Patents

Literature

267 results about "Iron copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper is an essential trace mineral present in all body tissues. Copper works with iron to help the body form red blood cells. It also helps keep the blood vessels, nerves, immune system, and bones healthy.

Method for removing heavy metals using an adsorbent

A method is presented for removing heavy metal anions from a fluid or gas medium containing metal anions. The method includes providing an adsorbent having deposited therein at least one oxygen-containing compound of at least one metal selected from the group consisting of iron, copper, and aluminum; and contacting a portion of the medium with the adsorbent. The oxygen-containing compound may be incorporated into the carbon by impregnation or dispersion of a suitable precursor of such a compound. The precursor may be further treated to yield the oxygen-containing compound. Such adsorbents are particularly useful for removing arsenic and / or selenium from the environment and may be used in treating drinking water sources.

Owner:CALGON CARBON

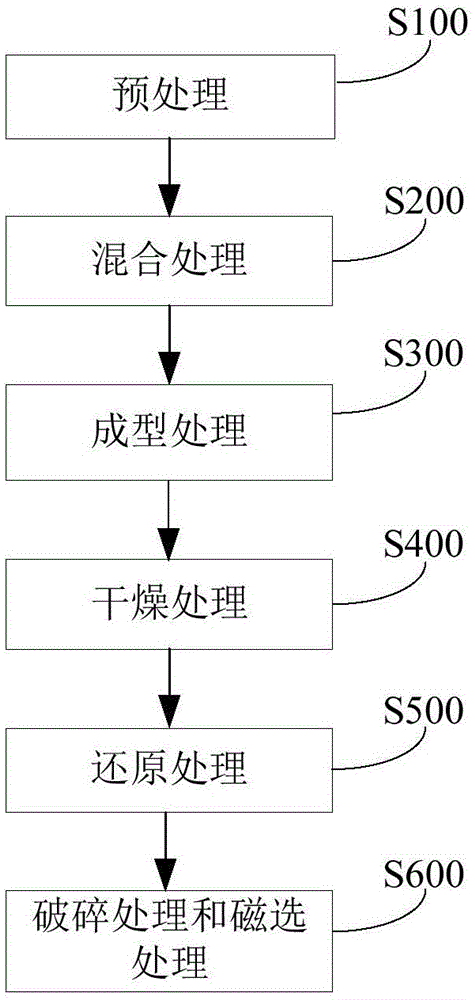

Method for treating copper slag

InactiveCN105039728AAchieve recyclingReduce consumptionProcess efficiency improvementProduct containing ironMixed materials

The invention discloses a method for treating copper slag. The method includes the steps that (1) the copper slag, a reducing agent and additives are pre-treated respectively; (2) the pre-treated copper slag, the pre-treated reducing agent and the pre-treated additives are mixed so that a mixed material can be obtained; (3) the mixed material is formed so that copper slag pellets can be obtained; (4) the copper slag pellets are dried so that the dried copper slag pellets can be obtained; (5) at the temperature of 1,350-1,550 DEG C, the dried copper slag pellets are reduced so that a solid reduced product containing iron-copper alloy particles and smoke containing lead and zinc can be obtained; and (6) the solid reduced product containing the iron-copper alloy particles is broken and magnetically separated so that the iron-copper alloy particles and tailings can be obtained respectively. According to the method, multiple metal elements in the copper slag can be comprehensively recycled, and the higher recovery rate is achieved.

Owner:SHENWU TECH GRP CO LTD

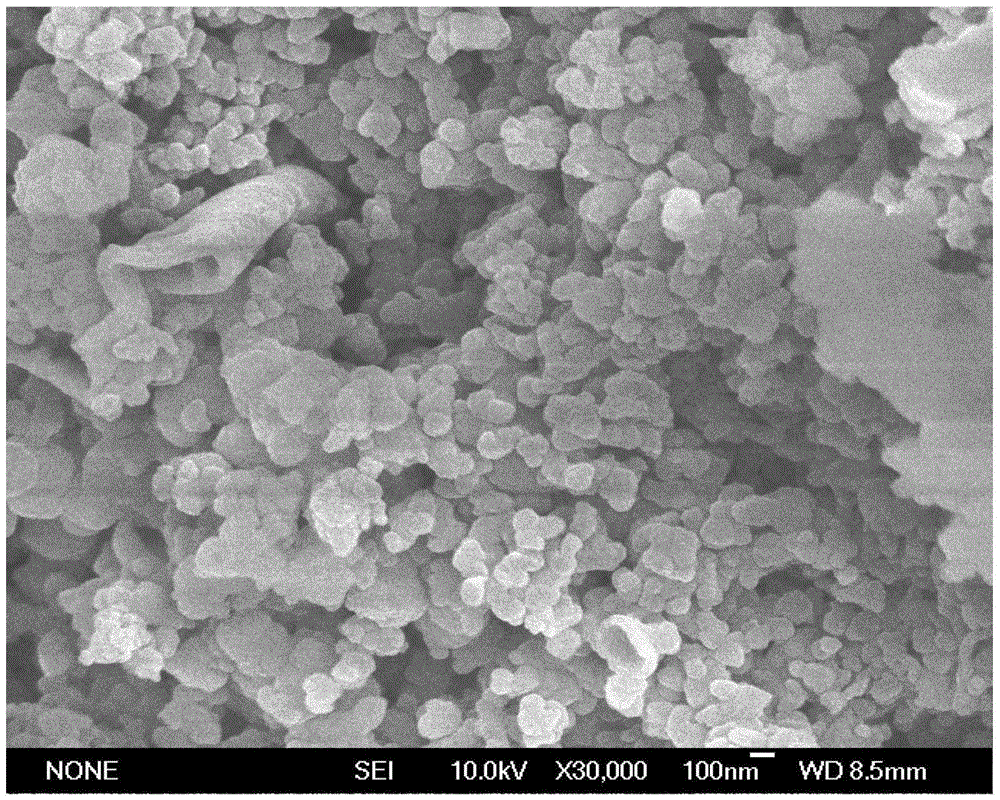

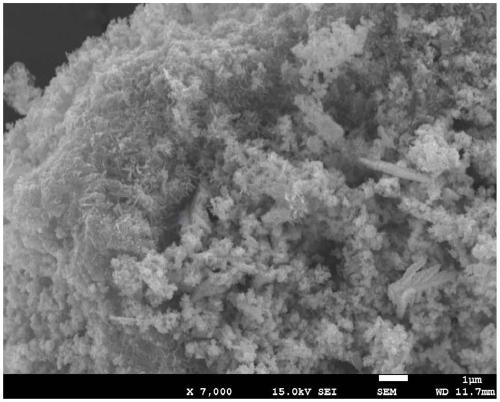

Method for green synthesis of nanometer zero-valent iron-copper bi-metal material and application

ActiveCN105458283AImprove stabilityReduce contentWater contaminantsContaminated soil reclamationIron saltsFiltration

The invention relates to a method for green synthesis of a nanometer zero-valent iron-copper bi-metal material and application. In one embodiment, the method includes the steps that 20-60 g of green tea is weighed, added in 1 L of distilled water and heated for 1 h at the temperature of 80 DEG, and after cooling is conducted to the room temperature, a green tea extracting solution is obtained after filtering; iron salt and copper salt are made into a mixed solution and stirred for 10 min at the temperature of 30-70 DEG C with the rate of 350 r / min; and the green tea extracting solution is added dropwise in the stirring process; the obtained solution is stirred for 20 min at the temperature of 30-70 DEG C with the rate of 350 r / min, and green synthesis nanometer zero-valent iron-copper suspension liquid is made; and the green synthesis nanometer zero-valent iron-copper suspension liquid is subjected to pumping filtration, green synthesis nanometer zero-valent iron-copper particles are obtained, washed through deionized water and absolute ethyl alcohol and put into a vacuum drying box to be dried for 12-48 h at the temperature of 40-70 DEG, and the green synthesis nanometer zero-valent iron-copper bi-metal material is obtained through grinding. According to the embodiment of the invention, the preparing technology is simple, the green tea extracting solution which is low in cost and easy to obtain serves as a biological activity reducing agent, reaction conditions are moderate, production cost is greatly reduced, and huge popularization and application potential is achieved in the field of repairing underground water and soil which are subjected to chromium pollution.

Owner:TAIYUAN UNIV OF TECH

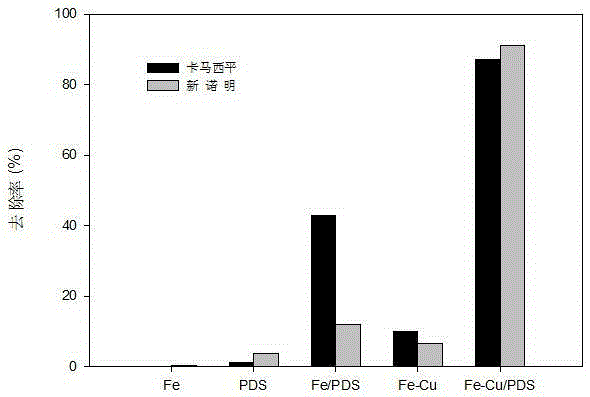

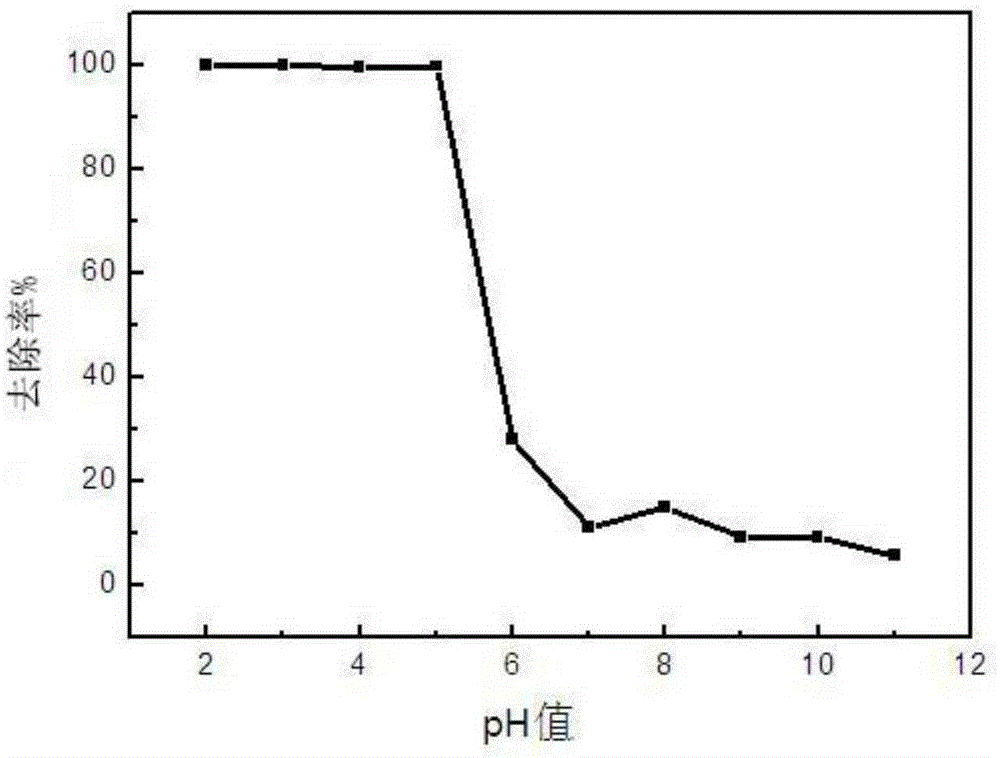

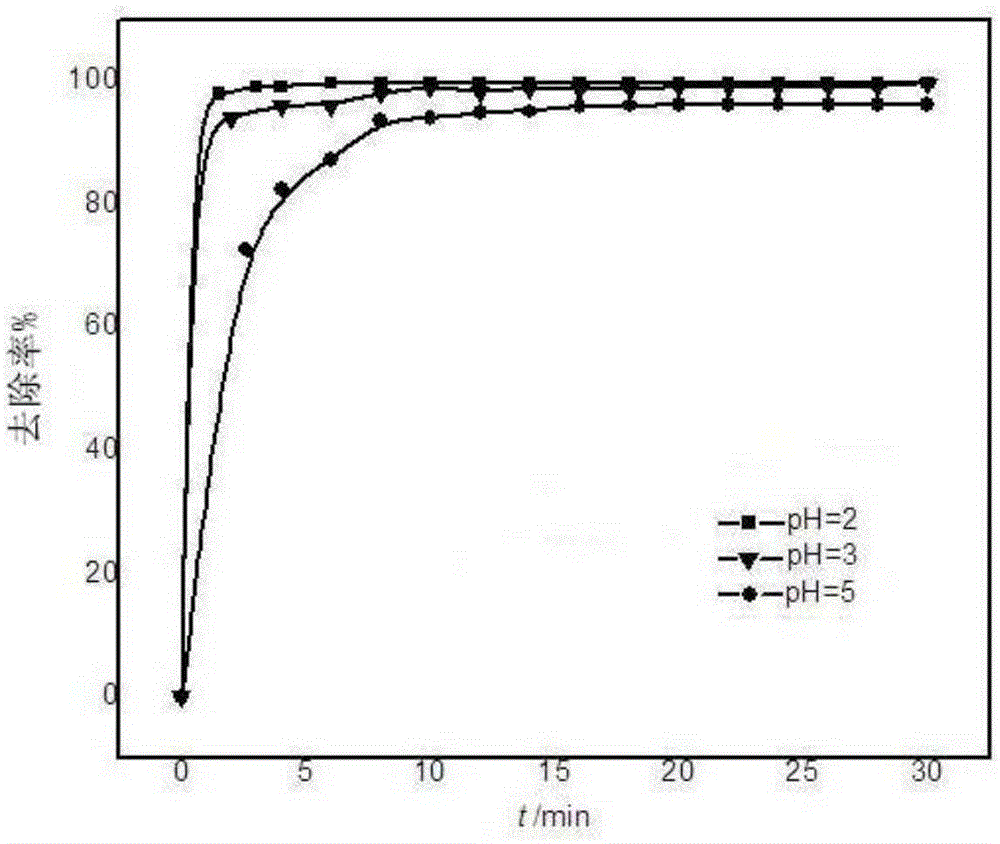

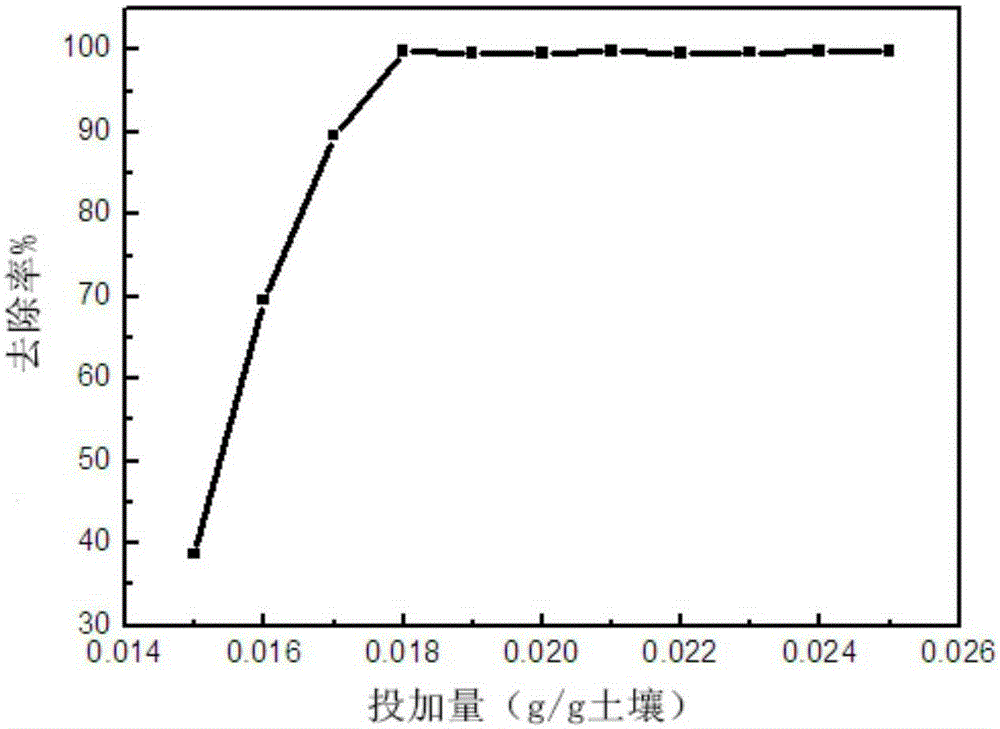

Water treatment method of zero-valent iron-copper bi-metal activated persulfate

InactiveCN105253983ASolve the problem of low production volumeRemove completelyWater contaminantsContaminated groundwater/leachate treatmentSulfate radicalsPolychlorinated biphenyl

The invention discloses a water treatment method of zero-valent iron-copper bi-metal activated persulfate. The water treatment method specifically comprises the steps that bi-metals including zero-valent iron and copper are added into water containing micro-pollutants, then persulfate is added, full mixing is performed, the bi-metals including the zero-valent iron and the copper are utilized to activate the persulfate so as to remove the micro-pollutants in the water. The water treatment method utilizes the bi-metals including the zero-valent iron and the copper to efficiently activate the persulfate so as to produce free sulfate radicals having strong oxidizing property, can achieve the purpose of quickly and thoroughly removing micro-pollutants, including multiple types of poisonous and harmful micro-pollutants in water, such as polychlorinated biphenyl, brominated flame retardants, drugs and personal care products (PPCPs) and algal toxin, and has the advantages of high activation efficiency, high oxidation and degradation efficiency of pollutants, wide pH using range, convenient operation and the like. The water treatment method can be applied to underground water remediation, treatment of industrial water (including electroplating wastewater, hospital wastewater, printing and dyeing wastewater and the like), drinking water treatment, wastewater treatment and the like.

Owner:SUN YAT SEN UNIV

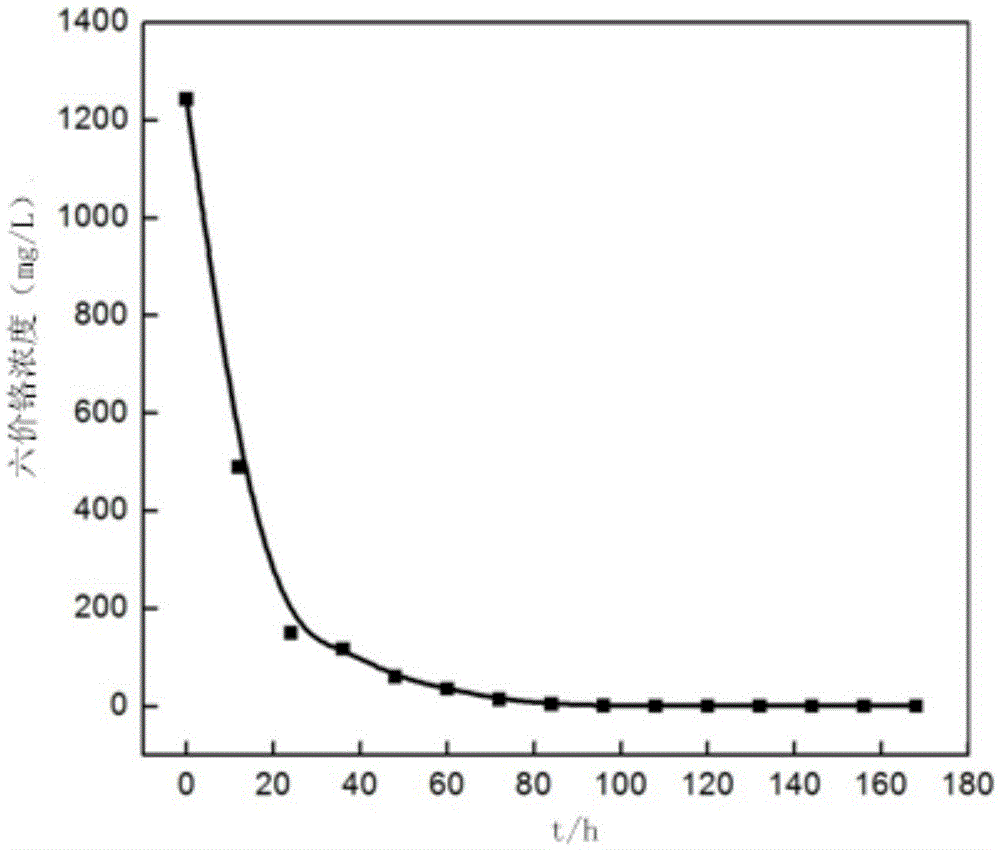

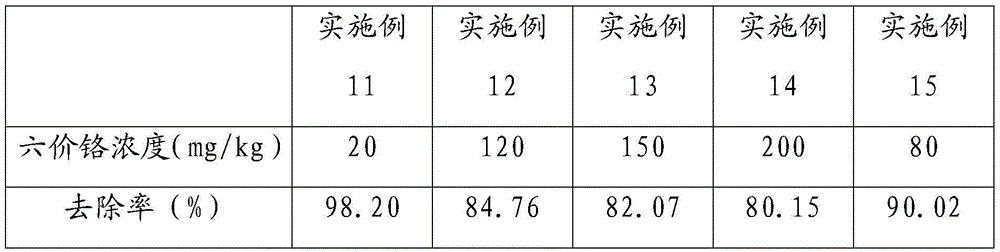

Preparation method and application of nano zero-valence iron and copper double-metal particles

ActiveCN105195758APrevent oxidationEasy to getContaminated soil reclamationNanotechnologyWater bathsIron salts

The invention relates to a preparation method and application of nano zero-valence iron and copper double-metal particles. In one embodiment, the preparation method comprises the following steps: adding an iron salt and a copper salt into a three-opening flask at a mol ratio of (3-10) to 1; taking 50mL-100mL of an ethanol solution to be added into the three-opening flask; stirring in a water bath at 20 DEG C to 60 DEG C for 10 minutes to 30 minutes; adding a hydroborate solution into the three-opening flask; after stirring for 10 minutes to 40 minutes, filtering to obtain sediment; washing the sediment with absolute ethyl alcohol and acetone respectively and then filtering; and putting the sediment into a vacuum drying box to be dried for 1 hour to 24 hours at 25 DEG C to 80 DEG C to obtain the nano zero-valence iron and copper double-metal particles. According to the embodiment provided by the invention, a preparation process is simple and the utilization is safe; and by adjusting the pH of chromium polluted soil, the application amount of the nano zero-valence iron and copper double-metal particles and a reaction temperature, hexavalent chromium in the chromium polluted soil can be rapidly reduced, so that the embodiment has a great application value in the field of repairing the chromium polluted soil.

Owner:TAIYUAN UNIV OF TECH

Water atomization ferrum-copper alloy powder and manufacturing method

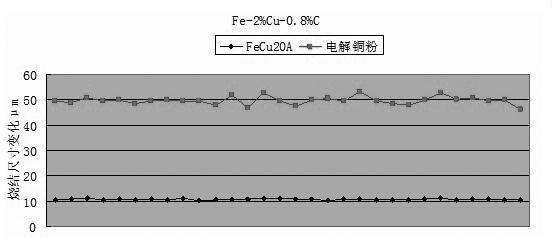

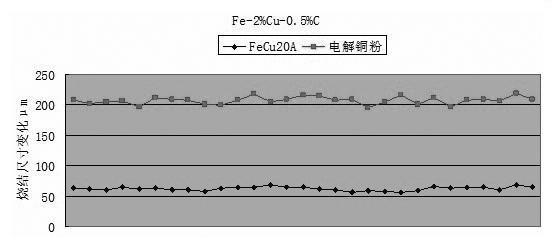

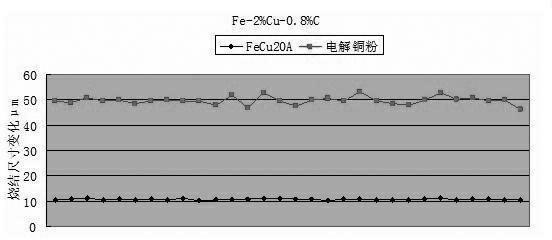

InactiveCN102554216AExcellent sintering dimensional change stabilityConducive to dimensional accuracy controlSulfurManganese

The invention relates to the technical field of powder metallurgy, in particular to water atomization ferrum-copper alloy powder and a manufacturing method, which are used for improving dimensional precision of powder metallurgy parts. Chemical components of the water atomization iron-copper alloy powder include 0-0.1% of C (carbon), 0-0.3% of Si (silicon), 0.05-0.5% of Mn (manganese), 0-0.05% of P (phosphorus), 0-0.05% of S (sulfur), 5-45% of Cu (copper) and the rest ferrum. The manufacturing method includes the steps of smelting, water atomization, drying, reduction and crushing. The powder serves as a copper additive for a series of copper-containing powder metallurgy parts with Fe-Cu-C, Fe-Ni(nickel)-Mo(molybdenum)-Cu-C and the like, has sintered dimensional change stability better than that of electrolytic copper powder, and is beneficial to controlling dimensional precision of sintered parts.

Owner:杭州屹通新材料股份有限公司

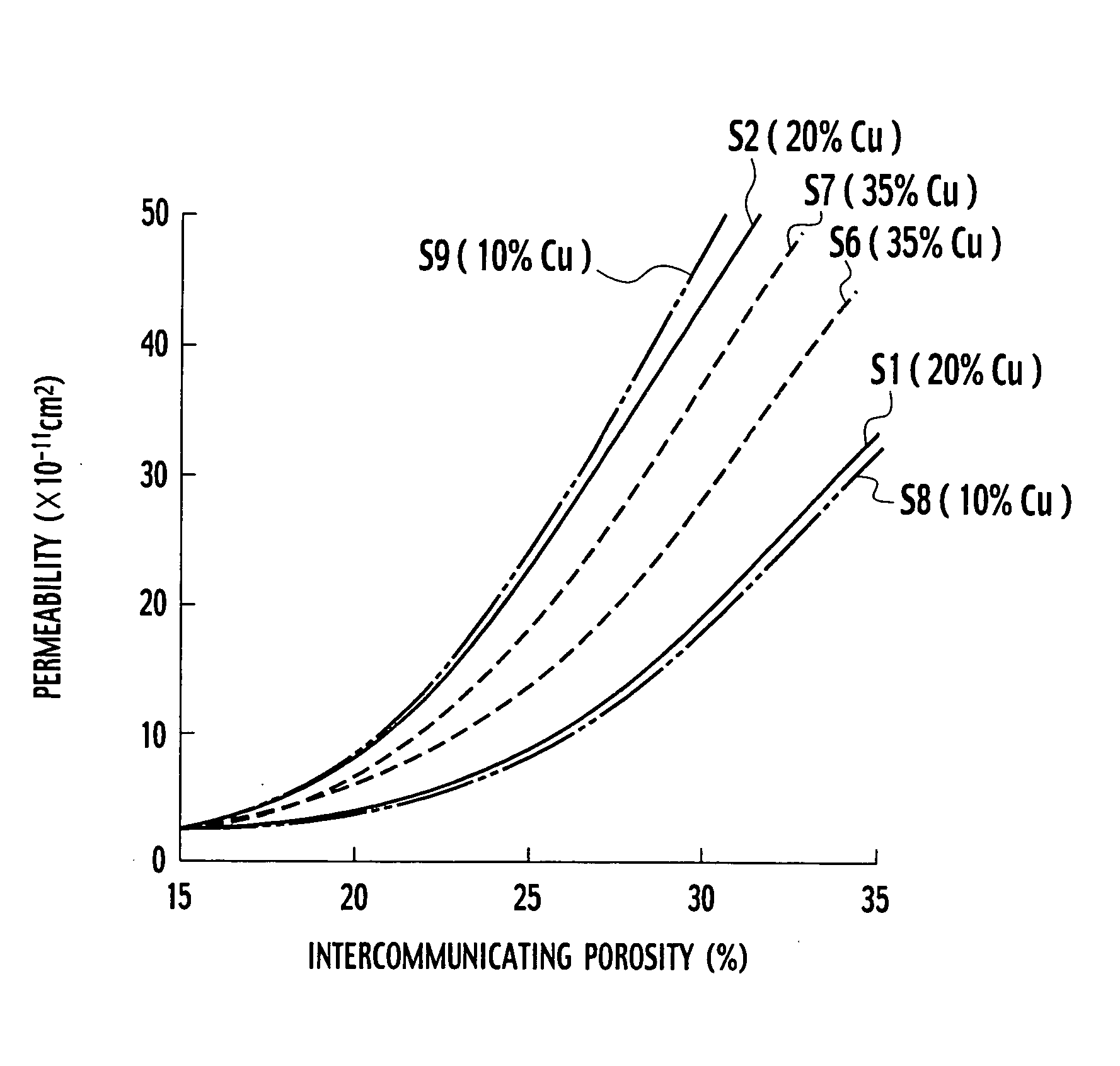

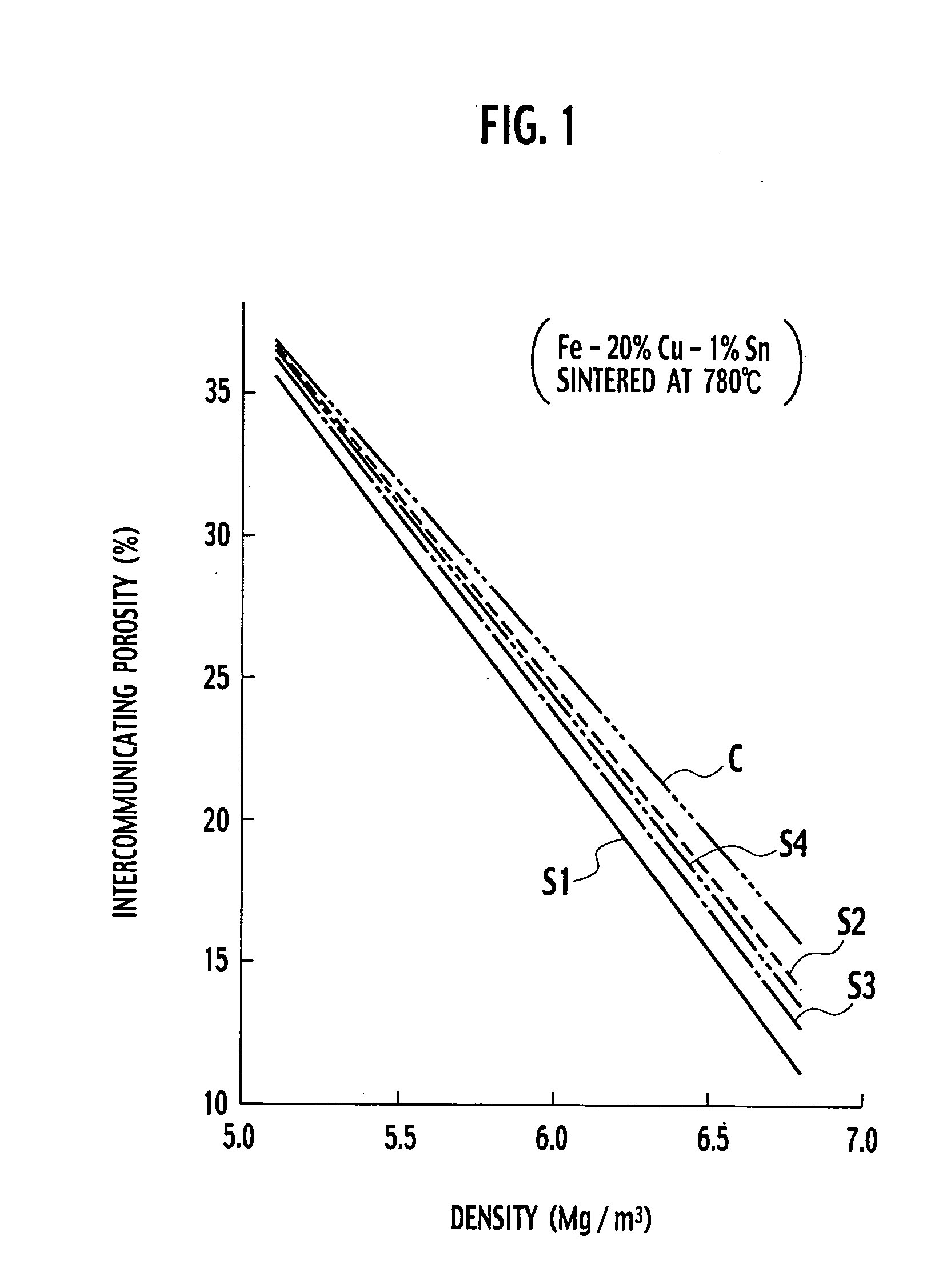

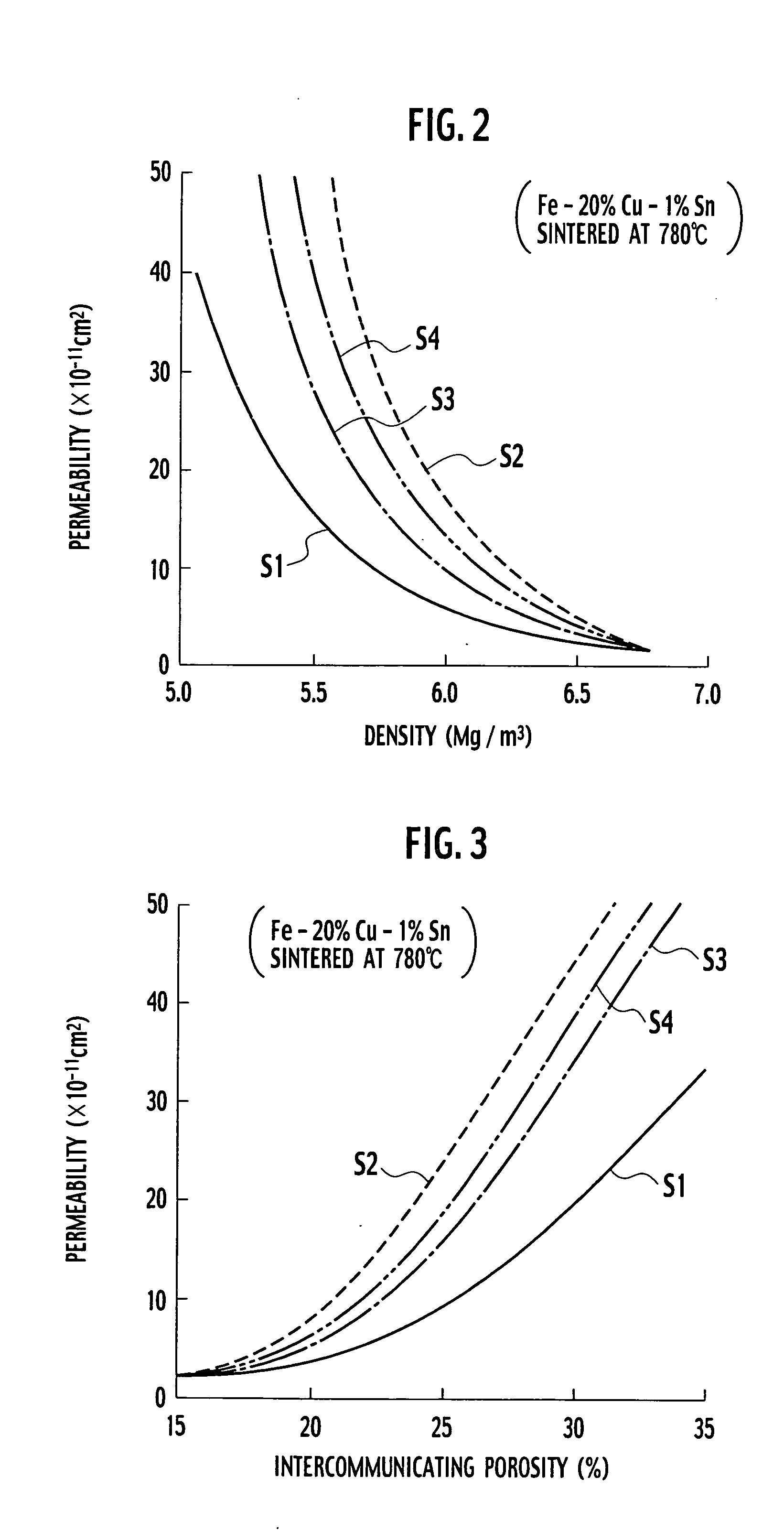

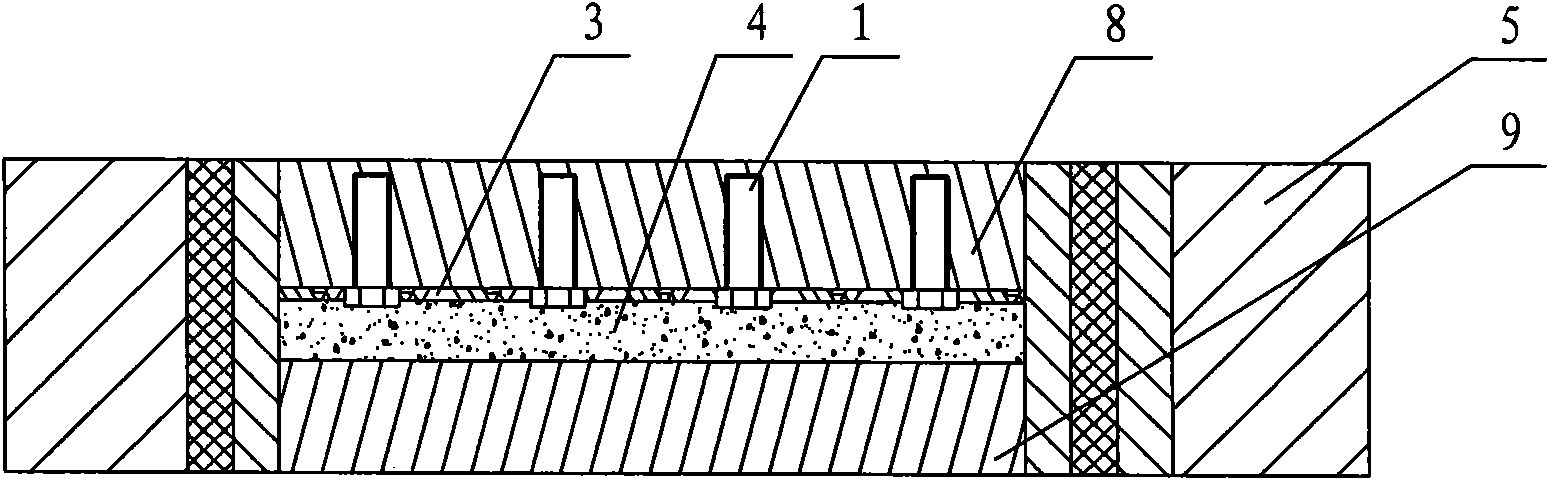

Manufacturing processes of sintered alloy and oil-impregnated sintered bearing

Disclosed is a manufacturing process of a sintered iron-copper base porous alloy and of an oil-impregnated sintered bearings, having the steps of: preparing a mixed powder comprising an iron powder, and at least one of a copper powder and a copper alloy powder; forming the mixed powder into a green compact; and sintering the green compact to obtain a sintered iron-copper base porous alloy. The iron powder contains a porous iron powder which has a particle size of 177 microns or less and a specific surface area of 110 to 500 m2 / kg according to a gas adsorption method. The sintered compact has high intercommunicating porosity and low permeability, and it is sized to prepare the sintered bearing into which a lubricating oil is impregnated.

Owner:HITACHI POWDERED METALS COMPANY

Superfine iron-copper alloy powder and preparation method thereof

The invention relates to superfine iron-copper alloy powder and a preparation method thereof. The superfine iron-copper alloy powder is prepared by using ferric oxalate powder at an industrial raw material stage and cupric oxide powder at an industrial raw material stage as raw materials through high-energy ball milling and hydrogen reduction and has a fisher particle size smaller than 1.0 microns and a oxygen content smaller than or equal to 0.5 percent by weight. The invention has the advantages that grains of the superfine iron-copper alloy powder are thinner, the physical and chemical properties are superior, and the manufacture cost is low.

Owner:惠州市新宏泰科技有限公司

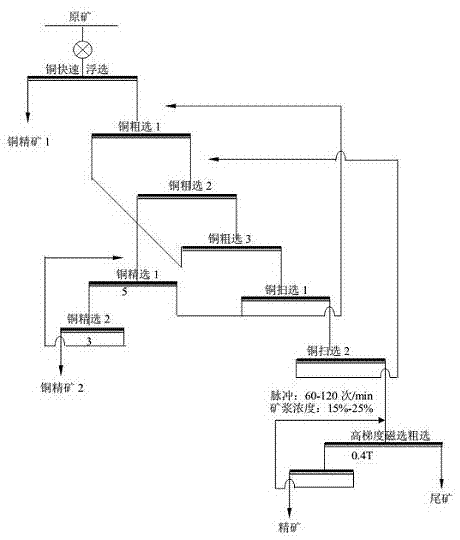

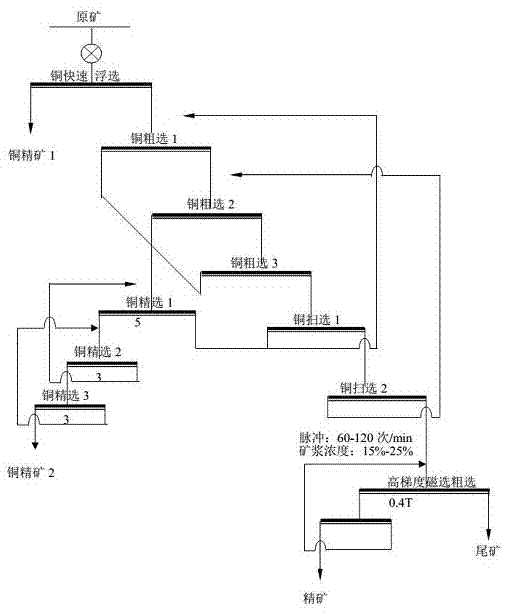

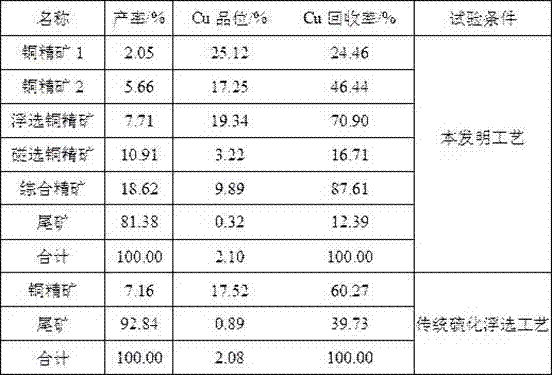

Method for recovering high-pelitic and high-iron copper oxide ore hard to treat

InactiveCN105435952ALight in massLarge specific surface areaWet separationCopper oxideMineral processing

The invention relates to a method for sorting high-pelitic and high-iron copper oxide ore hard to treat, and belongs to the technical field of mineral processing. After being ground, raw copper oxide ore is subjected to rapid flotation, so that a high-grade copper concentrate is obtained; then copper minerals hard to float are separated out through segmented flotation, and a low-grade copper concentrate is obtained; and finally a magnetic concentrate is obtained through high-gradient magnetic separation. Compared with a traditional copper oxide flotation method, the recovery rate of the method is higher by 15%-35%, and interference of mud and iron is avoided. The technological process is stable, high in adaptability, low in production cost, high in copper recovery rate and capable of being industrially implemented.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Process for preparing micro spherical Feito synthetic catalyst

InactiveCN1128667CReduce manufacturing costSimple processLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsCopper nitrateSlurry

A kind of preparation method of microspherical Fischer-Tropsch synthesis catalyst, mix ferric nitrate or ferric sulfate solution with lanthanum nitrate and copper nitrate or copper sulfate mixed solution, then add precipitating agent sodium carbonate or ammonia solution, the obtained iron-containing lanthanum copper After the precipitation slurry is washed and filtered to obtain a co-precipitation filter cake, the potassium silicate water glass solution is directly added to the wet slurry containing iron, lanthanum and copper, and the slurry is beaten and mixed evenly to obtain a catalyst slurry, which is then spray-dried and roasted to obtain a catalyst slurry. Spherical slurry bed Fischer-Tropsch synthesis iron-based catalyst. The invention simplifies the technological process, and the spray drying method has the characteristics of large processing capacity, low energy consumption, rapid catalyst formation, suitable for industrial continuous large-scale production and the like.

Owner:SYNFUELS CHINA TECH CO LTD

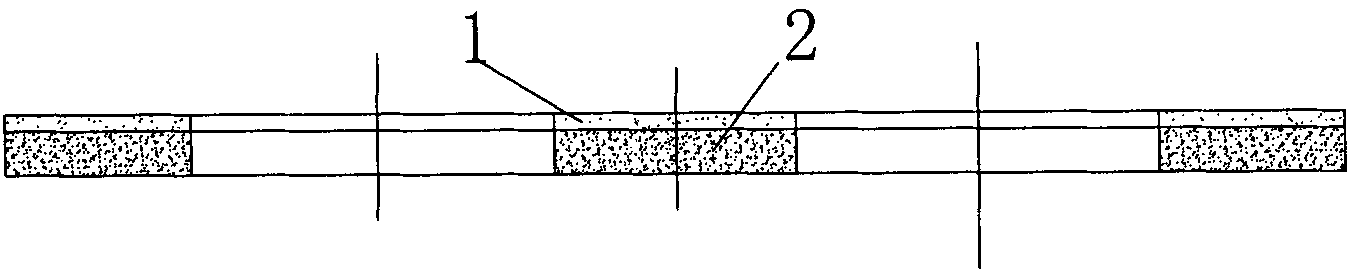

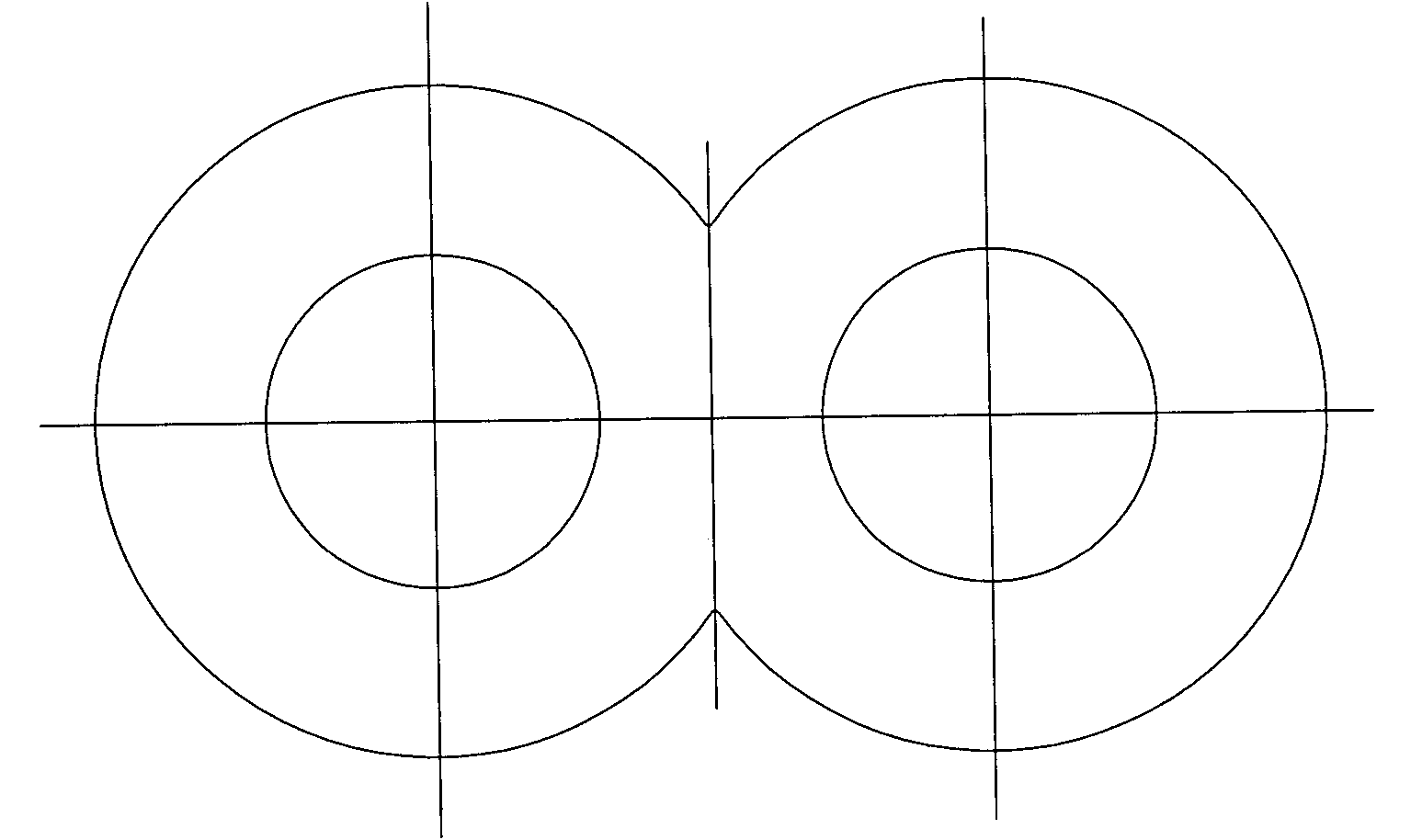

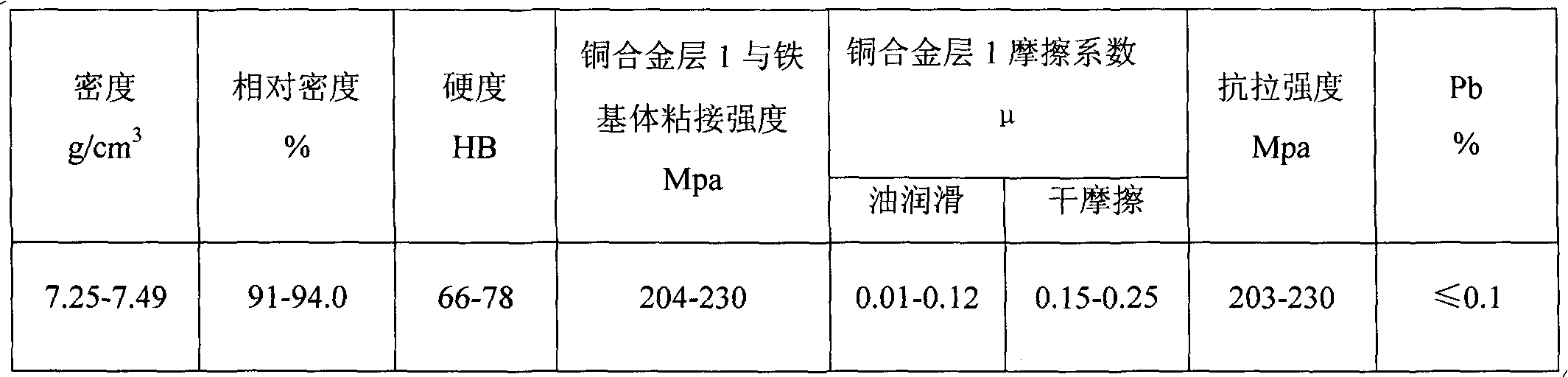

High strength self-lubricating iron-copper powder composite material and preparation method thereof

The invention relates to a high strength self-lubricating iron-copper powder composite material, a preparation method and application thereof. The composite material is characterized by comprising an iron alloy base body and a copper alloy base body as a surface layer, wherein the iron alloy base body contains Cu, C, Sn, Pb and Fe, and the copper alloy base body contains Ni, C, MoS2, Sn, Fe, Pb and Cu. The preparation method comprises the following steps of: respectively preparing copper alloy layer warm-pressing powder and iron alloy base body warm-pressing powder; filling the warm-pressing powder into a mould and then pressing once to form a green compact; sintering the green compact in the protection atmosphere; and shaping the sintered sintering compact in the mould so that the composite material is prepared. By the invention, the cost of parts can be greatly reduced on the basis of ensuring the use performance of the parts.

Owner:合肥波林新材料股份有限公司

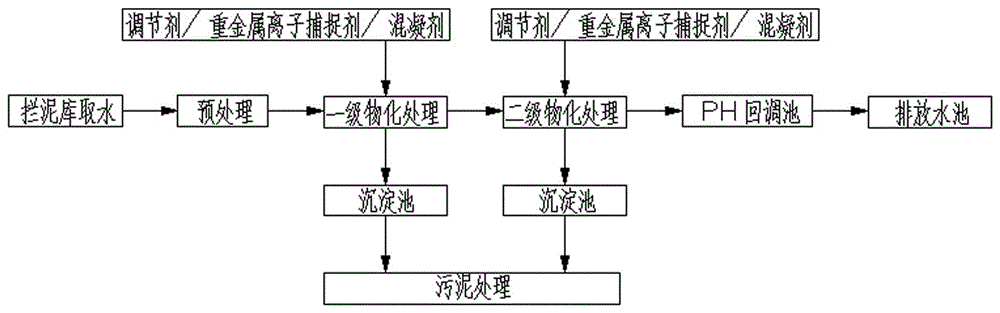

Wastewater treatment process of iron-copper-sulfur polymetallic mine slurry detention reservoir

InactiveCN105858969AAvoid back-melting phenomenonEasy to useWater contaminantsWaste water treatment from metallurgical processSludgeDissolution

The invention relates to a wastewater treatment process of an iron-copper-sulfur polymetallic mine slurry detention reservoir. The step includes the steps of 1,water intaking from the slurry detention reservoir, wherein wastewater can enter a slurry pool through a dirt leading pipe; 2, pretreatment, wherein impurities and sand particles are removed, homogeneity and averaged quantity are achieved, and meanwhile an oxidizing agent is fed to remove reducing substances; 3, preliminary physicochemical treatment, wherein a conditioning agent, coagulant, a heavy metal ion capturing agent and a flocculating agent are added, 4, secondary physicochemical treatment, wherein the conditioning agent, the coagulant, the heavy metal ion capturing agent and the flocculating agent are added, the PH value of wastewater is adjusted to 6.0-11.0, and zinc ions and various remaining metal ions are removed; 5, pH back conditioning; 6, slurry treatment, wherein slurry is dehydrated with a screw pump to form a dry filter cake. By means of the wastewater treatment process, the phenomenon of re-dissolution of heavy metal ions can be avoided; the treatment cost is low, less slurry is generated, and the situation of secondary pollution is avoided.

Owner:韶关市雅鲁环保实业有限公司

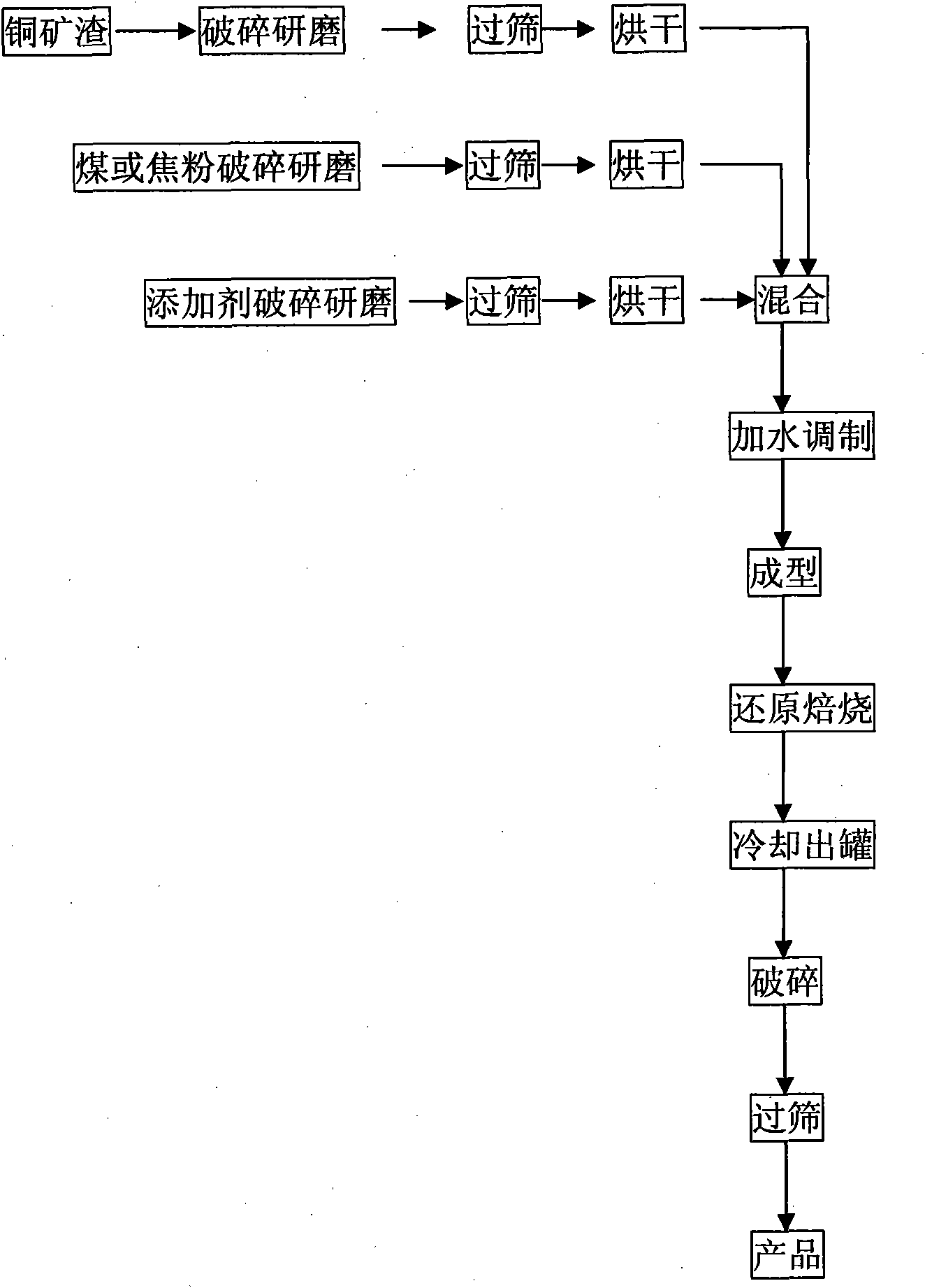

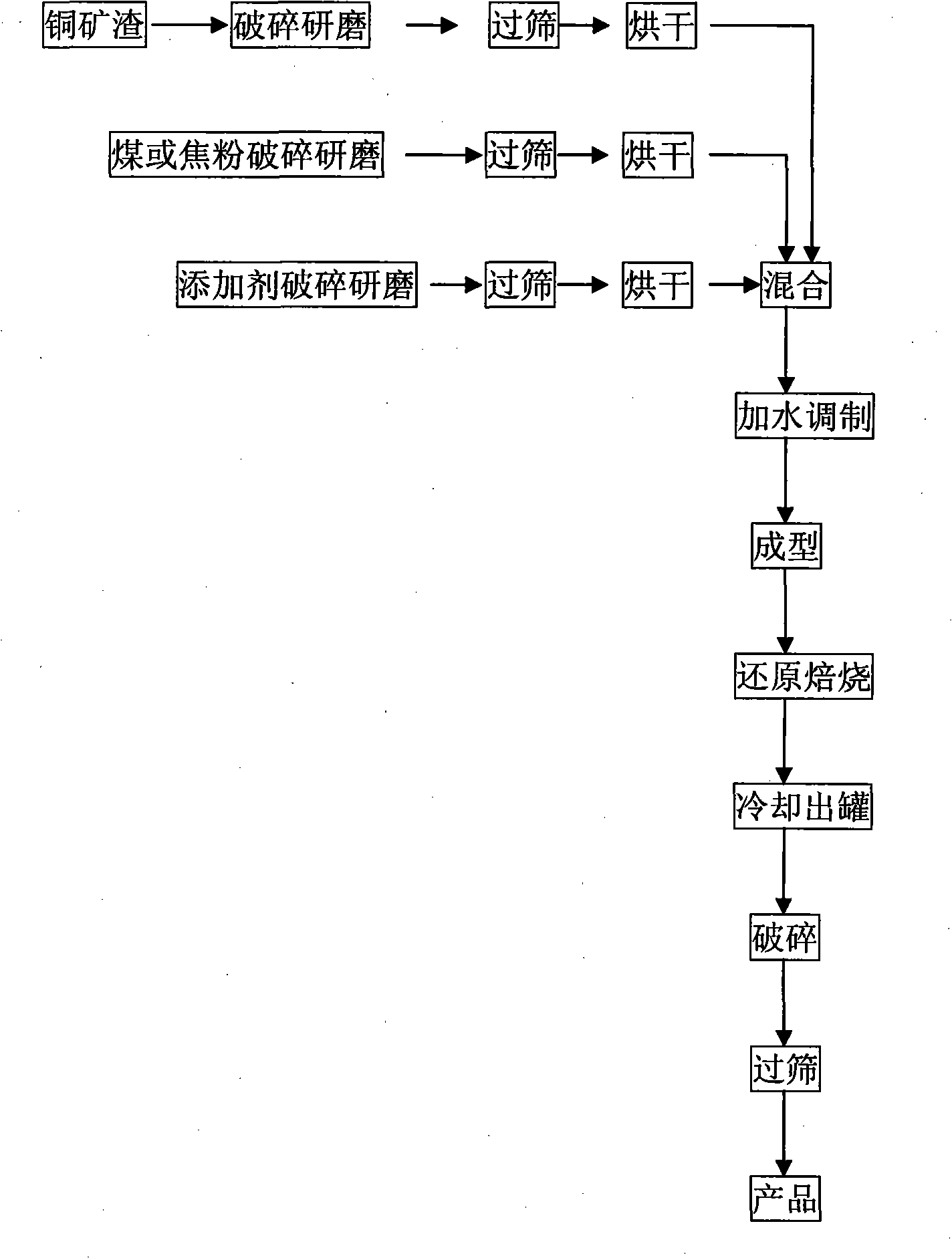

Micro-electrolytic environment-friendly filler, and production raw materials and preparation method thereof

InactiveCN101898818ARich sourcesReduce manufacturing costWater/sewage treatmentElectrolysisSolid particle

The invention discloses a micro-electrolytic environment-friendly filler which simultaneously comprises iron element, copper element and carbon element, has high-efficiency cleaning function and does not cause passivation, hardening and blockage, and production raw materials and a preparation method thereof. The filler is an iron and copper-containing and carbon-doped composite solid granular material; and the filler comprises the following components in percentage by mass: 55 to 88.5 percent of reduced iron, 1 to 10 percent of total copper, 0.5 to 5 percent of carbon and the balance of impurities. The production raw materials include copper slag and carbon in the mass ratio of (60-85) to (14-35). The iron, the copper and the carbon simultaneously exist in the filler grains, wherein the iron is used as an anode to release electrons; the copper and the carbon are used as a cathode discharging point; the total discharge area of the cathode is 20 to 40 percent larger than the total surface area of the filler; and thus the electrochemical activity of the filler in sewage is improved, an oxide film is prevented from being continuously formed on the surface of the filler grains, and the problem of passivation of the filler is completely solved. Only one filler exists in a micro-electrolysis system, so the problems of hardening and blockage of the system can be completely solved by repeated washing and periodic bed loosening.

Owner:喻宇琳 +1

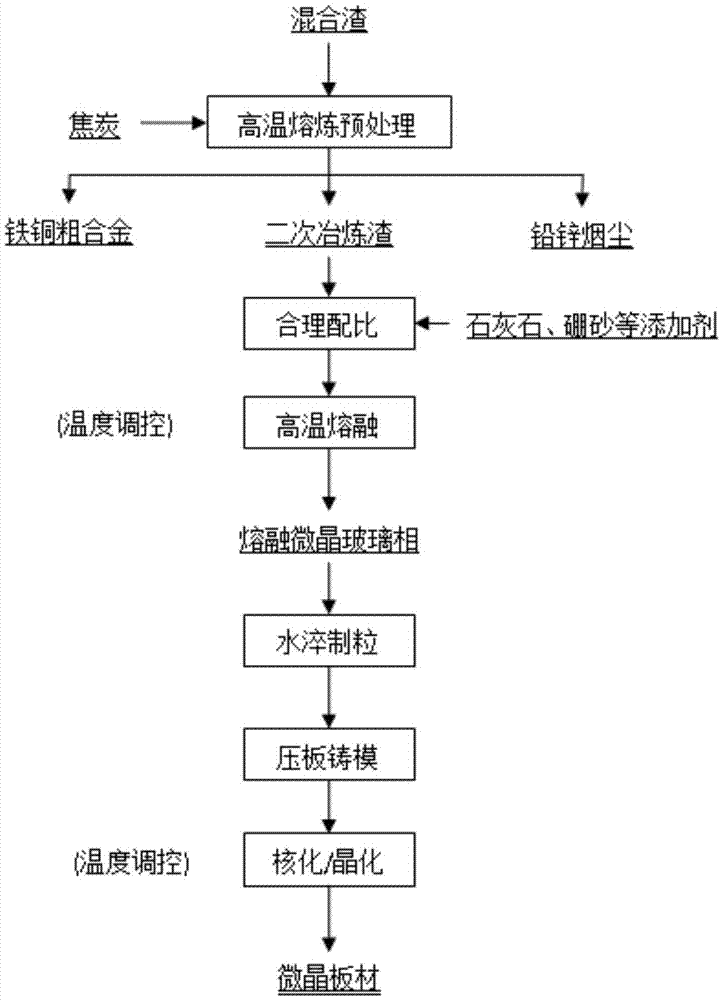

Comprehensive treatment method for mixed waste residues

The invention discloses a comprehensive treatment method for mixed waste residues. The comprehensive treatment method comprises the following steps that (1) the mixed waste residues are mixed with reducing agent coke for reduction smelting to obtain iron-copper alloy, lead-zinc smoke dust and secondary smelted slag; (2) lead-free cathode ray tube (CRT) glass, quartz sand and an additional agent are added for glass ceramic smelting according to components of the secondary smelted slag, and obtained molten glass microcrystalline phase is subjected to water quenching granulation to obtain glass ceramic particles; and (3) the obtained glass ceramic particles are subjected to pressing plate molding forming, formed materials are subjected to nucleation and crystallization treatment to obtain glass ceramic plates with good performance. The mixed waste residues are treated through a two-step high-temperature smelting method, valuable metal in the residues can be effectively recycled and enriched, and the technical process is simple. Meanwhile, the follow-up preparation of the glass ceramic plates is combined, so that economic profits are achieved.

Owner:HUNAN ZHONGDA JOINT INNOVATION & TECH DEV CO LTD

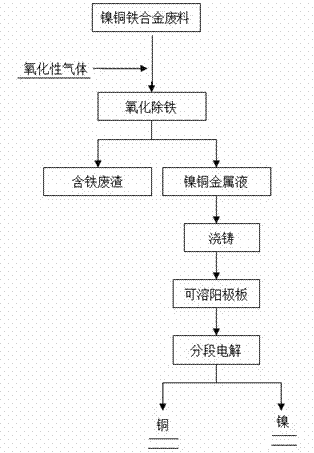

Method for recovering copper and nickel from nickel-iron-copper alloy waste

ActiveCN103498051ARemarkable process energy saving effectIncrease added valuePhotography auxillary processesProcess efficiency improvementMolten stateElectrolysis

The invention relates to a method for recovering copper and nickel from nickel-iron-copper alloy waste, belonging to the technical field of resource comprehensive utilization. The method comprises the following steps: oxidation for iron removal: heating the nickel-iron-copper alloy waste to obtain molten-state nickel-iron-copper alloy waste, then adding a slag former, and spraying oxidation gas to obtain molten metal and slag; first-stage electrolytic refining to recover copper: casting the obtained molten metal into a soluble anode, and then electrolyzing by taking a soluble anode plate as an anode, a stainless steel plate as a cathode and copper sulfate as electrolyte to obtain copper on the cathode; second-stage electrolytic refining to recover nickel: heating the electrolyte after the electrolytic refining to remove iron and copper and then feeding into a nickel electrolytic tank as the electrolyte for recovering nickel, and electrolyzing by taking an insoluble titanium plate as an anode and a stainless steel plate as a cathode to obtain nickel on the cathode. According to the method provided by the invention, the three processes of alloy structure damage, anode plate casting and oxidation for iron removal are coupled together, so that the energy saving effect of the process is remarkable.

Owner:KUNMING UNIV OF SCI & TECH

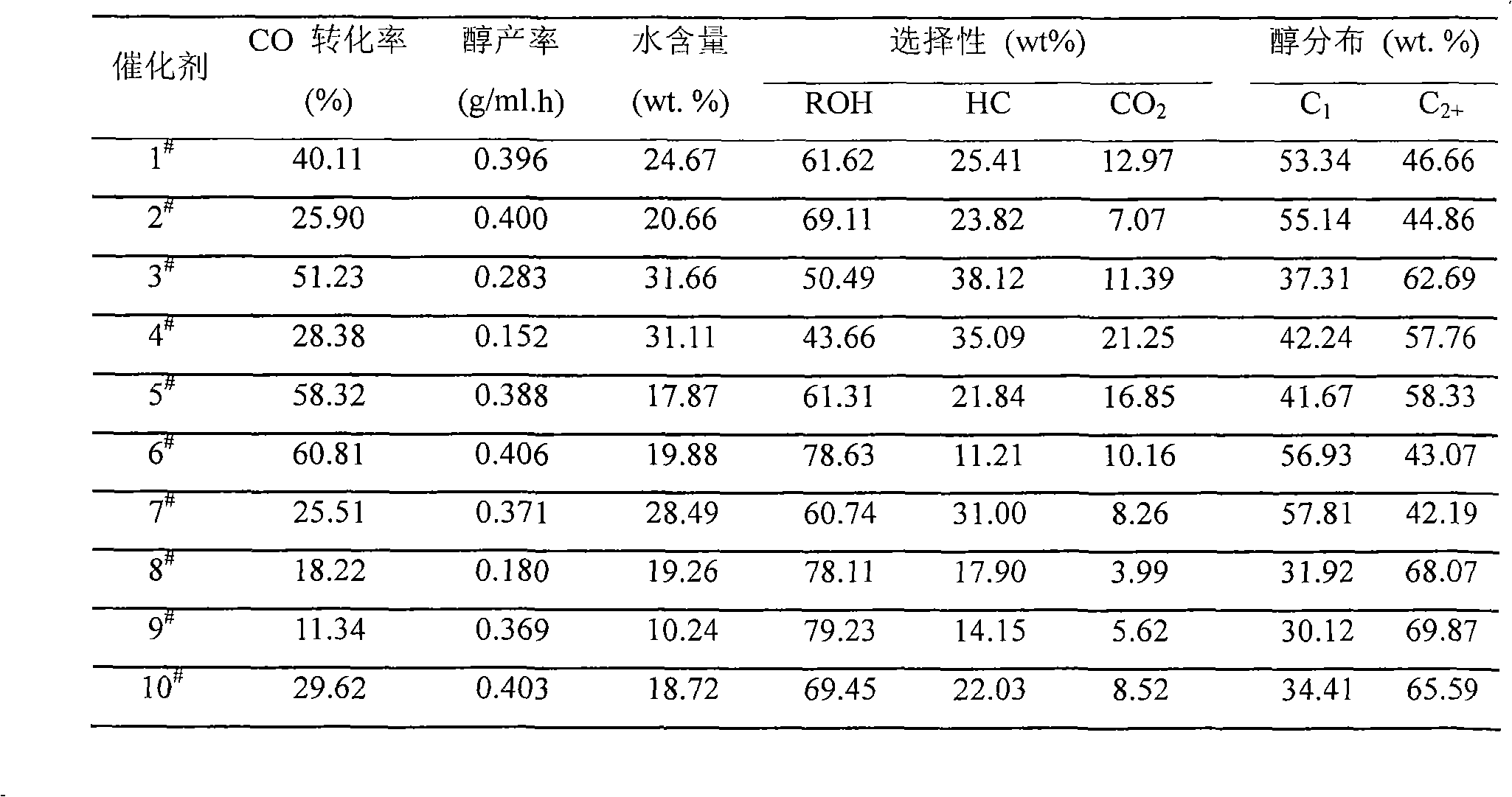

Iron-copper based catalyst for synthesizing low carbon mixed alcohol and production method and use

InactiveCN101327435AEasy to prepareEasy to operateOrganic compound preparationHydroxy compound preparationAlcoholCoprecipitation

The present invention relates to an iron-copper base catalyst synthesizing mixture of lower alcohols. In weight percentage, the iron-copper base catalyst consists of 20 percent to 60 percent of Cu, 15 percent to 60 percent of Fe, 0.4 percent to 20 percent of Mn, 0.4 percent to 30 percent of Zn and 0 percent to 5 percent of MA. The catalyst is prepared by a coprecipitation method. The iron-copper base catalyst has the advantages of simple preparation, easy operation, good reaction performance repeatability of the catalyst, realizing industrial amplification easily, good stability and high total alcohol selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

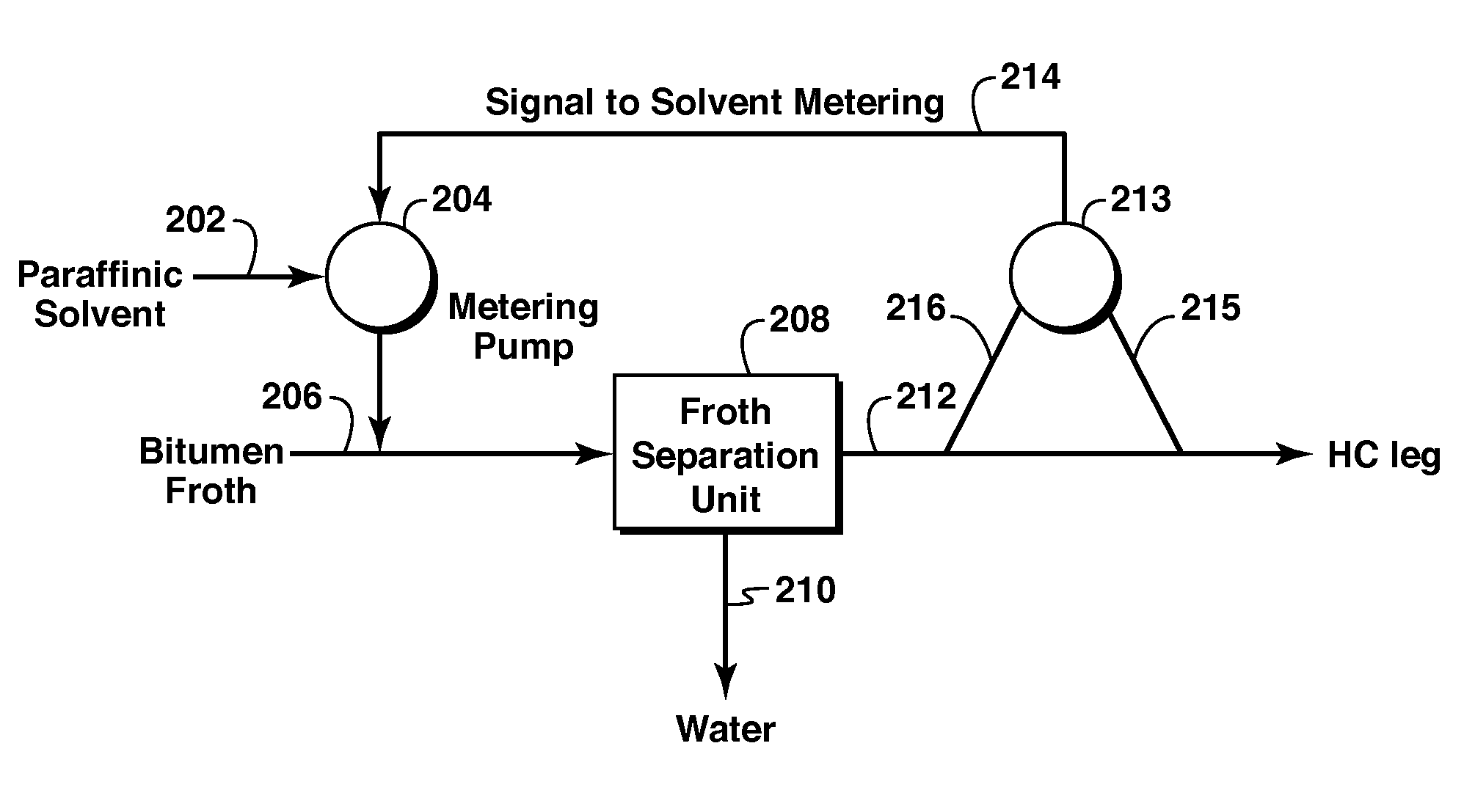

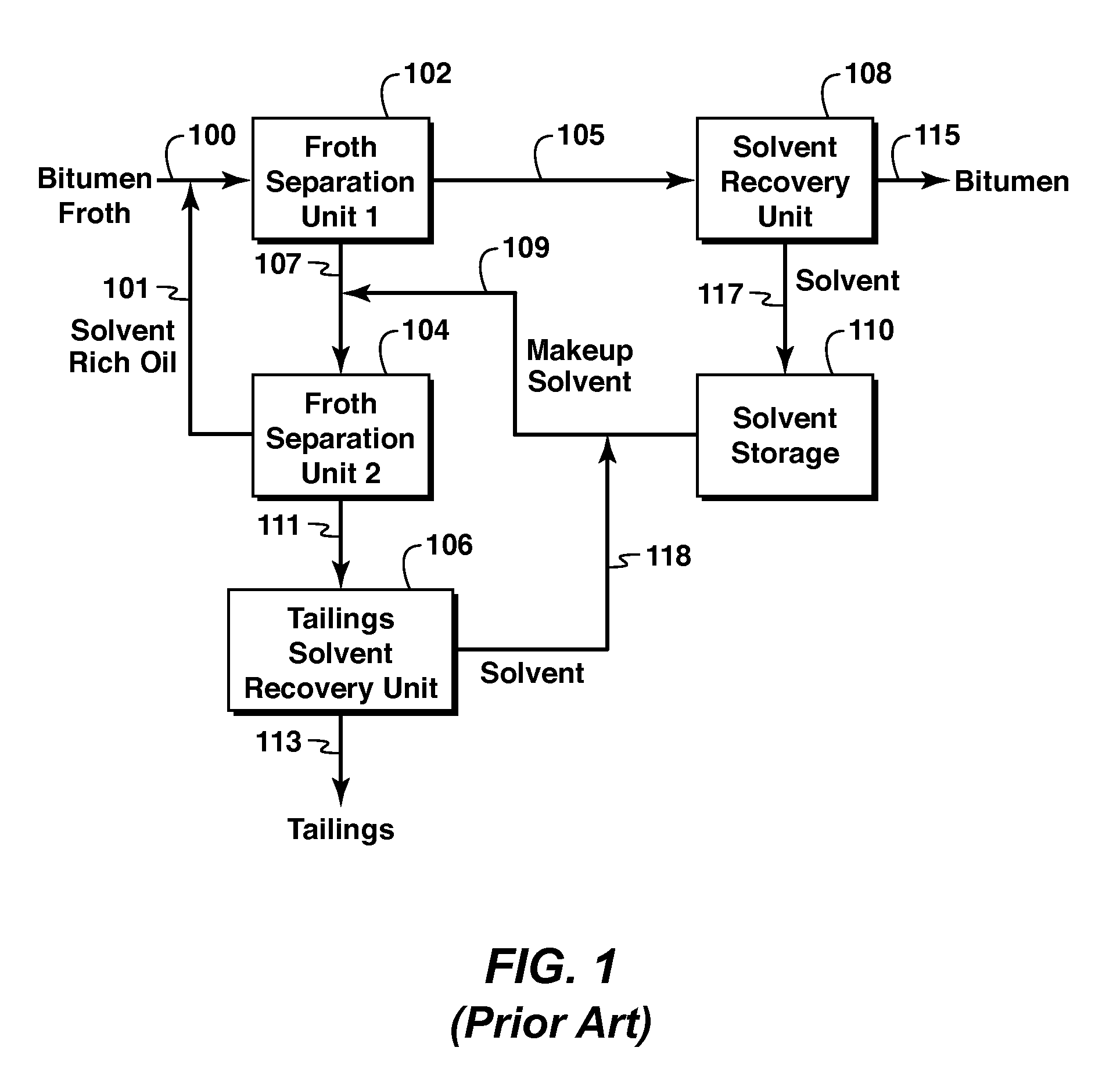

Method for using native bitumen markers to improve solvent-assisted bitumen extraction

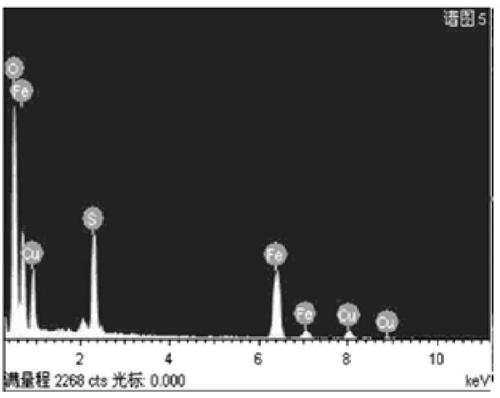

ActiveUS8449764B2Quality improvementMaterial analysis using wave/particle radiationX-ray spectral distribution measurementSulfurManganese

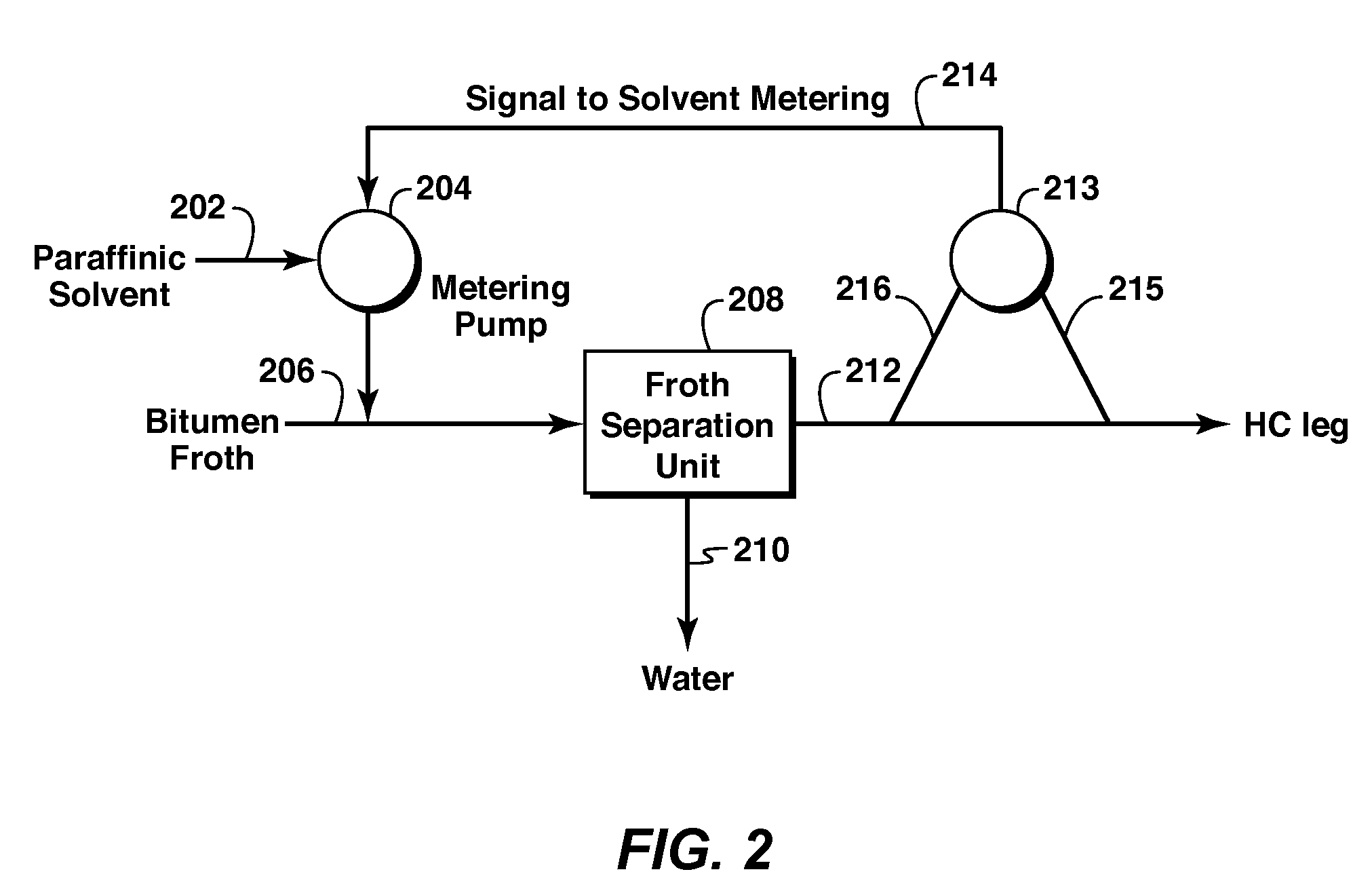

In solvent-assisted bitumen extraction, a native marker, for example: sulfur, nickel, vanadium, iron copper, or manganese, is used to control the solvent to bitumen ratio in a process stream such as a stream from a froth separation unit (FSU) and / or to measure hydrocarbon loss in a tailings solvent recovery unit (TSRU).

Owner:EXXONMOBIL UPSTREAM RES CO

Polishing Composition for Silicon Wafer

InactiveUS20090127501A1Avoid Metal ContaminationHigh removal rateOther chemical processesSemiconductor/solid-state device manufacturingWaferingCopper contamination

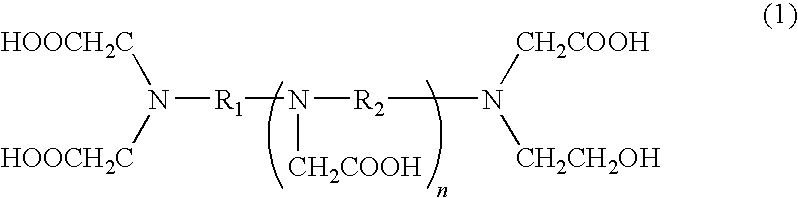

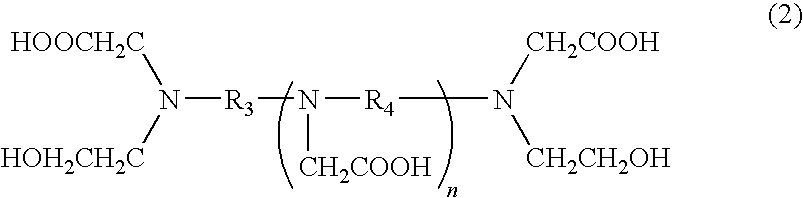

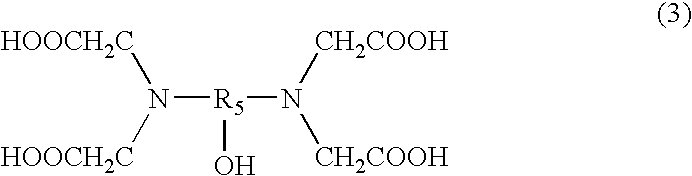

The present invention relates to a polishing composition for silicon wafer comprising silica, a basic compound, a polyaminopolycarboxylic acid compound having hydroxy group, and water. The polishing composition can prevent metal contamination by nickel, chromium, iron, copper or the like, particularly copper contamination in polishing of silicon wafer.

Owner:NISSAN CHEM IND LTD

Iron-based copper for treating organic sewage and sewage treatment method

InactiveCN102849824AImprove degradation efficiencyIncrease potential differenceWater/sewage treatmentElectrolysisElectrochemical degradation

The invention relates to an iron-based copper high-efficient microelectrolytic material which contains a lot of nonuniform iron-copper microelectrode primary batteries and is formed by coating copper on cast iron granular carrier surfaces in a crystal grain form by a chemical conversion method. When organic sewage flows through a fixed bed reactor formed by the material, the reaction efficiency is controlled by the flow rate. With the material and the fixed bed reaction technology, the problem of low electrochemical degradation efficiency of organic pollutant macromolecules in sewage by common granular iron-carbon microelectrolytic materials and granular iron-copper microelectrolytic materials in current sewage treatment process is solved.

Owner:WUHAN COMEON ENVIRONMENT ENG

Iron-copper oxide/copper base electrode material and preparation method thereof

ActiveCN108538609AMake up for the mismatch of positive and negative specific capacitiesIncrease energy densityHybrid capacitor electrodesCell electrodesCapacitanceFerric hydroxide

The invention provides an iron-copper oxide / copper base electrode material and a preparation method thereof. The iron-copper oxide / copper base electrode material is expressed as Fe3O4 / CuO / copper base.A copper hydroxide nanowire array, i.e. Cu(OH)2 / copper base, is grown on the copper base in an in-situ way; then ferric hydroxide is electrodeposited on the Cu(OH)2 / copper base in the electrolyte solution containing iron ions by using the method of potentiostatic electro-deposition so as to form the hollow tubular structure Fe(OH)3 / Cu(OH)2 / copper base; and then the ferric hydroxide is transformedinto ferric oxide and the copper hydroxide is transformed into copper oxide through high temperature roasting, and the hollow tubular structure is maintained so that the hollow tubular structure Fe3O4 / CuO / copper base material is obtained. The material has great super capacitance performance and is suitable for being used as the supercapacitor electrode material.

Owner:BEIJING UNIV OF CHEM TECH

Iron and copper ferrous sulfide loading composite material, preparation method and application thereof

ActiveCN111266572ASlow down the problem of passivation too fastWater Corrosion MitigationWater contaminantsWater/sewage treatmentCu2 ionsIron powder

The invention relates to an iron and copper ferrous sulfide loading composite material, a preparation method and application thereof. The composite material comprises iron and copper and ferrous sulfide loaded to the surfaces of the iron and copper. Copper in the iron and copper is loaded to the surface of iron. The composite material is relatively high in activity and reaction selectivity, and can be used in the fields of chromium containing sewage treatment, chromium polluted underground water repair and the like. The preparation method comprises the following steps of mixing a copper salt solution with iron powder primarily; and then mixing the mixed solution with an alkali metal vulcanized salt solution secondarily to obtain the iron and copper ferrous sulfide loading composite material. The preparation method recovers Fe2<+> generated in a replacement process of copper ions and iron powder and has the advantages of being simple in step and economical and effect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for absorbing and purifying hydrogen sulfide with EDTA (ethylene diamine tetraacetic acid) chelated iron copper compound system

InactiveCN102658002AReduce consumptionImprove removal efficiencyDispersed particle separationIron saltsSodium salt

The invention relates to a method for absorbing and purifying hydrogen sulfide with an EDTA (ethylene diamine tetraacetic acid) chelated iron copper compound system, which comprises the following steps: dissolving 1-10wt% of soluble iron salt in deionized water to prepare an iron salt solution; adding soluble copper salt and EDTA disodium salt into the iron salt solution in an iron salt / copper salt / EDTA disodium salt mass ratio of (1-5):1:1, thereby obtaining an EDTA chelated iron copper compound absorption solution; and introducing hydrogen sulfide gas with the concentration of 800-4000ppm to carry out absorption reaction. The method provided by the invention has the advantages of high removal efficiency, mild reaction conditions, low absorption solution cost, low raw material consumption, wide application range and the like, and is simple to operate.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Iron-copper composite oxide supported catalyst for room-temperature ozonolysis

InactiveCN103127942ASimple preparation processLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberSlurry

The invention discloses an iron-copper composite oxide supported catalyst for room-temperature ozonolysis, particularly relates to an ozonolysis catalyst and a preparation method of the ozonolysis catalyst, and relates to the fields of catalysis and environmental protection. Honeycomb ceramics or multi-hole foam metal or activation carbon fiber cloth is used as a carrier of the catalyst, iron-copper composite oxide is a main active component, and gold is an auxiliary active component. The preparation method mainly comprises: A. Fe2O3-CuO composite oxide powder is prepared through the adoption of a precipitation method; B. the powder is dispersed in water, the PH value of the water is adjusted to be 7-8, HAuCl4 solution is dropped in the water, and the PH value of the water is again adjusted to be 7-8; C. the suspension liquid is heated to 30-50 DEG C, reacts for 1-3 hours, and is filtered, washed, dried and roasted to obtain a target product; and D. deionized water and silica gel which are provided with a fixed ratio are added to the catalyst to be processed into seriflux, the carrier of the catalyst is placed in the seriflux, soaked, taken out and then dried and roasted. The catalyst prepared by adopting the method is simple in process, low in cost, and high in catalytic activity and stability for ozonolysis in the indoor air.

Owner:倪凯

Method for step recycling of iron, copper and noble metal from copper smelting waste slag

InactiveCN103882235AReduce viscosityRealize Cascade RecyclingRecycling and recovery technologiesMagnetic separationSlagMagnetite

The invention discloses a method for step recycling of iron, copper and noble metal from copper smelting waste slag. The method comprises the following steps: firstly, respectively crushing and treating copper smelting waste slag, a reducing agent carbon powder and an alkali substance caustic soda and a sodium salt anhydrous sodium sulfate into certain granularity, sufficiently and uniformly mixing the raw materials, pelletizing, adding alkali and performing reduction roasting at a high temperature, wherein the functions of the caustic soda and the anhydrous sodium sulfate are to reduce the viscosity of the slag, and effective aggregation of copper particles in the slag and sufficient enrichment of an iron component to magnetite phase are facilitated; after roasting is accomplished, performing magnetic selection to obtain magnetic concentrate (iron-copper component); and subsequently performing Nelson reselection to separate the copper and the noble metal in the magnetic concentrate. The magnetic tailings can be applied to the building industry and high-quality abrasive preparation. According to the method, the caustic soda and the anhydrous sodium sulfate are innovatively added, and Nelson reselection is adopted, so that step recycling of noble metal in the copper smelting waste slag is achieved, the method has the advantages of simplicity and convenience in process, high applicability, low production cost, no emission and the like, a novel method is provided for comprehensive utilization of the copper smelting waste slag, and remarkable economic benefits and social benefits are achieved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Multi-component composite catalytic zero-valent iron Fenton treatment method and device for industrial wastewater

ActiveCN105540931AReduce outputLow costWater treatment compoundsMultistage water/sewage treatmentSludgeWastewater

The invention relates to a multi-component composite catalytic zero-valent iron Fenton treatment method and device for industrial wastewater. The method comprises the following steps: adding an acid and H2O2 into the industrial wastewater to adjust the pH value to be 4.5-6.0, and allowing the industrial wastewater of which the pH value is adjusted to enter a Fenton-like reaction tank, wherein the Fenton-like reaction tank is filled with a multi-component composite catalytic filling pack which comprises iron-nickel alloy particles, iron-copper alloy particles, manganese-iron alloy particles, zeolite and hematite; after a 3.0-4.0 hours' reaction of the wastewater in the Fenton-like reaction tank, adding an alkali to adjust the pH value to be 7.8-8.0, adding a coagulant aid, allowing the mixture to enter a coagulating-sedimentation integrated tank, discharging water after finishing solid-liquid separation, and performing efflux disposal on iron-containing sludge. The method and the device have the advantages that raw materials are easy to obtain, the assembly is convenient and the cost is low.

Owner:DONGHUA UNIV

Reinforced iron-base alloy and method for preparing same

The invention discloses a reinforced iron-base alloy and method for preparing same, wherein the powder metallurgy iron-copper alloy (FTG70Cu3-35) is added with alloy elements Cr, which is in the form of high carbon ferro-chrome (CR-Fe) alloy powder.

Owner:HEFEI UNIV OF TECH

A kind of iron-copper base powder alloy brake pad and preparation method thereof

The invention relates to an iron-copper-based powder alloy brake block and a preparation method thereof. The powder material is formed by adding 30-50% of copper powder, 30-50% of iron powder, 1-6% of tin powder, 1-8% of molybdenum powder, 1-10% of silicon carbide, 1-7% of lead powder, 1-6% of molybdenum disulphide and 5-20% of flaky graphite in weight ratio. Preprocessing, burdening, mixing, pressing, sintering, cooling and machining are carried out on the raw materials, so that a sector powder alloy friction piece is formed, and the friction piece is paired with heat-resisting alloy steel or wear-resisting cast iron to form a friction couple. The iron-copper-based powder alloy brake block is applicable to an airplane multi-disc type brake device or the brake and the clutch of a heavy duty vehicle.

Owner:XIAN AVIATION BRAKE TECH

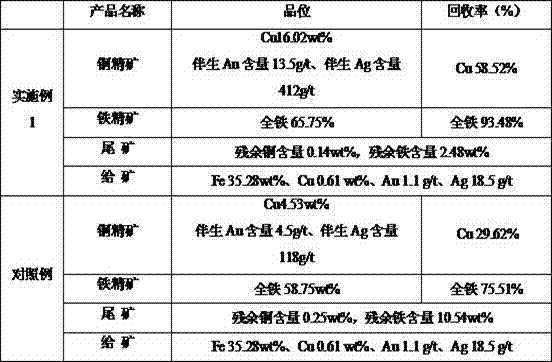

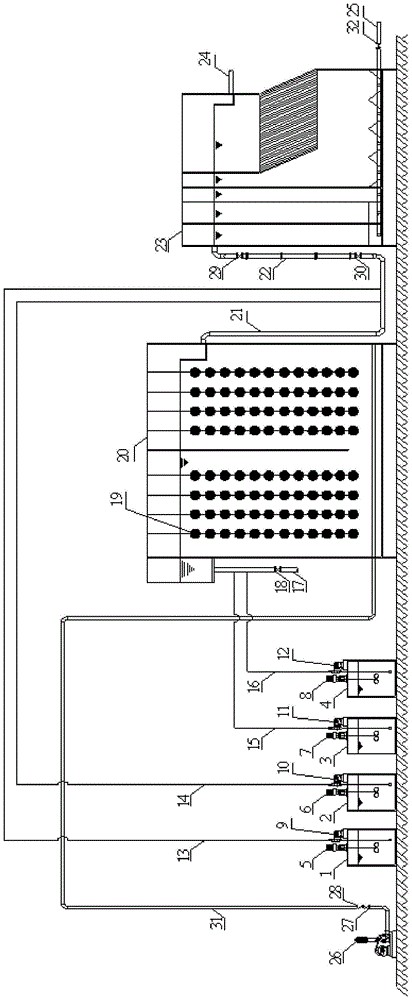

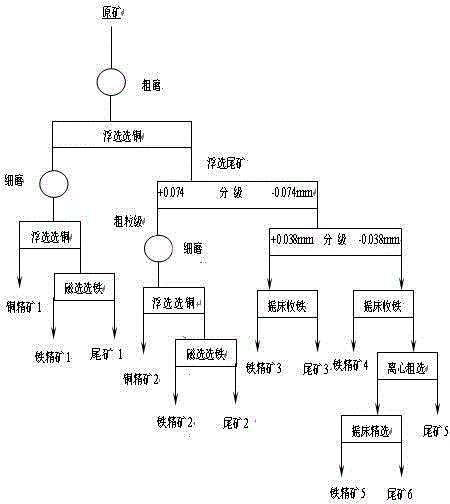

Beneficiation process for refractory micro-fine particle-graded iron-copper ore

ActiveCN104056714ANot prone to excessive crushingHigh recovery rateWet separationIronstoneGravity separation

The invention discloses a beneficiation process for refractory micro-fine particle-graded iron-copper ore. The beneficiation process for the refractory micro-fine particle-graded iron-copper ore comprises the following steps: (1) performing first flotation; (2) performing second flotation and first magnetic separation to obtain iron ore concentrate 1 and tailings 1; (3) performing third flotation and second magnetic separation to obtain copper ore concentrate 2 and tailings of the three times of flotation, and performing secondary magnetic separation on the tailings of the three times of flotation to obtain iron ore concentrate 2; (4) performing third magnetic separation and gravity separation to obtain iron ore concentrate 3, tailings 3, iron ore concentrate 4 and tailings 4; (5) performing combined beneficiation on the micro-fine particle-graded tailings: performing centrifuge roughing-table concentration on the tailings 4 obtained through the process to obtain iron ore concentrate 5 and tailings 5. The beneficiation process disclosed by the invention has the beneficial effects that during a separation process, stage grinding and stage separation are adopted, so that the over crushing phenomenon is not easy to occur on the iron ore concentrate, and the goals of early recovery and high recovery is achieved; copper and iron in the iron-copper ore are comprehensively recovered; moreover, during the utilization of tailings recovery, the recovery rate of the iron ore concentrate is improved by 10-20 percent; the beneficiation process for the refractory micro-fine particle-graded iron-copper ore has very good economic benefit.

Owner:TONGLING CHEM GRP XINQIAO MINING IND CO LTD

Iron-copper alloy powder and preparation method thereof

The invention discloses iron-copper alloy powder and a preparation method thereof. The iron-copper alloy powder is prepared from the following raw materials in percentage by mass: 10-30 percent of copper oxide powder and 70-90 percent of iron-copper pre-alloyed powder. The preparation method comprises the following steps: selecting the copper oxide powder prepared through roasting and crushing, uniformly mixing the copper oxide powder and the iron-copper pre-alloyed powder according to a ratio, carrying out active diffusion sintering on the mixture in a reducing atmosphere, crushing and sieving the mixture subjected to sintering, and finally preparing the iron-copper alloy powder. The iron-copper alloy powder is lower in apparent density and good in formability, has the apparent density being 2.5-3.0g / cm<3> and the green strength being 12-15MPa, makes up for the deficiencies in the prior art and broadens the application market.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Diamond rubbing block and fabricating method thereof

ActiveCN101934500AReduce the temperatureGood self-sharpeningOther chemical processesAbrasion apparatusAdamiteSilicon

The invention relates to a diamond rubbing block which comprises a tool bit arranged on a clamping seat, wherein the tool bit comprises the following raw materials in percent by weight: 10-25 percent of iron-silicate pre-alloyed powder, 30-50 percent of iron-copper pre-alloyed powder, 10-40 percent of copper-tin pre-alloyed powder, 1-15 percent of nickel powder and the balance of diamond. The diamond rubbing block is fabricated by the steps of: mixing the iron-silicate pre-alloyed powder, the iron-copper pre-alloyed powder, the copper-tin pre-alloyed powder and the nickel powder into a mixture, and based on the total weight of the mixture, charging 3.5-5.5 wt% of the diamond into the mixture. The weight ratio of iron and silicate in the iron-silicate pre-alloyed powder is 8-9:1, the weight ratio of iron and copper in the iron-copper pre-alloyed powder is 2-3:1, and the weight ratio of copper and tin in the iron-tin pre-alloyed powder is 4-6:1. The invention has the characteristics of simple and reasonable structure, short sintering time, high production efficiency, long service life, good quality stability and wide application range.

Owner:广东奔朗新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com