Method for smelting and extracting platinum metal from alumina-supported petrochemical catalyst

A petrochemical catalyst, alumina carrier technology, applied in the direction of improving process efficiency, can solve the problems of complex tail liquid treatment process, high viscosity, high ion concentration in solution, avoid waste liquid treatment and filtration difficulties, and strong material adaptability , the effect of efficient capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

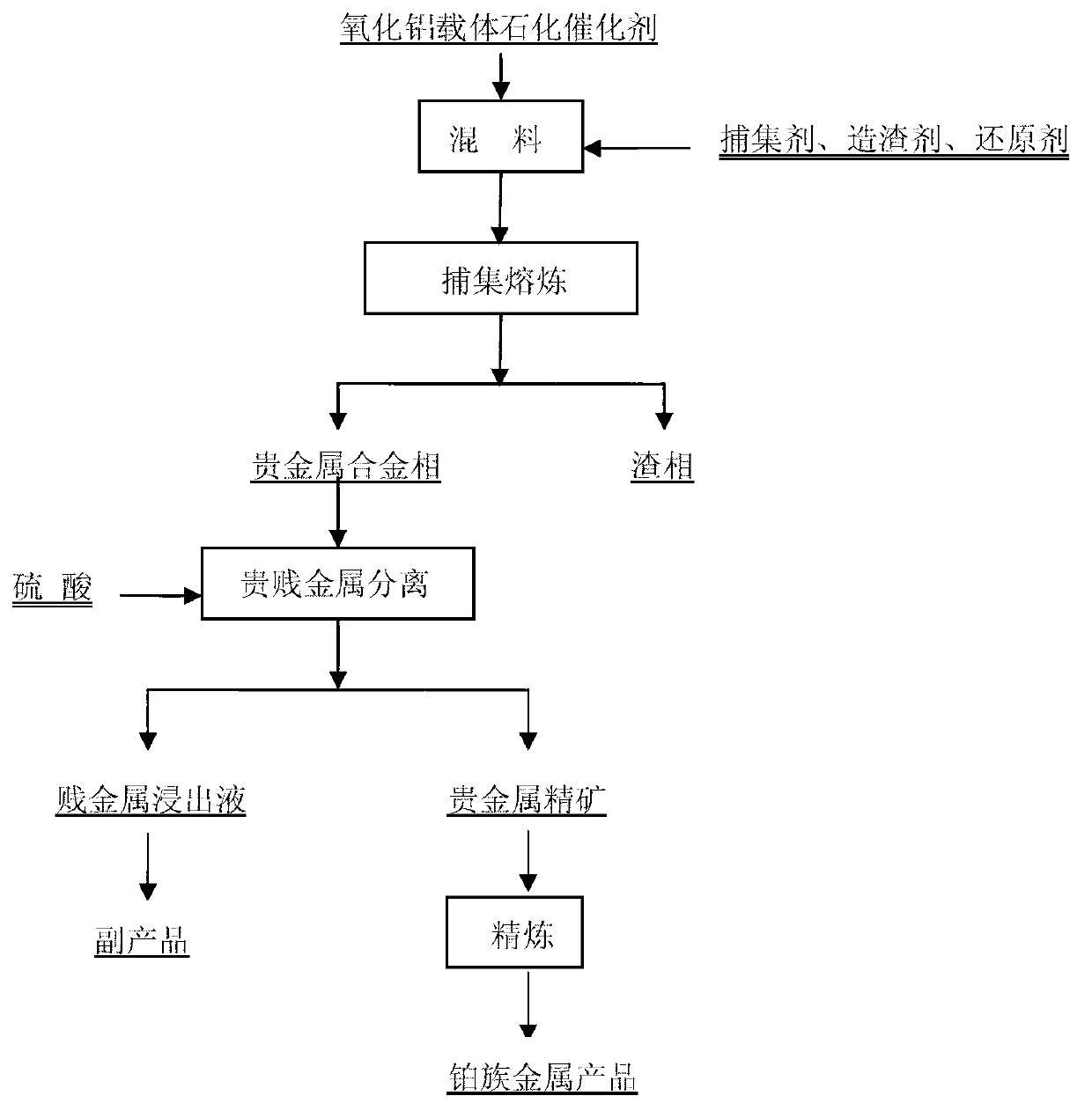

[0025] Example 1, see attached figure 1 , Weigh 25 grams of ≥ 100 mesh alumina carrier petrochemical catalyst (containing palladium 1865g / t), add 50 grams of iron oxide, 10 grams of carbon powder, 25 grams of sodium salt, mix well, put it into a No. 3 clay graphite crucible, and place The temperature was raised to 1400° C. in the muffle furnace, and the temperature was kept constant for 30 minutes. The separated slag phase was taken out, the slag weighed 56.85 grams, and contained 6.54 g / t of palladium. Precious metal alloy phase powder, add 4 N sulfuric acid solution, solid-liquid ratio S:L=1:12. The reaction temperature is room temperature at the beginning, after the reaction is slow, the temperature is raised to 70°C, stirred at constant temperature for 4 hours, filtered, the palladium content in the filtrate is all <0.0005 g / L, the obtained precious metal concentrate is added with 6N hydrochloric acid, the reaction temperature is 90°C, and the reaction time For 8 hours, ...

Embodiment 2

[0026] Embodiment 2, see attached figure 1 , weigh 25 grams of ≥ 100 mesh alumina carrier petrochemical catalyst (containing palladium 1865g / t), add 25 grams of iron copper powder, 5 grams of carbon powder, 25 grams of sodium salt, mix well, put it into a clay graphite crucible No. 3, and place The temperature was raised to 1400° C. in the muffle furnace, and the temperature was kept constant for 30 minutes. The separated slag phase was taken out, the slag weighed 42.02 grams and contained 151g / t of palladium. Precious metal alloy phase powder, add 4 N sulfuric acid solution, S:L=1:12. The reaction temperature is room temperature at the beginning, after the reaction is slow, the temperature is raised to 70°C, stirred at constant temperature for 4 hours, filtered, the palladium content in the filtrate is all <0.0005 g / L, the obtained precious metal concentrate is added with 6N hydrochloric acid, the reaction temperature is 90°C, and the reaction time For 8 hours, the oxidizin...

Embodiment 3

[0027] Embodiment 3, see attached figure 1 , weigh 25 grams of ≥100 mesh alumina carrier petrochemical catalyst (containing platinum 2200g / t), add 25 grams of iron oxide, 5 grams of carbon powder, 25 grams of sodium salt, mix well, put it into a No. 3 clay graphite crucible, and place The temperature was raised to 1400° C. in the muffle furnace, and the temperature was kept constant for 30 minutes. The separated slag phase was taken out, the slag weighed 49.44g and contained 8.50g / t of platinum. Precious metal alloy phase powder, add 4 N sulfuric acid solution, S:L=1:12. The reaction temperature is room temperature at the beginning, after the reaction is slow, the temperature is raised to 70°C, stirred at constant temperature for 4 hours, filtered, the palladium content in the filtrate is all <0.0005 g / L, the obtained precious metal concentrate is added with 6N hydrochloric acid, the reaction temperature is 80-90°C, The reaction time is 8 hours, the oxidant is sodium chlorat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com