Method for purifying phosphogypsum by using hydrocyclone

A technology of hydrocyclone separation and phosphogypsum, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve the problems of large tail gas pollution, large primary investment, secondary pollution, etc., and achieve separation operation. Low cost, reduced water consumption, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

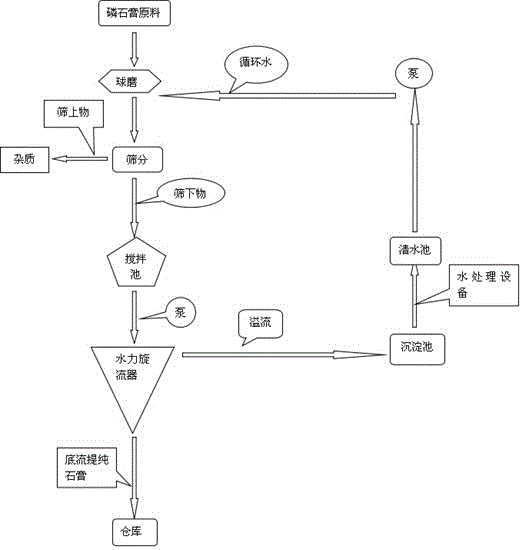

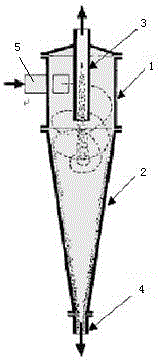

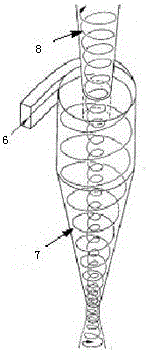

[0035] Concrete purification example one: choose phosphogypsum with a calcium sulfate dihydrate content of 70% as a raw material, mix phosphogypsum and water at a ratio of 20:80 by weight and then grind to form a slurry, that is, phosphogypsum and water After mixing, put it into a beater for beating for 30 minutes, filter and sieve the ground slurry through a 40-mesh square hole sieve, remove impurities left on the hole sieve, and filter the slurry that can pass through the hole sieve Put it into the stirring tank for stirring; while stirring, pump the slurry in the stirring tank into the hydrocyclone, control the pressure of the feed inlet of the hydrocyclone to 0.1Mpa, and the slurry at a rate of 5m / s The speed enters the cylindrical barrel at the upper end of the hydrocyclone from the feed port along the tangential direction, and then the slurry is purified and separated by the hydrocyclone, and the separated impurities follow the flow of water from the hydrocyclone. The ov...

Embodiment 2

[0036] Embodiment 2: choose phosphogypsum with a calcium sulfate dihydrate content of 75% as raw material, mix phosphogypsum and water at a ratio of 30:70 by weight and then grind to form a slurry, that is, after mixing phosphogypsum with water Put it into the beater and beat for 45 minutes, filter and sieve the ground slurry through a 40-mesh square hole sieve, remove the impurities left on the hole sieve, put the filtered slurry that can pass through the hole sieve into Stir in the stirring tank; while stirring, the slurry in the stirring tank is pumped into the hydrocyclone, and the pressure of the feed inlet of the hydrocyclone is controlled to be 0.2Mpa, and the slurry flows from the hydrocyclone at a speed of 8m / s. The feed inlet enters the cylindrical barrel at the upper end of the hydrocyclone along the tangential direction, and then the slurry is purified and separated by the hydrocyclone, and the separated impurities follow the overflow of the water from the hydrocycl...

Embodiment 3

[0037]Embodiment 3: choose phosphogypsum with a calcium sulfate dihydrate content of 80% as raw material, mix phosphogypsum and water at a ratio of 15:85 by weight and then grind to form a slurry, that is, after mixing phosphogypsum with water Put it into the beater for beating for 90 minutes, filter and sieve the ground slurry through a 60-mesh square hole sieve, remove the impurities left on the hole sieve, put the filtered slurry that can pass through the hole sieve into Stir in the stirring tank; while stirring, the slurry in the stirring tank is pumped into the hydrocyclone, and the pressure at the inlet of the hydrocyclone is controlled to be 0.3Mpa, and the slurry flows from the hydrocyclone at a speed of 10m / s. The feed inlet enters the cylindrical barrel at the upper end of the hydrocyclone along the tangential direction, and then the slurry is purified and separated by the hydrocyclone, and the separated impurities follow the overflow of the water from the hydrocyclon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com