Black finishing varnish for automobile as well as preparation method and application thereof

A technology for finishing varnishes and automobiles, applied in the field of varnishes, can solve problems such as insufficient blackness of the paint film, achieve high gloss, prevent excessive oven temperature, and have excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

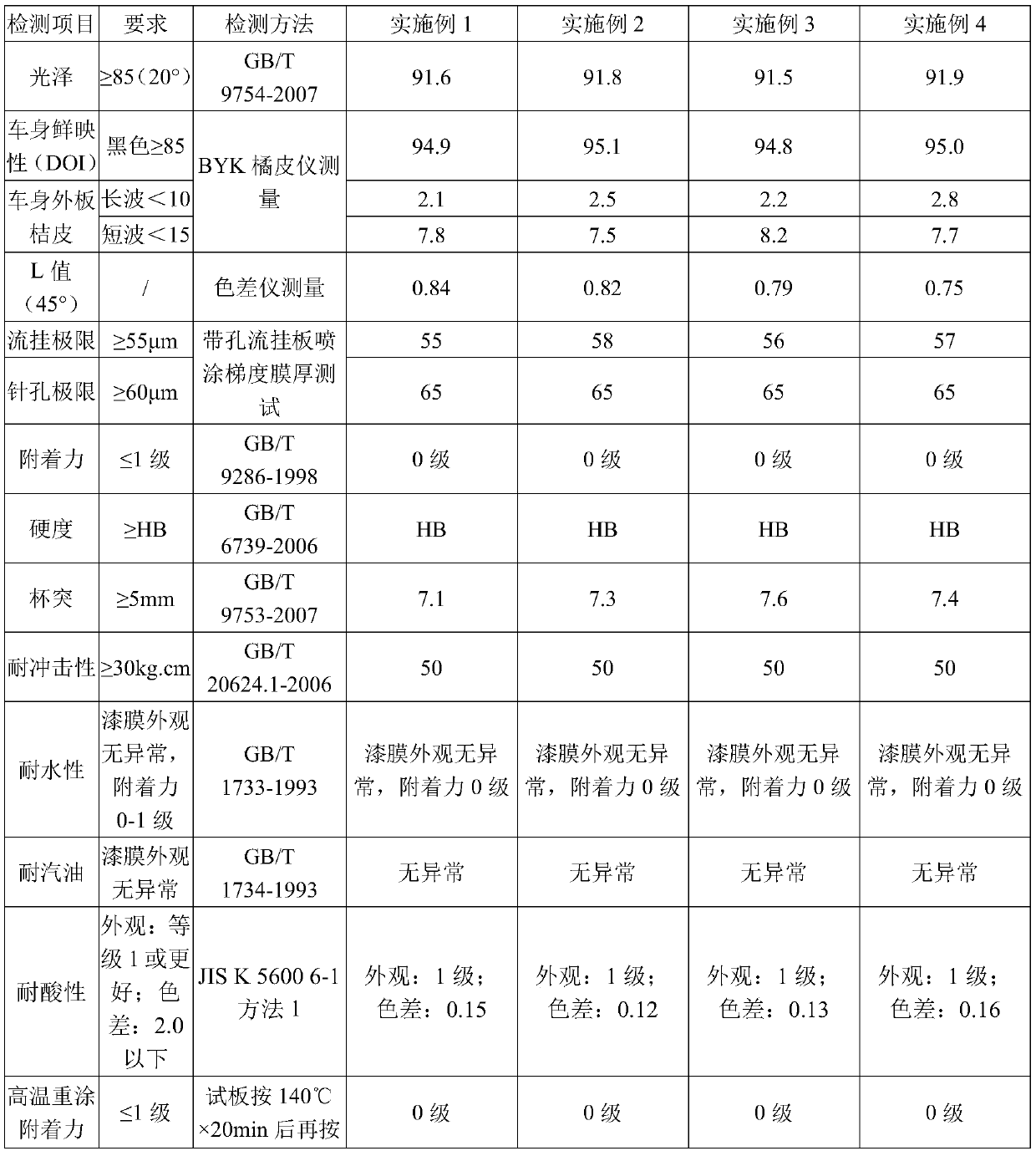

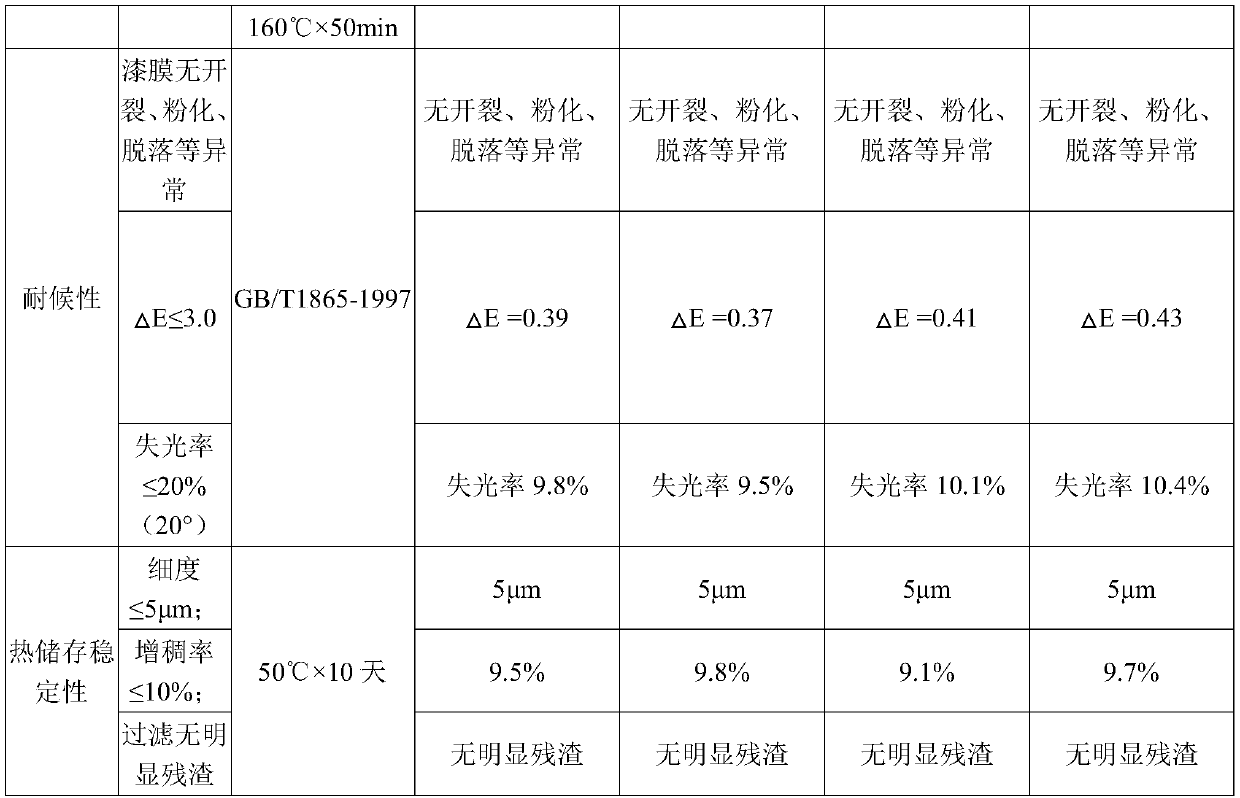

Examples

preparation example Construction

[0045] In a specific embodiment, the preparation method of the above-mentioned automotive yellowing-resistant varnish for sealing strips includes:

[0046] (1) Mix 0.5-1.0 parts of ultraviolet absorber, 0.4-1.0 parts of light stabilizer and 4-8 parts of mixed solvent to obtain the first mixture; 3-6 parts of reactive microgel, 2-5 parts Mix 1-2 parts of butyl etherified amino resin with 4-10 parts of mixed solvent to obtain the second mixture; mix 1-2 parts of xylene with 0.1-0.5 parts of degassing agent to obtain the third mixture; mix 40-60 parts of thermosetting acrylic resin , 15-25 parts of butylated amino resin, 4-10 parts of epoxy modified thermosetting acrylic resin, 0.1-0.5 parts of antioxidant additives, 0.1-1 parts of leveling agent, 0.1-1.0 parts of defoamer, 0.4- 0.8 parts of black pulp were mixed evenly to obtain the fourth mixture;

[0047] (2) Add the first mixture, the second mixture, and the third mixture to the fourth mixture in turn under stirring, and aft...

Embodiment 1

[0066] A kind of black finishing varnish for automobile, formula as shown in table 1

[0067] The formula of varnish in table 1 embodiment 1

[0068] serial number components number of copies 1 S-150 solvent oil 5 2 THASORB UV-234 0.9 3 RIASORB UV-292 0.45 4 S-150 solvent oil 2 5 Butanol 2 6 Trimethyl orthoacetate 1 7 AZS-1230 5 8 CYMEL 1158 2.5 9 Xylene 1 10 GK-19 0.2 11 Setalux 1766VB-64 54 12 CYMEL 1158 17.5 13 ACS-1284 6 14 BYK 355 0.5 15 BYK-323 0.1 16 BYK 051 0.3 17 SP M-350-1(T)9904A BLACK UDP 0.4 18 BYK ES80 0.15 19 S-100# solvent oil 1

[0069] The preparation method of the black finish varnish for automobile of the present embodiment may further comprise the steps:

[0070] The first step is to take a steam jacketed cylinder, add component 1 and ground the container for 5 minutes, add component 2 to the container, start...

Embodiment 2

[0076] A kind of black finishing varnish for automobile, formula as shown in table 2.

[0077] The formula of varnish in table 2 embodiment 2

[0078] serial number components number of copies 1 S-150 solvent oil 4 2 CHISORB 234 0.9 3 TINUVIN 292 0.5 4 S-150 solvent oil 1.8 5 Butanol 1.8 6 Trimethyl orthoacetate 1.1 7 AZS-617 3 8 UVAN 20SE-60 3 9 Xylene 1.2 10 Benzoin GK-19 0.25 11 Setalux 1766VB-64 50 12 UVAN 20SE-60 23.5 13 ACS-1017 5 14 TEGO FLOW 370 0.45 15 TEGO FLOW 425 0.2 16 DISPARLON OX-750 0.15 17 SP M-70(T)BLACK FW-200P(10PWC) 0.5 18 Methanol 2.5 19 S-100# solvent oil 0.15

[0079] The preparation method of the black finish varnish for automobile of the present embodiment may further comprise the steps:

[0080] The first step is to take a steam jacketed cylinder, add component 1 and ground the container for 5 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com