Non-cylindrical scissor jack handle and elastic connection device thereof

A technology of elastic connection and jack, which is applied in the direction of lifting devices, hand-held tools, manufacturing tools, etc., can solve the problems of insufficient strength at the joint of the handle, inconvenient storage, and insufficient fast and convenient mechanical connection, etc., to achieve light weight, convenient storage, and ensure reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will further describe the present invention in conjunction with the accompanying drawings of the embodiments, which will help to understand the technical contents and effects of the present invention.

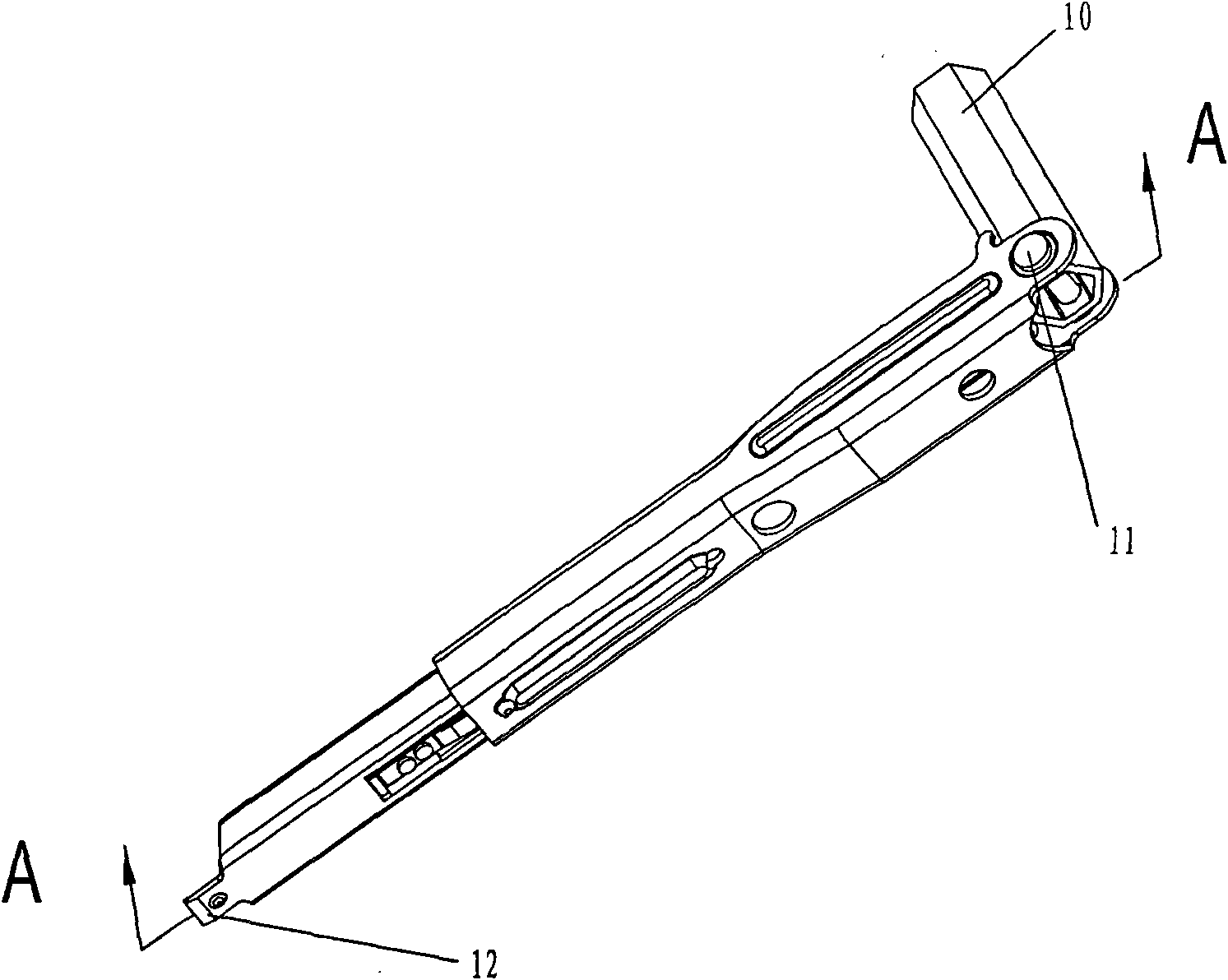

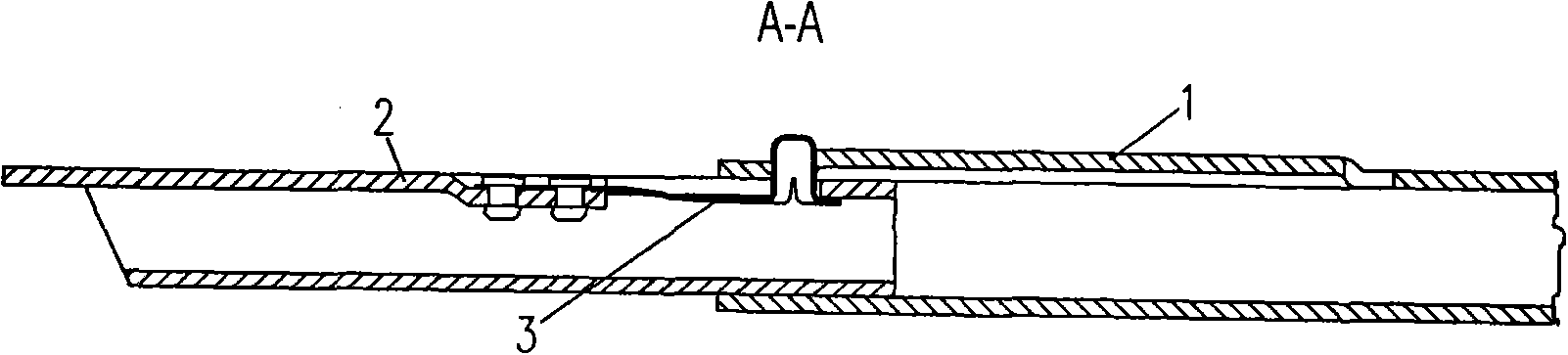

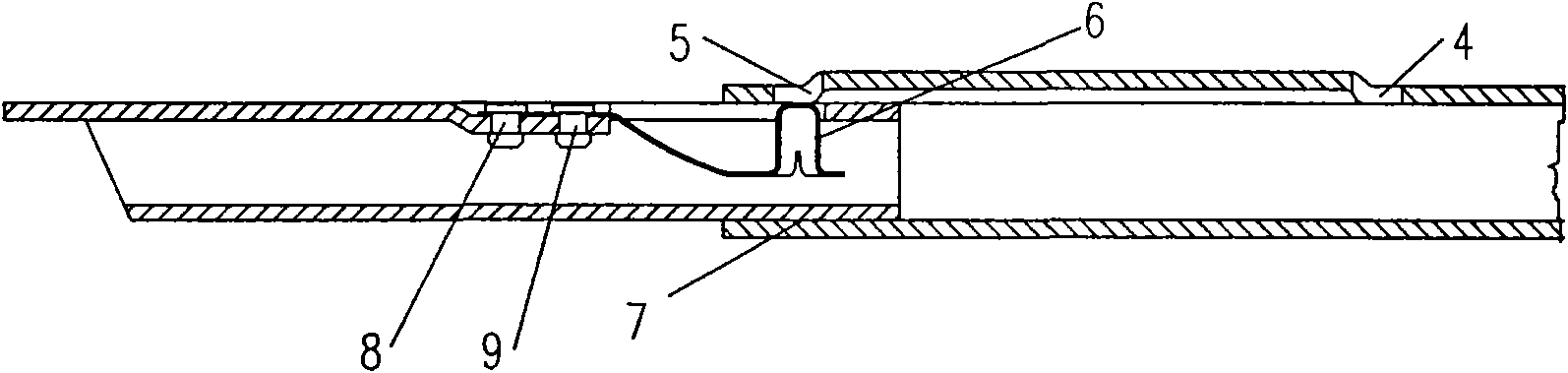

[0019] As shown in the accompanying drawings, as a complete combination of this type of jack operating handle, one end of the hexagonal sleeve 10 that engages the outer hexagonal head of the jack screw tail is rotationally connected with the front handle through a rotating pair 11, and its function is as a labor-saving lever. Realize jacking vehicle or heavy object with the screw rod of torsion scissor jack, the 2nd, can attach and dismantle wheel fastening bolt or nut, the 3rd, can utilize tire prying flange 12 to help operation dismantling tire. The hexagonal sleeve 10 can be rotated into the cavity of the front handle 1 under the action of the rotating pair 11, and the matching through holes 4 and 5 are preset in the appropriate position of the front hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com