Patents

Literature

473results about How to "Guaranteed moisture content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Road dust suppressant

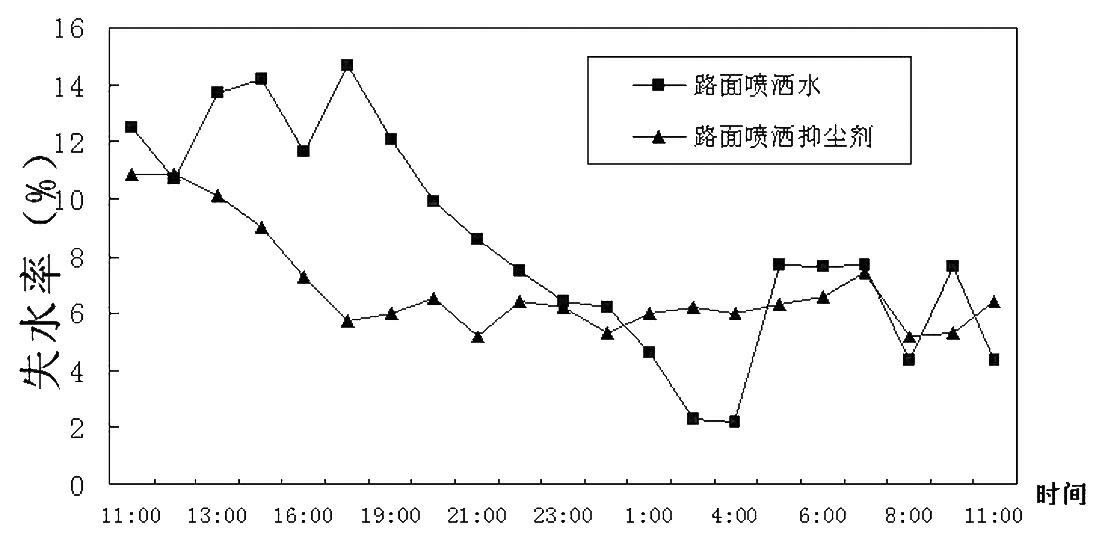

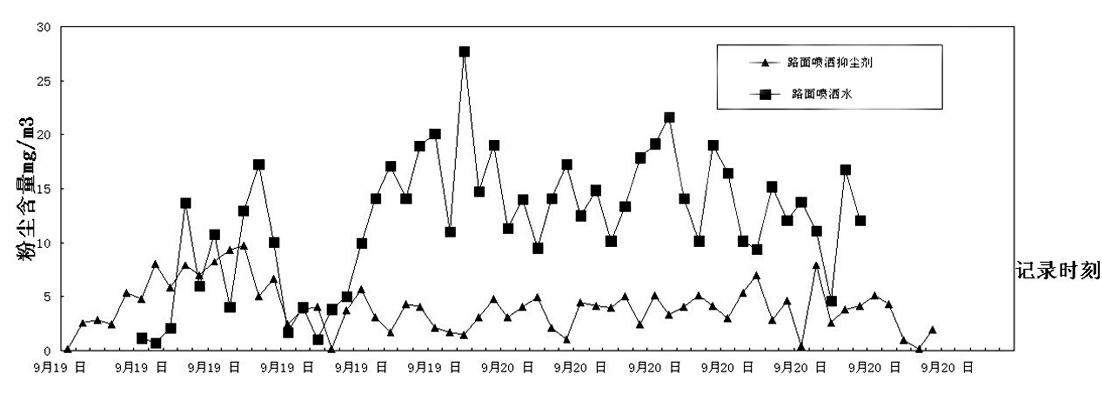

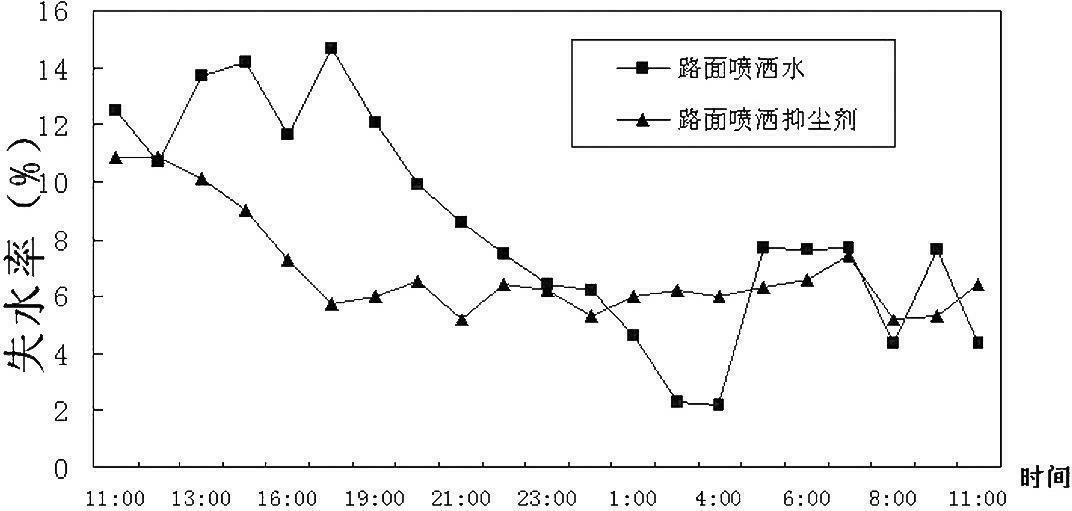

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

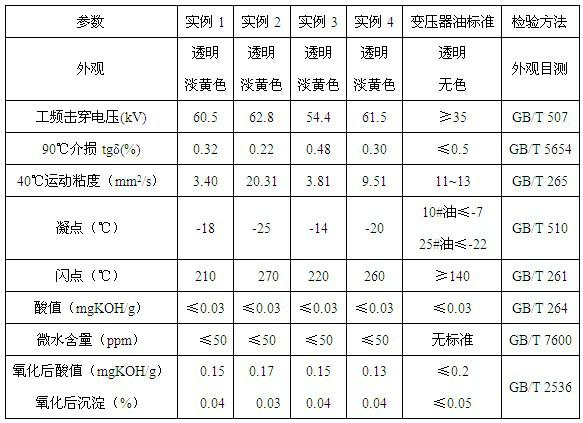

Vegetable insulating oil, and preparation method of vegetable insulating oil

InactiveCN102682869AImprove performanceReduce the temperatureLiquid organic insulatorsBase-materialsVegetable oilAnti oxidant

The invention relates to vegetable insulating oil based on vegetable oil, and a preparation method of the vegetable insulating oil. The insulating oil is prepared by the steps of using refined vegetable oil as raw material, carrying out ester exchange reaction on low-molecular alcohol, refining and washing after the reaction, rinsing, distilling under reduced pressure in order to remove water and alcohol, de-coloring, de-acidifying, filtering, de-watering deeply, finally adding antioxidant and pour point depressant. The insulating oil prepared by the method has the characteristics of high flashing point, low viscosity, low pour point, low acidity, low brackish water content, excellent dielectric constant, low dielectric loss and high breakdown voltage and has good physical and chemical performance and electrical performance.

Owner:CHINA ELECTRIC POWER RES INST

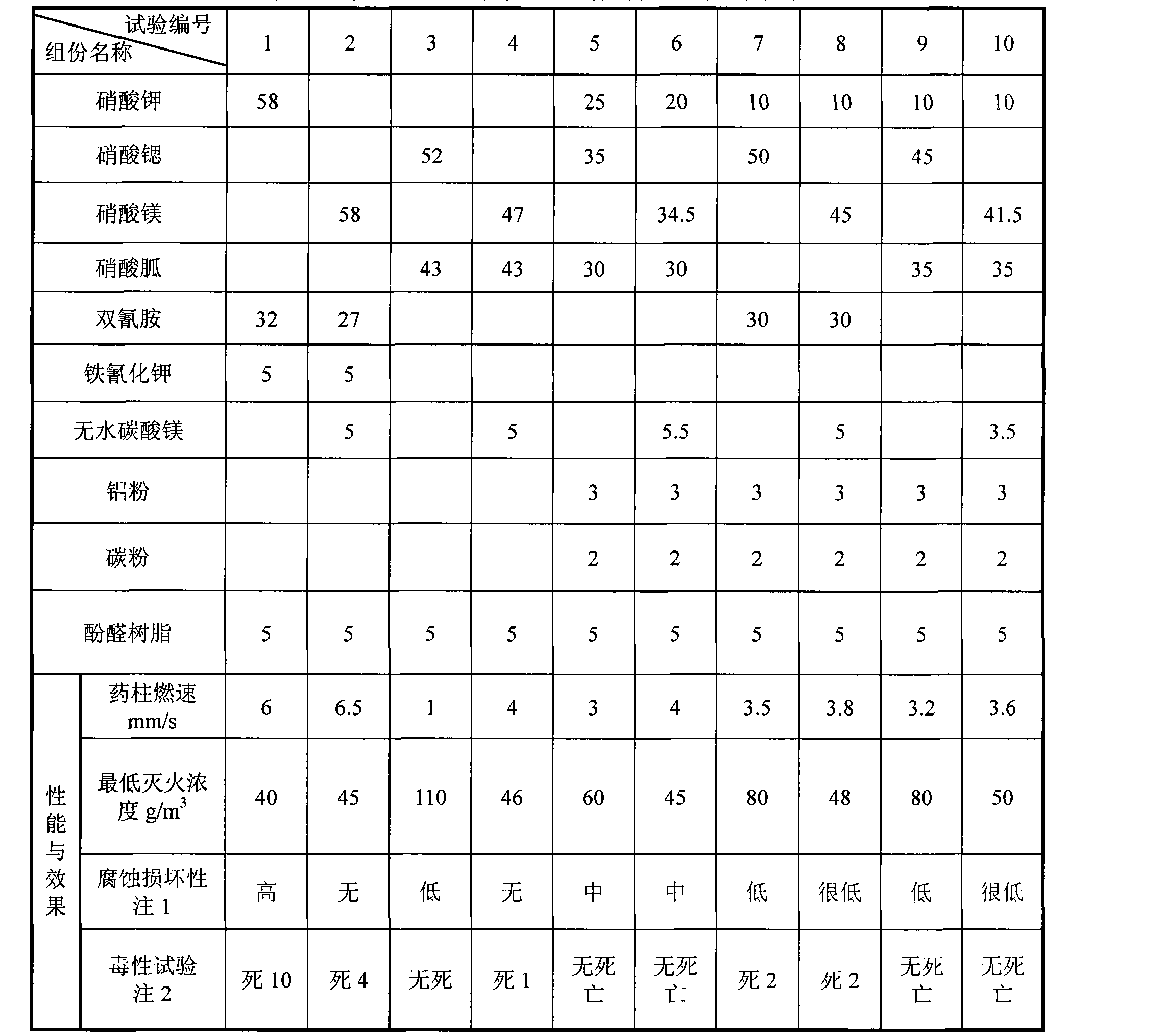

Extinguishment combination with hot gas sol

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

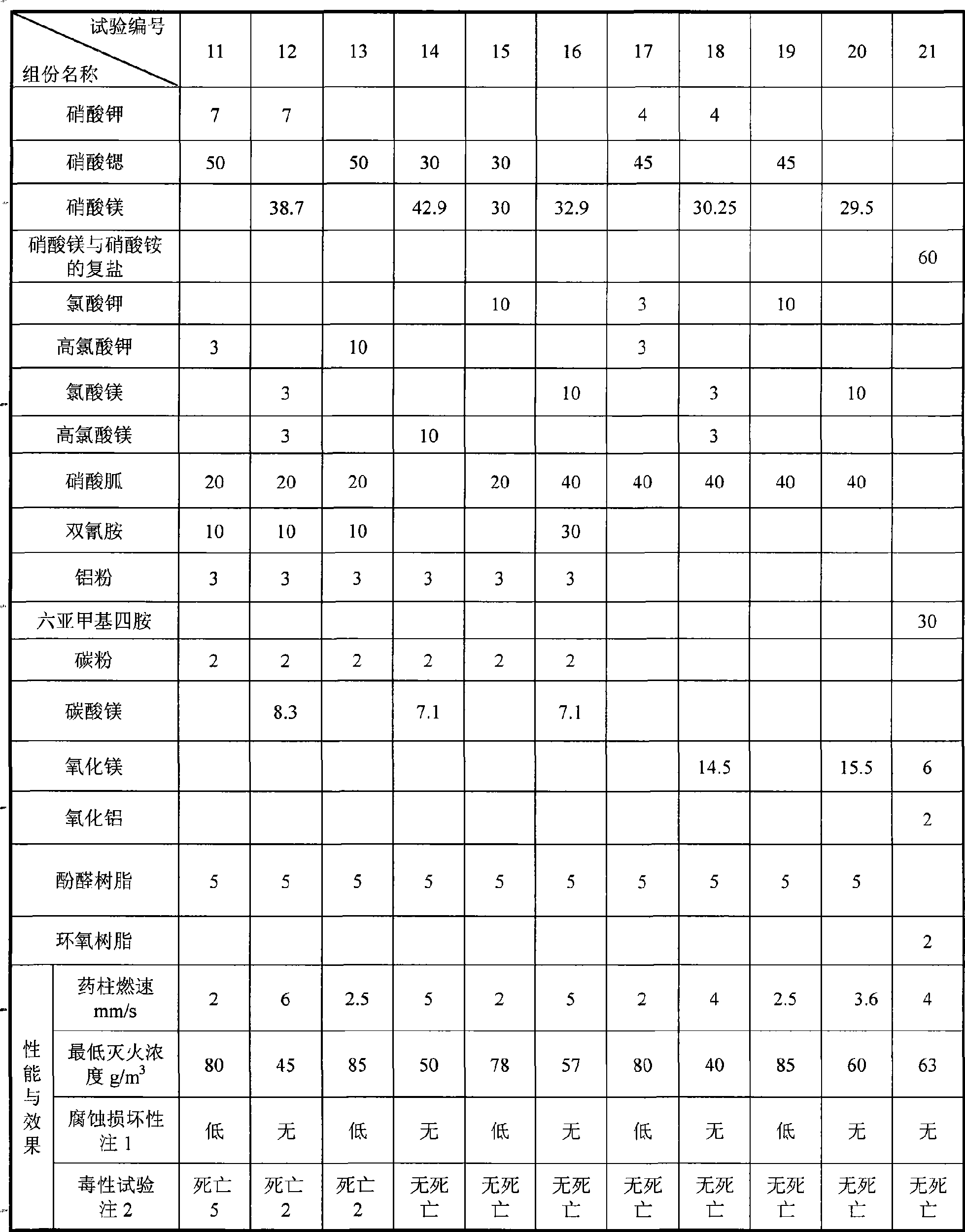

Waterside road broadened embankment structure and construction method thereof

ActiveCN103628378AImprove connection strengthImprove mechanical performanceRoadwaysClimate change adaptationEconomic benefitsStructural engineering

The invention relates to a waterside road broadened embankment structure, which is characterized in that the waterside side of a new embankment is provided with a waterproof maintenance pile, and the outer side of the maintenance pile is provided with a dumping stone weights body; the lower part of the new embankment is a solidified soil layer, the upper part of the new embankment is a lightweight filler layer, and the contact part of the solidified soil layer and the lightweight filler layer is provided with a horizontal reinforced body and a vertical reinforced body; a grouting strengthened body is arranged in an original embankment, and the front end of the grouting strengthened body is a reinforced connecting section; and the side slopes on the top surface and outer side of the new embankment and the two sides of the maintenance pile are respectively provided with a waterproof later, and the bottom of the dumping stone weights body is provided with an impervious blanket. According to the invention, the connection strength and integrity of the new and original embankments can be enhanced, an outside water body is prevented from permeating in the embankments from multiple beddings, and the anti-uplift performance of the embankment can be improved, therefore, the embankment structure has good technical and economic benefits. The invention also provides a construction method of the broadened embankment structure.

Owner:江苏镇江路桥工程有限公司

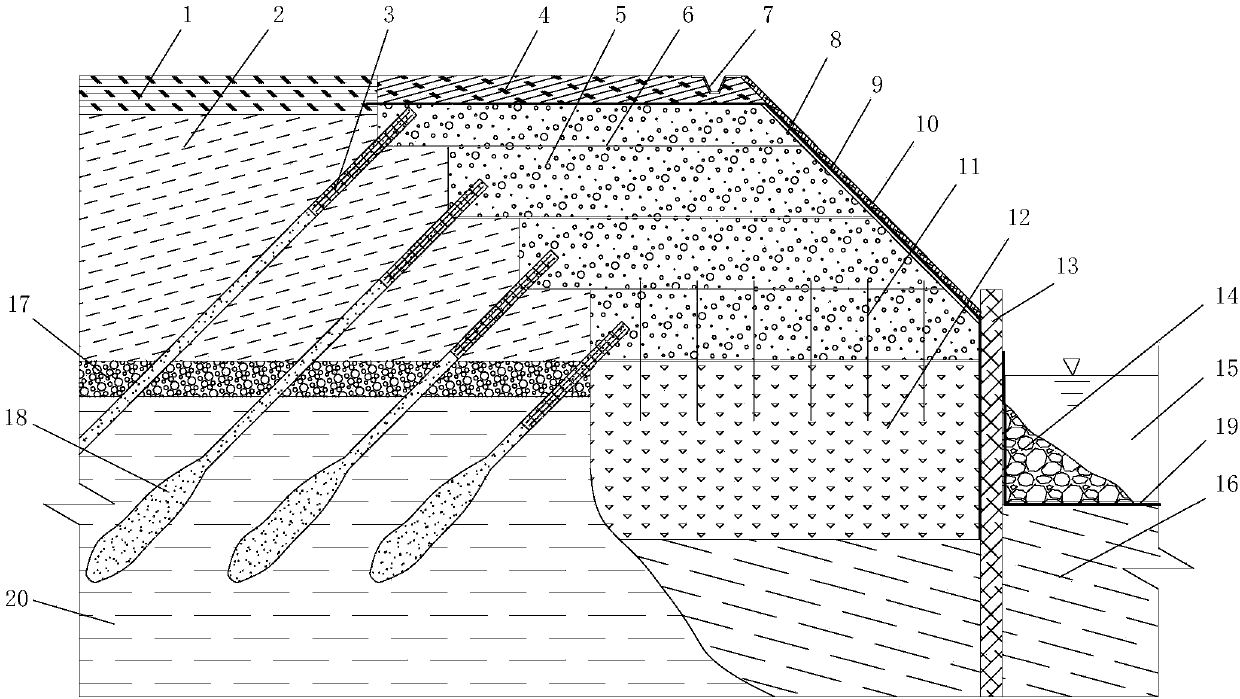

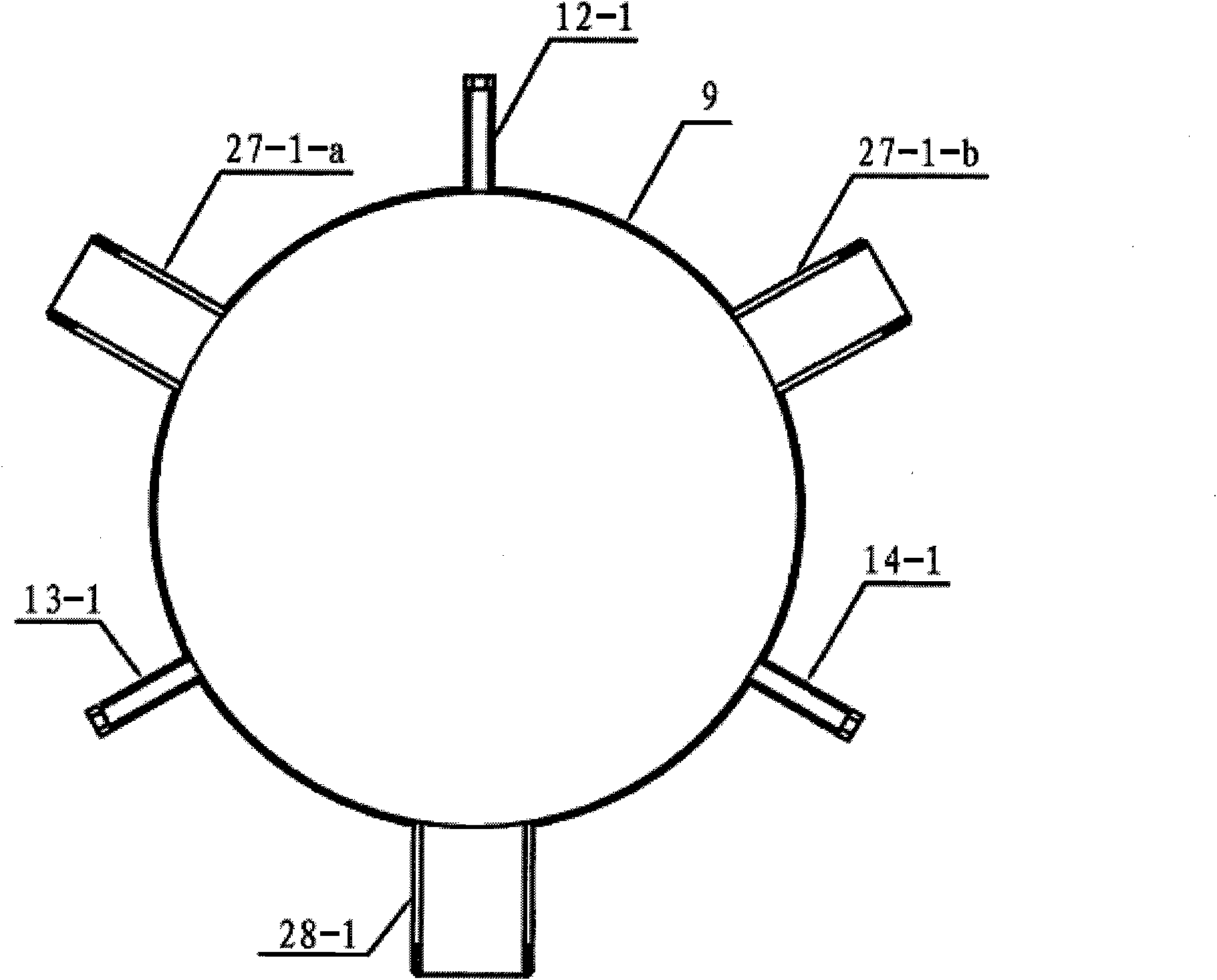

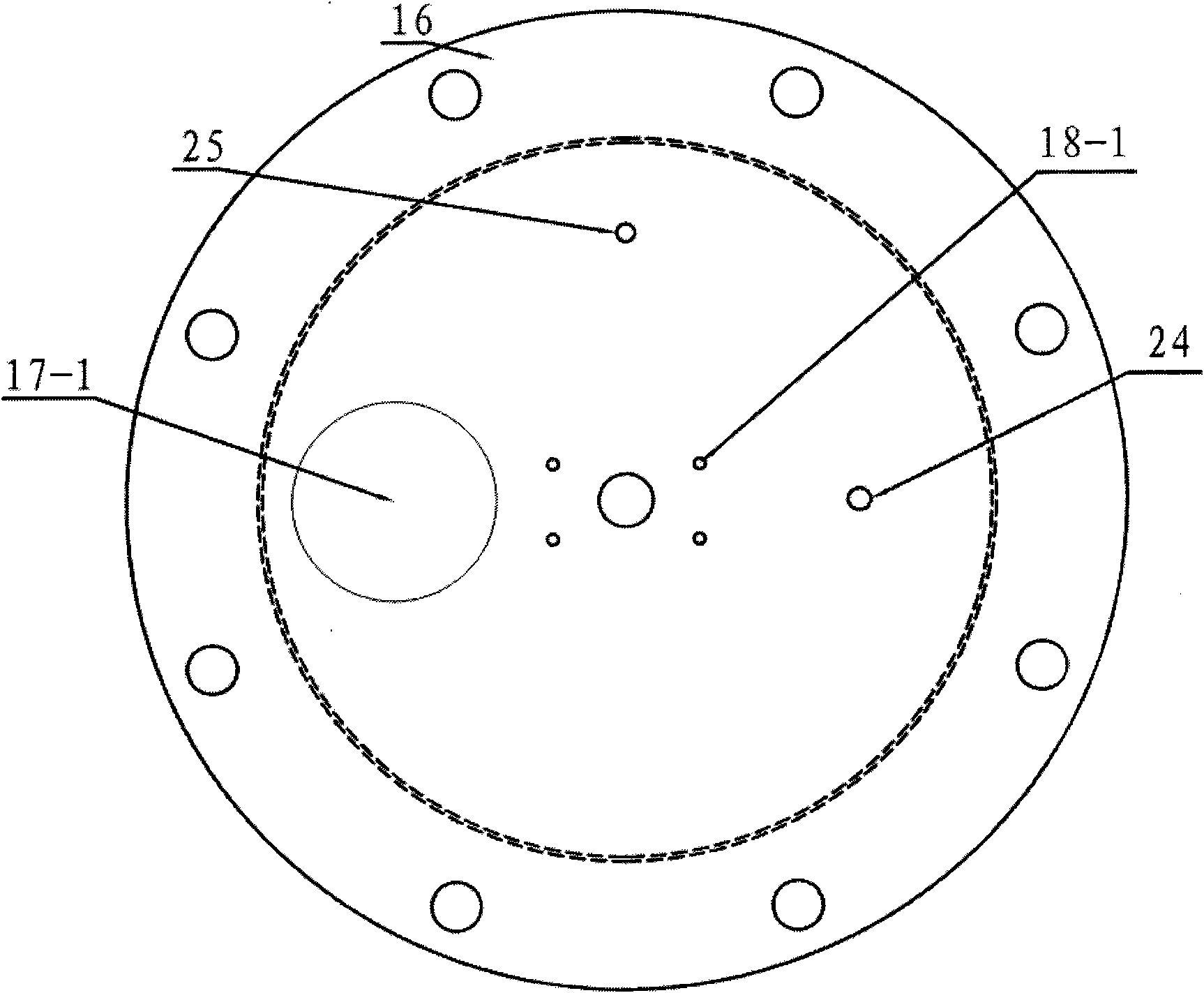

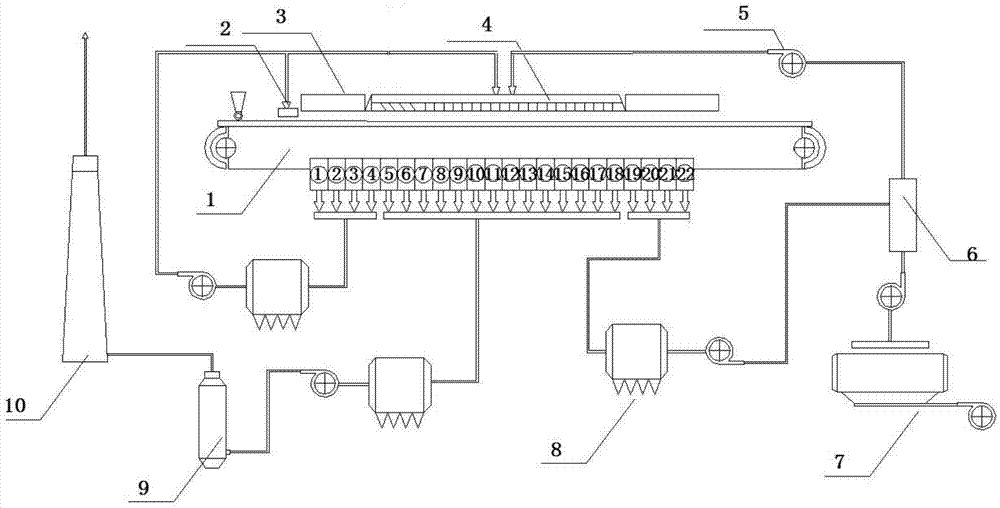

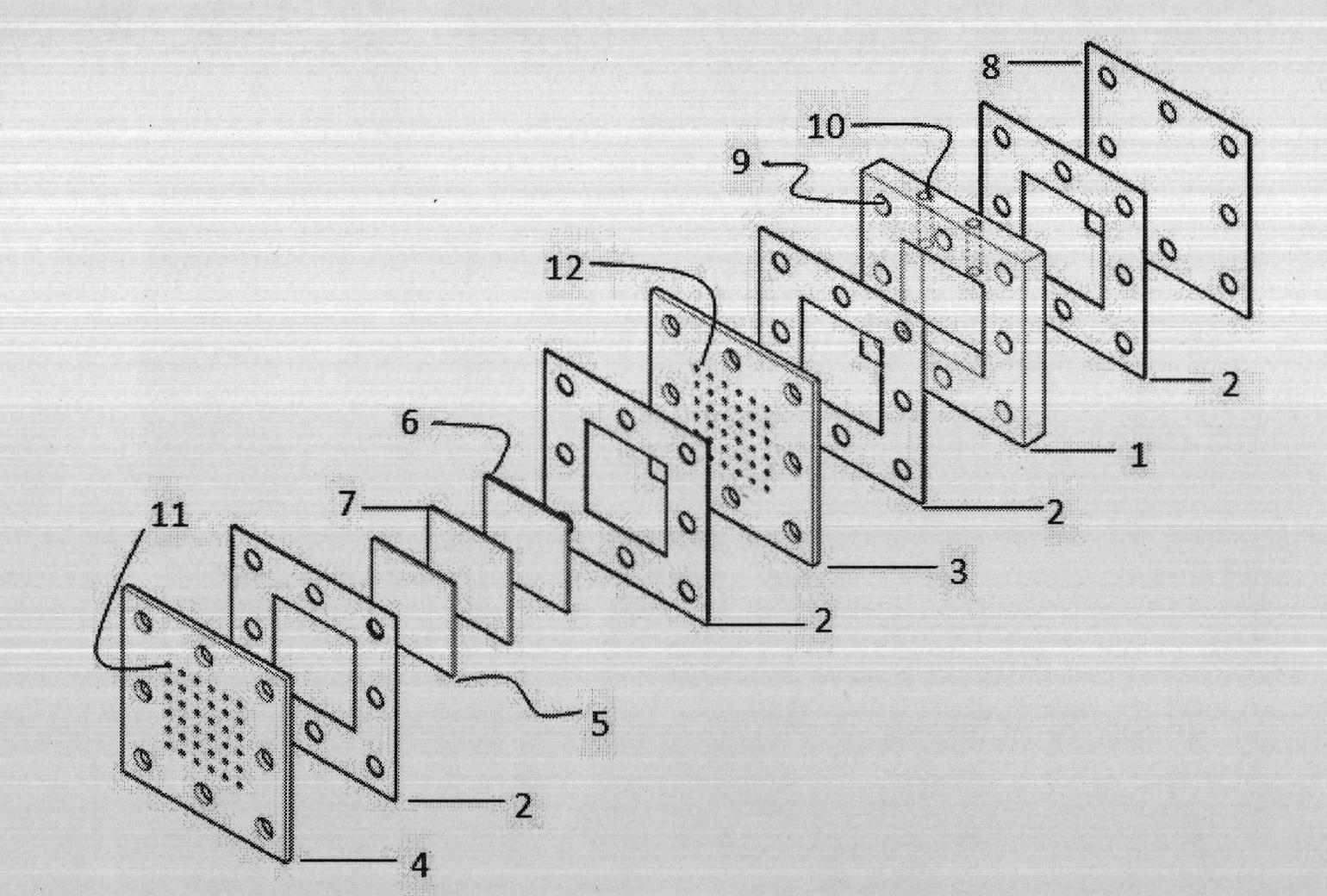

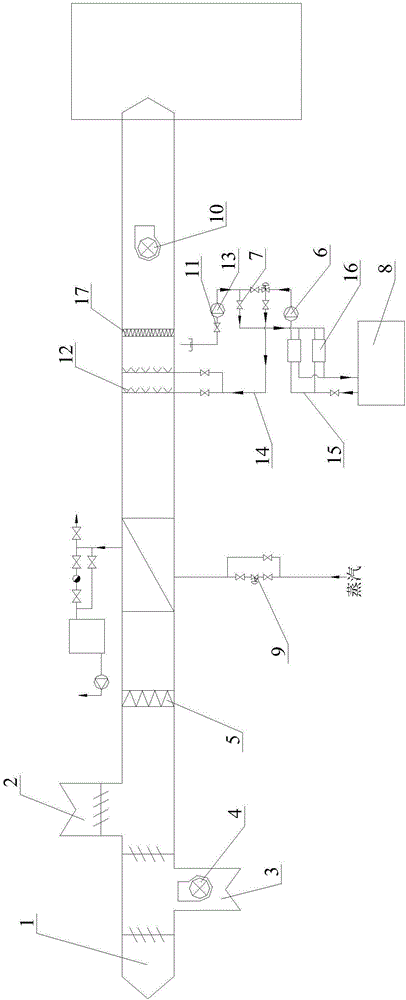

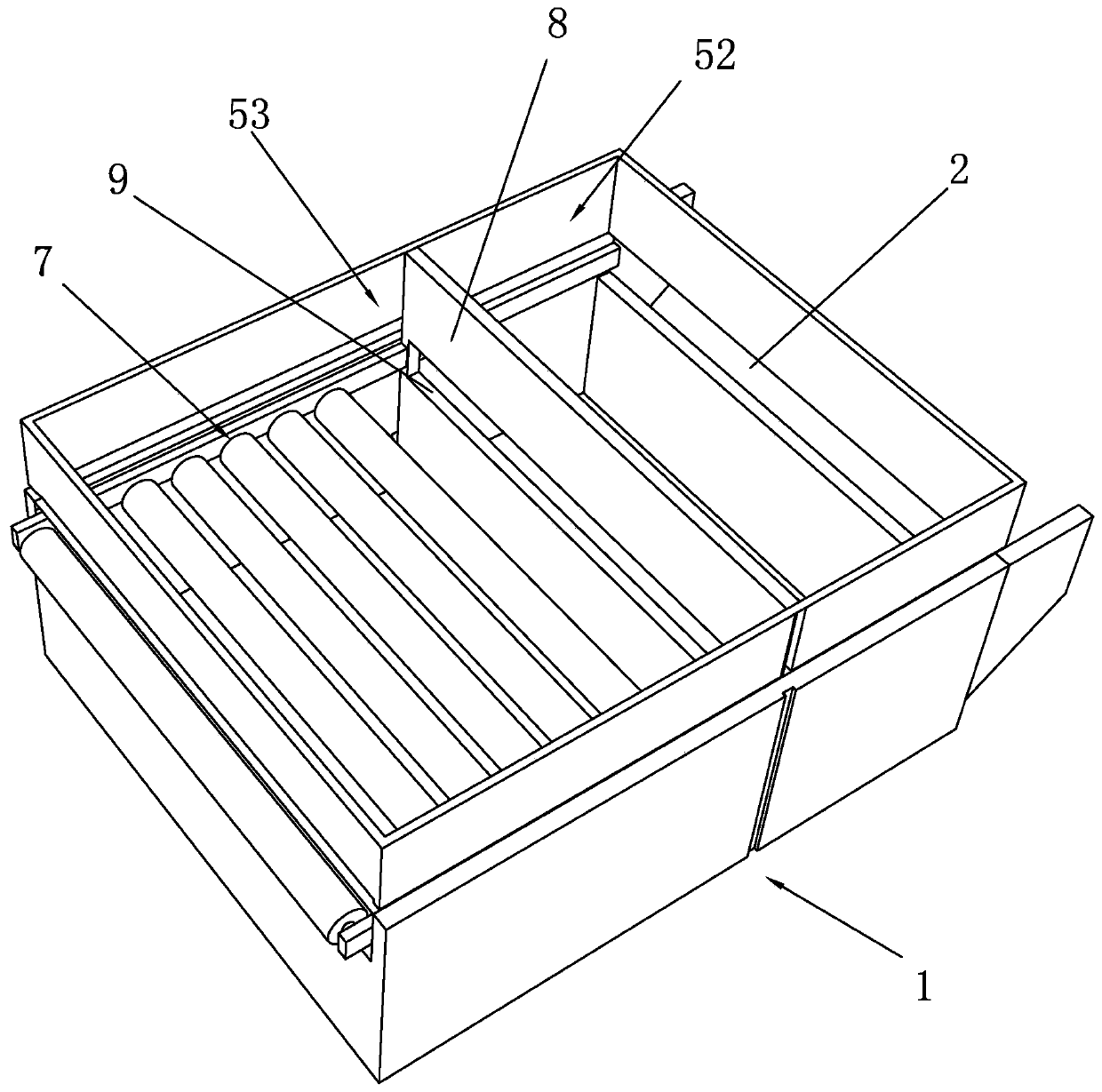

Organic waste treatment device for spatial permanent base

InactiveCN101791619AIncrease concentrationGuaranteed moisture contentBio-organic fraction processingSolid waste disposalAutomatic controlTemperature control mode

The invention provides an organic waste treatment device for a spatial permanent base, which mainly aims at the recycle problem of organic wastes (inedible plant biomass, excrement, kitchen garbage and the like) in a bio-regenerative life support system of a long-time and long-distance spatial manned base (such as permanent moon base and a mars base). The device consists of a fermentation tank body, a gas inlet pretreatment system, a gas outlet condensation system, a stirring system, a percolate collecting reflux system, a heating temperature control system, a tail gas treatment system, a sensor system and an automatic control system. The device can be used for both aerobic fermentation and anaerobic fermentation, can automatically monitor and adjust main indexes of a fermentation process, improves an oxygen consumption rate monitoring method, and improves the form of a stirrer and a temperature control mode. Biogas produced by fermentation is adsorbed by a plant culture medium. The percolate is refluxed into the material for compensating moisture brought out by the emitted gas.

Owner:BEIHANG UNIV

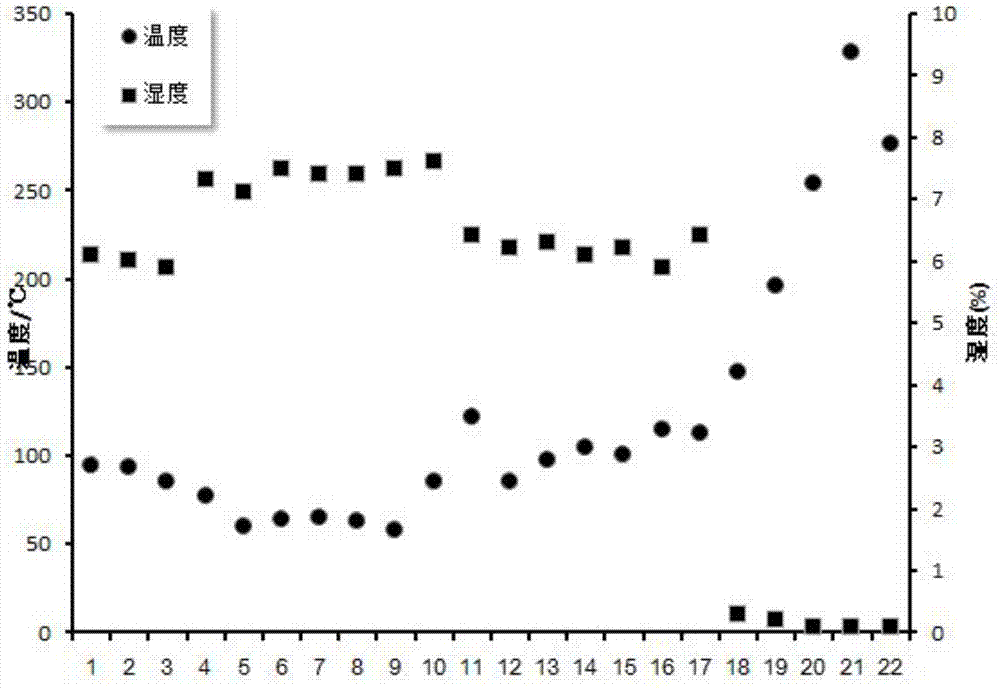

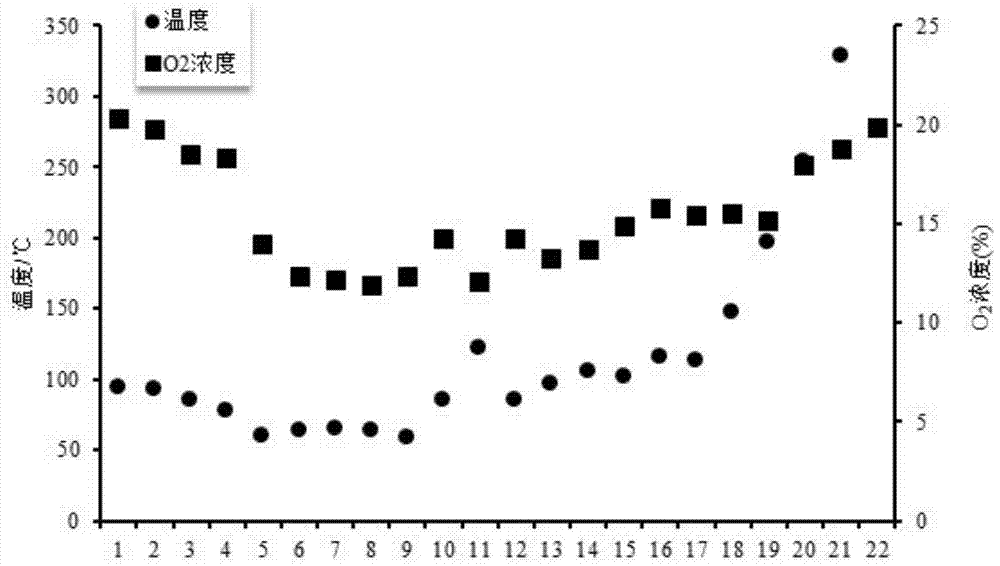

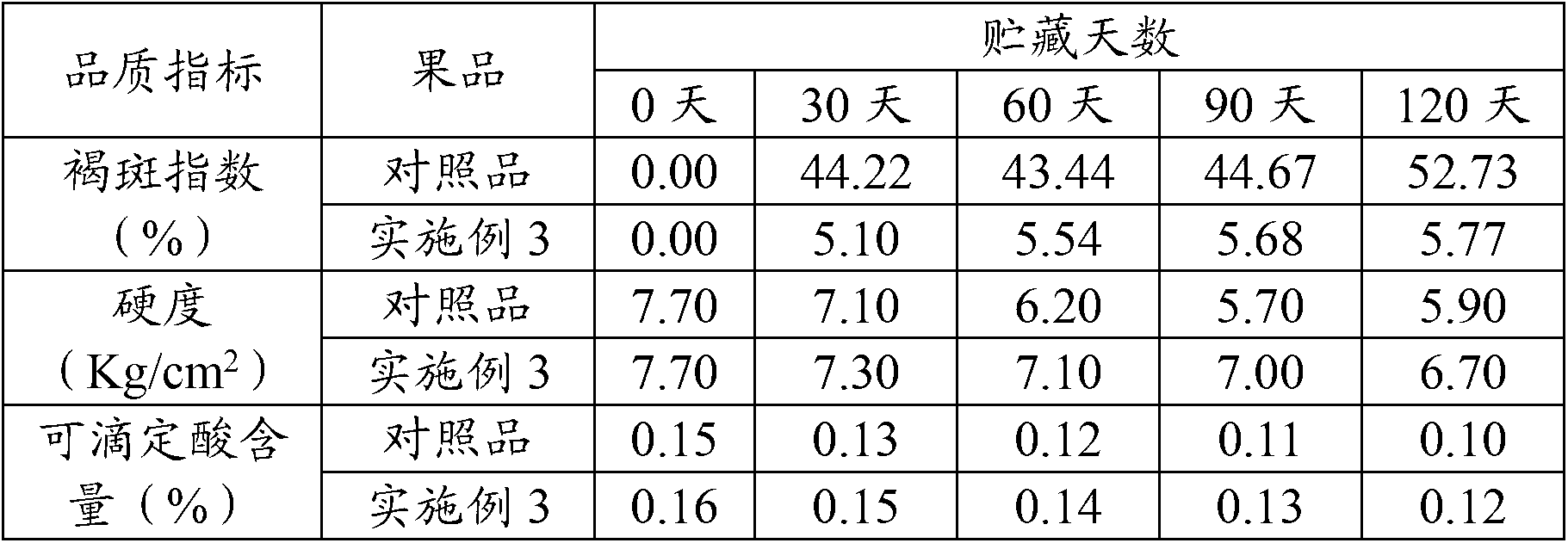

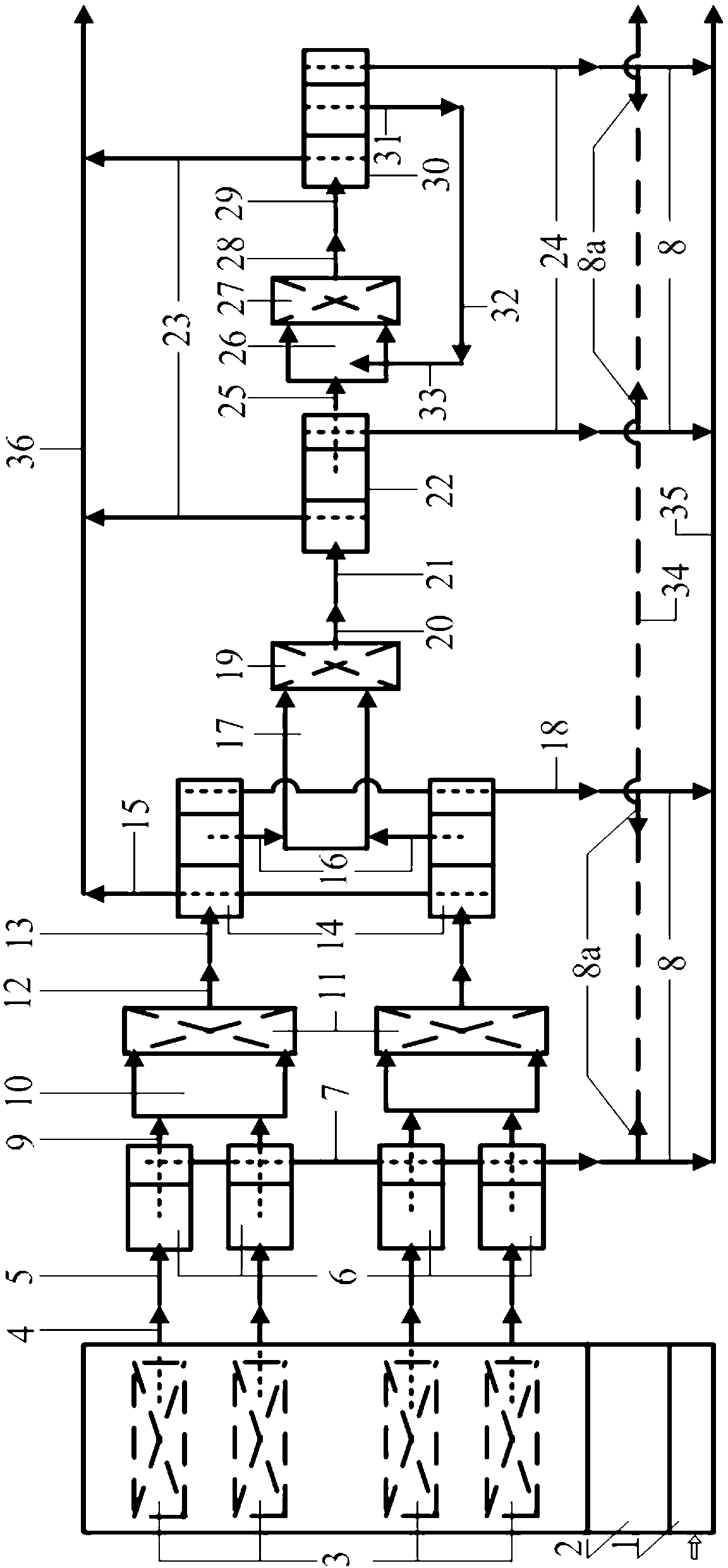

Sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system

ActiveCN104748567ARealize emission reduction controlEmission reductionGas treatmentDispersed particle separationHigh humidityHigh energy

The invention provides a sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system. According to the process, sintering flue gas is divided into low-temperature high-oxygen low-humidity section sintering flue gas, medium-temperature low-oxygen high-humidity section sintering flue gas and high-temperature high-oxygen low-humidity section sintering flue gas according to the emission characteristics of flue gas temperature and oxygen concentration and humidity. The low-temperature high-oxygen low-humidity section sintering flue gas is subjected to dust removal and then is led into a sintering machine for hot air sintering and hot air ignition. The medium-temperature low-oxygen high-humidity section sintering flue gas is subjected to dust removal and desulfurization treatment. The high-temperature high-oxygen low-humidity section sintering flue gas is mixed with cooling machine waste gas and then is led into the sintering machine for hot air sintering. The sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system can conduct staged utilization on flue gas waste heat, recover low-temperature sensible heat in flue gas, enable carbon monoxide left in the sintering flue gas to be secondarily combusted and reduce the energy consumption in the sintering process on the premise that the quality and yield of sintered ores are ensured. Cyclic flue gas utilization is achieved, the pollutant emission quantity of unit sintering ores and total emission quantity of the sintering flue gas are reduced, and the sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system have very high energy-saving emission-reduction value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

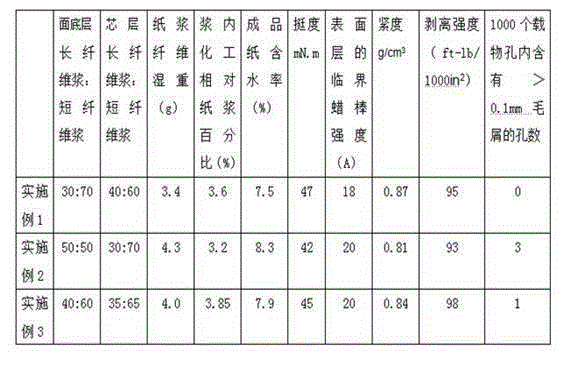

Paper for packaging carrier tape and preparation method thereof

ActiveCN104088199AHigh bonding strength between layersImprove surface strengthFlexible coversWrappersCardboardFiber

The invention discloses paper for packaging a carrier tape and a preparation method thereof. The paper and the preparation method are characterized in that the thickness of the paper for packaging the carrier tape is 0.25mm-1.00mm, the thickness deviation is plus or minus 0.02mm, the compactness is 0.80-0.95g / cm<3>, the moisture content is 6.0%-9.0%, the deflection is greater than or equal to 30mN.m, the peel strength between all the layers is greater than or equal to 80ftlb / 1,000in2, the critical wax rod strength of a surface layer is greater than or equal to 18A, and the residual rate of burrs (soft flocks) greater than 0.1mm in a carrying hole punched by using a punching mould is less than 5 / 1000. According to the paper for packaging the carrier tape and the preparation method thereof, by utilizing short fiber paper pulp subjected to pulp grinding treatment, and adding and spraying a high-molecular polymer resin adhesive, dry-strength resin, wet-strength resin, a stiffening agent, a sizing agent and the like into the paper pulp and between made wet paper sheet layers, a three-dimensional network structure is formed by bonding paper pulp fibers with various polymer resin macromolecules, so that paper boards have relatively high interlayer bonding strength, surface strength and stiffness, and the fibers are easier to cut off during punching to reduce the production of the soft flocks, so as to meet the quality requirements for the packaging the carrier tape.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

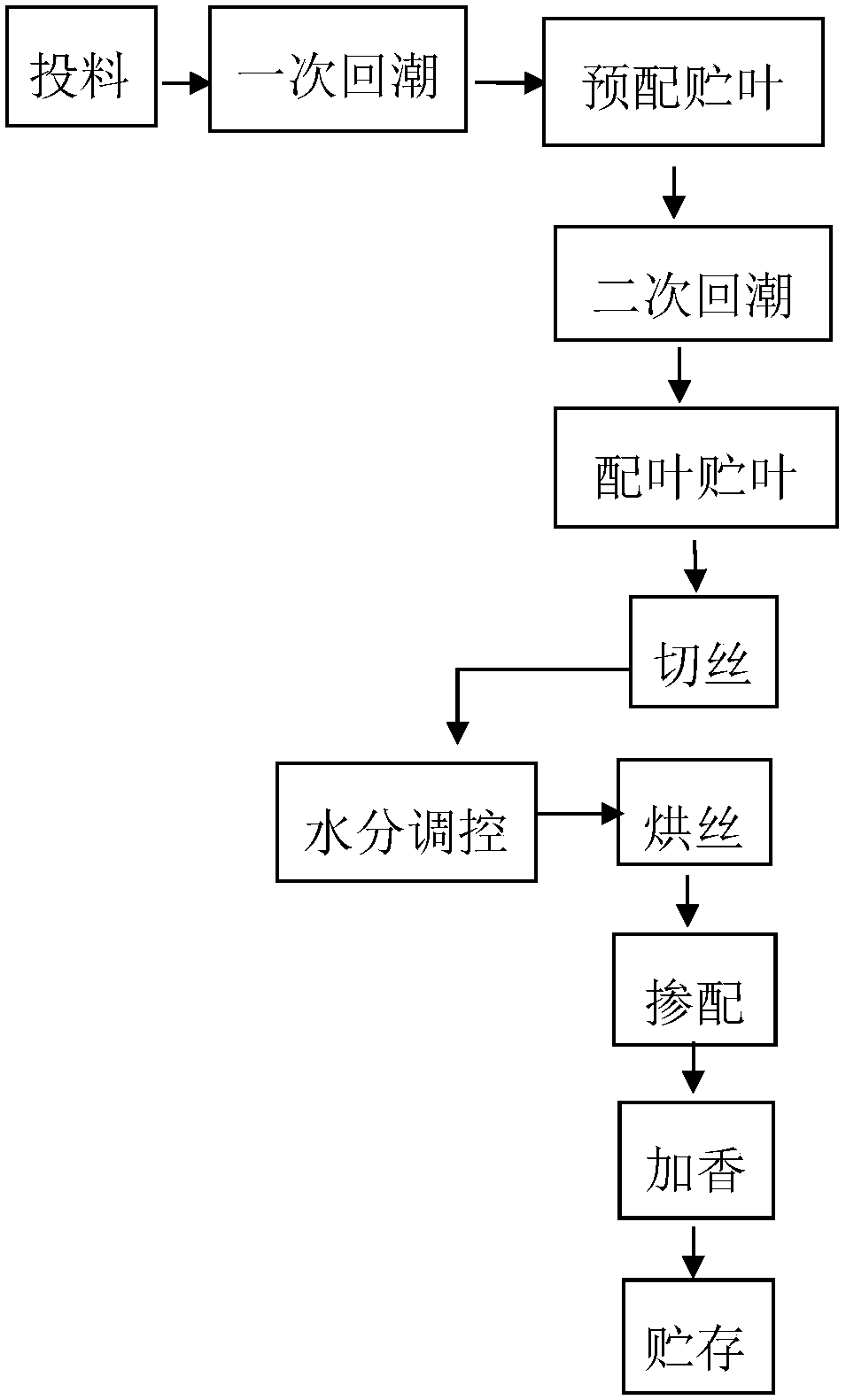

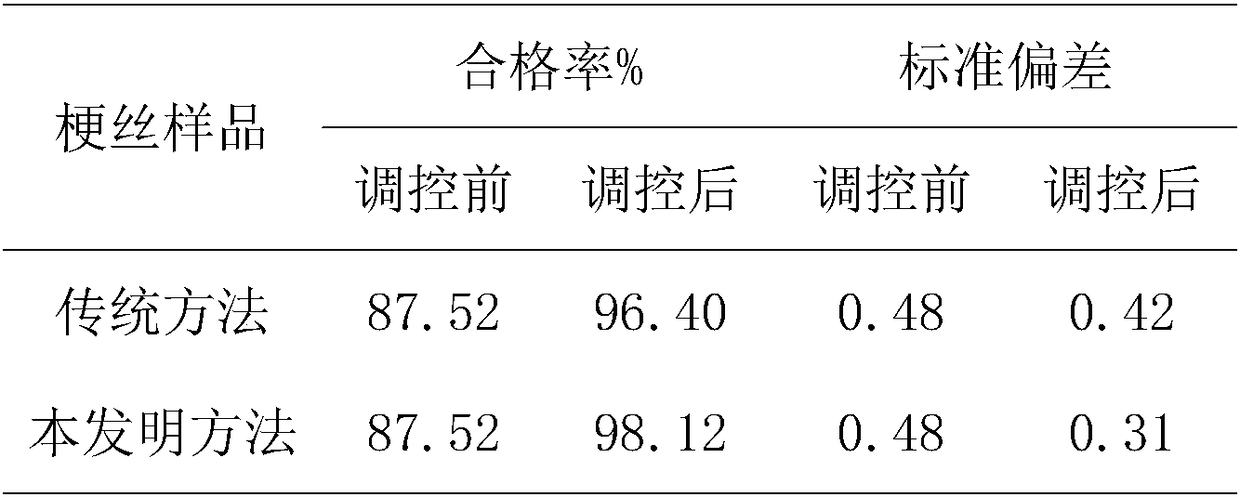

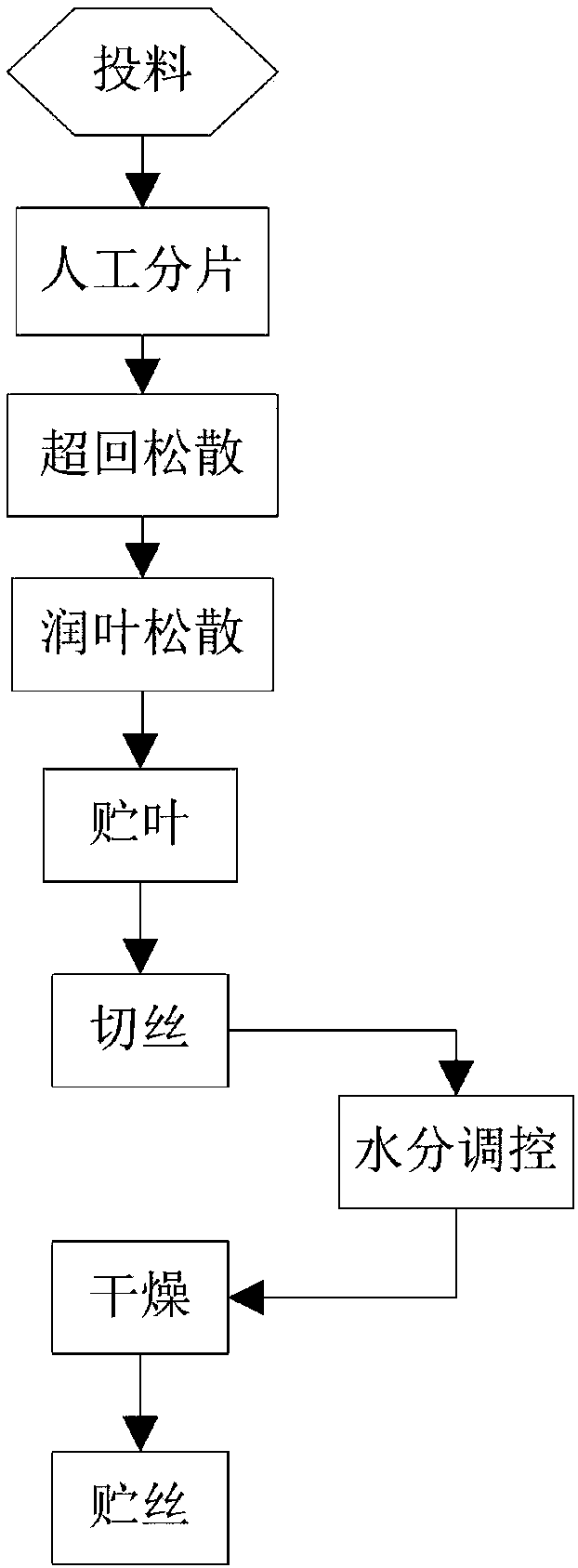

Method for improving tobacco shred preparing quality stability

InactiveCN108308691ASmall process changesRenovation investment is smallTobacco preparationEngineeringUltimate tensile strength

The invention provides a method for improving the tobacco shred preparing quality stability. The method specifically includes the steps of material putting, primary moisture regaining, stored leaf preparing, secondary moisture regaining, stored leaf distributing, shredding, moisture controlling, shred drying, mixing, flavoring and storing. The moisture controlling process is added after shredding,so the problems that due to the long process route, the material process water content is greatly influenced by the environment temperature and humidity and the shred drying inlet water content of different batches fluctuates obviously are solved, the incoming material water content of the shred drying process is stabilized, the stability of the water content of different batches of materials entering the shred drying process is ensured, the shred drying machine outlet material water content meets the processing requirement, and therefore the processing intensity and dewatering amount of theshred drying process of different batches are stabilized, and the stability of the sensory quality of shred drying outlet materials is ensured; compared with other methods, the method has the advantages of being small in technological change, small in refitting investment, capable of saving energy and reducing consumption and free of newly constructing or refitting of a factory.

Owner:HONGTA TOBACCO GRP

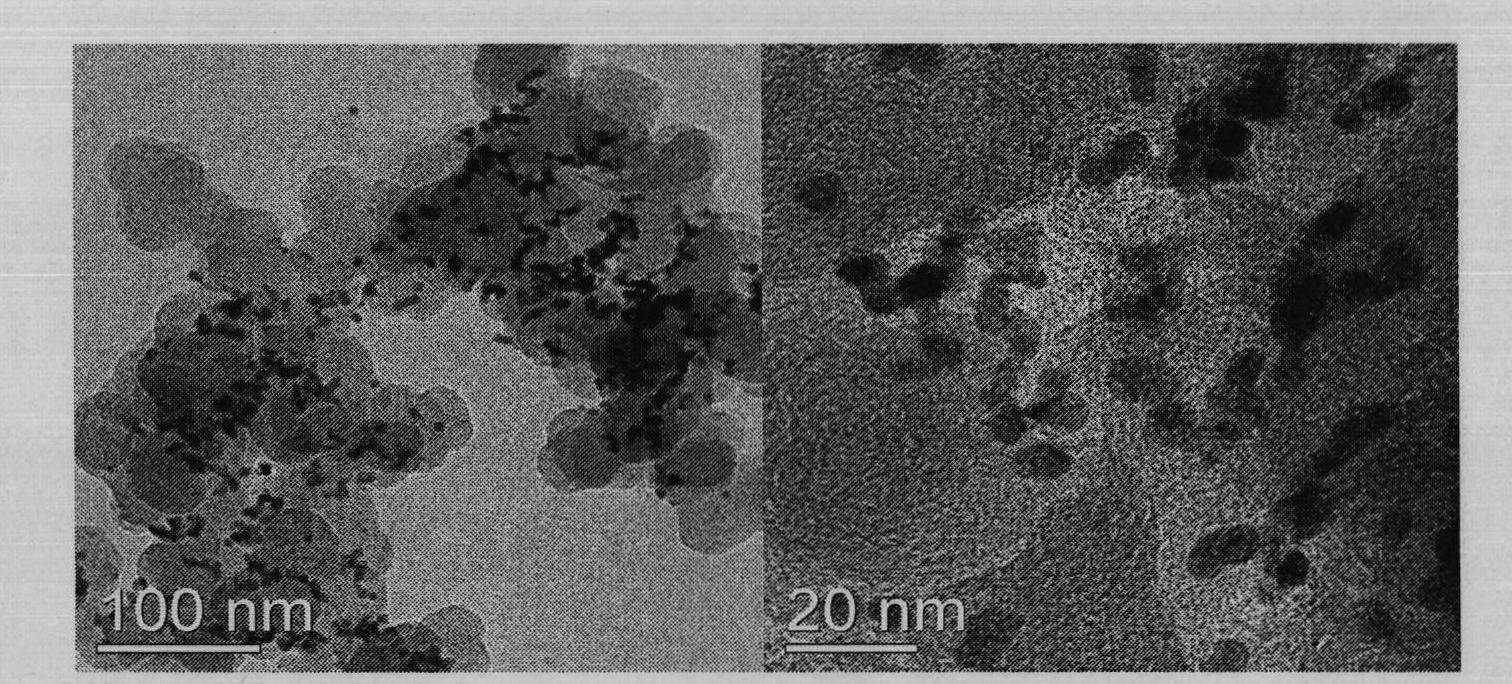

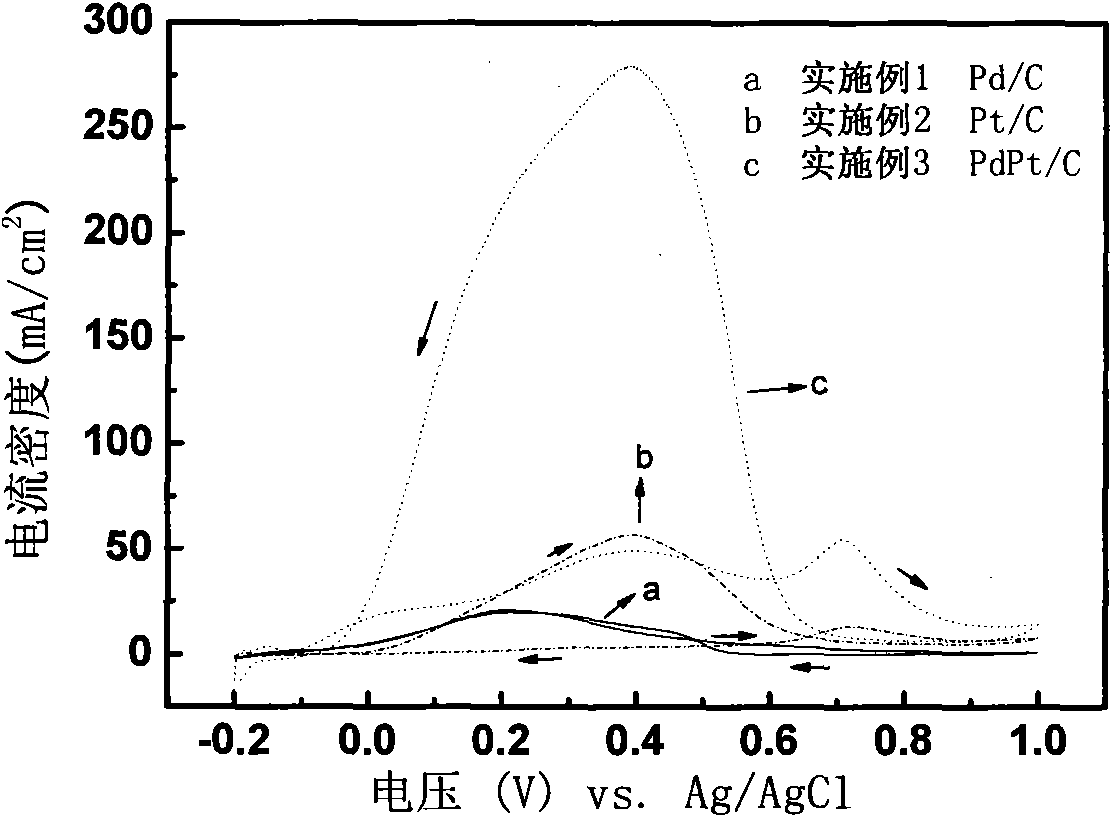

Air cathode-based miniature direct formic acid fuel cell

InactiveCN102136590AOvercome the disadvantage of being easily corroded by formic acidLower internal resistanceFuel cell heat exchangeCell electrodesProtonEngineering

The invention discloses an air cathode-based miniature direct formic acid fuel cell. A seal washer is respectively arranged inside an anode collector plate and a cathode collector plate; a membrane electrode is arranged between the two seal washers; one side, positioned on the cathode collector plate, of the membrane electrode is provided with a cathode gas diffusion layer; one side, positioned on the anode collector plate, of the membrane electrode is provided with an anode diffusion layer; an end plate is arranged outside the anode collector plate; a liquid storage cavity is reserved between the anode collector plate and the end plate; and a seal washer is arranged between the anode collector plate and the liquid storage cavity as well as between the liquid storage cavity and the end plate. In the cell, formic acid serves as a fuel; a proton exchange membrane on which a catalyst is sprayed serves as the membrane electrode; an air electrode is adopted directly; the structure is simple; the cell is convenient to detach; cell weight is reduced; reaction heat is collected effectively; the volatilization of the formic acid is reduced by a relatively closed system; and different discharge requirements of equipment on a power supply can be met by adopting different catalysts.

Owner:SOUTH CHINA UNIV OF TECH

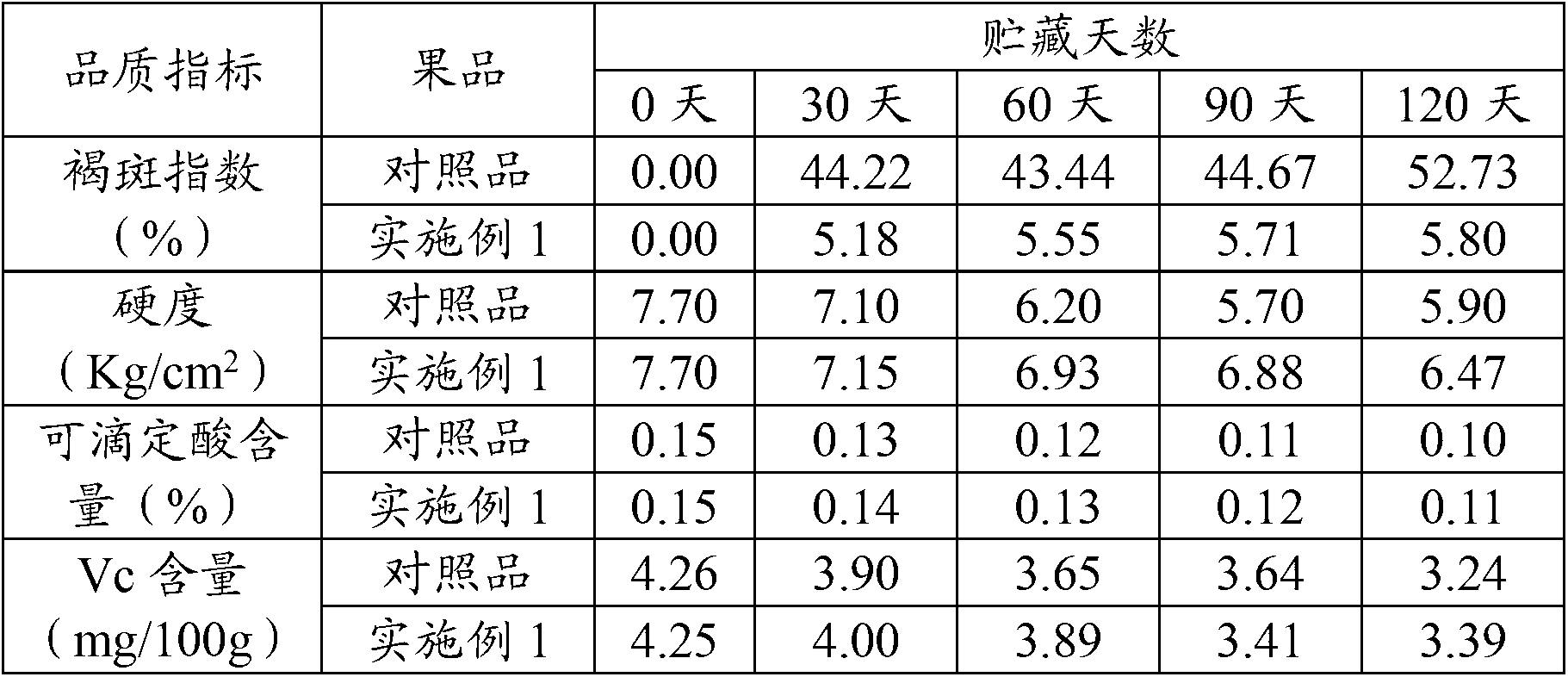

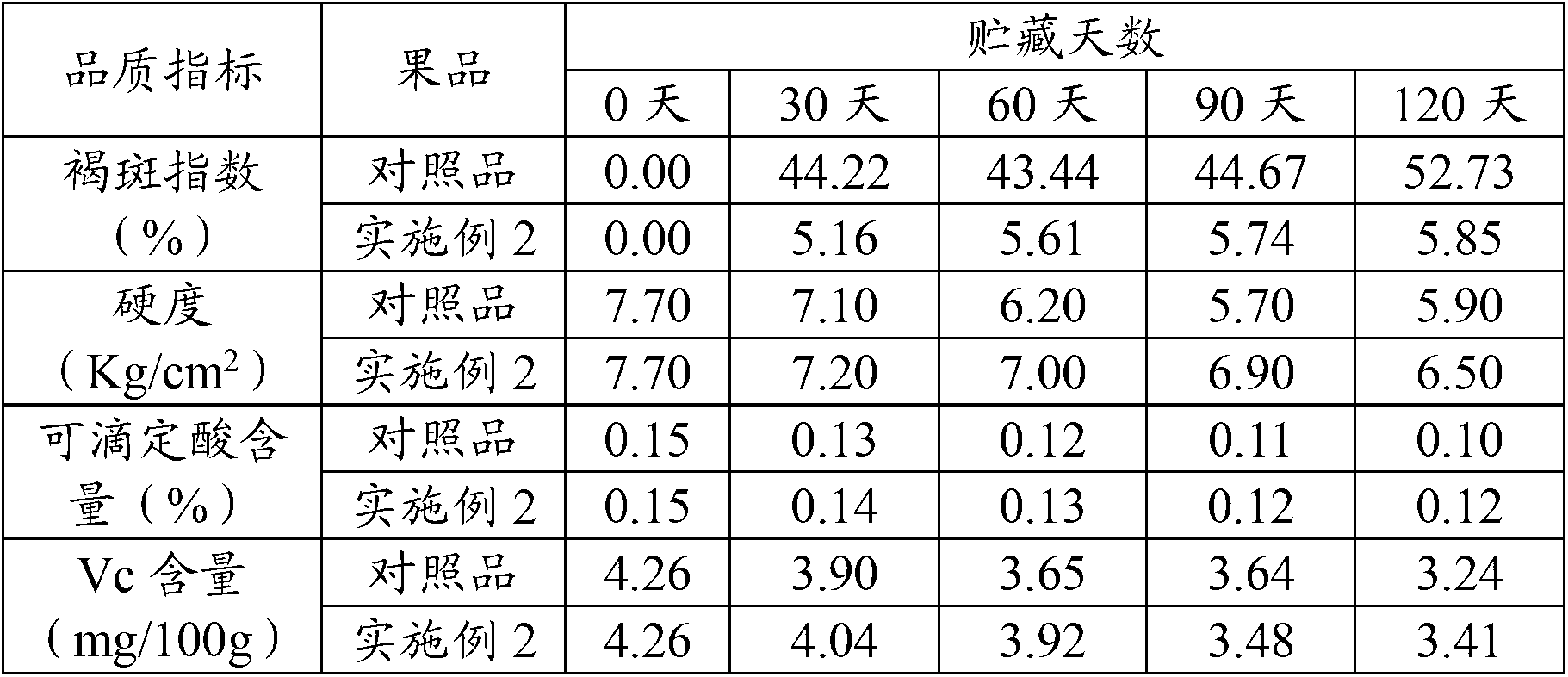

Storage and fresh-keeping comprehensive treatment method for Huangguan pears

ActiveCN103053675ALow costImprove storage qualityFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingFlavorFilm coating

The invention discloses a storage and fresh-keeping comprehensive treatment method for Huangguan pears. The comprehensive treatment method comprises seven steps of harvesting in the optimum period, calcium supplementing treatment, film coating treatment, 1-methylcycloproene treatment, packaging, pre-cooling and refrigerating; and the method comprises the steps of pre-cooling in the harvesting period and after the harvesting period as well as other treatment steps, all the steps are interlocked and indispensable, and the method has a good fresh-keeping effect. The method disclosed by the invention can effectively control the phenomena that the Huangguan pears are softened, wilted and decayed, and have superficial browning spots and thinned flavors, and the like in the process of storage, thereby facilitating the original flavor and quality of fruits.

Owner:HEBEI ACADEMY OF AGRI & FORESTRY SCI INST OF GENETICS & PHYSIOLOGY

Air conditioning system for spinning workshop and control method

InactiveCN106545937AReduce consumptionGuaranteed moisture contentMechanical apparatusSpace heating and ventilation safety systemsFrequency changerSpinning

The invention discloses an air conditioning system for a spinning workshop. The system comprises an exhaust adjusting window, a fresh air adjusting window, a return air adjusting window, a condensation pump, a cooling adjusting valve, a heating adjusting valve, a shower nozzle and a water circulation system and further comprises a frequency converter, a temperature and humidity and flow detection piece, a central controller unit and a monitoring unit. The invention further discloses a regulating method for the air conditioning system. The method comprises the steps of: the central controller unit calculates indoor and outdoor enthalpy values of the spinning workshop by applying an enthalpy value calculating formula and compares results; when the outdoor enthalpy value is greater than the indoor enthalpy value, the exhaust adjusting window and the fresh air adjusting window are closed, and the return air adjusting window is thoroughly opened, and the central controller unit controls freeze water and / or steam heating to adjust air; and when the outdoor enthalpy value is smaller than the indoor enthalpy value, the central controller unit firstly controls the exhaust adjusting window, the fresh air adjusting window and the return air adjusting window in real time according to a set value, and then regulates by combining the freeze water and / or steam heating. By utilizing a natural energy source, consumption of steam and freeze water is reduced, and consumption of electrical energy is reduced.

Owner:河南华东工控技术有限公司

High-efficiency dust suppressant for urban roads

InactiveCN109082265AImprove bonding effectStrong material strengthOther chemical processesWater contentChemistry

The invention discloses a high-efficiency dust suppressant for urban roads. The dust suppressant consists of the following components in percentage by mass: 0.1-40 % of water retaining agent, 0.1-40 %of adhesive, 0.1-5.0 % of wetting agent, 0.01-5 % of accelerator, and 20-80 % of water. The accelerator and the adhesive contained in the dust suppressant have more reaction sites, wherein the accelerator can react with main effective adhesive substances for curing reaction crosslinking in the process of spraying and drying of the dust suppressant, and thus the bonding effect of the adhesive is enhanced, the acting force between dust is strengthened, and a combination, which finally forms, has stronger material strength, and can resist the shearing force and pressure of vehicles on the road surface to a greater extent, so that the dust suppression effect is enhanced. The water retaining agent in the dust suppression agent is a high-efficiency water-absorbing substance, ensures the road surface to keep a certain water content, and can be matched with the wetting agent to adapt to different environments in different regions and ensure the dust suppression effect of the roads.

Owner:ZHEJIANG UNIV

Method of maintaining tender texture and flavour of frozen fresh water shrimp and crab

InactiveCN1823630AReduce oxidationIncrease moisture contentFood preservationFood preparationShrimpAntioxidant

A method for maintaining the tender texture and taste of frozen fresh-water shrimp, crab, or other aquatic products with shell includes such steps as washing the fresh living ones, immersing in the solution of water preserving agent and antioxidant, steaming, quick freezing, vacuum packing and cold storage.

Owner:JIANGNAN UNIV

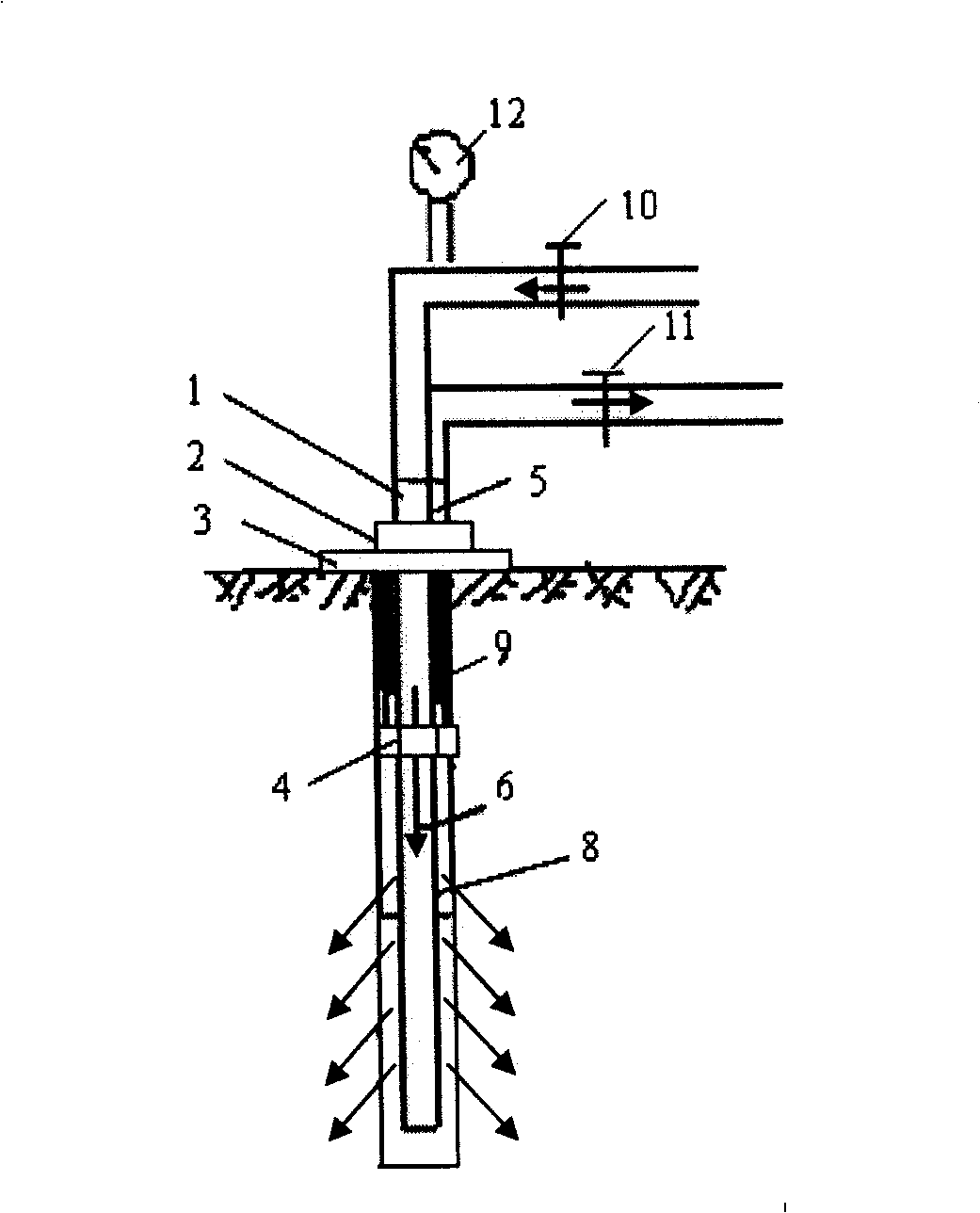

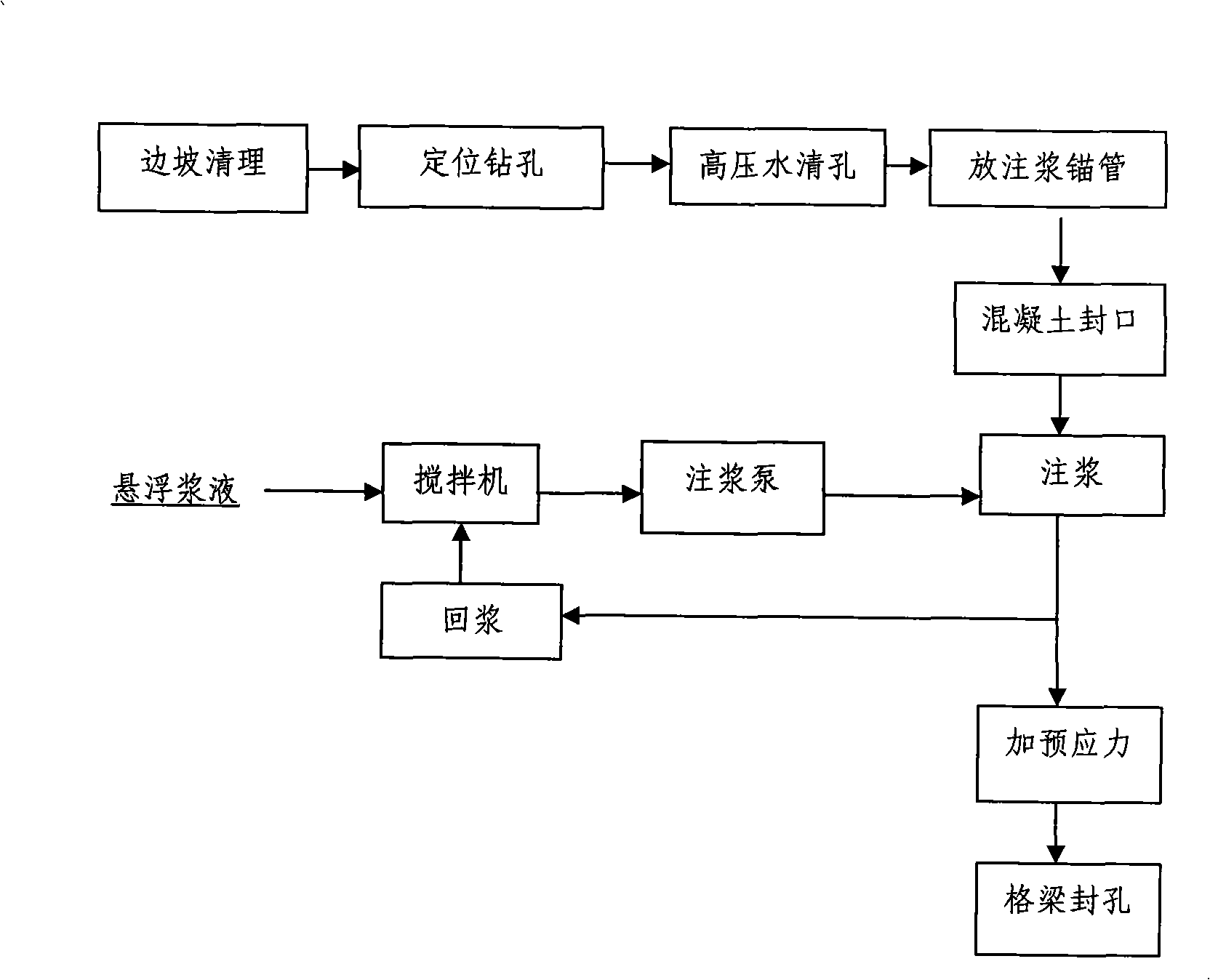

Weak surface rock slope grouting method and anchor tube for grouting

InactiveCN101260672ASimple structureEffectively retain moistureExcavationsBulkheads/pilesSlurryUltimate tensile strength

The invention discloses a weak-plane rock side slope grouting method and an anchor pipe for grouting. An anchor hole is drilled; the diameter of the anchor hole is more than the outside diameter of the anchor pipe body of at least 100 mm; the anchor pipe is placed in the anchor hole; concrete is filled in the anchor hole mouth; suspended grout in a double layer stirring mill is pressed to the anchor pipe for grouting by a grouting pump; when the grouting flow rate is more than the flow rate of grout absorption by rock or the grouting pressure is larger than the shearing resisting intensity of fissure filling in a shallow layer rock body, a grout returning valve is started in order that the grout in the hole returns to a grout storage barrel of the double layer stirring mill for circulating grouting. The weak-plane rock side slope grouting method and the anchor pipe for grouting effectively solve the difficult problems that the prior pressing in type grouting is easy to leak the grout, can not completely fill the fissure and can not be suitable for reinforcing the shallow layer. The circulating grouting method of the invention enlarges the grouting scope, improves the injection rate by the single hole, can effectively reinforce the water seepage and corrosion resisting capacity in the interlayer of the side slope and improve the stabilizing capacity of the whole side slope. The anchor pipe of the invention has the advantages of simple structure, easy manufacture and low costs.

Owner:CENT SOUTH UNIV

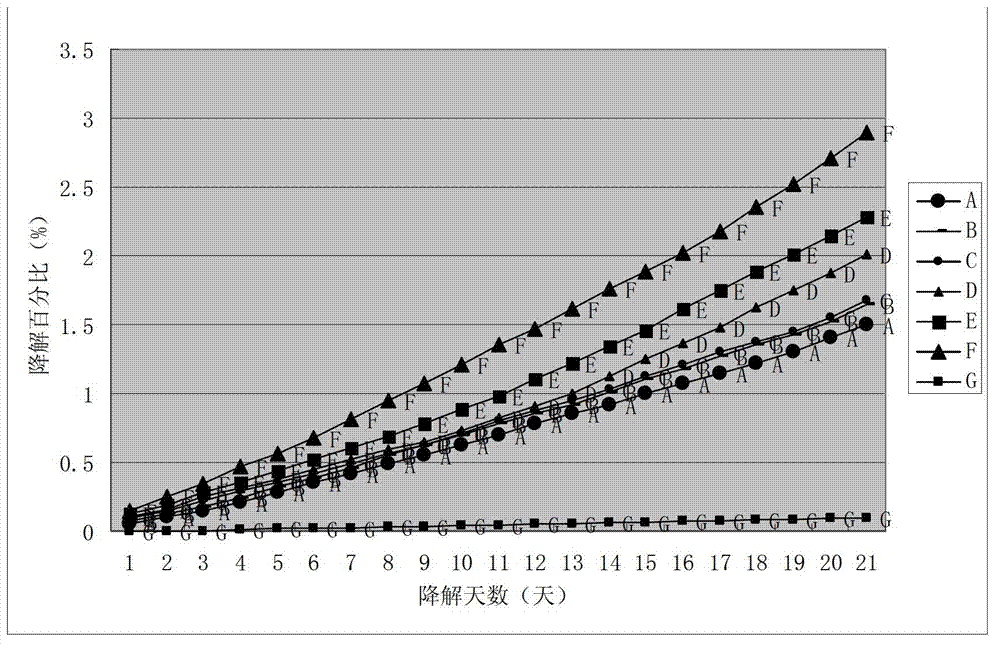

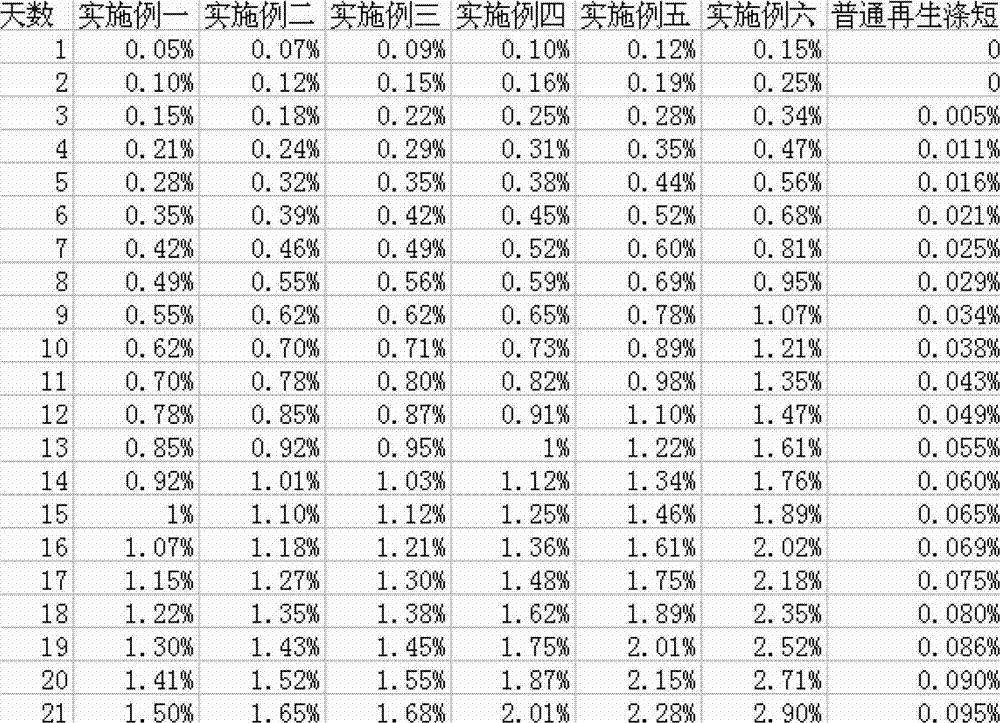

Preparation method of biodegradable regenerated polyester staple fibers

ActiveCN102828276APrevent volatilizationBalanced moistureFilament forming substance formingArtificial filament heat treatmentPolyesterPolymer science

The invention discloses a preparation method of biodegradable regenerated polyester staple fibers, which is characterized by comprising the steps of drying spinning materials by a vacuum drum, mixing with biodegradable master batch dried by a master batch drying system at the feed inlet of a screw extruder; preparing primary fibers after mixing and fusing by the screw extruder and extruding by a spinneret plate; cooling primary fibers by an annular blowing device; successively carrying out winding, falling, bundling and time balancing on the primary fibers in a constant temperature and constant-humidity room; stretching the primary fibers in oil bath and stream respectively; performing curling, relaxation heat setting, cutting and packaging to obtain biodegradable regenerated polyester staple fibers, wherein physical properties and mechanical properties of the biodegradable regenerated polyester staple fibers produced by the method do not change, and therefore, the subsequent processing and usage are not influenced; after being used, the fibers can be decomposed into inert humus, carbon dioxide and water in a microorganism-enriching environments such as refuse landfill or composting site, thereby returning to nature and achieving real biodegradation.

Owner:福建鑫华股份有限公司

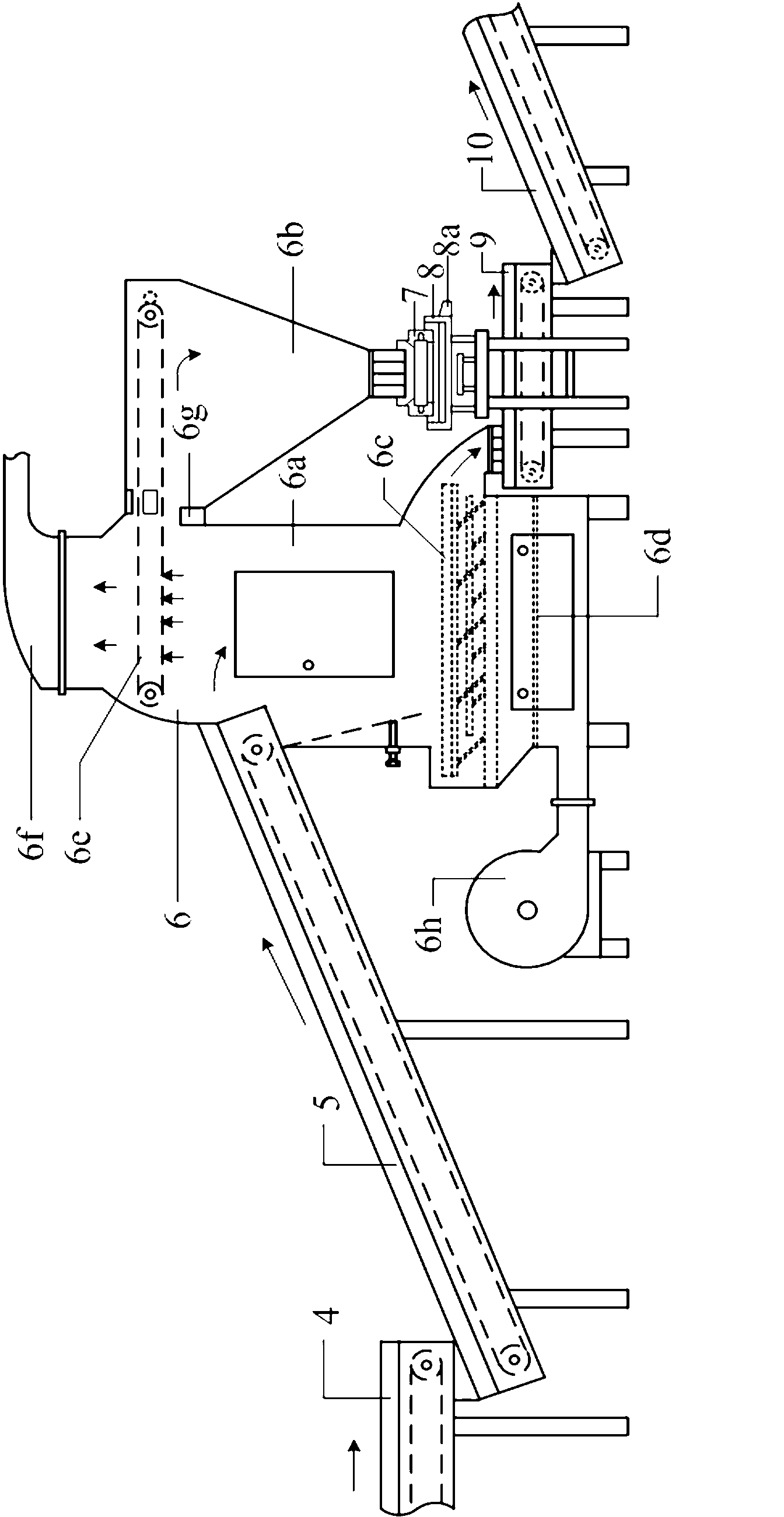

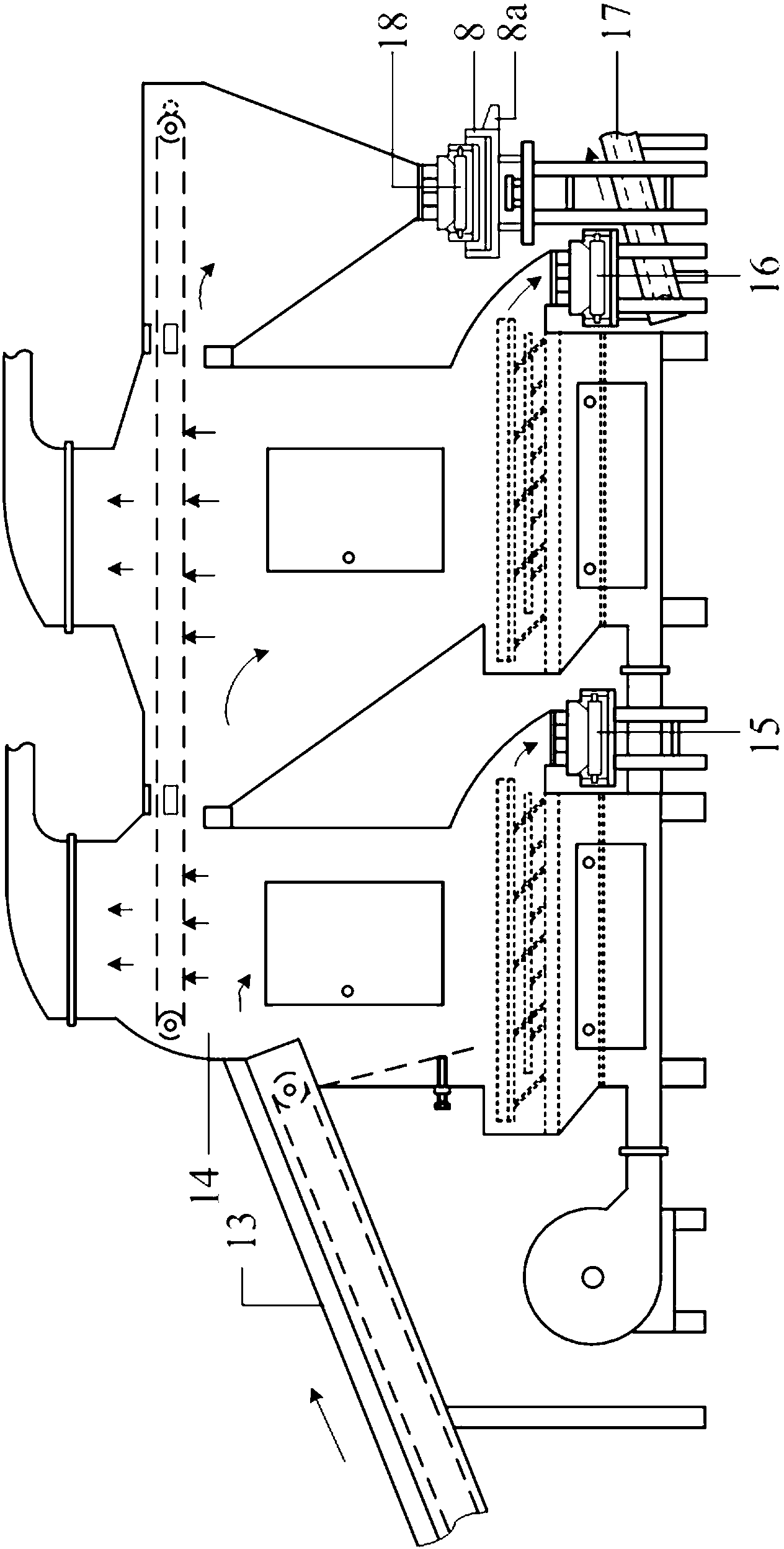

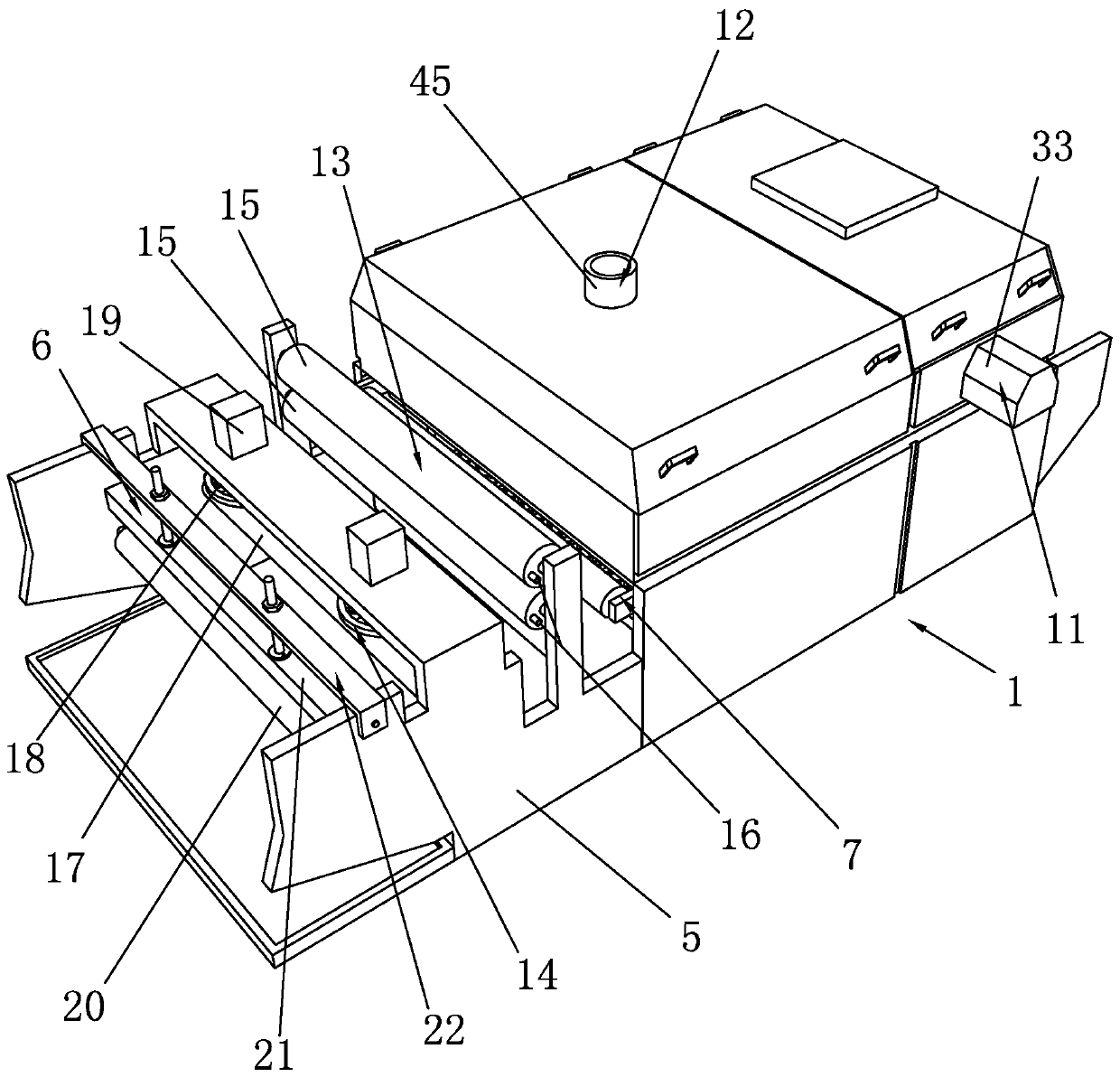

Efficient and energy-saving threshing and air separation process and equipment

ActiveCN103263074ALayout specificationImprove production continuityTobacco treatmentGas current separationProcess engineeringAir separation

The invention relates to an efficient and energy-saving threshing and air separation process and equipment, belonging to the technical field of tobacco material air separation processes and equipment. Four air pressure type double-storehouse air separators are arranged between a first-stage threshing unit and a second-stage threshing unit and connected with one another in parallel, two air pressure type three-storehouse air separators are arranged between the second-stage threshing unit and a third-stage threshing unit and connected with each other in parallel, and air pressure type three-storehouse air separators are arranged between the third-stage threshing unit and a fourth-stage threshing unit as well as behind the third-stage threshing unit and the fourth-stage threshing unit and connected with each other in series. Materials are conveyed by a conveying belt and a vibration groove instead of a conventional air pipeline, so that the materials are not easy to block, the temperature and moisture loss of the materials are reduced, the grinding probability of the materials due to drying is reduced, the transmission power is low, the energy consumption and the noise are greatly reduced, and the large-medium sheet rate of discharged tobacco sheets is increased.

Owner:HONGTA TOBACCO GRP

Straw rubbing process

The invention provides a straw rubbing process, which comprises the following operating steps: 1) carding raw material straws, removing sundries, such as broken pieces and the like, and cutting fringe pulling ends away; 2) rolling the straws with a continuous roll squeezer; 3) softening the straws with vapor; 4) drying the straws and controlling water content; 5) rubbing the straws with a straw rubbing machine to obtain straw threads and removing dust during the rubbing process; and 6) screening the straw threads to extract the straw threads with lengths not less than 5cm and diameters of 1 to 3mm. The process has the advantages of simple operation, easy implementation, low cost, high efficiency, no pollution to the environment, relatively longer silky fibers and high mechanical strength, and is mainly used for manufacturing products, such as a vegetation carpet, a green pad and the like.

Owner:SICHUAN UNIV

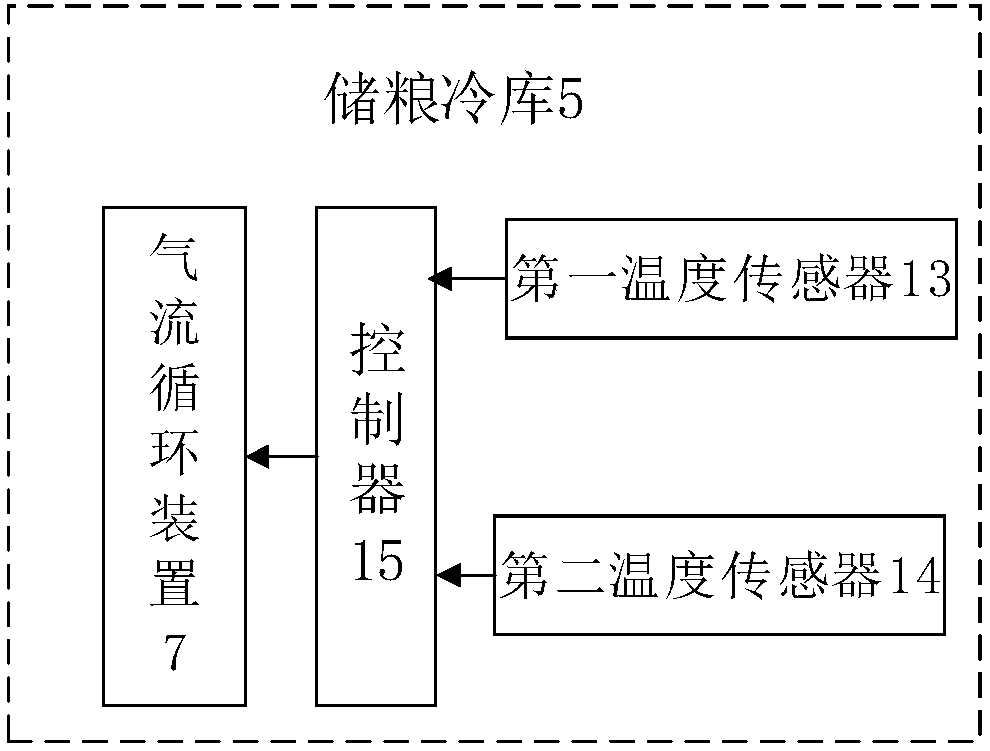

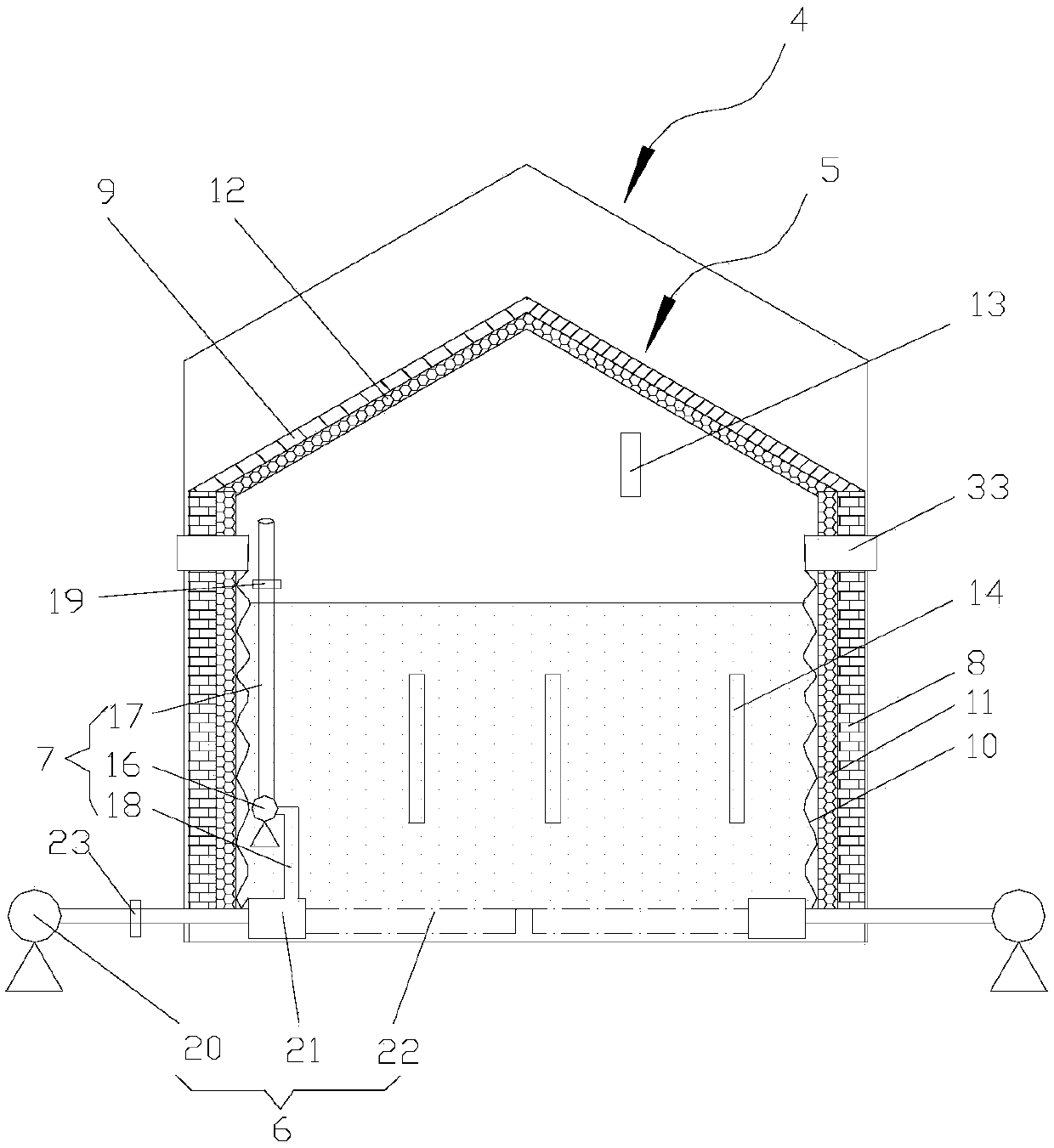

Grain storage refrigeration house and grain storage method

ActiveCN107896650AIncrease moistureImprove qualityAgriculture tools and machinesHarvested fruit hanging devicesTemperature controlMoisture condensation

The invention relates to a grain storage refrigeration house and a grain storage method, the grain storage refrigeration house comprises a grain storage bin body, a sealed grain storage refrigerationhouse is arranged in the grain storage bin body, grain is stored in the grain storage refrigeration house, and at least one set of air supply mechanism 6 is arranged at the bottom of the grain storagerefrigeration house; at least one set of air circulation device is arranged in the grain storage refrigeration house and used for pumping the air above the grain surface in the grain storage refrigeration house to the grain bottom for internal circulation; a controller controls operation of the air circulation device according to the received temperature of the a first temperature sensor; or thecontroller controls operation of the air circulation device according to the temperature difference of the first temperature sensor and a second temperature sensor. According to the grain storage method, air is conveyed in winter and used for internal circulation in next summer, the temperature difference of the grain surface and the inside of a grain heap is reduced, moisture condensation cannotoccur to the grain heap, the condition of grain mildewing is avoided accordingly, ageing is not easy to occur to the grain and the good moisture can be kept, and the stored grain quality is improved.

Owner:谷晓辰

Immobilized method and application of petroleum degrading bacteria

ActiveCN103773752AGood repair effectSimple preparation processContaminated soil reclamationOn/in organic carrierContaminated soilsActivated carbon

The invention discloses an immobilized method and application of petroleum degrading bacteria. The method includes the following steps: mixing and pretreating carrier materials of wheat straw, corn straw, wheat bran, leaves and walnut shell activated carbon; inoculating an activated petroleum degrading bacterium seed liquid, and carrying out adsorption culture; and filtering out an upper bacterial suspension under aseptic conditions, rinsing the carrier materials with sterile water, transferring the carrier materials adsorbed with bacteria to a new petroleum degrading bacterium seed liquid, repeating several times to reach saturation of the bacteria adsorbed by the carrier materials, so as to obtain the immobilized particles. The invention uses the natural organic materials and natural inorganic materials as carriers to overcome the defects of the individual usage of inorganic carrier or organic carrier; adsorption method is employed to realize immobilization of petroleum degrading bacteria; and the prepared immobilized petroleum degrading bacteria can be applied to in-situ remediation of petroleum contaminated soil to reach good effect, and is an environmentally friendly product which can be popularized and applied.

Owner:CHINA PETROLEUM & CHEM CORP +1

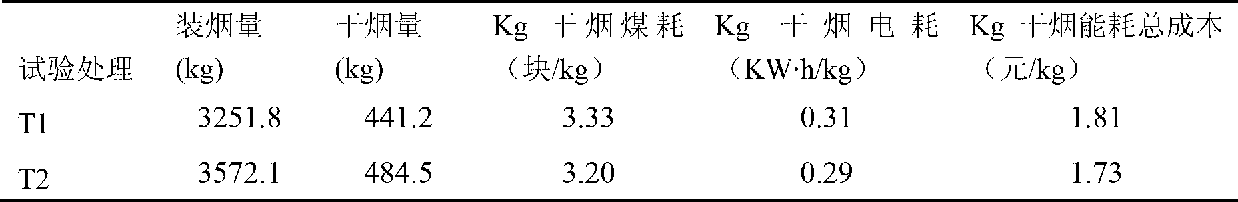

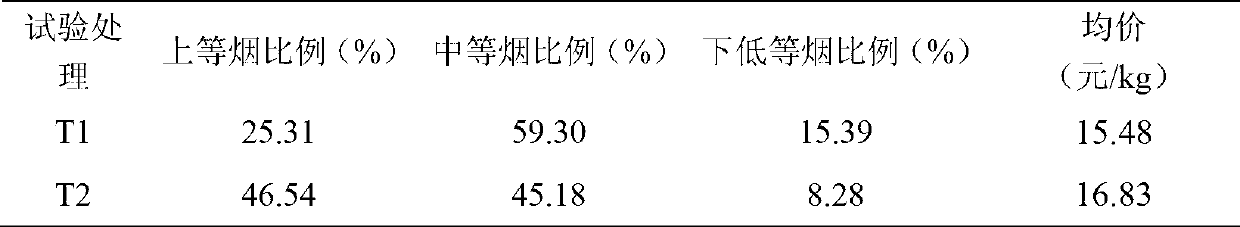

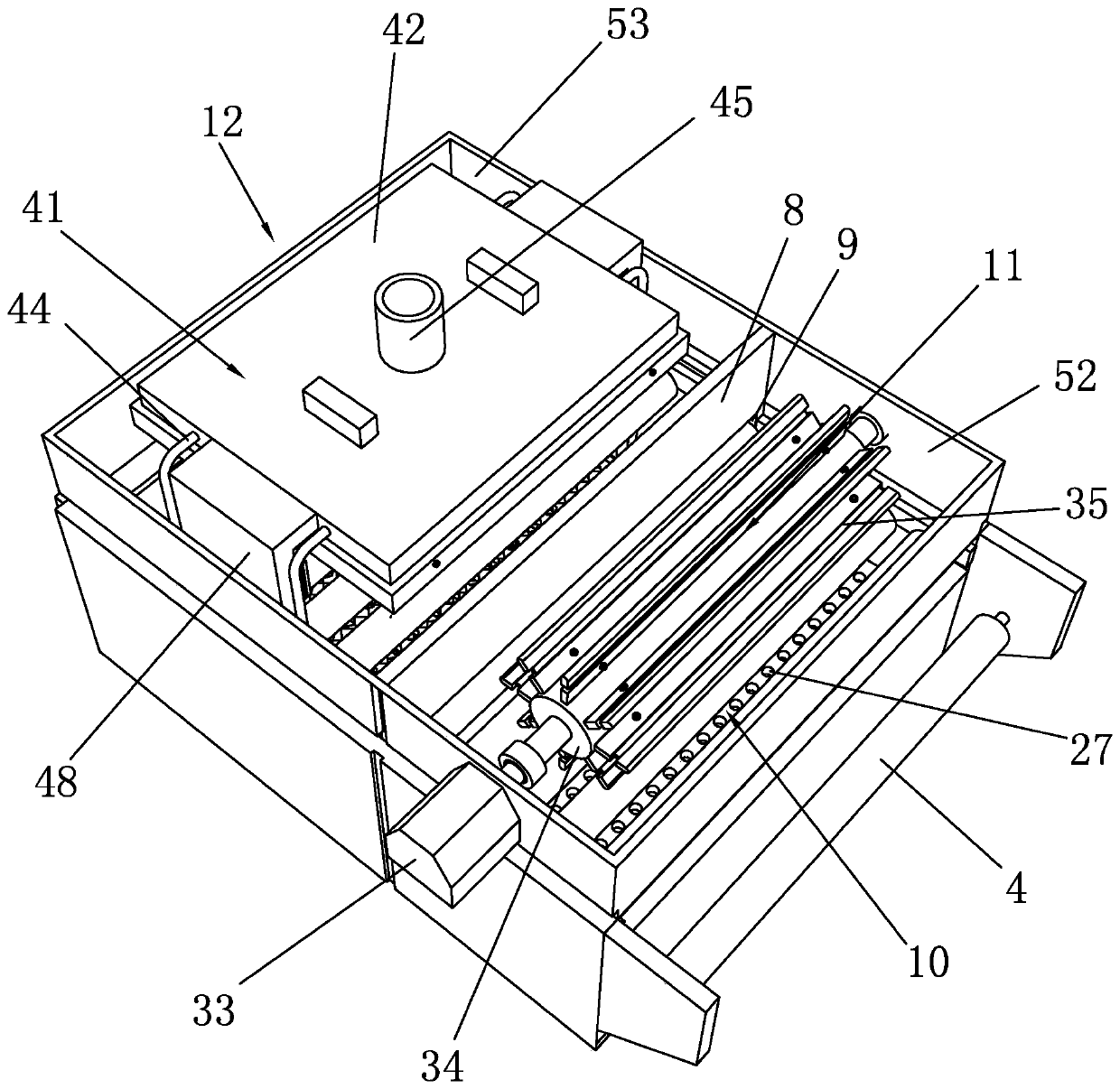

Tobacco leaf prewilting baking process for bulk curing barn

InactiveCN102987540ALarge amount of smokePromote post-ripening and physiological and biochemical reaction processTobacco preparationCuring of tobaccoLeaf blade

The invention provides a tobacco leaf prewilting baking process for a bulk curing barn. The tobacco leaf prewilting baking process for the bulk curing barn provided by the invention comprises the concrete steps of clamping the collected fresh tobacco leaves with a weaving pole or a tobacco clamp, prewilting on a shady tobacco hanging frame, so that the tobacco leaves meet prewilting requirement, then transferring the tobacco leaves into the bulk curing barn, and warming for twice to meet the yellowing requirement, wherein 2-3cm of apex of the tobacco leaves from a bottom shed to a middle shed is in an almost dry state; then warming for twice and baking until the tobacco leaves are dried into large winding drums and leaf blades are absolutely dry; and then warming at the speed of 0.5 DEG C per hour until the temperature is increased to 68 DEG C, controlling wet bulb temperature to be 42-43 DEG C, and maintaining rotating speed of a fan to be 720 revolutions until stems of the tobacco leaves are completely dry. By adopting the tobacco leaf prewilting baking process provided by the invention, tobacco leaf stacking capacity of the bulk curing barn is greatly increased, baking energy consumption is reduced, and the problem that starch content of the tobacco leaves after being baked and mixed colour tobacco proportion are high is solved, so that economic character of the tobacco leaves after being baked is improved.

Owner:TOBACCO RES INST OF HUBEI PROVINCE

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

Soil conditioner and preparation method thereof

InactiveCN106966780AGuaranteed oxygen contentGuaranteed moisture contentCalcareous fertilisersAgriculture tools and machinesPorosityMicrobial agent

The invention provides a soil conditioner and a preparation method thereof. The soil conditioner comprises, by weight, 12 to 20 parts of plant ash, 5 to 10 parts of phosphorous slag, 5 to 9 parts of quicklime, 2 to 5 parts of zeolite, 2 to 5 parts of attapulgite, 1 to 3 parts of Yilong seaweed ooze, 2 to 5 parts of Chinese magnoliavine residues, 2 to 5 parts of large-flowered skullcap root residues, 20 to 30 parts of straw, 8 to 13 parts of hickory nut shells, 0.02 to 0.04 part of rotenone, 10 to 15 parts of mangosteen shells, 3 to 5 parts of an EM microbial agent, 7 to 20 parts of urea phosphate, 8 to 14 parts of urea, 10 to 15 parts of biochemical potassium fulvate and 9 to 12 parts of gamma-polyglutamic acid. The invention has the beneficial effects that the soil conditioner has high porosity and has specific adsorption effect on heavy metal ions; the soil conditioner can adjust the pH value of soil, is rich in trace elements and can elemental N, elemental P and elemental K at the same time; and the soil conditioner allows soil to maintain high porosity and to be long in fertility maintenance time and good in water retention performance.

Owner:嵊州市派特普科技开发有限公司

Southern Chinese year potted landscpe cultivating method

InactiveCN1774987AGuaranteed moisture contentTightly boundHorticulture methodsHuman bodyLand preparation

The present invention relates to a method for cultivating Chinese yew by utilizing pot. Said method includes the following steps: a), soil detection; b), cleaning and land preparation; c), seed seedling selection and cultivation; d), applying fertilizer in soil; e), cultivating seedling and f), transplanting. The Chinese yew grown in the pot can be used for releasing beneficial gas to human body to produce the action of sterilization and purifying air.

Owner:褚菊芬

Screening method of rice field seedling-raising mud

ActiveCN108901757AGuaranteed moisture contentAvoid damageGrowth substratesCulture mediaProduction rateShake up

The invention discloses a screening method of rice field seedling-raising mud. Screening is carried out by adopting a rice field seedling-raising mud screening machine. Soil blocks firstly enter intoa crushing area in a mud stirring conveying device through a feed hopper of the rice field seedling-raising mud screening machine; a first stirring shaft and a second stirring shaft rotate to drive soil crushing rods to crush the soil blocks and stir the crushed soil blocks for forming small granules; the small granules are driven by a conveying spiral to enter a spiral propulsion area; the smallgranules are mixed with water to form mud; the mud flows into a vibrating screen body through a stirring discharge guide plate; after the mud is shaken up and down by a vibrating transverse groove body and a vibrating sieving body, mud with a particle diameter smaller than the diameter of vibrating sieving hole falls into a mud collecting box, so that the mud required for the seedling raising is obtained; and impurities and the like remaining on the vibrating sieving body gradually moves forward along with the moving of the vibrating sieving body, and falls into an impurity collecting box. Thescreening effect is remarkable, the labor intensity is effectively reduced, and the productivity is improved.

Owner:HUNAN AGRICULTURAL UNIV

Dried fruit sesame pancakes and making method thereof

InactiveCN101803666AChange the form of a single raw material varietyGreat tasteConfectionerySweetmeatsSesamumBiology

The invention relates to dried fruit sesame pancakes and a making method thereof. The dried fruit sesame pancakes are made by mixing, forming and slicing the following raw materials by weight parts: mixing 40-50 parts of sesame, 2-10 parts of dried fruit particles with the grain diameters of 2-3 mm, 30-40 parts of syrup and 5-10 parts of granulated sugar and have the thickness of 2-3 mm. The making method comprises the following steps of: roasting the sesame, crushing and drying the dried fruit and adding the granulated sugar to candy; and mixing the sesame, the dried fruit and the decocted syrup, congealing, forming and slicing. The invention changes a single raw material variety mode of traditional sesame pancakes and adds a plurality of tastes. The dried fruit sesame pancakes have sweet taste, crisp mouthfeel and light and thin shapes, thereby being a leisure food for the young and the old, suiting different consumption needs, and having favorable market prospects.

Owner:尹相成

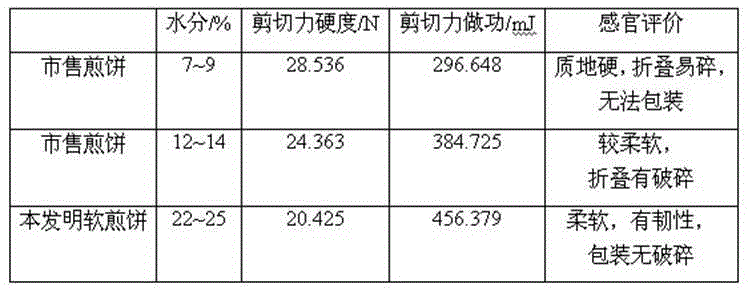

Soft fermented coarse pancake and producing method thereof

ActiveCN103814993AUnique and diverse flavorsThe ingredients are scientific and reasonableDough treatmentBakery productsSodium bicarbonateCarrageenan

The invention discloses a soft fermented coarse pancake and a producing method thereof. The soft fermented coarse pancake is made of raw materials including one of brown rice, sorghum, corn and millet, rice, flour, soybean, xanthan gum, carrageenan, sodium bicarbonate, ammonium bicarbonate, polydextrose, sodium pyrophosphate and sodium dehydroacetate. The producing method includes the steps: taking one of the brown rice, the sorghum, the corn and the millet as a main ingredient, and adding the rice, the flour and the soybean to mix well prior to adding water for soaking; adding water and grinding for fermentation; adding the xanthan gum, carrageenan, the sodium bicarbonate, the ammonium bicarbonate, the polydextrose, the sodium pyrophosphate and the sodium dehydroacetate to mix well to form coarse pancake paste; placing the coarse pancake paste on a griddle and evenly rolling the same into thin pancakes; evenly spraying sterile water on the pancakes and cooling the same to the indoor temperature to obtain soft fermented coarse pancakes. The soft fermented coarse pancake and the producing method thereof have the advantages that water content of the coarse pancakes can be increased; the coarse pancakes are soft and flexible in material, good in chewiness, easy to carry stuffing or vegetables for consumption, excellent in taste and worthy of high edible value.

Owner:BENXI ZHAIXIANG ECOLOGICAL AGRI

Fine processing process and production equipment for organic rice

InactiveCN105170222AGuaranteed biological activityGuaranteed NutrientsGrain treatmentsAdditive ingredientEngineering

Provided is a fine processing process for organic rice. Processing time is selected to be from the middle ten days of December to the first ten days of February in the next year, and the outdoor temperature is minus 10 DEG C or lower. The processing process includes the following steps of fine selection, unshelling, whitening, classification, color sorting and polishing, packing, quality inspection, large packing and warehousing; the finished organic rice is stored in the environment with the temperature ranging from 0 DEG C to 5 DEG C, and the storage time is no longer than 240 days since the organic rice is warehoused. As for the organic rice obtained through the method, it can be effectively guaranteed that the water content of the finished rice is controlled to range from 12% to 16%, the biological activity and nutritional ingredients of the organic rice are guaranteed, and nutrient matter loss is reduced to the minimum. The organic rice processed through the fine processing process and production equipment for the organic rice can be stored under the cold storage environment of a refrigerator for 6-8 months without losing activity, and even the unsealed organic rice can still be stored for 2-4 months under the cold storage environment of the refrigerator without losing activity.

Owner:沈阳久兴粮谷加工有限公司

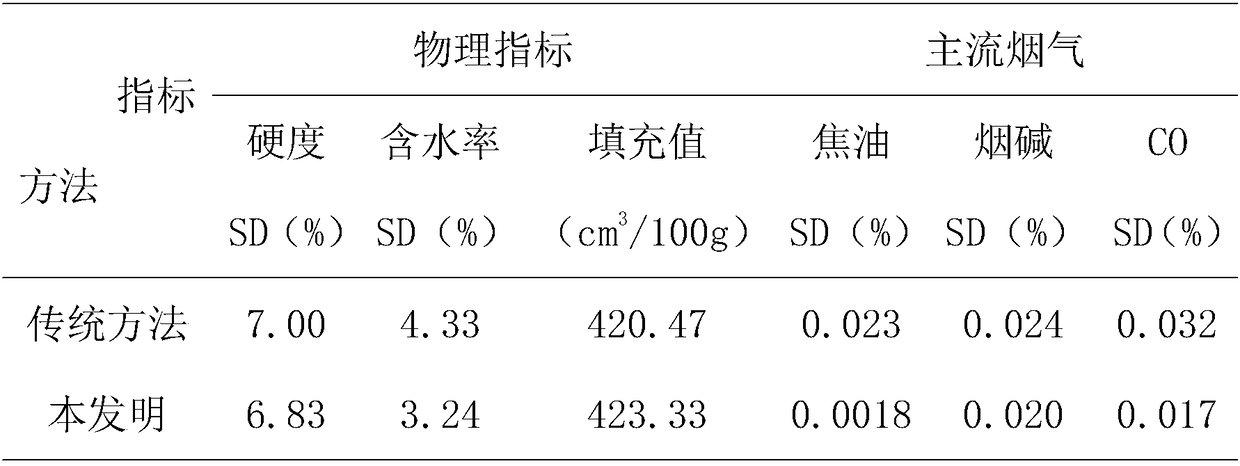

Method for improving tobacco shred making quality of reconstituted tobacco

InactiveCN108185504AImprove sensory qualityImprove processing strength and stabilityTobacco preparationMoisture absorptionEngineering

The invention provides a method for improving the tobacco shred making quality of reconstituted tobacco. The method comprises the specific steps of putting, manual fragmentation, super-return loosening, tobacco moistening and feeding, tobacco storage, shredding, moisture regulation and control, drying and tobacco shred storage. The process of moisture regulation and control is added, and the problems are solved that the technological path is long, the reconstituted tobacco has special moisture absorption performance, the water content in the material process is excessively influenced by the temperature and humanity of the environment, and accordingly the water content of batch-to-batch drying inlets is obviously fluctuated; the water content of shredded materials is stable, the stability of batch-to-batch moisture of the materials which enter the drying process is guaranteed, the water content of materials of drying outlets meets the processing requirement, the stability of the processing intensity and dewatering amount in the batch-to-batch tobacco shred drying process is achieved, and the stability of the smoking quality of the reconstituted tobacco shreds of tobacco shred dryingoutlets is guaranteed. Compared with other methods, the method has the advantages that the technological path is less changed, the reconstitution investment is low, the energy is saved, the consumption is lowered, and meanwhile workshops do not need to be newly built or rebuilt.

Owner:HONGTA TOBACCO GRP

Double-surface eurotium cristatum culturing technology of Fuzhuan tea

ActiveCN106912632ADiscriminant qualityAchieve surface bloomingPre-extraction tea treatmentHigh humidityWater content

The invention discloses a double-surface eurotium cristatum culturing technology of Fuzhuan tea. The double-surface eurotium cristatum culturing technology of the Fuzhuan tea is capable of efficiently realizing eurotium cristatum growth on surfaces of the Fuzhuan tea; moreover, the double-surface eurotium cristatum culturing technology is good in eurotium cristatum culturing effect, free of manual operation during eurotium cristatum culturing process, and low in manpower cost. The double-surface eurotium cristatum culturing technology comprises the following stages: (1), a high-temperature high-humidity stage, namely controlling the temperature of a eurotium cristatum culturing room at 26-29 and the humidity at 70-80% for 4-8 days; (2), a medium-temperature medium-humidity stage, namely controlling the temperature of the eurotium cristatum culturing room at 24-26 DEG C and the humidity at 55-65% for 4-5 days; (3), a low-temperature low-humidity stage, namely controlling the temperature of the eurotium cristatum culturing room at 18-22 DEG C and the humidity at 45-55% for 6-8 days; and (4), a drying stage, namely carrying out ventilated drying on the Fuzhuan tea until the water content is 12% or lower so as to finish the double-surface eurotium cristatum culturing. Being shaped by carrying out pressing, the Fuzhuan tea prepared by the double-surface eurotium cristatum culturing technology has a thickness of 2-5 centimeters.

Owner:SHAANXI JINGYANG JINGCHANGSHENG FUZHUAN TEA CO LTD

Standardization planting technology of cold-highland-area aconitum vilmorimianum kom

InactiveCN105532237ARipe fullyImprove fertilityPlant cultivationCultivating equipmentsDiseasePest control

The invention discloses a standardization planting technology of cold-highland-area aconitum vilmorimianum kom. The standardization planting technology includes the steps of 1, planting area selecting; 2, soil preparing; 3, seed selecting; 4, standardization cultivating; 5, field managing; 6, disease and pest preventing; 7, harvesting. By means of the planting technology of cold-highland-area aconitum vilmorimianum kom, a regular effect and a reasonable effect are achieved, the yield can be increased, quality can be guaranteed, and high-quality raw materials can be provided.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com