Waste tire recovery device capable of separating sidewall

A waste tire and recycling device technology, applied in the rubber field, can solve the problems of cumbersome process, time-consuming and labor-intensive, low efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

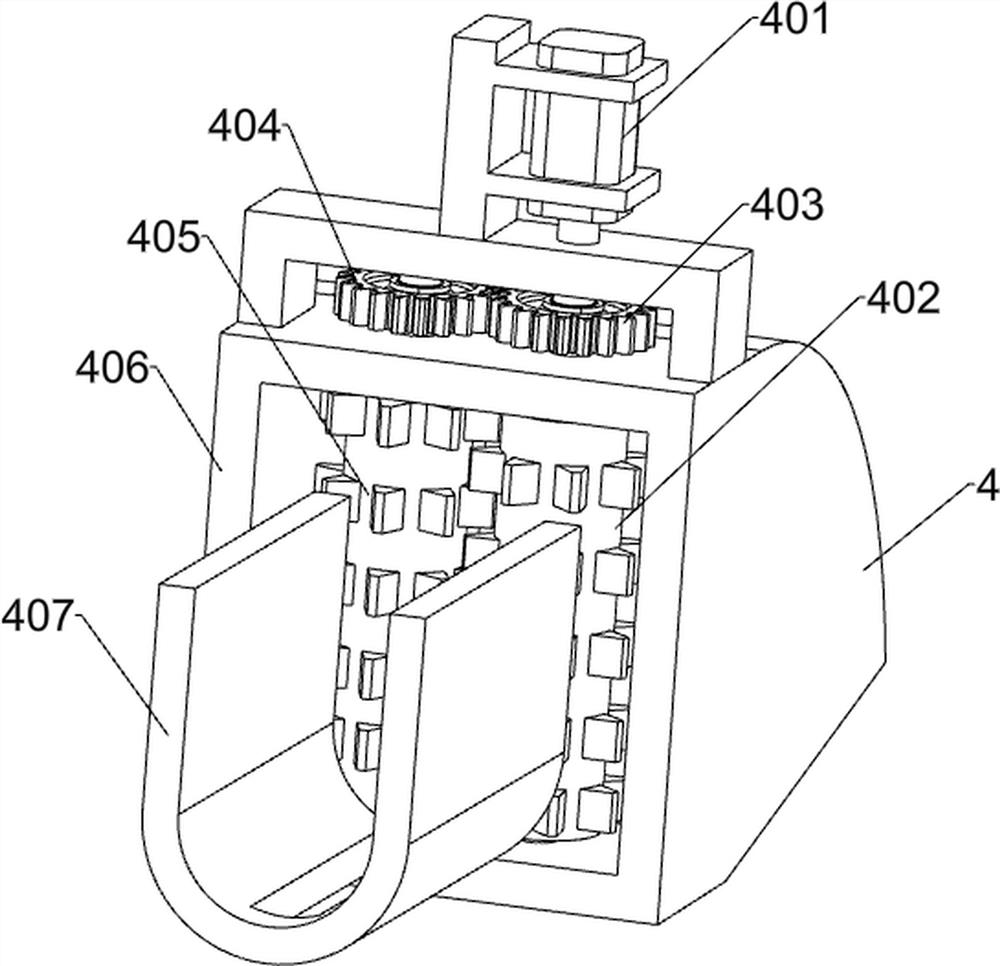

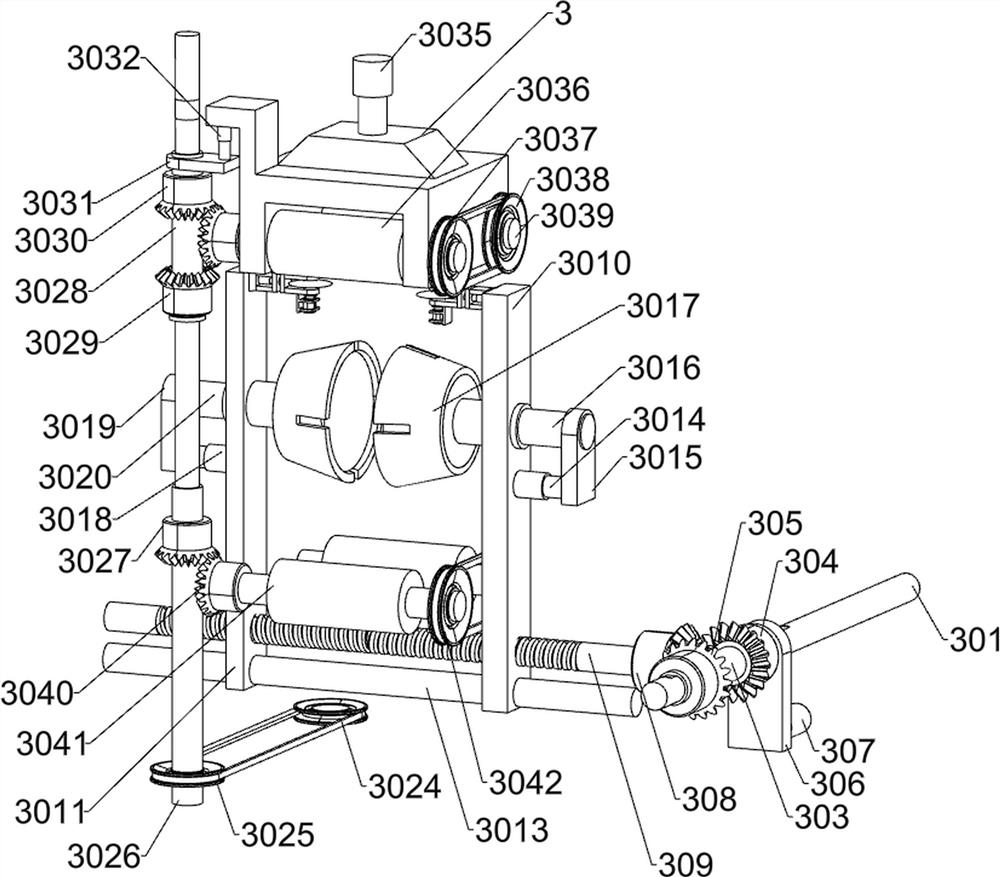

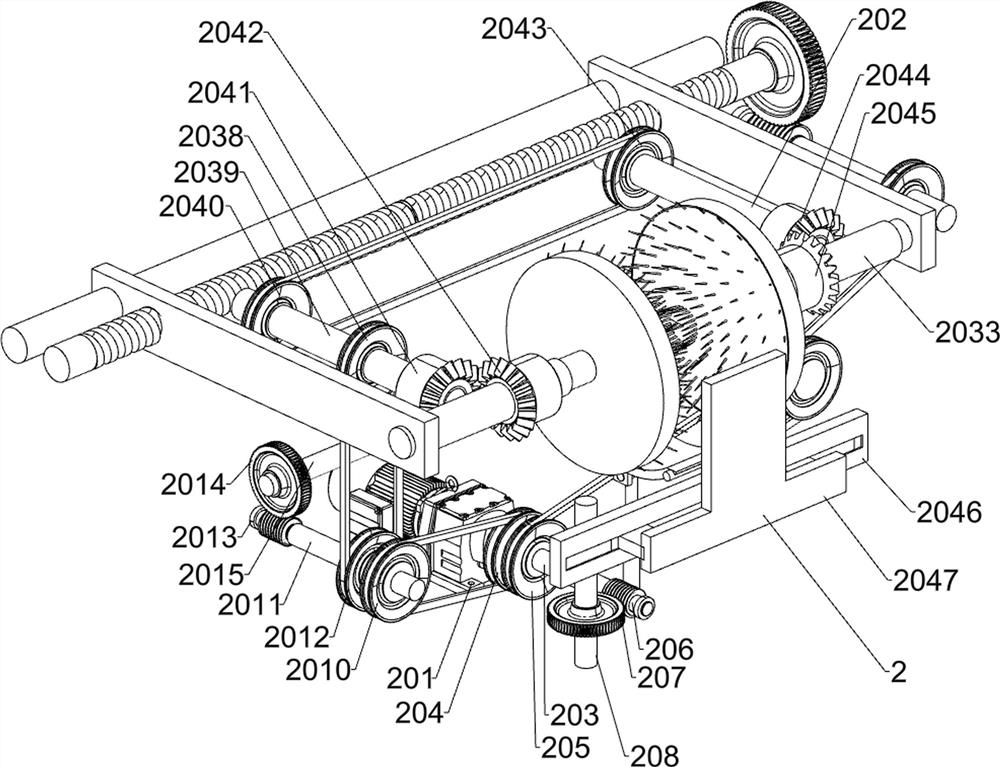

[0028] A waste tire recovery device that separates the tire wall, such as Figure 1-8 As shown, it includes an underframe 1, a cleaning unit 2, a tire wall separation unit 3, a crushing unit 4, a first collecting box 5, a second collecting box 6 and a control panel 7; the underframe 1 is connected with the cleaning unit 2; the bottom The frame 1 is connected with the tire wall separating unit 3; the bottom frame 1 is connected with the crushing unit 4; the bottom frame 1 is connected with the control panel 7; the bottom frame 1 is connected with; the cleaning unit 2 is connected with the tire wall separating unit 3; A first collection box 5 is arranged below the crushing unit 4 ; a second collection box 6 is arranged below the crushing unit 4 .

[0029] When in use, place the waste tire recycling device separated from the tire wall at the desired location, then connect the external power supply, and start the device through the control panel 7; first use the cleaning unit 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com