Foam-dry fog dust suppression technology for ultrafine particle dust discharged disorderly

A technology for disorganized emission and fine particle dust, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc. It can solve the problems of long installation time, blockage of screening machines, and high cost of dust, so as to improve utilization rate, Reduce processing costs, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

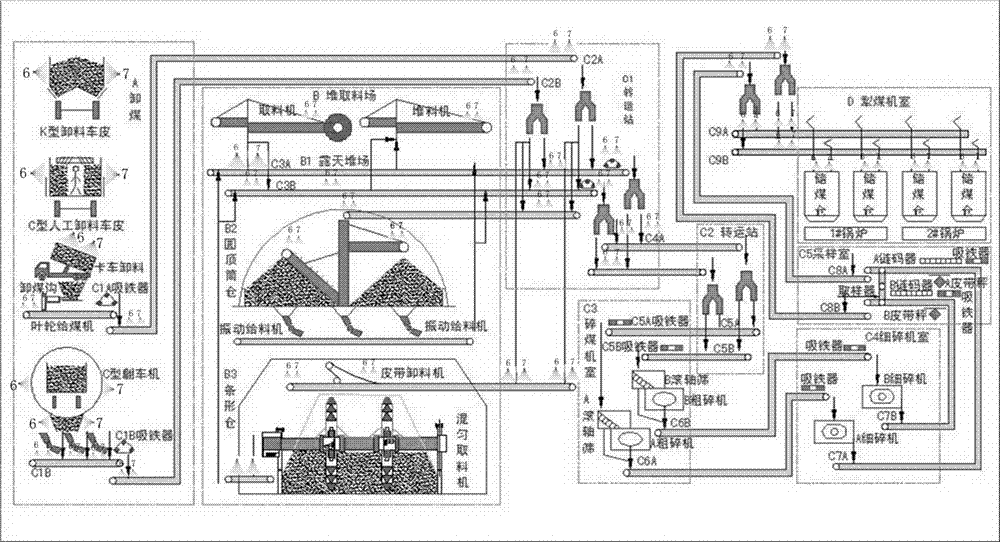

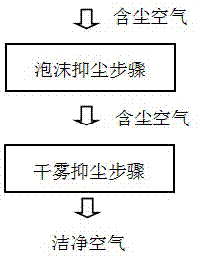

[0014] See figure 1 According to the present invention, a foam dry fog dust suppression process for fugitive emission of ultrafine particle dust comprises the following steps.

[0015] Step 1: Foam dust suppression at the dust generation point. When the dust discharged from materials in the closed and semi-enclosed places of unorganized emission sources such as crushing, screening, transportation, loading and unloading, construction, etc. Foam dust suppression, through single or multiple double-fluid nozzles or high-pressure single-fluid nozzles spraying foam on the dust emission source dust above or around the outer side of the dust emission source, the entire fugitive emission fine Particle dust PM2.5 dust production point area is covered by foam for preliminary dust suppression. Coarse dust in the air is aggregated from small particles to large particles through the interception with the foam, inertial collision, diffusion, etc., and finally settles down together with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com