Patents

Literature

31results about How to "Good dust suppression effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency environmental-friendly dust suppressant as well as preparation method and application thereof

ActiveCN106833533AHigh moisturizing rateImprove dust suppression efficiencyOther chemical processesParticulatesPreservative

The invention provides a high-efficiency environmental-friendly dust suppressant as well as a preparation method and application thereof. The high-efficiency environmental-friendly dust suppressant disclosed by the invention solves the problems that the conventional product is single in function, secondary pollution is introduced and the like, has wide application and is particularly applicable to roads with less dust particles, for example, the dust suppressant is used for capturing and adsorbing TSP (Total Suspended Particulates), PM10, PM2.5 and nitric oxides. The high-efficiency environmental-friendly dust suppressant disclosed by the invention is mainly prepared by mixing the following components by weight: 0.1-10% of polyvinyl alcohol, 0.1-5% of sodium silicate, 10-50% of glycerin, 0.01-5% of a surfactant, 0-5% of a preservative, and the balance of water.

Owner:NITTO QINGDAO TECH RES INST CO LTD

Road dust suppressant as well as preparation method and application thereof

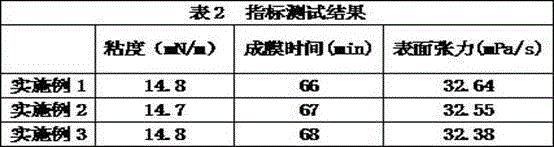

InactiveCN108587568AExcellent overall performanceGood dust suppression effectOther chemical processesChemistryEmulsion

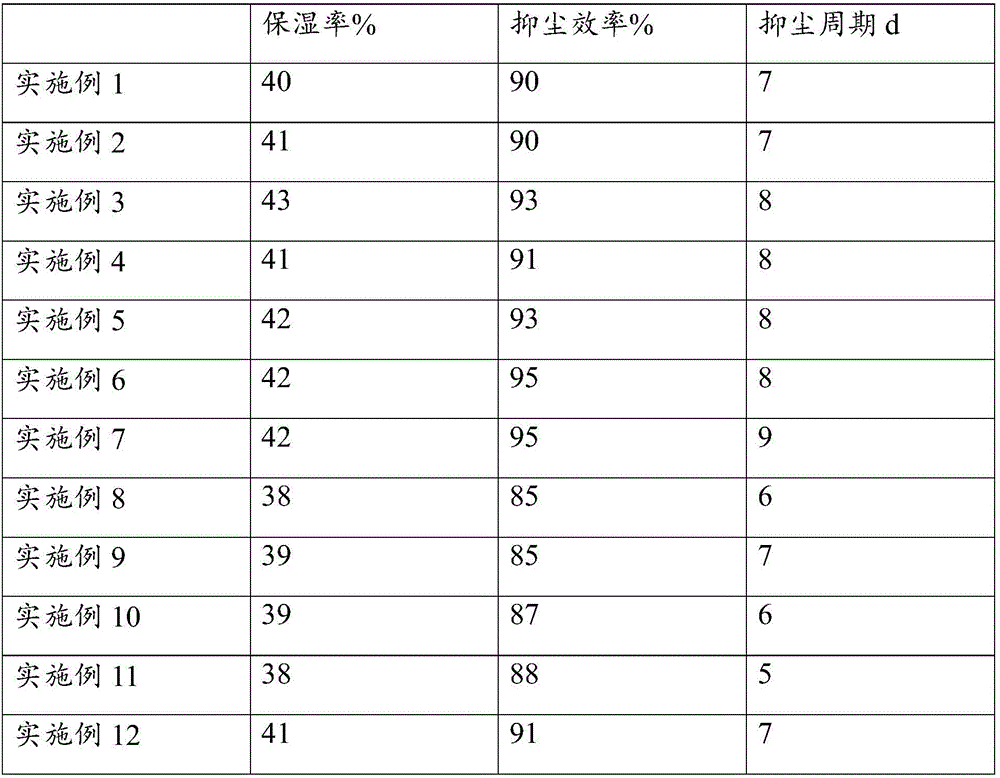

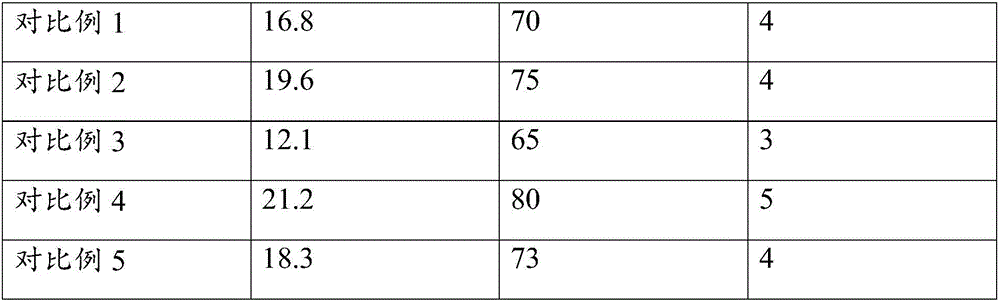

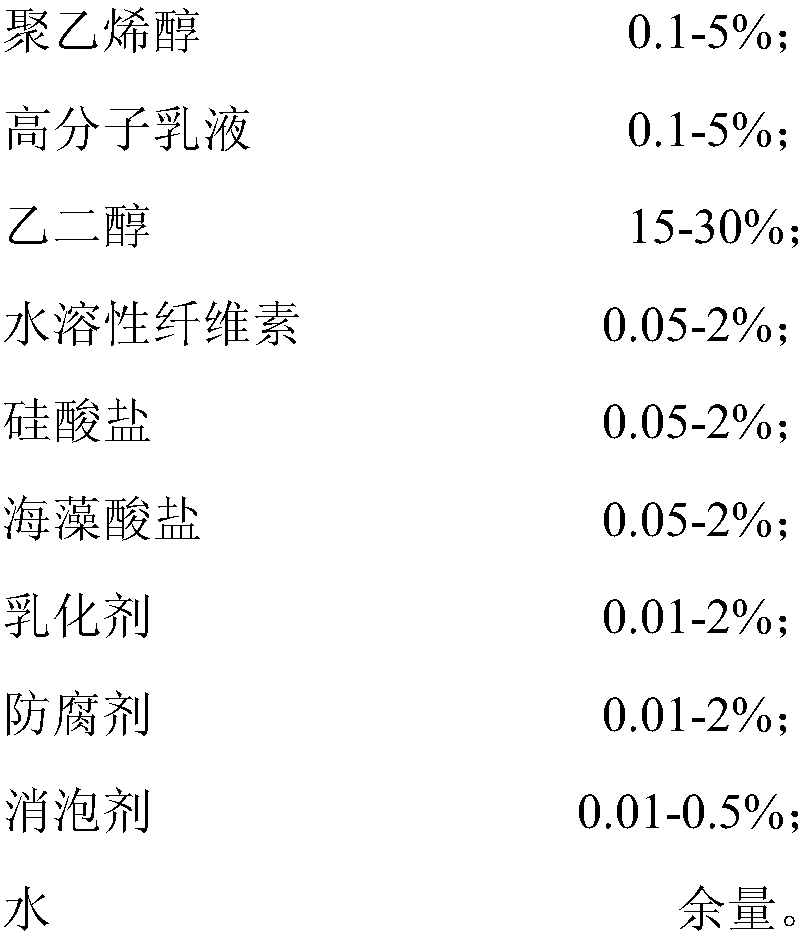

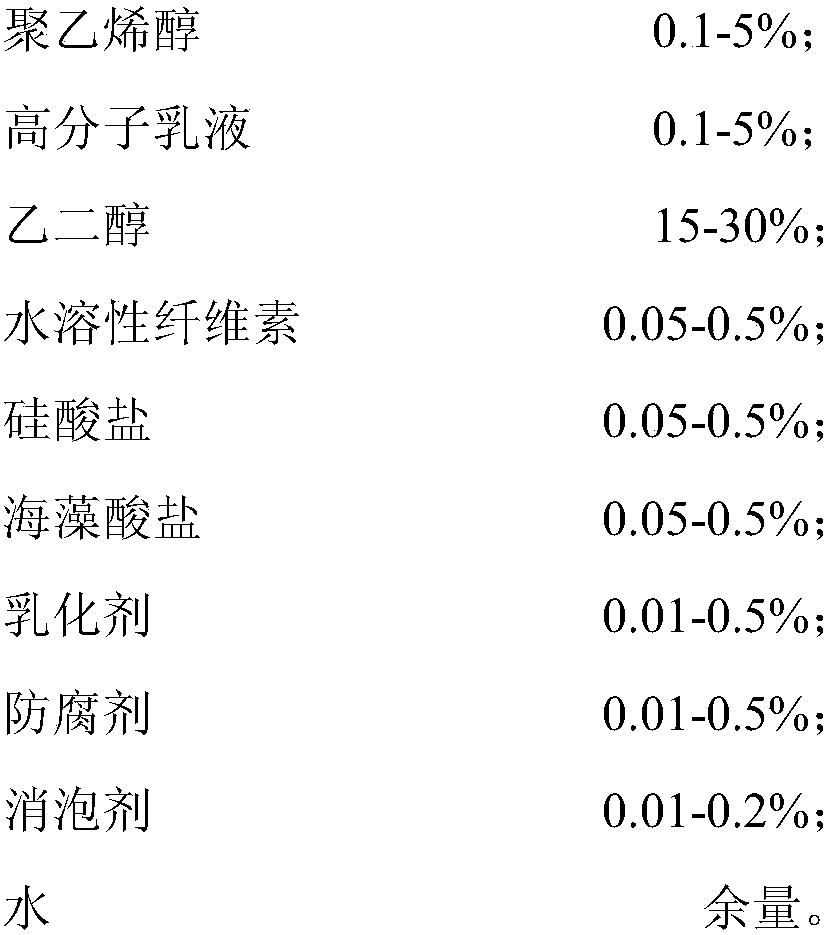

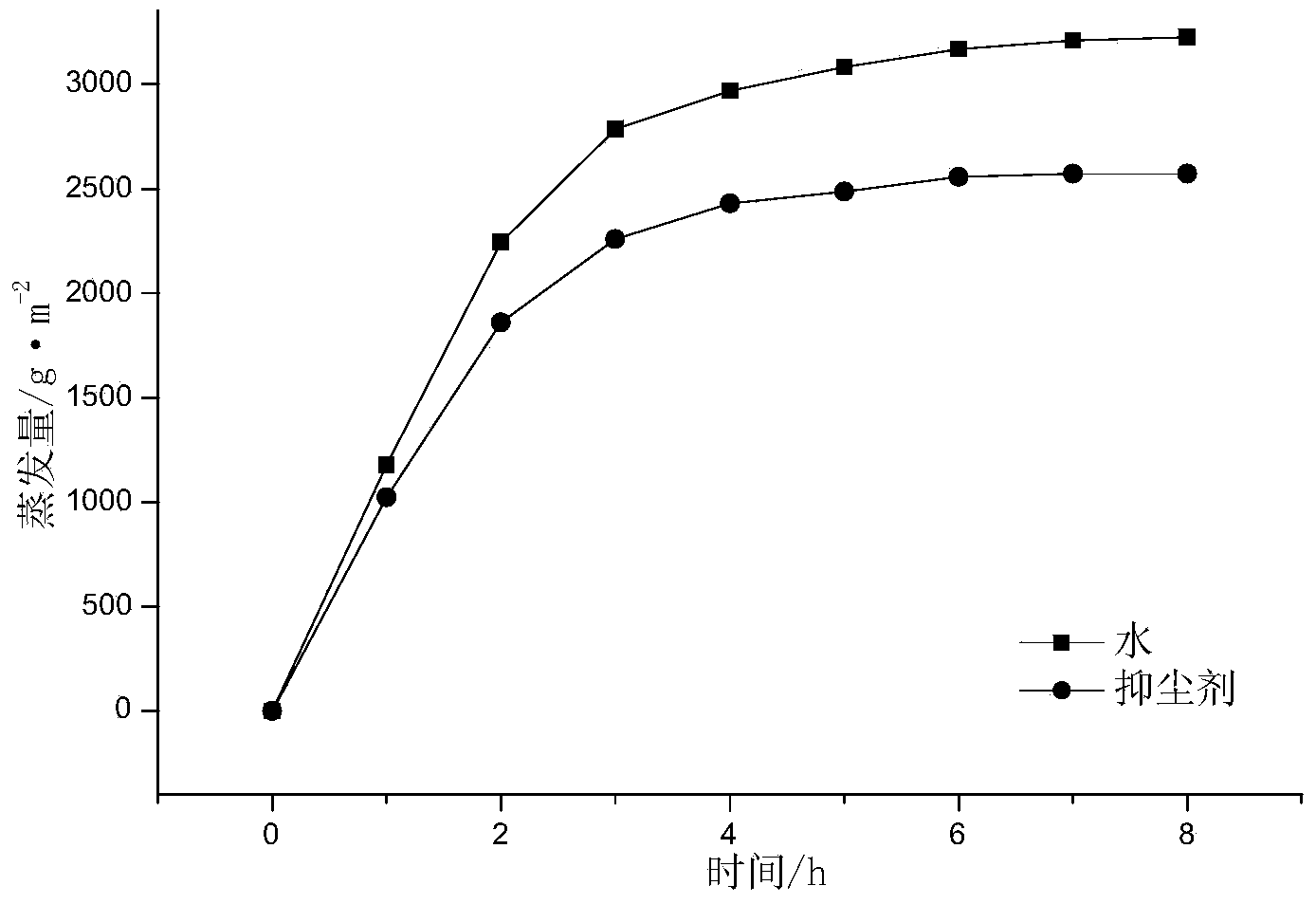

The present invention discloses a road dust suppressant as well as a preparation method and application thereof, and belongs to the field of environmental protection for flying dust prevention and control. The present invention provides a novel road dust suppressant, which comprises the following components in percentage by weight: 0.1-5% of polyvinyl alcohol, 0.1-5% of high-molecular emulsion, 15-30% of ethylene glycol, 0.05-2% of water-soluble cellulose, 0.05-2% of silicate, 0.05-2% of alginate, 0.01-2% of emulsifier, 0.01-2% of preservative, 0.01-0.5% of defoamer and the balance of water. The road dust suppressant of the present invention, with particular components in particular proportions, can meet the standard requirements in tests on physical and chemical indexes and properties, and is safe, environmentally friendly, and very suitable for the control of flying dust pollution of roads such as urban roads, construction roads and the like. Thus, an effective solution is provided for improving the atmospheric environment and reducing the haze pollution.

Owner:BEIJING RUI HONGXING TECH CO LTD

Dust suppressant, preparation method and application thereof in coal transportation

ActiveCN108485606ALess corrosiveGood dust suppression effectOther chemical processesDust removalPolyvinyl alcoholPreservative

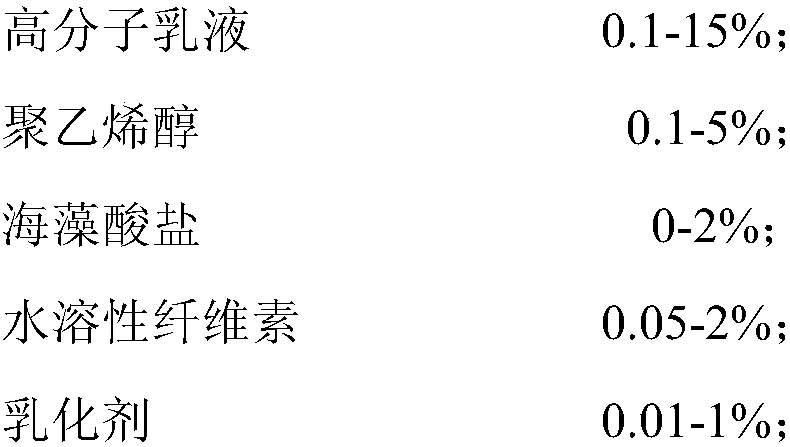

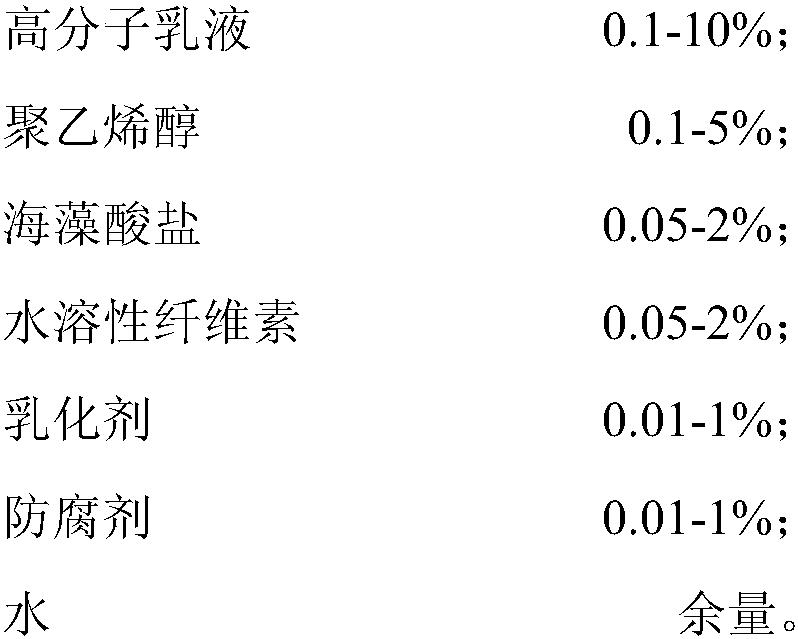

Belonging to the environmental protection field of fugitive dust control, the invention discloses a dust suppressant, a preparation method and application thereof in coal transportation. The inventionprovides a novel dust suppressant, which comprises the following components by mass percentage: 0.1-15% of a polymer emulsion, 0.1-5% of polyvinyl alcohol, 0-2% of alginate, 0.05-2% of water solublecellulose, 0.01-1% of an emulsifier, 0.01-1% of a preservative, and the balance water. By adopting specific components and proportion, the dust suppressant provided by the invention can meet the regulations and requirements of Chinese railway industry standard TB / T3210.1-2009 for dust suppression effect, toxicological indicators, corrosiveness and other performance indexes, and has excellent comprehensive performance.

Owner:青岛中科睿海科技有限公司

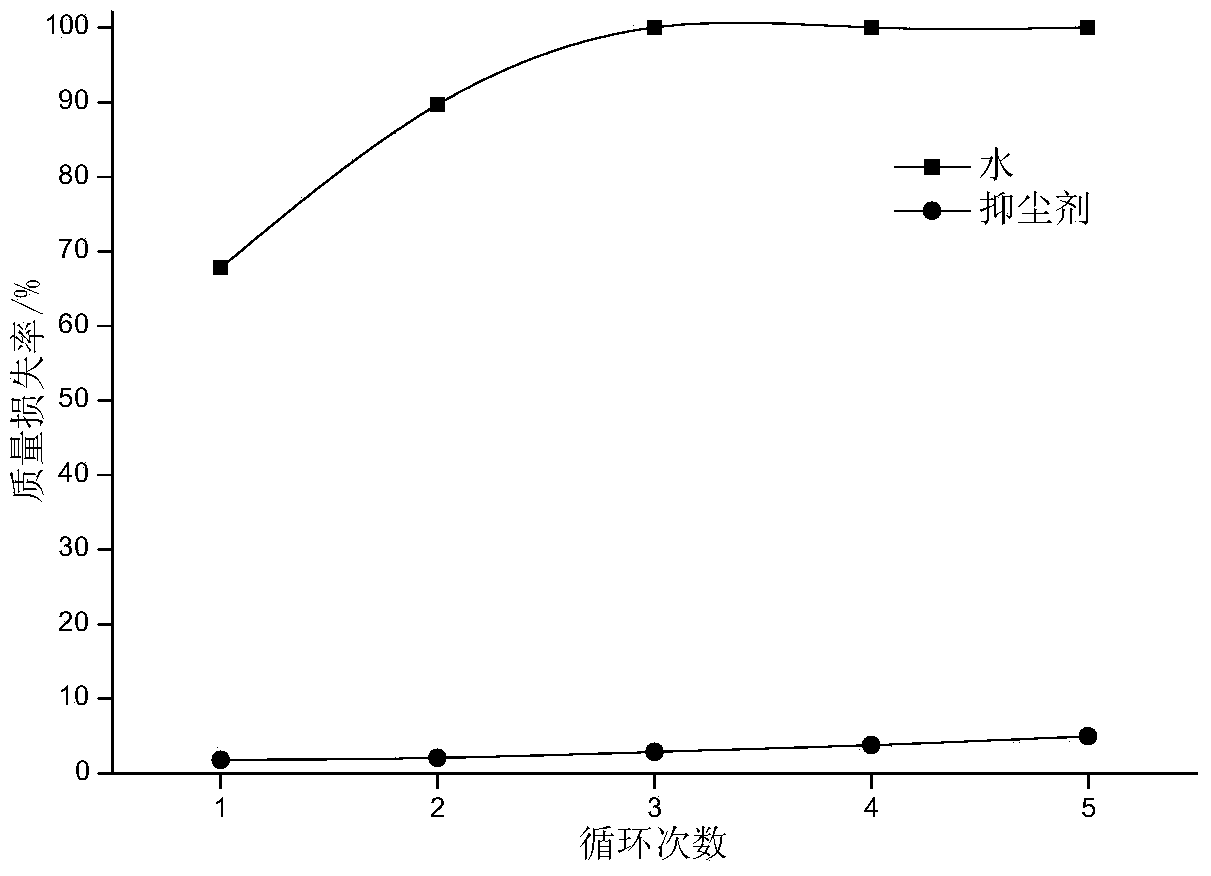

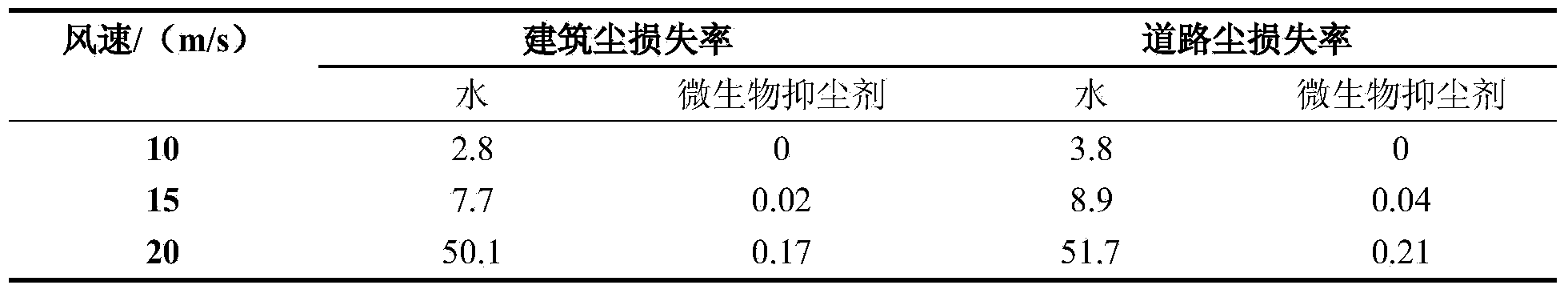

Dust suppressing agent prepared on basis of microorganisms and use method thereof

InactiveCN103773314APromote hydrationImprove the consolidation effectOther chemical processesMicroorganismAtherion elymus

The invention discloses a dust suppressing agent prepared on the basis of microorganisms and a use method thereof. The microorganism dust suppressing agent is prepared by mixing a bacterium solution and a calcium-ion solution by proper matching ratio. The use method of the dust suppressing agent comprises the following steps: the dust suppressing agent is uniformly sprayed on the surfaces of raise dusts; according to the actual need, the used amount of the dust suppressing agent for treating the raise dusts with the stacking volume being 1m<3> is 300-400L, and the 1-3 treating times are carried out according to the effect need. The dust suppressing agent has the advantages that the dust suppressing effect is obvious, the evaporative resistance, the wind-erosion resistance and the durability are respectively and greatly superior to those of the sprinkling mode for suppressing dusts when in raise-dust treatment, the greenhouse gas CO2 is absorbed in the reaction process, no toxic and harmful substance is generated, and the environmental friendliness and the economy are good.

Owner:SOUTHEAST UNIV

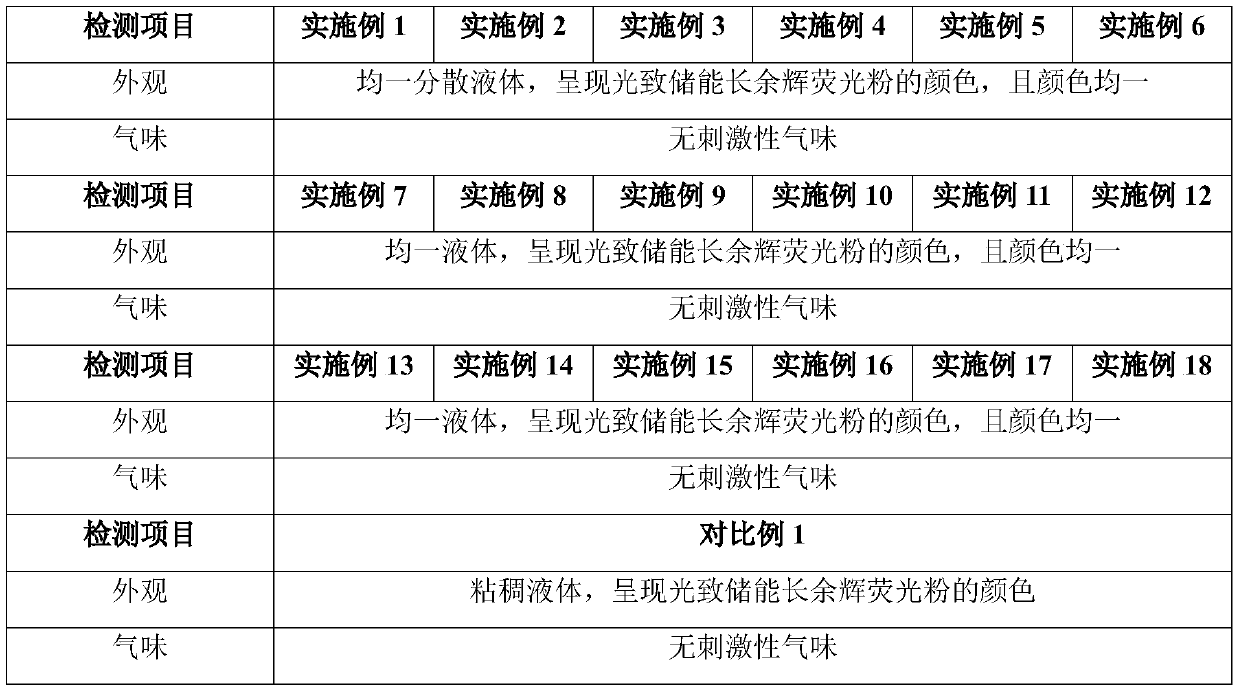

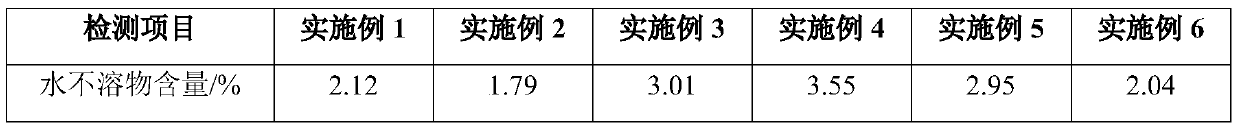

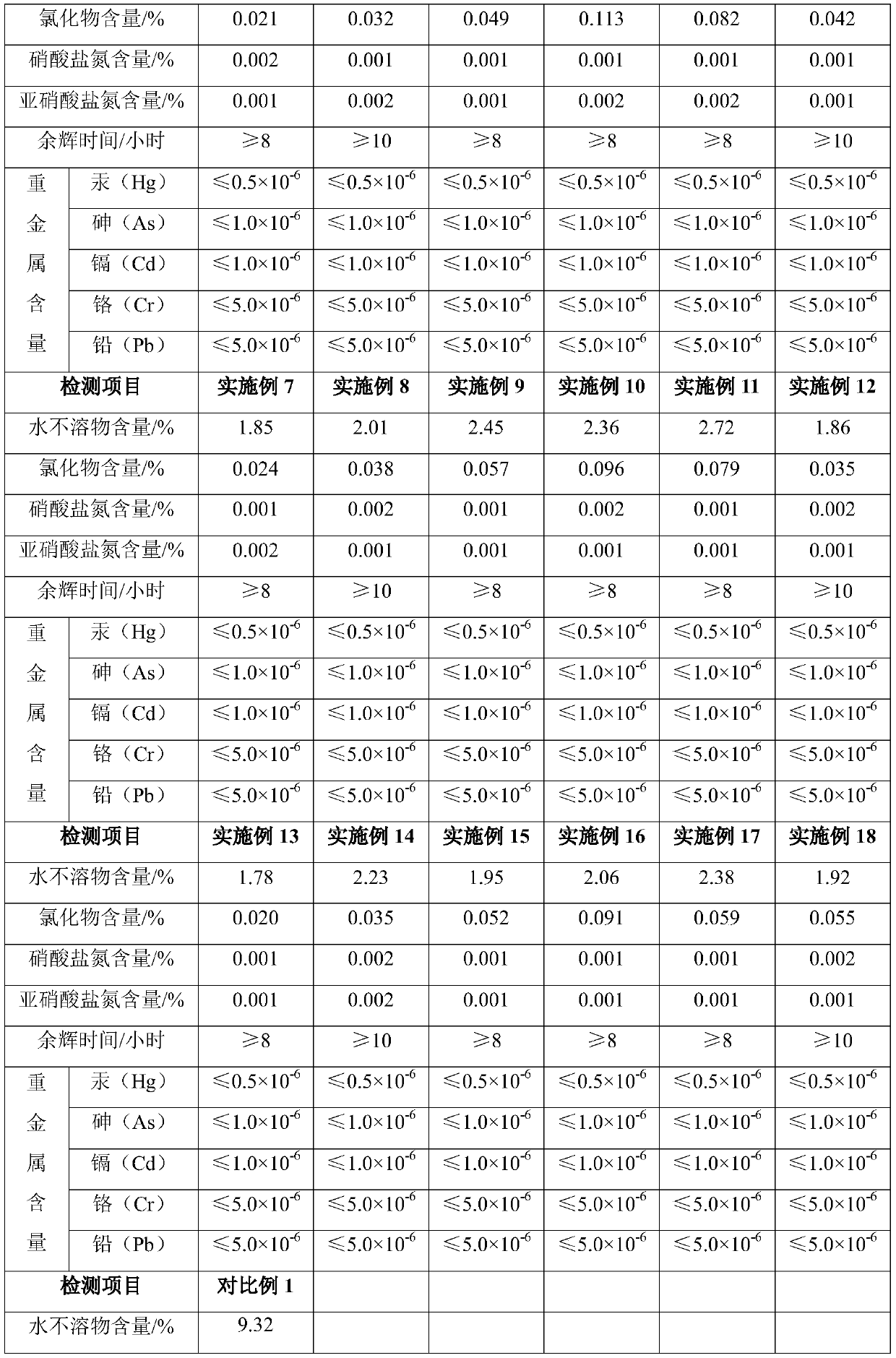

Environment-friendly dust suppressant with self-luminous function

PendingCN110835519AGood dust suppression effectNo irritating smellOther chemical processesPlanting seedEngineering

The invention provides an environmentally-friendly dust suppressant with a self-luminous function. The dust suppressant comprises, by mass, 0.1-20% of a water-soluble polymer, 0-10% of polyol, 0.01-15% of water-soluble modified plant polysaccharides, 0.01-15% of a dispersing aid, 0.1-30% of a luminous component, 0.01-5% of a preservative, and the balance of water. The environmentally-friendly dustsuppressant with the self-luminous function has the advantages of excellent dust suppression effect, uniformity in color, no pungent smell, small content of water-insoluble substances, no blocky or flocculent precipitate, convenience in production, high luminance and long afterglow time, can be repeatedly excited, and can be used as a roadbed or a wind shield wall warning of a construction site to avoid scratching of vehicles during night operation and improve the night operation safety. The environmentally-friendly dust suppressant has very small corrosivity to steel and harm to plant seeds,and can meet the use requirements of night operation warning of construction sites such as coal mines and the like.

Owner:QINGDAO RUIHONGXIN ECO TECH CO LTD

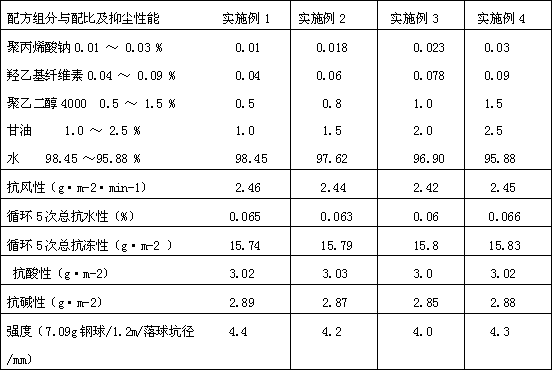

Compound chemical dust suppressant as well as preparation method and application thereof

ActiveCN103289647AEasy to prepareSimple on-site operationOther chemical processesGlycerolPolyethylene glycol

The invention relates to a compound chemical dust suppressant as well as a preparation method and an application thereof. The compound chemical dust suppressant is characterized by comprising the following components in percentage by mass according to the formula: 0.01-0.03% of sodium polyacrylate, 0.04-0.09% of hydroxyethyl cellulose, 0.5-1.5% of polyethylene glycol 4000, 1.0-2.5% of glycerin and the balance of water. The preparation method comprises the following steps of: firstly, respectively preparing all the components into aqueous solutions, and then, mixing all the components according to the mass proportions. The compound chemical dust suppressant is good in dust suppressing effect, wide in raw material source, simple in operation, high in performance cost ratio, free of toxicity and corrosion, easy to degrade under a natural condition, free of secondary pollution and suitable for popularization for dust prevention in mine tailing pond regions and road transportation dry beach regions thereof.

Owner:ANSTEEL GRP MINING CO LTD

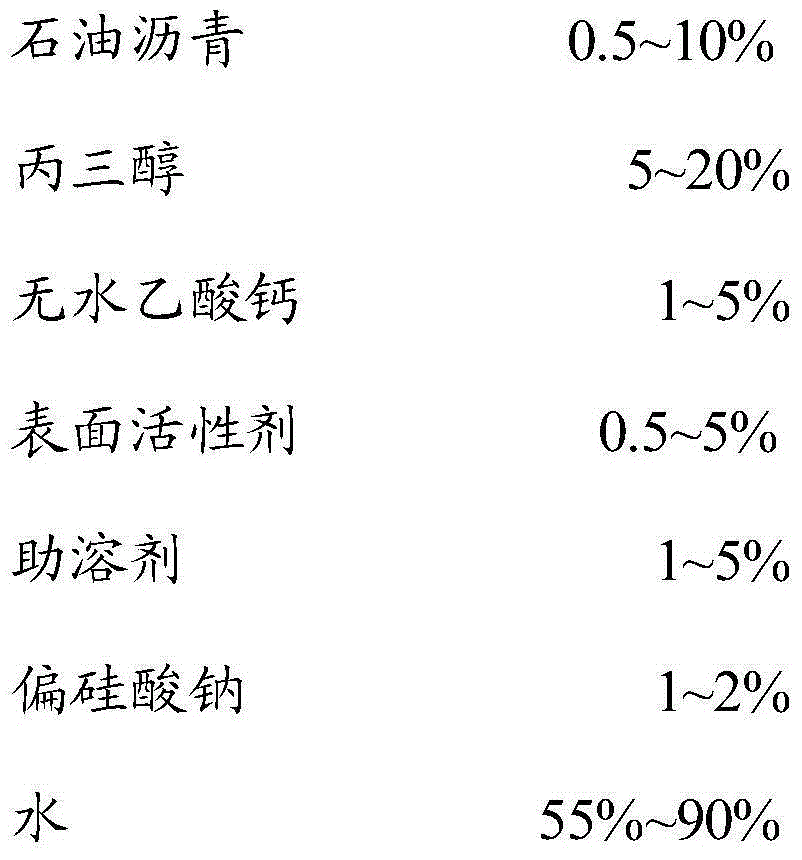

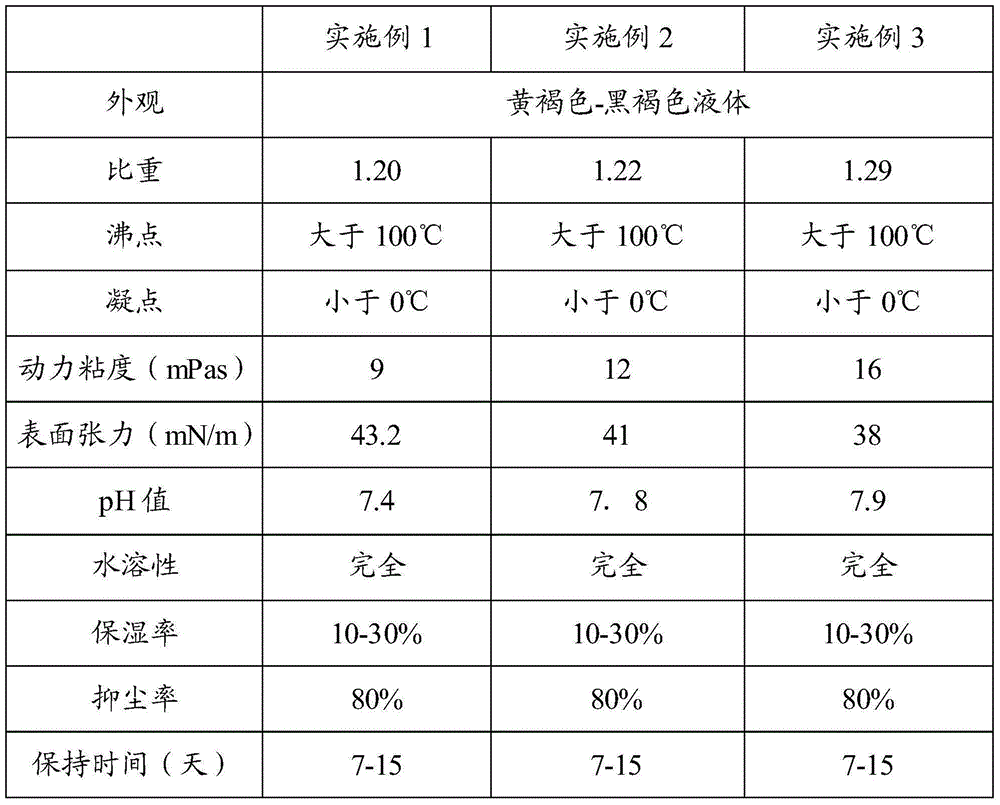

Road dust depressor and preparation method thereof

InactiveCN105018032ASolve road dust problemGood dust suppression effectOther chemical processesBuilding insulationsMoisture retentionChemistry

The invention discloses a road dust depressor and a preparation method thereof. The road dust depressor is prepared from 0.5-10% of petroleum asphalt, 5-20% of glycerol, 1-5% of anhydrous calcium acetate, 0.5-5% of a surfactant, 1-5% of a cosolvent, 1-2% of sodium metasilicate and 55%-90% of water. The preparation method includes: at room temperature, adding deionized water into a reaction kettle, starting stirring and conducting heating to 50DEG C, adding anhydrous calcium acetate in batches, after complete dissolving, adding glycerol, after dissolving, adding the surfactant, road asphalt, the co-solvent and sodium metasilicate in order, performing stirring dissolving to a homogeneous phase so as to obtain a brown-black brown aqueous solution, and carrying out standing, cooling and filling, thus obtaining a finished product. The road dust depressor has good moisture retention, moisture absorption and adhesion, and has remarkable dust suppression effect and long dust suppression period. The product is safe to use, has no corrosion to metal, is non-toxic, can be biodegradable, has no influence to vegetation, is an environment friendly product, and can be widely applied to dust control of unpaved roads, urban asphalt pavement, strip mine roads and the like.

Owner:宁夏浤森环保科技有限公司

Energy-saving and environment-friendly flying dust suppressing agent specially for cement and preparation method thereof

InactiveCN106701021AReduce consumptionGood dust suppression effectOther chemical processesDecompositionYard

The invention discloses an energy-saving and environment-friendly flying dust suppressing agent specially for cement and a preparation method thereof. The energy-saving and environment-friendly flying dust suppressing agent is specially used for raw meal stored in a raw meal homogenizing silo of a cement production enterprise, and comprises the following components in percent by weight: 10%-20% of a decomposition-promoting component, 30-45% of a water-absorbing and moisturizing component, 5%-8% of a soaking and wetting component, 1%-4% of a stabilizing component and the balance of water. When the product is sprayed to a storage yard of the raw meal homogenizing silo, an obvious dust suppressing effect can be maintained in 30 days. The energy-saving and environment-friendly flying dust suppressing agent disclosed by the invention has the advantages that under the action of the decomposition-promoting component, when raw materials sprayed by the product are used for producing clinkers, the effect of reducing consumption of tailings can be realized, and economic values can be created for the cement production enterprise.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Construction site dust suppressant and preparation method thereof

InactiveCN104312537AGood dust suppression effectDust suppression cycle is longOther chemical processesChemistryDodecylsulfonic acid

The invention discloses a construction site dust suppressant which is prepared from the following components in parts by weight: 66 parts of high-substituted hydroxyproxyl cellulose, 50 parts of lignocellulose, 20 parts of polylactic acid, 4 parts of zinc dialkyl dithiophosphate, 6 parts of starch aluminum octenylsuccinate, 1 part of sodium dodecyl sulfate, 8 parts of zinc stearate, 6 parts of propyl trimethoxy silane and 25 parts of deionized water. A preparation method of the construction site dust suppressant comprises the following steps: (1) preparing the high-substituted hydroxyproxyl cellulose, the lignocellulose and the polylactic acid into powder more than 200 meshes and stirring uniformly; (2) adding the zinc dialkyl dithiophosphate, the starch aluminum octenylsuccinate, the sodium dodecyl sulfate, the zinc stearate and the propyl trimethoxy silane into the deionized water, heating to 50-58 DEG C and stirring for 40-50 minutes under an ultrasonic condition; and (3) uniformly stirring the mixture in the step (1) with the mixture in the step (2) and carrying out vacuum drying at 20 DEG C to obtain the construction site dust suppressant.

Owner:张家口恒灏环保科技有限公司

Environment-friendly curing agent and preparation method thereof

InactiveCN102559144ANot corrosiveThe formula is scientific and reasonableOther chemical processesPotassium triphosphateGlycerol

The invention relates to an environment-friendly curing agent, and belongs to the field of environment friendliness. The curing agent comprises the following raw materials in part by weight: 100 parts of water, 2 to 5 parts of straw, 1 to 3 parts of starch, 0.1 to 0.3 part of calcium oxide and 0.4 to 0.8 part of glycerol. A preparation method comprises the following steps of: stirring 2 to 5 parts of straw and 100 parts of water in a reactor uniformly, heating until the water is boiled, stopping heating and cooling; preparing 1 to 3 parts of starch and 0.1 to 0.3 part of calcium oxide to form a solution, adding the solution into the cooled reactor; continuing to heat the reactor to be boiled, stopping heating, cooling and adding 0.4 to 0.8 part of glycerol and 0.025 to 0.5 part of potassium triphosphate. The invention provides the environment-friendly curing agent which has a good dust suppression effect, is non-toxic, harmless, safe and energy-saving, and does not have corrosiveness and pollution to environment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

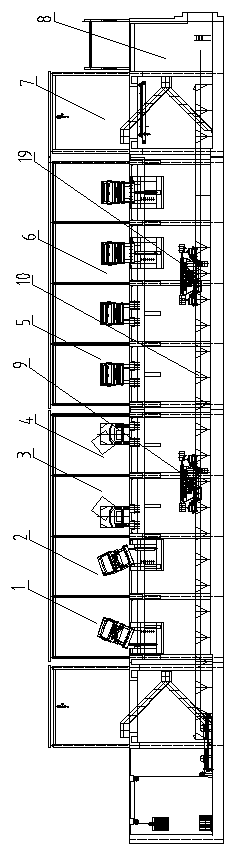

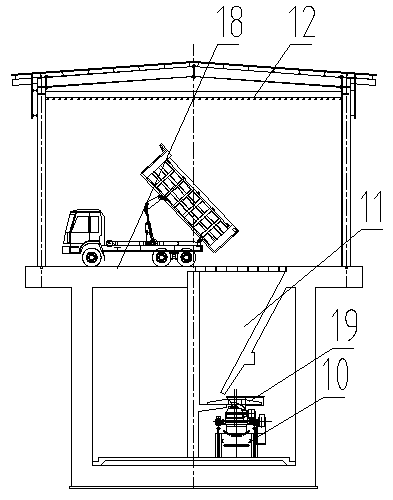

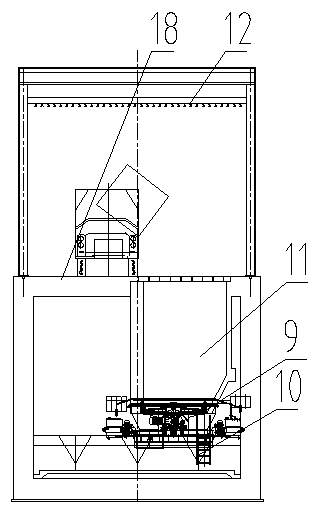

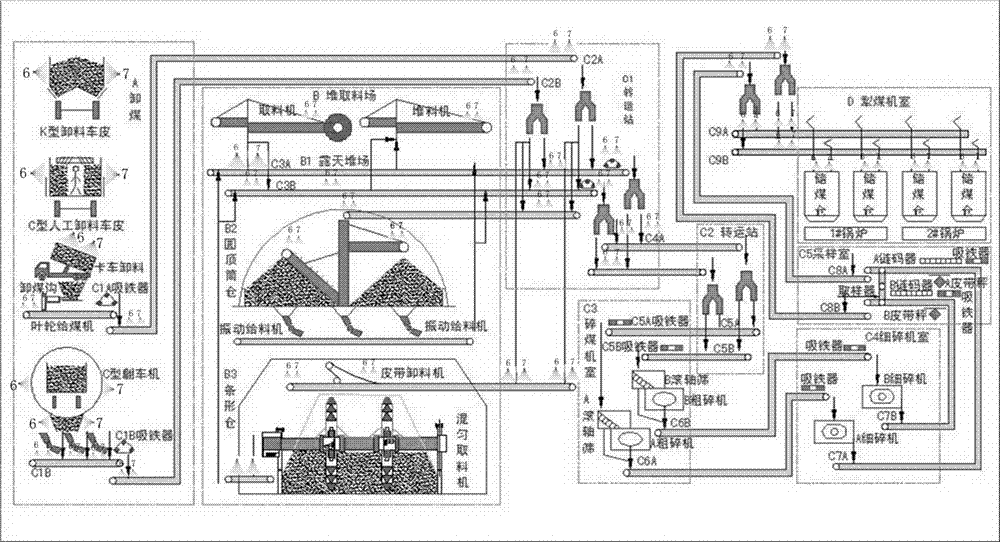

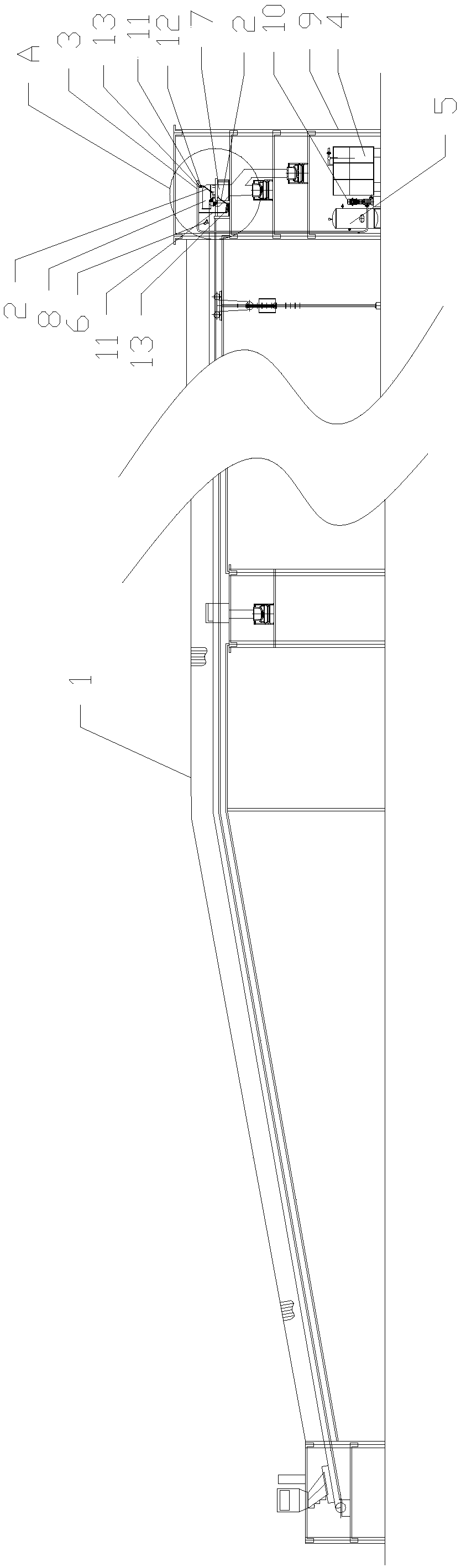

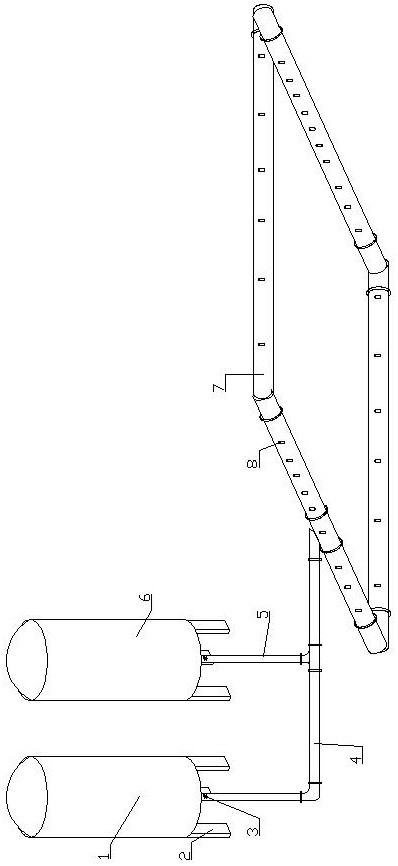

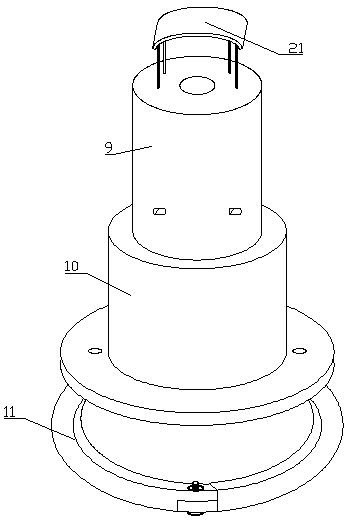

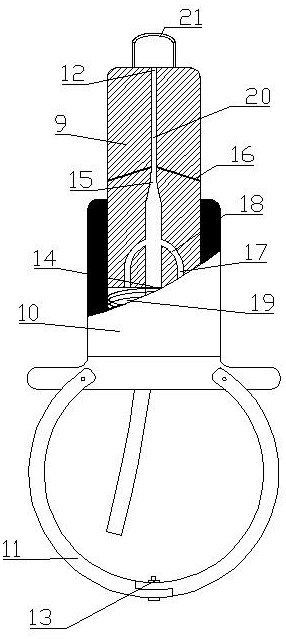

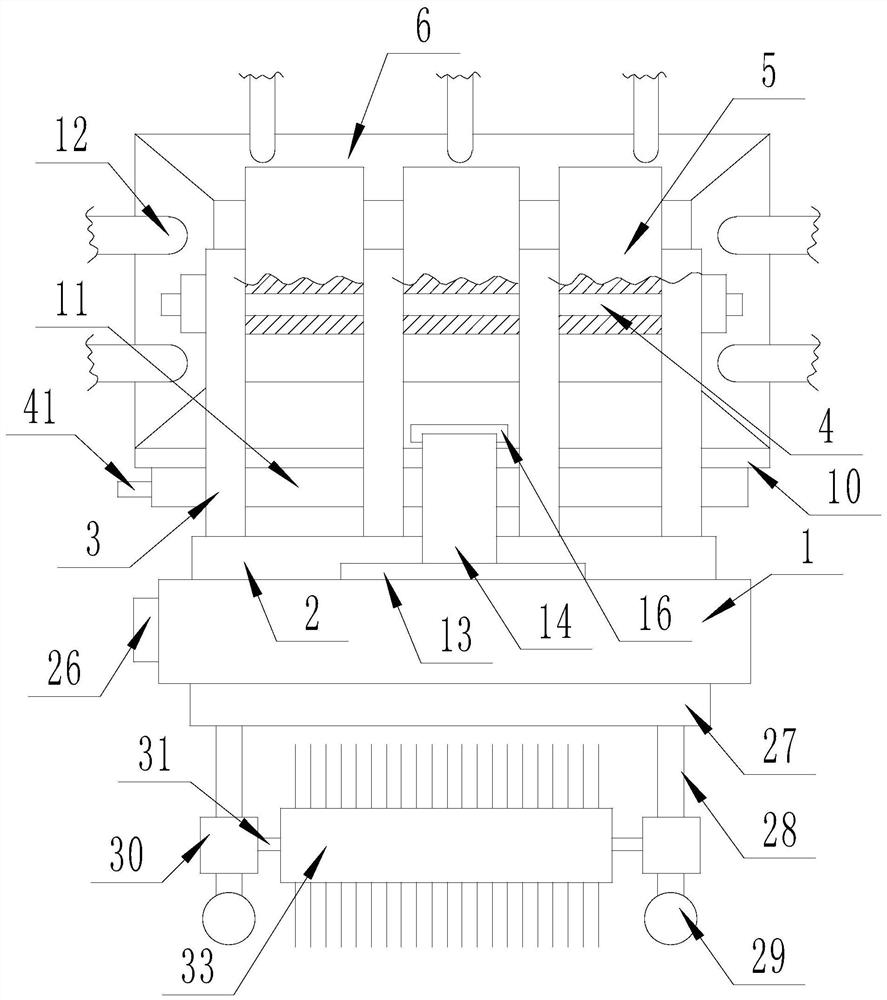

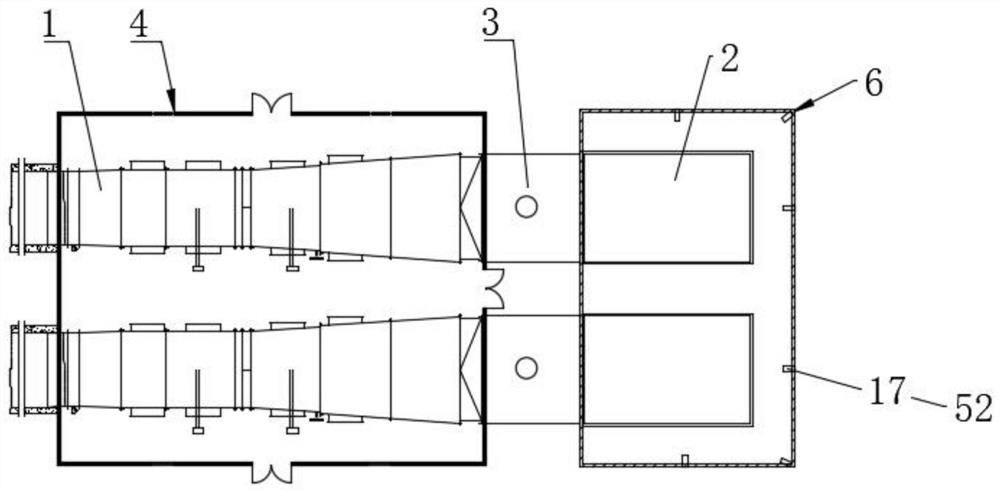

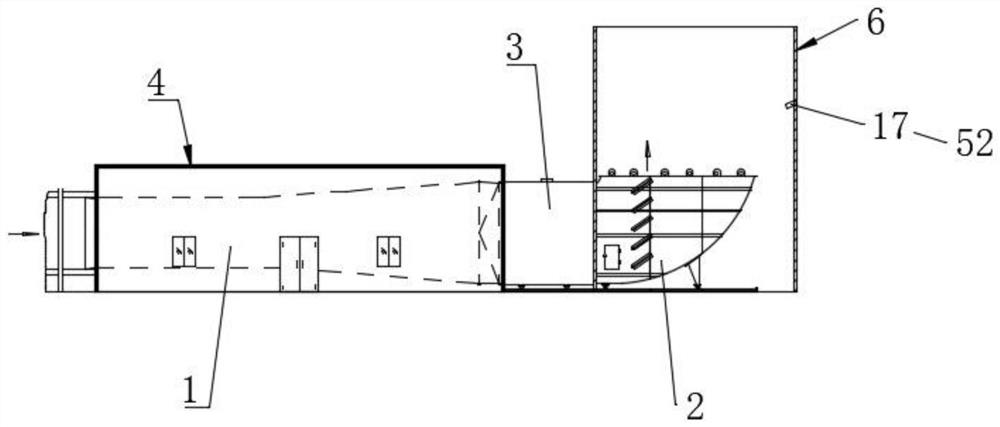

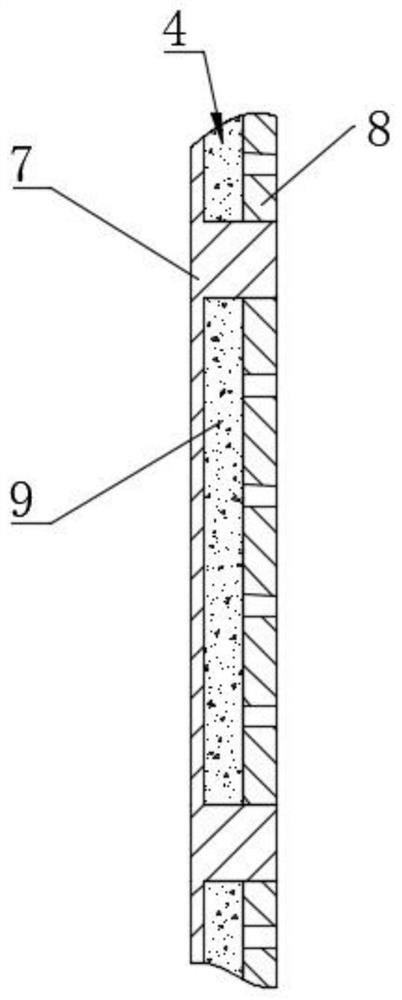

Material receiving system for automobile

The invention provides a material receiving system for an automobile. The material receiving system is provided with four or more material receiving bins (1, 2, 3, 4, 5 and 6). The material receiving bins are provided with unloading platforms, material receiving grooves (11), feeding machines (9 and 19) and belt conveyors (10). The material receiving bins adapt to automobile back-tip unloading or automobile side-tip unloading or dump truck self-discharging back-tip unloading or dump truck self-discharging side-tip unloading. The material receiving bin (6) adapting to automobile back-tip unloading comprises a first overturning platform (13) close to the material receiving groove (11) end and hinged to a dump truck platform foundation (15), and the two ends are connected with the dump truck platform foundation (15) and a first hydraulic oil cylinder (14) hinged to the first overturning platform (13) respectively. The material receiving bins (1 and 2) adapting to automobile side-tip unloading comprise second overturning platforms (16) close to the corresponding material receiving grooves (11) and hinged to corresponding dump truck platform foundations (15), and the two ends are connected with the unloading platform foundation (15) and second hydraulic oil cylinders (17) hinged to the corresponding second overturning platforms (16) respectively.

Owner:TIDFORE INT ENG

Method for preparing efficient biodegradable sand-fixation dust suppressant

InactiveCN106085360AGood dust suppression effectImprove permeabilityOther chemical processesEmulsionEther

The invention relates to a method for preparing an efficient biodegradable sand-fixation dust suppressant and belongs to the technical field of dust suppressants. The method for preparing the efficient biodegradable sand-fixation dust suppressant, provided by the invention, is used for solving the problem of dust suppressants on the market at present that the majority of the dust suppressants are high in viscosity, thus the dust suppressants are poor in atomization effect and even difficult in atomization, and dust cannot be rapidly wetted. According to the method, the efficient biodegradable sand-fixation dust suppressant is prepared through modifying degradable, non-toxic and pollution-free corncobs, which serve as a raw material, by a pre-emulsifying process of emulsion polymerization so as to prepare an alkali-treated corncob powder grafted acrylate emulsion, then, compounding the alkali-treated corncob powder grafted acrylate emulsion with polyethylene glycol octylphenyl ether with efficient wetting property, and carrying out water dilution. The efficient biodegradable sand-fixation dust suppressant prepared by the method can be used for rapidly wetting the dust and coagulating small granular rice coal into large granules, thereby having a good dust suppression effect.

Owner:仇颖超

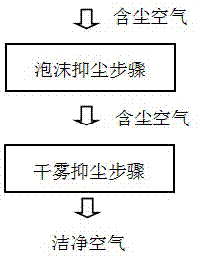

Foam-dry fog dust suppression technology for ultrafine particle dust discharged disorderly

ActiveCN103657301AIncrease profitReduce moisture contentUsing liquid separation agentMetallurgySpray nozzle

The invention discloses a foam-dry fog dust suppression technology for ultrafine particle dust discharged disorderly. The foam-dry fog dust suppression technology comprises the following steps: 1, foam dust suppression on a dusty point: performing foam dust suppression on the dusty point with dust discharged by materials during smashing, screening, conveying, loading, unloading, removing and construction in inorganization emission source closed and semi-closed places, and spraying foams to the dusty point through a single or a plurality of double-fluid nozzles or a high-pressure single-fluid nozzles; 2, dry fog dust suppression: enabling the dust obtained in the step 1 to enter dry fog layers sprayed by a single or a plurality of double-fluid dry fog spraying guns or high-pressure single-fluid dry fog spraying guns to cover fine particle dust production point regions. Ultrafine dust PM2.5 and PM0.1 is gathered from small particles into large particles under the action of retention, inert collision, dispersion, adsorption and the like between the foams and the dry fogs and is finally subsided and adsorbed to the surfaces of the materials together with broken foam liquid drops; therefore, the dust can be fundamentally prevented from being externally dispersed, and the materials can effectively suppress dust dispersion in the whole process.

Owner:QINHUANGDAO CLOUD CUBE ENVIRONMENTAL ENG

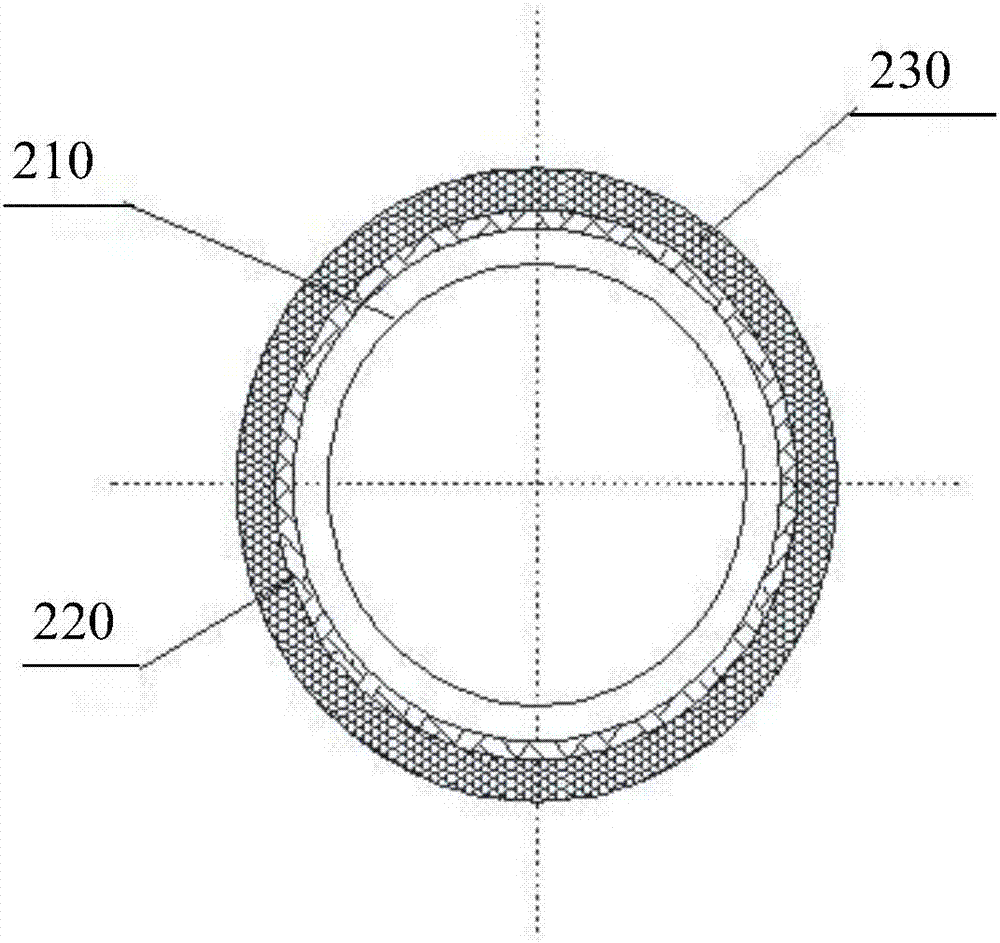

Dust suppression device for slag-tapping or ash-discharge process of power plant

ActiveCN107140447AReduce water consumptionEasy to cleanHuman health protectionUsing liquid separation agentWater savingAtomizer nozzle

The invention discloses a dust suppression device for a slag-tapping or ash-discharge process of a power plant. The dust suppression device comprises a dust suppression soft screen, a dust suppression outer screen and a dust-suppression jetting device, wherein the dust suppression soft screen is arranged below a slag tapping hole in a peripheral mode, and is concentric with the center of the slag tapping hole; the dust suppression outer screen can be arranged at the outer side of the dust suppression soft screen in a sliding mode, and is connected with the outer side of a slag receiving vehicle; and the dust-suppression jetting device is arranged between the dust suppression soft screen and the dust suppression outer screen, and can spray fog drops for settling dust. According to the dust suppression device for the slag-tapping or ash-discharge process of the power plant disclosed by the invention, double layers of dust suppression screens are matched with the dust-suppression jetting device, so that water consumption is reduced, and cleaning is easy; ad moreover, a calculating formula for a mist spraying angle of an atomizing spray nozzle is further given, so that better dust suppression effect and water-saving effect can be obtained.

Owner:JILIN UNIV

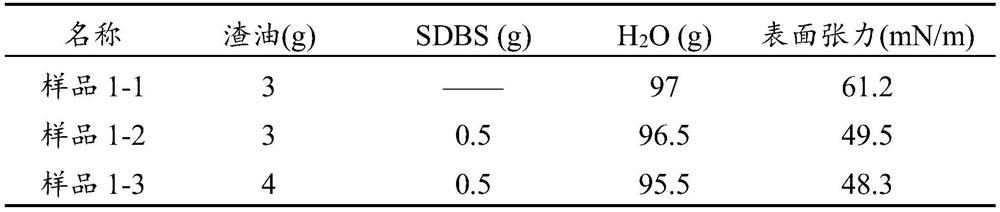

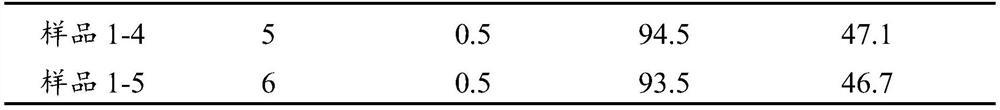

Composite dust suppressant as well as preparation method and application thereof

ActiveCN113512405AIncrease stickinessGood evaporation resistanceOther chemical processesDust removalPhysical chemistryEnvironmental engineering

The invention relates to the technical field of dust suppressants, and provides a composite dust suppressant. According to the composite dust suppressant provided by the invention, the evaporation resistance of the composite dust suppressant is improved by adding the residual oil, the gelatinized starch and the non-cationic water-soluble polymer; through multiple cooperation of the strong electrolyte, the non-cationic water-soluble polymer, the non-cationic surface active agent and the chelating agent, the surface tension of the dust suppressant is reduced to about half of that of water, so that the dust suppressant has excellent wettability to dust; by adding halide, the freezing resistance of the dust suppressant is improved, and the dust suppressant cannot be frozen at the temperature of -26.6 DEG C to-20.3 DEG C. The composite dust suppressant obtained by the invention has a good dust suppression effect, and can effectively reduce the dust concentration in the open pit coal mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Dust suppressant and preparing method and using method thereof

InactiveCN109706094AGood dust suppression effectStrong permeabilityBacteriaOther chemical processesSporosarcina pasteuriiUrea

The invention relates to a dust suppressant, and a preparing method and a using method thereof. The dust suppressant is prepared from a Sporosarcina pasteurii solution and nutritive salt. The nutritive salt includes a calcium source and urea. The dust suppressant is prepared by mixing a Sporosarcina pasteurii culture product with a nutrition solution prepared from the nutritive salt. Beneficial effects of the dust suppressant are that the dust suppressant can effectively reduce water used for conventional water spraying to suppress dust, and can obviously reduce raised dust pollution in an ashstorage yard; the dust suppressant is safe to use and green and provides an environmentally friendly treatment method.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

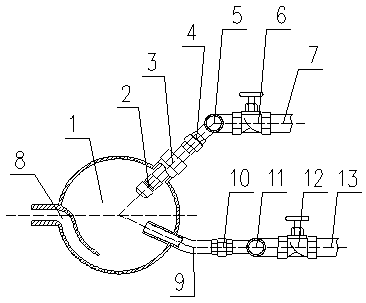

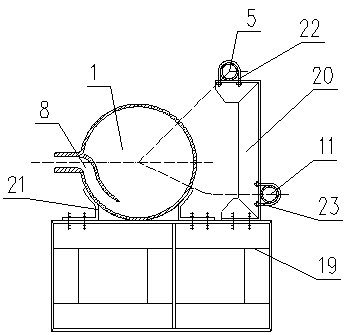

Belt conveyor dust suppression device

InactiveCN109019083AApplicableGood dust suppression effectControl devices for conveyorsLoading/unloadingLine tubingSpray nozzle

The invention relates to a belt conveyor dust suppression device which comprises a belt conveyor, a high-pressure water spray nozzle, a line penetrating pipe, a water tank, a gas storage tank and a camera. Two high-pressure water spray guns are symmetrically installed on the two sides of a feeding hopper at the right end of the belt conveyor through flange bolts, two high-pressure water spray gunsare symmetrically installed on the two sides of a belt conveyor head cover on the belt conveyor through flange bolts, a transit frame is arranged at the right end of the belt conveyor, and the watertank, the gas storage tank and a multi-stage pressurized water pump motor are arranged on the bottom of the transit frame. The water tank is connected with the multi-stage pressurized water pump motor, the multi-stage pressurized water pump motor is connected with the high-pressure water spray guns through water pipelines, the gas storage tank is connected with the high-pressure water spray guns through air pipelines, and valves are arranged at the front ends of the water pipelines and the air pipelines. The belt conveyor dust suppression device fully utilizes an aerodynamic principle and a fluid mechanics principle, and has applicability and good dust suppression effect.

Owner:青州中联水泥有限公司

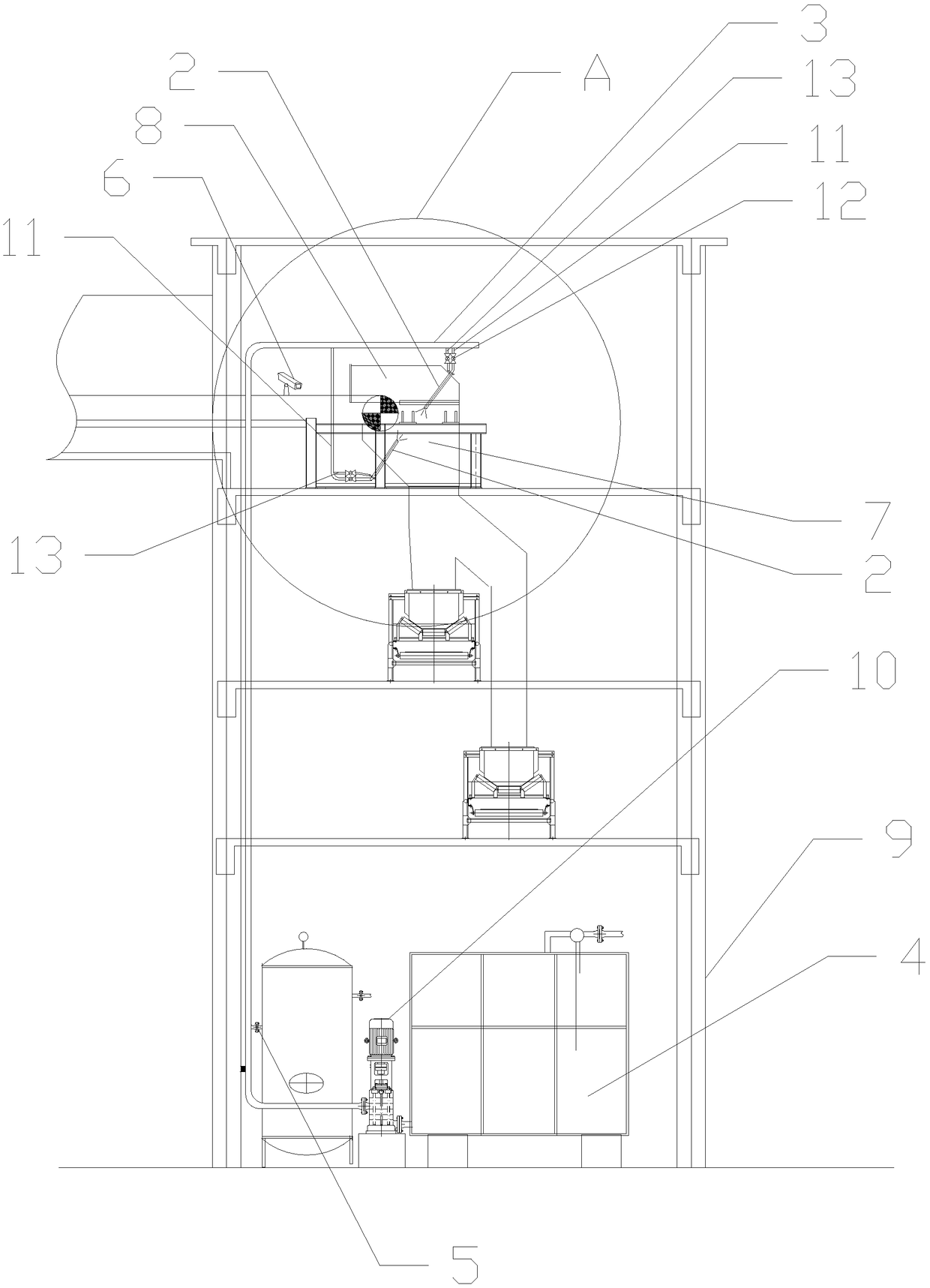

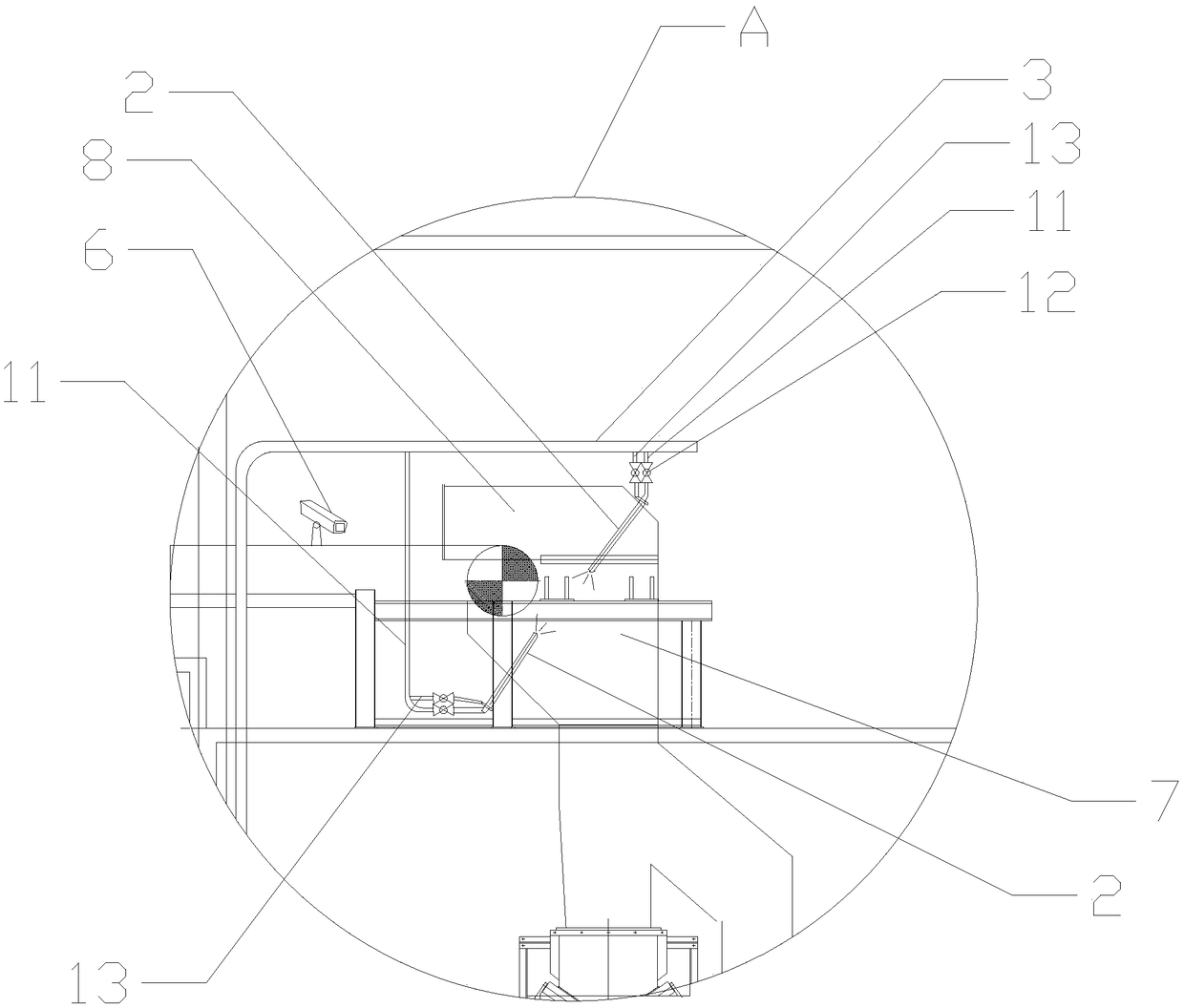

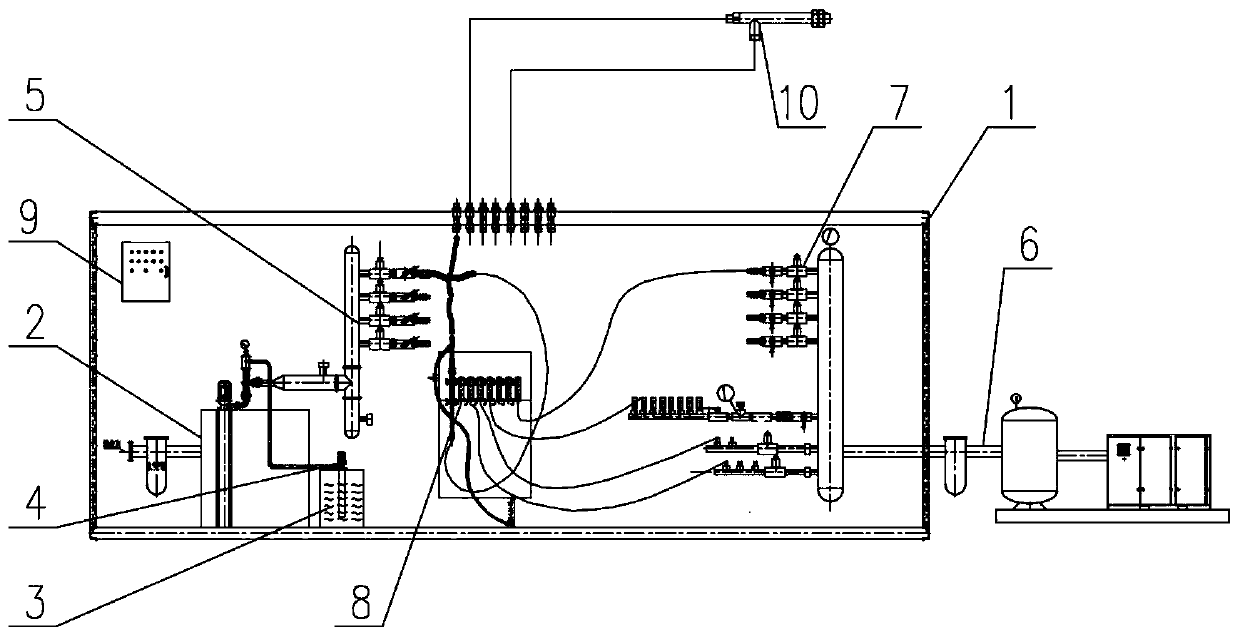

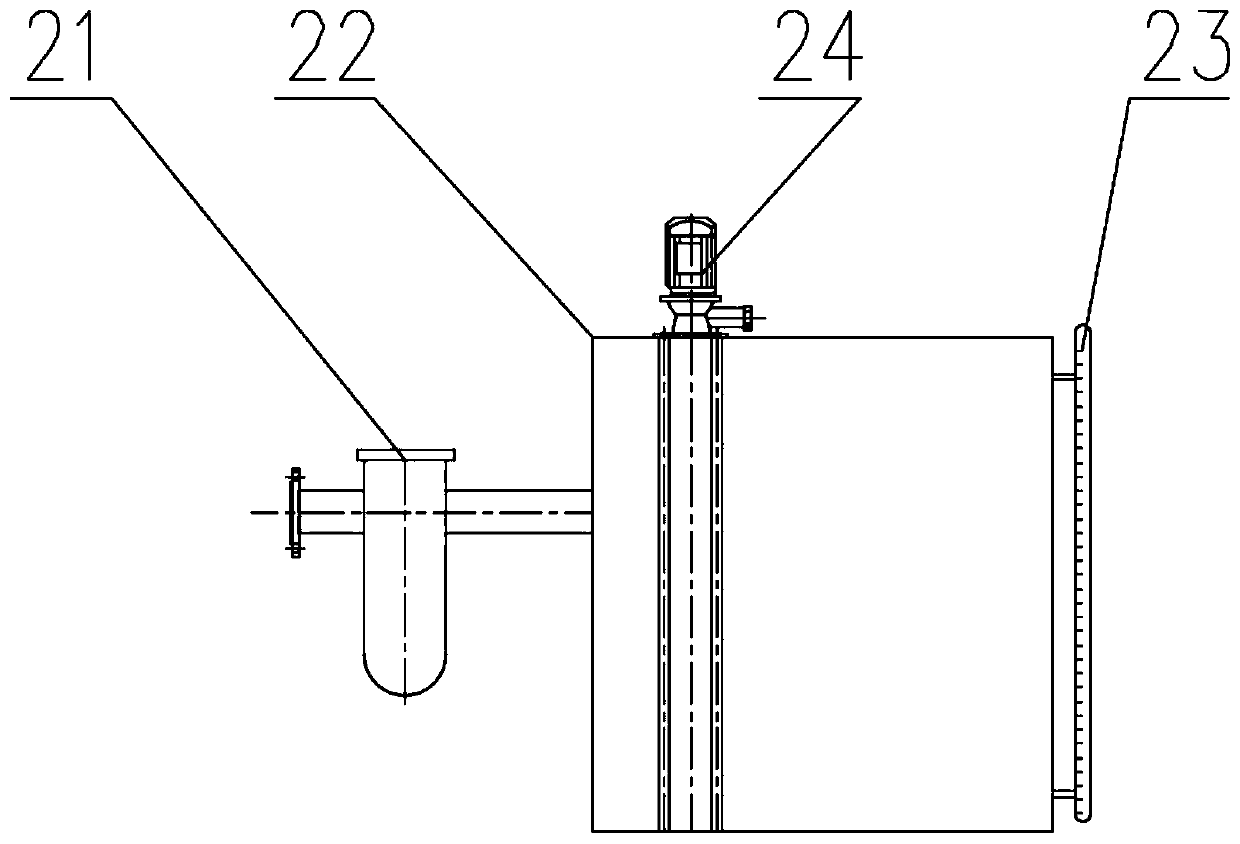

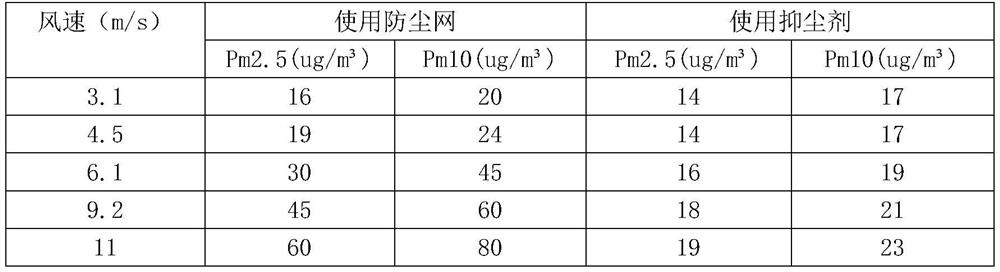

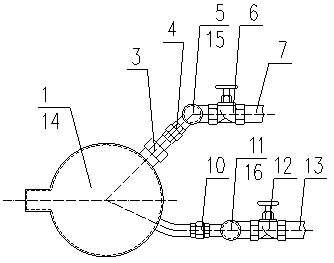

Dust suppressant dry fog dust suppression system and method

PendingCN110548357AGood dust suppression effectSave waterUsing liquid separation agentSeparation devicesWater resourcesEngineering

The embodiment of the invention discloses a dust suppressant dry fog dust suppression system. The dust suppressant dry fog dust suppression system comprises a main box and a system controller, the main box is internally provided with a water supply system, a dust suppressant supply system, a mixed liquid valve group, a gas path valve group and a comprehensive regulating device which are controlledby the system controller, the outlet ends of the water supply system and the dust suppressant supply system are jointly connected with the mixed liquid valve group and the mixed liquid valve group isconnected with the gas path valve group through the comprehensive regulating device, the gas path valve group is externally connected with an air supply system, and the comprehensive regulating device is externally connected with terminal spray equipment. According to the dust suppressant dry fog dust suppression system, after mixed liquid formed through purified water provided by the water supply system and a dust suppressant provided by the dust suppressant supply system is metered and distributed, and after the gas spraying pressure is adjusted, the mixed liquid is ejected from the terminal spray equipment, the better dust suppression effect is achieved, efficiency is improved more than 80% than a traditional method, and the water consumption is 10%-20% of dry fog dust suppression, a lot of water resources can be saved, the dust suppressant dry fog dust suppression system can be flexibly applied to multiple complex or special working conditions, sewage is not produced, and the costis low.

Owner:北京牧之科技有限公司 +1

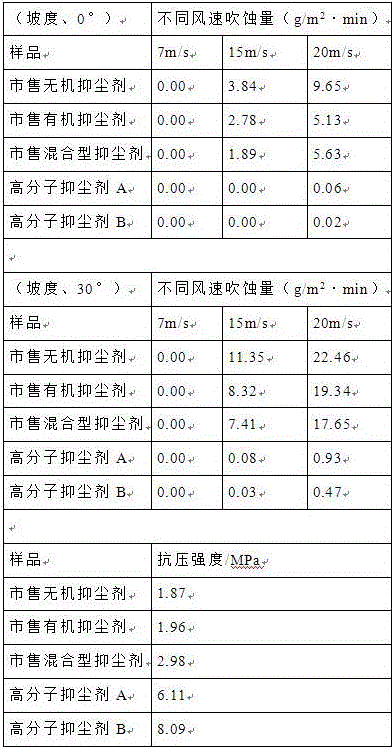

High-polymer dust suppressant

ActiveCN106318322AGood dust suppression effectGood coagulationOther chemical processesClimate change adaptationDesertificationHigh polymer

The invention discloses a high-polymer dust suppressant, belonging to the field of dust suppression. The high-polymer dust suppressant comprises a polymer molecule (C18H29O3S)m-(C3H5)n-(C3H4N)z, wherein m>=10, n>=115, and z>=15; and the polymer molecule has a spacial three-dimensional network structure. The high-polymer dust suppressant can prevent and treat open dust sources, can be widely used in coal / metal / nonmetal mining areas, mineral slag stock grounds, coal / ore powder transportation, mineral earthwork storage unloading areas, building evacuation, under-construction road way sides, thermal power plants, cement plants, steel plants, metallurgic plants, dust workshops, artificial beaches, desertification areas and other locations, has favorable wind erosion resistance and compression strength, can display the dust suppression effect for a long time, avoids environmental pollution caused by flying dust or abundant waste of resources (such as coal powder), and has the characteristic of environment friendliness.

Owner:CHENGDU KEHENG ENVIRONMENTAL PROTECTION TECH

Tailing surface layer consolidation material based on lysinibacillus sphaericus and application thereof

ActiveCN112409989AGood dust suppression effectDifficulties in realizing resource utilizationOther chemical processesOrganic fertilisersEnvironmental engineeringChloride

The invention belongs to the technical field of environmental protection, and particularly relates to a tailing surface layer consolidation material based on lysinibacillus sphaericus. The material comprises the following components in percentage by mass: 15-50% of metal tailing sand, 3-15% of lysinibacillus sphaericus bacterial liquid, 1-10% of urea, 3-15% of anhydrous chloride, 1-6% of potassiumalginate and the balance of water. The preparation method comprises the following steps: respectively crushing the weighed metal tailing sand, urea, anhydrous chloride and potassium alginate, sievingwith a 100-150-mesh sieve, mixing, adding the lysinibacillus sphaericus bacterial liquid and water, and uniformly mixing to obtain the tailing surface layer consolidation material. The using method comprises the steps that the tailing surface layer consolidation material is sprayed to the surface layer of the tailing pond, and 200 L of the tailing surface layer consolidation material is sprayed to the surface of every 500 m < 2 > of the tailing pond. The tailing surface layer consolidation material provided by the invention can form a stable consolidation layer on the surface layer of the tailing pond to achieve a good dust suppression effect, and the material is convenient to obtain, environment-friendly, simple in use method and low in cost.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Concentrated environment-friendly dust suppressant and preparation method thereof

The invention relates to a concentrated environment-friendly dust suppressant and a preparation method thereof. The preparation method specifically comprises the following steps of: 1) adding 100g ofpolyvinyl alcohol into 800ml of a water-in-water type reversed-phase anionic polyacrylamide emulsion with a molecular weight of 6,000,000 and a solid content of 30%, performing swelling for 5h, and then conducting stirring for 30min to obtain 900ml of an aqueous phase solution; and 2) adding 35ml of a styrene-acrylic emulsion with a solid content of 40%-50% into the aqueous phase solution, then adding 65ml of glycerol, and mixing the substances uniformly to obtain 1L of the concentrated environment-friendly dust suppressant. The environment-friendly dust suppressant has the advantages that: the environment-friendly dust suppressant has excellent stability of high flash point and low freezing point, an environment-friendly function is completely realized, a good dust suppression effect is achieved, and reagents used in the environment-friendly dust suppressant are all safe and environment-friendly products.

Owner:王阁中

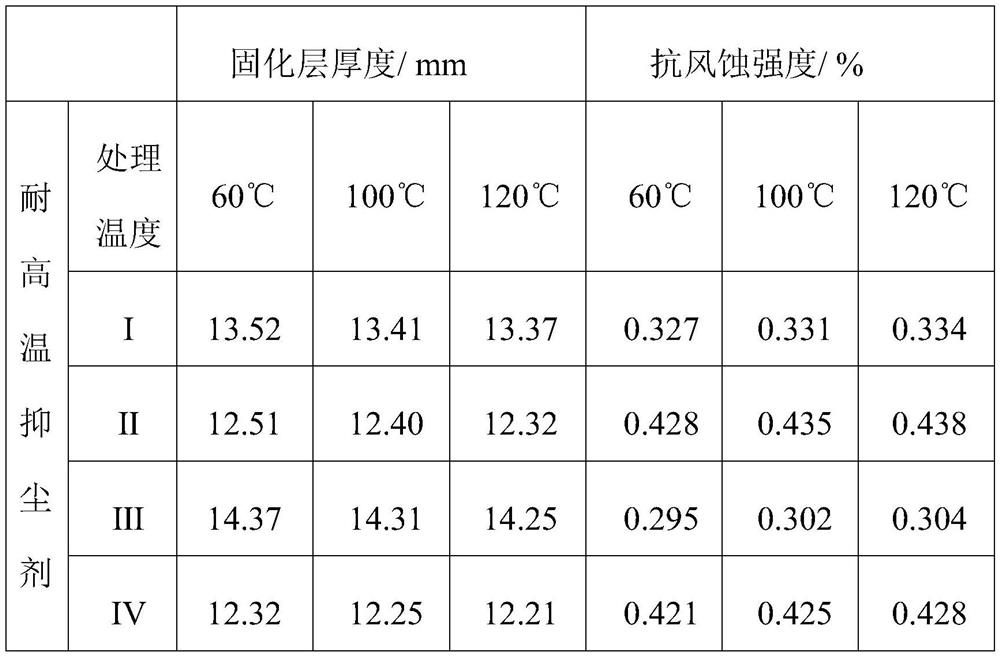

High-temperature-resistant semi-coke dust suppressant and preparation method thereof

PendingCN113684005AGood adhesionGood film formingOther chemical processesCarboxymethyl starchToxic gas

The invention provides a high-temperature-resistant semi-coke dust suppressant and a preparation method thereof. The dust suppressant is prepared from the following components in percentage by mass: 30-60% of modified starch, 1-5% of an emulsifier, 20-50% of a film-forming agent, 1-3% of an initiator, 1-3% of borax and the balance of water, wherein the modified starch is etherified starch with high substitution degree, and is at least one of hydroxypropyl starch, carboxymethyl starch and hydroxypropyl carboxymethyl starch. The preparation method comprises the following steps: heating and dissolving a film-forming agent and water under a stirring condition; conducting cooling, adding an emulsifier, and conducting stirring for reaction; then adding an initiator for reaction, then adding modified starch for three times for constant-temperature graft copolymerization reaction, and then conducting cooling to room temperature; and finally, adding a borax solution to carry out cross-linking reaction. The prepared high-temperature semi-coke dust suppressant can resist the high temperature of 120 DEG C, and is high in adhesiveness, good in film-forming property and excellent in dust suppression effect; and the dust suppressant does not contain environmental pollutants such as heavy metals and toxic gases, is free of environmental pollution and easy to degrade, and belongs to an environment-friendly product.

Owner:WUHAN UNIV OF SCI & TECH

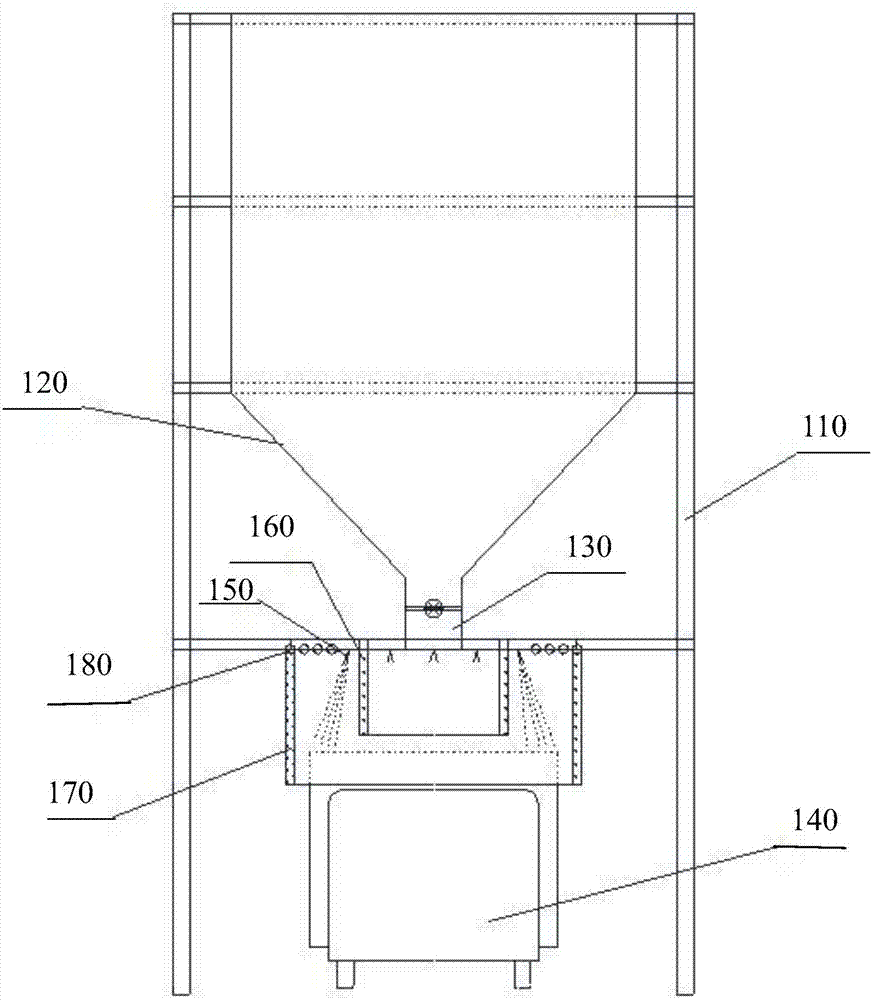

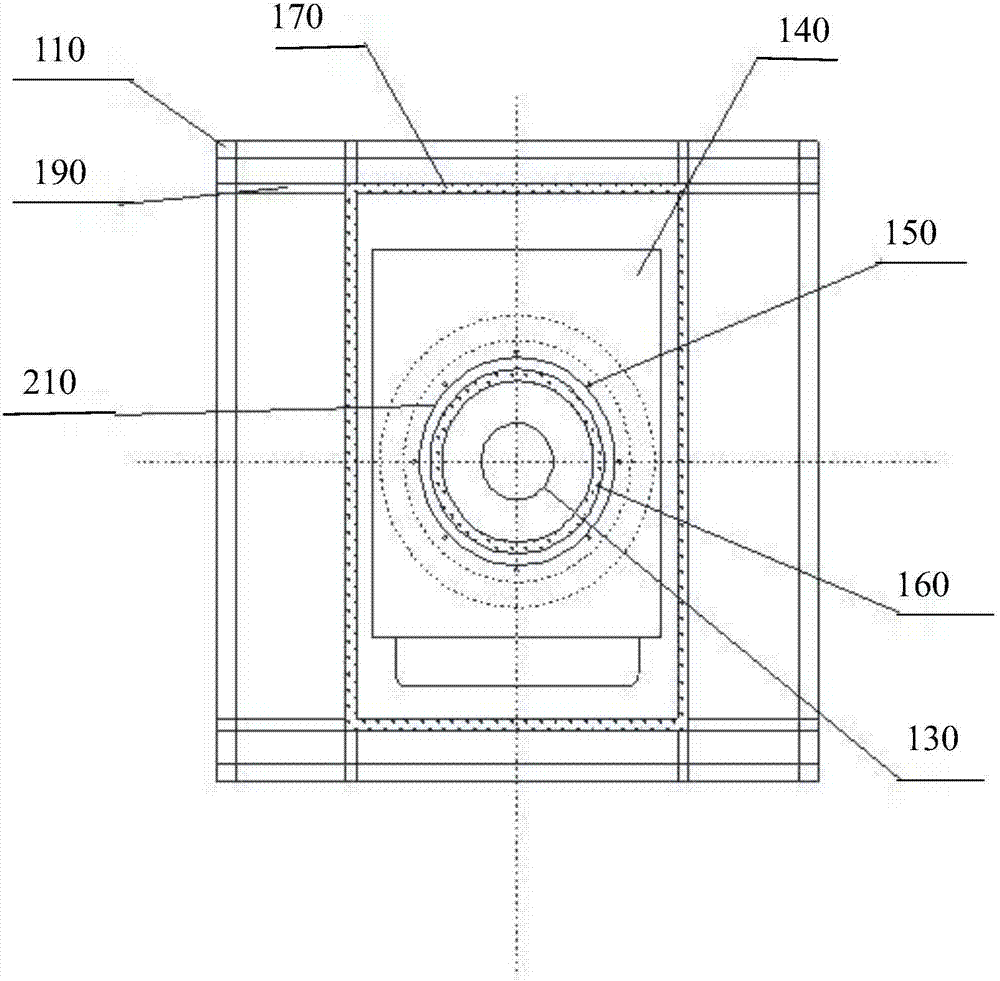

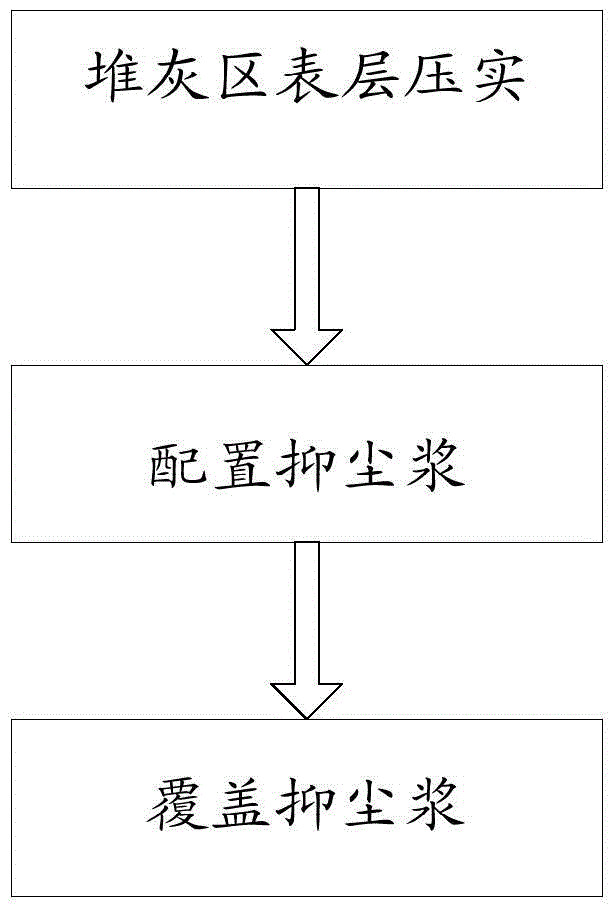

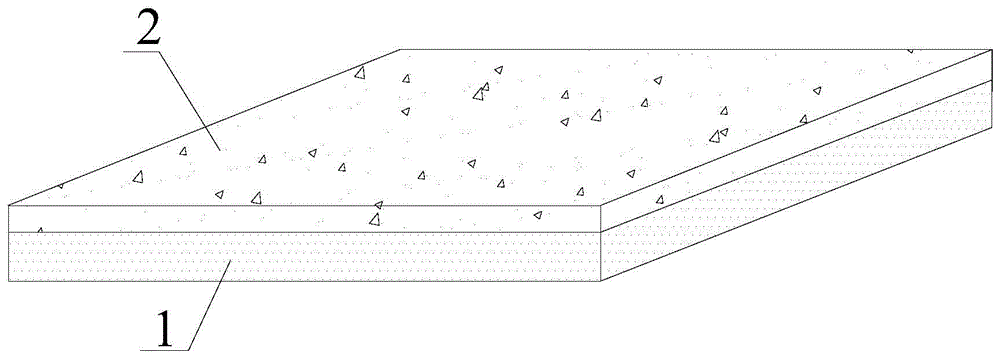

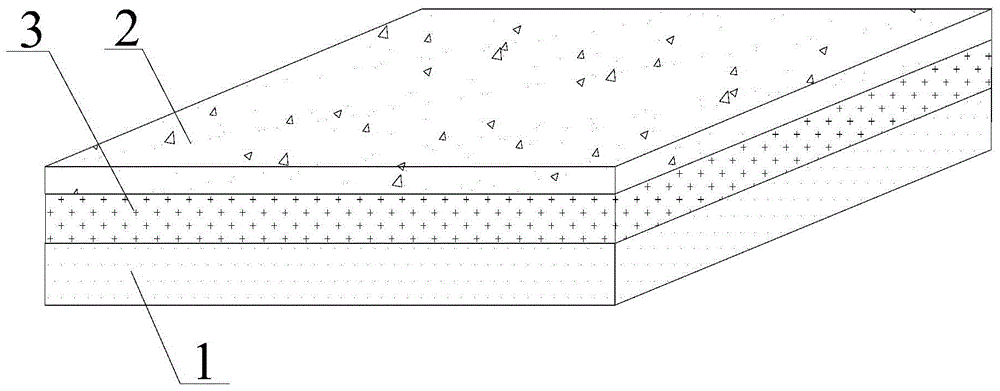

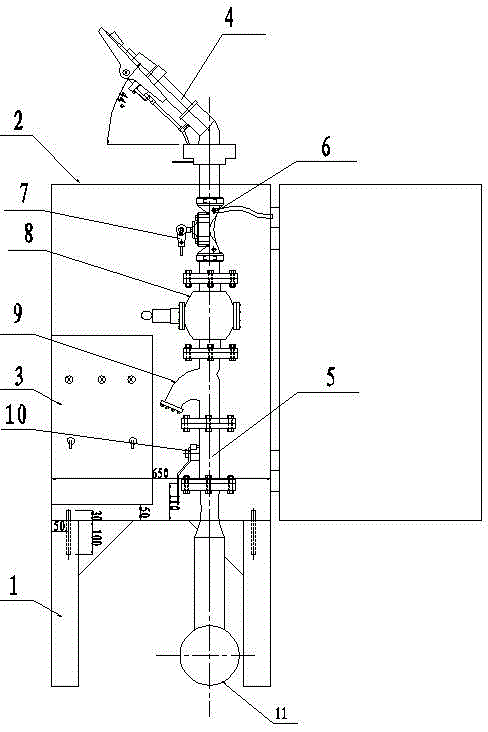

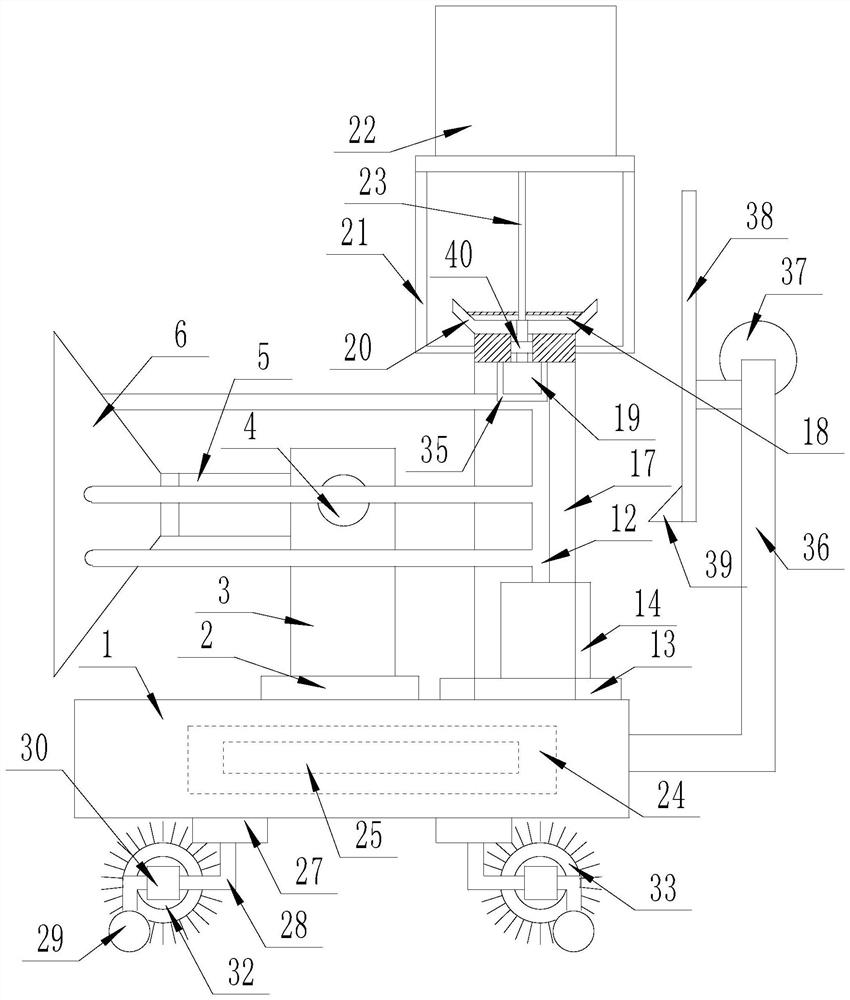

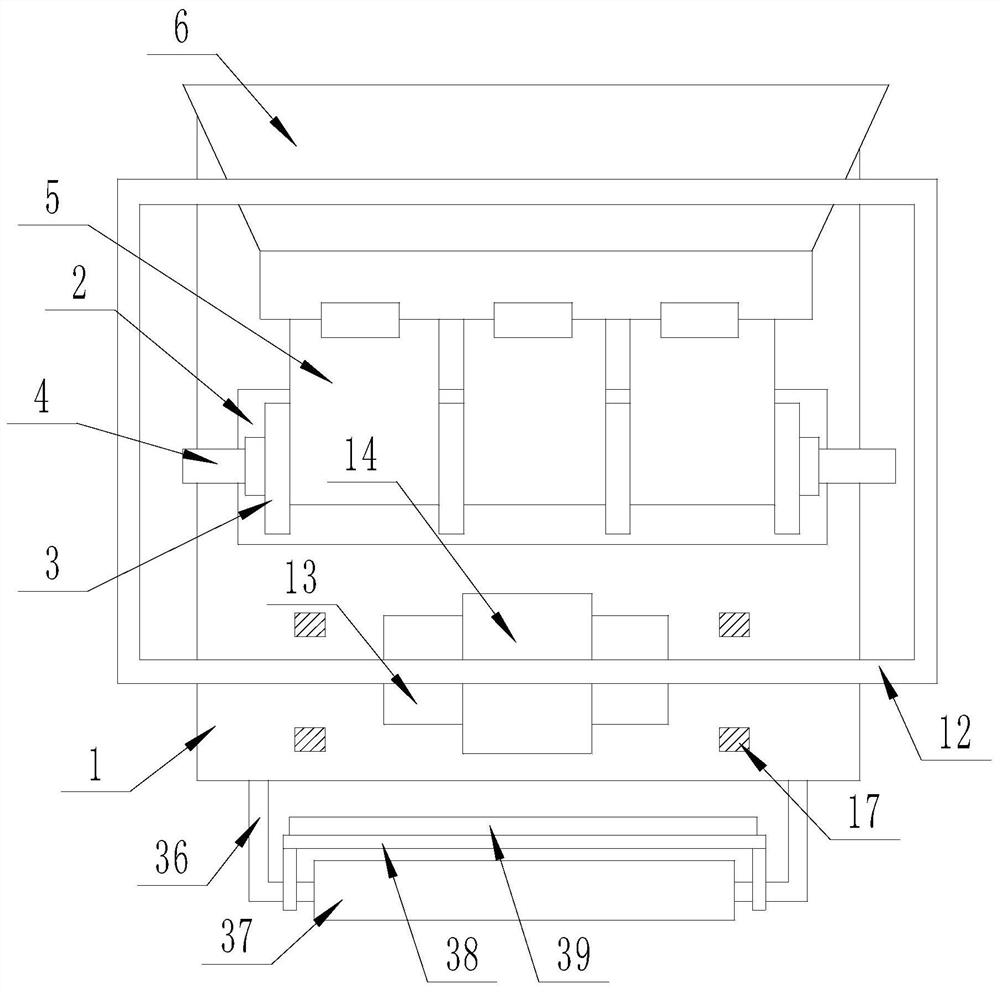

A coal-fired power plant ash storage yard and industrial tailings dust suppression process and device

The invention relates to fields of dust suppression processes and devices, and particularly relates to an ash storage field for a coal-fired power plant and a dust suppression process and a device for industrial tailings. The dust suppression process comprises the following steps: ash stack region surface layer compaction, namely spraying water to an ash stack layer surface layer, and carrying out mechanical compaction or water-stable compaction; dust suppression slurry preparation, wherein the raw materials of the dust suppression slurry are formed by mixing of water, cement, aggregate and an auxiliary material; covering the dust suppression slurry, namely spraying the dust suppression slurry. According to the ash storage field for the coal-fired power plant and the dust suppression process and the device for industrial tailings provided by the invention, construction equipment is simple to operate and high in operation efficiency during construction; the construction equipment is capable of spraying 800-1,000m<2> per hour; dust suppression films are free of maintenance after being molded; the period of validity with different time limits can be set according to the difference of the strength and the thickness of the dust suppression films; the dust suppression films, which are relatively long in period of validity, can be subjected to a secondary spraying operation at an interval of a dust suppression period; therefore, the materials are saved by over about 30%; the dust suppression effect is relatively good.

Owner:赵立虎

Spray gun station

InactiveCN103143215AFlexible layoutGood dust suppression effectUsing liquid separation agentSolenoid valveAgricultural engineering

The invention discloses a spray gun station, and relates to the technical field of spray dust removal systems. The spray gun station disclosed by the invention comprises a spray gun station platform, a protection box is arranged above the spray gun station platform, an electric control box is arranged in an inner cavity of the protection box, a self-head-swaying spray gun is arranged above the protection box, the lower end of the self-head-swaying spray gun is connected with a spray gun pipeline, the spray gun pipeline is arranged in the protection box in a penetrating way, and the spray gun pipeline, from top to bottom, is sequentially provided with an automatic water escape valve, a solenoid valve, a pressure reducing valve, a filter and a ball valve; and the lower end of the spray gun pipeline is connected with a main water supply pipeline. According to the invention, pressure water is conveyed by using a pipeline, and a nozzle is arranged flexibly, therefore, the spray gun station disclosed by the invention is especially applicable to dust removal application occasions with multiple dust production points.

Owner:YANGZHOU YEYUN METALLURGICAL EQUIP FACTORY

Multi-stage dust falling systemand method for construction site

InactiveCN112827292AReduce concentrationPlay a dust effectUsing liquid separation agentSeparation devicesEnvironmental engineeringDust particles

The invention discloses a multi-stage dust falling system and method for a construction site. The system comprises a high-pressure gas pipeline, a water pipeline and a water spraying assembly. The tail end of the water pipeline communicates with the high-pressure gas pipeline, and the water spraying assembly is connected to the tail end of the high-pressure gas pipeline; the water spraying assembly comprises a water spraying shell, and the water spraying shell is provided with a front end inlet, a tail end outlet, a water channel, a particle inlet and an atomizing plate; the atomizing plate is positioned behind the tail end outlet, and the atomizing plate and the tail end outlet are arranged at an interval; a suction channel is arranged in the water channel, and the inner diameter of the suction channel is gradually reduced from front to back; and the particle inlet is located at the tail end of the suction channel and located in the water spraying shell. The device disclosed by the invention can achieve a dust falling effect, dust falling is carried out in two stages in the whole process, and part of dust particles are sucked into the water spraying shell through the suction channel; and a part of dust particles are wrapped by water mist dispersed from the atomizing plate and water, the dust falling effect can be achieved through a small amount of water, meanwhile, the two-stage dust falling effect is better, and implementation is convenient.

Owner:郑州电力职业技术学院

Construction site dust suppression environmental protection device

InactiveCN112915658AEasy to useEasy to collectDispersed particle filtrationUsing liquid separation agentEnvironmental engineeringMechanical engineering

The invention discloses a construction site dust suppression environmental protection device, which comprises a strip-shaped bearing base, a dust suppression and environmental protection mechanism is arranged on the upper surface of the strip-shaped bearing base, and a moving mechanism is arranged on the lower surface of the strip-shaped bearing base. The device has the beneficial effects that the device is relatively convenient to use, facilitates dust collection at various angles, facilitates large-area collection, facilitates centralized placement of dust, facilitates dust falling by spraying rainwater, also facilitates rotating dust cleaning during movement, facilitates collection, and has a good dust suppression effect.

Owner:金迁

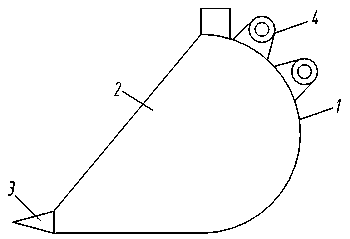

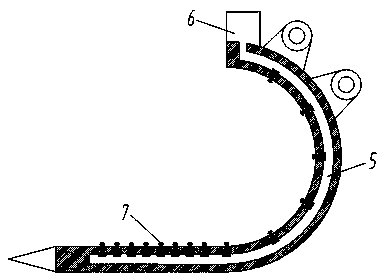

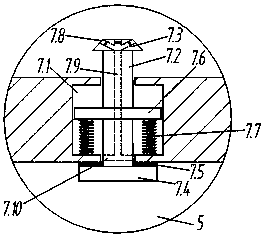

Bucket

InactiveCN109356213AGood dust suppression effectEffective dust suppressionMechanical machines/dredgersEngineeringWater spray

The invention provides a bucket which comprises a bottom plate, a side plate, a bucket tooth and hinged seats, wherein the side plate is arranged on the two sides of the bottom plate; the bucket toothis arranged on the edge of the front part of the bottom plate; the hinged seats are arranged on the bottom plate and is used for being connected with driving pieces; a water cavity is formed in the bottom plate; a water pump is arranged on the bottom plate; water spraying devices are arranged on the inner side of the bottom plate; water is pumped into the water cavity from an external water tankby the water pump, and is sprayed out through the water spraying devices; a hollow cavity is formed in the bottom plate; the water spraying devices are provided with main rods, water spray heads, pushplates 7.4, seal rings, supporting plates, springs, water spray holes, channels and water inlets. The bucket is good in dust suppression effect.

Owner:马鞍山迪斯福工业设计有限公司

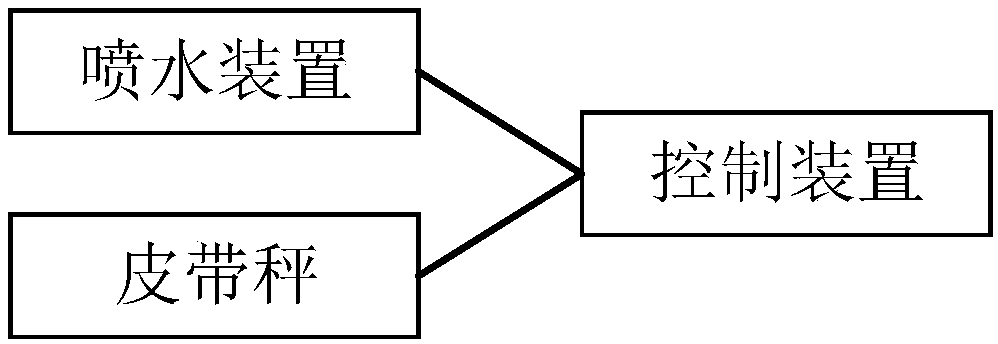

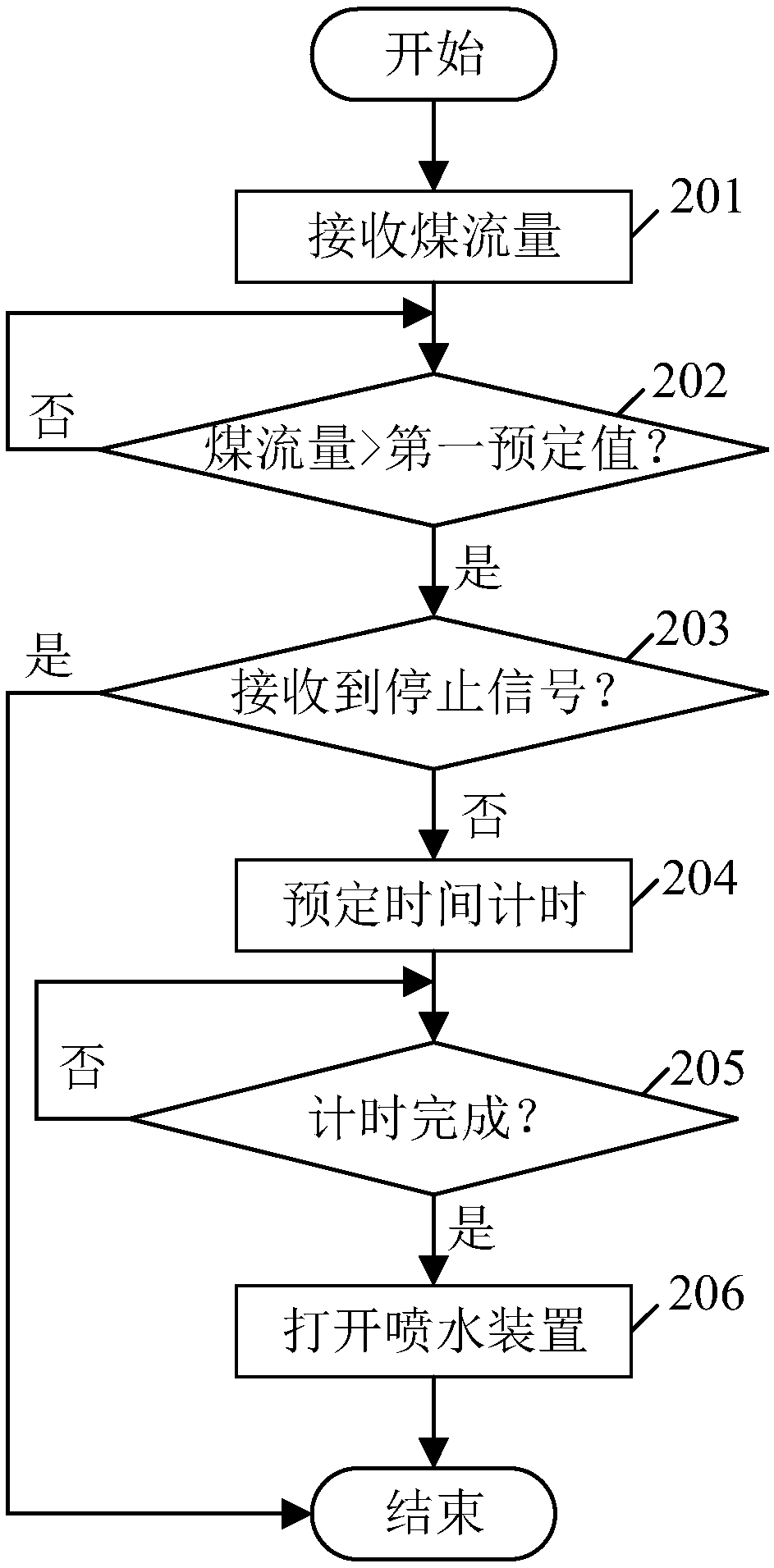

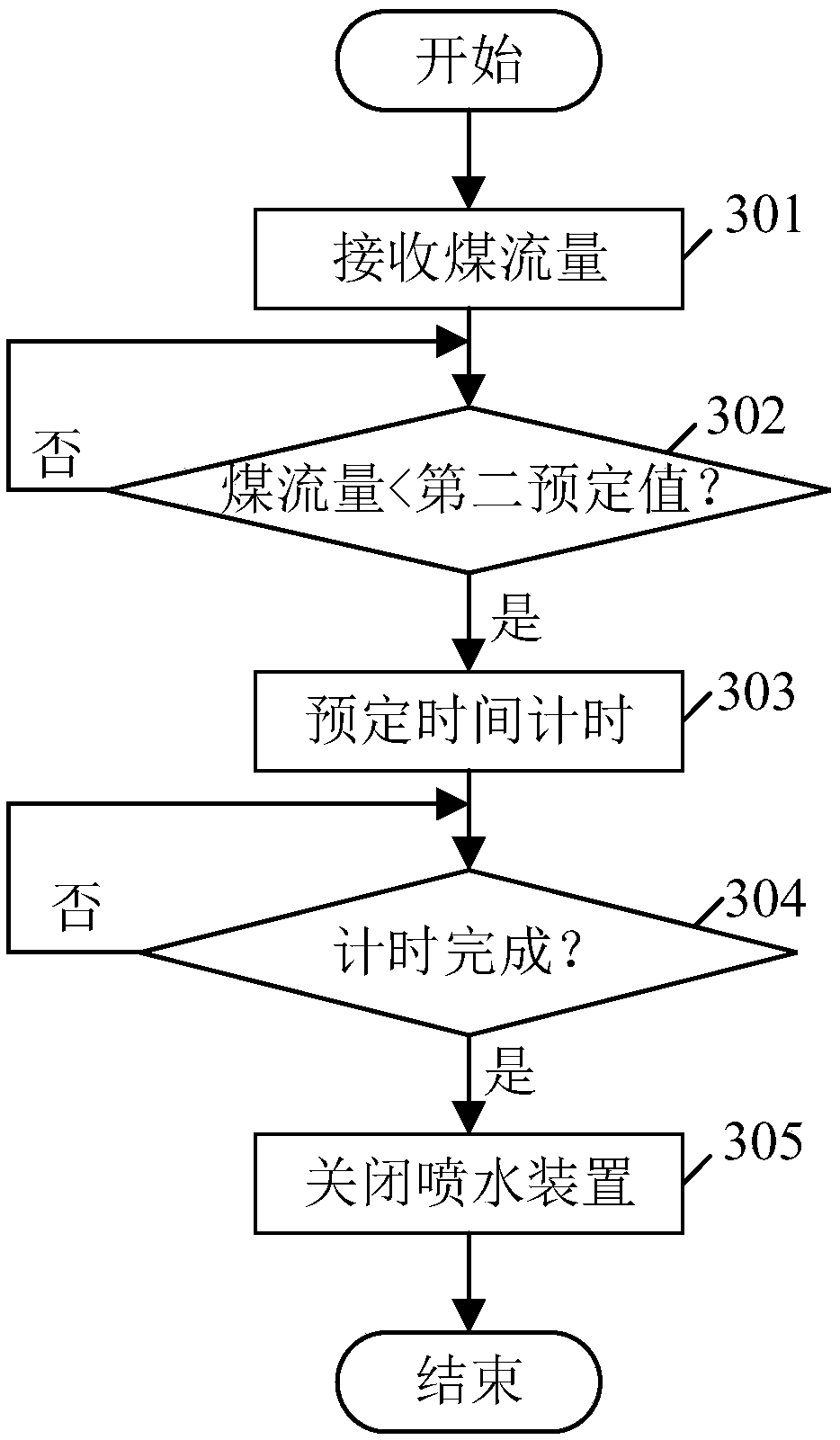

Apparatus, system and method for suppressing coal dust

ActiveCN109230650AIncrease humidityGood dust suppression effectConveyorsLoading/unloadingTowerWater spray

The invention provides an apparatus, system and method for suppressing coal dust, and belongs to the technical field of coal dust suppression in a coal transportation process. The apparatus for suppressing coal dust comprises: a water spray device installed in a transfer tower and used for spraying water to a belt conveyor downstream of the transfer tower; and a belt scale used for weighing the coal flow rate on the belt conveyor upstream of the transfer tower; and a control device for turning on or off the water spray device according to the coal flow rate. The apparatus, by installing the water spray device in the transfer tower and turning of or off the water spray device in the transfer tower according to the coal flow rate upstream of the transfer tower, increases the humidity of thecoal, achieves a good coal dust suppression effect in the processes when the coal is a belt line of the transfer tower and a ship loader loading process, and has a great effect on the clean productionof a port.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Coal mine fan noise and dust control equipment and control method thereof

ActiveCN112664483AReduce noiseImprove the noise reduction effectPump componentsDust removalDust controlNoise

The invention discloses coal mine fan noise and dust control equipment and a control method thereof. The coal mine fan noise and dust control equipment comprises a fan, a diffuser and a connecting pipe used for connecting the fan with the diffuser. The coal mine fan noise and dust control equipment comprises a sound insulation cover arranged on the fan, a flow guide and noise reduction mechanism arranged in the connecting pipe, a dust suppression barrier arranged on the diffuser, the sound insulation cover comprises a first frame, and a first sound absorption plate and a first sound absorption lining are sequentially arranged on the first frame from inside to outside; the flow guide and noise reduction mechanism comprises a sound absorption cylinder and a sound absorption layer, the sound absorption cylinder and the sound absorption layer are arranged on the inner wall of the connecting pipe from inside to outside, a flow guide and noise reduction assembly is installed in the sound absorption cylinder, and a plurality of silencing holes are formed in the sound absorption cylinder; and the dust suppression barrier comprises a second frame, a second sound absorption plate and a second sound absorption lining are arranged on the second frame, and a high-pressure spraying dust removal mechanism acting above a diffuser outlet is further arranged on the second frame. Noise generated by the fan can be remarkably reduced, the noise elimination effect is good, and the ideal dust suppression effect is achieved.

Owner:山东能源集团鲁西矿业有限公司

Air curtain generating device for dust fall of construction site road and using method thereof

InactiveCN111408220ADoes not affect trafficThe process principle is simpleUsing liquid separation agentWater savingEnvironmental engineering

The invention particularly relates to an air curtain generating device for dust fall of a construction site road. The device is characterized in that the device comprises an air curtain generating cylinder, a water mist system, an air supply system, a main water pipe, a main air pipe, a water source and a fan, the water mist system and the air supply system convey air and water to a mixing cavityin the air curtain generation cylinder through a water mist spray head and an air spray head correspondingly, so that compressed air with water mist is formed in the air curtain generating cylinder, curtain-shaped wet mist airflow is sprayed out of the compressed air through the flow guide nozzle of the air curtain generating cylinder, rising of flying dust on the road surface is stopped after meeting the curtain-shaped airflow, the flying dust gradually descends to the road surface under the action of the water mist of the wet mist airflow, and therefore the purpose of dust falling is achieved. Pedestrians and vehicles are not influenced during operation of the device, road washing slurry is not generated, and water conservation and emission reduction are facilitated.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com