Patents

Literature

2141 results about "Process design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemical engineering, process design is the choice and sequencing of units for desired physical and/or chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components.

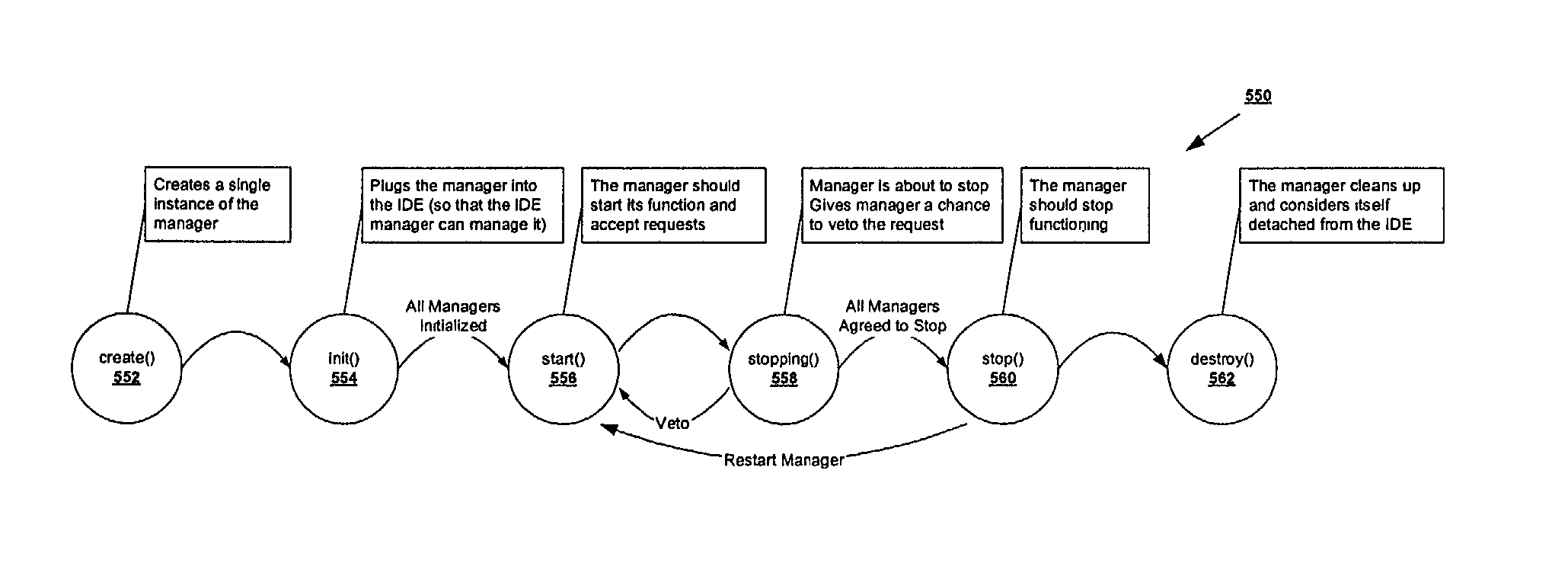

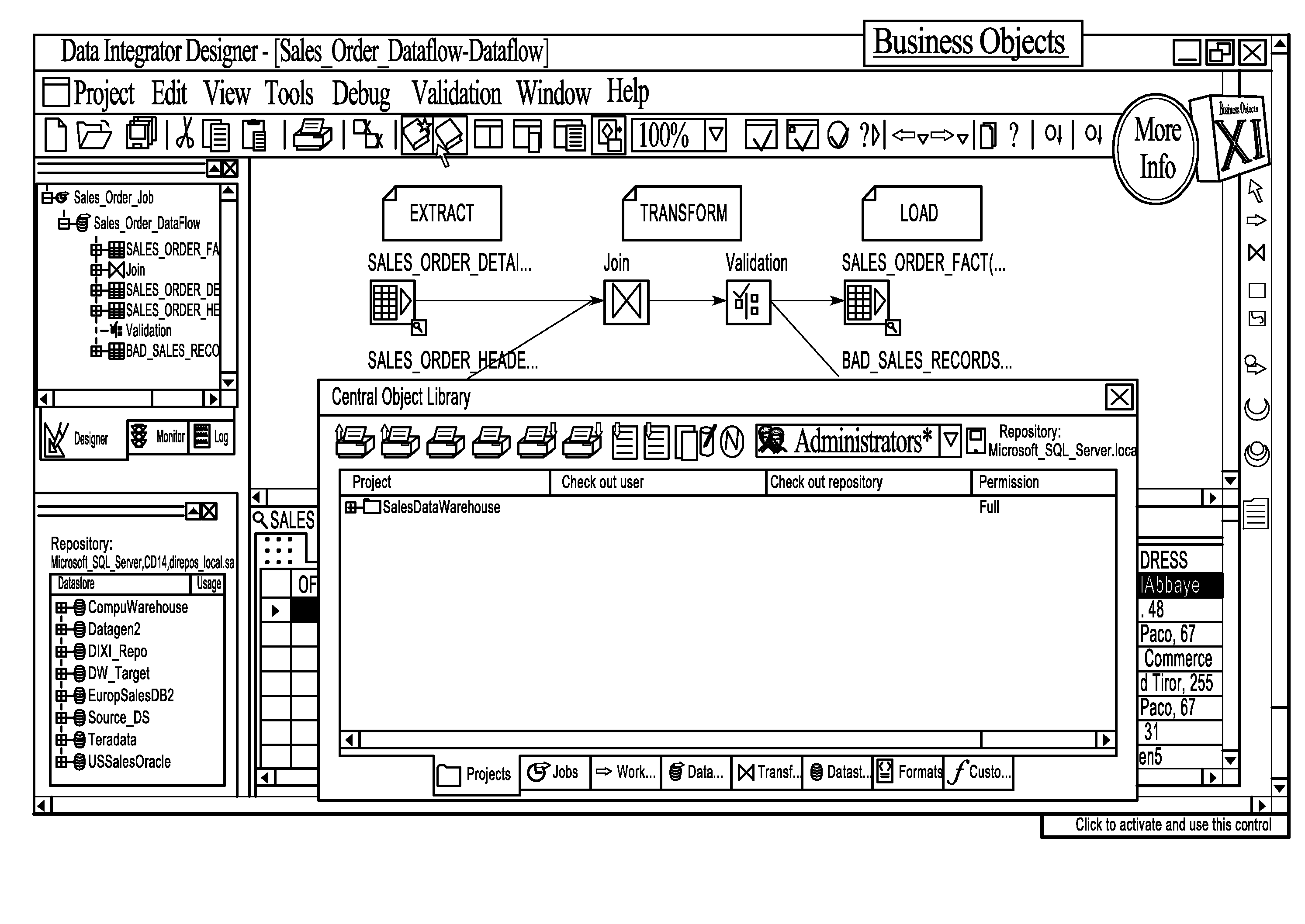

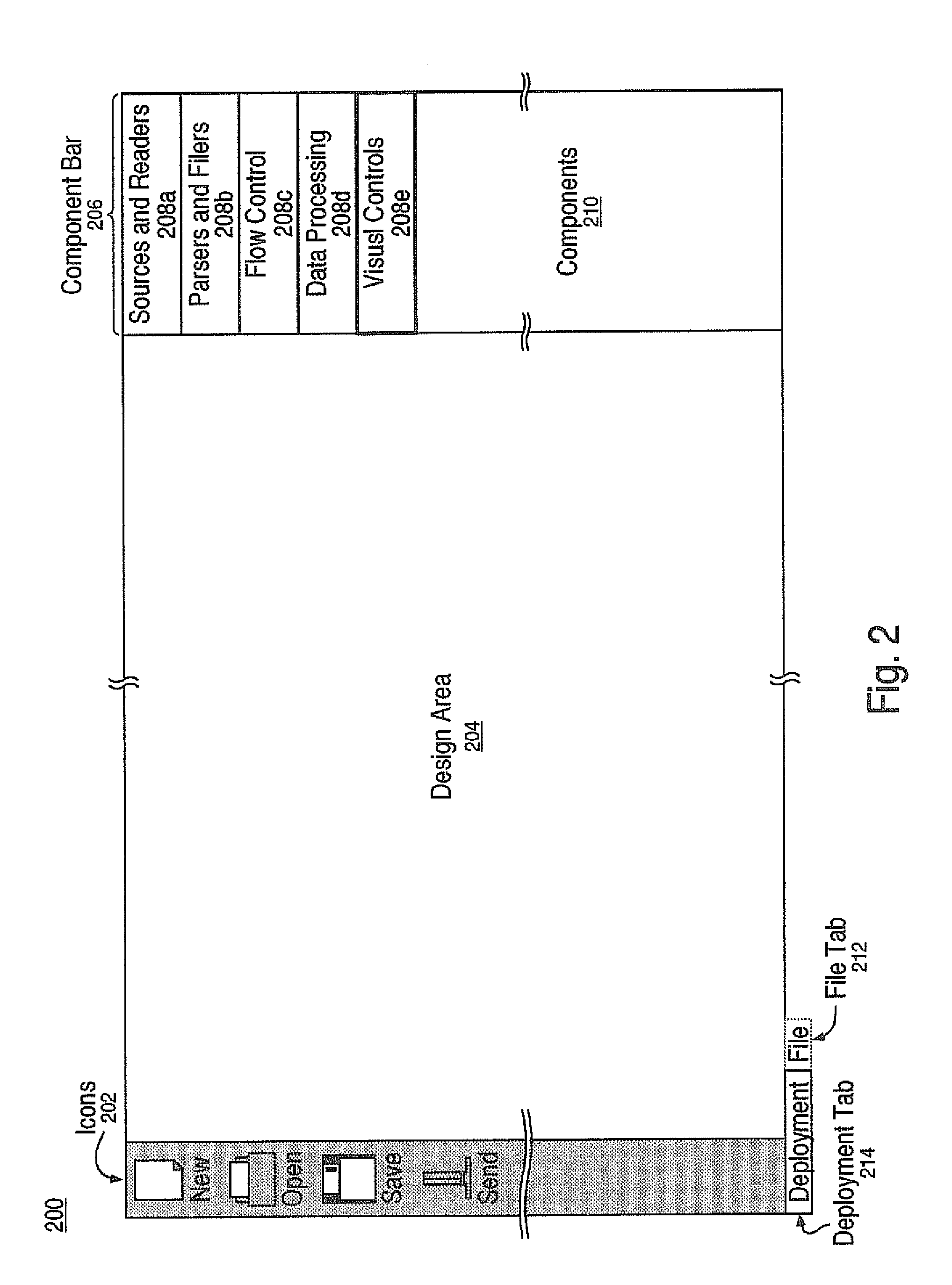

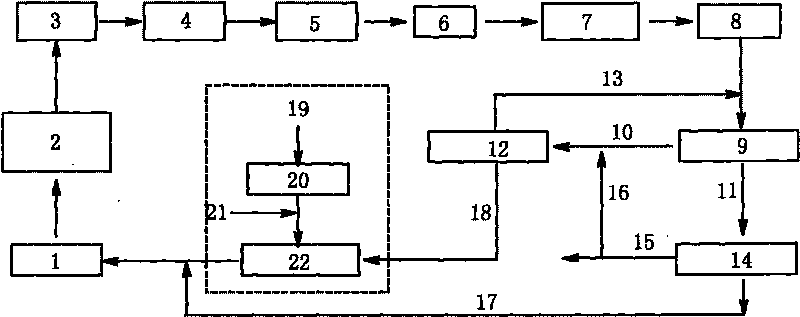

System and method for building multi-modal and multi-channel applications

ActiveUS7917888B2Quick buildEliminate needDigital data processing detailsSoftware designWork flowHuman–computer interaction

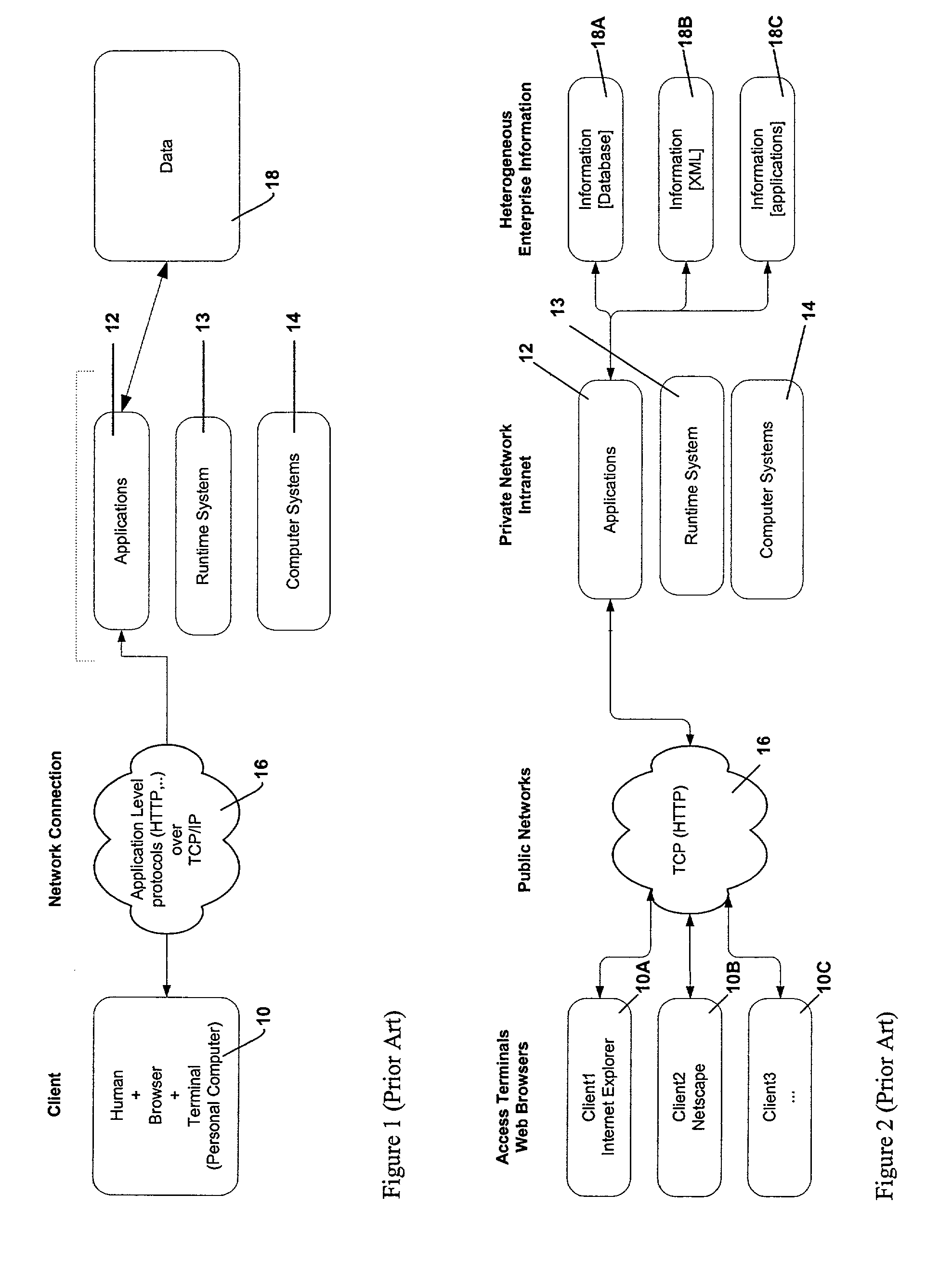

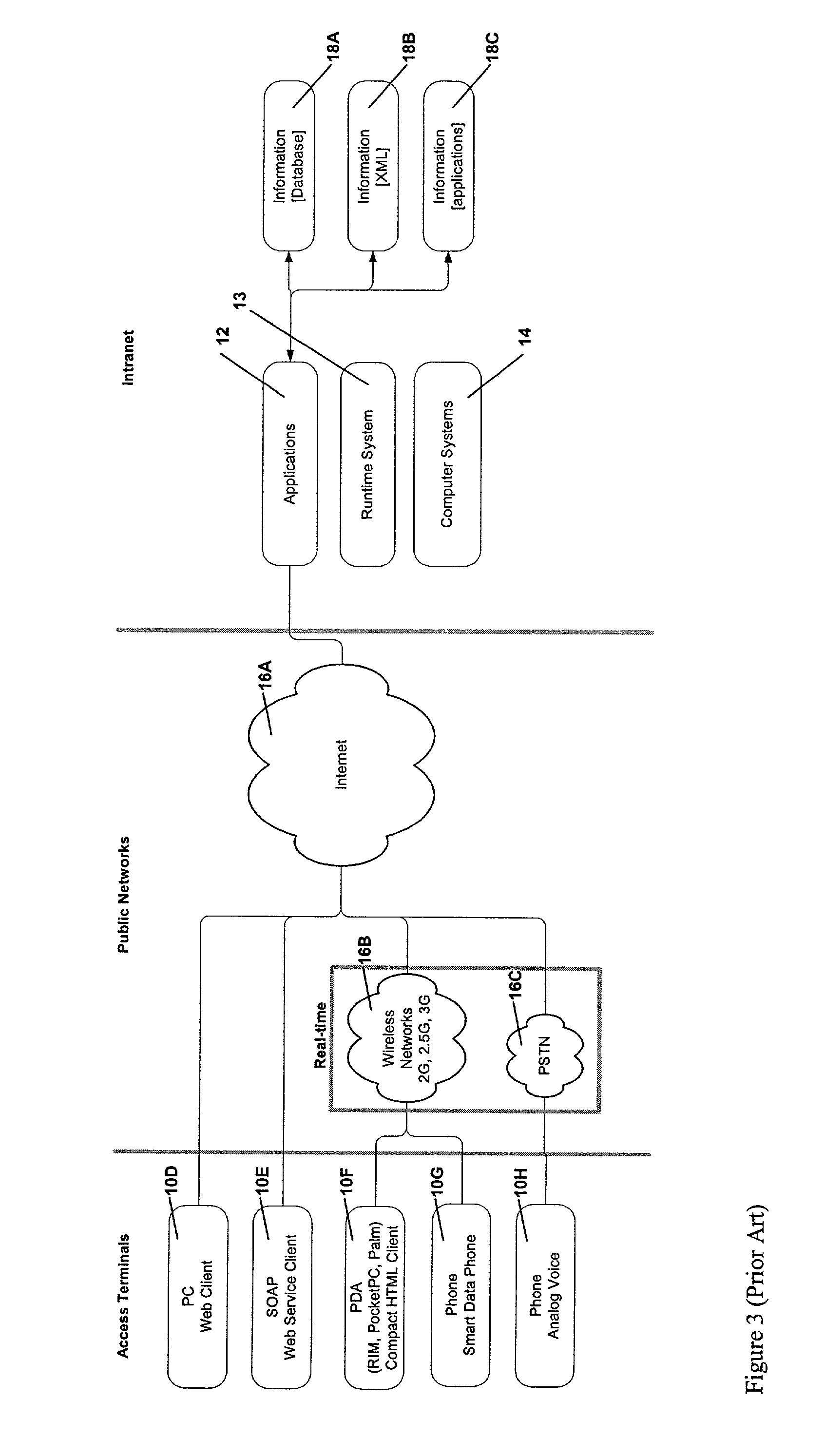

A system and method are provided for visually building multi-channel and multi-modal applications. The system includes a process design module for designing application workflow, an integration design module for integrating data sources into the application; a presentation design module for designing application views; a media library; and a componentization module, for packaging designed workflow into reusable components. The system further includes an interactive development / design environment (IDE). The IDE provides a graphical user interface for allowing a developer to visually interact with and operate modules. The system allows a developer to design a single application that can operate across multiple network standards, devices, browsers and languages, and that operate in one or more modes, such as real-time, off-line and asynchronous modes.

Owner:SYMBOL TECH LLC

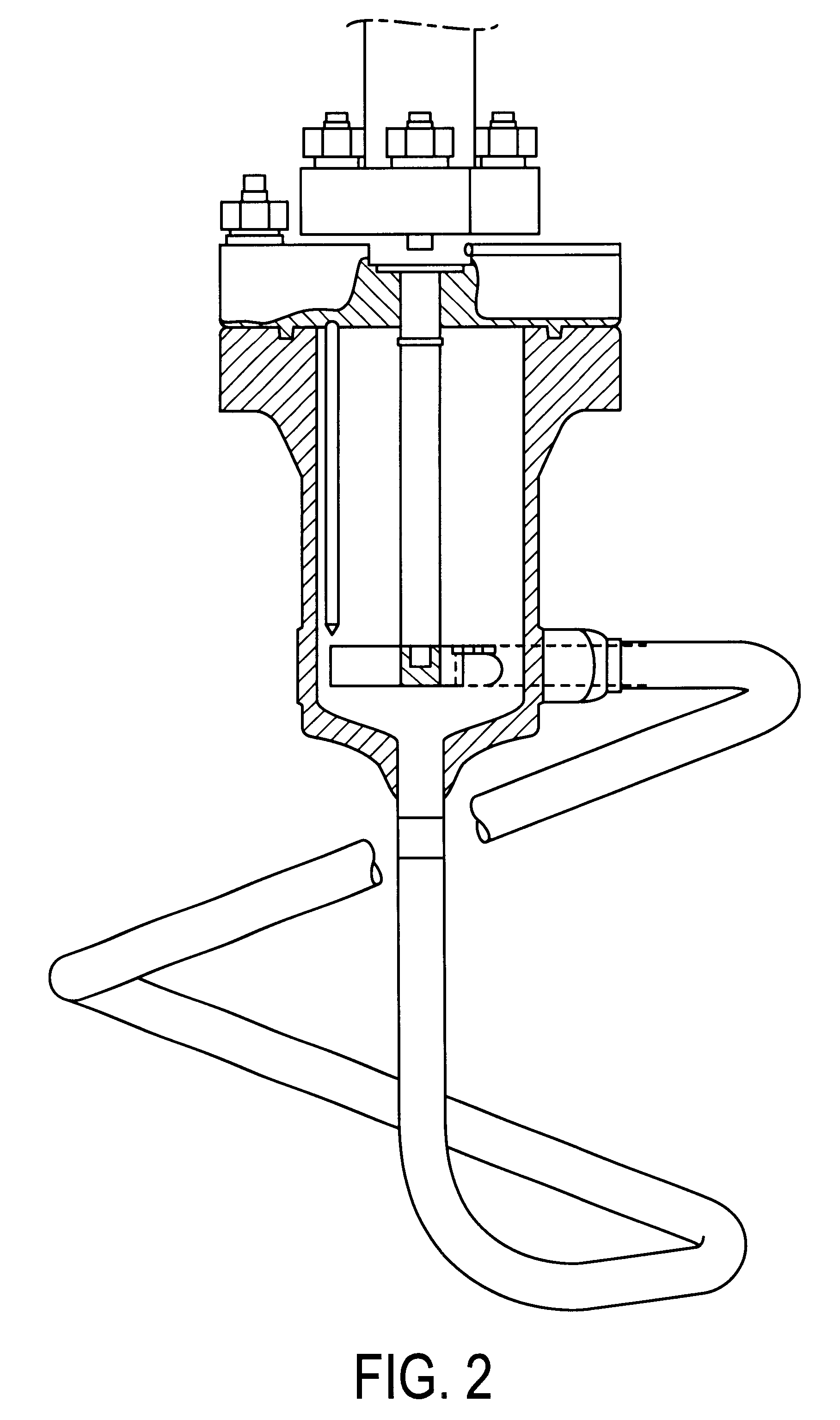

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

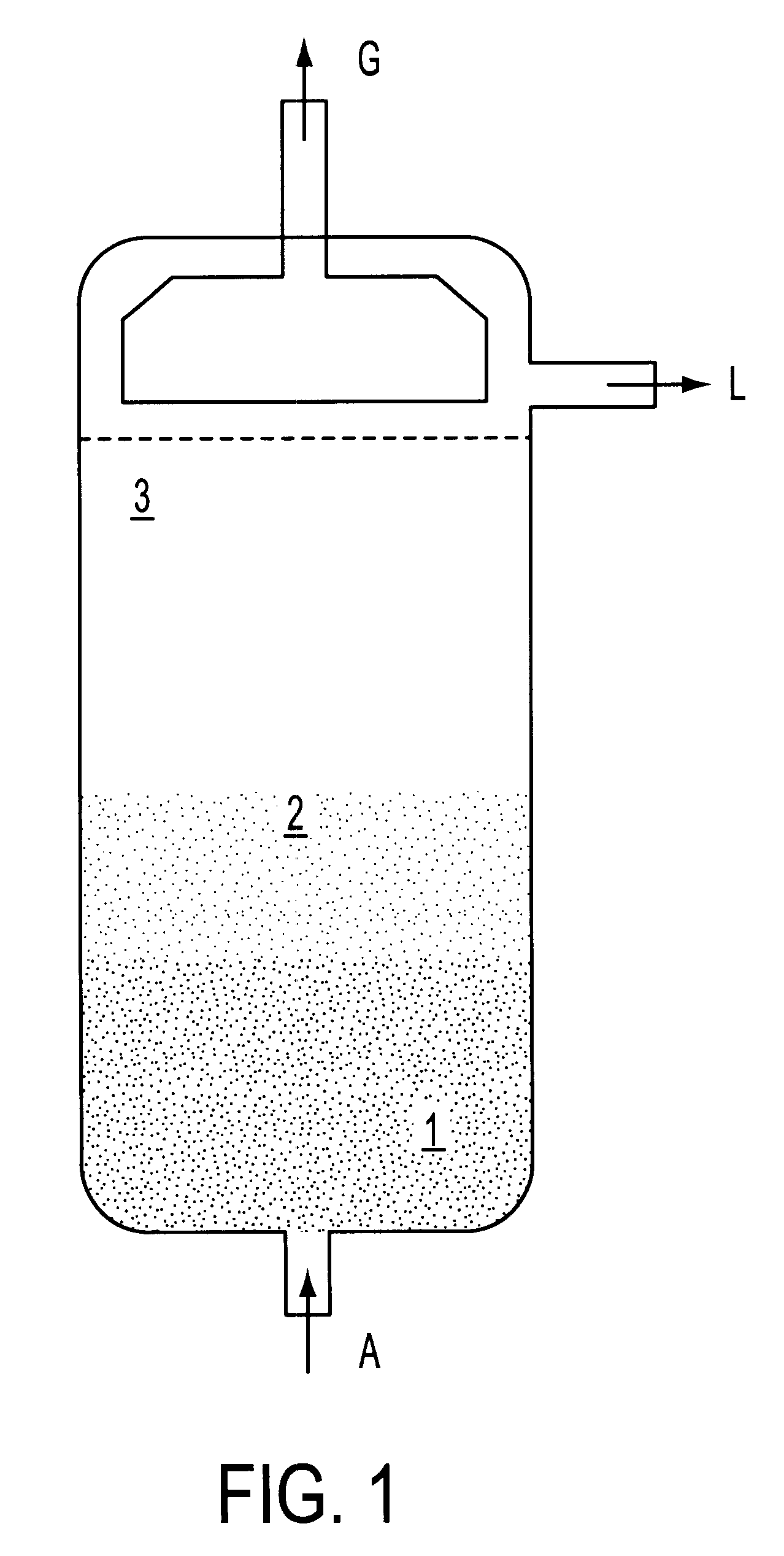

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

System, multi-tier interface and methods for management of operational structured data

ActiveUS20090125796A1Reduce the impactEasy to moveExecution for user interfacesInput/output processes for data processingSubject-matter expertObject based

Owner:AVRO COMPUTING

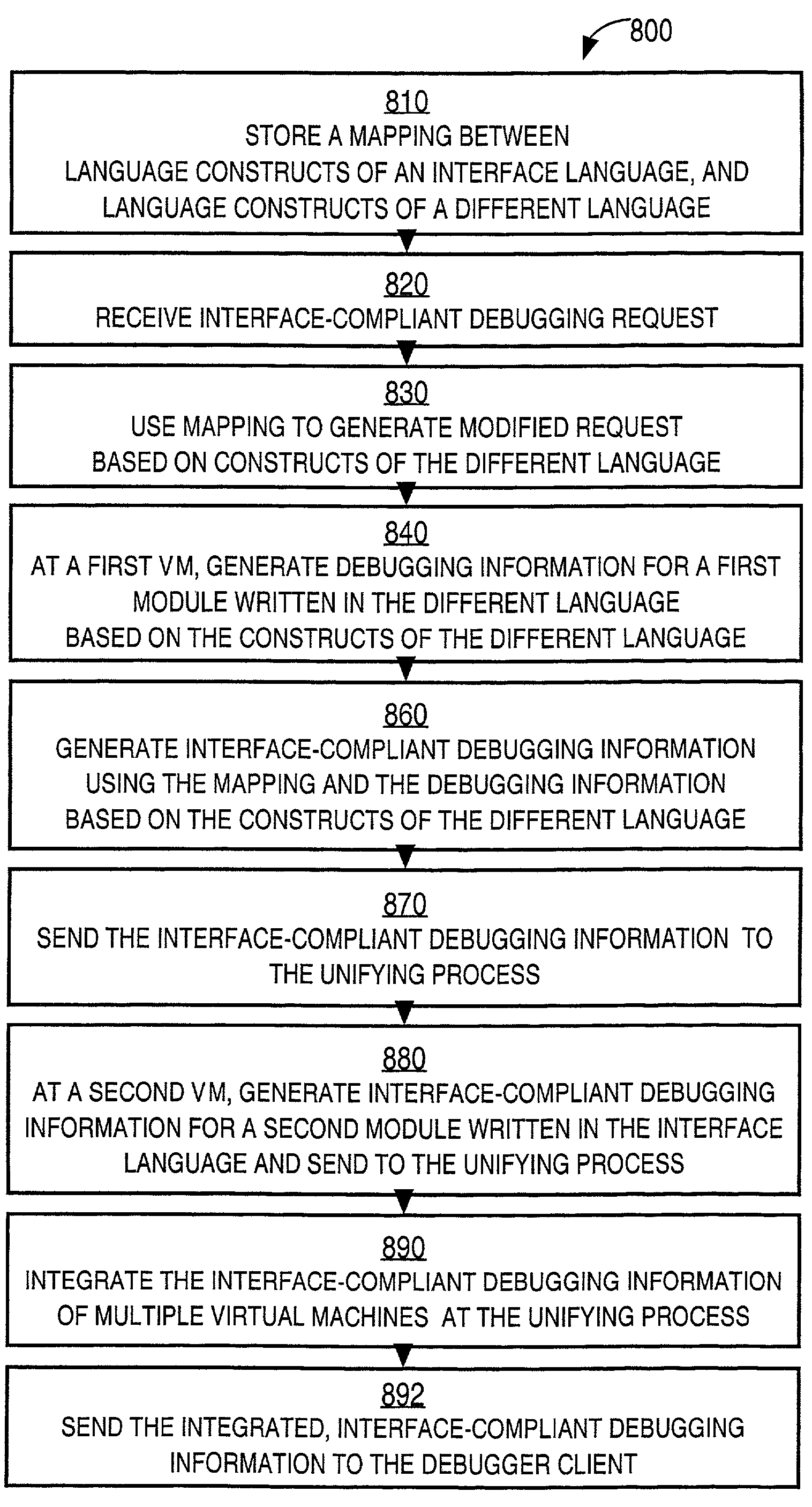

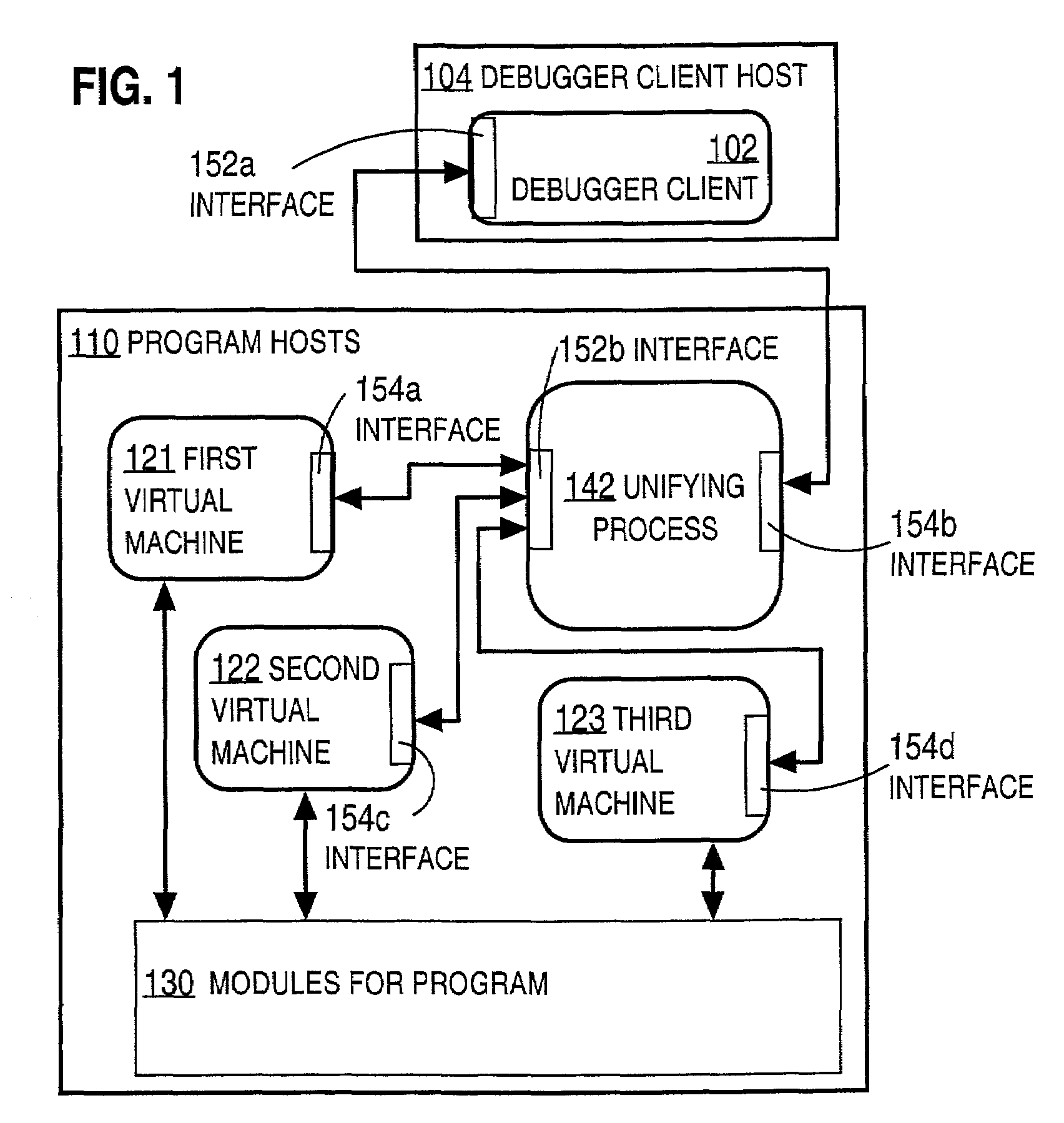

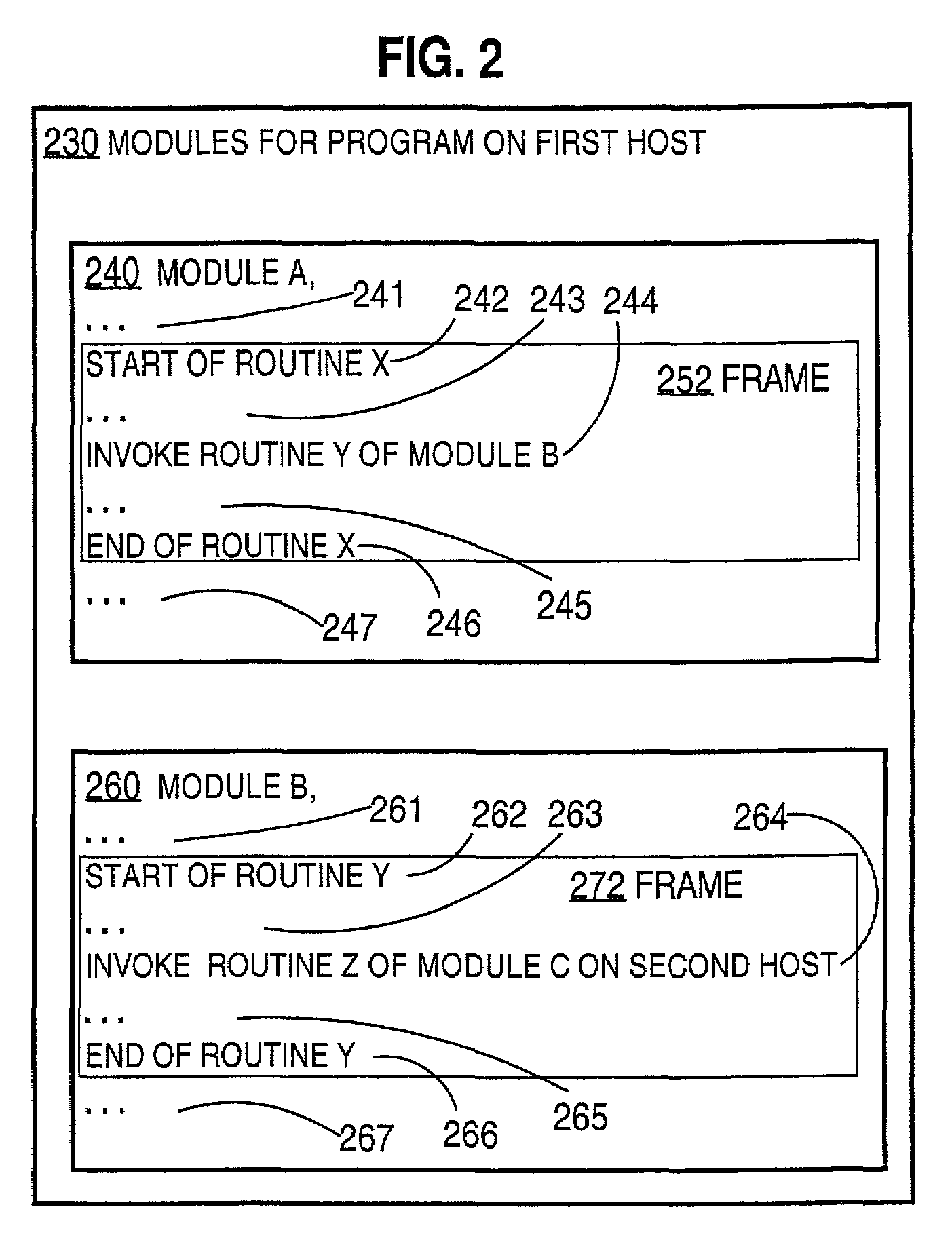

Techniques for debugging computer programs involving multiple programming languages

ActiveUS7107578B1Error detection/correctionSpecific program execution arrangementsLanguage constructProcess design

Techniques for debugging a computer program that includes multiple modules written in multiple languages allow machines for the multiple languages to interface with a single debugger client using a standard interface. The techniques include storing a mapping that maps language constructs of a first language into language constructs of a second language. While a first machine is executing a first module that is written in the first language, the mapping is used to generate debugging information based on language constructs of the second language. The debugging information is sent to a debugger process designed for debugging programs written in the second language.

Owner:ORACLE INT CORP

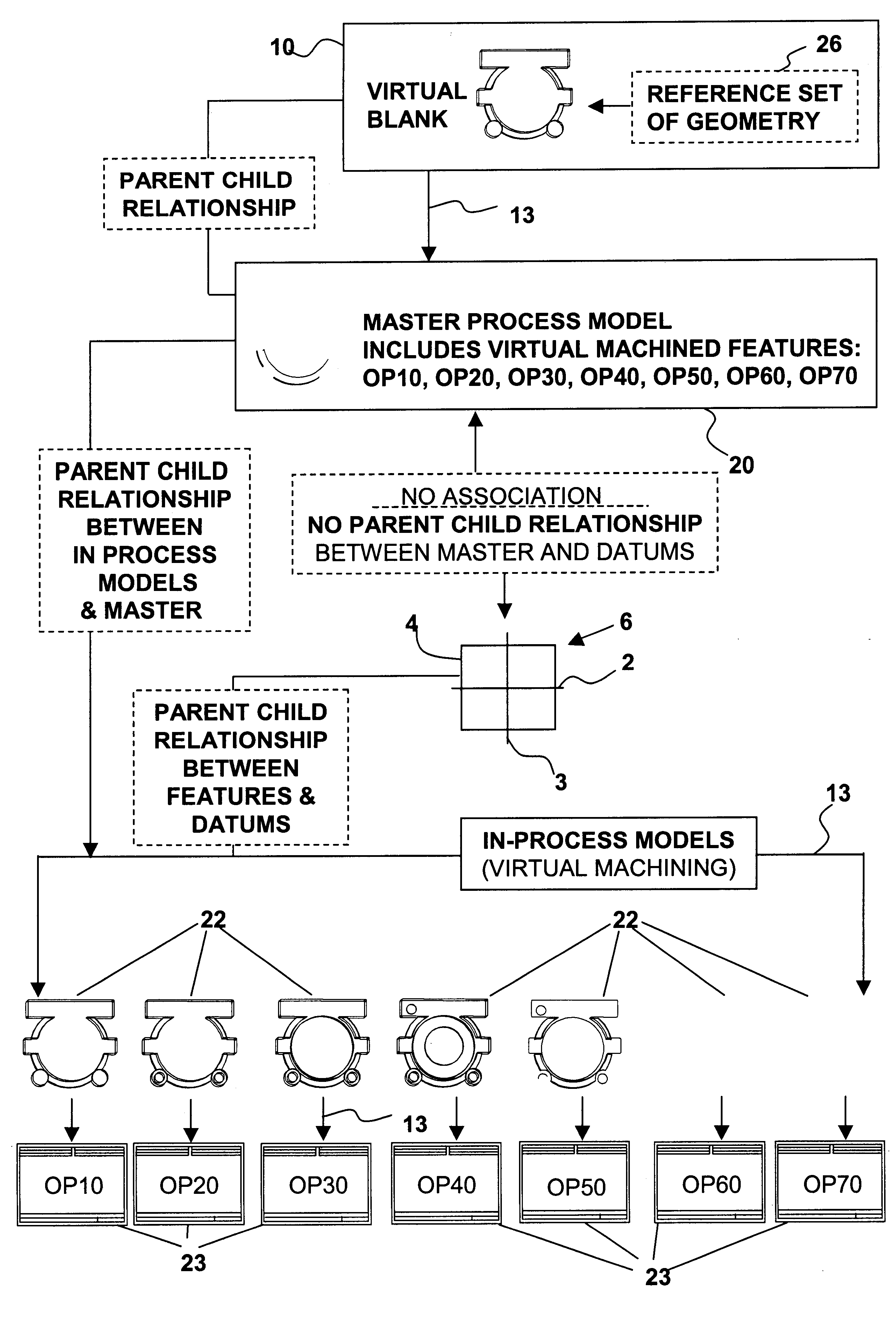

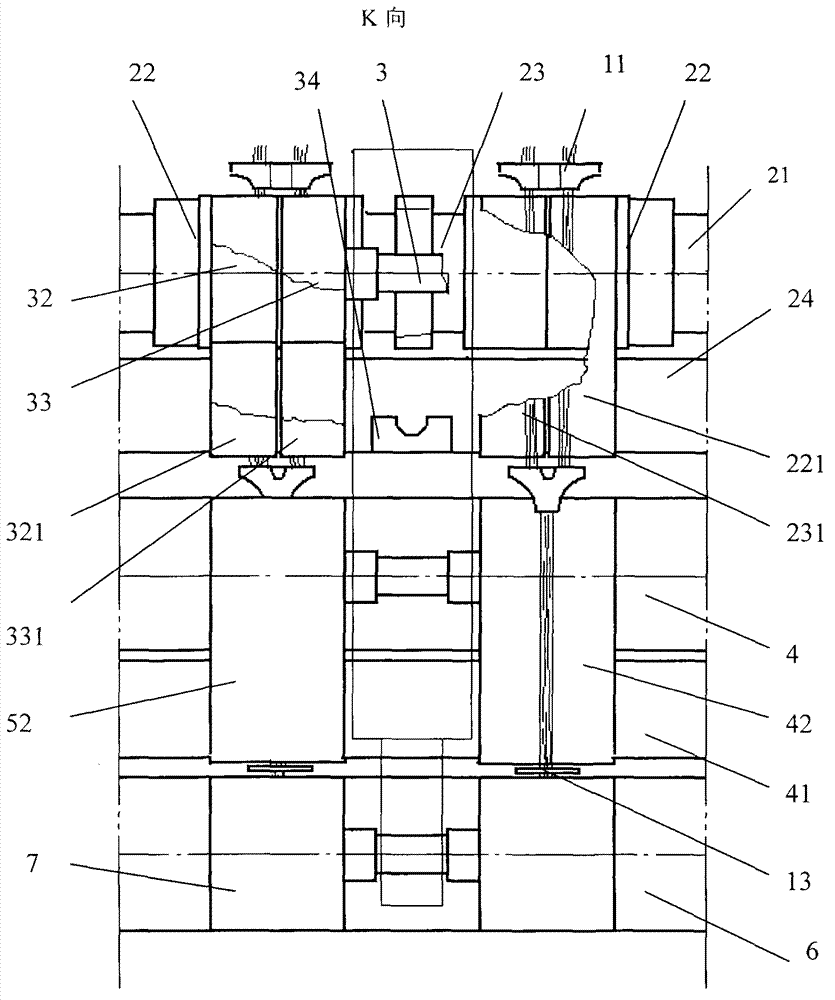

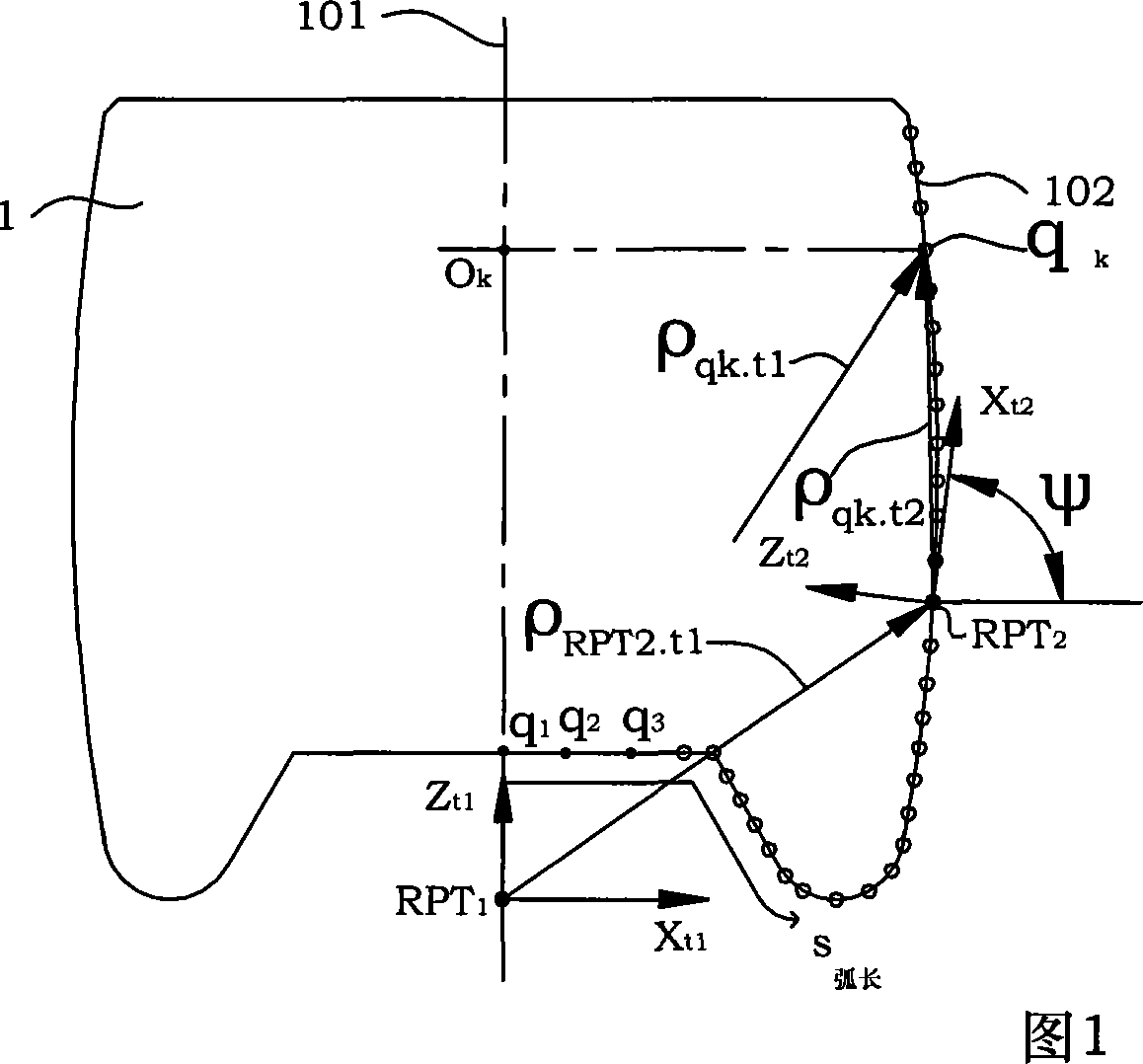

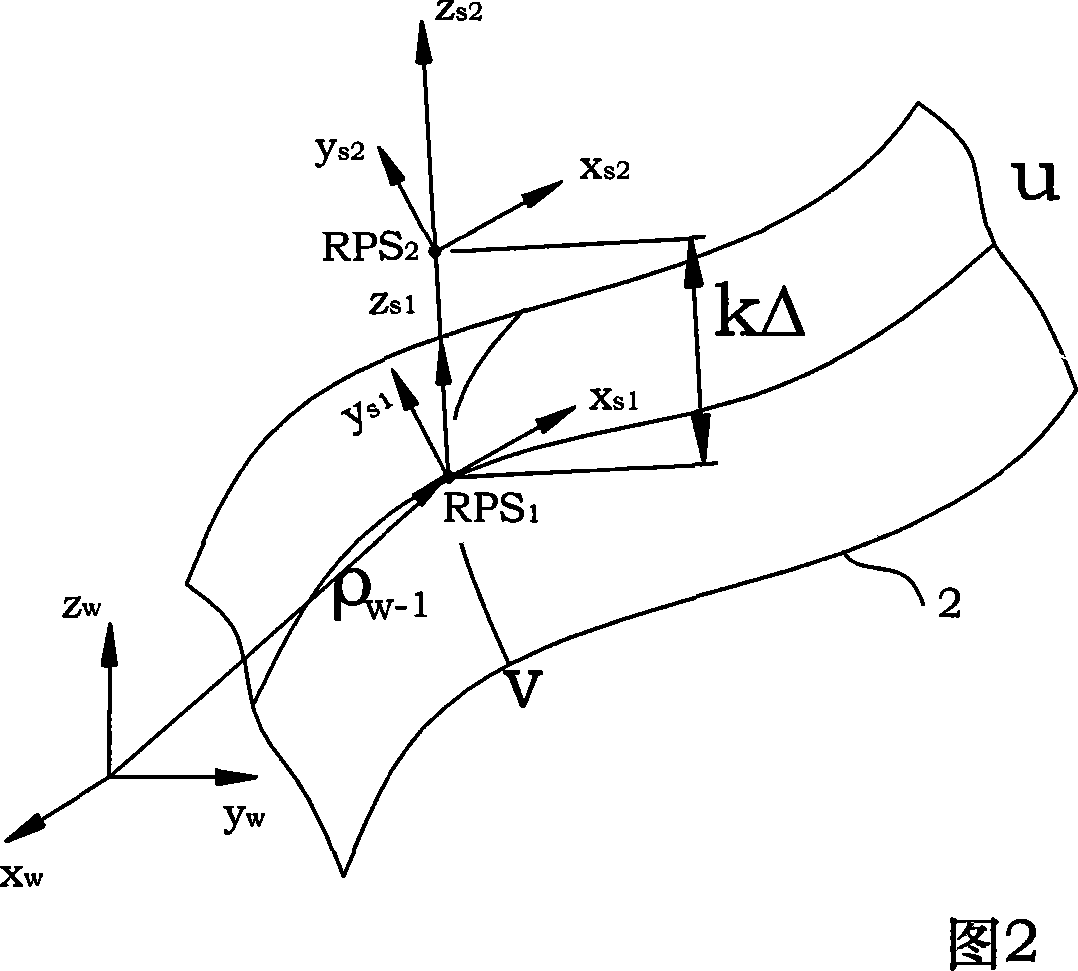

Spacecraft assembly simulation technique-based virtual assembly system and virtual assembly method

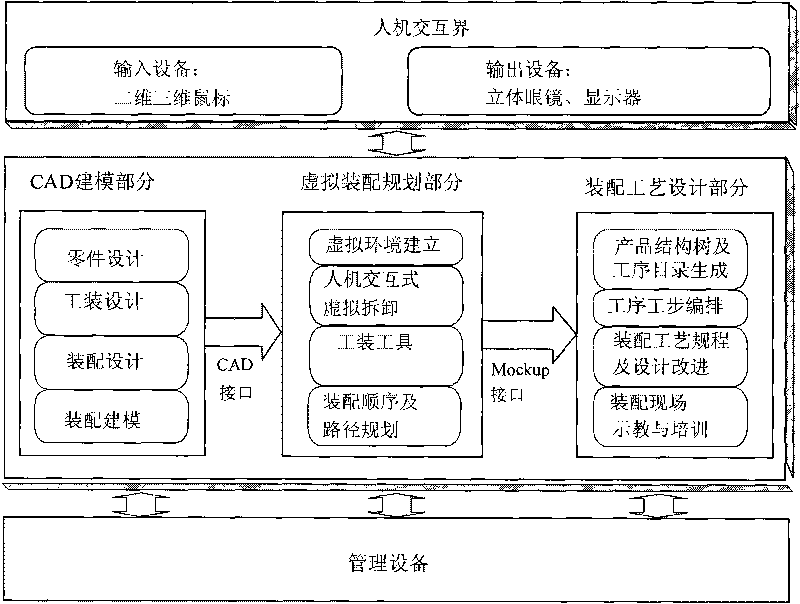

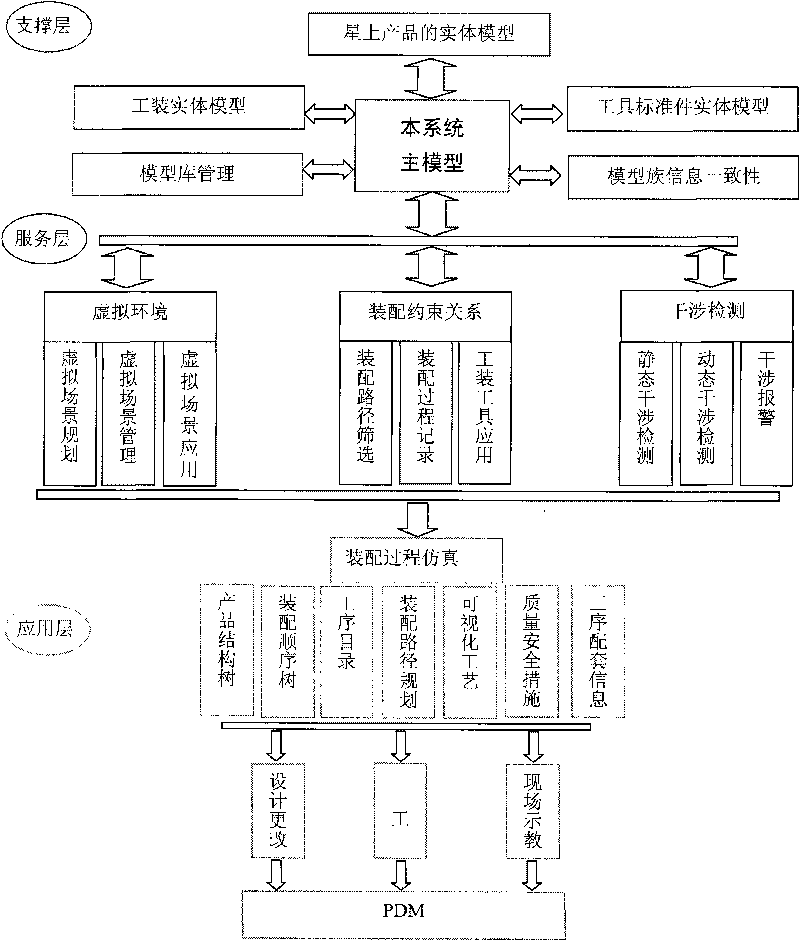

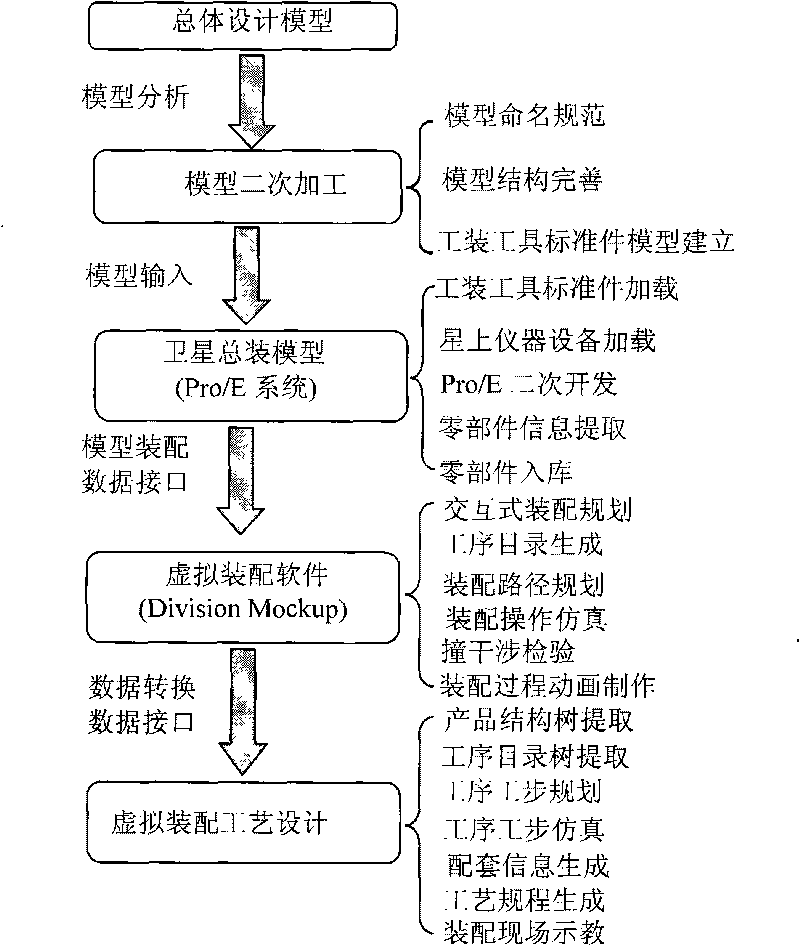

The invention relates to a spacecraft assembly simulation technique-based virtual assembly system. The virtual assembly system comprises a CAD modeling module, a virtual assembly planning module and an assembly process design module, wherein the CAD modeling module is used for designing components and tooling tools, and assembling the components together by defining a series of matching constraint relations so as to obtain an assembling model of products; the virtual assembly planning module is used for establishing a geometrical constraint-based virtual environment, planning an optimized assembly sequence according to disassembly directions, disassembly tools and precedence constraint information recorded in the virtual environment for execution, verifying the optimized assembly sequence, and performing simulation evaluation in the virtual environment; and the assembly process design module is used for designing a product structure tree and a process step catalog, editing process steps and assembling a technological process. The CAD modeling module is connected with the virtual assembly planning module through a CAD modeling interface so that models generated in the CAD modeling module are guided into the virtual assembly planning module; and the process planning result in the virtual assembly planning module is guided into the assembly process design module through a Mockup interface.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

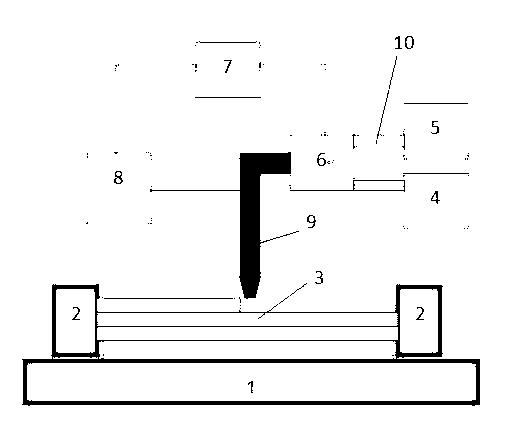

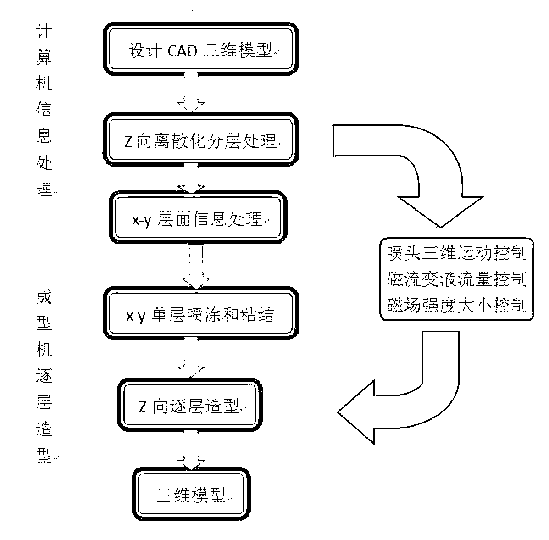

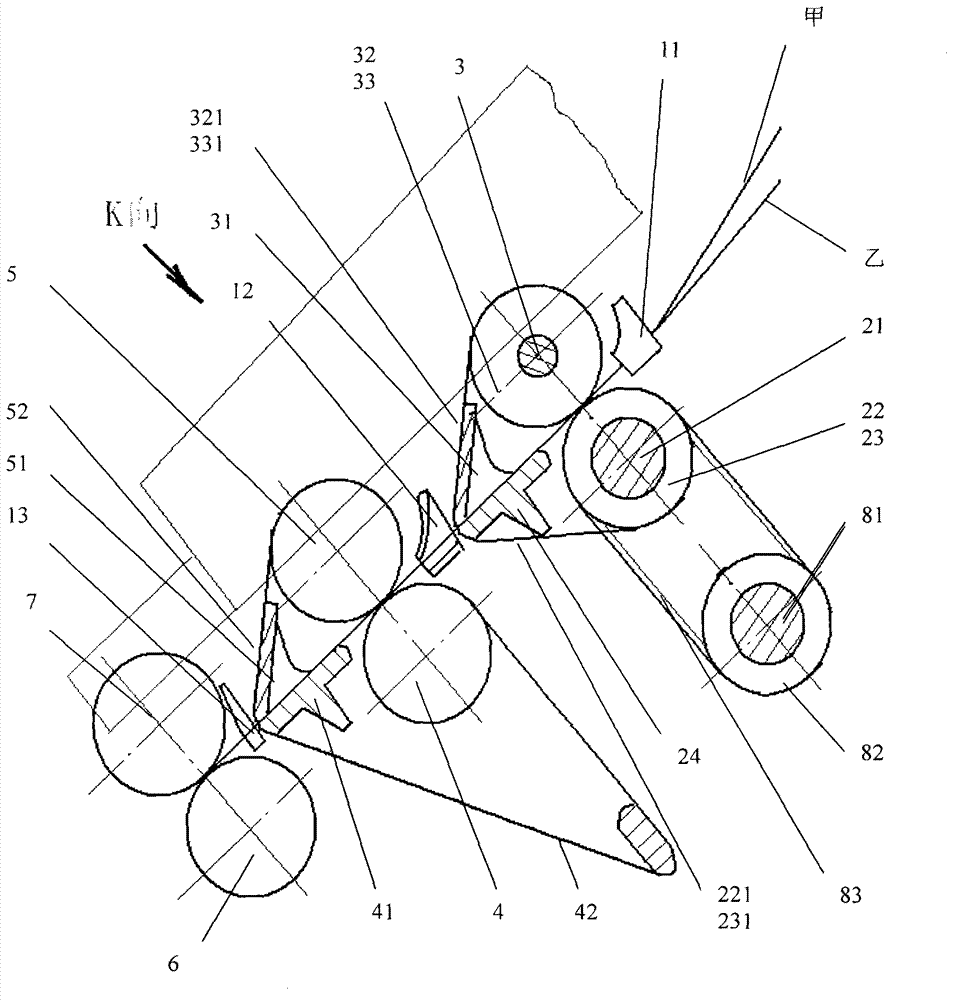

Magnetorheological-material-based 3D (Three-Dimensional) printing type rapid prototyping device and method

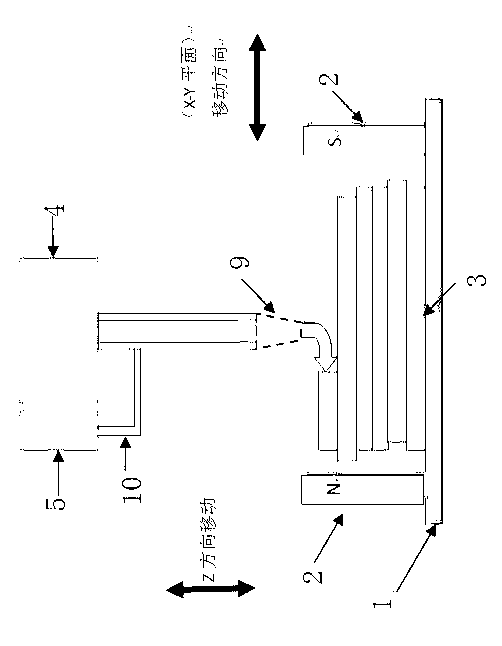

The invention relates to a magnetorheological-material-based 3D (Three-Dimensional) printing type rapid prototyping method and device. According to the principle of magnetorheological effect, a magnetorheological material is used as a 3D printing raw material; and a 3D solid model is constructed by spraying the magnetorheological material on a workbench with a magnetic field, rapidly solidifying and prototyping the sprayed magnetorheological material, and then depositing the treated material layer by layer. A computer is provided with three control circuits; one circuit is used for controlling the flow of a driving pump, namely the flow at a spray head; another circuit is used for controlling the 3D motion of the spray head through a servo mechanism; and the rest circuit is used for controlling colour mixing and allocating of a colourized ink box. The magnetorheological material is solidified and prototyped by utilizing the magnetic field generated by an electromagnet. According to the magnetorheological effect of the magnetorheological material, a temperature control module in the traditional melting, spraying and rapid prototyping type 3D printing method is replaced by the magnetic field; in addition, the device disclosed by the invention is also different from a high-pressure electric field required by an electrorheological fluid effect, has the advantages of being simple in structure, low in energy consumption and cost, capable of realizing the microminiaturization and the like, and can be applicable to the fields of process design, art and entertainment, prosthesis model and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

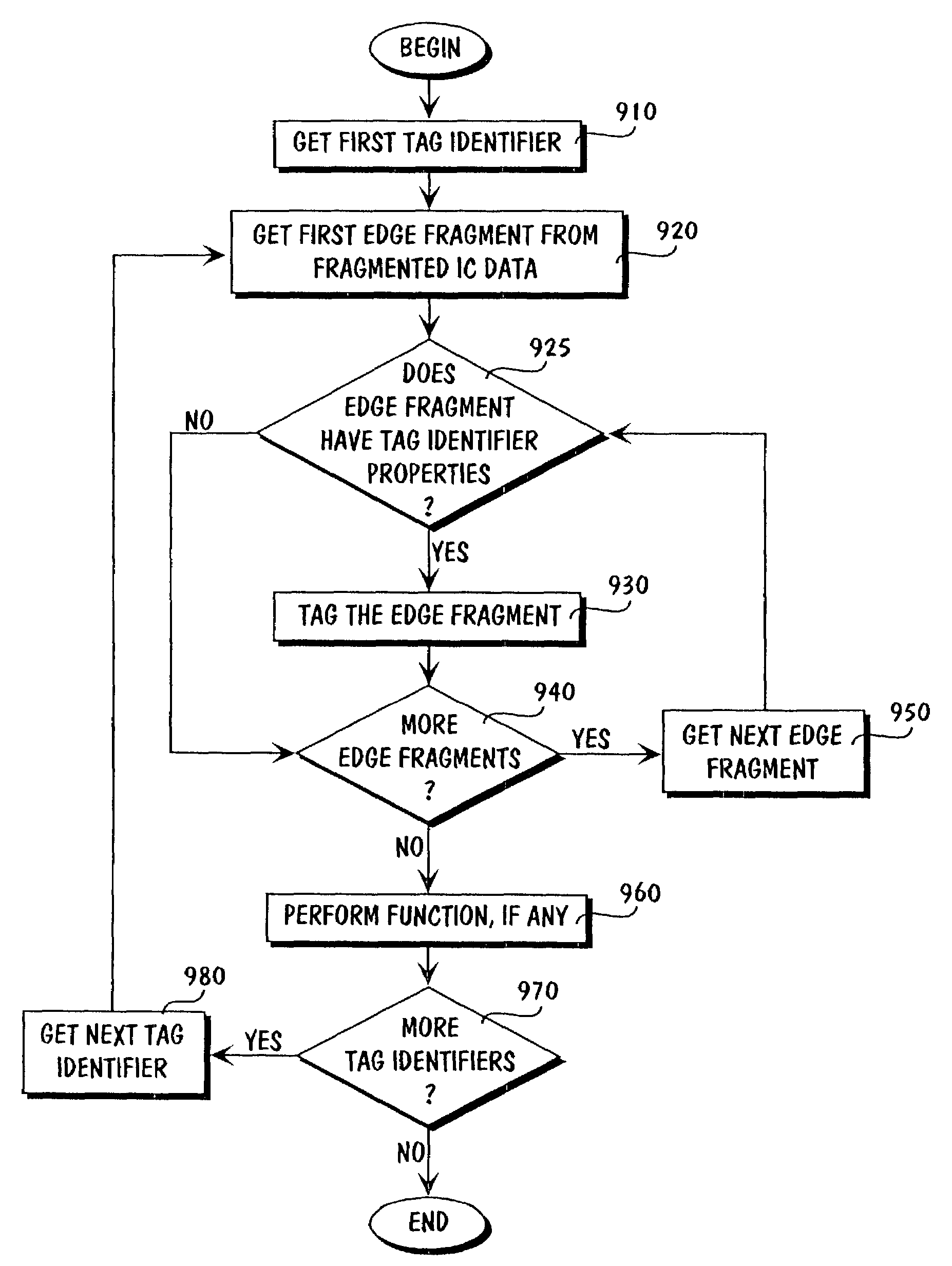

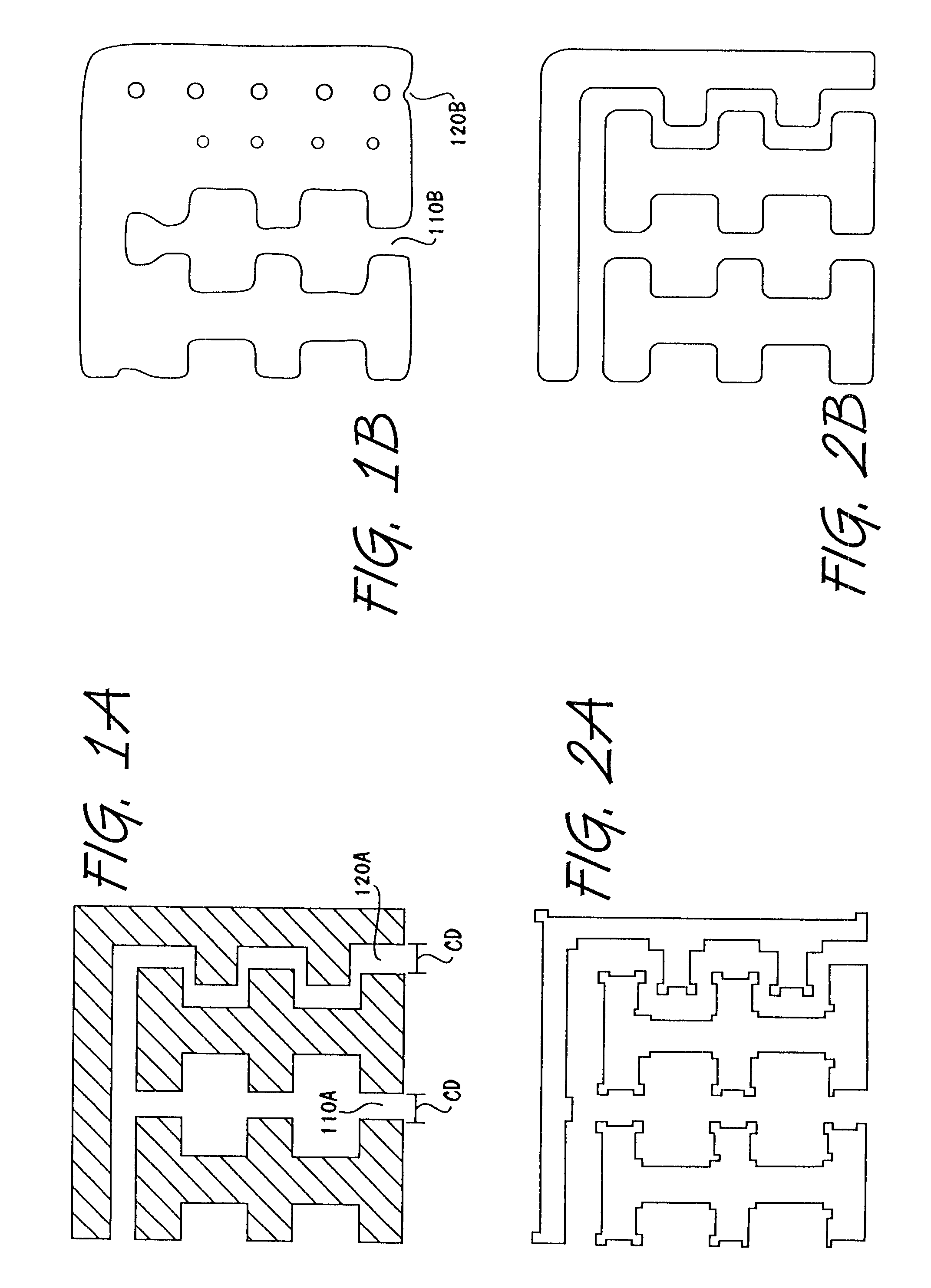

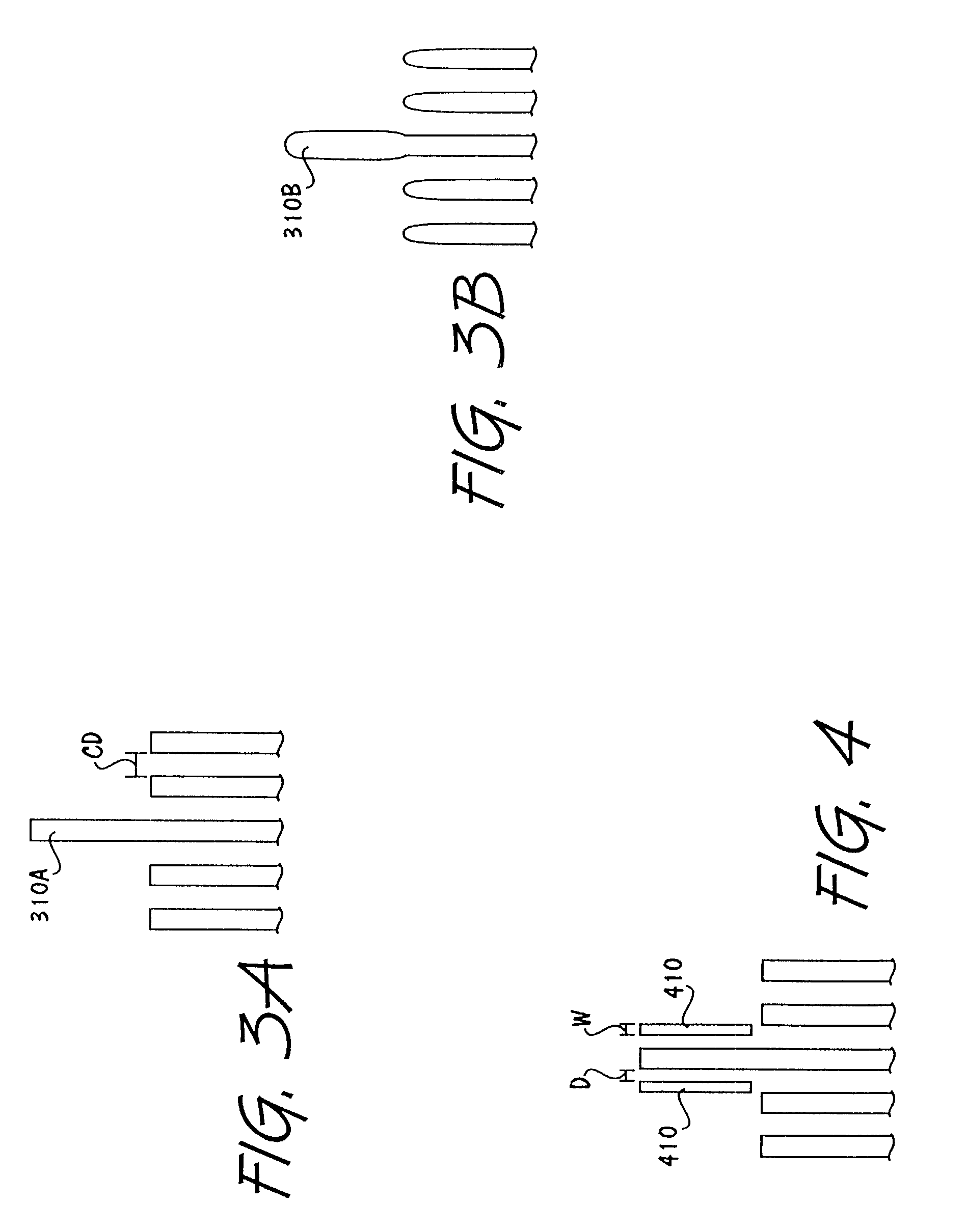

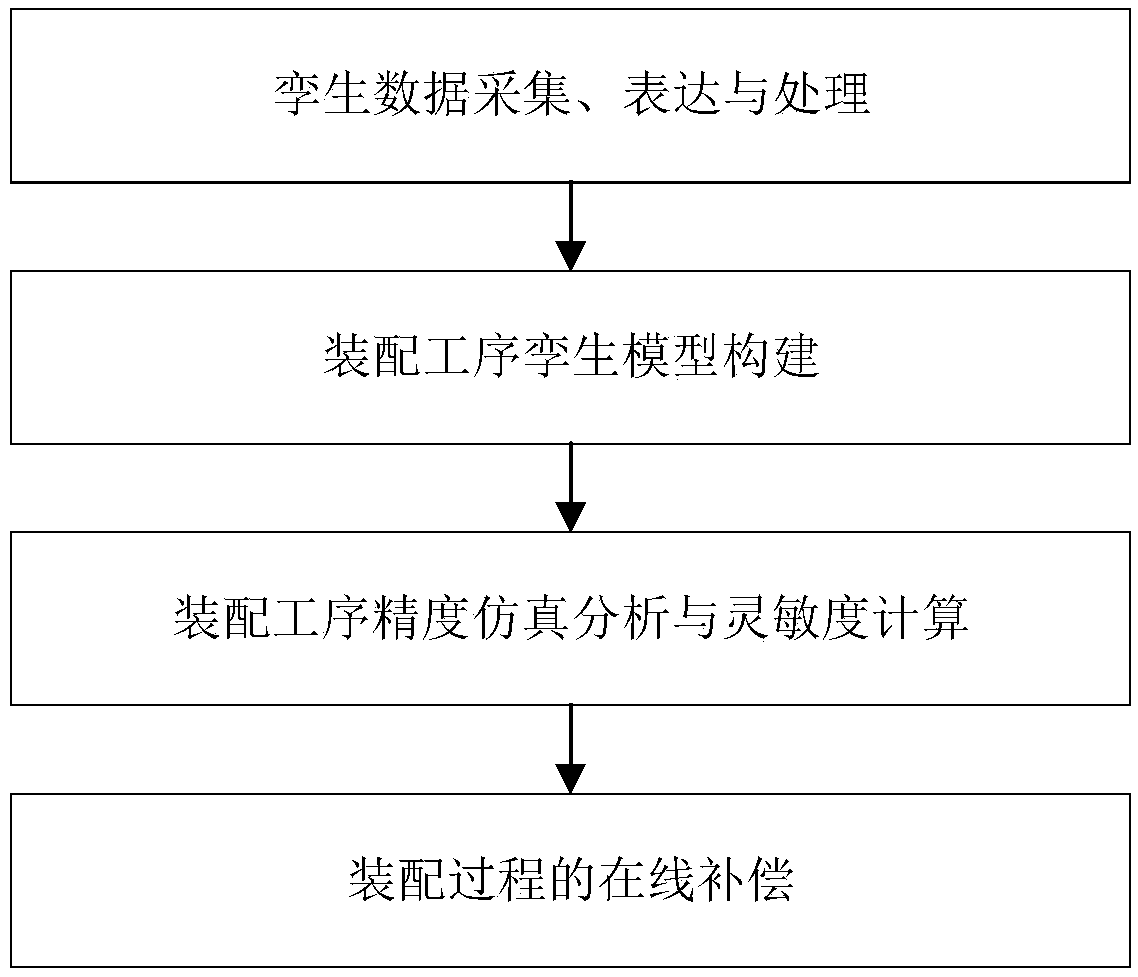

Mixed-mode optical proximity correction

InactiveUS7024655B2Photomechanical exposure apparatusMicrolithography exposure apparatusTreatment designEngineering

A mask is prepared by processing design data with various combinations of rule-based and model-based optical proximity correction. In one embodiment, the design data is first processed with a set of optical proximity correction rules to produce a rule-corrected design. The rule-corrected design is examined to identify a set of features to process with model-based optical proximity correction. Then, the set of features are processed with the model-based optical proximity correction.

Owner:COBB NICOLAS B

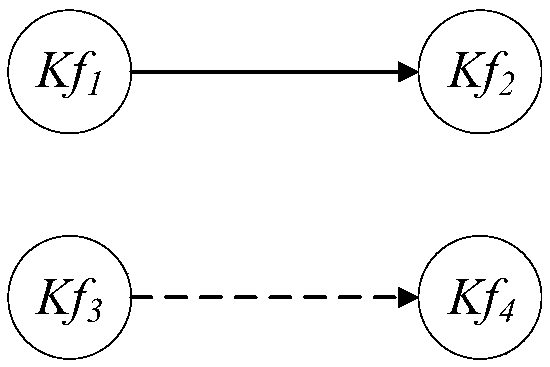

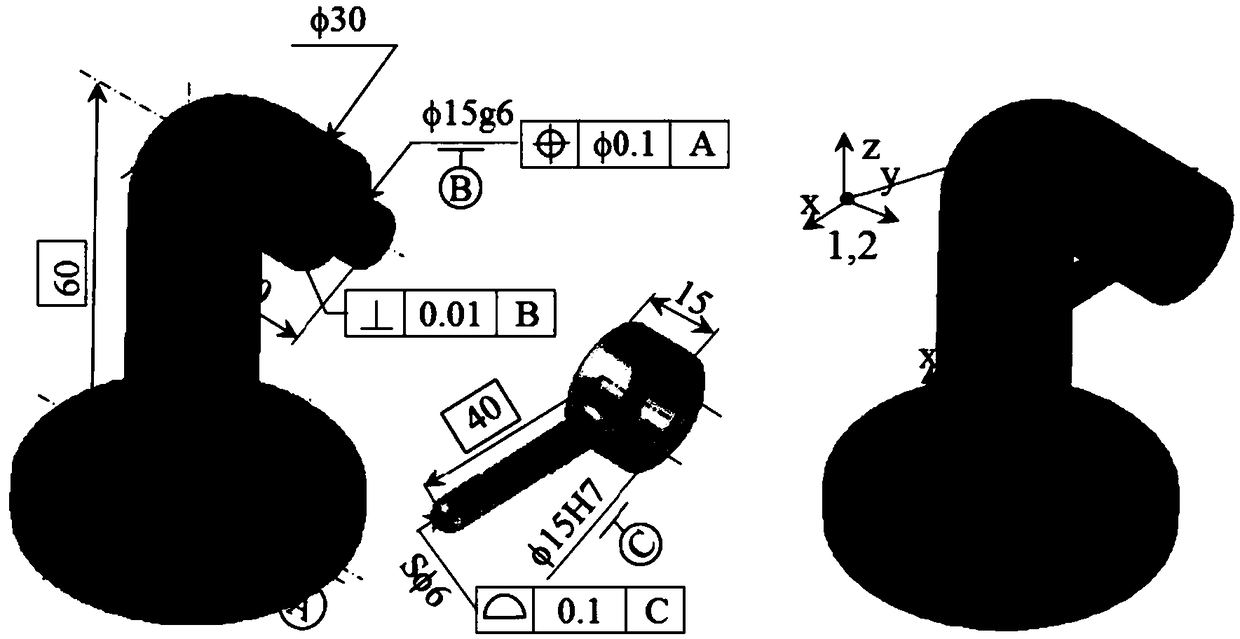

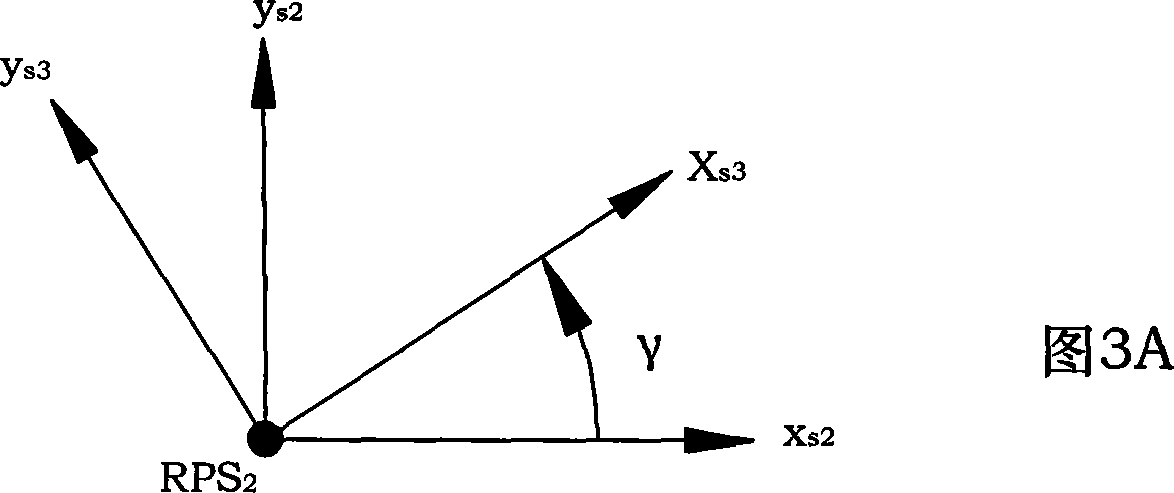

Digital twinning-based assembly precision simulation analysis method and system

InactiveCN109445305ARealize scientific assemblyQuality improvementSimulator controlInformation spacePhysical space

The invention discloses a digital twinning-based assembly precision simulation analysis method and system. According to the digital twinning-based assembly precision simulation analysis method and system, as for key processes in complex product assembly, the twin data of a physical assembly site are collected and processed, and twin data information is expressed and stored; an assembly process model is obtained in a 3D assembly process design system, and the assembly process model is reconstructed based on the twin data, so that an assembly process twin model is generated; the assembly processtwin model is introduced into commercial assembly tolerance analysis software, so that assembly precision simulation and sensitivity calculation can be performed; and the online compensation and precise control of the assembly process are performed according to assembly process precision simulation analysis results. With the digital twinning-based assembly precision simulation analysis method andsystem of the invention adopted, the deep fusion of the physical space and information space of the assembly site can be realized. The method and system are of great significance for realizing the intelligent closed-loop control of a complex product assembly process and improving assembly quality and efficiency.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Adsorptive separation of gas streams

Owner:AIR PROD & CHEM INC

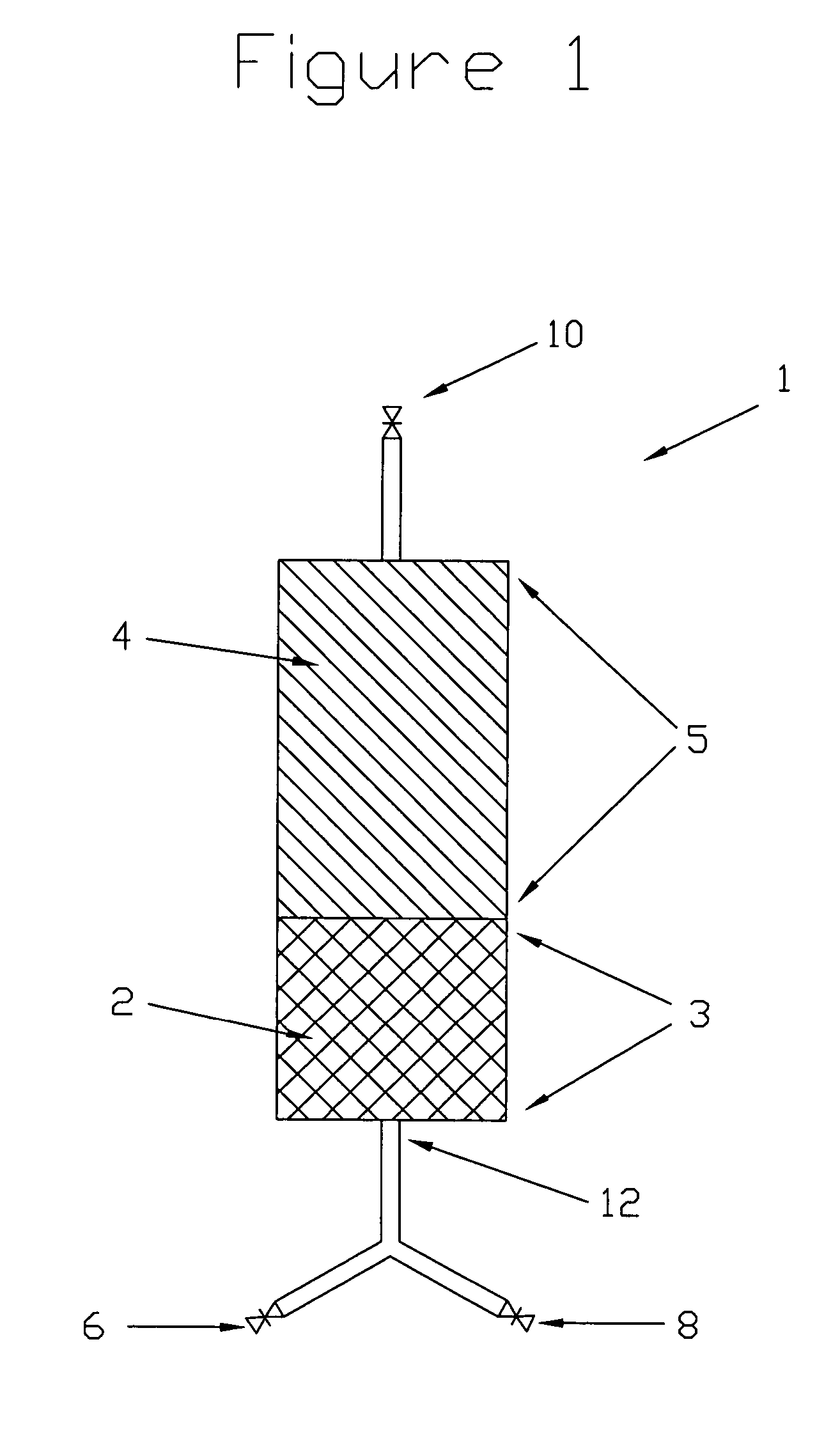

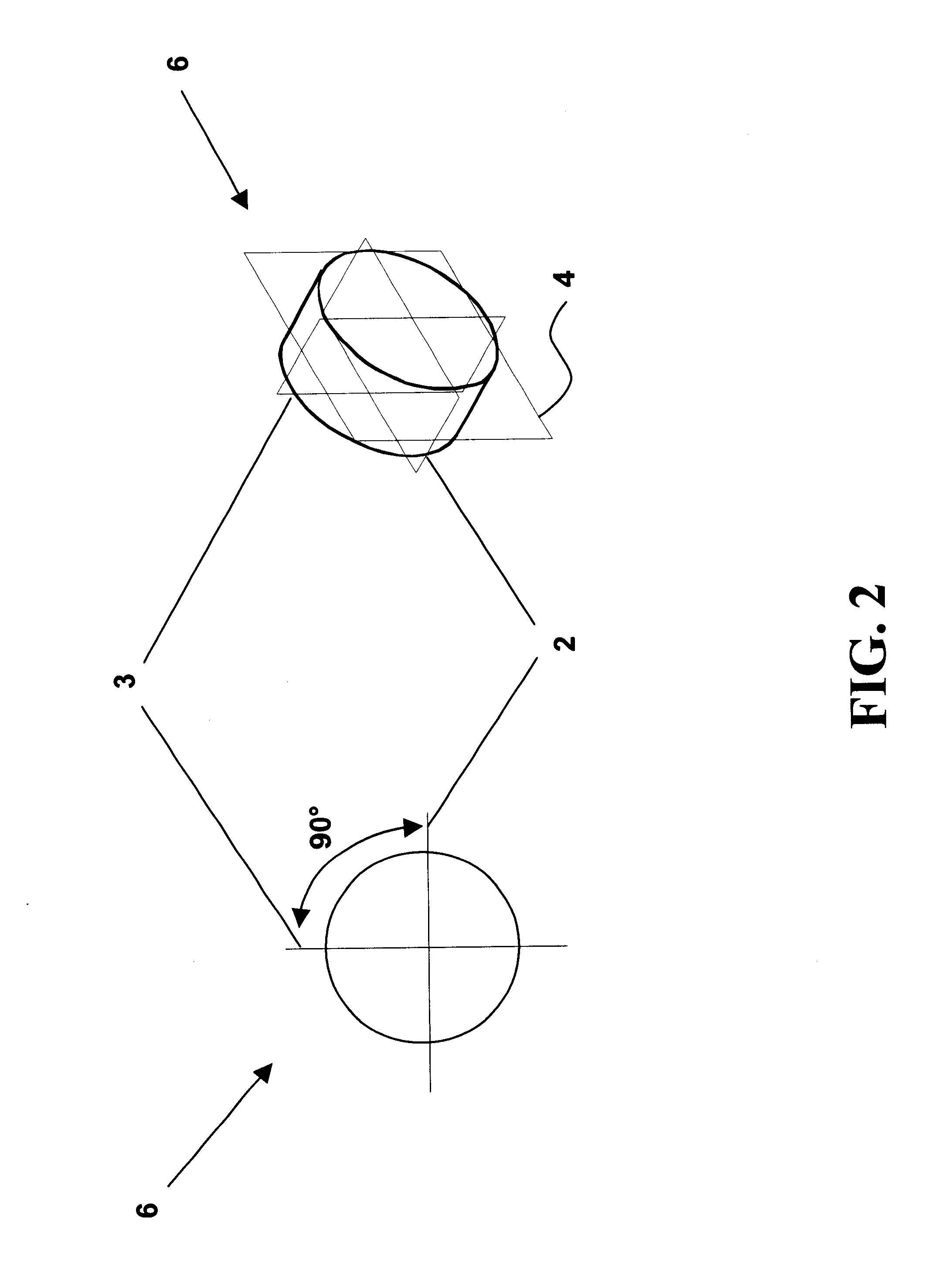

Horizontally-structured CAD/CAM modeling for virtual concurrent product and process design

Disclosed herein is a method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design, comprising: selecting a blank for machining into an actual part establishing a coordinate system; and creating a master product and process concurrent model comprising: a virtual blank corresponding to the blank; a manufacturing feature; virtual machining of the manufacturing feature into the virtual blank; where the manufacturing feature exhibits an associative relationship with the coordinate system. The method also includes generating a product drawing of the actual part; and generating machining instructions to create the actual part by machining the manufacturing feature into the blank. Also disclosed herein is a horizontally structured CAD / CAM model for concurrent product and manufacturing processes comprising: a blank for machining into an actual part; a coordinate system; and a master product and process concurrent model comprising: a virtual blank corresponding to the blank; a manufacturing feature; the manufacturing feature virtual machined into the virtual blank; and the manufacturing feature exhibiting an associative relationship with the coordinate system. Further disclosed is a storage medium encoded with a machine-readable computer program code for horizontally structured CAD / CAM modeling. The storage medium including instructions for causing a computer to implement the method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design. Additionally disclosed is a computer data signal for horizontally structured CAD / CAM modeling. The computer data signal comprising code configured to cause a processor to implement a method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design.

Owner:STEERING SOLUTIONS IP HLDG +1

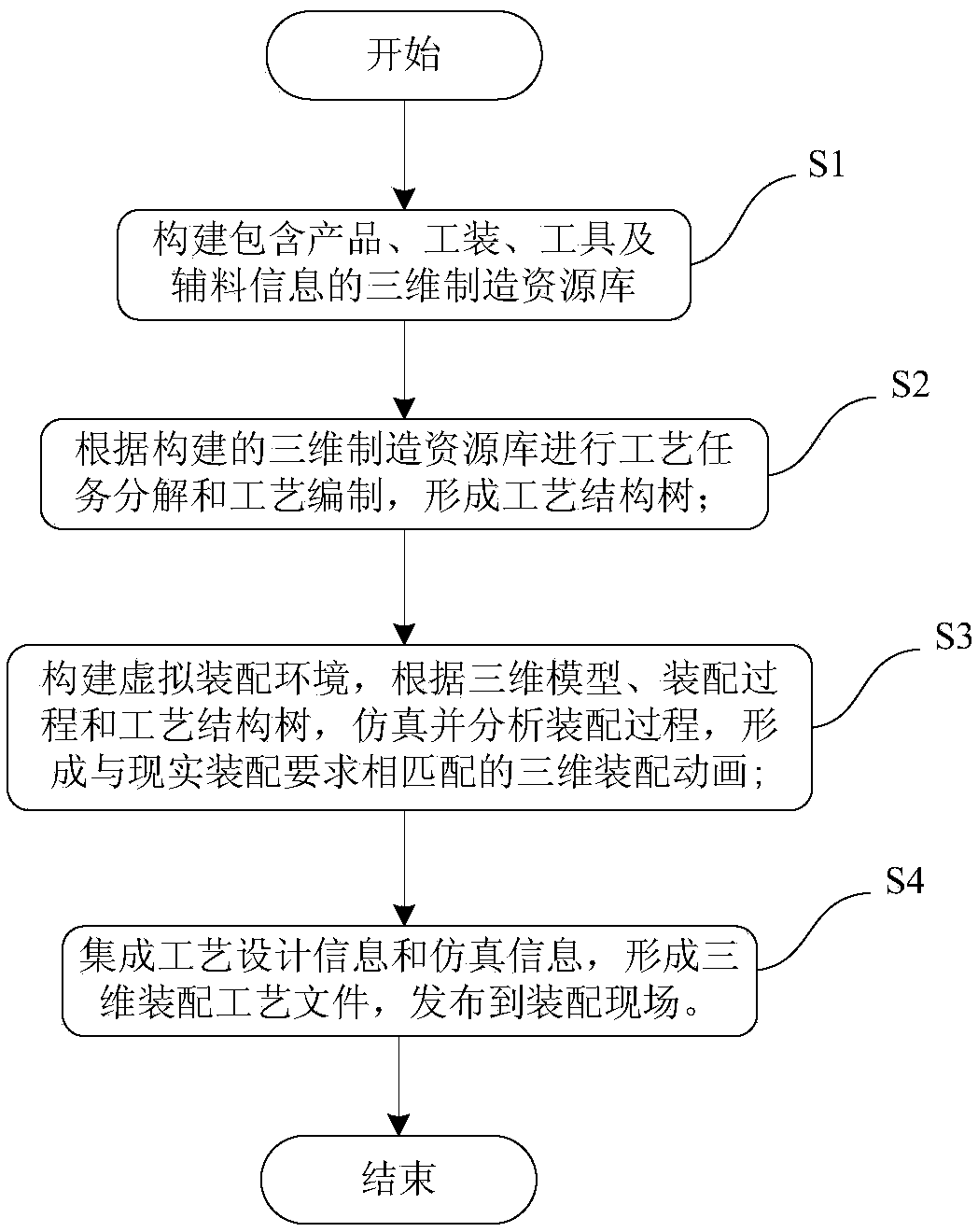

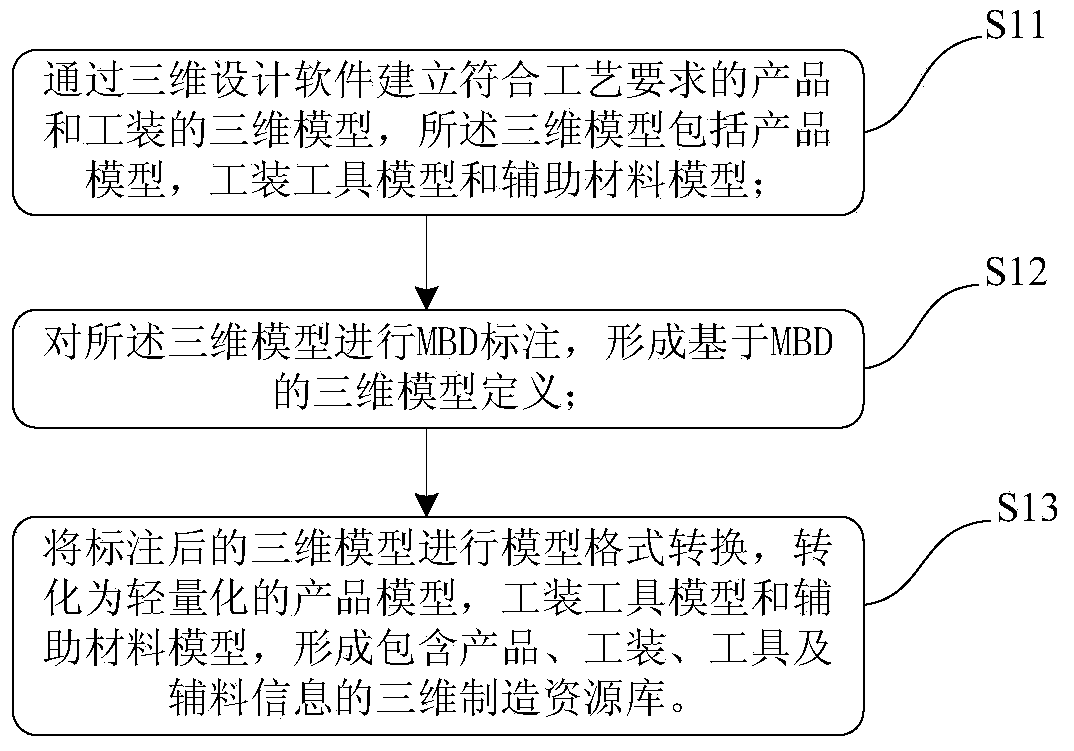

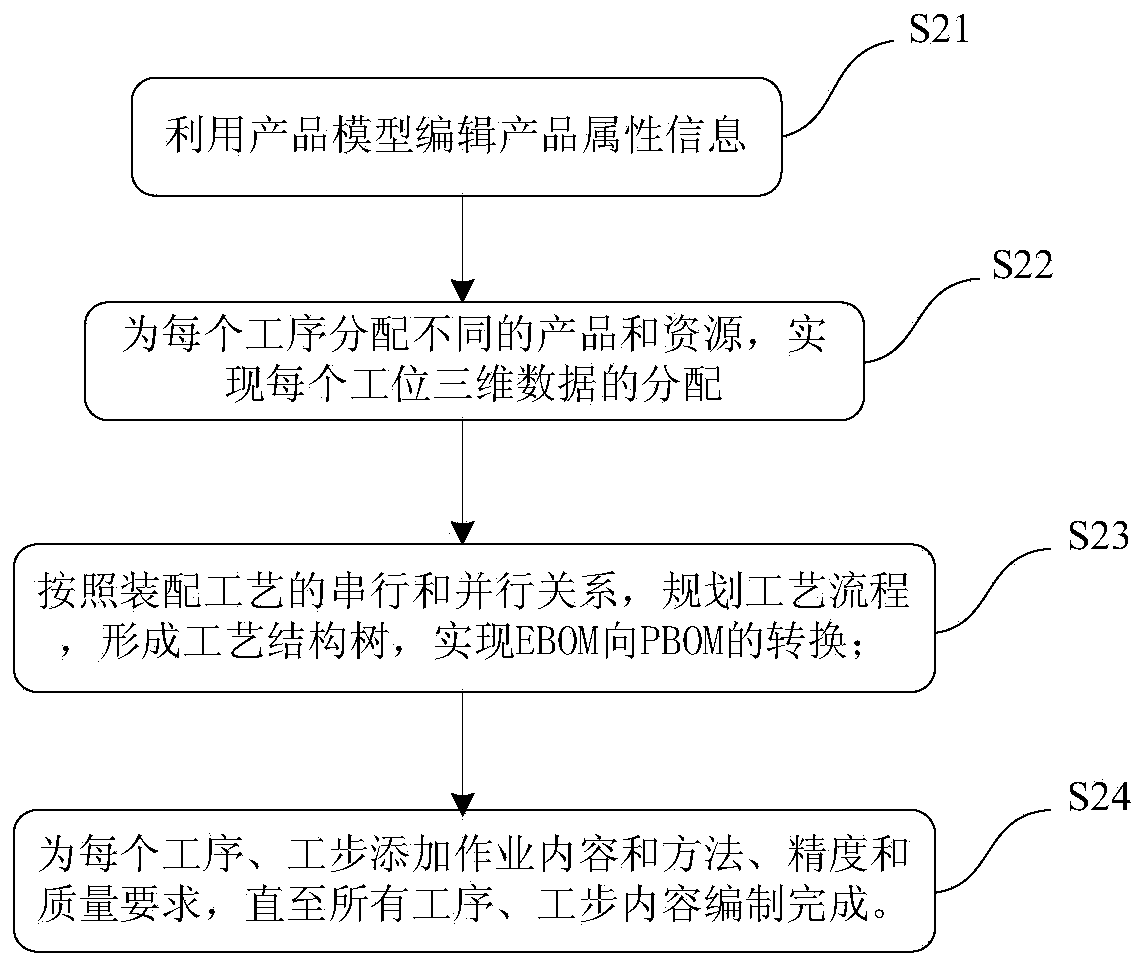

Three-dimensional assembly process generation method and system for aerospace product

InactiveCN103413004AAddressing the information gapAccurate visualizationAnimationSpecial data processing applicationsAnimationInformation gap

The invention provides a three-dimensional assembly process generation method and system for an aerospace product. The system comprises a three-dimensional manufacturing resource library building module, a three-dimensional assembly process design module, a three-dimensional assembly process simulation module and a three-dimensional assembly process release module, the three-dimensional manufacturing resource library building module is used for building a three-dimensional manufacturing resource library containing product, fixture, tool and auxiliary material information, the three-dimensional assembly process design module is used for decomposing process tasks and planning a process according to the built three-dimensional manufacturing resource library to form a process structure tree, the three-dimensional assembly process simulation module is used for building a virtual assembly environment and simulating and analyzing the assembly process according to a three-dimensional model, the assembly process and the process structure tree to form a three-dimensional assembly animation meeting actual assembly requirements, and the three-dimensional assembly process release module is used for integrating process design information and simulation information, forming a three-dimensional assembly process file and releasing the three-dimensional assembly process file to an assembly site. Accurate and visual three-dimensional visual means are provided for aerospace product assembly, so that the problem of information gaps among three-dimensional product design, three-dimensional process design and three-dimensional assembly site implementation in the prior art can be solved.

Owner:SHANGHAI JIAO TONG UNIV

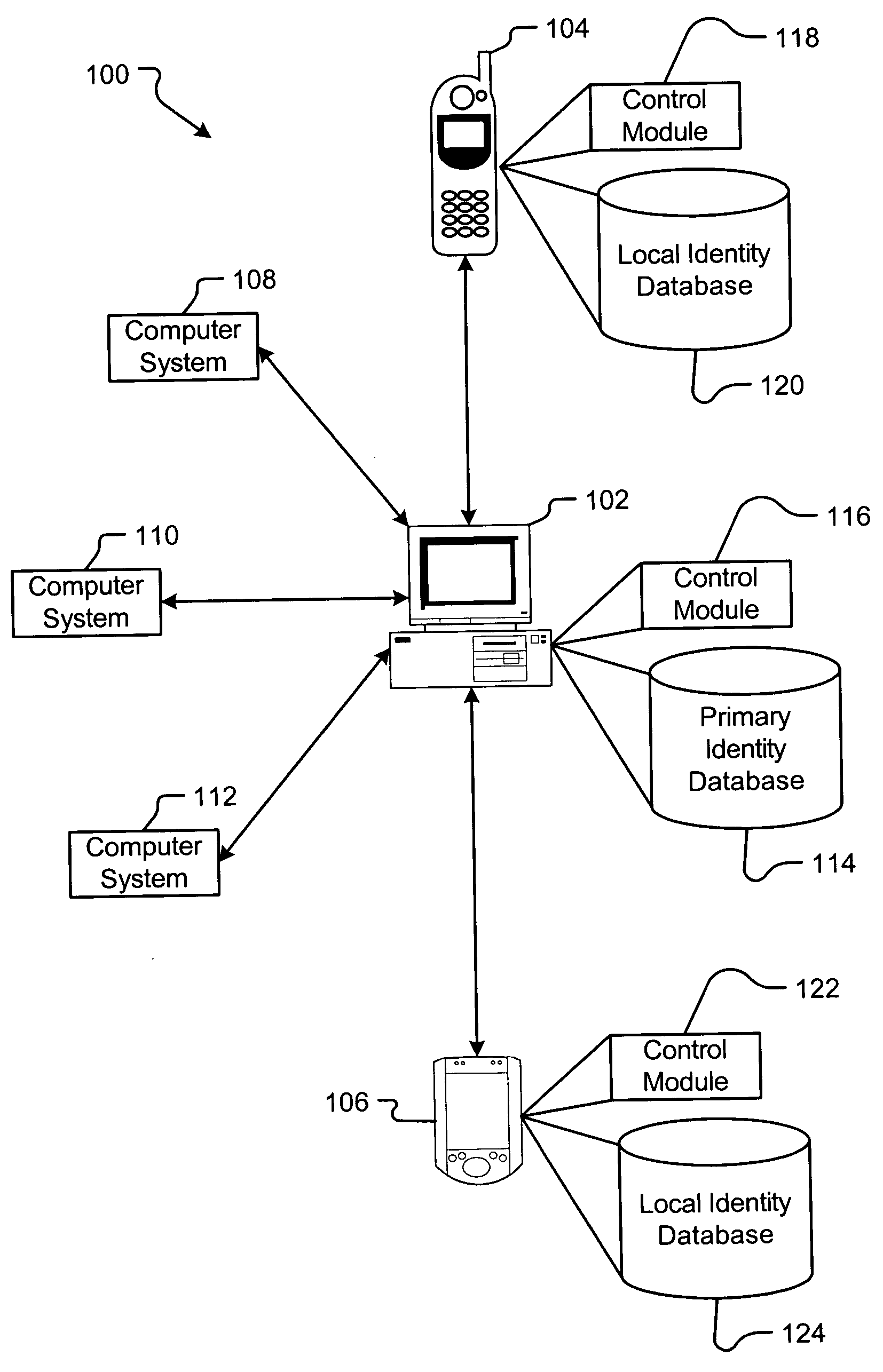

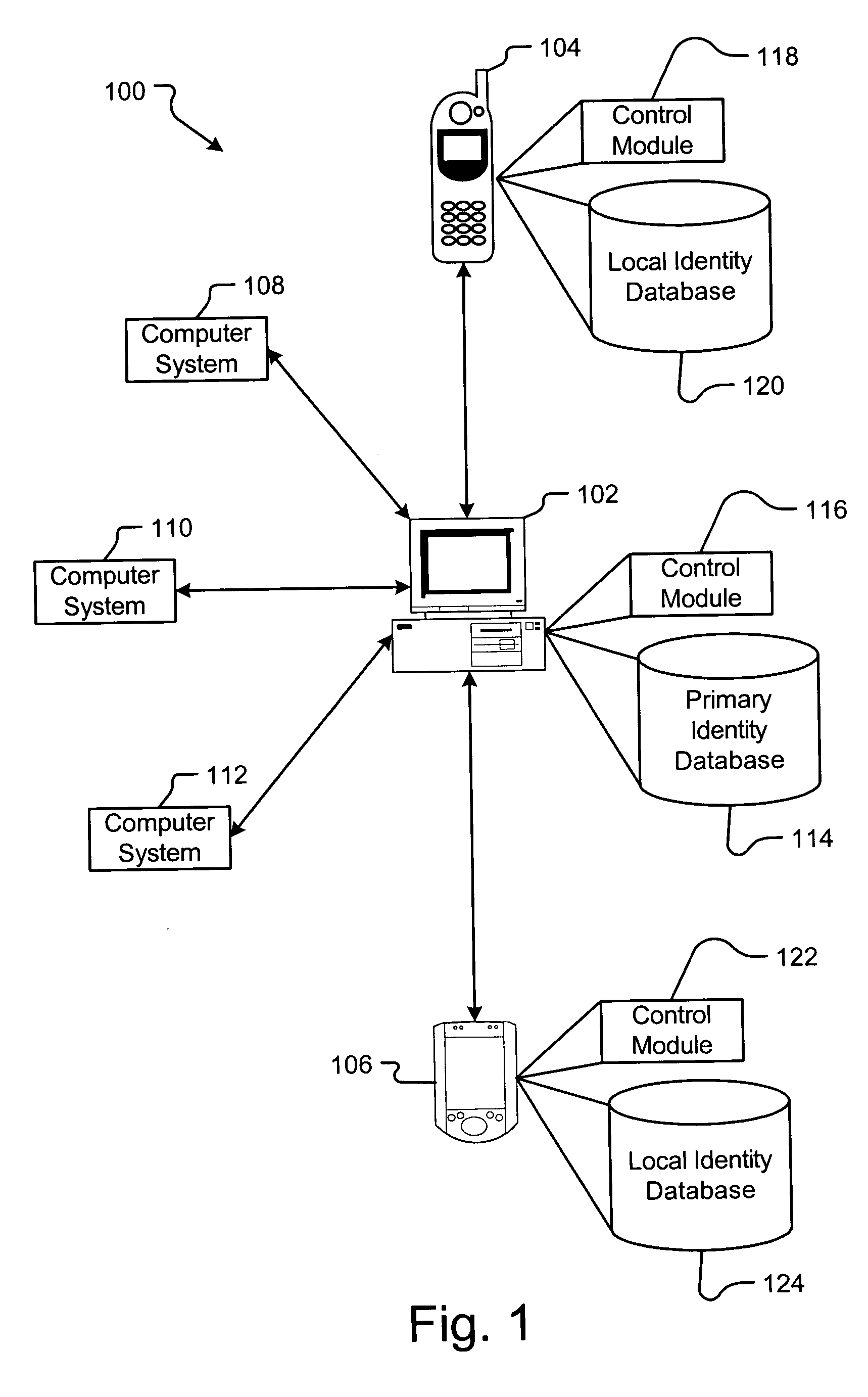

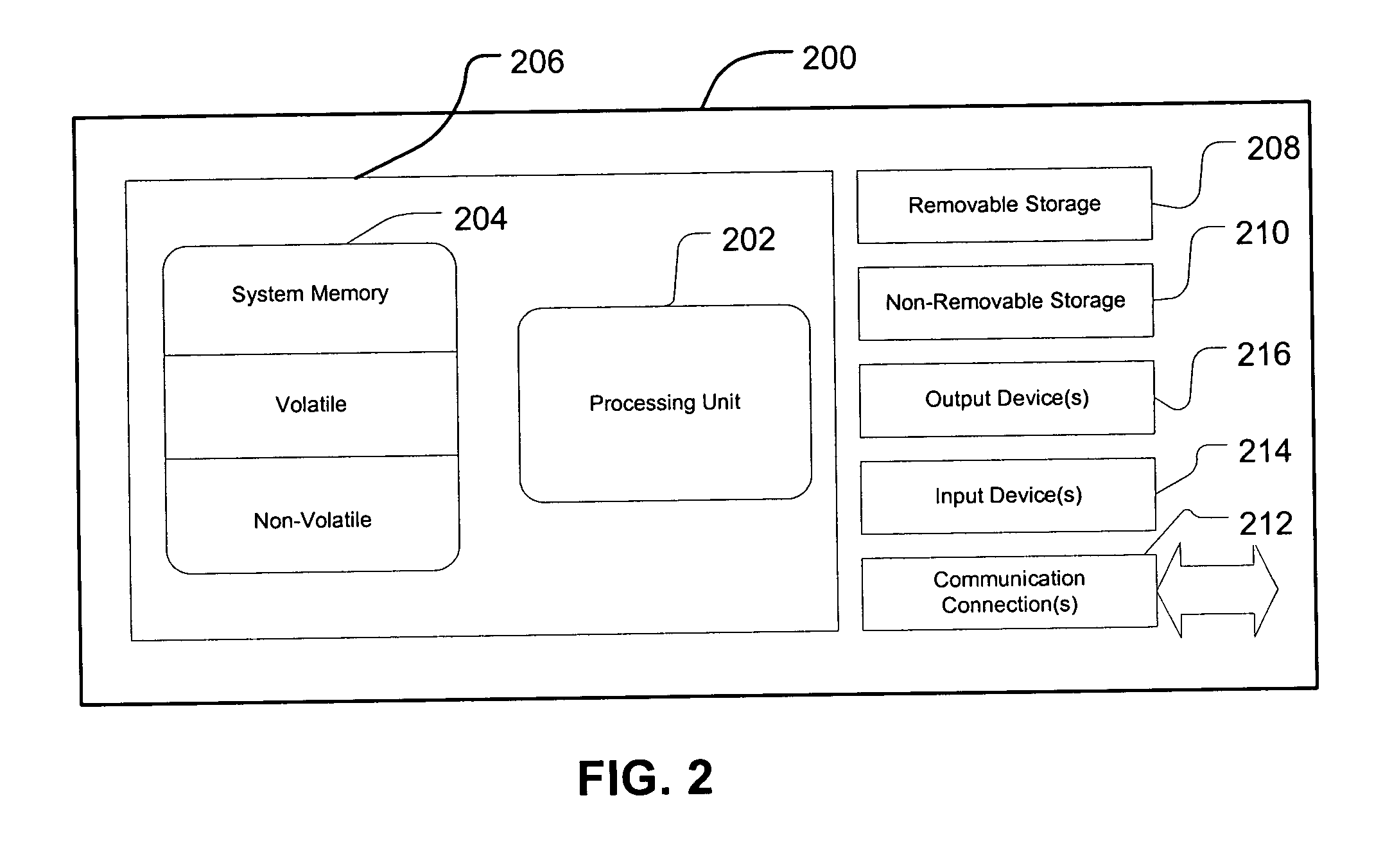

Method and system for synchronizing identity information

ActiveUS20050091290A1Data processing applicationsDigital data processing detailsDisparate systemProcess design

An identity system and method that stores identity information related to different principals and stores the identities on different or disparate systems such that the different systems can use the identities. A synchronization process synchronizes identity information and rules based on identity information between a primary computer system and a disparate secondary computer system. Accordingly, the secondary computer system has a representative database of identity information following receipt of the converted information, wherein the representative database is representative of a primary database of identity information stored on the primary computer system. In order to synchronize a conversion may take place. The conversion process may be performed by a dedicated process designed for the secondary system. Alternatively, the conversion is performed by a generalized process using mapping tables designed to convert identity information into multiple different formats.

Owner:MICROSOFT TECH LICENSING LLC

In situ hardening paste, its manufacturing and use

InactiveUS20090048145A1Reduce the burden onIncrease resistanceImpression capsPeptide/protein ingredientsDiseaseActive agent

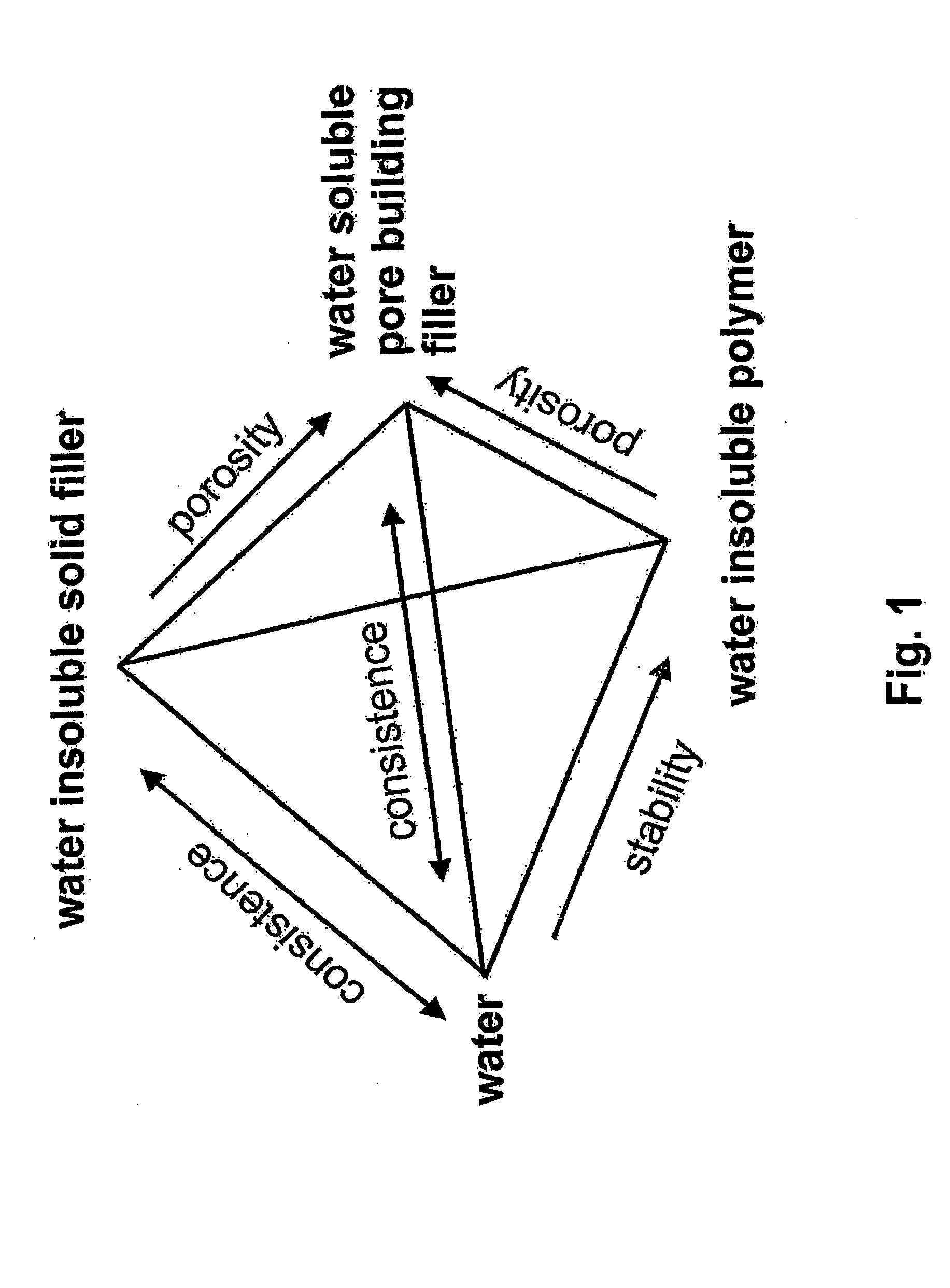

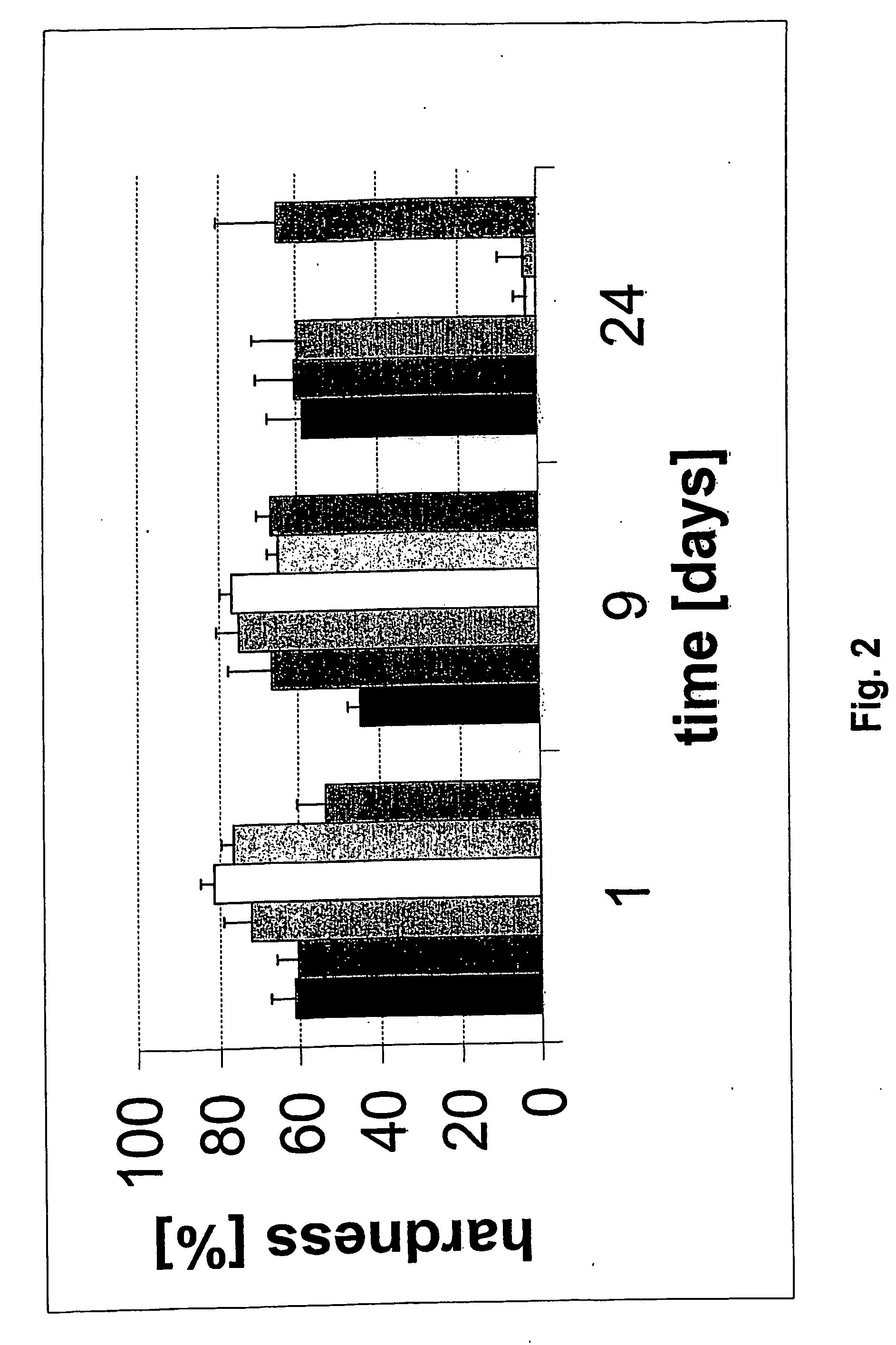

An in-situ-hardening paste, containing an organic or inorganic filling material, a biodegradable polymer and a water soluble polymeric plasticizer was developed as a delivery system for an active agent with scaffold properties in the field of tissue regeneration. The hardened paste is sufficient mechanical stable to can be used as bone and cartilage replacement matrix. All components are full biocompatible, preferably bioresorbable and certified for parenteral application. The sustained release of peptides and proteins can be modulated by the composition and process design. The invention encompasses a pharmaceutical composition comprising the paste of the invention and relates to the use of said paste for the preparation of a pharmaceutical composition to be used for bone augmentation, for treating bone defects, for treating degenerative and traumatic disc disease, for treating bone dehiscence or to be used for sinus floor elevation.

Owner:SCIL TECH GMBH

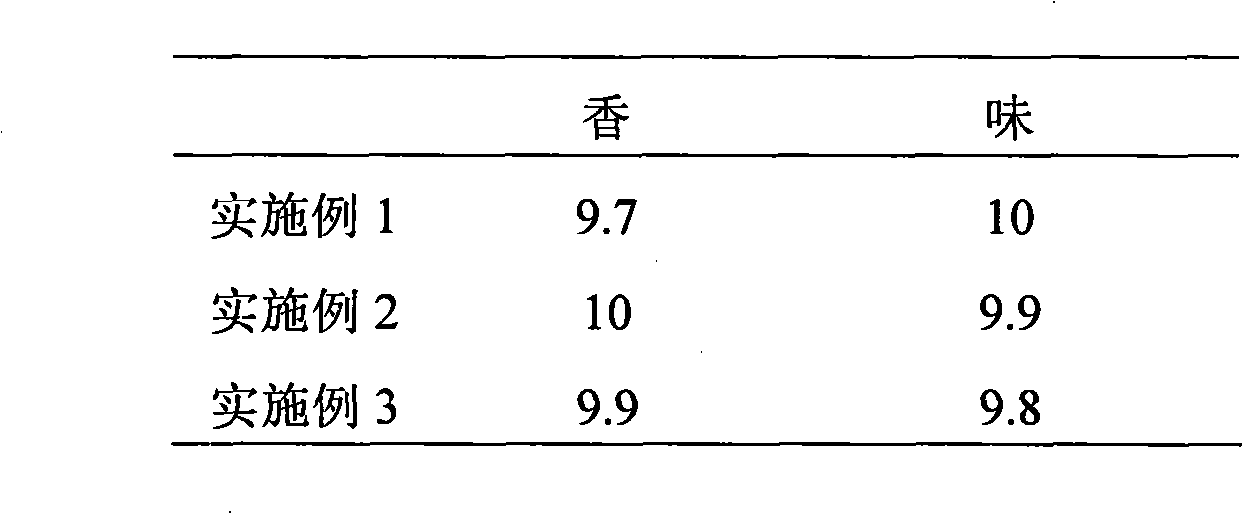

Preparation method of beef chili paste

InactiveCN101623083ASpicy and deliciousLong lastingFood preparationMonosodium glutamateAdditive ingredient

The invention belongs to the food field, which discloses a preparation method of beef chili paste. The method comprises the following steps: weighing the following ingredients according to certain proportion: beef, red chillies, groundnut kernels, white sesame seed, broad bean paste, scallion, ginger, garlic, groundnut oil, sesame oil, salt, monosodium glutamate, white granulated sugar, liquor and spice; dicing the beef, and adding appropriate spice into the beef and uniformly stirring the mixture after water is separated by frying; chipping and then mixing the red chillies, the ginger, the scallion and the garlic, and then frying the mixture till water is separated; deep-frying the groundnut kernels; frying the broad bean paste water is separated; mixing the fried diced beef, the red chillies, the ginger, the scallion, the garlic, the groundnut kernels and the broad bean paste, and then adding the white sesame seed, the salt, the monosodium glutamate, the white granulated sugar, the liquor and the balance spice, and stirring the mixture uniformly while frying; mixing and boiling the balance groundnut oil and the sesame oil, and soaking the materials which are fried and stirred uniformly after being cooled. The preparation method has the advantages that the method is convenient and simple, the process design is reasonable, and the prepared beef chili paste is characterized in that the paste is spicy and hot, fresh and fragrant, spicy but not dry, fresh but not greasy, the taste quality is lasting, and the people are not tired of always eating the beef chili paste.

Owner:辛保山

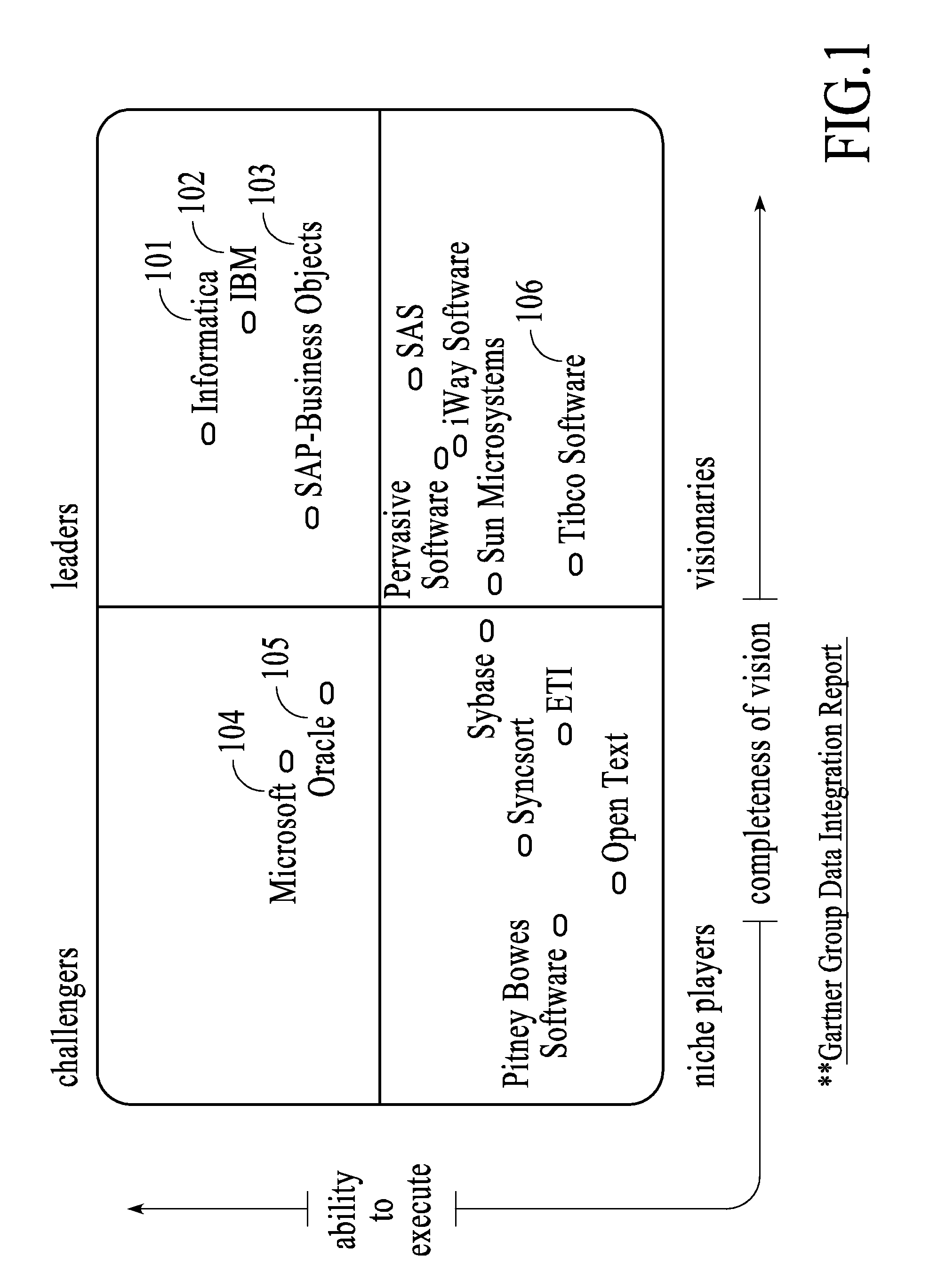

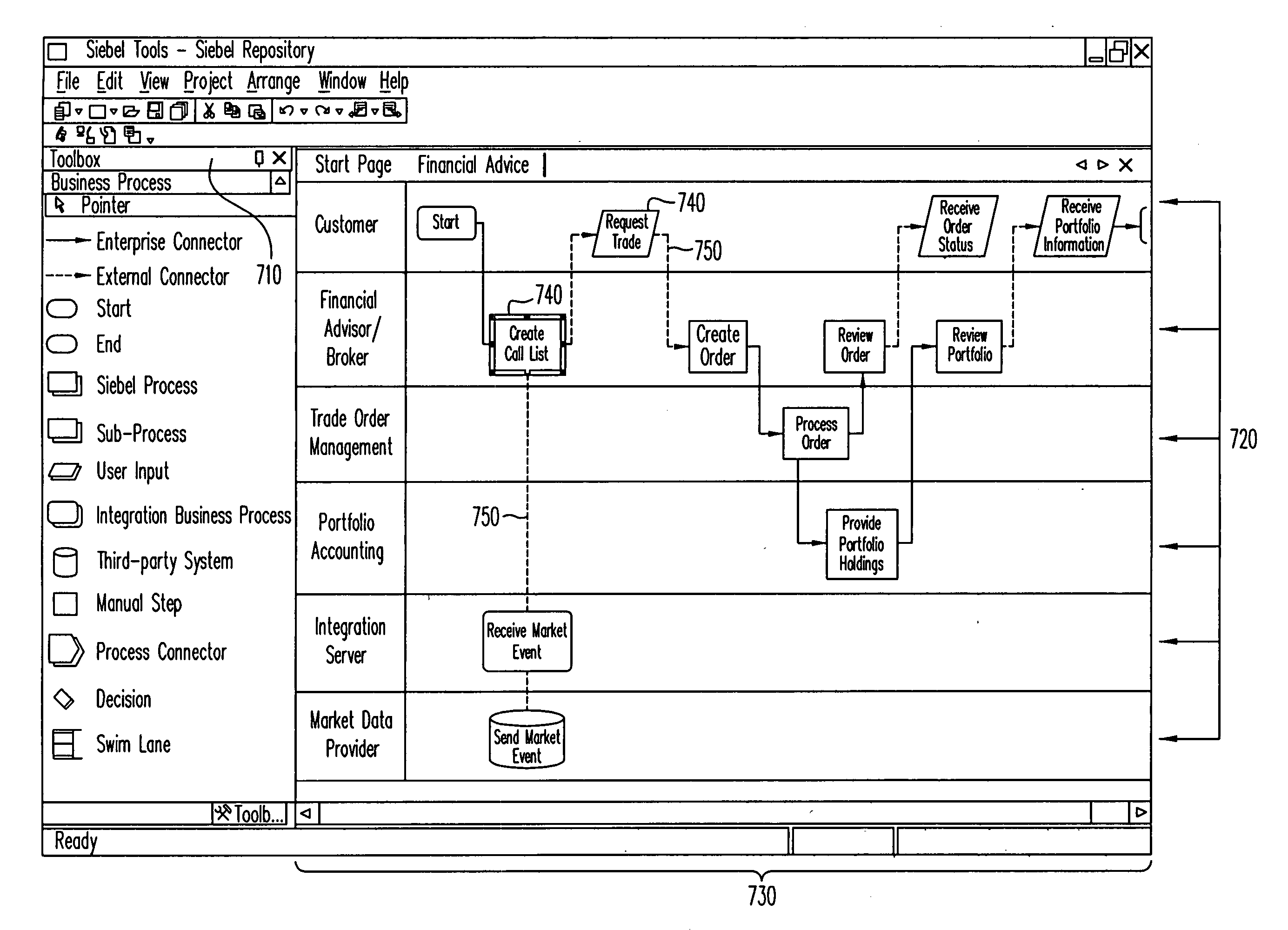

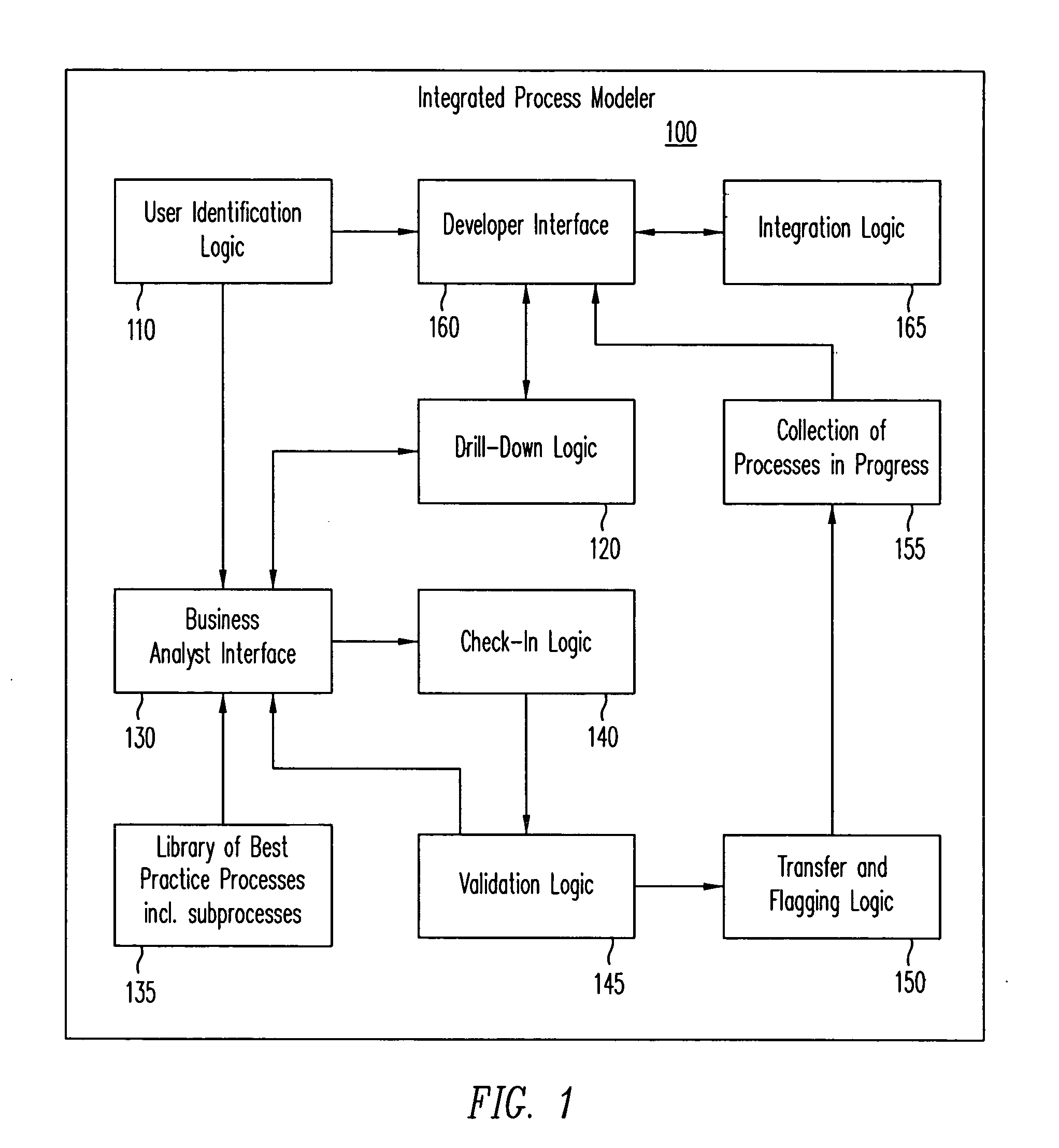

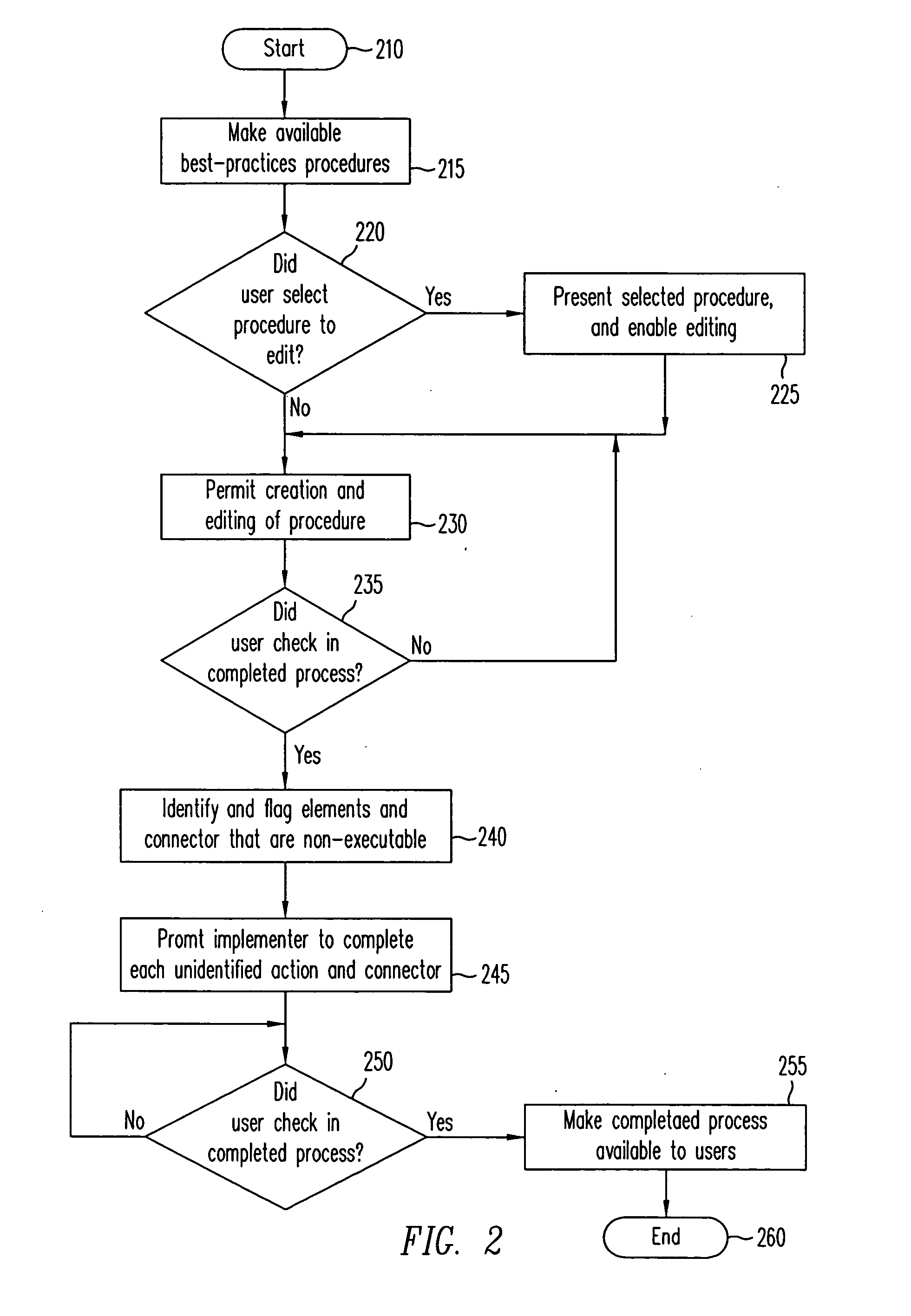

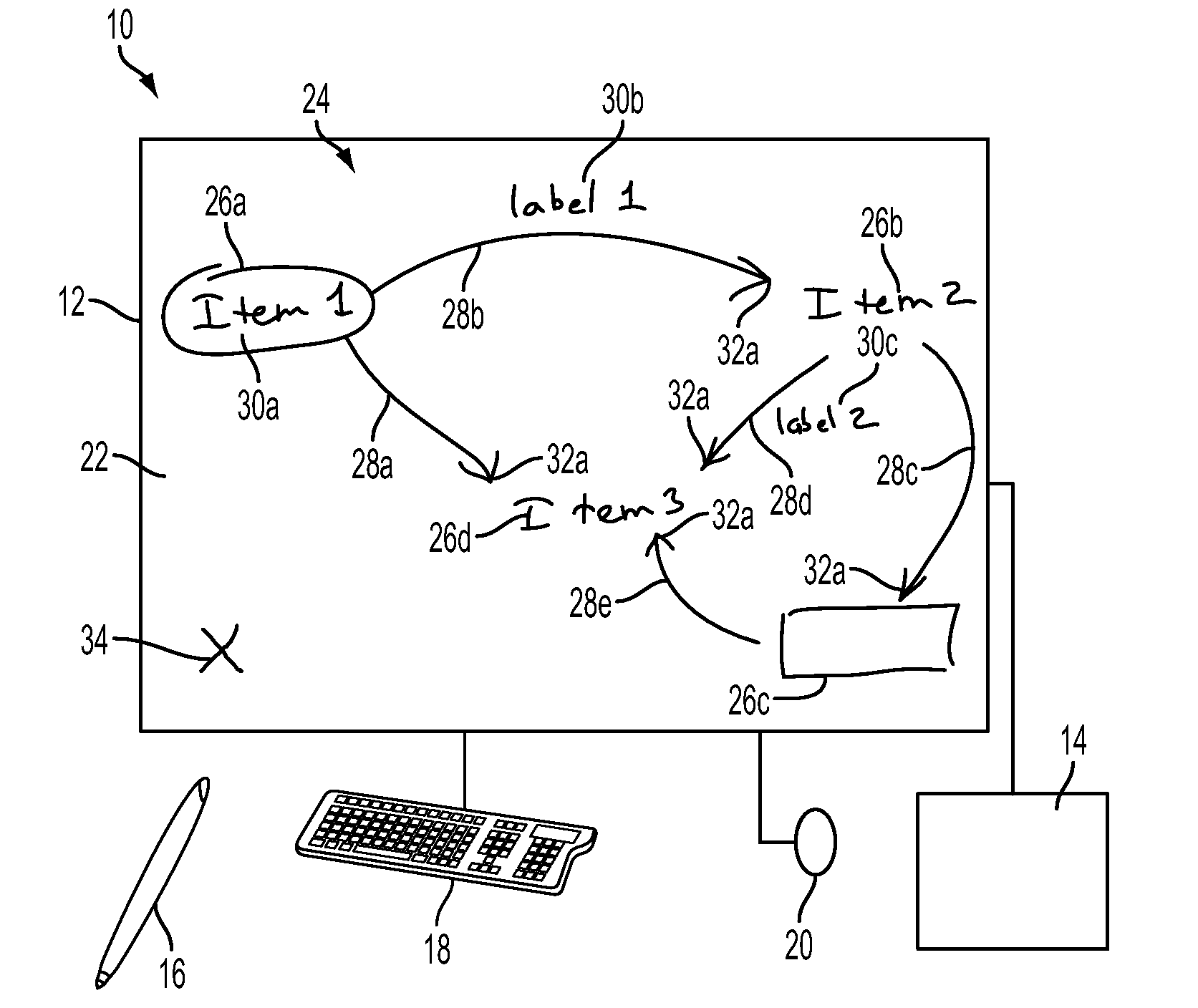

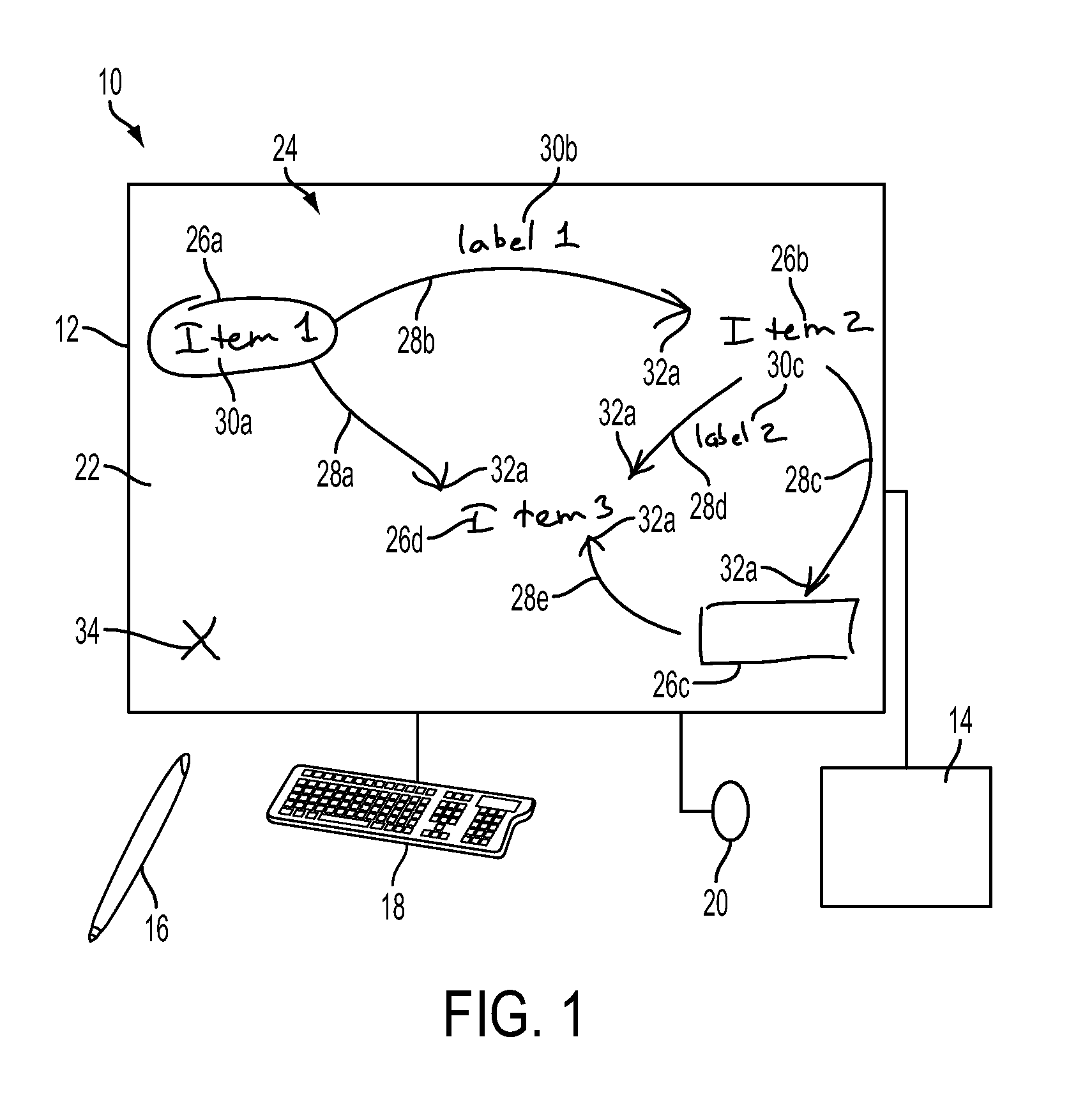

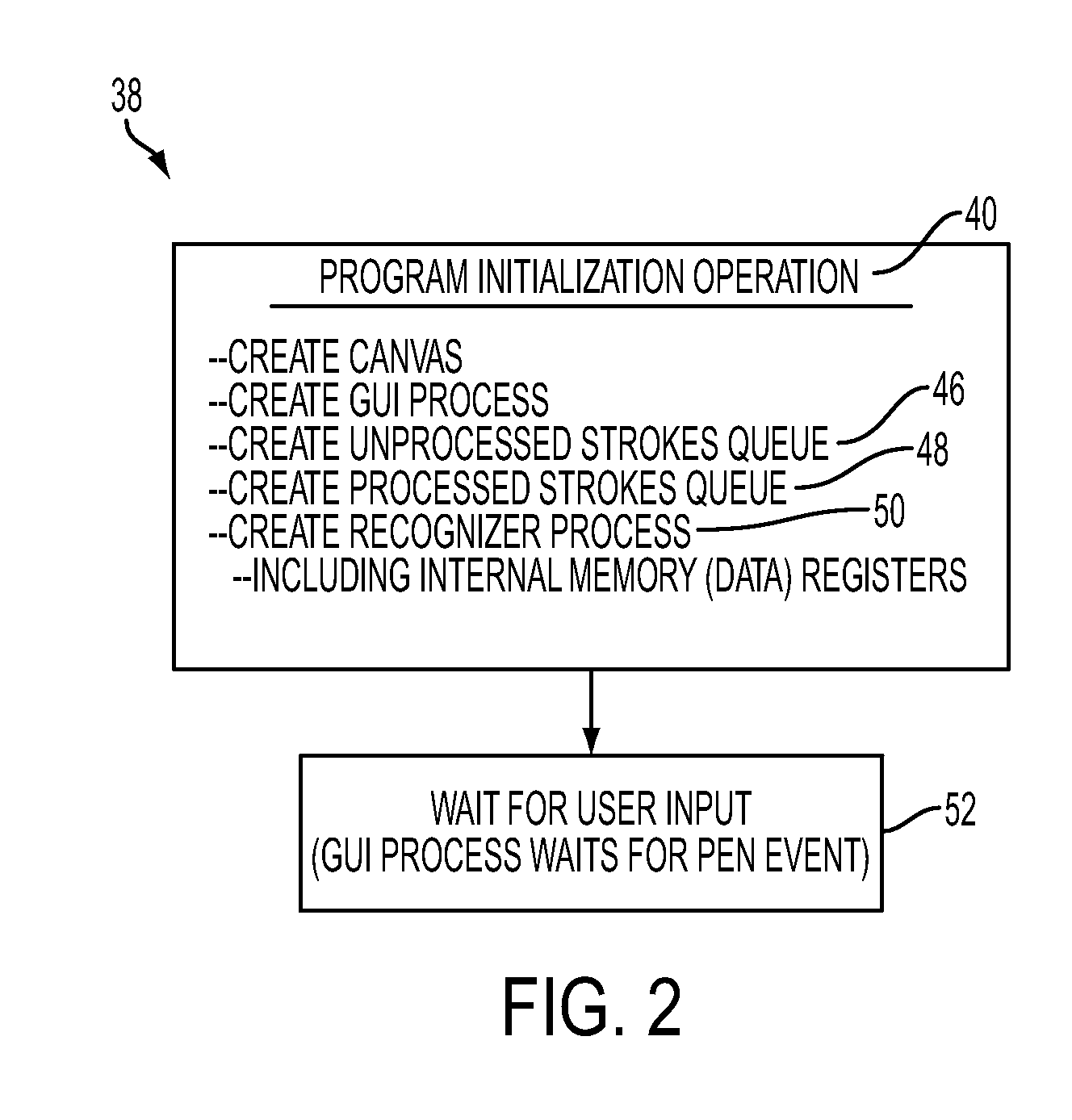

Method and apparatus to present an integrated process modeler

A method and apparatus for an integrated process modeler is described. The modeler comprises a non-technical interface to permit design of a business process by a non-technical use and a technical interface to implement substeps of the process to automate technical aspects of the process by a technical user, using the same process modeler. The resulting process designed to be used by non-technical employees, to automatically lead the non-technical employees through the business process.

Owner:SIEBEL SYST INC

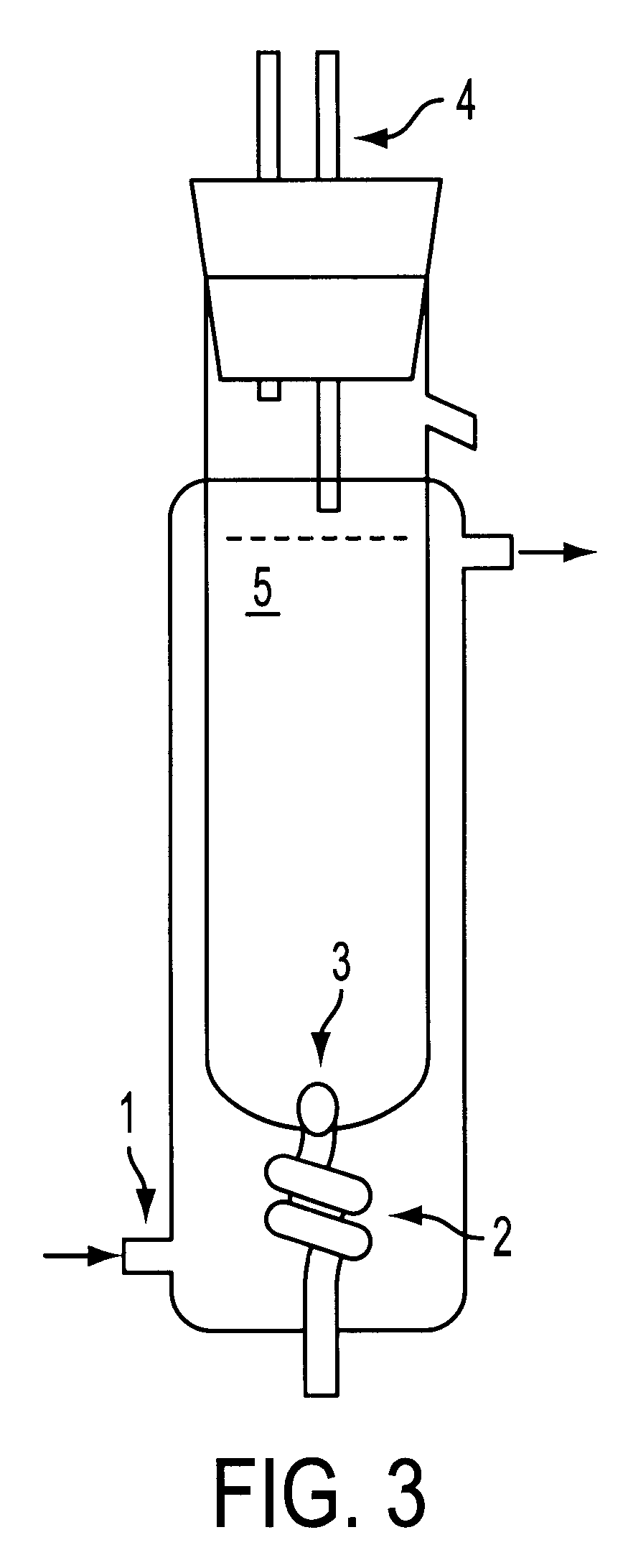

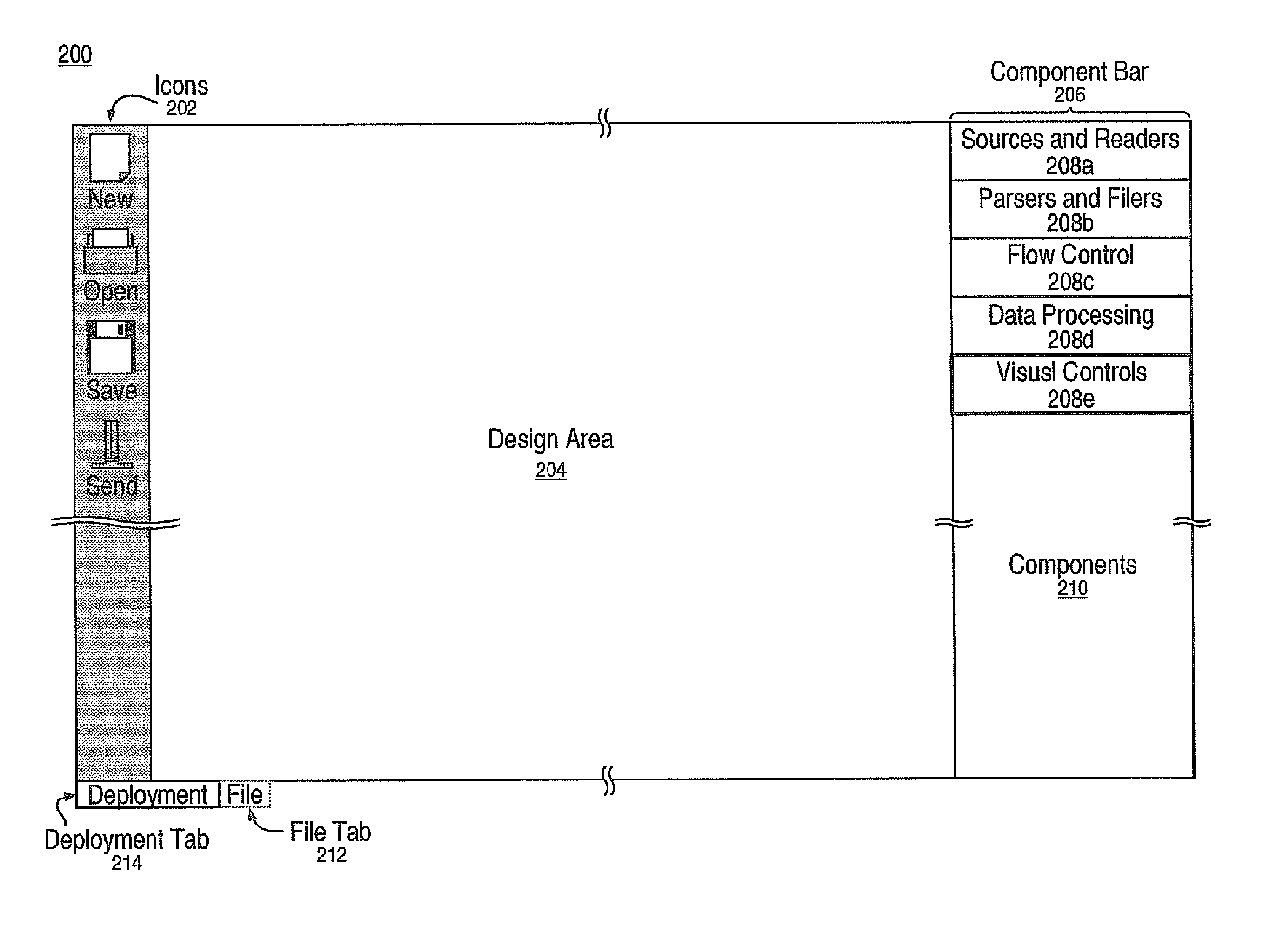

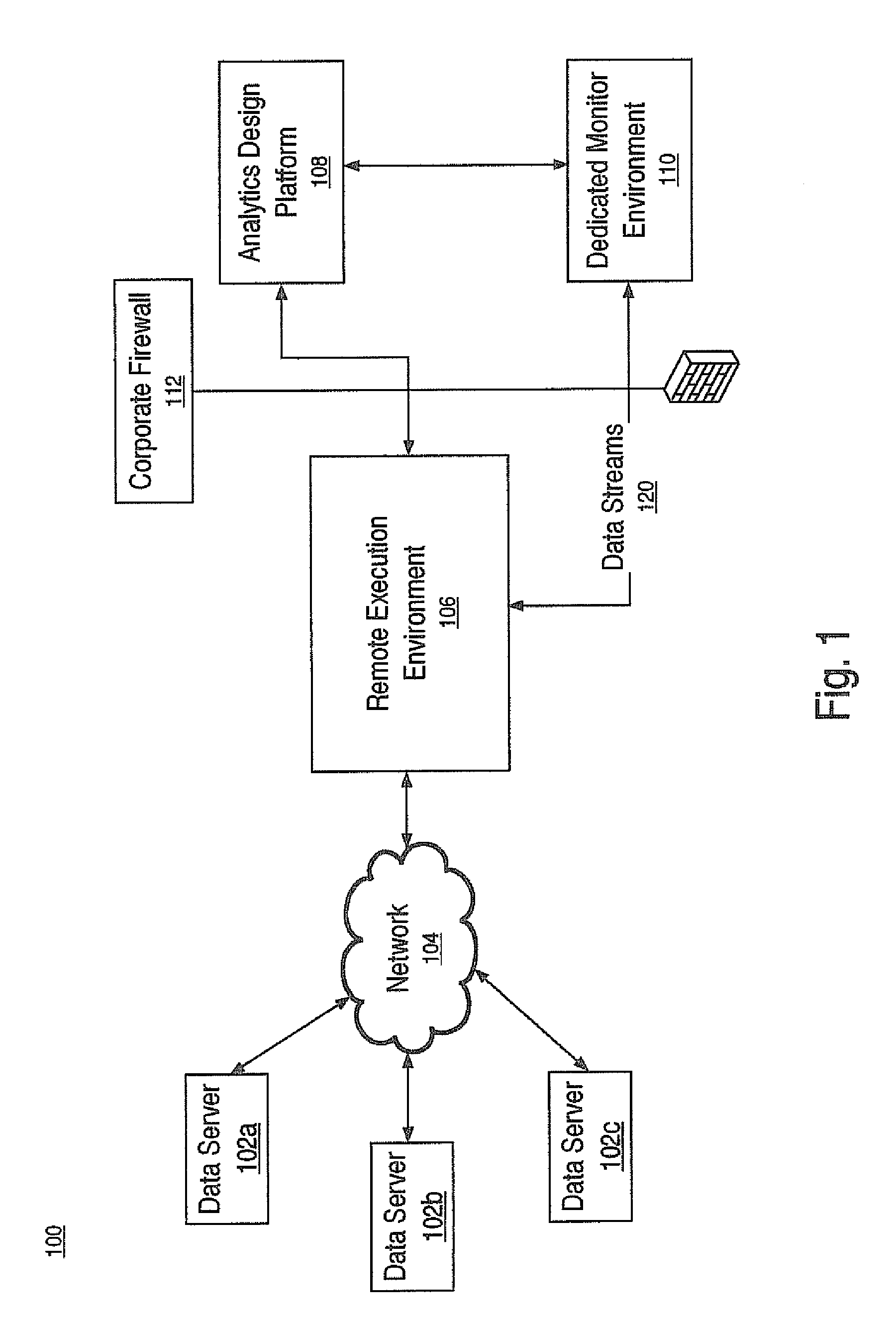

System and method for analytic process design

InactiveUS20110302551A1Efficient developmentDatabase management systemsVisual data miningData displayElectronic systems

Embodiments of the present invention are directed to a method and system for developing an analytic process. The method includes displaying, within an electronic system, a plurality of components operable to be used for designing a data analysis process. A user makes a selection of a data access component from the plurality of components. The data access component is operable for configuring access to a data source. The method further includes the user making a selection of a data selection component from the plurality of components and a data display component. The data selection component is operable for selecting data accessed via the data access component. The data display component is operable for configuring display of data based on the data selection component. Configuration data corresponding to the data access component, the data selection component, and the data display component can then be stored.

Owner:ACCENTURE GLOBAL SERVICES LTD

Optimization method and process using tree searching operation and non-overlapping support constraint requirements

InactiveUS20080235211A1Digital data information retrievalDigital data processing detailsTheoretical computer scienceProcess design

A method and process provides a selection process designed to select optimized results from a plurality of possible results represented in a search tree. A tree search is employed, wherein bounds are used to prune at least one node or branch of the search tree. A non-overlapping support constraint in conjunction with the tree search is invoked to further prune the search tree. An optimized search tree is stored into a memory, following the invoking of the non-support constraint, and the optimized search tree is employed in additional processing operations.

Owner:PALO ALTO RES CENT INC

Method for producing propylene oxide

ActiveCN101735177AReduce investmentAchieve recyclingOrganic chemistryDispersed particle separationProcess designSodium hydroxide

The invention discloses a chemical production method, in particular a novel green production process for propylene oxide. In the method, the process design is carried out by using bipolar membrane, electrodialysis, antiosmosis, air flotation, heat exchange, oxidation, and other technology. In the production process, sodium hydroxide replaces the conventional calcium hydroxide and generates sodium chloride through reaction; the sodium chloride generates hydrochloric acid and sodium hydroxide by the bipolar membrane technology; and the hydrochloric acid is recovered, and the sodium hydroxide and water can be recycled. Therefore, no new sodium hydroxide is needed and no wastewater is discharged in the production of the propylene oxide. The sodium hydroxide is added at the preliminary stage of the production of the propylene oxide, and the input amount of the sodium hydroxide is controlled between 5 and 15 percent. The novel green production process for the propylene oxide has the advantages that: the recycling of the water, sodium chloride and sodium hydroxide is realized, the effects of zero discharge and input reduction of production materials are substantially achieved, and finally better social and economic benefits are achieved. The novel green production process for the propylene oxide can be widely applied to the chlorohydrin production in China.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

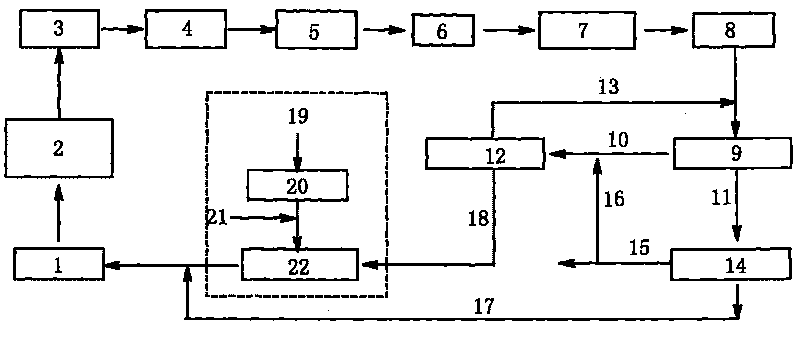

Method for smelting and extracting platinum metal from alumina-supported petrochemical catalyst

The invention discloses a method for smelting and extracting platinum metal from an alumina-supported petrochemical catalyst, and the method comprises the following steps: mixing the alumina-supported petrochemical catalyst with a trapping agent, a reductant and a slag forming agent and then smelting to trap the platinum metal from the alumina-supported petrochemical catalyst to obtain subsidiary product and alloy containing the platinum metal; using a sulfuric acid solution to dissolve the alloy containing the platinum metal to separate noble metal and base metal so as to obtain noble metal ore; and refining the noble metal ore to obtain the platinum metal product. The method disclosed by the invention has the characteristics that the process design does not produce wastewater, the wastewater treatment and filtration difficulty in a wet treatment process of the alumina-supported petrochemical catalyst are avoided, the recycling rate is higher than 98%, and the product purity is 99.95%.

Owner:KUNMING INST OF PRECIOUS METALS

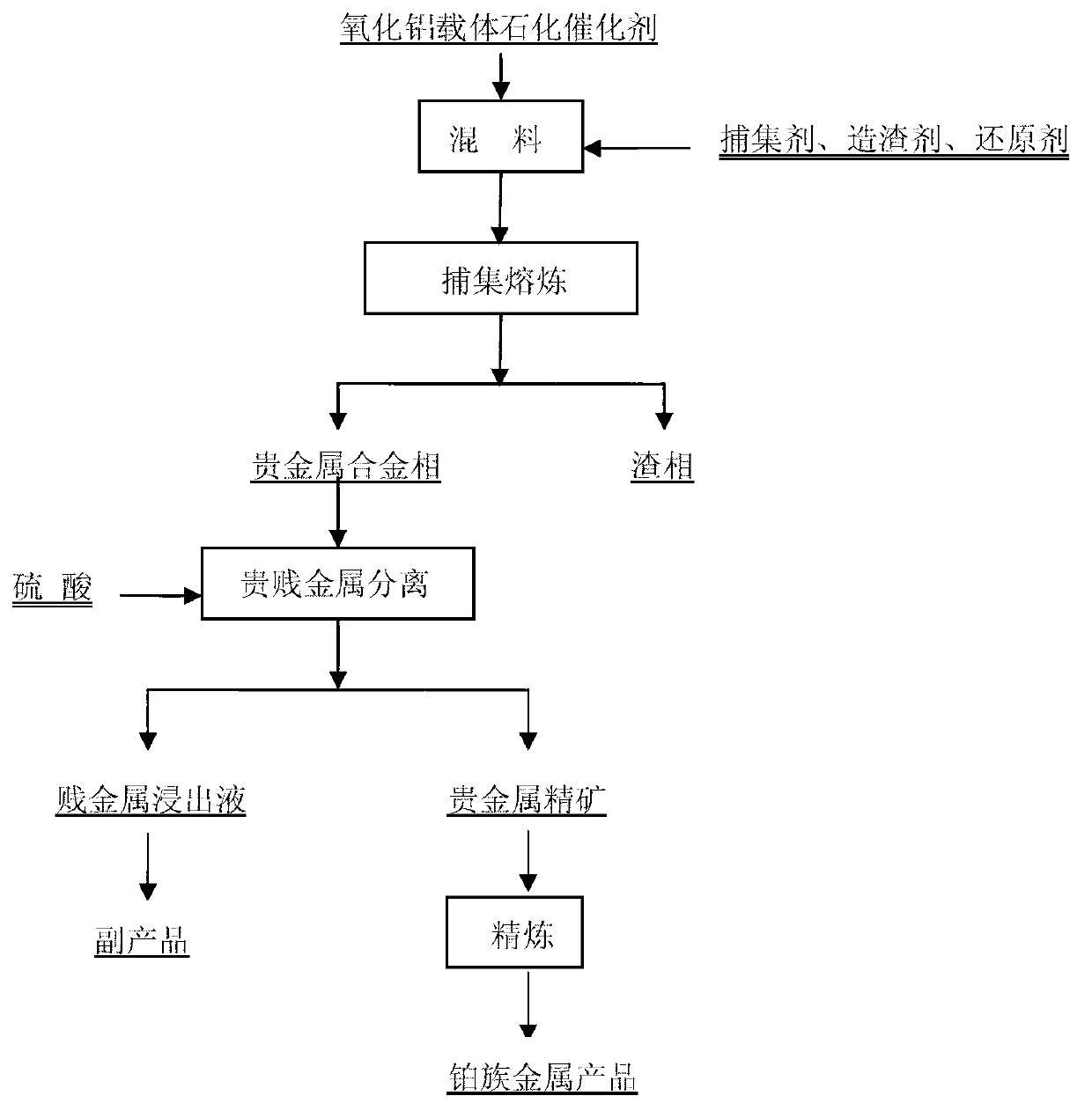

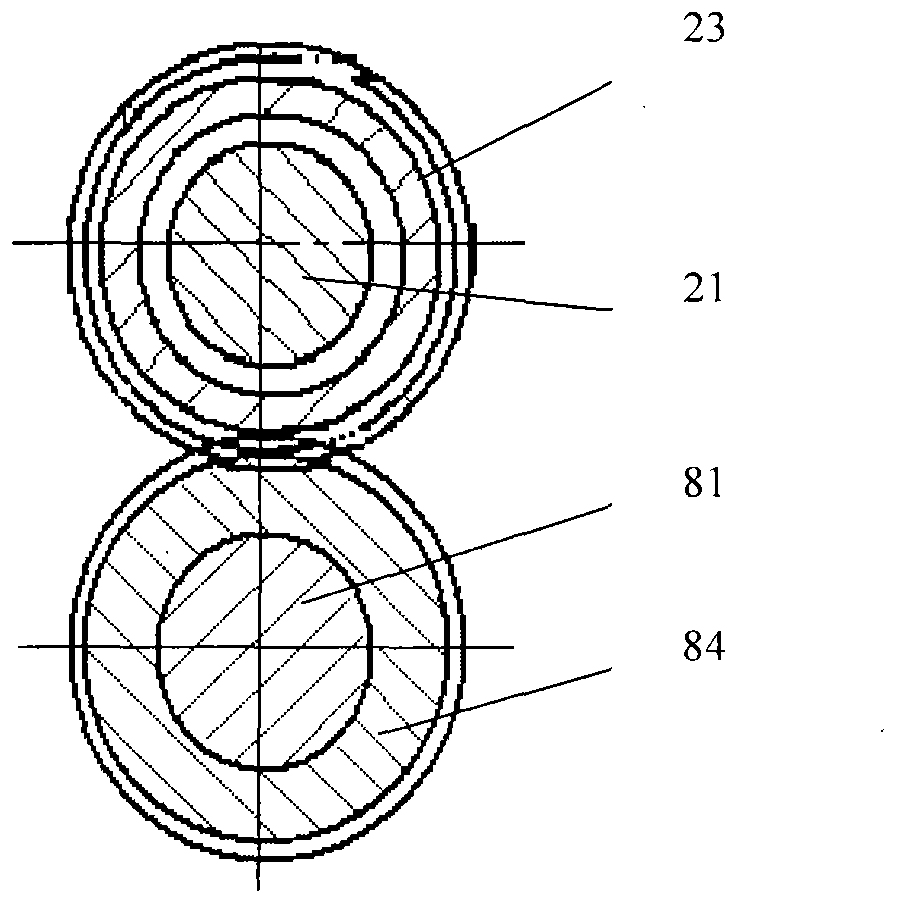

Method for spinning section-color yarns and drafting mechanism for spinning

The invention discloses a method for spinning section-color yarns and a drafting mechanism for spinning. At the rear drafting area of the drafting mechanism, leather rings are used for guiding and controlling yarns, namely a group of upper leather rings and a group of lower leather rings are used for controlling two groups of fiber fringes respectively, so for the rear drafting area of the drafting mechanism, the capacity of controlling free fibers is improved, when the drafting ratio at the rear area is changed greatly in sections, the stability of drafting of each sectional process is kept, and evenness and a sectional color effect of section-color resultant yarns are ensured. In the respect of product process design, the drafting ratio of the rear area is increased, and the transition length of the two groups of fibers between every two sections is shortened.

Owner:陈伟雄

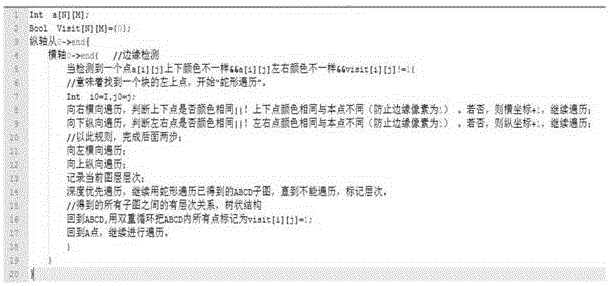

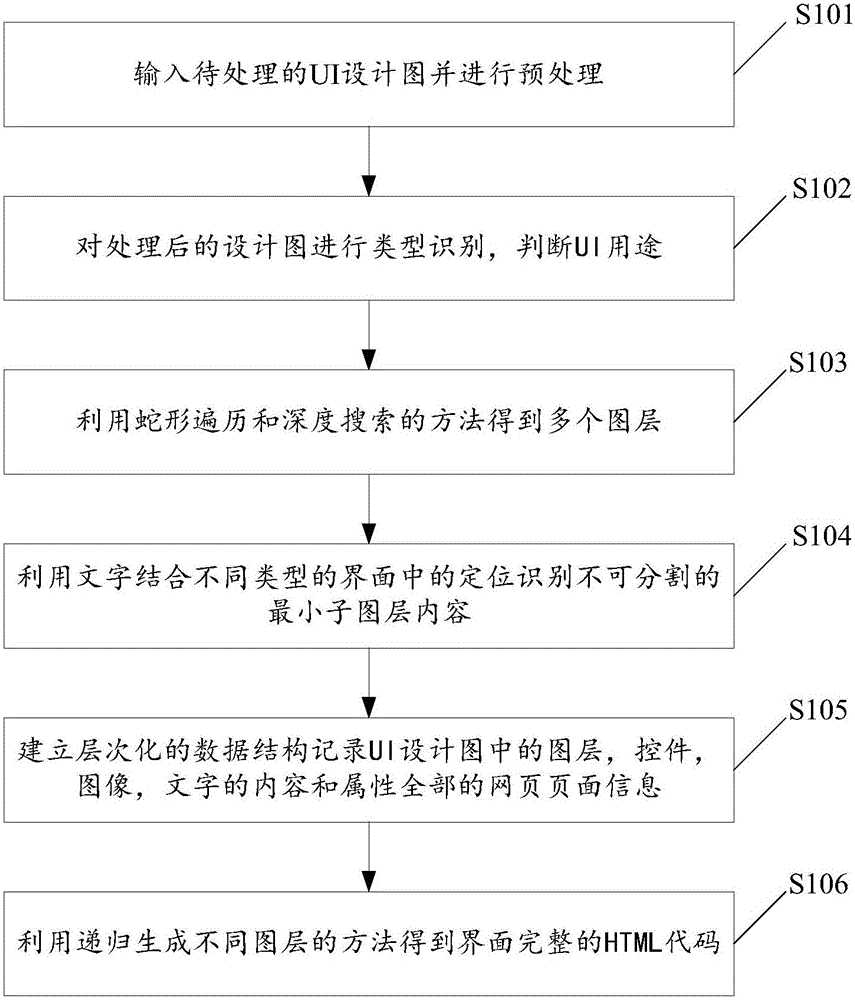

Image-based interface code generation method and system

ActiveCN105930159AImprove picture qualityImprove conversion efficiencySoftware engineeringSpecific program execution arrangementsCode conversionProcess design

Embodiments of the invention disclose an image-based interface code generation method and system. The method comprises the steps of inputting a to-be-processed UI design graph and performing preprocessing; performing type identification on the processed design graph and judging use of a UI; obtaining a plurality of graphic layers by utilizing snake-like traversal and deep search methods; identifying indivisible minimum sub-graphic layer content in combination with positioning in different types of interfaces by utilizing texts; establishing a hierarchical data structure for recording webpage information of the graphic layers in the UI design graph, controls, images, text content and attributes; and obtaining a complete HTML code of the interface by utilizing a method for generating different graphic layers by recursion. According to the embodiments of the method and system, the code conversion efficiency of the image interface is enhanced and the user experience is improved.

Owner:SUN YAT SEN UNIV

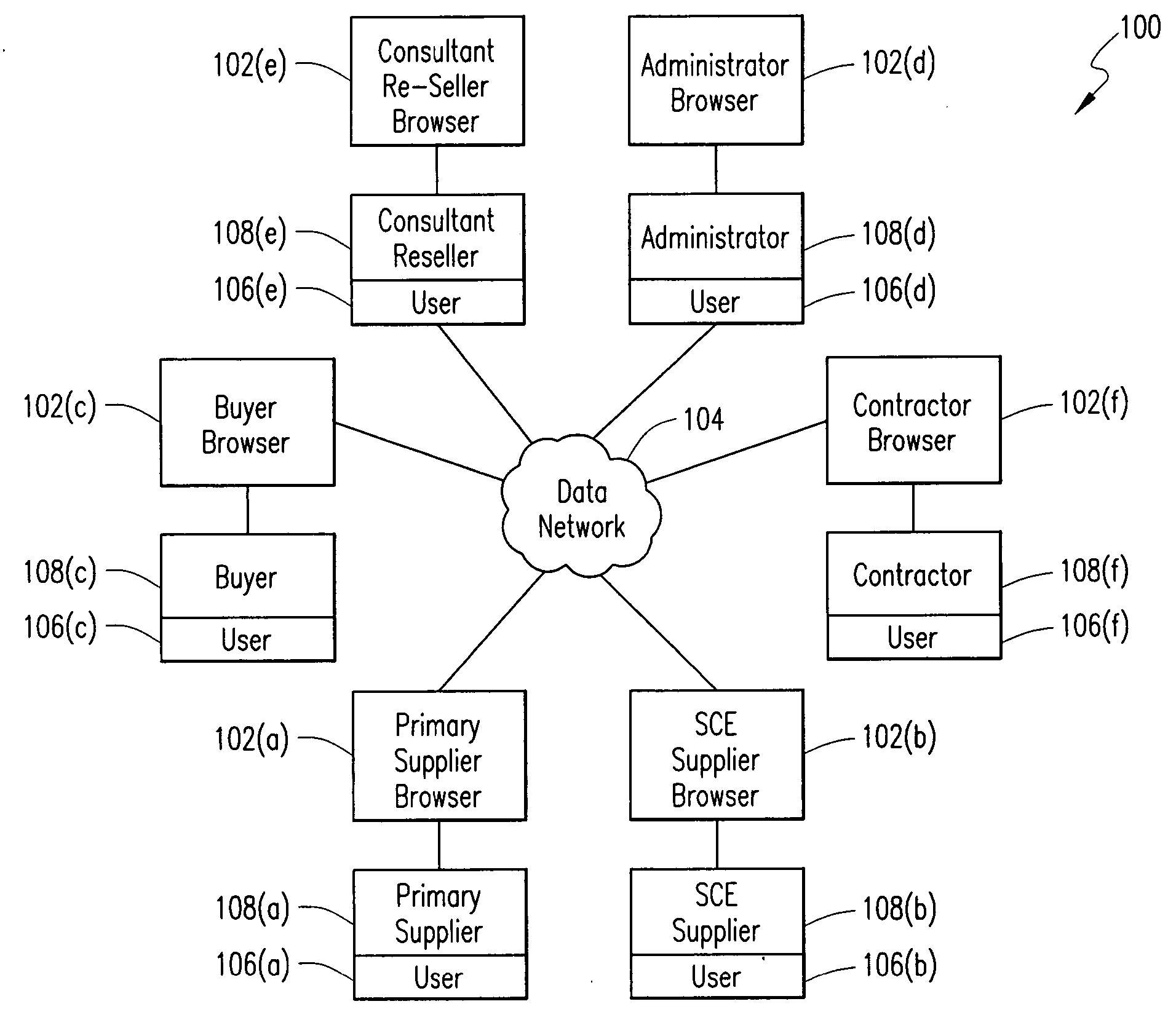

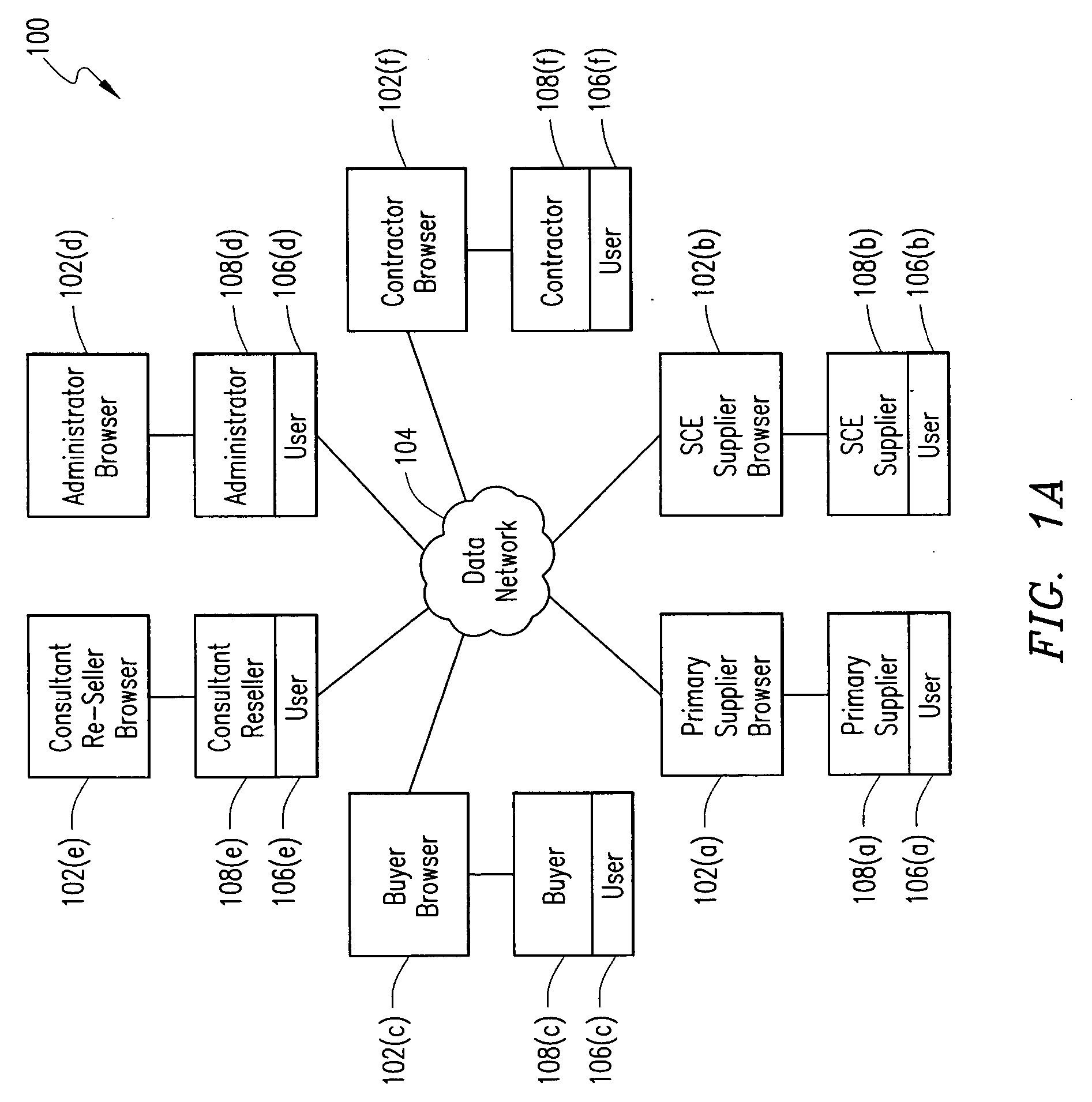

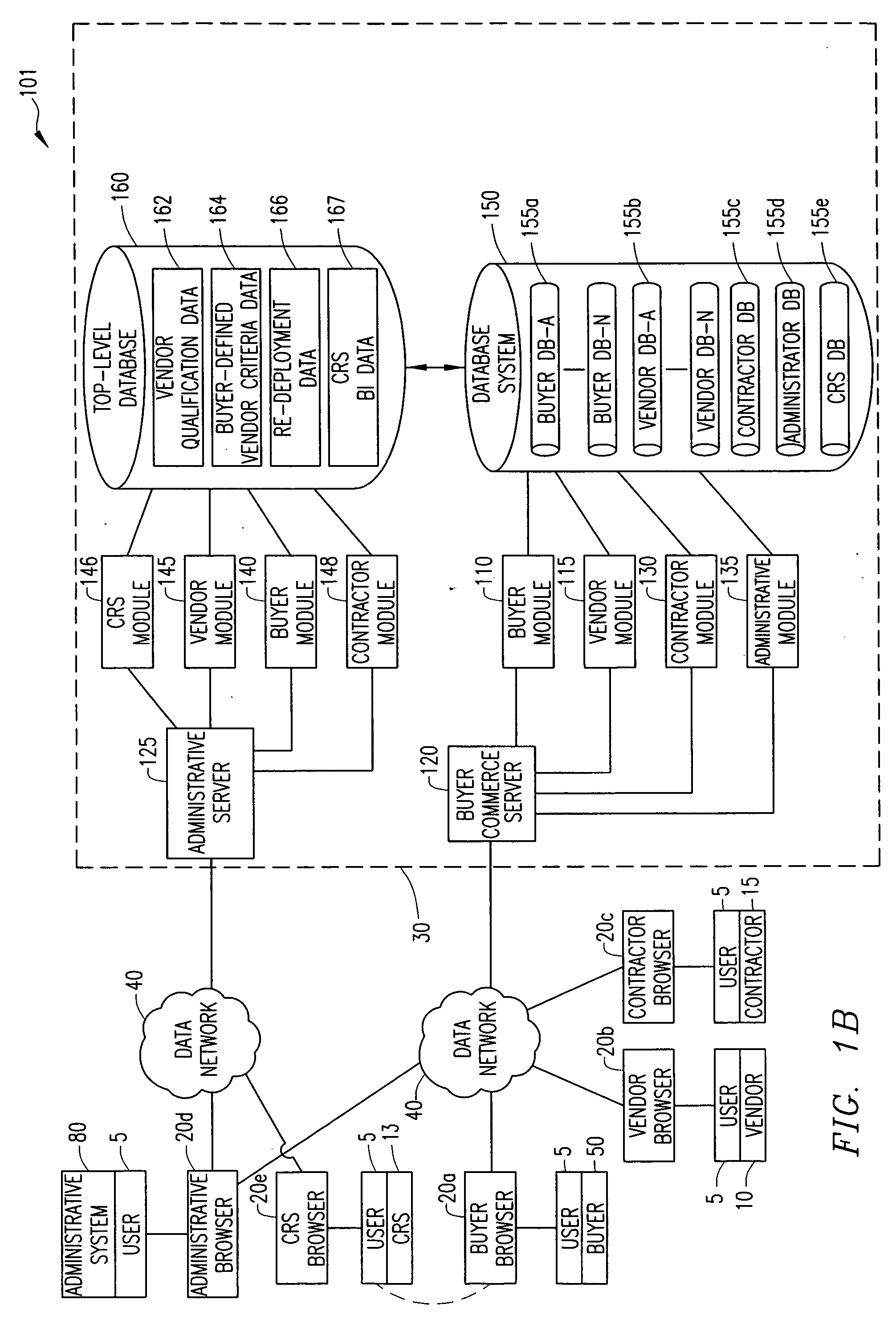

Method of and system for consultant re-seller business information transfer

A computer system for storing of business information to be transferred from a consultant to a buyer includes a database system for maintaining configurable business information organized into a plurality of information components and a server connected to the database system and connectable to the buyer and the consultant. The server is operable to receive a selection of an information component and configure the information component in accordance with consultant instructions. The configuration includes establishing a data value library and creating an information setting the server is operable to integrate the information setting into at least one work flow entity and integrate the at least one work flow entity into a process design. This Abstract is provided to comply with rules requiring an Abstract that allows a searcher or other reader to quickly ascertain subject matter of the technical disclosure. This Abstract is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:IQNAVIGATOR

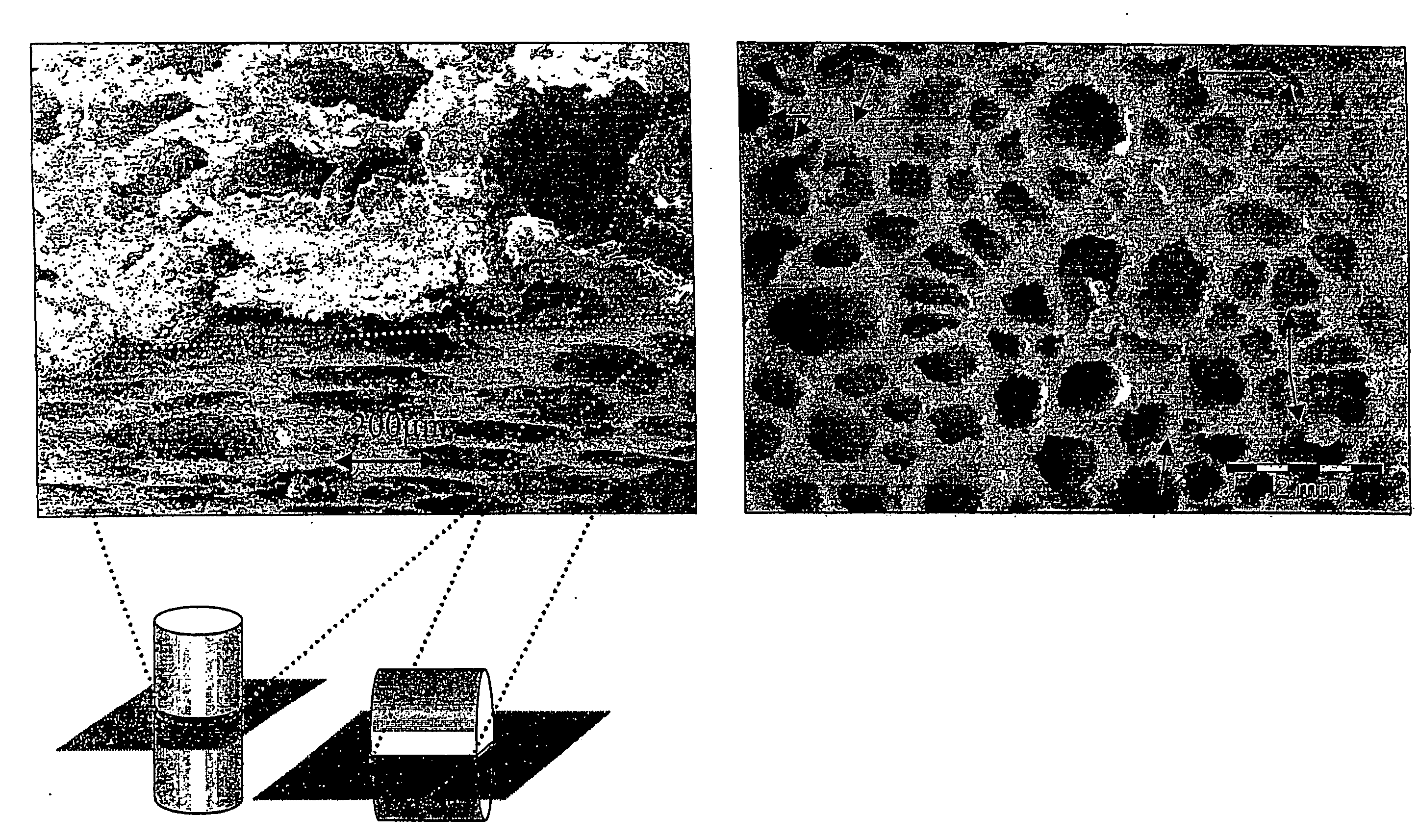

Saw devices, processes for making them, and methods of use

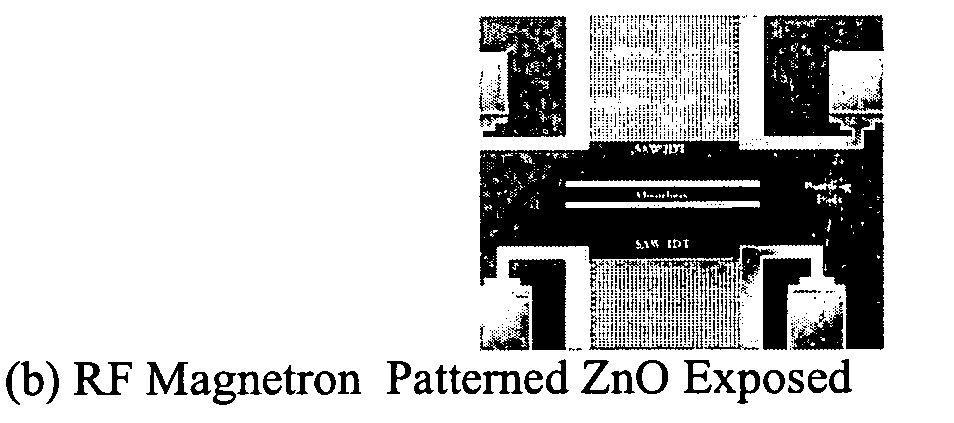

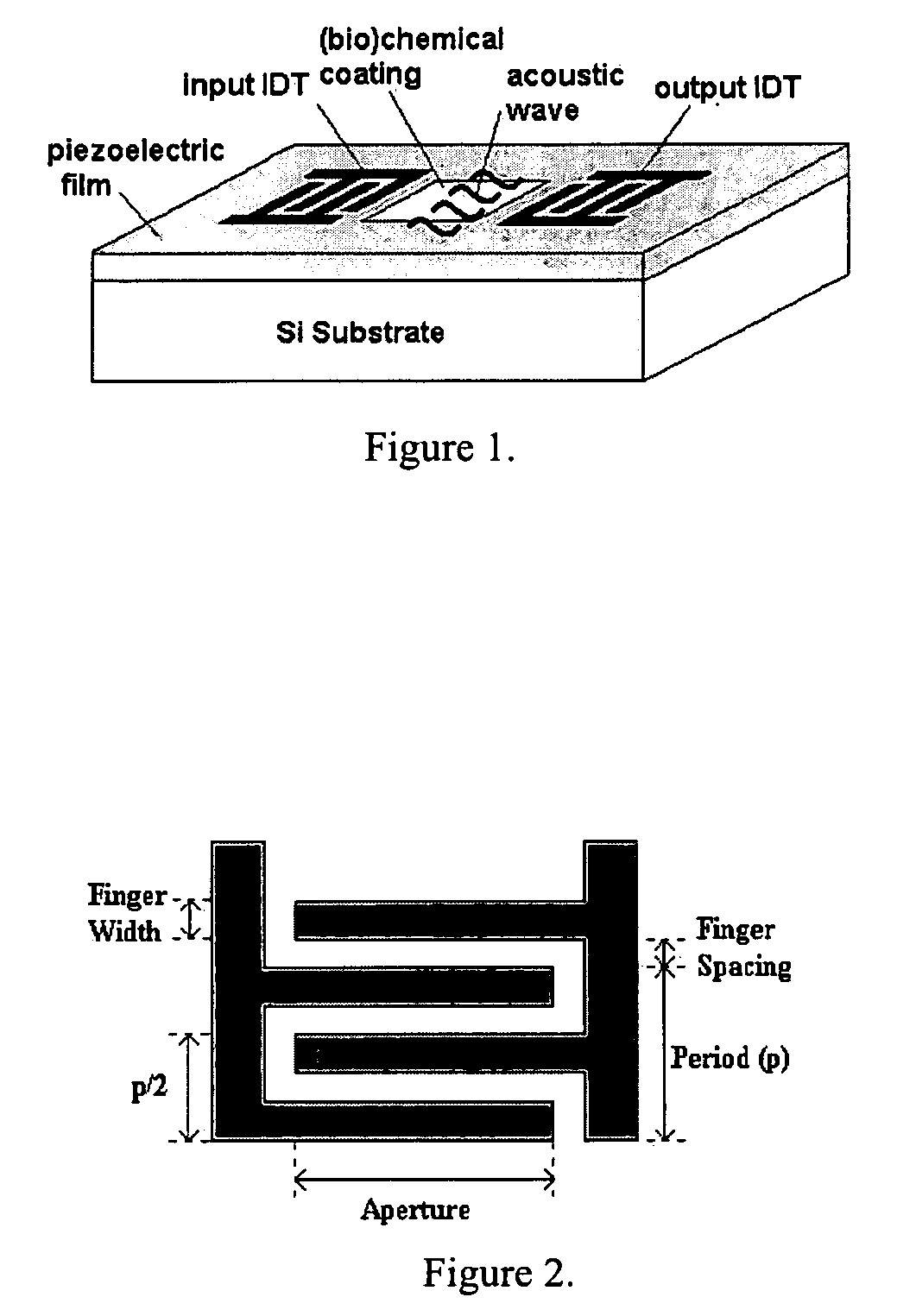

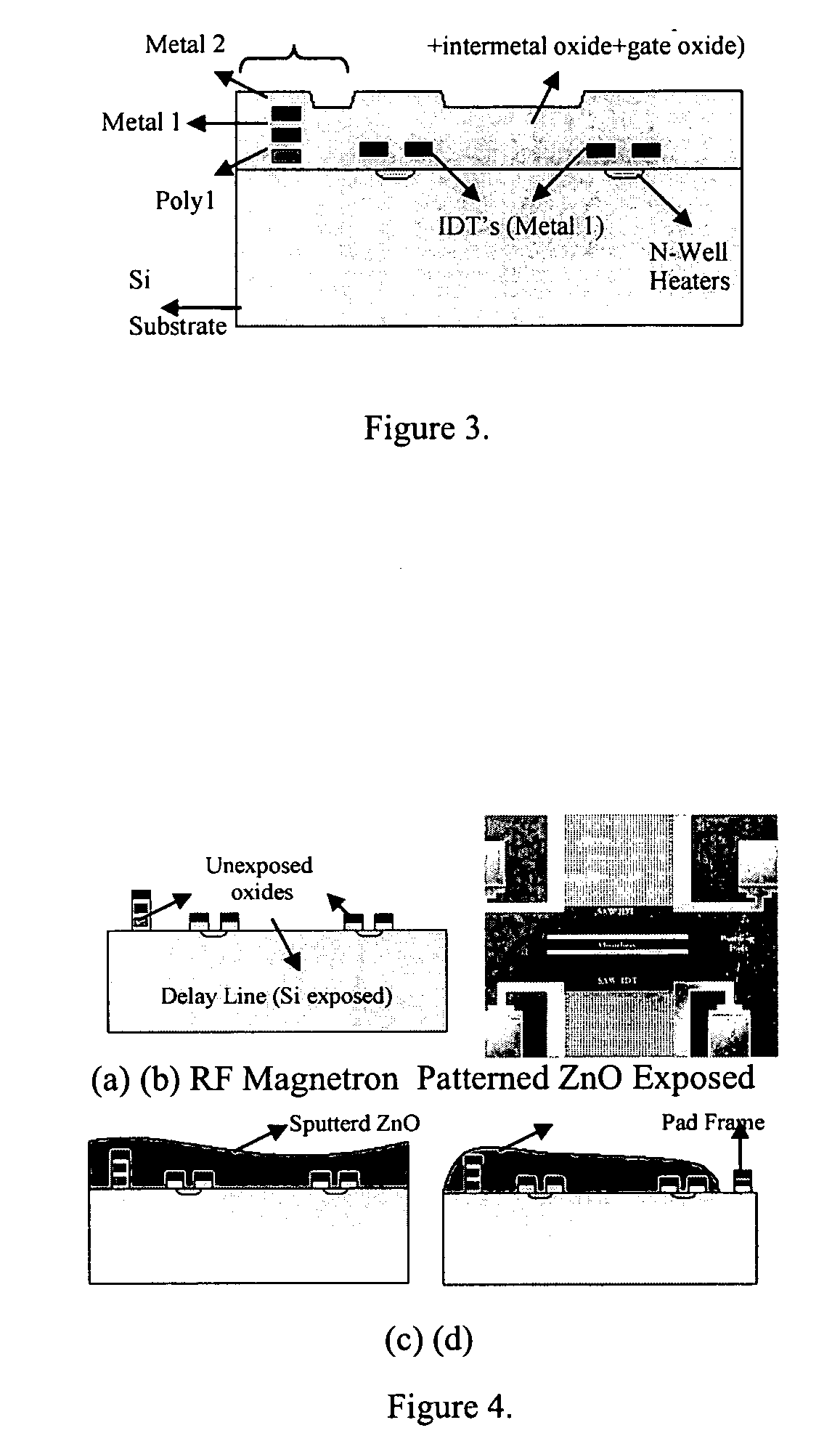

ActiveUS20080230859A1Improved biosensor arrangement performanceQuick checkPiezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesTemperature controlCMOS

The design, fabrication, post-processing and characterization of a novel SAW (Surface Acoustic Wave) based bio / chemical sensor in CMOS technology is introduced. The sensors are designed in AMI 1.5 μm 2 metal, 2 poly process. A unique maskless post processing sequence is designed and completed. The three post-processing steps are fully compatible with any CMOS technology. This allows any signal control / processing circuitry to be easily integrated on the same chip. ZnO is used as the piezoelectric material for the SAW generation. A thorough characterization and patterning optimization of the sputtered ZnO was carried out. The major novelties that are introduced in the SAW delay line features are: The embedded heater elements for temperature control, compensation and acoustic absorbers that are designed to eliminate edge reflections and minimize triple transit interference. Both of these attributes are designed by using the CMOS layers without disturbing the SAW performance.

Owner:GEORGE WASHINGTON UNIVERSITY

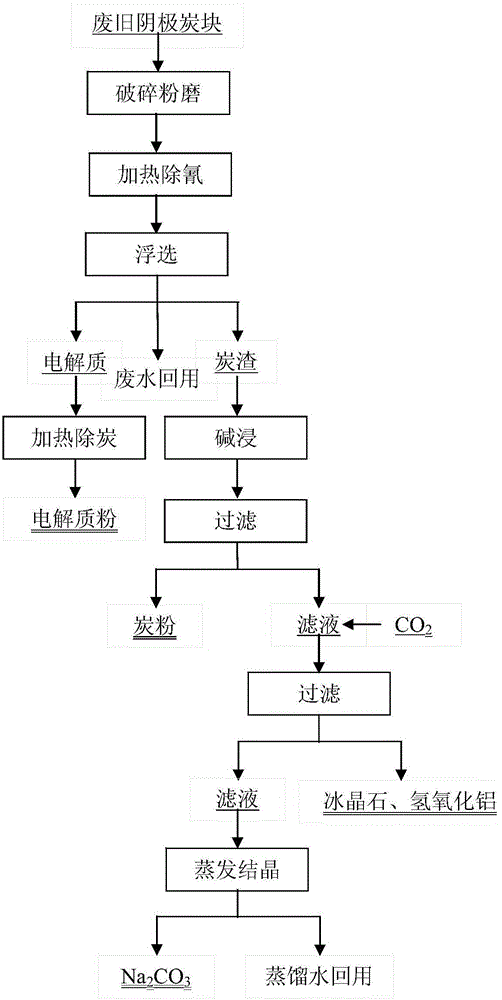

Comprehensive recovery method of waste and old cathode charcoal block of aluminium electrolytic tank

ActiveCN106064813AReduce consumptionShorten the alkaline leaching timeAluminium fluoridesAluminium oxides/hydroxidesRecovery methodElectrolysis

The invention relates to a comprehensive recovery method of waste and old cathode charcoal block of an aluminium electrolytic tank, and belongs to the technical field of comprehensive utilization of industrial solid waste resources. The method is as below: crushing and grinding waste and old cathode charcoal block of the aluminium electrolytic tank at 200-400 DEG C, insulating, removing cyanide, conducting flotation separation on the material with cyanide removed to obtain carbon slag and electrolyte slag, heating the electrolyte slag at 550-800 DEG C to remove carbon impurities, so as to obtain an electrolyte powder, removing to soluble substances in the electrolyte slag by alkali leaching to obtain a carbon powder with high purity, and precipitating a mixture of cryolite and aluminium hydroxide form the alkali leaching liquid by CO2. The invention has the advantages of reasonable process design, simple process, high treatment efficiency, high recovery rate and recycling rate of each material and no secondary pollution, and is applicable to large-scale industrial application.

Owner:CENT SOUTH UNIV

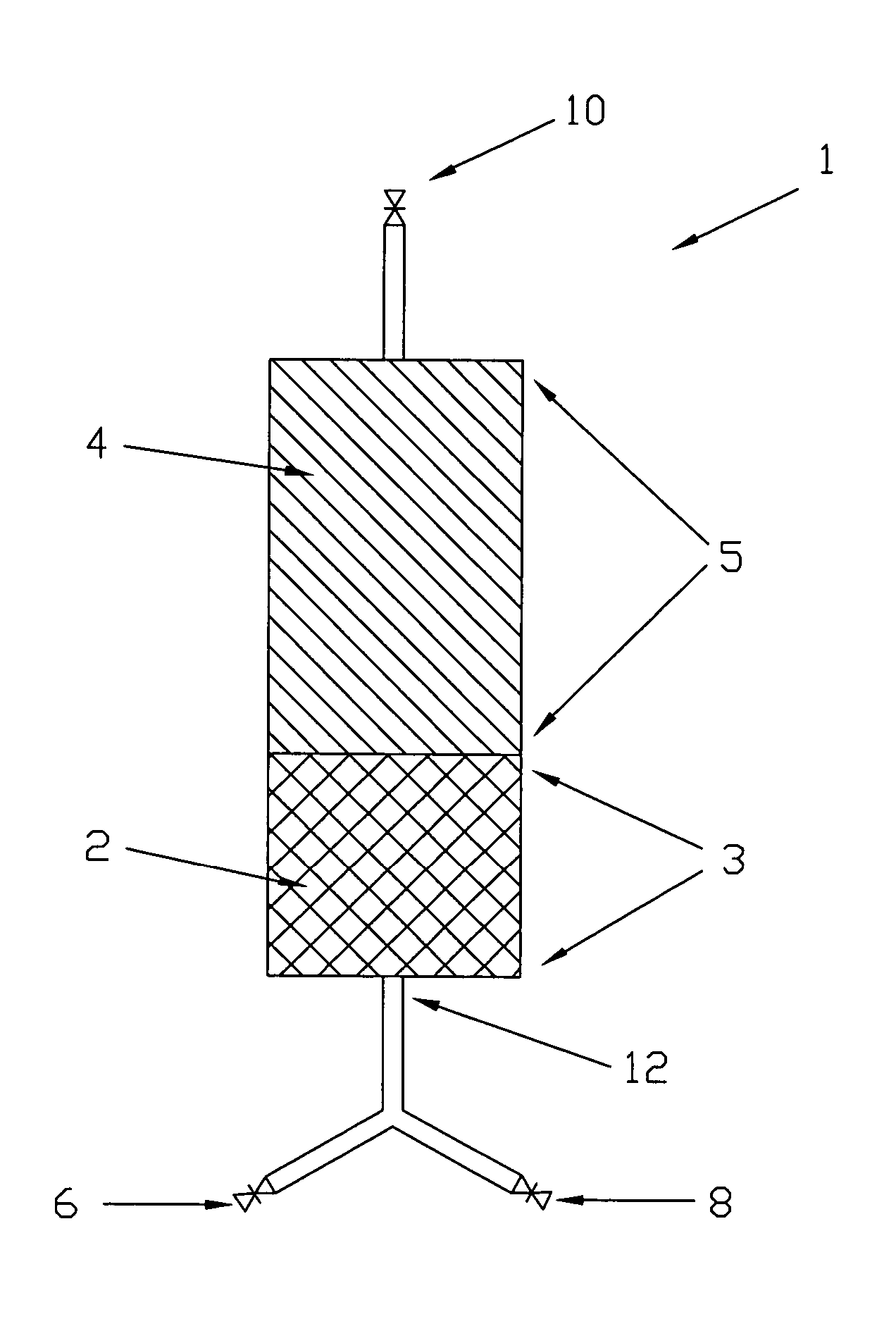

Screening apparatus for water treatment with membranes

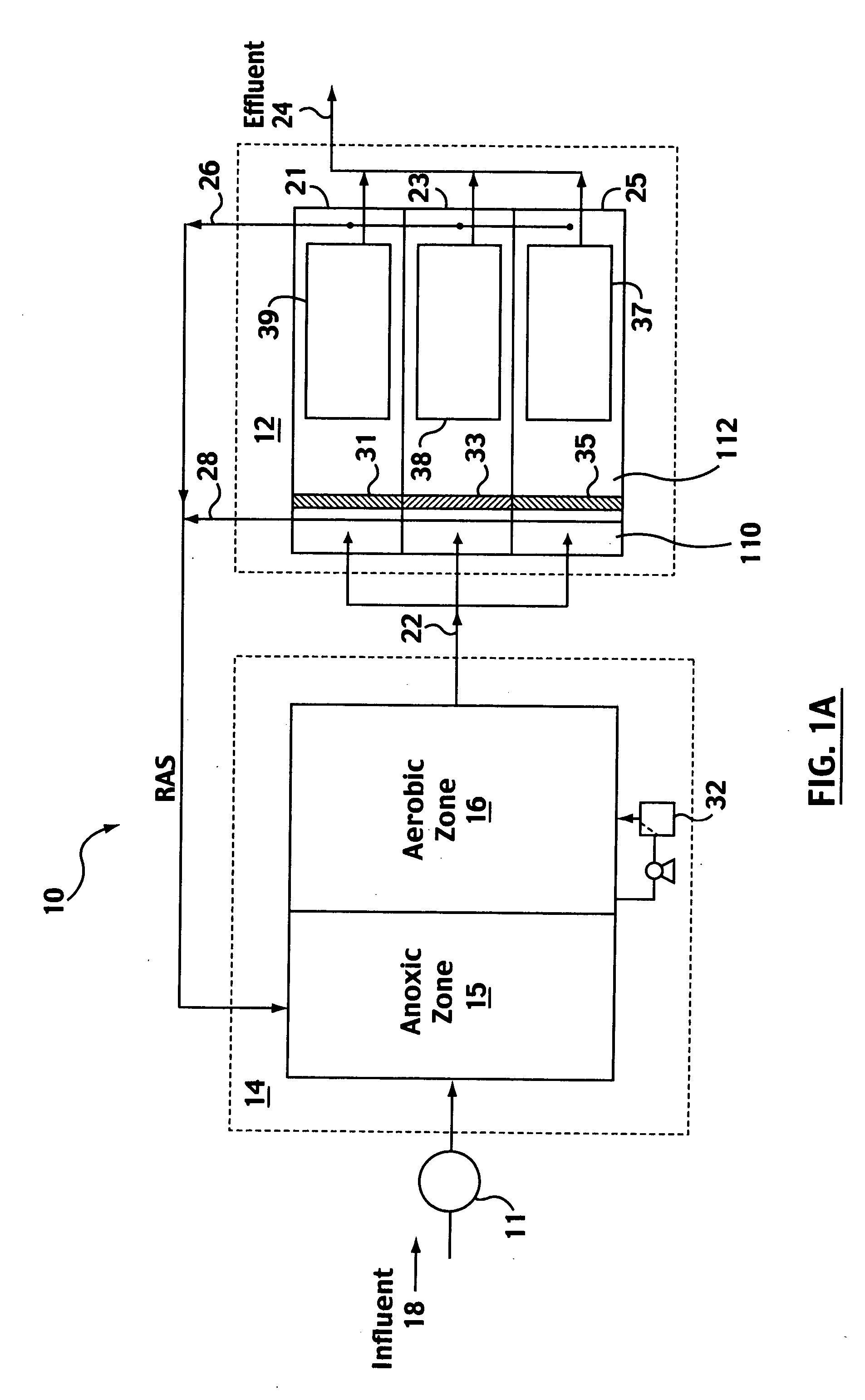

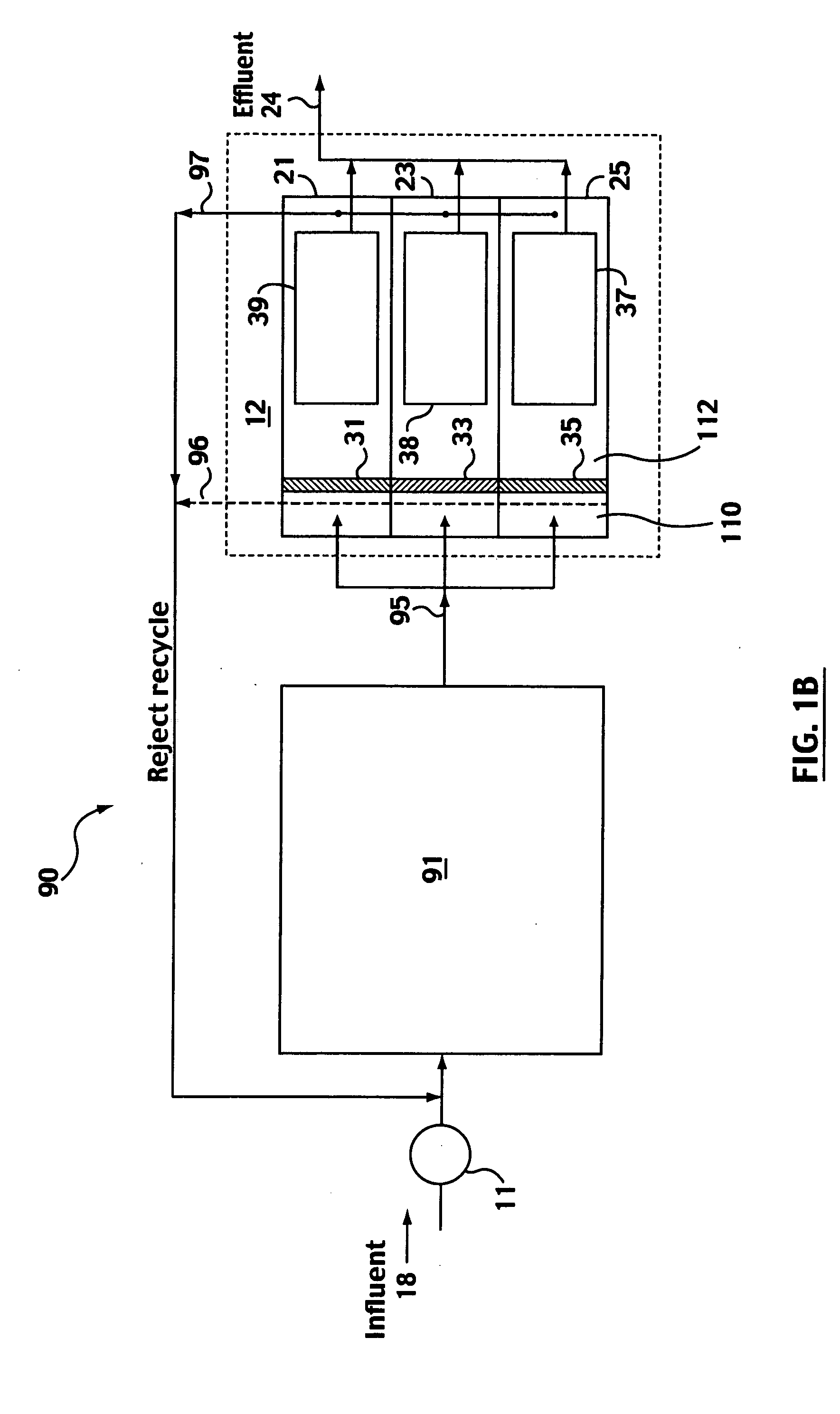

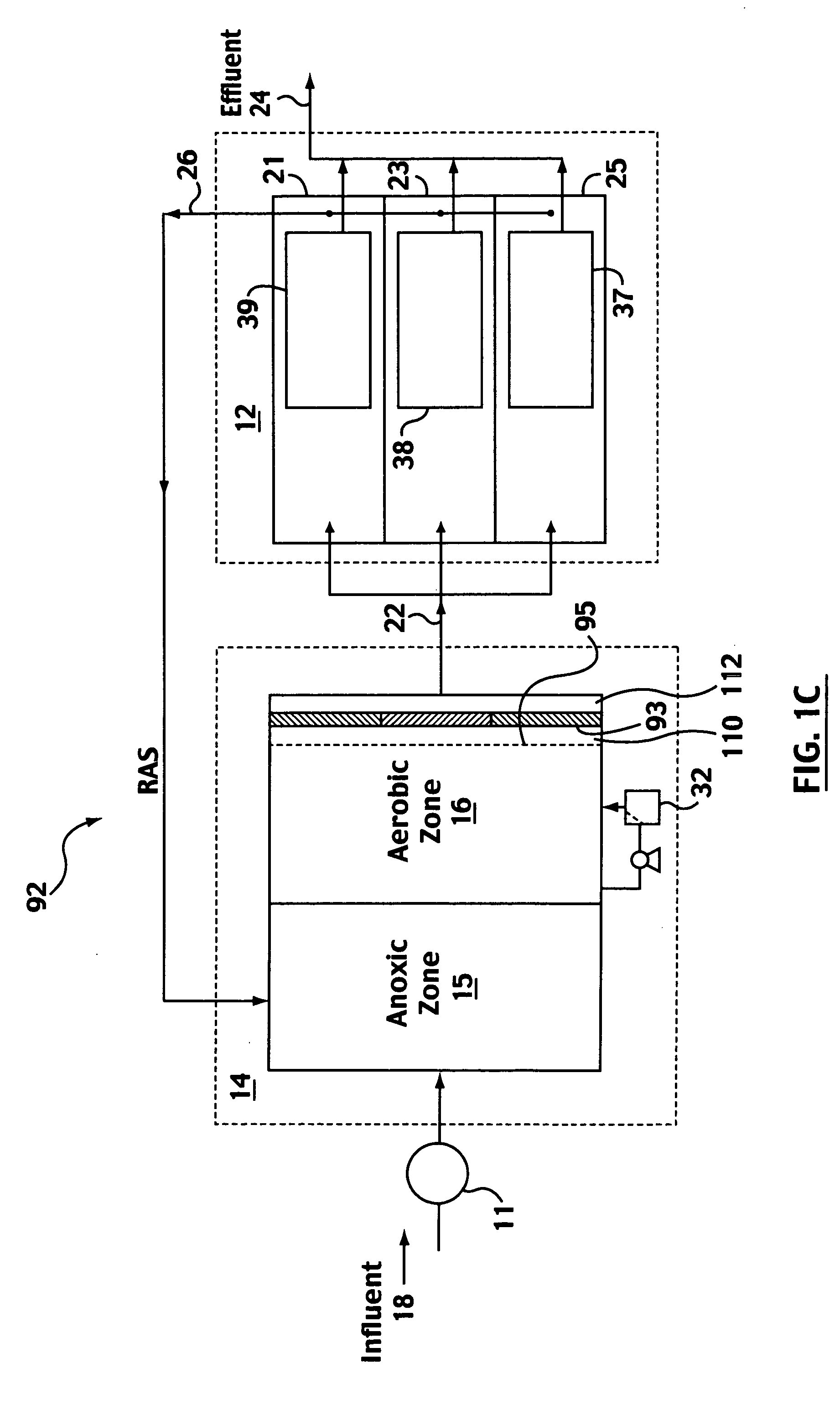

InactiveUS20060008865A1UltrafiltrationTreatment involving filtrationWater treatment systemProcess design

A static screen used upstream of a membrane assembly within a water treatment system has a screening surface with a number of openings distributed over its area. Liquid flows through the screening surface to reach the membrane assembly. Various shapes of screening surfaces are described including undulating panels and geometric shapes. Methods for cleaning the screen are described including aeration and backwashing. Various treatment systems or process designs incorporating the screen are described.

Owner:ZENON ENVIRONMENTAL INC

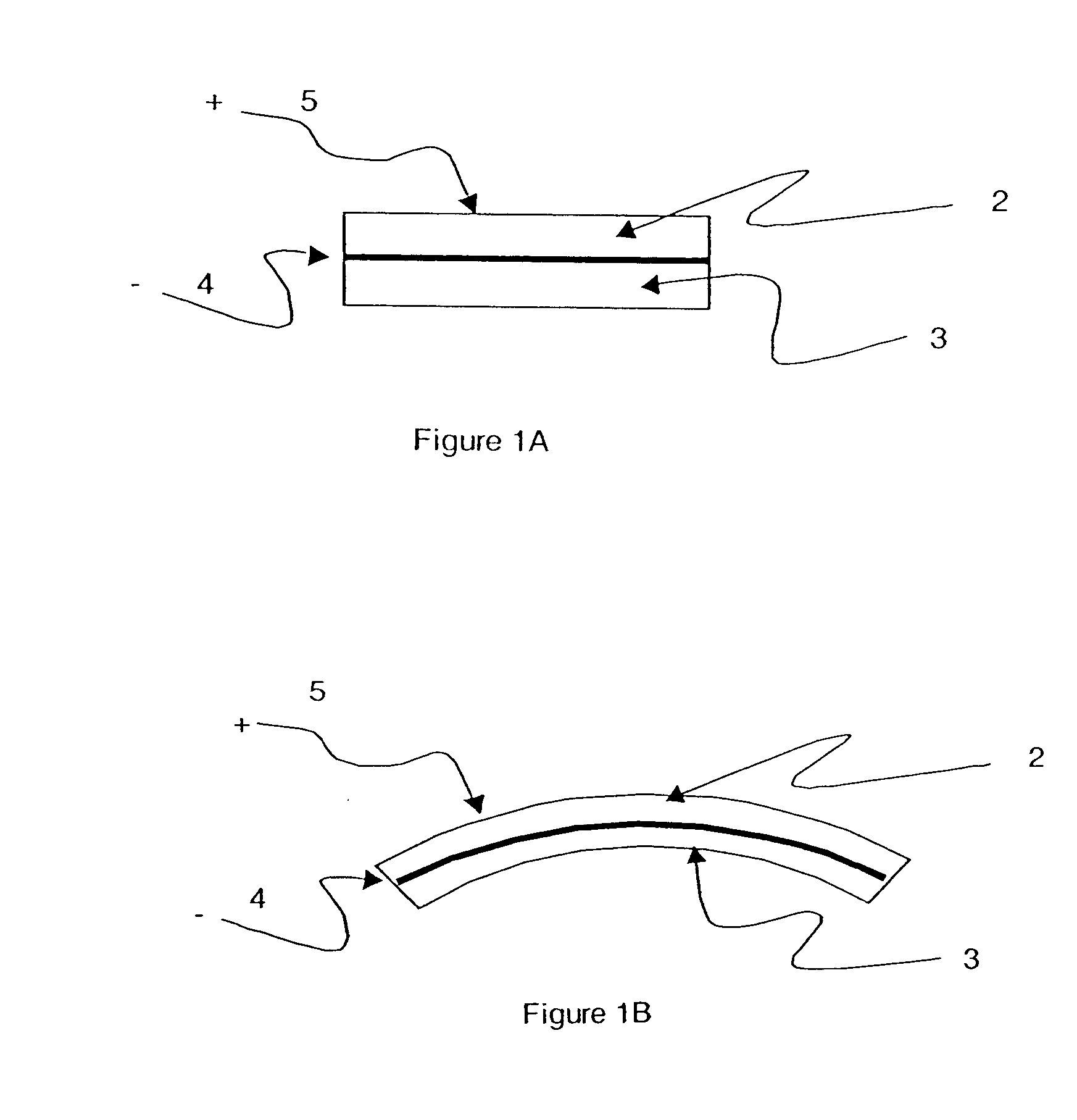

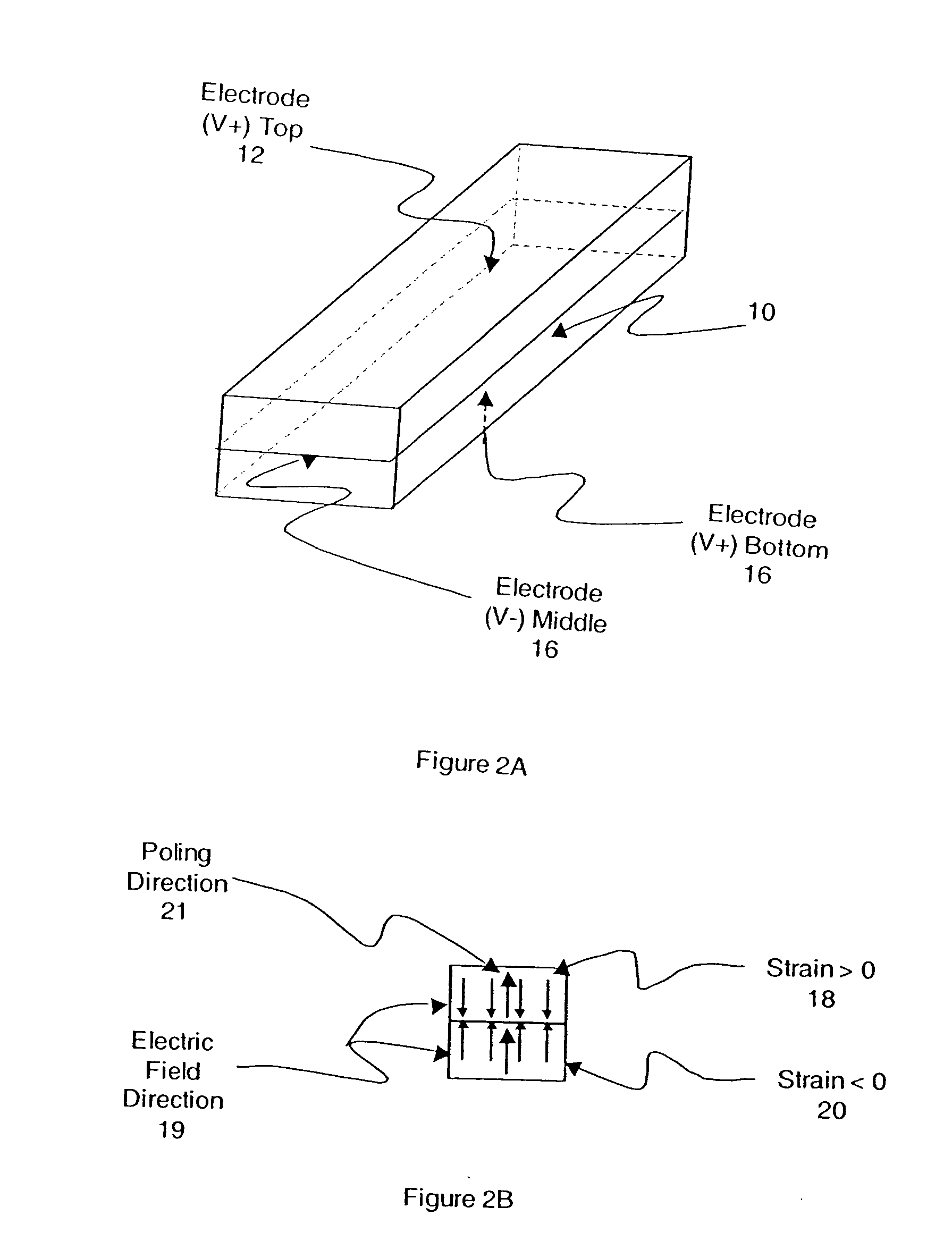

Bending actuators and sensors constructed from shaped active materials and methods for making the same

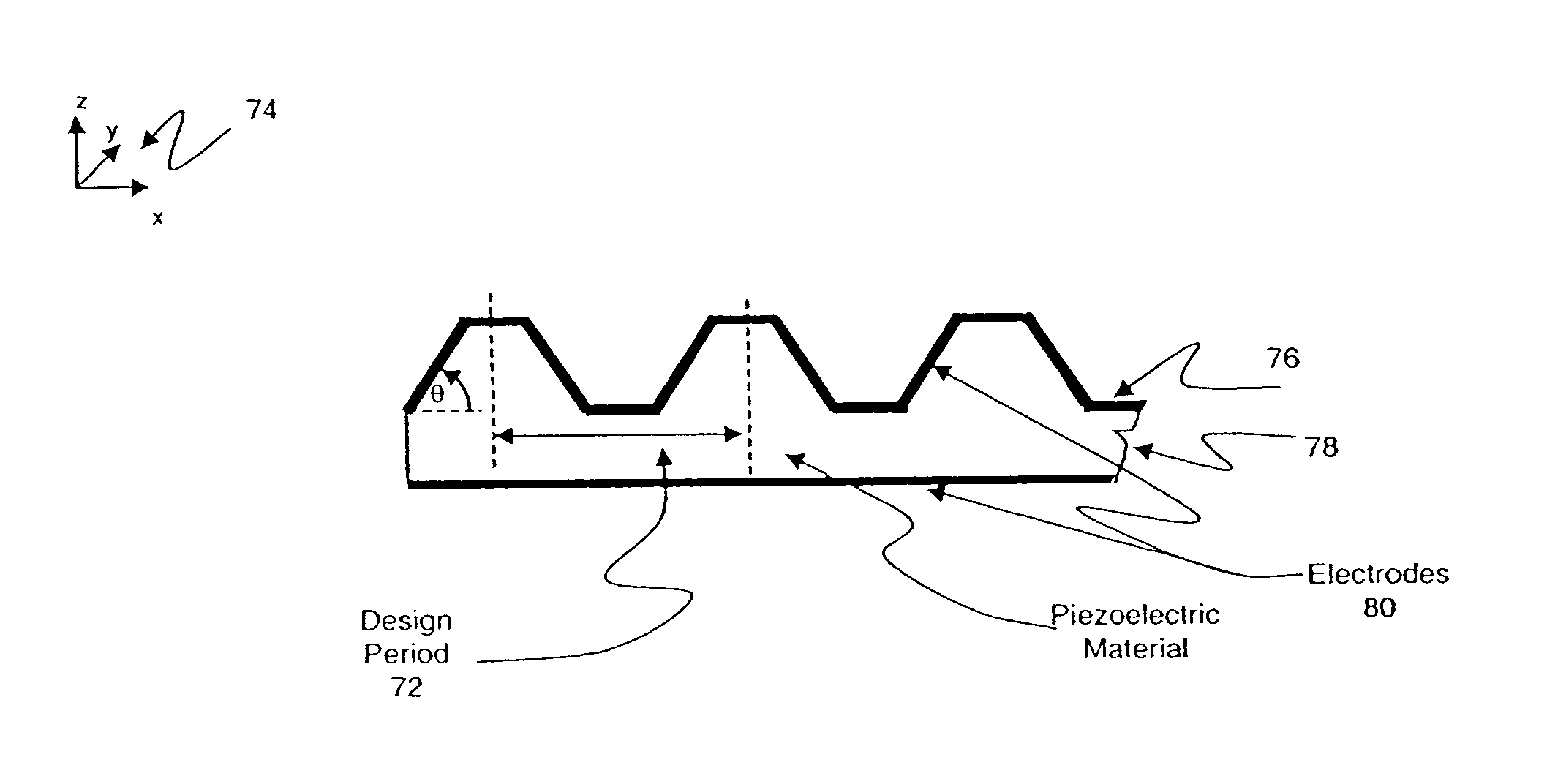

InactiveUS20040056567A1Increase stiffnessMagnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrode placementUniform field

Bender devices are demonstrated by developing non-uniform fields within a homogeneous, non-planar single slab active member material of non-uniform thickness through geometrical constraints and electrode placement. Single slab actuators are demonstrated for semiconductor designs including MEMS applications. Single slab bender periodic designs are demonstrated to be well suited for MEMS fabrication. Shaped actuators having a topological pattern formed across at least one portion are demonstrated to induced strain at the patterned portion of the actuator, causing the patterned portion to flare into open and close positions upon application of an external field. Voltage transformers, spark generators, power sources, and sensors are developed using the non-planar, homogeneous, single slab active member material of non-uniform thickness. Last, semiconductor process design techniques are demonstrated for periodic and other non-planar single slab actuators.

Owner:MONODRIVE

Cutter spacing optimizing method for cydariform knife tool multiple coordinates line width processing

InactiveCN101063880AAvoid Artificial Adjustment WorkIncrease programming automationTotal factory controlNumerical controlProcess optimizationLine width

This invention relates to one bump knife tool multi-coordinate wide row process optimization method, which comprises the following steps: isolating the tool into one set of intense latitude lines according to its process type; through computation on each latitude line distance to process design curve to get error distribution function; accordingly establishing wide computation method and restrains to form tool optimization module. To avoid backward adjust, the part is selected with one control point and to determine one point beyond for one relative initial position from one point in program public error and the selection point.

Owner:BEIHANG UNIV

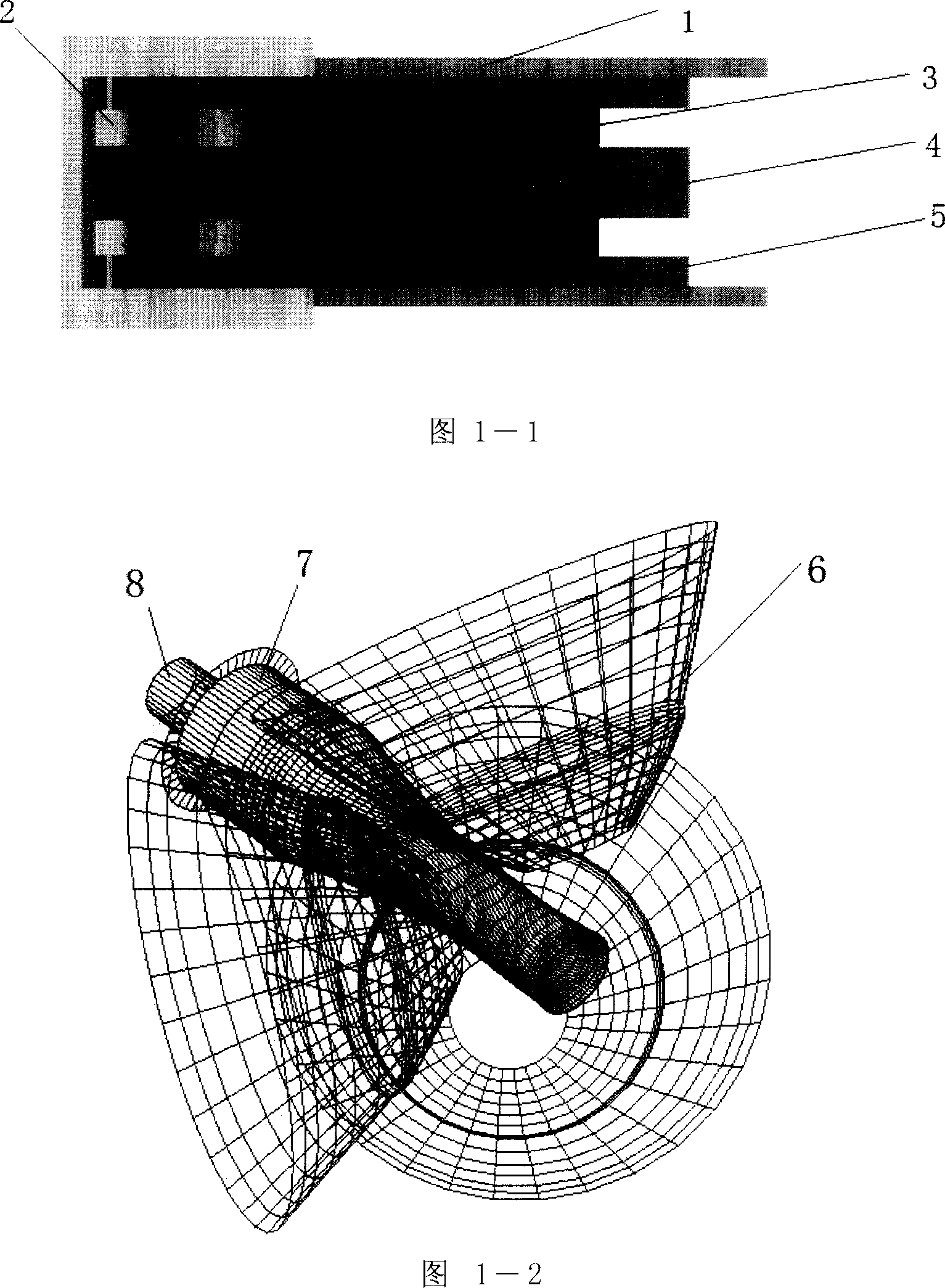

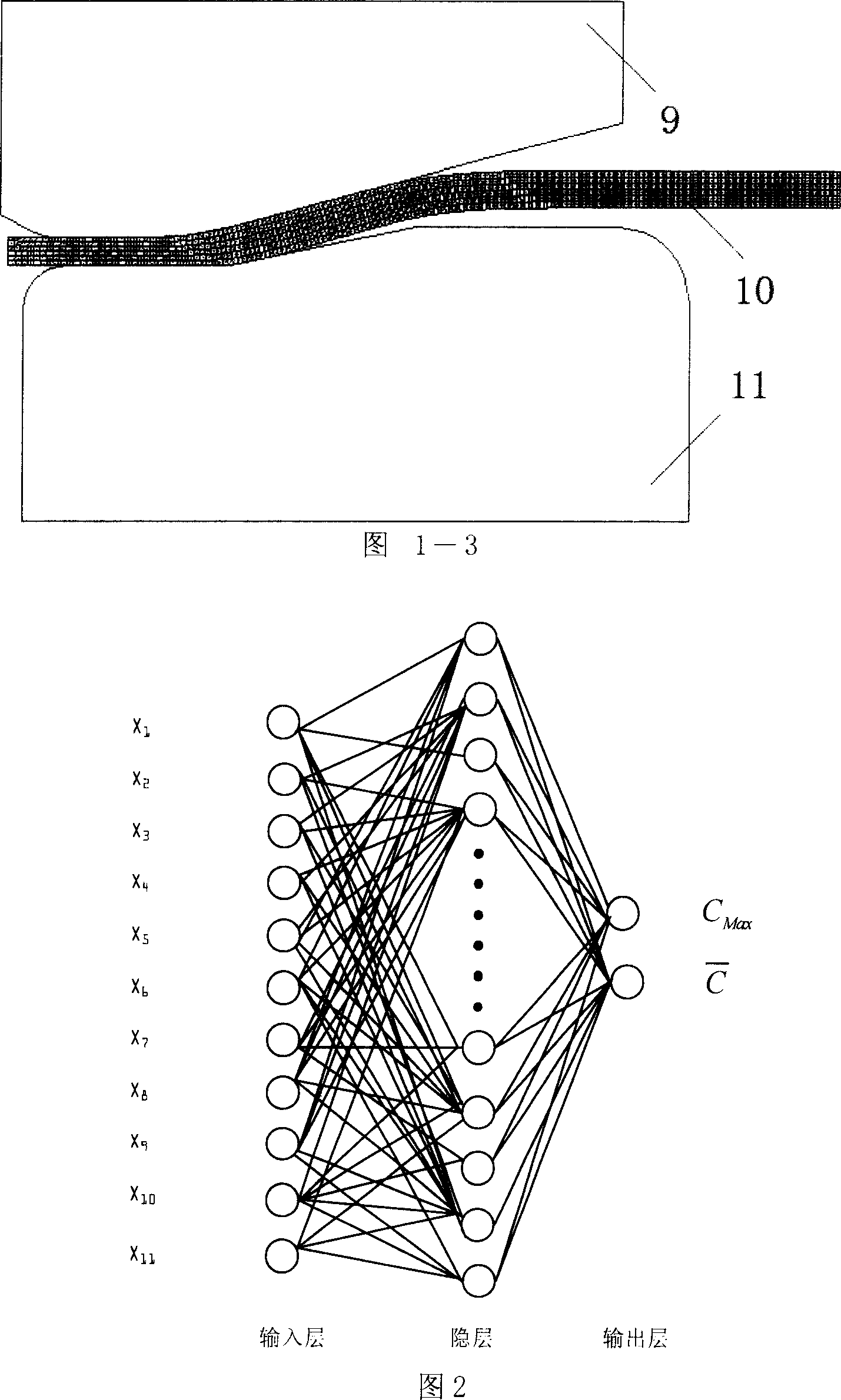

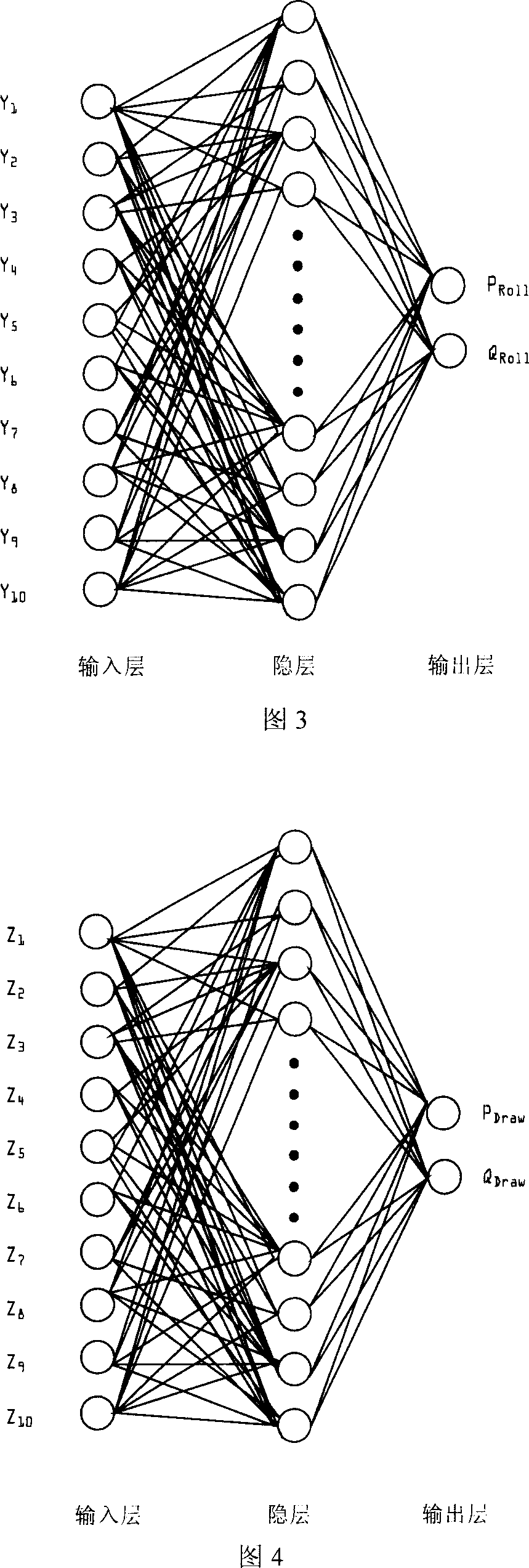

Copper-alloy pipe-material casting-milling technology parameter designing and optimizing method

InactiveCN1979496AOptimizing Graphical Result ExpressionAvoid breakingPhysical realisationSpecial data processing applicationsNerve networkMachining deformation

The invention discloses a method for designing and optimizing cast-rolling process parameters of copper alloy tubing, using database as design basic, using nerve network as design method of process parameters and indexes, and using genetic algorithm as process parameter optimizing means, integrating nerve network, genetic algorithm, finite element simulation, experiment design, CAD parameterized design and database technique into the process design and parameter optimization, designing and optimizing the cast-rolling process parameters of the copper alloy tubing. And the invention has high automation degree, and can be applied to machining deformation of copper alloy tubing, and make personnel short of special knowledge able to make accurate and standard machining process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

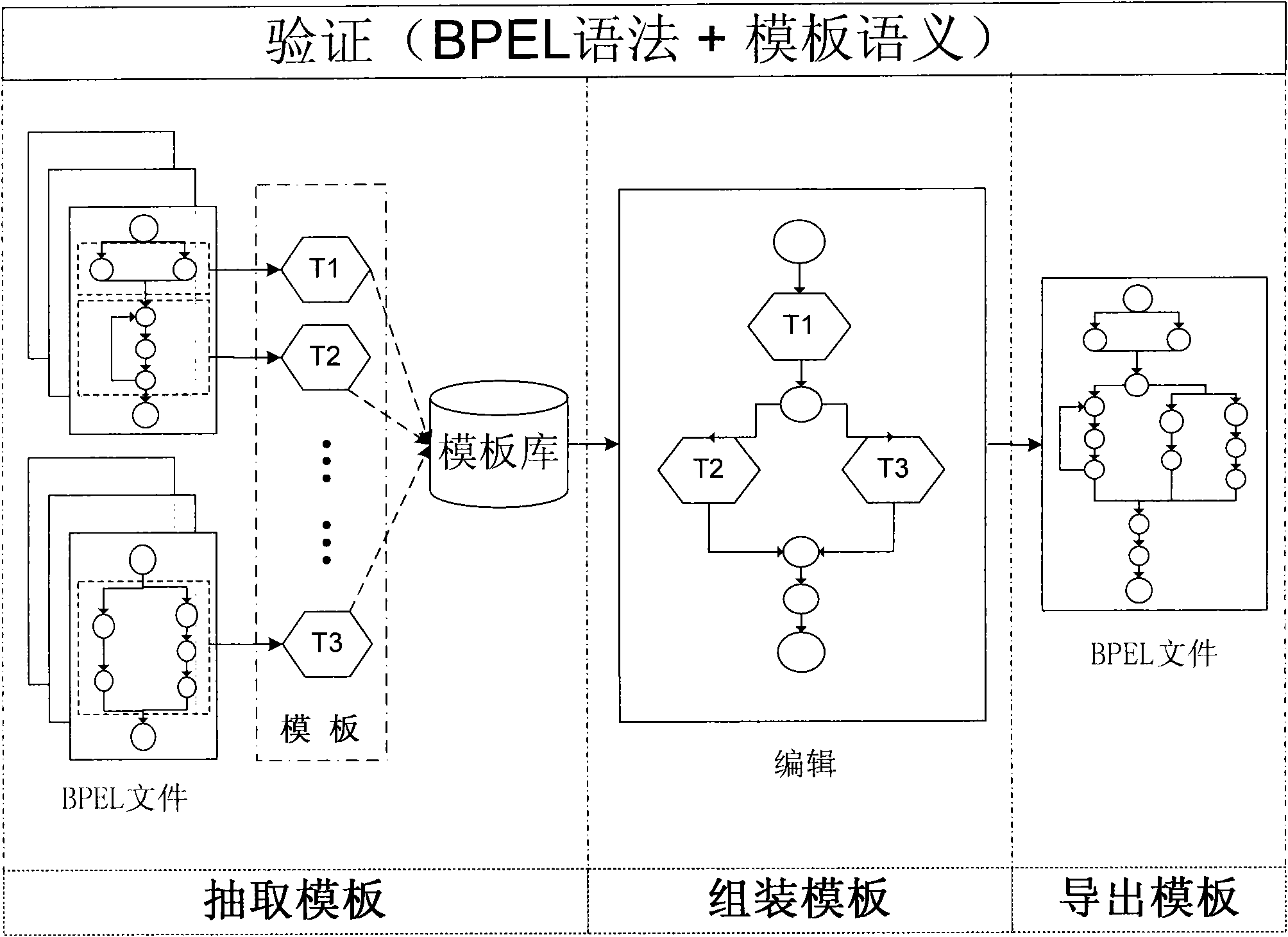

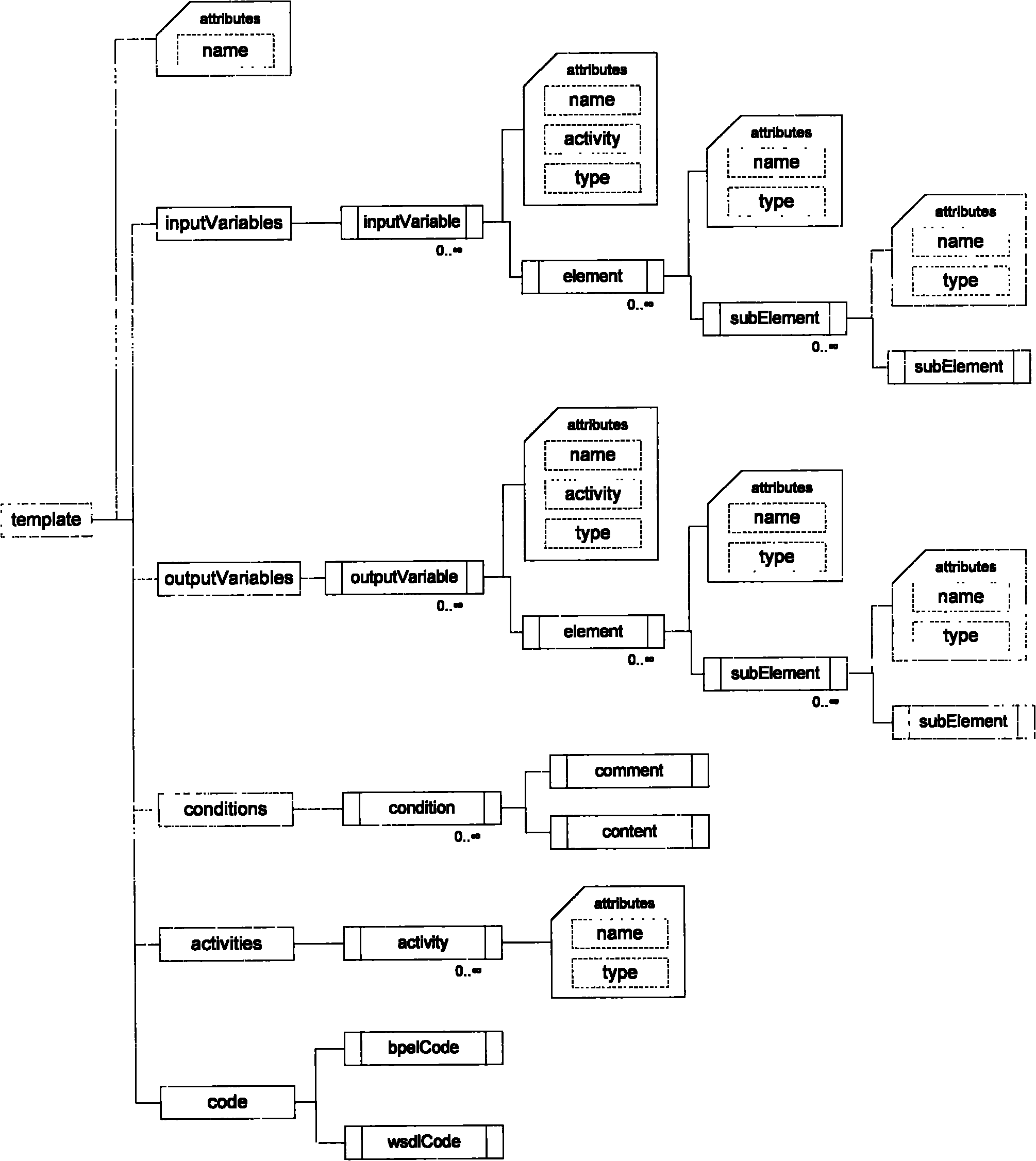

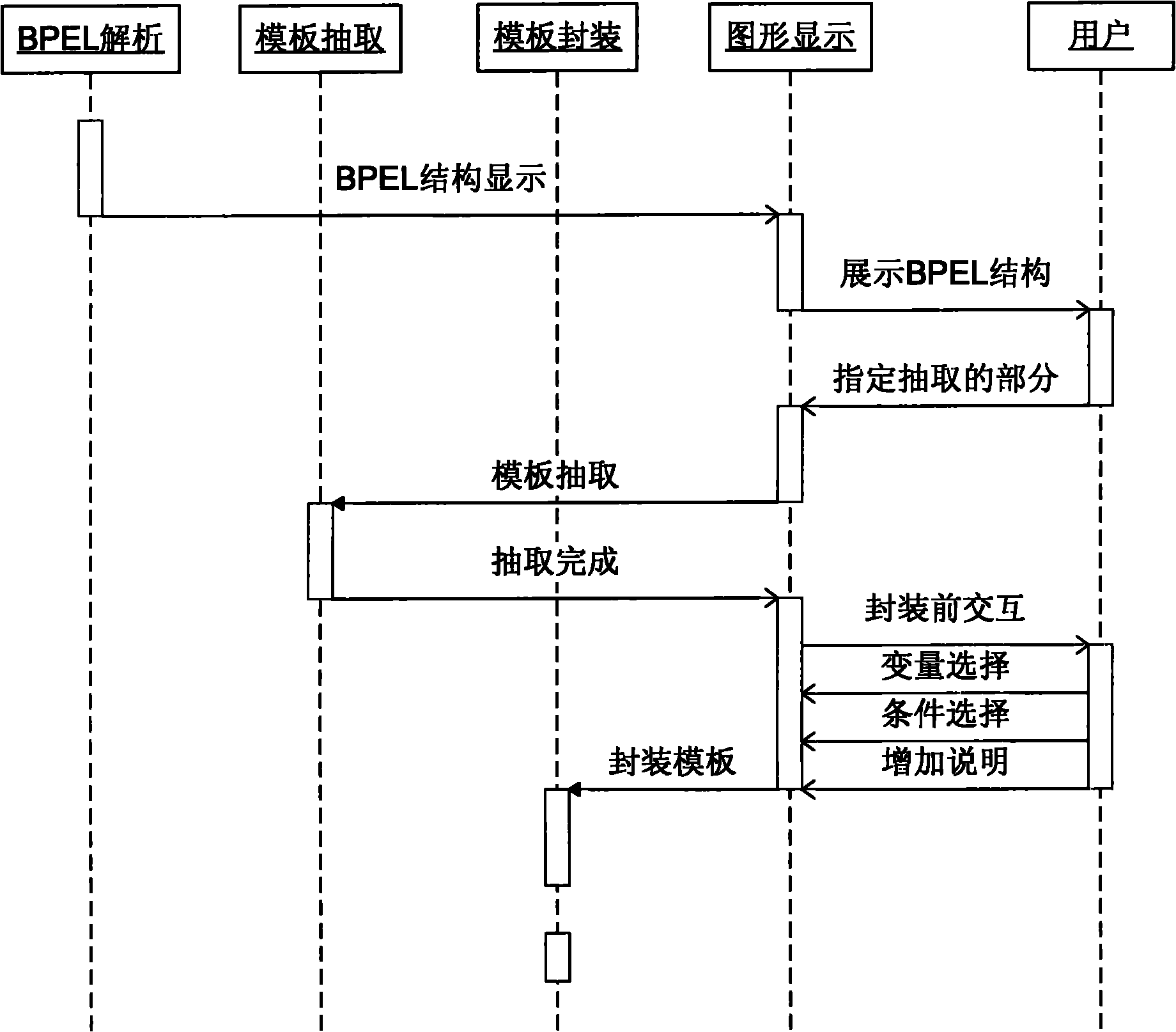

Method and system for realizing BPEL sub-process multiplexing based on template in service-oriented environment

InactiveCN101777004AReduce the work of secondary developmentIncrease flexibilityProgram controlMemory systemsService compositionMultiplexing

The invention discloses a method and a system for realizing BPEL sub-process multiplexing based on a template in a service-oriented environment. The method comprises the following steps of: performing model definition on the template to store related information which is needed when a BPEL sub-process is extracted for multiplexing; resolving an existing BPEL file and a related WSDL file, establishing a BPEL model and a WSDL model, extracting the needed BPEL sub-process from the existing BPEL file according to the established models, and encapsulating the extracted sub-process into the template and storing the template into a template base; and reading template information from the template base during development and calling the template to a BPEL process visualized development window to ensure that a user also can call the template to assist process design and development when developing the BPEL process, and the unification of a template mechanism and the BPEL process development can be realized. The method can realize the BPEL sub-process multiplexing, can greatly reduce work load of developers, improves the development efficiency of service combination, and shortens the development cycle by a pre-designed intra-industry common process template or a user-defined multiplexing template.

Owner:BEIJING UNIV OF POSTS & TELECOMM

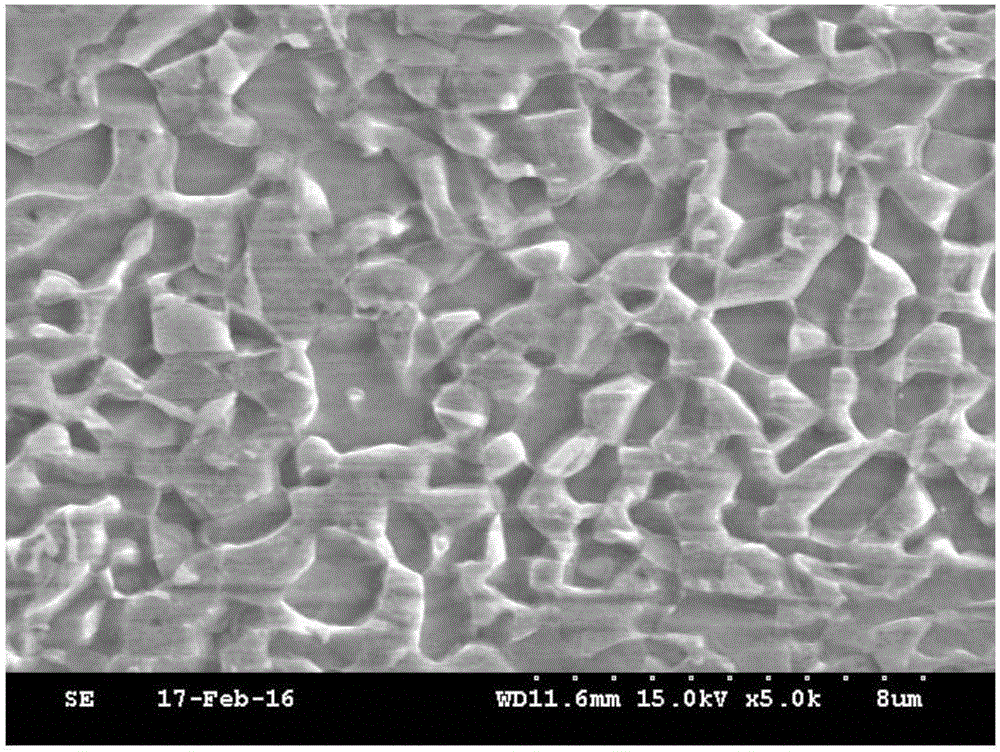

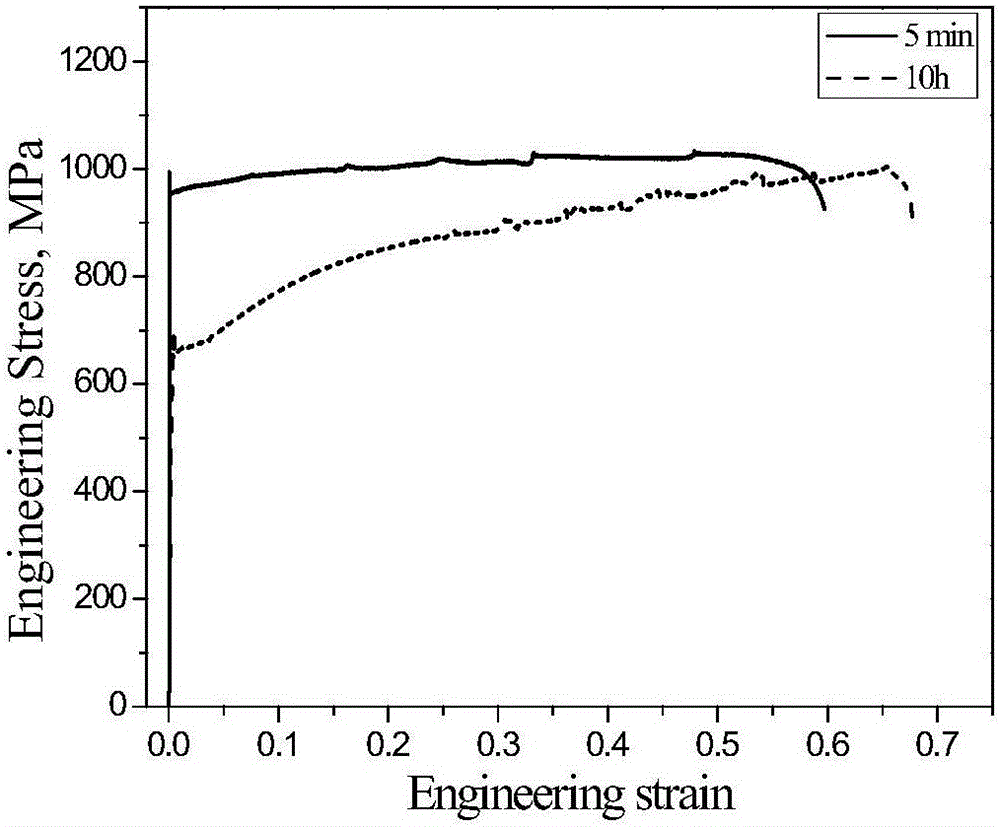

Cold rolled medium manganese steel with ultra-high strength and ductility product and preparation method thereof

The invention relates to cold rolled medium manganese steel with an ultra-high strength and ductility product and a preparation method thereof, and belongs to the technical field of steel for automobiles. The key point of the cold rolled medium manganese steel with the ultra-high strength and ductility product and the preparation method thereof lies in that partitioning of alloy elements is realized by reasonable chemical components and process designs. The components comprise, by mass percentage, 0.25-0.35% of C, 7.0-9.5% of Mn, and 2-2.9% of Al, with the balance being Fe and inevitable impurities. According to the preparation method, a stable retained austenite phase with an enough percentage is obtained by hot rolling, hot rolling annealing, acid pickling, cold rolling (rolling reduction is greater than or equal to 20%) and annealing in a specified temperature interval. Accordingly phase transformation induced plasticity takes place during deforming, finally the strength of extension of the obtained medium manganese steel is 900-1300 MPa, the elongation percentage is 50-80%, and the strength and ductility product increases to 60 GPa.% or above and is up to 90 GPa.%.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com