Patents

Literature

70results about How to "Meet the mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

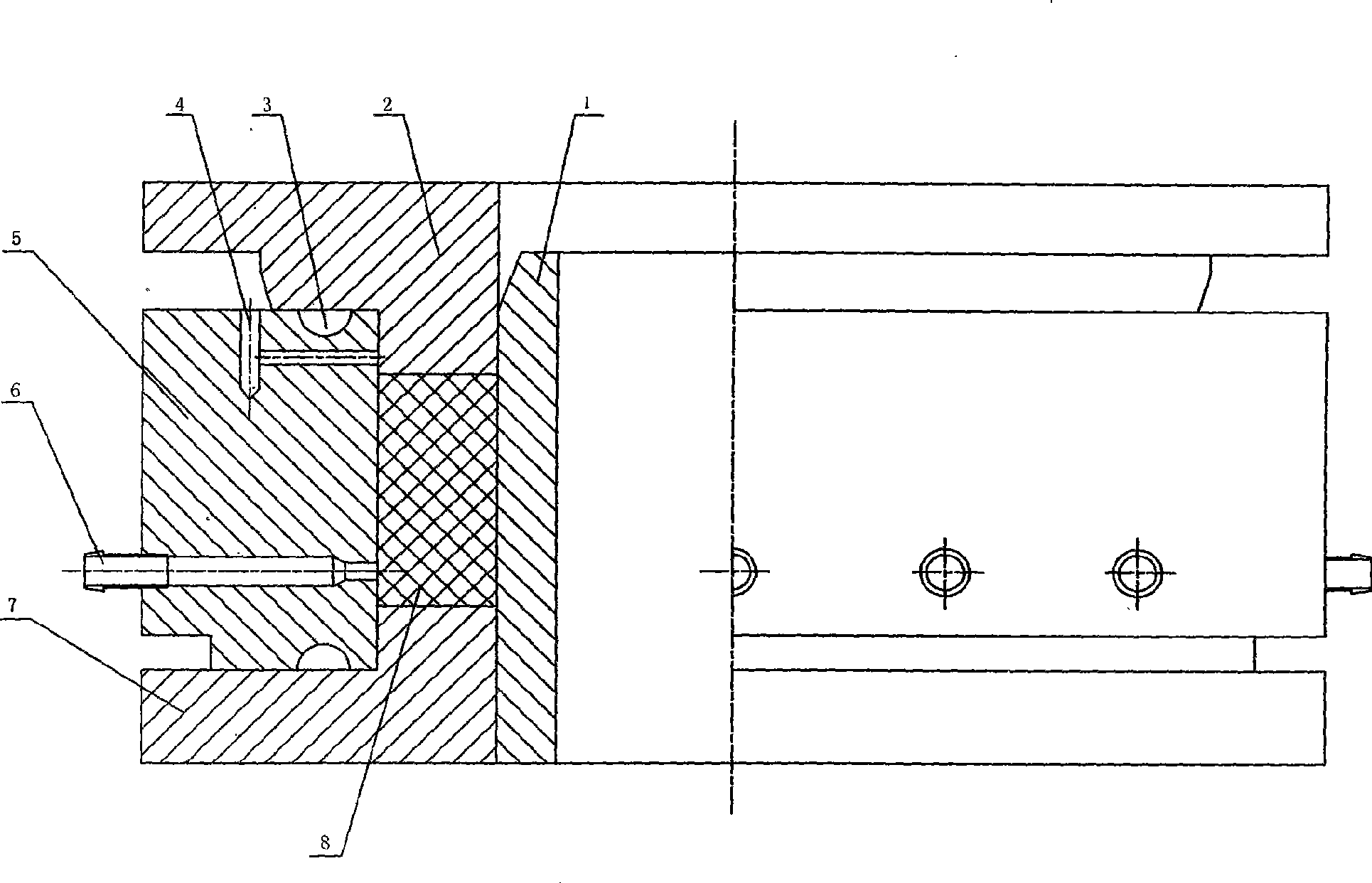

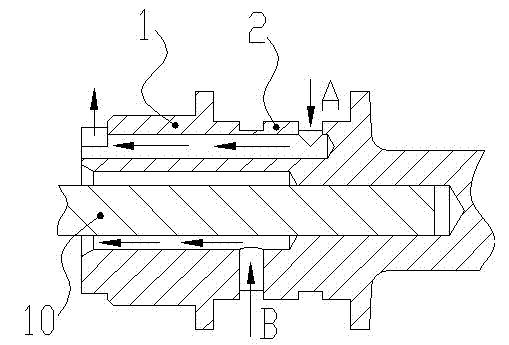

Electronic control unit for motor vehicle braking systems

InactiveCN1898112AMeet electromechanical requirementsMeet electromechanical requirements such as mechanical strengthServomotor componentsCooling/ventilation/heating modificationsElectricityElectronic structure

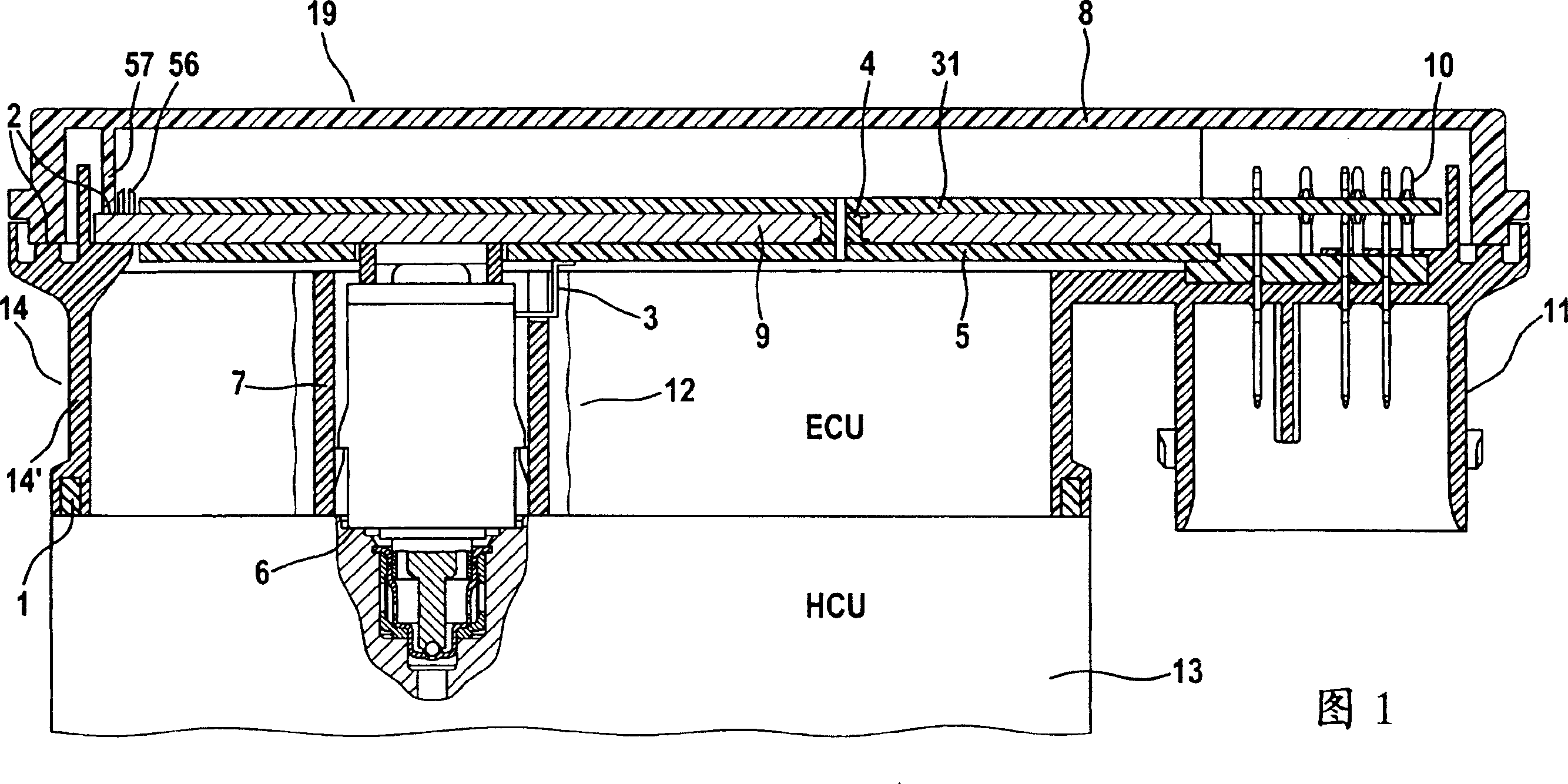

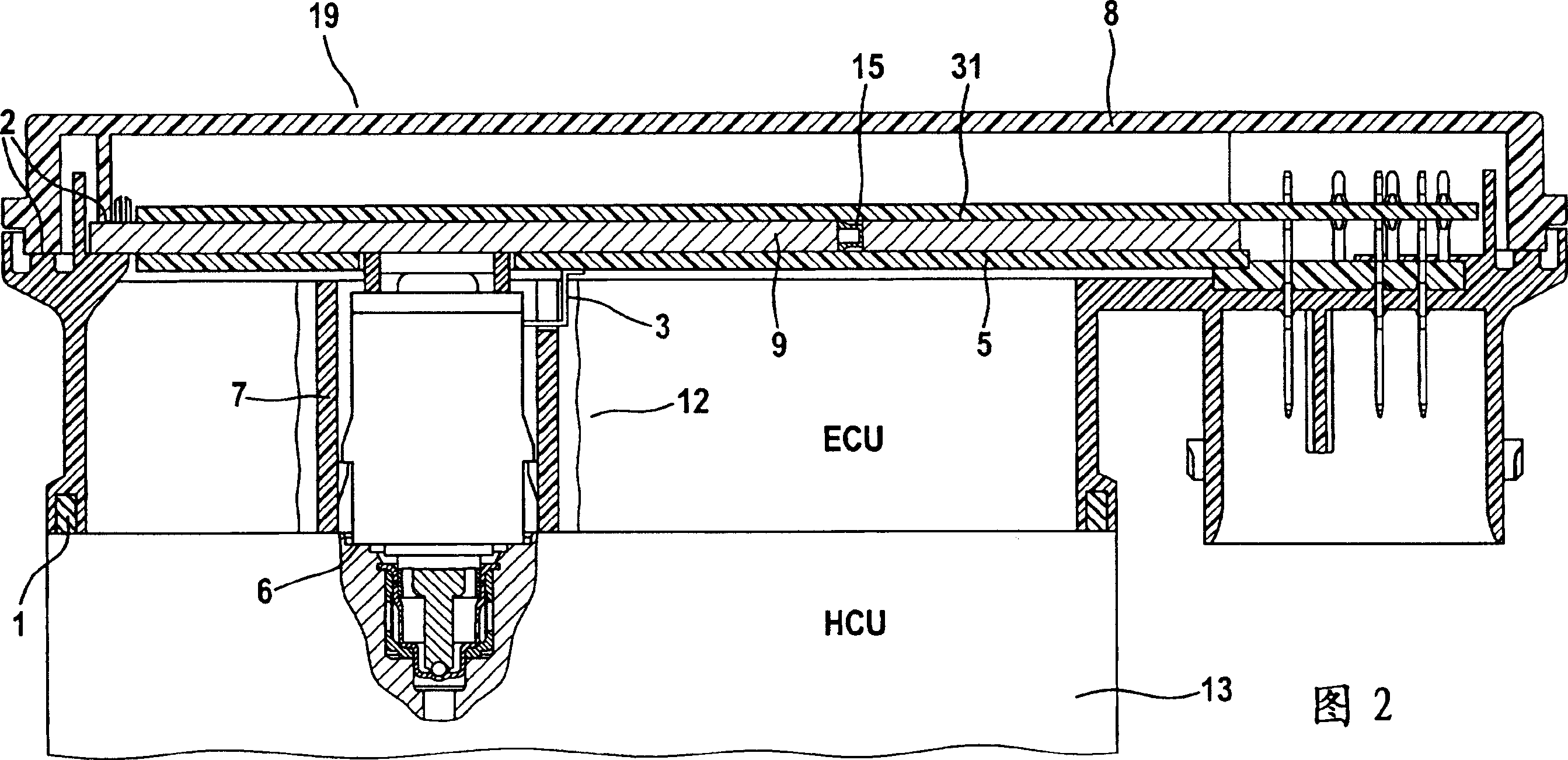

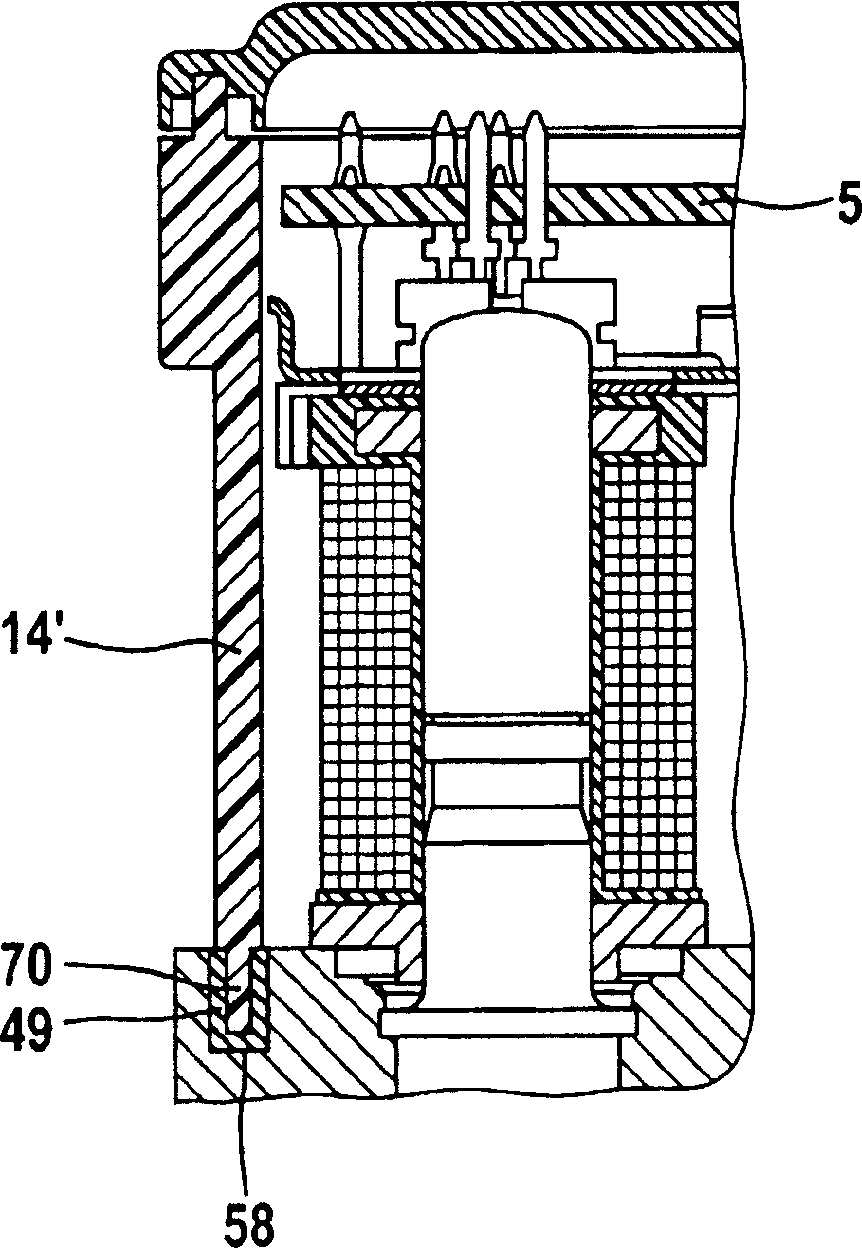

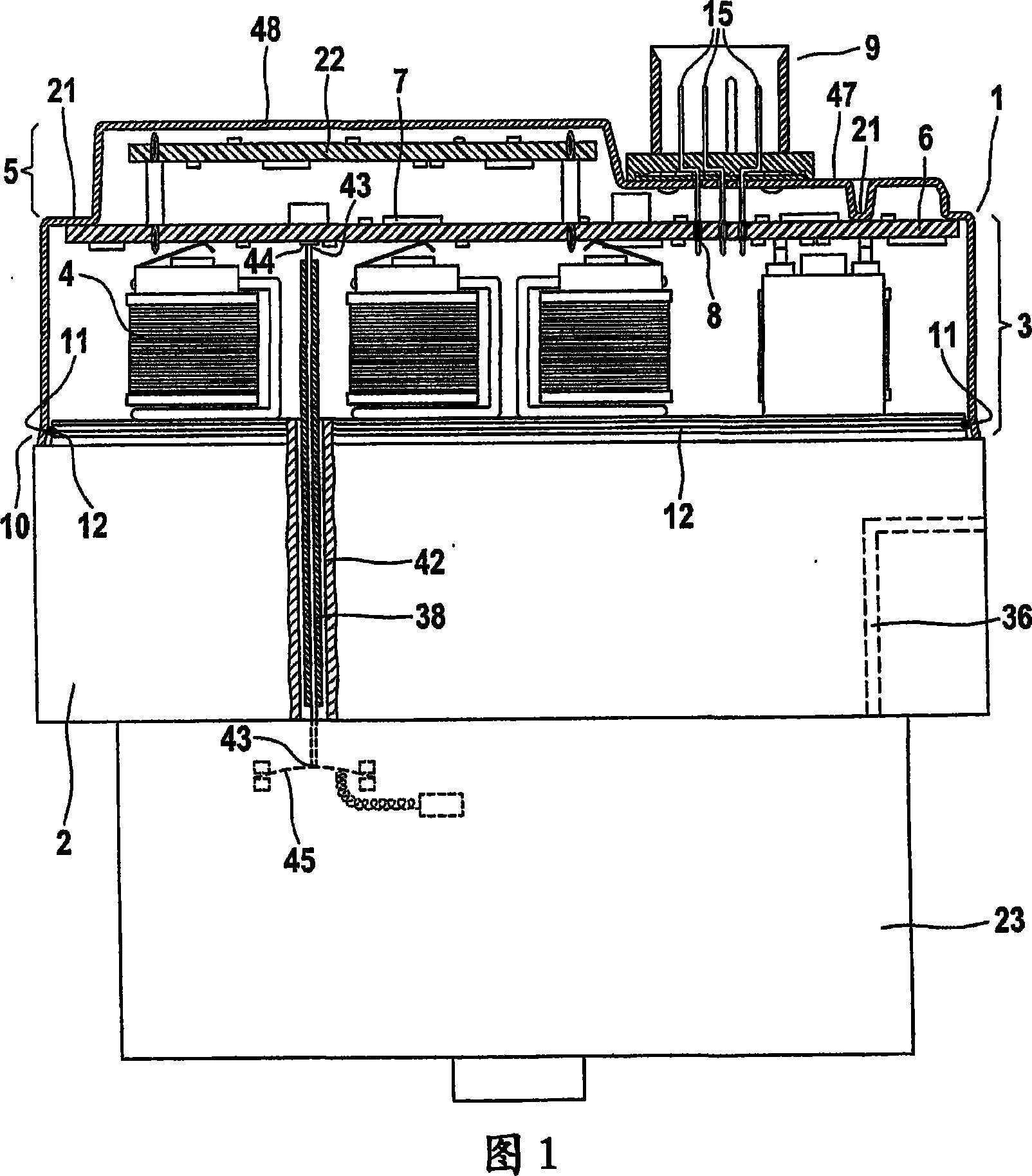

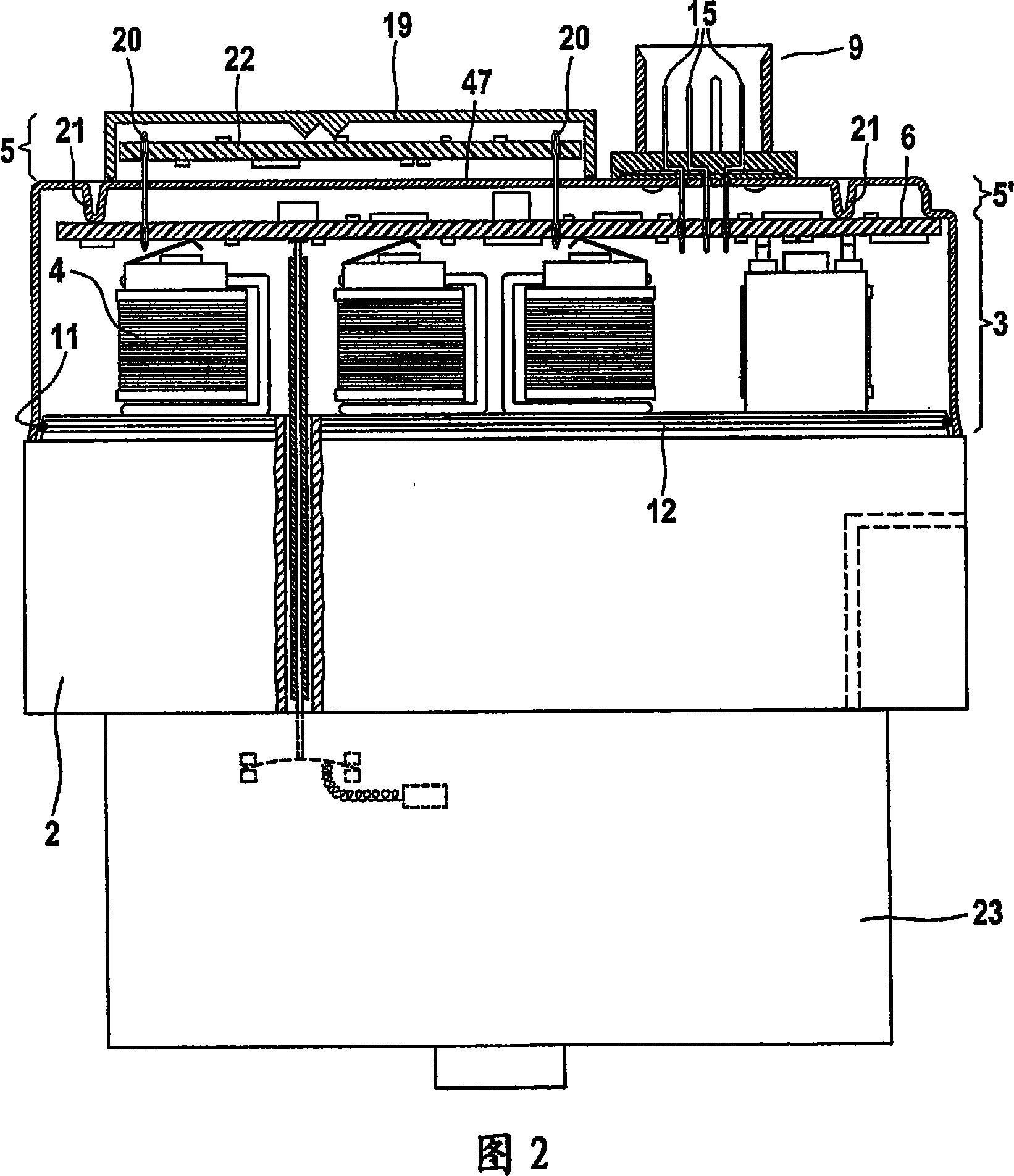

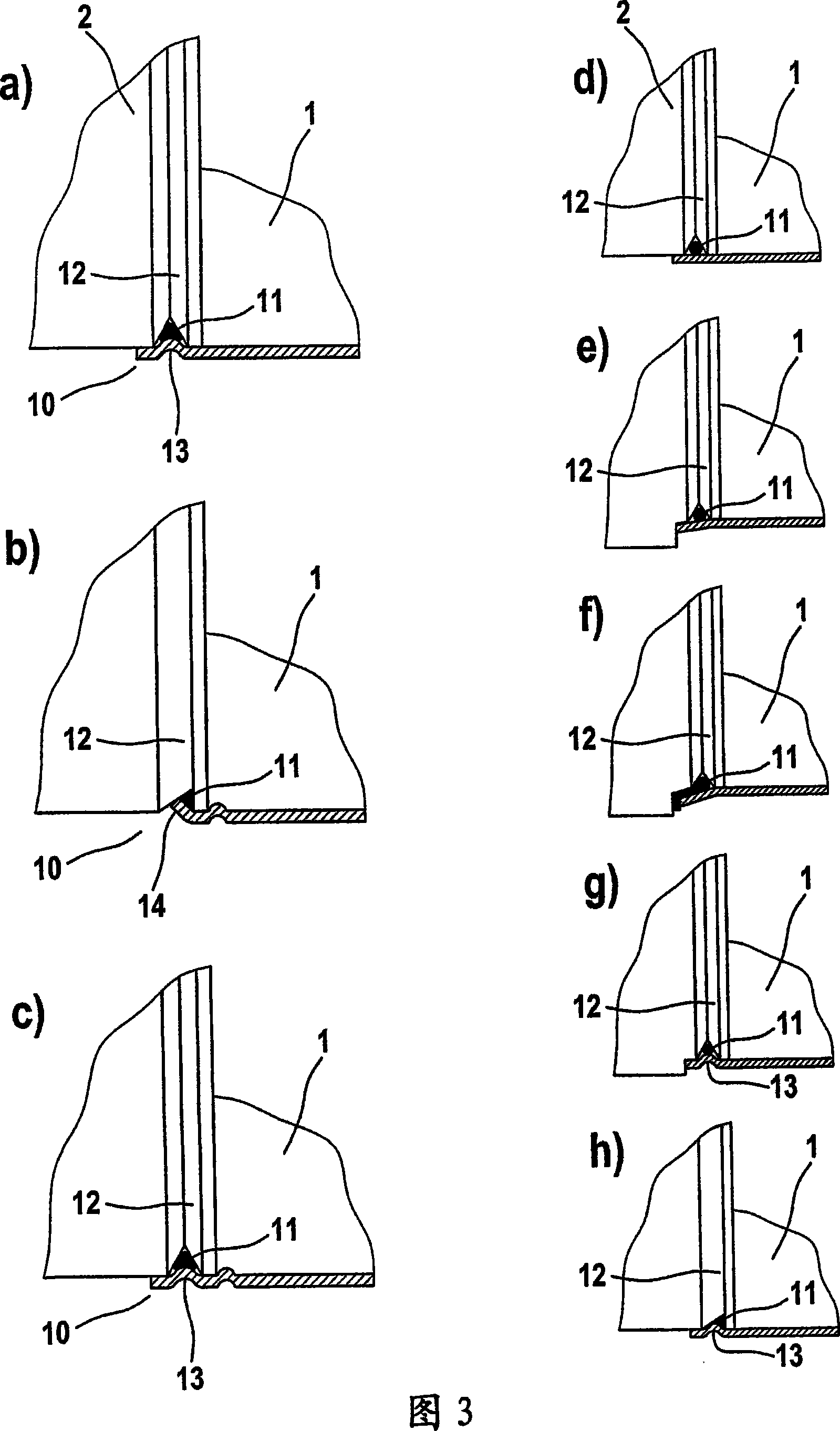

The invention relates to an electronic control unit (14), in particular in motor vehicle braking systems, which is connected to a hydraulic unit (13) by means of a magnetic connector. Said electronic control unit comprises: an area formed by the housing walls (14'), said area being used to receive several valve coils (12) which are arranged in said area, a housing cover (8, 35), at least one first circuit board (31, 5) which is used to receive electric and / or electronic components and an electric contact part and one first heat conducting plate (9, 32) which is used to guide heat away from the electronic components. The first heat conducting plate is connected in a flat manner to the first circuit board, and at least one heat connecting element (4, 15) which produces a thermal bridge between the first circuit board(s) and the first heat conducting plates, is provided. The invention also relates to a pump drive unit which co-operates with said control unit, whereby a motor base plate (22), for the electronic power components of the motor, is provided. The invention further relates to an electrohydraulic control device, wherein one or several elongate heat conducting elements (172) are arranged, said elements being in contact with the hydraulic block (13) and the cooling element (9) in order to form a thermal bridge. One longitudinal side of the heat conducting elements (172) is connected, in a positive or non-positive fit, to the hydraulic block or to the cooling element (9) and the opposite longitudinal sides thereof (1712) are arranged on the hydraulic block or the cooling element without the detachable non-positive fit connection.

Owner:CONTINENTAL TEVES AG & CO OHG

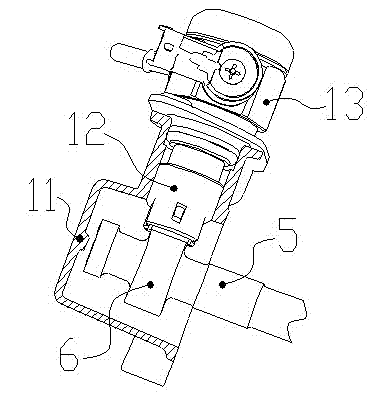

Electrohydraulic pressure control device for automotive brake systems

InactiveCN101084142AMeet electromechanical requirementsMeet the mechanical strengthBraking componentsElectrical apparatus contructional detailsEngineeringElectron

The present invention relates to a electrohydraulic pressure control device for vehicle braking system. The device comprises a electron control unit (1) connecting with hydraulic pressure component (2). The control unit comprises a shell volume area (3) which can contain multiple valve loops (4), a shell cover area (5, 5') of the control unit shell, at least a first print circuit board (6) which is arranged with electric and / or electronic component as well as a electric coupling device (8) of conjugation plug, at least an adapter (38) of a motor unit which is used to joint hydraulic pressure unit, the adapter extends and passes through the hydraulic pressure component. The adapter comprises one or more electric pressure contact points (43) on one end or two, the electric pressure contact points push down on one or more interfaces (44, 45) through elastic force.

Owner:CONTINENTAL TEVES AG & CO OHG

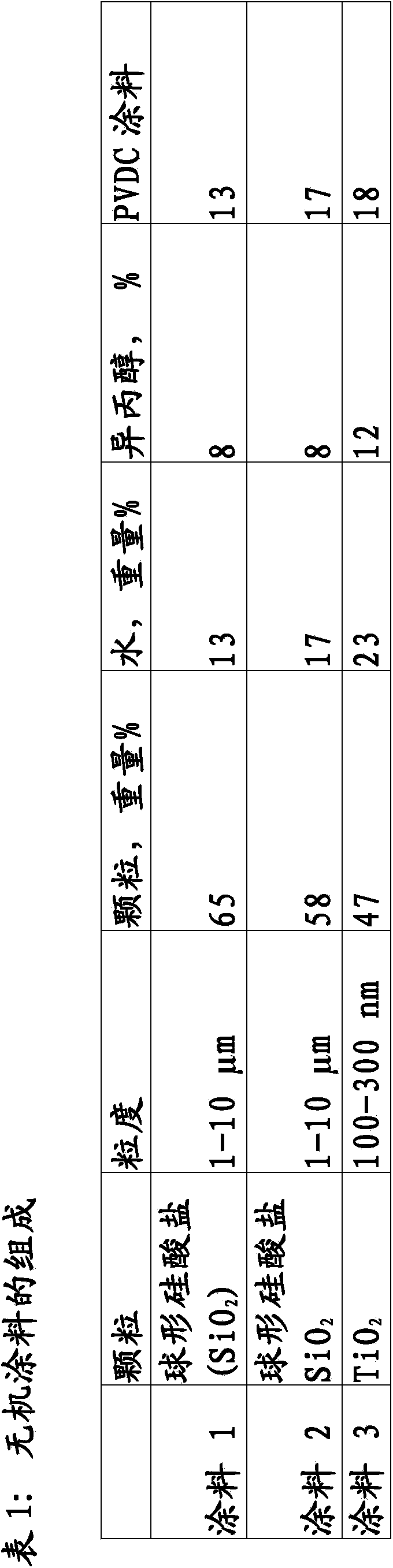

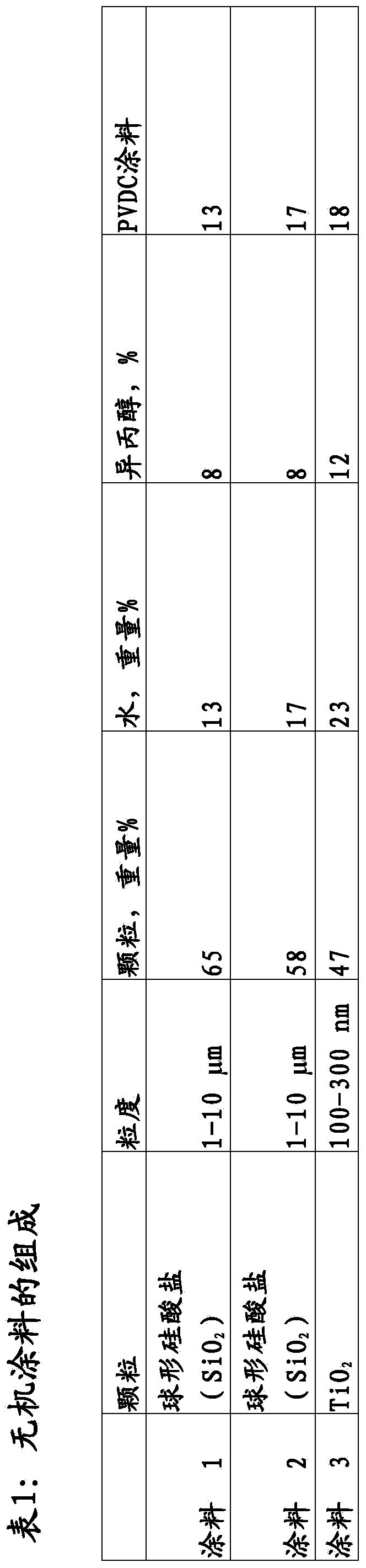

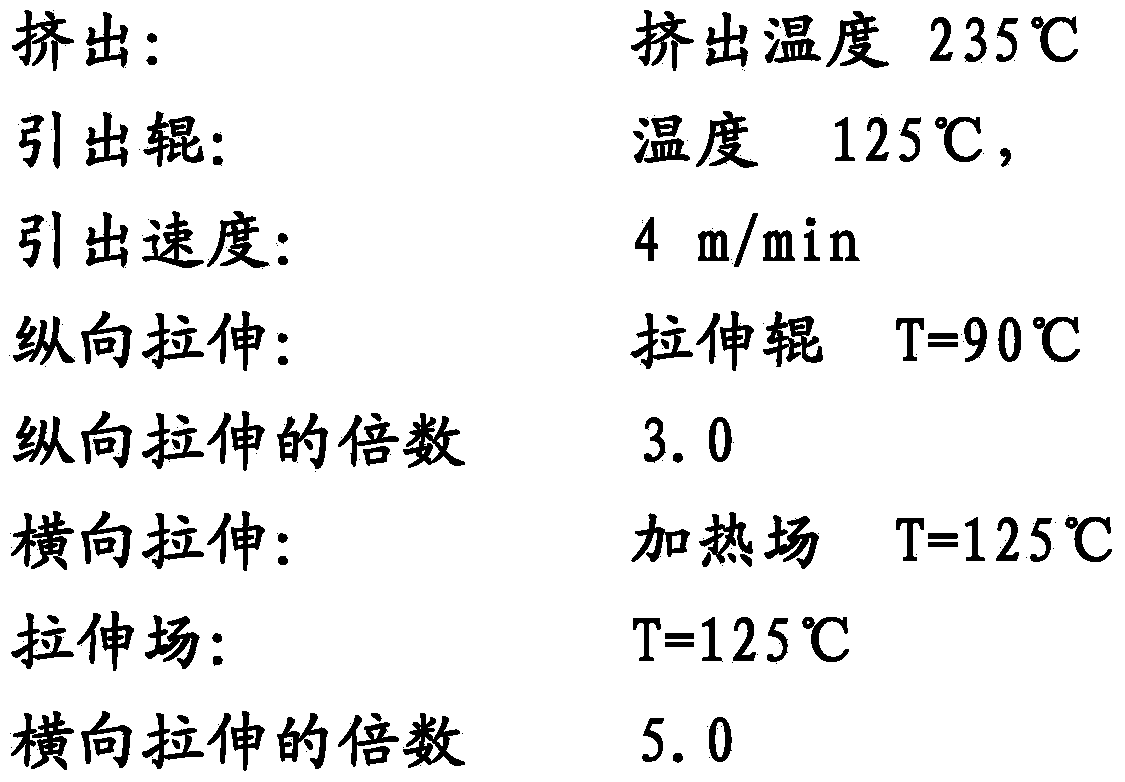

Highly-porous separator film with a coating

InactiveCN103988336AMeet the mechanical strengthRequirements for low tearing tendencySynthetic resin layered productsLi-accumulatorsAlkaline earth metalHigh energy

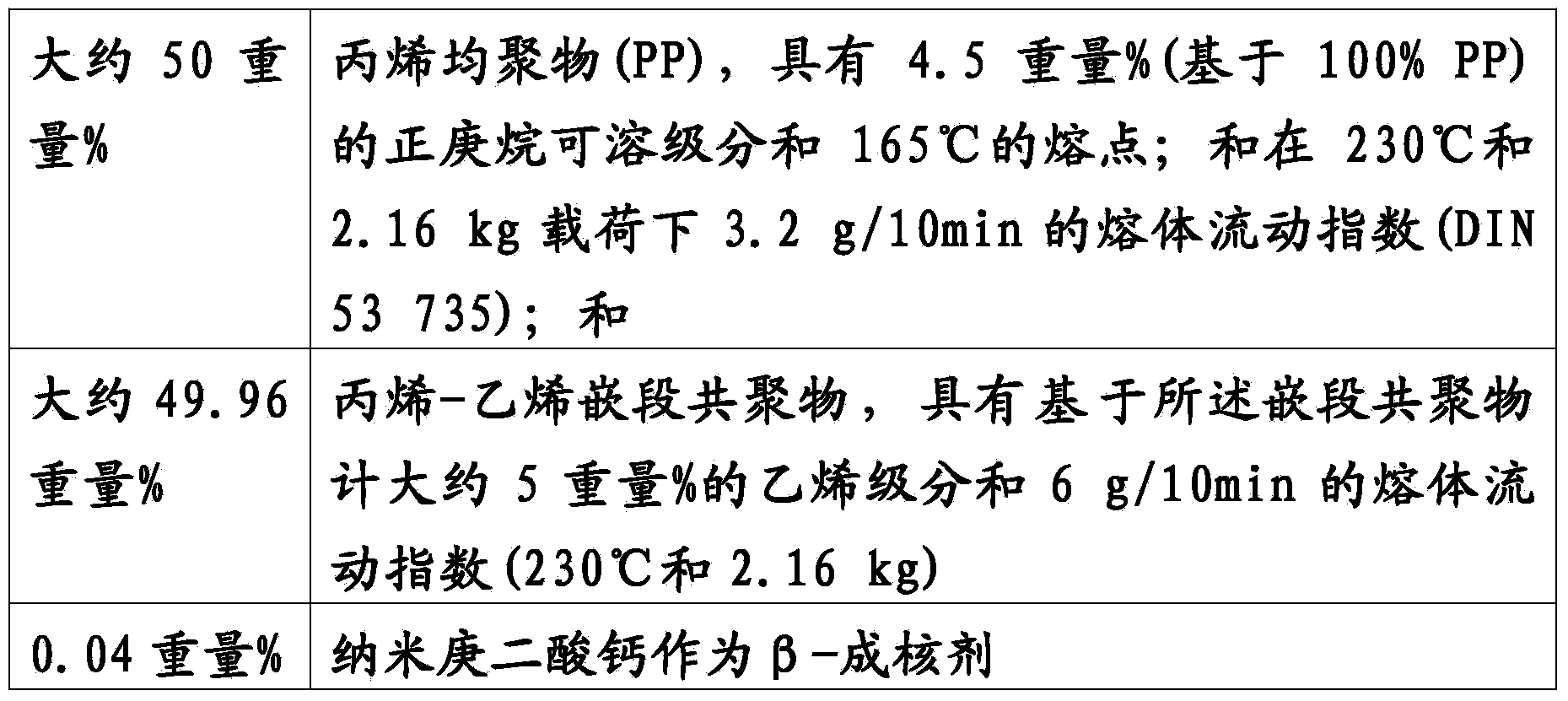

The invention relates to a bi-axially oriented, single or multi-layered porous film comprising at least one porous layer that contains at least one propylene polymer, (i) the porosity of this porous film being between 30% and 80%, (ii) the permeability of the porous film being <1000s (Gurley value), and this being characterized in that (iii) said porous film has an inorganic, preferably ceramic, coating and that (iv) the coated porous film has a Gurley value of <1500s. In addition, the invention also relates to a method for producing such a film as well as to the use thereof in high-energy or high-power systems, particularly in lithium, lithium-ion, lithium-polymer, and alkaline-earth batteries.

Owner:TREOFAN GERMANY GBMH & CO KG

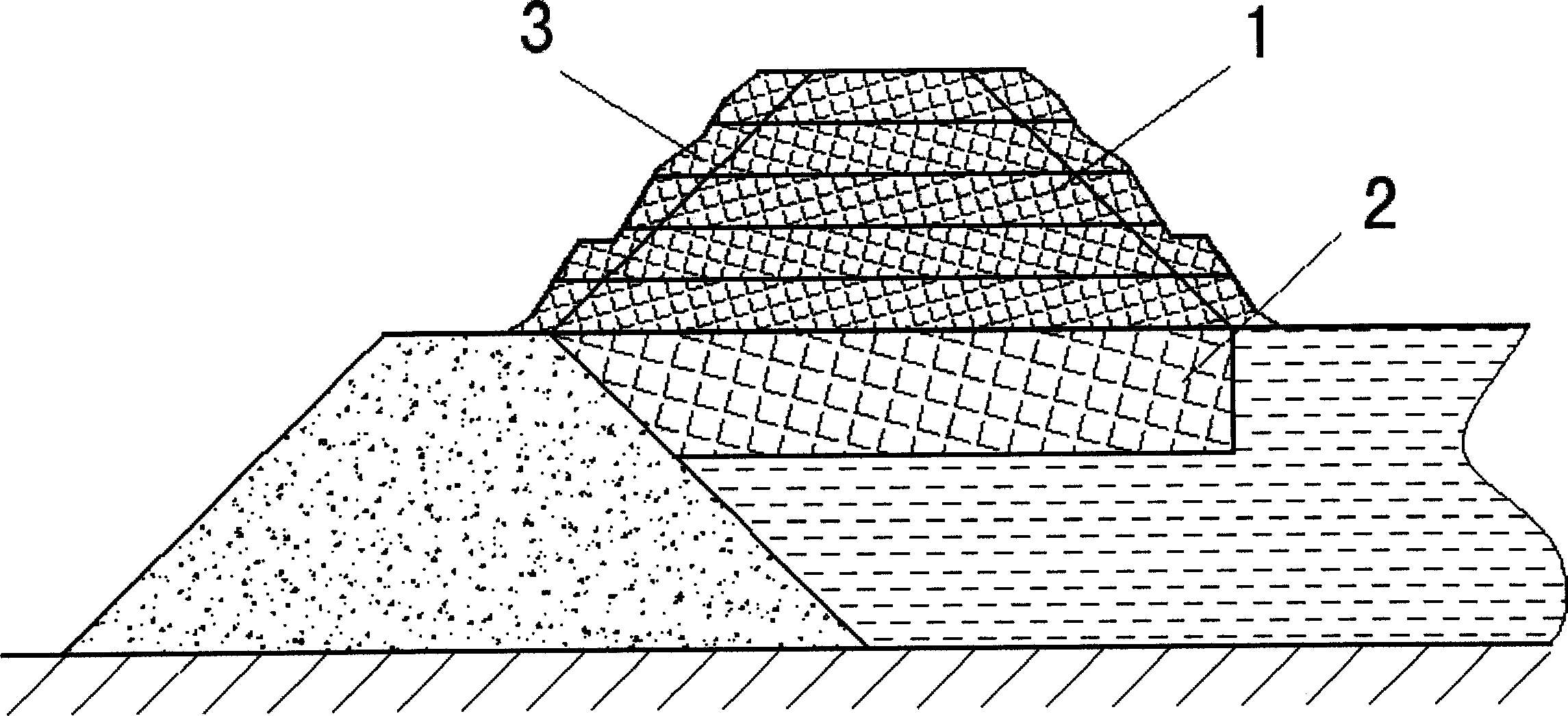

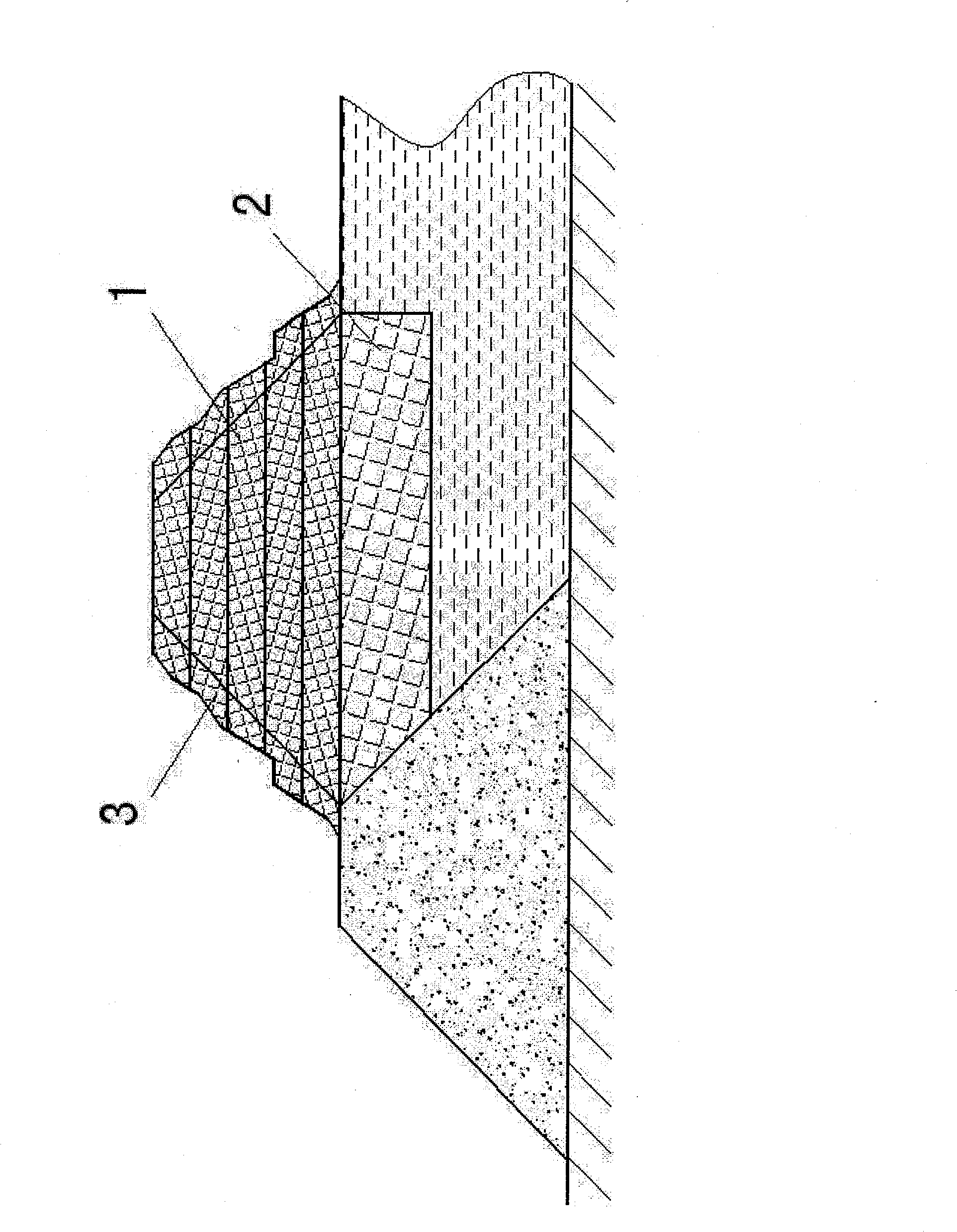

Sub-dam construction method of Bayer process red-mud dry-stacking field

ActiveCN1850666AIncrease storage capacityMeet the mechanical strengthSludge treatmentEmbankmentsBayer processEngineering

The invention discloses a subdam constructing method using Bayer red mud dry storage ground, constructing a subdam on the red mud on inner edges of an initial-stage dam staked with red mud, and comprising the steps of: batching, subdam foundation firming, subdam body rolling moudling, and subdam body finishing. And it is aimed at the red mud dry storing mode in the Bayer production, able to meet mechanical strength for stabilizing the red mud storage ground in the dry storing mode, and able to obtain larger storage capacity in a limited storage ground area.

Owner:GUIYANG AL-MG DESIGN & RES INST

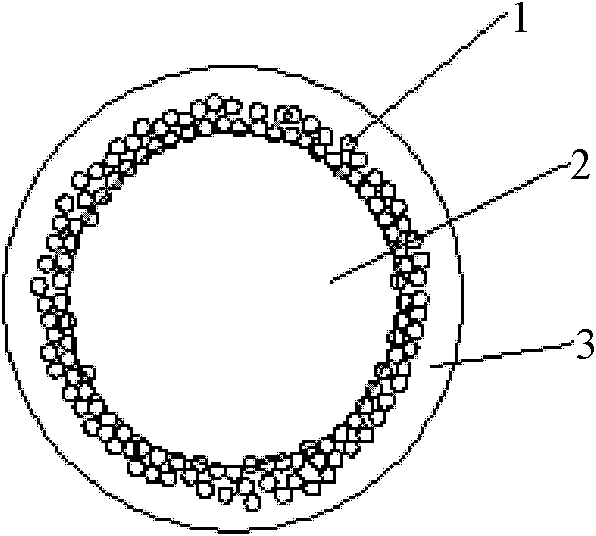

Electronic ink microcapsule and preparation method thereof

ActiveCN102641703ALow dielectric constantGood chemical stabilityInksMicroballoon preparationLow voltageElectrophoresis

The invention relates to an electronic ink microcapsule and a preparation method thereof. The electronic ink microcapsule comprises a capsule wall and a capsule core (2), wherein the capsule wall comprises a gelatin layer (1) and a silicasol layer (3). The electronic ink microcapsule is prepared from gelatin and silicasol by complex coacervation. In the electronic ink microcapsule provided by the invention, since the alkaline silicasol is used as a solid stabilizer and the capsule wall has a low dielectric constant, the electronic ink microcapsule can be driven by low voltage, thus the energy consumption and cost are reduced. Moreover, since the silicasol has good chemical stability and can generate a condensation reaction with gelatin to form tight combination, the barrier property of the microcapsule wall against the electrophoretic medium is obviously improved, so that the capsule wall meets the requirements for mechanical strength and flexibility simultaneously, and the microcapsule can be applied to flexible display.

Owner:BOE TECH GRP CO LTD

Multifunctional insulating baffle

ActiveCN103915781AGood technical effectAvoid irregular installationApparatus for overhead lines/cablesButt jointPush pull

The invention discloses a multifunctional insulating baffle. The multifunctional insulating baffle comprises two insulating baffle bodies. Each insulating baffle body is provided with a telescopic insulating hook. The two sides of the insulating baffle bodies are provided with guide rails. The guide rails are connected with push-pull folded wings. The edge of each insulating baffle body is provided with a semicircular groove. The positions, at the two ends of the semicircular grooves, of the insulating baffle bodies are provided with locking type safety buckles. According to the multifunctional insulating baffle, the length of the telescopic insulation hooks can be adjusted according to the distance between upper-layer wires and lower-layer wires on site, so the problem that the wires can not be hung on the hooks due to the fact that the distance between the upper-layer wires and the lower-layer wires is larger than the length of the hooks of an original insulating hanging plate can be solved, and the phenomenon that the problem makes it inconvenient for operating personnel to climb up electric poles can be avoided; the stretching length of the insulating baffle can be adjusted according to the operation environment on site so that the wires can be hung regularly; meanwhile, the wires can be hung firstly and the stretching length of the insulating baffle can be adjusted secondly, and then the problems that the insulating baffle is hung irregularly and the safe distance is difficult to control in the hanging process due to a complex ambient environment and dense devices are avoided; furthermore, a certain mechanical strength can be met, and meanwhile it can be guaranteed that the two insulating baffle bodies are in butt joint with each other firmly and reliably.

Owner:STATE GRID CORP OF CHINA +1

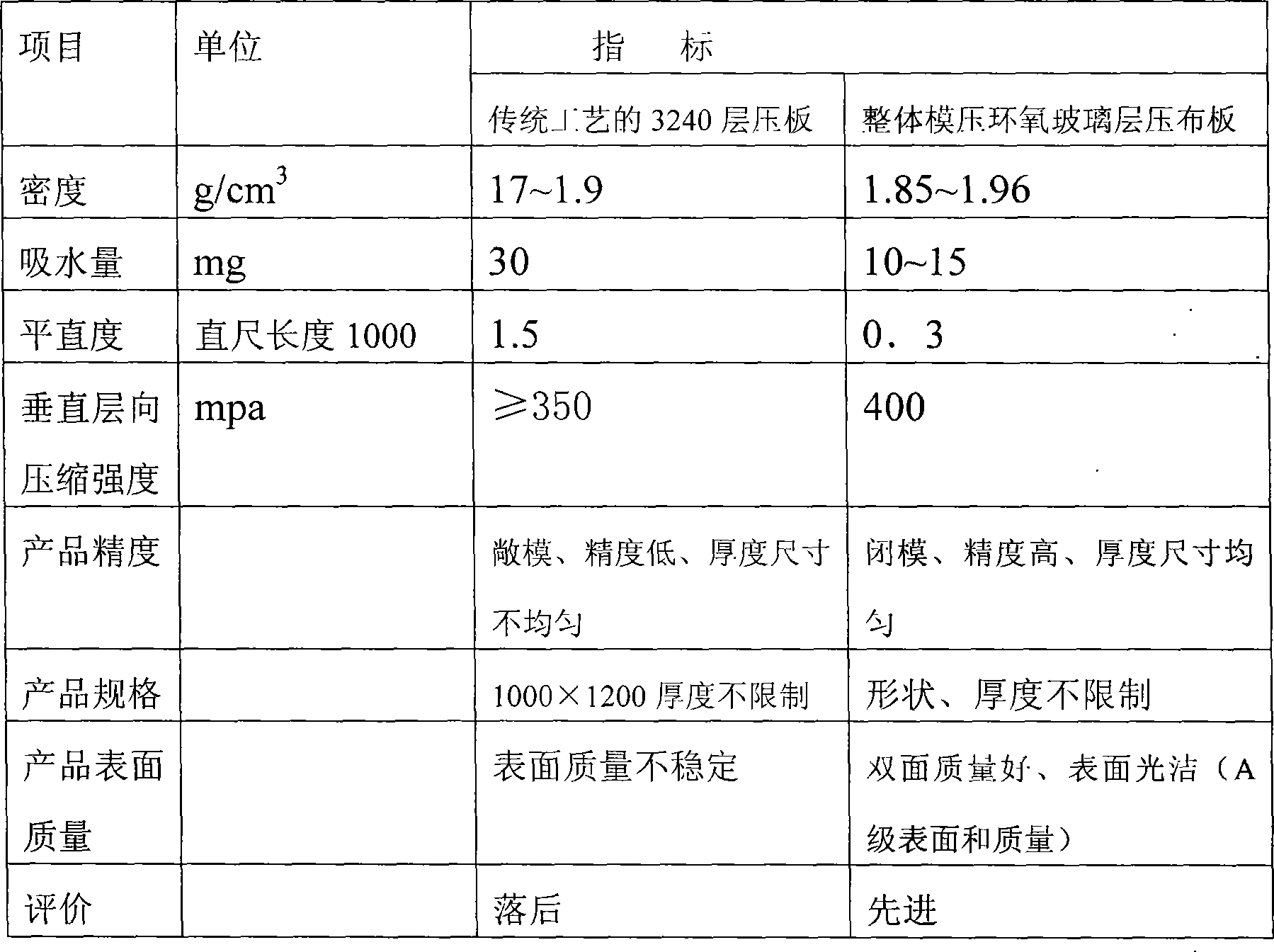

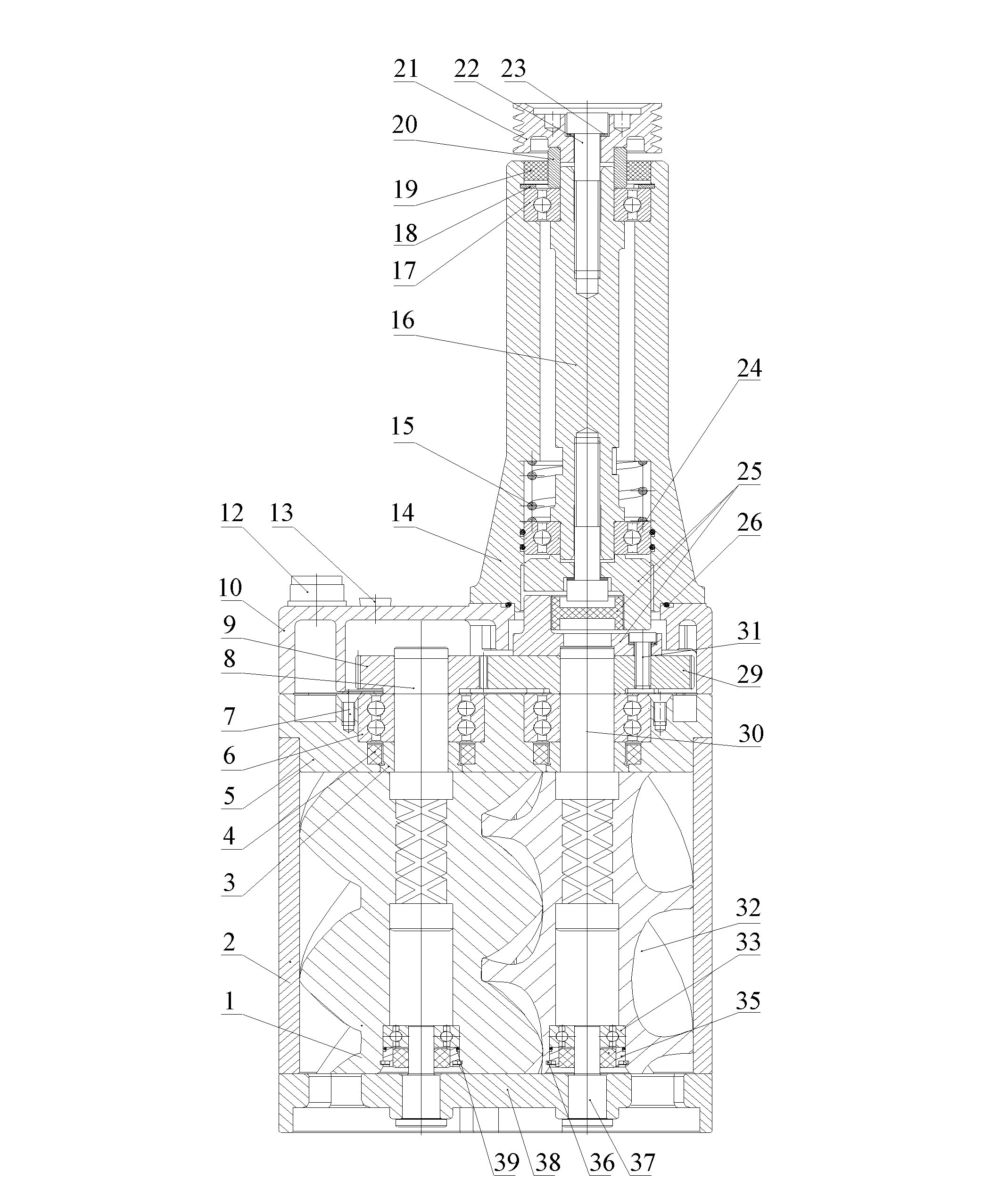

Process for manufacturing integral molding epoxy glass fibre laminated insulating joint pad

The invention provides a process for manufacturing a laminated insulating joint spacing piece by integrally moulding epoxy glass fibers, which relates to improvement of the process for manufacturing epoxy glass fiber laminated cloth, and comprises the following steps: 1) manufacturing a mould; 2) cutting fibers of each layer; 3) coating a mold release agent; 4) laying each fiber layer in the mould; 5) mixing epoxy resin and a curing agent, and degassing; 6) injecting glue; and 7) pressure forming and curing. The process has the advantages that the dimension of a gasket can be ensured by the dimension of the mould without lapping because of the adoption of mould forming, the micro air gap of the final product is reduced because of the adoption of a degassing process, and the requirements on electric insulation, mechanical strength, surface form and position tolerance and leak resistance are satisfied.

Owner:SHENYANG YONGYE IND

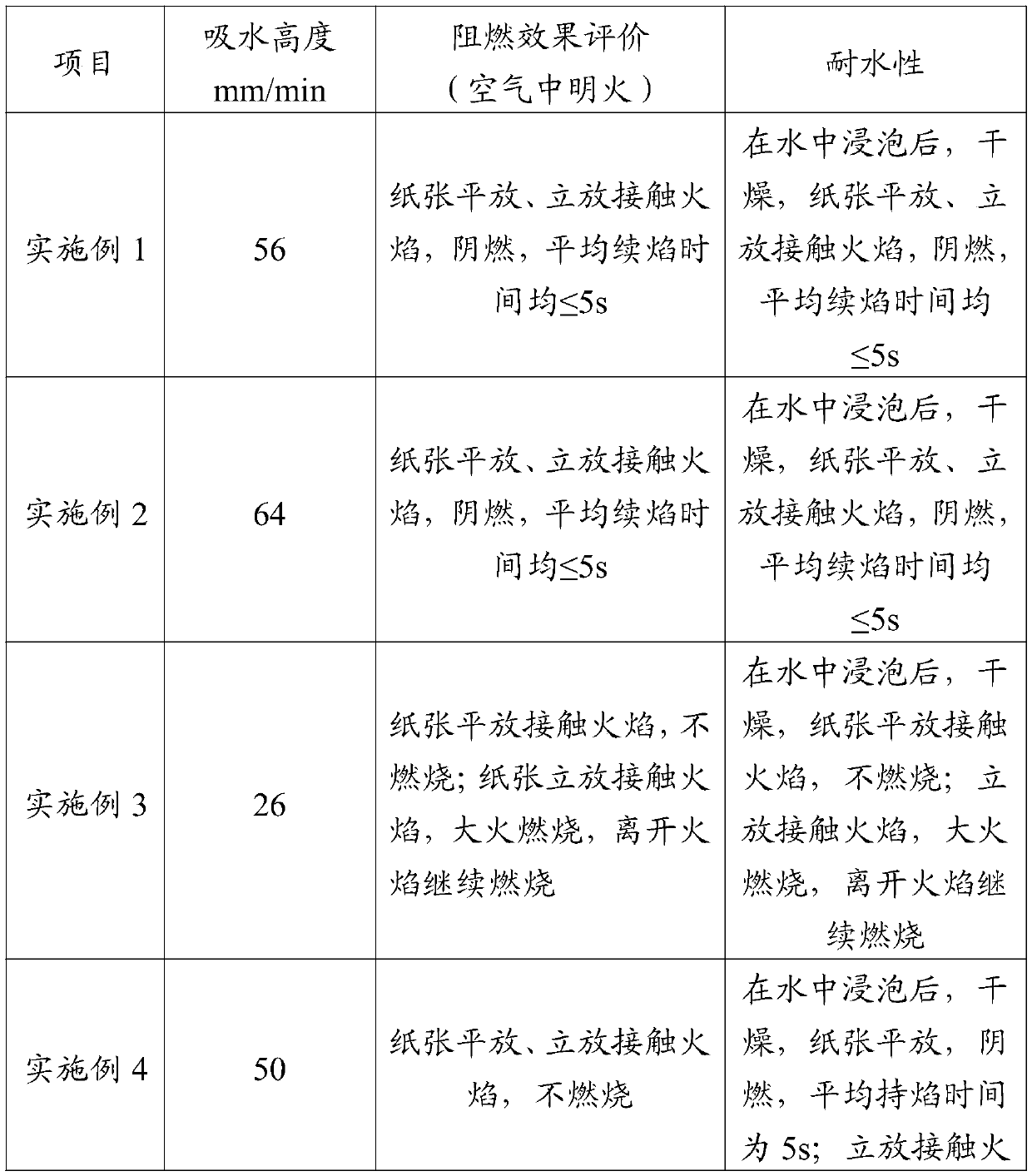

Waterproof and flame-retardant paper, and preparation method and application thereof

InactiveCN110644288AImprove water absorptionImprove water resistanceDefoamers additionSpecial paperPolymer sciencePlant fibre

The invention provides a waterproof and flame-retardant paper, and a preparation method and an application thereof, and belongs to the technical field of materials. The waterproof and flame-retardantpaper comprises fibers and assistants; the fibers comprise 70-90 wt% of flame-retardant fibers and 10-30 wt% of plant fibers; and the assistants comprise a wet strength agent and a defoaming agent, the using amount of the wet strength agent is 0.5-1.0% of the mass of the fibers, and the using amount of the defoaming agent is 0.01-0.1% of the mass of the fibers. The waterproof and flame-retardant paper has excellent water absorption, water resistance and flame retardancy, still has excellent flame retardancy after being soaked in water, has the advantage of low cost, and is suitable for being industrially applied.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

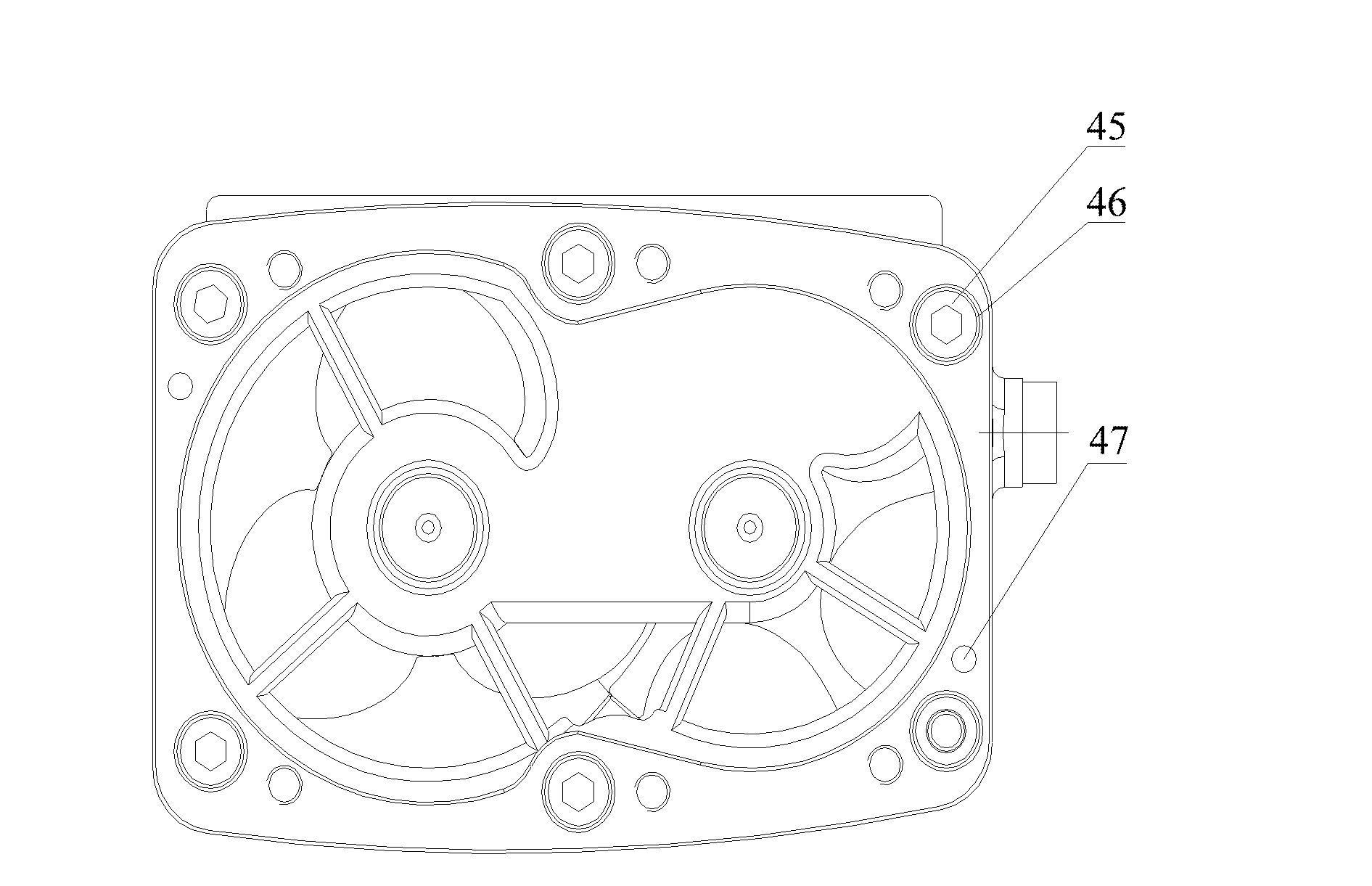

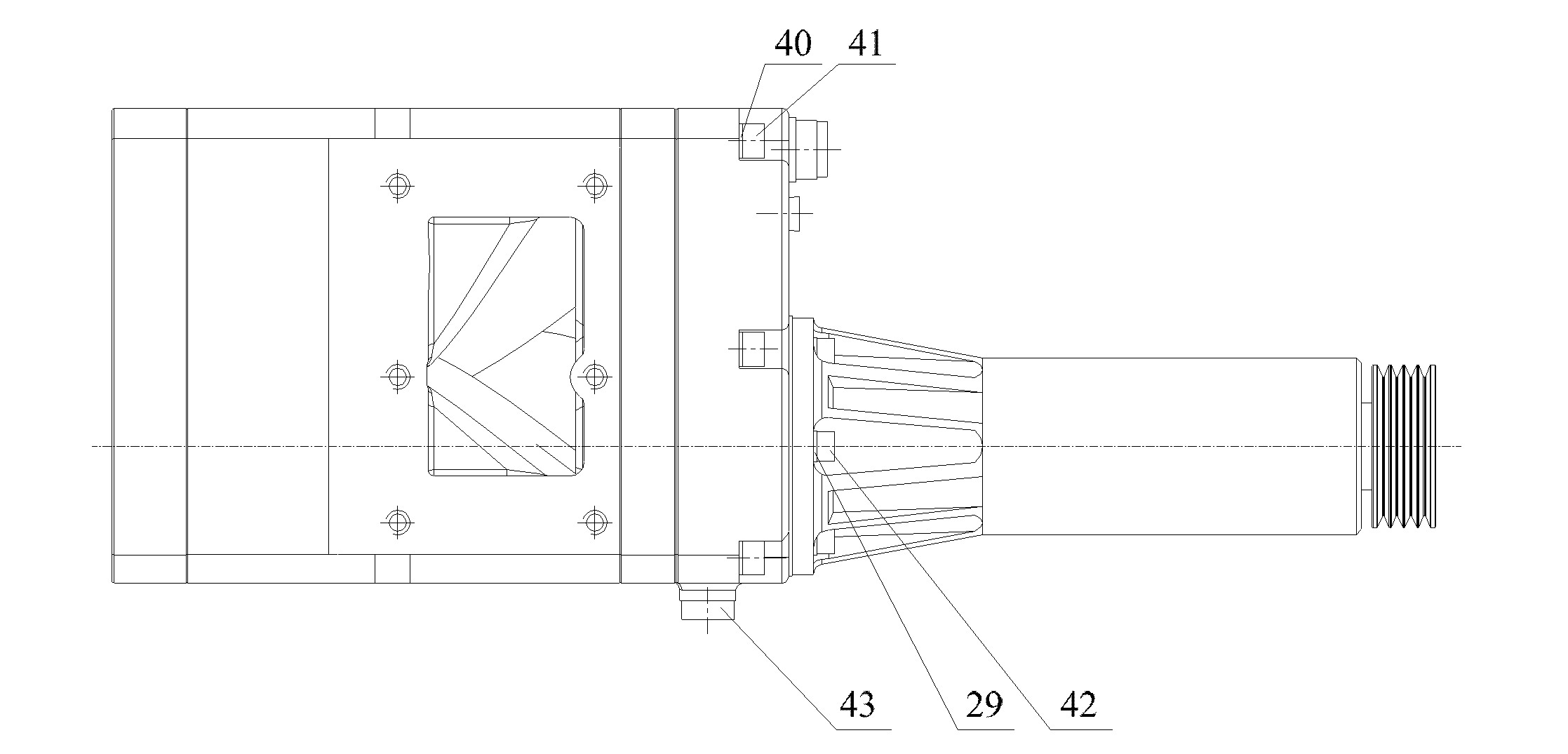

Oil-free double-screw compressor

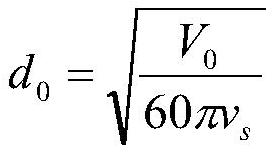

InactiveCN102352843AReduce processing difficultyMeet the mechanical strengthRotary piston pumpsRotary piston liquid enginesOil freeEngineering

The invention discloses an oil-free double-screw compressor. A male rotor is coaxially fixedly provided with a first axis embedding member and a female rotor is coaxially fixedly provided with a second axis embedding member; the first axis embedding member and the second axis embedding member are pivoted on a bearing block and are movably sealed together with the bearing block; the first axis embedding member and the second axis embedding member are hinged with an end cover of a synchromesh gear cavity; one end, which is located in the synchromesh gear cavity, of the first axis embedding member is fixedly connected with a small synchromesh gear; and one end, which is located in the synchromesh gear cavity, of the second axis embedding member is fixedly connected with a big synchromesh gear. Shaped line screw thread parts of the male rotor and female rotor of the oil-free double-screw compressor are manufactured from certain special materials which do not need to be subjected to heat treatment or certain special materials which are machined by other means difficult to deform, and the second axis embedding member of the female rotor and the first axis embedding member of the male rotor are manufactured from materials which meet the mechanical strength requirements, so that the machining difficulty of the male rotor and the female rotor is reduced when the special materials are used, and the application range of the oil-free double-screw compressor is widened.

Owner:江西隆恒科技有限公司

High-porosity separator film with coating and shut down function

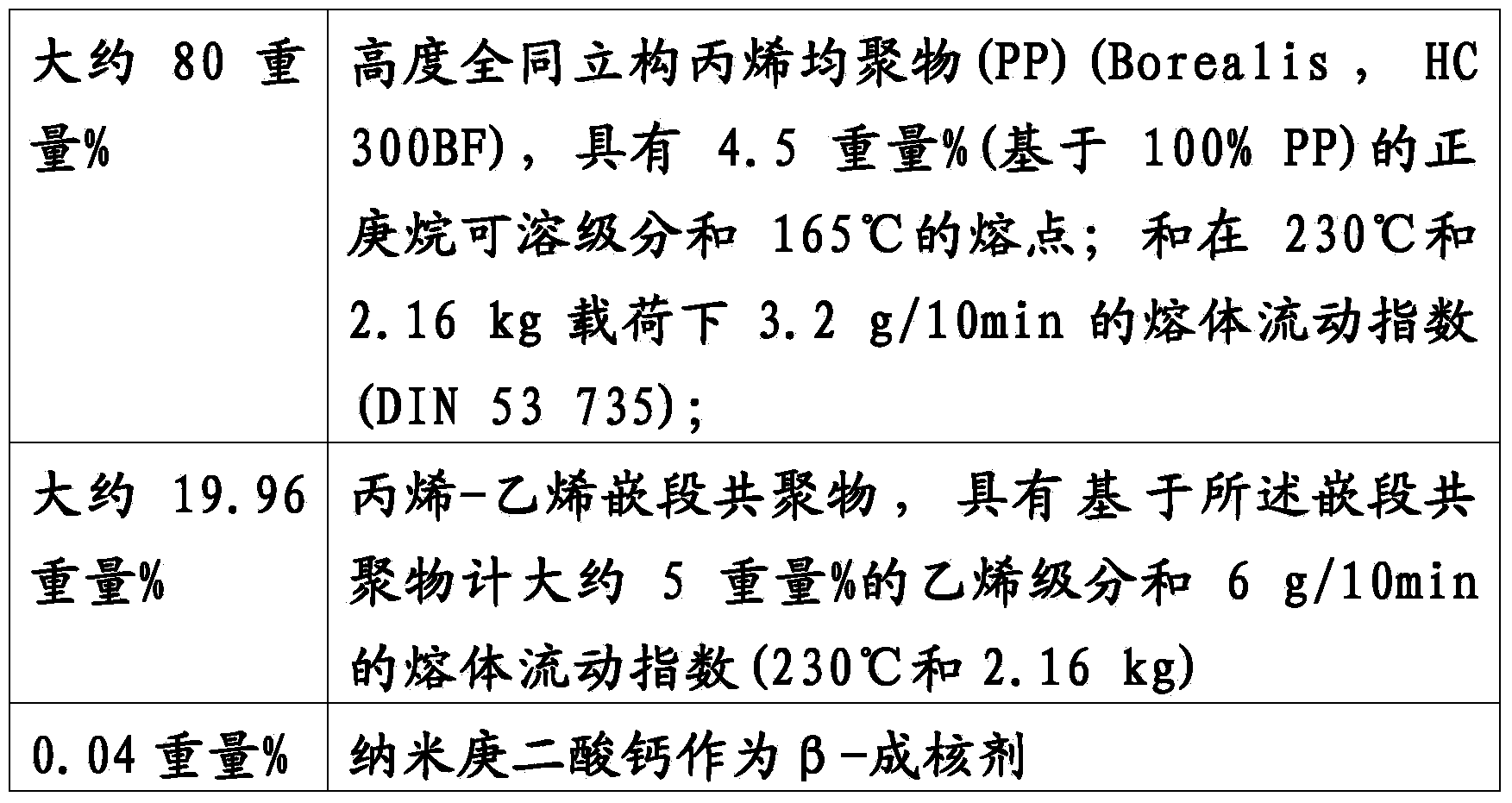

InactiveCN103998240AMeet the mechanical strengthRequirements for low tearing tendencySynthetic resin layered productsLi-accumulatorsHigher PowerPorous layer

The invention relates to a biaxially oriented single-layer or multilayer porous film, which comprises at least one porous layer, wherein said layer contains at least one propylene polymer and polyethylene, (i) the porosity of the porous film is 30% to 80%, and (ii) the permeability of the porous film is < 1000 s (Gurley value), characterized in that (iii) the porous film has an inorganic, preferably ceramic, coating, (iv) the coated porous film has a Gurley value of < 1500 s, and (v) the coated porous film has a Gurley value of > 6000 s when said film is heated above 140 DEG C for 5 min. The coated, porous film has a double safeguard. The invention further relates to a method for producing such a film and to the use thereof in high-energy or high-power systems, in particular in lithium, lithium-ion, lithium-polymer and alkaline-earth batteries.

Owner:TREOFAN GERMANY GBMH & CO KG

Fabrication method for fracture fixator

InactiveCN101879086APromote healingMeet the mechanical strengthInternal osteosythesisComputer designArtificial bone

The invention discloses a fabrication method for a fracture fixator, which includes the following steps: scanning the fracture and the corresponding healthy-side part of a patient, and acquiring initial data; adopting three-dimensional software to convert the initial data into a three-dimensional model, so that a skeleton model at the fracture and the corresponding healthy-side part of the patient is obtained; utilizing the three-dimensional software to carry out a fixation analysis on the skeleton model at the fracture and design a fracture fixator model; preparing bioactive artificial bone material; converting the designed fracture fixator model into a rapid prototyping file format, and feeding the prepared bioactive artificial bone material as prototyping material into a rapid prototyping machine to produce the fracture fixator. The invention has the advantage that the rapid prototyping technique, the three-dimensional computer design and the bioactive artificial bone material are combined to fabricate degradable fracture fixators adapted to different parts and different degrees of individualized shape designs.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

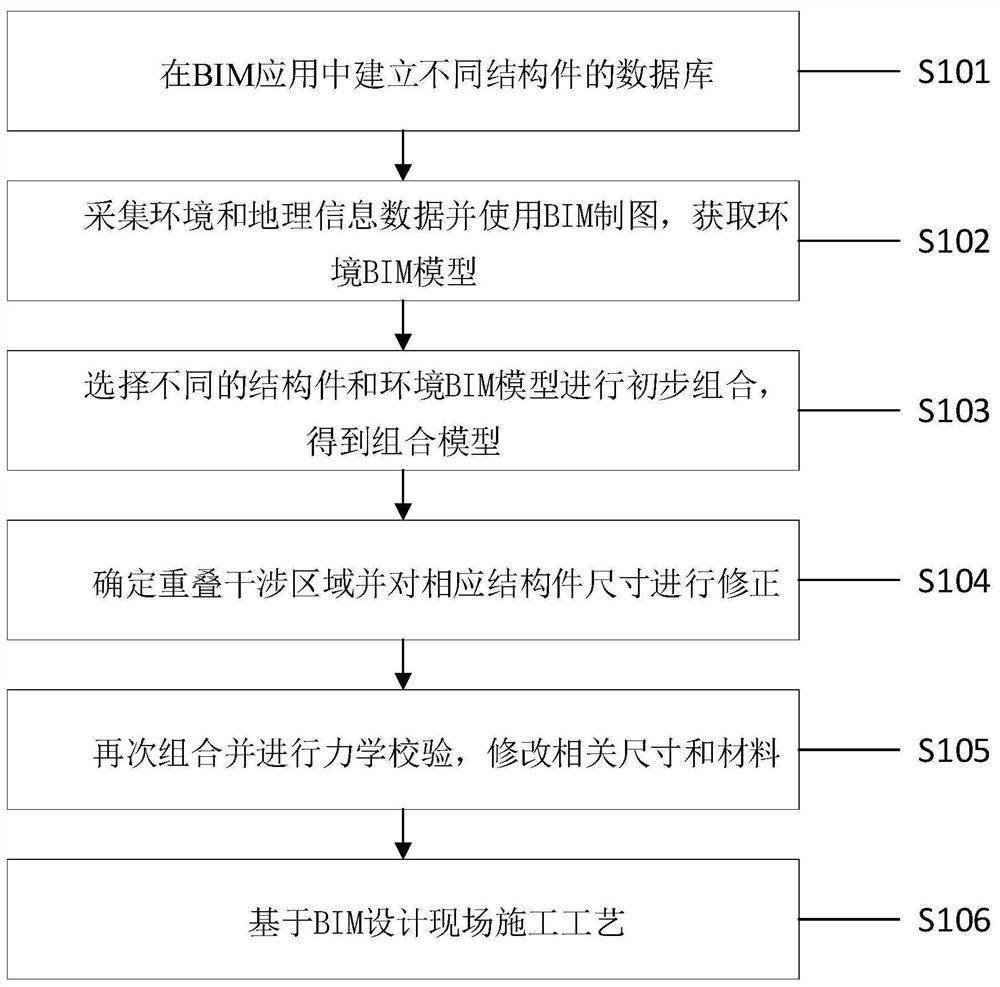

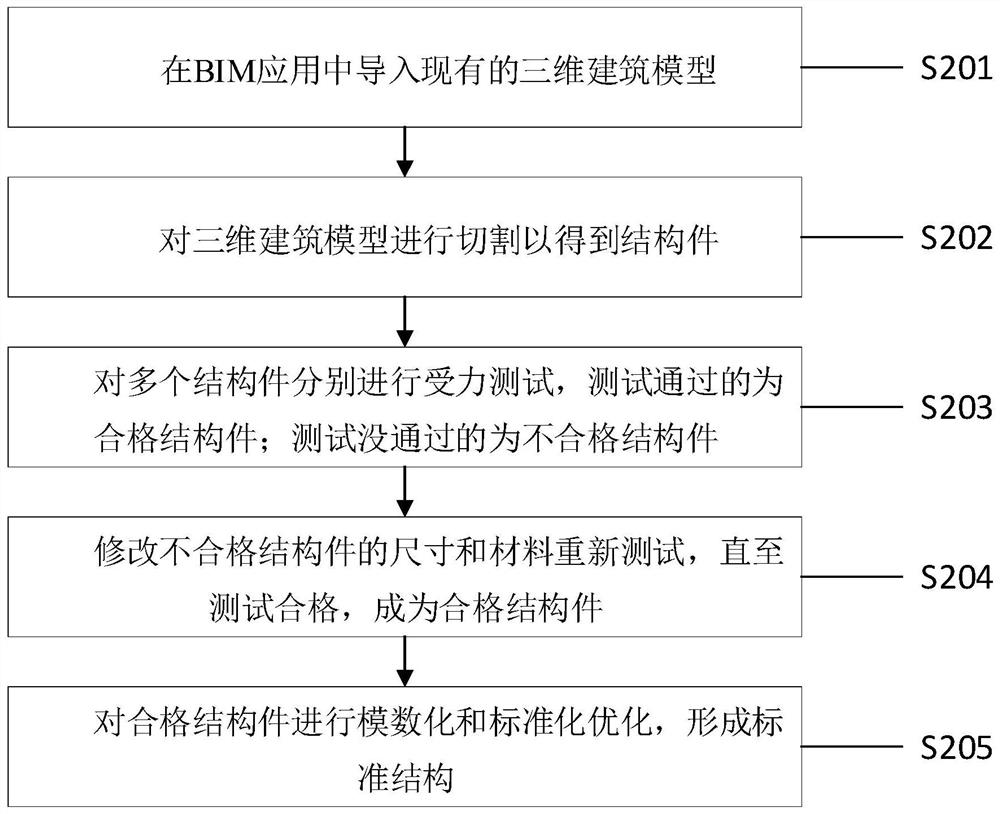

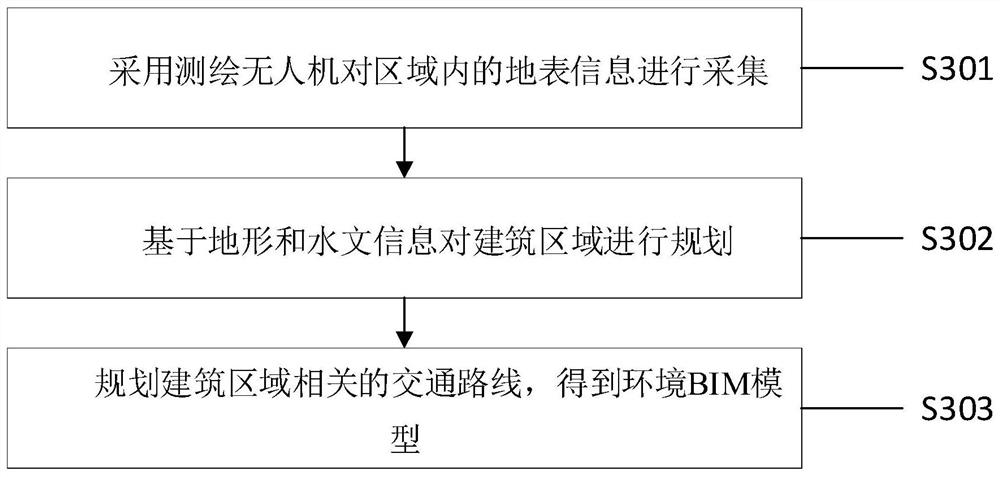

Fabricated building construction scheme based on BIM technology

PendingCN111859507AAssembly does not interfereMeet the mechanical strengthGeometric CADBuilding material handlingConstruction engineeringInformation data

The invention discloses a fabricated building construction scheme based on a BIM technology. The fabricated building construction scheme comprises the steps: establishing databases of different structural parts in a BIM application; collecting environment and geographic information data and using BIM drawing to obtain an environment BIM model; selecting different structural parts and environment BIM models for preliminary combination, and obtaining a combined model; determining an overlapping interference area and correcting the size of the corresponding structural member; performing combiningagain, carrying out mechanical verification, and modifying related sizes and materials; and designing an on-site construction process based on the BIM. Standardized design is carried out on a structural member; different structural parts are selected for preliminary combination, an overlapping interference area is used for size correction, and finally mechanical verification is carried out, so that it is ensured that all the structural parts are assembled without interference and collision, the mechanical strength required by design can be met after organization is completed, and the assembling efficiency can be improved.

Owner:HUAIAN TESTING CENT FOR CONSTR ENG +1

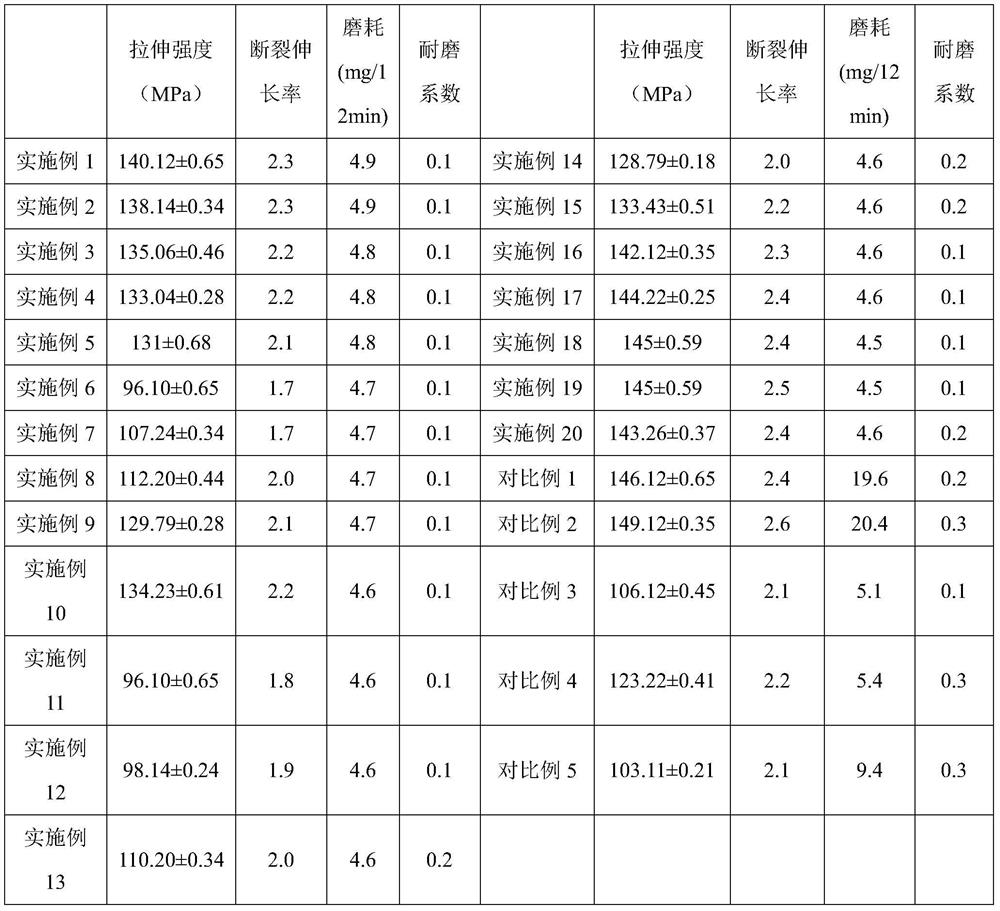

High-strength and high-wear-resistance carbon fiber reinforced polyphenylene sulfide composite material and preparation method thereof

The invention provides a high-strength and high-wear-resistance carbon fiber reinforced polyphenylene sulfide composite material which comprises the following components in parts by weight: 61-70 parts of polyphenylene sulfide, 21-30 parts of carbon fibers, 8-18 parts of polytetrafluoroethylene, 1-2 parts of a compatilizer, 0.1-0.4 part of a surface treating agent, 1-2 parts of a lubricant and 0.1-2 parts of a coupling agent, the weight-average molecular weight of the polyphenylene sulfide is 10000-15000, the carbon fibers are short carbon fibers, and the fiber length is 40-70 mm; the invention also provides a preparation method of the carbon fiber reinforced polyphenylene sulfide composite material. The tensile strength of the prepared carbon fiber reinforced polyphenylene sulfide composite material is larger than or equal to 95, the abrasion is smaller than 5, the friction coefficient is smaller than 0.2, and the requirements of an air conditioner sliding block for the mechanical strength and friction performance of the polyphenylene sulfide composite material can be met. The method is simple in processing operation, low in raw material cost, environment-friendly and pollution-free, has great social benefits and economic benefits, and is suitable for popularization.

Owner:JINLING INST OF TECH

System and method for sampling and monitoring atmospheric pollutants discharged by rural household cooking range

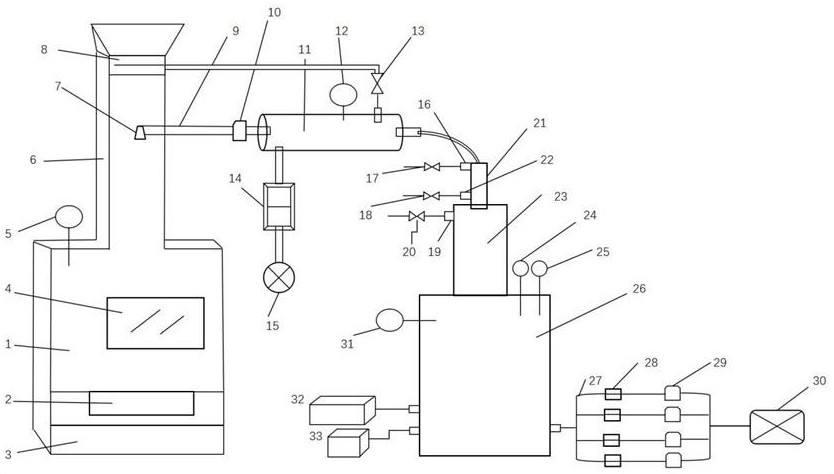

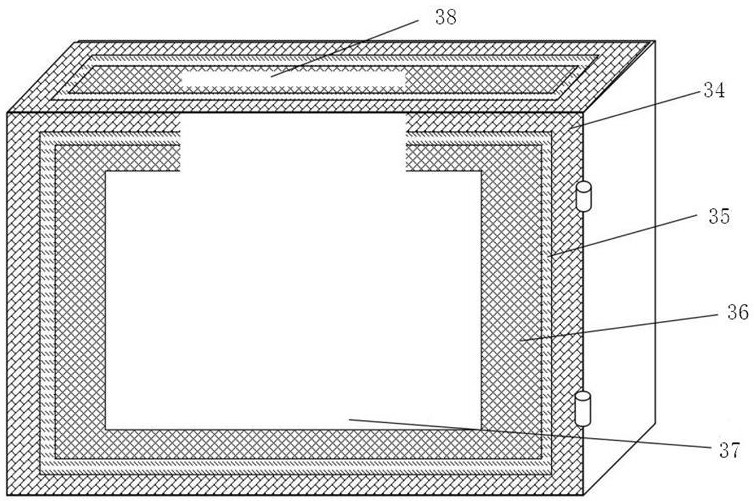

PendingCN112577787AWith online calibration functionImprove reliabilityWithdrawing sample devicesParticle suspension analysisFlue gasHearth

The invention discloses a system and method for sampling and monitoring atmospheric pollutants discharged by a rural household cooking range. The system comprises a combustion furnace, a sampling gun,a pre-dilution pipe, a dilution system and a sampling system. According to the invention, the combustion furnace part adopts the design of a combustion furnace with a changeable hearth, so that the emission condition of a pollution source is better restored; the pre-dilution pipe is additionally arranged, so that the dilution ratio adjusting range is expanded; flue gas purification is added, andstrict conditions of a laboratory are met; and offline sampling, online monitoring analysis and multi-channel grading sampling can be taken into consideration, a complete combustion flue gas emissiontotal amount particle sample is obtained, an online calibration function is achieved at the same time, the fluctuation situation of concentration sections of all orders in the combustion process is deeply understood and complemented with one another, the reliability is high, and the discharge characteristics of the stationary pollution source can be studied more comprehensively.

Owner:GUIZHOU ACAD OF ENVIRONMENTAL SCI & DESIGNING

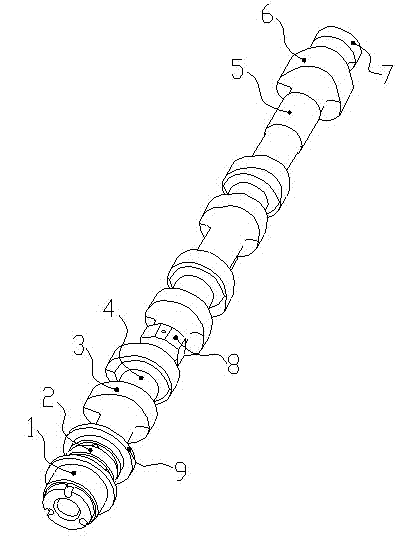

Variable valve timing and direct-injection gasoline engine cam shaft

InactiveCN103711536AMeet the mechanical strengthNo carburizing and tempering requiredValve arrangementsMachines/enginesVariable valve timingCylinder head

A variable valve timing and direct-injection gasoline engine cam shaft comprises a variable valve timing oilway, three pairs of air change cams and a high-pressure oil pump drive cam. The variable valve timing oilway is arranged on the first section and the second section cam shaft journals close to the front end of the cam shaft and comprises a phase advance oilway and a phase lag oilway. The air change cams are arranged on the middle section of the cam shaft at certain intervals. The included angle among the air change cams evenly distributed is 120 degrees. The high-pressure oil pump drive cam is disposed at the rear end of the cam shaft, three tips are evenly disposed on the cam, and the width of the cam is larger than that of each aeration cam. The variable valve timing and direct-injection gasoline engine cam shaft is reasonable and simple in structure and convenient to machine, the problems that the arranging space of the cam shaft is insufficient and the structural strength of the cam shaft cannot be guaranteed are solved, large modification on key parts such as a cylinder head and a cylinder head cover is not needed, part universality is increased, and the cam shaft is quite applicable to small-displacement engines with compact structures.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Formula and technology of unfired honeycomb ceramic regenerator

The invention discloses a formula of an unfired honeycomb ceramic regenerator. According to industry routines, the formula is obtained through the steps of: firstly compounding a main formula according to the following raw materials in percentage by mass: 80%-86% of corundum mullite, 10%-12% of kaolin, 3%-5% of alumina micro-powder and 1%-3% of monox micro-powder; then compounding an auxiliary formula through using the total mass of the raw materials of the main formula as a benchmark, wherein the auxiliary formula comprises the following components in percentage by mass: 6% of chopped zirconium-aluminum ceramic fibers, 2.5% of carboxyl methycellulose and 0.5% of stearic acid; and then compounding liquid according to the total mass of the raw materials of the main formula and the auxiliary formula, wherein the liquid comprises the following components in percentage by mass: 20% of water and 5%-7% of aluminum phosphate. The invention further discloses a corresponding technology. According to the formula and the technology which are disclosed by the invention, a manufacture cost is lowered, energy consumption is reduced, a qualified drying rate of products achieves 98%, compressive strength is larger than or equal to 8MPa, and breakage requirements of transporting and mounting the unfired honeycomb ceramic regenerator are satisfied.

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH

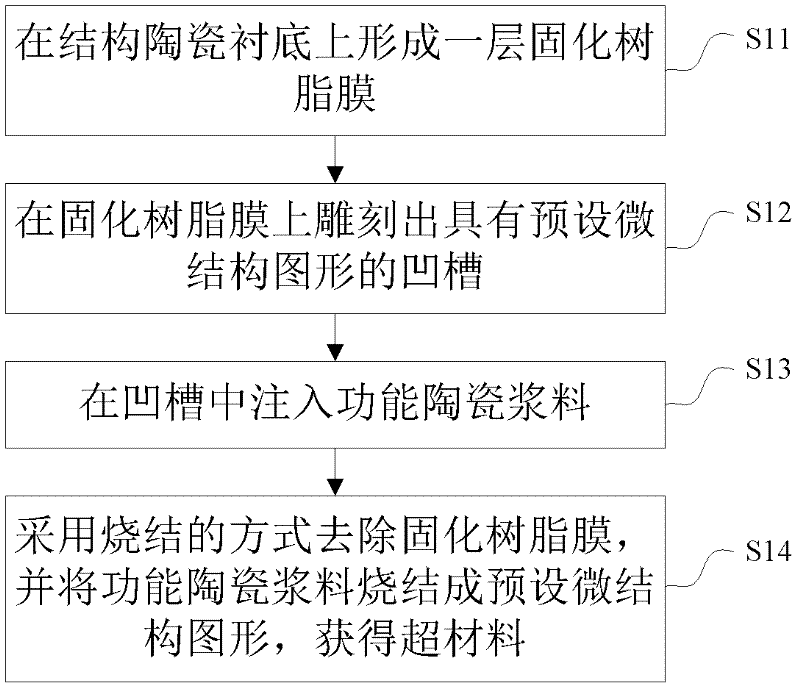

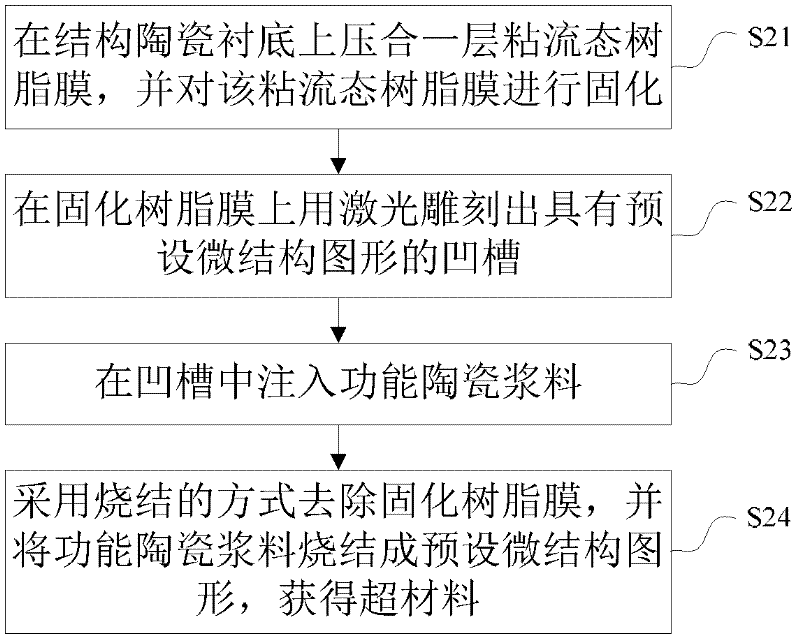

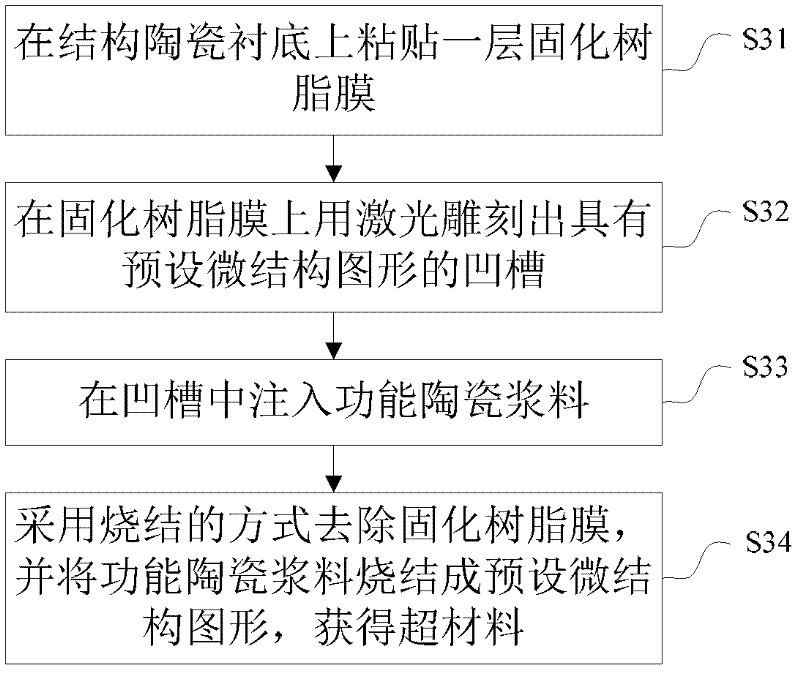

Metamaterial and preparation method thereof

The invention provides a method for preparation a metamaterial. The method for preparation the metamaterial comprises the following steps of: forming a layer of cured resin film on a structral ceramic substrate; graving a groove with a predetermined mirostructure pattern on the cured resin film; injecting functional ceramic slurry into the groove; removing the cured resin film by sintering; sintering the functional ceramic slurry to form the predetermined microstructure pattern; and obtaining the metamaterial. The other embodiment of the invention further provides the metamaterial. The metamaterial comprises the structural ceramic substrate, and the functional ceramic adhered with the upper surface of the structural ceramic substrate, wherein the functional ceramic has the predetermined microstructure pattern. Therefore, the metamaterial with high mechanical strength, heat stability and electromagnetic properties is achieved.

Owner:KUANG CHI INST OF ADVANCED TECH +1

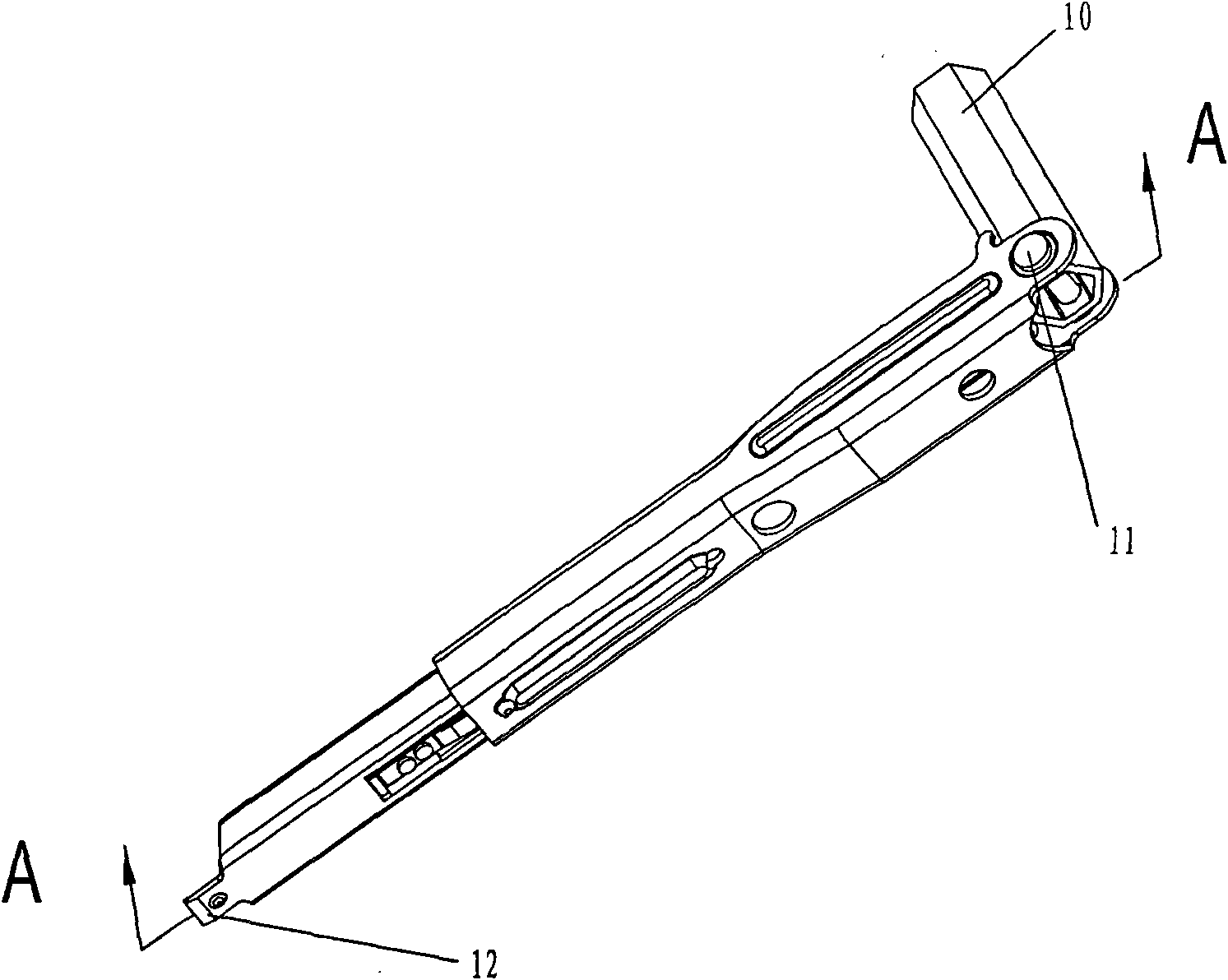

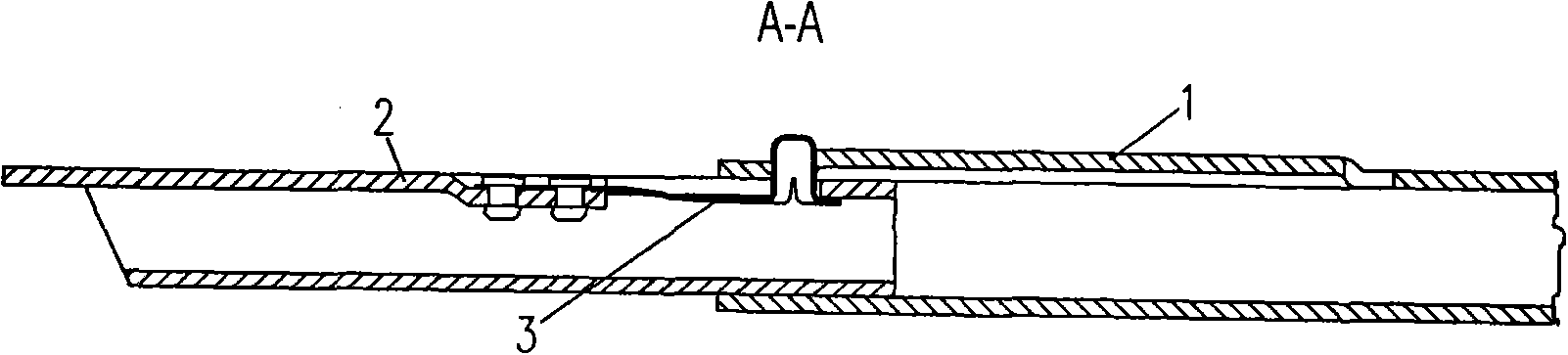

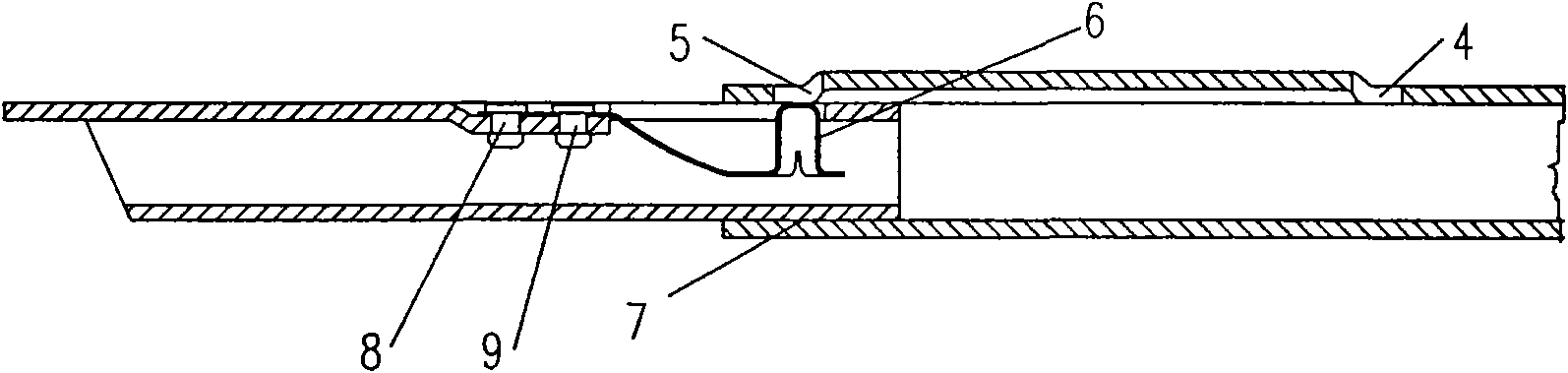

Non-cylindrical scissor jack handle and elastic connection device thereof

InactiveCN101607683AGuaranteed reliabilityEasy to combineMechanical apparatusLifting devicesJackscrewEngineering

The invention discloses a non-cylindrical scissor jack multisegment operation handle and an elastic connection device thereof. In the jack handle, the anterior segment handle is provided with two through holes in hole and shaft fit with locking pin shafts; the posterior segment handle is provided with two prefabricated holes for riveting in advance, and is connected in series with an elastic metal plate with the locking pin shafts by two rivets which are squeezed; the anterior segment handle and the posterior segment handle are made into non-cylindrical fit which can better transfer torque moment; and the locking pin shafts are pressed on the body of the elastic metal plate. The jack handle and the connection device have the advantages of conveniently combining the length of the operation handle to adapt to jacking on different loads, ensuring the reliability of the handle when the handle is used, and facilitating accommodating after use.

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

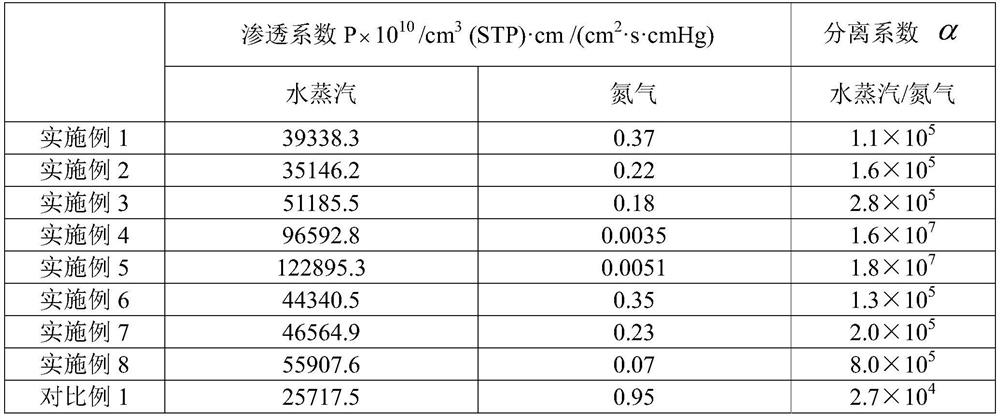

Gas dehumidification film, preparation method and application thereof

InactiveCN112808036AMeet the mechanical strengthImprove permeabilitySemi-permeable membranesDispersed particle separationInorganic saltsMembrane permeabilization

The invention provides a gas dehumidification membrane, a preparation method and application thereof. The gas dehumidification membrane is prepared from polyether-b-polyamide and a hydrophilic electrolyte, wherein the mass ratio of the polyether-b-polyamide to the hydrophilic electrolyte is 3:7-9:1, the polyether-b-polyamide is a block copolymer, and the hydrophilic electrolyte comprises an organic electrolyte sodium salt and / or a hydrophilic inorganic salt. According to the invention, the gas dehumidification membrane prepared by compounding the hydrophilic electrolyte and the polyether-b-polyamide is high in permeability, good in gas selectivity, good in stability, capable of preferentially permeating water vapor, high in water vapor separation performance, mild in operation condition, easy to repeat, beneficial to industrialization and suitable for industrial production, and can be applied to dehumidification of gases such as air, nitrogen, hydrogen, natural gas, synthesis gas or pyrolysis gas and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Environment-friendly vegetable protein based efficient water and fertilizer slow/controlled-release material

InactiveCN104003800AEnvironmentally friendlyExcellent slow and controlled release characteristicsFertilizer mixturesSoil scienceFoaming agent

The invention provides an environment-friendly vegetable protein based efficient water and fertilizer slow / controlled-release material. The slow / controlled-release material is prepared from the following components in parts by mass: 30-80 parts of thermoplastic vegetable proteins, 20-60 parts of resin, 5-7 parts of graft modification substances, 1-5 parts of initiator, 2-5 parts of foaming agent and 2-5 parts of lubricating agent. A slow / controlled-release fertilizer prepared on the basis of the slow / controlled-release material provided by the invention has the initial nutrient release rate of less than 13.0% after being soaked in 25-DEG C static water for 24h, the accumulated nutrient release rate of less than 78.0% within 28d and the accumulated release rate of more than 92.6% within the nutrient release period. The effective utilization ratio of nutrients in the fertilizer is increased by more than 35.9%, so that the usage amount and fertilization times of the fertilizer can be greatly reduced, the effective utilization rate of the fertilizer can be increased, and the ecological environment destruction caused by the fertilizer can be effectively relieved.

Owner:XINJIANG HUIER AGRI GRP CO LTD

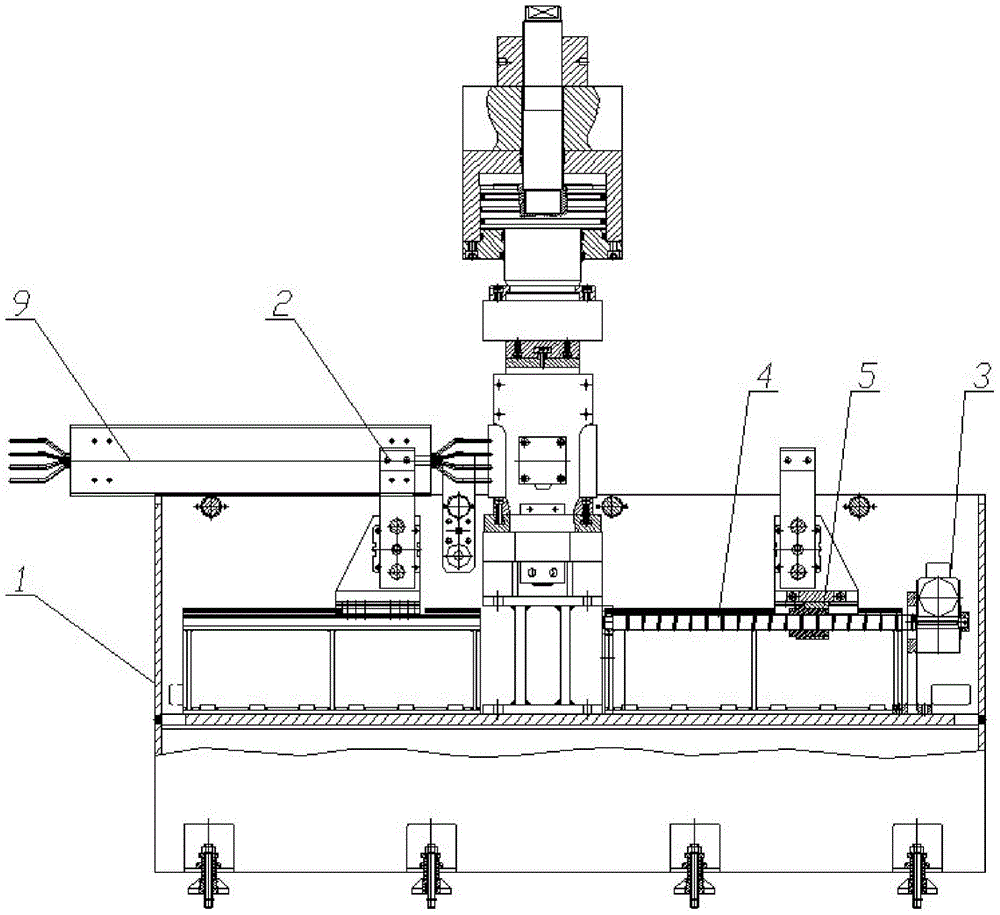

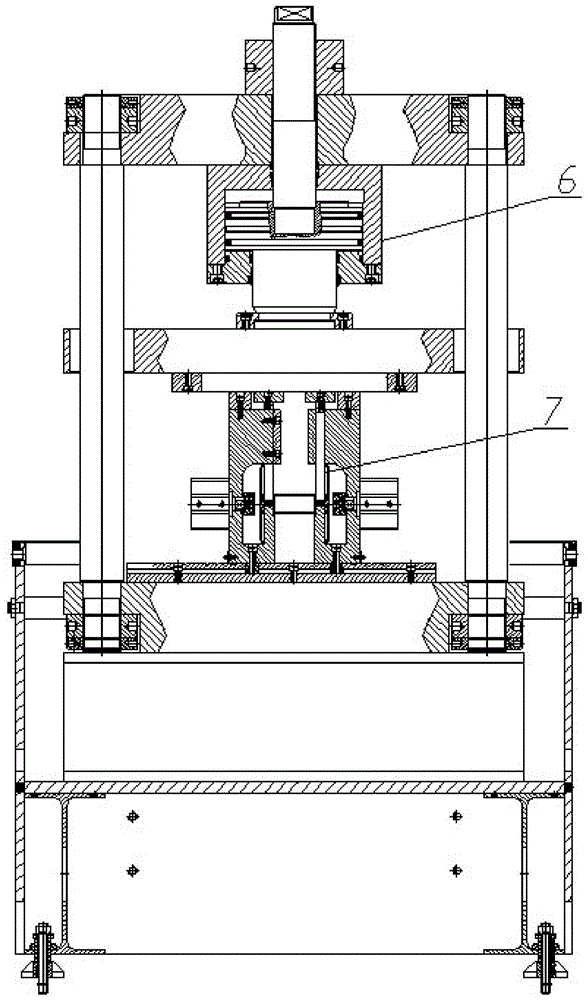

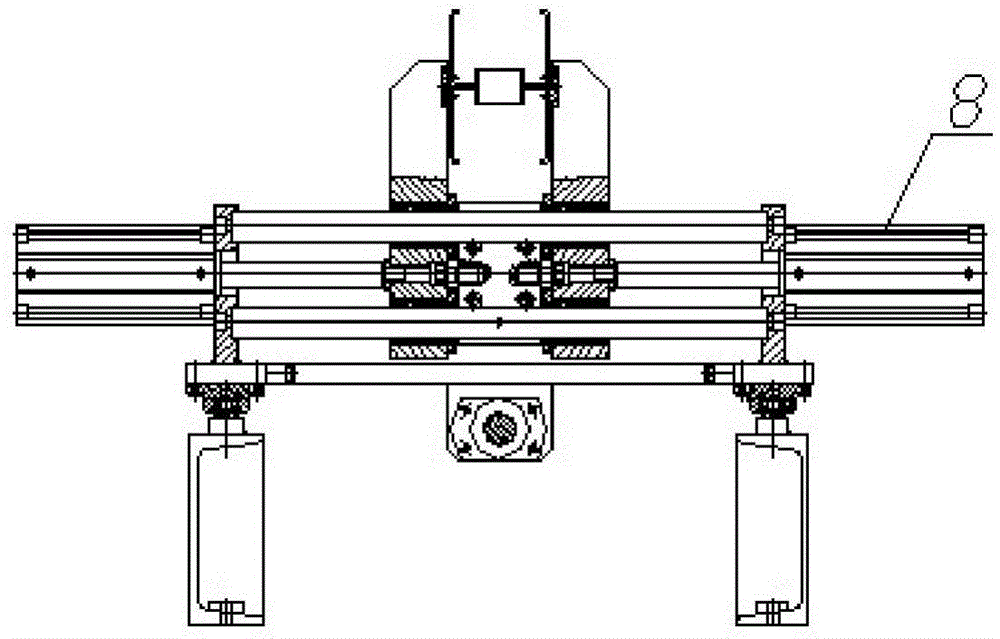

Bus riveting protection line

InactiveCN104384362ARealize automated assemblyAutomated assembly does not requireShaping toolsMetal-working feeding devicesNumerical controlUltimate tensile strength

The invention provides a bus riveting protection line which is a special device designed to be matched with the machining of rivetable side cover plate profiles of new buses. An upper cover plate can be fixedly connected with a lower cover plate without the machining of any connection hole after upper cover plate profiles and lower cover plate profiles of a bus are fed, the mechanical strength required by a housing of the bus can be met, the bolt connection is not required, and accordingly the number of parts is reduced; the labor intensity of workers is reduced due to the numerical control production; the automatic assembly of the bus can be implemented, fasteners are not required by the integral assembly, meanwhile the manual operation is not required by the integral assembly process, and accordingly the production cost is saved and meanwhile the labor intensity of the production personnel is reduced.

Owner:JIANGSU HUAPENG INTELLIGENT ELECTRICAL

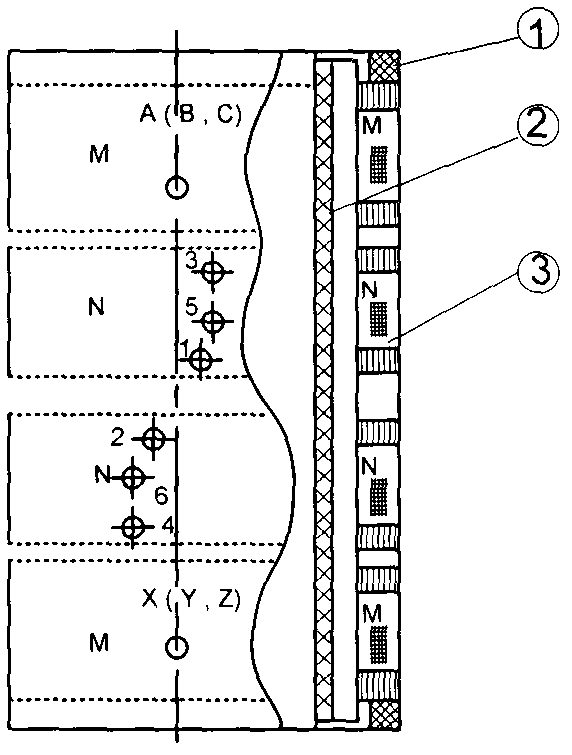

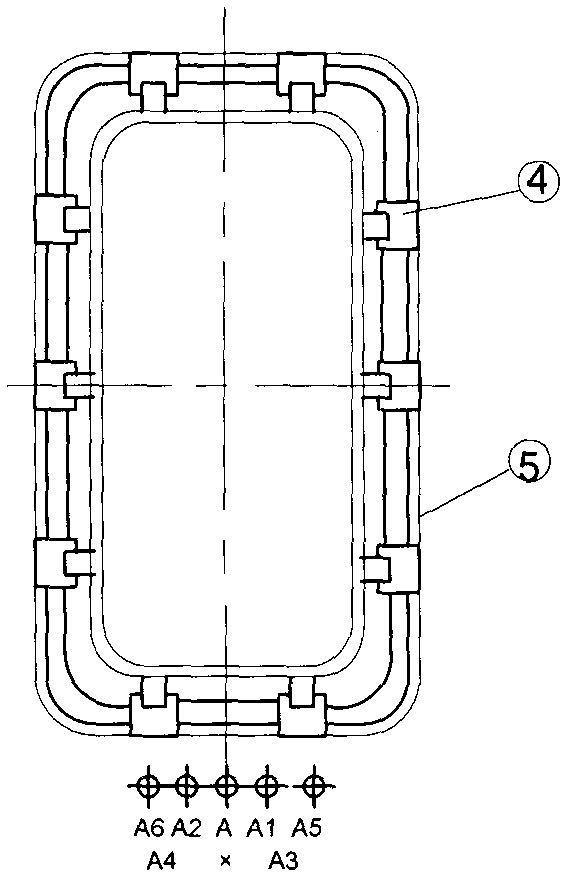

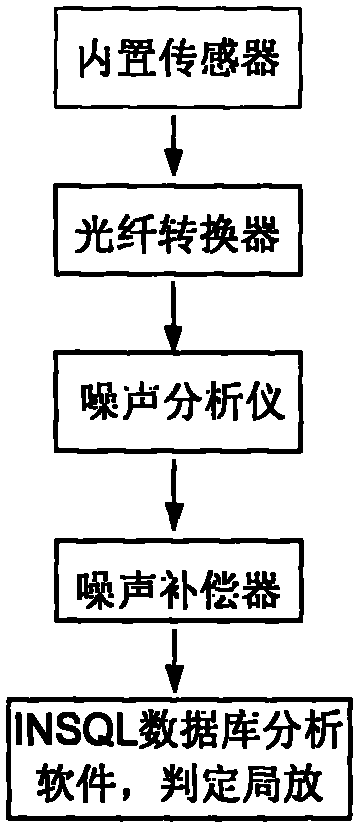

Amorphous alloy dry-type transformer coil insulating structure and method of removing local discharge signal noise

InactiveCN102592806AHelps soakNice appearanceTesting dielectric strengthTransformers/inductances coils/windings/connectionsUniform fieldTransformer

The invention discloses an amorphous alloy dry-type transformer coil insulating structure and a method of removing local discharge signal noise. The amorphous alloy dry-type transformer coil insulating structure comprises a coil end (1), coil segments, a coil winding (3) and an outer coil part (5), and the amorphous alloy dry-type transformer coil insulating structure is characterized in that the coil end (1) is a rectangular end ring with beautiful outline and strong mechanical strength; the coil segments are isolated by dovetail cushion blocks, so that the space is enough to facilitate the heat dissipation and complete impregnation of impregnating varnish; and the coil winding (3) is wound in a rectangular cylindrical structure, the outer coil part (5) is subjected to bundling, vacuum pressure drying, varnish impregnating and curing processes so as to guarantee uniform field intensity distribution and strong anti-short circuit capability. In the local discharge monitoring process, a sensor collects a discharge signal and sends the discharge signal to a noise analyzer, and the noise analyzer separates the periodical narrow-band interference and white noise in the noise; and compensation signals with equal compensation size and opposite polarities are compensated, a real local discharge signal can be obtained, and a technician can accurately judge the insulating problem of the amorphous alloy dry-type transformer.

Owner:JIANGSU HONGAN TRANSFORMER

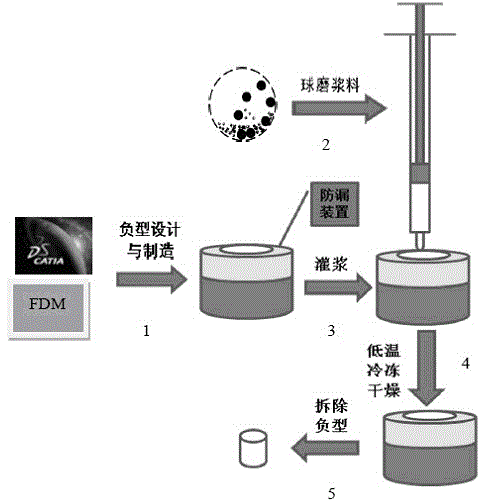

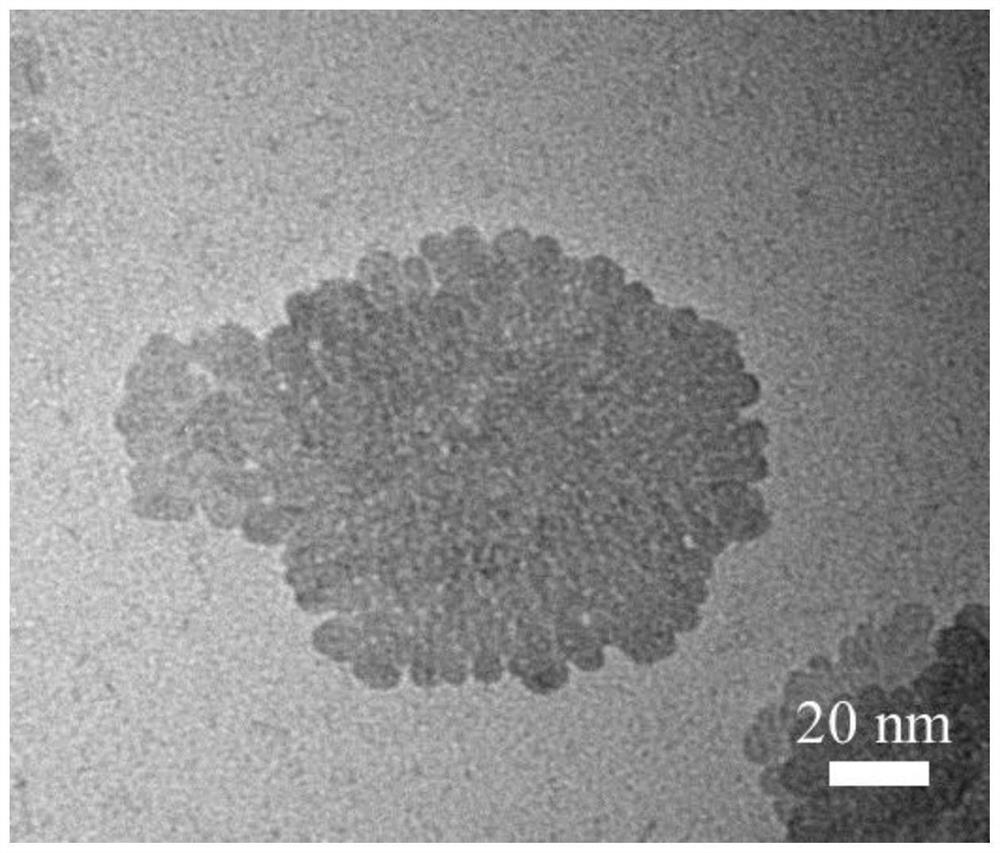

Preparation method of nano material-based bionic bone scaffold

The invention discloses a preparation method of a nano material-based bionic bone scaffold. The preparation method comprises following steps: a negative die is prepared via fused deposition modeling; dissolved biomaterial PLGA is mixed with nano-grade beta-TCP powder, and an obtained mixture is mixed uniformly using a vibration grinder; an obtained slurry is injected into the negative die via negative pressure method, and the negative die is delivered into a freeze dryer for freeze drying; and the negative die is removed so as to obtain the nano material-based bionic cone scaffold. The nano material-based bionic cone scaffold is capable of satisfying requirements on scaffold materials, structures, and strength; controllable adjustment on appearance and porosity is realized; customized manufacturing of scaffolds implanted at bone defect parts is realized; success rate of complex bone defect treatment in clinic is increased effectively; and application prospect in clinic is promising.

Owner:SHANGHAI UNIV

Sub-dam construction method of Bayer process red-mud dry-stacking field

ActiveCN100534935CMeet the mechanical strengthIncrease storage capacitySludge treatmentEmbankmentsRed mudEngineering

The invention discloses a method for constructing a sub-dam of a red mud dry storage yard in the Bayer method. The sub-dam (1) is constructed on the red mud along the inner edge of the initial dam that has been filled with red mud, and the construction method of the sub-dam is as follows Several steps are completed: material preparation, reinforcement of the dam foundation, rolling forming of the dam body, and dam body repairing. The present invention is aimed at the red mud dry storage method produced in the Bayer process, and the sub-dam construction method invented can meet the mechanical strength required for the storage yard stability of the red mud dry storage method, and can be used in a limited Larger storage capacity is obtained on the storage area.

Owner:GUIYANG AL-MG DESIGN & RES INST

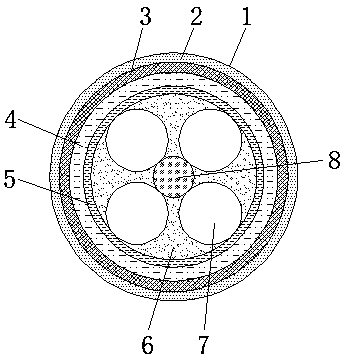

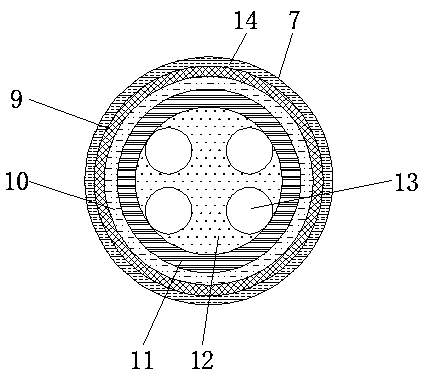

A flexible refractory cable with a ceramic elastomer sheath

InactiveCN109036686AExtend your lifeMeet the needs of mobile layingClimate change adaptationFlexible cablesElastomerYarn

The invention discloses a flexible refractory cable with ceramic elastomer sheath, including protective jackets, the outer part of the protective jacket is provided with a polyurethane elastic extrusion cladding layer, aramid yarn is arranged on the inner wall of the polyurethane elastic extrusion cladding, one side of the aramid yarn inner wall is provided with a ceramic silicon rubber extrusioncladding layer, A loose sleeve is arranged inside the protective sleeve, a PVC insulating coating is arranged outside the loose sleeve, a metal woven net is arranged on the inner wall of the PVC insulating coating, a glass fiber protective layer is arranged on one side of the inner wall of the metal woven net, and cable wires are arranged inside the loose sleeve. The invention solves the problemsof poor abrasion resistance, poor waterproofing and fireproofing performance, insufficient softness, low service life and the like of the existing flexible refractory cable.

Owner:ANHUI STAR CABLE

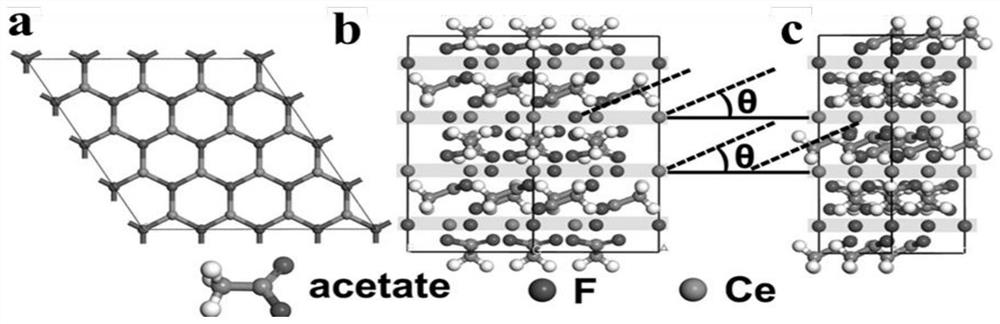

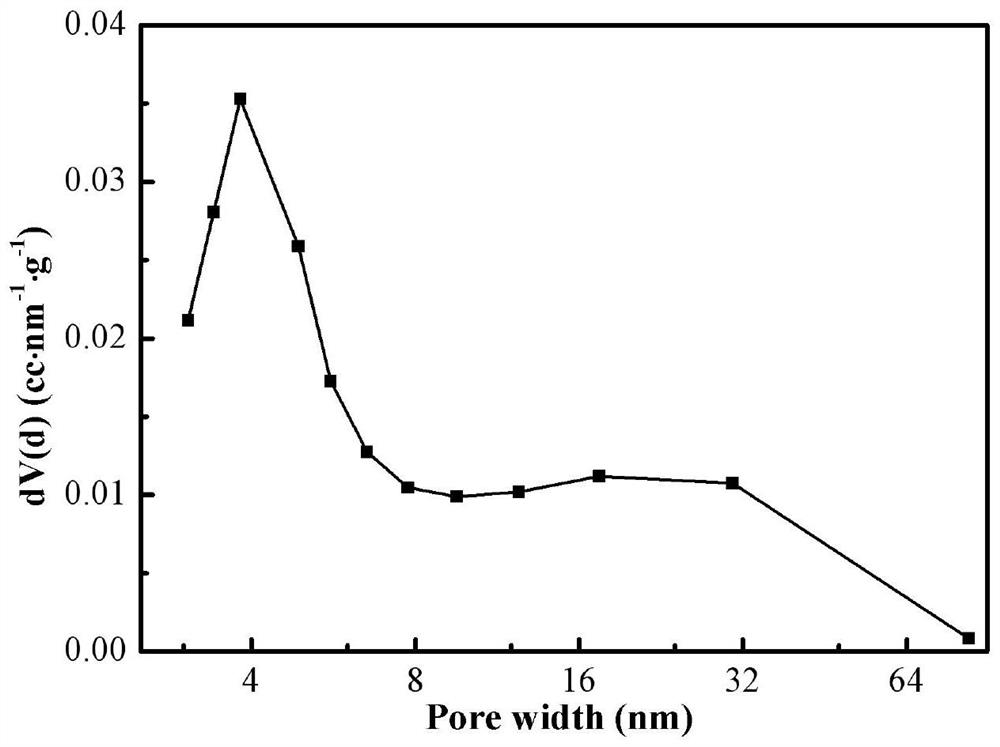

Cerium fluoride porous nanosheet regulated mixed matrix membrane, preparation method and application thereof

ActiveCN113896220AHigh selectivityImprove permeabilityMaterial nanotechnologySemi-permeable membranesPhysical chemistryMaterials science

The invention discloses a cerium fluoride porous nanosheet regulated mixed matrix membrane, a preparation method and application thereof, and belongs to the technical field of gas separation membranes. Specifically, the invention discloses a cerium fluoride porous nanosheet, which is formed by arranging fluorine-cerium monatomic layers and acetate radicals which are alternately stacked between the layers, wherein the fluorine-cerium monatomic layers are formed by arranging fluorine atoms and cerium atoms in a six-membered ring honeycomb form. The invention further provides a cerium fluoride porous nanosheet regulated mixed matrix membrane composed of the cerium fluoride porous nanosheet and a polymer matrix. The invention also provides a preparation method of the cerium fluoride porous nanosheet and a preparation method of the cerium fluoride porous nanosheet regulated mixed matrix membrane, wherein the preparation method is simple to operate. According to the invention, the cerium fluoride porous nanosheet filled polymer matrix membrane is applied to gas dehumidification / humidification, water vapor is permeated preferentially, and the high separation performance on water vapor is achieved.

Owner:TIANJIN POLYTECHNIC UNIV

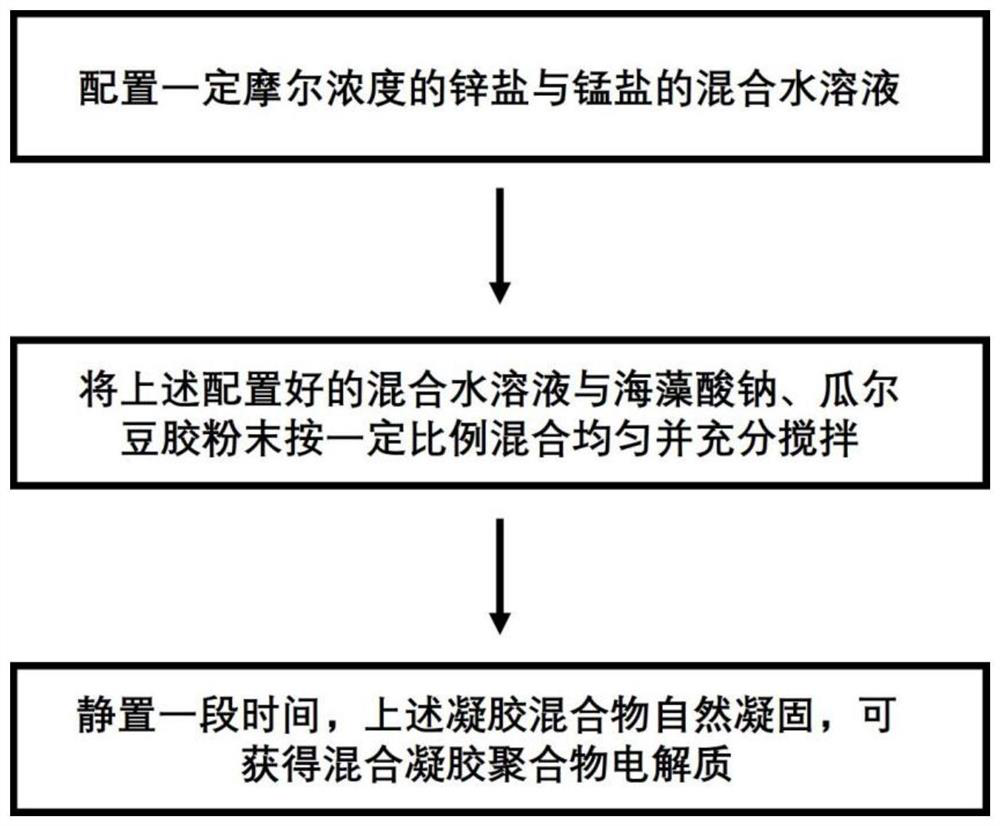

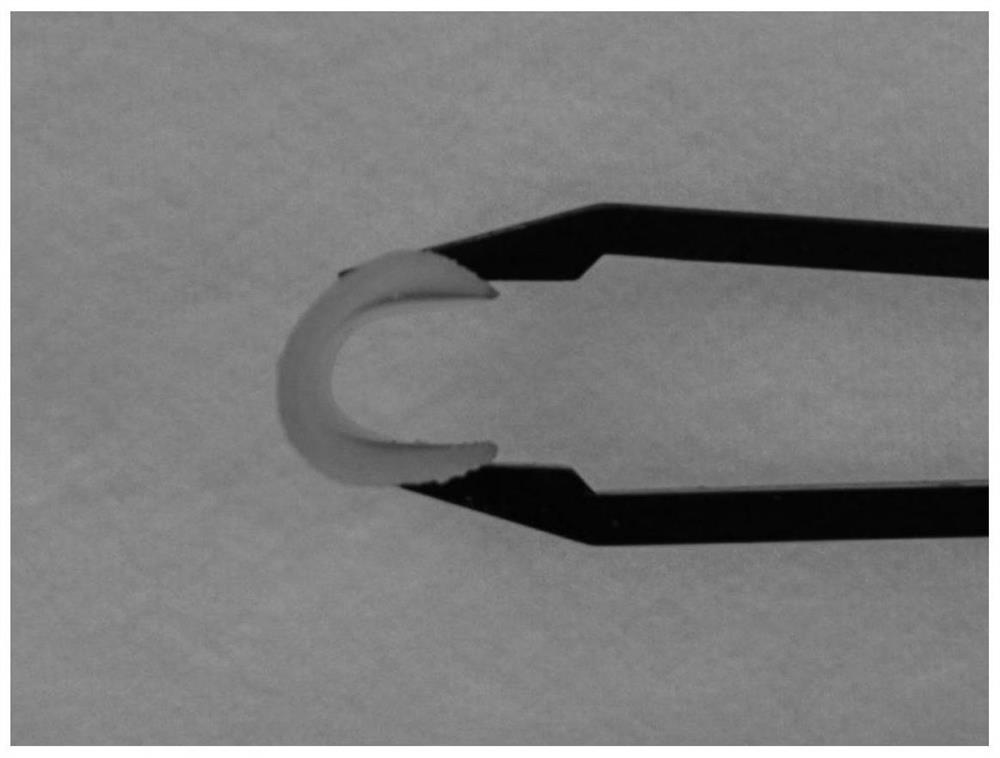

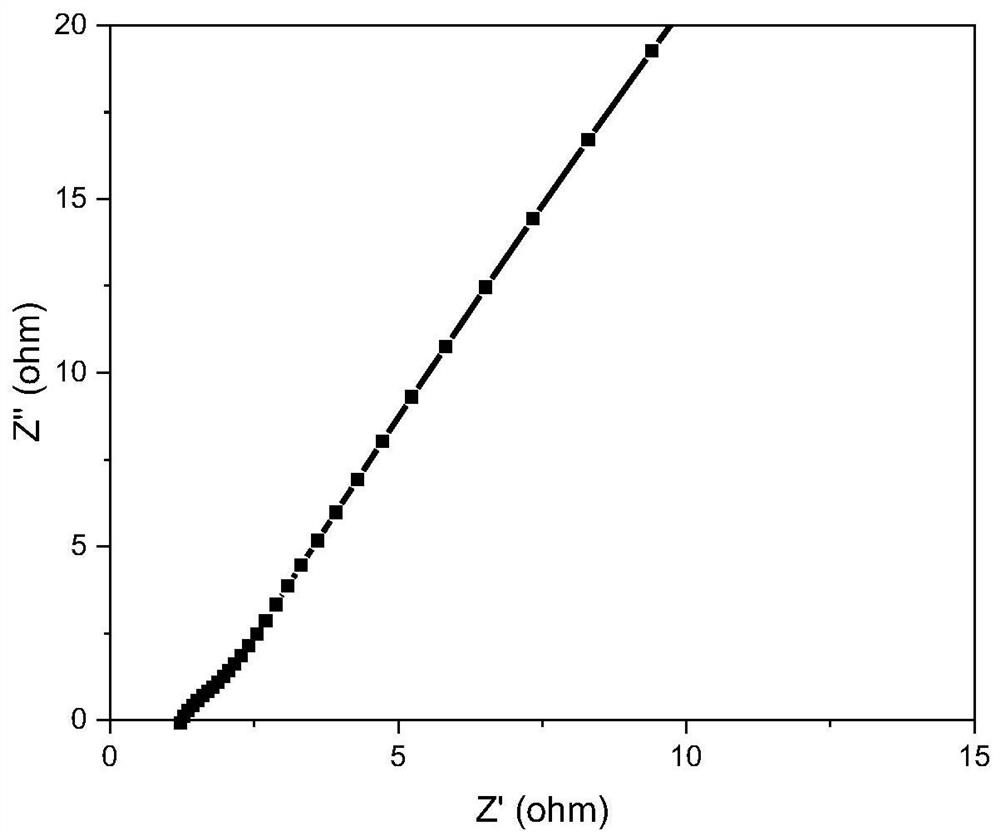

Mixed gel polymer electrolyte and preparation method thereof, and all-solid-state zinc ion battery

InactiveCN112615066AImprove ionic conductivityExtended service lifeFinal product manufactureSecondary cellsGuar gumElectronic conductivity

The invention provides a mixed gel polymer electrolyte. The mixed gel polymer electrolyte comprises mixed gel and an electrolyte doped into the mixed gel, wherein the mixed gel comprises sodium alginate and guar gum; and the electrolyte comprises a zinc salt. The sodium alginate-guar gum (SAGG) mixed gel polymer electrolyte has high ionic conductivity (10-50 mS / cm), is beneficial to improving the overall cycle and rate capability of a battery, has certain mechanical strength, can meet the design requirements of flexible devices, and has good application and development prospects when used as a flexible energy storage device of flexible wearable secondary electronic equipment. Meanwhile, the SAGG mixed gel polymer electrolyte can inhibit the growth of negative electrode zinc dendrites and prolong the service life of the battery. The invention also provides a preparation method of the mixed gel polymer electrolyte and an all-solid-state zinc ion battery.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

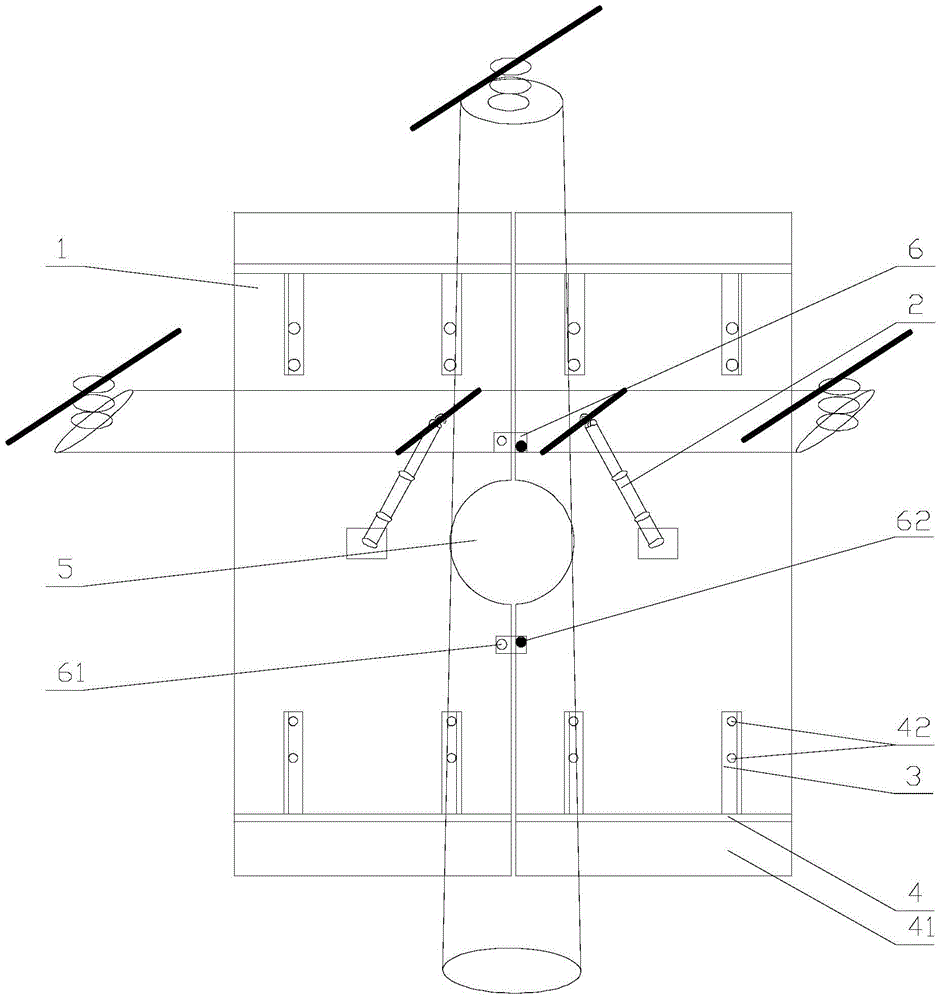

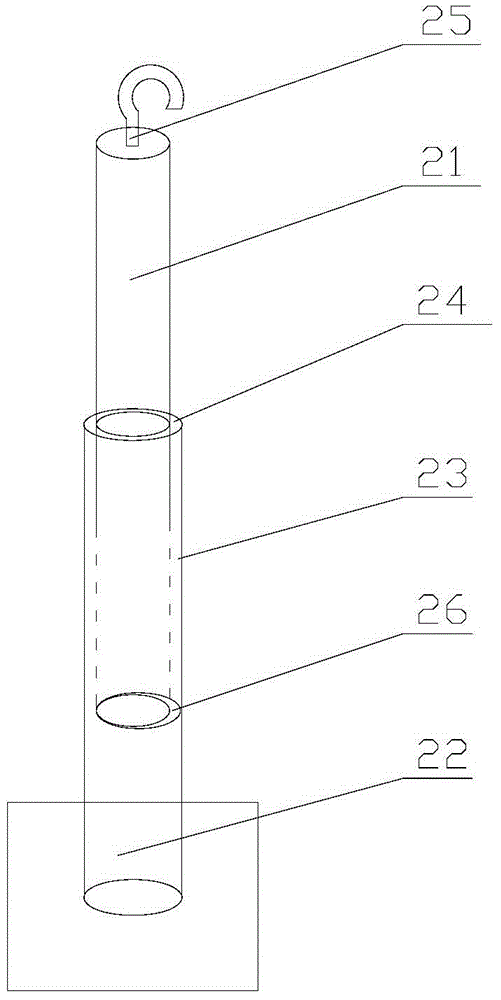

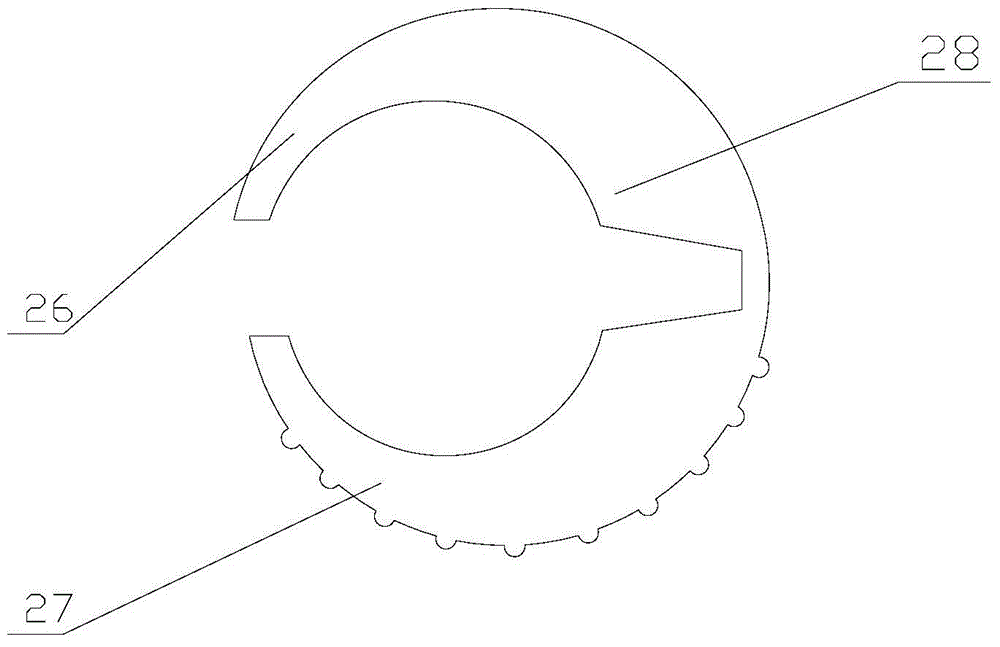

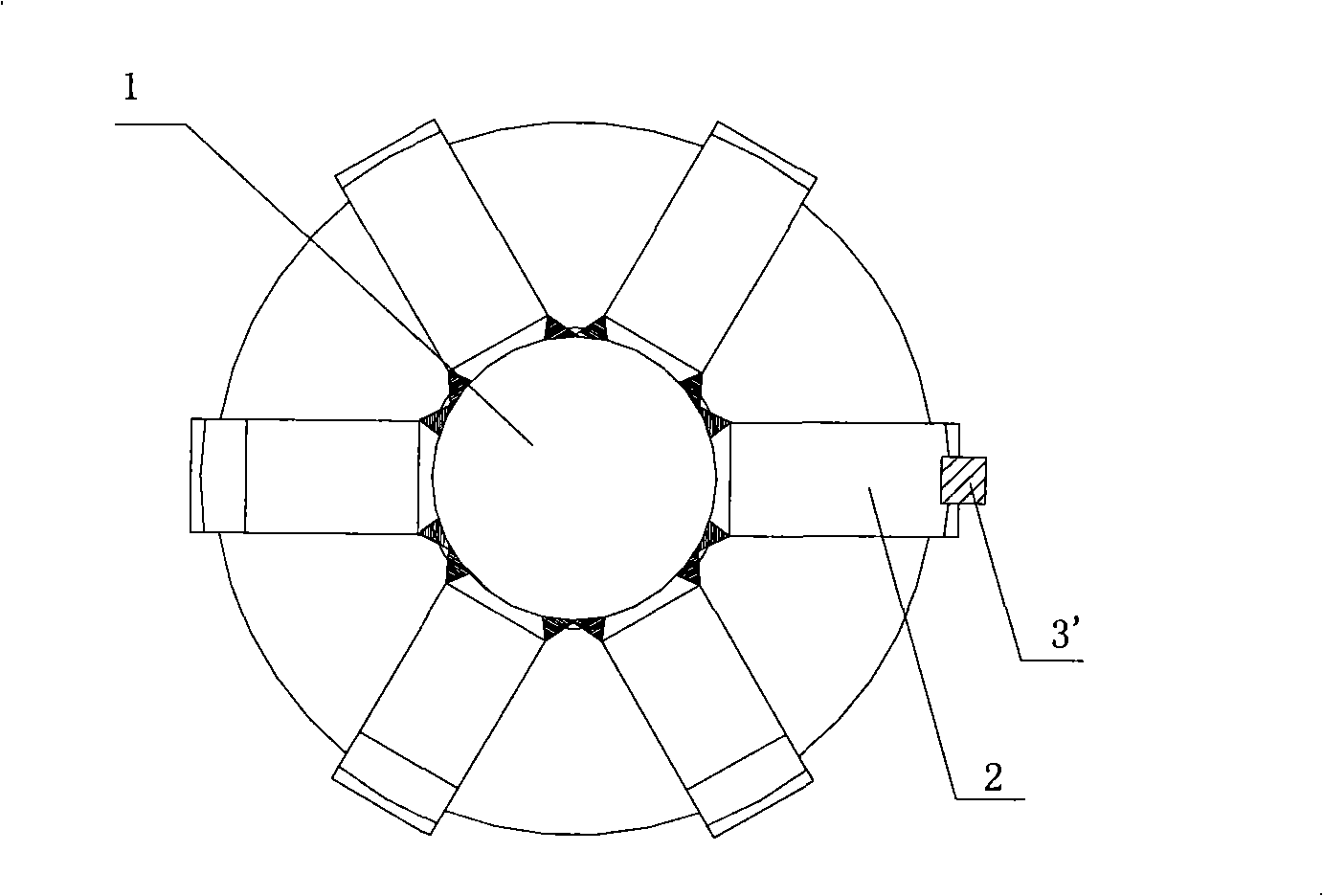

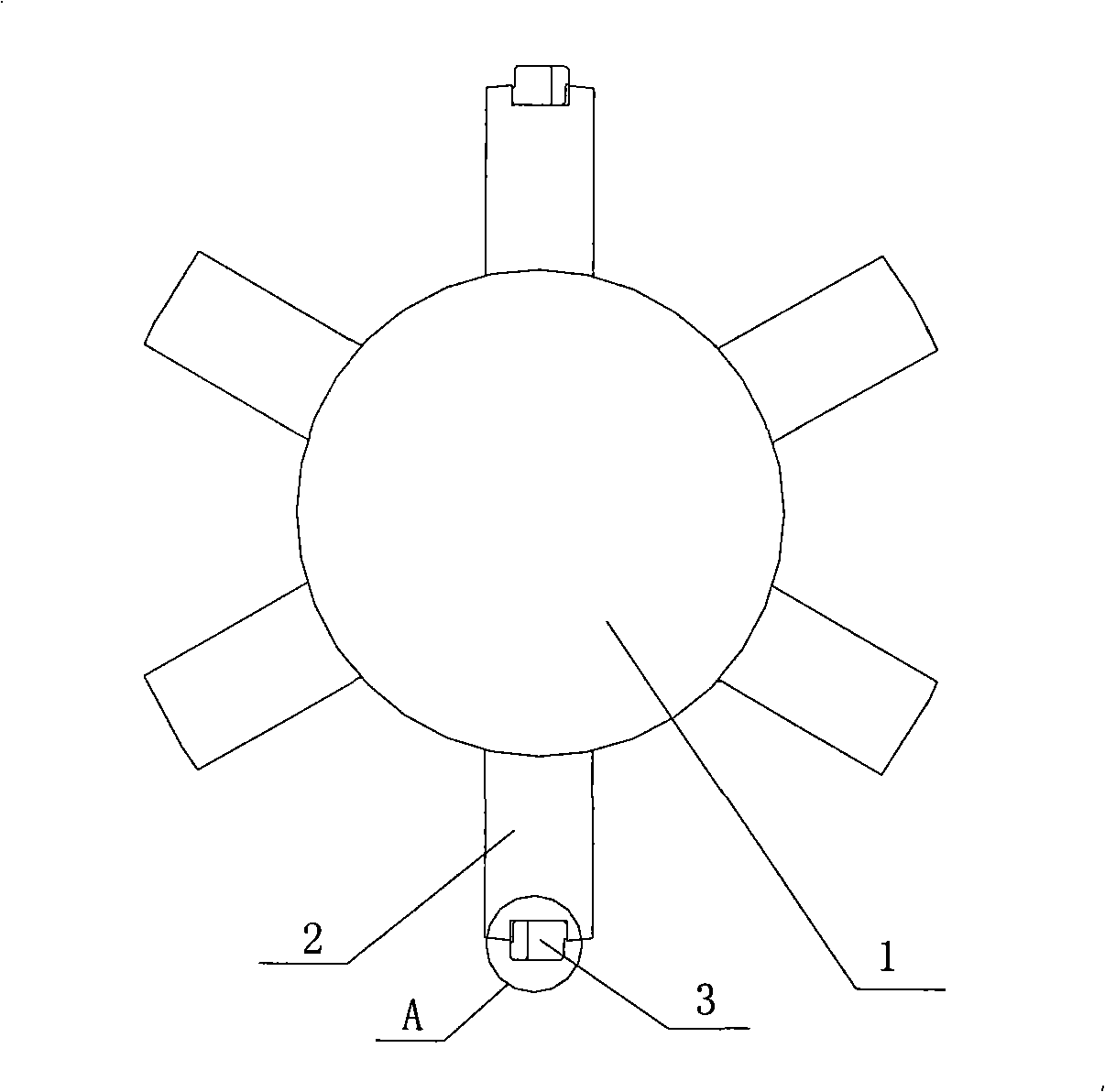

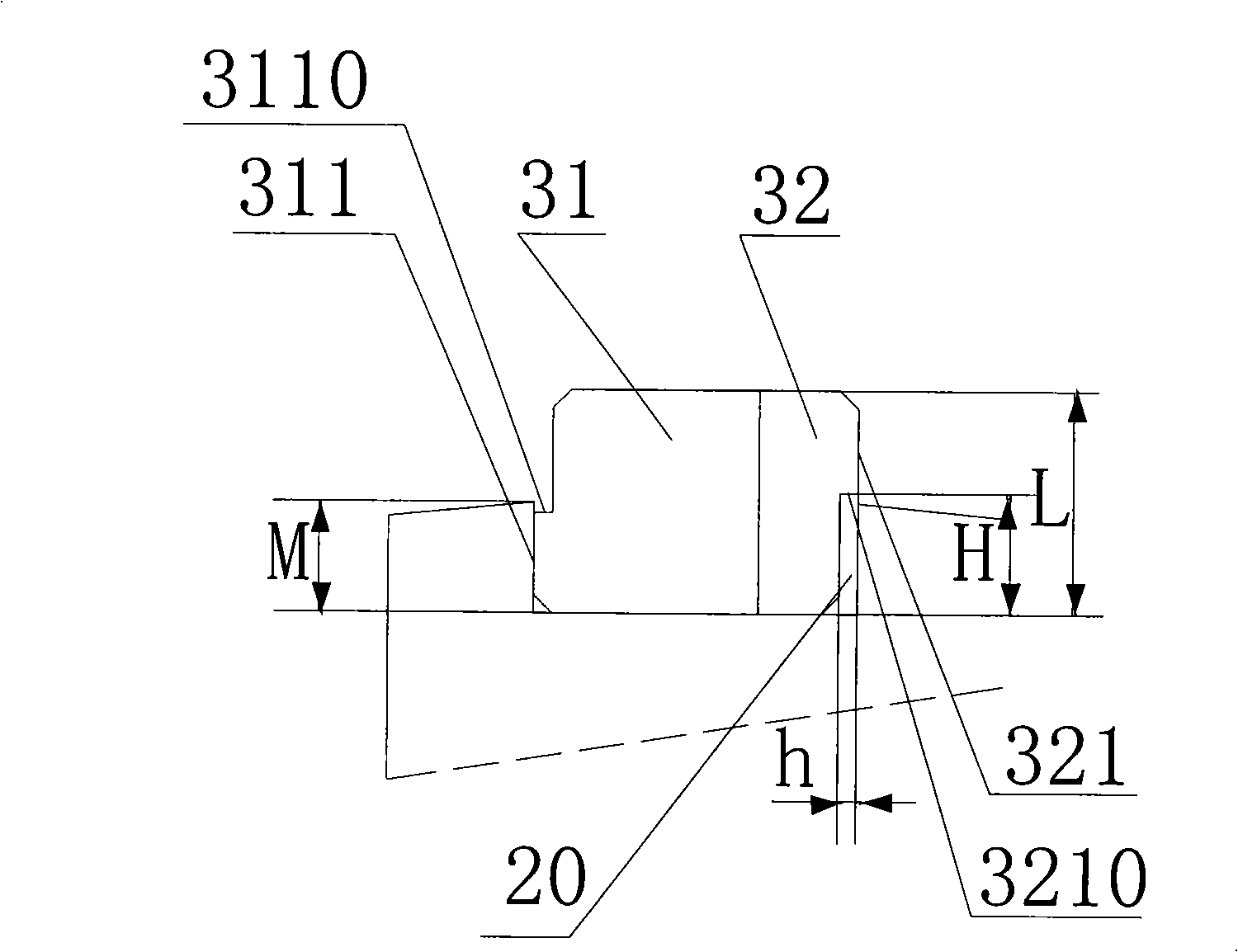

Key structure for large load motor iron core and rotating shaft transmitting torque, and installation method thereof

ActiveCN101294592AMeet the mechanical strengthEasy to assembleMagnetic circuit rotating partsKey type connectionsHigh volume manufacturingEngineering

The invention discloses a structure of a key of heavy-load motor iron core and rotating shaft transmission torque and an installation method thereof. The structure comprises an iron inner circle provided with at least a pair of key slots opposite to each other for 180 DEG; a plurality of welding webs uniformly distributed on the peripheral surface of a motor rotating shaft; key slots corresponding to the iron core key slots opened on outer rings of the welding webs and a key embedded in the key slots; wherein the key is composed of a pair of taper keys in parallel with the same structure; one lateral surface of each taper key is an inclined plane, and the other lateral surface of the taper key is step-shaped, namely, the middle lower part of the lateral surface is provided with a right angle shaped depression; the pair of key slots is matched with the opposite key slot walls of the iron core and the welding web through the step-shaped lateral surface, and the opposite inclined planes of the key slots are combined by the form of inclination complementation. The adoption of the structure of the key of heavy-load motor iron core and rotating shaft transmission torque of the invention can meet the mechanical strength of the motor when the overload is three times more than load; furthermore, the structure is convenient for assembly and easy for mass production.

Owner:上海电气集团上海电机厂有限公司

Cereals alcohol-soluble protein conduit and preparation method thereof

ActiveCN101757692AGood mechanical propertiesImprove mechanical propertiesCatheterProsthesisProtein solutionBiocompatibility Testing

The invention relates to a cereals alcohol-soluble protein conduit and a preparation method thereof in the field of biomedical technology; the method comprises the following steps: cereals alcohol-soluble protein and organic solvents are mixed to obtain protein solution; after the protein solution is extracted by a mold, drying treatment is carried out and the protein pipe is demoulded from the mold; secondary extraction is carried out to the protein pipe, so as to form a nanoscale spherical structure surface outside, and then form fixation is carried out; finally, conducting polymer is deposited on the protein conduit surface, so as to prepare the conductive cereals alcohol-soluble protein conduit. In the invention, the cereals alcohol-soluble protein is used as raw materials, and the protein conduit has good biocompatibility and degradation, is suitable for preparing tissue engineering conduits and is helpful for regeneration and functional rehabilitation of damaged tubular shaped soft tissues.

Owner:SHANGHAI JIAO TONG UNIV

High-reliability image sensor wafer-level fan-out packaging structure and method

ActiveCN111354652AUnlimited thicknessSize reduction in XY directionSemiconductor/solid-state device detailsSolid-state devicesChip sizeSolder ball

The invention provides a high-reliability image sensor wafer-level fan-out packaging structure and method. The high-reliability image sensor wafer-level fan-out packaging structure comprises a substrate, a CIS chip, and solder balls. A photosensitive area of the CIS chip is arranged facing one surface of the substrate and the CIS chip is connected with one surface of the substrate through an areaaround the photosensitive area, a gap at the welding position of the CIS chip and the substrate is sealed through a light shielding material, and a back surface and a side surface of the CIS chip aresubjected to integral plastic package through a plastic package layer; the solder balls are arranged on a surface of the plastic package layer, and an RDL layer of the substrate is fanned out to the surface of the plastic package layer through through holes formed in the plastic package layer and is connected with the solder balls. According to the high-reliability image sensor wafer-level fan-outpackaging structure, the problem that RDL wiring cannot be achieved due to the fact that the size of a chip is miniaturized but functions are integrated in wafer-level packaging is solved, and the problems that a traditional substrate fan-out process is high in cost and low in yield can be solved.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com