Patents

Literature

68results about How to "Moisturize well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

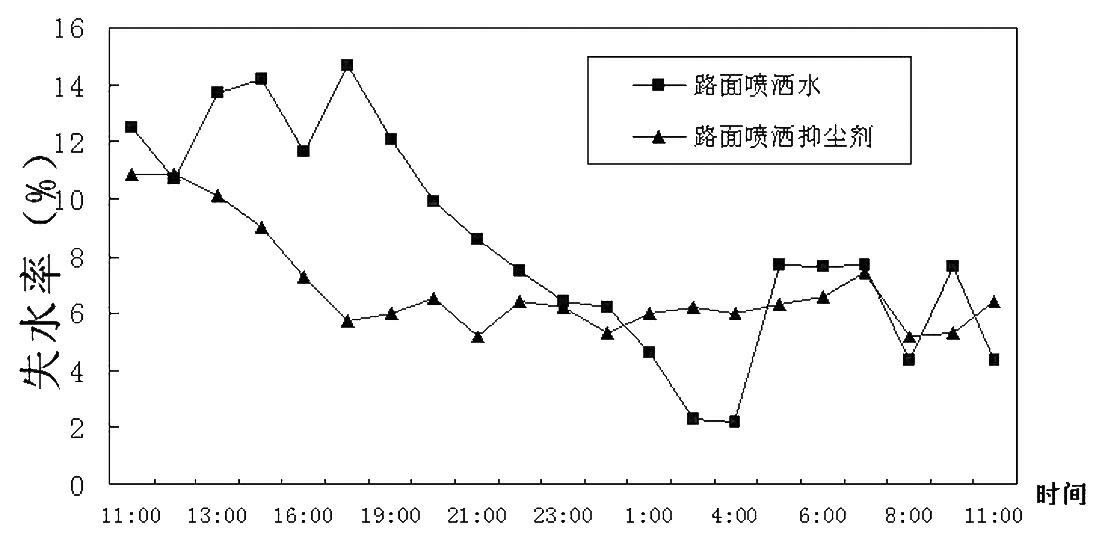

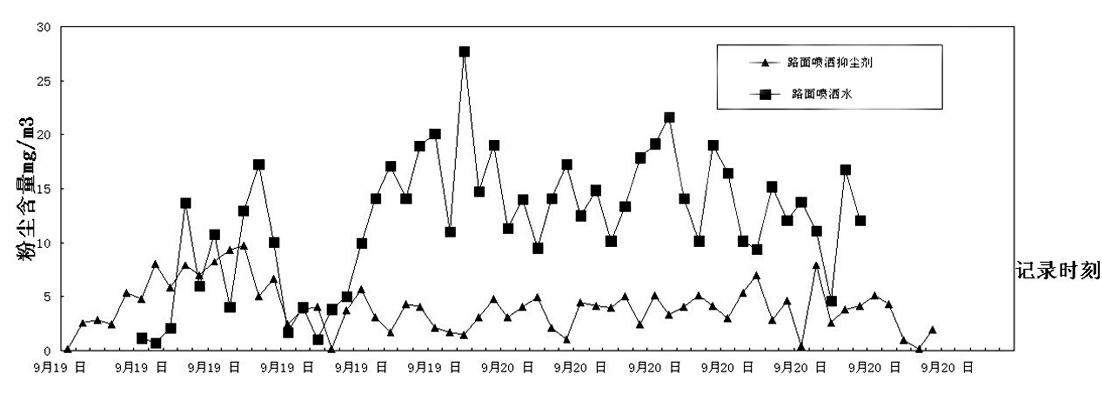

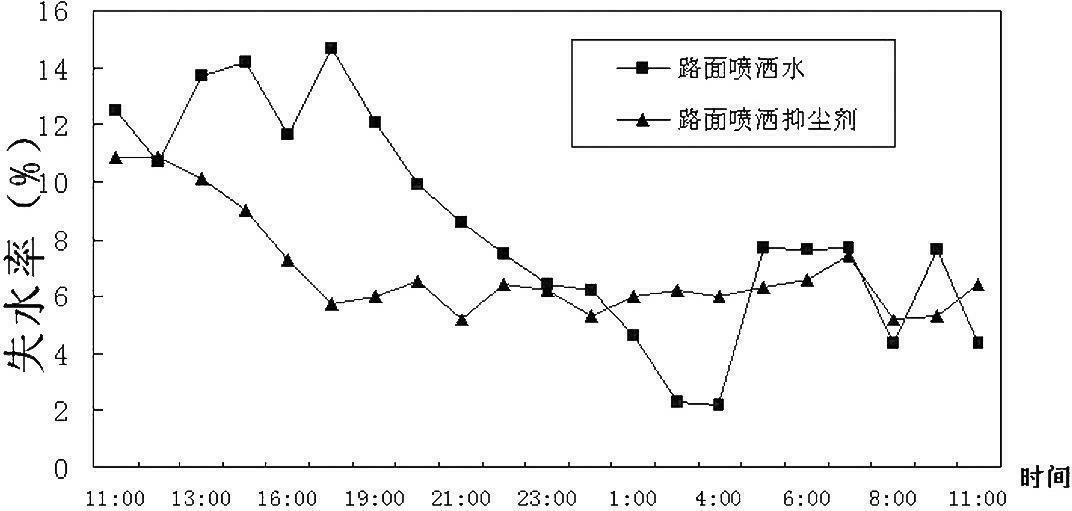

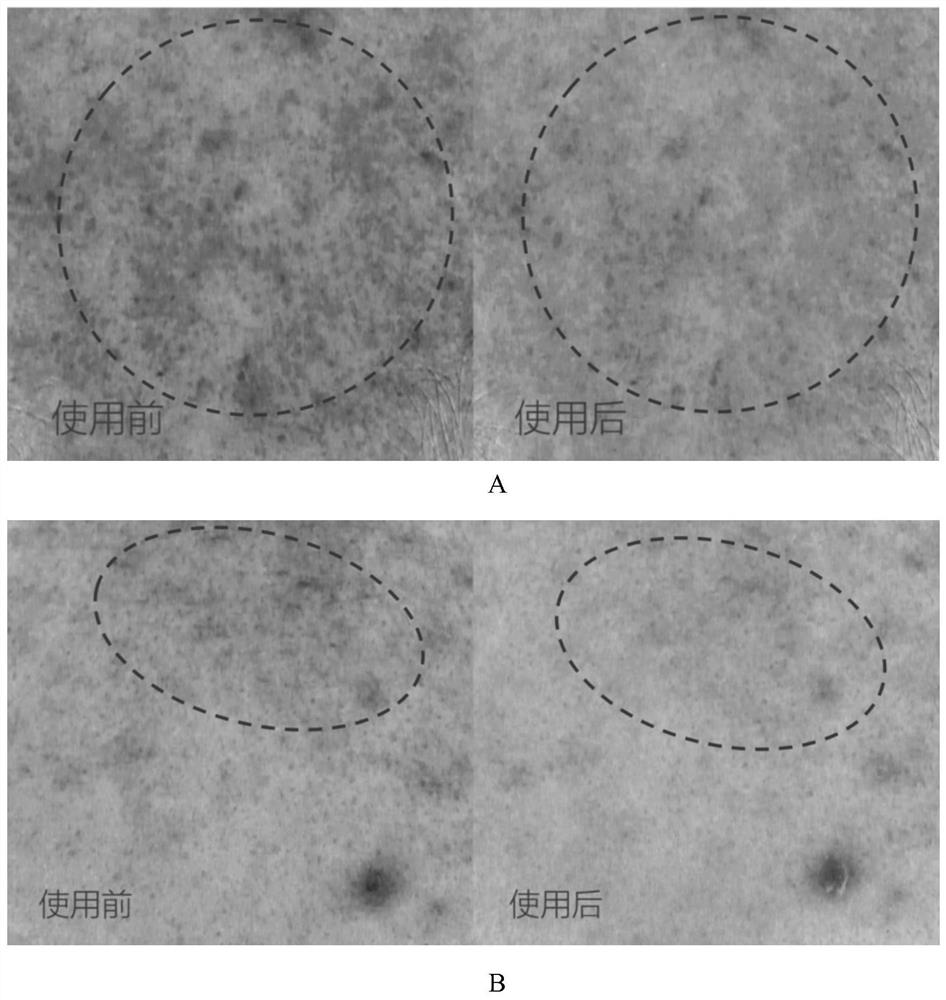

Road dust suppressant

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

Hair washing and conditioning combination made of natural vegetable

InactiveCN101032457APromote circulationPromote blood circulationCosmetic preparationsHair cosmeticsYolkOil and grease

The hair washing and protecting composition of natural plant components is compounded with tea seed oil or tea cake powder in 75-96 weight portions and ginger powder in 1-30 weight portions as main components, as well as natural vegetable oil in 2-8 weight portions and yolk powder in 1-2 weight portions, with the natural vegetable oil being mint oil, lavender oil, olive oil or sesame oil. It may have different compounding ratio for fitting different hairs. The hair washing and protecting composition of the present invention has functions of eliminating oil and grease, eliminating scurf, stopping itching, improving blood circulation, protecting hair, restoring hair, and improving sleep quality.

Owner:鞠萍 +1

Soothing, repairing and moisturizing face cream and preparation method thereof

ActiveCN112315882ASoothing and repairingSoothing, repairing and moisturizingCosmetic preparationsToilet preparationsCyclohexanolAntiinflammatory Effect

The invention discloses soothing, repairing and moisturizing face cream and a preparation method thereof. The face cream is mainly prepared by compounding bisabolol, 4-tert-butyl cyclohexanol, a plantsoothing component, a skin conditioner and a moisturizer, wherein the plant soothing component and the bisabolol have instant itching relieving and anti-inflammatory effects; the 4-tert-butyl cyclohexanol can immediately relieve the burning feeling and the pricking feeling, and the skin conditioner can repair the skin; and the moisturizer has moisturizing and moistening effects, and can soften the skin and lock the skin moisture. The face cream is mild, non-irritant, safe, free of toxic and side effects, can effectively moisturize and repair skin and repair couperose skin, and is suitable forbeing used by crowds with partial sensitive skin and more sensitive skin.

Owner:山东福瑞达生物股份有限公司

Dust-suppression foaming agent

InactiveCN101824302AImprove adsorption capacityStrong foaming ratioOther chemical processesCelluloseFoaming agent

The invention discloses a dust-suppression foaming agent used for coal mine excavating work surfaces. The dust-suppression foaming agent comprises the following raw material ingredients in percentage by weight: 15 to 20 percent of sodium dodecyl benzene sulfonate, 20 to 25 percent of lauryl sodium sulfate, 2 to 4 percent of wetting agent, 1 to 3 percent of foam improver, 1 to 2 percent of sodium cellulose glycolate and 50 to 60 percent of water. All ingredients are proportionally mixed and uniformly stirred at the room temperature. The generation of dust can be suppressed from a source. The invention can effectively prevent the diffusion of the dust and inhabit the occurrence of pneumoconiosis for easy-dust-generation operation places such as work surfaces of integrated mining and integrated excavating. The foam is fine and has small grain diameter and high viscosity, the dust grains with small grain diameter can be easily humidified, the absorption performance on the dust is strong, the foam coverage surface is wide, foaming times are high, the maximum foaming times can reach 12 times, the dust suppression efficiency on full dust is as high as 96 to 99 percent, and the dust suppression efficiency on respiratory dust is as high as more than 90 percent.

Owner:张仁贵

Infant chapping-prevention and skin-care composition for enhancing skin barrier function and preparation method thereof

ActiveCN108969446AImproves barrier efficacyRepair chapped skinCosmetic preparationsToilet preparationsSkin barrier functionAnti freezing

The invention provides an infant chapping-prevention and skin-care composition. The infant chapping-prevention and skin-care composition is prepared from the following components: an anti-freezing andmoisturizing composite component, an active polysaccharide pre-mixed solution, a compound plant extract matrix solution, a ceramide nano-lipid pre-dispersant, an oil-phase base solution and a water-phase base solution. The composition has the effect of enhancing a skin barrier function and good air pollution isolation performance and can be used for assisting to repair chapped skin; the composition has mild properties and no irritation and is especially suitable for the skin of infants.

Owner:FUJIAN MENGJIAOLAN DAILY CHEM

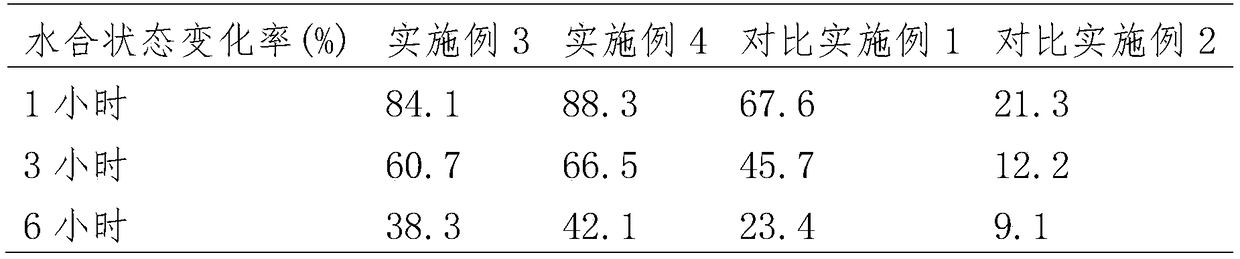

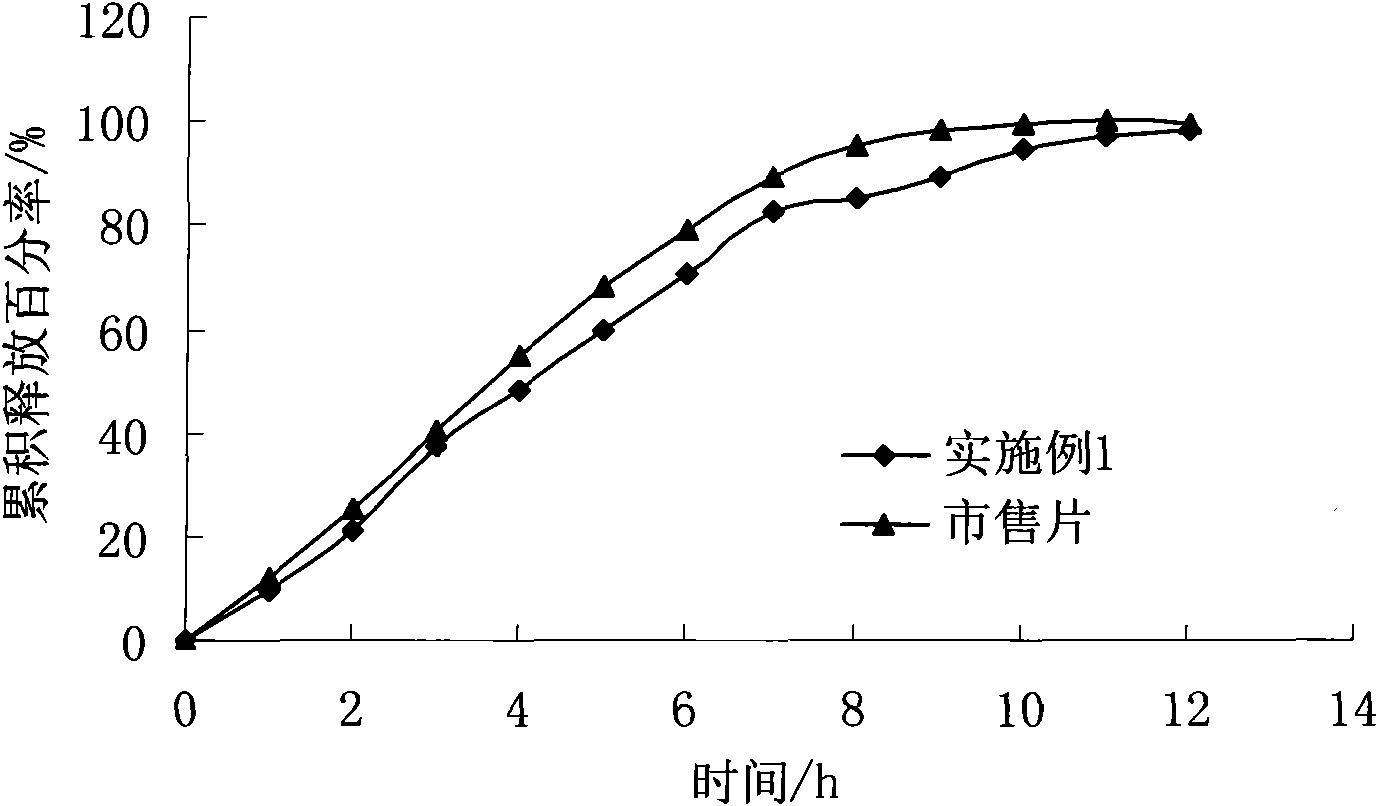

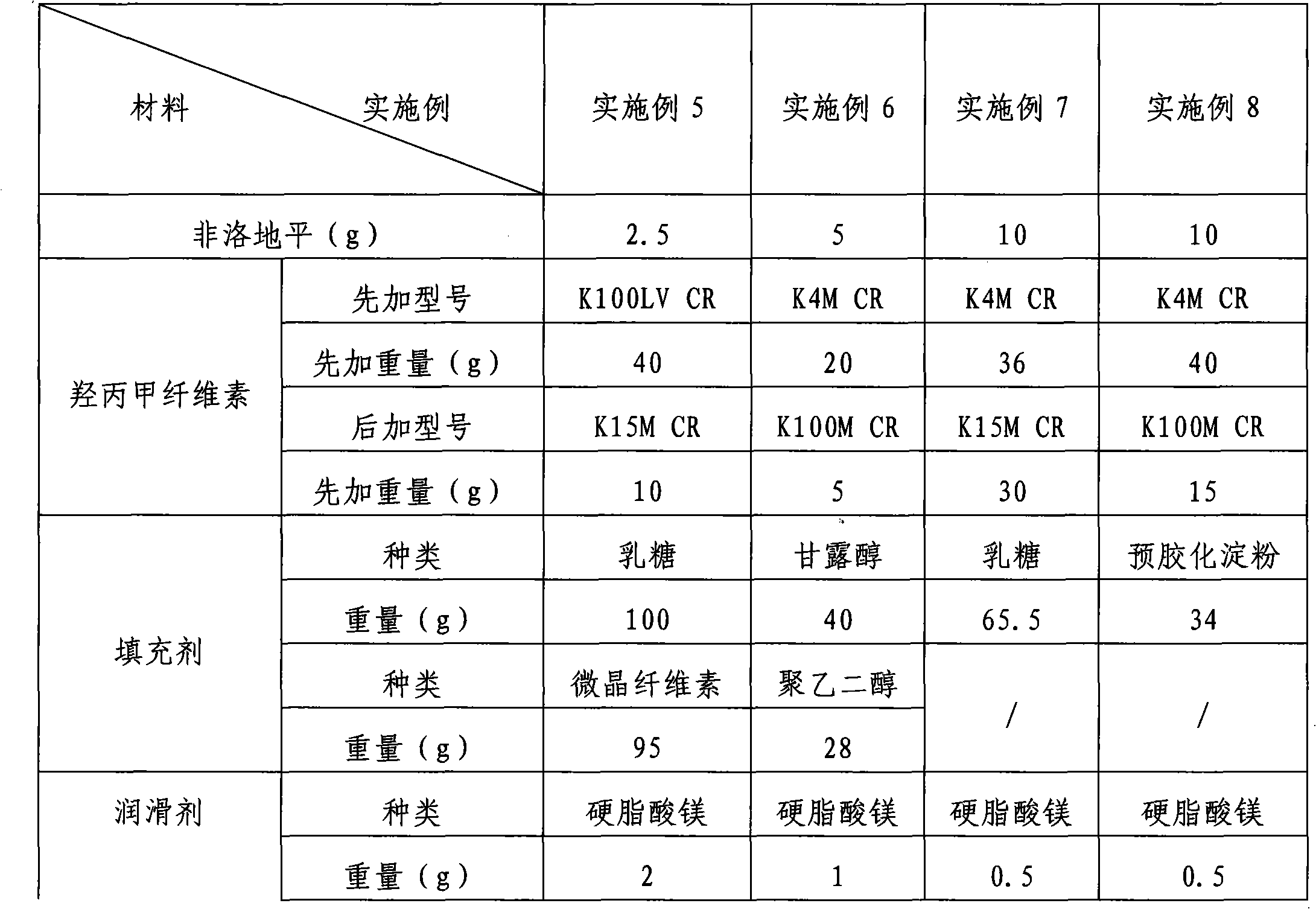

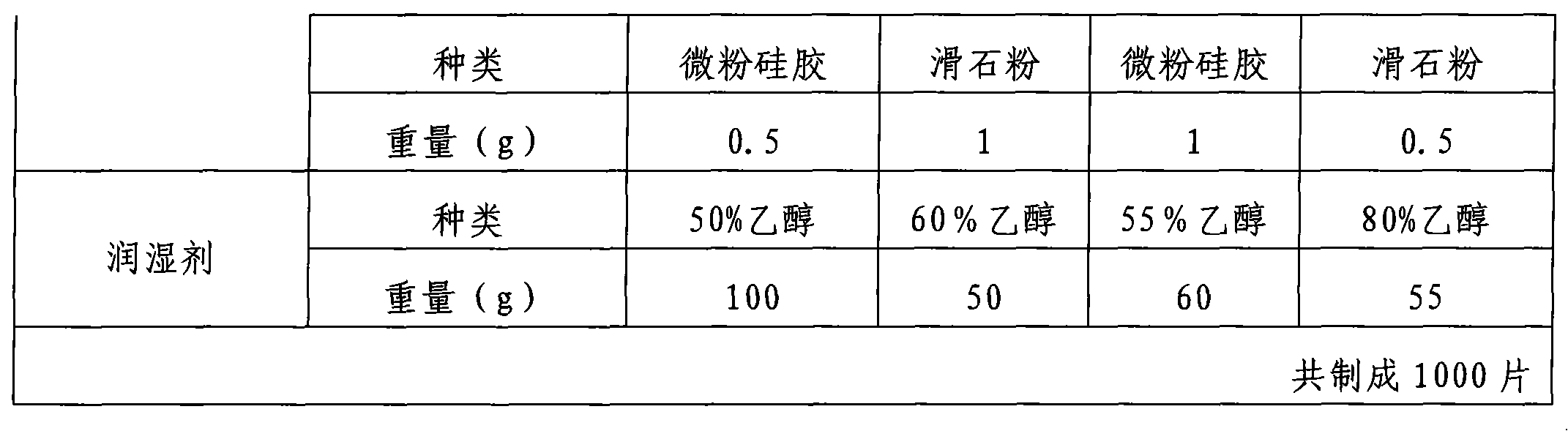

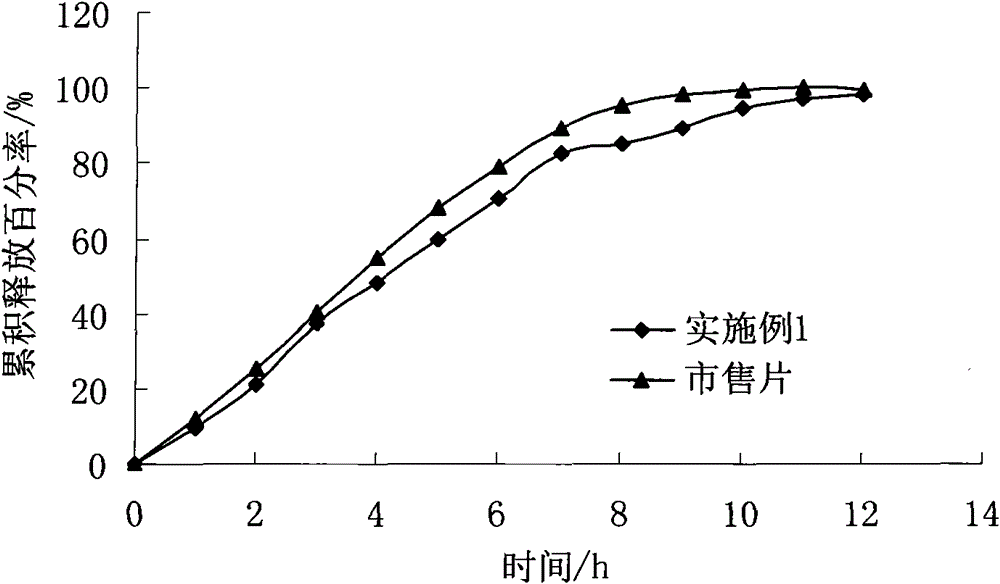

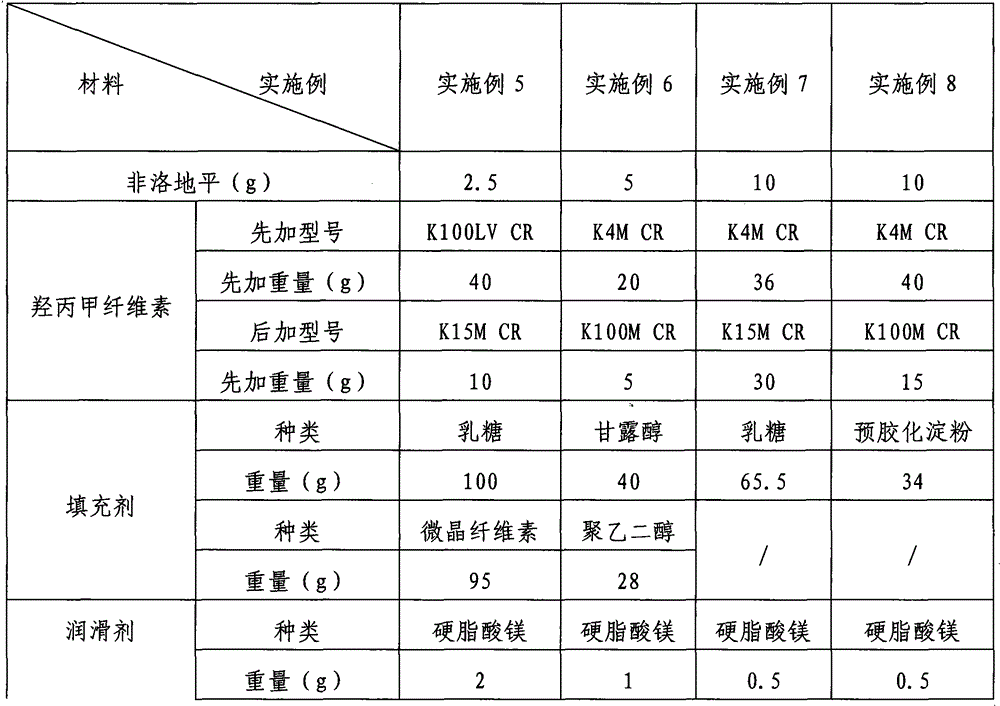

Preparation method of felodipine sustained release tablets

ActiveCN101843598ASuitable for industrialized mass productionHigh yieldOrganic active ingredientsPharmaceutical non-active ingredientsSustained Release TabletFiller Excipient

The invention discloses a preparation method of felodipine sustained release tablets. The method is characterized by comprising the following steps of: mixing felodipine accounting for 1-10 percent of the total component weight, a part of hydroxypropyl methylcellulose accounting for 20-55 percent of the total component weight and a filler; and wetting by using a wetting agent to carry out wet granulation; after wet granules are dried at low temperature, mixing the dried granules with residual hydroxypropyl methylcellulose; adding a lubricating agent and then tabletting to prepare cores containing main drugs; and coating by using a coating material to obtain the felodipine sustained release tablets. The preparation method is easy to control and suitable for industrial scale production, has high product yield and reduces the production cost. Compared with merchant like preparations, the felodipine sustained release tablets obtained by using the preparation method has similar in vitro release curve.

Owner:CHANGZHOU PHARMA FACTORY

Environment-friendly type all-purpose adhesive and method of production

InactiveCN1570006ALower surface energyImprove cohesive strengthHydrocarbon polymer adhesivesChemistryEthyl ester

The invention discloses an environment-friendly type all-purpose adhesive, which is prepared from SBS, and petroleum resin, polymerized resin, colophonium, terpene resin, cyclohexane, methylene chloride, acetic acid ethyl ester, No.6 solvent oil, and dichloroethanes. The invention also discloses the process for preparing the all-purpose adhesive.

Owner:马历新

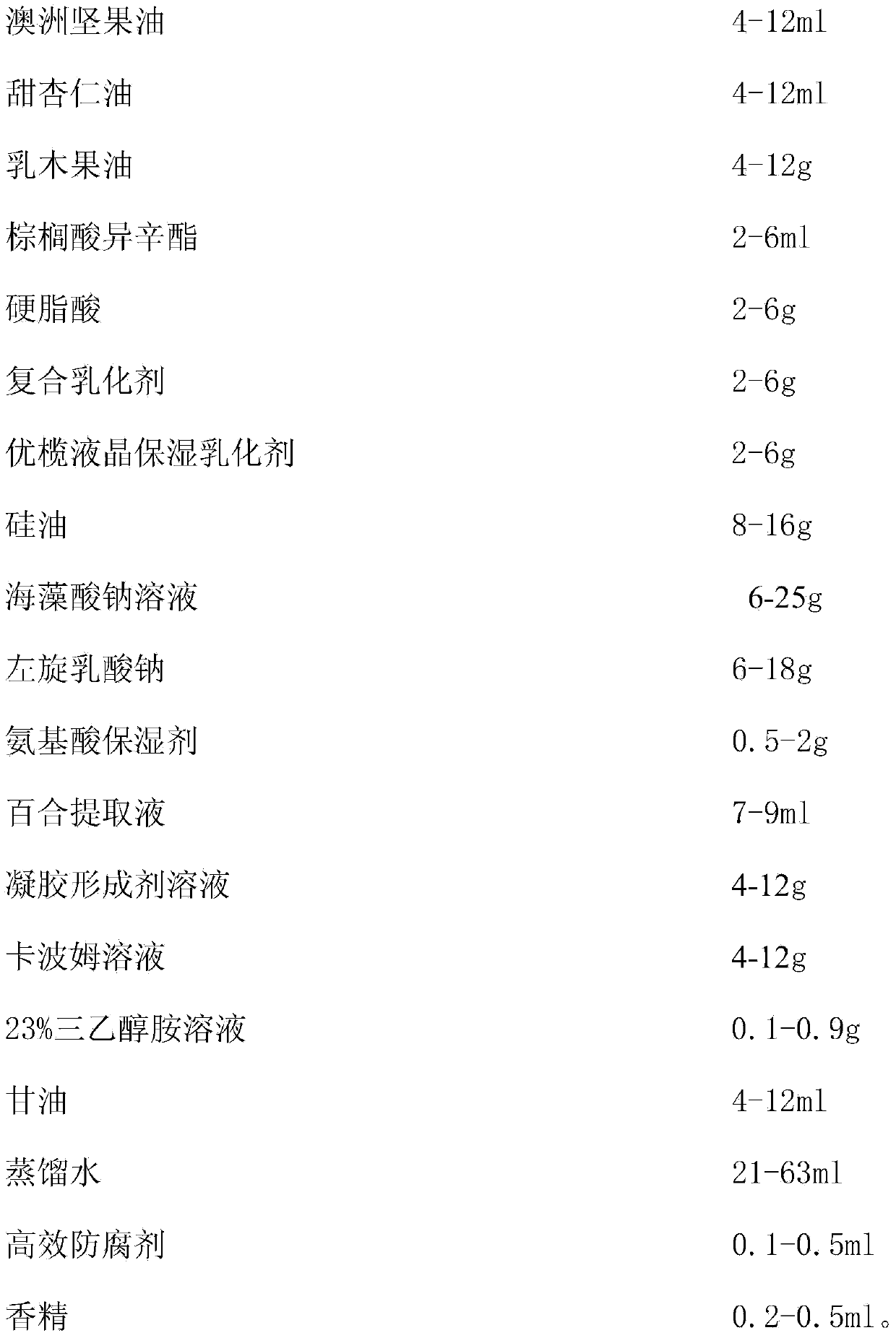

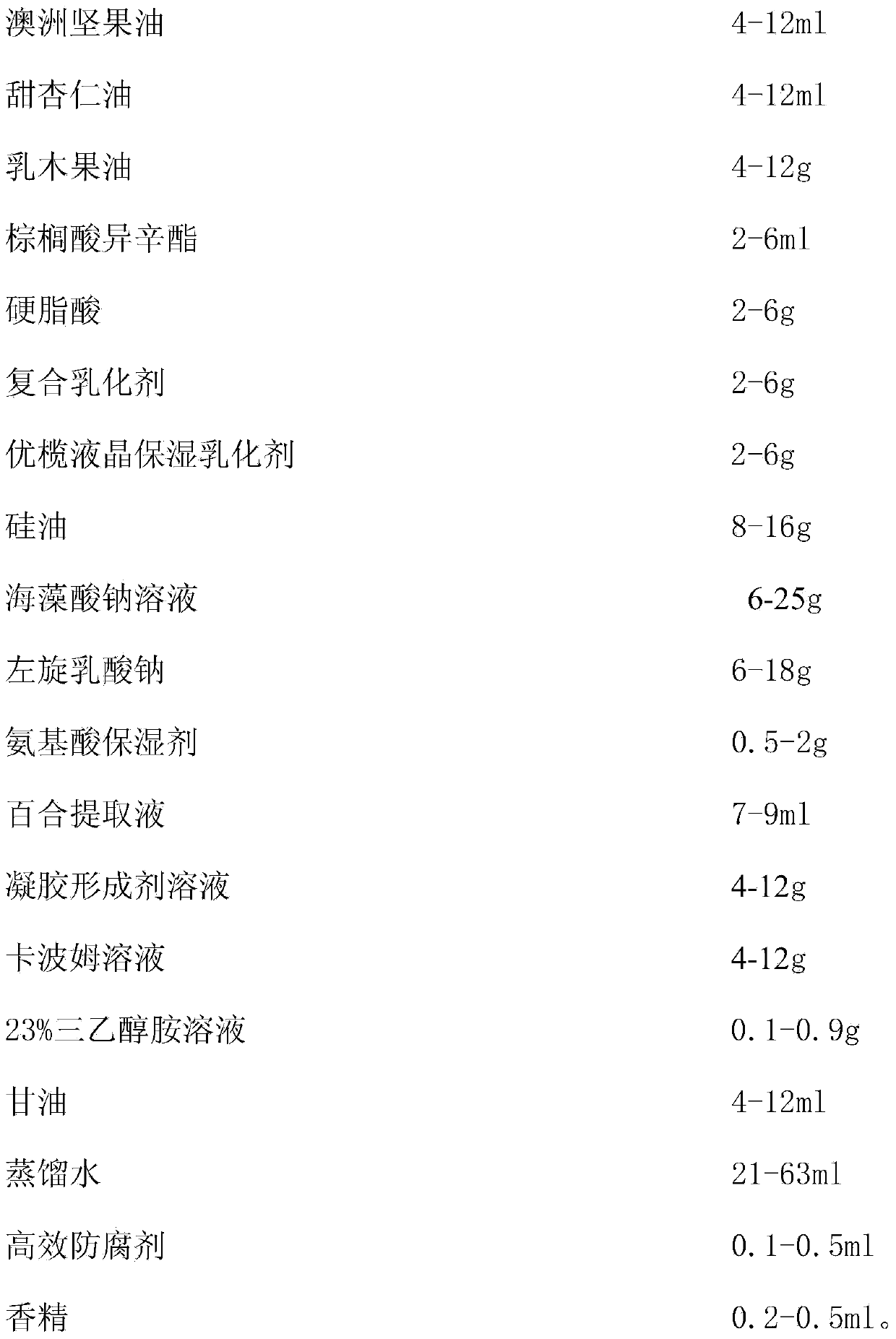

Shining, moisturizing and skin-finishing cream and preparation method thereof

ActiveCN103989601ANot easily oxidizedImprove permeabilityCosmetic preparationsToilet preparationsSodium lactateAdditive ingredient

The invention relates to shining, moisturizing and skin-finishing cream and a preparation method thereof. The cream comprises the following matters: macadimia nut oil, sweet almond oil, shea butter, isooctyl palmitate, stearic acid, a compound emulsifier, a superior olive liquid crystal moisturizing emulsifier, silicone oil, a sodium alginate solution, left-handed sodium lactate, an amino acid moisturizer, a lily extracting solution, a gel formation agent solution, a Carbomer solution, a 23% triethanolamine solution, glycerol, distilled water, an efficient preservative and essence. Compared with the prior art, a lot of natural plant components are added into the cream prepared by the invention, so that the cream is suitable for various skins. On the one hand, facial cells are accelerated to regenerate by lily essence, left-handed sodium lactate and the like to realize the shining effect. On the other hand, natural plant oils such as macadimia nut oil and sweet almond oil are used, so that the facial skin has the moisturizing and skin-finishing effect, metabolism is accelerated, moisture of skin is prevented from losing, and the facial skin is ruddy and glossy.

Owner:江西登云健康美业互联有限公司

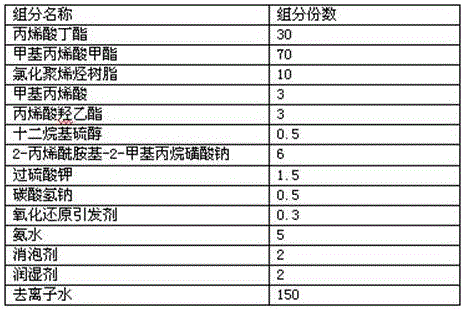

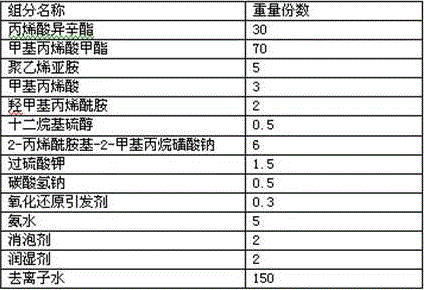

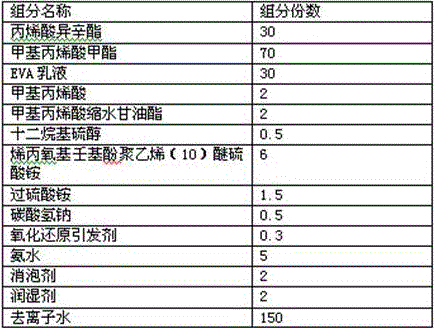

Hydrophobic under-coating paint for polyolefin film and preparation method of hydrophobic under-coating paint

The invention provides hydrophobic under-coating paint applied to a poor-polarity polyolefin film. The under-coating paint is prepared from the following components in parts by weight: 30-50 parts of soft monomers, 50-70 parts of hard monomers, 5-30 parts of vinyl monomers, vinyl monomer synthetic resin, vinyl monomer synthetic emulsion or polyethyleneimine, 1-10 parts of acidic functional monomers, 1-10 parts of cross-linking monomers, 2-6 parts of a reaction type emulsifying agent, 0.5-2 parts of an initiating agent, 0.1-1 part of lauryl mercaptan, 0.5-2 parts of an antifoaming agent, 0.5-2 parts of a wetting agent and 140-160 parts of deionized water by an emulsion polymerization method, wherein the vinyl monomers are vinyl acetate, vinyl ester of tertary carboxylic acids, butadiene, isoprene, vinyl chloride or vinylidene chloride, the vinyl monomer synthetic resin is chlorinated polyolefin resin, and the vinyl monomer polymerization emulsion is an EVA emulsion. The under-coating paint disclosed by the invention is low in cost, has favorable adhesive force to the polyolefin films, and can provide favorable ink-printing adaptability. The invention further provides a preparation method of the under-coating paint.

Owner:汕头市龙湖昌丰化工有限公司

Terbinafine nano milk-like liquid antifungal medicine and its preparation

InactiveCN1927181AEvenly distributedGood stabilityOrganic active ingredientsAntimycoticsChemistryDermatophyte

The invention discloses a terbinafine nanometer antifungal which is prepared by terbinafine, oil, surfactant, water according to the following method: First, the said raw materials are unloaded and weighed and reserved, then surfactants and oil is blended and mixed; terbinafine is added into cosurfactant and completely dissolved; the solution with terbinafine dissolved in it is added to the homogeneous mixed surfactant and oil, stirring uniform, finally, distilled water is slowly added dropwise, dropwising and stirring until the stable, homogeneous, transparent terbinafine nanometer antifungal is obtained. The drug with small particles, small viscosity, good fluidity and good nature stability, can reach through the skin and get into the blood circulation, inhibit squalene cycloxygenase, so as to treat the dermatophyte infection and many deep mycotic infection with a drastic therapeutic effect, and what is more the preparation of the invented products is simple, low energy consumption and without special equipment the drug can be mass produced.

Owner:NORTHWEST A & F UNIV

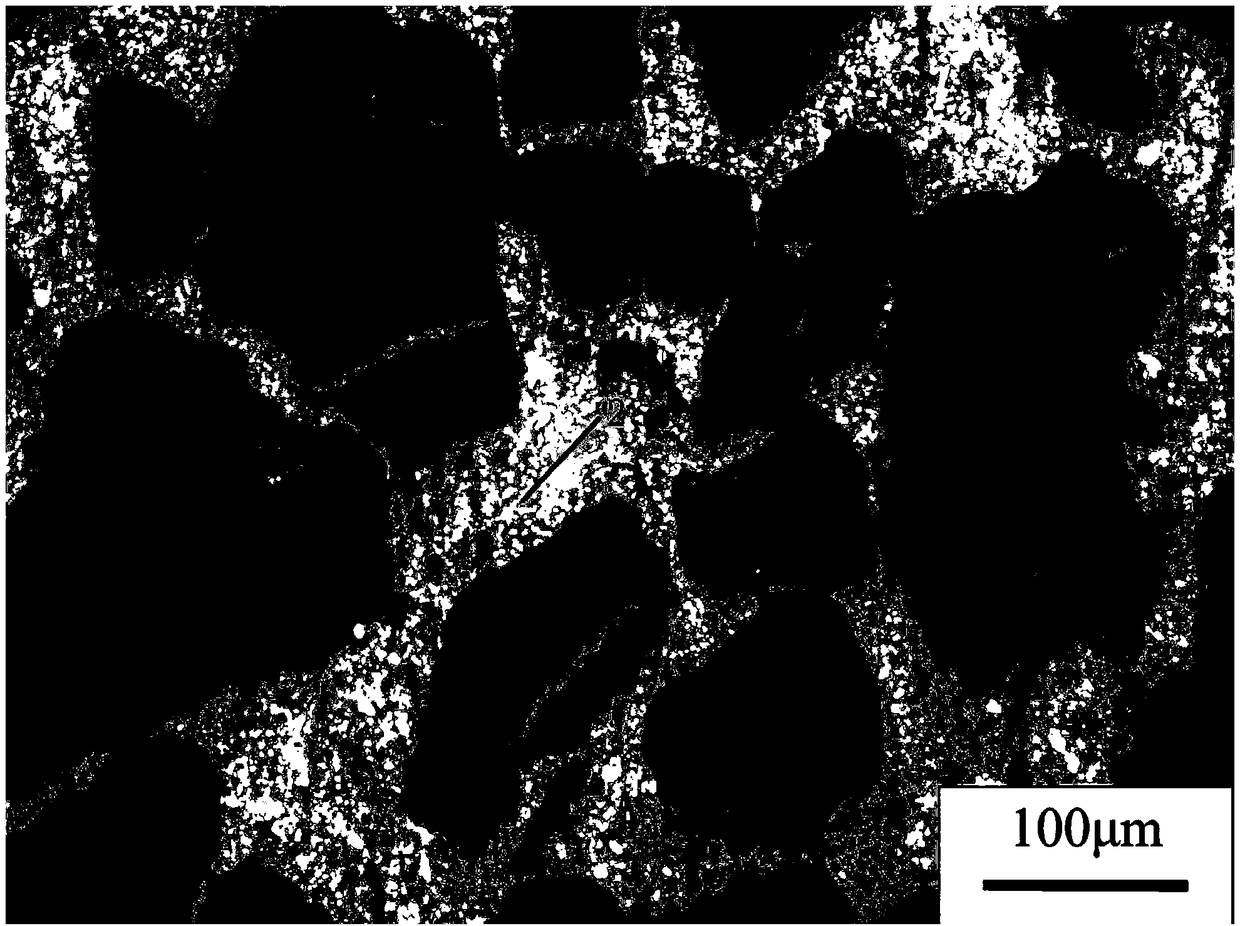

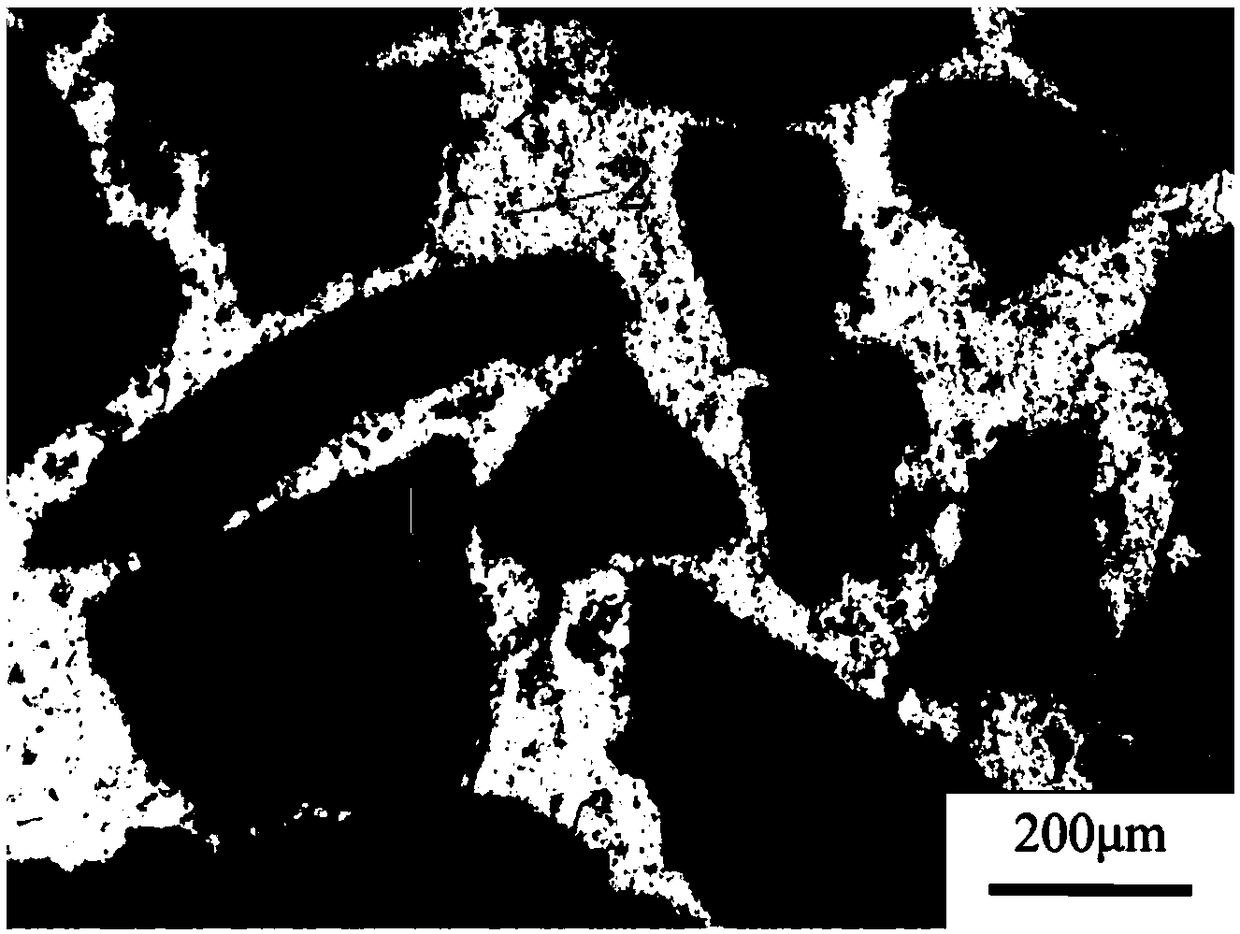

Method for preparing cluster-like aluminum based composite material by using recycled SiCp/Al composite material

The invention relates to a method for preparing a cluster-like aluminum based composite material, in particular to a method for preparing the cluster-like aluminum based composite material by using arecycled SiCp / Al composite material in order to solve the problems that the plasticity and toughness of an SiCp / Al composite material prepared through an existing method are poor, the recycling difficulty of the SiCp / Al composite material is high, and the breaking efficiency of the composite material in the preparation process of the SiCp / Al composite material of a cluster-like structure is low. The method includes the steps that firstly, the waste composite material is cleaned, dried and screened; secondly, the composite material powder is subjected to liquid nitrogen ball milling; thirdly, aprefab is prepared in a cold pressing mode; fourthly, a mold is preheated, and aluminum metal is melted; and fifthly, infiltration of molten aluminum is carried out. The method has the beneficial effects that the composite material prepared in the invention is the cluster-like composite material, and is high in compactness, good in tensile strength and plasticity, low in cost and low in technicaldifficulty, and the microstructure design of the material is easy to achieve. The method is suitable for preparing the cluster-like (SiCp / Al) / Al composite material.

Owner:HARBIN INST OF TECH

Anti-decolorization lipstick raincoat composition and preparation method thereof

InactiveCN109864896APrevent sticking cupAvoid crackingCosmetic preparationsToilet preparationsGas phaseFumed silica

The invention relates to the field of cosmetics, in particular to an anti-decolorization lipstick raincoat composition and a preparation method thereof. The lipstick raincoat composition disclosed bythe invention consists of polyperfluoromethyl isopropyl ether and fumed silica. A preparation method of the lipstick raincoat comprises the following steps: mixing the polyperfluoromethyl isopropyl ether with the fumed silica, and conducting stirring to obtain a mixture A; and homogenizing the mixture A to obtain the lipstick raincoat composition. The lipstick raincoat composition is smeared overthe lipstick on lips to form a protective film; the lipstick is prevented from being stained with a cup, and the effect of protecting the lipstick from being stained with the cup is good. Besides, thecomposition disclosed by the invention is good in moistening and moisturizing effects, capable of preventing lip cracking, good in stability under a high-temperature condition, free of a cup stainingphenomenon when the temperature is relatively high, non-toxic and harmless in components and good in safety.

Owner:广州果感生物科技有限公司

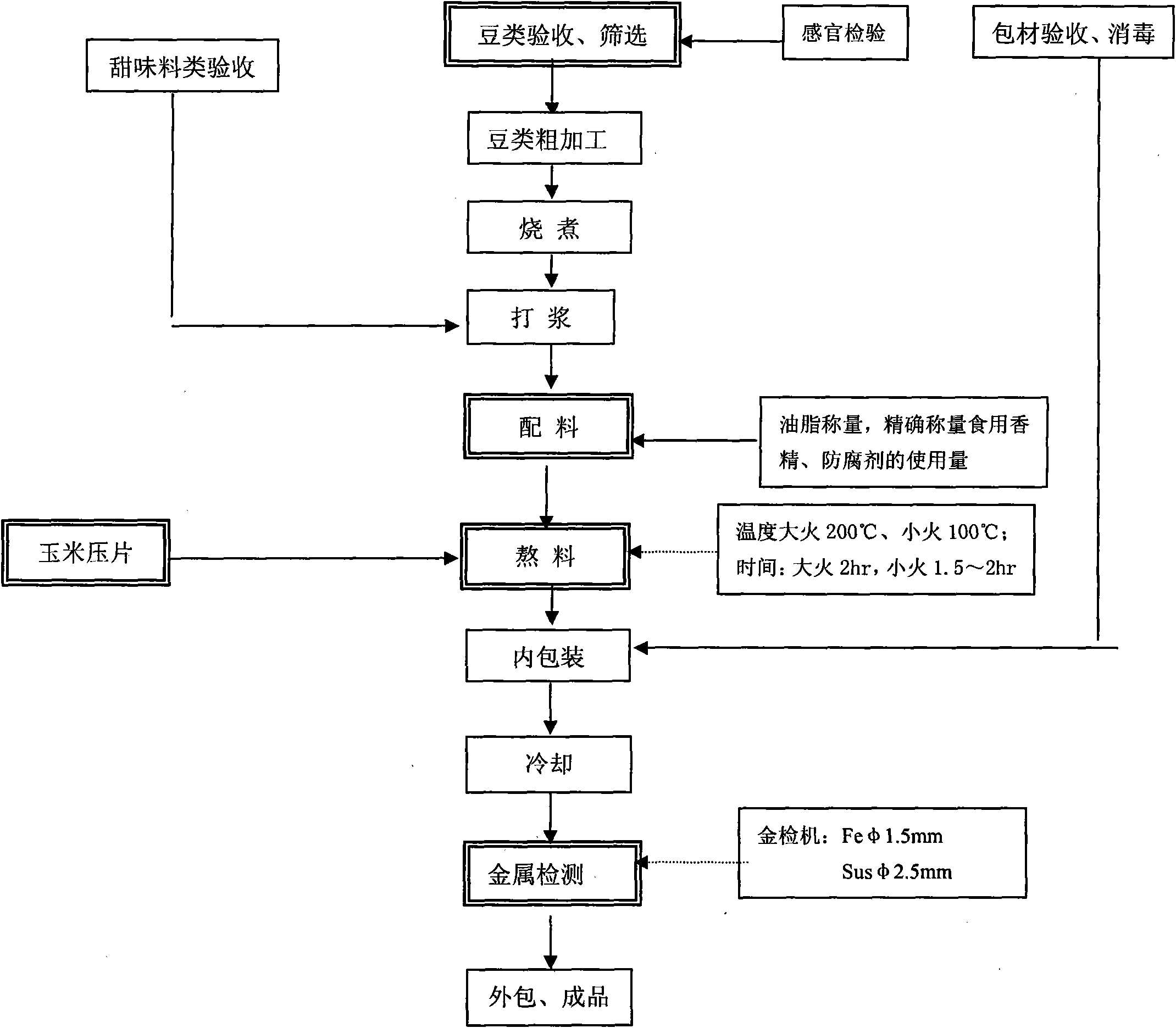

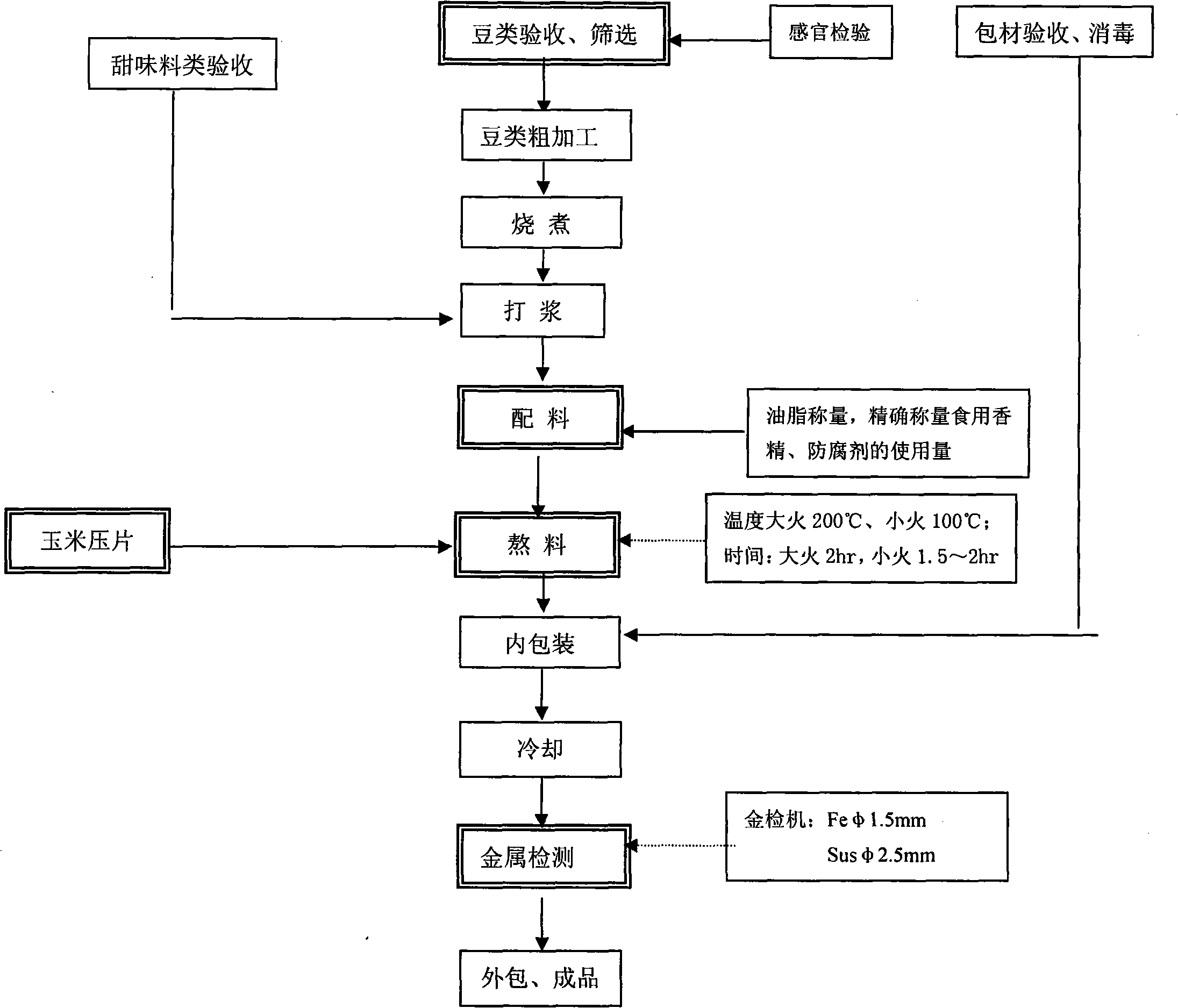

Corn paste stuffing and production method thereof

InactiveCN101869132AGreat tasteFocus on premium featuresBakery productsStarch gelatinizationPreservative

The invention relates to a corn paste stuffing and a production method thereof. The corn paste stuffing comprises the following raw materials in percentage by weight: 20 to 30 percent of beans, 25 to 40 percent of corn, 30 to 42 percent of sweetener, 9 to 18 percent of grease, 0.2 to 0.4 percent of edible essence and 0.03 to 0.1 percent of preservative. The production method comprises the following steps of: inspecting, accepting and treating the raw materials, comprising rough processing of washing and peeling of the beans; cooking the beans to make starch in the beans form paste; mixing and pulping the cooked beans and the sweetener; weighing the grease, the essence and the preservative, accurately controlling the using amount of the auxiliary materials, and putting the auxiliary materials into the pulped mixture; pressing the corn to form pressed corn; boiling materials with a wok, namely boiling the mixture added with the auxiliary materials for 3.5 to 4 hours, then adding the pressed corn into the boiled mixture, and fully and uniformly blending various raw materials together; and packing the cooked stuffing and cooling the stuffing to obtain a finished product. The corn paste stuffing produced by the method has the characteristics of visible granules, floppy mouthfeel and high nutrition reserving degree.

Owner:常州市鑫灿食品有限公司

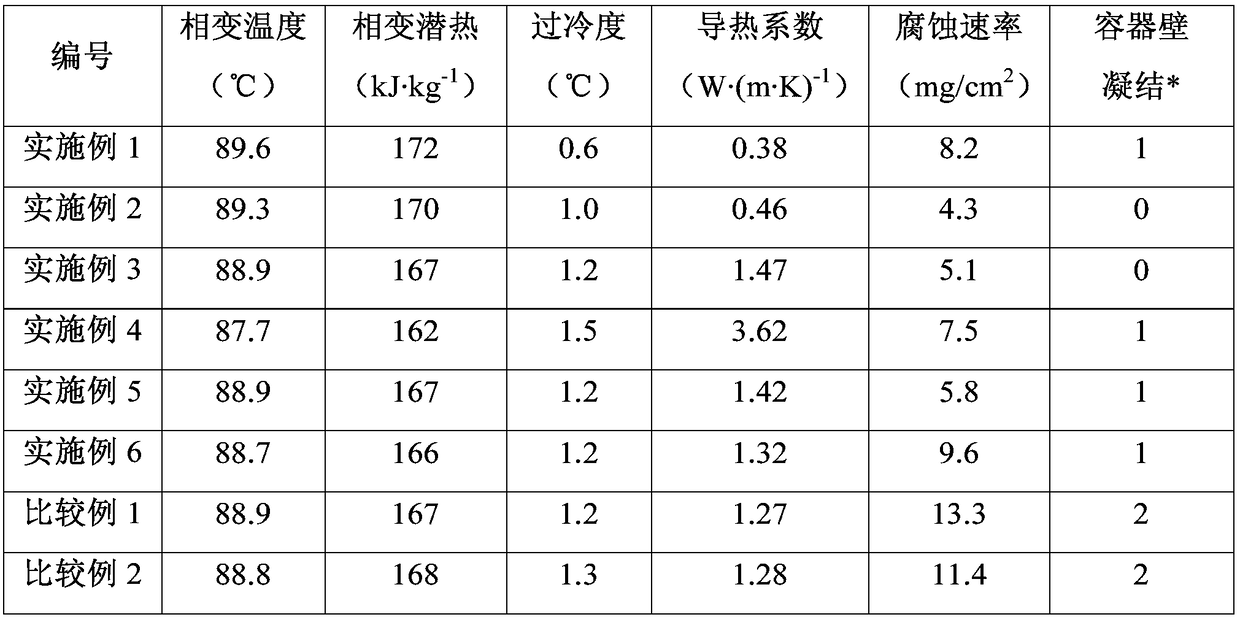

89 DEG C phase change material (PCM)

ActiveCN108251074AHigh thermal conductivityMaintain phase change heat storage performanceHeat storage plantsHeat-exchange elementsWorking temperatureCogeneration

The invention relates to the technical field of energy storage materials, in particular to a 89 DEG C phase change material (PCM) and a preparation method and application thereof. The material is prepared from the following components of, in parts by weight, 100 parts of magnesium nitrate hexahydrate, 0.5-5 parts of graphite, 0.5-10 parts of thickeners, 0.1-2 parts of corrosion inhibitors, 0.1-2 parts of surface active agents and 0.1-1 part of a coloring agent. The89 DEG C phase change material can solve the problems that a material is prone to be condensed on the surface of a thermal conductive pipe, the corrosion performance is high, the thermal conductivity is poor, and the material is prone to leak to cause dangers. The phase change temperature of the material is matched with the working temperature of a heat supply net, and the material can be applied to phase change energy storage heat exchangers in a combined heat and power generation system.

Owner:北京今日能源科技发展有限公司 +1

Method for preparing cluster-like aluminum based composite material by using recycled SiCp/Al composite material

The invention relates to a method for preparing a cluster-like aluminum based composite material, in particular to a method for preparing the cluster-like aluminum based composite material by using arecycled SiCp / Al composite material in order to solve the problems that the plasticity and toughness of an SiCp / Al composite material prepared through an existing method are poor, and the recycling difficulty of the SiCp / Al composite material is high. The method includes the steps that firstly, the waste composite material is cleaned, dried and screened; secondly, the composite material powder issubjected to ball milling; thirdly, a prefab is prepared in a cold pressing mode; fourthly, a mold is preheated, and aluminum metal is melted; and fifthly, infiltration of molten aluminum is carried out. The method has the beneficial effects that the composite material prepared in the invention is the cluster-like composite material, and is high in compactness, good in tensile strength and plasticity, low in cost and low in technical difficulty, and the microstructure design of the material is easy to achieve. The method is suitable for preparing the cluster-like aluminum based composite material.

Owner:HARBIN INST OF TECH

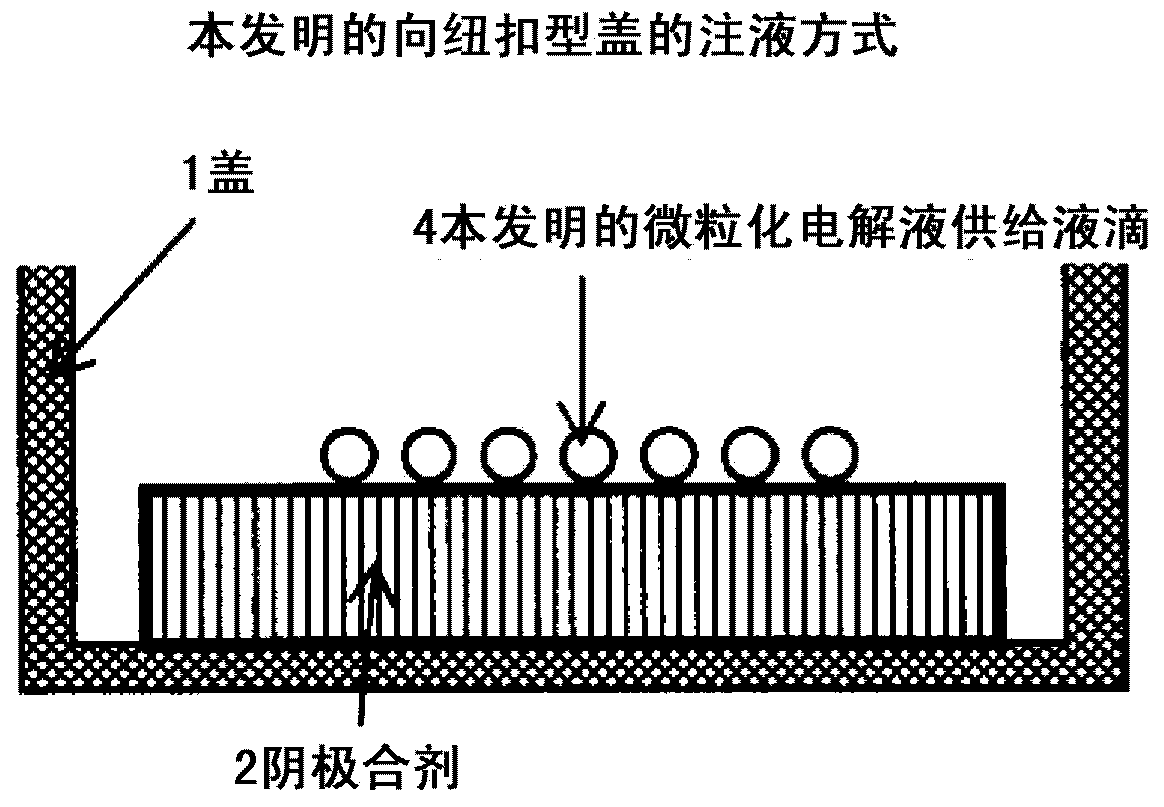

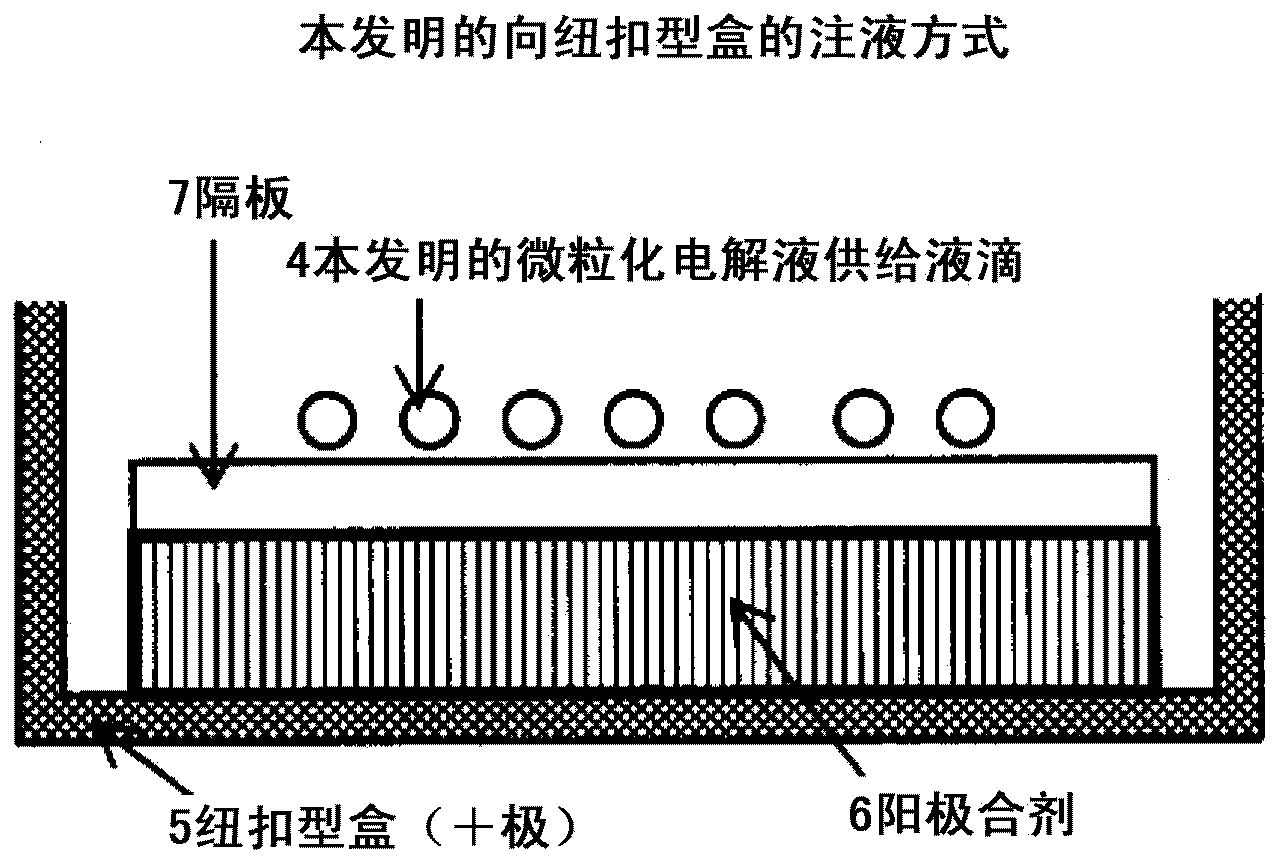

Electrochemical element

InactiveCN103748647ARapid rationEasy to break awayHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorHigh concentrationEngineering

The purpose of the present invention is to provide an electrochemical element to which a high-concentration and high-viscosity electrolyte is supplied. The electrolyte is dispersed and supplied instantaneously to the electrochemical element in a small fixed quantity.

Owner:FUJIKIN INC +1

Hands-washing liquid with antibacterial and no-washing effect

InactiveCN109260115AMoisturize wellImprove repair effectCosmetic preparationsToilet preparationsAlcoholExtracted grape seeds

The invention discloses a bacteriostatic repair hand washing liquid, which is composed of the following raw materials in parts by weight: alcohol 40-50 part, glycerin 10-13 part, squalane 5-8 part, grape seed extract 1-3 part, bread tree extract 2-5 part, pomegranate seed extract 1-3 part, aloe extract 2-6 part, honeysuckle extract 2-5 part, chamomile extract 1-2 part, seabuckthorn oil 0.5-1 part,clove essential oil 1-3 part, surfactant 0.5-1 part, deionized water 6-10 part, sodium hyaluronate 1-3 part, and emollient 5-8 parts. The invention doe not need to be clean with water after use, theinvention only needs to gently apply a little on the hand and allow the hand to be naturally dried, and the property is particularly mild, the persistent bacteriostasis can also make the skin of bothhands tender and smooth, and the hands can be cared.

Owner:凌工二号(大连)科技有限公司

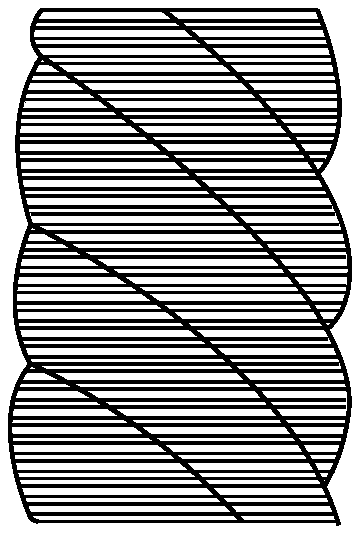

Random packing tower for high-precision separation

InactiveCN109464823AReduce gapMoisturize wellChemical/physical/physico-chemical processesFractional distillationEngineeringTower

The invention relates to a random packing tower for high-precision separation. The random packing tower comprises a tower body, a tower bottom and a condensing unit, wherein the tower body comprises multiple packing sections which are connected one another, the packing sections are filled with random packing, an isolating layer is arranged at the inner bottom of each packing section, exchange holes are formed in the surfaces of the isolating layers, and diameter of the exchange holes is smaller than outer diameter of the random packing; the random packing is of a hollow hexagonal spirochete structure, and the cross section of the random packing is in a regular hexagon shape. Compared with traditional spherical or other shaped random packing, the packing has higher space utilization rate when filled in unit space, a gap between the random packing is reduced, and mass transfer dead zones are reduced; the random packing is of the hollow hexagonal spirochete structure and is formed by metal wires through bending and winding, so that a liquid can be well dispersed to form a film, the packing surface is easily wet by the liquid, a better gas-liquid channel and mass transfer surface are obtained, a gas-liquid contact area is increased, and heat and mass transfer efficiency is further improved.

Owner:TIANJIN TIANYUAN WEIYE CHEM TECH CO LTD

Decoloration-resistant lipstick sealer and preparation method thereof

PendingCN108815019APrevent sticking cupPrevent fadingCosmetic preparationsToilet preparationsTectorial membraneAdditive ingredient

The invention discloses a decoloration-resistant lipstick sealer. The lipstick sealer is prepared from the following ingredients in parts by weight: 0.5-6 parts of polydimethylsiloxane and polydimethylsiloxane / vinyl polydimethylsiloxane crosslinking copolymer, 5-15 parts of polydimethylsiloxane, 60-70 parts of spherical silicon resin powder, 2-3 parts of jojoba oil, 1-3 parts of shea butter and 0.1-1 part of tocopherol. The product can be smeared on lipstick coated on lips, and forms a layer of protection film to separate the lipstick from external environment, so that the lipstick is effectively prevented from sticking a cup and decoloration; consumers do not need to frequently fix make-up, so that the waste of time is avoided, and the embarrassed situation caused by problems such as cupsticking is avoided; the lipstick sealer is convenient and efficient to use, moderate in price, and suitable for popularization and application; when smeared on the lips, the lipstick sealer feels smooth, fresh and cool, has very good moistening and moisturizing effects, and can increase moisture of lip skin and prevent the lips from drying and chapping, thereby further recovering and maintainingthe natural resilience of the lips.

Owner:广州市蔻萝生物科技有限公司

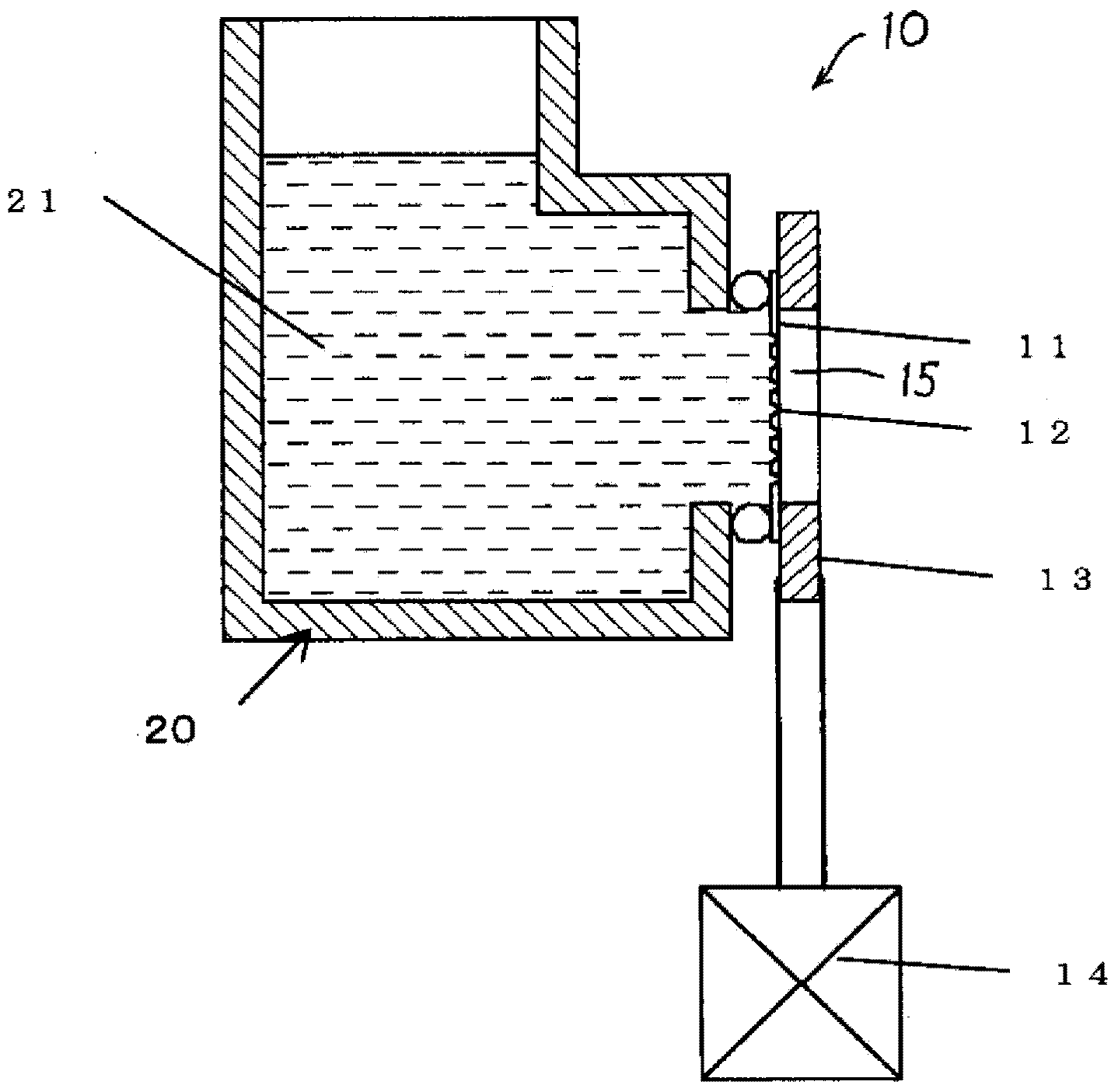

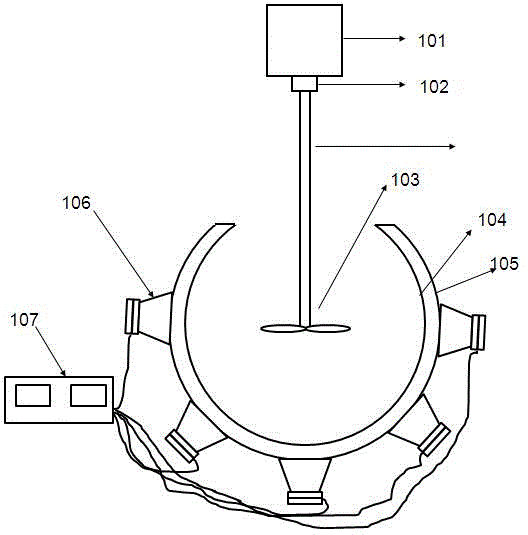

Ultrasonic stirring apparatus for lithium ion battery electrode slurry

Stirring homogenate is a key process during manufacture of a lithium ion secondary battery, and aims at homogenizing a slurry as much as possible. A present widely-known technology employs a motor for driving a stirring paddle for stirring the slurry, the stirring intensity generated by the stirring manner is not uniform in different positions in a slurry barrel, especially when the slurry viscosity is relatively high and the slurry is adhered to barrel walls, barrel corners and other places with relatively large curvature, and additionally, after a solid material is just added into the material barrel, the solid material is inclined to float at the surface of the wetted slurry or attach to barrel walls. During production, the solution is that the slurry or the solid material adhered to barrel walls is artificially stripped off, otherwise the stirring time is prolonged. According to the technical scheme, a spherical slurry stirring barrel is employed, a stirring paddle rotates at the sphere center, the periphery of the spherical material barrel is uniformly provided with ultrasonic transducers which give ultrasonic waves at the same time at the same phase, so that the ultrasonic superposed amplitude at the geometric center position of the spherical material barrel is increased, and violently cavitation mixing effect is generated at the center of the slurry stirring barrel. At the same time, the ultrasonic transducers attaching to the slurry stirring barrel enable the barrel walls to generate high-frequency mechanical oscillation, and the oscillation generates violent acting force at the interface between the metal barrel walls and the slurry because of abrupt change of density and elastic modulus. The comprehensive effect is that the solid material is easily wetted, and the wetted slurry is easy to homogenize.

Owner:WUXI HUAZHEN NEW ENERGY TECH

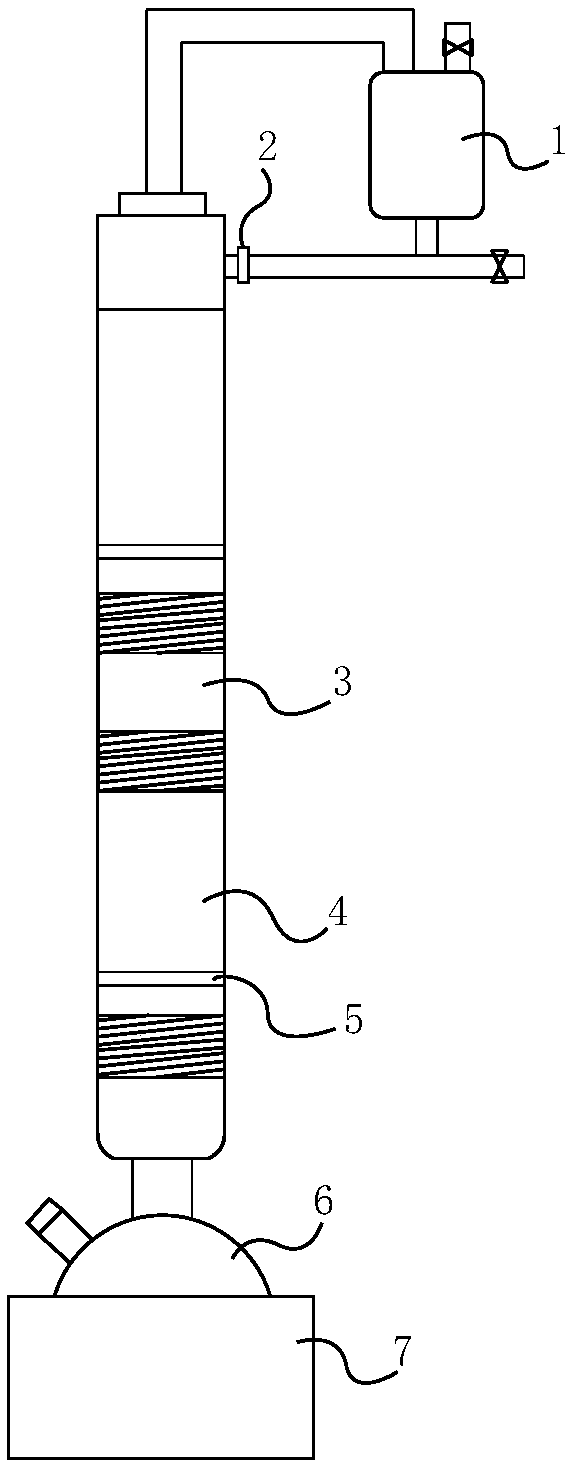

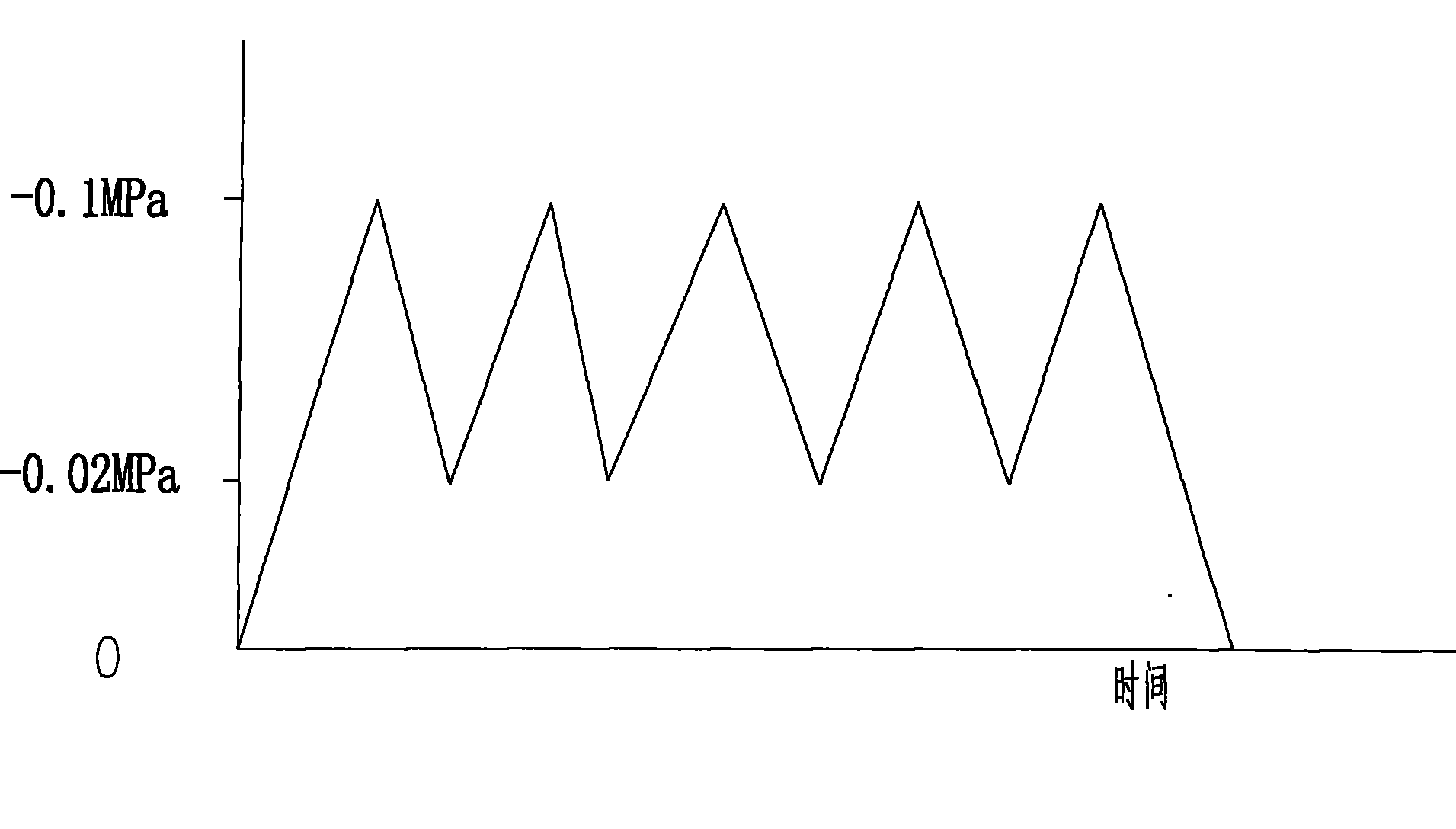

Liquid injection and humidity method for lithium ion battery

InactiveCN101267033BWet evenlyMoisturize wellFinal product manufactureCell component detailsPressure cycleInternal resistance

The invention relates to an improvement of wetting method of lithium-ion battery liquid injection, characterized in that negative pressure wetting is negative pressure cycle changed wetting in -0.1MPa to -0.02MPa vacuum. Electrical core absorbs electrolyte wetly, uniformly and quickly because of using cycle changed negative pressure, the battery reaches liquid injection requirement only 12 to 15 minutes when the flexible packaging is 2000 mA, the time of liquid injection wetting is saved about 1 / 2 compared with the time of original constant negative pressure wetting, and consistency of internal resistance and capacity of battery is improved greatly, the consistency can improve at least about 10 percent compared with the original technology wetting. In addition, the realizing way of changing negative pressure circularly is simple, and need not increase equipment investment basically, and has low use-cost, and is easy to implement.

Owner:JIANGSU DIO ENERGY SCI TECH

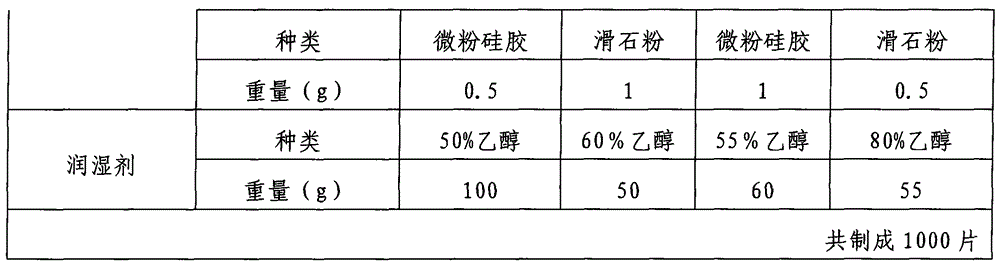

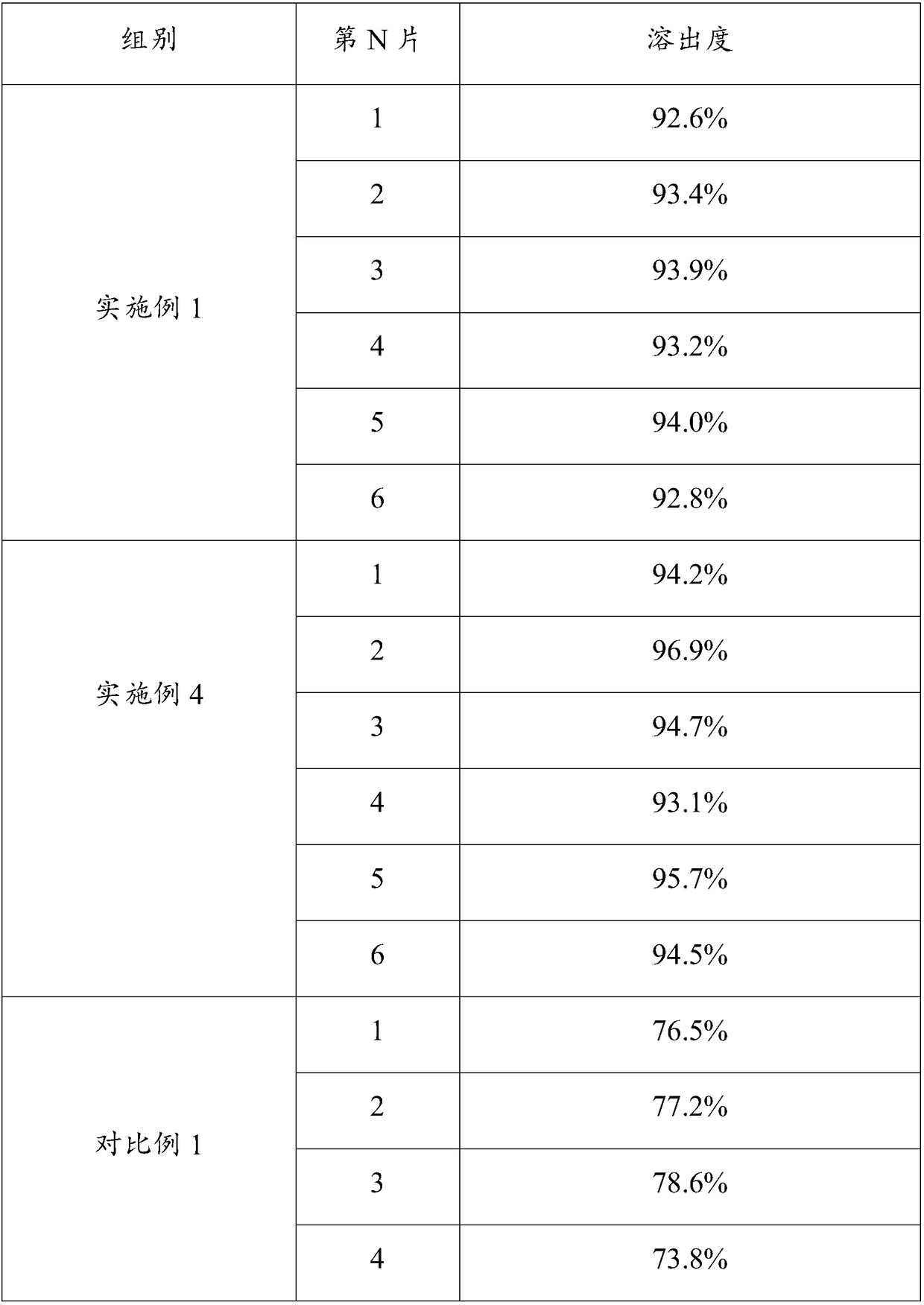

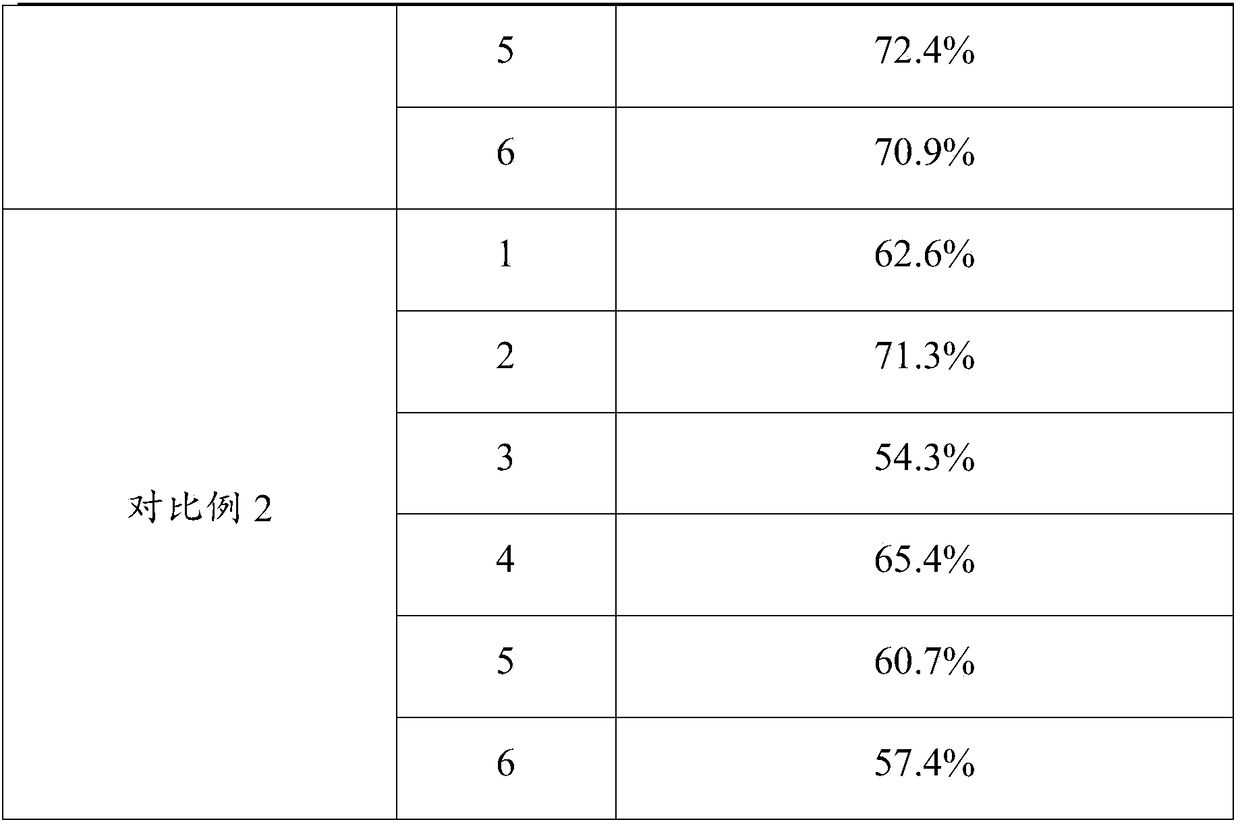

The preparation method of felodipine slow-release tablet

ActiveCN101843598BSuitable for industrialized mass productionHigh yieldOrganic active ingredientsPharmaceutical non-active ingredientsSustained Release TabletFiller Excipient

The invention discloses a preparation method of felodipine sustained release tablets. The method is characterized by comprising the following steps of: mixing felodipine accounting for 1-10 percent of the total component weight, a part of hydroxypropyl methylcellulose accounting for 20-55 percent of the total component weight and a filler; and wetting by using a wetting agent to carry out wet granulation; after wet granules are dried at low temperature, mixing the dried granules with residual hydroxypropyl methylcellulose; adding a lubricating agent and then tabletting to prepare cores containing main drugs; and coating by using a coating material to obtain the felodipine sustained release tablets. The preparation method is easy to control and suitable for industrial scale production, has high product yield and reduces the production cost. Compared with merchant like preparations, the felodipine sustained release tablets obtained by using the preparation method has similar in vitro release curve.

Owner:CHANGZHOU PHARMA FACTORY

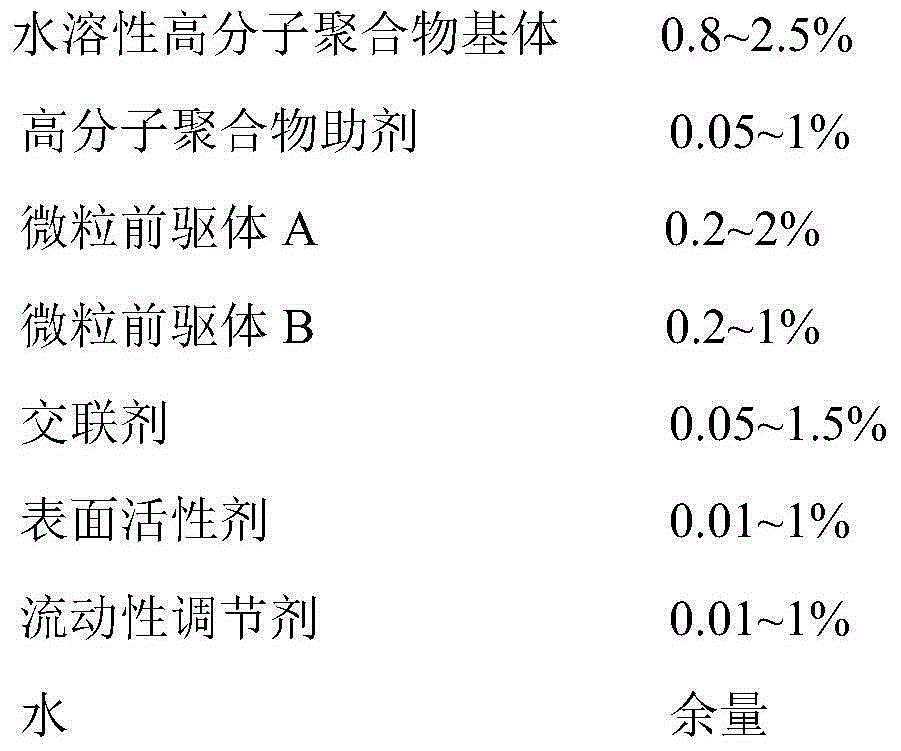

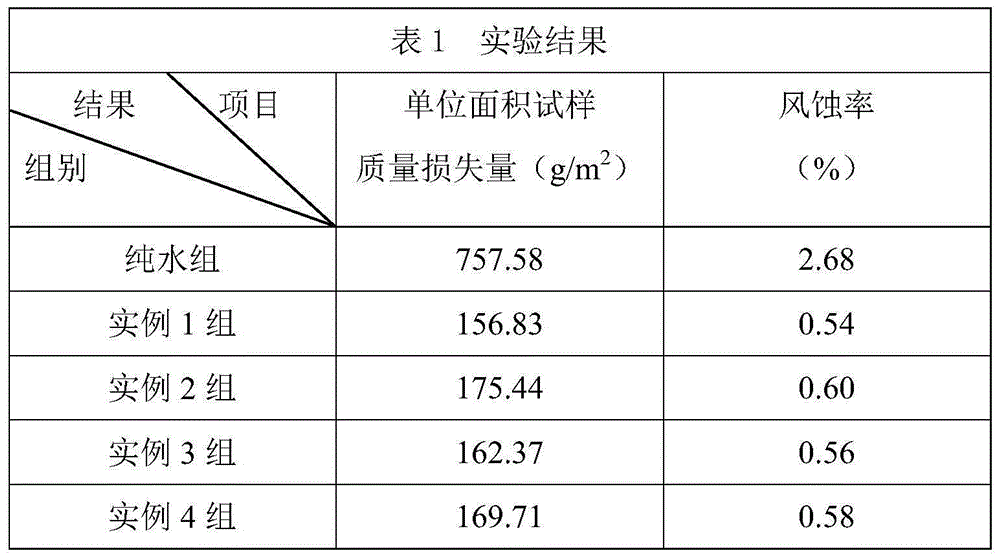

Environment-friendly construction site dust suppressant and preparing method thereof

The invention discloses environment-friendly construction site dust suppressant and a preparing method thereof. The dust suppressant comprises, by weight, 0.8% to 2.5% of water-soluble macromolecule polymer matrix, 0.05% to 1.5% of macromolecule polymer builder, 0.2% to 2% of A particle precursor, 0.2% to 1% of B particle precursor, 0.05% to 1.5% of cross-linking agent, 0.01% to 1% of surface active agent and 0. 01 % to 1% of mobility modifier. Raw materials of the dust suppressant are industrial grade drugs and industrial water, and the dust suppressant can be produced under normal pressure and temperature and have no pungent odor and is low in cost. The purpose of the environment-friendly construction site dust suppressant is to govern swirling dust caused by open-air source on the construction site, and the dust suppressant is used in material piles and road surfaces, can form a layer of a solidification shell and have the advantages of being small in solidification shell crack, long in duration and environmentally friendly. The dust suppressant is beneficial to the physical and psychological health of constructors, reduces the waste of raw materials, maintains good environment around a construction unit and can produce great economic benefits and social benefits.

Owner:天津筑品科技有限公司 +1

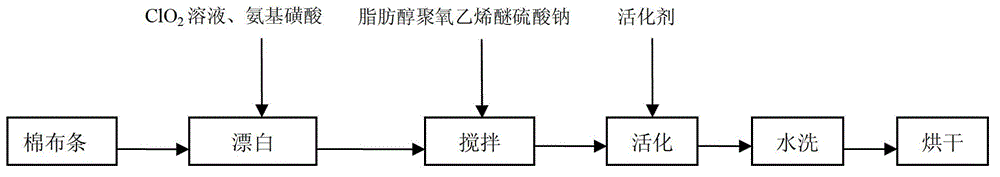

Method for bleaching cotton fabric by chlorine dioxide

InactiveCN103334291AHigh whitenessImprove bleaching effectBleaching apparatusSocial benefitsChlorine dioxide

The invention discloses a method for bleaching a cotton fabric by chlorine dioxide. The method comprises the following operating steps: 1, mixing a chlorine dioxide solution with a sulfamic acid solution according to a volume ratio of 50:1, and uniformly stirring; 2, adding cotton cloth strips to a mixed solution obtained in step 1 for fully immersing the cotton cloth strips, adding fatty alcohol polyoxyethylene ether sodium sulfate, and bleaching at 35-45DEG C through stirring for 2min by a stirrer each 30min when the pH value of the bleaching system is 3-4; 3, adding a 2mol / L activator to a solution obtained 120-150min after the bleaching treatment, and uniformly stirring; and 4, allowing a solution obtained in step 3 to stand for 30min, taking out cloth samples, washing with water, and drying in an oven at 120DEG C for 3-4h. The method has the advantages of bleaching efficiency and technological controllability increase, bleaching time shortening, wastewater treatment cost saving, environmental pollution reduction, and obvious economic and social benefits.

Owner:GUANGXI UNIV

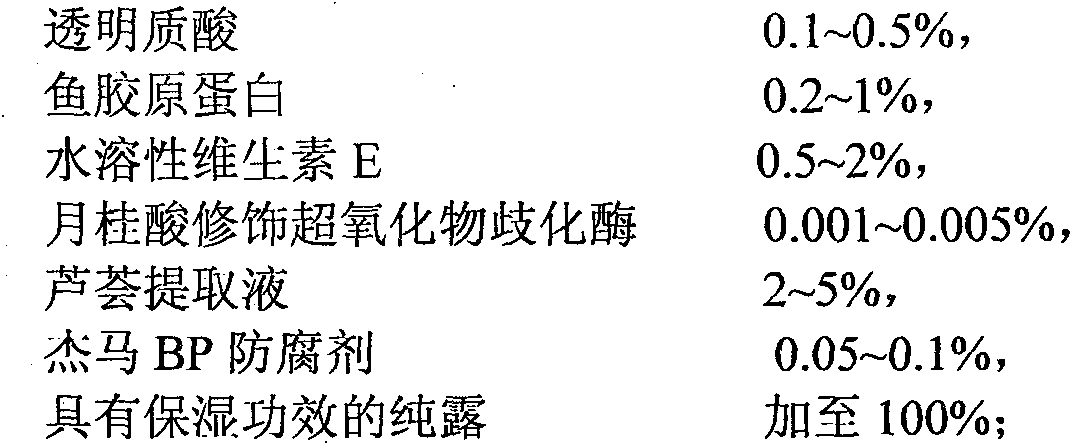

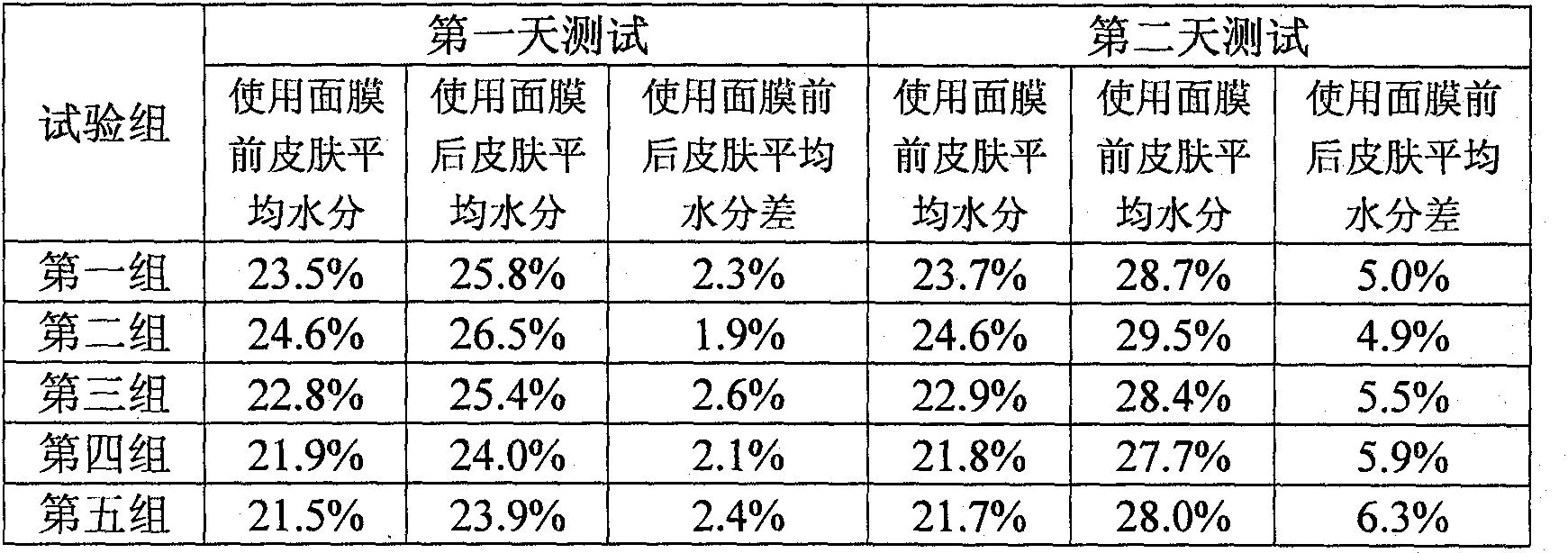

Hydrolat moisturizing facial mask

InactiveCN102935055BMoisturize wellStay hydratedCosmetic preparationsToilet preparationsPreservativeHamamelis virginiana

The invention discloses a hydrolat moisturizing facial mask. The method comprises the following steps: putting a hydrolat with moisturizing efficacy into a container, then adding hyaluronic acid, fish collagen, water soluble vitamin and lauric acid modified superoxide dismutase into the container, and stirring the solution until the solution is completely dissolved; then adding aloe extracting solution and supguard GM-BP preservative into the solution, and uniformly stirring, uniformly dripping the obtained liquid onto a non-woven fabric facial mask, then conducting sealed packaging to obtain a product, namely the hydrolat moisturizing facial mask. The hydrolat with moisturizing efficacy includes rose hydrolat, witch hazel hydrolat, jasmine hydrolat, marigold hydrolat, sandalwood hydrolat and the like, and any one of the hydrolat or combination of any two or more of the hydrolat can be adopted. The hydrolat moisturizing facial mask prepared by adopting the method disclosed by the invention has the advantages that the moisturizing effect is prominent, and the mask is safe and can not irritate a human body, and the like.

Owner:深圳市妍倩科技有限公司

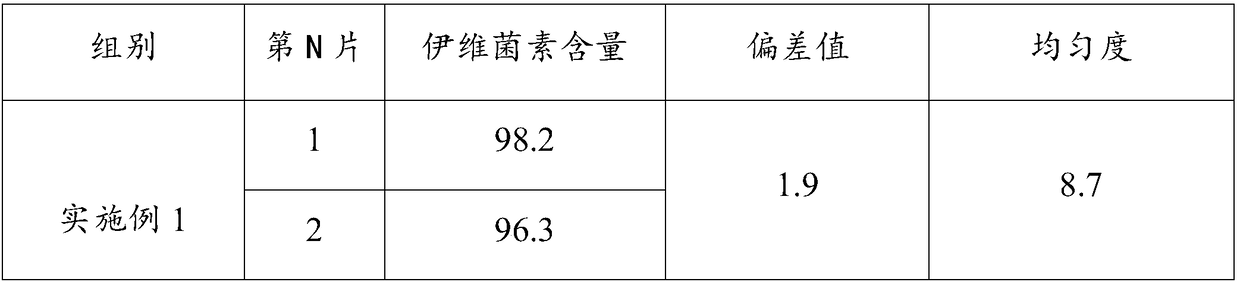

Preparation method of ivermectin preparation and ivermectin preparation

InactiveCN108079006AHigh dissolution rateImprove uniformityOrganic active ingredientsPharmaceutical non-active ingredientsSoft materialsLubricant

The invention relates to a preparation method of an ivermectin preparation and the ivermectin preparation. The preparation method of the ivermectin preparation comprises the following steps: (1) weighed ivermectin is ground, and the grain size of the ivermectin is controlled at 120 mu m to 130 mu m; (2) the ground ivermectin, part of screened filler and a screened disintegrating agent are first premixed, so that an intermediate is prepared; and the intermediate and the rest of the screened filler are uniformly mixed, so that a mixture is obtained; (3) a binder solution, the concentration of which is 0.1 percent (w / v) to 10 percent (w / v), is prepared; (4) the mixture and the binder solution are uniformly mixed, so that a soft material is obtained; (5) the soft material is granulated, driedand finished, so that granules are produced; (6) a screened lubricant and the granules are uniformly mixed, and tabletting is carried out, so that the ivermectin preparation is obtained. The ivermectin preparation prepared by the preparation method has high dissolubility and good uniformity.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

Environment-friendly type all-purpose adhesive and method of production

InactiveCN1247725CImprove cohesive strengthHigh bonding strengthHydrocarbon polymer adhesivesAcetic acidAdhesive

The invention discloses an environment-friendly type all-purpose adhesive, which is prepared from SBS, and petroleum resin, polymerized resin, colophonium, terpene resin, cyclohexane, methylene chloride, acetic acid ethyl ester, No.6 solvent oil, and dichloroethanes. The invention also discloses the process for preparing the all-purpose adhesive.

Owner:马历新

Shoes use sterilization, deodorization, nourishment and bonding agent

InactiveCN1635041AAuxiliary curative effect is goodIncrease nutritionFootwearChloroprene adhesivesBeriberiTrace element

The invention discloses a shoes use sterilization, deodorization, nourishment and bonding agent, which comprises (by weight ratio) adhesives 35-45%, bactericidal agent 18-45%, nourishing agent 12-39%, trace element 1.4-2.2%, i.e. selenium 0.4-0.8%, zinc 1-1.4%, flavoring agent 1-1.4%. The binding agent is neoprene rubber, the bactericidal agent is benzene carboxylic acid, the nourishing agent is whole milk powder or skimmed milk powder, the flavoring agent is milk perfume compound.

Owner:FUJIAN SANSD RUBBER & PLASTIC

Galangal and tsaoko amomum fruit sunscreen emulsion and preparation method thereof

PendingCN112472629AWith sun protectionWith whiteningCosmetic preparationsToilet preparationsBiotechnologyAntioxidant

The invention discloses a galangal and tsaoko amomum fruit sunscreen emulsion. The sunscreen emulsion is prepared from the following raw materials in percentage by weight: 6%-8% of liquid oil, 3%-4% of solid oil, 2%-3.5% of a fat-soluble and / or water-soluble natural emulsifier, 3%-4% of a humectant, 2%-3% of a fat-soluble and / or water-soluble additive, 0.05%-0.12% of a chelating agent, 1%-2% of anatural antioxidant, 0.6%-1.2% of a fat-soluble and / or water-soluble natural preservative, 2%-5% of galangal essential oil and 1%-3% of tsaoko amomum fruit essential oil, and the balance being deionized water. According to the invention, galangal essential oil and tsaoko amomum fruit essential oil, which are extracted from natural medicinal fragrant plants and have sun-screening components are applied to the sun-screening emulsion, so that the green, natural and non-irritant sun-screening emulsion with the effects of whitening, moistening, sun-screening, repairing, diminishing inflammation, resisting bacteria, resisting oxidation and the like is prepared.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

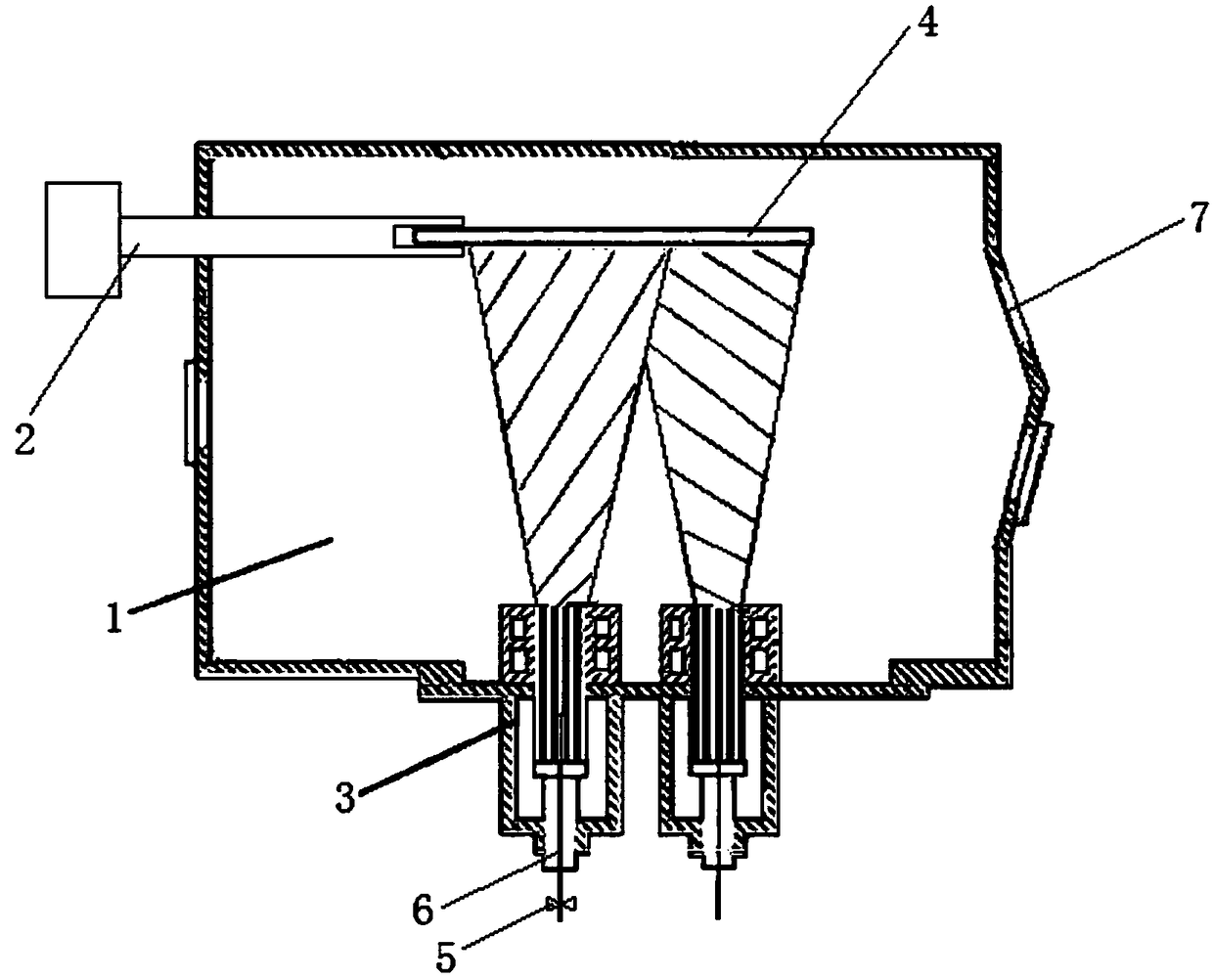

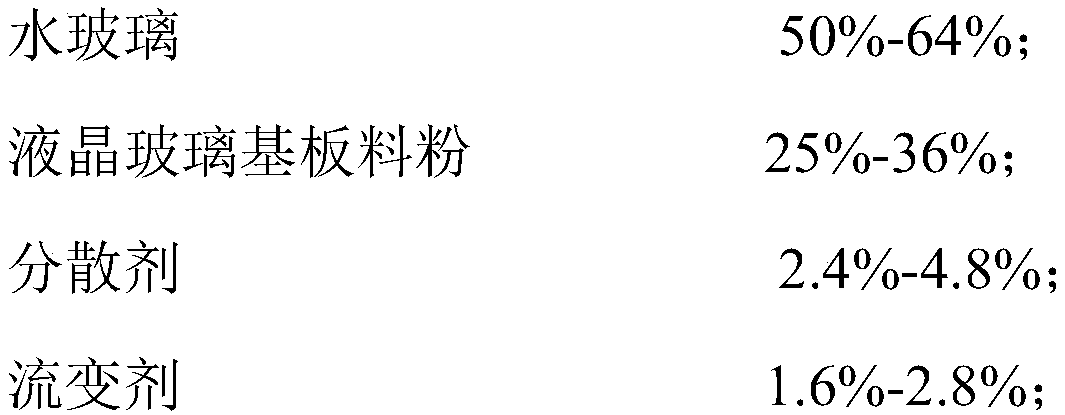

Surface coating slurry of platinum heating wire as well as preparation method and coating device of surface coating slurry

The invention provides surface coating slurry of a platinum heating wire as well as a preparation method and a coating device of the surface coating slurry. The coating slurry comprises 50% to 64% ofwater glass, 25% to 36% of liquid crystal glass substrate powder, 2.4% to 4.8% of a dispersant, 1.6% to 2.8% of a rheological agent and 5% to 15% of a water glass curing agent; the raw materials are mixed, a pH value is adjusted to 10-11, and ball-milling is performed to obtain the surface coating slurry. The coating device comprises a chamber, a rotating mechanism and a crucible, wherein the rotating mechanism is disposed on a side wall of the chamber, fixedly connected with one end of the platinum heating wire and used for driving the platinum heating wire to rotate around the axial direction; the crucible is disposed at the bottom of the chamber, and is opposite to the platinum heating wire and used for holding the surface coating slurry; and a high pressure gas flow tube is inserted into the bottom of the crucible. The surface coating slurry provided by the invention is sprayed by adopting stamping, and the coating has good bonding performance with the platinum heating wire, is noteasy to fall off, and can effectively prevent the platinum heating wire from being oxidized and volatilized at high temperature.

Owner:IRICO DISPLAY DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com