Method for estimating plane strain breaking tenacity KIC of high-strength steel

A technology of fracture toughness and plane strain, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve complex, time-consuming and difficult to test problems, and achieve the effect of saving experimental time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

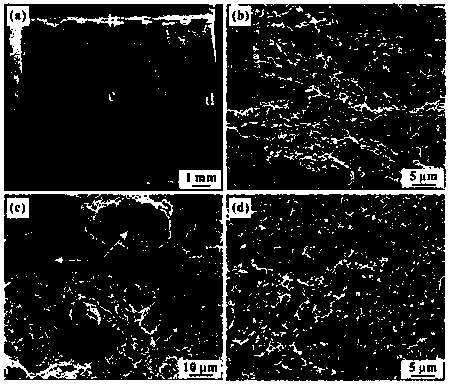

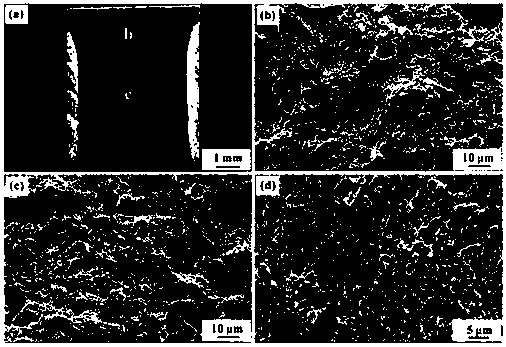

Method used

Image

Examples

Embodiment 1

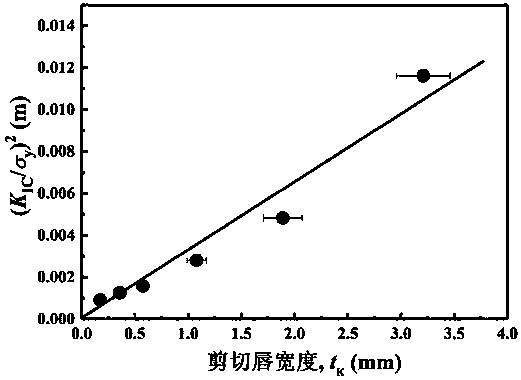

[0054] This embodiment uses impact toughness to predict the fracture toughness of several high-strength steels, including AISI 4340 steel, 18Ni maraging steel, 51CrV4, AISI 4147 and other high-strength steels. The specific steps are as follows:

[0055] Step 1: Perform a tensile test to obtain the yield strength σ of the high-strength steel y ;

[0056] Step 2: Carry out the Charpy impact test at room temperature to obtain the impact toughness α k ;

[0057] Step 3: Calculate K by formula (1) IC , the estimated value and the experimental value are shown in Figure (7), the error is within 10%, and the two coincide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com