Copper-alloy pipe-material casting-milling technology parameter designing and optimizing method

A technology of process parameters and parametric design, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of knowledge combination explosion in knowledge base, difficulty in acquiring knowledge of reasoning machine, complicated forming process, etc., and achieve low cost , Long product development cycle and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

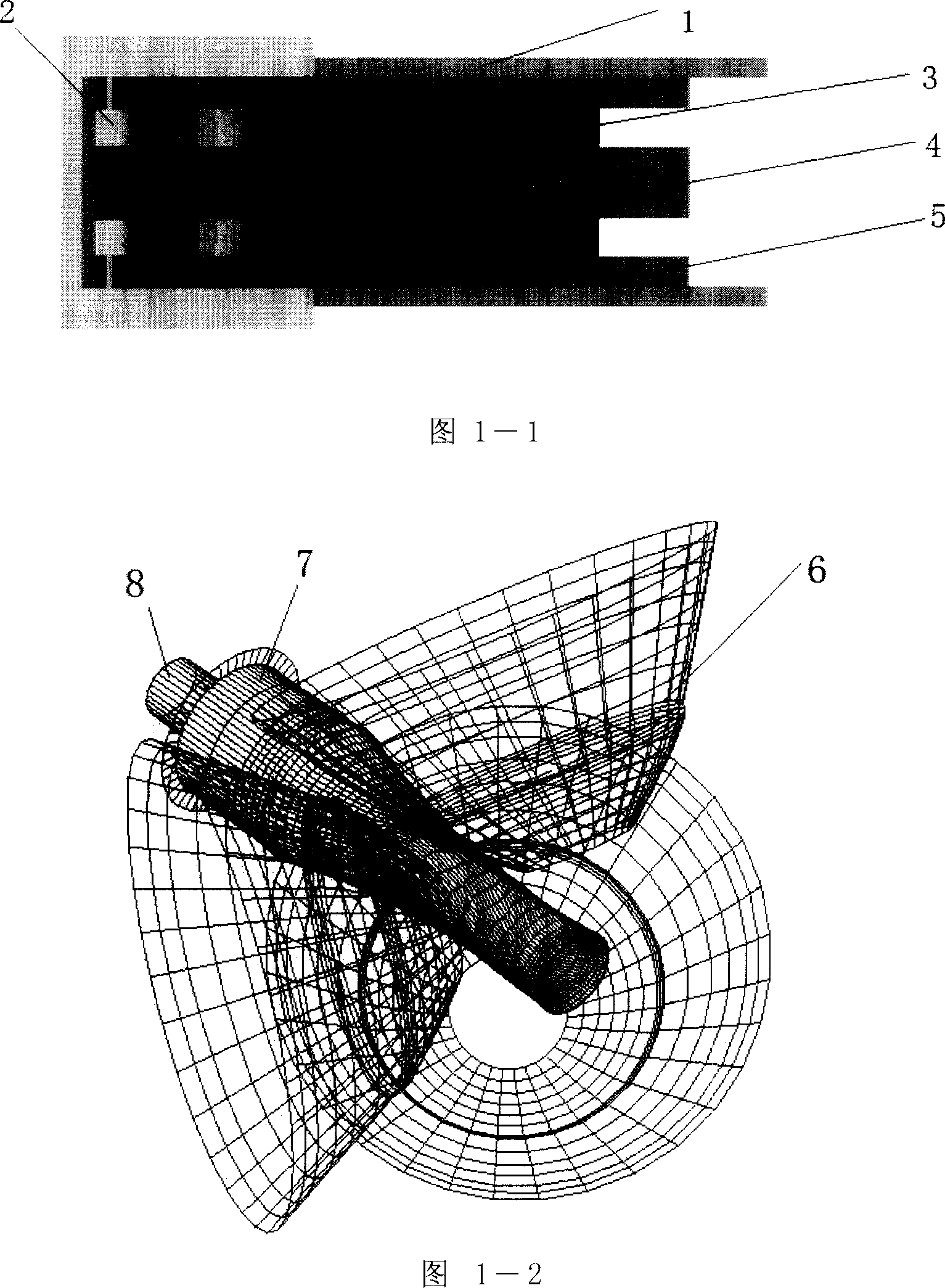

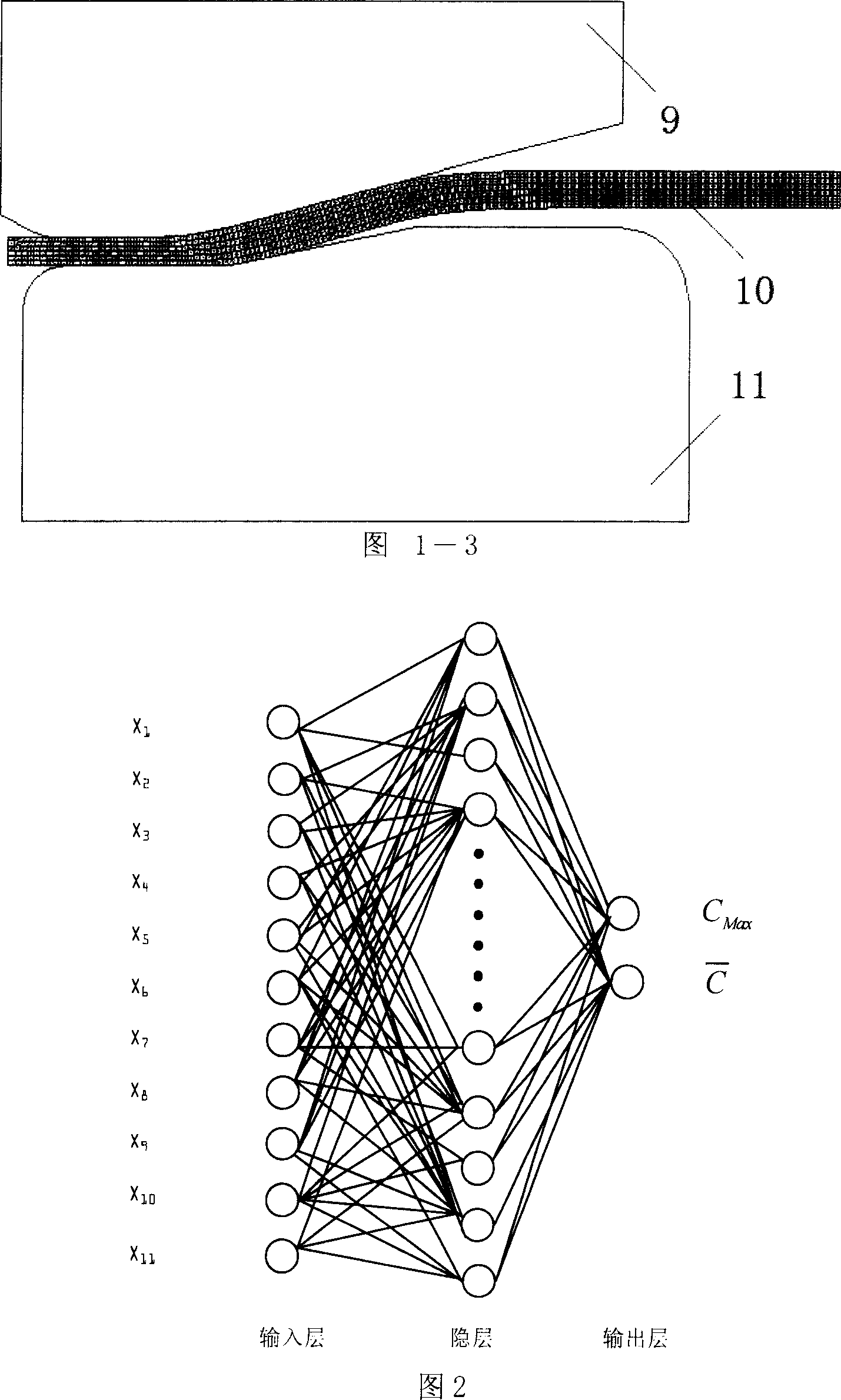

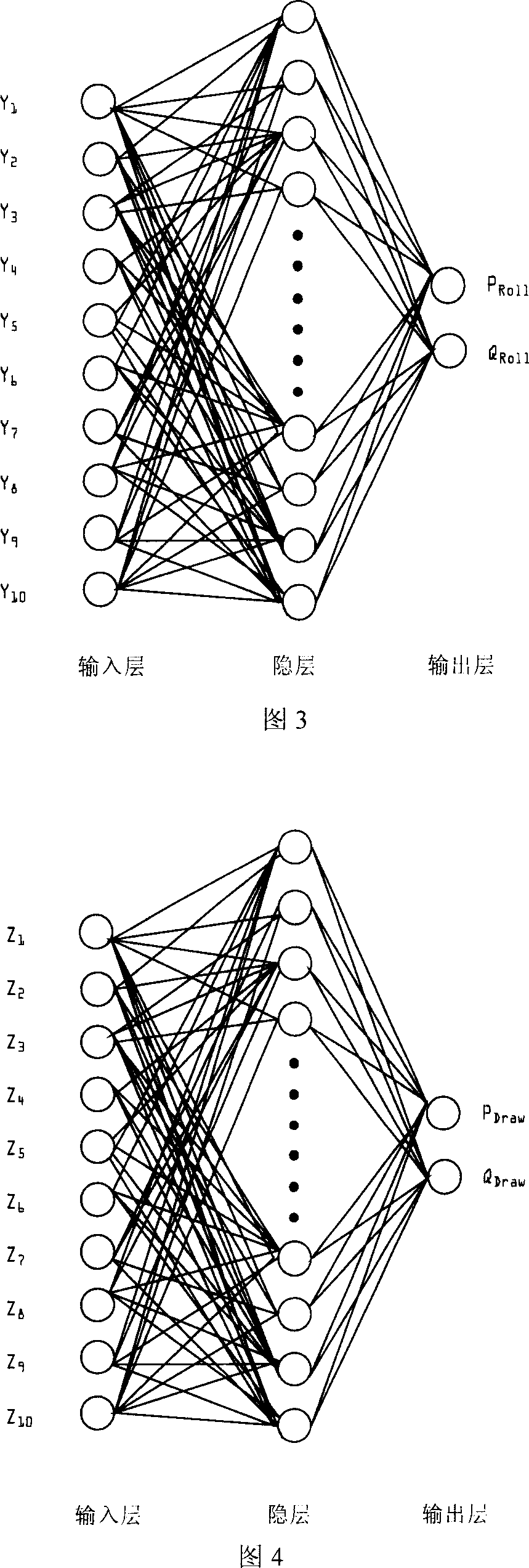

[0038] The present invention applies neural network, genetic algorithm, finite element simulation, test design, CAD parametric design, and database technology to process design and parameter optimization, and integrates them comprehensively to optimize the design of each process step of copper alloy pipe casting and rolling. , to get the optimal process parameters. Process parameter design includes: horizontal continuous casting billet drawing system, optimization design of cooling system; velocity field calculation and rolling parameter design of three-roll planetary rolling; Parameter optimization design.

[0039] details as follows:

[0040] 1) Establish the database of horizontal continuous casting, three-roll planetary rolling and moving core drawing, and use the database as the basis for parameter design and optimization. The production data, standard data and temporary data of these three processes in the factory are stored in the database. Factory production data in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com