Patents

Literature

12943 results about "Rivet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the tail. On installation, the rivet is placed in a punched or drilled hole, and the tail is upset, or bucked (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, pounding creates a new "head" on the other end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the factory head and the deformed end is called the shop head or buck-tail.

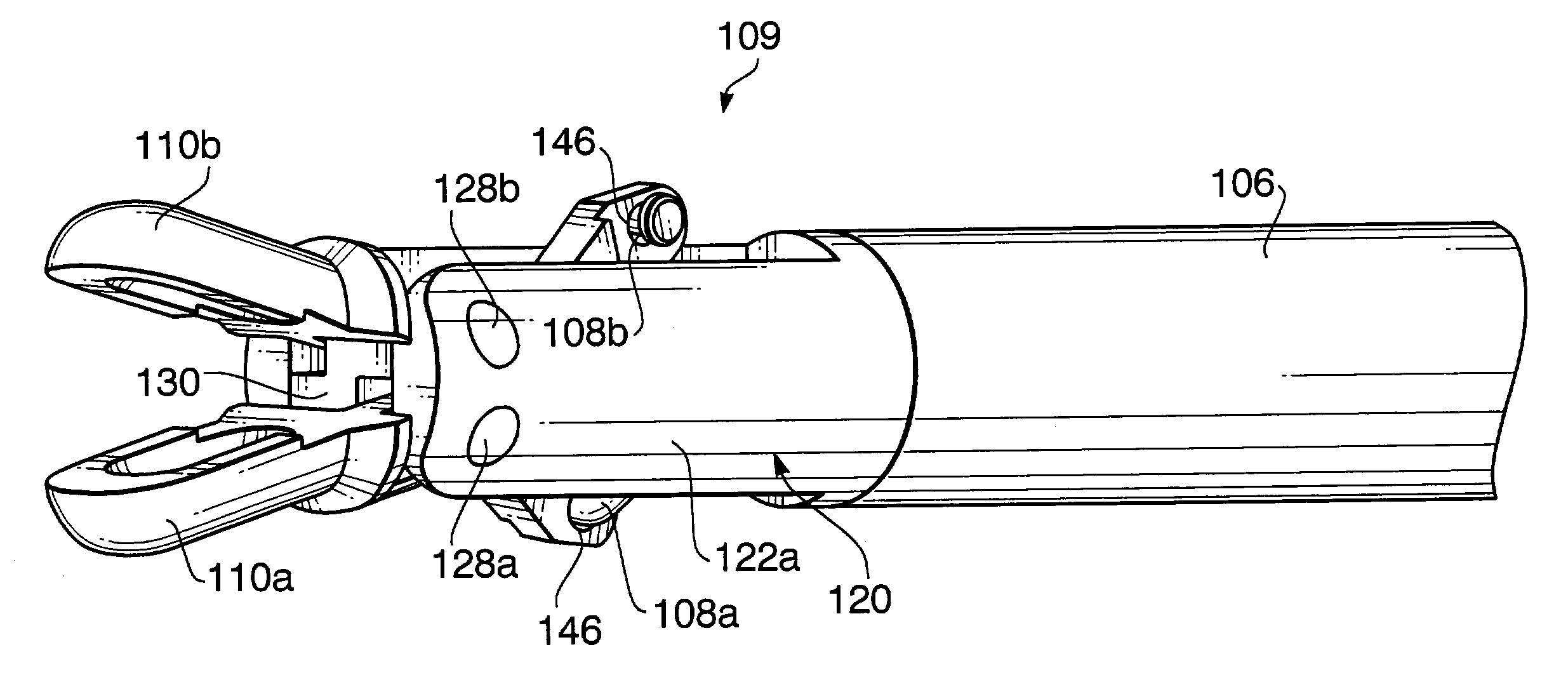

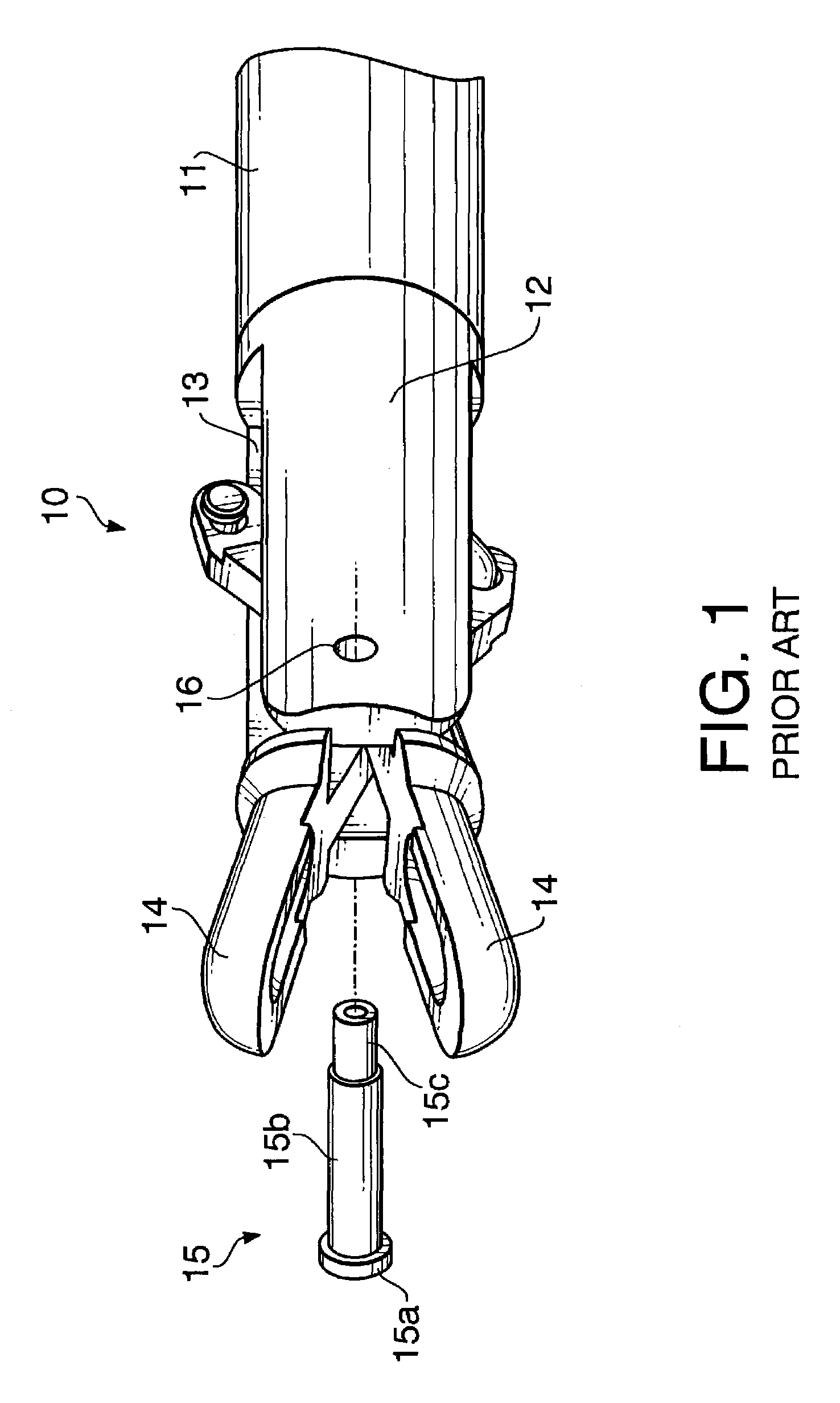

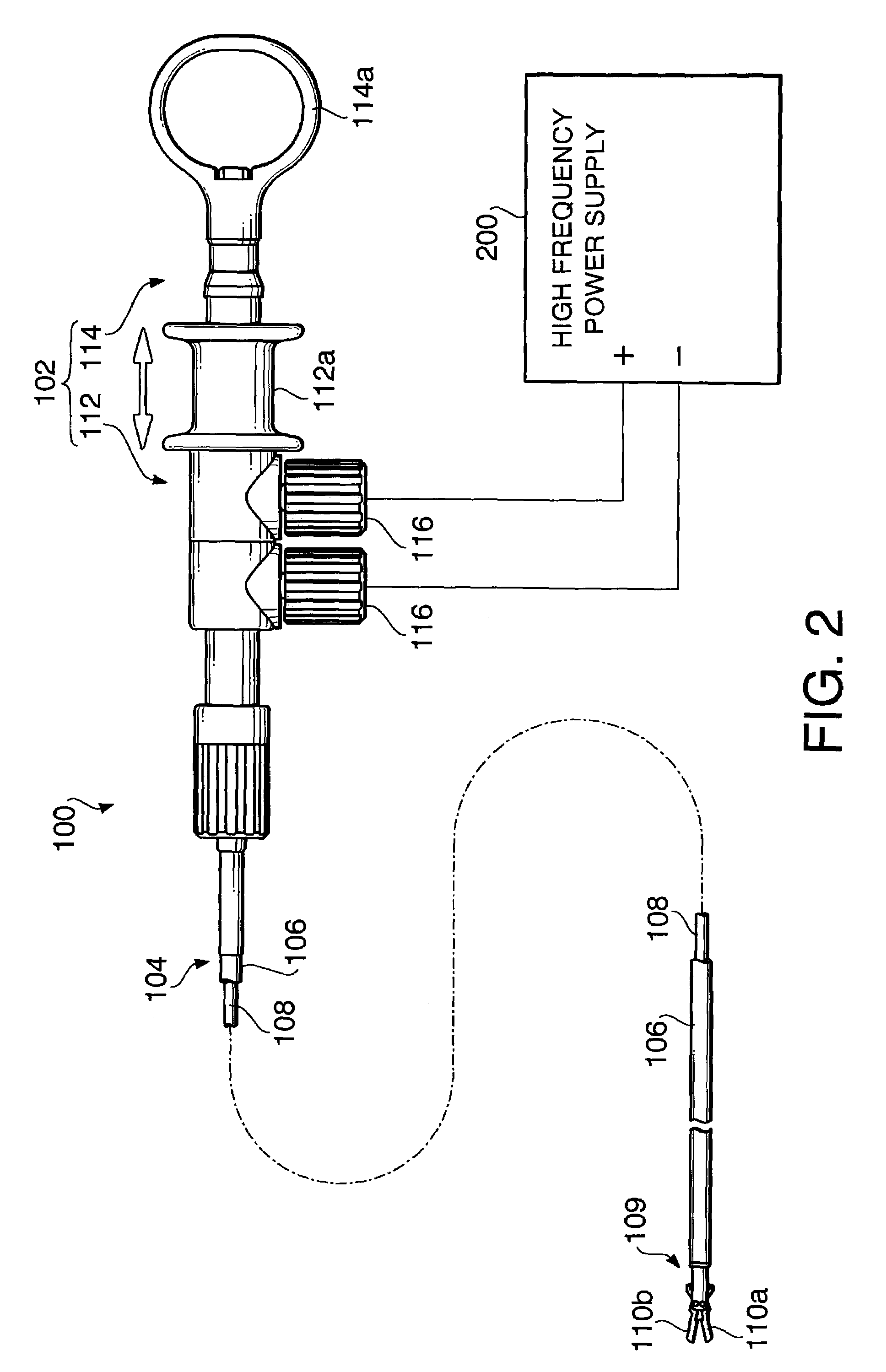

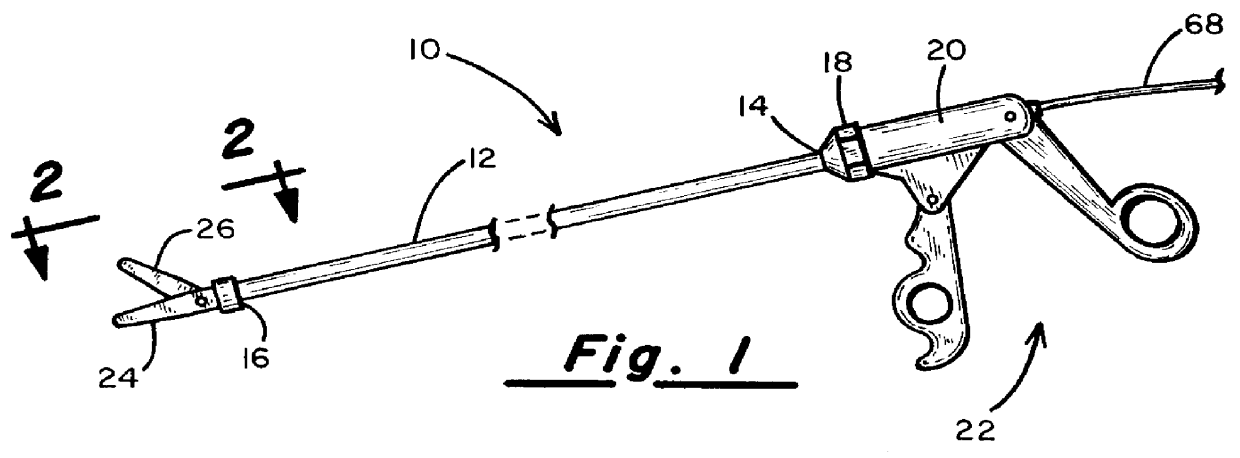

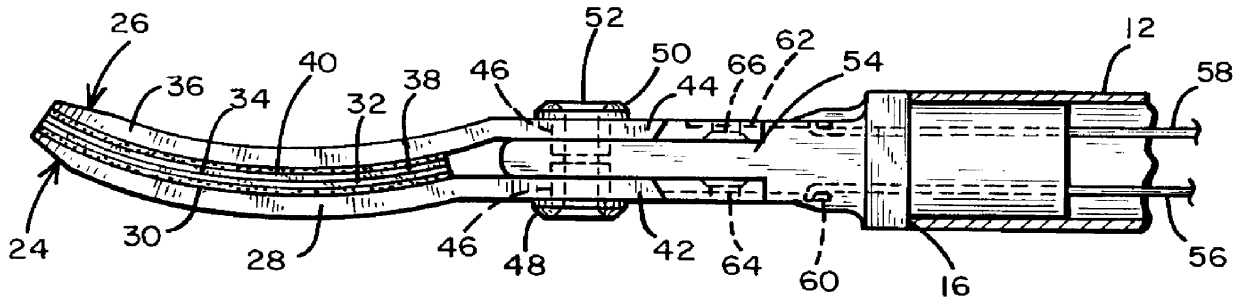

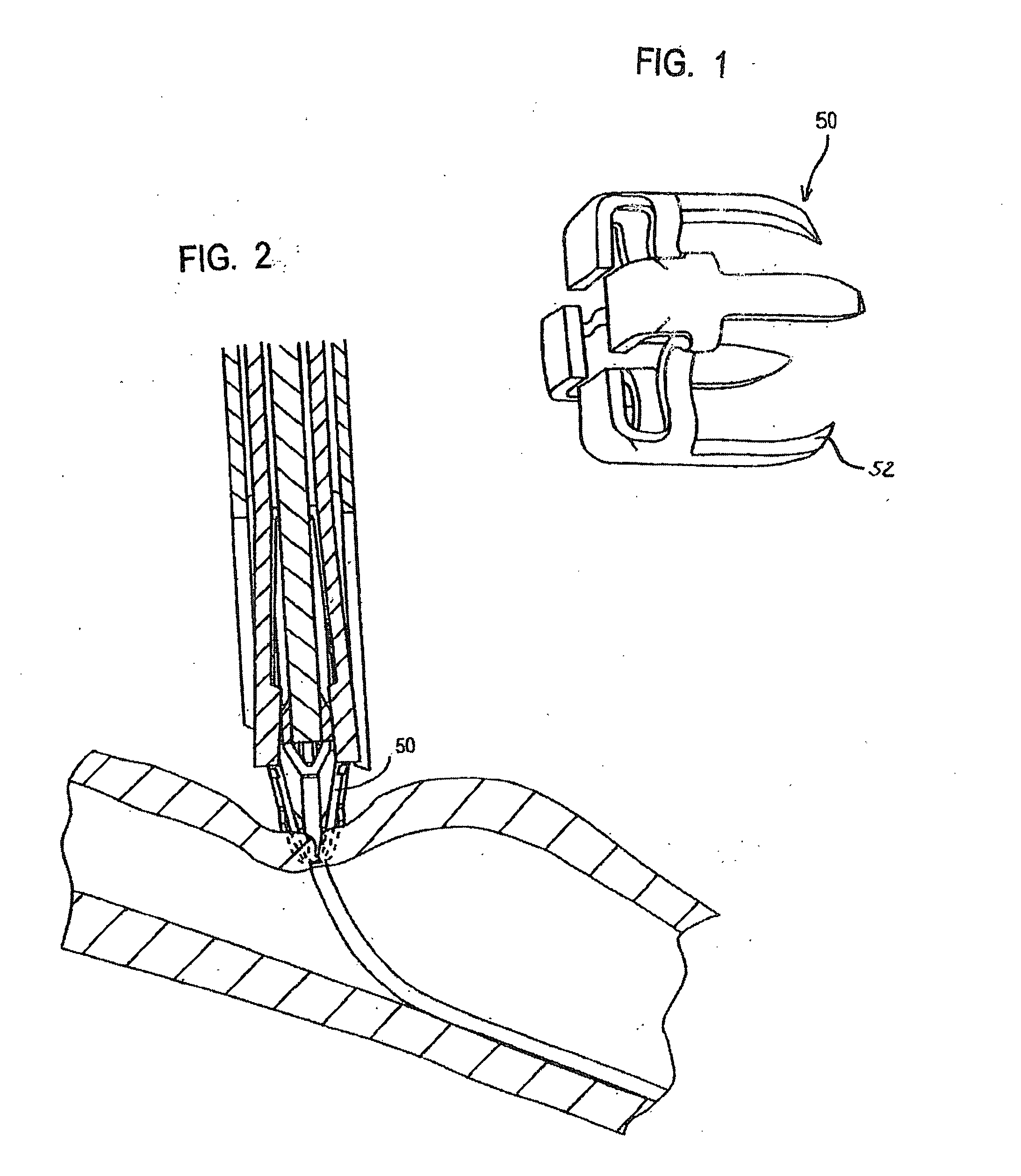

Endoscopic forceps instrument

An endoscopic forceps instrument has an inserting portion to be inserted into a body cavity through an endoscope, a clevis, a pair of rivets, and a pair of opposing jaws. The clevis is coupled to a distal end of the inserting portion. The pair of rivets is coupled to the clevis. Each of the rivets has a tip end that is swaged in order to fix the rivet to the clevis. The pair of opposing jaws is pivotably coupled to respective rivets so as to be movable between an open position and a closed position. The pair of rivets is arranged in parallel to each other. Further, the pair of rivets is arranged such that the tip ends thereof, which are swaged and therefore having relatively low mechanical strength, are located and swaged at opposite sides of the clevis.

Owner:HOYA CORP

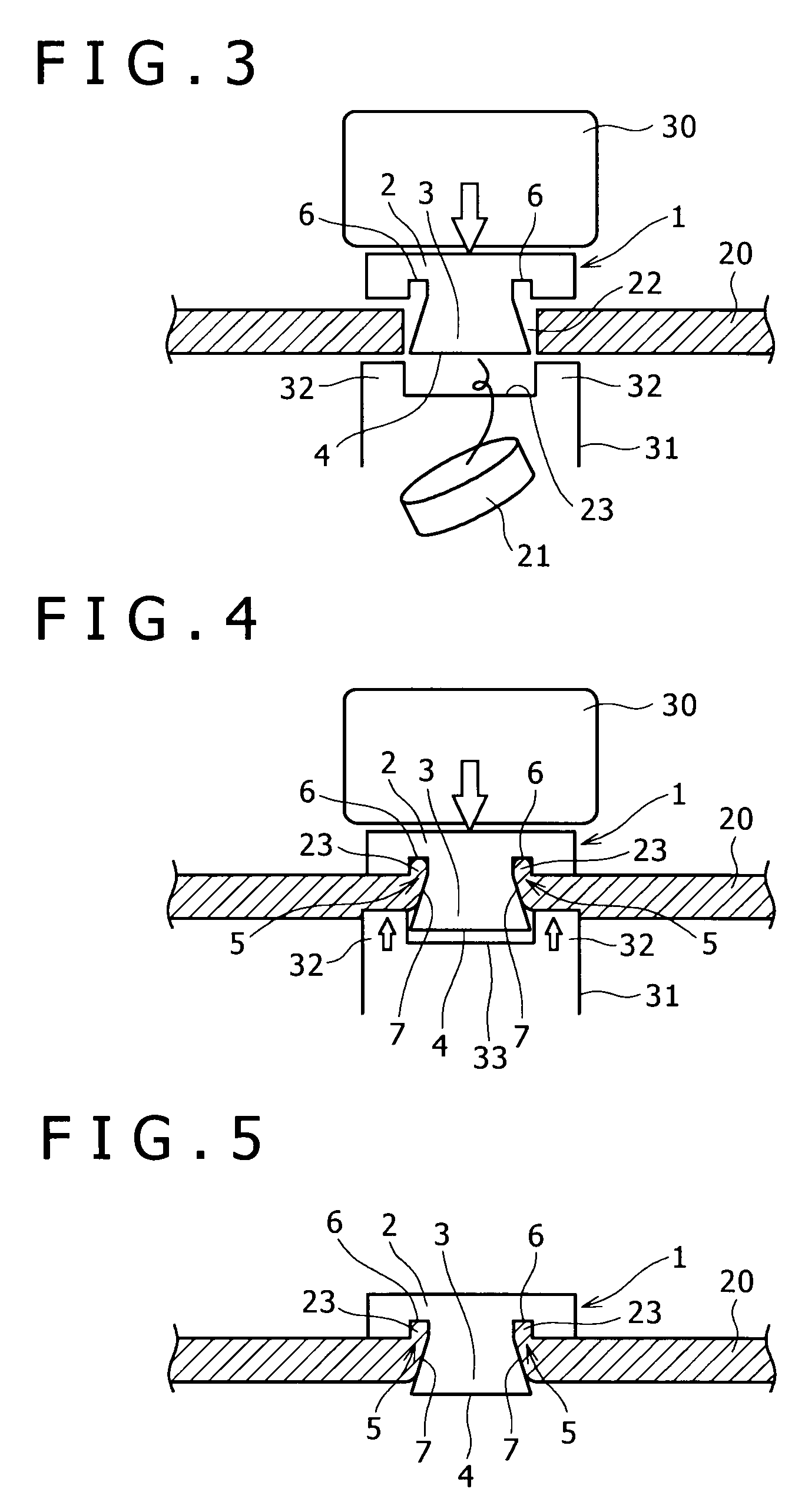

Apparatus for rivetting

Owner:GUNYANG ITT

Surgical scissors with bipolar coagulation feature

A bipolar electrosurgical scissors for use in open or endoscopic surgery has a pair of opposed blade members pivotally joined to one another and to the distal end of the scissors itself by a rivet which extends through a insulated bushing member. Each of the blade members comprises a blade support and a blade itself, each fabricated from metal, such as stainless steel. The blades are affixed to their associated supports by means of a suitable adhesive or adhesive composite material such as a fiberglass reinforced epoxy exhibiting dielectric properties. Cutting is performed, steel-on-steel, without causing a short circuit between the two blade supports which themselves function as the bipolar electrodes.

Owner:THE GOVERNOR & COMPANY OF THE BANK OF SCOTLAND

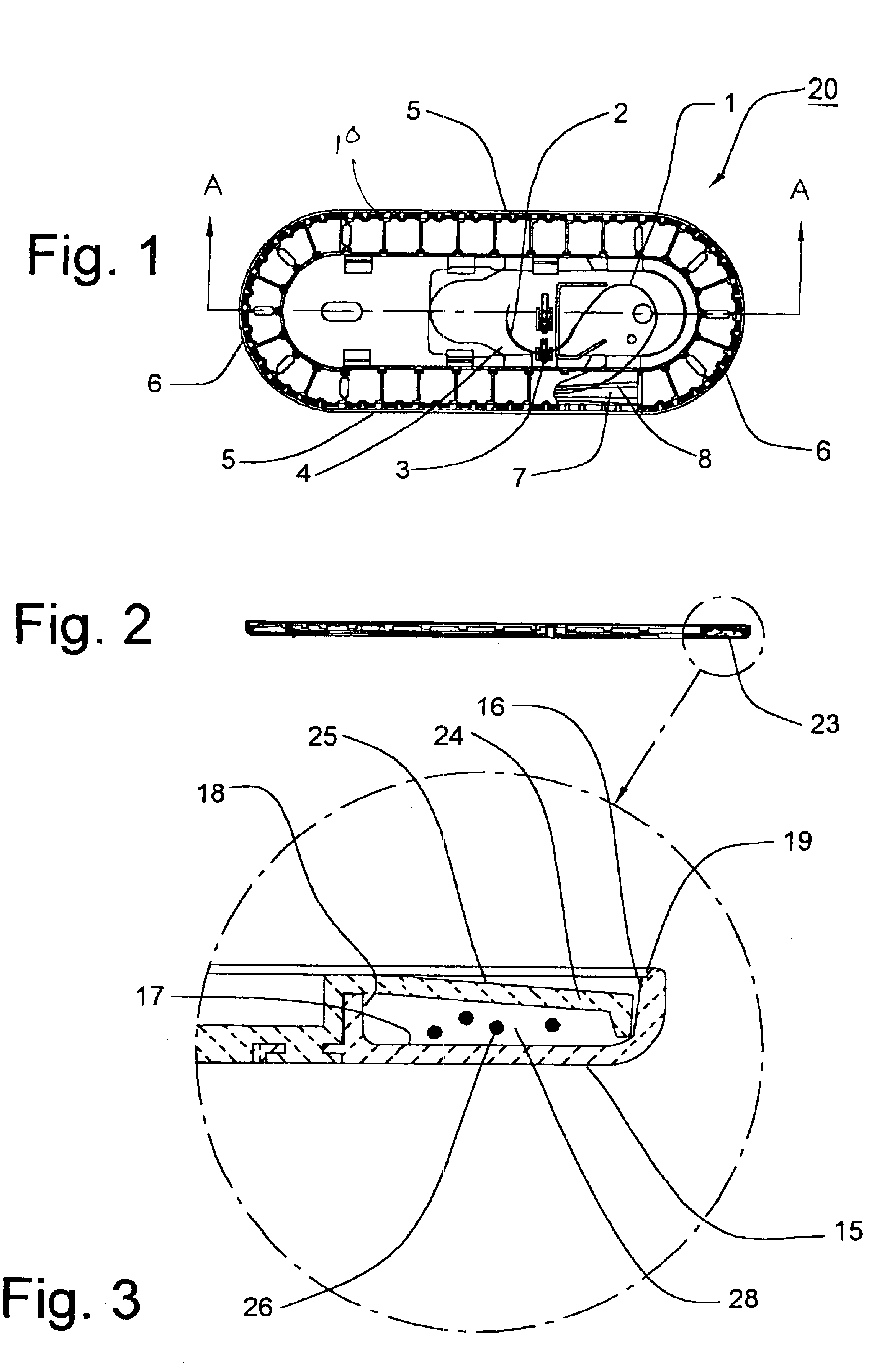

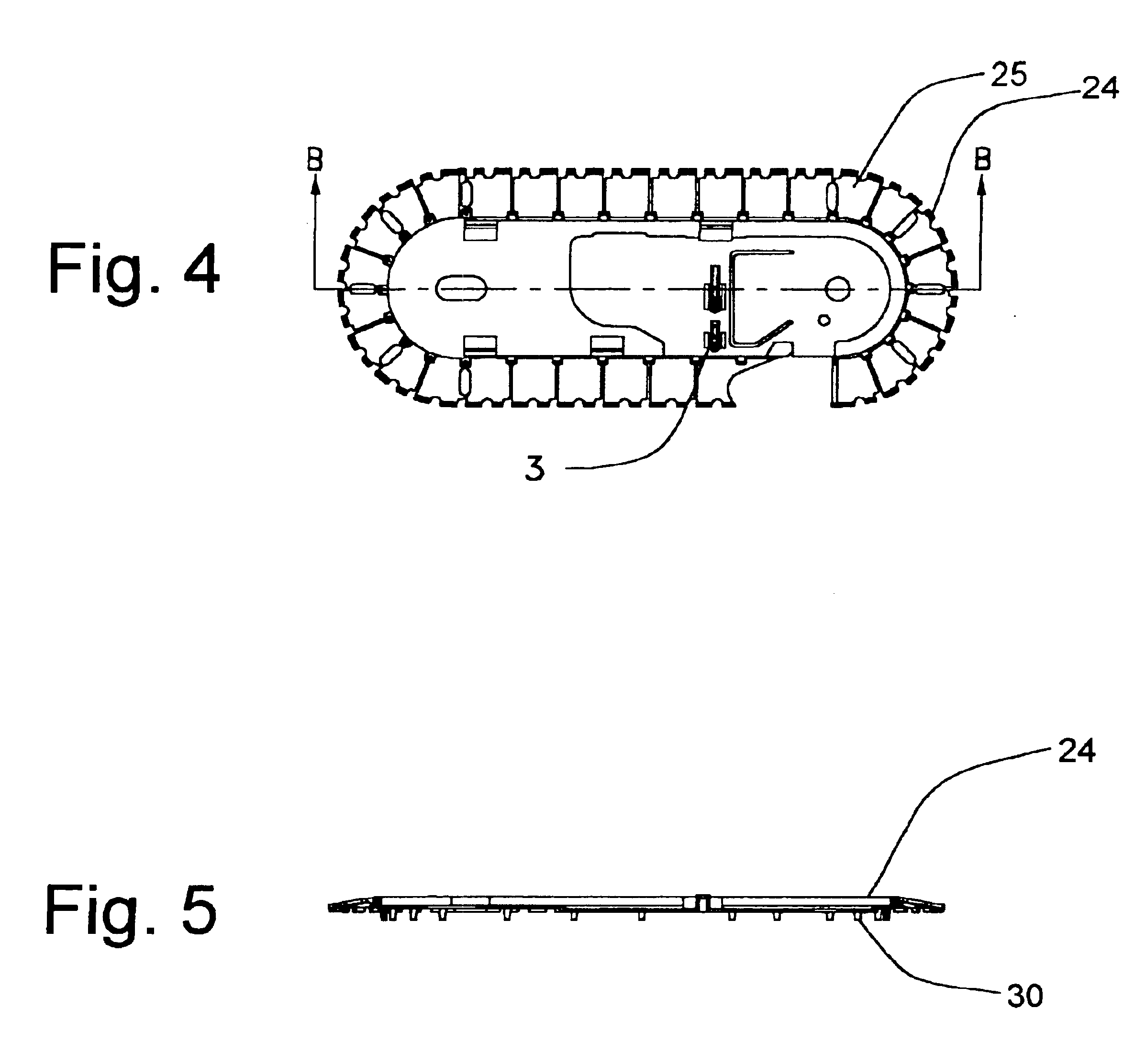

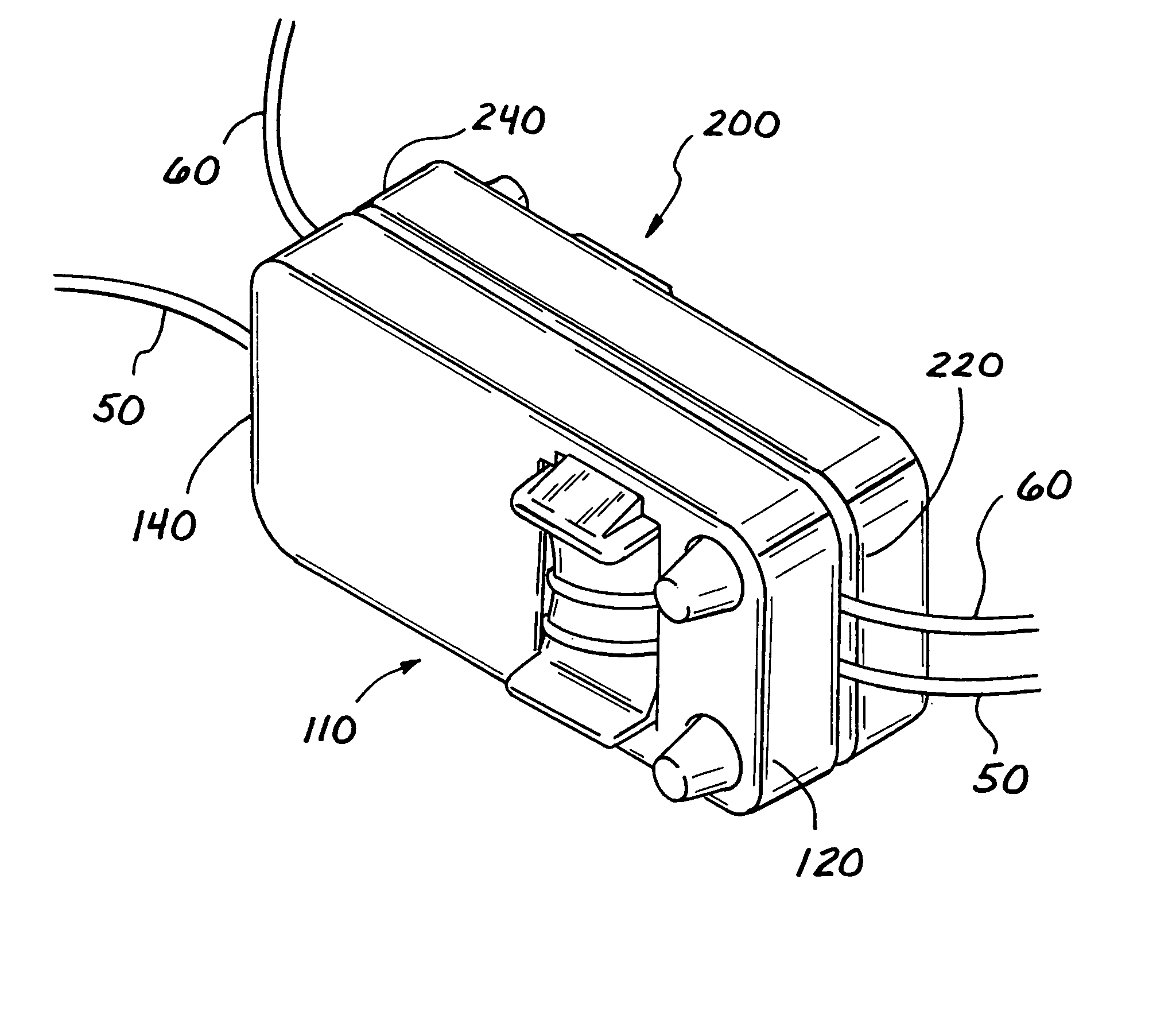

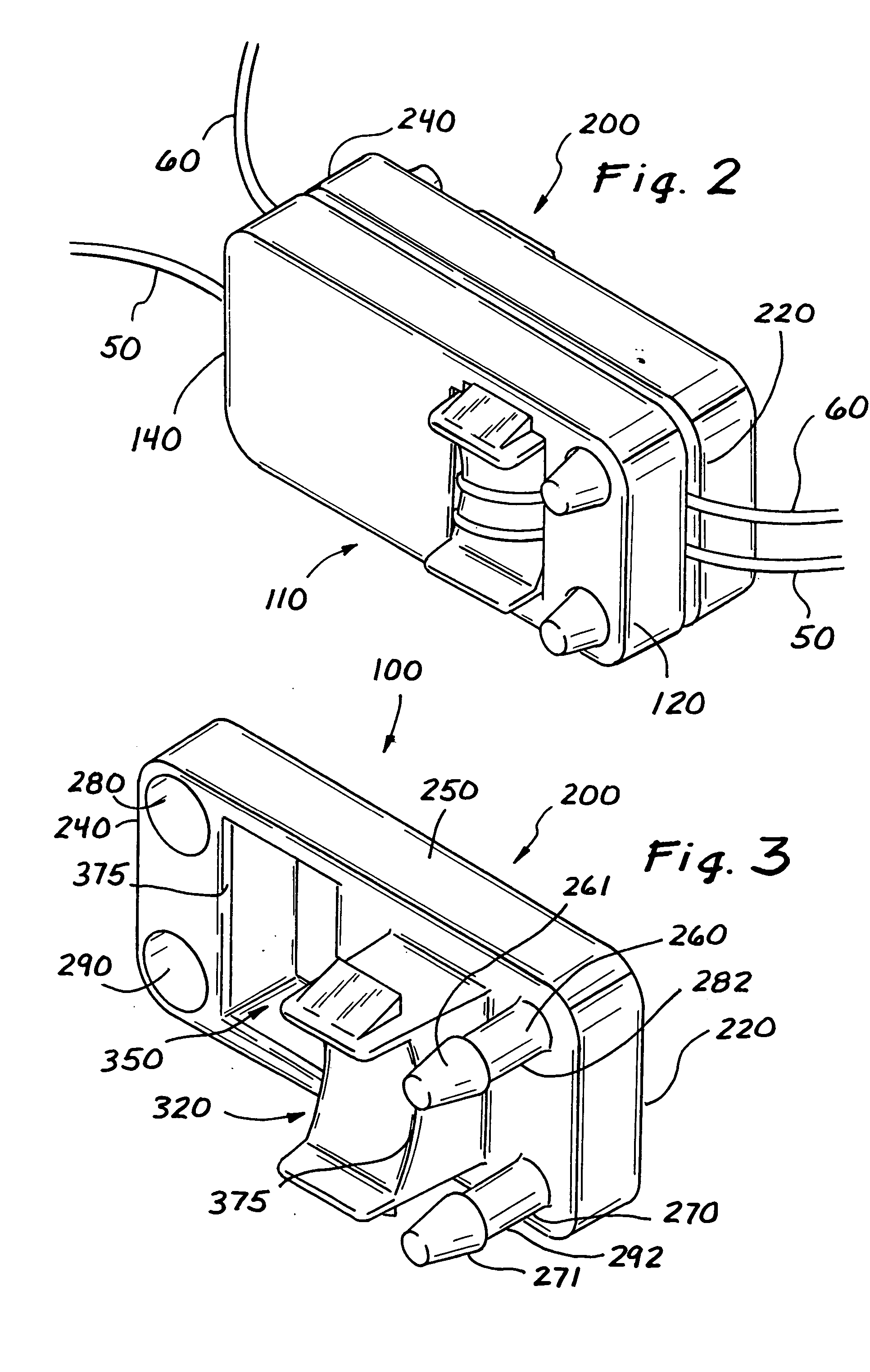

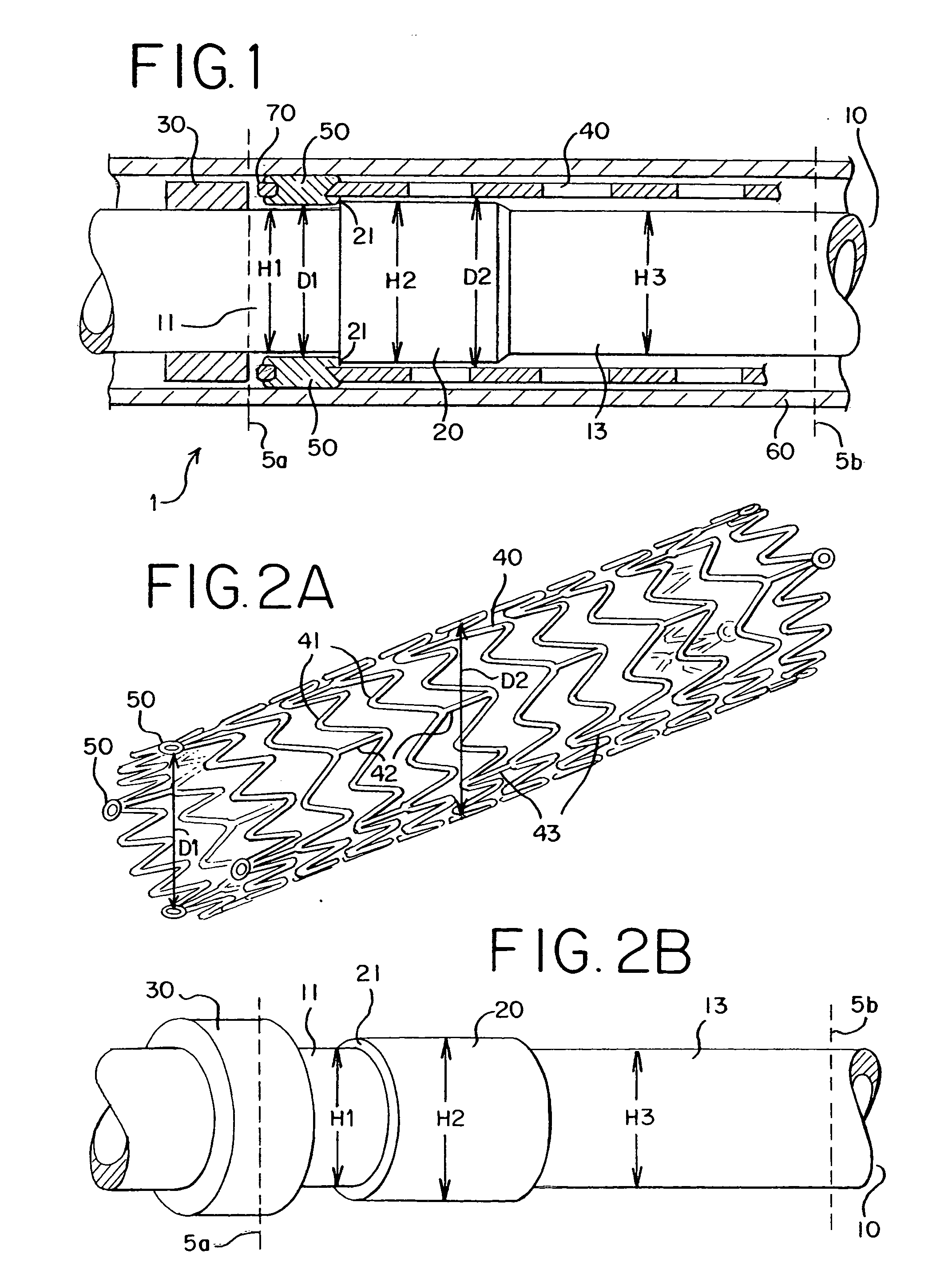

Method for assembling a package for sutures

InactiveUS6915623B2Not slowing downReduce manufacturing costSuture equipmentsSurgical needlesCounterboreUltrasonic generator

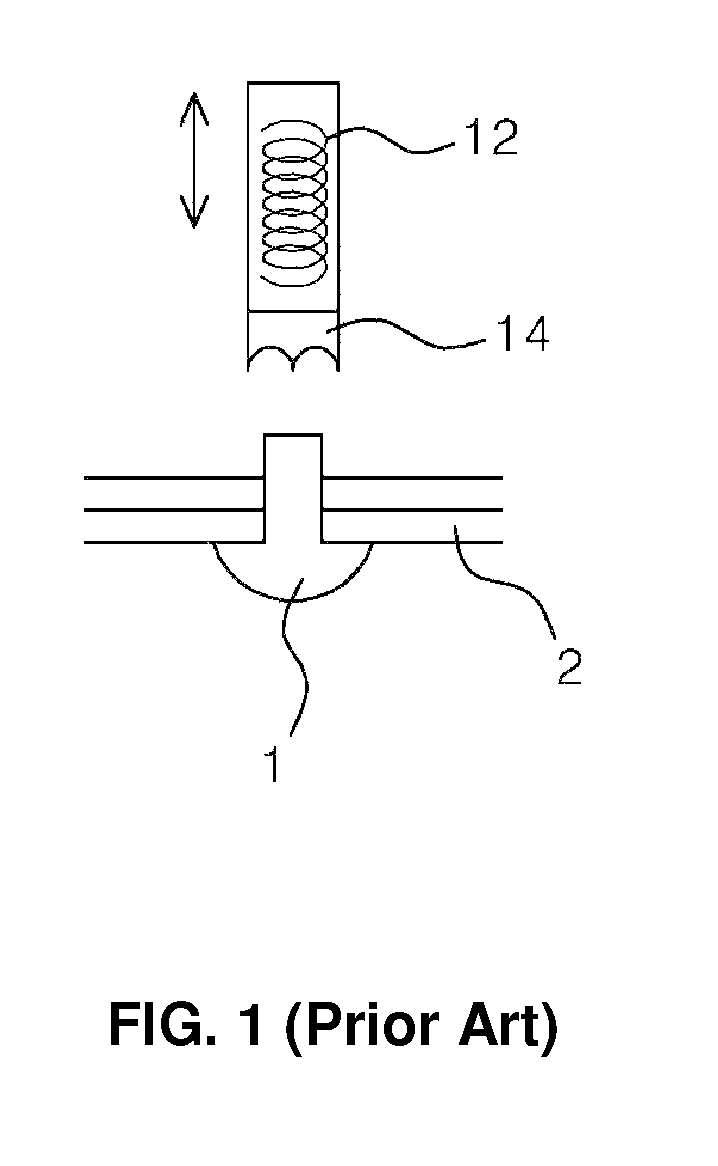

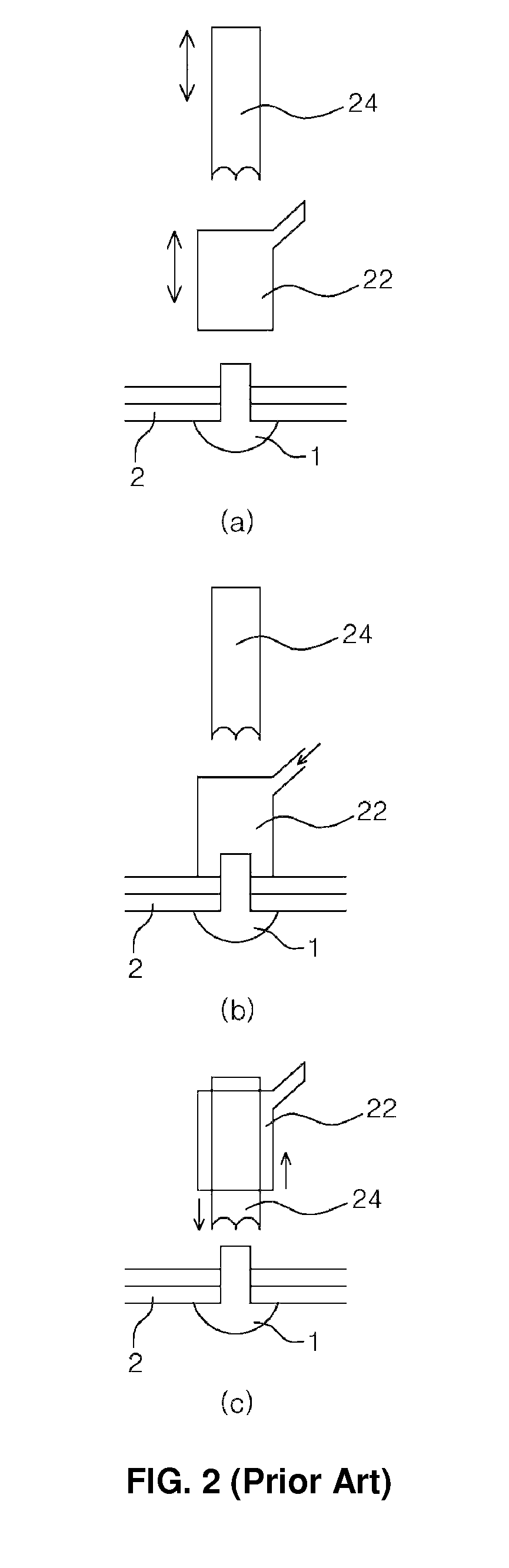

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity. The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

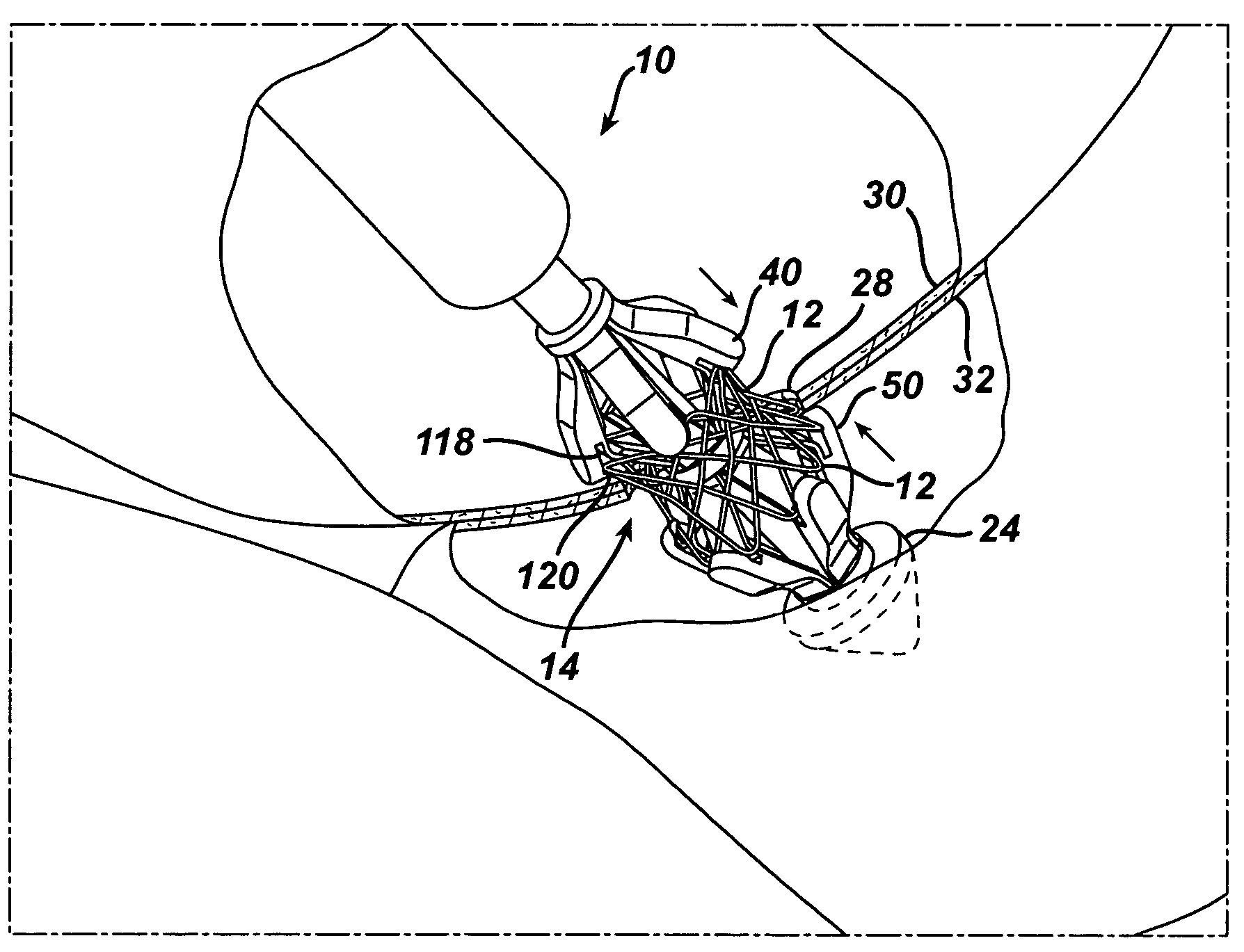

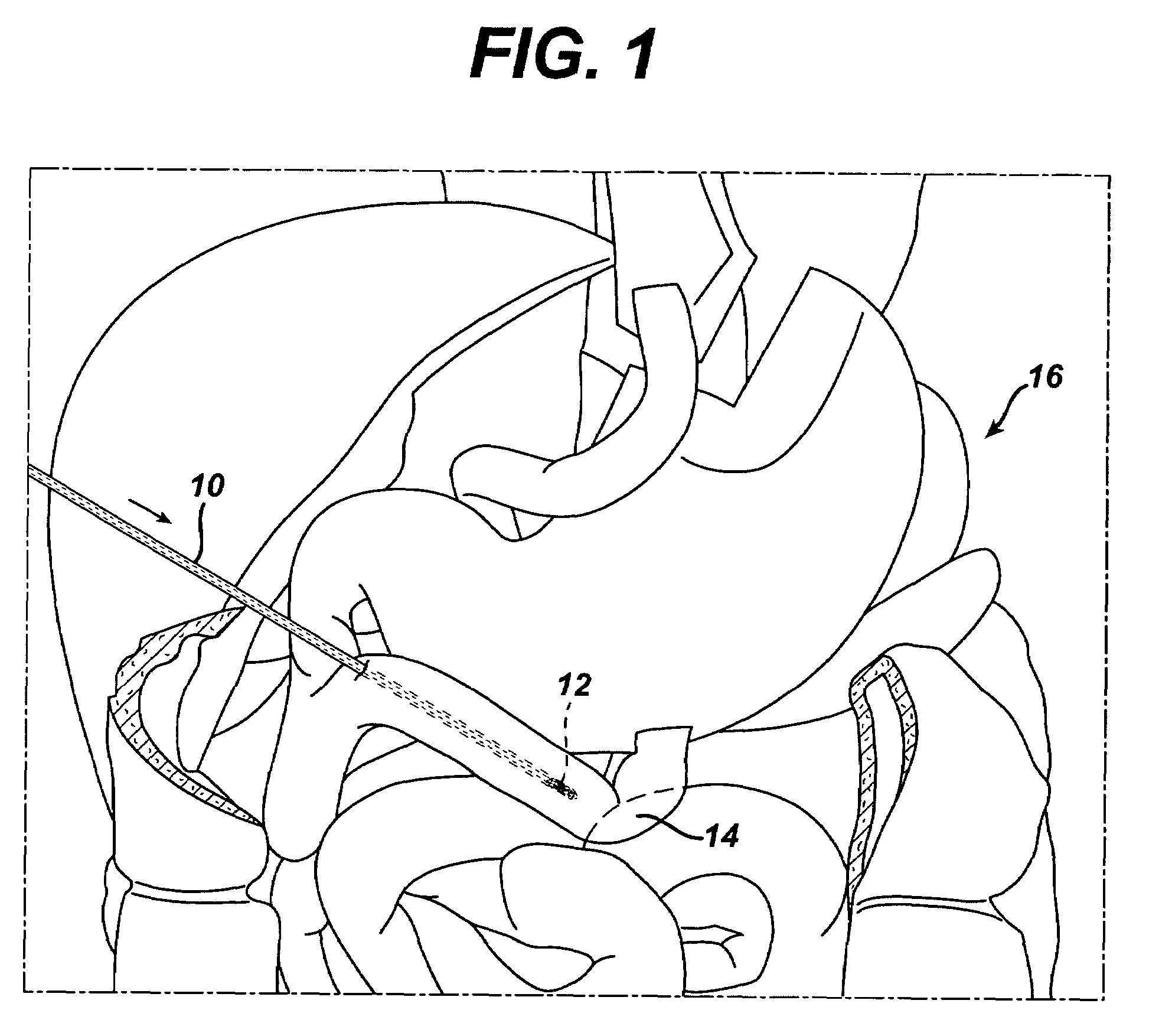

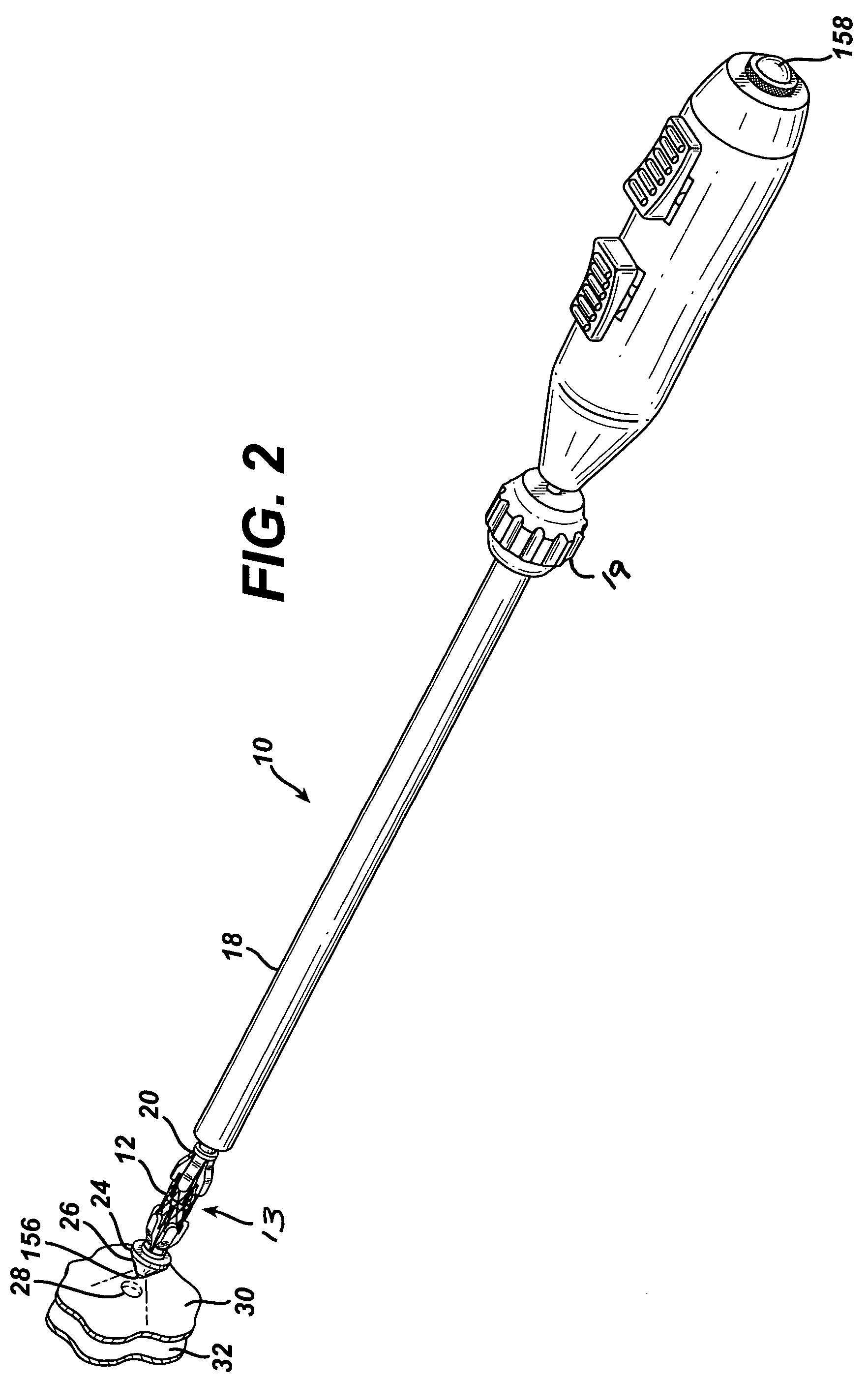

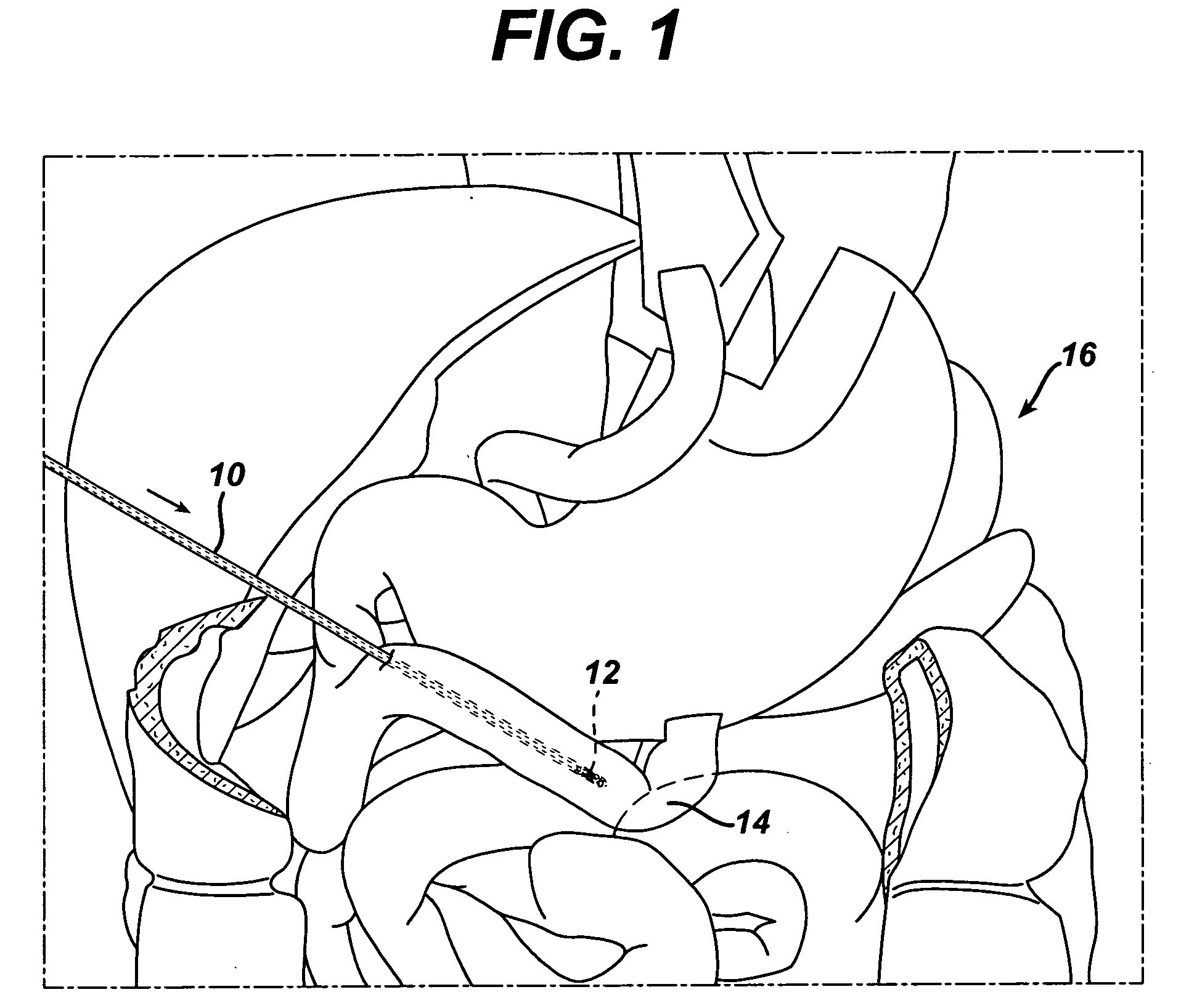

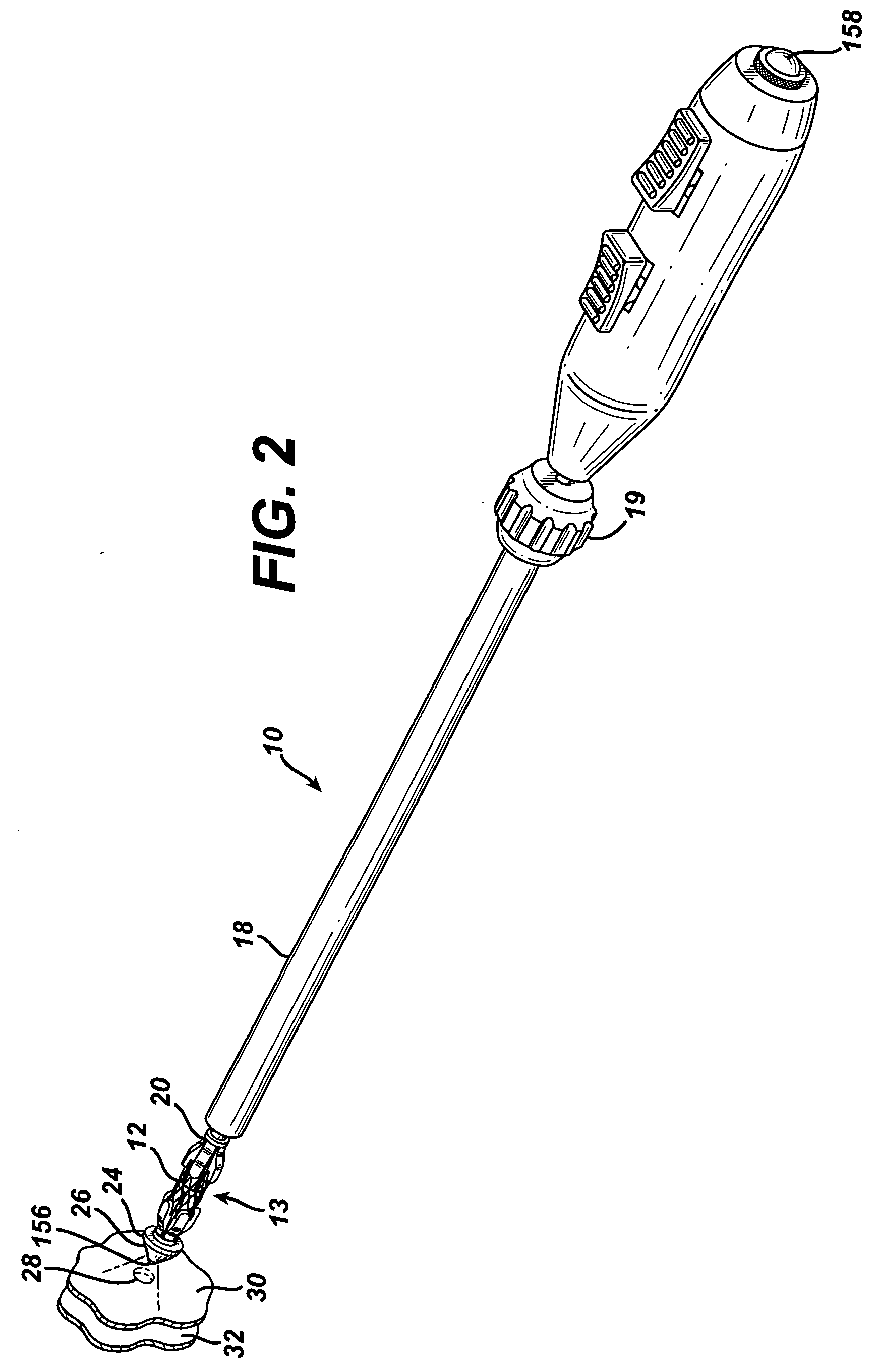

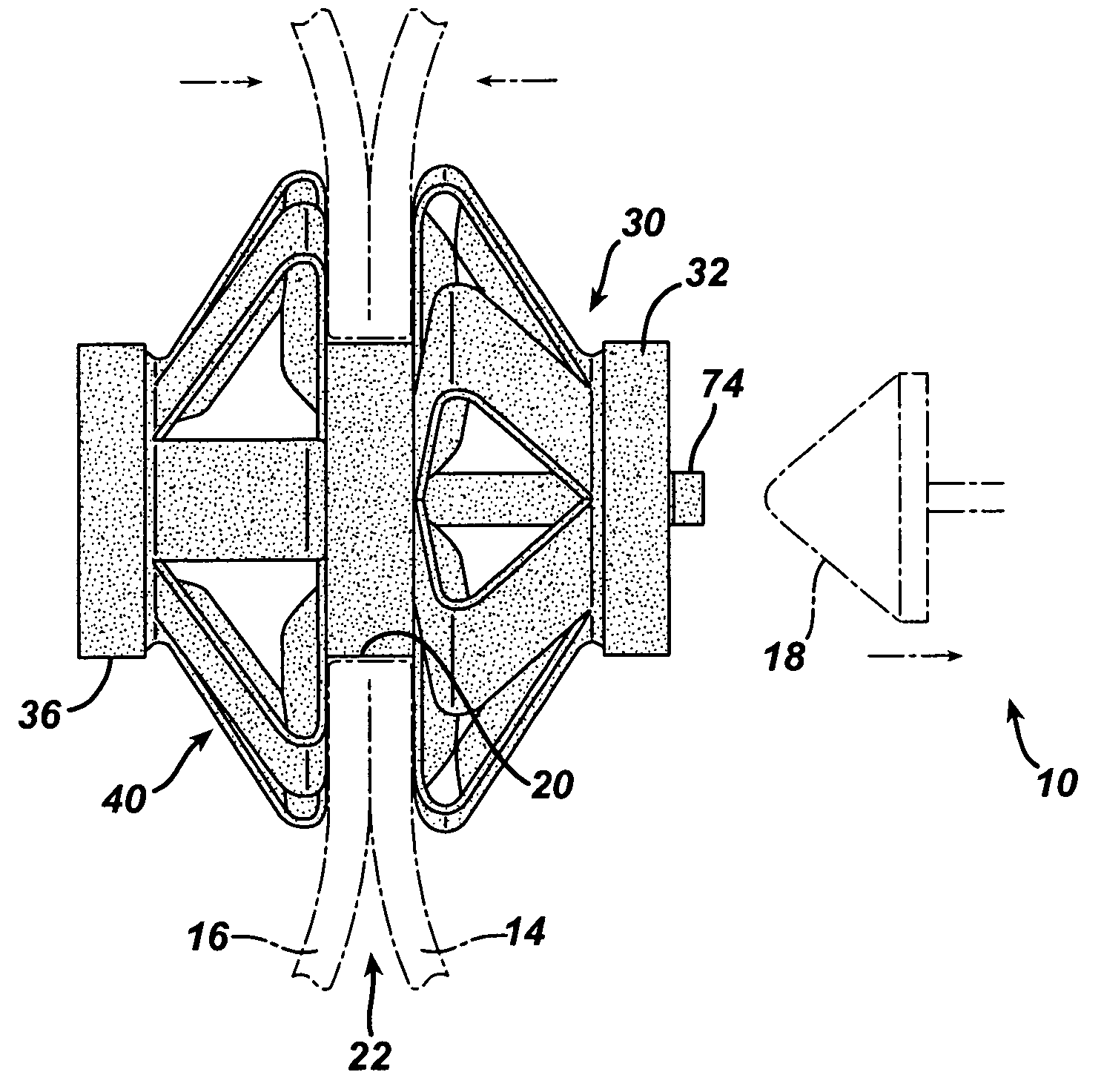

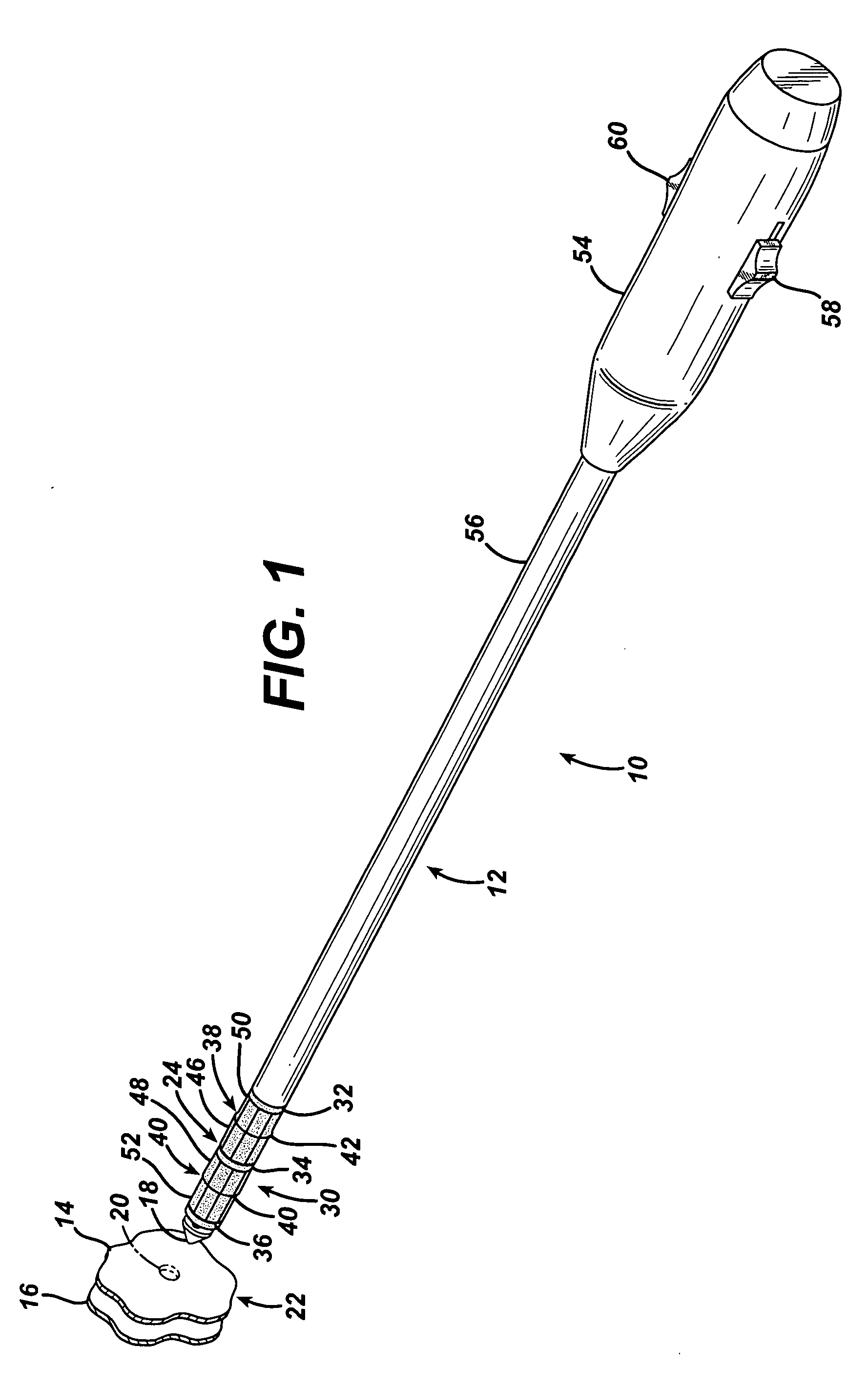

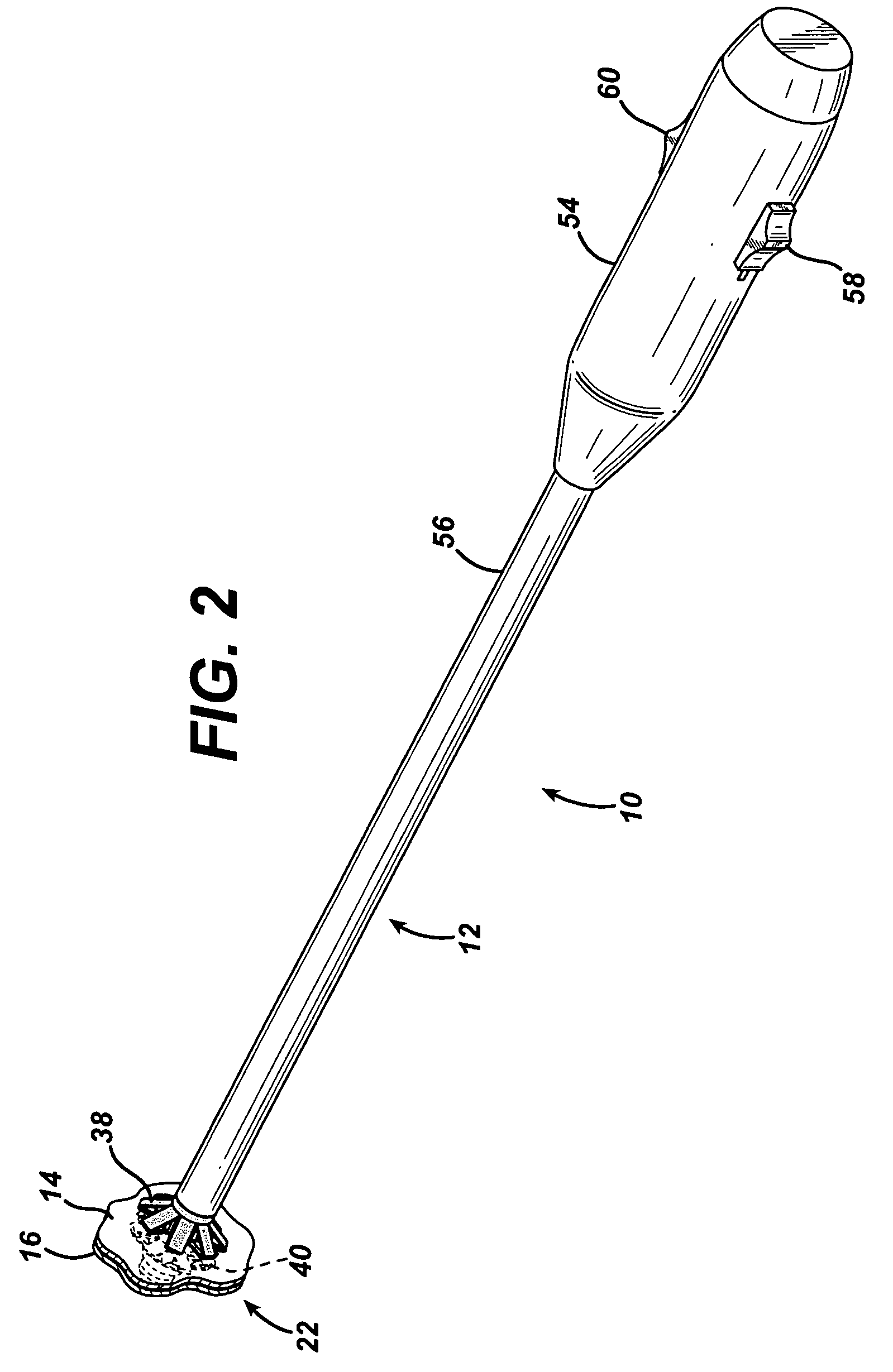

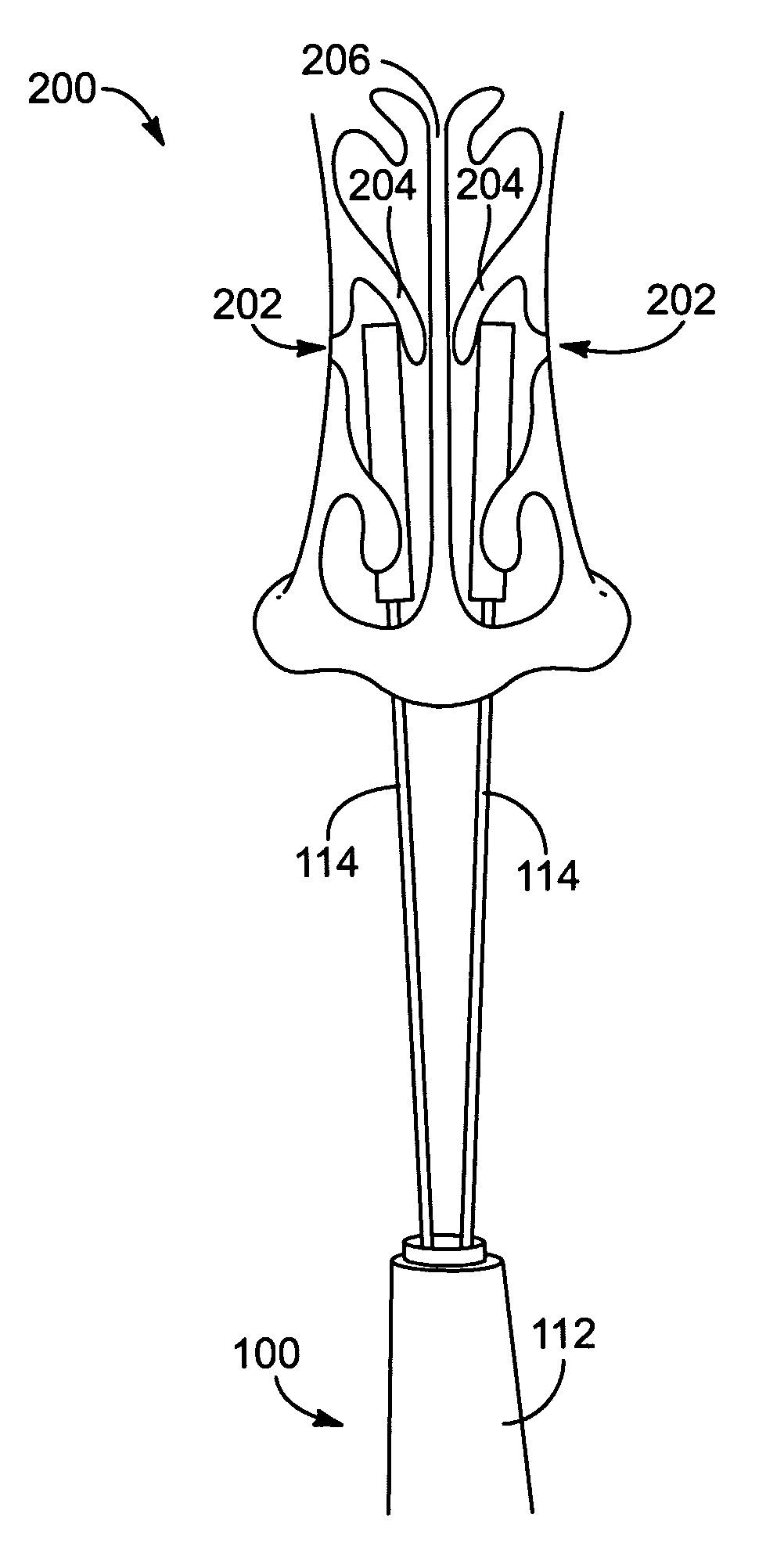

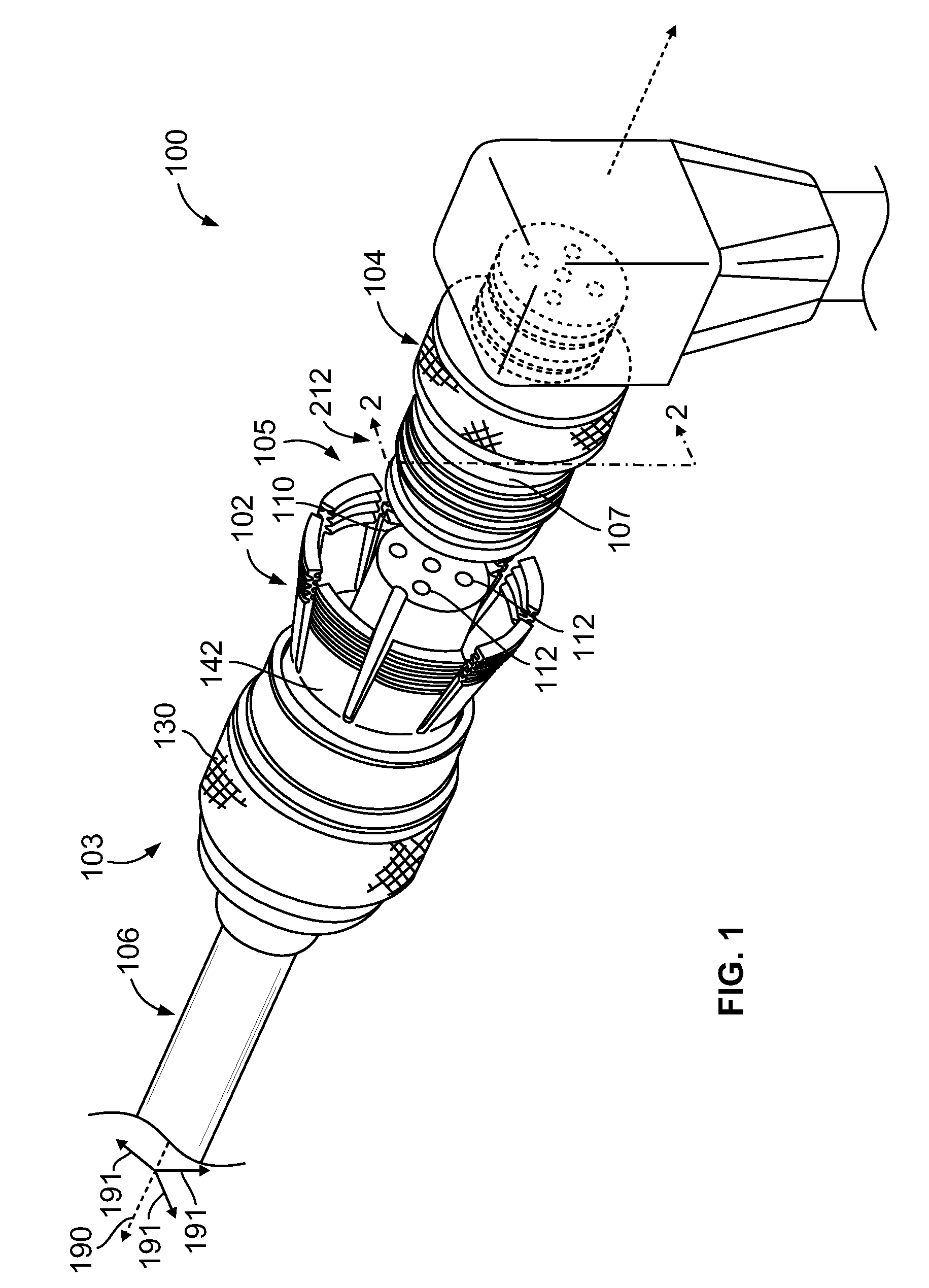

Single lumen anastomosis applier for self-deploying fastener

A surgical tool or applier facilitates laparoscopic or endoscopic implantation through a single bodily tissue lumen of an anastomotic ring device for forming a hollow rivet type of attachment between tissue lumens. In addition to forming a puncture between apposite tissue walls at the anastomosis site, the applier assists or wholly actuates the anastomotic ring device and is retracted to deploy the actuated ring device. Illumination incorporated into a distal portion of a cannula enables confirmation of deployment.

Owner:ETHICON ENDO SURGERY INC

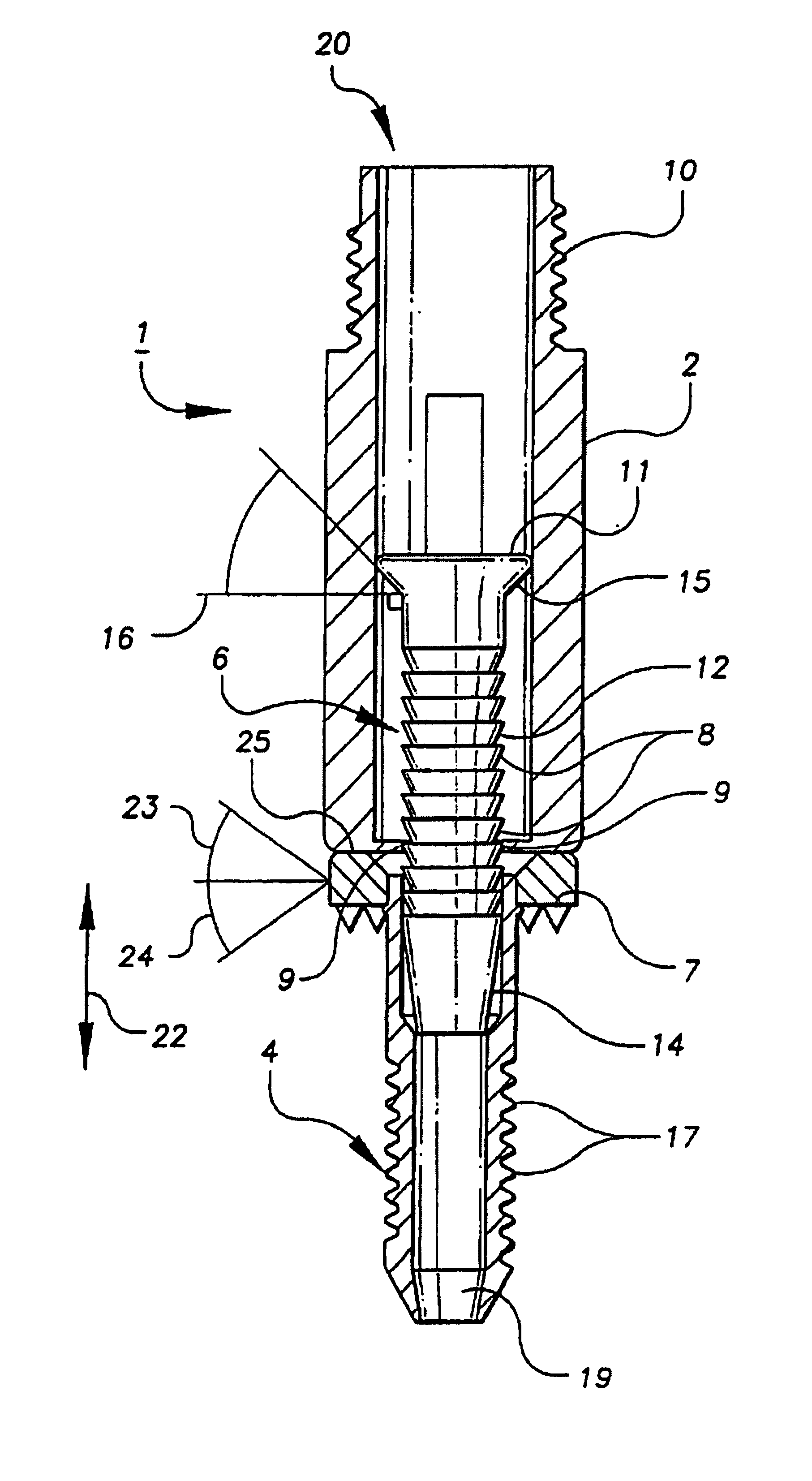

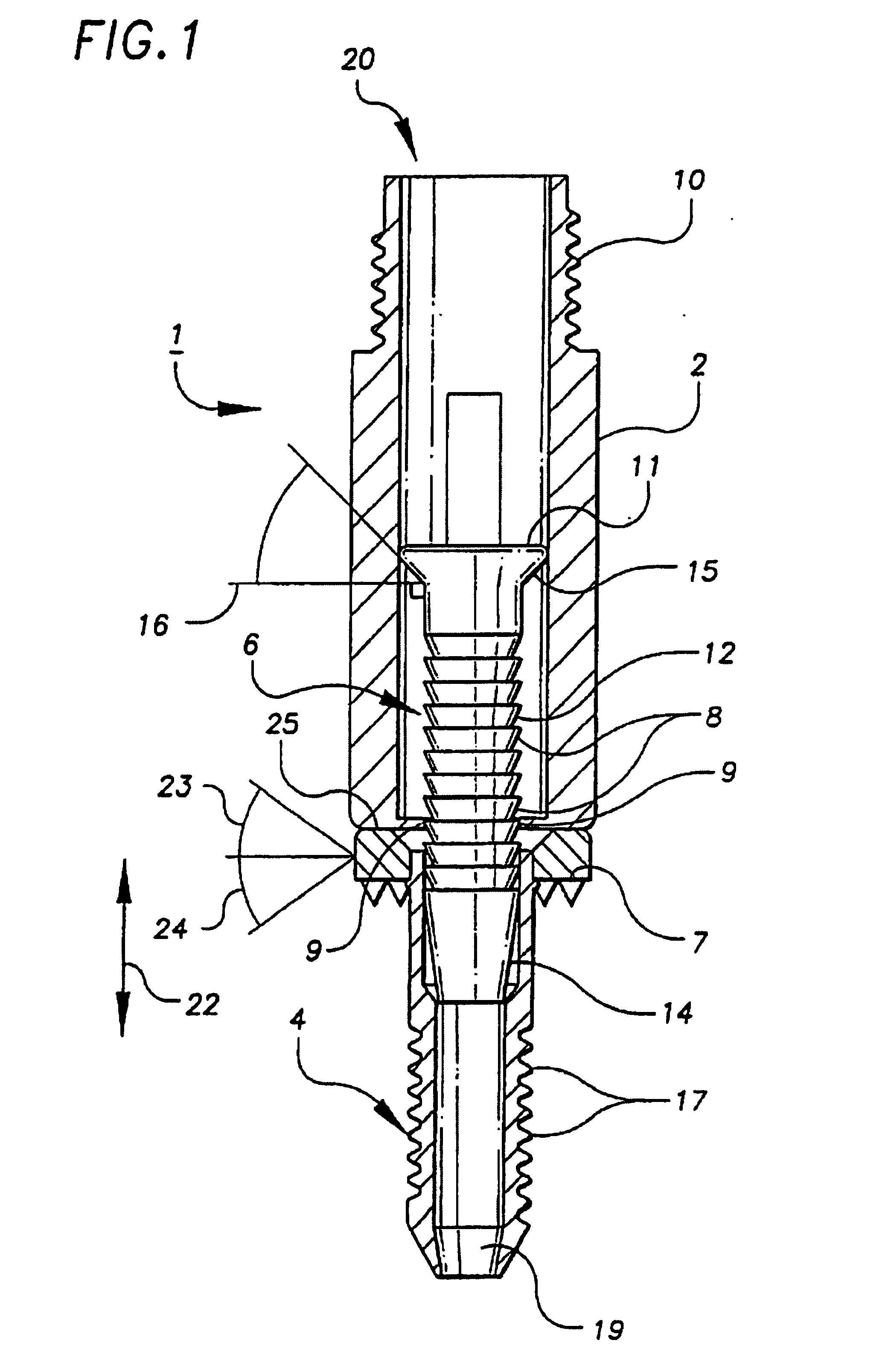

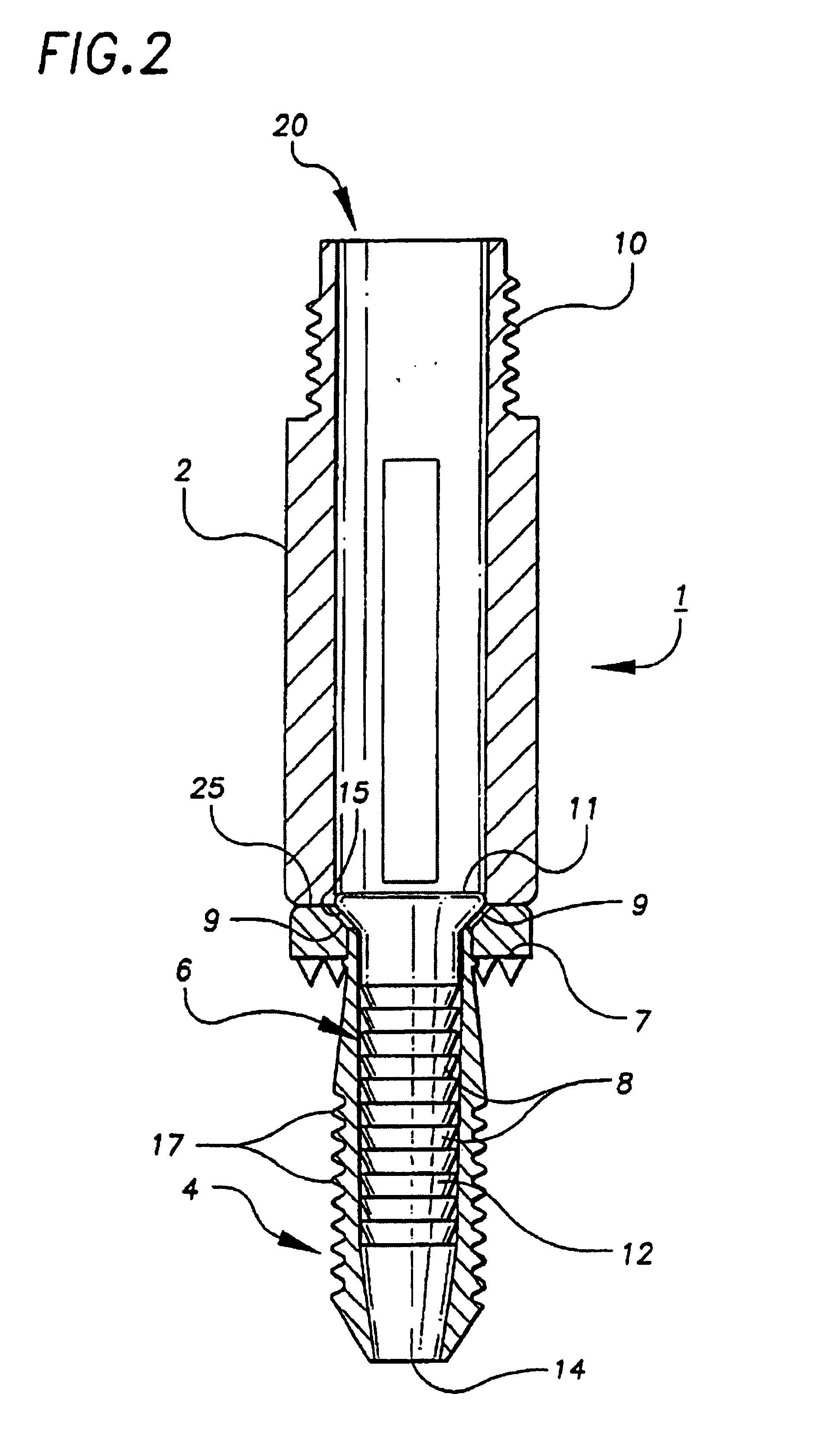

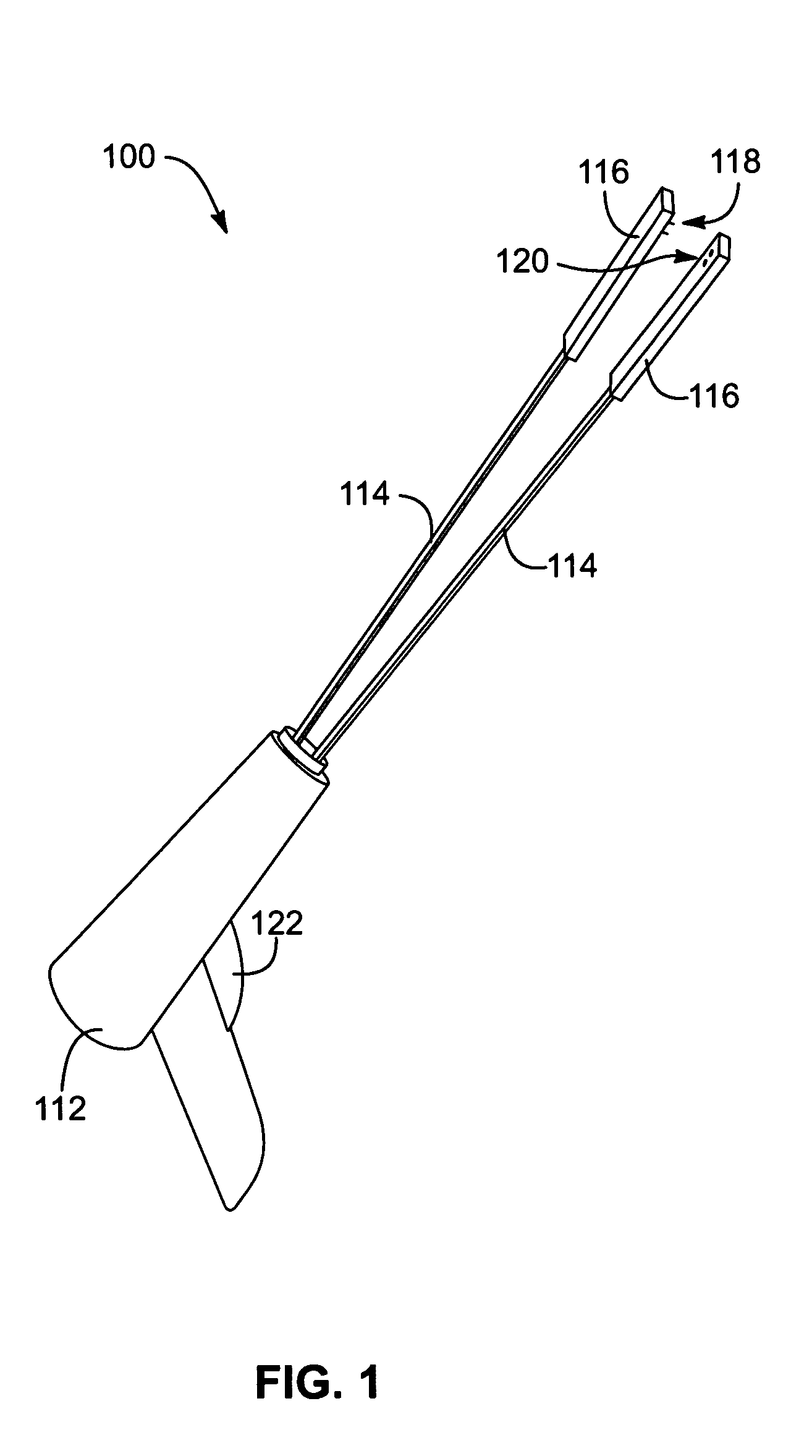

Bone anchor and deployment device therefor

A rivet-like bone anchor has a floating washer at its head that can adapt to an angled bone surface and, thereby, better secure a tissue thereto. The anchor includes a rivet, an expandable sleeve, and a washer. The rivet includes a head and an elongate body having proximal and distal ends, the head being mounted on the proximal end of the elongate body. The expandable sleeve has an inner bore adapted to receive the rivet body. The washer “floats” at a proximal end of the sleeve. As the rivet is inserted into sleeve, the sleeve expands into an interference fit with the bone. The head of the rivet, moreover, forces the floating washer into contact with the tissue at an angle that conforms to that of the underlying bone surface. A deployment tool permits the anchor to be deployed without application of unnecessary counterforce. The tool includes an outer tube, the distal end of which can hold the anchor housing, e.g., via a screw fit. A rod, which is slidably disposed within the bore of the tube, can be used to push the rivet into the expandable sleeve so that the sleeve expands into the bone, so that the floating washer is forced into position against the bone surface, and so that anchor is broken away from the housing. This can be effected, for example, by squeezing the distal ends of the outer tube and the rod together, e.g., in the manner that the end of a syringe is squeezed.

Owner:INNOVASIVE DEVICES

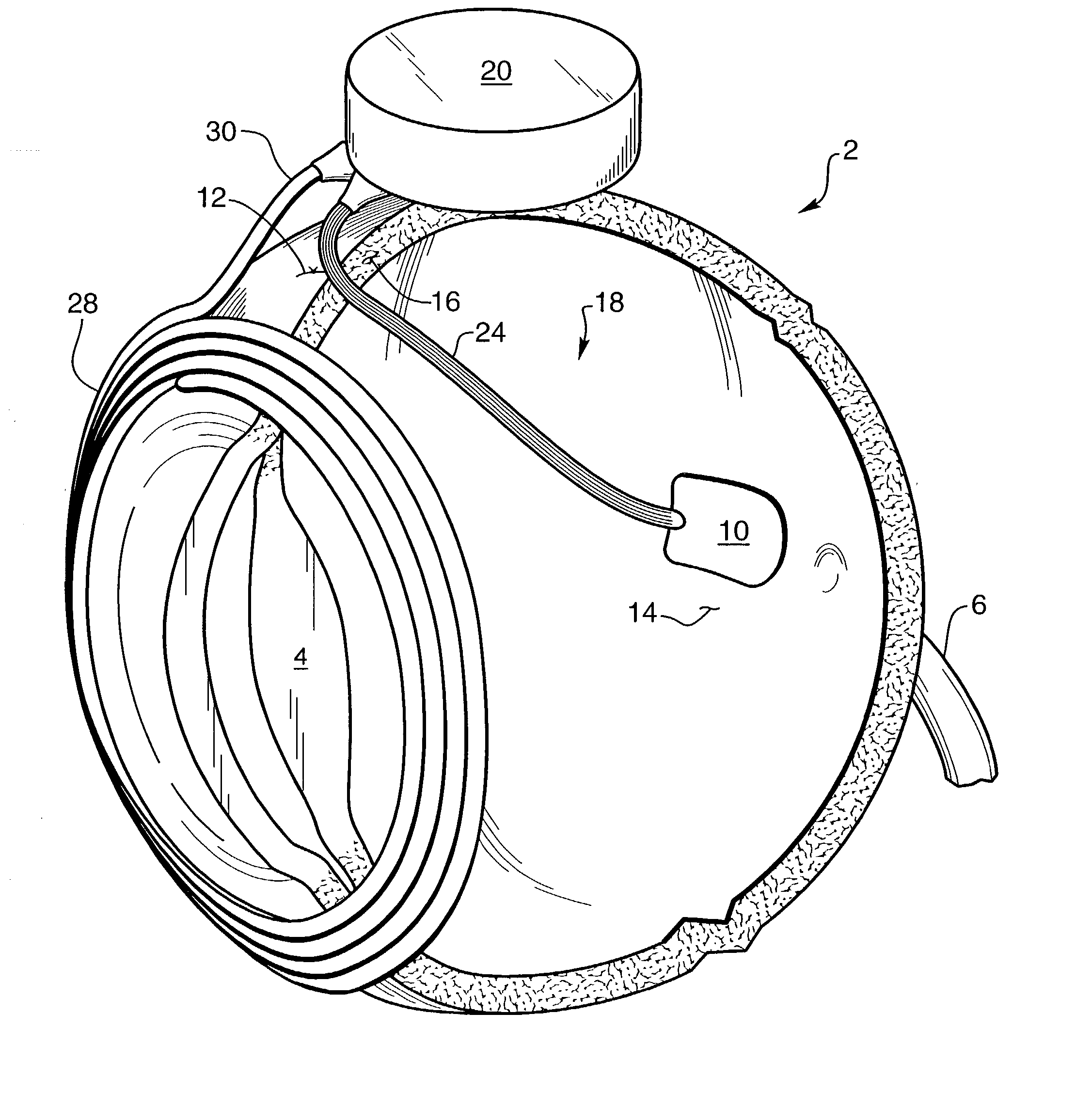

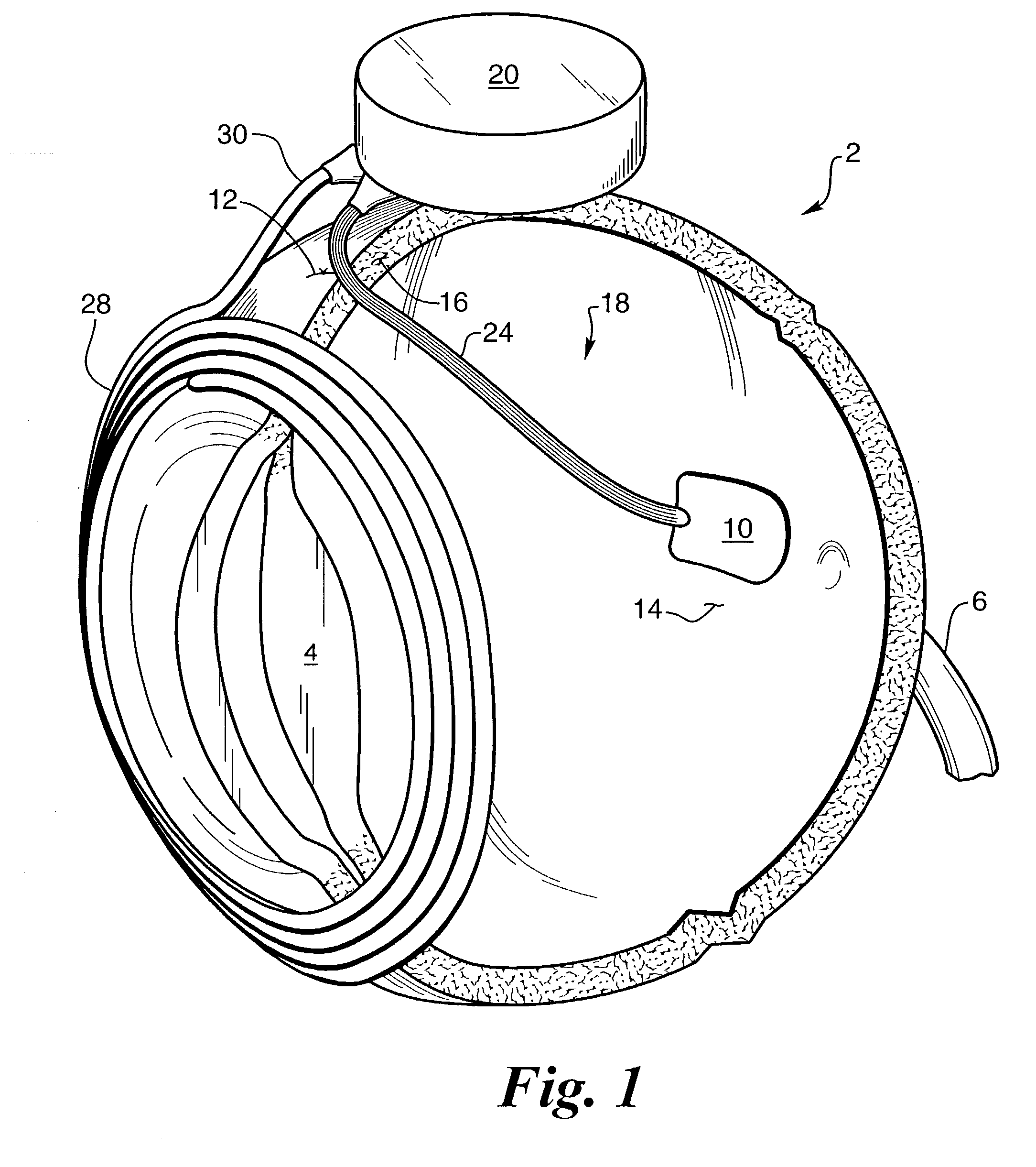

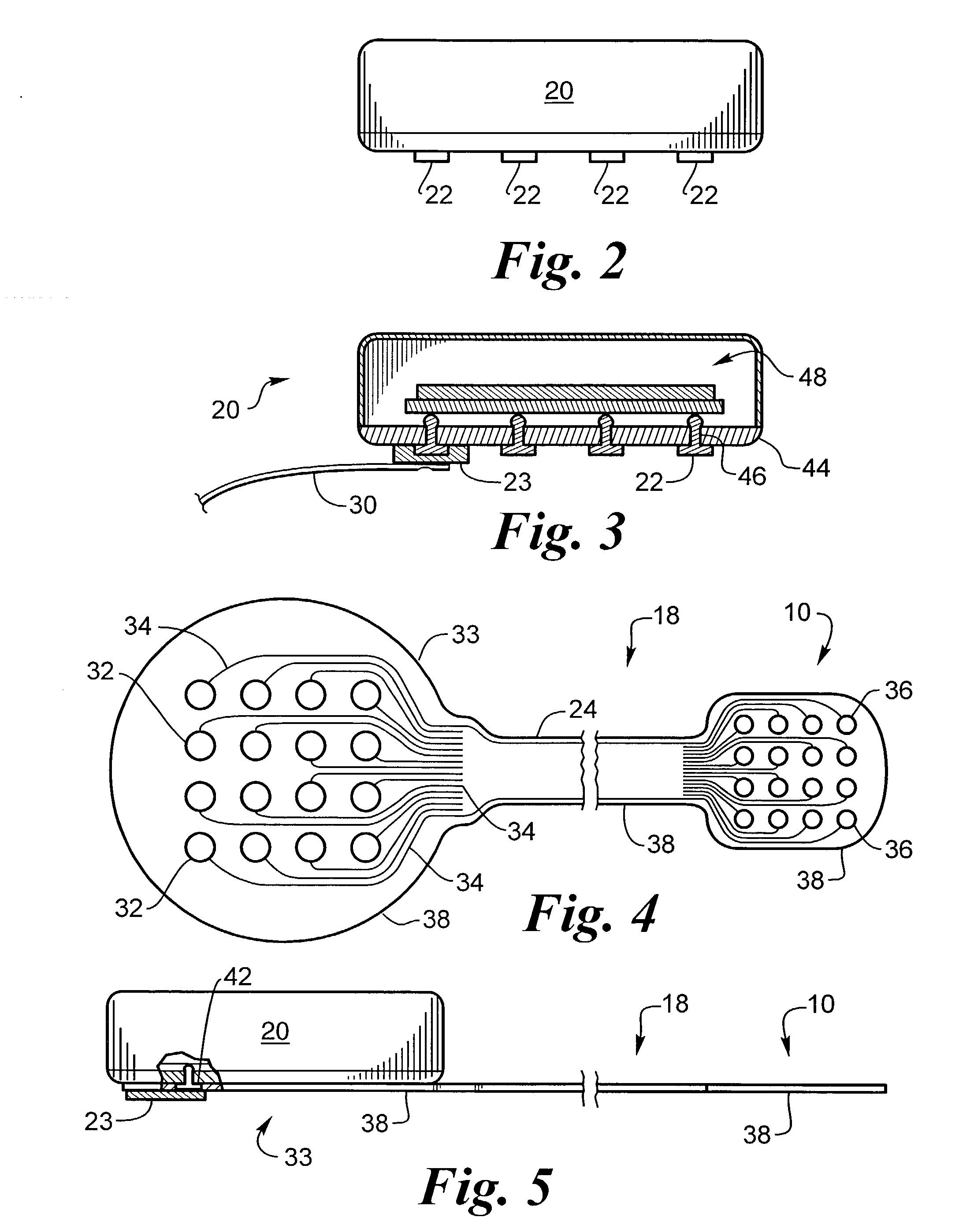

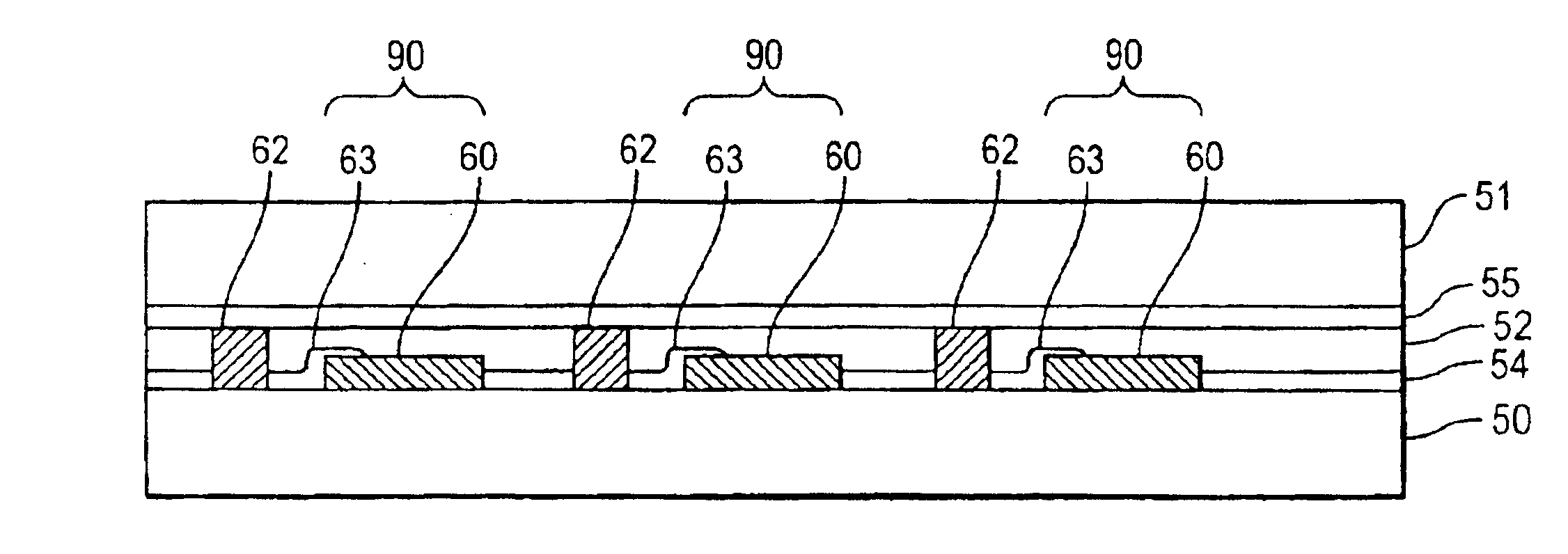

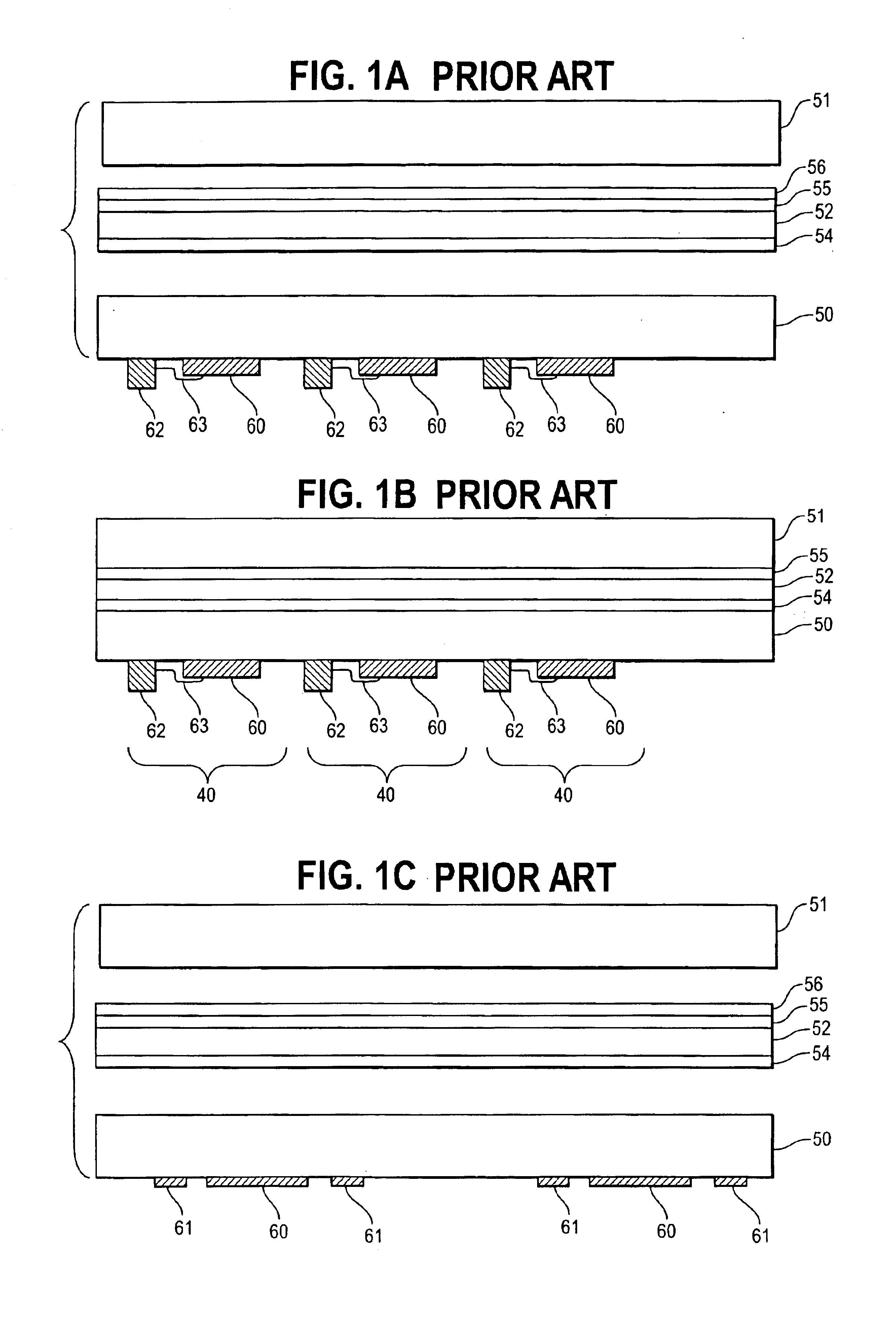

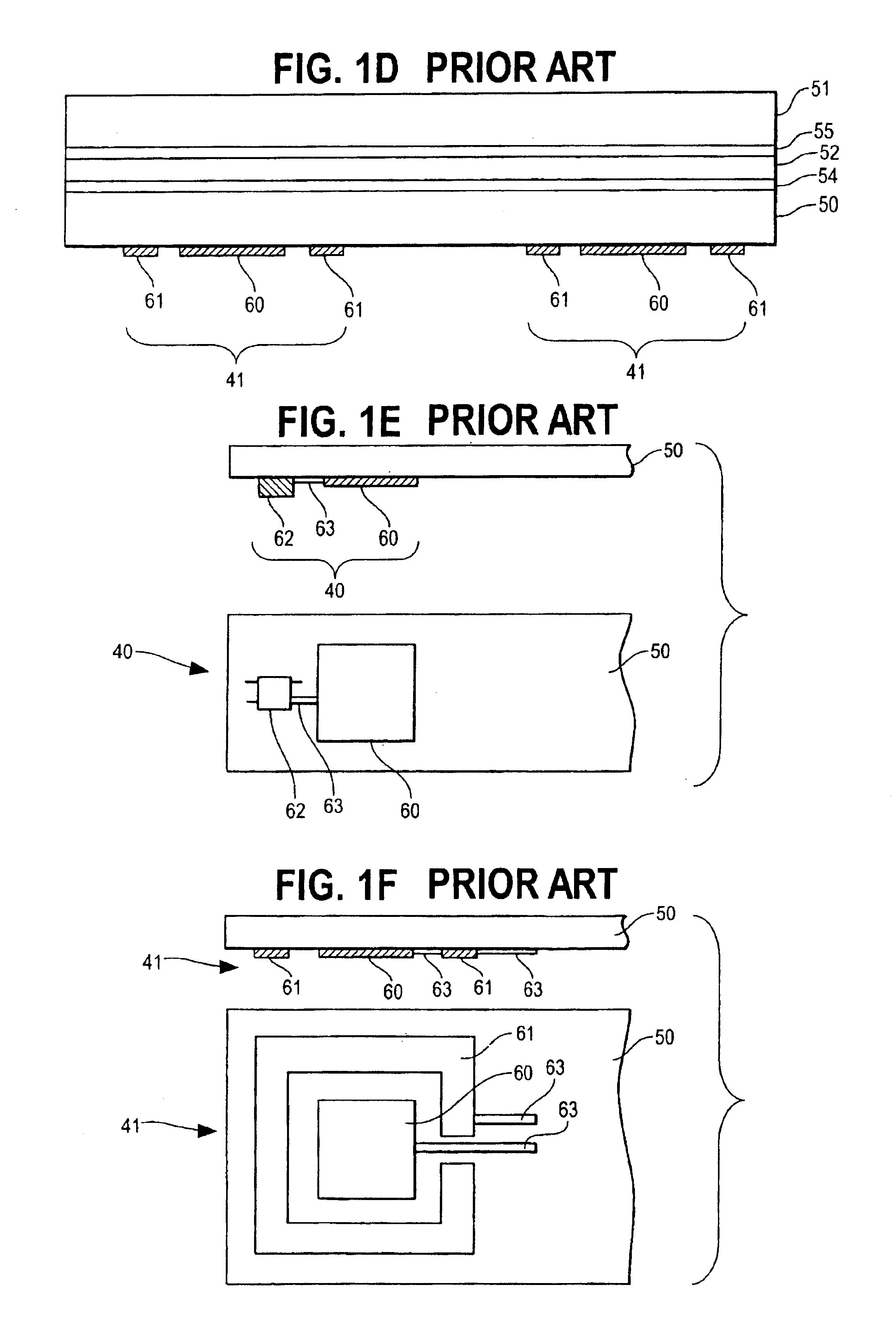

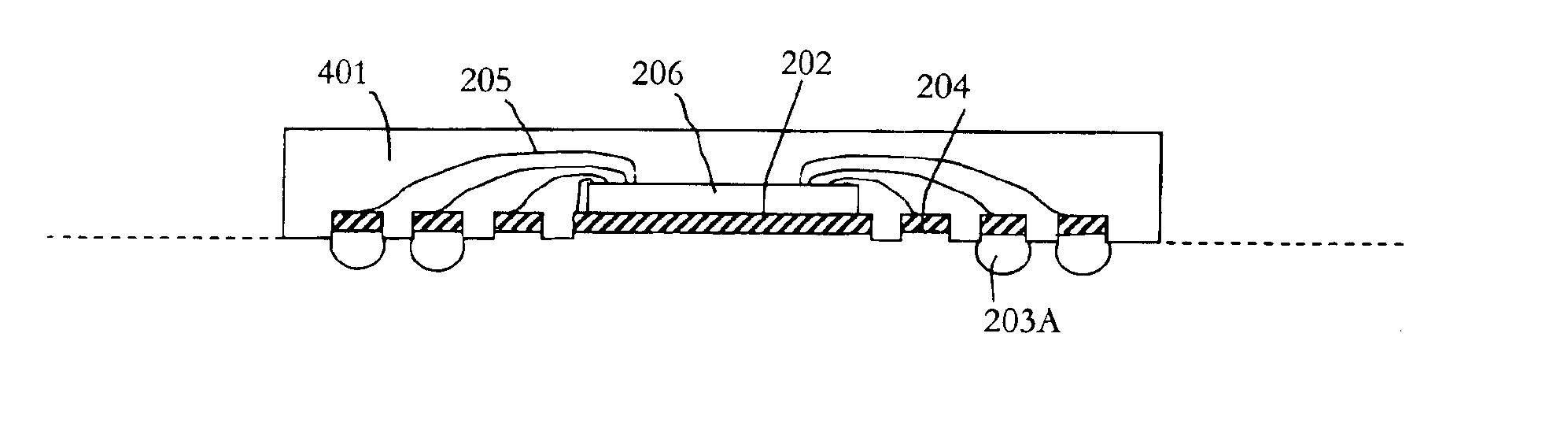

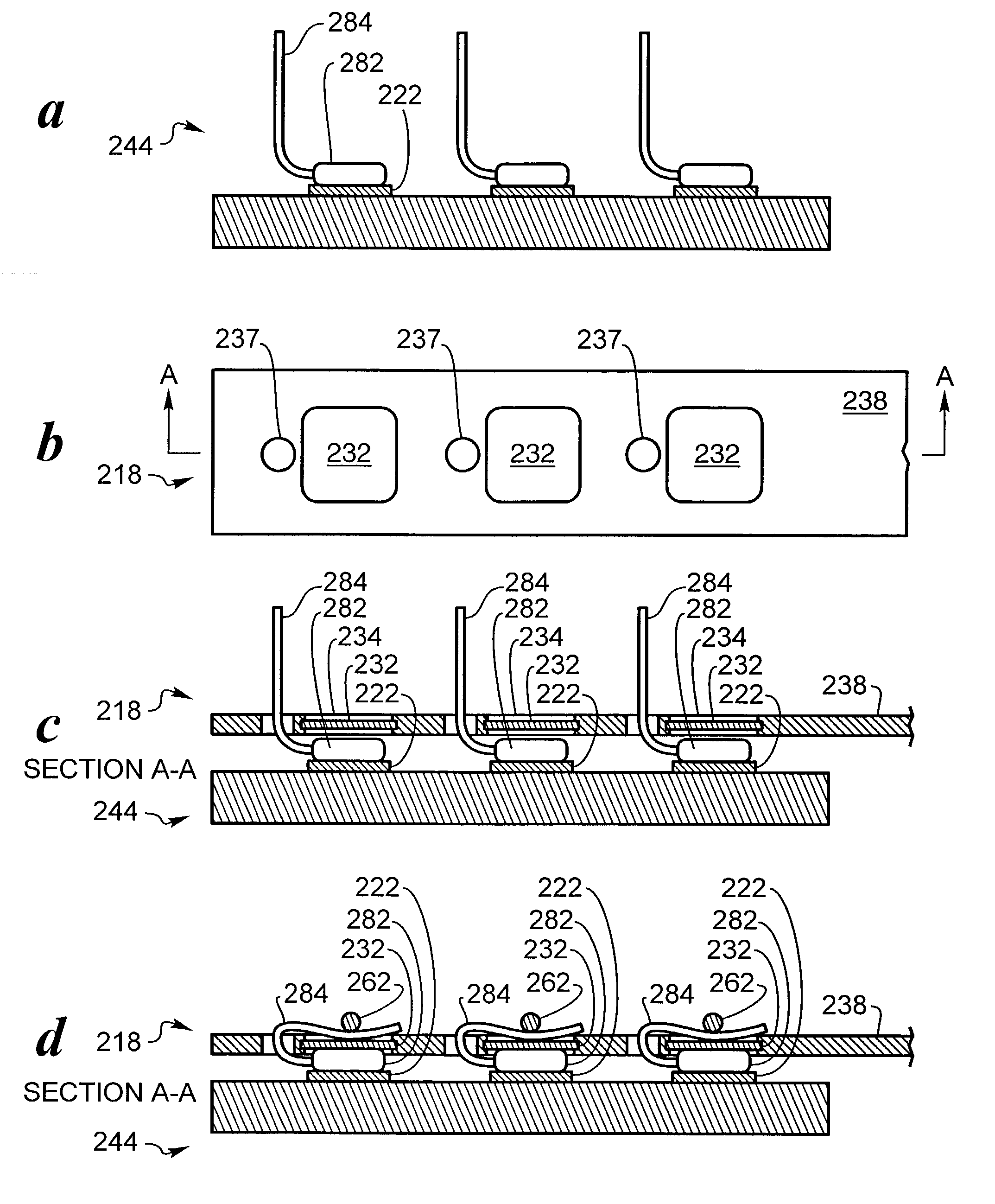

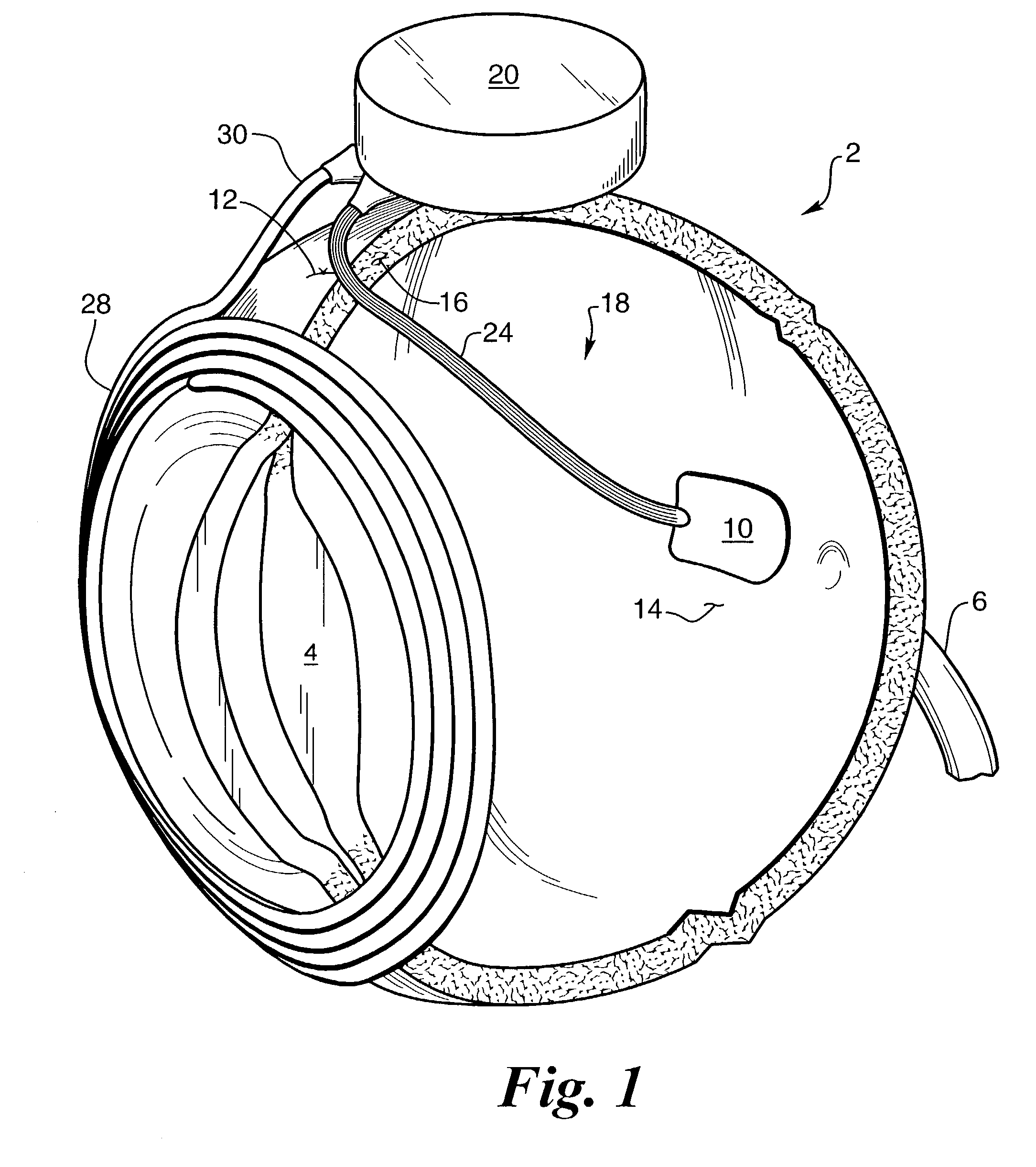

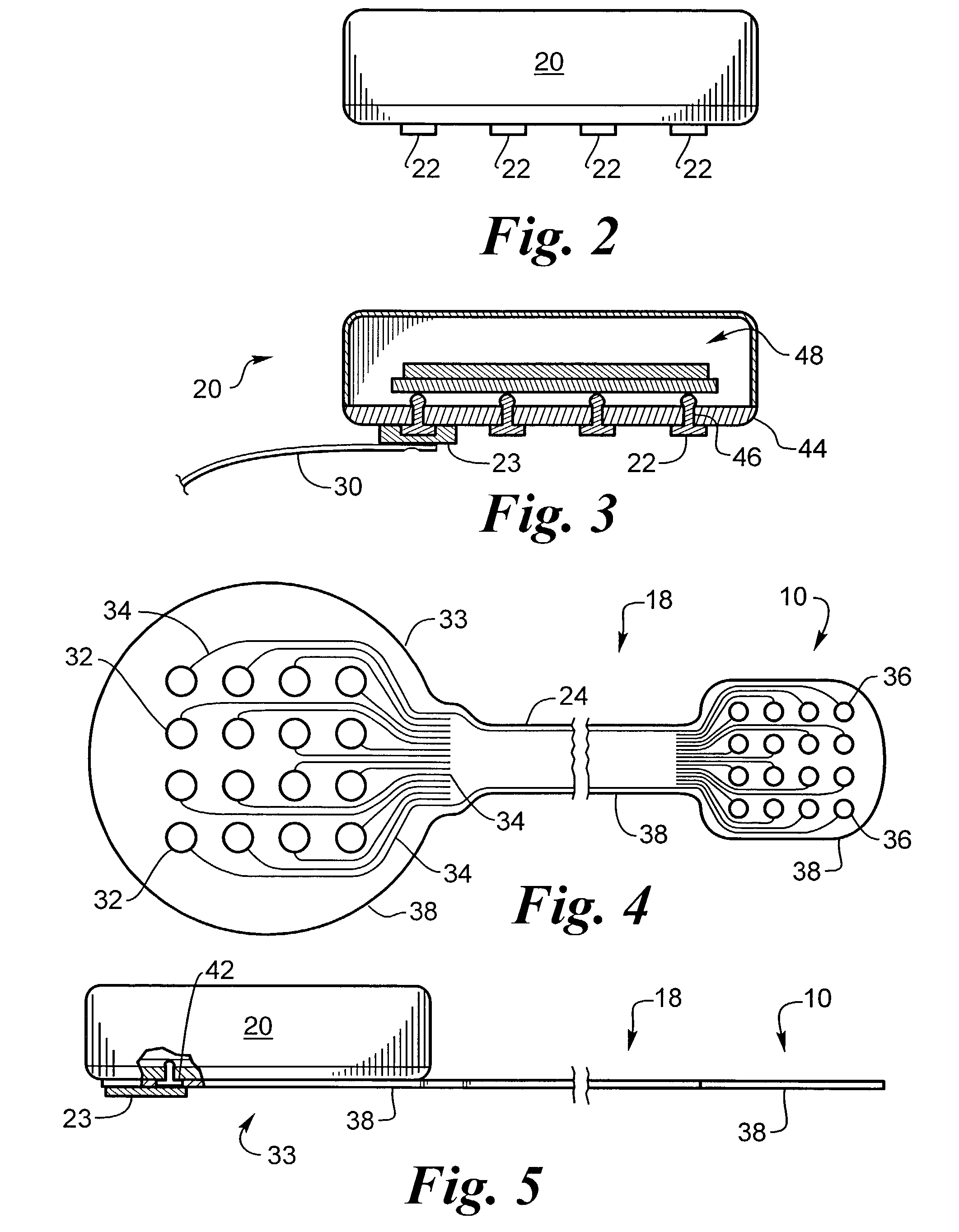

Biocompatible bonding method and electronics package suitable for implantation

ActiveUS20030233134A1Uniform propertySemiconductor/solid-state device detailsSolid-state devicesFlexible circuitsHermetic seal

The invention is directed to a method of bonding a hermetically sealed electronics package to an electrode or a flexible circuit and the resulting electronics package, that is suitable for implantation in living tissue, such as for a retinal or cortical electrode array to enable restoration of sight to certain non-sighted individuals. The hermetically sealed electronics package is directly bonded to the flex circuit or electrode by electroplating a biocompatible material, such as platinum or gold, effectively forming a plated rivet-shaped connection, which bonds the flex circuit to the electronics package. The resulting electronic device is biocompatible and is suitable for long-term implantation in living tissue.

Owner:CORTIGENT INC +1

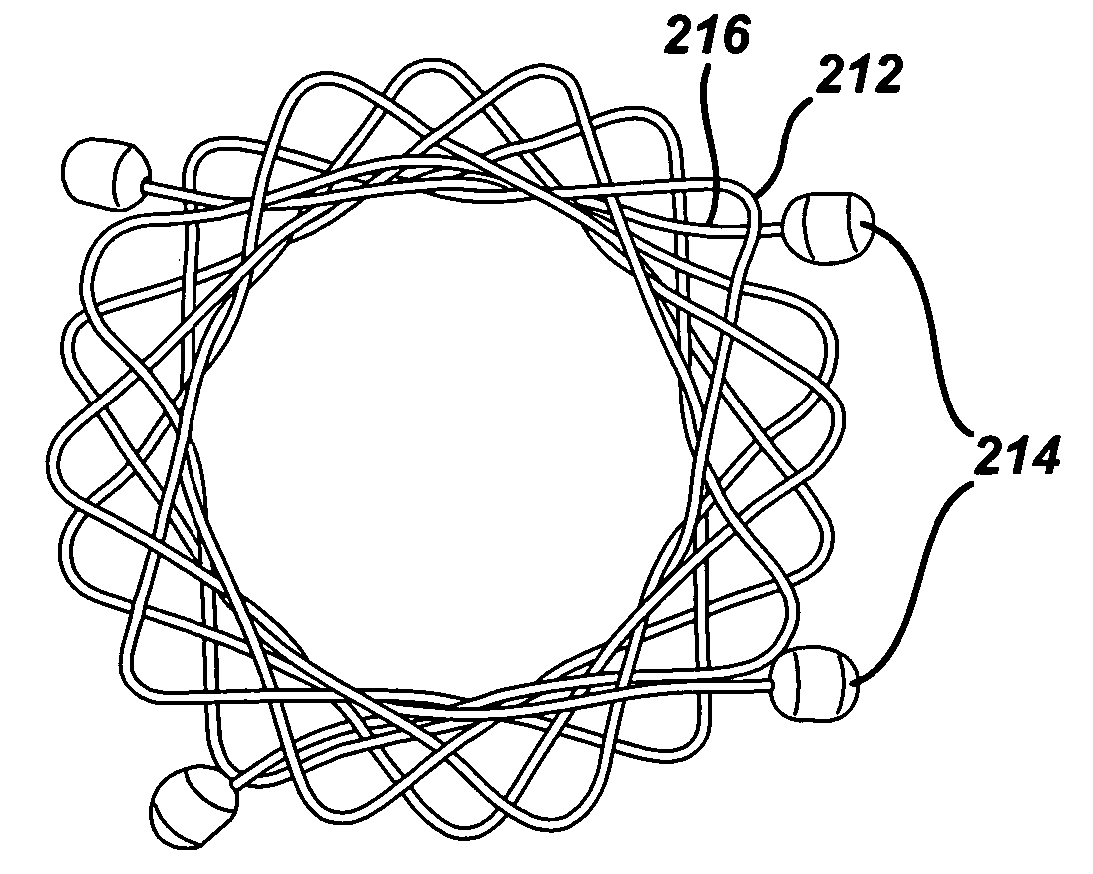

Anastomosis wire ring device

InactiveUS20050070934A1Reduce manufacturing costEasy to driveBlood vesselsSurgical veterinaryRing deviceMemory effect

An anastomotic ring device for forming a hollow rivet (ring) attachment between tissue lumens facilitates laparoscopic or endoscopic implantation by including features that facilitate actuation from a stressed, generally cylindrical shape. Economical manufacturer is achieved by weaving open ended strands into a generally cylindrical stent shape that is imparted with a Shape Memory Effect (SME) to actuate to a hollow rivet (ring) shape. Alternatively or in addition to SME inherent in the woven strands, an actuating force may be received from a helical spring element incorporated into the ring. Self-actuating ring devices are enhanced by forming woven strands into petals that diverge from opposing petals such that the strands encounter less friction when actuating. Each of these features alone or in combination enhance clinical use of anastomotic ring devices, such as a bariatric gastric bypass procedure.

Owner:ETHICON ENDO SURGERY INC

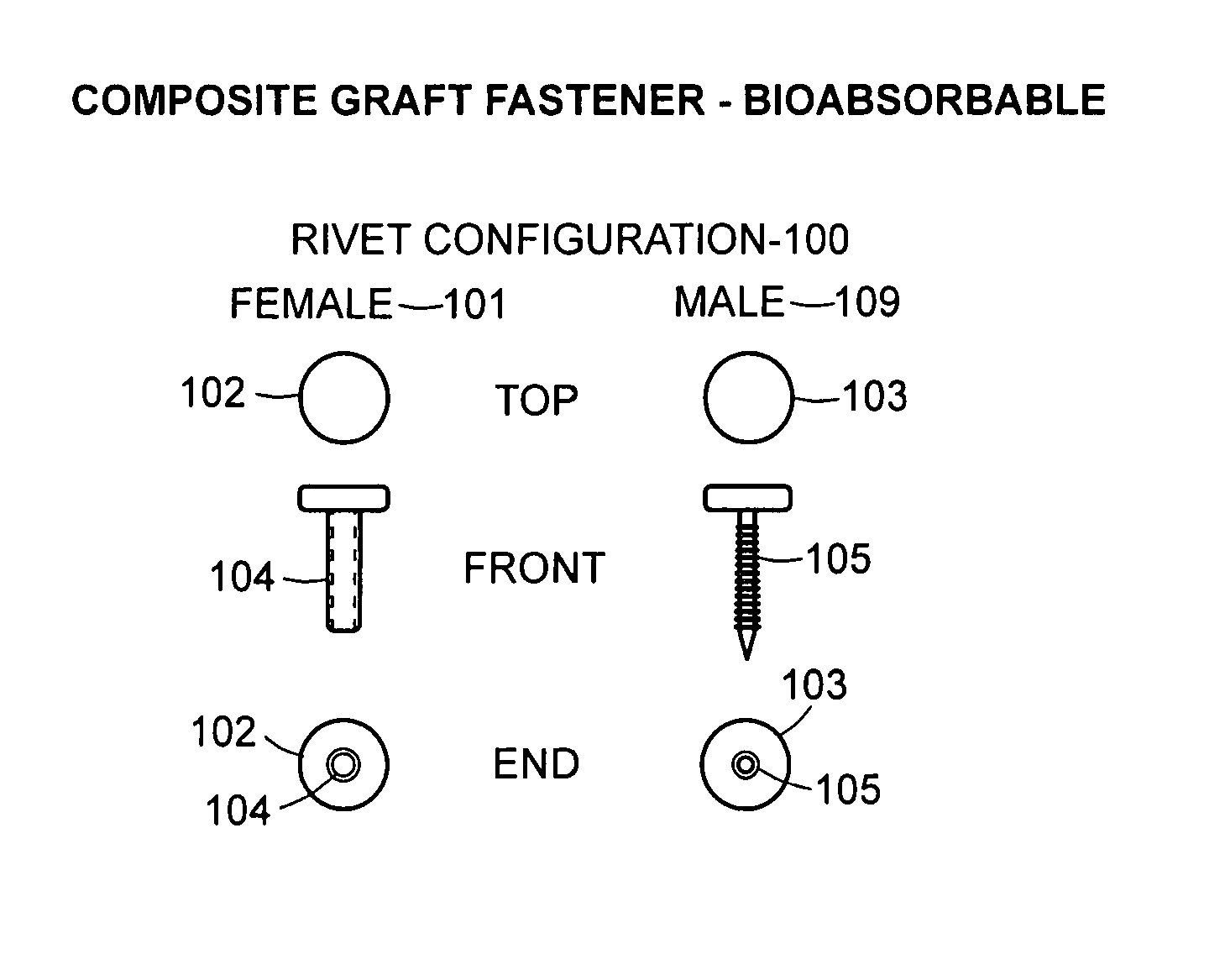

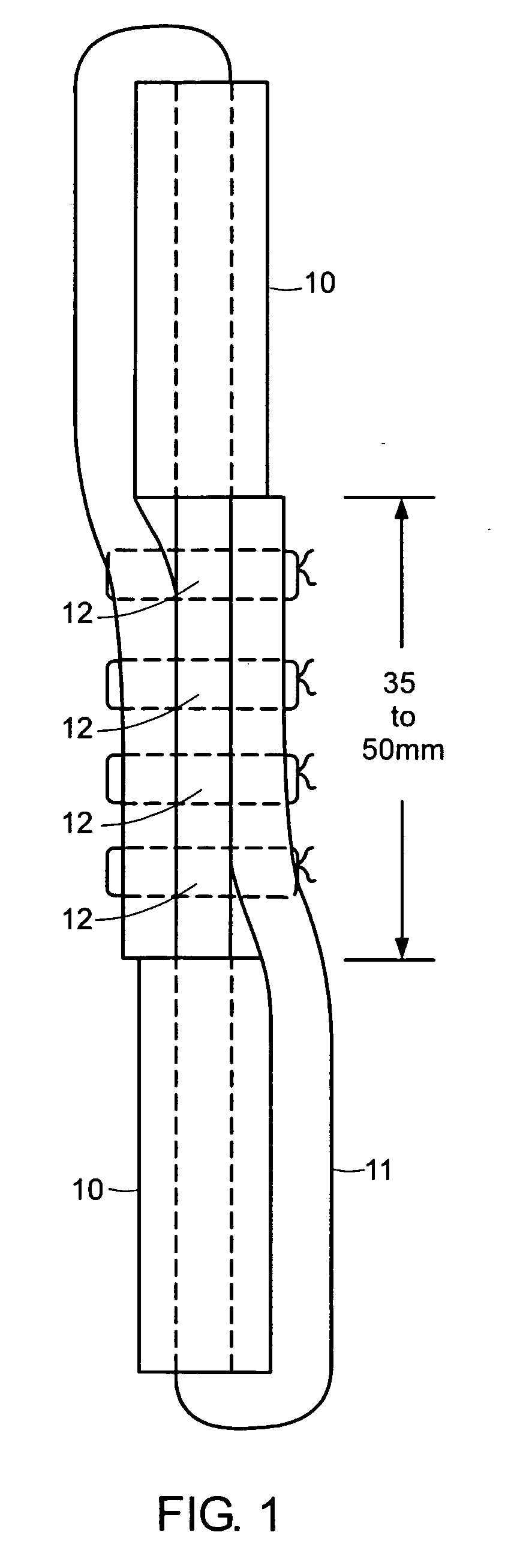

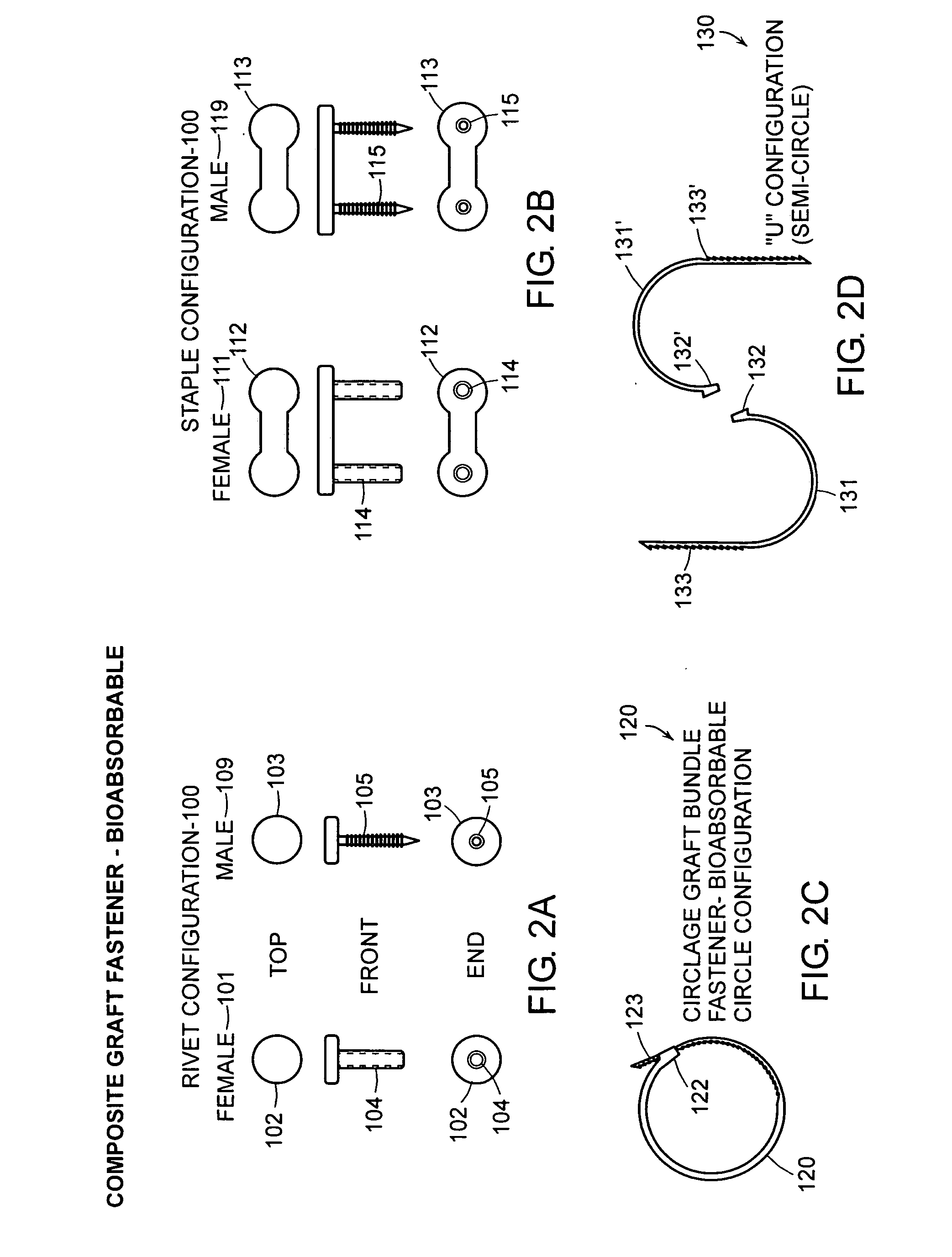

Bioabsorbable fasteners for preparing and securing ligament replacement grafts

A bioabsorbable implantable device for replacing sutures in construction of a composite graft in ligament replacement surgery. In certain embodiments the device has a female component and a male component where the female component receives and secures the male component. In other embodiments the components of the device are in the shape of a rivet or a staple. The bioabsorbable implantable devices can be used for securing tendon grafts to bone blocks and for holding together the fibers of the tendon graft when the bone-tendon-bone graft is inserted into a patient during surgery. The bioabsorbable implantable device may also be part of a package for use in surgery. The package includes a sterile container for holding at least a graft that is of a predetermined length and width. The package may also include bone blocks. The package is marked as to the graft size including the width and the length of the graft. The graft and the bone blocks may be autogenous, allogenic or constructed from man-made materials.

Owner:MCGUIRE DAVID A

Molded/integrated touch switch/control panel assembly and method for making same

InactiveUS6897390B2Overcomes shortcomingSimple manufacturing processStampsContact surface shape/structureEngineeringInjection moulding

Touch switches are integrated with thermoformable, injection molded, and other substrates to yield integrated touch switch / control panel assemblies. The ensuant assemblies can include ridges, depressions, anchors, overlaps, rivets and bezels or other housings. They can have any combination of flat and curved surfaces. Further, such assemblies can be incorporated into components of other assemblies, such as automobiles.

Owner:TOUCHSENSOR TECH

Single lumen access deployable ring for intralumenal anastomosis

Creating an anastomosis, or the surgical formation of a passage between two normally distinct vessels or lumens, is enhanced by an applier that introduces a ring device without the need for a separate anvil to form a hollow rivet shaped attachment. Moreover, the ring device may be advantageously formed in a cylindrical shape from molded polymer material or stamped from sheet metal with proximal and distal rings connected by proximal and distal arms that respectively form hinged, ring shaped so appose tissue walls. A center ring or portion sits in the attachment site. The applier causes actuating by moving the rings relative to one another. A latching mechanism locks the rings in the actuating state.

Owner:ETHICON ENDO SURGERY INC

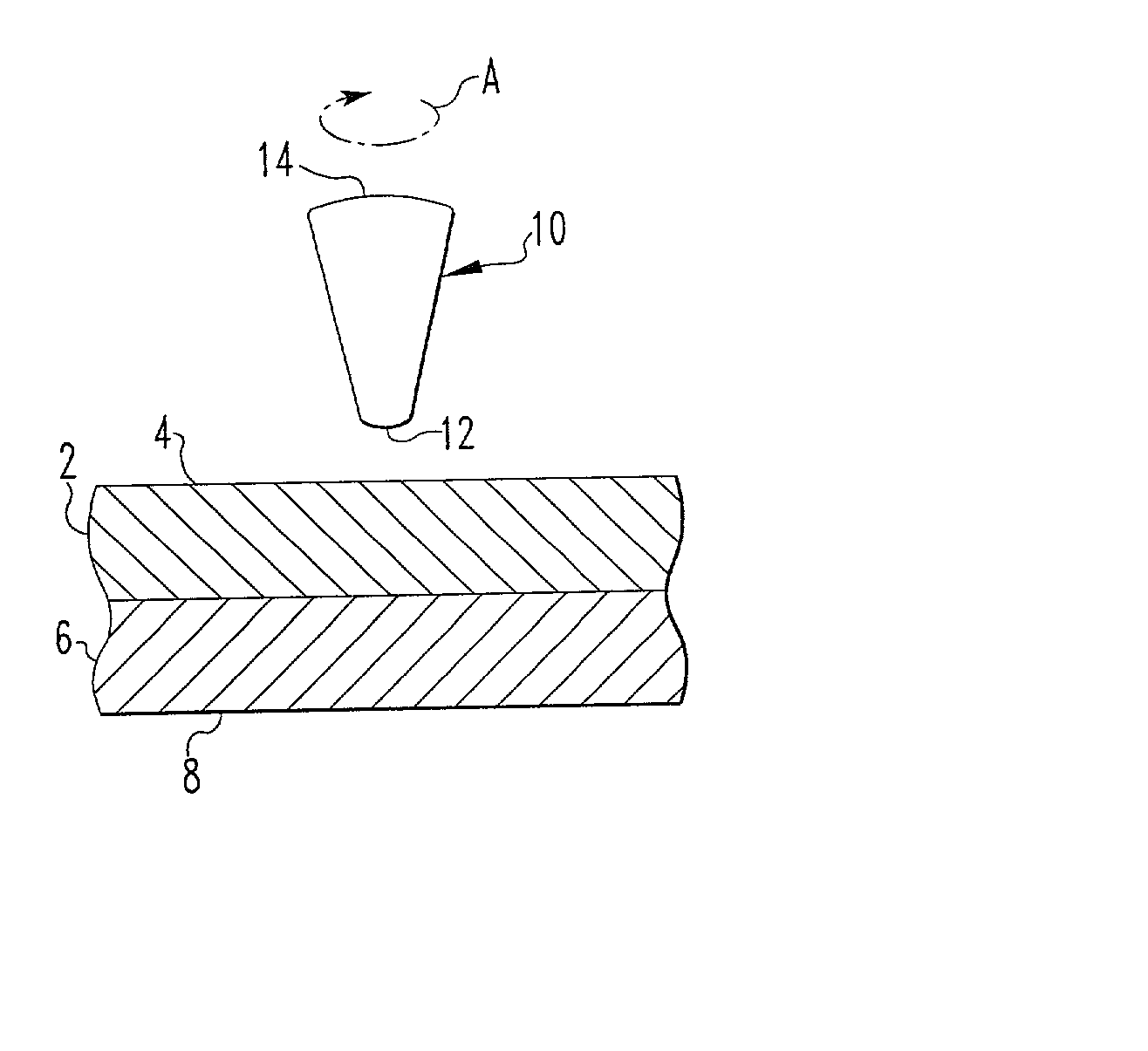

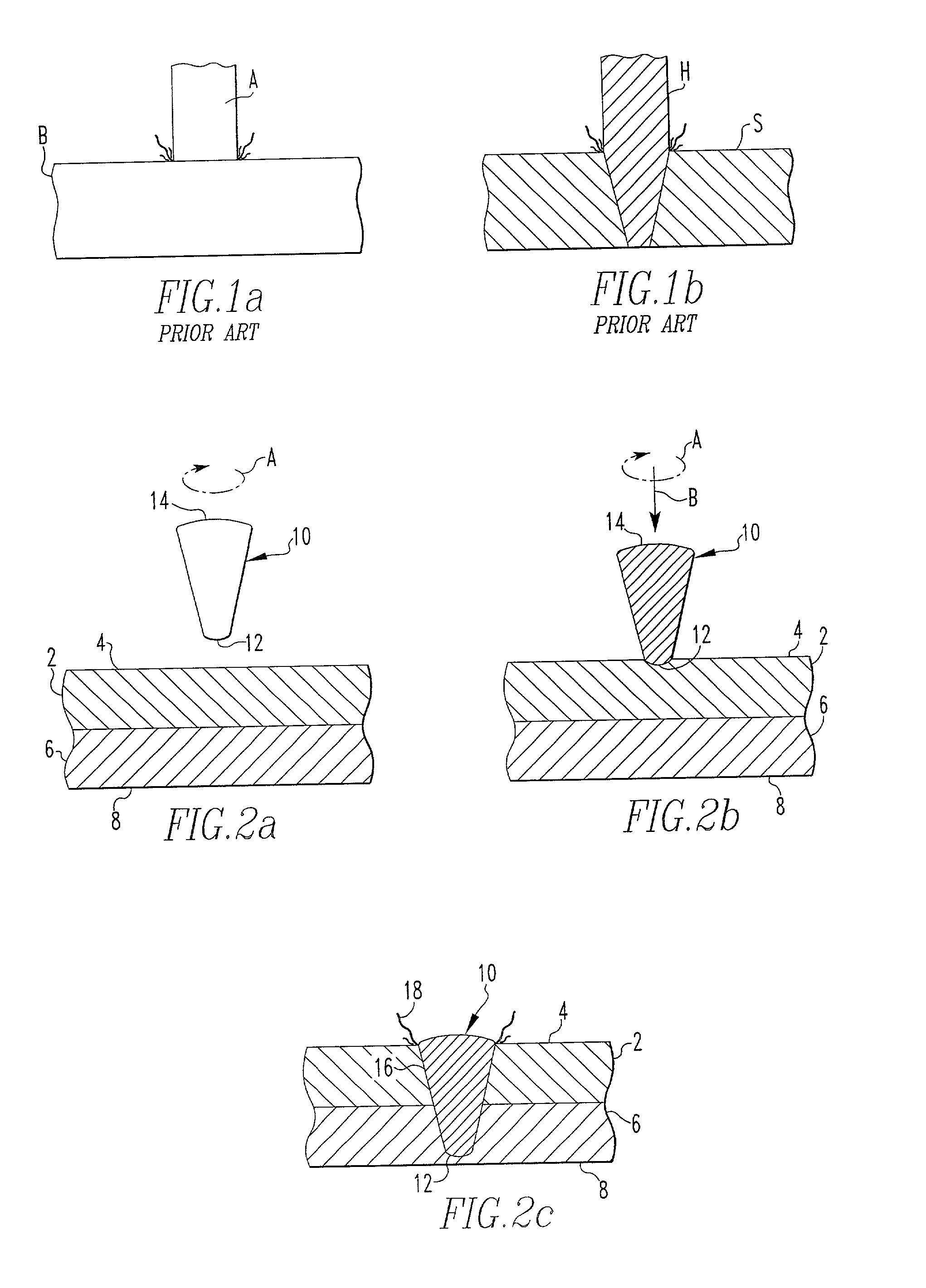

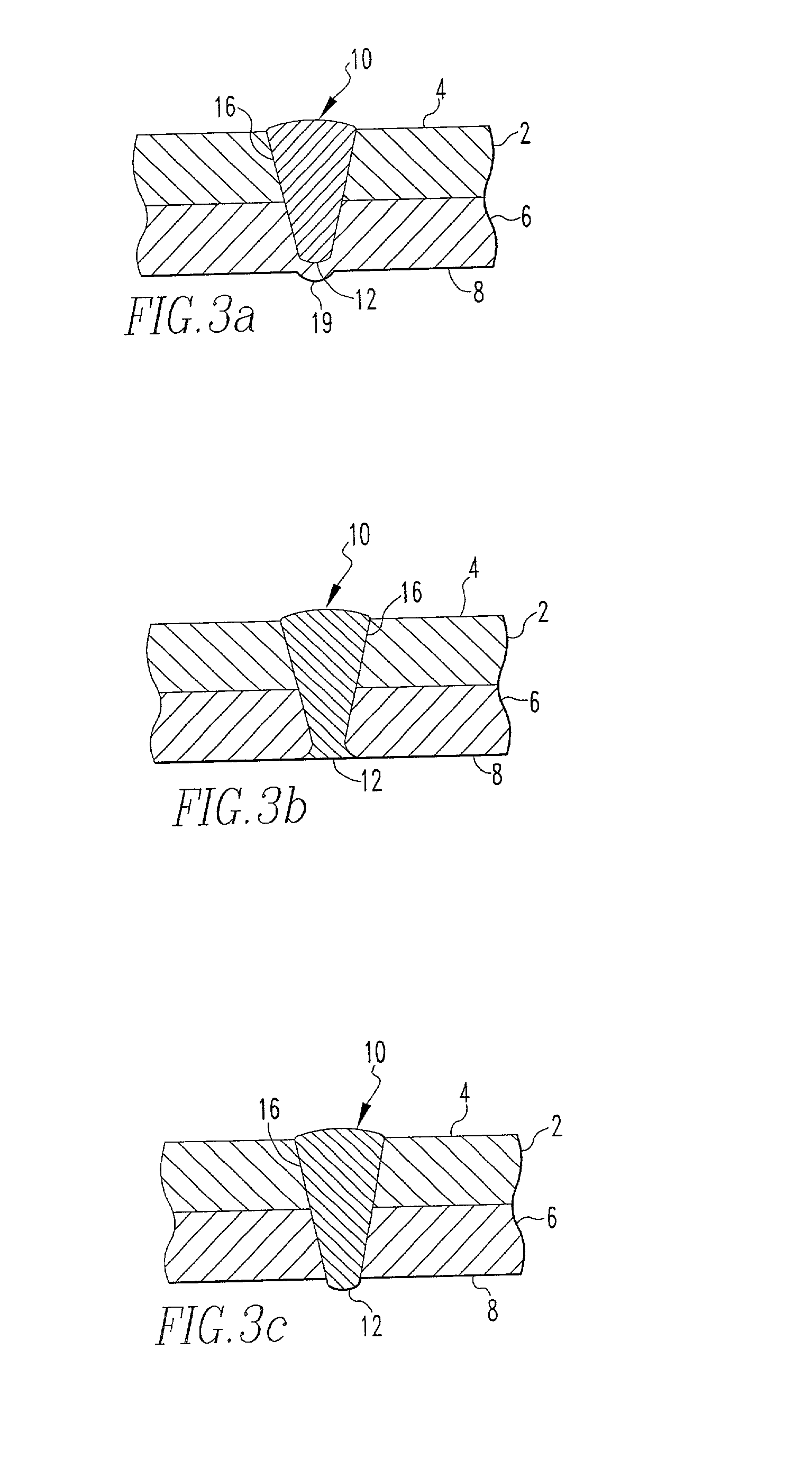

Friction plunge riveting

InactiveUS20020125297A1Welding/cutting auxillary devicesAuxillary welding devicesFriction weldingHardness

A method of joining a pair of metal components with a rivet having a hardness that is substantially similar to at least one of the metal components. The metal components are stack upon each other and the rivet is rotated and simultaneously plunged in the metal components under pressure to friction weld and metallurgically bond the rivet to the metal components.

Owner:ARCONIC INC

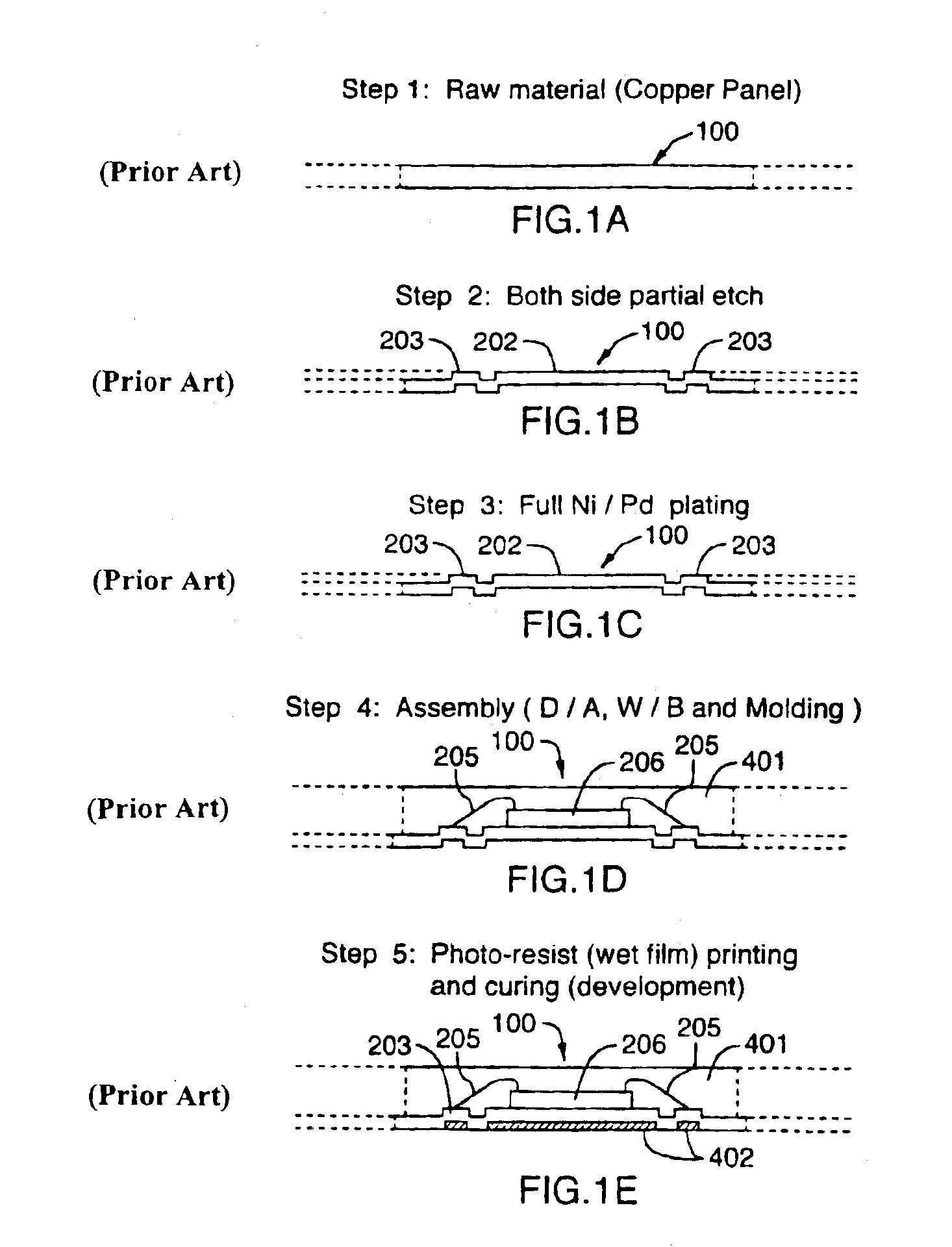

Leadless plastic chip carrier with etch back pad singulation

InactiveUS6933594B2Improve interlockEasy alignmentSemiconductor/solid-state device detailsSolid-state devicesEtchingPunching

A leadless plastic chip carrier is constructed by half etching one or both sides of the package design onto a leadframe strip so as to create unique design features such as power and / or ground ring surrounding the die attach pad, interlocking rivet head construction for the contact pads, and an interlocking pattern for the die attach pad. After wire bonding and molding, a further etching is performed to isolate and expose contact pads. Singulation of individual chip packages from the leadframe strip is then performed by saw singulation or die punching.

Owner:UTAC HEADQUARTERS PTE LTD

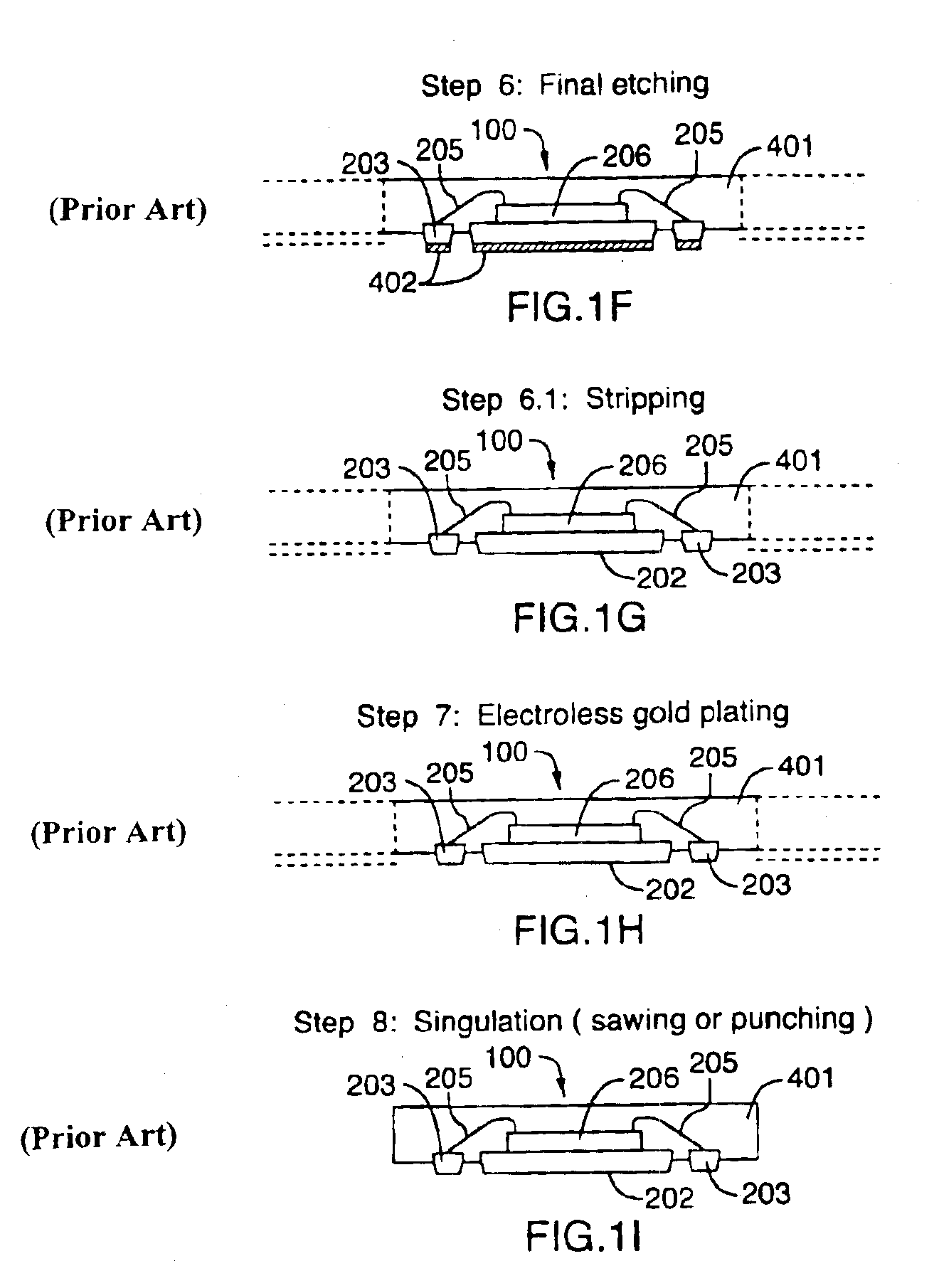

Apparatus, system, and method for middle turbinate medializer

An apparatus, system, and method are disclosed for medializing the middle turbinate following sinus surgery, thus preventing synacheiae, granulation tissue, and other complications of the prior art. The apparatus utilizes a fastening device configured to attach the middle turbinate to the nasal septum, a prong comprising a slender wand portion and a fastening module, and a handle configured to trigger deployment of the fastening means by activating the fastening module. The fastening device may be a staple, rivet, glue, or another similar device.

Owner:TAGGE BRYAN C

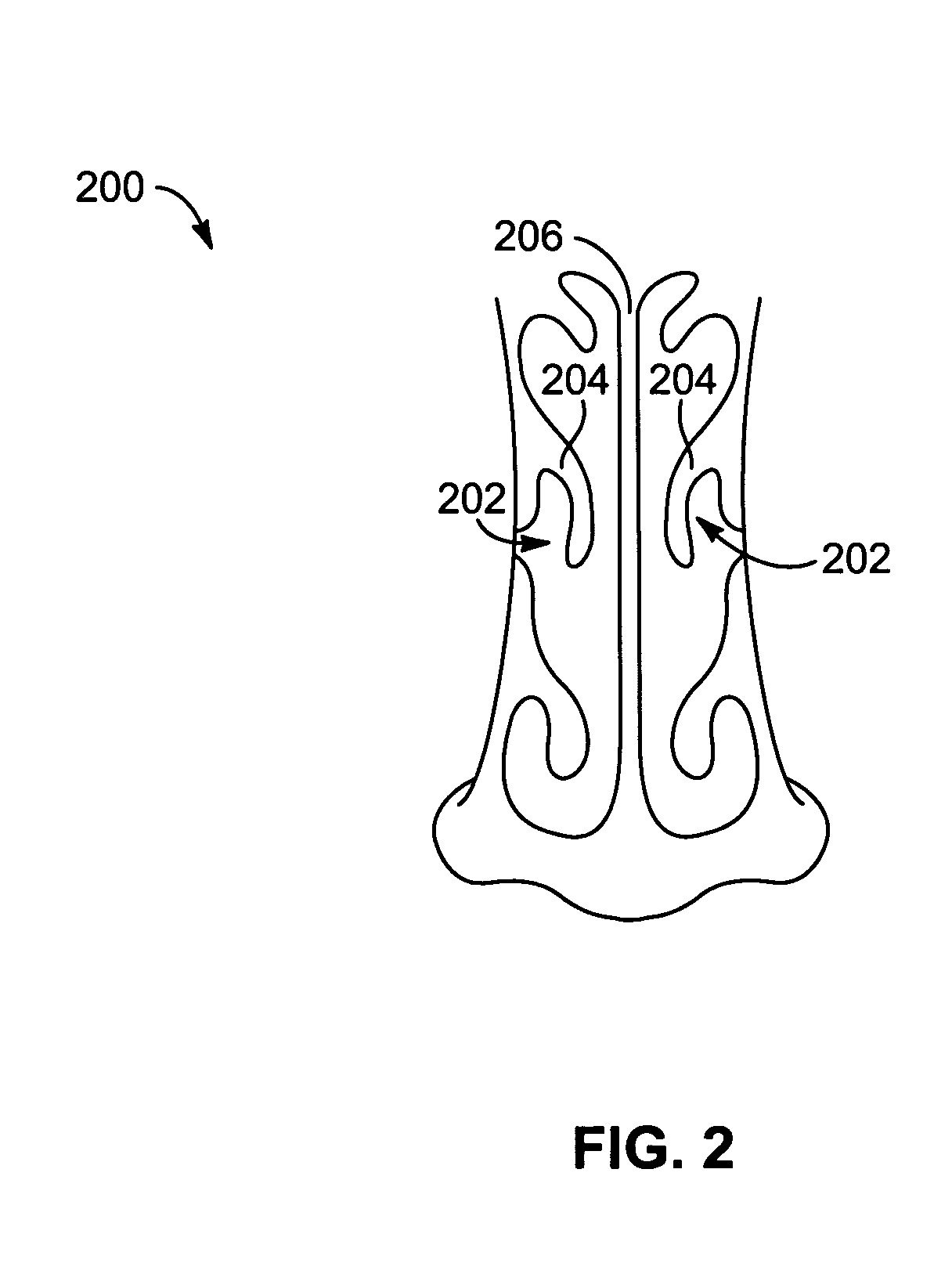

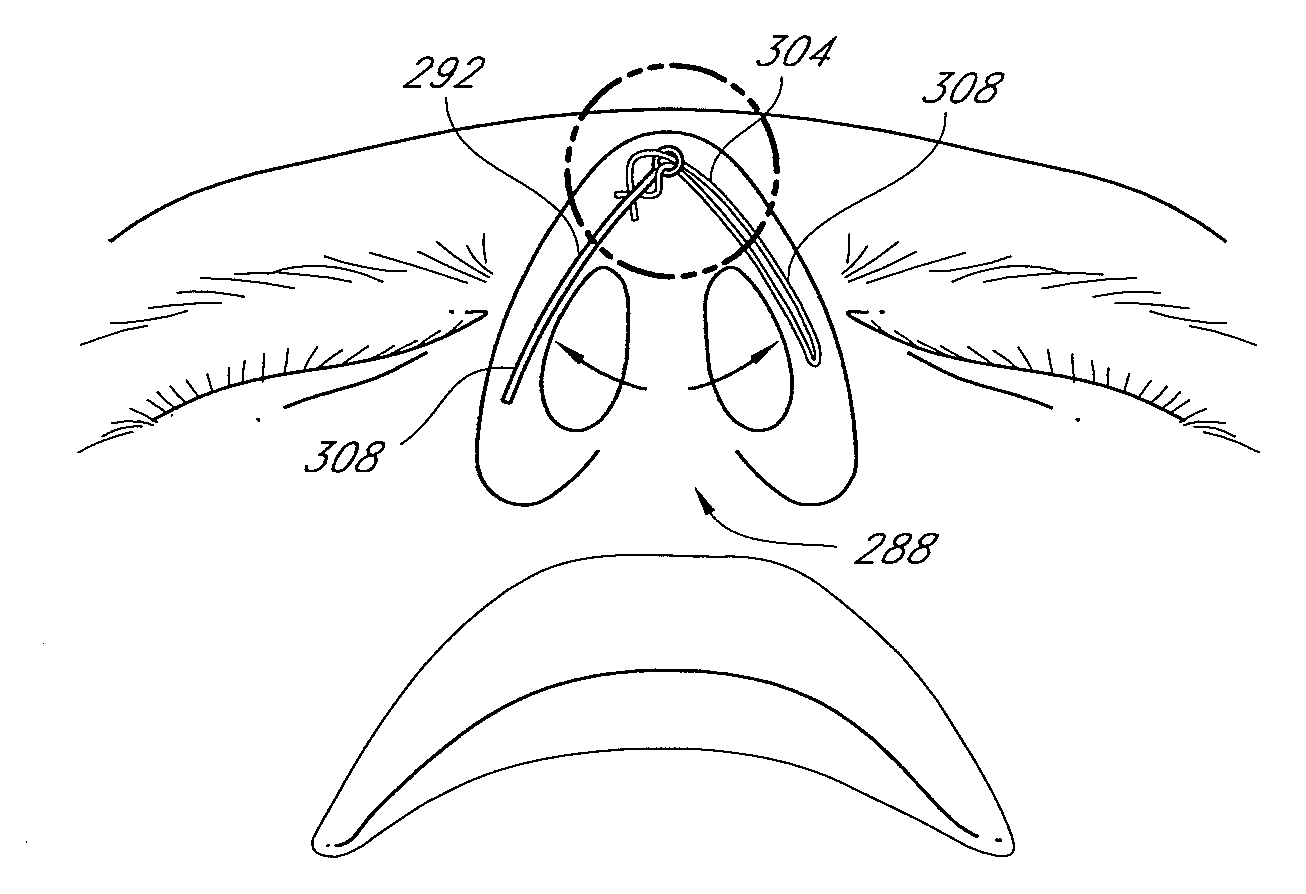

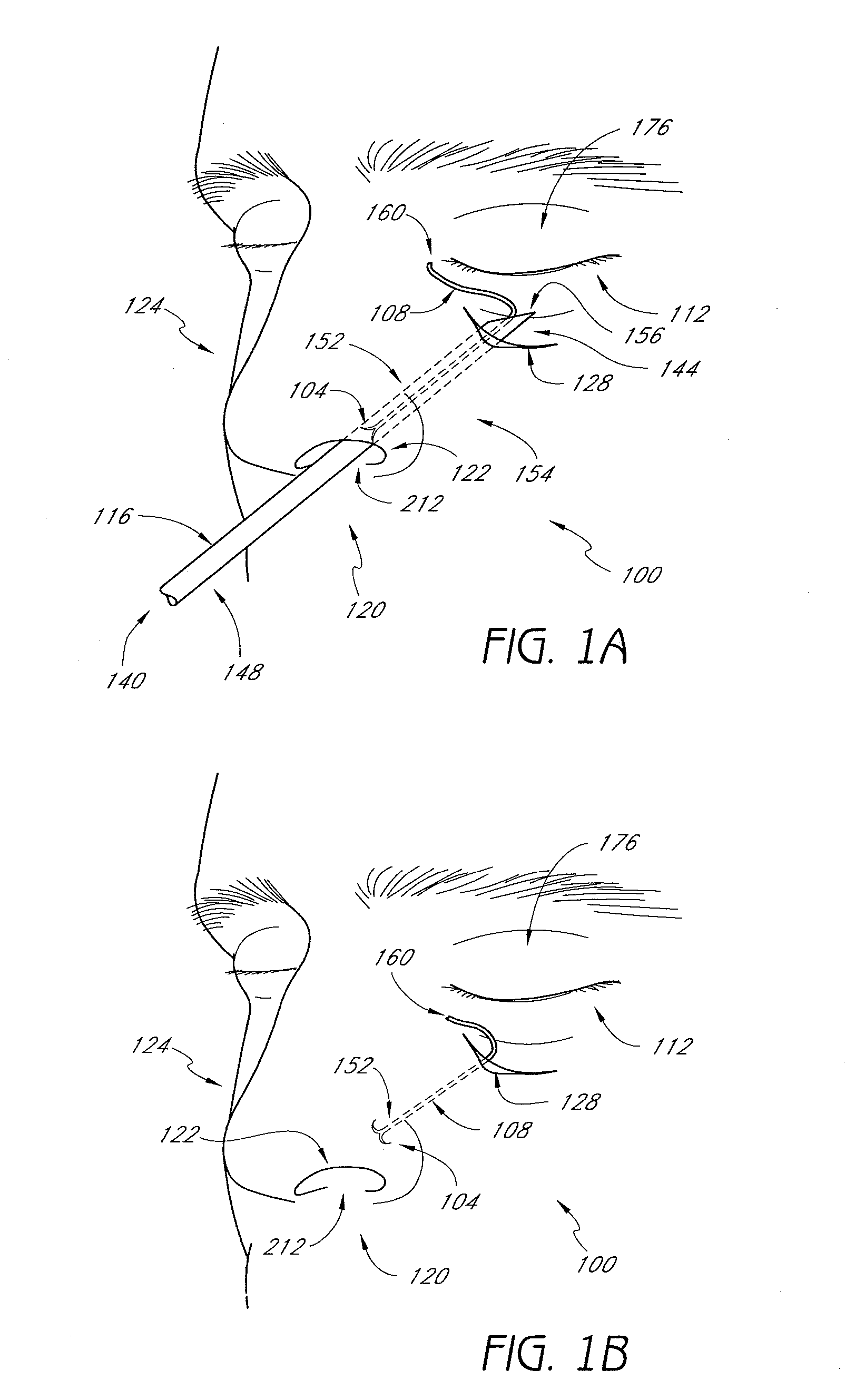

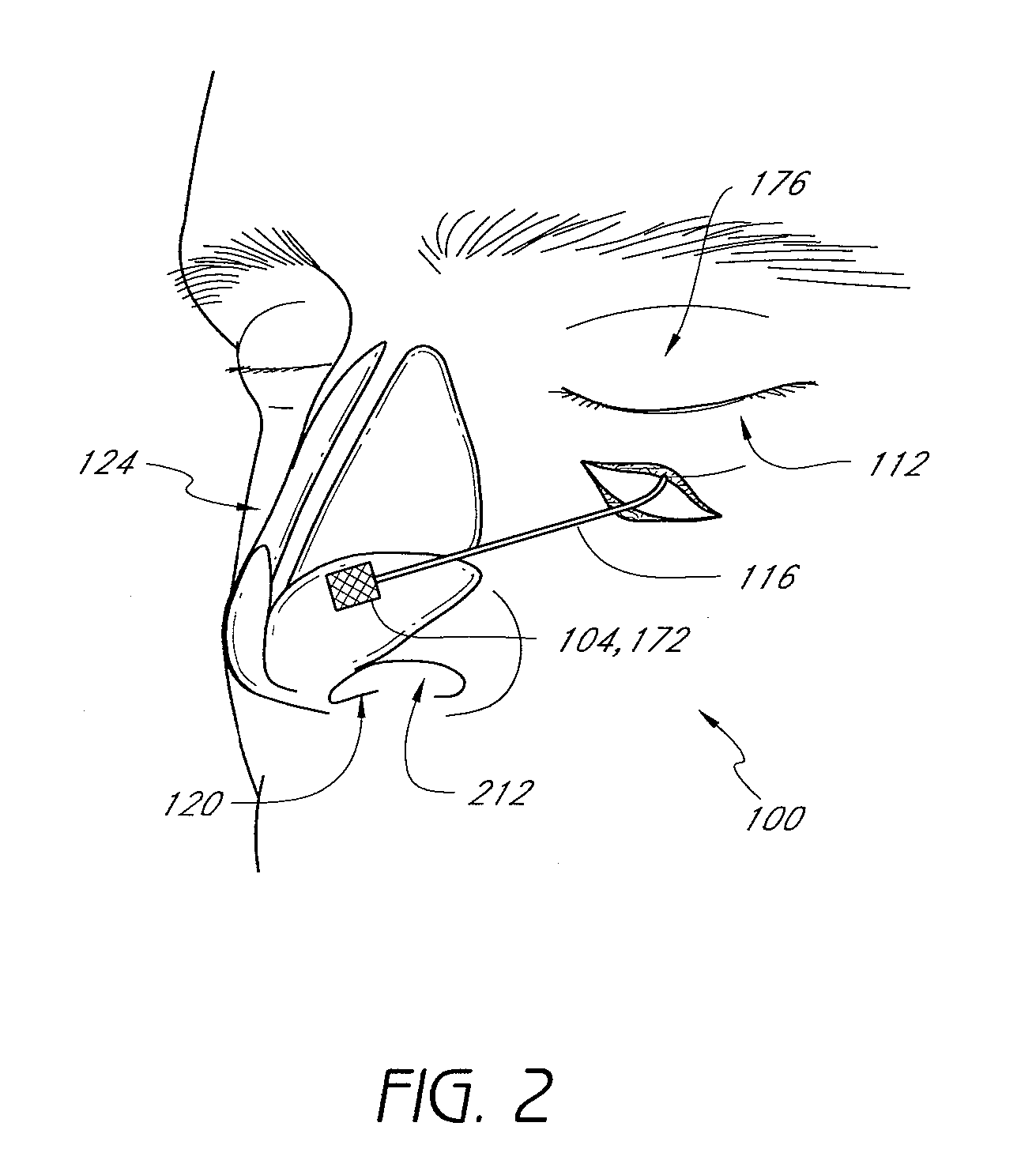

Methods and devices for rhinoplasty and treating internal valve stenosis

ActiveUS20080027480A1Increase the cross-sectional areaIncrease exposureSuture equipmentsNose implantsNasal cavityMitral valve stenosis

Methods and devices for rhinoplasty and treating nasal valve stenosis are disclosed herein. The nasal valve acts as a flow-limiter and can contribute to airway obstruction if resistance within the nasal valve is excessive. In one embodiment, a system for treating nasal valve stenosis includes a first elongate implant and a second elongate implant configured to support the nasal valves when implanted. The implants can be coupled together by connecting elements, such as eyelets, tethers, complementary socket joints, and button-rivet supports.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Electrical connector

According to the present invention there is provided a snap in locking cable connector with a cylindrical housing having an entry end aperture and an exit end aperture. The entry end aperture can accept the snap-in spring steel adapter of U.S. Pat. No. 6,080,933 as well as the exit end peripheral spring steel locking ring described in this patent to provide a connector that allows rapid and simplified installation of armored cable into a junction or circuit box. The cylindrical housing includes an annular groove or ridge about the inner periphery thereof in the area of the entry end for retention of the spring steel adapter. An electrical cable connector of this type that relies upon frictional or interference fit for retention of the spring steel adapter is also described. Retention of the spring steel adapter with a screw, rivet or similar fastener is also described.

Owner:ARLINGTON INDS

Biodegradable and/or bioabsorbable member for vascular sealing

An implantable, bioresorbable and / or biodegradable sealing member, such as a staple, clip, snap or rivet, is used for clamping vessels, vessel side-branches, aneurysms, or any other tube like body-parts or for sealing vascular access sites and wound site management. The implantable, bioresorbable and / or biodegradable member comprises a combination of materials which dissolve or degrade in the human body without any harmful effects on the person that wears the member.

Owner:BIOTRONIK VI PATENT

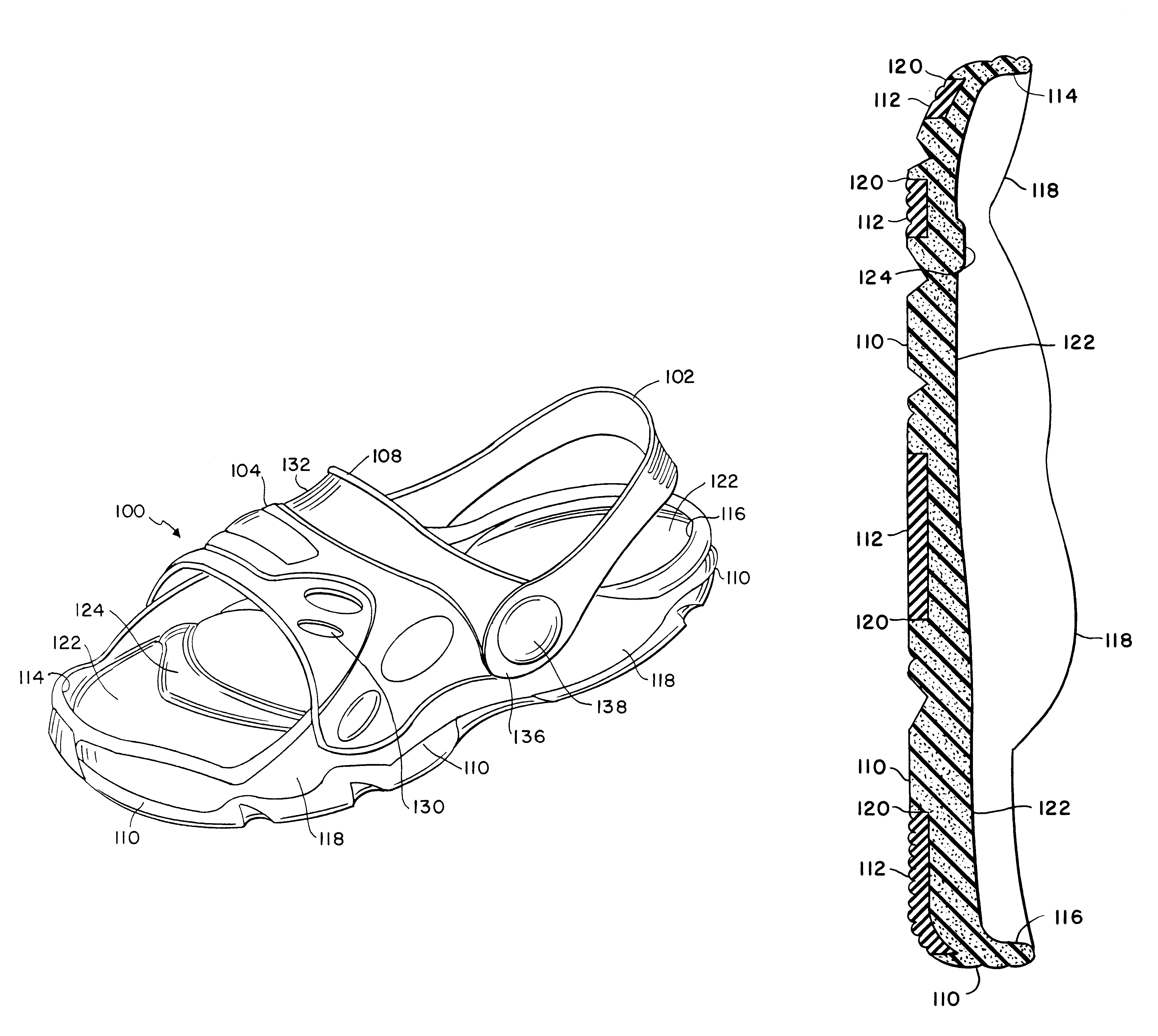

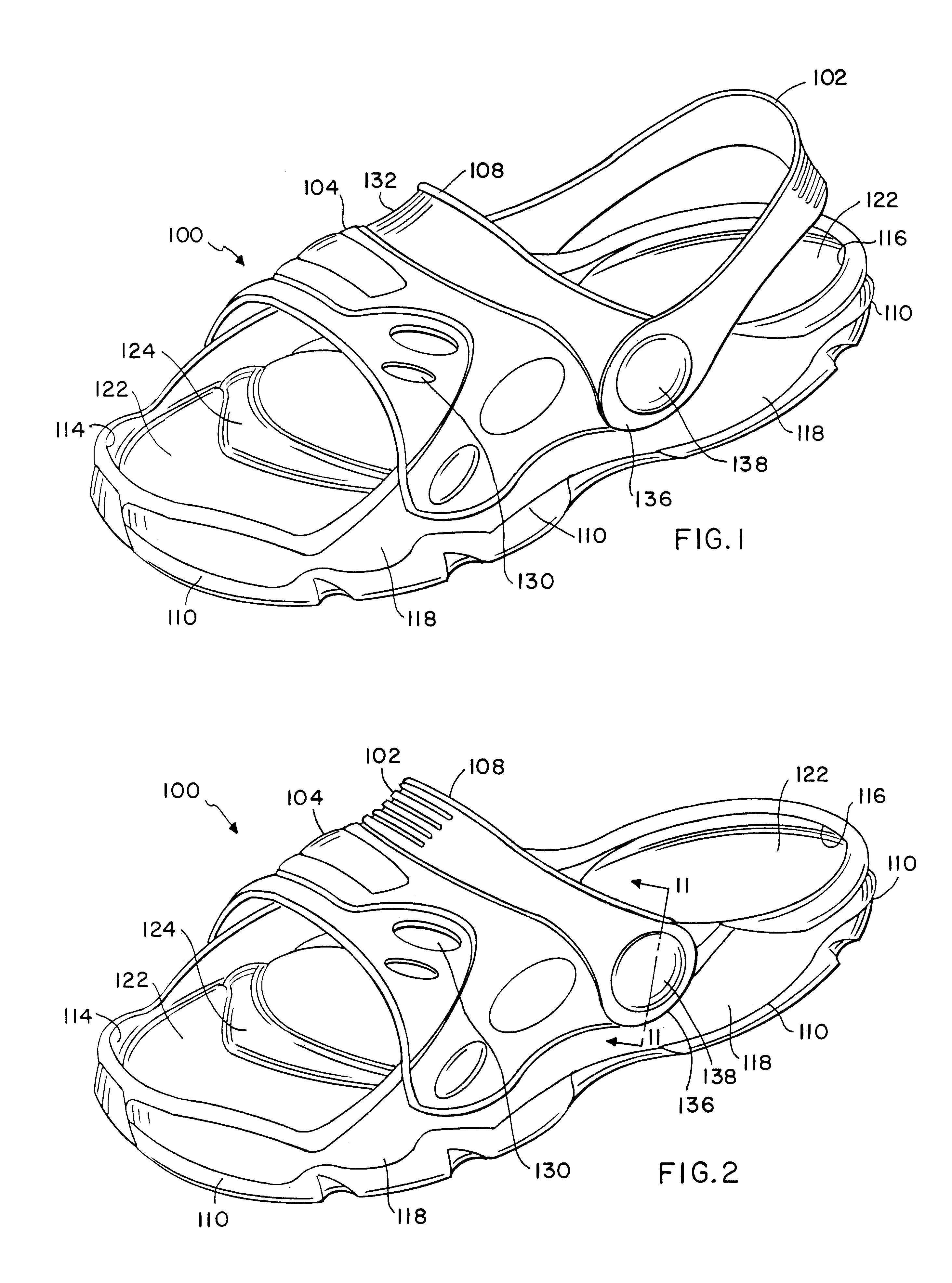

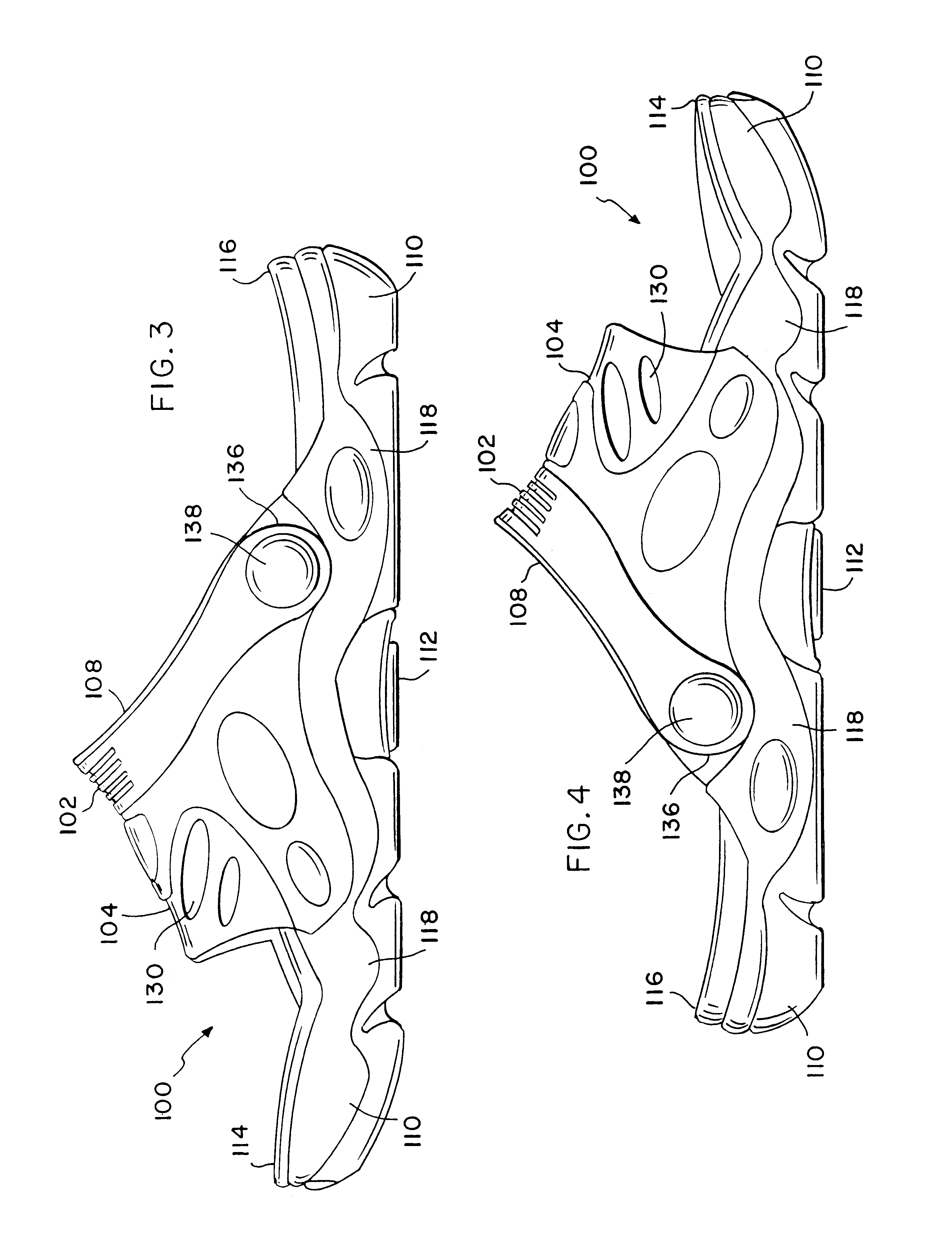

Convertible slide and method

A convertible slide and method for slide-type sandals typically used in the out-of-doors includes rubber and synthetic materials and exhibits a lightweight robust, high-strength, flexible construction including a midsole for supporting a foot. A vamp is securely attached to the midsole for covering the foot and includes a pair of outwardly extending studs for providing a pair of pivot points. A rear heel strap is provided for securing the convertible slide to the foot. The heel strap is rotatively connected to the pair of outwardly extending studs for rotating between a first lowered position about the heel of the foot and a second raised position above the vamp. Finally, an outsole is bonded to the midsole for contacting the ground surface. In a first alternative embodiment, the pair of outwardly extending studs is replaced by a pair of rivets while in a second alternative embodiment, the pair of outwardly extending studs is replaced by a pair of threaded screws.

Owner:SOUTH CONE

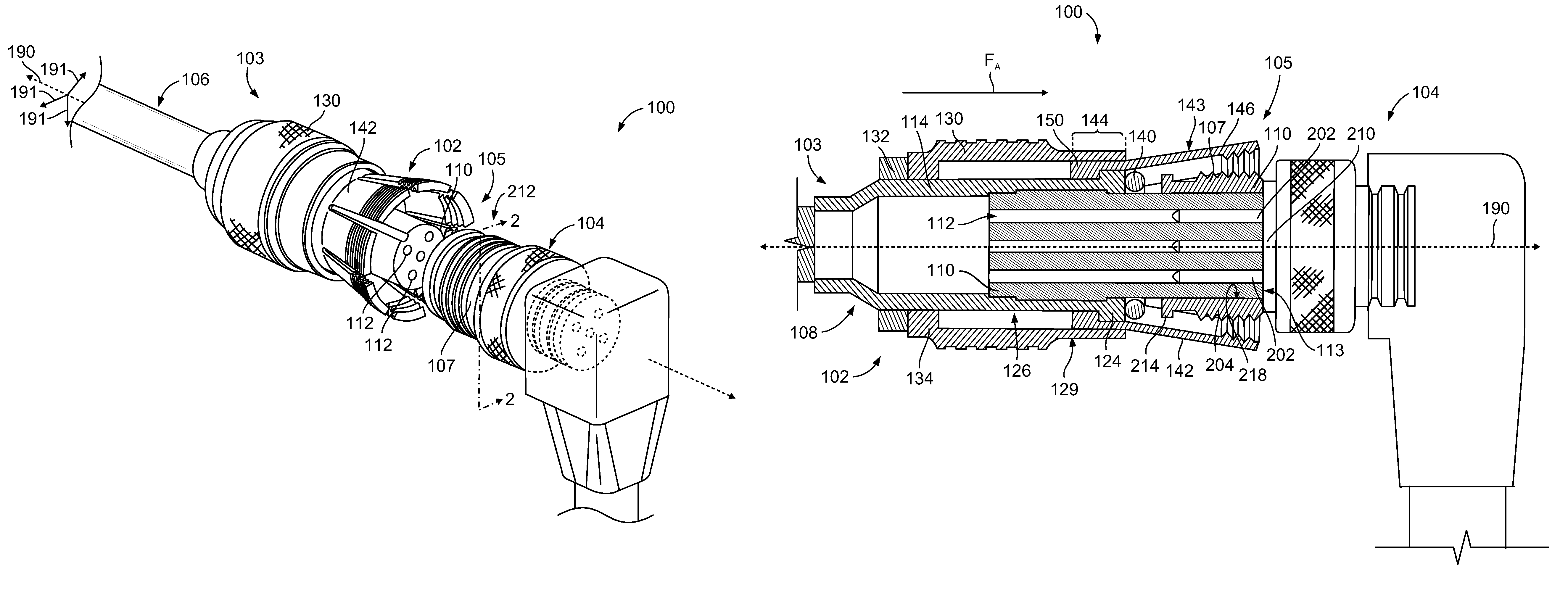

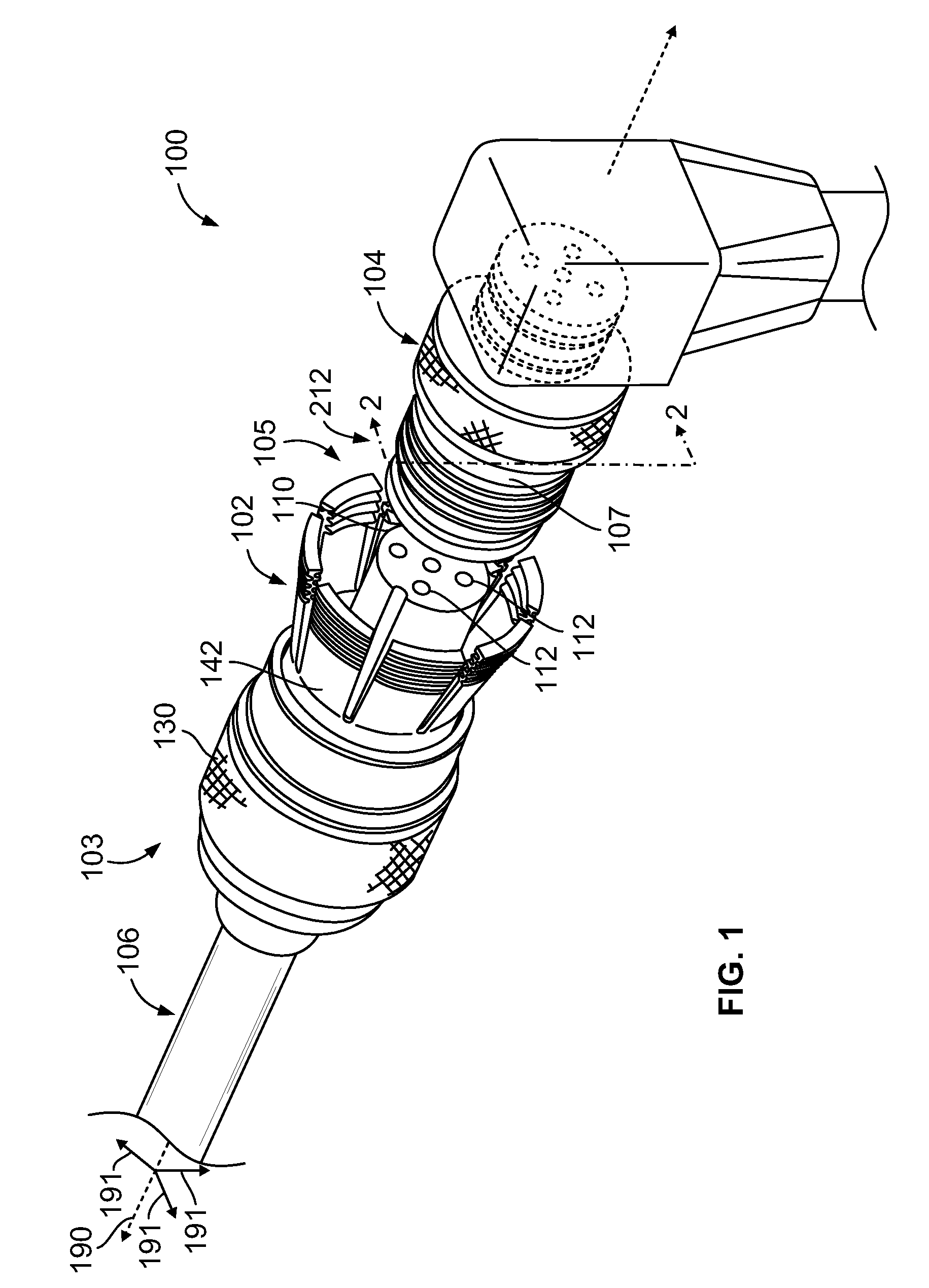

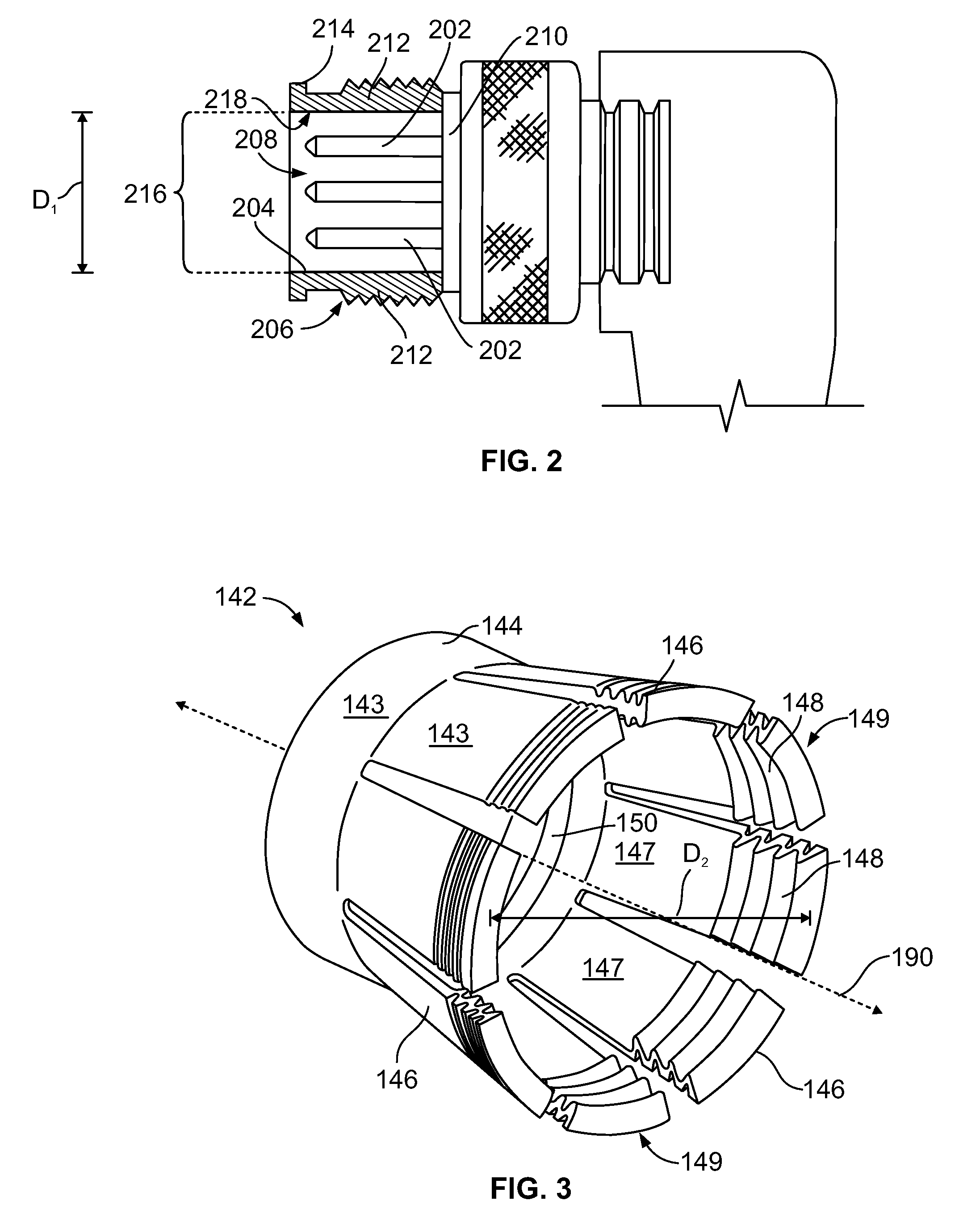

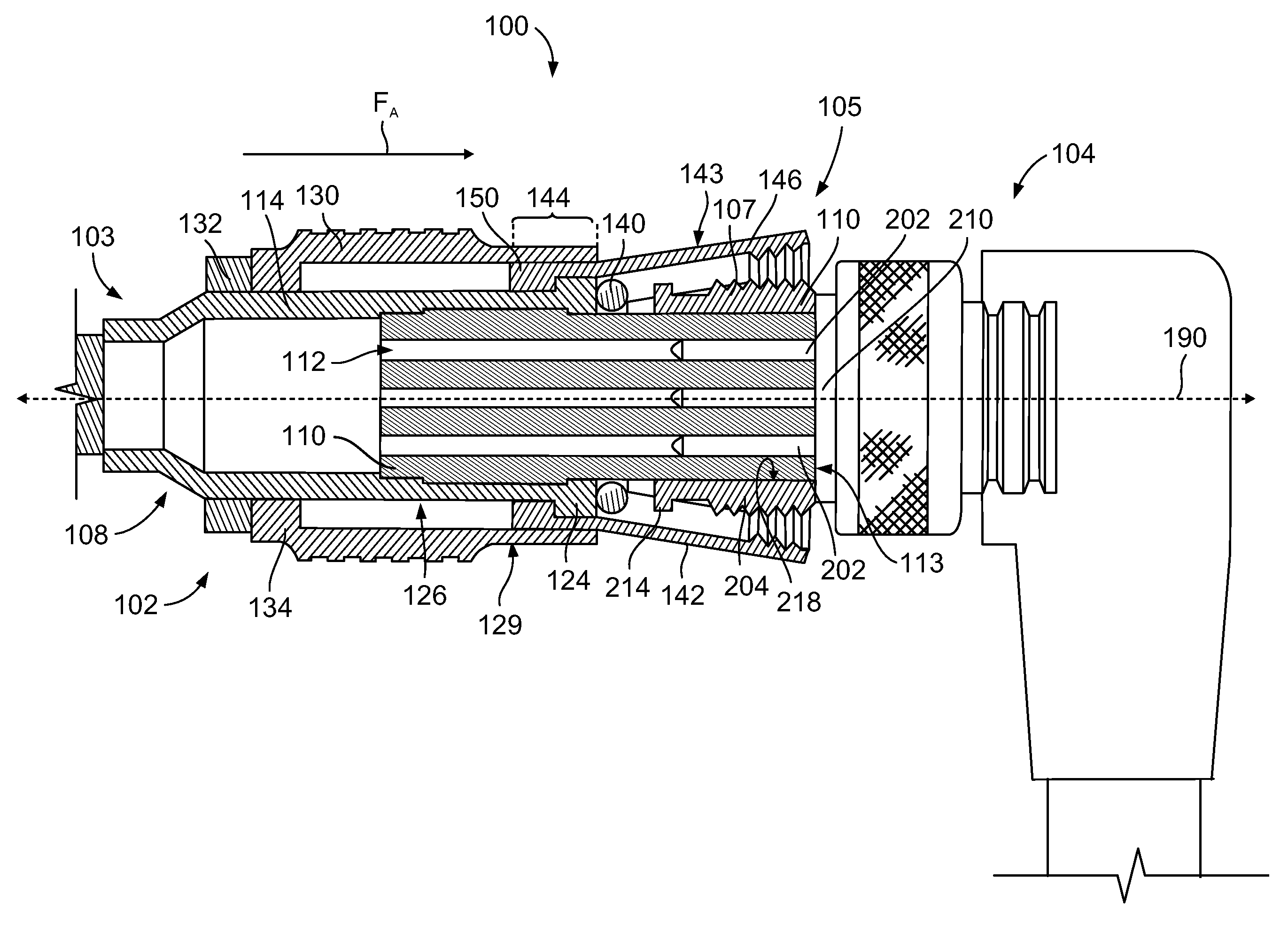

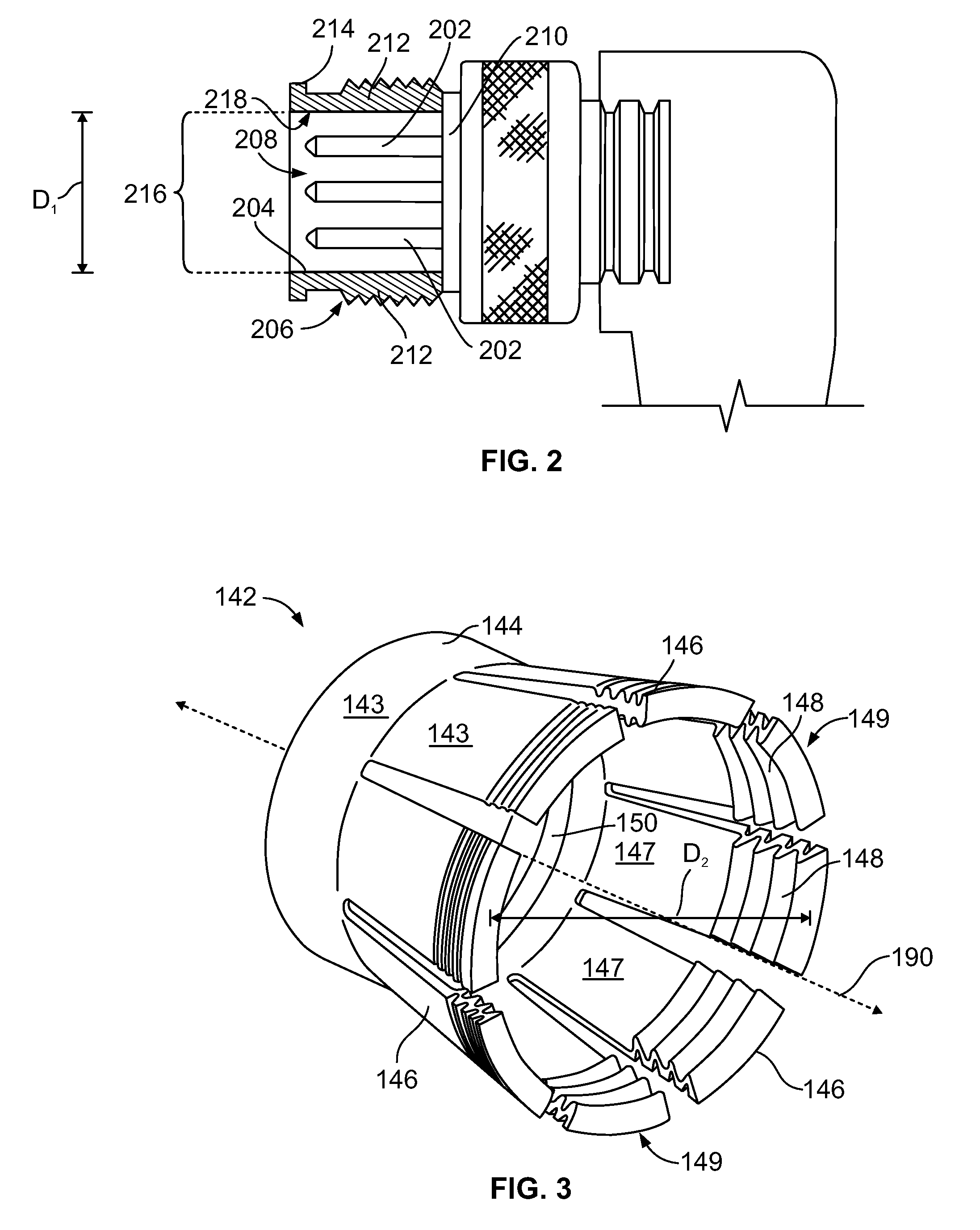

Connector having a sleeve member

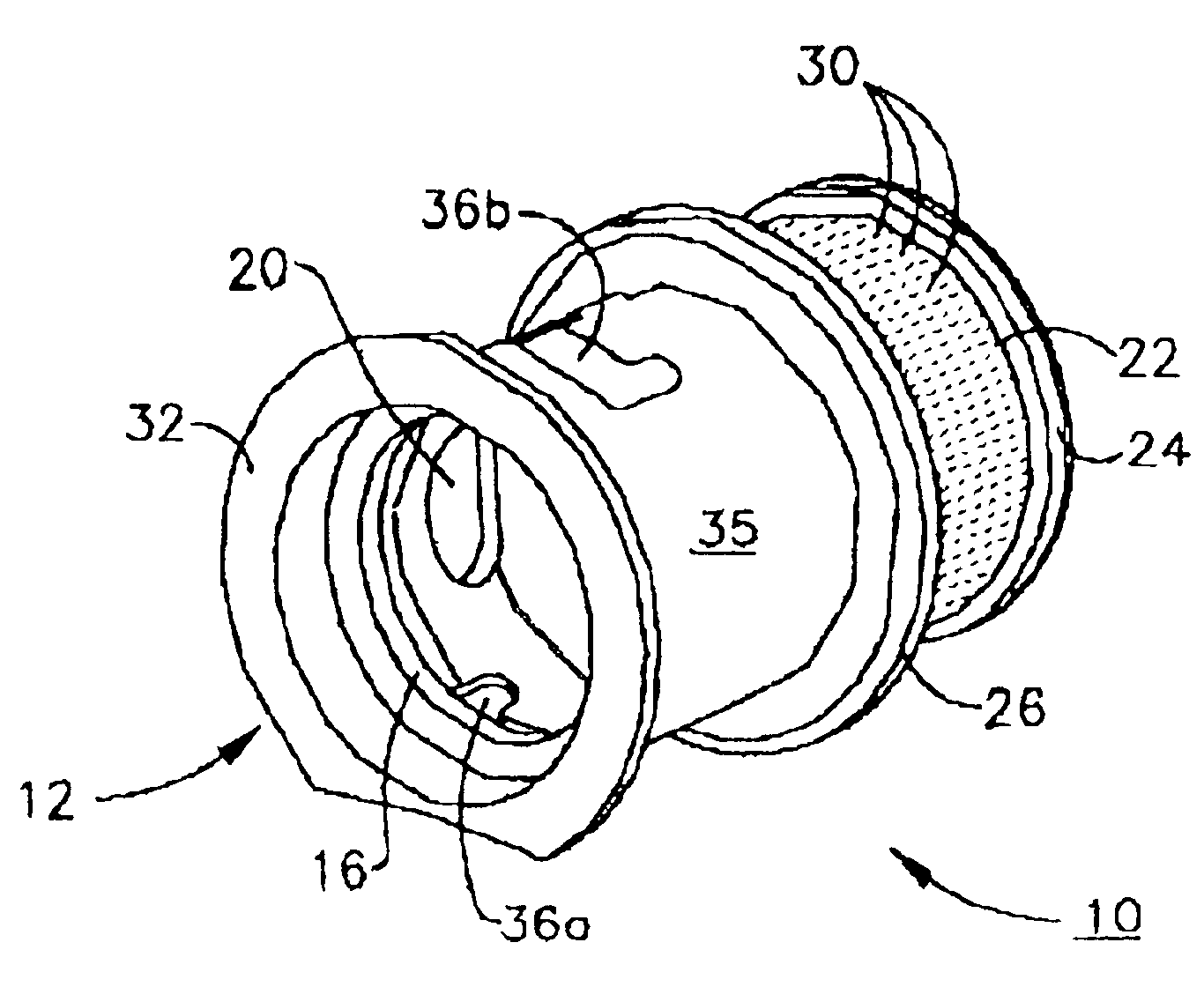

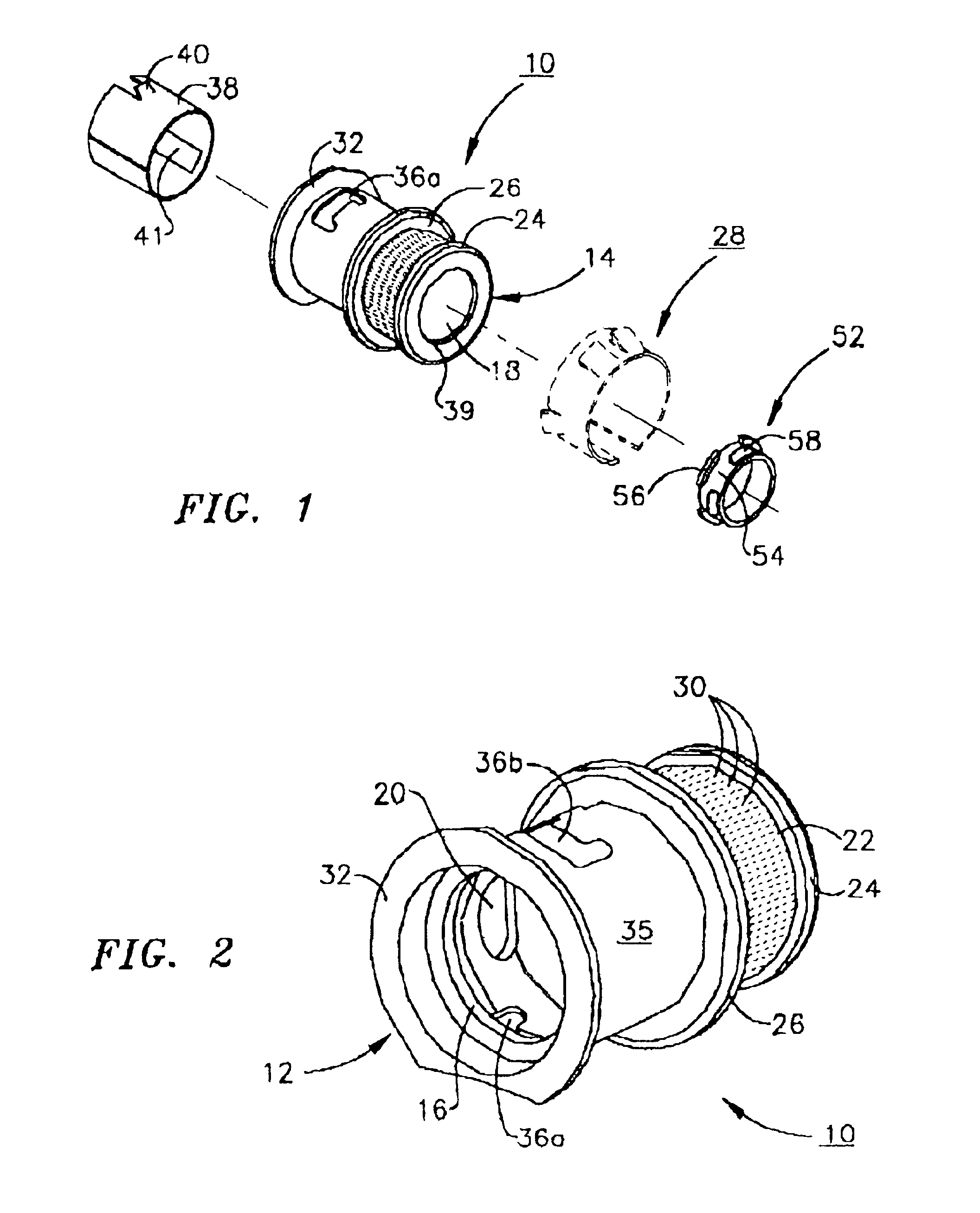

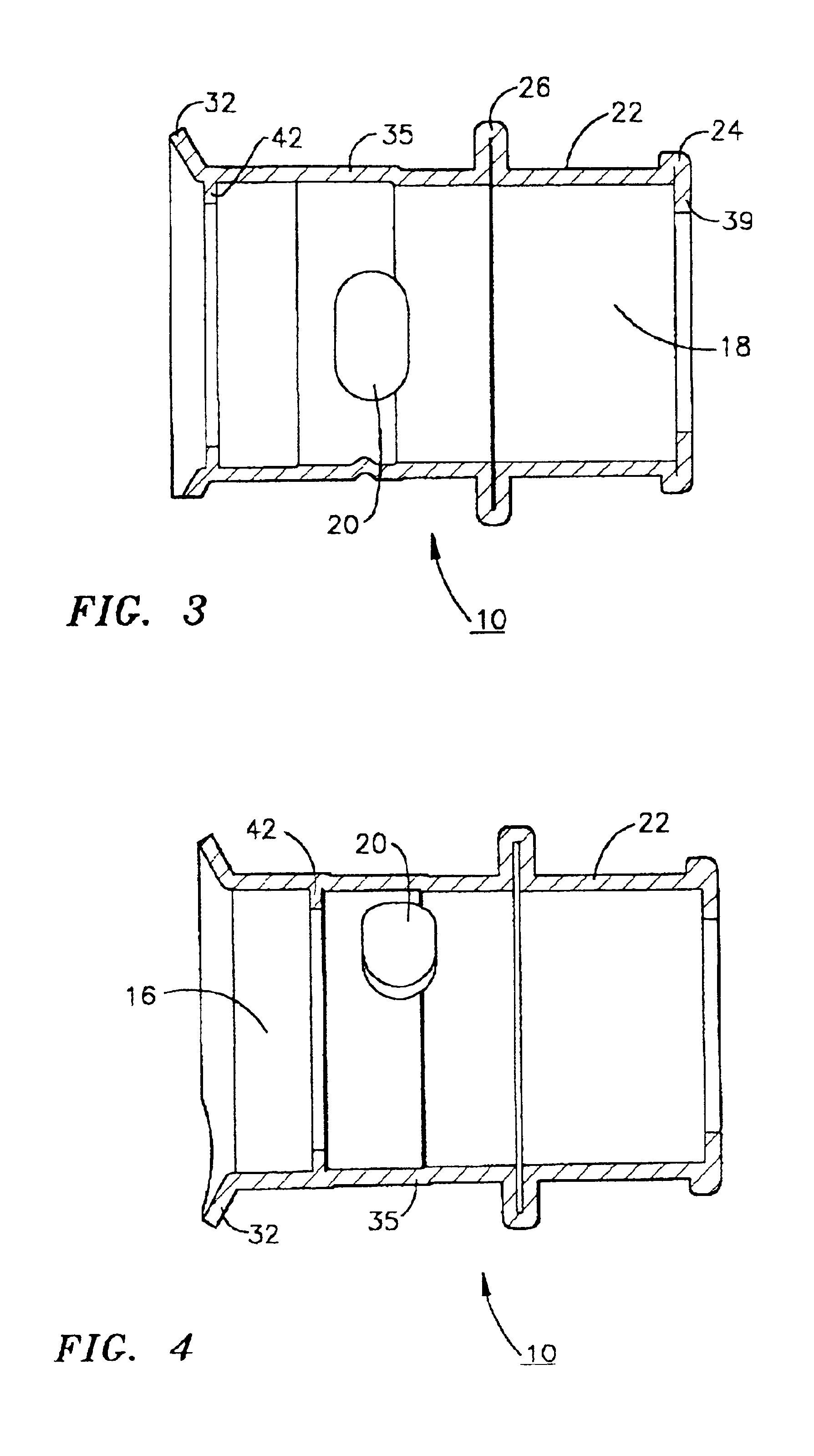

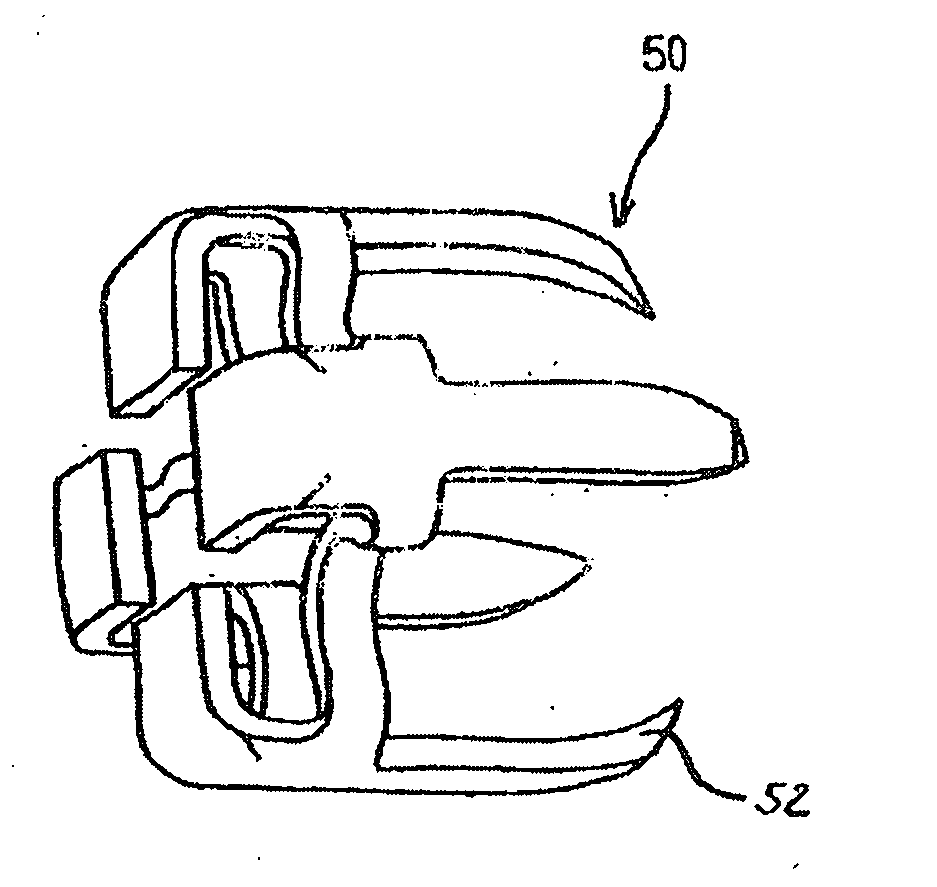

ActiveUS7892004B2Engagement/disengagement of coupling partsElectrically conductive connectionsMating connectionEngineering

A connector assembly configured to sealably engage with a mating connector. The connector assembly includes a plug assembly that has a mating end configured to be inserted into the cavity of the mating connector. The connector assembly also includes a collar that surrounds the plug assembly. The connector assembly also includes a sleeve member that is positioned between the collar and the plug assembly. The sleeve member surrounds the plug assembly about the central axis and includes a plurality of fingers that extend toward the mating end. The sleeve member is stamped and formed from a common piece of sheet material. The fingers are biased away from the central axis in a flared arrangement when the collar is in the withdrawn position. The lingers press against the wall surface of the mating connector when the collar is moved from the withdrawn position to the locked position.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

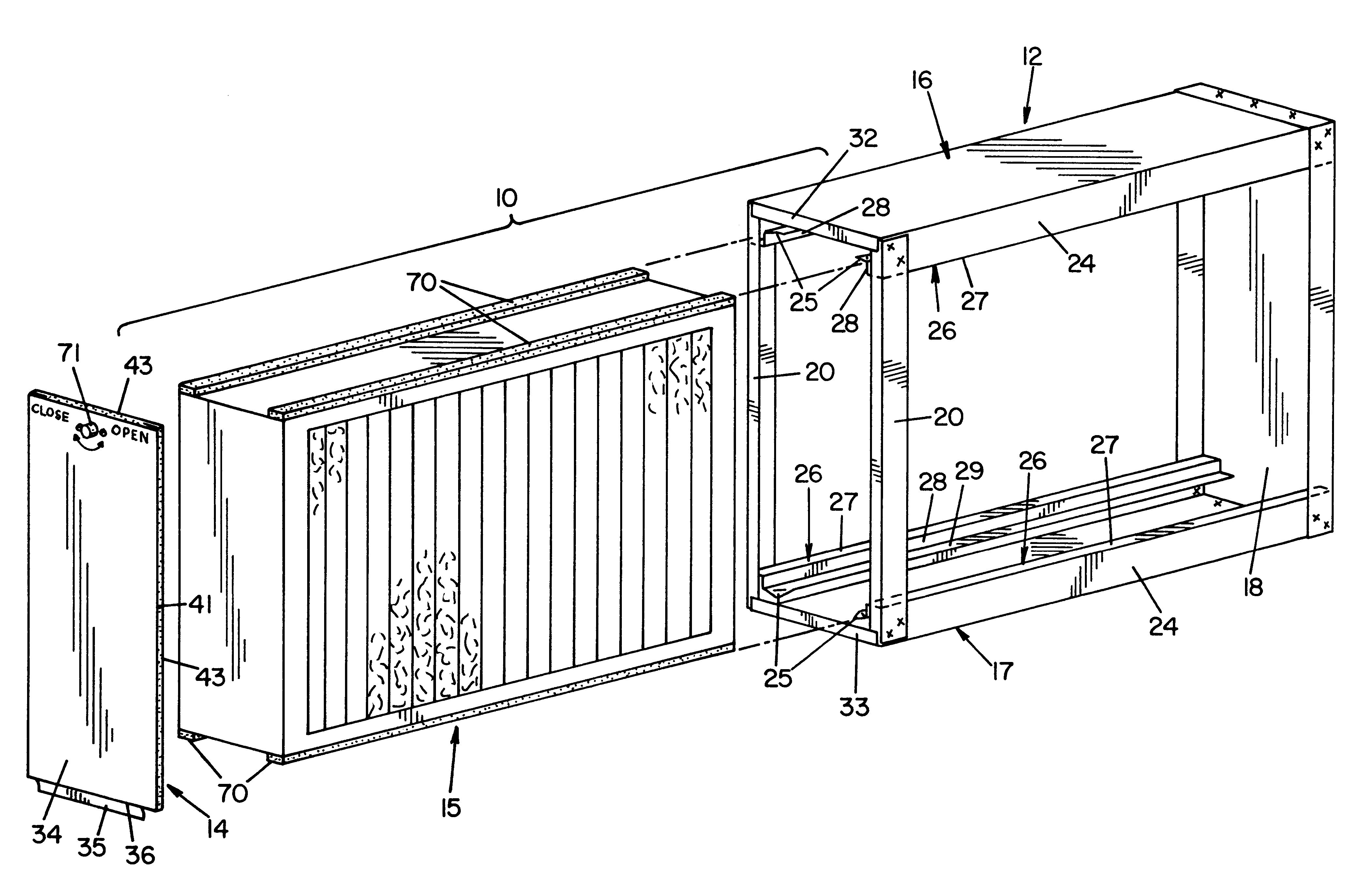

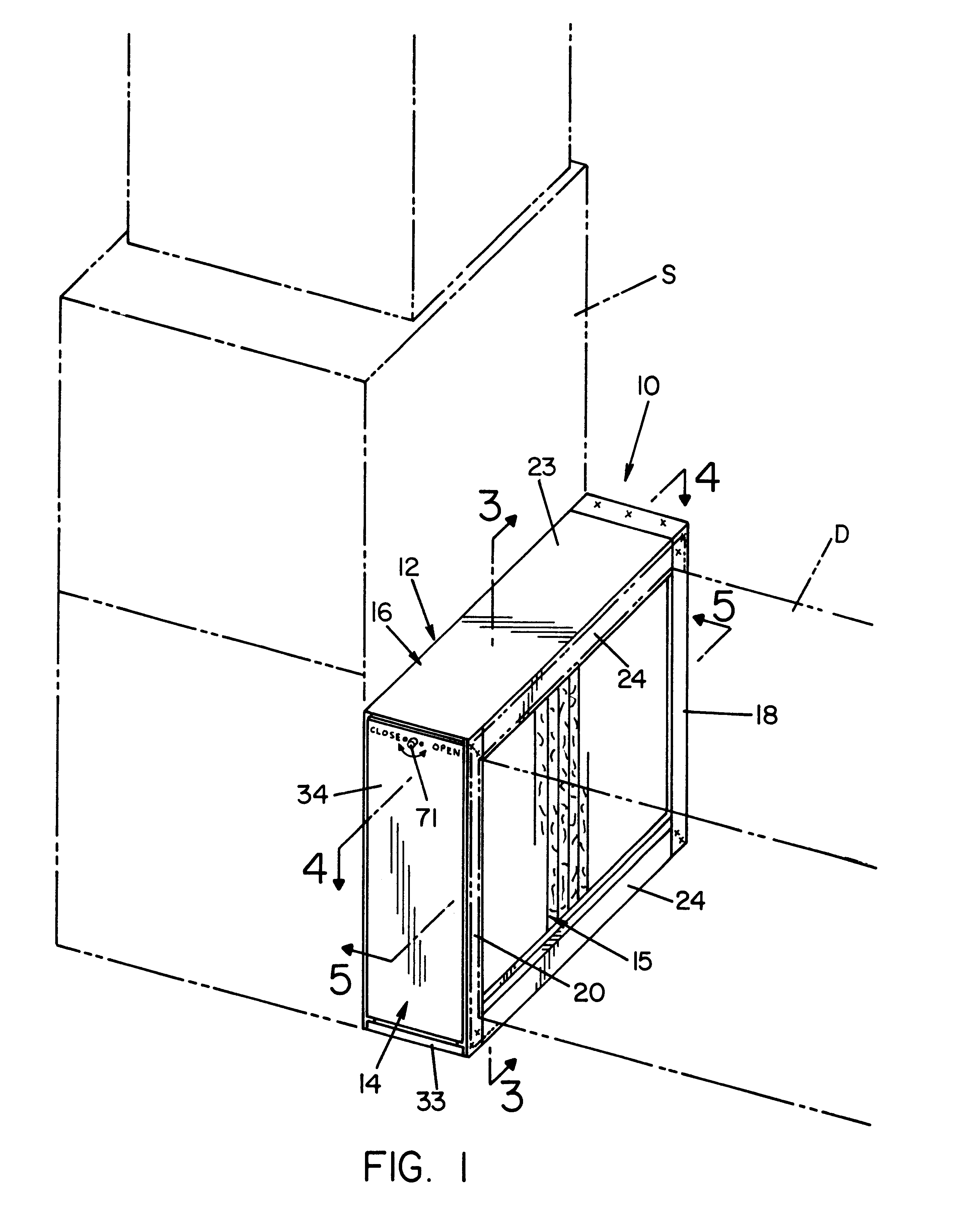

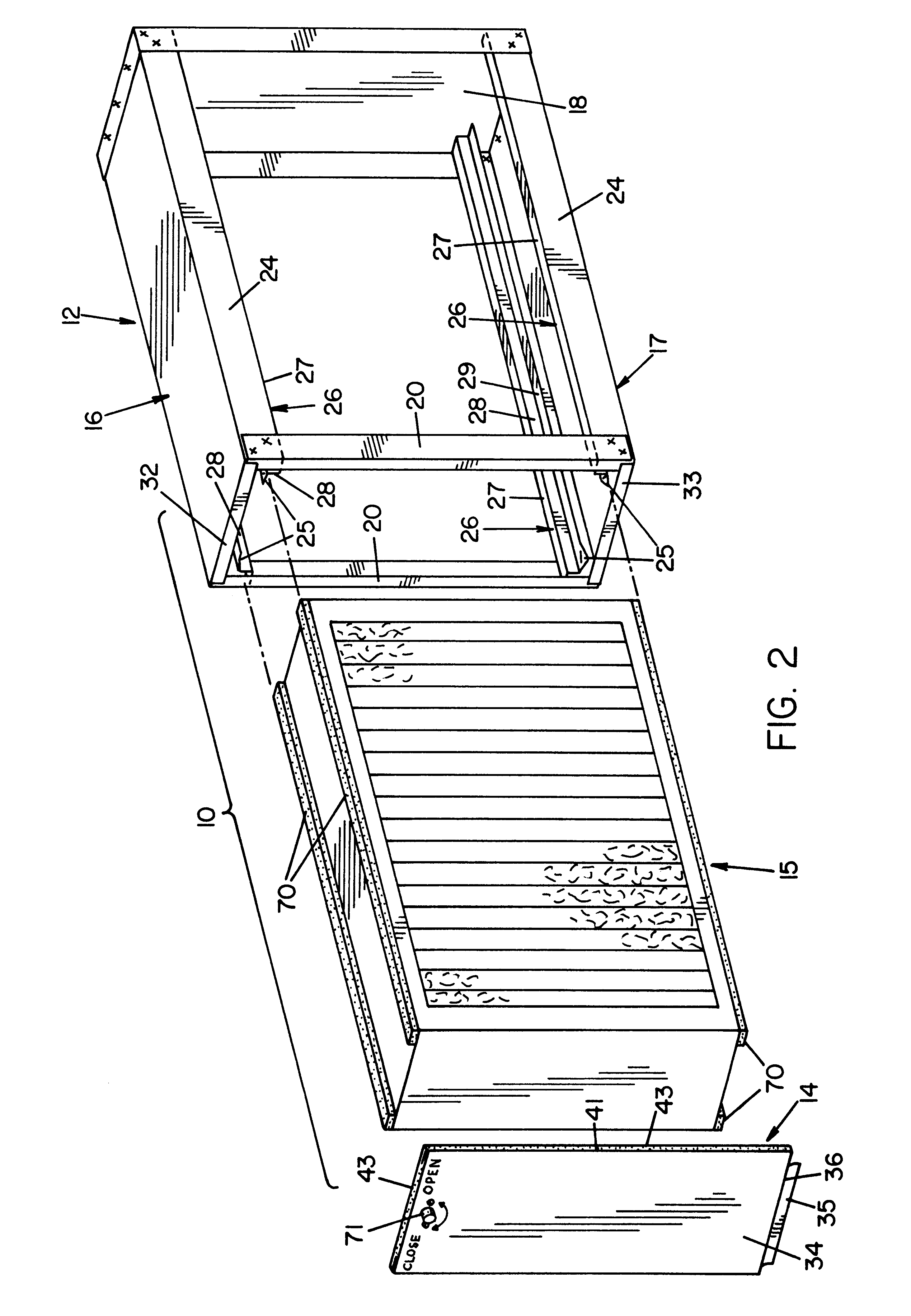

Media filter assembly having replaceable filter element

InactiveUS6264713B1Substantial structural integrityImprove sealingCombination devicesDispersed particle filtrationEngineeringMedia filter

A filter assembly is provided having a housing and a cover that communicate to retain a filter element. The housing has a top and a bottom spaced apart from each other, and a first pair of guide members is maintained beneath the top while a second pair of guide members is maintained above the bottom. The filter element is retained in the housing between the first and second pair of guide members thereby defining a first cavity between the top and the filter element and a second cavity between the bottom and the filter element. Fasteners, such as screws, rivets, nails and the like, may communicate with the cavities without damaging the filter element. The first and second pair of guide members allow for access to the internal surface area of the top and bottom of the housing such that fasteners or other installment means can be employed from the inside of the housing outwardly to the duct work or framework to which the filter assembly is to be attached.

Owner:SKUTTLE MFG

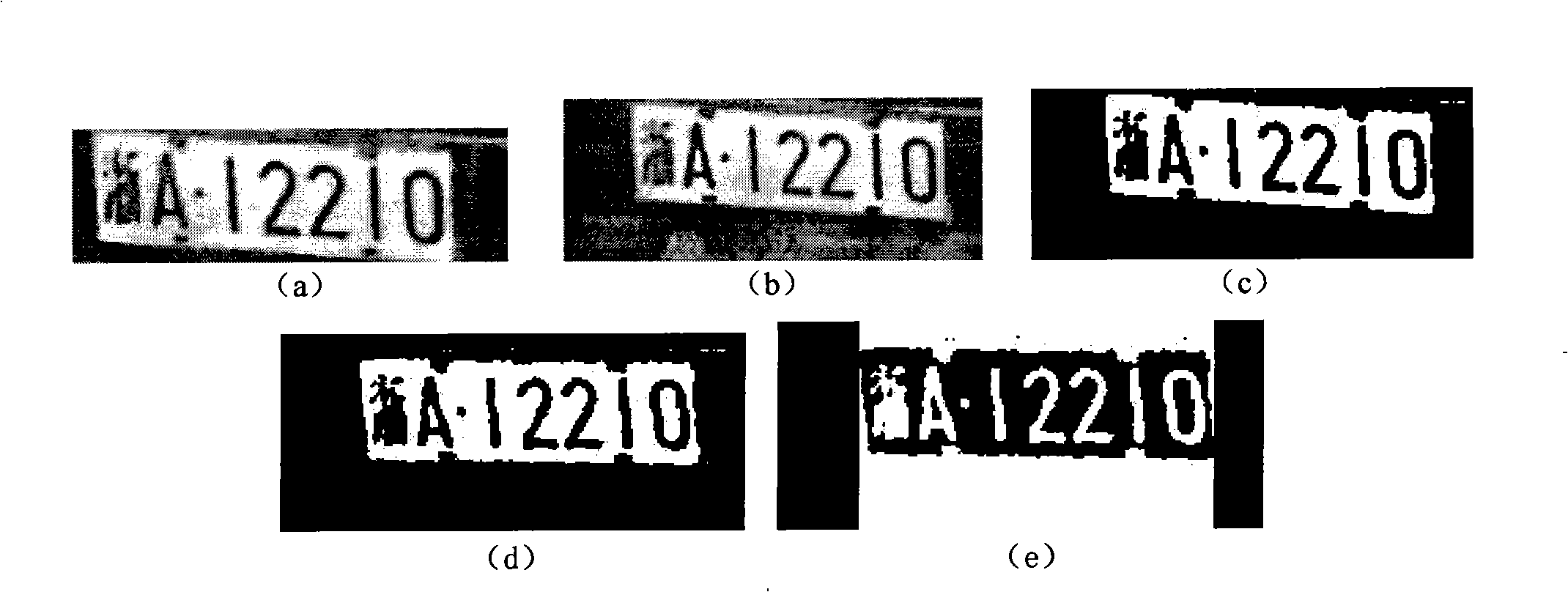

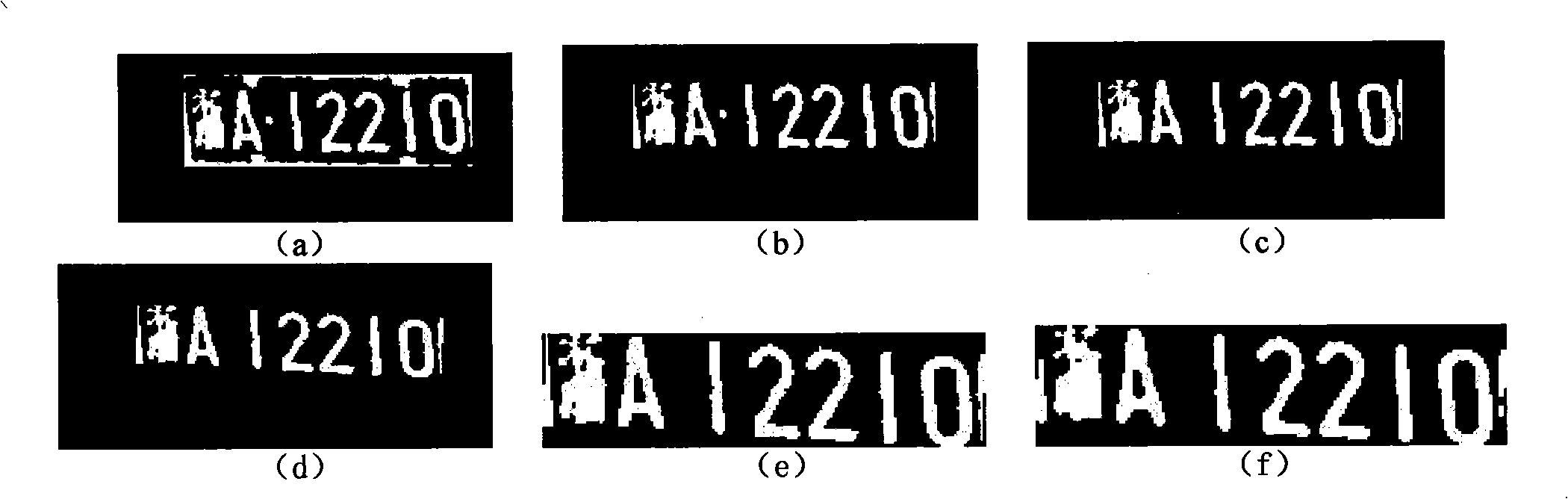

Method for recognizing license plate character based on wide gridding characteristic extraction and BP neural network

InactiveCN101408933AEliminate distractionsImprove robustnessCharacter and pattern recognitionPhysical realisationVertical projectionDot matrix

The invention discloses a vehicle license plate character recognition method based on rough grid feature extraction and a BP neural network. The method comprises the following steps: (1). preprocessing a vehicle license plate image to eliminate various interferences and obtain a minimum vehicle license plate region; (2). segmenting the vehicle license plate characters by combining vertical projection and a drop-fall algorithm; (3). screening the segmentation results to eliminate interferences of vertical frames, separators, rivets and the like; (4). normalizing the characters according to the position of a centre of mass; (5). taking each pixel of a normalized characters dot-matrix as a grid to extract the original features of the characters; (6). designing the BP neural network with a secondary classifier according to the situation of the vehicle license plate; and (7). reasonably constructing a training sample database to train the neural network, and adjusting the training samples by the recognition effect to realize accurate recognition of the network. The method effectively eliminates the noise interference, quickly and accurately segments the characters, steadily and effectively recognizes Chinese characters, and realizes the balance between real-time property and accuracy in the whole recognition course.

Owner:ZHEJIANG NORMAL UNIVERSITY

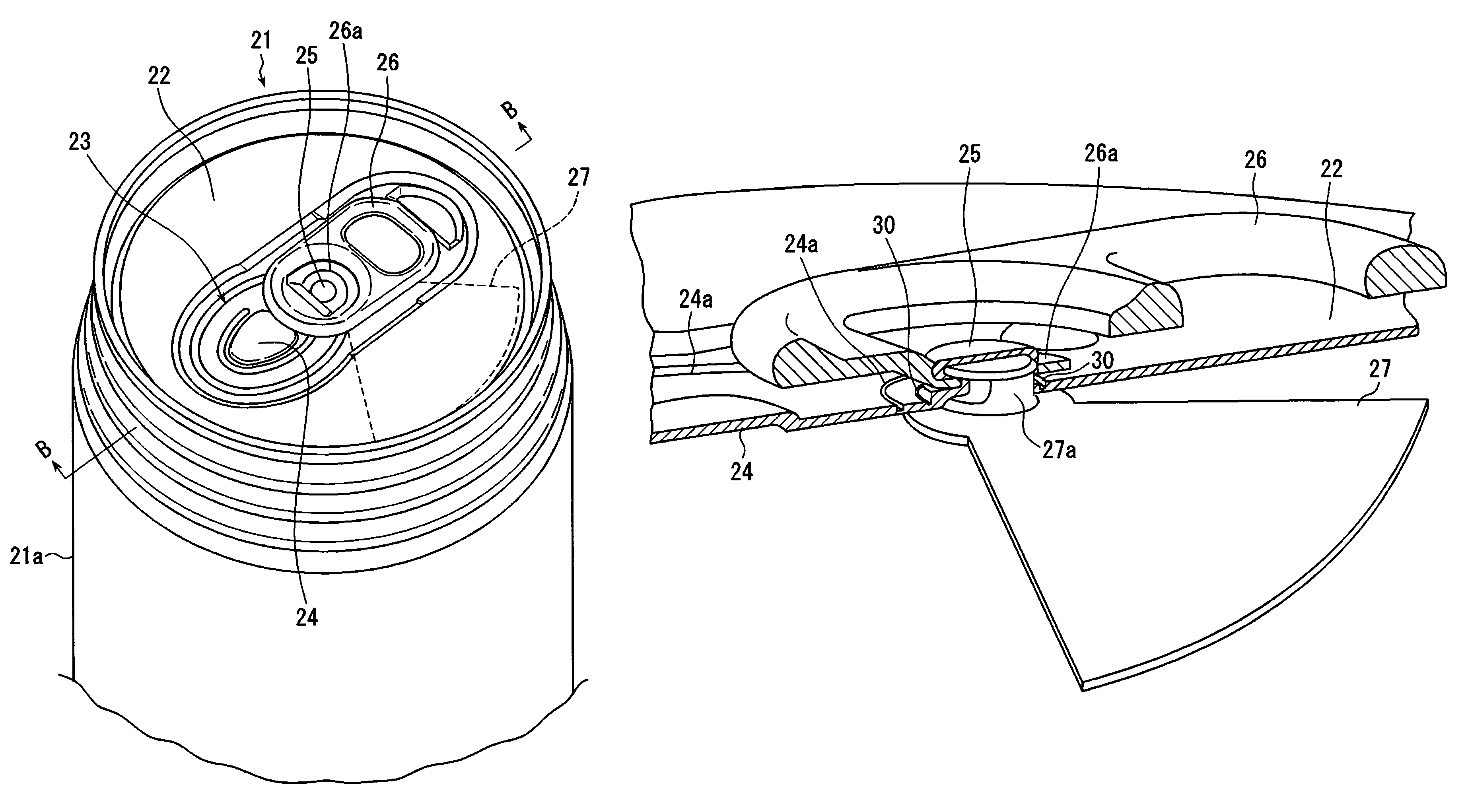

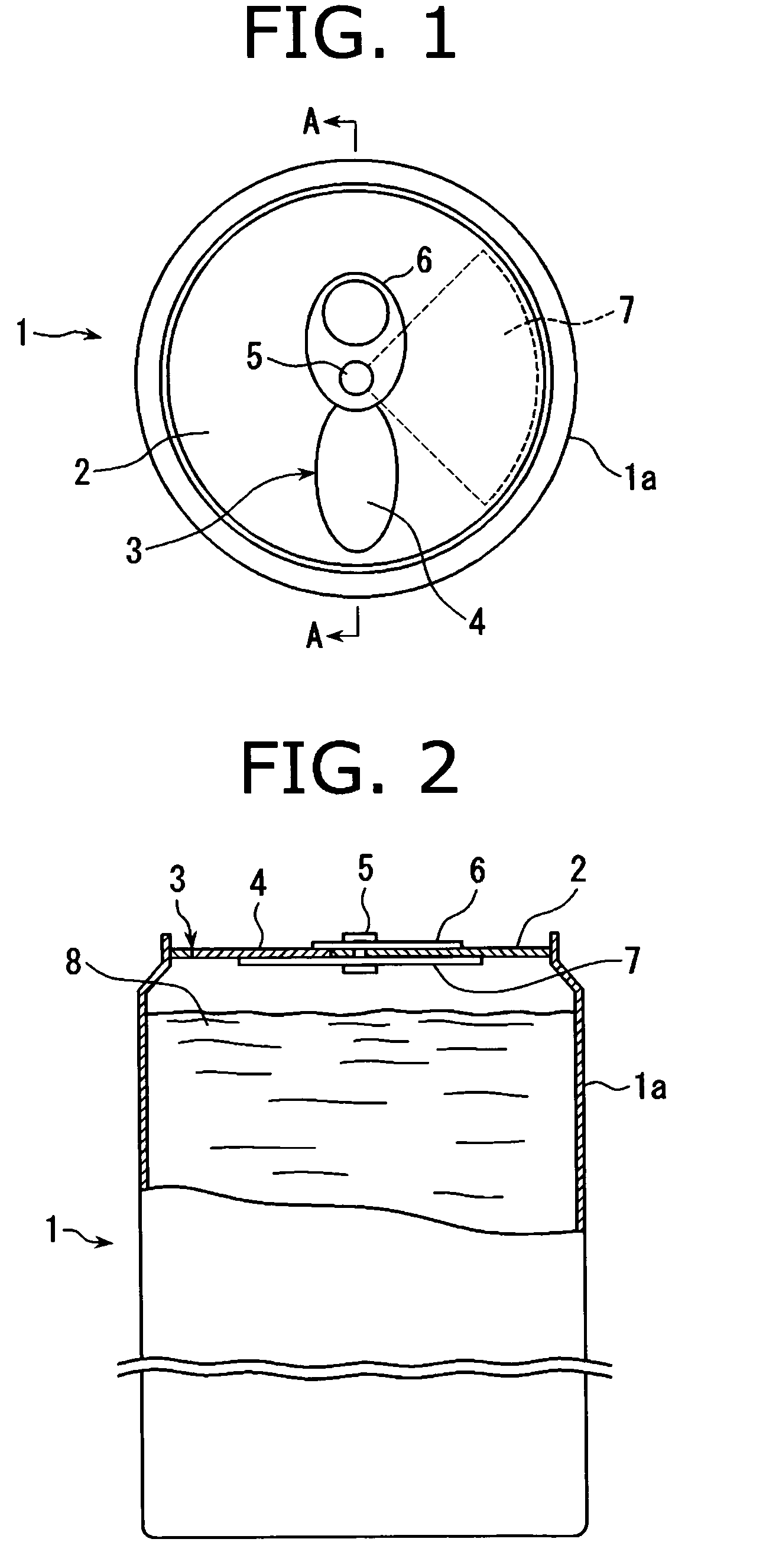

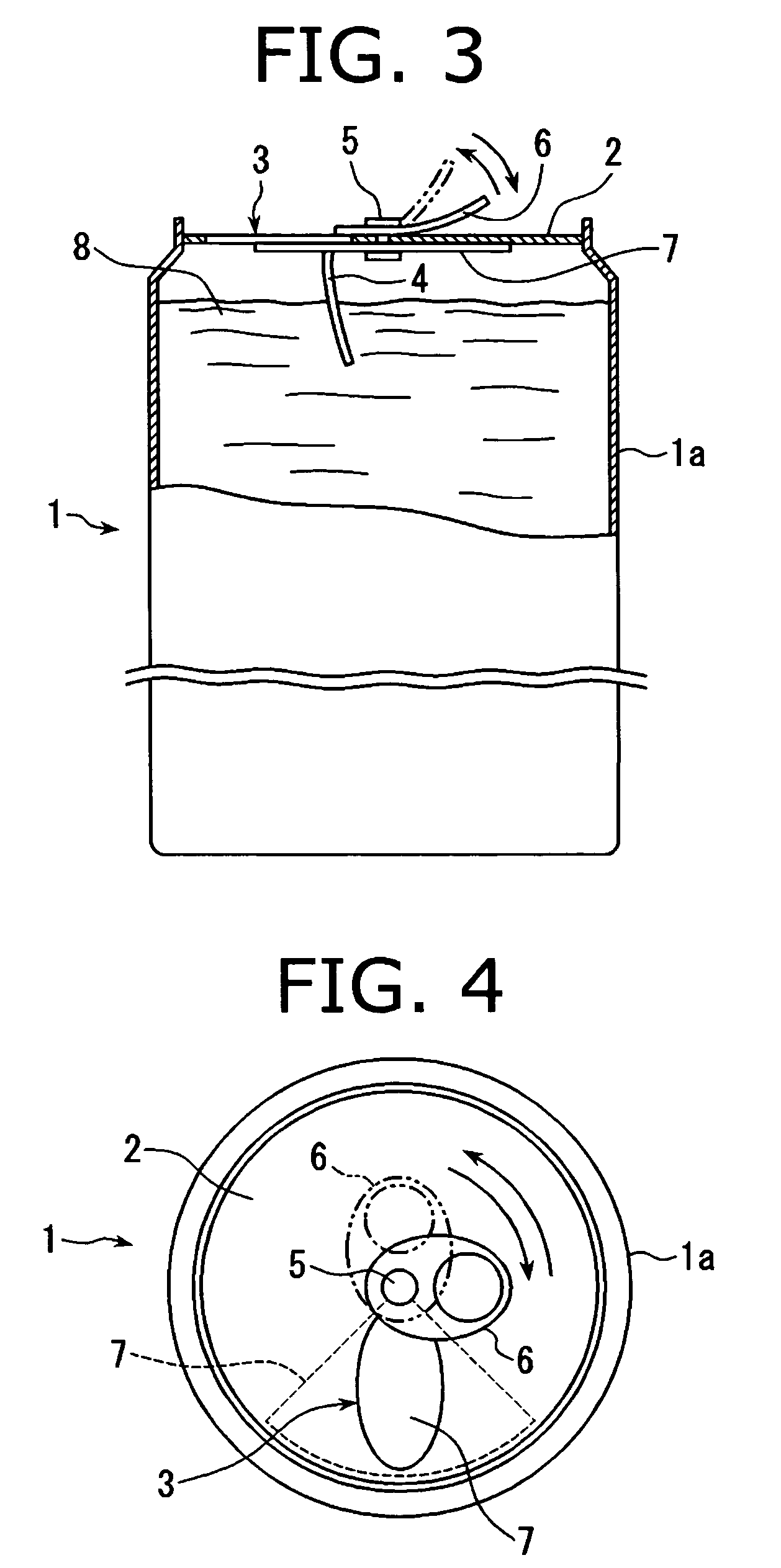

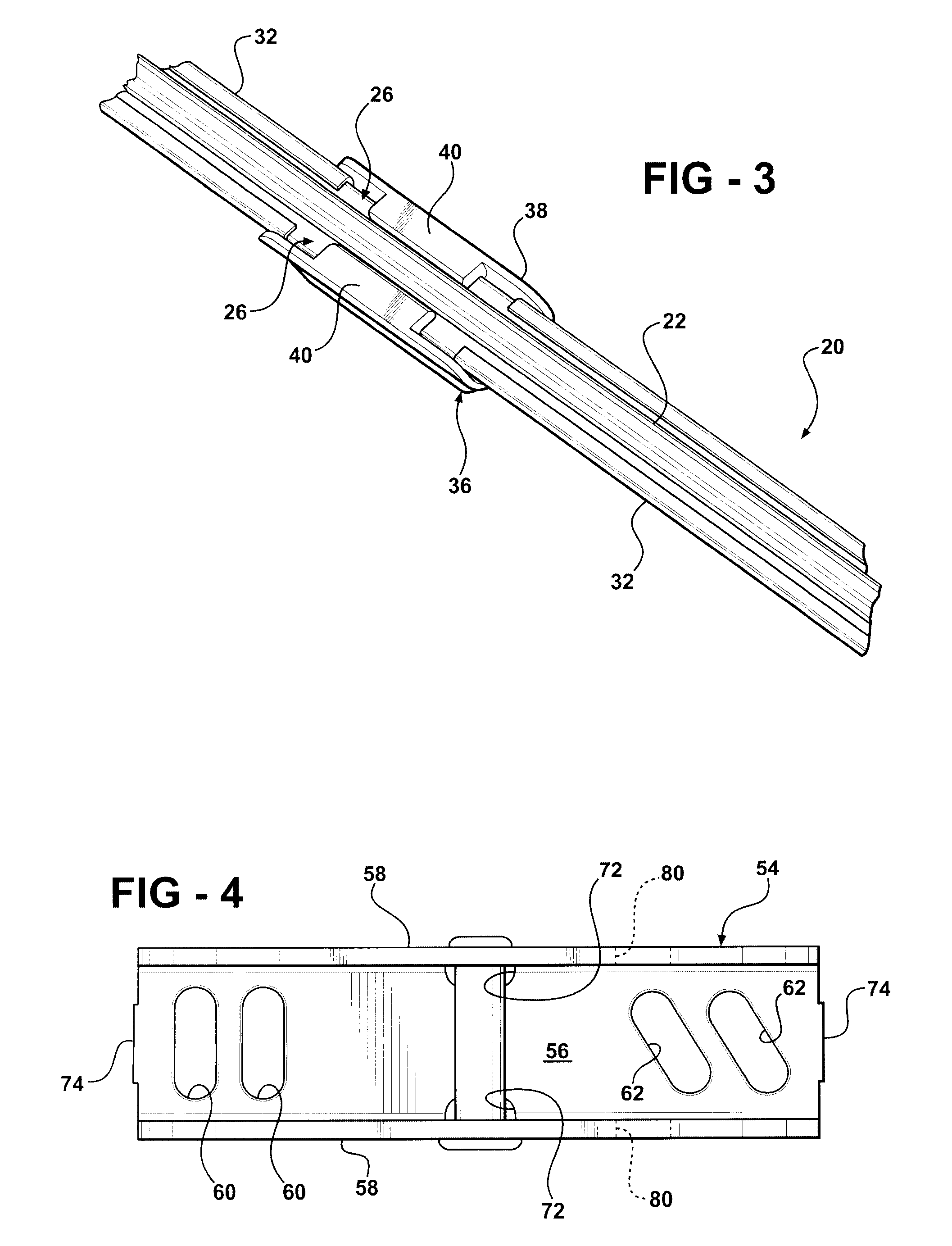

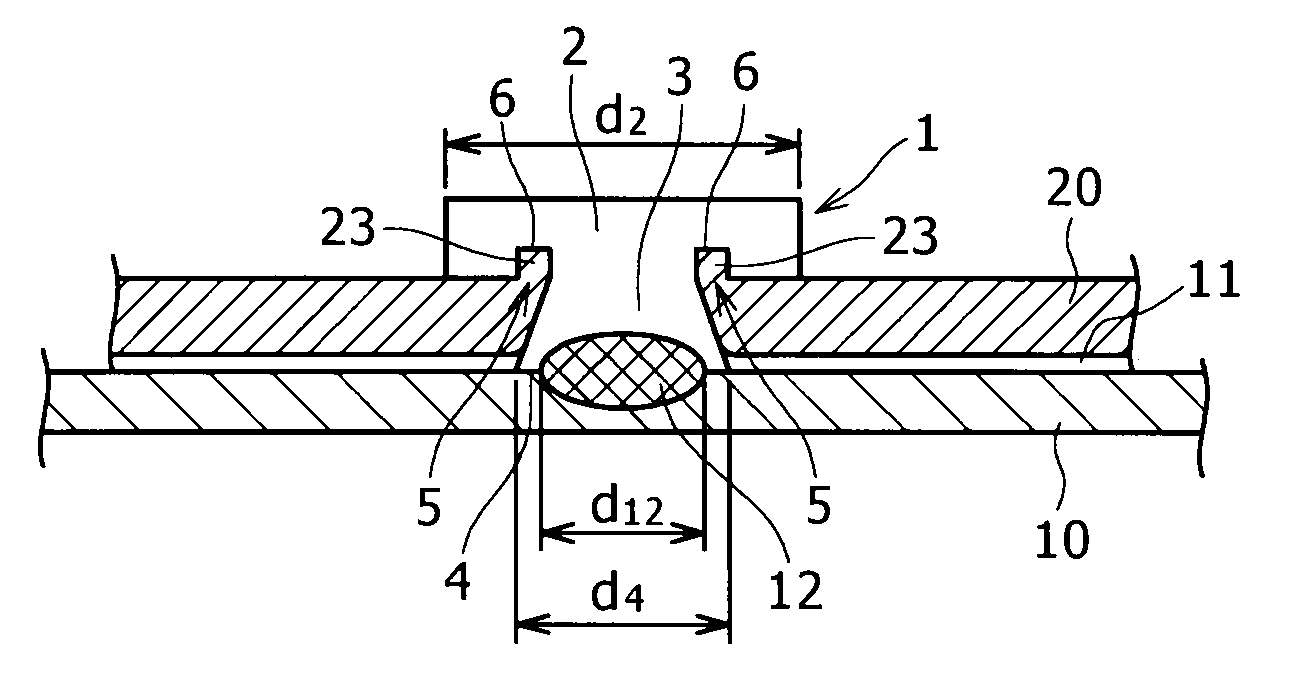

Can

InactiveUS7198168B2Heat exchangerAvoid heat exchangeLiquid flow controllersRefuse receptaclesEngineeringRivet

A can (1) having a spout that can, after opening, be securely resealed and can be opened and closed with an easy operation. The can (1) has a spout (3) that is opened by lifting and pulling a pull-ring (6) fixed on a top wall (2) of a can body (1a) with a rivet (5) to bend a sealing tongue portion (4) toward the inside of the can. Inside the top wall (2) and away from the spout (3), an internal sealing member (7) having a fan shape with its pivot mounted to the rivet and a size capable of sealing the spout (3) is disposed so as to be fixed to the rivet (5). After opening the spout (3), by rotating the pull-ring (6) around the rivet (5), the internal sealing member (7) is also rotated at the same time. As an interlocking mechanism therefor, the rivet (5) is rotatably supported by the top wall (2), and a base end of the pull-ring (6) and the pivot of the internal sealing member (7) are fixed to the rivet (5), respectively.

Owner:MIZUMA JYUNZI +5

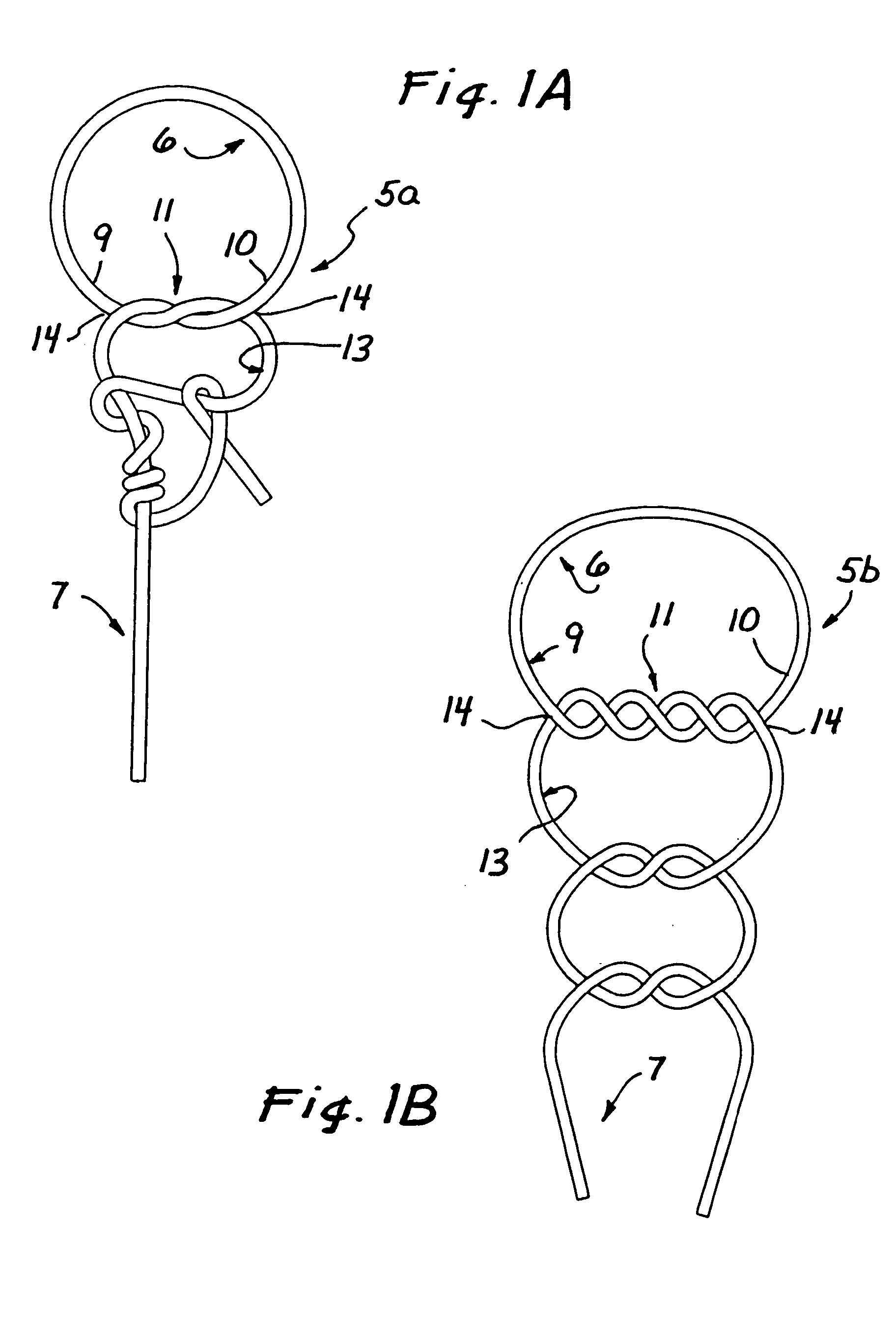

Interlocking suture clinch

The invention is directed to a suture clinch that may be placed upon suture extensions of a placed suture to securely lock the extensions in a desired location. The clinch operates to replace a tied knot and retain the suture in a fixed relationship with little or no damage to the suture itself. The clinch comprises a mating pair of interlocking members that restrict movements of the suture. The interlocking members may be placed upon the suture extensions from alongside the suture extensions and compressed to a first condition where the interlocking members may be advanced, retracted or adjusted, and subsequently further compressed to a second condition where the interlocking members are fully engaged to fully restrict the movement of the suture. In another aspect, the clinch may be provided in a flat form comprising a first component and a second component. The first and second components fit together in a mating relationship that entraps at least a portion of the suture between tractive faces of the first and second components, respectively. Each end of the first and second components may have a recessed central portion that leaves two extensions along the sides of each end of the components. The extensions of the second component are subsequently folded over the first component to provide secure entrapment of the suture between the tractive faces of the first and second components. The tractive faces operate to engage the suture and hold it securely in place without damaging or challenging the suture. The clinch may comprise of plastic, metallic materials such as stainless steel or titanium, or a combination of both where the plastic is chosen for its value as an atraumatic interface and the metal for its radiopacity or durability.

Owner:APPL MEDICAL RESOURCES CORP

Connector having a sleeve member

ActiveUS20090264003A1Satisfies requirementEngagement/disengagement of coupling partsElectrically conductive connectionsMating connectionEngineering

A connector assembly configured to sealably engage with a mating connector. The connector assembly includes a plug assembly that has a mating end configured to be inserted into the cavity of the mating connector. The connector assembly also includes a collar that surrounds the plug assembly. The connector assembly also includes a sleeve member that is positioned between the collar and the plug assembly. The sleeve member surrounds the plug assembly about the central axis and includes a plurality of fingers that extend toward the mating end. The sleeve member is stamped and formed from a common piece of sheet material. The fingers are biased away from the central axis in a flared arrangement when the collar is in the withdrawn position. The lingers press against the wall surface of the mating connector when the collar is moved from the withdrawn position to the locked position.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

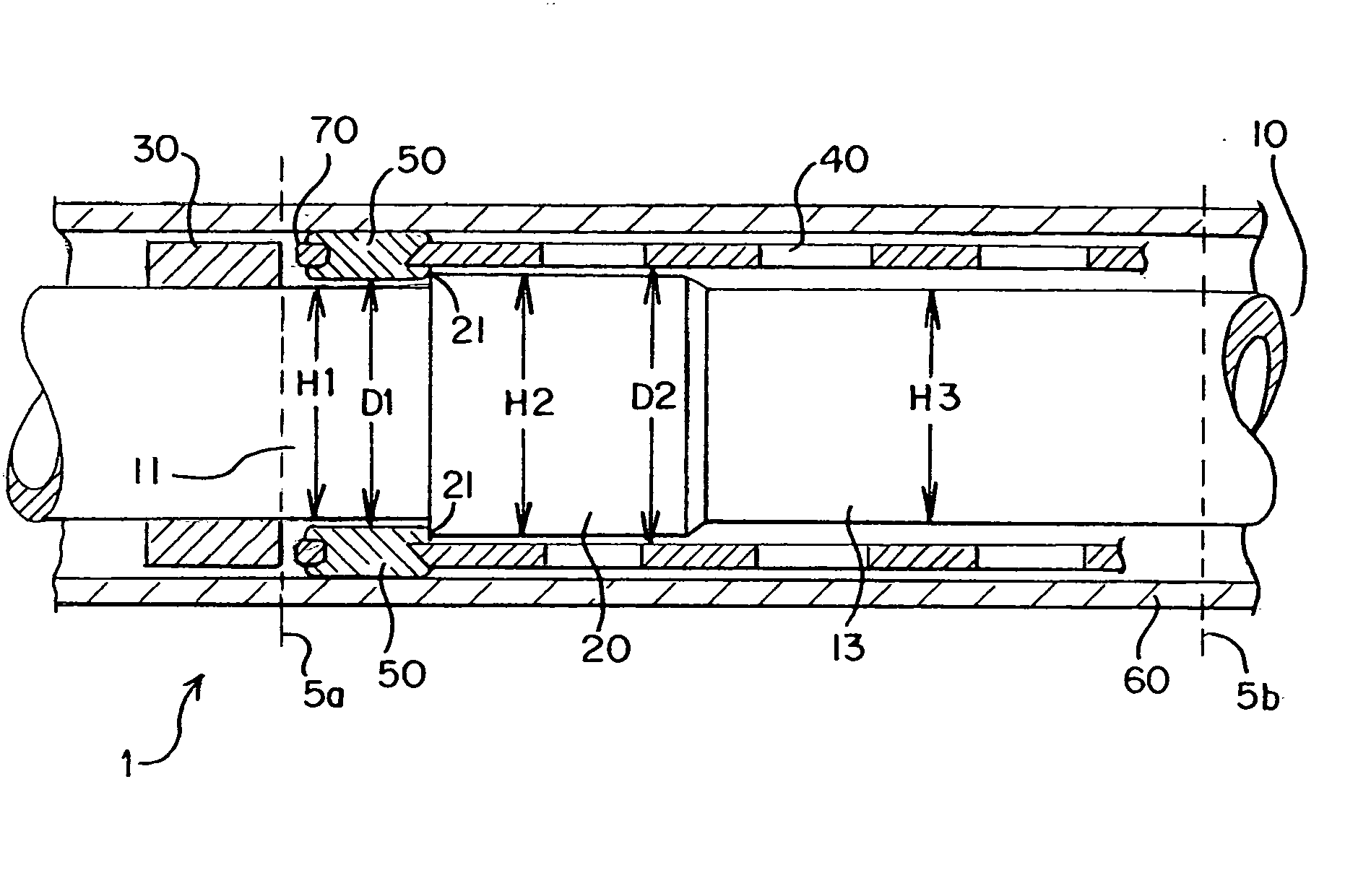

Stent delivery system allowing controlled release of a stent

A stent delivery system includes a stent having at least one eyelet and at least one rivet and a holder supporting the stent, wherein the holder includes a first section having a first diameter and a second section having a second diameter. A sheath covers the stent and the holder. The rivets are attached to each of the eyelets. A first inner diameter of the stent at the position of the rivets is smaller than a second inner diameter of the stent at other positions because the rivets protrude inwardly. A shoulder is formed on the holder due to the difference between the first diameter and the second diameter of the holder. The shoulder is positioned distally adjacent the rivets. The shoulder interferes with the protruding rivets, thereby restraining the longitudinal movement of the stent relative to the holder. Although the sheath is pulled back, the stent does not jump out of the stent delivery system. As a result, the stent delivery system allows the stent to be released in a controlled manner upon its deployment.

Owner:COOK MEDICAL TECH LLC

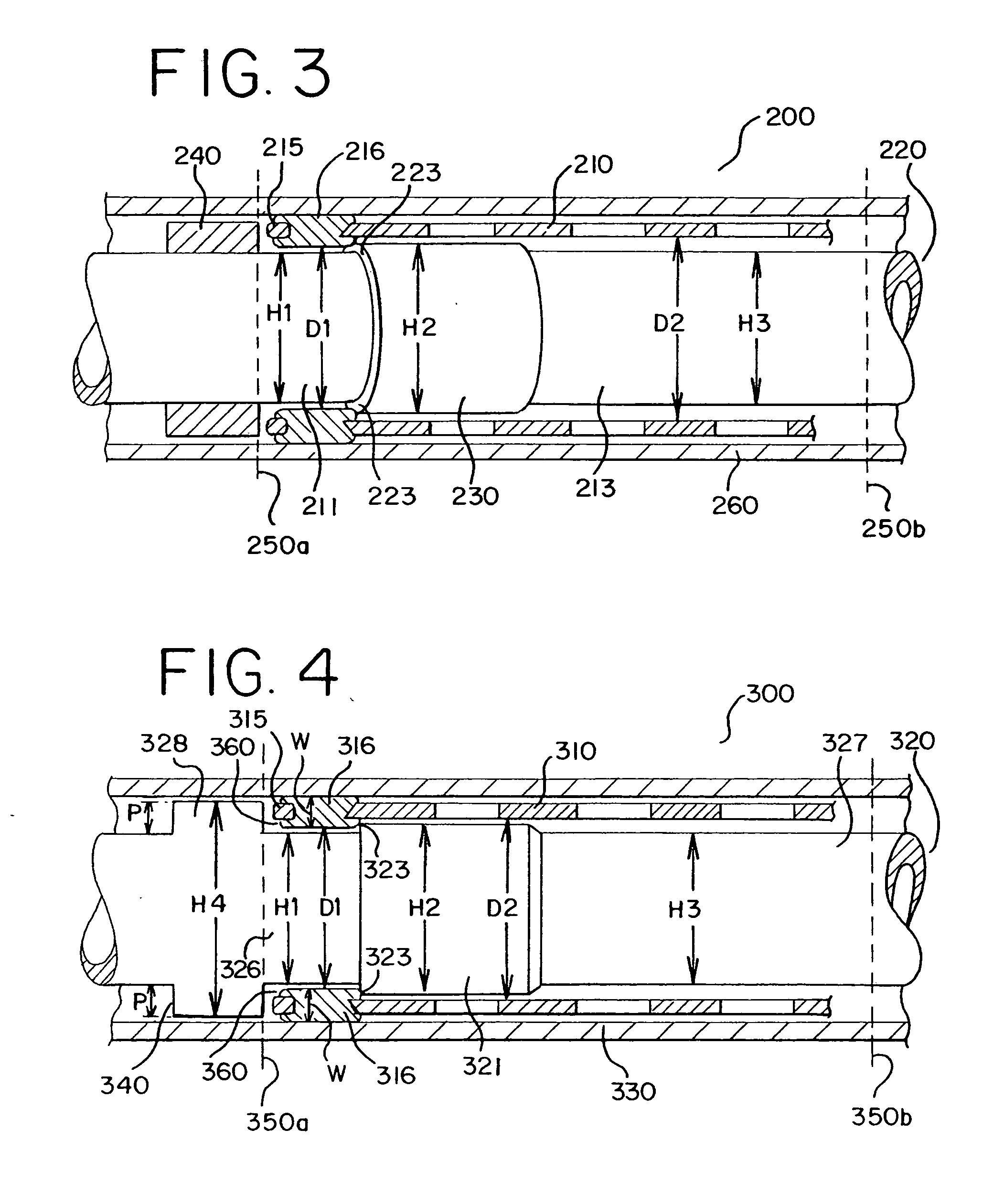

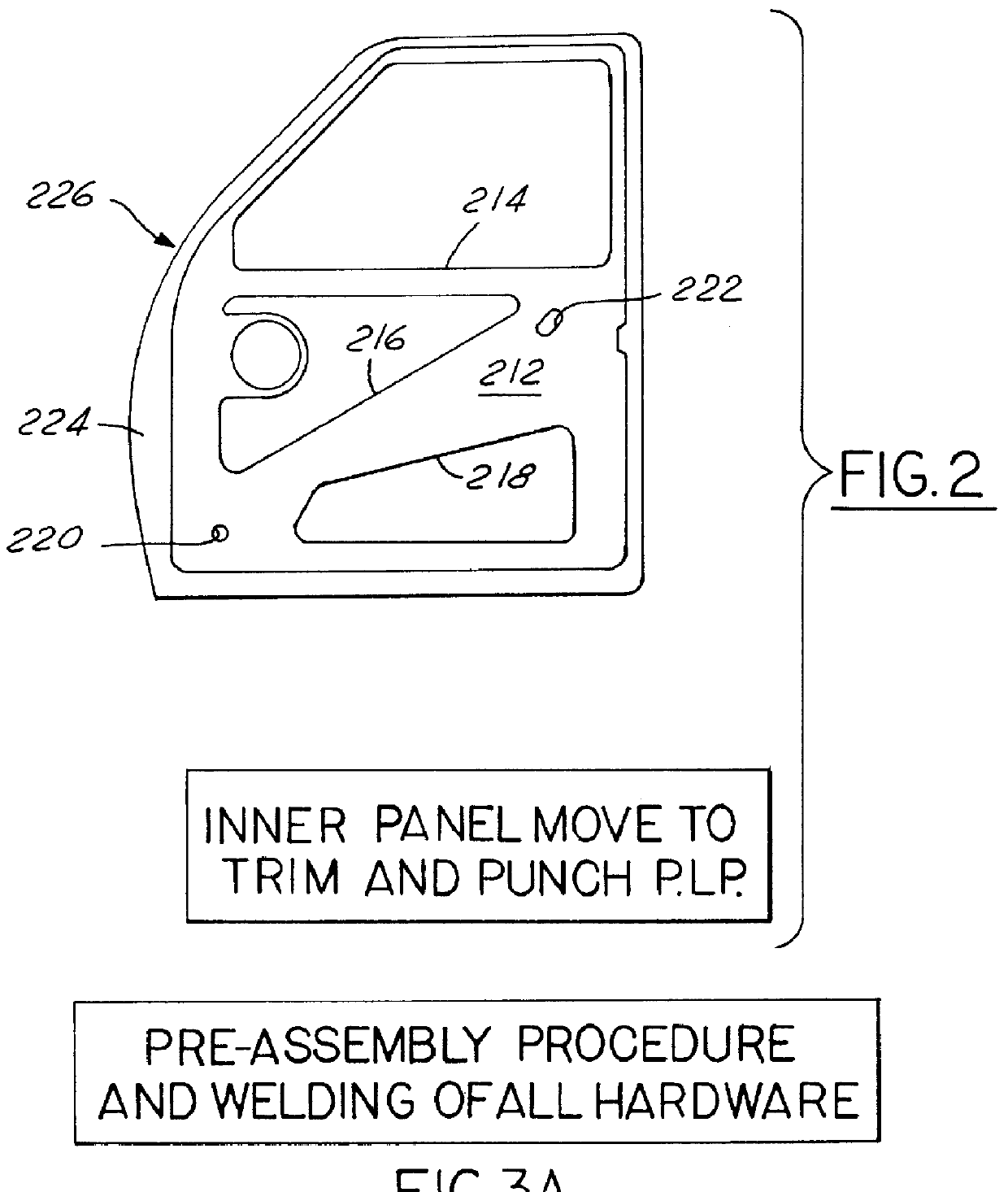

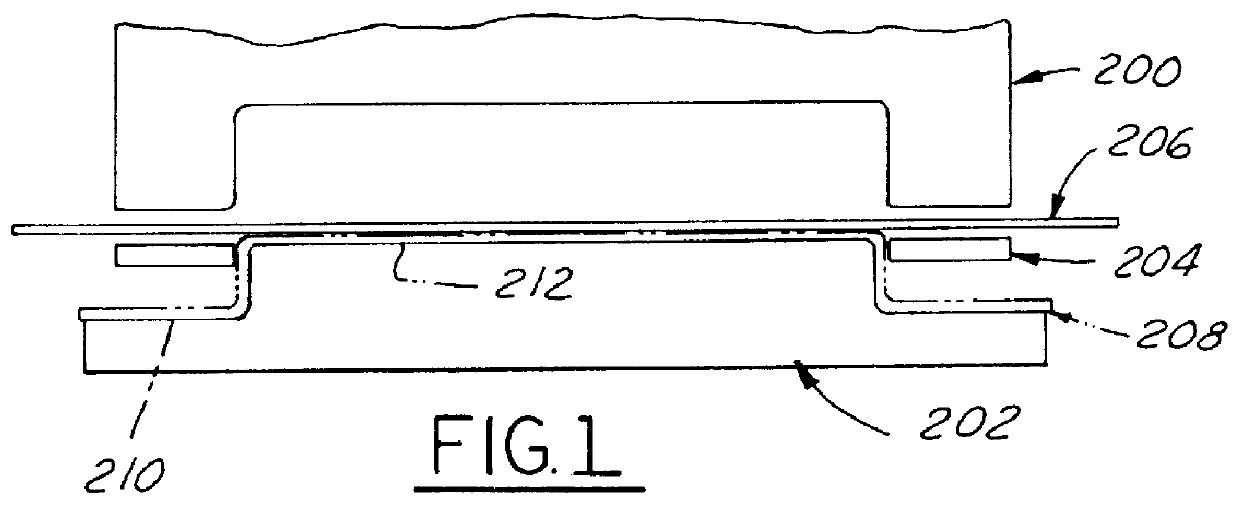

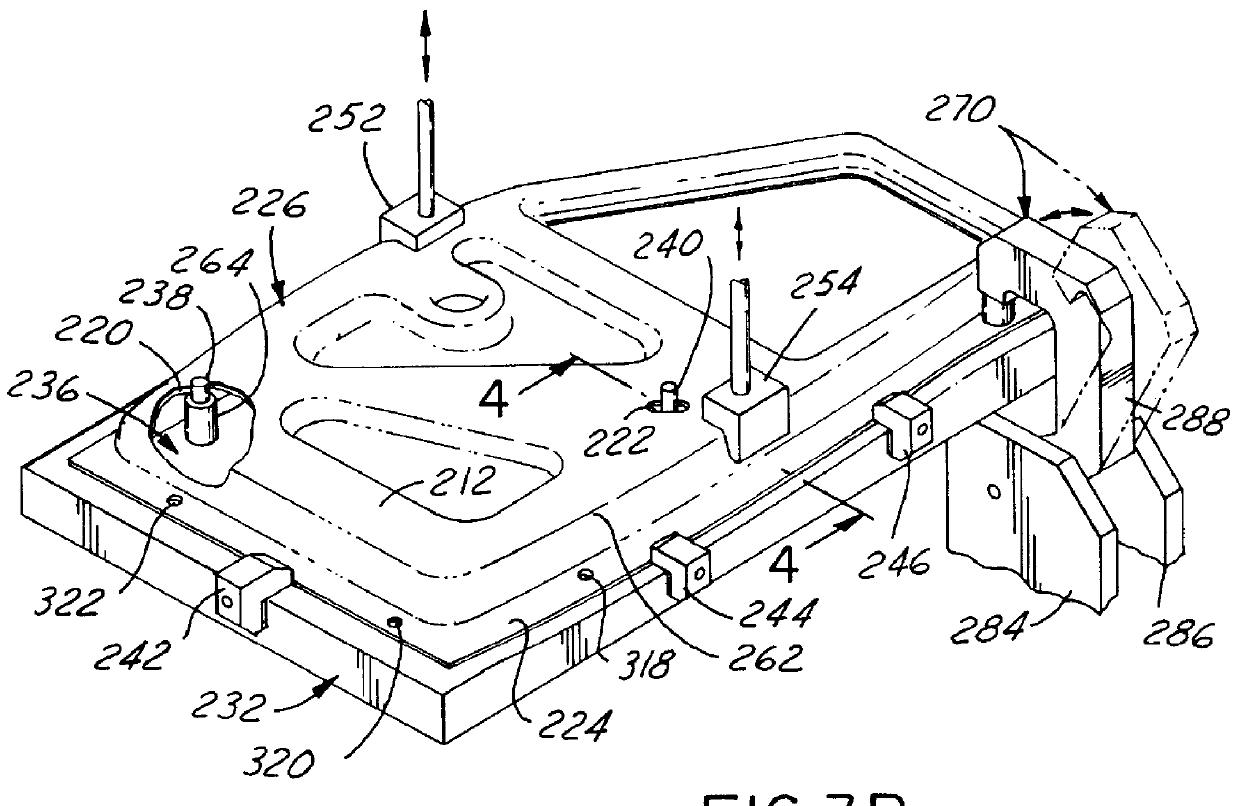

Hemming method and apparatus

InactiveUS6029334AImprove appearance qualityEliminate the problemForging hammersAssembly machinesEmbedmentRead through

Improved method and apparatus for interlocking hemmed together edges of inner and outer vehicle body panels with an improved interlock joint. The inner panel blank is draw stamped and provided with PLP holes in a stamping press. A plurality of conventional hardware components are then welded to the inner panel. Then interlock holes are formed by a piercing tool moving through the inner panel border from its outboard to its inboard side while the inner panel is held by clamps and PLP pins. The hole piercing punch thus leaves cold worked upset material slightly raised inboard, rather than outboard, around the pierced interlock hole margin. Then the inner panel subassembly is married to the outer panel and transferred to a hemming station and again precisely clamped and positioned by PLP pins, whereupon hemming press gates are operable for hemming the flange lip of the outer panel over the inner panel border. The final hemming steel of each gate carries staking punches that individually strike a precision registered portion of such hemmed lip to deform it into locking engagement with the associated interlock hole. The upset material is thus flattened and accurately worked into embedment into the interior surface of the hemmed flange lip, rather than into the interior surface of the outer panel, thereby avoiding creating read through problems on the outer panel.

Owner:UNOVA IP

Biocompatible bonding method and electronics package suitable for implantation

ActiveUS7142909B2Semiconductor/solid-state device detailsSolid-state devicesFlexible circuitsEngineering

The invention is directed to a method of bonding a hermetically sealed electronics package to an electrode or a flexible circuit and the resulting electronics package, that is suitable for implantation in living tissue, such as for a retinal or cortical electrode array to enable restoration of sight to certain non-sighted individuals. The hermetically sealed electronics package is directly bonded to the flex circuit or electrode by electroplating a biocompatible material, such as platinum or gold, effectively forming a plated rivet-shaped connection, which bonds the flex circuit to the electronics package. The resulting electronic device is biocompatible and is suitable for long-term implantation in living tissue.

Owner:CORTIGENT INC +1

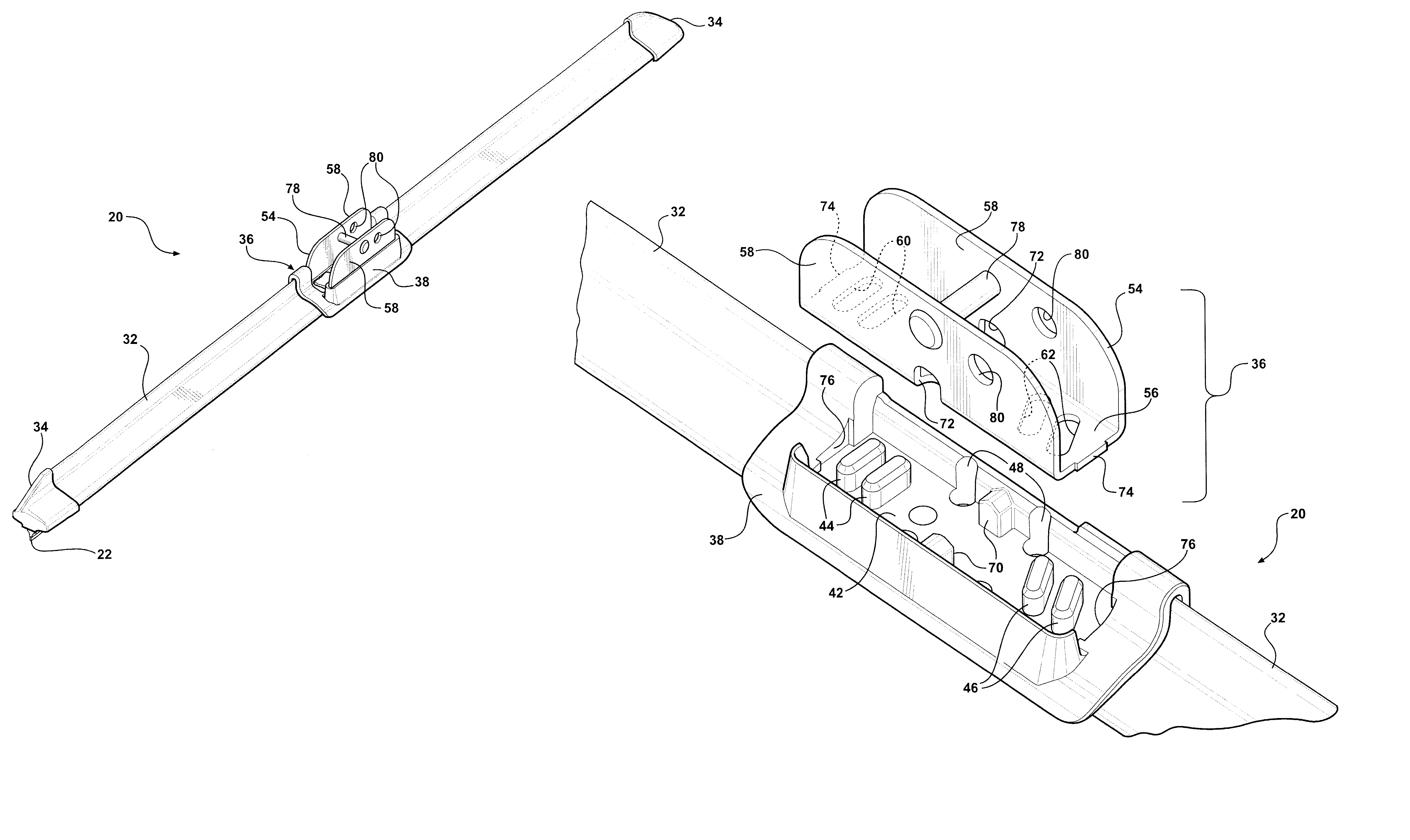

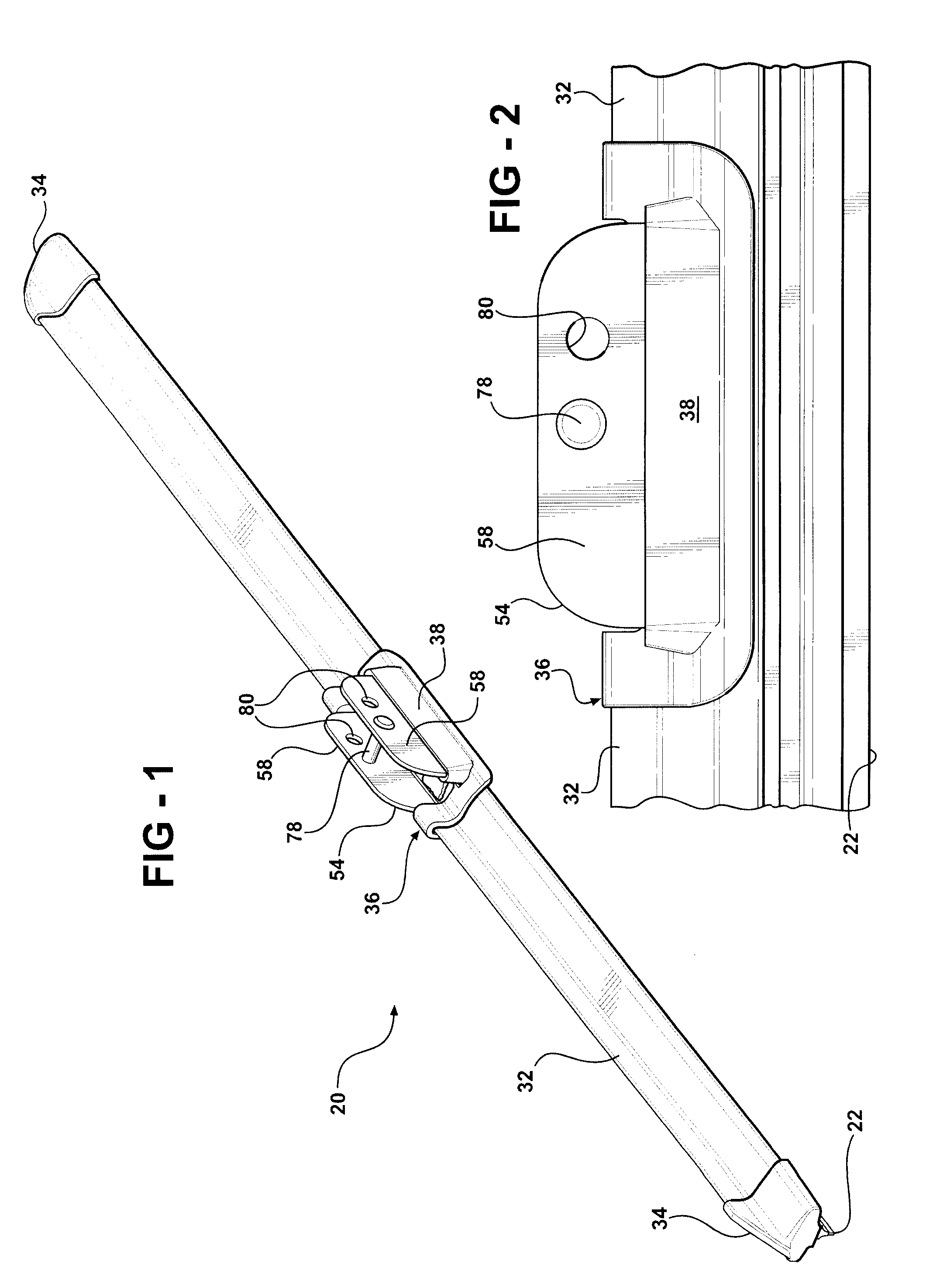

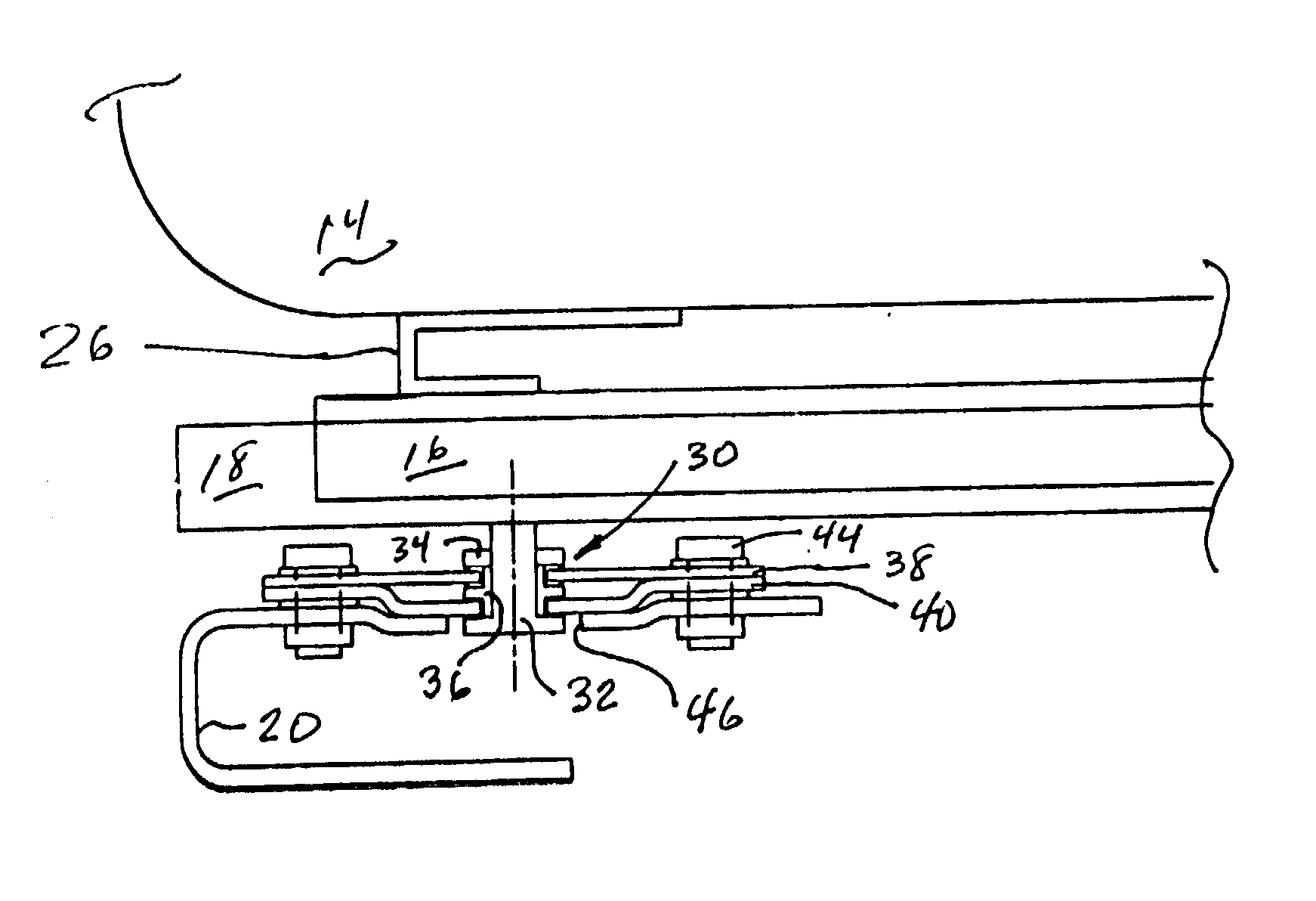

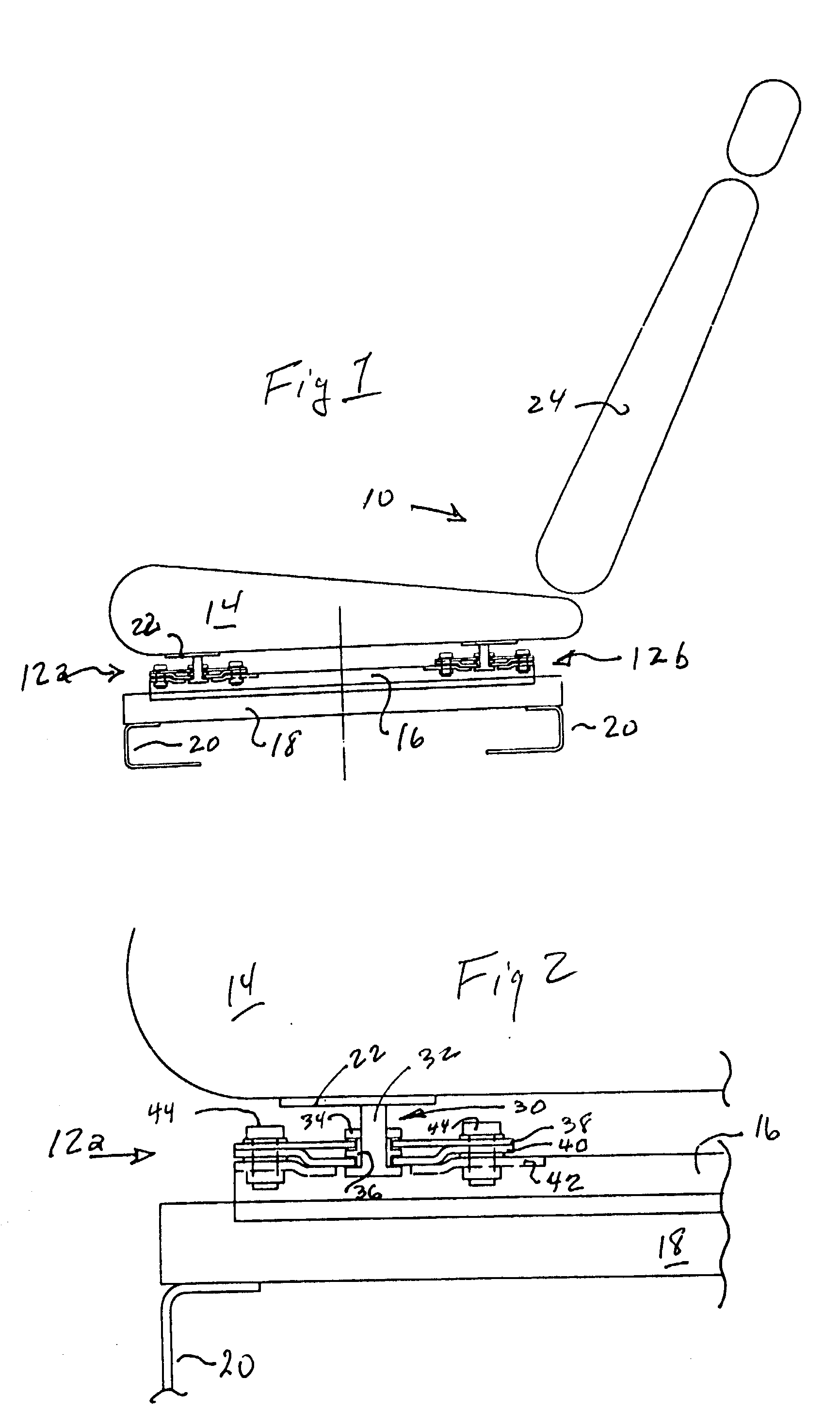

Two-piece connector for flat blade windshield wiper

ActiveUS7523522B2Easy to manufactureEasy to assembleWindow cleanersVehicle cleaningUltrasonic weldingHot melt

A central connecting device (36) for a flat blade style wiper blade assembly (20) includes a plastic intermediate base (38) that is fixed, such as by ultrasonic welding, to a pair of flexors (26) extending the length of the wiper blade assembly (20). The intermediate base (38) includes a recessed deck section (42) for receiving a metallic housing (54). The housing (54) is heat-staked in position to the intermediate base (38) to secure the two elements together as an integral unit. A rivet (78) extends transversely across the sidewalls (58) of the housing (54) for adjoining to a universal connector (82) or other suitable adaptor or by direction connection to the end of a wiper arm.

Owner:TRICO PROD CORP

Method for joining dissimilar metals of steel product and light metal product with each other

InactiveUS20090294410A1Overcome limitationsImprove joint strengthShrinkage connectionsSheet joiningSpot weldingUltimate tensile strength

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron—iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

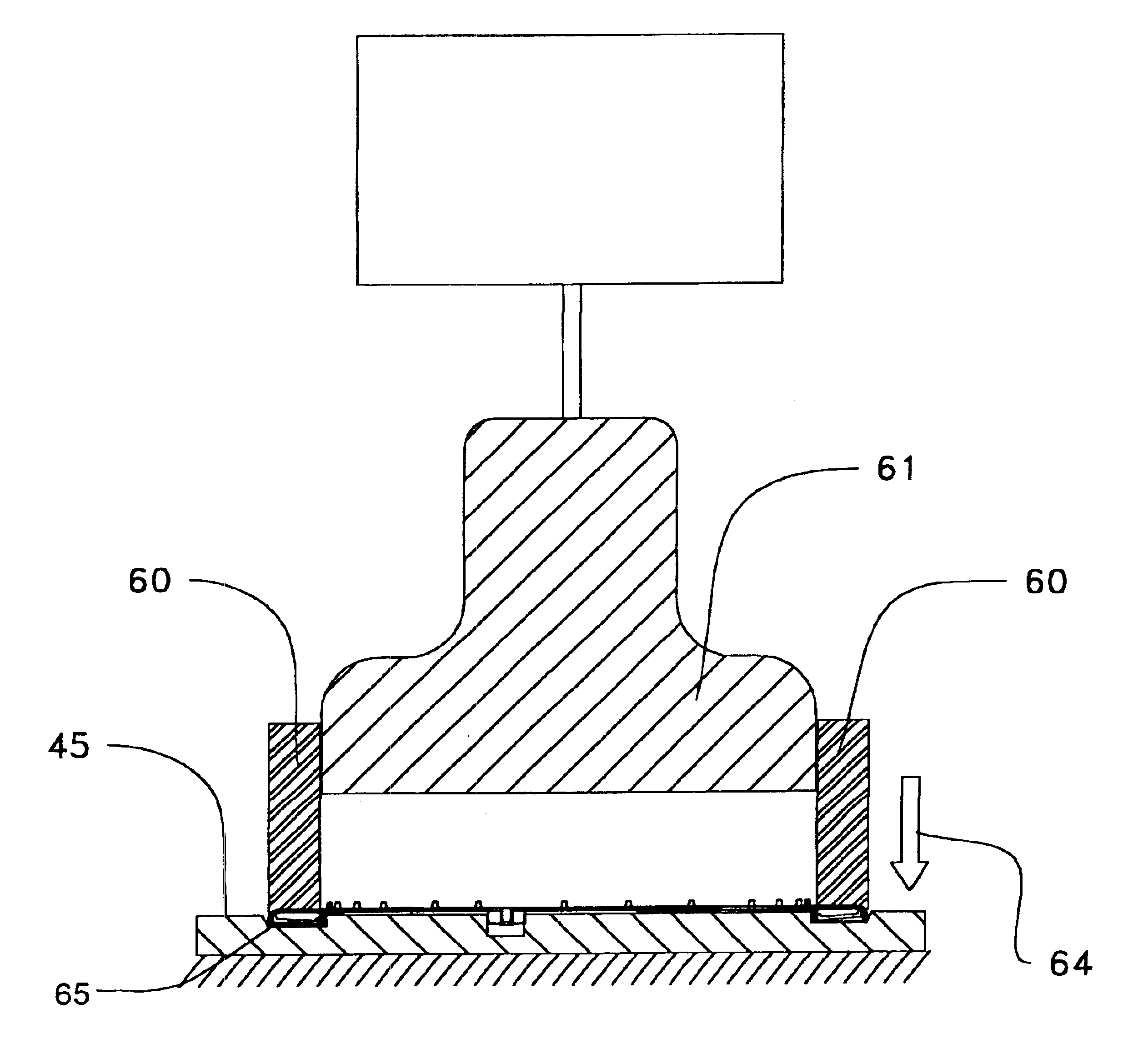

Weight sensors having centralized loose tolerance universal force and Mx/My moments overload stops

InactiveUS20030106723A1Increase angular travel permittedConvenient travelWeighing apparatus using elastically-deformable membersElectric devicesModularityAngular rotation

Automotive load cells having centralized, multi-axis, loose tolerance overload / limit stops provide improved strain gauge response. The modular, integrated stop assemblies magnify sensor substrate deflection by use of opposed concave (Belleville) springs are used in direct contact with the substrate to accommodate ±Z axis deflection and Mx / My moment angular rotation. A flanged guide member on the load stud permits a wide range of geometries. The substrate is thickened around the load stud hole and the outboard support bolt holes. Hollow rivets assist in design modularity. Strain gauges are placed at the yield zones symmetrically with respect to the X axis. The substrate hole Mx / My gap is larger than the stop bracket hole to insure a positive stop for Mx / My moments prior to yield. The inventive multi-axis stop assembly is used in any type load cell, including rectangular, thinned, notched, necked / dogbone, or cantilever substrates with any strain gauge layout configuration.

Owner:ROBERT BOSCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com