Cleaning solution and cleaning treatment method for preventing low-hardness pvc injection molded parts from spraying paint

A processing method and technology for injection molded parts, which are applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., which can solve the problems of low production efficiency, clean oil pollution, high production costs, etc., and reduce manual labor. The effect of strength, improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

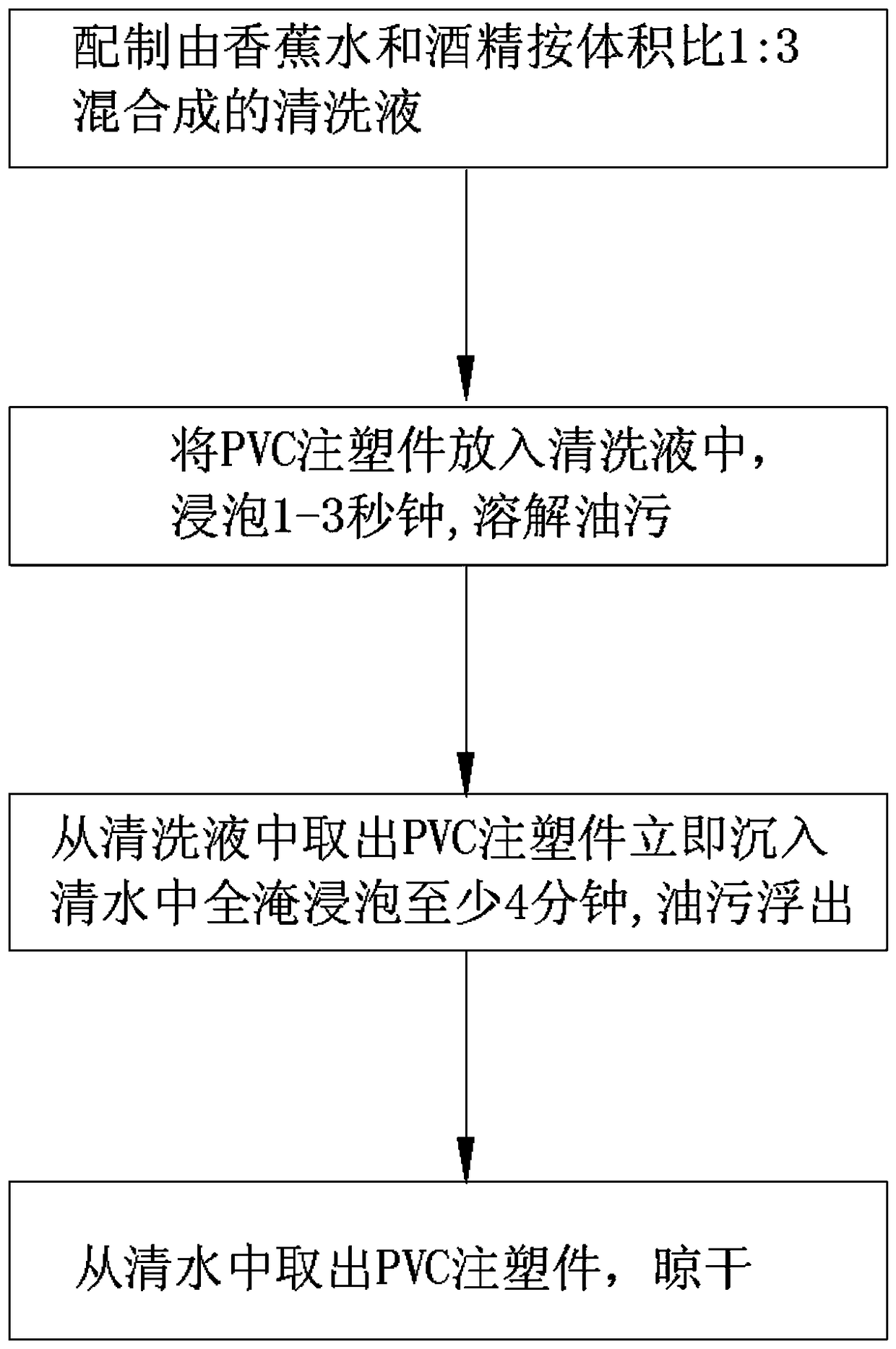

Image

Examples

Embodiment Construction

[0020] A cleaning solution for preventing low-hardness PVC injection molded parts from being sprayed and peeled off. The cleaning solution is prepared by mixing banana water and alcohol with an ethanol content ≥ 95% in volume ratio, and the ratio of banana water: alcohol is 1:3.

[0021] The composition of each substance in the described banana water of the present embodiment is by weight percentage:

[0022] 15% n-butyl acetate, 15% ethyl acetate, 10-15% n-butanol, 10% ethanol, 5-10% acetone, 20% benzene, and 20% xylene. Of course, the same effect can also be achieved by using banana water with other ingredients sold in the market.

[0023] The alcohol of the present embodiment can adopt the technical alcohol that ethanol content is 95%, adopts technical alcohol and can reduce the cost of alcohol. Of course, it is also possible to use ordinary alcohol with an ethanol content of 95.57%, or anhydrous alcohol with an ethanol content of 99.5%. The use of common alcohol or absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com