Patents

Literature

155results about How to "Wet evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machine

ActiveCN102121186AIncreases chances of spraying wash waterUniform supplyOther washing machinesWashing machine with receptaclesWash waterElectric motor

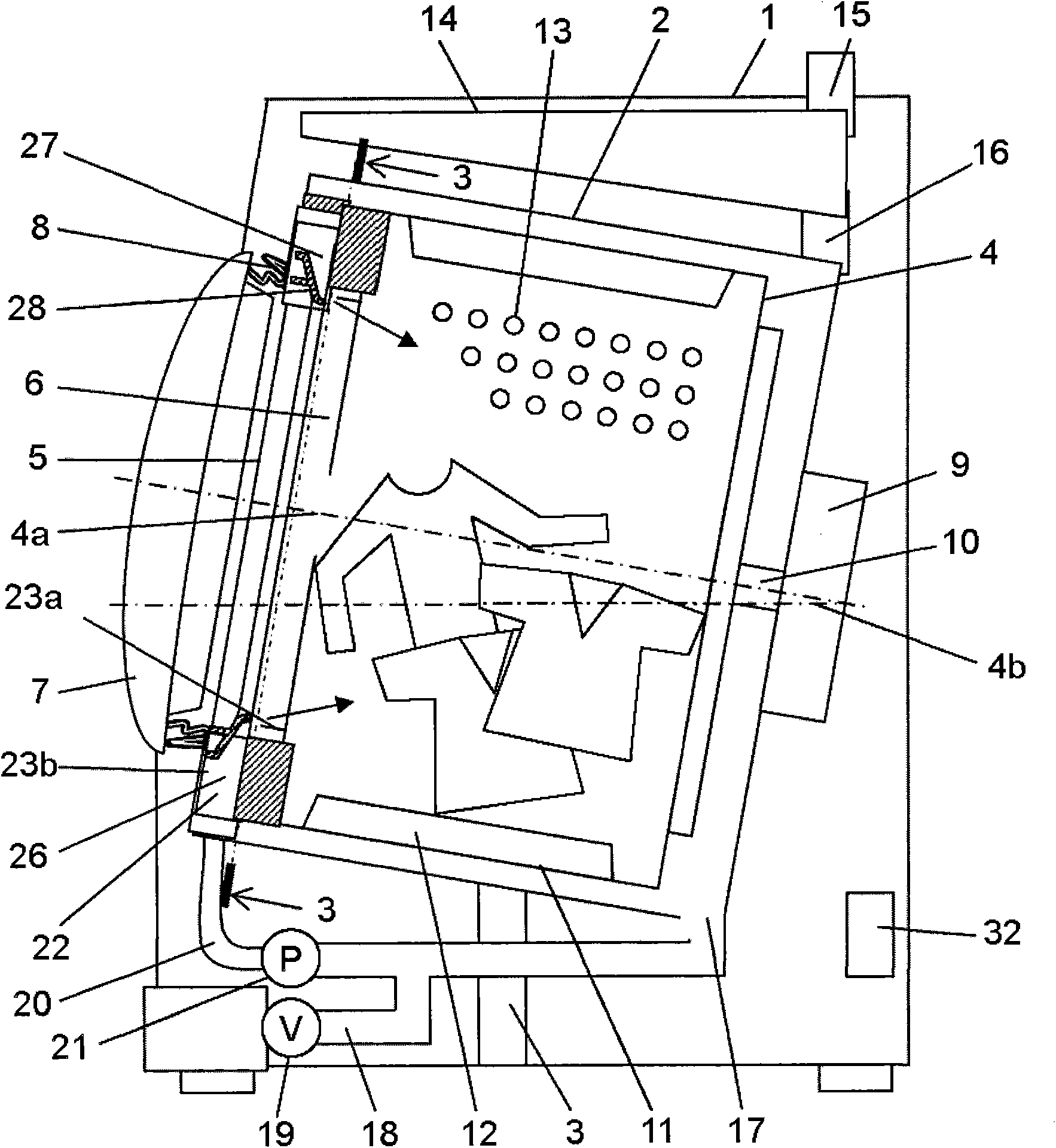

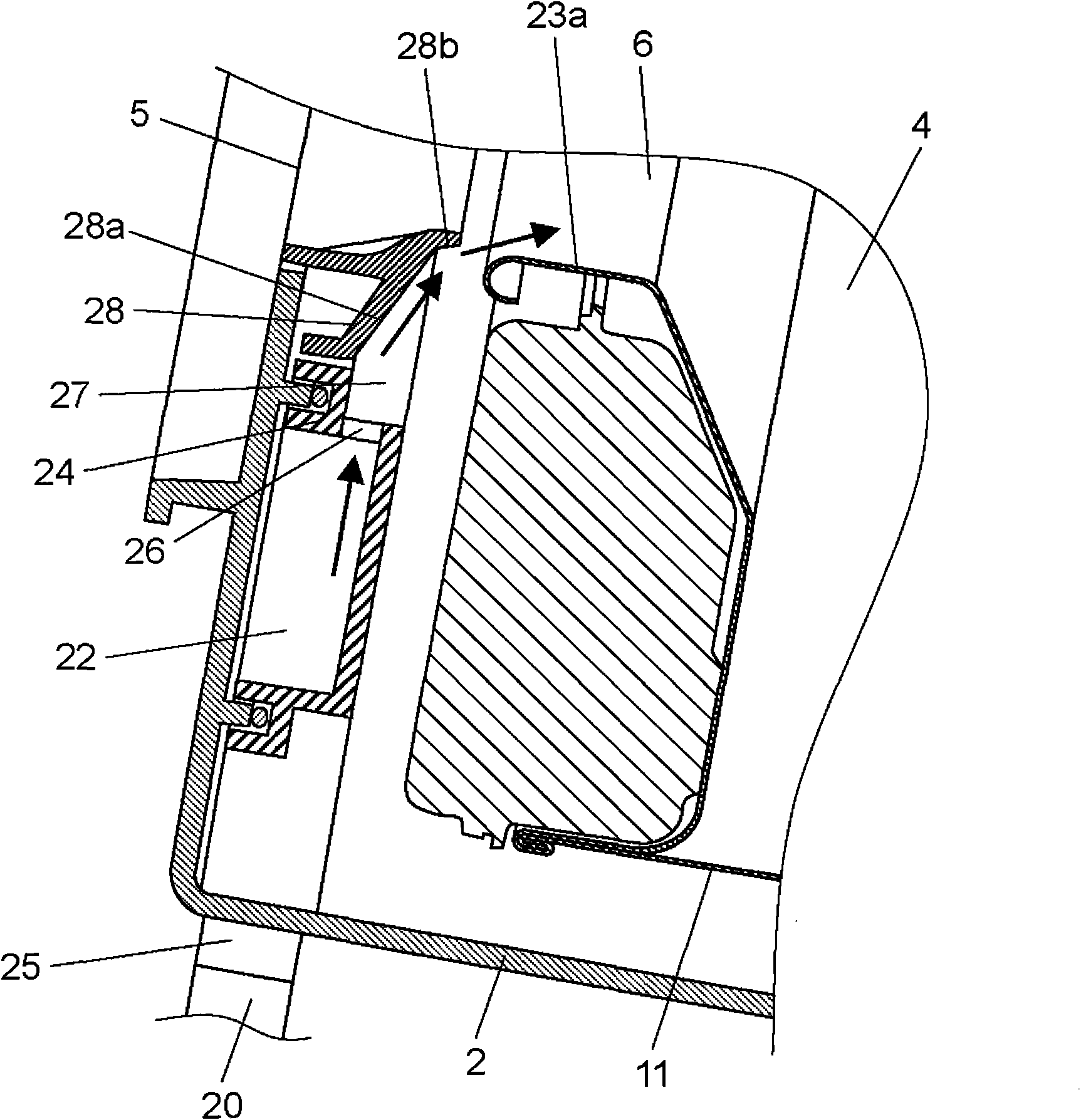

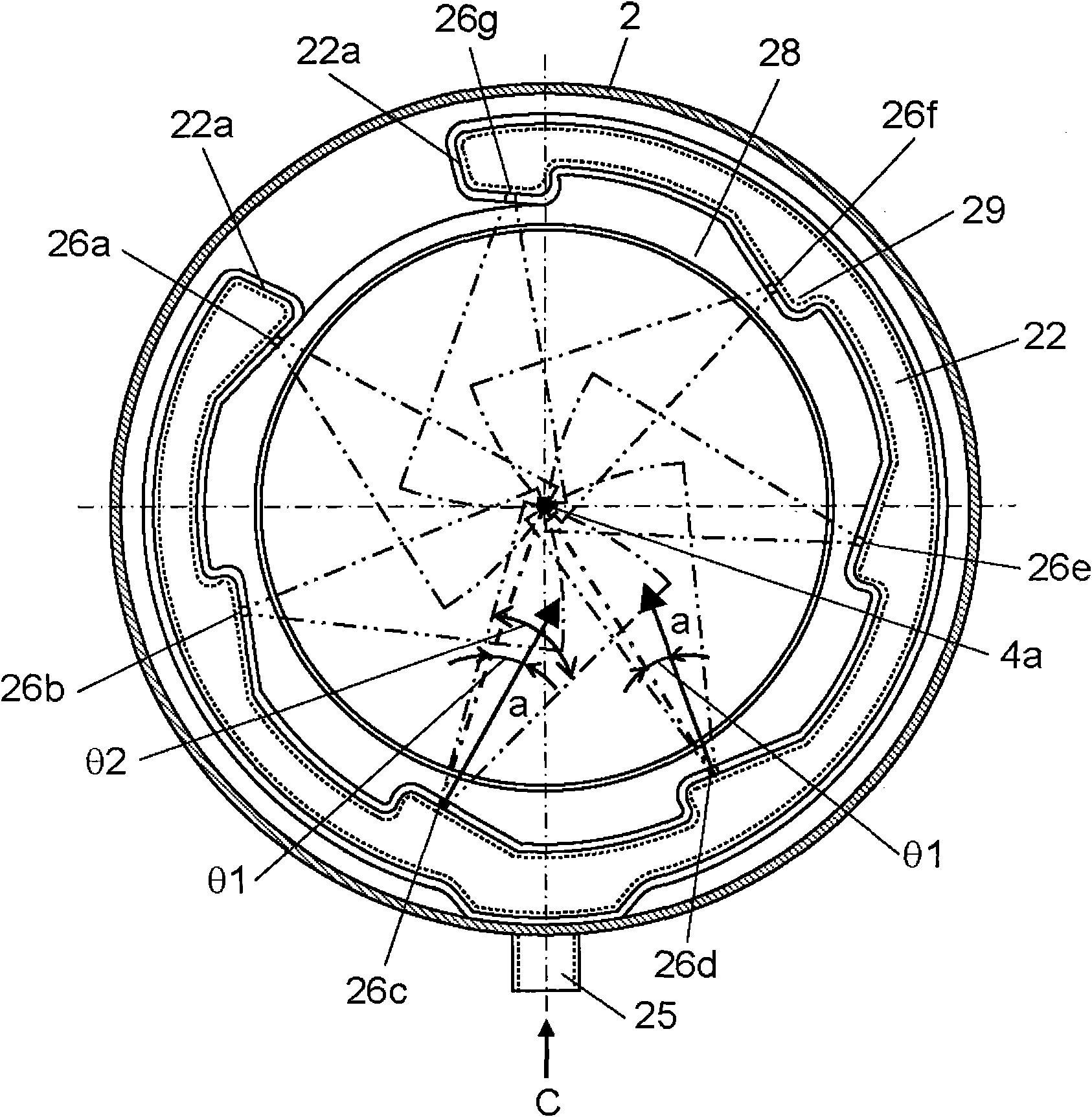

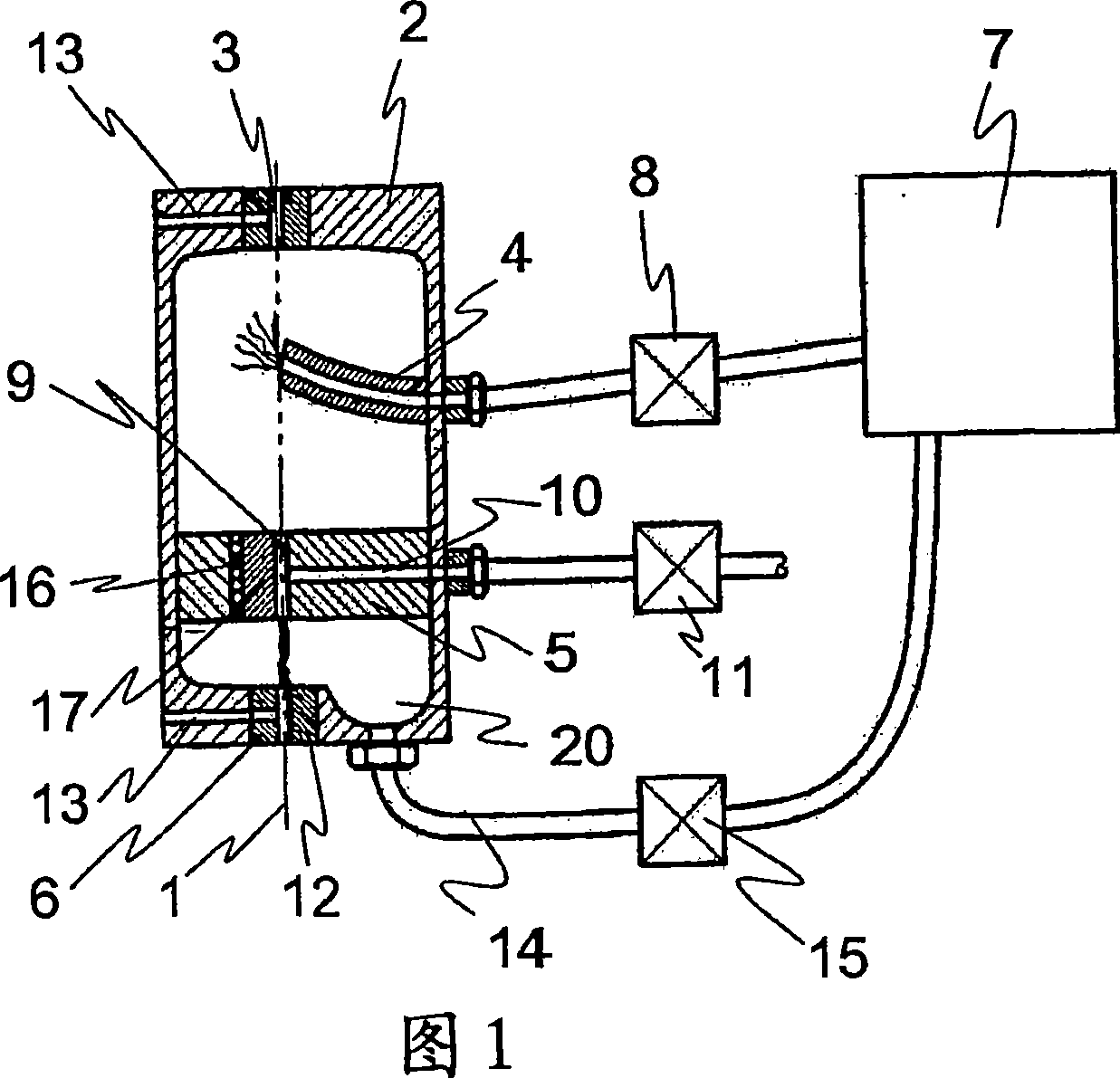

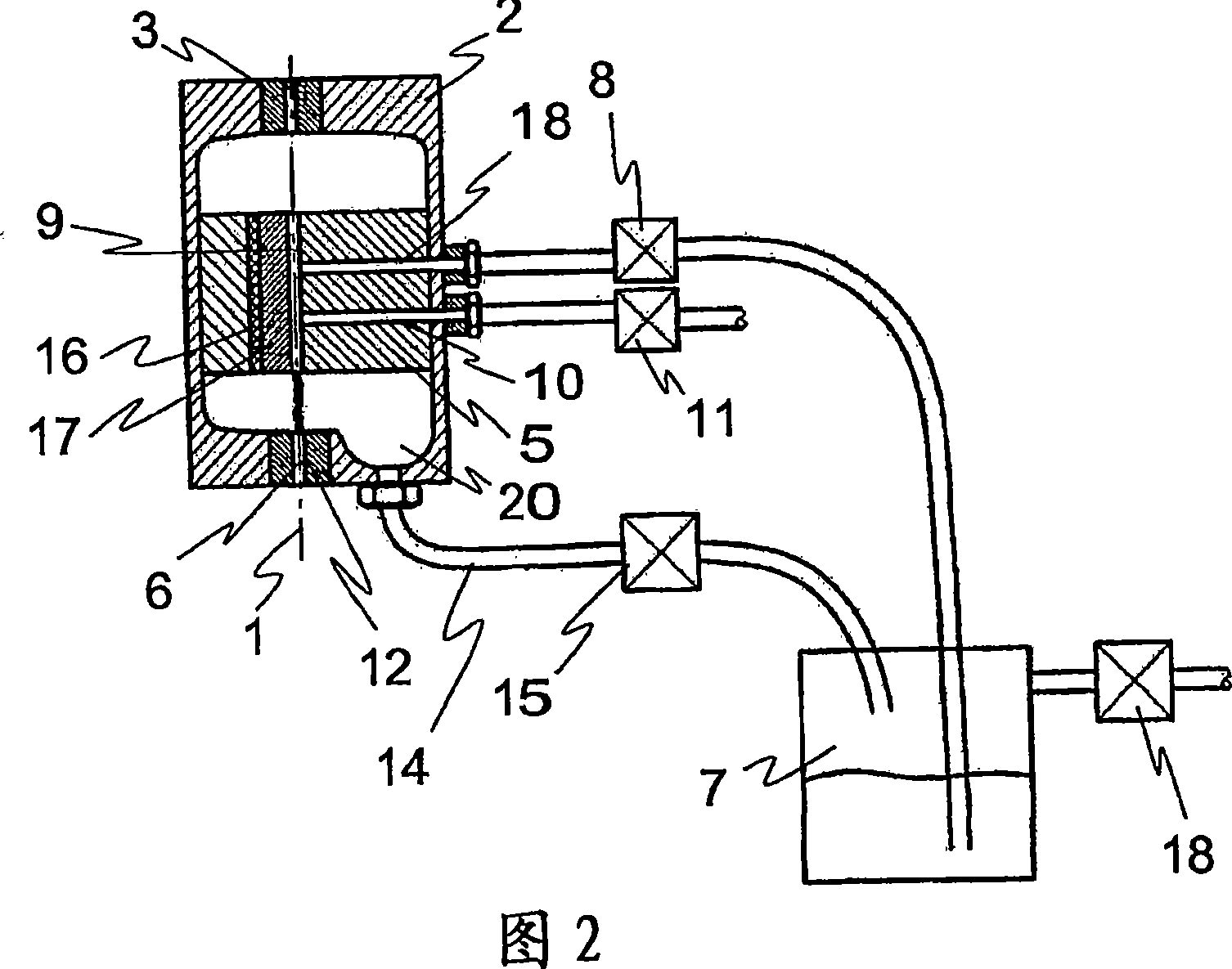

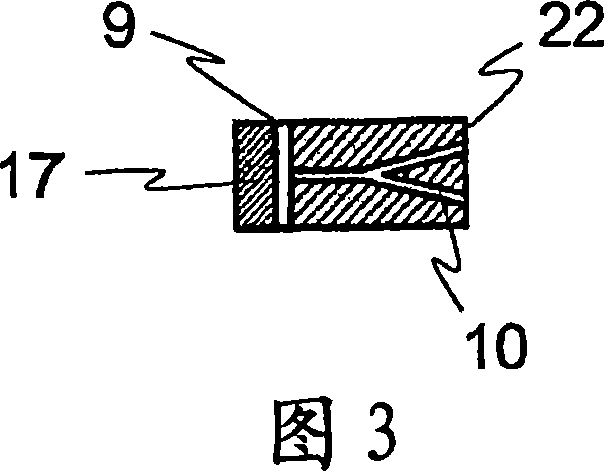

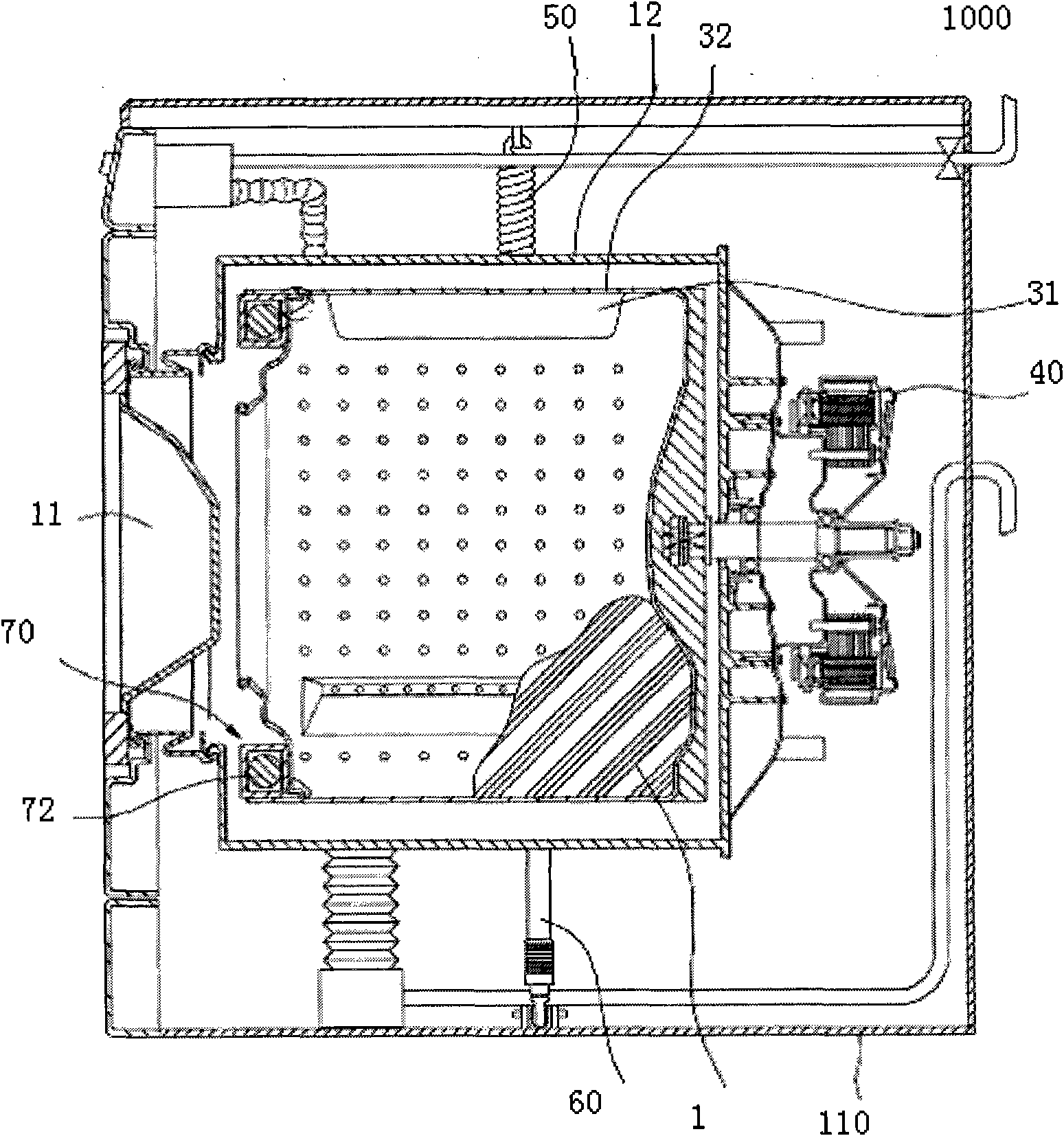

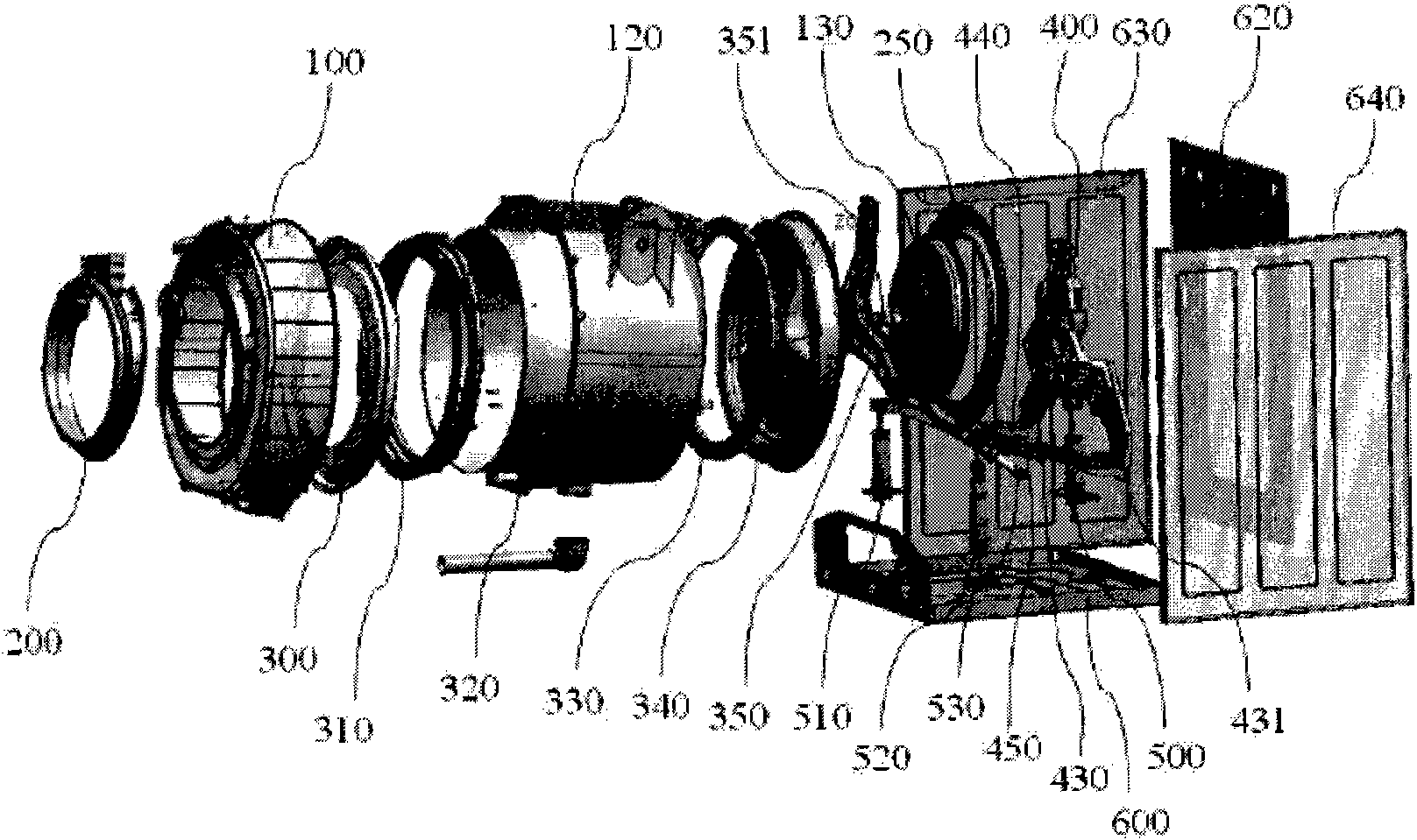

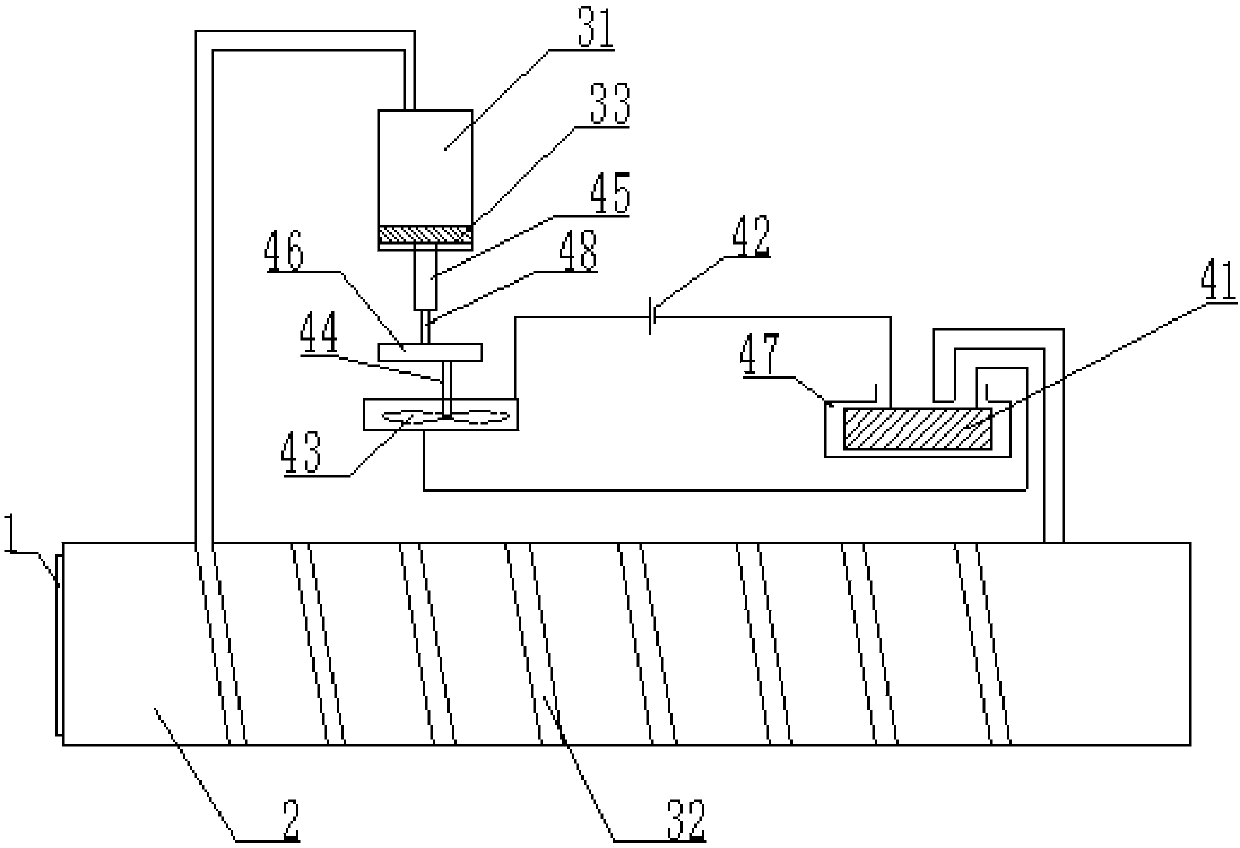

A drum-type washing machine includes a water tub for storing wash water, a rotary drum placed rotatably in the water tub and having an opening at the front, a motor for driving the rotary drum, a water circulating path for circulating the wash water stored in the water tub to the drum, a pump for conveying the wash water stored in the water tub to the water circulating path, multiple nozzles for jetting the wash water, conveyed to the nozzle water path by the pump, into the rotary drum, and a nozzle water path formed around a front face of the water tub for conveying the wash water from the water circulating path to the nozzles.

Owner:PANASONIC CORP

Dental adhesive composition

InactiveUS20060069181A1Optimized rheological behaviorEasy to handleImpression capsMedical preparationsAdhesiveAcid derivative

The present invention relates to a dental composition with optimized viscosity and / or rheological behavior. The present invention provides a dental composition comprising: (d) at least one carboxylic acid functional polymer, (e) at least one acid derivative with stronger acidity than the carboxylic acid functional polymer (a), substituted with at least one polymerizable ethylenically unsaturated group, (f) 0.1 to 10 weight % of water, wherein the carboxylic acid functional polymer (a) and the acid derivative (b) are present at least in an amount effective that the dental composition exhibit shear thinning and / or a viscosity from 1.0 to 20 Pa·s, when measured with a plate / plate geometry and at a shear rate of 0.5 to 1 s−1. It further relates to the use of this dental composition and to a method for preparing a dental adhesive.

Owner:3M ESPE

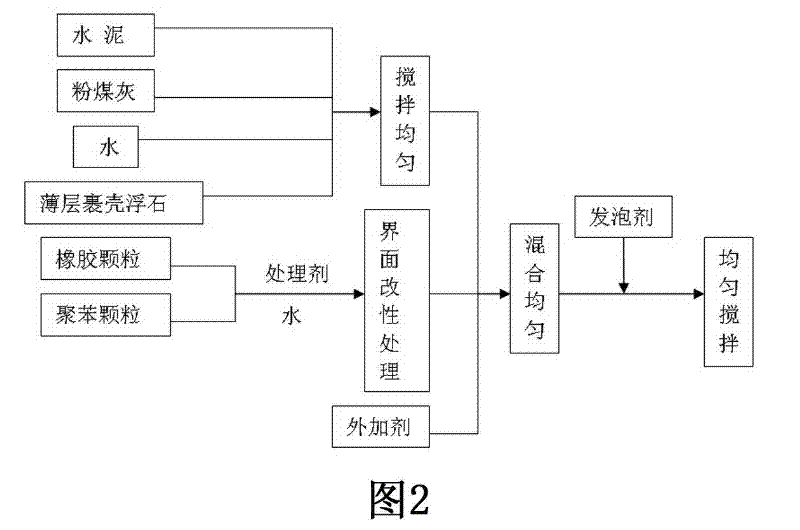

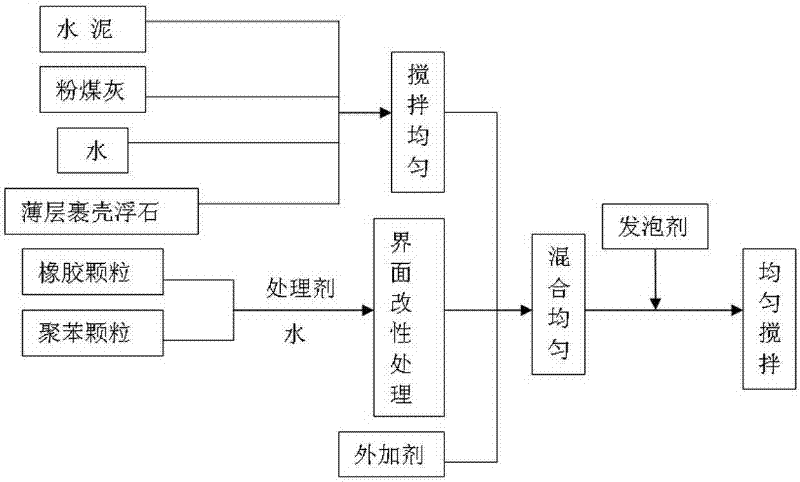

Multi-phase combined lightweight aggregate concrete and preparation method thereof

ActiveCN102206096ALow densityImprove toughnessSolid waste managementCeramicwareFiberThermal insulation

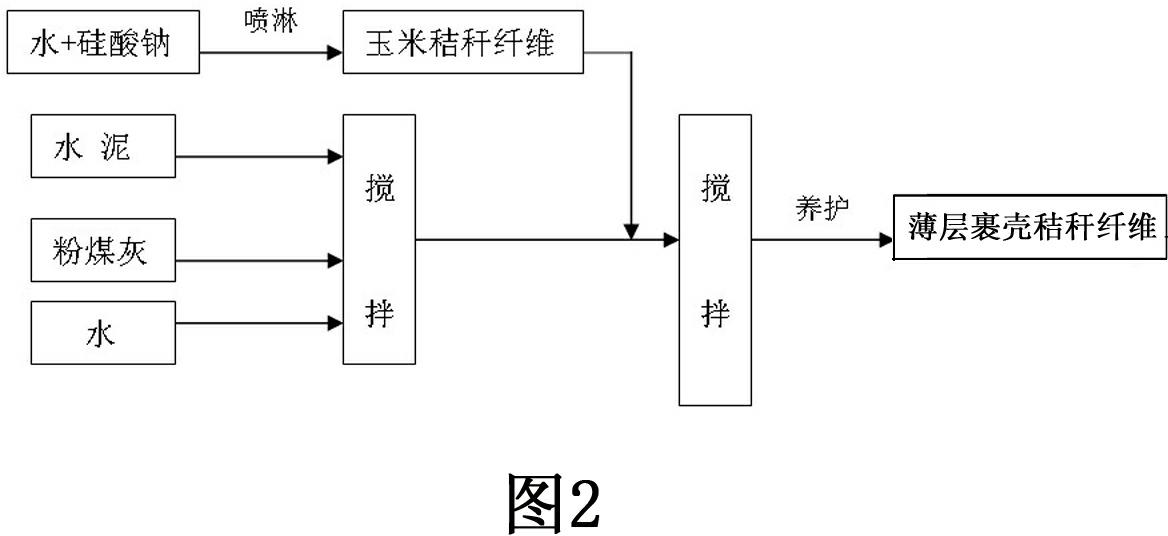

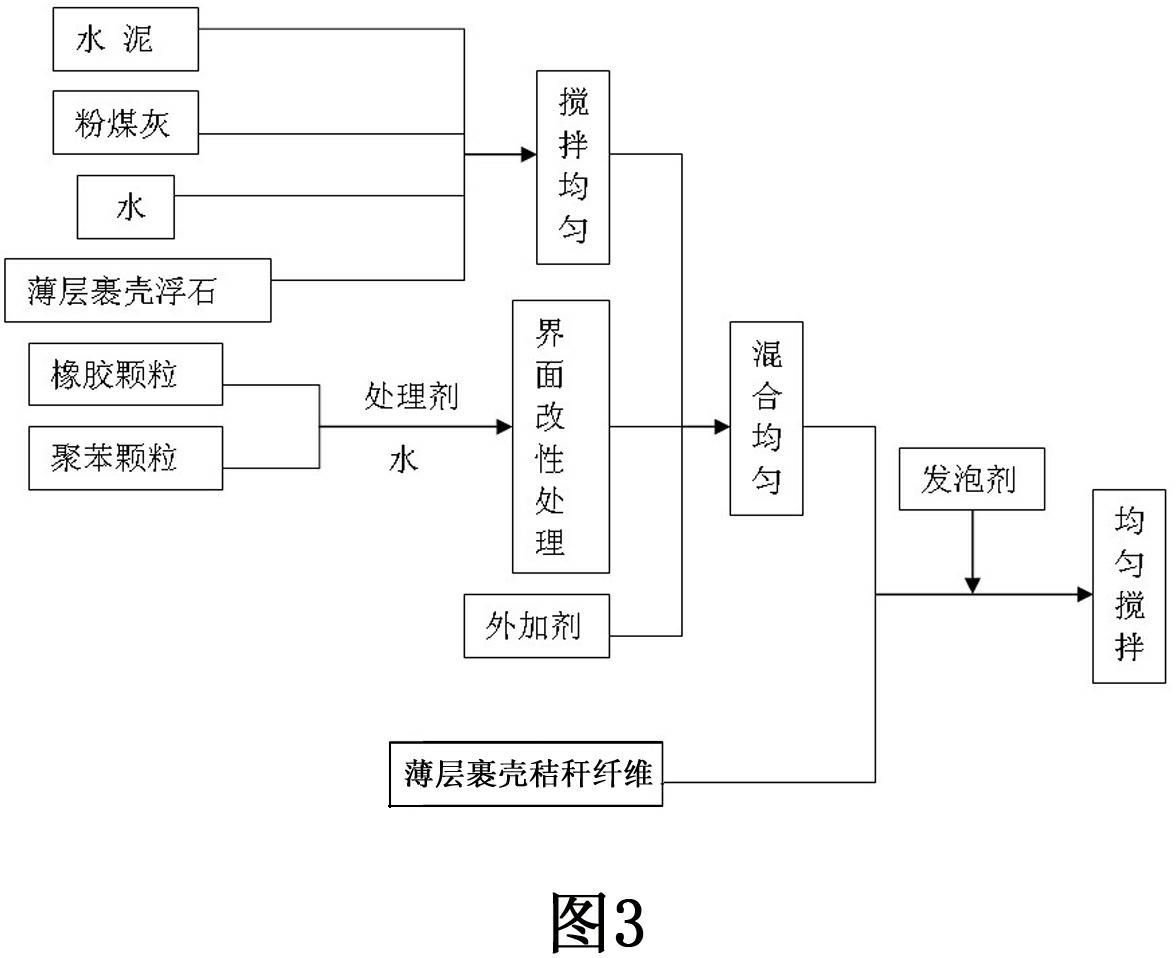

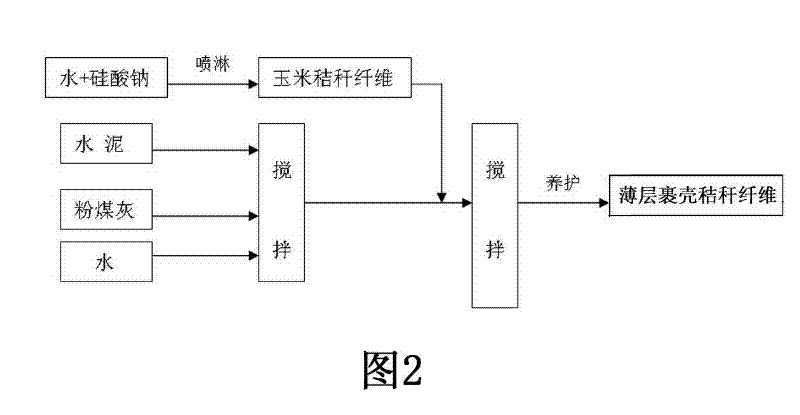

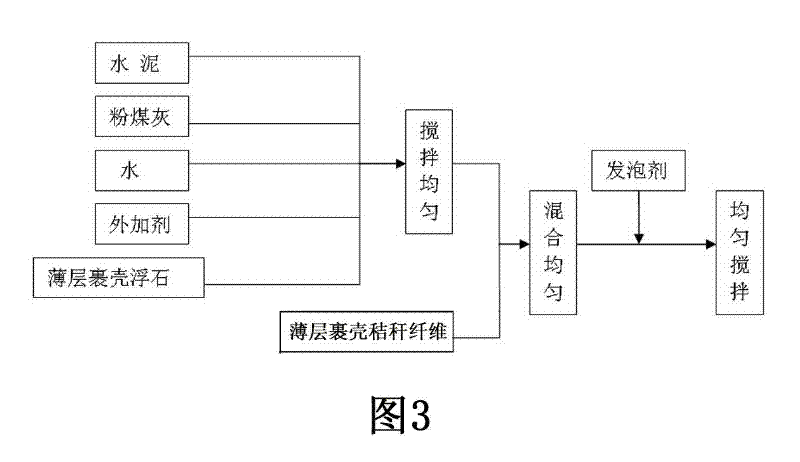

The invention discloses multi-phase combined lightweight aggregate concrete and a preparation method thereof. The multi-phase combined lightweight aggregate concrete is prepared from the following raw materials in part by weight: 1 part of cement, 0.40 to 0.50 part of fly ash, 1.836 to 2.219 parts of pumice sand, 0.028 to 0.043 part of corn straw fibers, 0.006 to 0.008 part of polyphenyl particles, 0.23 to 0.33 parts of rubber particles, 0.010 to 0.015 part of additive, 0.005 to 0.007 part of foaming agent, and 0.50 to 0.55 parts of water. The preparation method comprises the following steps:1, preparing thin-coating pumice sand and thin-coating straw fibers; 2, performing interference treatment of polyphenyl particles and rubber particles; 3, uniformly stirring the cement, fly ash, water, additive and thin-coating pumice sand; and 4, adding the polyphenyl particles, rubber particles and thin-coating straw fibers in turn, and continuing to stir. When the method is used, the mechanical performance of the lightweight aggregate concrete can be improved effectively, the thermal-insulation and heat-preservation performance is enhanced, and production cost is lowered.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

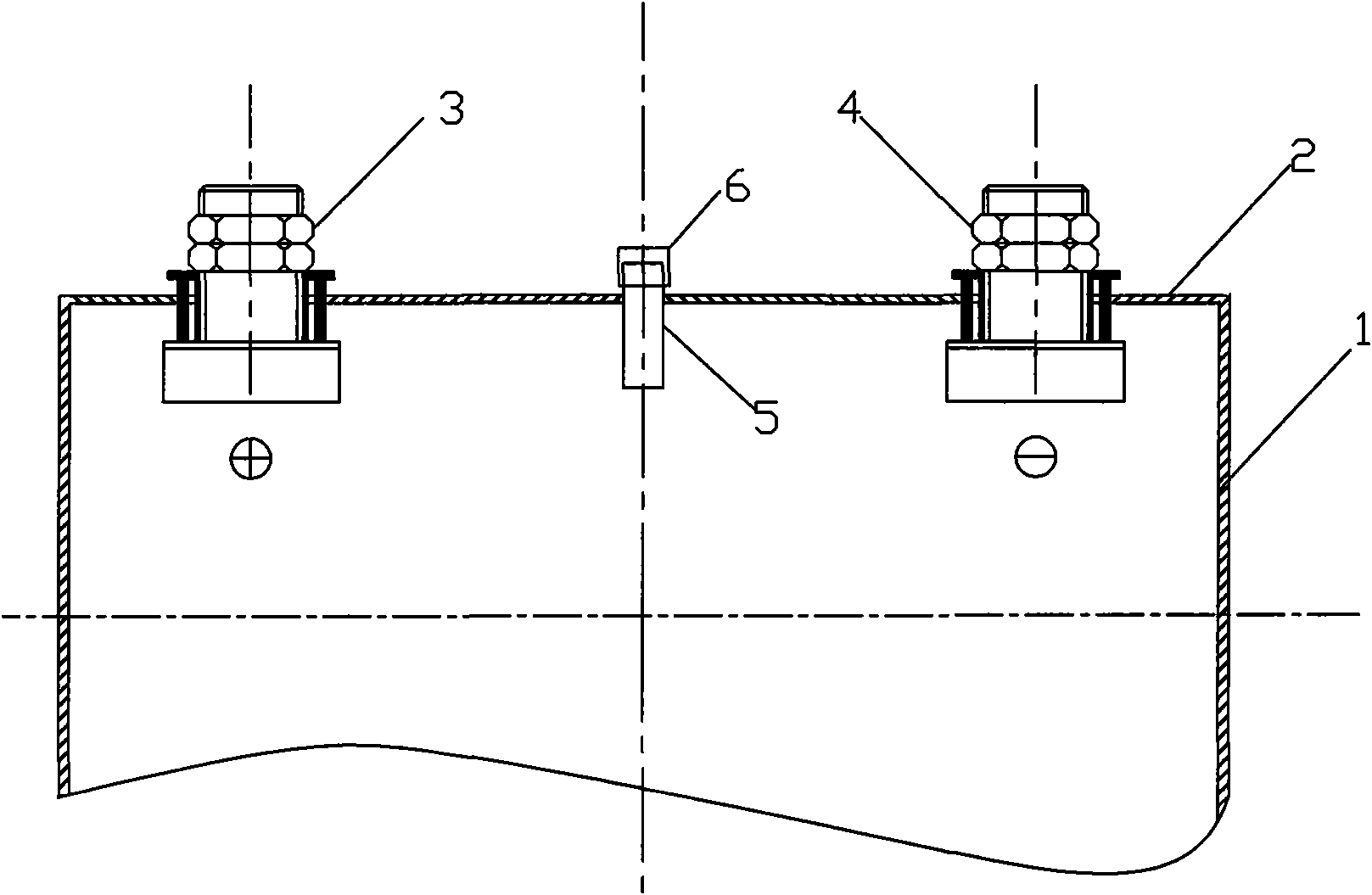

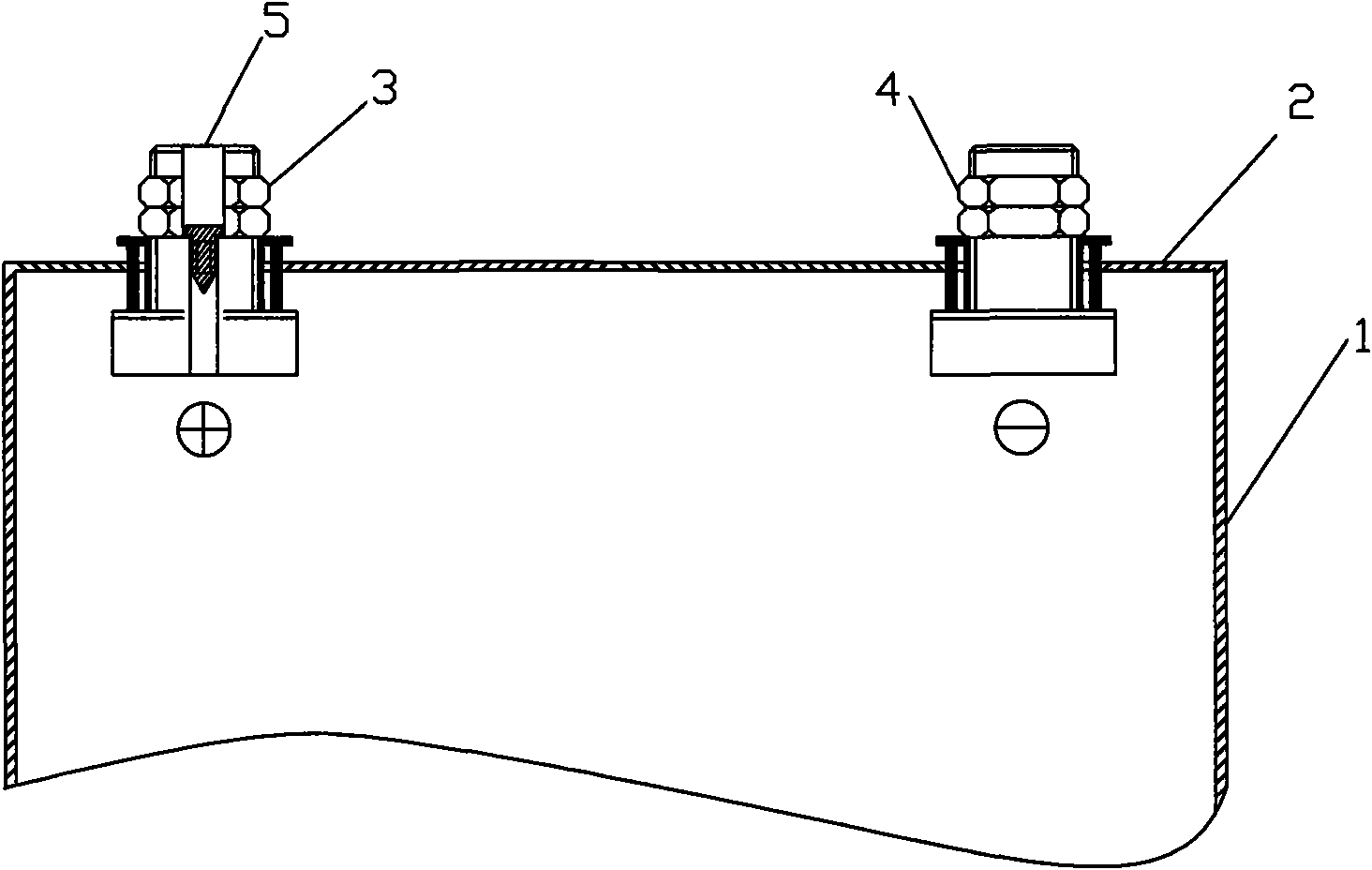

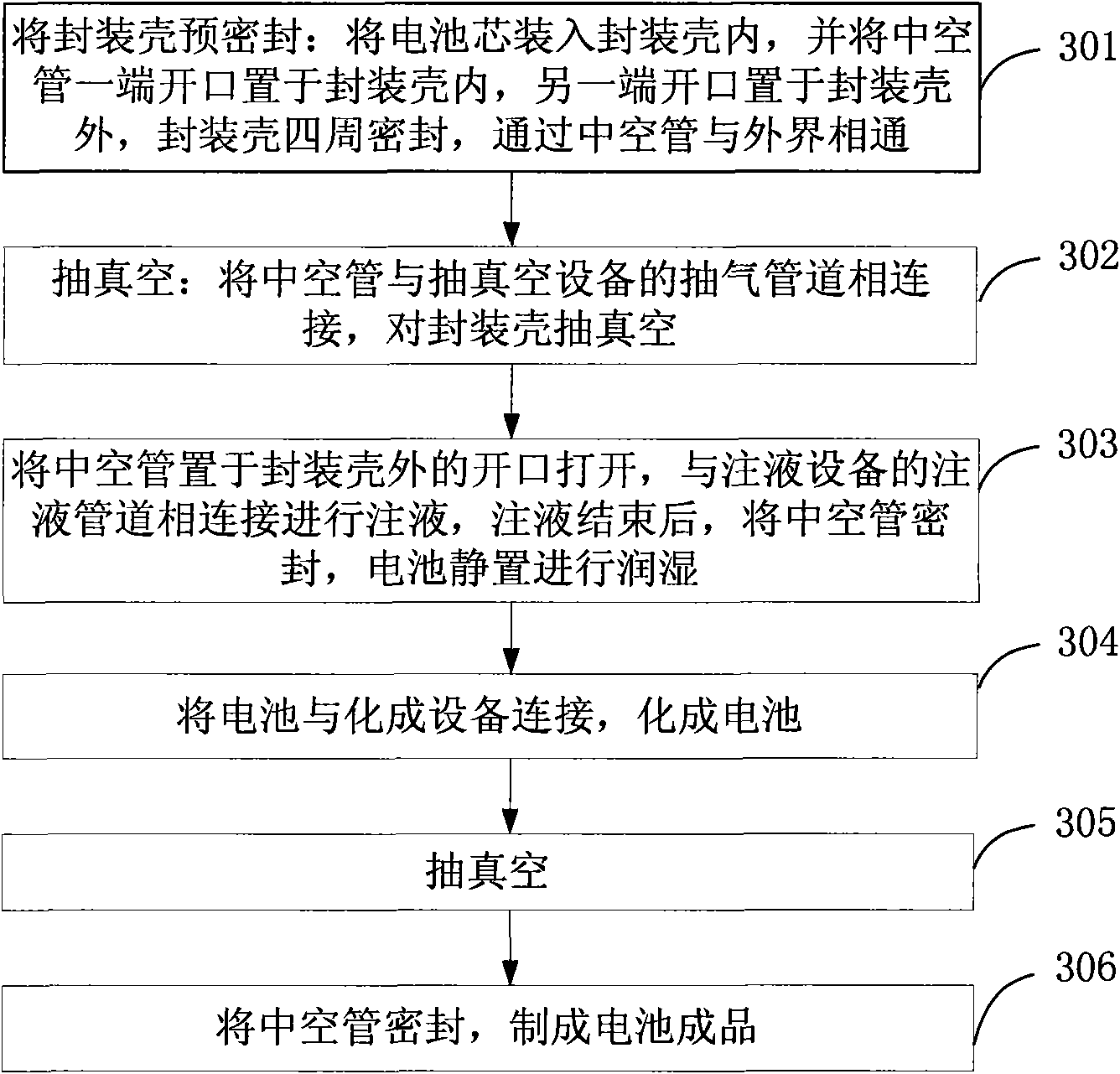

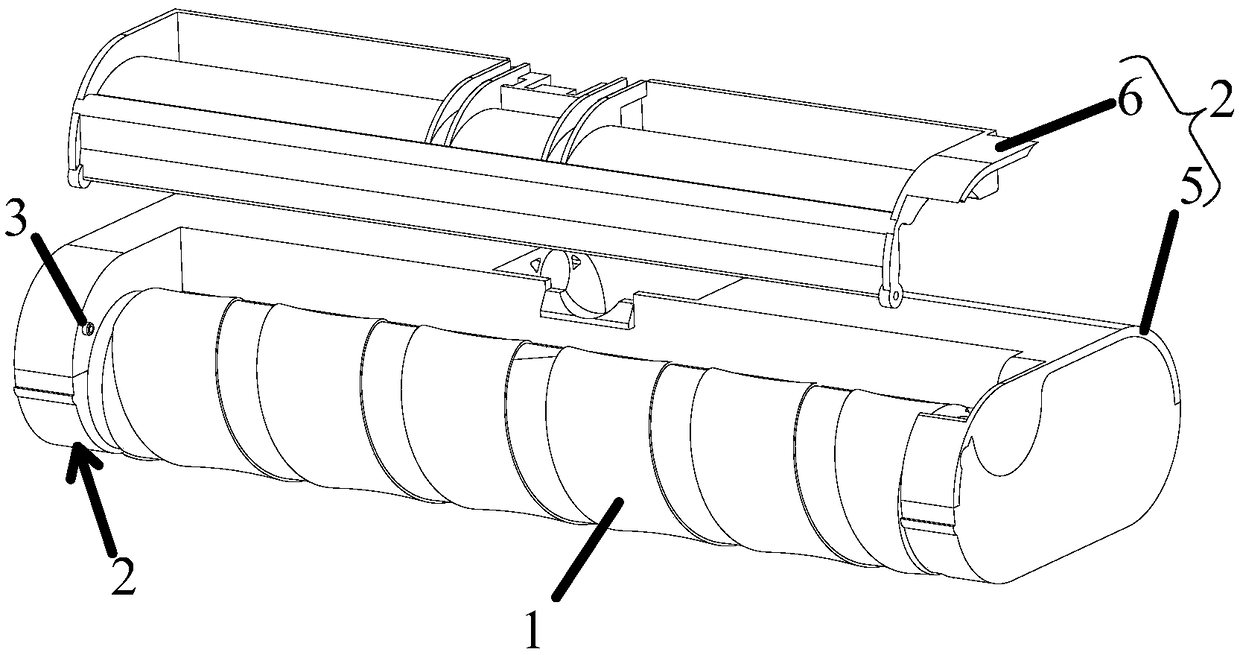

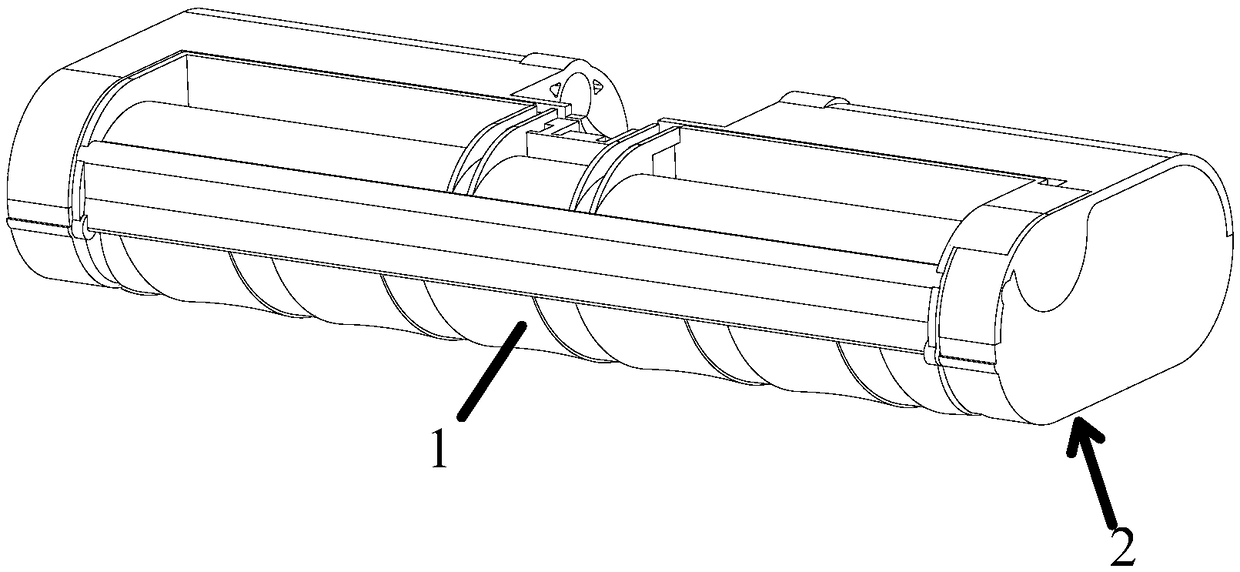

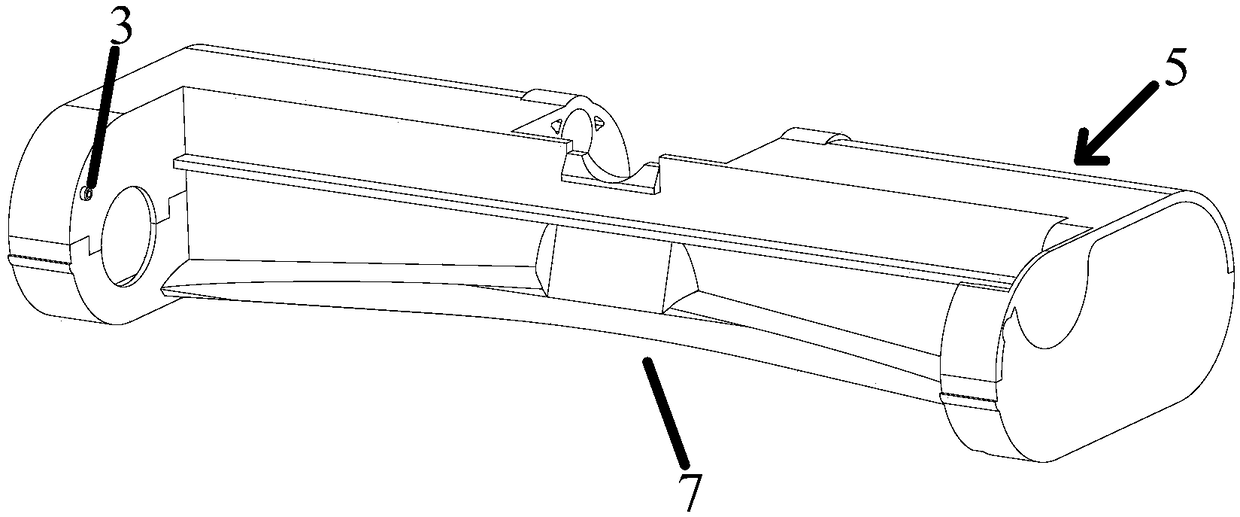

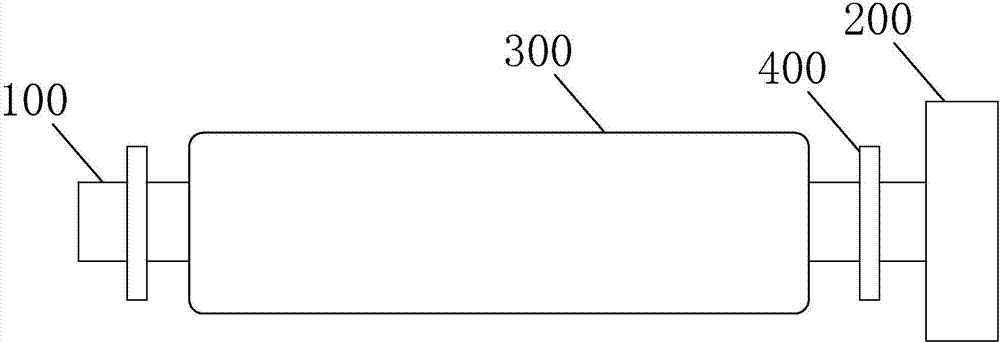

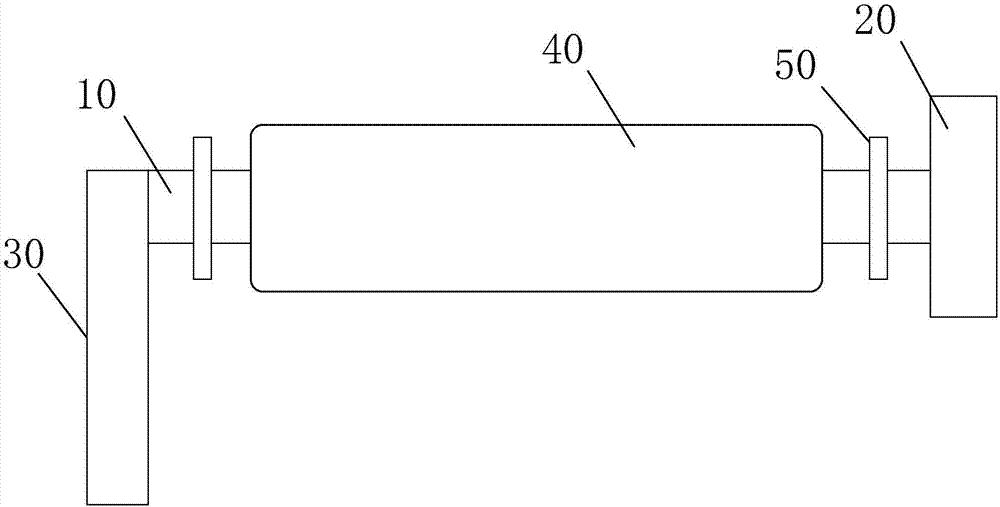

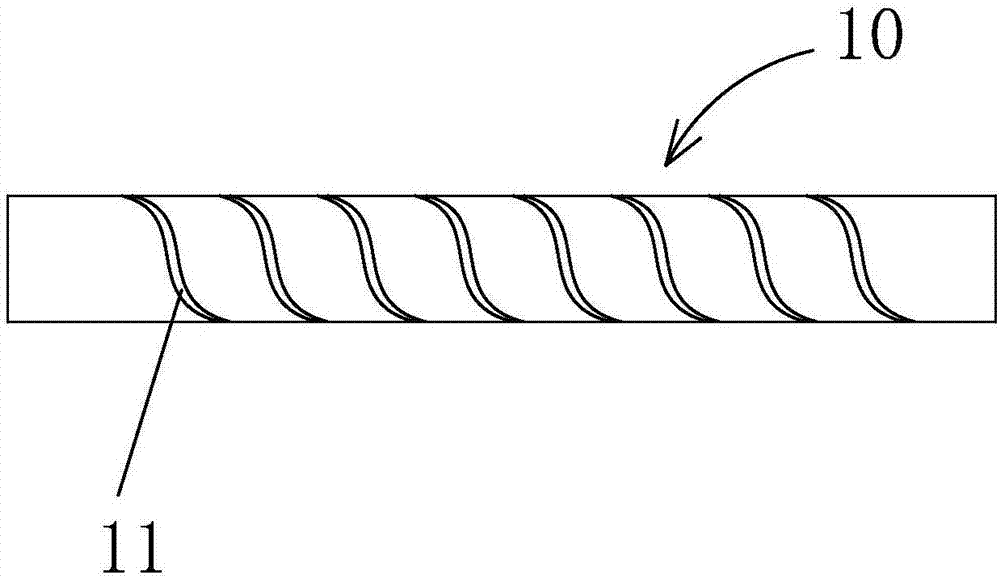

Production method and encapsulating shell of lithium ion battery

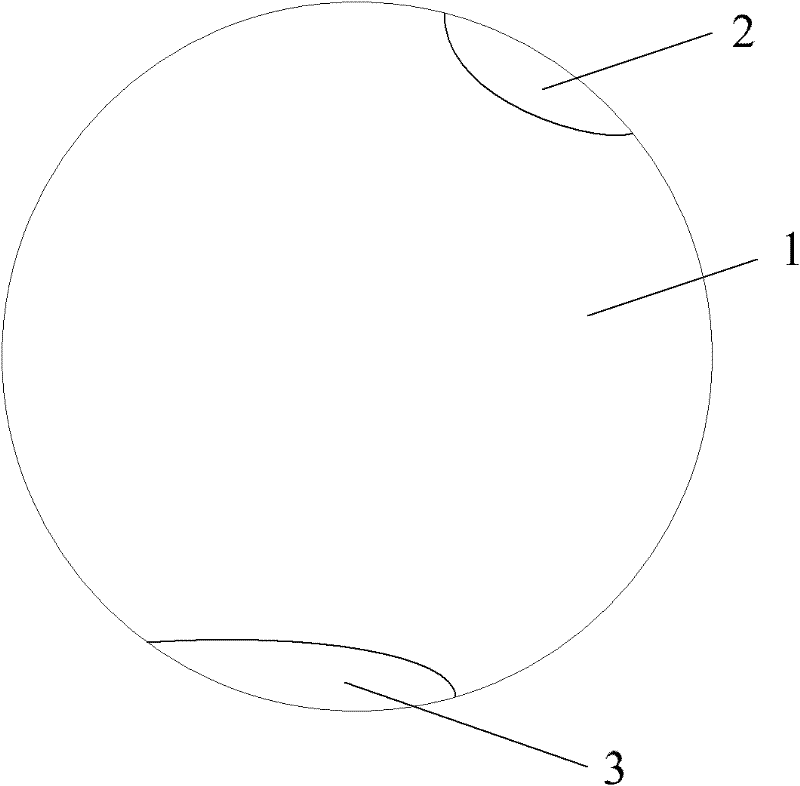

InactiveCN101552358AEasy to makeImprove performanceFinal product manufactureSmall-sized cells cases/jacketsBiochemical engineeringLithium-ion battery

The invention relates to a production method of a lithium ion battery, which comprises the following steps: a battery cell is installed in an encapsulating shell and an opening at one end of a hollow tube is arranged in the encapsulating shell while an opening at the other end thereof is arranged outside the encapsulating shell which is sealed at the periphery and communicated with the outside through the hollow tube; vacuumization: the encapsulating shell is connected with vacuumization equipment for vacuumizing through the hollow tube; electrolyte is added and set aside; formation and vacuumization; the battery is sealed to obtain the finished product of the lithium ion battery. The invention has simple production process, does not require such expensive equipment with low universality as filling equipment, moistening equipment and the like, and can avoid the corrosion of a battery shell by the electrolyte and improve battery performance.

Owner:林道勇 +1

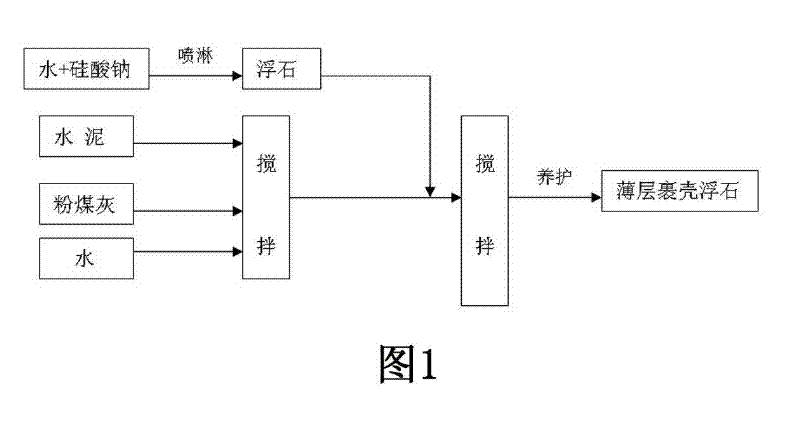

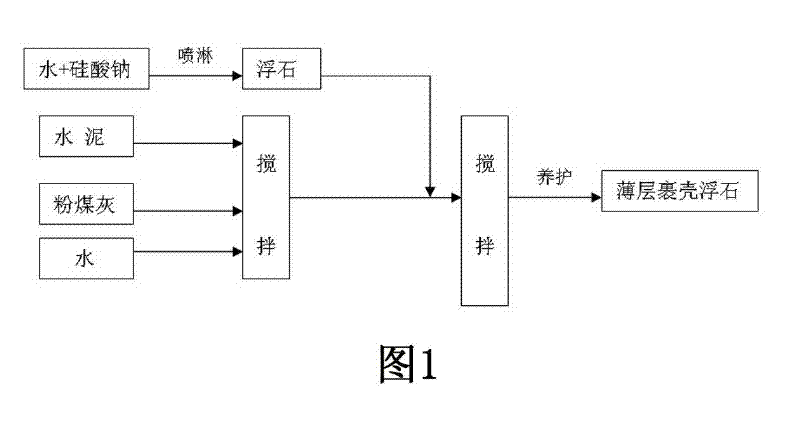

Polystyrene particle-rubber particle-pumice stone composite lightweight aggregate concrete and preparation method thereof

ActiveCN102219451AImprove impact resistanceImprove seismic performanceSolid waste managementCeramicwarePumice dustFoaming agent

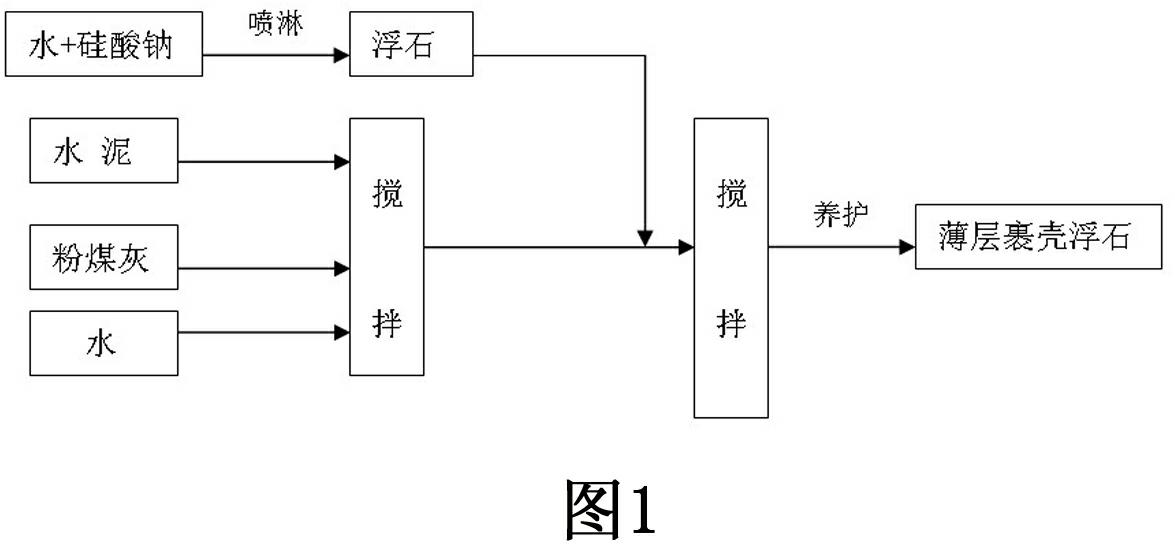

The invention discloses a method for preparing polystyrene particle-rubber particle-pumice stone composite lightweight aggregate concrete. The polystyrene particle-rubber particle-pumice stone composite lightweight aggregate concrete comprises the following raw materials in parts by weight: 1 part of cement, 0.40-0.50 part of coal ash, 0.80-1.20 parts of thin-layer cladded pumice sand, polystyrene particles and rubber particles, 0.010-0.015 part of admixture, 0.005-0.007 part of foaming agent, and 0.50-0.55 part of water. The preparation method comprises the following steps of: 1, preparing the thin-layer cladded pumice sand; 2, carrying out interface treatment on the polystyrene particles and the rubber particles; 3, adding the cement, the coal ash, the water, the admixture and the thin-layer cladded pumice sand to a stirring machine to be stirred according to proportions; 4, adding the polystyrene particles and the rubber particles subjected to the interface treatment in the stirring machine to be stirred continuously; and 5, after frothing, pouring the forthed foaming agent into the stirred mixture and uniformly stirring. According to the method disclosed by the invention, the mechanical property of the lightweight aggregate concrete is effectively improved; the thermal insulation performance is improved; and the production cost is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Device and method for applying a preparation to threads

InactiveCN1969069AWill not polluteUniform atomizationTextile treatment containersFilament/thread formingEngineeringBiomedical engineering

Owner:天科部件有限公司

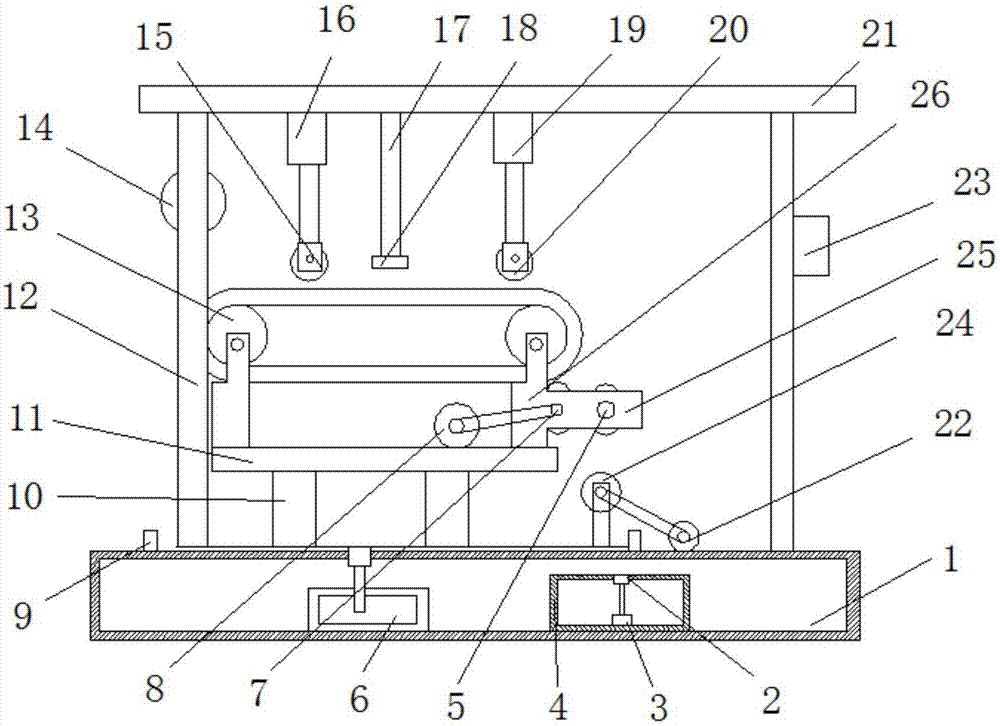

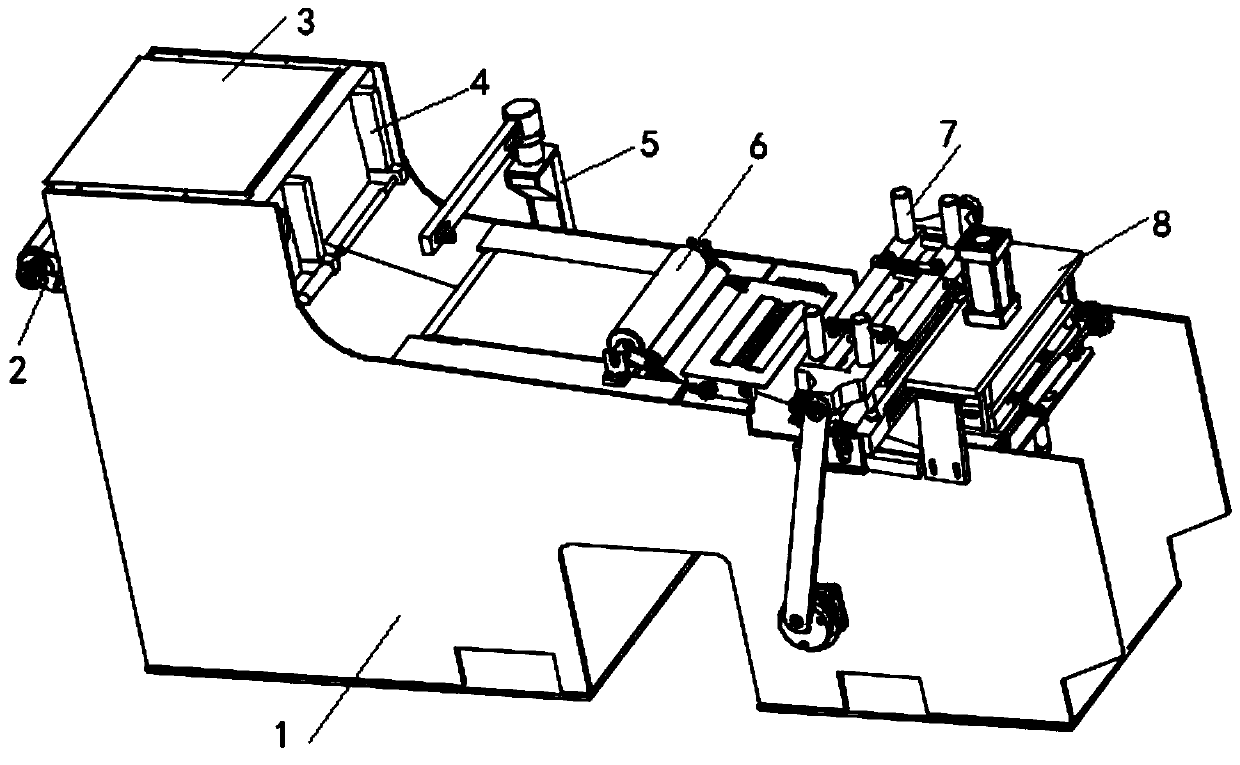

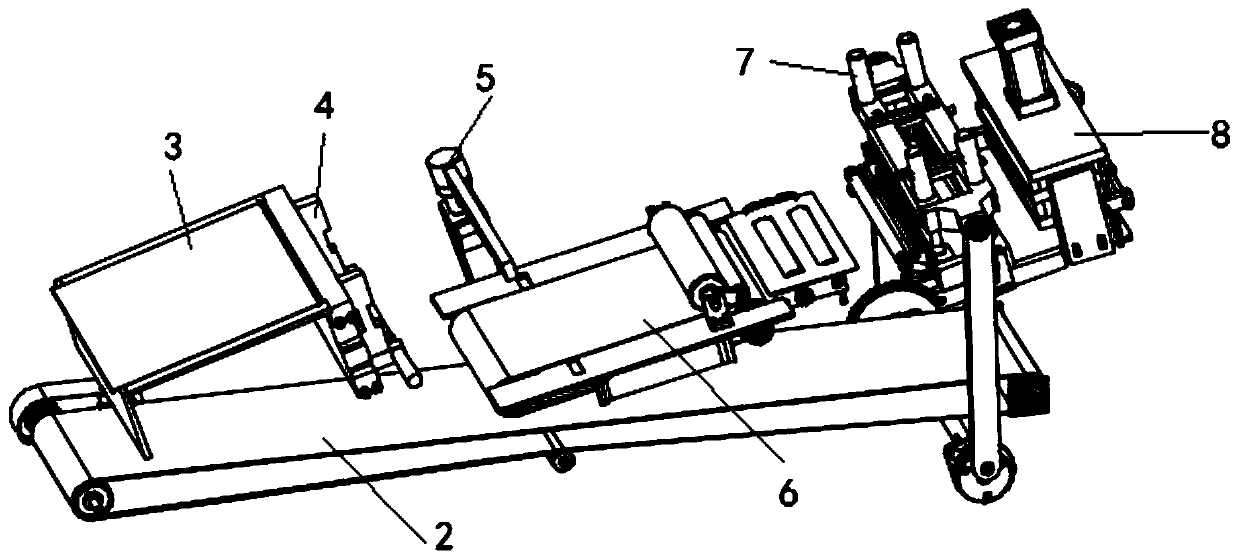

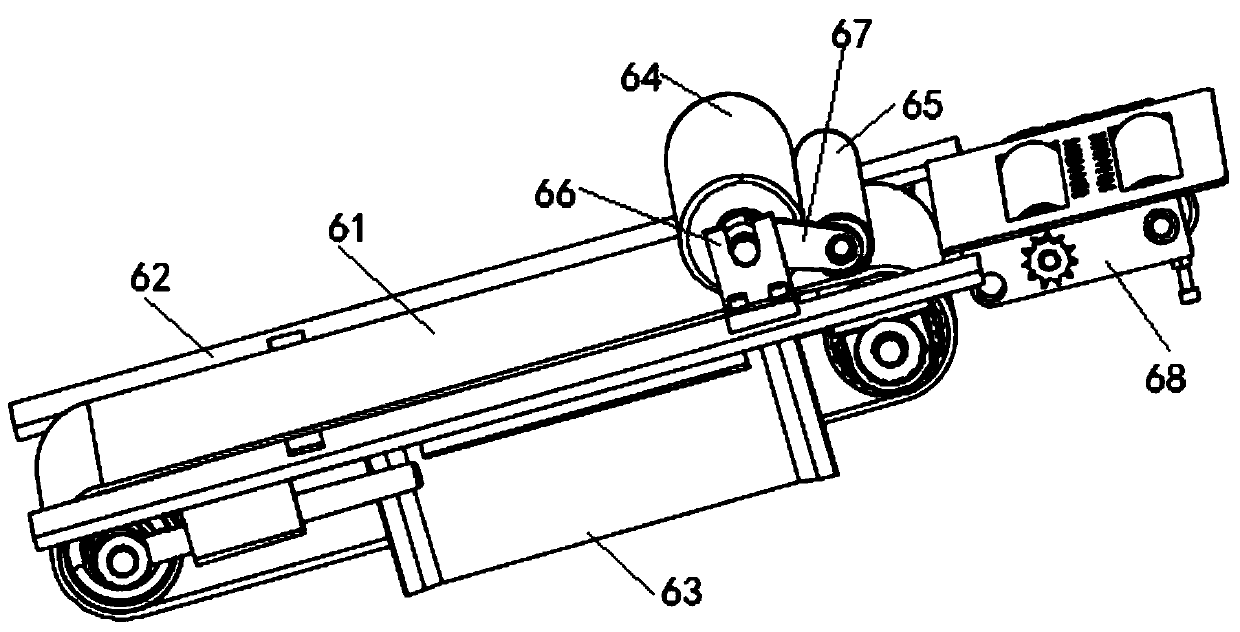

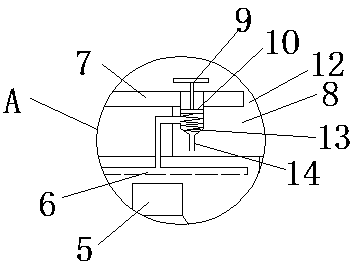

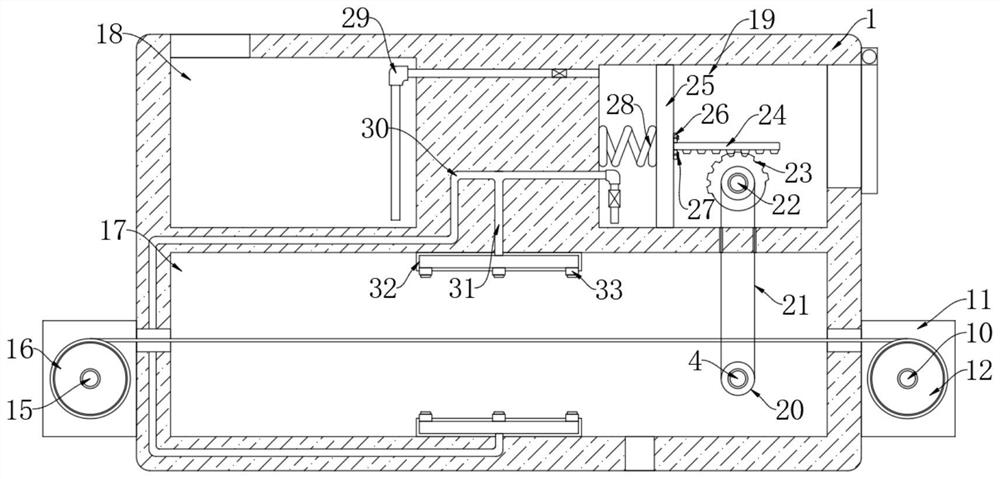

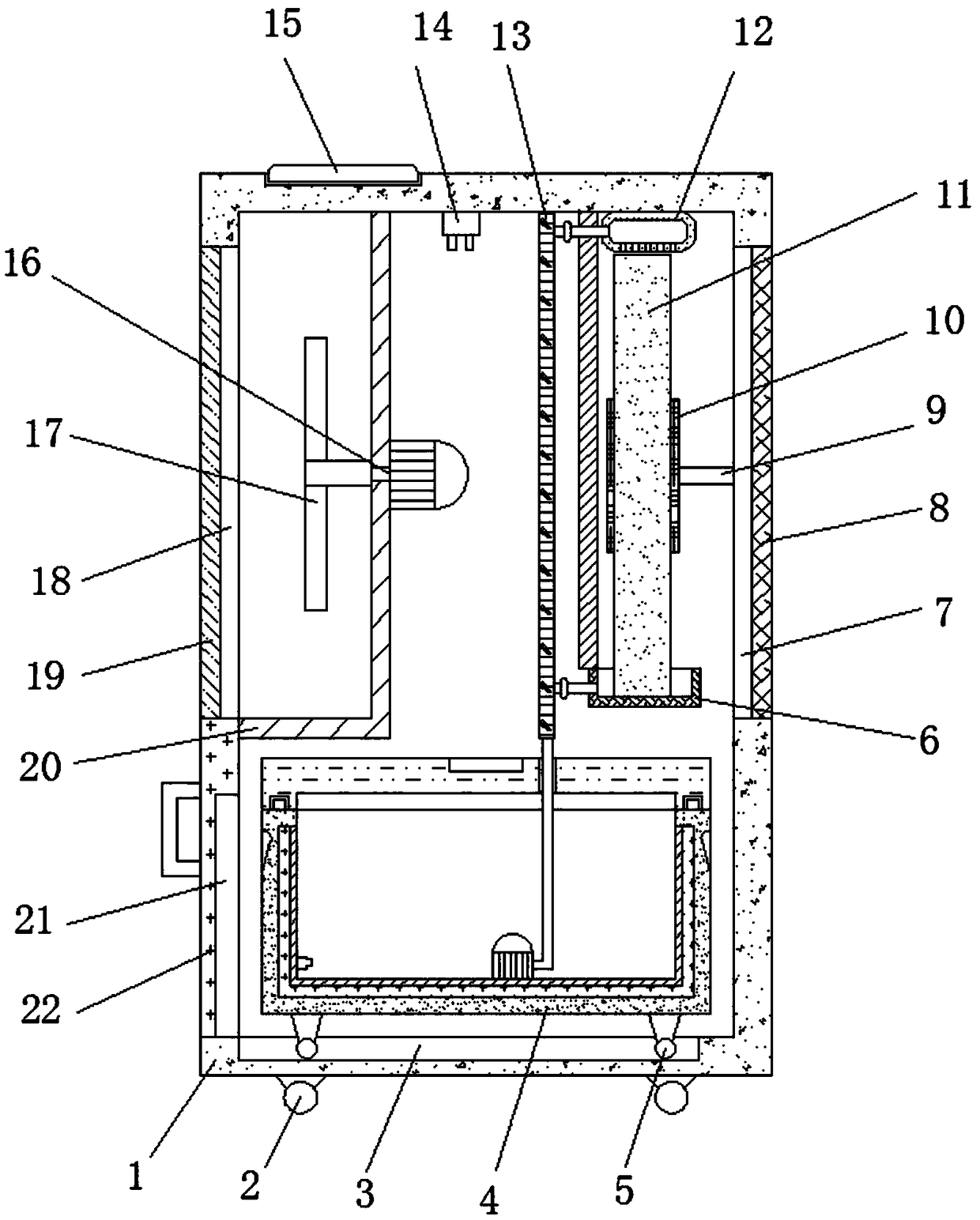

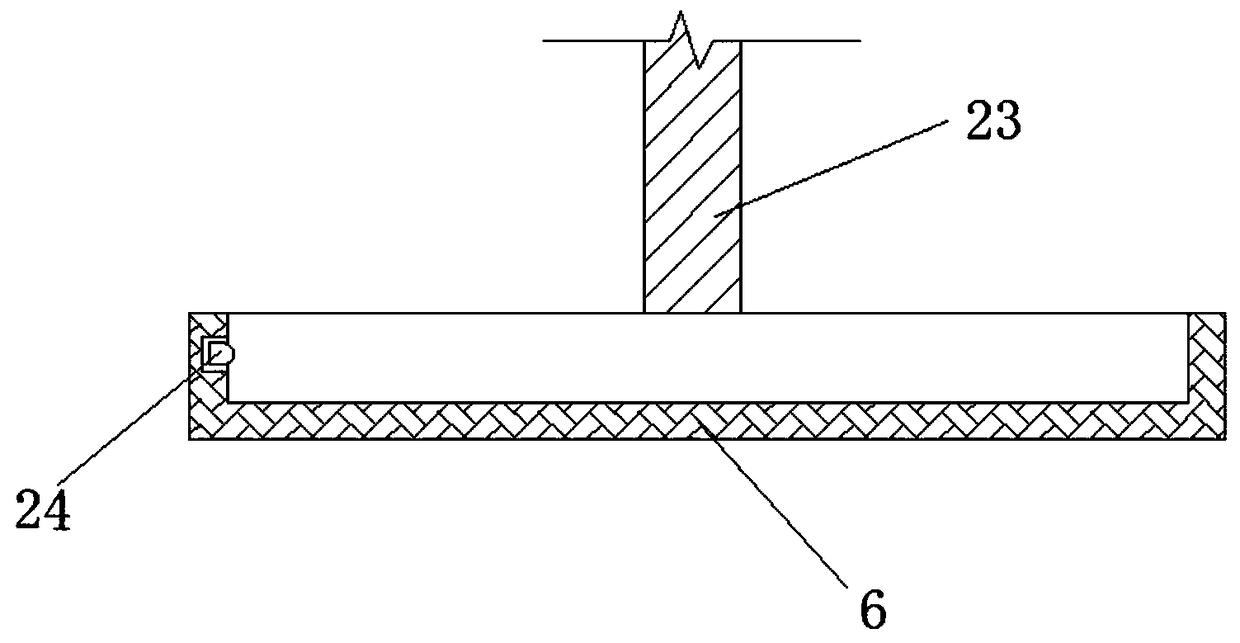

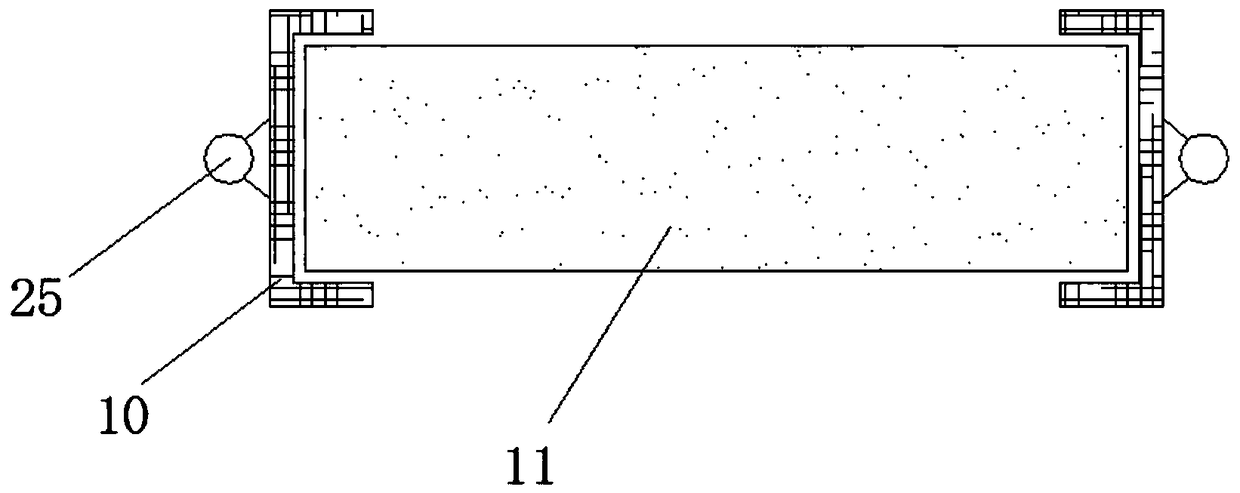

Novel wet tissue production non-woven wetting device

ActiveCN107338593AWet evenlyRegulate wettingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsLiquid storage tankPulp and paper industry

The invention discloses a novel wet tissue production non-woven wetting device which comprises a base, wherein a liquid storage tank is arranged on the lower surface inside the base; a liquid sucking pump is arranged on the lower surface inside the liquid storage tank. According to the novel wet tissue production non-woven wetting device, a cloth supply device is arranged right above a conveying device, so that the non-woven cloth is conveyed on the conveying device can be achieved; due to cooperation of a first guide roller and a second guide roller, the non-woven cloth can be conveyed along a specific route; due to the cooperation of the liquid sucking pump and nozzles, a wetting liquid can be uniformly sprayed to the non-woven cloth; due to the adoption of a flow adjusting valve inside the liquid sucking pump, the liquid sucking amount can be adjusted according to the wetting liquid expected by the non-woven cloth; due to the cooperation of a first liquid pressing roller and a second liquid pressing roller, the non-woven cloth is uniformly wetted, and excessive wetting liquids can be pressed out; due to the adoption of a speed reduction motor and a cloth collecting device, the speed of the cloth collection device in collecting cloth can be adjusted according to the non-woven cloth conveying speed.

Owner:同高纺织化纤(深圳)有限公司

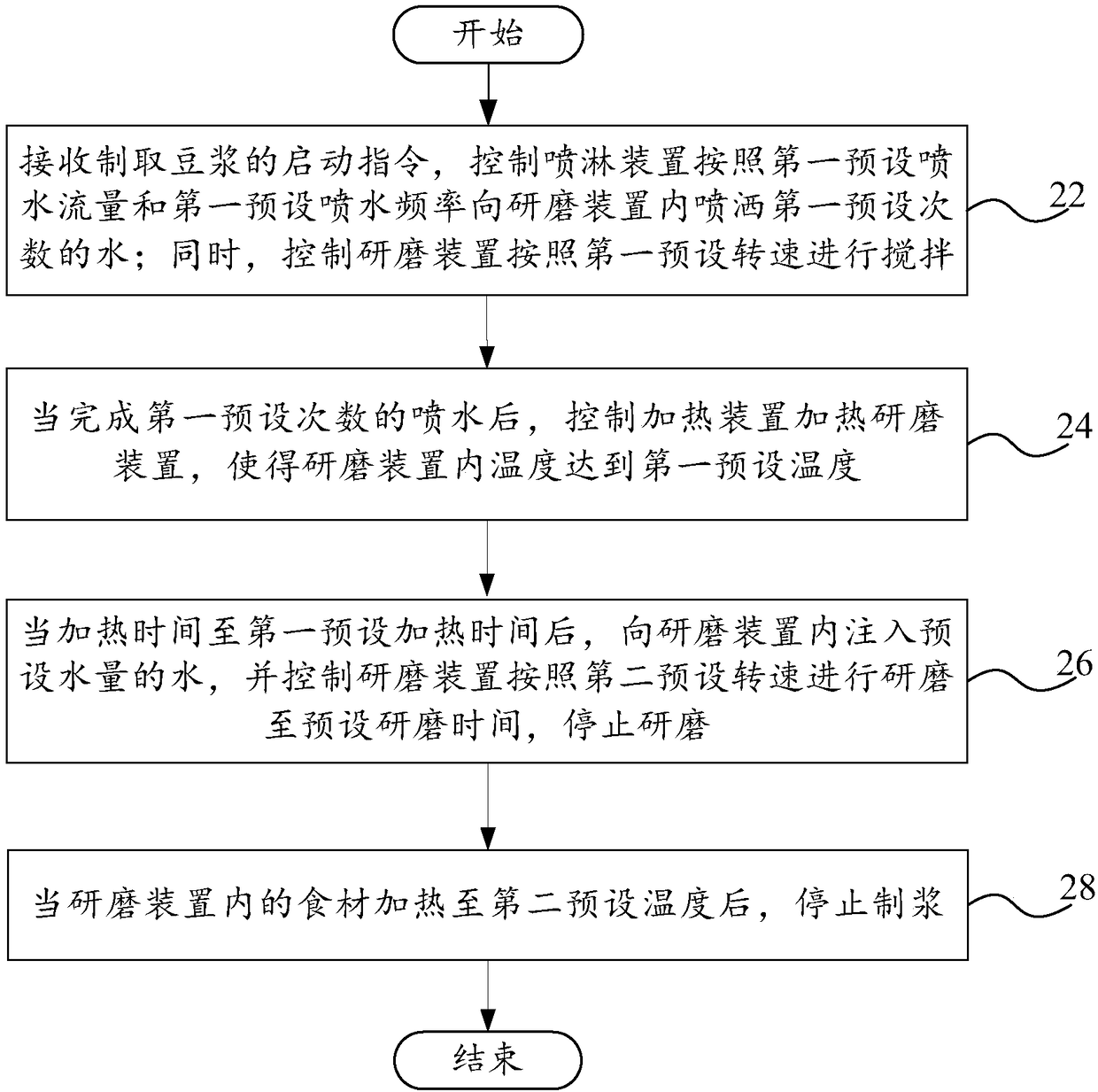

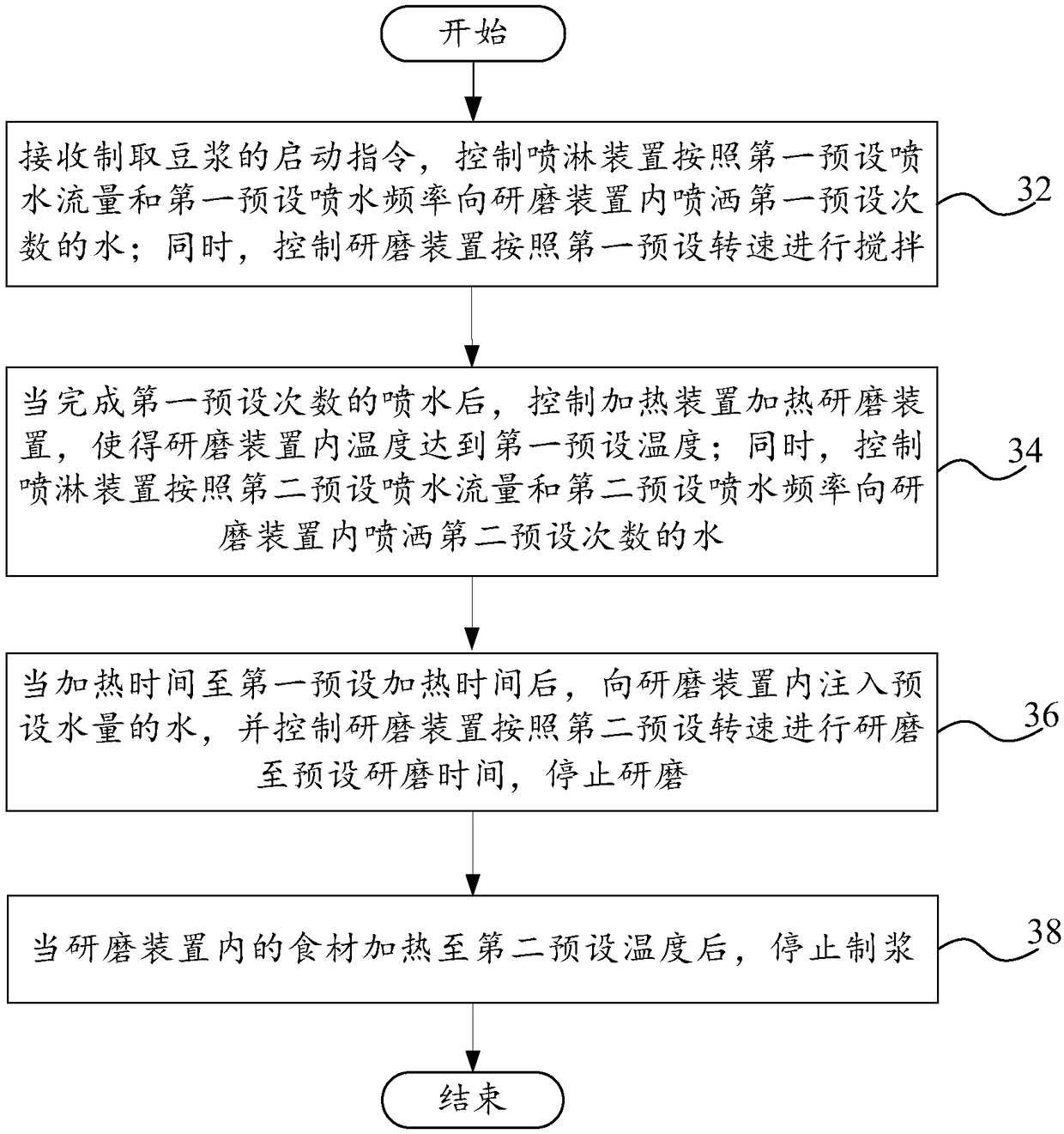

Cooking utensil, soybean milk making method and computer device

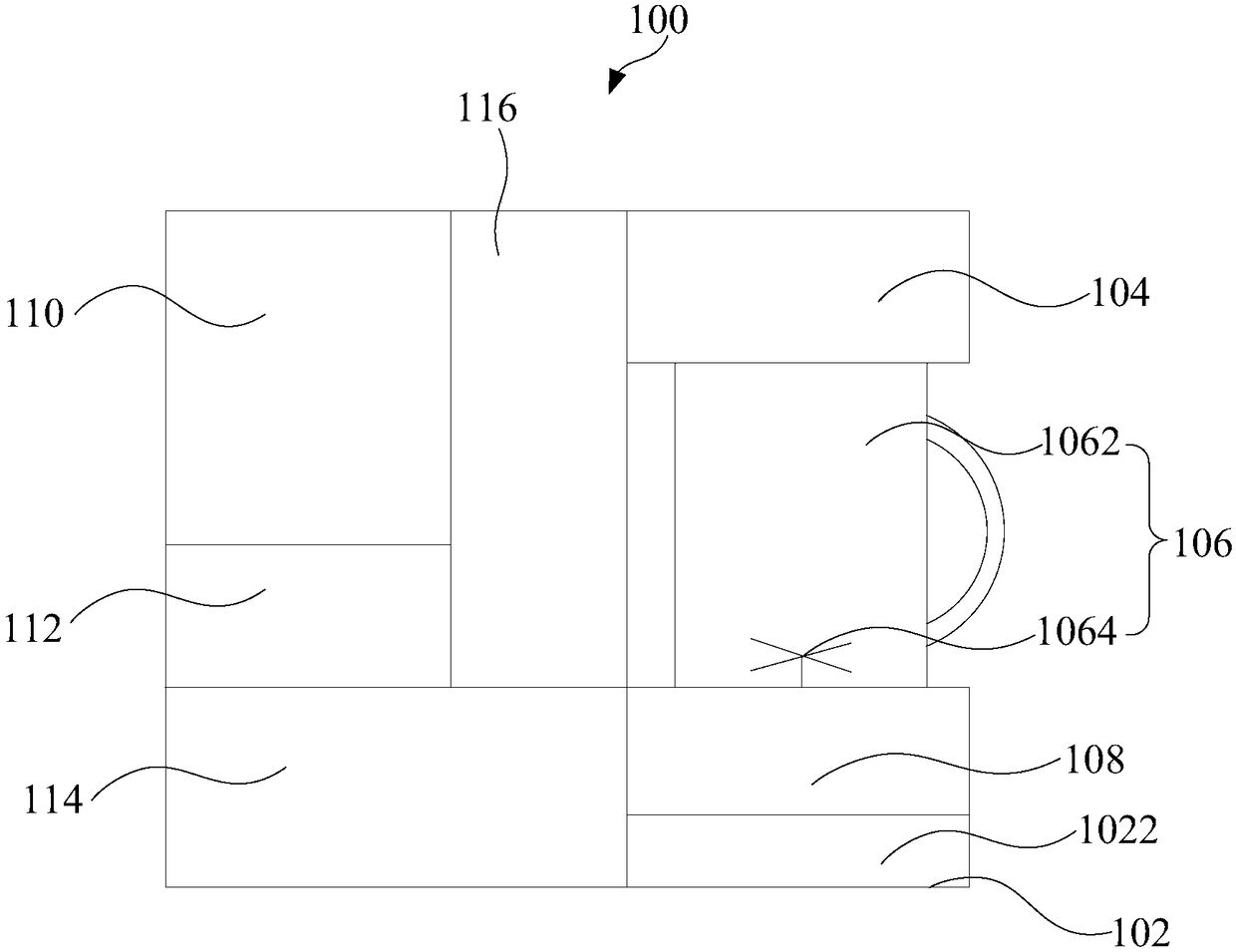

PendingCN109419387AImprove satisfactionHigh nutritional valueKitchen equipmentFood scienceEngineeringFood material

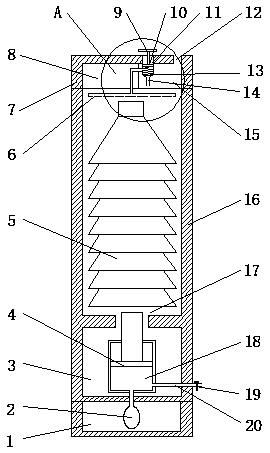

The invention provides a cooking utensil, a soybean milk making method, a computer device and a computer readable storage medium. The cooking utensil comprises a shell, a grinding device in the shell,a spraying device in the shell and a heating device in the shell, wherein the spraying device is located above the grinding device and provided with a water spraying opening; the heating device is located below the grinding device. According to the cooking utensil, the spraying device sprays water into the grinding device through the water spraying opening to make food materials wetted, and the heating device is used for heating the wetted food materials in the grinding device to generate wet hot steam for enzyme deactivation treatment of the food materials, so that the enzyme deactivation speed is increased, the cooking time is shortened, the application range of the cooking utensil is enlarged, and the use satisfaction degree of users is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Quenching oil capable of enabling bearing steel to automatically blacken after quenching

ActiveCN104451058ARealize automatic blackeningSave resourcesMetallic material coating processesQuenching agentsHardnessBase oil

The invention discloses quenching oil capable of enabling bearing steel to automatically blacken after quenching, belonging to the technical field of heat treatment and surface treatment of metals. The quenching oil comprises the following components in parts by weight: 17-19 parts of refined base oil, 0.2-0.6 part of cooling accelerating composite agent, 0.1-0.3 part of blackening composite agent, 0.2-0.5 part of brightening agent and 1-2 parts of surfactant. The quenching oil can ensure that bearing steel parts (including bearing rings, rollers and retainers) automatically blacken after quenching, not only can obtain ideal quenching hardness and metallographic structures and achieve the mechanical strength and toughness required by workpieces but also can achieve the effect that the surfaces automatically blacken, and is conducive to reducing coating and rust-proof retreatment of the surfaces after heat treatment, saving energy, reducing procedures and improving the efficiency.

Owner:马鞍山金泉工业介质科技有限公司

Pumice straw lightweight aggregate concrete and preparation method thereof

InactiveCN102219452ASolve processing problemsReduce weightSolid waste managementCeramicwareFiberThin shells

Pumice straw lightweight aggregate concrete and a preparation method thereof. The raw materials of the pumice straw lightweight aggregate concrete comprise, by weight, 1 part of cement, 0.40-0.50 part of fly ash, 2.05-2.55 parts of pumice sand, 0.03-0.05 part of corn straw fibers, 0.010-0.015 part of an additive, 0.005-0.007 part of a foaming agent, and 0.50-0.55 part of water. The preparation method provided by the invention comprises: Step 1, preparing thin shell pumice sand and thin shell straw fibers; Step 2, pouring the cement, fly ash, water and additive according to the ratio as well as the prepared thin shell pumice sand into a mixer with uniformly stirring; Step 3, pouring the thin shell straw fibers into the mixer with further stirring; Step 4, whisking the foaming agent, pouring the foaming agent into the above stirred substances, followed by stirring to produce the pumice straw lightweight aggregate concrete. According to the invention, the mechanical properties of the lightweight aggregate concrete are effectively raised, the heat insulation performance is enhanced, and the production cost is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Recipe for manufacturing nylon grinding blocks and method for manufacturing nylon grinding blocks by adopting recipe

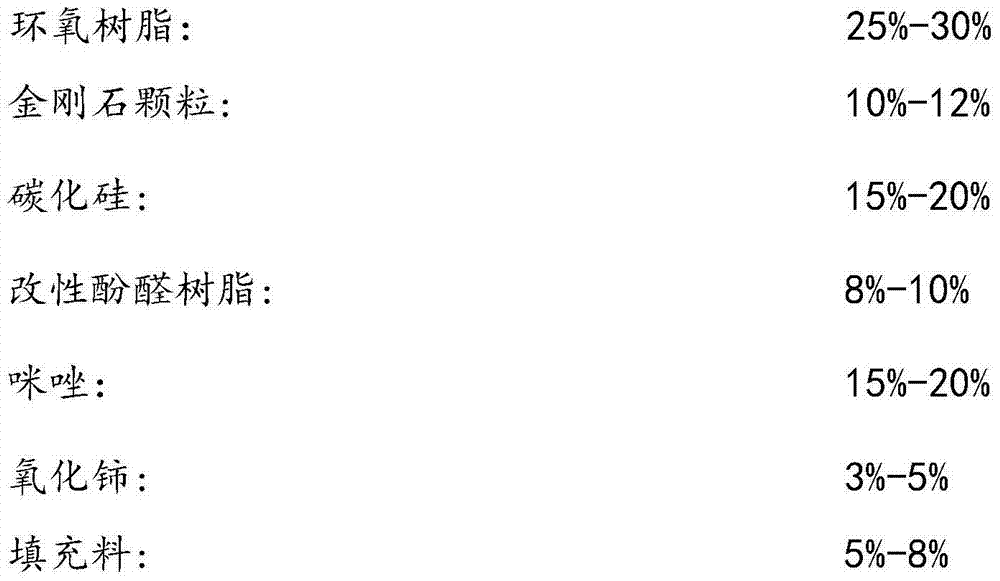

ActiveCN104325416AImprove wear resistanceExtended service lifeAbrasion apparatusGrinding devicesEpoxyWear resistant

The invention relates to a recipe for manufacturing nylon grinding blocks. The recipe consists of the following ingredients in percentage by weight: 25 percent to 30 percent of epoxy resin, 10 percent to 12 percent of diamond particles, 15 percent to 20 percent of silicon carbide, 8 percent to 10 percent of modified phenolic resin, 15 percent to 20 percent of imidazole, 3 percent to 5 percent of cerium oxide and 5 percent to 8 percent of filling materials, and the modified phenolic resin consists of 12 percent to 15 percent of methenamine, 3 percent to 5 percent of polyimide and 80 percent to 85 percent of phenolic resin. Through the combined action of the modified phenolic resin and the other ingredients, the integral wear-resistant performance and the heat resistance performance of the nylon grinding blocks are improved, and the holding force of grinding materials is improved. The invention also provides a method for manufacturing the nylon grinding blocks by adopting the recipe. The method comprises the steps of proportioning, material selection, soaking, piling lamination pressing, natural curing and drying curing. Through adopting the method, the holding force between the diamond particles and nylon fiber sheets can be well maintained, and the wear resistance of the nylon grinding blocks is enhanced.

Owner:福建易达新材料股份有限公司

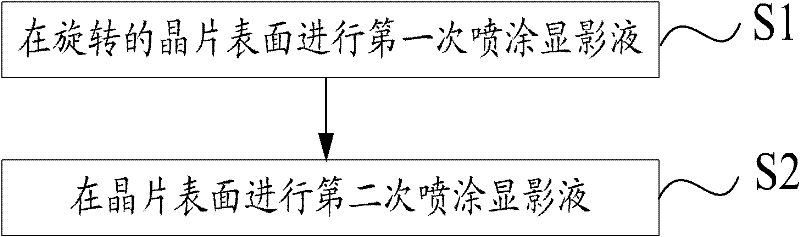

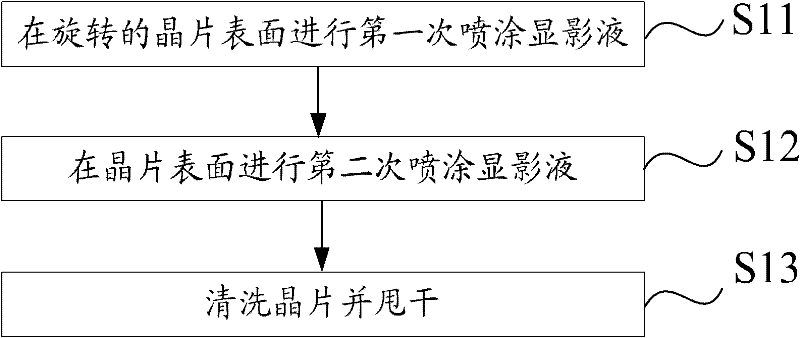

Developing method

InactiveCN102540769AReduce tensionThere will be no phenomenon of poor developmentPhotosensitive material processingEngineering

Embodiments of the invention disclose a developing method which comprises the following steps of: first spraying of a developer solution on a rotating wafer surface; second spraying of the developer solution on the wafer surface. According to the developing method provided by the invention, after the first spraying of the developer solution on the rotating wafer surface, the wafer surface is wetted uniformly, and thus the tension of the wafer surface is effectively reduced; therefore after the second spraying of the developer solution on the wafer surface, the developer solution sprayed for the second time is uniformly coated on the wafer; no poor development phenomenon occurs at the wafer edge, and the problem of non-uniform development of figures at different positions on the wafer is not caused; and thus the uniformity of device key dimensions is effectively improved.

Owner:CSMC TECH FAB1 +1

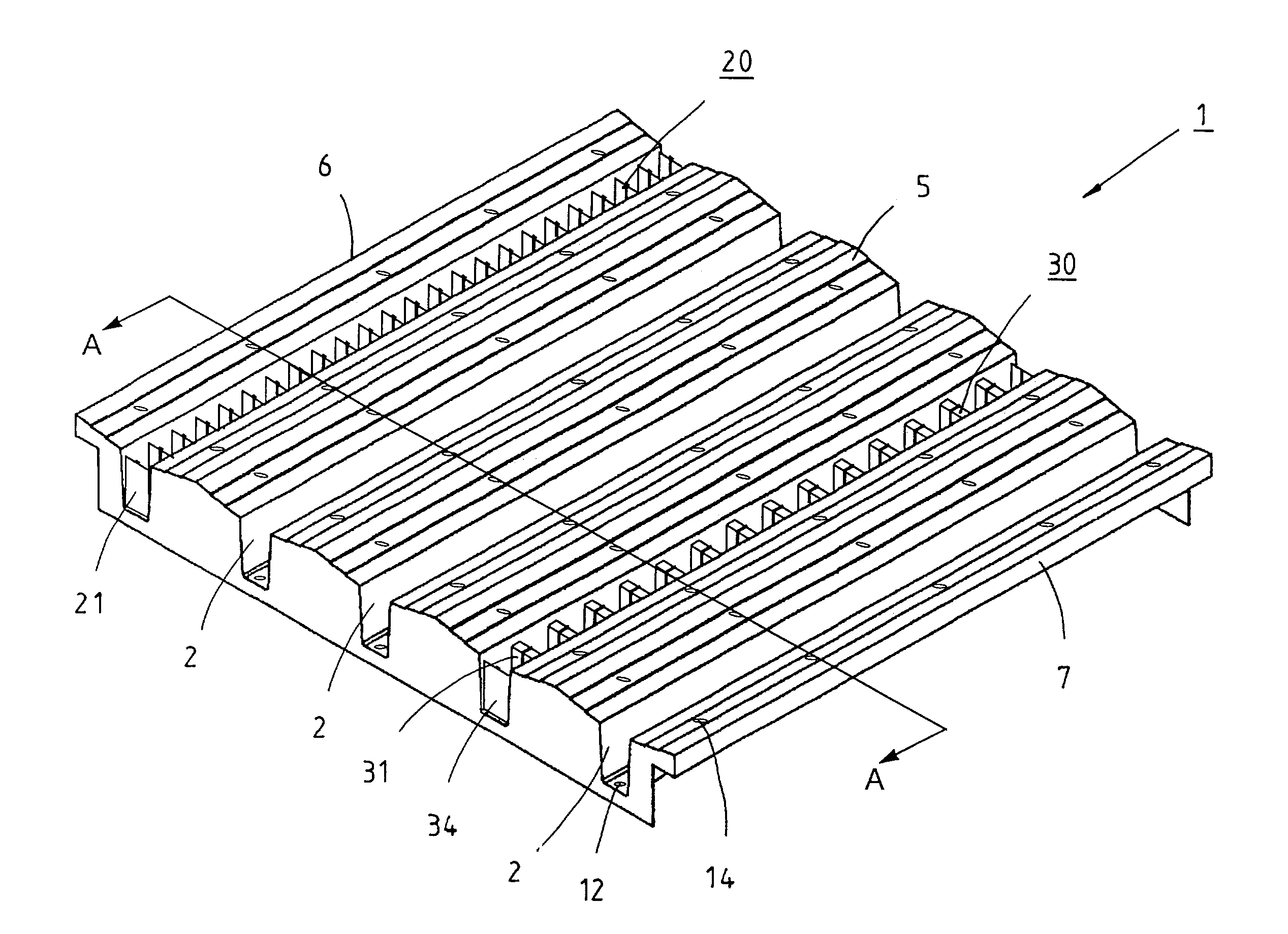

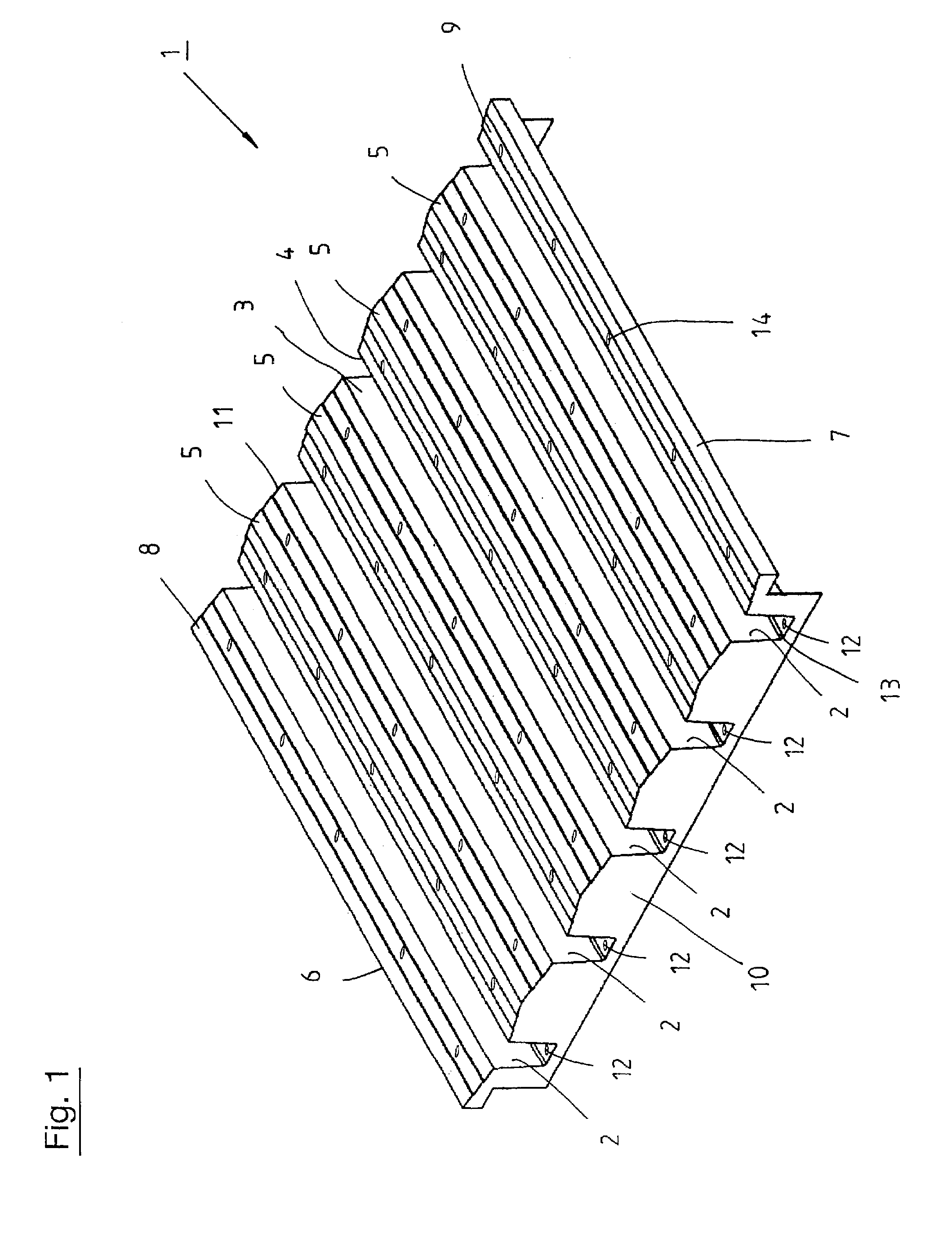

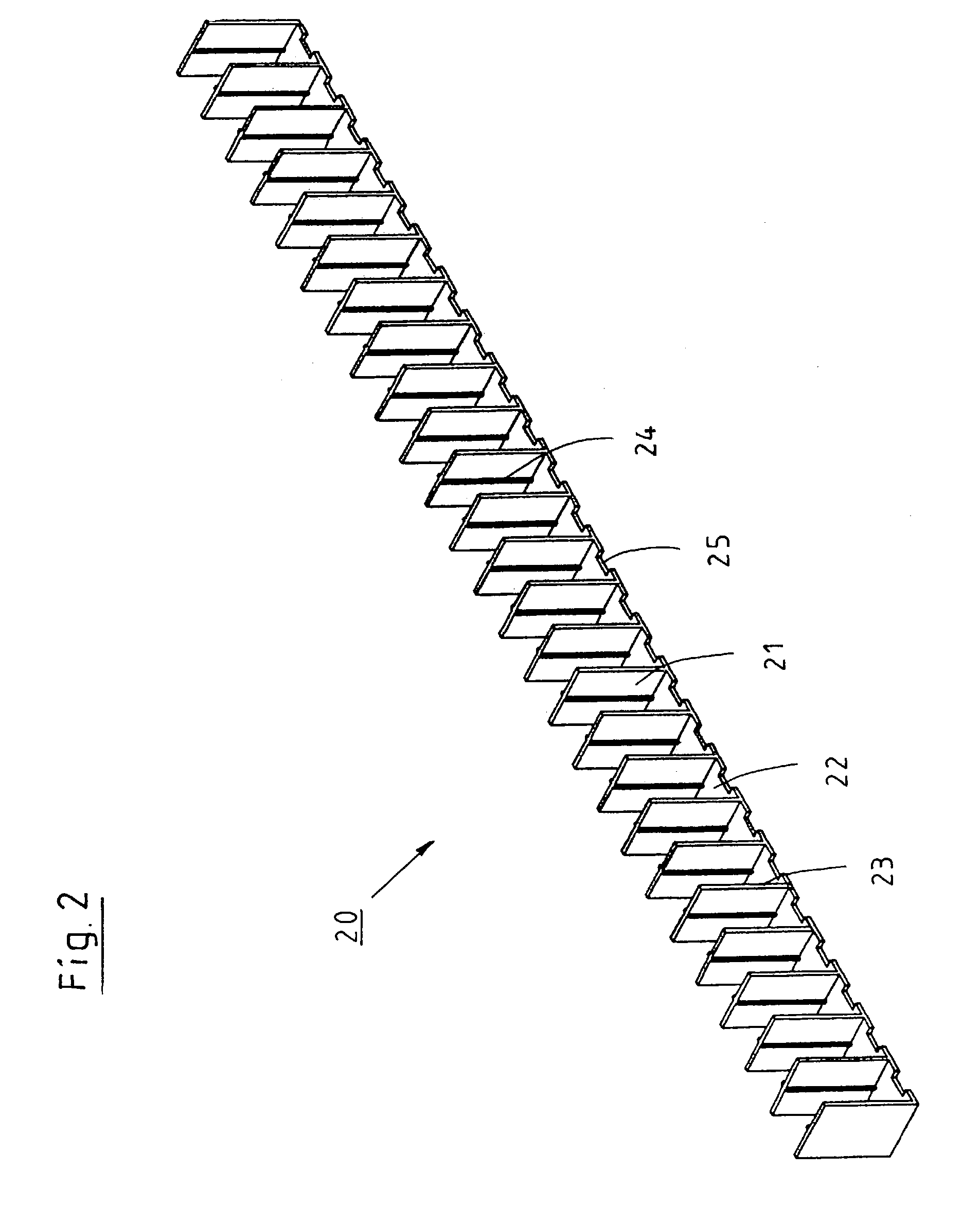

Culture tray for the rooting of young plants

InactiveUS7082718B2Easy to liftEasy lateral forcingCultivating equipmentsReceptacle cultivationEngineeringSeedling

A culture tray, in particular for the rooting of young plants, includes channels that run in parallel and at predefinable distances and serve to accommodate young plants. To enable removal of individual young plants preferably without harming them and to enable relatively economical consumption of water for the young plants the space for each young plant is limited by the sidewalls of the channel and across the longitudinal direction of the channel by partition webs. This arrangement will, in particular, ensure that the water is directly supplied to each plant space and, moreover, that the plants can be pushed sideways out of the culture tray by pushing out of the culture tray the web and ledge skeletons, and the plants are easy to take out, because there are then no sidewalls. The embodiment of the culture tray warrants uniform moistening of all existing plant spaces and ensures that even those plants receive enough water that are, for example, partly covered by large leaves of adjacent plants, since the water draining down the elevations flows into each individual plant space.

Owner:DUMMEN GRP BV

Cleaning head with a water spraying function and a wet vacuum cleaner having the cleaning head

PendingCN109171549AReduce manufacturing costsIncrease the cleaning areaSuction nozzlesEngineeringMechanical engineering

The invention discloses a cleaning head with a water spraying function and a wet vacuum cleaner with the cleaning head. The cleaning head with the water spraying function comprises a wiping head, a housing, and a water spraying mechanism, wherein the wiper head is accommodated in the housing; the water spraying mechanism includes a nozzle positioned at a side wall position of an inner cavity of the housing and disposed toward the wiper head and a liquid supply line communicating with the nozzle; and the nozzle is positioned outside an outer contour of the wiper head. The cleaning head with a water spraying function solves the problems that the spray head of the prior art cleaning head cannot be arranged on the outside of the wiper head, and the spray head cannot spray the liquid onto the part of the wiper head close to the inner wall of the shell, and the wiper head has a dry part, and cannot be uniformly wetted, thus leading to poor cleaning ability of the wiper head and even scratches on the cleaned surface.

Owner:GREE ELECTRIC APPLIANCES INC

Printing device used for clothing material processing and printing method thereof

ActiveCN111497431AIncrease temperatureGuaranteed stabilityCylinder pressesPlaten pressesProcess engineeringDyeing

The invention discloses a printing device used for clothing material processing and a printing method thereof. The printing device is sequentially provided with a pre-heating box, a regulating device,an image pick-up device, a flattening positioning device, an automatic printing frame and a shaping device from left to right. While the printing device processes the clothing material, the pre-heating box firstly performs heating treatment on the clothing material through hot air, so that a temperature of the clothing material is increased; the regulating device can be matched with the image pick-up device for regulating a transmission position of the clothing material in real time, so that position stability, in a transmission process, of the clothing material is guaranteed, and therefore,accuracy of the printing position is improved; the flattening positioning device sprays out high-temperature steam from the middle part of a flattening plate through a gas outlet, the passed clothingmaterial is heated, and the clothing material is uniformly wetted, then is printed and is finally heated, so that dyes are fixedly arranged on fibers, and printing and dyeing strength is improved, andtherefore, the printing device is suitable for industrial production, and improves production efficiency.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

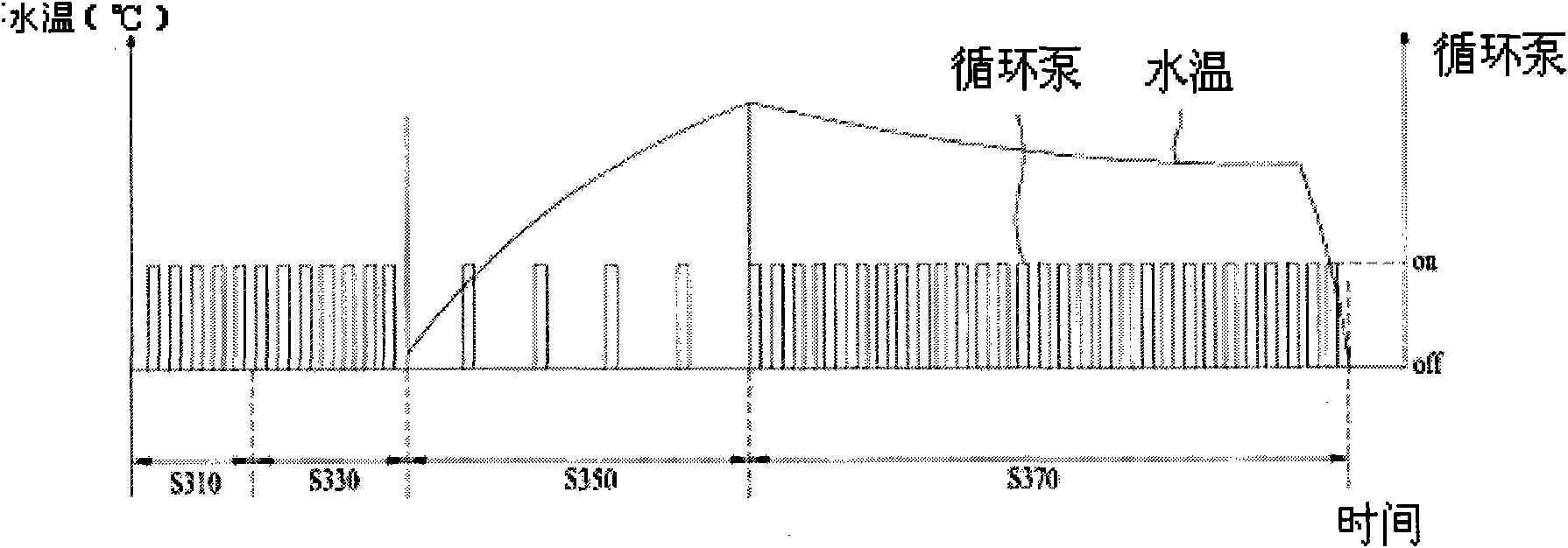

Control method for laundry device

InactiveCN101812788AWet evenlyImprove laundry effectOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

This invention discloses a control method for laundry device, the control method of this invention is characterized in that it includes: at least a washing bag soaking process driven by one of the roll driving motions such as step motion, rolling motion and alpha motion. In the control method of this invention, a washing bag soaking process is performed during a washing process so that the washing bag be soaked evenly and the wash property can be improved.

Owner:NANJING LG PANDA APPLIANCES

High shearing production method for film coating agent

ActiveCN101559231AOvercoming electrostatic attractionAvoid destructionPharmaceutical delivery mechanismPharmaceutical non-active ingredientsLow speedPlasticizer

The invention relates to a high shearing production method for a film coating agent. The innovation of the invention is that the production method comprises the following steps of: refining of a colorant, coating of the colorant, compounding of the coated colorant, and plasticization of a mixture. The invention provides the innovative high shearing production method for the film coating agent, adopts a high-speed shearing mode to perform dry dispersion on an insoluble colorant, coats a surfactant to prevent the colorant from agglomerating at the same time, finishescomplete mixing of a film former and even distribution of a plasticizer under low-speed shearing conditions, and has the advantages of high production efficiency, low energy consumption, good application performance of obtained finished products of the coating agents and the like.

Owner:TIANJIN BOKELIN MEDICINE PACKAGING TECH

Cooling and heat radiation structure of capacitor

The invention relates to the technical field of power system capacitors and particularly relates to a cooling and heat radiation structure of a capacitor, which comprises a cooling mechanism, a heat radiation mechanism and multiple parallel capacitor elements, wherein the capacitor element is coated with a layer of insulating paper; the cooling mechanism comprises a water tank and a water pipe; one side of the water tank is communicated with the water pipe, and the other side of the water tank is provided with a sliding piston; the water pipe is wound on the capacitor element coated by the insulating paper; the heat radiation mechanism comprises a power supply, a fan, a paper plate and a paper plate groove; the paper plate, the fan and the power supply are connected by wires; the fan is fixedly connected with a rotating shaft; the rotating shaft is connected with a speed reduction gear set through an input shaft; the output shaft of the speed reduction gear set is connected with a threaded rod; the threaded rod is connected with a casing; and the casing is fixedly connected onto the piston. The capacitor is cooled by using the water pipe to be wound on the capacitor and water to flow in the water pipe, the fan is also rotated, and the cooling and heat radiation effects of the capacitor are further enhanced.

Owner:宁波博恩电气有限公司

Sports teaching badminton storage device

InactiveCN107826498ASimple structureEasy to operateDispensing apparatusPackaging under vacuum/special atmospherePhysical educationHeavy weight

The invention discloses a badminton storage device for sports teaching, which comprises a protective shell, an air bag, an installation chamber, a piston rod, a shuttlecock, a nozzle, a bucket cover, an installation cavity, a pressure rod, a piston, a pump body, a water injection port, a spring, a suction pipe, Water tank, cylinder body, storage room, cavity, air valve and air outlet pipe. The badminton preservation device for physical education teaching of the present invention has simple structure, convenient operation, strong functionality and novel design. The device can humidify the badminton through the sprayed water mist, and the humidity can be better controlled, and the badminton can be kept inside the cylinder. Wet evenly, which can better avoid moldy due to excessive humidification or make the shuttlecock heavy and unusable. Through this device, it can be better and easier to take out the shuttlecock, and at the same time avoid damage to the rest of the shuttlecock after the shuttlecock has been taken out. The badminton will shake in the cylinder, so that the feathers of the shuttlecock will be deformed or fall off so that it cannot be used.

Owner:刘轩

Construction method for bedroom wall surface

The invention discloses a construction method for the wall surface of a bedroom, which comprises the following steps: 1) removing the original cement layer on the wall surface, then inspecting the wall surface, and filling the hole in the wall surface with cement mortar; 2) Use 3-5 parts of sand, 9-12 parts of latex powder, 7-9 parts of black cement, and 5-10 parts of water to mix evenly to make cement slurry, and the prepared cement slurry is uniform Apply to bedroom walls. The invention realizes the construction of the wall surface of the bedroom, thereby ensuring the reinforcement of the bedroom wall surface, avoiding the situation that the wall surface falls off and bulges, thereby ensuring the long-term use of the bedroom wall surface, and improving the living comfort of the residents Suspend the water-absorbent cotton cloth on the white cement layer by absorbing water, so as to moisturize the white cement layer, thereby avoiding cracks during the drying process, and at the same time ensuring uniform wetting of the white cement layer, and being able to Save water resources and reduce workload.

Owner:陈五二

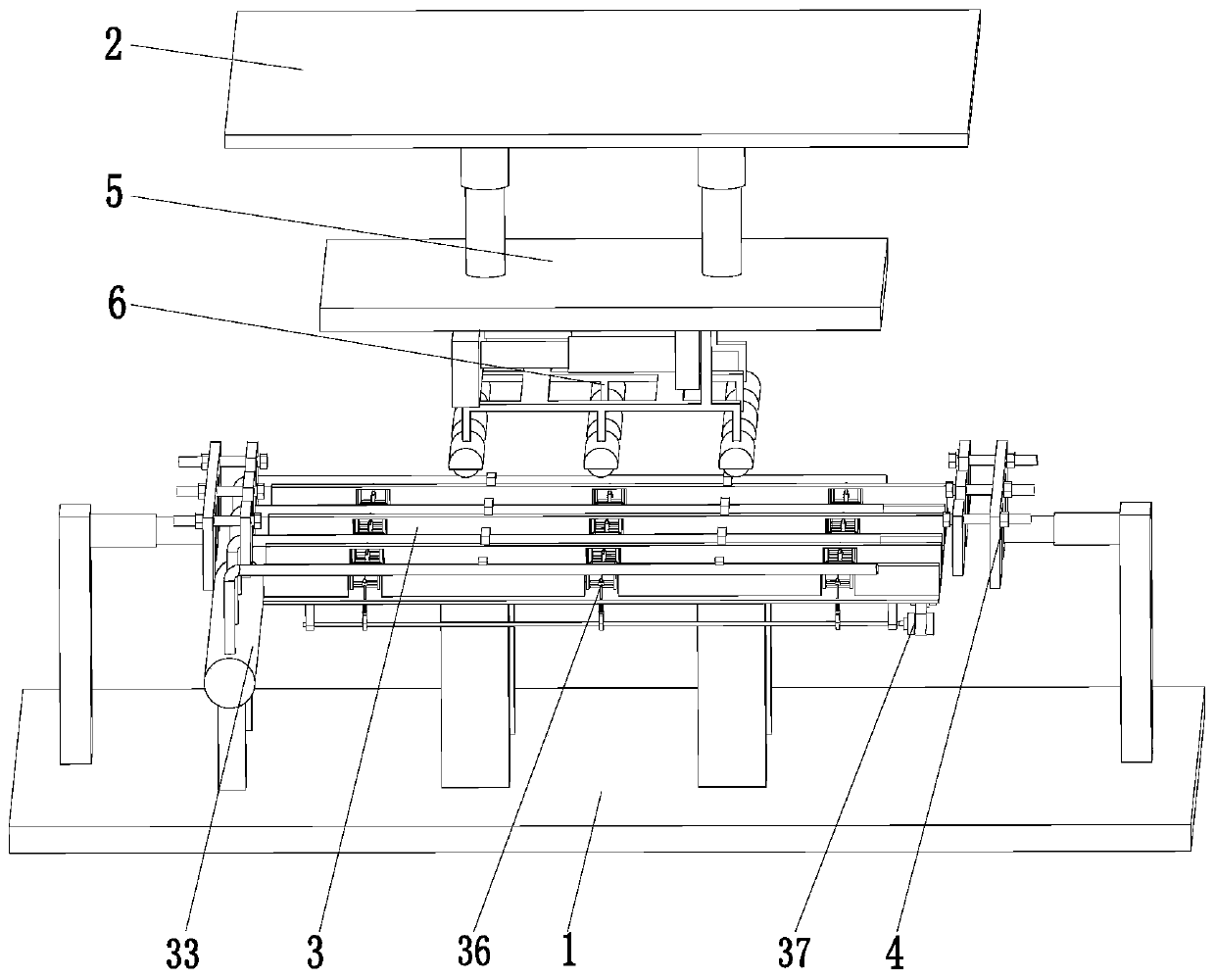

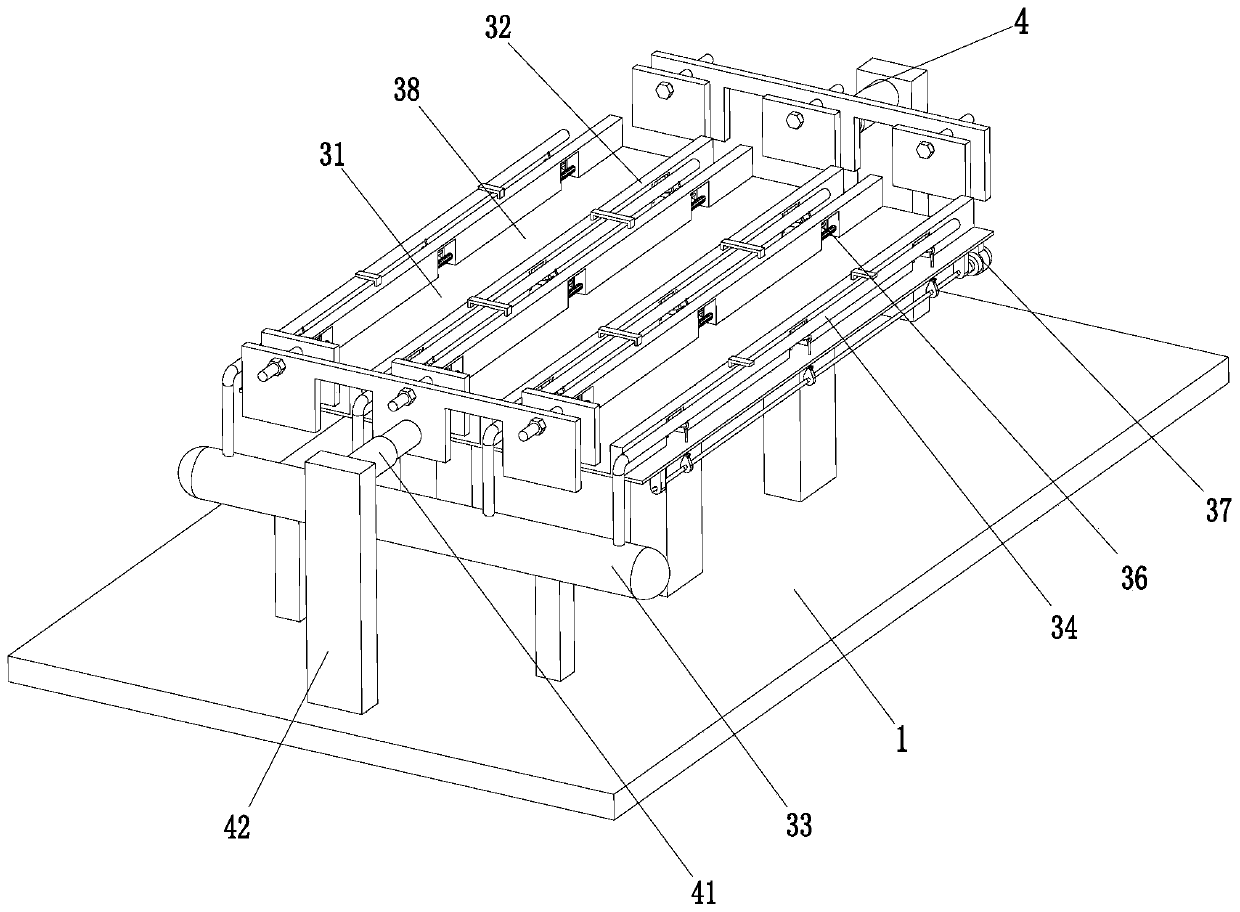

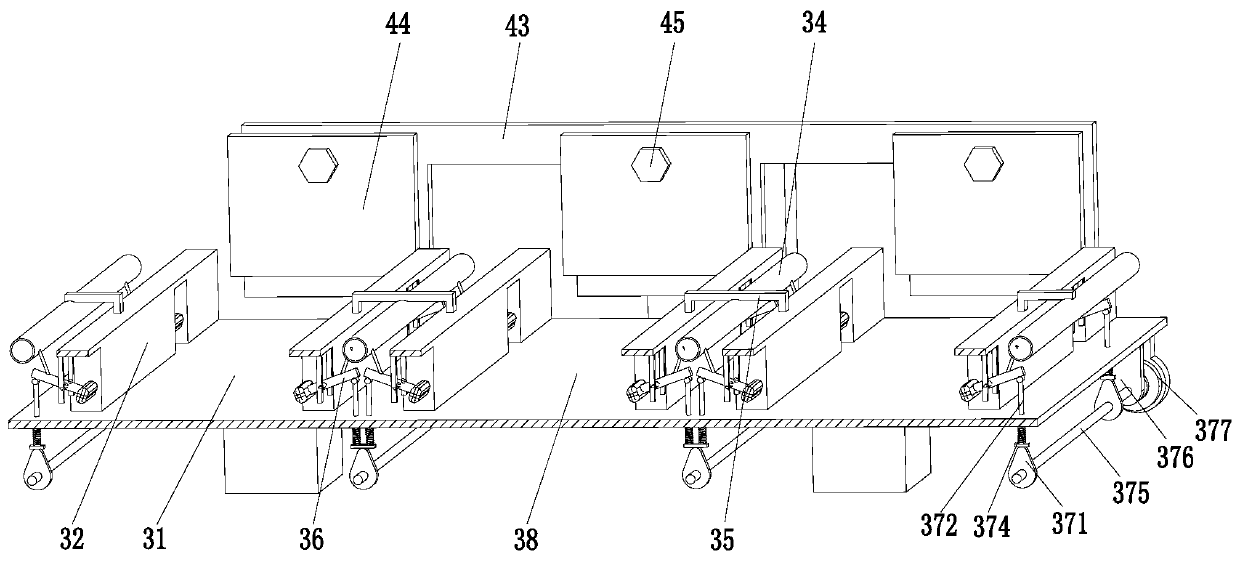

Hot pressing setting device and hot pressing setting method for ribbon fabric

InactiveCN110820191AEasy ironingImprove the effect of hot pressingHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention relates to a hot pressing setting device and hot pressing setting method for ribbon fabric. The hot pressing setting device for ribbon fabric comprises a bottom plate, a top plate, a hotsteaming device, leveling mechanisms, a pressing-down mechanism and an ironing mechanism; the top plate is arranged on a fixed surface, such as a wall surface, and the hot steaming device is arrangedabove the bottom plate; the bottom end of the hot steaming device is arranged in the middle of the top end of the bottom plate; the leveling mechanisms are symmetrically arranged on the left side andright side of the hot steaming device; the bottoms of the leveling mechanisms are mounted on the top end of the bottom plate; the top end of the pressing-down mechanism is mounted in the middle of the bottom end of the top plate and arranged on the upper left side of the bottom plate; the ironing mechanism is positioned below the pressing-down mechanism; the top end of the ironing mechanism is fitted on the bottom end of the pressing-down mechanism. The invention can solve the problems that, for instance, a ribbon cane not fully wetted by manual spraying wetting, and an iron easily scorches the part of the ribbon not fully wetted, so that product quality of the ribbon is affected, and that manual ironing of the ribbon has low production efficiency, so that the manual ironing is unable toadapt to large-scale production.

Owner:汪永超

Base plate cleaning equipment

InactiveCN107159602AEasy to cleanWet evenlySemiconductor/solid-state device manufacturingCleaning using toolsEngineeringMechanical engineering

The invention provides base plate cleaning equipment. The base plate cleaning equipment comprises a hollow bearing rod, a brush arranged on the outer surface of the bearing rod, a driving device connected with one end of the bearing rod, and a liquid inlet pipe rotationally connected with the other end of the bearing rod. A plurality of water outlets are formed in the bearing rod. Cleaning liquid is led into the bearing rod through the liquid inlet pipe. The cleaning liquid in the bearing rod is sprayed out from the multiple water outlets to the exterior of the bearing rod, so that the brush is wetted evenly and can be effectively cleaned, remaining particles in the brush are removed, the problem that during base plate cleaning, the particles in the brush are brought to the base plate and scratch the base plate is avoided, and the product yield rate and quality are improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

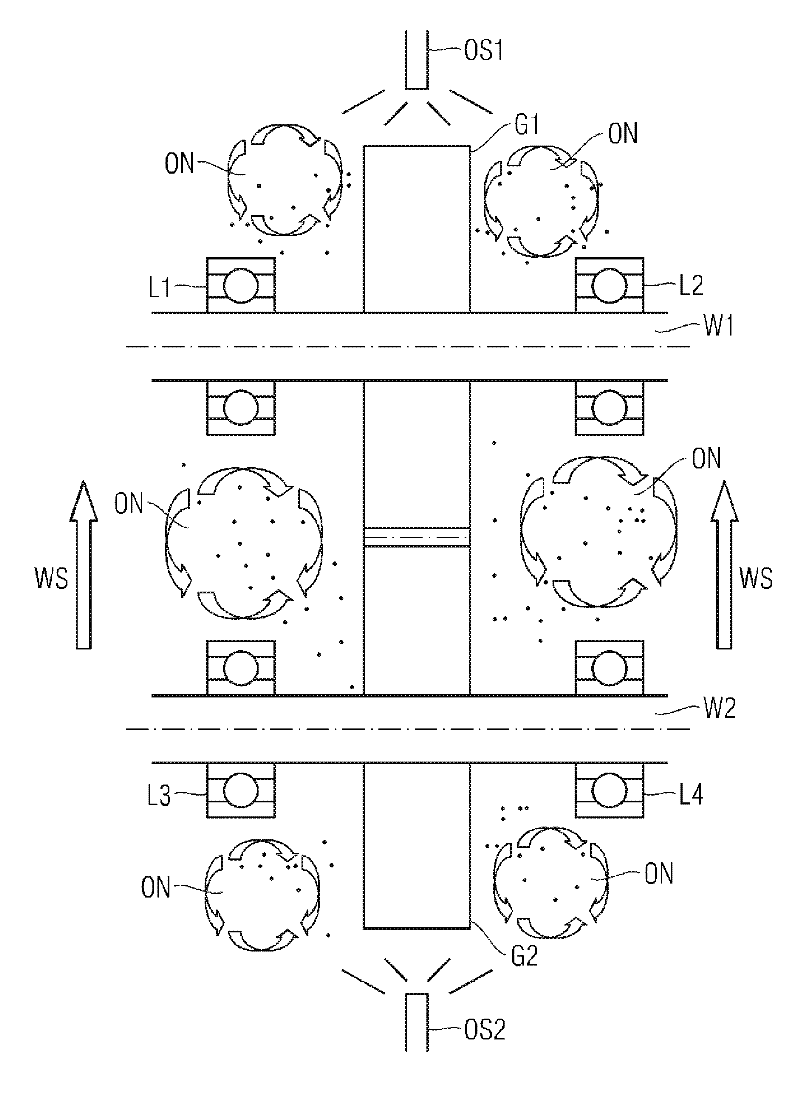

Device for spray lubricating wind turbine transmission

A device for spray lubrication of a wind turbine transmission is provided. The device includes a transmission enclosed by a housing, a first oil spray unit and a second oil spray unit. Both of the oil spray units are arranged in the interior of the housing. The first oil spray unit is embodied to spray oil at a first temperature in the interior of the transmission housing, while the second oil spray unit is embodied to spray oil at a second temperature in the interior of the transmission housing, wherein the first and the second temperature differ from each other.

Owner:SIEMENS AG

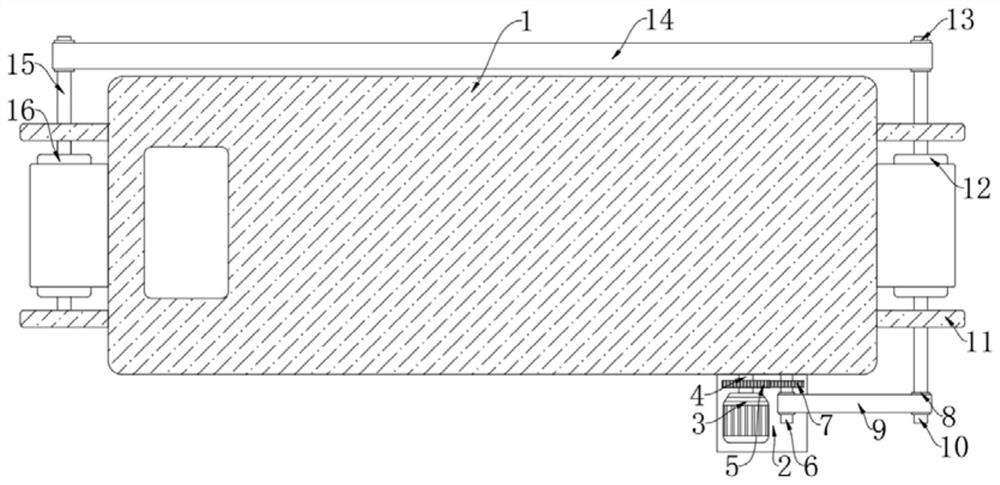

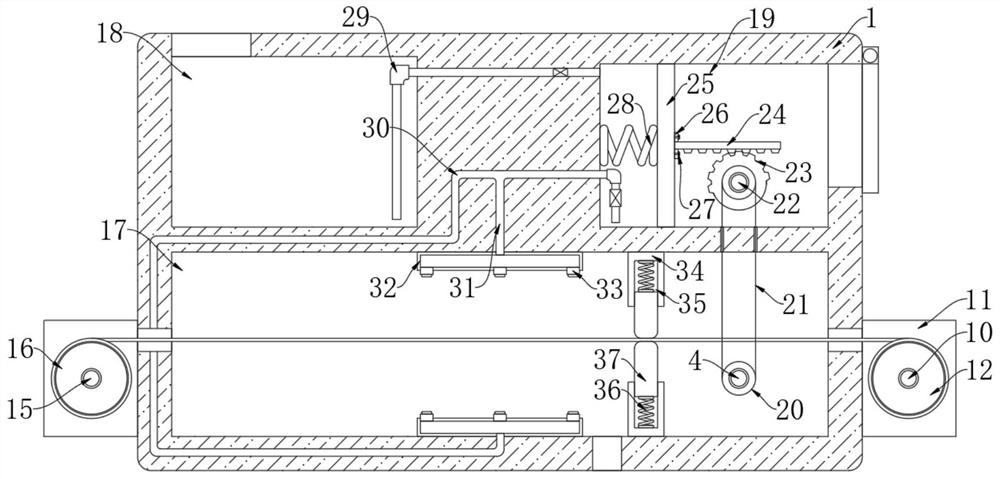

Humidifying device capable of controlling water quantity for non-woven fabric processing

PendingCN112301579AImprove wetting effectQuality improvementTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingProcess engineeringNonwoven fabric

The invention discloses a humidifying device capable of controlling water quantity for non-woven fabric processing. The humidifying device comprises a box body, wherein a spraying cavity is formed inthe box body, a water storage cavity and a rotating cavity are sequentially formed in the box body from left to right, the water storage cavity and the rotating cavity are both located above the spraying cavity, a water inlet in communication with the outside is formed in the inner top of the water storage cavity, an opening in communication with the outside is formed in the inner wall of the right side of the rotating cavity, and a sliding door is installed on the opening. According to the humidifying device, s motor drives a winding drum and a spraying device to operate at the same time, sothat a certain amount of water is sprayed to each section of non-woven fabric, the amount of water for humidifying can be controlled by replacing the specification of a rack, various types of non-woven fabric can be in the optimal water amount, the quality of the non-woven fabric is improved, double-sided spraying is conducted on the non-woven fabric, and the non-woven fabric is humidified more uniformly through the propping of propping blocks.

Owner:郑明增

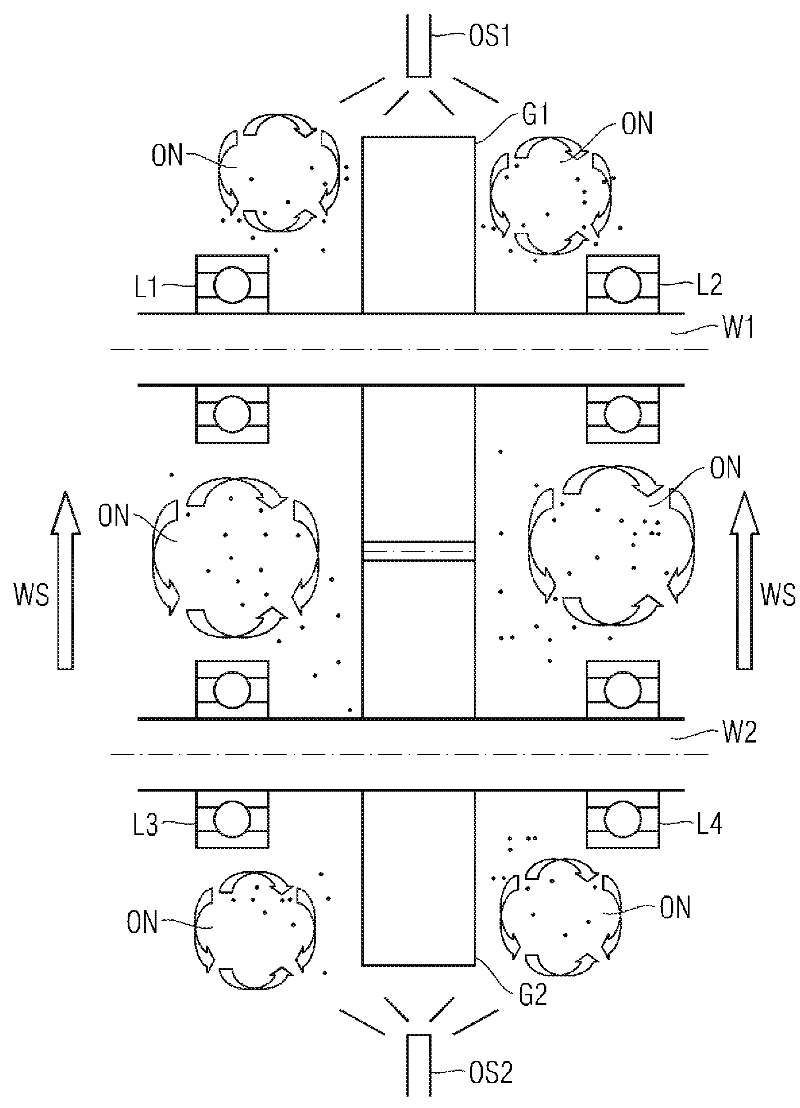

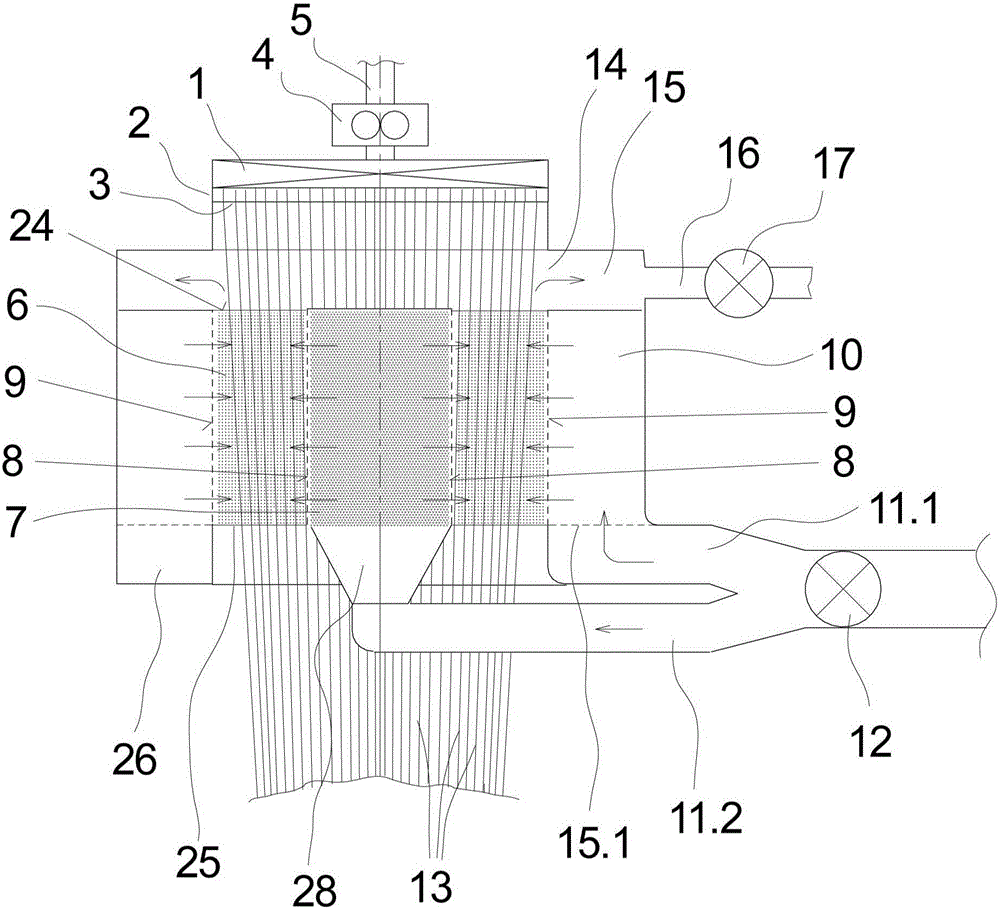

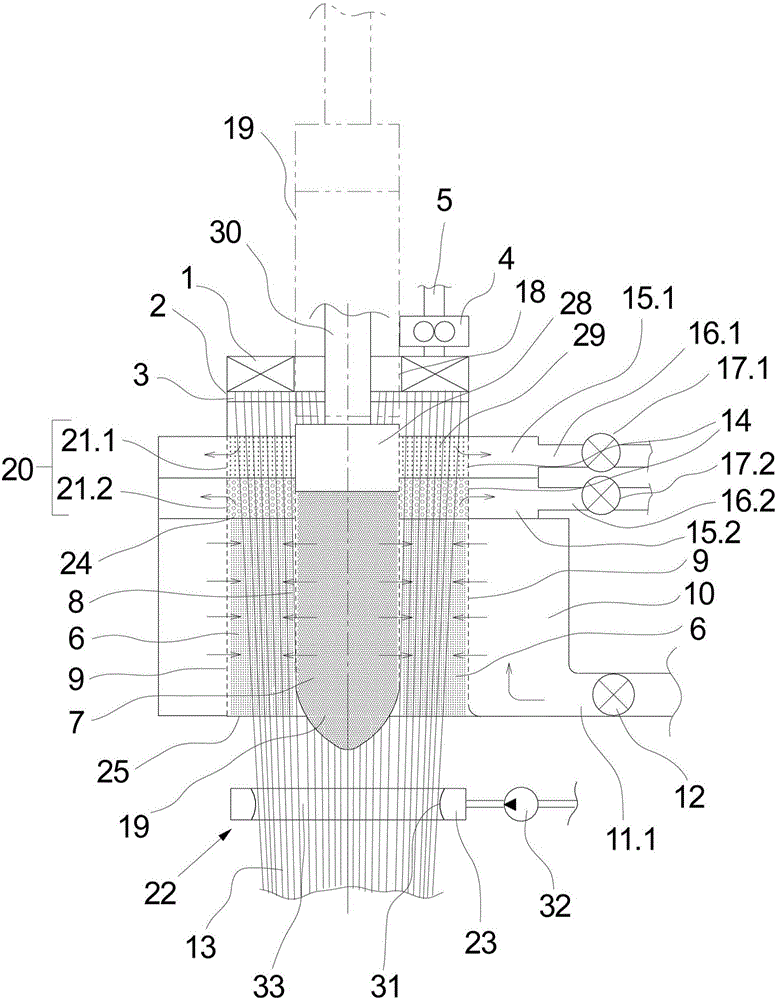

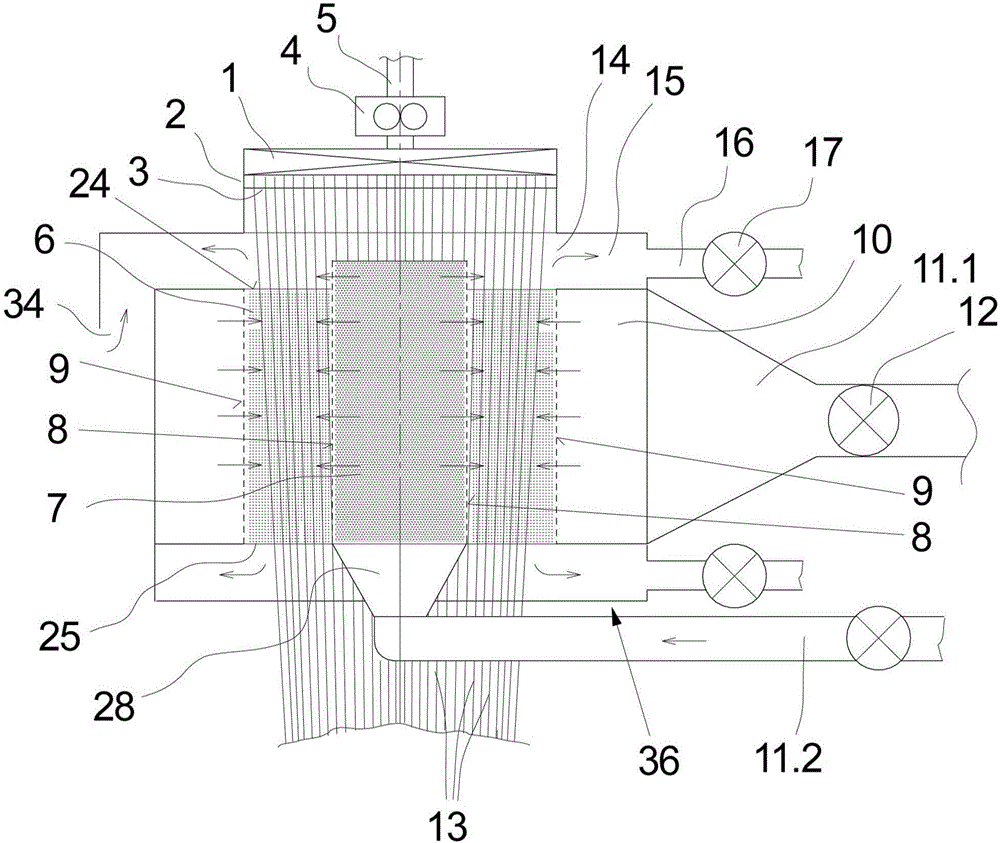

Apparatus for the melt spinning and cooling of filament family

A device for the melt spinning and cooling of a filament family with an annular spinning nozzle is described. Below the spinneret is formed an annular cooling well between an air-permeable inner wall and an air-permeable outer wall. The inner wall delimits an inner air chamber and the outer wall is assigned to an outer air chamber, the air chambers being at least connectable to a source of cooling air, so that radial cooling air streams can be generated. In order to obtain no turbulence flows, in particular, in the upper region at the inlet of the filaments, an outer suction opening, which opens into a suction chamber, is formed at an inlet of the cooling shaft below the spinning nozzle, the suction chamber being connectable to a vacuum source. It is thus advantageously possible to achieve a regulation of the cooling air flow in the upper region of the cooling shaft.

Owner:OERLIKON TEXTILE GMBH & CO KG

Separation and enrichment method for extracting wheat bran aleurone-layer contents by pure physical method

The invention discloses a separation and enrichment method for extracting wheat bran aleurone-layer cells by a pure physical method. The separation and enrichment method for extracting wheat bran aleurone-layer cells by the pure physical method comprises the following steps of performing vacuum infiltration treatment on pre-crushed wheat bran and carrying out microwave drying and heating so as toproduce micro-expansion effects, so that, preliminary separation of an aleurone layer from part of a transparent layer is realized; at the same time, ensuring uniform wetness, from the inside to the outside, of the wheat bran so as to make sure that the water content of the wheat bran contents is not too high; and then, carrying out gradient freezing treatment so as to slowly produce micro ice crystals, so that, adhesion force between the wheat bran layer, the transparent layer and the seed coat is reduced. Moreover, the water content of the wheat bran contents and the ice crystal formation rate are controlled, so that, loss of wheat bran aleurone-layer contents caused by freeze-drying is reduced; at the same time, stab-wound effects of the micro ice crystals on the aleurone-layer cells are realized while graded crushing treatment is carried out, so that, peeling and extracting of wheat bran aleurone layer from wheat bran are realized so as to effectively preserve nutrients in the wheat bran aleurone layer.

Owner:涡阳县丰华面业有限公司

Cooling fan based on information technology and capable of realizing remote control

InactiveCN108758915AEasy to disassemble and cleanWet evenlyMechanical apparatusLighting and heating apparatusRemote controlPulp and paper industry

The invention belongs to the technical field of information technology, and particularly discloses a cooling fan based on an information technology and capable of realizing remote control. The following scheme is adopted with regard to the problems of simple design structure, non-uniform wetting for a water curtain, and incapacity of realizing remote control: the cooling fan comprises a shell body, wherein first slide grooves are formed in the two ends of the inner wall of the bottom of the shell body separately, and two first movable wheels are slidably connected into the two first slide grooves separately; and the tops of the four first movable wheels are connected with the same water tank through fastening bolts, and the inner wall of the bottom and the inner wall of the periphery of the water tank are bonded with the same heat-insulation sponge. According to the cooling fan, detachment and cleaning for the water curtain are facilitated, and uniform wetting of water for the water curtain is ensured, so that the refrigeration effect is improved, wetting for the bottom of the water curtain is ensured, and the utilization rate of the water curtain is increased; the water curtain isprevented from being excessively wetted with water, and water drips into the shell body, so that taking for the water tank and water adding are facilitated; and moreover, heat insulation is carried out on water in the water tank, so that the refrigeration effect is improved, remote control is realized, and the cooling fan is convenient to use.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

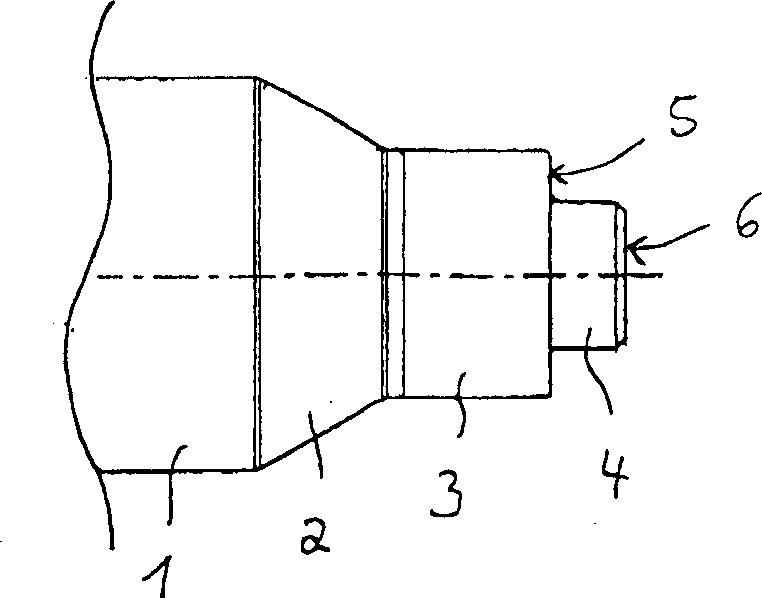

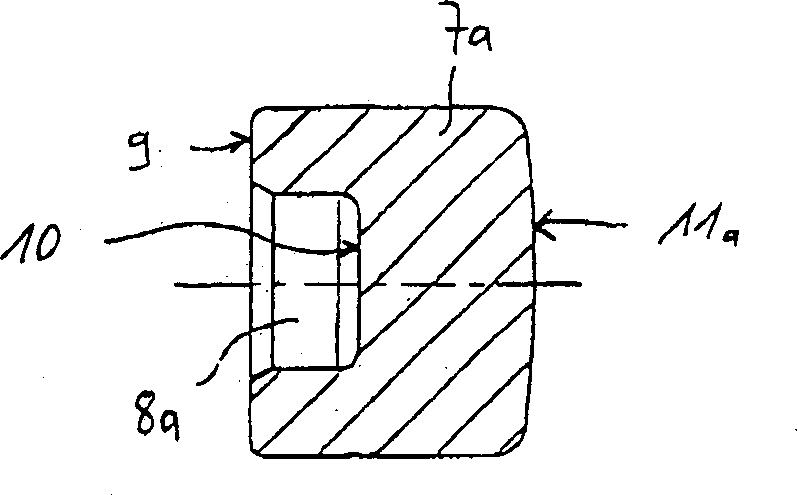

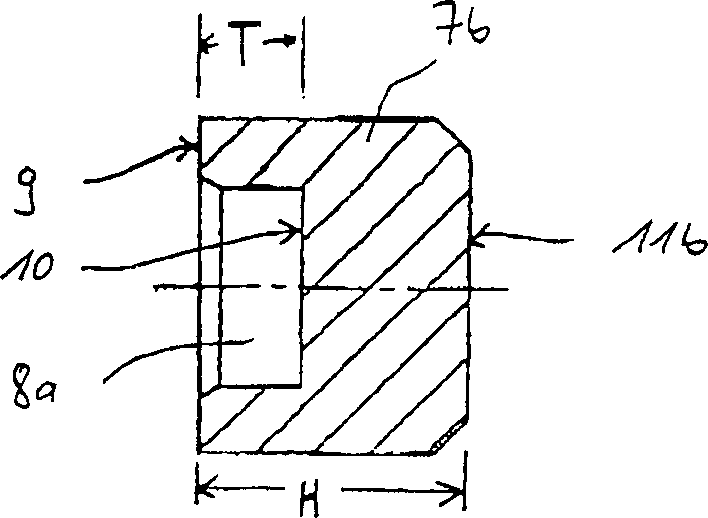

Spinning cup with one free end capable of being mounted with supporting spindle cap

The invention relates to a free-end spinning cup, which has a shaft (1) on which a support cap (7d) can be mounted on the free end of the shaft, the invention also relates to such a support cap, and the manufacture of a free end The method of spinning cups. According to the invention, the free-end spinning cup is designed such that the shaft (1) has a front facing surface (5, 6), and the supporting cap (7d) has an opposite facing surface (9, 10) for supporting The caps (7d) are aligned with respect to a plane perpendicular to the axis of the rotor and / or have inclined counter faces for aligning and coaxially aligning the supporting caps (7d) with the shaft (1).

Owner:RIETER INGOLSTADT SPINNEREIMASCHENBAU AG

Method for coating substrates with copper or silver

The invention relates to a method for coating substrates with a metal selected among copper and silver by evaporating said metal with the aid of ceramic evaporator crucibles. The inventive method is characterized in that an evaporator crucible is used that is made of an electrically conductive ceramic material and whose surface from which the metal is evaporated is provided with one of the following coatings: a) a coating made of at least one transition metal of subgroup 4 to 6 of the periodic system and / or the borides thereof; b) a coating made of a mixture of the metal that is to be evaporated and at least one transition metal of subgroup 4 to 6 of the periodic system and / or the borides thereof; c) a first coating made of at least one transition metal of subgroup 4 to 6 of the periodic system and / or the borides thereof and a coating which is applied thereto and is made of the metal that is to be evaporated. The inventive evaporator crucibles are provided with good initial wetting power for copper and silver such that the evaporation process can be carried out uniformly and with little splashing.

Owner:ESK CERAMICS GMBH & CO KG

Quenching oil preparation method

ActiveCN104451059ARealize automatic blackeningSave resourcesQuenching agentsQuenchingMaterials science

The invention discloses a quenching oil preparation method, belonging to the technical field of heat treatment and surface treatment of metals. The quenching oil comprises the following components in parts by weight: 17-19 parts of refined base oil, 0.2-0.6 part of cooling accelerating composite agent, 0.1-0.3 part of blackening composite agent, 0.2-0.5 part of brightening agent and 1-2 parts of surfactant. The quenching oil prepared by the preparation method has the advantages of good dispersibility, good stability, good heat transmissibility, and the like, can ensure that bearing steel parts (including bearing rings, rollers and retainers) automatically blacken after quenching, not only can obtain ideal quenching hardness and metallographic structures and achieve the mechanical strength and toughness required by workpieces but also can achieve the effect that the surfaces automatically blacken, and is conducive to reducing coating and rust-proof retreatment of the surfaces after heat treatment, saving energy, reducing procedures and improving the efficiency.

Owner:马鞍山金泉工业介质科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com