Cleaning head with a water spraying function and a wet vacuum cleaner having the cleaning head

A cleaning head and functional technology, applied in the direction of vacuum cleaners, cleaning equipment, suction nozzles, etc., can solve the problems of scratching the cleaning surface, poor cleaning ability of the wiping head, and the inability of the nozzle to spray liquid, etc., to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

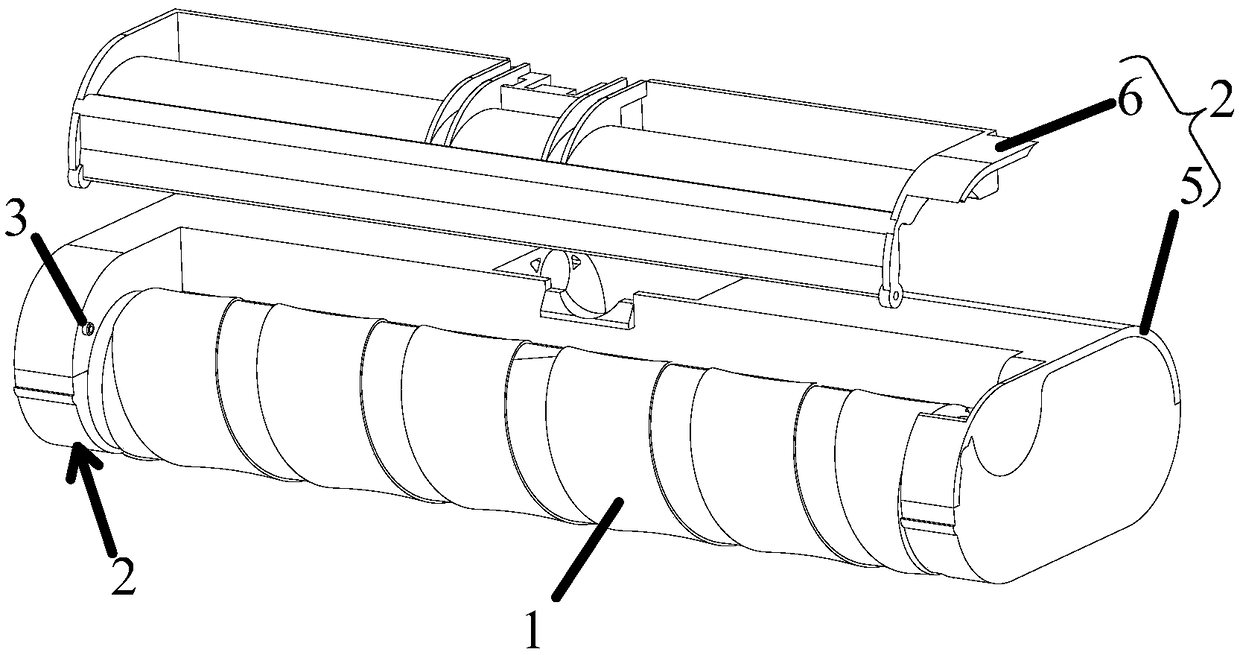

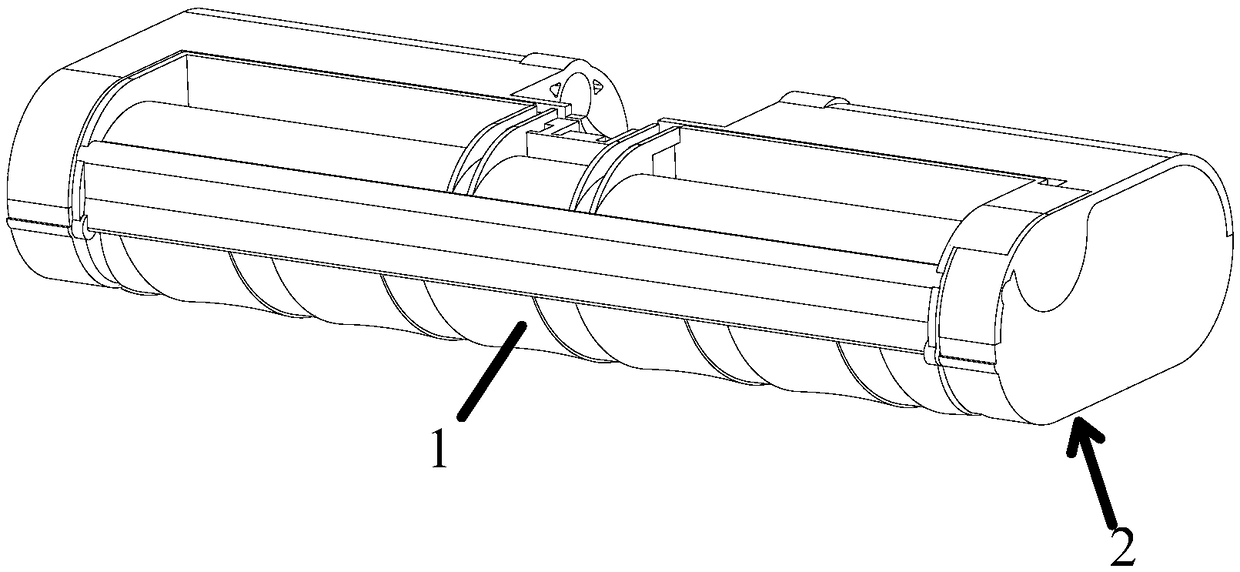

[0047] This embodiment provides a wet vacuum cleaner, including: a cleaning head with a water spray function and a dust suction mechanism, the suction port of the dust suction mechanism is connected to the inner cavity of the shell 2 that accommodates the cleaning head and its wiper head 1 Pass. The cleaning head, such as figure 1 with figure 2 shown, which includes

[0048] Wiping head 1 is a rolling brush rod that is driven to rotate;

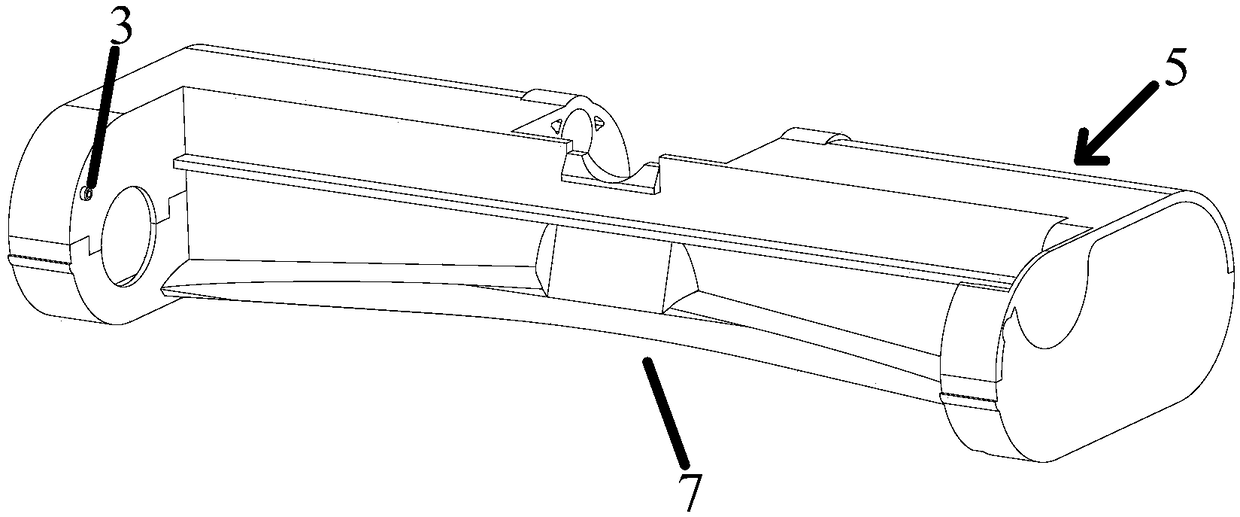

[0049] Shell 2, such as image 3 with Figure 4 As shown, it includes a base 5 and an upper cover 6 that is detachably connected to the upper part of the base 5, and the base 5 and the upper cover 6 enclose a long strip-shaped brush head that accommodates the rolling brush rod. The cavity 7, the base 5 is provided with a pipeline cavity 11 of a C-shaped structure for accommodating the liquid supply pipeline 4, such as Figure 7 with Figure 8 As shown, the liquid supply pipeline 4 includes a liquid supply main pipe 8 and two liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com