Method for producing low-carbon steel or low-alloy steel plate having submicron crystal grain

A low-alloy steel and manufacturing method technology, applied in the field of low-carbon steel or low-alloy steel plate manufacturing, can solve problems such as plastic instability, low uniform tensile elongation, complex manufacturing process, etc., and achieve a relaxed microstructure. requirements, good microstructure stability, and the effect of small grain growth tendency

Active Publication Date: 2005-01-19

BAOSHAN IRON & STEEL CO LTD

View PDF2 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the matrix phase grains are so fine (average size below 0.2 μm), the Achilles’ heel—plastic instability, which has only a small work hardening effect after yielding—results in low uniform tensile elongation. rate and high yield strength ratio (the ratio of yield strength to tensile strength is often higher than 0.9) [Jingtianfu et al. Journal of Materials Science Letters, 16(1997): 485, Tsuji et al. Scr.Mater., 46(2002): 305 ]

Therefore, iron and steel materials with too fine matrix phase grains are not only difficult or expensive to manufacture, but also have serious defects and application limitations.

To sum up, among the existing methods for preparing various submicron grain steels, some do not have large-scale industrial production; some have insurmountable difficulties in the implementation of large-scale industrial production, such as the manufacturing process is too complicated, the equipment The process requirements are too high, and there are certain requirements for the thickness of the original blank, so it stays in the non-production stage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

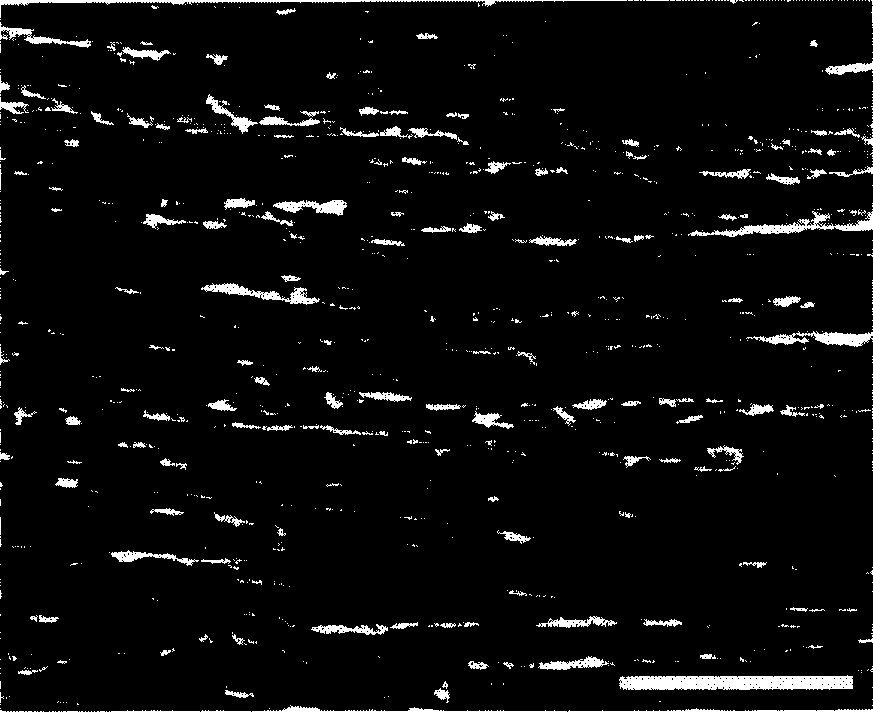

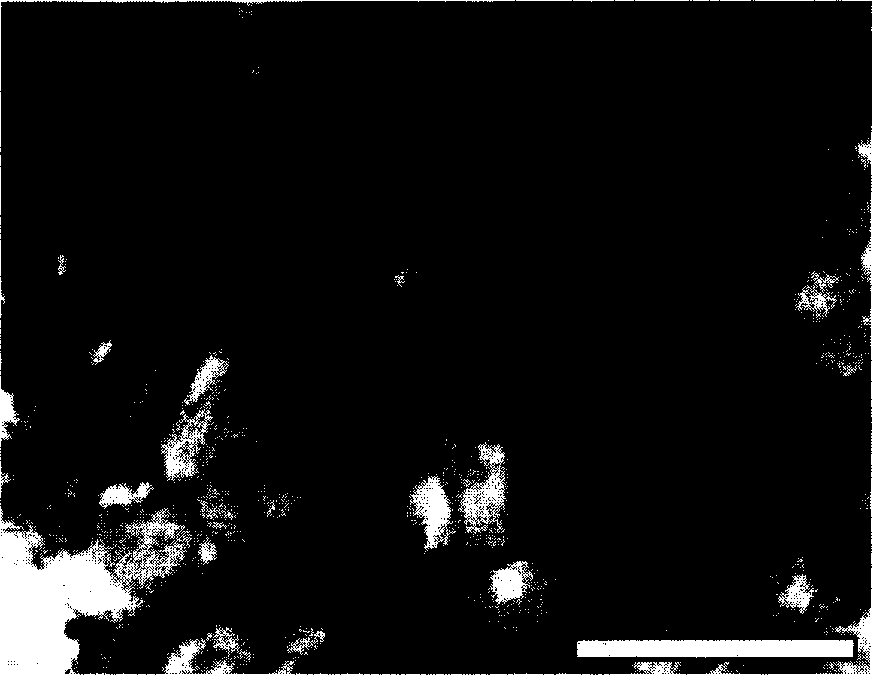

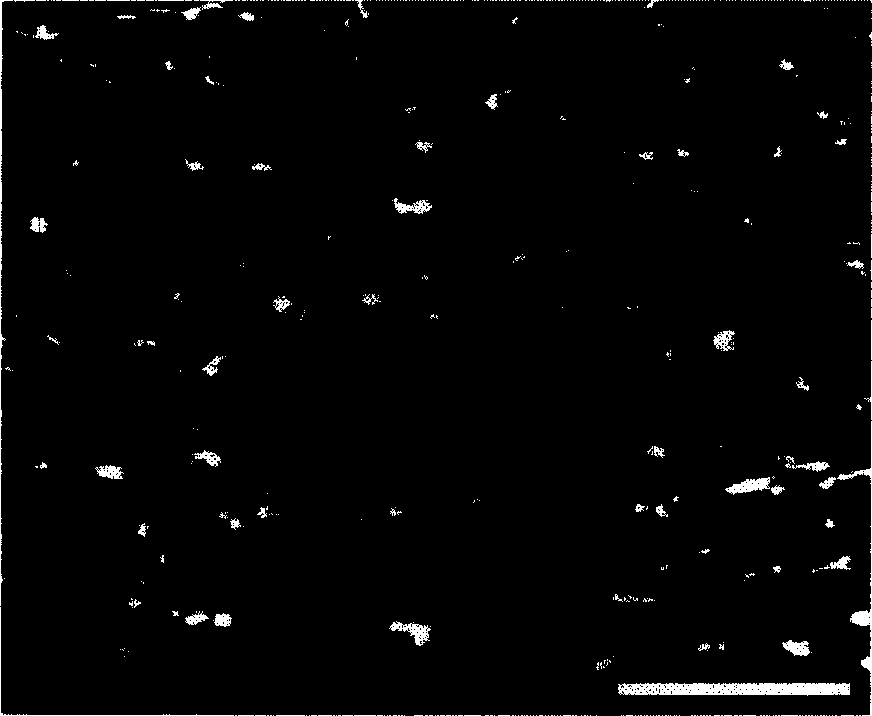

[0033] See Table 1 for the chemical composition of the steel plates in Examples EX1-8, and see Table 2 for the parameters of the process conditions. Samples are taken at the center of the steel plate thickness, and analyzed using a scanning electron microscope (SEM) and a transmission electron microscope (TEM) to observe the grain size and morphology of the submicron grain steel plate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for producing low-carbon steel or low-alloy steel plate having submicron crystal grain which comprises the steps of, subjecting the raw steel billets to austenizing treatment above Ac3 temperature, hot-rolling at the temperature of over Ar3, fast cooling after rolling, performing warm-rolling or cold rolling at the temperature range from 600 deg. C. to room temperature, direct cooling or roll bending after rolling.

Description

technical field [0001] The invention relates to a method for manufacturing low-carbon steel or low-alloy steel plate, in particular to low-carbon steel or low-alloy steel with submicron grains (that is, grain diameters within the range of 1.0 μm to 0.1 μm). Background technique [0002] Low carbon steel and low alloy steel are the most widely used steel grades in the application field of steel materials. In order to improve the strength of steel, it is common practice to add alloying elements such as Mn and Si or perform controlled rolling, controlled cooling, heat treatment, etc., or add microalloying elements such as Nb and V. However, for steel, it is not only required to have high strength, high toughness and other good comprehensive properties, but also to consider resource conservation (less alloy elements) and sustainable use (easy to recycle). Grain refinement is one of the few effective means. However, most of the existing manufacturing methods for industrialized ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D8/04

Inventor 毕刚宋洪伟史弼张俊宝曹涵清

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com