Patents

Literature

211 results about "Tire recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire recycling, or rubber recycling, is the process of recycling waste tires that are no longer suitable for use on vehicles due to wear or irreparable damage. These tires are a challenging source of waste, due to the large volume produced, the durability of the tires, and the components in the tire that are ecologically problematic.

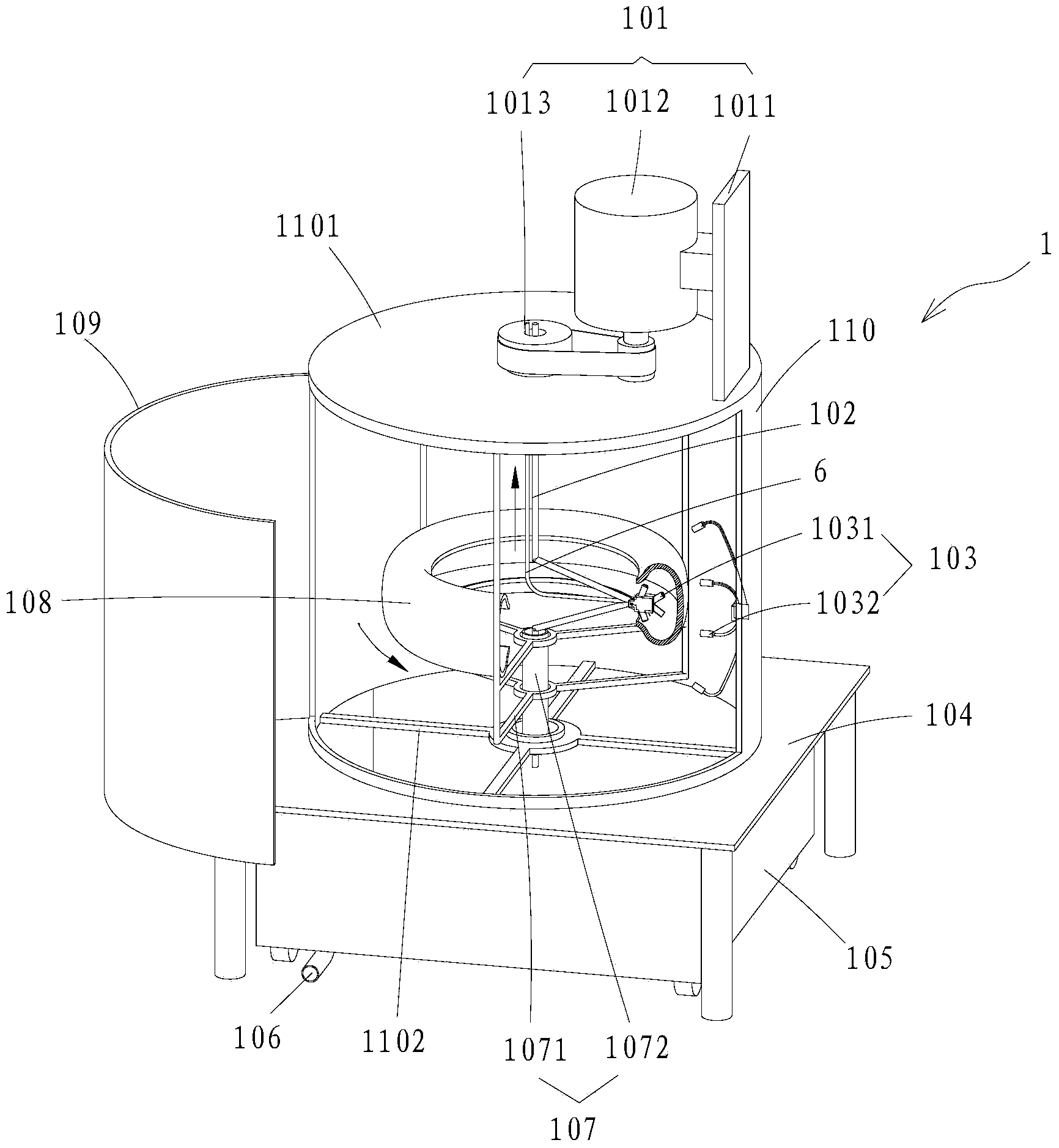

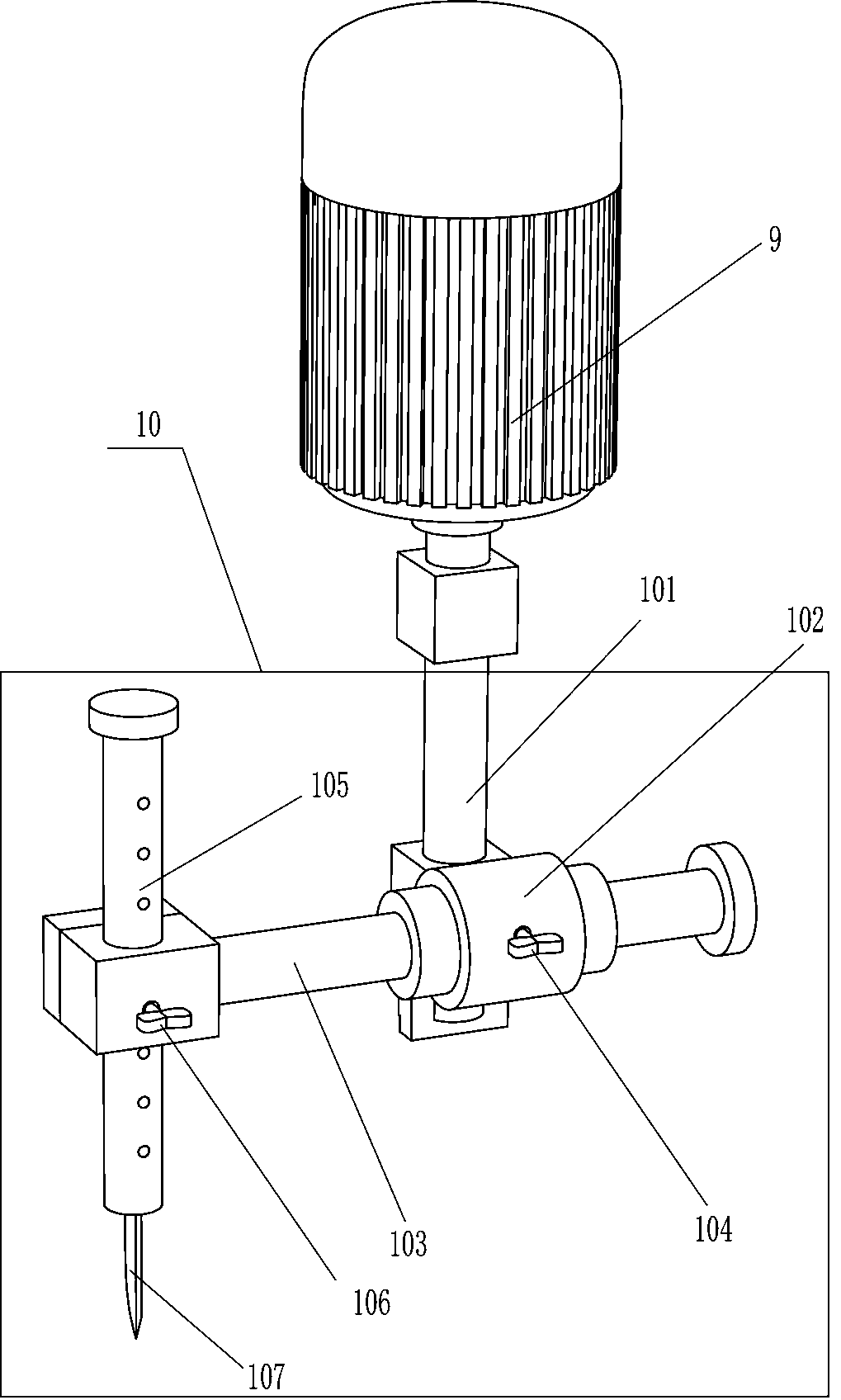

Waste tire recycling method and device

The invention provides a waste tire recycling method and device. The method comprises the following steps: placing a waste tire to be recycled on a workbench; driving the waste tire to rotate at a low speed with a driving device; arranging rotatable sprayers at the radial periphery of the waste tire, wherein at least two nozzles into which high-pressure water jets can be connected are arranged on each sprayer; starting a high-pressure water pump when all the nozzles are aligned with corresponding working positions of the waste tire, wherein water flows sprayed from the nozzles form high pressure water jet cutters to impact and cut the surface of the waste tire, and decompose the surface of the waste tire layer by layer, peeled rubber granules flow into recovery tanks with sprayed liquid, and wires and fiber are recycled in a centralized manner after being peeled off. As the high pressure water jet treatment technology is used for recycling the waste tire, the treatment process can be simplified, the production efficiency is improved, the energy consumption can be reduced effectively, the whole treatment environment is dust-free and smoke-free, and waste water of treatment can be recycled after filtering; meanwhile, as water jets serve as a non-contact tool, the problem of mechanical knife abrasion is solved, the halting time for maintenance can be shortened, and the treatment cost is reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

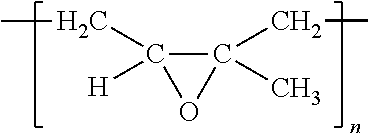

Storage stabilized devulcanized tire rubber modified asphalt composition and the process for its preparation

ActiveUS20160096960A1Good miscibilityImprove solubilityIn situ pavingsBituminous material adhesivesSynthetic rubberAsphalt

This invention relates to a storage stabilized recycled and devulcanized tire rubber modified asphalt composition, which comprises: 65.0 to 90.0% by weight of a neat asphalt, 3.0-50.0% by weight of a recycled and devulcanized rubber from used tires and / or other scrap rubbers, 0.01-15.0% by weight of a compatibilizer / stabilizer derived from Natural or Synthetic Rubbers, which composition passes the “cigar tube” softening point test difference of less than 5° C. between the top and bottom layers; and, the process for the said asphalt composition comprises mixing 65.0% to 90.0% by weight of a neat asphalt, 3.0 to 50.0% by weight of a recycled and devulcanized rubber from used tires, 0.01-10.0% by weight of a compatibilizer / stabilizer derived from Natural or Synthetic Rubbers, using high shear mixers at elevated temperatures of between 120° C. and 175° C. for between 15 minutes to 6 hours, to obtain storage stabilized asphalt composition that is stable in hot storage and transportation conditions.

Owner:PILLAI CHANDRASEKARAN RAMAYYA +1

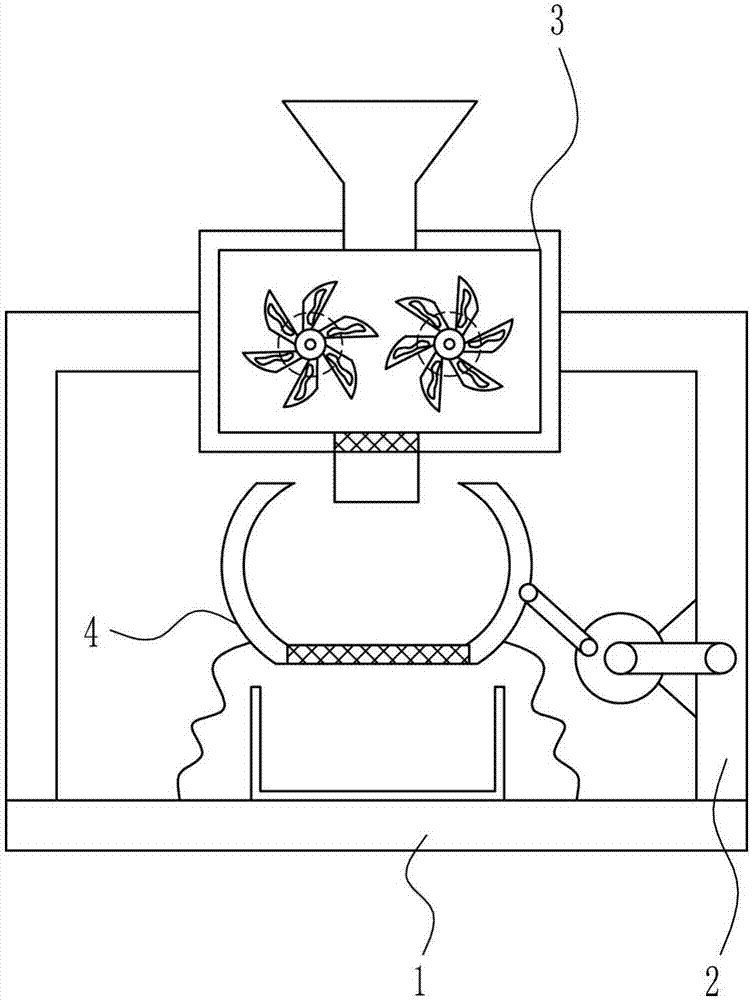

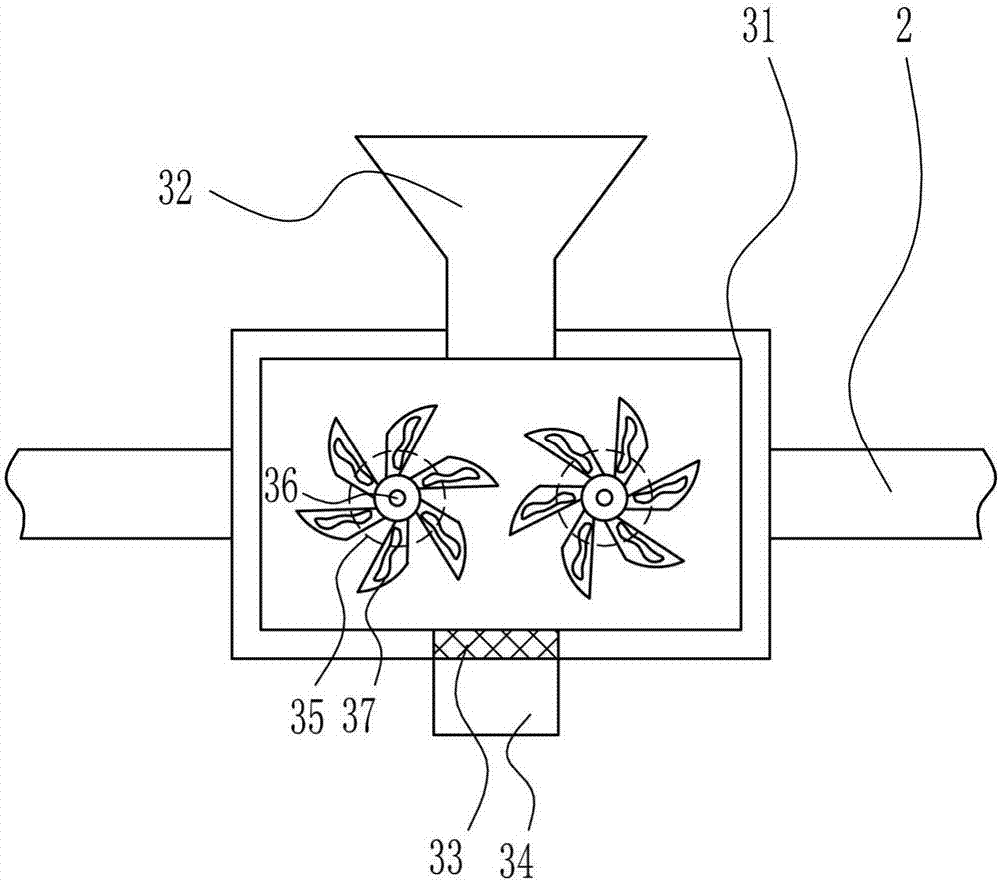

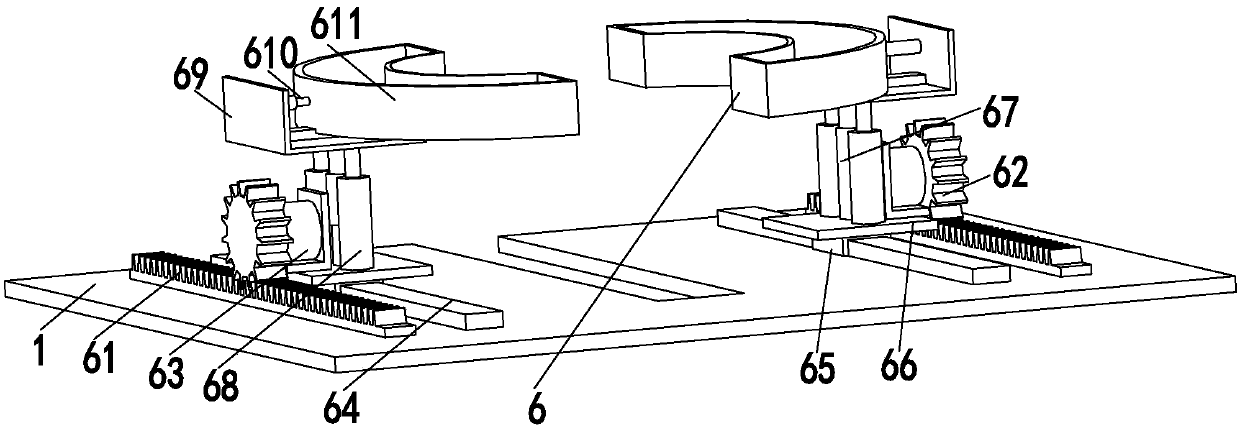

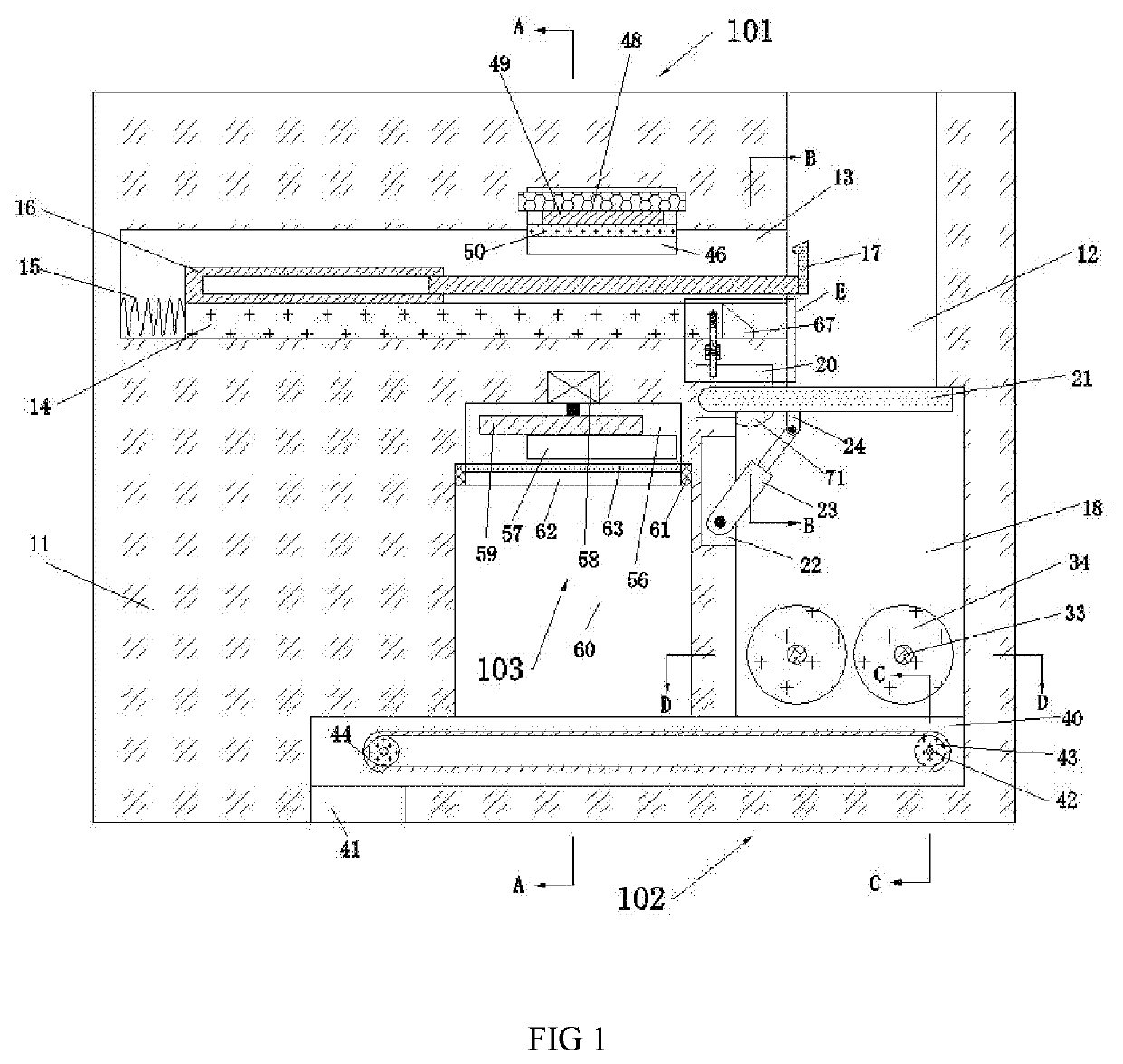

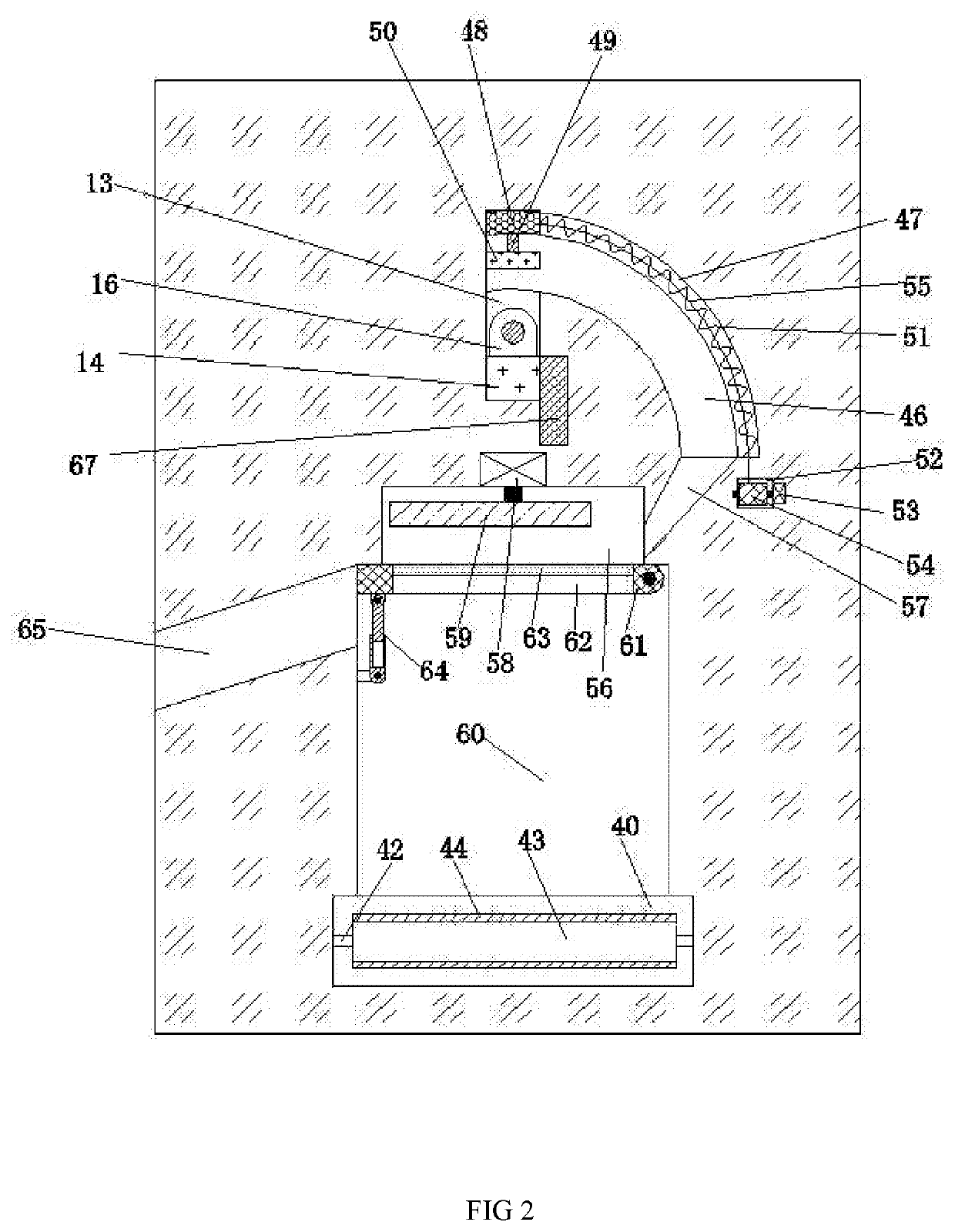

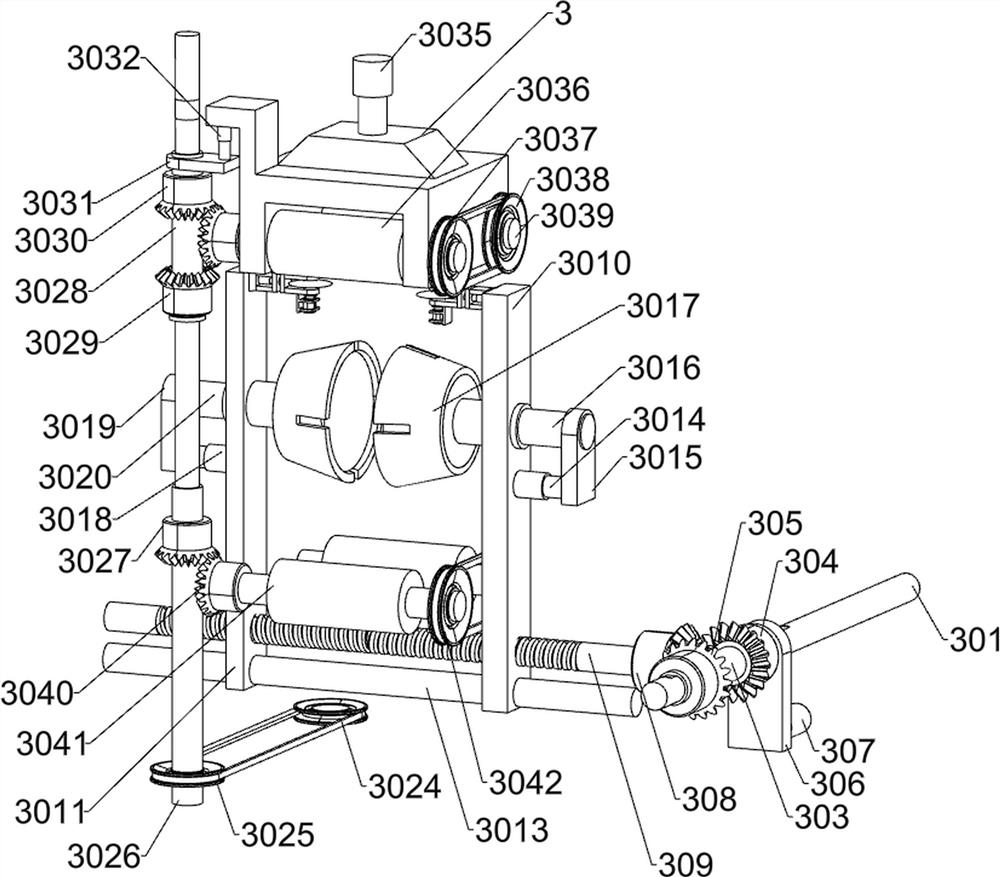

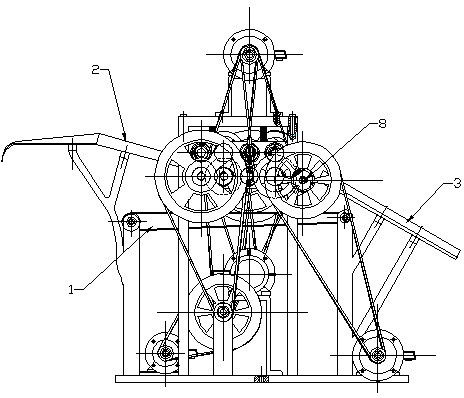

Crushing and screening equipment for automobile tire recycling

ActiveCN107009550AAvoid incomplete crushingTo achieve the screening effectSievingScreeningScreening effectTire recycling

The invention relates to crushing and screening equipment, in particular to crushing and screening equipment for automobile tire recycling. The technical problem to be solved is to provide the crushing and screening equipment which is used for automobile tire recycling and convenient to screen and controllable in feeding rate. To solve the technical problem, the crushing and screening equipment for automobile tire recycling is provided. The crushing and screening equipment comprises a bottom plate, L-shaped supports, a crushing device, a screening device and the like. The L-shaped supports are symmetrically arranged on the top of the bottom plate in a left-right manner. The crushing device is arranged between the two L-shaped supports. The screening device is arranged below the crushing device. According to the crushing and screening equipment for automobile tire recycling, a first operating crank is rocked to drive a screening frame to swing left and right, the screening effect is achieved, the feeding amount is adjusted by rocking a second operating crank, and it is avoided that crushing is not thorough due to the too large feeding amount.

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

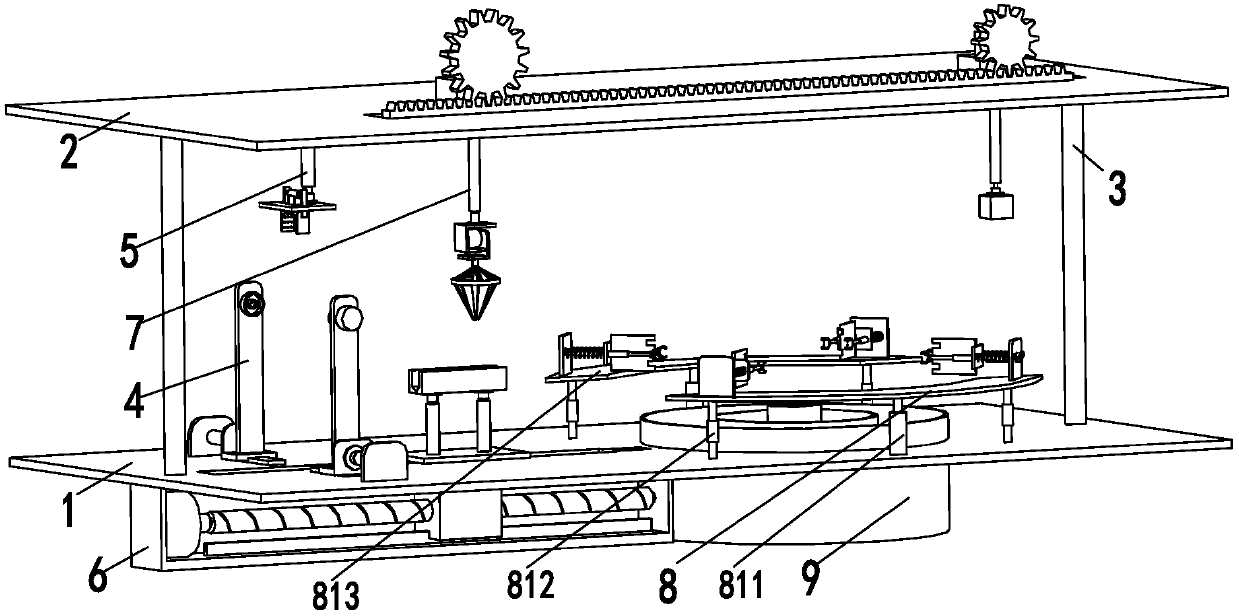

Full-automatic recycling environmental protection robot of bicycle waste wires

InactiveCN107738381AManual handling requiredManual handling is not requiredPlastic recyclingCleaning using toolsEngineeringManual handling

The invention relates to a full-automatic recycling environmental protection robot of bicycle waste wires. The environmental protection robot comprises a baseplate, a top plate, support columns, a locating device, a cleaning device, a moving device, a gripping device, a cutting device and a collecting box, and the right and left ends of the baseplate are provided with one support column separately; the top ends of the support columns are connected to the top plate, and the baseplate is provided with the locating device, the moving device and the cutting device from left to right in sequence; and the collecting box is installed below the cutting device, and the top plate is provided with the cleaning device and the gripping device from left to right in sequence. According to the environmental protection robot provided by the invention, the problems of required manual handling and cutting, high labor intensity, low working efficiency, potential safety hazards, low adjustability and so forth of the existing bicycle tire recycling technology can be solved, and the integrated functions of moving, cleaning, gripping and cutting the bicycle wires can be achieved.

Owner:储高鹏

Environmental recovery processing equipment for waste tires of new energy automobiles

InactiveCN107738384ASolve the costSolve labor intensityPlastic recyclingGrain treatmentsEnvironmental resistanceNew energy

The invention relates to environmental recovery processing equipment for waste tires of new energy automobiles. The environmental recovery processing equipment comprises a bottom plate, a connecting frame, a cleaning device, a mobile device, a cutting device, a collecting device and a smashing device, wherein the connecting frame is arranged on the bottom plate, and the cleaning device and the cutting device are arranged on the connecting frame in order from left to right; the mobile device is arranged at the lower end of the cleaning device, and the collecting device is arranged at the lowerend of the cutting device; and the smashing device is arranged on the right side of the collecting device, and the mobile device, the collecting device and the smashing device are all arranged on thebottom plate. The environmental recovery processing equipment can solve the problems of high labor cost, high labor intensity, low working efficiency, incomplete treatment, existence of potential safety hazard, etc. of the current automobile tire recovery technology, and can realize the function of automated recovery processing for the automobile tires.

Owner:盛珊瑜

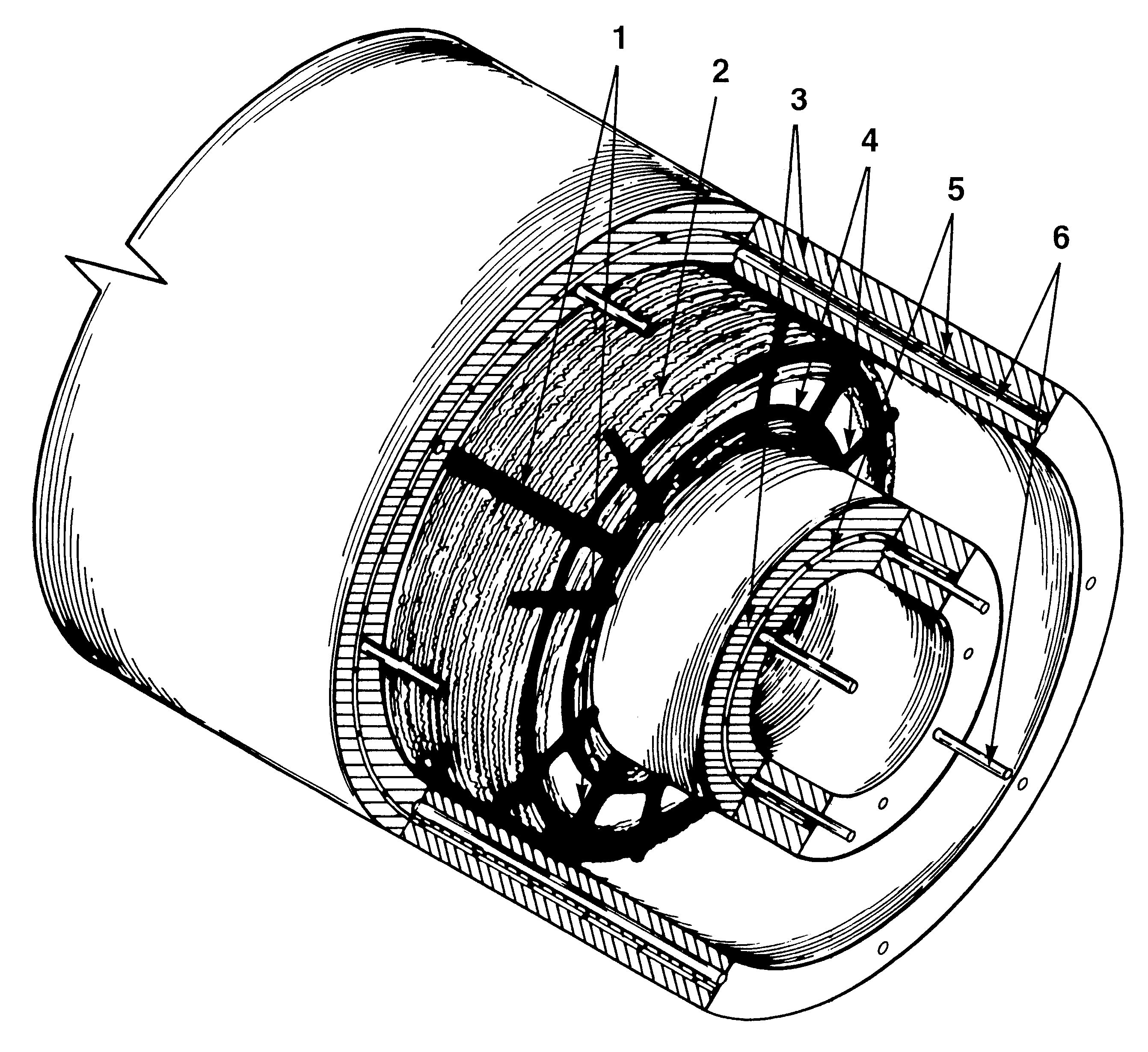

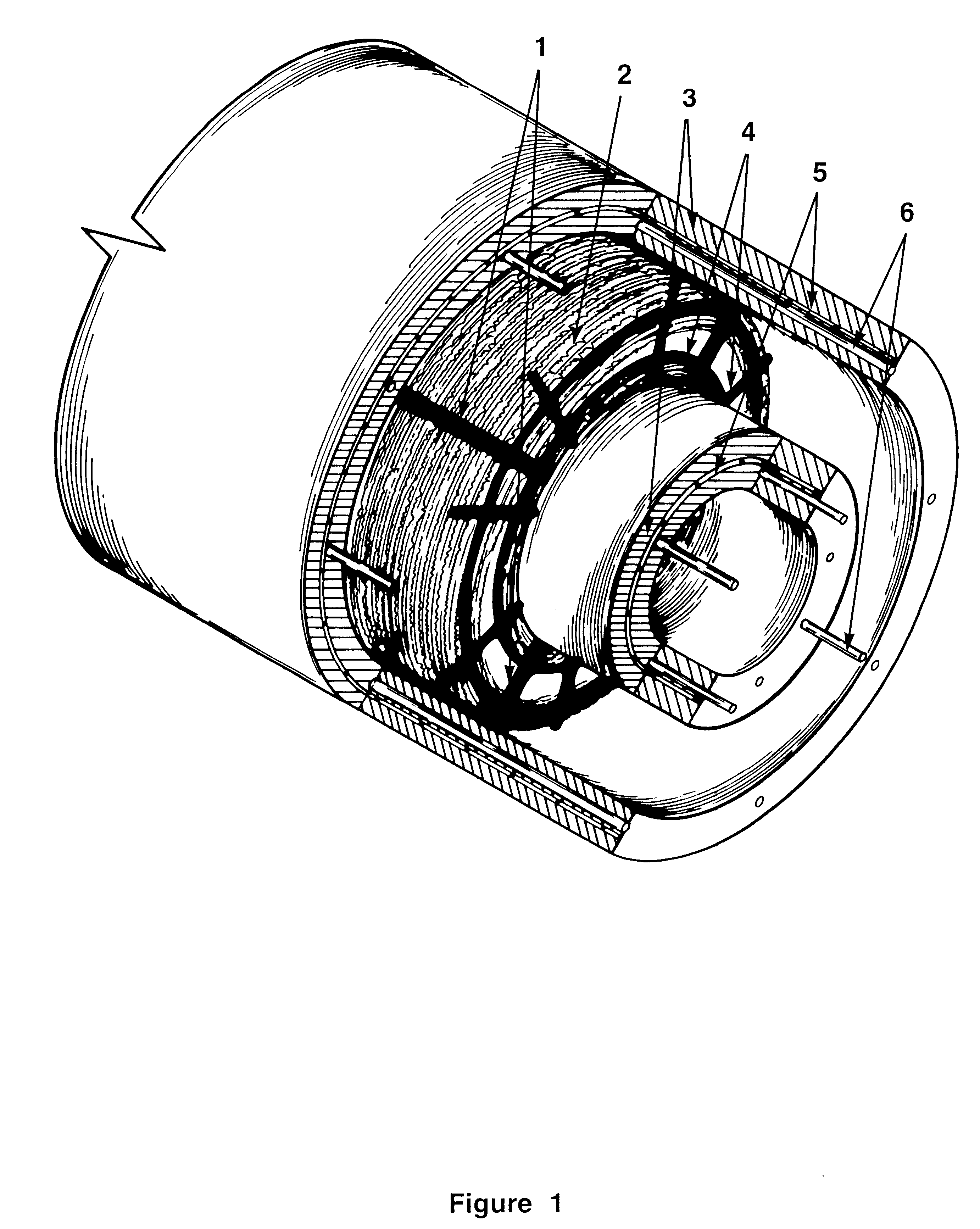

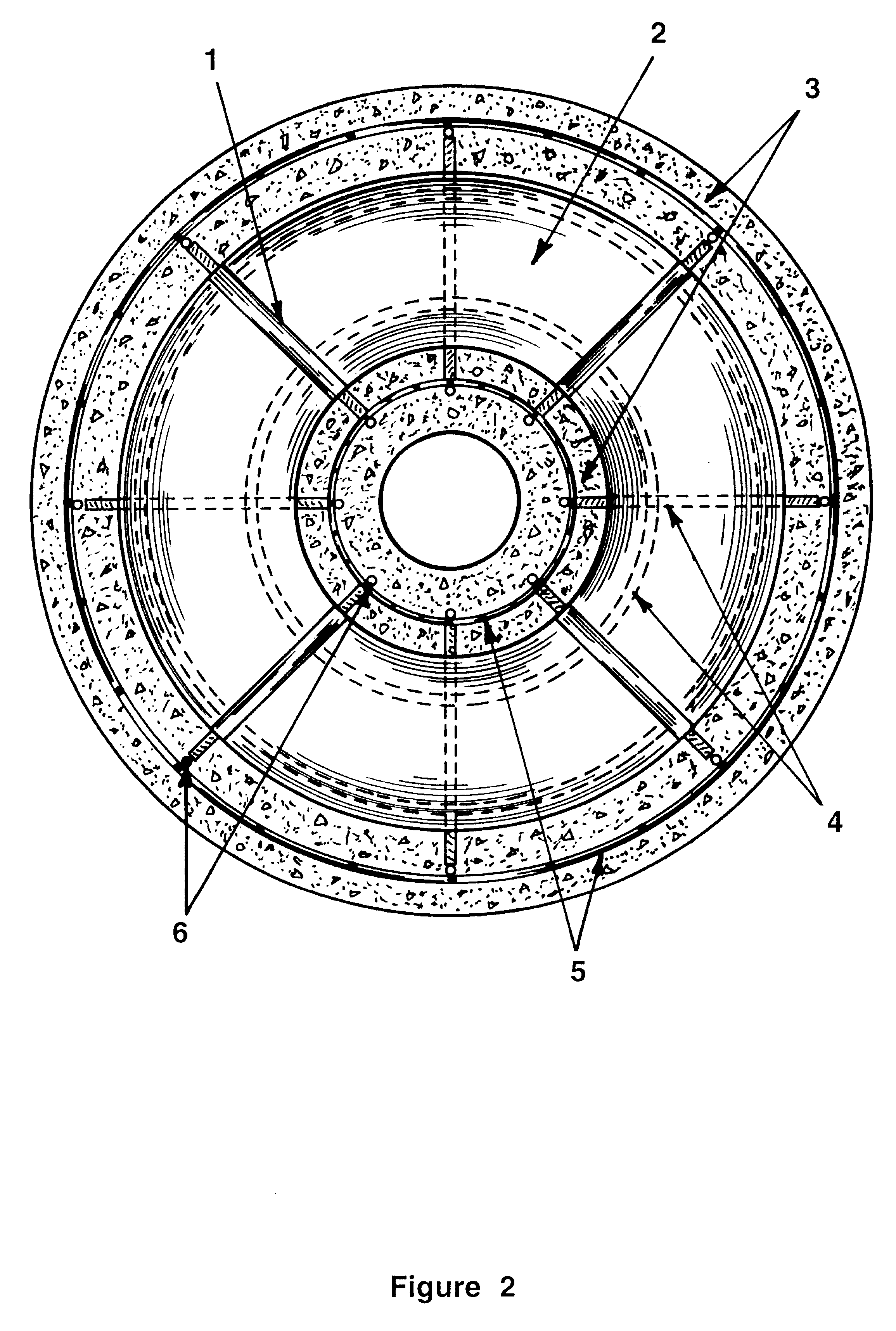

Tire recycling/disposal system and tire recycling/disposal annulet cylinder or construction block

A method and means for making and using three composite concrete construction components that share a common matrix. The articles are comprised of: discarded whole tires 2, axially aligned, with rebar formed washers 4, transversely placed at intervals between the tires 2. The tire bundle 2, with the washers 4, are compressed, banded with metal or fiber strapping 1, reinforced with wire mesh 5, and rebar rods 6, and encased in a concrete shell 3, to form: cylinders; rectangular-blocks; or, half blocks. The concrete composite articles can be molded with hollow cores and used individually or in multiple configurations to construct environmentally safe structures such as: artificial reefs, beach erosion inhibitors, jetties and artificial islands; imbricated walls for: highway dividers, noise abatement, retaining and security walls around airports and buildings. These composite concrete articles will allow for millions of discarded tires to be recycled into non-polluting, environmentally friendly structures for use in virtually any construction project.

Owner:EL ADUMBRATE LLC A FLORIDA LIMITED LIABILITY ALL MEMBER OF EL ADUMBRATE LLC ARE US CITIZENS NUMBER L06000078373

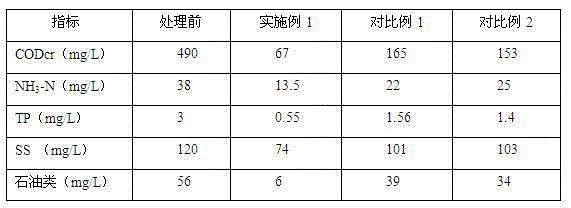

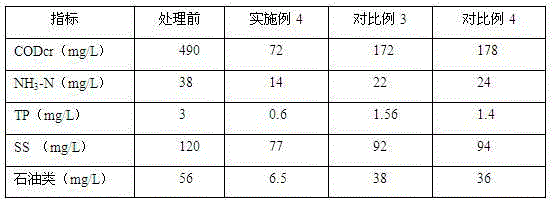

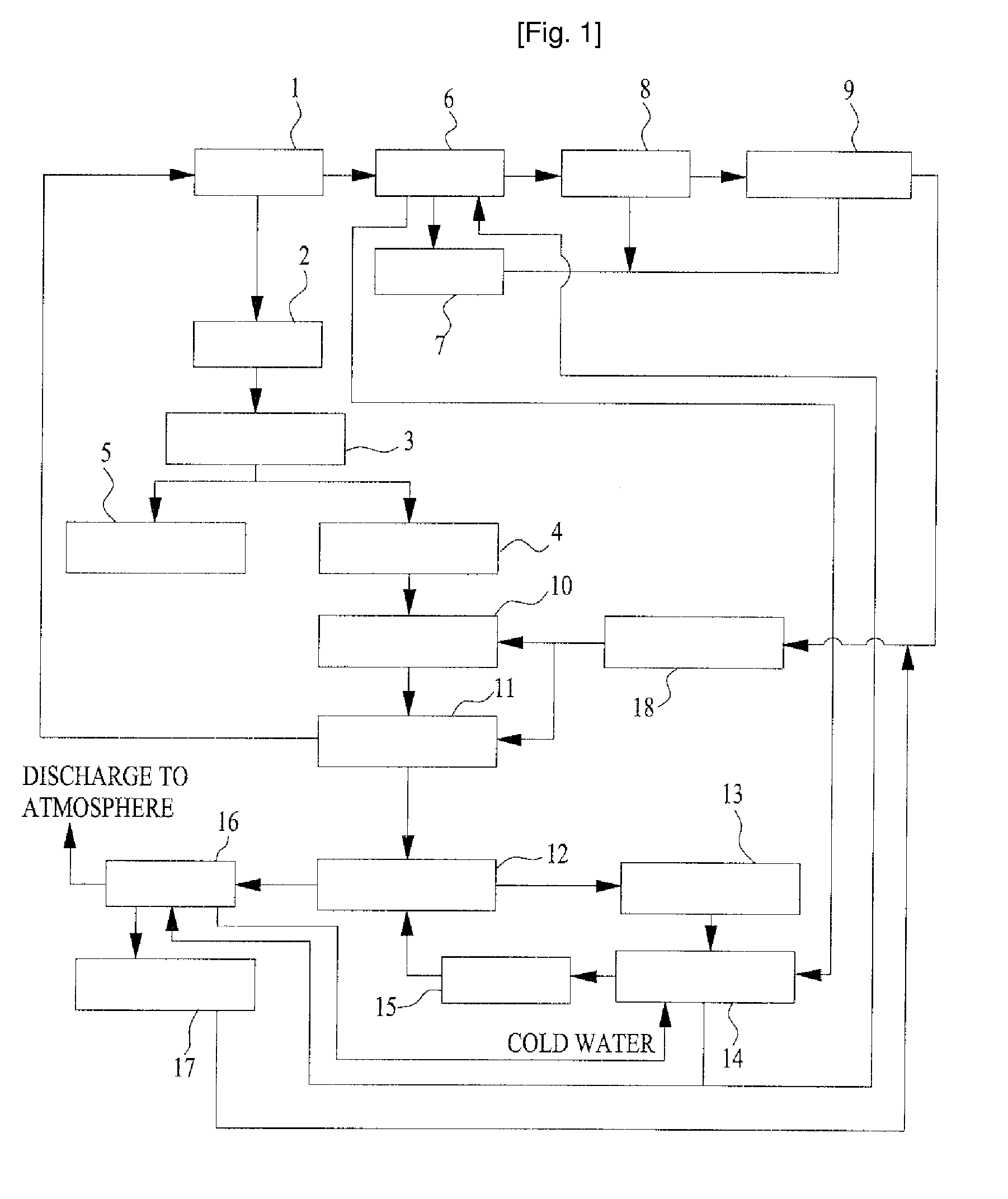

Treatment process for wastewater generated during recycling process of waste tire

InactiveCN104478168AHigh transparencyImprove water purification effectMultistage water/sewage treatmentBiological water/sewage treatmentEnvironmental resistanceFiltration

The invention belongs to the technical field of environment-friendly water treatment and particularly relates to a treatment process for wastewater generated during recycling process of a waste tire. The treatment process comprises the following steps: (1) adding acid into waste water for neutralization until the pH is 6.5-7.5; (2) adding an antifoaming agent into the waste water in the step (1), and performing antifoaming treatment for 3-6 hours by aeration; (3) adding a microorganism water purifying agent into the waste water in the step (2); (4) adding an enzyme preparation into the waste water in the step (3); and (5) feeding a water body in the step (4) into a sedimentation tank for filtration. By the adoption of a sewage treatment process, the water purification effect is good, the water purification speed is high, the safety is high, and secondary pollution is not caused; materials with adsorption capacity serve as raw materials, and microorganisms serve as auxiliary materials to treat sewage, so that the using range is wide, and treated water is extremely high in transparency and is recyclable.

Owner:SHANDONG YONGTAI CHEM GROUP

System, method and process of recovering oil from used automobile tires

InactiveUS20080017496A1Quick fixIndirect and direct heating destructive distillationSteam/vapor condensersCompressed natural gasProcess engineering

The invention is an apparatus and method for recovery of energy and by-products from automobile and truck tires. The tires are heated in an oxygen poor environment, and the off gases are condensed to recover a liquid oil product and compressible natural gas. The tires are reduces to ash and steel, both of which can be feed streams for other processes. The apparatus includes a condenser with cooled plates, and oil recovery structures.

Owner:THOMPSON DAVID BRENT

Technology for treating spent tyre and its used equipment

A technology for treating used tyres includes such steps as pretreating for cutting into blocks and dewatering, deep freezing for embrittlement, pulverizing and removing impurities. Its apparatus is composed of cutting machine, deep freezing root and pulverizer with hammer set, cutter and grinder.

Owner:赵宝林

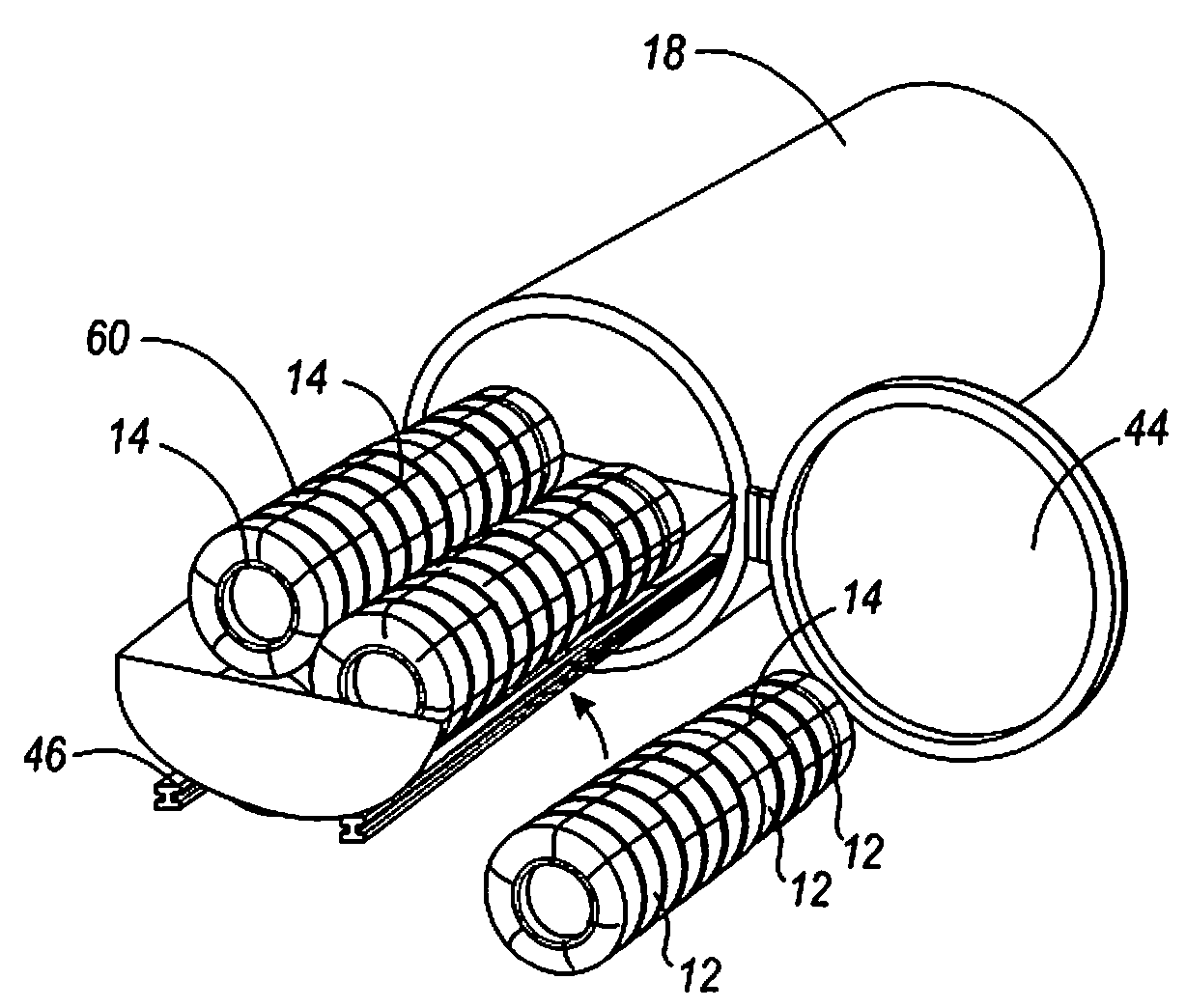

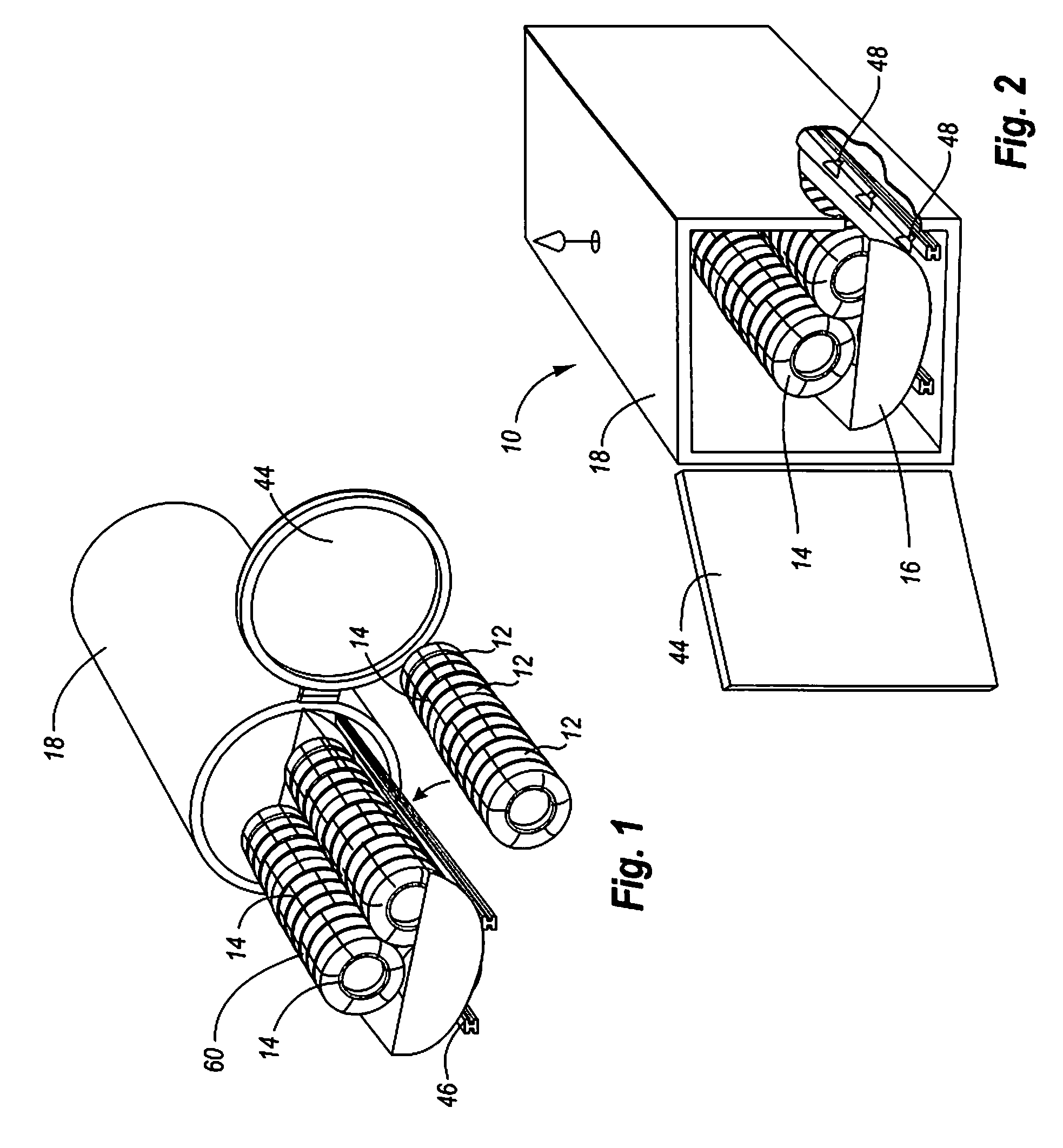

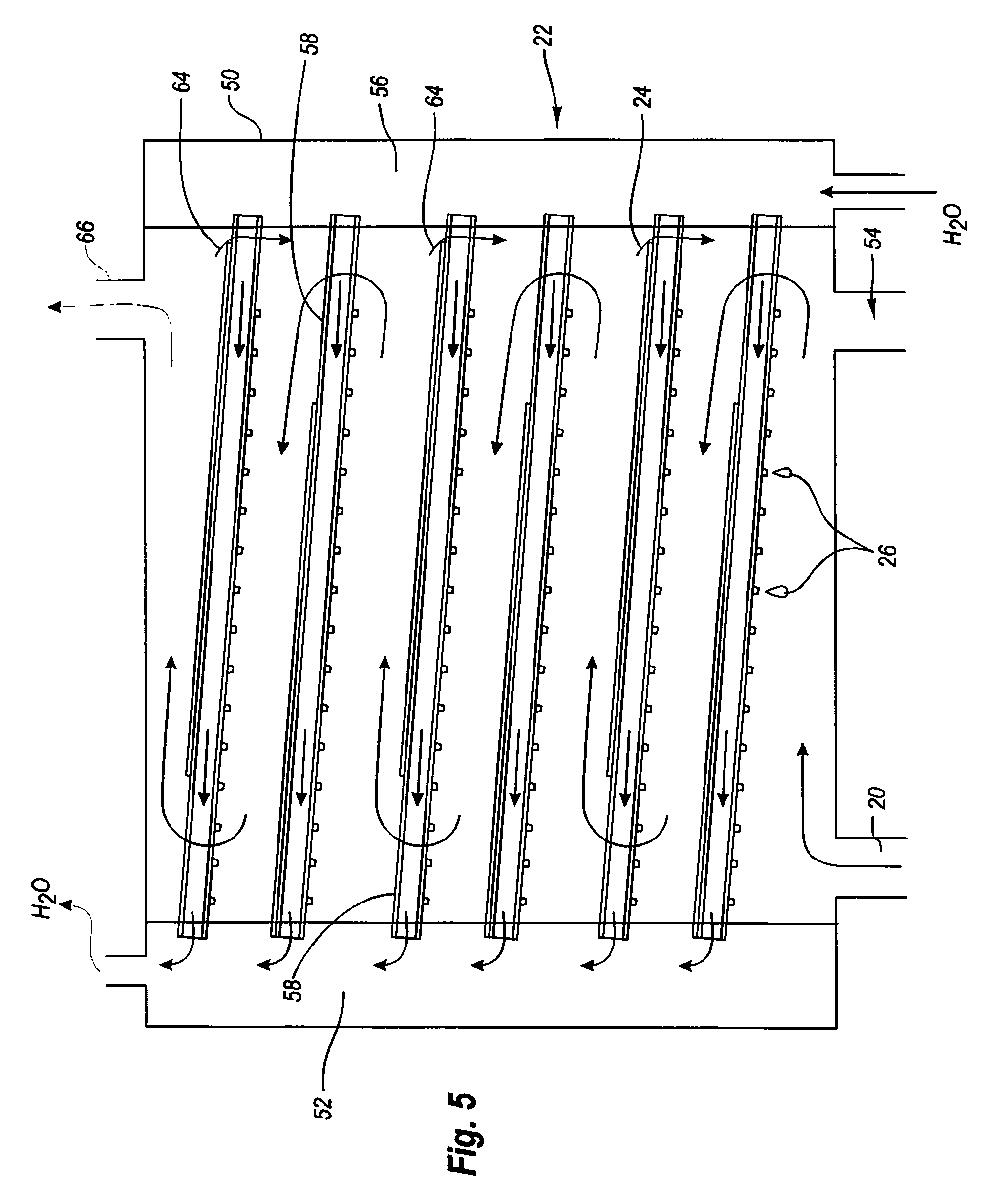

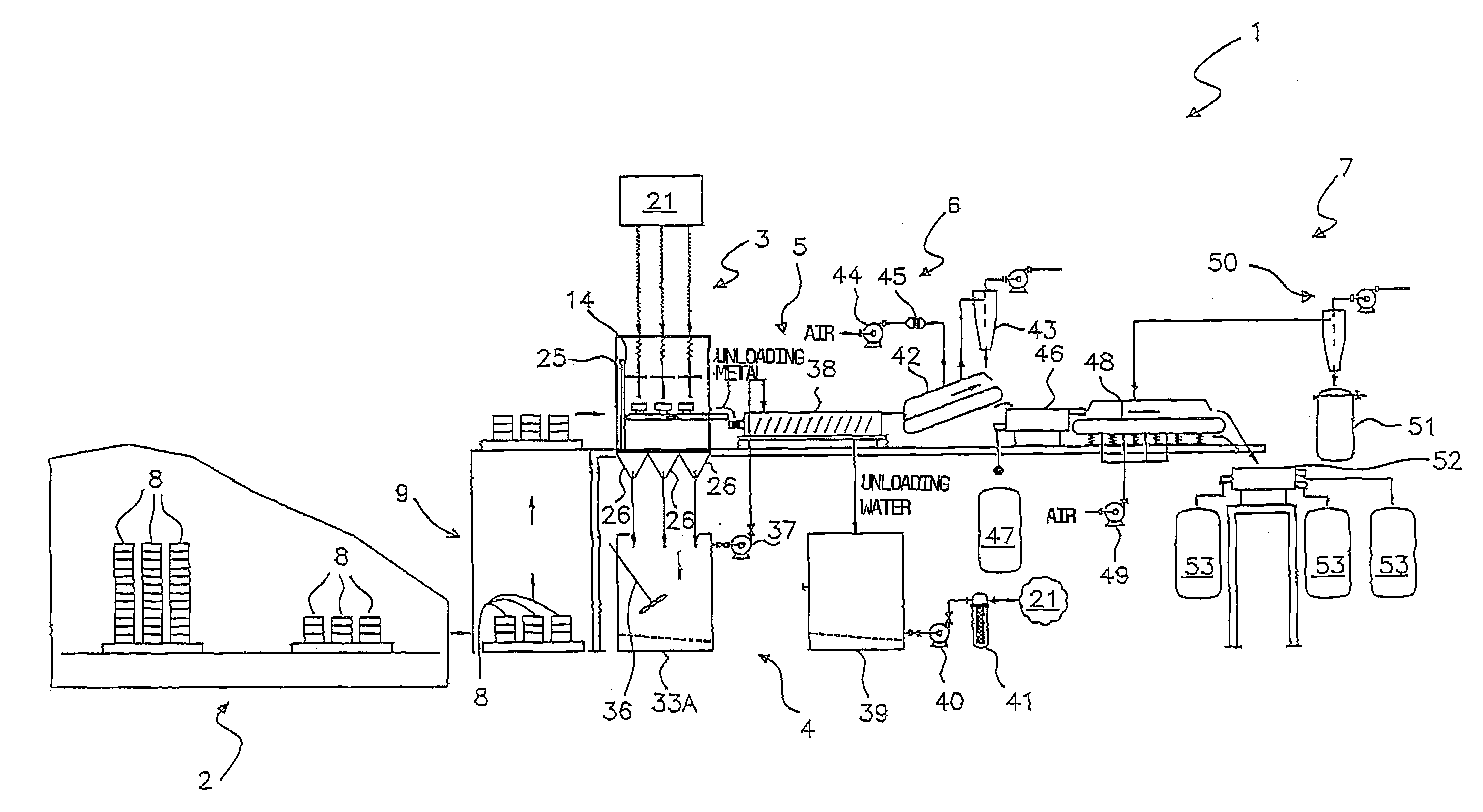

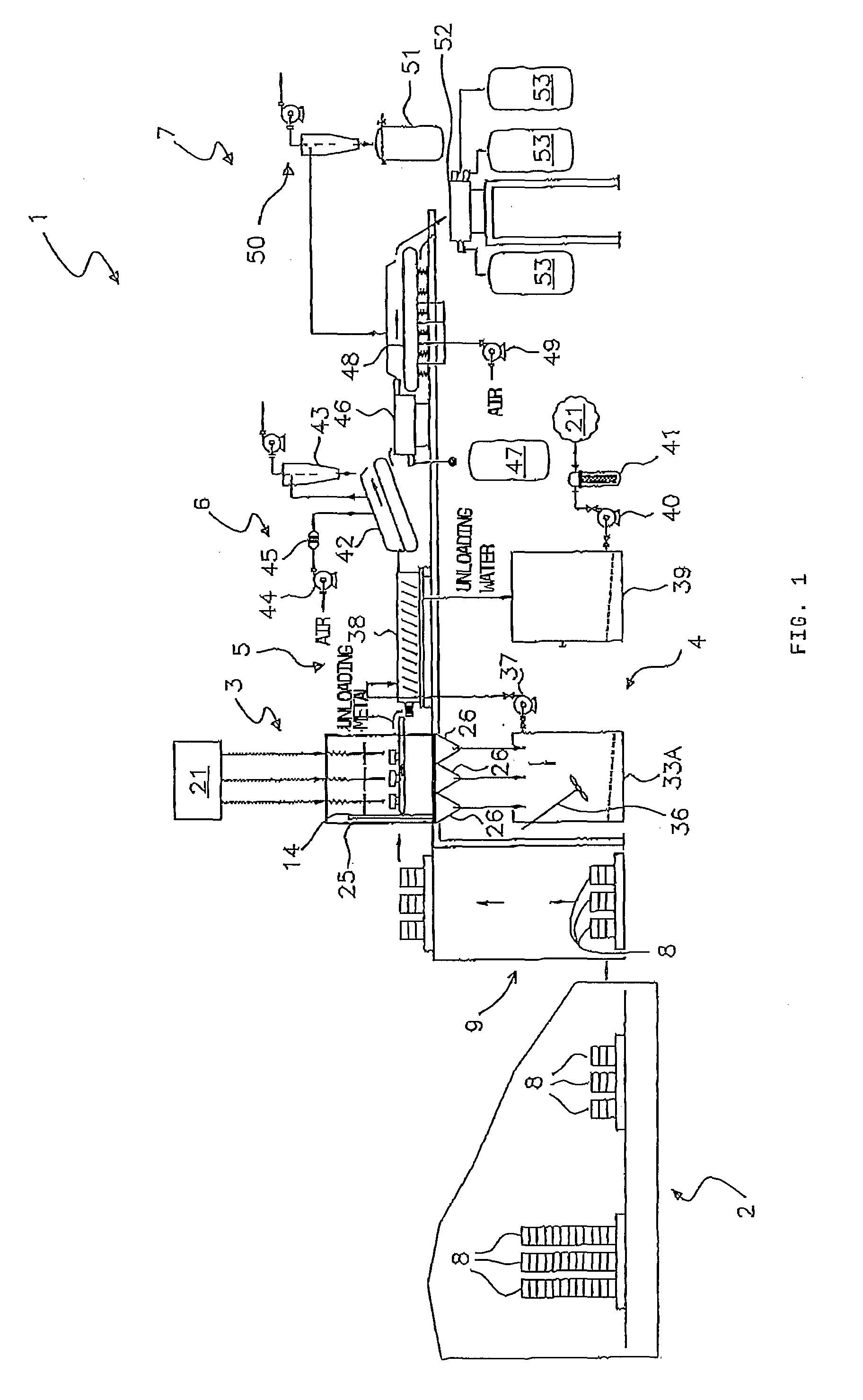

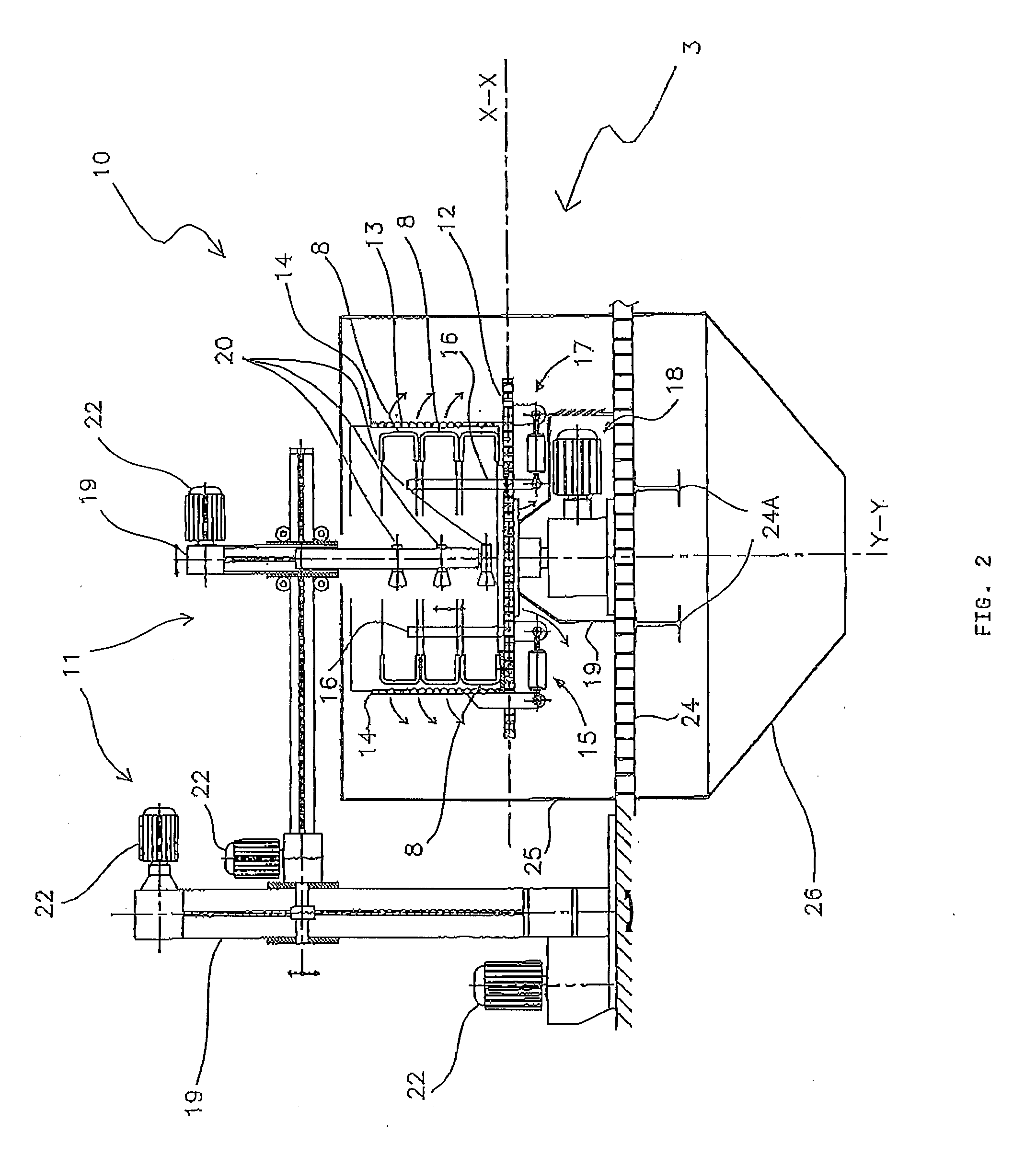

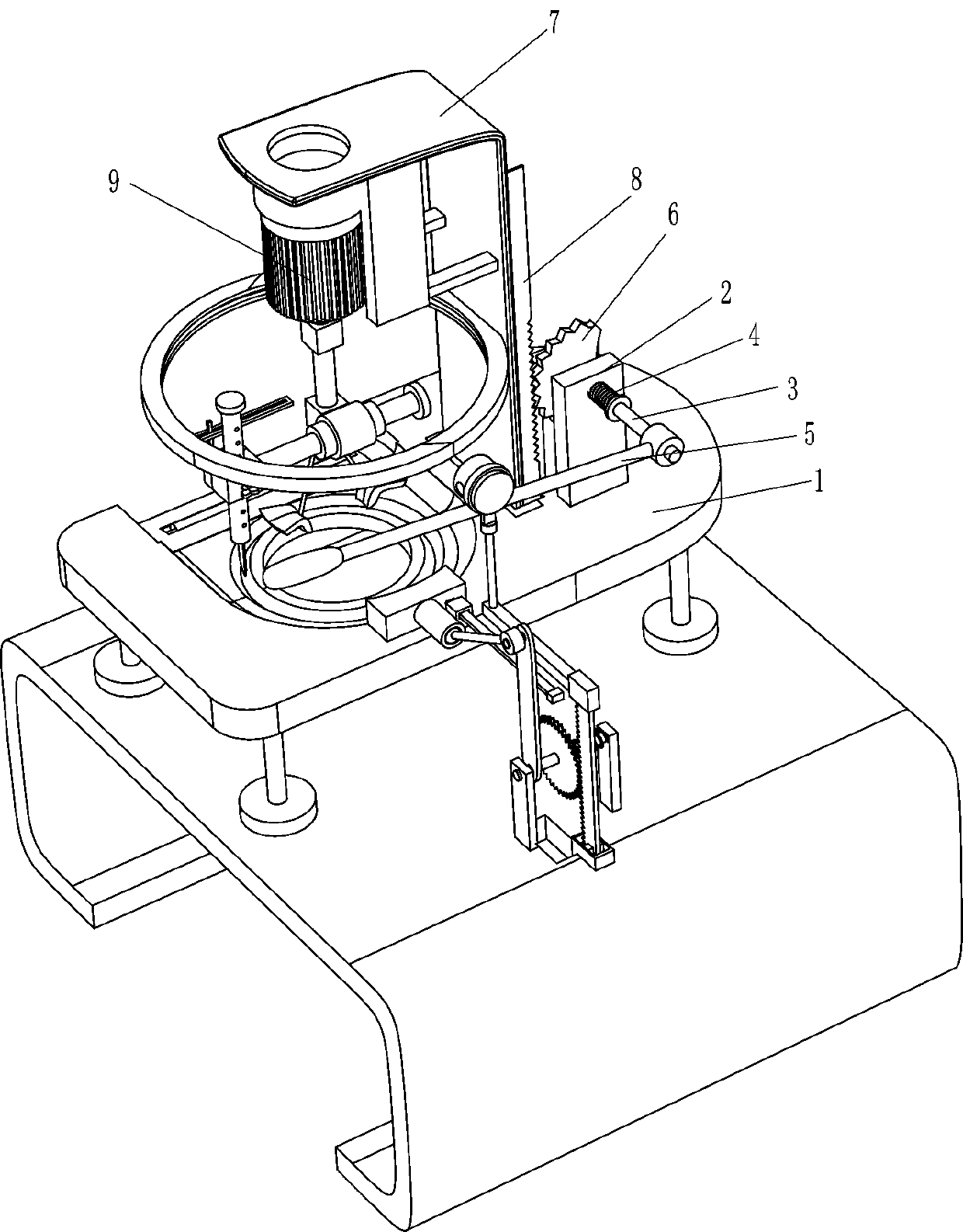

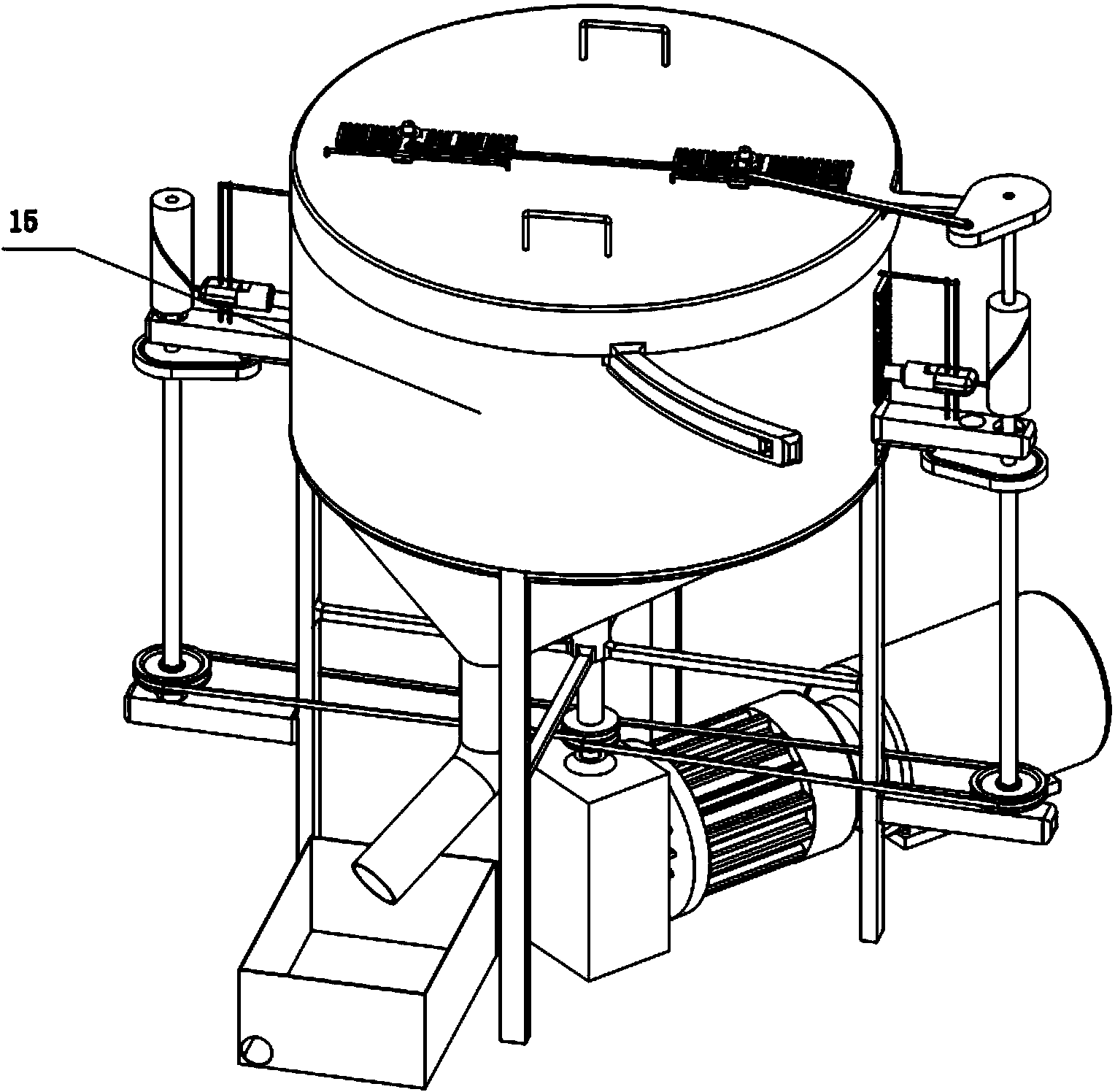

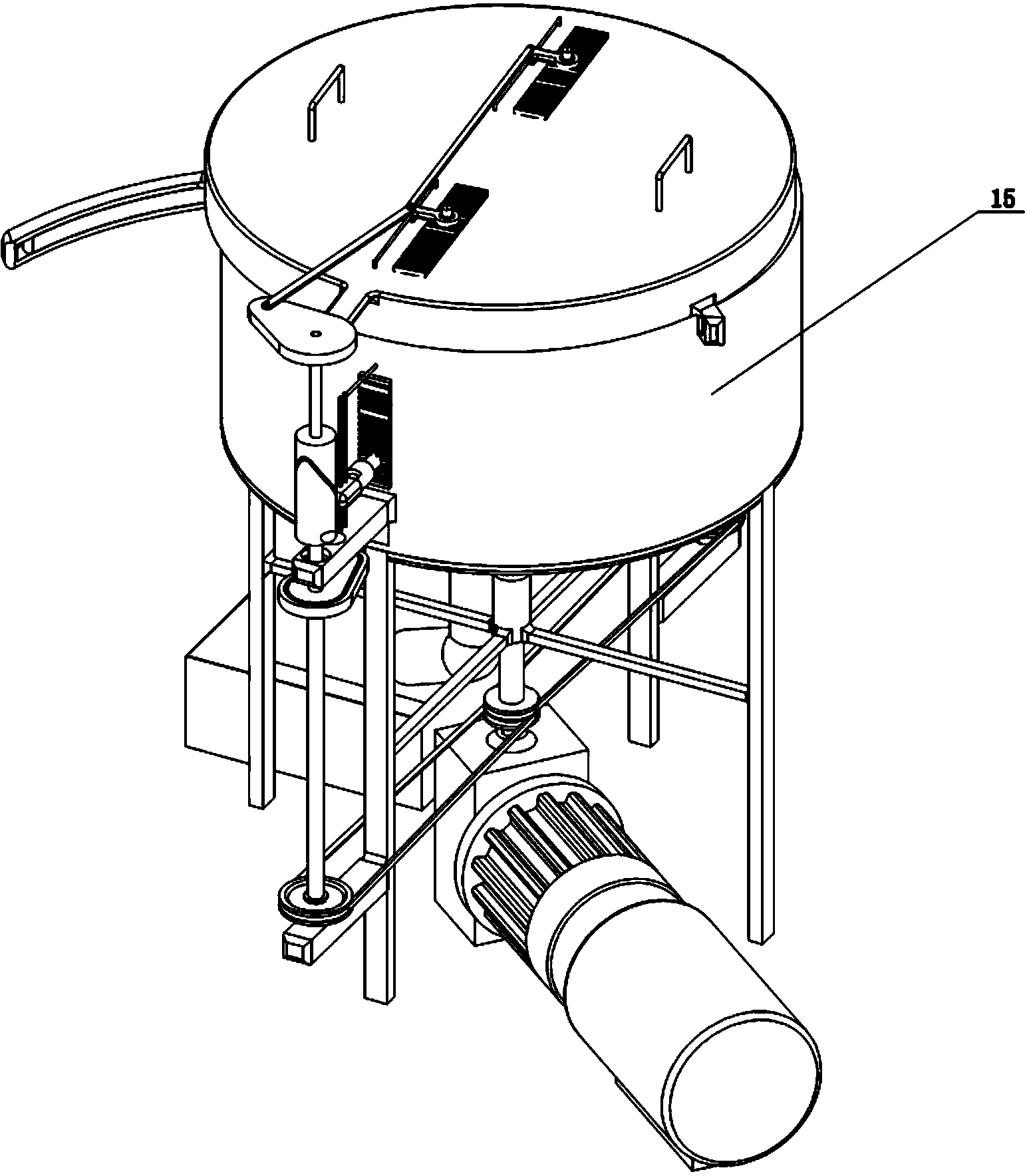

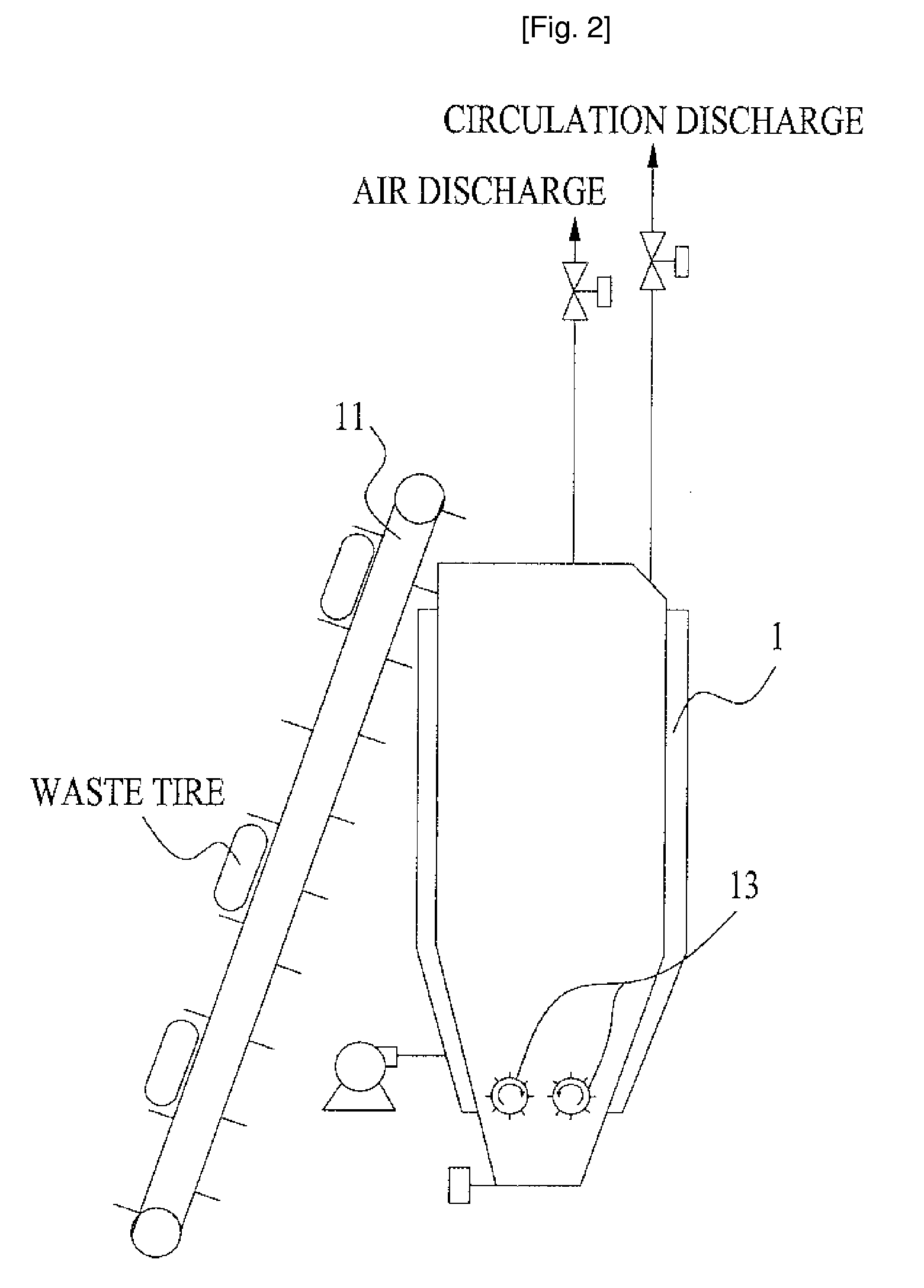

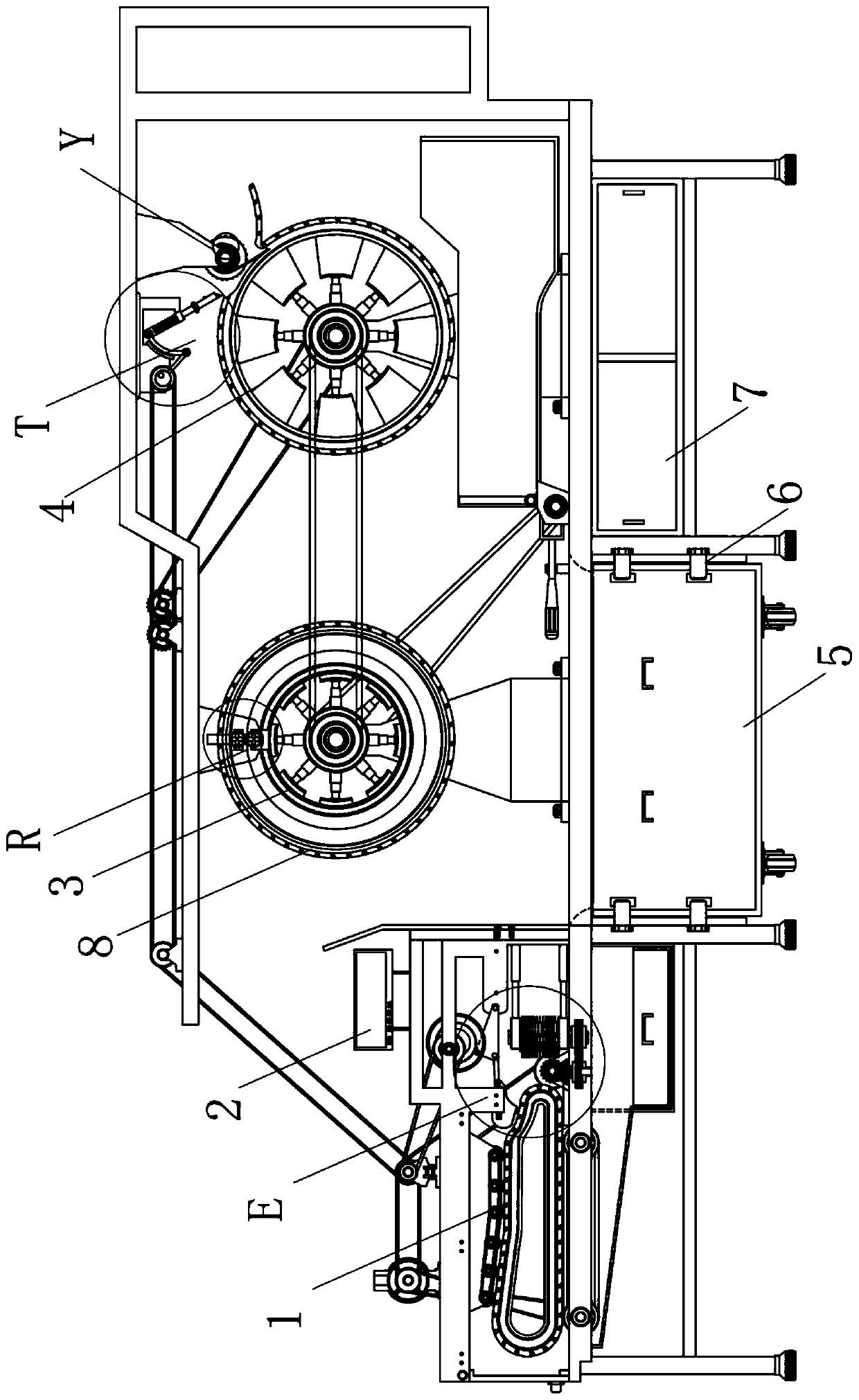

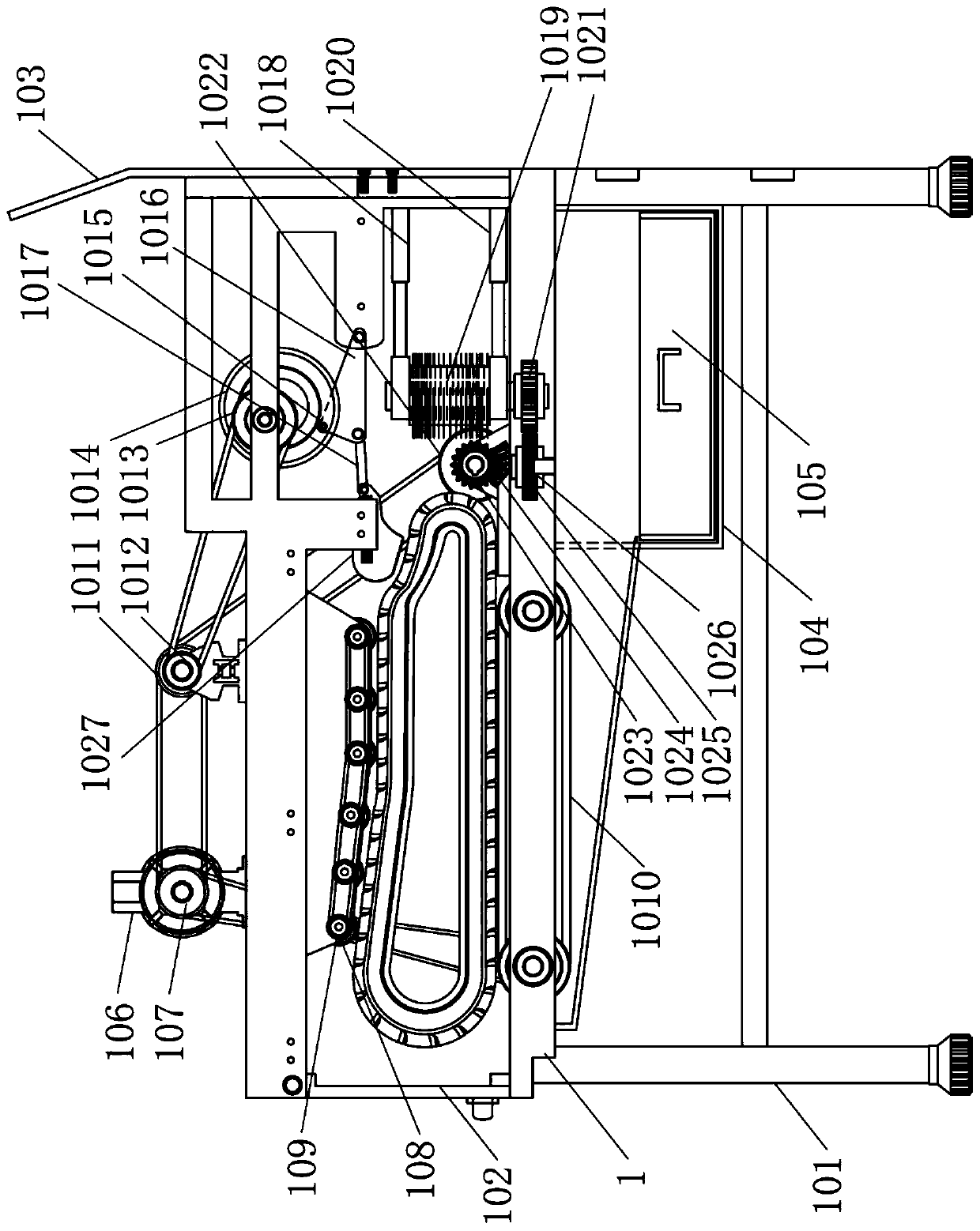

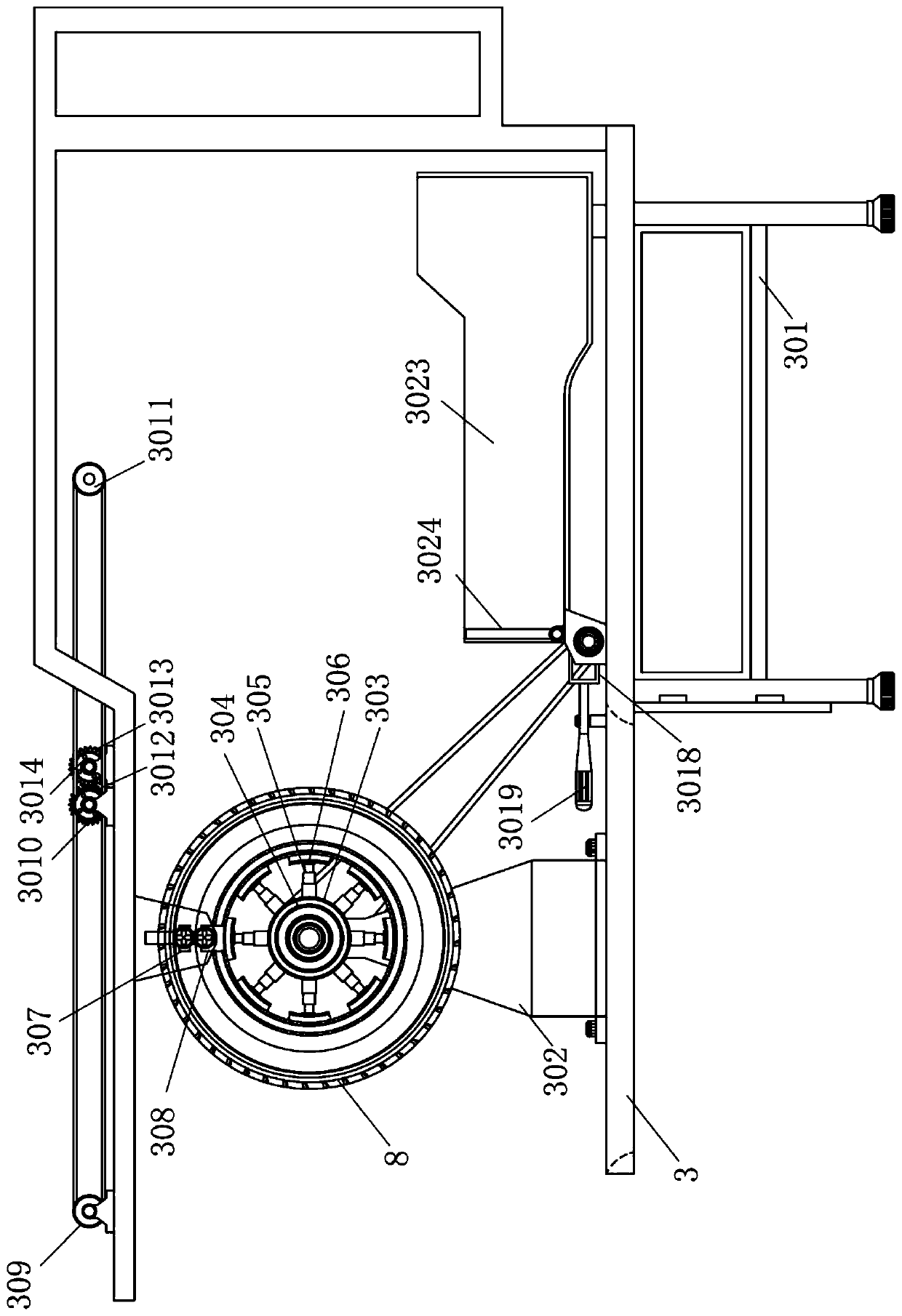

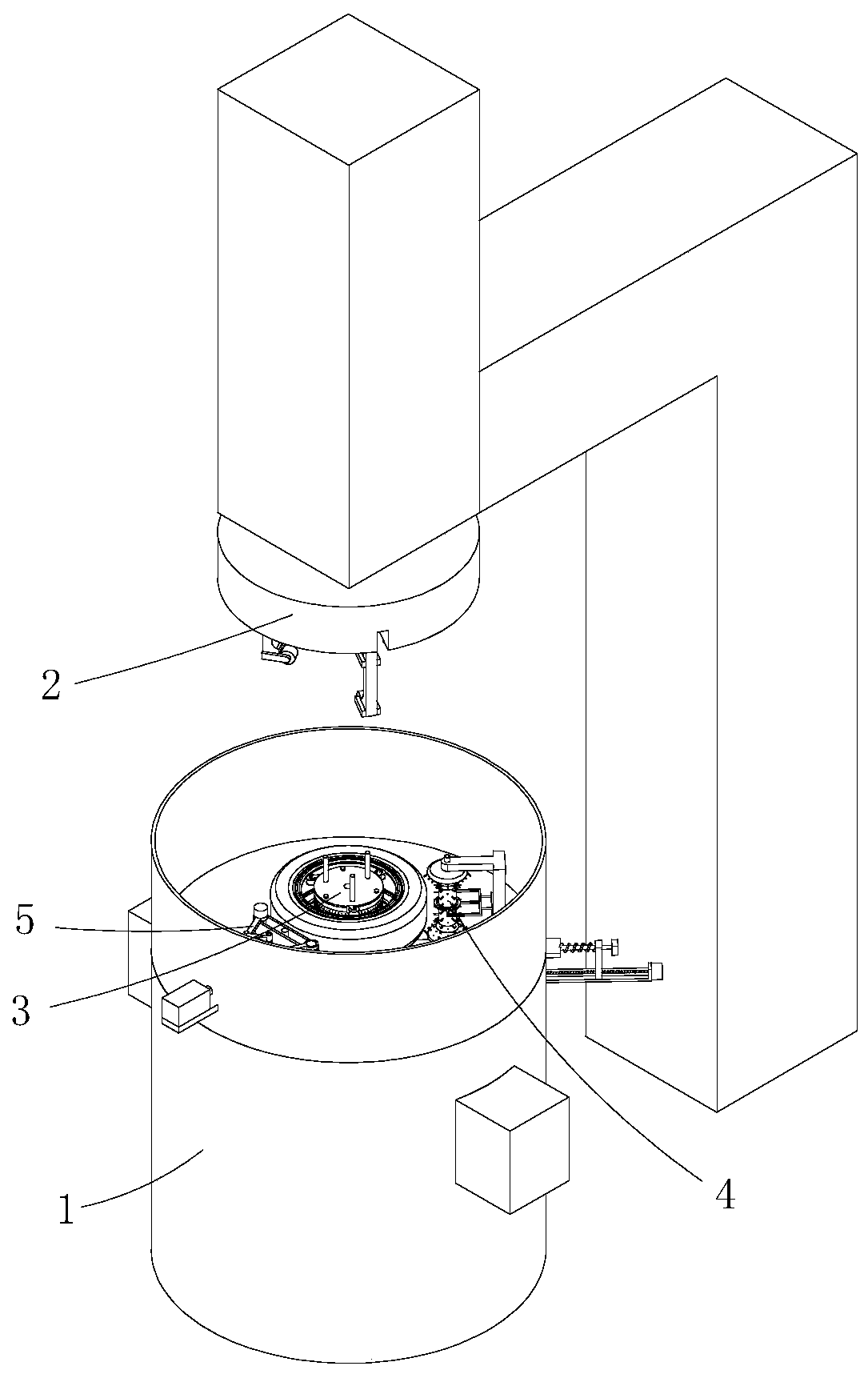

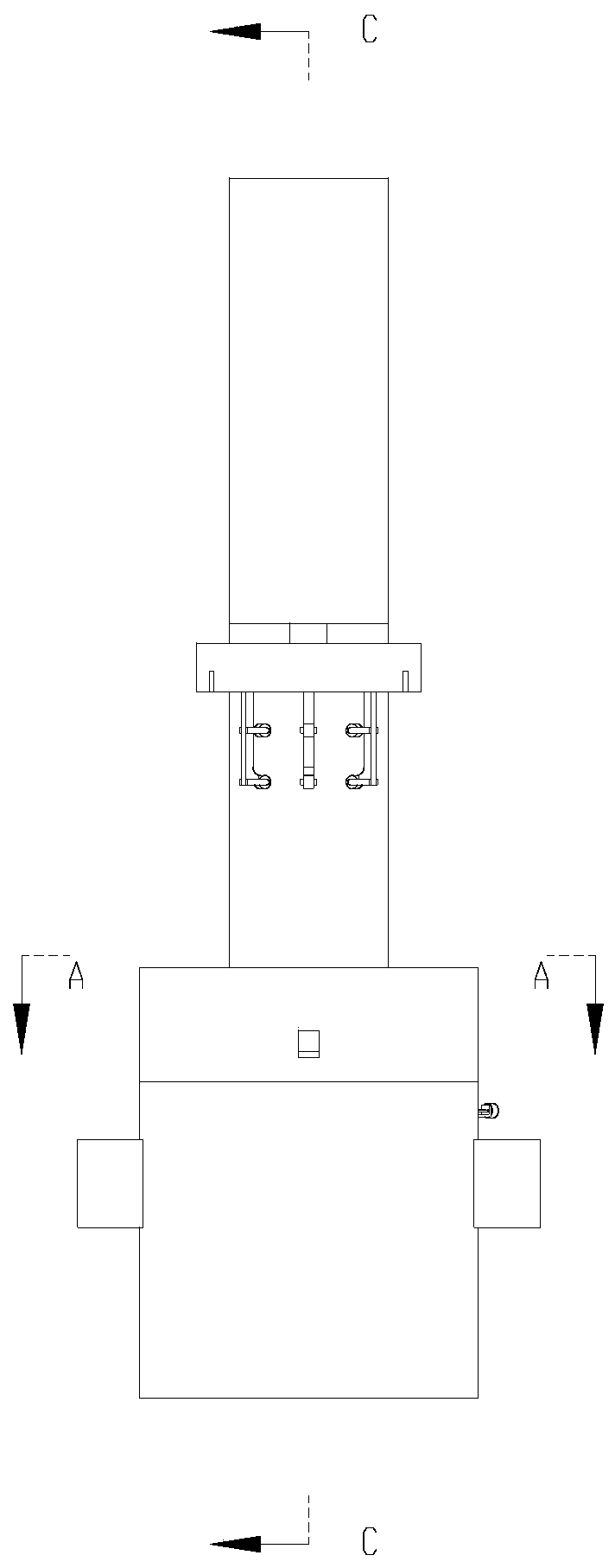

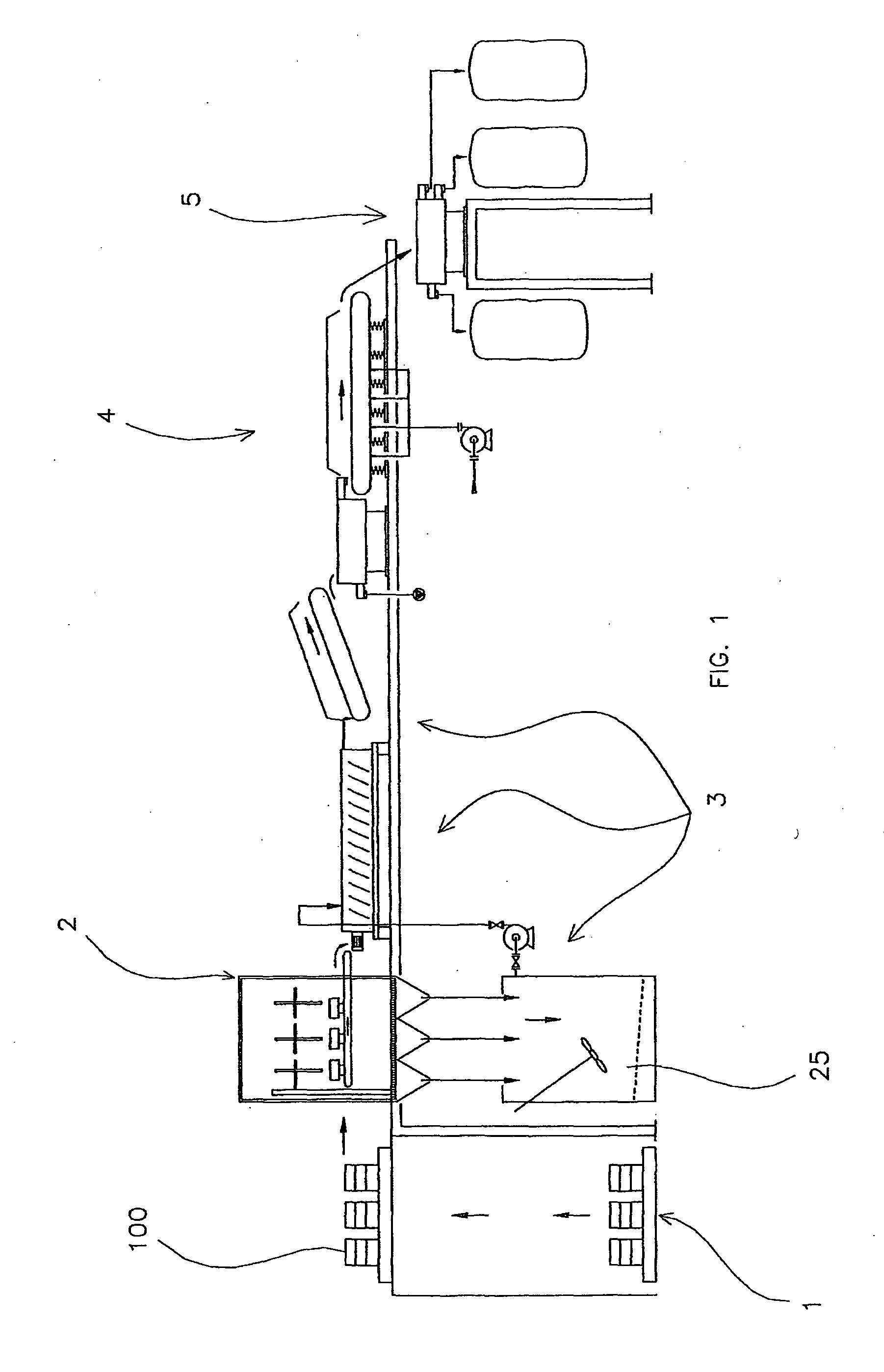

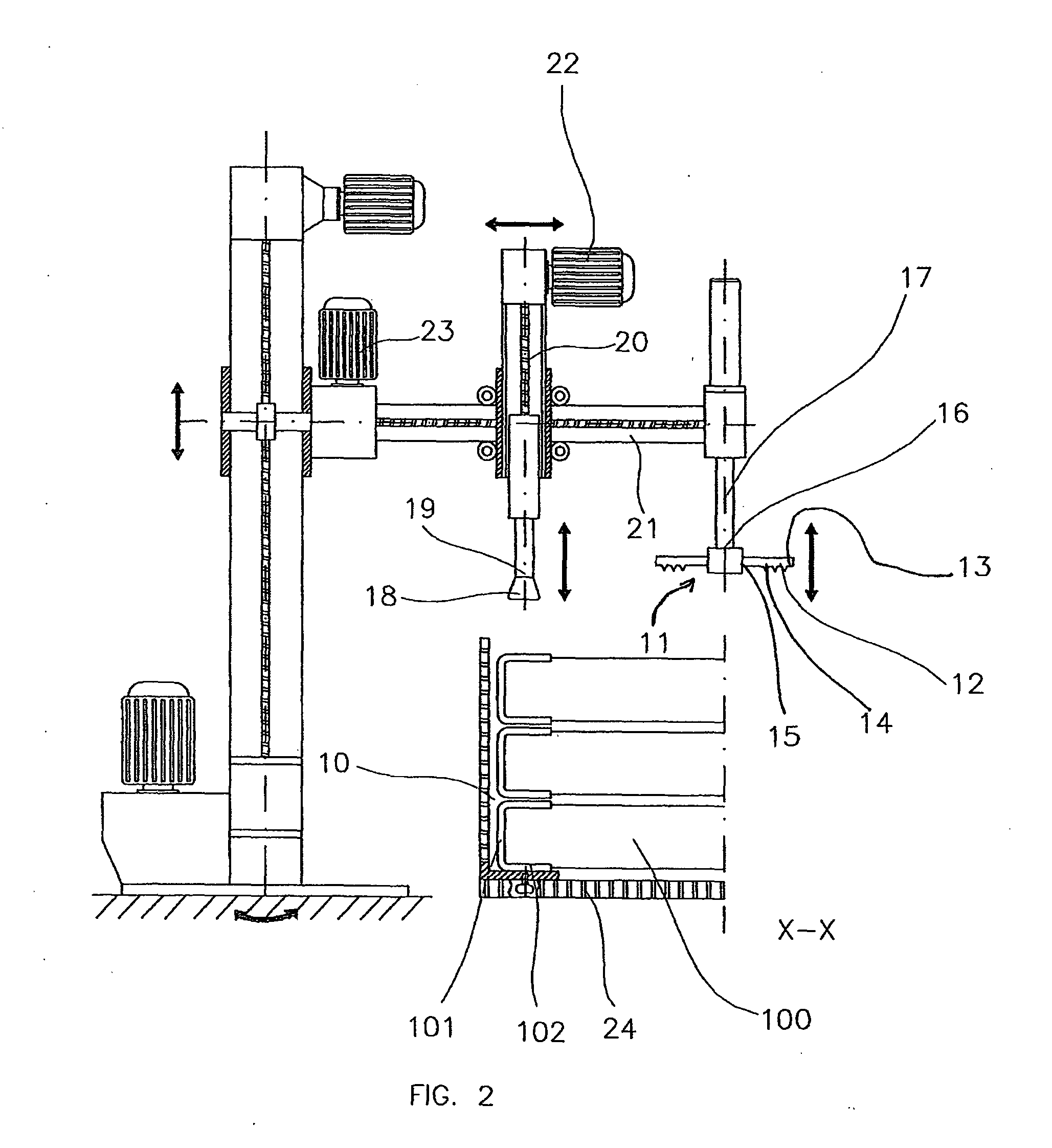

Plant for recycling tires

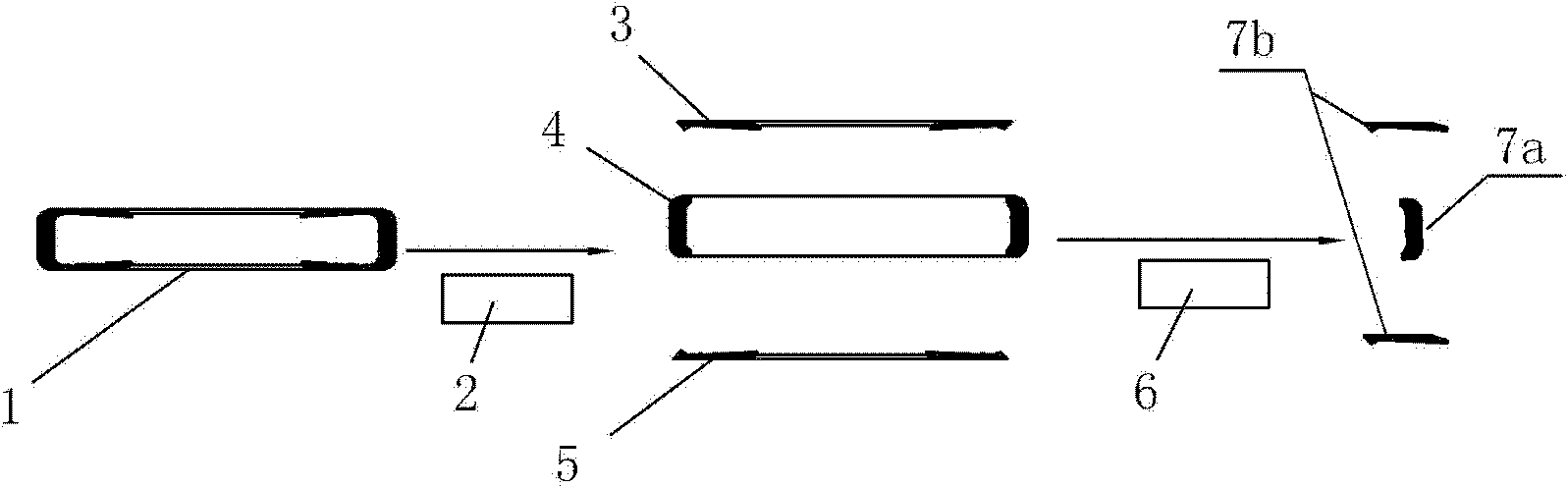

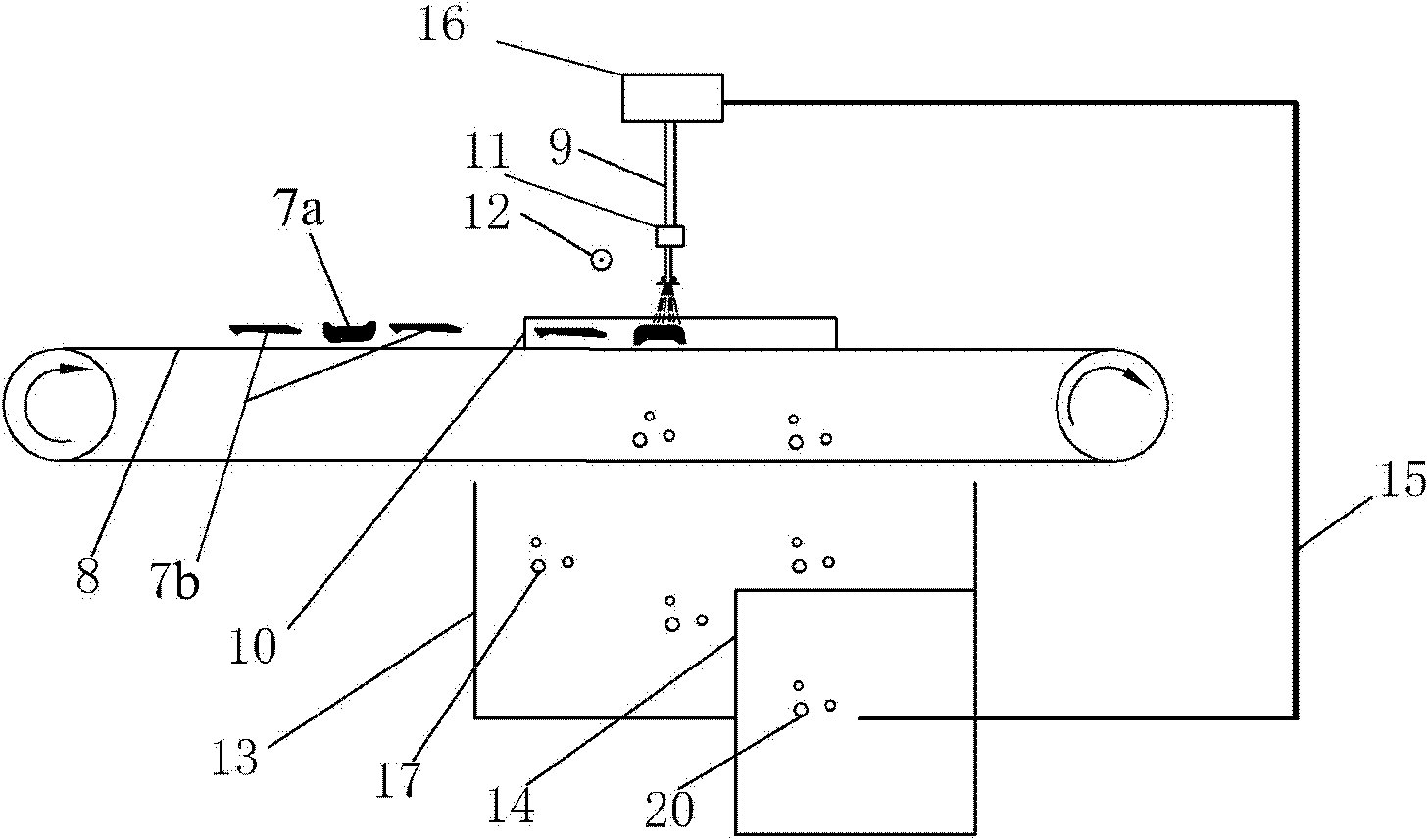

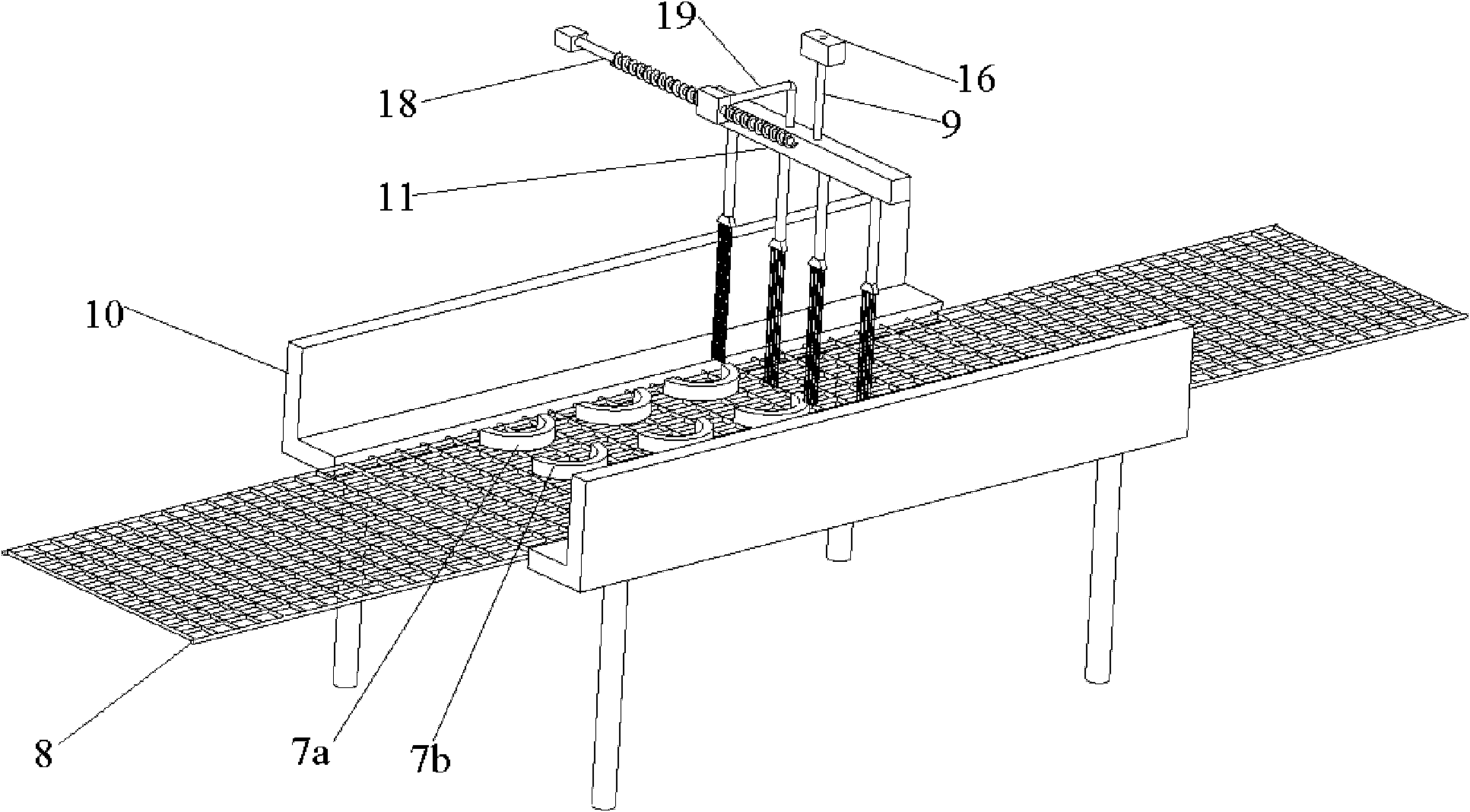

InactiveUS20110168818A1High material recovery rateImprove throughputPlastic recyclingTyresHigh pressureWorkstation

The present invention concerns a plant (1) for recycling tires using Water Jet technology, comprising a first workstation (2) for selecting and loading at least one tire (8) into a second workstation (3), said second workstation (3) being adapted to disintegrate said tires (8) loaded therein; Particularly, the second workstation (3) comprises an accessory (10) for support and retention of the tires, which has retaining means (13) that define a housing for said at least one tire (8), said retaining means (13) include a plurality of sectors (14) adapted to circumscribe said at least one tire (8), and first drive means (15) operably associated with said plurality of sectors (14) to cause said plurality of sectors to be reversibly displaced towards and away from a central portion of said support (12) to move between a first operating state (C1) and a second operating state (C2), and comprises a first Water Jet device (11) adapted to disintegrate said at least one tire (8) by delivering a high pressure fluid.

Owner:GREENTECH INNOVATION

Intelligent cleaning cutting robot for electric automobile waste tire

InactiveCN107891545ASolve the costSolve labor intensityPlastic recyclingCleaning using toolsEngineeringMechanical engineering

The invention relates to an intelligent cleaning cutting robot for an electric automobile waste tire. The intelligent cleaning cutting robot comprises a bottom plate, a connecting frame, a cleaning device, a moving device, a cutting device and a collecting device. The connecting frame is arranged on the bottom plate, and the connecting frame is sequentially provided with the cleaning device and the cutting device from left to right. The moving device is arranged at the lower end of the cleaning device. The moving device is arranged on the bottom plate. The collecting device is arranged at thelower end of the cutting device. The collecting device is arranged on the bottom plate. The intelligent cleaning cutting robot can solve the problems that in the existing automobile tire recycling technology, the labor cost is high, the labor intensity is high, the work efficiency is low, and potential safety hazards exist; the functions of automatic cleaning and cutting of the automobile tire canbe achieved; and the intelligent cleaning cutting robot has the beneficial effects that manual carrying is not needed, the labor cost is low, the labor intensity is low, and the work efficiency and safety are high.

Owner:储高鹏

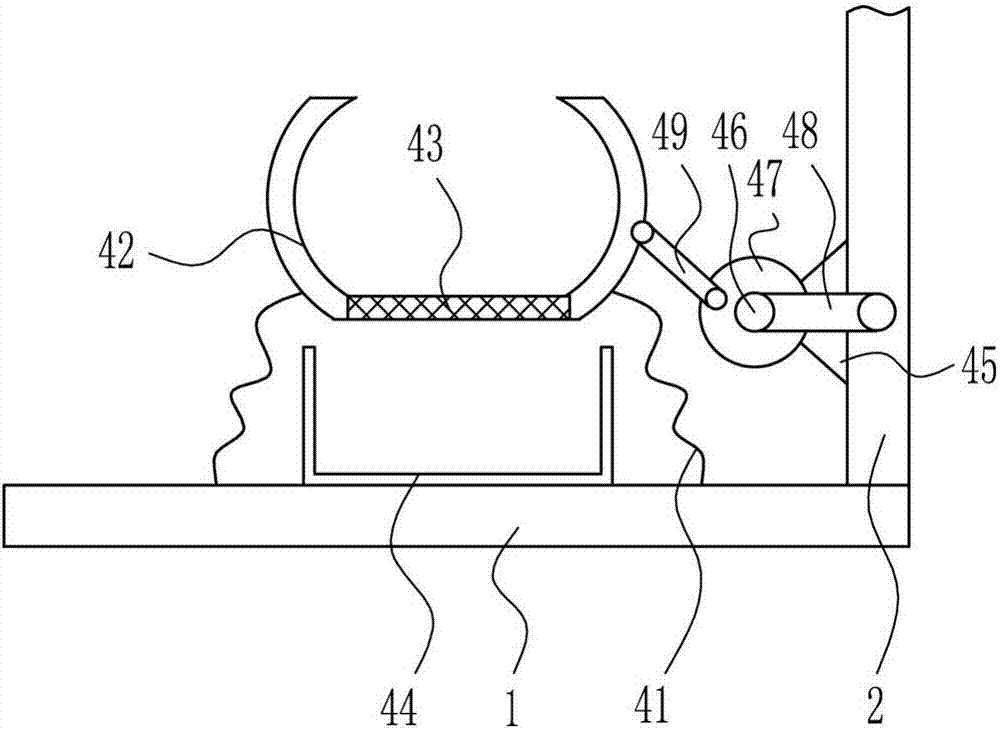

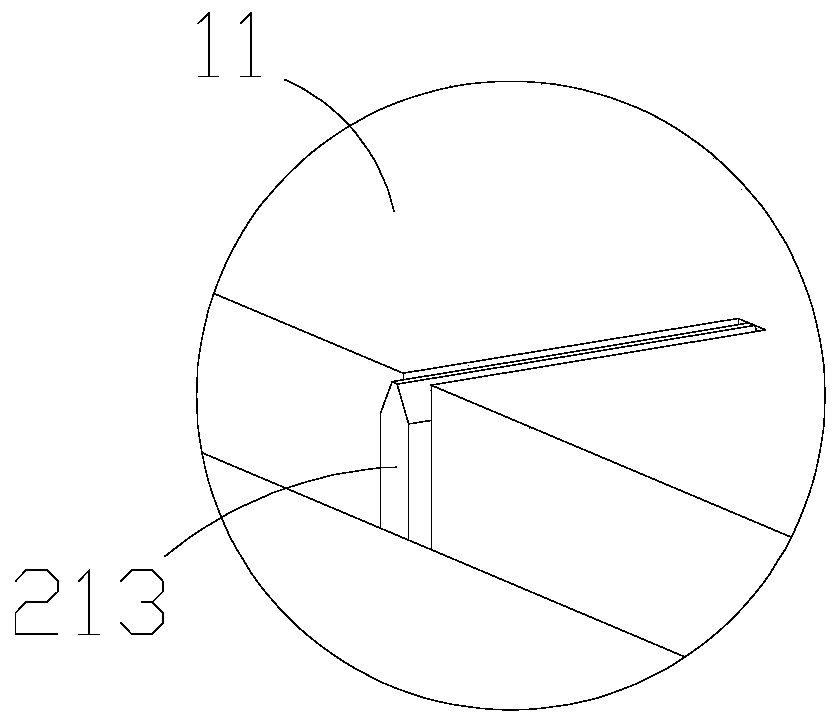

Tire recycling and cutting device

The invention relates to a cutting device, in particular to a tire recycling and cutting device. The technical problem is how to provide the tire recycling and cutting device capable of automaticallyrotating and cutting and automatically pushing out a cut tire. The tire recycling and cutting device comprises a support, a roller and the like, wherein the roller is embedded into one side of the support in a rotating manner. The tire recycling and cutting device can drive a cutter to rotate to cut a waste tire by means of a cutting device, meanwhile, can adjust the position of the cutter to cutwaste tires with different diameters and different thicknesses, presses the waste tire by using a second swing rod in the process that the cutter moves downwards to pierce the waste tire, so that thewaste tire can be fixed to avoid sliding in the process of piercing and cutting the waste tire, thus the cutting is better completed, and can push away the cut waste tire without manual operation by swinging a first swing rod upwards.

Owner:北京朋米科技有限公司

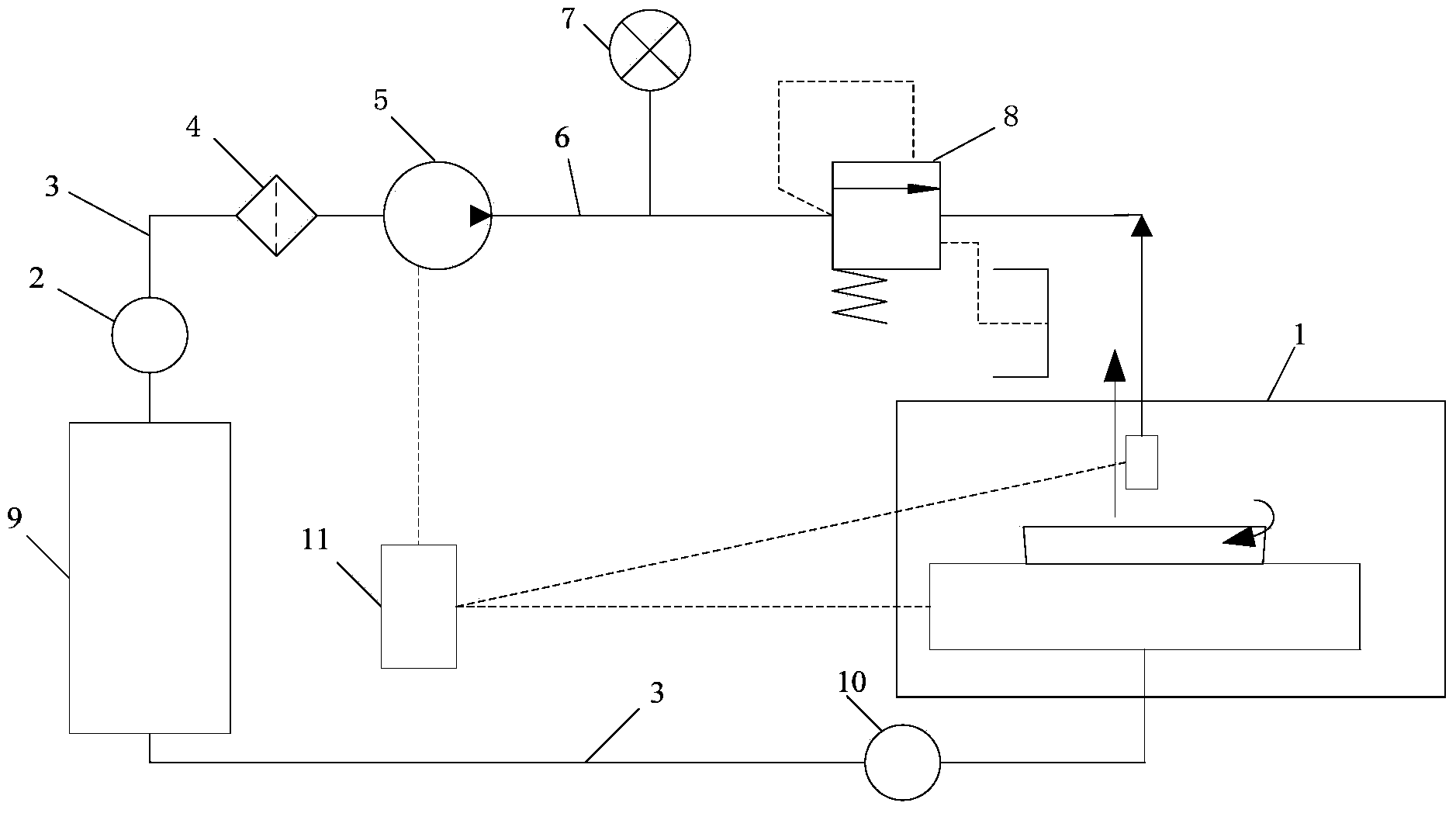

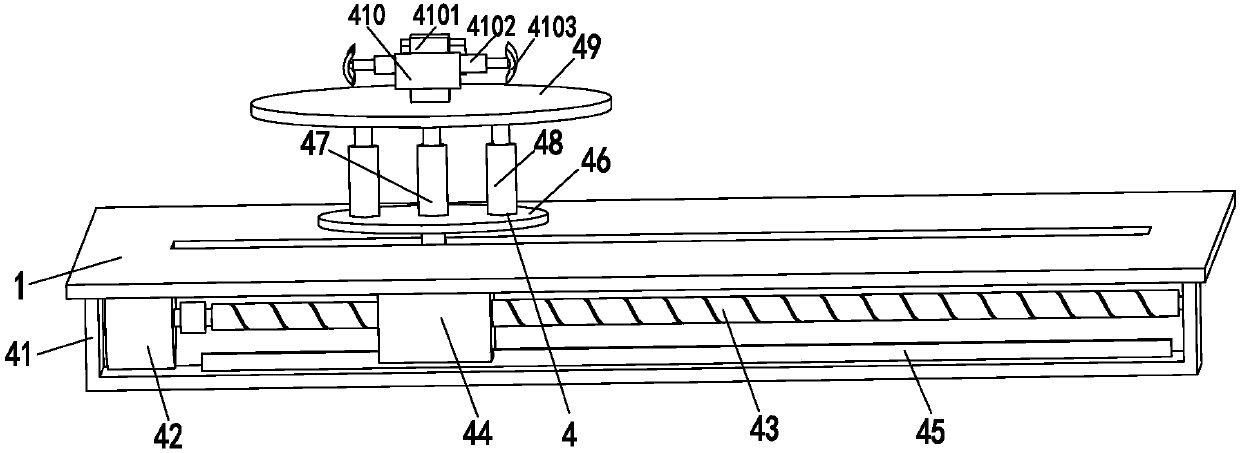

Method and device for industrialized recycling of waste tires based on ultra-high pressure water jet technology

ActiveCN102284469ANo desulfurization treatment requiredSmall granularitySolid waste disposalPlastic recyclingTire beadEngineering

The invention discloses a method and a device for industrially recycling a waste tire based on an ultrahigh pressure water jet technology. The method is characterized by comprising the following steps of: dividing the waste tire from which a hub is removed into a tire tread arc rubber block and a tire bead arc rubber block; and performing jet cutting on the tire tread arc rubber block and the tire bead arc rubber block by using ultrahigh pressure water jet which is from an ultrahigh pressure water generating device and carries an abrasive, adjusting the pressure of the water jet to ensure that the cutting pressure of the water jet is not enough to cut metal wires in the tire tread arc rubber block and the tire bead arc rubber block, cutting rubber in the tire tread arc rubber block and the tire bead arc rubber block into rubber powder particles, and taking the metal wires out to obtain the rubber powder particles. The method and the device are used for recycling the waste tire simply,practically, industrially and efficiently at high quality.

Owner:HEFEI UNIV OF TECH

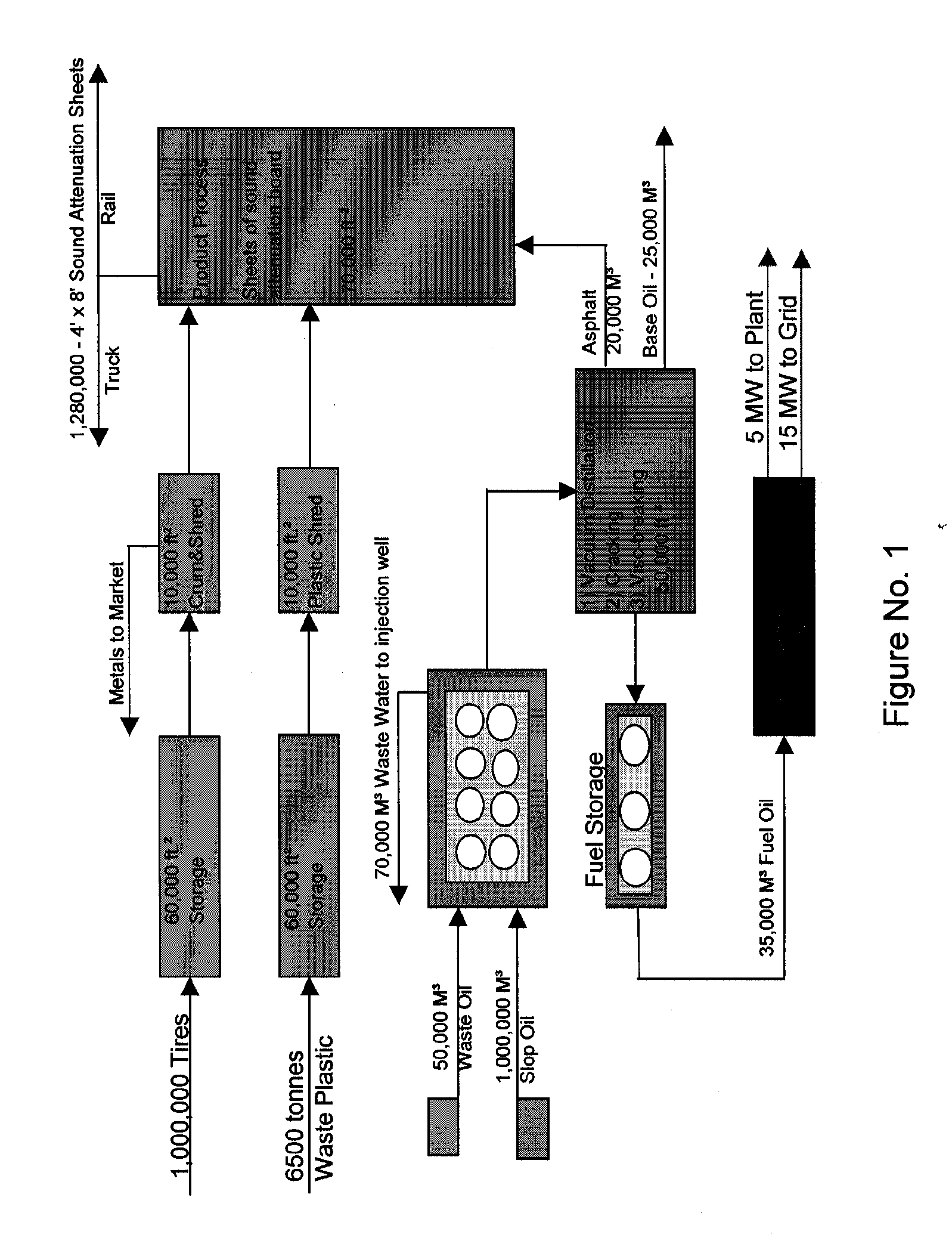

Waste oil, waste plastic, and waste tire recycling

A method for producing composite products combines recycled tire crumb, shredded plastics and asphalt produced from waste and slop oil.

Owner:ARRISON NORMAN +1

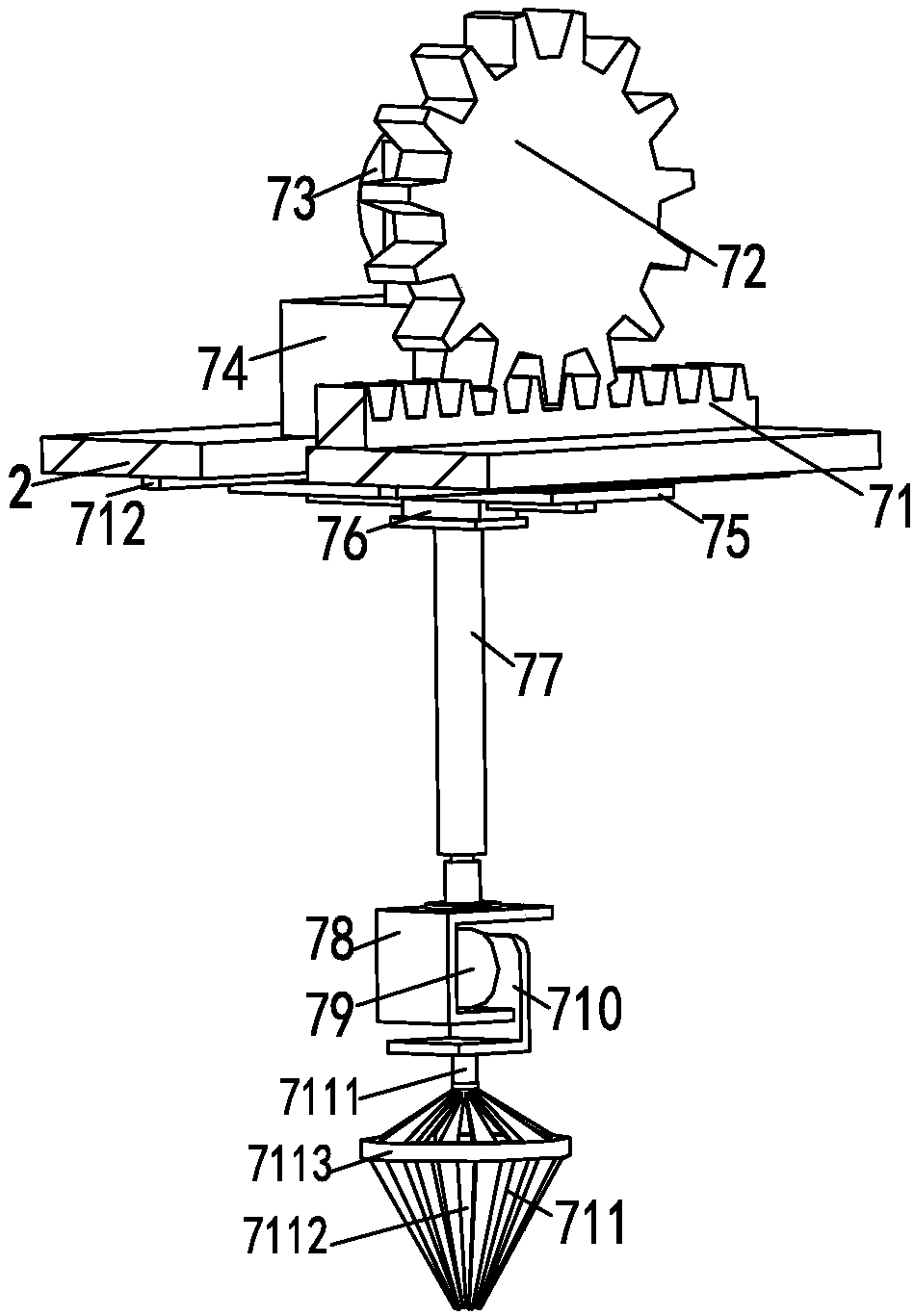

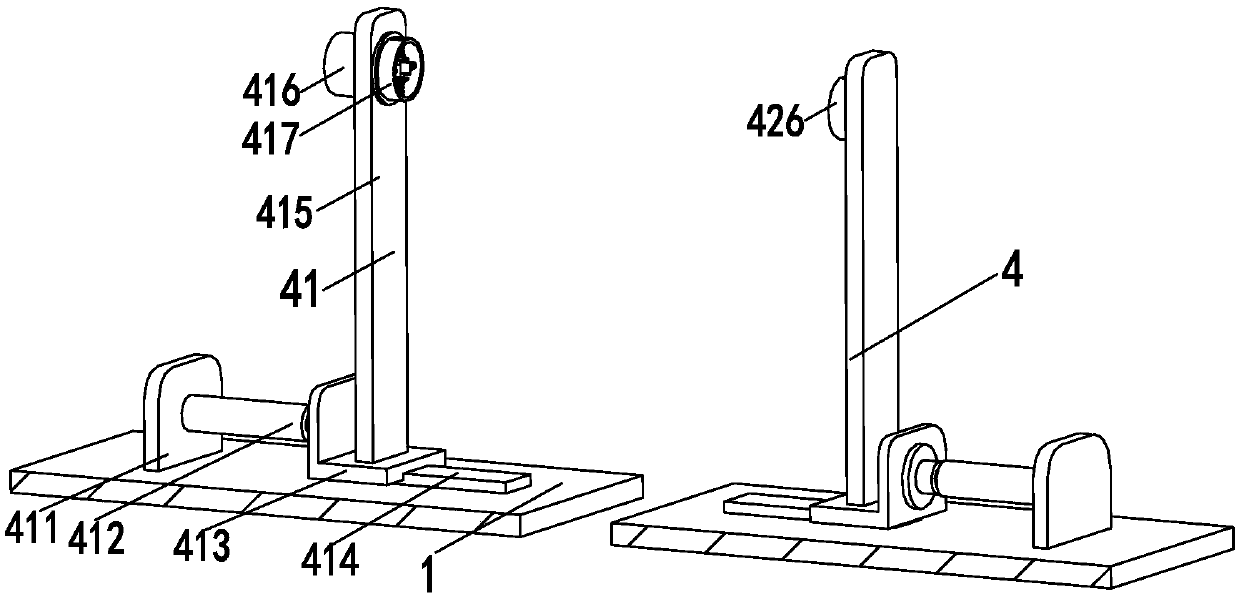

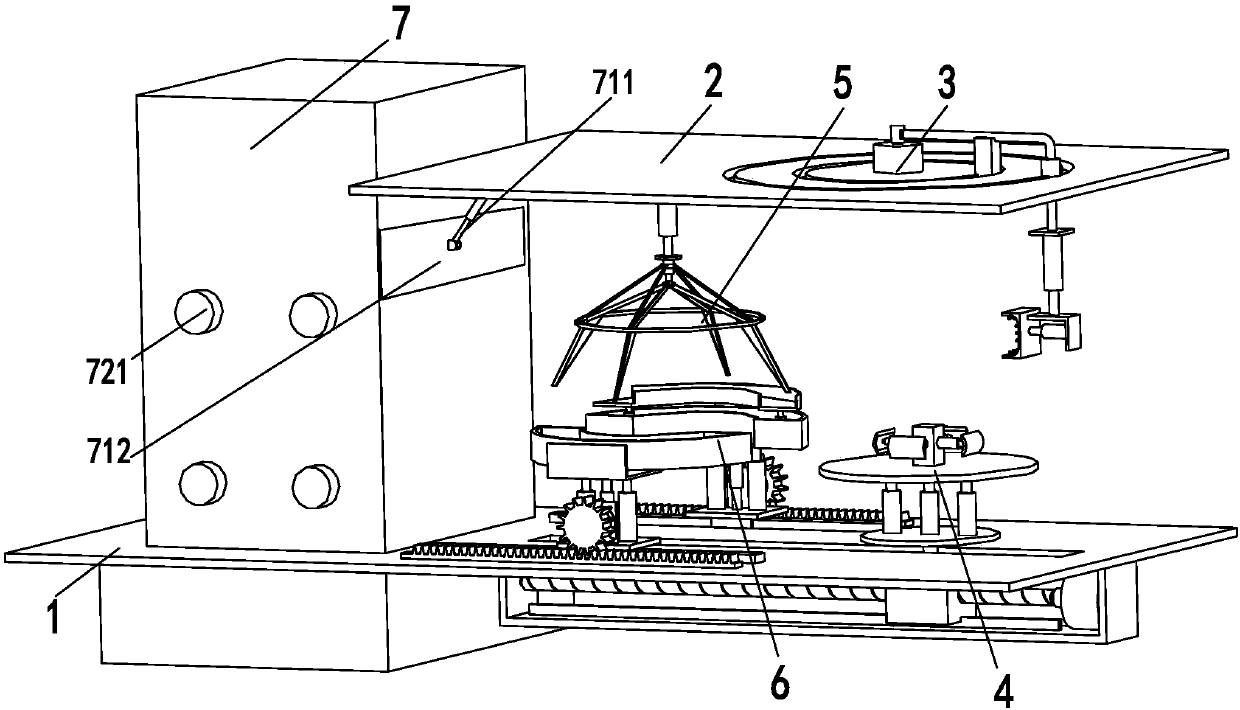

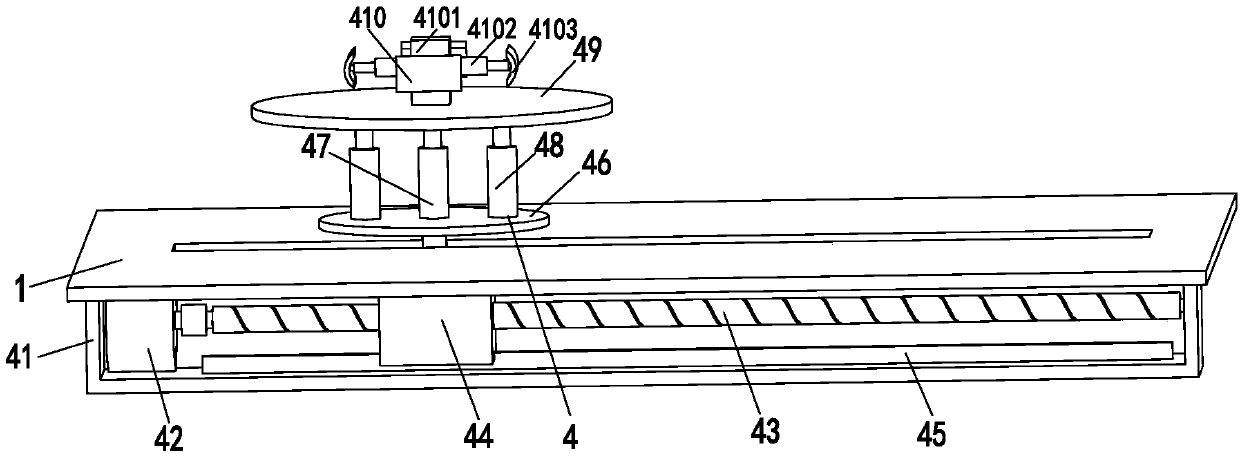

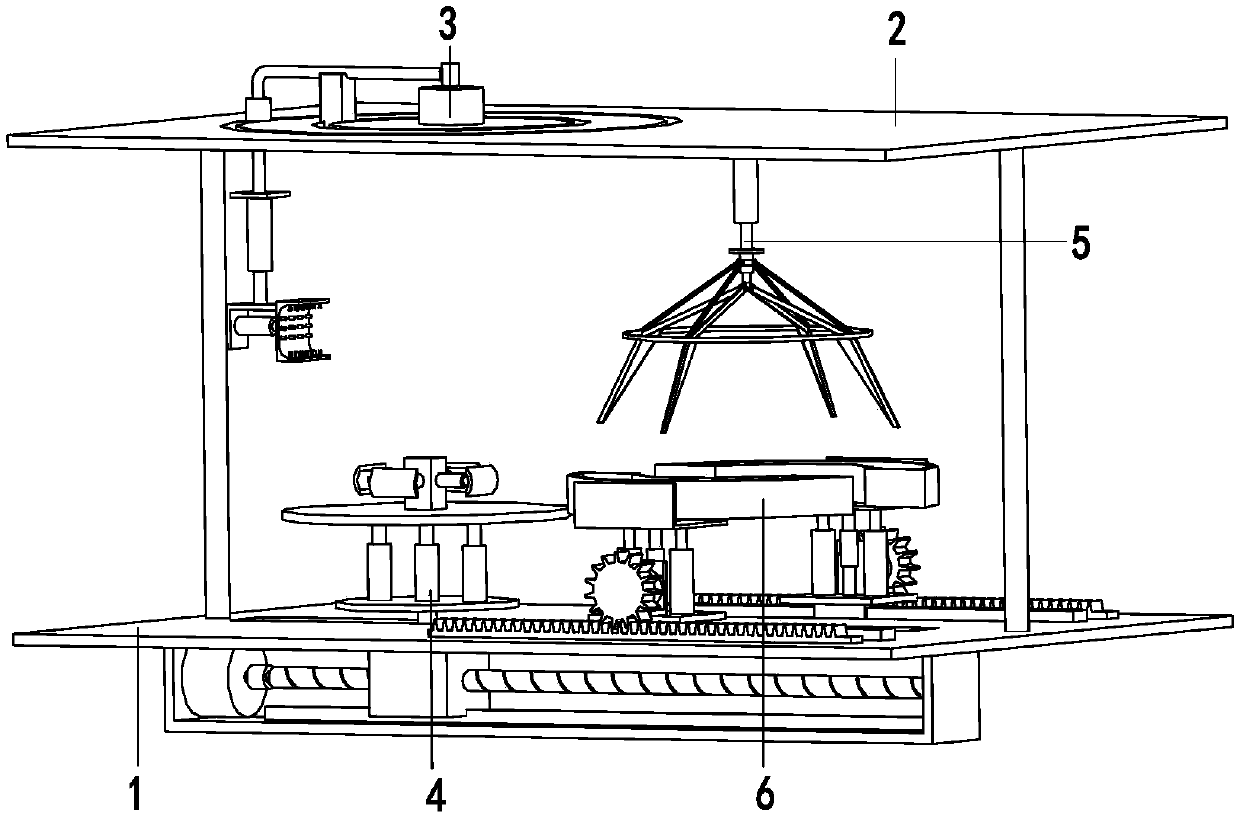

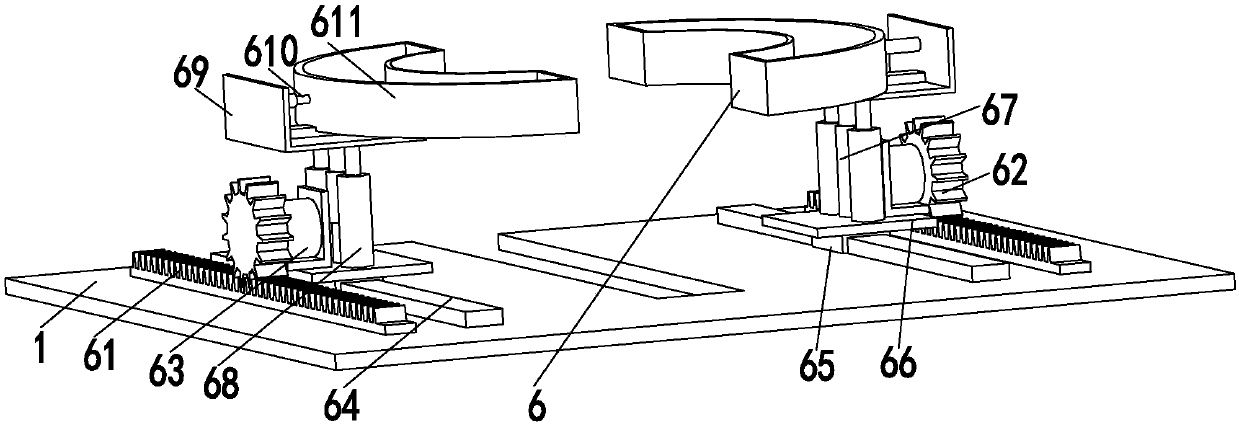

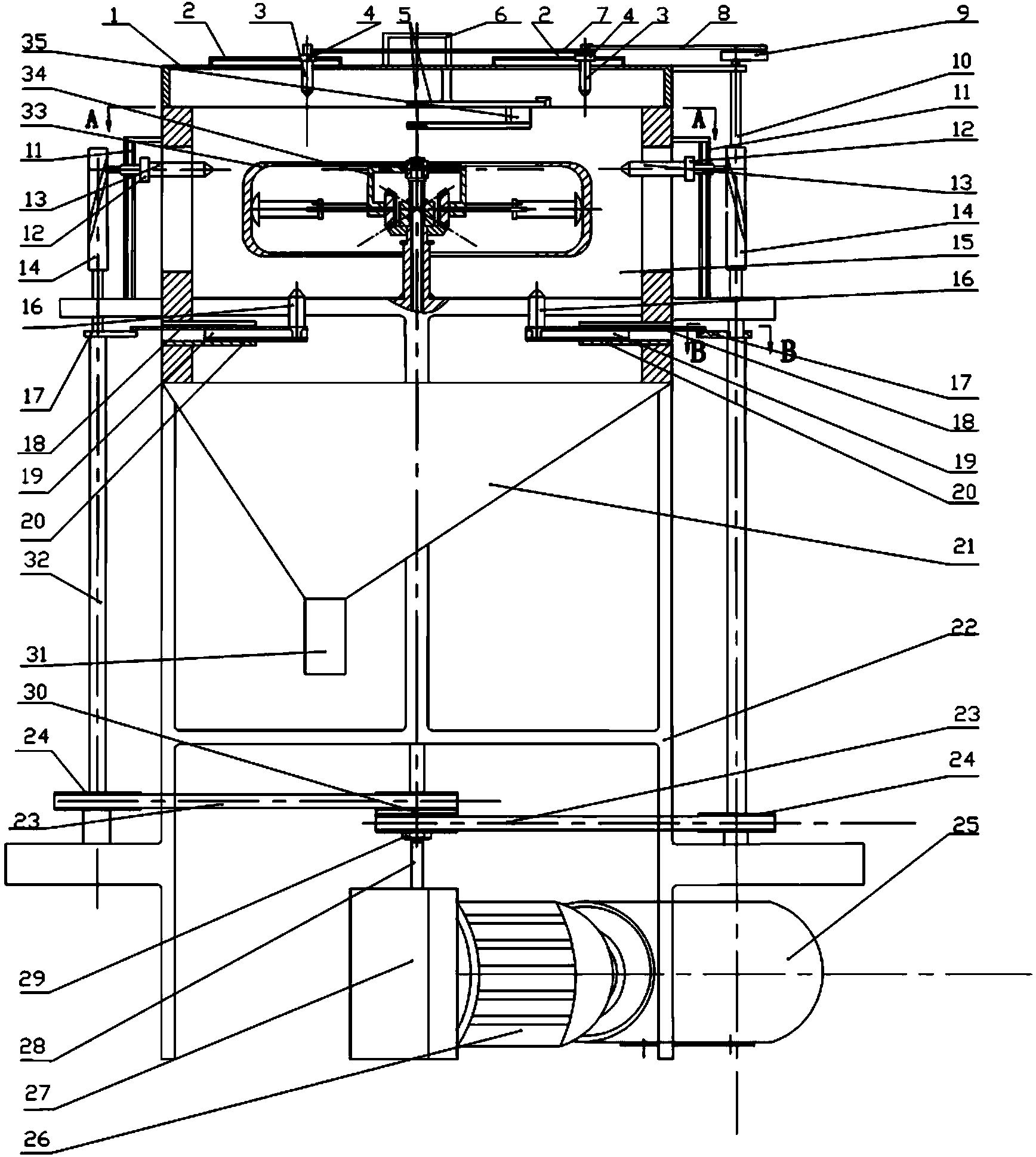

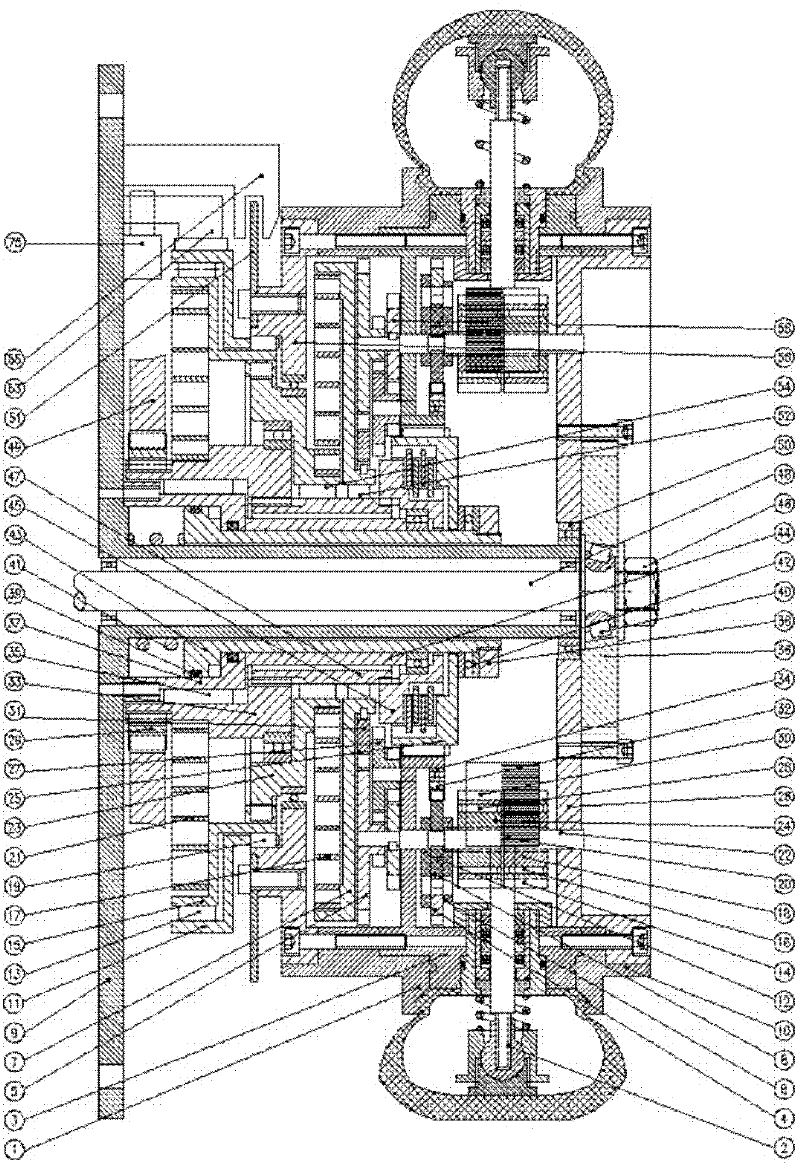

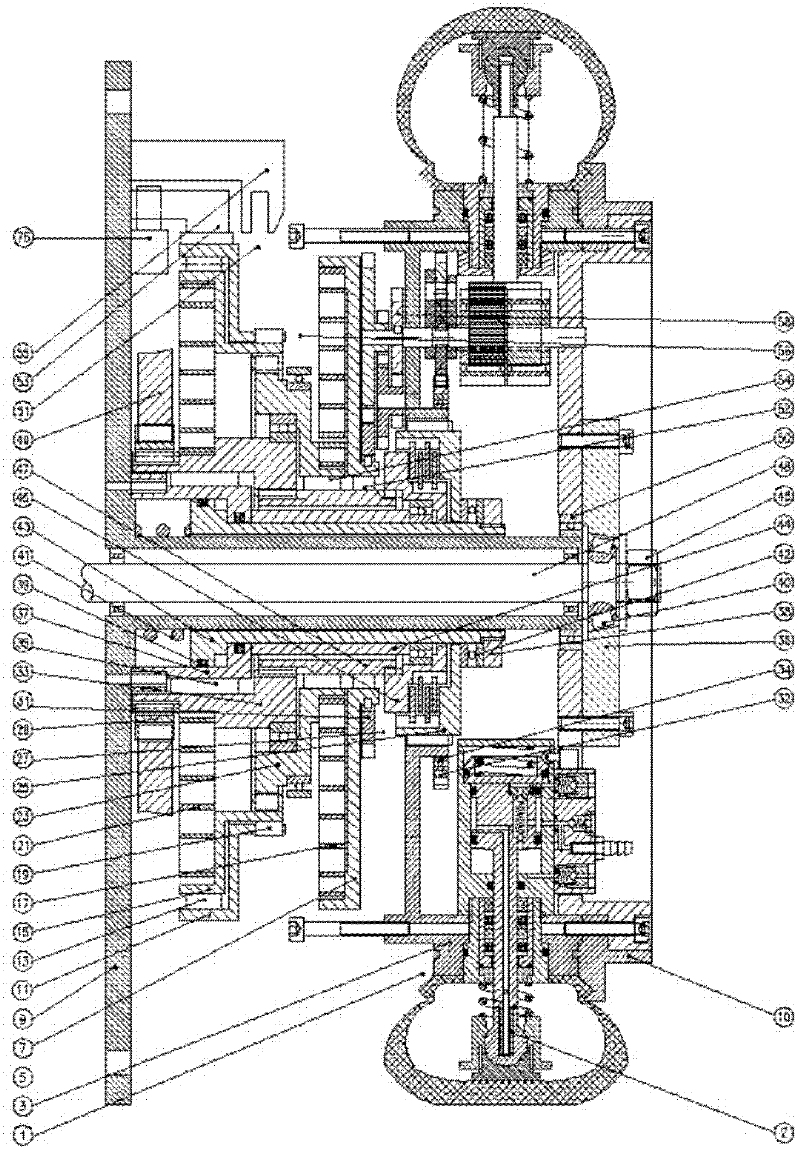

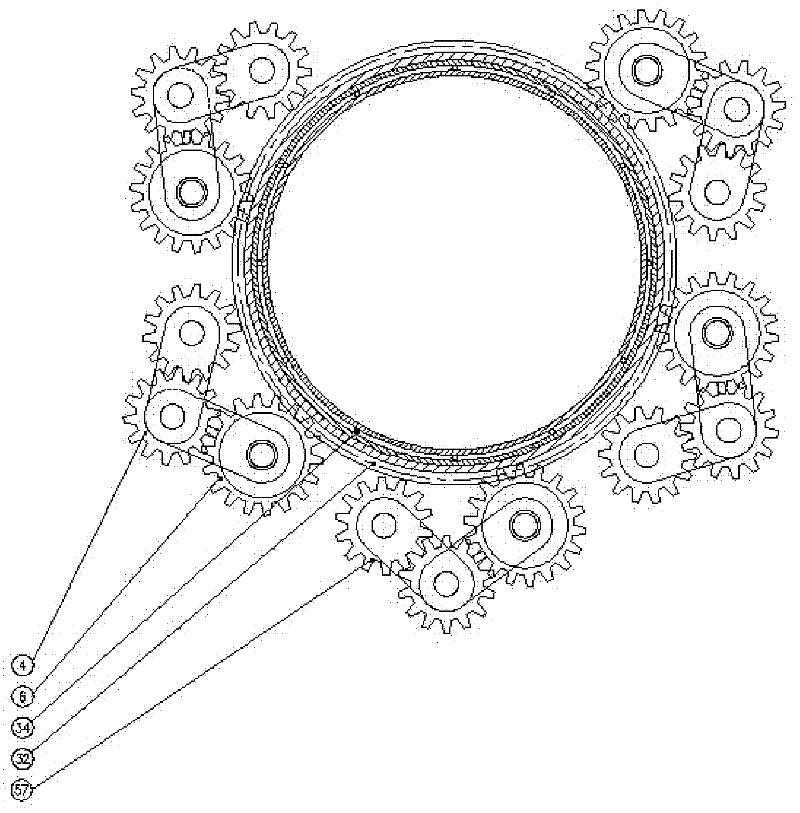

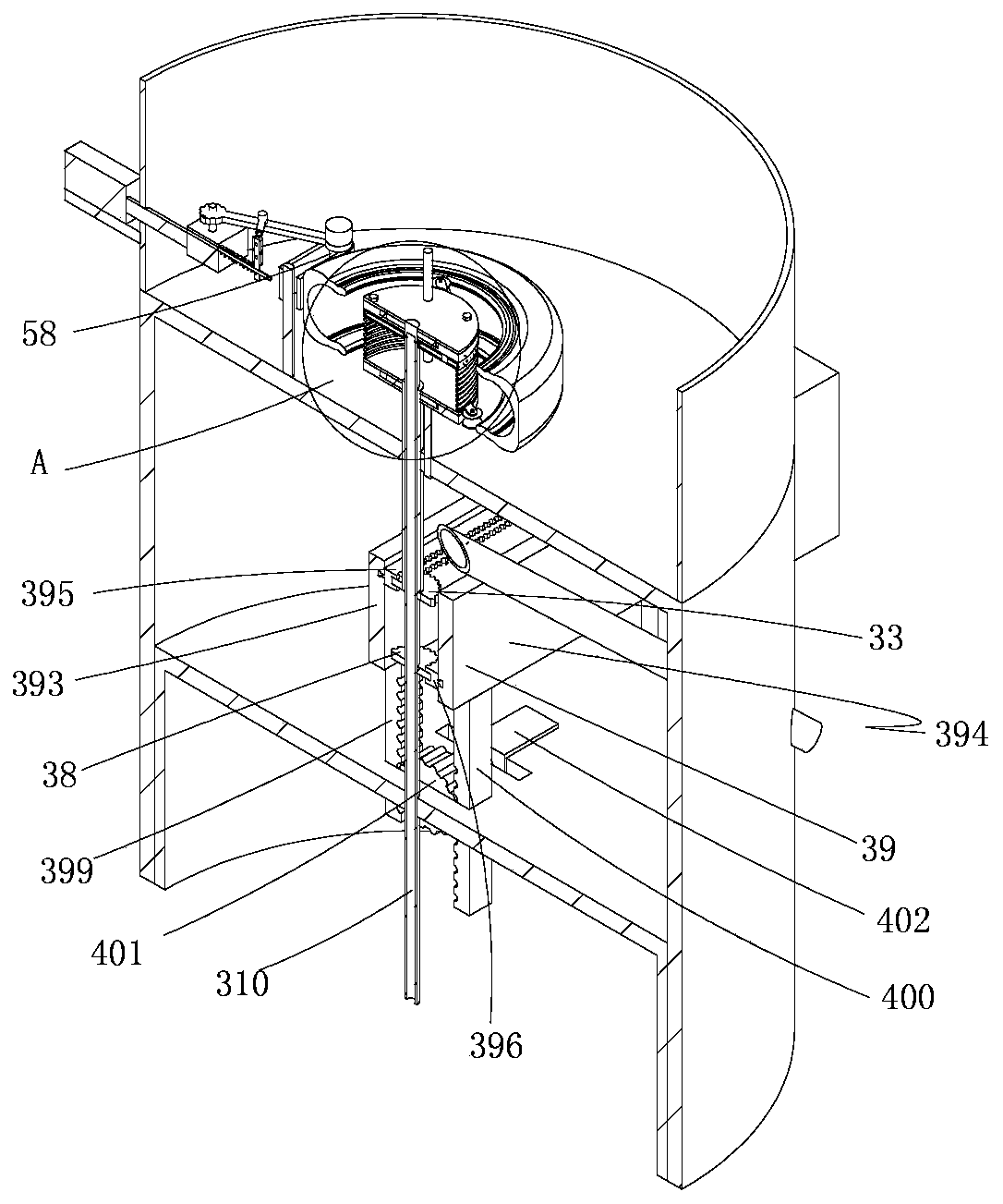

Tire recycling device for smashing waste tire based on high-pressure water jet

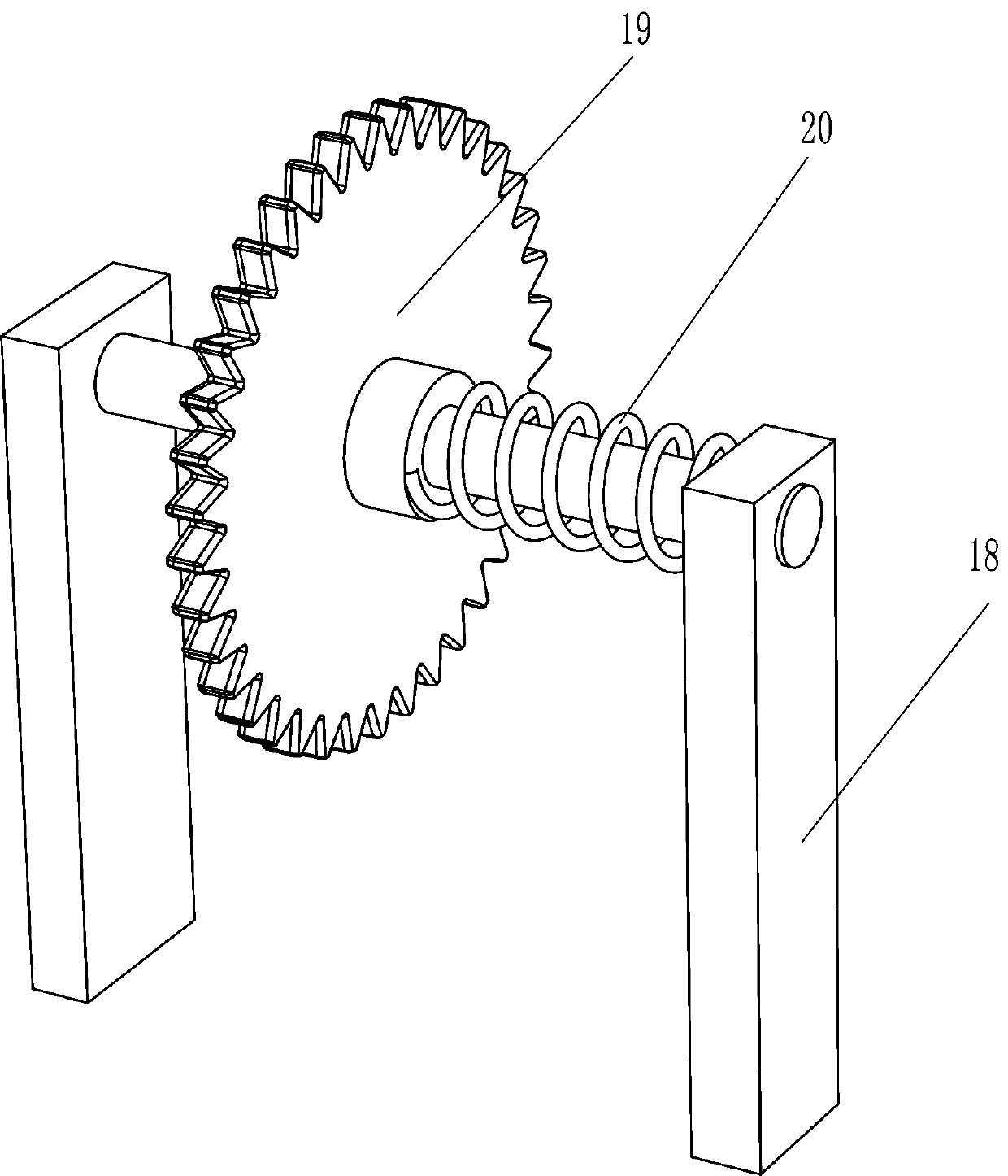

ActiveCN103963189ASmash thoroughlyAchieve rotationPlastic recyclingGrain treatmentsWire gauzeGear wheel

The invention discloses a tire recycling device for smashing a waste tire based on a high-pressure water jet. The tire recycling device is characterized by comprising a frame (22), wherein a smashing chamber (15) of which the top cover (1) can be opened is formed in the upper part of the frame (22); a tire clamping mechanism is arranged inside the smashing chamber (15); movable jet flow spray nozzles for jetting high-pressure water towards clamped tires are arranged in the up, down, left and right directions of the smashing chamber (15); the clamping mechanism comprises a main shaft (28), a clamping bracket (34), radial expansion arms, an electromagnetic chuck, bevel pinions (40) and a bevel gear wheel (41). The device provided by the invention does not need to initially disassemble waste tires, can adjust proper jet flow pressure, and does not destroy a steel wire gauze while completely smashing the rubber of the tire surface.

Owner:ANHUI UNIV OF SCI & TECH

Device and method for utilizing recovered pressure energy and inertia energy of pneumatic tire and application

InactiveCN102358183AImprove driving experienceNovel structureAuxillary drivesTyre measurementsPressure transmissionEngineering

The invention relates to the technical field of recovery and utilization of pressure energy and inertia energy of a pneumatic tire, in particular to a device and a method for utilizing recovered pressure energy and inertia energy of a pneumatic tire. The device comprises a combined type wheel body, a wheel spindle and a pneumatic tire pressure energy recovery device, wherein the pneumatic tire pressure energy recovery device is arranged on an inner ring of the combined type wheel body and is formed by a plurality of energy capturing devices arranged in a vacuum tire, and each energy capturing device is internally provided with an energy capturing rod. The device for utilizing the recovered pressure energy and the recovered inertia energy is characterized by also comprising a recovered pressure transmission and integration device, an inertia energy recovery and utilization device, a working condition operating control device, and a tire working condition monitoring device. The device provided by the invention has a novel structure, the pressure energy and the inertia energy of the tire can be effectively utilized through interaction of the energy capturing devices, and the device can well adapt to various conditions such as acceleration, braking, deceleration and the like.

Owner:郑乃时 +3

Disassembling and recycling technique for decrepit car

InactiveCN107512327AReduce the burden onEasy to cleanInorganic/elemental detergent compounding agentsVehicle dissasembly recoverySteering wheelCleansing Agents

The invention provides a disassembling and recycling technique for a decrepit car and relates to the field of decrepit car recycling. The disassembling and recycling technique comprises the following steps: (1) recycling and processing auto parts: recycling waste fuel, seats, batteries and tires and disassembling front and rear lamps and a steering wheel; (2) disassembling nonmetallic auto parts: disassembling the nonmetallic auto parts, such as automotive glass, of the decrepit car, and cleaning and recycling the nonmetallic auto parts with a dedicated glass cleaning agent after disassembling the same; (3) disassembling metallic auto parts: disassembling front and rear hoods, doors, bumpers, seats, an air conditioner and an engine; (4) cleaning a car frame with a car cleaning agent to facilitate subsequent materials to be crushed and recycled; (5) crushing and screening the car frame and gradually crushing a car body to a predetermined size by virtue of multistage crushing. The disassembling and recycling technique for the decrepit car realizes quick crushing and physical disassembly for screening and crushing separation of the car body of the decrepit car, and the material cleaning effect after the screening and recycling is good so as to reduce the pollution and enable metal, rubber, glass and other materials of the car body to be fully recycled.

Owner:广州科生环保科技有限公司

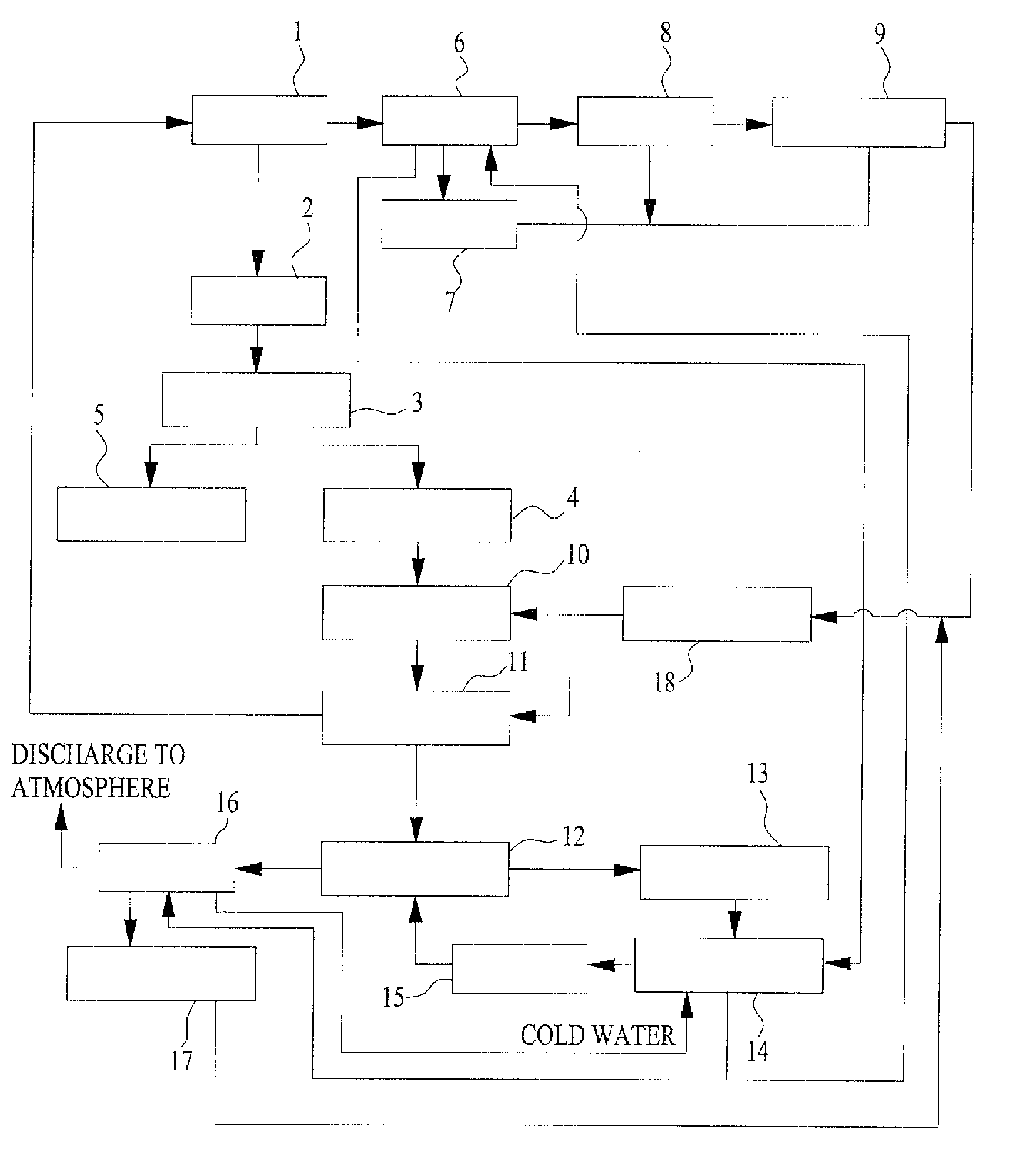

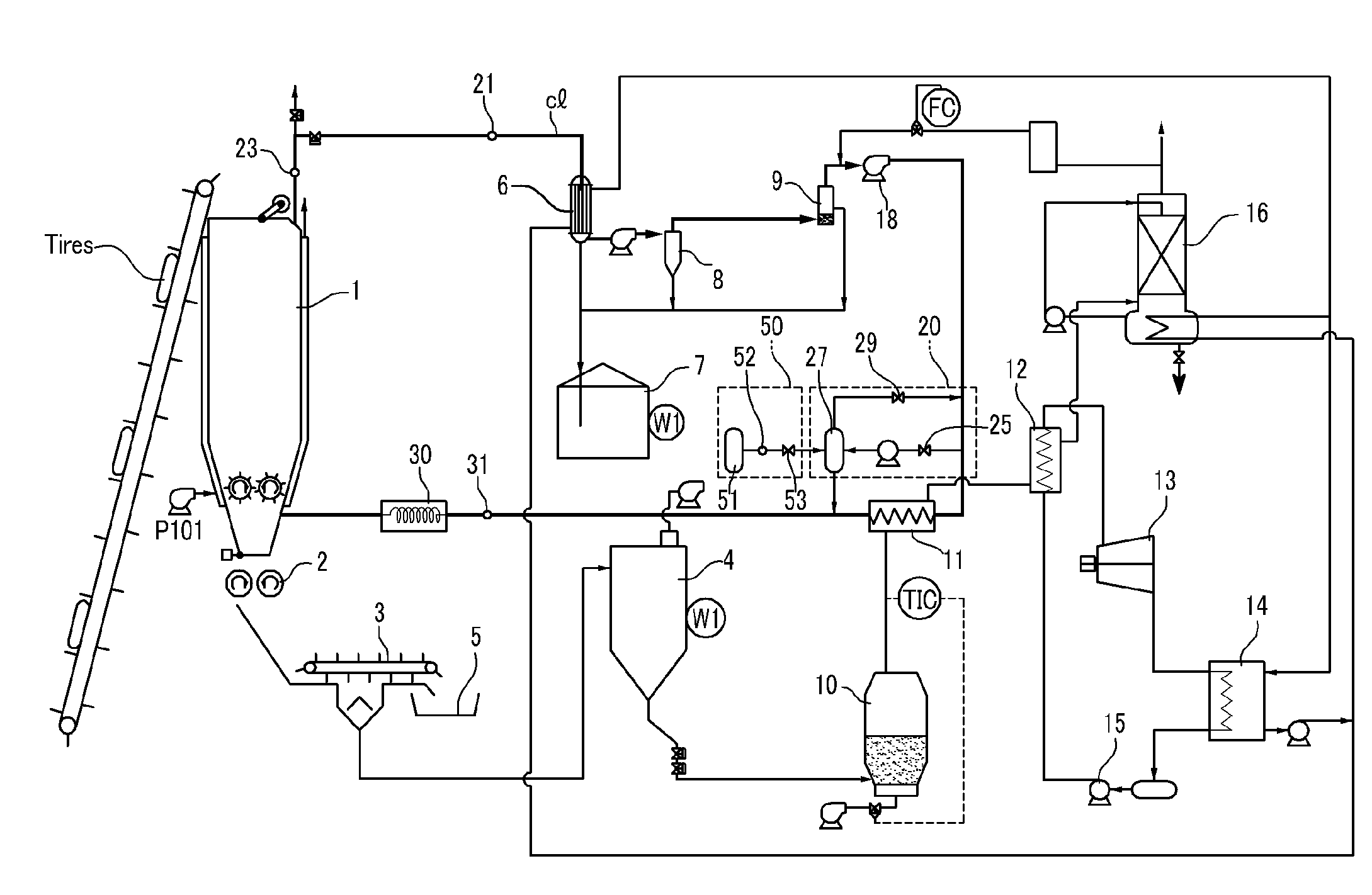

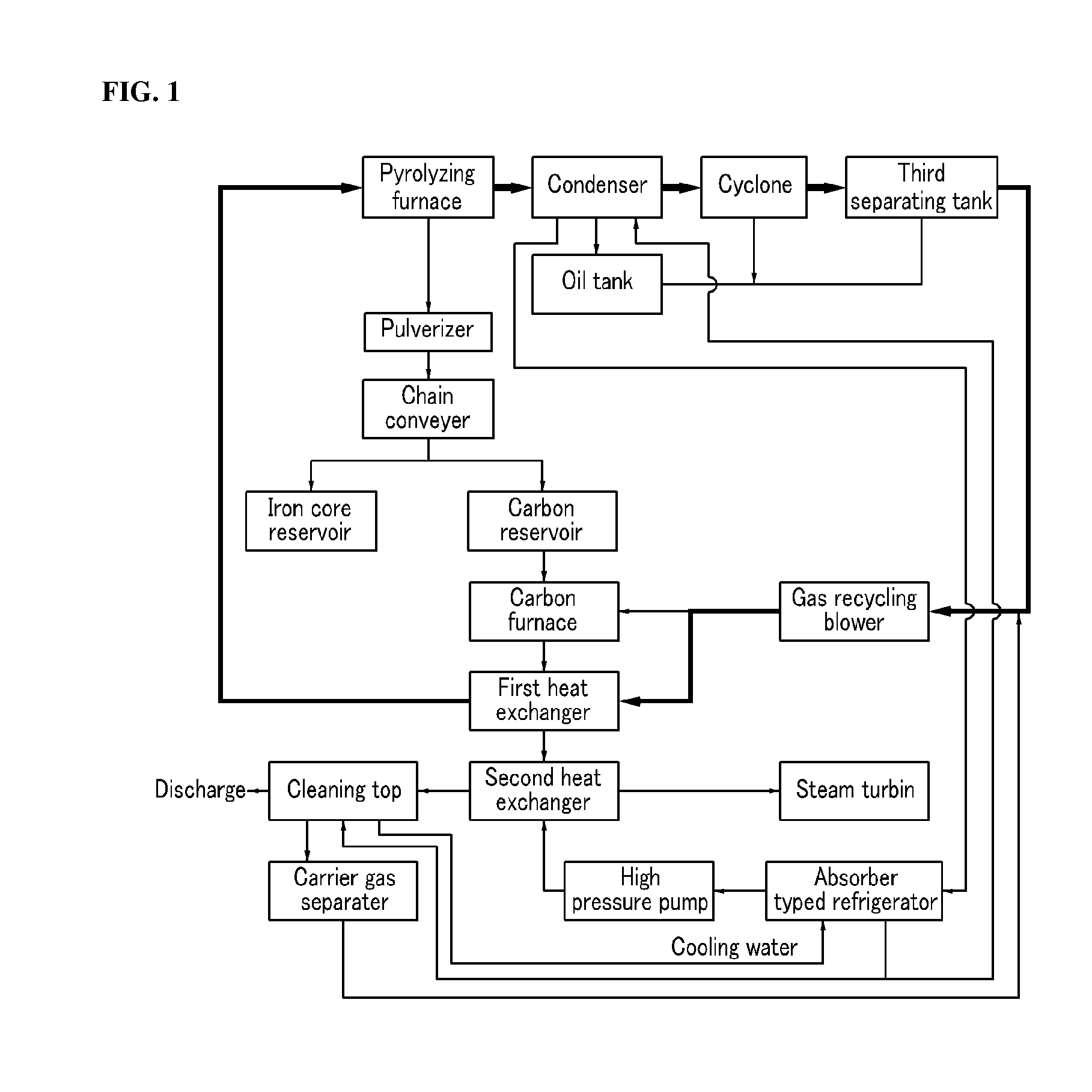

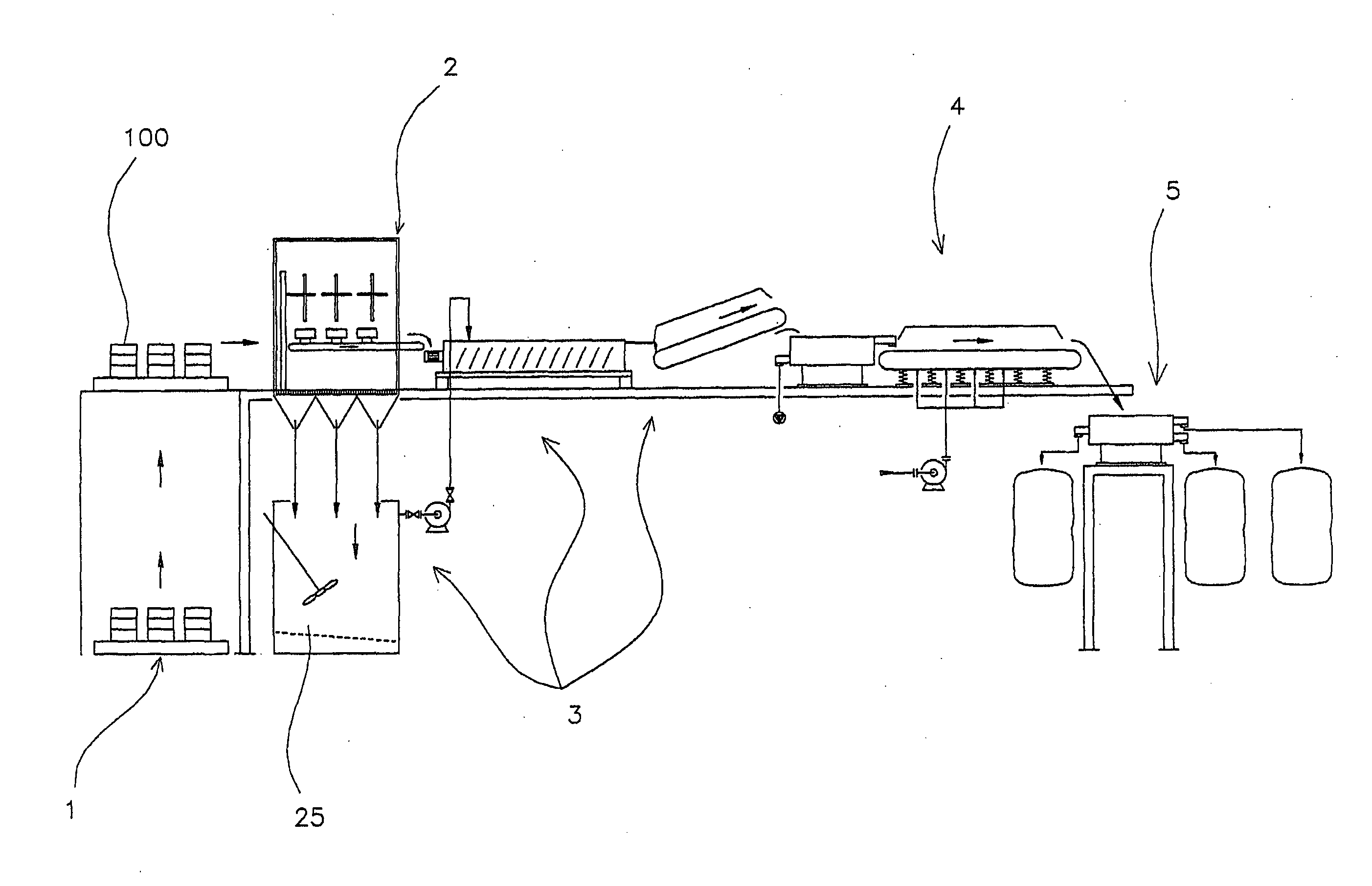

Waste-tire recycling system

InactiveUS20090200150A1Improve recycling efficiencyAvoid environmental pollutionCoke quenchingCombustible gas coke oven heatingAtmospheric airFuel oil

Disclosed is a system for recycling waste tires, which are industrial wastes, so as to protect our environment against pollution and promote recycling of industrial material. The waste-tire recycling system includes a pyrolyzing unit for pyrolyzing a waste tire by using a pyrolysis reactor, in which a CO or N gas circulates as a carrier gas, a decomposed residue processing unit for crushing a decomposed residue pyrolyzied by the pyrolysis reactor to separate the decomposed residue into carbon and an iron core, an oil collecting unit for cooling and condensing an exhaust gas discharged from the pyrolysis reactor to recover heavy oil from the gas, a carbon processing unit for supplying a heat source to the circulating carrier gas by using a hot exhaust gas generated when the carbon separated from the decomposed residue is burned up, and operating a steam turbine and an absorption refrigerator to generate electricity and cold water, an exhaust gas processing unit for clarifying the exhaust gas discharged from the carbon processing unit to discharge the clarified gas in an atmosphere, and recovering a part of the CO or N gas from the exhaust gas.

Owner:ADVANCED CONTROLS & ENG +1

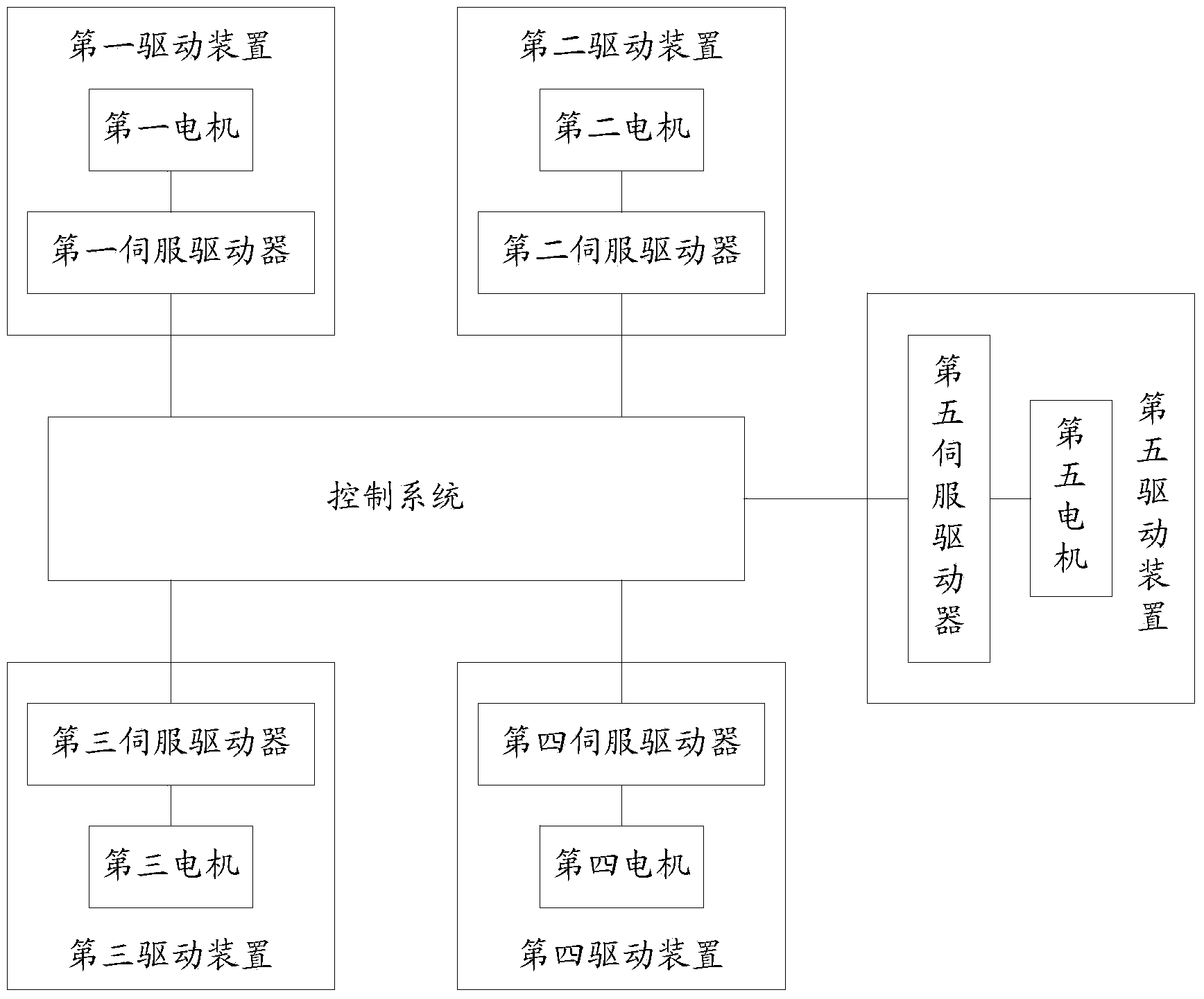

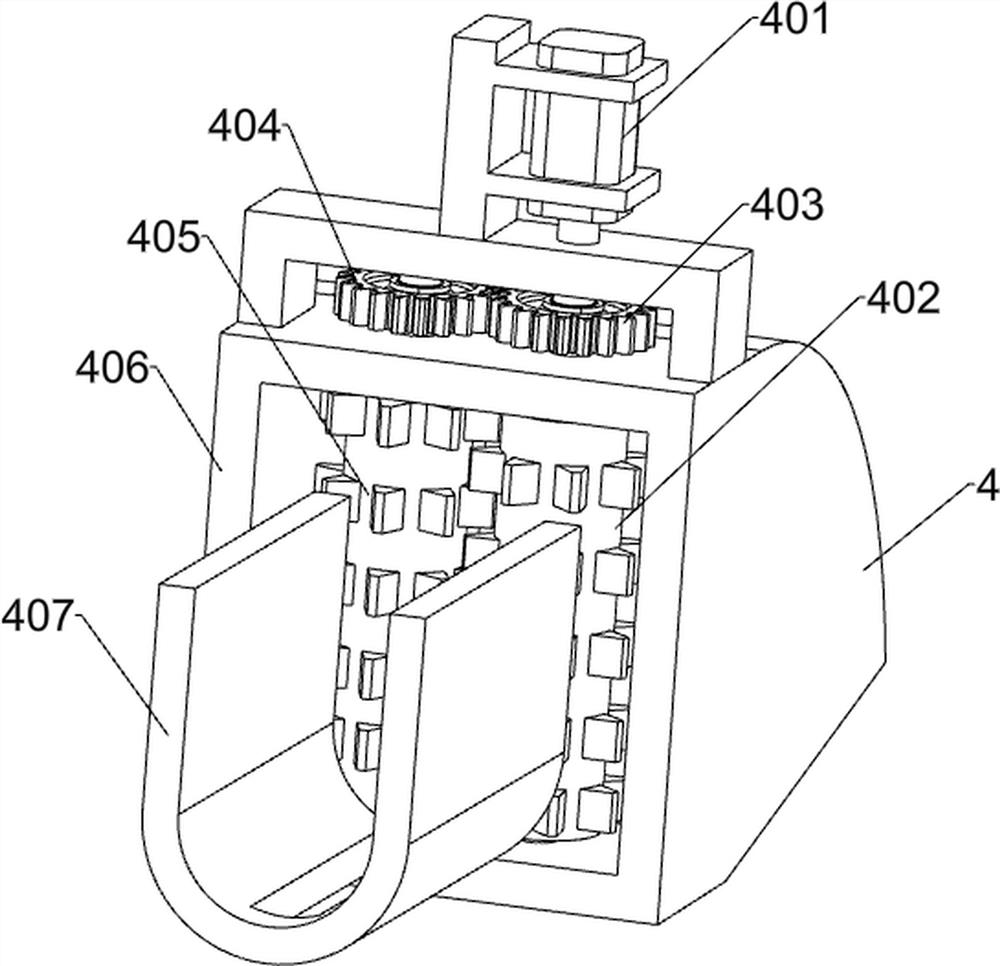

Device for recycling and recycling waste tires

InactiveUS20200139588A1Quickly and accurately pull outMaterial cost lotPlastic recyclingTyresElectric machineryIndustrial engineering

The invention discloses a device for recycling waste tires, which includes a machine body. The upper end of the machine body is provided with an inlet with an upward opening on the right side of the body. The left wall of the inlet is connected with a chute. The chute is provided with A steel wire removal device, a crushing cavity is connected to the lower wall of the inlet, and a crushing device is fixed in the crushing cavity. A twisting cavity is provided in the left wall of the crushing cavity and below the chute. A fourth motor is fixed in the wall, and an eccentric wheel is dynamically connected to the lower end of the fourth motor. The invention can quickly and accurately pull out the steel wire layer in the tire and twist the broken rubber stuck on the steel wire, so that the steel wire and the tire are cleaned. Recyclable materials such as rubber are separated. At the same time, the tires that have been torn out of the steel wire are broken into small pieces of rubber, which is convenient for the next processing, which not only saves the company a lot of material costs, but also saves a lot of time costs and labor.

Owner:WANG HUIMIAO

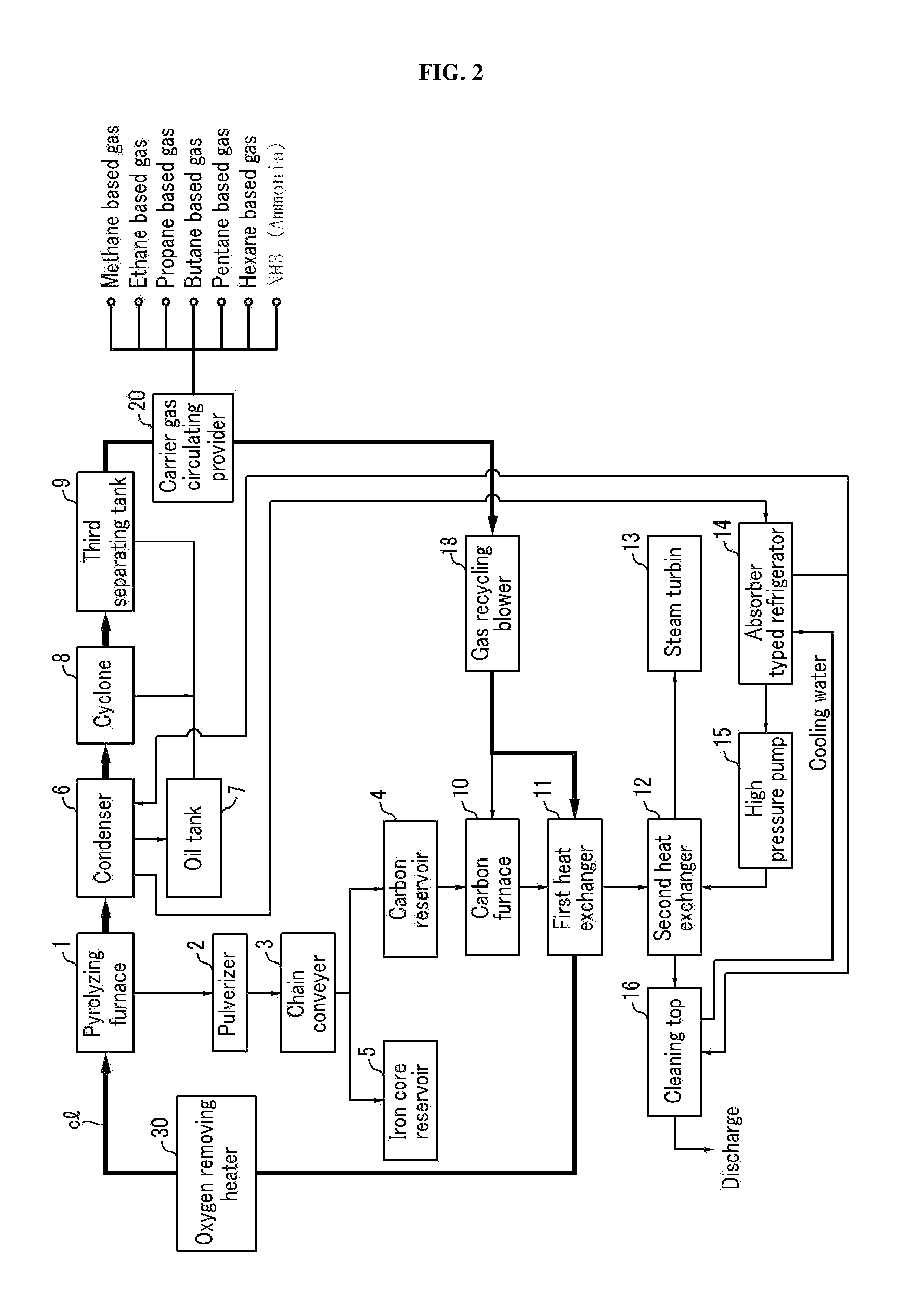

Waste tire recycling system

InactiveUS20110303525A1Improve convenienceThe system is stable and reliableProductsCombustible gas coke oven heatingProcess engineeringDirect heating

Disclosed is a waste tire recycling system. More particularly, the present invention relates to a waste tire recycling system having a pyrolysis furnace in which waste tires injected are recycled with a carrier gas and decomposed by a direct heating method, an oil-collecting means for cooling and condensing hot steam generated from the pyrolysis furnace and collecting oil, and a carrier gas recycling line through which a carrier gas is recycled back into the pyrolysis furnace via the pyrolysis furnace and the oil collecting means, the waste tire recycling system comprising a carrier gas feeder connected to one end of the carrier gas recycling line to selectively feed a carrier gas by controlling a valve, the carrier gas feeder having a filling element filled with a carrier gas containing at least one of methane, ethane, propane, butane, pentane, hexane and ammonia group components in a mixed form.

Owner:JEON YEONG MIN

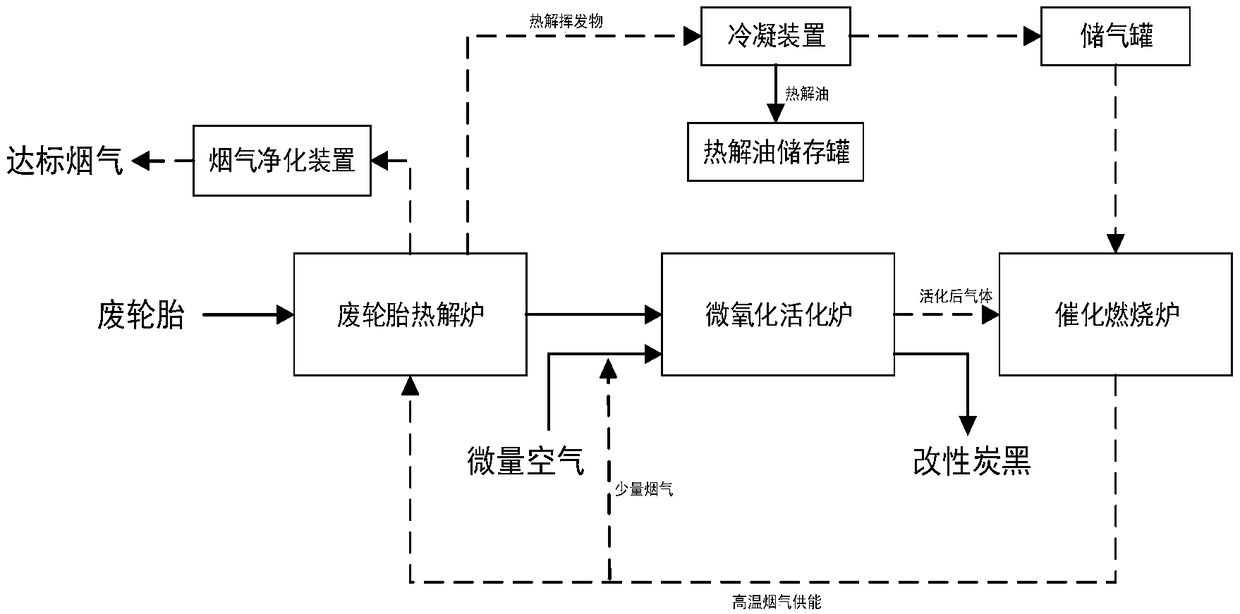

Scrap tire pyrolytic carbon black micro-oxidation and activation method

ActiveCN109096798AImprove surface propertiesHigh porosityPigmenting treatmentActivation methodPorosity

The invention belongs to the technical field of waste resource utilization. A scrap tire pyrolytic carbon black micro-oxidation and activation method comprises a scrap tire pyrolyzing furnace, a micro-oxidation and activation furnace, an air storage tank, a catalytic combustion furnace, a condensing plant, a pyrolytic oil storage tank and a flue gas purifying device. Compared with traditional pyrolytic carbon black, pyrolytic carbon black prepared by the scrap tire pyrolytic carbon black micro-oxidation and activation method provided by the invention has the advantages that most volatile components, carbon sediments and coking substances piled up on the surface of the carbon black are removed, the surface property of the pyrolytic carbon black is improved, the porosity of the pyrolytic carbon black is greatly increased, the surface activity of the pyrolytic carbon black is greatly enhanced, excellent raw materials are provided for follow-up applications of the pyrolytic carbon black inthe fields such as rubber, coatings, active carbons and asphalt modifiers, the follow-up commercial cost is reduced, the range of the pyrolytic carbon black application field is enlarged, and the advancing of a scrap tire recycling industry chain is promoted; and meanwhile, a gas product generated in each unit can enter the catalytic combustion furnace to be burned so as to provide energy for thescrap tire pyrolyzing furnace and the micro-oxidation and activation furnace; and therefore, the energy consumption is reduced, and the cost is saved.

Owner:DALIAN UNIV OF TECH

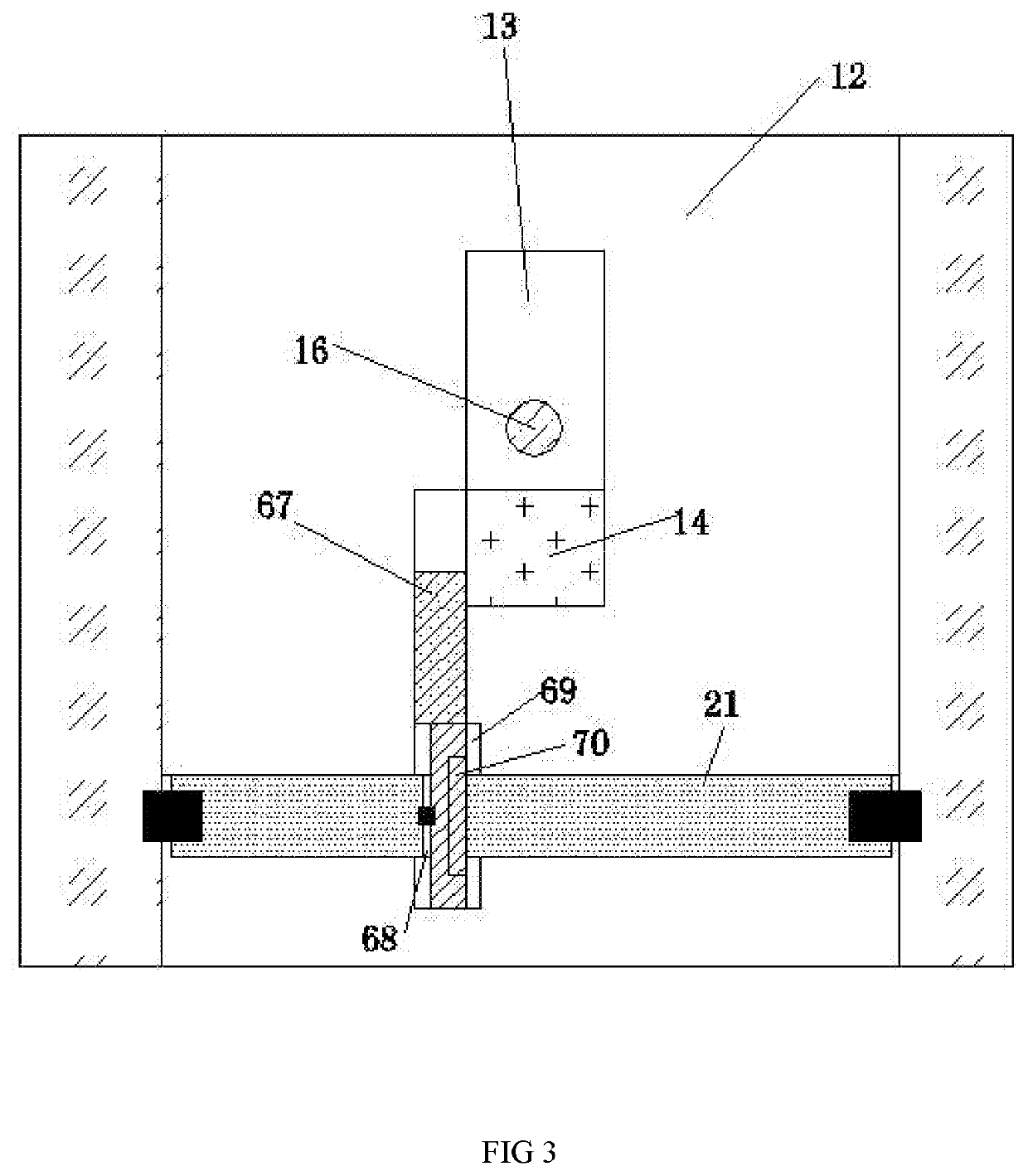

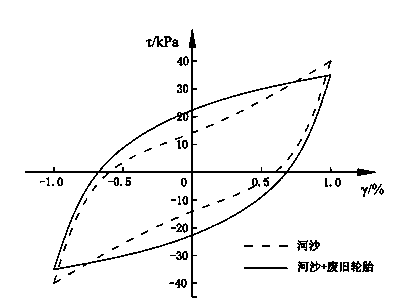

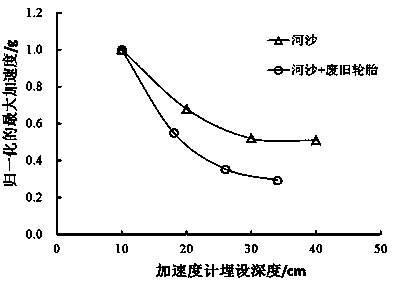

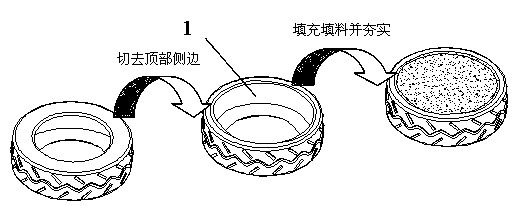

Junked tire vibration damping and isolating building foundation and construction method thereof

InactiveCN103967056AGood effect of vibration reduction and isolationSimplify the construction processProtective foundationUltimate tensile strengthSeismic wave

The invention discloses a junked tire vibration damping and isolating building foundation and a construction method thereof. The junked tire vibration damping and isolating building foundation is composed of junked tires, a junked tire composite pile foundation, a junked tire composite strip foundation, a junked tire composite raft foundation and a floor. After recycled and processed simply, the junked tires are arranged in a crisscross mode in sequence according to the sequence of the composite pile foundation below building pillars, the composite strip foundation below walls and the composite raft foundation below the floor, and the inner portions of the tires of all layers and the clearances are filled with earth and the earth is tamped. When shaking occurs, earthquake waves are reflected in the inner portions of the tires and among the tires, and energy is scattered and consumed. The elastic deformation of the tires and the friction slippage function among the internal stuffing consume most energy of the earthquake waves. Additional confining pressure generated by lateral restraint of tires under vertical pressure enables the intensity of the foundation to be improved obviously. According to the construction method, the junked tires are utilized, waste resources are recycled, black pollution is relieved, the vibration damping and isolating effects are good, the construction procedures are simple, and the application range is wide, and the construction method has remarkable economic, social and environmental protection effects.

Owner:HOHAI UNIV

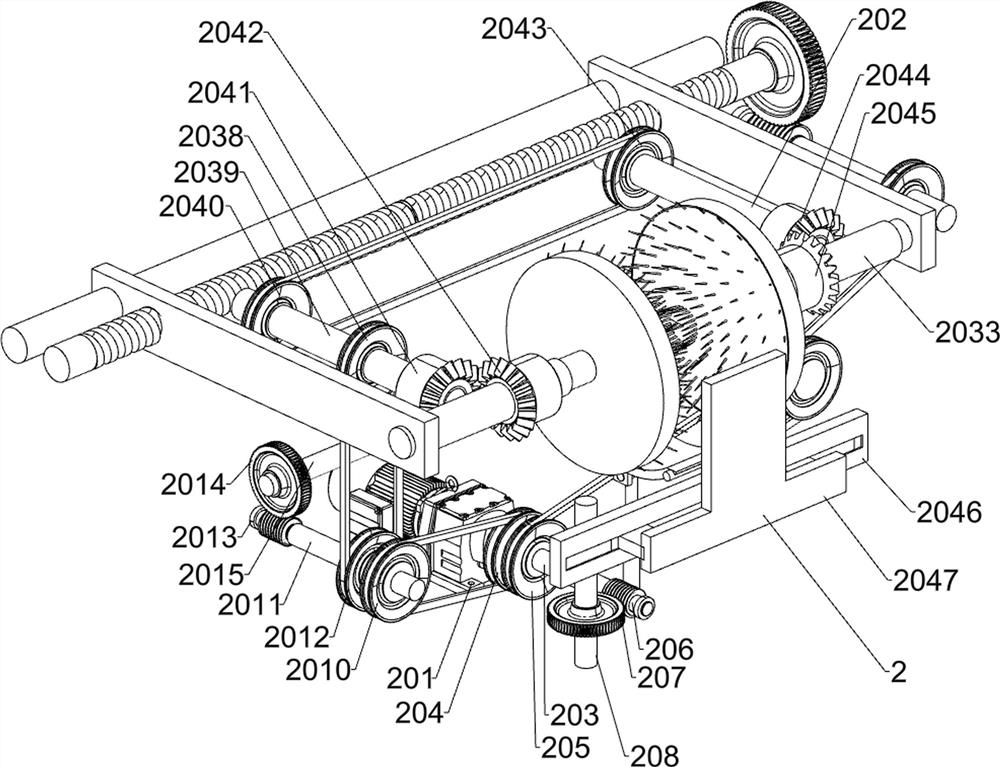

Rubber tyre recycling device

ActiveCN111070487AQuality improvementEasy to cleanPlastic recyclingMetal working apparatusProcess engineeringMechanical engineering

The invention relates to the field of rubber tyre recycling, in particular to a rubber tyre recycling device, and aims to solve the technical problem of providing the rubber tyre recycling device. Therubber tyre recycling device comprises a sand stone removing mechanism, a control screen, a steel ring separating mechanism, a steel wire gauze separating mechanism, a collecting trolley, a clampingbuckle, a storing cabinet and a waste tyre, wherein the control screen is arranged on the right side of the top of the sand stone removing mechanism; and the steel ring separating mechanism is arranged on the right side of the sand stone removing mechanism. The rubber tyre recycling device can simultaneously recycle a plurality of waste tyres, recycles complete steel rings of the waste tyres, efficiently cleans sand stones in crown cracks, also recycles steel wire gauze, greatly improves the quality after the waste tyres are smashed in the later period, also avoids the phenomenon that the generated sand stones damage the tool bit of a smashing knife, and is high in recycling speed, strong in stability and more convenient and fast to operate.

Owner:CHAOYANG HUAXING WANDA TIRE

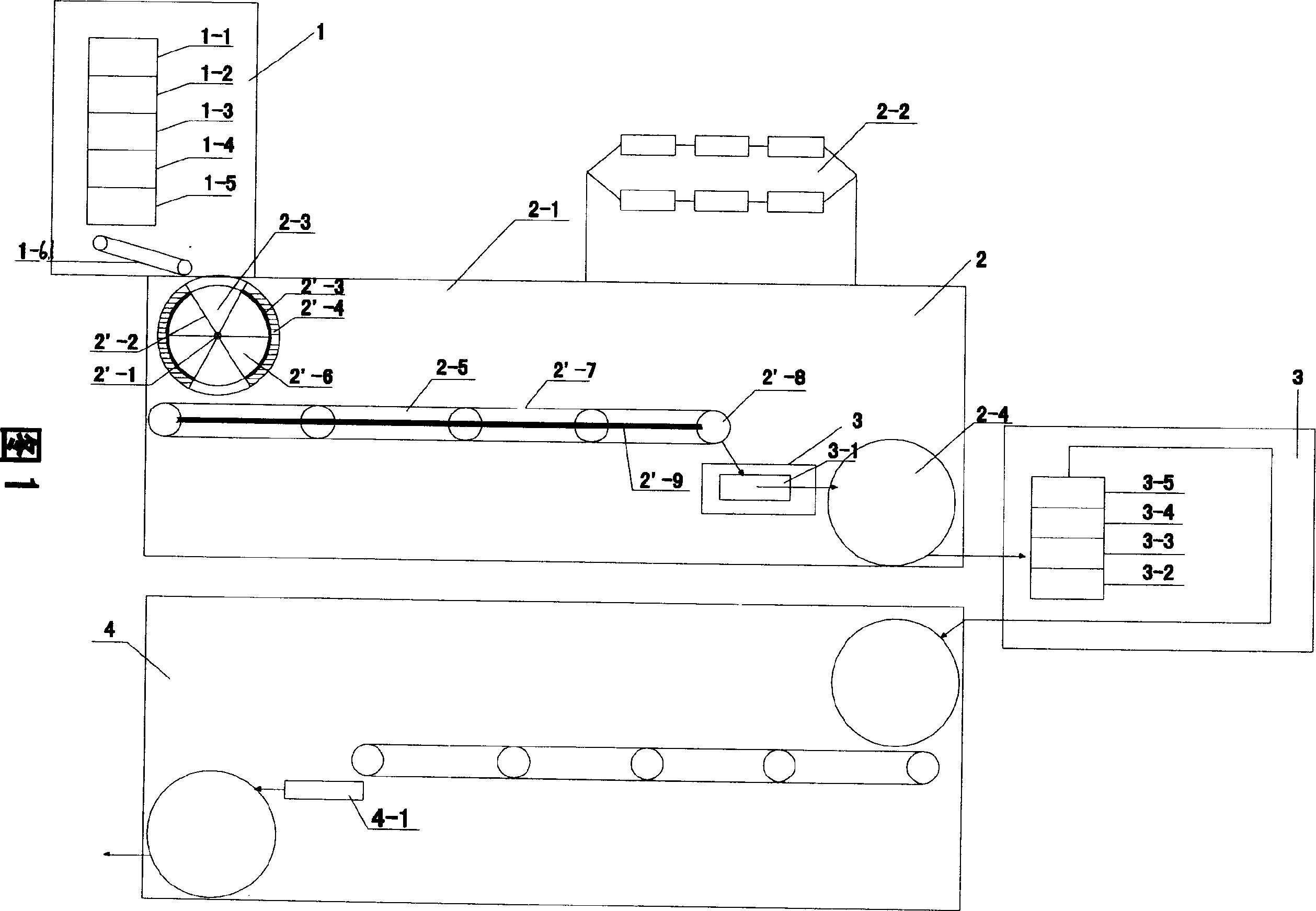

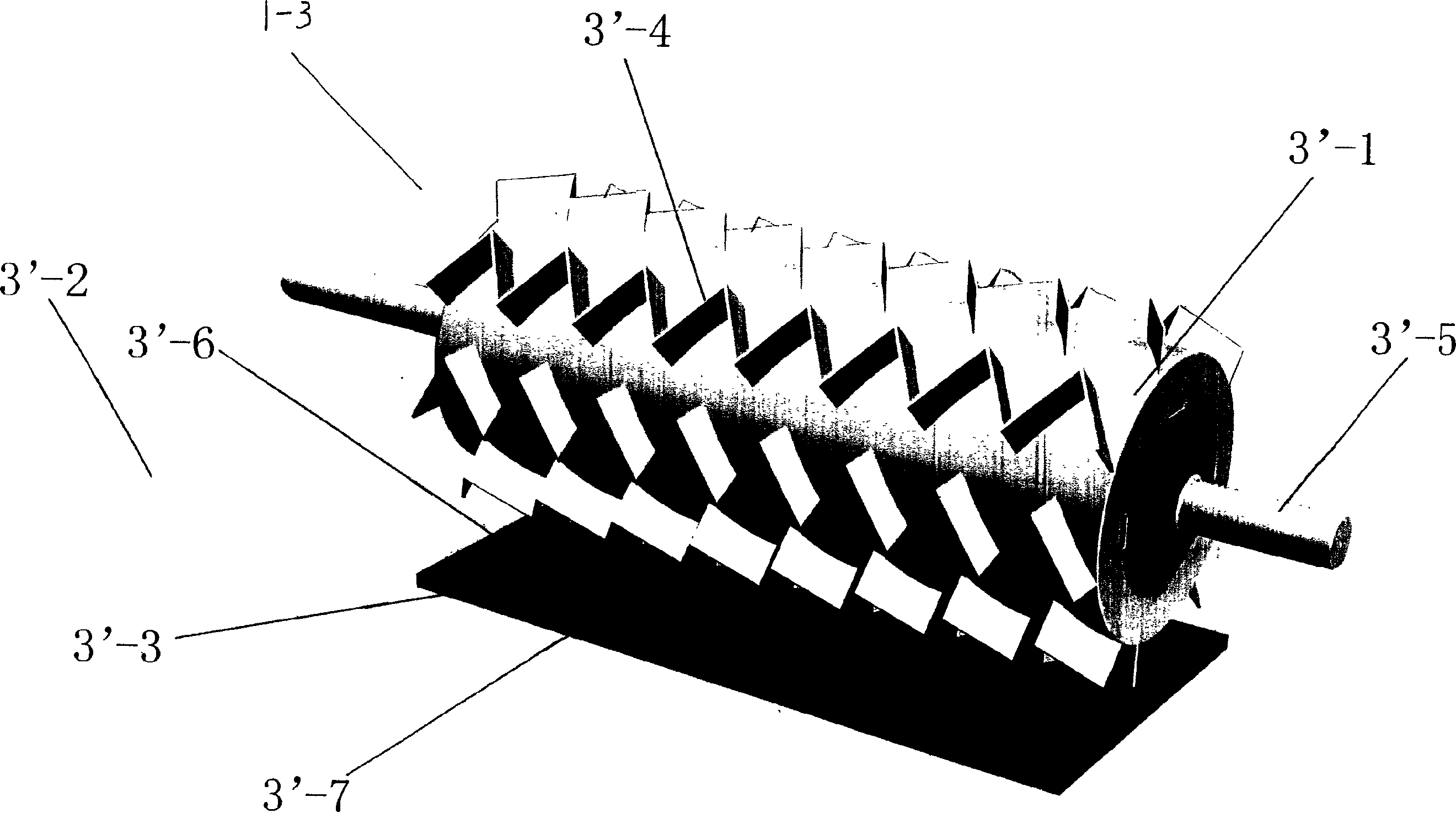

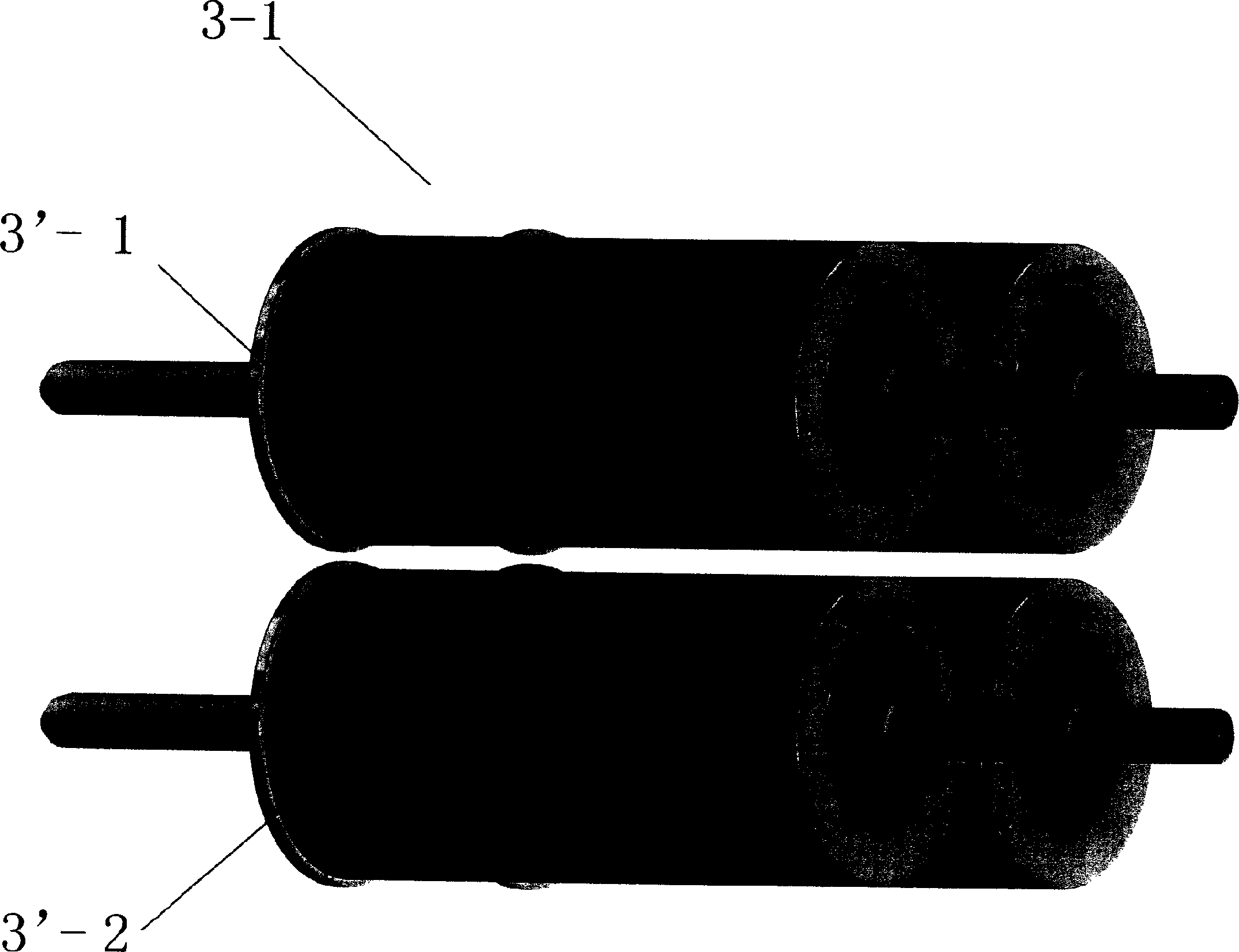

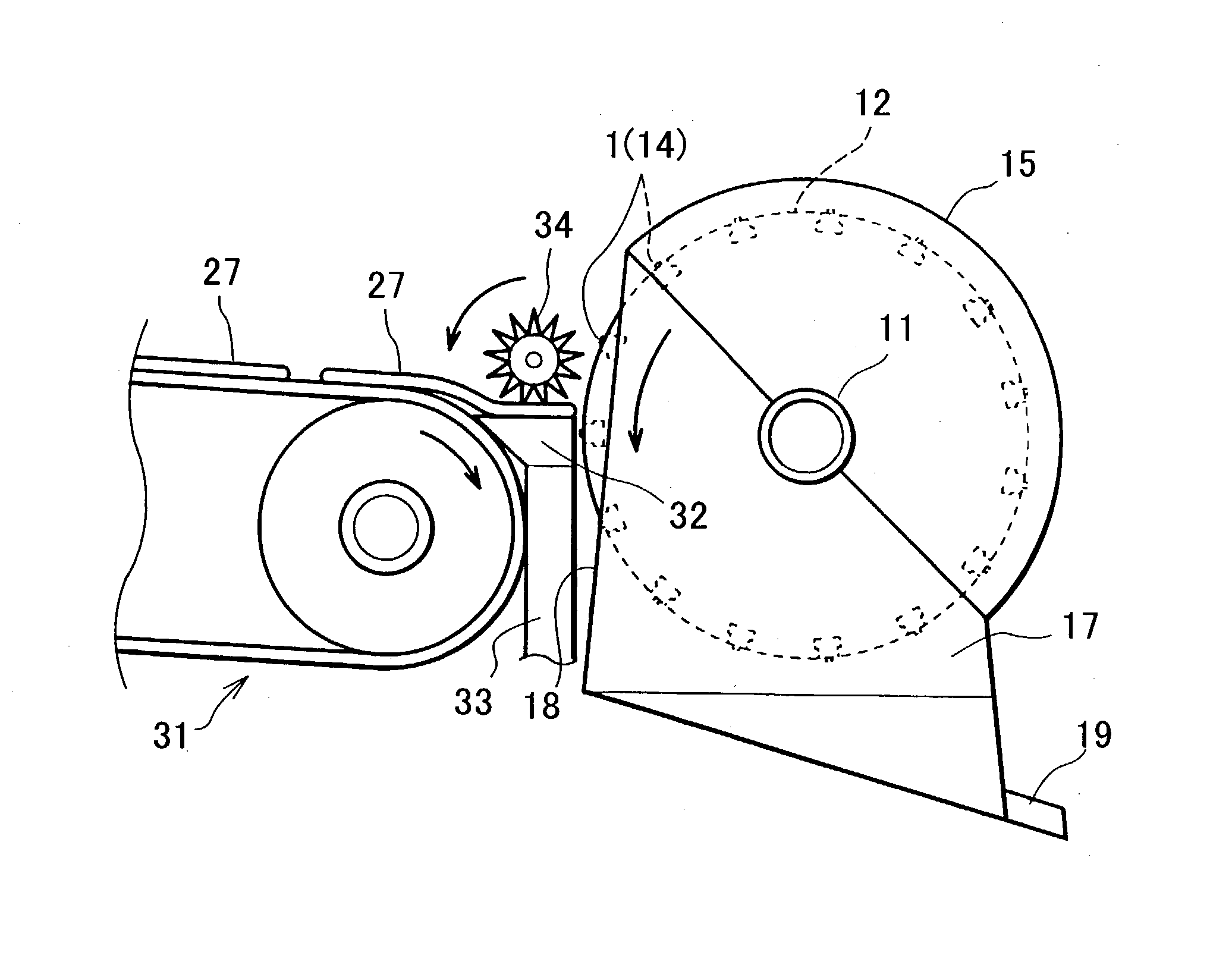

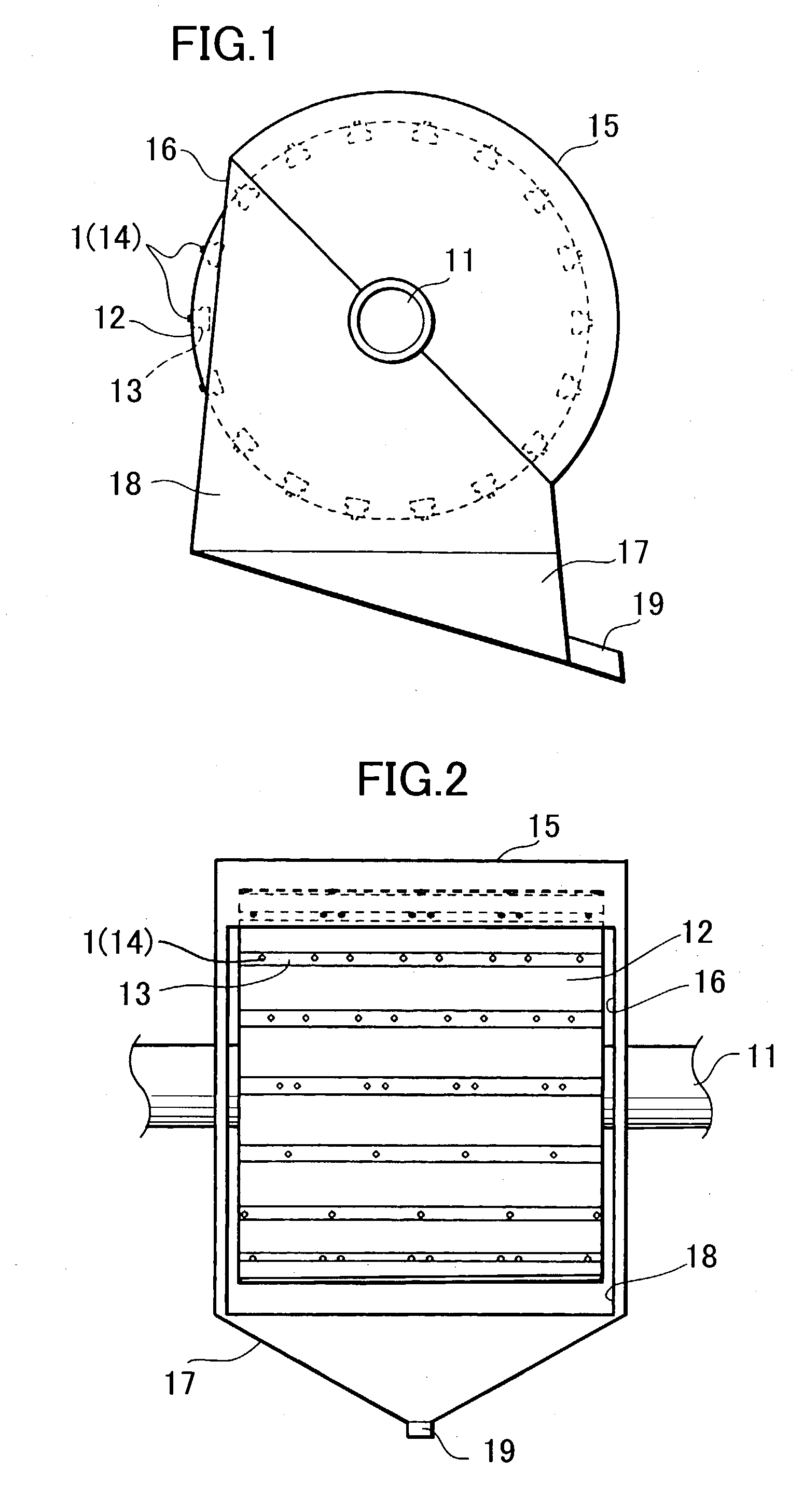

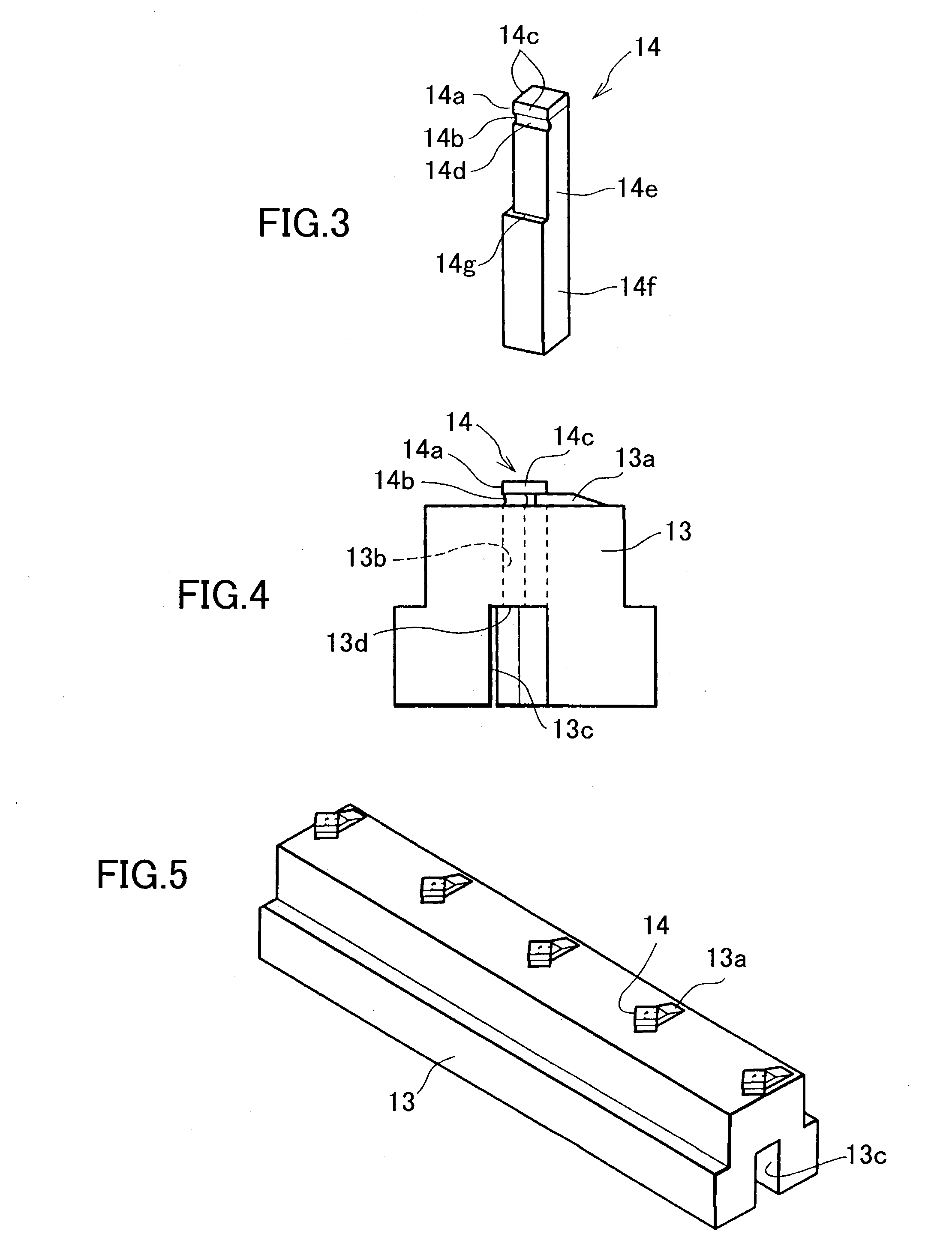

Tire recycling system and apparatus used therefor

A method of and an apparatus for treating worn tires comprising cutting the circumferential surface of the tire to a predetermined depth by a rotary cylinder having cutting blades each of a rhombic flat plate shape and subsequent separation of metal reinforcement components embedding the tire from the rubber component by RF induction heating that decomposes and carbonizes the rubber portion adjacent with the heated metal components, cutting by the rhombic blades enabling smooth and effective removal of surface tire layer, facilitating the succeeding RF heating and yielding useful cut rubber suitable to obtain variable recycle materials.

Owner:TAKASAKI TAKAO

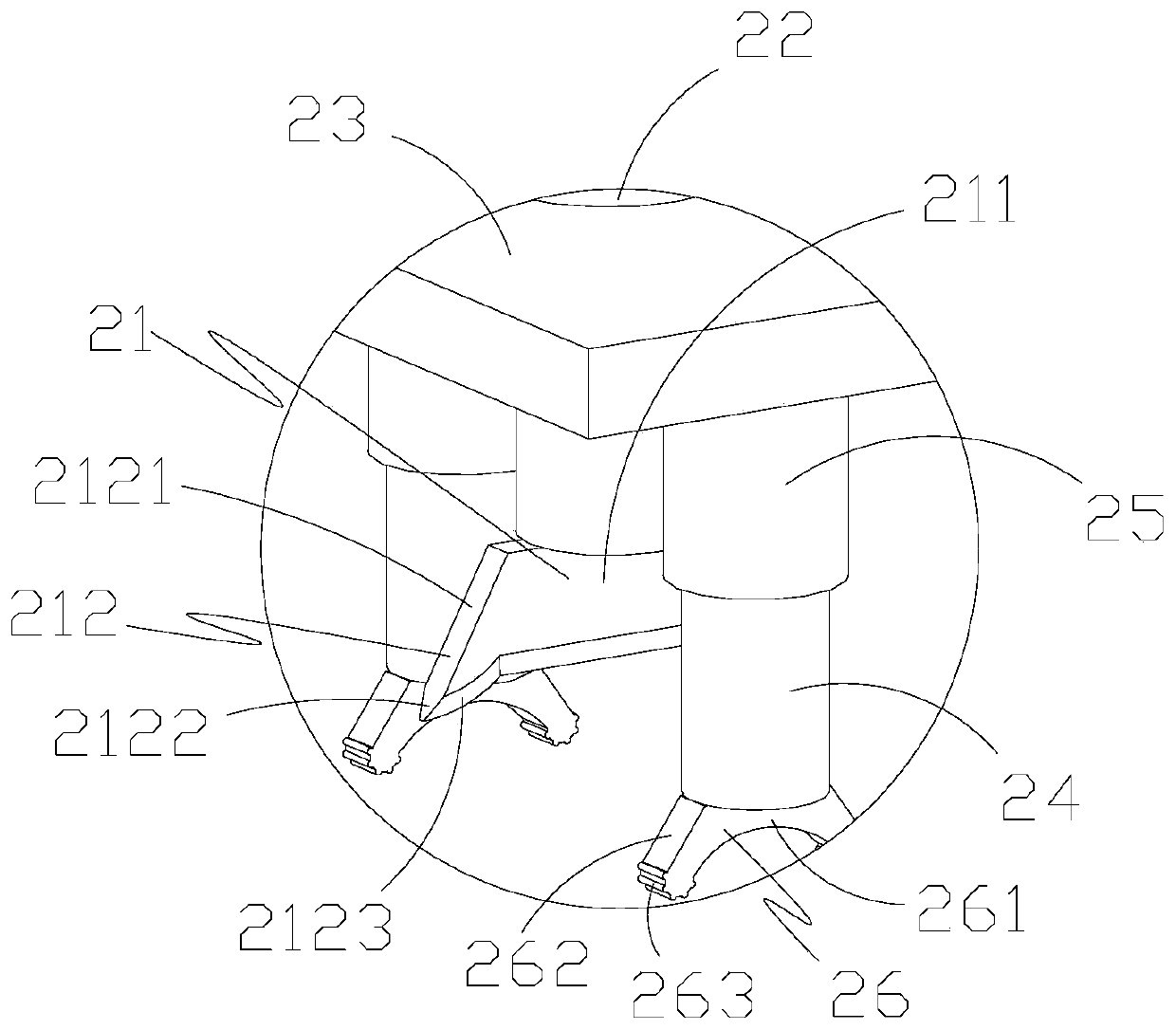

Cleaning equipment used before waste automobile tire recovery processing

InactiveCN111483078AAvoid wastingEasy to cleanPlastic recyclingCleaning using toolsMechanical engineeringWater spray

The invention discloses cleaning equipment used before waste automobile tire recovery processing. The cleaning equipment comprises a cleaning box, a feeding device arranged above the cleaning box, a clamping device used for fixing automobile tires and cleaning the inner walls of the automobile tires, a scrubbing device used for cleaning the outer walls of the automobile tires and a driving deviceused for driving the automobile tires to rotate in the cleaning process of the automobile tires. The clamping device is provided with a first shaft and a second shaft, the first shaft and the second shaft are correspondingly provided with a first chuck and a second chuck, and a driving assembly used for driving the first shaft and the second shaft to rotate relatively and move relatively is further included, and a water spraying disc is arranged at the lower end of the second chuck. The cleaning equipment can comprehensively clean the tires, and the tires can be cleaned more thoroughly.

Owner:王守 +1

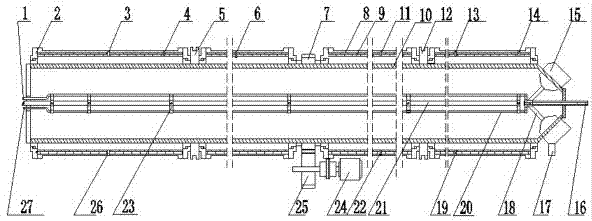

Thermal cracking treatment device for waste tires

InactiveCN104711005ALiquid hydrocarbon mixture productionHydrocarbon oils treatmentEngineeringCracking reaction

The invention relates to a waste tire recycling and reusing device, in particular to a thermal cracking treatment device for waste tires. A support shaft, a hollow shaft and a rotation kiln cylinder of a cracking furnace are coaxial, wherein an inlet is formed in the front end of the rotation kiln cylinder; an outlet is formed in the tail end of the rotation kiln cylinder; a thermal cracking solid collector is communicated with the outlet in the tail end of the rotation kiln cylinder; a discharging opening is formed in the thermal cracking solid collector; a through hole is formed in the hollow shaft and is communicated with an inner cavity of the rotation kiln cylinder; one end of the hollow shaft extends to the exterior of the rotation kiln cylinder; an inner heating system comprises an inner heating tube; an outer heating system comprises an outer cylinder; a high-temperature smoke inlet and a waste heat smoke outlet are formed in each heating area of the outer cylinder. Waste tires are cut into blocks, are subsequently fed into the rotation kiln cylinder of the cracking furnace and are moved to the outlet; the inner heating system and the outer heating system are used for simultaneously heating the rotation kiln cylinder; the high-temperature smoke generated by the combustible waste gases through the thermal cracking reaction enter the outer heating system and the inner heating system respectively.

Owner:WUXI RL PRECISION MACHINERY +1

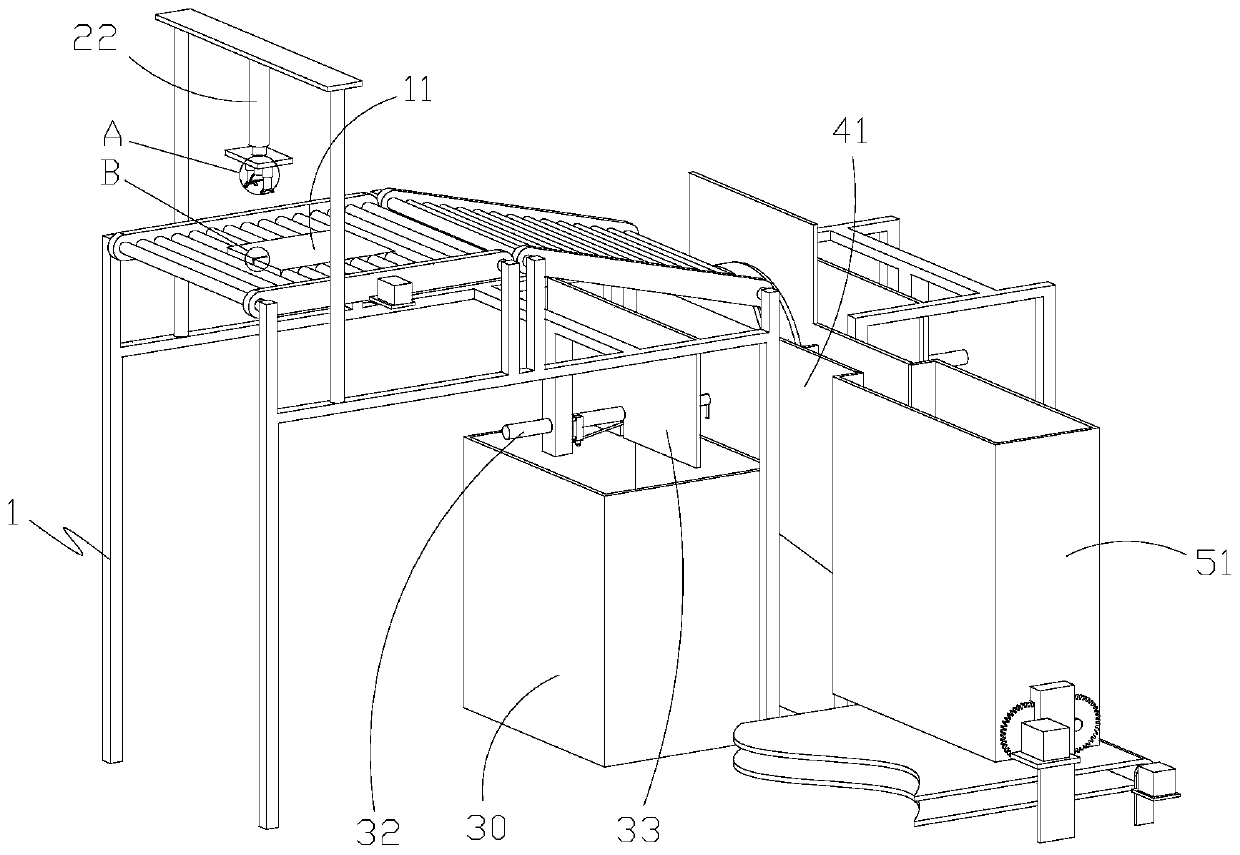

Waste tire recovery processing equipment

ActiveCN109834870APrevent movementGuaranteed cut offPlastic recyclingGrain treatmentsEngineeringWaste tires

The invention discloses waste tire recovery processing equipment. The waste tire recovery processing equipment includes a rack, a cutting device arranged on the rack, a wire drawing device matched with the cutting device and a crushing device matched with the wire drawing device, and the cutting device includes a cutting part which can move back and forth, a first driving part for driving the cutting part to move back and forth, a synchronous plate for connecting the cutting part and the first driving part and a compression structure for fixing tires; and a cutting table matched with the cutting part is arranged on the rack. According to the waste tire recovery processing equipment, by arranging the cutting device, steel wires are easier to pull out, the degree of deformation is low, winding is difficult, removing is easier even when the steel wires are winded, production is more time-saving and labor-saving, and the efficiency of the wiredrawing work is improved.

Owner:湖南启恒环保科技有限公司

Waste tire recovery device capable of separating sidewall

InactiveCN112372900AAchieve recyclingImprove efficiencySolid waste disposalPlastic recyclingProcess engineeringWaste tires

The invention relates to the field of rubber, in particular to a waste tire recovery device capable of separating out a sidewall. The technical problem of the invention is to provide a waste tire recovery device capable of separating out a sidewall. The waste tire recovery device capable of separating out the sidewall comprises an underframe, a cleaning unit, a sidewall separating unit, a crushingunit, a first collecting box, a second collecting box and a control screen, wherein the underframe is connected with the cleaning unit; the underframe is connected with the sidewall separation unit;the underframe is connected with the crushing unit; the underframe is connected with the control screen; the underframe is connected with the cleaning unit; and the cleaning unit is connected with thesidewall separation unit. According to the device, waste tires are recycled, sidewalls and treads are completely separated, the sidewalls are cleaned, the treads are partially crushed and collected,and manual treatment is replaced, so that the efficiency is improved.

Owner:谢杜川

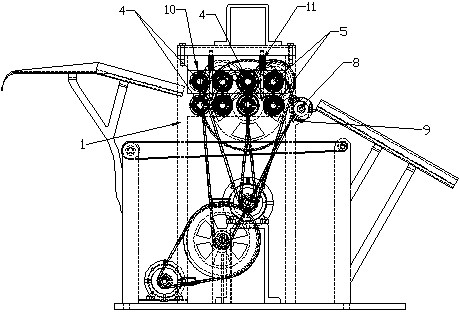

Junked tire recovery device

InactiveCN102601099AImprove working environmentImprove processing efficiencySolid waste disposalPlastic recyclingMilling cutterEngineering

The invention relates to a junked tire recovery device which is used for separately recovering rubber and steel wires in a junked tire. The junked tire recovery device comprises a stand, a feeding plate is arranged at the front part of the stand, a discharging plate is arranged at the back part of the stand, and at least two groups of cutters are arranged in the middle of the stand; each group of cutters comprises a pair of press roller shafts arranged up and down and a pair of milling cutter shafts arranged up and down; the pair of press roller shafts are provided with multiple pairs of press rollers at intervals, the pair of milling cutter shafts are provided with multiple pairs of cylindrical milling cutters at intervals, and the adjacent milling cutter and press roller are mutually staggered in axial positions; the milling cutters of each group of cutters commonly cover the whole width of the junked tire; and the press roller shafts and the milling cutter shafts are driven to rotate by a power device. The junked tire recovery device disclosed by the invention can smoothly separate the steel wires and the rubber in the junked tire and is high in recovery efficiency and stable and reliable in operation.

Owner:JIANGSU UNIV OF SCI & TECH

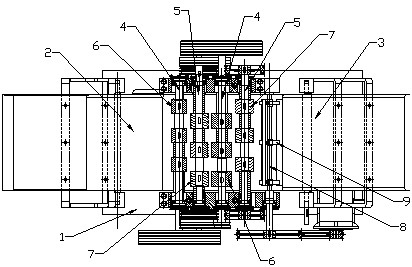

Scrap tire recycling plant

InactiveUS20110163190A1High purityGood yieldGas current separationPlastic recyclingEngineeringWaste tires

The present invention relates to a device, a plant and a method for disgregating scrap tires, which provide recycled material (rubber crumbs, metal, textile product) having a very high degree of purity. The device, plant and method of the present invention further provide a high yield of material per time unit. In practice, the present invention concerns disgregation of scrap tire shoulders.

Owner:GREENTECH INNOVATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com