Electronic control unit for motor vehicle braking systems

A technology of electronic control unit and hydraulic unit, which is applied in the direction of brakes, mechanical equipment, fluid pressure actuators, etc., to achieve the effects of favorable cooling, improved flexibility, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

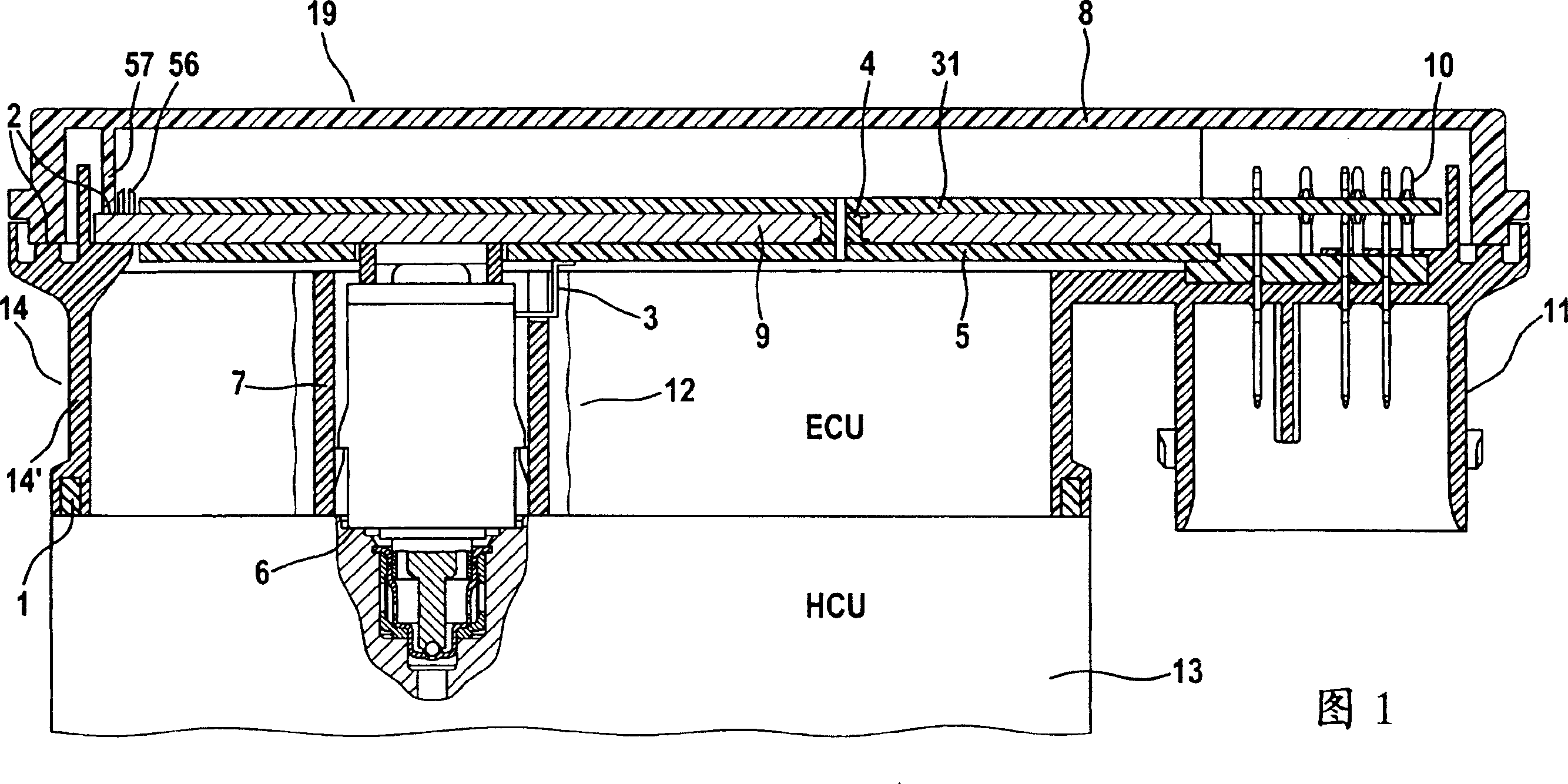

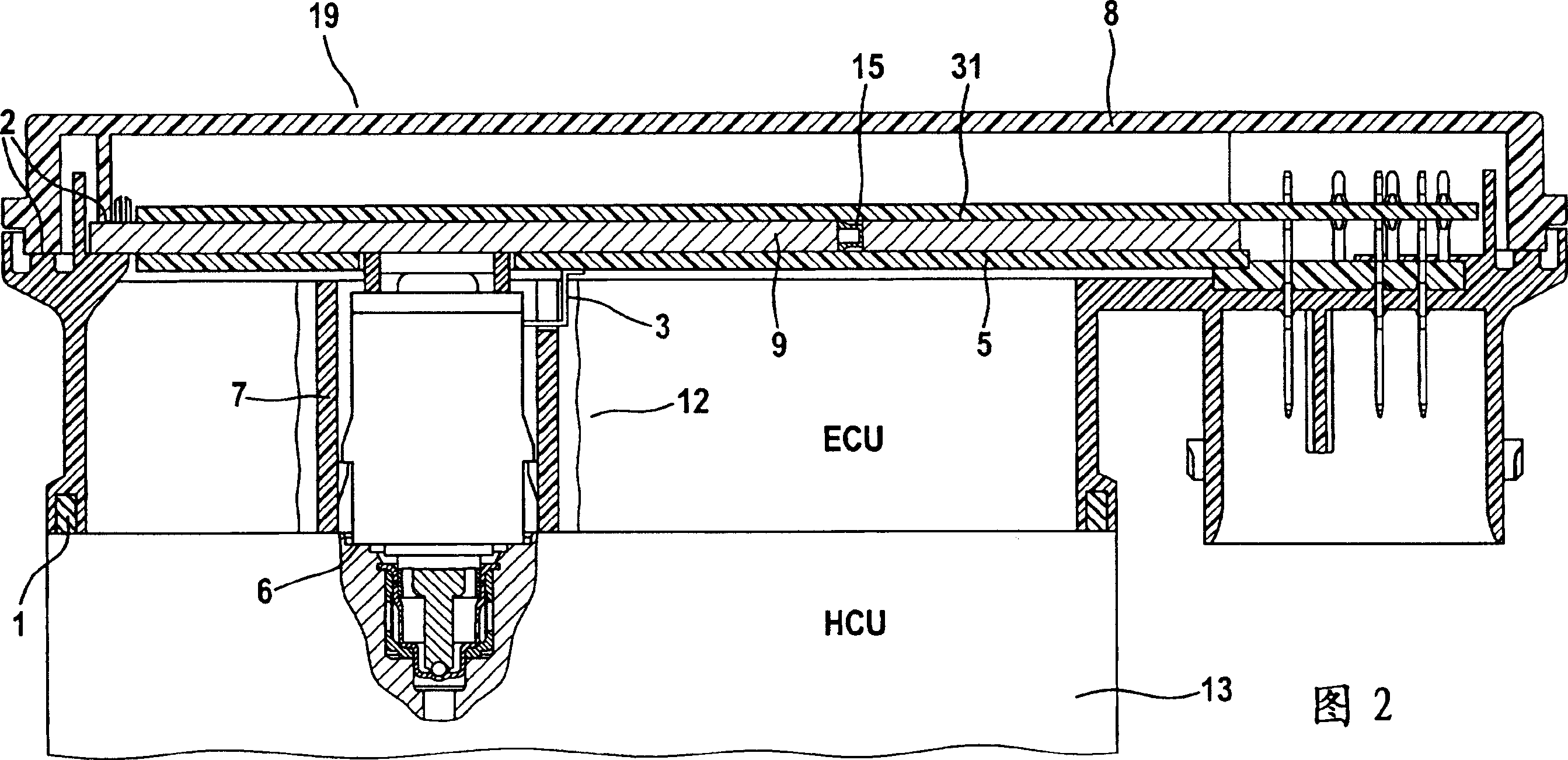

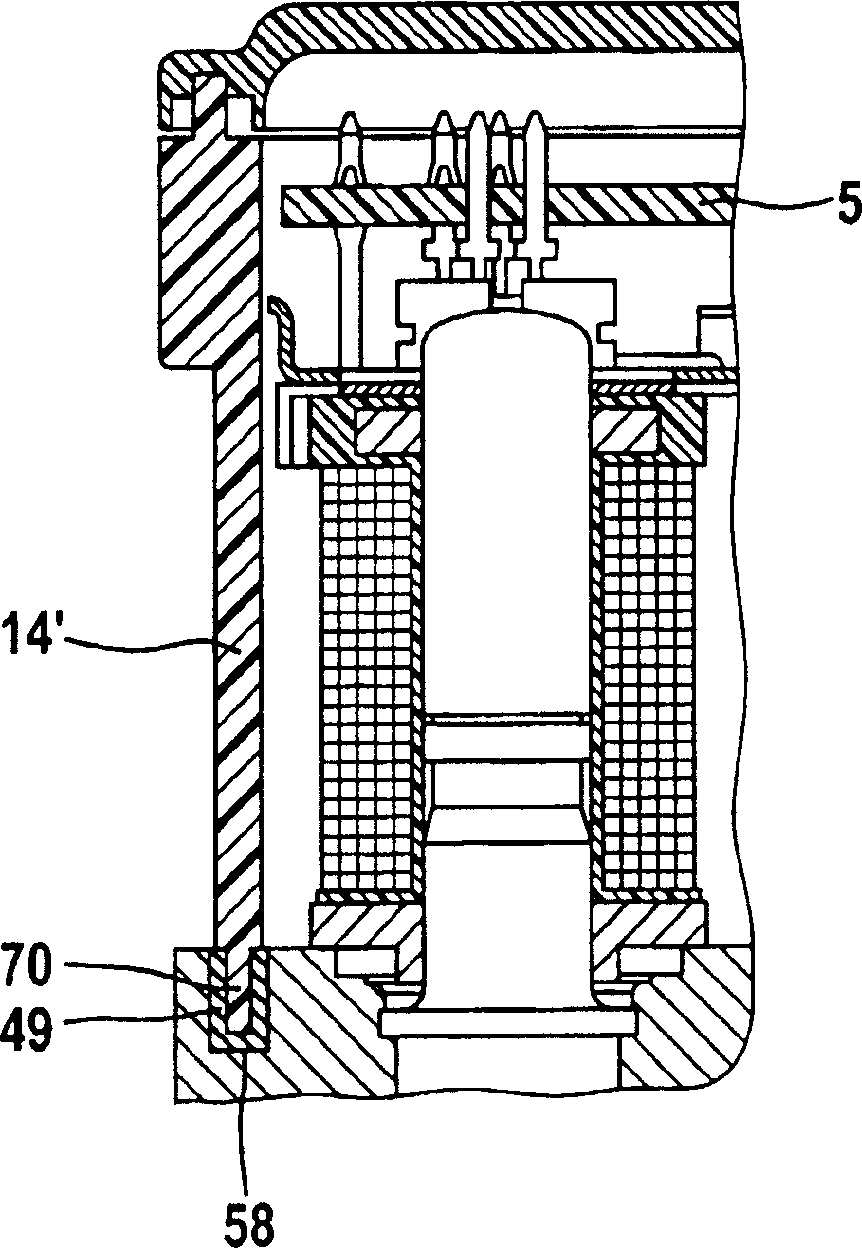

[0045]FIG. 1 shows the ECU 14 mounted on the HCU 13 . In the ECU, the assembly consisting of the printed circuit board 31 , the aluminum heat-conducting plate 9 and the further printed circuit board 3 is inserted into the controller housing 14 of the ECU. The housing 14 is sealed against the HCU in the region of the housing wall 14 ′ by means of the surrounding seal 1 . The sealing device 1 is preferably produced from a hose material and inserted into the housing groove. In the assembly consisting of the printed circuit boards 31 and 3 and the heat conducting plate 9, the cylindrical heat conducting body 4 (in this example only one heat conducting body is shown for simplicity) not only represents a heat conducting bridge, but also establishes the connection between the two printed circuit boards. Make electrical contact between the circuit boards 31 and 3. The heat conductor 4 is preferably made of the same material as the heat conductor plate 9 . This offers the advantage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com