Precipitation hardening martensitic stainless steel and long blade for steam turbine using the same

A technology of martensitic stainless steel and precipitation hardening, which is applied to the supporting elements of blades, furnace types, mechanical equipment, etc., can solve the problems of large amount of Cr addition, poor balance of strength and toughness, etc., and achieve excellent structural stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (Sample production)

[0044] In order to evaluate the correlation between the chemical composition of the precipitation-hardening martensitic stainless steel of the present invention, tensile strength, 0.02% yield point, Charpy impact absorbed energy, pitting potential, and microstructure, samples were produced. Table 1 shows the chemical composition of each sample.

[0045] First, use a high-frequency vacuum melting furnace (5.0×10 -3 Pa or less, 1600° C. or more), the raw materials are melted so that the composition shown in Table 1 is obtained. The obtained ingot was hot-forged using a press forging machine and a hammer forging machine, and formed into a square bar of width×thickness×length=100mm×30mm×1000mm. Next, the square bar was cut and processed into width×thickness×length=50mm×30mm×120mm, which was used as a stainless steel raw material.

[0046] Next, various heat treatments were performed on each stainless steel raw material using a box-type electric furn...

test approach )

[0048] For the tensile test, a test piece (distance between points: 30 mm, outer diameter: 6 mm) was prepared from each sample obtained above, and it was performed at room temperature according to JIS Z2241. As for the judgment criteria of tensile strength and 0.02% yield point, 1500 MPa or more and 1000 MPa or more were evaluated as "pass", and values smaller than the value were evaluated as "failure". In addition, elongation and reduction of area were evaluated as "pass" if they were 10% or more and 30% or more, respectively, and those that were less than the values were evaluated as "failure".

[0049] For the measurement of Charpy impact absorbed energy, a test piece having a 2 mm V-notch was prepared from each sample obtained above, and a Charpy impact test was performed at room temperature according to JIS Z2242. As for the judgment standard of the Charpy impact absorbed energy, 20 J or more was evaluated as "acceptable", and a value smaller than the value was evalua...

Embodiment 2

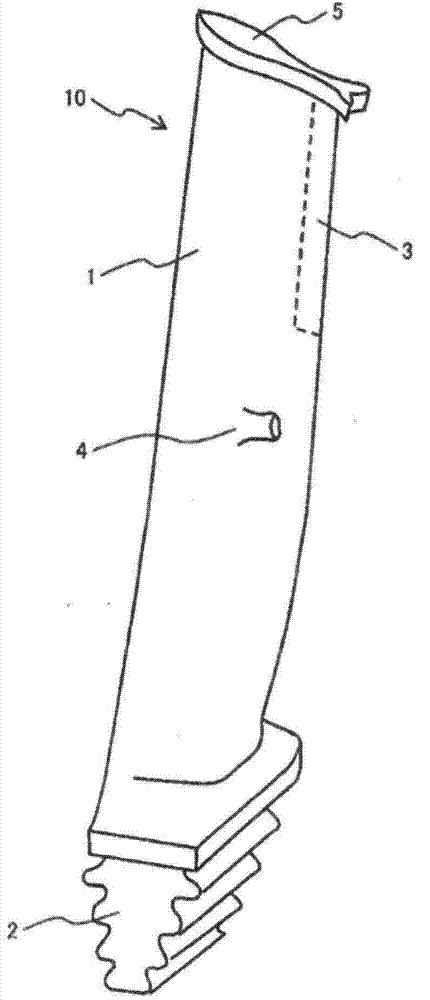

[0059] The steam turbine long blade using the present invention will be described. In the present embodiment, Alloy 1 described in Table 1, which is an inventive material, was used to produce long blades for an axial intake type steam turbine with a blade length of 48 inches. As a method of making long blades, first, at 5.0×10 -3 In the high vacuum state below Pa, through the chemical reaction of C+O→CO, vacuum carbon deoxidation is carried out to deoxidize molten steel. Next, it is formed into an electrode rod by forging and stretching. Electroslag remelting is performed by immersing the electrode rod in molten slag, self-melting it by Joule heat generated when an electric current is applied, and solidifying it in a water-cooled mold to obtain a high-quality steel block. Next, after hot forging, press forging is performed using a 48-inch blade die. Then, as a solution treatment, after heating and holding at 980° C. for 2.0 hours, forced cooling was performed to perform rap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com