Patents

Literature

51 results about "Lacquer thinner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lacquer thinner, also known as cellulose thinner, is usually a mixture of solvents able to dissolve a number of different resins or plastics used in modern lacquer. Previously, lacquer thinners frequently contained alkyl esters like butyl or amyl acetate, ketones like acetone or methyl ethyl ketone, aromatic hydrocarbons like toluene, ethers such as glycol cellosolves, and/or alcohols.

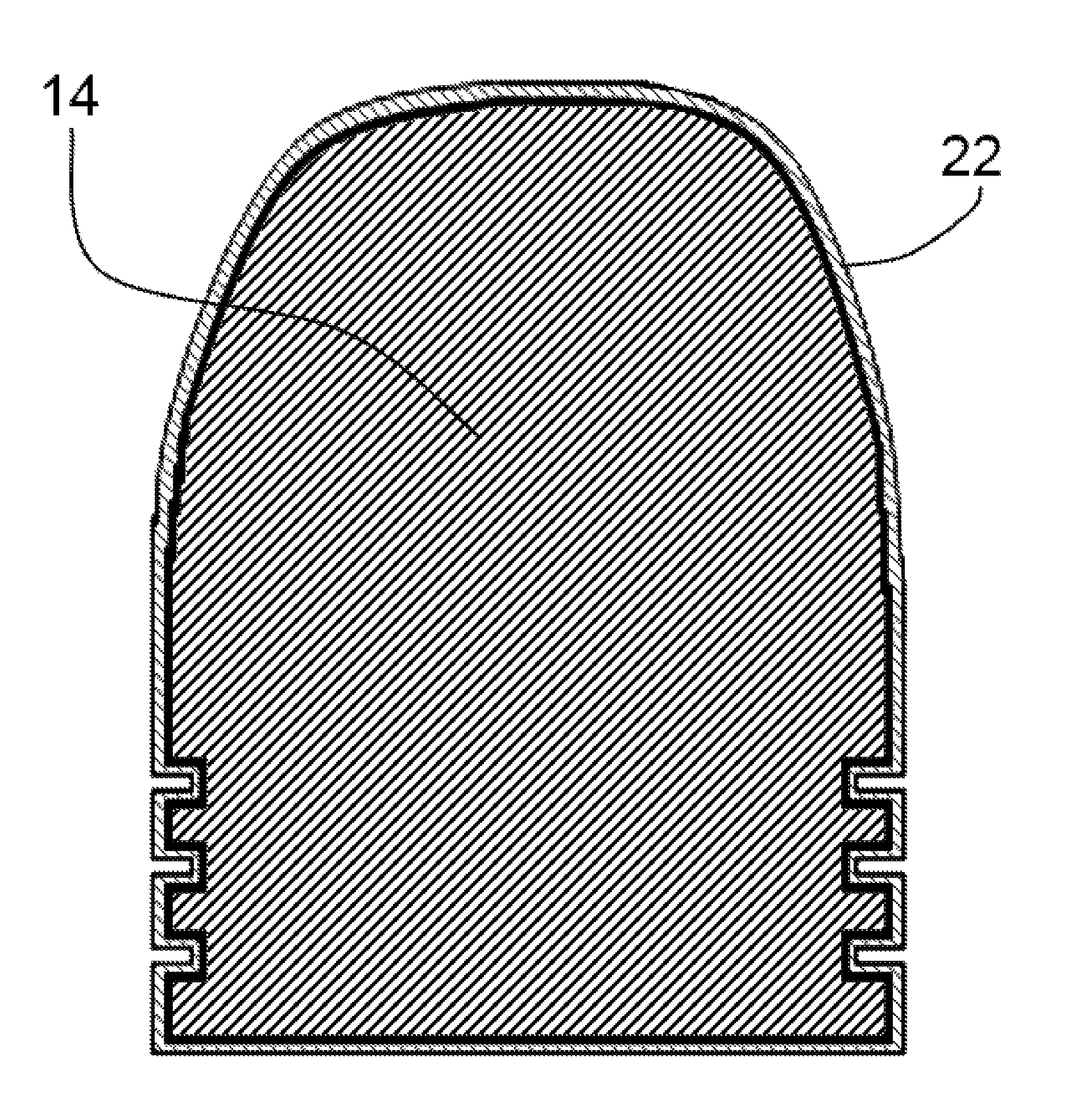

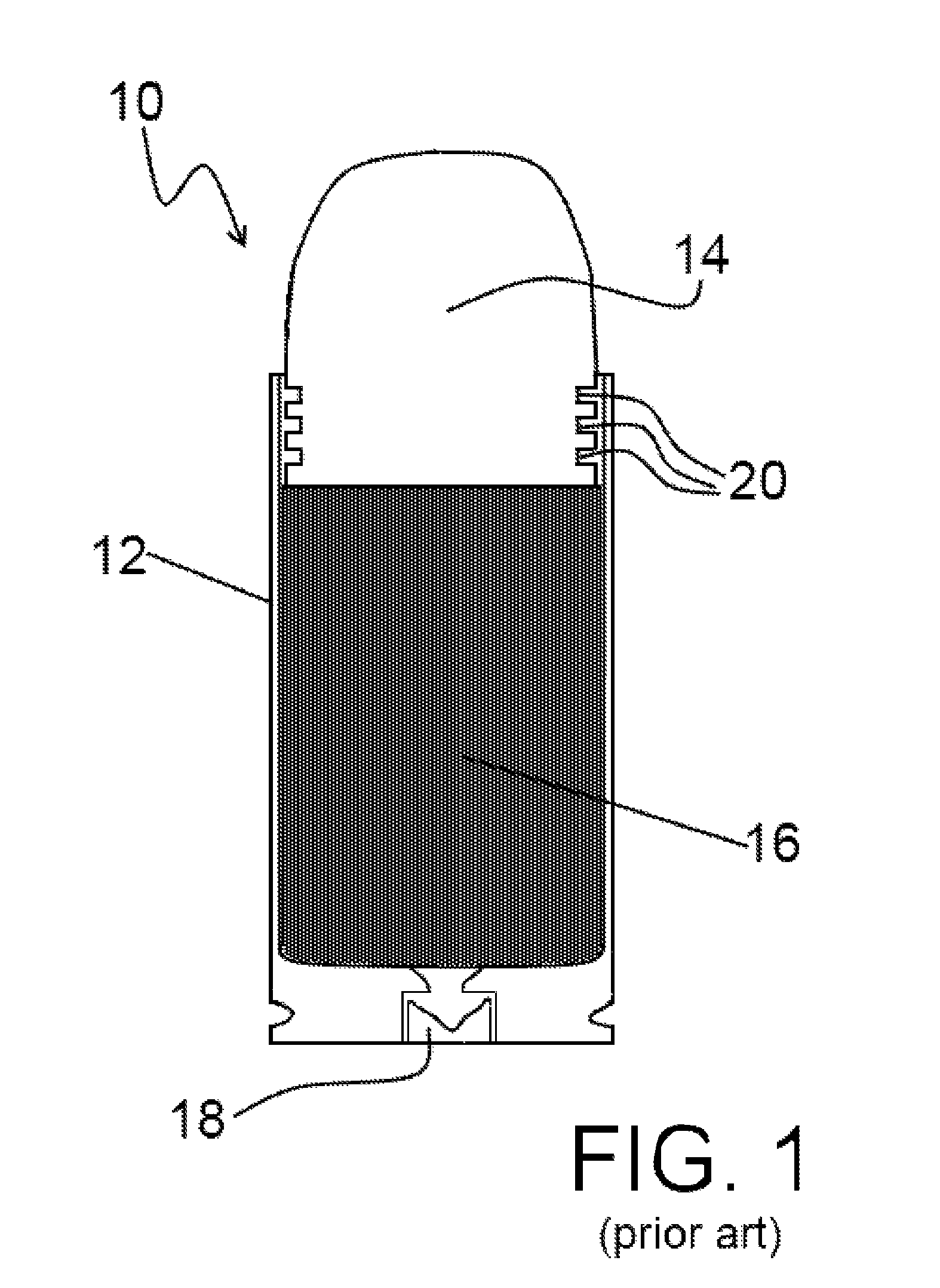

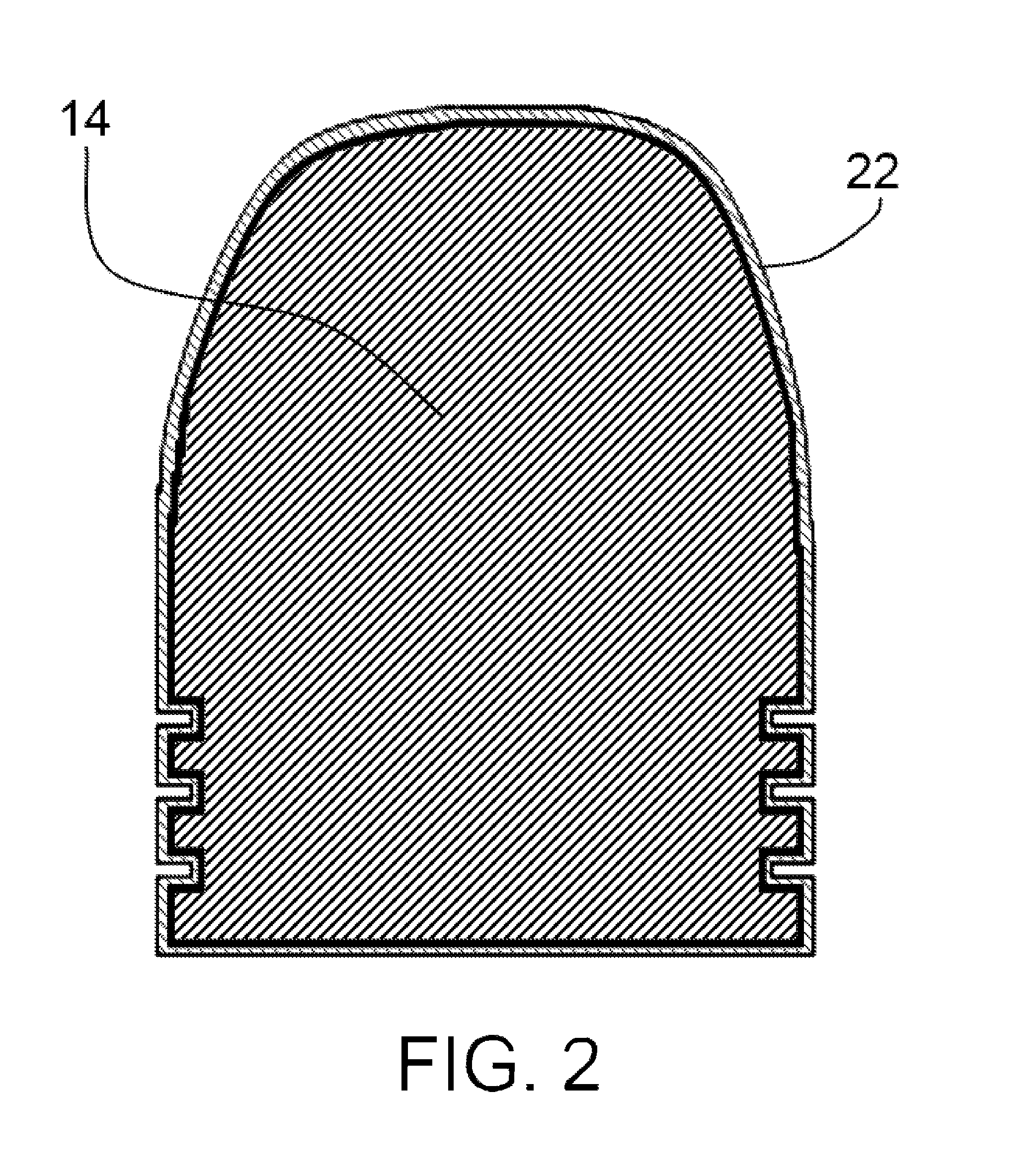

Enamel coated bullet, method of making an enamel coated bullet

ActiveUS9254503B2Reduces barrel depositsLess expensiveAmmunition projectilesLiquid surface applicatorsSufficient timeLacquer thinner

Owner:WARD TYLER

Steel surface treatment paint

InactiveCN104073041APrevent infiltrationHigh densityAnti-corrosive paintsGlycidyl methacrylateMaterials science

The invention discloses a steel surface treatment paint which comprises the following raw material ingredients in parts: 3-5 parts of phenyl hydroxide, 20-22 parts of epoxy resin, 18-20 parts of polyester resin, 12-15 parts of rosin resin, 10-12 parts of terpene resin, 8-10 parts of alkyd resin, 10-12 parts of amino resin, 15-18 parts of acrylic resin, 5-6 parts of a lacquer thinner, 8-10 parts of organosilicon oil, 5-8 parts of glycerine, 3-5 parts of ethyl acetate, 5-6 parts of activated zinc oxide, 5-6 parts of fast-dissolving sodium silicate, 3-6 parts of dimethyl malonate, 3-5 parts of glycidyl methacrylate, 5-8 parts of ferric hydroxide, 2-3 parts of polyvinyl alcohol, 20-25 parts of vinyl acetate-acrylic emulsion and 20-30 parts of acrylic emulsion. The steel surface treatment paint mainly plays a wetting and permeating effect on loose rust to separate and wrap the rust to prevent further development of rusting; meanwhile, after forming a film, the paint interacts with the rust by virtue of slow hydrolysis to form an acid complex to achieve the purpose of rust removal; the paint has stable properties, and increases the density of the paint film to prevent permeation of water and oxygen in air.

Owner:周彩球

Lacquer thinner

A lacquer or other coating thinner having a low volatile organic compound (VOC) rating which permits its use for cleaning and thinning in government regulated areas. The thinner has an acetone, methyl acetate or tertiary butyl acetate or mixture as a base. It has various non-hazardous ingredients which include a soy oil material, a dibasic ester and a glycol and carbonate ingredient such as tetrahydrofurfuryl alcohol.

Owner:BORTZ DISTRIBUTING CO

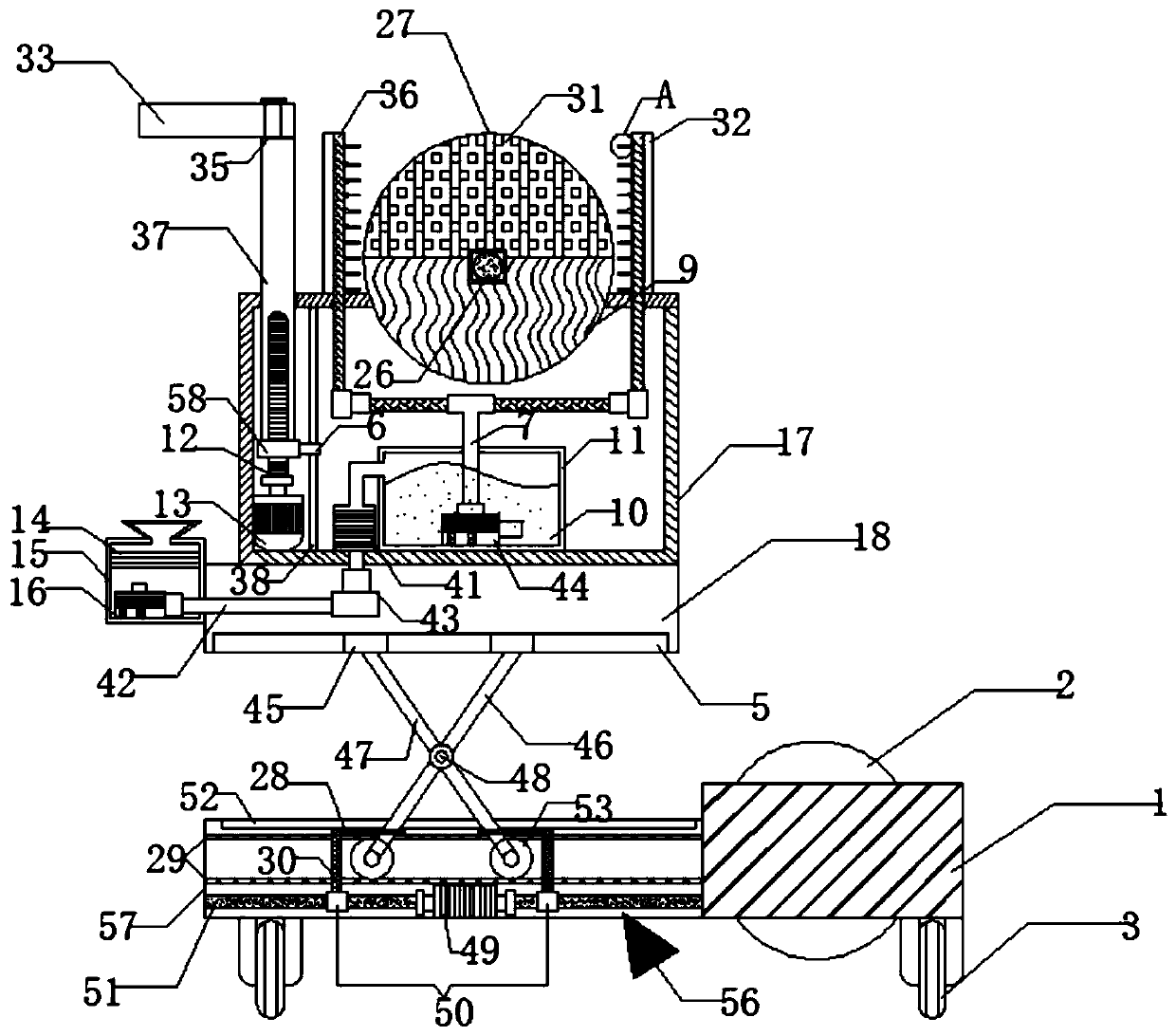

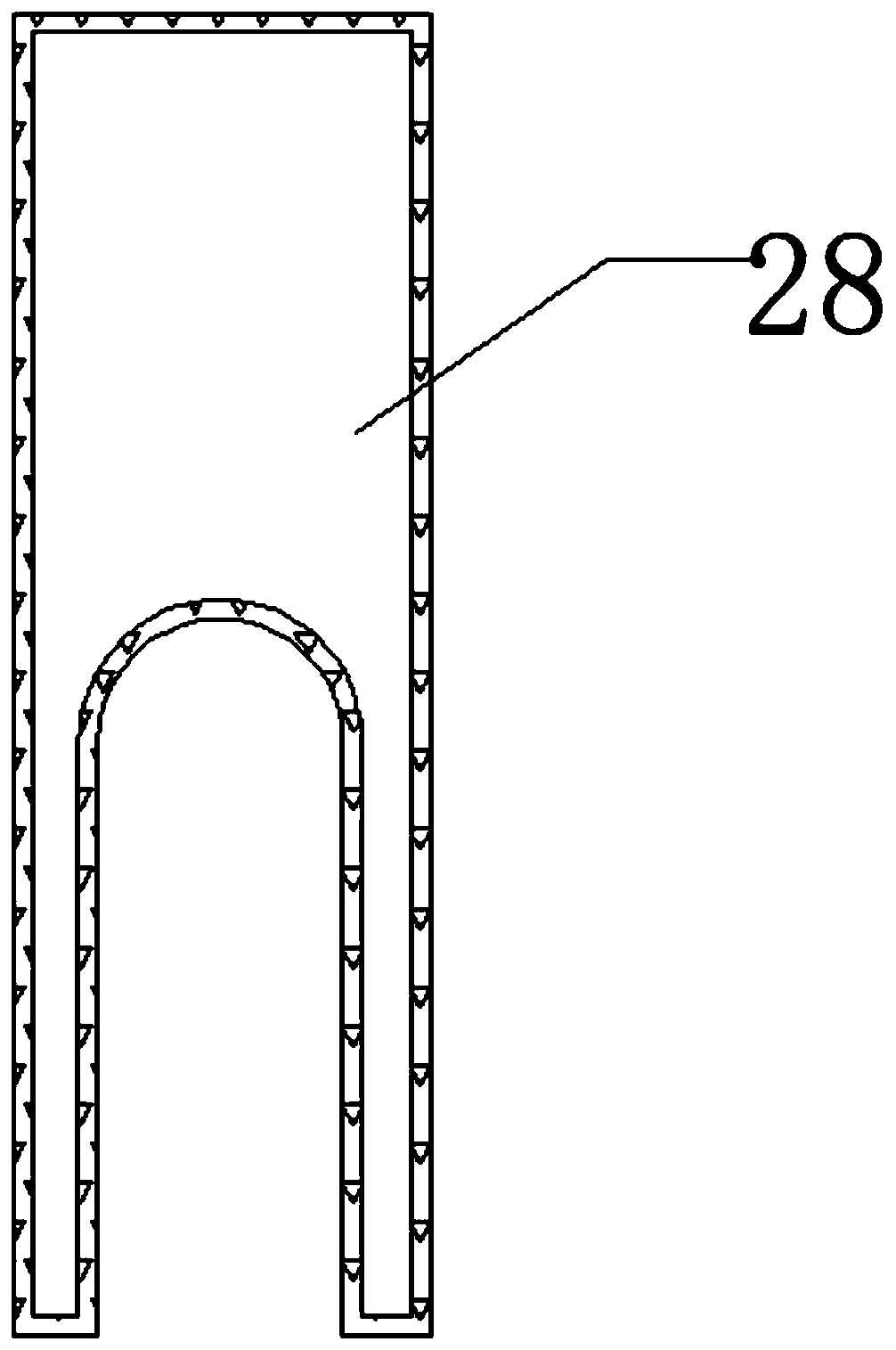

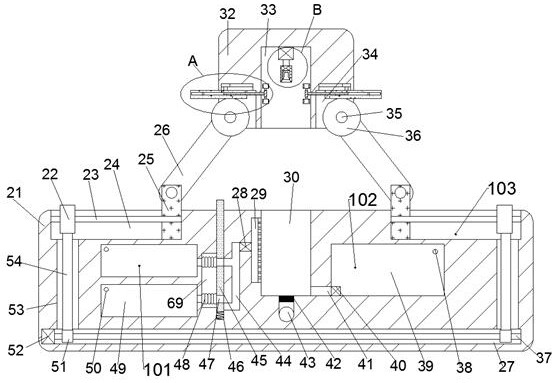

Municipal wall adlet cleaning device

InactiveCN110756467ASoak fastQuick moist softeningCleaning using toolsCleaning using liquidsLacquerLacquer thinner

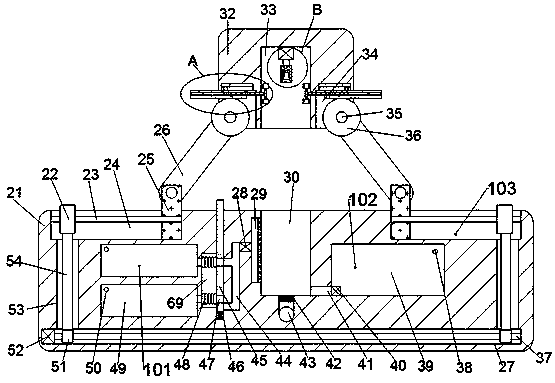

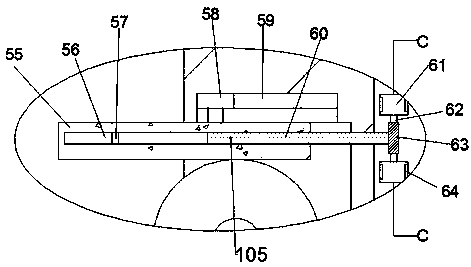

The invention relates to the technical field of environmental protection, and discloses a municipal wall adlet cleaning device. The municipal wall adlet cleaning device comprises a lifting structure;the lifting structure is arranged in a function box; the lifting structure consists of a ball screw, a first thread sleeve, a double-shaft motor, a first slide rod, a roller, a first connecting rod, asecond connecting rod, a hinging hinge, a slide hole, a fixed plate and an insertion rod; and the inner bottom of the function box is fixedly connected with the bottom of the double-shaft motor. In the municipal wall adlet cleaning device, a water collecting nozzle is arranged on one side of a water spraying tank for centralized shrinkage of thicker water currents in a water guide pipe to spray out, so that higher water current impact force can be generated, water can be quickly infiltrated into adlets, and adlet papers are quickly moisturized and softened; and lacquer thinners are sprayed out by the water collecting nozzle, so that glue behind the adlets can be quickly released to improve the working efficiency.

Owner:朱新宇

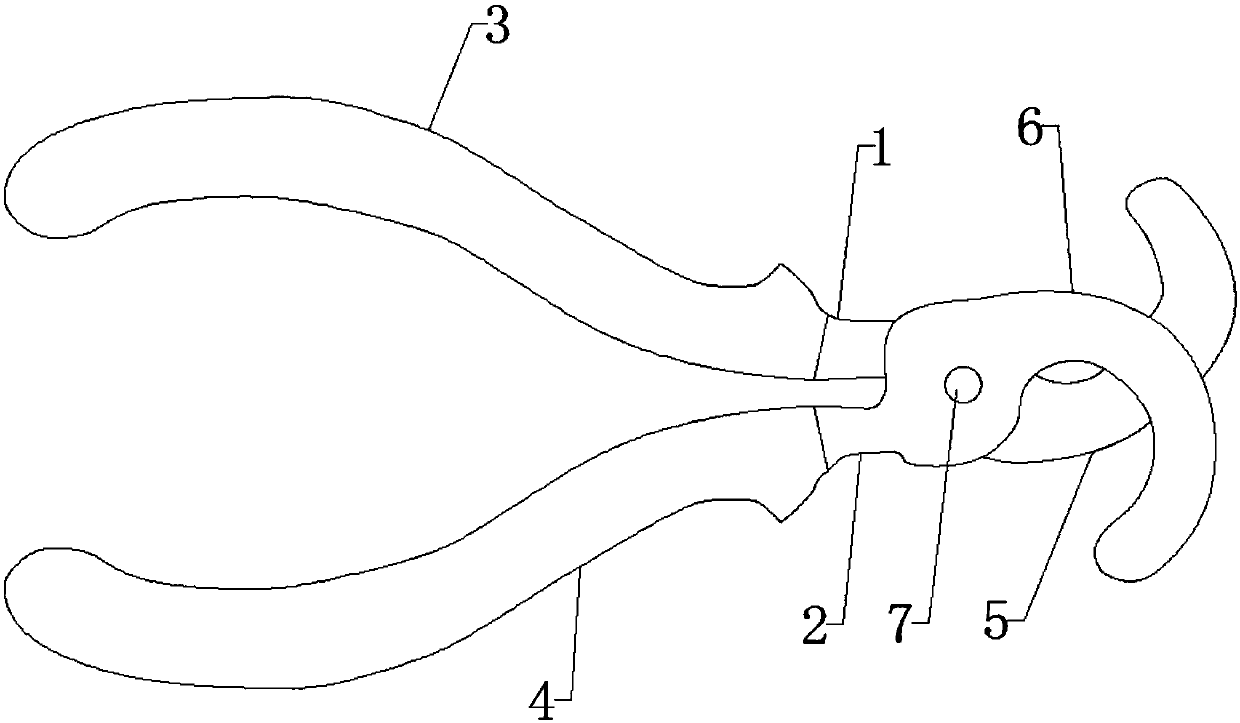

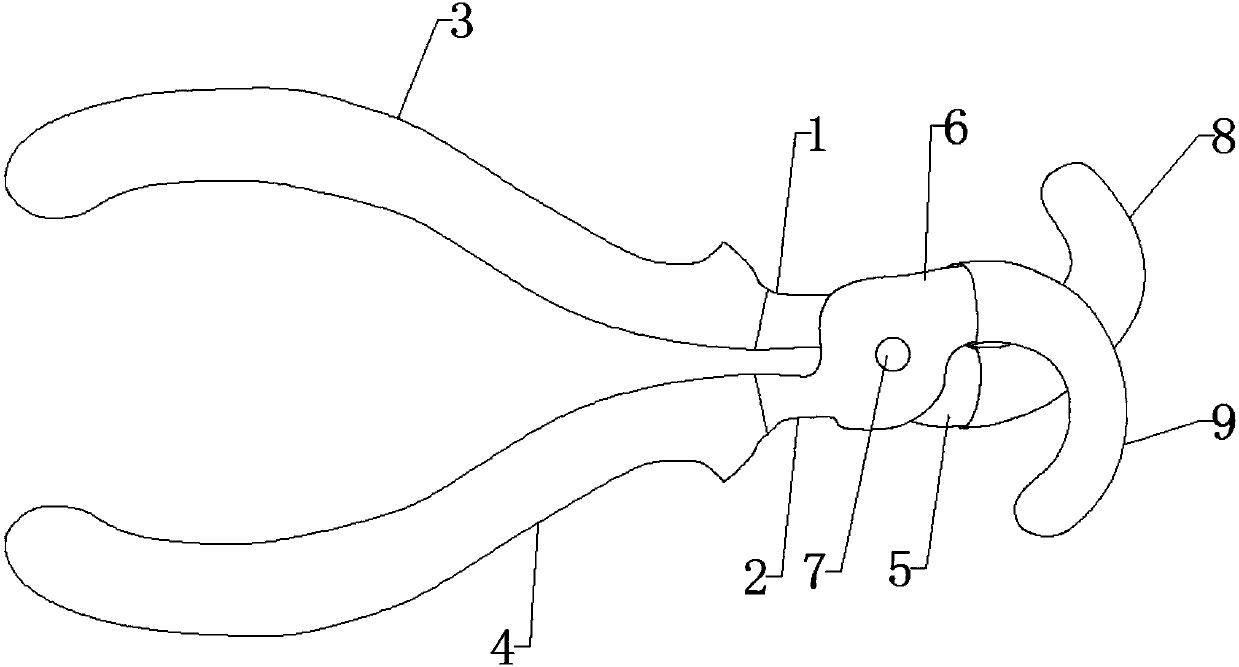

Method for manufacturing plant specimens

ActiveCN107047544ASolve bottlenecksFlexible size adjustmentDead plant preservationCyanoacrylateLacquer thinner

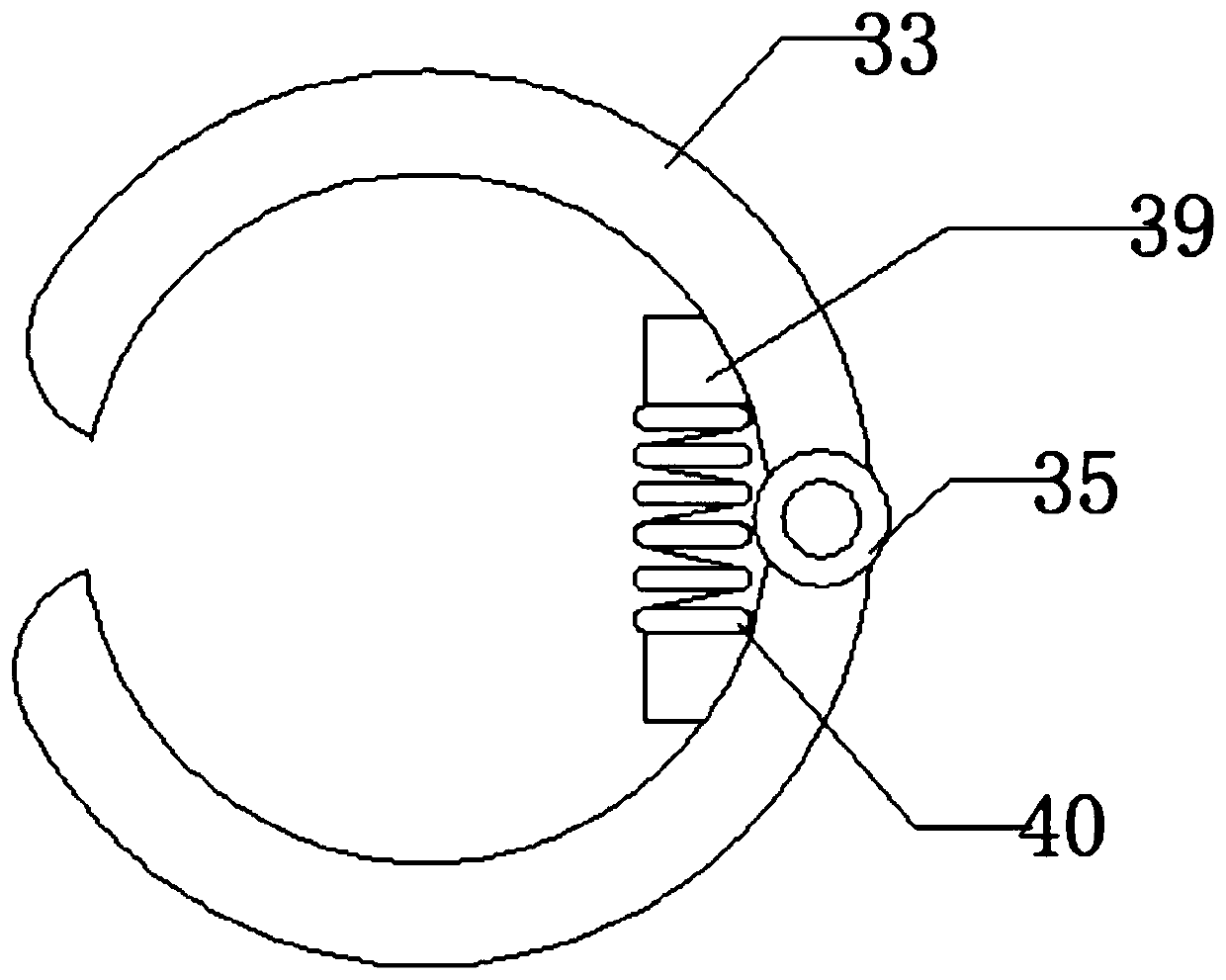

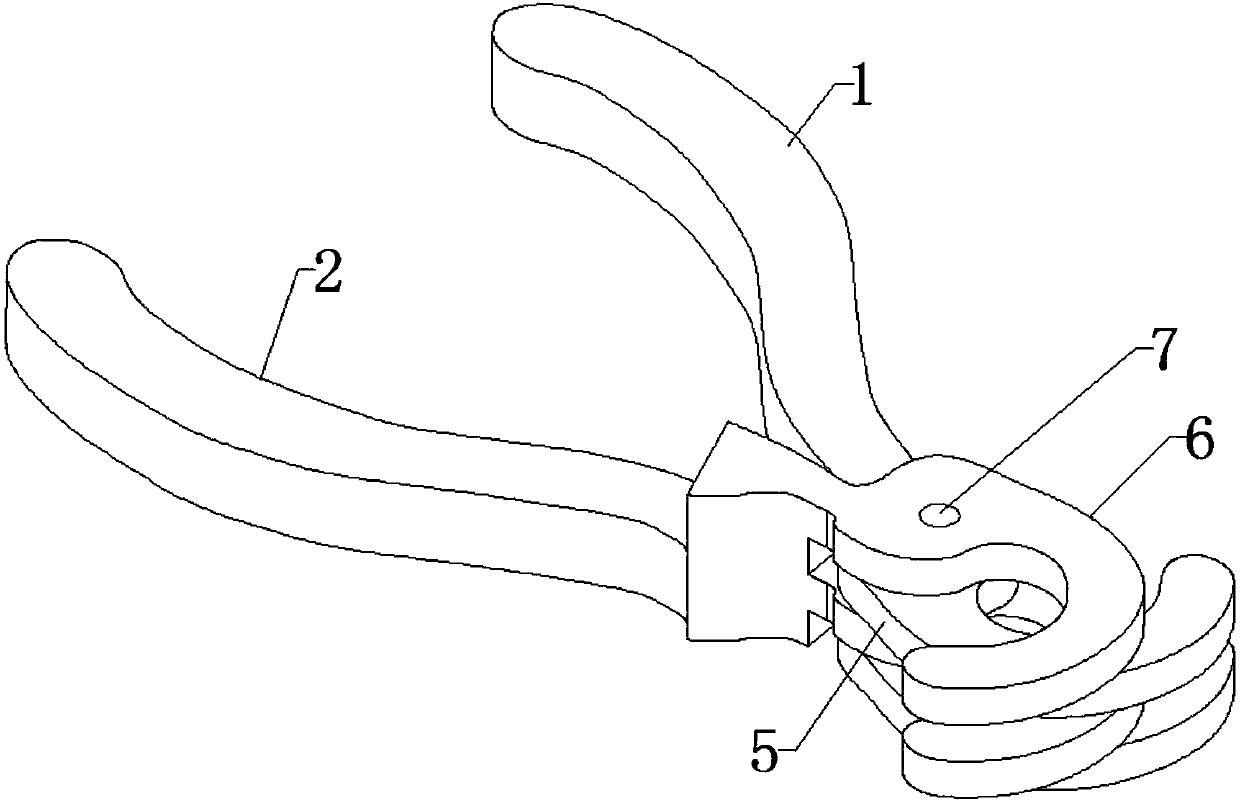

The invention discloses a method for manufacturing plant specimens. According to the method, on the basis of physiological structures and composition characteristics of plants and physicochemical properties and characteristics of traditional lacquer thinner, a mixed solution for manufacturing the plant specimens is prepared; the mixed solution is capable of effectively dissolving out fat soluble components on the surface and in the interior of the branches and stems of the plants; and the bottleneck problem encountered in the process of applying alpha cyanoacrylate compounds to the plant specimen manufacturing is solved. In the meantime, the invention designs cross type plant specimen fixing pincers which are used in the plant specimen manufacturing process and are capable of fixing plant roots and stems with different sizes. The method disclosed by the invention is low in cost and convenient to operate, is a plant specimen manufacturing method completely different from traditional plant herbarium and immersed specimen manufacturing methods and is also an innovation of the plant specimen manufacturing methods.

Owner:卞陆杰

Method for removing ink smudges of stone wall space floor tiles and reagent

InactiveCN106391517AClean up thoroughlyWill not be damagedChemical paints/ink removersCleaning using toolsStone wallLacquer thinner

The invention discloses a method for removing ink smudges of stone wall space floor tiles. The method includes the following steps that a lacquer thinner is sprayed onto the ink smudges of stone; ink already dissolved on the surface is wiped clean at once; the lacquer thinner is sprayed again; part of dissolved ink is wiped clean again; a sodium hypochlorite solution with the concentration being 6%-12% is smeared; wiping is performed; the solution on the stone surface is wiped clean; the sodium hypochlorite solution with the concentration being 6%-12% is smeared once again, so that the sodium hypochlorite solution is air-dried; and the process is completed. The invention further discloses a reagent adopted in the method for removing the ink smudges of the stone wall space floor tiles. The reagent comprises two parts of the lacquer thinner and two parts of the sodium hypochlorite solution with the concentration being 6%-12%. By means of the removing method and the reagent, the ink smudges placed on the stone surface or permeating into the stone can be removed, and the ink smudges can be removed thoroughly. Moreover, the stone surface cannot be damaged and corroded at all, and the natural color of the stone is restored. The method for removing the ink smudges of the stone wall space floor tiles and the reagent are further suitable for removing other kinds of ink smudges.

Owner:CHONGQING ZHONGYU MUNICIPAL ENVIRONMENTAL SANITATION +1

Screw propeller rust removing and painting device for civilian ship

ActiveCN110252571AAvoid harmKeep healthyLiquid spraying apparatusSpray boothsLacquer thinnerPropeller

The invention discloses a screw propeller rust removing and painting device for a civilian ship. The device comprises a device body in which a rust removing chamber is formed, wherein storing spaces are symmetrically formed at the upper part and the lower part of the left side of the rust removing chamber; a switch chamber is arranged at the right sides of the storing spaces; a rust removing agent is fed to an empty chamber through a second feeding port; lacquer thinner is fed through a first feeding port in the upper side; an anti-rust paint is fed through a first feeding port in the lower side; and then a screw propeller shaft is inserted into a clamping block. With the adoption of the device, a small screw propeller can be fully automatically subjected to rust removing and painting treatment; compared with a manual rust removing method, the device has the advantage that the efficiency is greatly improved; the rust removing and painting are carried out in a sealing condition, so that the corrosive damage of the rust removing agent to people can be prevented; and meanwhile, the damage of paint to respiratory tract of people can be prevented.

Owner:南通小松钢业有限公司

Cleaning agent for water pump impeller

The invention discloses a cleaning agent for a water pump impeller, and relates to the technical field of repairing and cleaning of water pumps. The cleaning agent is prepared from the following raw materials in parts by weight: 30-45 parts of white vinegar, 10-15 parts of rapeseed oil, 10-15 parts of saturated polybasic carboxylic acid, 10-15 parts of activated clay, 8-10 parts of tea-seed soil, 13-15 parts of dirt dispersion agent, 8-10 parts of corn flour, 3-5 parts of cooked rice powder, 8-10 parts of film forming resin, 10-15 parts of lacquer thinner, 3-5 parts of oxalic acid, 3-5 parts of clay powder, 1-2 parts of ferric trichloride, 1-2 parts of soda powder, and 1-1.5 parts of red phosphorus powder. With the adoption of the cleaning agent, dirt attached on the water pump impeller can be effectively removed, and moreover, the impeller corrosion caused by an aqueous cleaning agent can be prevented; the dirt attached to the impeller can be separated off, and thus the loss caused by the damage of the impeller can be avoided.

Owner:GUANGDE YULONG PUMP

Oil-resistant anti-rust paint and preparation method thereof

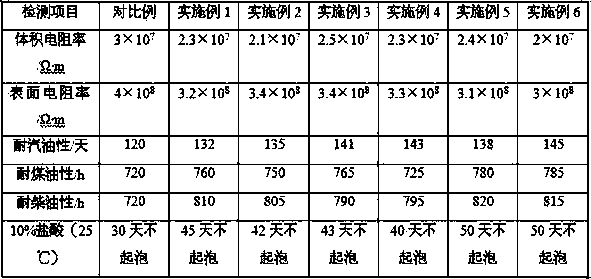

InactiveCN104046221AGood static conductivityImprove rust resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsXylylenePolymer science

The invention relates to an oil-resistant anti-rust paint and a preparation method thereof. The paint is prepared from the following raw materials in parts by mass: 17-28 parts of trimethylolpropane, 26-42 parts of toluene diisocyanate, 0.2-1.2 parts of butylated hydroxytoluene, 0.1-0.3 part of organobentonite, 2-5 parts of turpentine, 0.1-0.2 part of paraffin, 40-50 parts of xylene, 6-12 parts of high chlorinated polyethylene resin, 2.5-5 parts of titanium dioxide, 2.5-5 parts of mica powder, 1-4 parts of talcum powder, 0.1-0.22 part of diphenyl guanidine and 6-13 parts of banana oil. The oil-resistant anti-rust paint provided by the invention has the advantages of favorable static conductivity, favorable gasoline, kerosene and diesel resistance, favorable corrosion resistance and favorable anti-rust effect, is especially suitable for application on the oil pipe inner wall, and has favorable antistatic, anticorrosive and anti-rust actions.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

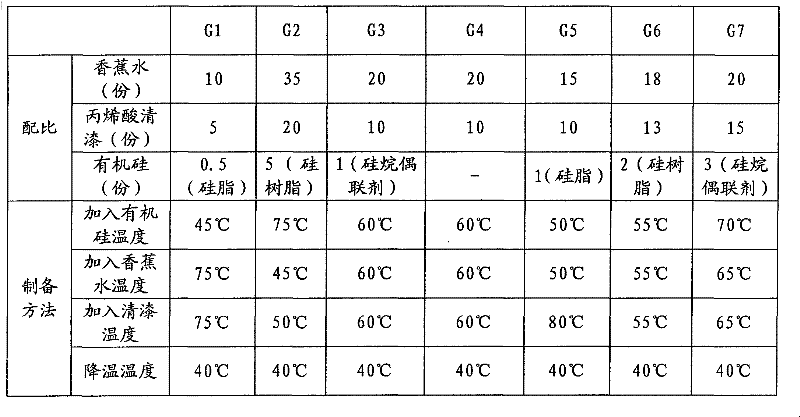

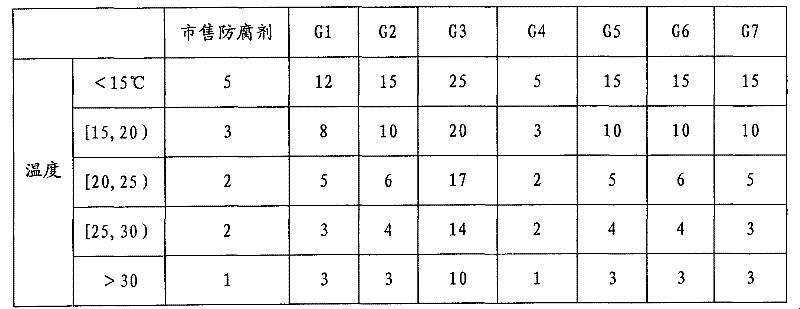

Corrosion preventive for being coated on surfaces of aluminium alloy plates and preparation method of corrosion preventive

InactiveCN102504658AAvoid electrochemical reactionsImprove anti-corrosion performancePretreated surfacesAnti-corrosive paintsLacquer thinnerLacquer

The invention belongs to corrosion protection techniques of aluminium alloy plates, particularly relates to corrosion preventive for being coated on the surfaces of the aluminium alloy plates, and further discloses a preparation method of the corrosion preventive. The corrosion preventive is prepared from the following components by part by weight: 10 to 35 parts of lacquer thinner, 5 to 20 parts of clear lacquer, and 0.5 to 5 parts of organosilicon. Through the adoption of the corrosion preventive electrochemical reaction on the surfaces of the aluminium alloy plates is prevented, dense protective films are formed on the surfaces of the aluminium alloy plates through the organosilicon, and the aluminium alloy plates are endowed with excellent anticorrosion performances. Compared with the corrosion preventive in the prior art, the corrosion preventive provided by the invention has stronger superior performances, and can be widely applied to surface corrosion protection of the aluminium alloy plates.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Life-cycle anhydrous cooling liquid

InactiveCN104087263AHigh boiling pointRaise the equilibrium temperatureHeat-exchange elementsPolyethylene glycolEthyl group

The invention discloses life-cycle anhydrous cooling liquid, comprising the following raw materials in parts: 30-35 parts of triethanolamine, 15-20 parts of triisopropanolamine, 10-12 parts of triethylamine, 5-11 parts of dichloromethane, 6-8 parts of triethylamine hydrochloride, 2-4 parts of ethyl acetate, 16-18 parts of ethyl alcohol, 12-20 parts of acetic acid, 5-6 parts of acetone, 6-8 parts of banana oil, 5-8 parts of polyethylene glycol, 2-3 parts of polyfluoroalkyl ethyl, 2-4 parts of 3-substituted sulfenyl-5-(2-hydroxyphenyl)-4H-1,2,4-triazole compound, 2-5 parts of oxalic acid, 3-6 parts of trichloroacetic acid, 3-5 parts of tartaric acid, 3-4 parts of azelaic acid, 2-3 parts of octanedioic acid, 3-5 parts of potassium sorbate, 3-6 parts of sodium glutamate, 2-3 parts of sodium carbonate, 2-3 parts of sodium hydroxide, 5-6 parts of silicone oil and 6-7 parts of Janus green. The life-cycle anhydrous cooling liquid does not contain water, so that the boiling point and the corrosion resistance of the cooling liquid and the balance temperature of an engine can be greatly improved, the engine can run at full load and high load, and vehicles can safely run in severe environments such as highlands, deserts and the like.

Owner:张慧玲

Efficient decontamination floor cleaner

InactiveCN104928065AGood decontamination effectGood antibacterial effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolystyreneCocamidopropyl betaine

Disclosed is an efficient decontamination floor cleaner. The raw materials of the cleaner include, by weights: 4 to 6 parts of methyl hydroxybenzene, 3 to 7 parts of dibutyl phthalate, 4 to 8 parts of cocamido propyl hydroxyl sultaine, 6 to 9 parts of hydrogenated castor oil, 5 to 10 parts of spices, 12 to 17 parts of polystyrene latex, 4 to 8 parts of sodium carbonate, 6 to 7 parts of beewax, 1.5 to 2.3 parts of diethylene triamine pentaacetic acid (DTPA) iron ammonium salt, 2 to 4 parts of bactericide B, 3 to 5 parts of eucalyptus oil, 8 to 14 parts of lacquer thinner, 7 to 12 parts of sodium alcohol ether sulphate, 0.1 to 0.2 part of flavour, 20 to 24 parts of sodium hydrogen carbonate and 5 to 10 parts of fatty alcohol-polyoxyethylene ether. The floor cleaner has the advantages the fine decontamination and bacteriostasis effects are achieved, the floor lustre is enhanced, floor ageing is prevented effectively, and the service life of the floor is prolonged.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

Cleaning agent used for composite wood floor and floor tile

ActiveCN103740485AAvoid damageExtended service lifeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEnvironmental resistanceCleansing Agents

The invention relates to a cleaning agent, and concretely relates to a cleaning agent used for composite wood floor and floor tile, and the cleaning agent comprises the following components by weight: 5-15 parts of banana oil, 5-10 parts of ethylene glycol butyl ether, 5-10 parts of glycerin, 5-15 parts of sodium ethoxylated alkyl sulfate, 5-15 parts of coconut oil fatty acid diethanolamide, 0.5-1.5 parts of sodium tripolyphosphate, 0-0.05 parts of essence and 100 parts of water. The cleaning agent employs a physical complex formulation method to prepare, the manufacturing process is simple, and has the advantages of environmental protection and no nuisance, and keep the refresh air, the employed components has low cost, and the adaption scope is wide, and the cleaning agent can be used for composite wood floor and various floor tiles, the cleaning effect is good, the working time is fast for 5 minutes from the operation beginning, according to the invention, the used glycerin and ethylene glycol butyl ether can form a layer of protection film on the surface of the floor, the protection film can protect the floor, the damage from outside to the floor can be reduced, and the floor usage life is prolonged.

Owner:济南市嬴磊信息科技有限公司

High-efficiency banana oil paint detergent

ActiveCN104277575AHigh activityImprove paint stripping effectChemical paints/ink removersLacquer thinnerSodium dodecylbenzenesulfonate

The invention relates to the field of detergents, particularly a high-efficiency banana oil paint detergent which is composed of the following components in parts by weight: banana oil, sodium dodecyl benzene sulfonate, sodium hydroxide, ethoxylated sodium alkyl sulfate, coconut diethanol amide, dichloromethane and deionized water. By using the banana oil as the solvent, the proportion of the anionic surfactant sodium dodecyl benzene sulfonate to the ethoxylated sodium alkyl sulfate is regulated in combination with the nonionic surfactant coconut diethanol amide, thereby obviously increasing the activity of the active group and enhancing the depainting effect and depainting efficiency.

Owner:佛山市南海区巨人化学品制造有限公司

Automobile maintaining agent and preparation method thereof

InactiveCN105969202AExtended service lifeImprove sun protection and antifreeze performanceOther chemical processesOrganic non-surface-active detergent compositionsPhosphateMoisture

The invention provides an automobile maintenance agent and a preparation method thereof. The maintenance agent is composed of the following components: ethylhexyl salicylate, Great Wall antifreeze, sodium bentonite, diatomaceous earth, attapulgite soil, hibiscus leaves, rice washing water, vinegar, soybean lecithin, silicone resin, calcium phosphate powder, cyclohexyl phosphate, banana water, kaolin, 48wt% potassium nitrate, 42wt% sodium nitrite, 10wt% sodium nitrate and water. The automobile maintenance agent of the present invention can not only be used for the maintenance of automobile glass to increase the service life of the glass, but also can be used for automobile body maintenance, which can significantly improve the sunscreen and antifreeze performance of the automobile surface, effectively remove the dust on the automobile surface, and lubricate and remove dust to the greatest extent. Rust and dehumidification; at the same time, the use of the curing agent of the present invention reduces the waste of water resources, and is environmentally friendly and pollution-free.

Owner:程嘉斌

Lacquer thinner

A lacquer or other coating thinner having a low volatile organic compound (VOC) rating which permits its use for cleaning and thinning in government regulated areas. The thinner has an acetone, methyl acetate or tertiary butyl acetate or mixture as a base. It has various non-hazardous ingredients which include a soy oil material, a dibasic ester and a glycol and carbonate ingredient such as tetrahydrofurfuryl alcohol.

Owner:BORTZ DISTRIBUTING CO

Preparation method for molybdenum disulfide base lubricating coat

ActiveCN100572599CSubstance lessSimple production processLiquid surface applicatorsBase-materialsLacquer thinnerFirming agent

The invention relates to a preparation method of a molybdenum disulfide-based lubricating coating, which relates to the technical field of chemical composition application. It is to wash, dry and phosphate the workpiece to be coated; then use molybdenum disulfide as a lubricant, epoxy resin as a binder, banana water as a diluent, and ethylenediamine as a curing agent. The prepared molybdenum disulfide-based lubricating coating is coated on the surface of the workpiece; under normal temperature conditions, it is naturally dried for 20-30 minutes to form a molybdenum disulfide-based lubricating coating. Compared with the prior art, it has the advantages of simple and convenient production process, low production cost and good product quality.

Owner:SICHUAN LIANMAO MACHINERY MFG

Cleaner for composite wood floors and floor tiles

InactiveCN107287045AAvoid damageExtended service lifeNon-ionic surface-active compoundsDetergent mixture composition preparationLacquer thinnerEther

The invention relates to a cleaner, in particular to a cleaner for composite wood floors and floor tiles. The cleaner is prepared from the following components in parts by weight: 5 to 15 parts of lacquer thinner, 5 to 10 parts of ethylene glycol butyl ether, 5 to 10 parts of glycerinum, 5 to 15 parts of lauryl alcohol polyoxyethylene, 5 to 15 parts of cocoanut fatty acid diethanolamide, 0.5 to 1.5 parts of sodium tripolyphosphate, 0 to 0.05 parts of essence and 100 parts of water. The cleaner has the beneficial effects that the cleaner is prepared through a physical complex method, and the preparation process is simple, environmentally-friendly and harmless and can keep air fresh; meanwhile, the adopted components are relatively low in cost and wide in application range; the cleaner can be applied to the composite wood floors and various floor tiles, is good in cleaning effect and takes a quick response; about 5 minutes is spent in working from the start of operation; meanwhile, by use of the glycerinum and the ethylene glycol butyl ether, a layer of protective film can be formed on the surface of each floor to protect the floor, so that damage from the outside to the floor is reduced, and the service life of the floor is prolonged.

Owner:JINAN HAOZE ENVIRONMENTAL PROTECTION TECH CO LTD

Banana water paint cleaning agent for fabric

ActiveCN104292961BHigh activityGood compatibilityChemical paints/ink removersCleansing AgentsSodium hydroxide

The invention relates to the field of cleaning agents and particularly relates to a lacquer thin paint cleaning agent for fabrics. The lacquer thin paint cleaning agent consists of the following components in parts by weight: lacquer thinner, sodium dodecyl benzene sulfonate, sodium hydroxide, sodium ethoxy alkyl sulfate, coconut fatty acid diethanol amide, dodecyl ethyoxyl sulphobetaine, cetyl trimethyl ammonium bromide, dichloromethane and deionized water. According to the lacquer thin paint cleaning agent for fabrics disclosed by the invention, cation surfactants sodium dodecyl benzene sulfonate and sodium ethoxy alkyl sulfate, a nonionic surfactant coconut fatty acid diethanol amide and an ampholytic surfactant dodecyl ethyoxyl sulphobetaine have good compatible effects; by virtue of a proportioning relationship of the four surfactants, the activities of active groups in the surfactants are increased to improve the paint removing effects and the paint removing efficiency; and the bactericidal effects of dodecyl ethyoxyl sulphobetaine and cetyl trimethyl ammonium bromide are utilized to meet the market needs.

Owner:TONGXIANG HENGFENG DYEING

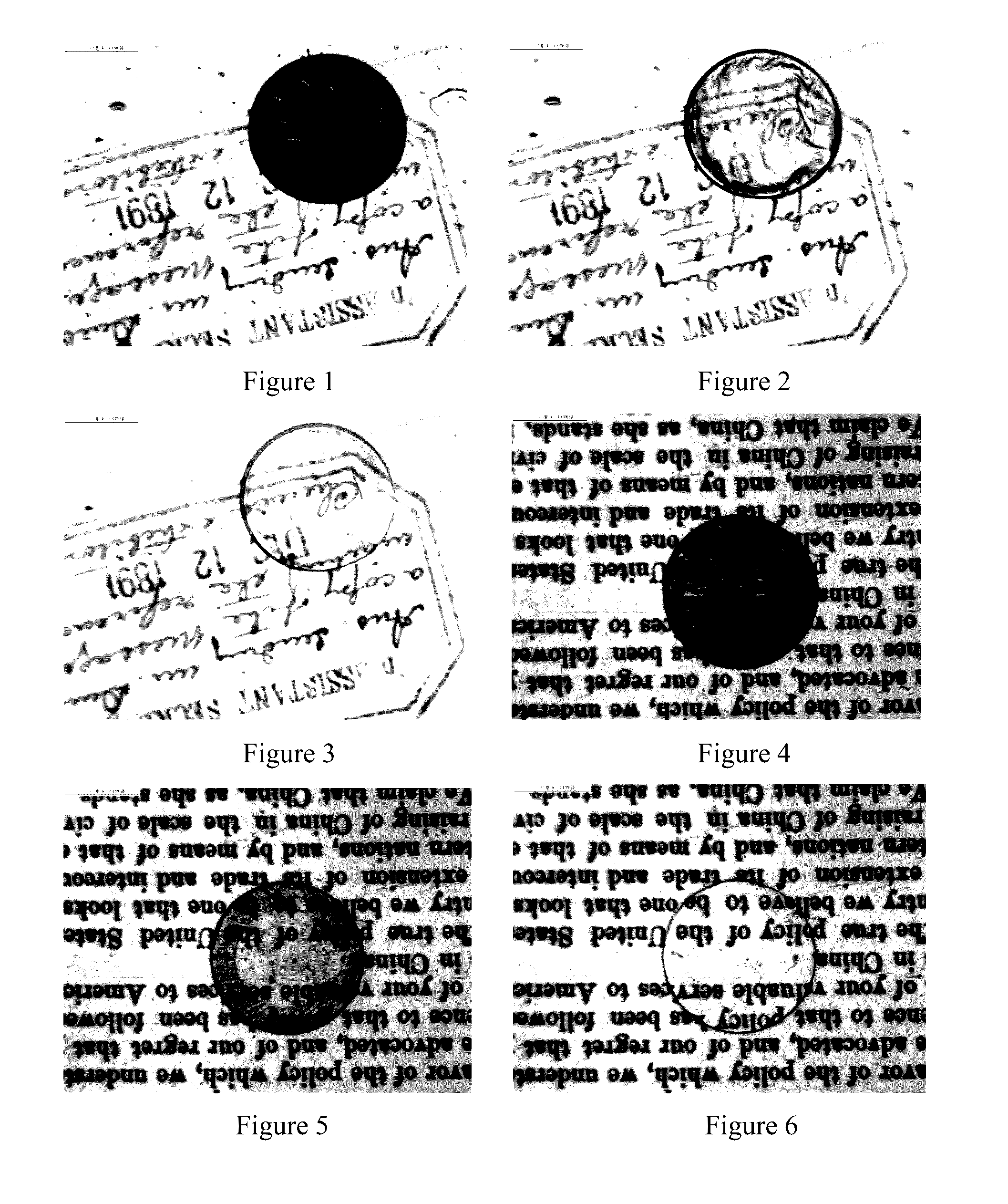

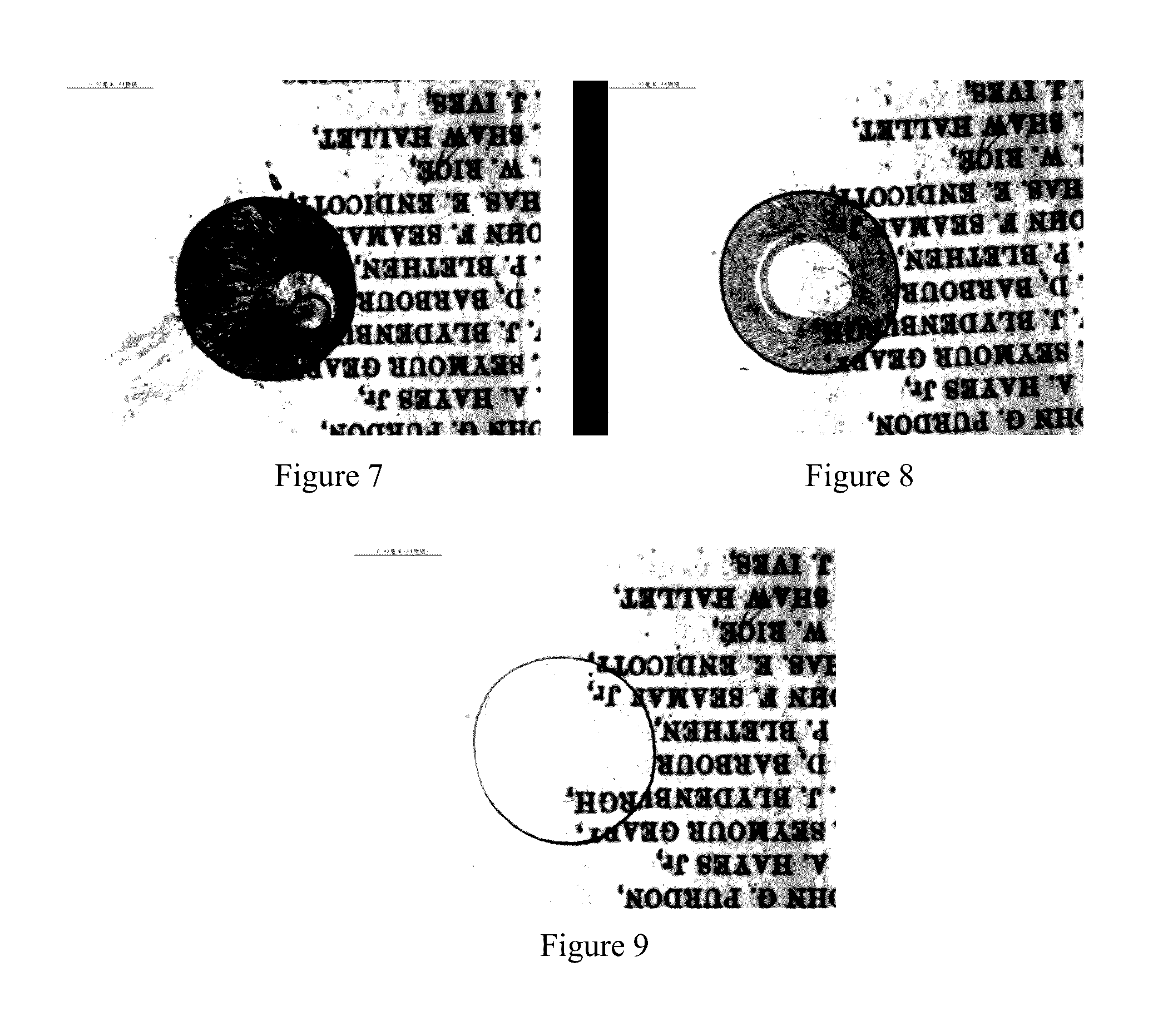

Restoration solution for cine film bubble and restoration method

ActiveUS9841666B2Good thermal stability and oxidation resistance and permeabilityImprove thermal stabilityPhotography auxillary processesCoatingsEmulsionSheet film

Owner:SHAANXI NORMAL UNIV

Restoration solution for cine film bubble and restoration method

ActiveUS20160377971A1Improve thermal stabilityImprove oxidation resistancePhotography auxillary processesPrints flatteningEmulsionSheet film

The present invention discloses a restoration solution for cine film bubble and a restoration method. The restoration solution comprises 100 parts by volume of n-butanol, 60 to 120 parts by volume of lacquer thinner having 5% by mass of ethyl cellulose, 8 to 20 parts by volume of diphenyl isooctyl phosphite, 2 to 10 parts by volume of bis (1,2,2,6,6-pentamethyl-4-piperidyl) sebacate, and 2 to 15 parts by volume of petroleum ether. The present invention integrates micro-restoration, bubble puncture and optical filling, and effectively restores a bubble having a diameter of 0.1 mm to 1 mm generated between a film base layer and an emulsion layer of a cine film. The present invention has advantages of simple method of operation, low cost and good controllability. And the used restoration solution has good thermal stability, oxidation resistance, and permeability, and can eliminate the phenomenon of light scattering within the bubble, so that patterns and writing of the original image data are explicitly presented, and a better restoration effect is achieved without damages to films. Therefore, the restoration solution has good application values and market prospects.

Owner:SHAANXI NORMAL UNIV

Efficient plastic coating for green furniture and plastic spraying process of efficient plastic coating

PendingCN113292889AIncrease percentageShorten drying timeSiccativesPretreated surfacesLacquer thinnerSolid wood

The invention relates to the field of high polymer materials, and particularly discloses an efficient plastic coating for green furniture, wherein the efficient plastic coating comprises the following components: polystyrene, tung oil, p-benzoic acid, polytetramethylene ether glycol, p-methoxyphenol, methyl silicone oil, trichloroethylene, banana oil, ethyl acetate and other auxiliary agents. A spraying process of the efficient plastic coating for green furniture comprises the following steps: S1, surface cleaning; S2, drying treatment; S3, preheating: carrying out preheating treatment on the efficient plastic coating for the green furniture, wherein the preheating temperature ranges from 45 DEG C to 50 DEG C; S4, plastic spraying: spraying the preheated efficient plastic coating for the green furniture to the surface of solid wood furniture; and S5, airing. The methyl silicone oil, the trichloroethylene, the banana oil and the ethyl acetate serve as a mixed solvent of polystyrene and tung oil, the percentage content of film forming components in the mixed solvent is increased, the surface drying time of the plastic coating is shortened, and the plastic spraying efficiency is improved.

Owner:临海市国盛泰工艺品股份有限公司

Steel plate paint remover and preparation method thereof

InactiveCN104356739ALeave no traceNo residueChemical paints/ink removersDiacetone alcoholBenzoic acid

The invention provides a steel plate paint remover and a preparation method thereof. The paint remover comprises the following raw materials in parts by mass: 55-75 parts of sodium gluconate, 12-22 parts of benzoic acid, 4-12 parts of diacetone alcohol, 4-12 parts of amyl acetate, 0.8-2.5 parts of hydroxypropyl cellulose, 1-3 parts of castor oil, 0.7-2 parts of dimethyl cellosolve, 1.5-7 parts of banana oil, 0.6-1.5 parts of sodium dodecylbenzenesulfonate, 0.6-1.5 parts of dimethyl adipate and 1-3 parts of polyethylene glycol. By the paint remover provided by the invention, various paints on the surface of the steel plate can be removed, no traces or residue is caused, the matrix cannot be corroded and the removal efficiency is high.

Owner:WUXI EPIC TECH

Ceramic tile detergent

InactiveCN106753879APromote reductionExtended service lifeAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsTurpentineDiethylenetriamine

The invention relates to the field of detergents, in particular to a ceramic tile detergent which consists of the following substances in parts by weight: 6-12 parts of nitrilotriacetic acid trisodium salt, 15-20 parts of turpentine, 8-12 parts of propylene glycol monomethyl ether, 15-25 parts of a lacquer thinner, 15-25 parts of oxalic acid, 4-6 parts of 2-amino-2-methyl-1-propyl alcohol, 1-3 parts of lauryl sodium sulfate, 15-25 parts of citric acid, 5-10 parts of glycolic acid, 2-3 parts of coconut fatty acid diethanol amine, 2-5 parts of polyoxyethylene fatty acid, 15-20 parts of hydroxyethyl cellulose, 1-2 parts of a diethylenetriamine pentaacetic acid iron-sodium complex, 5-8 parts of a waterproof agent, 3-5 parts of a corrosion inhibitor, 5-8 parts of perfume and 50-60 parts of water. The ceramic tile detergent provided by the invention is thorough in washing, the original feature of a ceramic tile can be rapidly recovered, a surface protection agent is available, a layer of a protection membrane is generated on the surface of the ceramic tile, due to addition of the waterproof agent, the phenomenon of slipping can be effectively avoided after the ceramic tile is washed, and due to addition of the corrosion inhibitor, the service life of the ceramic tile can be prolonged.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

Improved paint cleaning agent

InactiveCN104927478ACleans quickly and thoroughlyEasy to useChemical paints/ink removersSodium bicarbonatePhosphoric Acid Esters

An improved paint cleaning agent is prepared from, by weight, 15-25 parts of sodium bicarbonate, 8-14 parts of dodecyl ethyoxyl sulphobetaine, 12-18 parts of banana oil, 6-13 parts of dodecyl ethyoxyl sulphobetaine, 7-9 parts of coconut oil fatty acid diethanol amide, 10-17 parts of sodium hydroxide, 5-7 parts of polyoxyethylene ether, 8-18 parts of ethyl alcohol, 4-7 parts of solvent oil 200#, 15-20 parts of sodium carbonate, 6-12 parts of paraffin wax, 0.12-0.23 part of dodecyl phosphate salt, 25-45 parts of distilled water, 4-7 parts of glacial acetic acid, 8-14 parts of sodium ethoxylated alkyl sulfate and 2-4 parts of glycerol. The improved paint cleaning agent has the advantages of high cleaning speed, thoroughness in cleaning, no corrosivity to base materials, energy saving, consumption reduction, no toxicity, environment friendliness, excellent use effect and capability of meeting market demand.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

A kind of banana water paint cleaning agent

ActiveCN104277576BActive and effectiveImprove paint stripping effectChemical paints/ink removersLacquerLacquer thinner

The invention relates to the field of detergents, particularly a banana oil paint detergent which is composed of the following components in parts by weight: banana oil, sodium dodecyl benzene sulfonate, sodium hydroxide, sodium hydroxide, ethoxylated sodium alkyl sulfate, dichloromethane and deionized water. By using the banana oil as the solvent, the anionic surfactants sodium dodecyl benzene sulfonate and ethoxylated sodium alkyl sulfate are combined, thereby obviously displaying the activity of the anionic surfactant and enhancing the depainting effect and depainting efficiency.

Owner:南通北外滩建设工程有限公司

A device for removing rust and painting propellers of civil ships

The invention discloses a screw propeller rust removing and painting device for a civilian ship. The device comprises a device body in which a rust removing chamber is formed, wherein storing spaces are symmetrically formed at the upper part and the lower part of the left side of the rust removing chamber; a switch chamber is arranged at the right sides of the storing spaces; a rust removing agent is fed to an empty chamber through a second feeding port; lacquer thinner is fed through a first feeding port in the upper side; an anti-rust paint is fed through a first feeding port in the lower side; and then a screw propeller shaft is inserted into a clamping block. With the adoption of the device, a small screw propeller can be fully automatically subjected to rust removing and painting treatment; compared with a manual rust removing method, the device has the advantage that the efficiency is greatly improved; the rust removing and painting are carried out in a sealing condition, so that the corrosive damage of the rust removing agent to people can be prevented; and meanwhile, the damage of paint to respiratory tract of people can be prevented.

Owner:南通小松钢业有限公司

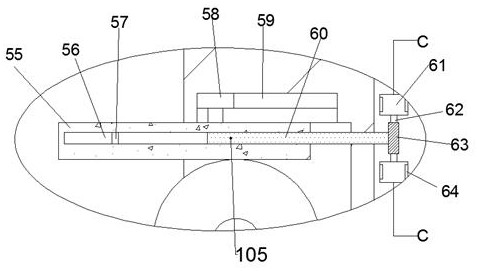

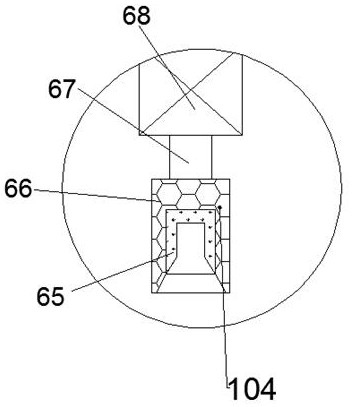

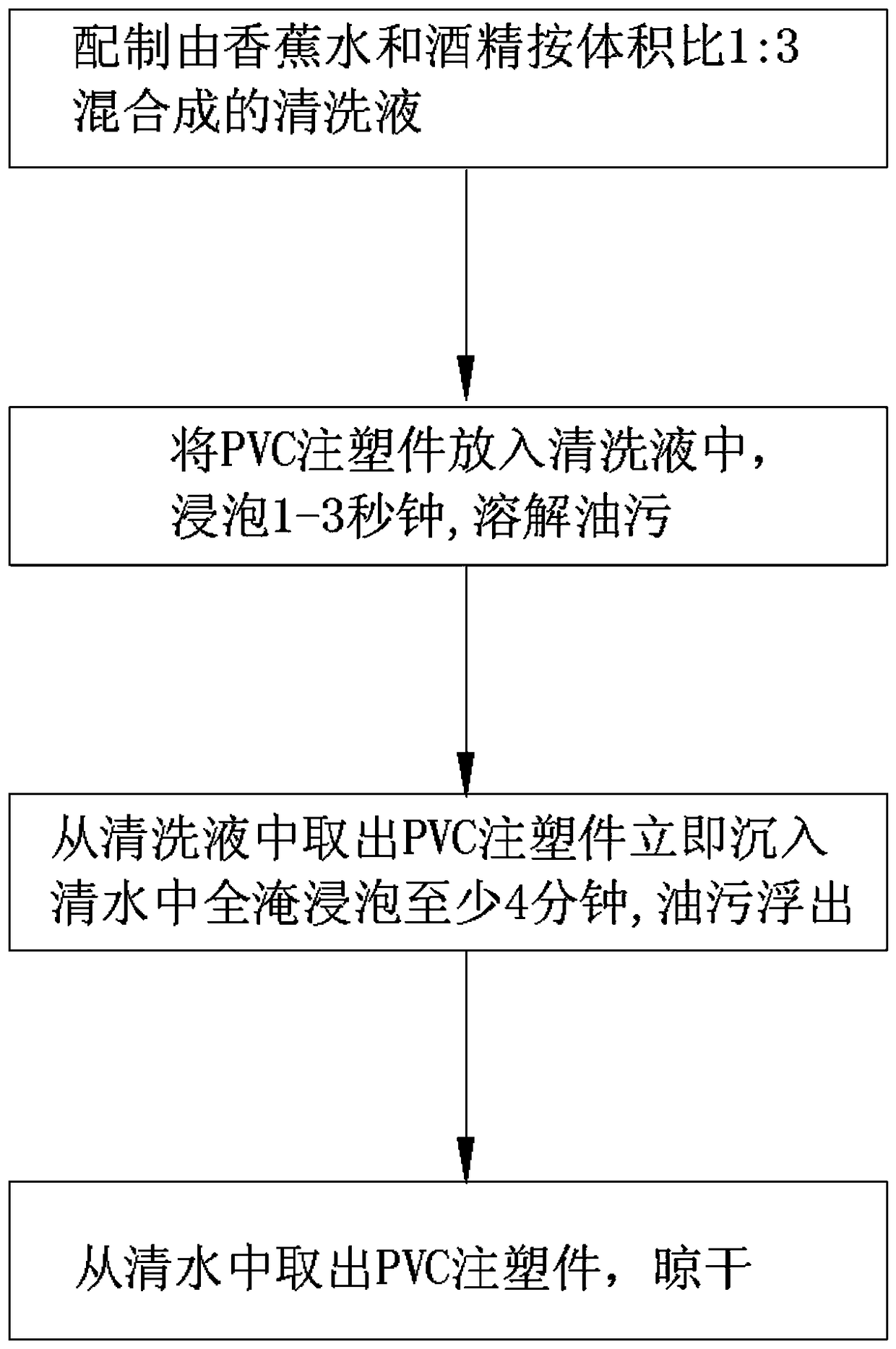

Cleaning solution and cleaning treatment method for preventing low-hardness pvc injection molded parts from spraying paint

ActiveCN104862128BPrevent paint peelingAffect healthOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsAlcoholLacquer thinner

The invention provides a cleaning solution capable of preventing a low-hardness PVC injection molded part from paint peeling-off and a cleaning treatment process. The cleaning solution is prepared by mixing a lacquer thinner and alcohol in which the content of ethanol is larger than or equal to 95% at the volume ratio of 1: 3. A face needing to the painted of the low-hardness PVC injection molded part is immersed into the cleaning solution to be wholly soaked for 1-3 seconds, so that oil fouling on the surface of the low-hardness PVC injection molded part is dissolved; then the low-hardness PVC injection molded part is taken out from the cleaning solution and immediately submerged into fresh water to be wholly soaked for at least 4 min, so that the dissolved oil fouling is separated from the surface of the low-hardness PVC injection molded part to emerge from water; the low-hardness PVC injection molded part is taken out and aired to be used for surface painting till the face needing to the painted of the low-hardness PVC injection molded part is clean in fresh water. After the low-hardness PVC injection molded part is subjected to cleaning treatment before painting, a paint sprayed on the surface of the low-hardness PVC injection molded part cannot peel off, so that the product quality of batch production is guaranteed, the labor intensity of workers is greatly reduced, and the long-lasting difficult-to-solve problem that the paint on the surface of the injection molded part peels off in the injection product manufacturing industry is effectively solved.

Owner:SICHUAN JINDEXING AUTO PARTS

Water pump impeller cleaning agent

The invention discloses a water pump impeller cleaning agent, and relates to the technical field of water pump maintenance cleaning. The cleaning agent is prepared from, by weight, 30-45 parts of white vinegar, 10-15 parts of colleseed oil, 10-15 parts of saturated polybasic carboxylic acid, 10-15 parts of activated carclazyte, 8-10 parts of camellia oil, 13-15 parts of dirt dispersion agent, 8-10parts of corn meal, 3-5 parts of cooked ground rice, 8-10 parts of film-forming resin, 10-15 parts of lacquer thinner, 3-5 parts of oxalic acid, 3-5 parts of clay powder, 1-2 parts of iron trichloride, 1-2 parts of soda powder and 1-1.5 parts of amoriphous phosphorus powder. By means of the cleaning agent, adhering dirty substances on the impellers of a water pump can be effectively removed, therusting of the impellers caused by using a water-based cleaning agent can be prevented, the dirty substances adhering to the impellers can be removed, and therefore the loss caused by impeller damageis prevented.

Owner:NINGBO ZEE AUTOMATION EQUIP

Rapid mounting-removing liquid and manufacturing method thereof

InactiveCN1244462CUnframed fastTo achieve the effect of fully automatic demountingPaperhangingChange colorIndustrial alcohol

The invention discloses a fast tearing-off liquor and preparing method, composed of the components according to bulk ratio, pure industrial alcohol 10-20%, pure banana oil 20-30%, pure xylene 50-60%, adding and uniformly shaking to make it. Its making method: adding in the pure industrial alcohol and pure banana oil to uniformly shake them, then adding in pure xylene and uniformly shake. Its character: the dismounting speed is fast; the dismounting effect is good and after dismounted, the painting and calligraphy is intact, not damaged, does not change color, and does not walk ink; its order and toxicity is small. It is applied to fast dismount the fast glue film mounted painting and calligraphy.

Owner:葛建军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com