Patents

Literature

165results about How to "Increase granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of TC4ELI titanium alloy bar

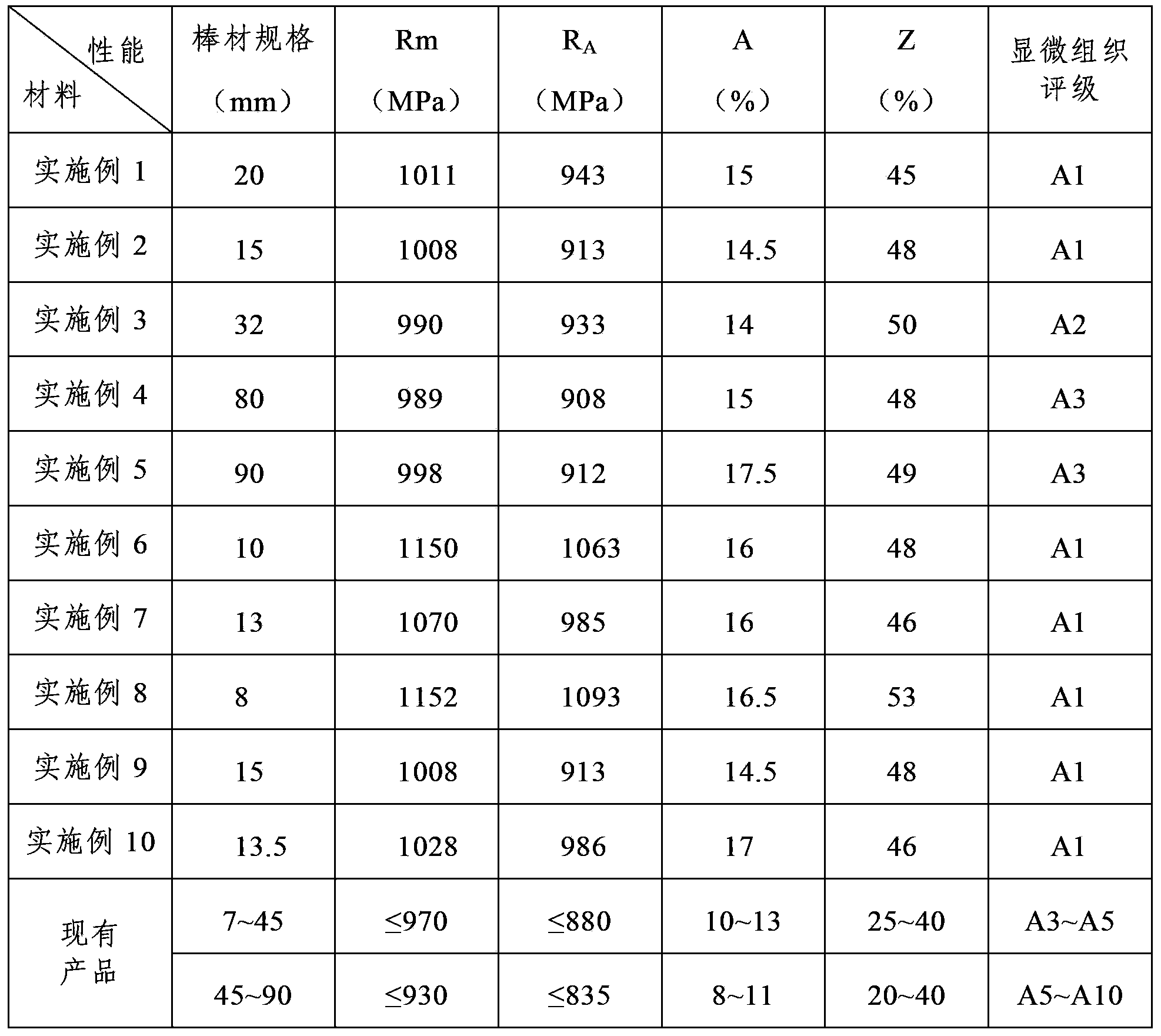

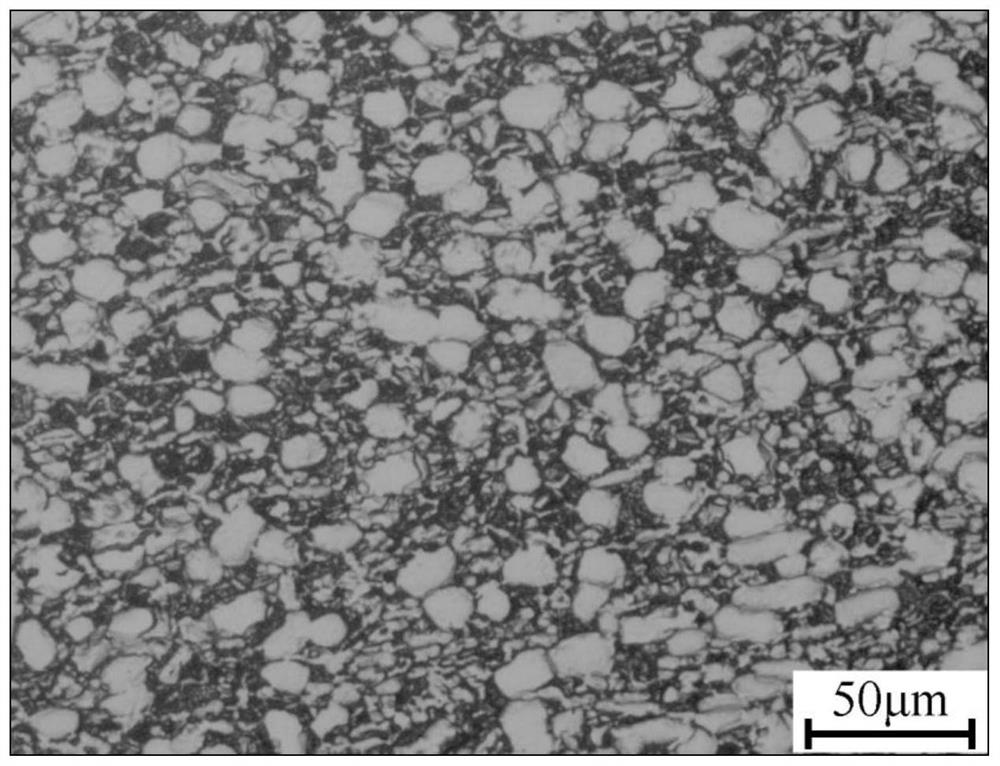

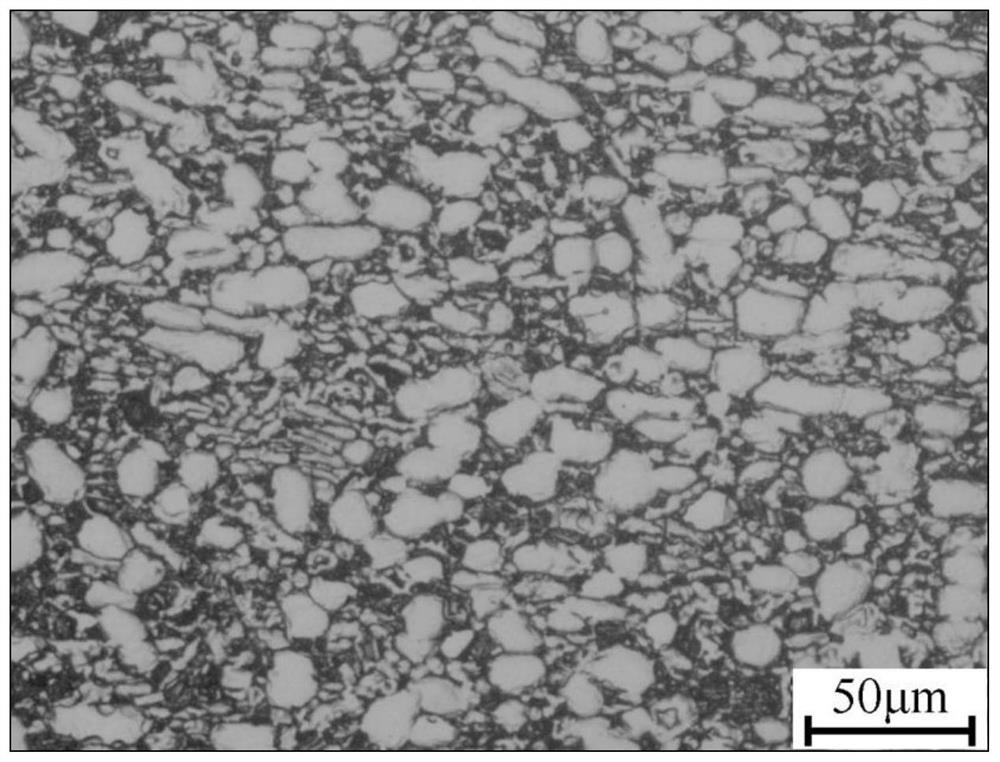

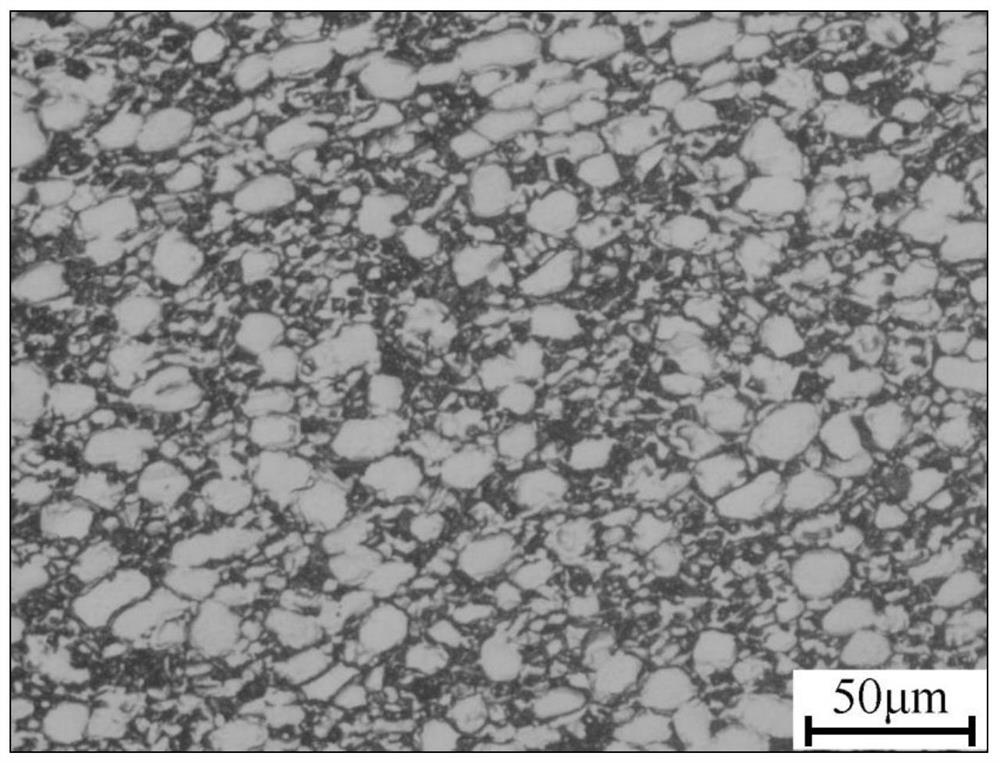

The invention provides a preparation method of a TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 15mm-90mm. The invention also provides a preparation method of the TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) rolling; (5) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 8mm-15mm. The preparation method is simple in process, strong in repeatability and suitable for large-scale industrial production; the TC4ELI titanium alloy bar prepared by adopting the preparation method is uniform and fine in structure, high in microscopic structure level and excellent in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

The invention discloses a processing method of a fine-grain superplastic TA15 titanium alloy medium-thickness plate. The processing method comprises the following steps that 1, vacuum consumable arc melting is carried out to obtain a TA15 titanium alloy cast ingot; 2, after heat preservation, a primary forging stock is obtained through upsetting, drawing, cogging and forging; 3, after heat preservation, a second-stage forging stock is obtained through beta-phase region upsetting and drawing forging; 4, upsetting and drawing forging in an alpha + beta two-phase region is carried out to obtain afourth-stage forging stock; 5, a forge piece is obtained through upsetting, drawing and finish forging; 6, after heat preservation, a first-fire rolled plate blank is obtained through first-fire rolling; 7, after heat preservation, a second-fire rolled plate blank is obtained through second-fire rolling; and 8, the TA15 titanium alloy medium-thickness plate is obtained through annealing treatment. According to the processing method of the fine-grain superplastic TA15 titanium alloy medium-thickness plate, the corresponding deformation temperature is selected and combined with multi-heating-number large-deformation upsetting and drawing forging, so that the TA15 titanium alloy cast ingot with a coarse structure is crushed under the large deformation, driving force is provided for recrystallization, the grain refinement and homogenization degree is improved, and the fine-grain superplasticity TA15 titanium alloy medium-thickness plate is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

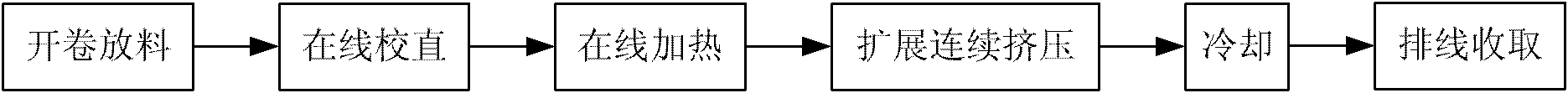

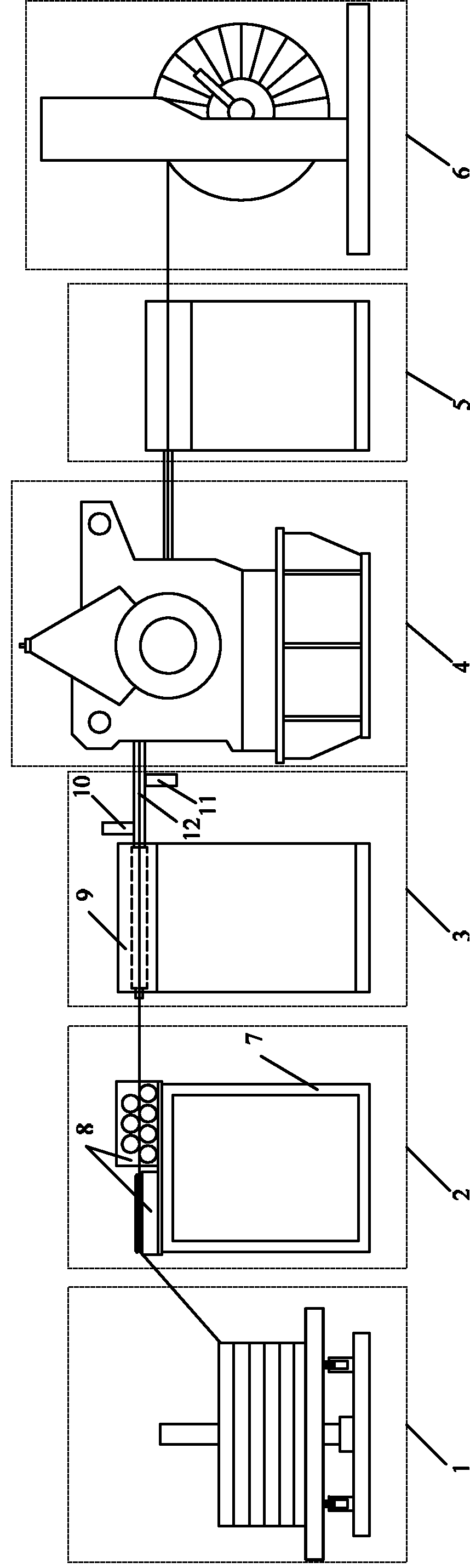

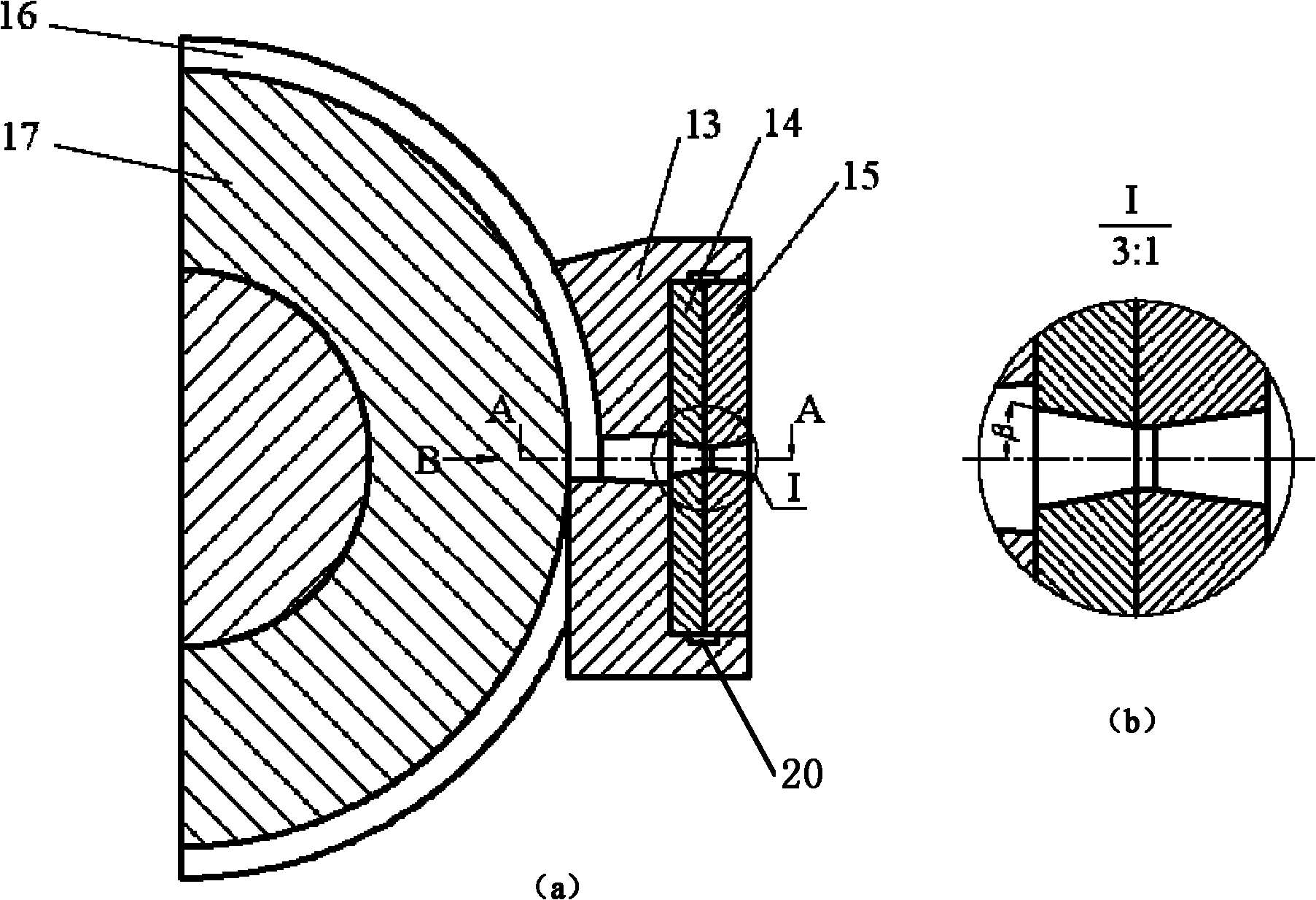

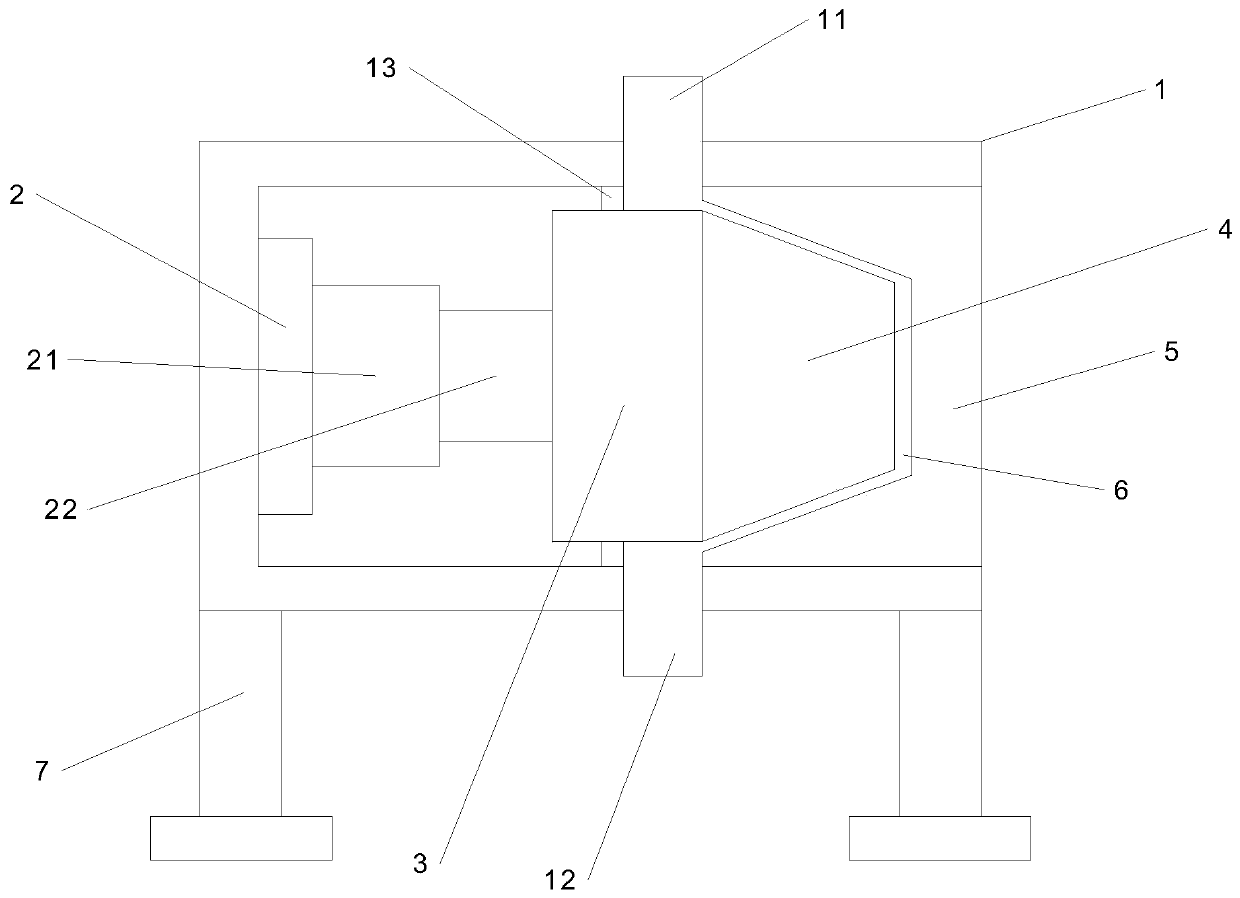

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

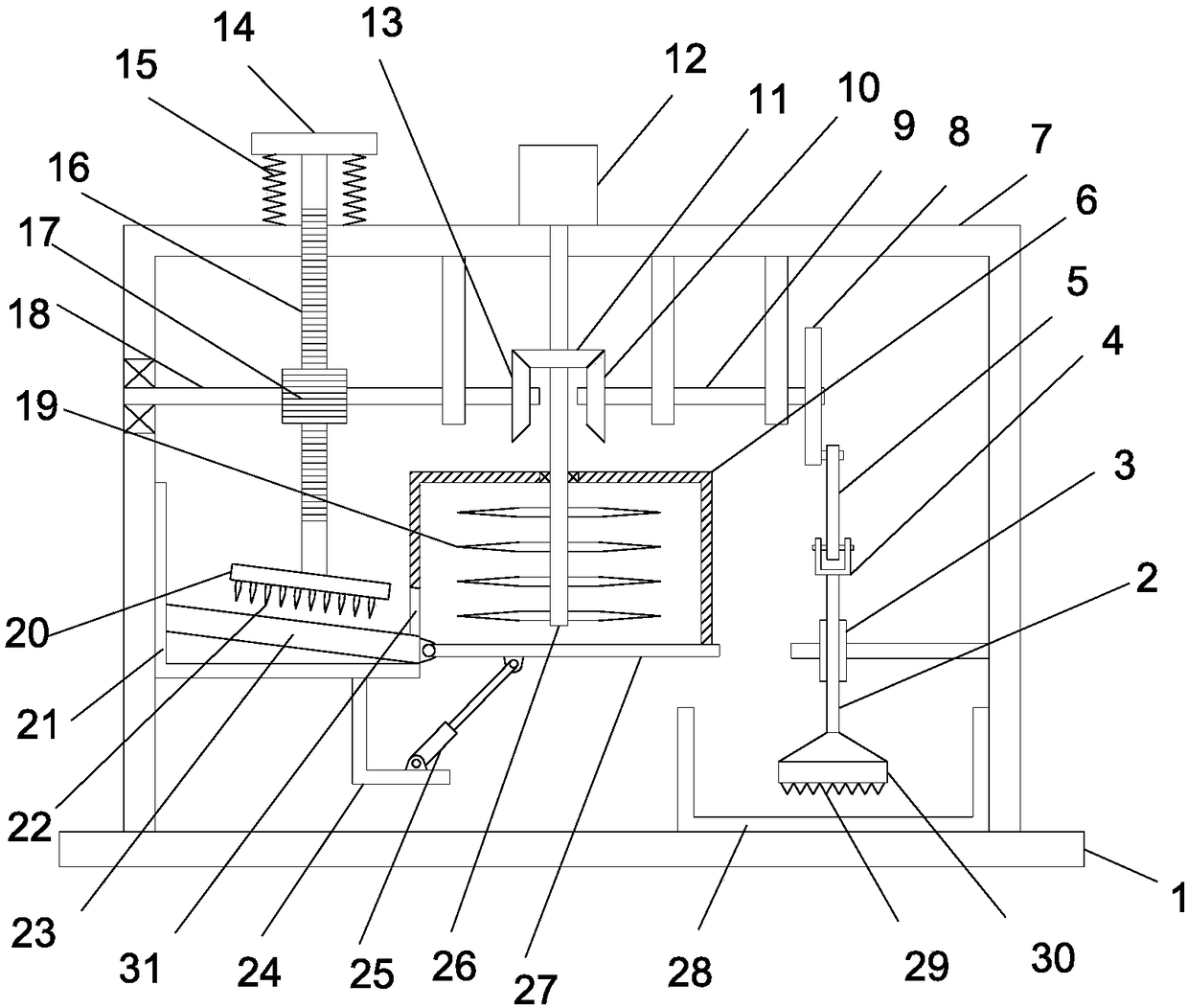

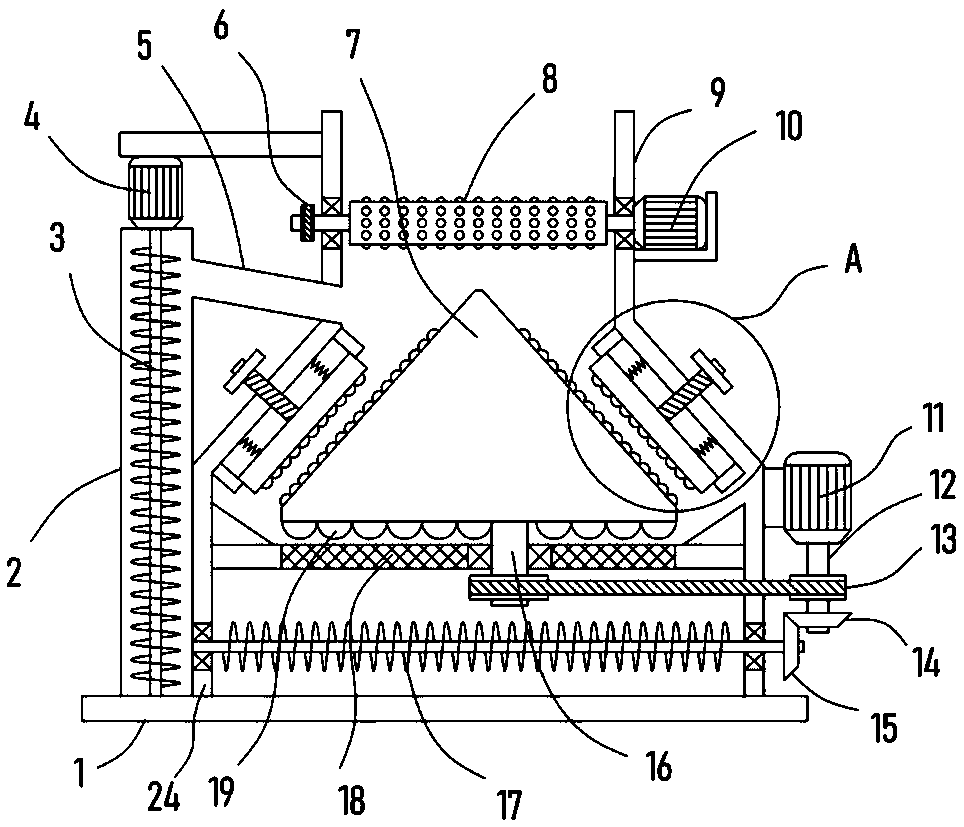

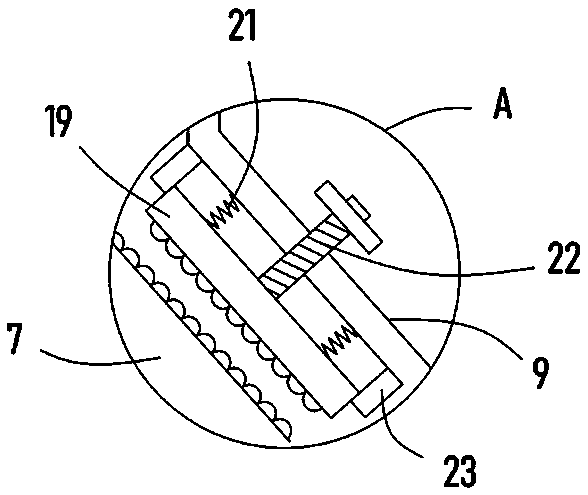

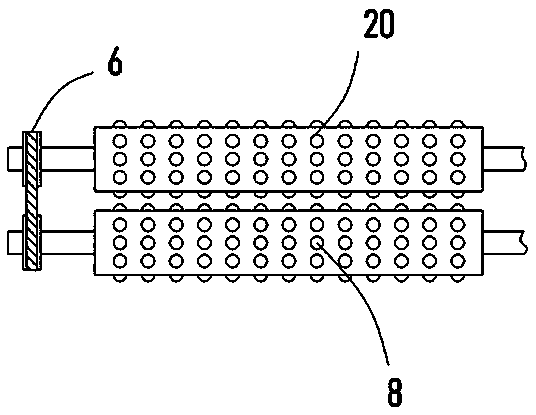

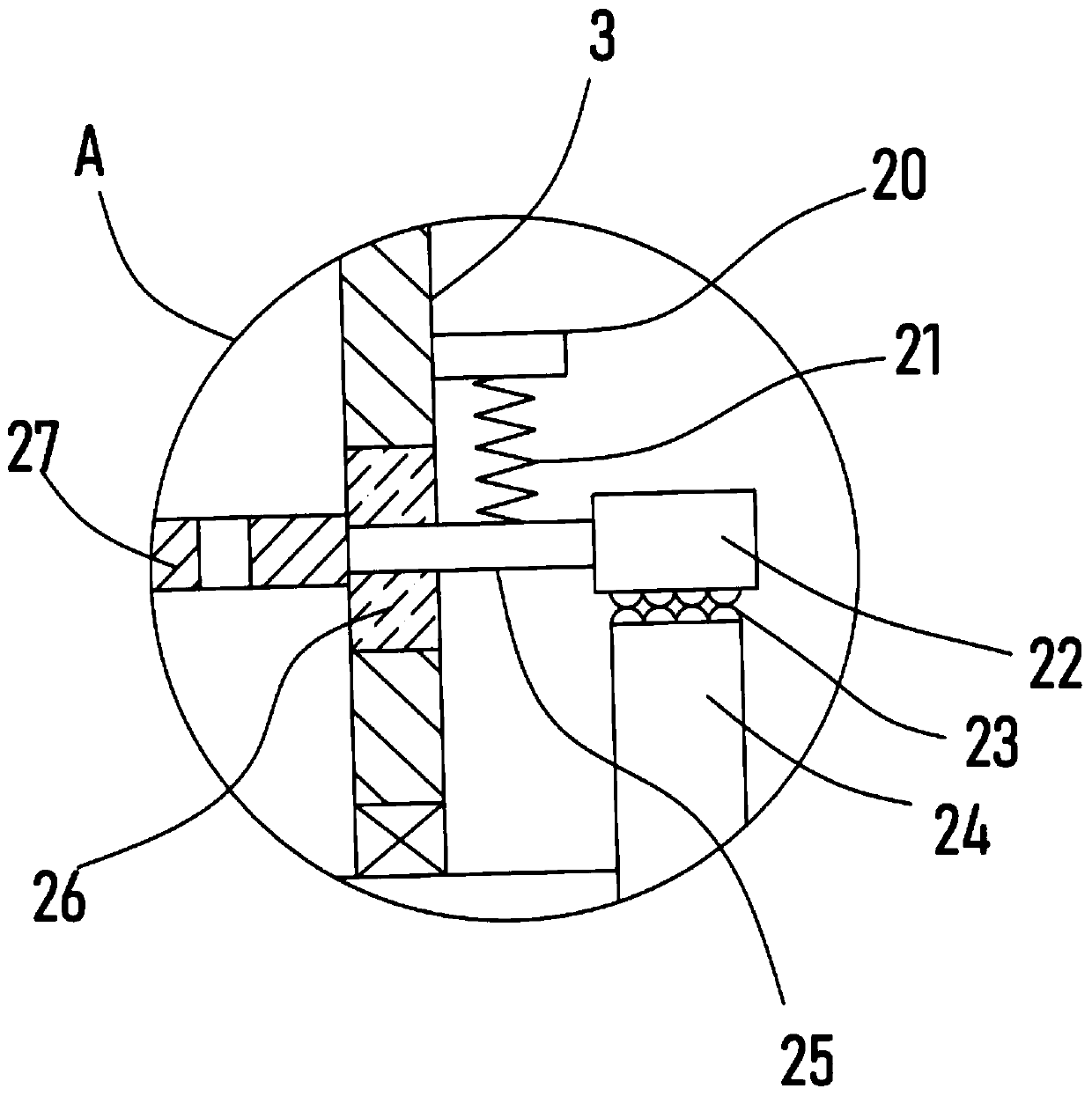

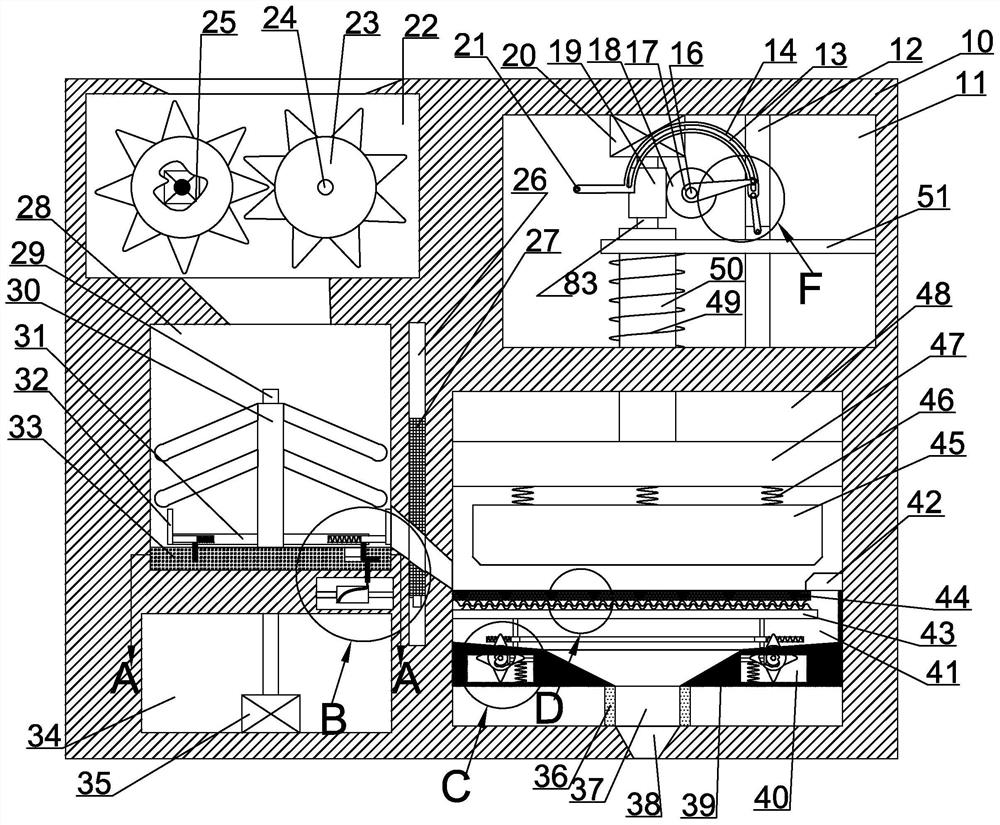

Forage refined processing device for producing livestock production

The invention discloses a forage refined processing device for producing livestock production. The forage refined processing device comprises a base plate, wherein a supporting framework is verticallyand fixedly arranged on the base plate; a second driven bevel gear which is in meshed connection with a driving bevel gear is fixedly arranged on a second driven shaft in a sleeving manner; a plurality of cutting blades are fixedly arranged at the bottom of a cutting pressure disc at equal intervals; a stamping block is positioned in a smashing groove; a driving rack upward extends above the supporting framework. The forage refined processing device disclosed by the invention has the advantages that the cutting pressure disc is driven by vertical reciprocation of the supporting framework to preliminarily cut and smash forage into segments in a feeding chute; a driving shaft drives smashing blades to rotationally cut the forage entering a smashing tank, so that secondary smashing and refining of the forage are realized; the stamping block is driven by vertical reciprocation of a stamping rod to perform repeated impact crushing on the forage in the smashing groove, and further third-time smashing of the forage is realized; by using three-time smashing action, the refining degree of the forage is greatly improved, as well as high smashing speed and good smashing effect are realized.

Owner:鄢海军

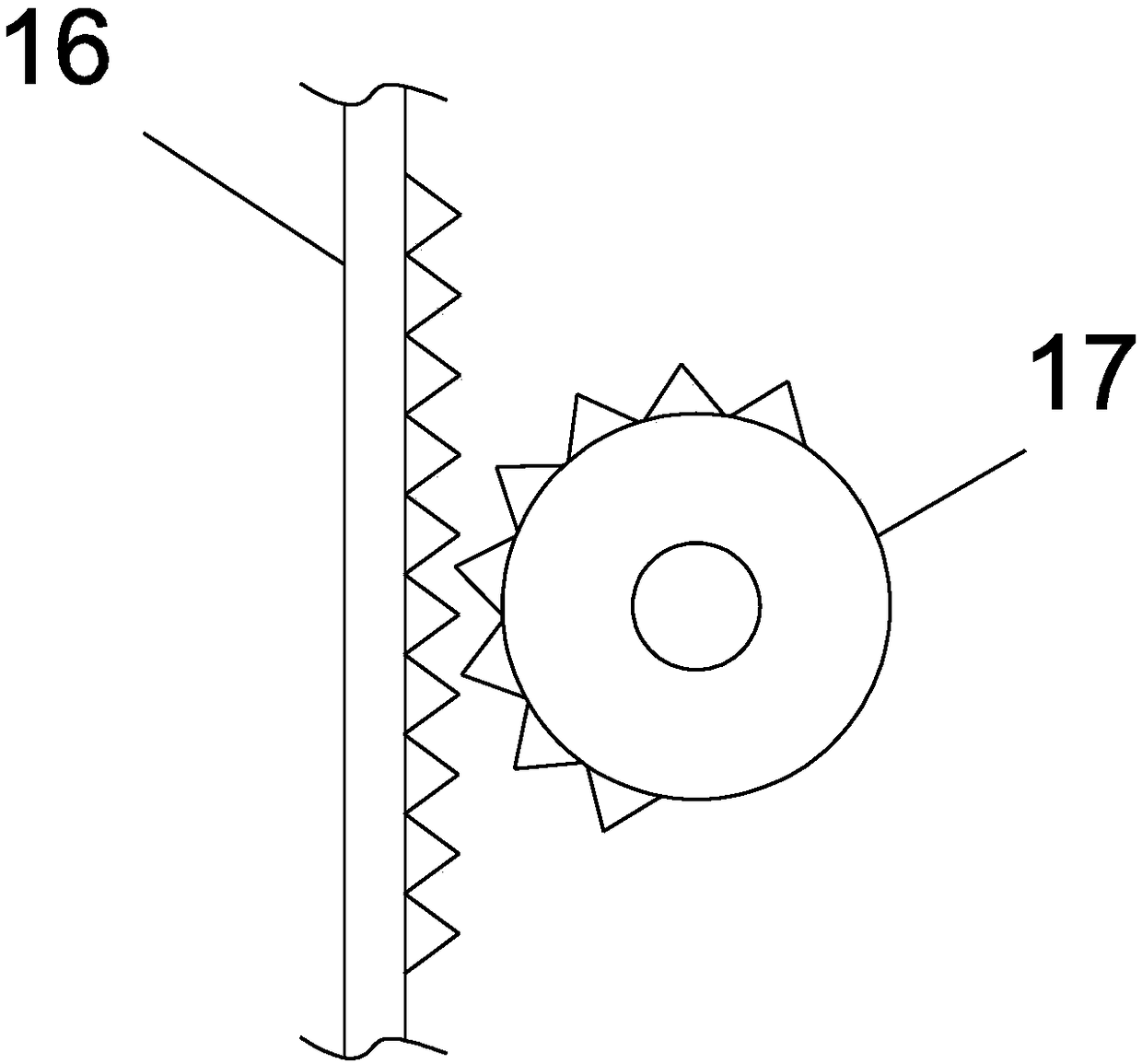

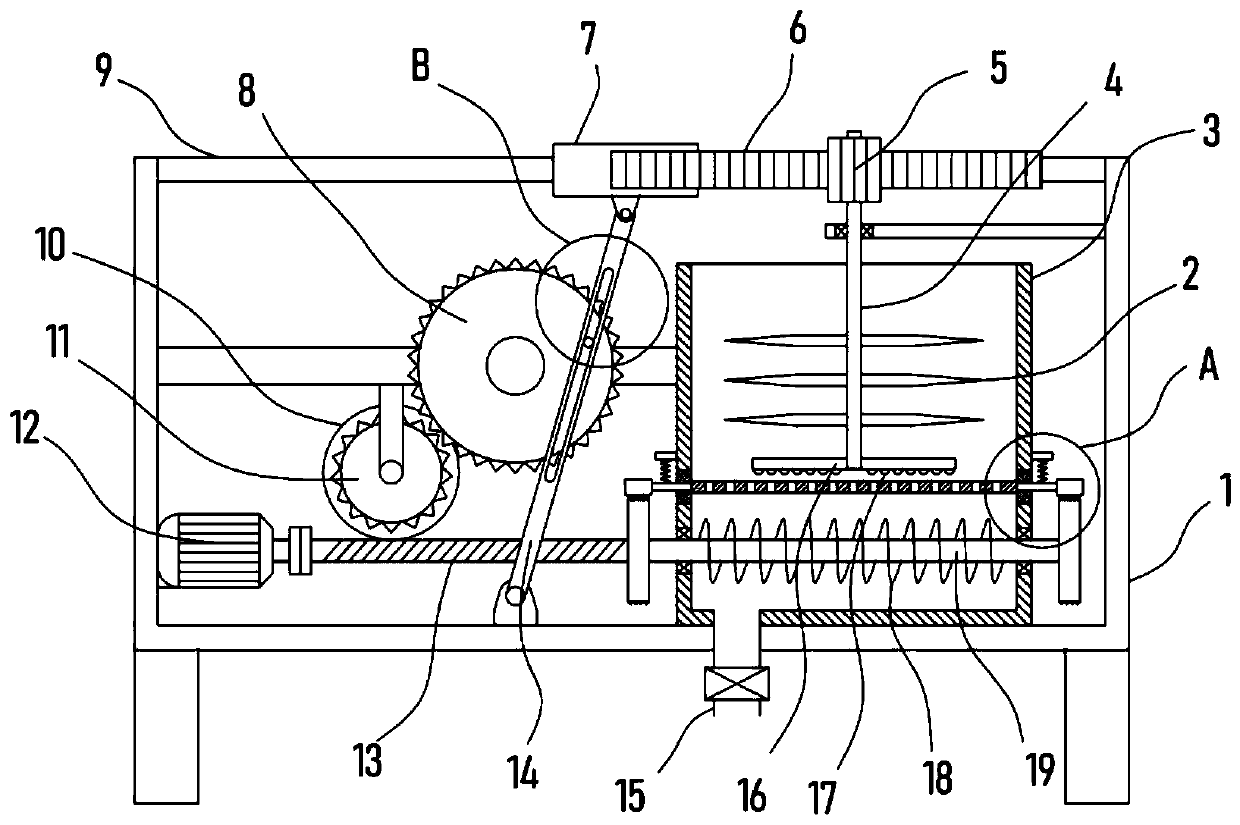

Grain coarse crushing device for agricultural production

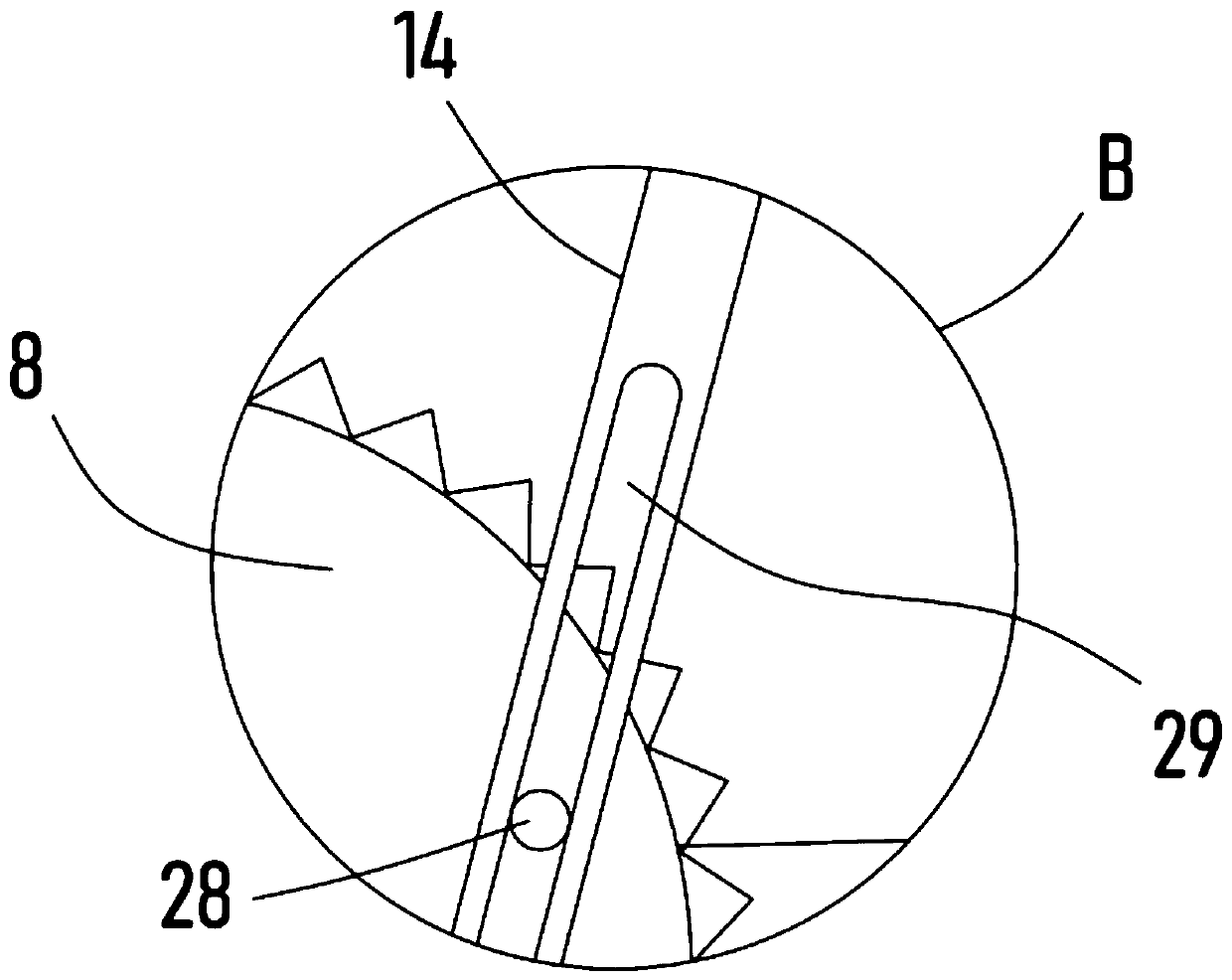

InactiveCN108393154AAchieve fragmentationIncrease granularitySievingScreeningDrive shaftSpiral blade

The invention discloses a grain coarse crushing device for agricultural production. The grain coarse crushing device comprises a crushing box, a first motor is fixedly installed at the top of the crushing box vertically, an output shaft of the first motor is coaxially and fixedly provided with a driving shaft extending into the crushing box, the surface of the driving shaft is fixedly provided with a driving belt wheel in a sleeved manner, the right end of a screen plate is hinged to the inner wall of the right side of the crushing box, the left end of the screen plate is fixedly provided withan extending plate extending to the exterior of the crushing box, and a fixing plate is fixedly installed on the outer wall of the left side of the crushing box; and a movable door is rotationally installed on the side wall of the crushing box through a hinge. According to the grain coarse crushing device, the grain particle crushing effect is achieved through rotation of a crushing blade, the rotating shaft is used for driving a longitudinal pulling plate to rotate to pull grains to the crushing blade to achieve secondary crushing, a spiral blade circulates the grains in a lifting barrel tothe crushing box to achieve the repeated crushing effect, the grain refining degree is greatly improved, crushing is more thorough, and the crushing efficiency is high.

Owner:COMMON TECH DEV CO LTD

Method for producing low-carbon steel or low-alloy steel plate having submicron crystal grain

The invention discloses a method for producing low-carbon steel or low-alloy steel plate having submicron crystal grain which comprises the steps of, subjecting the raw steel billets to austenizing treatment above Ac3 temperature, hot-rolling at the temperature of over Ar3, fast cooling after rolling, performing warm-rolling or cold rolling at the temperature range from 600 deg. C. to room temperature, direct cooling or roll bending after rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

Tungsten-based plasma facing material and preparation method thereof

ActiveCN102560292ALow sputtering yieldLow hydrogen isotope retentionMelting Point TemperaturePlasma-facing material

The invention discloses a tungsten-based plasma facing material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing tungsten powder and tungsten fiber by a powder mixing method which does not damage the tungsten fiber; and sintering to prepare a bulk fiber toughened tungsten-based material by a hot isostatic pressing process. The tungsten powder is one of pure tungsten powder, tungsten-rhenium alloy powder, and tungsten powder doped with carbide and oxide; and the tungsten fiber is a pure tungsten wire, a tungsten-rhenium alloy wire or the like. The tungsten-based plasma facing material has the advantages of high thermal conductivity, high melting point temperature, low sputtering yield, low hydrogen isotope retention and low vapor pressure, as well as low cost and greater toughness.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

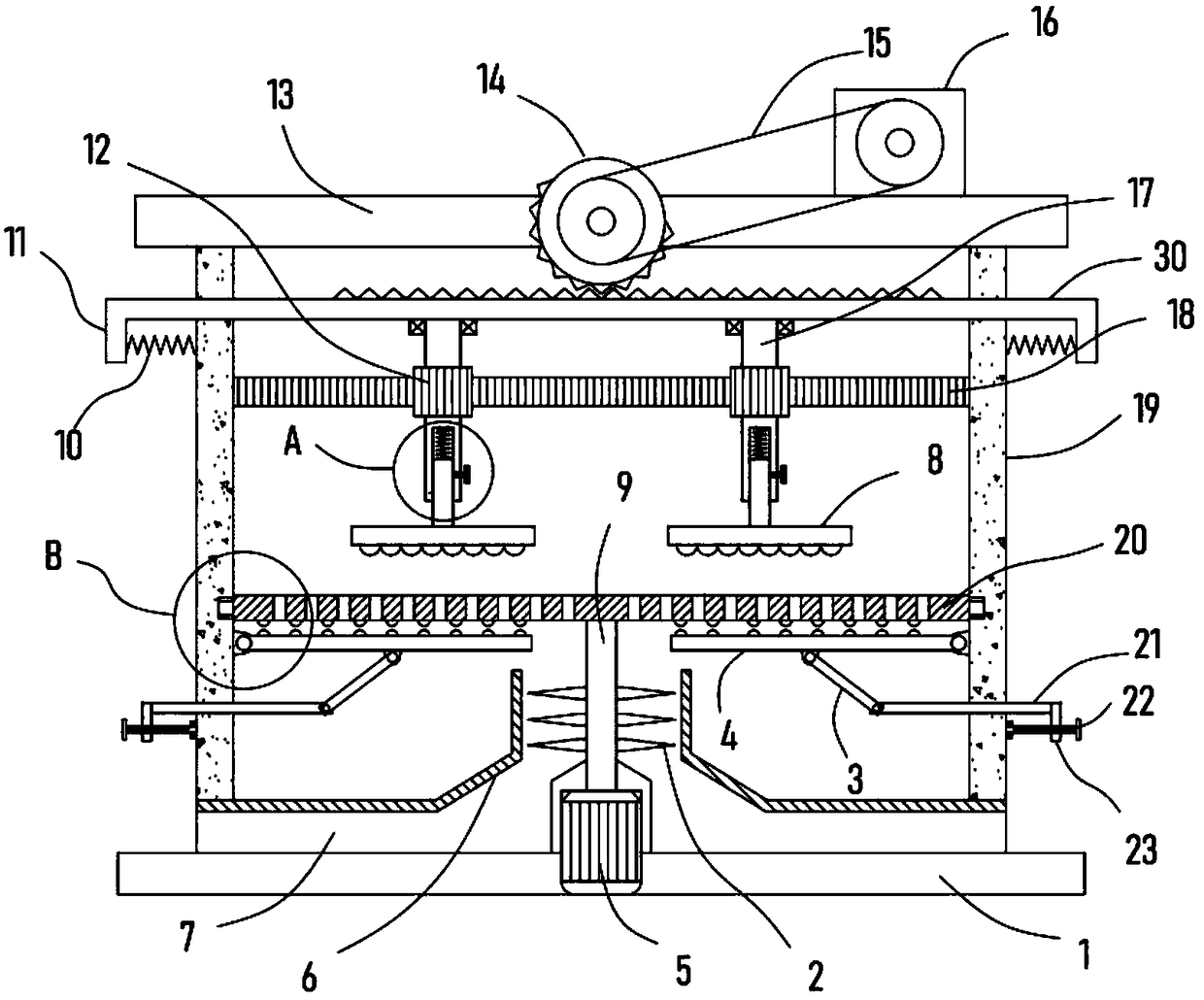

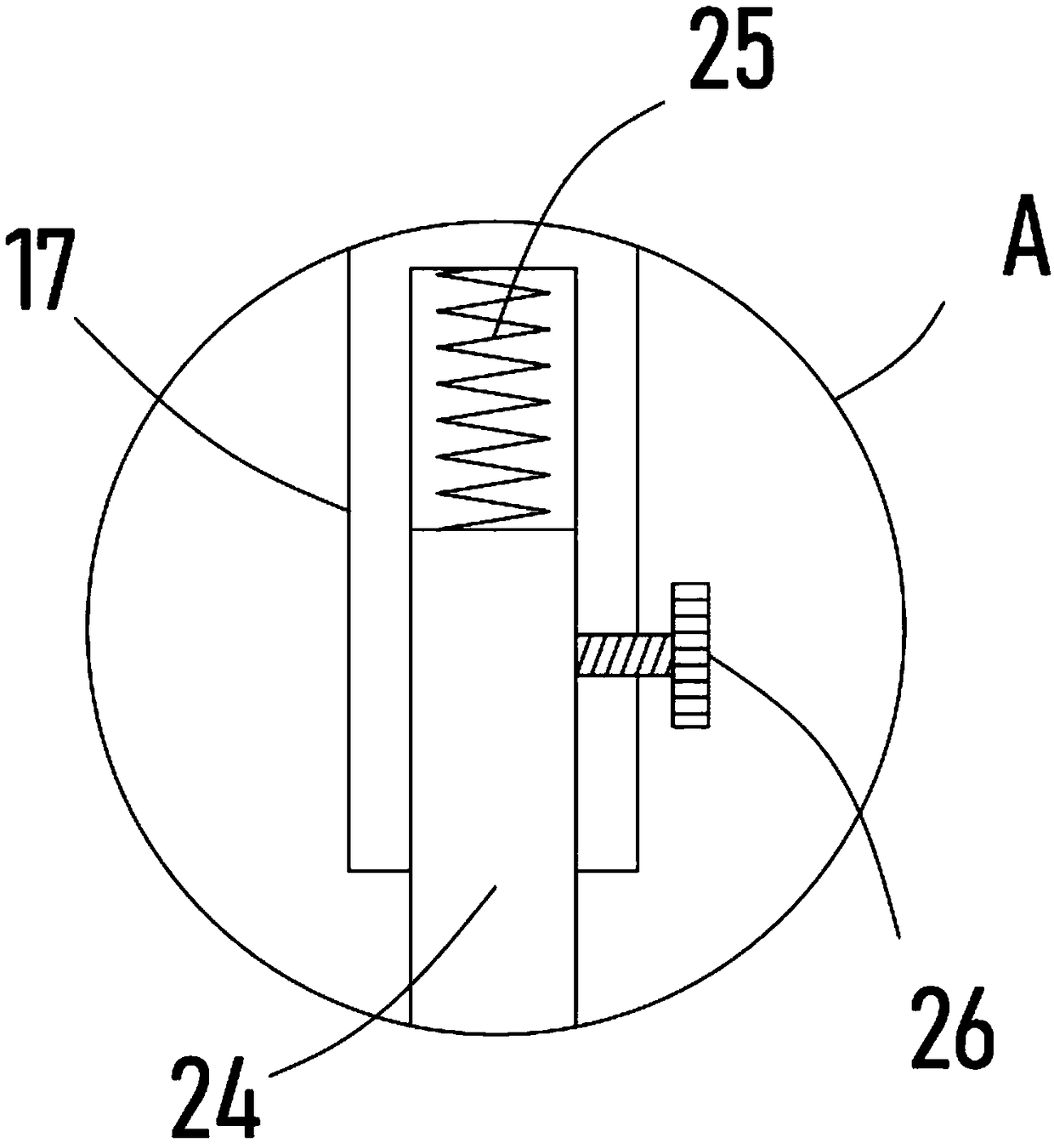

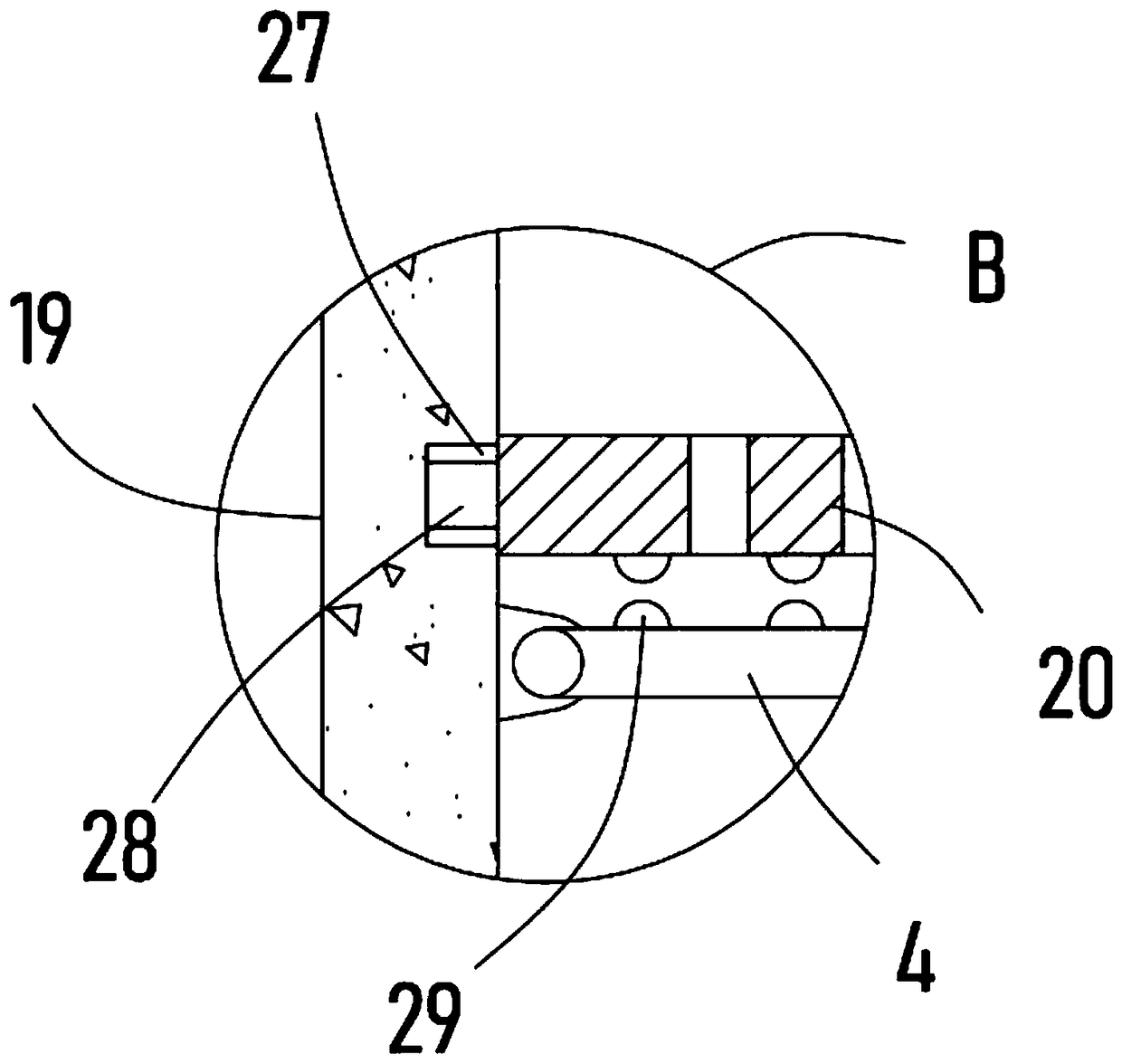

Breaking refining device used for concrete block reutilization

ActiveCN109277172APlay the role of sievingExpand the range of crushingCocoaGrain treatmentsScreening effectDrive shaft

The invention discloses a breaking refining device used for concrete block reutilization and relates to the technical field of building machines. The breaking refining device comprises a base and a smashing box fixed to the base. A top plate is fixed to the smashing box, and a screen tray is horizontally and rotationally arranged in the smashing box. A spur rack II is transversely installed in thesmashing box in a sliding manner, and the bottom of the spur rack II is connected with a transmission casing pipe in a pivot manner, wherein the transmission casing pipe is fixedly connected with a breaking pressing plate. The transmission casing pipe is fixedly sleeved with a cylindrical spur gear. By means of the breaking refining device, due to relative rotation of the breaking pressing plateand the screen tray, concrete blocks on the screen tray can be rotationally broken, the breaking pressing plate conducts transverse reciprocating motion while rotating, and the breaking range of the concrete blocks is greatly enlarged; the screen tray also has a screening effect, due to the cooperation of a grinding bottom plate and the screen tray, the effect of conducting secondary grinding on the primarily broken concrete blocks is achieved, and the refining degree is greatly promoted; and an arranged smashing blade rotates along with a driving shaft, the concrete grinding effect is greatlyimproved, and the refining degree is higher.

Owner:浏阳市飞宇混凝土有限公司

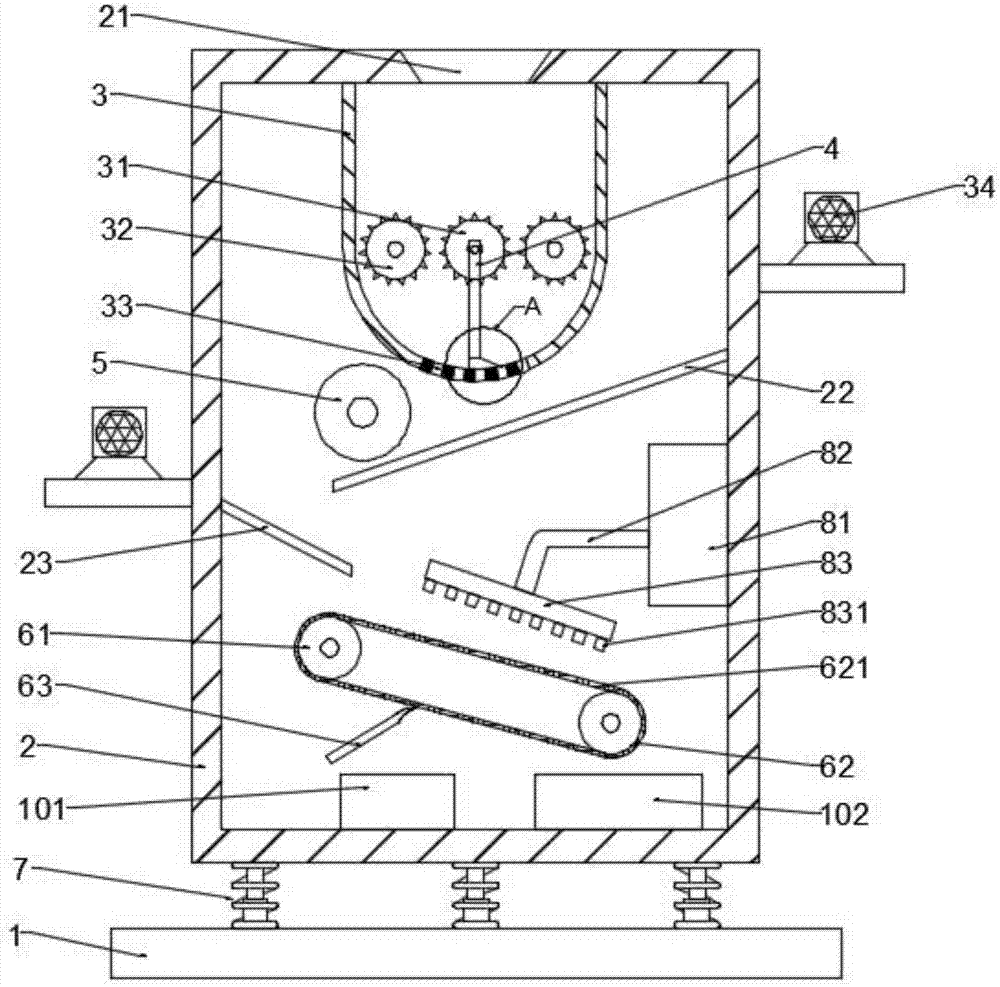

High-efficiency smashing and grinding integrated machine for traditional Chinese medicinal materials

InactiveCN107321474AIncrease granularityImprove work efficiencyGrain treatmentsFiltrationEngineering

The invention discloses a high-efficiency smashing and grinding integrated machine for traditional Chinese medicinal materials. The high-efficiency smashing and grinding integrated machine comprises a base, a machine body, a smashing box, a grinding roller and a crumb removing mechanism, wherein the machine body is arranged above the base; a shock absorber is arranged between the machine body and the base; and a first crushing roller is arranged at the central position of an inner cavity in the smashing box, second smashing rollers are symmetrically arranged on the two sides of the first grinding roller; an arc-shaped filter plate is arranged at the central position of the bottom of the smashing box; the front end surface of the first smashing roller is coaxially and fixedly provided with a material turning rod; a material turning plate is arranged at the end part of the material turning rod; a discharging plate which is inclined to the left is arranged below the smashing box, a grinding roller is arranged above the left side of the discharging plate; and the crumb removing mechanism is arranged below the discharging plate. The high-efficiency smashing and grinding integrated machine can effectively improve the refining degree of the traditional Chinese medicinal materials, ensures the use effect of the medicinal materials, and can remove iron dust in the medicinal materials and ensures the cleanliness of the medicinal materials.

Owner:吴鑫锋

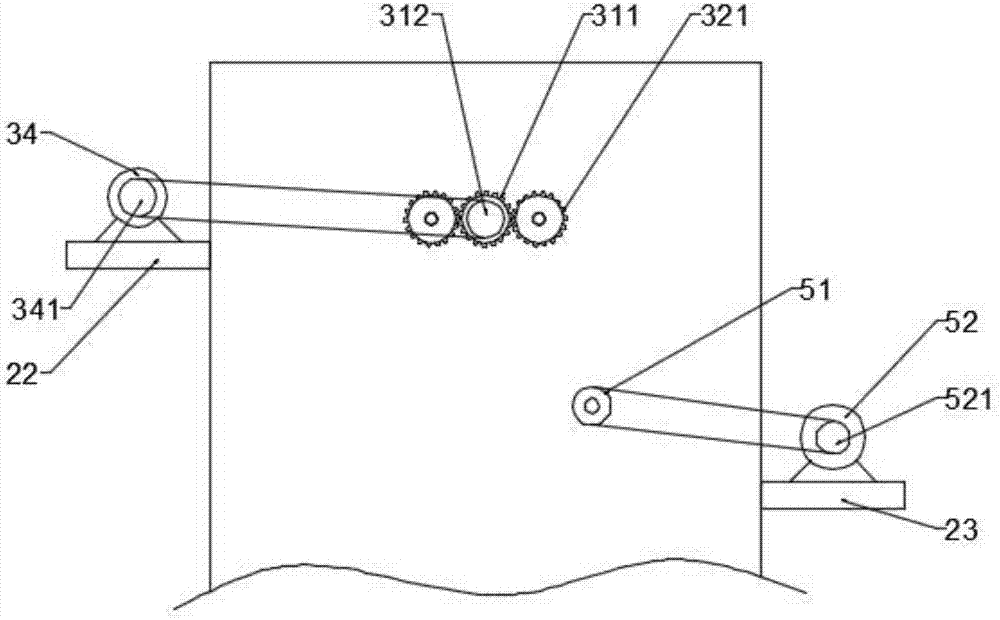

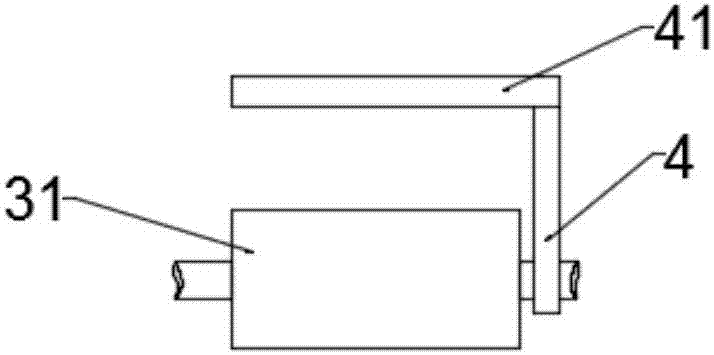

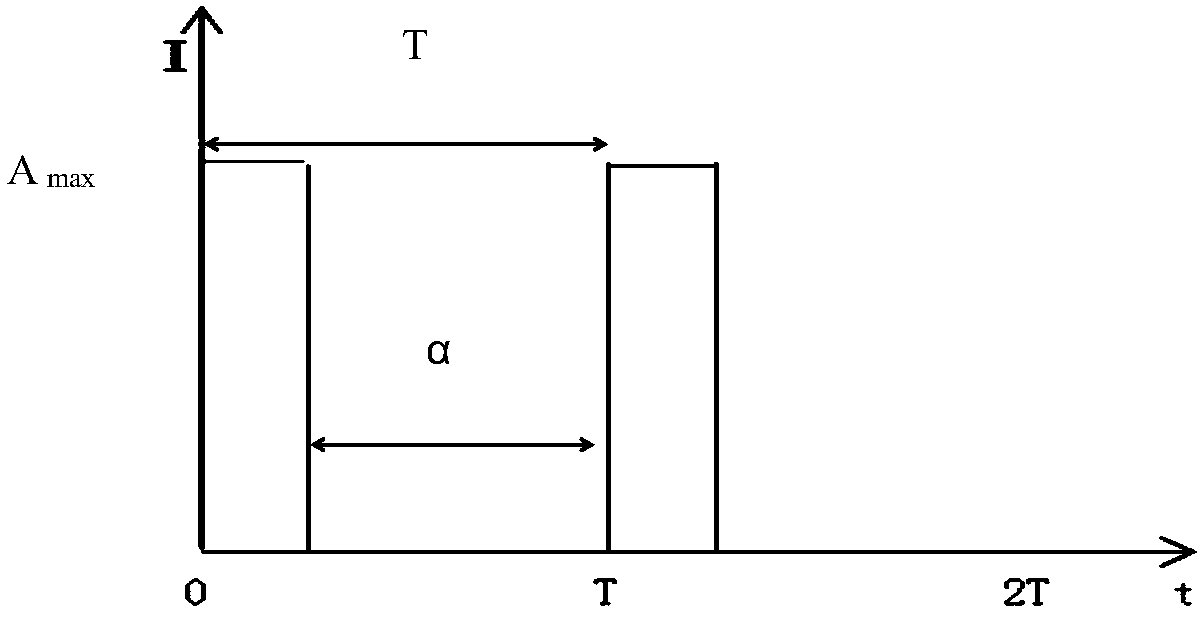

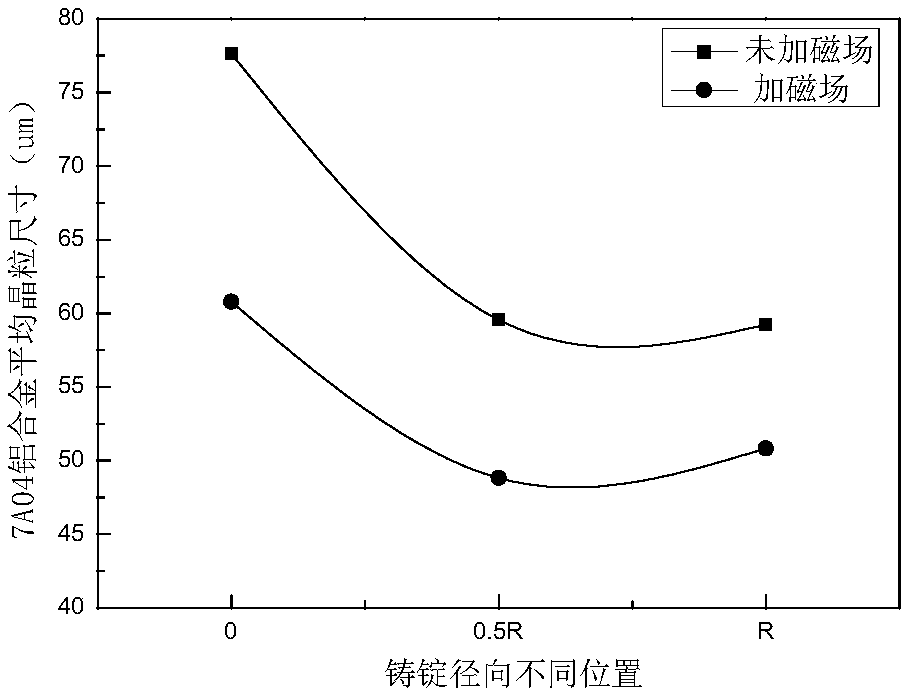

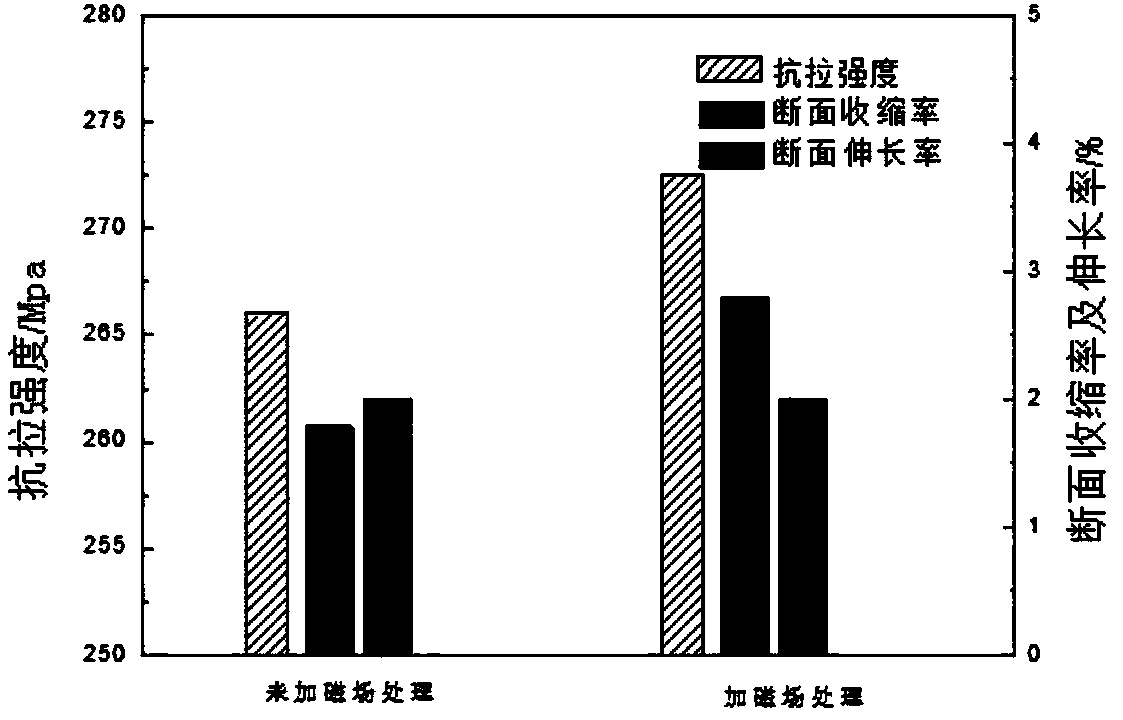

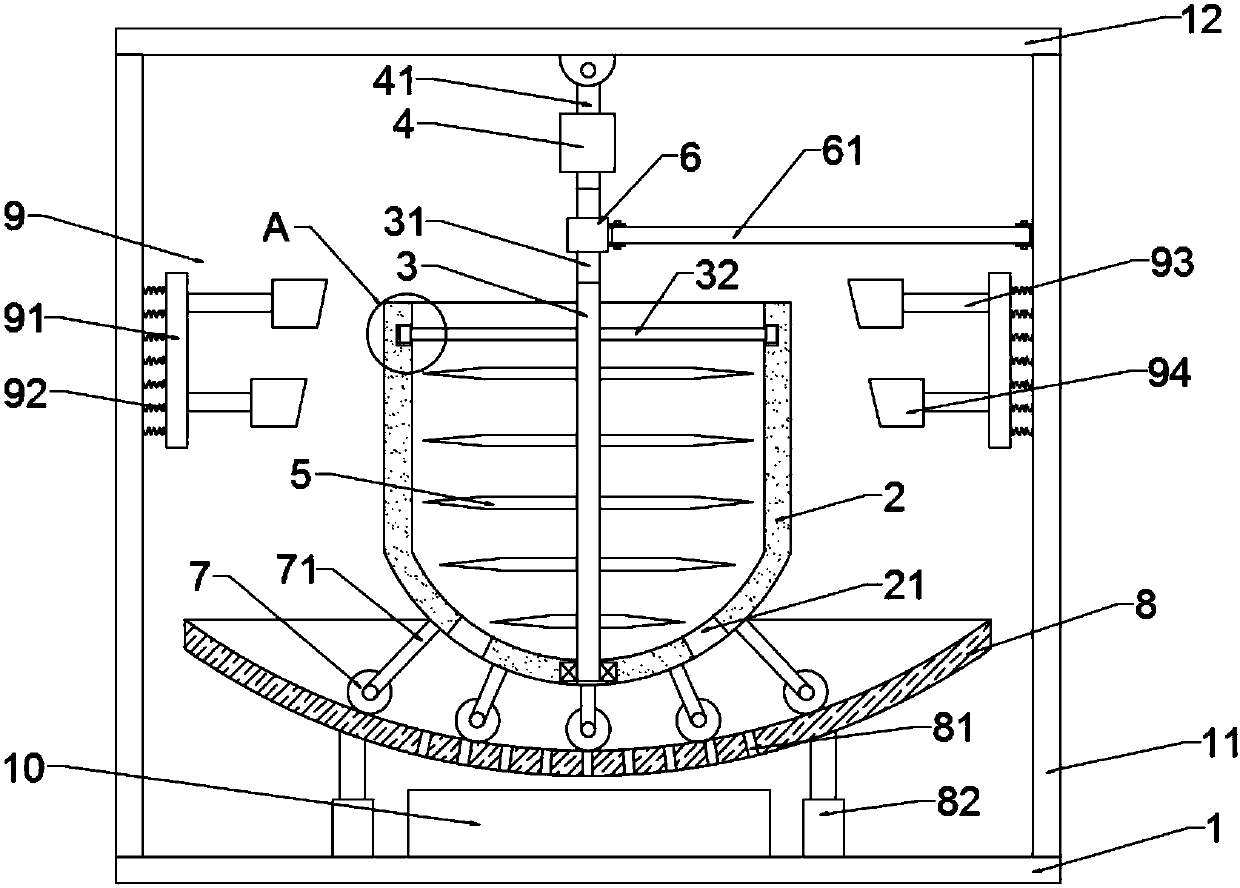

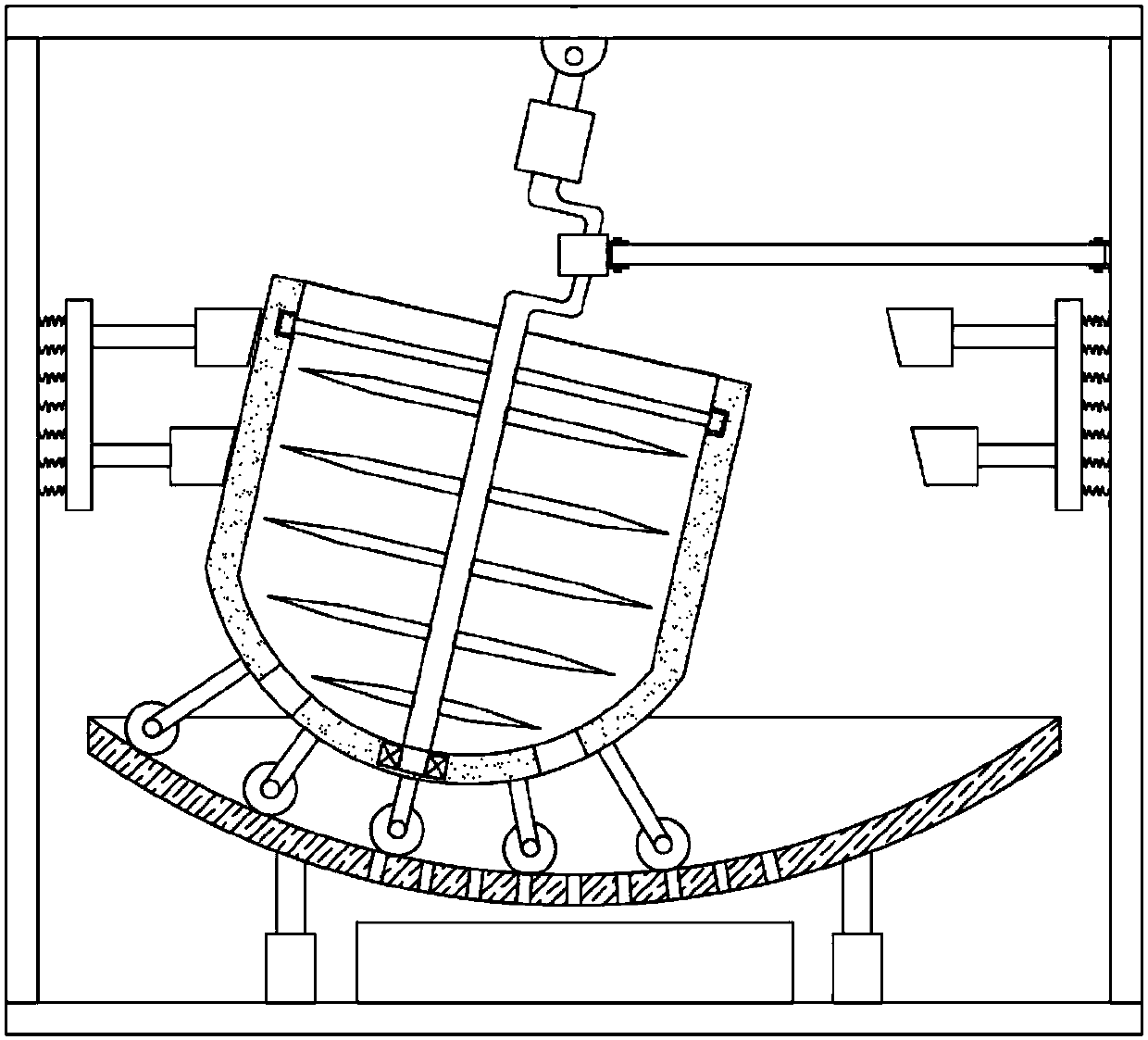

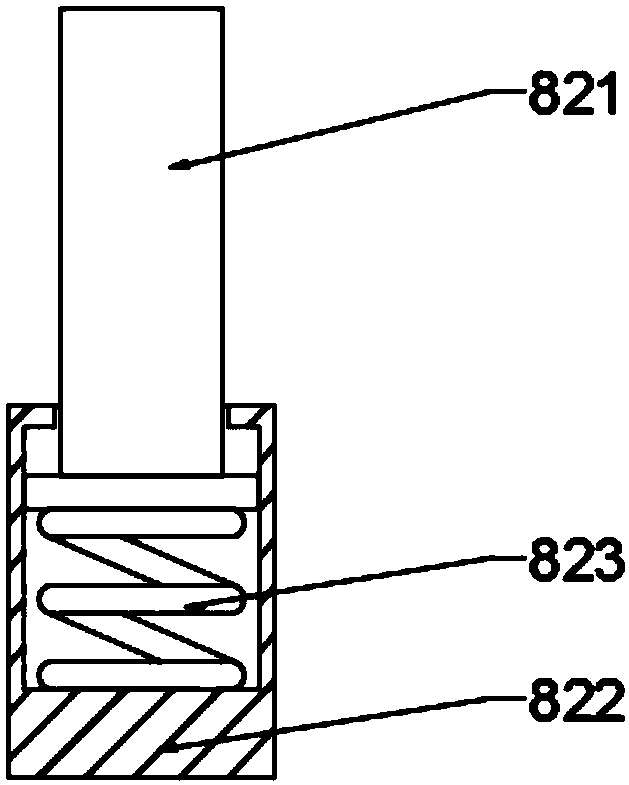

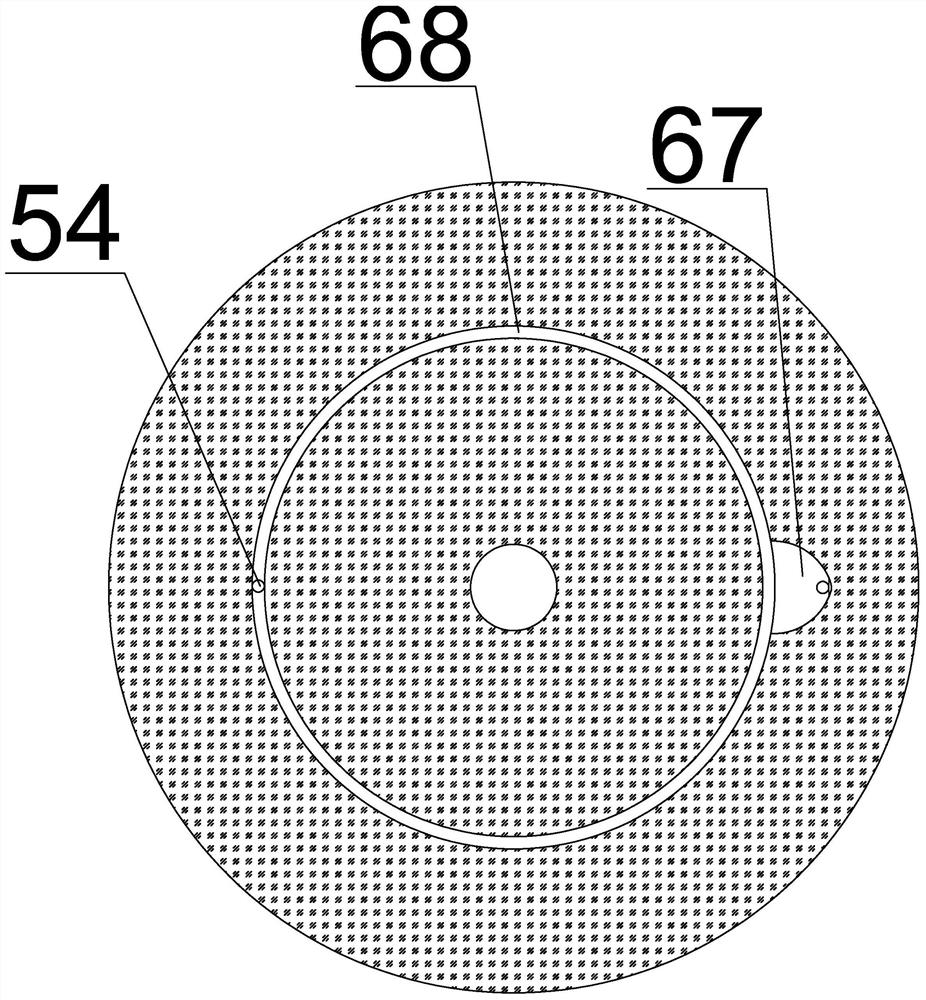

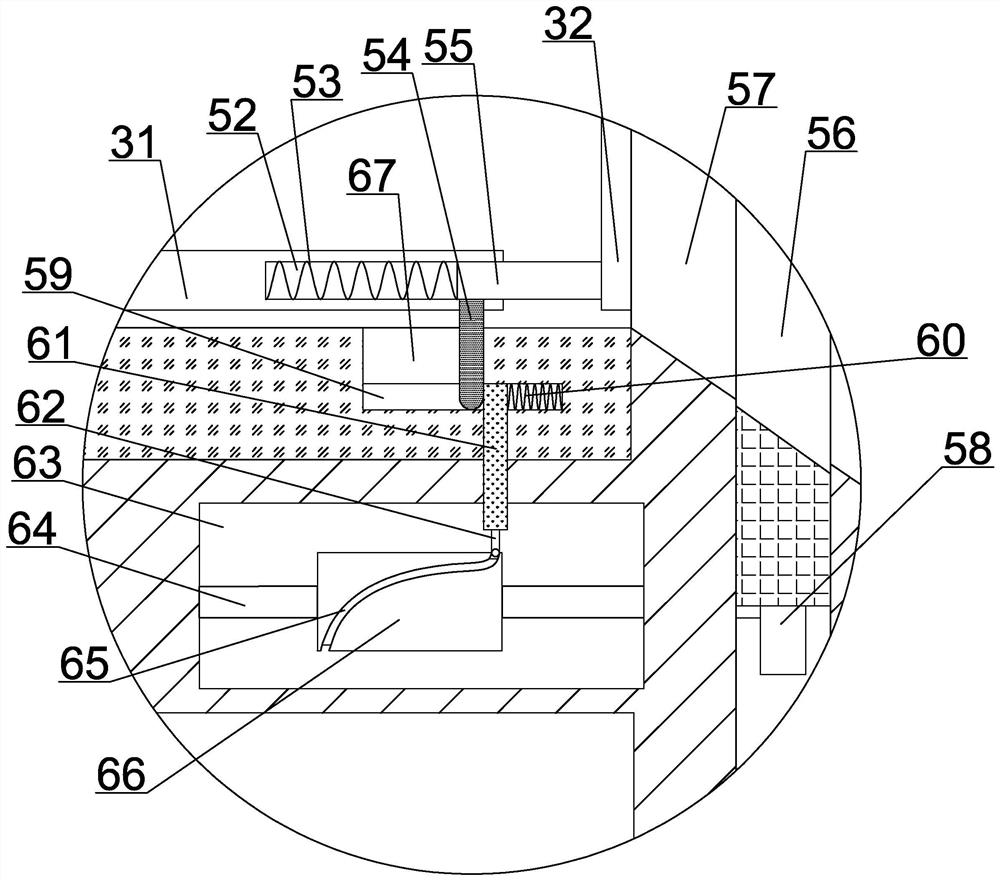

Device and method for refining electromagnetic energy grains

The invention discloses a device and a method for refining electromagnetic energy grains. The device is applied to semi-continuous casting equipment; an electromagnetic device comprises a silicon steel laminated core, a lifting platform, a lifting bracket and a coil; the coil is wound on the outer periphery of the silicon steel laminated core; a round hole is formed in the lifting platform; the silicon steel laminated core penetrates through the round hole, and is sleeved in the round hole of the lifting platform; the top end of the lifting bracket is connected to the lower surface of the lifting platform; the bottom end of the lifting bracket is detachably connected with a cast groove body; the lifting platform is supported by the lifting bracket; and the lifting bracket is used for adjusting the height of the lifting platform. The electromagnetic device performs electromagnetic energy processing on melts, so that the melts obtain electromagnetic energy generation transition, the grain refining degree of the melts is increased, and the mechanical performances and the deformation performance of ingots are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Iron-copper alloy powder and preparation method thereof

The invention discloses iron-copper alloy powder and a preparation method thereof. The iron-copper alloy powder is prepared from the following raw materials in percentage by mass: 10-30 percent of copper oxide powder and 70-90 percent of iron-copper pre-alloyed powder. The preparation method comprises the following steps: selecting the copper oxide powder prepared through roasting and crushing, uniformly mixing the copper oxide powder and the iron-copper pre-alloyed powder according to a ratio, carrying out active diffusion sintering on the mixture in a reducing atmosphere, crushing and sieving the mixture subjected to sintering, and finally preparing the iron-copper alloy powder. The iron-copper alloy powder is lower in apparent density and good in formability, has the apparent density being 2.5-3.0g / cm<3> and the green strength being 12-15MPa, makes up for the deficiencies in the prior art and broadens the application market.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Traditional Chinese medicinal material treatment device for improving refining degree

ActiveCN107812576AIncrease granularityAvoid stickingGrain treatmentsEngineeringTraditional Chinese medicine

The invention discloses a traditional Chinese medicinal material treatment device for improving the refining degree. The traditional Chinese medicinal material treatment device comprises a bottom plate, a smashing cylinder, a rotary shaft and a grinding bowl. Vertical frames are symmetrically fixed to the left side and the right side of the top of the bottom plate, and a top plate is connected tothe position between the tops of the vertical frames on the two sides. The top of the rotary shaft is connected with the output end of a motor, the motor is fixed to a mounting frame, the top of the mounting frame is hinged to the lower surface of the top plate, and the bottom of the rotary shaft is rotatably fixed to the bottom face of an inner cavity of the smashing cylinder. A section of bent axle is arranged on the rotary shaft, a sleeve is movably arranged on the bent axle in a sleeving mode, a gap exists between the sleeve and the bent axle, a connection rod is hinged to one side of thesleeve, and the other end of the connection rod is hinged to the left side face of the vertical frame on the right side. A grinding roller is arranged at the bottom of the smashing cylinder, and the grinding roller abuts against the inner cavity face of the grinding bowl. The traditional Chinese medicinal material treatment device can effectively improve the refining degree of the traditional Chinese medicinal materials so that the traditional Chinese medicinal materials can be better absorbed by a human body when the traditional Chinese medicinal materials are treated.

Owner:江西半边天药业有限公司

Efficient pepper grinding device for seasoning processing

The invention discloses an efficient pepper grinding device for seasoning processing, and relates to the technical field of pepper processing. The efficient pepper grinding device comprises a supportplate, wherein a grinding chamber is fixedly installed on the support plate, a second motor is fixed to the grinding chamber, a grinding roller I and a grinding roller II are in driving connection tothe grinding chamber by virtue of belt pulley mechanisms I, the grinding roller II is driven by a second motor, an eccentric grinding frustum is eccentrically and rotatably arranged in the grinding chamber, and grinding heads which are abutted with a metal net plate are uniformly fixed to the lower end of the eccentric grinding frustum. According to the efficient pepper grinding device, the grinding roller I and the grinding roller II rotate, so that peppers are preliminarily pulverized; the eccentric grinding frustum eccentrically rotates, so that the peppers are further ground; the peppers on the metal net plate are ground again by the grinding heads, and three-time grinding is performed, so that the pepper refining degree is greatly increased; and a transverse auger and a longitudinal auger are arranged, so that the circulation of the peppers is realized, repeated grinding is realized, the pepper refining degree is fully guaranteed, and the grinding efficiency is high.

Owner:李影

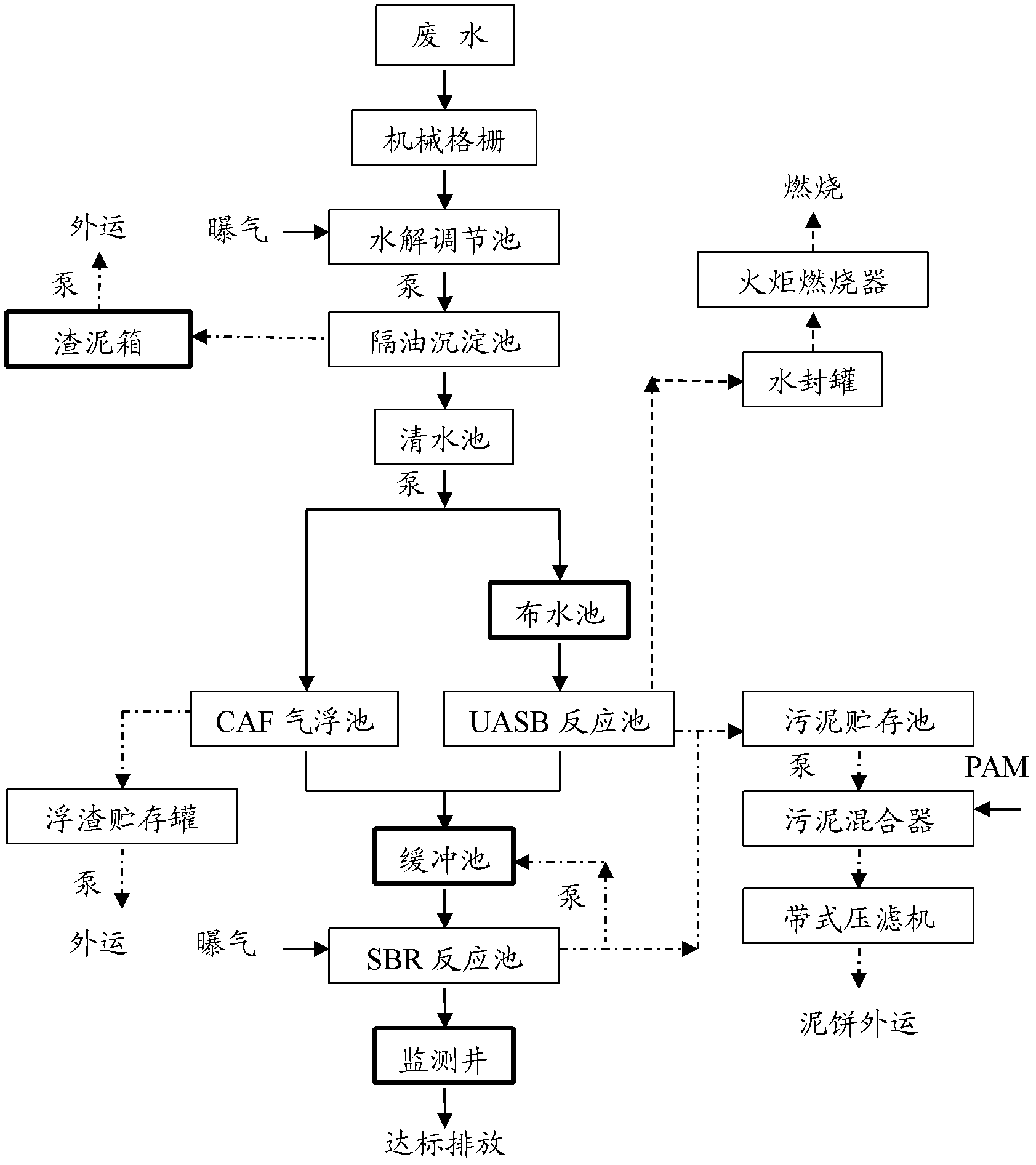

Method for treating wastewater from dairy processing

InactiveCN102503051ASolve the problem of insufficient deacidificationTroubleshoot follow-up issuesMultistage water/sewage treatmentSequencing batch reactorChemical oxygen demand

The invention belongs to the field of wastewater treatment and particularly relates to a method for treating wastewater from dairy processing, comprising the following steps: (1) discharging the wastewater into a hydrolyzing adjusting pool through a machinery grille to be subjected to hydrolysis and acidification; (2) making the wastewater subjected to hydrolysis and acidification in the hydrolyzing adjusting pool enter an UASB (upflow anaerobic sludge bed) through an oil removing settling pond and a clear water pool to be subjected to anaerobic treatment; and (3) making the wastewater treated in the UASB reactor enter an SBR (sequencing batch reactor) to be subjected to aerobic treatment. The water from the hydrolyzing adjusting pool is more beneficial for anaerobic bacteria to ferment and gasify and play a role so that the yield of biogas increases gradually, the saving of power consumed by the subsequent aerobic process is considerable, the COD (chemical oxygen demand) of the water is low, and the problem on the subsequent treatment of a large number of scrum can be solved. The yield of the aerobic sludge decreases by 30%-50%, and the sludge dewatering and external transporting expenses are saved.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

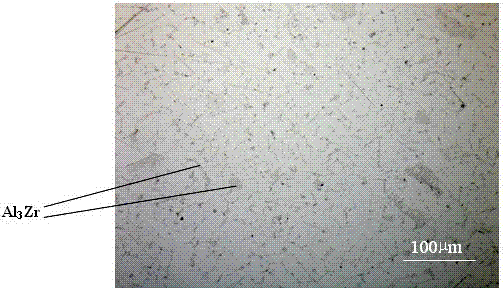

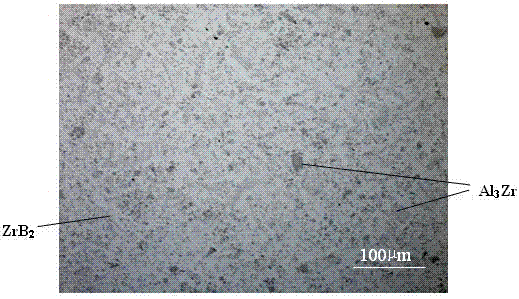

Alloy for refinement of magnesium and alloy grain thereof and preparation method of alloy

The invention provides an alloy for refinement of magnesium and an alloy grain thereof and a preparation method of the alloy. A grain refinement agent alloy is an aluminum-zirconium-boron intermediate alloy, and comprises the following components in percent by weight: 5-20 percent of Zr, 0.5-4 percent of B and the balance of Al. The invention has the beneficial effects that the intermediate alloy with excellent capacity of refining the magnesium and the magnesium alloy grain due to strong core forming capacity is invented, and a preparation method is provided; and the grain refinement agent can be industrially applied to casting deformation plastic processing of the magnesium and the magnesium alloy section, is high in refinement degree, and promotes the wide application of the magnesium in the industry.

Owner:SHENZHEN SUNXING LIGHT ALLOYS MATERIALS CO LTD

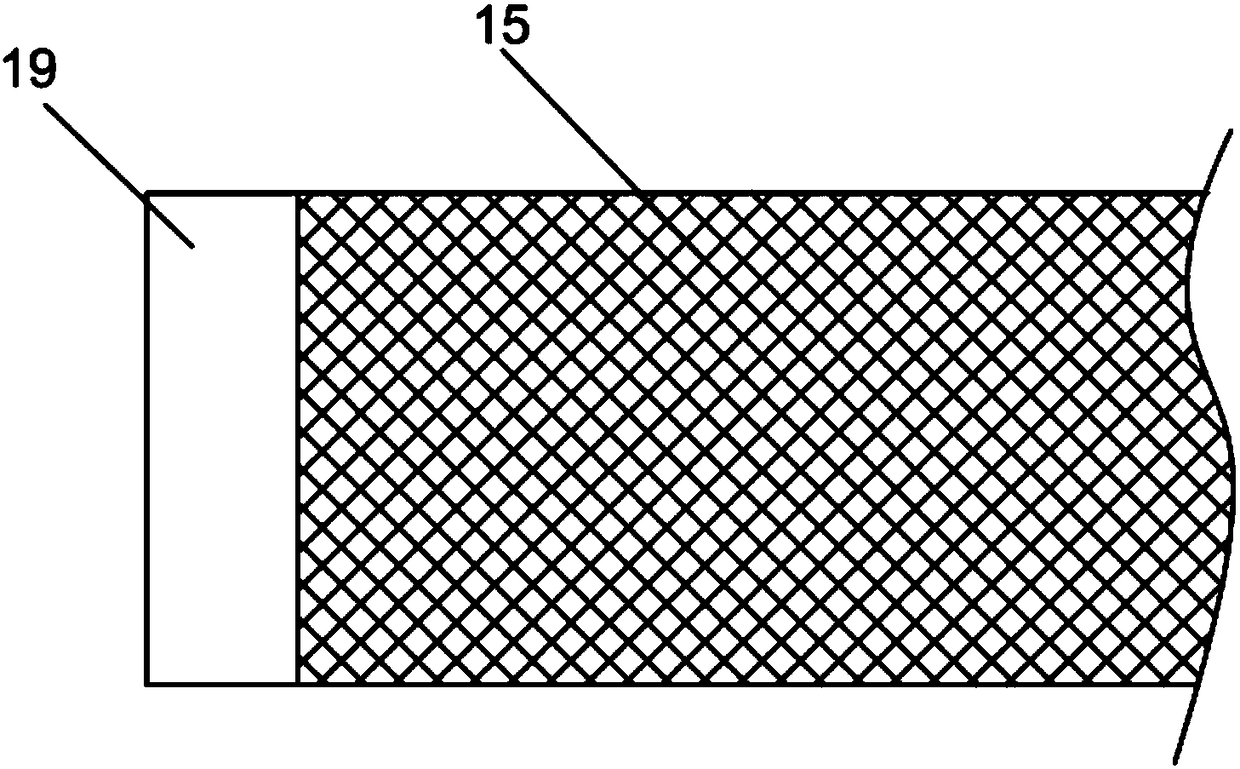

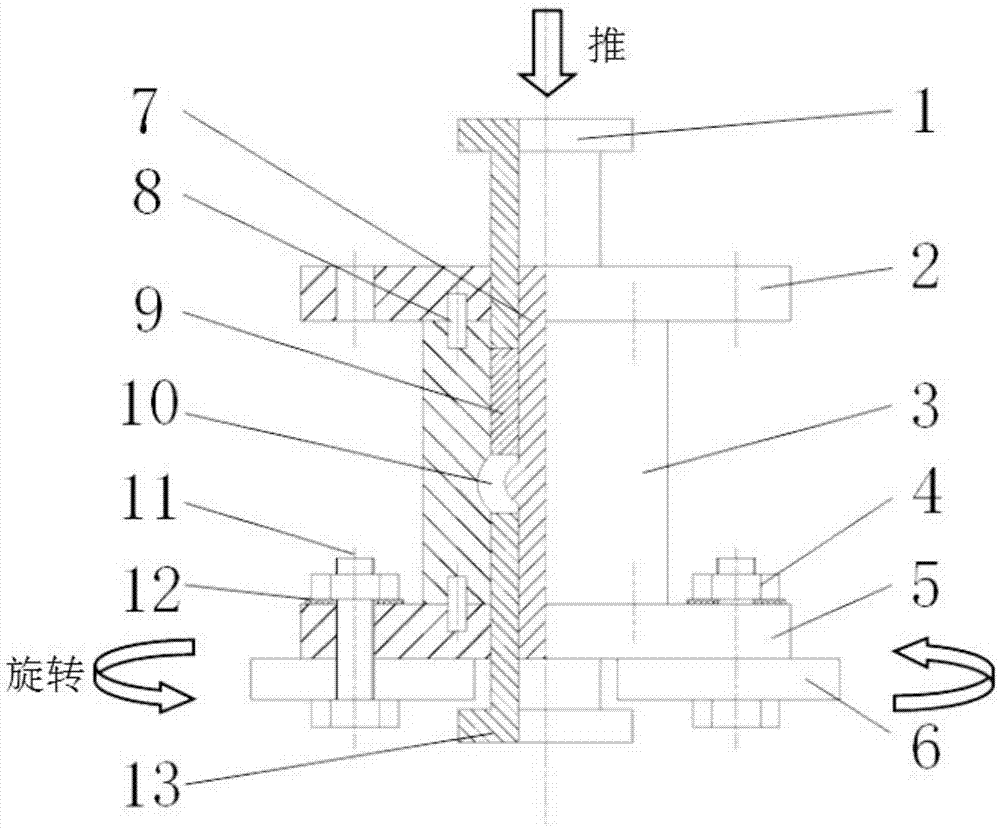

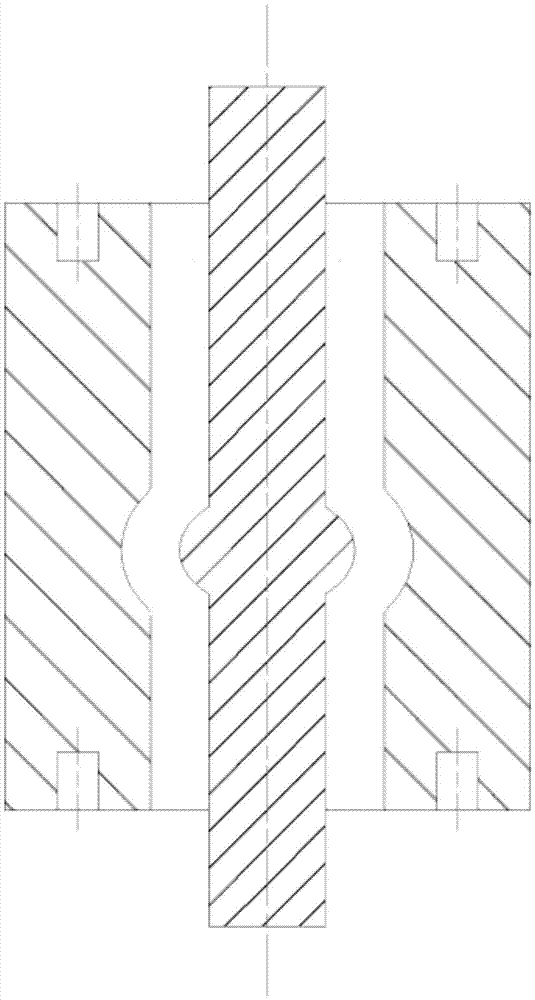

Bi-directional continuous shear deformation device and method

ActiveCN105436228AImprove shear uniformityReduce size dispersionShearing deformationStructural engineering

The invention provides a bi-directional continuous shear deformation device which comprises an axial hollow variable cross-section annular extrusion barrel, a variable cross-section core rod, an upper fixing pressure plate, a lower fixing pressure plate, an upper annular extrusion punch, a lower annular extrusion punch and a rotating working table, wherein the upper end of the variable cross-section annular extrusion barrel is connected with the upper fixing pressure plate, and the lower end of the variable cross-section annular extrusion barrel is connected with the lower fixing pressure plate; a groove is formed in the inner wall surface of the variable cross-section annular extrusion barrel; the variable cross-section core rod is arranged on the inner side of the variable cross-section annular extrusion barrel, and is provided with a bulge matched with the groove; the upper annular extrusion punch penetrates through a first through hole of the upper fixing pressure plate to be connected with the upper end of the variable cross-section core rod; the lower annular extrusion punch penetrates through a second through hole of the lower fixing pressure plate to be connected with the lower end of the variable cross-section core rod; and the lower fixing pressure plate is arranged on the rotating working table. According to the bi-directional continuous shear deformation device, a necking down zone in traditional reciprocating extrusion is transformed into a smoothly transitional continuous shear channel, so that the shear uniformity of tubular blanks in the cross section direction is improved.

Owner:SHANGHAI JIAO TONG UNIV

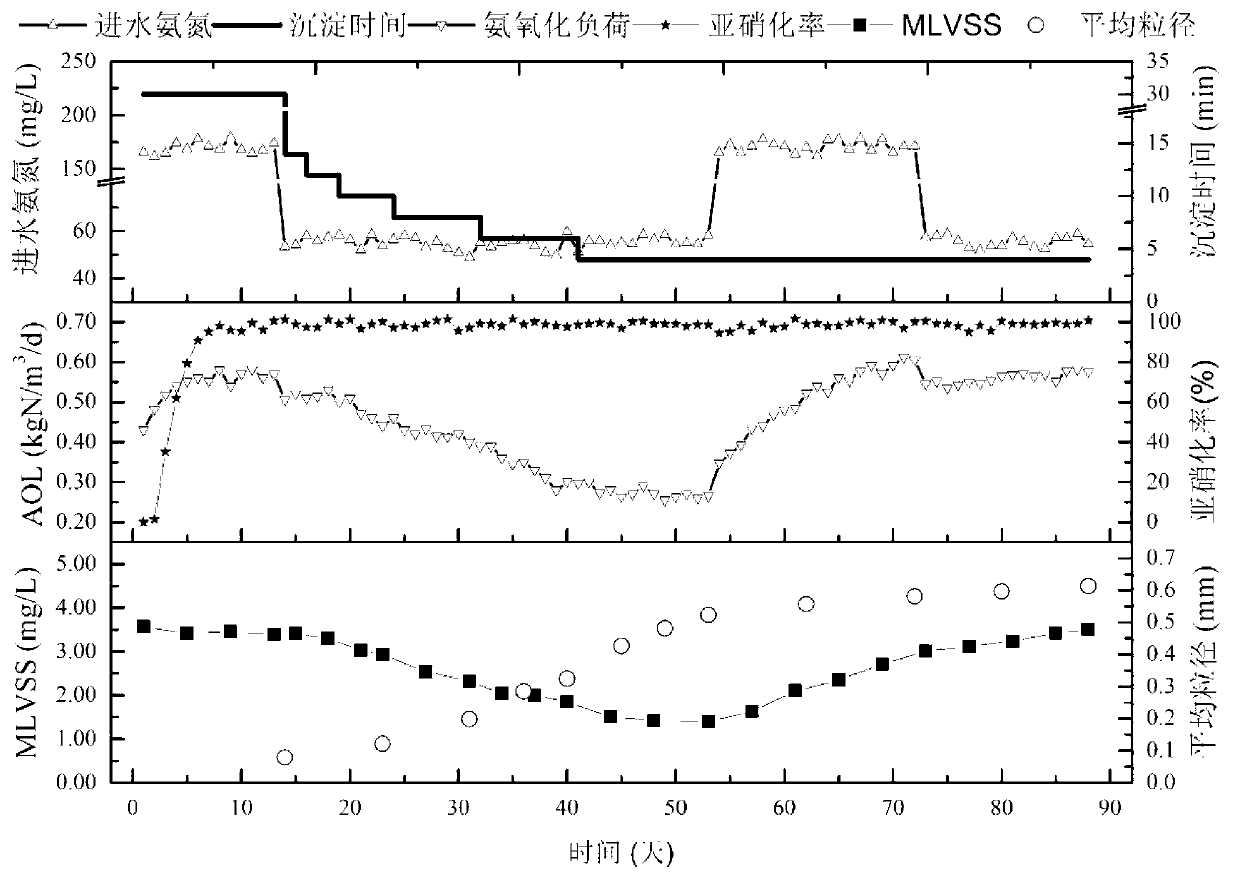

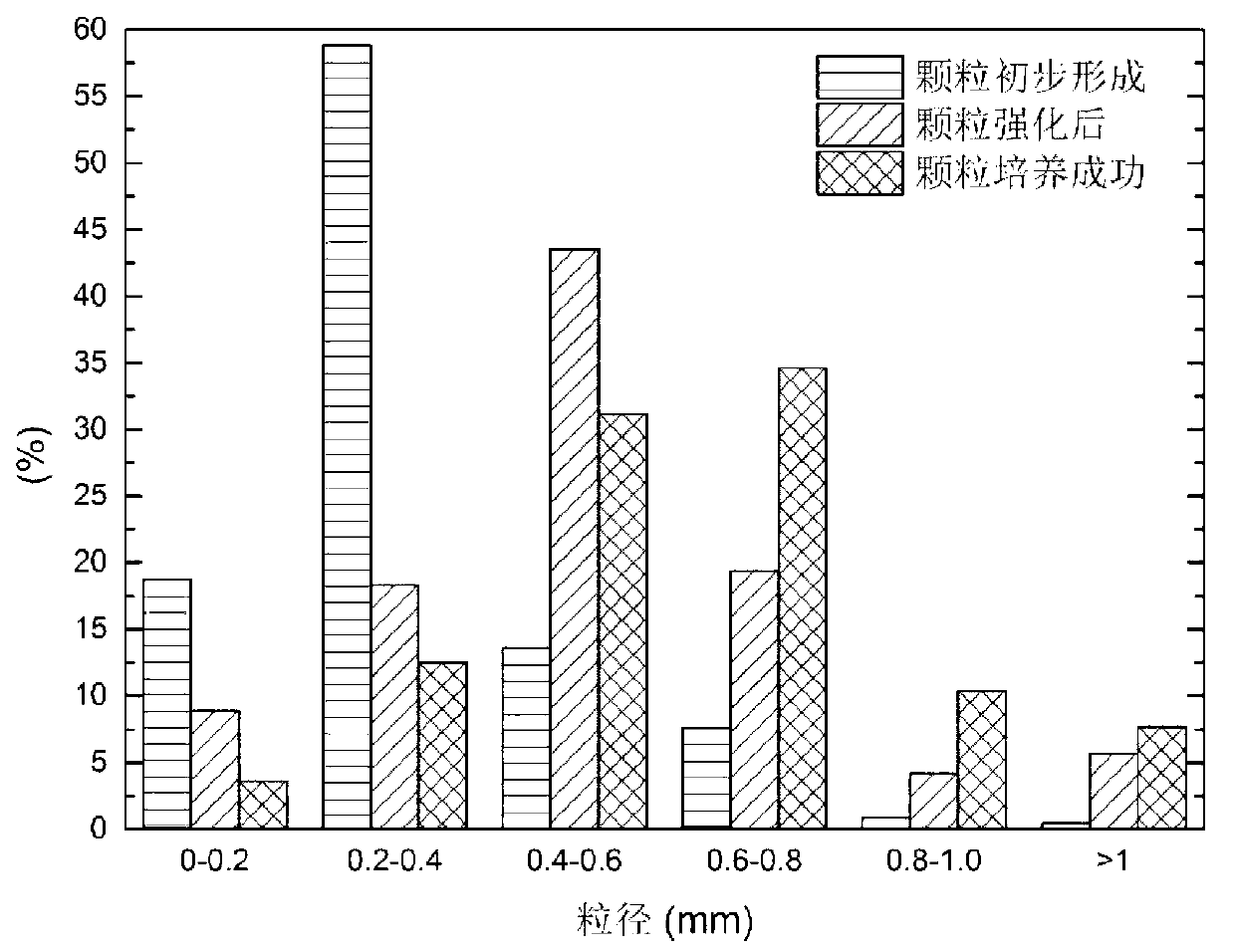

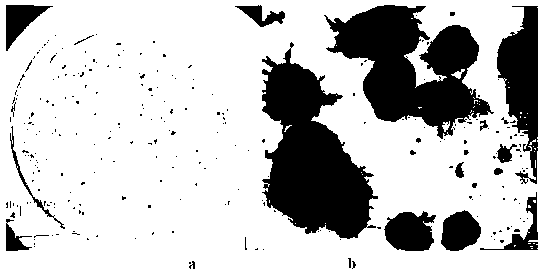

High-efficiency culture method of urban domestic sewage nitrosation granule sludge

ActiveCN103121750ANitrosation performance is goodIncrease granularitySustainable biological treatmentBiological water/sewage treatmentSequencing batch reactorDiameter ratio

The invention relates to a high-efficiency culture method of urban domestic sewage nitrosation granule sludge, and the high-efficiency culture method comprises the following steps of: adding ammonia nitrogen to domestic sewage through a nitrosation starting stage at 17-25 DEG C by adopting a columnar intermittent sequencing batch reactor with the height-diameter ratio of 5-15 to domesticate the nitrosation property of active sludge; a granule sludge culture stage: basically forming the granule sludge by taking the domestic sewage as intake water and controlling sedimentation time to gradually shorten the sedimentation time from 14 minutes to 6 minutes by taking 2 minutes as a gradient; a granule sludge intensifying stage: controlling the sedimentation time for 4 minutes, and continuously operating till a granular average particle diameter exceeds 0.4 mm; a processing capacity intensifying stage: adding the ammonia nitrogen to the domestic sewage, controlling the sedimentation time for 4 minutes, operating till ammonia oxidation loads exceed 0.5 kgN / m<3> / d, restoring the domestic sewage as the intake water, and finally culturing the high-efficiency nitrosation granule sludge with the ammonia oxidation loads exceeding 0.4 kgN / m<3> / d and the granular average particle diameter exceeding 0.5 mm. The nitrosation granule sludge prepared through the high-efficiency culture method disclosed by the invention has the characteristics of stability in nitrosation property, high sludge concentration, high processing capacity, and the like.

Owner:BEIJING UNIV OF TECH

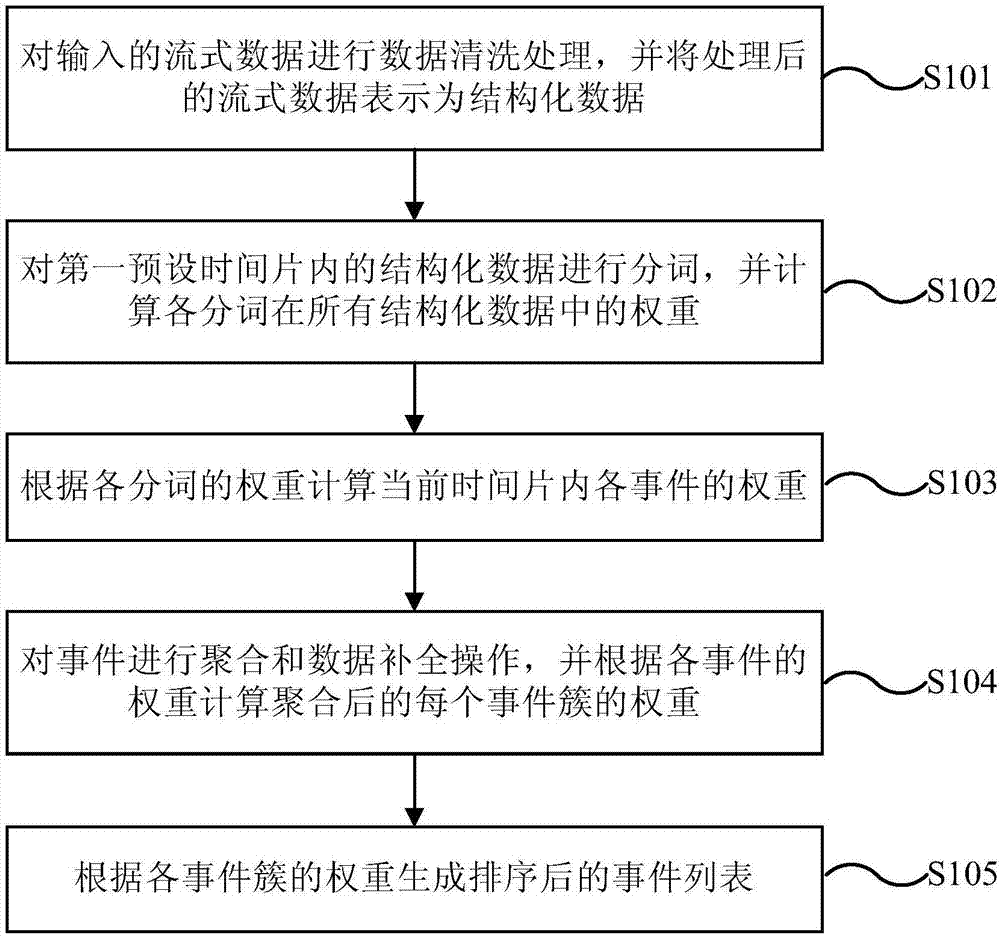

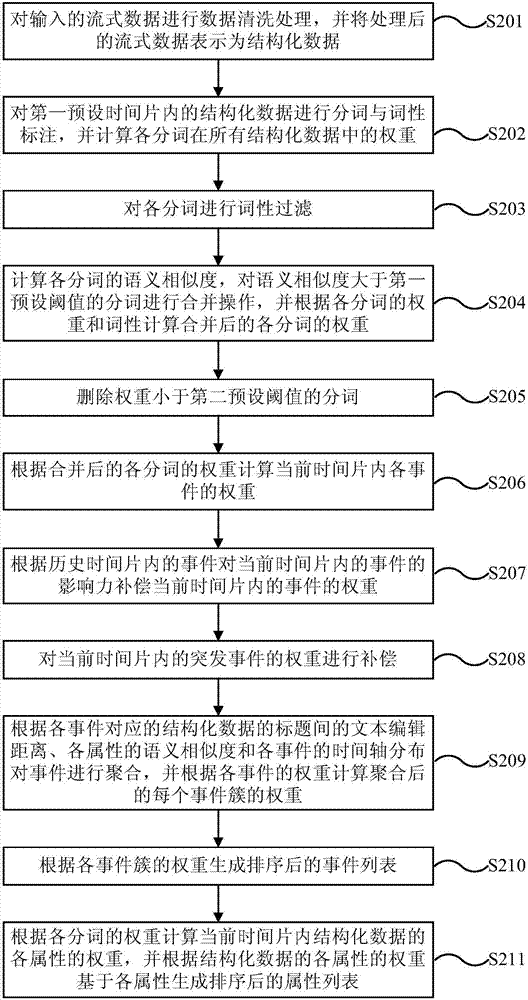

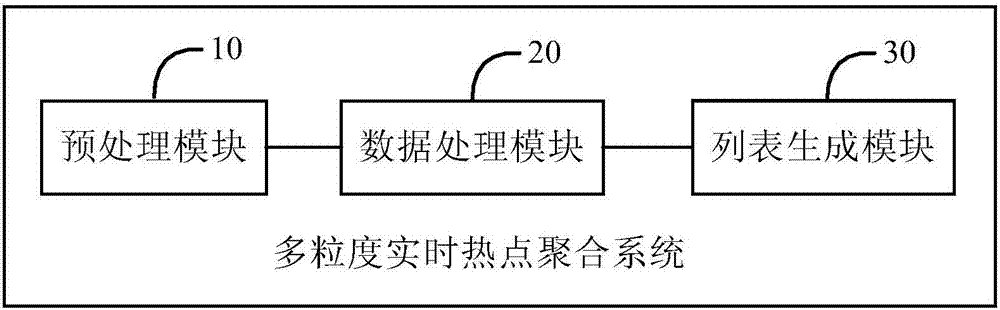

Multi-granularity real-time hot spot aggregation method

ActiveCN106874419AIncrease granularityEasy accessSemantic analysisRelational databasesStreaming dataData cleansing

The invention provides a multi-granularity real-time hot spot aggregation method, comprising: performing data cleaning processing on input streaming data, showing the processed streaming data in structural data; performing word segmentation on the structural data in first preset time slice, and calculating weight of each segmented word in all streaming data; according to the weight of each segmented word, calculating weight of each event in the current time slice; aggregating events, and according to the weight of each event, calculating weight of each event cluster after aggregation; and according to the weight of each event cluster, generating a sorted event list. The technical scheme improves granularity of a final event display result, and event integrity and accuracy, and provides convenience for a user to rapidly and accurately obtain hot spot information.

Owner:BEIHANG UNIV

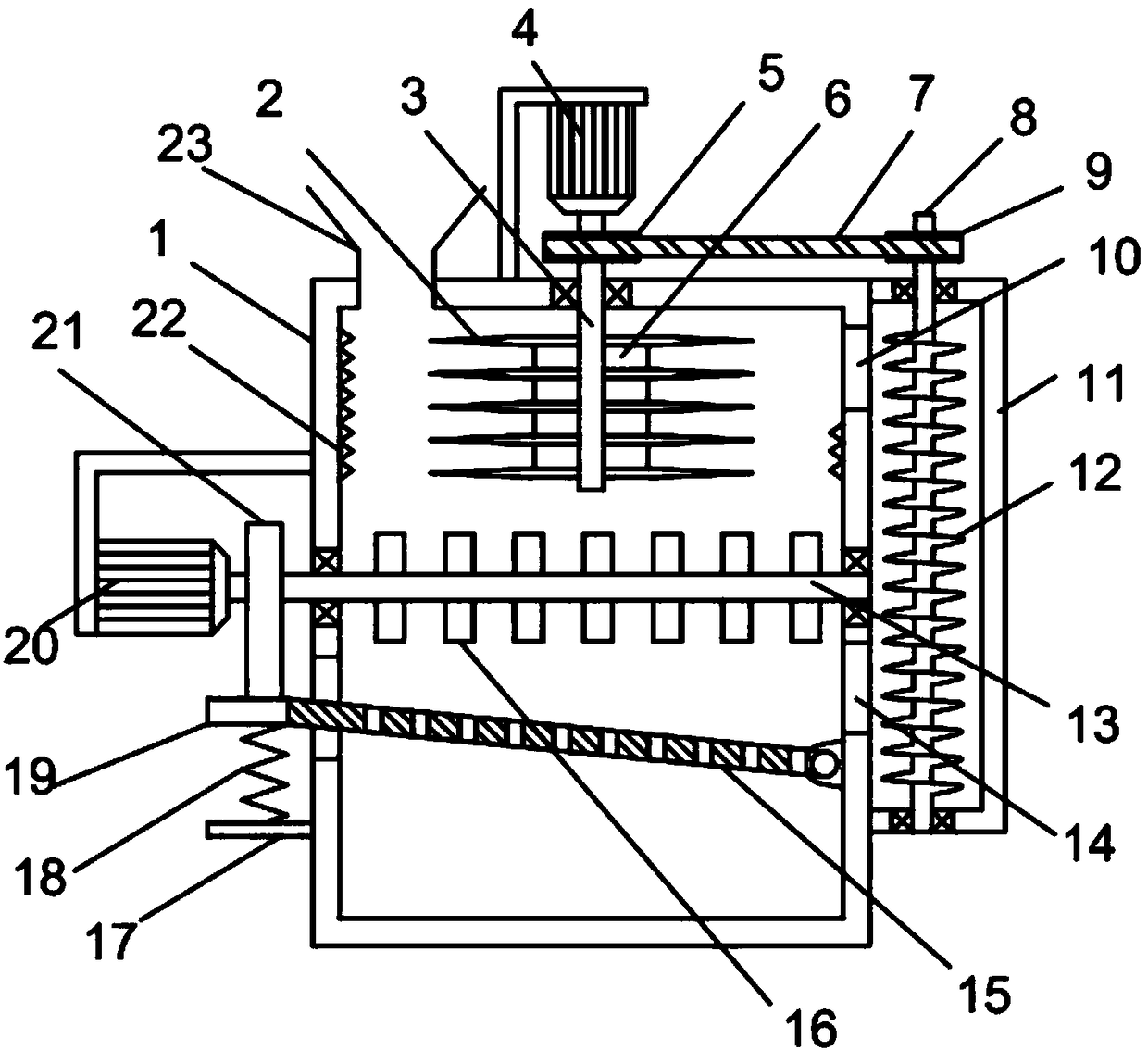

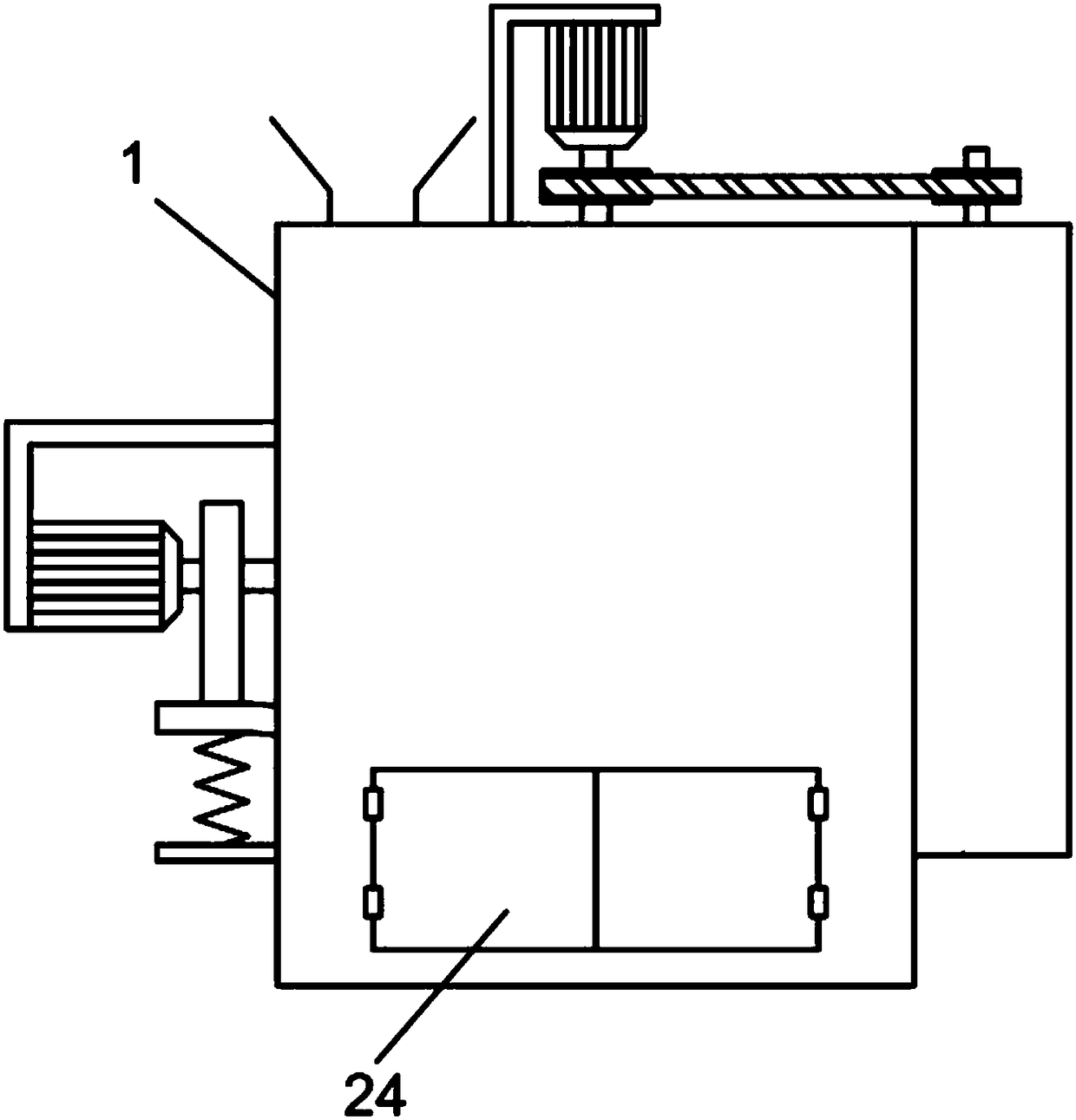

Feed grain crop breaking and refining device for livestock breeding

InactiveCN110252478AImprove refinementIncrease granularityFeeding-stuffCocoaLivestock breedingEngineering

The invention discloses a feed grain crop breaking and refining device for livestock breeding, and relates to the technical field of stockbreeding machines. The device comprises a supporting frame, a breaking groove is fixedly mounted in the supporting frame, a guide rod is horizontally and fixedly mounted on the top of the supporting frame, a breaking shaft capable of extending into the breaking groove is coaxially and fixedly mounted on a cylindrical straight gear, multiple cutting blades are fixedly mounted on the surface of the breaking shaft at equal intervals, and a discharging pipe is vertically mounted on the bottom of the breaking groove. The breaking shaft rotates to drive the cutting blades to sufficiently rotate and break fodder in the breaking groove, a horizontal plate drives a grinding block to grind the fodder, the fodder refining is promoted, a screen plate can vibrate up and down under the elastic effect of a vibration spring, grains which are sufficiently broken and ground on the screen plate can be separated from the grains which are not sufficiently refined, the feed grain crop grinding efficiency is higher, the grain refining degree is greatly improved, and it is ensured that the grains on the screen plate can be enough refined.

Owner:姚则梁

Nitride enhanced copper-based electrical contact composite material

InactiveCN105140057AHigh densityExcellent mechanical properties and electrical propertiesContactsContactorYttrium

The invention relates to a nitride enhanced copper-based electrical contact composite material, which comprises the following components in percentage by weight: 0.5 to 4 percent by nitride, 0.5 to 4 percent of bismuth, 0.1 to 0.6 percent of rare earth yttrium, 0.5 to 2.5 percent of yttrium oxide, and the rest is copper and other unavoidable impurities, wherein the nitride is titanium nitride or aluminum nitride. The material provided by the invention is made by a preparation method comprising the steps of preparing powder by atomization, proportioning, mixing and vacuum hot pressed sintering. The composite material takes copper as a base body, the main raw materials are rich in resources, the nitride is distributed in the copper base material uniformly and dispersedly in an enhanced phase mode, and the fineness degree of an internal organizational structure of the material is improved. The composite material not only has good electrical conductivity, thermal conductivity, welding resistance and arc ablation resistance, but also is excellent in mechanical property and abrasion resistance, can meet basic requirements of workpieces such as an electrical contact and the like for materials, and can be applied to low-voltage electrical apparatuses such as medium and low electrical-load power switches, relays, DC contactors, air switches and the like. Compared with a silver-based electrical contact material, the nitride enhanced copper-based electrical contact composite material is more advantageous in price-to-performance ratio.

Owner:UNIV OF JINAN

Preparation method of nano self-cleaning environment-friendly coating

InactiveCN111087835APrevent leakageReduce investmentAntifouling/underwater paintsPaints with biocidesOrganosolvPyrrolidinones

The invention discloses a preparation method of a nano self-cleaning environment-friendly coating. The preparation method comprises the following steps: firstly, putting a nano titanium dioxide colloid into a stirring reaction kettle; adding deionized water, ethanol and an organic solvent for reaction to prepare a nano titanium dioxide colloidal solution; adding the nano titanium dioxide colloidalsolution into a heating stirrer, meanwhile, adding zeolite, inorganic environment-friendly filler, polyvinylpyrrolidone and sodium benzoate at the same time, then performing a stirring reaction to prepare a nano titanium dioxide emulsion, adding the nano titanium dioxide emulsion into a stirring kettle, adding a thickening agent and a defoaming agent, thereby preparing the nano self-cleaning environment-friendly coating. The environment-friendly coating has super-hydrophobic and oleophobic performance and excellent self-cleaning performance. The invention further provides a ball milling device, the ball milling device is used for grinding and refining titanium dioxide particles, mixed materials roll in the wheel sand cutting groove formed in the ball milling device, grinding and refiningare achieved, and the ball milling effect is good.

Owner:骆瑜

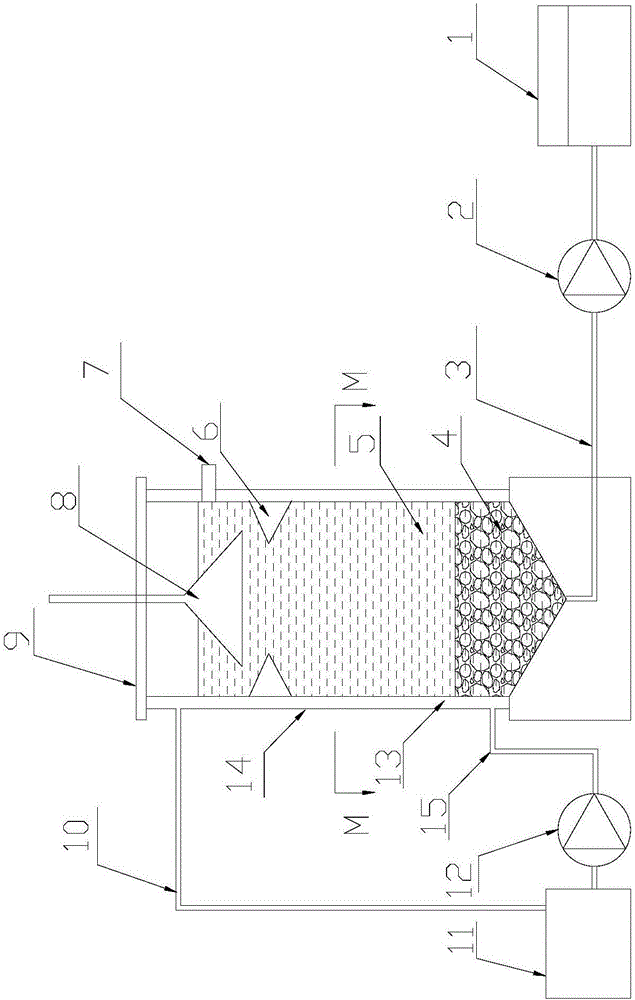

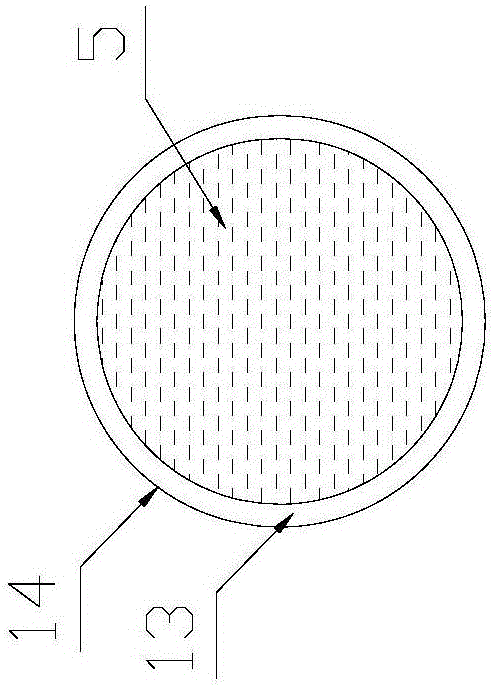

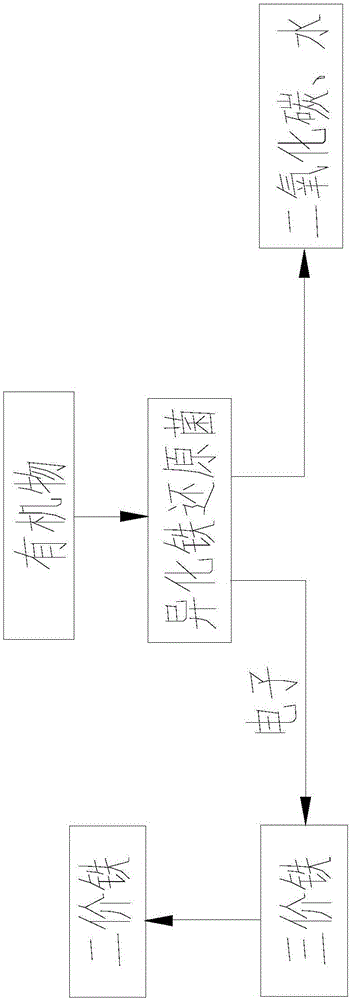

Process and device for treating Fenton iron mud by anaerobic microorganisms

InactiveCN107176777AEasy to handleIncrease granularityWater treatment compoundsWater contaminantsWater bathsChemical oxygen demand

A device for treating Fenton iron mud by anaerobic microorganisms comprises a barrel of an up-flow anaerobic sludge blanket reactor. Mud shields and a three-phase separation are arranged in the barrel, and a water inlet pipe is connected with the bottom of the barrel. The device is characterized in that the barrel is provided with a hollow thermal insulation cavity connected with a circulating water bath. A process for treating Fenton iron mud by the device includes: adding to-be-treated Fenton iron mud into a water feeding regulation tank, running the barrel of the up-flow anaerobic sludge blanket reactor, and controlling hydraulic retention time, temperature and pH; leading iron mud mixed wastewater into the barrel, and enriching dissimilatory iron-reducing bacteria by ferric iron in iron mud through ferric iron reducing action to remove organics in iron mud and wastewater and generate energy gas. The process and the device have advantages that effective removal of the organics in the iron mud is realized, wastewater chemical oxygen demand removal rate is increased, and methane yield is increased. The process and the device are especially suitable for treatment of organic wastewater with long-chain fatty acids and rich in aromatic hydrocarbon compounds of benzene, phenol and the like.

Owner:DALIAN UNIV OF TECH

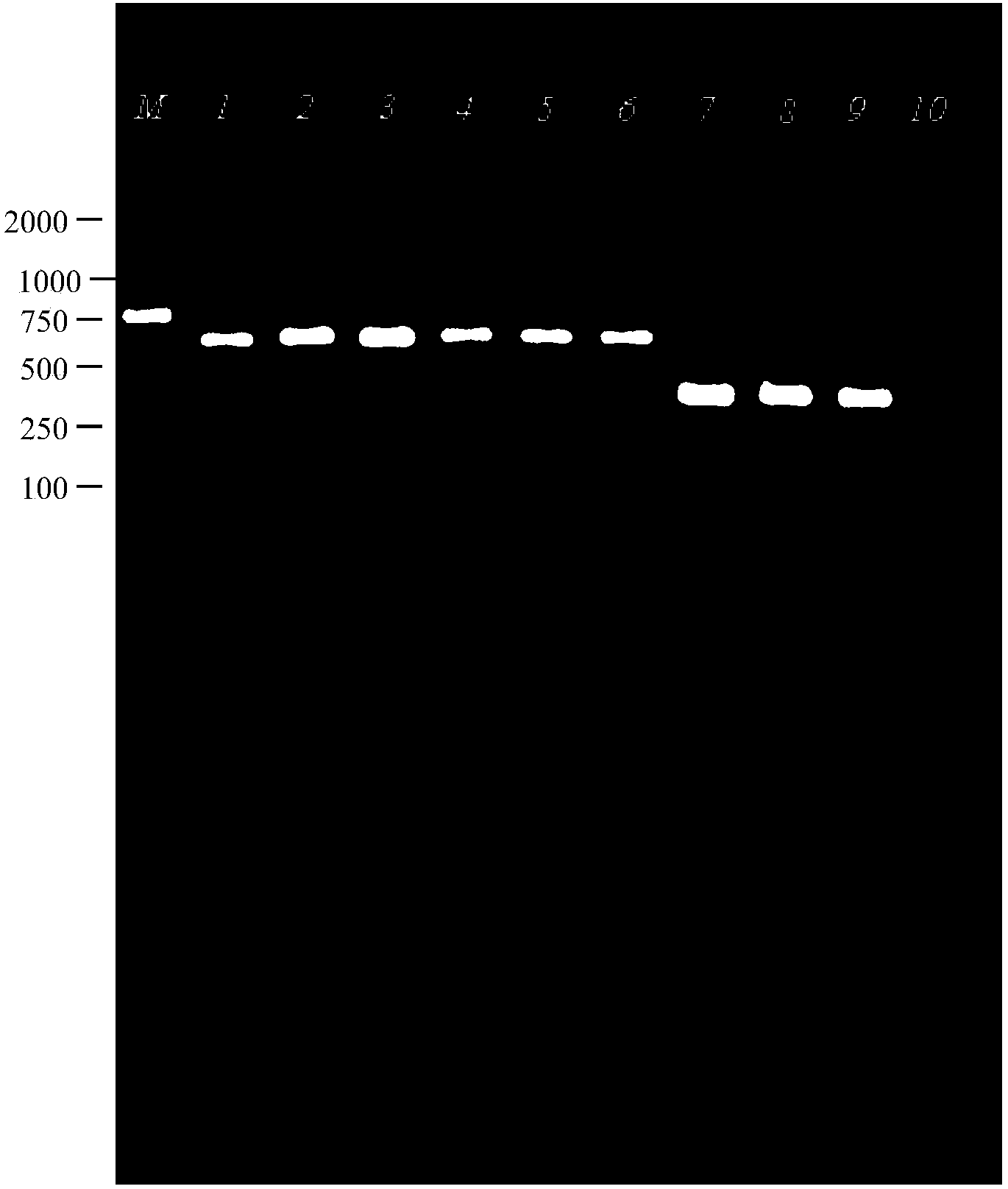

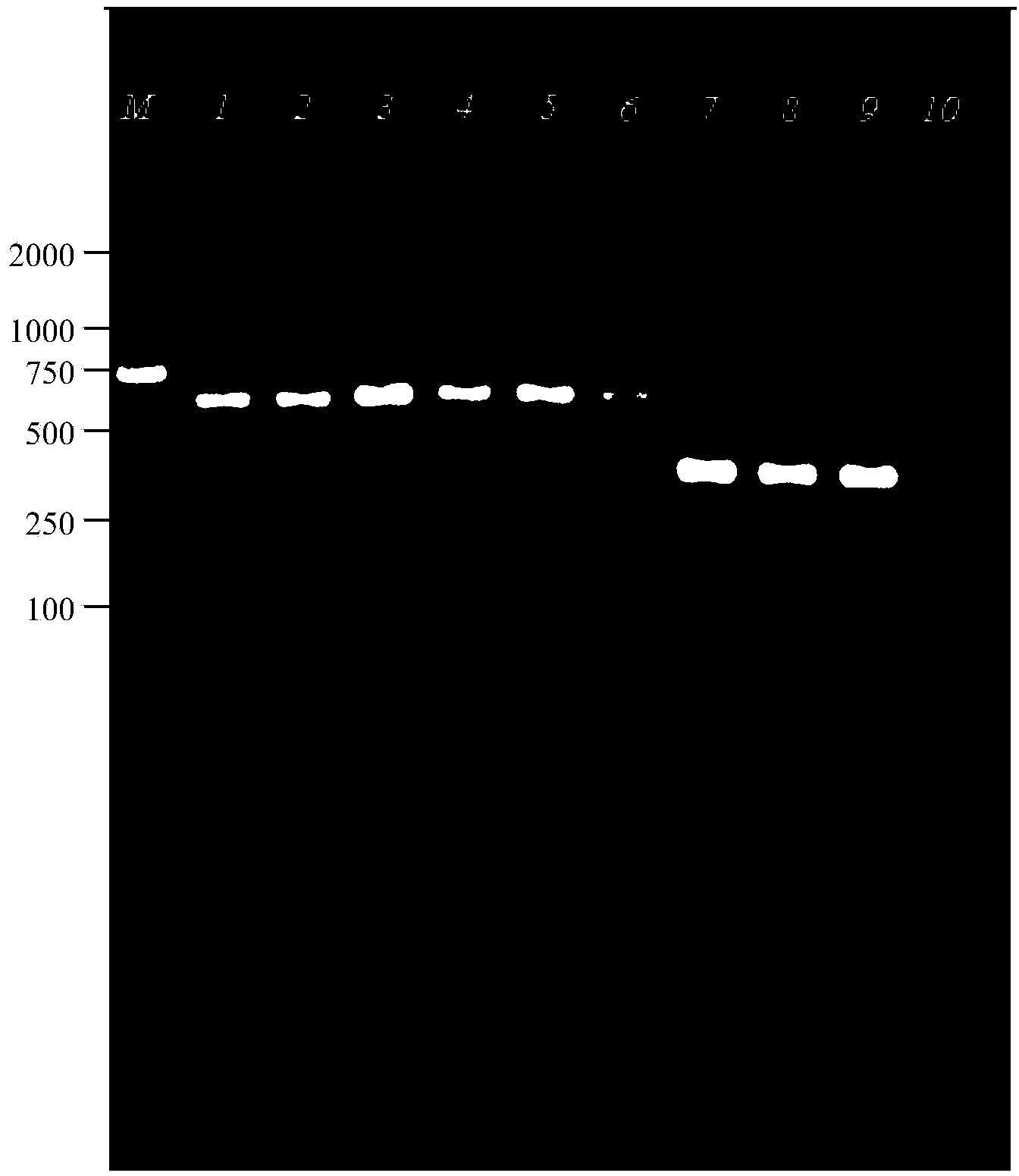

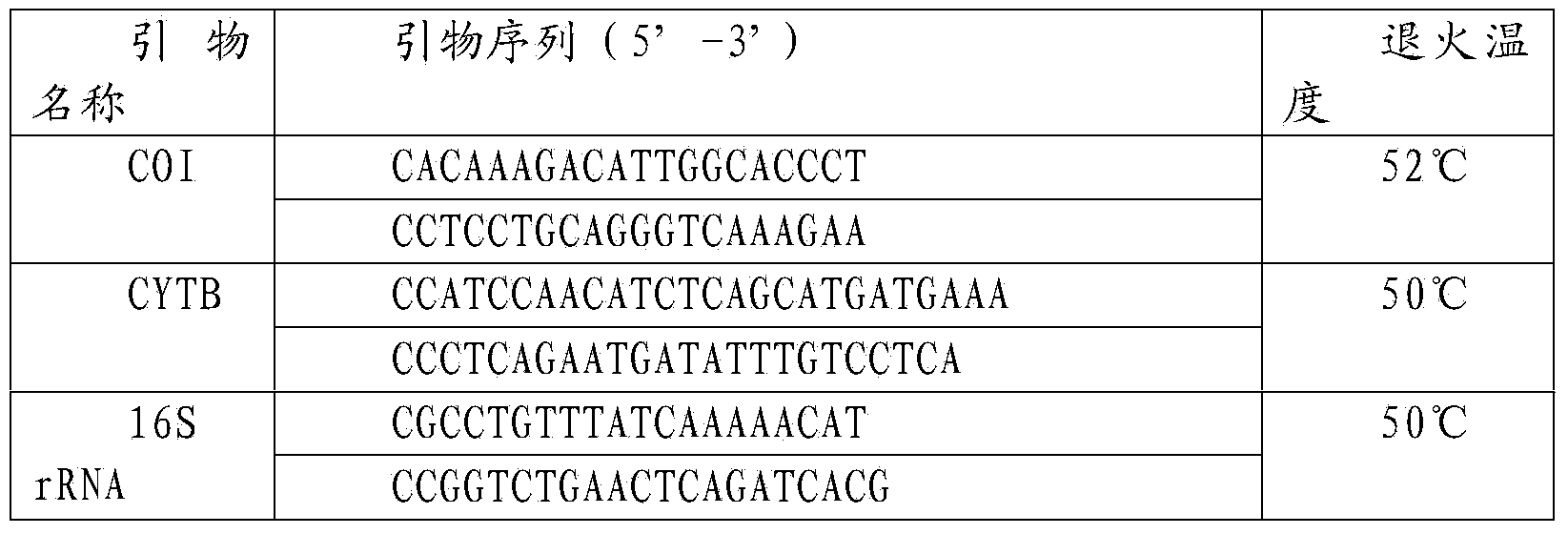

Method of extracting high-quality DNA (Deoxyribonucleic Acid) of fin product

The invention relates to a method of extracting high-quality DNA (Deoxyribonucleic Acid) of a fin product and belongs to the field of molecular biology associated research. The method comprises the following steps: (1) pre-treating a fin product sample, namely softening and smashing fins in a weak base solution; (2) splitting the pre-treated fin product sample by a CTAB (Cetyltrimethyl Ammonium Bromide) splitting solution; (3) extracting the DNA by balanced phenol and chloroform-isoamylol in steps; (4) adding a high-saline solution of isopropanol doubled in volume into an aqueous phase containing the DNA to obtain a DNA precipitate; washing the DNA precipitate by an ethanol solution with the volume fraction of 75%, fully drying, and then, dissolving the DNA precipitate and storing. The method of extracting the DNA of the fin product provided by the invention can be used for conveniently and efficiently obtaining the high-quality DNA of a fin tissue so as to avoid pollution by polysaccharide, collagen and other impurities.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

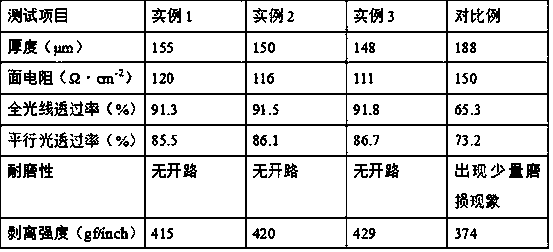

Preparation method for high-conductivity liquid crystal light-adjusting film

ActiveCN108107639AHigh light transmittanceImprove stabilityNon-linear opticsIndiumPotassium hydroxide

The invention relates to the technical field of the optical material preparation and in particular to a preparation method for a high-conductivity liquid crystal light-adjusting film. The method comprises the following steps: dissolving octan zinecnaty in isopropyl alcohol and adding diethanol amine and aluminum nitrate nonahydrate, to obtain transparent homogeneous sol; mixing stannous mono-sulphate, edetic acid and potassium hydroxide and dissolving in deionized water, to obtain complexing stannous mono-sulphate solution; adding polyvinylpyrrolidone powder and oxidation solution added with indium hydroxide to the complexing stannous mono-sulphate solution, to obtain reaction solution; adding indium tin oxide powder to the transparent homogeneous sol, to obtain transparent conductive solsolution, and to obtain a conductive liquid crystal film finally; bonding two sheets of the conductive liquid crystal films by coating with polyamide acid sol, to obtain transparent conductive film glass. In the method, the polyvinylpyrrolidone powder is dissolved in the complexing stannous mono-sulphate solution, the dissolving capacity of multiple types of organic molecules in the transparent homogeneous sol is enhanced, so the light transmission and the conductive performance of the transparent conductive film glass are improved, and the application prospect is extensive.

Owner:南京优写智能科技有限公司

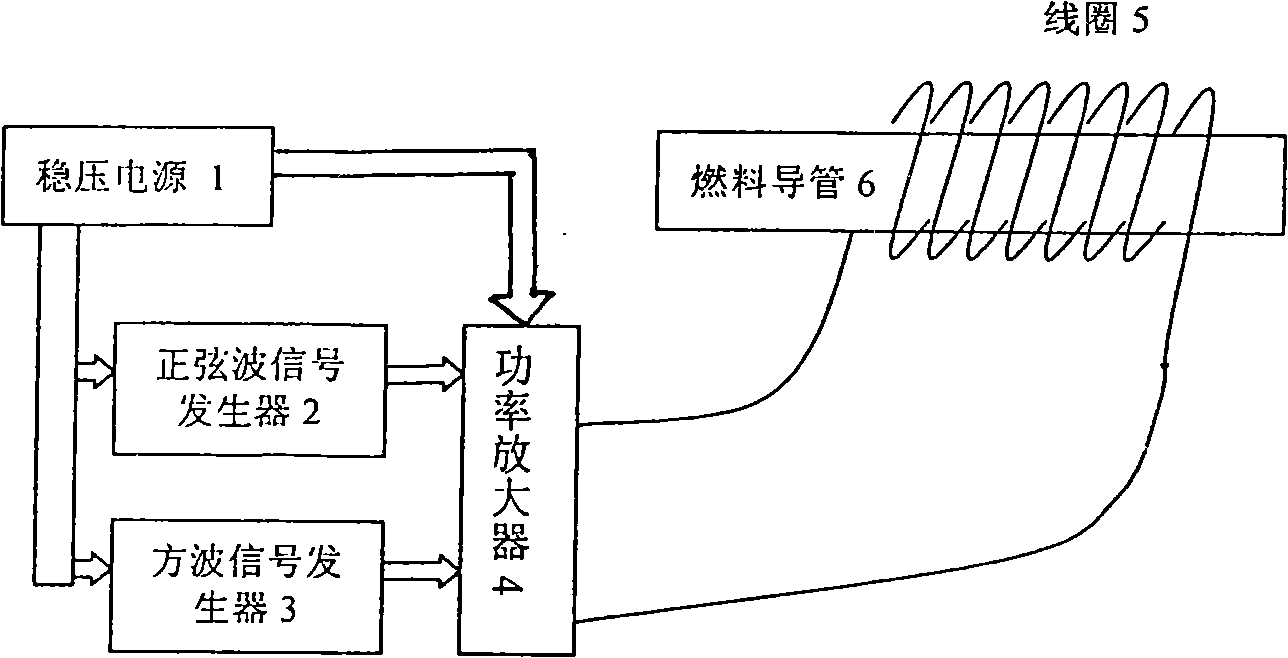

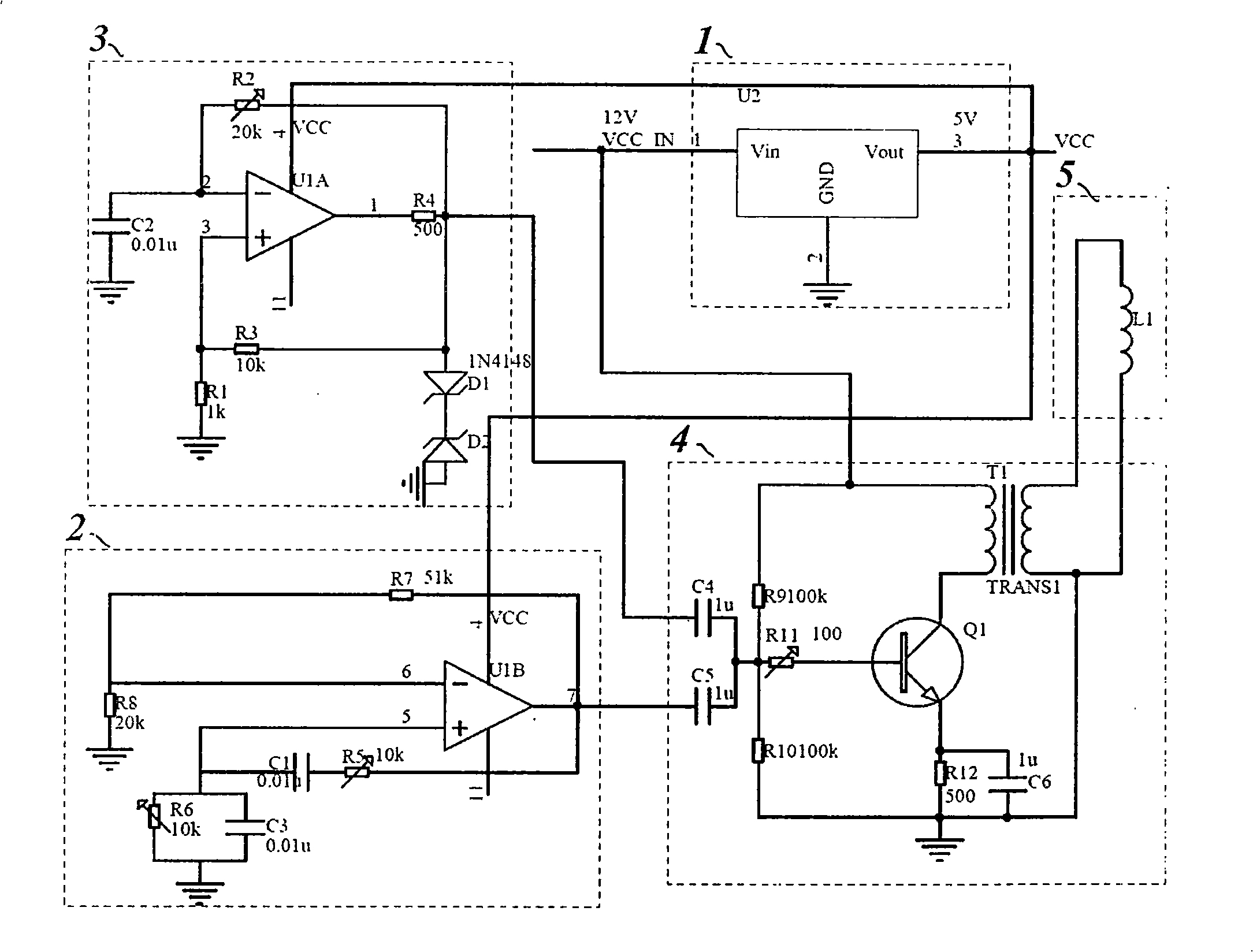

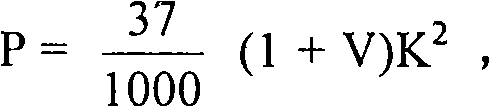

Fuel oil, gas energy-saving fine purification method and device

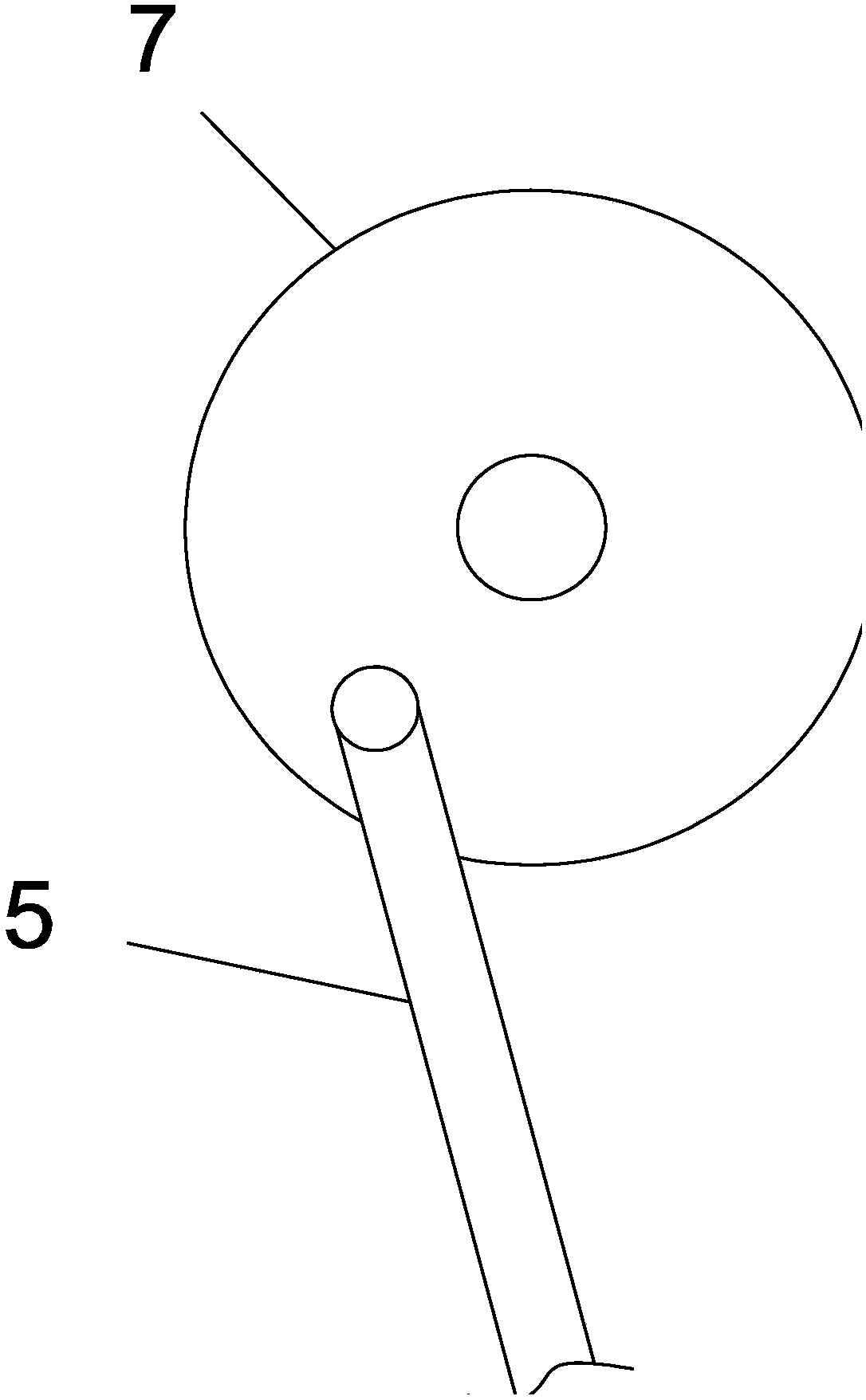

ActiveCN101270710AIncrease granularityBurn fullyInternal combustion piston enginesCombustion-air/fuel-air treatmentFuel oilEngineering

The present invention provides a fuel oil-gas energy-saving purifying processing method and a device thereof, which solves the problem of the prior method and device of not being capable of achieving ideal effect for liquid molecule morphological change. Liquid passes a conduit the outside of which is wrapped with a winding (5); the liquid passes the current power in watt of the winding (5) and then passes the alternating current on-off frequency in kHz. V is the flow of the liquid; the unit is g / s; M is the relative atomic weight of liquid molecule; K is the Van der Waals force constant of the liquid molecule.

Owner:陈良璞 +1

Device for recovery treatment of gypsum in orthopedic department

InactiveCN112403594AEffective fine-grained recyclingImprove refinement qualityCocoaGrain treatmentsMetallurgyPhysical chemistry

The invention discloses a device for the recovery treatment of gypsum in the orthopedic department. The device for the recovery treatment of the gypsum in the orthopedic department comprises a machinebody and is characterized in that a grinding space is formed in the machine body; a grinding mechanism used for grinding and refining the gypsum is arranged in the grinding space; a functional spaceis formed in the lower side of the grinding space; a screening mechanism used for screening refined gypsum is arranged in the functional space; a separation space is arranged on the left side of the functional space; a separation mechanism is arranged in the separation space and used for reducing adhesion between the gypsum and bandages; and the upper side wall of the separation space communicateswith a crushing space with an upward opening. According to the device for the recovery treatment of the gypsum in the orthopedic department provided by the invention, the gypsum can be effectively refined and recycled, and meanwhile, the gypsum bandages are prevented from being mixed into gypsum powder, so that the gypsum refining quality is greatly improved; and meanwhile, the gypsum powder is prevented from remaining on a grinding disc, so that the waste of gypsum powder adhesion is reduced, meanwhile, the grinding quality can be greatly improved, and the gypsum refining degree is increased.

Owner:赵炎

Culture method of aerobiotic active sludge

ActiveCN105417690AShorten the formation timeSimple methodNature of treatment waterSustainable biological treatmentSludgeWastewater

The invention discloses a culture method of aerobiotic active sludge, and belongs to the technical field of sludge culture. The method includes the steps that firstly, fresh moss is introduced into a septic tank, and anaerobic fermentation is performed till the moss turns yellow and black; secondly, cultured biological bacteria are introduced into the septic tank after fermentation, so that the surface of the fermented matter is covered with a layer of white hyphae and is in a slurry state; thirdly, kieselguhr is introduced into wastewater, stuffy exposure treatment is performed, then the prepared fermented matter in the slurry state is put into the wastewater, stuffy exposure treatment is performed again, and the faint yellow active sludge can be obtained. As proved by the embodiment, the formation time of the aerobiotic granular sludge is shortened by 80-85%; besides, the prepared sludge is high in granulation degree, a large amount of flocculent sludge is avoided, and thus the capacity in the wastewater treatment process is significantly improved.

Owner:重庆清禧环保科技有限公司

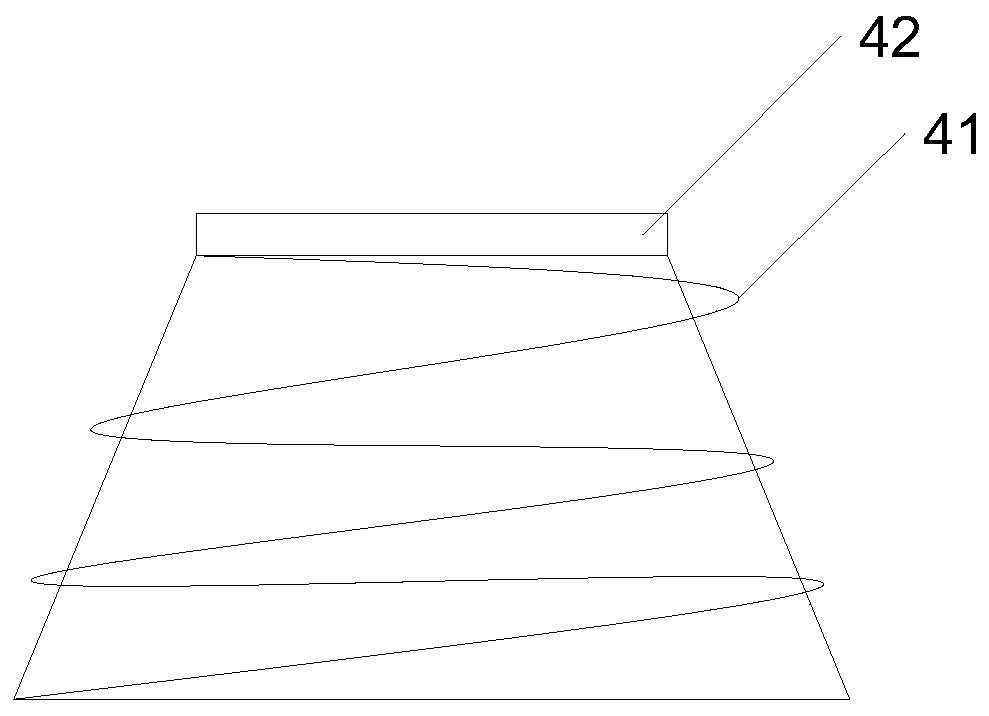

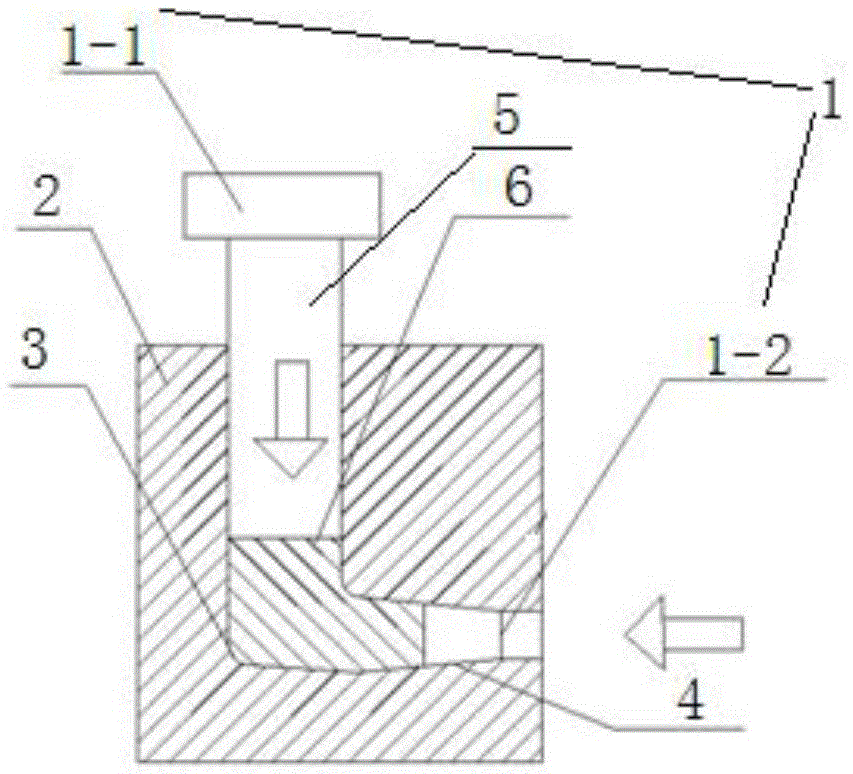

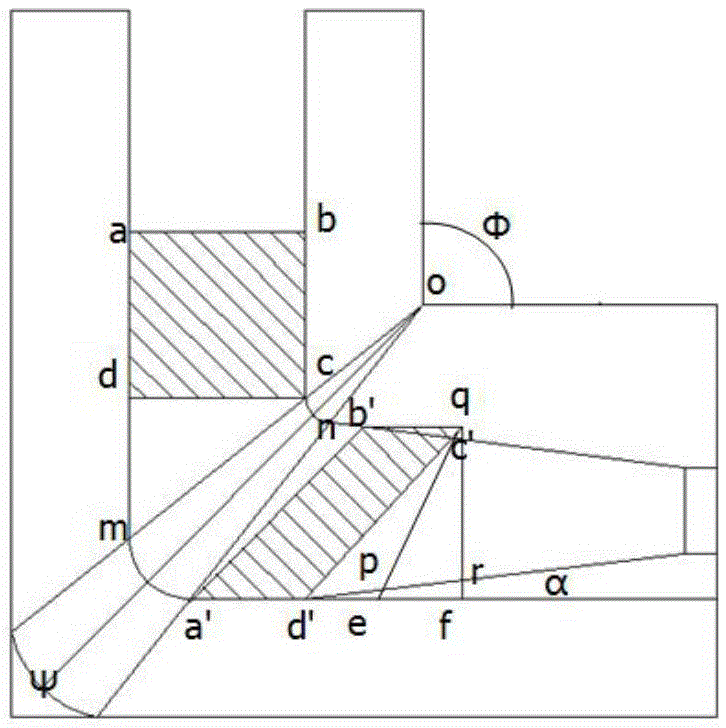

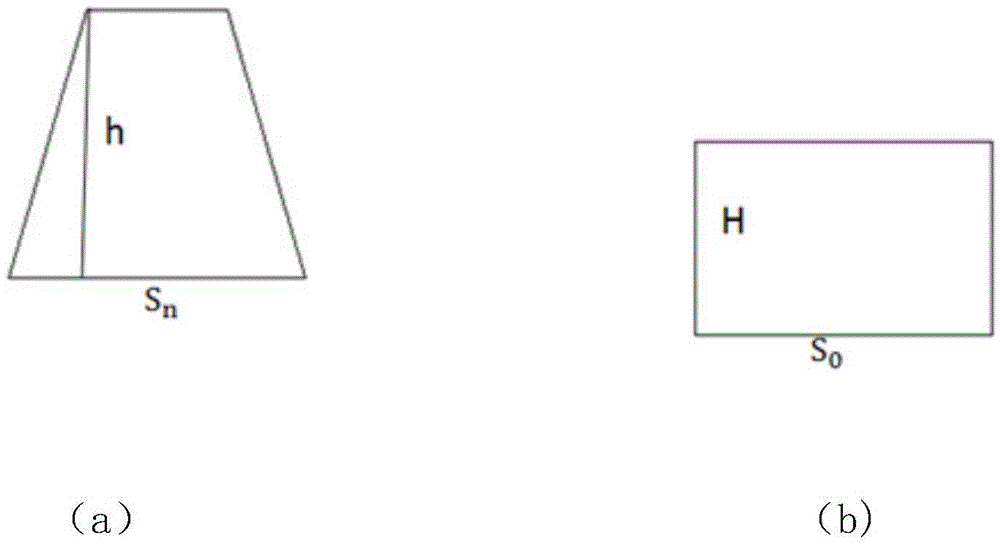

Device for preparing fine grains through variable section angular pressing and method thereof

The invention discloses a device for preparing fine grains through variable section angular pressing and a method thereof. The device comprises a die and a pressing rod. A cylindrical die cavity and a circular truncated cone die cavity are formed in the die. The taper of the circular truncated cone die cavity is alpha. The cylindrical die cavity and the circular truncated cone die cavity communicate mutually. A turn angle is formed in the connection position of the cylindrical die cavity and the circular truncated cone die cavity. Under the action of the pressing rod, a pressed workpiece reciprocates in the cylindrical die cavity and the circular truncated cone die cavity. According to the device disclosed by the invention, the cylindrical die cavity and the circular truncated cone die cavity are combined; the turn angle is formed, so that the pressed workpiece is subjected to continuous integral pressure in the turn angle position, pressing deformation force exerted on the pressed workpiece is more uniform under shear stress, and the grains are improved in fineness and more uniform. Through the pressing method disclosed by the invention, the conditions of nonuniform deformation and even non-deformation of the middle of the workpiece in the cyclic variable section pressing process are eliminated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

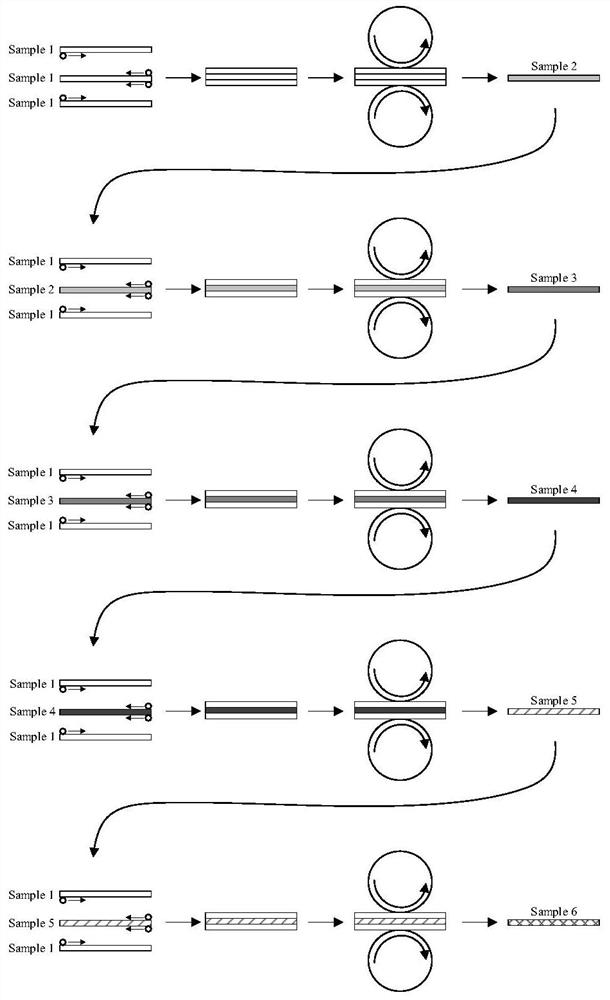

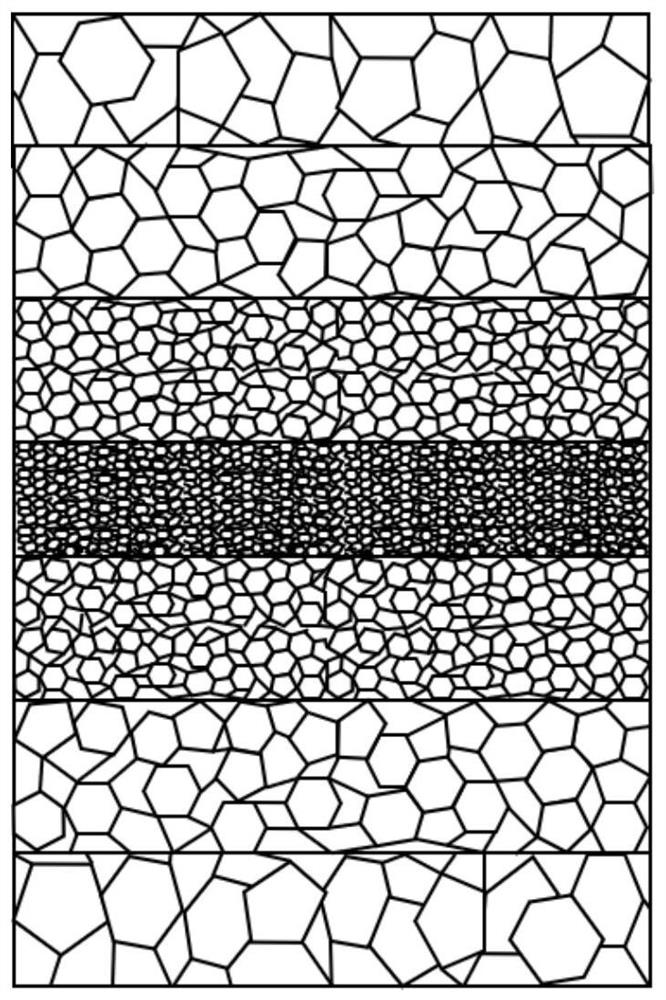

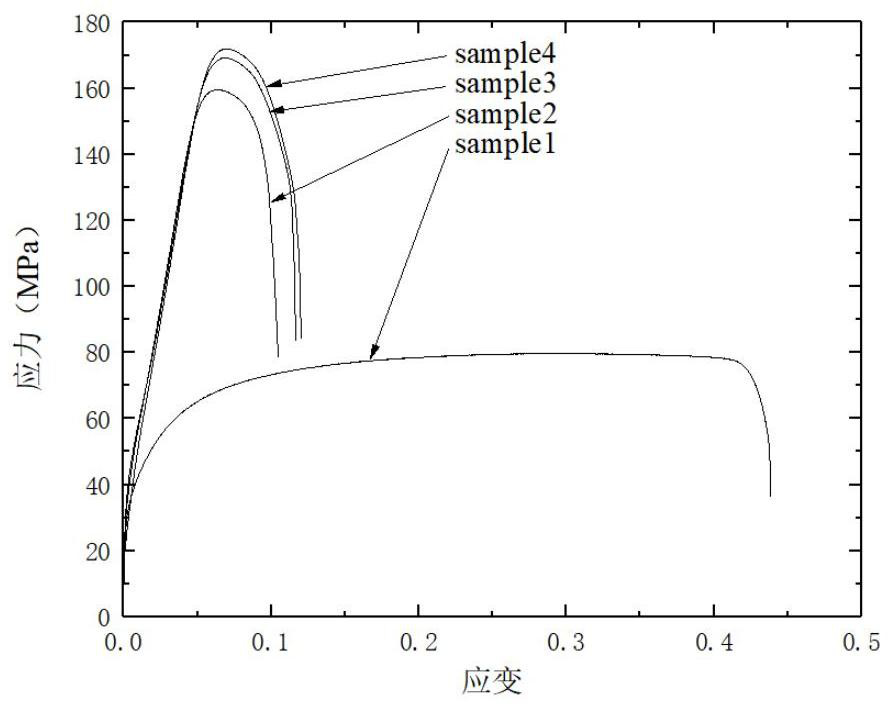

Method for preparing gradient structure metal material through incremental-cumulative ply rolling

ActiveCN112845587AIncrease productivityIncrease granularityAuxillary arrangementsMetal rolling arrangementsMetallic materialsToughness

The invention provides a method for preparing a gradient structure metal material through incremental-cumulative ply rolling. The method comprises the steps of a) selecting five or more metal plates in the same specification, and carrying out heat treatment on the plates; b) treating to-be-combined surfaces of the plates obtained after heat treatment; c) carrying out ply rolling on three treated plates to serve as core layers; d) placing another two treated plates on the upper surface and the lower surface of the material obtained through ply rolling correspondingly and machining the two treated plates and the material obtained through ply rolling till the sizes of the two treated plates and the size of the material obtained through ply rolling are the same; e) rolling the three layers of plates stacked together so as to complete one time of incremental-cumulative ply rolling; and f) repeating the step d and the step e, and carrying out 3-5 times of incremental-cumulative ply rolling passes so as to obtain the required gradient structure plates. Through the incremental-cumulative ply rolling method, the refining degree gradient of the microstructure of the material from the surface layers to the cores is adjusted and controlled to be increased, and thus the material has high strength and good toughness.

Owner:CENT SOUTH UNIV

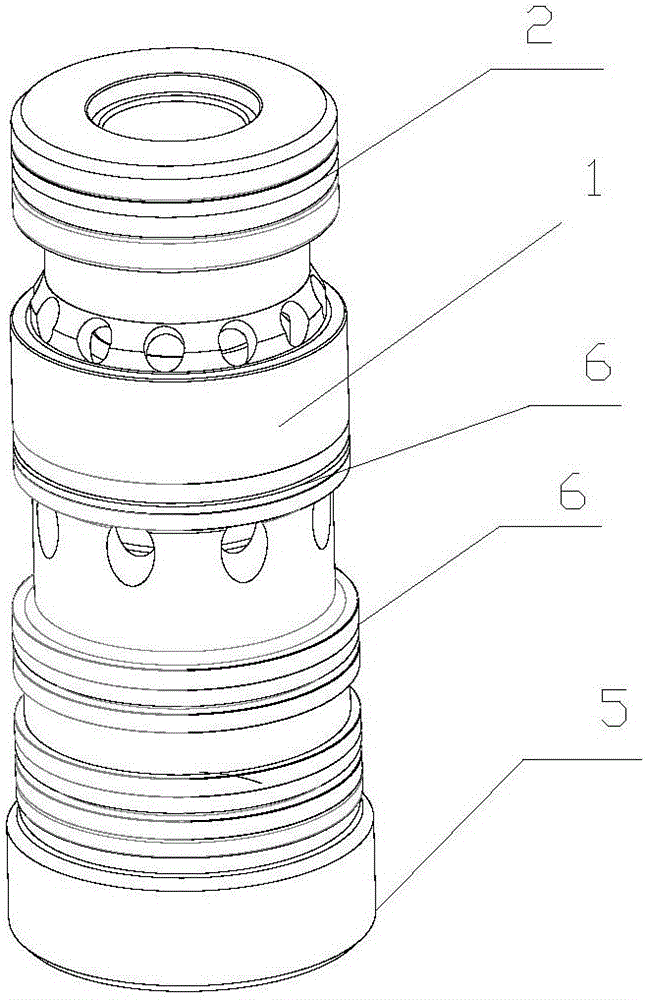

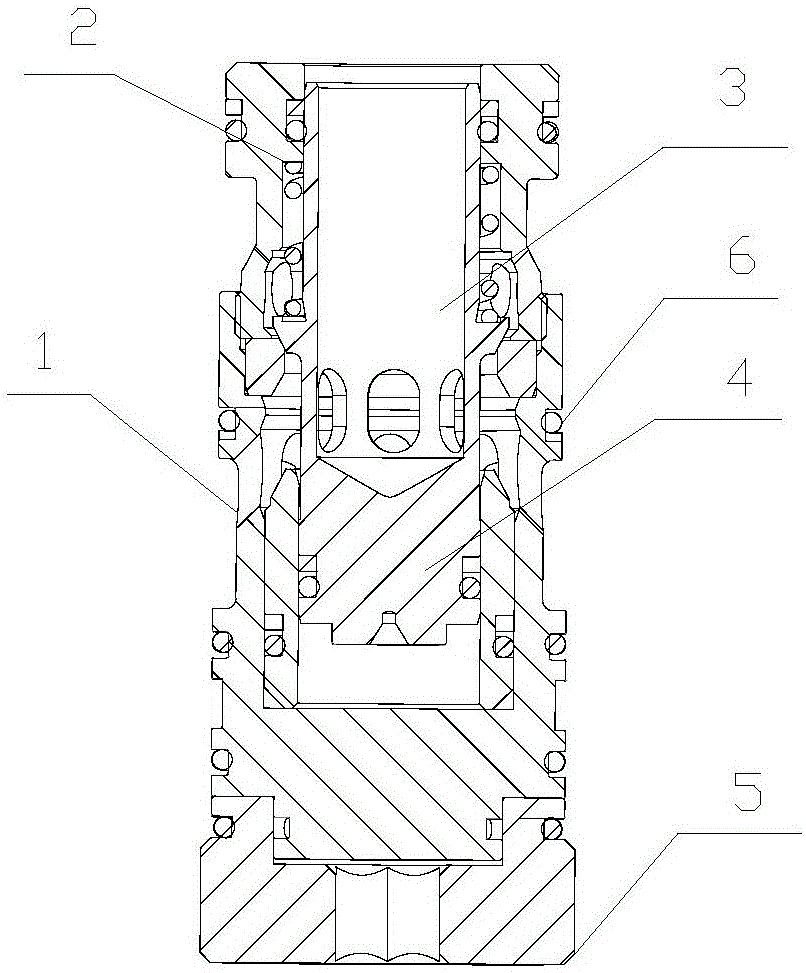

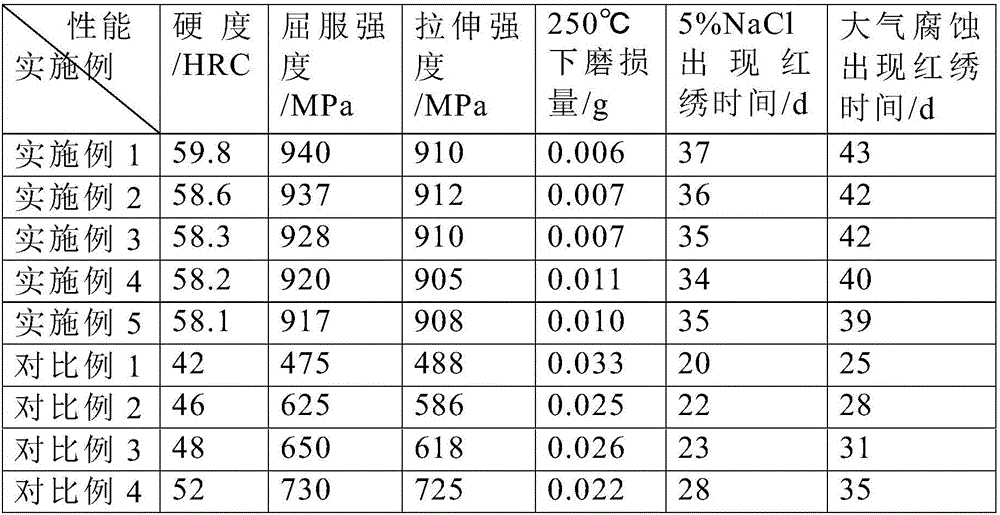

Main valve element for reversing valve

InactiveCN106286885AImprove performanceImprove organizational stabilityServomotor componentsMultiple way valvesMechanical engineeringToughness

The invention relates to a main valve element for a reversing valve. The main valve element comprises a lower valve sleeve, a valve element and an upper valve sleeve internally provided with a piston. The lower valve sleeve is inserted into the upper valve sleeve to be connected with the upper valve sleeve. The valve element is located in the lower valve sleeve and stretches into the piston. The upper valve sleeve is provided with an opening which is covered with an end cover. The upper valve sleeve, the lower valve sleeve and the valve element are all made of alloy steel. The alloy steel comprises 0.10-0.15% of C, 1.5-2.0% of Cr, 0.22-0.35% of Si, 0.8-1.2% of Mn, 0.045-0.06% of Al, 0.03-0.05% of N, 0.25-0.35% of Mo, 0.025-0.04% of Cu, 0.005-0.022% of S, 0.08-0.15% of V, 0.08-0.15% of RE, no more than 0.015% of P and the balance Fe. The main valve element is high in toughness and good in anti-tempering stability, cold-hot-fatigue resistance and high-temperature abrasion resistance.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com