High-temperature-resistant semi-coke dust suppressant and preparation method thereof

A high-temperature-resistant, dust-suppressant technology, applied to chemical instruments and methods, and other chemical processes, can solve the problems of reducing the amount of addition, failing to achieve heat resistance, and reducing dust suppression effects, etc., to achieve strong adhesion and cost-effectiveness. Good film performance and excellent dust suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

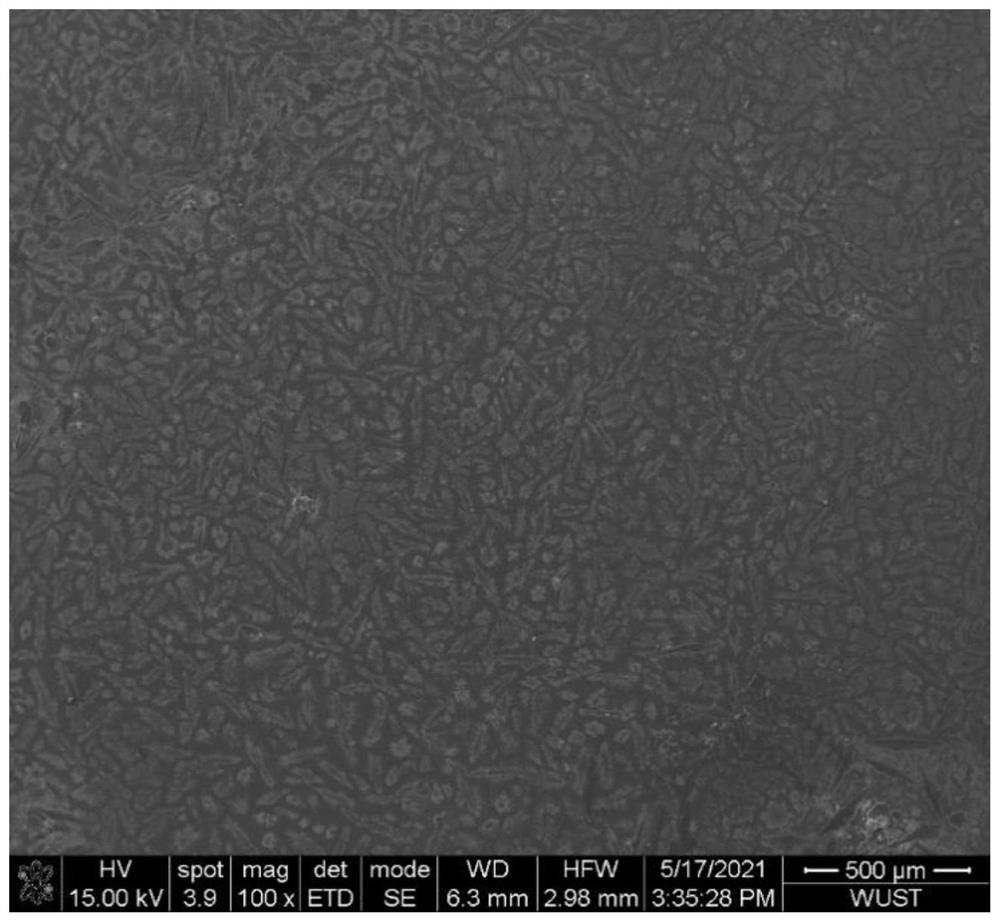

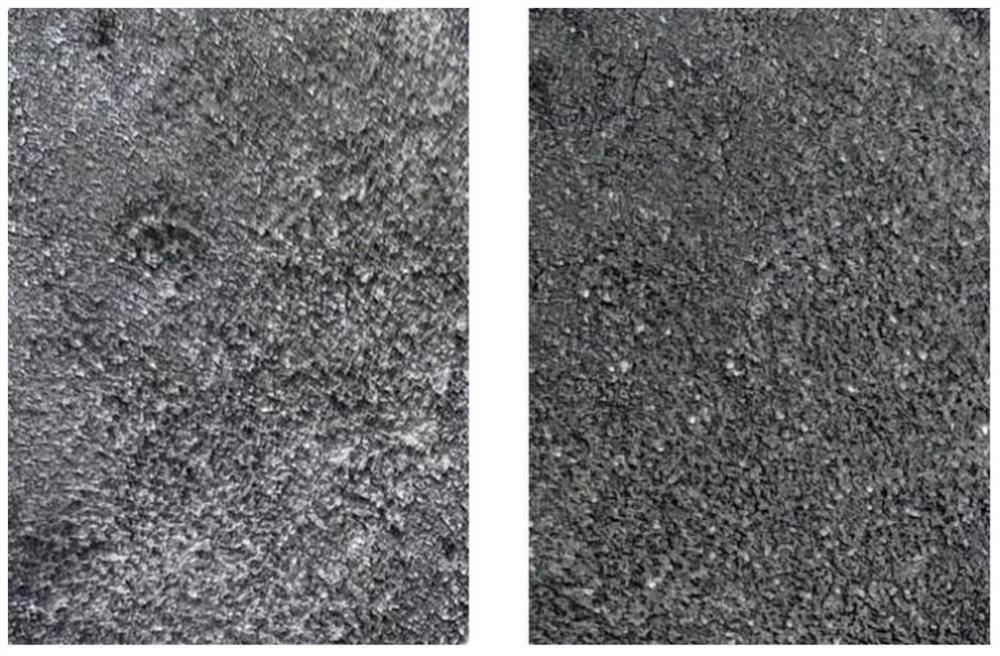

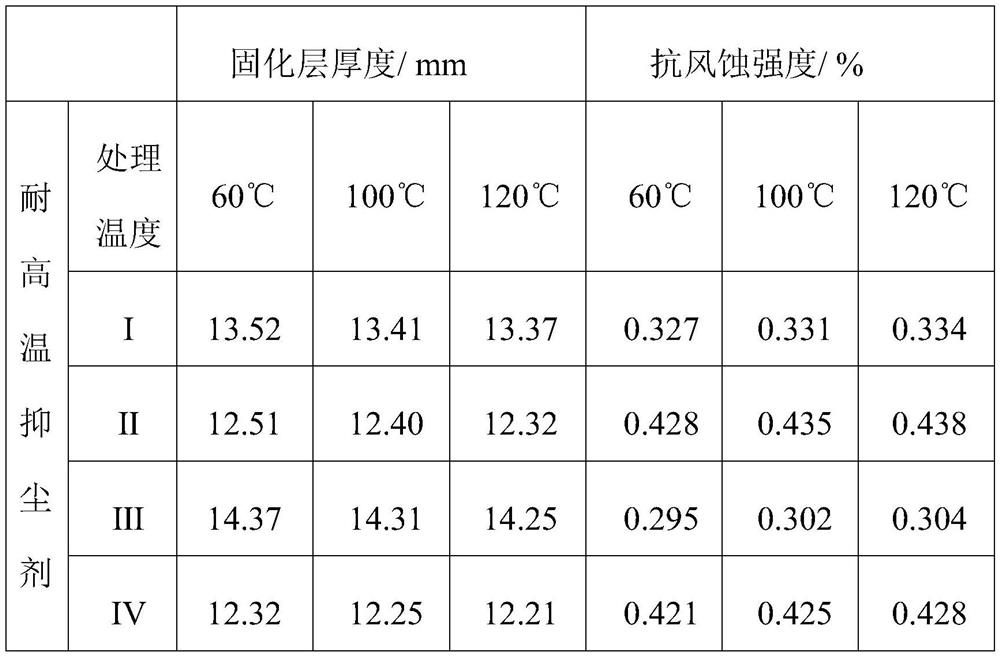

Image

Examples

Embodiment 1

[0031] The high temperature-resistant blue carbon dust suppressant, its preparation raw materials are: carboxymethyl starch 30g; sodium lauryl sulfate 1g; acrylic resin 50g; potassium persulfate 1g; borax 3g; water 15g.

[0032] The preparation method of the dust suppressant is as follows: (1) Add acrylic resin and water into a four-necked bottle equipped with a stirrer, a thermometer, a reflux device, and a heater, and dissolve it completely under a stirring environment of 50r / min. (2) adjust the temperature to 30°C, and add sodium lauryl sulfate to react for 30 minutes under a stirring environment of 200r / min; (3) add potassium persulfate to react for 30 minutes, and then add carboxymethyl starch to the Carry out constant temperature graft copolymerization reaction in the solution for 30 minutes, cool to room temperature; (4) Add 2% borax solution to carry out crosslinking reaction for 30 minutes, after the reaction is completed, the high temperature resistant blue carbon dus...

Embodiment 2

[0034] The high temperature-resistant blue carbon dust suppressant, its preparation raw materials are: 30g of hydroxypropyl starch; 1g of sodium lauryl sulfate; 50g of acrylic resin; 1g of potassium persulfate; 3g of borax; 15g of water.

[0035] The preparation method of the dust suppressant is as follows: (1) Add acrylic resin and part of water into a four-necked bottle equipped with agitator, thermometer, reflux device and heating, and make it completely Dissolve; (2) adjust the temperature to 40°C, and add sodium lauryl sulfate to react for 30 minutes under a stirring environment of 150 r / min; (3) add potassium persulfate to react for 30 minutes, and then add hydroxypropyl starch in three times on average Carry out constant temperature grafting copolymerization reaction in the solution for 30 minutes, cool to room temperature; (4) Add 2% borax solution to carry out crosslinking reaction for 30 minutes, after the reaction is completed, the high temperature resistant semi-car...

Embodiment 3

[0037] High temperature resistant blue charcoal dust suppressant, its preparation raw materials are: 30g of hydroxypropyl carboxymethyl starch; 1g of sodium dodecylbenzenesulfonate; 50g of acrylic resin; 1g of potassium persulfate; 3g of borax; 15g of water.

[0038]The preparation method of the dust suppressant is as follows: (1) Add acrylic resin and water into a four-necked bottle equipped with a stirrer, a thermometer, a reflux device, and a heater, and dissolve it completely under a stirring environment of 120r / min. (2) Adjust the temperature to 55°C, and add sodium dodecylbenzenesulfonate to react for 30 minutes under a stirring environment of 250r / min; (3) Add potassium persulfate to react for 30 minutes, and then add hydroxypropyl carboxymethyl starch Add to the solution three times on average for constant temperature graft copolymerization reaction for 30 minutes, and cool to room temperature; (4) add borax solution with a concentration of 2% for crosslinking reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com