Patents

Literature

364results about How to "Avoid heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

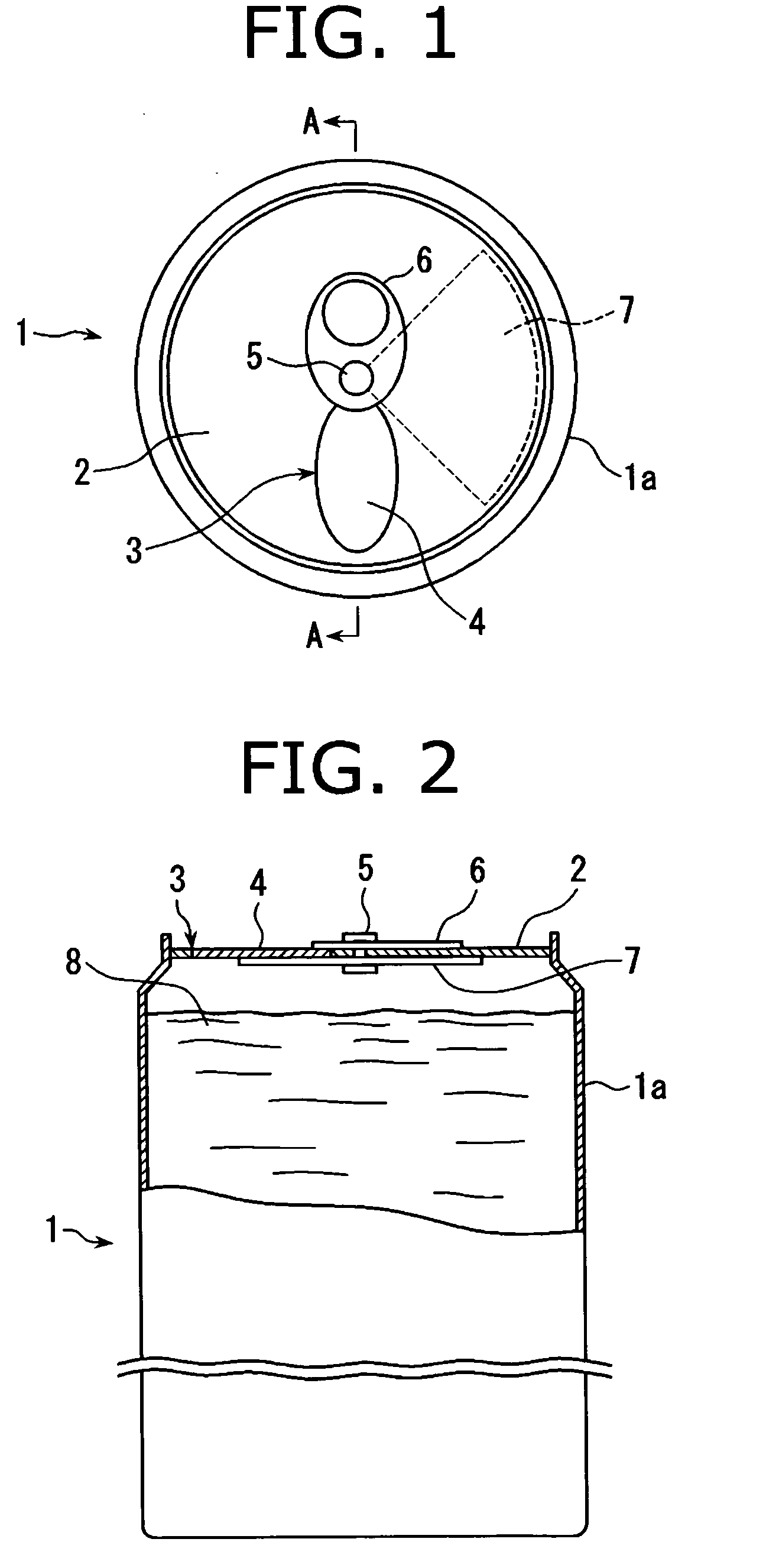

Can

InactiveUS7198168B2Heat exchangerAvoid heat exchangeLiquid flow controllersRefuse receptaclesEngineeringRivet

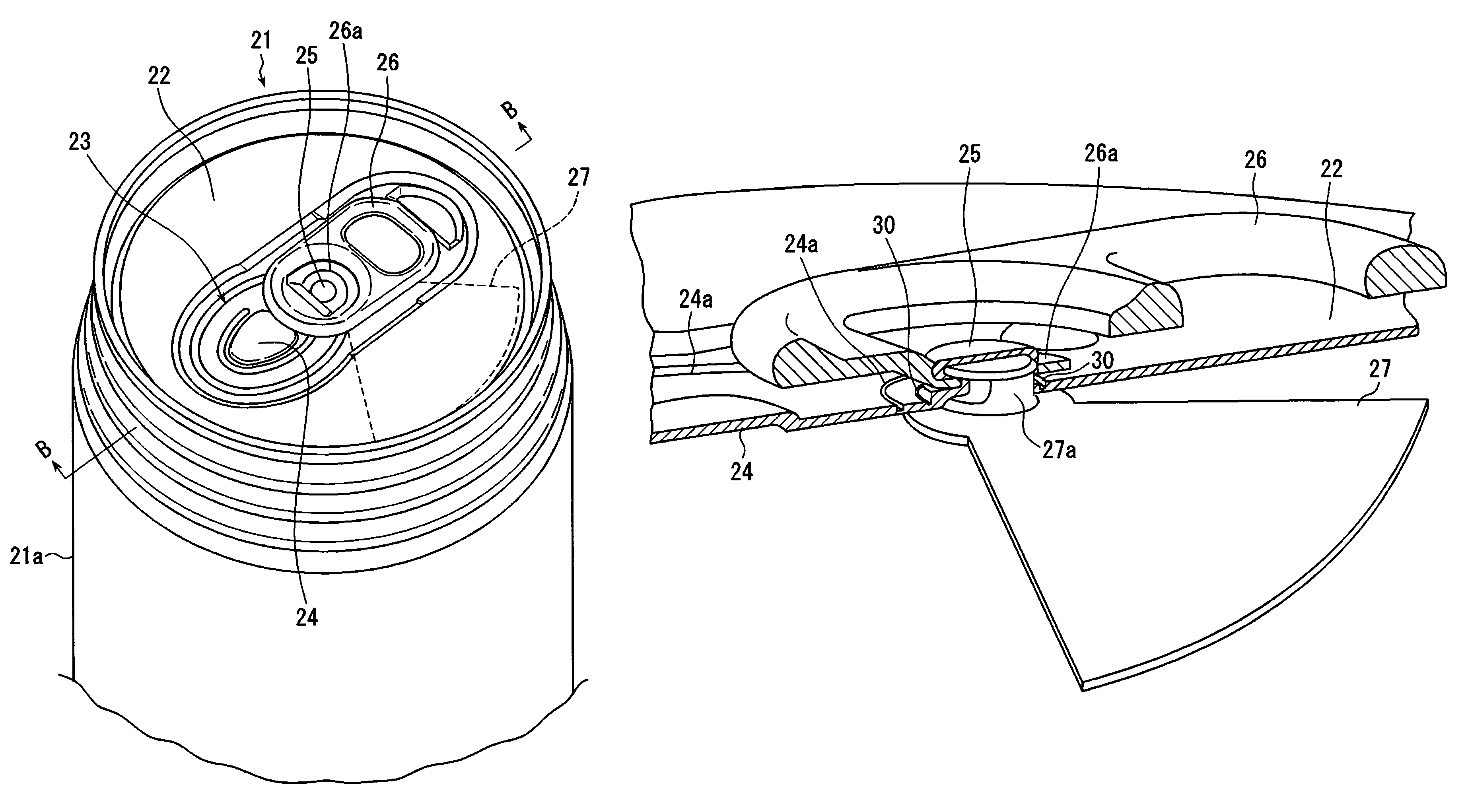

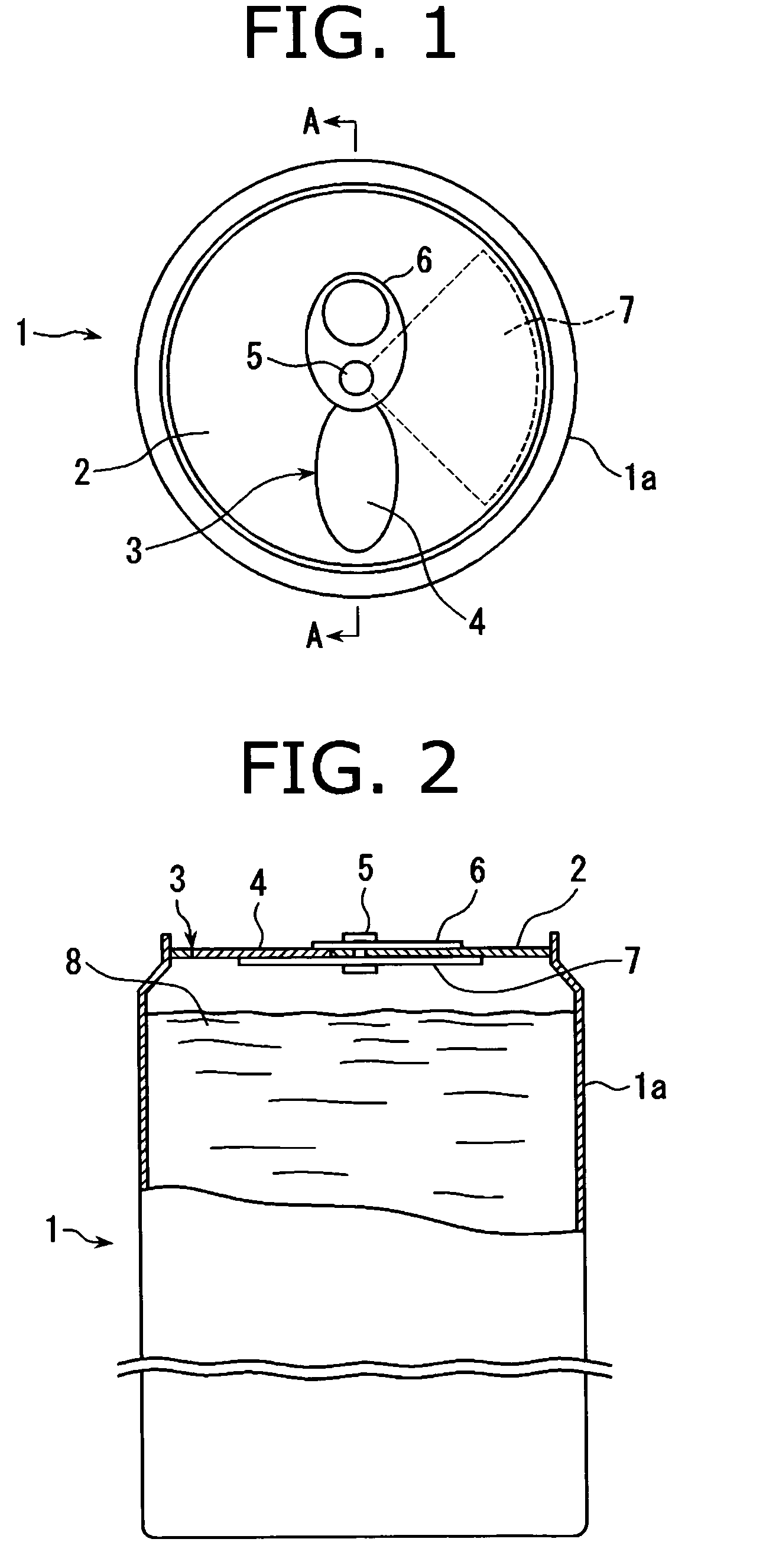

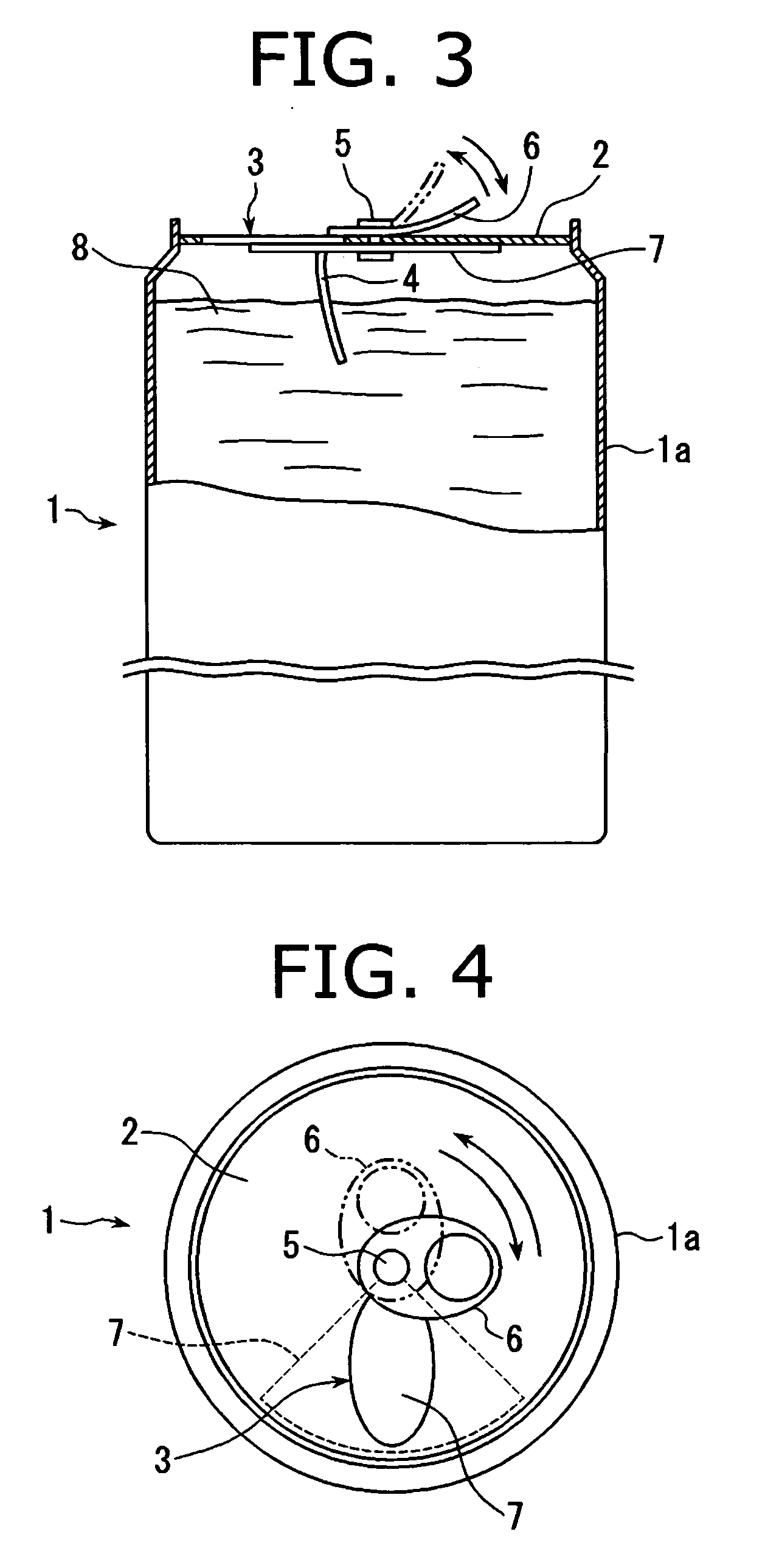

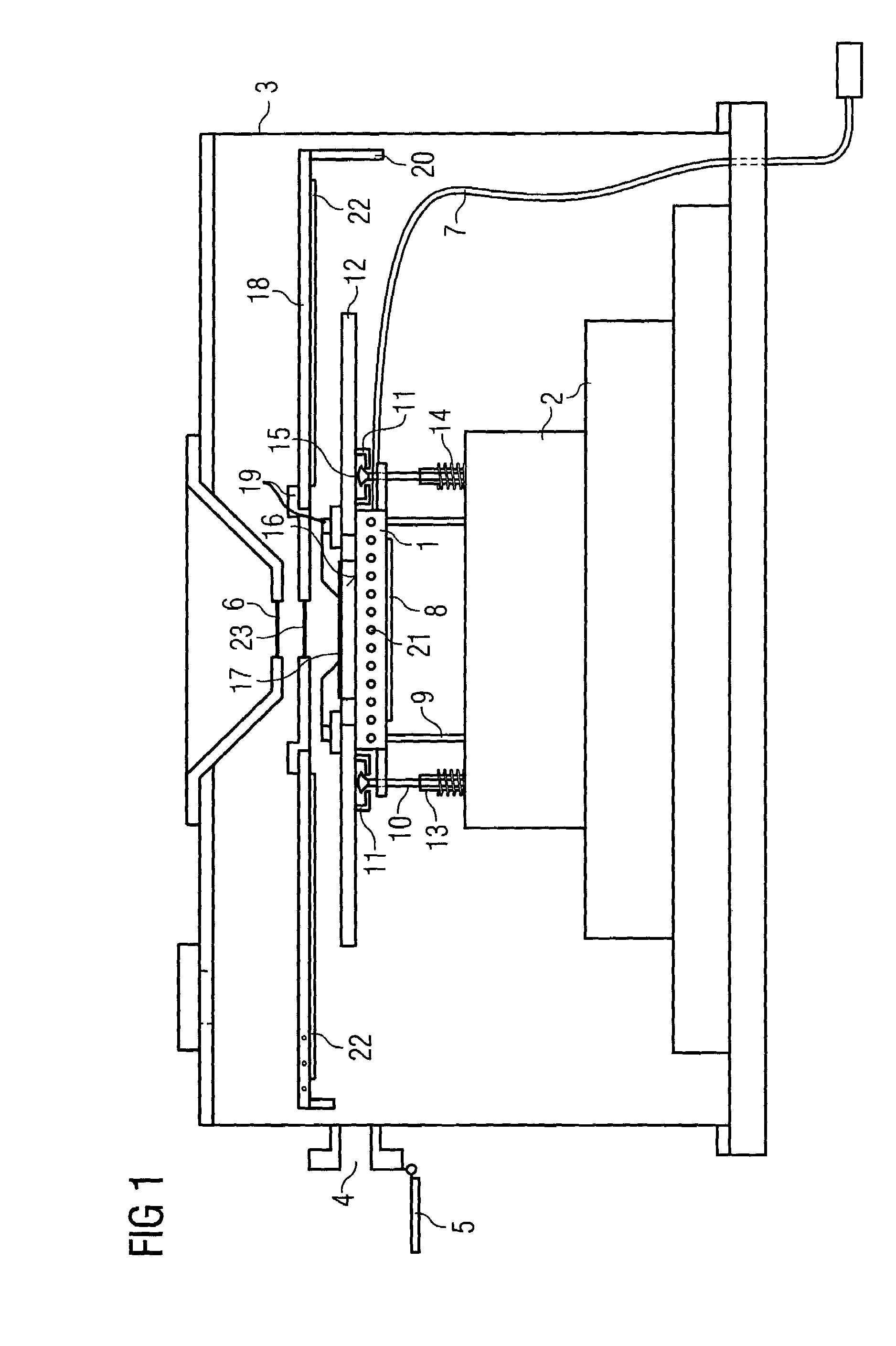

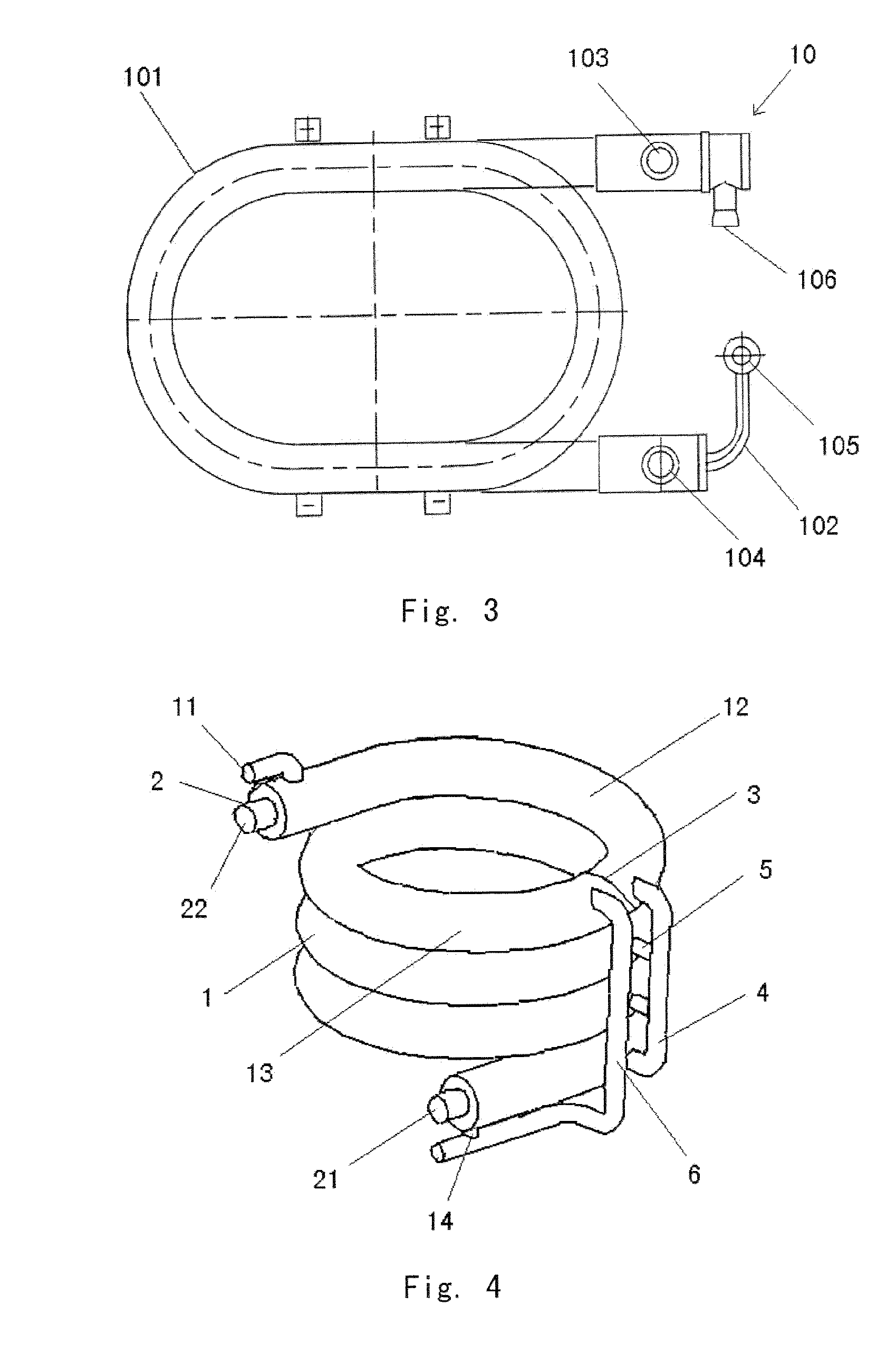

A can (1) having a spout that can, after opening, be securely resealed and can be opened and closed with an easy operation. The can (1) has a spout (3) that is opened by lifting and pulling a pull-ring (6) fixed on a top wall (2) of a can body (1a) with a rivet (5) to bend a sealing tongue portion (4) toward the inside of the can. Inside the top wall (2) and away from the spout (3), an internal sealing member (7) having a fan shape with its pivot mounted to the rivet and a size capable of sealing the spout (3) is disposed so as to be fixed to the rivet (5). After opening the spout (3), by rotating the pull-ring (6) around the rivet (5), the internal sealing member (7) is also rotated at the same time. As an interlocking mechanism therefor, the rivet (5) is rotatably supported by the top wall (2), and a base end of the pull-ring (6) and the pivot of the internal sealing member (7) are fixed to the rivet (5), respectively.

Owner:MIZUMA JYUNZI +5

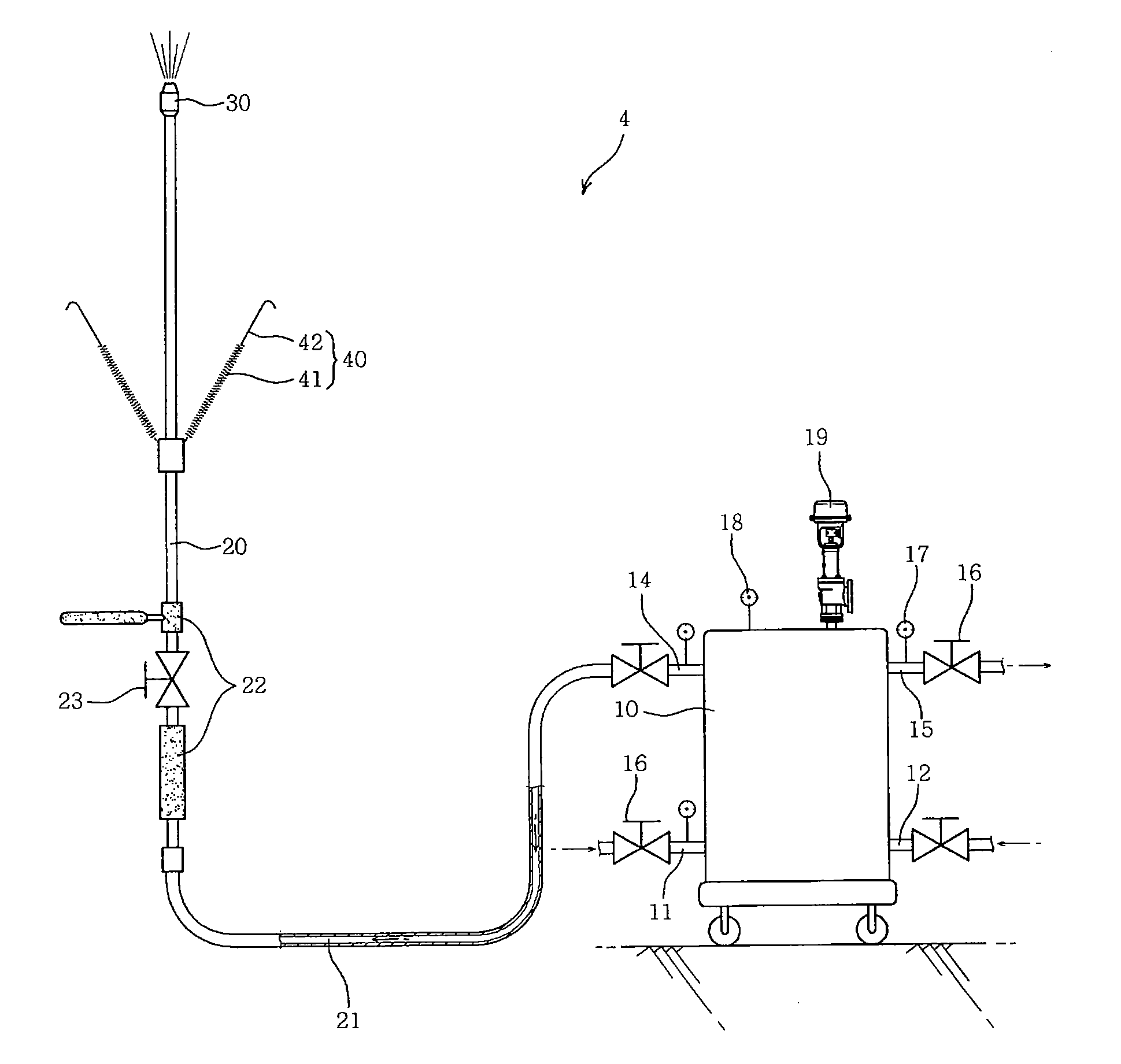

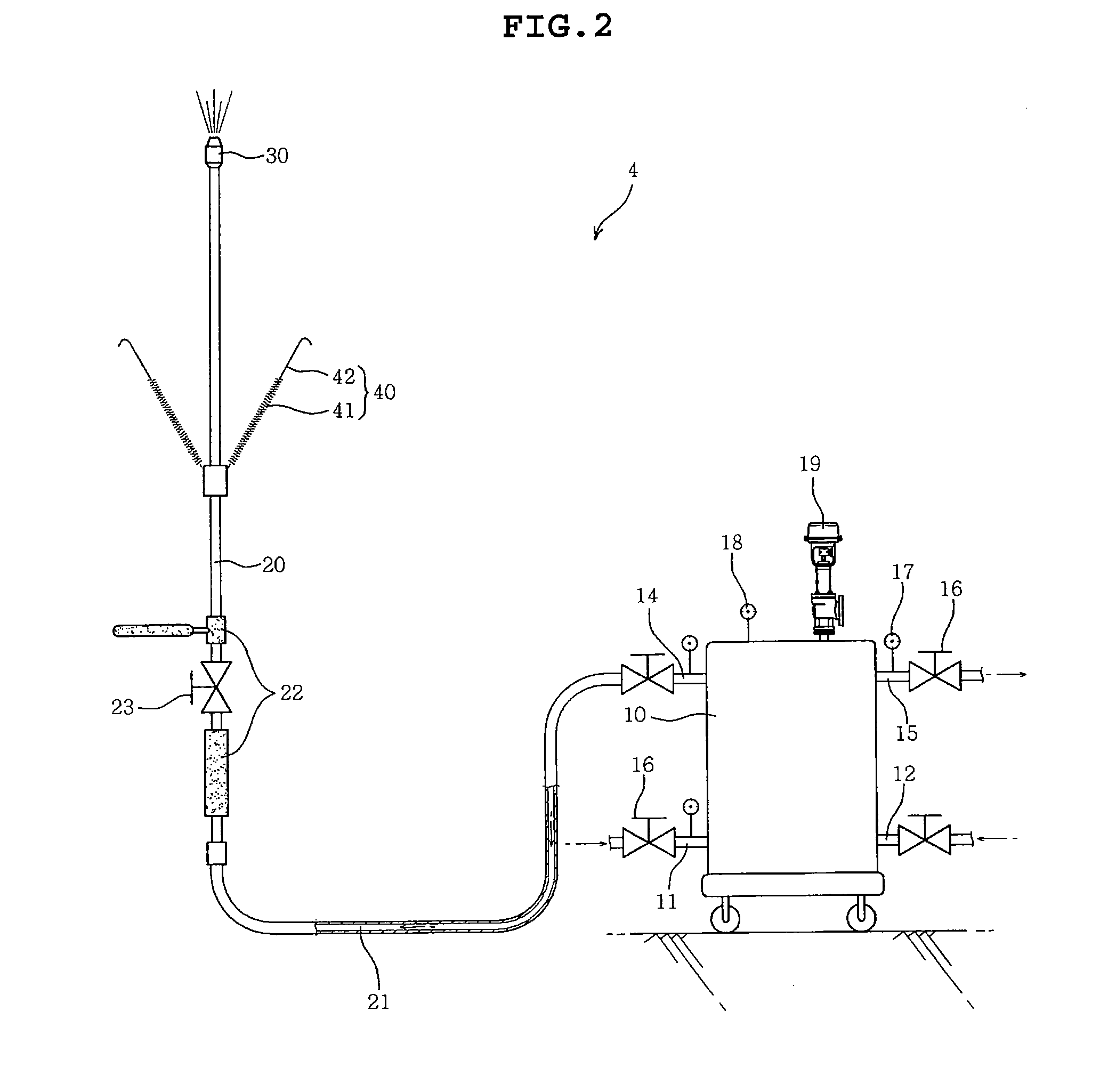

Hydrogen gas generation system

InactiveUS7105033B2ReducingAvoid heat exchangePhotography auxillary processesElectrolysis componentsChemistryAqueous solution

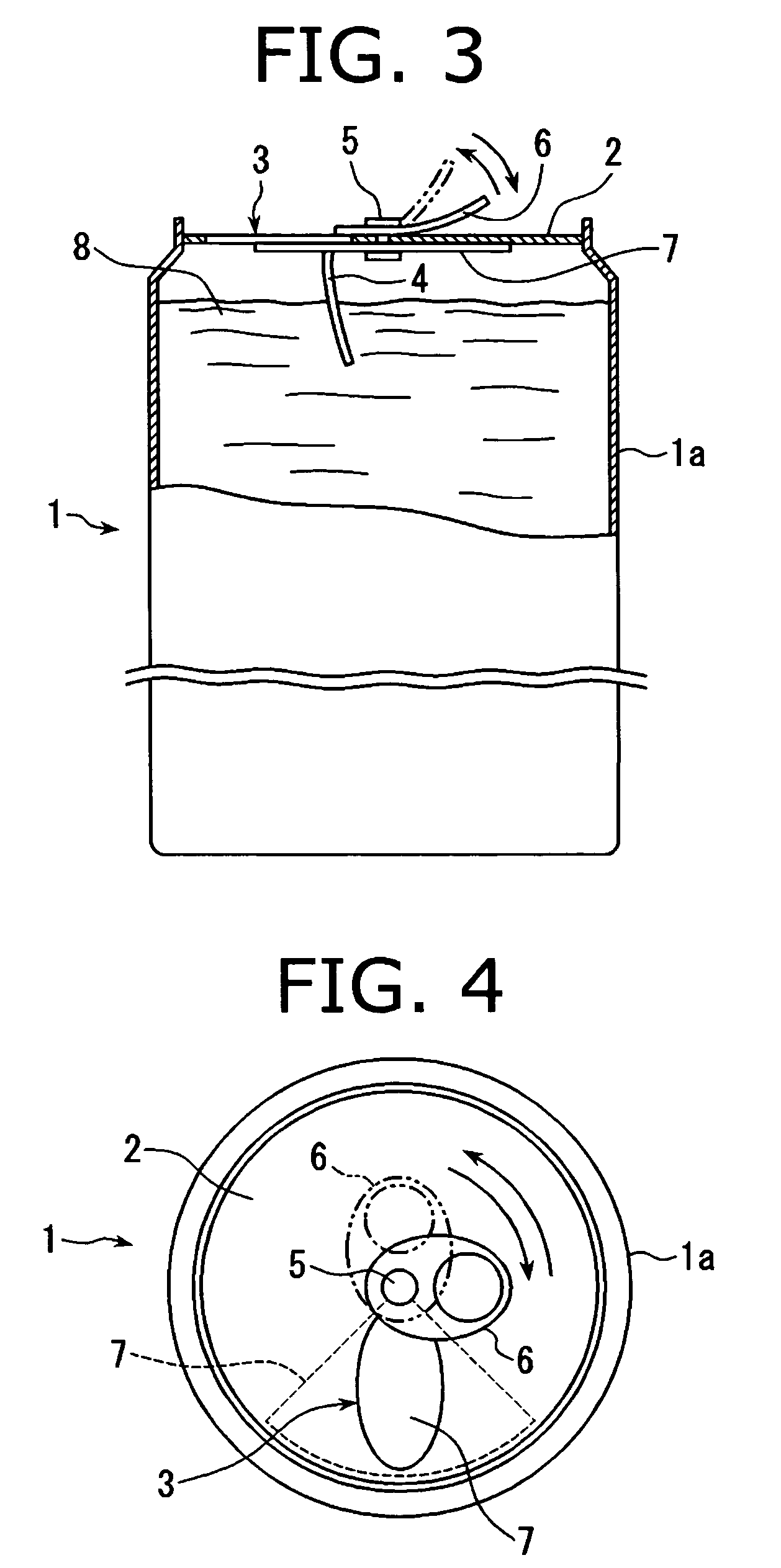

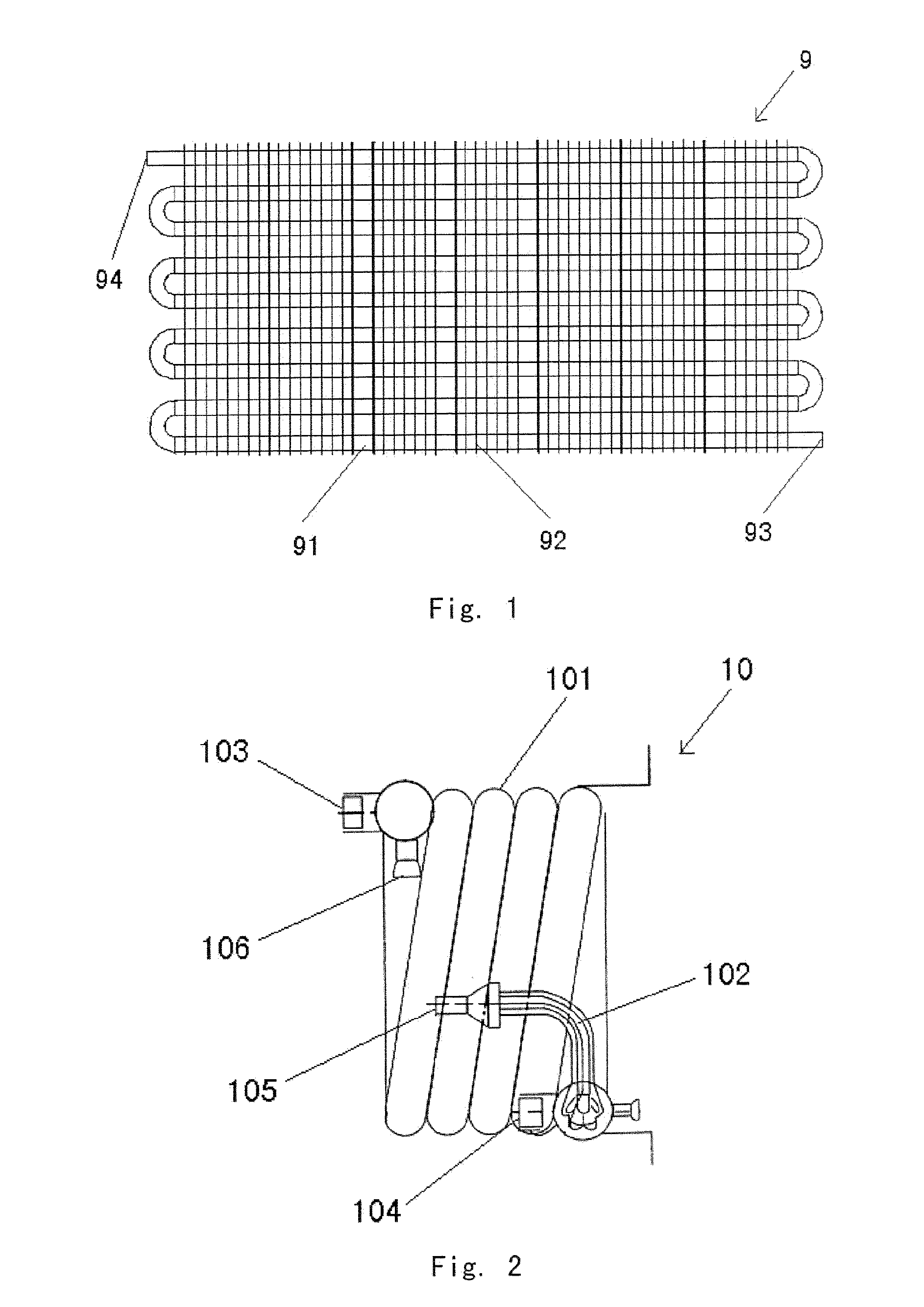

A system for generating hydrogen gas utilizes a volume exchange housing for the storage of a fuel material that reacts to generate hydrogen gas and a hydrogen separation chamber. The system includes a gas permeable membrane or membranes that allow hydrogen gas to pass through the membrane while preventing aqueous solutions from passing therethrough. The system is orientation independent. A throttle valve is also used to self regulate the reaction generating the hydrogen gas.

Owner:SILICON VALLEY BANK

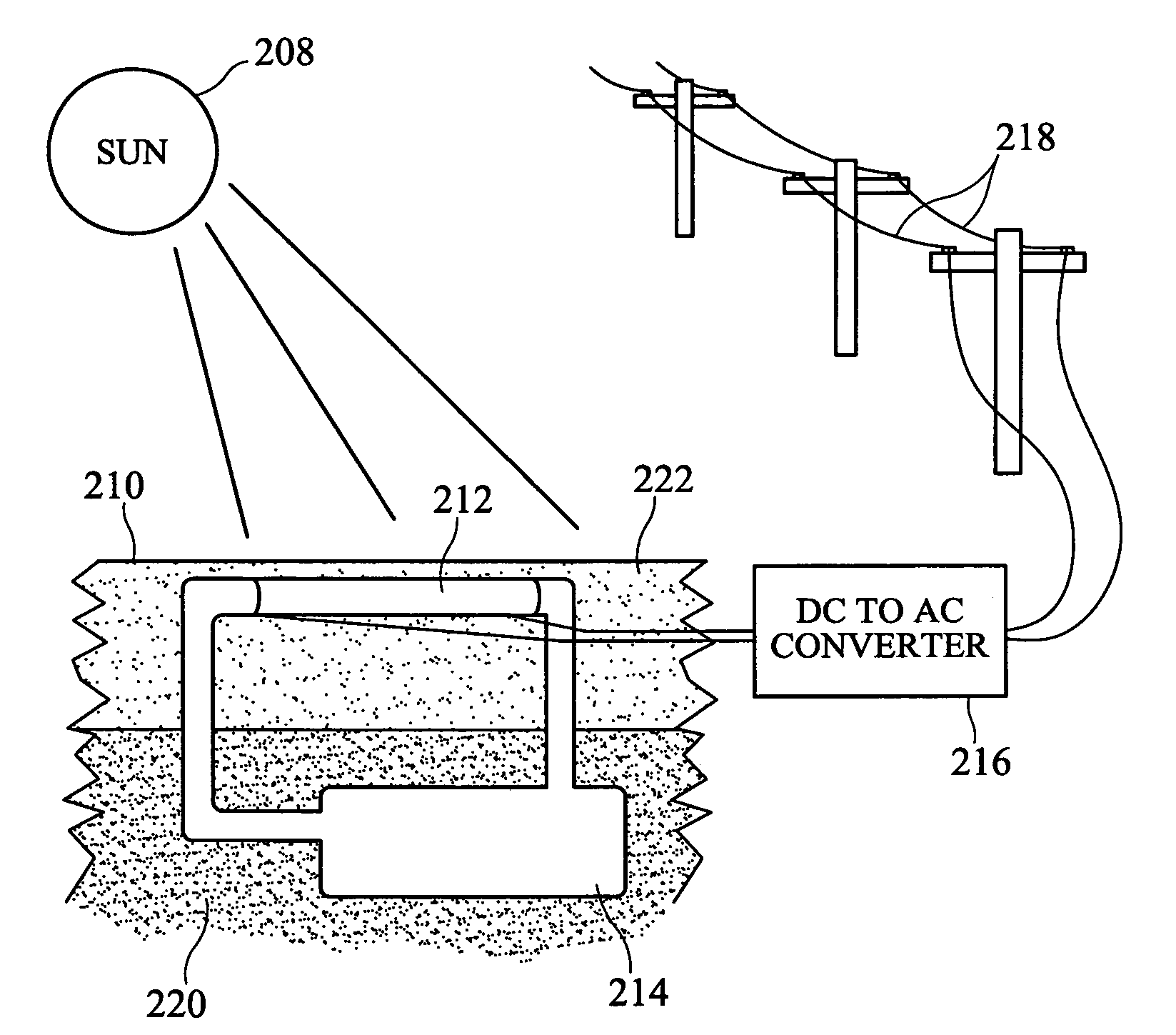

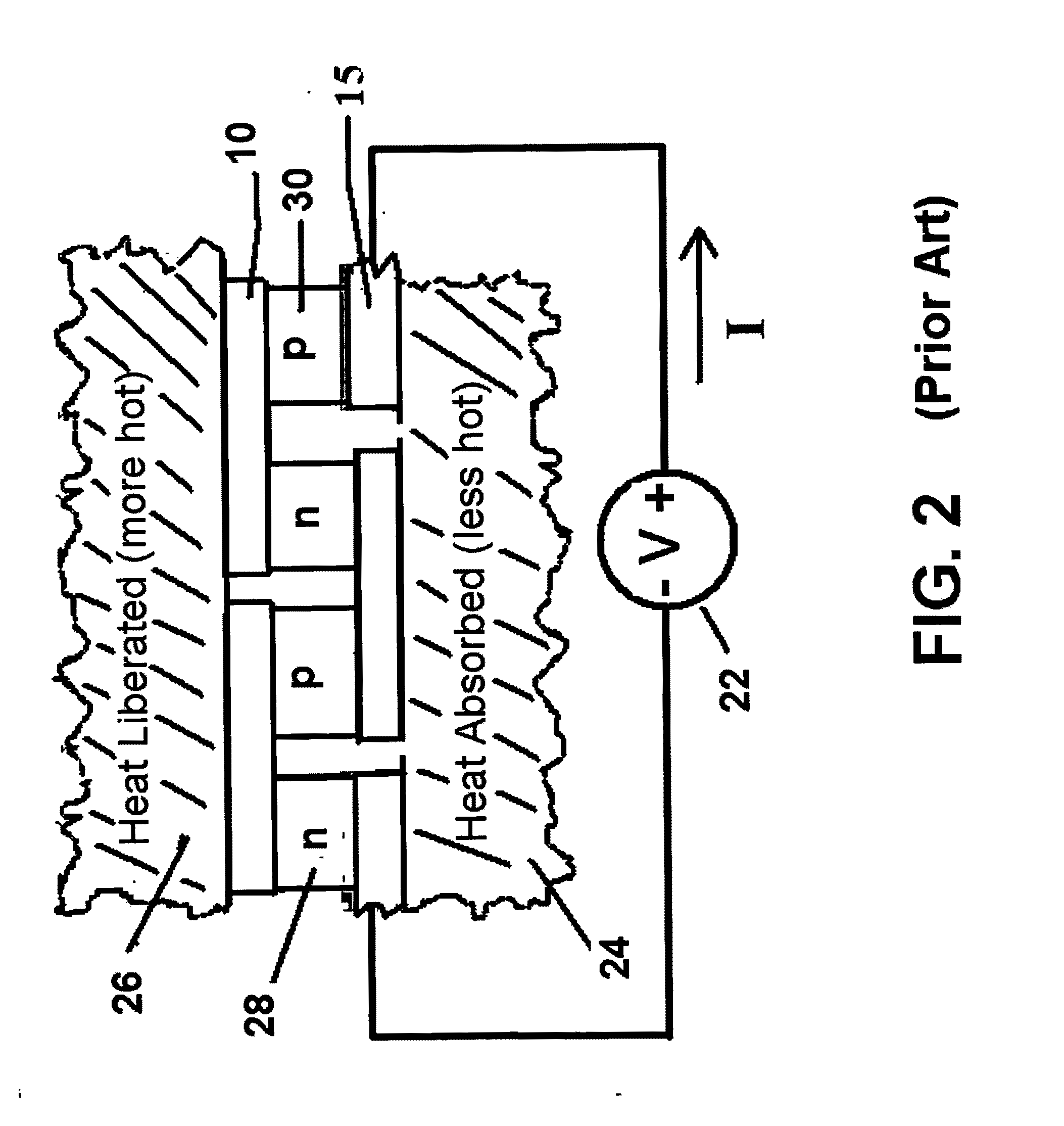

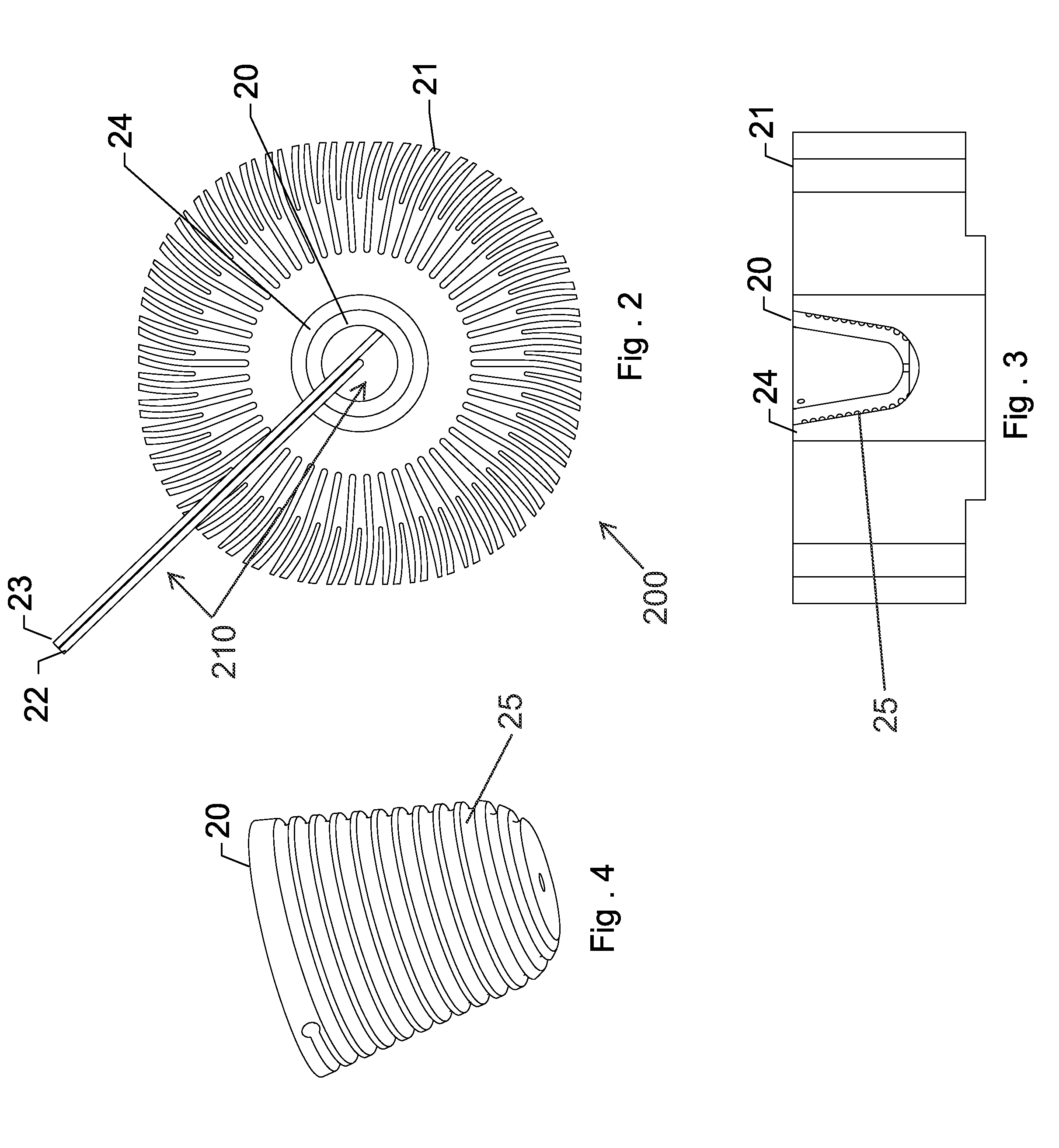

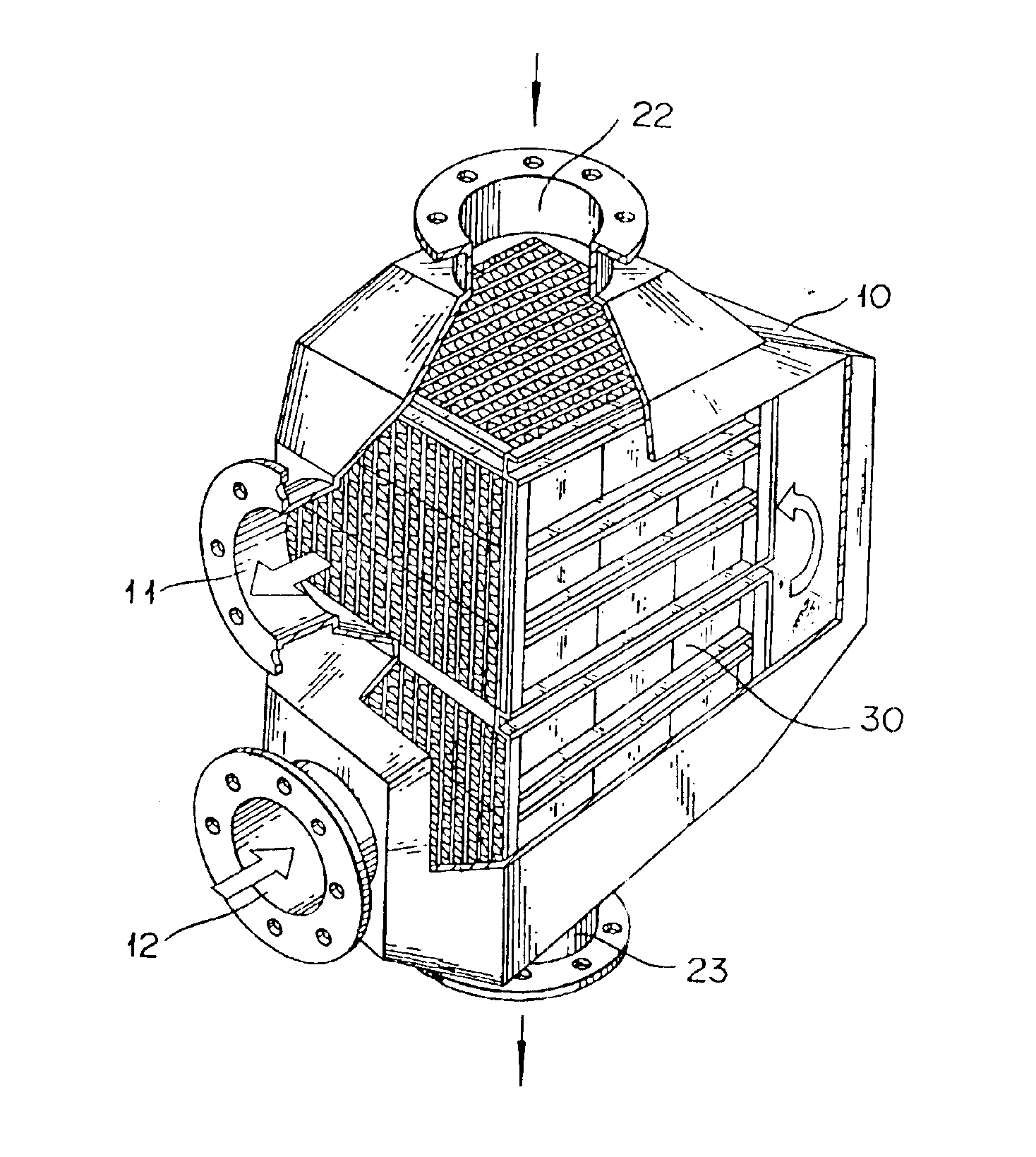

Thin walled thermoelectric devices and methods for production thereof

InactiveUS20100154855A1Increased power levelIncrease power levelThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThin walledEngineering

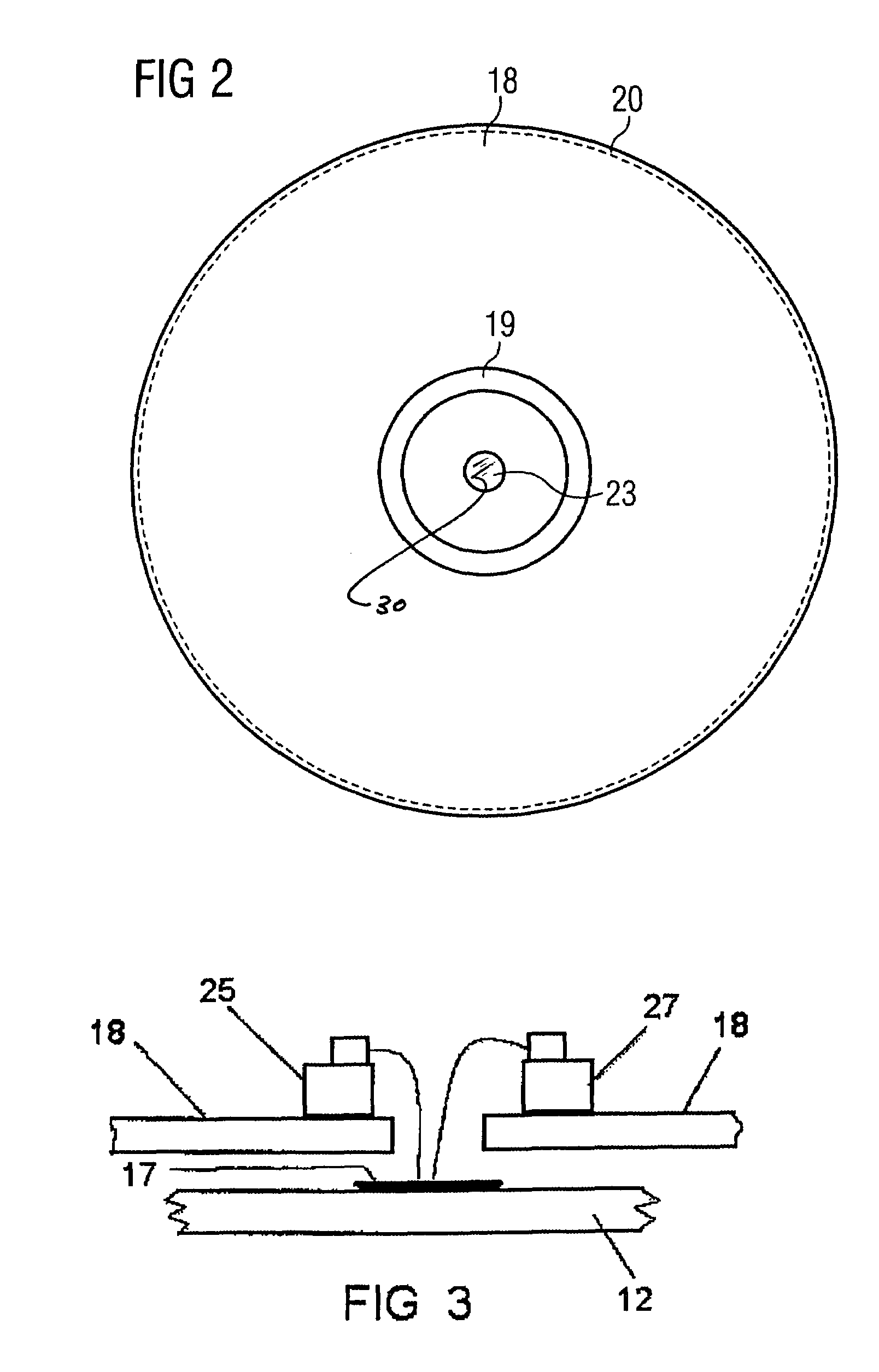

A thermoelectric generator is built into the wall of a heat exchanger by applying coatings of dielectric, electrical conductor and N-type and P-type thermoelectric materials. A tubular heat exchanger lends itself to the application of coatings in annular rings, providing ease of manufacture and a structure that is robust to damage.

Owner:NEMIR DAVID +2

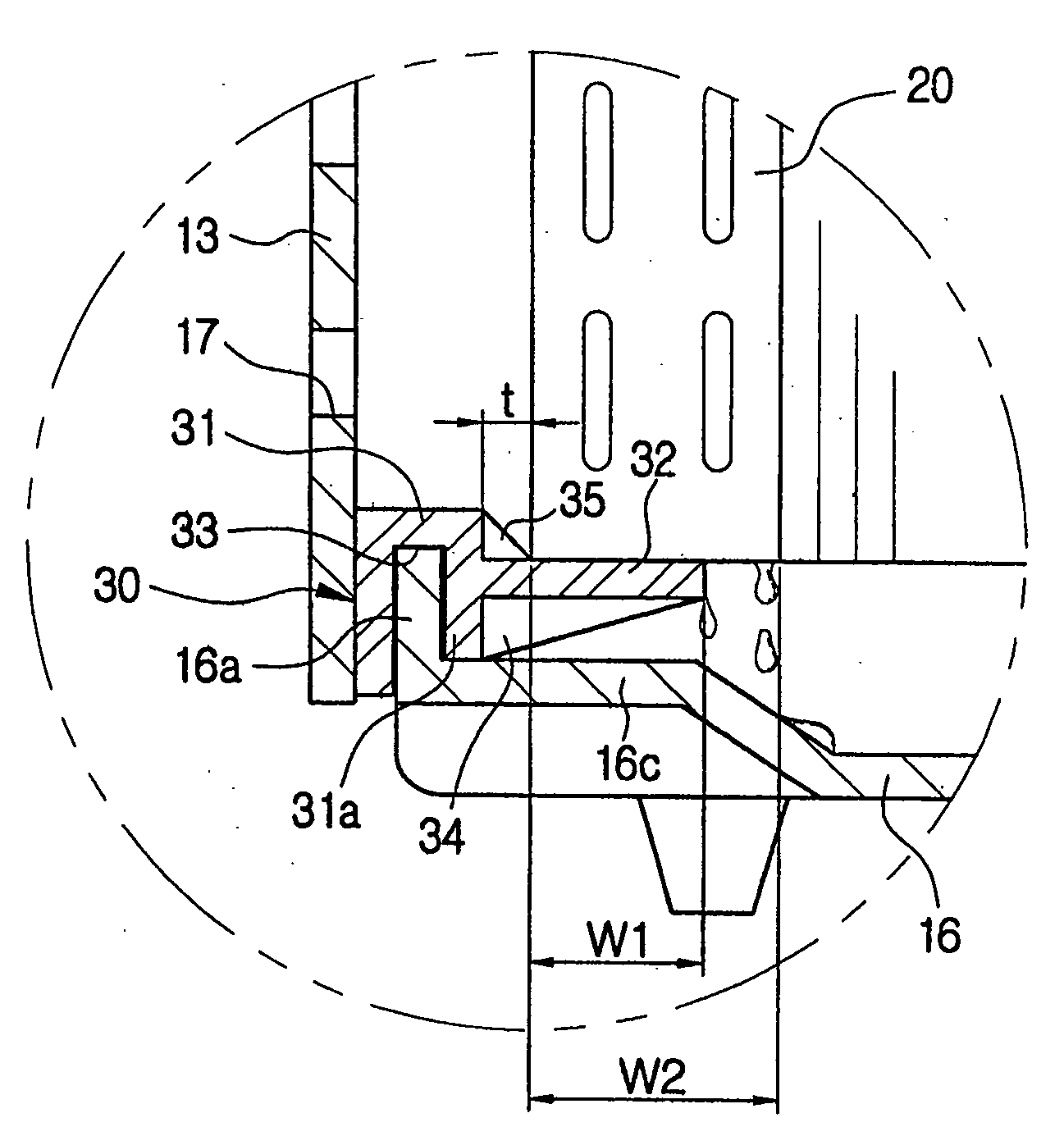

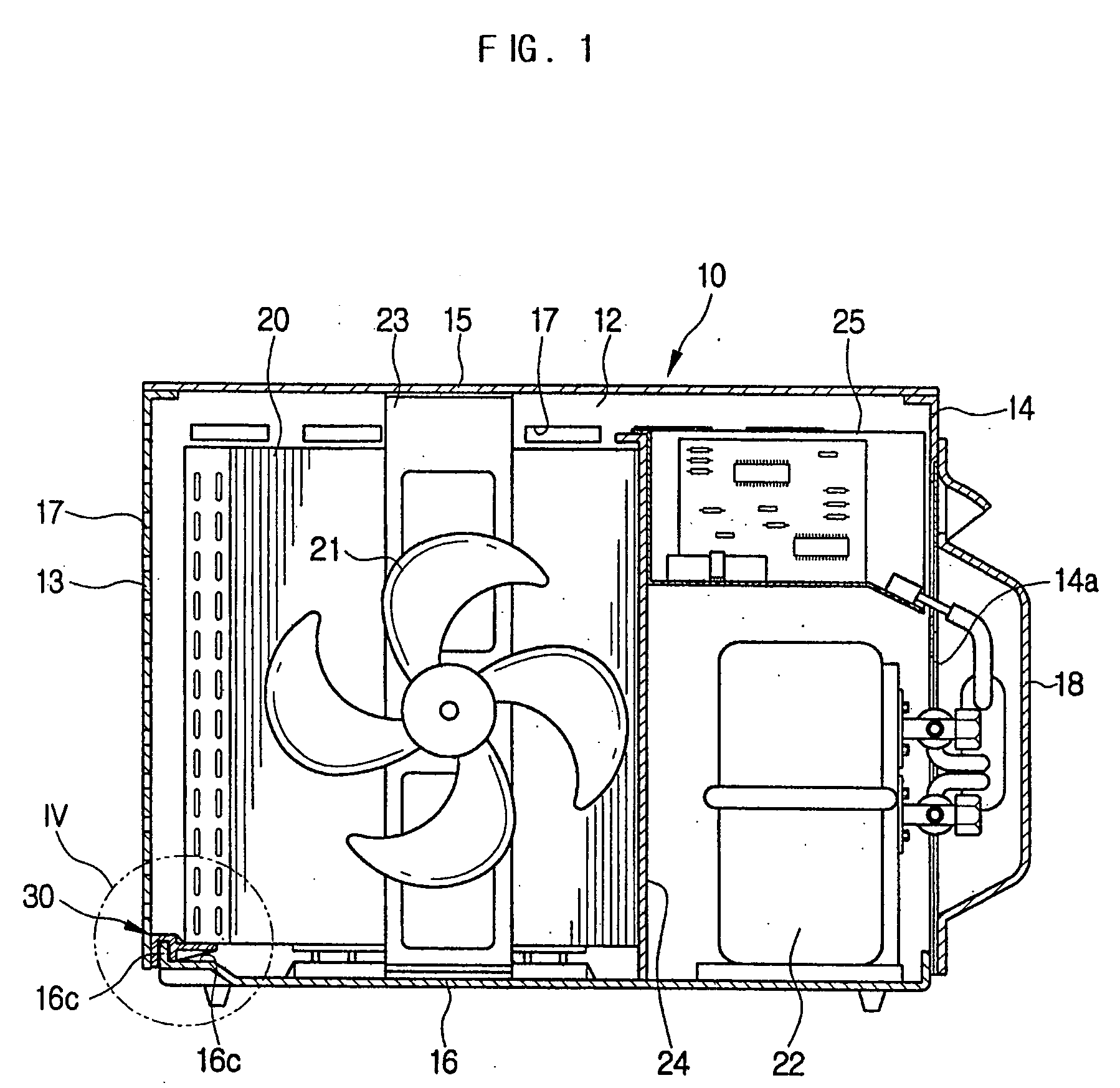

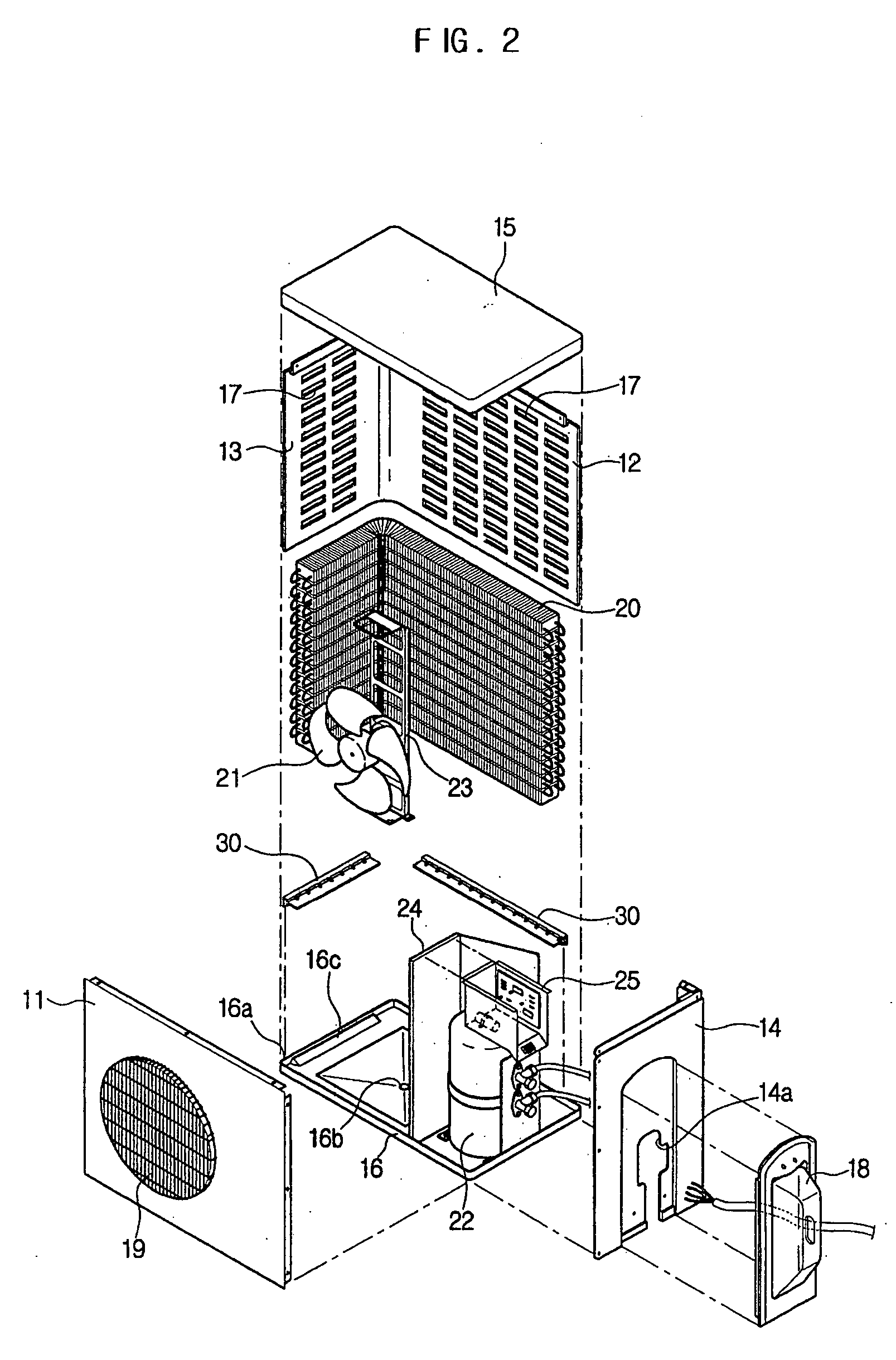

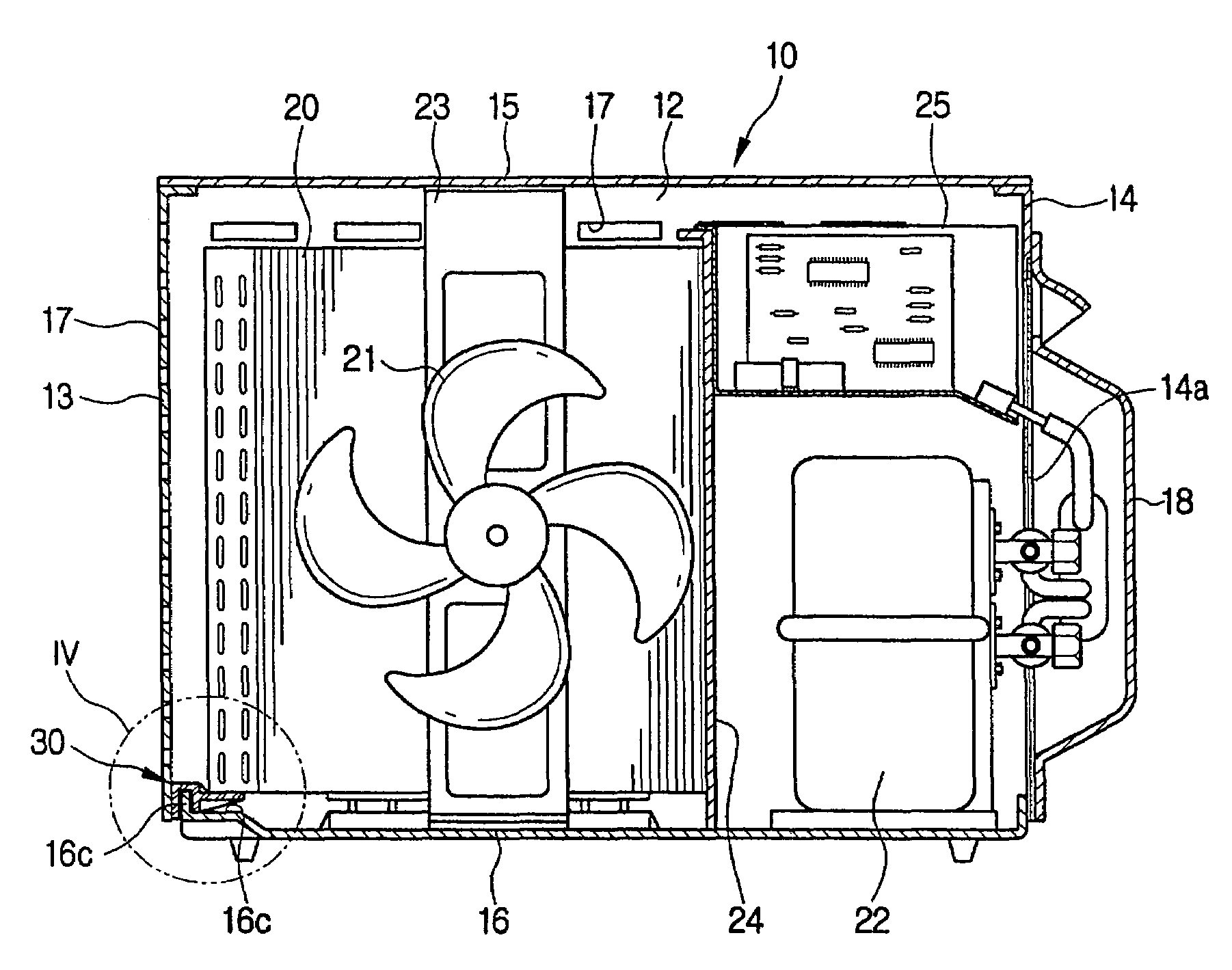

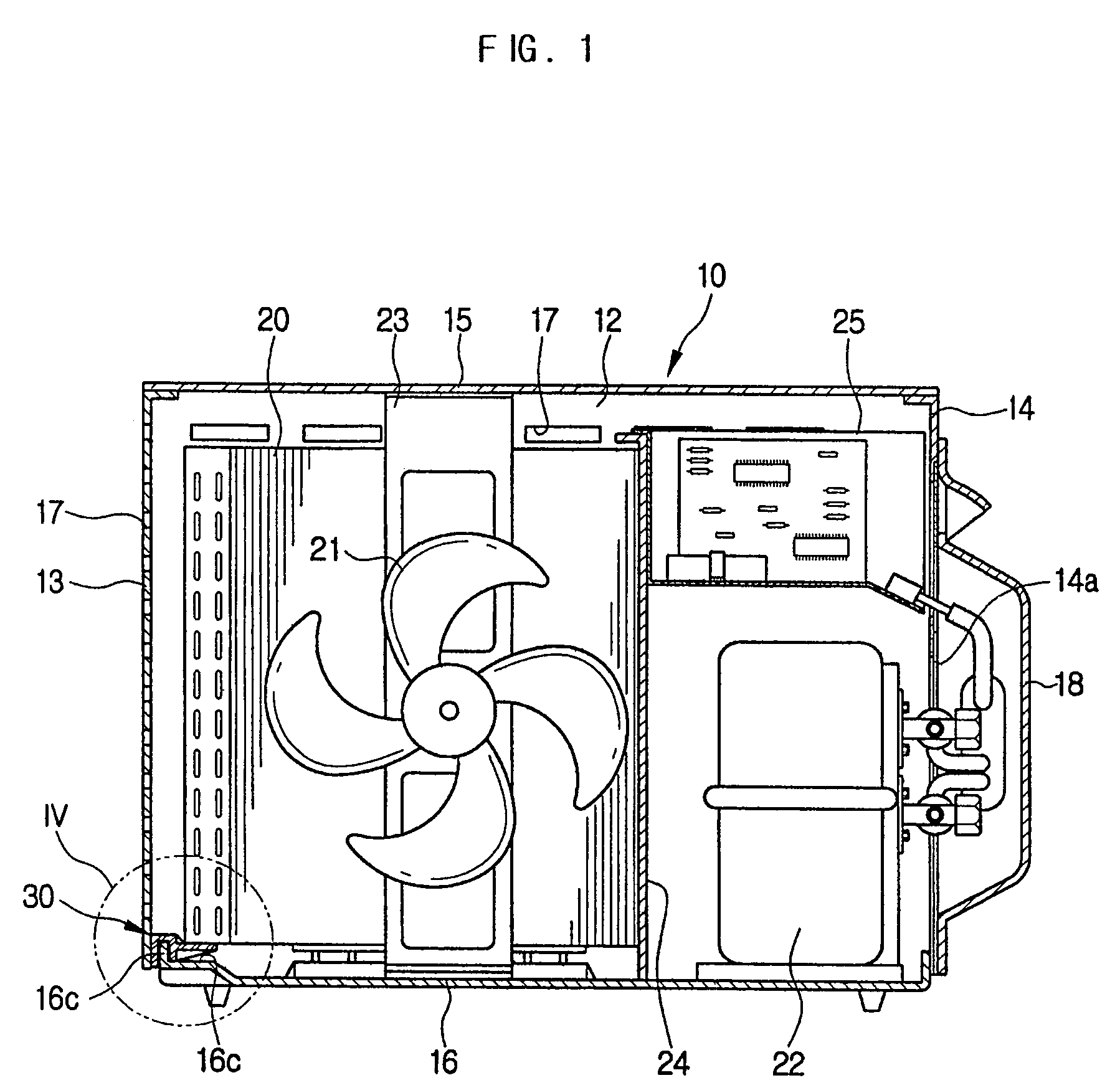

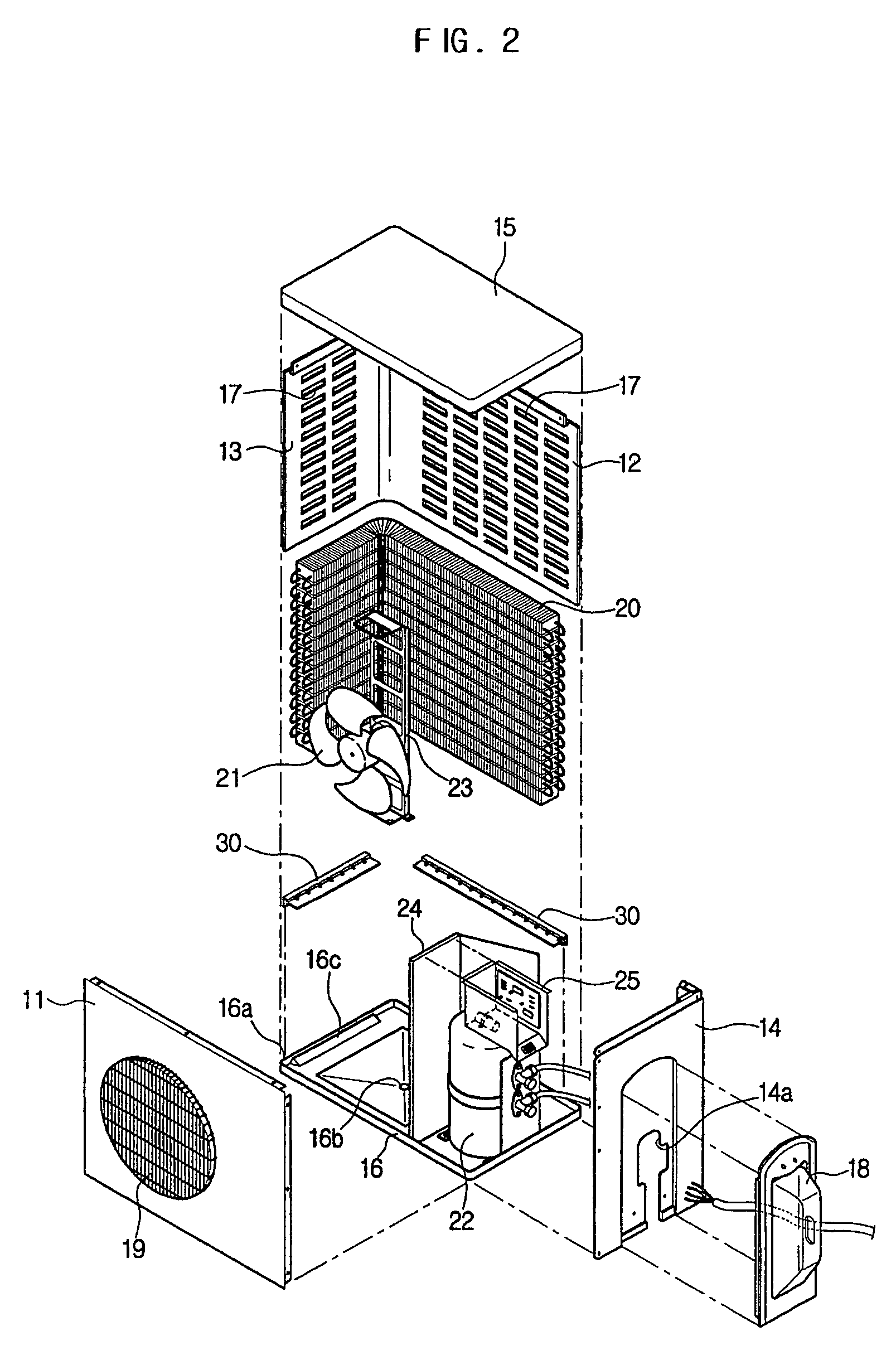

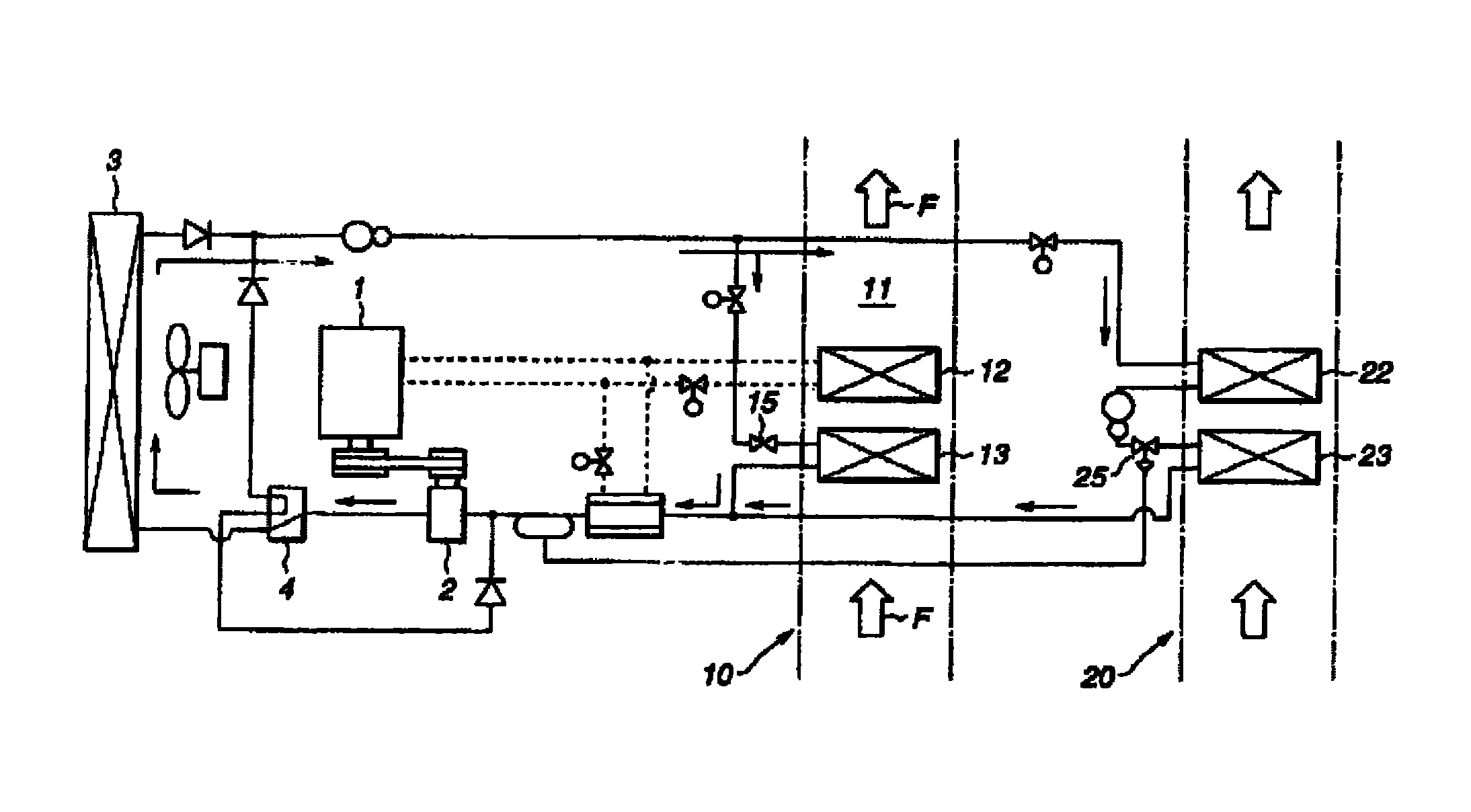

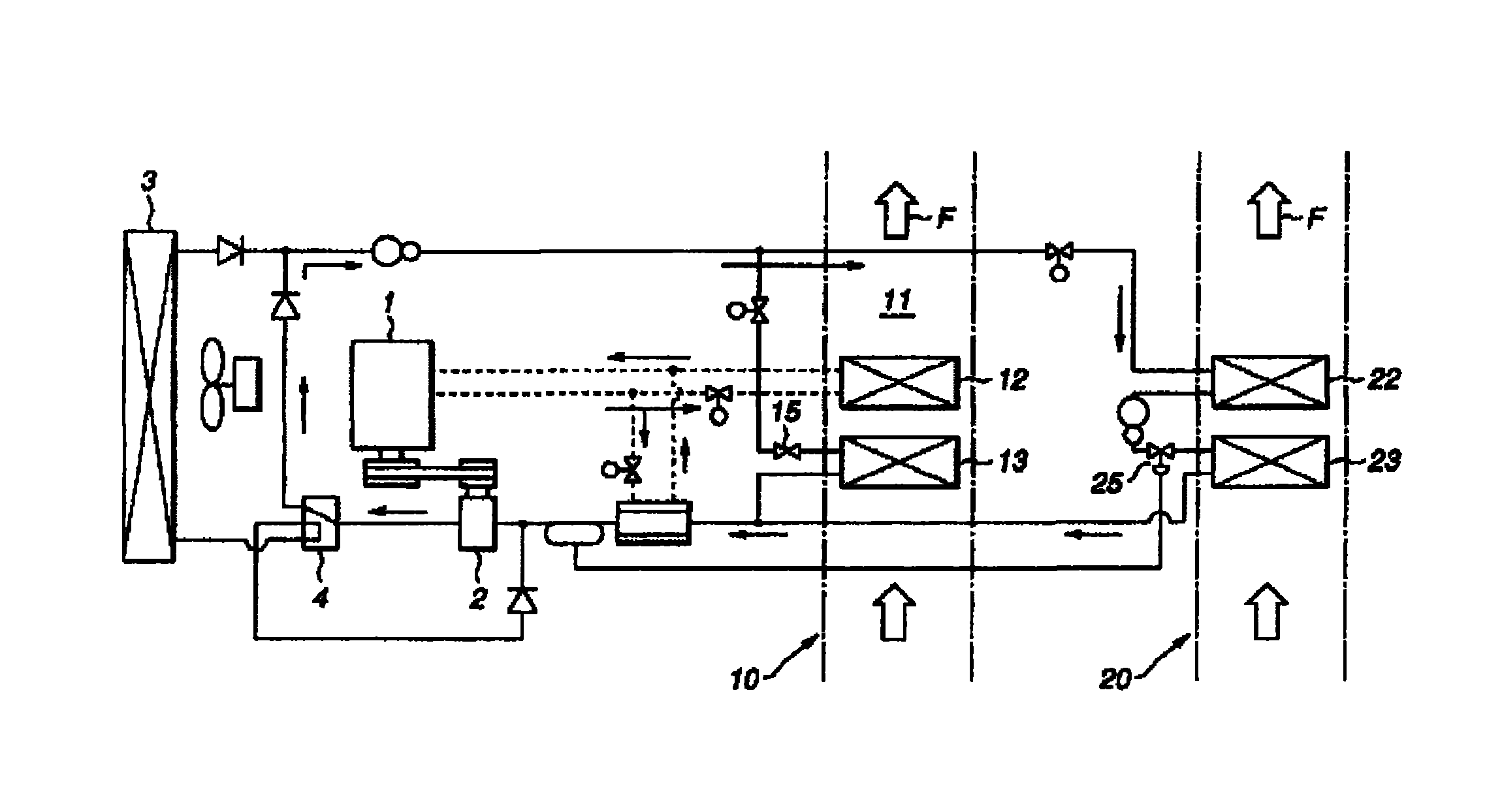

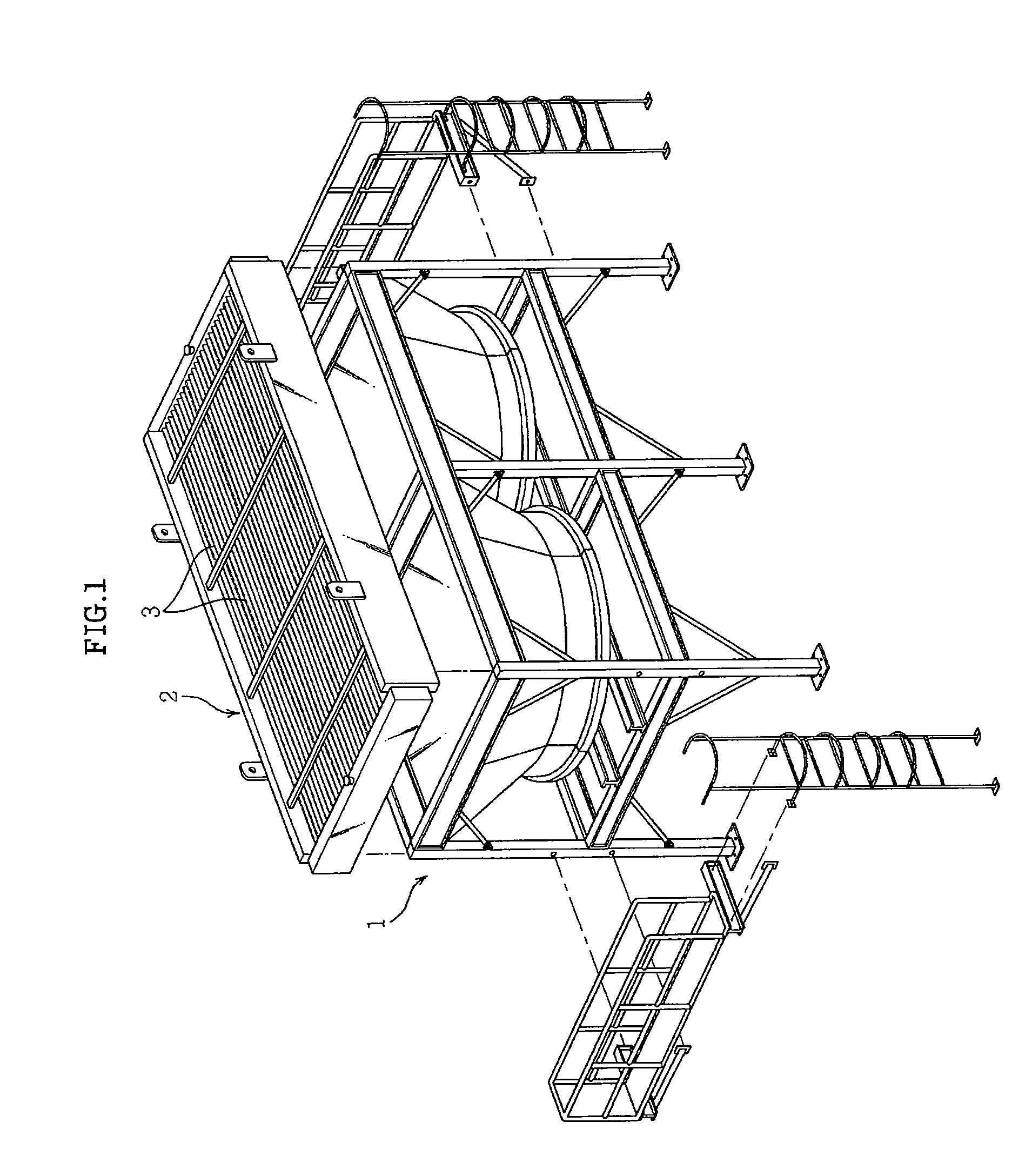

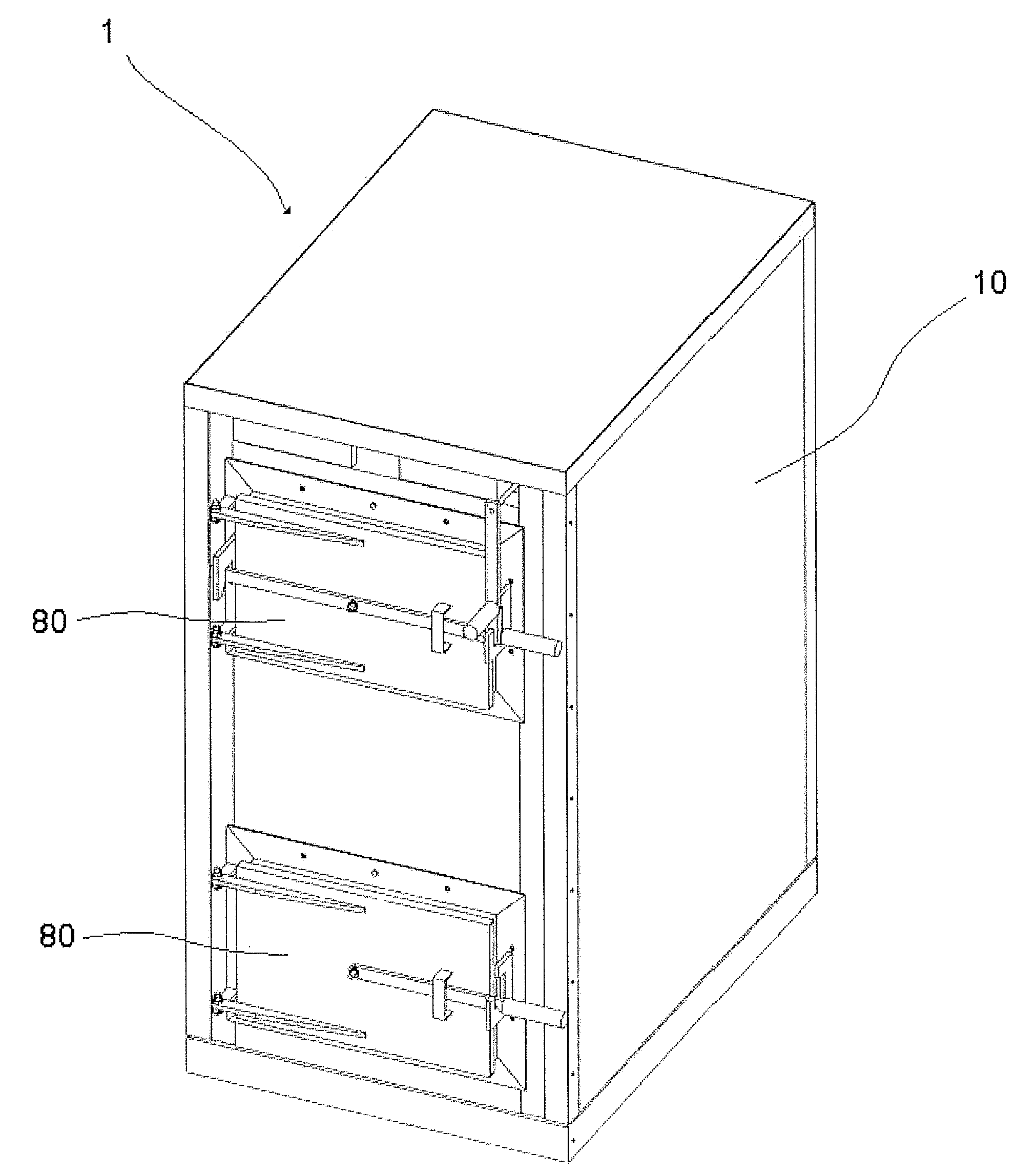

Outdoor unit for air conditioner

InactiveUS20050034471A1Easy dischargePreventing the condensed water from freezingThermal insulationCondensate preventionMechanical engineeringWaste management

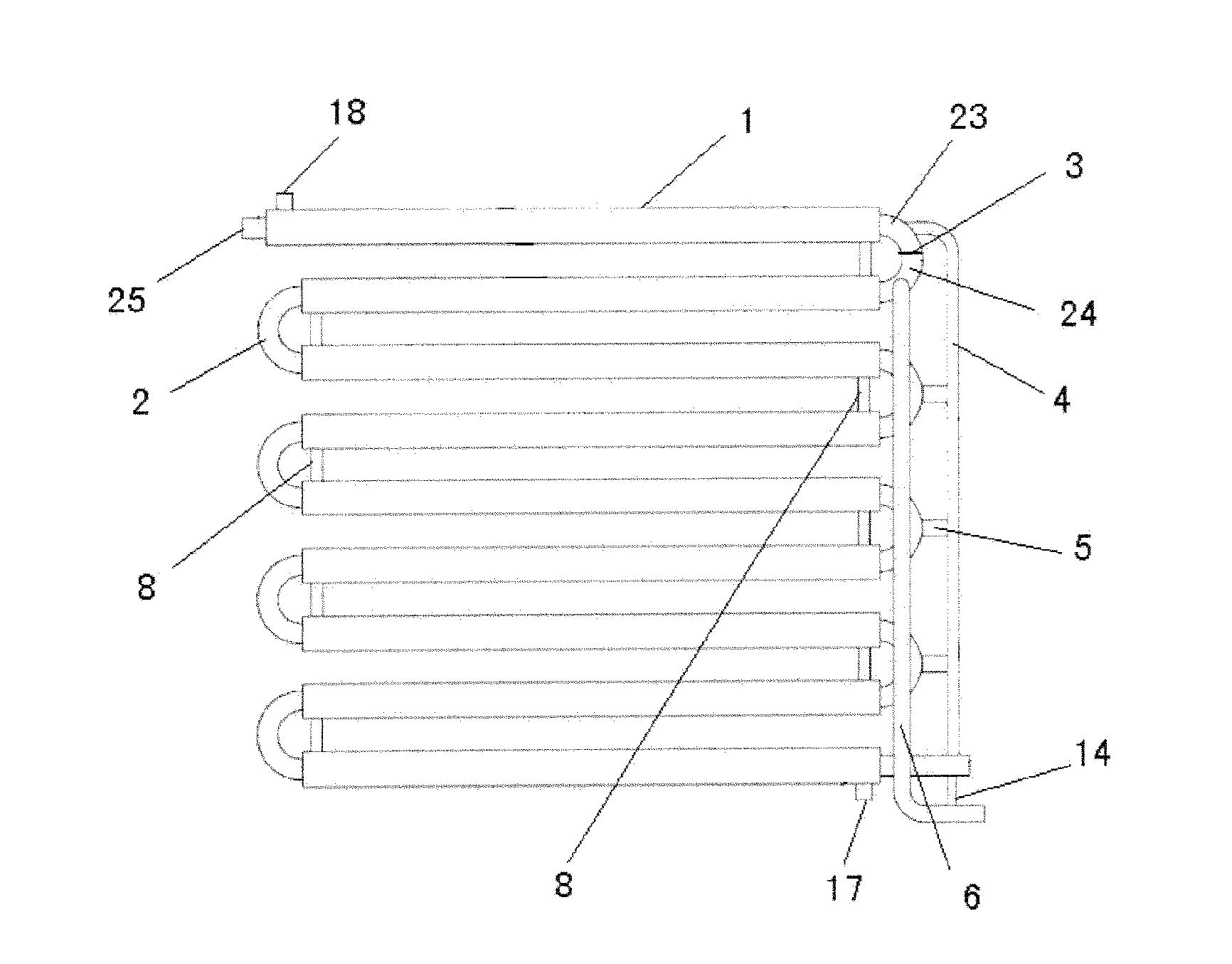

An outdoor unit for an air conditioner allows condensed water generated from an outdoor heat exchanger to be easily discharged, and prevents coldness from the outdoor heat exchanger from being transmitted to a bottom of the outdoor unit, thus preventing freezing of the condensed water on the bottom. The outdoor unit includes a cabinet having a bottom panel, an outdoor heat exchanger installed in the cabinet, and a support member made of heat insulating material supporting the outdoor heat exchanger with a spacing between a lower end of the outdoor heat exchanger and the bottom panel of the cabinet, to prevent condensed water generated from the outdoor heat exchanger from freezing.

Owner:SAMSUNG ELECTRONICS CO LTD

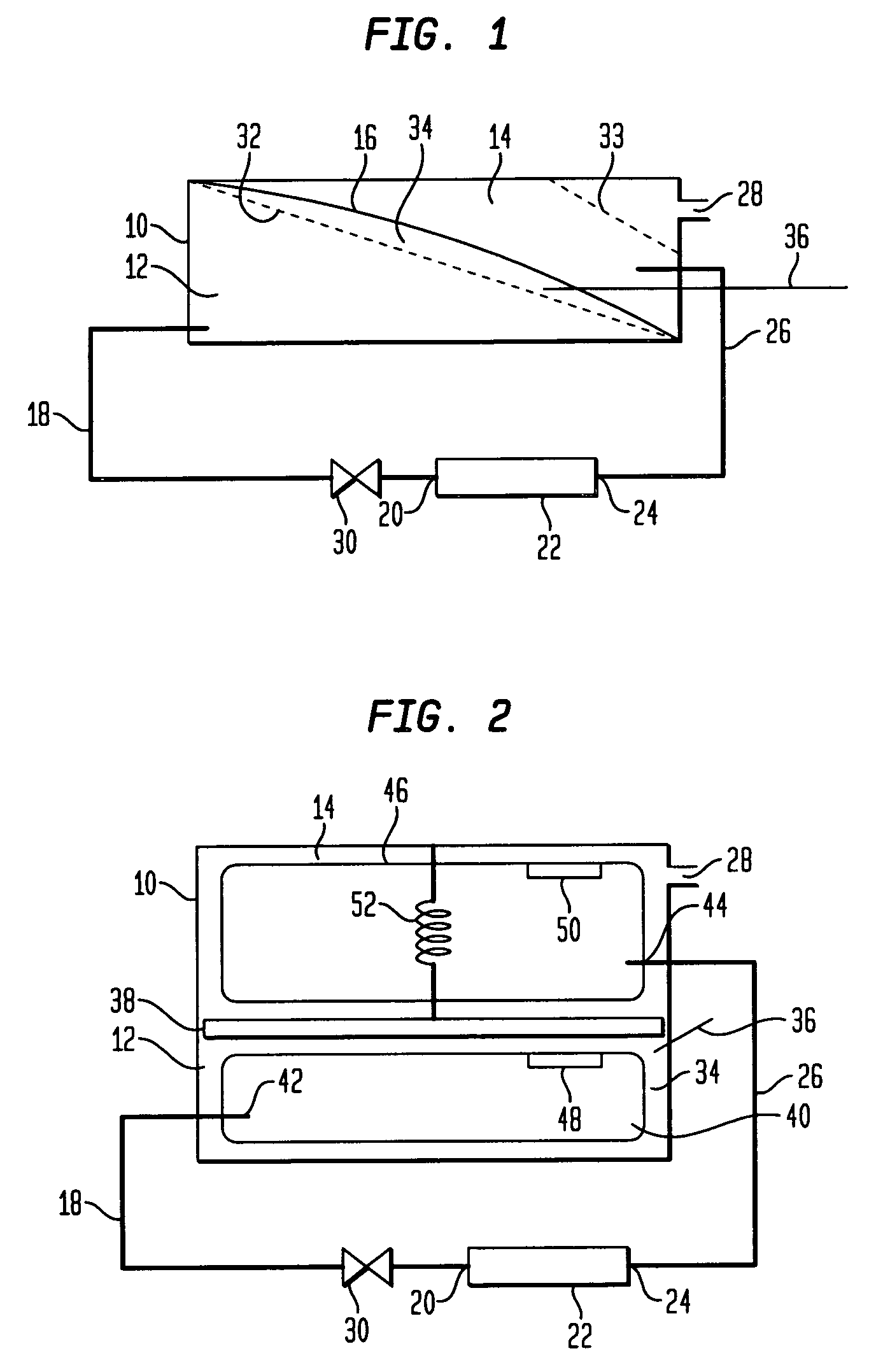

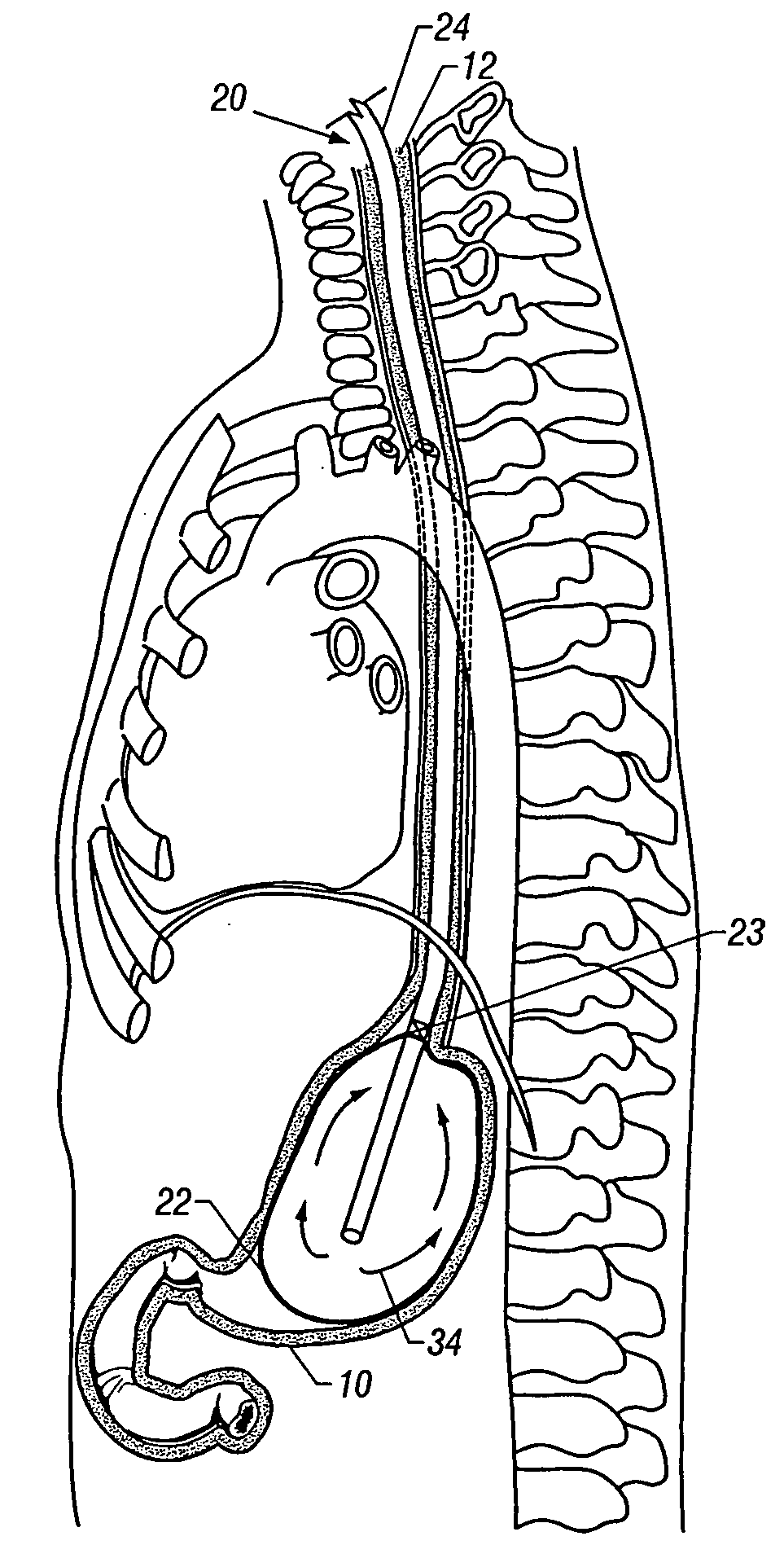

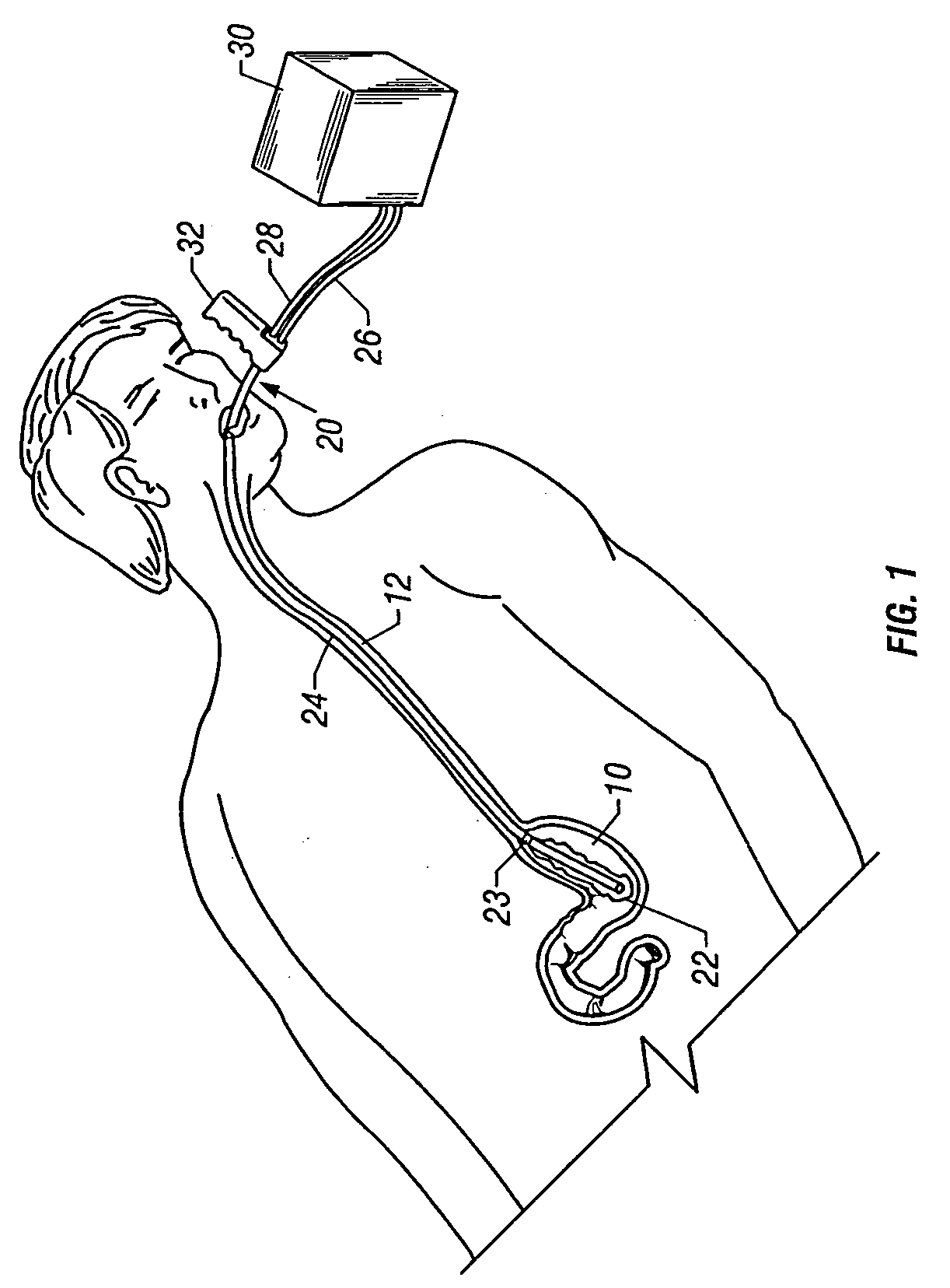

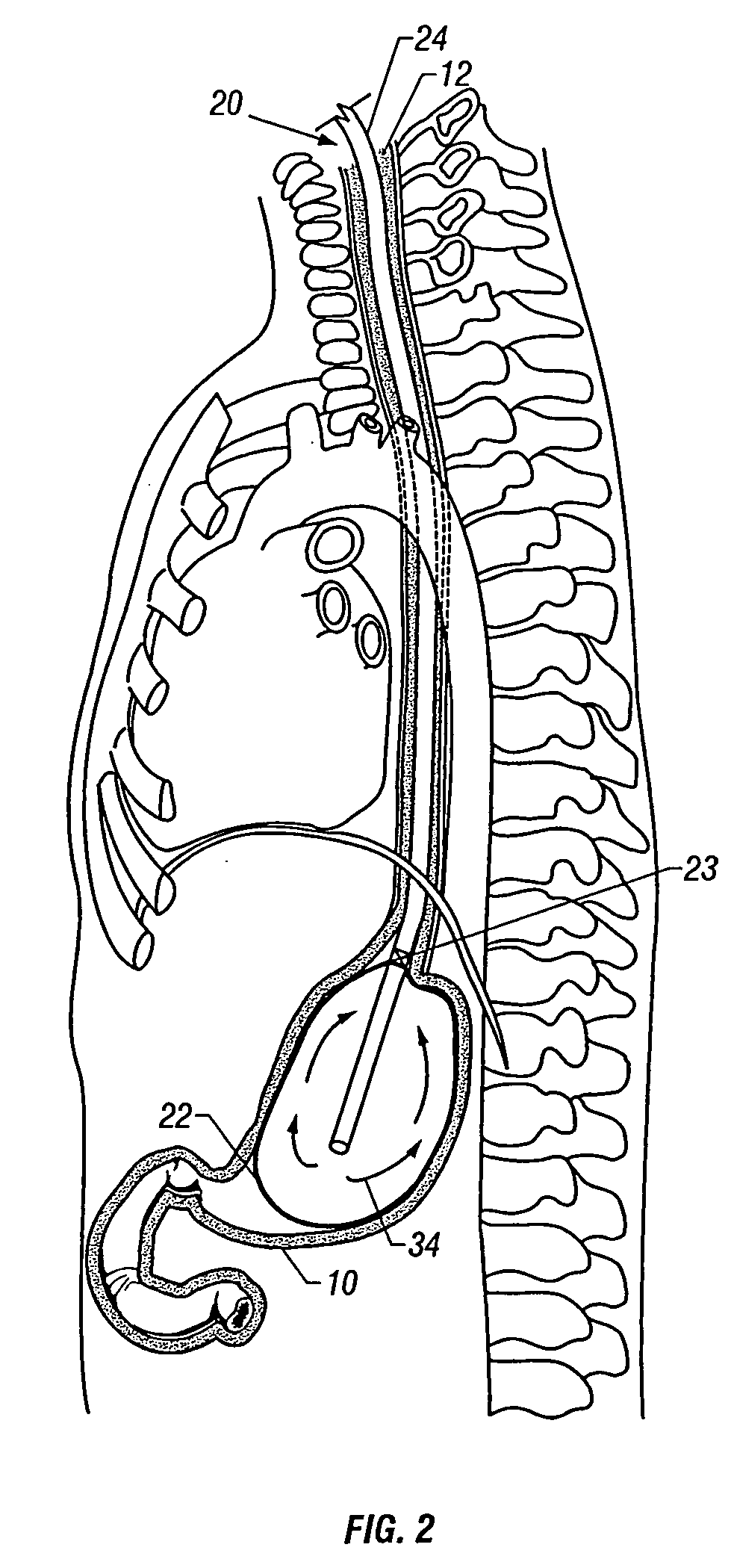

Method for gastric cooling using balloon catheter

InactiveUS20060253095A1Optimize locationGood removal effectDiagnosticsSurgeryAutomatic controlClosed loop

A balloon catheter is used in a closed-loop heat exchange system for manipulating the temperature of a patient. The balloon catheter is positioned in the stomach of the patient, and then expanded with a heat exchange fluid delivered through a lumen formed in the shaft of the catheter. The balloon catheter comes into contact with the wall of the stomach, and the stomach substantially conforms around the expanded balloon catheter. The heat exchange fluid is allowed to flow continuously into and out of the balloon catheter. Heat is exchanged between the balloon catheter and the stomach so as to controllably alter the temperature of at least a portion of the patient. Anti-shivering mechanisms and automatic control based on temperature feedback from the patient may be used in connection with the heat exchange system.

Owner:ZOLL CIRCULATION

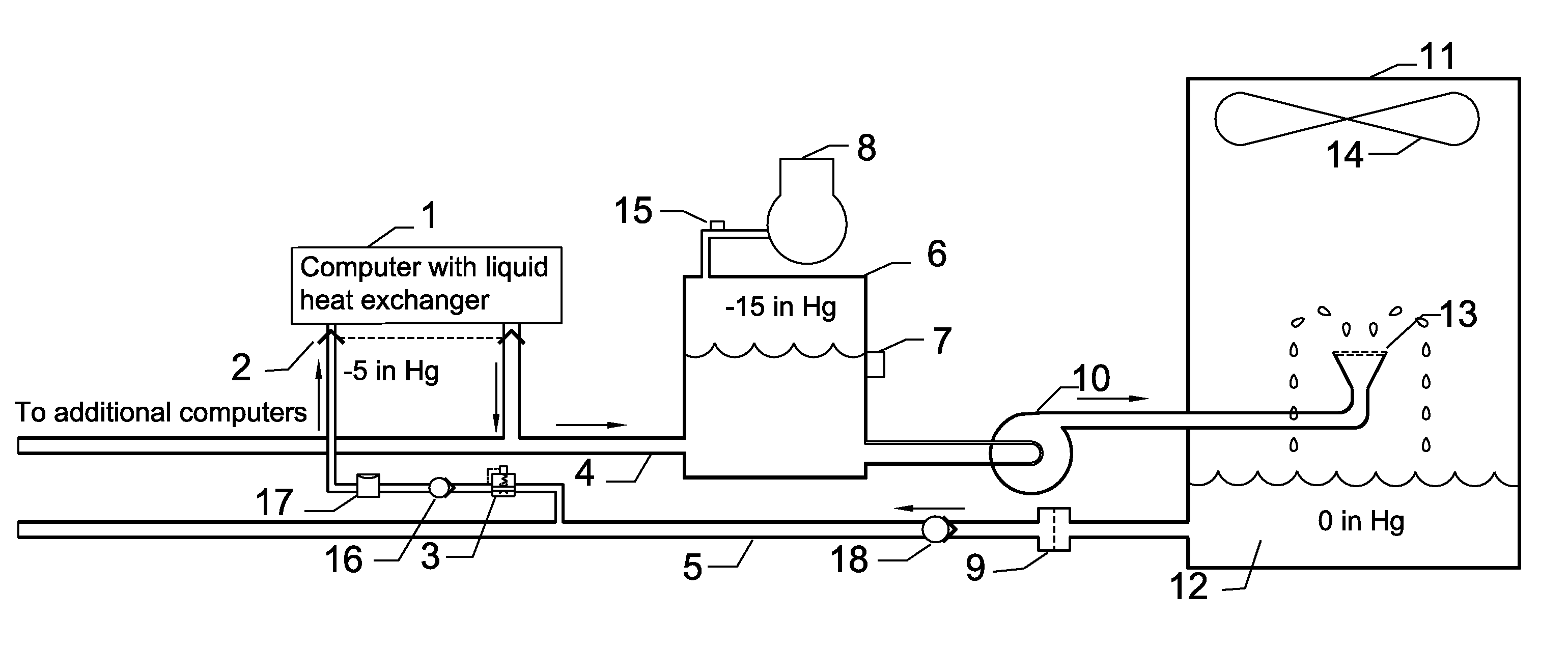

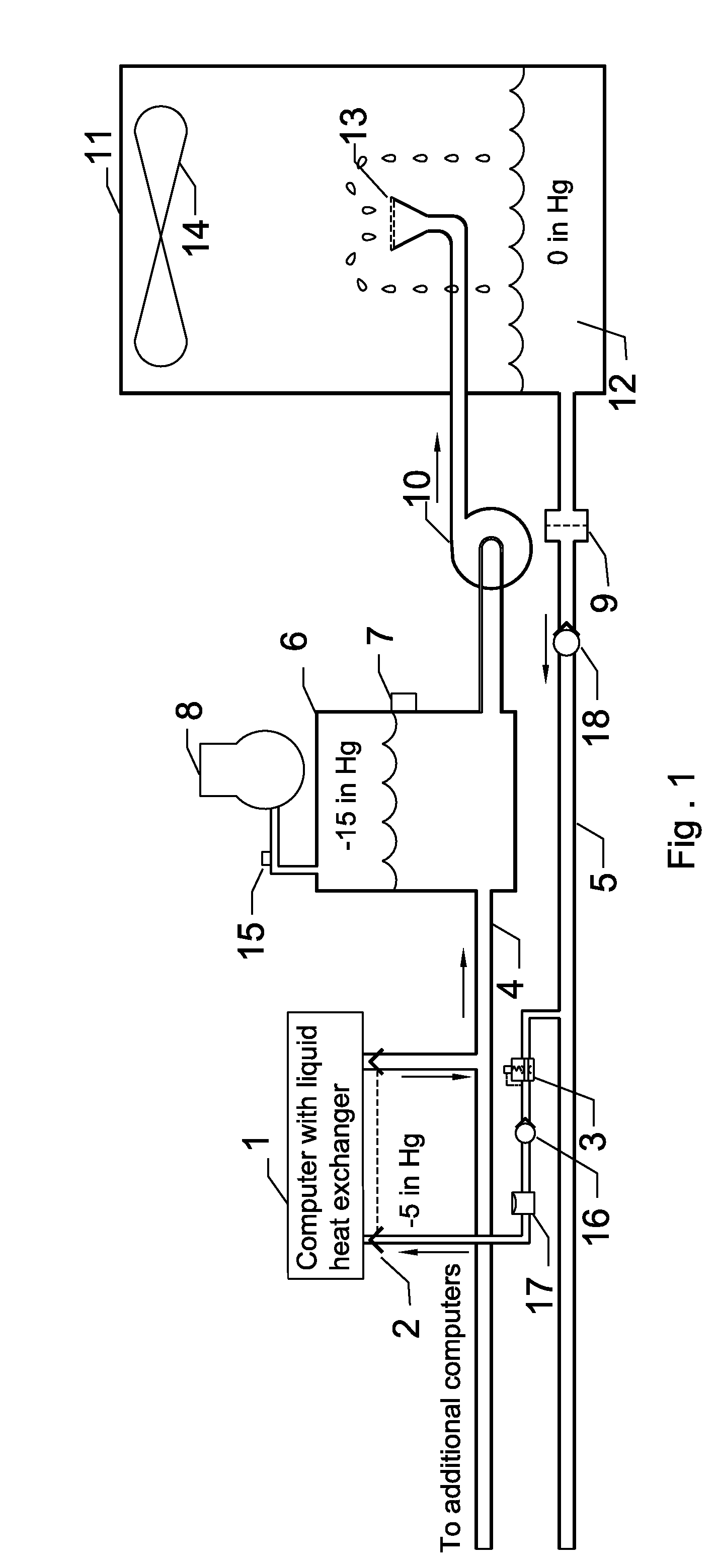

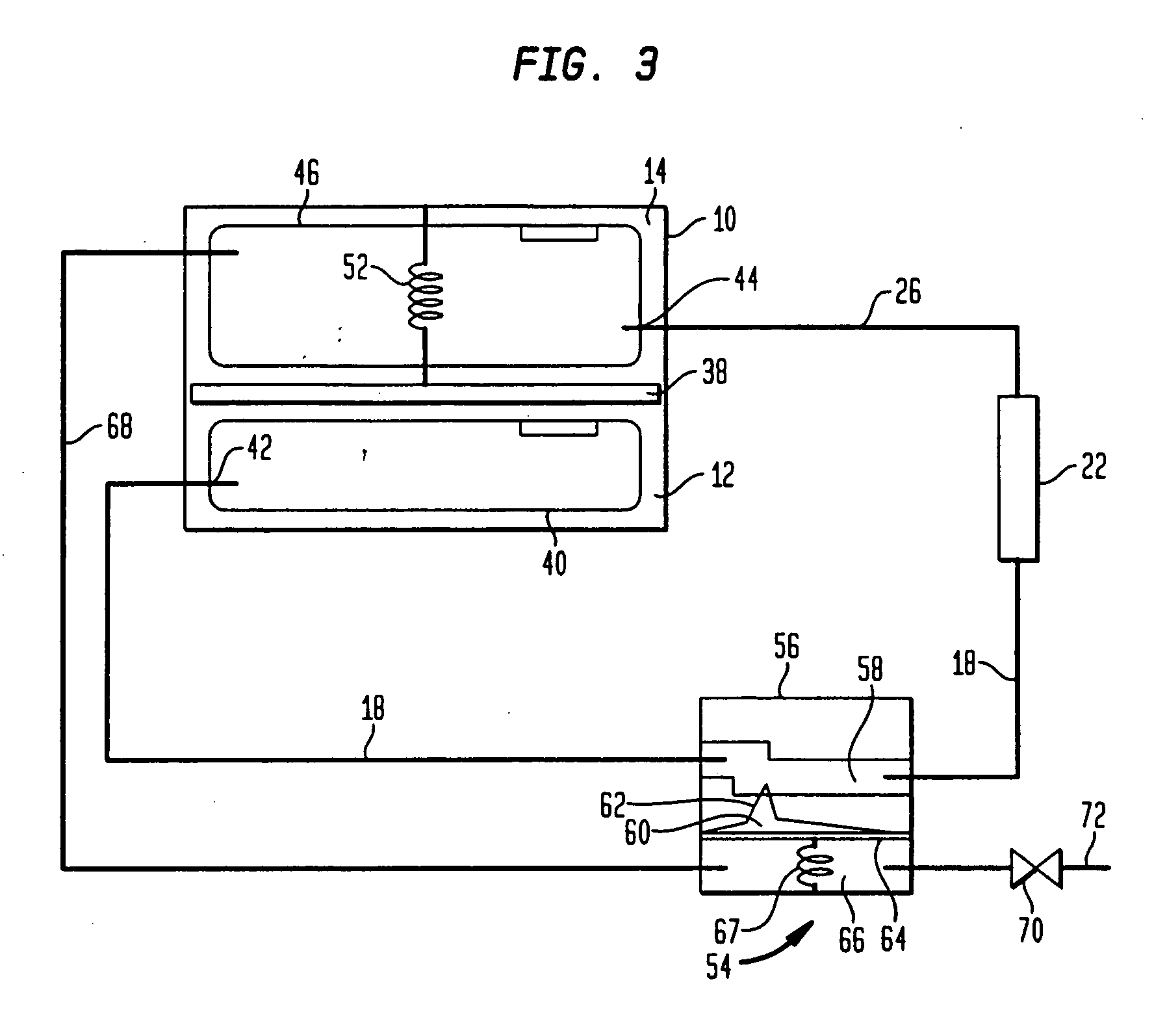

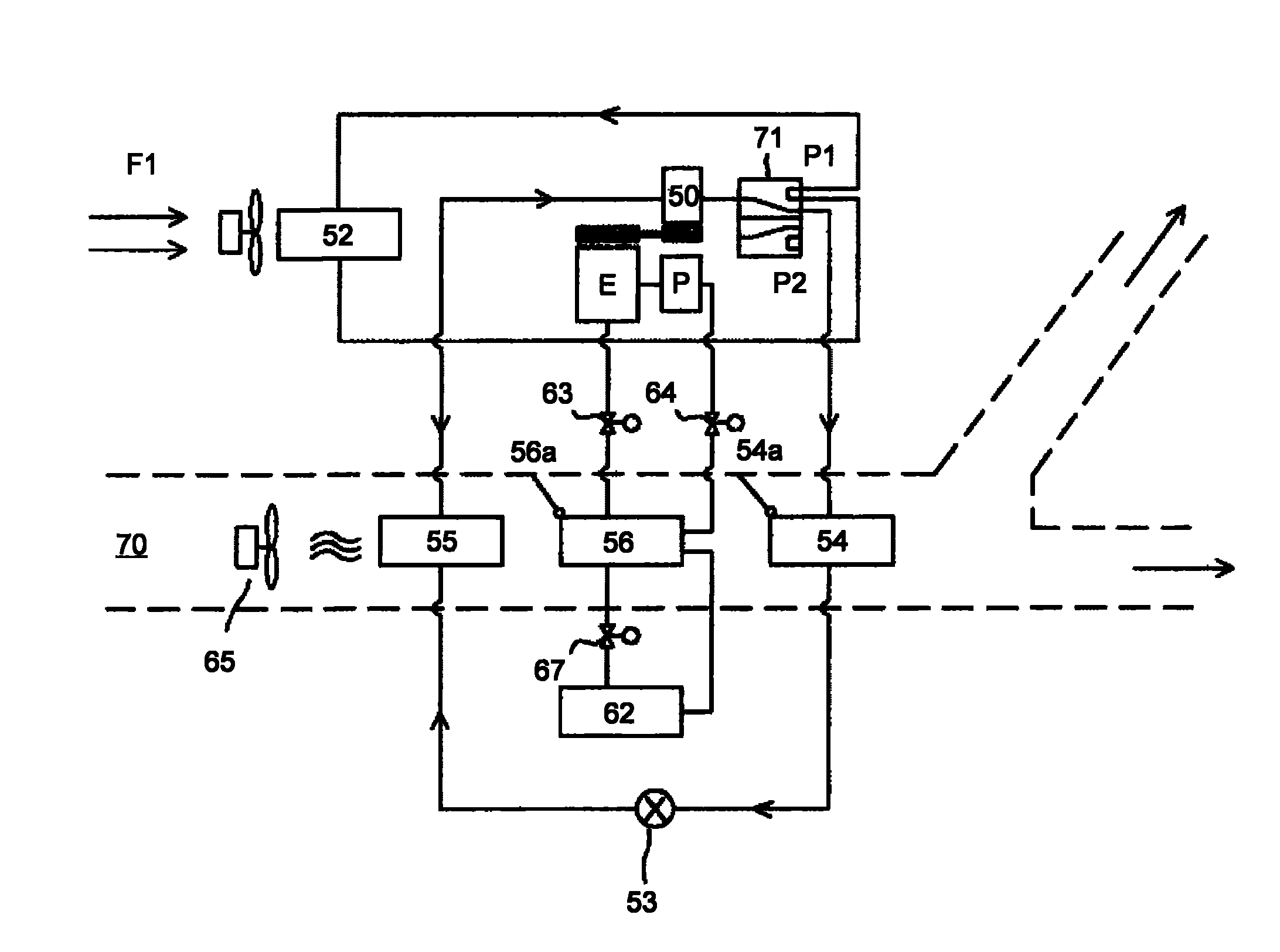

Vacuum Pumped Liquid Cooling System for Computers

InactiveUS20110253347A1Avoid cloggingAvoid heat exchangeDigital data processing detailsHeat exhanger finsLiquid cooling systemAir cooling system

A reliable, leak tolerant liquid cooling system with a backup air-cooling system for computers is provided. The system may use a vacuum pump and a liquid pump in combination to provide negative fluid pressure so that liquid does not leak out of the system near electrical components. The system distributes flow and pressure with a series of pressure regulating valves so that an array of computers can be serviced by a single cooling system. The system provides both air and liquid cooling so that if the liquid cooling system does not provide adequate cooling, the air cooling system will be automatically activated. A connector system is provided to automatically evacuate the liquid from the heat exchangers before they are disconnected.

Owner:CHILLDYNE

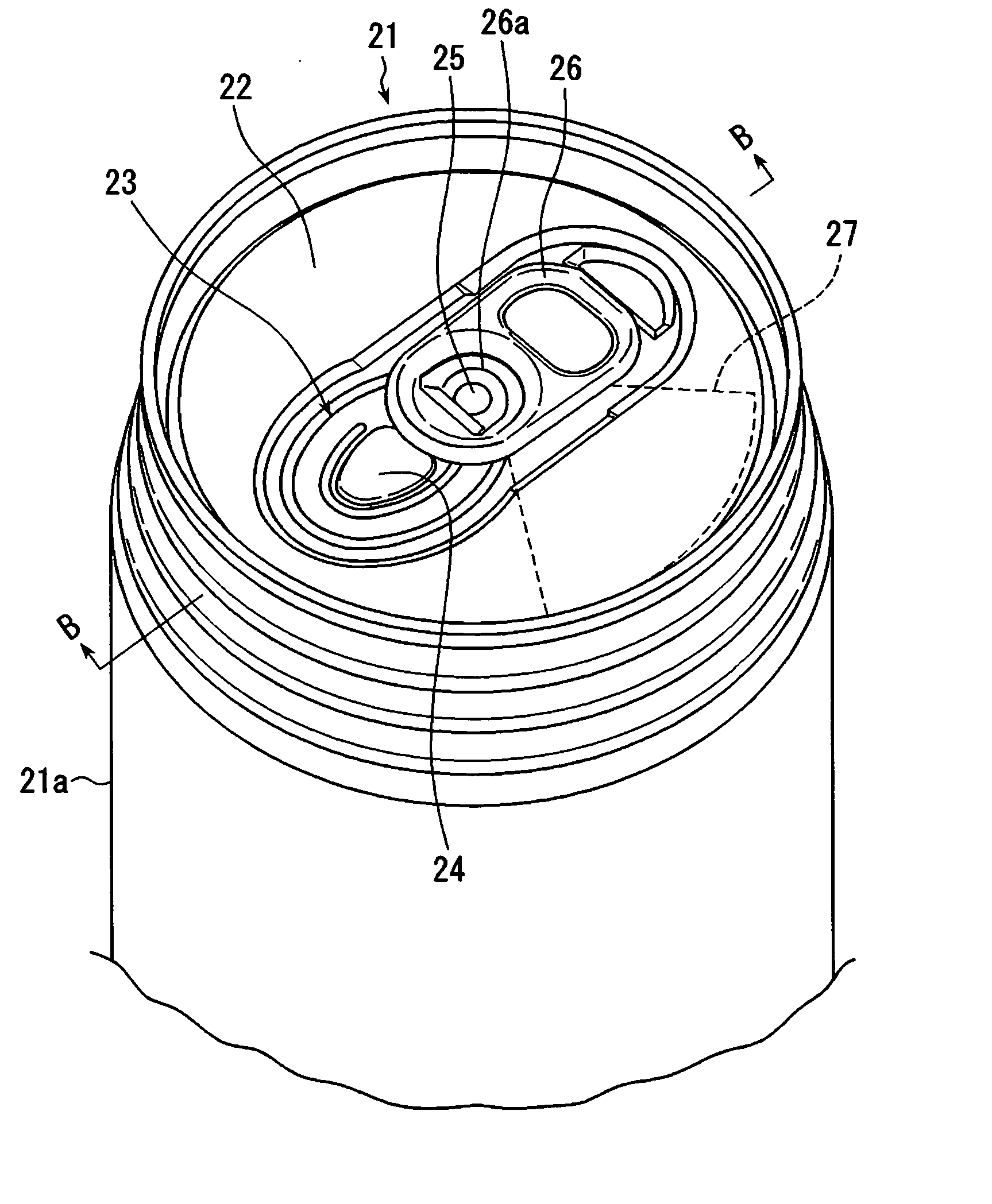

Can

InactiveUS20050115969A1Heat exchangerGood airtightnessLiquid flow controllersRefuse receptaclesEngineeringRivet

A can (1) of which spout after opening can be securely resealed and can be opened and closed with an easy operation is provided. The can (1) has a spout (3) that is opened by lifting and pulling a pull-ring (6) fixed on a top wall (2) of a can body (1a) with a rivet (5) to bend a sealing tongue portion (4) toward the inside of the can. Inside the top wall (2) and away from the spout (3), an internal sealing member (7) having a fan shape with its pivot mounted to the rivet and a size capable of sealing the spout (3) is disposed to be fixed to the rivet (5). After opening the spout (3), by rotating the pull-ring (6) around the rivet (5), the internal sealing member (7) is also rotated at the same time. As an interlocking mechanism therefor, the rivet (5) is rotatably supported by the top wall (2), and a base end of the pull-ring (6) and the pivot of the internal sealing member (7) are fixed to the rivet (5), respectively.

Owner:MIZUMA JYUNZI +5

Air cleaner

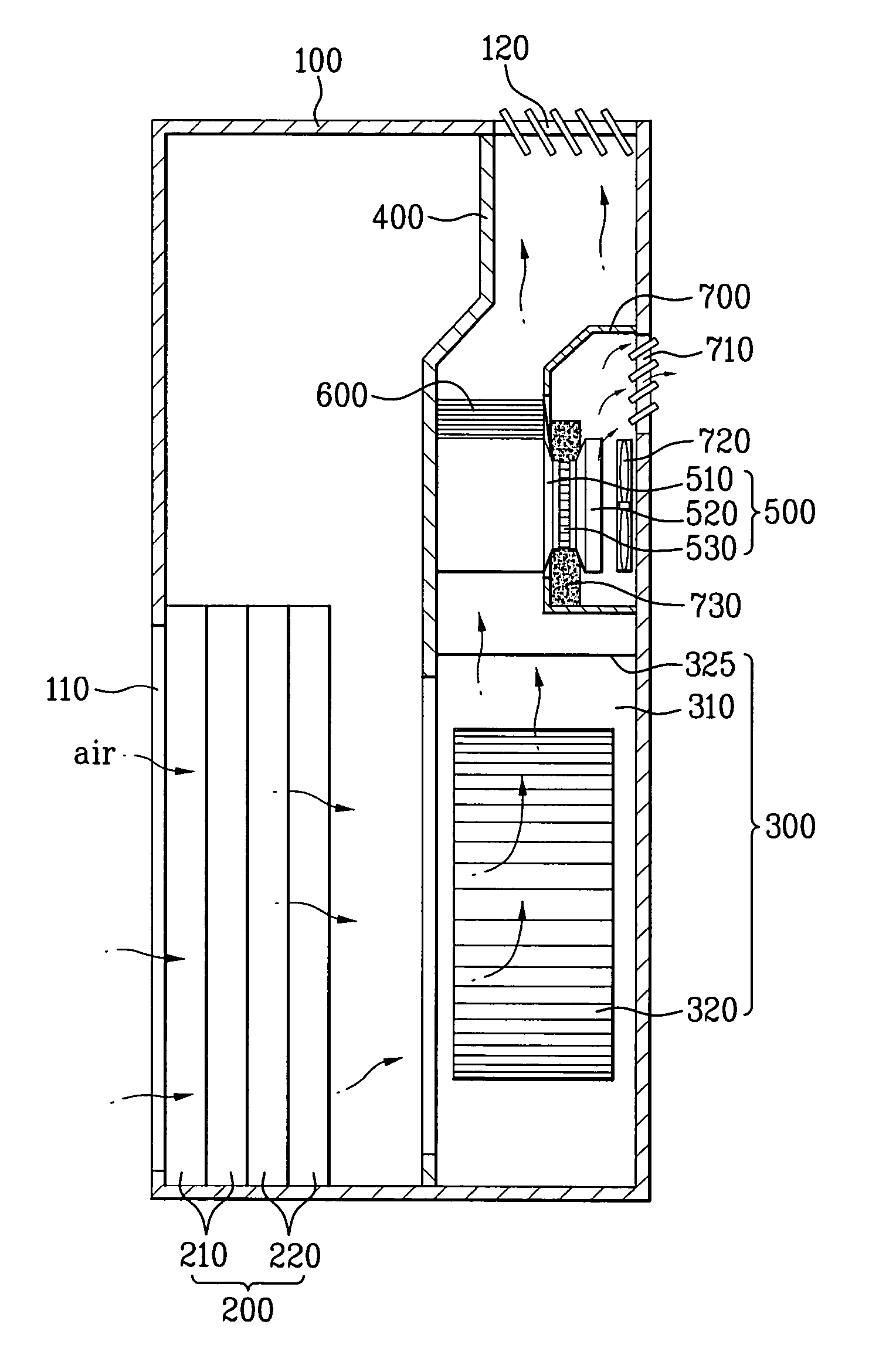

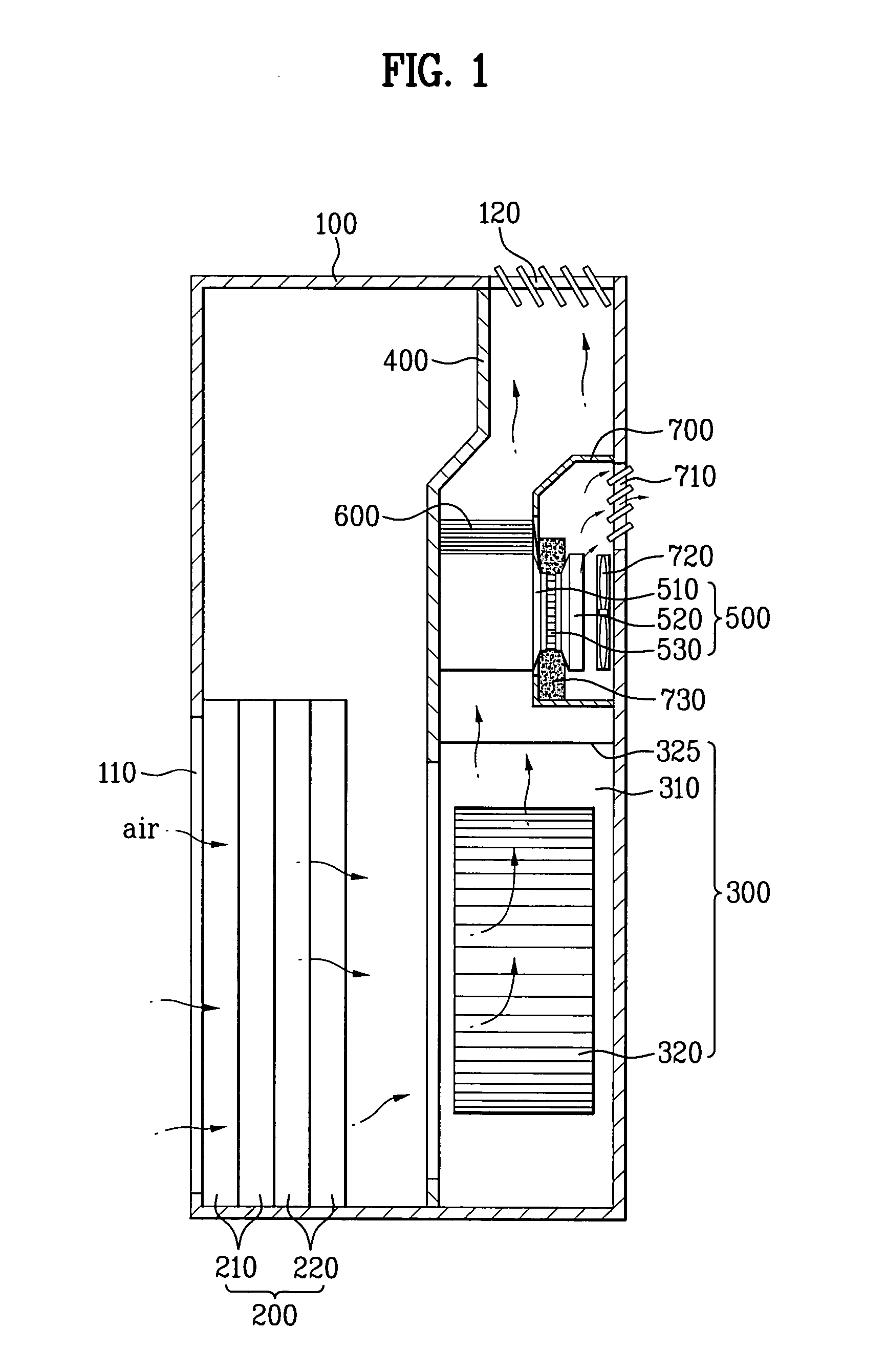

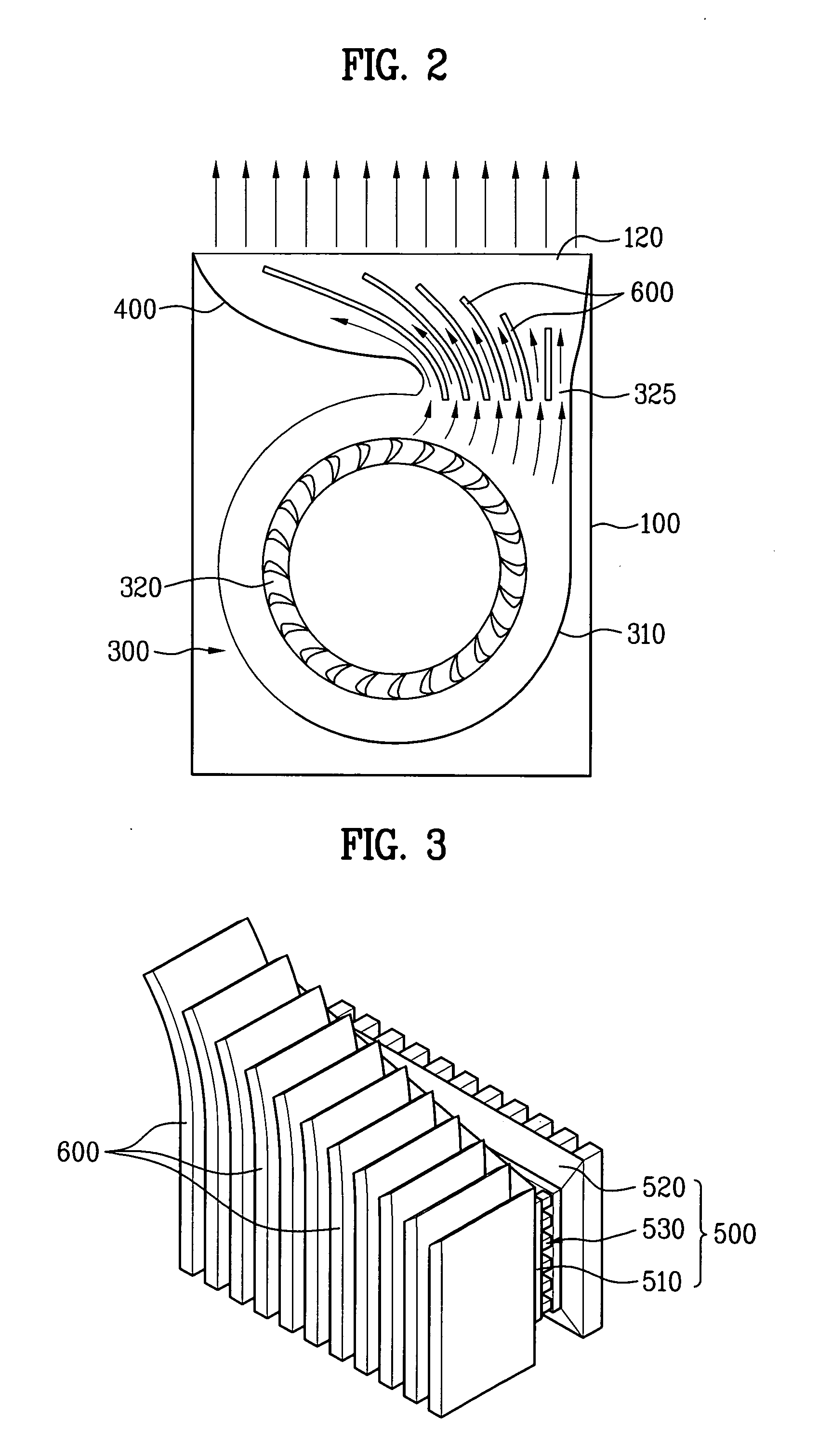

InactiveUS20050081556A1Avoid heat exchangeMechanical apparatusDispersed particle filtrationHeat exchangerAir cleaners

Air cleaner including a case having an inlet and an outlet, a fan inside of the case, for drawing air through the inlet and discharging the air through the outlet, a filter assembly inside of the case for cleaning the air drawn into the case through the inlet, a heat exchanger inside of the case for heating or cooling the air drawn into the case, selectively, and a plurality of fins between the fan and the outlet for guiding the air drawn into the case to the outlet, thereby ventilating the room.

Owner:LG ELECTRONICS INC

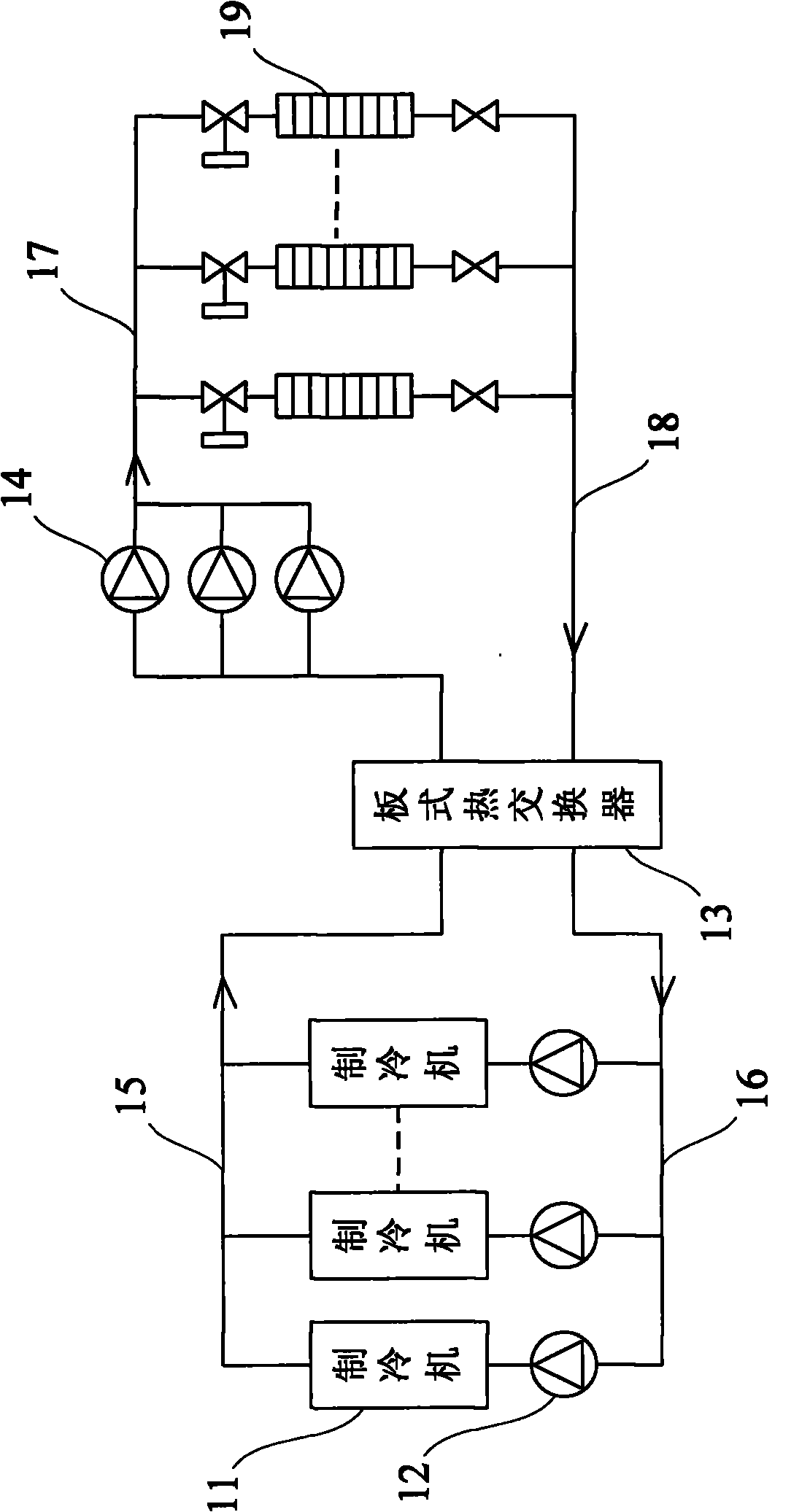

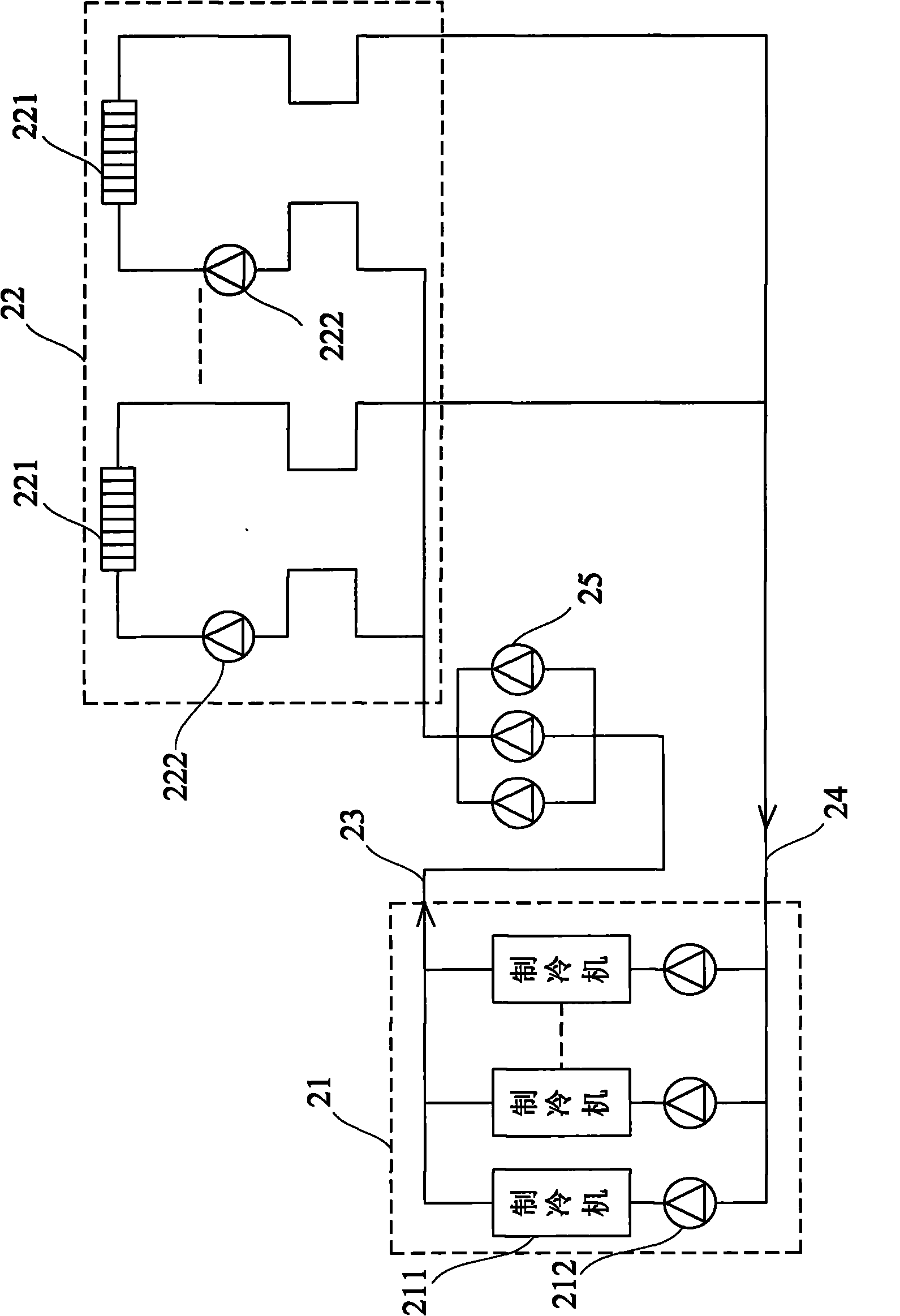

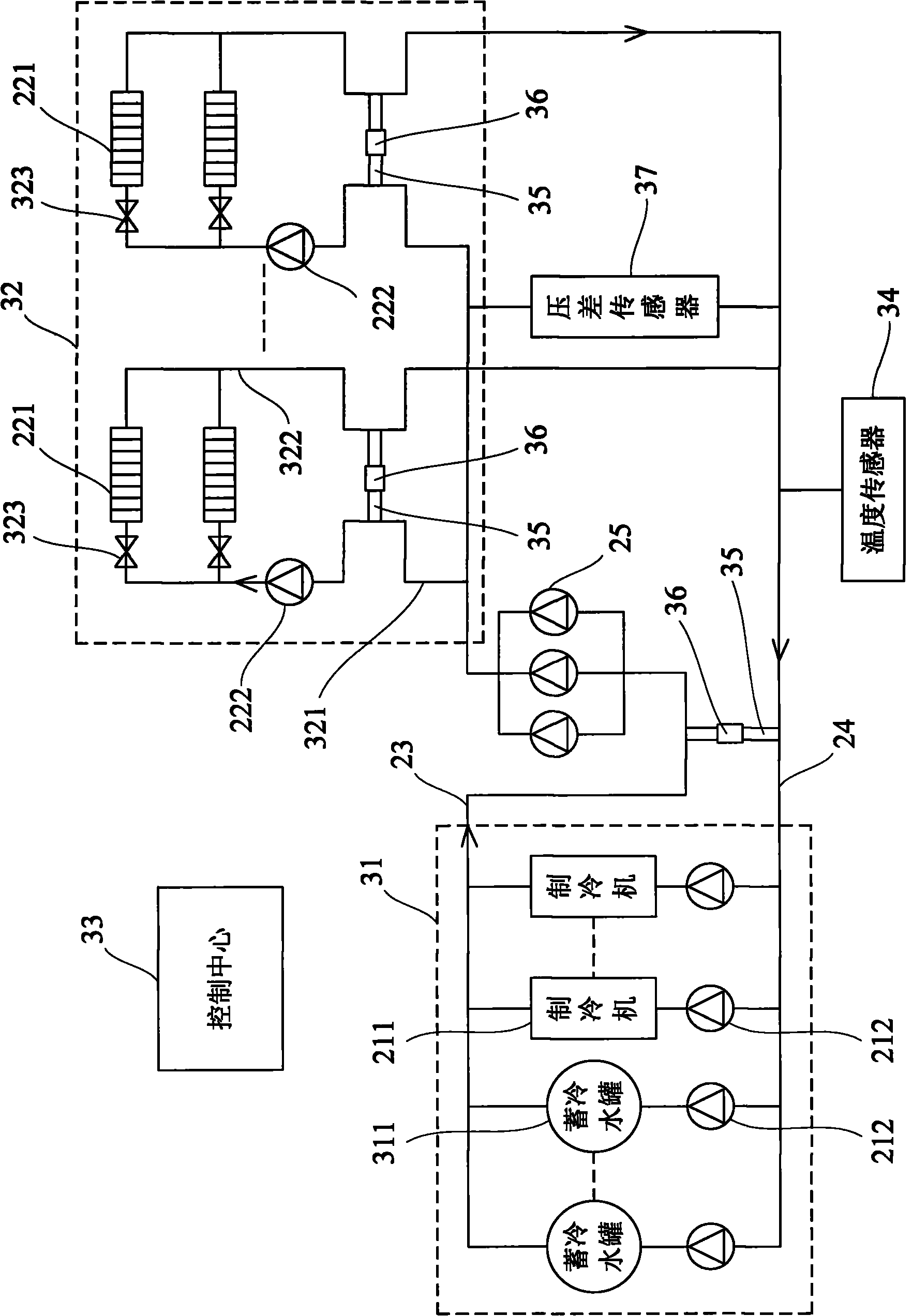

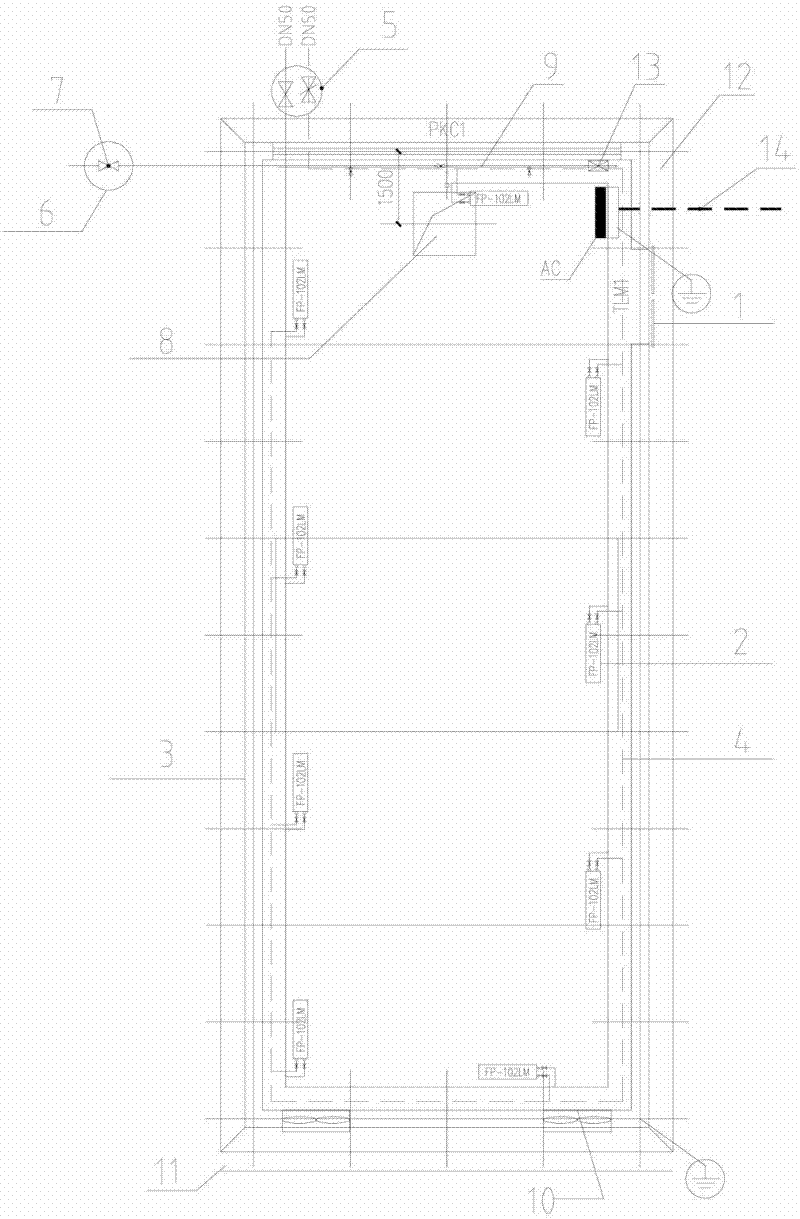

Chilled water direct supply system and method

InactiveCN101865496ALow input costEasy to installSpace heating and ventilation safety systemsLighting and heating apparatusChilled waterCooling capacity

The invention provides a chilled water direct supply system and a method. The system comprises an energy center, a thermal exchange station and at least one secondary pump; wherein the energy center is connected with the thermal exchange station by a master water supply pipe and a master return pipe. The energy source center, which is composed of at least one refrigerator and at least one primary pump, is used for preparing the chilled water; the refrigerator is in series connection with the primary pump and is arranged between the master water supply pipe and the master return pump. The thermal exchange station, which is composed of at least one draught fan and at least one triplex pump, is used for consuming cooling capacity of the chilled water; the draught fan is in series connection with the triplex pump and is arranged between the master water supply pipe and the master return pipe. The secondary pump arranged on the master water supply pipe is used for transmitting the chilled water outputted from the energy center to the thermal exchange station. The invention has the advantages of low cost and energy loss rate as well as small occupied area.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

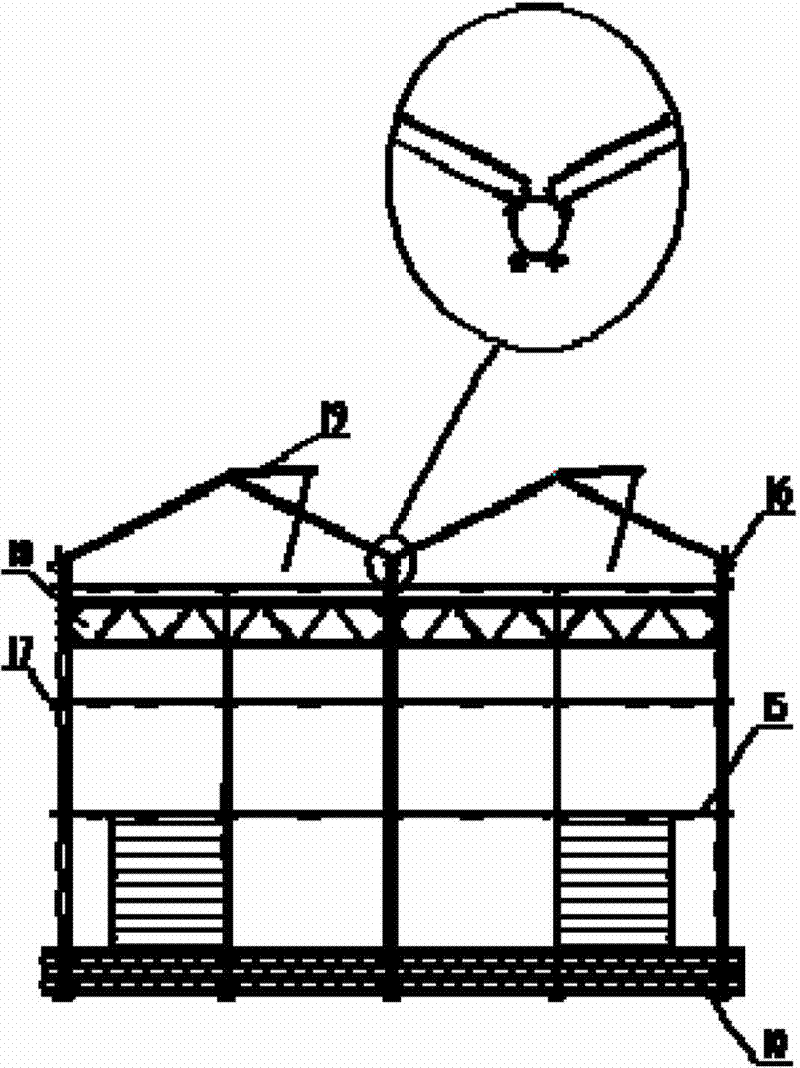

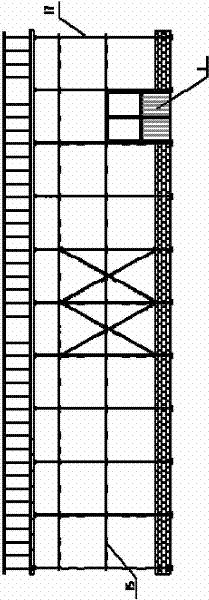

Double-layer aluminum gutter greenhouse

InactiveCN102550332AStrong bending resistanceReduce section sizeClimate change adaptationGreenhouse cultivationAutomatic controlEngineering

The invention discloses a double-layer aluminum gutter greenhouse, which is composed of a main body structure, a cover material and an ancillary facility, wherein the main body structure comprises upright columns, composite beams, water troughs and wall beams; the ancillary facility comprises a ventilation system, a heating system, a power distribution system and an automatic control system; the water trough adopt aluminum gutters, and the aluminum gutters are aluminum structure devices which have the functions of rainwater collection, condensate collection and drainage. According to the double-layer aluminum gutter greenhouse, the anti-bending performance is strong, the sectional dimension is smaller than that of a steel gutter, the shading area is small, and the problem of condensate collection in the greenhouse is solved; a middle cavity is used for separating air inside and outside the greenhouse, so that the heat loss of the steel gutter is reduced; and besides, the double-layer aluminum gutter greenhouse has the properties of dew collection and heat insulation and provides a good growing environment for seedling breeding.

Owner:BEIJING KINGPENG INT HI TECH CORP

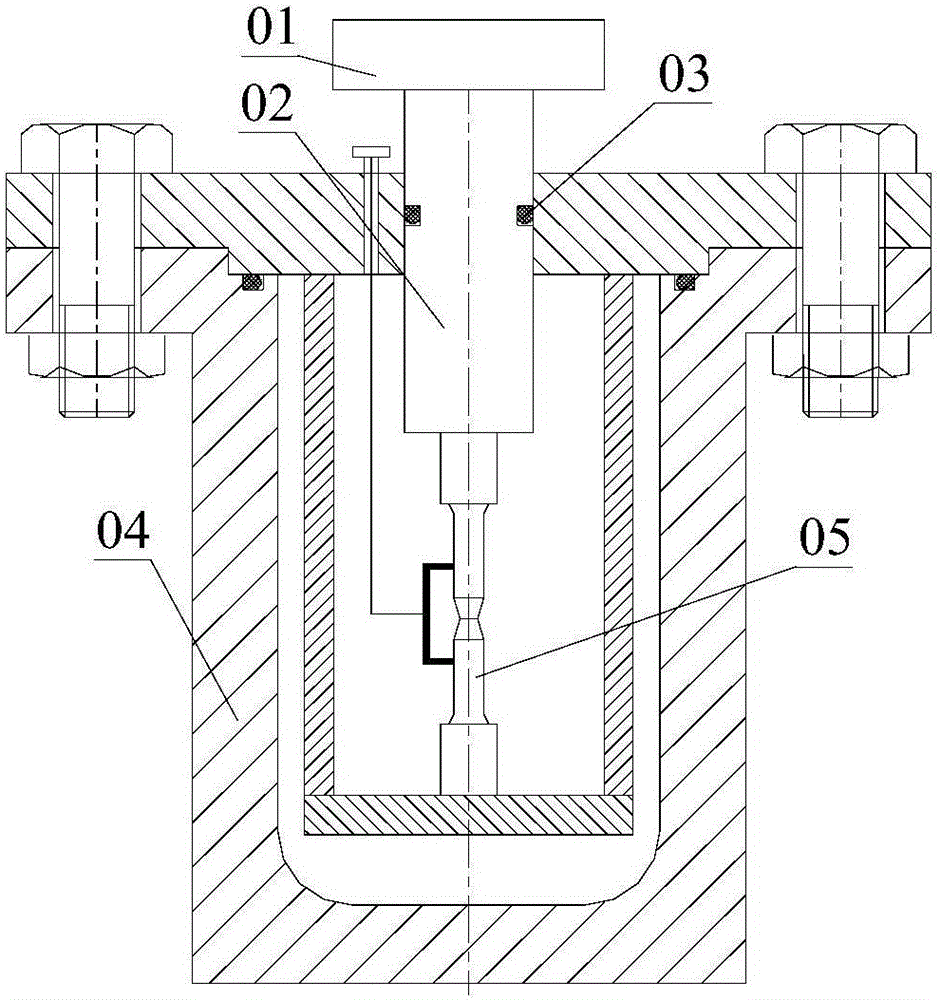

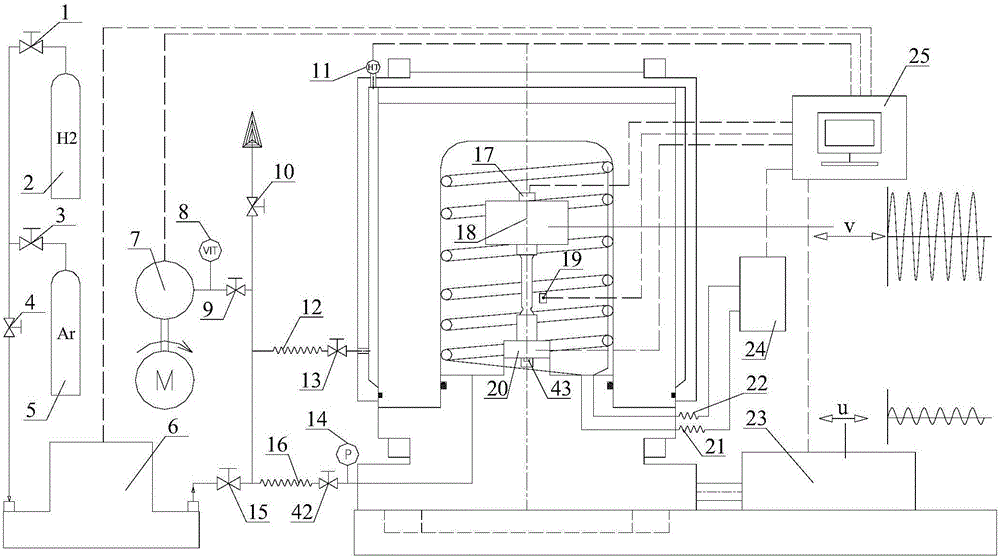

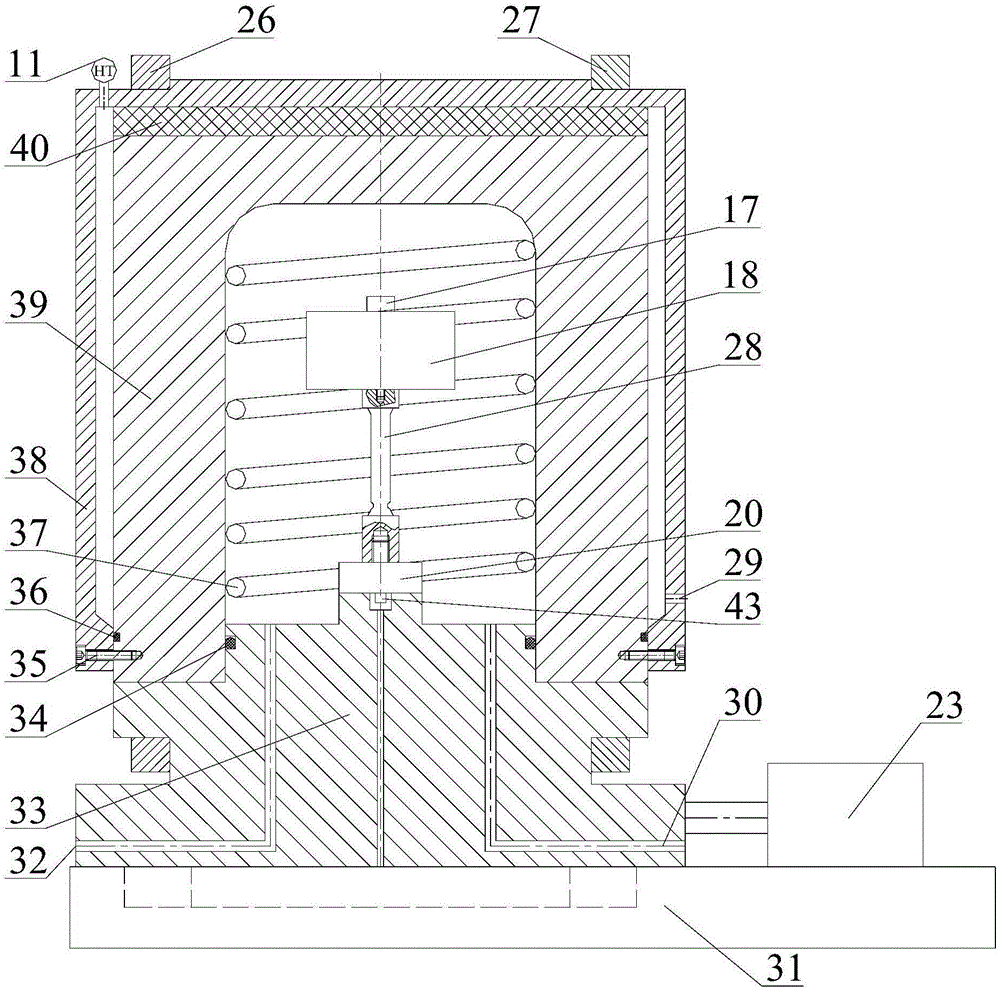

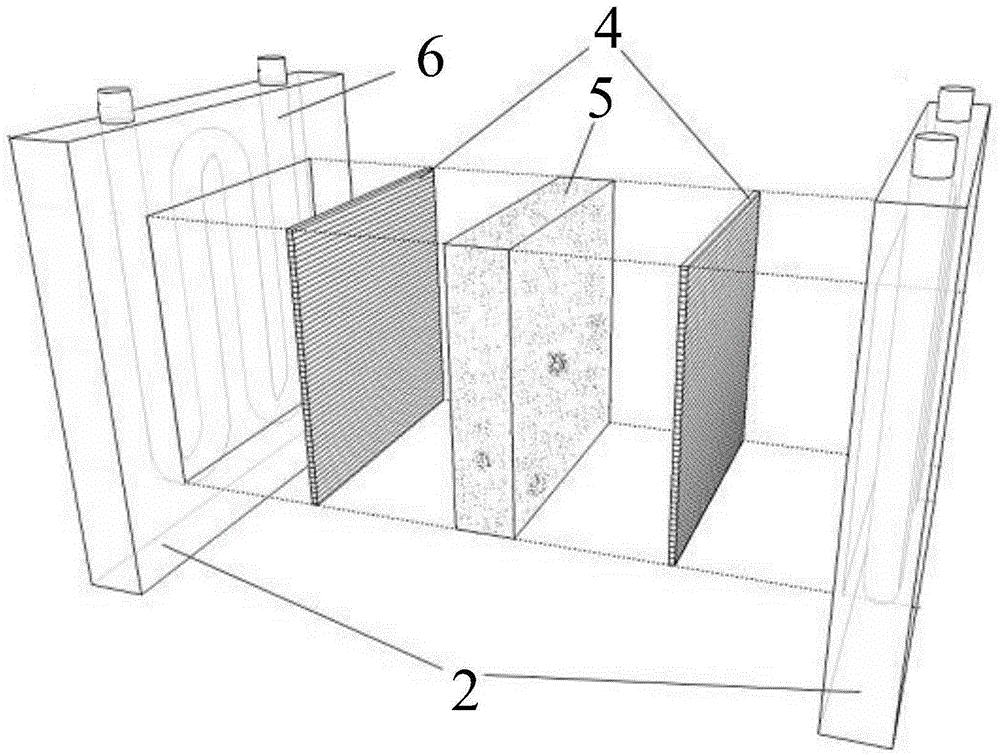

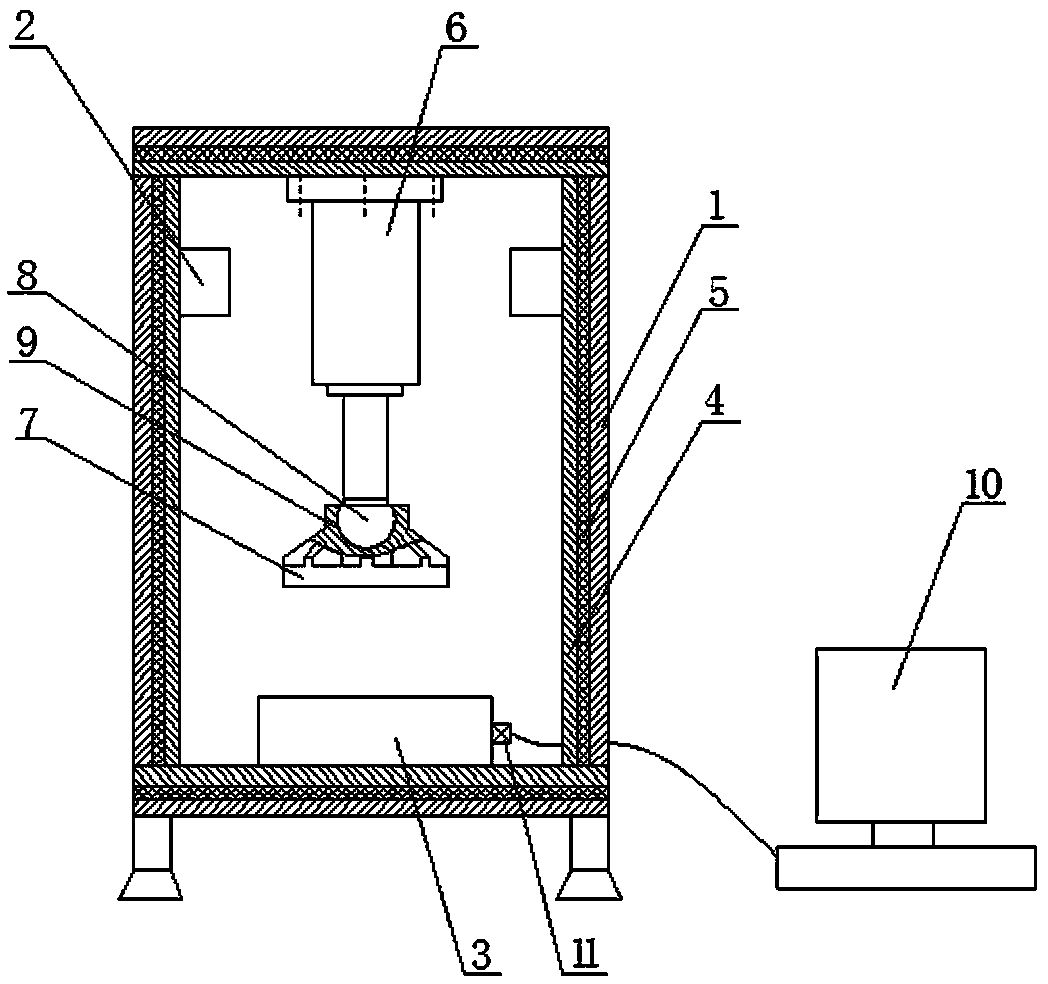

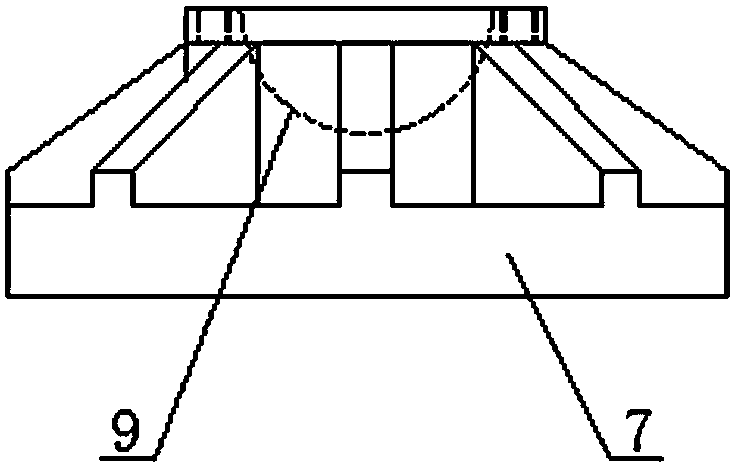

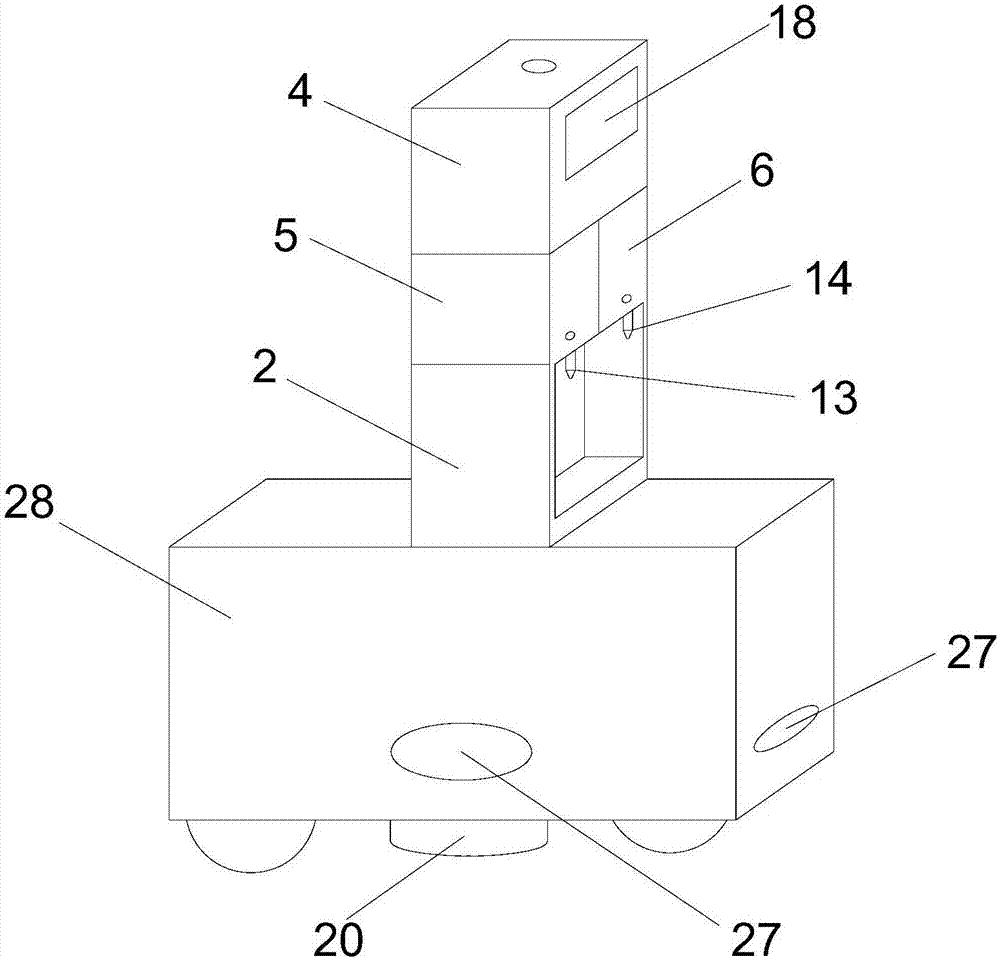

Non-dynamic sealing quick open type test device of material fatigue performance under high-pressure hydrogen environment

ActiveCN106018139AEliminate Hydrogen Leakage and Frictional Power LossIncrease test loading frequencyMaterial strength using repeated/pulsating forcesHigh pressure hydrogenMaterial fatigue

The invention discloses a non-dynamic sealing quick open type test device of a material fatigue performance under a high-pressure hydrogen environment. The test device mainly comprises an environmental box module, an air source module, a supercharger, a vacuum pump, a heat transfer module and an industrial personal computer. The test device of the material fatigue performance under the high-pressure hydrogen environment can be realized without a dynamic sealing structure, especially, a high-cycle or high-frequency fatigue test under the high-pressure hydrogen environment can be realized, the quick opening and closing of the test device and the real-time monitoring of health conditions of equipment can be realized, and the test device has high-efficiency and safe high and low temperature test function.

Owner:SOUTH CHINA UNIV OF TECH

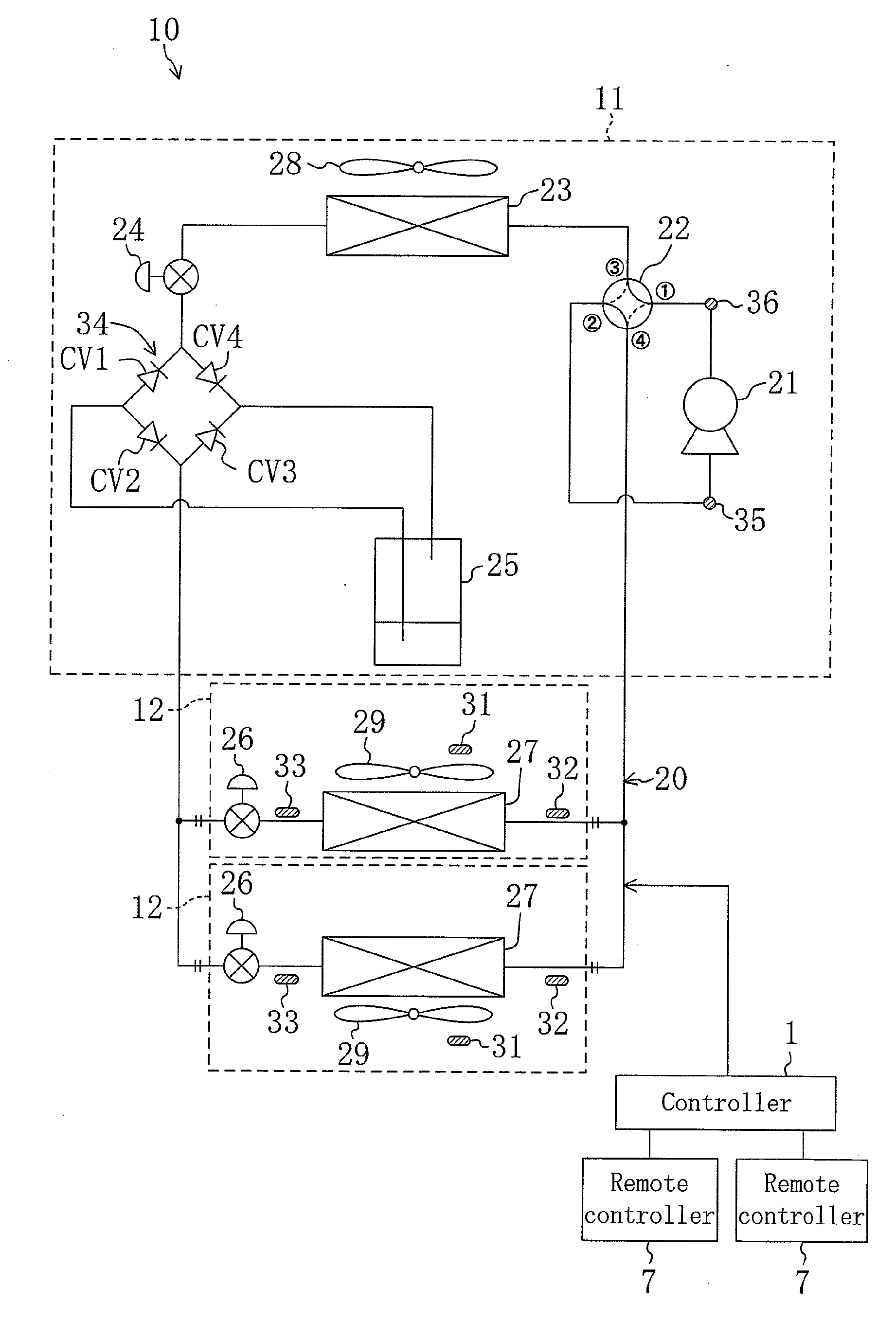

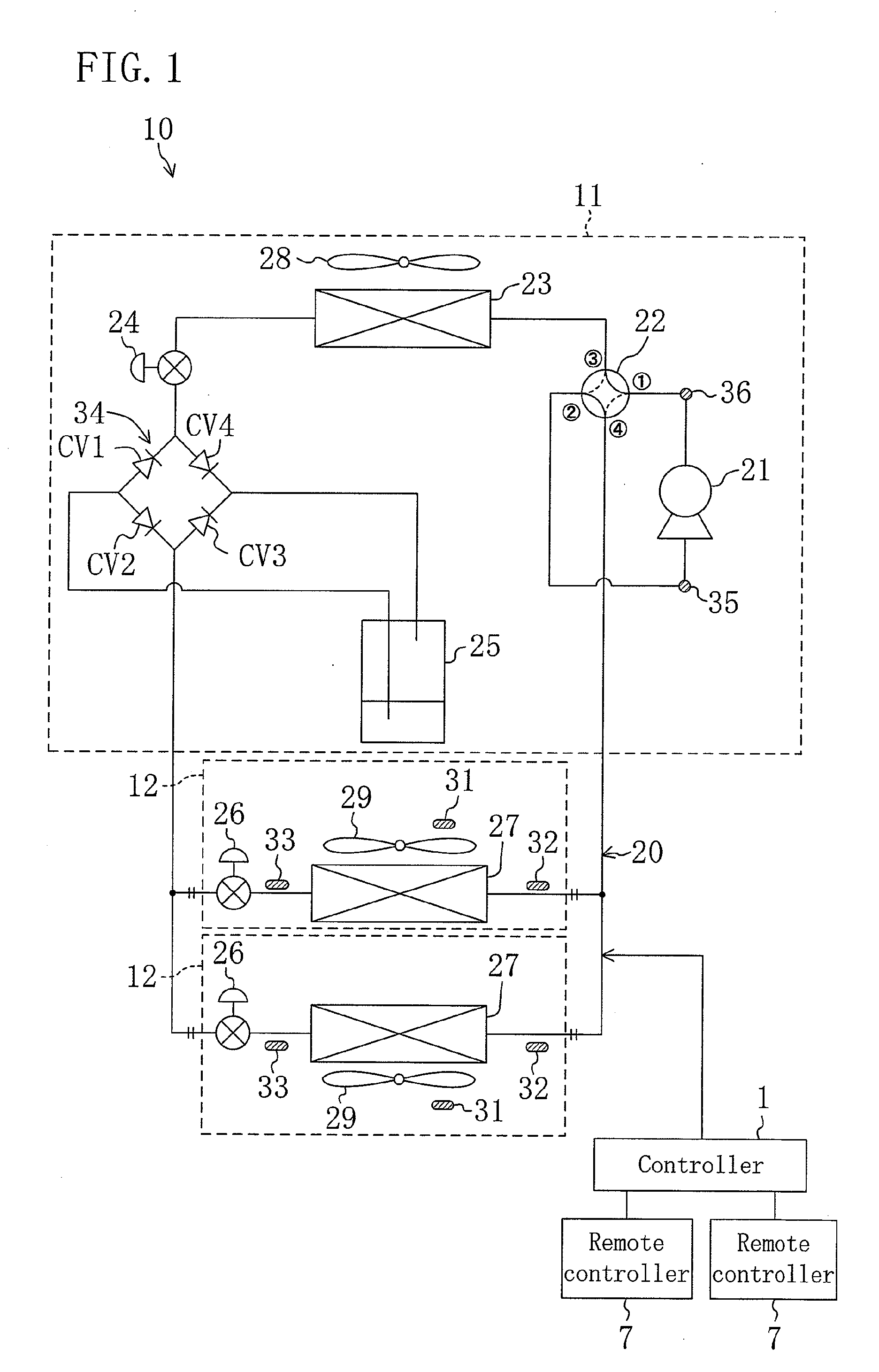

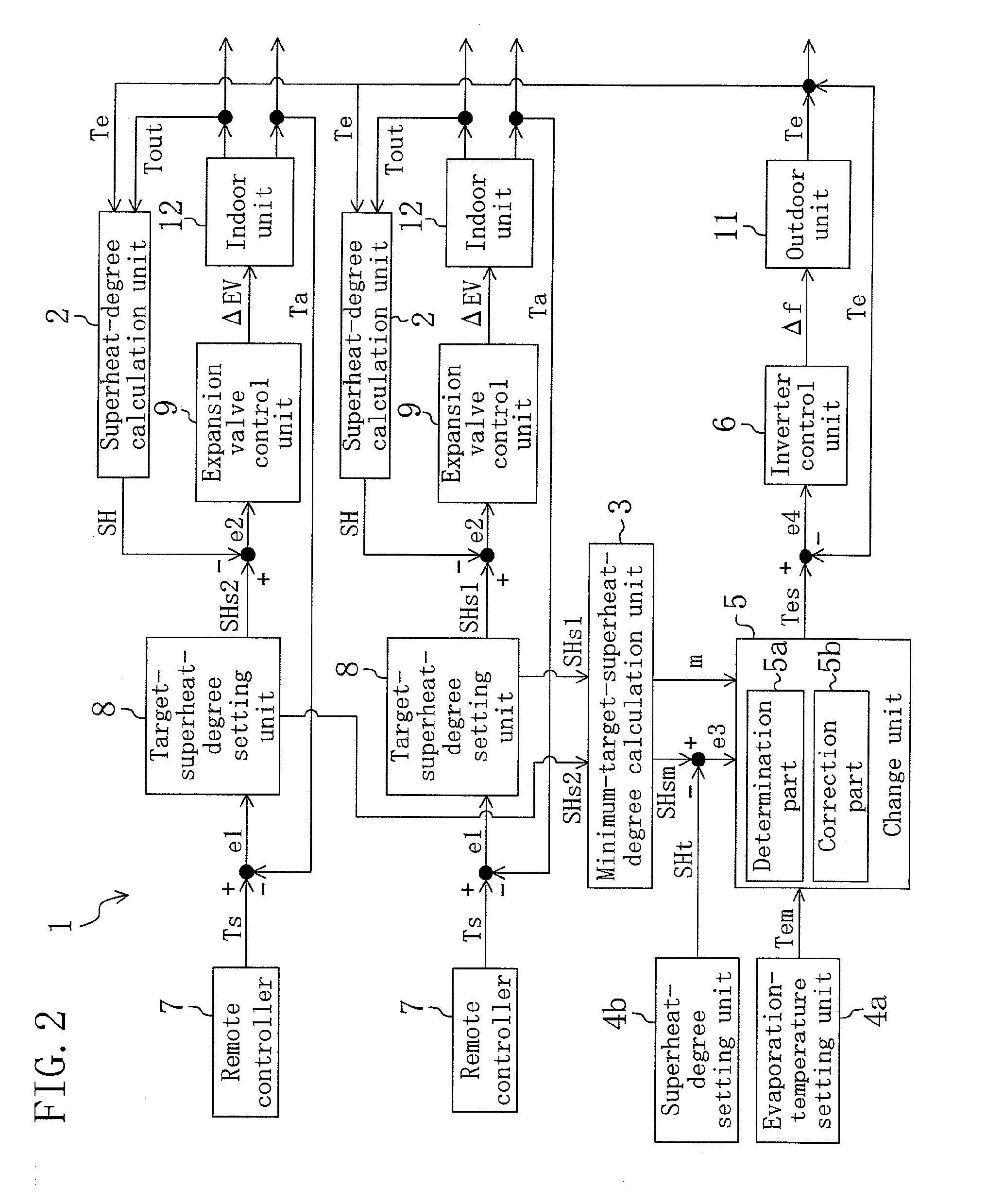

Refrigeration system

ActiveUS20110023534A1Reduce power consumptionReduction factorCompression machines with non-reversible cycleCompression machines with several evaporatorsProcess engineeringRefrigeration

An air conditioner (10) includes a refrigerant circuit (20) including a plurality of indoor heat exchangers (27). A controller (1) for controlling operation of the air conditioner (10) includes a change unit (5) configured to change a set temperature Tem to a value larger than a current value when the minimum target superheat degree SHsm of target superheat degrees SHs determined for the respective indoor heat exchangers (27) is higher than a predetermined value SHt.

Owner:DAIKIN IND LTD

Outdoor unit for air conditioner

InactiveUS7210305B2Easy dischargePreventing the condensed water from freezingThermal insulationCondensate preventionEngineeringHeat exchanger

An outdoor unit for an air conditioner allows condensed water generated from an outdoor heat exchanger to be easily discharged, and prevents coldness from the outdoor heat exchanger from being transmitted to a bottom of the outdoor unit, thus preventing freezing of the condensed water on the bottom. The outdoor unit includes a cabinet having a bottom panel, an outdoor heat exchanger installed in the cabinet, and a support member made of heat insulating material supporting the outdoor heat exchanger with a spacing between a lower end of the outdoor heat exchanger and the bottom panel of the cabinet, to prevent condensed water generated from the outdoor heat exchanger from freezing.

Owner:SAMSUNG ELECTRONICS CO LTD

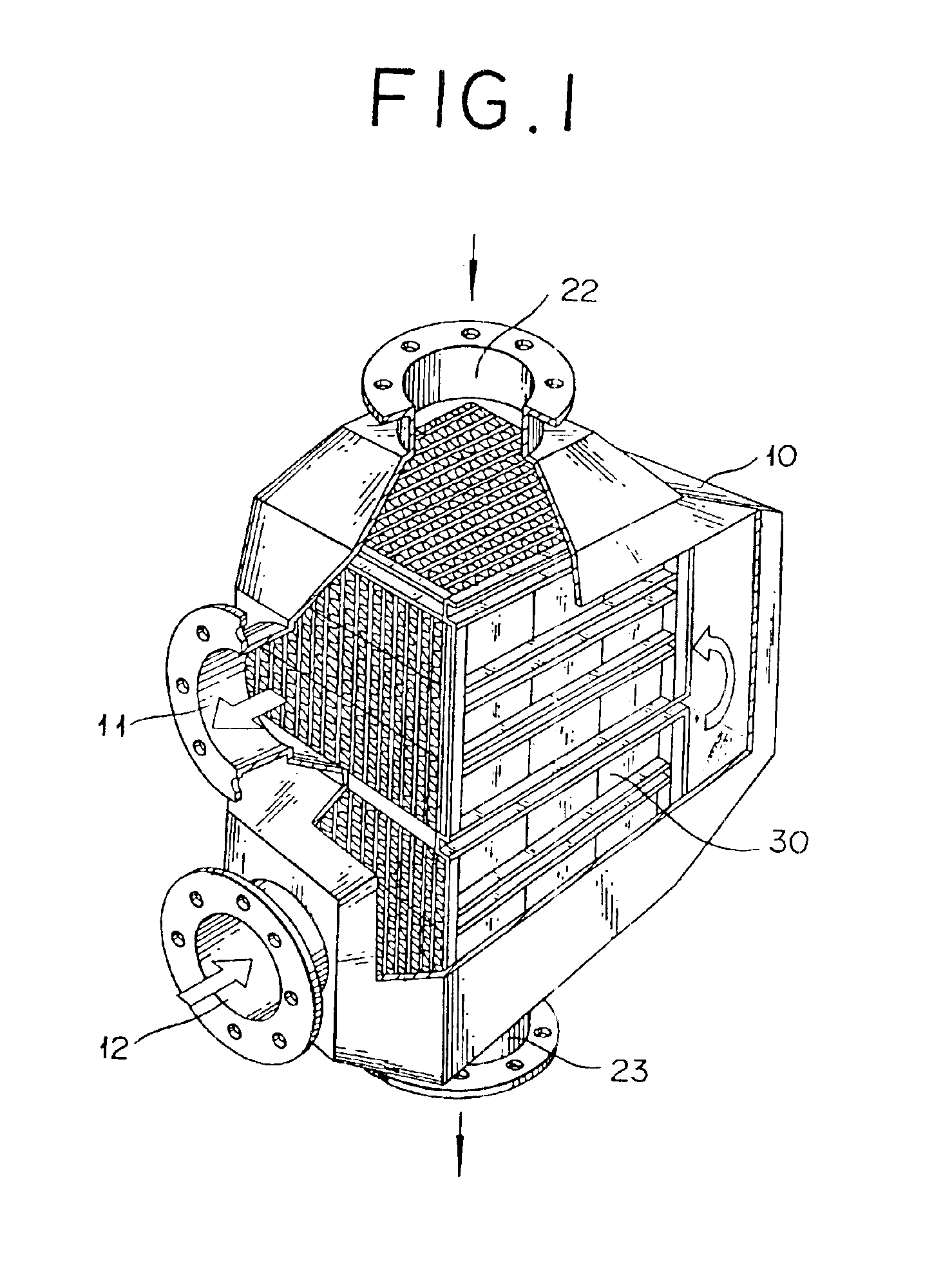

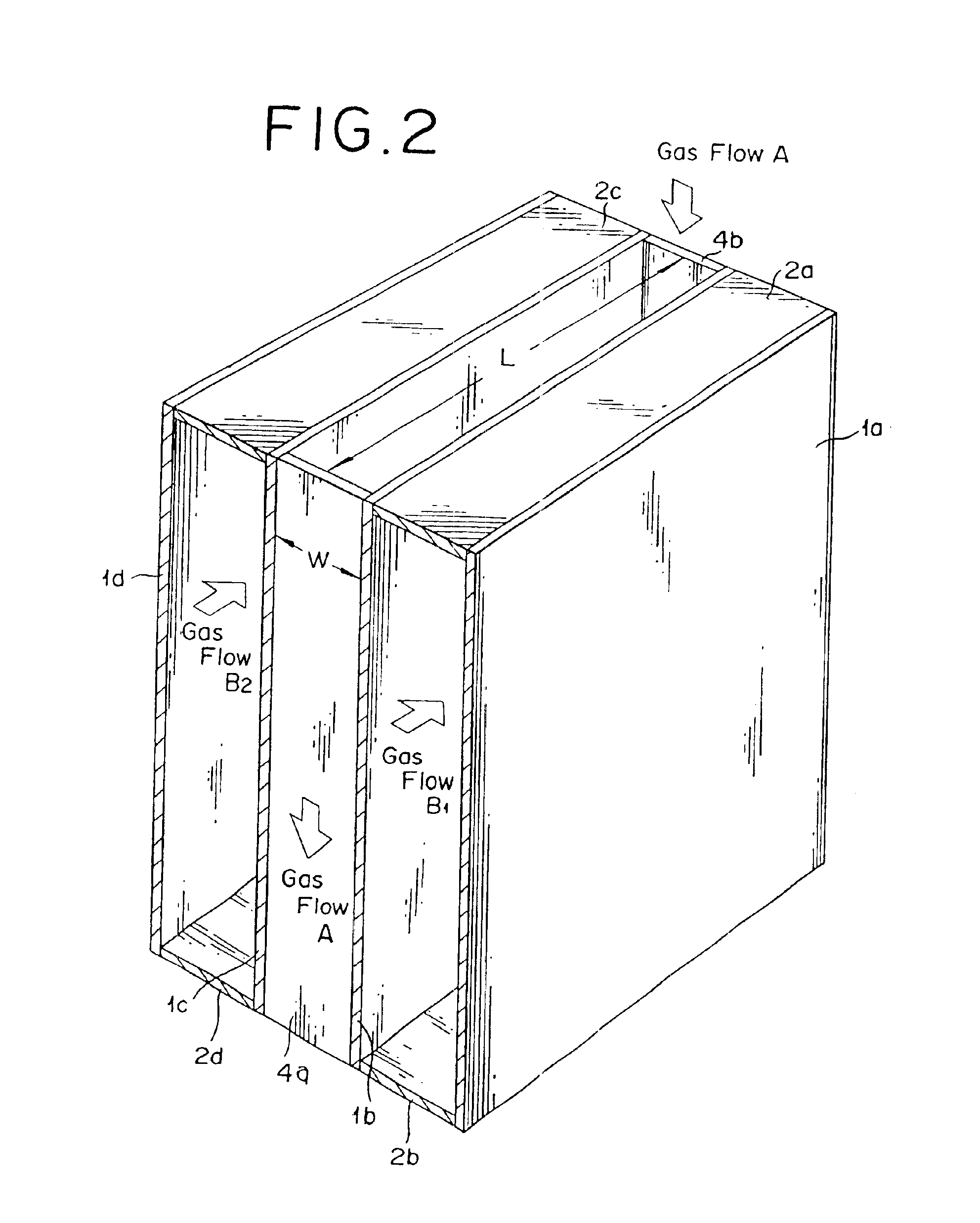

Method for preventing plate type heat exchanger from blockage

InactiveUS6848501B2Avoid heat exchangeAvoid cloggingProcess control/regulationCorrosion preventionMeth-Gas passing

In an apparatus provided with a plate type heat exchanger as a heater and / or a cooler and operated to treat a gas containing an easily blocking substance, a method for preventing the plate type heat exchanger from being blocked is disclosed which is characterized by i) setting the width of a flow path on a plate of the plate type heat exchanger in the apparatus in a range of 6-25 mm and ii) setting the average flow rate of the gas passing the plate type heat exchanger in the apparatus per unit cross-sectional area of the flow path on the plate in the range of 3-15 m / s. In the exchange of heat of an easily blocking substance by the use of a plate type heat exchanger, a method for preventing the plate type heat exchanger from blockage is disclosed which has the plate type heat exchanger provided in the port for introducing a gas containing an easily blocking substance with a gas dispersion plate. This invention, in the heat exchange of an effluent gas emanating from a process for the production of (meth)acrylic acid or an ester thereof or the disposal of the gas, significantly allays blockage of the interior of the plate type heat exchanger.

Owner:NIPPON SHOKUBAI CO LTD

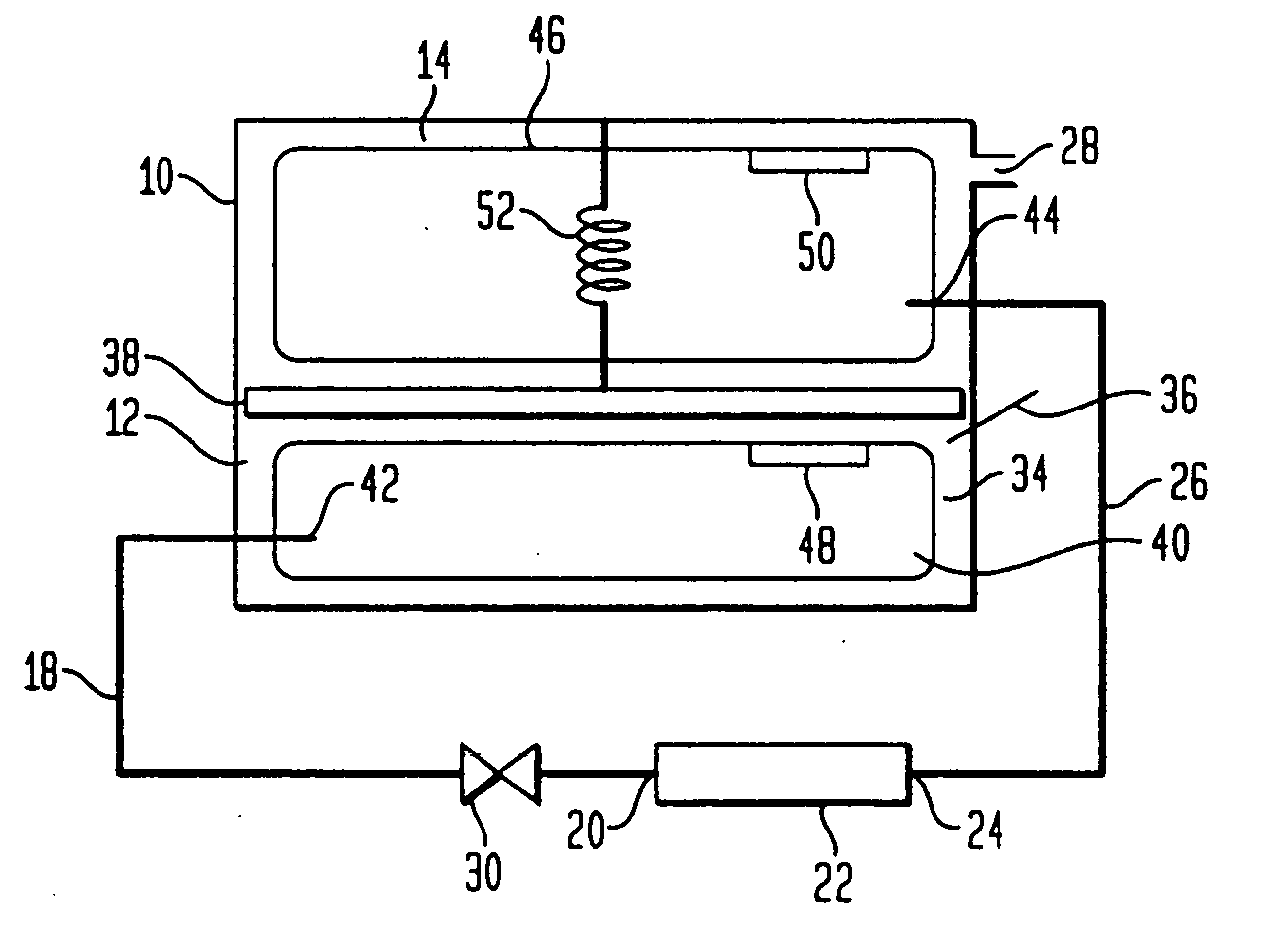

Hydrogen Gas Generation system

InactiveUS20060236606A1Avoid heat exchangeLower the volumePressurized chemical processLevel controlHydrogenAqueous solution

A system for generating hydrogen gas utilizes a volume exchange housing for the storage of a fuel material that reacts to generate hydrogen gas and a hydrogen separation chamber. The system includes a gas permeable membrane or membranes that allow hydrogen gas to pass through the membrane while preventing aqueous solutions from passing therethrough. The system is orientation independent. A throttle valve is also used to self regulate the reaction generating the hydrogen gas.

Owner:SILICON VALLEY BANK

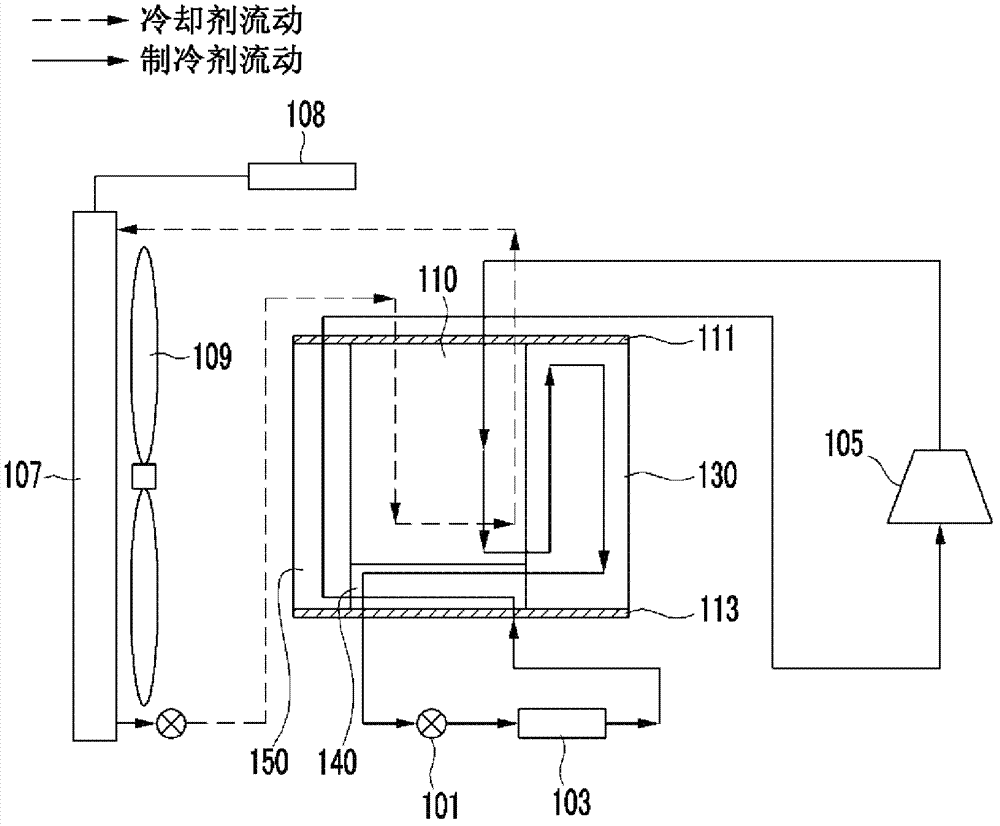

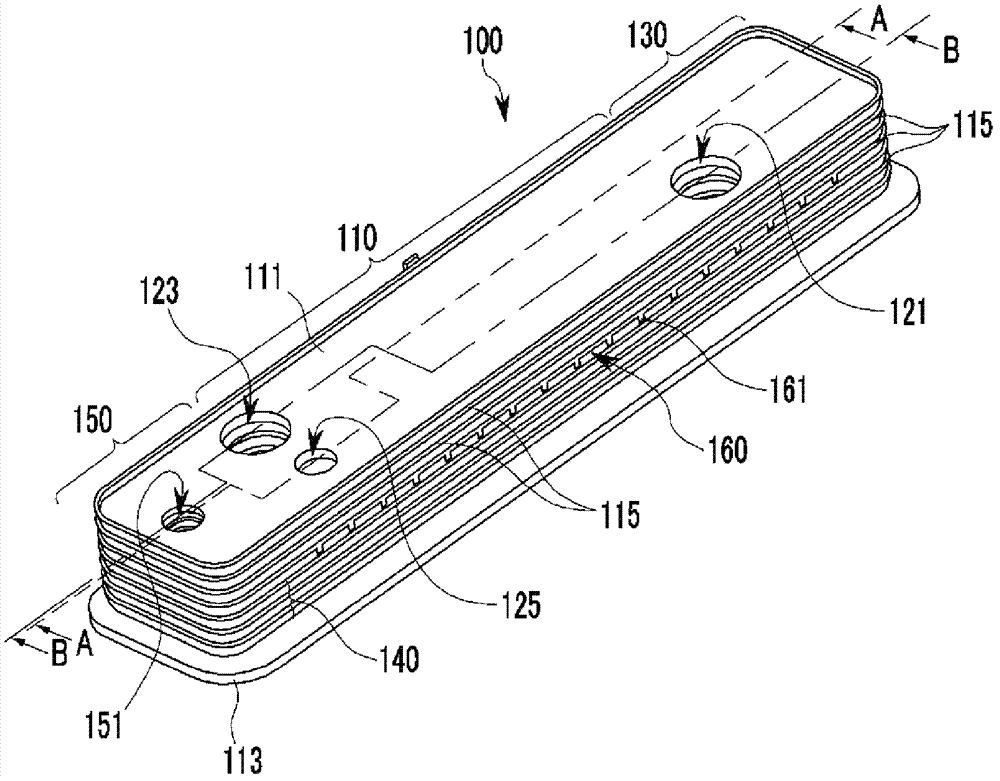

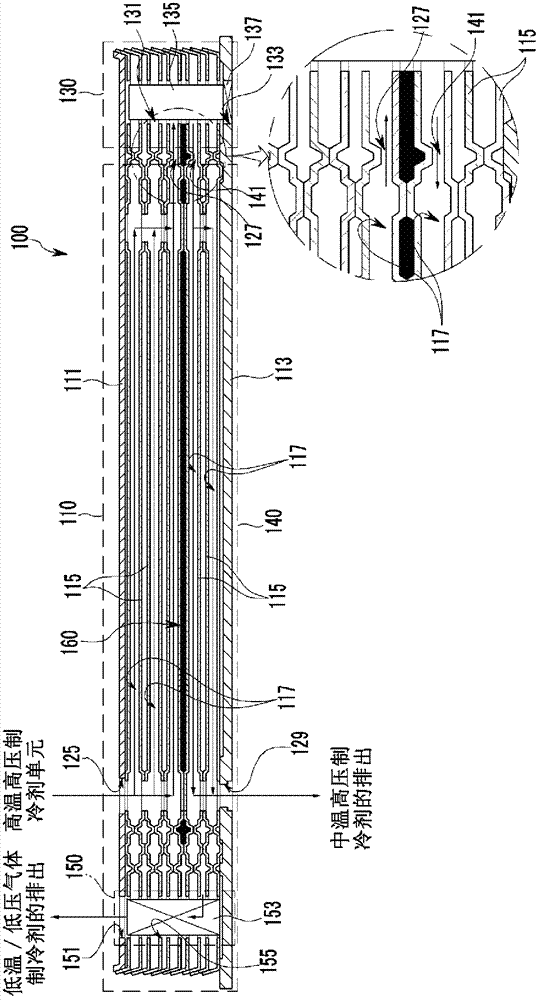

Condenser for vehicle and air conditioning system for vehicle

ActiveCN102788452AReduce the numberOptimize layoutEvaporators/condensersVehicle heating/cooling devicesLiquid stateEngineering

A condenser may include a main radiating portion including a plurality that is formed by laminating a plurality of plates, a receiver drier portion integrally formed at one side end of the main radiating portion, a supercooling radiator that is integrally formed at a lower portion of the main radiating portion, and an accumulator portion integrally formed with the main radiating portion and the other end portion of the supercooling radiator. An air conditioning system may include an expansion valve, an evaporator, and an electrically driven compressor, a water cooler condenser, and a heat exchanger, wherein a liquid state refrigerant of a middle temperature and high pressure passing the water cooler condenser exchanges heat with a low temperature / pressure refrigerant passing the evaporator in the heat exchanger.

Owner:HYUNDAI MOTOR CO LTD +1

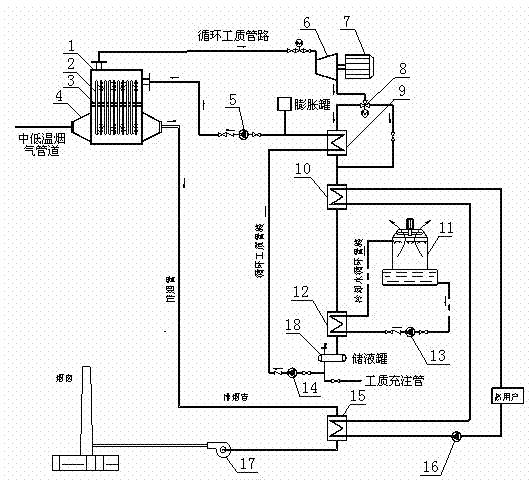

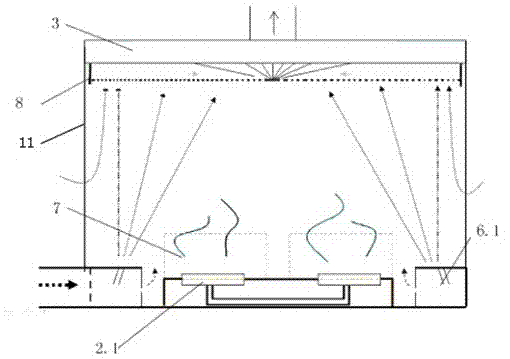

Power generation system for waste heat of medium and low temperature flue gas with cylinder organic medium evaporation

InactiveCN102401592AAvoid leakage of working fluidAvoid efficiencyIndirect heat exchangersSteam engine plantsWorking fluidOrganic Rankine cycle

The invention provides a power generation system for waste heat of medium and low temperature flue gas with cylinder organic medium evaporation, and belongs to the technical field of energy and environment. The invention comprises a heat pipe system, a working medium circulation loop of organic Rankine cycle, a medium and low temperature flue gas exhausting pipeline, a heating hot water loop and a cooling water loop, wherein an ascending pipe and a descending pipe of a boiler are replaced by heat pipes, the flue gas heat exchanger and the boiler cylinder are an integrally cylindrical structure, and is separated to the upper boiler cylinder and the lower flue gas heat exchanger by two layers of insulation partition, the lower end of the heat pipe is arranged in flue gas heat exchanger, the upper end is arranged in the boiler barrel, toluene, dichlorotrifluoroethane, propane and pentafluoropropane are used as working medium, and 20% volume of the softening desalted water is used as the heat pipe working fluid. The invention has advantages of little space occupation, small heat exchange between heat pipe and air, high efficiency of heat exchange, convenient heat pipe replacement, being capable of avoiding the heat exchanger pipe corrosion and the working medium leakage and other advantages, and being capable of adjusting the exhaust regenerative heat of organic Rankine cycle according to the heating load demands.

Owner:KUNMING UNIV OF SCI & TECH

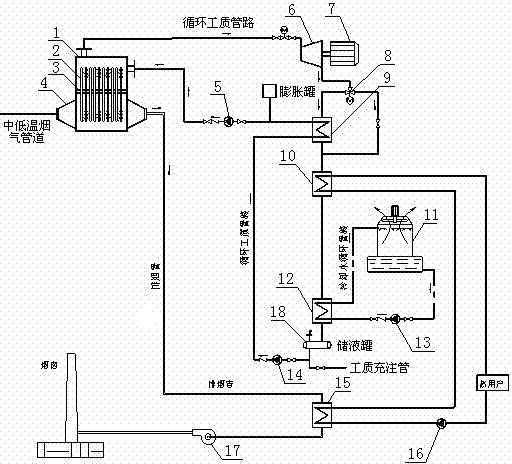

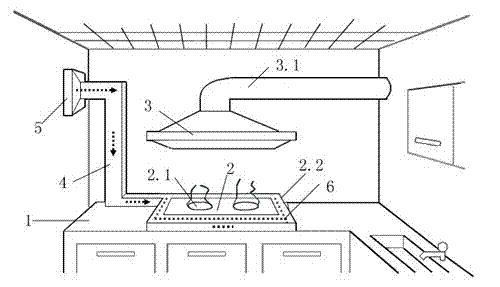

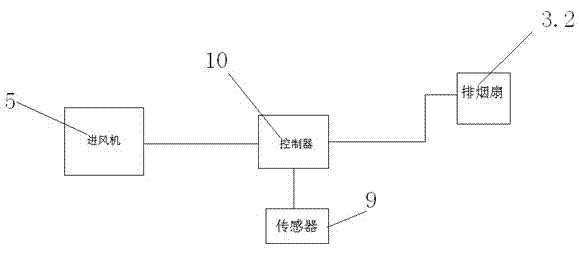

Smoke insulation and heat insulation fresh air system capable of realizing kitchen air conditioner environment

InactiveCN103090436AGuaranteed freshPrevent proliferationDomestic stoves or rangesLighting and heating apparatusFresh airEnvironmental engineering

The invention relates to a smoke insulation and heat insulation fresh air system capable of realizing a kitchen air conditioner environment. The smoke insulation and heat insulation fresh air system comprises an oven tool arranged on a hearth and a range hood arranged right above the hearth, wherein a flow guiding cover is arranged below the range hood, the oven tool is provided with an air curtain generator, and the air curtain generator comprises a frame type shell sleeved on the periphery of the oven tool; one side of the frame type shell is connected with an air inlet pipe which is communicated with the frame type shell, an air inlet of the water inlet pipe is provided with an air inlet machine and is communicated with exterior, and a gas channel is formed at an inner cavity of the frame type shell; and an upper panel of the frame type shell is provided with a flow guiding groove, the two sides of the flow guiding groove are provided with positioning side plates which are inwards inclined and are connected with the upper panel, and the flow guiding groove is internally provided with an ejector. The smoke insulation and heat insulation fresh air system provided by the invention realizes the insulation of indoor air in a kitchen and oil pumping smoke in the hearth, heat exchange and oil smoke diffusion caused by gas convection are avoided, a relatively sealed outer circulating system is formed between a gas oven tool and oil pumping smoke equipment, waste gas and oil smoke are discharged, and accessible insulation is realized, ventilation and oil smoke problems are completely solved, and the realization of the air-conditioned kitchen becomes possible.

Owner:卫修华

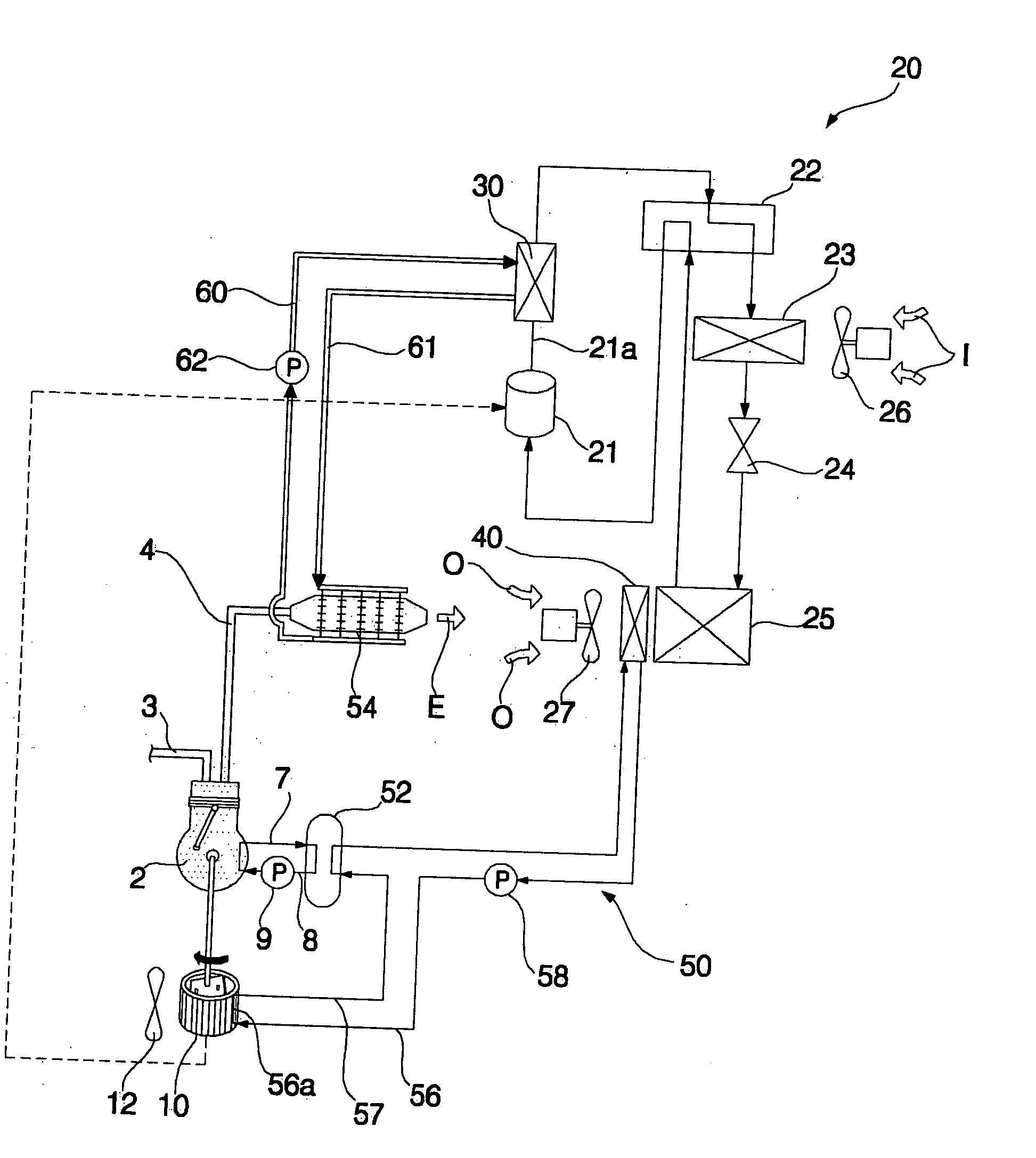

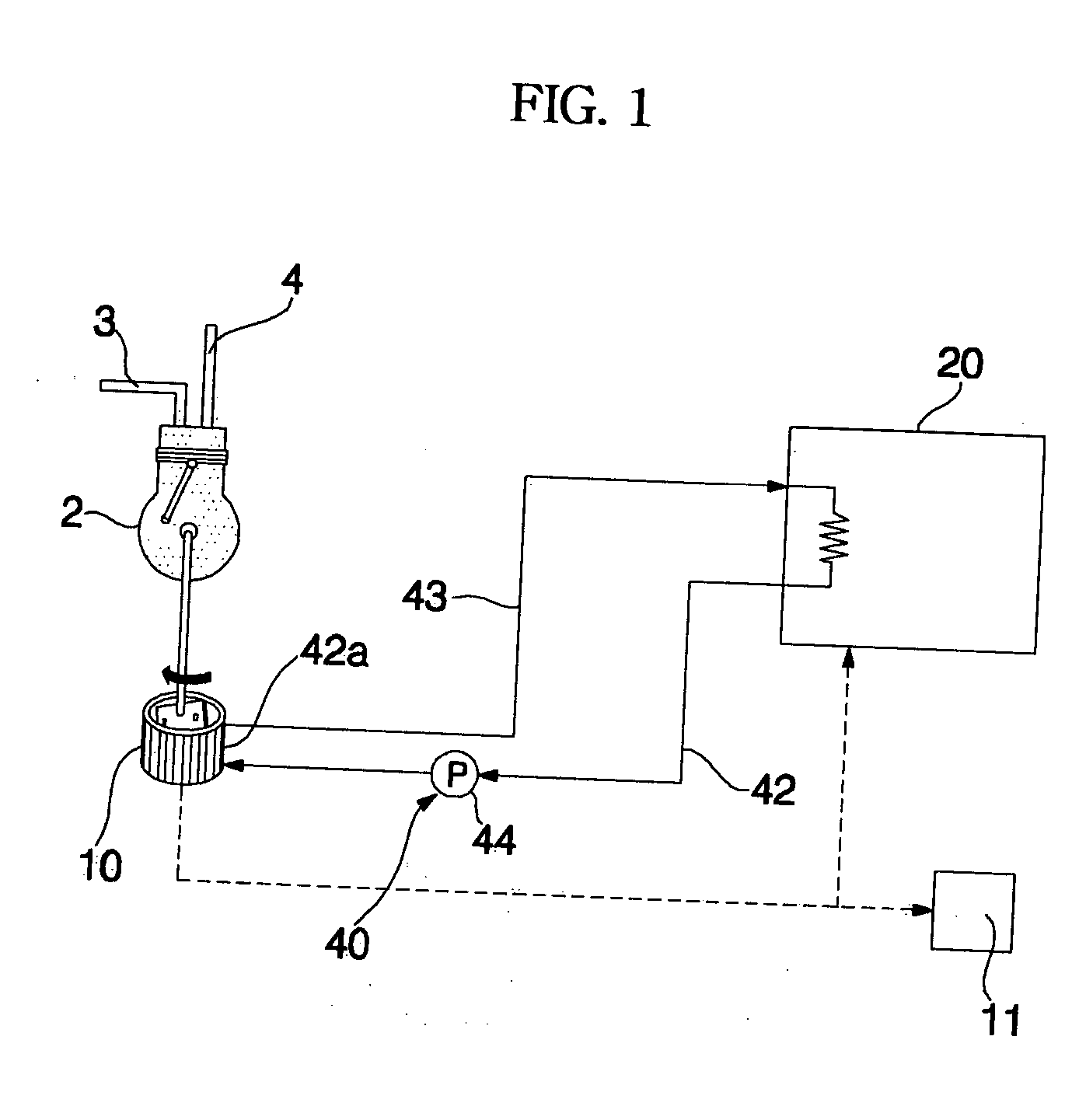

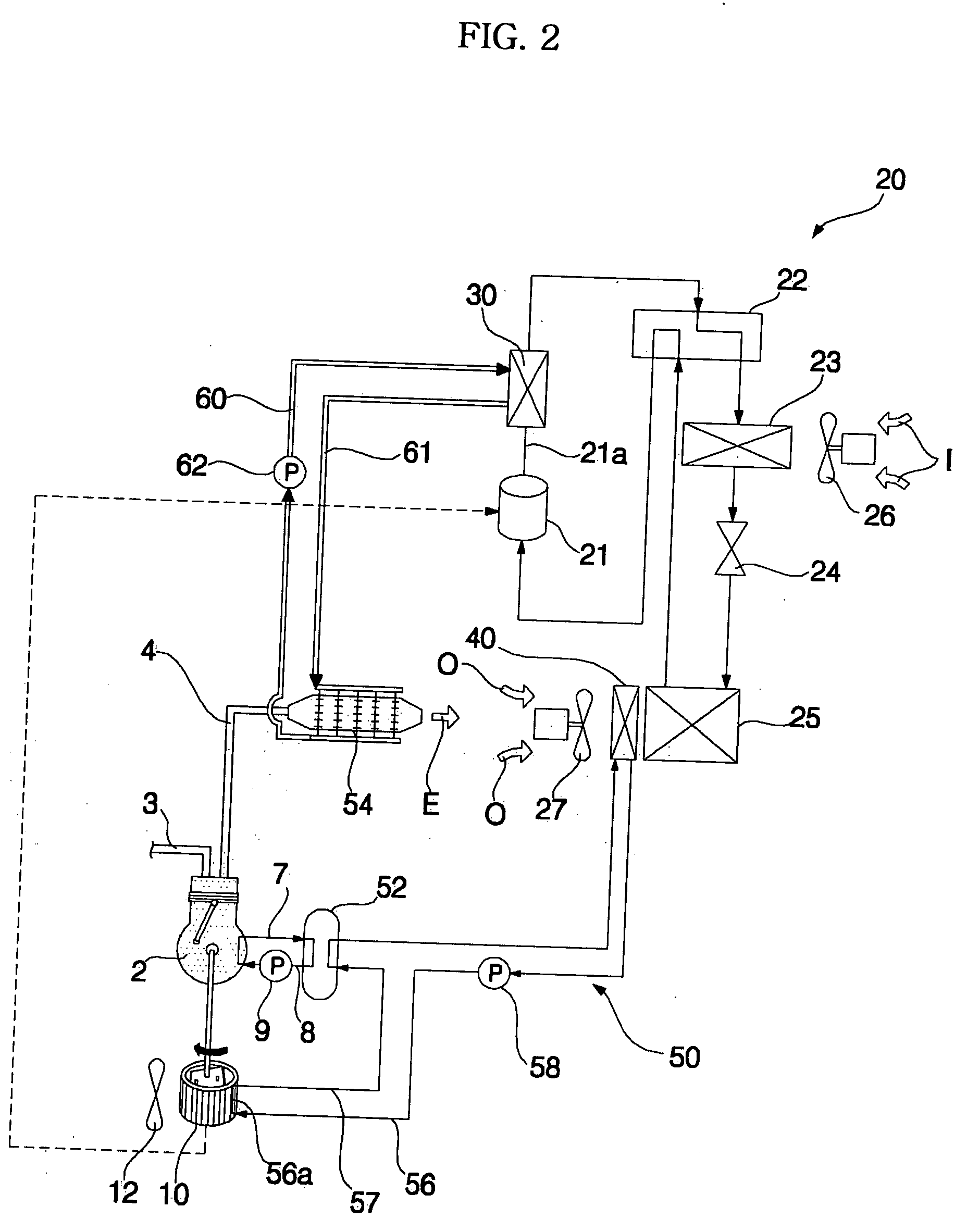

Cogeneration system

InactiveUS20060037348A1Improve energy efficiencyRelease heatAir-treating devicesClimate change adaptationWaste heat recovery unitElectricity

A cogeneration system including an engine, a generator connected to an output shaft of the engine to generate electricity, and a waste heat recoverer to recover waste heat of the generator and to transfer the recovered waste heat to a heat consumer. Since waste heat of the generator is supplied to the heat consumer, the cogeneration system exhibits a high energy efficiency while achieving release of heat from the generator.

Owner:LG ELECTRONICS INC

Heat-recovery vehicle air conditioner

InactiveCN102059930AAvoid enteringAvoid heat exchangeAir-treating devicesVehicle heating/cooling devicesFour-way valveEngineering

The invention discloses a heat-recovery vehicle air conditioner. The heat-recovery vehicle air conditioner comprises a circulation loop and a hot air core, wherein the circulation loop is formed by a compressor, a two-position four-way valve, a condenser, a throttling element and heat exchange equipment; the hot air core forms a fluid loop with a motor mechanism of a vehicle; the fluid loop formed by the hot air core and the motor comprises a fluid pump; and stop valves are arranged on both an inflow side and an outflow side of the hot air core. By using the heat-recovery vehicle air conditioner, when the vehicle stops transitorily, the hot air core is disconnected from the motor by closing the stop valves on the two sides of the hot air core so as to prevent the heat of the motor from entering the hot air core, and simultaneously prevent the cold energy of the hot air core from entering the motor. In addition, the hot air core is connected with an energy accumulator; when the air conditioner operates, excessive heat or cold energy are stored in the energy accumulator; when the air conditioner stops, the stop valves of the energy accumulator are closed to prevent heat exchange between the energy accumulator and the hot air core; when the air conditioner is restarted again, the heat exchange is performed between the energy accumulator and the hot air core to release the heat or the cold energy in the energy accumulator to the hot air core.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD

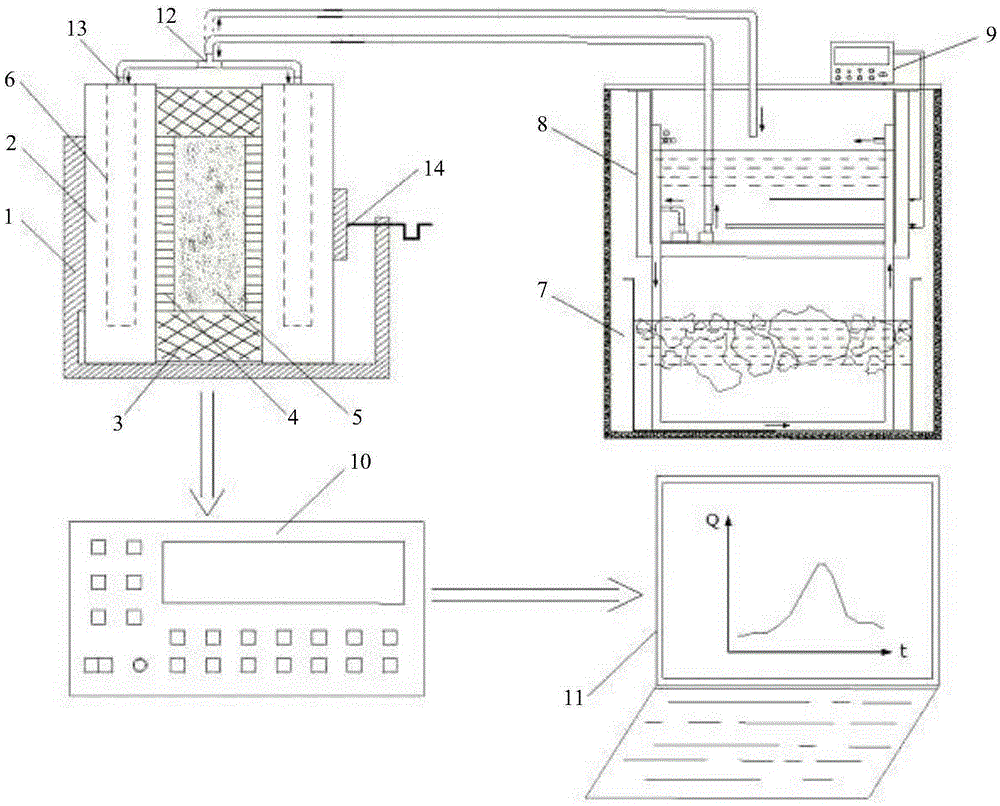

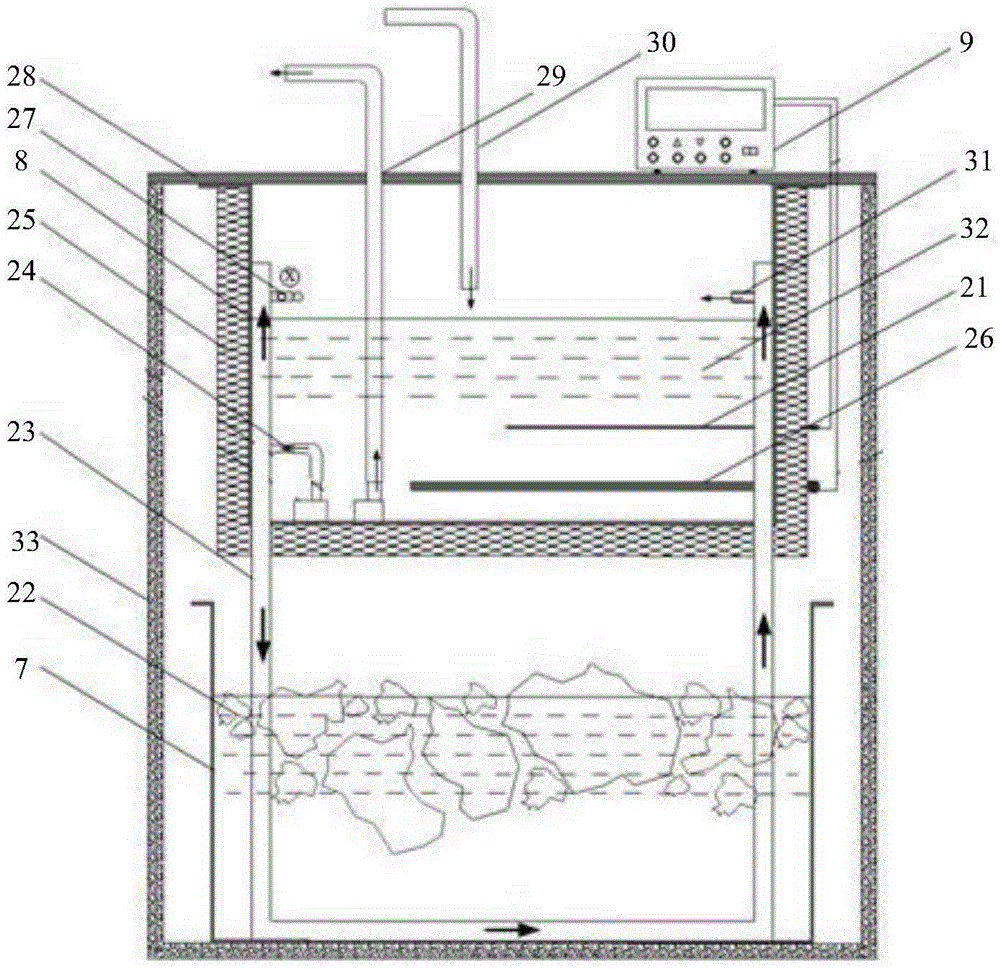

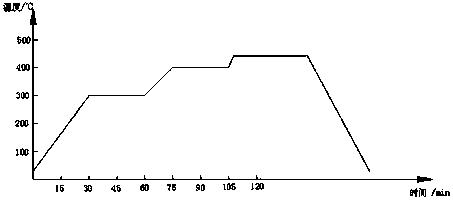

Test device and test method for latent heat of composite phase-change material

ActiveCN105424741ATrue reflection of thermal propertiesReduce mistakesInvestigating phase/state changeHeat flowEngineering

The invention discloses a test device for latent heat of a composite phase-change material. In the test device, a sample of the composite phase-change material is clamped by means of two plate heat-flow meters having equal area to form a sandwich structure. Two constant-temperature aluminum plates having larger area are respectively fixed to exteriors of the two plate heat-flow meters tightly. A groove can be formed in each constant-temperature aluminum plate to allow the plate heat-flow meter to be installed therein. Peripheries of the plate heat-flow meters and the sample are sealed by means of a heat preservation material to fix the plate heat-flow meters and the sample in the central zones of the constant-temperature aluminum plates. The temperature of the sample is accurately controlled through the constant-temperature aluminum plates. The temperature of the constant-temperature aluminum plates is accurately controlled through a constant-temperature device. The plate heat-flow meters detect the heat flow quantity in the sample during temperature increasing and temperature reducing, so that sensible heat and latent heat of the sample can be obtained by measuring absolute heat adsorbed by and released from the sample of the composite phase-change material in a series of small-range temperature increasing and temperature reducing processes through the plate heat-flow meters, and then simply calculating the detect results through a formula. The invention also discloses a test method for the latent heat of the composite phase-change material.

Owner:雄安绿研检验认证有限公司

Apparatus for cleaning tube fins of air fan cooler for heat exchanger

InactiveUS20090101183A1Environment-friendly cleaningAvoid damageCleaning using liquidsTrickle coolersPlate heat exchangerChiller

Owner:SK ENERGY CO LTD (KR)

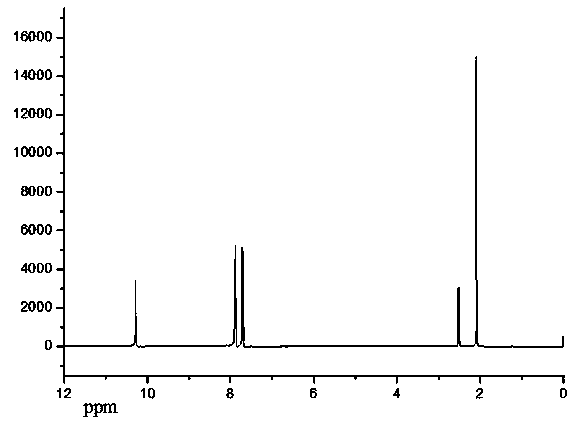

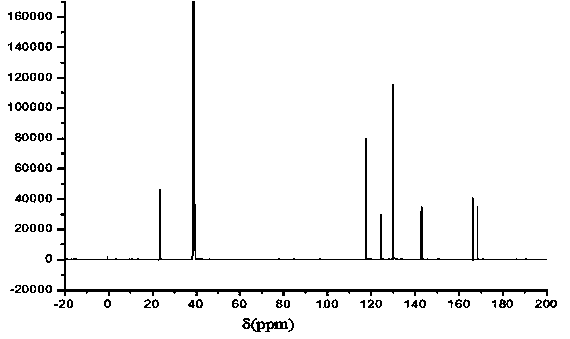

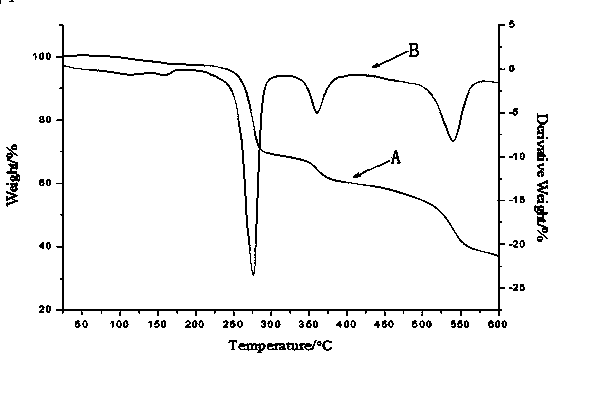

P-N expanded reaction type flame retardant and preparation method thereof

InactiveCN104072759AWith smoke suppressionEfficientGroup 5/15 element organic compoundsFiltrationEnd-group

The invention discloses a P-N expanded reaction type flame retardant p-(carboxyphenyl-amino)-(carboxyphenyl-amidoethyl) phenylphosphine oxide and a preparation method thereof. The preparation method comprises the following steps: (a) adding a p-aminobenzoic acid solution into glacial acetic acid; (b) adding triethylamine and mixed solution obtained in the step (a) into a 2-carboxethylphenyl hypophosphorous acid solution, stirring at a high speed and reacting for 2 hours, raising the temperature to 80 DEG C, reacting for 4 hours, cooling, hydrolyzing, performing suction filtration, washing and drying to obtain white powder, namely the P-N expanded reaction type flame retardant. The defects that harmful gases are generated by general flame retardants, the environment is polluted, fuming is caused and the mechanical property is influenced are overcome, the P-N expanded reaction type flame retardant has double-carboxyl end groups, effective flame retardant components are bonded to a PA66 main chain, an inherently flame retardant effect is achieved, and the flame retardant has the advantages of harmlessness, smoke inhibition, high efficiency, environmental friendliness and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Dynamic pressurized tempering furnace for tempering saw blade matrix and tempering process

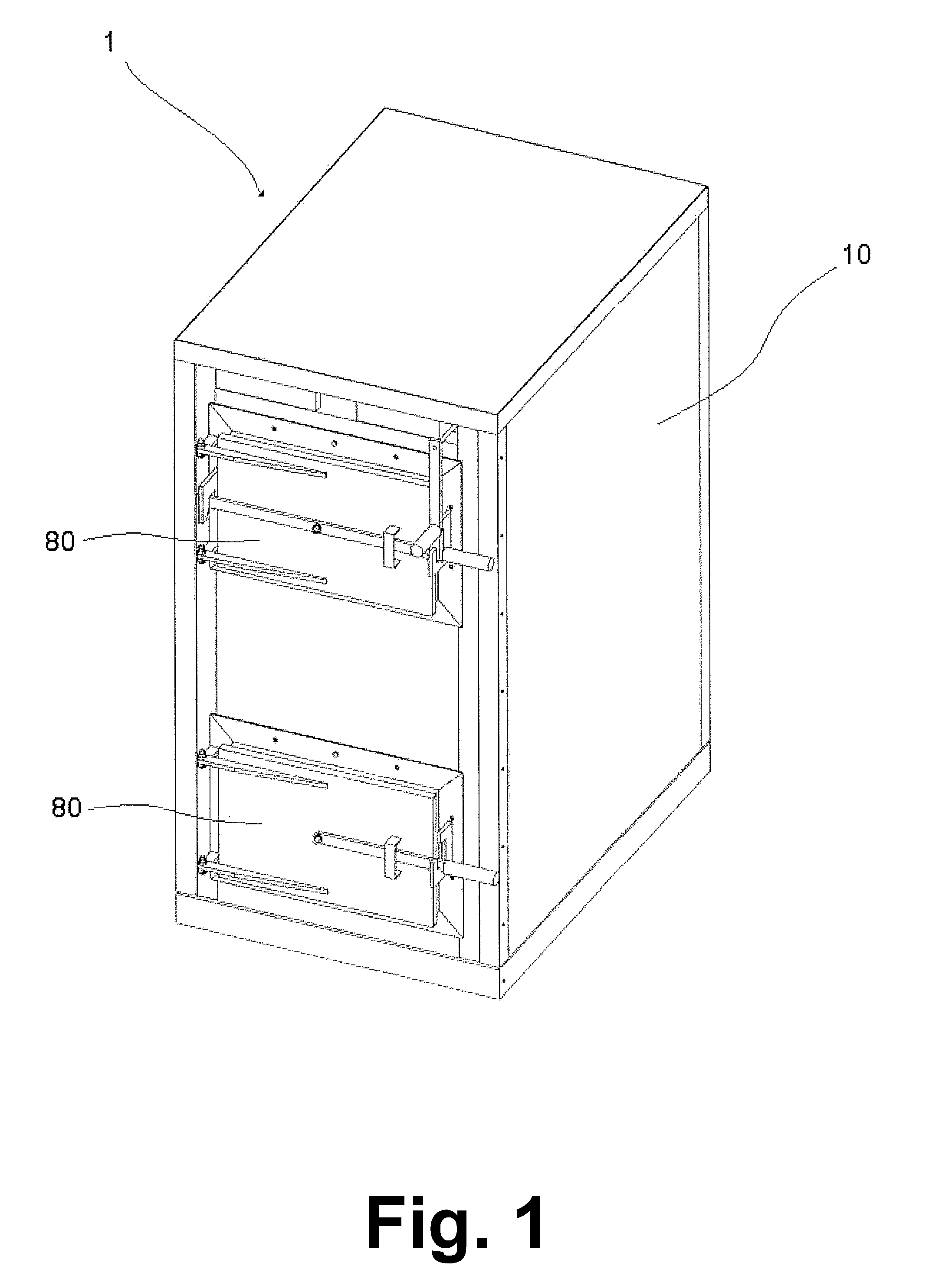

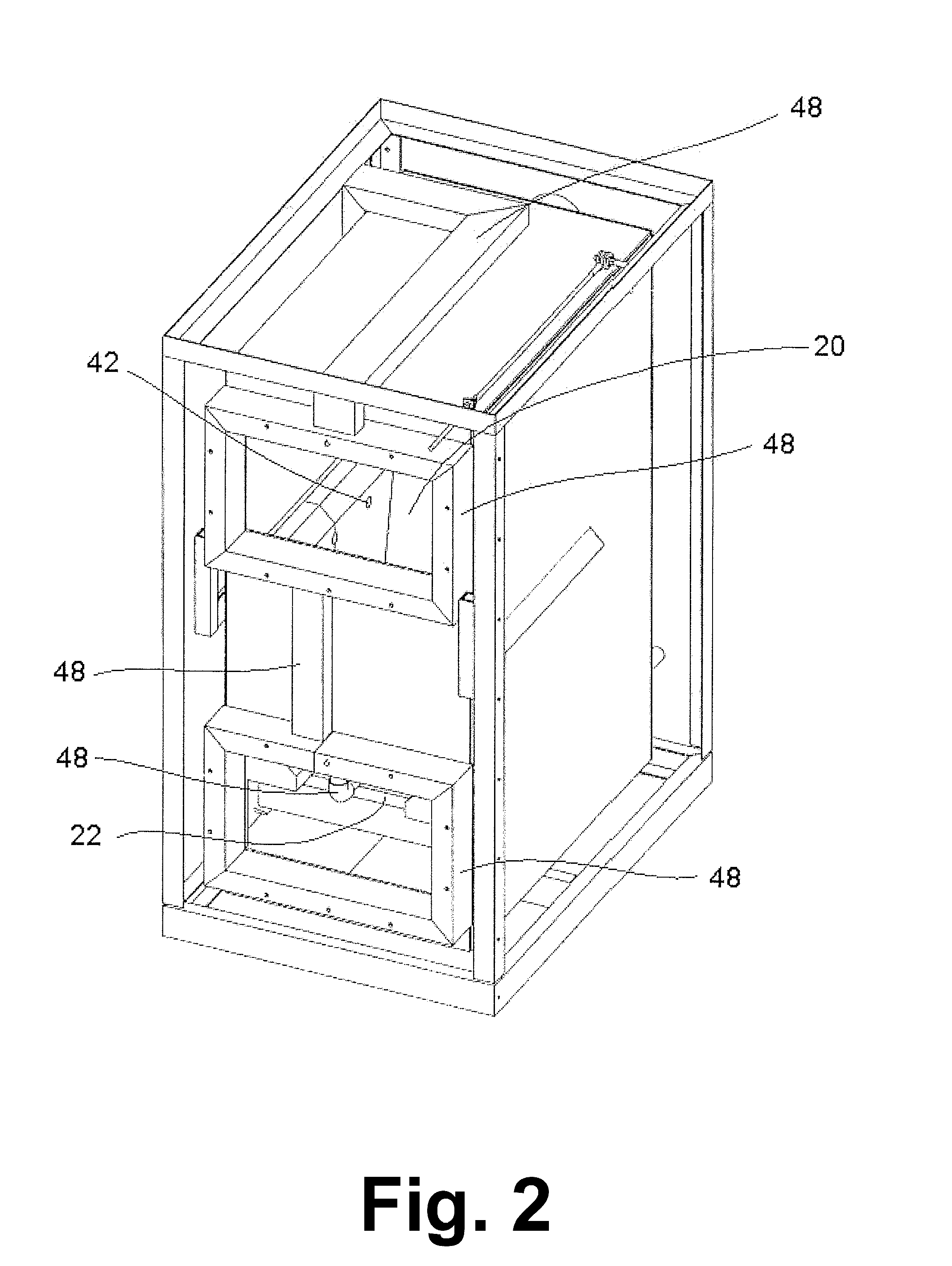

InactiveCN103981354AAvoid heat exchangeAvoid damageFurnace typesHeat treatment process controlFire protectionDisplay device

The invention discloses a dynamic pressurized tempering furnace for tempering a saw blade matrix. The dynamic pressurized tempering furnace comprises a furnace body (1), a heating device (2) and a bearing platform (3), wherein the heating device (2) and the bearing platform (3) are both arranged in the furnace body (1); the inner wall of the furnace body (1) is provided with a fire protection layer (4); an oil cylinder (6) is vertical to the top of the furnace body (1) and is arranged in the furnace body (1); the bottom of a piston rod of the oil cylinder (6) is provided with a spherical boss (8); a pressure head (7) is internally provided with a spherical groove (9). The dynamic pressurized tempering furnace also comprises a controller, a display (10) and a temperature sensor (11), wherein the controller is connected with the oil cylinder (6) and the heating device (2). The dynamic pressurized tempering furnace is compact in structure, capable of automatically regulating the angle of the pressure head according to the planeness of a saw blade and convenient for workers to operate. After being subjected to thermal treatment by the dynamic pressurized tempering furnace, the saw blade matrix is uniform in crystalline phase tissue, small in internal residual stress and low in saw blade planeness less than 0.03mm.

Owner:成都壹佰科技有限公司

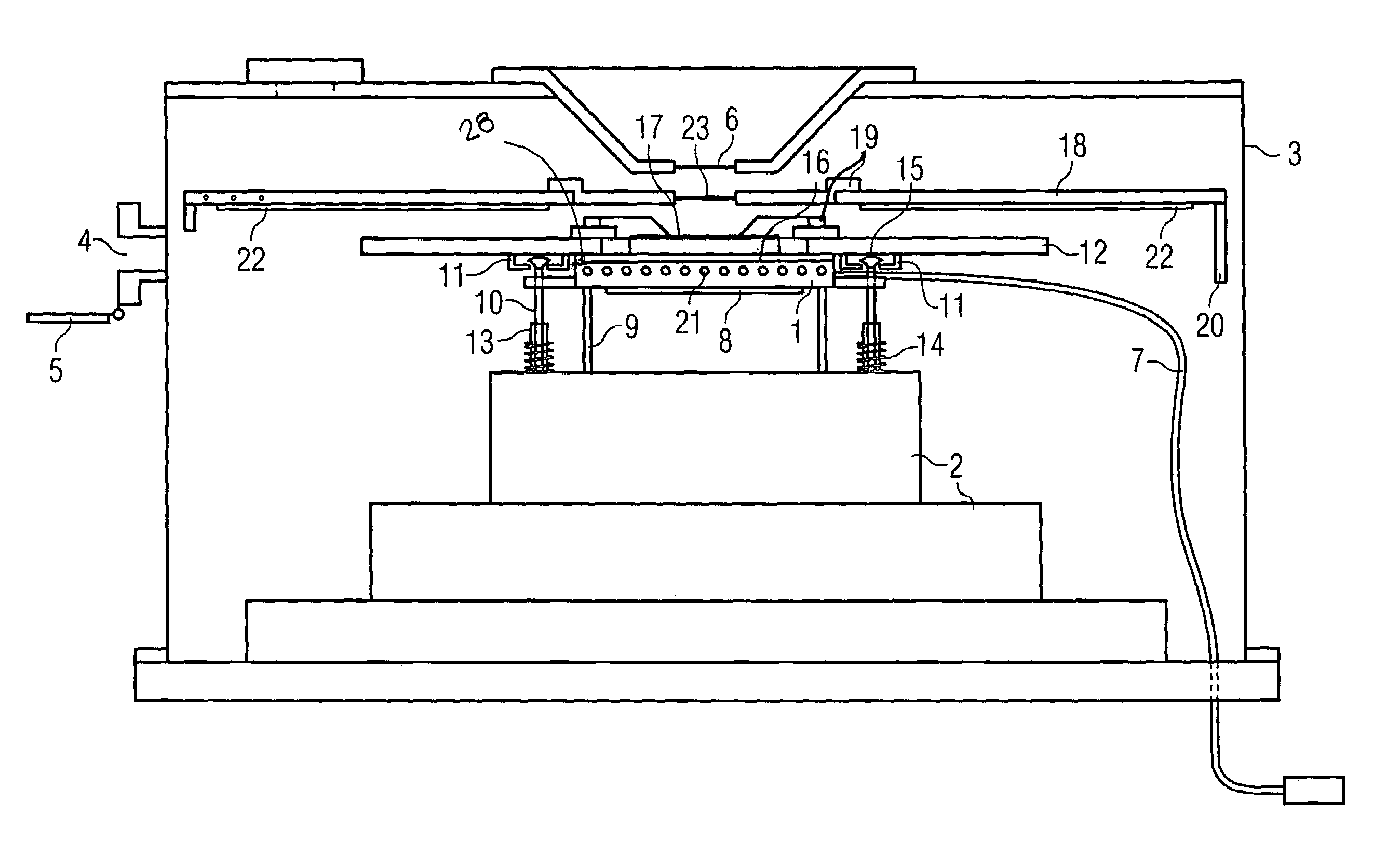

Test apparatus for testing substrates at low temperatures

InactiveUS7046025B2Easy to controlLow mobilityElectronic circuit testingFault location by increasing destruction at faultRoom temperatureEngineering

A test apparatuss for testing substrates at low temperatures has a chuck, which can be displaced in the working area by means of a chuck drive, the temperature of which can be controlled using heating and cooling means. The chuck has a receiving surface for receiving a test substrate and holding means for fixing a substrate carrier which receives the test substrate. Spatially and thermally defined test conditions are maintained with minimal energy and labor costs both at room temperatures and at low temperatures. This is achieved by providing a vacuum chamber which surrounds the working area of the chuck. The chuck is on one side thermally decoupled from the uncooled chuck drive and on the other side is thermally connected in a releasable manner to the test substrate. The cooled chuck and the cooled test substrate are shielded from the thermal radiation of the surrounding uncooled assemblies by means of a directly cooled thermal radiation shield.

Owner:CASCADE MICROTECH

Liquid-Vapor Separating Method and a Liquid-Vapor Separating Type Evaporator

InactiveUS20100126213A1Reduce consumptionImprove efficiencyCompression machines with non-reversible cycleEvaporators/condensersEngineeringSuperheated steam

A liquid-vapor separating method and a liquid-vapor separating type evaporator, the method includes the following steps: (i) provide a partition device (3) in the upper portion of the evaporated liquid pipe, the partition device (3) divides the evaporated liquid pipe into a superheating section (12) and an evaporating section (13); (ii) a liquid-vapor separating pipe (4) is connected to the superheating section (12) near the partition device (3), an evaporated liquid feeding pipe (6) is connected to the evaporating section (13) near the partition device (3), several vapor guiding pipes (5) are respectively provided in the pipe of the evaporating section (13), the vapor guiding pipes (5) are respectively connected with the liquid-vapor separating pipe (4); vapor inside the pipe can flow out, and is separated into vapor and liquid in the liquid-vapor separating pipe (4), then the vapor enters the superheating section (12) and is superheated; the superheated vapor is discharged from a vapor outlet (11); (iii) the residual liquid separated from the liquid-vapor separating pipe (4) and the residual liquid in evaporating section (13) are together sent to the evaporated liquid feeding pipe (6) through a return pipe (14), and back to the evaporating and heat-exchanging process of evaporated liquid.

Owner:TSINGHUA UNIV

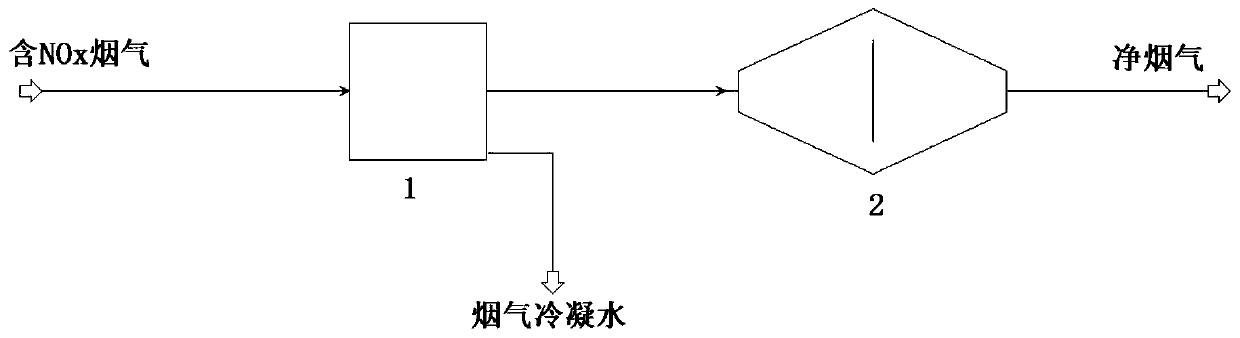

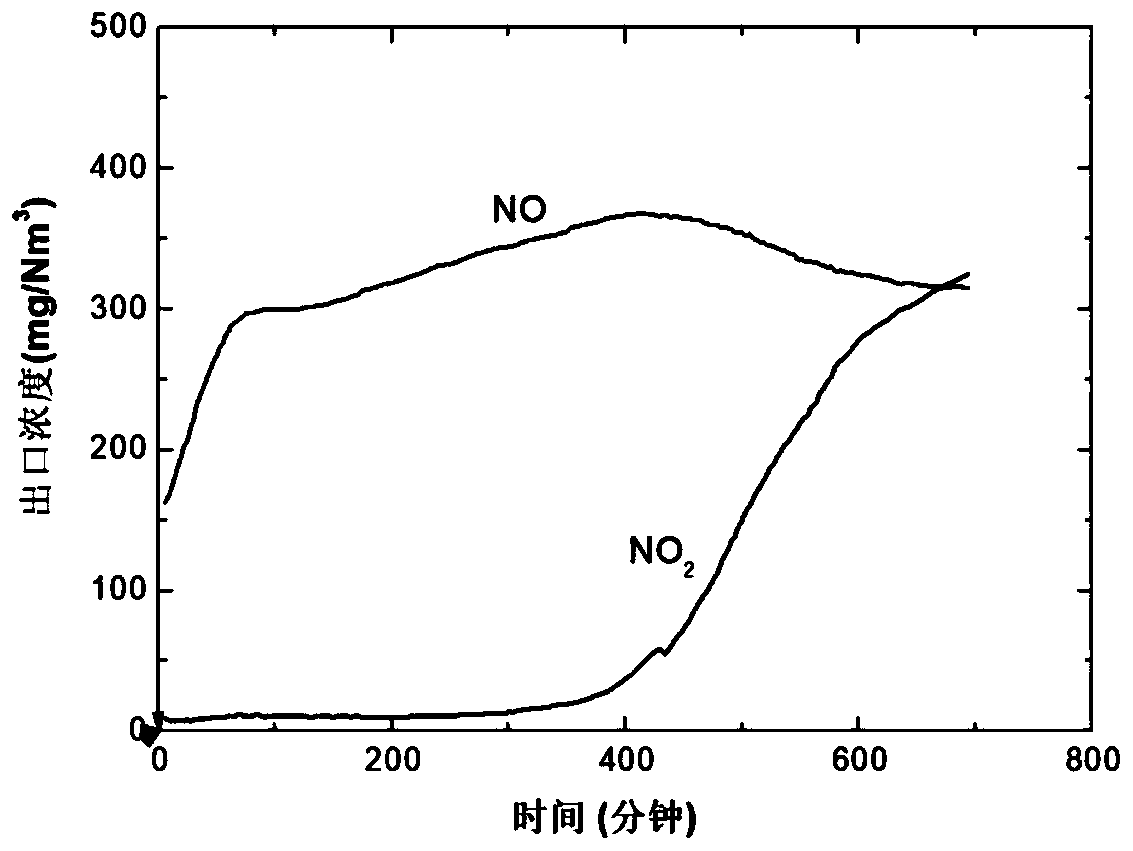

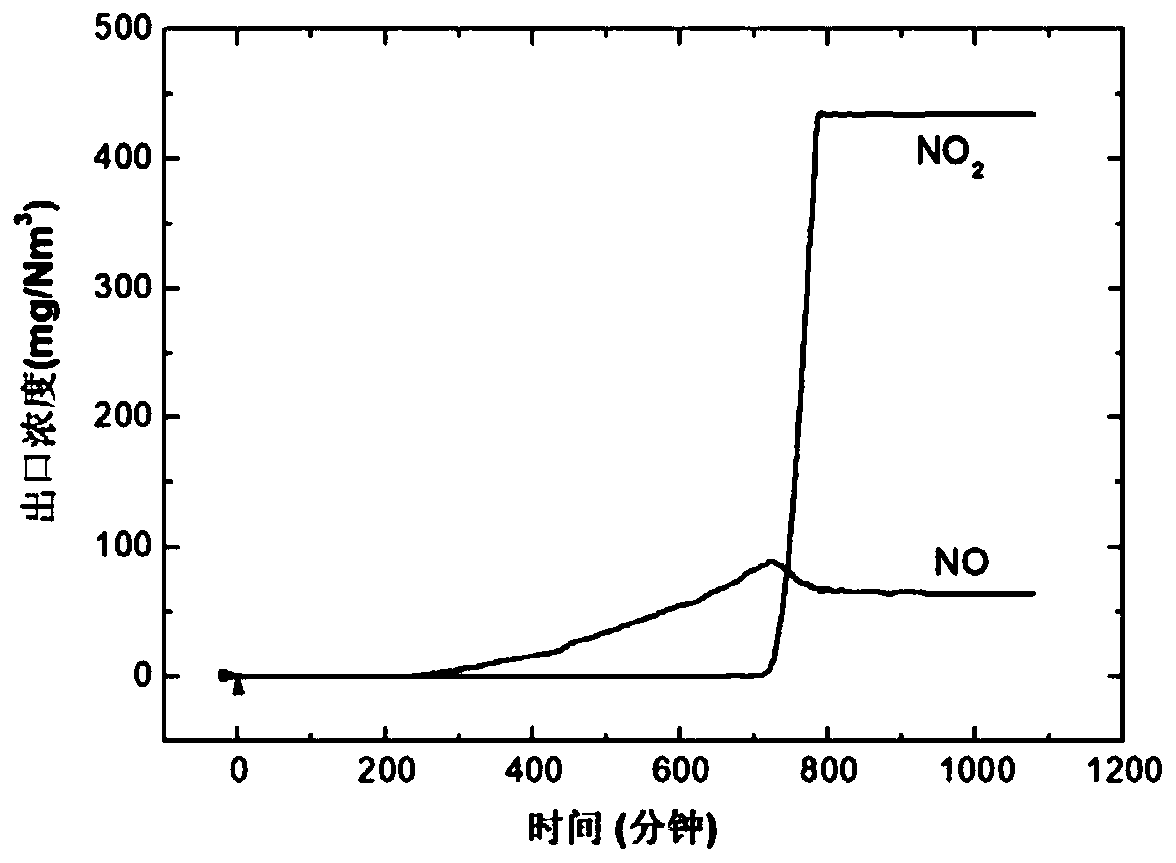

Low-temperature adsorption denitration method for flue gas

InactiveCN110743313ARealize escaping secondary pollution dischargeAchieve recyclingNitrous oxide captureGas treatmentPtru catalystThermodynamics

The invention discloses a low-temperature adsorption denitration method for flue gas. The method comprises the following steps: the flue gas is subjected to dust removal and desulfurization, the desulfurized flue gas is pressurized, the pressurized flue gas is pre-cooled, the pre-cooled flue gas is cooled to a room temperature or below by using a flue gas cooling system, the flue gas with a temperature lower than the room temperature enters a low-temperature denitration system, physical adsorption denitration is performed in the low-temperature denitration system, the flue gas after denitration is used to pre-cool the flue gas after dust removal and desulfurization, and clean flue gas that absorbs heat enters a chimney to be discharged. The method uses the physical adsorption denitration,simultaneously directly adsorbs and removes NO2 and NO to realize direct NOx adsorption and removal, eliminates the use of a catalyst and reducing agent NH3 in a traditional SCR denitration process, eliminates secondary pollution emission of ammonia escape, and does not need a pre-process for oxidizing NO; the method has a high NOx removal rate, and can realize NOx zero emission; a large amount ofacidic condensate water is precipitated during the cooling of the flue gas, so that the water consumption in a power plant is reduced; and the method does not need to use chemicals such as a denitration catalyst, a reducing agent and an oxidant, thereby reducing the operating costs.

Owner:CHINA HUANENG GRP CO LTD +1

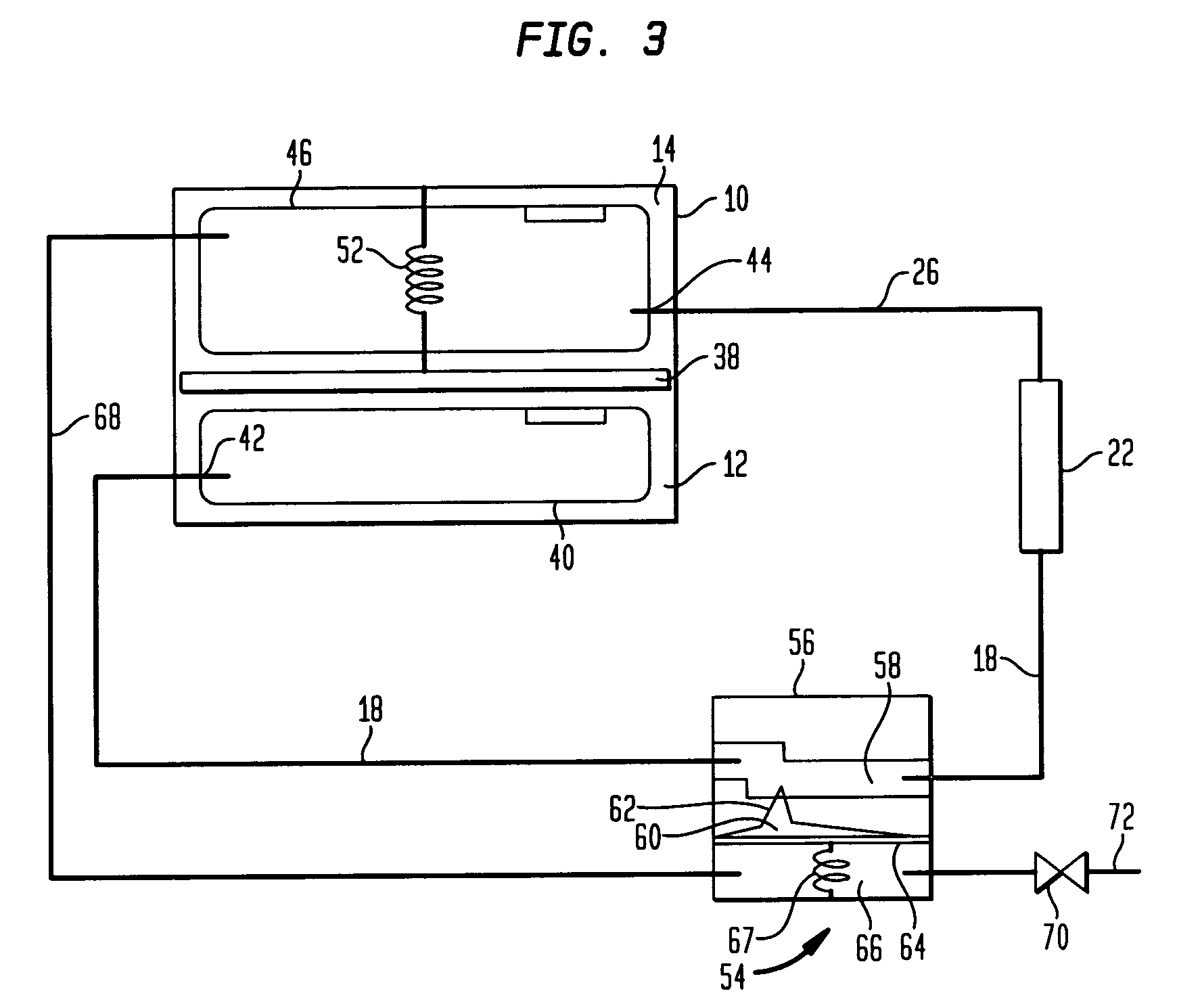

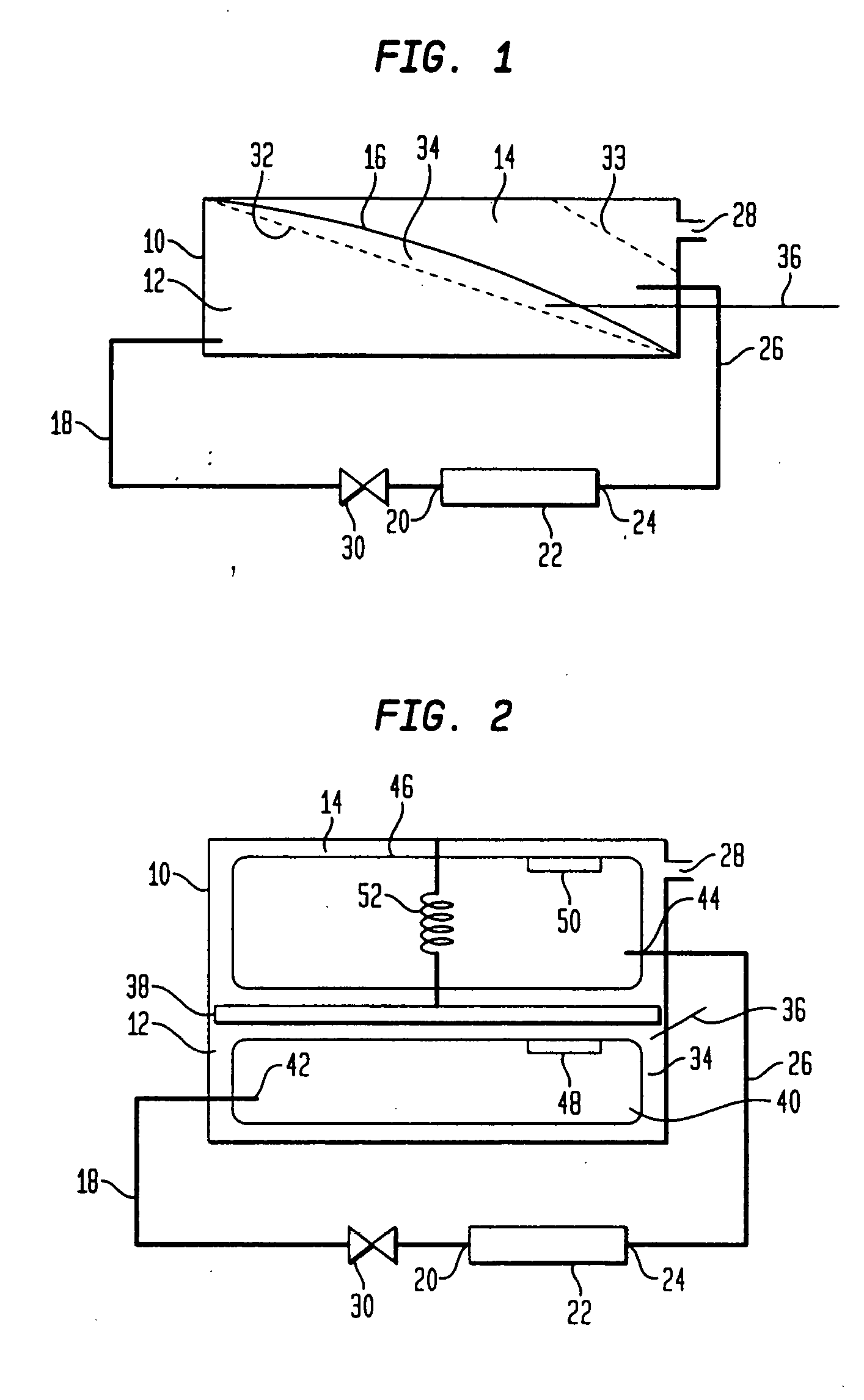

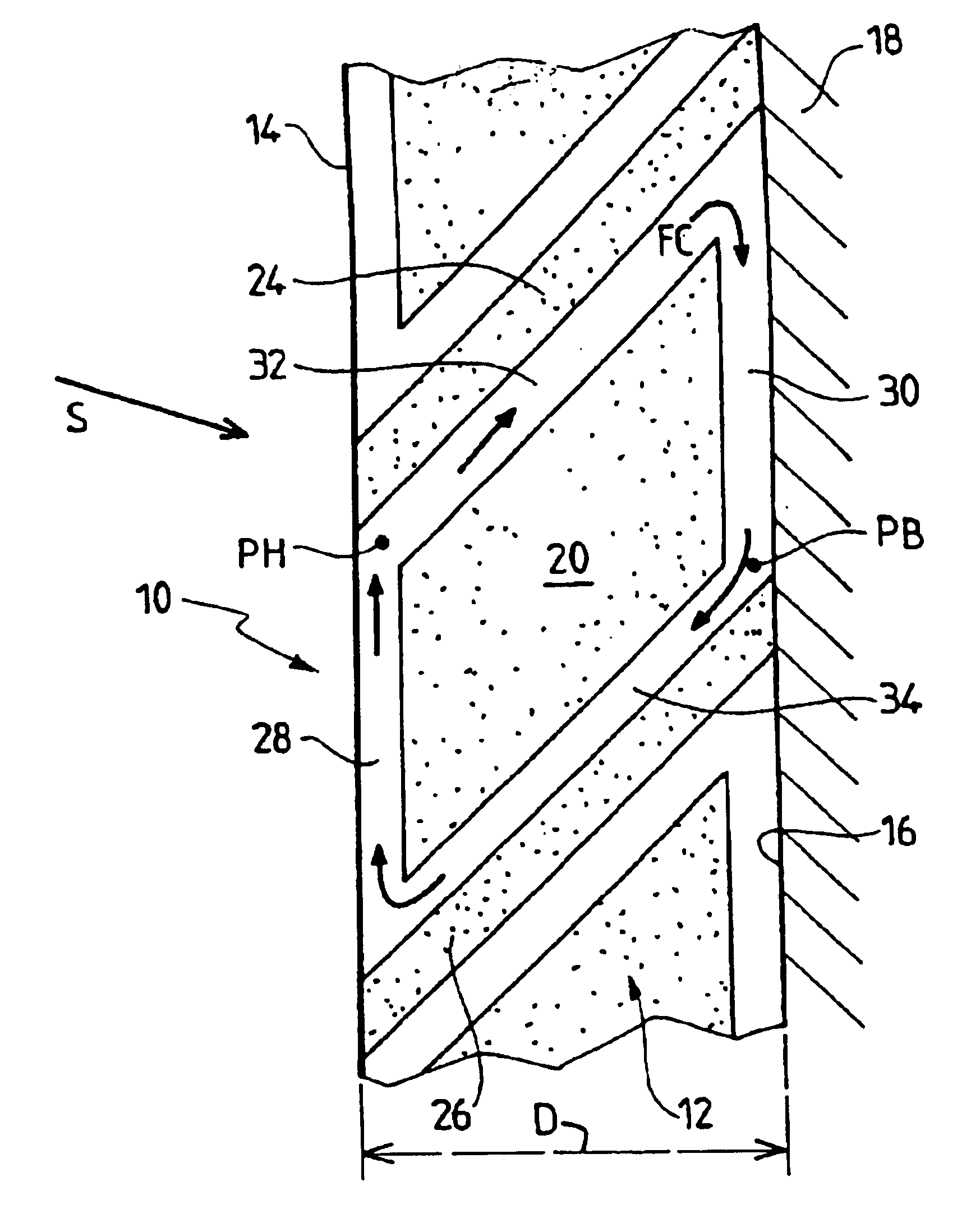

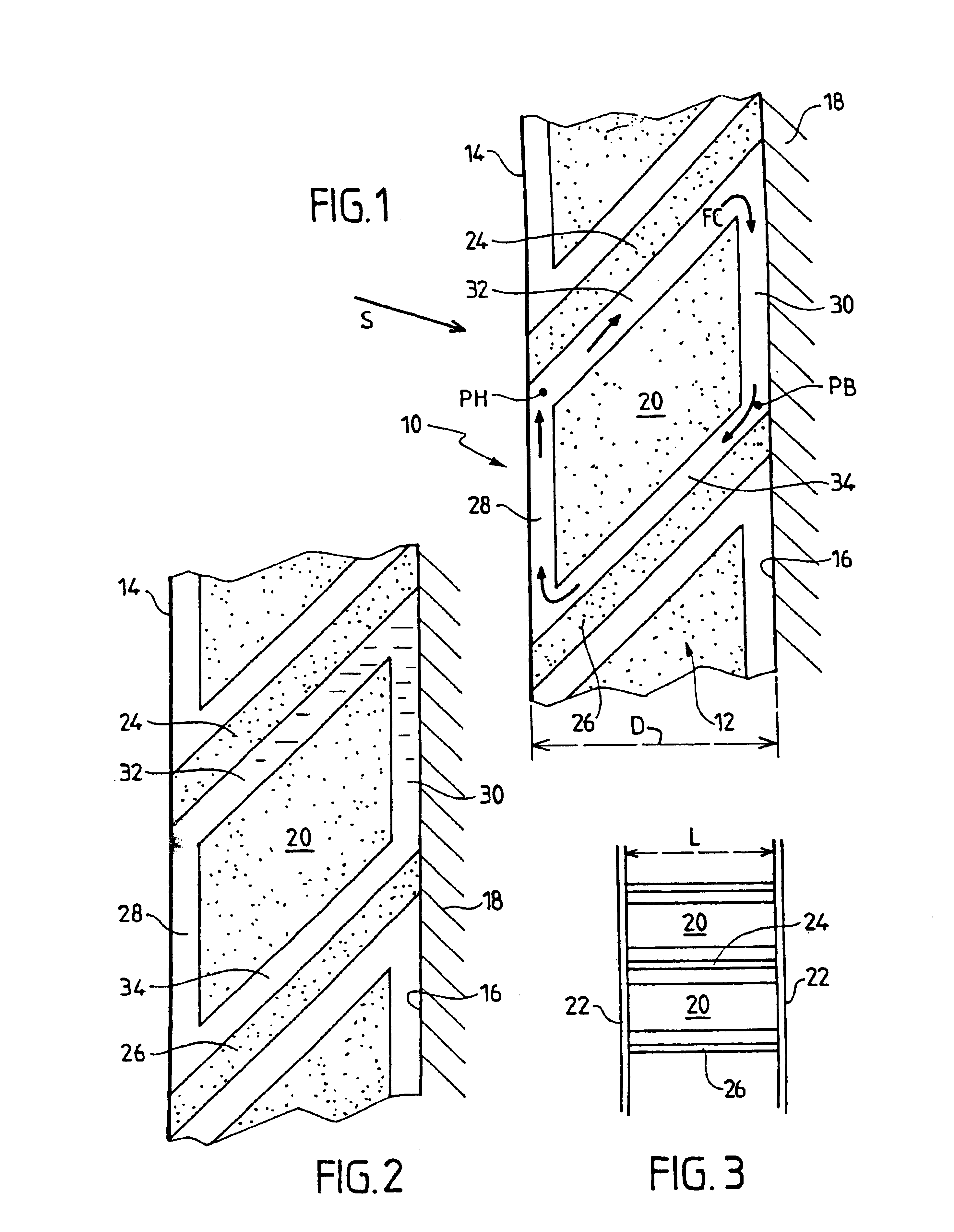

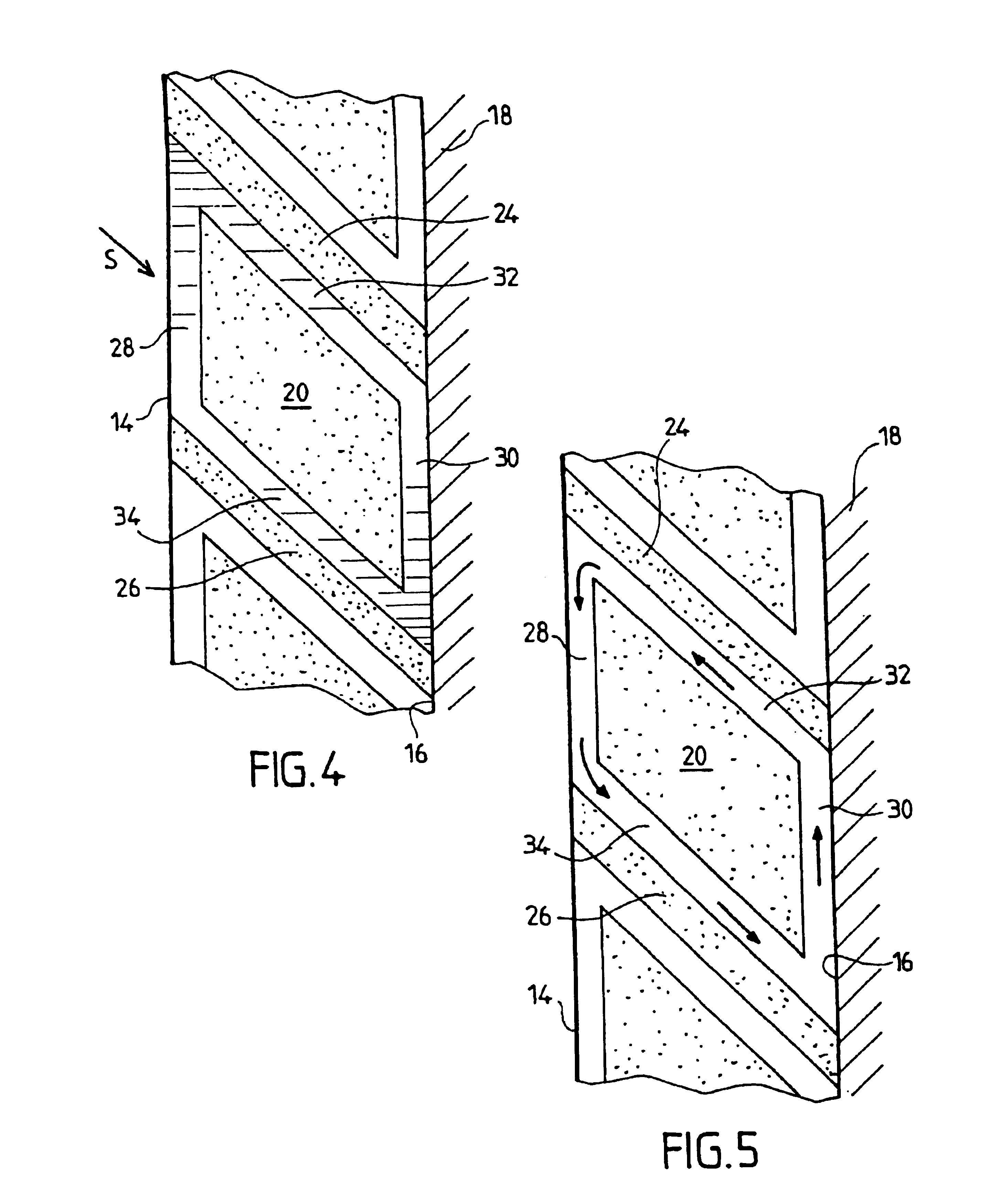

Device for heat transfer between two walls

InactiveUS6860322B1Avoid heat exchangeSolar heating energySolar heat devicesComputer moduleClosed loop

The invention concerns a heat transfer device comprising an insulating module (12) designed to be inserted between a first wall (14) and a second wall (16) to define a closed loop wherein flows a heating medium (FC) which comprises a first channel (28) extending substantially vertically along the first wall (14) and a second channel (30) extending substantially vertically along the second wall (16), the first channel and the second channel being mutually offset in the vertical direction to define a low channel and a high channel, as well as an upper channel (32) and a lower channel (34) linking the first channel and the second channel, such that heating medium (FC) flows freely or is blocked naturally in the loop when on the basis of the respective temperatures of the high channel and the low channel. The invention is particularly useful for heating or cooling buildings.

Owner:RYLEWSKI EUGENIUSZ

Combustion apparatus

InactiveUS20080035137A1Clean and smokeless burnExtended shipping timeLighting and heating apparatusCombustion-air/flue-gas circulation for stovesNuclear engineeringSolid fuel

An improved solid fuel combustion apparatus intended for use in residential or light commercial settings capable of sustaining a controlled, continuous blue flame burn, resulting in high efficiency heat output with low emissions and low ash. The combustion apparatus is further capable of being thermostatically controlled, turning off combustion of the fuel when a desired temperature is reached and automatically re-igniting when more heat is called for, and also comprises improved safety features.

Owner:FEDERICO DOMINIC J

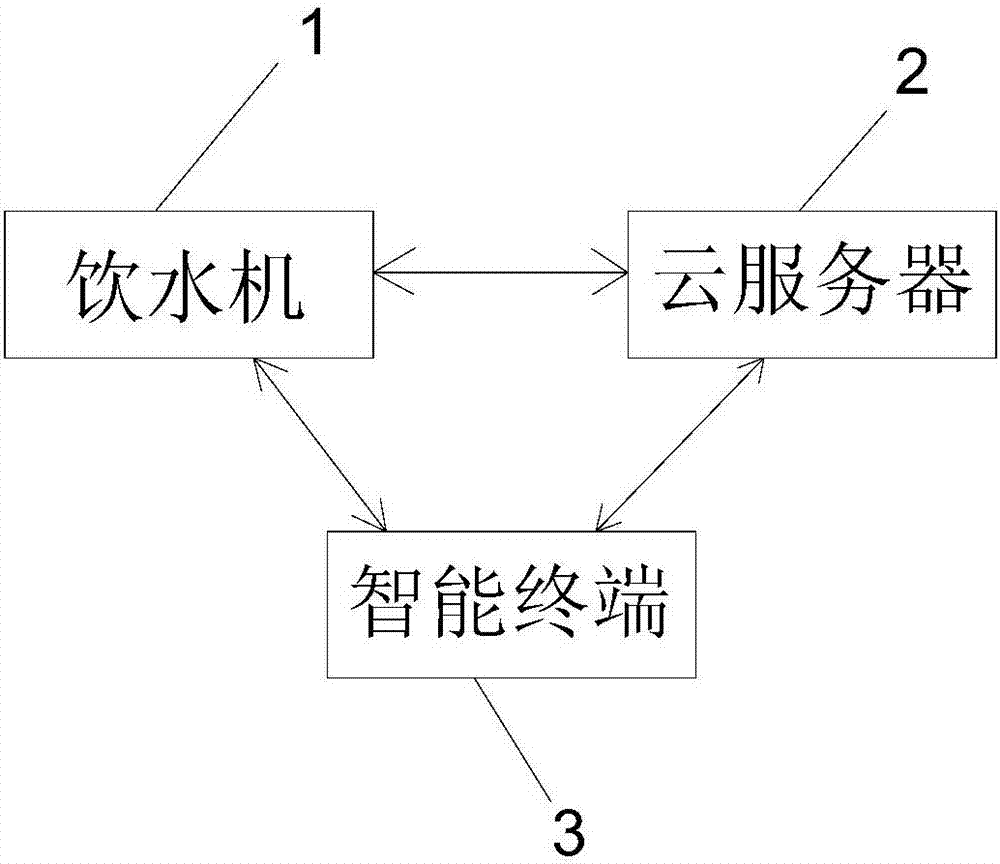

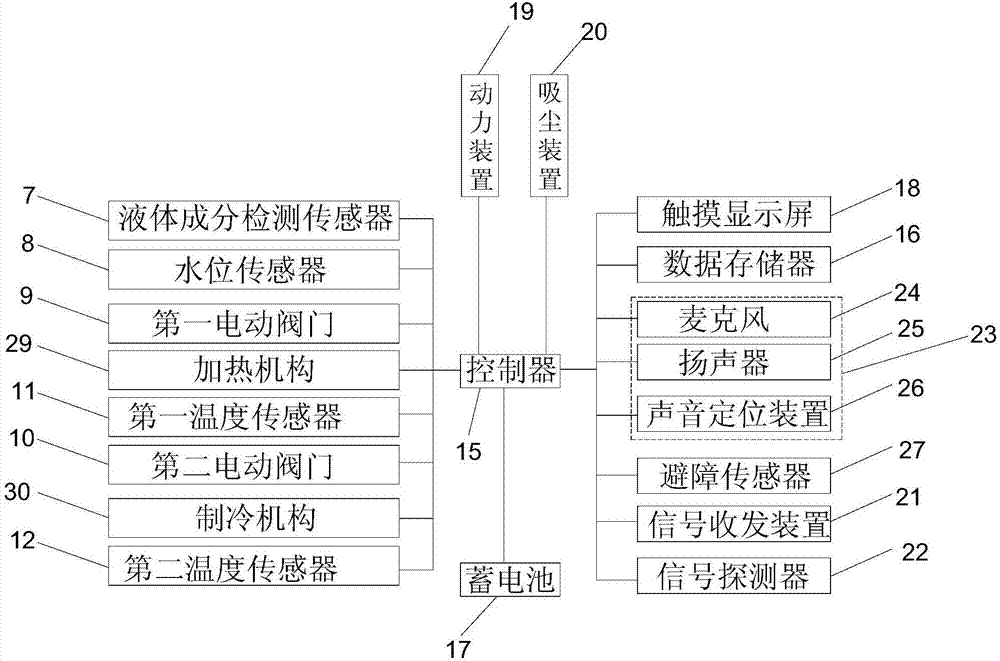

Remote-controlled drinking water robot based on smart terminal

InactiveCN107065662AAvoid heat exchangeGood insulationProgramme controlTransmission systemsControlled drinkingAgricultural engineering

The invention relates to the technical field of smart home, and particularly relates to a remote-controlled drinking water robot based on a smart terminal. The drinking water robot comprises a water dispenser, a cloud server, and a smart terminal. The water dispenser is connected with the cloud server. The cloud server is connected with the smart terminal. The smart terminal is equipped with an APP of the water dispenser. Users can remotely control the water dispenser by operating the APP. The drinking water robot can bring great convenience to people's life, has strong practicability, and is suitable for popularization in the field.

Owner:GUANGXI XIAIJIA DRINKING WATER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com