Patents

Literature

902results about How to "Improve the effect of dust suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient environment-friendly dust suppressant as well as preparation method and application thereof

ActiveCN106957633AHigh moisturizing rateImprove dust suppression efficiencyOther chemical processesNitric oxideSodium silicate

The invention provides an efficient environment-friendly dust suppressant as well as a preparation method and application thereof. The efficient environment-friendly dust suppressant can solve the problems of single function, possibility of causing secondary pollution, and the like, of the present product, is widely applied and is especially suitable for roads with small dust particles, such as, capturing and absorbing for total suspended particulates, PM10, PM2.5 and nitric oxide. The efficient environment-friendly dust suppressant provided by the invention is prepared by mixing the following components by weight percent: 0.1-7% of latex, 0.1-6% of modified starch / modified cellulose, 0.1-5% of sodium alga acid, 0.1-8% of polyvinyl alcohol, 0.1-8% of sodium silicate, 10-60% of glycerol, 0.01-5% of surfactant and the balance of water.

Owner:NITTO QINGDAO TECH RES INST CO LTD

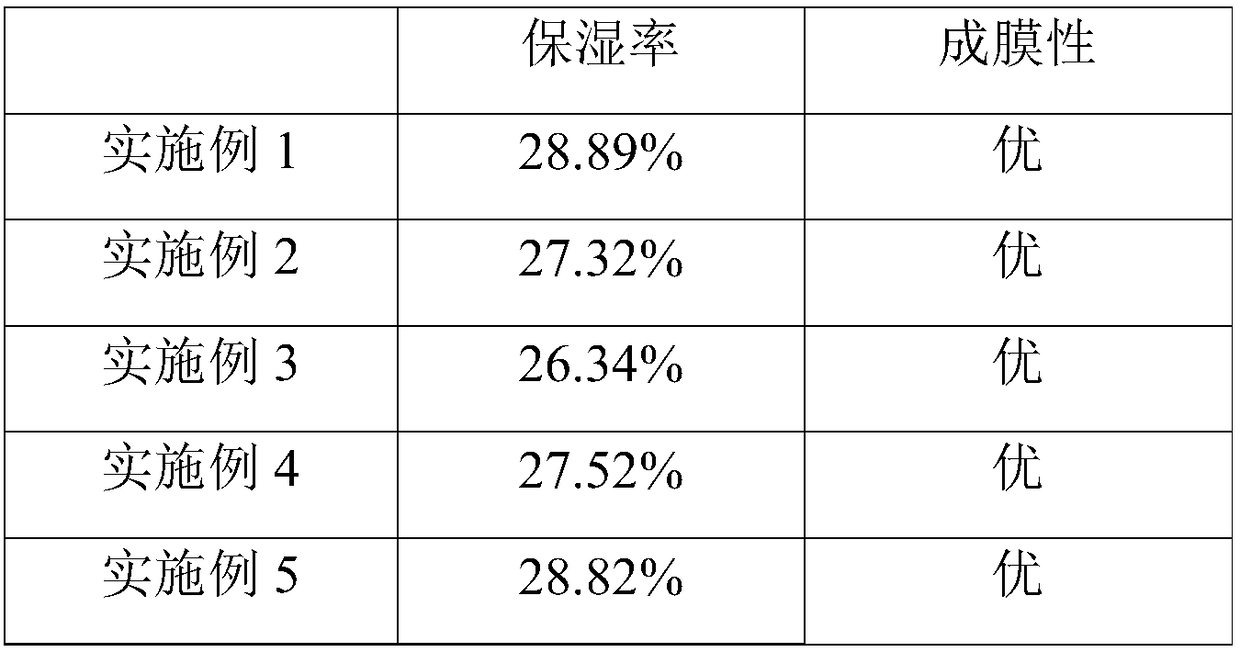

Dust suppressant as well as preparation method, using method and application thereof

InactiveCN108192570AImprove dust suppression efficiencyStrong persistenceOther chemical processesRoad surfaceEnergy consumption

The invention discloses a dust suppressant as well as a preparation method, a using method and application thereof, and relates to the technical field of dust suppressants. The dust suppressant is mainly prepared from the following components by weight percent: 0.15-6% of crusting agent, 0.05-5% of co-dispersant, 0-2% of auxiliary materials and the balance of water. The crusting agent is preparedfrom a natural high molecular polymer; the co-dispersant is prepared from a polyoxyethylene type nonionic surfactant. The dust suppressant provided by the invention is environmentally friendly, high in dust suppression efficiency and long in duration time, has higher moisturizing rate and excellent film forming property, has a sustainable dust suppressing effect after the road surface is dry, andalso has the characteristics of being low in transportation cost, convenient and fast to use, and the like. The preparation method and the using method of the dust suppressant are simple and easy to implement; the preparation method is convenient to operate and control, and low in energy consumption and cost, thus being very suitable for industrial production. When in use, the dust suppressant canbe sprayed after being diluted with water, thus being convenient to use and good in effect.

Owner:天津圣洁环保科技有限公司

Solid dust suppressant

InactiveCN104817997AHigh bonding strengthGuaranteed moisture contentOther chemical processesBursting strengthMoisture absorption

A solid dust suppressant is prepared by mixing 40-90% of a water-soluble high molecular polymer, 5-40% of water-soluble high molecular glue, 0-25% of a moisture absorption humectant, 0.5-5% of a flexibilizer, 1-5% of an antiseptic and 3-10% of an osmotic agent, and has the characteristics of high film forming strength, low brightness and moderate viscosity. The viscosity (at 25DEG C), the pH value, the wind loss rate (under 30mm / s wind speed 5mins, %), the cured layer thickness, the film tensile strength, the film elongation at break and the material bursting strength of the solid dust suppressant are not lower than 8.0mPa.s, 6.0-7.0, not greater than 0.40, not lower than 11.25mm, greater than 11mpa, greater than 13% and greater than 0.05mpa respectively, and the solid dust suppressant realizes difficult brittle rupture after film formation, has a long effective dust suppression time and an ideal dust suppression effect.

Owner:INNER MONGOLIA BORAN TECH CO LTD

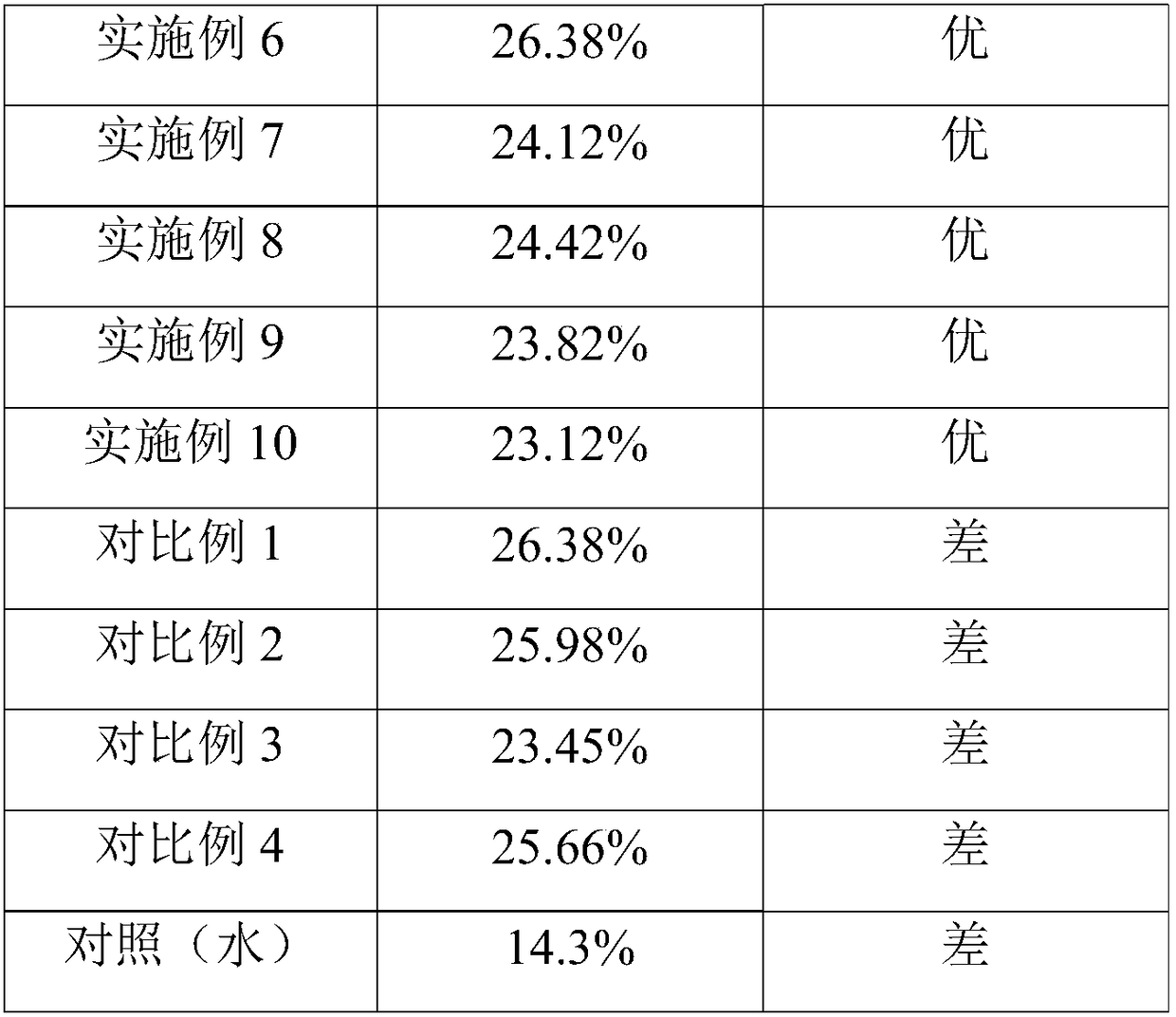

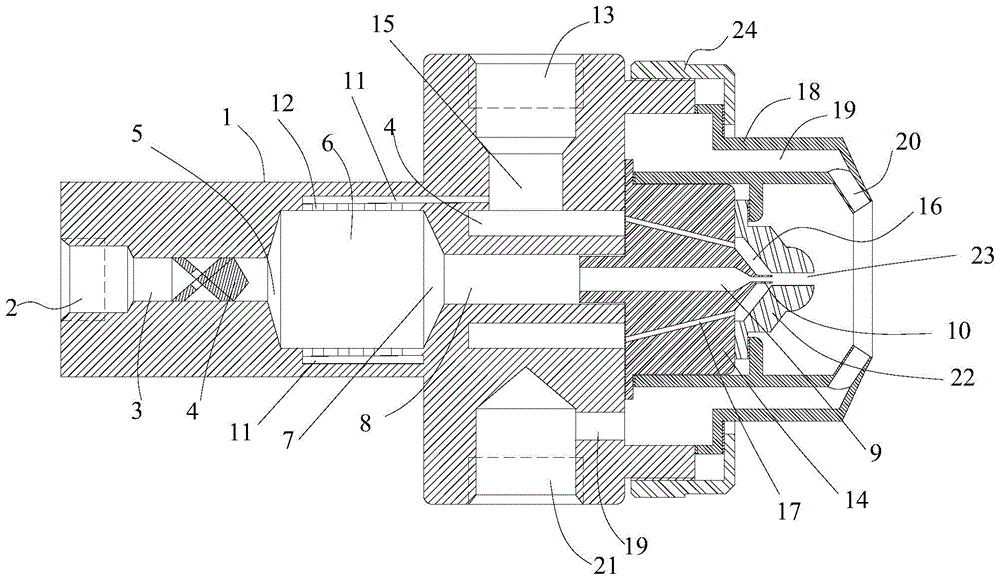

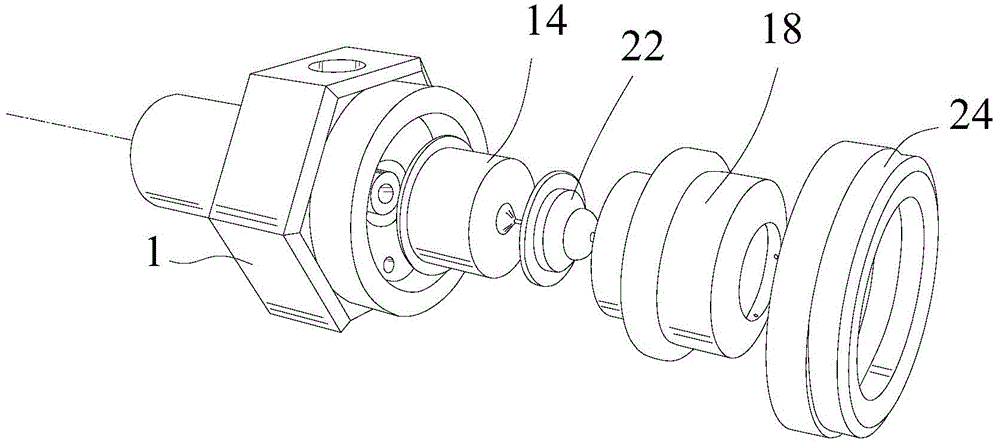

High-low pressure and internal-external hybrid air atomizing nozzle

ActiveCN104874498AImprove the effect of dust suppressionIncrease the fog angleLiquid spraying apparatusWater flowSpray nozzle

The invention discloses a high-low pressure and internal-external hybrid air atomizing nozzle. According to the invention, the first atomization process includes the following steps: water flows enter via a water inlet, and begin to rotate at a high speed after passing by a rotation core; the water flows then enter an atomizing chamber via a variable diameter structure, encounter gas which is sprayed from a low pressure through hole, and are impacted and fragmented into a mixture of gas and water, thus completing the first atomization. A second atomization process includes steps that: the mixture of gas and water enters a nozzle core, then is sprayed out together with the gas which is sprayed out from a low pressure nozzle channel, and subsequently encounters air at an outlet, thus completing the second atomization process. A third atomization is achieved when a high pressure nozzle channel impacts the sprayed-out water mist at with a high pressure and has the water mist fragmented and atomized. The three atomization processes make full use of the gas which is supplied at a low pressure ranging from 0.3 MPa to 0.5 MPa in shearing and fragmenting the water flows, and of the gas which is supplied at a high pressure gas ranging from 1MPa to 1.5MPa in further decreasing a particle size and increasing atomizing angles, which results in the super-fine water mist with an average particle size smaller than 20 [mu]m, an atomization angle up to the range from 115 DEG to 135 DEG, and an efficient ejection range of 7-10 m.

Owner:SHANDONG UNIV OF SCI & TECH

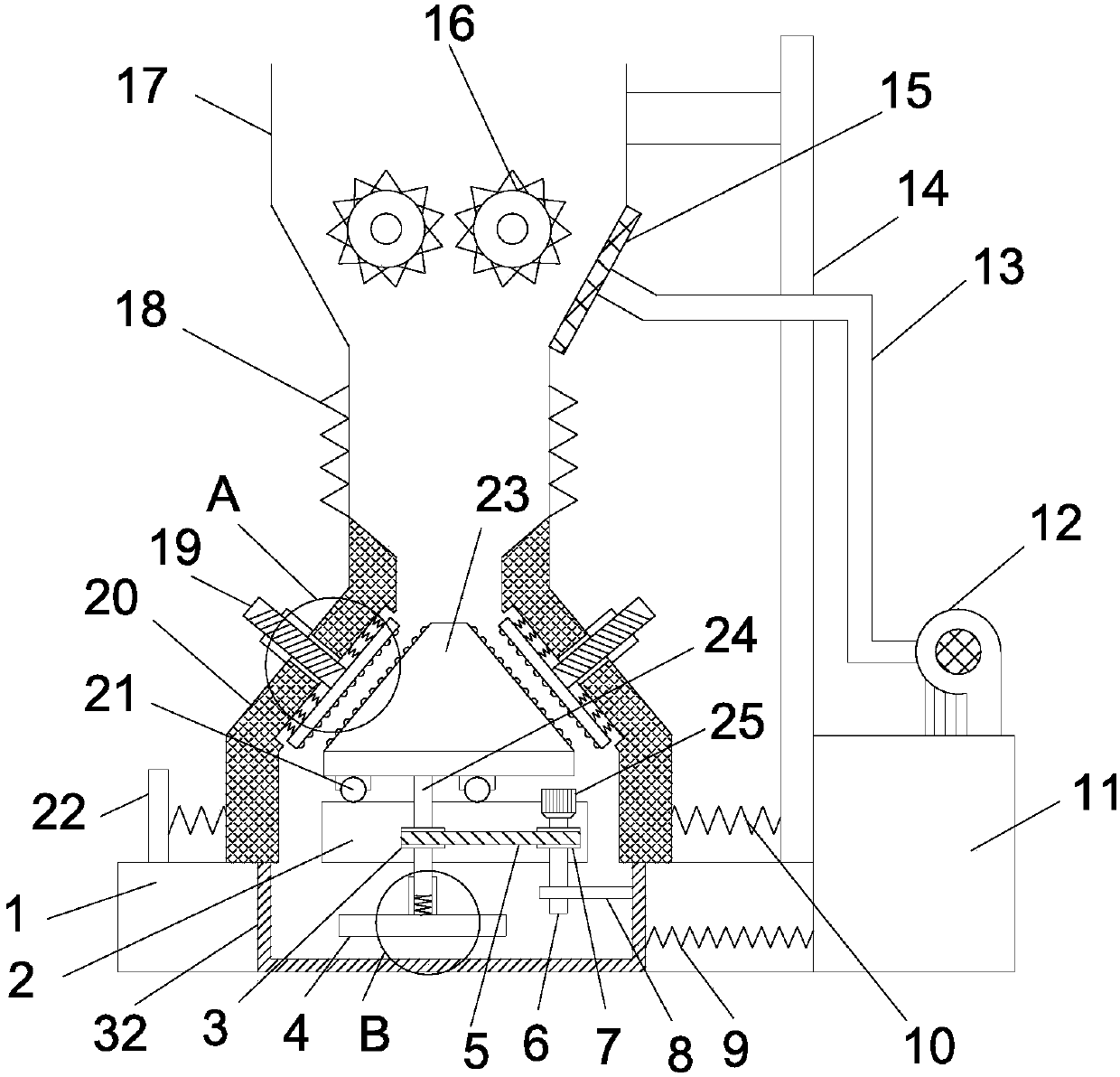

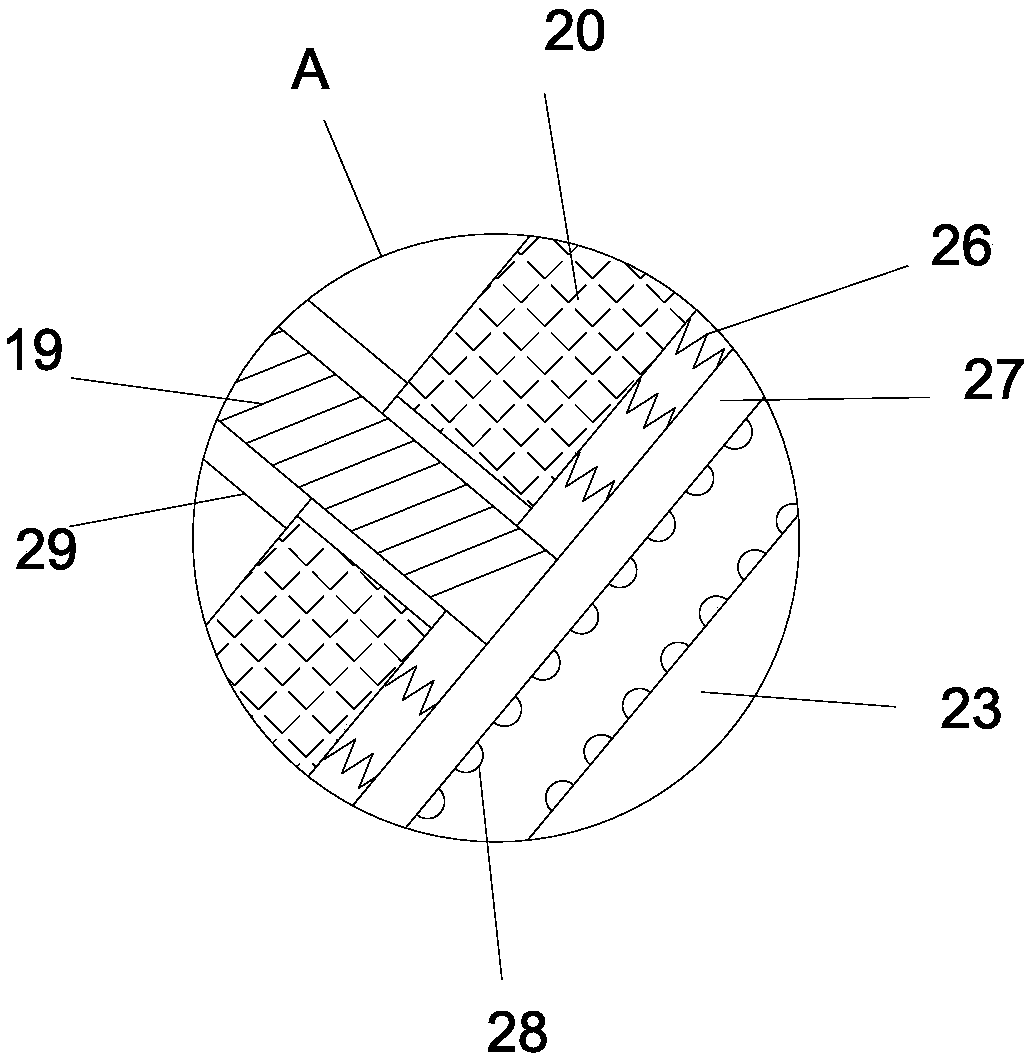

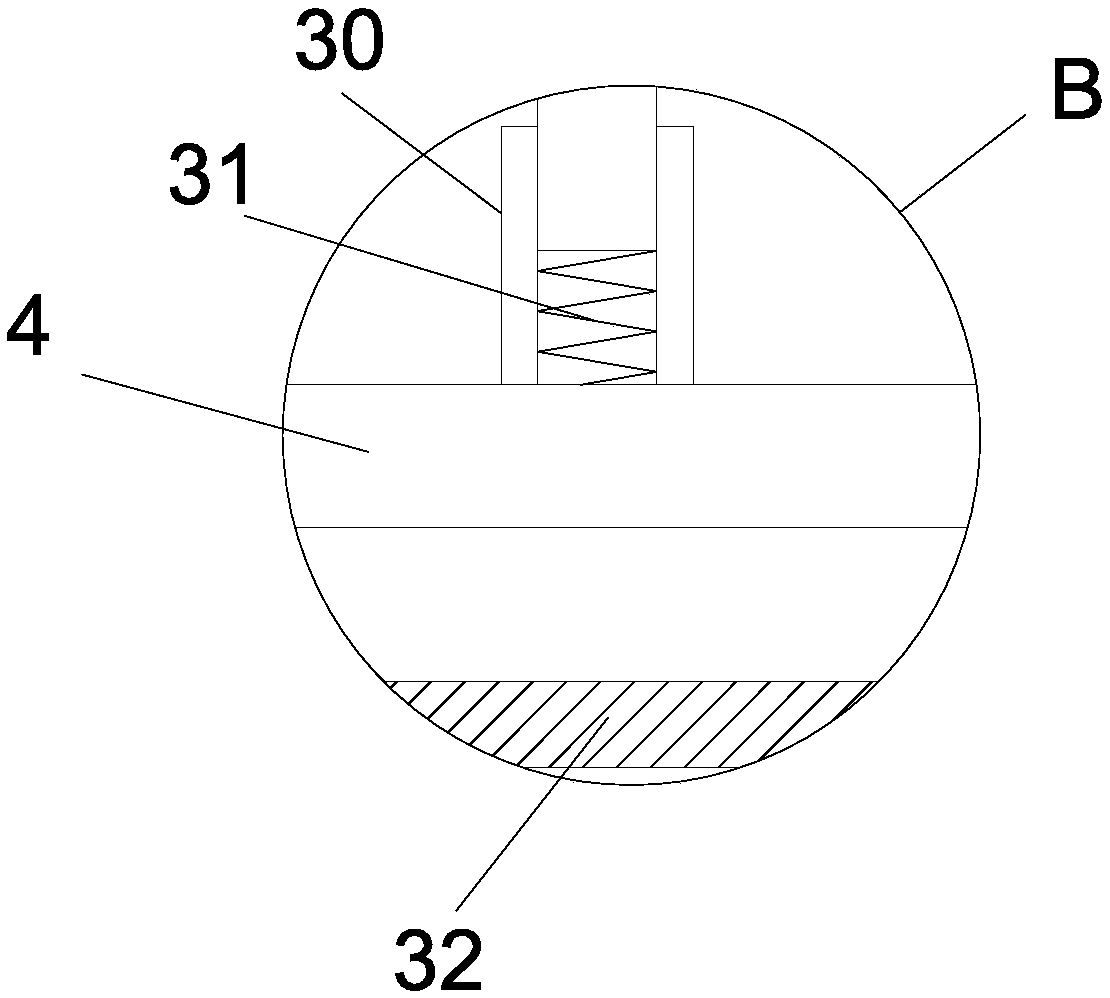

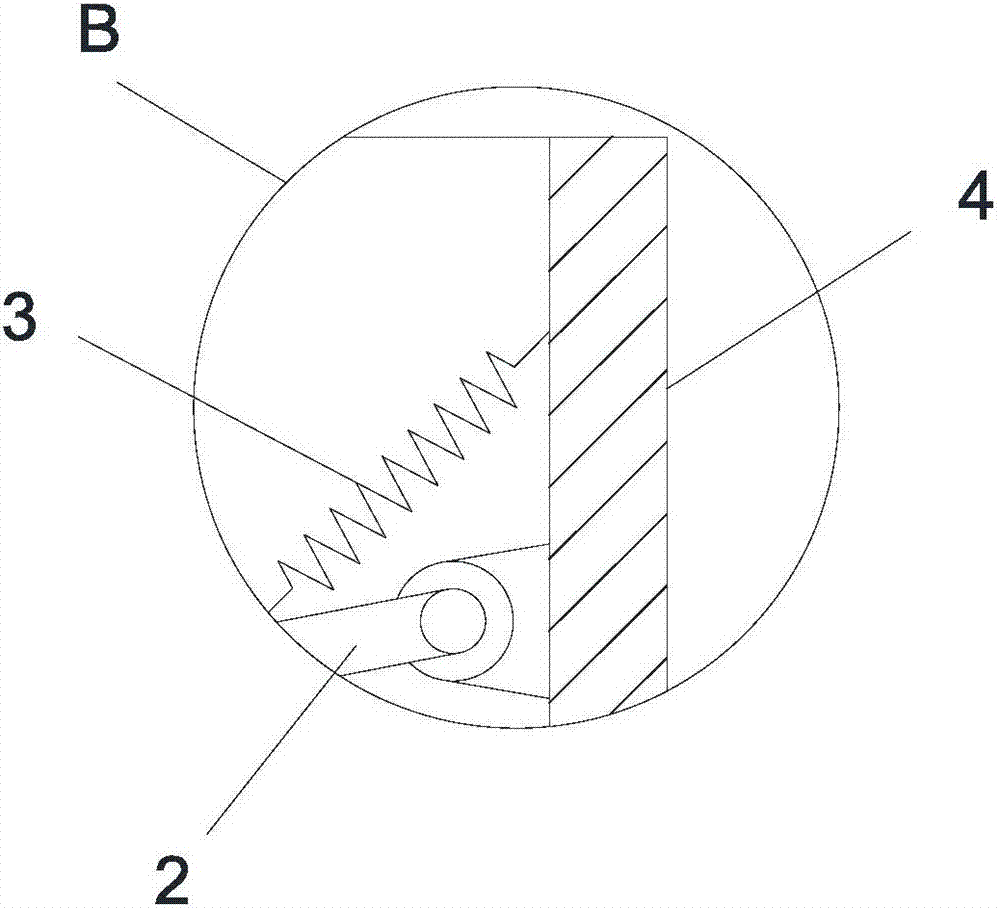

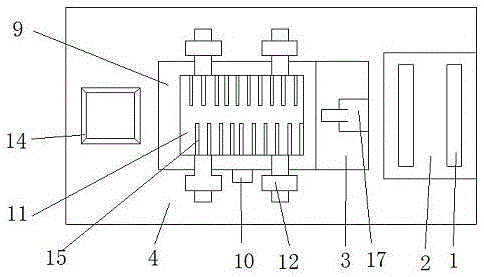

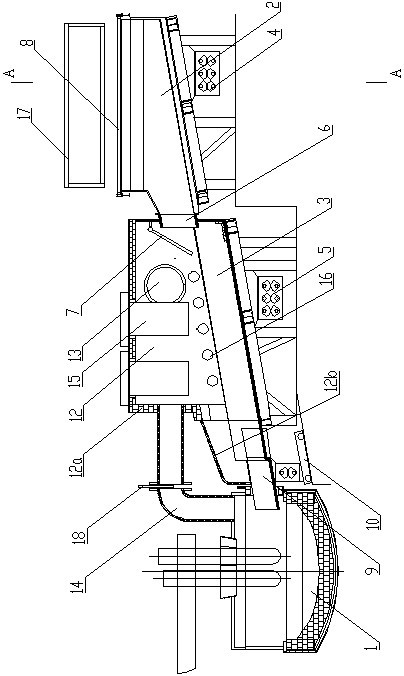

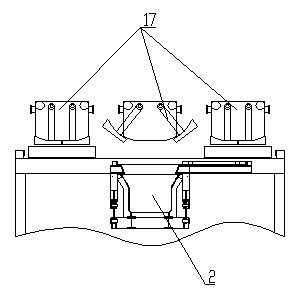

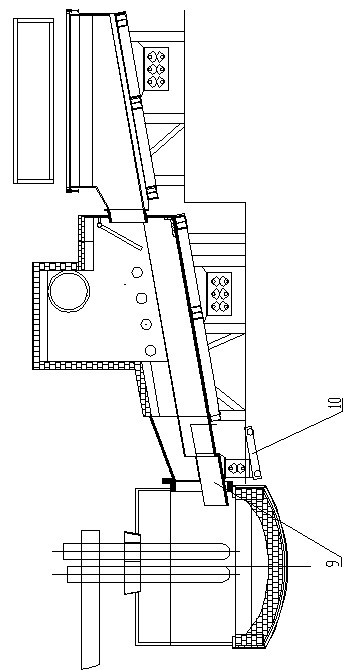

Eccentric rotary cone type stone crushing device for mineral processing

InactiveCN107552138AIngenious structureReasonable designDirt cleaningGrain treatmentsAbsorption effectEngineering

The invention discloses an eccentric rotary cone type stone crushing device for mineral processing, which comprises a bottom box with a hollow structure inside the bottom box, and a grinding basket is horizontally slidable inside the bottom box, and a grinding basket is connected with the inner wall on the right side of the bottom box. The first return spring, the driven shaft is rotated in the bearing table, the driven shaft is provided with a driven pulley, the driven shaft extends into the grinding basket, and the side wall of the conical cover plate is slidingly provided with thread positioning The inside of the grinding basket is connected to the flexible bellows through the channel formed by the bearing platform, the crushing cone and the conical cover plate; the design of the invention is reasonable, and the distance between the pressing plate and the crushing cone can be adjusted according to the specific ore size. The adjustment is stronger, the eccentrically set driven shaft drives the crushing cone to rotate, and the conical cover plate can move left and right under the action of the second return spring, which has a good buffering and shock absorption effect and prevents the ore from crushing the cone Stuck, greatly reducing the failure rate and improving work efficiency.

Owner:浙江燕思志网络科技有限公司

Coal dust suppression agent and method of preparing the same

InactiveCN101508884ALow costEasy to operateOther chemical processesLoading/unloadingCarboxymethyl celluloseSocial benefits

The invention relates to a coal dust suppression agent and a preparation method thereof. The coal dust suppression agent comprises 0.5-1.5wt% of sodium carboxymethyl cellulose, 0.5-1.5wt% of sodium carboxy nethyl, 0.1-0.3wt% of glycerol and 96.7-98.9wt% of water. The coal dust suppression agent can be mixed at normal temperature without needing any other warming-up devices; after being mixed at the normal temperature, the coal dust suppression agent is sprayed or coated on the coal of carriage, so that a solidifying layer is formed on the coal, and dust pollution along the line and dust loss of the coal when in the railway transport can be avoided. Furthermore, the coal dust suppression agent does not cause environmental pollution, and has great economic benefit for railway transport and coal customer as well as social benefit for environmental protection. The method of the invention is simple in operation, low in cost and good in dust suppression effect.

Owner:BEIJING UNIV OF CHEM TECH

Colorful environment-friendly dust suppressant and preparation and use methods thereof

ActiveCN106928901AImprove the effect of dust suppressionImprove permeabilityOther chemical processesEmulsionPreservative

The invention discloses a colorful environment-friendly dust suppressant and a preparation method and a use method thereof, which belongs to the field of environment-friendly dust suppression. The colorful environment-friendly dust suppressant contains the following components in percentage by weight: 1.0-10% of modified cellulose, 0.1-5% of emulsion, 0.01-0.5% of a wetting agent, 0.2-15% of antifreeze humectant, 5-30% of pigment and filler, 0.1-0.5% of a preservative, and the balance of water. The colorful environment-friendly dust suppressant disclosed by the invention has the following advantages: the sources of raw materials are wide, the use is convenient, the dust suppression and encrustation effects are good, and the dust suppression construction region management is convenient.

Owner:山东润涵新材料科技有限公司

Power plant coal conveying system environment-friendly type composite dust depositing agent

The invention discloses a power plant coal conveying system environment-friendly type composite dust depositing agent, which comprises the following components by weight: 20-40% of surfactant, 1-20% of coagulation agent, 30-40% of moisture absorbent, 0.1-1% of antifoaming agent and the balance of water. The dilution proportion of the dust depositing agent can be freely adjusted between 1: 200 and 1: 2000, dust depositing can be rapidly realized, and reentrainment of dust can be avoided in a long time.

Owner:SHANGHAI YICHEN AUTOMATION TECH

Compound dust suppression agent for coal mine and preparation method of compound dust suppression agent

InactiveCN102465711AGood dust suppression effectWide range of raw materialsDust removalFire preventionAluminium chlorohydrateRespirable dust

The invention discloses a compound dust suppression agent for a coal mine and a preparation method of the compound dust suppression agent. The compound dust suppression agent comprises the following components in percent by mass: 0.05-1.00 percent of fatty alcohol-polyoxyethylene ether (JFC), 0.05-1.00 percent of sodium dodecyl benzene sulfonate (SDBS), 0.01-0.50 percent of polyacrylamide (PAM), 0.02-0.50 percent of polymeric aluminium (PAC) and the balance of water. The compound dust suppression agent disclosed by the invention has the advantages that the components are water-soluble materials, can be directly sprayed by using the original water spraying system of the mine, have wide sources, do not generate any harmful gases, and are non-toxic and tasteless; and the compound dust suppression agent is convenient for construction, and has better dust suppression effect of respirable dust in comparison that of the prior art.

Owner:SHANDONG UNIV OF SCI & TECH

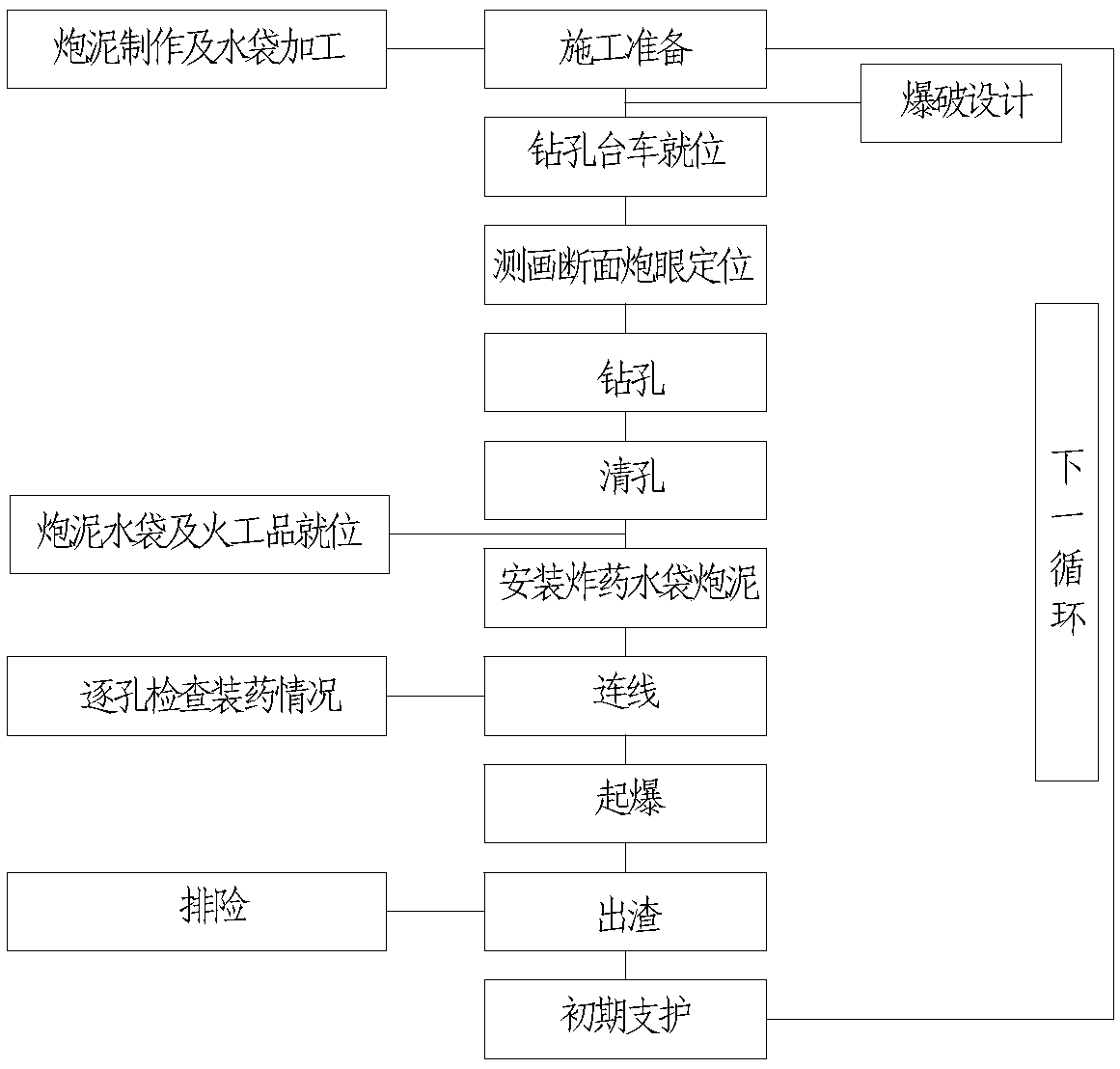

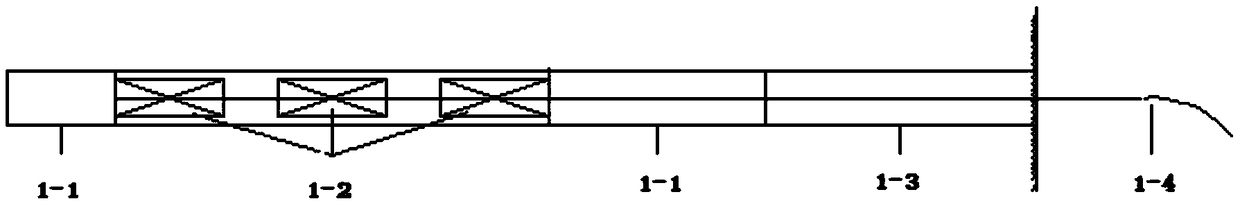

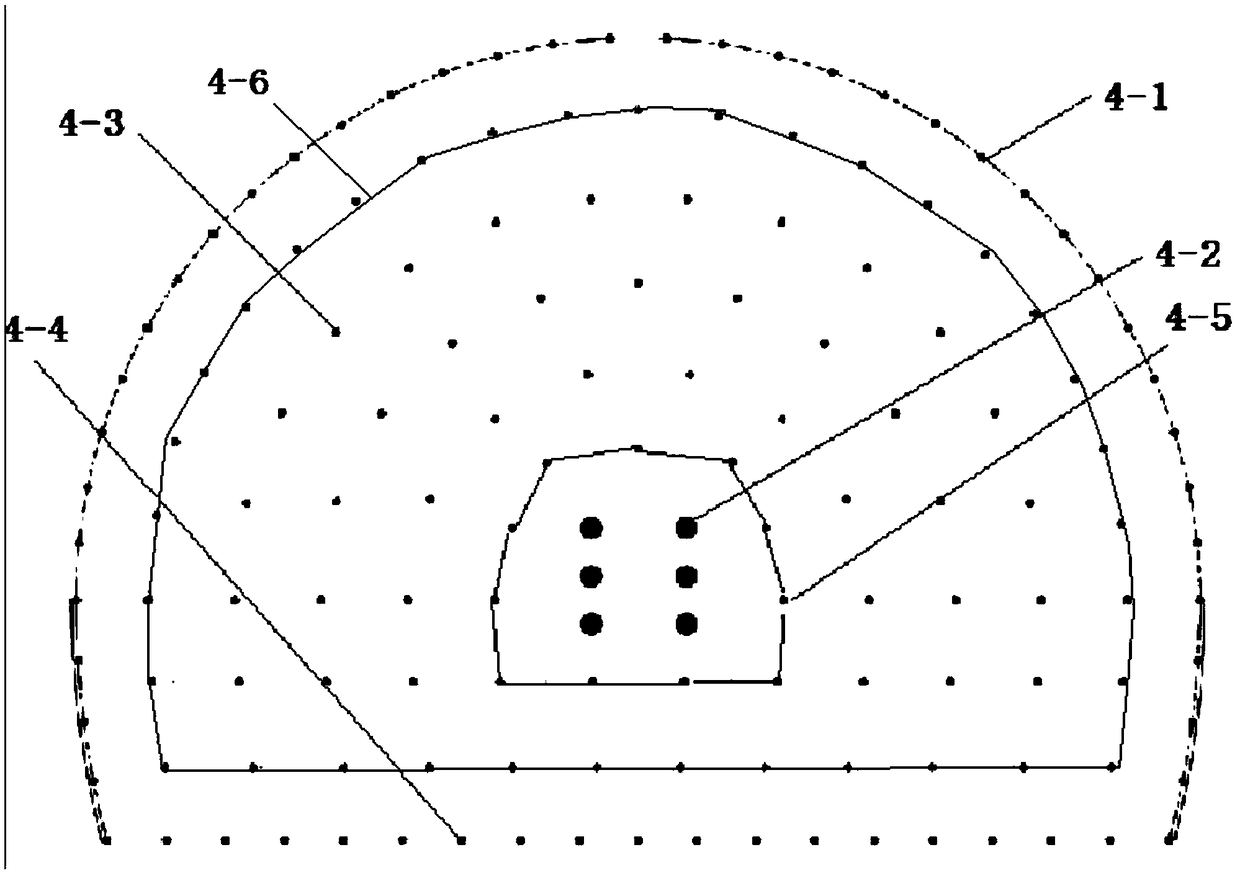

Tunnel excavation water pressure blasting construction method

InactiveCN109373840AImprove the construction environmentIncrease profitBlastingTunnelsGeomorphologyDetonation

The invention discloses a tunnel excavation water pressure blasting construction method. The tunnel excavation water pressure blasting construction method comprises the following steps of (1) arranging a trolley in place and conducting danger elimination; (2) measuring, distributing and drilling holes; (3) installing explosives, water bags and stemming, wherein the peripheral holes are excavated on the arc edge of the tunnel face of a tunnel, and the explosives, the water bags and stemming are installed in the following manners of air spacing, decoupling charge and the explosive quantity at hole bottoms more than that of other parts; cut holes are drilled in an inclined mode, and the included angle between the cut holes and the excavation face is 65 degrees-75 degrees; the continuous coupling charge method is adopted for loosening holes, relief holes, inner ring holes and bottom plate holes, blasting caps are buried into hole bottom cartridges, and energy gathering holes face orifices;the water bags are arranged at the hole bottoms of shot holes, and the water bags are arranged again after completion of explosive charging, and the holes are blocked through the stemming; (4) detonating a detonating network; (5) conducting after-detonation check and misfire processing; and (6) withdrawing the explosives to the warehouse. Through the tunnel excavation water pressure blasting construction method, the energy of explosives can be made full use of, environmental pollution can be reduced, and the cost can be saved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

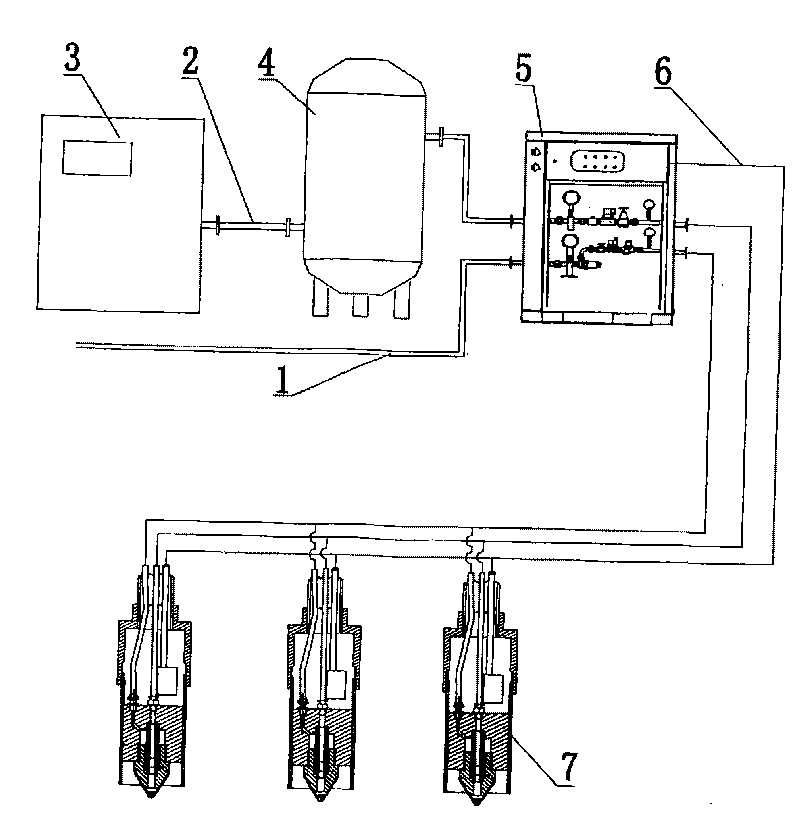

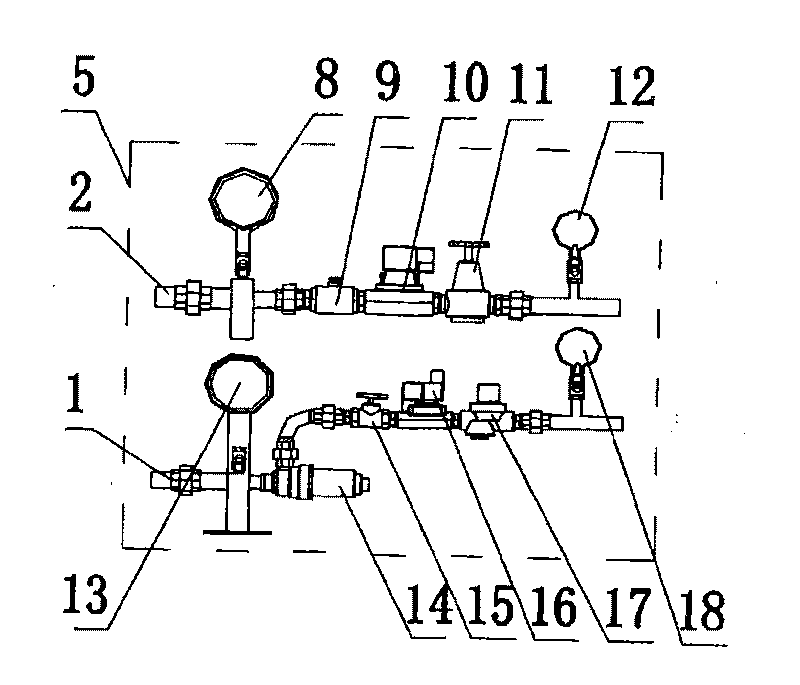

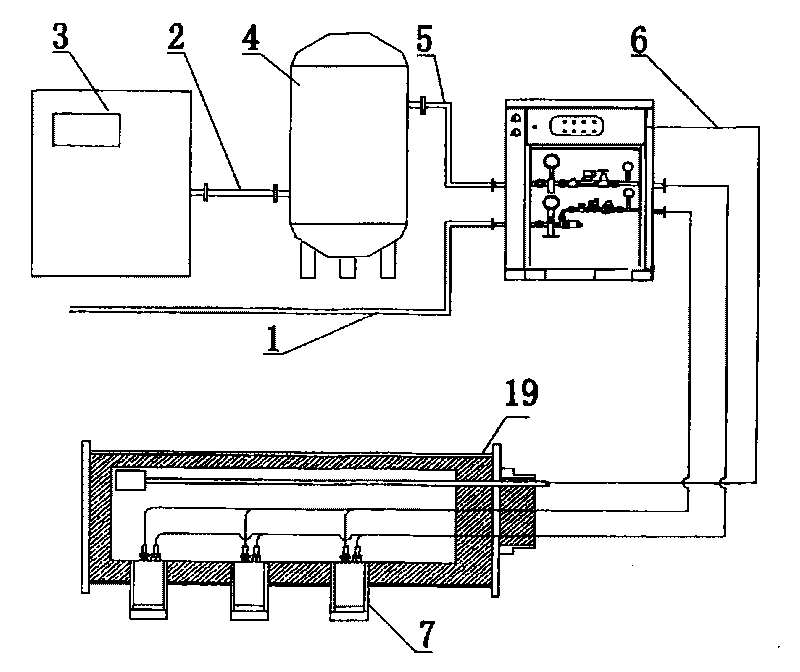

Method and equipment for suppressing dust with dry mist

InactiveCN101757825ASimple system structureLow water consumptionUsing liquid separation agentDirt cleaningElectrical controlSystem structure

The invention relates to a method and equipment for suppressing dust with dry mist. The method for suppressing dust with dry mist is characterized in that a plurality of atomizing nozzles are arranged in parallel on a disorderly discharged dust drift outlet of a dust generation point and are used for spraying the dry mist having the particle size of less than 10 Mum and making the sprayed dry mist form into a dry mist curtain to prevent the dust generated in the dust generation point from diffusing outwards to pollute the environment. The equipment for suppressing dust comprises a water supplying pipeline, an air supplying pipeline, an air compressor, an air storage tank and a control box. The air supplying pipeline, the water supplying pipeline and an electrical control pipeline which are led out of the control box are respectively connected with the air inlets, the water inlets and tracing band inlets of the atomizing nozzles which are arranged in parallel. The micro-size dry mist is sprayed to form a dry mist curtain to suppress dust. The micro-size dry mist spraying system equipment adopts the air compressor to supply compressed air, and the water and the air enter the atomizing nozzles in two branches. The micro-size dry mist spraying system equipment has simple structure, low running cost, wide application range and good dust suppression effect, consumes less water and works stably and reliably.

Owner:QINHUANGDAO CAPITAL STARLIGHT ENVIRONMENTAL TECH CO LTD

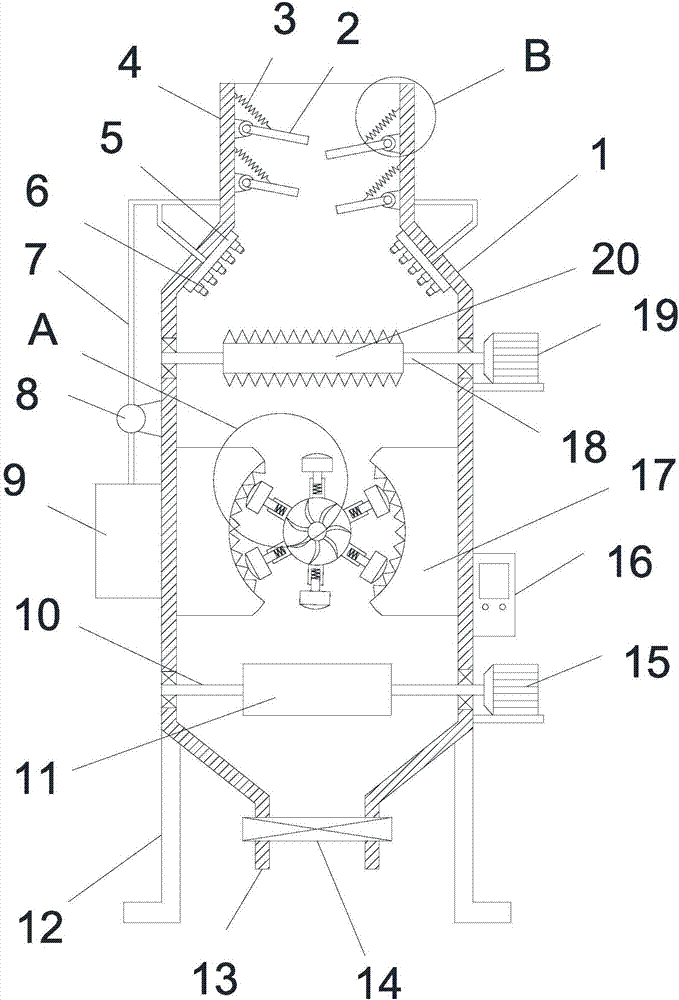

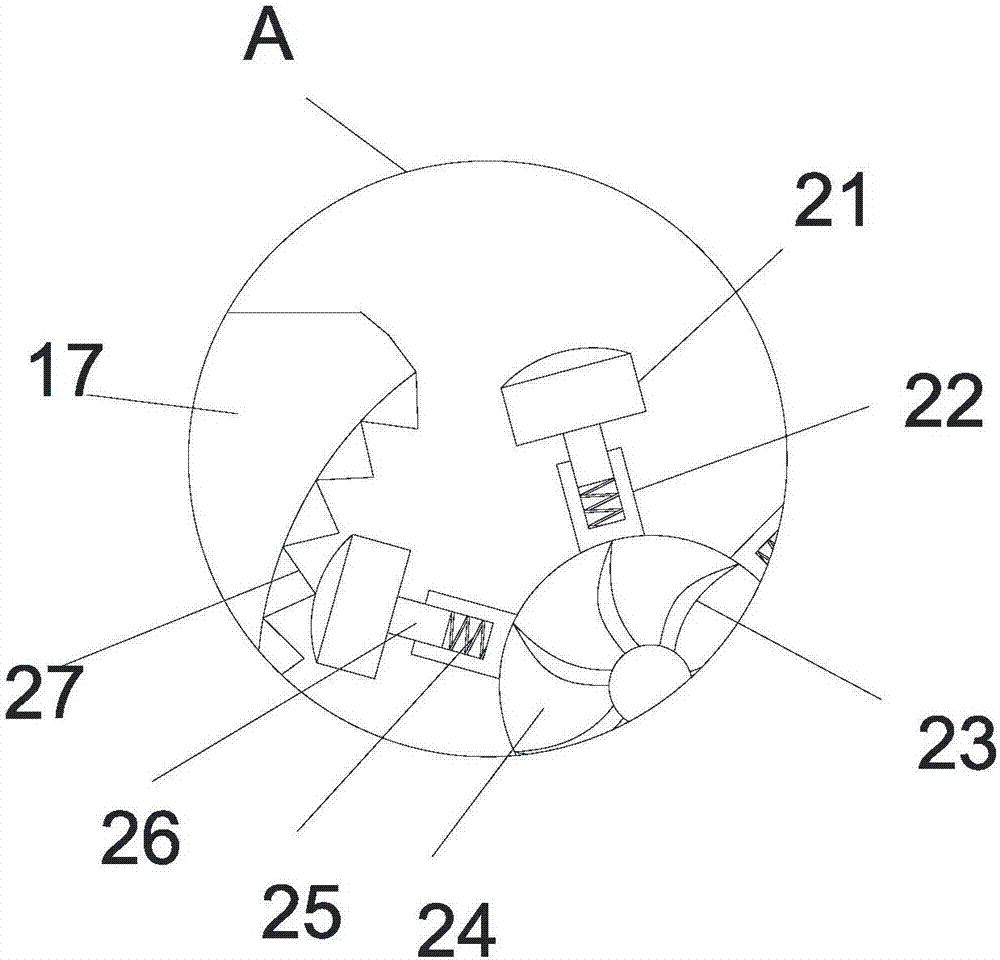

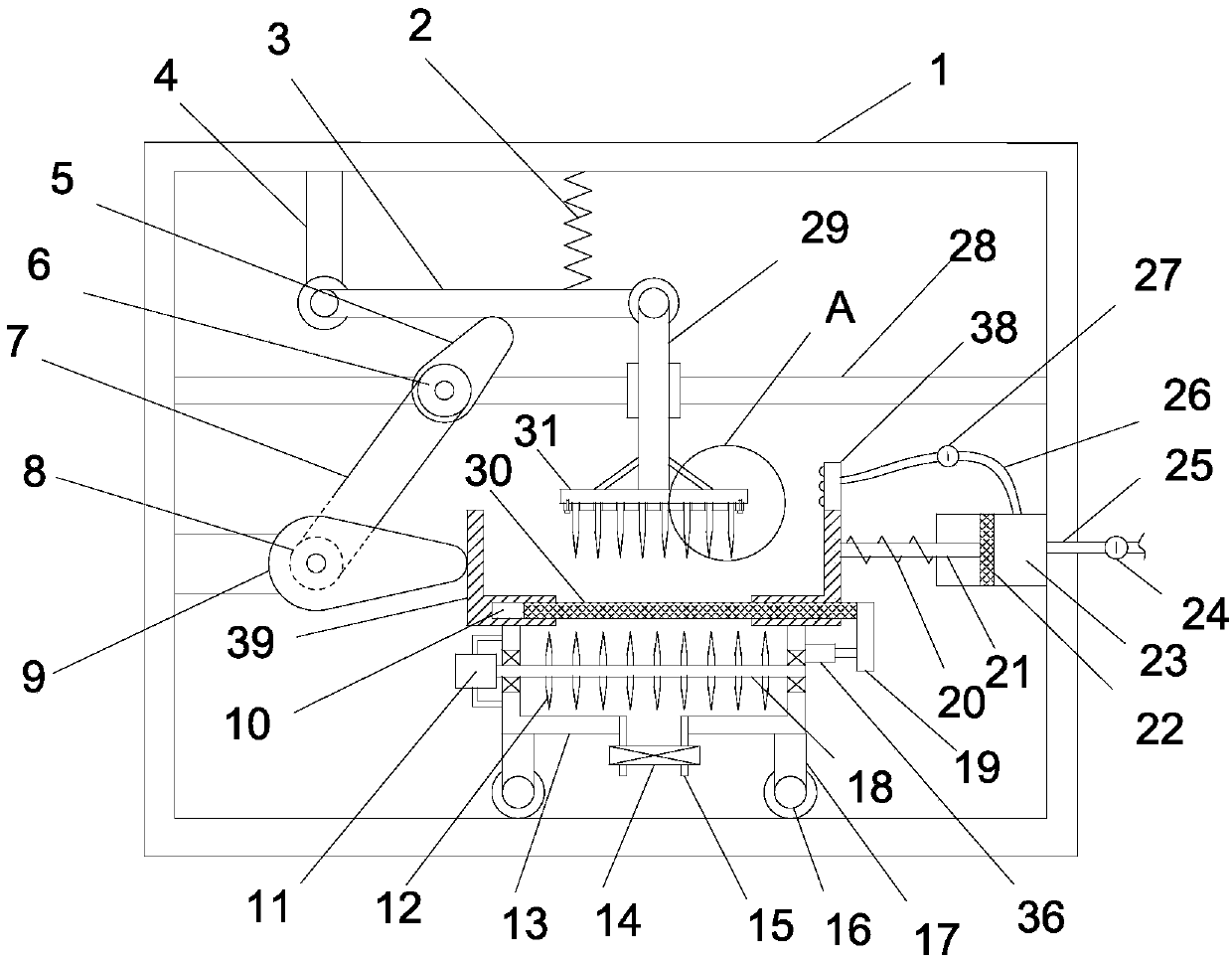

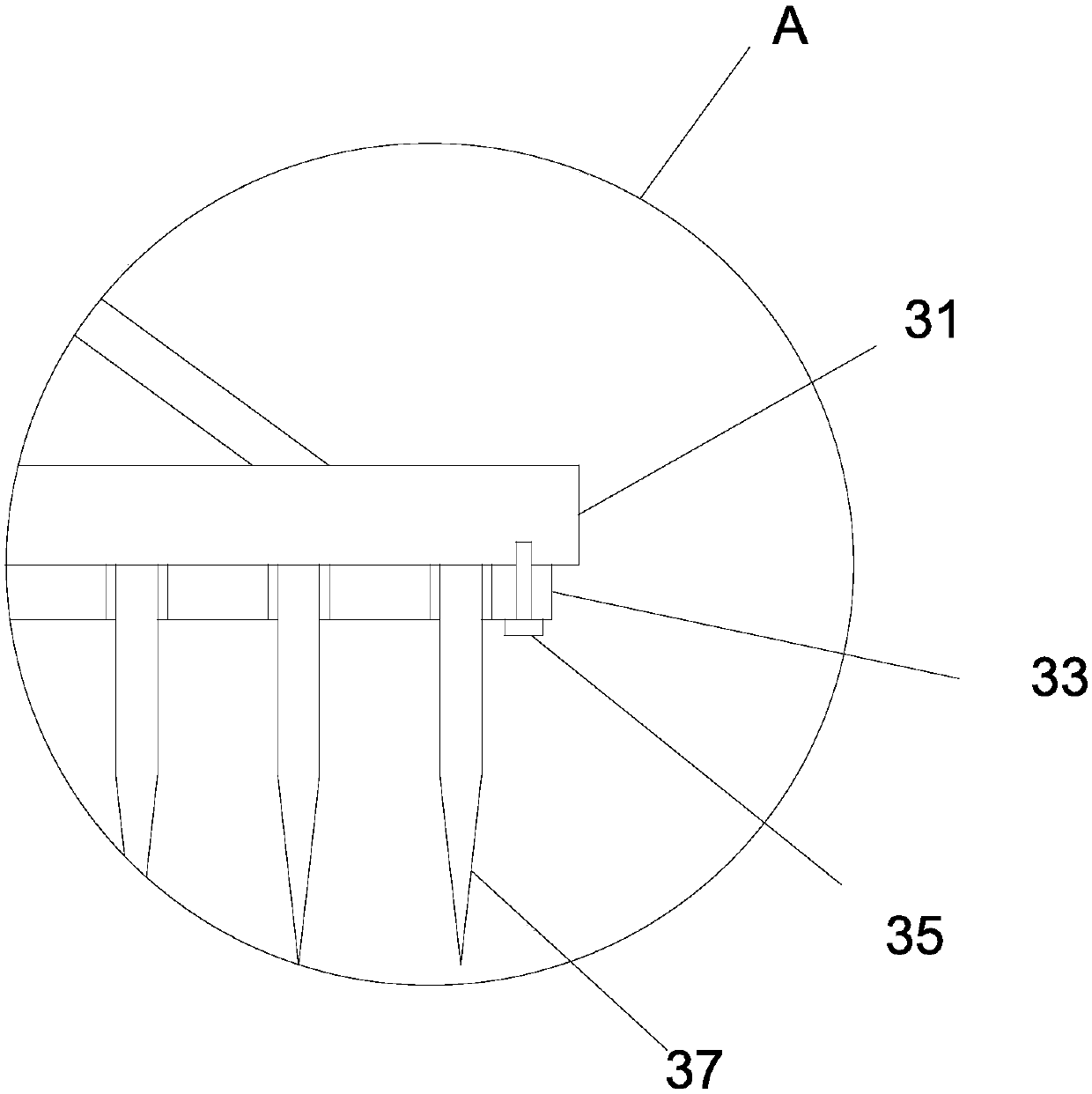

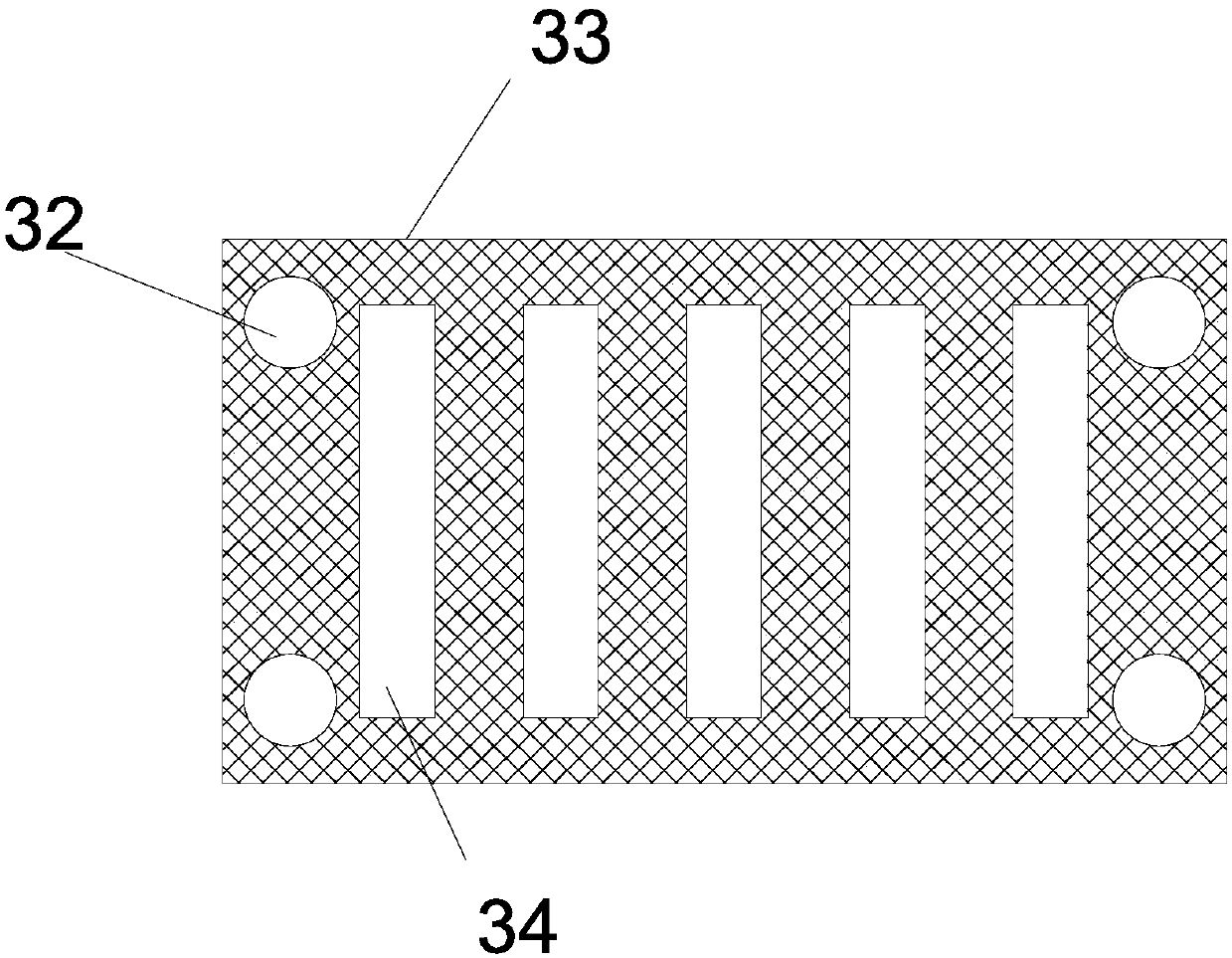

Efficient crushing device for construction waste

InactiveCN107457030AReduce the impactImprove crushing efficiencyUsing liquid separation agentDirt cleaningFailure rateArchitectural engineering

The invention discloses a high-efficiency crushing device for construction waste, which comprises a crushing box, a feeding pipe is arranged on the top of the crushing box, a water collecting tray is arranged on the inner wall of the crushing box, and several nozzles are uniformly arranged on the surface of the water collecting tray, and the crushing box There is a water tank on the outer wall on the left side, and a catheter is connected between the water tank and the water collection tray, and a water pump is installed on the catheter; the left and right inner walls of the crushing box are symmetrically equipped with limiting extrusion plates, and the sliding device inside the sleeve There is a sliding shaft, a damping spring is arranged in the sleeve, and the crushing pressure head is in contact with the sawtooth; a control box is provided on the outer wall on the right side of the crushing box, and the control box is electrically connected with the electromagnet plate; The crushing efficiency is high and the crushing effect is sufficient; the buffer plate buffers and absorbs the garbage entering the crushing box, reduces the impact on the crushing roller, improves the stability of the device, reduces mechanical loss and failure rate, and avoids construction The concentrated falling of garbage leads to uneven crushing.

Owner:李明超

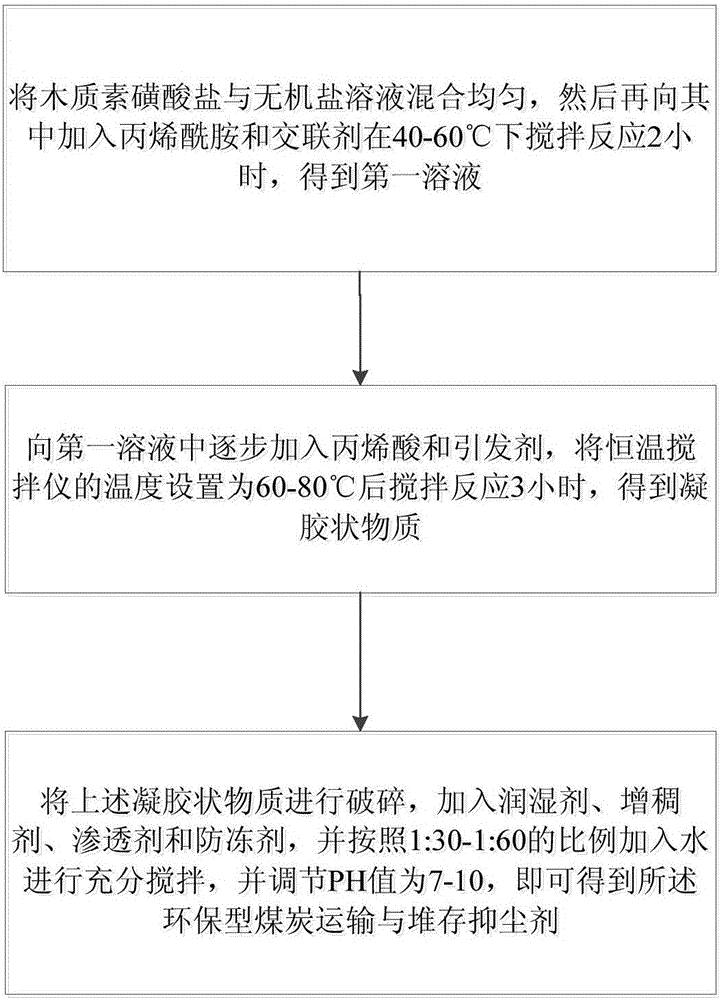

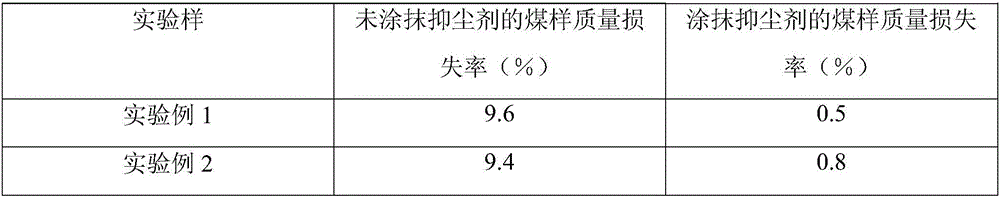

Environmentally-friendly coal transporting and stockpiling dust inhibitor and preparation method thereof

ActiveCN105950116ASuppress flyingImprove wettabilityOther chemical processesInorganic saltsLignosulfonates

The invention discloses an environmentally-friendly coal transporting and stockpiling dust inhibitor and a preparation method thereof. The dust inhibitor comprises, by mass, 5-10% of lignosulfonate, 5-10% of acrylamide, 10-15% of acrylic acid, 0.5-1.4% of a wetting agent, 0.4-0.9% of a thickener, 0.3-0.5% of an osmotic agent, 0.2-0.5% of an antifreeze agent, 0.05-0.1% of an initiator, 0.5-0.8% of a cross-linking agent, 0.2-0.5% of an inorganic salt, and the balance of water. A finally generated gel state substance has an obviously better coal wrapping effect than spraying, and can form a stable protection layer after the gel state substance is sprayed on the surface of coal. The dust inhibitor has the advantages of good wetting effect, fast solidification speed, and large hardness and obvious dust inhibiting effect of the formed protection layer.

Owner:SHANDONG UNIV OF SCI & TECH

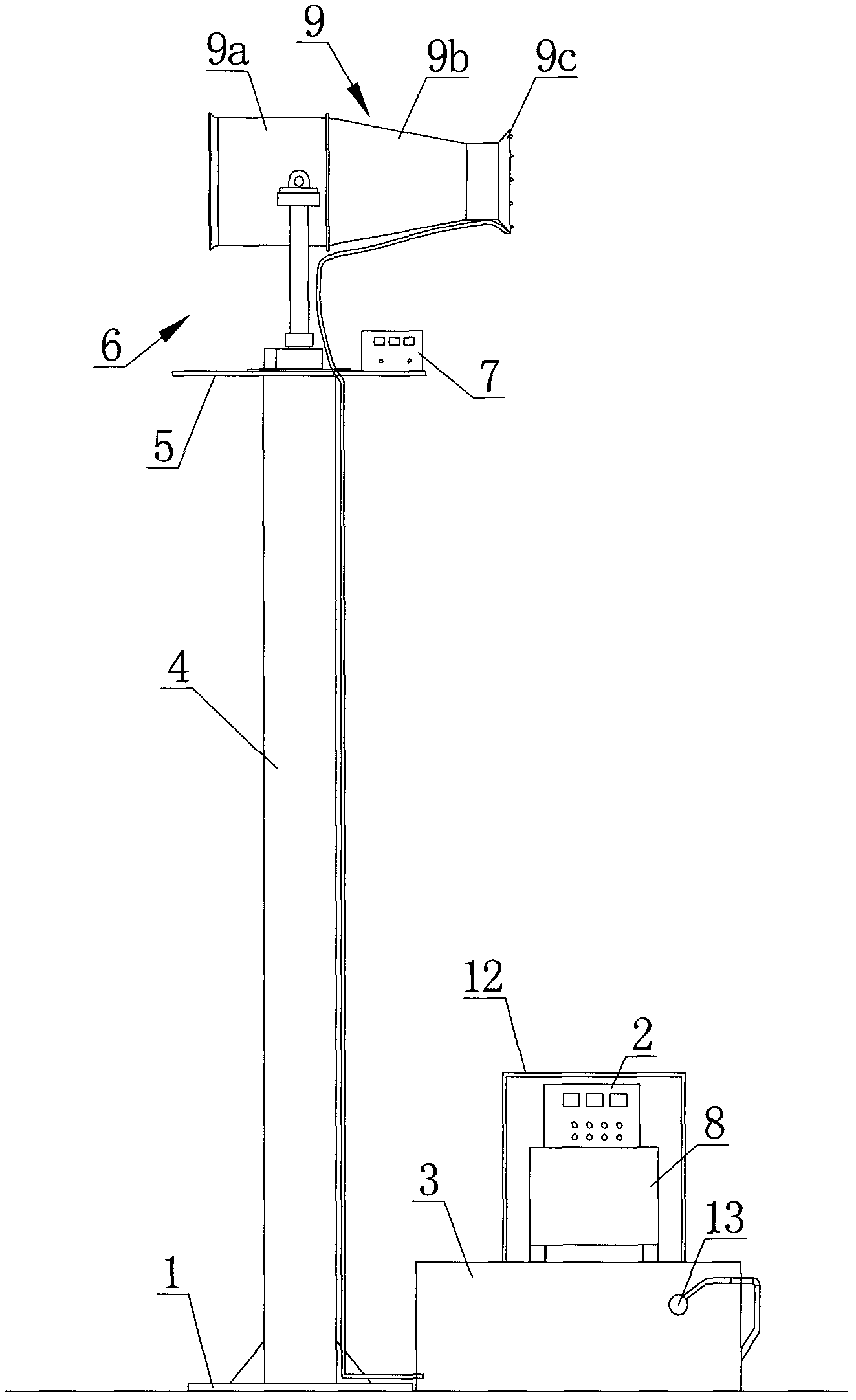

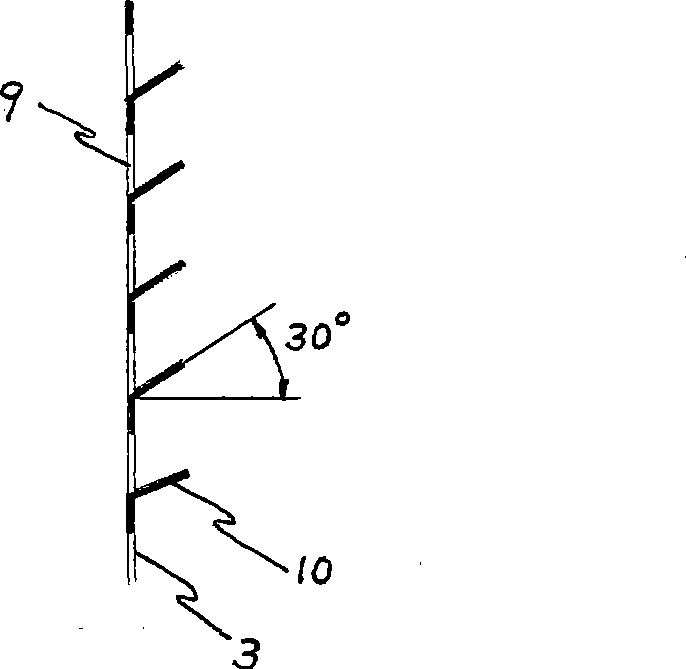

Street lamp pole type water mist dust fall device for controlling PM 2.5 air quality from exceeding standard

InactiveCN102614728AGood dust removalCompact structureUsing liquid separation agentElectrical controlEngineering

The invention discloses a street lamp pole type water mist dust fall device for controlling PM 2.5 air quality from exceeding standard, and belongs to the technical field of dust fall equipment. The street lamp pole type water mist dust fall device has the technical key point of comprising a pole and tower pedestal, wherein an electrical control device and a water tank are arranged on the side edge of the pole and tower pedestal; the pole and tower pedestal is provided with a supporting pole; the top of the supporting pole is provided with a supporting platform; the supporting platform is provided with a water mist dust fall spray mechanism and a PM 2.5 monitoring device; the water mist dust fall spray mechanism is connected with the water tank through a pipeline; the pipeline is provided with a booster pump; and the electrical control device is in circuit connection with the water mist dust fall spray mechanism, the PM 2.5 monitoring device and the booster pump respectively. The invention aims to provide the street lamp pole type water mist dust fall device for improving PM 2.5 air quality from exceeding standard, which has the advantages of compact structure, convenience for use and good dust fall effect; and the street lamp pole type water mist dust fall device is mainly used for control and improvement of PM 2.5 air quality of urban roads.

Owner:广东风华环保设备股份有限公司

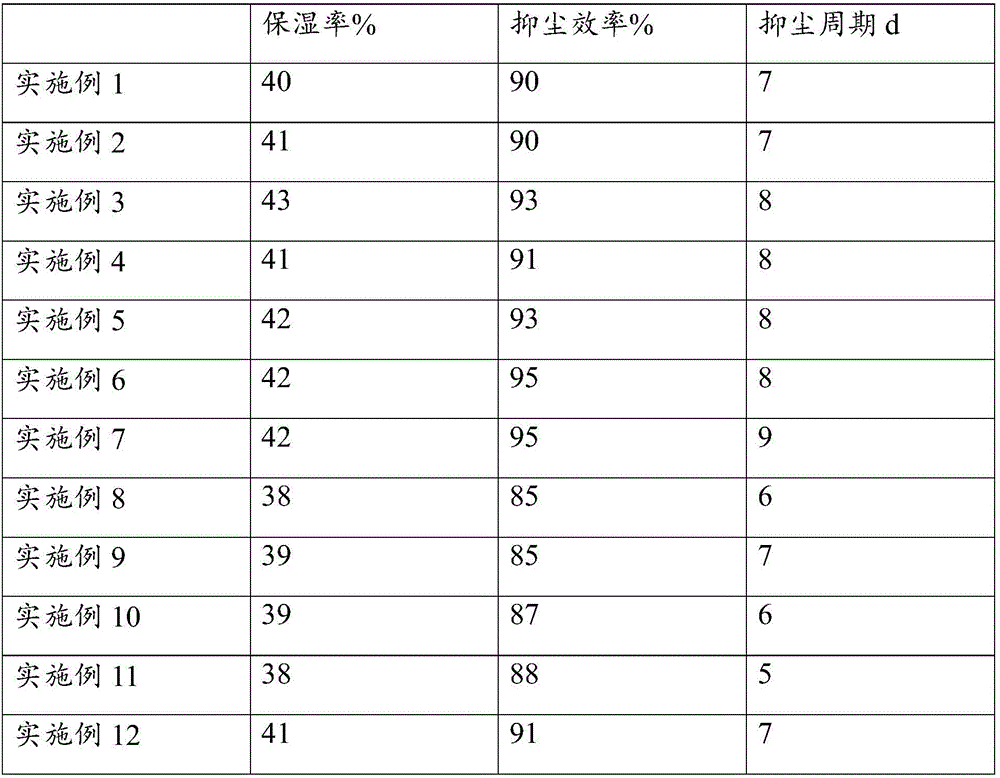

High-efficiency environmental-friendly dust suppressant as well as preparation method and application thereof

ActiveCN106833533AHigh moisturizing rateImprove dust suppression efficiencyOther chemical processesParticulatesPreservative

The invention provides a high-efficiency environmental-friendly dust suppressant as well as a preparation method and application thereof. The high-efficiency environmental-friendly dust suppressant disclosed by the invention solves the problems that the conventional product is single in function, secondary pollution is introduced and the like, has wide application and is particularly applicable to roads with less dust particles, for example, the dust suppressant is used for capturing and adsorbing TSP (Total Suspended Particulates), PM10, PM2.5 and nitric oxides. The high-efficiency environmental-friendly dust suppressant disclosed by the invention is mainly prepared by mixing the following components by weight: 0.1-10% of polyvinyl alcohol, 0.1-5% of sodium silicate, 10-50% of glycerin, 0.01-5% of a surfactant, 0-5% of a preservative, and the balance of water.

Owner:NITTO QINGDAO TECH RES INST CO LTD

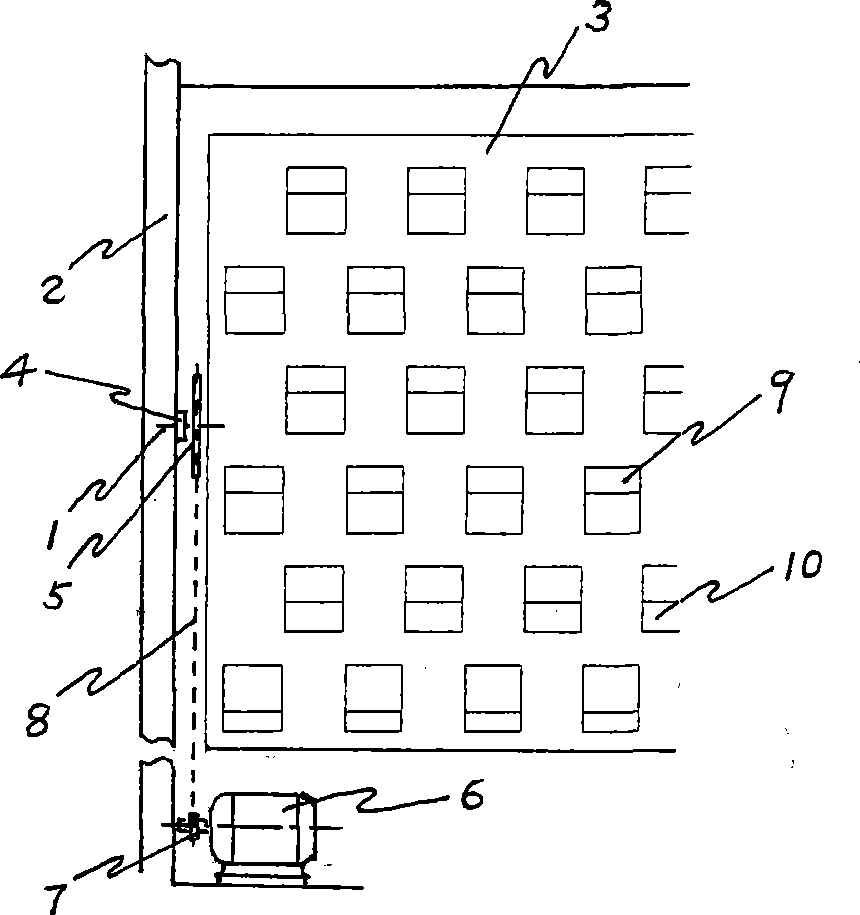

Wind-proof dust-suppression method for open bulk materials stacking field, and its wind-proof dust-suppression net and use

The invention relates to a wind and dust resisting method for an open stacking site of bulk materials, a wind and dust resisting net and the application thereof. The method comprises the following steps: a concrete base is built around the material stacking site; a support steel structure is fixed on the concrete base; the support steel structure is provided with net leaves of the wind and dust resisting net; a main flow wind surface is provided with wind resisting net leaves, and other secondary flow wind surfaces are provided with dust resisting net leaves; the height at which the net leaves are arranged is more than the stacking height of the material stack; the opening ratio of the net leaves is 20 percent to 50 percent and the like. 1 to 3 rows of wind resisting net leaves in the middle of the main flow wind surface are provided with a turnover mechanism. Net holes are long holes or elliptic holes, one side of the net hole is punched into a flanging guide fin which has a certain angle and has guide function. The boundary layer separation, the vortex and the permeation flow are eliminated or reduced effectively, the angle of the dust resisting net can be regulated according to wind directions; and the effect of resisting dust, especially secondary blowing dust can be improved greatly. The invention can be widely applied to the open stacking site of bulk materials in ports, coal mines, coal fired power plants, etc.

Owner:QINGDAO UNIV OF SCI & TECH

Straw crushing device for livestock breeding

InactiveCN107624387AFully crushed and refinedGuaranteed normal cuttingShaking/oscillating/vibrating mixersUsing liquid separation agentSlagScrew thread

The invention discloses a straw crushing device for livestock breeding. The straw crushing device includes an operating room, a horizontal rod is fixedly arranged inside the operating room in a horizontal mode, a sliding rod is arranged penetratingly on the horizontal rod in a vertical sliding mode, the upper end of the sliding rod is connected with the end, away from a hanging rod, of a rotatingplate in a hinged mode, a number of cutting blades are arranged at equal spacing on the bottom of a connecting plate, locking screws are arranged on screw holes in a penetrating mode, and the lockingscrews are connected with the connecting plate in threaded fit; a number of crushing blades are arranged on the surface of a rotating shaft uniformly, and a water inlet pipe connected with an externalwater source is arranged on a water drawing sleeve. The straw crushing device for livestock breeding is ingenious in structure and convenient to operate, and a first crushing effect is achieved through straws receiving the cutting handling of the cutting blade and then receiving the rotary cutting and crushing of the crushing blades, the situation that longer straws clamp crushing blades is avoided, meanwhile the straws receive full crushing refinement, the straws sandwiched between the cutting blades or stuck on the cutting blades can be removed through the removal of a slag filter plate, and the normal cutting of the straws by the cutting blades is ensured.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

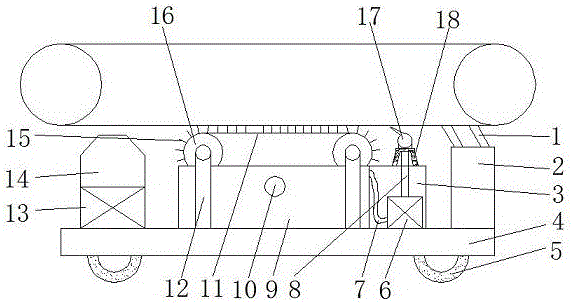

Cleaning device for mining conveyer belt

The present invention discloses a cleaning device for a mining conveyer belt. The cleaning device comprises a cleaning device base. A water tank is mounted in the middle of an upper end of the cleaning device; a support, located at an outer side of the water tank, is disposed in the middle of the upper end of the cleaning device; a driving cleaning wheel is mounted on an upper portion of the support; a water pump, located on a right side of the water tank, is mounted on the upper end of the cleaning device base; the water tank is connected to the water pump by means of a water pipe; a water pump protective rack is mounted at an outer side of the water pump; a sprayer support is disposed on an upper end of the water pump protective rack, and a sprayer for spraying water is disposed on an upper en dog the sprayer support; an upper end of the water pump is connected to the sprayer for spraying water by means of a water outlet pipe; a tool rest is disposed at a right side of the upper end of the cleaning device base; a scraper is disposed on an upper end of the tool rest; an air feeder is disposed at a left side of the upper end of the cleaning device base; and a heating stove is mounted on an upper end of the air feeder. The cleaning device for a mining conveyer belt is capable of well cleaning and drying the mining conveyer belt, and capable of prolonging the service life of the mining conveyer belt.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

Composite dust suppressant, and preparation method and use method thereof

InactiveCN102703031ADust production process is simpleLow costOther chemical processesPolyvinyl alcoholGlycerol

The invention relates to a composite pulverized coal dust suppressant, and a preparation method and use thereof. The composite pulverized coal dust suppressant comprises calcium chloride and sodium silicate with the ratio of two to one, 0.6 to 1.2% of polyvinyl alcohol, 4 to 6% of glycerol, 0.3 to 0.5% of surface active agent and water in balancing amount. The composite pulverized coal dust suppressant has the advantages as follows: all the chosen materials are common materials, which are nontoxic and harmless and can be naturally degraded, so that no secondary pollution can be caused; the preparation process is simple; after the composite pulverized coal dust suppressant is sprayed on the surface of bulk mineral material, a curing layer can be formed on the surface of bulk mineral material; the curing layer can bond grains on the surface of the bulk mineral material together so as to prevent wind and fix dust; therefore, the composite pulverized coal dust suppressant has certain economical and environmental benefits.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

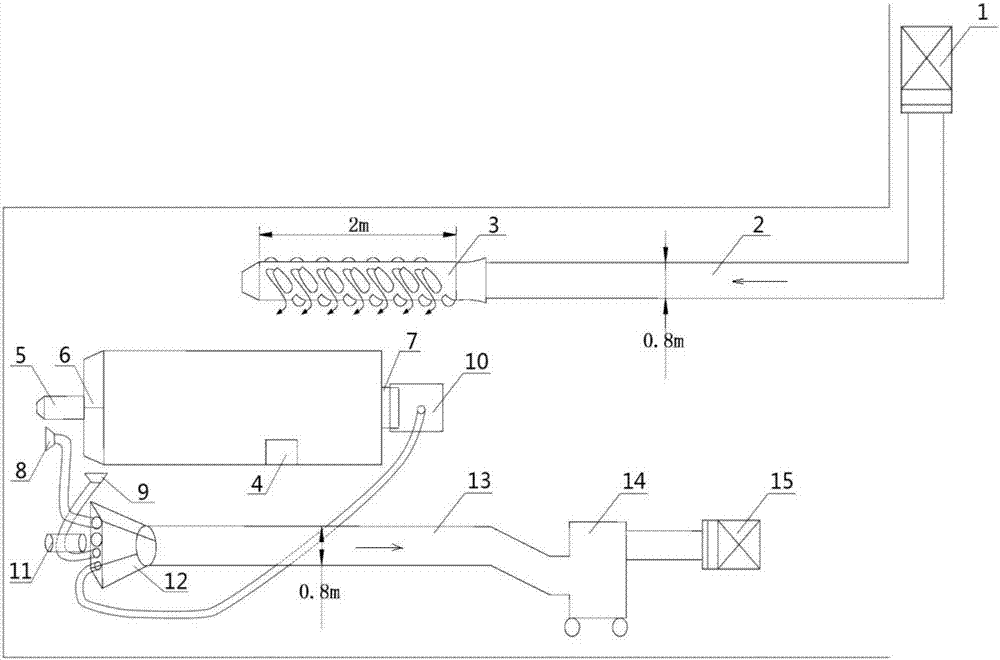

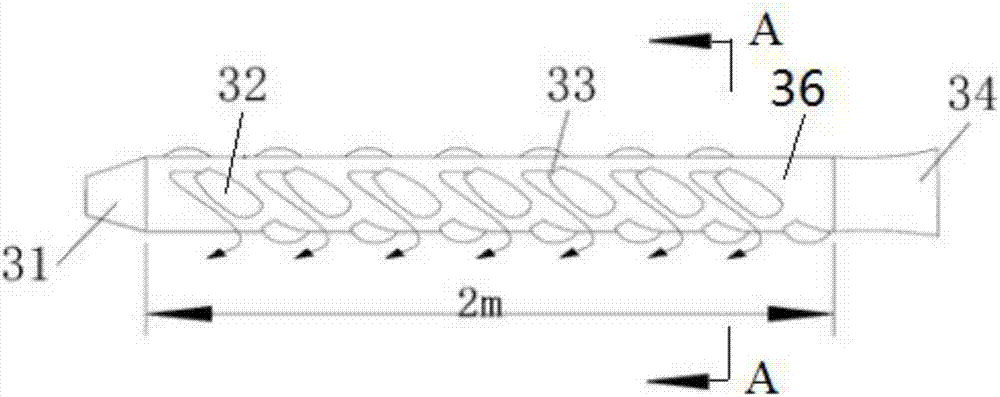

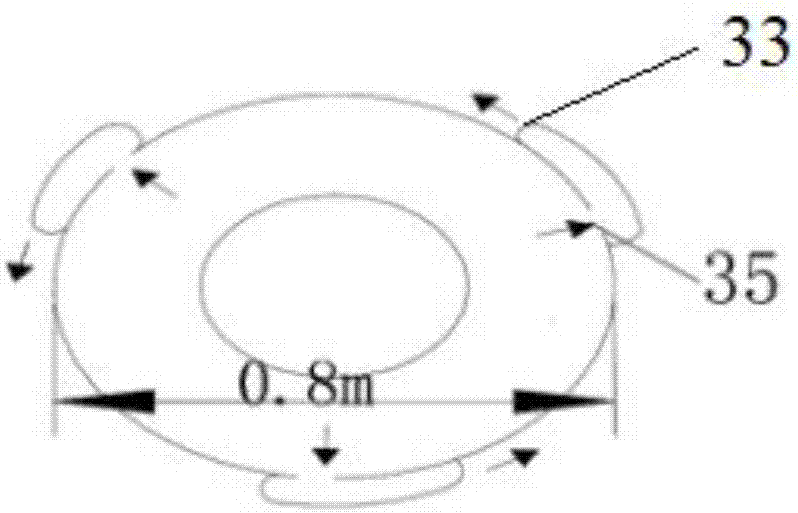

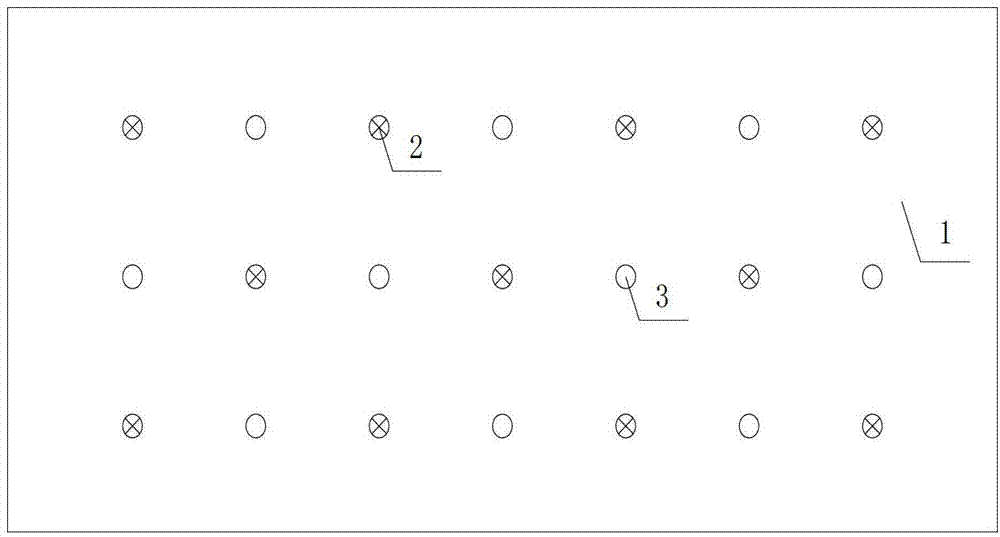

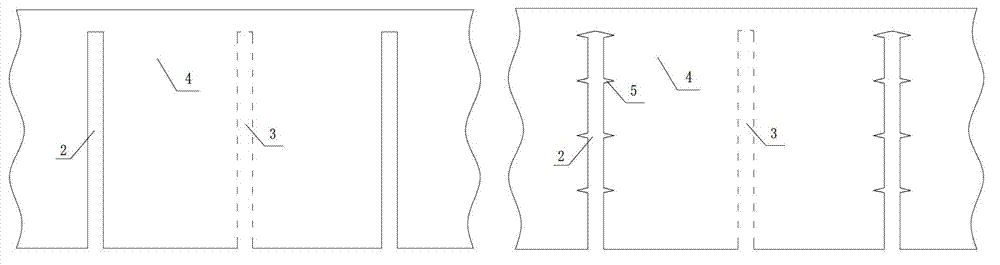

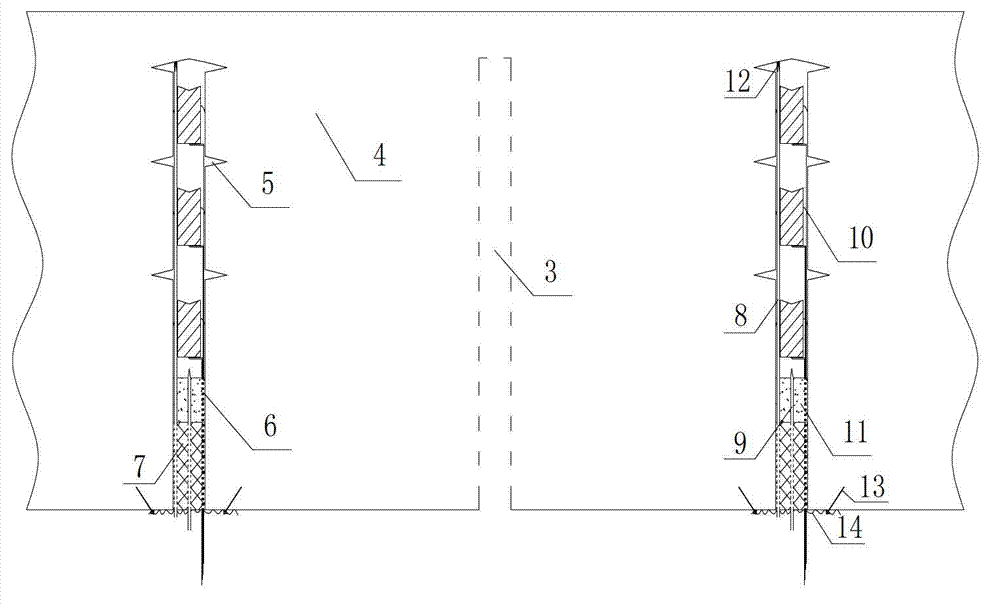

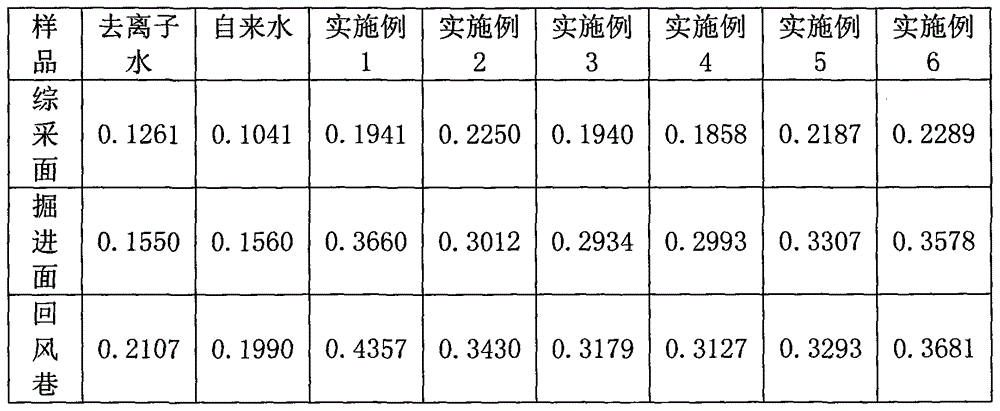

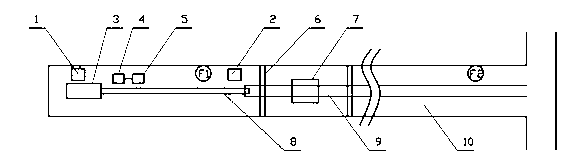

Dust removing system for fully-mechanized coal mining workface

PendingCN107218074AImprove working environmentReduce dust concentrationDust removalFire preventionMining engineeringDust control

The invention discloses a dust removing system for a fully-mechanized coal mining workface. The system includes a dust control system installed on one side of a roadheader, a dust suction system and a dust collecting system installed on the other side of the roadheader, wherein the dust control system comprises a press-in type fan, a press-in type air duct and a wall-attached air duct which are connected with each other in turns; the dust suction system comprises a first suction hood for sucking dust on the cutting head position of the roadheader, a second suction hood for sucking dust on the insertion board position of the roadheader, a third suction hood for sucking dust on the break-of-bulk-point position of a scraper conveyor and belt conveyor, a dust suction air duct and a suction hood assembly box, and the first suction hood, the second suction hood, the third suction hood and the dust suction air duct are all connected to the suction hood assembly box; the dust collecting system comprises an extraction type air duct, a dust remover and an extraction type fan which are connected with each other in turns, and the extraction type air duct is connected to the suction hood assembly box. The dust removing system for the fully-mechanized coal mining workface can effectively control diffusing and spreading of dust in underground roadways, has a good dust suction effect and high dust collecting efficiency, and can greatly reduce the dust concentration of the fully-mechanized coal mining workface.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Hard roof directional pressurized explosion control method

InactiveCN103206903AImprove the utilization rate of explosion energyGood effect of dust suppressionBlastingDrill holeCoal

Disclosed is a hard roof directional pressurized explosion control method. Special drilling arrangement, loading structures and hole sealing manners are selected according to self-conditions of a roof, pressurized explosion transferring media is used to fully expel air in cracks, the characteristics of low compressing performance and high dynamite utilization rate of the pressurized explosion transferring media is utilized to perform directional or non-directional control explosion to slotted drilling holes or complete drilling holes, and expansion and pulse of the pressurized explosion transferring media are utilized for secondary loosening and weakening of surround rock of the drilling holes to accelerate development and penetrating of the roof cracks and strengthen presplitting weakening of the hard roof. The method mainly includes parallelly drilling holes and alternately loading dynamites at intervals; cutting grooves of the drilling holes; and explosion safety protection. The method is convenient to implement, simple to operate, low in cost and wide in application range, and can be popularized in loosening and weakening of common roofs or top coal and coal layers.

Owner:CHINA UNIV OF MINING & TECH

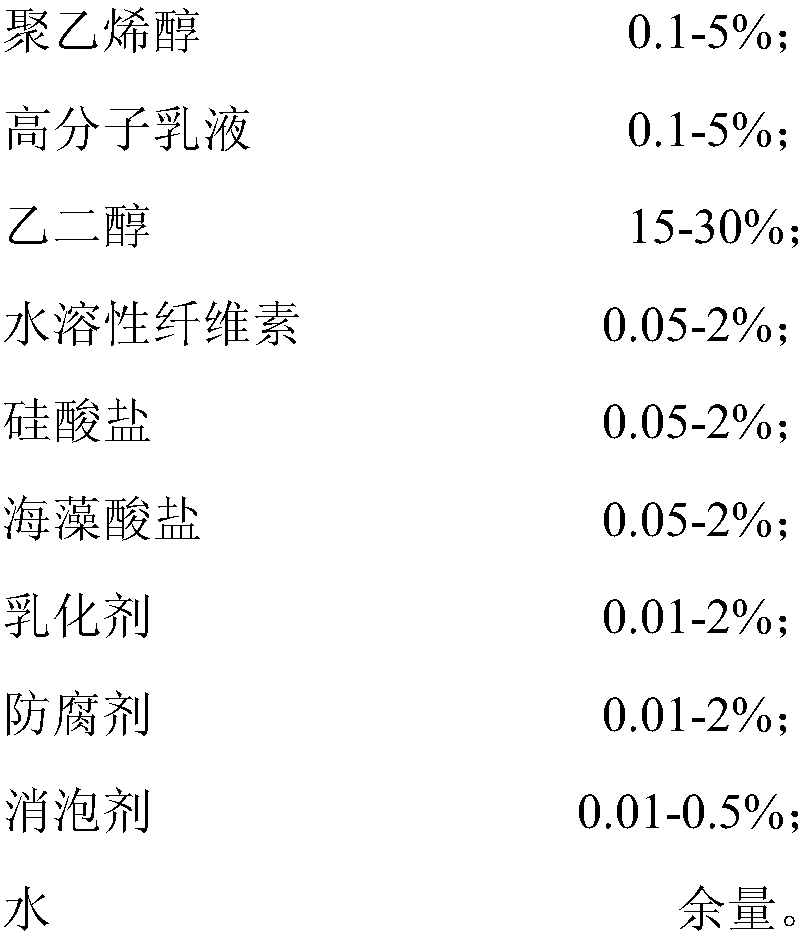

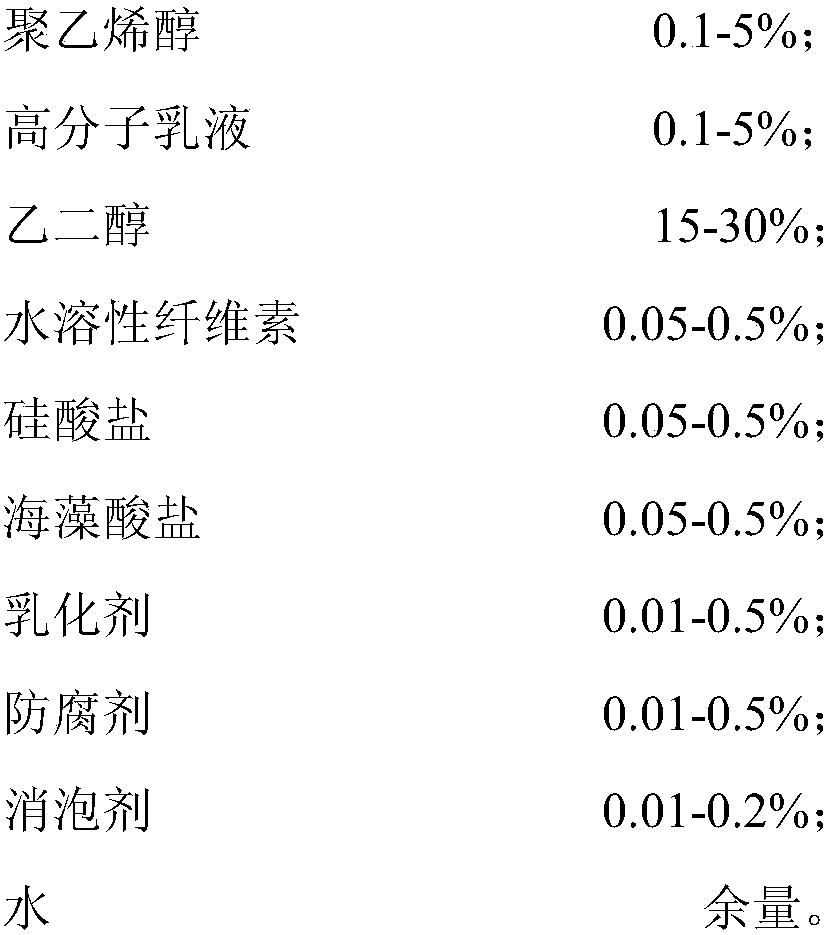

Road dust suppressant as well as preparation method and application thereof

InactiveCN108587568AExcellent overall performanceGood dust suppression effectOther chemical processesChemistryEmulsion

The present invention discloses a road dust suppressant as well as a preparation method and application thereof, and belongs to the field of environmental protection for flying dust prevention and control. The present invention provides a novel road dust suppressant, which comprises the following components in percentage by weight: 0.1-5% of polyvinyl alcohol, 0.1-5% of high-molecular emulsion, 15-30% of ethylene glycol, 0.05-2% of water-soluble cellulose, 0.05-2% of silicate, 0.05-2% of alginate, 0.01-2% of emulsifier, 0.01-2% of preservative, 0.01-0.5% of defoamer and the balance of water. The road dust suppressant of the present invention, with particular components in particular proportions, can meet the standard requirements in tests on physical and chemical indexes and properties, and is safe, environmentally friendly, and very suitable for the control of flying dust pollution of roads such as urban roads, construction roads and the like. Thus, an effective solution is provided for improving the atmospheric environment and reducing the haze pollution.

Owner:BEIJING RUI HONGXING TECH CO LTD

Pollution-free road surface dust depressor and application method thereof

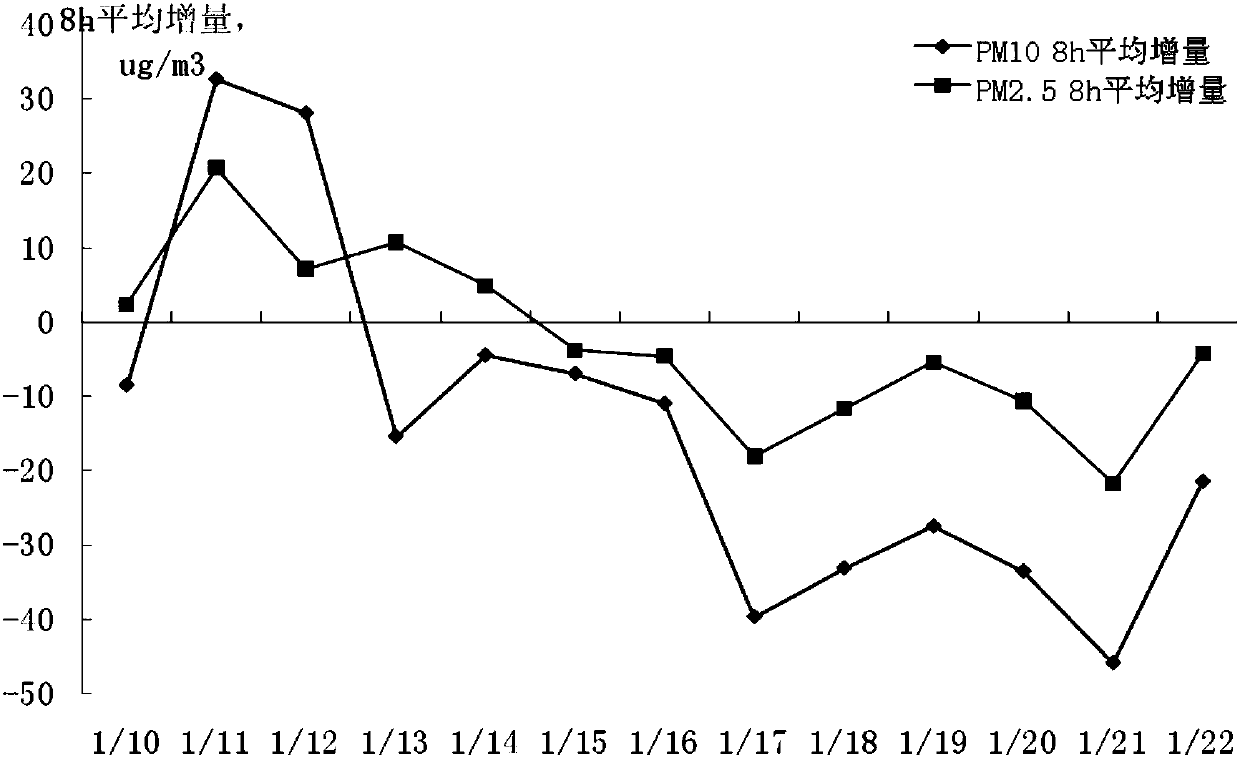

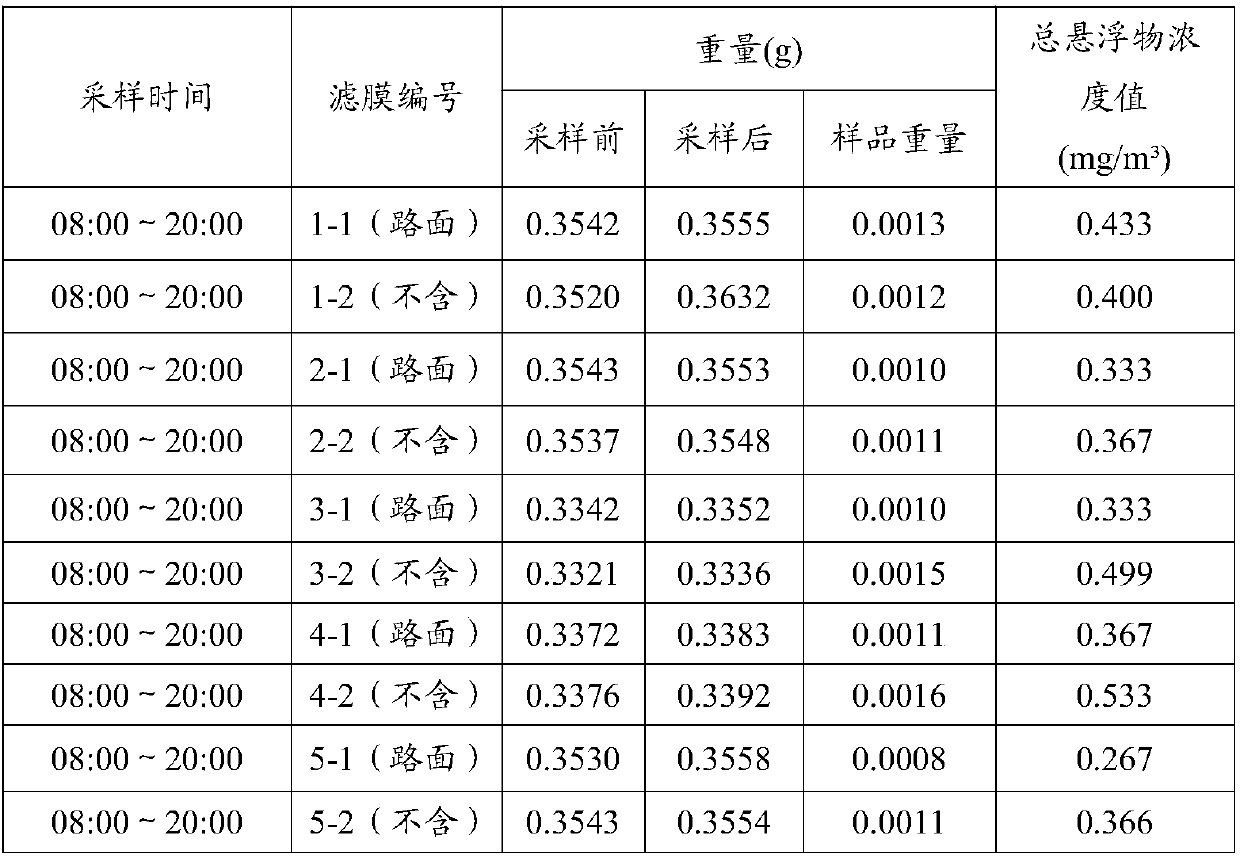

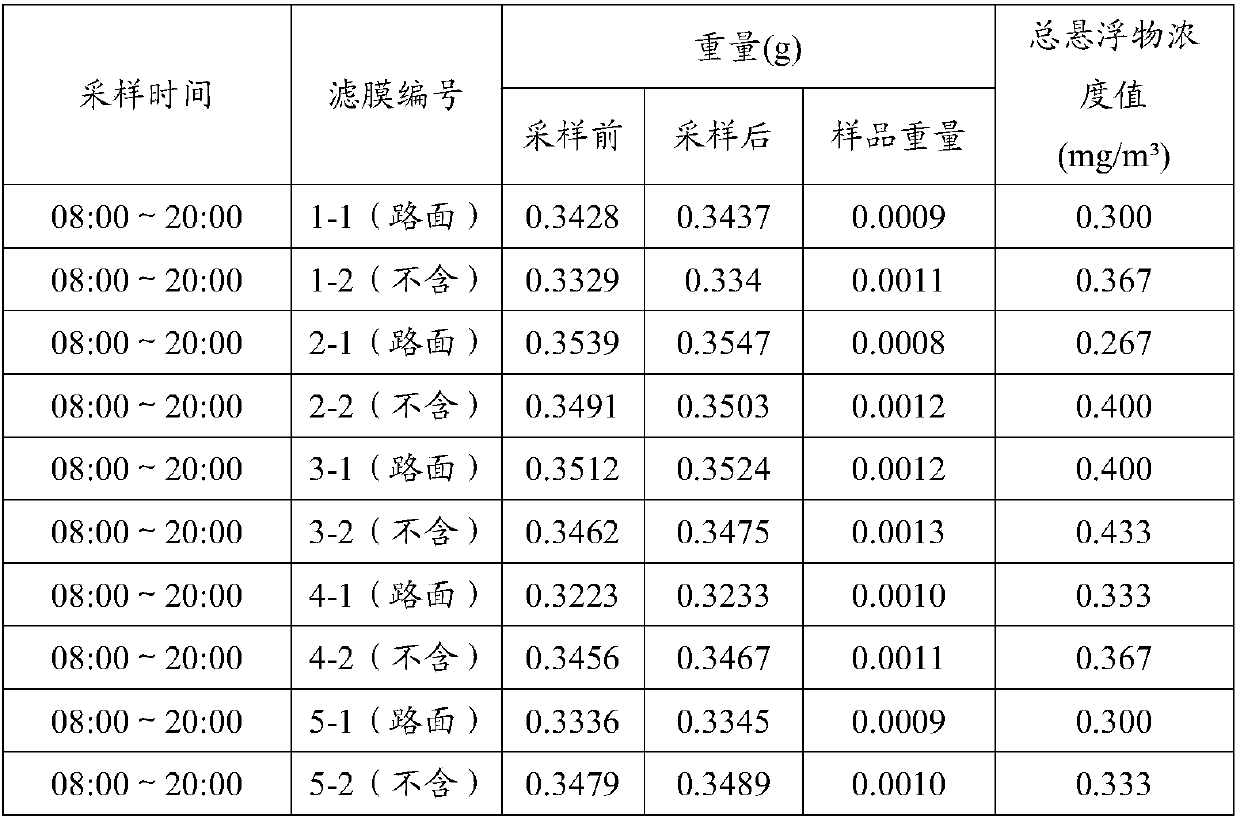

ActiveCN107603564ANo side effectsLow priceOther chemical processesRoad cleaningNear roadRoad surface

The invention relates to a pollution-free road surface dust depressor and an application method thereof. The pollution-free road surface dust depressor is prepared from the following components in parts by weight: 2.0 to 4.0 parts of a moisture absorbent, 0.5 to 2.2 parts of a humectant and 0.3 to 1.0 part of a binding agent. After the road surface dust depressor provided by the invention is sprayed, the average reduction capability of PM10 (Particulate Matter 10) can reach 36.8mu g / m<3> and the average reduction capability of PM2.5 (Particulate Matter 2.5) can reach 20.1mu g / m<3>. When the road surface dust depressor provided by the invention is sprayed, the condition that the concentration of particulate matters is increased, caused by a vehicle, can be effectively inhibited, and the concentration of atmospheric particulate matters in a near road surface range can also be reduced. A sprayed road surface still has a good dust depression effect, and the effective time can last for 2 to3 weeks.

Owner:兰州天际环境保护有限公司

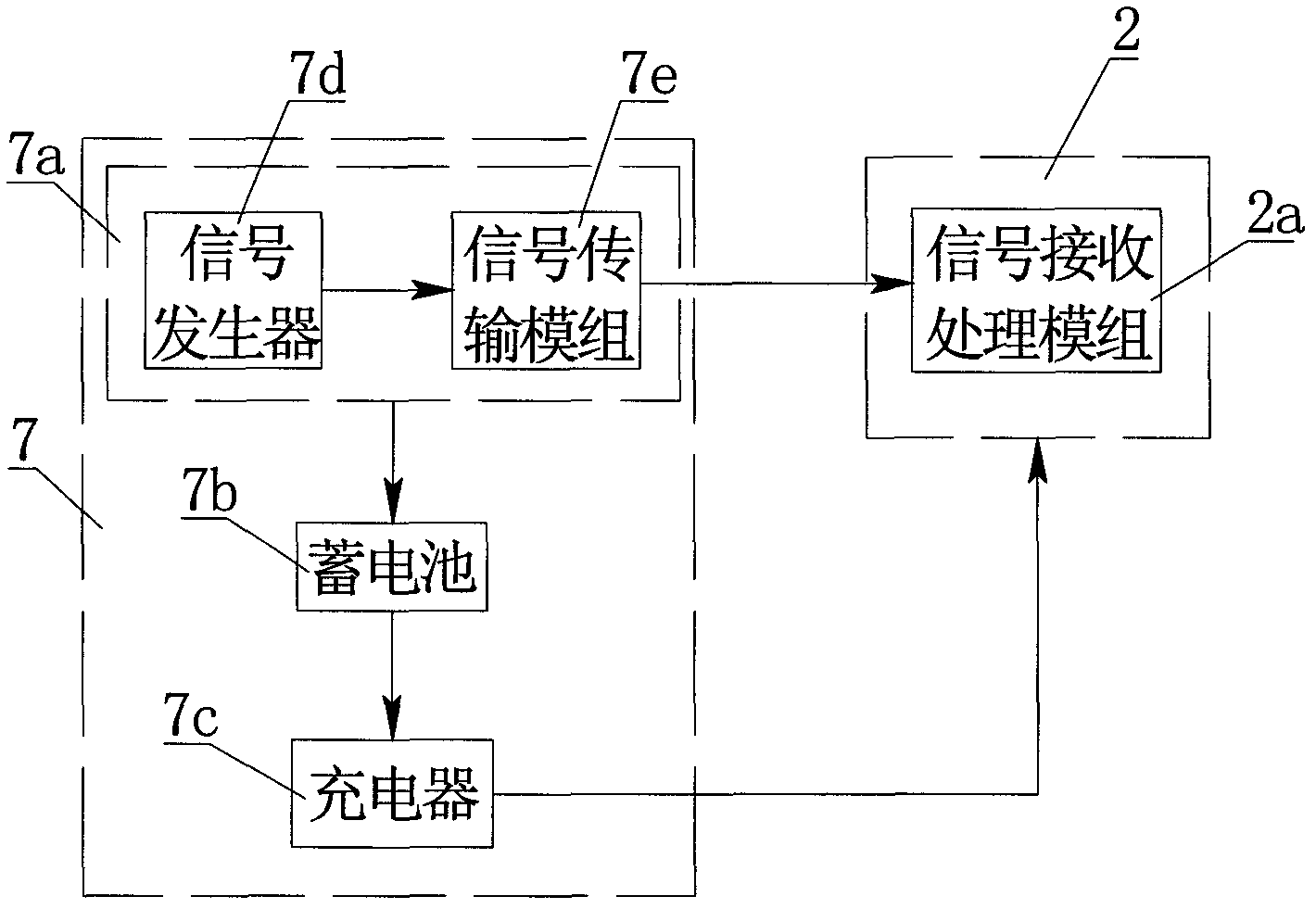

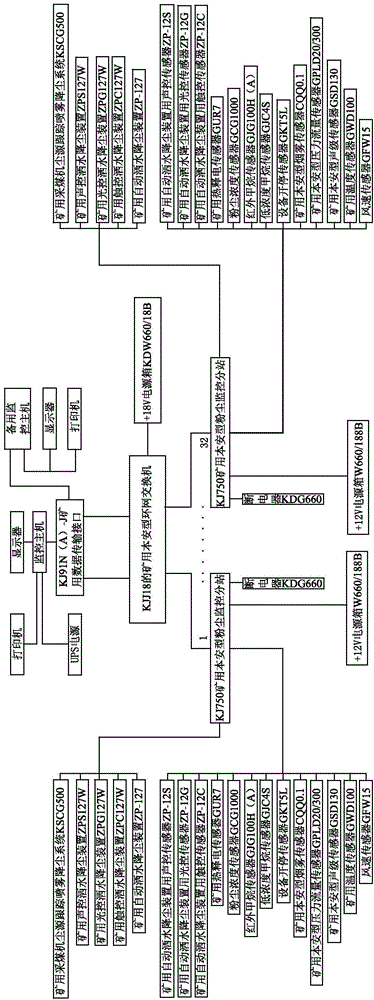

Mining dust monitoring system and method

InactiveCN104533524AReduce concentrationComprehensive dust suppressionMining devicesDust removalState parameterElectrical devices

The invention provides a mining dust monitoring system and method. Sensors with different functions transmit detected down-hole environmental parameters and electrical equipment operating state parameters to a monitoring substation, and meanwhile send the related environmental parameters to an intelligent dust removal device; the intelligent dust removal device carries out dust removal work according to working parameters and the environmental parameters, and transmits operating state parameters of the intelligent dust removal device to the monitoring substation; the monitoring substation packages received data of the sensors and the intelligent dust removal device, and sends the data to a looped network switch; the looped network switch sends the data to a data transmission interface, and the data transmission interface transmits the data to a monitoring host through a cable; the monitoring host resolves, stores, analyzes and displays the data after receiving the data; an operator learns the down-hole environment and the electrical equipment operating state according to the displayed data, sets control parameters, and controls all kinds of down-hole electrical equipment to work, and therefore the problems that monitoring over the down-hole environment is not comprehensive, the dust removal effect is poor, and the electrical equipment operating state can not be learned comprehensively are solved.

Owner:HUAINAN RUNCHENG TECH

Preparation method of control agent for coal dust pollution

InactiveCN101575500ALow costWide variety of sourcesOther chemical processesBuilding constructionsPolyvinyl alcoholDust control

The invention relates to a preparation method of a control agent for coal dust pollution. The preparation method adopts the components with the following weight portions: 1 to 3 portions of polyvinyl alcohol (PVA), 2 to 3 portions of industrial starch, 1 to 1.5 portions of glutinous rice flour, 85 to 95 portions of water, 1 to 2 portions of polyoxyethylene nonylphenol ether and 1 to 2 portions of sodium humate. The control agent is prepared by mixing and evenly stirring the materials. The sodium humate contains 40 percent to 60 percent of humic acid and 10 percent to 20 percent of natrium. The control agent is characterized by low cost, wide material source, stable performance, wide application, innocuity and harmlessness, low corrosion rate, no odor and the like, as well as high inhibition rate, remarkable dust suppression effect, good frost resistance performance and the like. The technique that blending the control agent and spraying the control agent on the surface are combined is adopted in large-sized coal mines, ports and coal storage in China, thus realizing dust control and flame retardancy during production, storing and transporting processes of coals.

Owner:SHIJIAZHUANG XINBANGER ENERGY SAVING TECH CO LTD

Dust inhibitor and preparation method thereof

InactiveCN105176493AGood dispersionImprove visibilityOther chemical processesGlycerolPolyethylene glycol

The present invention discloses a dust inhibitor and a preparation method thereof, wherein the dust inhibitor comprises the following raw materials by mass: 0.001-4.50% of a surfactant, 0.001-4.00% of an alcohol auxiliary agent, 0.005-3.00% of an inorganic salt additive, and the balance of water, wherein the alcohol auxiliary agent is at least one selected from ethanol, ethylene glycol, glycerol, n-butanol and polyethylene glycol. According to the present invention, the dust inhibitor is mainly used in the wet spraying dust falling process and can be rapidly dispersed in water; during the use, the dust inhibitor is added to water for spraying dust falling, rapid wetting and flocculation agglomeration are performed on the dust produced during mining, blasting construction and other production processes along with the mist droplet spraying so as to promote the dust to rapidly fall and improve the spraying dust falling efficiency; and the dust inhibitor can further be added to the dust inhibition bag or water flooding so as to improve the blasting dust falling efficiency or water flooding dust falling efficiency.

Owner:舒新前

Comprehensive dustproof technology of fully mechanized excavation face based on dust segregation

InactiveCN102852544AFull Dustproof WorkGood effect of dust suppressionDust removalFire preventionMining engineeringCoal dust

The invention relates to a comprehensive dustproof technology of a fully mechanized excavation face based on dust segregation. The dustproof technology integrates a series of comprehensive dust proof measures of dust segregation, dust reduction, dust removing and the like. Firstly, coal bed high-pressure water injection is implemented to reduce the generation amount of coal dust; secondly, an excavator is utilized to perform inside and outside spray to reduce dust, and water curtain is use for performing segregation between space and space to further reduce dust; and thirdly, segregation chambers are utilized to segregate people from dust to further improve the dust reduction effect. Aimed at three aspects of mine dust sources and transmission routes and self-protection of staff, the comprehensive dustproof technology combines prevention and treatment, so that the technology is not only safe and convenient, but also can perform dustproof work systematically and comprehensively; the dust reduction effect is obvious, and the broad practicability is provided.

Owner:TAOYUAN COAL MINE HUAIBEI MINING

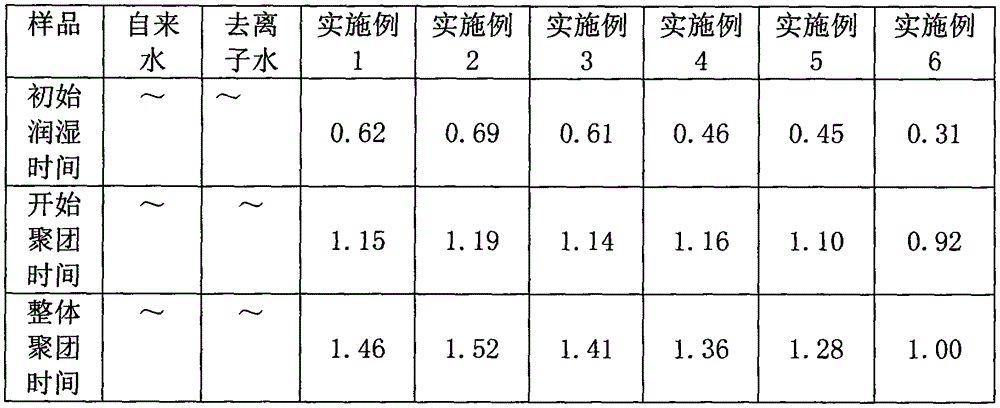

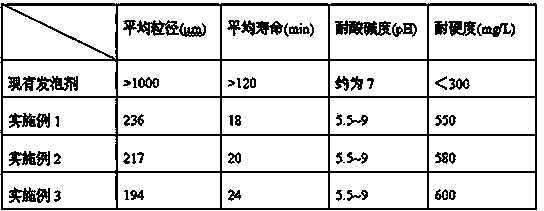

Compound foaming agent used for depositing dust and preparation method thereof

InactiveCN103361035AGood acid and alkali resistanceImprove hard water resistanceOther chemical processesDust removalRespirable dustAlkyl polyglycoside

The invention discloses a compound foaming agent used for depositing dust and a preparation method thereof. The compound foaming agent is prepared from following materials by weight: 5-8 parts of an alkyl polyglucoside, 20-25 parts of a fatty alcohol-polyoxyethylene ether, 9-14 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 1-2 parts of 2-ethyl hexyl succinate sodium sulfonate and 51-65 parts of water. The compound foaming agent has advantages of good acid and alkali resistance and hard-water resistance, strong foaming capability, fine and rich foams, small bubble sizes, moderate stability, large dust contacting area, good adhesiveness and wettability, enhanced dust depositing effects, enhanced capturing capability for respirable dust in particular, no toxicity, no harm, no skin irritation, rapid and complete biodegradation, selection of raw materials common in market and low cost. The compound foaming agent has wide applicability in the field of dust deposition using foams.

Owner:CHINA UNIV OF MINING & TECH +1

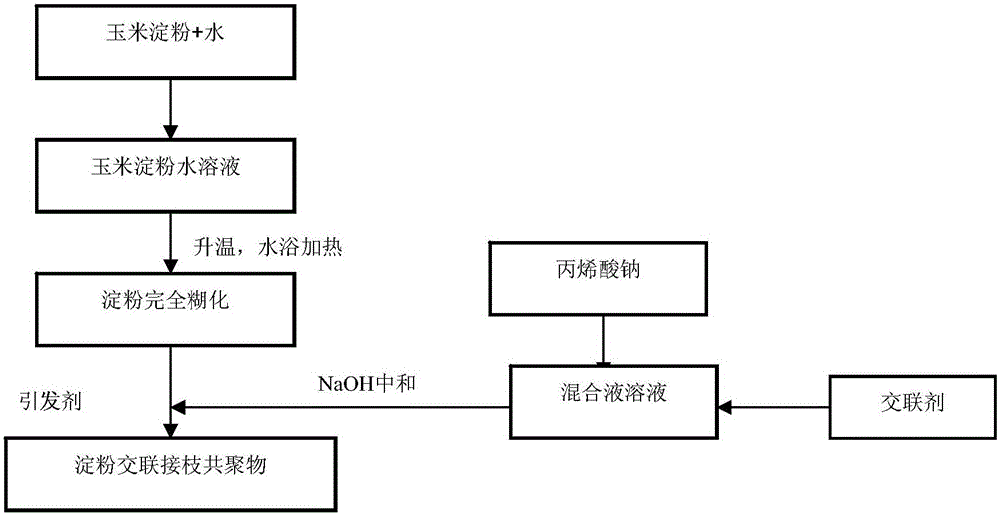

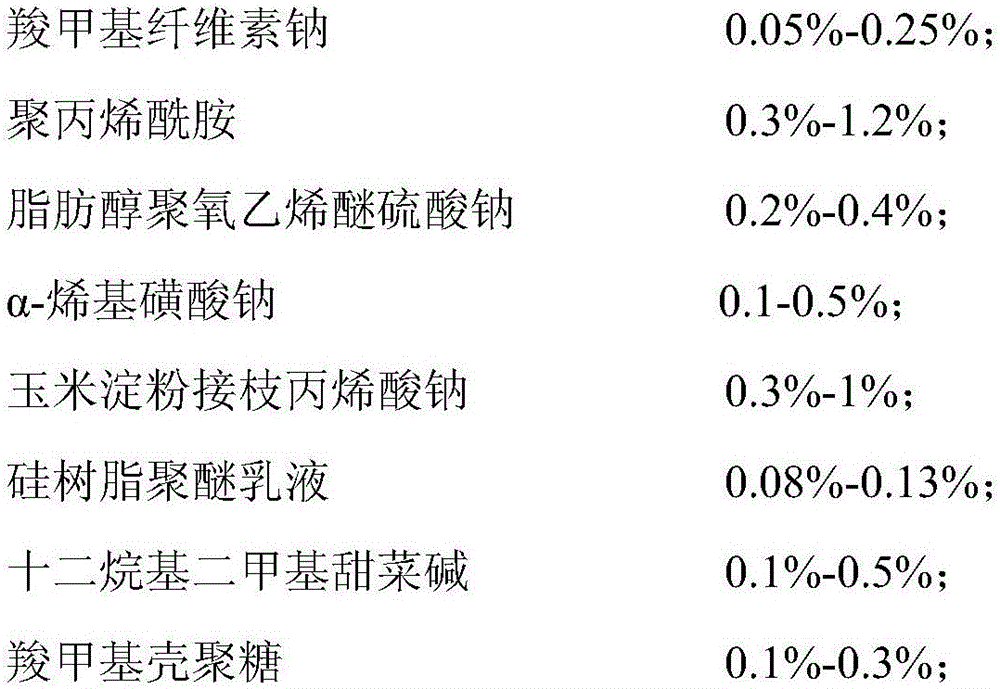

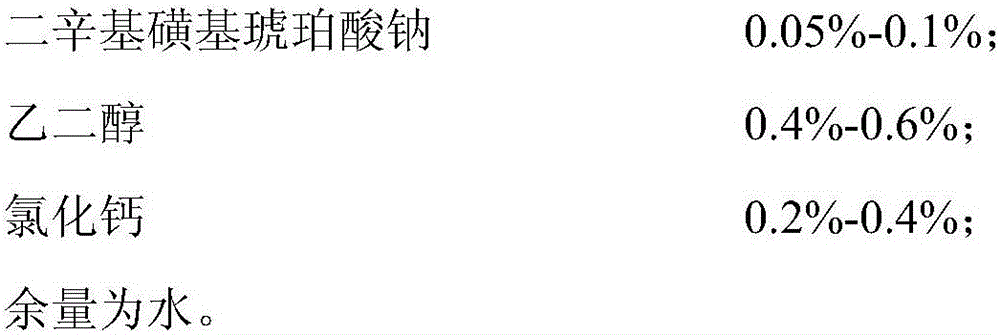

Wetting agent capable of inhibiting dust flying

ActiveCN105860933AReduce surface tensionImprove wettabilityOther chemical processesTransportation and packagingCorn starchSodium carboxymethylcellulose

The invention discloses a wetting agent capable of inhibiting dust flying. The wetting agent comprises 0.05-0.25% of sodium carboxymethyl cellulose, 0.3-1.2% of polyacrylamide, 0.2-0.4% of polyoxyethylene fatty alcohol sodium sulfate, 0.1-0.5% of sodium alpha-alkenylsulfonate, 0.3-1% of corn starch grafted sodium acrylate, 0.08-0.13% of silicone resin polyether emulsion, 0.1-0.5% of dodecyldimethylbetaine, 0.1-0.3% of carboxymethyl chitosan, 0.05-0.1% of dioctyl sodium sulphosuccinate, 0.4-0.6% of ethanediol, 0.2-0.4% of calcium chloride and the balance of water. The sprayed fog drops can quickly capture and wrap the dust particles, thereby increasing the particle settling speed. The sprayed fog drops can be covered on the dust on the coal rock surface and ground surface to prevent secondary flying dust, thereby enhancing the dust removal efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com