Method for producing liquid organic fertilizer by using organic fertilizer

A technology of organic sludge and organic fertilizer, applied in the direction of organic fertilizer, sewage/sludge fertilizer, sludge treatment, etc., can solve problems such as unfavorable extraction of organic fertilizer, limited degree of hydrolysis, reduction of degradation of macromolecular organic matter, etc. Low cost, reliable operation and high dewatering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

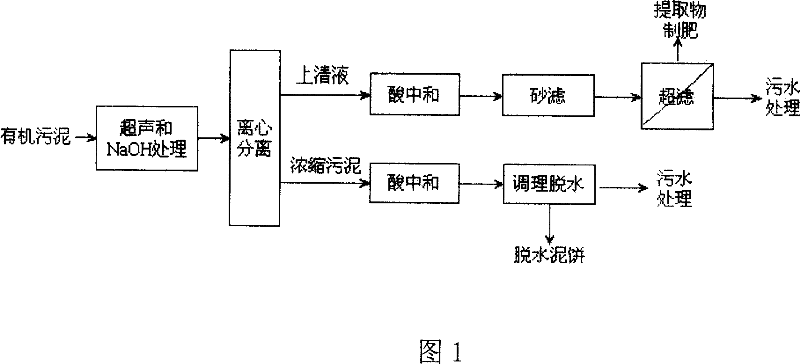

[0016] The invention provides a method for making liquid organic fertilizer by using organic sludge. Fig. 1 shows that the present invention utilizes organic sludge to produce the method flow diagram of liquid organic fertilizer, the following embodiment according to the flow diagram is as follows.

[0017] The remaining concentrated sludge produced by an urban sewage treatment plant has a water content of 98%, an organic matter content of 78%, and a pH of 6.86.

[0018] Add sodium hydroxide to the sludge to make the concentration reach 1.2kg / m 3 , stirring for 30 minutes, and then 20kHz ultrasonic treatment for 10 minutes, the sound energy density is 0.1W / cm 3 . The treated sludge enters the centrifuge and is separated under the condition of a separation factor of 1000 to obtain concentrated sludge and supernatant with a water content of 92%. The chemical oxygen demand (COD) of the supernatant is 11864mg / L, humic acid The content is 2136mg / L. The concentrated sludge is ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com