Patents

Literature

55 results about "Charpy impact test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material's notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition. It is widely applied in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disadvantage is that some results are only comparative.

Nondestructive testing method for metal material fracture toughness

InactiveCN103063508ANo damageThe detection process is fastStrength propertiesMaterial under testMetallic materials

The present invention discloses a nondestructive testing method for metal material fracture toughness, and the method mainly includes: performing Charpy impact tests to samples of different damage degrees to obtain the brittle transition temperatures of the samples; performing ultrasonic secondary harmonic measurement to the samples of each type of the damage degrees to obtain the second harmonic ultrasound nonlinearity parameter normalized value of the samples of the type of the damage degree; obtaining the fracture strength factor of the samples of each type of the damage degrees via the fracture toughness tests or by reference of fracture empirical formulas, and making a calibration curve for nondestructive testing fracture toughness; performing ultrasonic secondary harmonic measurement to a metal material under test to obtain the second harmonic ultrasound nonlinearity parameter normalized value of the metal material under test; and obtaining the fracture toughness value of the metal material under test by using the calibration curve. The nondestructive testing method for metal material fracture toughness of the invention is capable of performing testing and evaluation of material fracture toughness of in-service metallic components, and providing a reliable basis for the security service of the metal materials.

Owner:EAST CHINA UNIV OF SCI & TECH

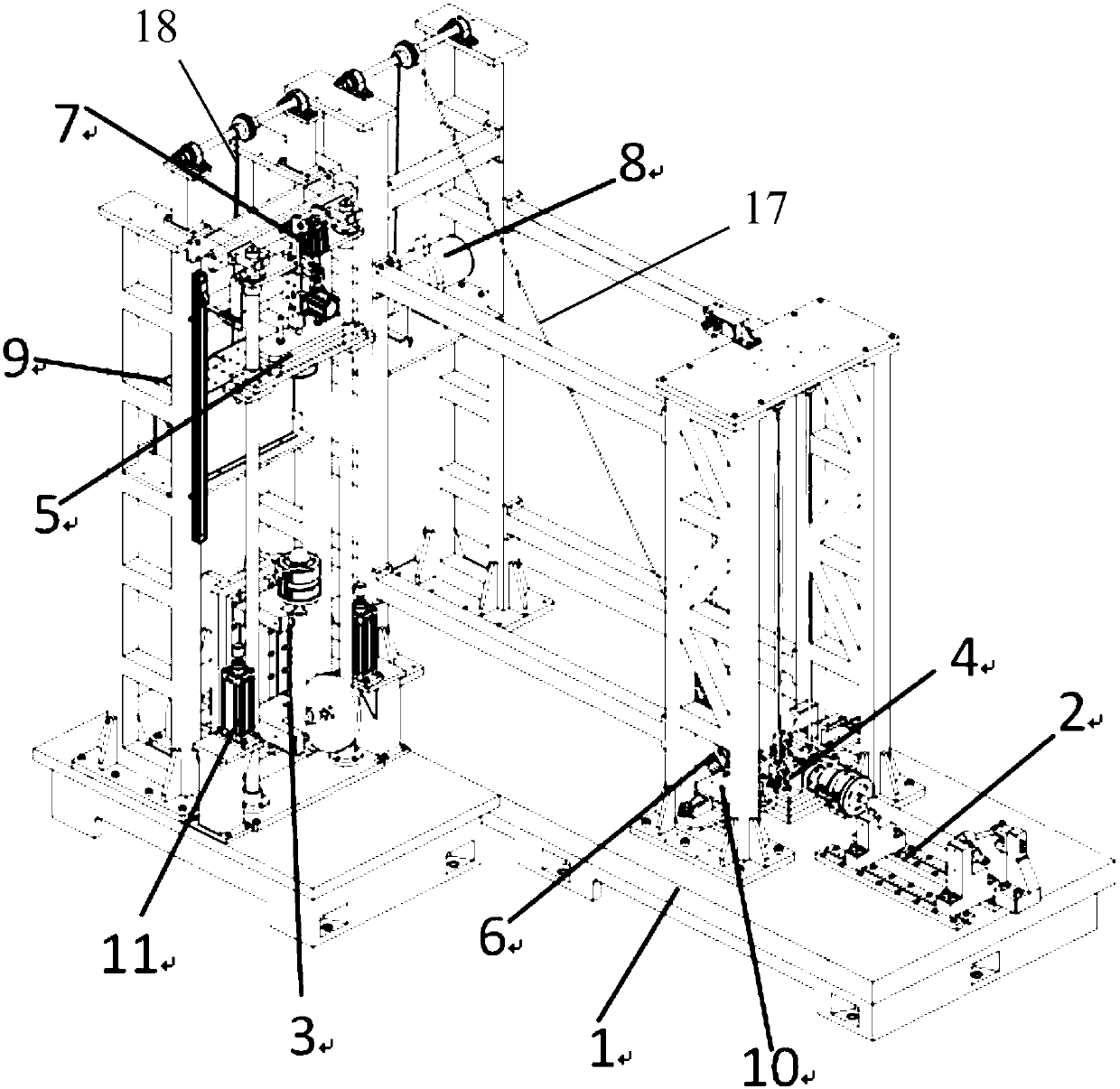

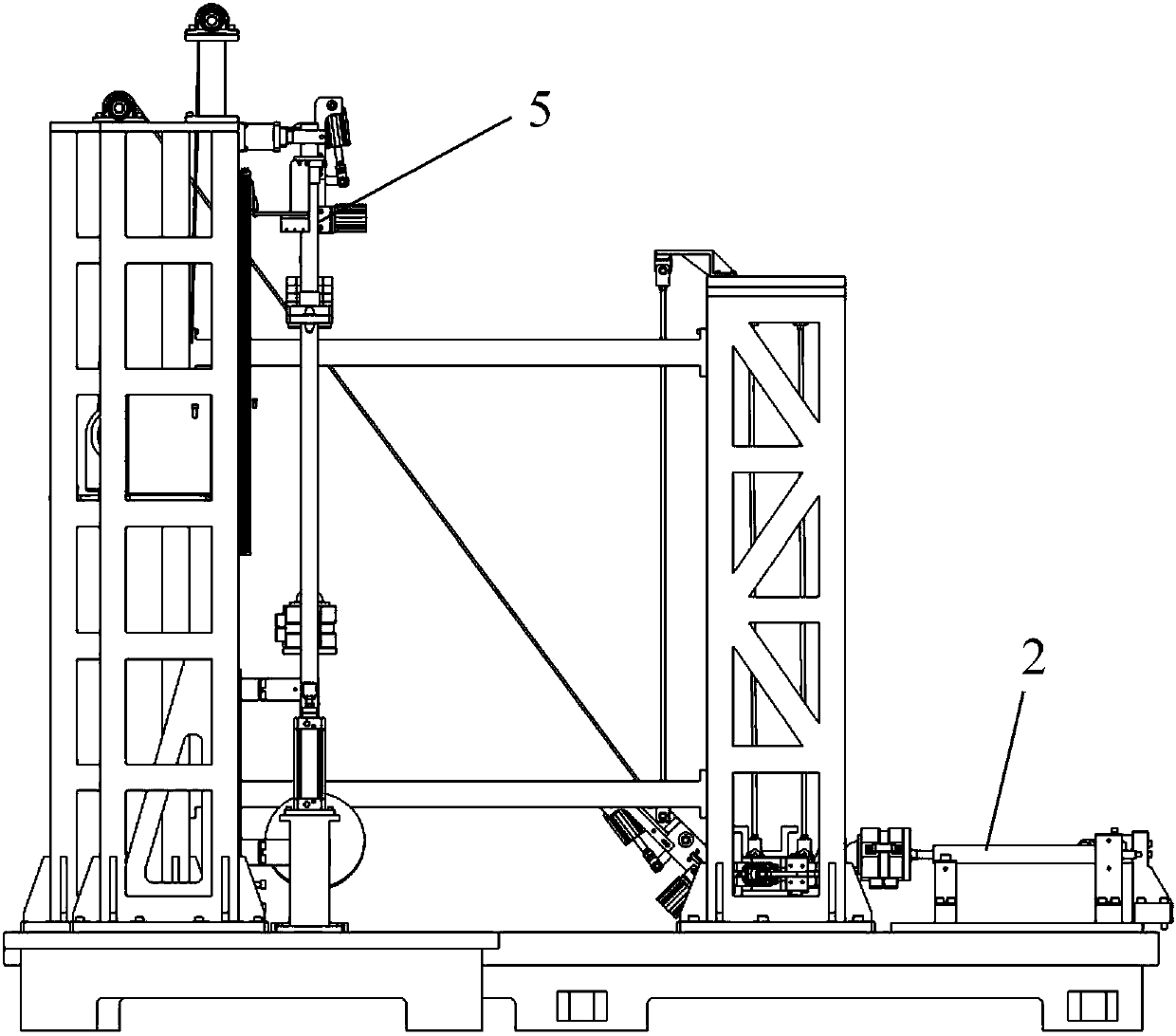

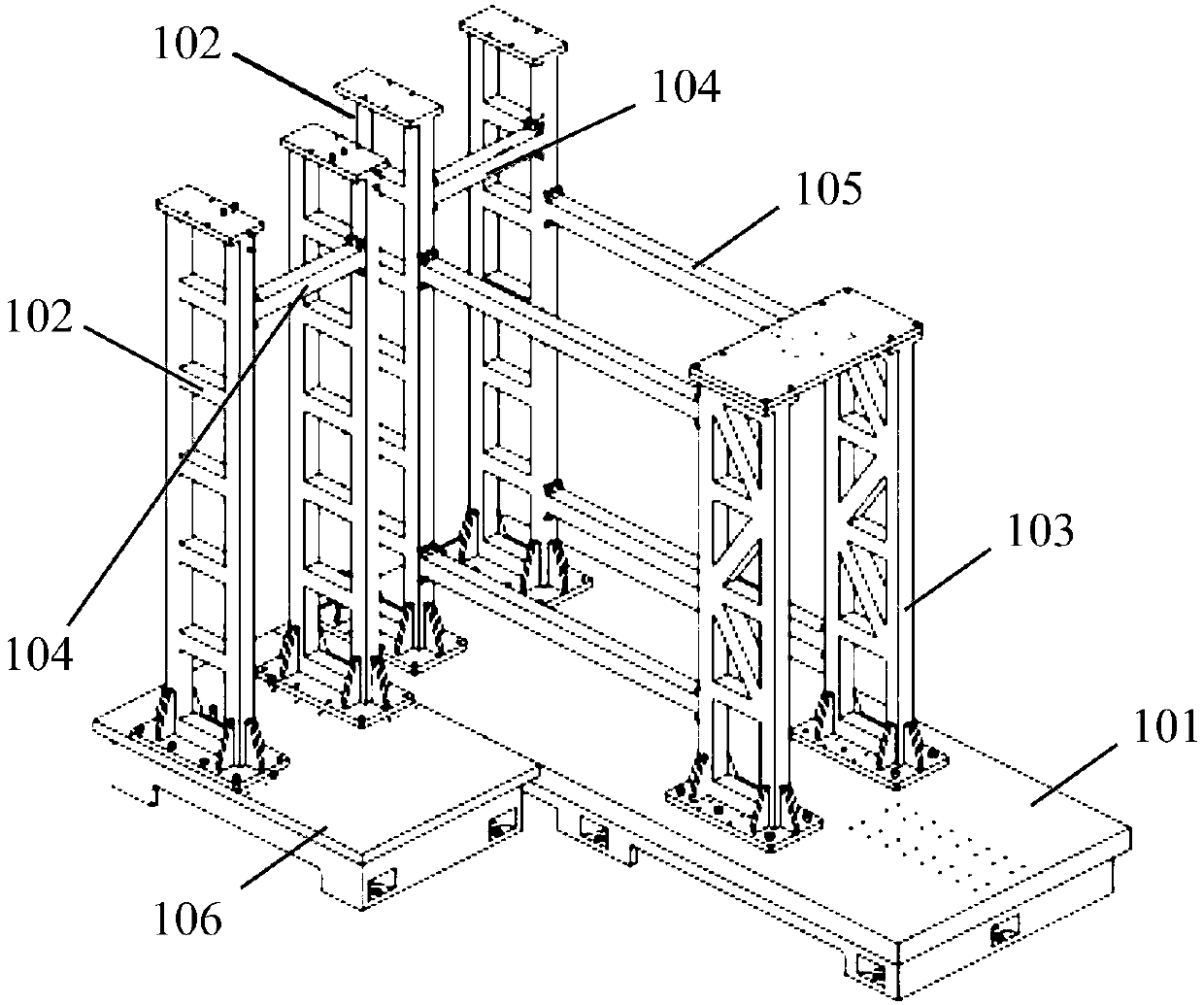

Automobile steering component integrated impact test bench and detection method thereof

PendingCN107817119APrecise shock load capabilityRealize remote controlVehicle steering/rolling behaviourShock testingFree fallingTest sample

Owner:山东凯帝斯工业系统有限公司

Fe-Mn-Al-C series medium-manganese low-temperature steel and preparation method thereof

The invention discloses a Fe-Mn-Al-C series medium-manganese low-temperature steel and a preparation method thereof. The Fe-Mn-Al-C series medium-manganese low-temperature steel comprises the chemicalingredients of, in percentage by mass, 12-15% of Mn, 4.5-5% of Al, 0.1-0.12% of C and the balance Fe and inevitable impurity elements. According to the Fe-Mn-Al-C series medium-manganese low-temperature steel and the preparation method thereof, the austenite tissue volume fraction of the low-temperature steel is larger than or equal to 47.7%, the impact energy of a -80 DEG C charpy impact test islarger than or equal to 33 J, after forging and multipass rolling are performed on a steel blank of the same ingredients with the Fe-Mn-Al-C series medium-manganese low-temperature steel, quenching+tempering heat treatment is performed on an obtained rolled blank, the Fe-Mn-Al-C series medium-manganese low-temperature steel with excellent impact toughness at low temperature is prepared, and the preparation method for the Fe-Mn-Al-C series medium-manganese low-temperature steel is simple.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

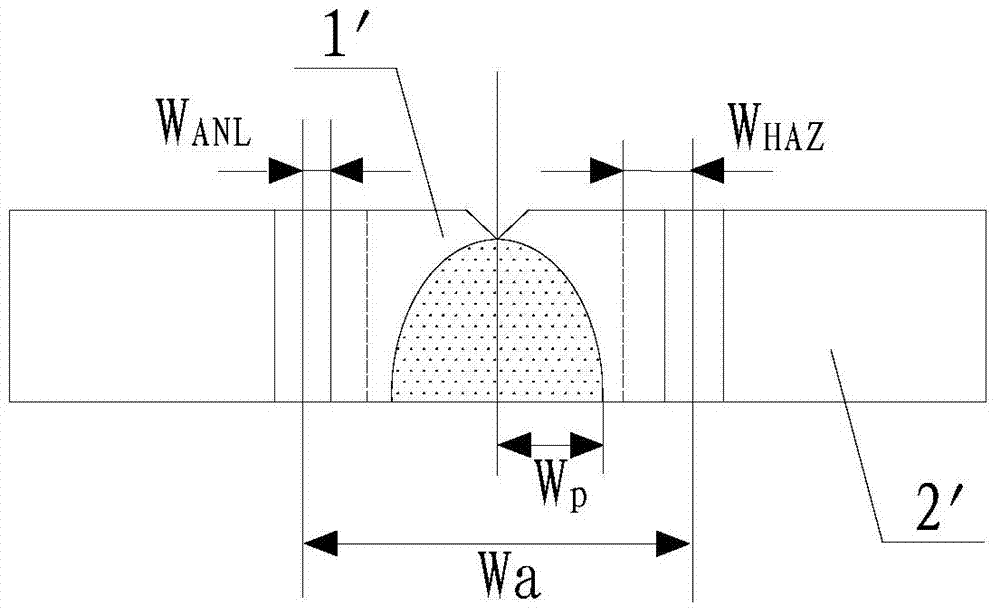

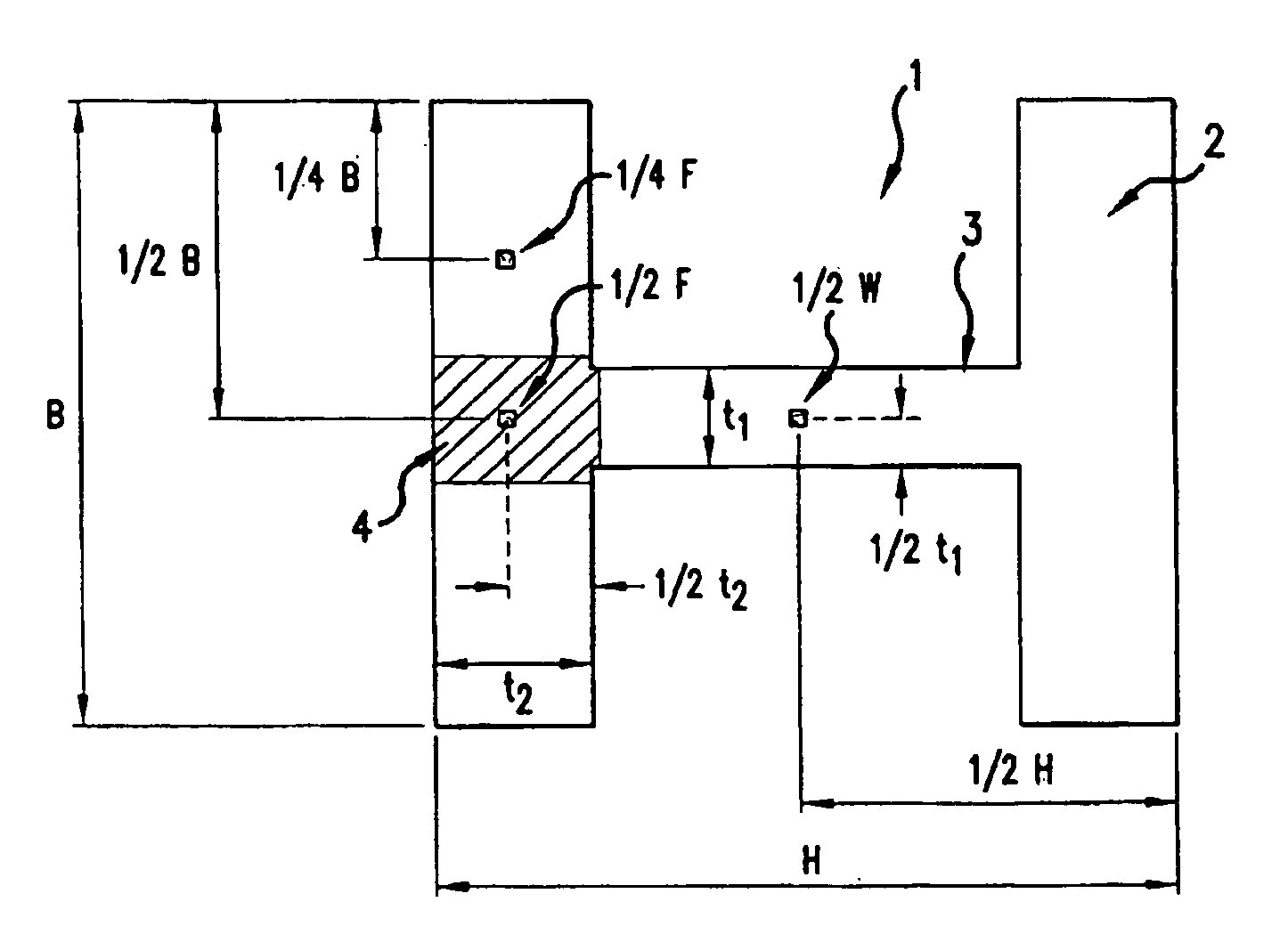

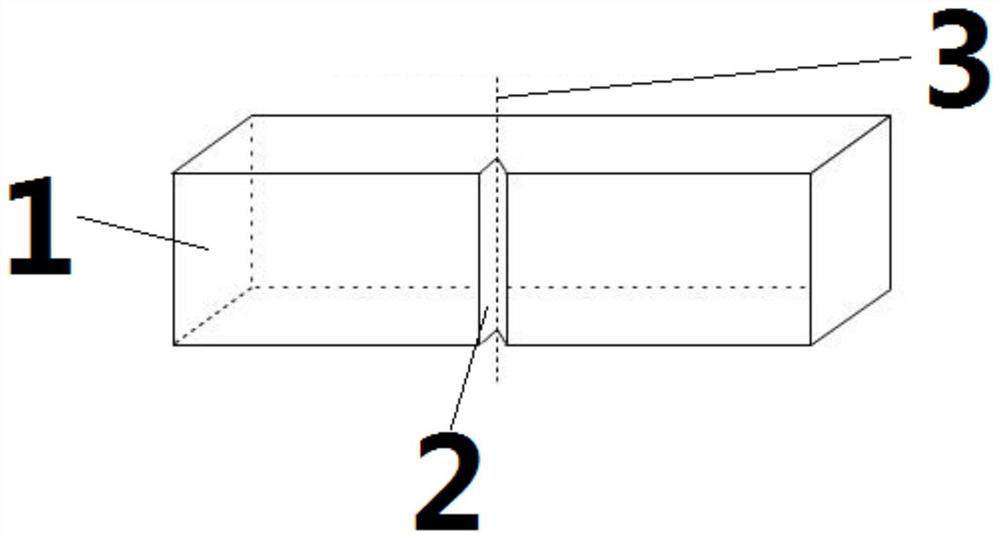

Judgment method for minimum inserting section size in Charpy impact test sample recombination technology

InactiveCN103870679AReasonable judgmentAccurate judgmentNuclear energy generationNuclear monitoringTest sampleCharpy impact test

The invention relates to a judgment method for a minimum inserting section size in a Charpy impact test sample recombination technology. The judgment method comprises the following steps: preparing a recombinant test sample, testing Vickers hardness, monitoring a thermoelectric couple, carrying out metallographic observation and determining a lower limiting value Wa,min, and checking T41J, T56J and FATT (Fracture Appearance Transition Temperature) performance characteristic parameters and the like. After the lower limiting value Wa,min is determined, independent test samples are established for the T41J, T56J and FATT performance characteristic parameters of an original test sample and the recombinant test sample to carry out variance homogeneity judgment, so as to judge whether the performances are changed or not before and after the test sample is recombined; the judgment of the Wa,min is more reasonable, more accurate and more scientific.

Owner:SUZHOU NUCLEAR POWER RES INST +1

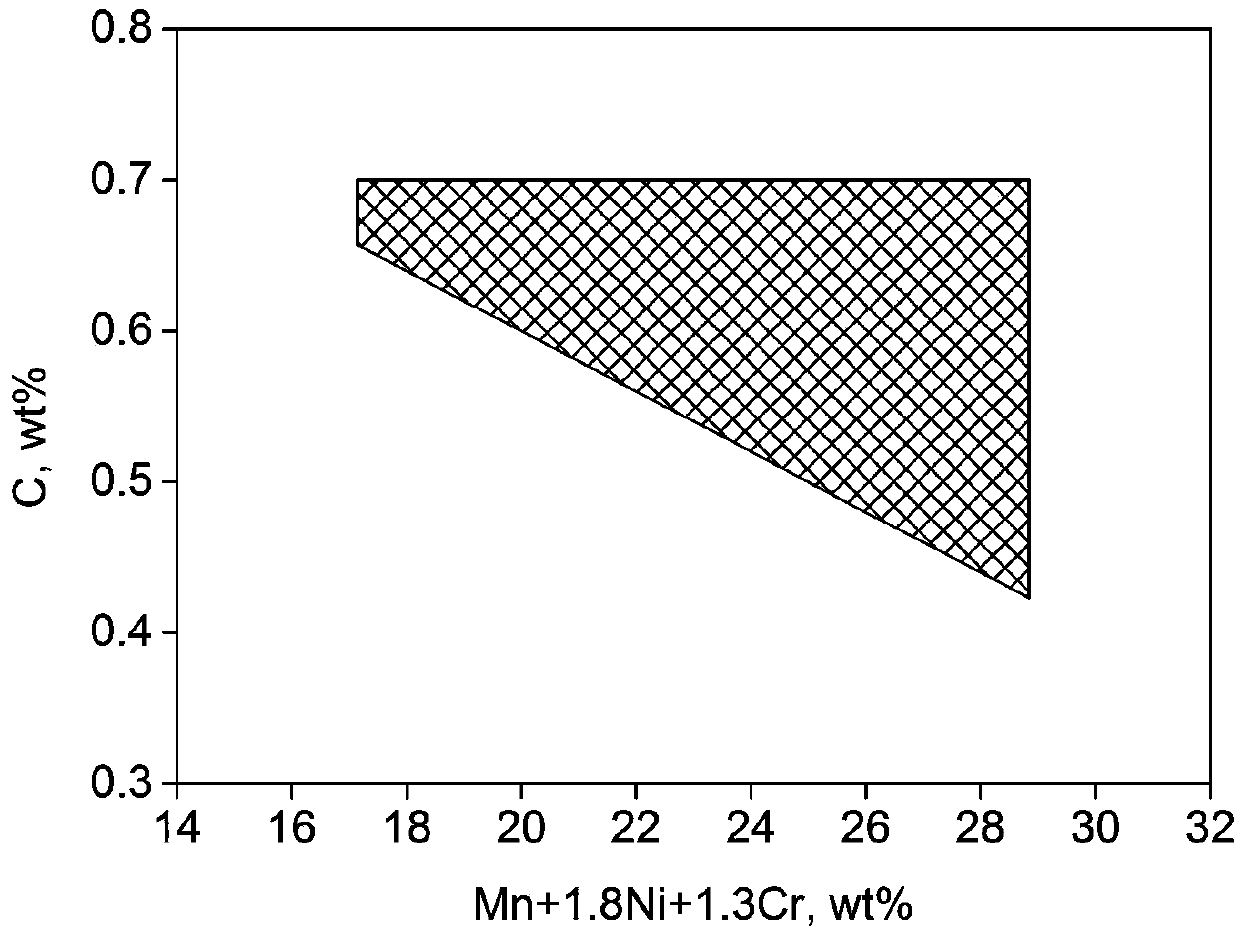

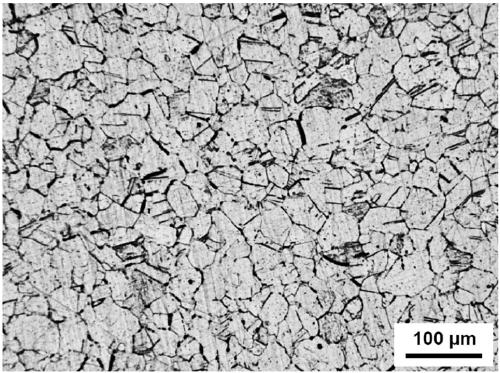

Austenite low-temperature steel and preparation method thereof

The invention discloses austenite low-temperature steel and a preparation method thereof. The austenite low-temperature steel is prepared from the chemical components in mass fraction: 14 to 20 percent of Mn, 0.3 to 1.3 percent of Ni, 2 to 5 percent of Cr, C meeting the conditions that 50C+Mn+1.8Ni+1.3Cr is larger than or equal to 50 percent and C is less than or equal to 0.7 percent, 0.02 to 0.1percent of Nb, larger than 0 and less than or equal to 0.6 percent of Si, larger than 0 and less than or equal to 0.3 percent of Al, larger than 0 and less than or equal to 0.12 percent of N, and thebalance Fe and inevitable impurity elements. The volume fraction of an austenite structure of the low-temperature steel is larger than or equal to 97 percent, the average grain diameter is less than or equal to 80mum, and the charpy impact test impact energy at minus 196 DEG C is larger than or equal to 80J. The preparation method comprises the steps of heating, deforming and cooling a steel billet with the same chemical component of the austenite low-temperature steel, adopting a process combining high-temperature thermomechanical treatment and water toughening treatment, and preparing to obtain the high-manganese low-nickel micro-niobium austenite low-temperature steel with excellent impact toughness. The preparation method is simple.

Owner:NANJING IRON & STEEL CO LTD

Resin molded article

The present invention pertains to a resin formed article obtained by forming a resin composition that comprises a cycloolefin resin and a styrene-based thermoplastic elastomer, the styrene-based thermoplastic elastomer having a weight average molecular weight of 20,000 to 150,000, and having a difference in refractive index (ΔnD) of more than −0.002 to less than +0.002 with respect to the cycloolefin resin, the resin composition having a residual ratio of 0.10 wt % or less when analyzed based on the residue on ignition test method specified in the Japanese Pharmacopeia, the resin composition having a light transmittance (optical path length: 3 mm) of 55% or more with respect to light having a wavelength of 450 nm when the resin composition is formed in a shape of a sheet having a thickness of 3.0 mm, and subjected to light transmittance measurement, and the resin composition having a Charpy impact strength of 5 to 40 kJ / m2 when the resin composition is formed to have a thickness of 4.0 mm, a length of 80.0 mm, and a width of 10.0 mm, and subjected to the notched Charpy impact test specified in JIS K 7111-1 at 23° C.

Owner:ZEON CORP

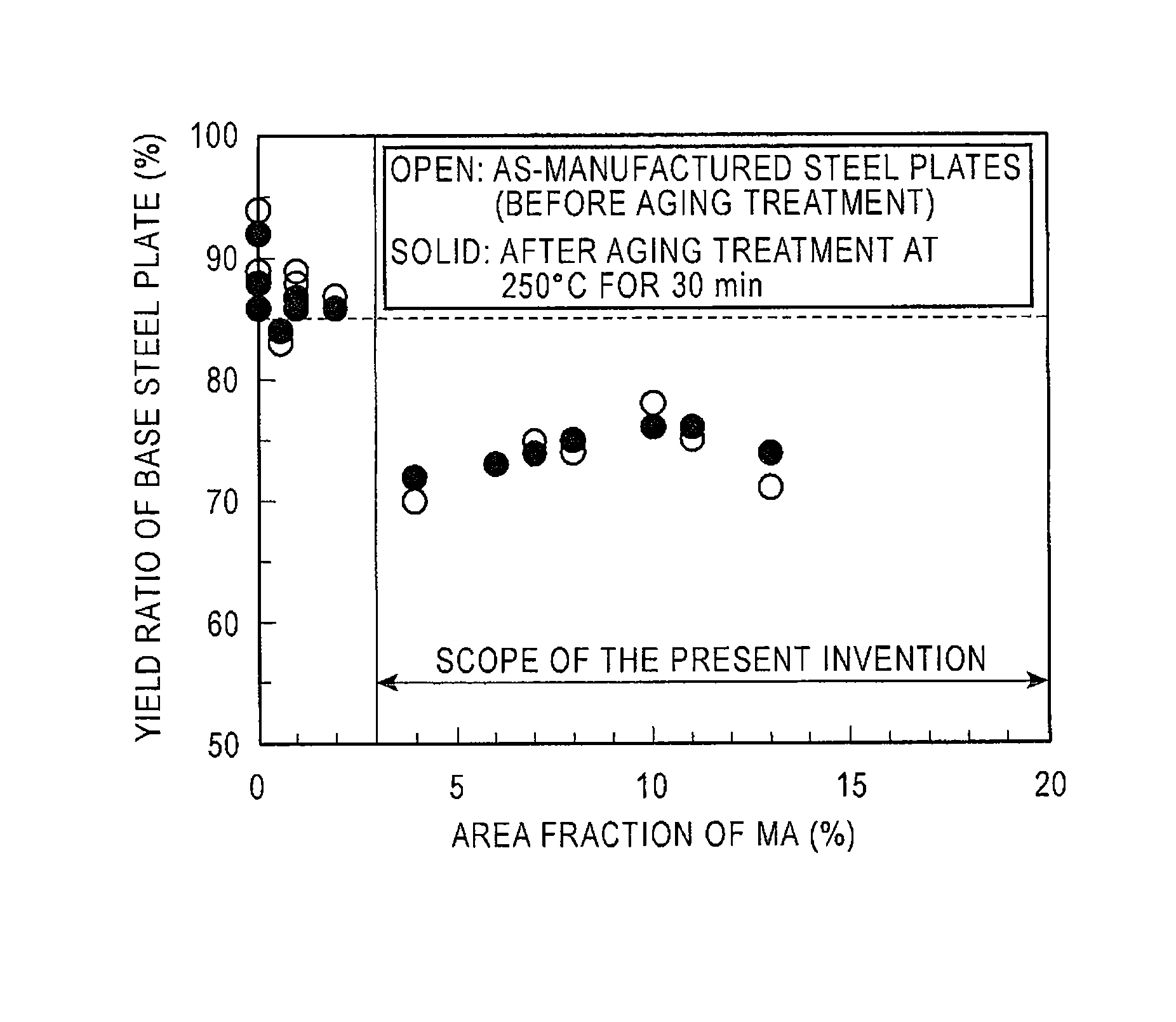

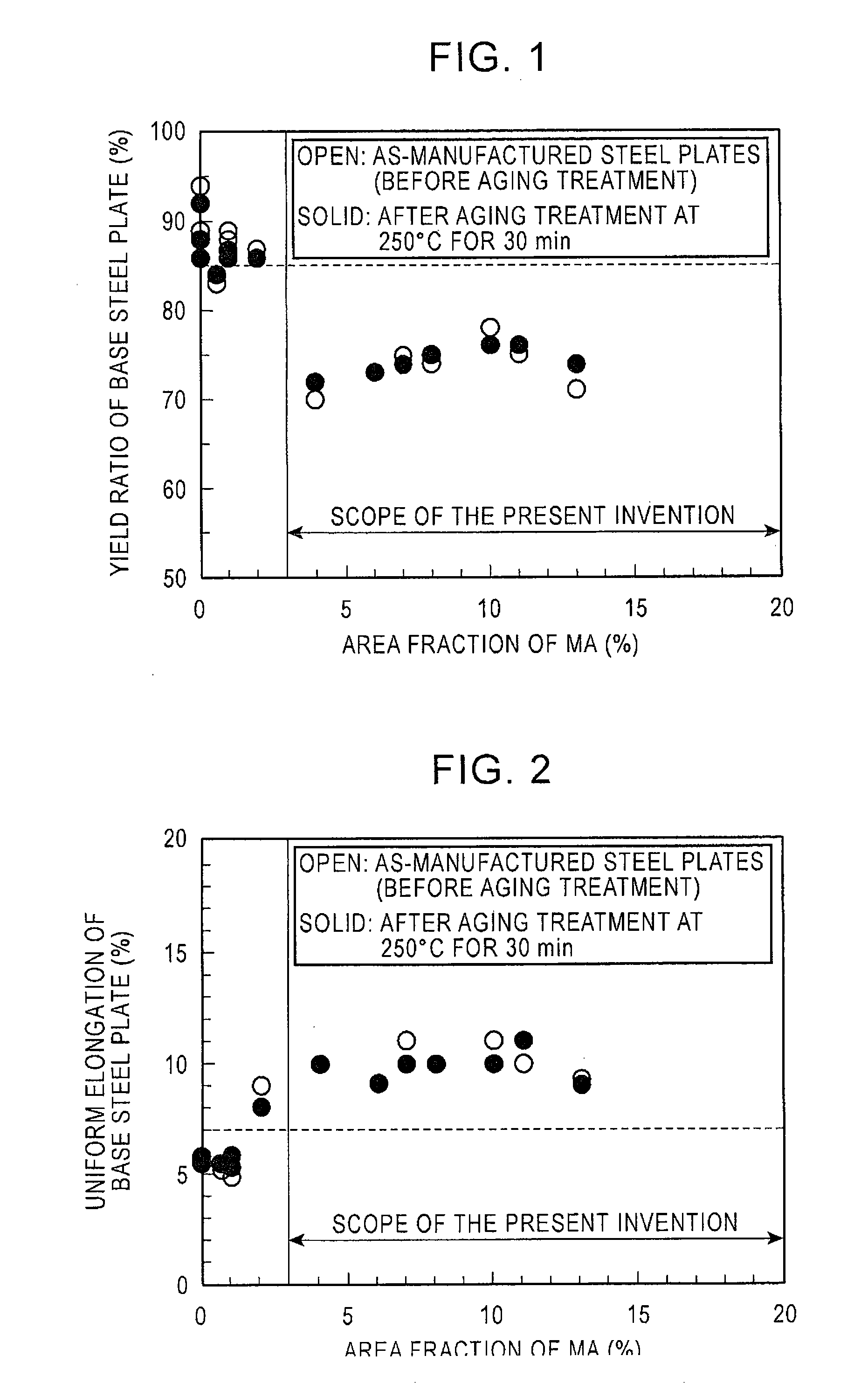

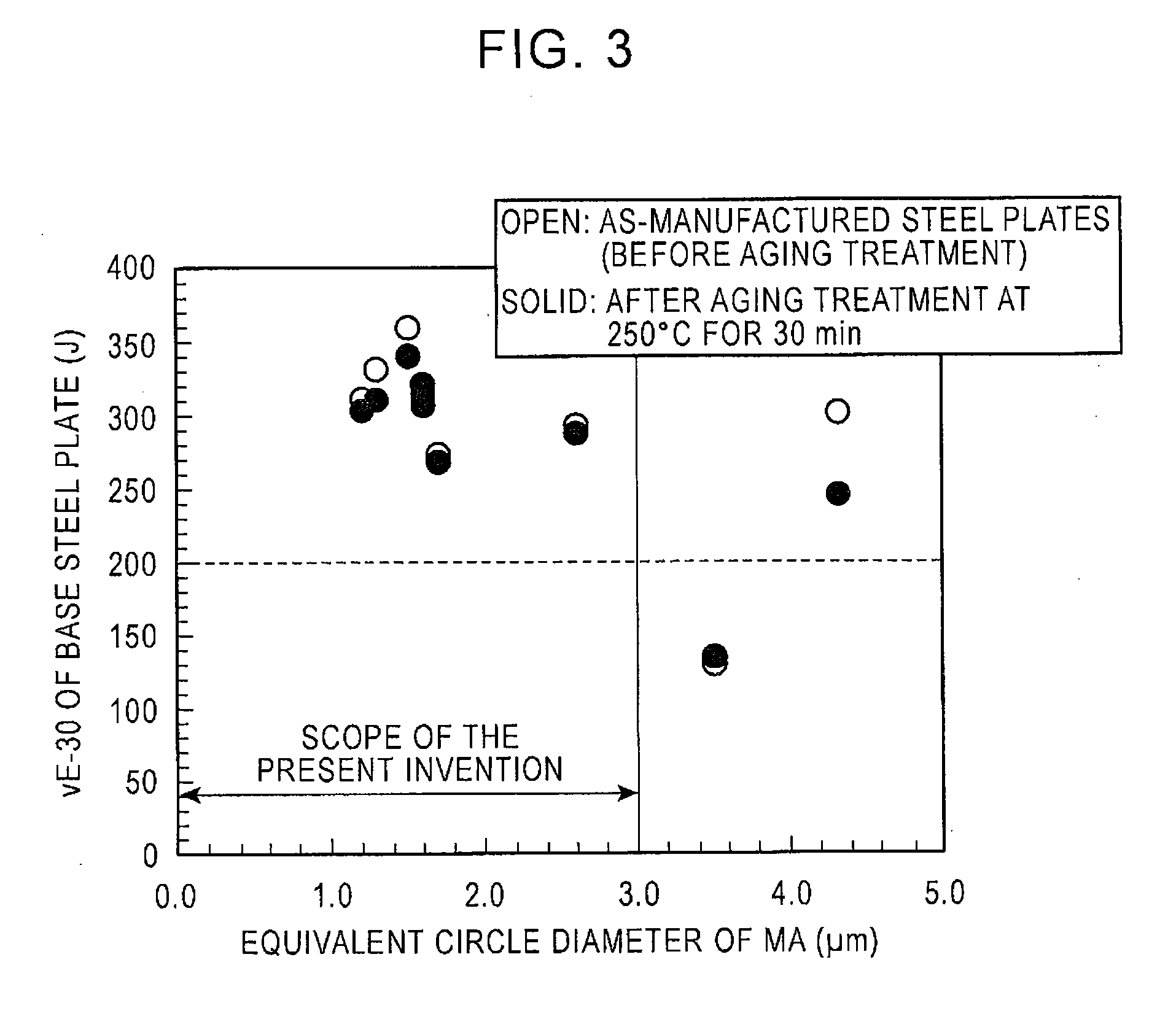

Low yield ratio, high strength and high toughness steel plate and method for manufacturing the same

ActiveUS8778096B2Improve toughnessGuaranteed toughnessFurnace typesHeat treatment furnacesAbsorbed energyCharpy impact test

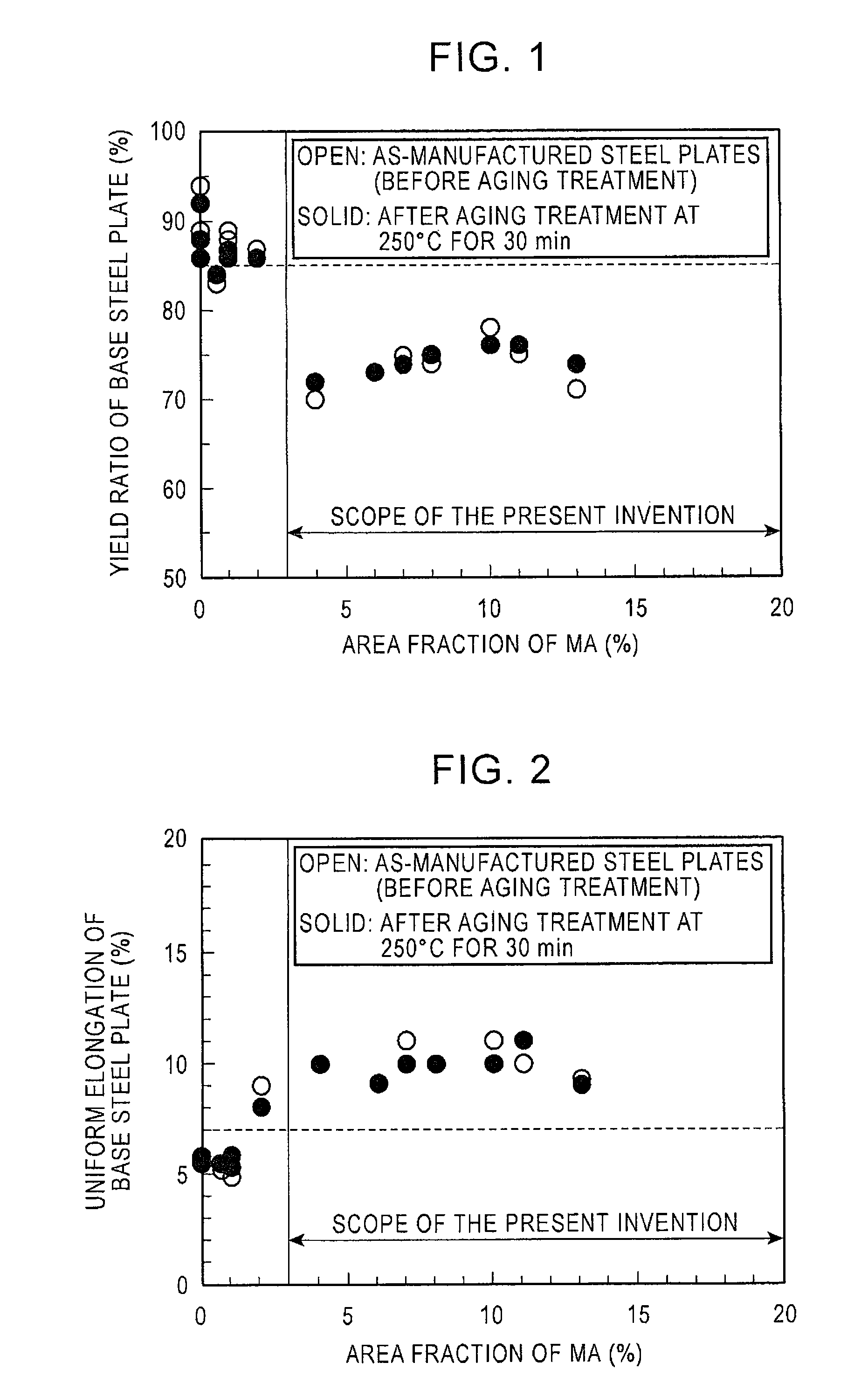

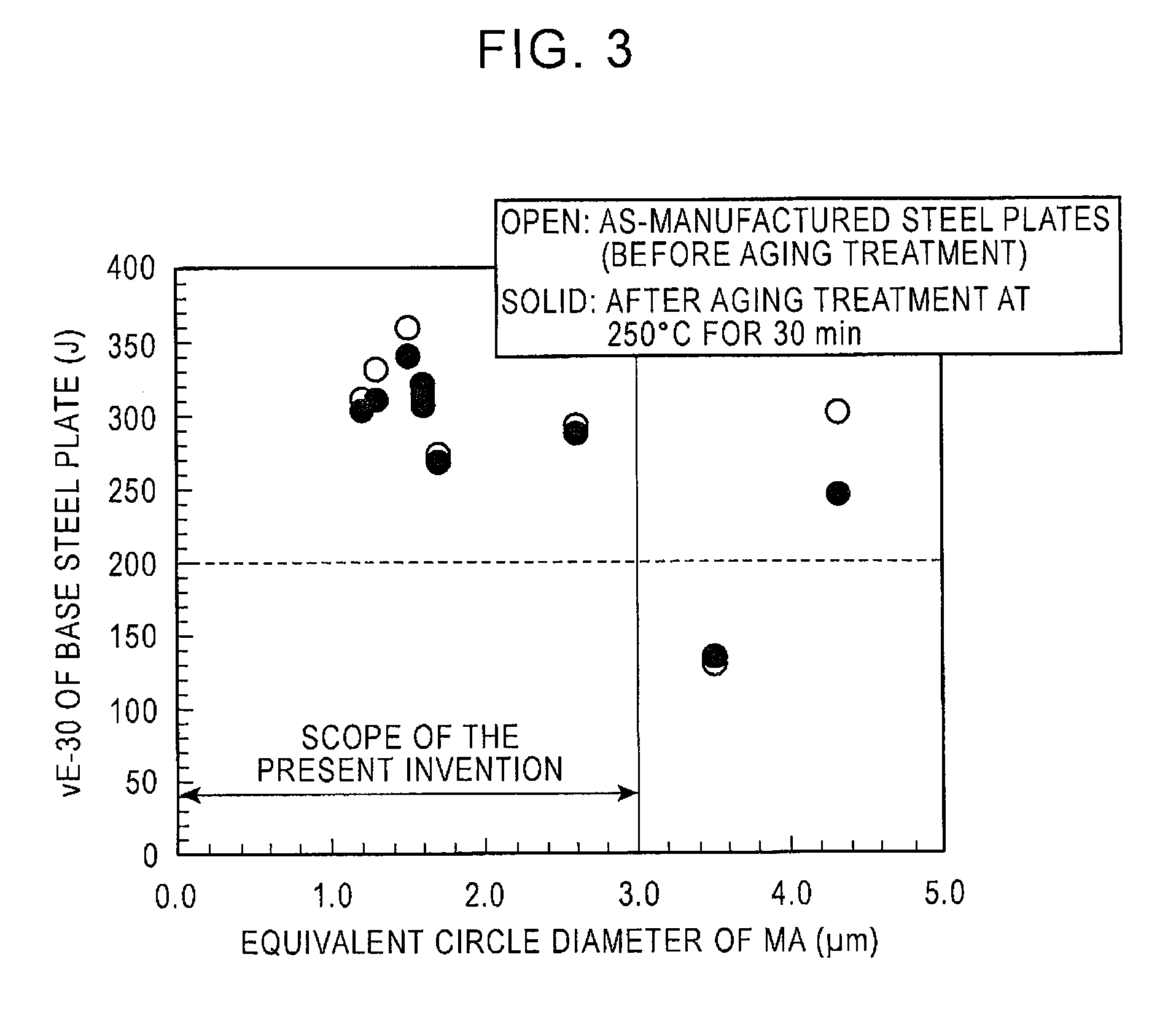

Provided is a low yield ratio, high strength and high toughness steel plate having excellent strain ageing resistance equivalent to API 5L X70 Grade or lower and a method for manufacturing the same. The steel plate has a metallographic microstructure that is a three-phase microstructure including bainite, M-A constituent, and quasi-polygonal ferrite, the area fraction of the bainite being 5% to 70%, the area fraction of the M-A constituent being 3% to 20%, the remainder being the quasi-polygonal ferrite, the equivalent circle diameter of the M-A constituent being 3.0 μm or less. The steel plate has a yield ratio of 85% or less and a Charpy impact test absorbed energy of 200 J or more at −30° C. before or after being subjected to strain ageing treatment at a temperature of 250° C. or lower for 30 minutes or less.

Owner:JFE STEEL CORP

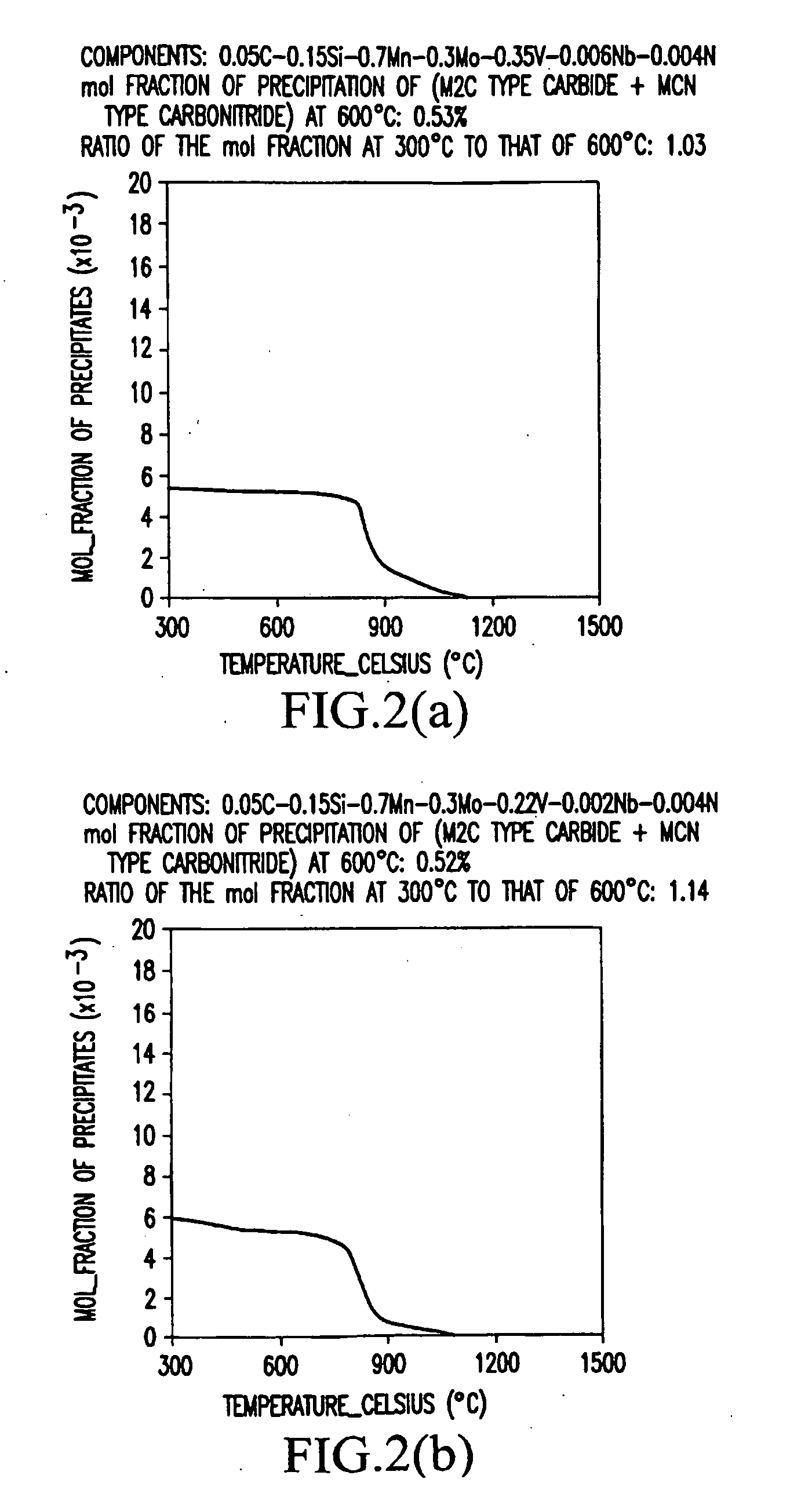

Shaped steel excellent in fire resistance and producing method therefore

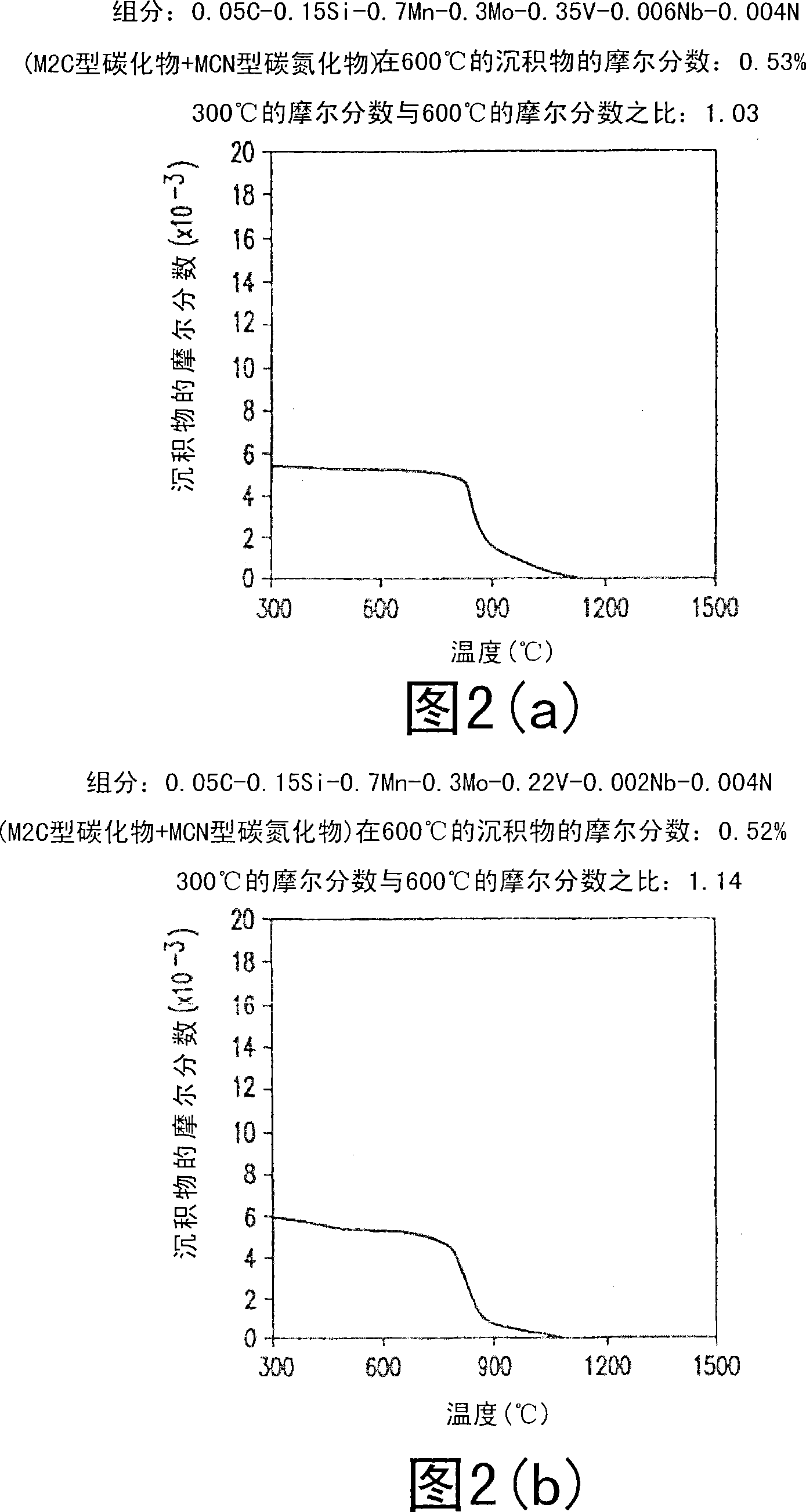

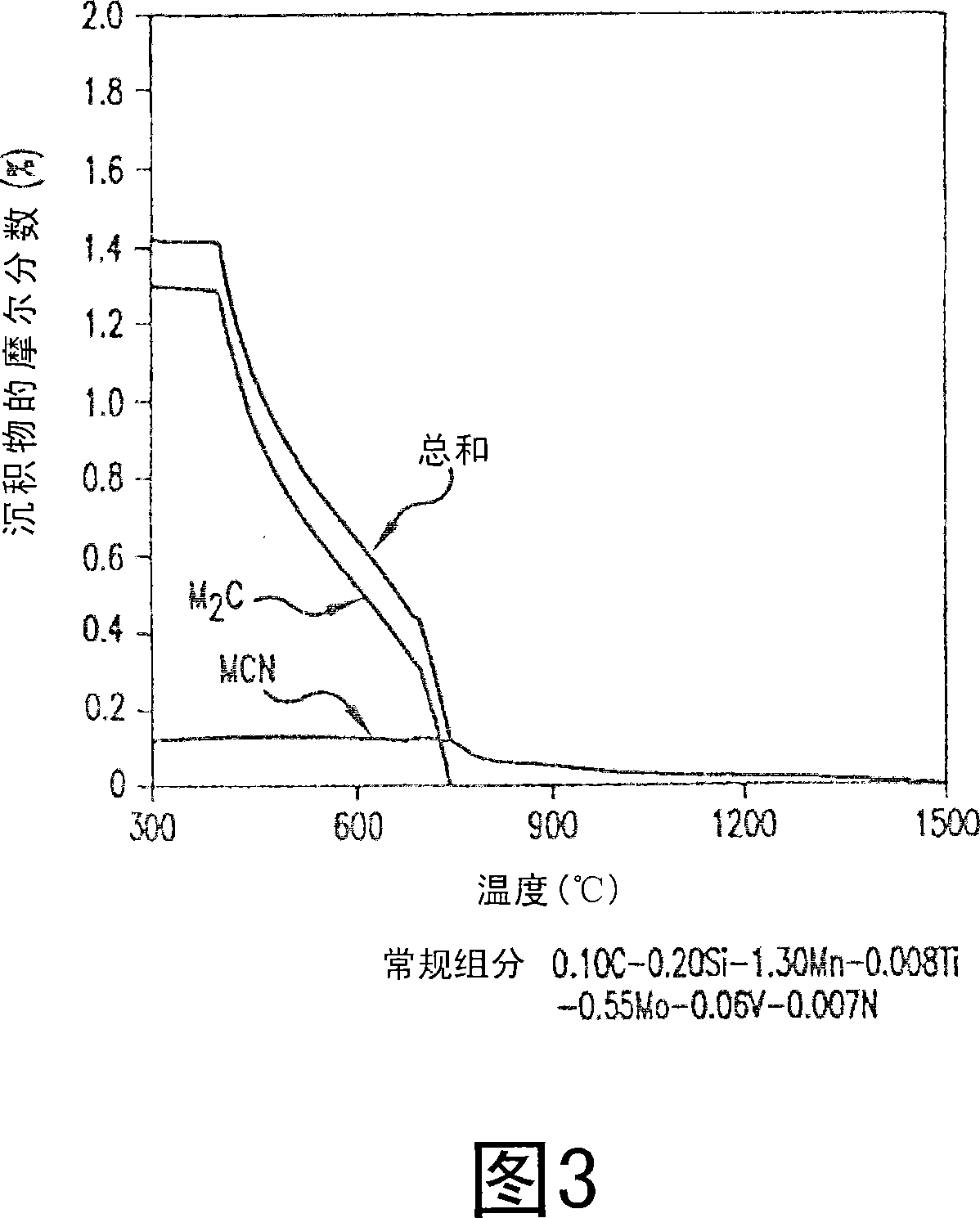

A shaped steel, such as H-shaped steel, excellent in fire resistance, where a flange portion has 50% or more of a ratio of strength, 80 % or less of yield ratio, and 100 J or more of impact strength of Charpy impact test at 0 DEG C, wherein the ratio of strength = (proof stress of 0.2% at 600 DEG C) / (yield strength at room temperature), and a producing method thereof are provided. The shaped steel comprises in mass percent (%): C: 0.03-0.15; Mo: 0.1- 0.6; V <= 0.35; and N: 0.002-0.012, and the balance being iron and residual impurities, wherein (x) a mol fraction of precipitate of alloy carbides and alloy carbonitrides at 600 DEG C is 0.3 % or more, and (y) the ratio of the mol fraction of precipitate of alloy carbides and alloy carbonitrides at 300 DEG C to the mol fraction of precipitate of alloy carbides and alloy carbonitrides at 600 DEG C is 2.0 or less.

Owner:NIPPON STEEL CORP

Low yield ratio, high strength and high toughness steel plate and method for manufacturing the same

ActiveUS20120241057A1Yield ratio decreaseIncrease of uniform elongationFurnace typesHeat treatment furnacesAbsorbed energyCharpy impact test

Provided is a low yield ratio, high strength and high toughness steel plate having excellent strain ageing resistance equivalent to API 5L X70 Grade or lower and a method for manufacturing the same. The steel plate has a metallographic microstructure that is a three-phase microstructure consisting of bainite, M-A constituent, and quasi-polygonal ferrite, the area fraction of the bainite being 5% to 70%, the area fraction of the M-A constituent being 3% to 20%, the remainder being the quasi-polygonal ferrite, the equivalent circle diameter of the M-A constituent being 3.0 μm or less. The steel plate has a yield ratio of 85% or less and a Charpy impact test absorbed energy of 200 J or more at −30° C. before or after being subjected to strain ageing treatment at a temperature of 250° C. or lower for 30 minutes or less.

Owner:JFE STEEL CORP

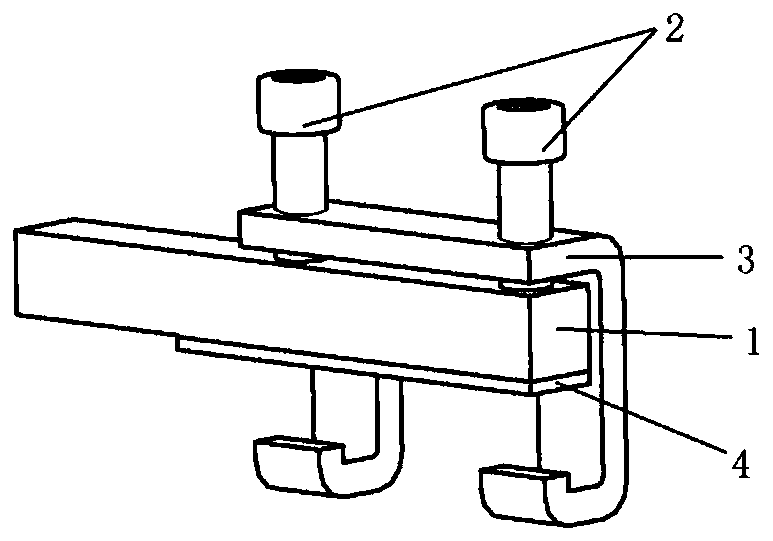

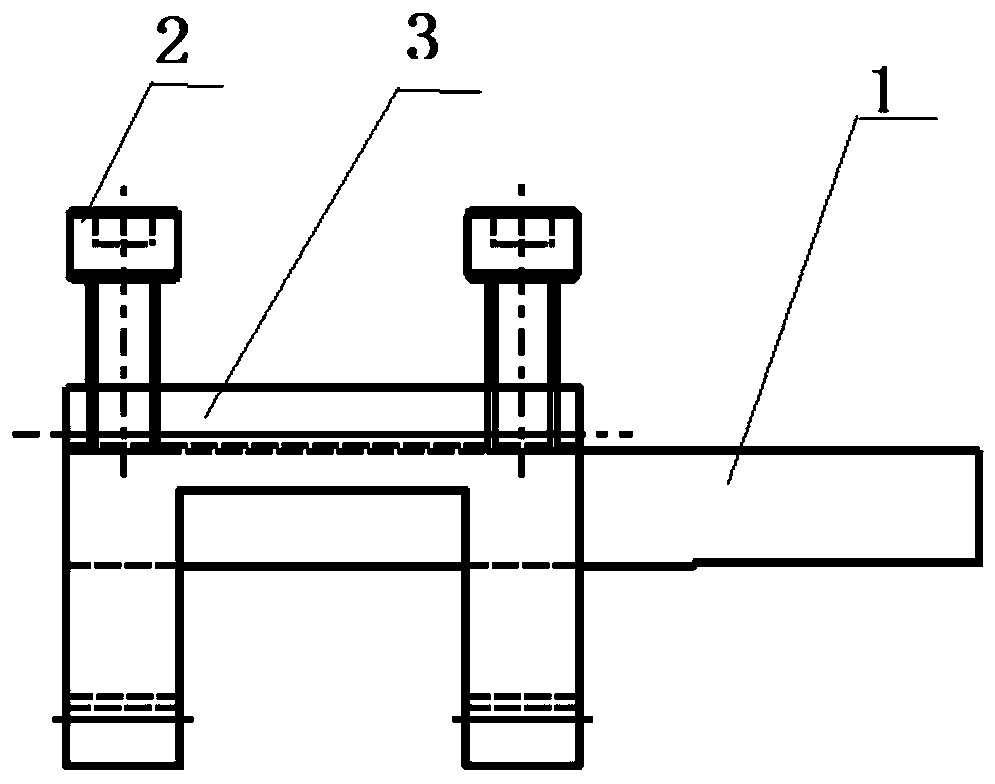

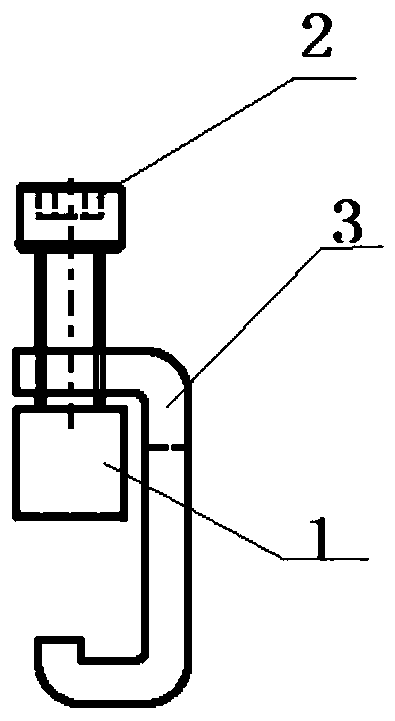

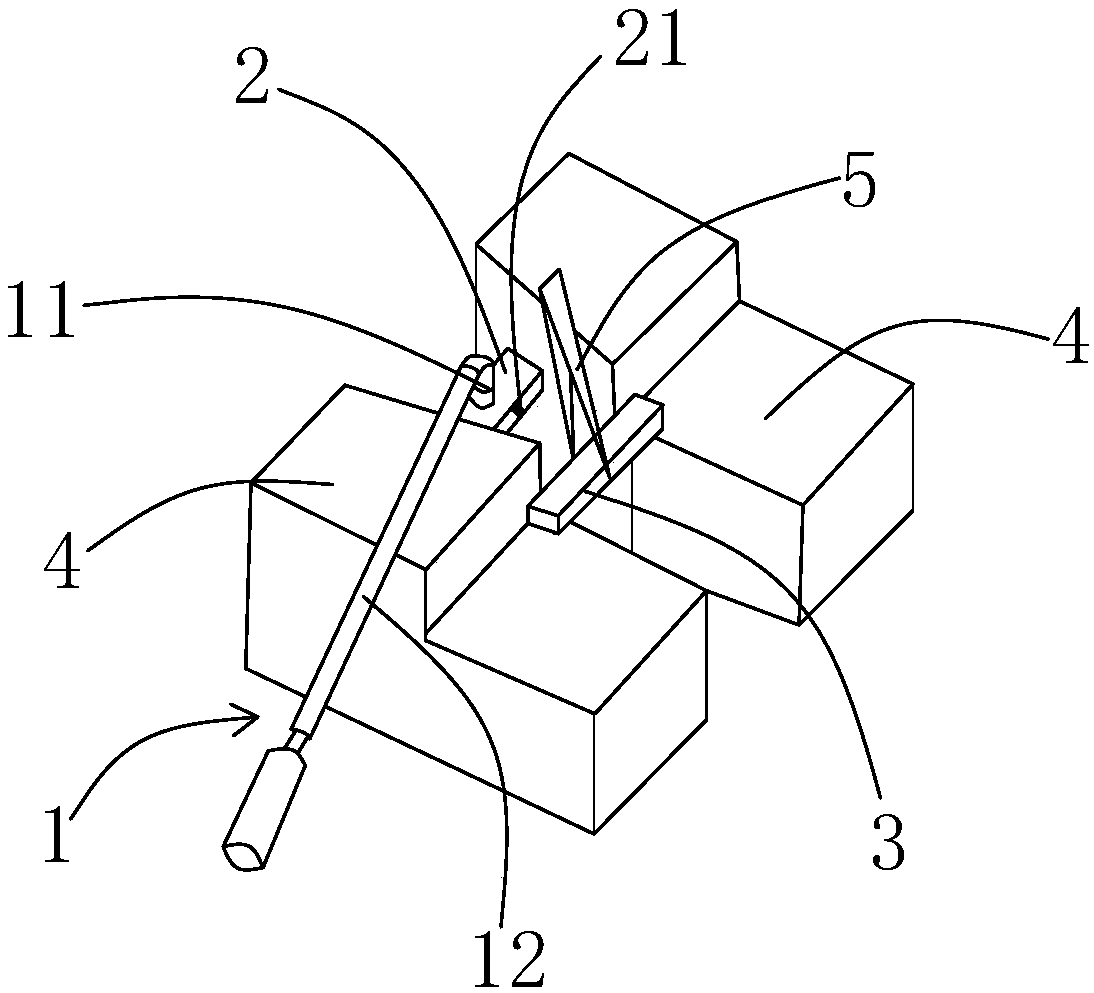

Sample clamping device for thin plate impact performance detection and test method

PendingCN111024492ASolve the phenomenon of warpingGuaranteed accuracyMaterial strength using repeated/pulsating forcesSheet steelThin slab

The invention relates to a sample clamping device for thin plate impact performance detection and a test method, and belongs to the technical field of metallurgical detection. The device comprises a jaw supporting block (1), a fastening bolt (2), a clamping hook (3), a gasket (4) and a sample wafer concave table (7). And the clamping hooks (3) are fixed on the impact test bed cross beam (5) and the impact test bed (6) through the fastening bolts (2). The sample clamping device for detecting the impact performance of the thin plate is adopted to detect the impact performance of the thin plate,so that the phenomenon that a sample piece is easy to warp in the impact process when the Charpy impact test is used for evaluating the low-temperature brittleness of the high-strength thin steel plate is solved, the low-temperature impact strength of the high-strength thin steel plate is evaluated, and the accuracy of a test result is ensured. The device is simple to manufacture and convenient tooperate.

Owner:TANGSHAN IRON & STEEL GROUP +1

Production technique of ring forge piece

The invention discloses a production technique of a ring forge piece. Q345D steel is selected as a war material, and the raw material is forged to obtain the ring forge piece. The production techniquefurther comprises the following steps that a, the ring forge piece is heated to be 1200-1240 DEG C and subjected to heat preservation for 2 h; b, after heat preservation is finished, the ring forge piece is taken out and subjected to drawing-out, the deformation quantity is 50-55%, upsetting is conducted, the deformation quantity is 60-65%, and the final deformation temperature is controlled to be 1000-1050 DEG C; c, ring grinding is conducted till the needed size of the ring forge piece is achieved, the deformation quantity is 40-50%, the final deformation temperature is controlled to be 850-900 DEG C, and the wall thickness of the ring forge piece is 90-120 mm; and d, air cooling is conducted till the room temperature is achieved. According to the production technique of the ring forgepiece, drawing-out, upsetting and ring grinding are conducted at the same fire time, and by controlling the deformation quantities of drawing-out, upsetting and ring grinding and the temperatures after drawing-out, upsetting and ring grinding, the yield strength of the produced ring forge piece reaches 360 MPa or more, and when the ring forge piece is subjected to a Charpy impact test of a V-shaped notch under the temperature of minus 20 DEG C, the average value of impact work of the ring forge piece reaches 120 J or more.

Owner:WUXI BAOLU FORGING +1

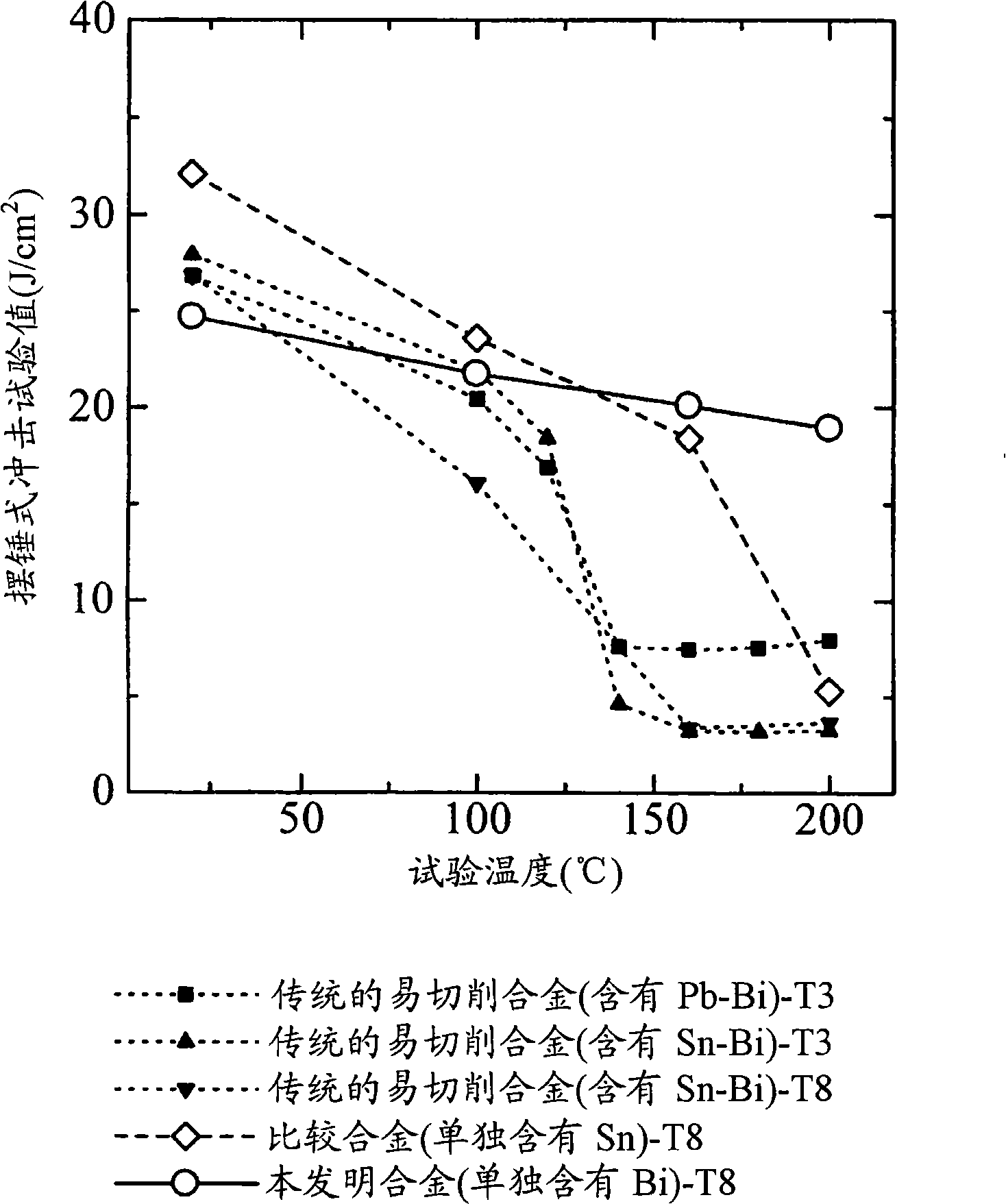

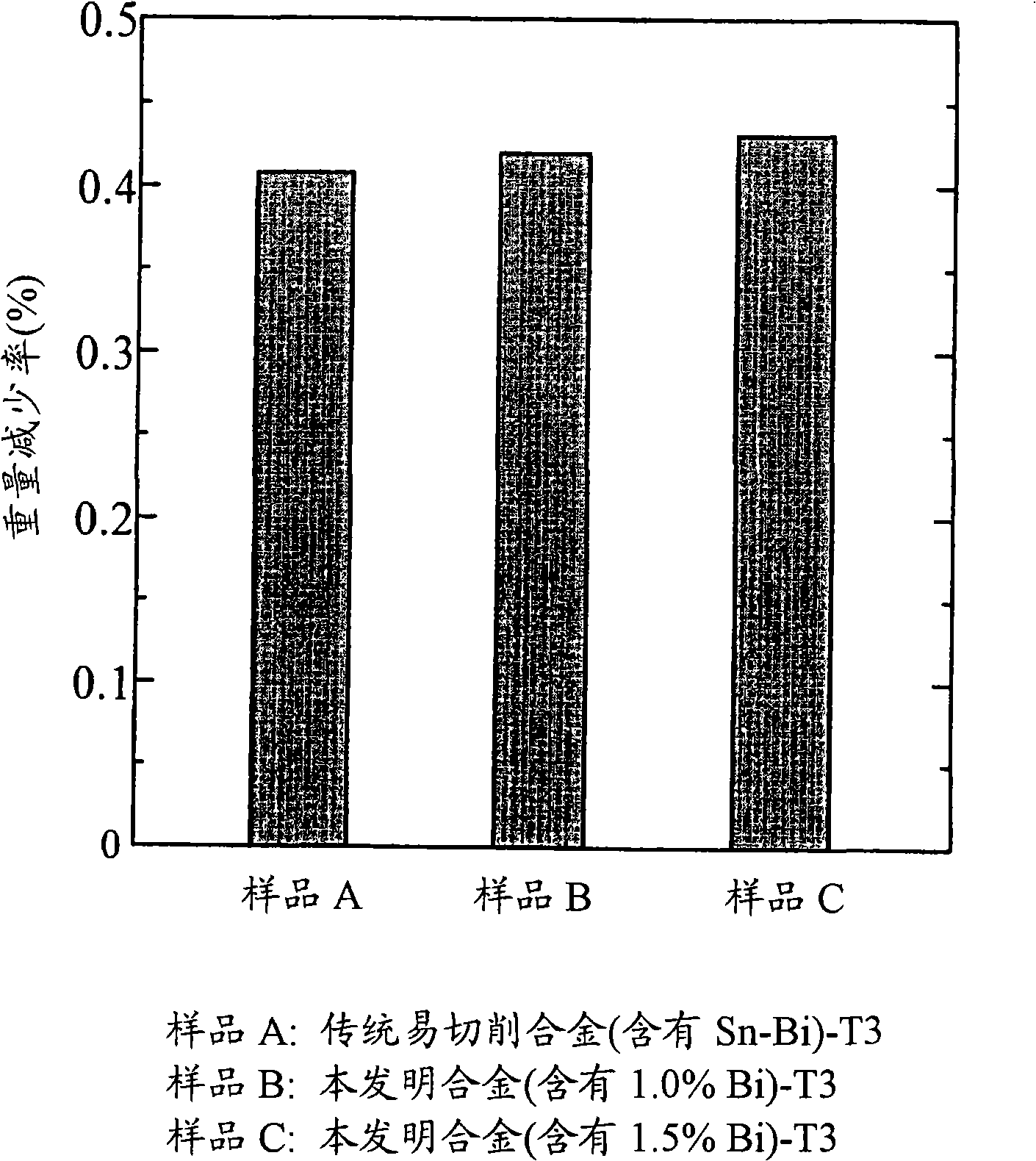

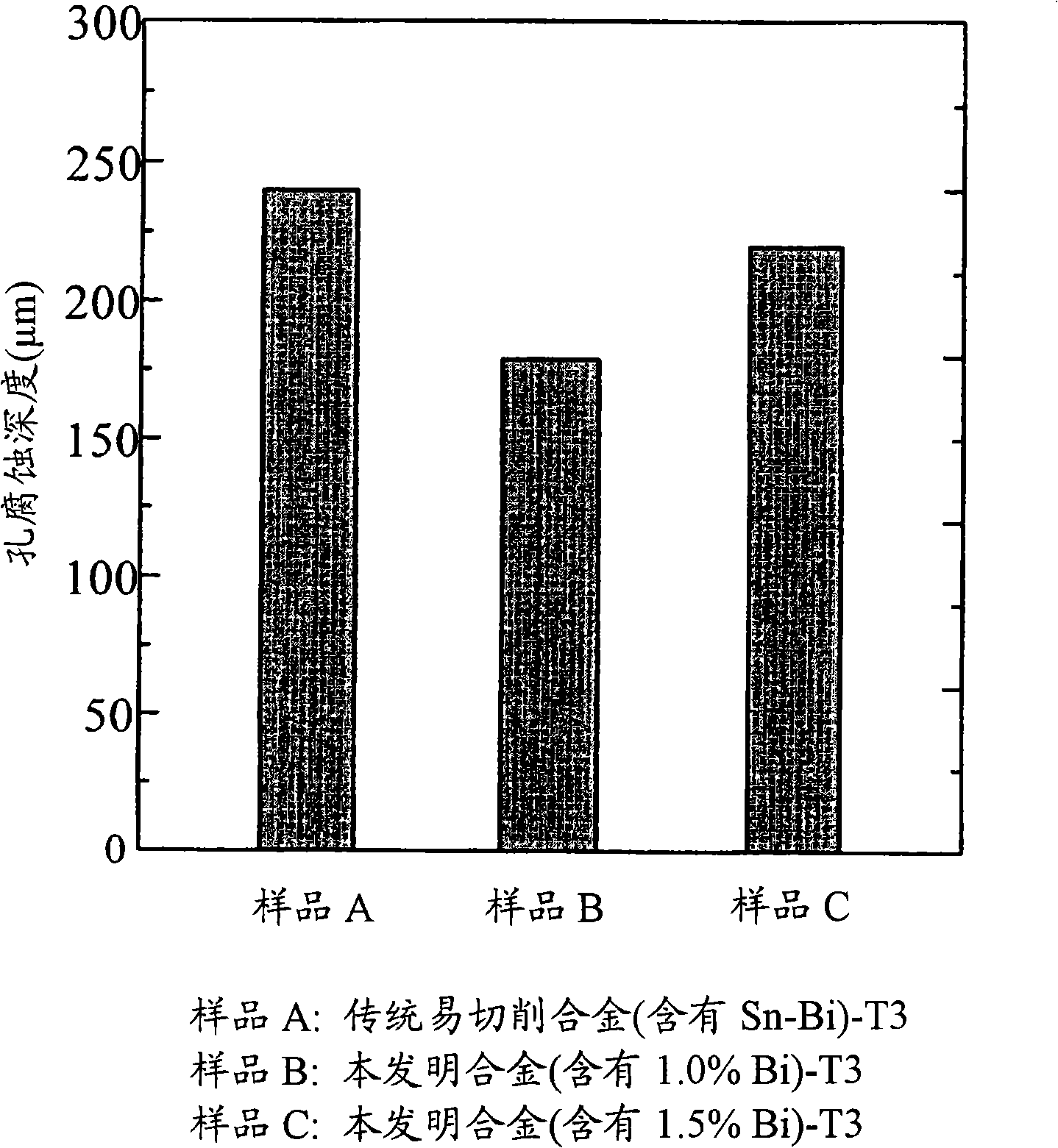

Free-cutting aluminum alloy extrudate with excellent brittle resistance at high temperature

ActiveCN101278065AMaintain machinabilityInhibit high temperature embrittlementRoom temperatureCharpy impact test

A free-cutting aluminum alloy extrudate having excellent brittle resistance at high temperatures which contains 3-6 mass% Cu and 0.9-3 mass% Bi, with the remainder being Al and unavoidable impurities. When the extrudate is examined in a Charpy impact test, the temperature at which the Charpy impact value is one-half the value at room temperature is 180 DEG C or higher.

Owner:FURUKAWA SKY ALUMINUM CORP

Age-hardening steel

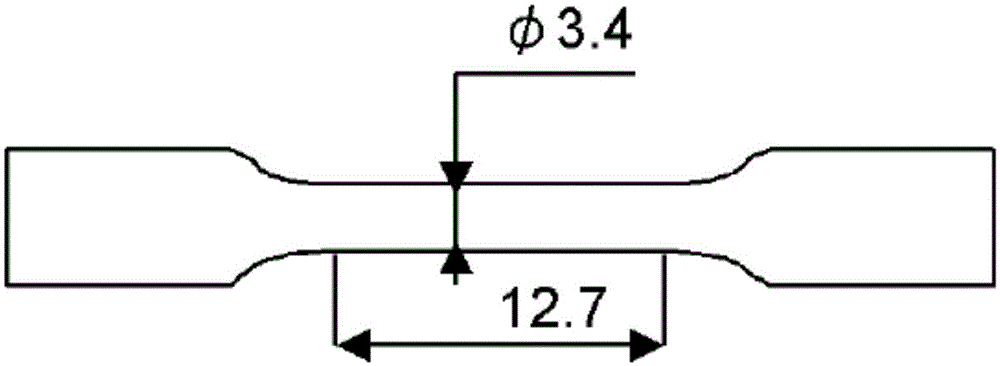

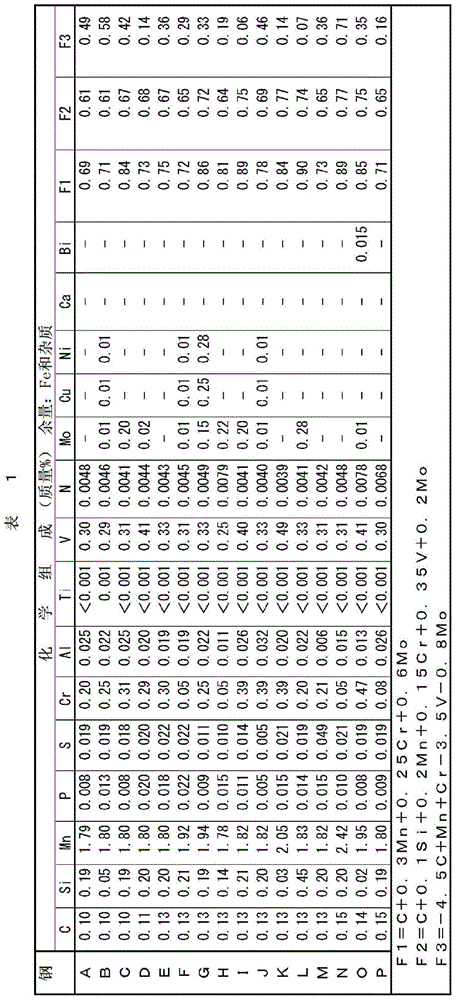

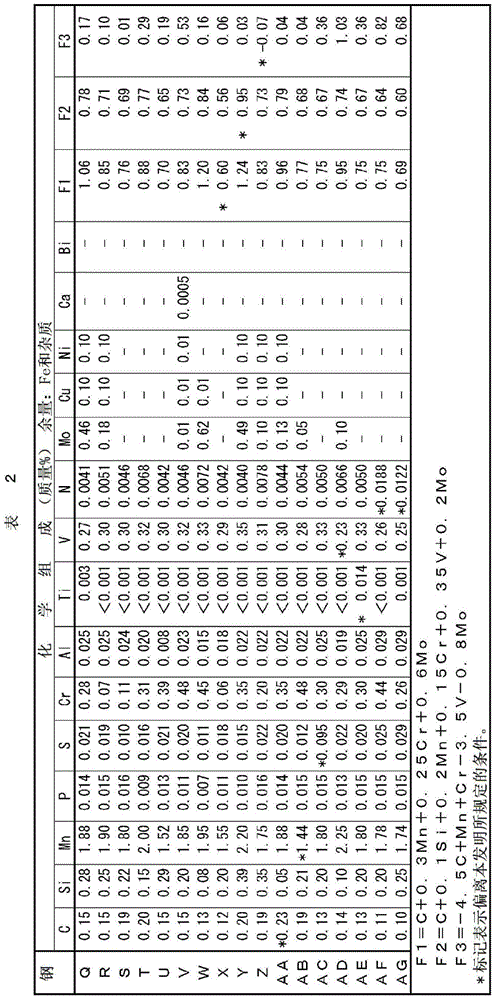

ActiveCN105164297AGuaranteed fatigue strengthImprove toughnessFurnace typesHeat treatment furnacesMachine partsCharpy impact test

The invention provides age-hardening steel having a chemical composition containing 0.05 to 0.20% of C, 0.01 to 0.50% of Si, 1.5 to 2.5% of Mn, 0.005 to 0.08% of S, 0.03 to 0.50% of Cr, 0.005 to 0.05% of Al, 0.25 to 0.50% of V, 0 to 1.0% of Mo, 0 to 0.3% of Cu, 0 to 0.3% of Ni, 0 to 0.005% of Ca, 0 to 0.4% of Bi and a remainder made up by Fe and impurities, wherein the following formulae P <= 0.03%, Ti < 0.005% and N < 0.0080% are satisfied in the impurities, and the following formulae [C+0.3Mn+0.25Cr+0.6Mo >= 0.68], [C+0.1Si+0.2Mn+0.15Cr+0.35V+0.2Mo <= 0.85] and [-4.5C+Mn+Cr-3.5V-0.8Mo >= 0.00] are satisfied. The age-hardening steel has hardness of 290 HV or less before being subjected to an aging treatment, also has an amount of hardening of 25 HV or more and fatigue strength of 350 MPa or more when subjected to an aging treatment, and also has an absorption energy of 16 J or more at 20 DEG C after being subjected to an aging treatment as evaluated by a Charpy impact test that is carried out using a U-notched standard test specimen having a notch depth of 2 mm and a notch root radius of 1 mm. Therefore, the age-hardening steel is extremely suitable as a material for machine parts.

Owner:NIPPON STEEL CORP

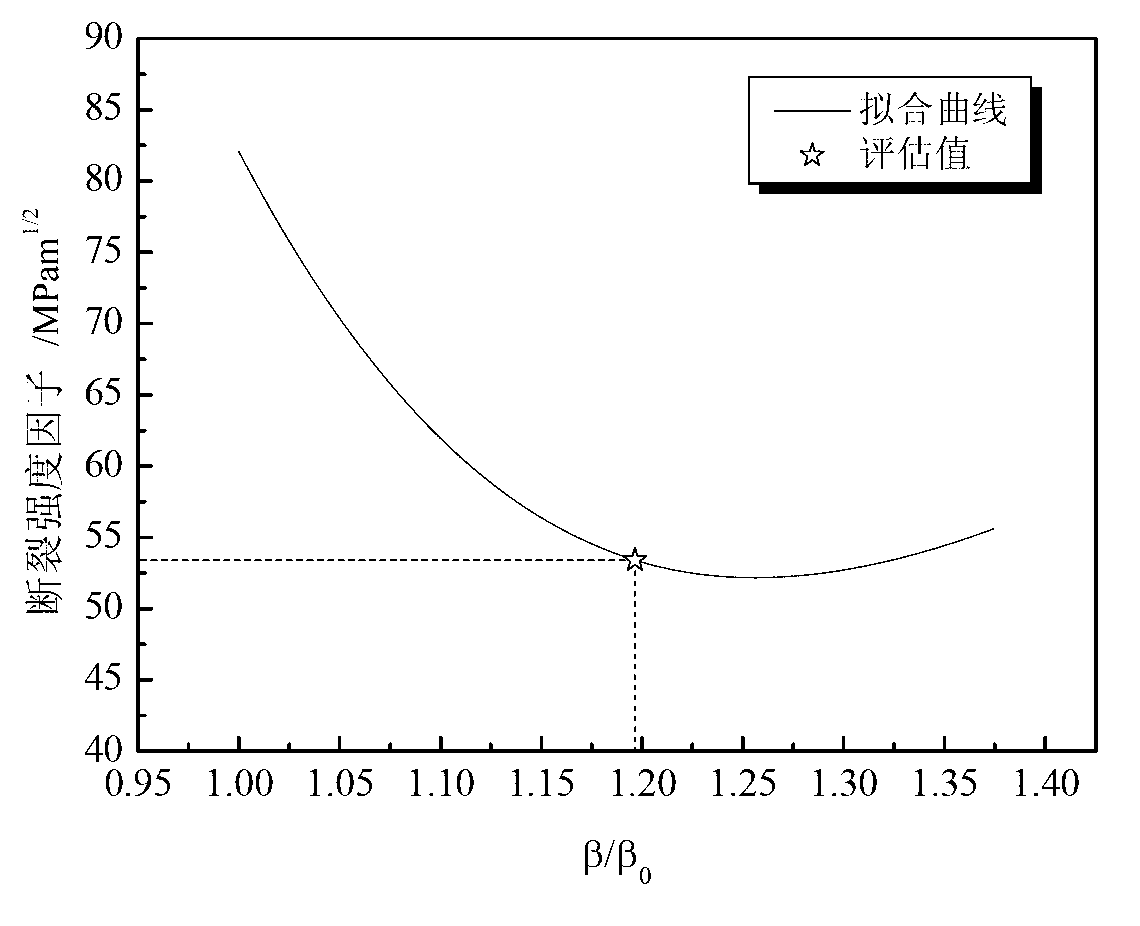

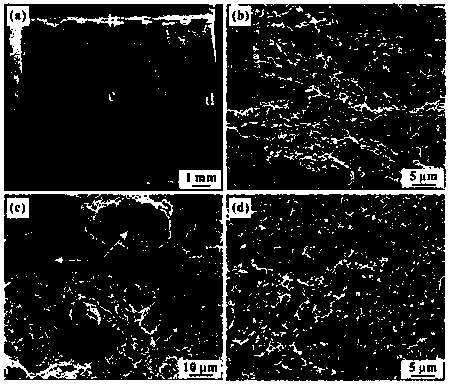

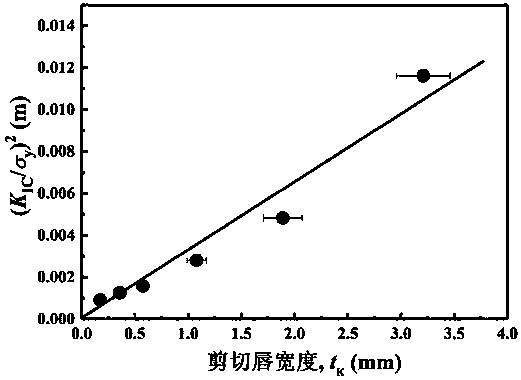

Method for estimating plane strain breaking tenacity KIC of high-strength steel

InactiveCN108956266AAccurate estimation of fracture toughnessEstimates are simple and efficientStrength propertiesMetallic materialsPerformance index

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

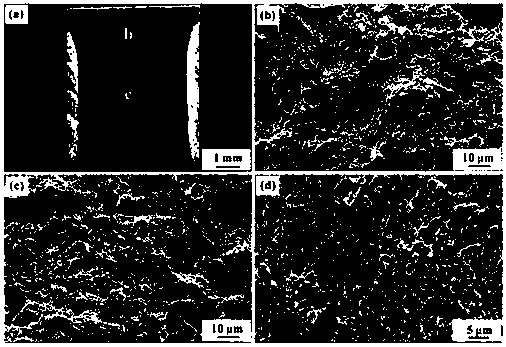

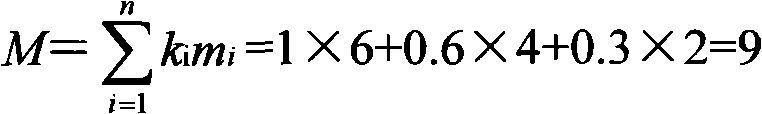

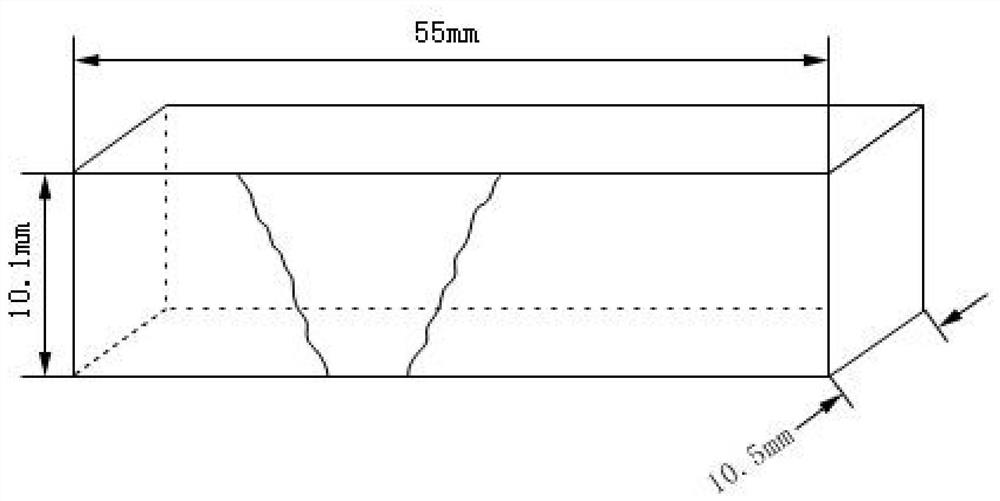

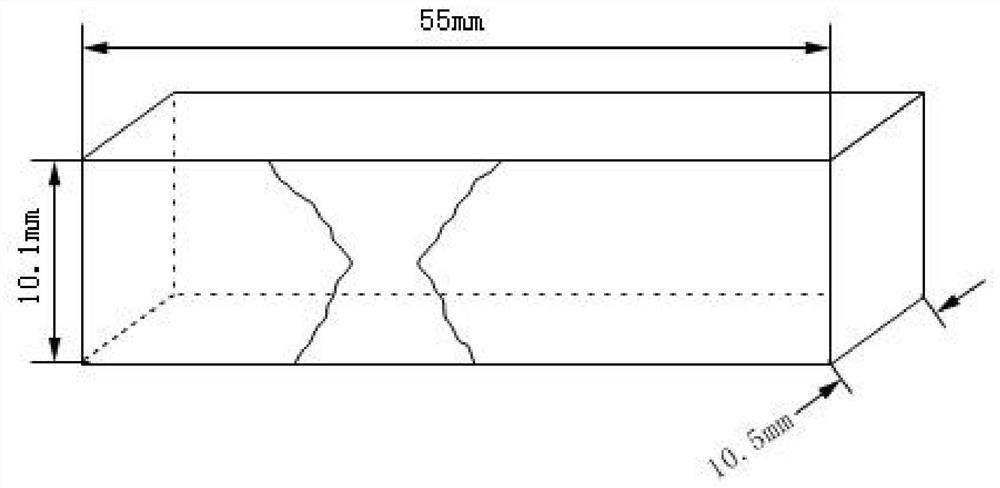

Pipeline steel Charpy specimen fracture separation degree grading method

ActiveCN102042929AImprove crack arrest toughnessEnsure safetyStrength propertiesCrazingWeight coefficient

The invention relates to a pipeline steel Charpy specimen fracture separation degree grading method, which comprises the following steps of: (1) for a specimen having fracture separation in a Charpy test, measuring the lengths of separation cracks on specimen fractures, and endowing the cracks with different scores m according to the lengths of the separation cracks; (2) sorting according to the lengths of cracks on the fractures, and endowing the differently sorted fracture separation cracks with different weight coefficients k; (3) adding each product of a scores mi of each fracture separation crack on the specimen fracture and a weight coefficient ki to obtain a total sore M of the fracture separation of the specimen; and (4) dividing the fracture separation degree into four grades, namely I grade, II grade, III grade and IV grade according to the total score M. If the specimen fracture separation coefficient exceeds a certain grade, a series temperature impact toughness test is carried out, a rise platform parameter is calculated, factors such as a pipeline transportation parameter, material toughness property and the like are comprehensively considered according to a calculation result, and a control measure is taken for the fracture separation of the material.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

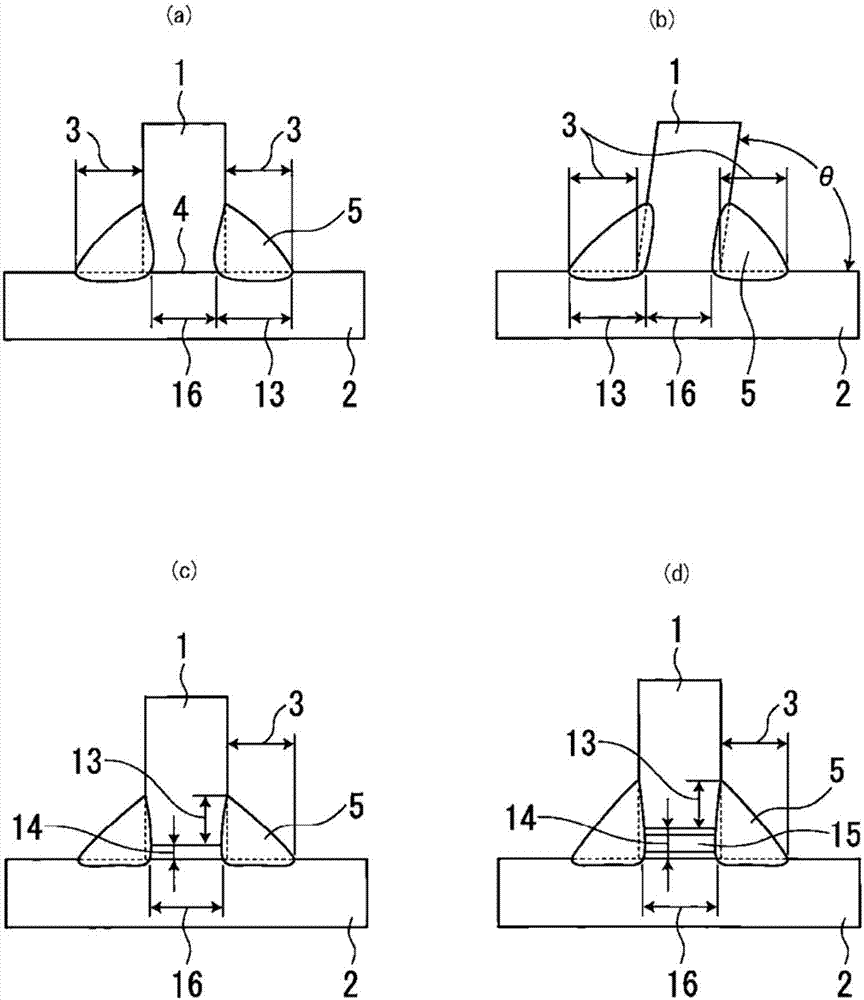

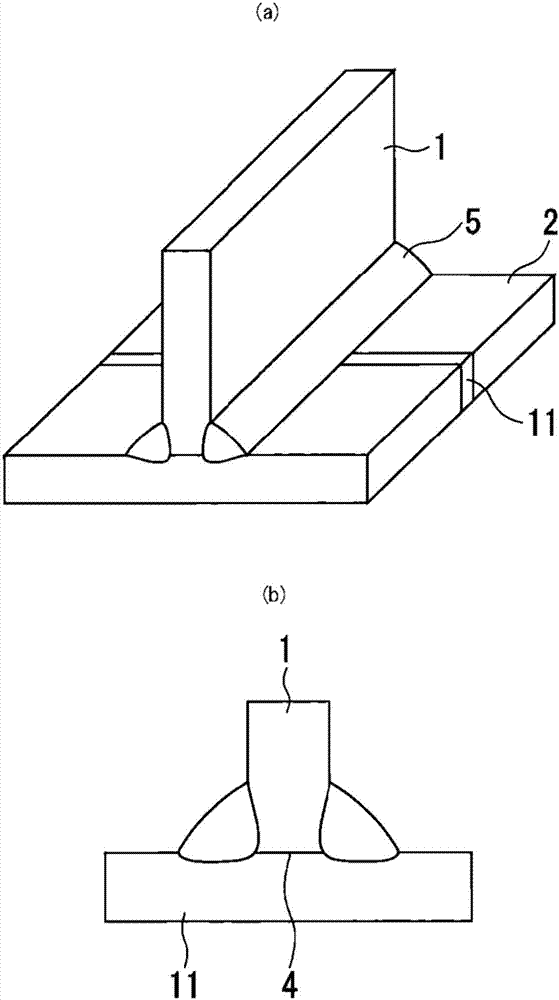

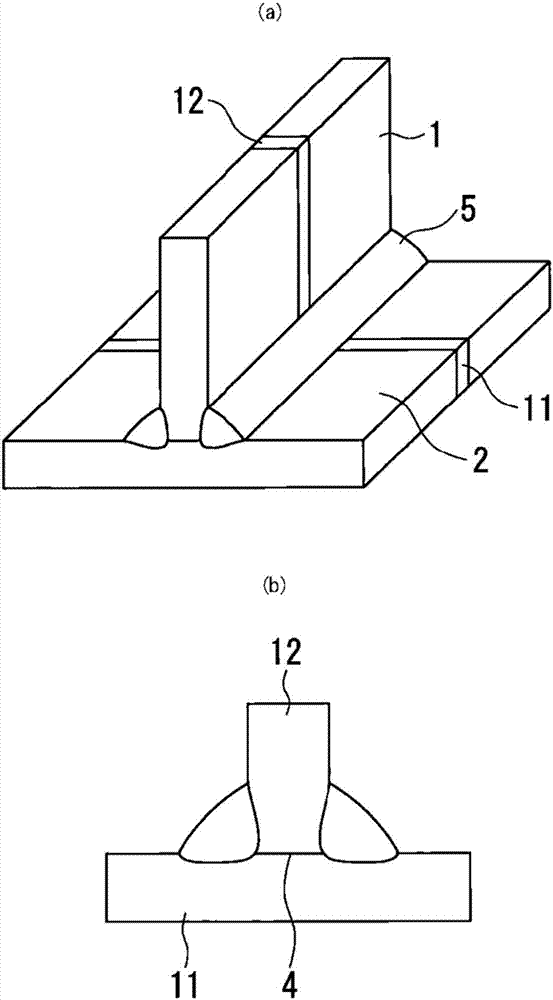

Welded structure

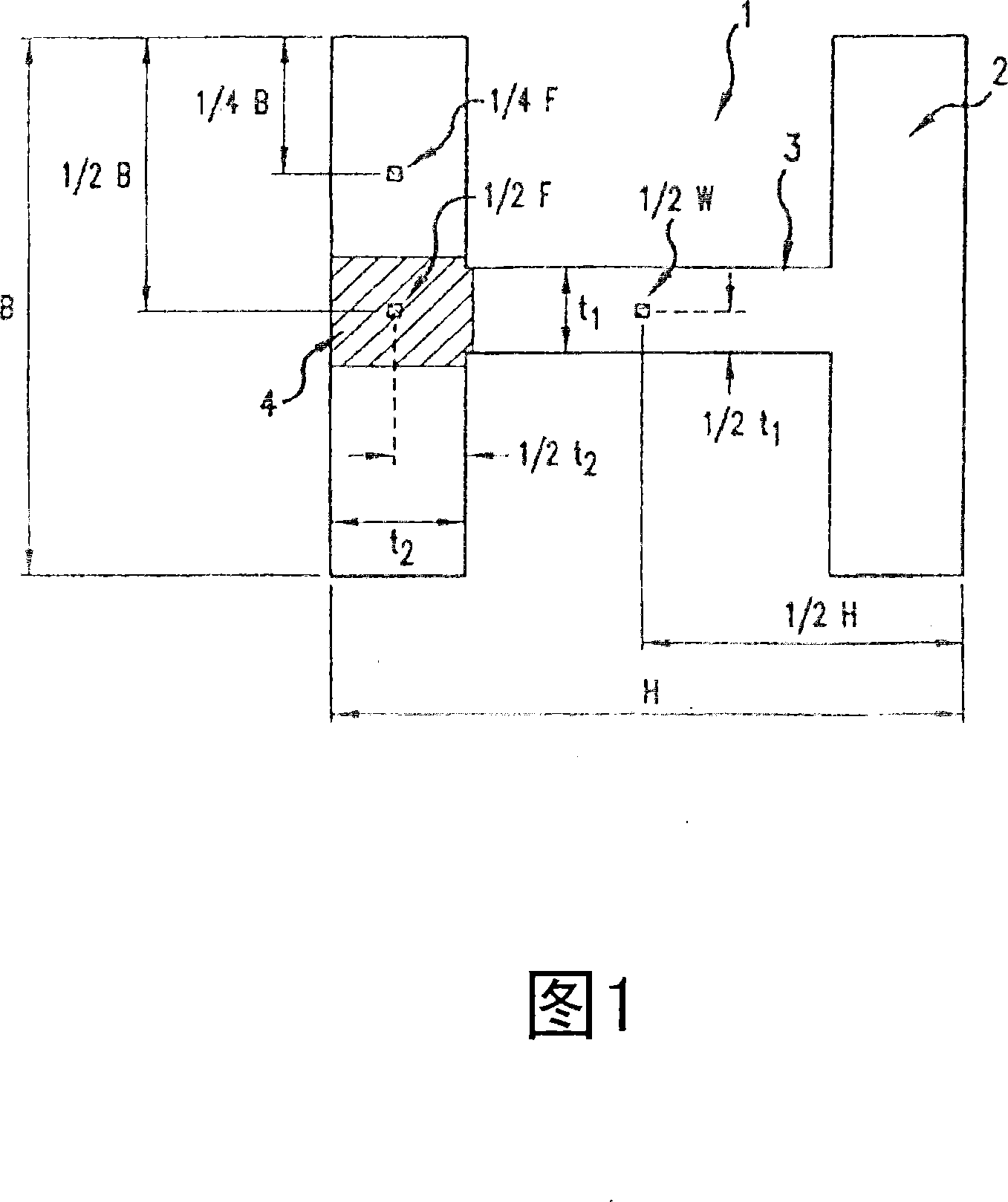

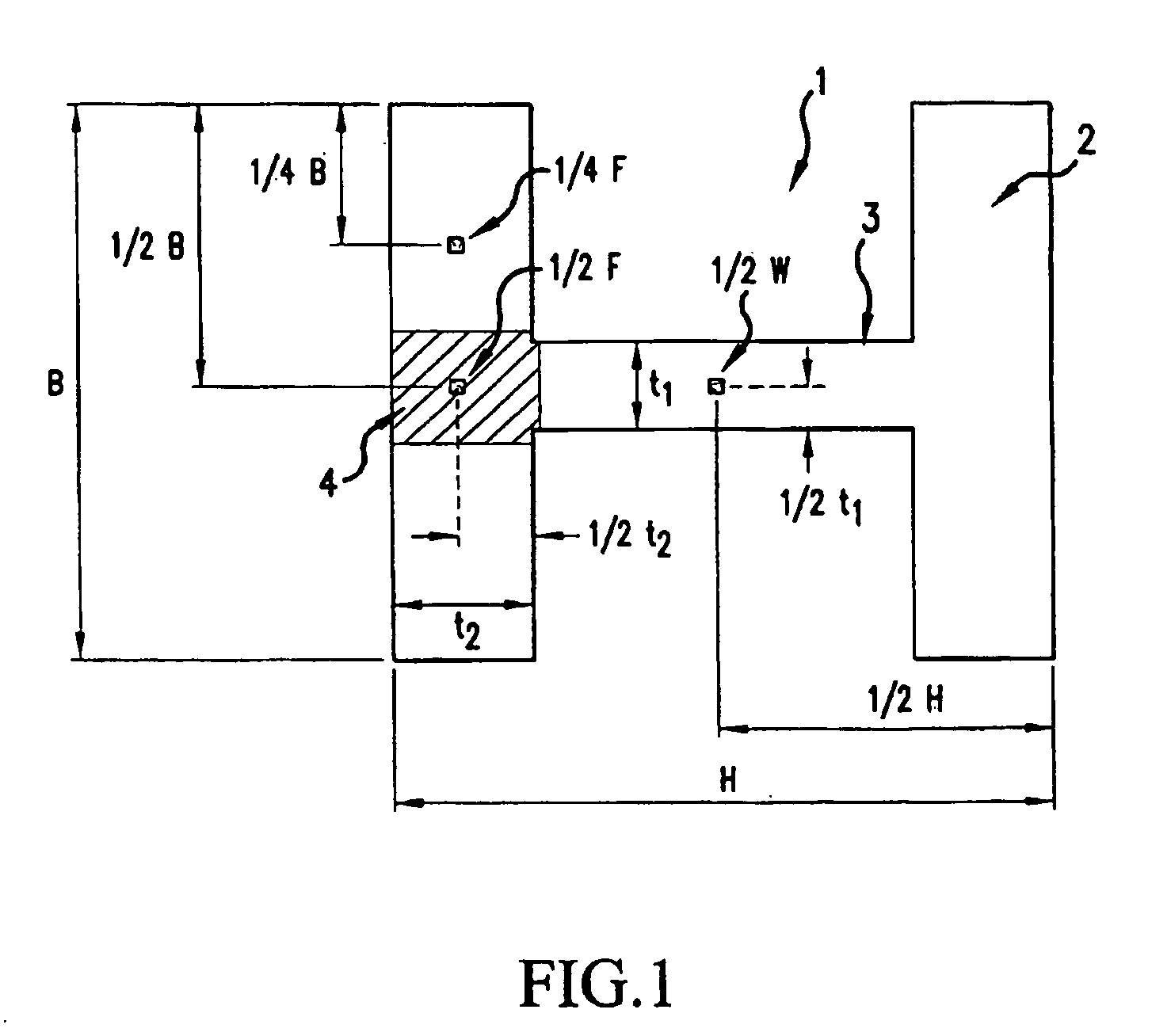

ActiveCN107405713AEnsure safetyAvoid the risk of brittle failureVessel partsArc welding apparatusFillet weldLeg length

This welded structure comprises a fillet welded joint which joins a joining member (1) and a joined member (2) having a plate-thickness of 50 mm or larger, in which an end face of the joining member (1) is in contact with a surface of the joined member (2). The weld leg length (3) and the welding width (13) of the fillet welded joint are each larger than 16 mm. A surface of the fillet welded joint at which the end face of the joining member (1) is in contact with the surface of the joined member (2) includes a non-welded part (4) at which the cross section of the fillet welded joint is not smaller than 95% of the plate-thickness (tw) of the joining member (1). Further, regarding a fillet welded metal (5) of the fillet welded joint, a predetermined relationship is satisfied between the Charpy impact test fracture transition temperature (vTrs (DEG C)) of the fillet welded metal (5) and the plate-thickness (tf) of the joined member (2), or among the temperature (vTrs (DEG C)), the thickness (tf), and a value (L) which is the lower between the weld leg length (3) and the welding width (13).

Owner:JFE STEEL CORP +1

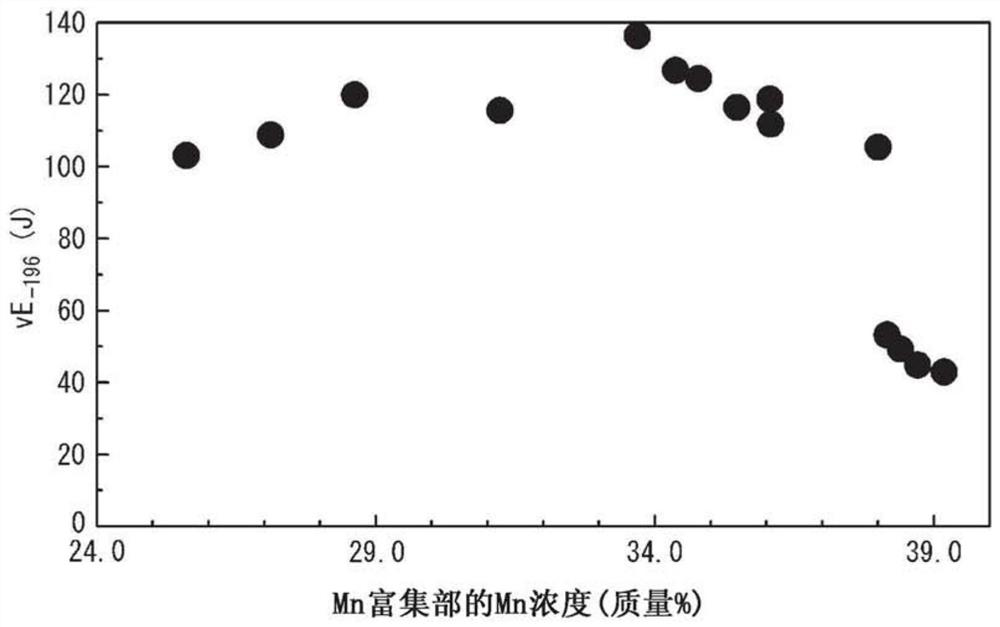

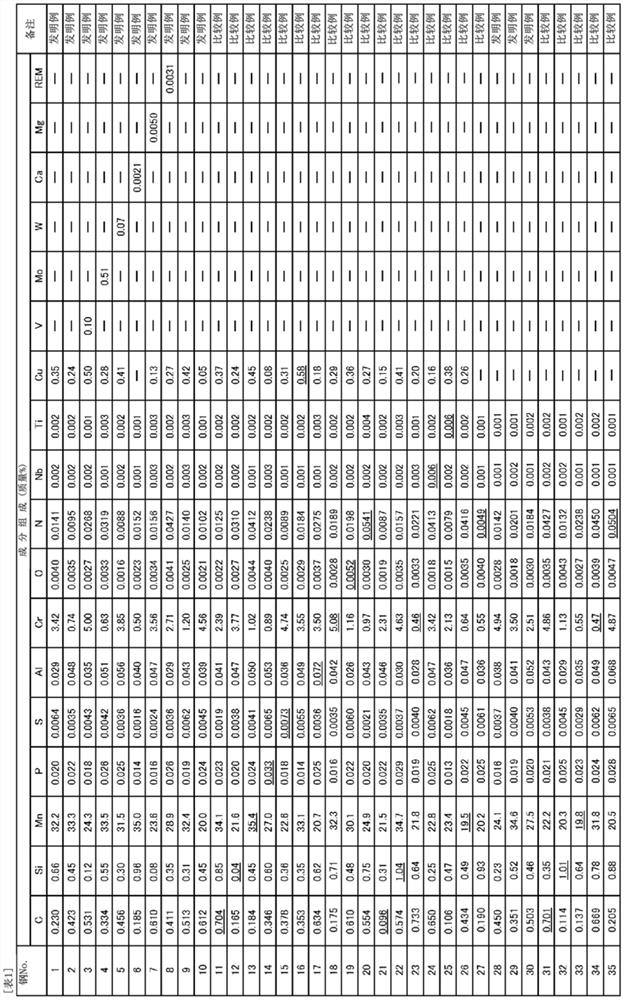

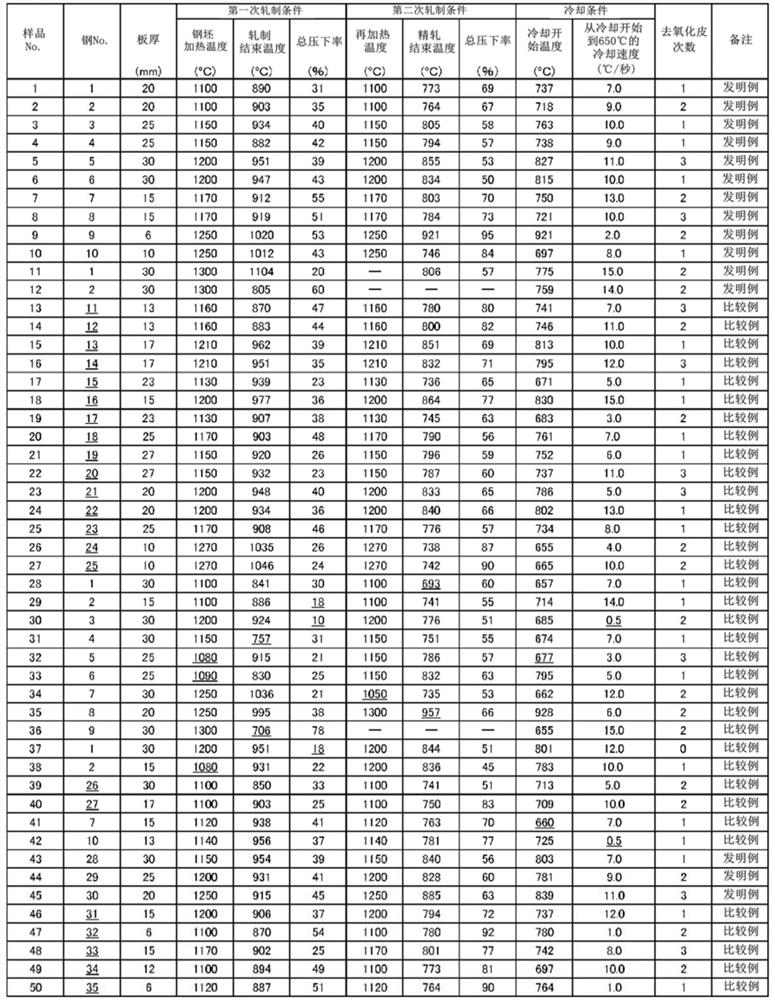

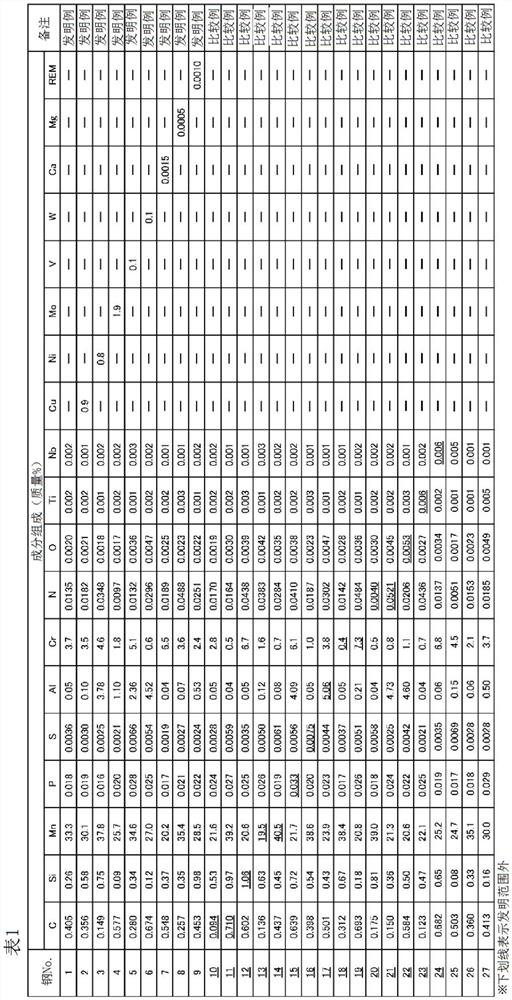

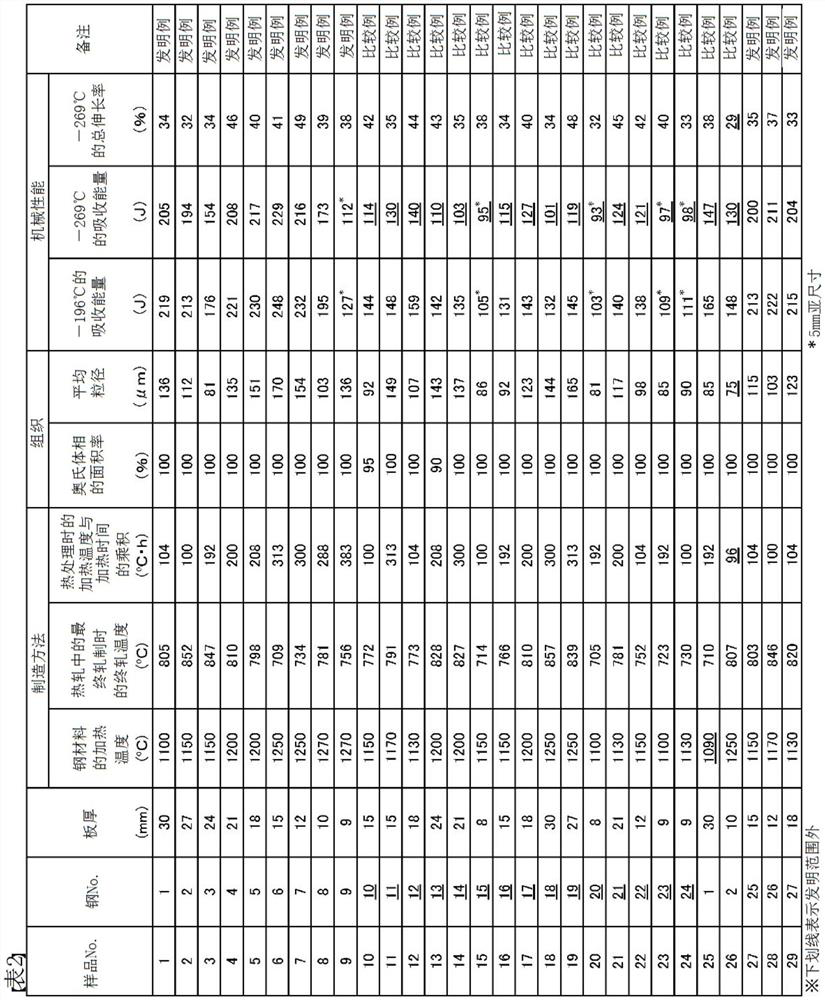

HIGH-Mn STEEL AND METHOD FOR PRODUCING SAME

PendingCN112513307AImprove low temperature toughnessImprove surface propertiesFurnace typesHeat treatment furnacesPhysical chemistryCharpy impact test

Provided is a high-Mn steel having excellent low-temperature toughness and surface characteristics. The high-Mn steel includes, in mass%, C: 0.100% to 0.700%, Si: 0.05% to 1.00%, Mn: 20.0% to 35.0%, P: 0.030% or less, S: 0.0070% or less, Al: 0.010% to 0.070%, Cr: 0.50% to 5.00%, N: 0.0050% to 0.0500%, O: 0.0050% or less, Ti: 0.005% or less, and Nb: 0.005% or less; with the balance being Fe and unavoidable impurities, and has a microstructure with ostenite as matrix, wherein the Mn concentration in an Mn-concentrated portion in the microstructure is 38.0% or less, or the average kernel averagemisorientation (KAM) value is 0.3 or greater; the yield strength is 400 MPa or greater; the absorption energy vE-196 from a Charpy impact test at -196 DEG C is 100 J or greater; and the percent brittle fracture is less than 10%.

Owner:JFE STEEL CORP

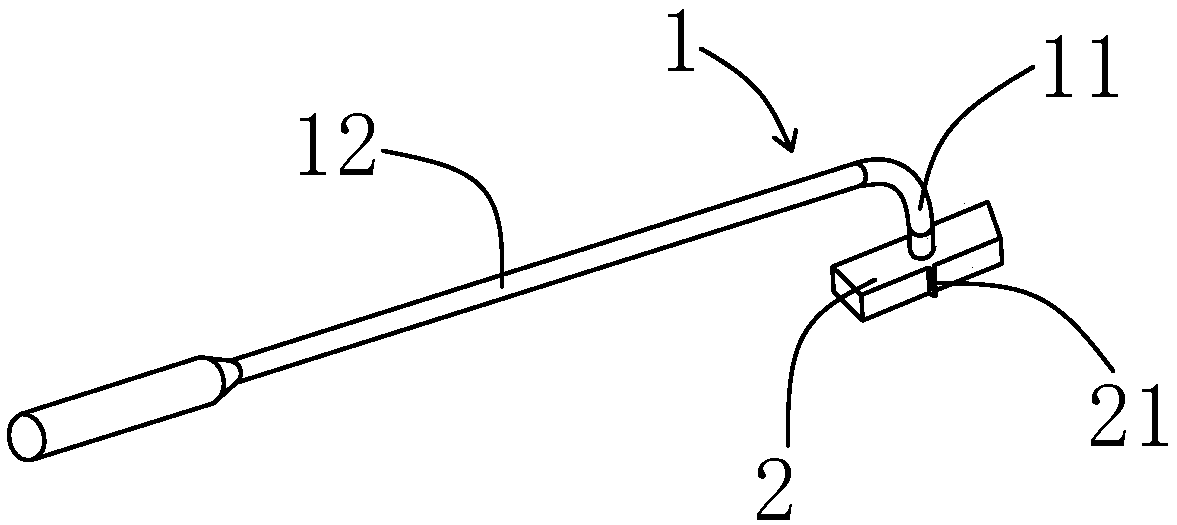

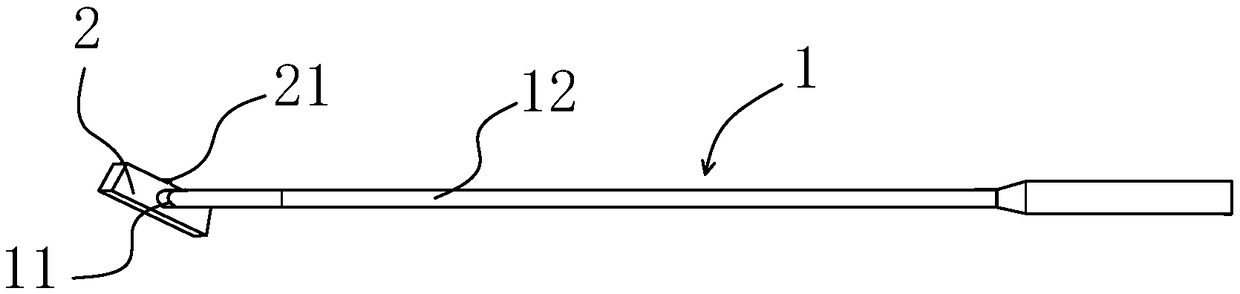

Alignment tool for Charpy impact test and working method thereof

ActiveCN108956277AEffective positioningRapid positioningStrength propertiesSoftware engineeringCharpy impact test

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Shaped Steel Excellent in Fire Resistance and Producing Method Therefor

A shaped steel, such as H-shaped steel, excellent in fire resistance, where a flange portion has 50% or more of a ratio of strength, 80% or less of yield ratio, and 100 J or more of impact strength of Charpy impact test at 0° C., wherein the ratio of strength=(proof stress of 0.2% at 600° C.) / (yield strength at room temperature), and a producing method thereof are provided. The shaped steel comprises in mass percent (%): C: 0.03-0.15; Mo: 0.1-0.6; V≦0.35; and N: 0.002-0.012, and the balance being iron and residual impurities, wherein (x) a mol fraction of precipitate of alloy carbides and alloy carbonitrides at 600° C. is 0.3% or more, and (y) the ratio of the mol fraction of precipitate of alloy carbides and alloy carbonitrides at 300° C. to the mol fraction of precipitate of alloy carbides and alloy carbonitrides at 600° C. is 2.0 or less.

Owner:NIPPON STEEL CORP

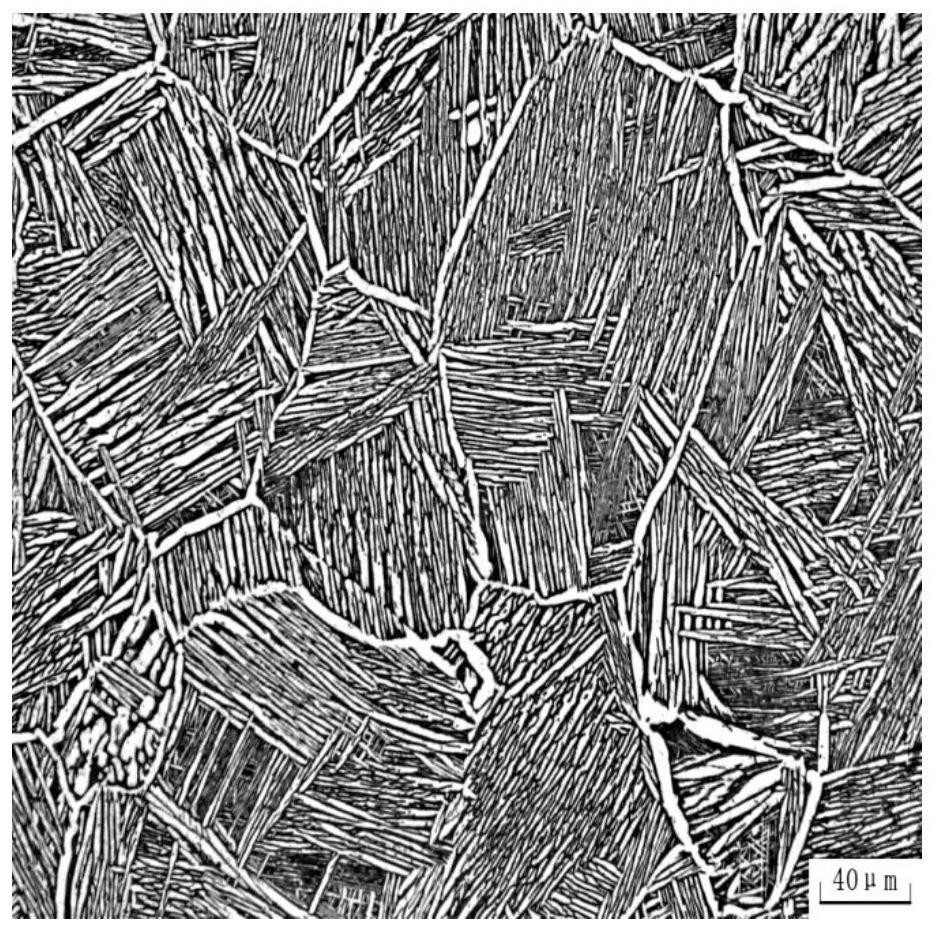

Pipe for 105ksi titanium alloy petroleum drill rod and manufacturing method

InactiveCN112442613AFill gaps in the manufacturing processEasy to operateCharpy impact testTitanium alloy

The invention discloses a pipe for a 105ksi titanium alloy petroleum drill rod and a manufacturing method. A pipe body mainly comprises Al, Mo, V, Zr and Ti, physical mechanical property evaluation iscarried out on the pipe, tensile strength Rm, yield strength R0.2 and elongation A of the pipe are tested, Charpy impact test (V-shaped notch, longitudinal direction and room temperature) is carriedout to test impact energy of the pipe, and a metallographic structure is observed by a metallographic microscope. The measured numerical values can meet the mechanical property requirement of the 105ksi-grade drill rod, the blank of the manufacturing process of the 105ksi-grade titanium alloy petroleum drill rod pipe body at home and abroad is filled up, and the operation steps are simple.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

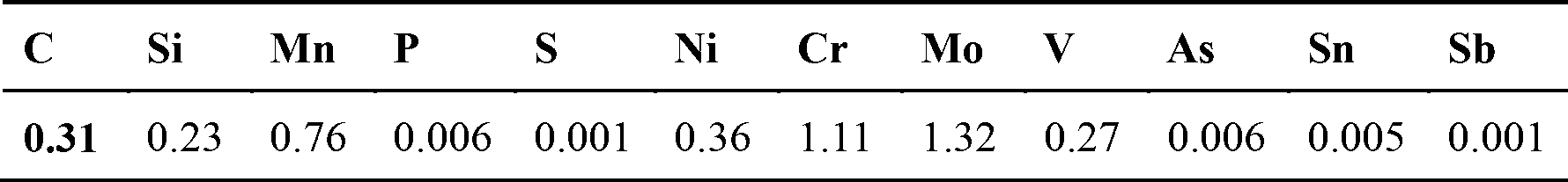

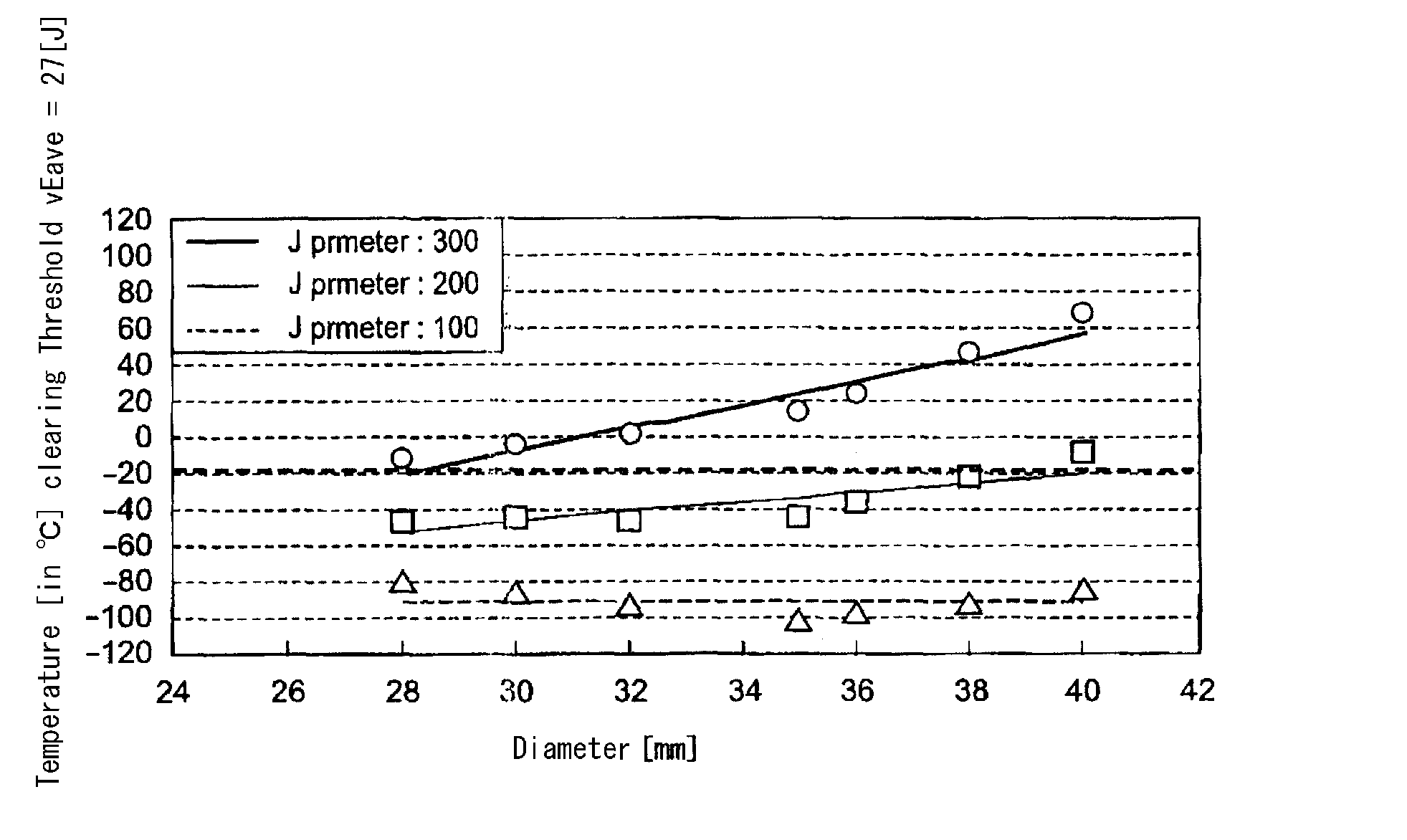

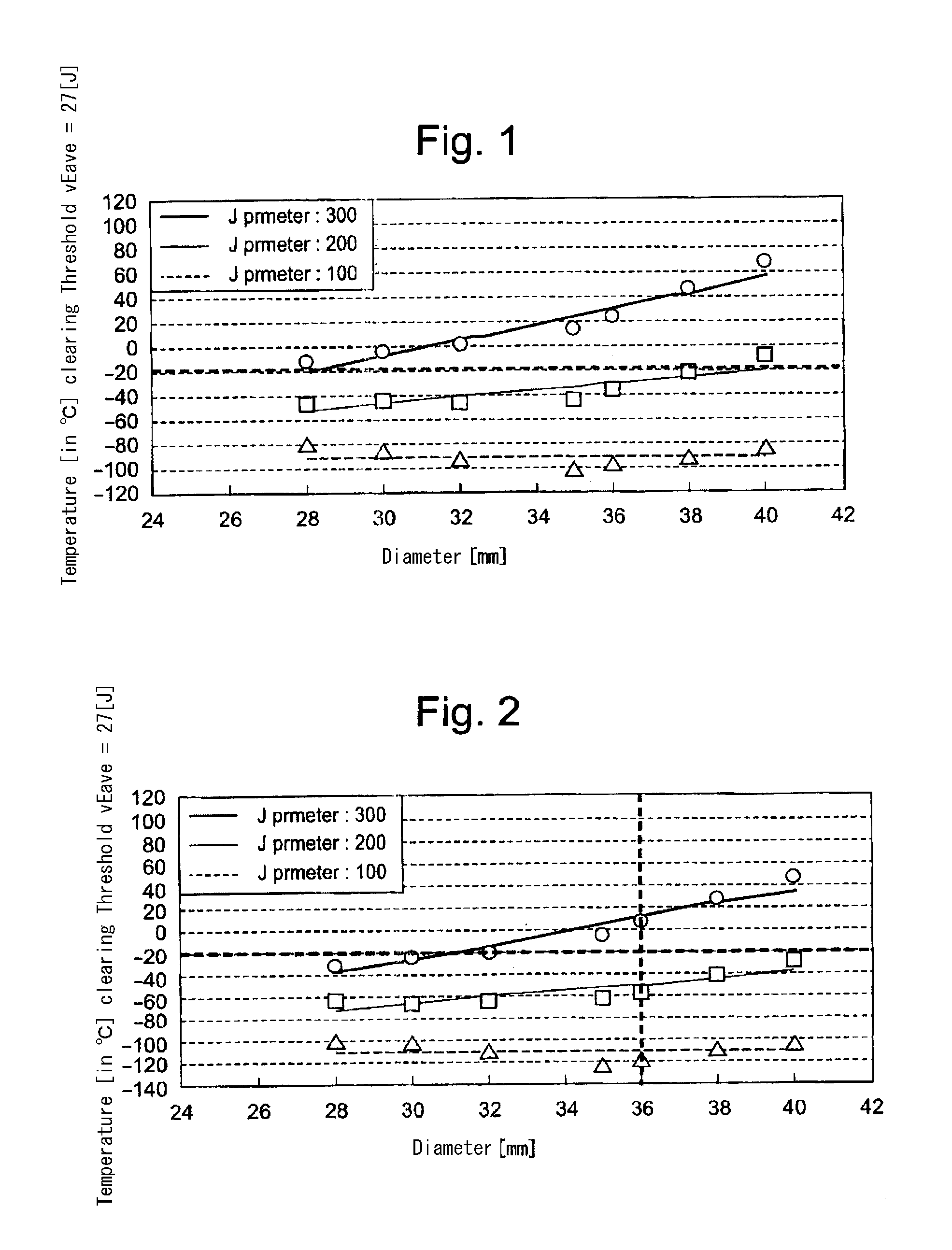

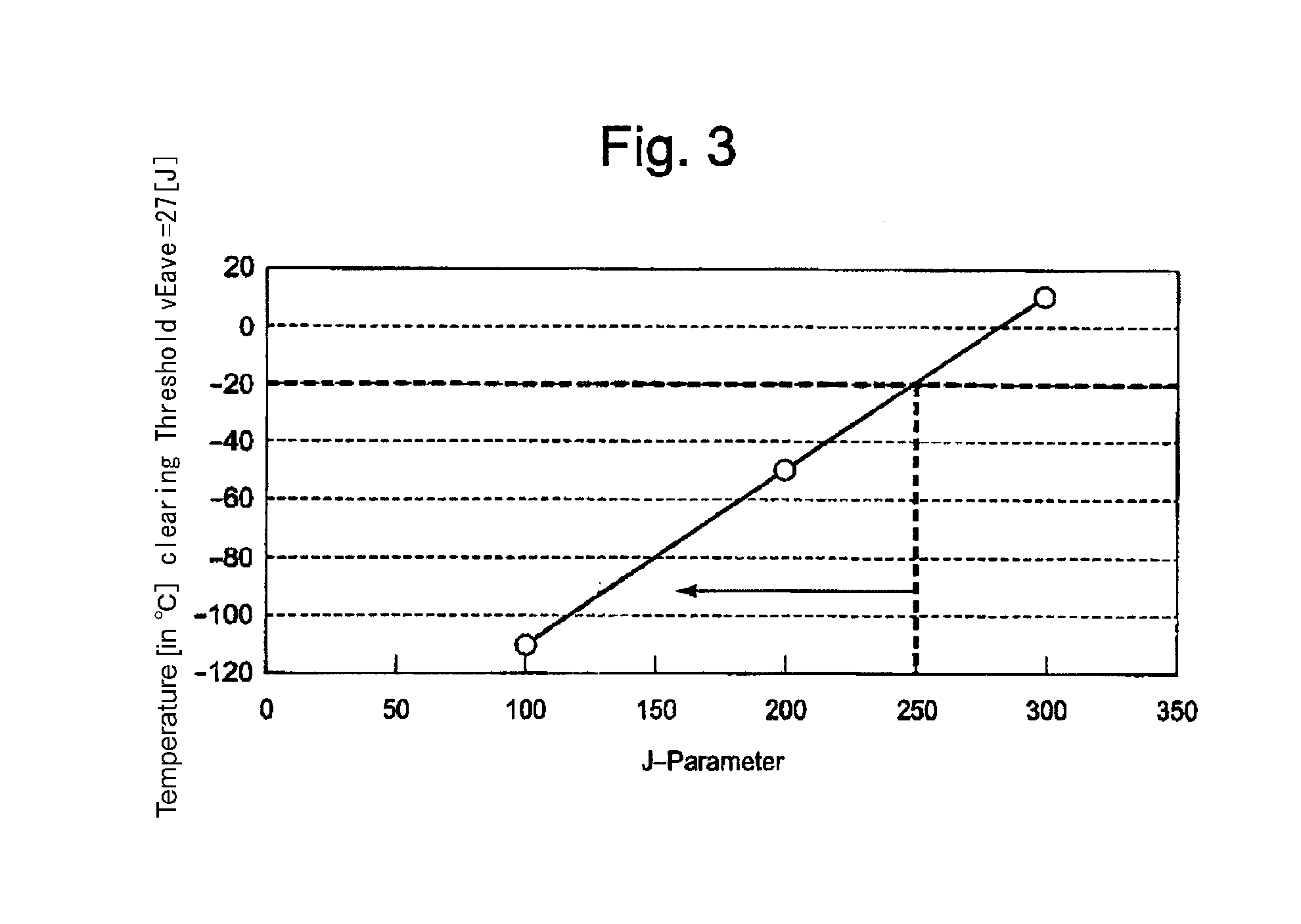

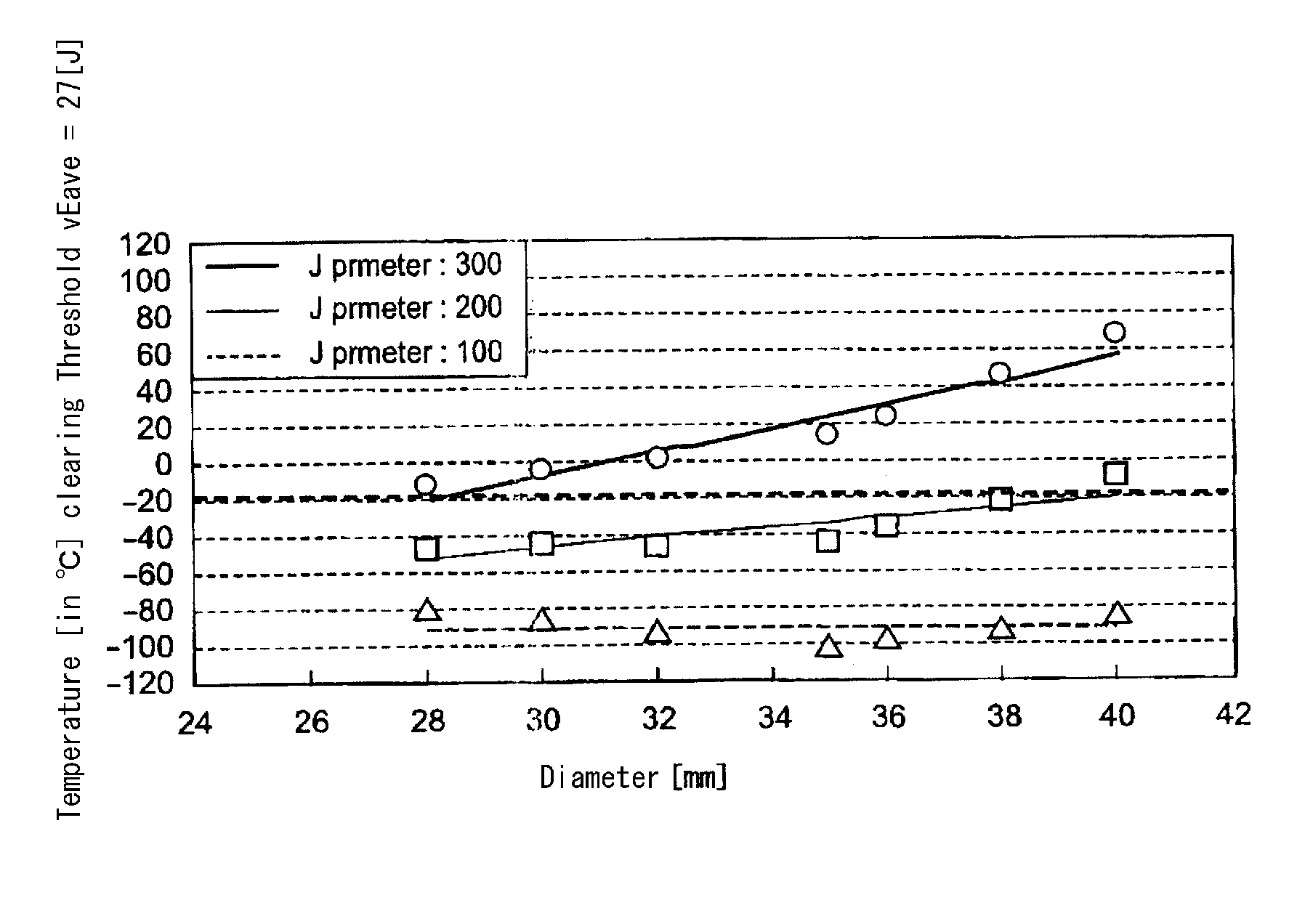

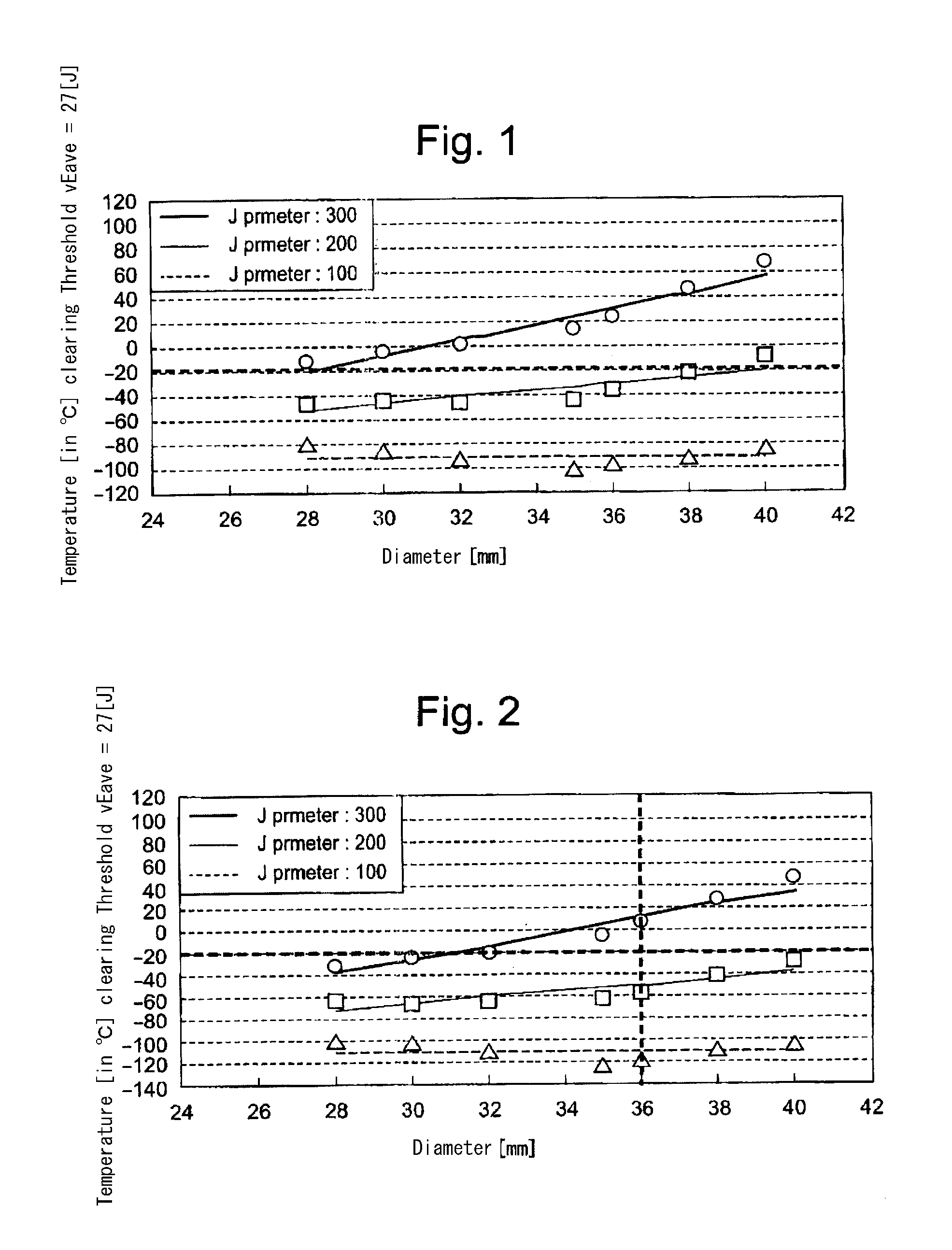

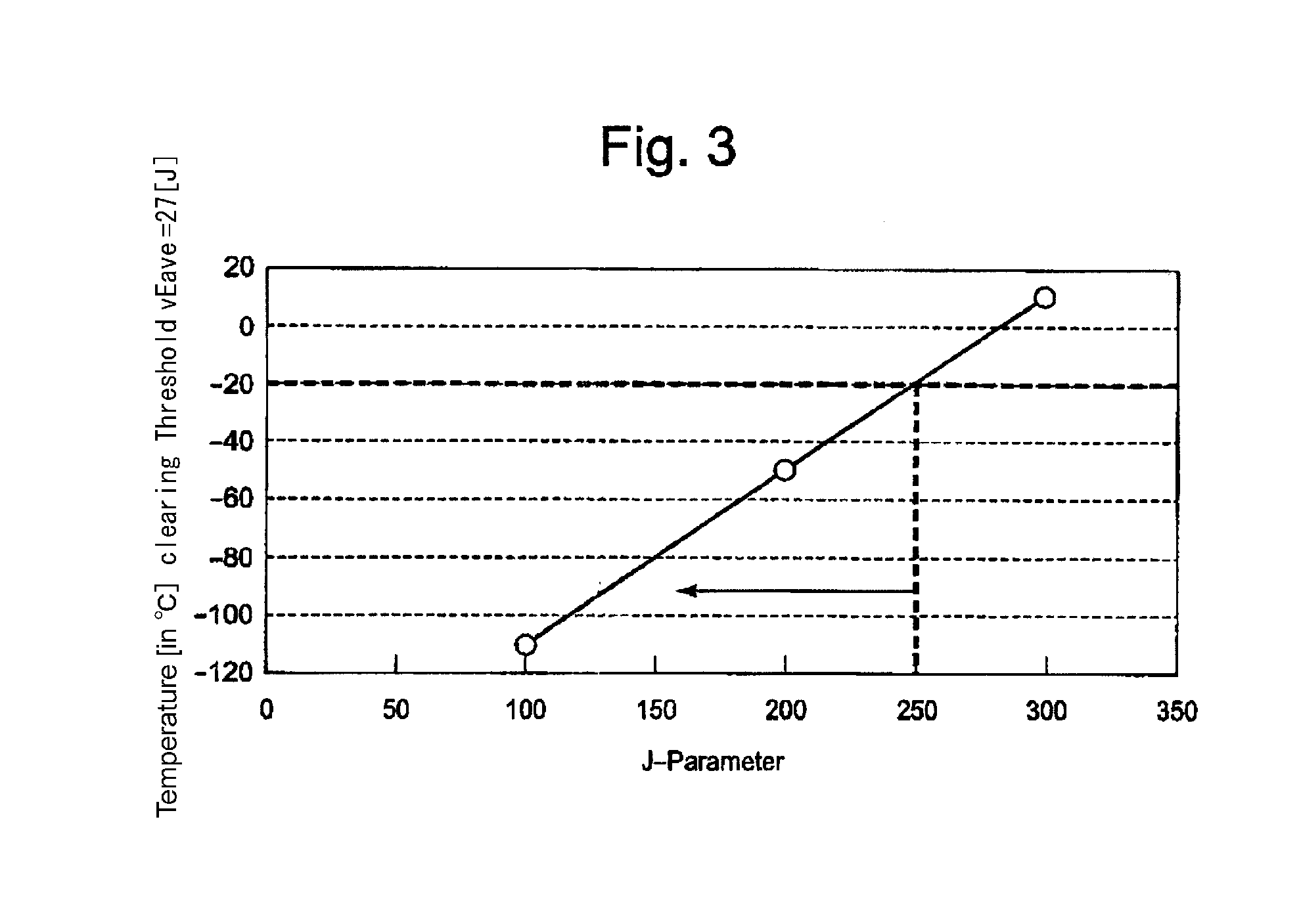

Method for inspecting bolts

InactiveUS8645080B2Shorten inspection timeSimplify workMachine part testingDigital computer detailsManganeseEngineering

A testing method for the bolt to be used under the conditions of excessive wind force by which bolts made of Cr—Mo steel can be separated into a group of bolts usable in cold areas and a group of bolts unusable in cold areas without conducting Charpy impact test involving complicated operation, specifically, a testing method for determining whether bolts made of heat-treated Cr—Mo steel are usable or unusable in cold areas, wherein the determination is conducted on the basis of both J parameter calculated by formula: J=(Si %+Mn %) (P %+Sn %) 104 (wherein P %, Si %, Mn % and Sn % are contents (mass %) of phosphorus (P), silicon (Si), manganese (Mn) and tin (Sn) respectively as disclosed in the inspection certificate of the Cr—Mo steel) and bolt diameter.

Owner:MITSUBISHI HEAVY IND LTD

Duplex stainless steel and method for manufacturing same, and duplex stainless steel pipe

PendingUS20220228231A1Improve corrosion resistanceImprove the environmentFurnace typesHeat treatment furnacesCharpy impact testSS - Stainless steel

The invention is intended to provide a duplex stainless steel and a method for manufacturing same. A duplex stainless steel pipe is also provided. A duplex stainless steel of the present invention has a specific composition, and has a microstructure containing an austenitic phase and a ferrite phase. The duplex stainless steel satisfies the following contents for C, Si, Mn, Cr, Mo, Ni, N, Cu, and W in the formula (1) below, and has a yield strength YS of 655 MPa or more, and an absorption energy vE−10 of 40 J or more as measured by a Charpy impact test at a test temperature of −10° C.0.55[% C]−0.056[% Si]+0.018[% Mn]−0.020[% Cr]−0.087[% Mo]+0.16[% Ni]+0.28[% N]−0.506[% Cu]−0.035[% W]+[% Cu*F]≤0.94 (1)

Owner:JFE STEEL CORP

A production process of ring forging

The invention discloses a production technique of a ring forge piece. Q345D steel is selected as a war material, and the raw material is forged to obtain the ring forge piece. The production techniquefurther comprises the following steps that a, the ring forge piece is heated to be 1200-1240 DEG C and subjected to heat preservation for 2 h; b, after heat preservation is finished, the ring forge piece is taken out and subjected to drawing-out, the deformation quantity is 50-55%, upsetting is conducted, the deformation quantity is 60-65%, and the final deformation temperature is controlled to be 1000-1050 DEG C; c, ring grinding is conducted till the needed size of the ring forge piece is achieved, the deformation quantity is 40-50%, the final deformation temperature is controlled to be 850-900 DEG C, and the wall thickness of the ring forge piece is 90-120 mm; and d, air cooling is conducted till the room temperature is achieved. According to the production technique of the ring forgepiece, drawing-out, upsetting and ring grinding are conducted at the same fire time, and by controlling the deformation quantities of drawing-out, upsetting and ring grinding and the temperatures after drawing-out, upsetting and ring grinding, the yield strength of the produced ring forge piece reaches 360 MPa or more, and when the ring forge piece is subjected to a Charpy impact test of a V-shaped notch under the temperature of minus 20 DEG C, the average value of impact work of the ring forge piece reaches 120 J or more.

Owner:WUXI BAOLU FORGING +1

A detection method of iron body shape based on infrared thermal imaging technology

The invention provides an infrared thermal imaging technology based measurement method, and in particular provides an infrared thermal imaging technology based iron shape detecting method. The methodis characterized in that infrared light transmitted from the surface layer of an impact sample is collected based on the theory that metal materials have thermal radiation difference; different thermal images can be obtained based on different transmitting rates of \ infrared light transmitted from a crystal area and a ductile area; boundary points of the crystal area can be found from the thermalimages, and then a fracture of the impact sample can be measured. According to the method, the thermal imaging treatment technology is carried out; the manual fracture measuring and analyzing operation is replaced by the high-accuracy infrared measuring system based infrared thermal image measuring method, thus the shortage of high influence of the temperature and environment on image collectingof simple CCD cameras can be overcome, and the fracture shape can be measured in metal charpy impact test in the field of metal material test; and meanwhile, the calculated area of the crystal area can be used for measuring the fiber section rate and the side expansion rate of the fracture, drawing a ductile-brittle transformation curve, solving Tk, and measuring the outline dimension of the sample as well as the gap size.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

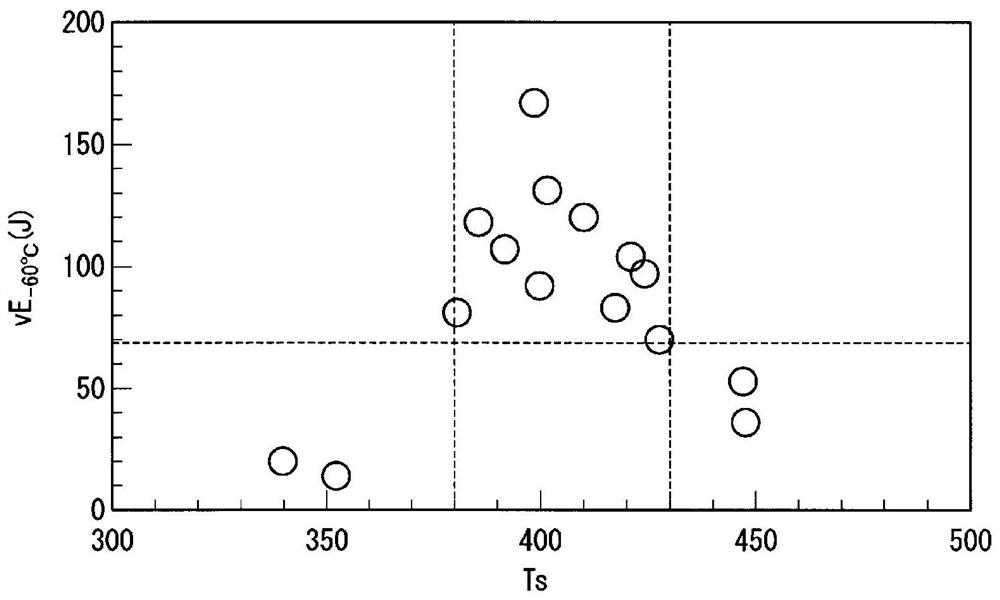

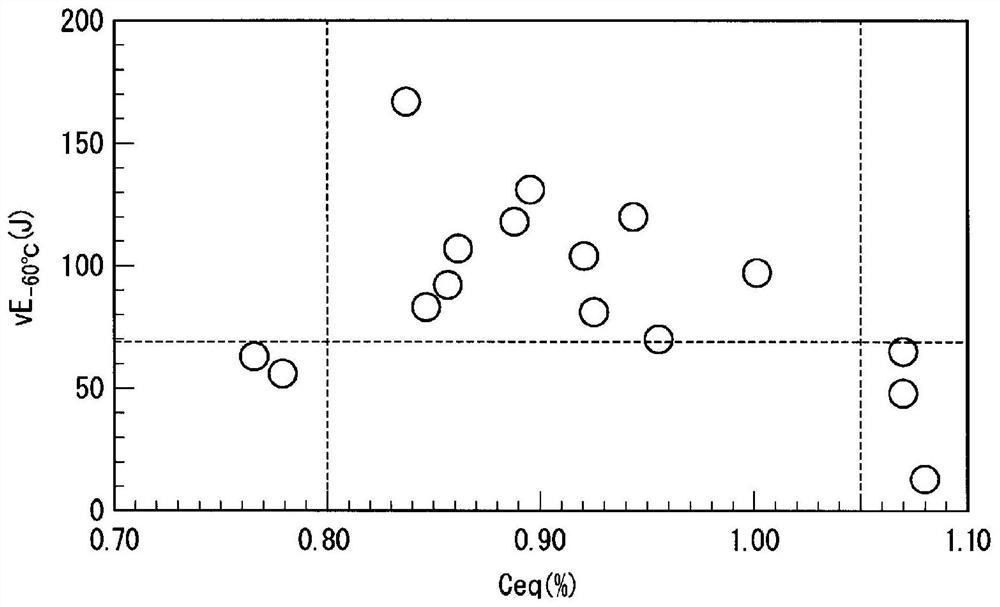

High-strength steel sheet with excellent low-temperature toughness

ActiveCN108603258BImprove low temperature toughnessHigh strengthChemical compositionCharpy impact test

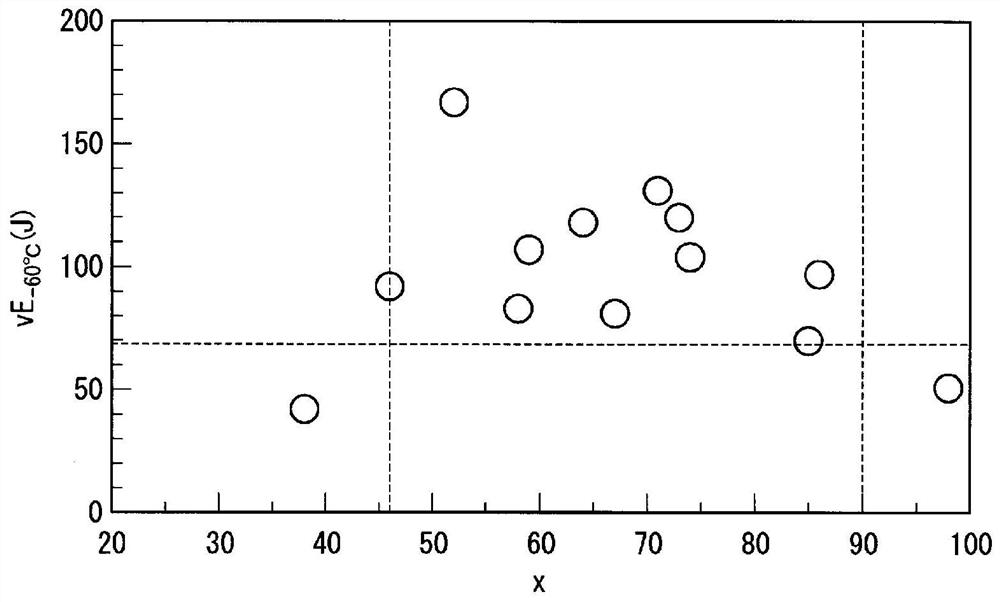

The high-strength steel plate contains C: 0.08% to 0.15%, Mn: 0.80% to 1.60%, Ni: 3.00% to 4.50%, Cr: 0.50% to 1.00%, and Mo: 0.50% to 1.00%, in mass % , Al: 0.020% to 0.085%, N: 0.0020% to 0.0070%, B: 0.0005% to 0.0020%, the plate thickness tmm exceeds 200mm and is less than 300mm, in the chemical composition, Ts is 380 to 430, Ceq is 0.80 ~1.05, Ac1 is 580~647, x is 46~90, by area%, the total amount of martensite and bainite is 99%~100%, the tensile strength is 780MPa~930MPa, the central part of the plate thickness is The absorbed energy obtained by the Charpy impact test at ‑60°C is 69J or more.

Owner:NIPPON STEEL CORP

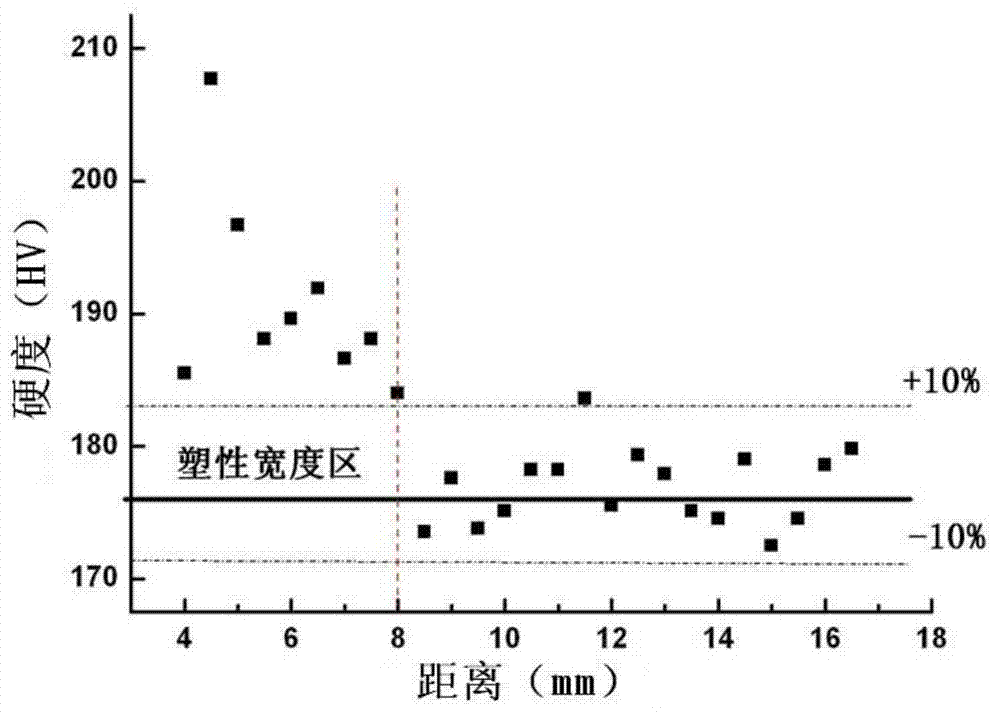

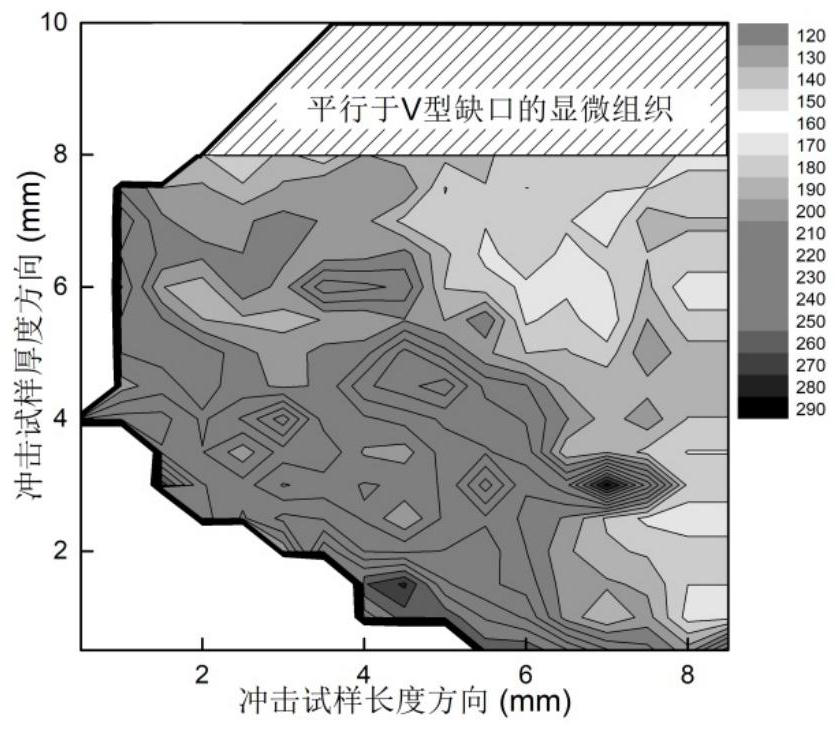

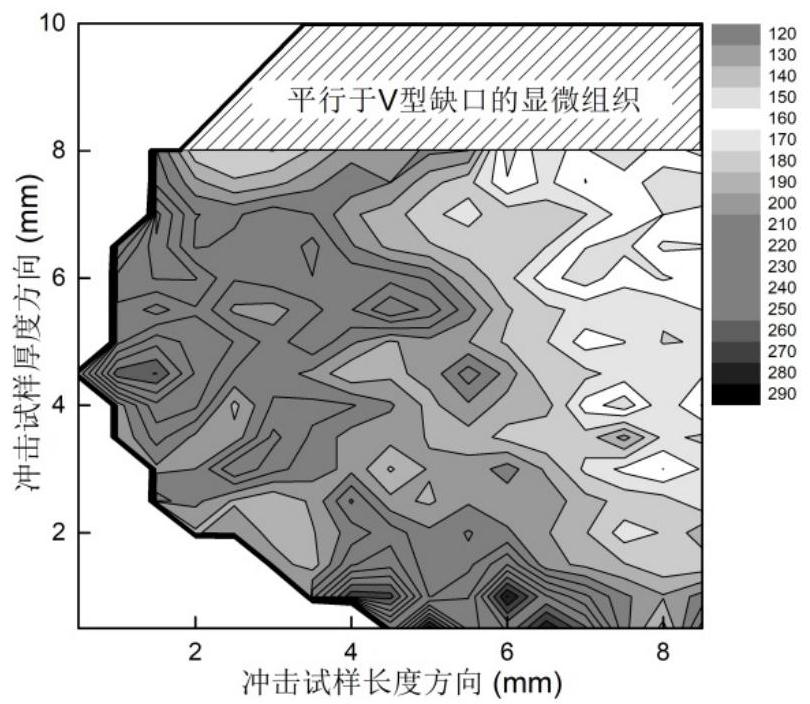

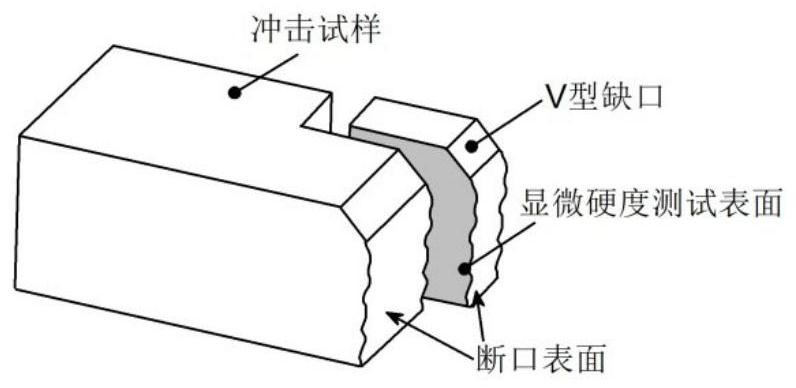

Method for qualitatively evaluating crack arrest toughness of steel plate by utilizing impact fracture microhardness distribution

ActiveCN112098249ALow costHigh speedMaterial strength using single impulsive forceInvestigating material hardnessCharpy impact testImpacted fracture

The invention discloses a method for preliminarily evaluating the crack arrest toughness of a steel plate by utilizing impact fracture microhardness distribution. According to the method, the potential of the Charpy impact test is further excavated by taking the existing impact test as a detection means, and the approximate crack arrest toughness Kca of the undetected steel plate is preliminarilyevaluated by comparing the deformation conditions of the microstructure near the impact fracture of the steel plate without crack arrest toughness Kca detection and the known crack arrest toughness Kca steel plate; and a reference is provided for subsequent further inspection. According to the evaluation method, the crack arrest performance of the crack arrest steel plate can be rapidly judged, areference basis is provided for subsequent identification work, the operability is high, the implementation difficulty is small, and the crack arrest steel trial-production cost is remarkably reduced.

Owner:NORTHEASTERN UNIV +1

A kind of fe-mn-al-c series medium manganese low temperature steel and preparation method thereof

The invention discloses a Fe-Mn-Al-C series medium-manganese low-temperature steel and a preparation method thereof. The Fe-Mn-Al-C series medium-manganese low-temperature steel comprises the chemicalingredients of, in percentage by mass, 12-15% of Mn, 4.5-5% of Al, 0.1-0.12% of C and the balance Fe and inevitable impurity elements. According to the Fe-Mn-Al-C series medium-manganese low-temperature steel and the preparation method thereof, the austenite tissue volume fraction of the low-temperature steel is larger than or equal to 47.7%, the impact energy of a -80 DEG C charpy impact test islarger than or equal to 33 J, after forging and multipass rolling are performed on a steel blank of the same ingredients with the Fe-Mn-Al-C series medium-manganese low-temperature steel, quenching+tempering heat treatment is performed on an obtained rolled blank, the Fe-Mn-Al-C series medium-manganese low-temperature steel with excellent impact toughness at low temperature is prepared, and the preparation method for the Fe-Mn-Al-C series medium-manganese low-temperature steel is simple.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for Determining the Machining Position of Notches in Charpy Impact Test Specimens

ActiveCN112975282BCharpy impact test is reliableThe test results are accurate and reliablePreparing sample for investigationEngineeringWeld seam

The invention provides a method for determining the notch processing position of a Charpy impact test sample applied in the technical field of dynamic mechanical performance test methods. During surface welding, the three straight lines a1, b1, and c1 are parallel to each other, and a1 is located between b1 and c1. A1, b1, c1 and the fusion line divide the Charpy impact sample weld and the base metal into four parts: base metal Ⅰ Zone 101, base metal zone II 102, weld zone I zone 103, weld zone II zone 104, assume that the area of base metal zone I 101 is A1, the area of base metal zone II 102 is B1, and the area of weld zone I 103 is C1. The area of seam II area 104 is D1, and a1 moves between b1 and c1. With the movement of a1, the values of A1 / B1 and C1 / D1 also change continuously. When A1 / B1=C1 / D1, the position of a1 is Charpy The position of the center line of the notch of the impact sample and the method of the present invention can solve the problem of positioning the processing position of the notch of the Charpy impact sample for the material at the weld fusion line in the Charpy impact test of the existing welding process approval.

Owner:WUHU SHIPYARD CO LTD

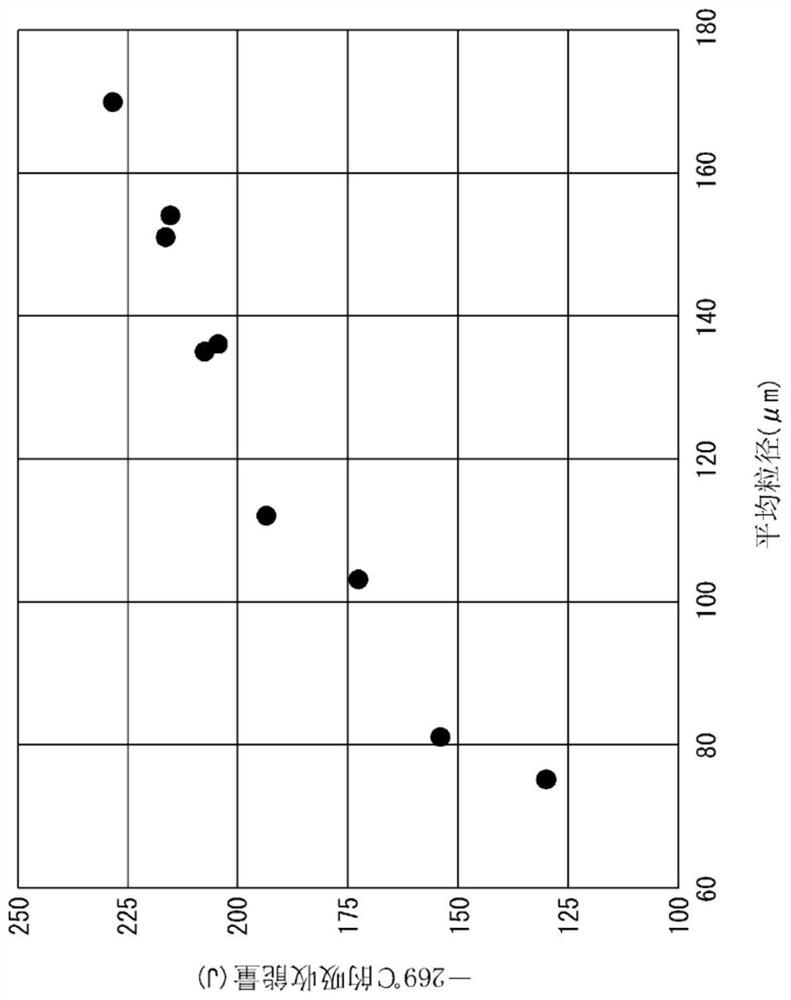

Steel and method for manufacturing same

ActiveCN114302977AImprove securityExtend your lifeFurnace typesHeat treatment furnacesCharpy impact testAustenite

This steel has a component composition containing, in mass%, 0.100-0.700% of C, 1.00% or less of Si, 20.0-40.0% of Mn, 0.030% or less of P, 0.0070% or less of S, 0.01-5.00% of Al, 0.5-7.0% of Cr, 0.0050-0.0500% of N, 0.0050% or less of O, 0.005% or less of Ti, and 0.005% or less of Nb, with the remainder being Fe and unavoidable impurities, has a microstructure having austenite as a base phase and an average particle diameter of 80 [mu] m or more, and has an absorption energy of 150 J or more in a Charpy impact test at-269 DEG C, and the total elongation in a tensile test at-269 DEG C is 30% or more.

Owner:JFE STEEL CORP

Method for inspecting bolts

InactiveUS20110166796A1Shorten inspection timeSimplify workMachine part testingTesting metalsManganeseEngineering

A testing method for the bolt to be used under the conditions of excessive wind force by which bolts made of Cr—Mo steel can be separated into a group of bolts usable in cold areas and a group of bolts unusable in cold areas without conducting Charpy impact test involving complicated operation, specifically, a testing method for determining whether bolts made of heat-treated Cr—Mo steel are usable or unusable in cold areas, wherein the determination is conducted on the basis of both J parameter calculated by formula: J=(Si %+Mn %) (P %+Sn %) 104 (wherein P %, Si %, Mn % and Sn % are contents (mass %) of phosphorus (P), silicon (Si), manganese (Mn) and tin (Sn) respectively as disclosed in the inspection certificate of the Cr—Mo steel) and bolt diameter.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com