Patents

Literature

859results about How to "Small dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Road dust suppressant

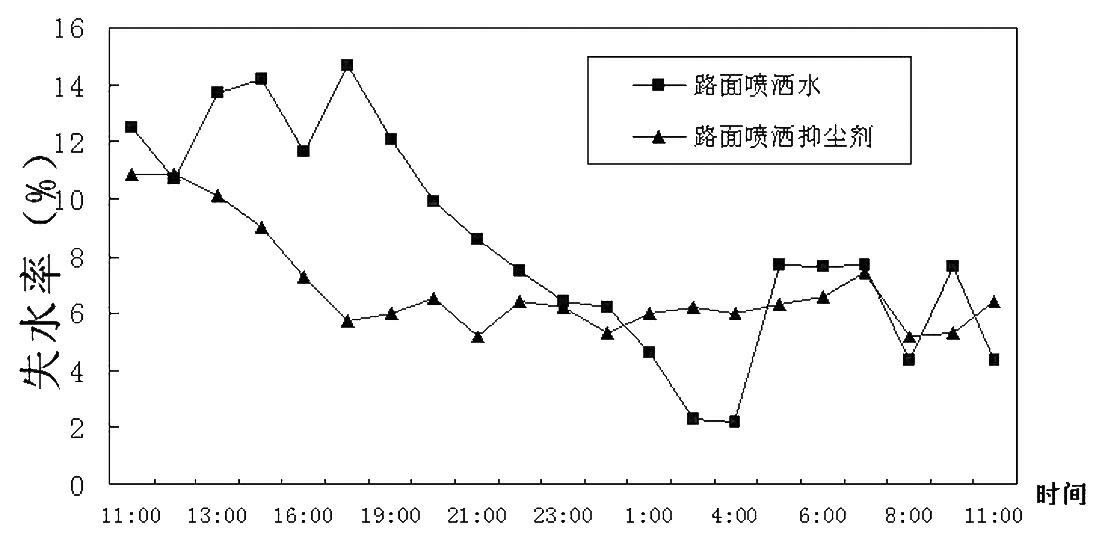

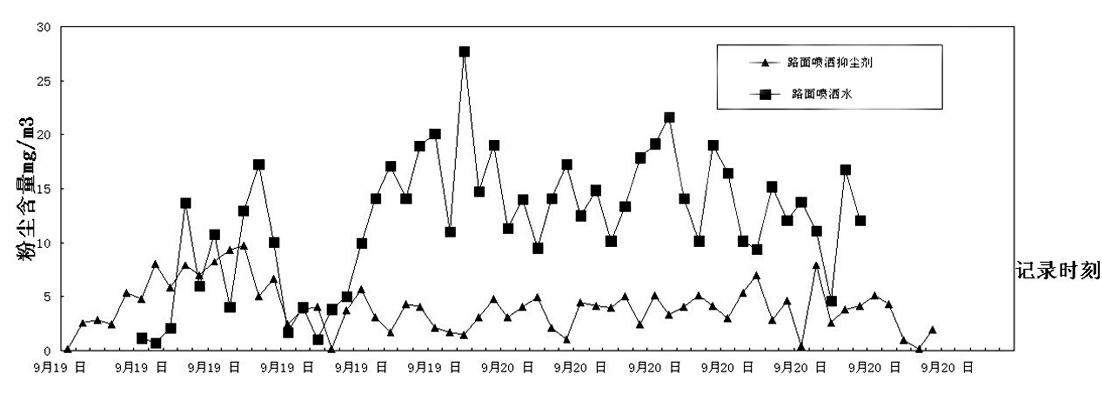

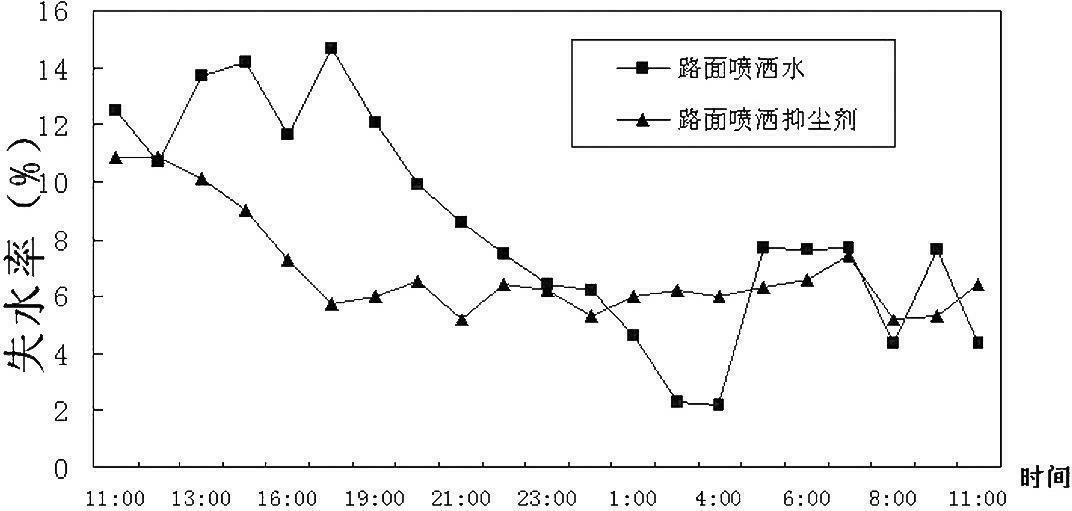

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

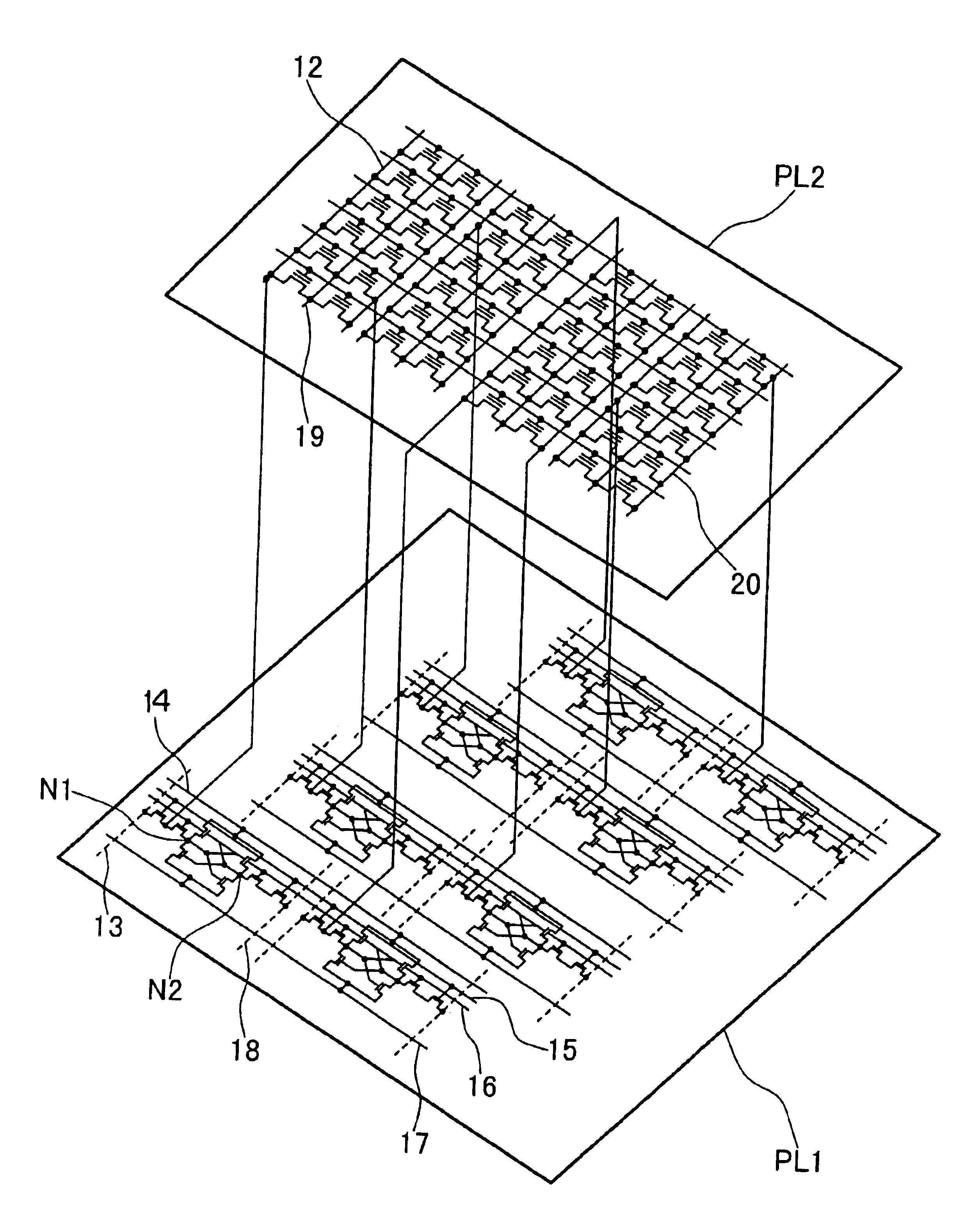

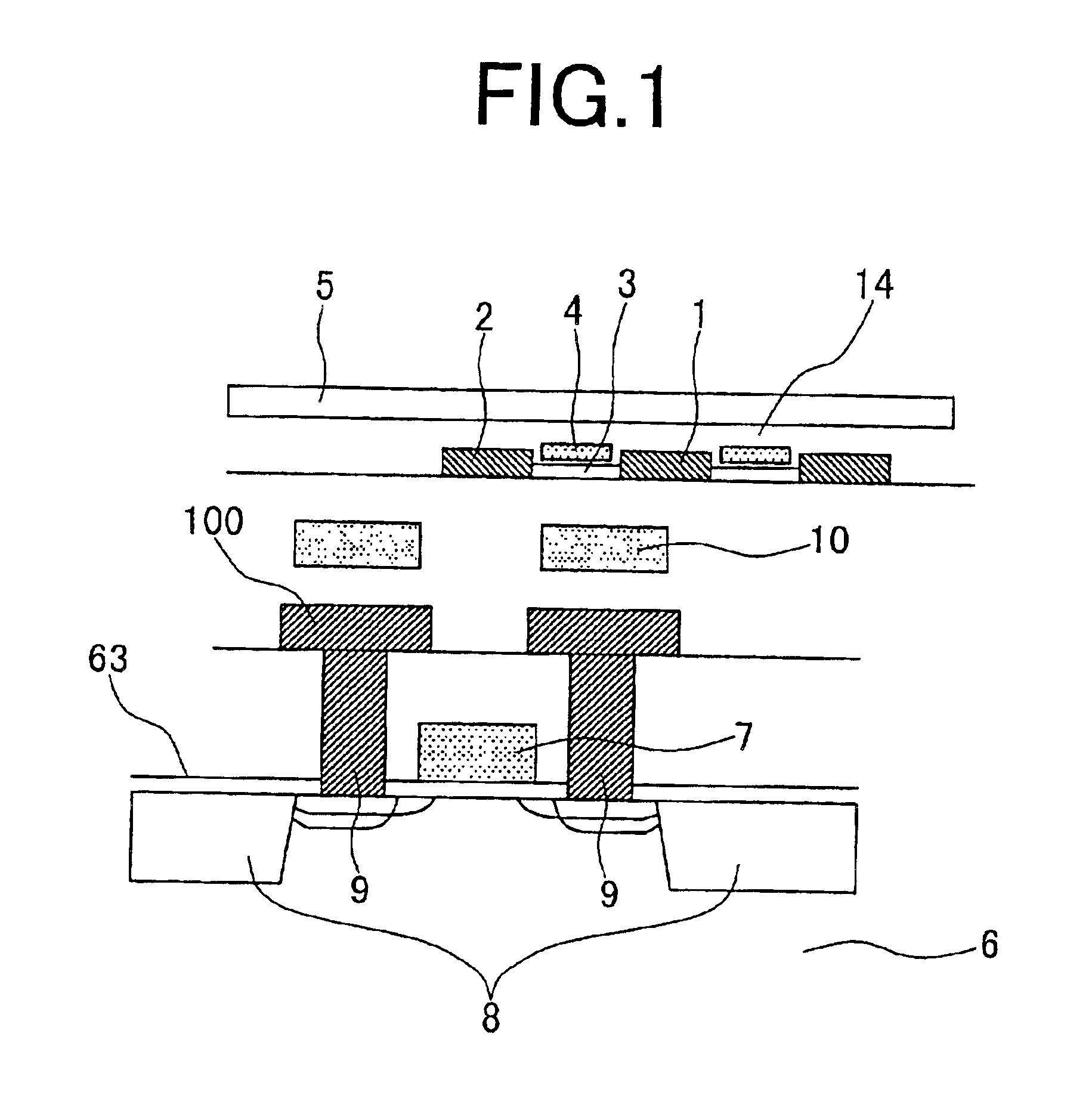

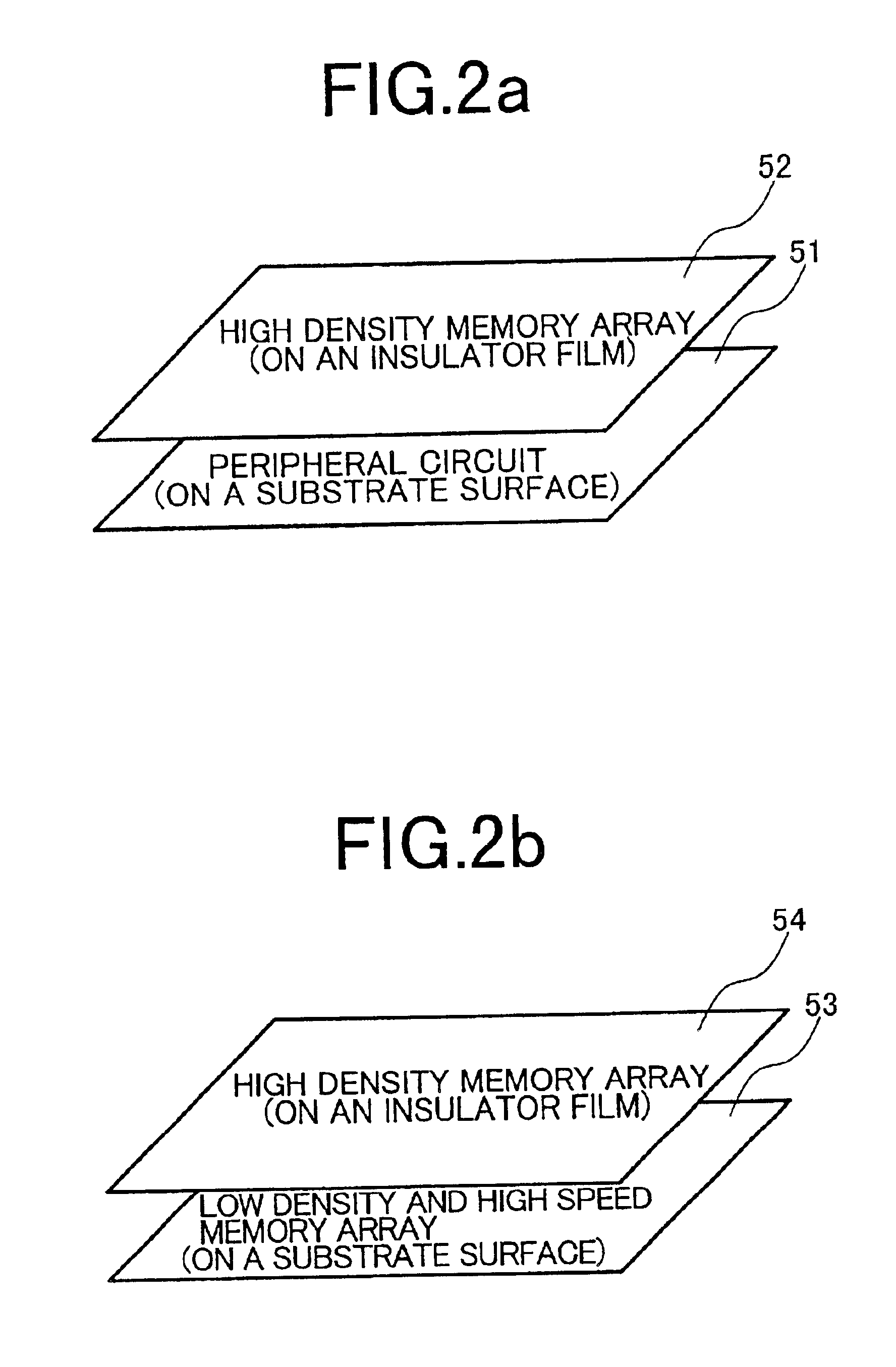

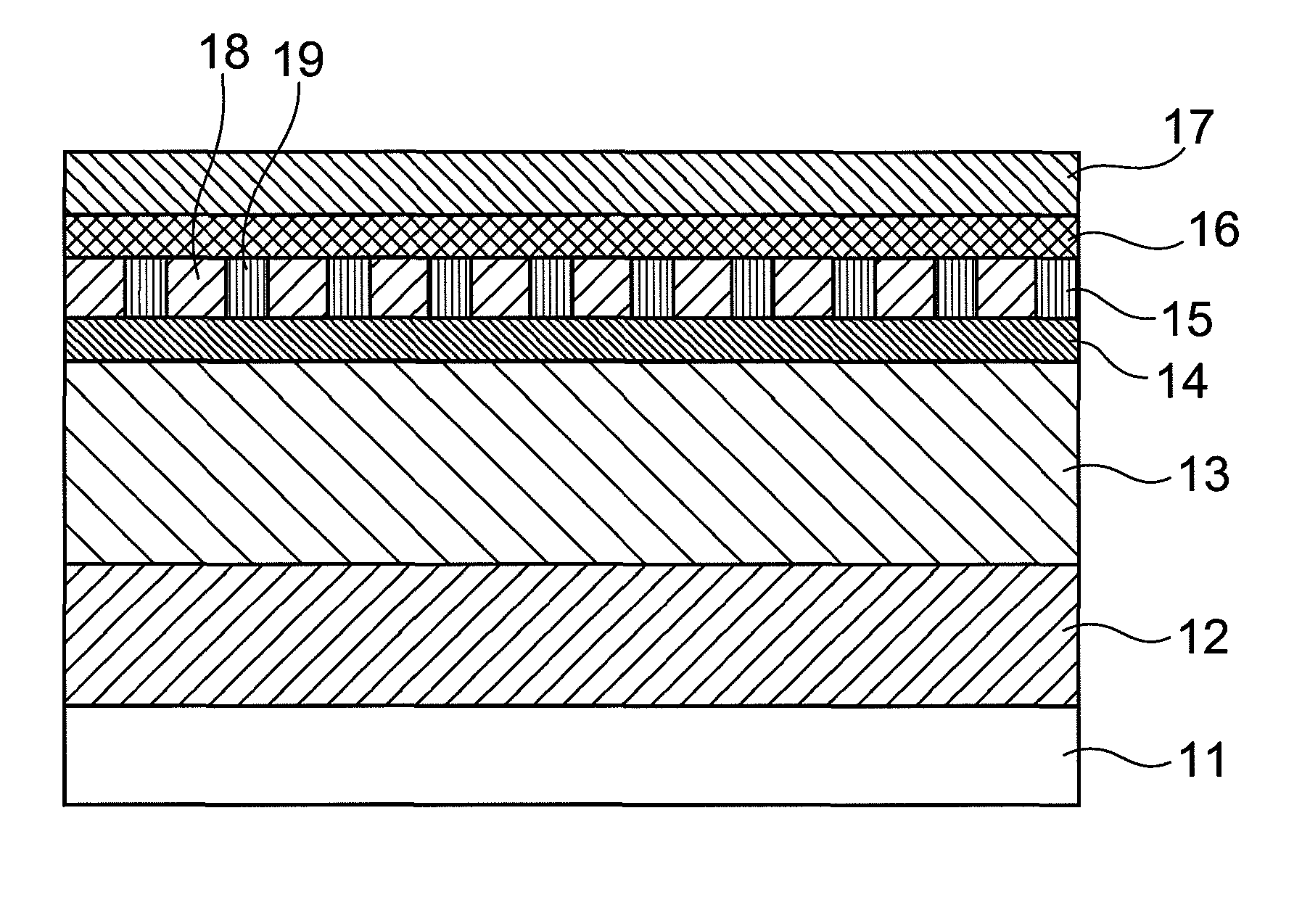

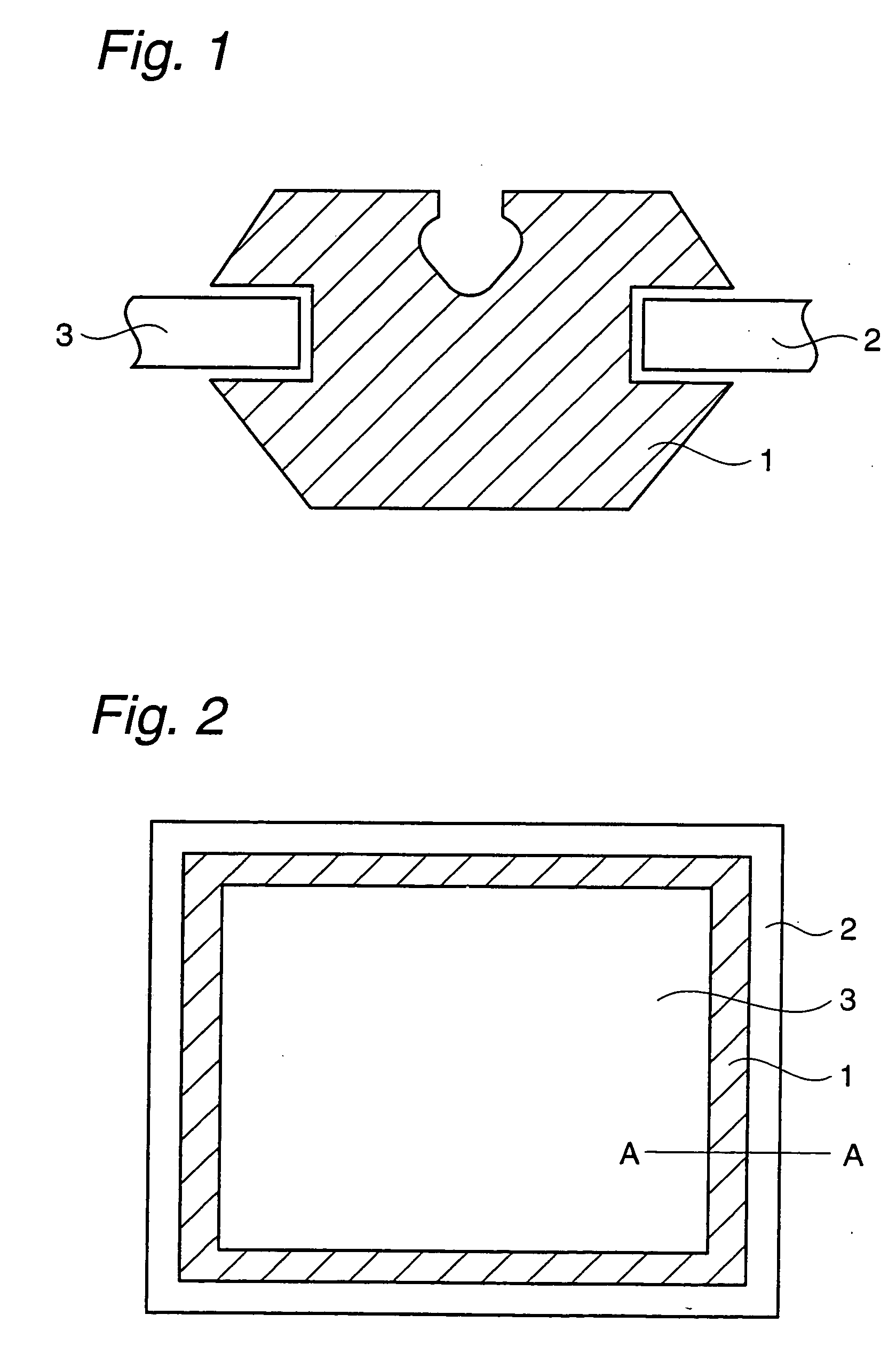

Semiconductor device having different types of memory cell arrays stacked in a vertical direction

InactiveUS6839260B2Fast rewritingLittle increasing of memory areaTransistorSemiconductor/solid-state device detailsEngineeringSubstrate surface

To provide a semiconductor memory device capable of fast rewriting with a small area, and / or large-capacity operation with a small area or fast operation and low power consumption operation, peripheral circuits such as logic circuit, buffer memory and sense circuit or part thereof are formed on a semiconductor substrate surface, and memory cells are provided thereon with an insulator film interposed therebetween.

Owner:HITACHI LTD

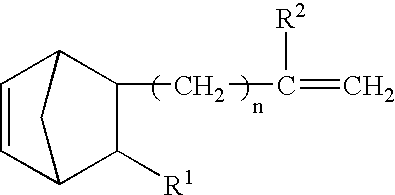

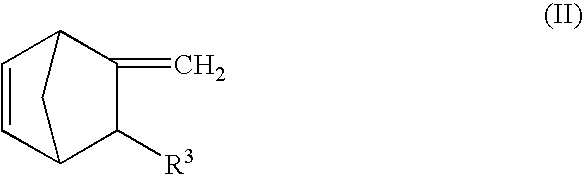

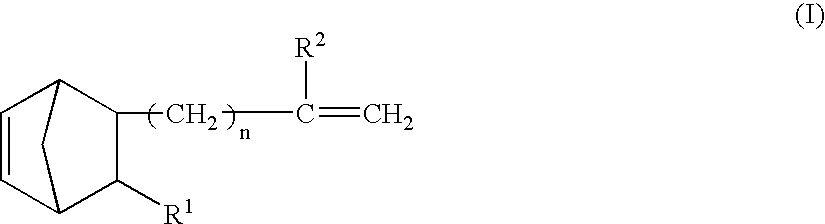

Crosslinkable rubber compositions and use thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC +1

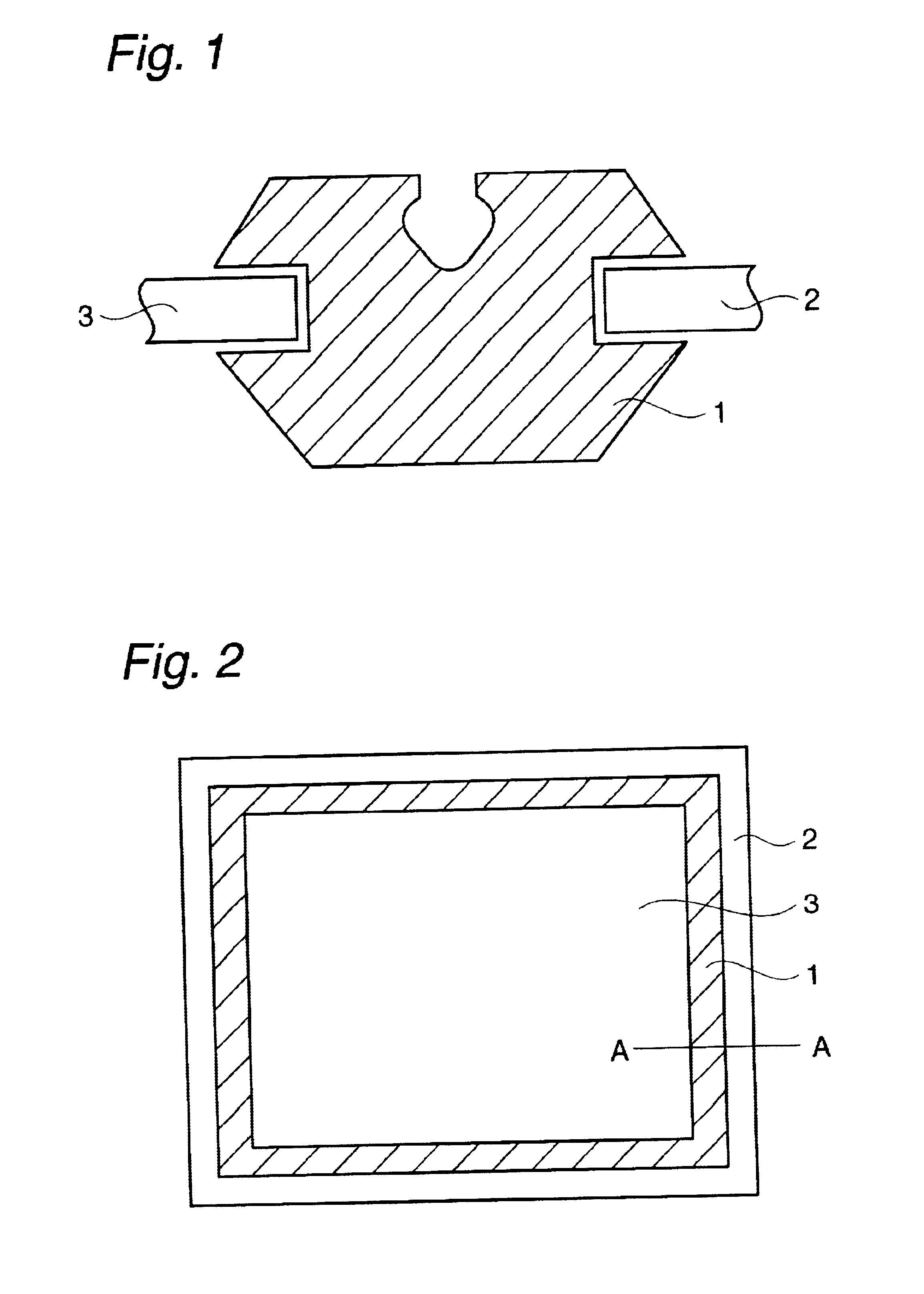

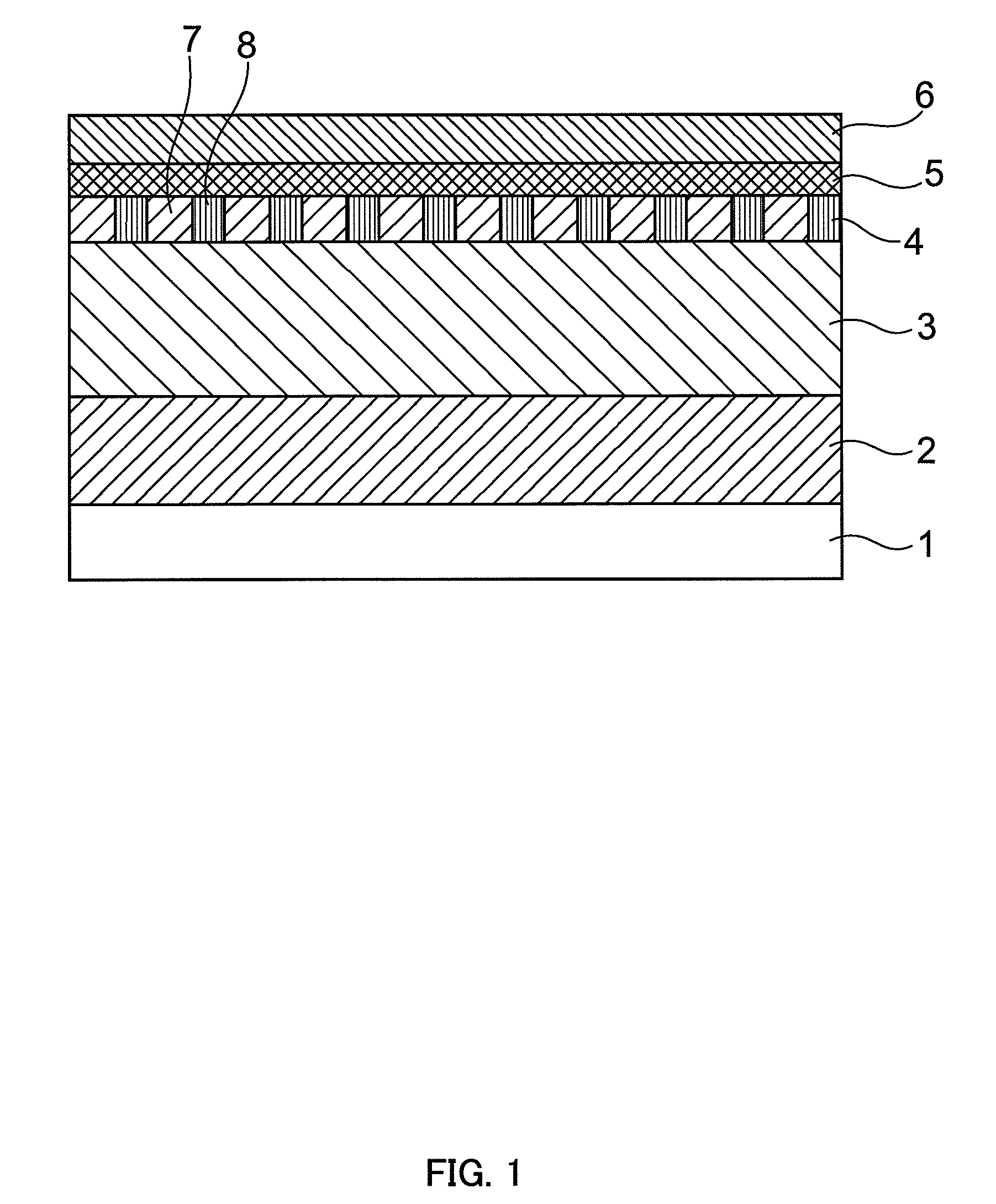

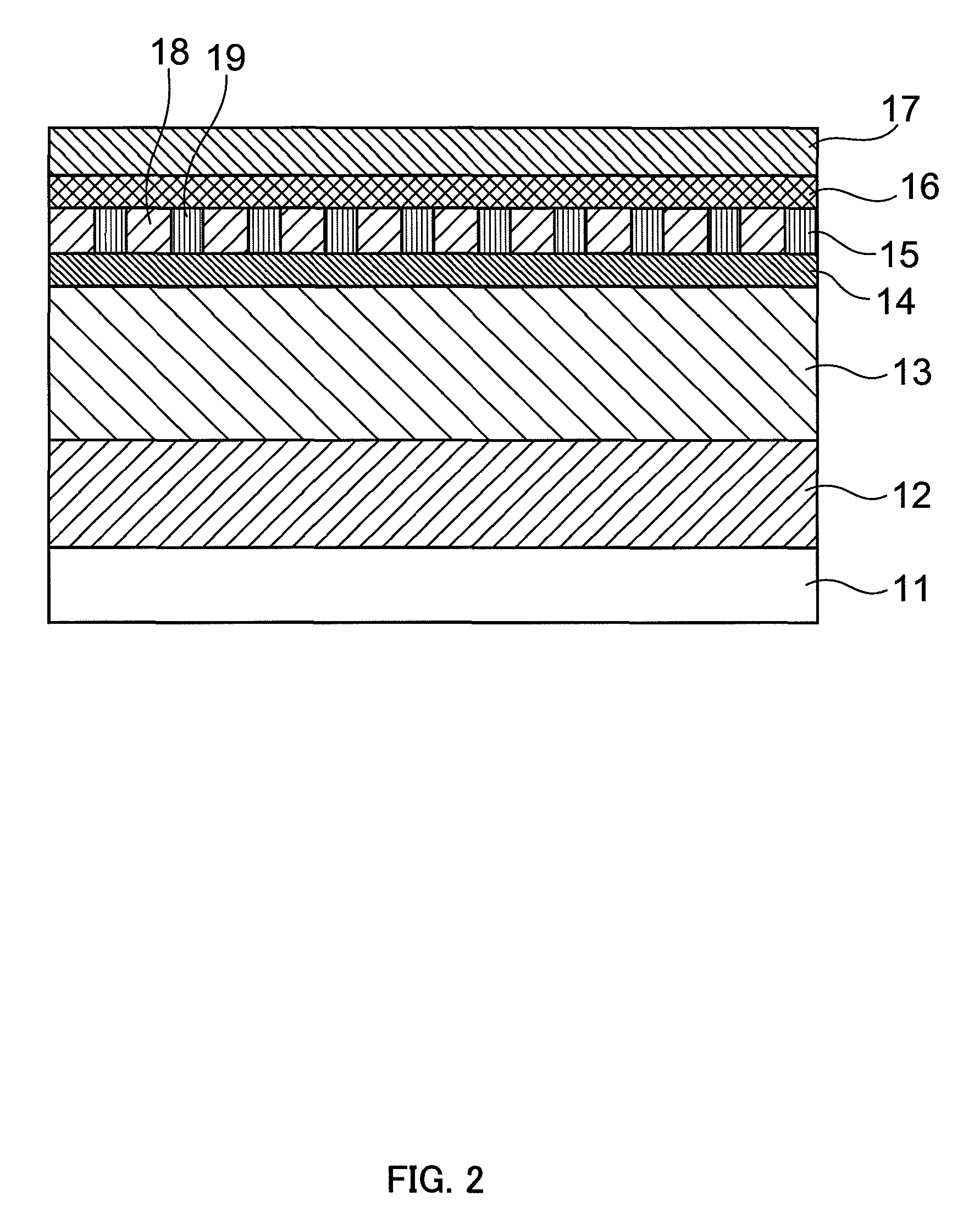

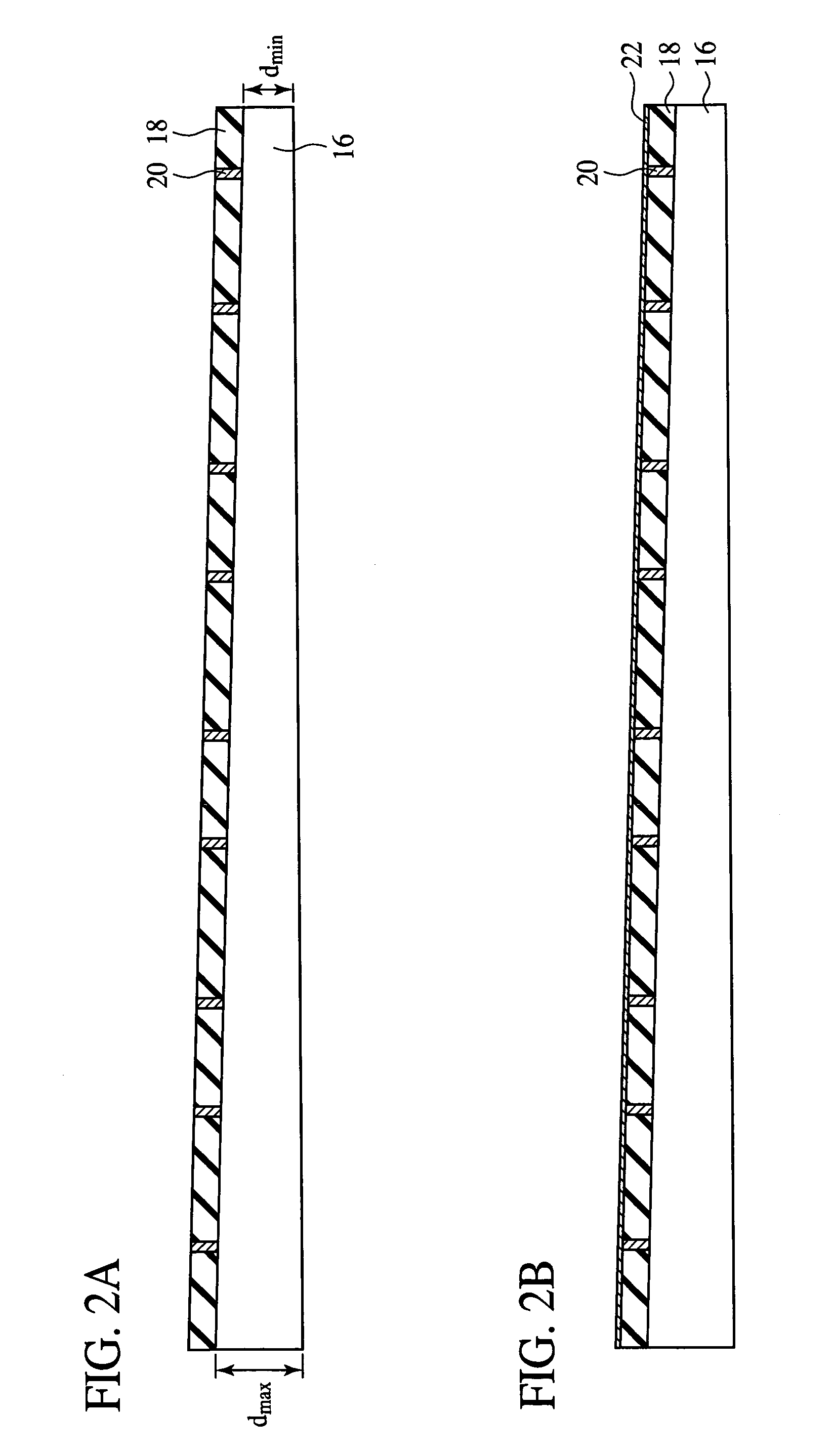

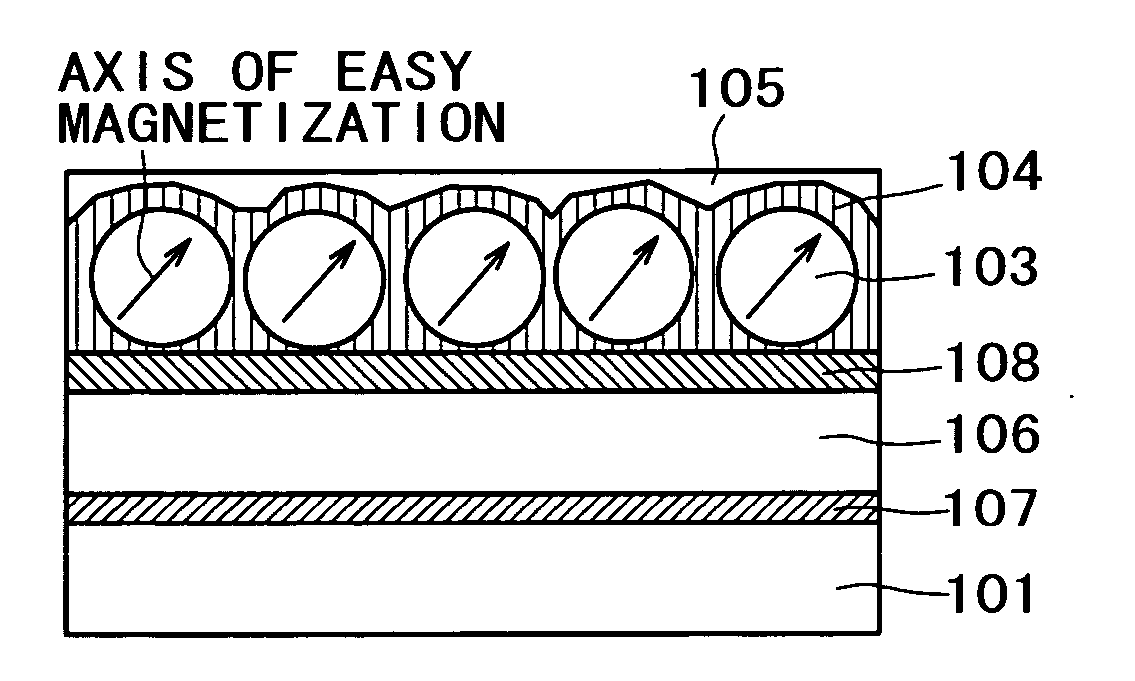

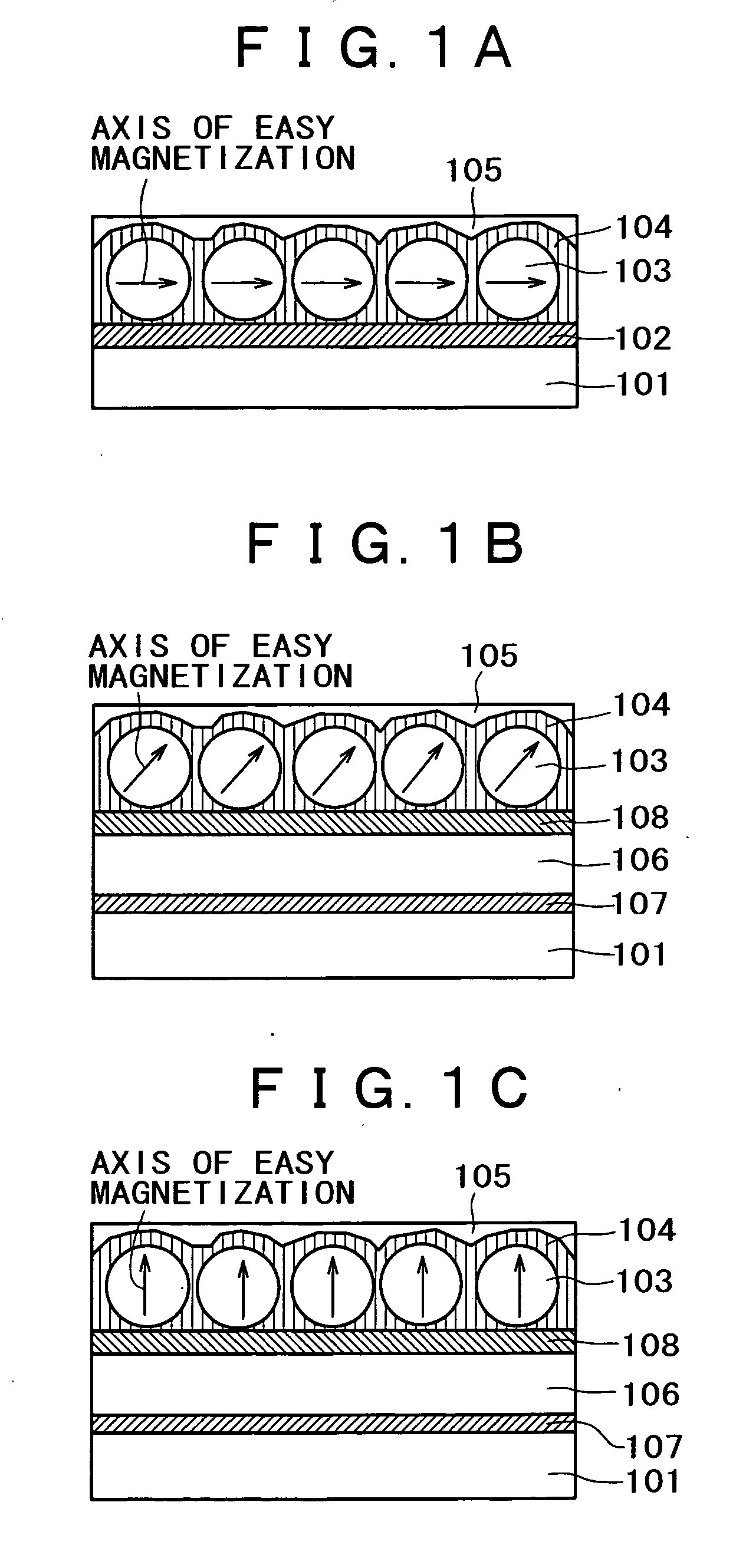

Magnetic recording medium with guard layer between auxiliary and magnetic recording layers and manufacturing method of the magnetic recording medium

ActiveUS8605388B2Improve recording densityThin thicknessRecord information storageDisk carriersMagnetizationNon magnetic

It is an object to manufacture magnetic recording media with the high recording density. Since nonmagnetic portions (8) with a predetermined pattern are formed in a recording auxiliary layer (4) formed on a magnetic recording layer (3), it is possible to actualize a magnetic recording medium where magnetic portions (7) and the magnetic recording layer (3) immediately below the portions (7) are recording units. The nonmagnetic portions (8) are formed by non-magnetization using ion implantation, and it is thereby possible to manufacture magnetic recording media with the high recording density.

Owner:WESTERN DIGITAL TECH INC +1

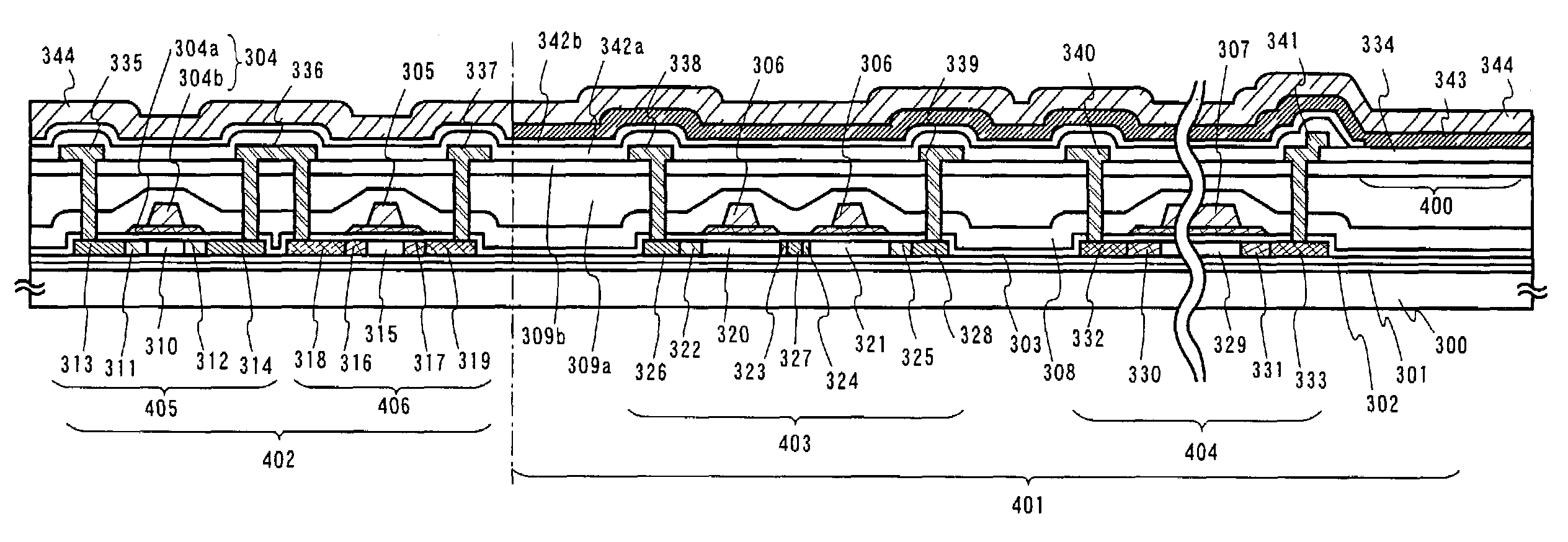

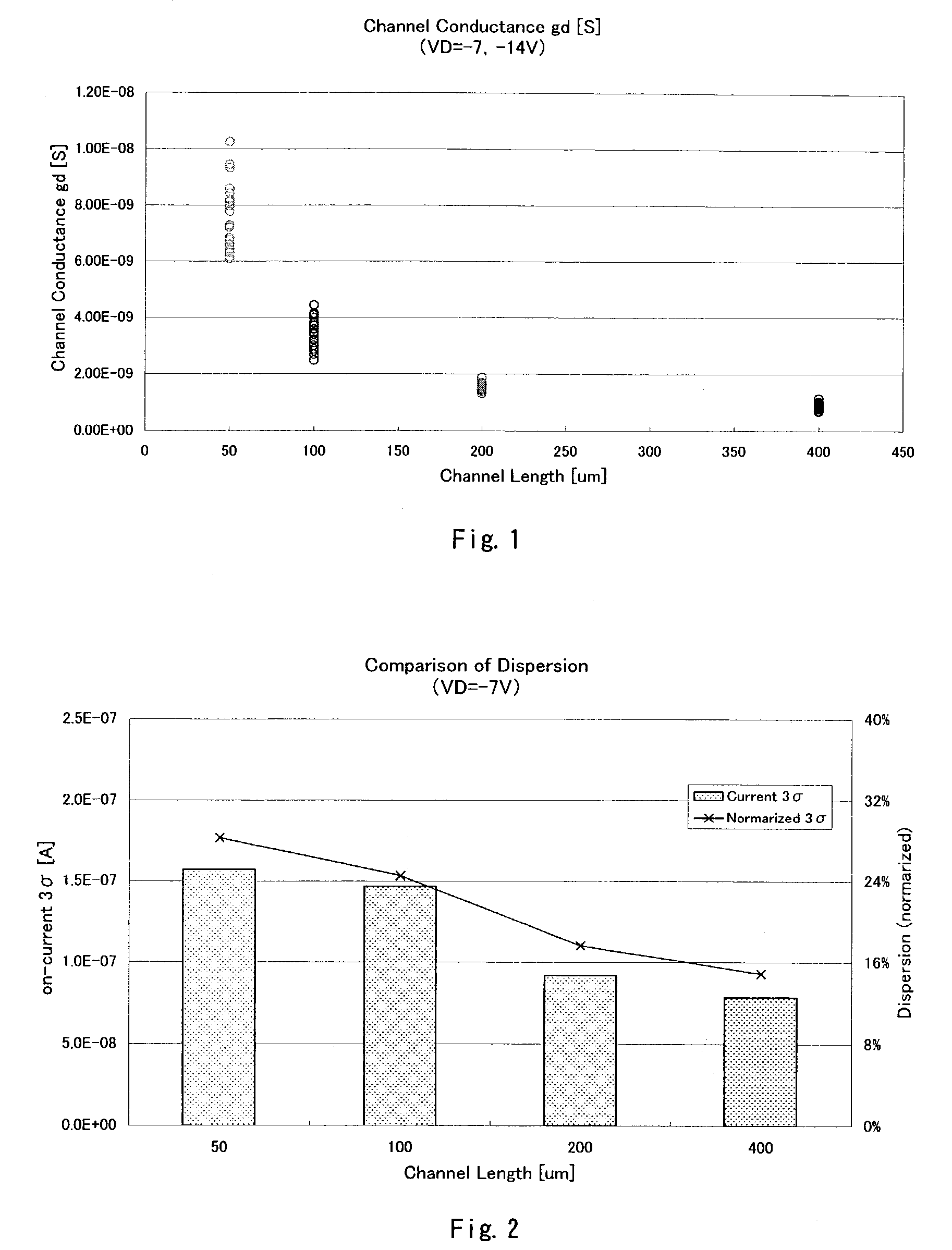

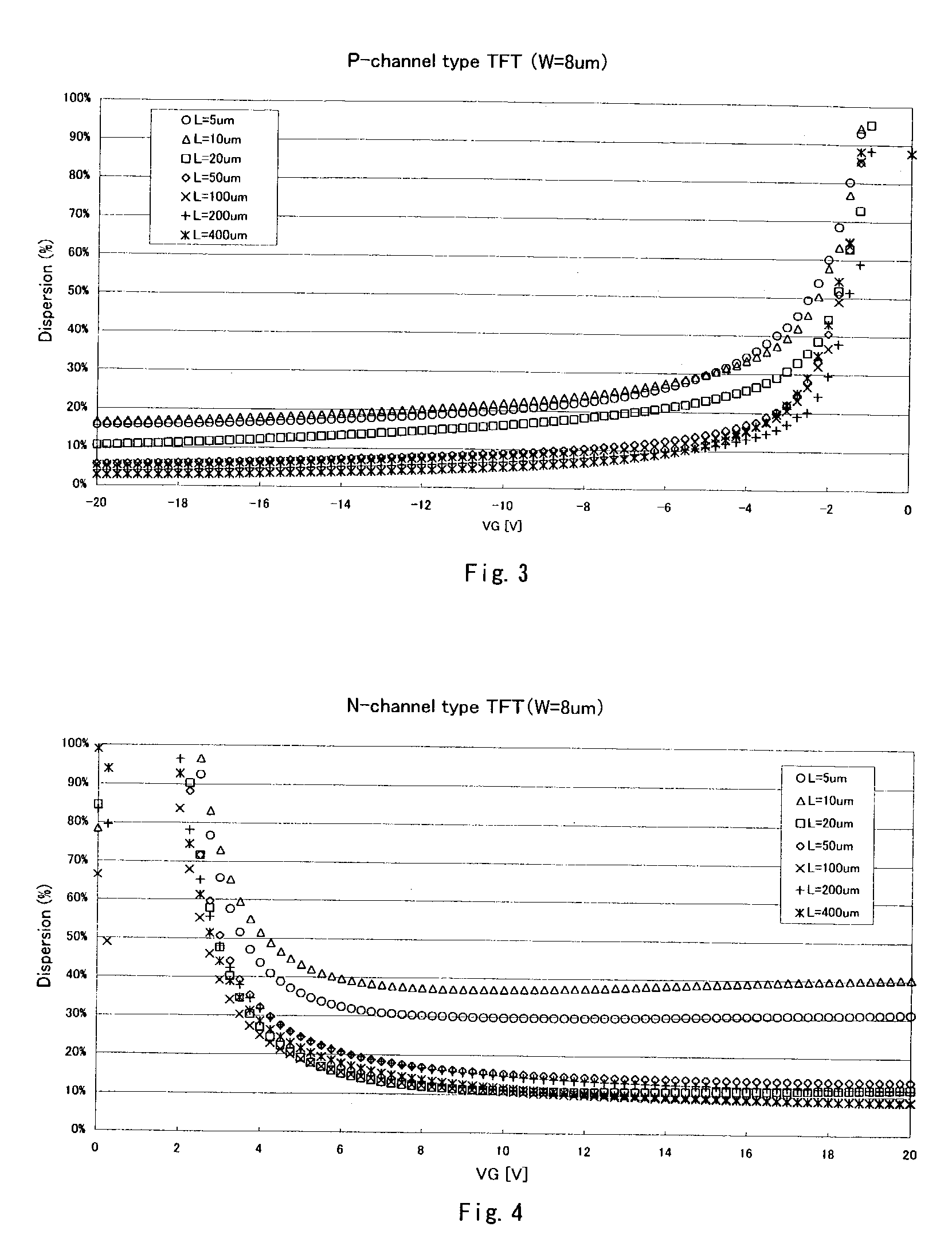

Light emitting device having TFT

InactiveUS7723721B2Channel conductance gd smallerConstant brightnessTransistorElectroluminescent light sourcesEngineeringGate voltage

The present invention provides a TFT that has a channel length particularly longer than that of an existing one, specifically, several tens to several hundreds times longer than that of the existing one, and thereby allowing turning to an on-state at a gate voltage particularly higher than the existing one and driving, and allowing having a low channel conductance gd. According to the present invention, not only the simple dispersion of on-current but also the normalized dispersion thereof can be reduced, and other than the reduction of the dispersion between the individual TFTs, the dispersion of the OLEDs themselves and the dispersion due to the deterioration of the OLED can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

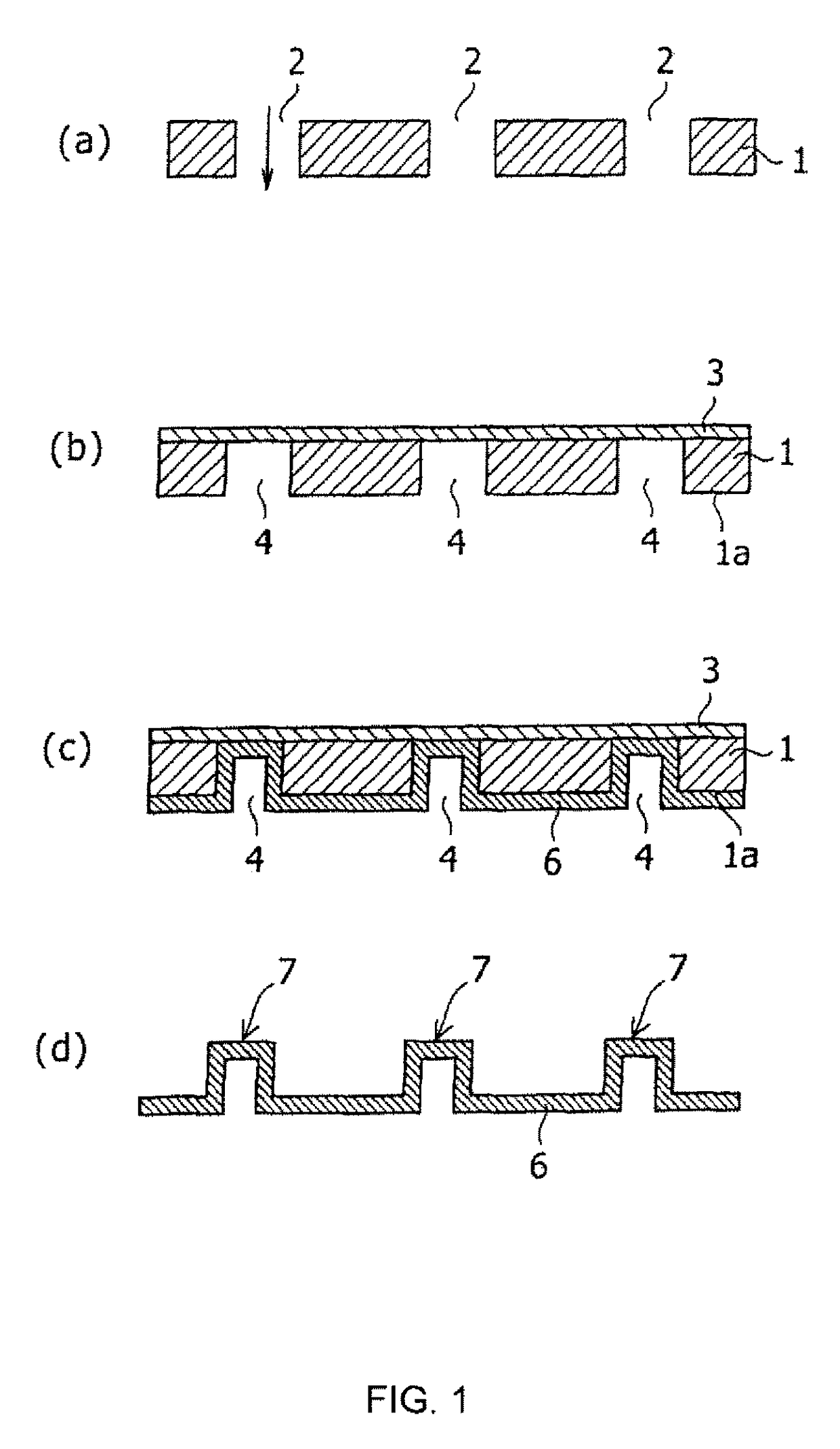

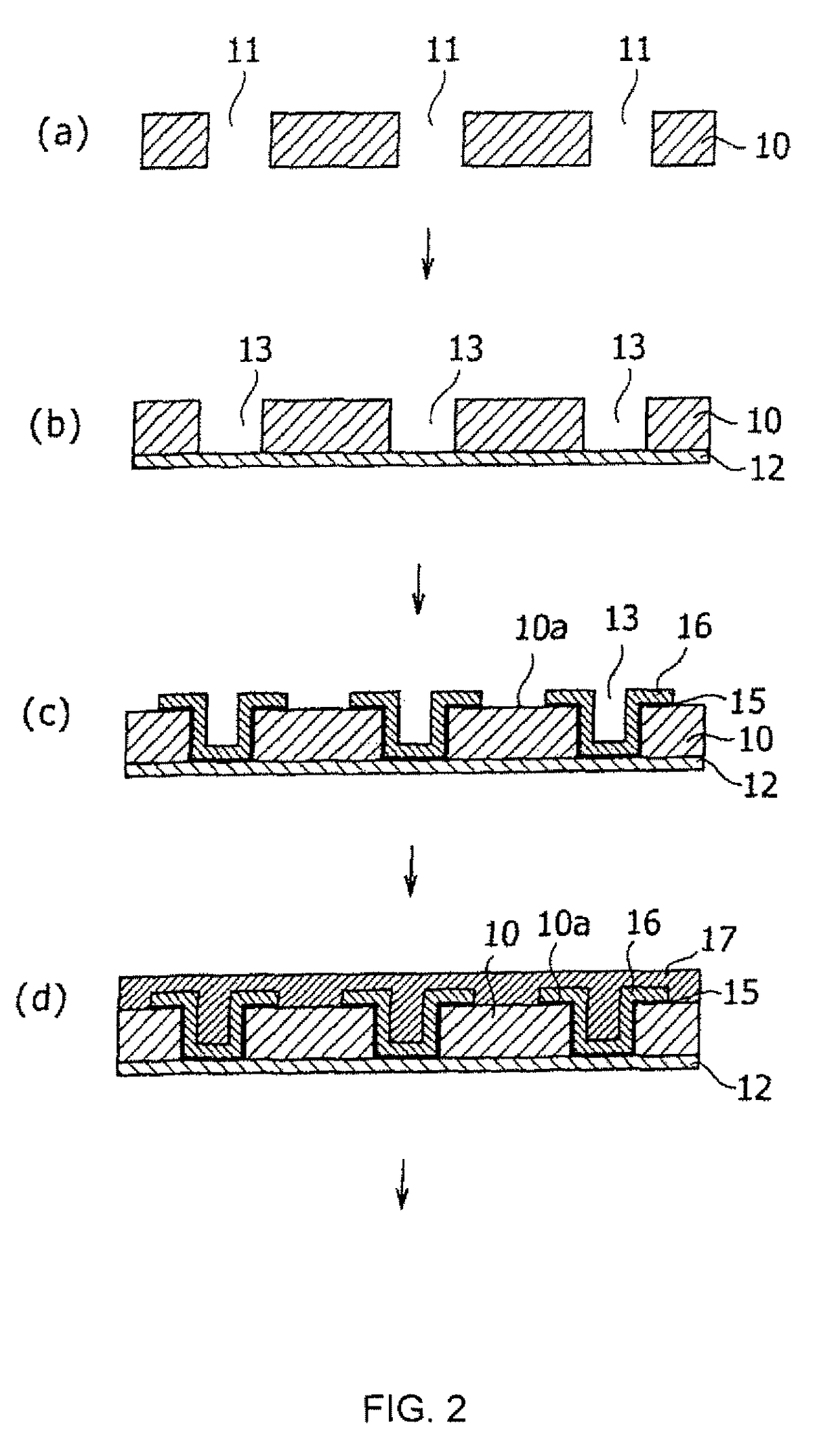

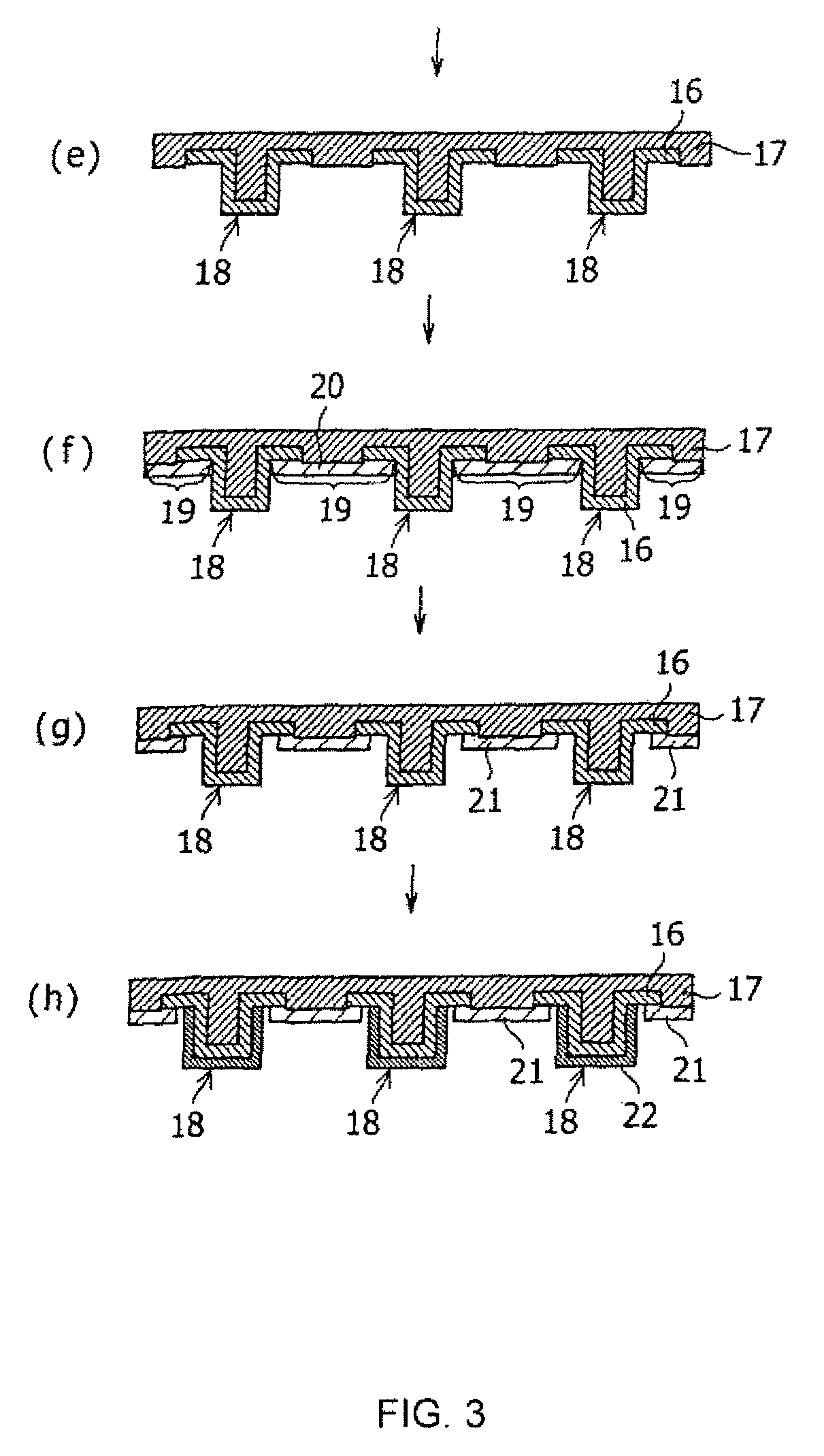

Bump structure formed from using removable mandrel

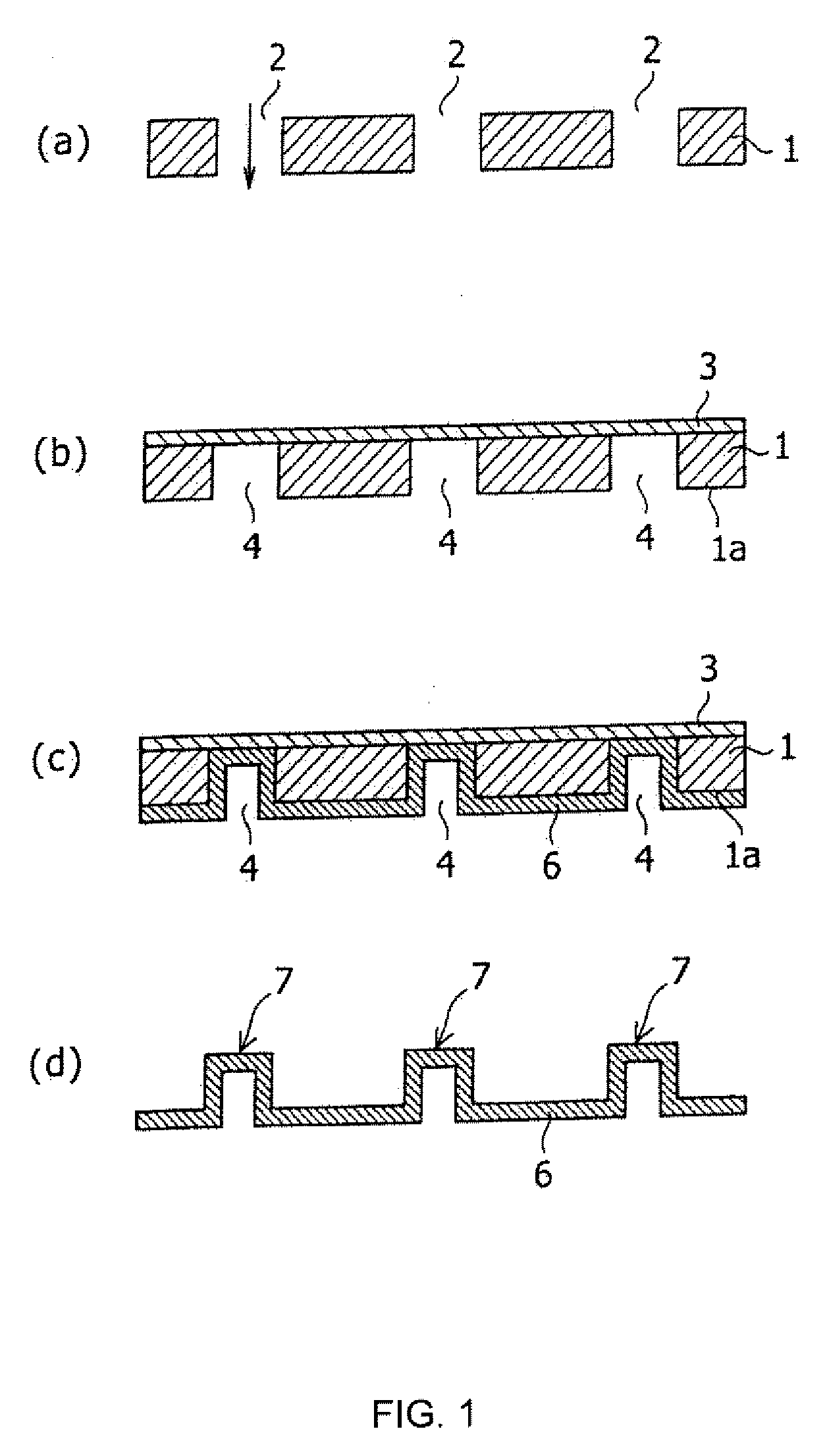

InactiveUS8119516B2High aspect ratioFine pitchSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringInterconnection

A method for forming a bump structure and a bump structure for conductive interconnection with another element having at least one of microelectronic devices or wiring thereon, used as an electric connection in an electronic circuit, includes the steps of forming a mandrel by steps including forming at least one opening extending through a bump-forming die body in the thickness direction thereof and positioning a bump-forming die lid on a surface of the bump-forming die body so as to cover one end of the opening and to thereby define a bump-forming recess. The bump-forming die body may be comprised of a metal sheet. A metal layer is formed at least on an inner surface of the bump-forming die lid exposed within the bump-forming recess. The mandrel is removed so as to expose the metal layer and form a bump structure.

Owner:INVENSAS CORP

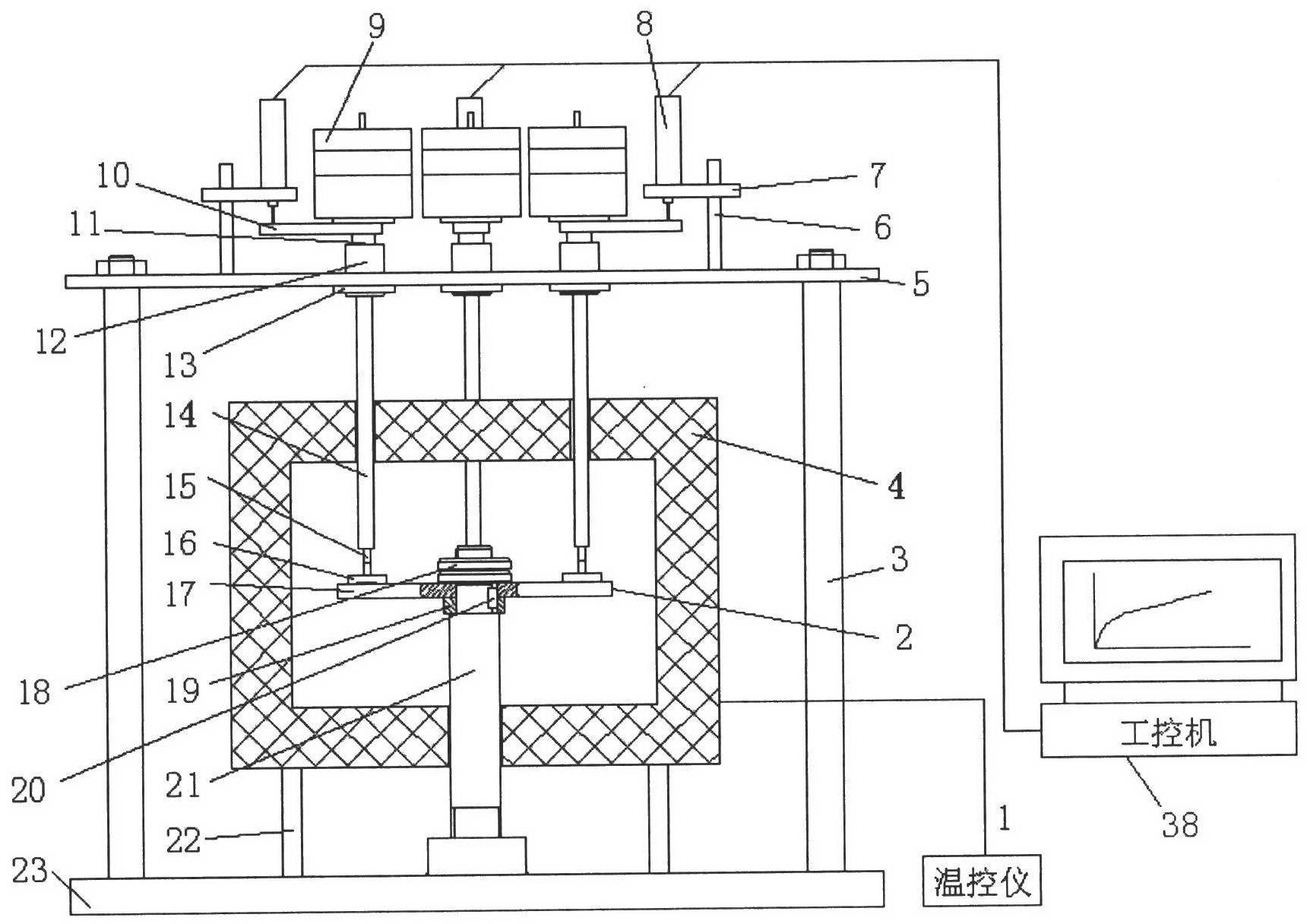

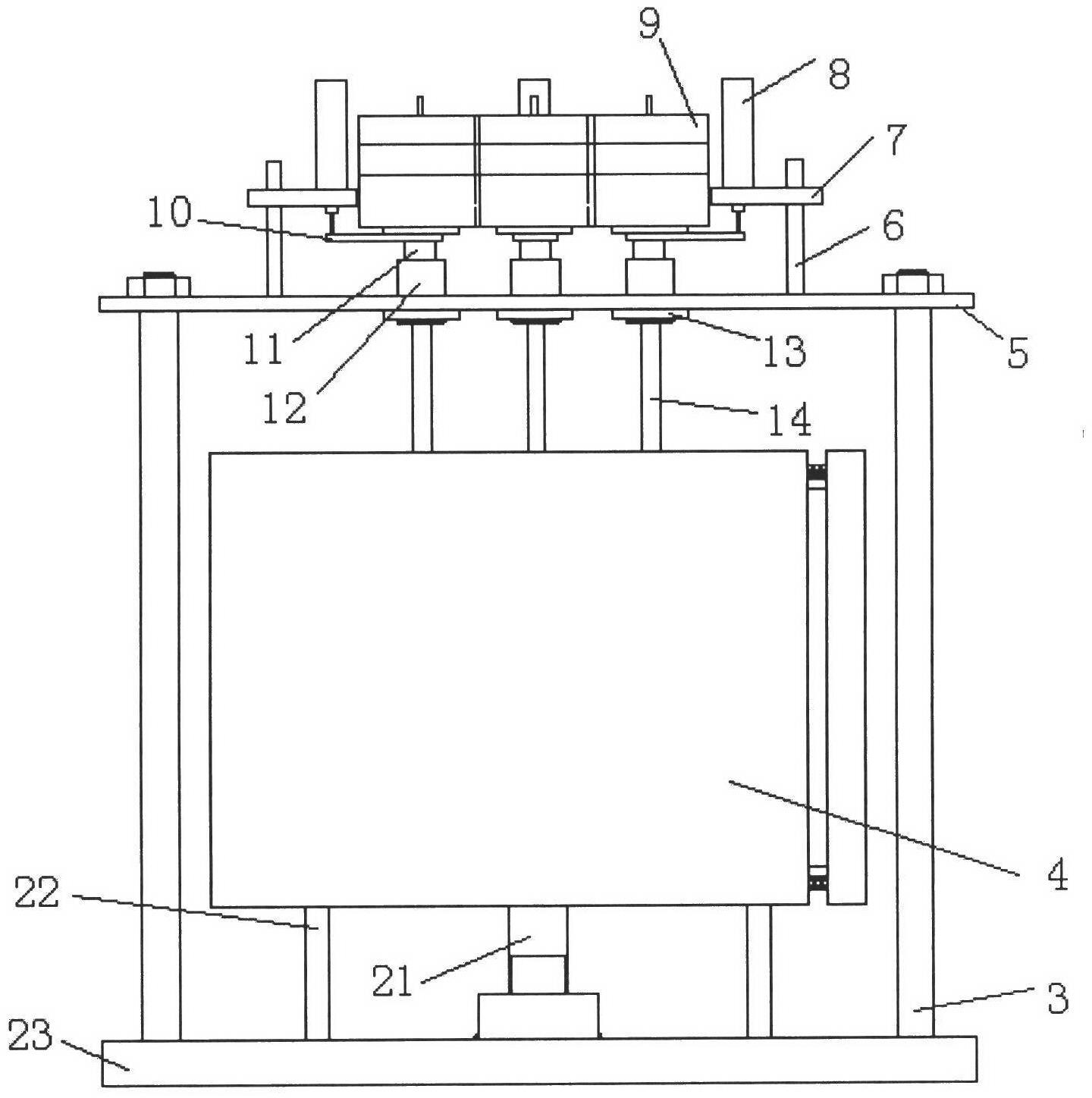

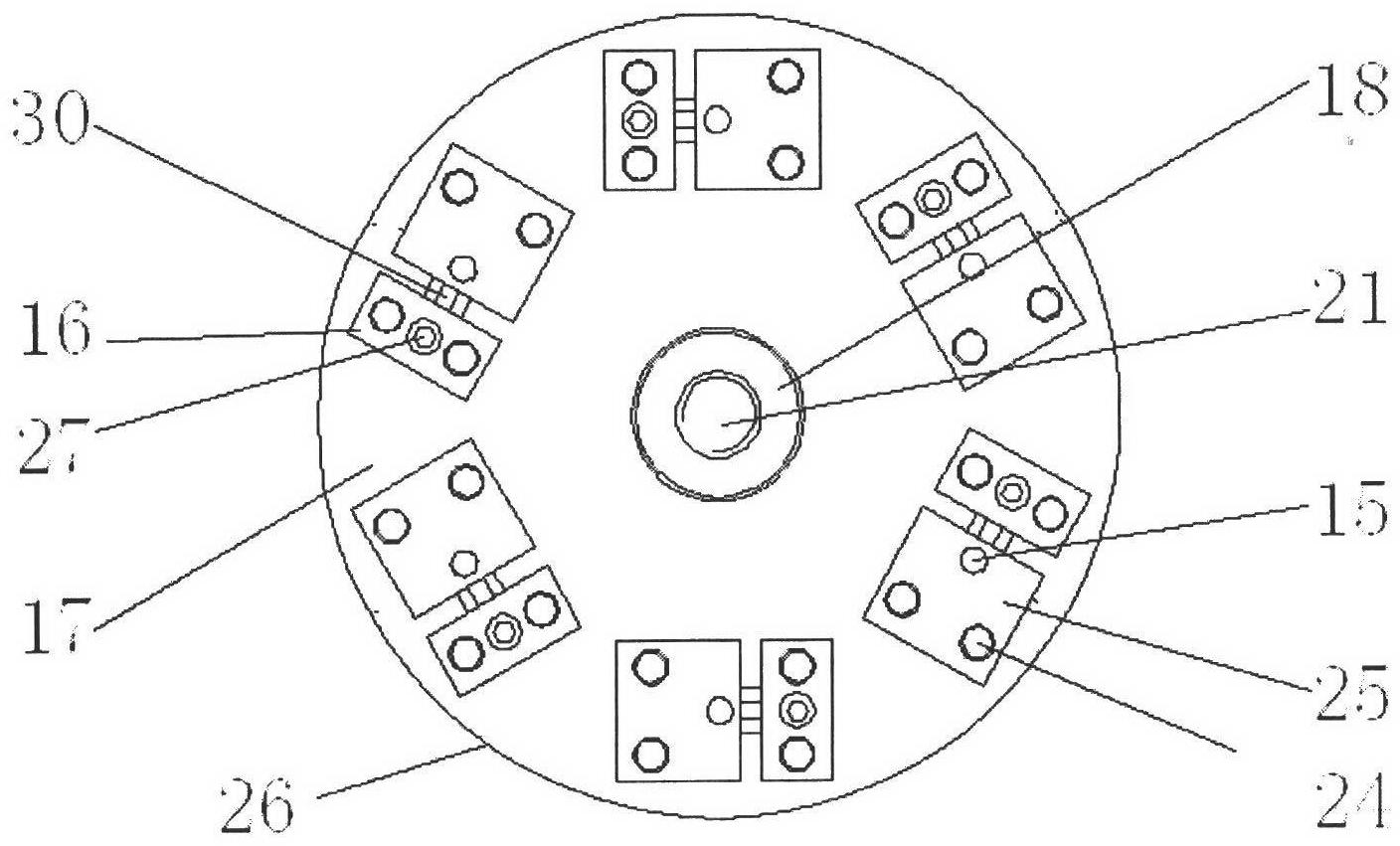

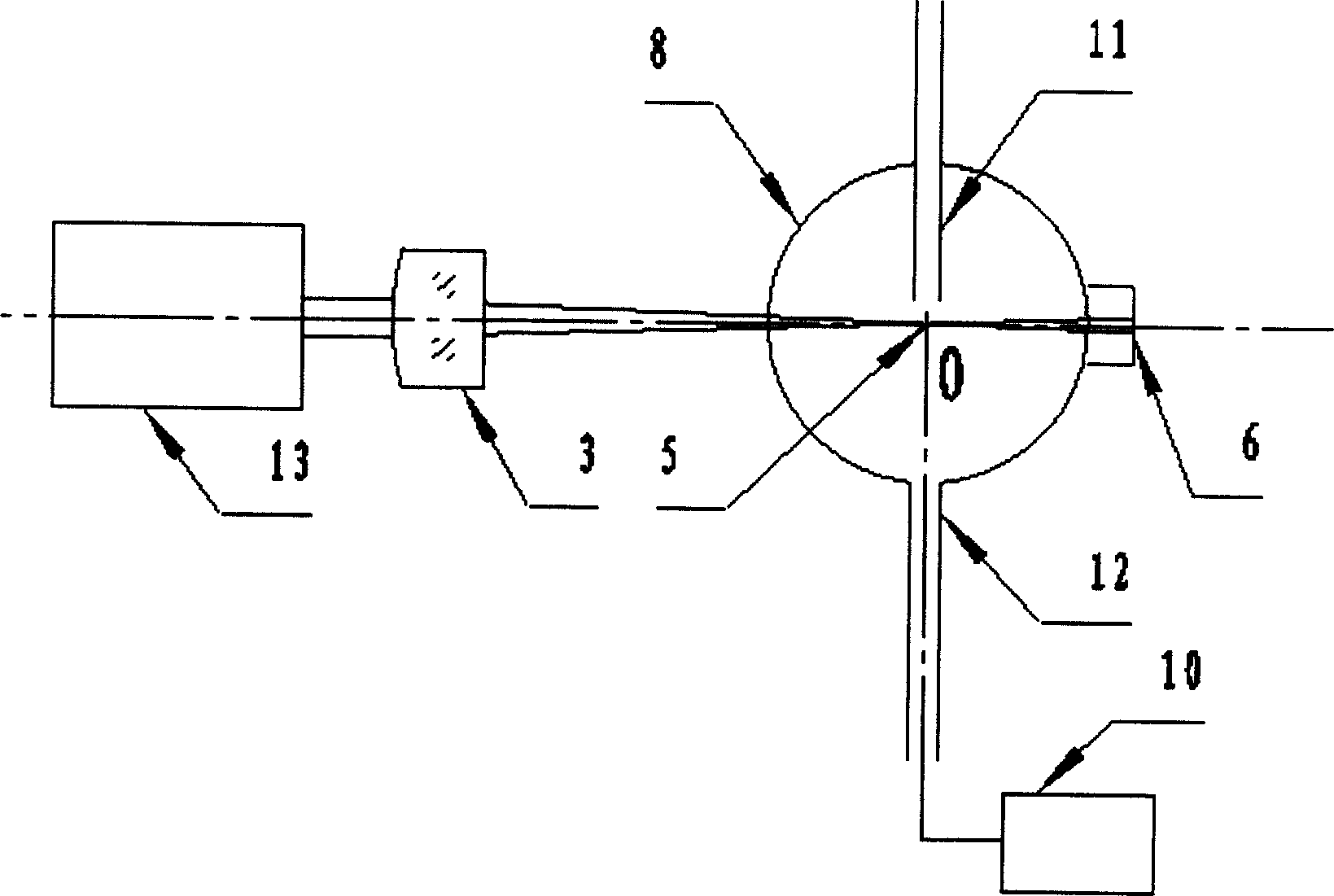

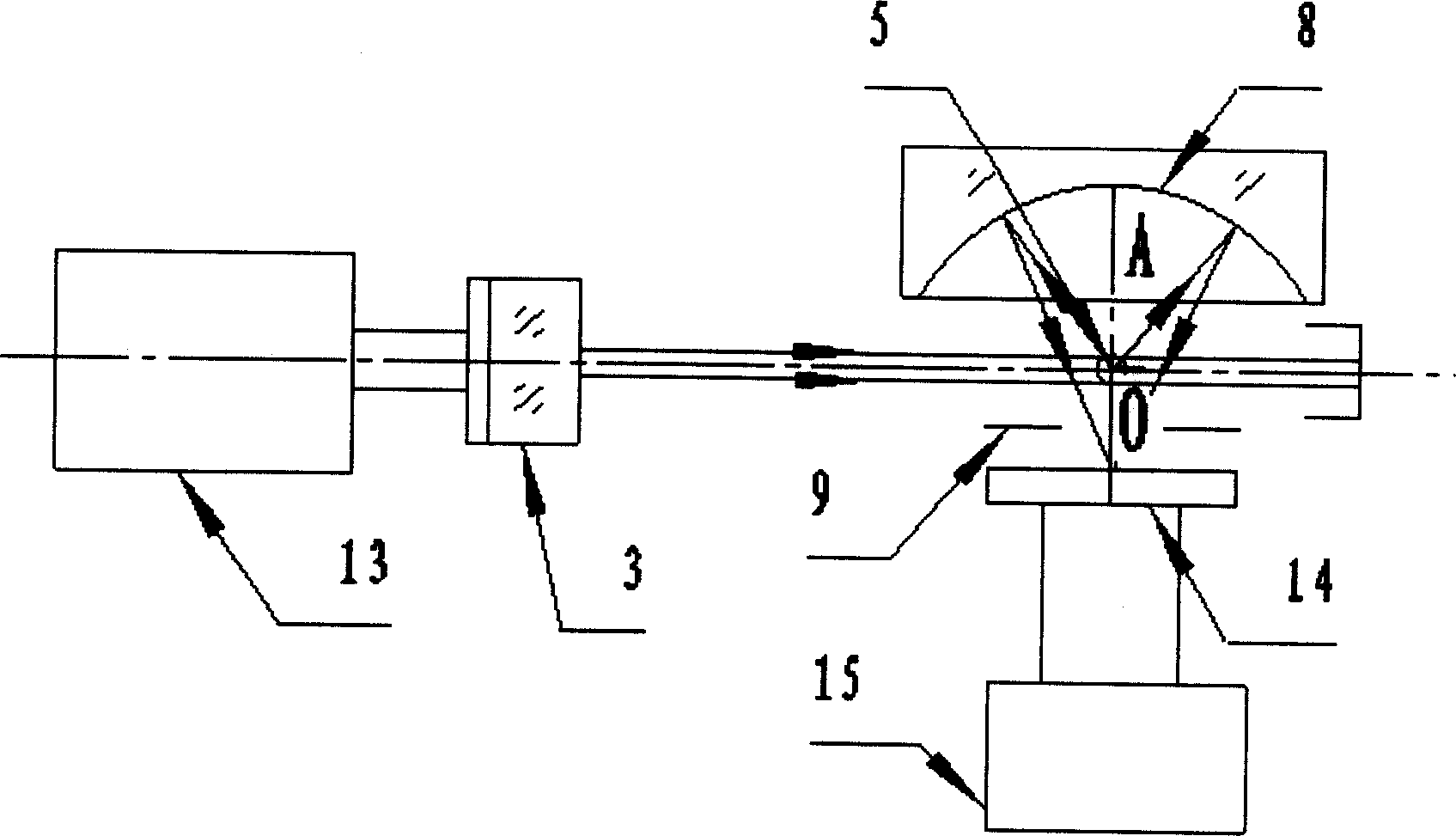

Multi-head miniature test specimen creep experiment device and test method

ActiveCN102519803ASmall dispersionReduce creep test timeMaterial strength using tensile/compressive forcesHeating systemLow load

The invention provides a multi-head miniature test specimen creep experiment device and a multi-head miniature test specimen creep test method. The device comprises a loading system, a clamping system, a heating and temperature control system, a measuring system and an external support frame, wherein the loading system adopts the poise top vertical loading and is positioned at the upper part of the external support frame, the clamping system is fixedly arranged on the external support frame, is positioned at the lower part of the loading system and is placed inside the heating system, the heating system is connected with the bottom of the external support frame and is externally connected with the temperature control system, the measuring system is connected with the loading system and the external support frame and is placed at the upper part of the support frame, and all independent parts are connected into a multi-head creep device system by the external support frame. The experiment device and the test method have the advantages that the problem that the existing creep experiment device cannot carry out multi-head miniature test specimen creep experiments under the low-load condition is solved, the test method and the device capable of simultaneously carrying out creep experiments on a plurality of identical or different-size miniature test specimens under the certain work condition are provided, and the creep experiments in different types such as cantilever beam test specimens, three-point bending, four-point bending and small punch test can also be realized through replacing clamps.

Owner:EAST CHINA UNIV OF SCI & TECH

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC

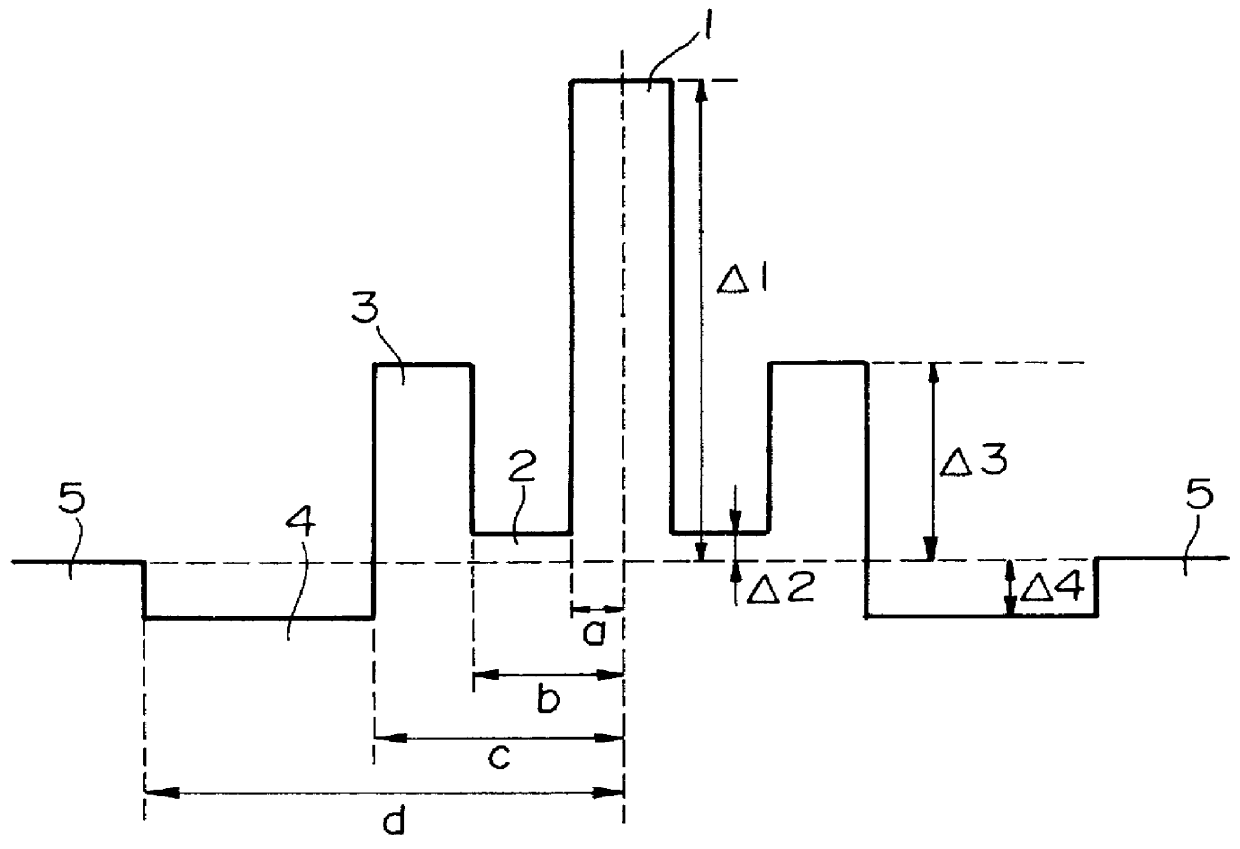

Dispersion shifted optical fiber

InactiveUS6091873AReduce nonlinear effectsReduce dispersionOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingDispersion-shifted fiberWdm transmission systems

A dispersion-shifted optical fiber (DS-fiber) is structured so that it has nearly zero chromatic dispersion in the 1.55 mu m wavelength band and, at the same time, achieves both reduced non linear effects and low dispersion slope. In particular, dispersion slope is reduced to a level sufficient for the fiber to be used for wavelength division multiplexing (WDM) applications. The properties of the fiber are developed such that chromatic dispersion in the 1.55 mu m band is nearly zero but not zero, effective cross section area is 45 DIFFERENCE 70 mu m2, bending loss is 0.1 DIFFERENCE 100 dB / m, dispersion slope is 0.05 DIFFERENCE 0.08 ps / km / nm2, and the cutoff wavelength is such that transmission is always single-mode transmission within the 1.55 mu m band. Such a DS-fiber has sufficiently large effective cross section area Aeff, low bending loss and small dispersion slope to make the fiber suitable for use in WDM transmission systems.

Owner:FUJIKURA LTD

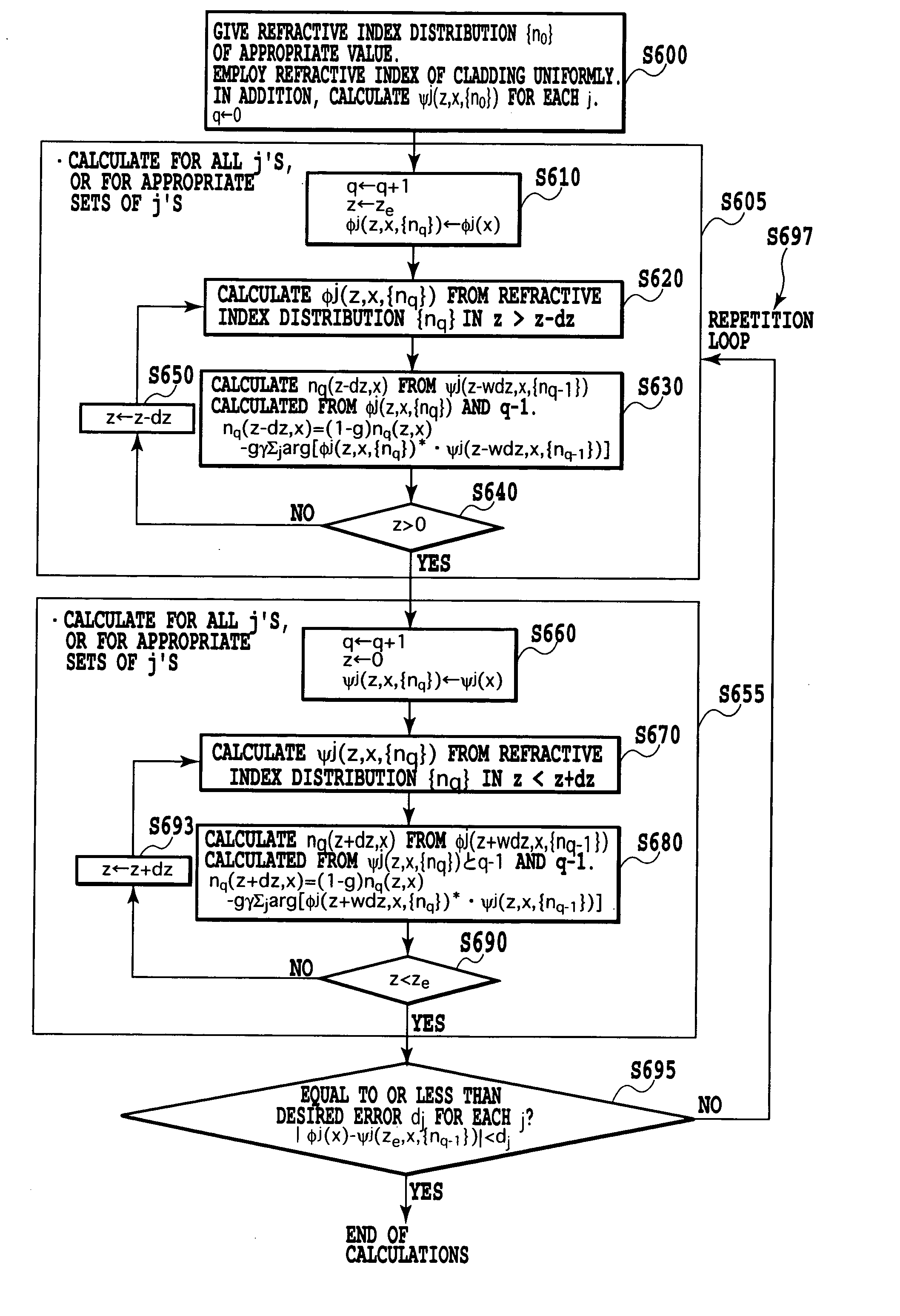

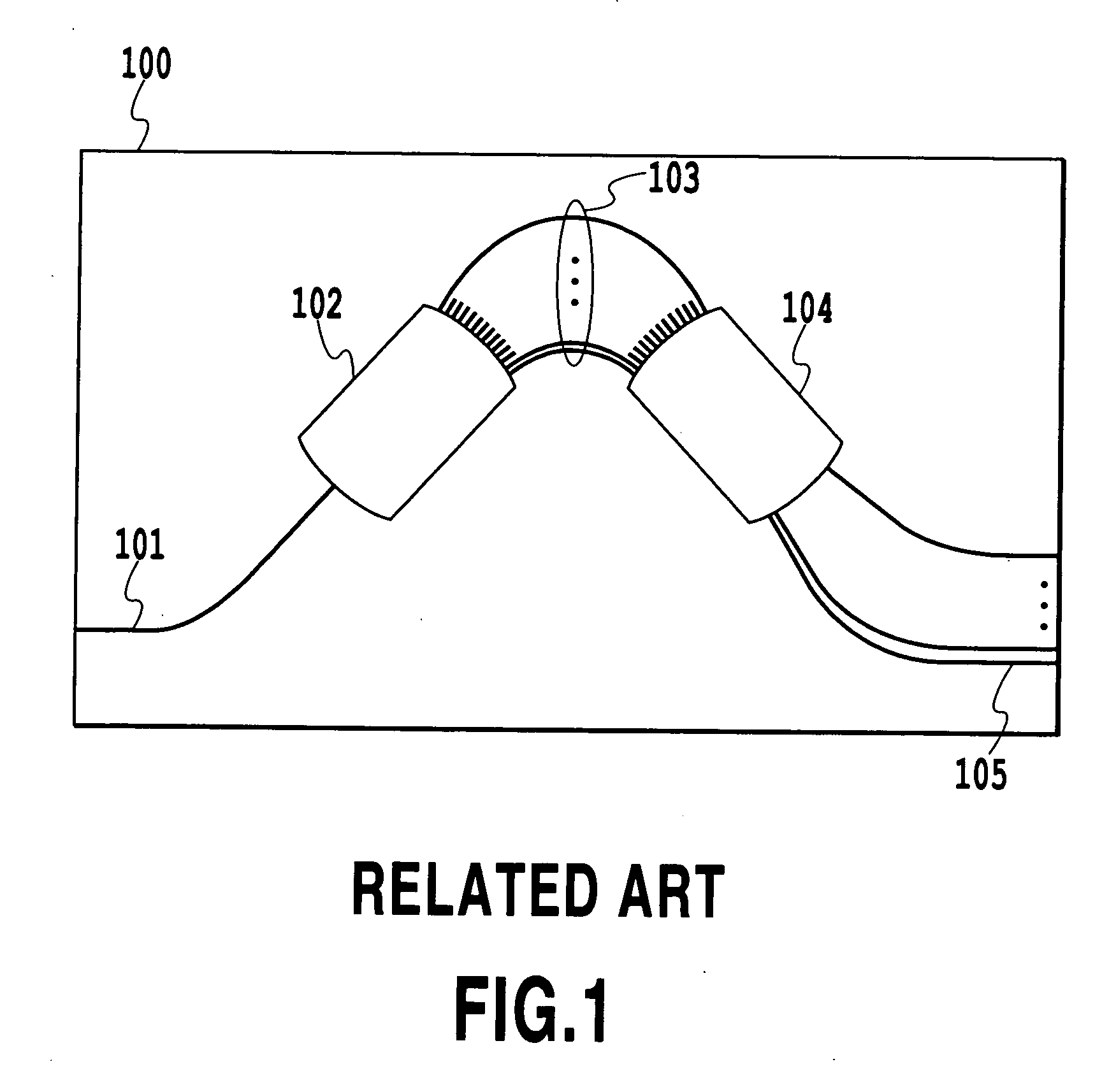

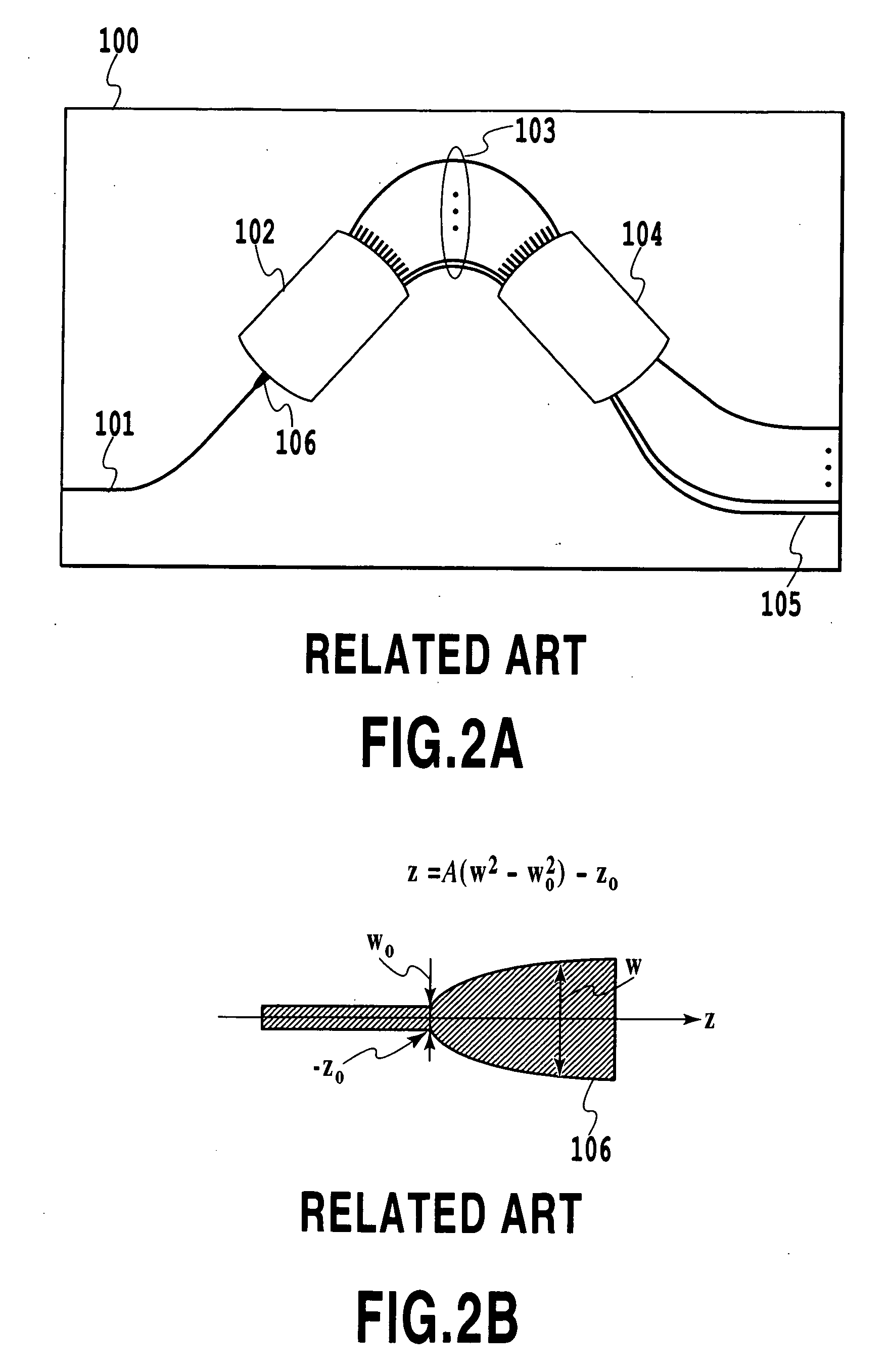

Wave transmission medium and waveguide circuit

ActiveUS20060126992A1Effective controlImprove efficiencyCoupling light guidesOptical waveguide light guidePhase differenceForward propagation

A wave transmission medium includes an input port 3-1 and an output port 3-2. A field distribution 1 and a field distribution 2 are obtained by numerical calculations. The field distribution 1 is a field distribution of the propagation light (forward propagation light) launched into the input port 3-1. The field distribution 2 is a field distribution of the phase conjugate light (reverse propagation light) resulting from reversely transmitting from the output port side an output field that is expected to be output from the output port 3-2 when an optical signal is launched into the input port 3-1. According to the field distributions 1 and 2, a spatial refractive index distribution is calculated such that the phase difference between the propagation light and reverse propagation light is eliminated at individual points (x, z) in the medium.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

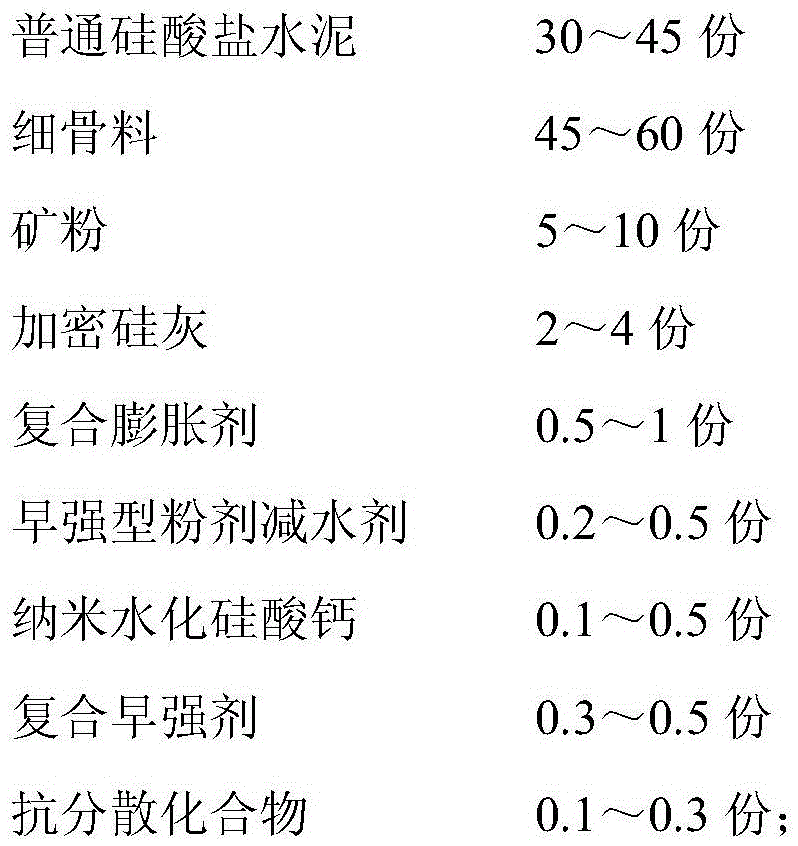

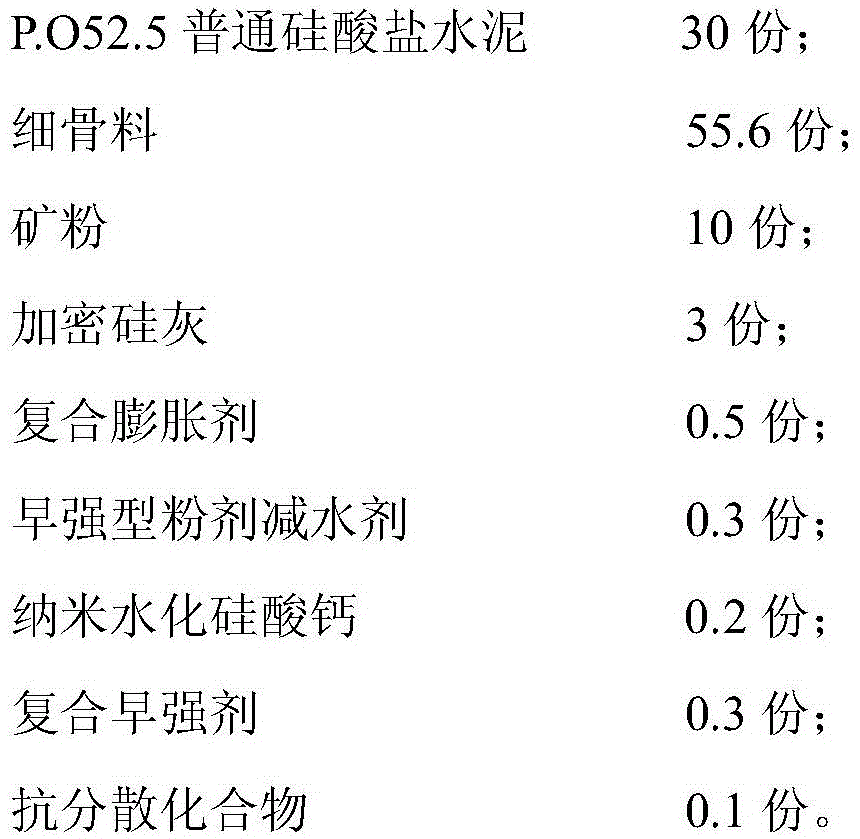

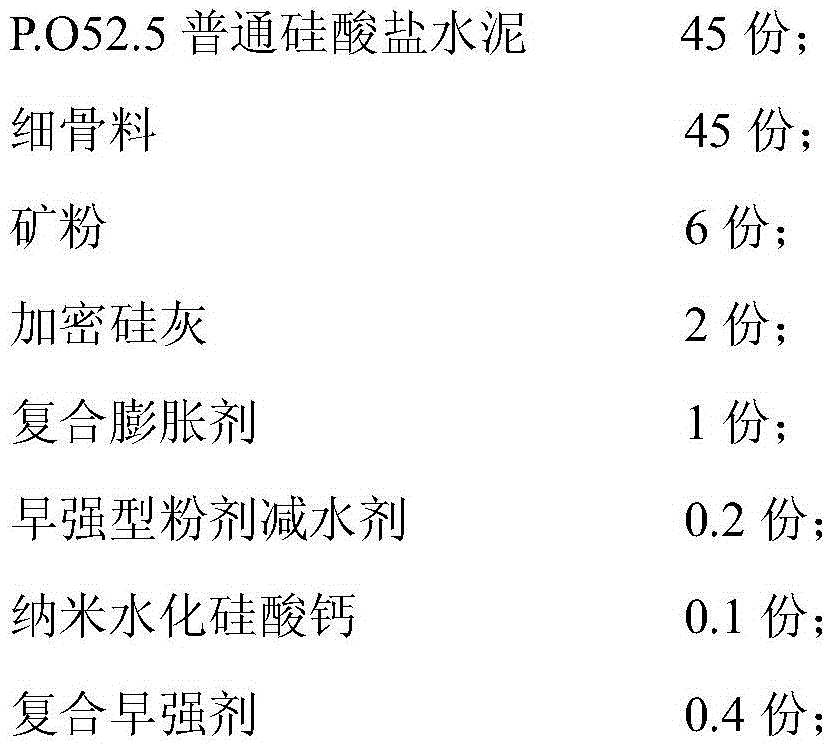

Low-temperature early-strength high-strength underwater grouting material

ActiveCN105622006AEnhance early compressive strengthImprove early strengthCalcium silicateWater reducer

The invention provides a low-temperature early-strength high-strength underwater grouting material. The low-temperature early-strength high-strength underwater grouting material consists of the following ingredients in parts by weight: 30-45 parts of ordinary Portland cement, 45-60 parts of fine aggregate, 5-10 parts of mineral powder, 2-4 parts of encryption silica fume, 0.5-1 part of a compound expanding agent, 0.2-0.5 part of an early-strength powdery water reducer, 0.1-0.5 part of nano hydrated calcium silicate, 0.3-0.5 part of a compound early-strength agent and 0.1-0.3 part of a dispersion-resistant compound. The low-temperature early-strength, low-temperature high-strength and dispersion resistant properties of the low-temperature early-strength high-strength underwater grouting material in water are improved at the same time in the four aspects of reducing the void ratio of the aggregate, optimizing the expanding components and improving the nano early strength and the dispersion resistance, the construction performance, such as the water holding performance and the viscosity, of the grouting material are remarkably improved, the 1d strength and the 28d strength of the grouting material under the undersea low-temperature condition are effectively improved, and the underwater dispersion resistance of the grouting material can be greatly improved. The low-temperature early-strength high-strength underwater grouting material has favorable low-temperature early-strength, low-temperature high-strength and underwater dispersion resistant functions.

Owner:JIANGSU SOBUTE NEW MATERIALS

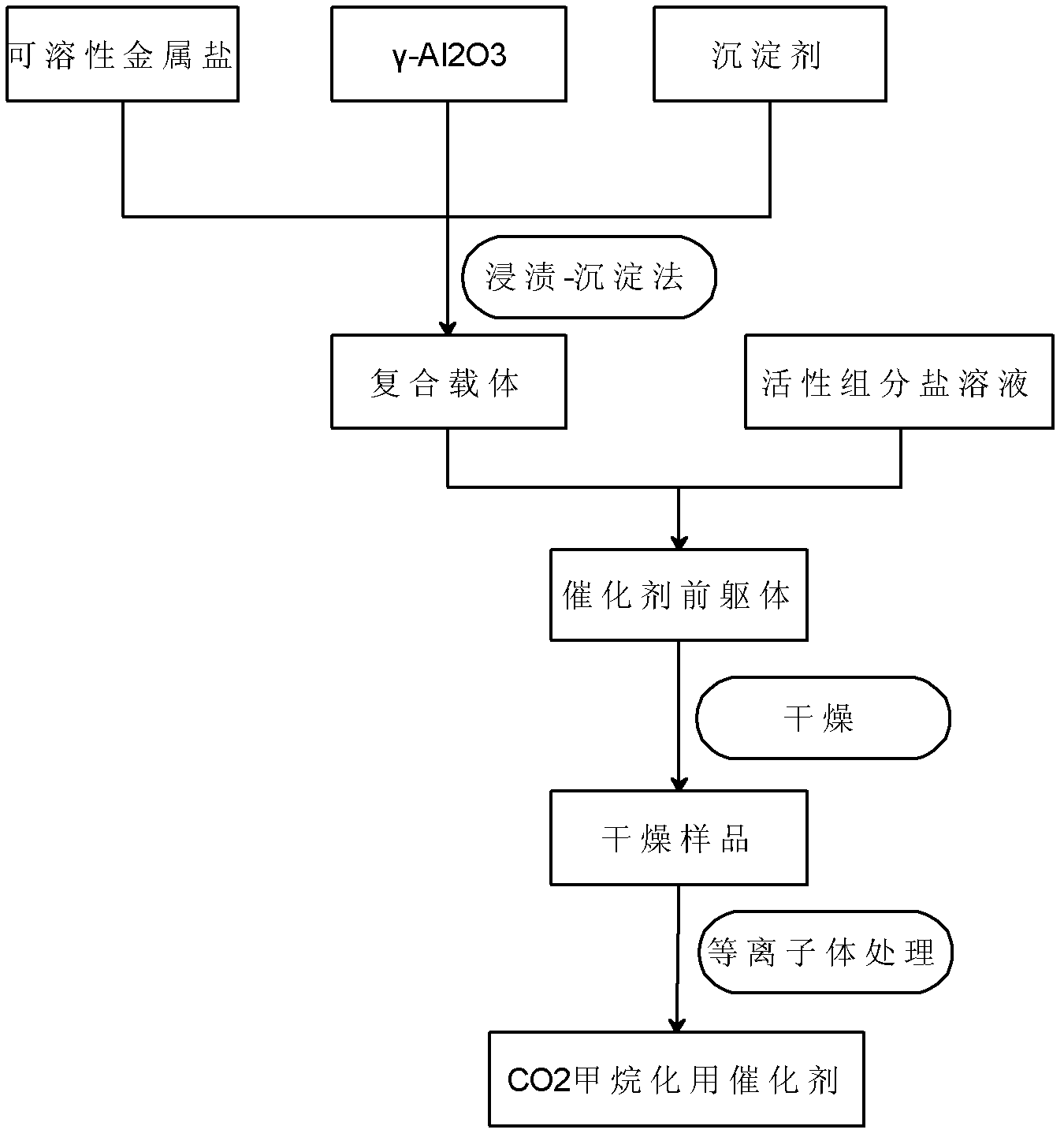

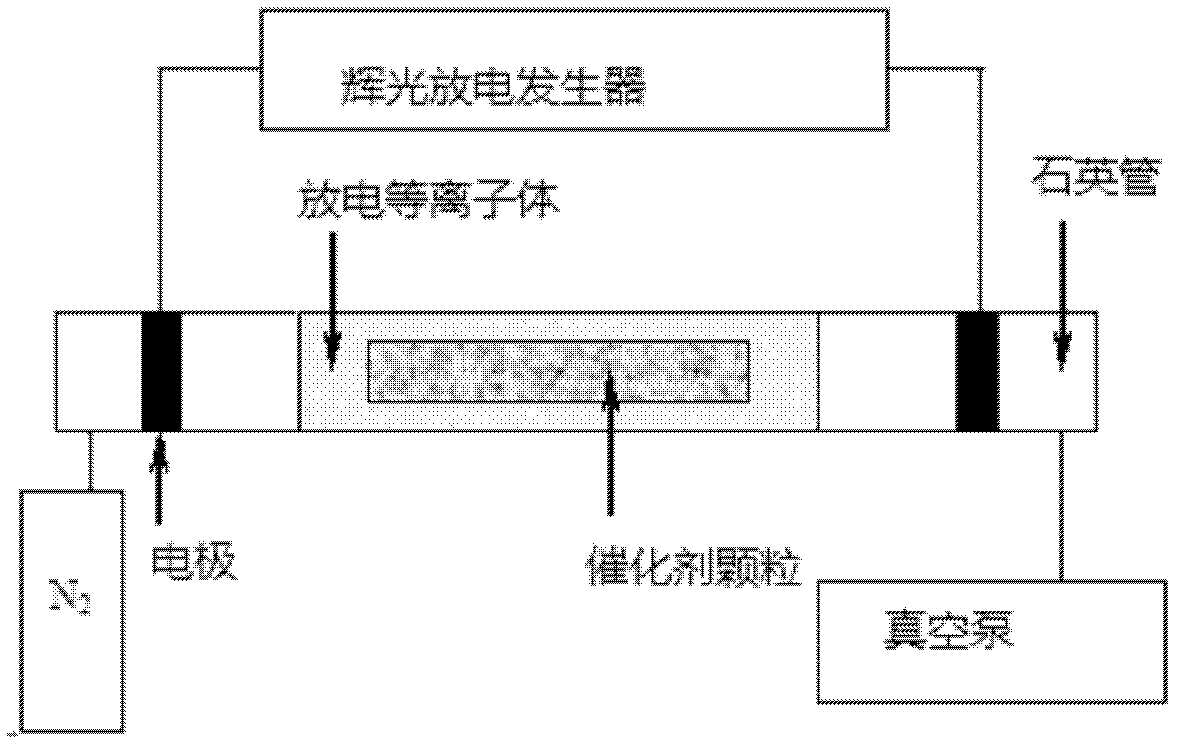

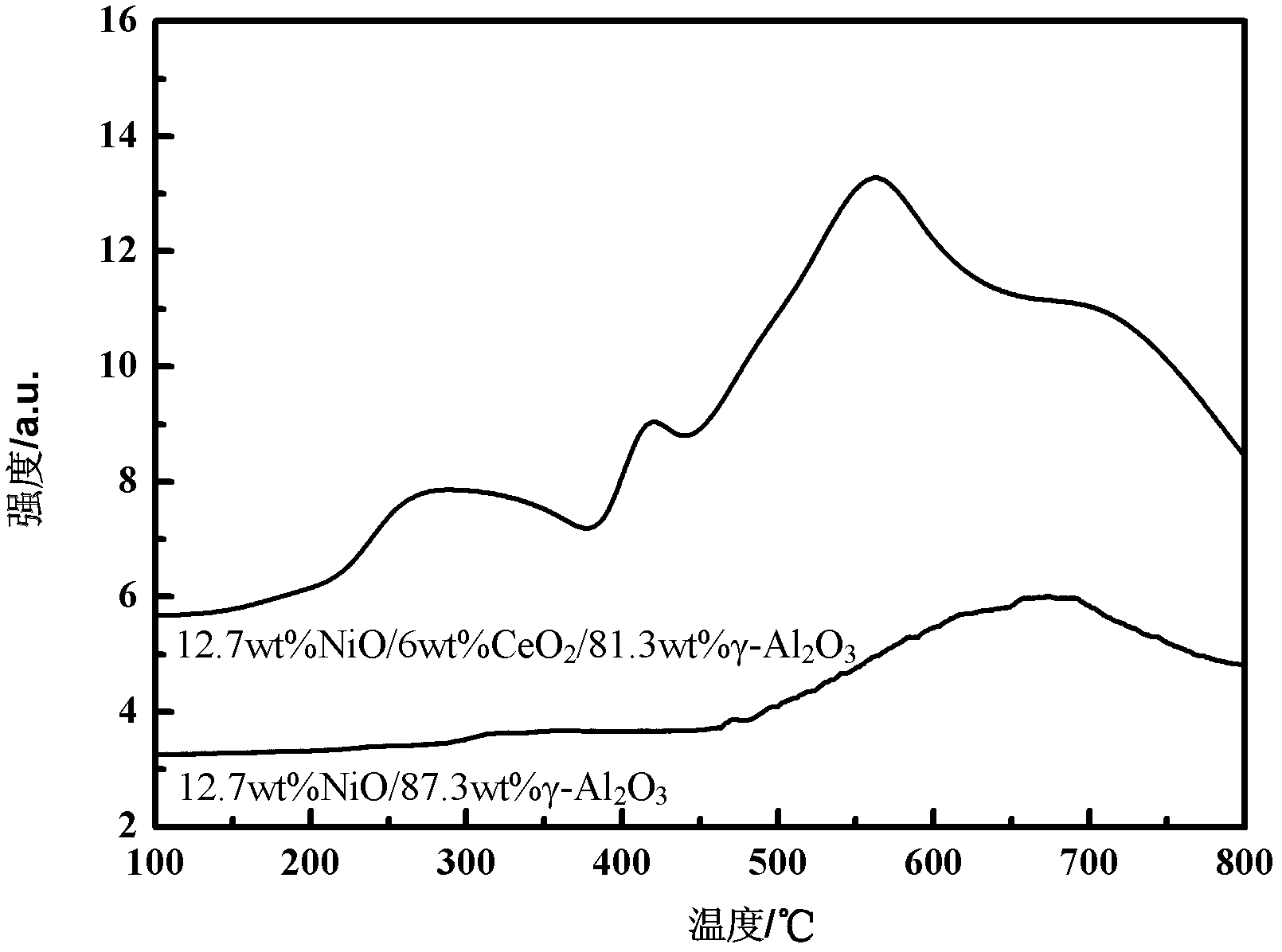

Catalyst for carbon dioxide methanation and preparation method thereof

InactiveCN102600854ASmall particle sizeEvenly dispersedHydrocarbon from carbon oxidesCatalyst activation/preparationChemistryWater soluble

The invention discloses a catalyst for carbon dioxide methanation and a preparation method of the catalyst, belonging to the technical field of carbon dioxide methanation. The catalyst for carbon dioxide methanation is composed of a composite carrier and an active ingredient at a ratio of 84-90wt%:10-16wt%, wherein the composite carrier is composed of gamma-Al2O3 and water soluble metal oxide at a mass ratio of 77-86:2-10; and the active ingredient is Ni which exists in the catalyst in a form of NiO. The catalyst is high in activity, low in cost and better in stability, and can be used for carbon dioxide methanation reaction under normal pressure condition.

Owner:SICHUAN UNIV

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Process for forming a bump structure and bump structure

InactiveUS20090121351A1High aspect ratioFine pitchSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringInterconnection

A method for forming a bump structure and a bump structure for conductive interconnection with another element having at least one of microelectronic devices or wiring thereon, used as an electric connection in an electronic circuit, includes the steps of forming a mandrel by steps including forming at least one opening extending through a bump-forming die body in the thickness direction thereof and positioning a bump-forming die lid on a surface of the bump-forming die body so as to cover one end of the opening and to thereby define a bump-forming recess. The bump-forming die body may be comprised of a metal sheet. A metal layer is formed at least on an inner surface of the bump-forming die lid exposed within the bump-forming recess. The mandrel is removed so as to expose the metal layer and form a bump structure.

Owner:INVENSAS CORP

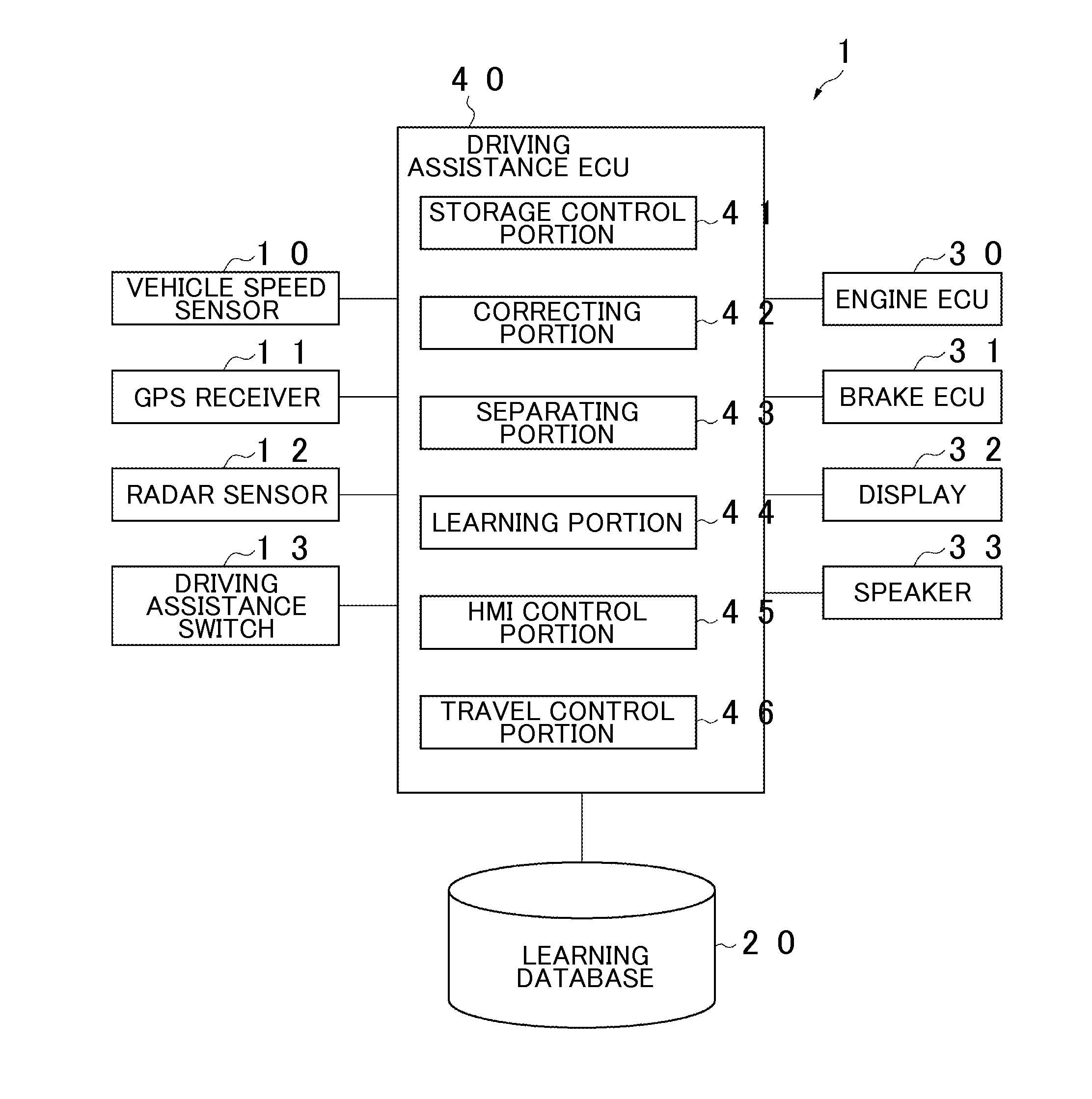

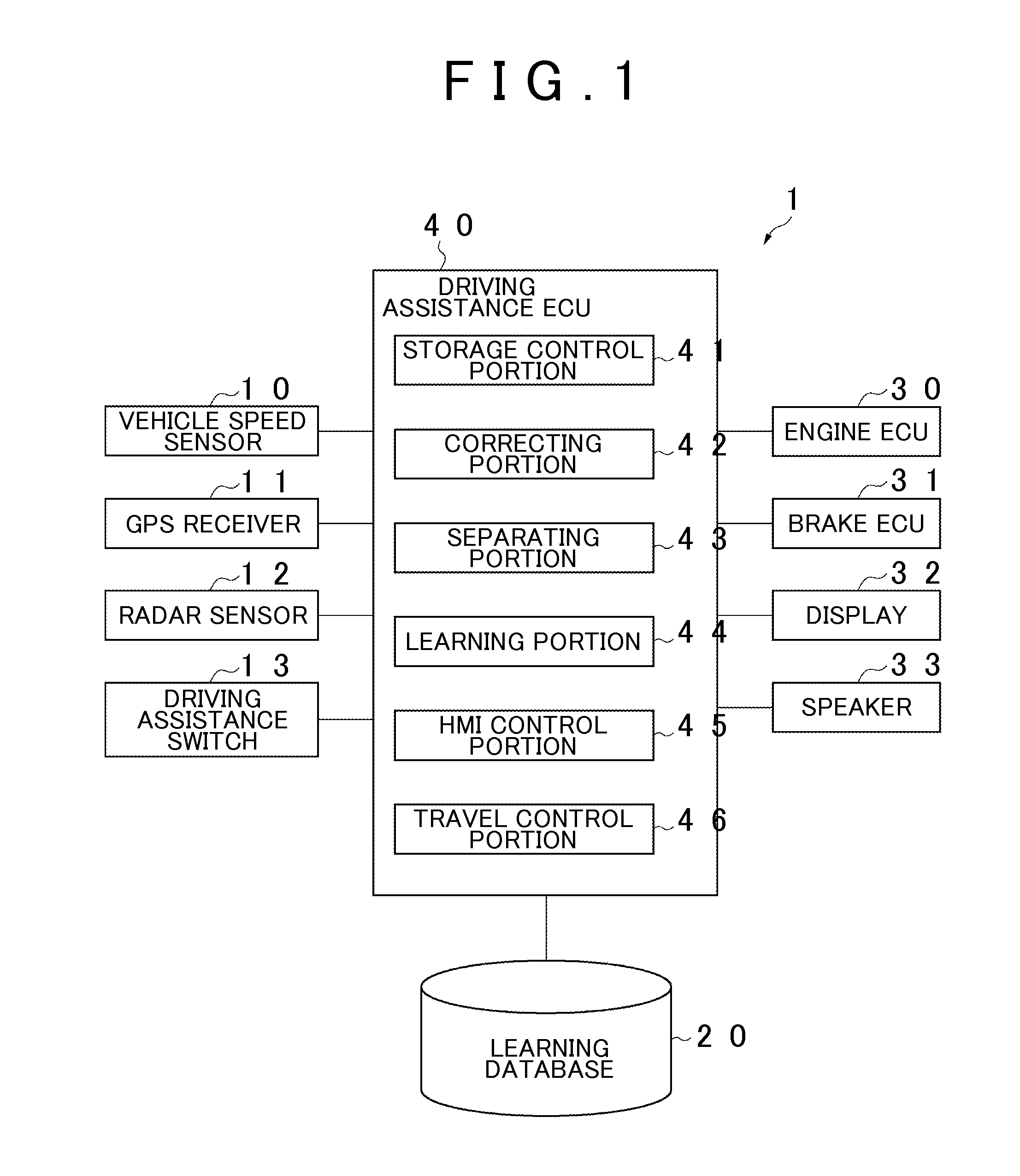

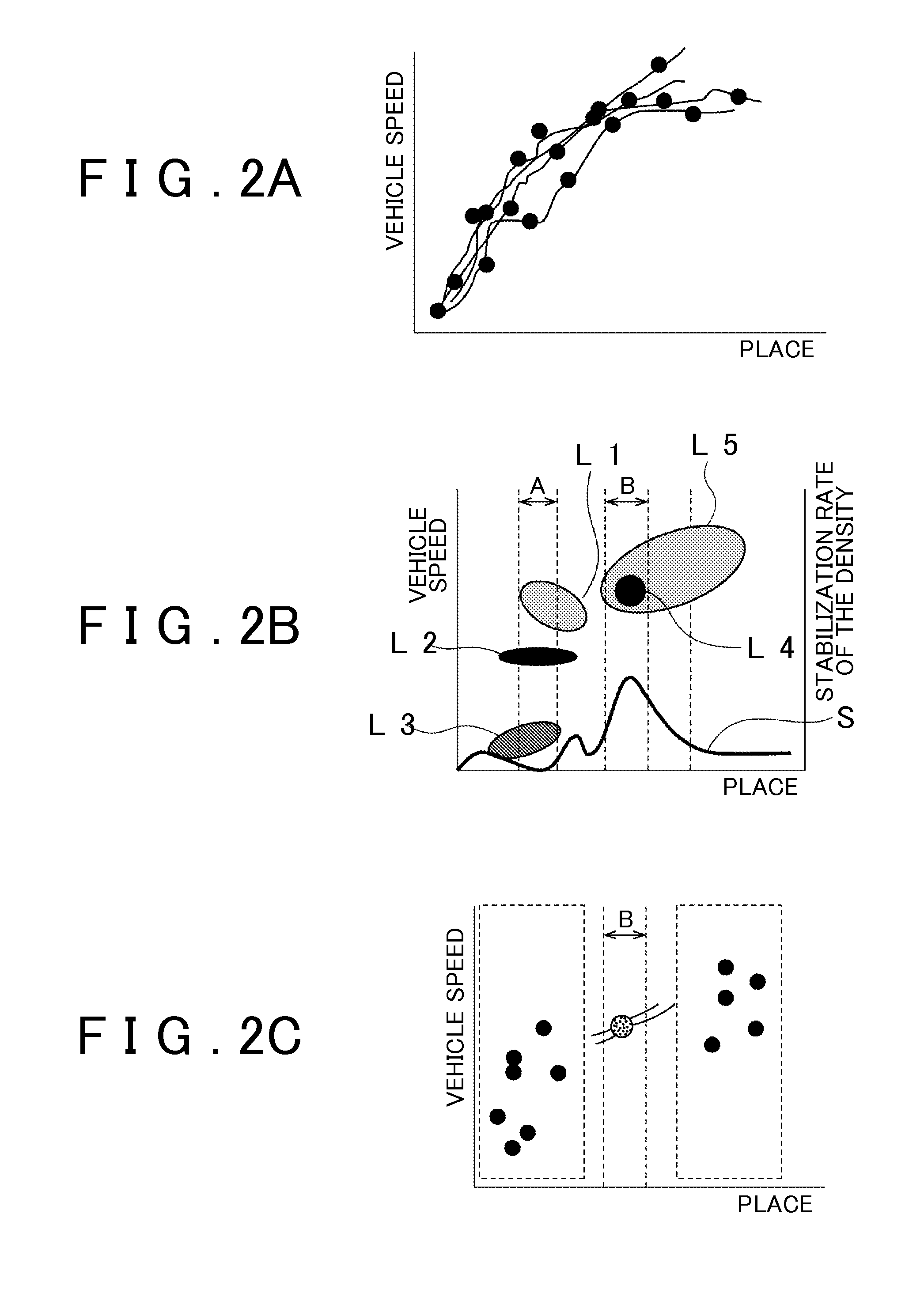

Driving assistance device

InactiveUS20150073620A1Reduce the amount requiredReduce storage capacityDigital data processing detailsVehicle position/course/altitude controlDriver/operatorEngineering

A driving assistance device including: a storage portion, configured to store a vehicle speed, an acceleration and deceleration tendency at the same place on a travel route respectively for a plurality of times during a time in which a driver performs acceleration and deceleration operations; a learning portion, configured to distinguish a plurality of object vehicle speeds from a plurality of vehicle speeds at the same place stored in the storage portion, and learn the vehicle speeds at the same place based on the plurality of vehicle speeds with small dispersion when the dispersion of the plurality of vehicle speeds identified as object is small; and a driving assistance portion, configured to perform driving assistance based on the vehicle speed learned by the learning portion, when the vehicle travels at a place where the vehicle speed is learned after learning of the learning portion.

Owner:TOYOTA JIDOSHA KK

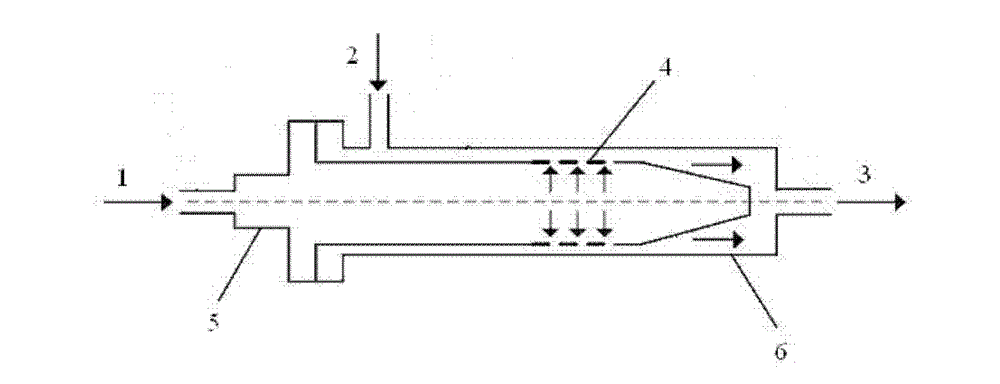

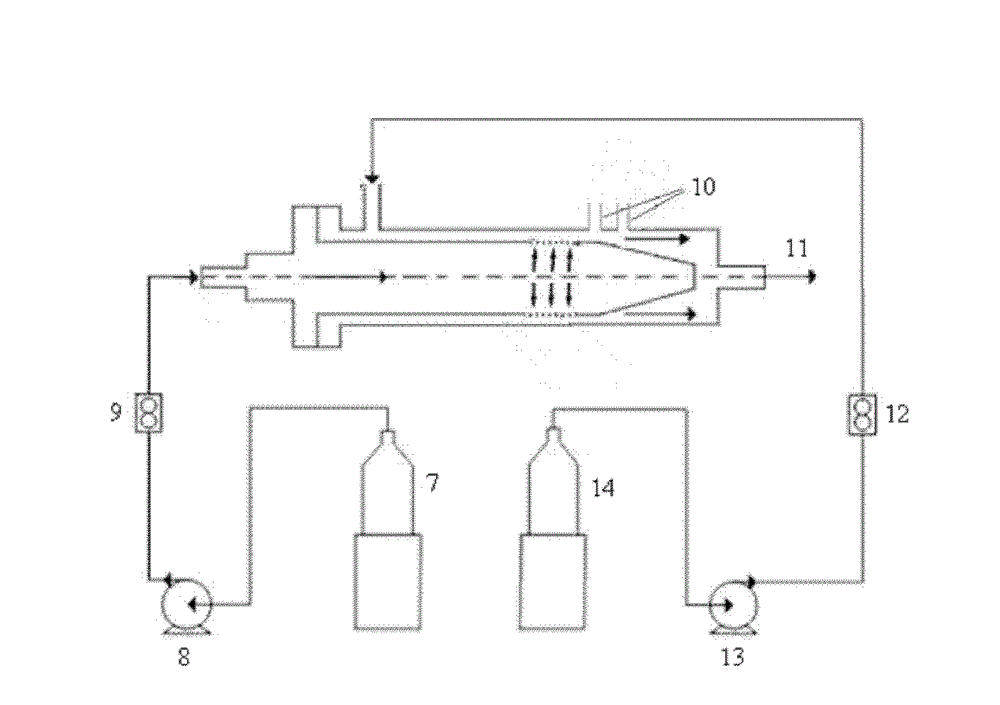

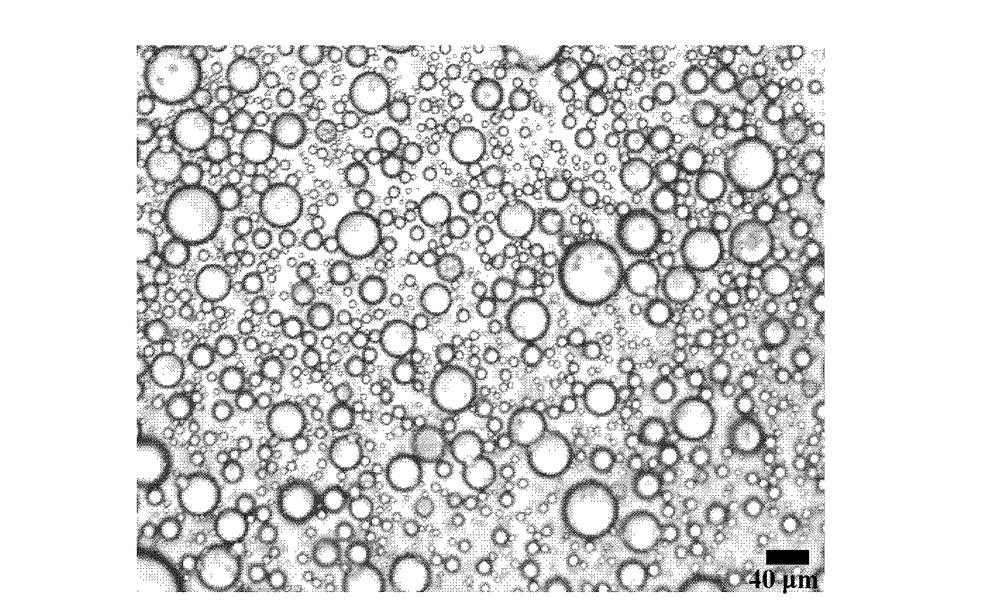

Method for preparing monodisperse emulsion

InactiveCN102794119AUniform particle sizeQuality improvementFlow mixersMixing methodsContact formationEmulsion droplet

The invention discloses a method for preparing monodisperse emulsion and belongs to the technical field of emulsion. The monodisperse emulsion is prepared by using a tube-in-tube annular channel reactor; a continuous phase is introduced into an outer tube of the tube-in-tube annular channel reactor, a disperse phase is introduced into an inner tube of the tube-in-tube annular channel reactor, and the continuous phase and the disperse phase fully contact on micropore parts to form the emulsion; and according to the method, equipment is simple, cost is low, flux is high, and continuous operation can be realized, so that the preparation cycle can be greatly shortened, and production efficiency is improved. The emulsion prepared by the method is high in quality, stable in performance, and high dispersibility; and emulsion droplets are uniform in particle size.

Owner:BEIJING UNIV OF CHEM TECH

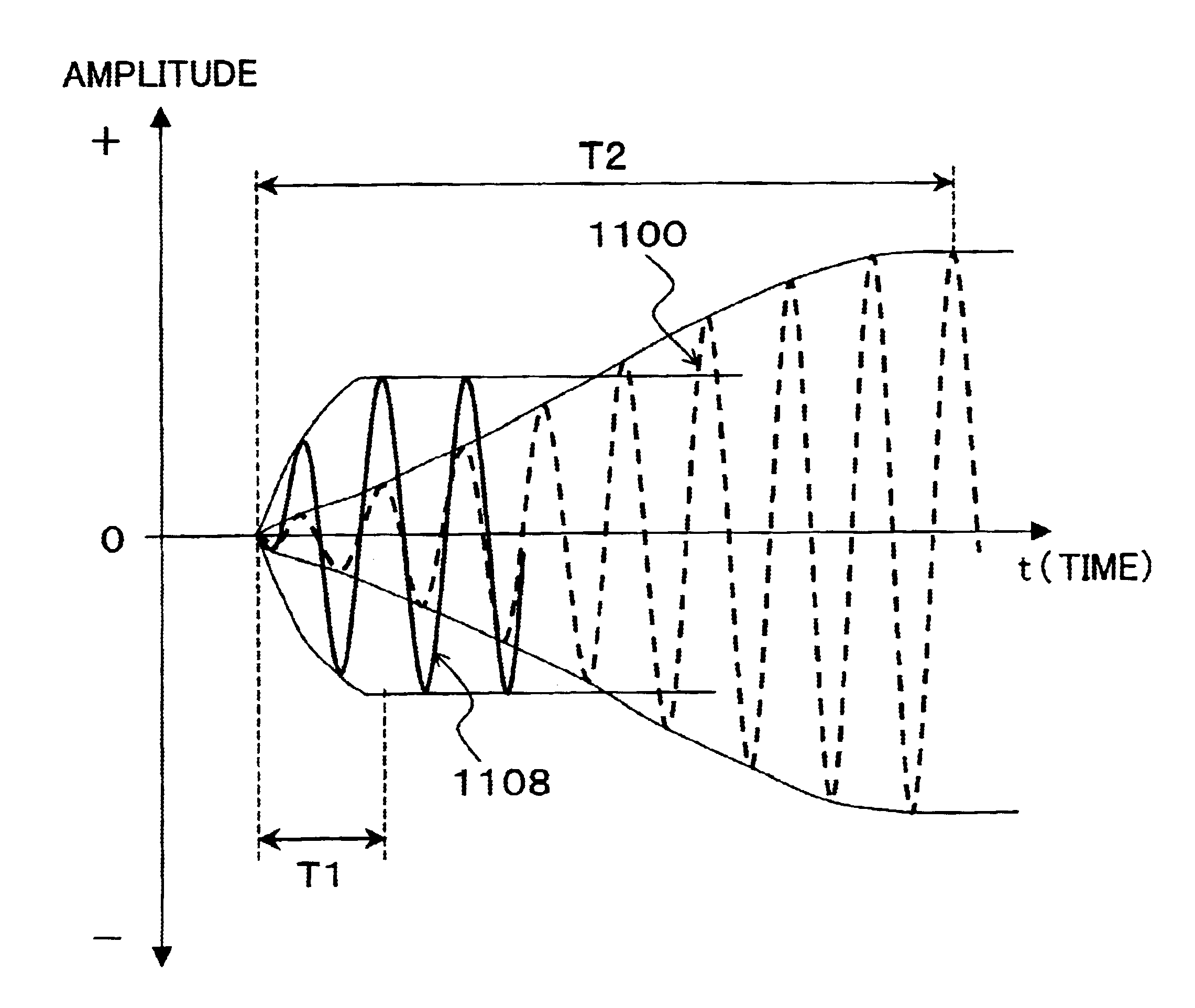

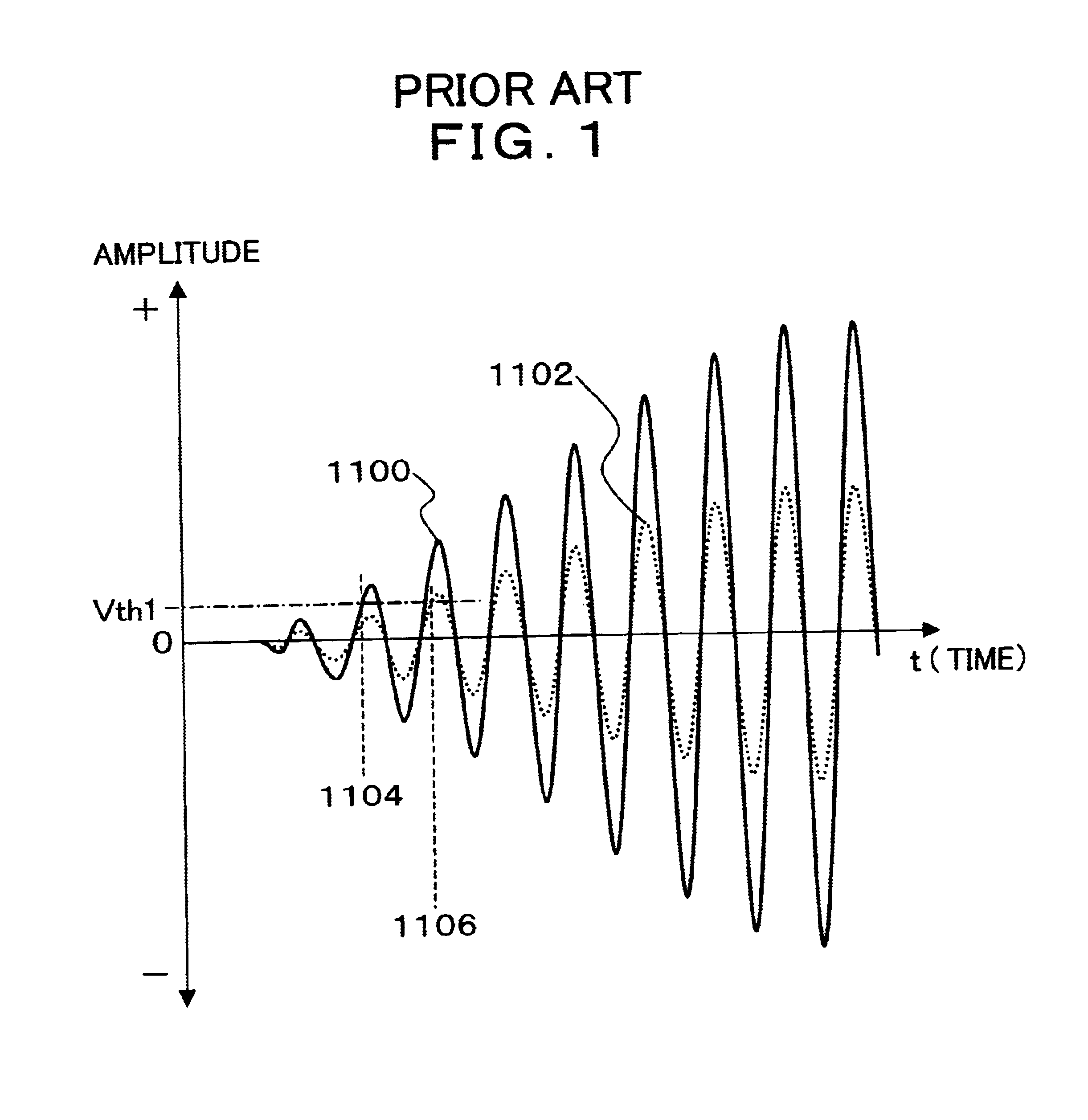

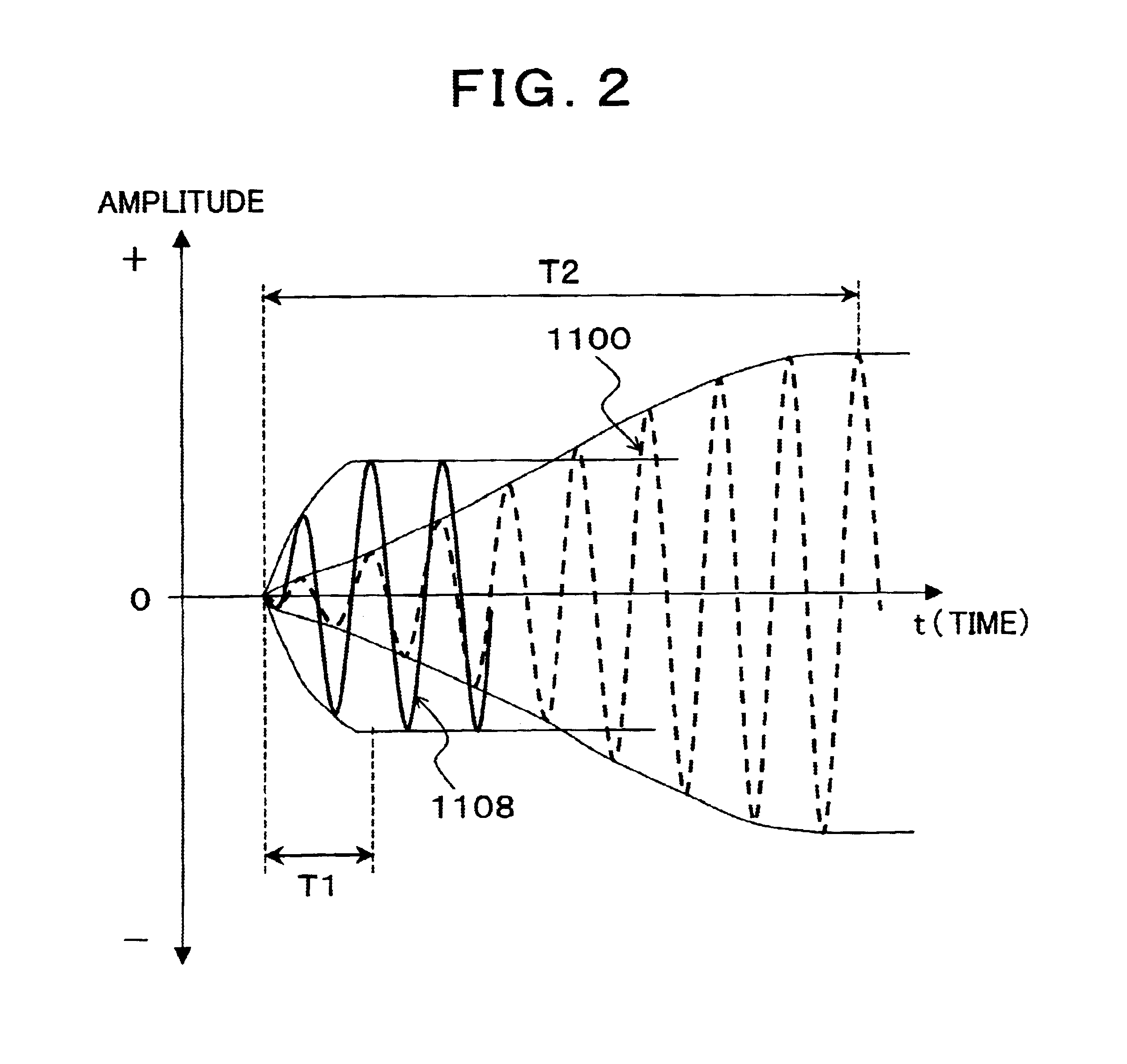

Ultrasonic length measuring apparatus and method for coordinate input

InactiveUS6944557B2High precision length measurementSimple configurationMaterial analysis using sonic/ultrasonic/infrasonic wavesStatic/dynamic balance measurementMeasurement deviceUltrasound

An ultrasonic length measuring apparatus measures the number of times a waveform of an ultrasonic wave signal crosses a threshold value, detects the crossing timing at, for example, a waveform having a maximal amplitude after a predetermined number of times counting from a first crossing point, measures the time period from the transmission start of the ultrasonic wave by the transmission unit to the detected crossing timing and calculates the length based on the time measured. A coordinate inputting apparatus includes a pen for transmitting an ultrasonic wave and a coordinate inputting apparatus for inputting coordinate positions of the pen based on a propagation time of the ultrasonic wave transmitted by the pen and received by a plurality of ultrasonic wave receivers. The receiver includes at least a pair of ultrasonic receivers for receiving the ultrasonic wave transmitted by the pen.

Owner:FUJITSU LTD

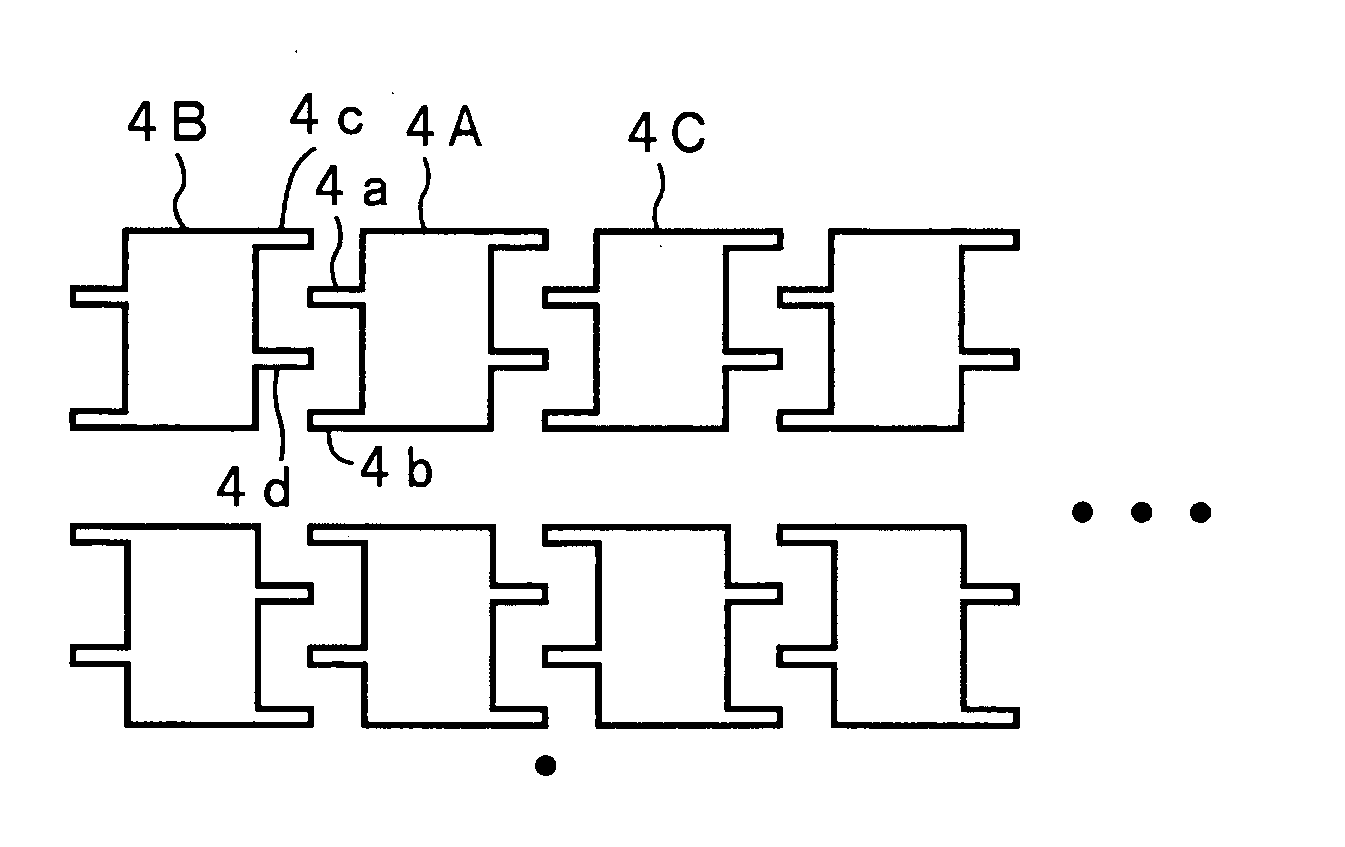

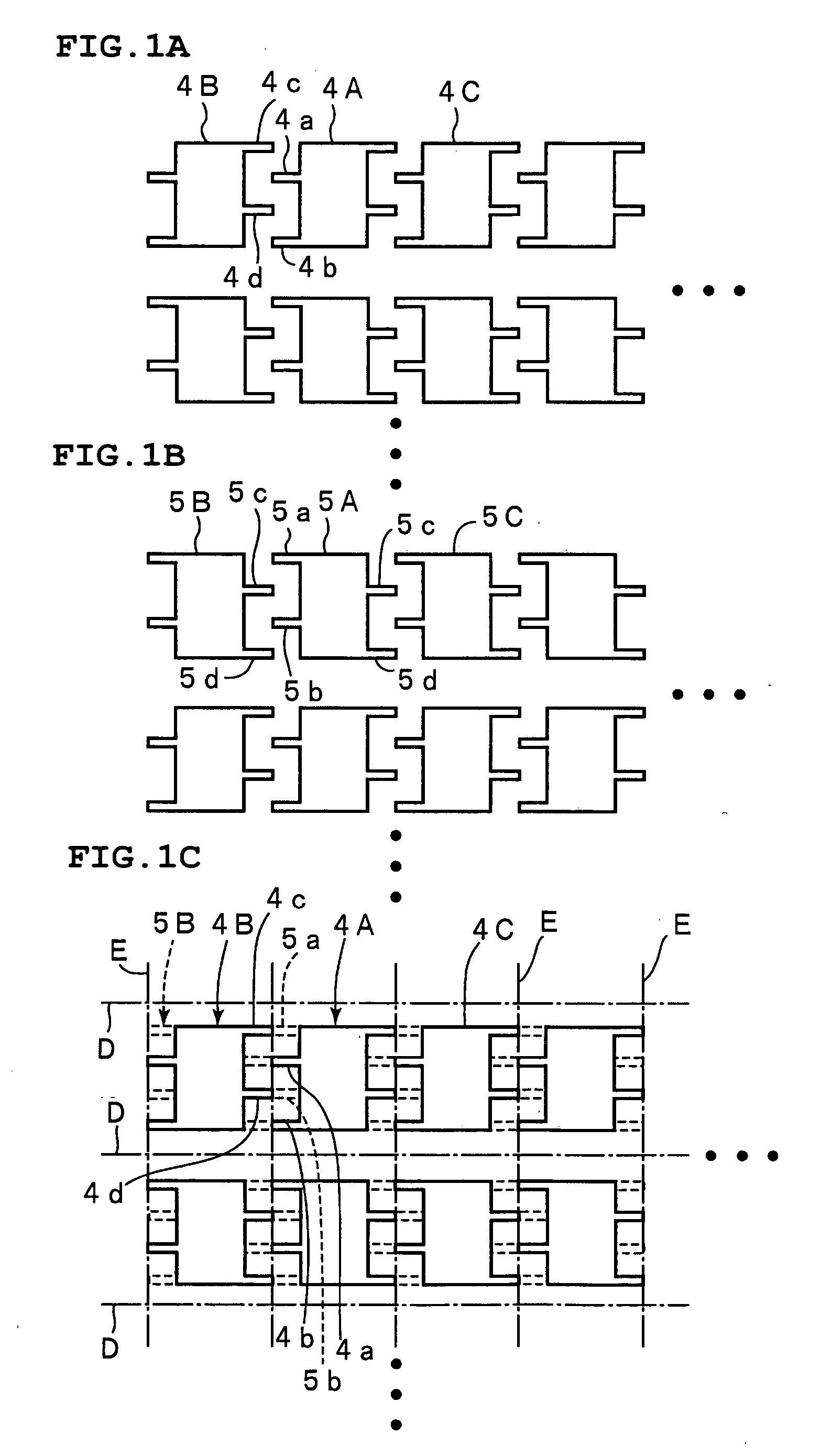

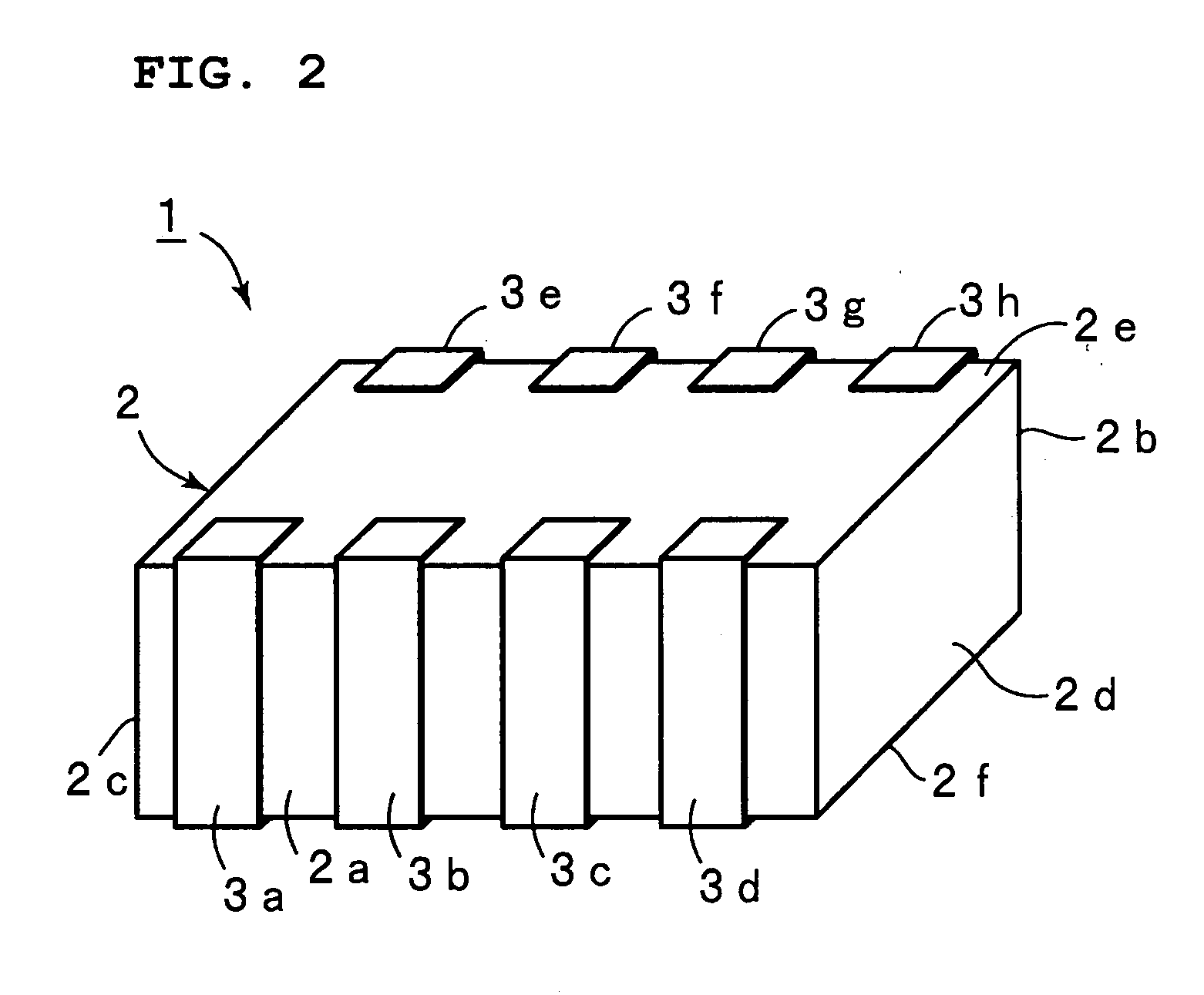

Method of producing multi-terminal type laminated ceramic electronic component

ActiveUS20050067086A1Improve accuracyImprove printing accuracyMultiple fixed capacitorsFixed capacitor dielectricElectronic componentMaterials science

In a method of producing a multi-terminal type laminated ceramic electronic component in which internal electrodes are embedded in a sintered ceramic member, and the internal electrodes have plural first lead-out electrodes led out to a first side surface and plural second lead-out electrodes led out to a second side surface, the plural second lead-out electrodes of one of the adjacent internal electrodes in each internal electrode pattern are not continuous with the plural first lead-out electrodes of the other of the adjacent internal electrodes, and the plural second lead-out electrodes and the plural first lead-out electrodes are alternately arranged in a direction that is substantially perpendicular to the direction of a line connecting the first and second side surfaces.

Owner:MURATA MFG CO LTD

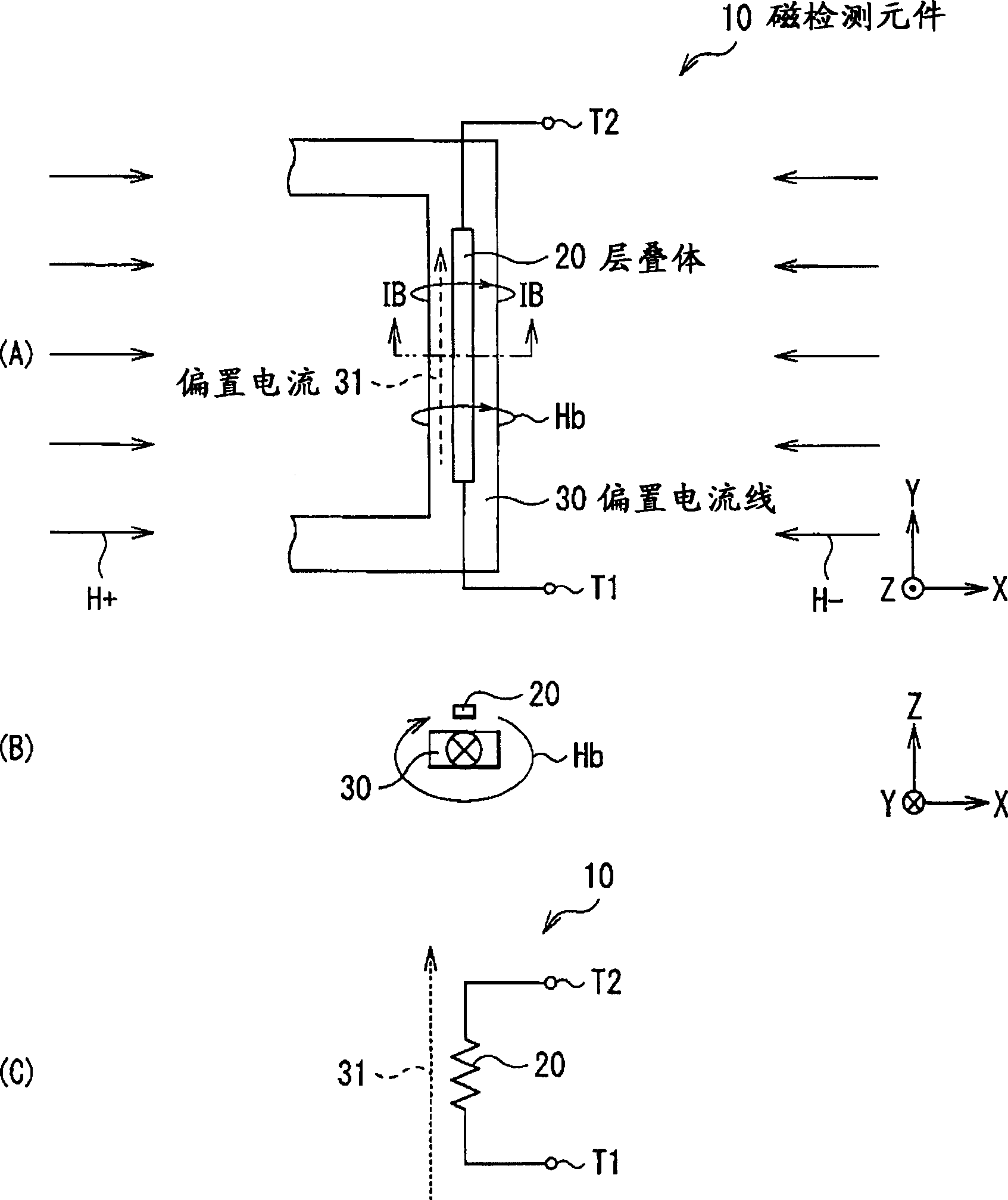

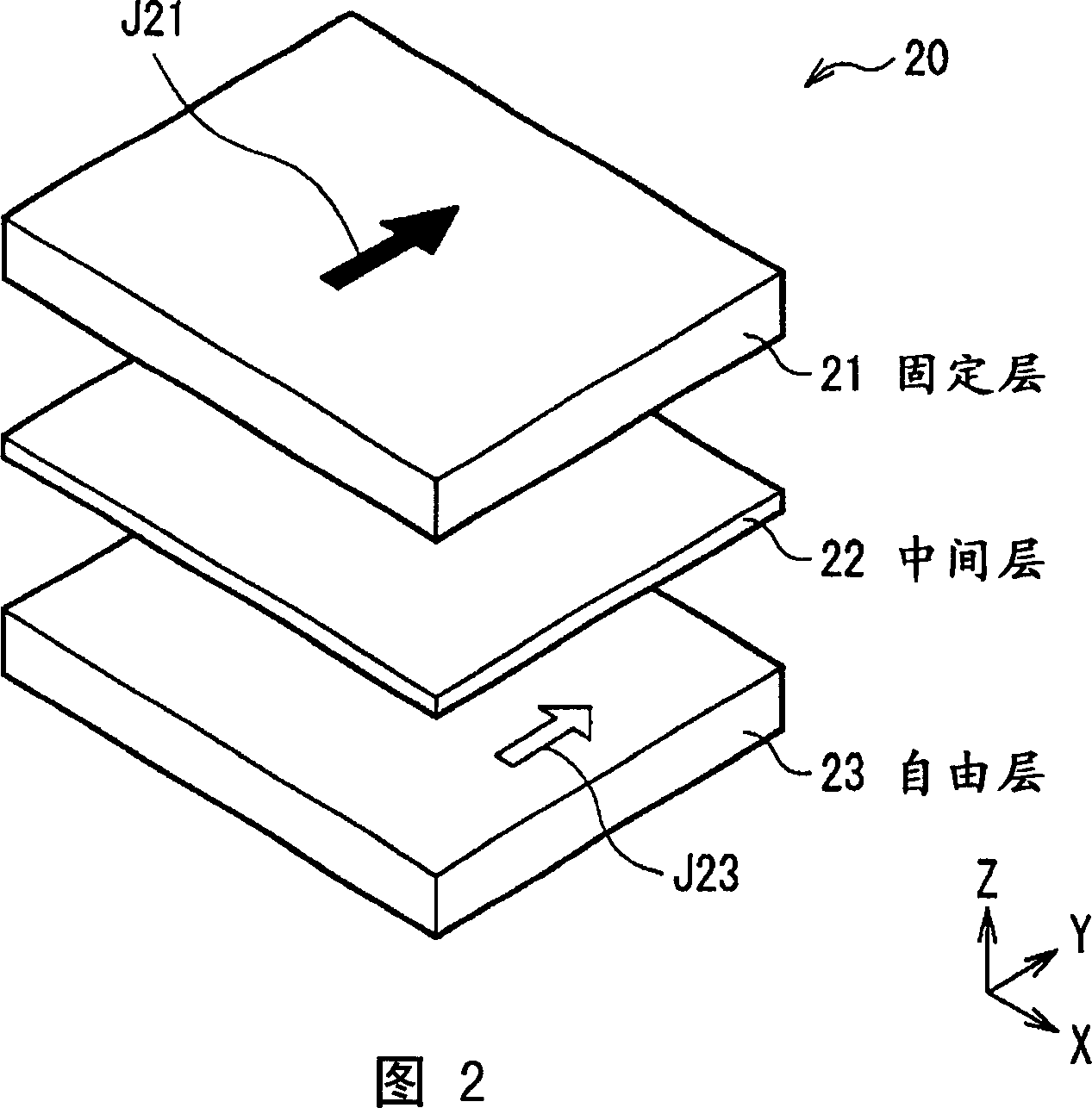

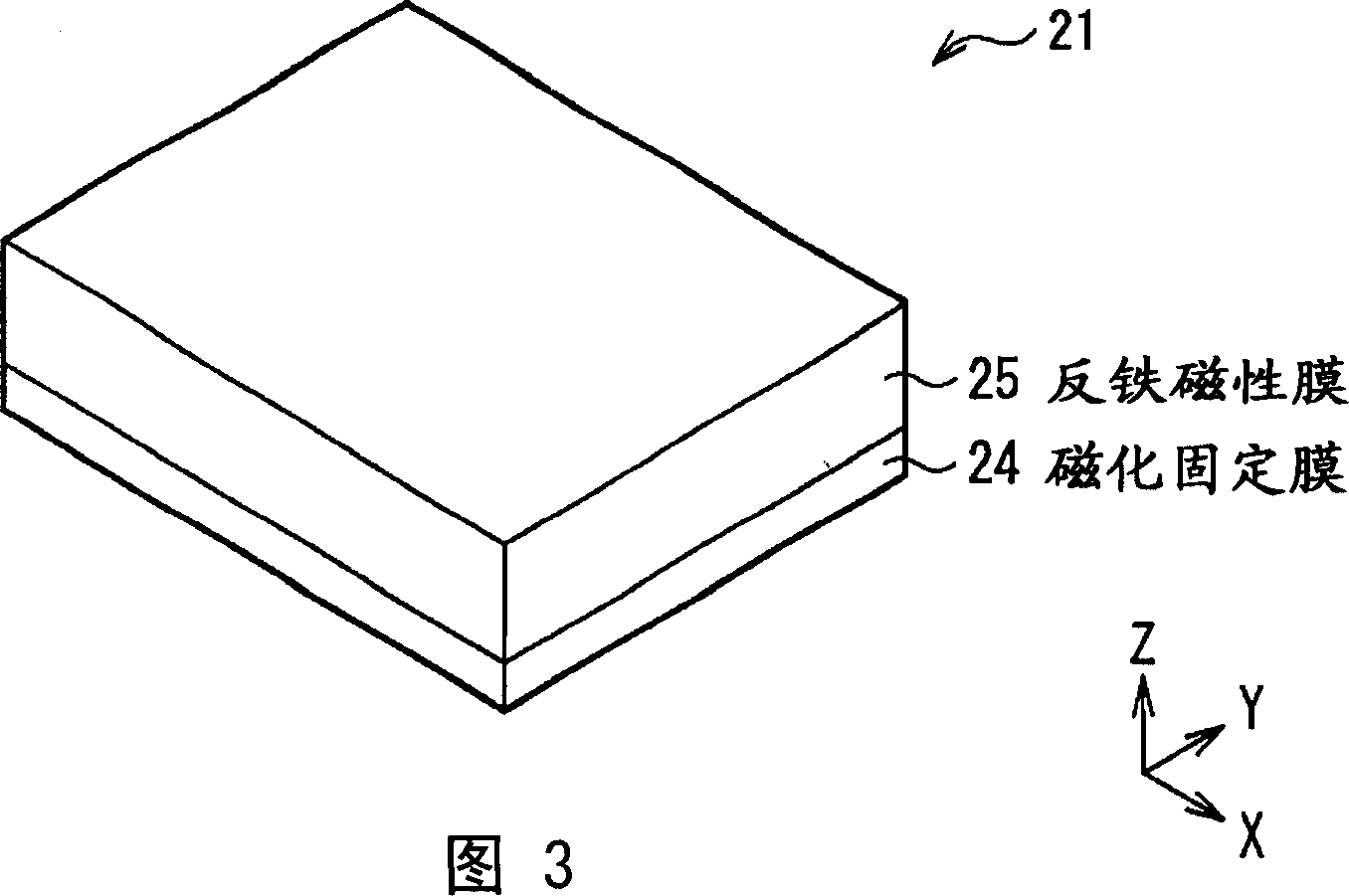

Magnetic sensing device, method of forming the same, magnetic sensor, and ammeter

ActiveCN1657967ASuppression hysteresisReduce offsetNanostructure applicationNanomagnetismHysteresisElectrical resistance and conductance

Owner:TDK CORPARATION

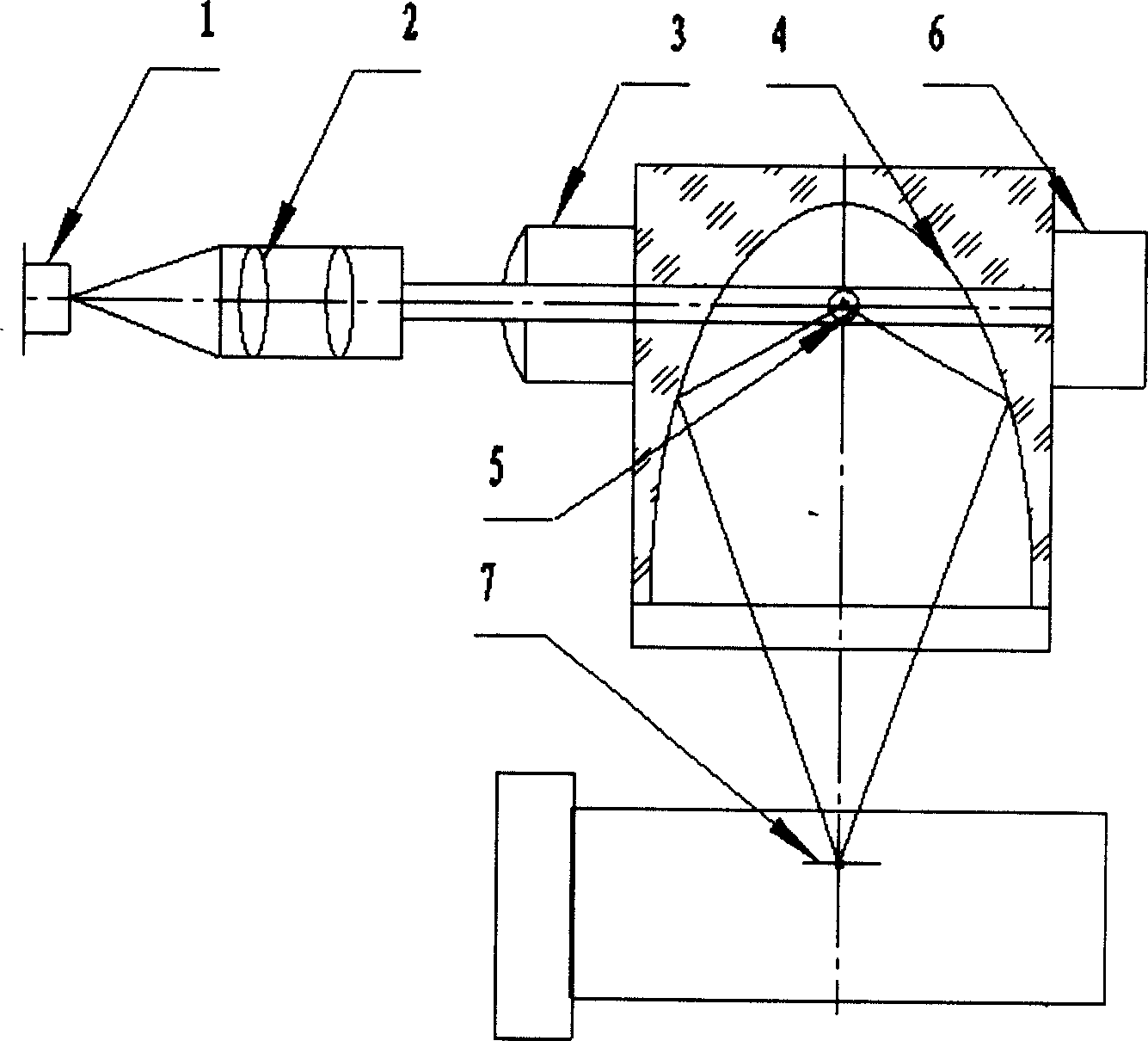

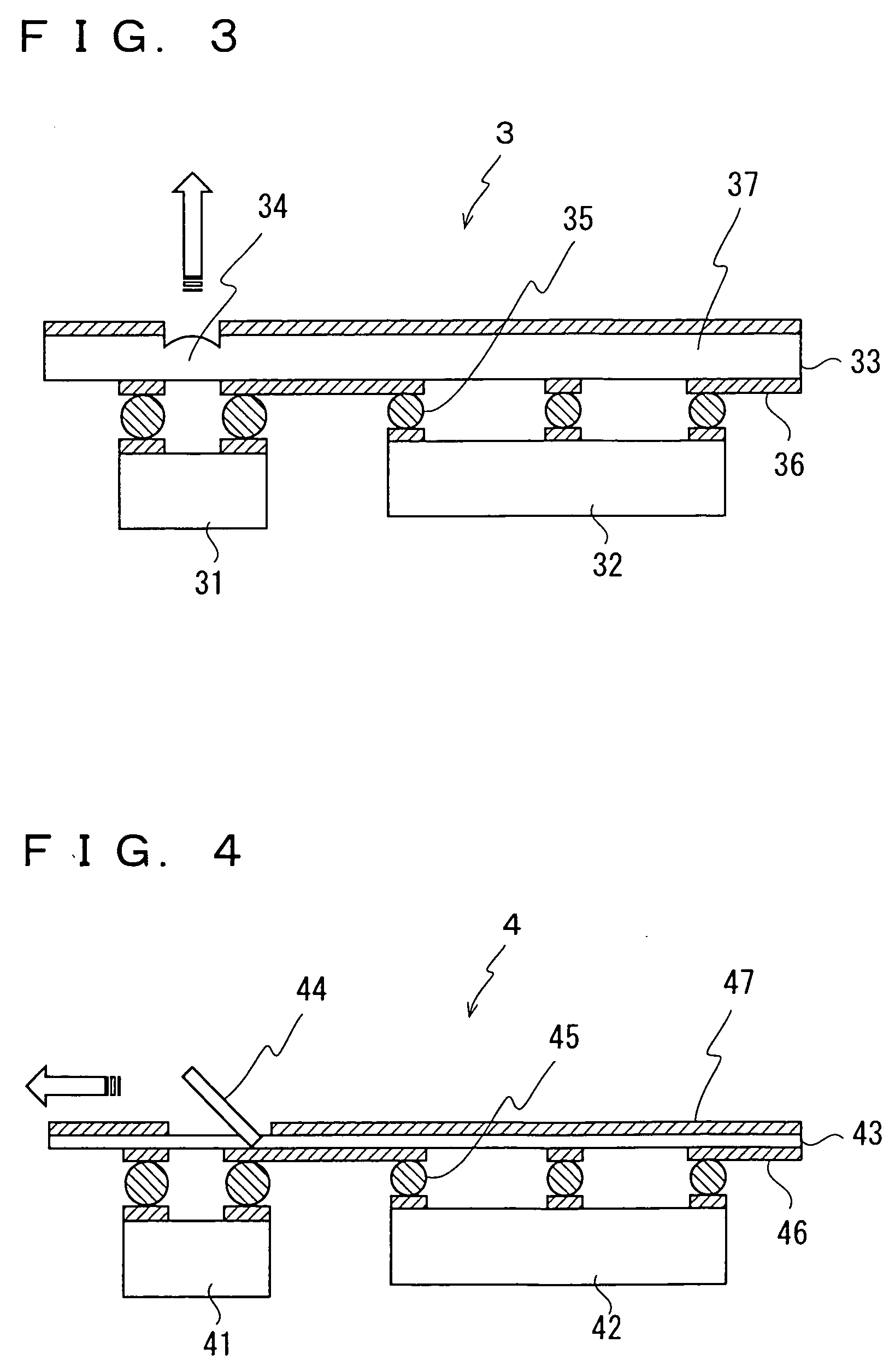

Micro optical sensor for laser dust particle counter

ActiveCN1570604AIncrease light intensityImprove light uniformityIndividual particle analysisCounting efficiencyLong axis

A micro optical sensor of laser dust particle counter, which is characterized by its components, which comprises the following: there is cylinder mirror, spherical mirror and light trap located orderly in the direction of light beam of laser source components. The spherical mirror is located in the right side of the cylinder mirror and light-sensitive area and that of light-electricity detector are located on both sides around the sphere center of spherical mirror, which satisfies the image relationship of geometry optics; vision diaphragm which is suited for the shape of light sensitive-area is located in front of light-electricity detector; the light-electricity detector employs photoelectric diode of high sensitivity or micro photoelectric multiplier tube sealed with metal; A band pass preposition enlarging circuit is fixed in the shell of scatter body of optics sensor with the same width of pulse frequency of scattering light.

Owner:上海镭慎光电科技有限公司 +1

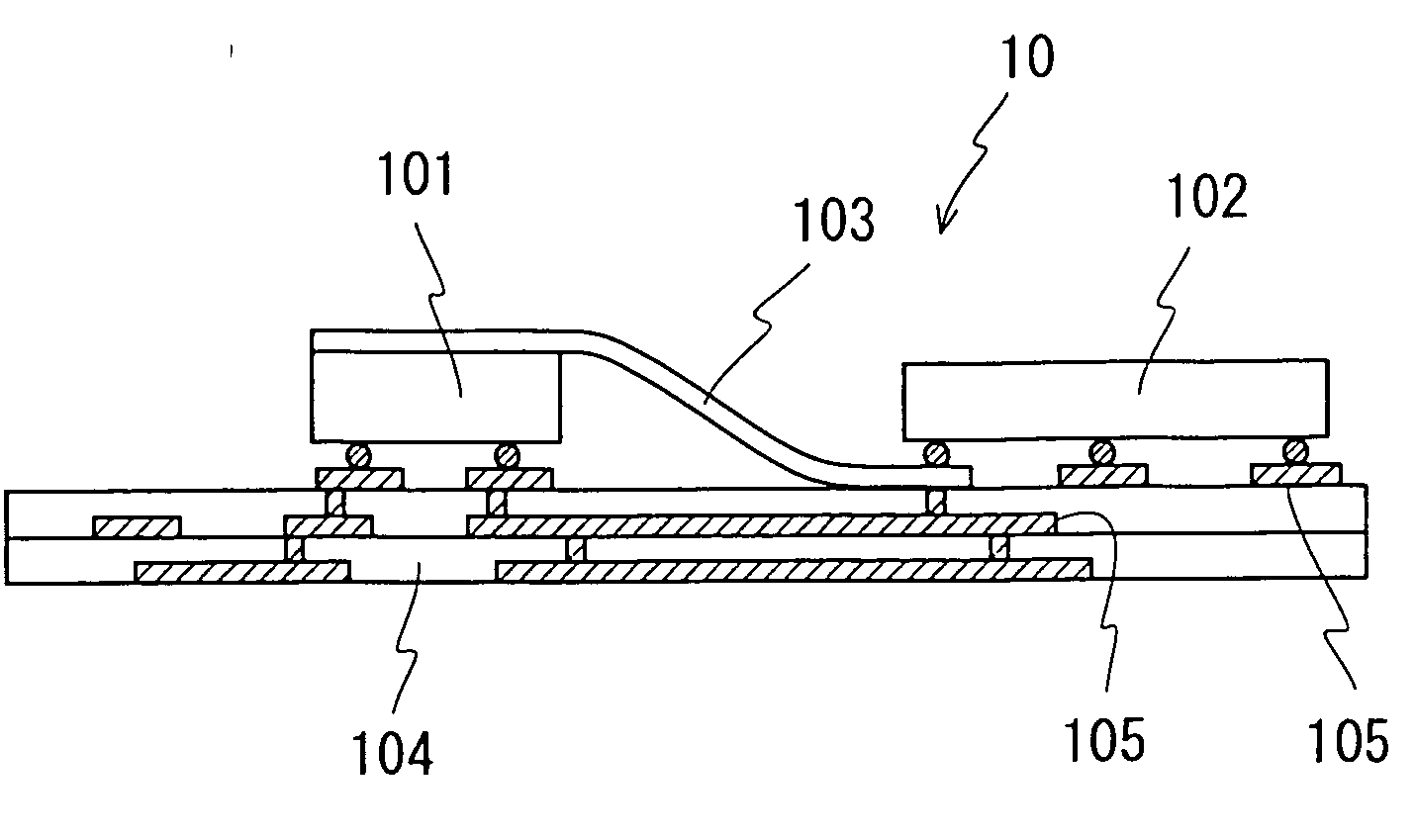

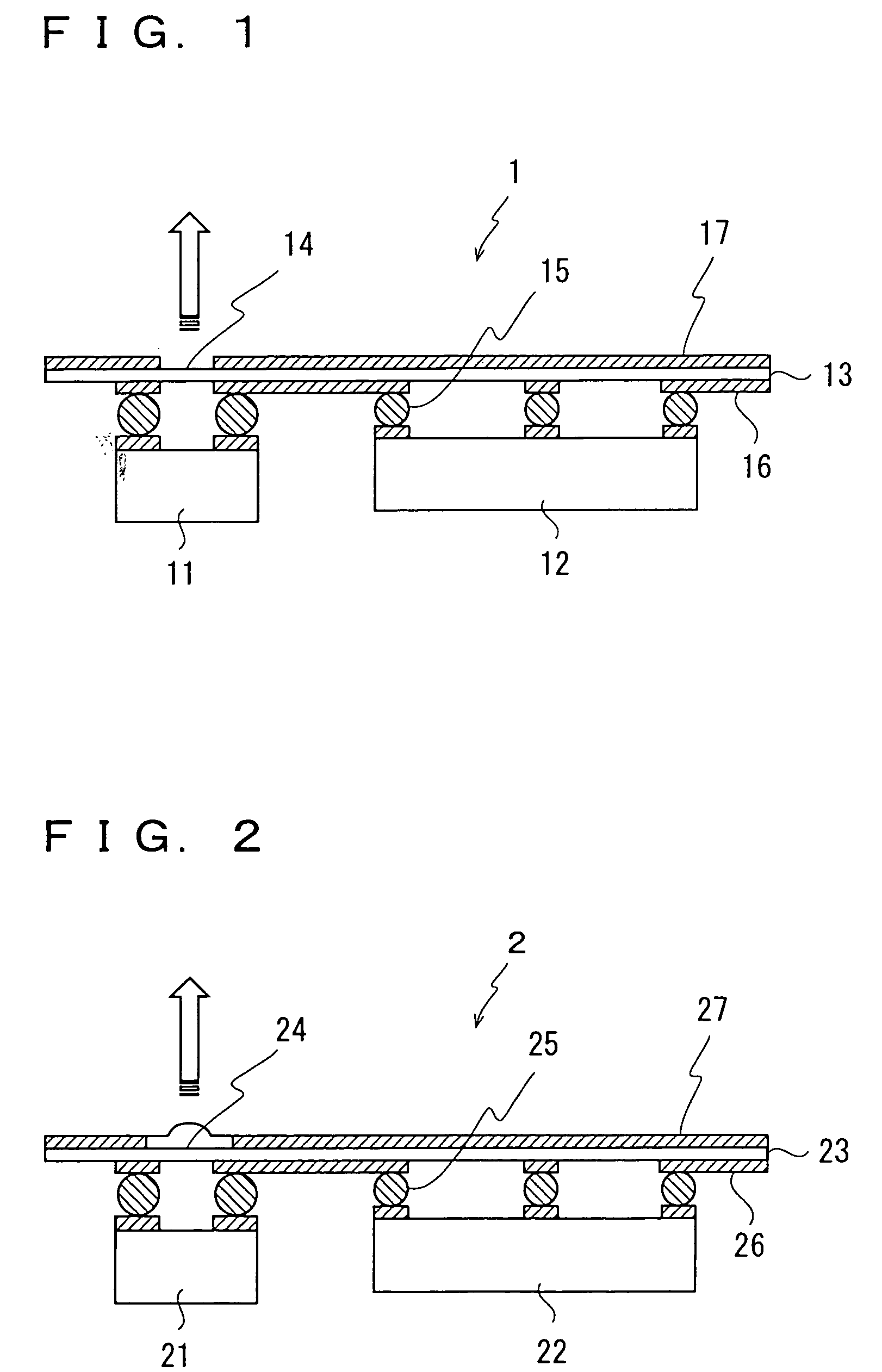

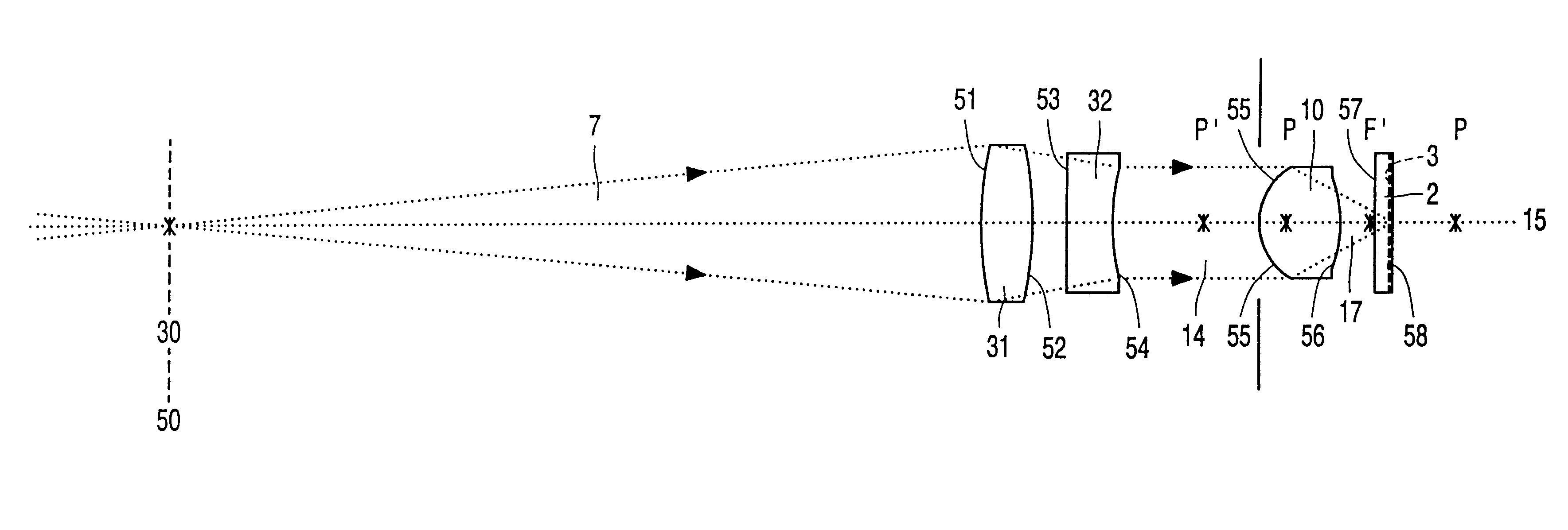

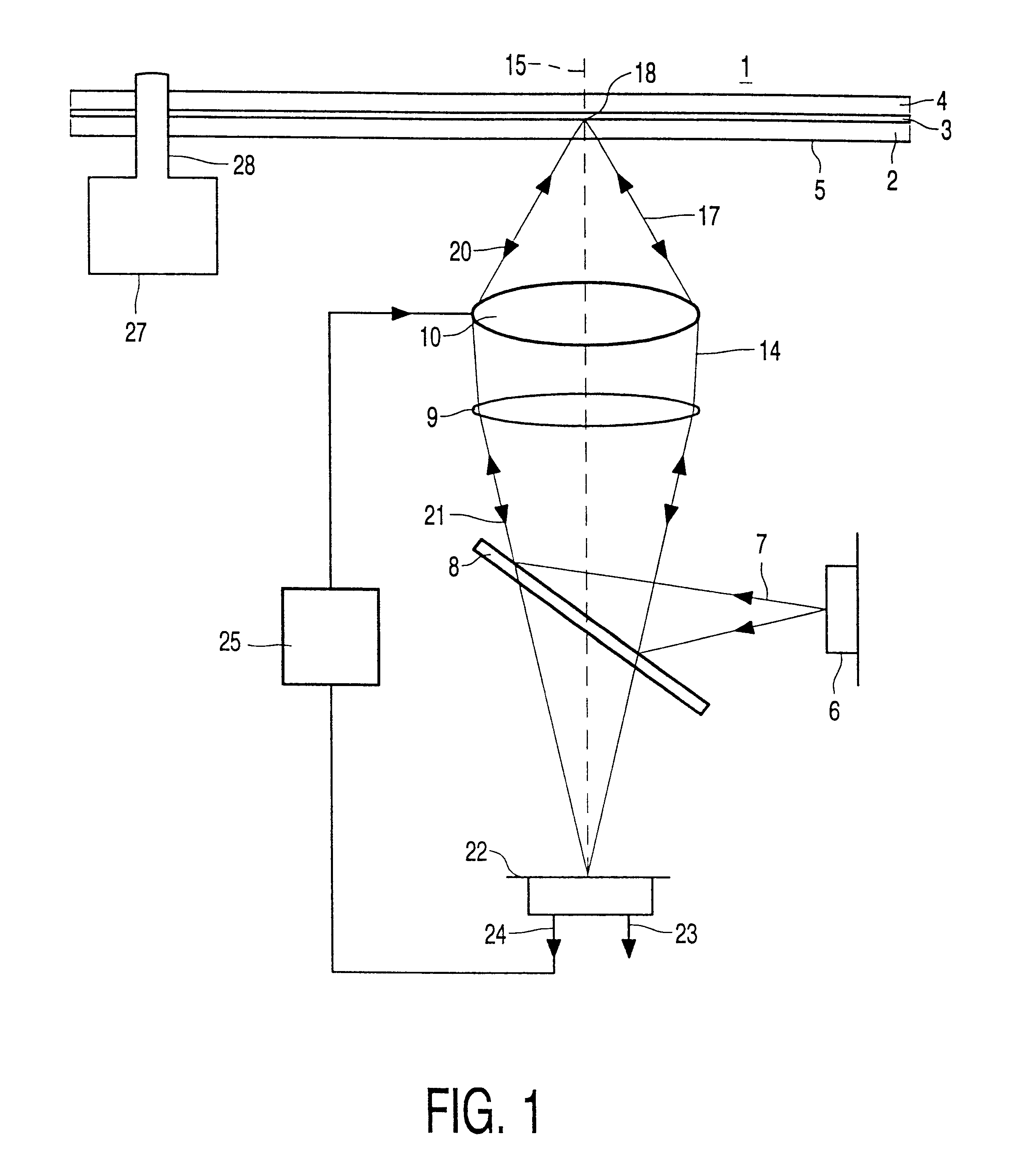

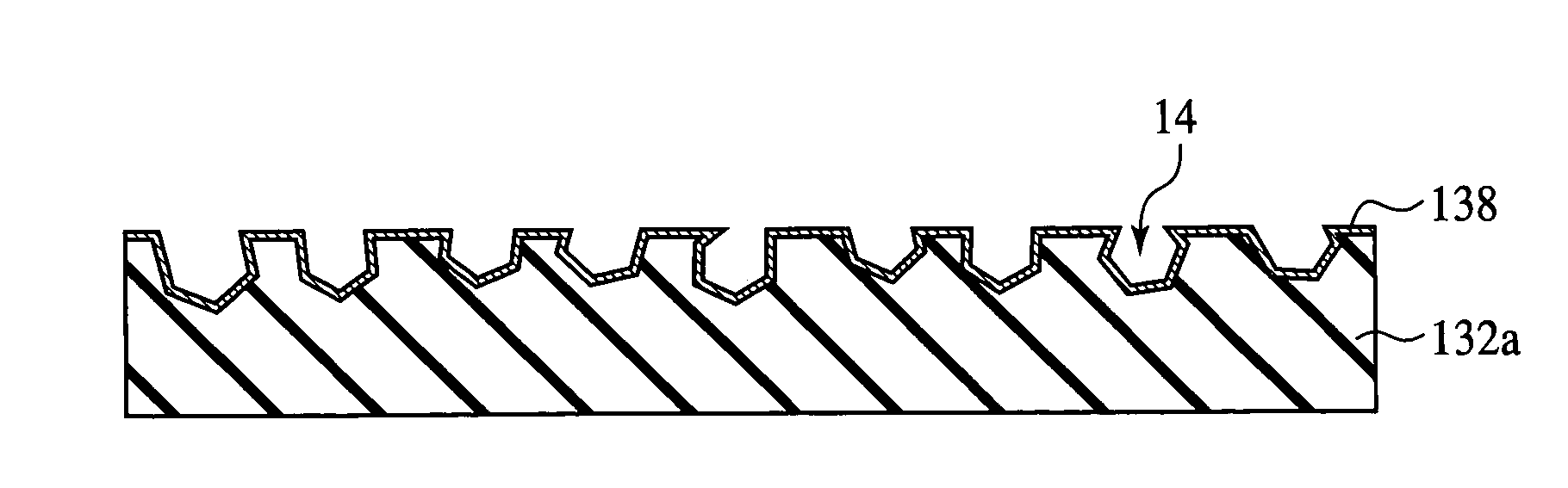

Optoelectronic hybrid integrated module and light input/output apparatus having the same as component

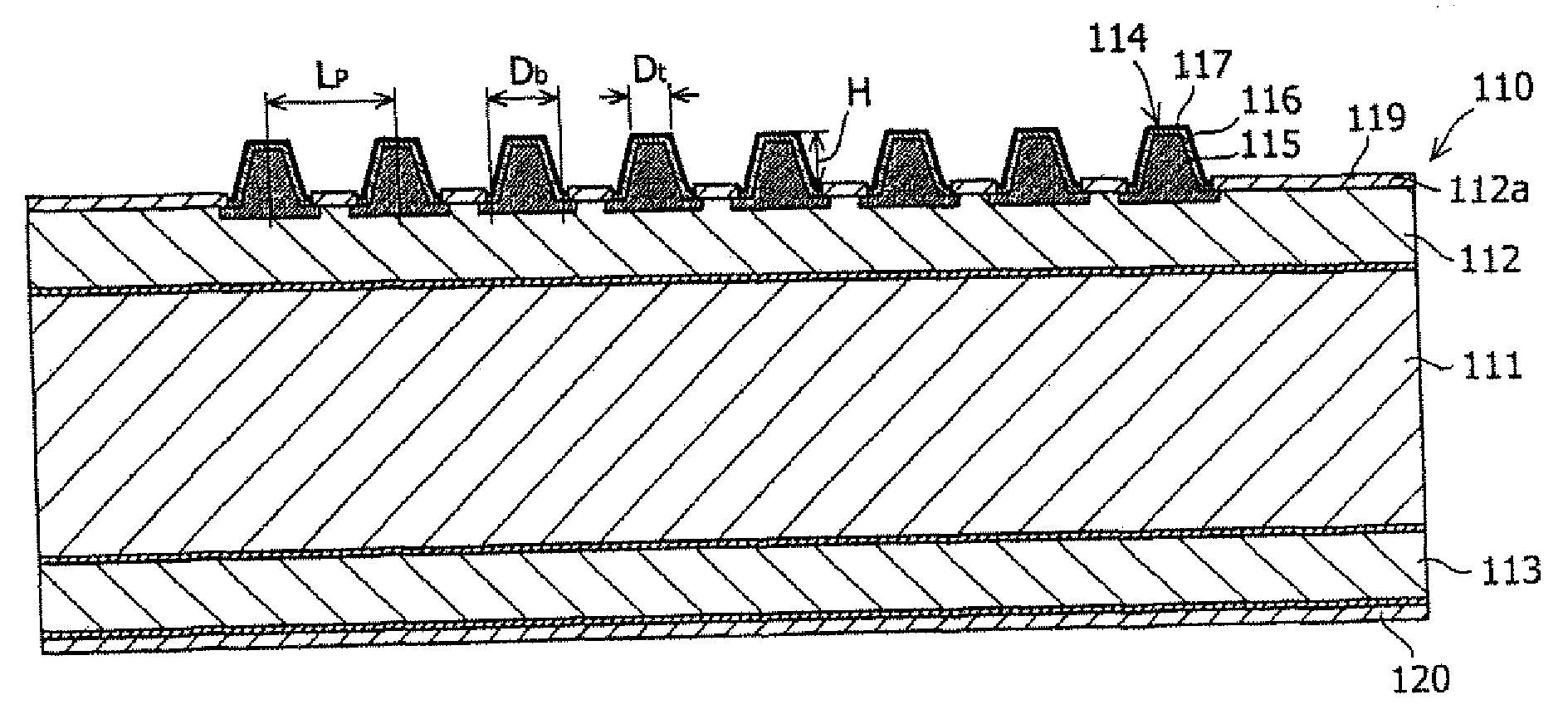

InactiveUS20050180679A1Low number of componentsReduce the number of processesSemiconductor laser structural detailsSolid-state devicesCouplingOptical axis

On the back surface of a transparent plate having a light extracting part 14 for outputting lights to the outside, an electrode 16 for wiring, and an electrode 17 for an electromagnetic shield, an optical device 11 is flip-chip mounted right under the light extracting part 14, an a driver IC 12 is flip-chip mounted at a desired position with metal bumps 15. When currents driving the optical device 11 flow from the driver IC 12 according to an electric logical signal from the outside, an optical signal is emitted from the optical device 11, and is output to the outside through the light extracting part 14. The light extracting part 14 may be provided with a light coupling material or an optical axis converter.

Owner:NEC CORP

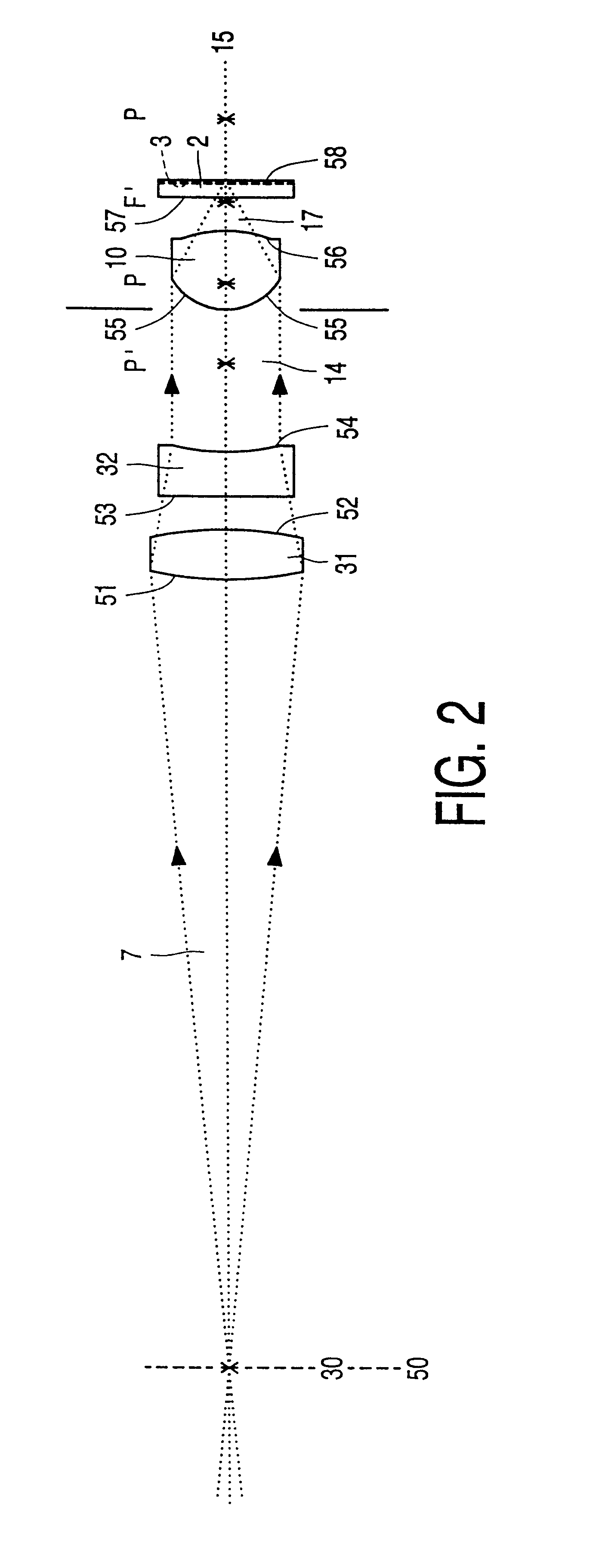

Optical lens system and scanning device provided with such a system

InactiveUS6317276B1Improve optical qualitySignificant valueOptical beam sourcesRecord information storageHigh densityLight beam

In a lens system for focusing a divergent beam in a small spot and comprising a collimator lens and an objective lens, the collimator lens is composed of a positive plastics lens element and a negative glass lens element. This collimator corrects the temperature-dependent spherical aberration of the objective lens. This lens system is very suitable for a scanning device and an apparatus for reading / writing high-density optical discs.

Owner:U S PHILIPS CORP

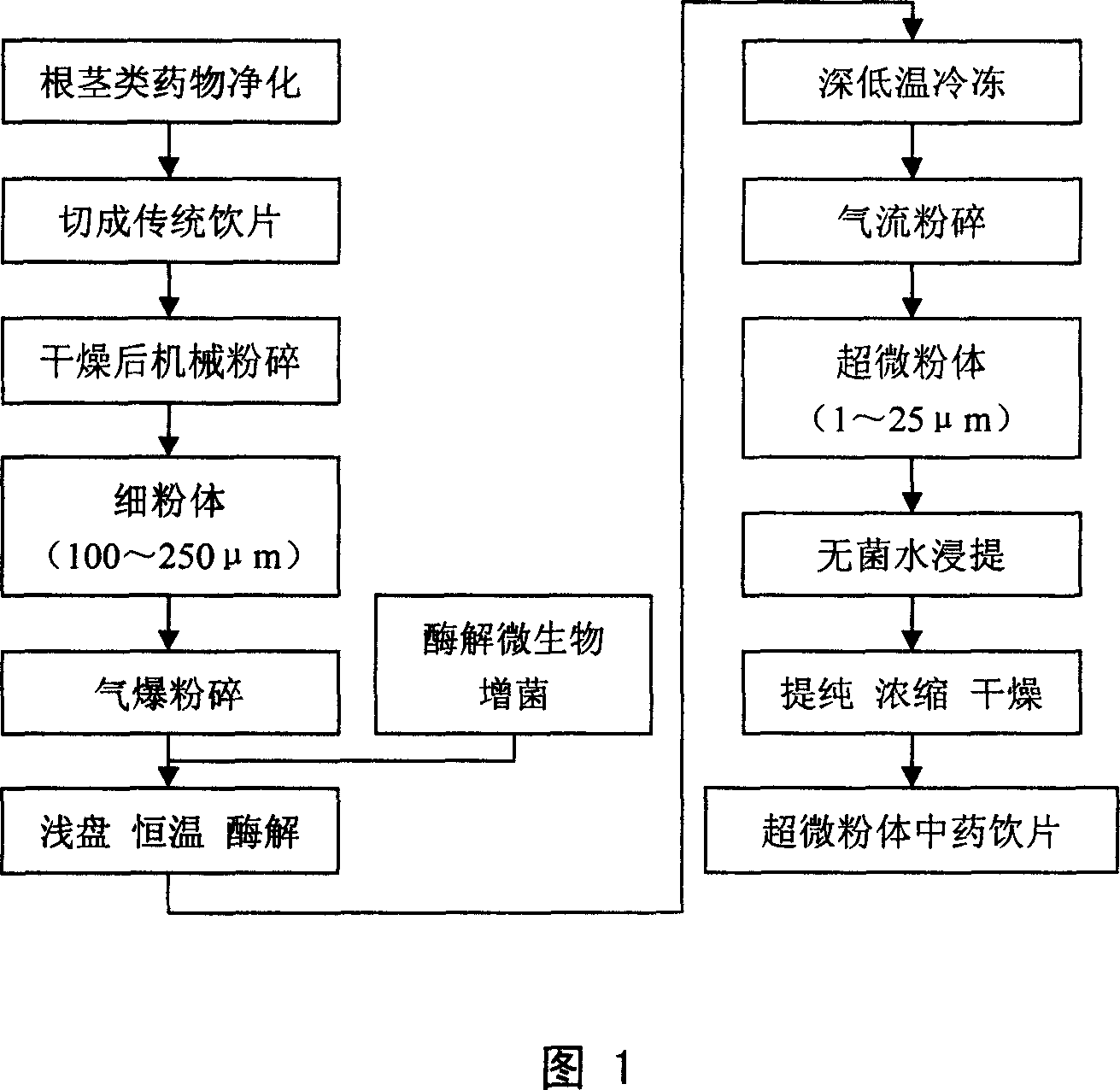

Super micronization method for botanical medicinal, product obtained thereby and use thereof

InactiveCN1994331AAvoid damageIncreased enzymolysis ratePowder deliveryPlant ingredientsEnzymeMicronization

The invention relates to a method for making stem drug containing xylon and cellulose into ultra micro powder, wherein said method comprises that: mechanically breaking; exploding via steam, treating at low temperature, breaking via airflow, enzyme hydrolyzing via microbe enzyme and extracting and separating. The invention also provides relative product and its application for preparing drug, transferring drug element, etc.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

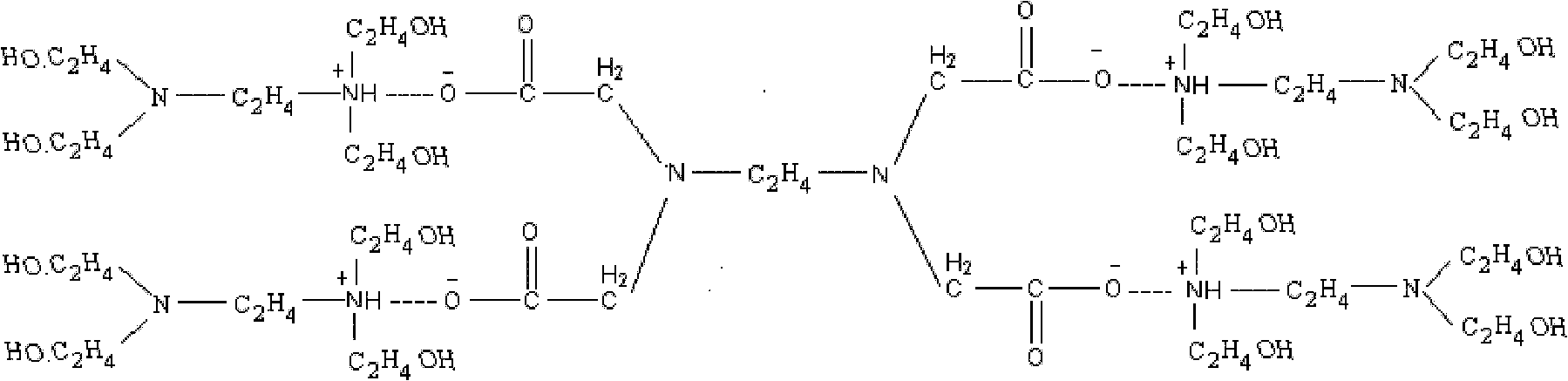

Method for preparing CMP (Chemically Mechanical Polishing) solution for sapphire substrate material

InactiveCN102010669ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesSurface finishMaterial removal

The invention relates to a method for preparing a CMP (Chemically Mechanical Polishing) solution in a high-precision surface finishing process of a sapphire substrate material. In the method, a nano SiO2 abrasive material is adopted for the polishing solution, wherein the abrasive material has the concentration of 30-50wt% and the particle diameter of 15-100nm so as to benefit material removal and surface leveling. The pH value of the polishing solution is 9-13, which not only benefits effective removal but also guarantees the stability of silica sol; and in a preparation process, a negative pressure stirring preparation method is adopted under a closed system, and pollutions of organic matters, large particles, metal ions and the like brought by the traditional preparation methods of compounding, mechanical stirring and the like are prevented so that the requirement on ultra cleanness is met.

Owner:TIANJIN JINGLING MICROELECTRONIC MATERIALS CO LTD

Chemical mechanical polishing solution for large-sized silicon wafers and preparation method thereof

ActiveCN101870852AImprove consistencyReduce hardnessPolishing compositions with abrasivesCompound (substance)Cleansing Agents

The invention relates to a chemical mechanical polishing solution for large-sized silicon wafers and a preparation method thereof, and the chemical mechanical polishing solution is mainly applied to the ultraprecision machining of large-sized semiconductor silicon substrate slices, and can obtain a nanometer-level ultrasmooth surface. The polishing solution consists of the following components inpercentage by weight: 5 to 50 percent of silicon dioxide abrasive, 1 to 10 percent of pH value regulator, 0.01 to 5 percent of surfactant, 0.01 to 0.05 percent of cleaning auxiliary, 0.01 to 2 percent of chelator and the balance of deionized water; and the silicon dioxide is added in the state of silicasol. Under proper polishing technological conditions, the polishing solution prepared with the components according to the contents can obtain a high-quality polished surface and meet the requirement of the semiconductor industry on the surface quality and removal rate of silicon substrate slices, and moreover, the invention has the advantages of low cost, easy cleaning, low corrosiveness and the like, and has a good application prospect.

Owner:BEIJING GRISH HITECH

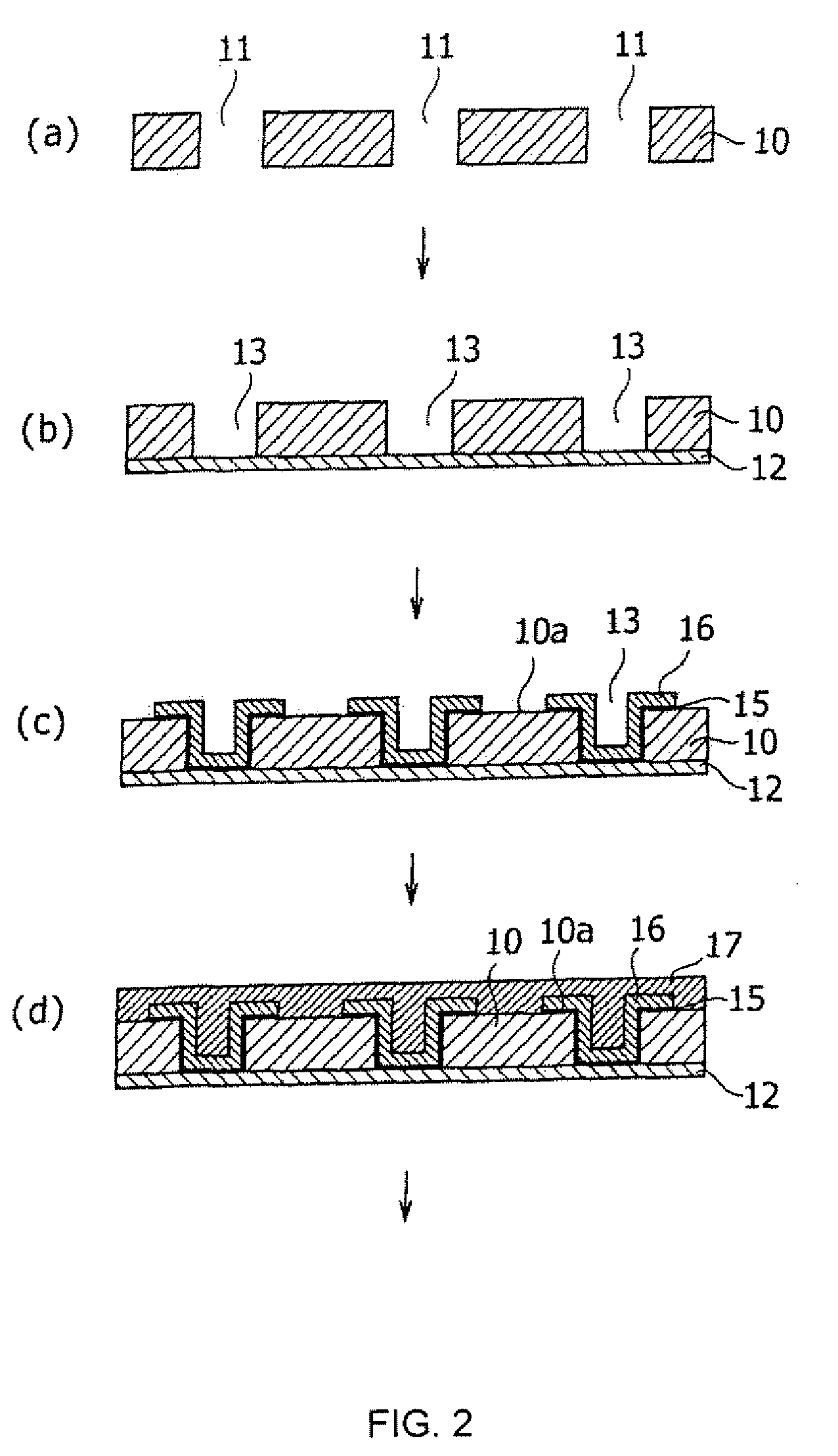

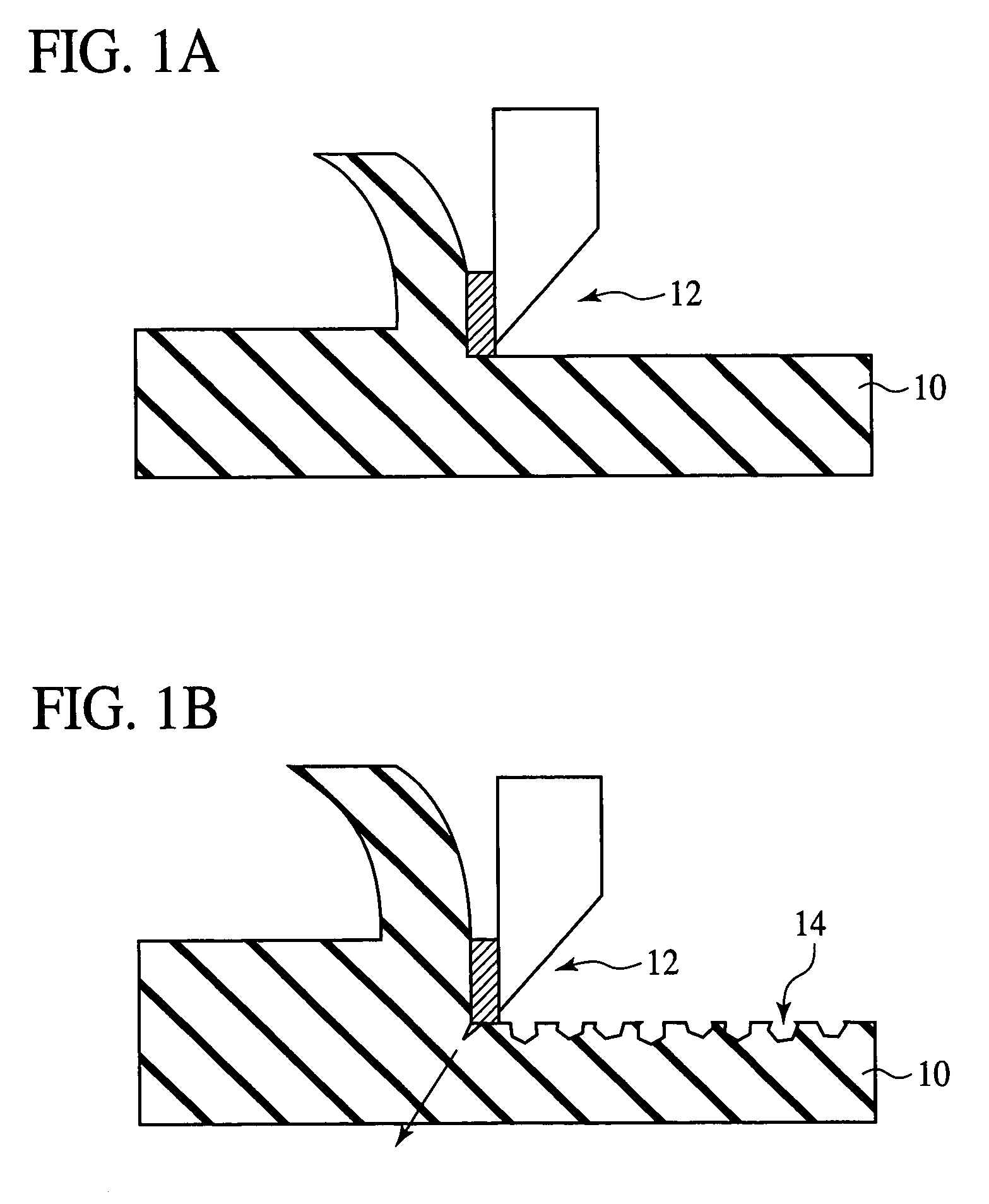

Plating method, semiconductor device fabrication method and circuit board fabrication method

InactiveUS7670940B2Well formedImprove adhesionSemiconductor/solid-state device detailsPrinted circuit aspectsResistInterconnection

The plating method comprises the step of forming a resin layer 10 over a substrate 16; the step of cutting the surface part of the resin layer 10 with a cutting tool 12; the step of forming a seed layer 36 on the resin layer 10 by electroless plating; and the step of forming a plating film 44 on the seed layer 36 by electroplating. Suitable roughness can be give to the surface of the resin layer 10, whereby the adhesion between the seed layer 36 and the resin layer 10 can be sufficiently ensured. Excessively deep pores are not formed in the surface of the resin layer 10, as are by desmearing treatment, whereby a micronized pattern of a photoresist film 40 can be formed on the resin layer 10. Thus, interconnections 44, etc. can be formed over the resin layer 10 at a narrow pitch with high reliability ensured.

Owner:FUJITSU LTD

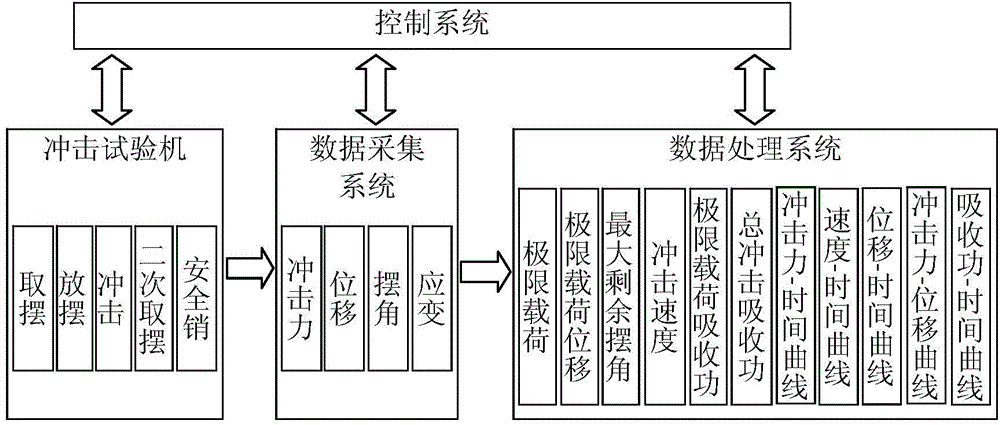

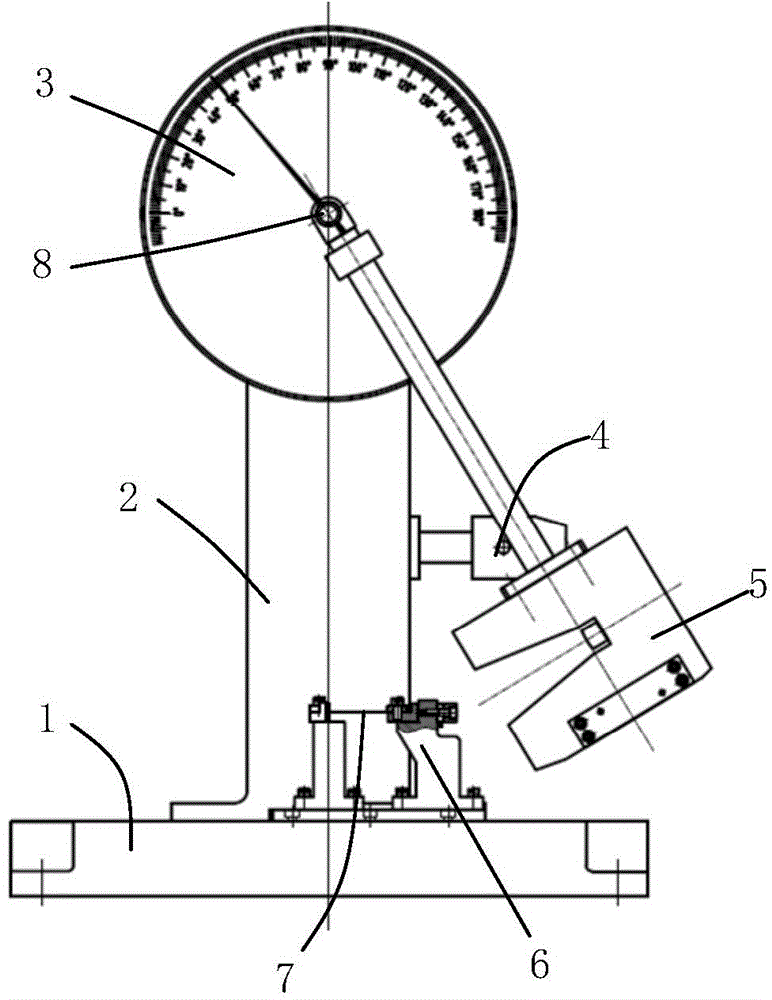

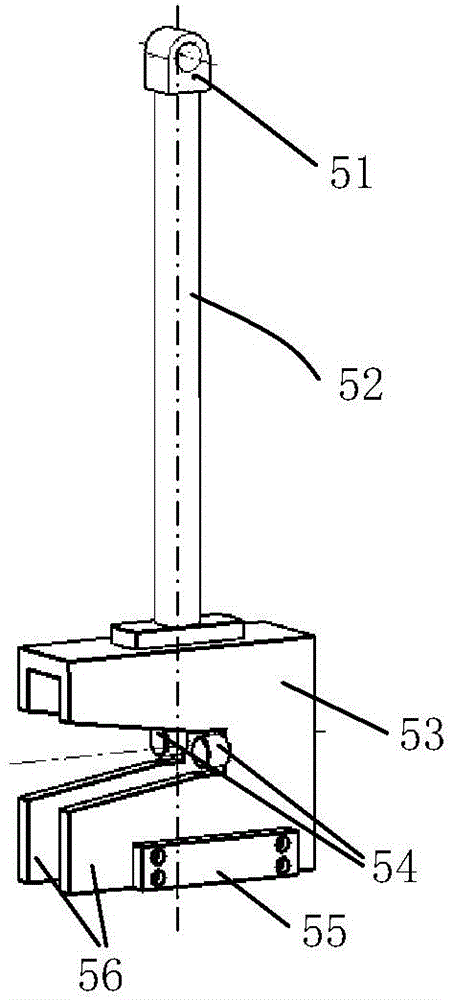

Metal sheet spot-welding joint impact performance test device and method

Provided is a metal sheet spot-welding joint impact performance test device composed of an impact tester, an impact fixture, a control system, a data acquisition system, and a data processing system. When the device is used to test the impact performance of a spot-welding joint, the two ends of a test sample are respectively fixed to a movable jaw and a fixed jaw of the impact fixture, a pendulum bob is used to apply impact load to the spot-welding joint to break the spot-welding joint, the data acquisition system acquires the impact on the spot-welding joint measured by a force measuring sensor arranged between the fixed jaw and a fixed jaw support, the displacement of the free end of the test sample measured by a laser displacement sensor arranged on the side of the movable jaw and the angle of the pendulum bob, and the data processing system gives the limit load, limit load displacement, limit load impact absorption energy, total impact absorption energy, impact-time curve, displacement-time curve, speed-time curve, impact-displacement curve and impact absorption energy-time curve characterizing the impact performance of the spot-welding joint to evaluate and study the impact performance of the spot-welding joint.

Owner:NORTHEASTERN UNIV

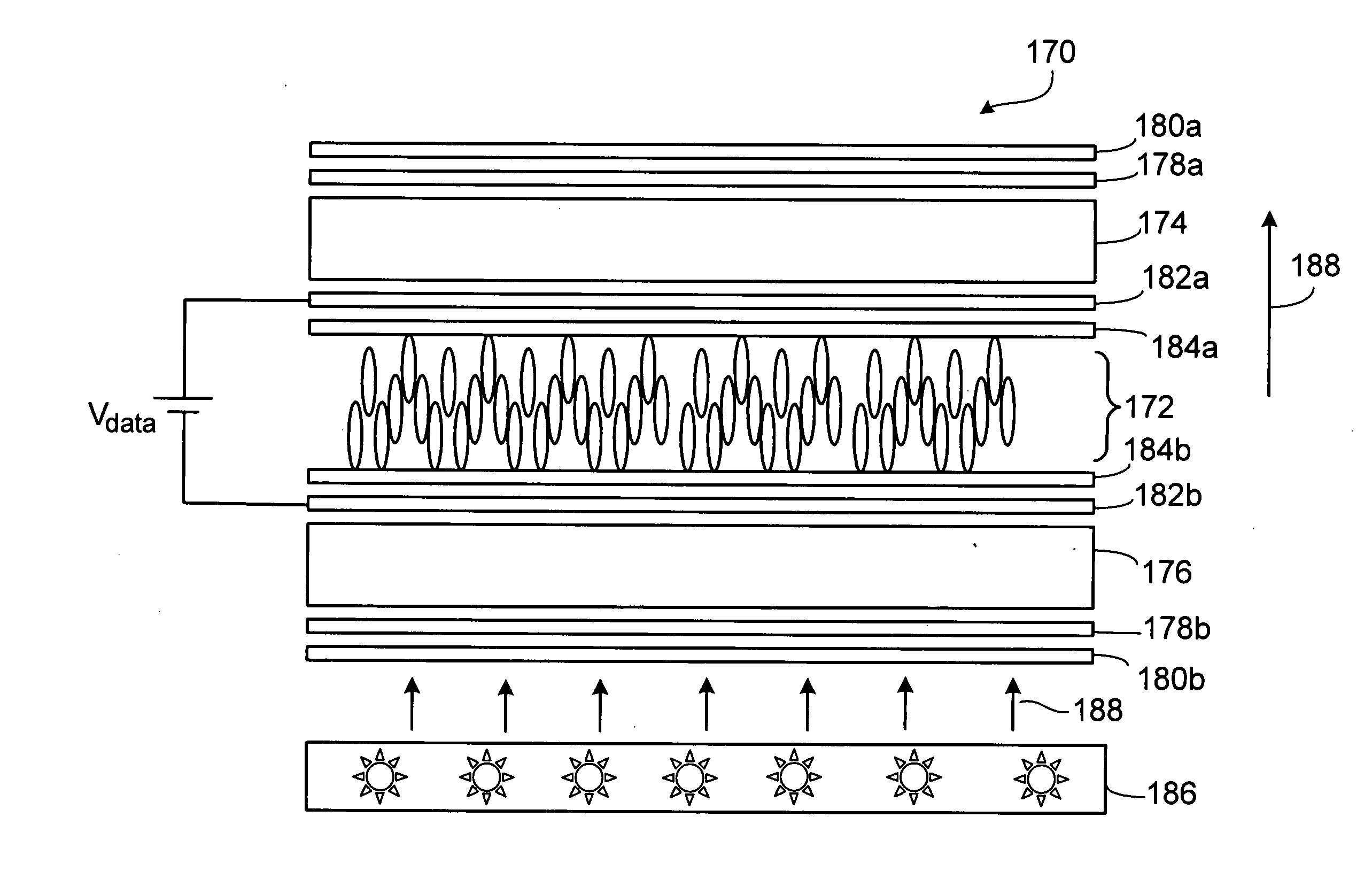

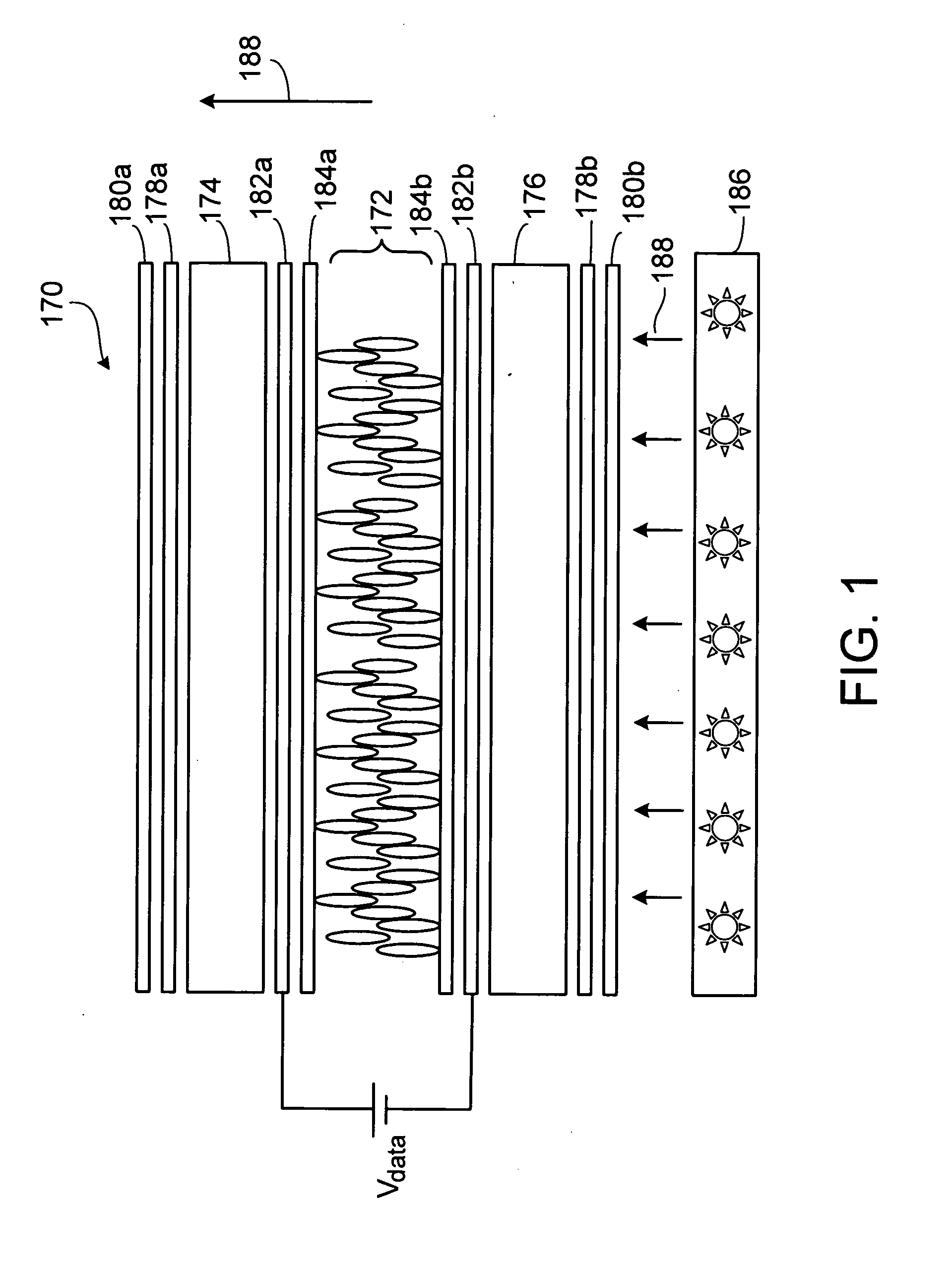

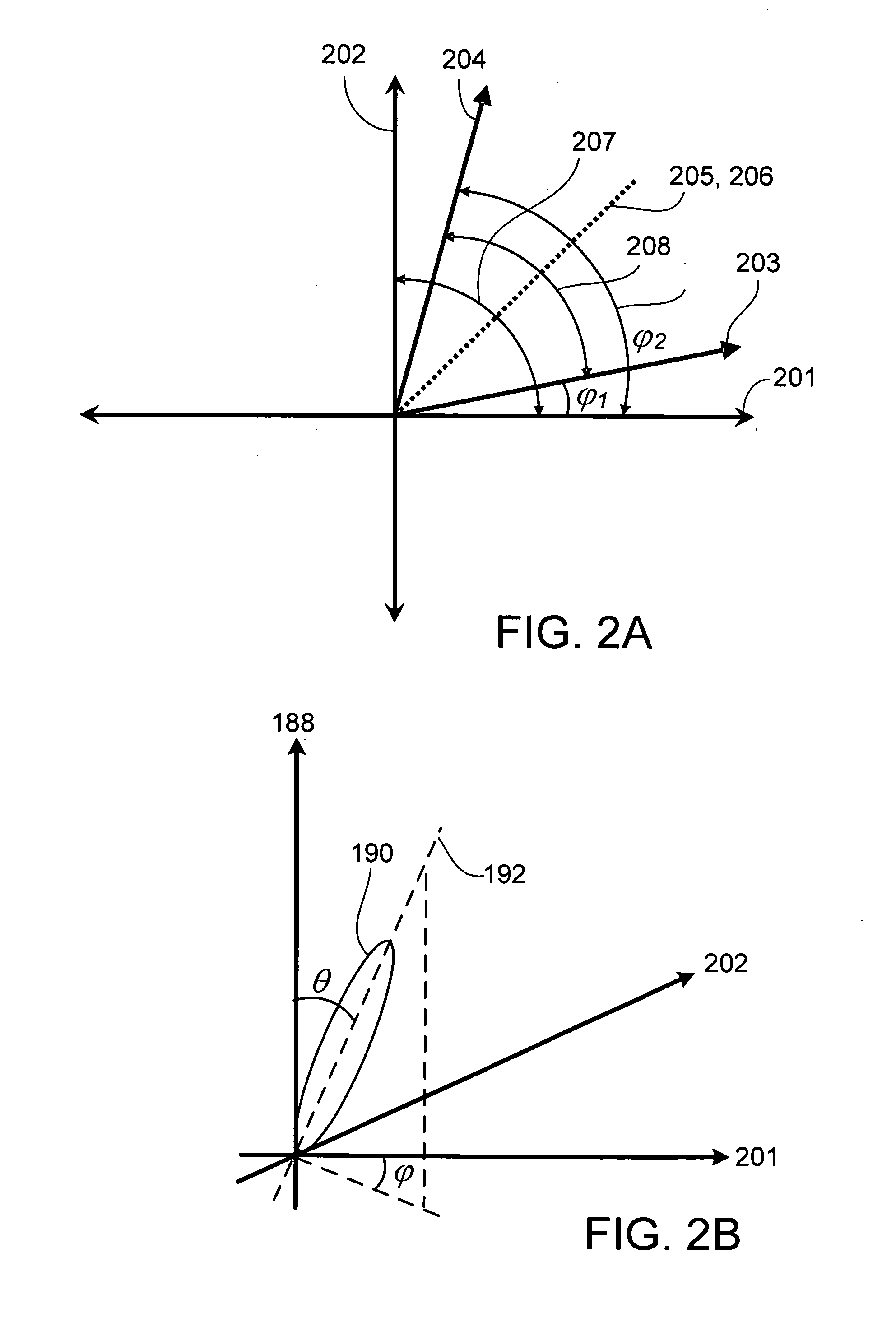

Liquid crystal display

InactiveUS20080151149A1Small dispersionLiquid crystal compositionsNon-linear opticsChemistryElectric field

A liquid crystal display includes a first substrate having a first electrode and a first alignment film, a second substrate having a second electrode and a second alignment film, and a liquid crystal layer having liquid crystal molecules between the first and second substrates. The liquid crystal layer is doped with a chiral material that tends to induce a twist in directors of the liquid crystal molecules when an electric field is applied to the liquid crystal layer using the first and second electrodes. The first alignment film has a first alignment direction, the second alignment film has a second alignment direction, and the first and second alignment films have orientations that tend to induce a twist in the directors when an electric field is applied to the liquid crystal layer, in which the direction of twist induced by the first and second alignment films is different from the direction of twist induced by the chiral material. The display includes a reflective layer to reflect external light that passes a first portion of the liquid crystal layer. The external light is modulated by the first portion of the liquid crystal layer.

Owner:INNOLUX CORP +1

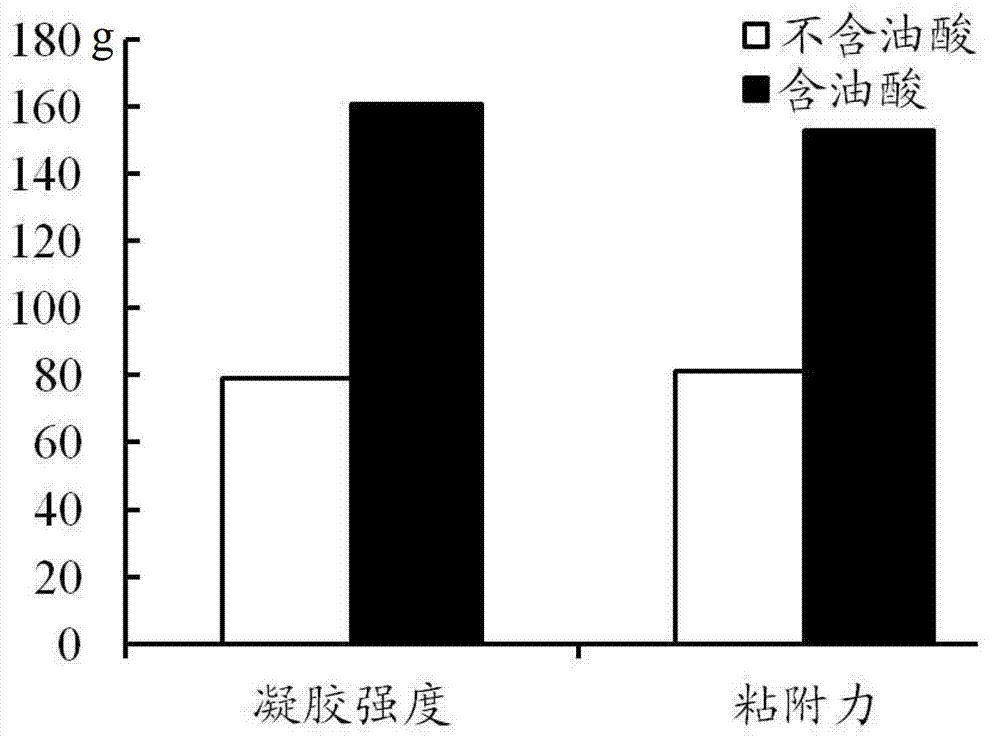

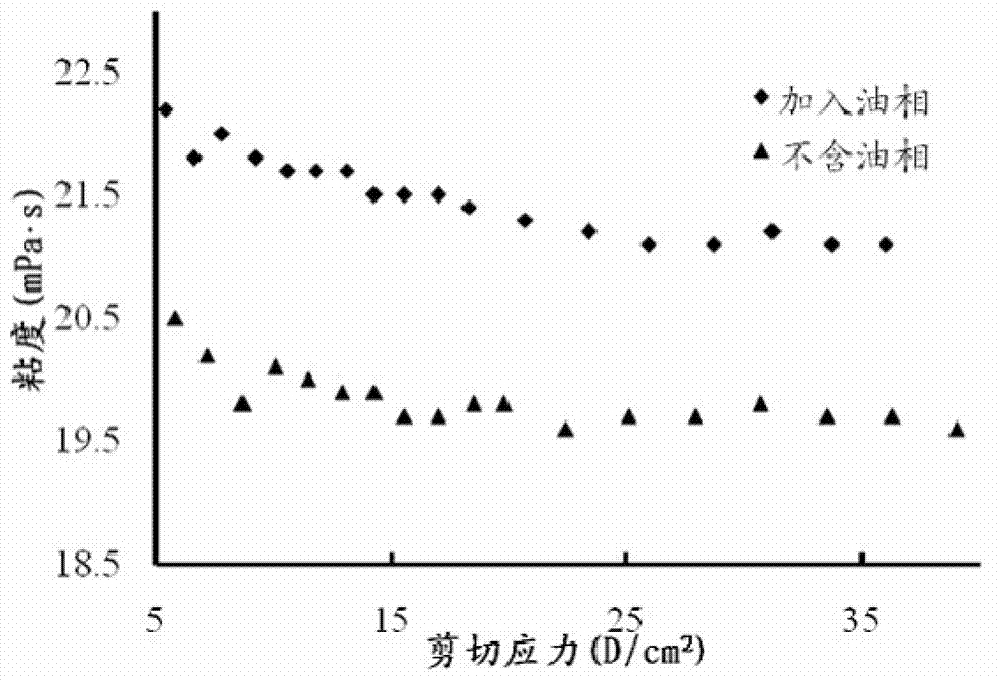

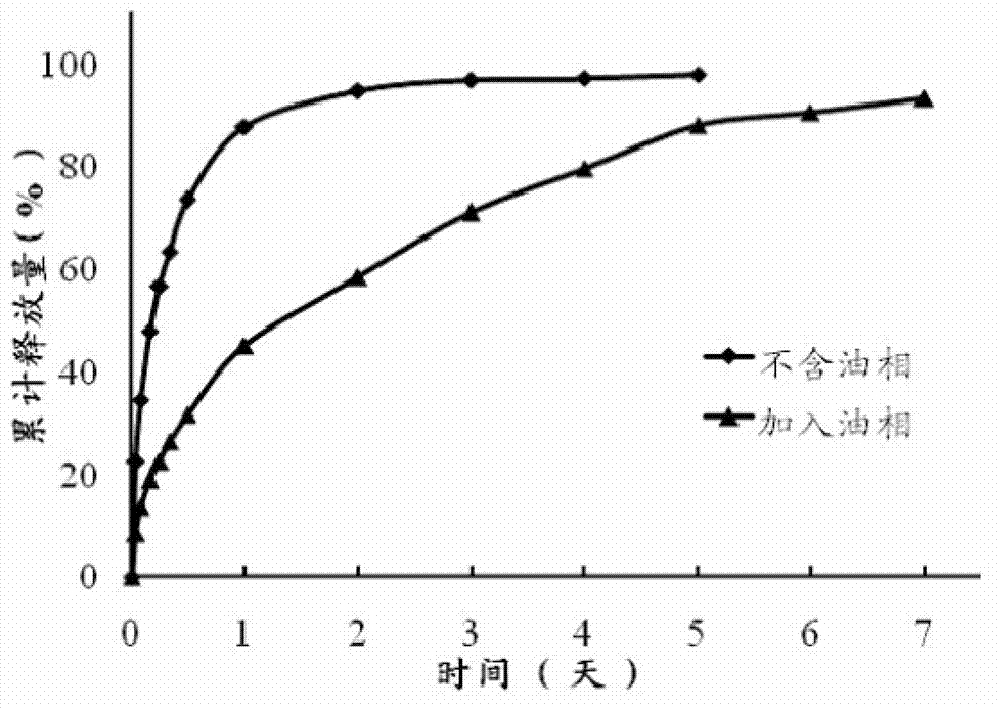

Precursor suspension of lyotropic liquid crystal and preparation method thereof

ActiveCN103040741AHigh viscosityHigh strengthSolution deliveryEmulsion deliveryOrganic solventUltimate tensile strength

The invention discloses a precursor suspension of a lyotropic liquid crystal. The precursor suspension comprises lyotropic liquid crystal material, organic solvent, oil phase and a drug, wherein the weight percentage of the oil phase in the precursor suspension is 2-50 percent, the weight percentage of the drug in the precursor suspension is 1-30 percent, and the weight ratio of the lyotropic liquid crystal material and the organic solvent in the precursor suspension is 2-9:1. According to the invention, through the adding of the oil phase into the precursor suspension, the stability of the suspension is improved, the sedimentation rate is reduced, and the strength and the adhesive force of the gel formed are enhanced at the same time; the gel formed in the body is more liable to stay at a lesion location and less liable to be relocated and the shape is less liable to be damaged by the mechanical motion of the body, so that the drug therapy can be located effectively; and the preparation technology is simple and the precursor suspension of the lyotropic liquid crystal is a partial slow-release drug delivering system provided with a favorable perspective.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

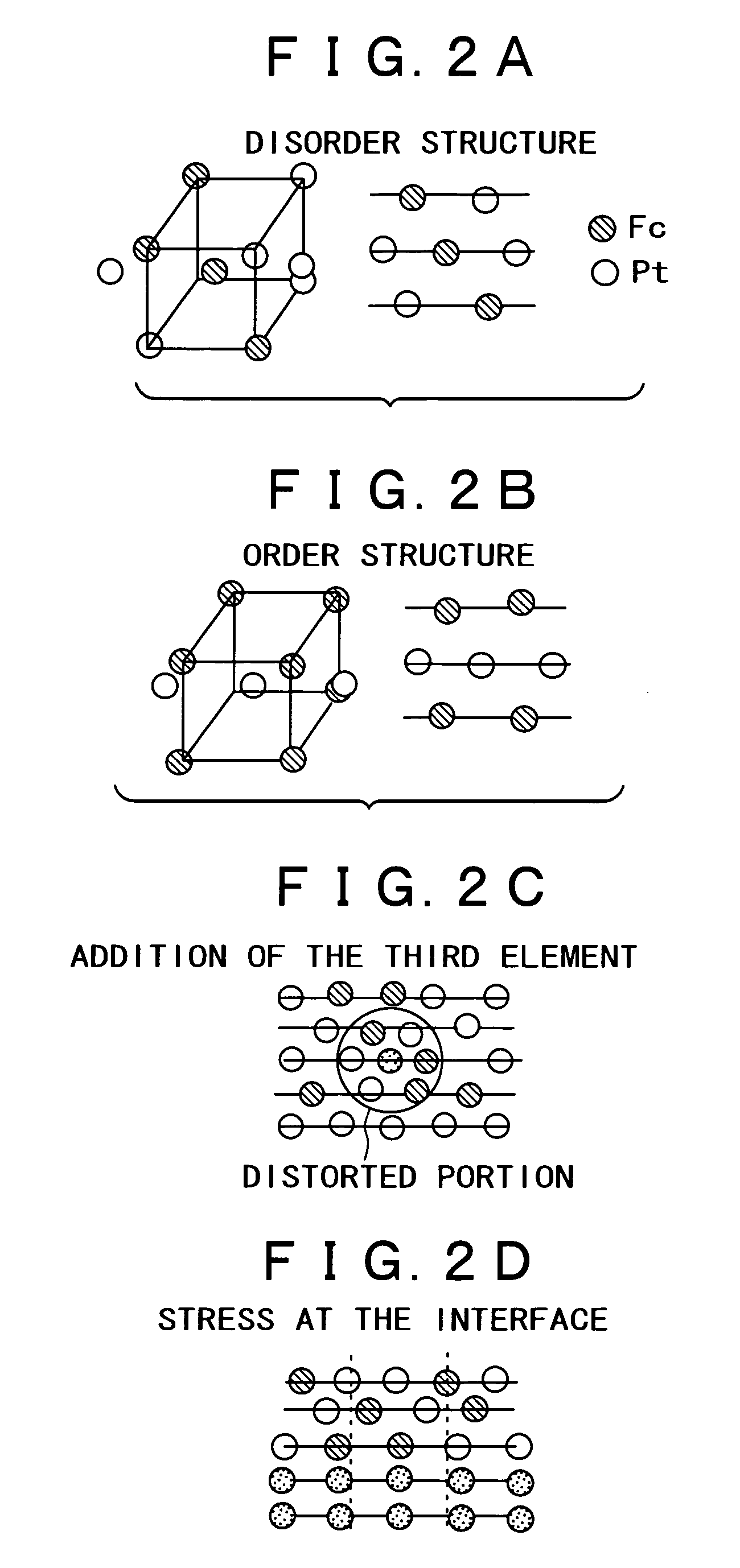

Magnetic recording medium and hard disk drive using the same, and manufacturing method thereof

InactiveUS20060153976A1Reduce the overall diameterReduce dispersionRecording by magnetic meansNanomagnetismNanometreHard disc drive

A magnetic recording medium, a hard disk using the same, and a manufacturing method thereof are provided. In one example, the magnetic nano-particle medium is formed by depositing a magnetic nano-particle colloid on a substrate, wherein the axes of easy magnetization of respective crystalline particles are aligned with high accuracy. A layer of L10 alloy nano-particles which will exhibit magnetic properties through an order-disorder transition, and arranged at a substantially uniform spacing on a substrate, and a carbon-containing covering film for surrounding these nano-particles and making the spacing substantially uniform are provided. To the L10 alloy of the nano-particles, at least one non-magnetic element is added, or a covered layer comprising at least one non-magnetic layer is formed therearound. This makes it possible to implement a magnetic recording medium wherein the average diameter of nano-particles is small, and the nano-particle diameter dispersion is small, and the axes of magnetic anisotropy are aligned.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com