Patents

Literature

3328results about How to "Achieve reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resource utilization process of organic hazardous waste

ActiveCN111185460AHarmlessAchieve reductionSolid waste disposalTransportation and packagingFluid phaseSlag

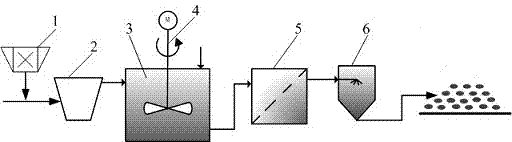

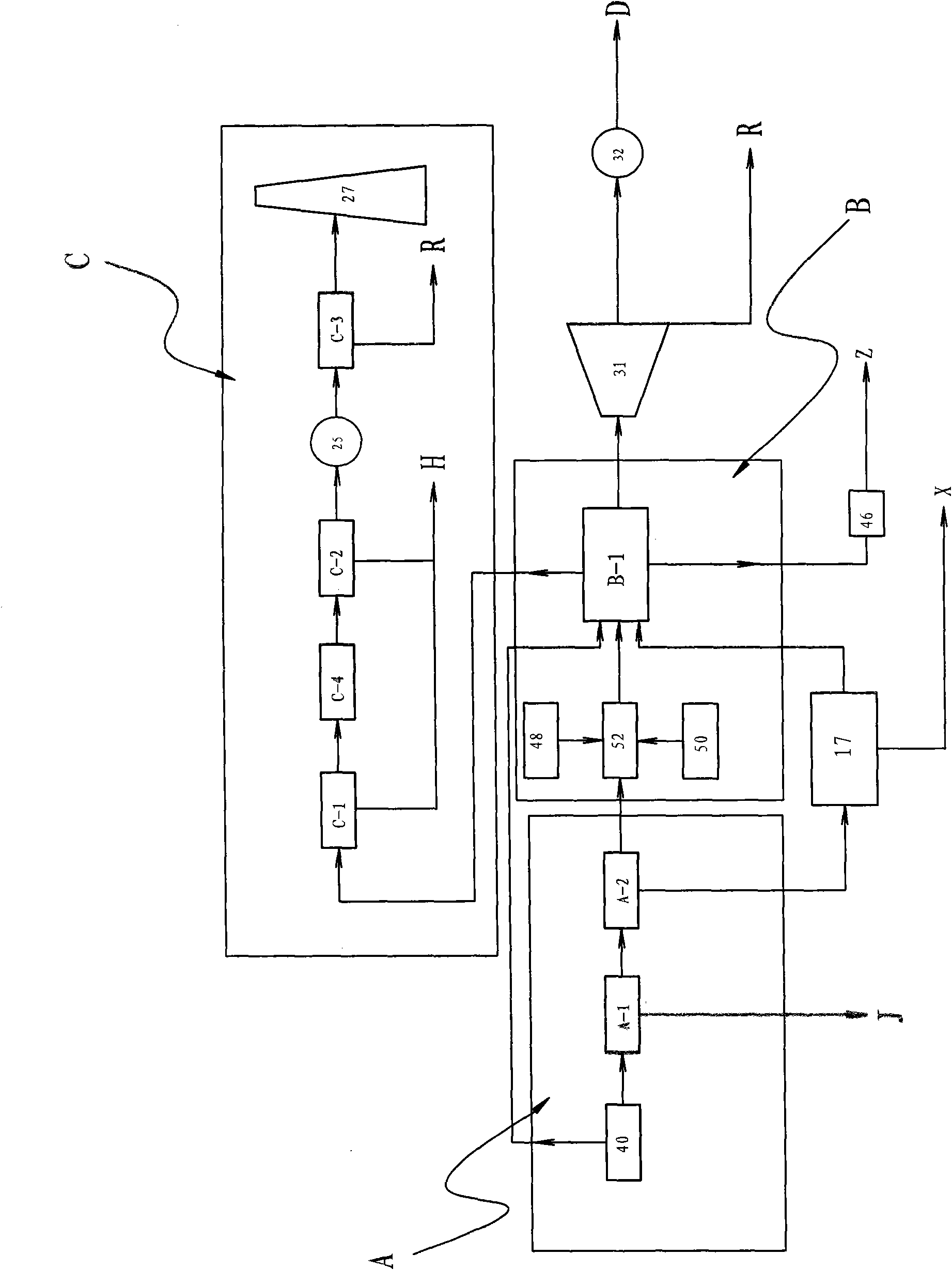

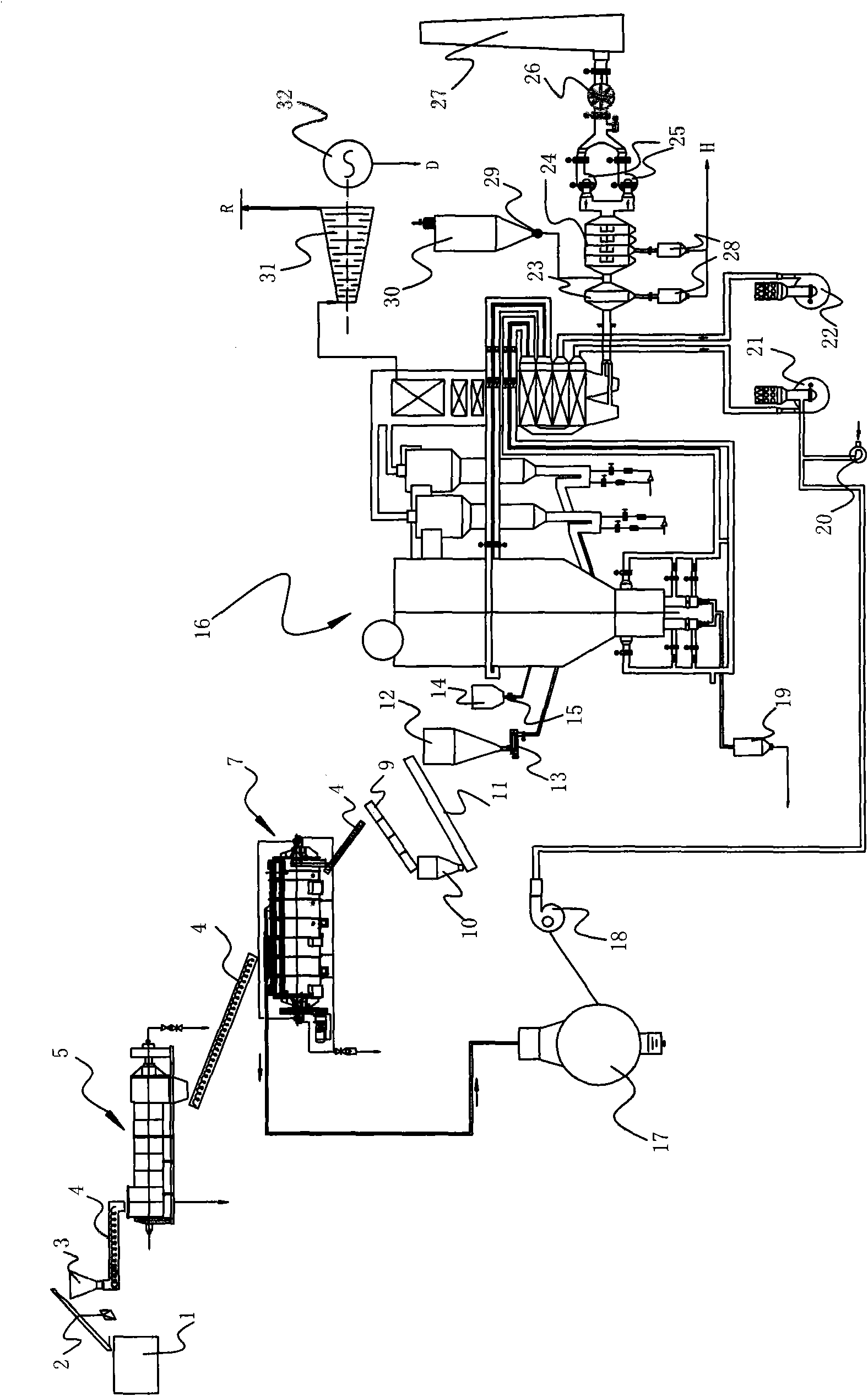

The invention discloses a resource utilization process of organic hazardous waste. The resource utilization process includes the steps that classified storage and treatment of solid-phase, solid-liquid mixing and liquid-phase organic hazardous waste are carried out; solid-phase crushing, grinding and screening treatment is carried out; solid-liquid mixing is carried out after solid-liquid separation, solid-phase grinding and liquid-phase sedimentation separation treatment is carried out; direct liquid-phase sedimentation is carried out; then after solid-liquid mixing, a fluxing agent is addedfor stirring, a stabilizer and a dispersing agent are added for slurrying, the slurry is fed into a gasifier, and the obtained gas is used as fuel gas after being subjected to cooling, dedusting, spraying and desulfuration; slag tapping and vitrification slag discharge are carried out; and waste water is recycled. The resource utilization process has the beneficial effects that solid phase, solid-liquid mixing and liquid-phase comprehensive treatment, harmless treatment and slag discharge are realized.

Owner:杰瑞邦达环保科技有限公司

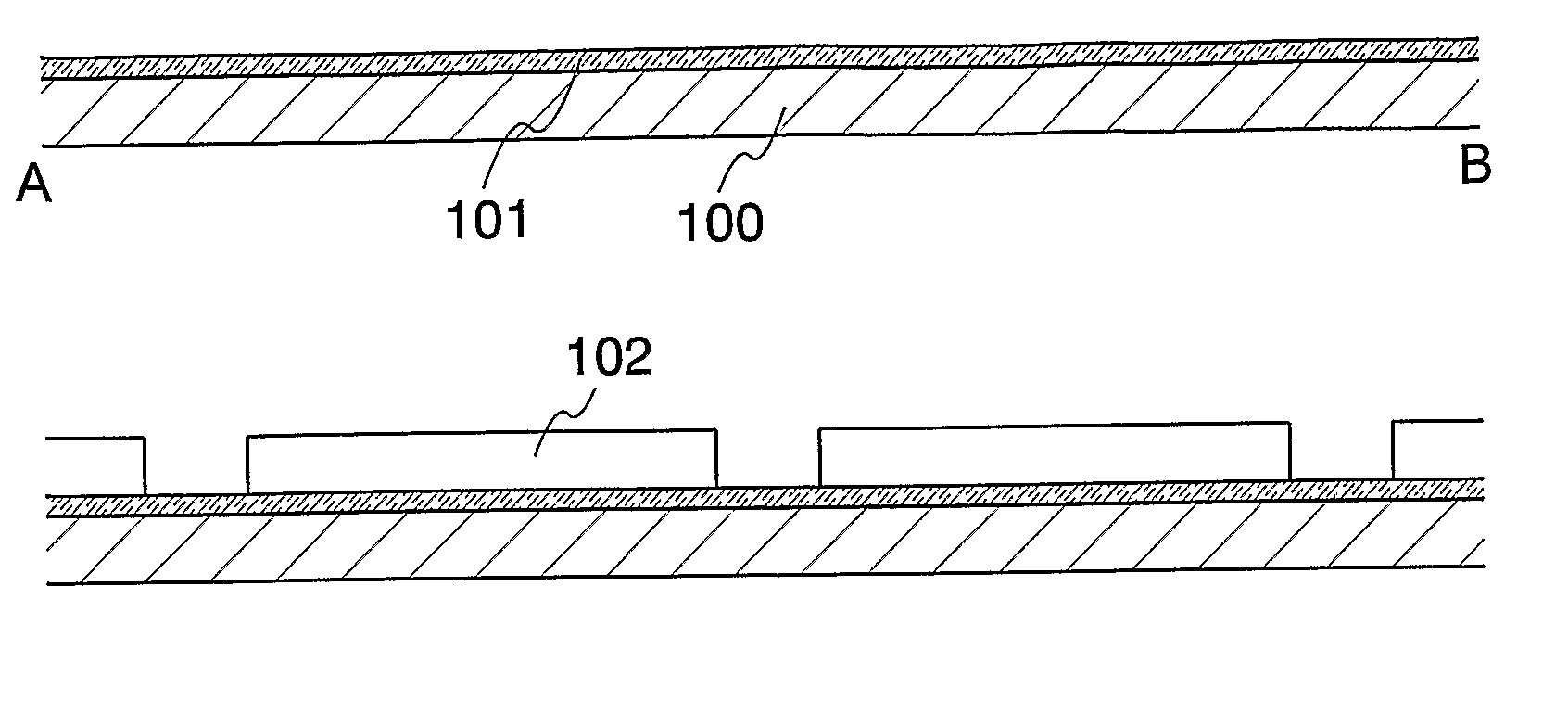

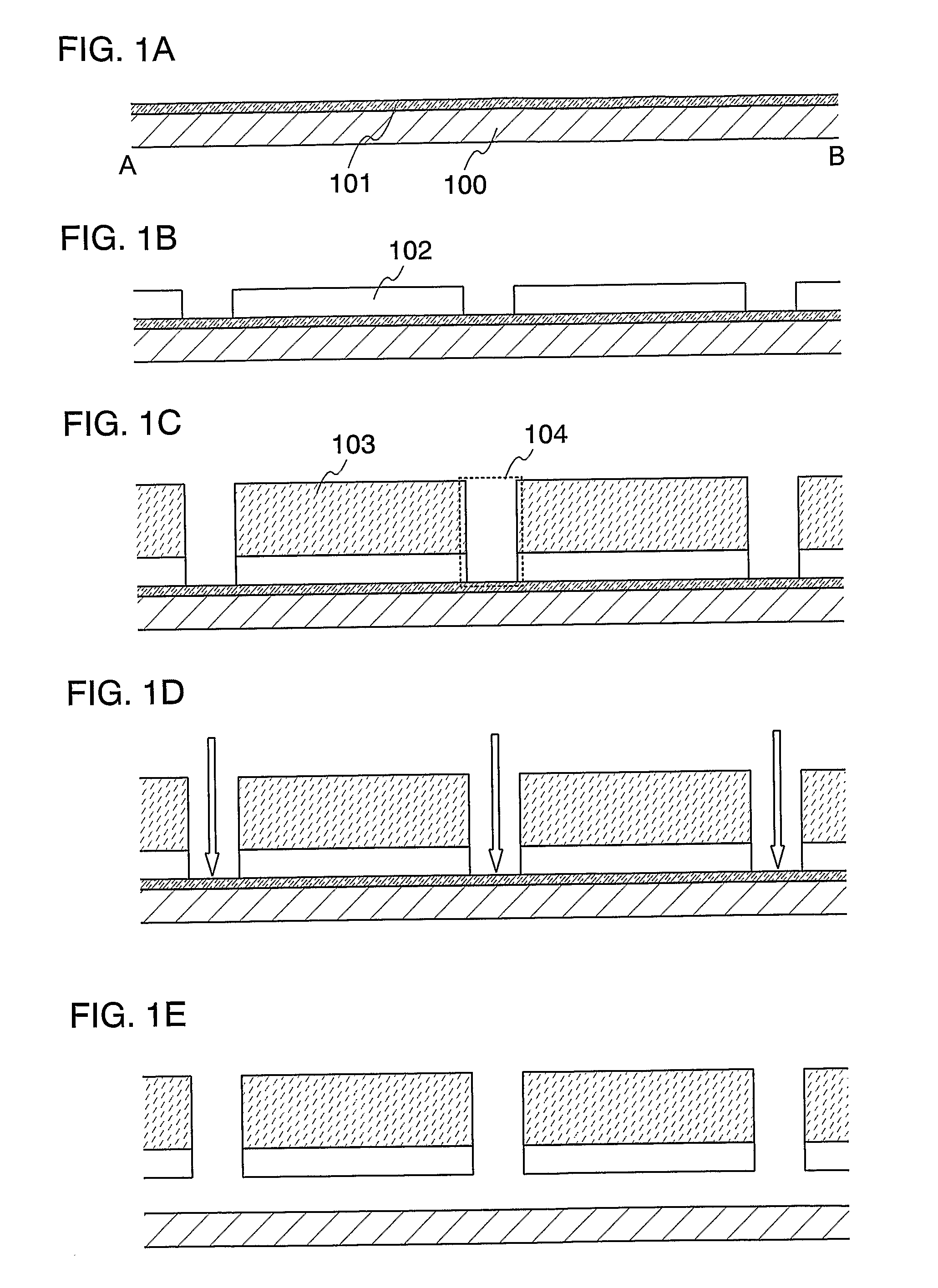

Method For Manufacturing Semiconductor Device

InactiveUS20070196999A1Improve efficiencyCost reductionSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

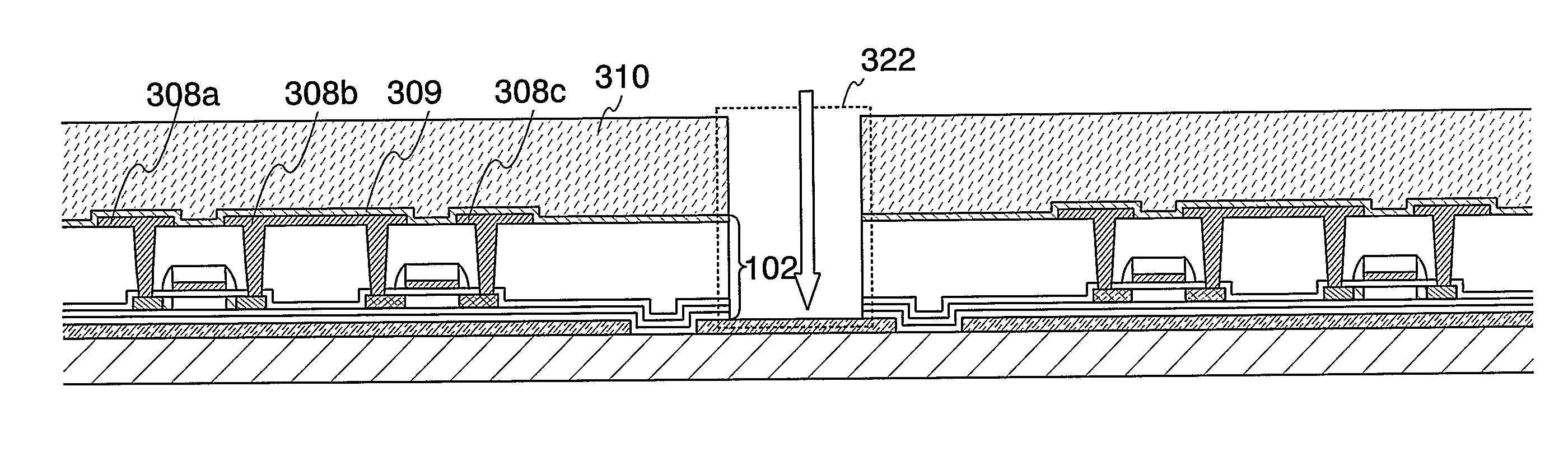

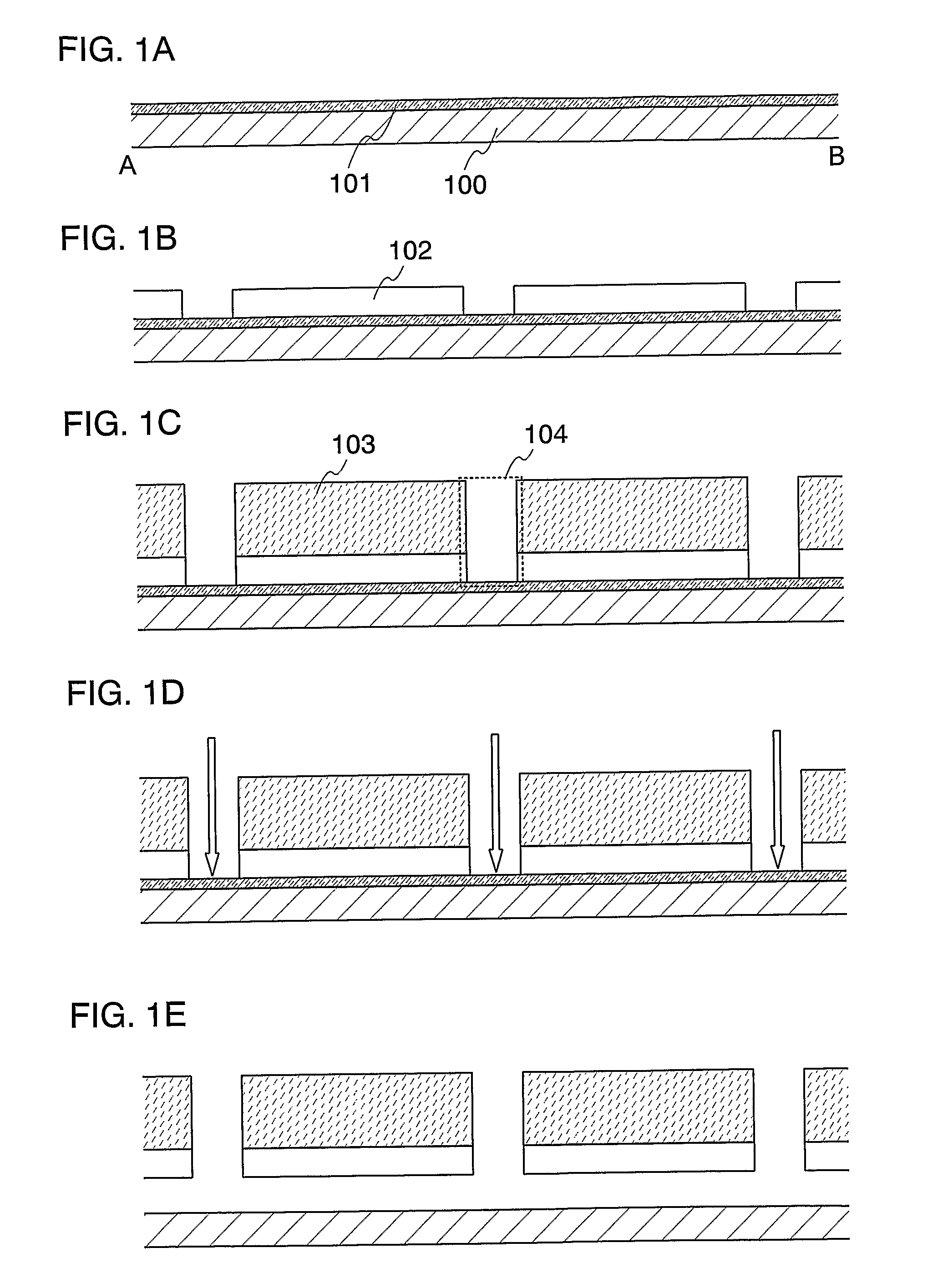

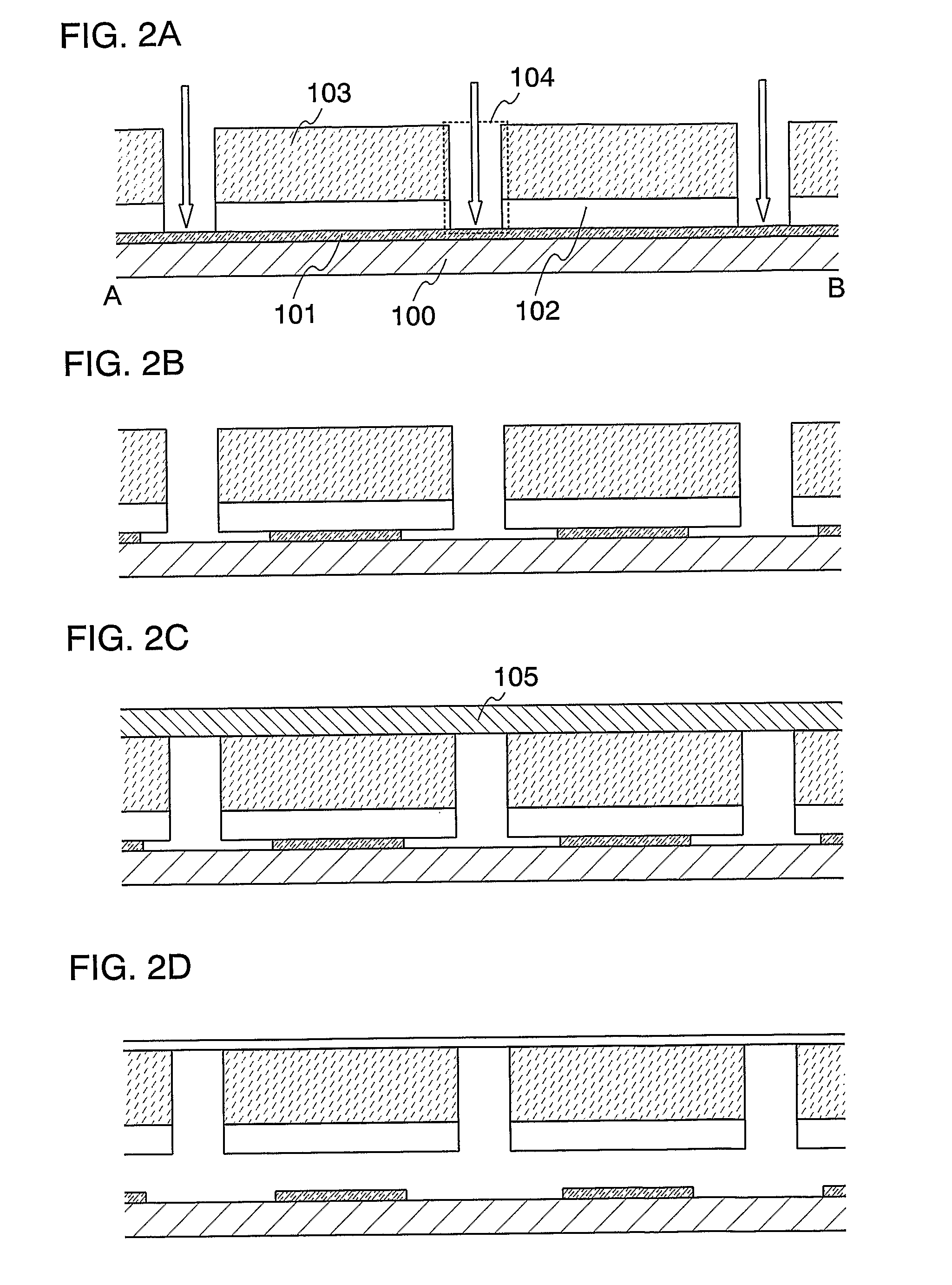

A release layer formed over a substrate; at least one of thin film integrated circuits is formed over the release layer; a film is formed over each of the at least one of thin film integrated circuits; and the release layer is removed by using an etchant; thus, the at least one of thin film integrated circuits is peeled from the substrate. A semiconductor device is formed by sealing the peeled thin film integrated circuit by lamination or the like.

Owner:SEMICON ENERGY LAB CO LTD

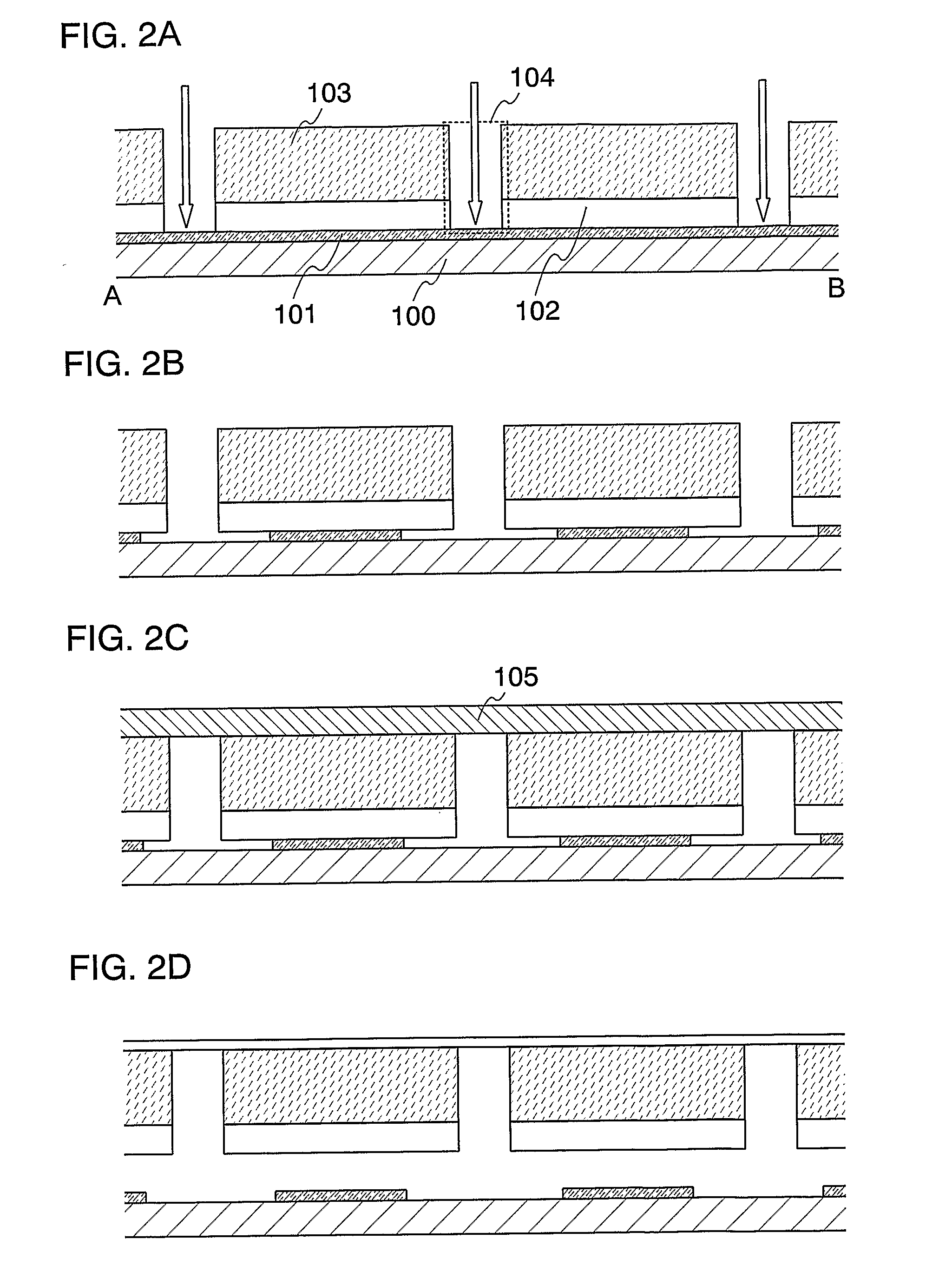

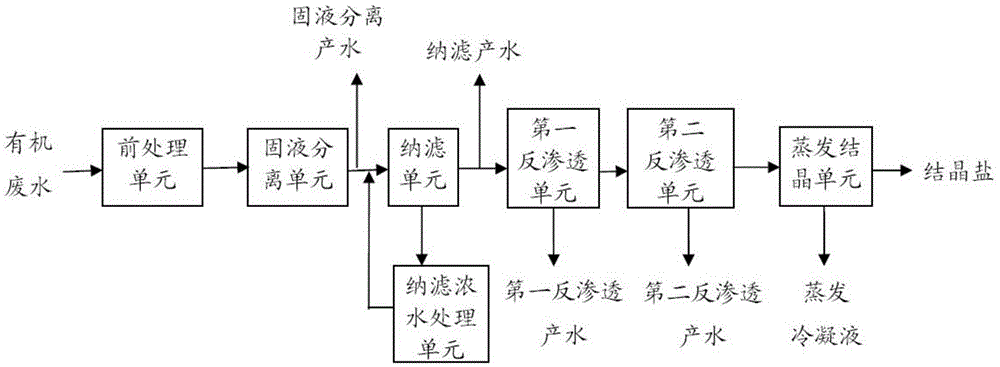

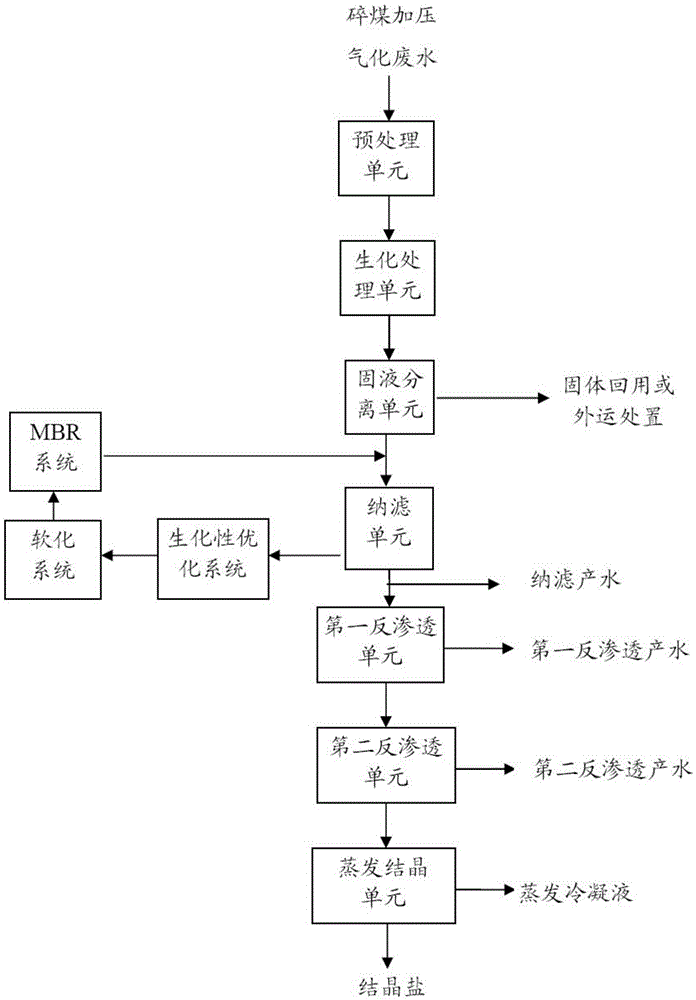

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

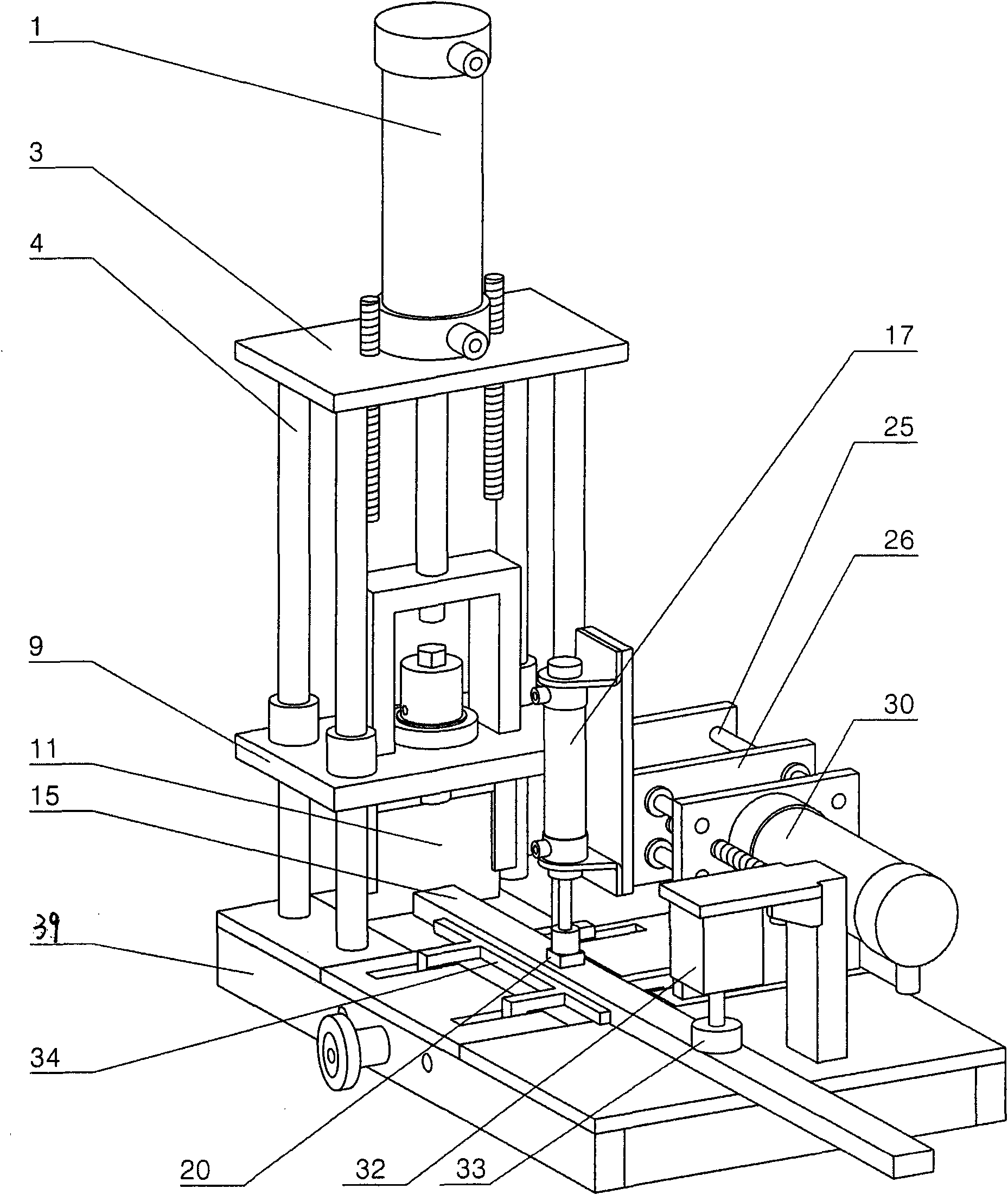

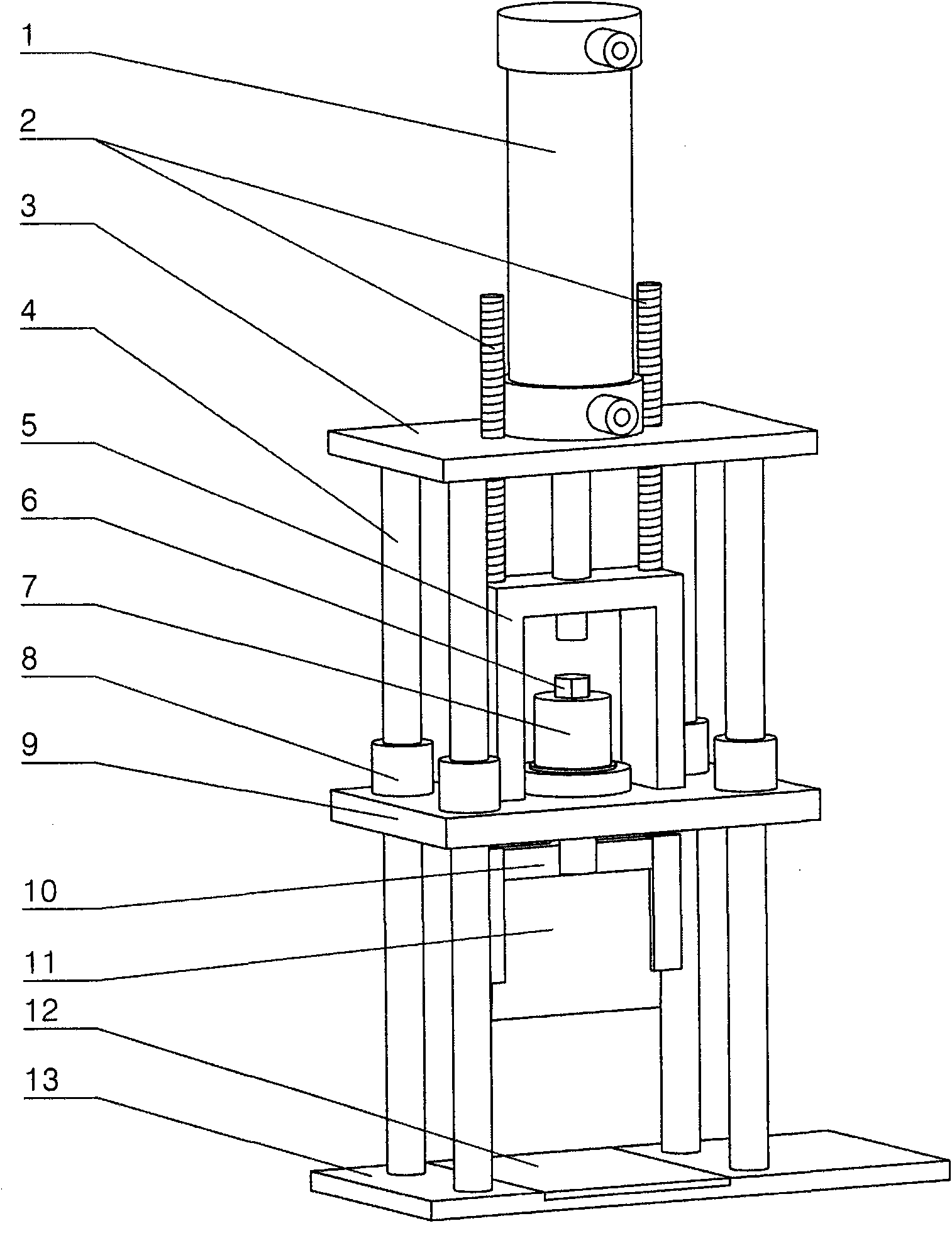

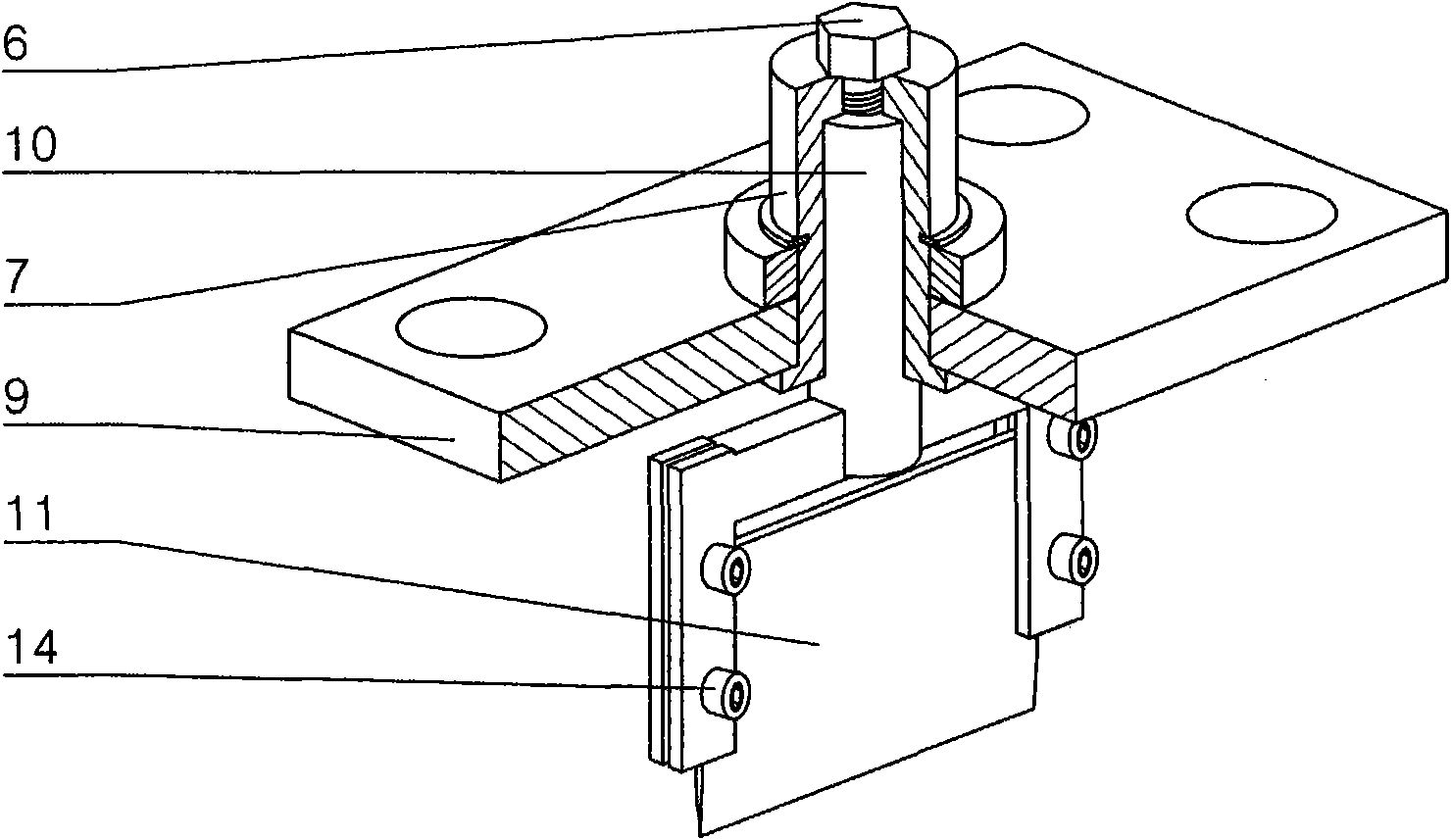

Pneumatic rubber cutting device

InactiveCN101683740AAchieve reductionOvercome the shortcomings of high energy consumption and poor flexibilityMetal working apparatusArticle deliveryControl systemEngineering

The invention discloses a pneumatic rubber cutting device which comprises a frame, wherein a cutter mechanism, a push mechanism, a press mechanism and a limit mechanism are arranged on the frame, andair cylinders respectively corresponding to the mechanisms are used as power sources. In the pneumatic rubber cutting device adopting the technical scheme, a piston of a cutter air cylinder of which the stroke can be adjusted can drive a cutter to do cutting actions; actions of a piston of a push air cylinder of which the stroke can be adjusted can drive a press head air cylinder fixed on a presshead air cylinder seat plate; and the press head air cylinder can drive a friction piece to press a strip rubber blank onto an air distribution panel. When the air distribution panel is pressed, an air cushion layer is formed between the air distribution panel and the upper plane of the strip rubber blank so as to ensure that friction force becomes quite small. A press air cylinder drives a presshead to press the strip rubber blank, and the limit mechanism carries out transverse limit on the strip rubber blank. A pneumatic control system and an electric control system control each air cylinder to cyclically act according to a certain order so as to cut the strip rubber blank, thereby overcoming the defect of poor cutting accuracy of a mechanical type transmission rubber cutting mechanismat present.

Owner:LUOHE LOUFOR STATIONERY MFG

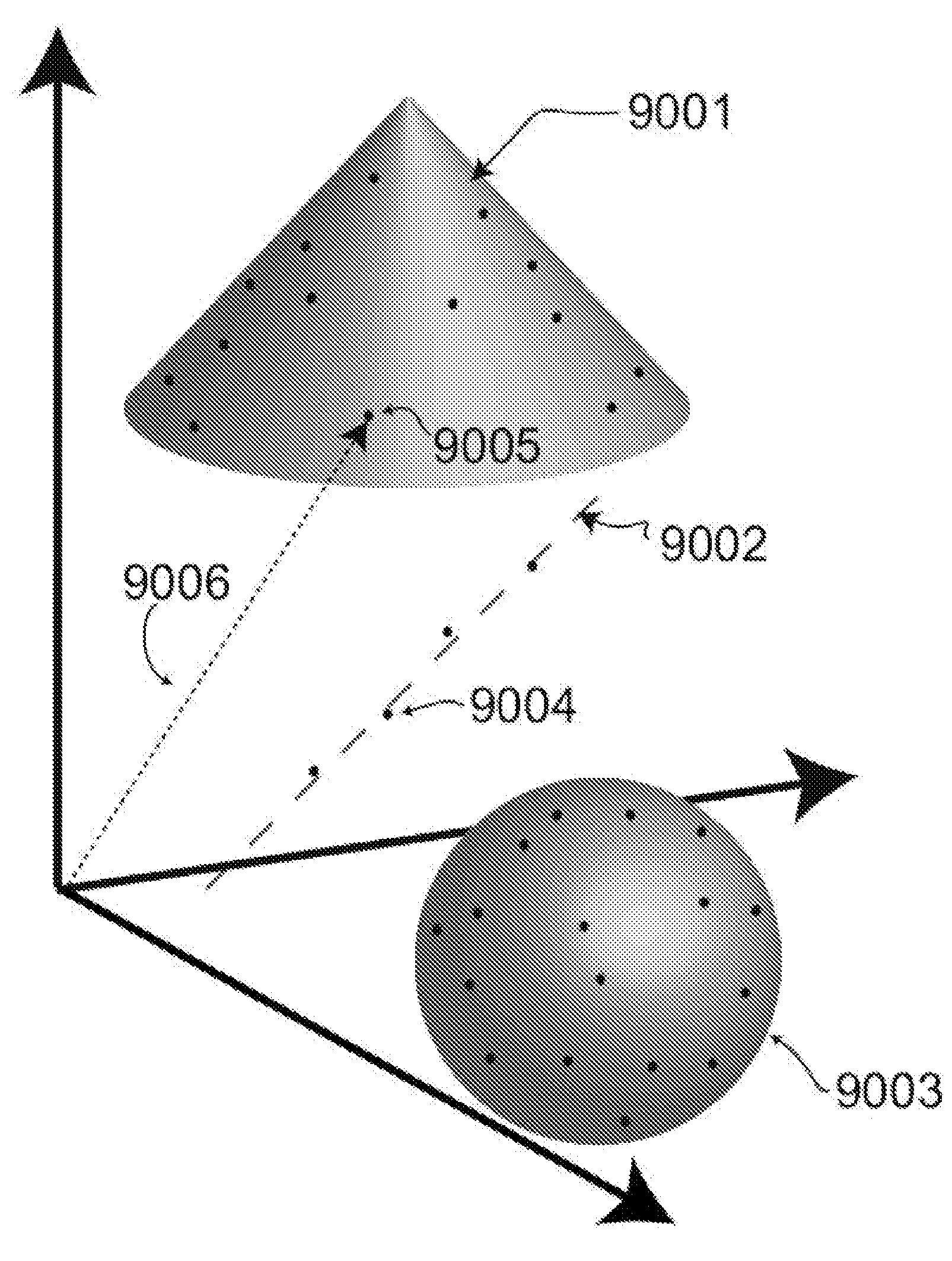

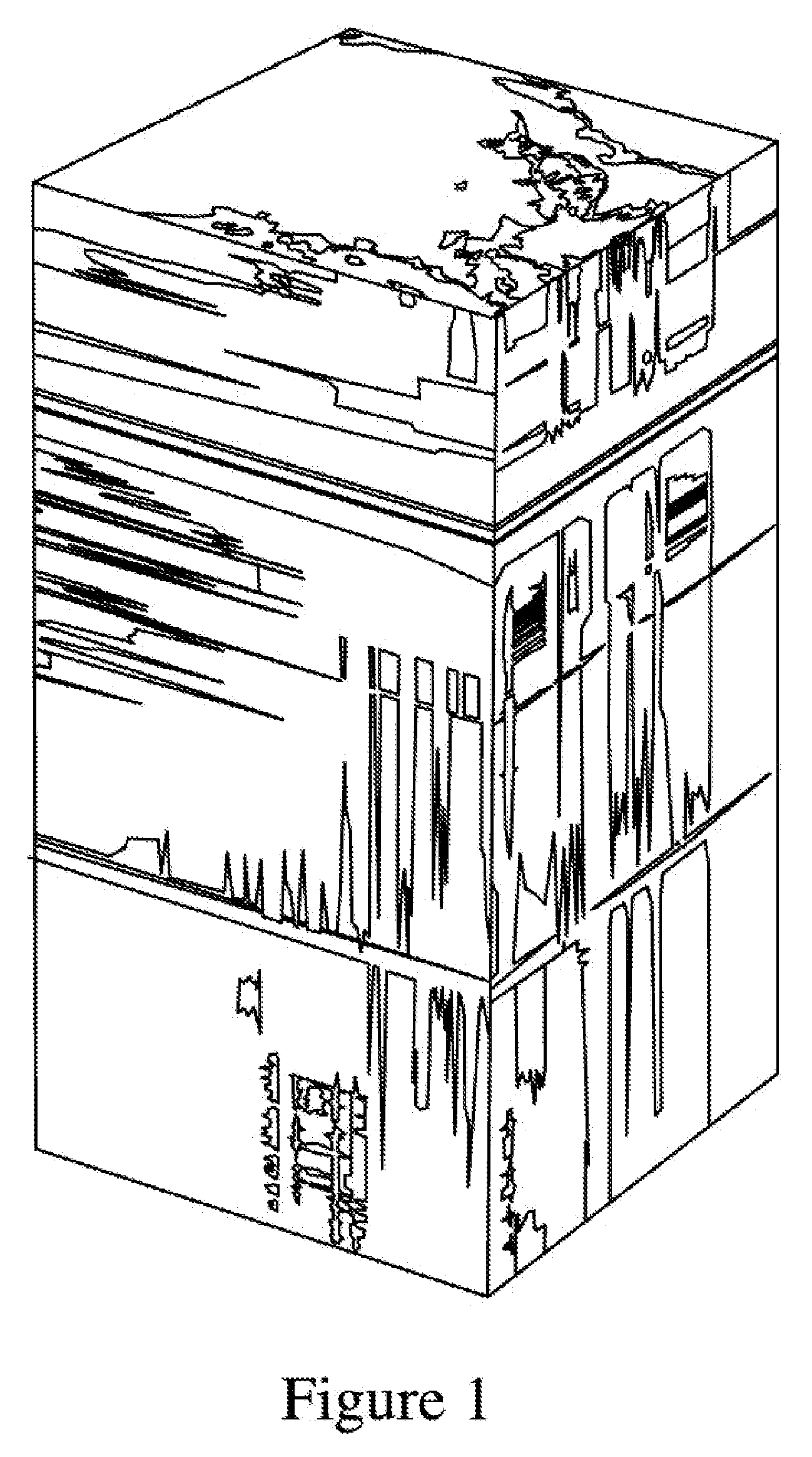

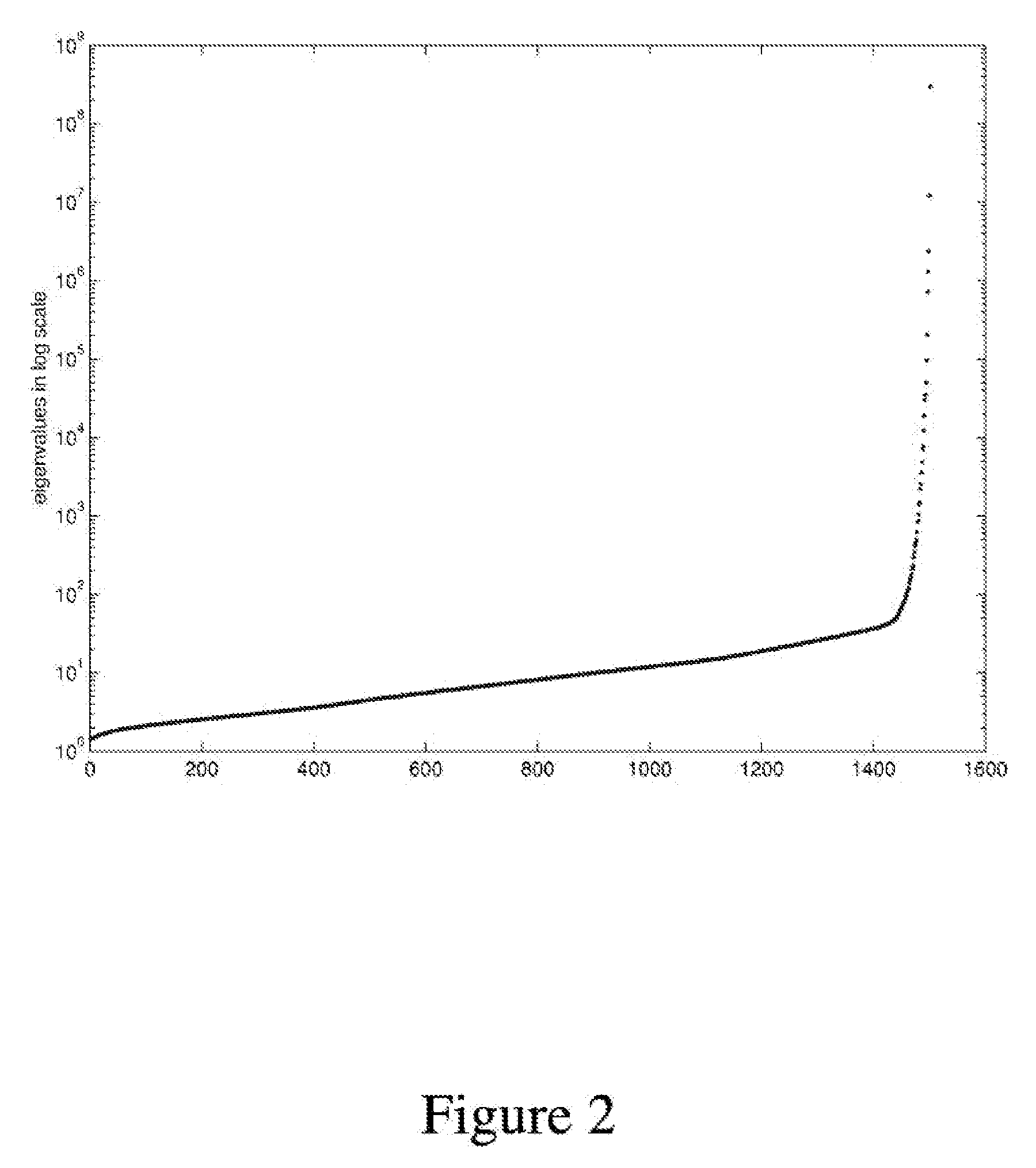

Lossless compression algorithm for hyperspectral data

InactiveUS20090018801A1Improve the level ofSmall sizeCode conversionCharacter and pattern recognitionSatellite dataData set

Lossless compression techniques provide efficient compression of hyperspectral satellite data. The present invention combines the advantages of a clustering with linear modeling. A number of visualizations are presented, which help clarify why the approach of the present invention is particularly effective on this dataset. At each stage, the algorithm achieves an efficient grouping of the data points around a relatively small number of lines in a very large dimensional data space. The parametrization of these lines is very efficient, which leads to efficient descriptions of data points. The method of the present invention yields compression ratios that compare favorably with what is currently achievable by other approaches.

Owner:SEC OF COMMERCE UNITED STATES OF AMERICA

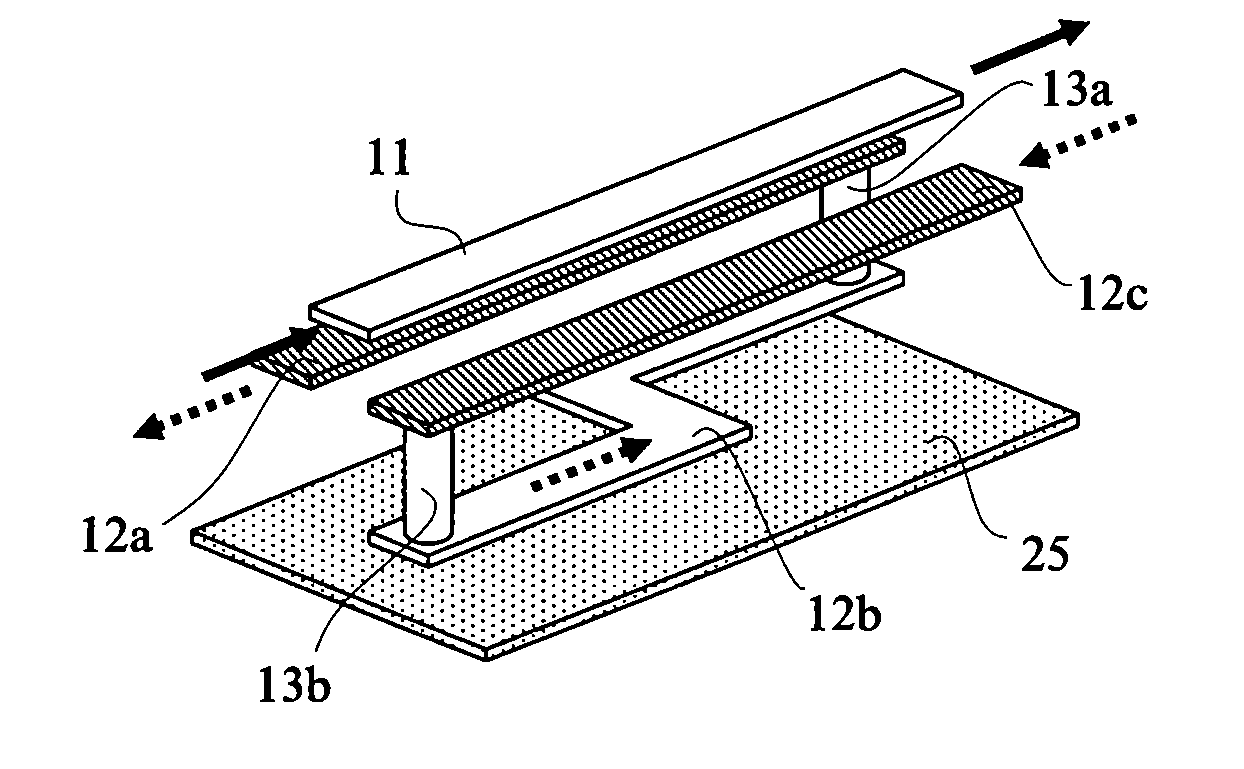

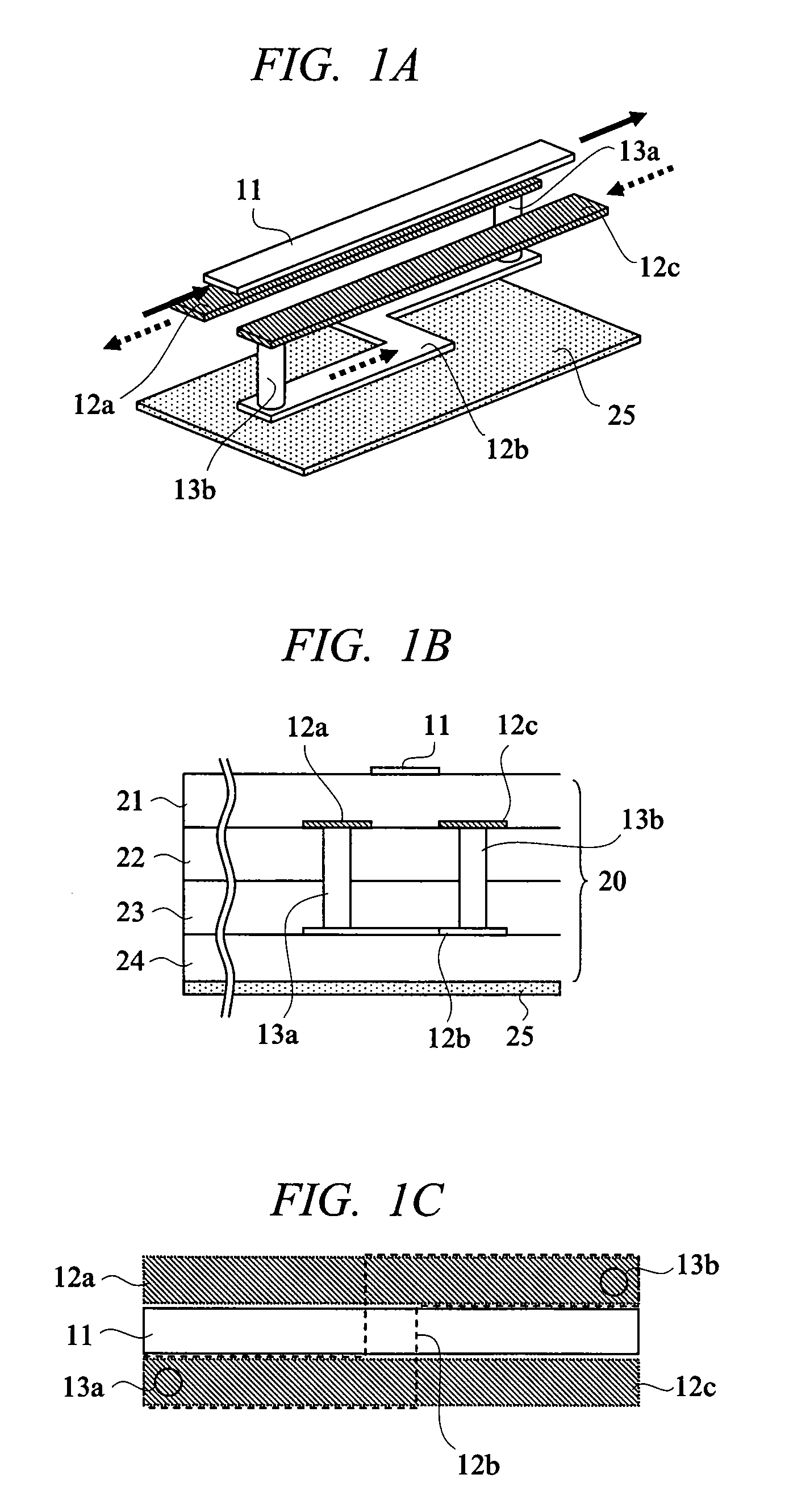

Directional coupler and RF circuit module

InactiveUS20080070519A1Per unit area is increasedGenerate efficientlyResonant long antennasElectric pulse generatorCouplingGround plane

A directional coupler with a high coupling per unit area and small variations in characteristic at manufacturing capable of achieving a high directivity easily and an RF circuit module provided with the directional coupler are achieved. A main-line is provided on a front surface of a multi-layer substrate, a ground plane is provided on a back surface of the multi-layer substrate. On an inner layer immediately under the main-line, two lines in parallel with the main-line are provided, and one line is provided on a layer closer to the ground plane than the two lines. By connecting the two lines and the one line with vias, a sub-line with a shape of a winding of a loop is formed. In the sub-line, a main component of a vector vertically penetrating the loop is horizontal with respect to the ground plane.

Owner:RENESAS ELECTRONICS CORP

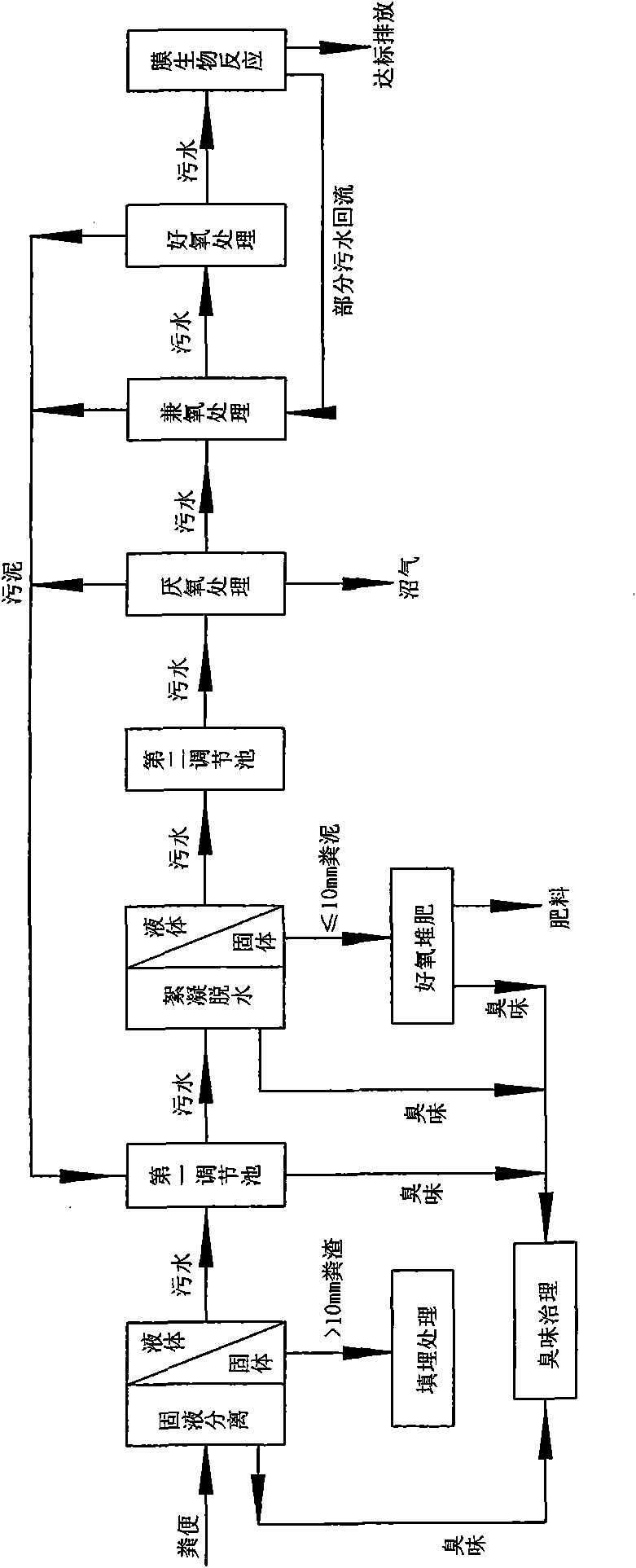

Excrement centralized processing method

ActiveCN101654318AAvoid cloggingCOD removalBio-organic fraction processingSludge treatment by de-watering/drying/thickeningFlocculationFeces

The invention relates to an excrement centralized processing method, comprising the steps of solid-liquid separation, flocculation water removing, aerobic compost treatment, anaerobic sewage treatment, facultative anaerobic sewage treatment, aerobic sewage treatment, membrane anaerobic reacting sewage treatment and odor treatment. Treated with the processing method of the invention, the urban night soil is 100% decontaminated, is 99.7% minimized and the excrement sludge is completely changed into resource.

Owner:北京昊业怡生科技有限公司

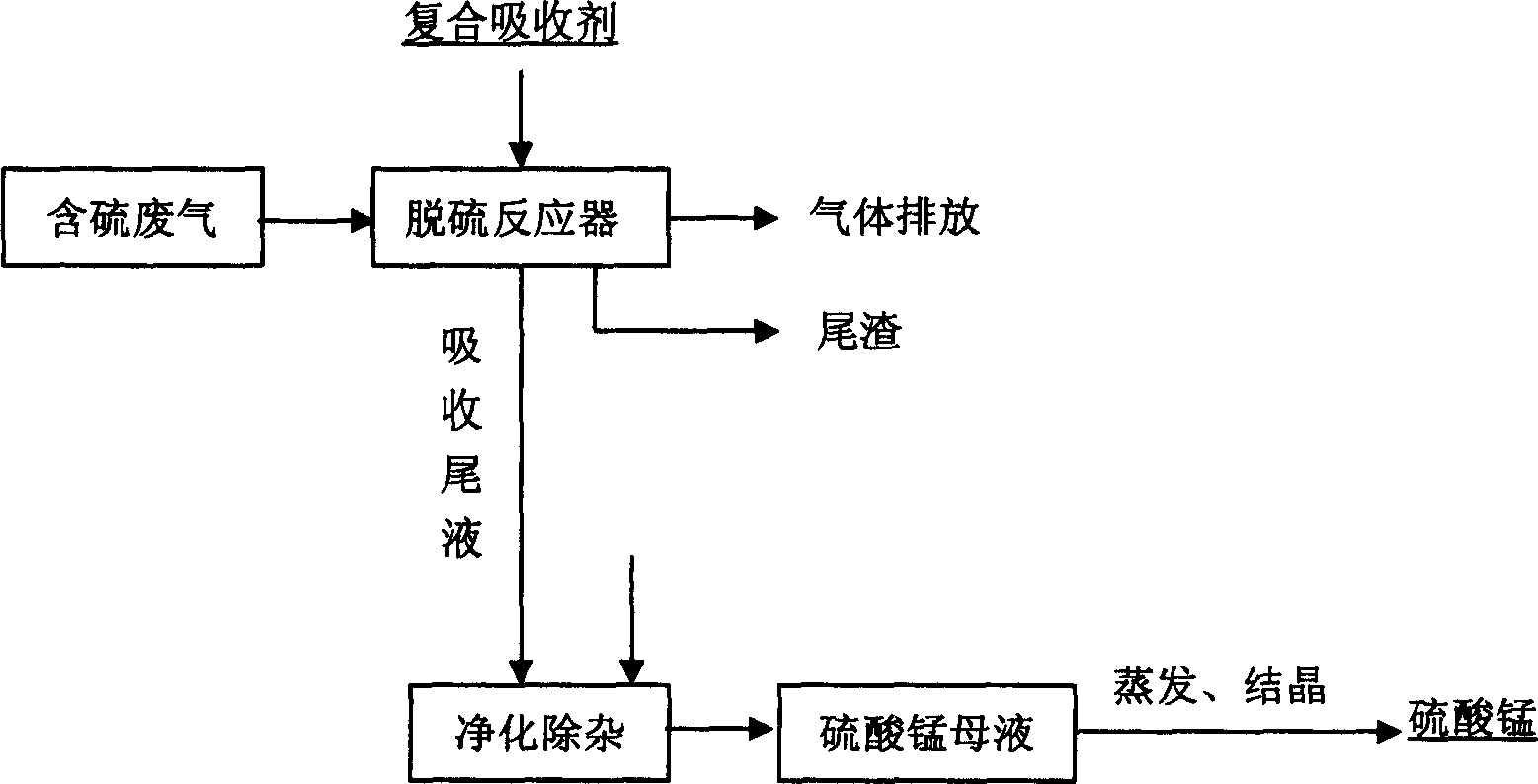

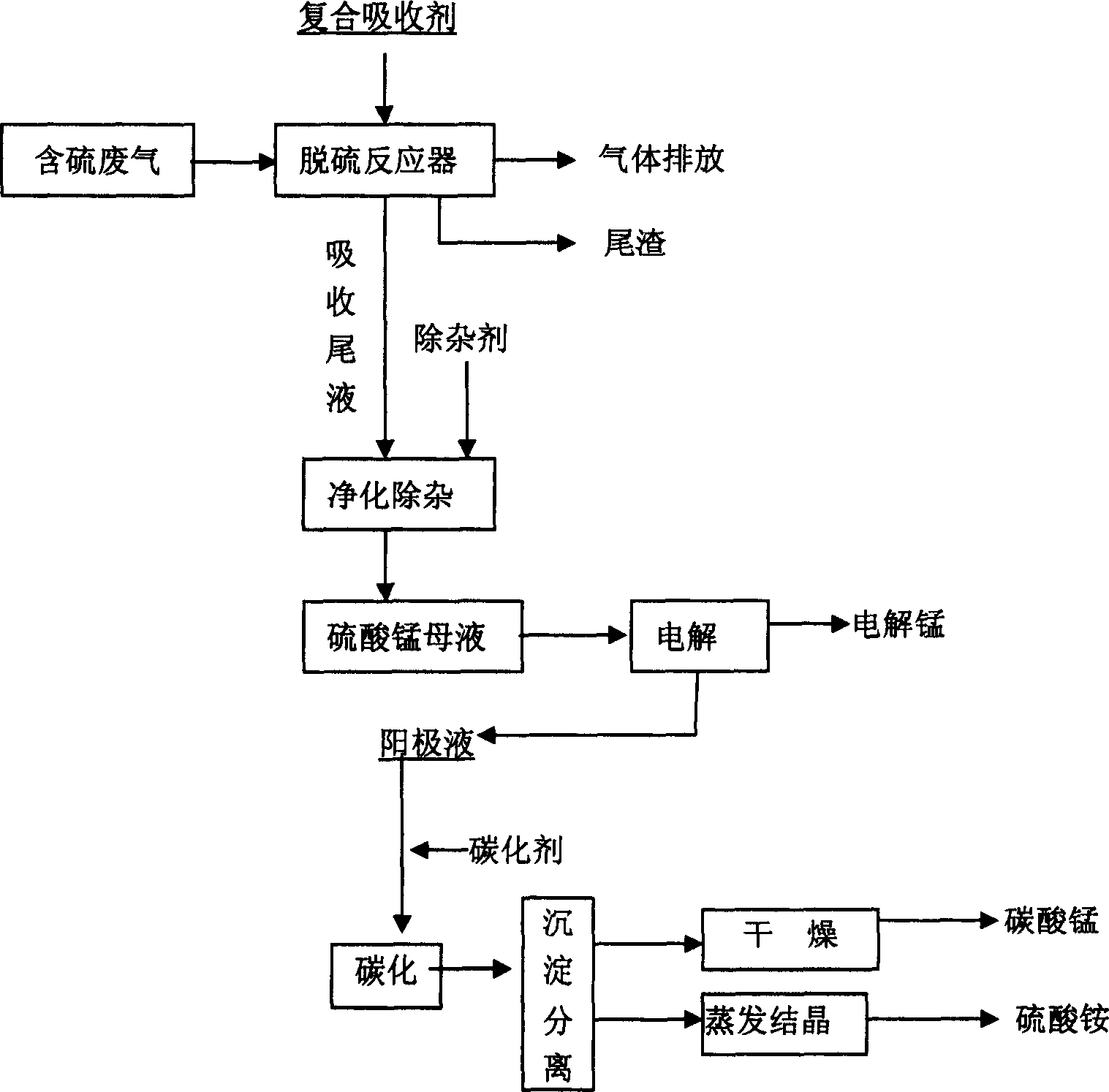

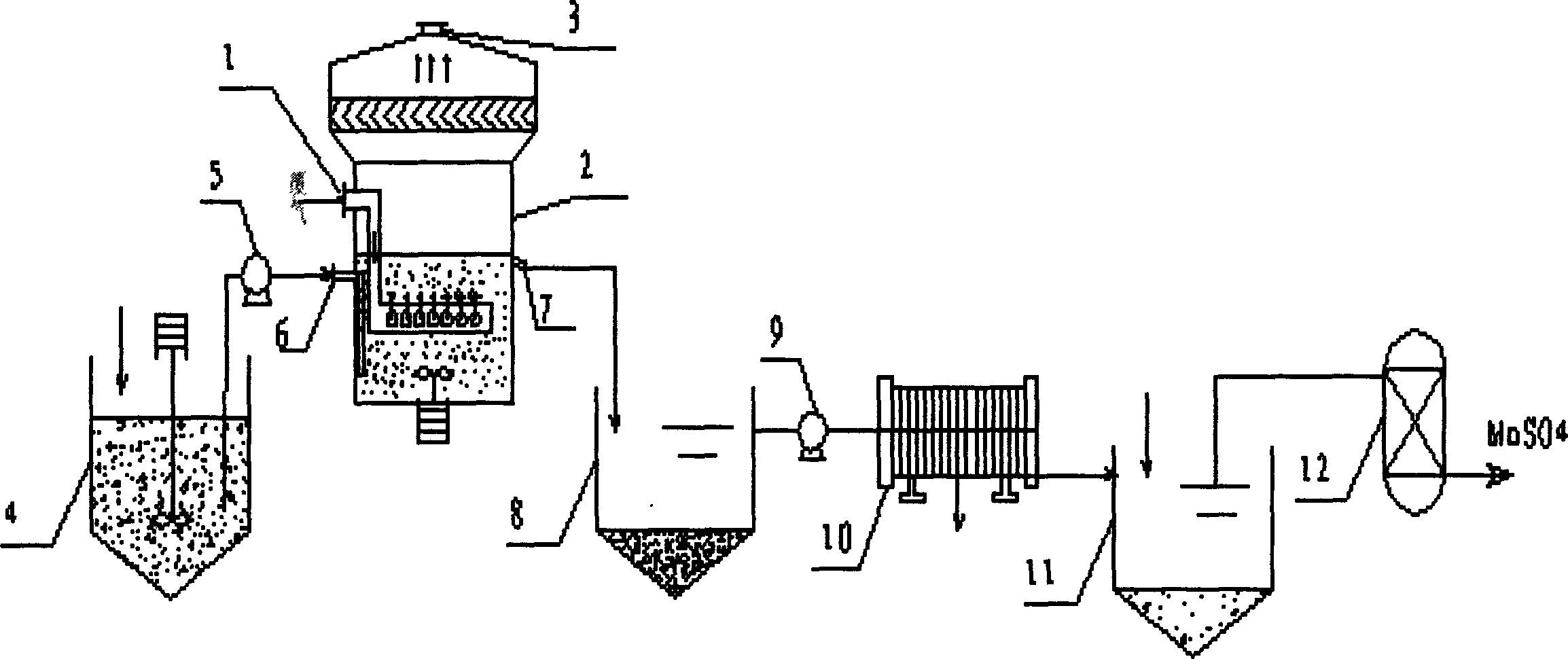

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

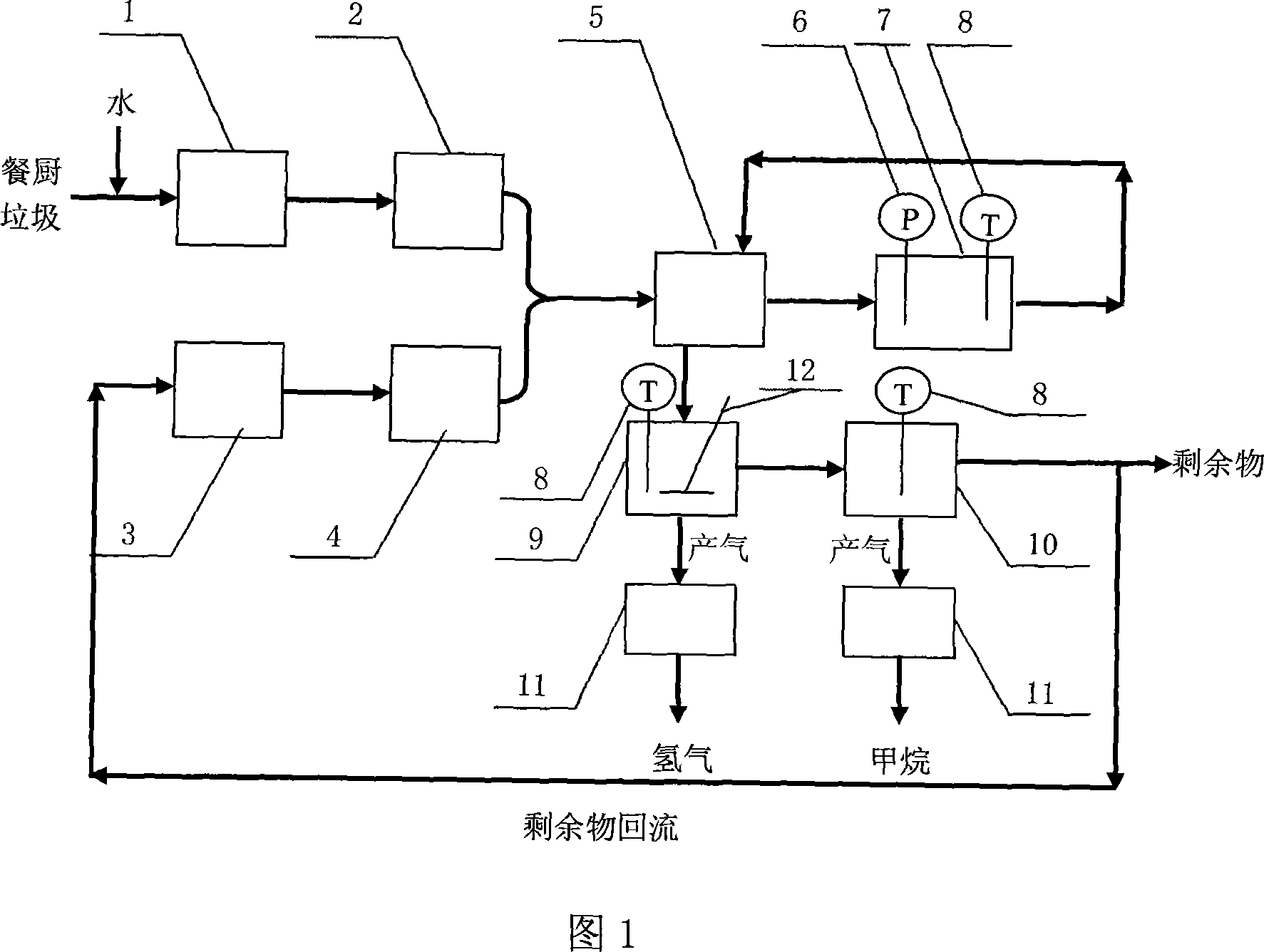

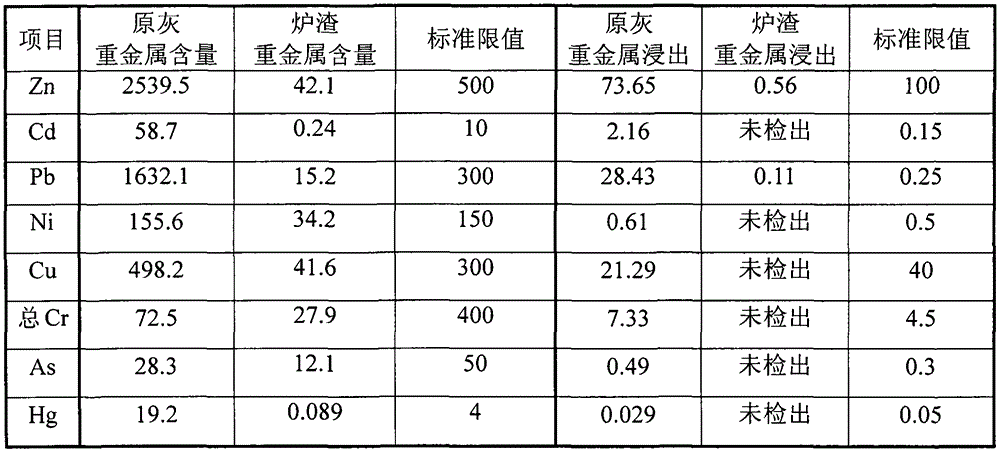

Method for producing hydrogen and methane by kitchen waste diphasic anaerobic fermentation

InactiveCN101134684APH controlLow running costBio-organic fraction processingClimate change adaptationHydrogenSludge

The biphase anaerobic fermentation process of kitchen refuse to produce hydrogen and methane includes the following steps: 1. sorting kitchen refuse and mixing with water in certain amount; 2. mixing with sludge from sewage treating yard and heat treatment; 3. heat exchange between heat treated mixture and mixture without through heat treatment; 4. anaerobic fermentation of the heat treated mixture in the first phase to produce hydrogen; 5. anaerobic fermentation of the residue from the first phase fermentation in the second phase to produce methane; and 6. using the residue from the second phase fermentation as fertilizer or returning to replace sludge serving as hydrogen producing bacteria source. The process is simple, can recover the biomass energy from kitchen refuse effectively, and has no secondary pollution.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

Method for treating solid organic wastes by biological method

InactiveCN101709006AAchieve recyclingAchieve reductionBio-organic fraction processingAnimal corpse fertilisersEcological environmentFermentation

The invention relates to a process for treating solid organic waste resources (food residues, domestic garbage, vegetable market garbage, wastes and leftovers of slaughter houses and food products factories, beer lees, distilled spirit lees, stevia rebaudiana residues, Chinese medicinal herbal dregs and the like), which comprises the following steps of: removing impurities (plastic bags, bottle caps, napkins, metals and the like) from solid organic wastes; adding mixed bacteria, an enzyme preparation and auxiliary materials into the organic wastes; stirring the mixture and controlling the temperature by hot blast; performing fermentation treatment on the mixture by adopting a staged temperature raising method; and drying and crushing the mixture to obtain an organic fertilizer. The invention finds a process capable of effectively treating the solid organic wastes, which can convert the solid organic wastes into the organic fertilizer by using microorganisms to change the organic wastes into valuable and realize the recycling use and the quantity reduction of waste resources; besides, the used microorganisms are harmless to human and the ecological environment.

Owner:TIANJIN UNIV OF SCI & TECH

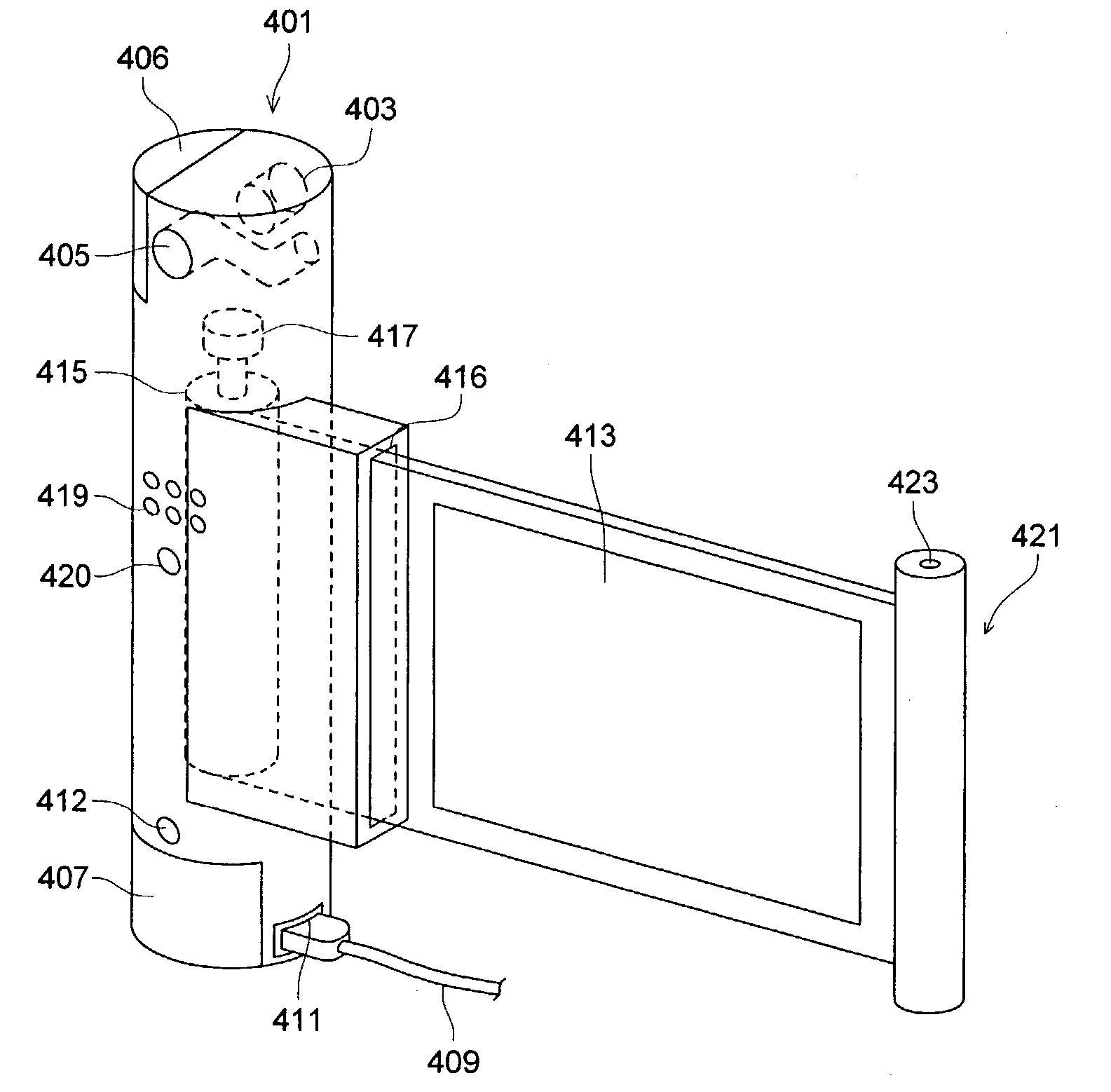

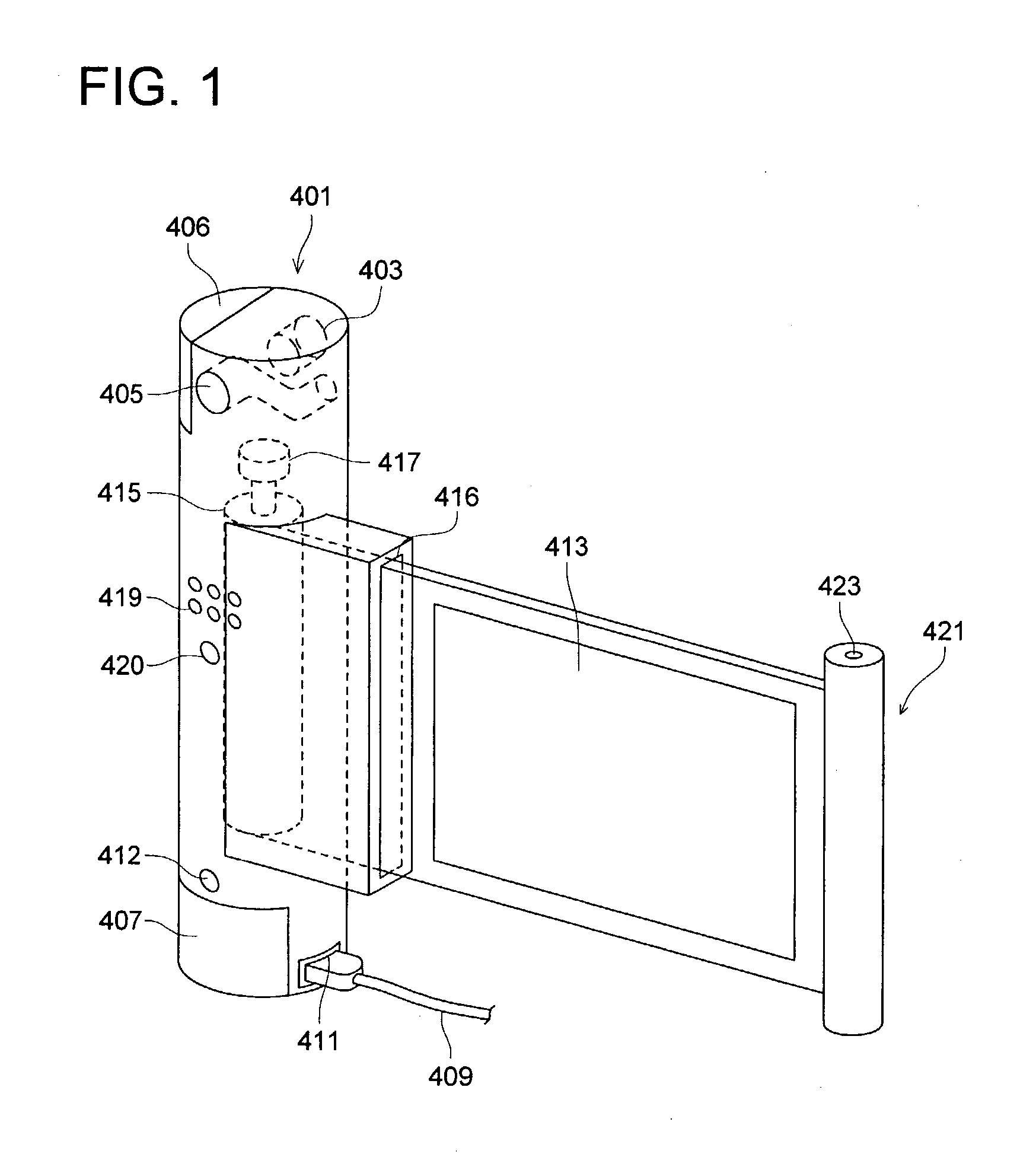

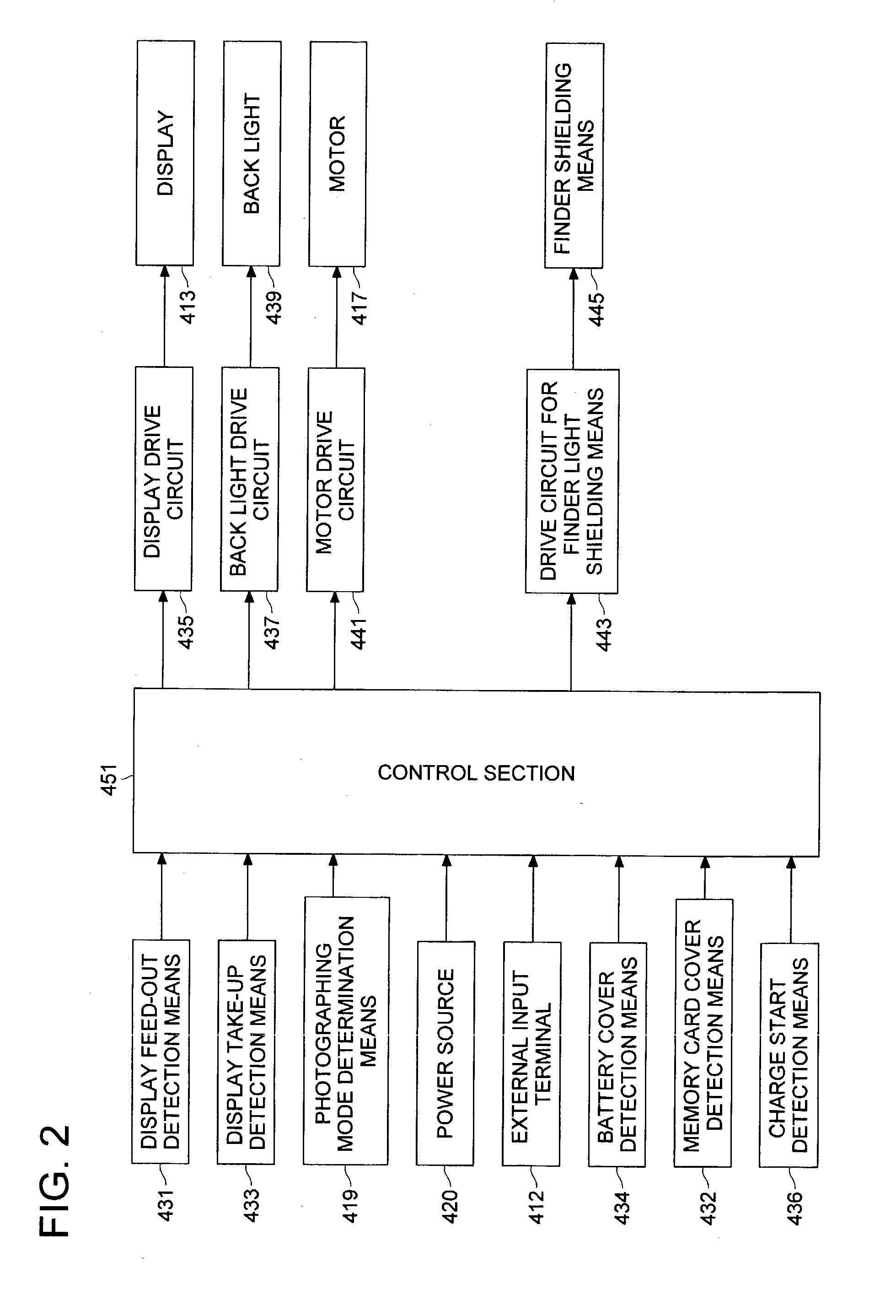

Camera having flexible display

InactiveUS7184086B2Achieve reductionTelevision system detailsDigital data processing detailsCamera lensComputer graphics (images)

A camera includes a columnar camera main body portion having a photographing lens, and a flexible display for displaying an image of an object to be photographed through the photographing lens, in which one end of the flexible display is attached to the camera main body portion, and which is provided so as to be taken-up into the camera main body portion.

Owner:KONICA CORP

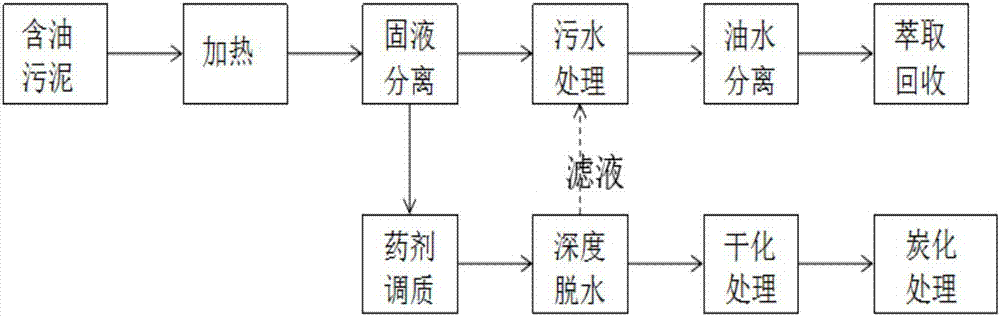

Treating method for oily sludge

InactiveCN106957136AThe treatment method is simple and effectiveSimple processSludge treatment by de-watering/drying/thickeningAgriculture tools and machinesChemistryPyrolysis

The invention provides a treating method for oily sludge and relates to the technical field of oily sludge treatment. The treating method provided by the invention comprises the following steps: heating and stirring oily sludge, standing and then performing solid-liquid separation, thereby acquiring oily mud and oily liquid; introducing the oily liquid into a sewage treatment system for performing oil-water separation, and extracting and purifying the separated oil; adding a reagent into the oily mud for tempering; after tempering, deeply dewatering, thereby acquiring dewatered oily mud and filtrate; performing oil-water separation on the filtrate; performing drying treatment and pyrolysis carbonizing treatment on the dewatered oily mud. The treatment method provided by the invention is simple, convenient and efficient and can realize the reduction, harmless and recycling treatment of the oily sludge, the whole treating process flow operation occupies less area and the investment cost is low.

Owner:安徽省通源环境节能股份有限公司

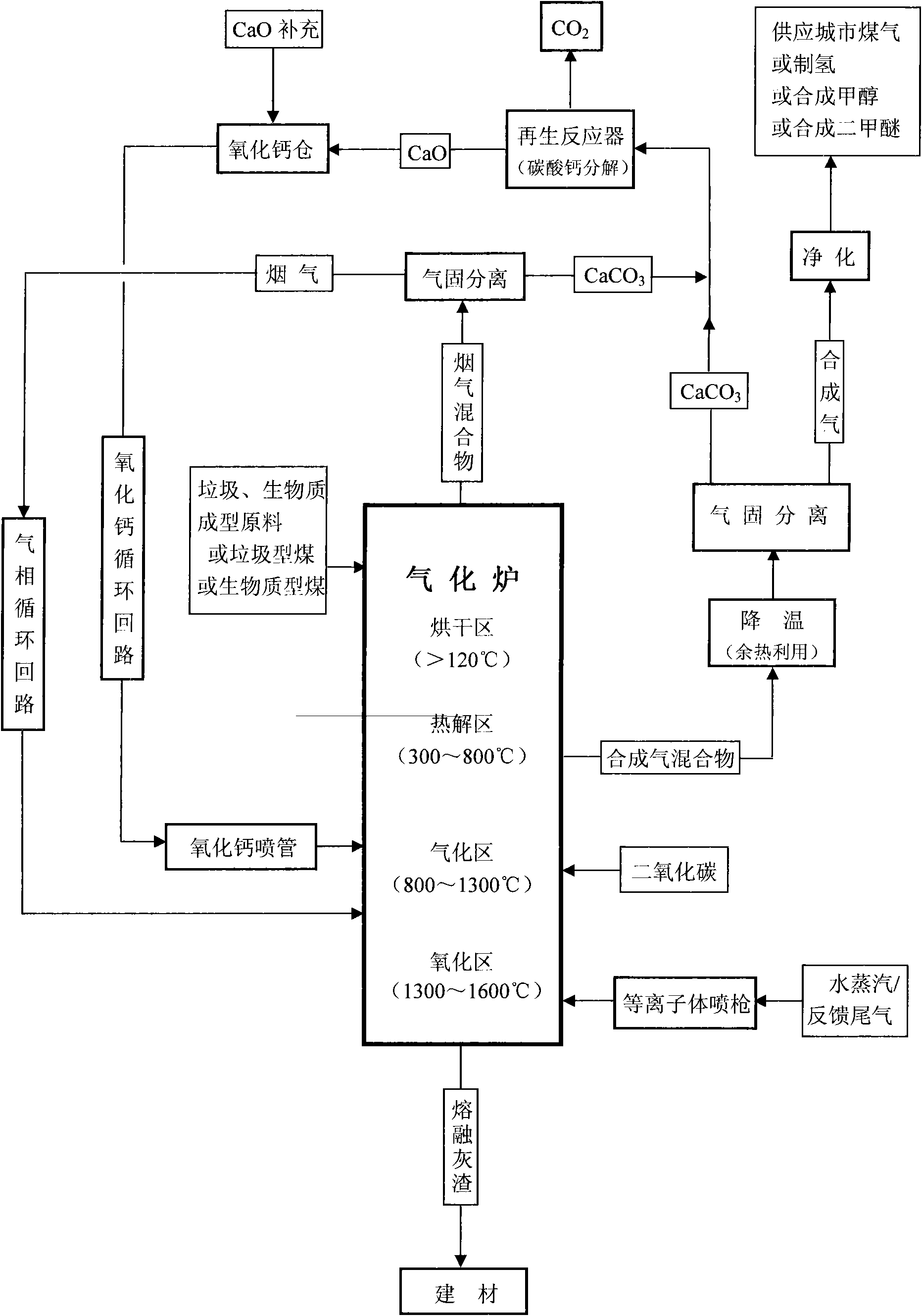

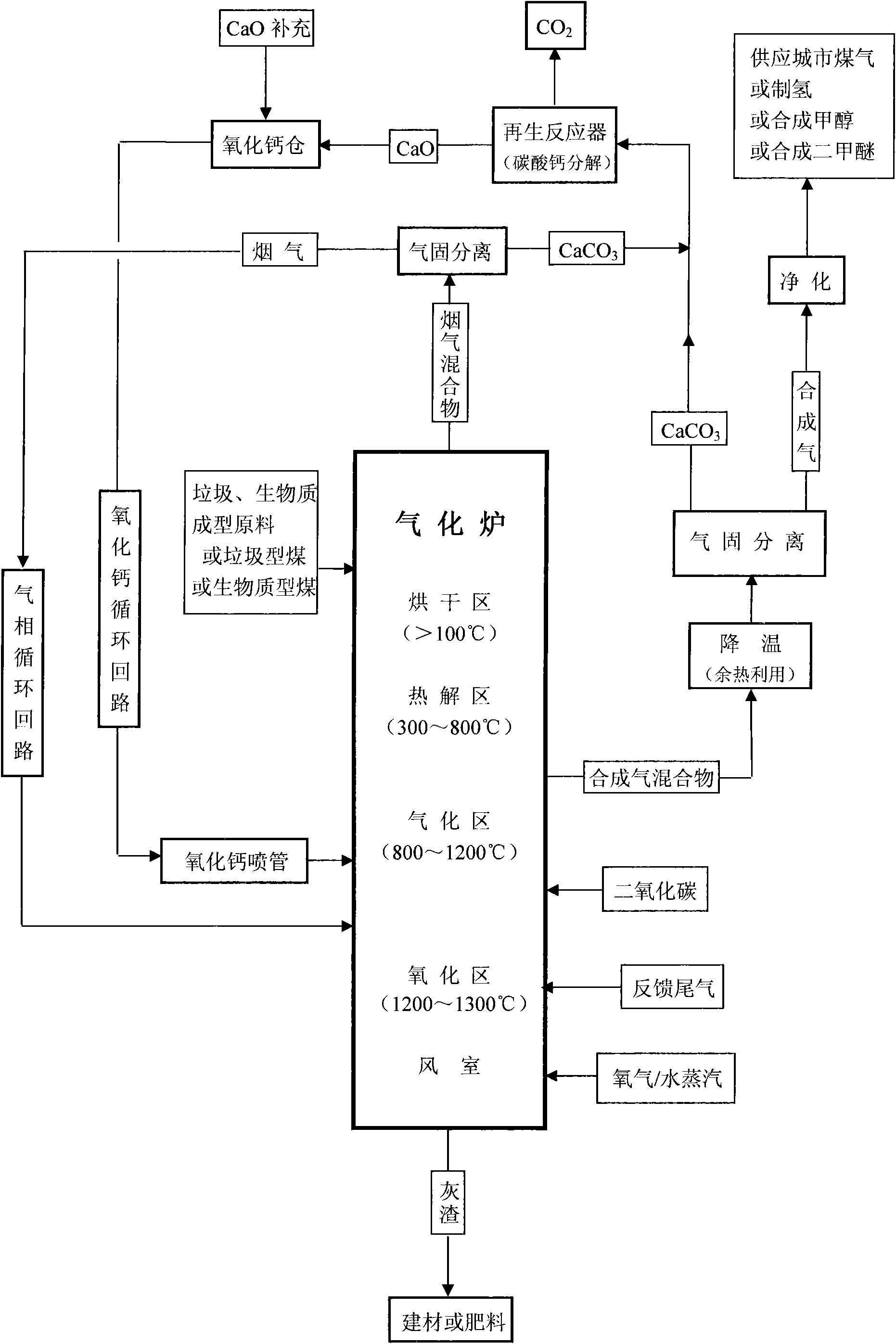

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

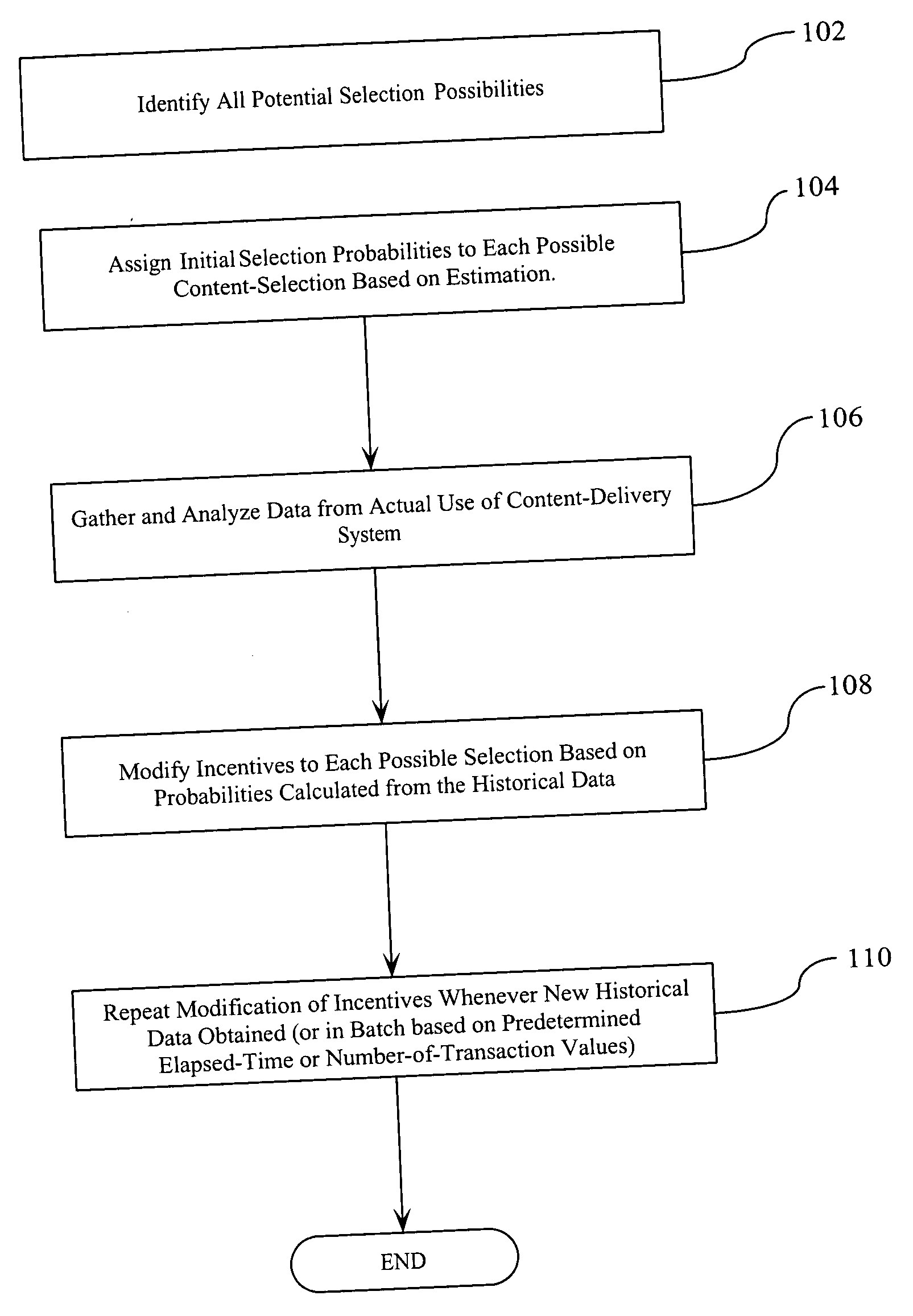

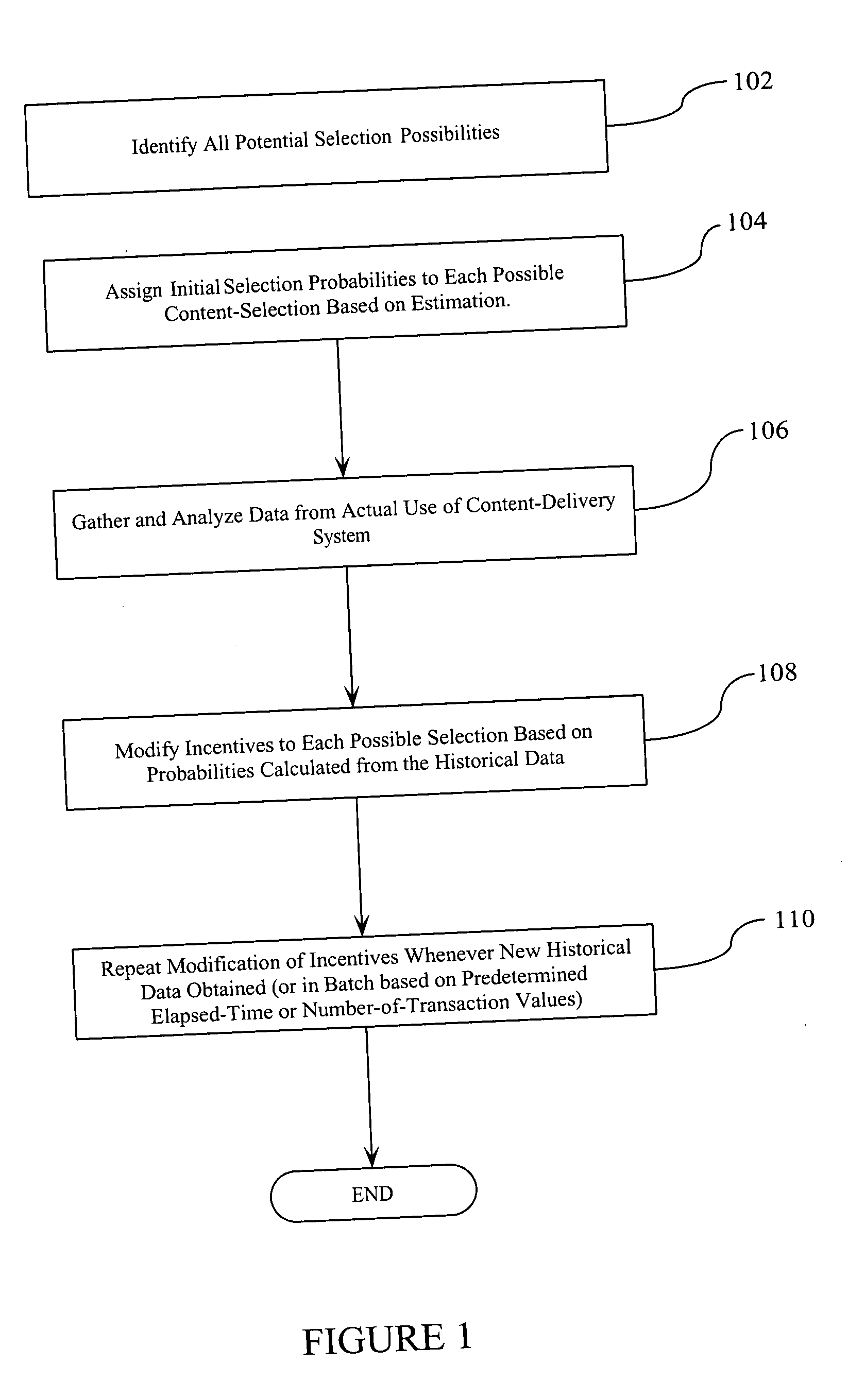

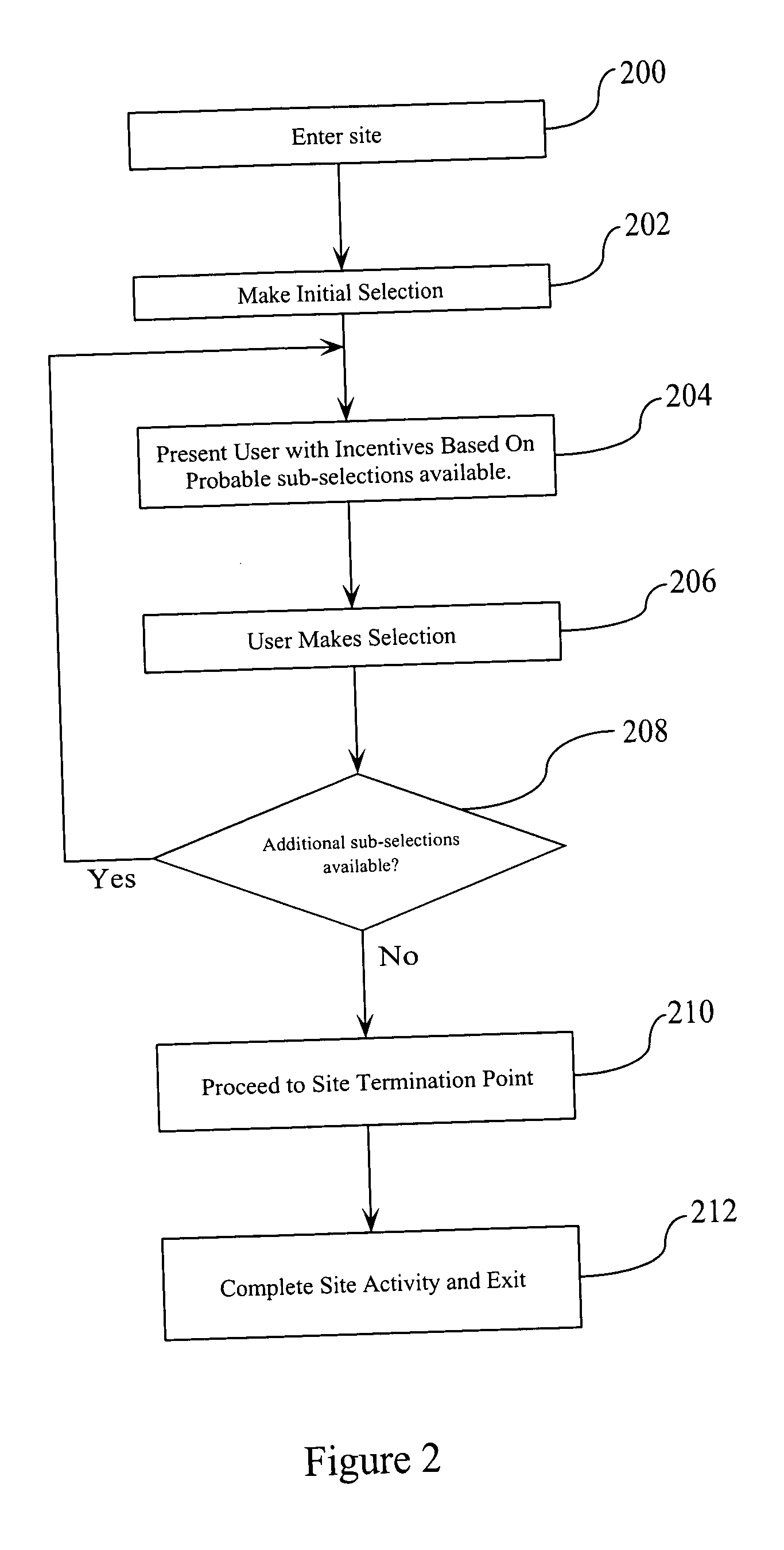

Incentive-based website architecture

ActiveUS20050071221A1Raise the possibilityMargin is maximizedSpecial data processing applicationsMarketing

The present invention applies gaming theory and well-understood sales processes and techniques to allow the operator of an interactive sales medium to control what is displayed to a user of the medium in a manner that signals their intentions (e.g., looking for a lower price, looking for a particular incentive, etc.) so that the “strategies” being used by the consumer can be identified and exploited to lead the consumer to a desired end choice. In particular, upon identification of the strategies being used by the consumer, incentives (e.g., gradually increasing rewards and / or decreasing “punishments”) are presented to the consumer in such a way that the margins achieved by an eventual sale are slowly decreased with each presentation of the incentives to the consumer. Since the presentation of each incentive increases the likelihood the consumer will make a purchase, margins are maximized for the seller.

Owner:TERRACE LICENSING LLC

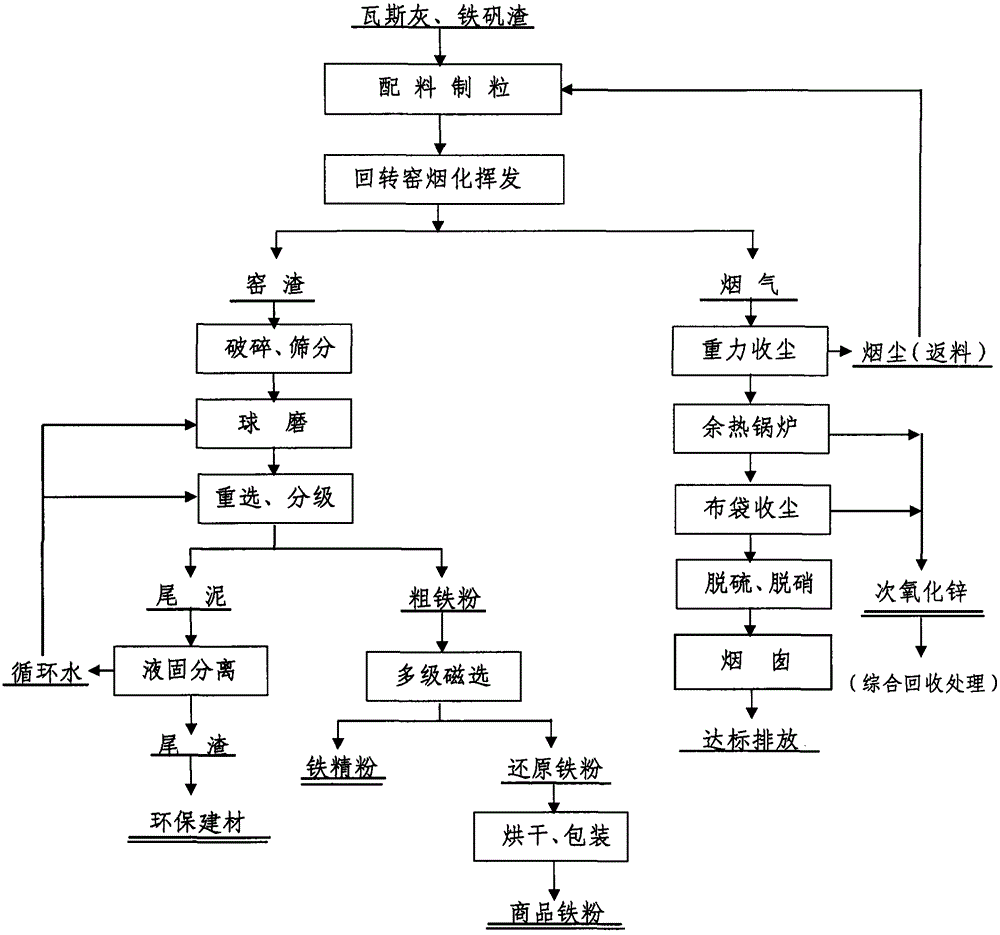

Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

ActiveCN104911356AImprove the level of comprehensive utilizationAchieve reductionProcess efficiency improvementSlagHigh energy

The invention provides a comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag. By combining advantages of low iron content and rich carbon of gas ash and characteristics of high iron content and rich precious metals of ferrovanadium slag, and by the adoption of a rotary-kiln fire method fuming enrichment technology, the material undergoes comprehensive recovery. Advanced equipment such as a waste heat boiler, a negative-pressure bag collector, a pneumatic emulsification desulfurization tower and the like are configured to carry out efficient recovery and harmless environmental-protection processing of flue gas so as to achieve the purpose of clean production. By a beneficiation combined method, iron-containing kiln slag undergoes high added-value exploitation. Thus, the environmental protection problem of resource disposition is solved, and the effect of comprehensive utilization with low energy consumption, high yield and high added-value is achieved. Problems of short kiln age, high energy consumption and low concentration of SO2 during the treating process of ferrovanadium slag can be solved by the technology provided by the invention, and problems of poor iron separation effect and overhigh content of fluorine and chlorine in zinc hypoxide also can be solved. The technology has good economic benefit and high popularization and practical value.

Owner:北京事竟成有色金属研究所

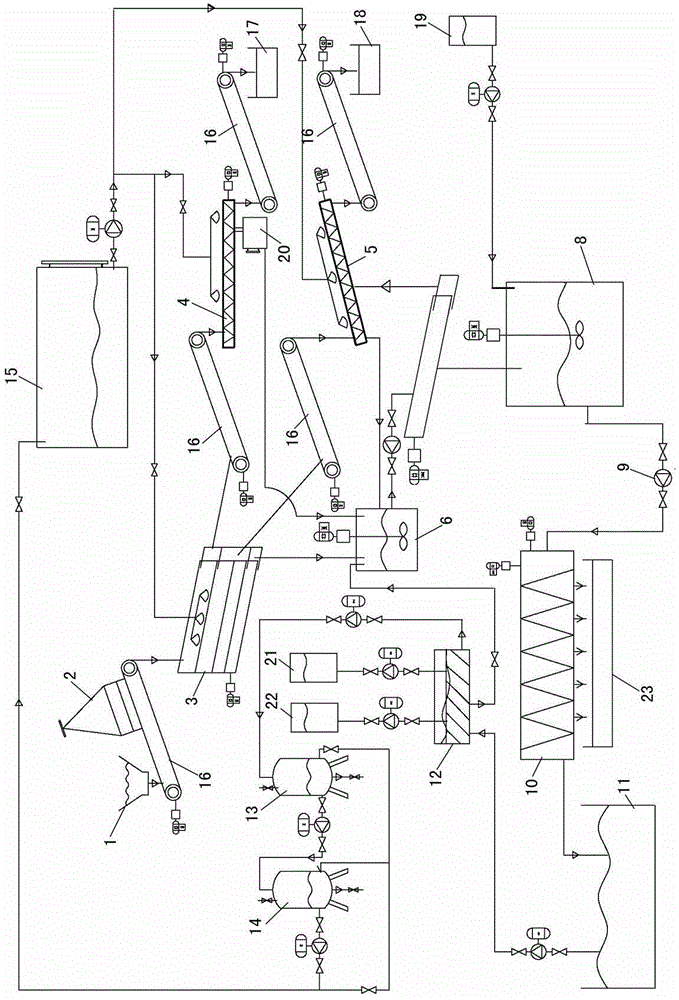

Soil washing restoration system based on reduction concentration design concept and method thereof

ActiveCN104475441AShort stayImprove production efficiencyContaminated soil reclamationSoil washingCompound (substance)

The invention discloses a soil washing restoration system based on a reduction concentration design concept and a method thereof. The washing restoration system comprises the following four module units which are sequentially connected with one another: a feeding and screening unit, an ore washing unit, a sludge dewatering unit and a tail-end sewage treatment recycling unit. The pollutants on the surface of coarse particles are eluted, transferred and concentrated into the filter-pressed mud cake by virtue of washing, so that pollutant-containing fine particles in contaminated soil can be effectively separated from crude particles such as gravel and grit. The repaired and discharged clean gravel and grit can be directly recycled to serve as building material. According to the system, purified water serves as a washing solution, so that secondary pollution caused by addition of a chemical washing agent is avoided, and the washing solution is treated by a tail-end sewage treatment system so as to be recycled. The reduction of remediation of contaminated soil is realized, the comprehensive repair cost is greatly reduced, the washed and discharged materials can be recycled, the contaminated soil is repaired, and a novel profit point is created.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

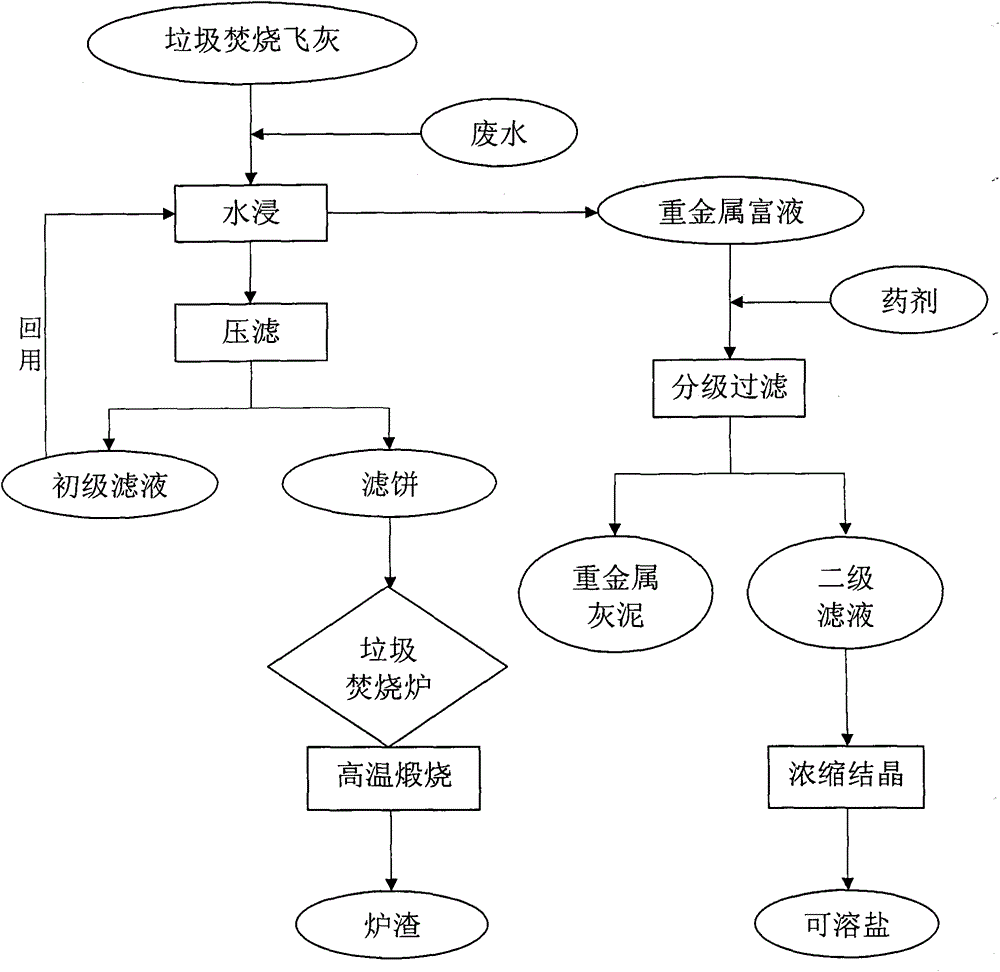

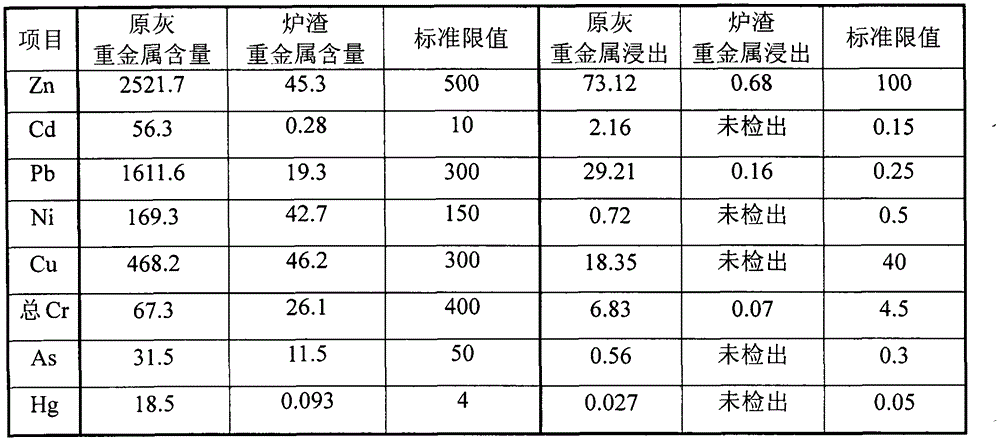

Technology for reducing waste incineration fly ash via water logging pretreatment

InactiveCN104084415AAchieve separationLoss of mobilitySolid waste disposalReduction treatmentResource utilization

The invention relates to a technology for reducing waste incineration fly ash via water logging pretreatment, and the technology is particularly suitable for the treatment of waste incineration fly ash with salt content higher than 20%. A water logging dechlorination manner is used for treating waste incineration fly ash; by prolonging the logging time, the water consumption is greatly reduced, a subsequent wastewater treatment process is simplified at the same time and a soluble salt resource is recycled; before fly ash enters into a furnace, most of heavy metals and chlorine salts are removed, a matrix of fly ash is purified, and by virtue of existing incineration equipment of waste incineration power plants, pollutants such as dioxin are thoroughly degraded, so that the overall normal running of a waste incineration line is ensured and the harmless and reduction treatment of waste incineration fly ash is realized. The technology has a characteristic of correct in-situ treatment, and is simple in process and low in investment and operation costs; by gathering most of heavy metals and salts in heavy metal plaster and gathering little of the two in secondary fly ash, the reduction of waste incineration fly ash is realized, and then a favorable foundation is laid for the subsequent further treatment or resource utilization.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Process for treating excess sludge

ActiveCN1569699ARealize recycling of resourcesSmall volumeSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisMembrane bioreactorAnaerobic reactor

Disclosed is a method and equipment for treatment of polluted fluid, wherein ferrum family flocculating agents of a finite concentration are charged into the membrane bioreactor, in which they are subject to domestication and become compact biological ferrum sludge with improved property.

Owner:TSINGHUA UNIV

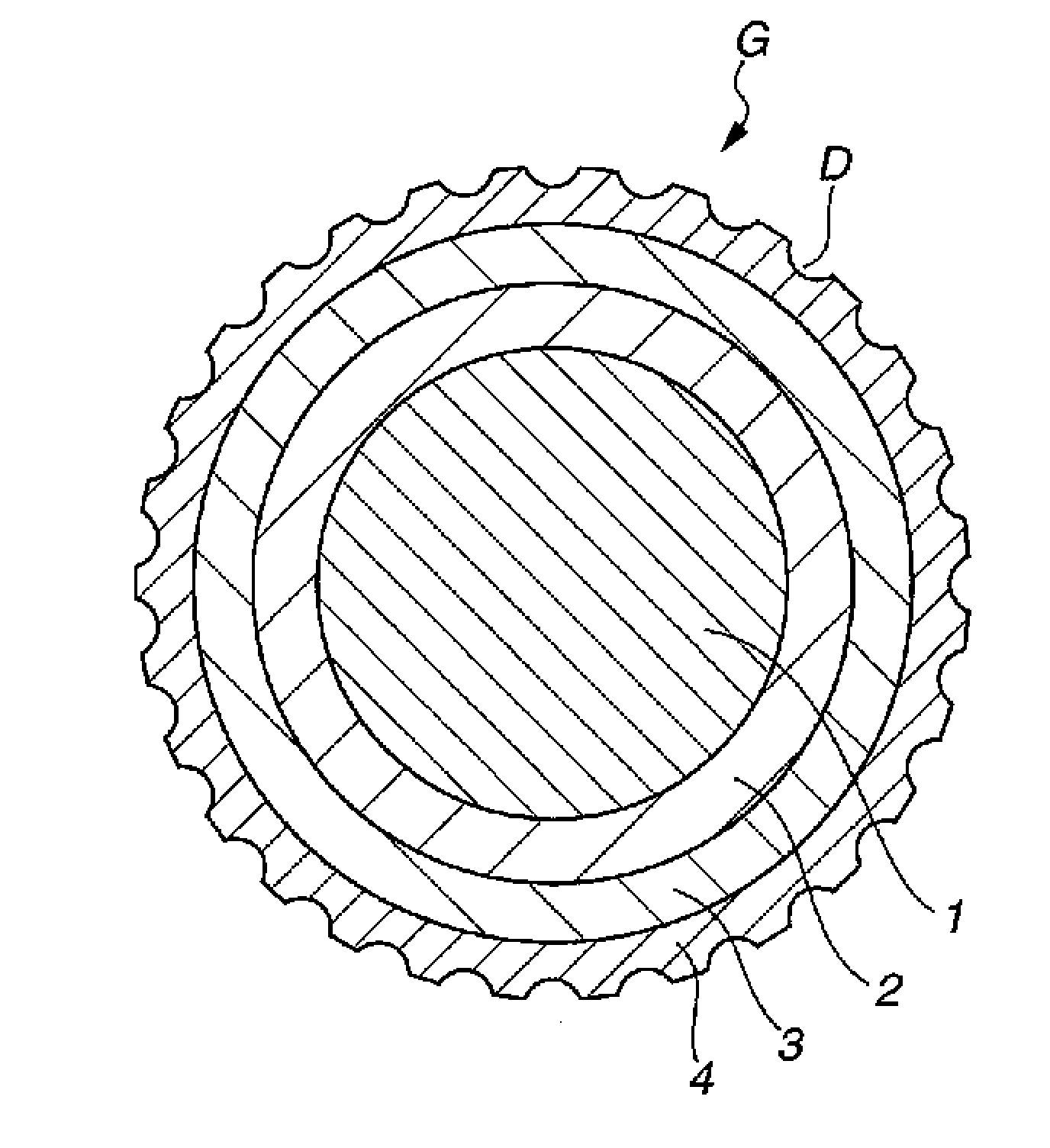

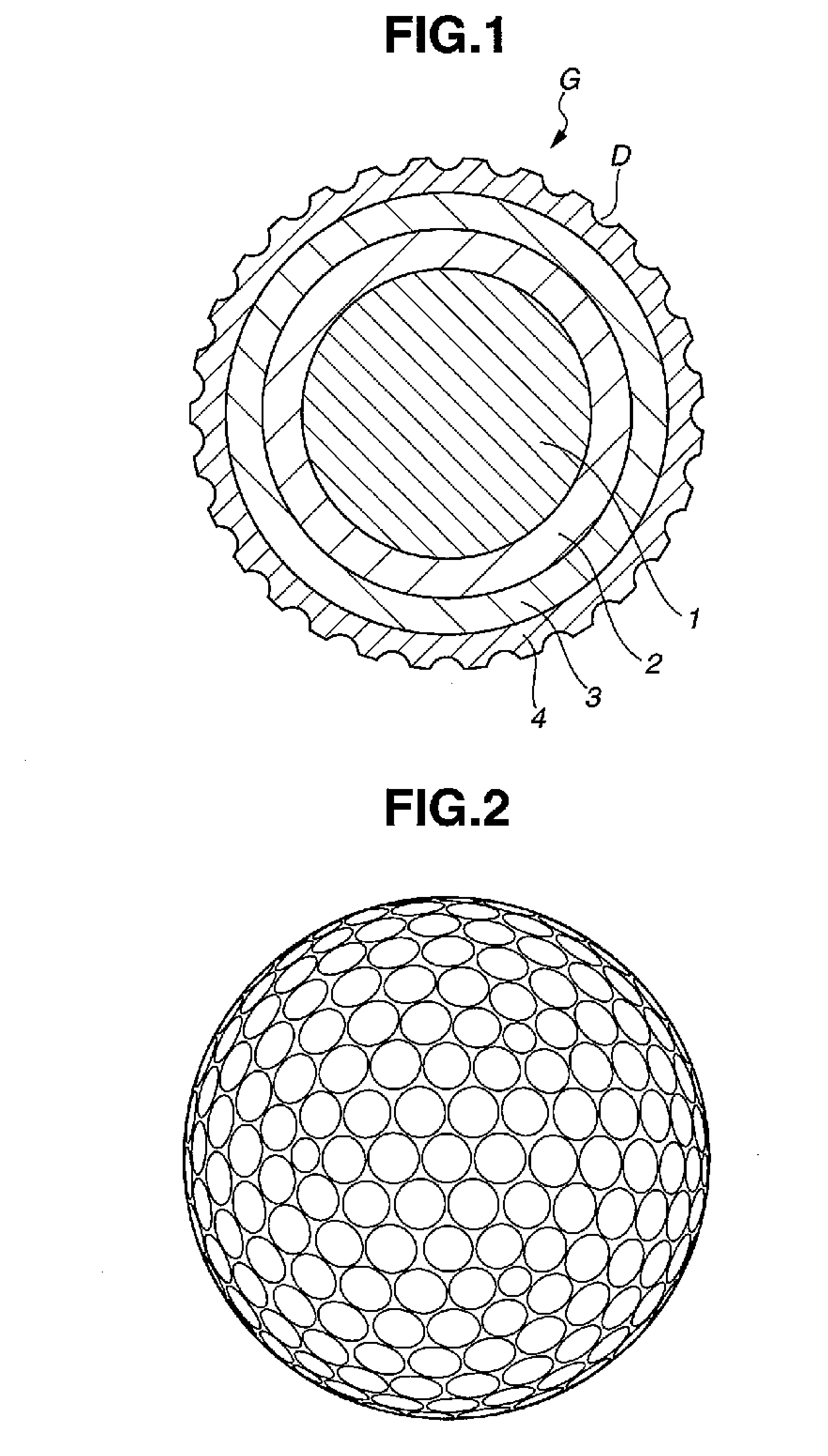

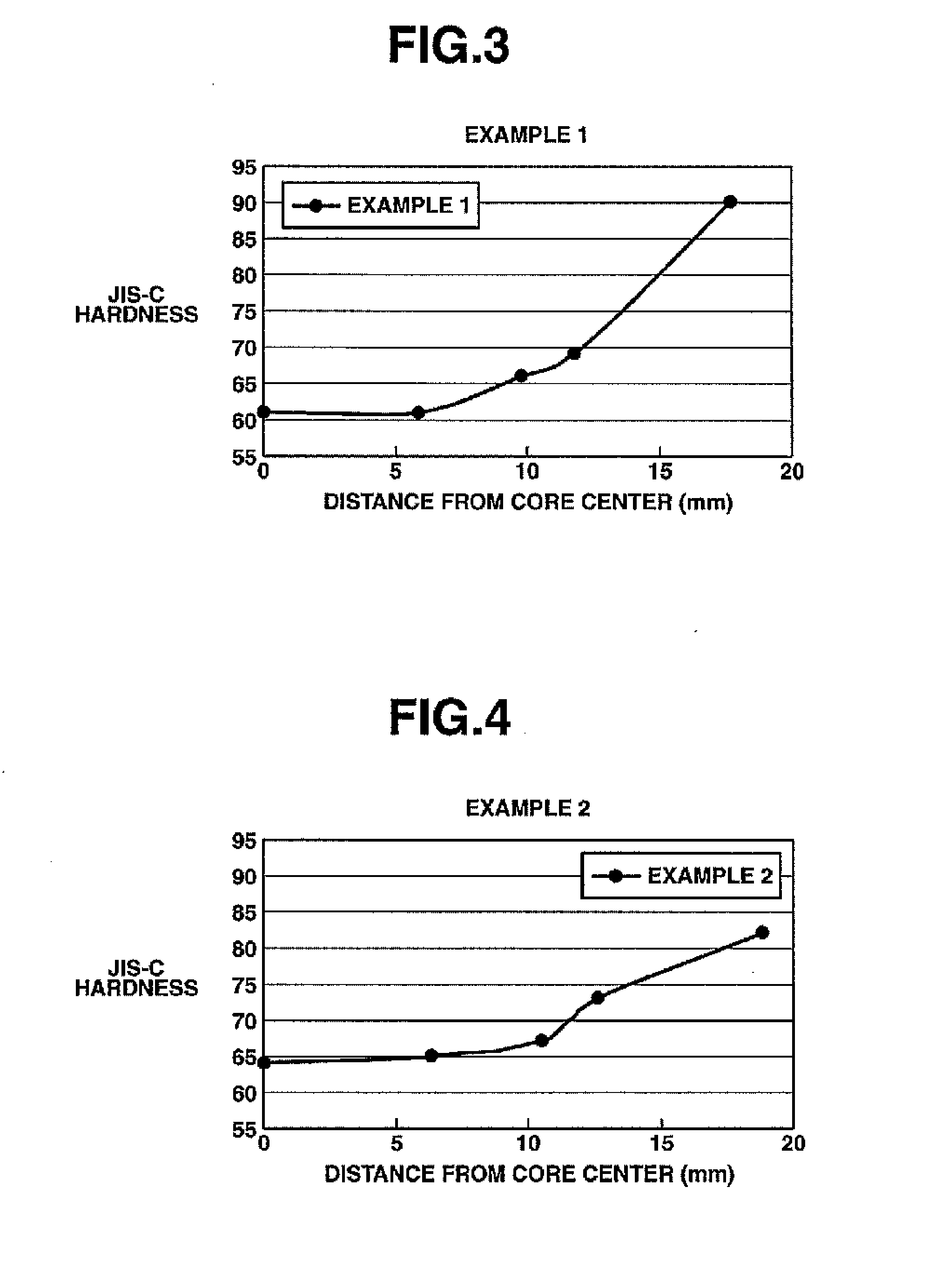

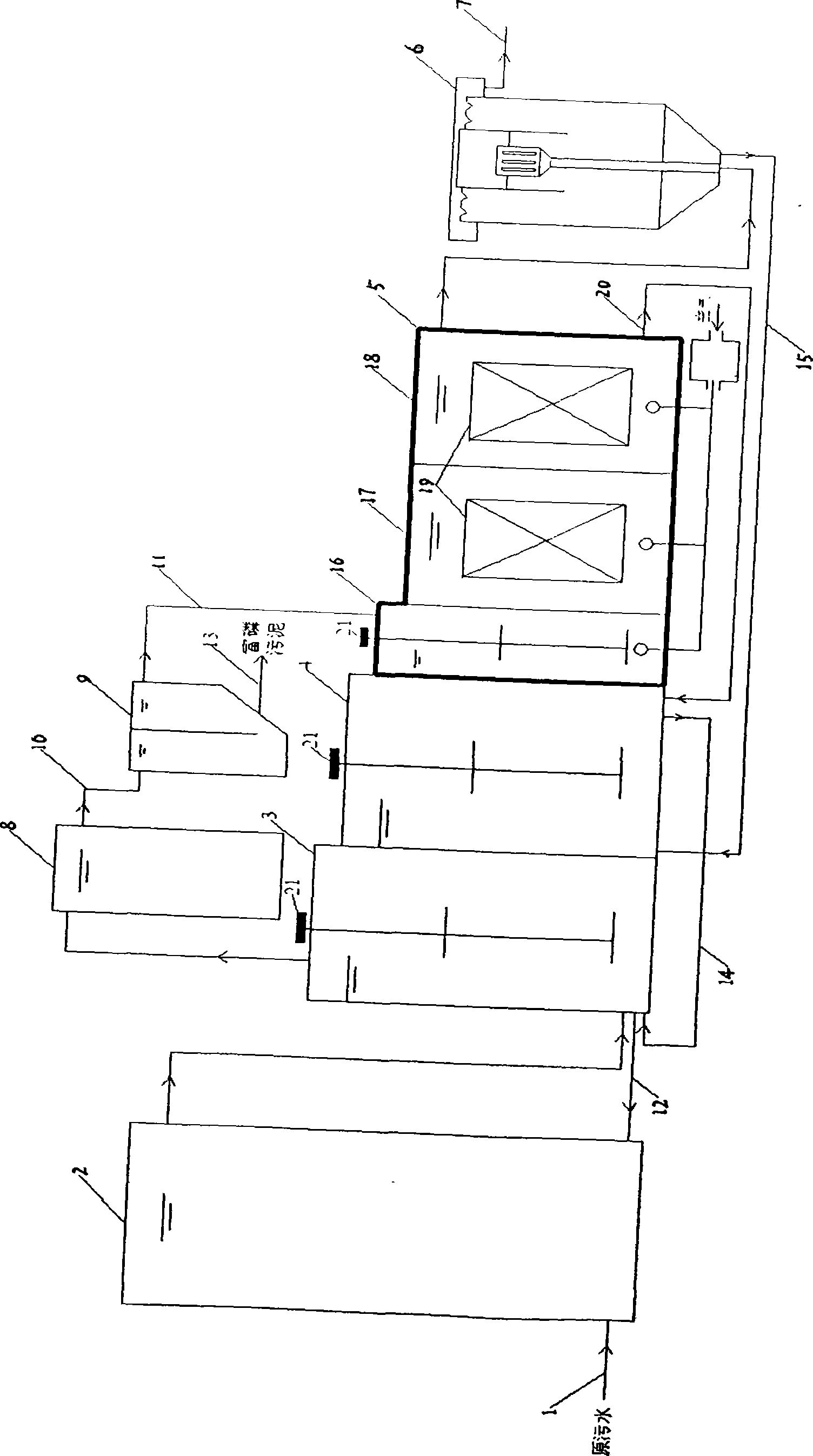

Golf ball

ActiveUS20140100059A1Improve crack resistanceSatisfactory distanceGolf ballsSolid ballsHardnessGolf Ball

The invention provides a golf ball having a core and ah cover of at least one layer. The core has a cross-sectional hardness which, letting R (mm) be the radius of the core, A be the JIS-C hardness at a center of the core, B be the JIS-C hardness at a position R / 3 mm from the core center, C be the JIS-C hardness at a position R / 1.8 mm from the core center, D be the JIS-C hardness at a position R / 1.3 mm from the core center, and E be the JIS-C hardness at a surface of the core, satisfies the formulas (1) D−C≧7, (2) C−B≦7, (3) (D−C)−(C−B)≧7, and (4) E−A≧16.

Owner:BRIDGESTONE SPORTS

Dephosphorization and denitrification, mud decrement and phosphorus recovery integrated sewage treatment device and method thereof

InactiveCN101544453AImprove system synchronous denitrification and dephosphorization capacityReduce pool capacityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentContinuous flowChemistry

Owner:CHONGQING UNIV

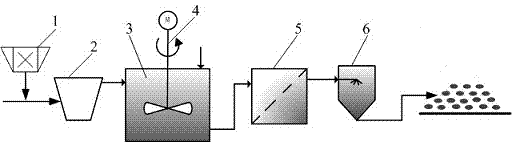

Method and device for preparing formed sludge fuel

InactiveCN102212403AImprove dehydration effectImplement resourcesSludge treatment by de-watering/drying/thickeningBiofuelsSludgeSolid fuel

The invention discloses a process method for preparing a derived solid fuel by using sludge, and the method comprises the following steps: feeding dehydrated wet sludge with the moisture content of 70-85% and biomass at a weight ratio of 50:(1-10) into a tempering kettle, introducing less water, evenly stirring, adding a tempering agent the mass of which is 0-20% of that of dried solid sludge, stirring for 2-10 minutes continuously, removing most of water by a dehydrator, forming, and naturally drying for 24 hours, thus obtaining the derived sludge solid fuel. The invention also discloses a device for preparing a formed sludge fuel. The device comprises a straw crusher, a feeder, the tempering kettle, the stirrer, the fuel hydrator and a fuel forming machine, wherein the stirrer is positioned at the top of the tempering kettle, a stirring shaft is coincident with the axis of the tempering kettle and inserted into the tempering kettle, the outlet of the straw crusher is connected with the inlet of the feeder, the outlet of the feeder is connected with the inlet of the tempering kettle, the outlet of the tempering kettle is connected with the inlet of the fuel dehydrator, and the outlet of the fuel dehydrator is connected with the inlet of the fuel forming machine.

Owner:JIANGSU XINFA ENVIRONMENTAL PROTECTION TECHCO

Method for manufacturing semiconductor device

InactiveUS7927971B2Low costImprove production efficiencySemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

A release layer formed over a substrate; at least one of thin film integrated circuits is formed over the release layer; a film is formed over each of the at least one of thin film integrated circuits; and the release layer is removed by using an etchant; thus, the at least one of thin film integrated circuits is peeled from the substrate. A semiconductor device is formed by sealing the peeled thin film integrated circuit by lamination or the like.

Owner:SEMICON ENERGY LAB CO LTD

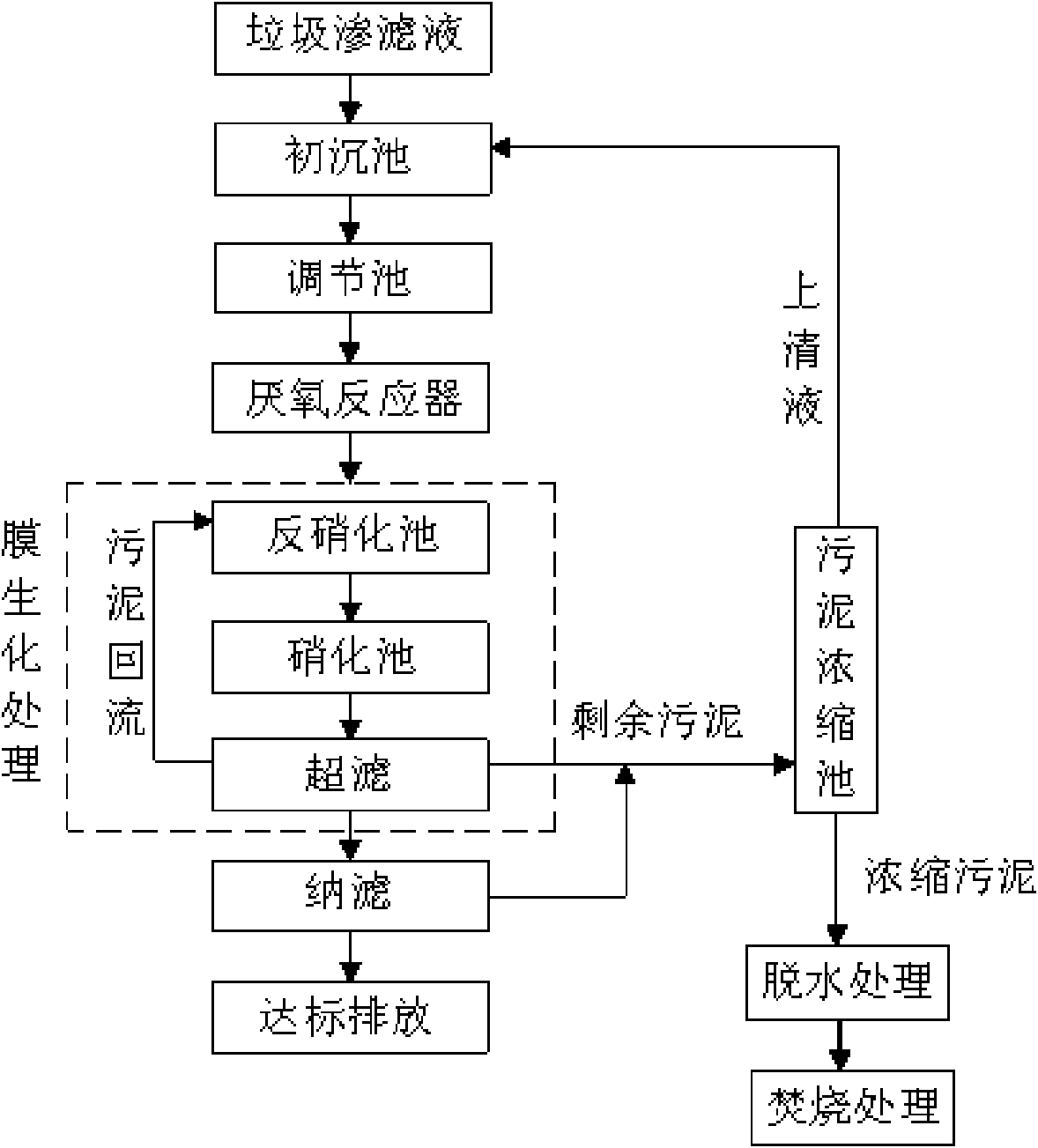

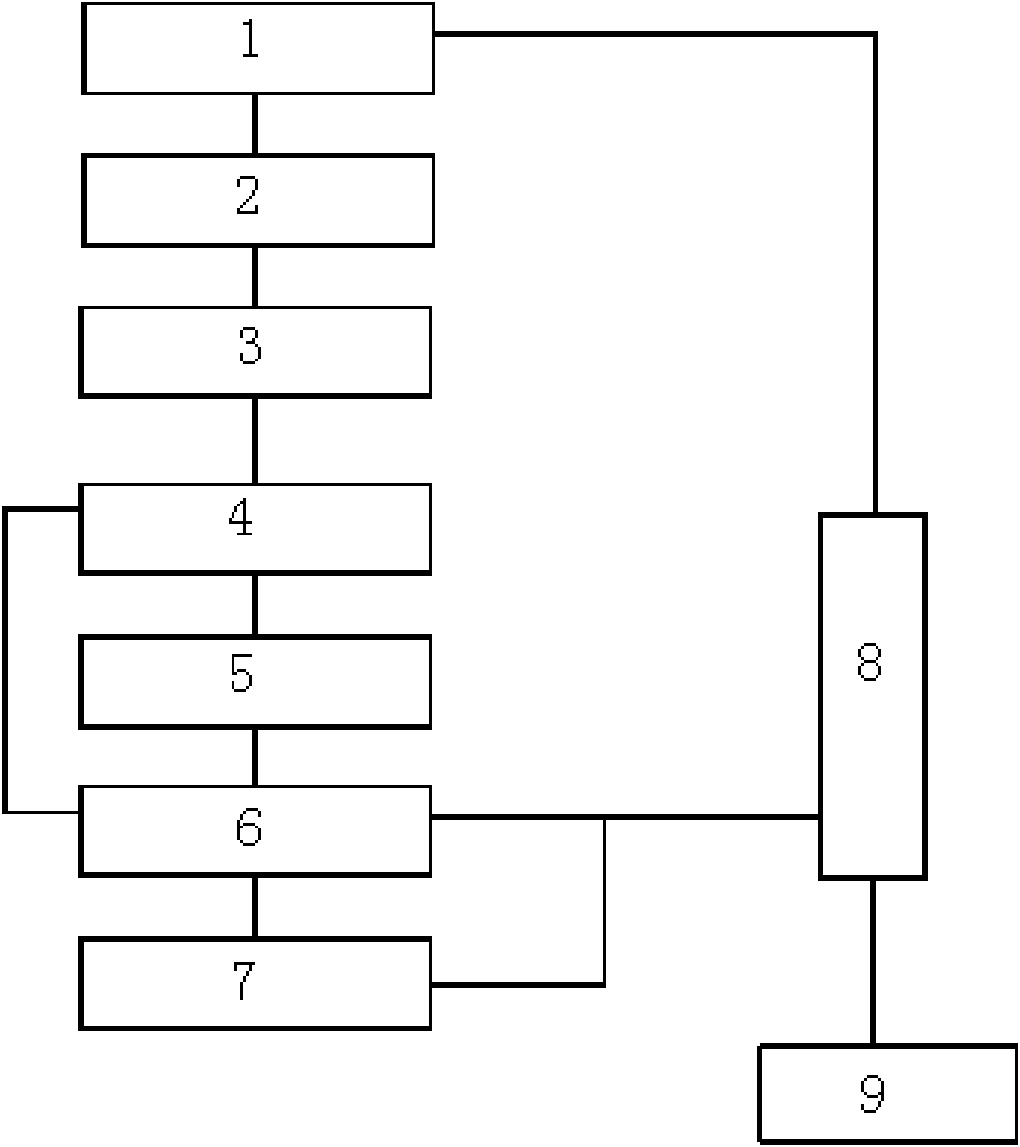

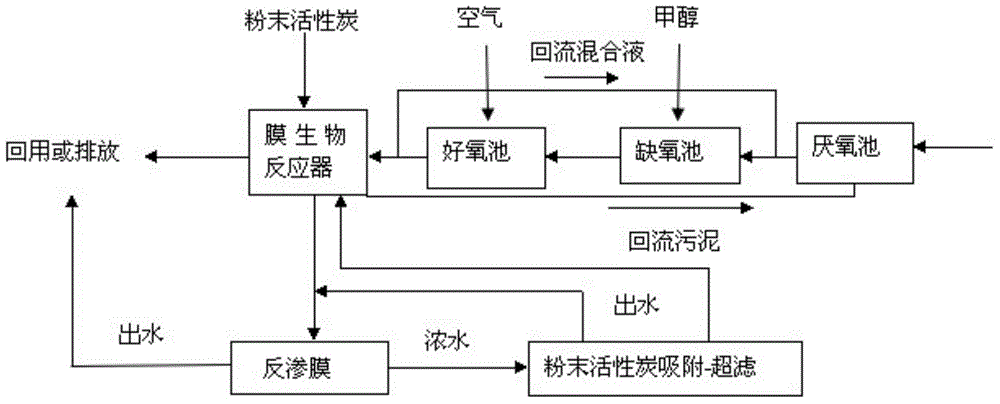

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

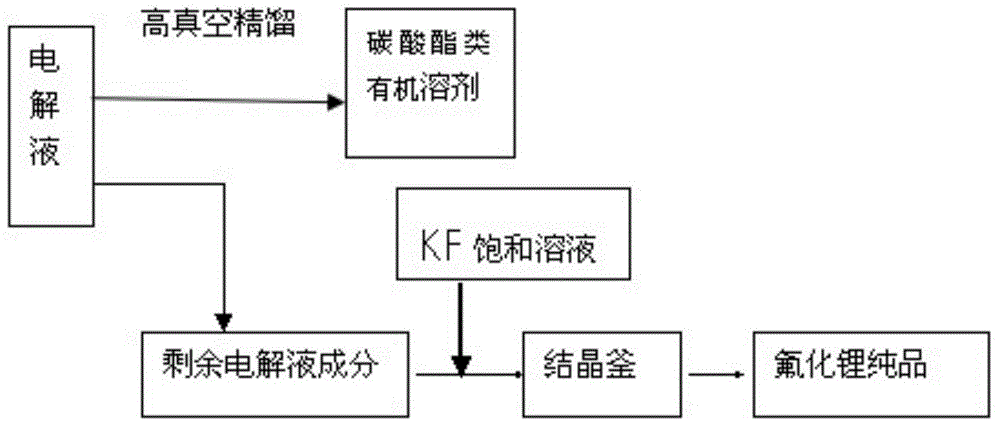

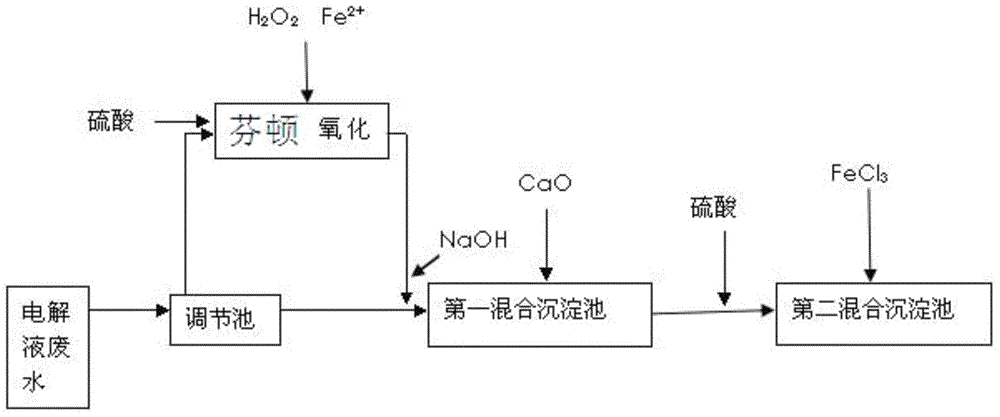

Method for recovery treatment of waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater

InactiveCN104628217AImprove biodegradabilityOvercome incompletenessDispersed particle separationWater/sewage treatmentUltrafiltrationFiltration

The invention discloses a method for recovery treatment of a waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater. Three treatment units are employed for treatment. Firstly, the waste-and-old electrolyte is treated. Then, waste gas resulting from the reaction of the electrolyte is pumped into the waste water for absorption, so that the waste gas can be removed during a waste water treatment process; the lithium battery waste water is treated by a Fenton agent through oxidation to obtain improved biodegradability of the waste water; and reaction precipitates are removed through flocculent sedimentation and the obtained water is treated through combination of A2 / O and MBR membrane separation. Finally, the outlet water goes through a RO reverse osmosis unit to ensure the quality of the outlet water. Combination technology of active carbon powder adsorption and ultra-filtration is employed to remove organic pollutants of the concentrated water resulting from the RO unit, so that the water after treatment can meet the requirements of RO high-quality reuse water. According to the invention, imperfection of an existing technical method of waste-and-old lithium battery recovery and treatment is overcome, and quantitative reduction, harmlessness, and reutilization of waste water treatment of the waste-and-old electrolyte are realized.

Owner:天津卡特化工技术有限公司

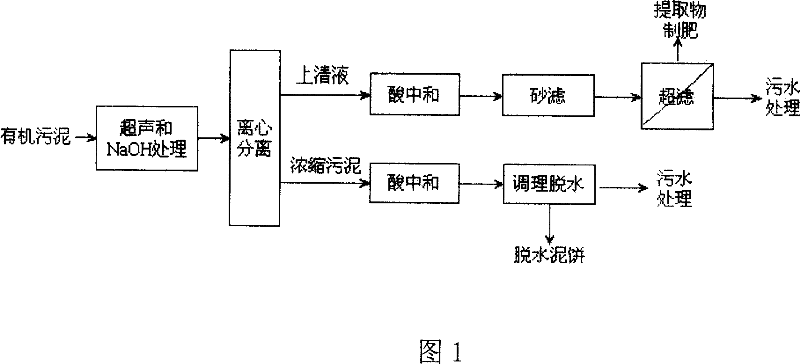

Method for producing liquid organic fertilizer by using organic fertilizer

InactiveCN101037354AImprove cracking efficiencyImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningClimate change adaptationUltrafiltrationHumic acid

The invention discloses method of producing liquid organic fertilizer by organic belonging to solid wastes disposal field, including: co-treating the residual sludge with 98 percent moisture content by ultrasound and sodium hydroxide to make the organic matters dissolve out; getting concentrated sludge and supernatant fluid after centrifugation; dehydrating the concentrated sludge after neutralization in a routine method; sand leaching and ultrafiltration treating the supernatant fluid twice after centrifugation to get a concentrated liquid containing macromolecule organic matter such as humic acid and the filtrate containing low molecular organic matter; the filtrate entering into the sewage treating plant for a primary treatment. Disposed dehydrated sludge cake has 70-80 percent moisture content and a reduction of the content of organic matter of 30-50%. The concentrated liquid by ultrafiltration is mainly composed of macromolecule organic matter and with a low content of heavy metal, and can be an organic liquid fertilizer, and complies the rule of using green food fertilizer. The invention is suitable for the sludge with a high organic matter content such as residual sludge and digested sludge.

Owner:TSINGHUA UNIV

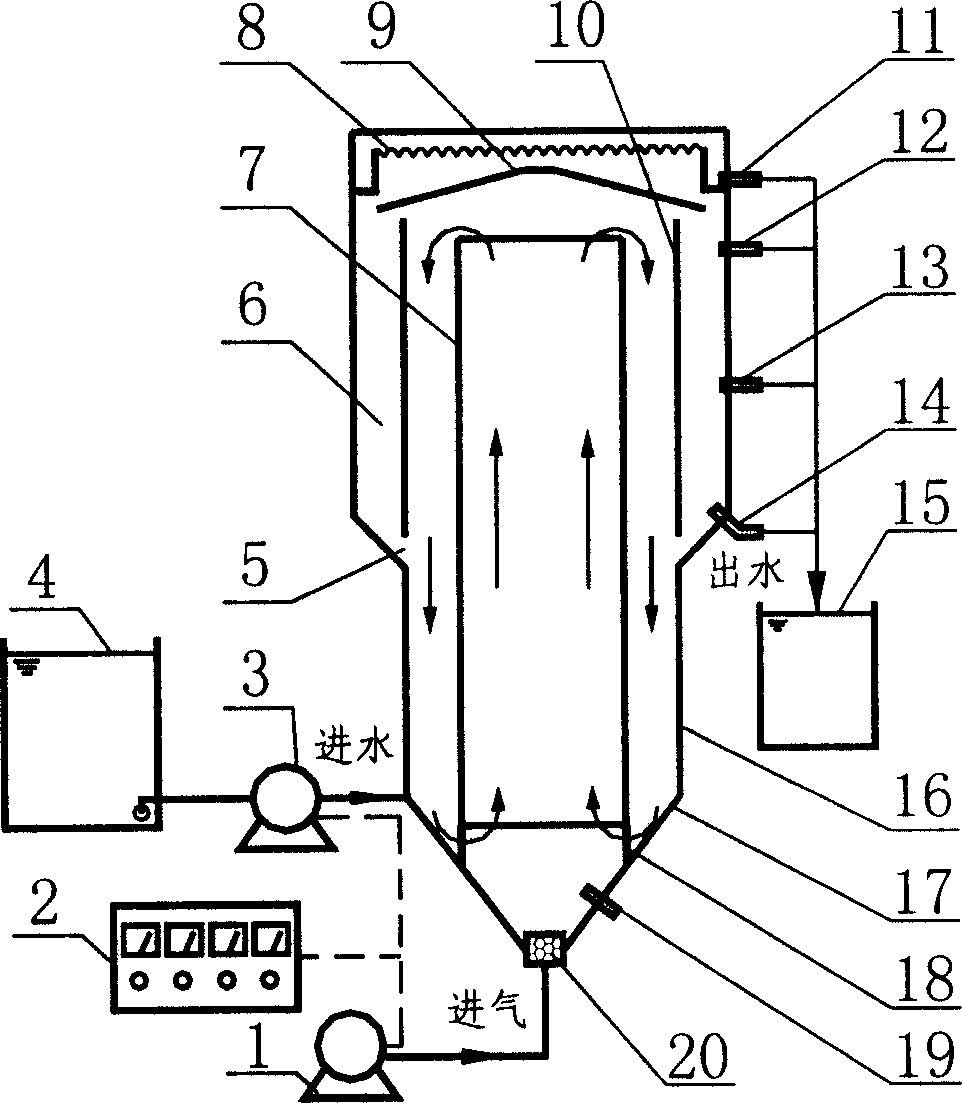

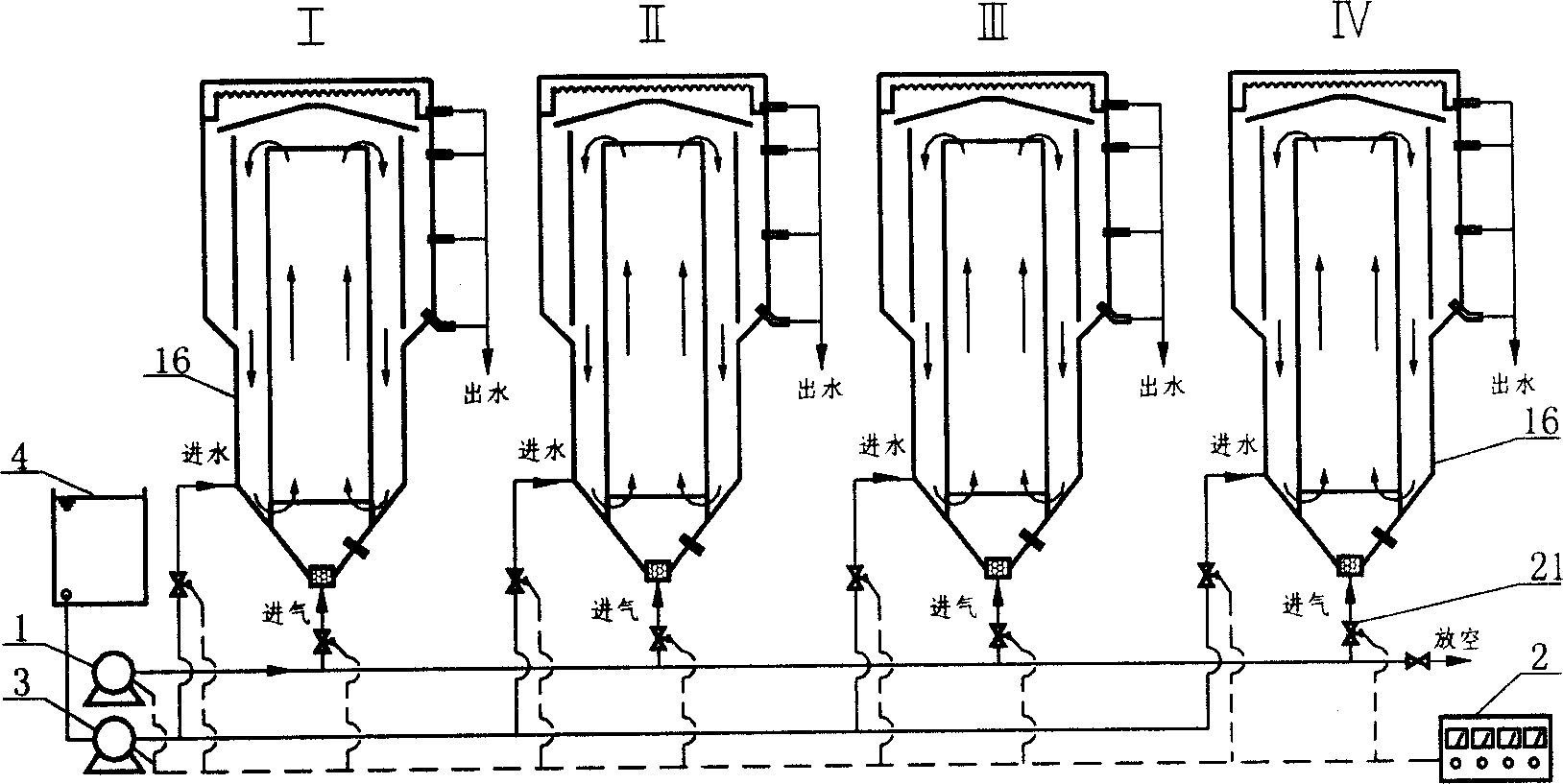

Sequential air lifting circulation waste water biological treatment reactor and its process

InactiveCN1911835AImprove the mixing effectImprove mass transfer efficiencyTreatment with aerobic and anaerobic processesHigh concentrationAnaerobic aerobic

The efficient sequencing batch type air lifting circular flow waste water treating bioreactor in alternative anoxia-anaerobic-aerobic process includes one squared or cylindrical reactor unit, one water inlet unit and one water outlet unit as well as one aerating system. The reactor unit includes one reactor body, one triphase separator, conic bottom, air lifting circular flow guide tube and upper deflecting baffle. The present invention also discloses corresponding technological process. By means of the sequencing batch type air lifting circular flow waste water treating bioreactor and the corresponding technological process, double target of oxidizing non-degradable organic pollutant and biological denitrification may be reached in the same reactor, the treated high concentration non-degradable nitrogenous industrial organic waste water may reach the drainage standard, and the residual sludge amount may be reduced by over 80%.

Owner:SOUTH CHINA UNIV OF TECH

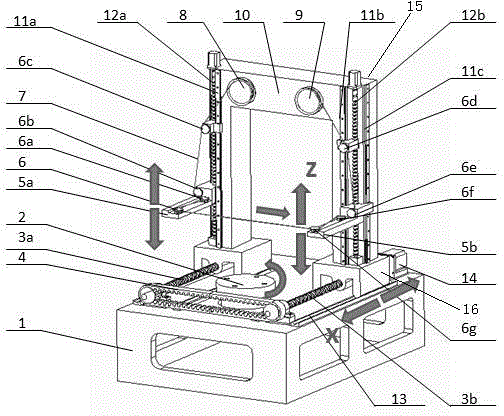

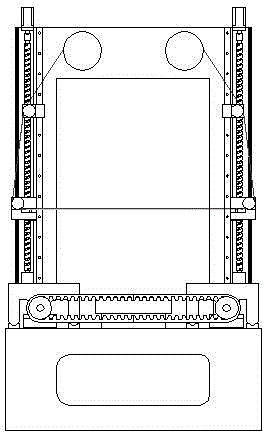

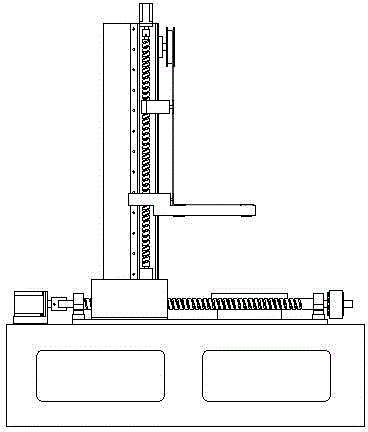

Horizontal diamond wire cutting machine tool

ActiveCN104890036AEasy clampingAvoid breakingMetal working apparatusStone-like material working toolsWire cuttingEngineering

Disclosed is a horizontal diamond wire cutting machine tool. The horizontal diamond wire cutting machine tool comprises a tool body (1), the tool body (1) is provided with a rotary worktable (2) for fixing workpieces, a portal frame (15), and a guide wheel group on the portal frame (15), wherein the portal frame (15) can be driven by an X-direction transmission mechanism on the tool body to move in an X direction. The horizontal diamond wire cutting machine tool is characterized in that the beam (10) of the portal frame (15) is provided with a pay-off drum (8) and a take-up drum (9), the stand columns on both sides of the portal frame (15) are respectively provided with an extending plate, and the cantilever end of each extending plate is provided with a cantilever end guide wheel; the extending plates on both sides are driven by the same or a separated Z-direction transmission mechanism to move up and down along the stand columns to control the height and accordingly to maintain a horizontal state so that a diamond wire on the cantilever end guide wheels on the cantilever ends can maintain a horizontal state and participate in cutting of the workpieces. The horizontal diamond wire cutting machine tool is convenient to fixe and high in machining efficiency and yield rate.

Owner:TAIZHOU CHEN HONG NC EQUIP MFG CO LTD +2

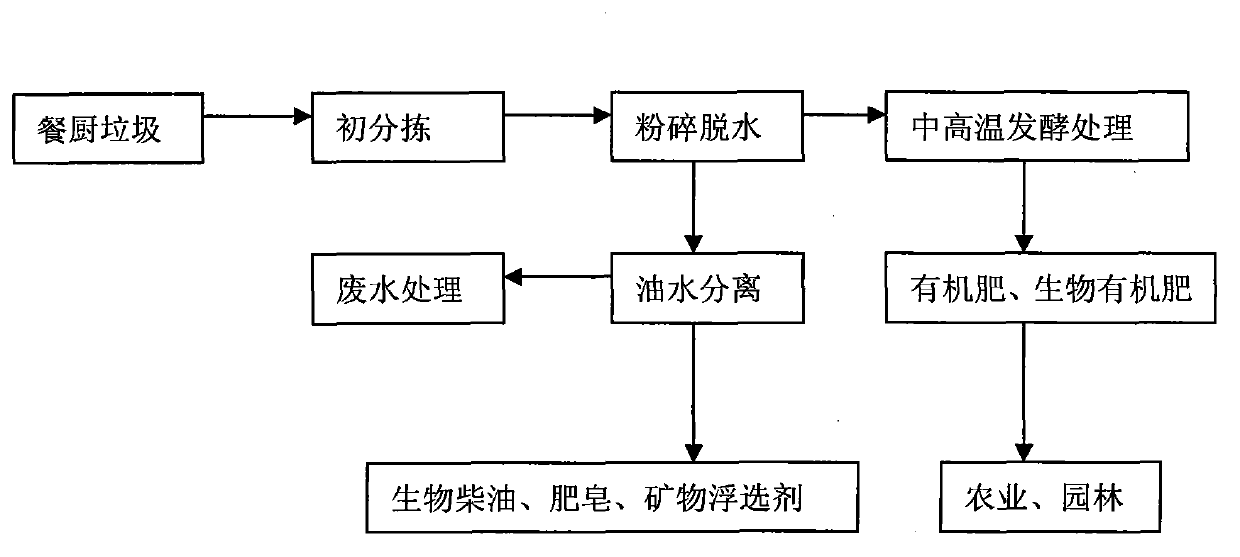

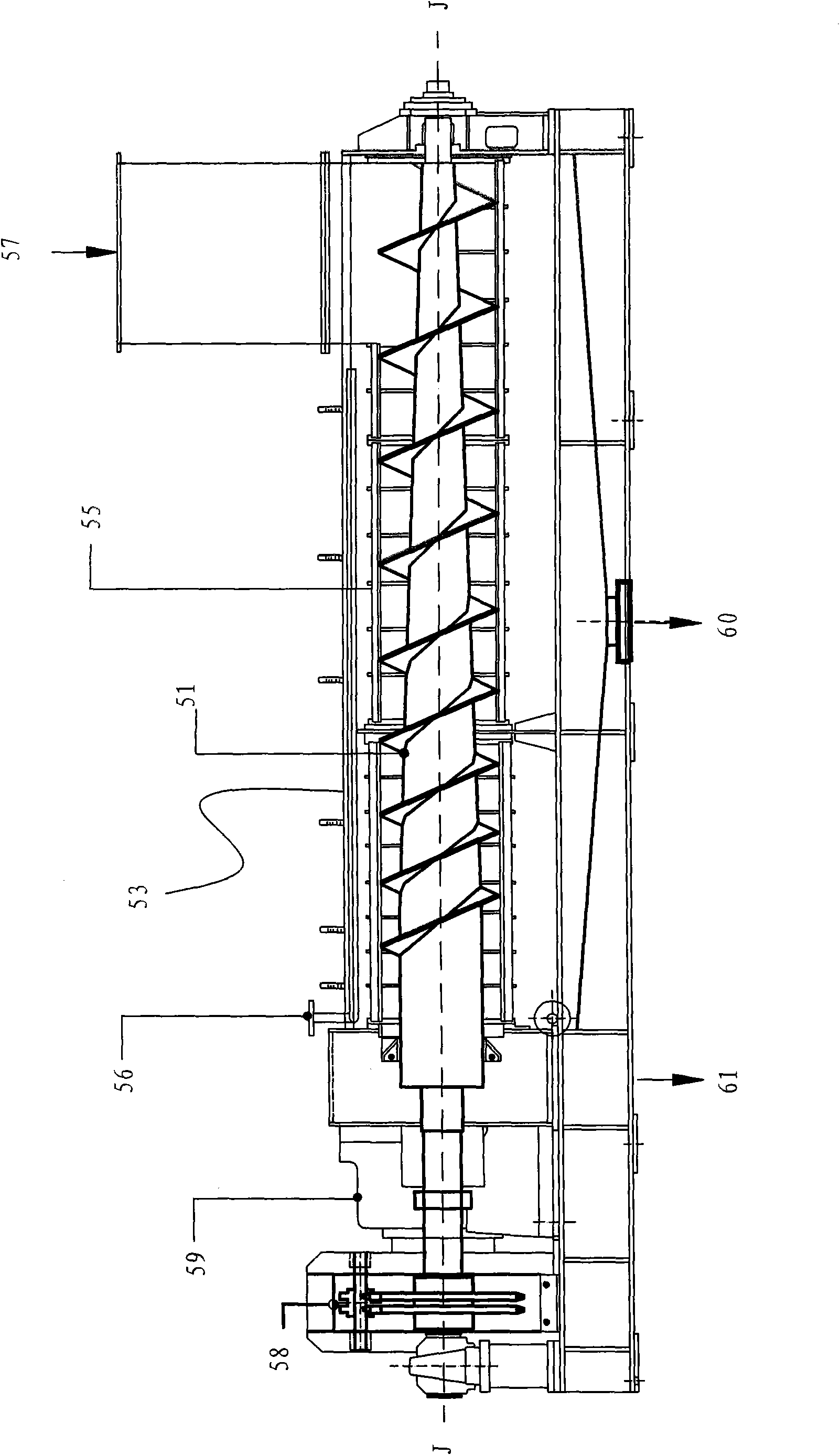

Kitchen waste on-site treatment method

ActiveCN103121859AAchieve reductionHarmlessBio-organic fraction processingClimate change adaptationOil and greaseSites treatment

The invention relates to a kitchen waste on-site treatment method which comprises the following steps of: (1) primary sorting of kitchen waste: when the kitchen waste is collected, sorting out hard waste such as plastic, metals, ceramic pieces, big bones and the like; (2) grinding and dehydration: feeding the kitchen waste after primary sorting into a grinding and dehydration system, separating out water and oil in the kitchen waste by a spiral extrusion draining system, feeding the water and oil into an oil-water separation system, grinding solid matters in the kitchen waste at the same time, and feeding the ground product into a fermentation treatment system; (3) medium and high-temperature fermentation treatment: conveying the solid matters extruded and ground in step (2) into a fermentation bin, treating for 15-25 days to end the fermentation, and discharging; and (4) oil-water separation: conveying the water and oil separated out from the kitchen waste into a waste liquid collection tank, and separating oil from wastewater under the effect of gravity. The method provided by the invention solves the problem of high energy consumption of a high-temperature technology, and realizes reduction, harmlessness and resource treatment of the kitchen waste.

Owner:北京世纪阿姆斯生物工程有限公司

Sludge treatment method and sludge treatment system

ActiveCN102153256AHarmlessAchieve reductionCombination devicesSludge treatment by de-watering/drying/thickeningCombustionTreatment system

The invention provides a sludge treatment method which comprises the following steps: drying: drying sludge through a drying device; combusting: feeding the sludge dried in the drying step to a combustion furnace, mixing a combustion improver with the dried sludge, and carrying out mixed combustion; and tail gas treatment: treating the tail gas generated in the combustion step, and discharging. The sludge treatment system comprises the combustion furnace and a tail gas treatment device, wherein the combustion furnace is used for burning the sludge; and the tail gas treatment device is used for treating the tail gas generated after the sludge is burned by the combustion furnace. The sludge treatment system is characterized by further comprising a sludge drying device and a sludge conveyer, wherein the sludge drying device is arranged in front of the combustion furnace and is used for drying the sludge to be burned by the combustion furnace; and the sludge conveyer is convenient for delivery of the sludge in the sludge drying device. The method and system provided by the invention have the advantages that the cost is low, and effect is good.

Owner:JIAXING NEW JIES THERMAL POWER +1

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com