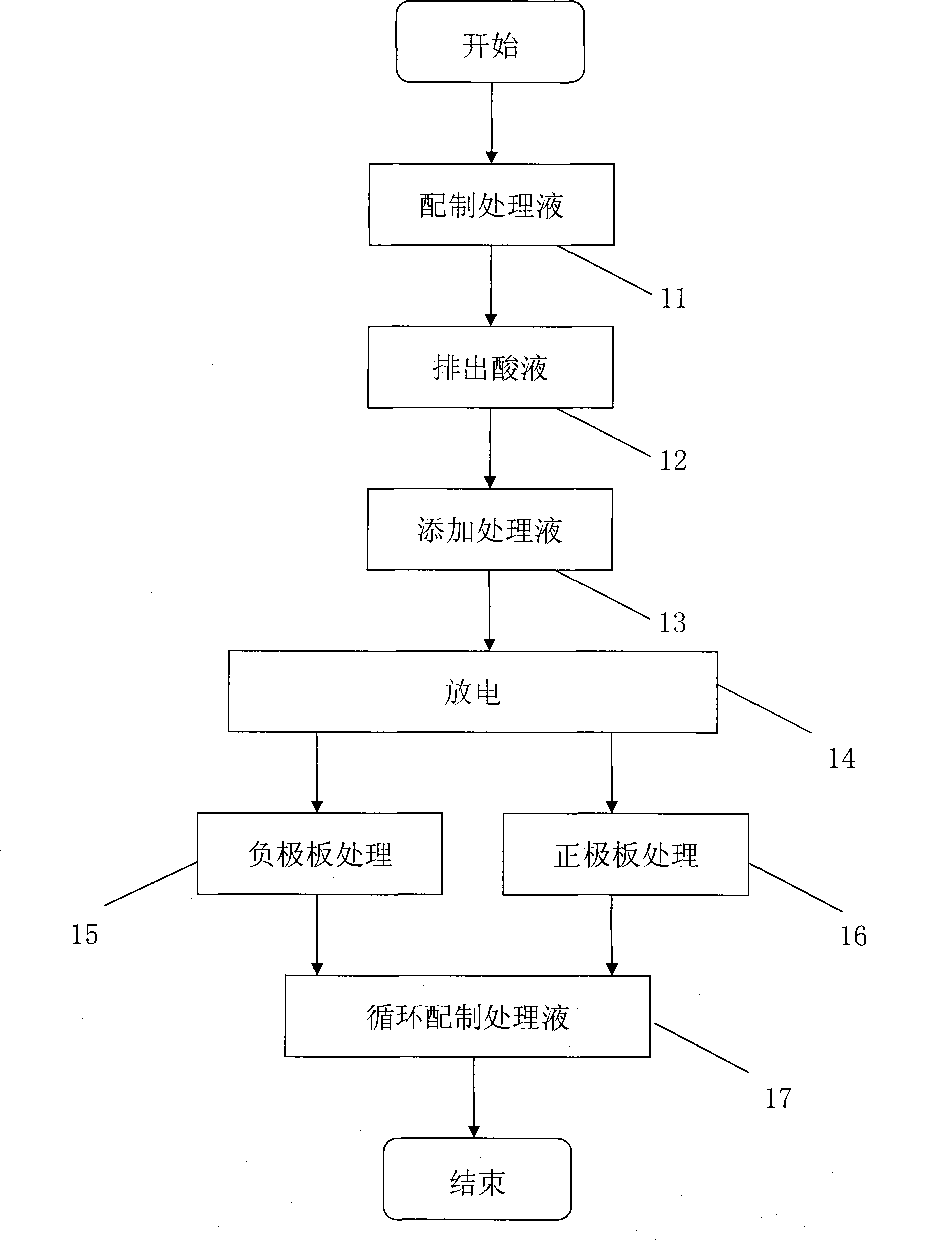

The invention discloses a discharge washing-free treatment process for lead-acid accumulator formation plates, which comprises the steps of formulating treatment fluid, exhausting acid liquor, adding treatment fluid, discharging, treating a negative plate, treating a positive plate and cyclically formulating treatment fluid and the like in turn. The invention further discloses a reverse charging washing-free treatment process for lead-acid accumulator formation plates, which comprises the steps of formulating treatment fluid, making a treatment tank, adding treatment fluid, inserting the negative plate, inversely charging, treating the negative plate, cyclically formulating treatment fluid and washing the positive plate and the like. The utility model treats the formation plates with the discharge or reverse charging processes, which can reach the required treatment effects without washing, and has extremely low water consumption in the process of treatment, can realize the cyclical utilization, reaches zero emission effect, and greatly relieves the pressure of environment protection. The plates can generate PbSO4 to attach on the surface of plate holes in the process of discharge, which can play the role of protection, and prevents the negative plate from further being oxidized, thereby increasing the dry-charged property of plates.

Owner:CHAOWEI POWER CO LTD

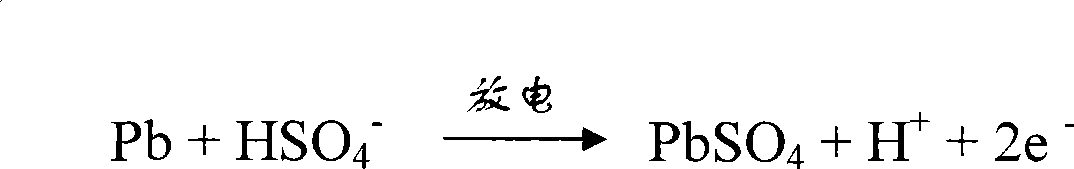

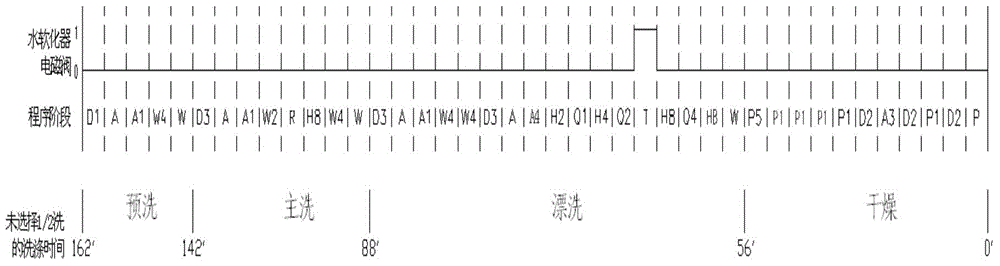

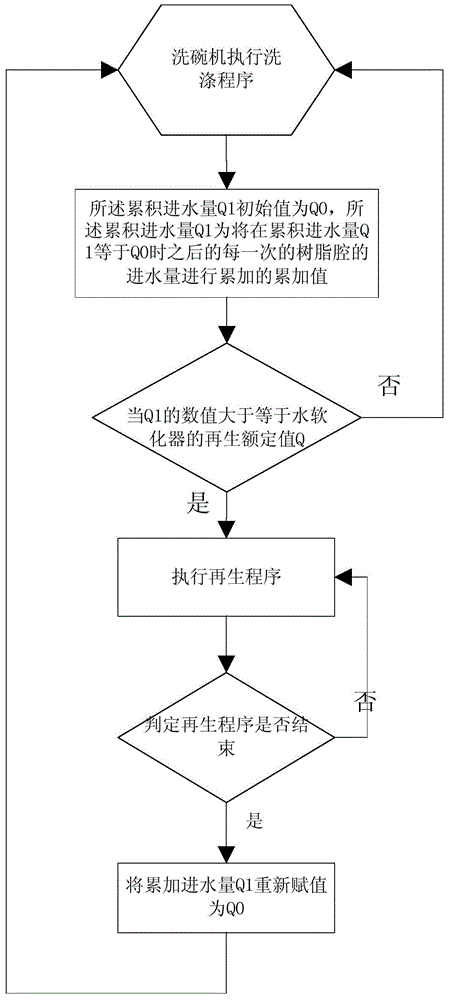

Dish-washing machine water saving method and dish-washing machine

ActiveCN105266740ALow water consumptionReduce water consumptionTableware washing/rinsing machine detailsHome appliance efficiency improvementSalt waterEngineering

The invention relates to the technical field of household electrical appliances, and especially relates to a dish-washing machine water saving method, comprising a water softening apparatus. The water softening apparatus comprises a salt chamber used to store saturated salt water, and a resin chamber used to store resin. A pipe communicates the salt water and the resin chamber. The pipe is provided with a one-way valve. The method is characterized in that through comparing accumulated water inflow Q1 entering the resin chamber with a regeneration rated value Q set by the water softening apparatus, whether to control the water softening apparatus to perform regeneration operation or not is determined according to a comparison result. Also disclosed is a dish-washing machine which uses the dish-washing machine water saving method. Regeneration after a washing process each time of a conventional dish-washing machine is changed into an independent regeneration program module, and when water inflow of the dish-washing machine reaches the rated value of the water softening apparatus, the regeneration is performed, so as to achieve an objective of reducing water consumption of the dish-washing machine.

Owner:QINGDAO HAIER DISHWASHER

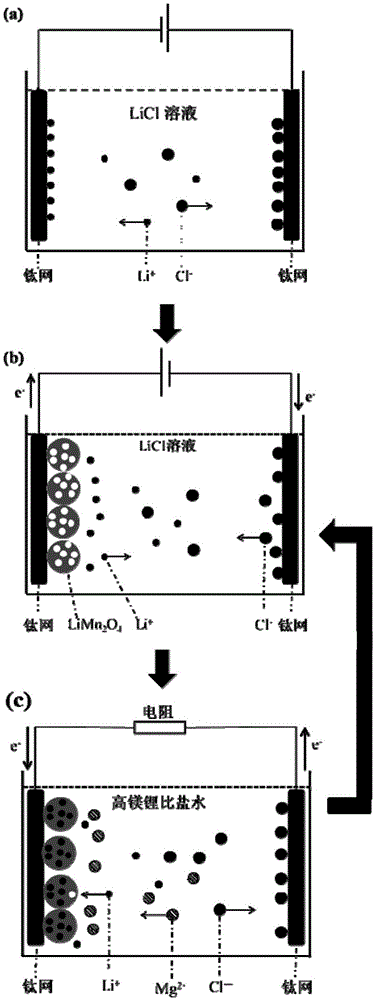

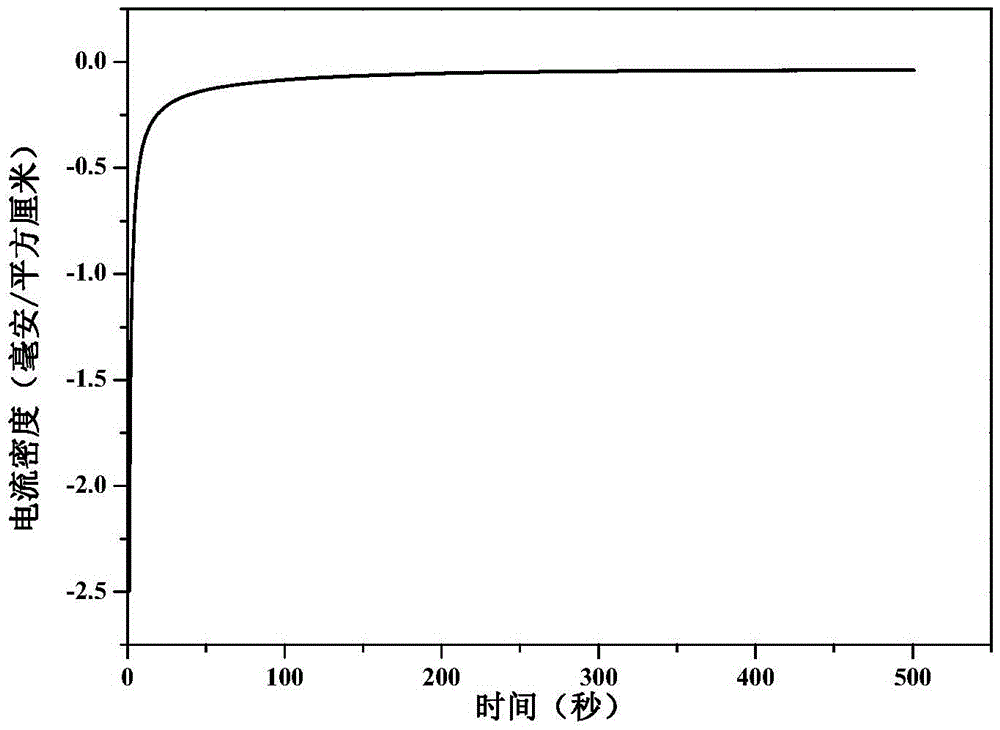

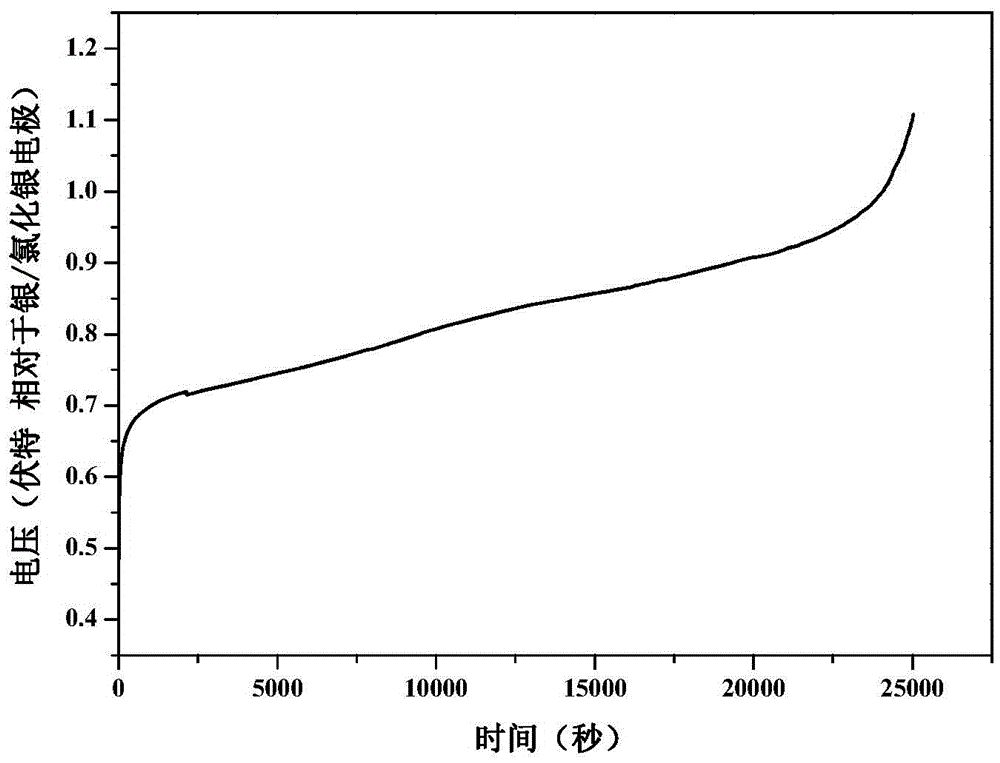

Method for extracting lithium salt from high magnesium-lithium ratio saline water in electrochemical way

ActiveCN105600807ALow water consumptionOvercome high water consumptionAlkali metal chloridesChemical industrySaline water

The invention relates to a method for extracting lithium salt from high magnesium-lithium ratio saline water in an electrochemical way, belonging to the technical field of lithium salt chemical industry. The method comprises the steps of enabling a titanium mesh current collector to be evenly coated with spinel type LiMn2O4 so as to be taken as a working electrode, and taking a titanium mesh as a counter electrode to form an electrochemical lithium extraction system; in an LiCl solution, enabling the LiMn2O4 working electrode and the titanium mesh counter electrode to be respectively connected with a positive pole and a negative pole of a power supply for charging, enabling lithium ions to be separated out from LiMn2O4 to form a lithium ion sieve; enabling the electrode system to discharge in the high magnesium-lithium ratio saline water to enable the lithium ions to be selectively embedded into the lithium ion sieve, and carrying out charge and discharge cyclic operation to realize electrochemical extraction of lithium salt. The method has the advantages that the lithium salt is efficiently and rapidly extracted; furthermore, the problem that the solution loss of the lithium ion sieve, the corrosion of equipment and environmental pollution which are caused by strong acids such as hydrochloric acid and the like can be avoided. In the lithium salt extraction process, the method relates to the conversion of electric energy and chemical energy, thus being used as an electrochemical energy storage device at the same time.

Owner:BEIJING UNIV OF CHEM TECH

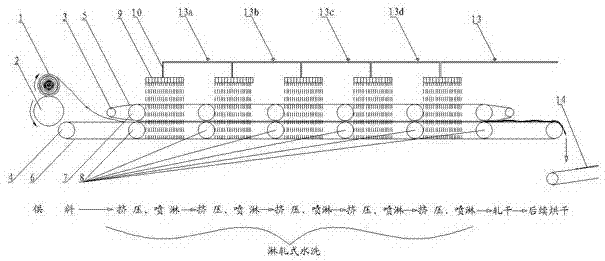

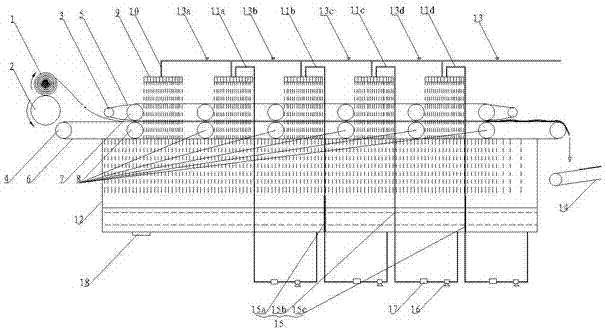

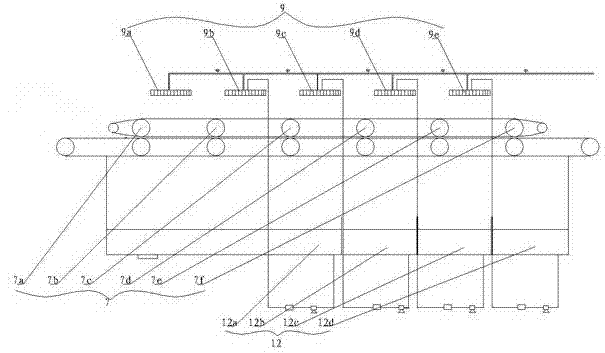

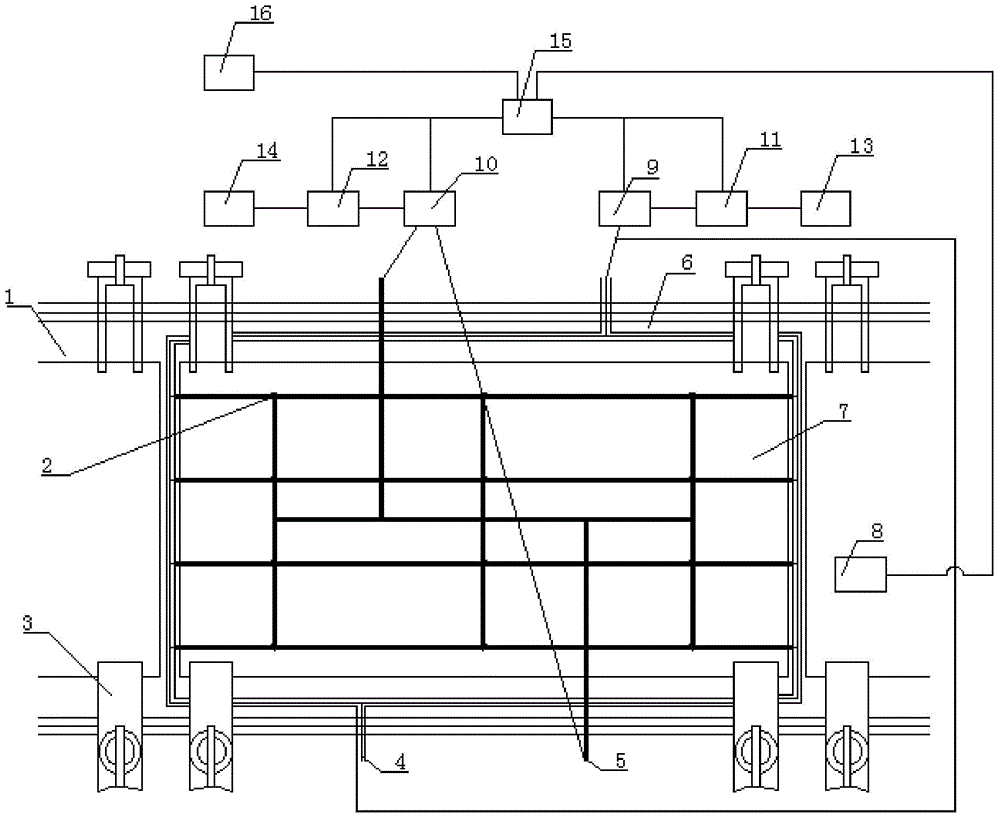

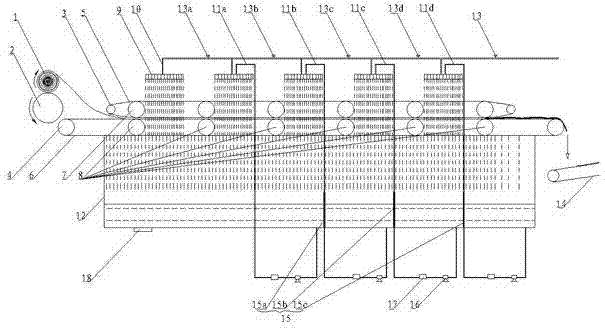

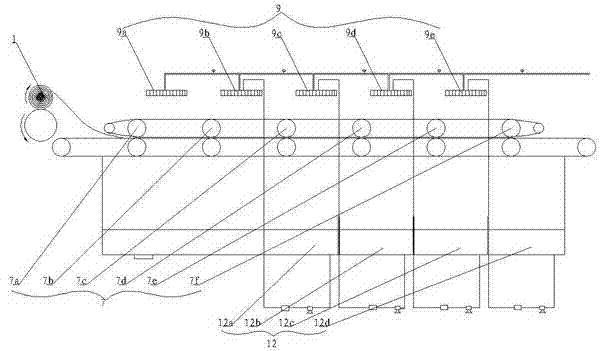

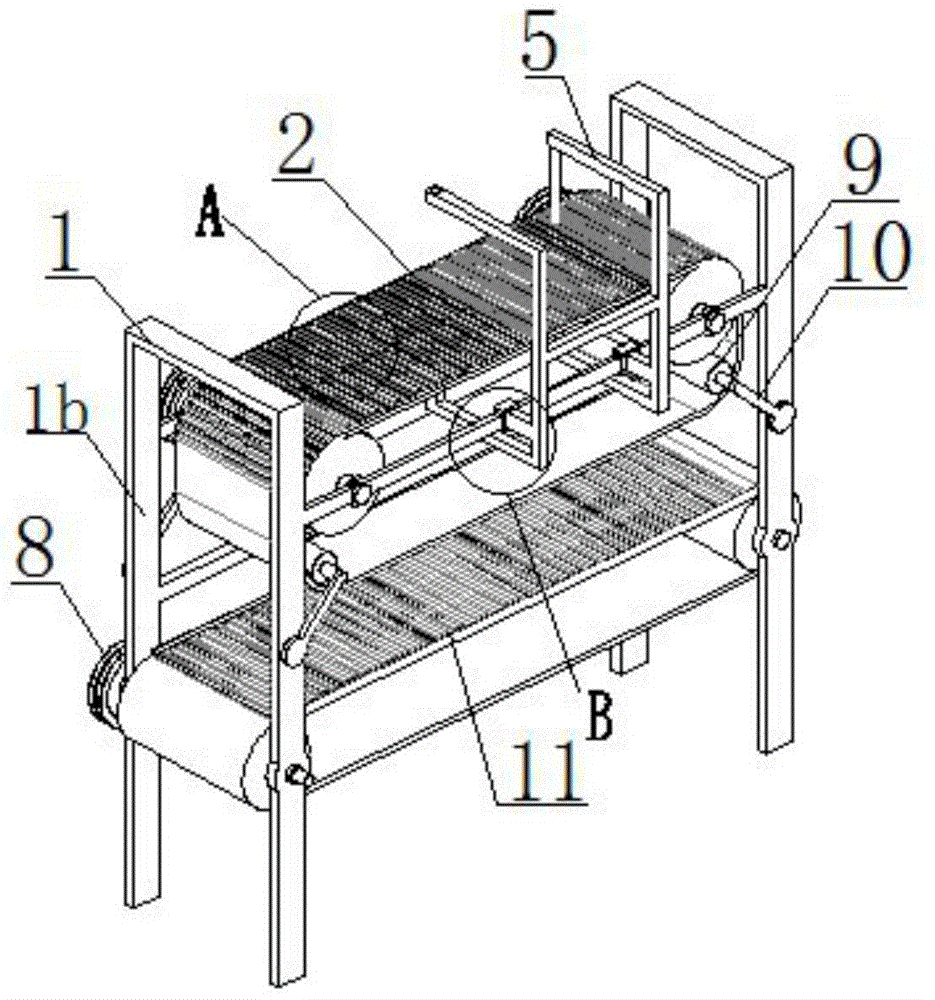

Spray-rolling type loose fiber washing process

ActiveCN103774362ALow water consumptionLow costLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingFiber

The invention relates to a spray-rolling type loose fiber washing process, and belongs to the technical field of loose fiber dyeing. Dyed loose fibers are conveyed to a spray-rolling type washing device, while the loose fibers are horizontally clamped by a guide belt to be conveyed, a plurality of groups of spray-rolling type washing with alternative squeezing and spraying is carried out on the loose fibers, and the loose fibers are washed, rolled to be dry, and output. The spray-rolling type loose fiber washing process has the advantages that dyeing is even, water consumption is small, and the working procedure is simple.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

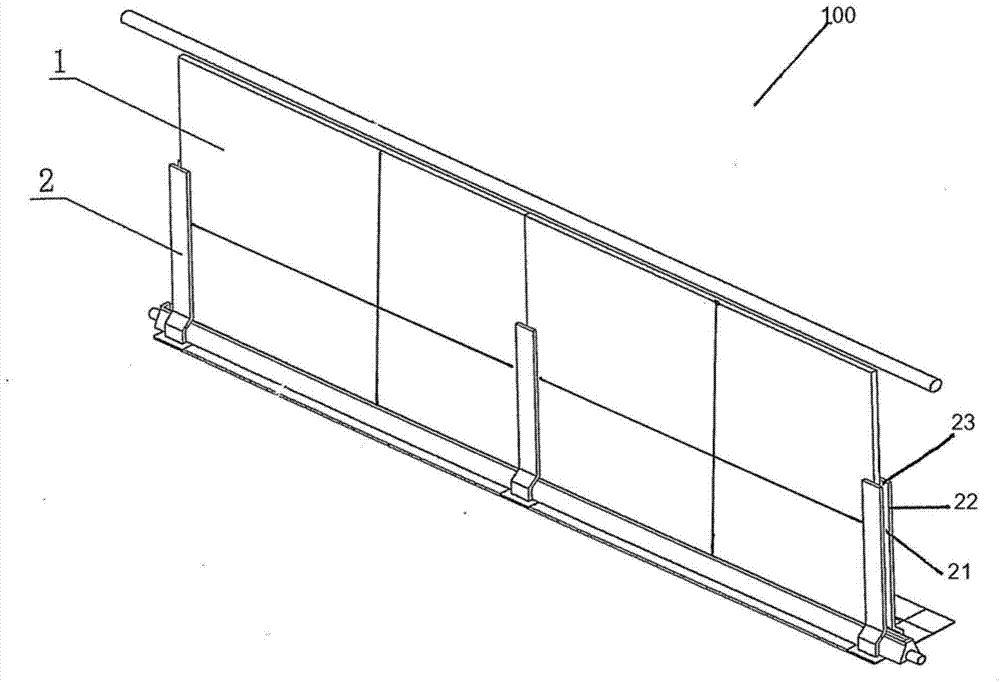

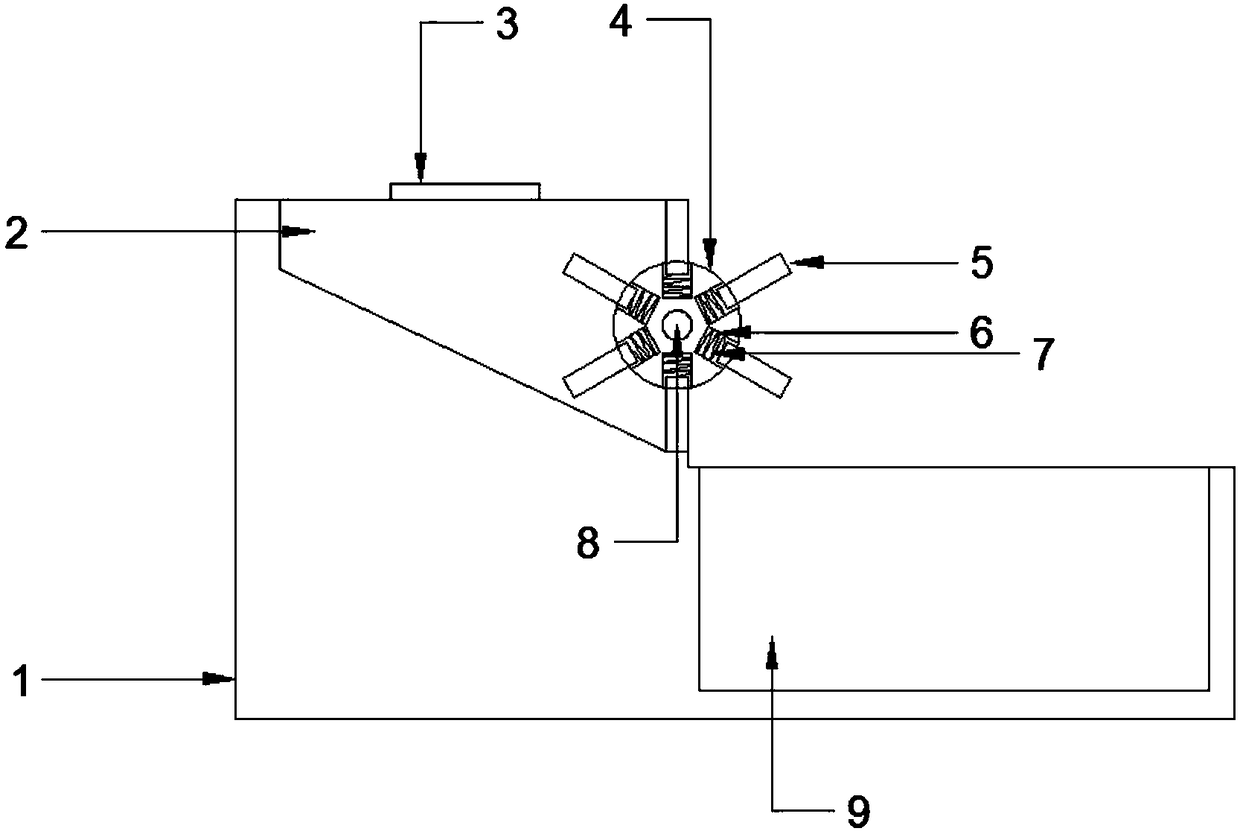

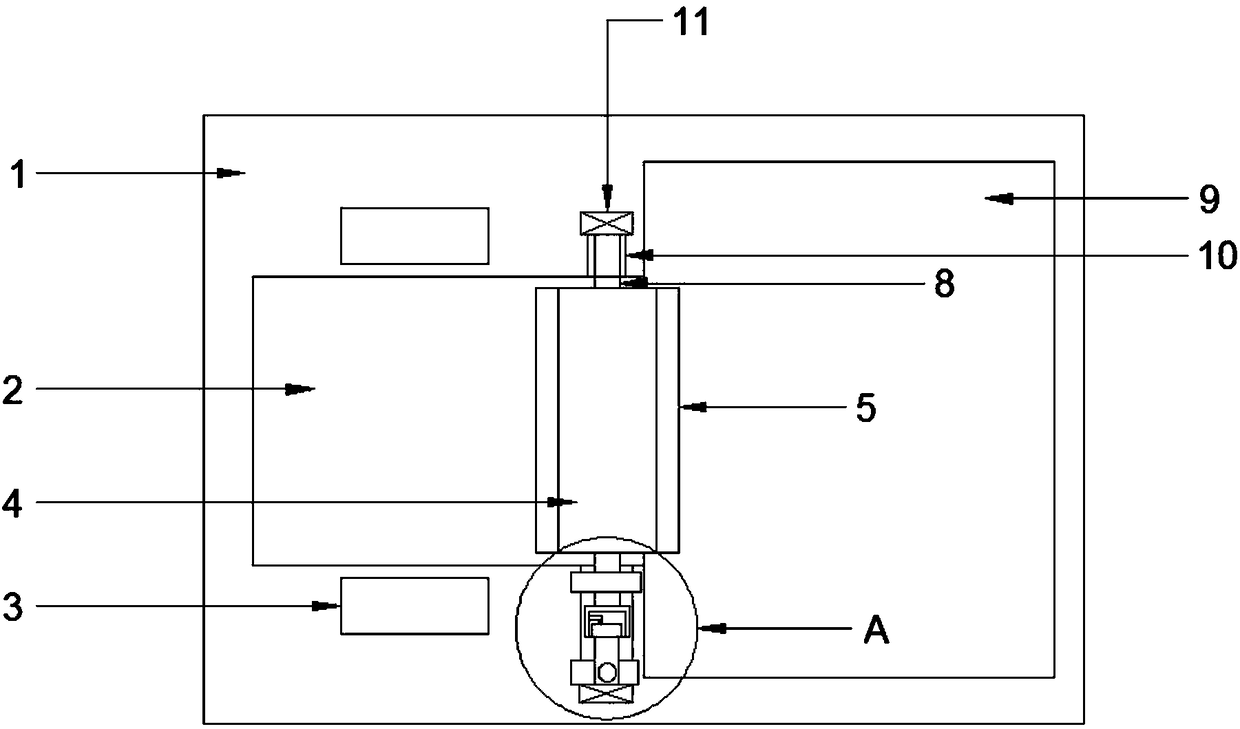

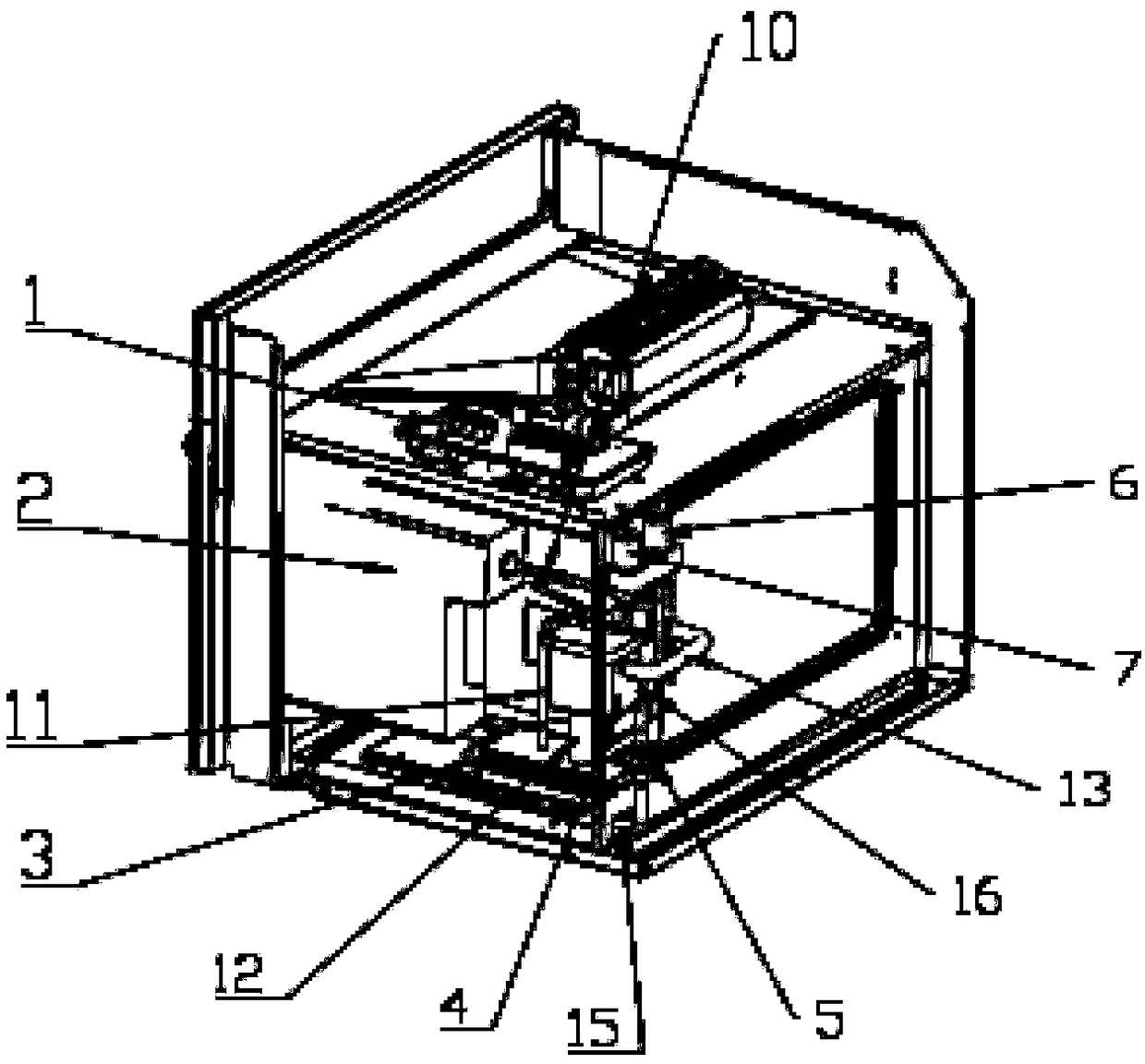

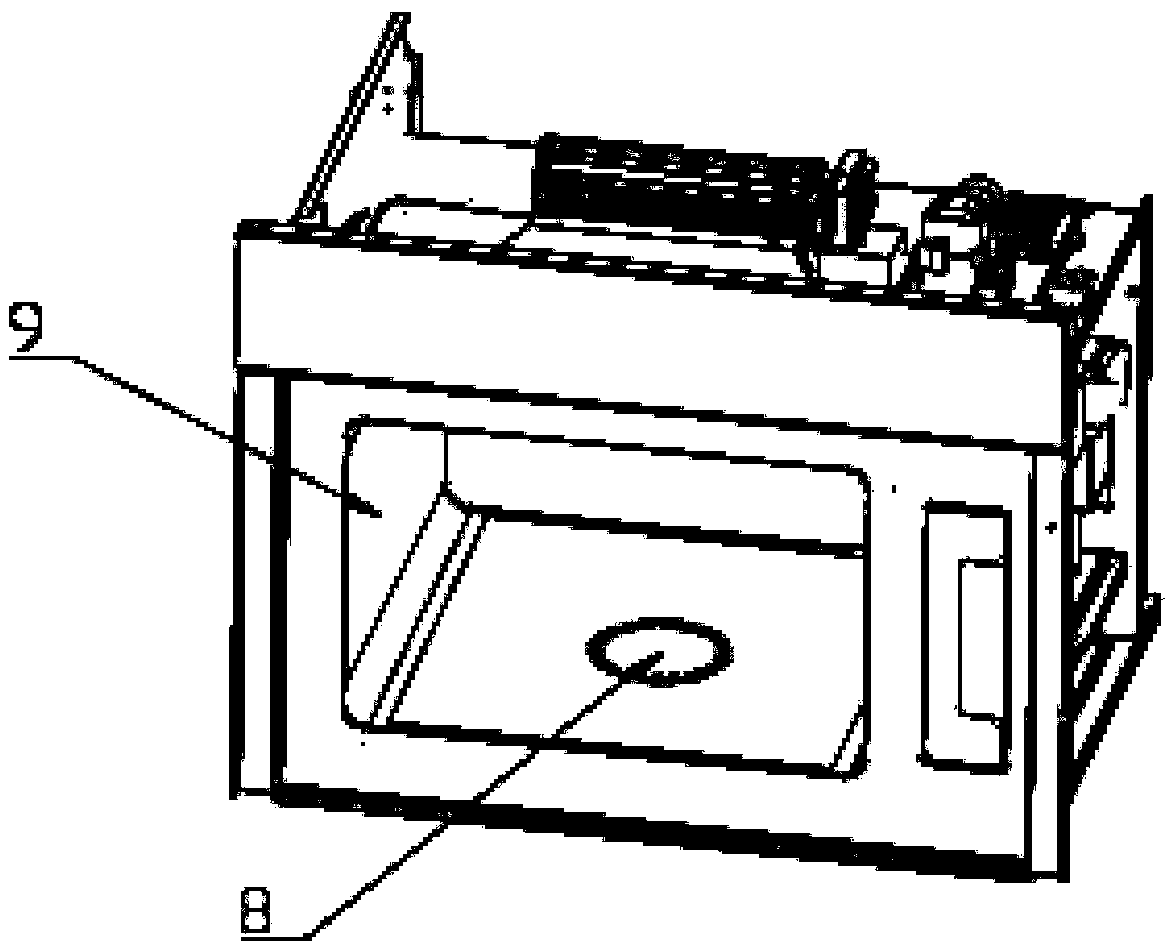

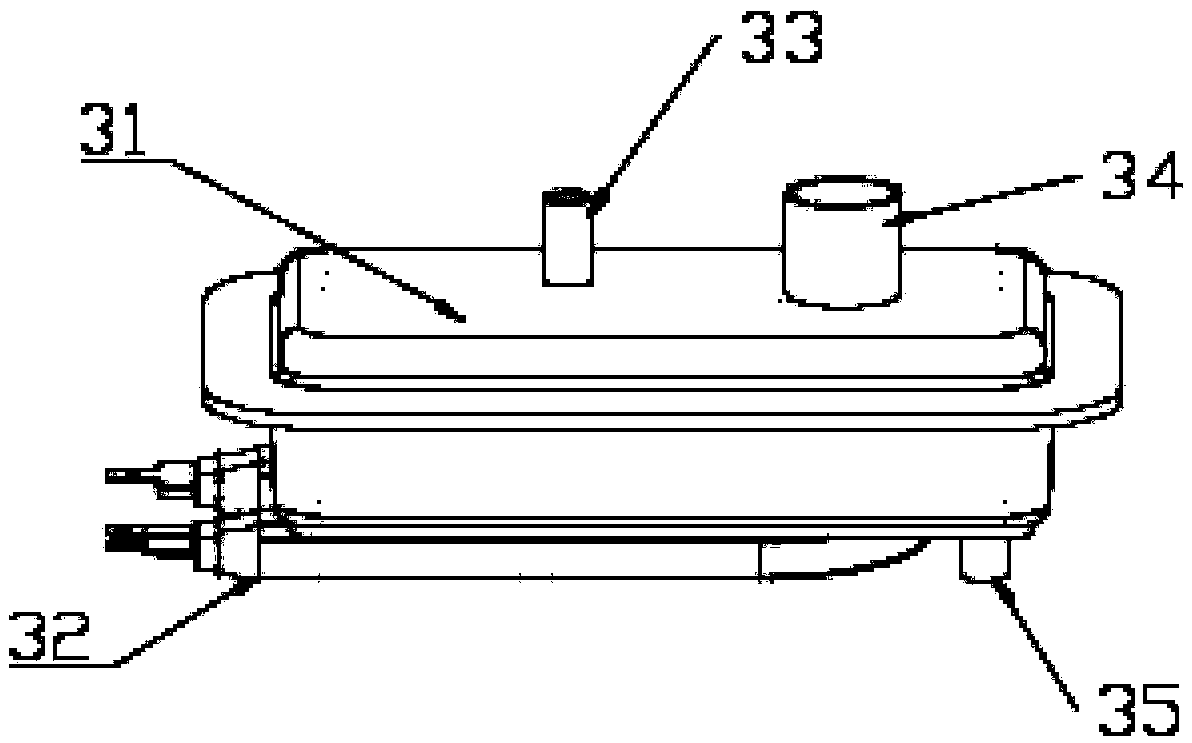

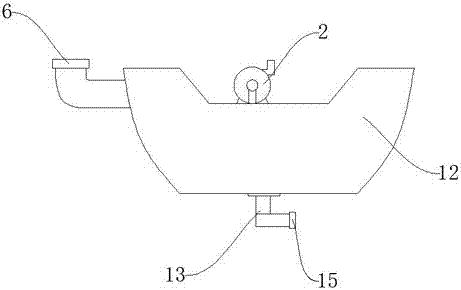

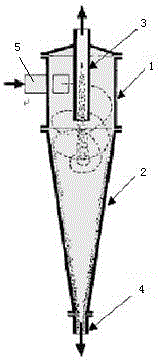

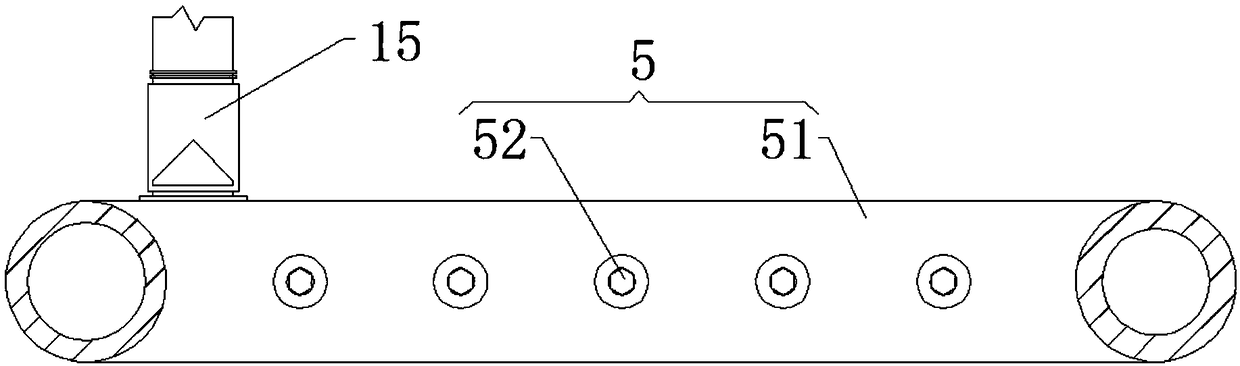

Mining air mist dust settling device in restricted space and application method of mining air mist dust settling device

ActiveCN104061012AReduce water consumptionLow water consumptionDust removalFire preventionCoalPetrochemistry

The invention discloses a mining air mist dust settling device in a restricted space and an application method of the mining air mist dust settling device, and belongs to the field of safety and environmental protection equipment during a mine production process. The mining air mist dust settling device in the restricted space is characterized in that during the coal production and transport process of working equipment taking pressure fluid as a power source under the control of a control unit, when coal dust pollution is generated at the time when the logistics direction of transported coal is changed, various actions or paces are realized through the device to achieve the goal of coal dust settling in the working field. The mining air mist dust settling device in the restricted space and the application method of the mining air mist dust settling device disclosed by the invention are widely suitable for various control executive devices in systems and industries of mining, petrochemistry, metallurgy, electric power, environmental protection and the like.

Owner:TAIYUAN UNIV OF TECH

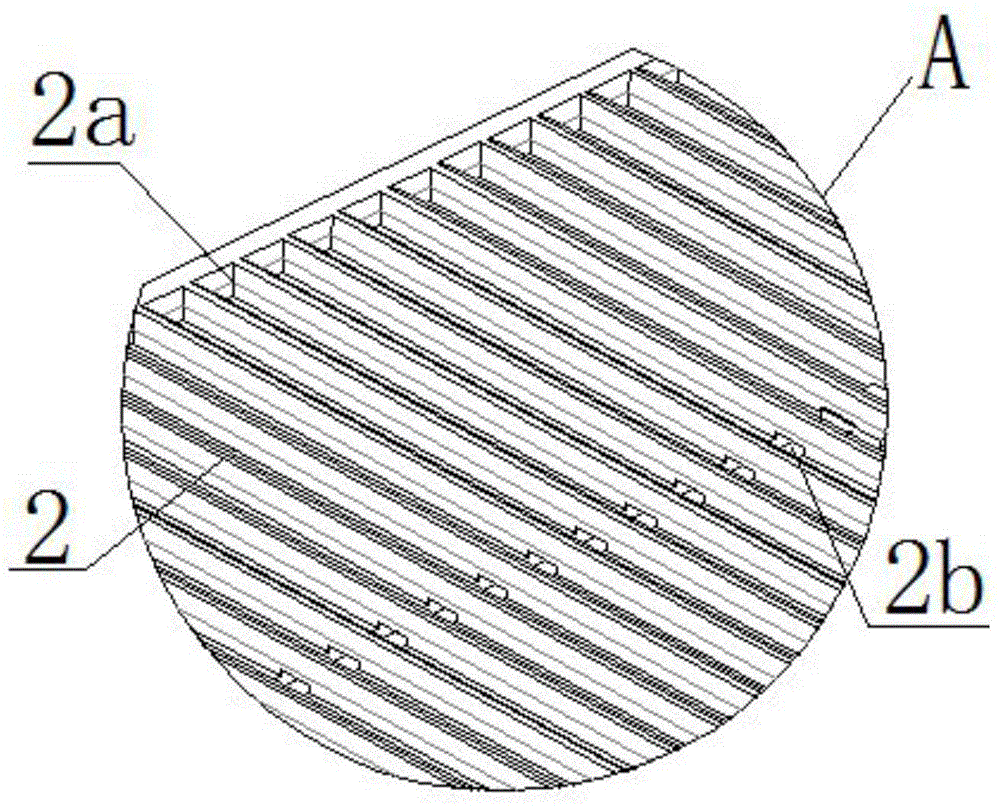

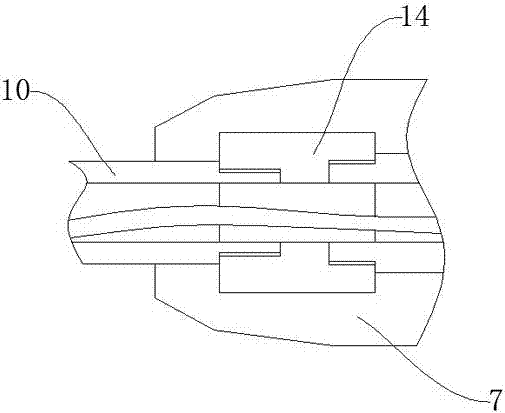

Spray-rolling type loose fiber washing machine

ActiveCN103774359AImprove washing efficiencyLow water consumptionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingEngineering

The invention relates to a spray-rolling type loose fiber washing machine, and belongs to the technical field of loose fiber dyeing. The spray-rolling type loose fiber washing machine comprises a cotton conveying roller, a transmission component and a spraying component. The cotton conveying roller is arranged in front of the transmission component, the transmission component is composed of a guide belt, a roller and a drive roller, the guide belt is horizontally arranged, and the drive roller drives the guide belt to move synchronously with the cotton conveying roller. The spraying component is located above the guide belt and used for washing the loose fibers below the spraying component, and the roller is matched with the guide belt to be mounted and used for squeezing the loose fibers which are conveyed to the guide belt through the cotton conveying roller. The spray-rolling type loose fiber washing machine is used for a loose fiber washing process, and has the advantages of being even in dyeing, small in water consumption, simple in process, and the like.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

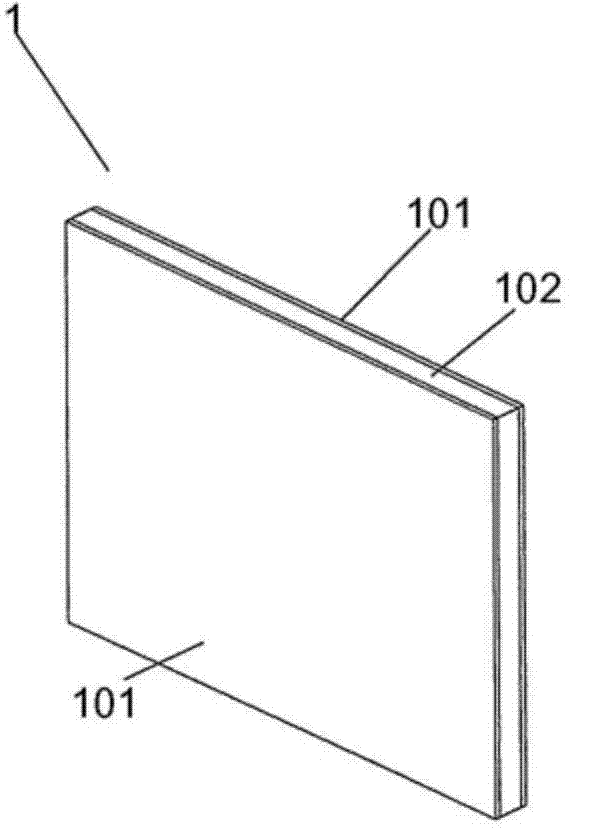

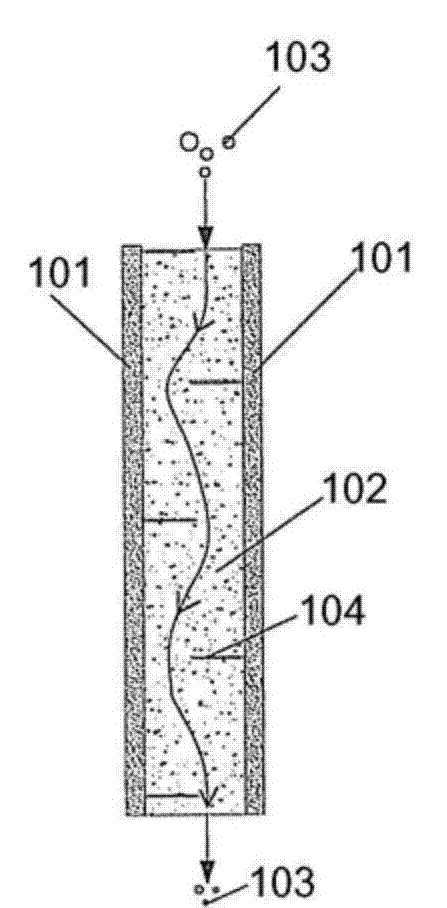

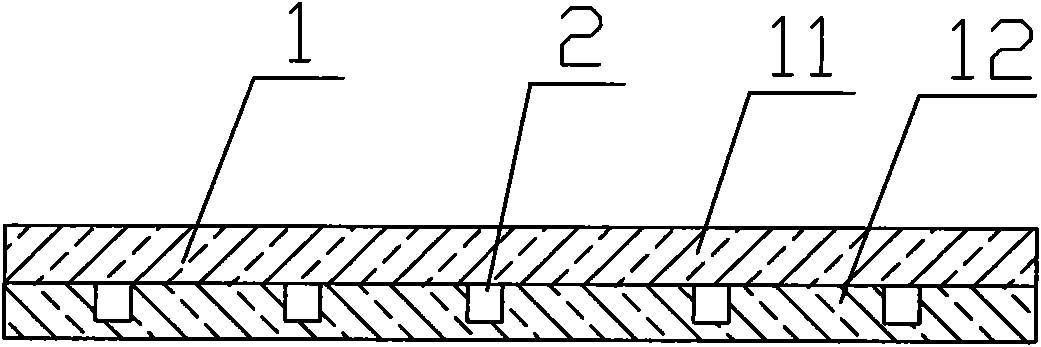

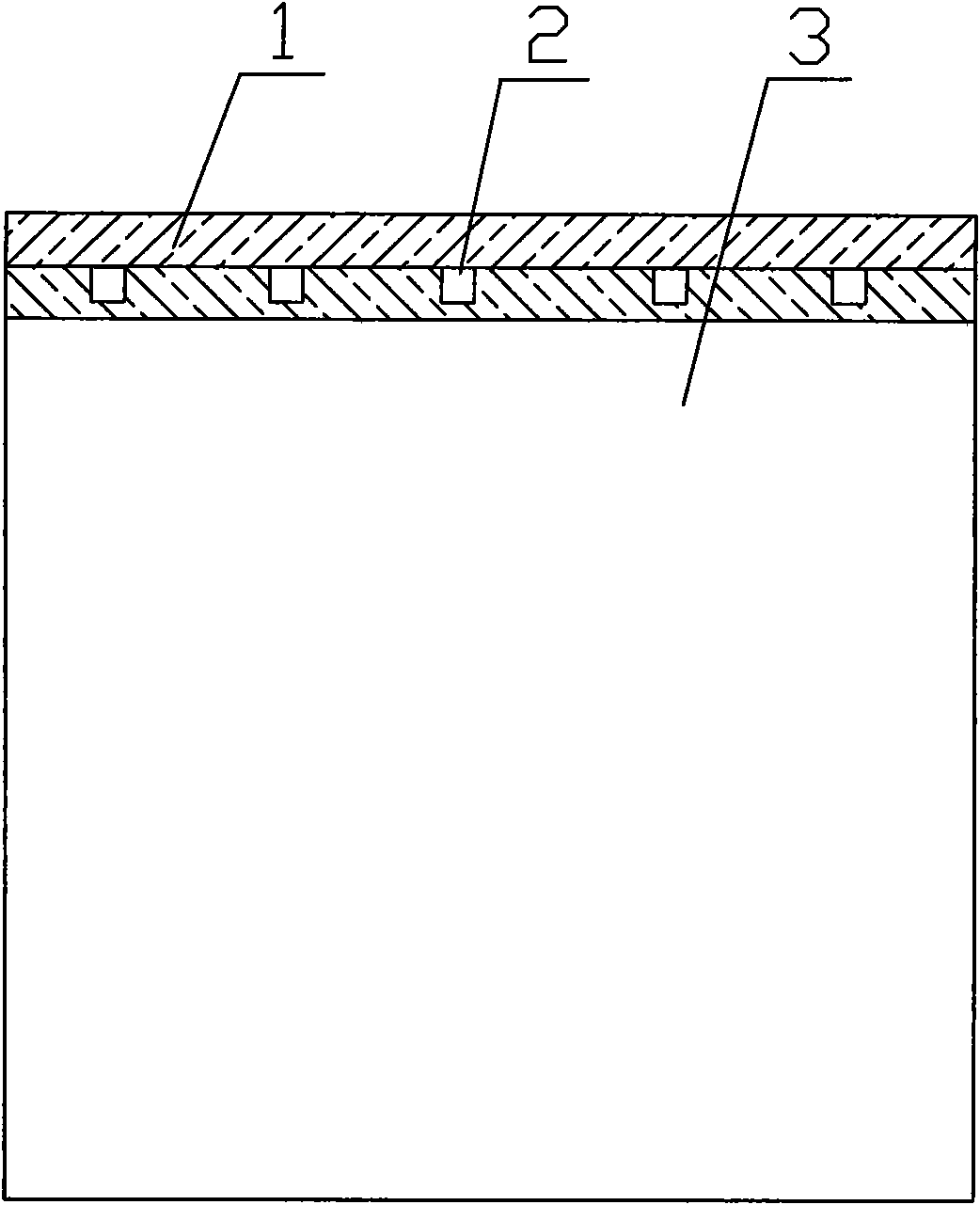

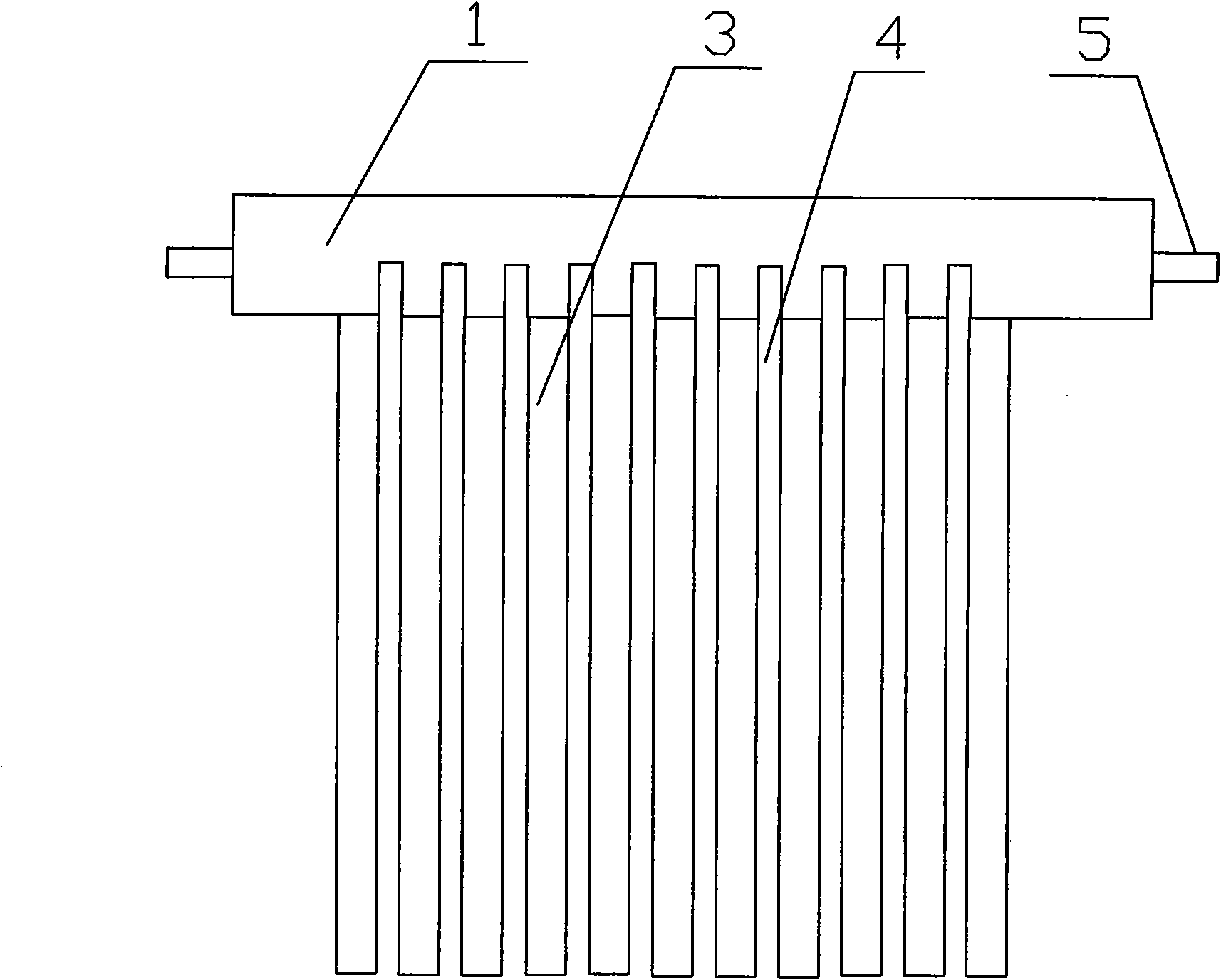

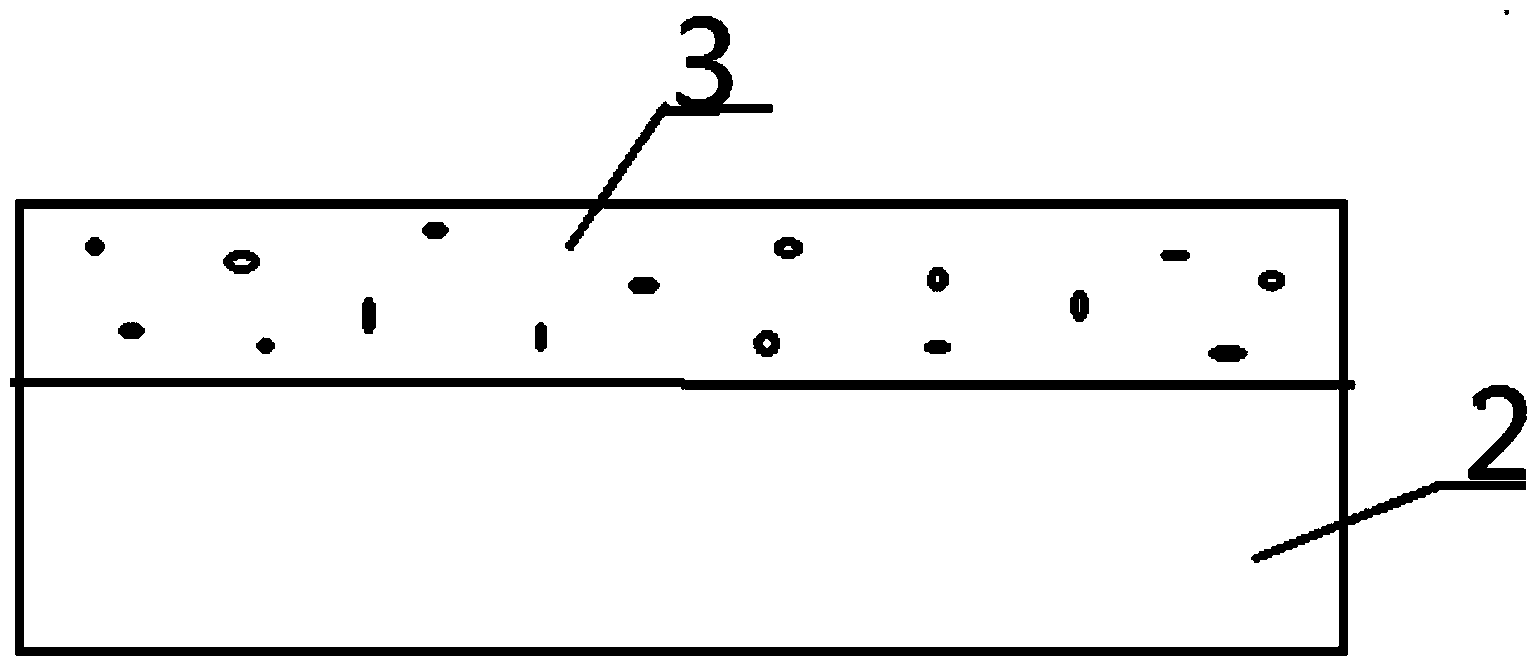

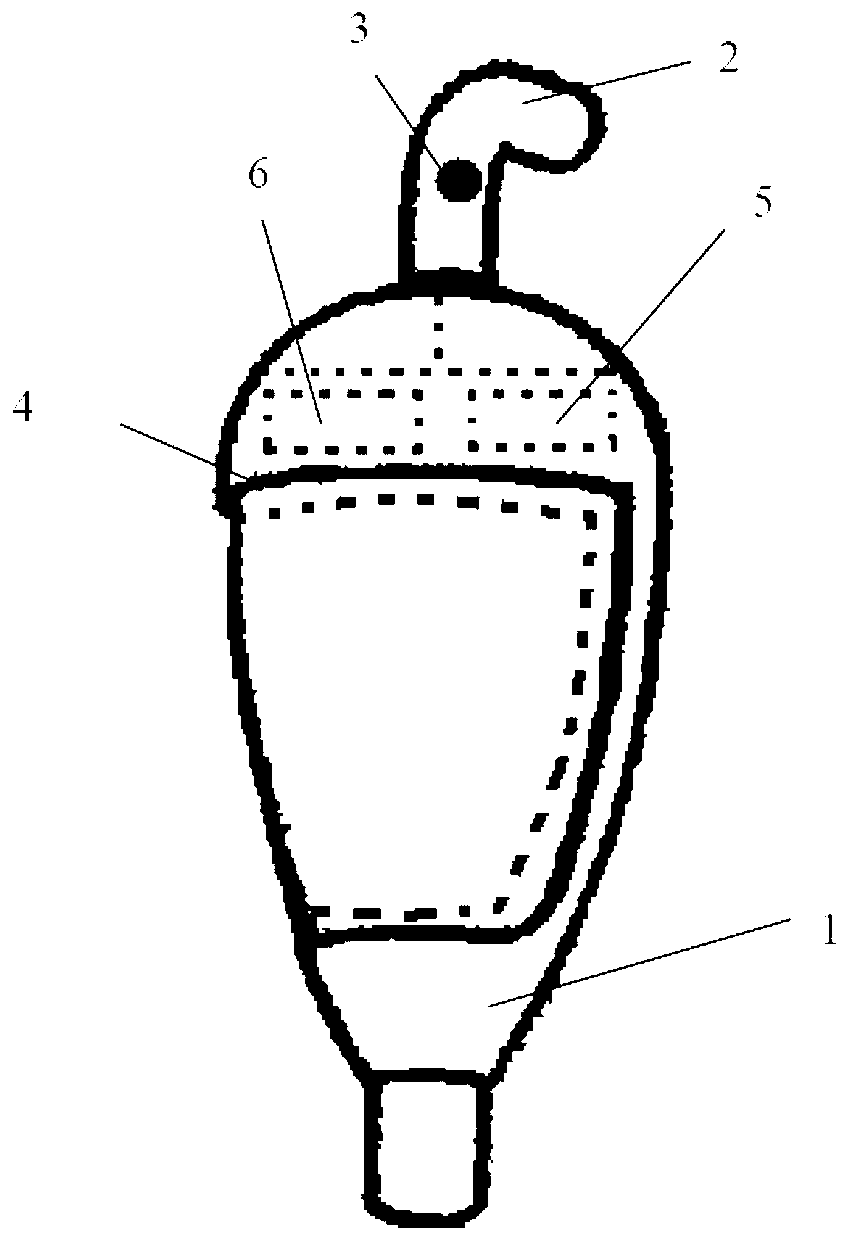

Surface growth type culture plate having sandwich structure, surface growing culture system and surface growing culture method

InactiveCN104328030ALow water consumptionGrow fastBioreactor/fermenter combinationsBiological substance pretreatmentsNutrientSuper absorbent

The invention relates to a surface growth type culture plate having a sandwich structure which comprises outer plates and a core part which is located inside the outer plates, wherein the outer plate is made from rigid water adsorption seepy material plate and the core part is made from a water absorption water-locking material such as a molecular sieve, glass sands, a non-woven fabric, high density sponge, cotton cloth, high molecular water-absorbent resin, super absorbent fibers or a polyurethane water absorbent. The core part is arranged between the outer plates on two sides. The invention further relates to a culture unit which comprises the culture plate, a surface growing culture system and a method for culturing aquatic organisms by using the surface growing culture system. The invention aims at solving the problem that a photobioreactor system for microalgae culture is high in manufacturing and maintenance costs, low in space utilization ratio and low in production efficiency. According to the invention, not only is the culture system economic and cheap, but also the utilization efficiency of light energy, carbon sources and nutrients by microalgae is high and the synthesizing and accumulating speed of secondary metabolites is fast, so that the biomass yield and the secondary metabolism yield in unit floor area or the unit reactor volume or area are improved to a great extent.

Owner:STATE DEV & INVESTMENT +1

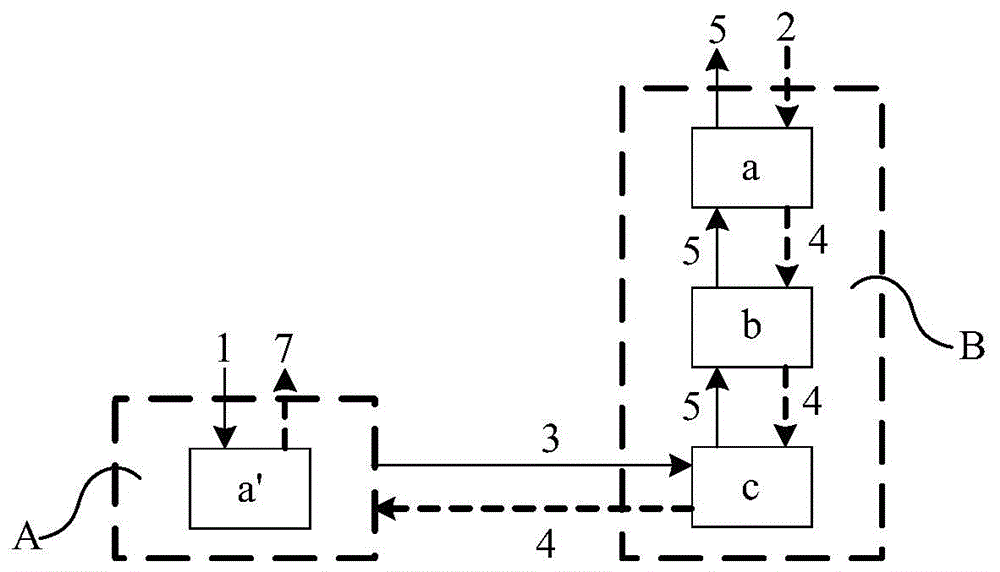

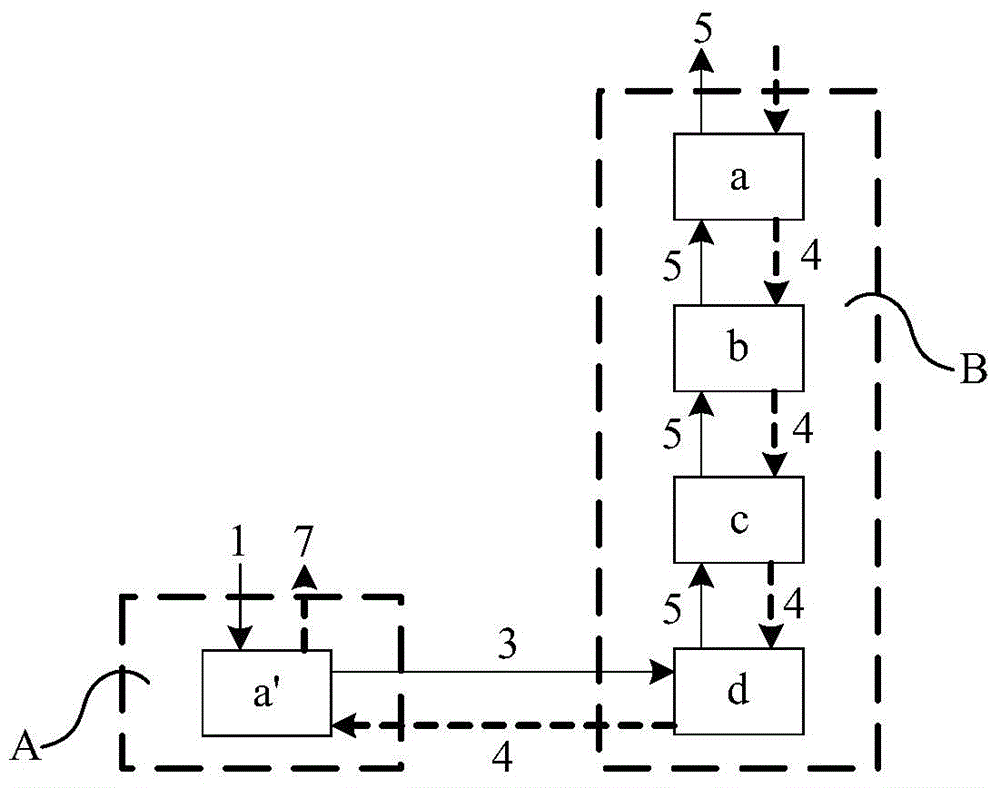

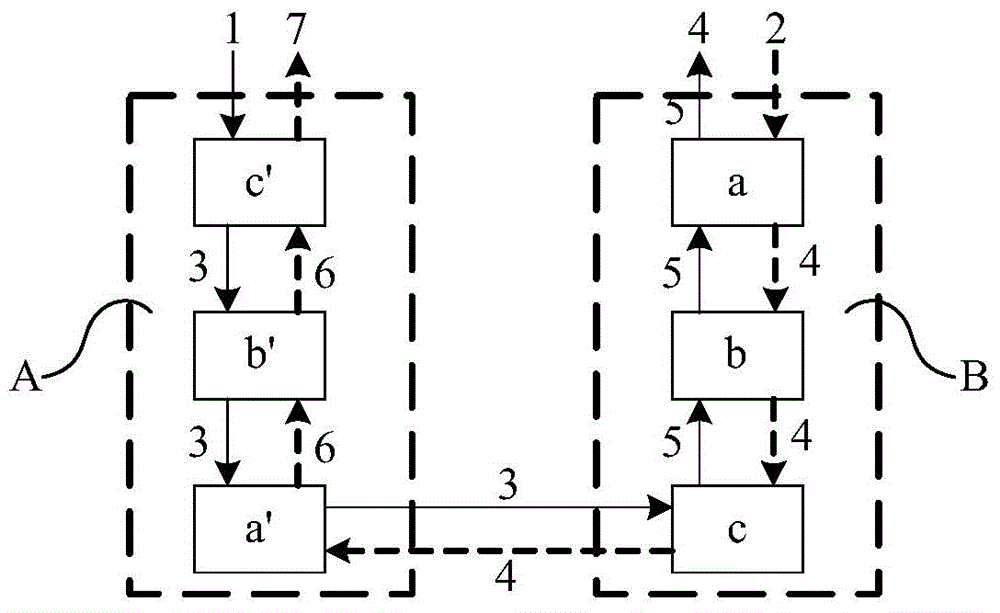

Recovery method for potassium catalyst in coal catalytic gasification ash

ActiveCN104815673ALow water consumptionReduce energy consumption for concentrationCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsChemistryDigestion

The invention relates to the field of coal catalytic gasification, particularly to a method for recovery of potassium catalyst in coal catalytic gasification ash. While reducing water consumption and lowering energy consumption, the method can enhance the total recovery rate of potassium in ash, and overcomes the defects of large water consumption, low concentration of potassium recovered solution, high energy consumption of the evaporation and concentration process in the recovery technology of the prior. The recovery method provided by the embodiment of the invention includes: a washing section, and a digestion section containing at least two-stage digestion reaction. In the washing section, coal catalytic gasification ash is subjected to washing, and the obtained washing slag enters the reactor of the last stage digestion reaction to serve as the raw material of the last stage digestion reaction. In the digestion section, the potassium solution generated by a former stage digestion reaction enters the reactor of a next stage digestion reaction, the solid product enters the reactor of the former stage digestion reaction to serves as the raw material of the former stage digestion reaction, and the potassium solution in the reactor of the last stage digestion reaction enters the washing section.

Owner:ENN SCI & TECH DEV

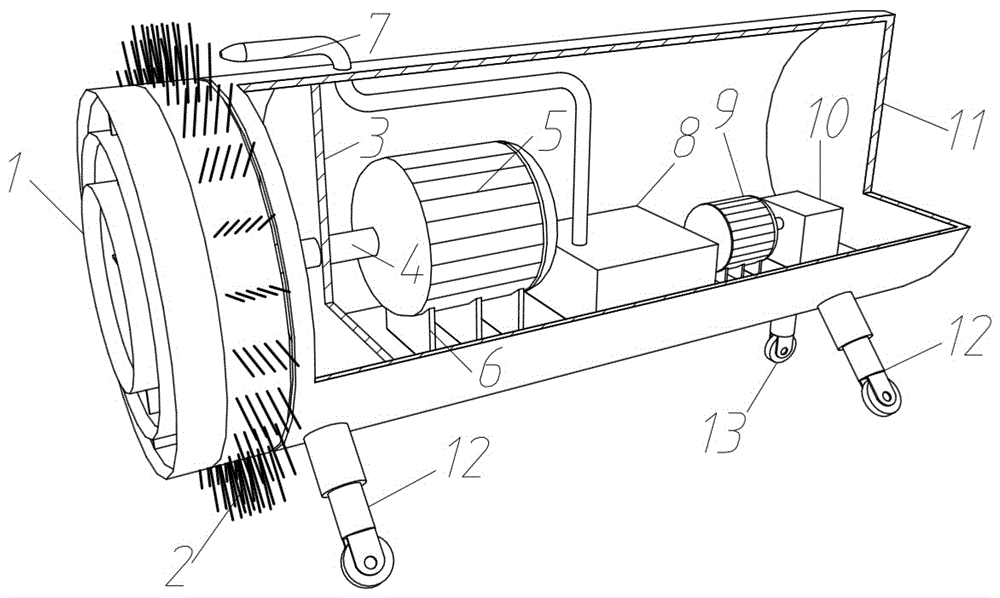

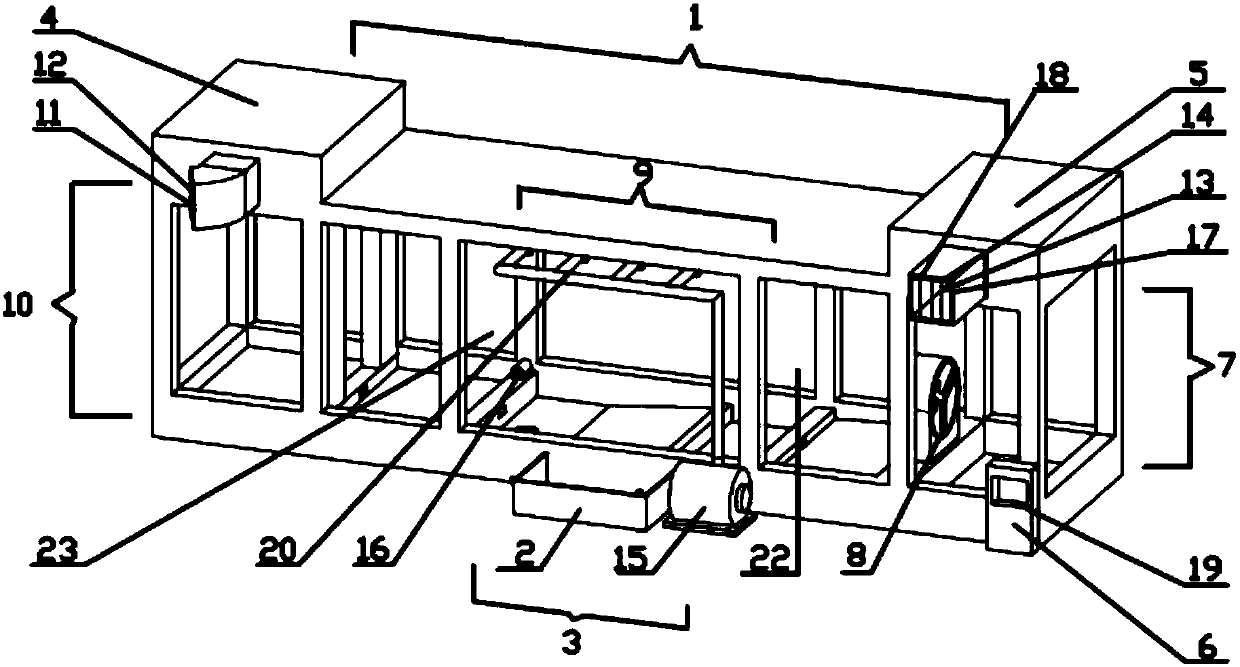

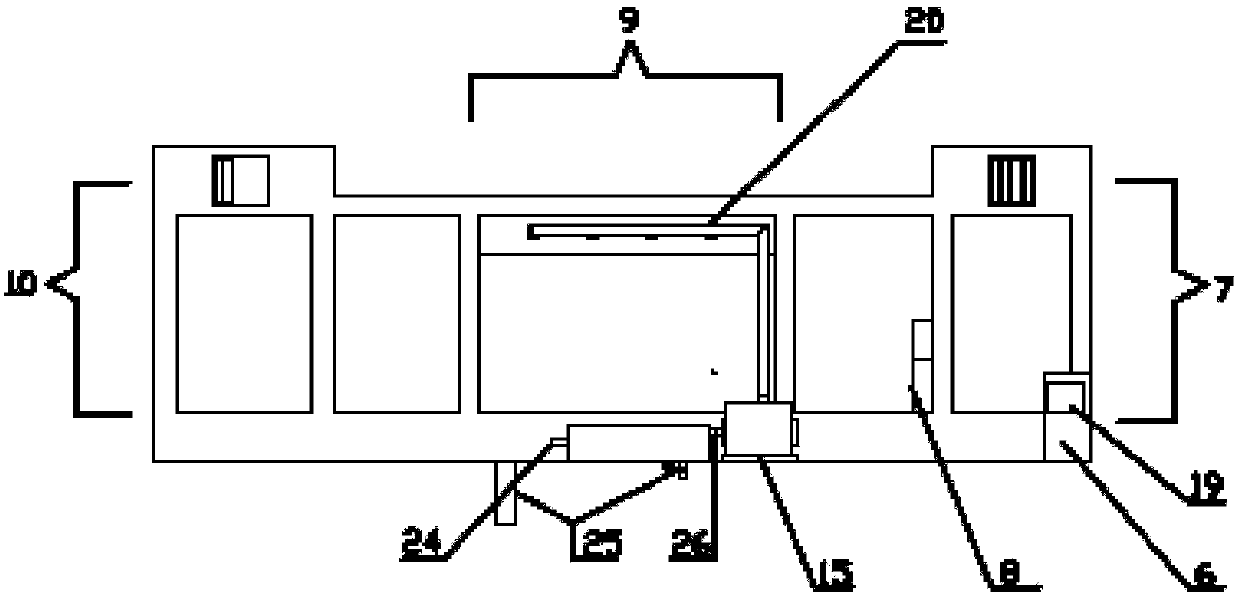

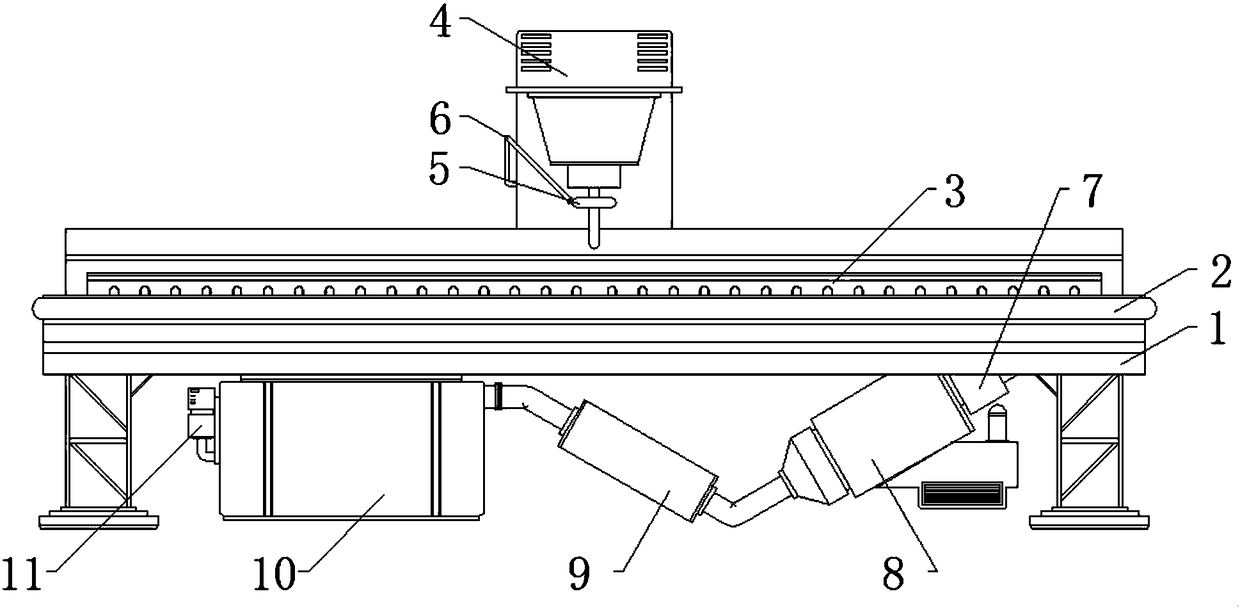

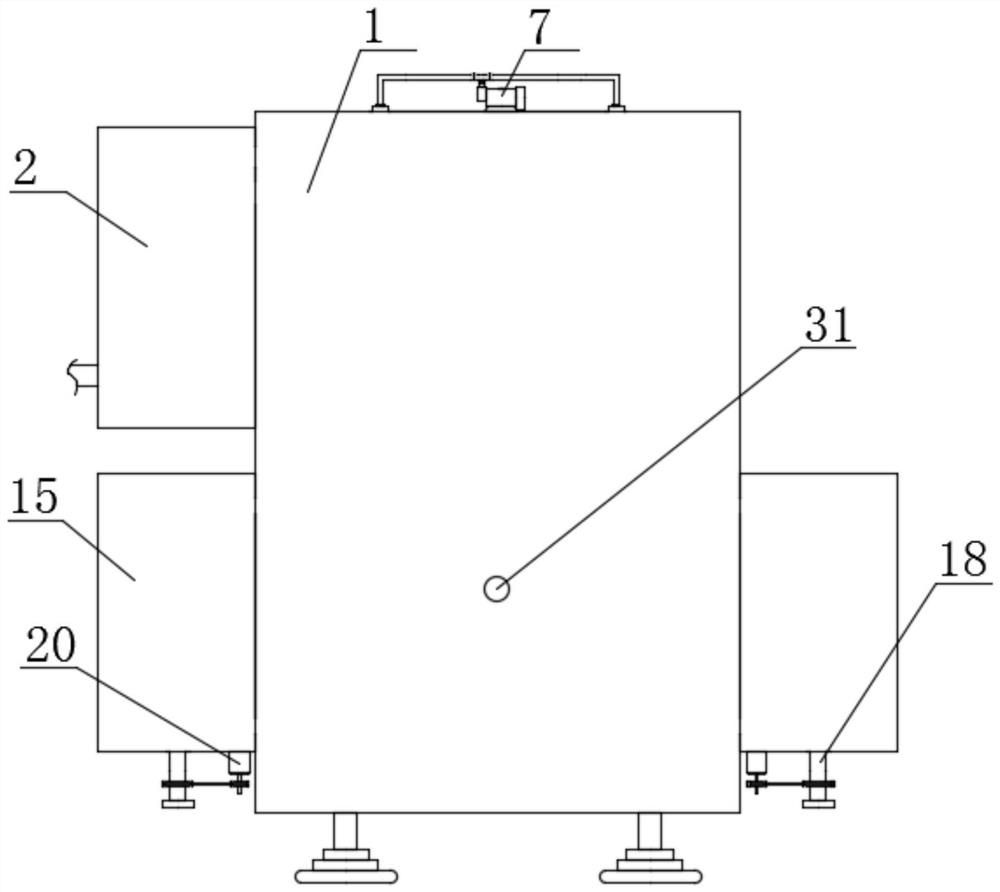

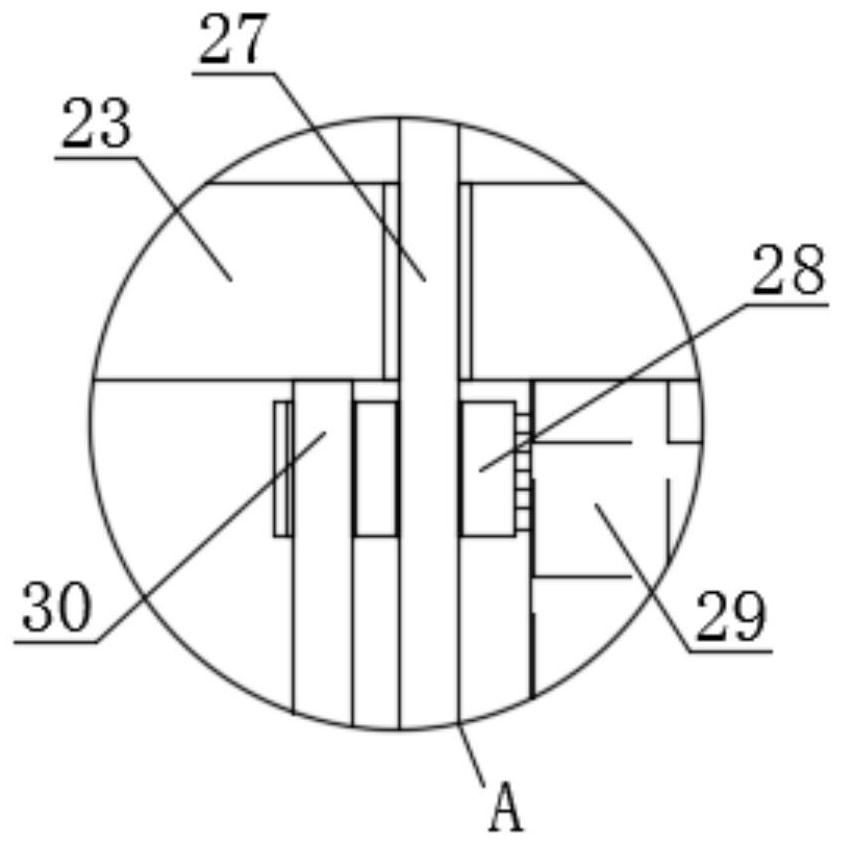

Large/medium-caliber water feeding pipe cleaning device

ActiveCN105945012ALess damage to the tube wallLow water consumptionHollow article cleaningWire brushDrive motor

The invention provides a large / medium-caliber water feeding pipe cleaning device. The large / medium-caliber water feeding pipe cleaning device is characterized by comprising a shell; a walking system is arranged below the shell; a detachable annular tool bit is arranged at the front end of the shell; an annular steel wire brush is connected out of the annular tool bit; the annular tool bit is connected with a driving motor; and a high-pressure water gun is arranged on the back upper side of the annular steel wire brush. The large / medium-caliber water feeding pipe cleaning device has the beneficial effects of little damage on pipe walls, low water consumption, low secondary pollution on pipes, high removal rate of growth rings, capability of removing harder growth rings and adaption to large and medium water feeding pipes with different calibers. The large / medium-caliber water feeding pipe cleaning device is simple in structure, convenient for operation and low in workload of constructors.

Owner:苏州市自来水有限公司

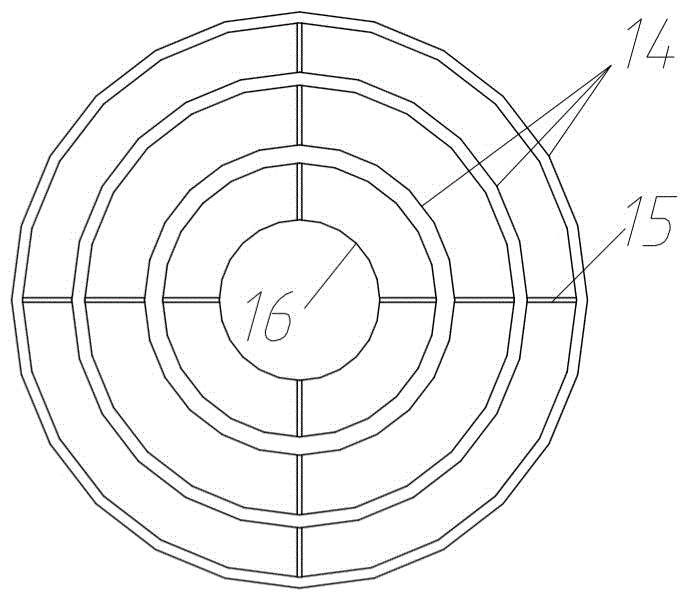

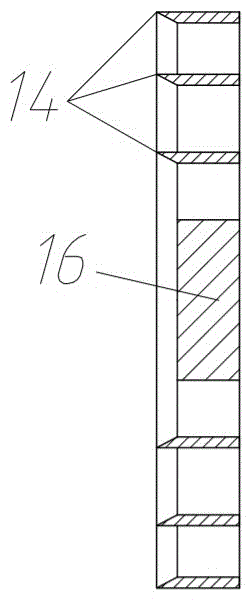

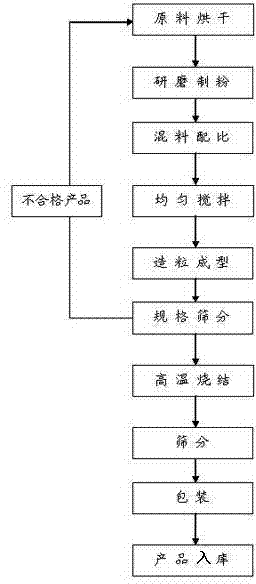

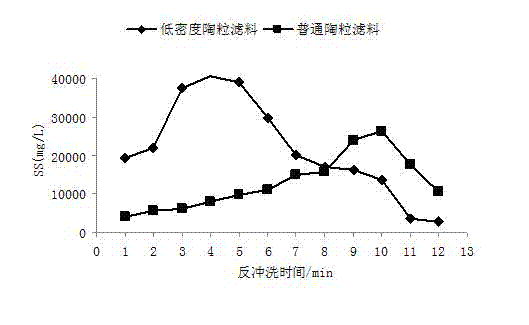

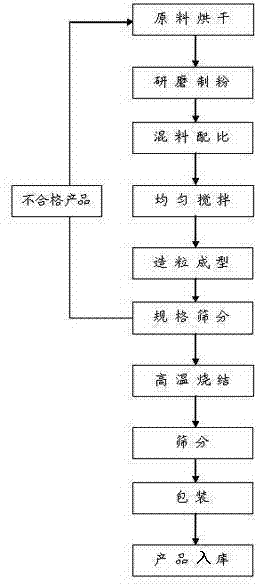

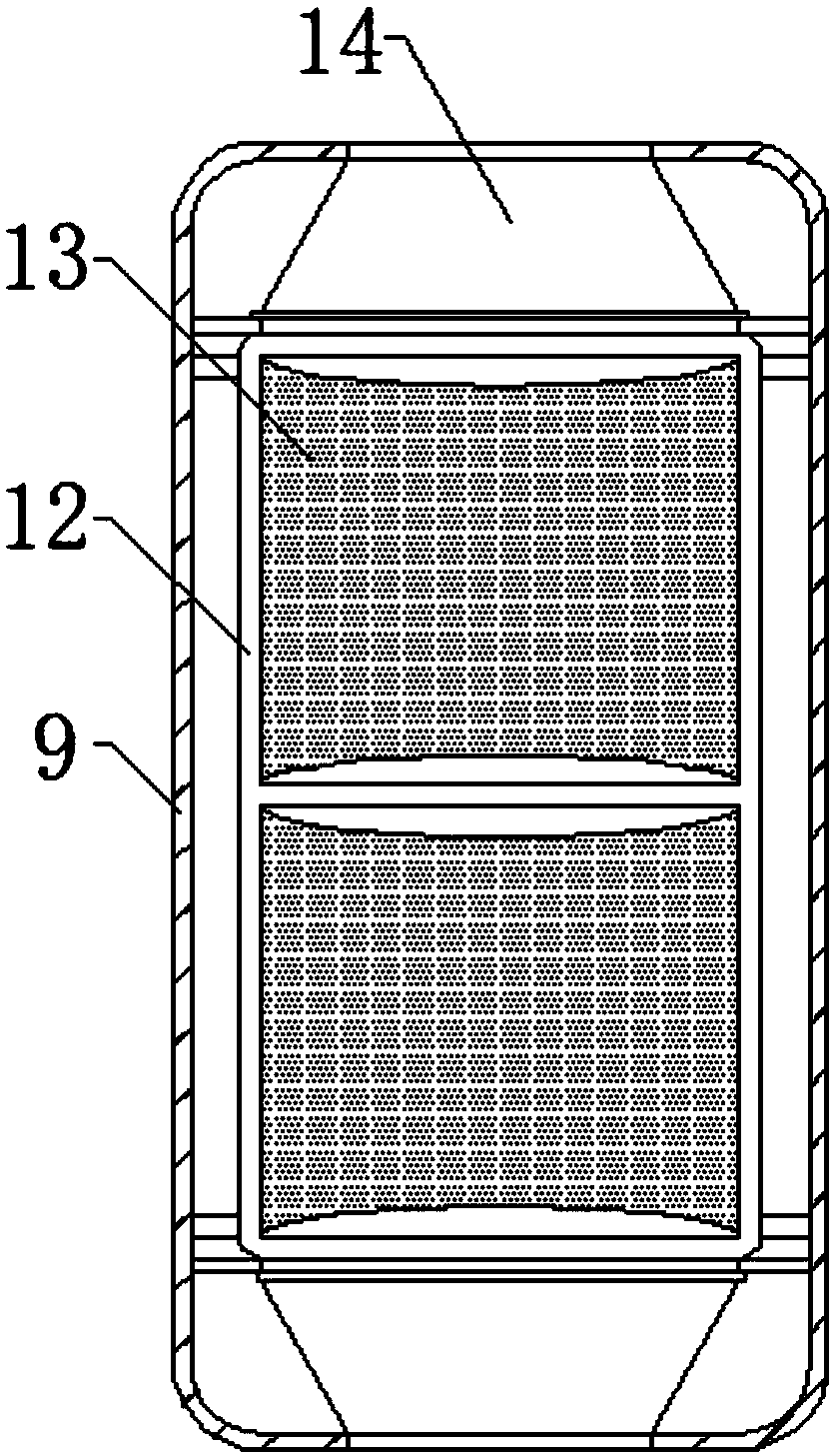

Low-density ceramsite filter material for biological aerated filter and preparation method thereof

InactiveCN102258913AReduce energy consumptionLow water consumptionSustainable biological treatmentFiltration separationFilter materialHigh surface

The invention relates to a low-density ceramsite filter material for a biological aerated filter, and a preparation method thereof. The invention provides the low-density ceramsite filter material for the biological aerated filter, and the low-density ceramsite filter material is mainly prepared from Guizhou soil, clay, pottery clay, Yichun soil, pore former, adhesive and a charcoal material. Theinvention also provides a preparation method for the low-density ceramsite filter material. The invention has the advantages that: the Guizhou soil, clay, pottery clay, Yichun soil, pore former, adhesive and charcoal powder are used as raw materials, so that the excellent physical properties such as a large specific surface area, and high surface roughness and mechanical strength and the like of the low-density conventional heavy ceramsite filter material are kept, the density of the low-density ceramsite filter material is reduced well so as to reduce energy consumption during backwashing, contribute to complete backwashing, and avoid the problem that the filter material is hardened during long-term running and the like, the production cost and the waste water treatment cost are greatly reduced, and the popularization and application of the biological aerated filter process can be facilitated.

Owner:谭海燕

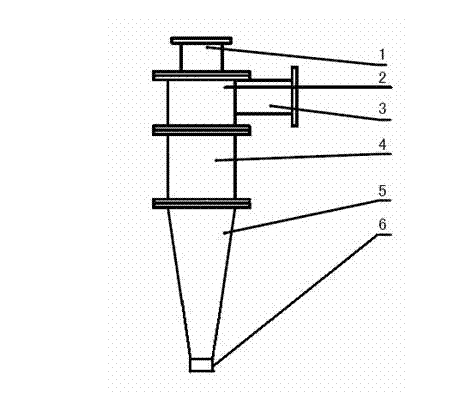

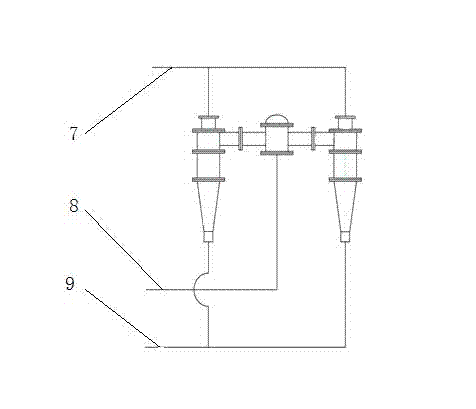

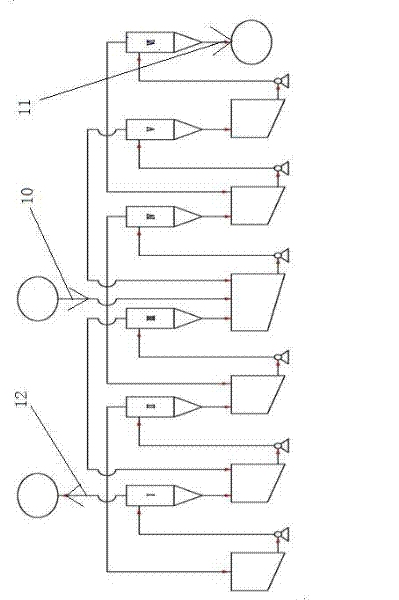

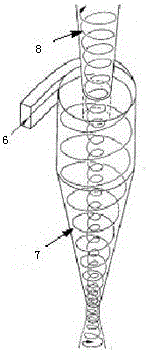

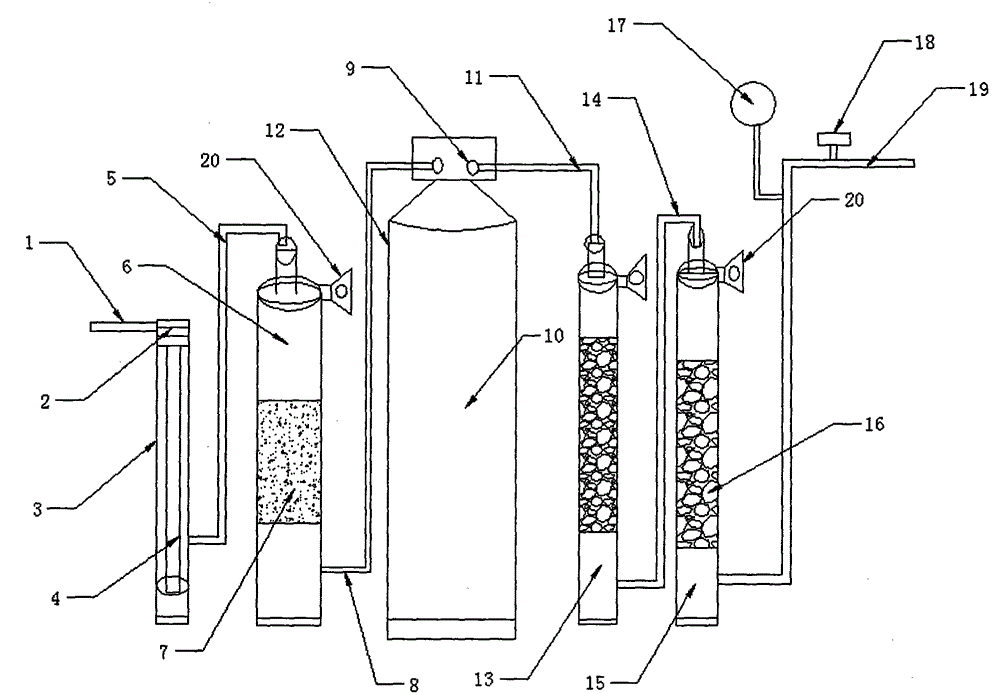

Device and process for separating silicon carbide waste mortar

ActiveCN102502636AReduce the alkali washing processLow water consumptionSilicon carbideWork in processSmall footprint

The invention relates to a method for extracting silicon carbide, which is characterized by being composed of at least three groups of cyclones, wherein each group is composed of at least two cyclone separators which are connected in parallel; a bottom flow operating of each cyclone separator in each group is respectively connected with a bottom flow general pipe; an overflowing opening of each cyclone separator is connected with an overflowing general pipe; the bottom flow general pipe of the previous cyclone group is connected with the overflowing general pipe of the next cyclone group and a feeding tank of the cyclone; the feeding tank is respectively connected with a feeding pipe of each cyclone separator of the cyclone group through a feeding pump; a raw material pipe is communicated with the feeding tank of the middle cyclone group; semi-product silicon carbide powder liquid is discharged by the bottom flow general pipe of the tail-grade cyclone group; silicon powder liquid is discharged by the bottom flow general pipe of the first-grade cyclone group; the silicon carbide powder liquid is treated by processes of acid washing, dehydration and drying to obtain finished-product silicon carbide. According to the invention, an alkali washing link in the traditional process is reduced and the method has the advantages of low water consumption amount, great processing capability, high level and recycling rate of the finished-product silicon carbide, small occupied area and the like; and the method further has the advantages of obviously reducing the production cost, improving the economic benefits and alleviating the labor intensity of production staff.

Owner:WEIHAI HAIWANG HYDROCYCLONE

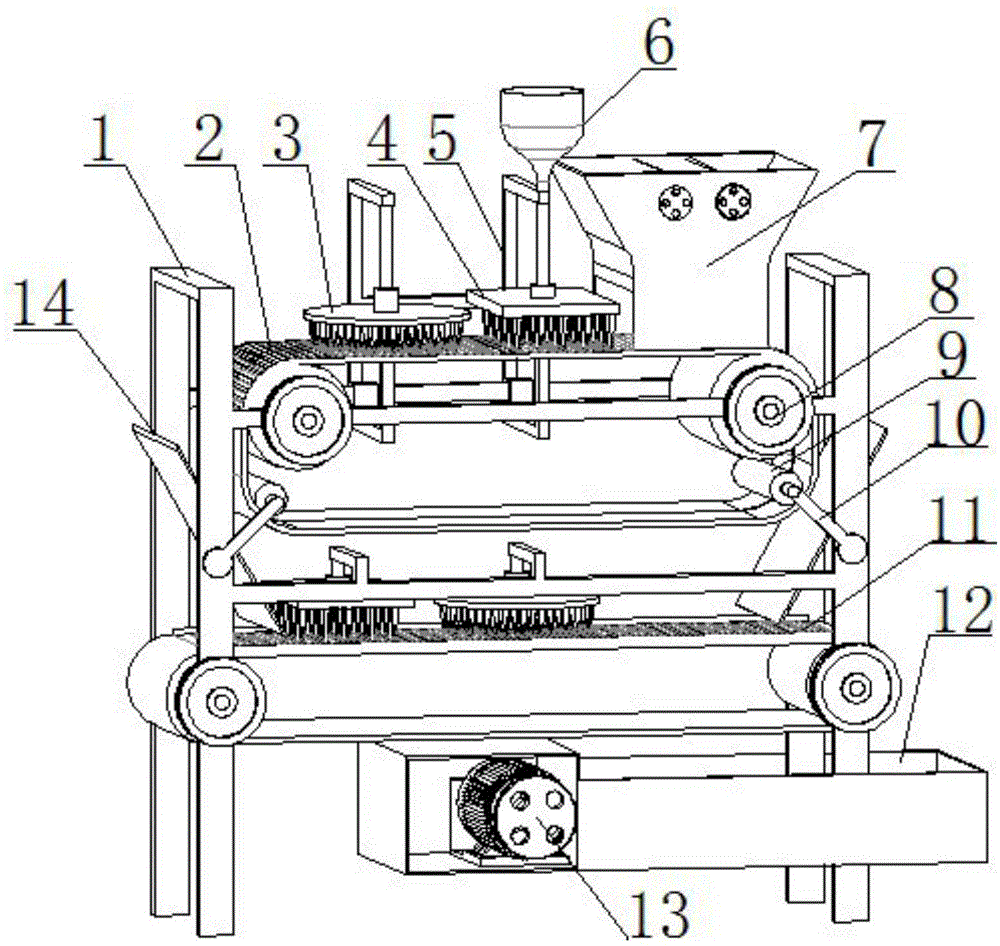

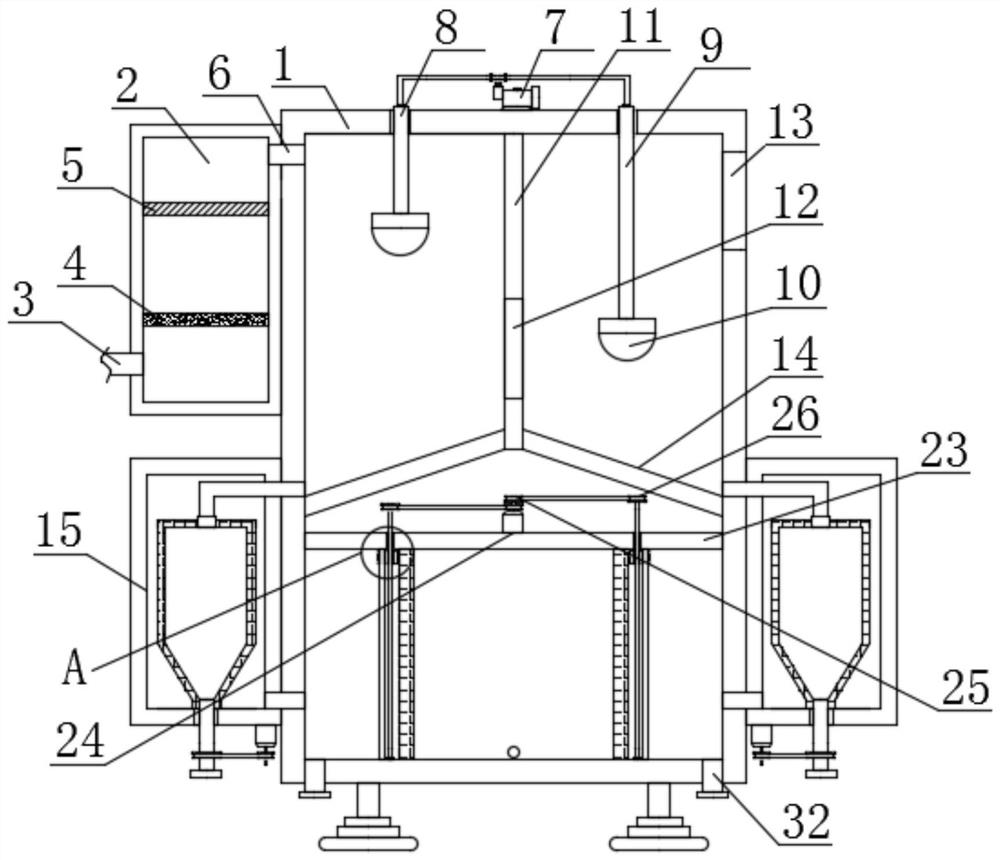

Chopstick cleaning device

ActiveCN104939782AGood cleaning effectLow water consumptionTableware washing/rinsing machine detailsHome appliance efficiency improvementEngineeringSmall hole

The invention relates to a chopstick cleaning device. The chopstick cleaning device comprises a rack, a first conveying belt, a feed hopper, belt pulleys, a second conveying belt, a collecting box, a motor, baffles, electric brushes, aligning brushes, a support, a long-neck container, small rollers and telescopic rods, wherein chopstick grooves are formed in surfaces of the first conveying belt and the second conveying belt, rectangular grooves are also formed in the first conveying belt, the electric brushes are disc-shaped, the support comprises rod pieces, a small hole, a short shaft, a friction strip and sliding grooves, one electric brush is connected with the lower end of the short shaft, the neck of the long-neck container is embedded in the small hole, one aligning brush is connected with the lower end of the long-neck container, one end of each telescopic rod is hinged to a vertical rod, and the other end of each telescopic rod is connected with the corresponding small roller. The device consumes a smaller amount of water and has the better cleaning effect in the cleaning process and has the characteristics of low manufacturing cost and practicability.

Owner:ANHUI UNIV OF SCI & TECH

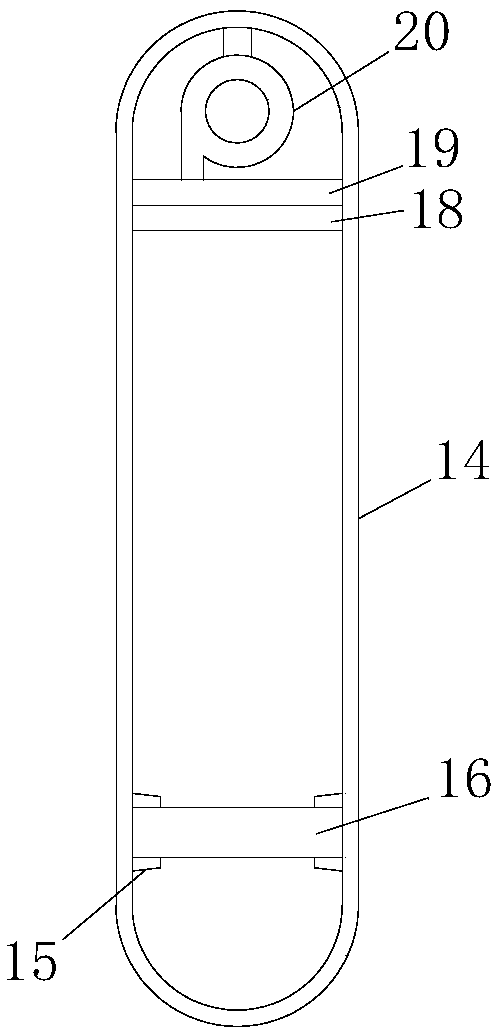

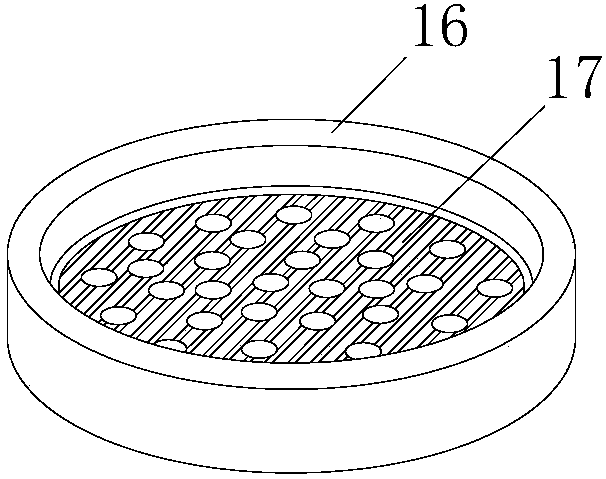

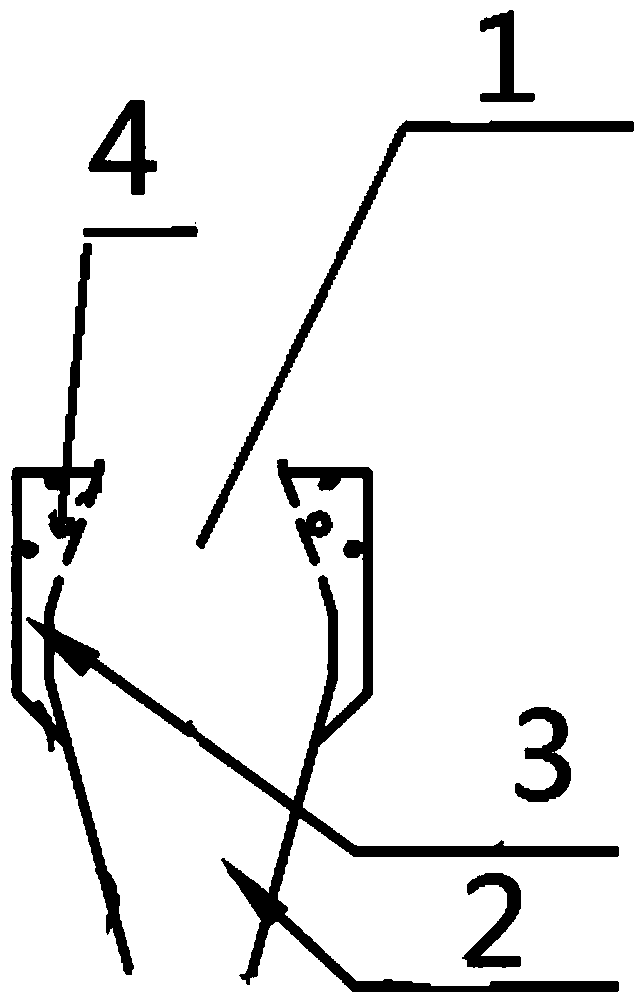

Method and loading plate for degumming cleaning silicon wafer

InactiveCN102486989ALow water consumptionGood cleaning effectSemiconductor/solid-state device manufacturingFine working devicesWater pipePorous channel

The invention relates to a method and a loading plate for degumming cleaning a crystalline silicon solar cell silicon wafer. The method mainly comprises the following steps of: bonding silicon blocks onto the loading plate distributed with porous channels, cutting the silicon blocks on a multiline cutting machine, simultaneously cutting through the porous channels of the loading plate, then connecting the porous channels with a water pipe, introducing tap water, leading the water to flow down from cut gaps, and washing away mortar bonded in the silicon wafer. By the use of the method, not only can the water consumption be greatly reduced and can water be saved by 70%, but also the cleaning effect is good, the staining rate is reduced, the quality of a product is improved, the rate of A-grade products can be improved by 1.5-2%, the cleaning time is shortened, and the labor productivity is improved by 33%; and for the loading plate for cleaning, the structure is simple, the manufacturing cost is low, the use is convenient and the production cost and the manufacturing cost of the silicon wafer are reduced.

Owner:TIANWEI NEW ENERGY HLDG +1

Water-saving type industrial washing machine

InactiveCN107780119AIncrease profitLow water consumptionOther washing machinesWashing machine with receptaclesElectric machineryWater pipe

The invention discloses a water-saving type industrial washing machine. The water-saving type industrial washing machine comprises a machine body, wherein a water inlet valve is mounted on the top ofa cavity of the machine body; a water inlet tube is mounted at a water inlet end of the water inlet valve; a clamping sleeve is mounted on the inner wall of the machine body; a washing drum is slidably mounted in a slot of the clamping sleeve; a partition is mounted at the bottom of the cavity of the machine body; a water storage groove is formed in the top of the partition; a rotating motor is mounted at the bottom of the inner wall of the machine body; a rotating plate is mounted at the bottom of the washing drum; and an output end of the rotating motor penetrates through the partition and is connected with the rotating plate at the bottom of the washing drum. The water-saving type industrial washing machine is provided with a circular water-saving mechanism, the utilization rate of water resources is greatly increased, meanwhile, water consumption for clothes washing every time is reduced, clothes and the like are placed in the washing drum at first, then the washing drum communicates with a water inlet tube, water flows into the washing drum through the water inlet valve, the rotating motor starts to drive the rotating plate to rotate, then the washing drum is driven to rotate,and thus, the clothes in the washing drum are cleaned by centrifugal force.

Owner:FANCHANG QINGXIN WASHING CO LTD

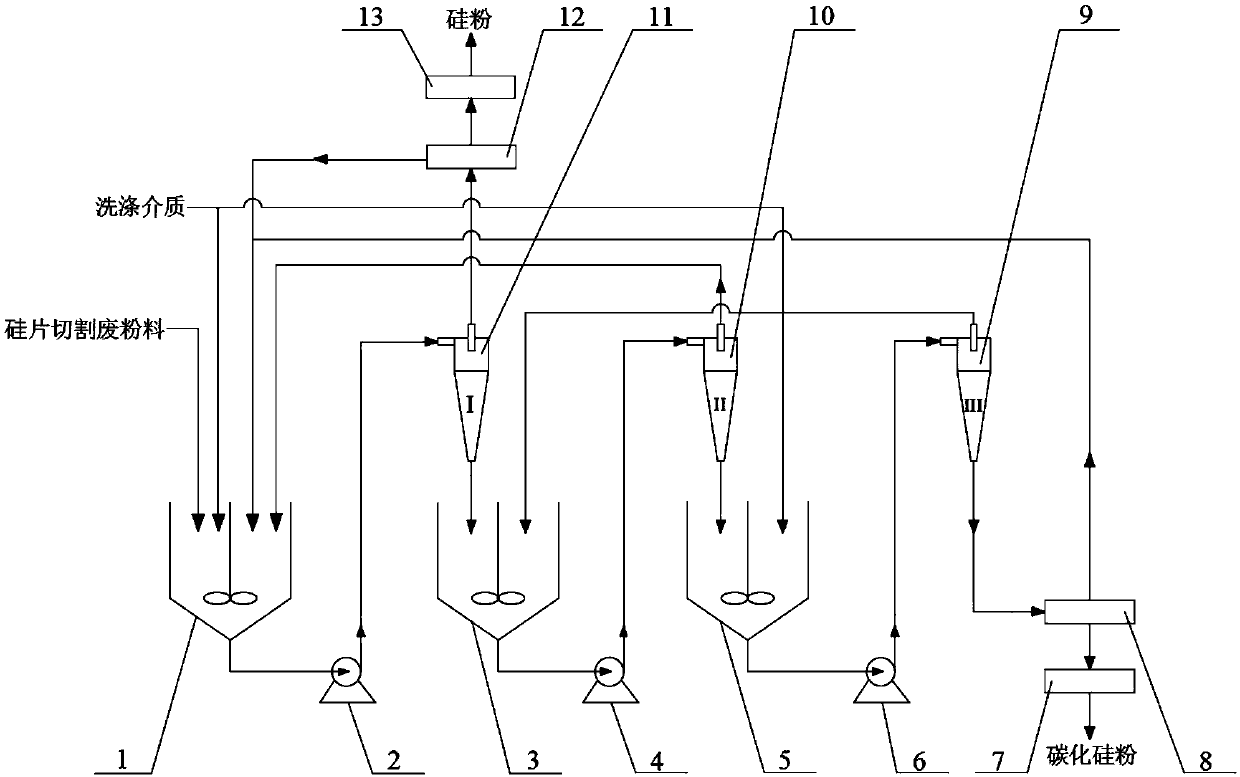

Process for separating and recovering cutting waste powder material of solar silicon wafer

InactiveCN108046269AImprove separation efficiencyLow water consumptionSilicon carbideSilicon compoundsScrapMaterials science

The invention provides a process for separating and recovering a cutting waste powder material of a solar silicon wafer. The process is characterized by comprising a rotational flow washer, a stirringmaterial barrel, a pump, a solid liquid separator I, a solid liquid separator II, a drier I and a drier II. The cutting waste powder material of the solar silicon wafer is fully dispersed by a washing medium in the stirring material barrel to prepare an even suspension, the main ingredients of the even suspension are silicon and silicon carbide, the suspension is tangentially pumped into the rotational flow washer through a pump and is subjected to multi-level countercurrent washing, a silicon suspension is discharged from an overflow pipe of the primary-level rotational flow washer, a silicon carbide suspension is discharged from an underflow pipe of the tail-level rotational flow washer, the suspension is subjected to solid liquid separation and is dried to obtain a silicon powder and asilicon carbide powder. The process separates and extracts the cutting waste powder material of the wafer to recycle the resource, the continuous high-precision separation of the silicon and the silicon carbide is realized, the cutting waste material is prevented from be discharged to cause environment pollution, the process has the advantages of low water consumption, environment protection, high product purity and the like, and the production cost and the labor intensity are reduced.

Owner:CHANGZHOU UNIV

Toilet pit blocked by ratchet wheel and roller

ActiveCN108451423AEnsure hygieneLow water consumptionBathroom accessoriesAgainst vector-borne diseasesEngineeringToilet

The invention discloses a toilet pit blocked by a ratchet wheel and a roller. The toilet pit comprises a toilet foundation. A pit is formed in the top of the toilet pit foundation. A cesspit is arranged on the right side of the toilet foundation. Pedaling blocks are fixed to the top face of the toilet foundation. The roller is arranged on a bottom groove wall of the pit. Scraping plates are arranged in extensible grooves in the circumferential side face of the roller. The roller is fixed to a follow-up bearing and a support bearing rotationally through a roller rotating shaft. The support bearing is fixed into a rear hole wall of a driving rotation shaft groove. A ratchet wheel ring is arranged in the middle of the driving rotation shaft groove. An inner rotating disc is arranged in the ratchet wheel ring. A clamping block is fixed to the edge of a rear faceplate of the inner rotating disc rotationally. A rotating rod groove is formed in the tail end of the front side of the driving rotation shaft groove. A driving rotation shaft in the rotating rod groove is fixed into the inner wall of the rotating rod groove through a driving bearing rotationally. A driving rotation rod is fixedto the rod wall of the driving rotation shaft vertically. The toilet pit has the advantages that filth in the pit can be discharged quickly through back-and-forth pulling of the ratchet wheel ring, so that sanitation of toilets is improved, and water consumption is lowered.

Owner:泉州憨鼠教育咨询有限公司

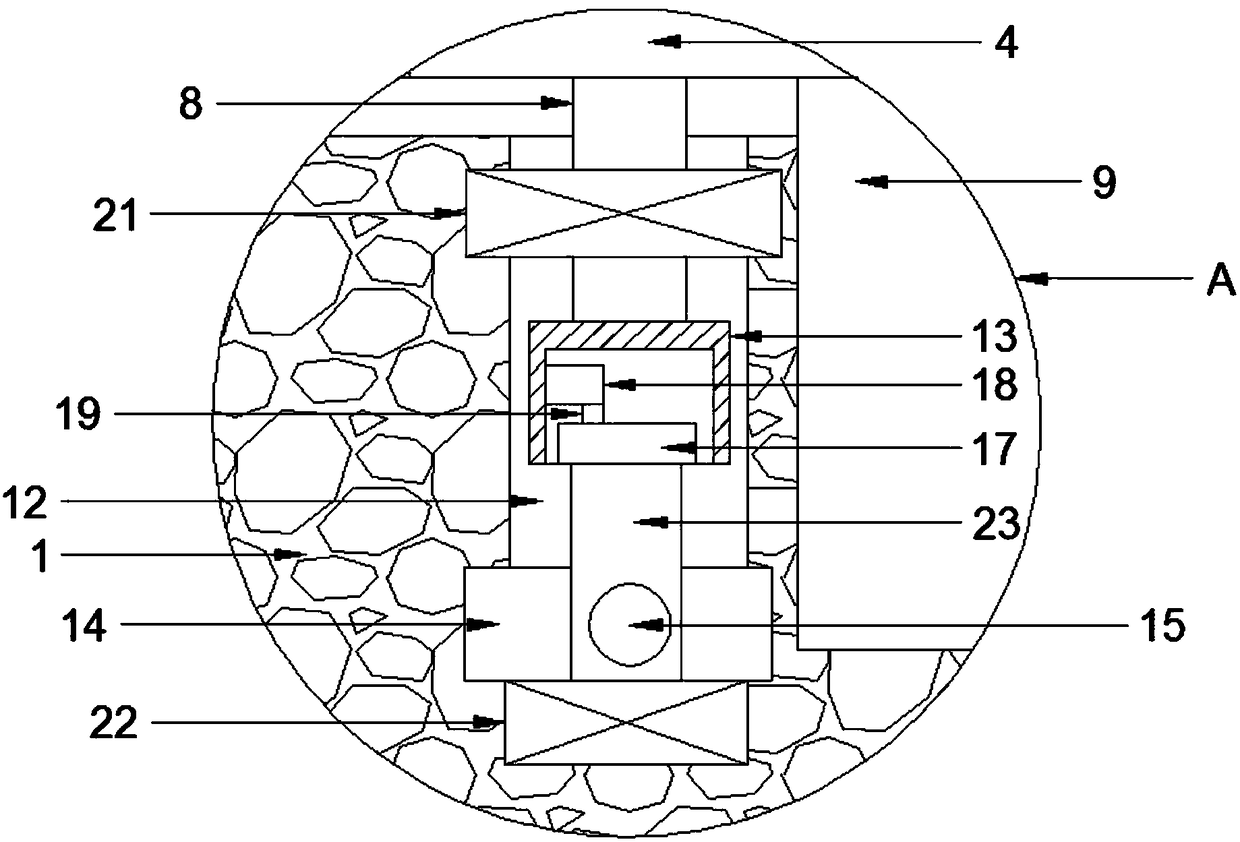

Detachable water draining tube

The invention discloses a detachable water draining tube. The detachable water draining tube comprises a U-shaped tube and water inlet and outlet tubes, wherein the left end opening of the U-shaped tube is higher than the right end opening, and the right end opening is fixedly connected to the water outlet tube; a connecting part is arranged in the left end opening of the U-shaped tube, the water inlet tube is arranged on the upper part of the U-shaped tube, a short tube is arranged on the bottom of the U-shaped tube and is used for communicating the U-shaped tube with the outside, and a sealing cover is arranged on the short tube. During use, the connecting part is connected to a water draining opening of a hand washing sink, and water fills the U-shaped tube through the water inlet tube, so that residual sewage in the pipeline can be washed away; the left end opening of the U-shaped tube is higher than the right end opening, a backward water flow phenomenon is avoided; if the U-shaped tube needs to be cleared, the sealing cover can be opened, and a clearing tool is used for clearing the U-shaped tube conveniently. Moreover, the detachable water draining tube is small in water consumption, simple in structure, low in manufacturing cost, capable of improving the sealing effect with a sealing gasket, and capable of controlling the size of water flow according to the actual situation with a control valve.

Owner:GUANGXI UNIV

Metallurgical slag waste heat recovery equipment and method

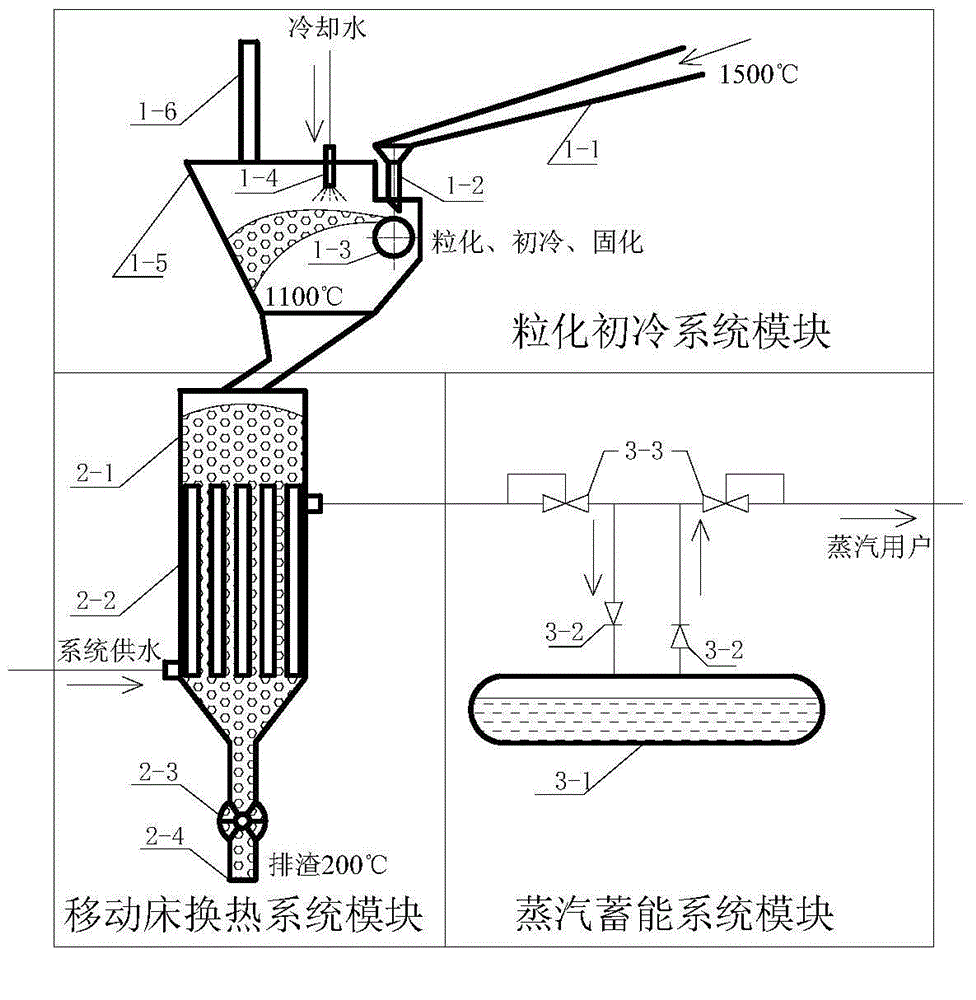

ActiveCN104946826AEfficient recyclingLow water consumptionIncreasing energy efficiencyRecycling and recovery technologiesMetallurgical slagMoving bed heat exchanger

The invention discloses metallurgical slag waste heat recovery equipment and a method. The metallurgical slag waste heat recovery equipment comprises a granulation primary-cooling system module and a moving bed heat exchange system module, wherein the granulation primary-cooling system module comprises a metallurgical slag tank, a hopper feeder, a granulation wheel, an atomizer and a granulation primary-cooling box body; the moving bed heat exchange system module comprises a slag storage bin, a moving bed heat exchanger and a slag discharge wheel; high-temperature molten metallurgical slag is fed to the granulation wheel through the hopper feeder from the metallurgical slag tank from top to bottom, is crushed through the granulation wheel and flies out in the tangential direction, the metallurgical slag is in contact with cooling water mist provided by the atomizer in the flying process and subjected to water quenching to generate surface-cured metallurgical slag particles and water vapor, the metallurgical slag particles enter the slag storage bin and the water vapor is discharged out; and the metallurgical slag particles in the slag storage bin are constantly supplied to the moving bed heat exchanger, the moving bed heat exchanger is provided with a shell and a pipeline, the metallurgical slag particles move in the shell from top to bottom, the pipeline is arranged in the shell and water flows in the pipeline from bottom to top. The invention further provides a method adopting the equipment.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

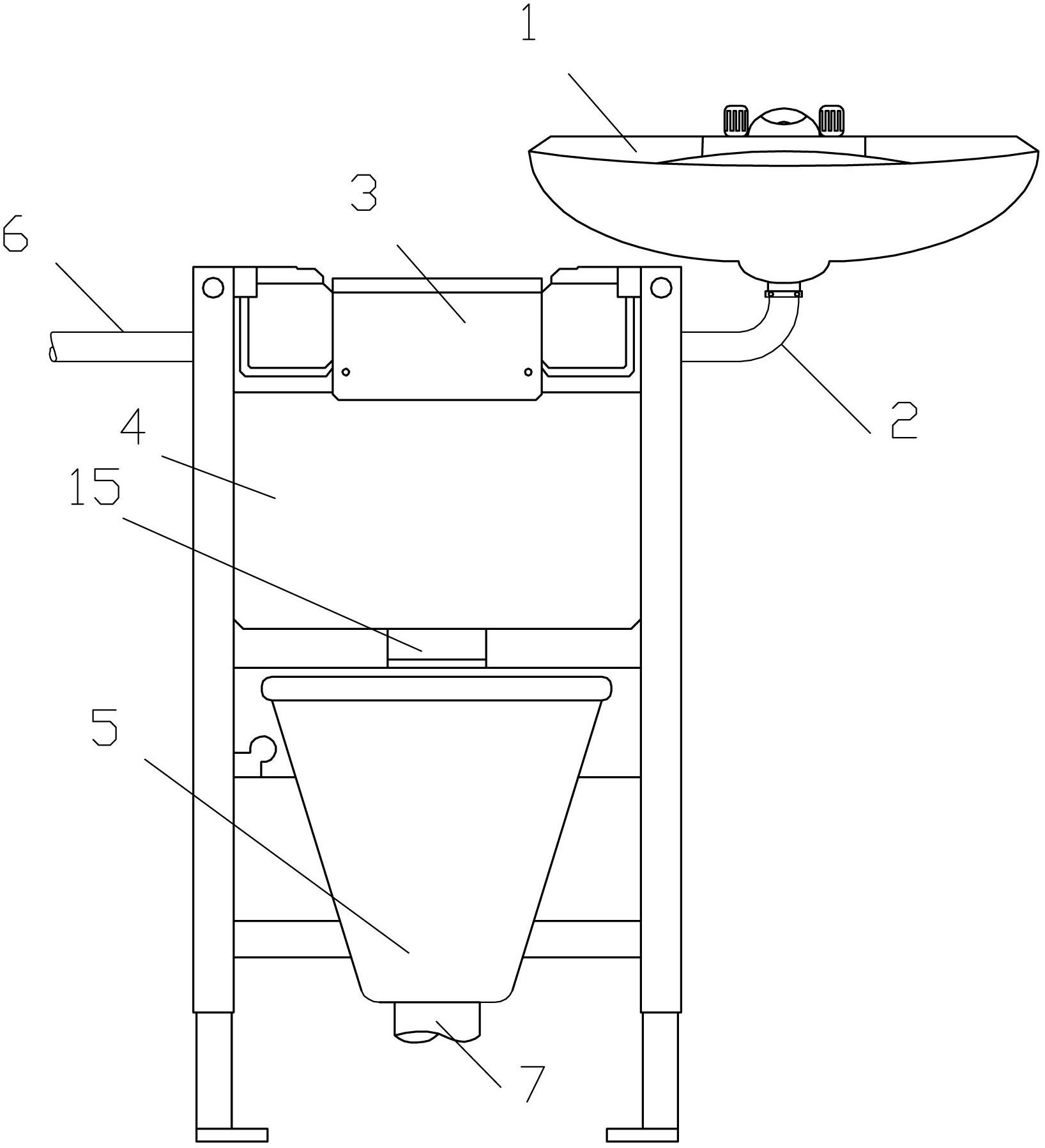

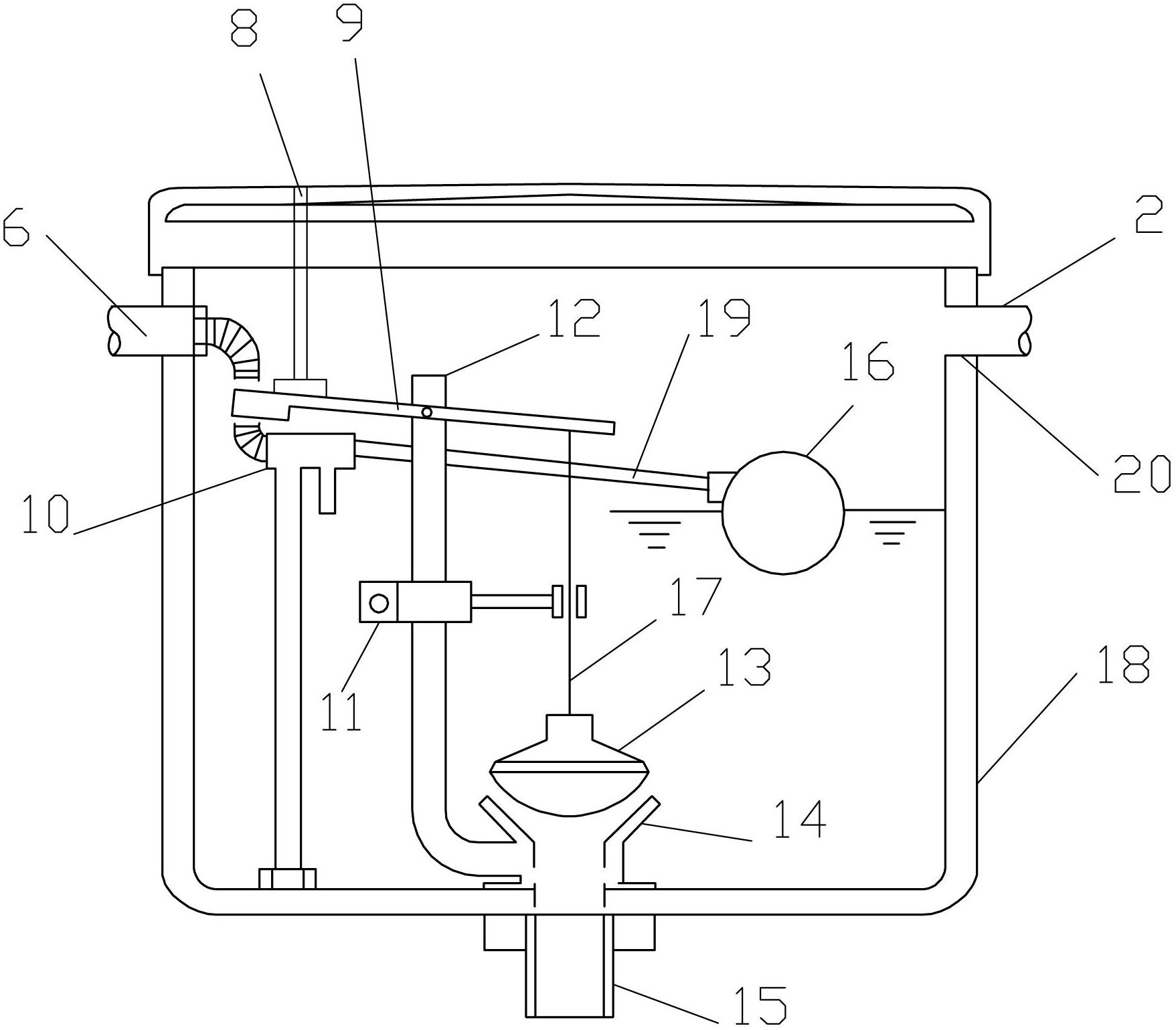

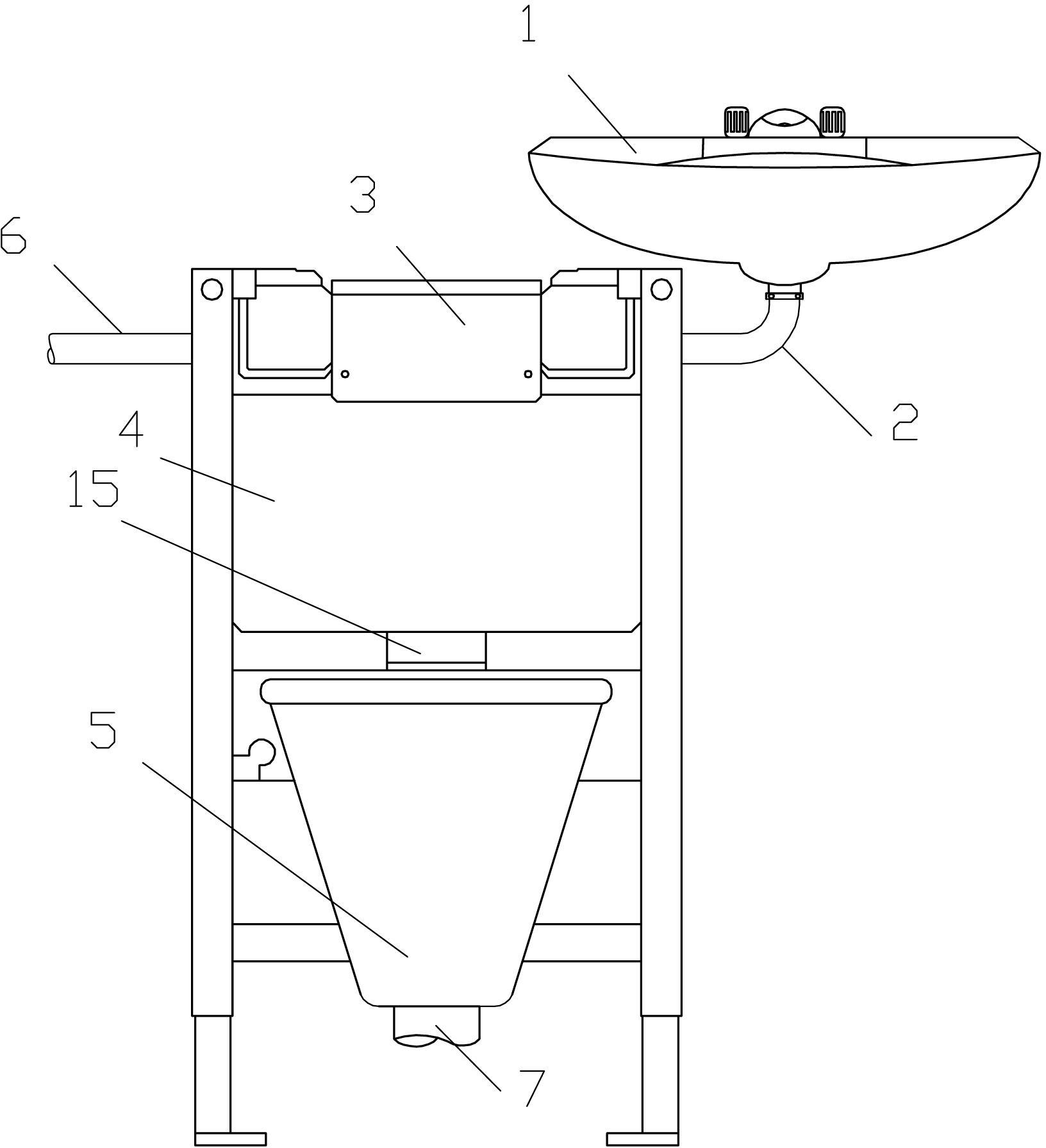

Environment-friendly water-saving wash basin and closestool integrated sanitary fitting

InactiveCN102677760ATake advantage ofLow water consumptionWater closetsFlushing devicesPipingBall valve

The invention provides an environment-friendly water-saving wash basin and closestool integrated sanitary fitting and relates to a sanitary fitting. The sanitary fitting is used for solving the problems that the water resource is seriously wasted and the use ratio of the water resource is lower when the traditional water tank and closestool are cleaned. The environment-friendly water-saving wash basin and closestool integrated sanitary fitting further comprises a wash basin and a wash basin draining pipe, wherein a button rod, a float ball valve, a guiding device, an overflow pipe, a ball valve, a valve base, a washing pipe, a float ball, a connecting rope and a lever are all located in the water tank; the wash basin draining pipe passes through a connecting hole and communicates the wash basin with the water tank; a button passes through the water tank and is connected with one end of the button rod; the valve base is located at the bottom in the water tank and is communicated with the washing pipe; the button rod and the lever are hinged with an outer side wall of the overflow pipe; the guiding device is arranged on the overflow pipe and is located under the lever; one end of the connecting rope is fixedly connected with the other end of the button rod; the other end of the connecting rope is fixedly connected with the ball valve by passing through the guiding device; one end of the lever is fixedly connected with the float ball valve; and the float ball is arranged at the other end of the lever. The environmental-friendly water-saving wash basin and closestool integrated sanitary fitting is applied to a washing room.

Owner:HARBIN INST OF TECH

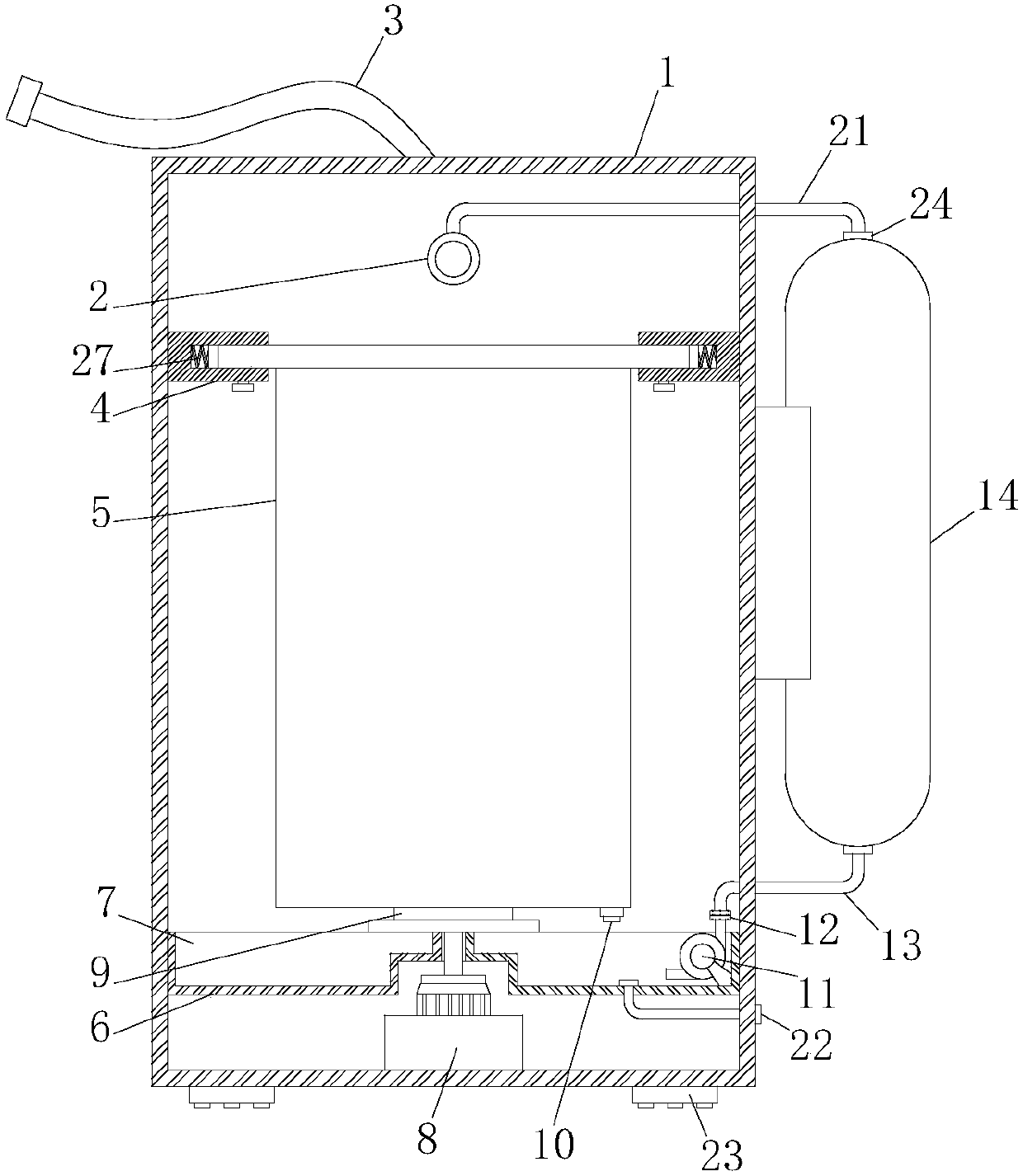

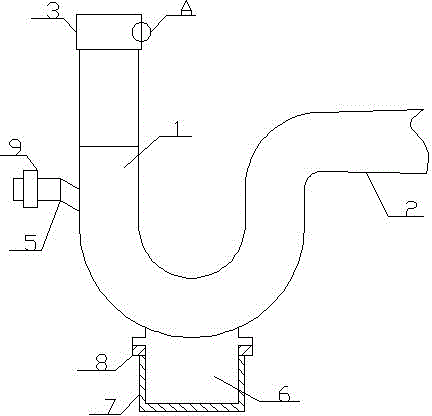

Steam heating system

A steam heating system comprises a control system, a water storage device, a main external steam generating device, a water-steam separating device, a water inlet pump, an auxiliary internal steam generating device, a cavity and a three-way water pipe, wherein the main external steam generating device is provided with a water inlet pipe, the water inlet pump, the water storage device and the waterinlet pipe of the main external steam generating device are connected through the three-way water pipe, the control system is electrically connected with the water inlet pump to control the work of the water inlet pump, a first steam guiding pipe is arranged between the main external steam generating device and the water-steam separating device, a second steam guiding pipe is arranged between thewater-steam separating device and the cavity, the main external steam generating device is arranged beside the cavity and comprises a shell and a first heating element located at the bottom of the shell, and the auxiliary internal steam generating device is arranged under the cavity and comprises a body and a second heating element located at the bottom of the body. The steam heating system can effectively achieve rapid temperature rise in the cavity, improve the cooking heating speed and reduce water consumption and electricity consumption and the amount of accumulated condensed water at thebottom in the cavity.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

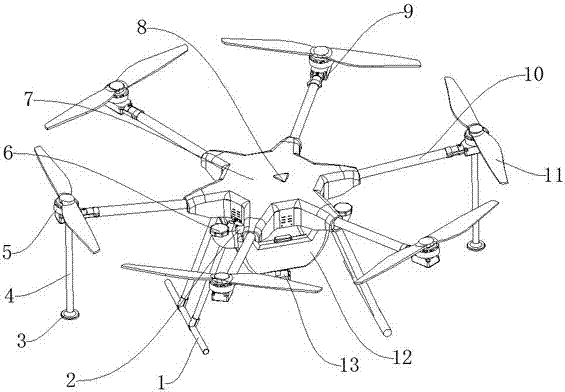

Cooling water supplying device for nursery stock nursing

PendingCN107409802AEasy to operateLow water consumptionAircraft componentsWatering devicesPipingSpray nozzle

The invention discloses a cooling water supplying device for nursery stock nursing. The cooling water supplying device includes a control box and a water storage tank; a wireless signal transmitter is arranged on the top of the control box; rotation arms are fixed on the periphery of the control box through connection members; brushless motors are fixed on end portions of the rotation arms through hoops; rotor wings are arranged on power shafts of the brushless motors; water spraying pipes are arranged on two opposite rotor wings; spraying nozzles are arranged under the water spraying pipes; the water storage tank is arranged under the control box; a water pump is arranged on an upper part of the center of the water storage tank; a sealing cover is arranged on a water inlet pipe arranged on a side surface of the water storage tank; a drainage pipe is arranged on the bottom of the water storage tank; and a dragline valve is arranged on the drainage pipe; and undercarriages are arranged on two sides of the water storage tank. The beneficial effects of the invention are that the cooling water supplying device is simple and convenient to operate, can achieve remote control, is less in water consumption, can save water resources, and can reduce the cost of nursery stock cultivation.

Owner:DEQING GREEN SUNSHINE ECOLOGICAL AGRI CO LTD

Low-moisture coke quenching box and coke quenching method using same

The invention provides a low-moisture coke quenching box which firstly carries out primary coke quenching on high-temperature coke spraying cold water formed after carbonization, and then carries out secondary coke quenching on the coke by utilizing much vapor produced in spraying water, so that low-moisture coke is formed after coke quenching is completed; compared with the problems that the coke quenching method in the prior art cannot carry out precise control on temperature of coke-quenched semi coke, the moisture content of the coke-quenched semi coke is still higher and the coke quality is poor, the low-moisture coke quenching method disclosed by the invention can be used for not only precisely controlling the temperature of the coke-quenched coke at 70-80 DEG C, but also effectively reducing the water consumption in a coke-quenching process, so that the moisture content of the coke-quenched semi coke is low and is about 1-2%, secondary drying is avoided, and coal gas consumption is not needed; besides, produced vapor and carried dust and poisonous gas can be returned to a furnace for utilization, and excessive vapor is guided out by a pipeline and intensively treated, so that secondary pollution is avoided.

Owner:HUADIAN HEAVY IND CO LTD

Household constant temperature and humidity square bin system

ActiveCN107894046AReduce electricity consumptionLow water consumptionMechanical apparatusSpace heating and ventilation safety systemsWater circulationWater supply

The invention discloses a household constant temperature and humidity square bin system which comprises a constant temperature and humidity air forming square bin, a water pool, a water supply and drainage system, an air supply pipeline, an air return pipeline and a central control cabinet, wherein the constant temperature and humidity air forming square bin comprises an air return and suction unit, a draught fan, a water circulation and spraying unit and an air supply unit; the air return and suction unit is provided with a window and can directly communicate with the outside world through the window; the air return and suction unit is further provided with a connector and can be connected with the air return pipeline through the connector; and the draught fan is arranged between the airreturn and suction unit as well as the water circulation and spraying unit. The household constant temperature and humidity square bin system disclosed by the invention has the advantages that the pollution is avoided, the electric energy consumption is low, the water consumption is low, the noise is low, the air change rate is low, the room temperature and humidity are moderate, and the human body feels comfortable. Meanwhile, due to a square bin structure, the household constant temperature and humidity square bin system further has the advantages of being simple and convenient to transport,mount and dismount, small in occupied area, low in investment, and high in operability.

Owner:WUHAN TEXTILE UNIV

Agricultural machine casting quenching unit

InactiveCN108277332AUniform temperatureLow water consumptionFurnace typesHeat treatment furnacesQuenchingWater pipe

The invention discloses an agricultural machine casting quenching unit which comprises a water tank and a filter. A quenching chamber is arranged on one side of the interior of the water tank, an airdrying chamber is arranged on the other side of the interior of the water tank, an adjusting mechanism is vertically installed at the middle portion of the upper portion of the water tank, a top support is horizontally installed on one side of the upper portion of the adjusting mechanism, a lifting mechanism is installed on one side of the upper portion of the top support, one side of a straight rod is sleeved with an object containing basket in a sleeving manner, a circulation pump is arranged outside the side, close to the quenching chamber, of the water tank, a water inlet of the filter isconnected to the other end of a guide rail pipe, and a water outlet of the pressure water tank communicates with the quenching chamber through a guide pipe. According to the agricultural machine casting quenching unit, water is guided to the interior of the filter through a water guide pipe to be filtered and then conveyed into the pressure water tank for temporary storage, then the water is appropriately conveyed back to the interior of the quenching chamber for supplementing for internal water amount, water consumption is reduced, the water using efficiency is improved, and the environment is protected.

Owner:郑伟杰

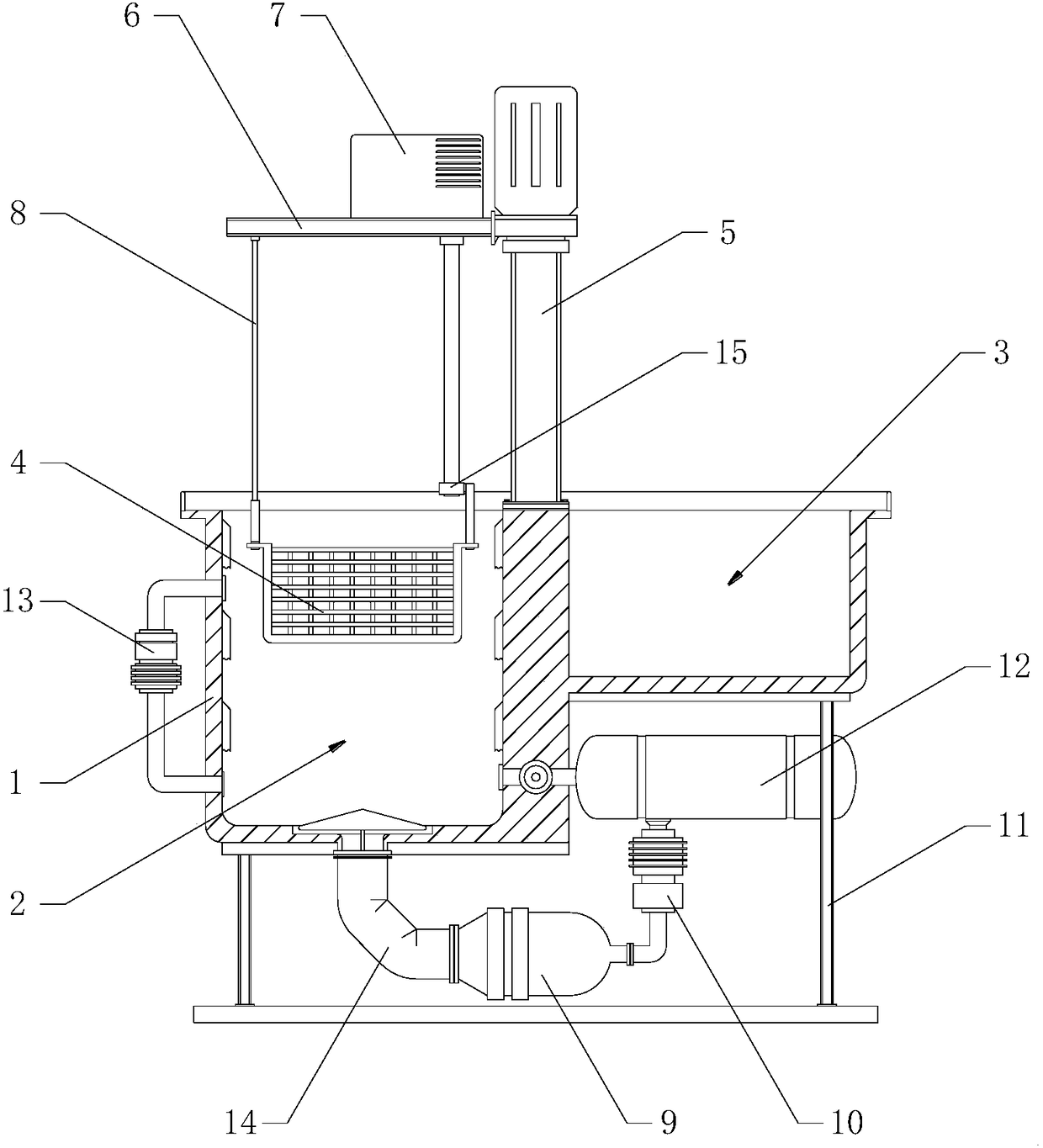

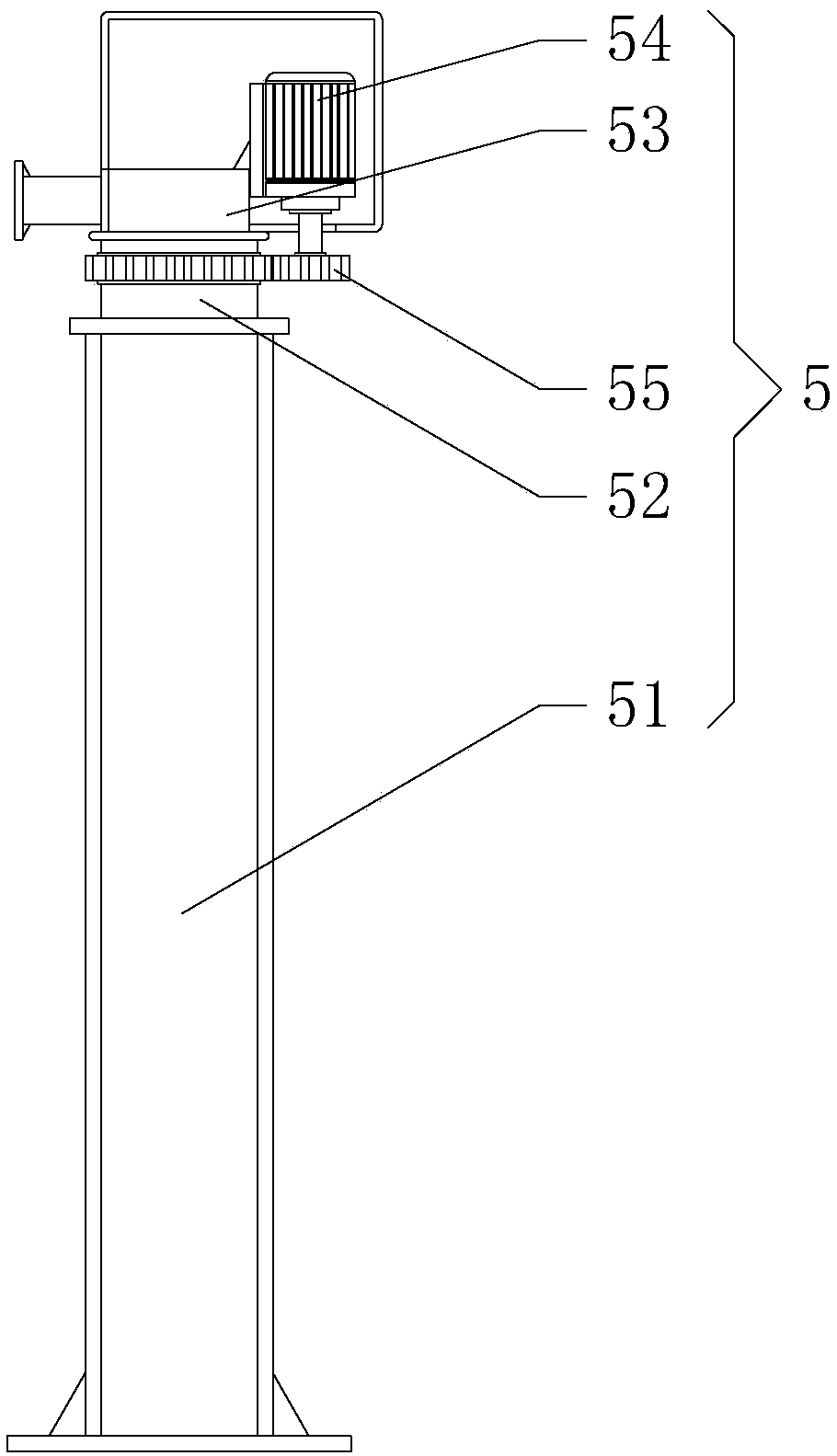

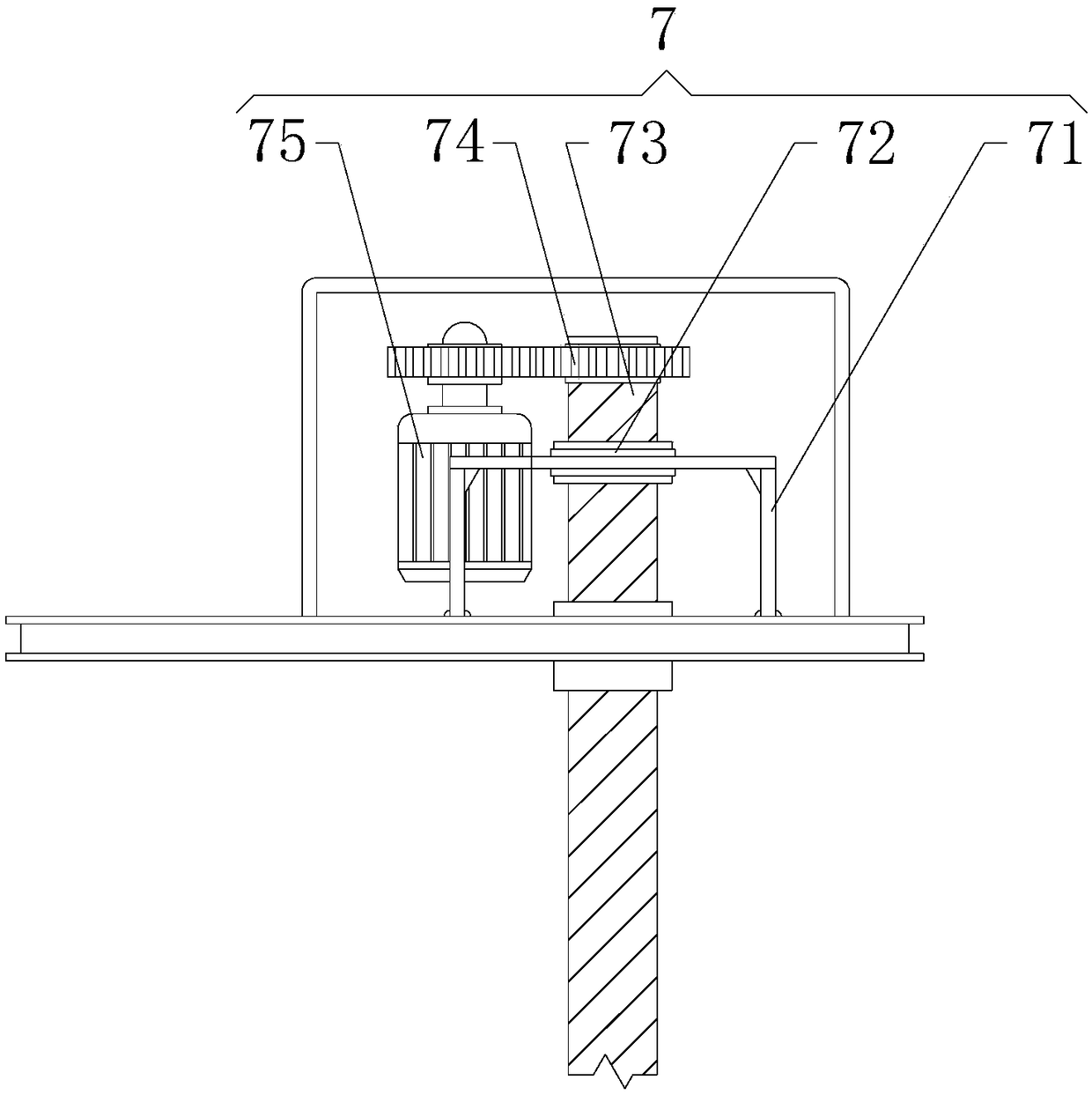

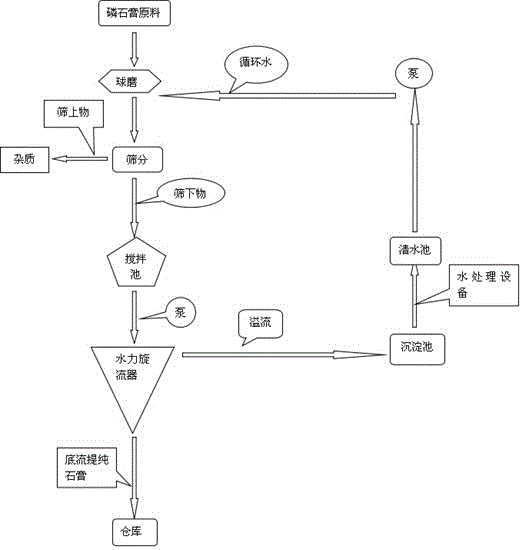

Method for purifying phosphogypsum by using hydrocyclone

The invention relates to a method for purifying phosphogypsum by using hydrocyclone. The method comprises the following steps: mixing the phosphogypsum with water according to the weight part ratio of 5-40: 60-95, and then grinding the mixture into slurry; sieving the slurry obtained in the step A by using a square hole sieve with meshes of 40-100, and stirring the slurry capable of passing through the sieve in a stirring pond; pumping the slurry in the stirring pond in the hydrocyclone while stirring, and purifying and separating the slurry by the hydrocyclone under the condition that the pressure of a feeding opening of the hydrocyclone is 0.1-0.4 Mpa so that impurities which are separated out flow out from an overflowing opening of the hydrocyclone along with the water and enter a settling pond and the high-purity phosphogypsum obtained by purification flows out from a discharging opening of the hydrocyclone; and naturally filtering out water from the phosphogypsum slurry obtained by purification or centrifugally separating the phosphogypsum slurry to obtain the high-purity phosphogypsum. By the method, water consumption in a purification process can be reduced.

Owner:柳州紫荆技术转移中心有限公司

Environmental-protection drilling machine for machining

InactiveCN108436589AProtect environmentLow water consumptionMaintainance and safety accessoriesDrill bitEngineering

The invention discloses an environmental-protection drilling machine for machining. The environmental-protection drilling machine for machining comprises a base and a filter box; a water tank is horizontally fixed on the upper surface of the base through a fastening bolt; a worktable is horizontally welded and fixed in the water tank; a drill bit is mounted on one side at the upper part of the base; an annular spraying pipe is mounted at the tail end of a water conveying pipe; the annular spraying pipe is mounted at the external of the drill bit; a chip collecting device is mounted on one sideof the lower part of the base; a water inlet of the chip collecting device is connected with a water outlet of the water tank through a guide pipe; a water outlet of the chip collecting device is connected with an inlet end of a sewage pump through a guide pipe; an outlet end of a filter box is connected with a water inlet of the water tank through a guide pipe; and a booster pump is mounted at the external of a water outlet of the water tank. Chips mixed in water are collected in a centralized manner for compression packing to achieve later treatment, so that emission of the chips into the external environment is reduced, the utilization efficiency of resources is improved, and higher environmental protection is achieved.

Owner:叶华飞

Novel pissoir

ActiveCN103161214ALow water consumptionImprove cleaning effectUrinalsLavatory sanitoryVapor generatorExternal connection

A novel pissoir comprises a pissoir body and a water inlet tube. A water inlet is formed in the upper portion of an inner cavity of the pissoir body, an inductive switch is arranged in the water inlet tube, and a drain outlet is formed in the bottom of the inner cavity of the pissoir body. The novel pissoir further comprises a cover plate and a vapor generator which is used for generating vapor, wherein the cover plate covers an opening of the pissoir body, the cover plate is connected with a driving mechanism which is used for driving the cover plate to cover the opening or break away from the opening, a vapor tube of the vapor generator is communicated with a first interface of a communication valve, a second interface of the communication valve is communicated with an external connection water inlet tube, and a third interface of the communication valve is connected with the water inlet. The novel pissoir can effectively reduce the water consumption and improve the cleaning effect.

Owner:浙江诺云康智能科技有限公司

Technology for preparing water rich in hydrogen at normal temperature with soft water as base material

InactiveCN106315941AReduce consumable costsLow water consumptionMultistage water/sewage treatmentHigh activityPower consumption

The invention discloses a technology for preparing water rich in hydrogen at normal temperature with soft water as a base material. According to the invention, water flow with a certain pressure is allowed to pass through an ultraviolet sterilizer for sterilization, then pass through a super filter to filter out suspended solids and bacteria in water, then pass through a water softener to adjust the content of calcium and magnesium ions in water and finally pass through a stainless steel tank filled with crystal, quartz sand and obsidian so as to obtain hydrogen-rich water containing active hydrogen; and the treated hydrogen-rich water is allowed to pass through a stainless steel tank filled with medical stone so as to improve the pH value of water. The water production technology provided by the invention enables water to produce hydrogen at normal temperature, is low in cost of consumables, water consumption and power consumption, and better accords with the law of nature; the technology allows domestic water to be rich in active hydrogen, so domestic water is greener and healthier; and water produced by using the technology has high activity and better facilitates absorption by the human body.

Owner:夏云光

Waste gas circulation treatment device of coating mechanical equipment

PendingCN111644008AImprove the effectLow water consumptionCombination devicesGas treatmentElectric machineryMechanical equipment

The invention provides a waste gas circulation treatment device of coating mechanical equipment, and relates to the technical field of waste gas treatment. The waste gas circulation treatment device comprises a shell, wherein an adsorption box is fixedly connected to the top of the left side face of the shell, a gas inlet pipe fixedly communicates with the left side face of the adsorption box, a first filter screen and a second filter screen are fixedly connected into the adsorption box, and a gas conveying pipe fixedly communicates with the top of the right side face of the adsorption box. The invention discloses a waste gas circulation treatment device of coating mechanical equipment. By means of a partition plate, air holes, a first spraying pipe, a second spraying pipe and a spraying head, the effect of carrying out secondary spraying treatment on the waste gas is achieved, the waste gas treatment effect is improved, so that it is guaranteed that waste gas emission reaches the national emission standard; by means of the filtering box, the centrifugal filtering barrel, the connecting pipe, the first driven wheel, the first motor and the first driving wheel, the effect of filtering and recycling waste gas is achieved, the water consumption during waste gas treatment is reduced, and the national requirements for energy conservation and emission reduction are met.

Owner:昆山市圣吉川工业自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com