Low-temperature adsorption denitration method for flue gas

A low-temperature denitration and flue gas technology, applied in the field of flue gas denitrification, can solve the problems of secondary pollution discharge, difficult industrial application, high operation cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

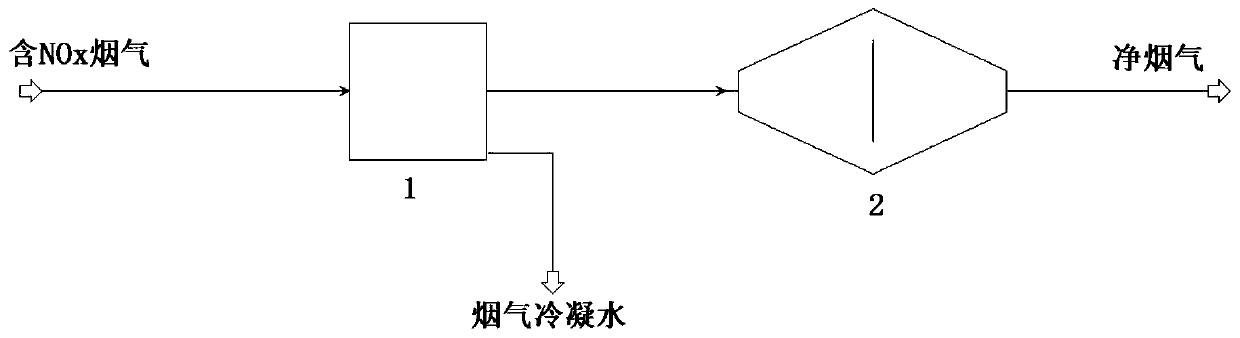

Image

Examples

Embodiment 1

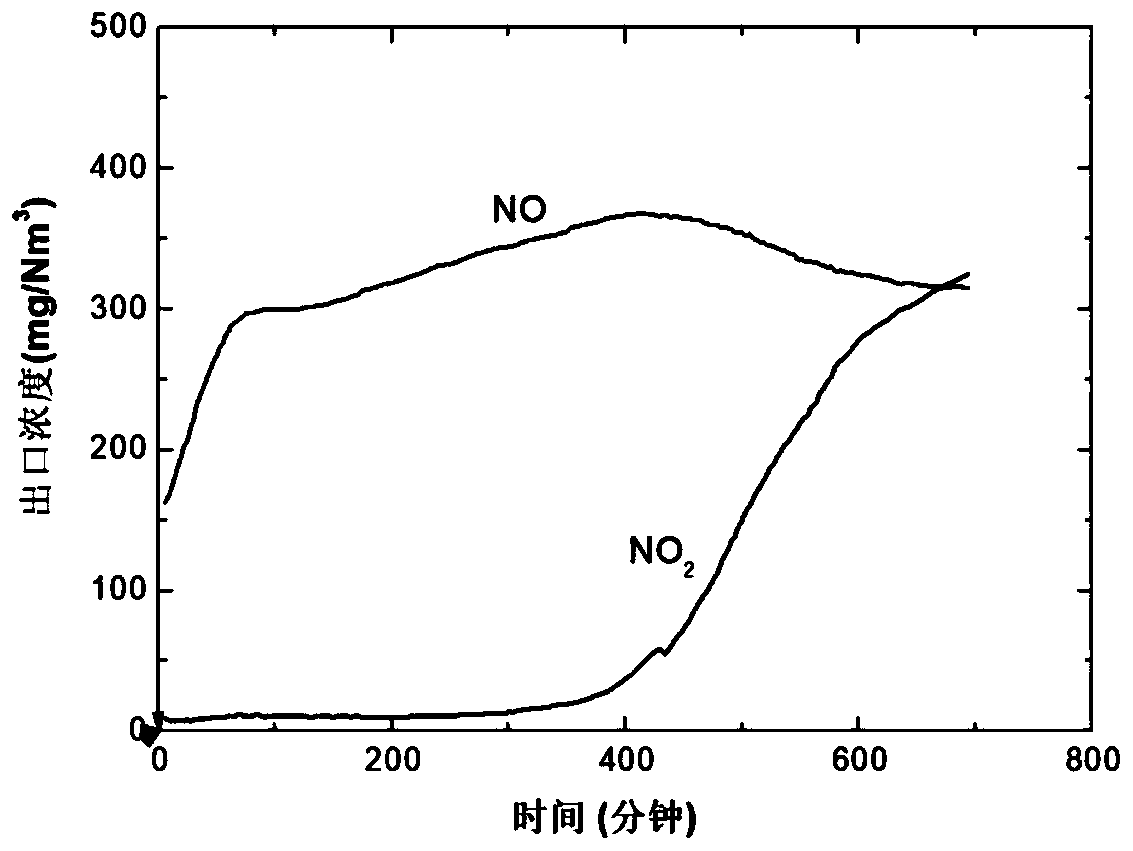

[0041] Embodiment 1: NO content is 500mg / Nm 3 The temperature of the flue gas is lowered to 0°C, and the flow rate of 1L / min flows through 5g of activated carbon (space velocity = 6000h -1 ), the NOx content of the flue gas after passing through the activated carbon bed has a relationship with time as shown in the attached image 3 shown. The activated carbon bed breakthrough time and effective NOx adsorption capacity are shown in Table 1.

Embodiment 2

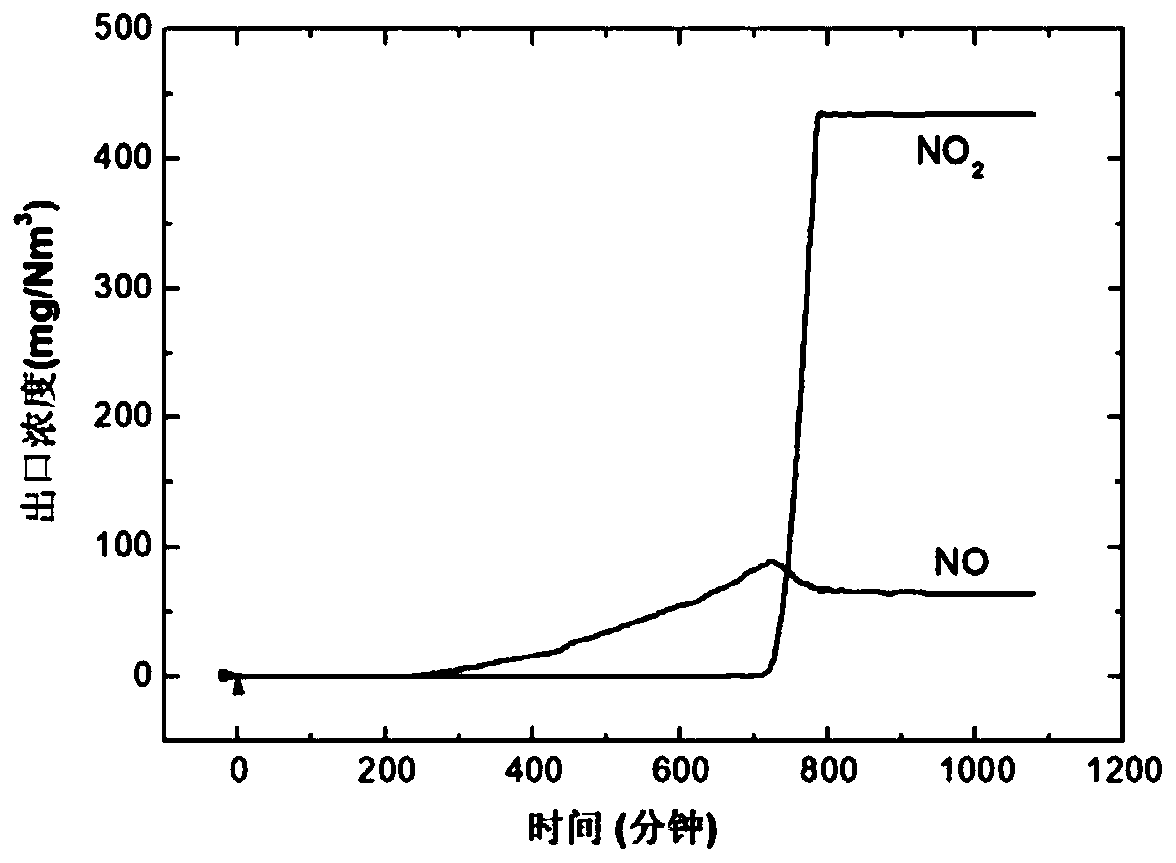

[0042] Embodiment 2: By the same method as in Example 1, the difference is that the temperature of the flue gas is reduced to -30°C; the NOx content of the flue gas after passing through the activated carbon bed has a relationship with time such as Figure 4 shown. The activated carbon bed breakthrough time and effective NOx adsorption capacity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com