Remote-controlled drinking water robot based on smart terminal

An intelligent terminal and remote control technology, applied in program control, computer control, general control system, etc., can solve the problems of single function and remote control of water dispenser, and achieve the effect of ensuring safety, good heat preservation and water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment.

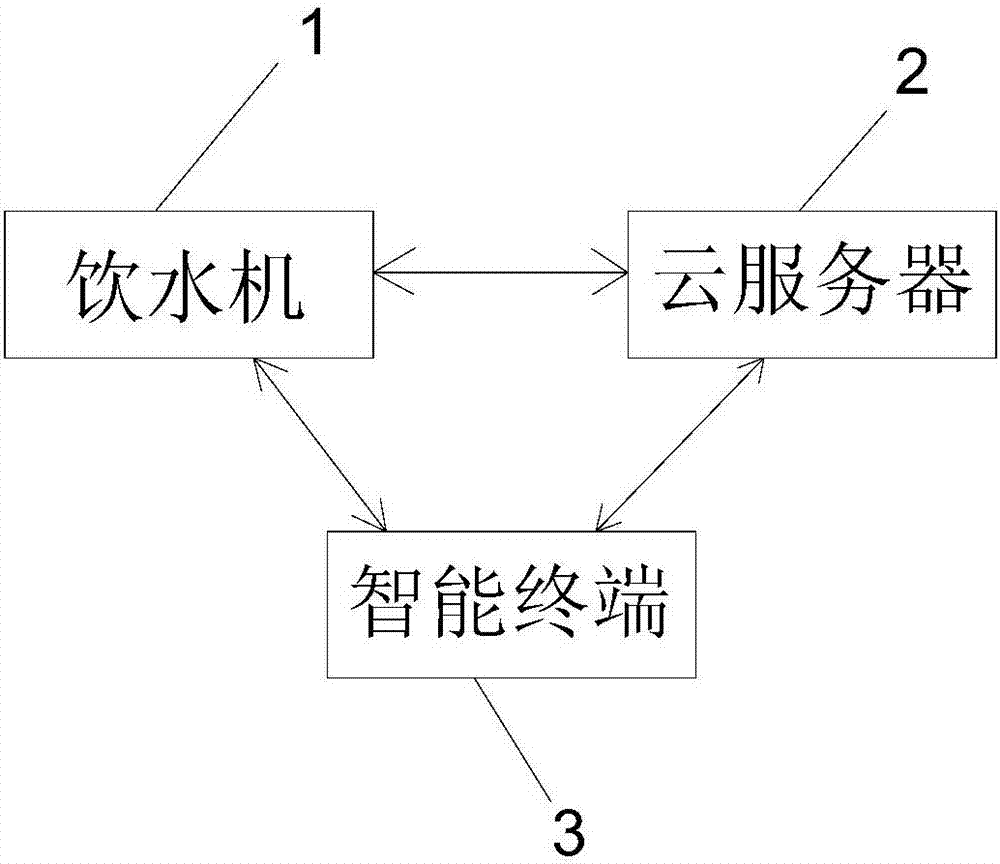

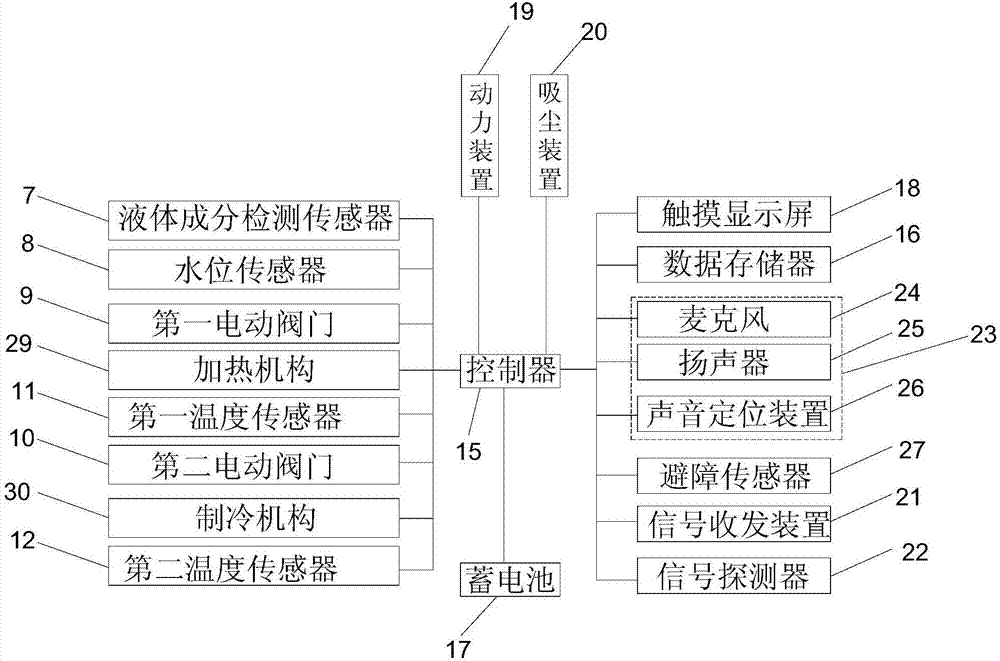

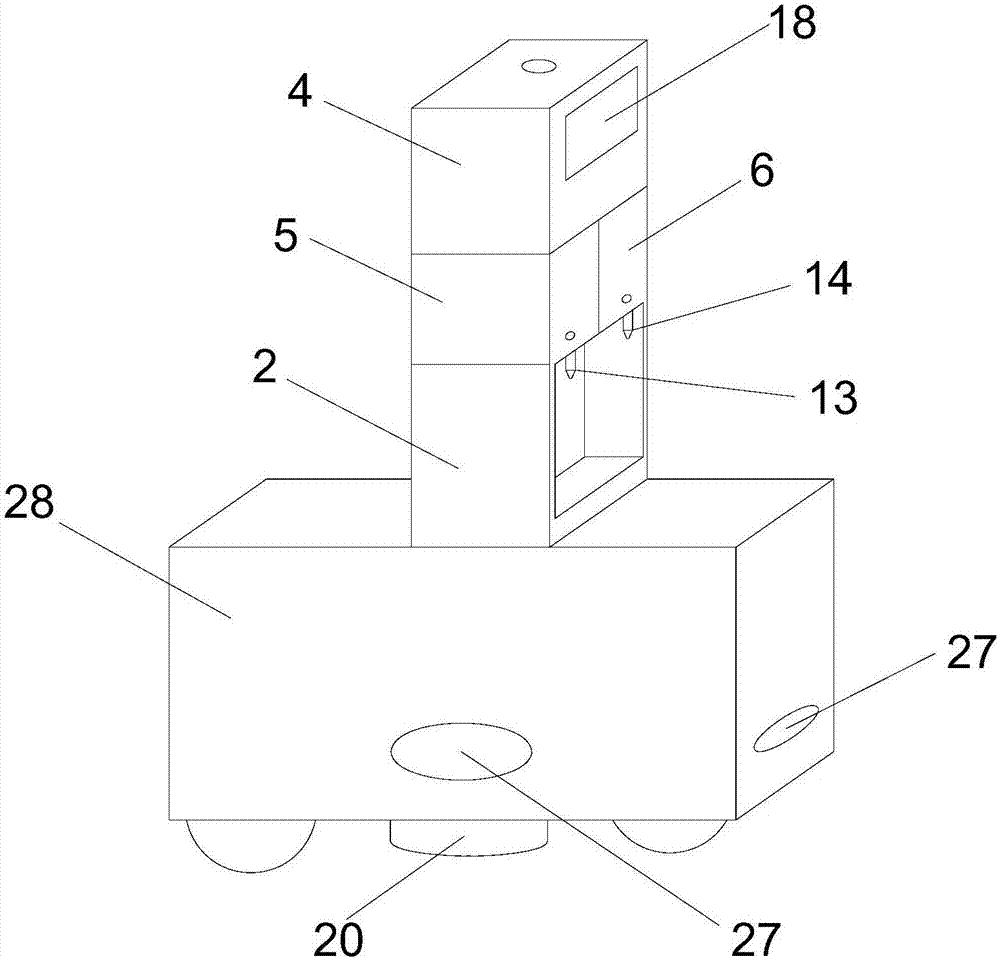

[0026] Such as figure 1 , figure 2 and image 3 , a drinking water robot based on intelligent terminal remote control, including a water dispenser 1, a cloud server 2 and an intelligent terminal 3, the water dispenser 1 is provided with a water storage tank 4, a heating chamber 5 and a cooling chamber 6, the water storage tank 4 A liquid component detection sensor 7 and a water level sensor 8 are arranged on the inner wall of the tank. The water storage tank 4 communicates with the heating chamber 5 through the first electric valve 9. The heating chamber 5 is provided with a first temperature sensor 11 and a heating mechanism 29 , the outside of the heating chamber 5 is connected to a hot water valve 13; the water storage tank 4 communicates with the cooling chamber 6 through a second electric valve 10, and the cooling chamber 6 is provided with a second temperature sensor 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com