Patents

Literature

306results about How to "Improve organizational stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

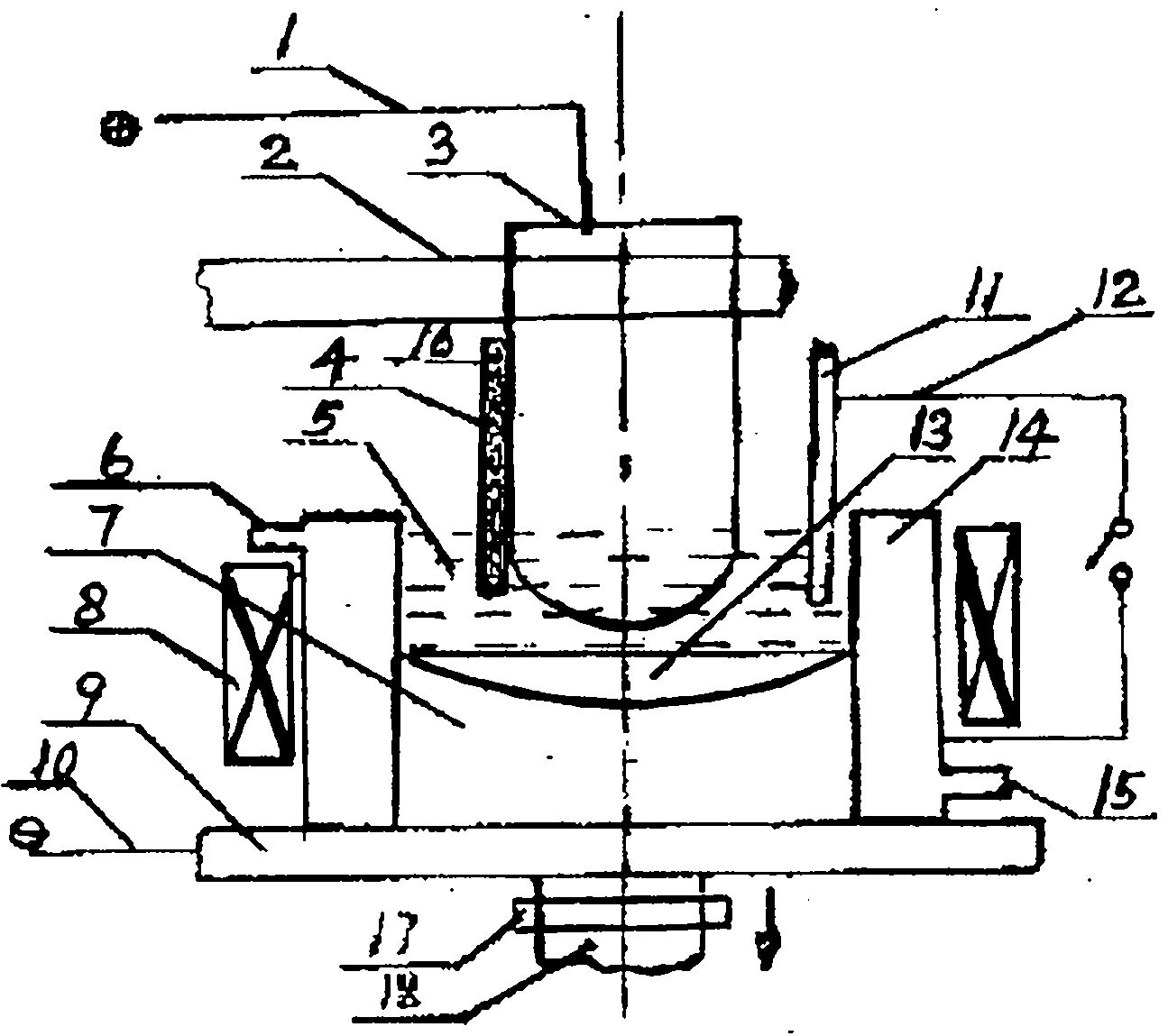

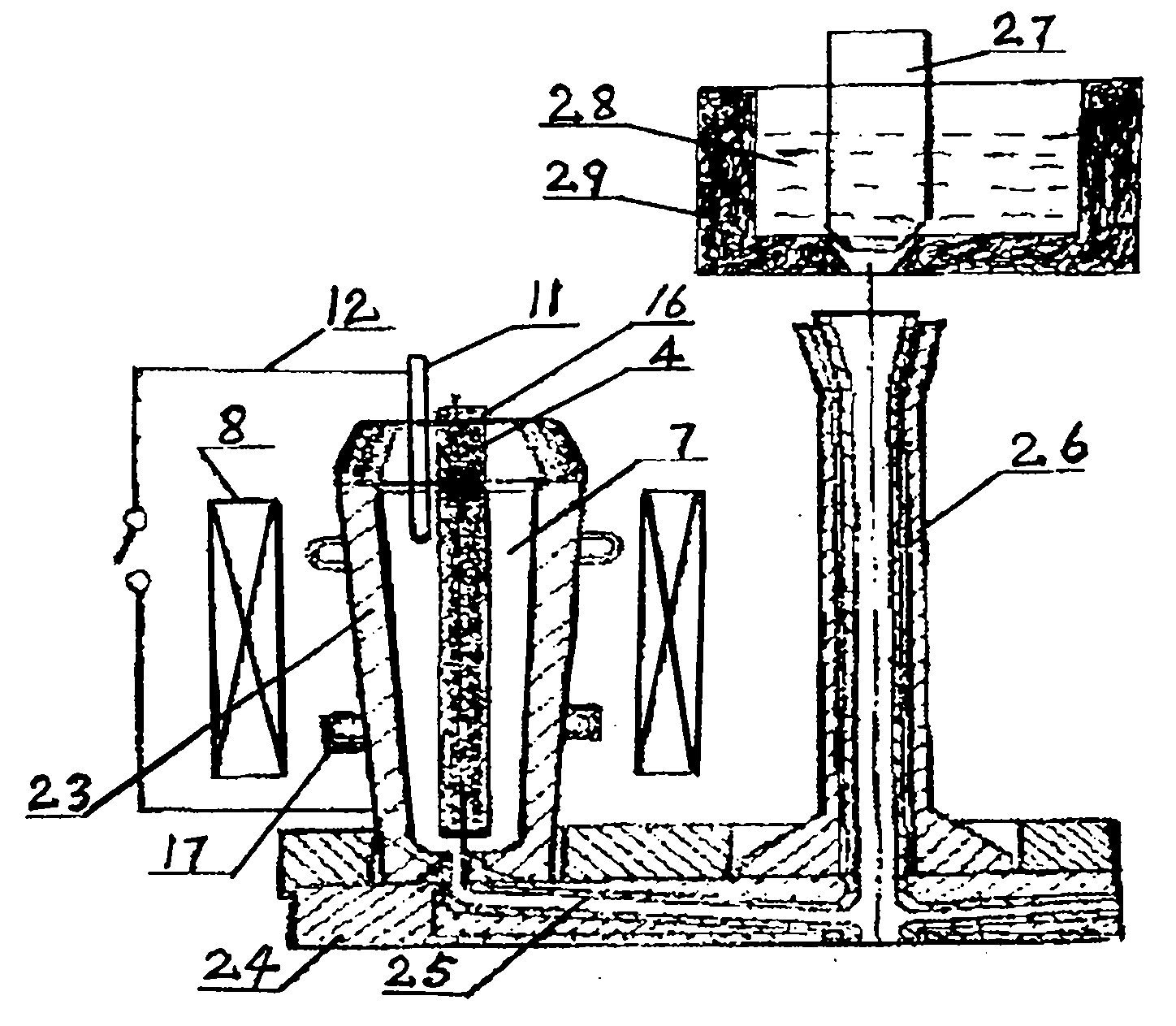

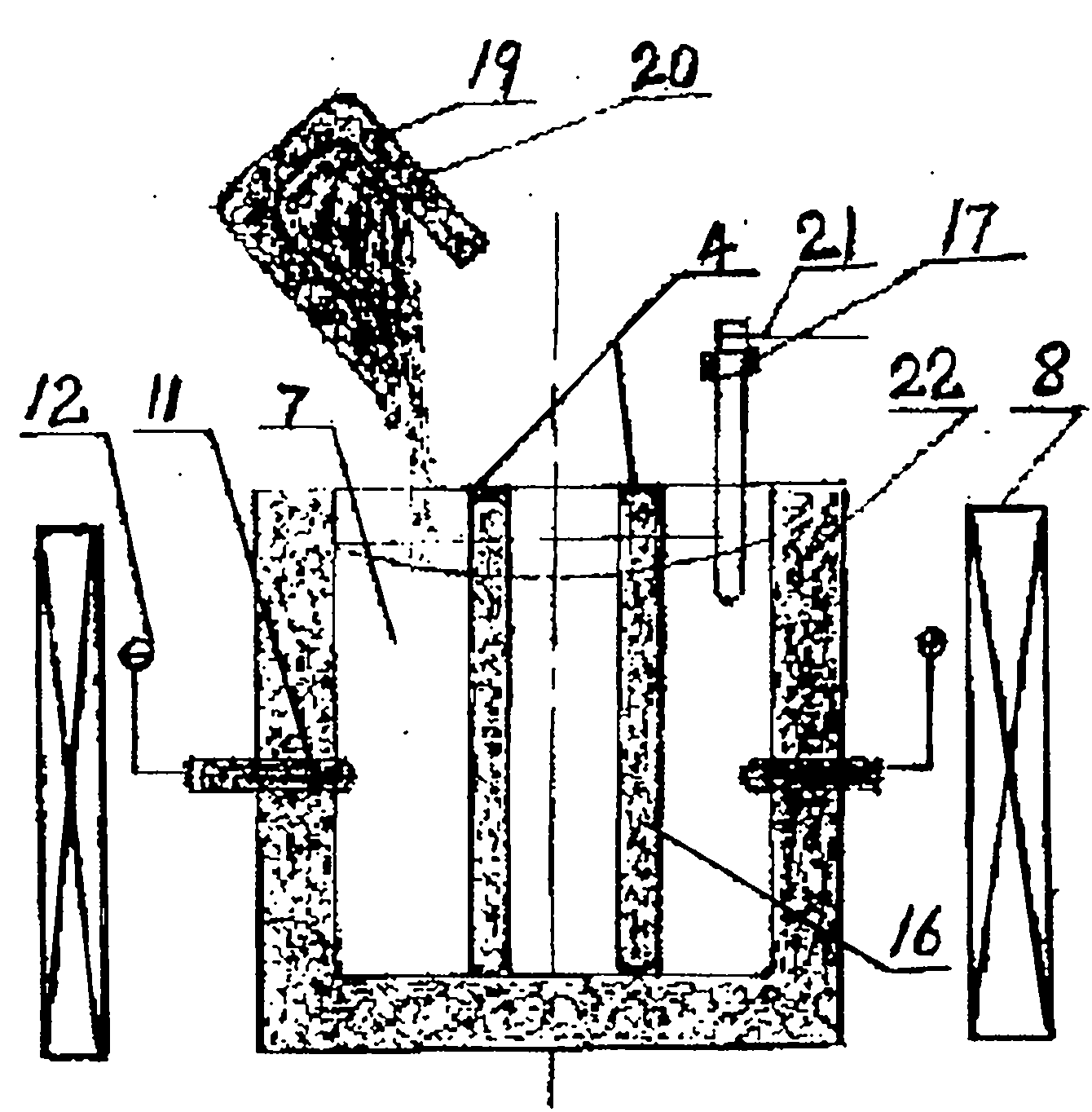

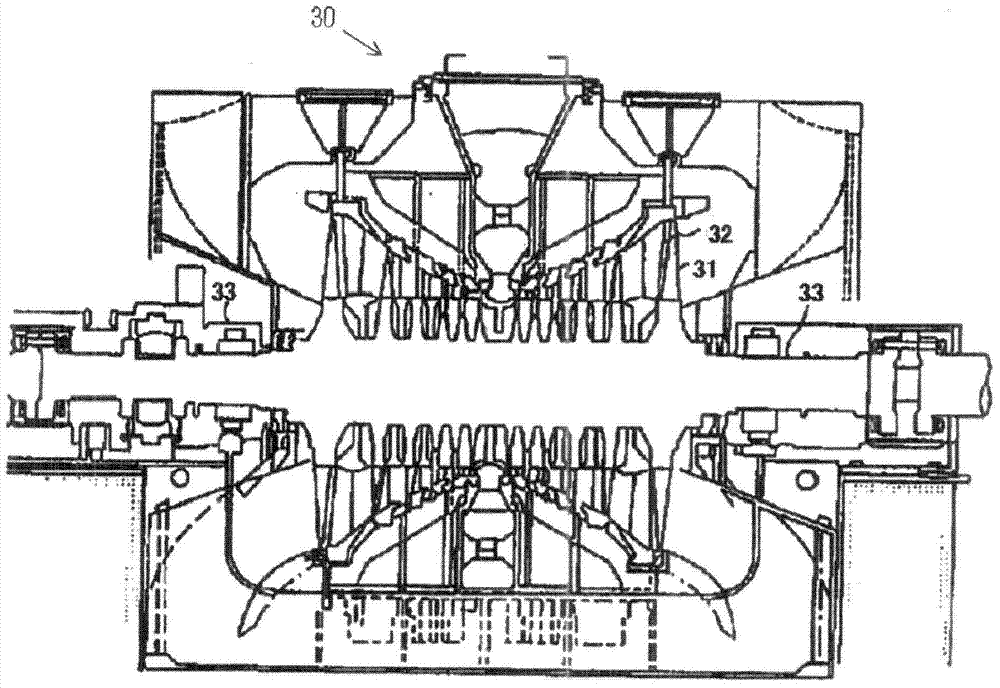

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

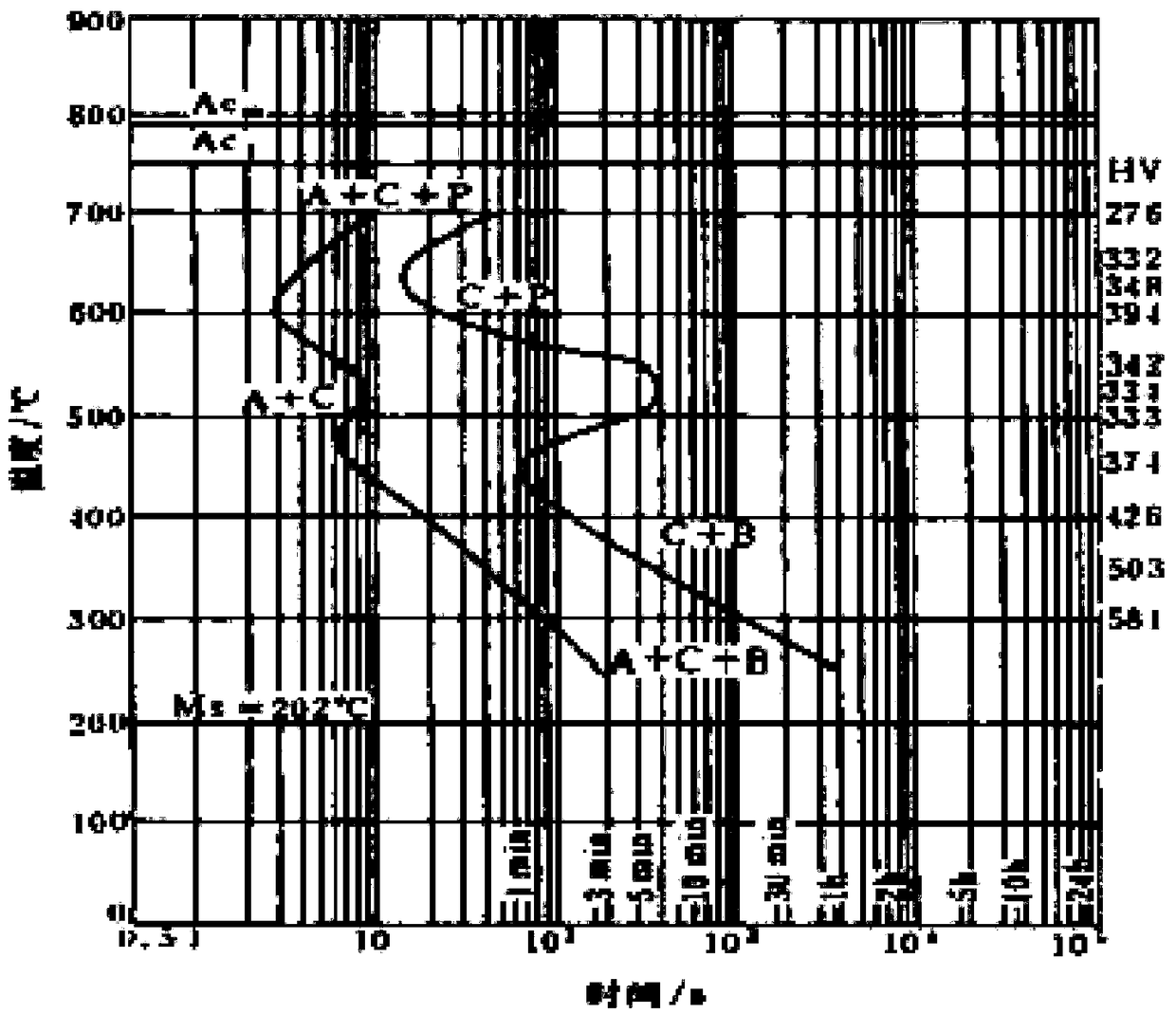

Wearproof and tough quasi bainite points and rails and their production

A high-strength and high-toughness antiwear quasi-bainite rail for switch contains C (0.1-0.4 wt.%), Si (0.8-2.0), Mn (0.8-3.3), Cr (0-2.0), Mo (0.1-0.8), N (10-150 ppm), Al (0-0.005) and Fe (rest), and is made up through smelting in converter, reinfing, treating with RE, vacuum degassing, conticasting, rolling, air cooling to 400 deg.C, slow cooling to 200 deg.C and natural cooling. Its advantages are uniform hardness in cross section, high strength, toughness and stability, and high antiwear performance.

Owner:ANGANG STEEL CO LTD +1

Fresh and cool enzymolysis grain beverage and preparation method thereof

The invention provides a fresh and cool enzymolysis grain beverage and a preparation method thereof, relating to a non-alcoholic beverage. The invention aims to provide a fresh and cool enzymolysis grain beverage which retains original nutrition and functional components of grains and is fine, fresh and cool in taste, stable in product composition and low in viscosity, and a preparation method thereof. The beverage is prepared from the following raw materials: 8-12% of grains, 0.01-0.2% of sodium citrate, 0.01-0.4% of emulsifier, 0.05-0.5% of stabilizer, 1.0-2.3% of processing auxiliary agent and the balance of water. The preparation method comprises the steps of: pre-cooking or baking the grains, carrying out colloid milling and homogenizing, adding the processing auxiliary agent, carrying out enzymolysis, then inactivating the enzyme, separating, and filtering to obtain coarse fiber and a material liquid C; adding the material liquid C, sodium citrate, emulsifier and stabilizer to hot water, diluting to certain volume with blending water to obtain a blended liquid, cooling, then conveying to an ultrahigh-temperature instantaneous sterilizing system, preheating, degassing, homogenizing, and then carrying out ultrahigh-temperature instantaneous sterilizing; and filling the blended liquid after ultrahigh-temperature instantaneous sterilizing, and then packaging.

Owner:XIAMEN HUIERKANG FOOD

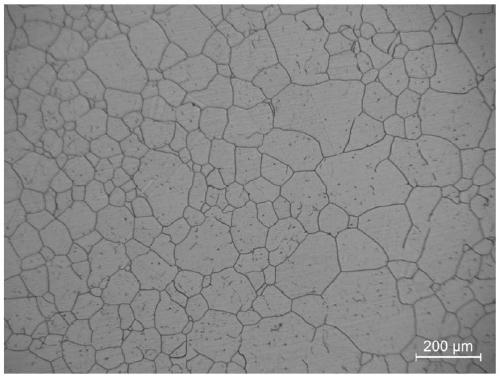

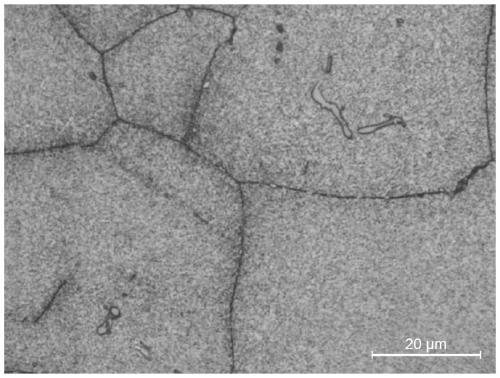

Gamma''strengthened high performance casting nickel-based high-temperature alloy

ActiveCN101372730AMeeting the needs of precision casting casingsImprove organizational stabilityStructural stabilityAero engine

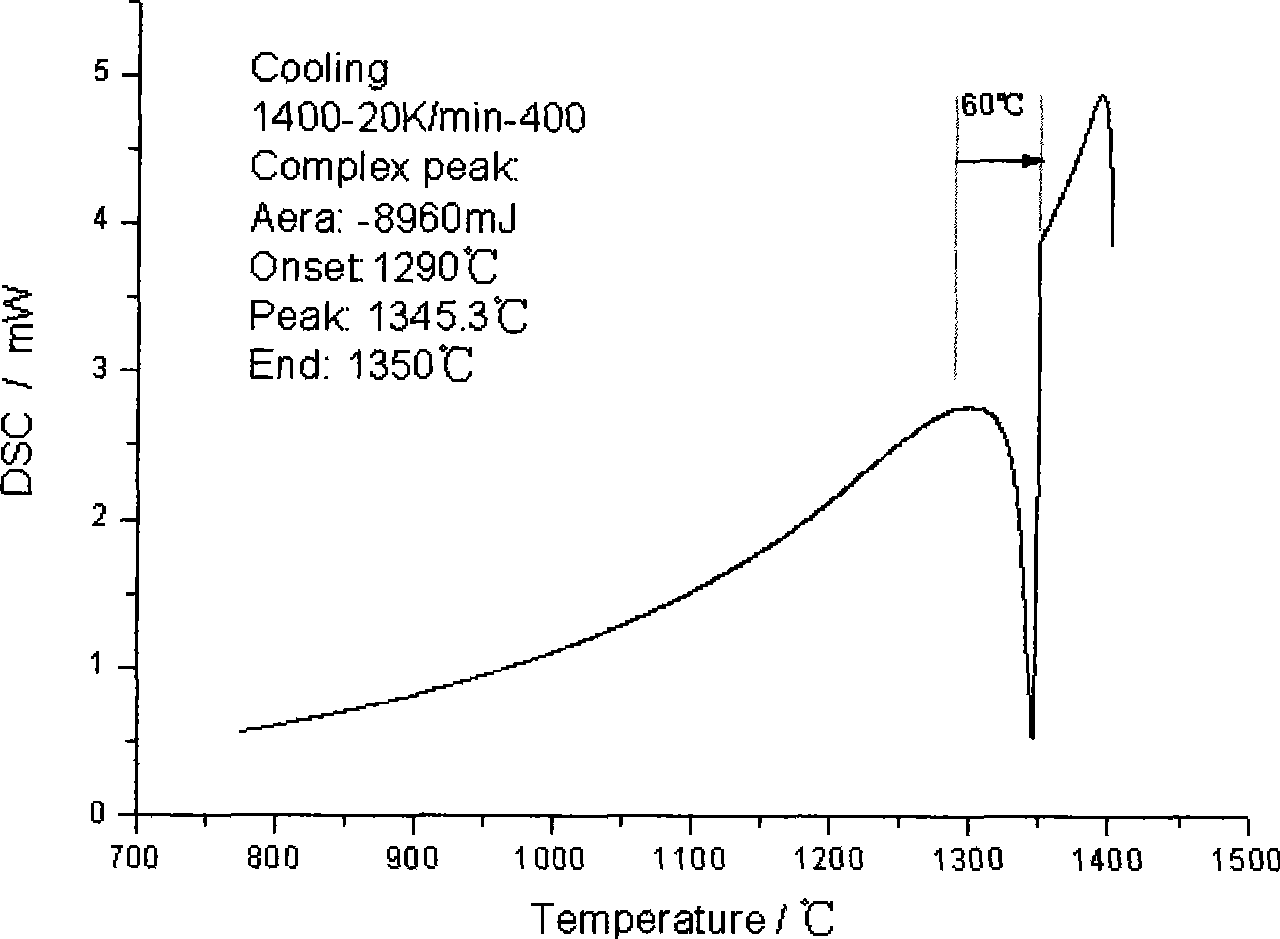

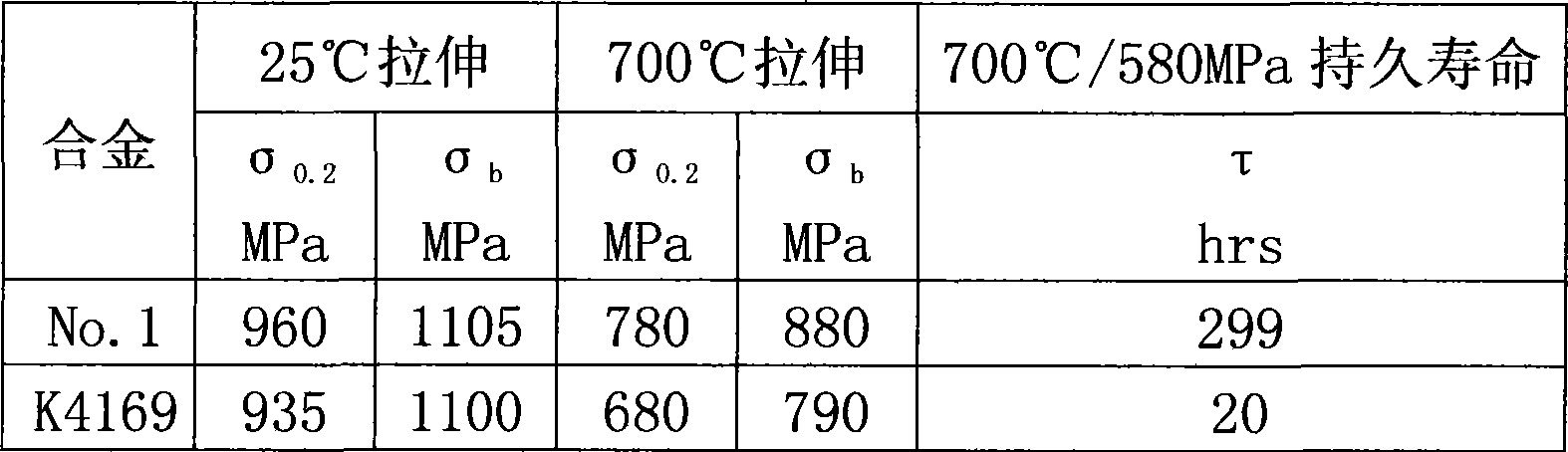

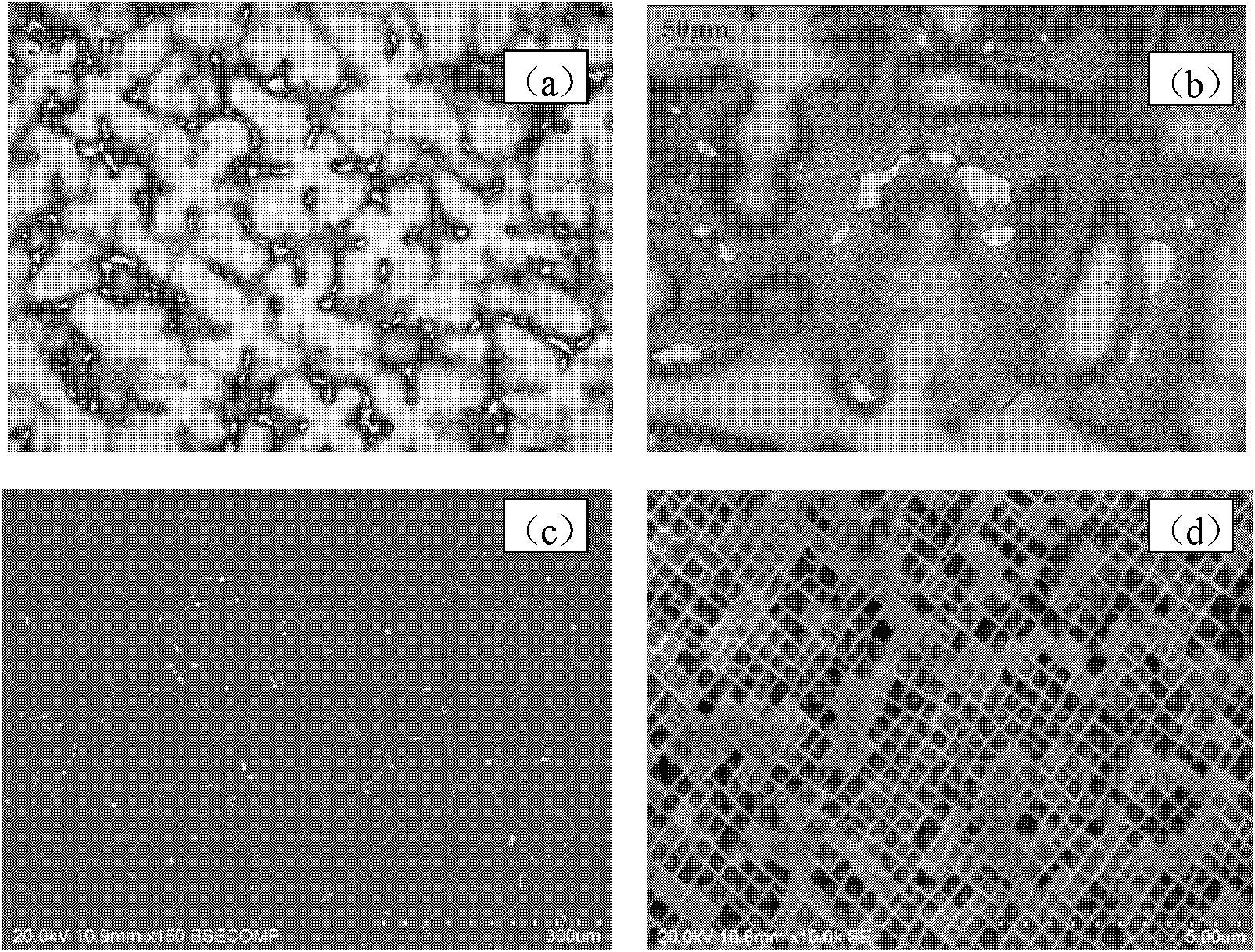

The invention provides a gamma' intensified high-performance cast nickel-based high-temperature alloy, which is characterized in that the alloy comprises the compositions by weight percentage as follows: 0.007 to 0.07 percent of C, 0.007 to 0.09 percent of B, 0 to 0.10 percent of Ce, 0 to 0.10 percent of Y, 10.0 to 15.0 percent of Co, 15.0 to 20.0 percent of Cr, 1.0 to 4.0 percent of Mo, 0.2 to 3.0 percent of Al, 0.5 to 3.0 percent of Ti, 0 to 3.0 percent of W, 2.0 to 6.0 percent of Nb, 0 to 6.0 percent of Ta, and the residual amount of Ni, wherein, the contents of impurities by weight percentage are as follows: less than or equal to 0.01 percent of S, less than or equal to 0.01 percent of P, less than or equal to 0.2 percent of Si, less than or equal to 0.0005 percent of Pb, less than or equal to 0.0001 percent of Bi, less than or equal to 0.2 percent of Mn, and less than or equal to 0.5 percent of Fe. The invention changes the alloying compositions, not only has higher high-temperature mechanical performance, but also has excellent long-term application structural stability at 700 DEG C, and can meet the requirement of a cartridge receiver of an airspace engine or an aero-engine with higher service temperature and higher performance requirement.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

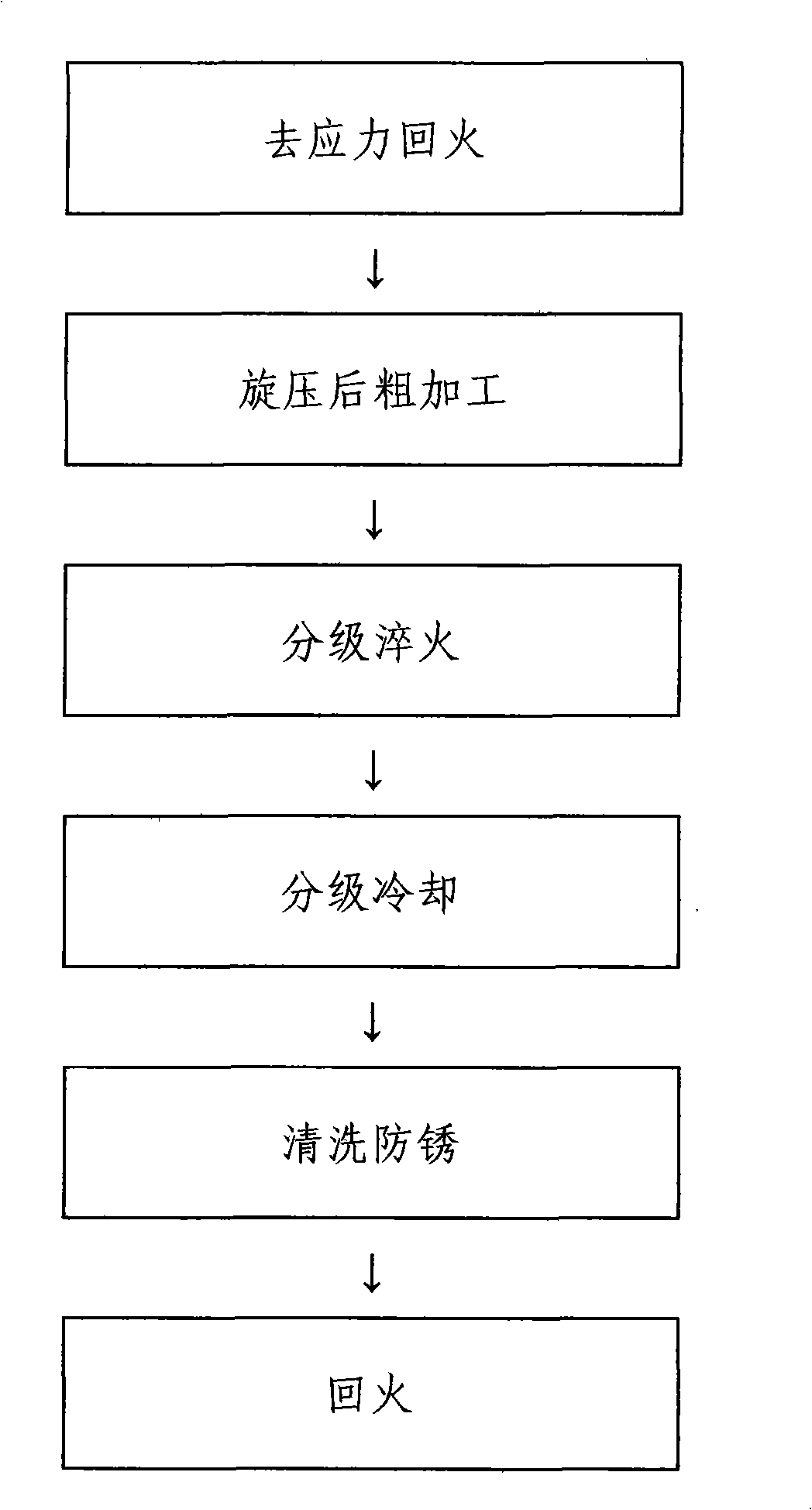

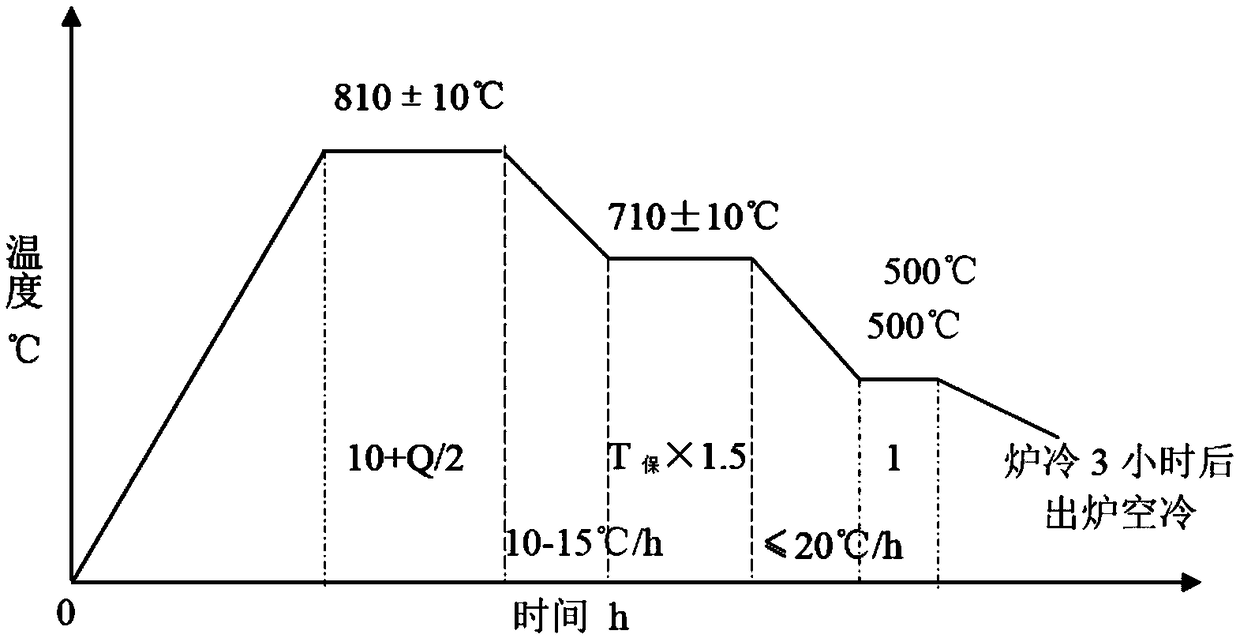

Composite heat treatment method for 30CrMnSiA steel thin wall spinning cylinder-shape element

InactiveCN101265514AImprove organizational stabilityEasy to processFurnace typesQuenching agentsQuenchingMachining

A compound heat treatment method of 30CrMnSiA steel to thin wall cylindrical shaped element with large diameter and thin wall thickness by spinning is characterized in that the method comprises a preferable 'stress tempering-interrupted quenching-tempering' heat treatment combination. The method comprises the steps of: stress tempering a workpiece while releasing the residual stress of the workpiece to a certain extent by controlling the tempering temperature and temperature holding time; conducting interrupted quenching by preheating, heating with a salt-bath furnace, cooling with a nitrate thermostatic bath and air cooling, washing to remove residual salt or alkaline liquid on the surface of the workpiece, and performing passivation and anti-corrosive treatment; and placing the workpiece into a well type tempering furnace or a special tempering furnace to conduct tempering treatment. The workpiece subjected to compound heat treatment has the advantages of high processing precision, high hydraulic pressure test strength, and low deformation liability of the following machining operation.

Owner:江南工业集团有限公司

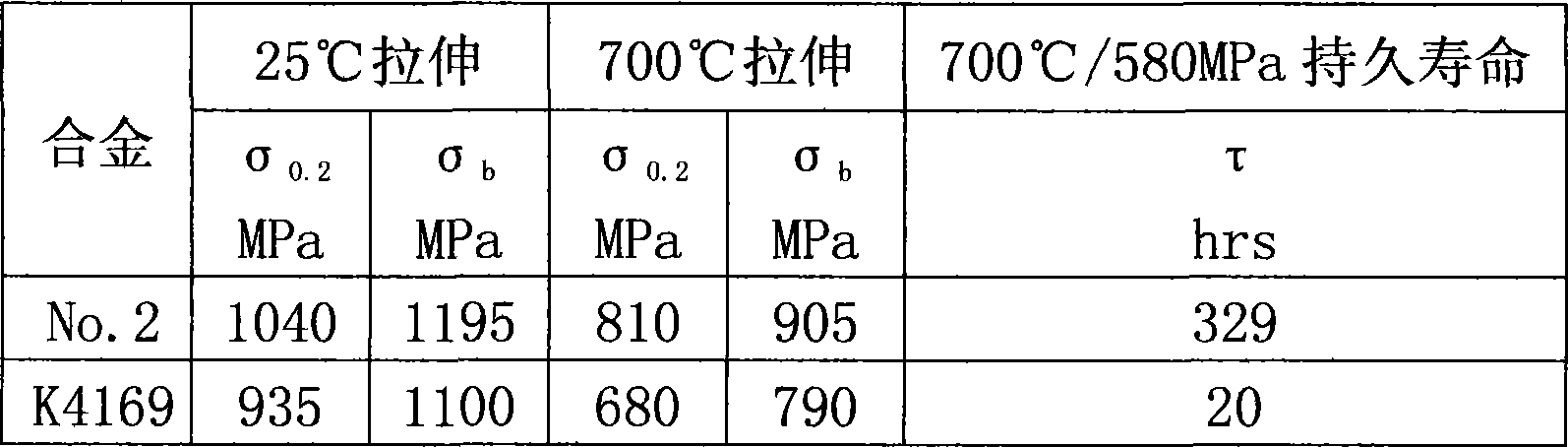

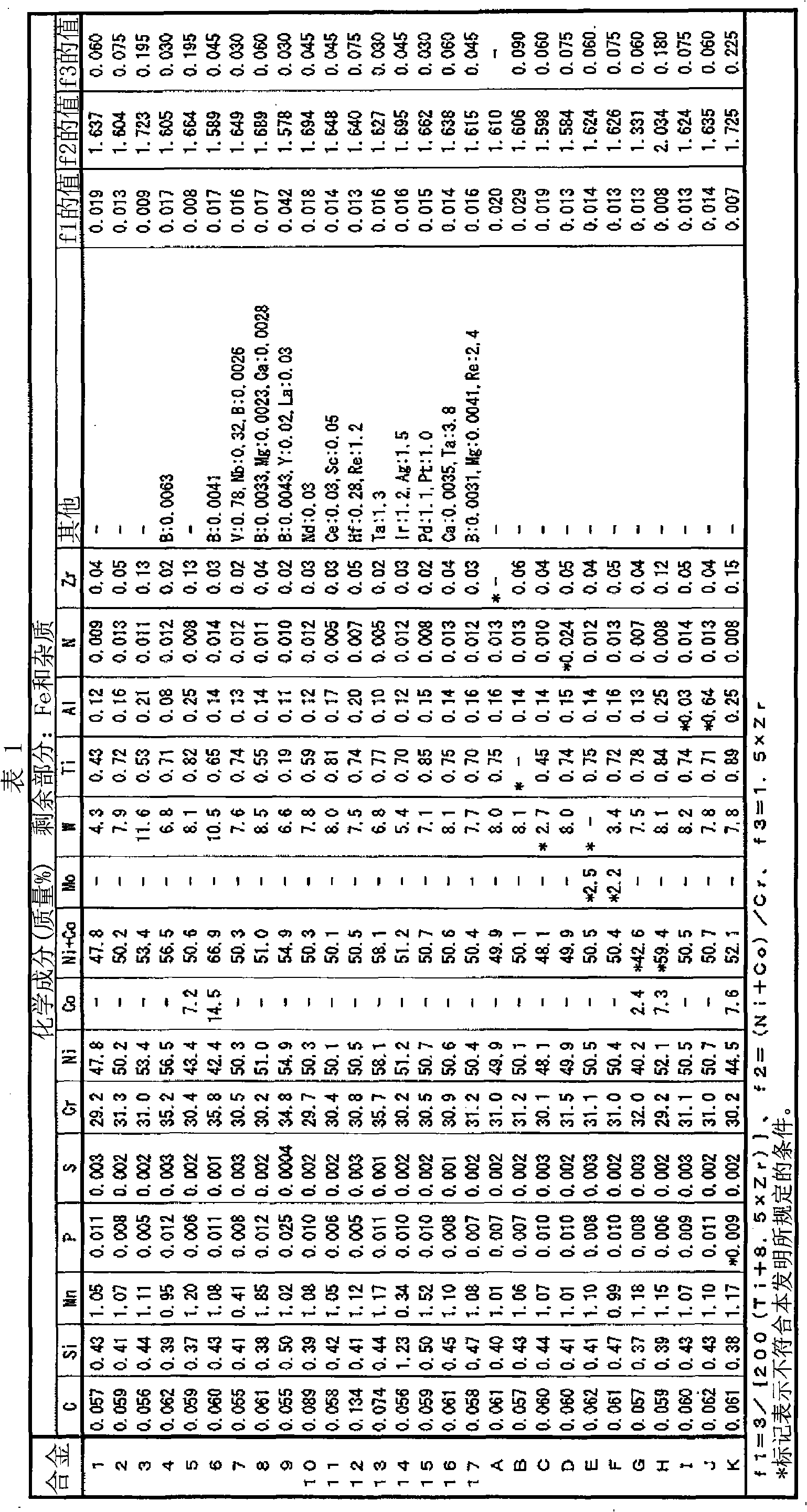

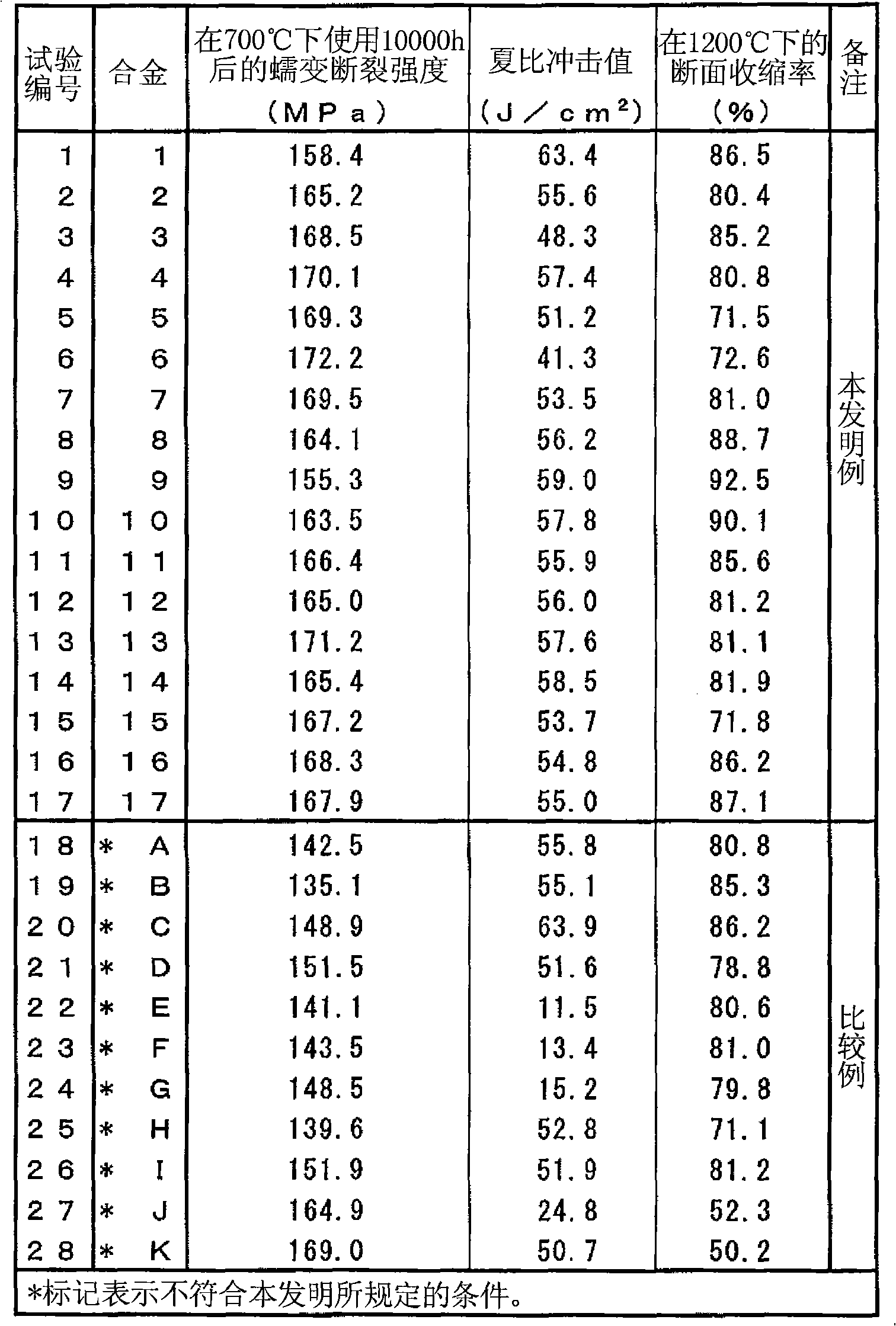

Heat-resistant austenitic alloy, heat-resistant pressure-resistant member comprising the alloy, and process for producing the same

A heat-resistant austenitic alloy which contains 0.02-0.15%, excluding 0.02%, C, up to 2% Si, up to 3% Mn, up to 0.03% P, up to 0.01% S, 28-38% Cr, 40-60%, excluding 40%, Ni, up to 20% (including 0%) Co, 3-15%, excluding 3%, W, 0.05-1.0% Ti, 0.005-0.2% Zr, and 0.01-0.3% Al and has a N content up to 0.02% and a Mo content less than 0.5%, with the remainder being iron and impurities, and which satisfies relationships (1) to (3). The alloy has a high creep rupture strength, has satisfactory toughness even when used at a high temperature over long, and has excellent hot workability. This heat-resistant austenitic alloy may contain a specific amount of one or more elements selected from Nb, V, Hf, B, Mg, Ca, Y, La, Ce, Nd, Sc, Ta, Re, Ir, Pd, Pt, and Ag. P<=3 / {200(Ti+8.5Zr)} (1) 1.35Cr<=Ni+Co<=1.85Cr (2) Al>=1.5Zr (3).

Owner:NIPPON STEEL CORP

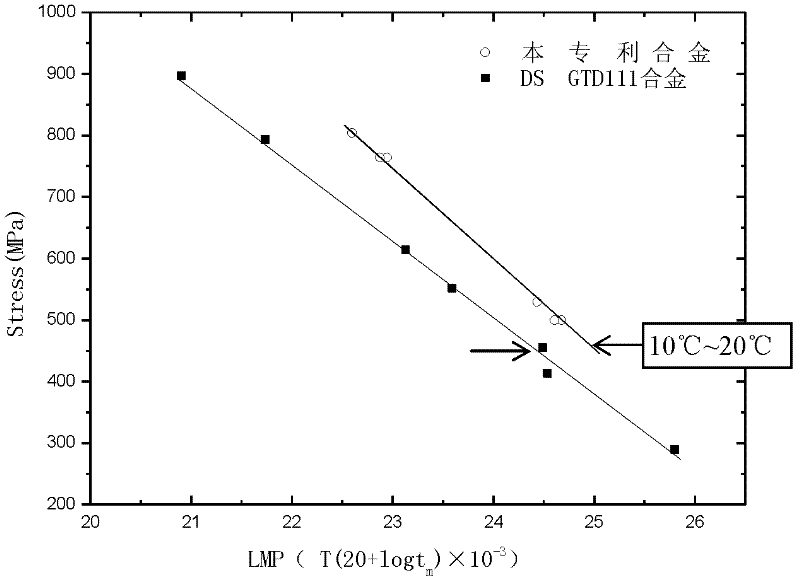

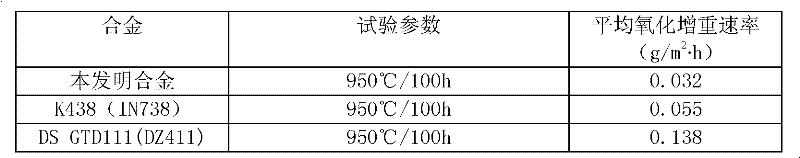

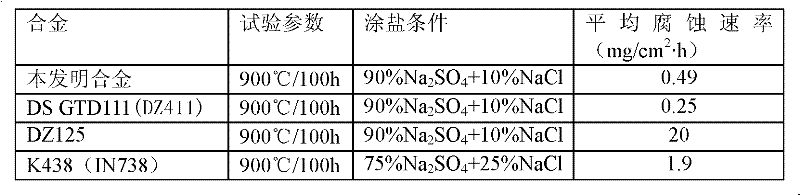

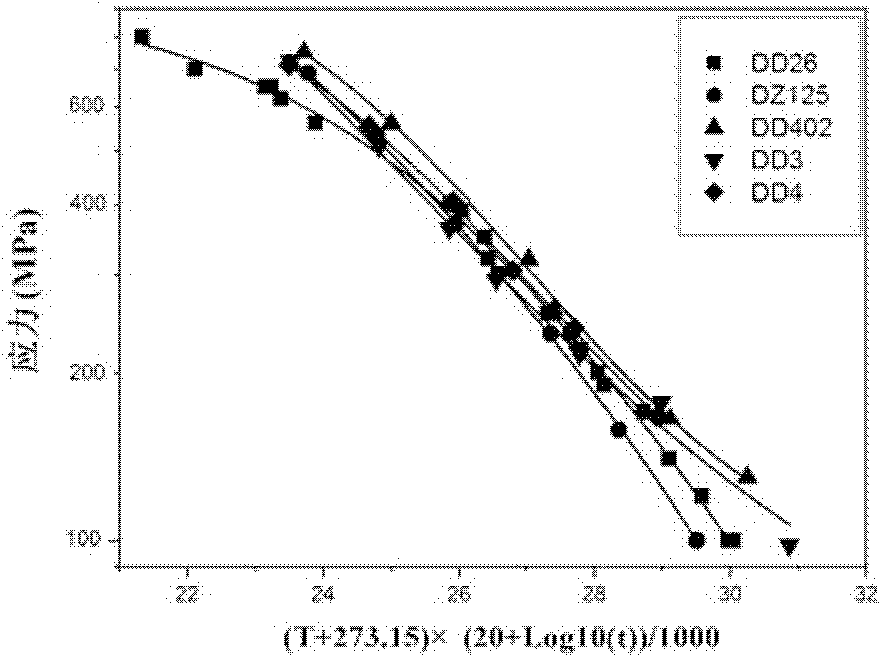

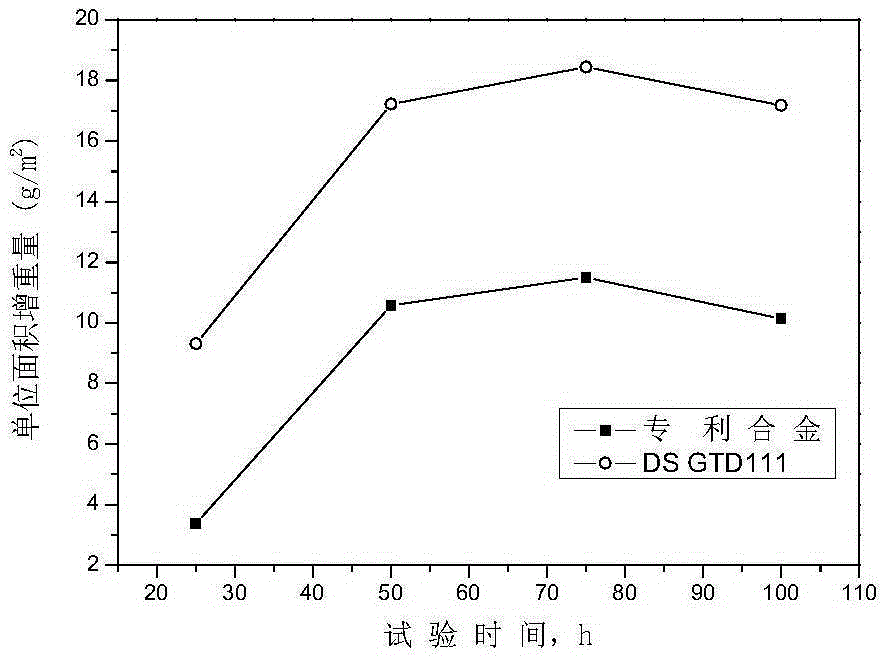

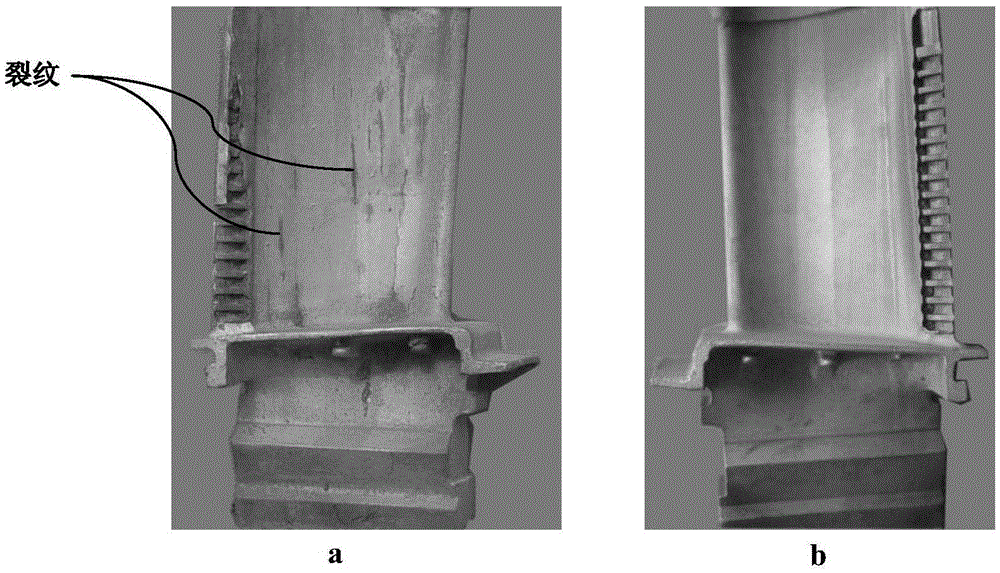

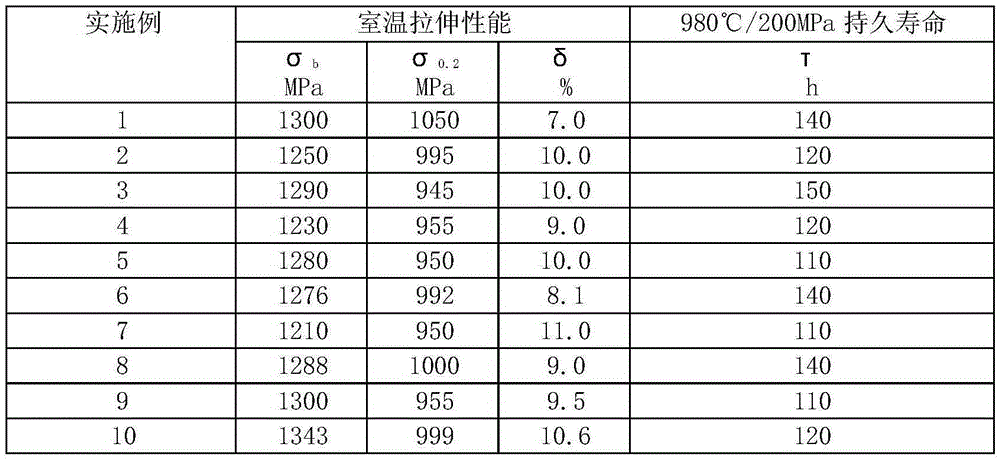

Novel directed nickel-base high temperature alloy

ActiveCN102653832AGuaranteed StrengthControl hot corrosion resistanceChemical compositionMetallic materials

The invention belongs to the field of metallic materials and relates to a novel directed nickel-base high temperature alloy for hold end parts and components of a gas turbine. The chemical ingredients of the alloy and mass percents of the chemical ingredients are as follows: 3.0-5.5% of Al, 0.5-4.0% of Ti, 9.0-12.0% of Cr, 5.0-7.0% of Ta, 7.0-10.0% of Co, 4.0-7.0% of W, 1.0-3.0% of Mo, 0-2.0% of Hf, 0-4% of Re, 0.02-0.15% of C, 0.002-0.02% of B, and the balance of nickel. The novel directed nickel-base high temperature alloy disclosed by the invention has good high temperature strength, tissue stability, casting performance and high temperature and hot corrosion resistance, no TCP phase is separated out after the alloy is aged at 900 DEG C for 50000h, the salt coated hot corrosion resistance of the alloy disclosed by the invention at 900 DEG C is close to that of a DS GTD111 alloy, and the temperature bearing capability of the alloy disclosed by the invention is 10-20 DEG C higher than that of the DS GTD111 alloy, so that the alloy disclosed by the invention is suitable for casting directed thin-walled hollow casting.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

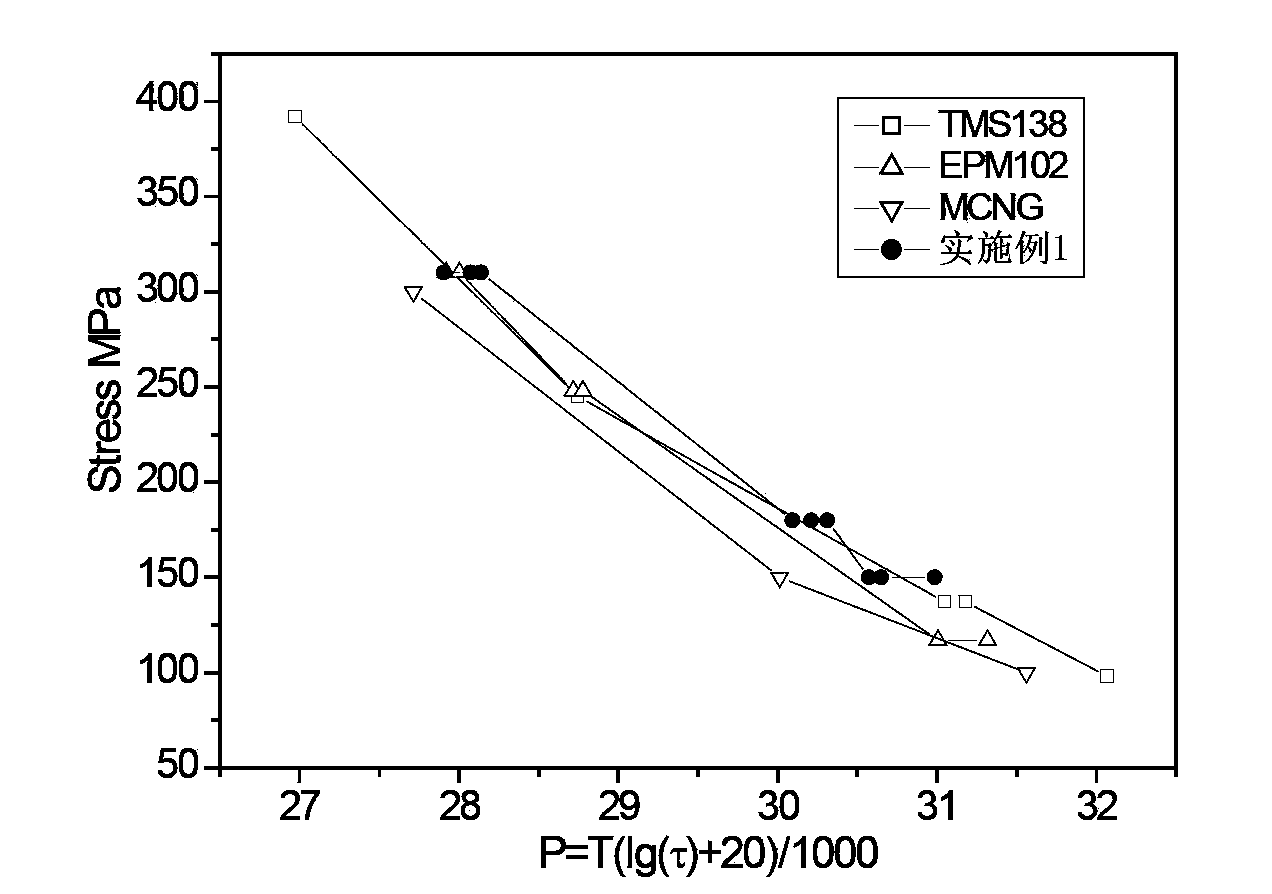

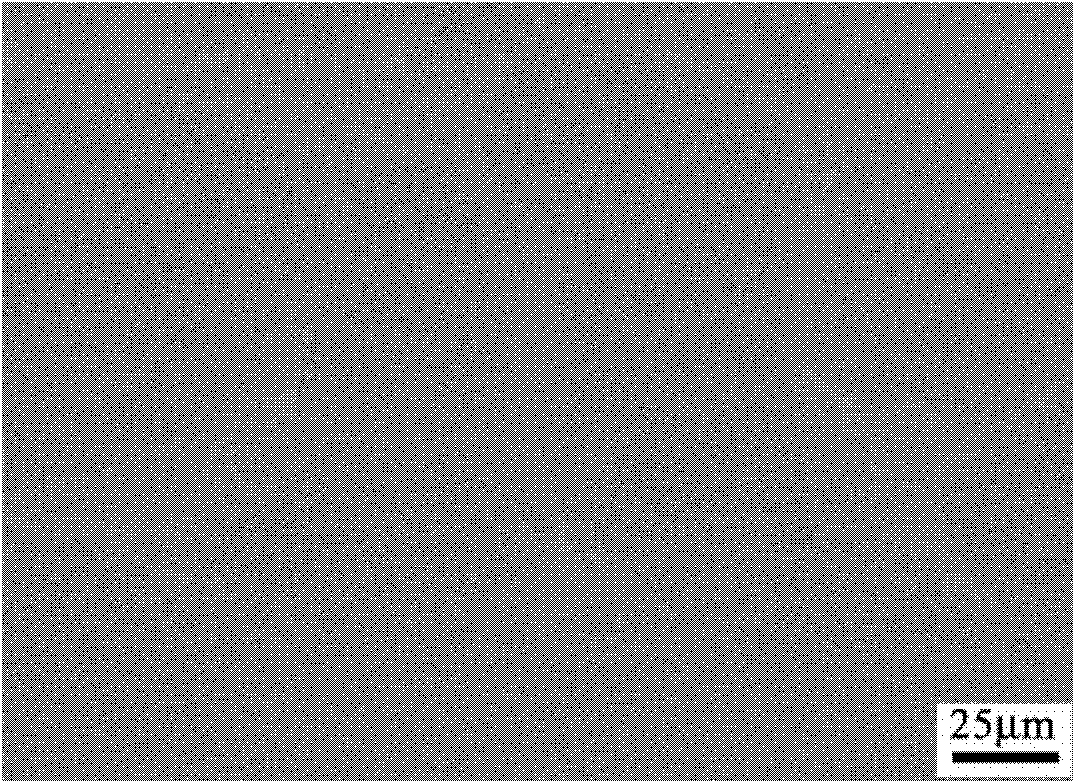

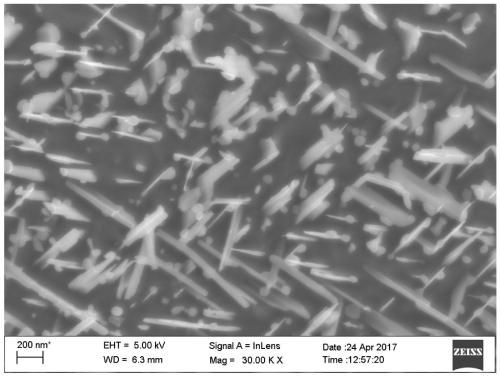

Fourth-generation single-crystal high temperature alloy with high strength and stable structure and preparation method thereof

InactiveCN103382536AHigh durabilityImprove organizational stabilityPolycrystalline material growthAfter-treatment detailsChemical compositionSingle crystal

The invention relates to the field of high-strength single-crystal high temperature alloys and especially provides a fourth-generation single-crystal high temperature alloy with high strength and a stable structure and a preparation method thereof. The alloy is mainly applicable to aero-engine blade materials used at a temperature higher than 1100 DEG C. Chemical components of the alloy comprise, by weight, 3 to 5% of Cr, 5 to 12% of Co, 6 to 8% of W, 0.1 to 2% of Mo, 4.5 to 6% of Re, 2 to 4% of Ru, 5.5 to 6.5% of Al and 6 to 10% of Ta, with the balance being Ni. The preparation method comprises the following steps: preparing a single-crystal blade or test rod under the conditions that temperature gradient of a single crystal growth furnace is in a range of 40 K / cm to 80 K / cm, casting temperature is 1480 to 1550 DEG C, shuttering temperature is consistent with the casting temperature and a growth rate is 4 to 8 mm / min; and then carrying out solid solution homogenization treatment, high temperature aging treatment and low temperature aging treatment so as to allow the alloy provided by the invention to have high endurance strength. The alloy has a life of no less than 100 h in endurance conditions of a temperature of 1140 DEG C and a pressure of 137 MPa and has endurance strength equivalent to the endurance strength of an EPM102 alloy; and the alloy has the advantages of good structure stability at a high temperature, a wide heat treatment window and easily controllable solid solution treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

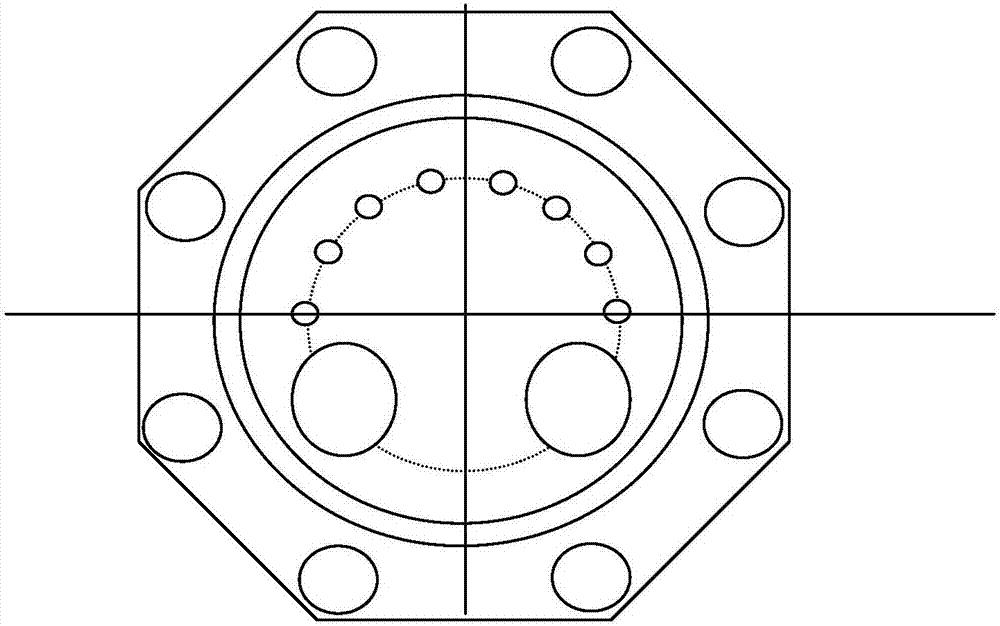

Quartz flexure accelerometer

ActiveCN107102168AGuaranteed rangeGuaranteed accuracyAcceleration measurement using interia forcesAccelerometerMagnetic poles

The invention provides a quartz flexure accelerometer which can improve the measurement precision, is good in sealing performance, and is high in stability. The accelerometer comprises a servo circuit and a meter. The meter comprises an upper torquer, a detection quality assembly, a lower torquer, and a housing. The upper torquer comprises a compensation ring, a magnetic steel, a magnetic pole piece, and an upper yoke. The lower torquer comprises a compensation ring, a magnetic ring, a magnetic pole piece, and a lower yoke. The detection quality assembly comprises a gold-plated film quartz pendulous reed and two torquer coils which are pasted on the quartz pendulous reed.

Owner:青岛智腾微电子有限公司

Cobalt-based high-temperature alloy wire and preparation method thereof

InactiveCN110983113ADecreased high temperature strengthImprove high temperature strengthDouble phaseOxidation resistant

The invention provides a cobalt-based high-temperature alloy wire which is prepared from the following chemical components in percent by mass: 0.06-0.12% of C, less than or equal to 0.3% of Si, 1-1.8%of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 19.2-20% of Cr, 9.5-10.5% of Ni, 14.2-15.5% of W, less than or equal to 2.8% of Fe, less than or equal to 0.4% of other impurities and the balance Co. By adding 19.2-20% of Cr, the cobalt-based high-temperature alloy wire has excellent corrosion resistance, and a condition that high-temperature strength is decreased as aresult of a double phase area as the content of Cr is too high to promote generation of an epsilon-Co phase and a sigma phase is avoided. Elements such as massive Co, 14.2-15.5% of W and 19.2-20% ofCr and the like in the cobalt-based alloy can reduce stacking fault energy, so that the high-temperature strength of the alloy is improved. The content of W is controlled at 19.2-20%, so that it is ensured that a condition of prominent work hardening of the alloy, difficulty in cold processing and poor stability as the too high W content is avoided. As the cobalt-based high-temperature alloy wirecontains 9.5-10.5% of Ni, the tissue stability of the alloy is improved favorably, and precipitation of a Co7W6 phase is reduced. By adding 1.1-1.8% of Mn, the oxidation resistance of a Ni-Cr alloy isimproved effectively.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

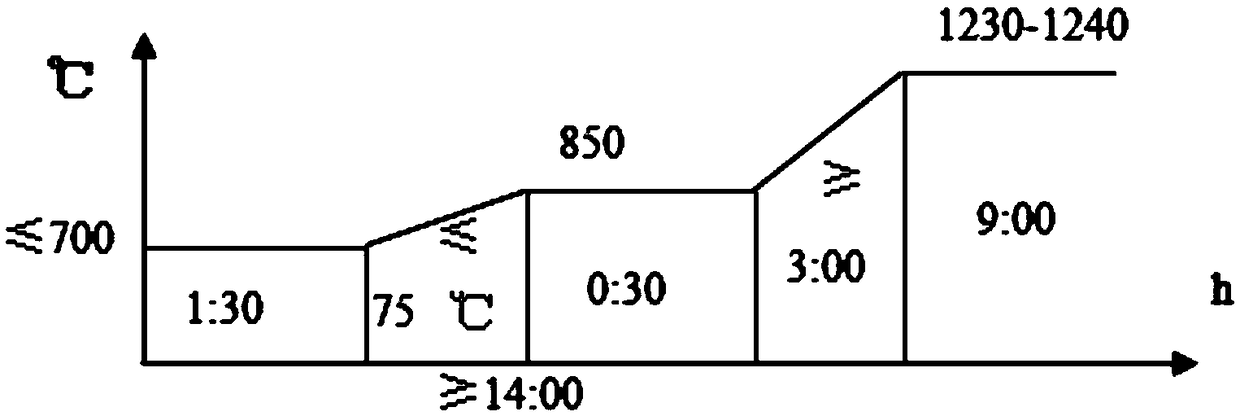

Method for manufacturing nanometer antibacterial ceramic glaze layers

The invention belongs to the field of inorganic nonmetal materials, particularly discloses a method for manufacturing nanometer antibacterial ceramic glaze layers, and relates to methods for manufacturing ceramic glaze layers. Antibacterial elements are added into ceramic glaze layer bases to carry out antibacterial disinfection on the ceramic glaze layers. Precursors for superfine powder of the nanometer antibacterial ceramic glaze layers comprise 45-60% of SiO<2>, 10-14%of Al<2>O<3>, 7-10% of CaO, 5-7% of ZnO, 2-5% of CuO, 3-6% of MgO, 1-3% of TiO<2> and 0.2-2% of Ag<2>O. The method includes filling graphite containers with the precursors for proportionally preparing the superfine powder of the nanometer antibacterial ceramic glaze layers; preserving heat for 120min-240min under argon atmosphere protection and the condition of temperatures of 1250-1400 DEG C to carry out synthesis; adding absolute ethyl alcohol into a ball-mill to carry out mechanical ball-milling for 24 hours so as to obtain the superfine precursor powder with crystal grain sizes of 30-80nm. The method has the advantages that metal grains of zinc, copper, magnesium and silver are fine and are uniformly distributed in glaze layers, the diameters of the metal grains are 30-80nm, and antibacterial elements can be quickly, durably and continuously released.

Owner:SHANDONG JIANZHU UNIV

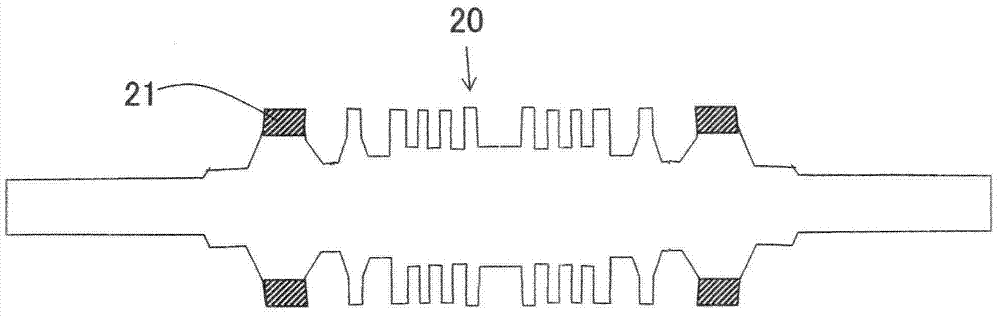

Ni seamless steel pipe and manufacturing method thereof

ActiveCN101328560AImprove organizational stabilityStrengthening and grain refinementTemperature control deviceMetal rolling arrangementsCorrosionHeating furnace

The invention relates to a nickel-based seamless steel pipe which comprises the following compositions in percentage by weight: 0.05 to 0.15 percent of C, 0.20 to 0.35 percent of Si, 0.35 to 0.60 percent of Mn, 3.20 to 3.80 percent of Ni, 0.01 to 0.3 percent of Cu, 0.01 to 0.4 percent of Mo, 0.001 to 0.05 percent of Ti, 0.01 to 0.1 percent of V, 0.005 to 0.039 percent of Al, less than or equal to 0.015 percent of P, less than or equal to 0.008 percent of S, less than or equal to 0.01 percent of O, less than or equal to 0.004 percent of N, the balance being Fe and inevitable impurities; and the ratio of Ca to S is more than or less than 1. The method for manufacturing the nickel-based seamless steel pipe comprises the following steps that: a pipe blank produced by continuous casting or continuous rolling is heated at a temperature of between 1180 and 1280 DEG C, rolled and separated from a bar mold at a temperature of between 950 and 1050 DEG C, is sent to a reheating furnace, is kept at a temperature of between 850 and 1000 DEG C, is subjected to rolling, air cooling at a cooling speed of between 10 and 30 DED C / min, kept at a temperature of between 800 and 900 DEG C, tempered, kept at a temperature of between 600 and 700 DEG C and tempered, thereby manufacturing a finished pipe. The nickel-based seamless steel pipe can be used for impacting a pressure container with a toughness of more than or equal to 18 J under the conditions of having a low temperature of between 80 and 101 DEG below zero and containing methanol and other corrosion mediums.

Owner:BAOSHAN IRON & STEEL CO LTD

Bearing steel material with long service life and machining method thereof

The invention discloses bearing steel material with long service life and a machining method thereof. The bearing steel material with the long service life comprises, by weight percentage, 0.95-1.05% of C, 0.15-0.35% of si, 0.25-0.45% of Mn, 1.40-1.60% of Cr, 0.05-0.09% of Ni, 0.02-0.05% of M0, smaller than or equal to 0.05% of Al, 0.05-0.08% of Cu, smaller than or equal to 0.01% of P, smaller than or equal to 0.008% of S, smaller than or equal to 0.0025% of Ti, smaller than or equal to 0.002% of O, smaller than or equal to 0.04% of As, smaller than or equal to 0.03% of Sn, smaller than or equal to 0.005% of Sb, smaller than or equal to 0.002% of Pb, smaller than or equal to 0.001% of Ca and the balance Fe. The bearing steel material with the long service life has high elastic limit, tensile strength and contact fatigue strength, has high hardening capacity and necessary hardenability so that the high wear resistance can be guaranteed, has certain impact toughness, has good dimensional stability or structure stability, can resist chemical corrosion and can effectively reduce the phenomena of fatigue flaking, jamming, ferrule breakage, wear and corrosion.

Owner:建龙北满特殊钢有限责任公司

High-end bearing steel material for machine tool and production process thereof

ActiveCN110257716AImprove purityEvenly distributedProcess efficiency improvementElectric furnaceRare-earth elementNumerical control

The invention relates to a high-end bearing steel material for a machine tool and a production process of the high-end bearing steel material, and belongs to the technical field of special steel smelting. The high-end bearing steel material for the machine tool and the production process of the high-end bearing steel material aim to solve the problem that the properties such as wear resistance and contact fatigue strength of an existing bearing steel material cannot meet the requirements of a high-end numerical control machine tool, and the production process comprises electric furnace treatment, LF refining and VD process, die casting, hot delivery / cover cooling, primary heating rolling cogging, slow cooling, secondary heating rolling and spheroidizing annealing. Ni, Mo and rare earth elements are added on the basis of existing bearing steel, the content of Al and Cu is strictly controlled, and a good mechanical property index is provided for steel materials, and the produced bearing steel material has high elasticity limit, tensile strength, contact fatigue strength and wear resistance, can effectively reduce the phenomena of material fatigue flaking, clamping and the like and is applicable to manufacturing a bearing ring and a rolling body and needle with the wide size range for the machine tool.

Owner:建龙北满特殊钢有限责任公司

Rare earth microalloying bearing steel and preparation method thereof

ActiveCN109457081AHigh elastic limitImprove hardenabilityFurnace typesHeat treatment furnacesSlow coolingMaterials science

The invention discloses rare earth microalloying bearing steel and a preparation method thereof and belongs to the technical field of bearing steel manufacturing. According to the technical aim, the performance of the bearing steel is improved. According to the rare earth microalloying bearing steel, converter, LF-RH refining and square billet continuous casting are carried out, electroslag remelting is carried out after scaling of a prepared continuous casting billet, then cover cooling and pit cooling are carried out, and then primary heating rolling cogging is carried out; after annealing or slow cooling is carried out, checking and cleaning are carried out, and a primary rolled steel billet is prepared and subjected to secondary heating rolling; and after stack cooling or slow coolingis carried out, a secondary rolled steel billet is prepared and subjected to spheroidizing annealing, straightening, polishing or scaling, flaw detection, cleaning and checking are carried out, and then the rare earth microalloying bearing steel is prepared. The content design ingredient of Nb ranges from 0.010% to 0.45%, and the rare earth microalloying bearing steel is suitable for being used for manufacturing various bearing rings and rolling elements and roller pins within a wide size range.

Owner:建龙北满特殊钢有限责任公司

Nickel-based high temperature alloy and manufacturing method thereof

ActiveCN106636760AImprove creep resistanceImprove organizational stabilitySolution treatmentImpurity

The invention discloses a nickel-based high temperature alloy and a manufacturing method thereof. The nickel-based high temperature alloy comprises the following components in percentage by weight: 0.06-0.15% of C, 0.25-0.55% of Si, 0.40-0.95% of Mn, 0.05-3.00% of Fe, 1.0-5.0% of Co, 0.05-0.50% of Al, 0.01-0.09% of Ti, 20.0-24.0% of Cr, 0.01-0.40% of Nb, 0.90-3.0% of Mo, 12.0-15.0% of W, 0.10-1.0% of Re, 0.001-0.009% of B, 0.8-2.0% of Ce, 0.8-1.8% of Ru, 0.3-3.0% of Hf, 2.0-5.0% of Ta, 0.05-0.35% of V and the balance of nickel and inevitable impurities. The nickel-based high temperature alloy disclosed by the invention has the advantages that materials are prepared in a certain proportion, homogenization treatment is carried out on the alloy for three times, high temperature forging is carried out on the alloy, and solution treatment, heat preservation and cooling are carried out; and by adopting the technical scheme of the invention, the strength, fatigue resistance and corrosion resistance of the alloy at high temperature can be effectively improved.

Owner:宁国市华成金研科技有限公司

Low-cost nickel-base single crystal high-temperature alloy and preparation method thereof

ActiveCN103173865AImprove high temperature strengthLow costPolycrystalline material growthAfter-treatment detailsSingle crystal superalloySingle crystal

The invention discloses a low-cost nickel-base single crystal high-temperature alloy and a preparation method thereof. The low-cost nickel-base single crystal high-temperature alloy comprises the following components in percentage by weight: 0.1-0.18% of C, 4.3-5.6% of Cr, 8-10% of Co, 10.9-12.5% of W, 0.9-1.3% of Mo, 1.2-1.6% of Nb, 5.65-6.25% of Al, 0.9-1.3% of Ti, 0.01-0.1% of Hf, 0.001-0.015% of B, 0.0005-0.025% of Ce, 0.0005-0.025% of Y and the balance of Ni. The alloy has the advantages of low preparation cost, high creep strength, high fatigue resistance, high structure stability, favorable single crystal casting property, favorable weldability and favorable coating property, and can be directly used in an as-cast state.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

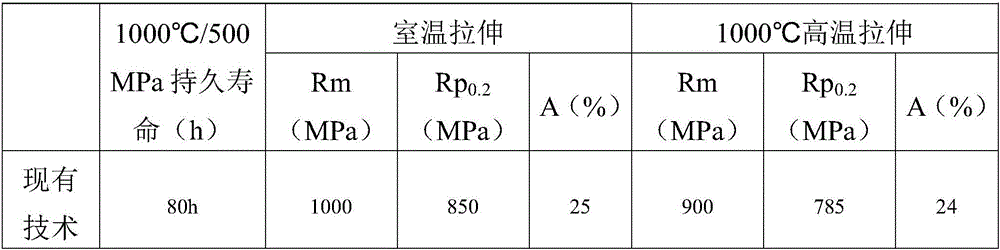

Low-chromium corrosion-resistant high-strength polycrystal high-temperature alloy and preparation method thereof

The invention provides a low-chromium corrosion-resistant high-strength polycrystal high-temperature alloy and a preparation method thereof. The low-chromium corrosion-resistant high-strength polycrystal high-temperature alloy is prepared from the components meeting the following range requirements in percentage by mass: 15-18% of Cr, 15-20% of Co, 0.5-1.5% of Ti, 3.5-4.5% of Al, 5-8.5% of W, lessthan or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 0.5-1.5% of Nb, 0.03-0.08% of C, and the balance of Ni. After smelting, homogenizing treatment is conducted, hot rolling is conducted, and finally, heat treatment is conducted. According to the low-chromium corrosion-resistant high-strength polycrystal high-temperature alloy, the tensile yield strength of the alloy at the room temperature is higher than 850 MPa, the tensile yield strength of the alloy at the temperature of 850 DEG C is higher than 550 MPa, and the weight change of the alloy is smaller than 0.2 mg / cm<2> after the alloy is corroded in the 850 DEG C high-temperature flue gas environment (N2-15%CO2-3.5%O2-0.1%SO2) for 500 hours. In addition, the alloy has the excellent structure stability during 850 DEG C heat exposure.

Owner:CHINA HUANENG GRP CO LTD +1

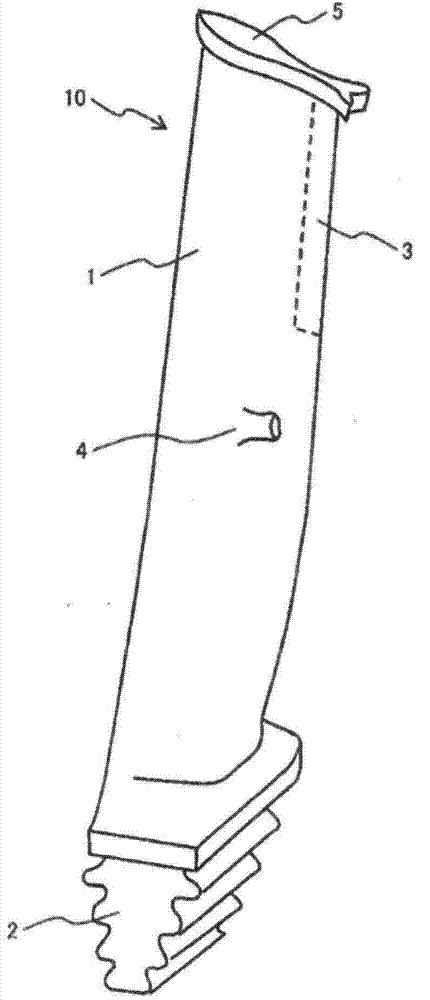

Precipitation hardening martensitic stainless steel and long blade for steam turbine using the same

InactiveCN103774048AImprove organizational stabilityExcellent mechanical propertiesBlade accessoriesFurnace typesMartensitic stainless steelMechanical property

A precipitation hardening martensitic stainless steel is provided with excellent mechanical property and corrosion resistance and contains, by mass, 0.1% or less of C; 0.1% or less of N; 10.0% ~ 15.0% of Cr; 10.0% ~ 15.0% of Ni; 0.5% ~ 2.5% of Mo; 1.0% ~ 3.0% of Al; 1.0% or less of Si; 1.0% or less of Mn, and the rest is Fe and inevitable impurities. A steam turbine long blade (10) is made of the precipitation hardening martensitic stainless steel.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

High temperature alloy material for engine turbine and preparation method thereof

The invention relates to a high temperature alloy material for an engine turbine. The high temperature alloy material comprises components according to weight percentage: 0.22-0.28% of C, 2.1-2.2% of Mn, 0.45-0.61% of Si, 18.3-19.2% of Cr, 8.25-10.4% of Mo, 3.50-3.80% of W, 0.05-0.35% of Al, 0.18-0.27% of Cu, 5.0-9.2% of Fe, 1.0-1.1% of B, 3.15-3.45% of Ti, 6.7-8.2% of Co, 0.12-0.18% of Zr, 1.12-1.38% of Nb, and the balance of Ni and inevitable impurities, and a preparation method which is matched with the material is provided. The prepared blank is reasonable in component design, and is matched with characteristics of reasonable thermal processing technology, convenient production organization, strong field operability and strong apparatus universality, so that the quality of the produced high temperature alloy large-sized turbine disk product is high, the structure property meets the standard requirements, the production efficiency is high, and the economic benefit and the social benefit are obvious.

Owner:北京金恒博远科技股份有限公司

Production method for cryopreserved acellular dermal matrix, and cryopreserved acellular dermal matrix produced thereby

ActiveCN102573945AImprove organizational stabilityWon't hurtDead animal preservationTissue cultureSucroseCuticle

The present invention relates to a production method for cryopreserved acellular dermal matrix and to cryopreserved acellular dermal matrix produced thereby, and more specifically it relates to a method in which a cryopreservation agent is made by adding sucrose to basic components consisting of glycerol and a basic solution and in which the resulting solution is used in the cryopreservation of skin tissue from which the cells in the epidermis and dermis have been removed, and relates to cryopreserved acellular dermal matrix produced thereby.

Owner:IND ACADEMIC COOP FOUND HALLYM UNIV

Third-generation nickle base monocrystal high temperature alloy with stable texture and preparation method

ActiveCN111455220AImproved creep propertiesEnsure organizational stabilityPolycrystalline material growthAfter-treatment detailsSingle crystal superalloyDirectional solidification

The invention discloses third-generation nickle base monocrystal high temperature alloy with a stable texture and a preparation method thereof. The third-generation nickle base monocrystal high temperature alloy is composed of Al, Ta, W, Re, Mo, Cr, Co, Hf and Ni; and W and Ni are added in the form of Ni-W intermediate alloy. Directional solidification is adopted to prepare monocrystal alloy; through multistep high temperature long-time solid solution homogenization treatment, high temperature aging treatment and low temperature aging treatment, the third-generation nickle base monocrystal high temperature alloy is free of incipient melting and precipitation of TCP phase to lower the TCP precipitation tendency, so that alloy reducing Re content reaches the performance level of the third-generation nickle base monocrystal high temperature alloy, and the obtained nickle base monocrystal high temperature alloy has higher intermediate and high temperature strength, excellent instant tensile property and creep property and high texture stability.

Owner:苏州高晶新材料科技有限公司

Manufacturing method of molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tube

ActiveCN106180254APerformance impactImprove mechanical propertiesNuclear energy generationCooling arrangementMolten salt reactorHeat treated

The invention discloses a manufacturing method of a molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tube. The manufacturing method comprises the steps that firstly, hot extrusion treatment is conducted on a molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy tube blank which is provided with a through hole, so that a pierced billet for cold rolling is obtained, wherein the extrusion temperature of the hot extrusion treatment is 1220-1250 DEG C, and the extrusion ratio is 5-12; secondly, the pierced billet obtained in the first step is cold rolled to be a tube of a required specification, wherein in the cold rolling process, the single-pass rolling reduction of each pass is 20%-70%, and after each pass is completed, intermediate heat treatment and acid pickling are conducted on the tube firstly, and then rolling of the next pass is conducted, wherein the intermediate heat treatment temperature is 1180-1220 DEG C; and thirdly, final heat treatment is conducted on the tube of the required specification in the temperature range from 1180 DEG C to 1220 DEG C. The invention further discloses the molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tube and a structural member for a molten salt reactor. By the adoption of the manufacturing method, various specifications of molten-slat-corrosion-resisting nickel-molybdenum-chromium alloy seamless tubes meeting molten salt reactor use requirements can be efficiently manufactured.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI +1

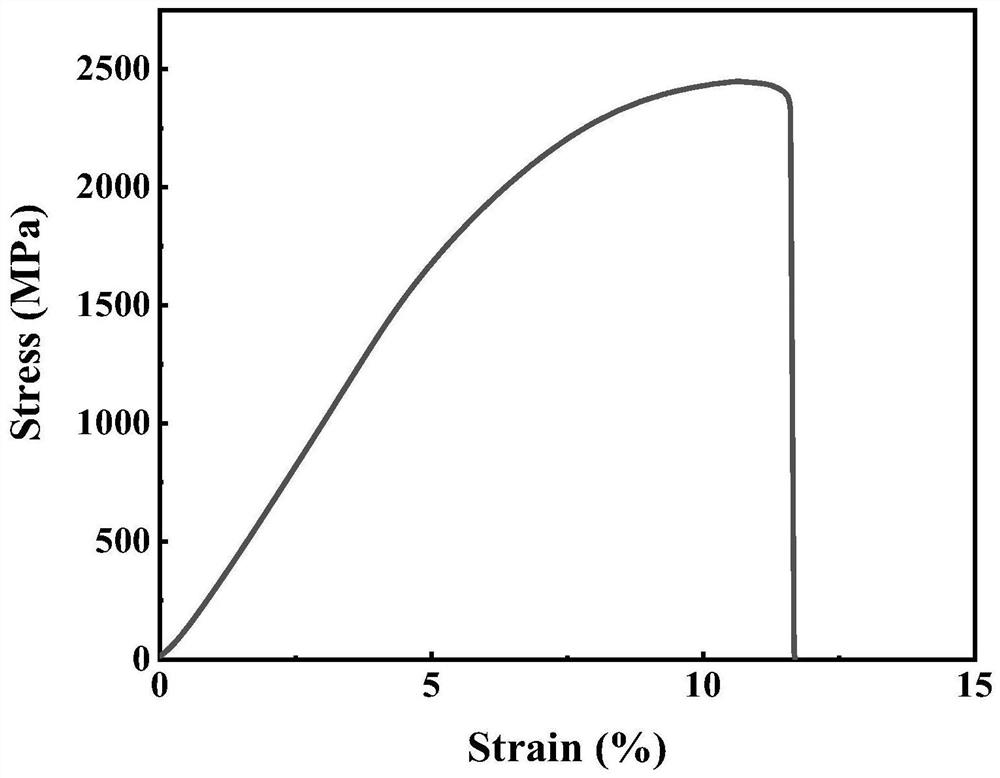

Precipitation strengthened heat resistant steel and preparation process thereof

ActiveCN107587080AReduce the ductile-brittle transition temperaturePromote precipitationRoom temperatureIngot

The invention relates to precipitation strengthened heat resistant steel and a preparation process of the precipitation strengthened heat resistant steel. The components of an alloy meet the followingrange requirements by mass percent: 003-0.06% of C, 6-10% of Ni, 8-13% of Cr, 1.5-2.4% of Al, less than or equal to 3% of Co, less than or equal to 0.1% of Nb, less than or equal to 0.1% of Zr, and the balance of Fe; the prepared alloy is smelted into an alloy mother liquid and is finally prepared into an alloy ingot; the alloy ingot is rolled into a sheet at the temperature range of 850-1100 DEGC; and the rolled sheet is subjected to solid solution treatment and aging treatment to obtain the precipitation strengthened heat resistant steel. The heat resistant steel is excellent in room temperature toughness and has an excellent strength property at the same time. The room temperature tensile strength of the alloy is not lower than 1000 MPa, the yield strength exceeds 900 MPa, the room temperature elongation percentage is higher than 12%, and the reduction of area is higher than 50%.

Owner:CHINA HUANENG GRP CO LTD +1

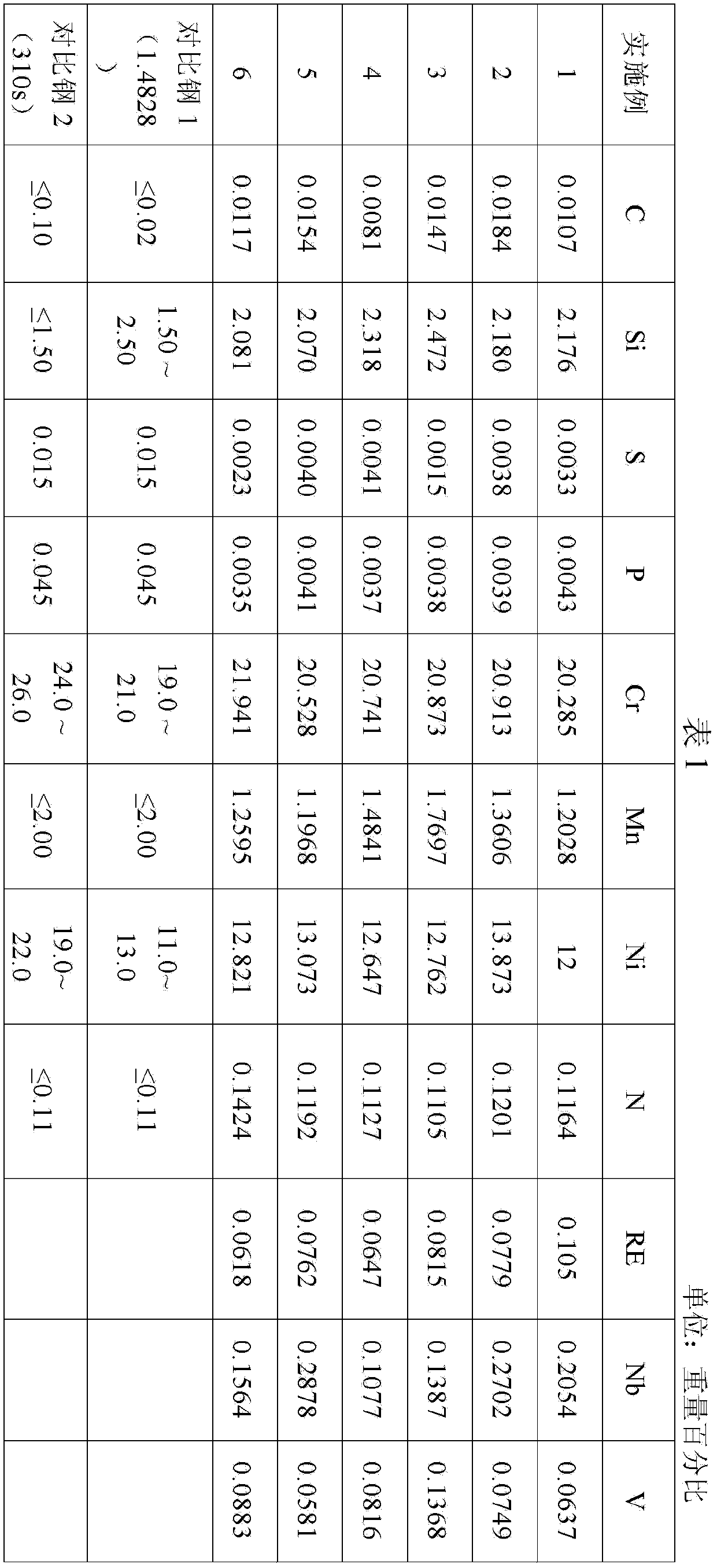

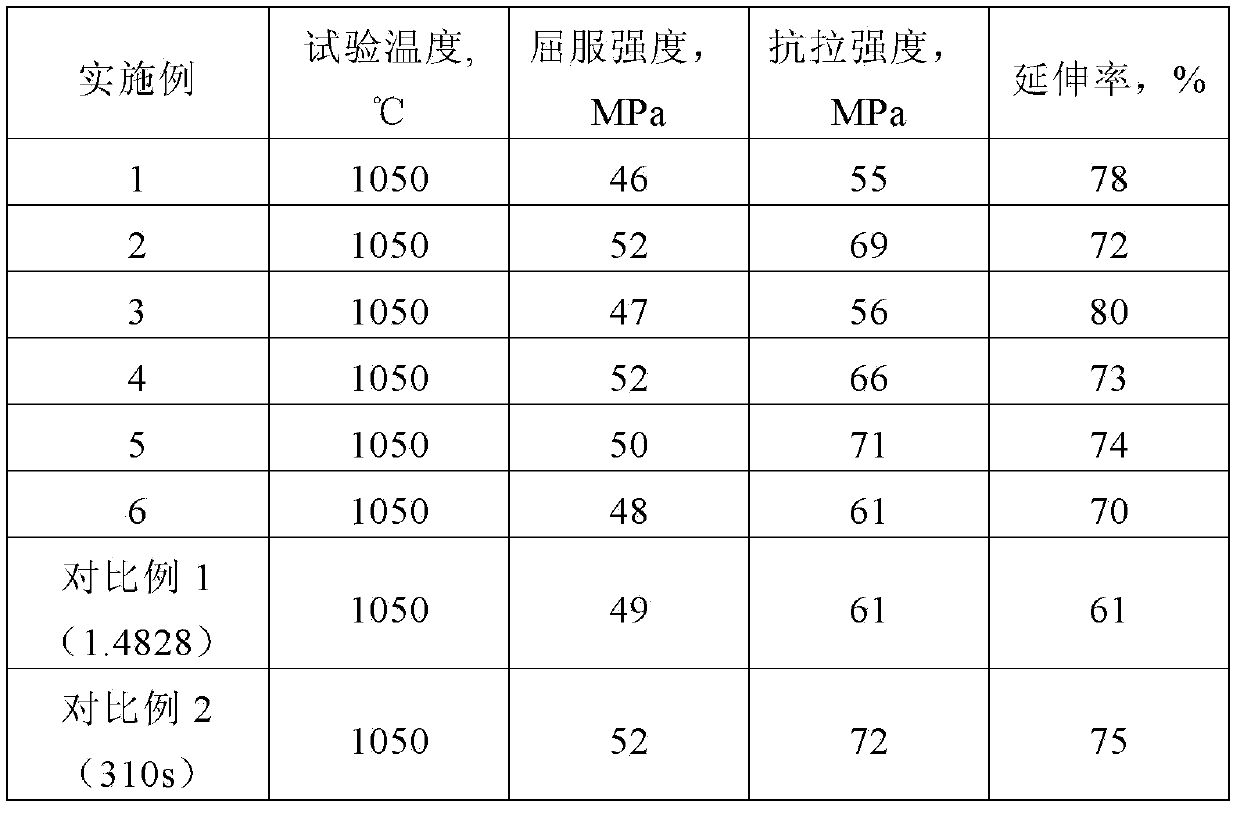

Austenite heat-resistance stainless steel resisting high temperature oxidation

ActiveCN103741065AImprove high temperature oxidation resistanceReduce C contentChemical compositionHeat resistance

The invention discloses an austenite heat-resistance stainless steel resisting high temperature oxidation. The austenite heat-resistance stainless steel comprises the chemical components in percentage by weight: below 0.02 percent of C, 2.0-2.5 percent of Si, 1-2 percent of Mn, 20-22 percent of Cr, 12-14 percent of Ni, 0.11-0.15 percent of N, less than 0.035 percent of P, less than 0.005 percent of S, 0.06-0.11 percent of Ce+La+Y, 0.05-0.15 percent of V, 0.1-0.3 percent of Nb and the balance of Fe and inevitable impurities, wherein (Cr+1.5Si+0.5Nb) / (Ni+0.5Mn+20N) is not less than 1.4 and not more than 1.6, and (Nb+V) is not less than 1.5(C+N) and is not more than 0.35 percent. The austenite heat-resistance stainless steel disclosed by the invention has good high temperature strength, oxidation resistance and formation property, and meets the requirements of continuous rise of use temperature of an automobile exhaust system and environment protection; the use temperature of the austenite heat-resistance stainless steel can reach 1050 DEG C; the requirements on the continuously raised use temperature of an automobile exhaust air system is continuously raised and environment protection are met.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Oil bushing steel and manufacturing process thereof

ActiveCN101153373AImprove hardenabilityImprove toughnessTemperature control deviceHeat treatment process controlChemical compositionHeating furnace

The invention relates to an oil bushing steel and the manufacturing process thereof, wherein, the chemical composition of the steel is as follows: 0.28wt percent to 0.35wt percent of C, 0.1wt percent to 0.4wt percent of Si, 0.8wt percent to 1.6wt percent of Mn, 0.4wt percent to 0.6wt percent of Mo, 0.8wt percent to 1.2wt percent of Cr, 0.05wt percent to 0.10wt percent of V, less than or equal to 0.005wt percent of S, 0.01wt percent to 0.04wt percent of Al and the rest, Fe and other inevitable impurities; the manufacturing process of the steel is as follows: the tube blank made by continuous casting or continuous rolling is perforated by a perforator after heating in a heating furnace and is under tube rolling under 950 DEG C to 1,050 DEG C; the tube blank is fed into a reheating furnace after releasing from a rod and then is fed into a tension-reducing mill or a stretcher after holding under 800 DEG C to 1,000 DEG C for air cooling after rolling; finally, after holding under 860 DEG C to 1,000 DEG C and quenching, the tube blank is under tempering under 600 DEG C to 660 DEG C holding to be made into production tube. The steel has excellent hardenability and higher structural stability and can ensure that an oil well oil bushing not only can obtain 1,000MPa to 1,200MPa yield strength, but also can meet the requirements of more than 70J transverse ballistic work and more than 90J ballistic work.

Owner:BAOSHAN IRON & STEEL CO LTD

High-temperature alloy casting resistant to high-temperature hot corrosion

ActiveCN105349842AImprove mechanical propertiesGood long-term aging tissue stability at high temperatureFoundry mouldsFoundry coresMetallic materialsHigh-temperature corrosion

The invention belongs to the field of metal materials and relates to a high-temperature alloy casting which is resistant to high-temperature hot corrosion and is used for a part at the hot end of a gas turbine. Alloy comprises, by mass, 3.8%-6.0% of Al, 0.5%-3.5% of Ti, 10.0%-12.0% of Cr, 5.0%-7.0% of Ta, 8.0-10.0% of Co, 4.0%-7.0% of W, 1.0%-3.0% of Mo, 0-3.0% of Hf, 0-4% of Re, 0.02%-0.15% of C, 0.002-0.02% of B and the balance nickel. According to the high-temperature alloy casting resistant to high-temperature hot corrosion, the Al / Ti value, the content of Hf and the ratio of the content of Hf to the content of C and B are adjusted, so that the casting performance of the alloy is improved, and the high-temperature burning hot corrosion performance of the alloy is improved. Thus, the gas turbine high-temperature alloy more suitable for hollow blade casting is obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

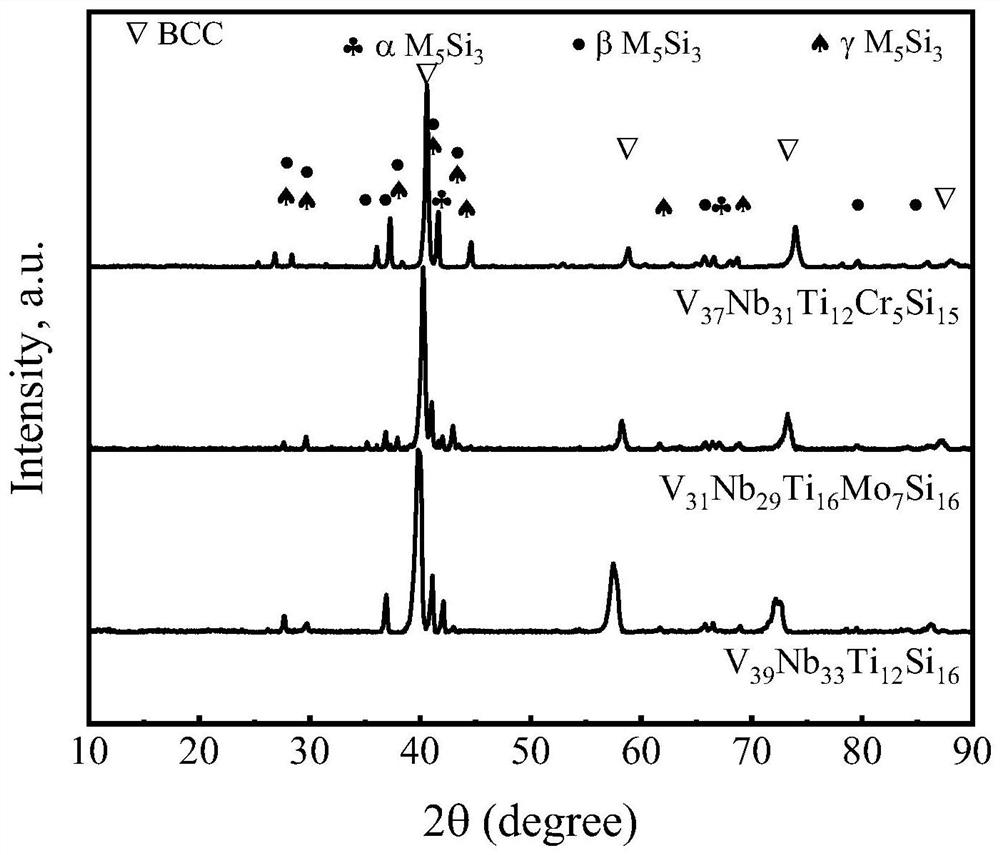

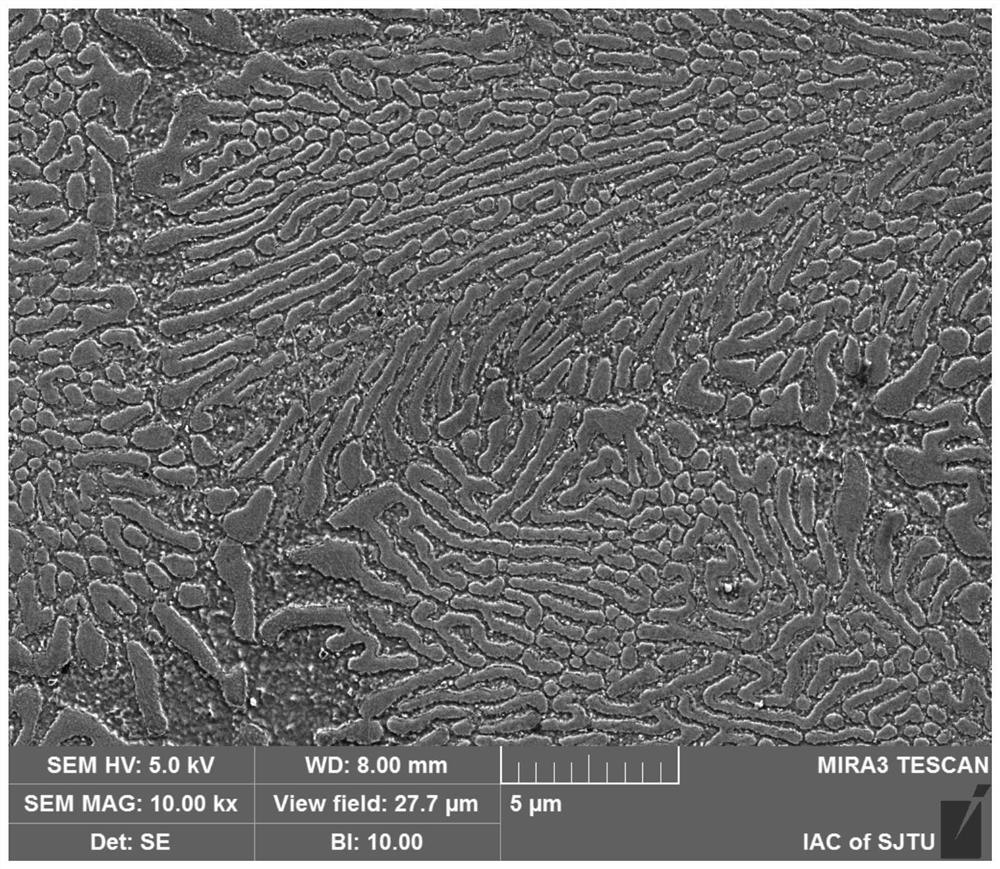

Light refractory high-temperature-resistant eutectic high-entropy alloy and preparation method thereof

ActiveCN112981208AImprove high temperature performanceHigh phase contentChemical compositionHigh entropy alloys

The invention discloses a light refractory high-temperature-resistant eutectic high-entropy alloy and a preparation method thereof. The chemical component expression of the light refractory high-temperature-resistant eutectic high-entropy alloy is VaNbbMcSid, wherein M is one or more elements of Ti, Zr, Ta, Mo, Cr and Al, and a, b, c and d in the chemical expression respectively represent the molar percentages of the corresponding elements and meet the following relations: 0<a<= 45, 0<b<=35, 0<c<=35, 10<=d<=20, and a+b+c+d=100. The alloy is of a lamellar eutectic structure composed of a VNbM solid solution phase of a body-centered cubic structure and a (VNbM)5Si3 ordered compound phase of a tetragonal or hexagonal structure, has density far lower than that of a nickel-based and cobalt-based high-temperature alloy and an ultrahigh melting point, and has certain room-temperature plasticity, high high-temperature strength and excellent casting performance, thereby meeting the requirements for advanced high-temperature structural materials.

Owner:SHANGHAI JIAO TONG UNIV

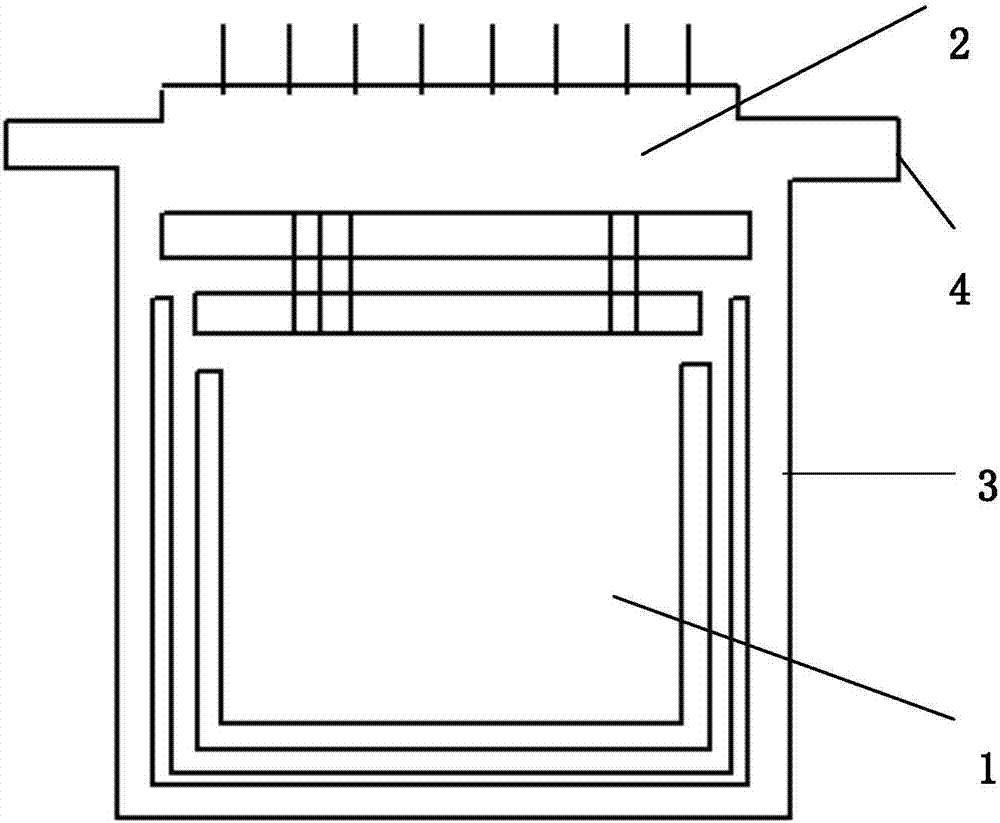

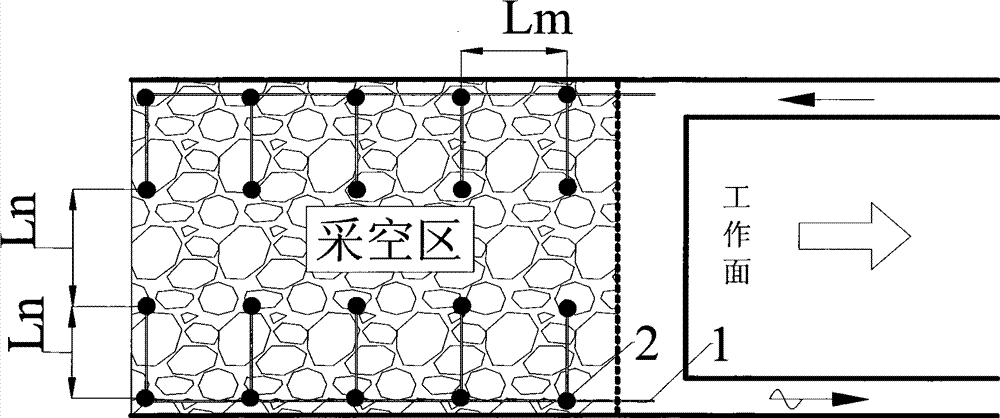

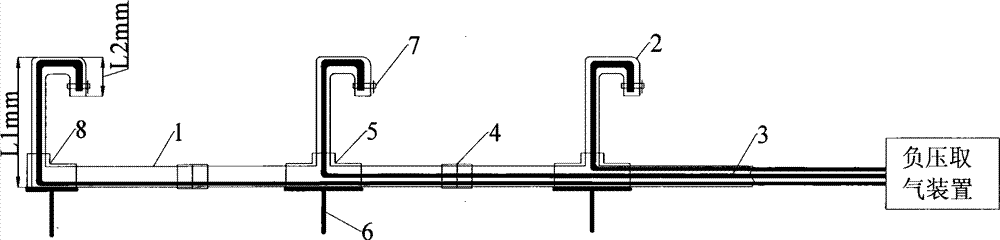

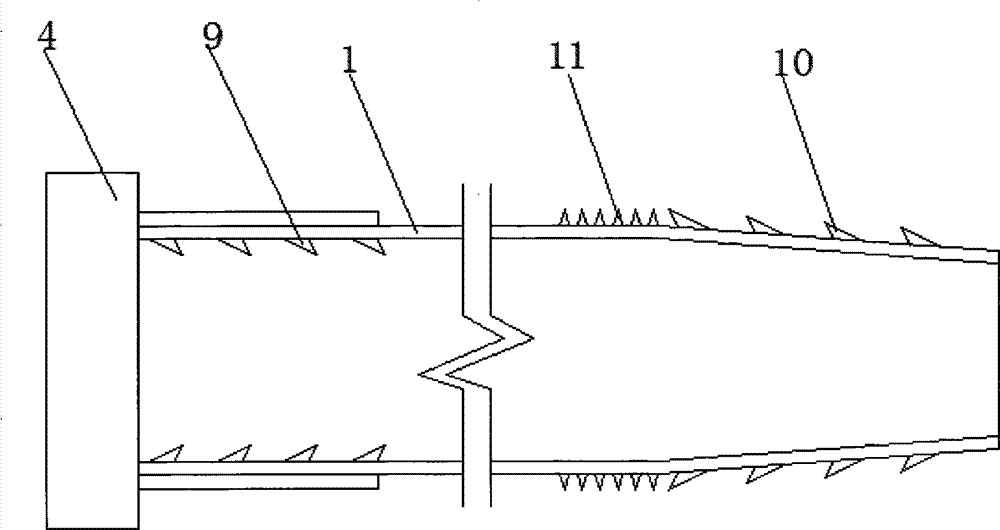

Coal spontaneous combustion gas marker acquiring device for goaf

InactiveCN104847346AAvoid frackingHigh strengthBorehole/well accessoriesCoal spontaneous combustionEngineering

The invention discloses a coal spontaneous combustion gas marker acquiring device for a goaf. The coal spontaneous combustion gas marker acquiring device comprises high-pressure pipes (1) arranged along an oxidation and heating zone and the air return shaft direction, the high-pressure pipes (1) are axially and fixedly connected by connecting casings (4), the middle of each high-pressure pipe (1) is provided with a detector pipe (2) communicated with the inside of the high-pressure pipe (1), a plurality of binding pipes (3) connected with an air sucking pump are arranged in the high-pressure pipes (1), the other ends of the binding pipes (3) extend into the detector pipes (2) and the ends of the binding pipes (3) are fixed at the ends of the detector pipes (2) by fixing clamps (7). The coal spontaneous combustion gas marker acquiring device is resistant to high pressure and high in strength, the pipeline is protected from cracking by rock mass collapse of the goaf, and bending can meet actual arrangement needs within a certain radius; the high-pressure pipes are rubber pipes and are resistant to high temperature and anti-ageing, service lives of the high-pressure pipes are prolonged, oxidation and corrosion under the action of high-temperature smoke and water steam can be prevented, and the coal spontaneous combustion gas marker acquiring device is durable and has excellent structure stability.

Owner:XIAN UNIV OF SCI & TECH

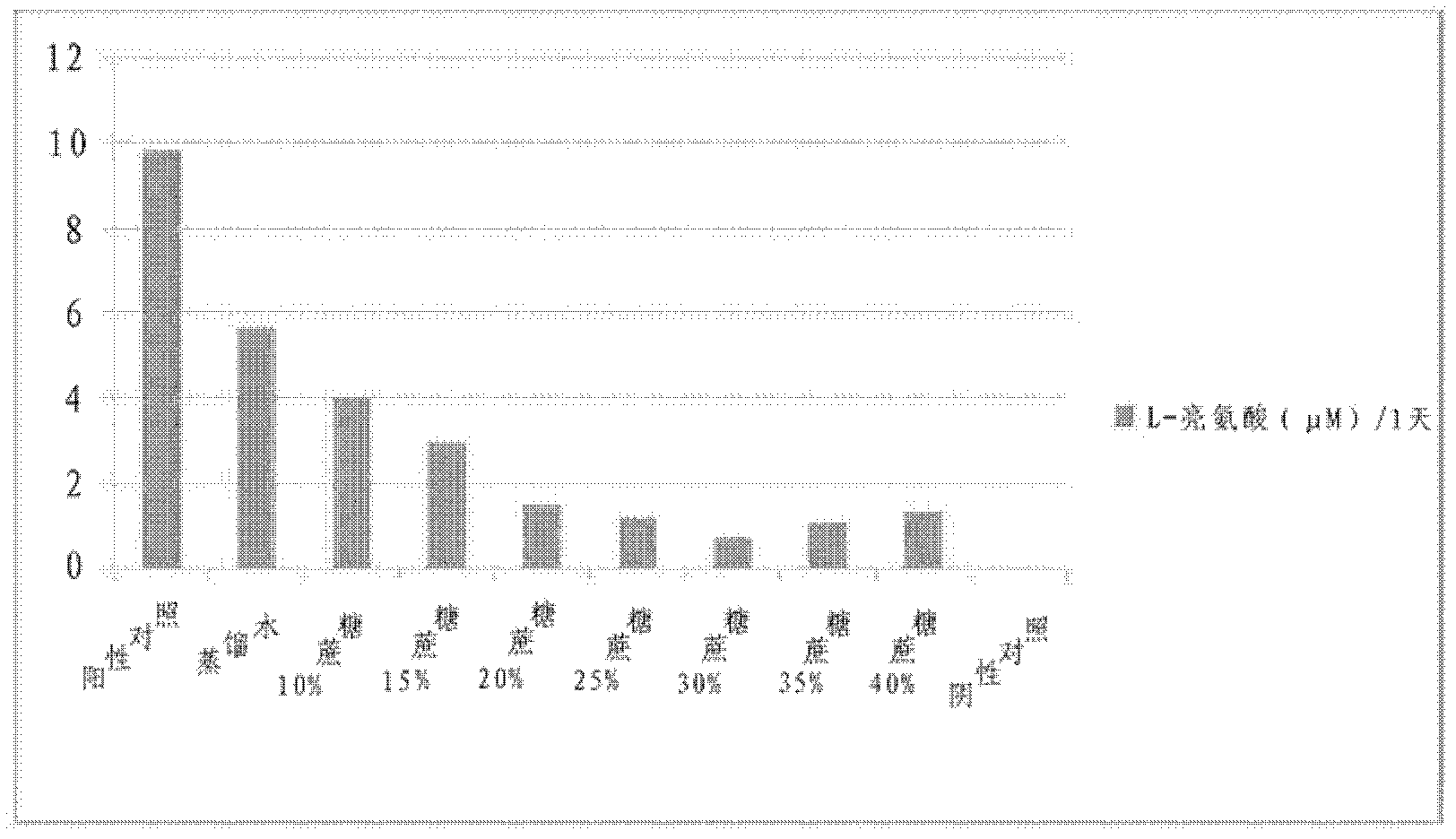

Preparation method of Xinhui dried tangerine peel enzyme beverage

InactiveCN109566945AGreat tasteGood organizational stabilityFood homogenisationNatural extract food ingredientsAdditive ingredientHigh pressure

The invention discloses a preparation method of Xinhui dried tangerine peel enzyme beverage. By adopting four industrial advanced unique processes such as natural fermentation and chelating process, low-high-pressure bidirectional homogenizing, high-temperature instantaneous sterilization and low-high-temperature canning, the specific nutritional ingredients of Xinhui orange, dried tangerine peel,rhizoma polygonati, fructus lycii, fructus crataegi and the like can be maximally reserved; and in the prepared Xinhui dried tangerine peel enzyme beverage, the content of crude polysaccharide and total flavonoids is increased, the extraction rate is high, the taste is good, and the tissue state stability is good.

Owner:广东新宝堂生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com