Method for catalytic cracking treatment of waste/used tires

A technology for catalytic cracking and waste tires, applied in the field of waste tire recycling, can solve the problems of difficult to effectively use rubber products, low recovery rate of pyrolysis oil and gas, low surface activity, etc., to shorten the required time, reduce the reaction temperature, The effect of reducing carbon deposits and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

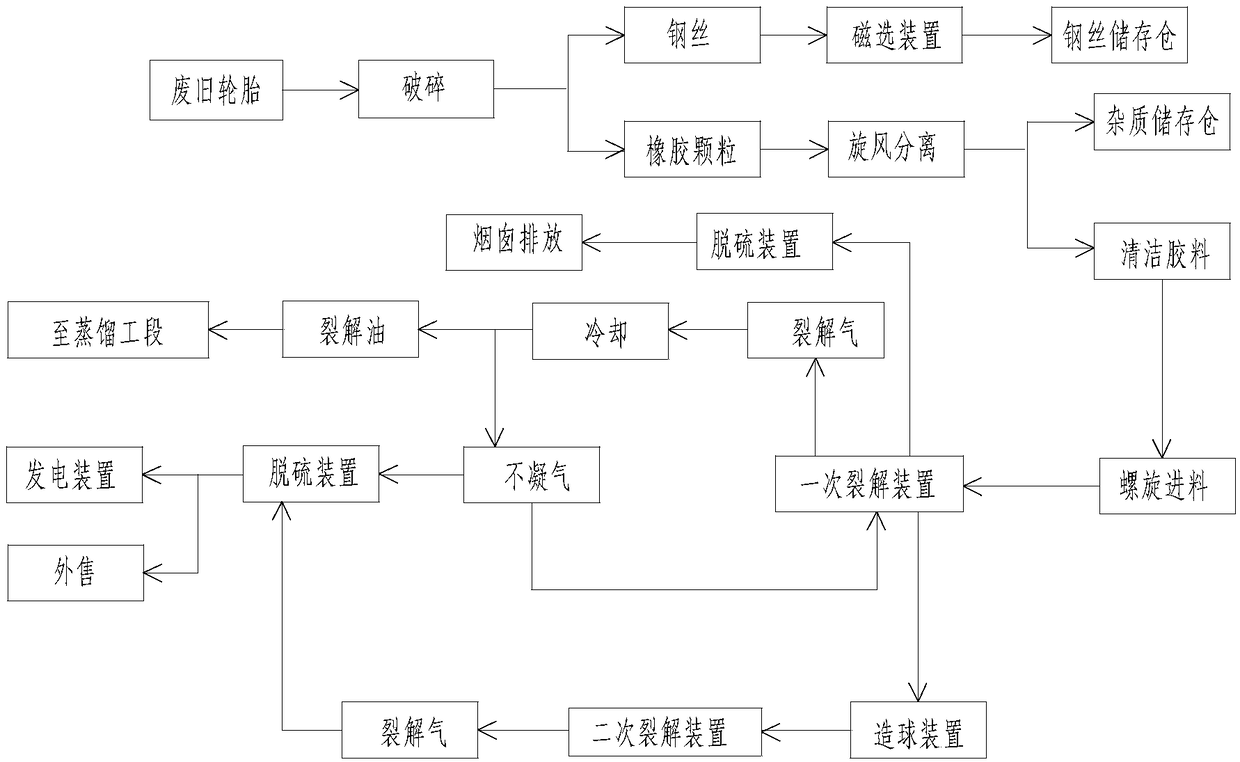

[0022] The method for treating waste tires by catalytic cracking includes raw material pretreatment, primary catalytic cracking, secondary cracking, distillation and desulfurization processes;

[0023] The primary catalytic cracking process is to mix the clean rubber with a particle size of 2mm and the organic waste of the heat-conducting hydrogenation agent according to the mass ratio of 1:0.2 and add them to a vacuum catalytic cracking furnace for cracking, wherein the cracking temperature is 500°C. The solid phase residence time is 10 minutes. The cracked gas produced by cracking is divided into non-condensable gas and cracked oil after cooling. A part of the non-condensable gas is stored, and a part is used as fuel to heat the vacuum catalytic cracking furnace, while the cracked oil enters the next distillation process. , the solid cracking product enters the secondary cracking process.

[0024] The secondary cracking refers to mixing the solid cracking product and the bin...

Embodiment 2

[0026] The method for treating waste tires by catalytic cracking includes raw material pretreatment, primary catalytic cracking, secondary cracking, distillation and desulfurization processes;

[0027] The primary catalytic cracking process is to mix the clean rubber with a particle size of 8mm and the waste engine oil of the heat-conducting hydrogenation agent according to the mass ratio of 1:0.5 and add them to the vacuum catalytic cracking furnace for cracking, wherein the cracking temperature is 650°C, solid The phase residence time is 18 minutes. The cracked gas produced by cracking is divided into non-condensable gas and cracked oil after cooling. A part of the non-condensable gas is stored, and a part is used as fuel to heat the vacuum catalytic cracking furnace, while the cracked oil enters the next distillation process. The solid cracking product enters the secondary cracking process.

[0028] The secondary cracking refers to mixing the solid cracking product and the ...

Embodiment 3

[0030] The method for treating waste tires by catalytic cracking includes raw material pretreatment, primary catalytic cracking, secondary cracking, distillation and desulfurization processes;

[0031] The primary catalytic cracking process is to mix clean rubber with a particle size of 10 mm and heat-conducting hydrogenation agent waste plastics according to a mass ratio of 1:0.6 and add them to a vacuum catalytic cracking furnace for cracking, wherein the cracking temperature is 700 ° C, solid The phase residence time is 20 minutes. The cracked gas produced by cracking is divided into non-condensable gas and cracked oil after cooling. A part of the non-condensable gas is stored, and a part is used as fuel to heat the vacuum catalytic cracking furnace, while the cracked oil enters the next distillation process. The solid cracking product enters the secondary cracking process.

[0032] The secondary cracking refers to mixing the solid cracking product and the binder produced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com