Patents

Literature

5951 results about "Antifoam agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

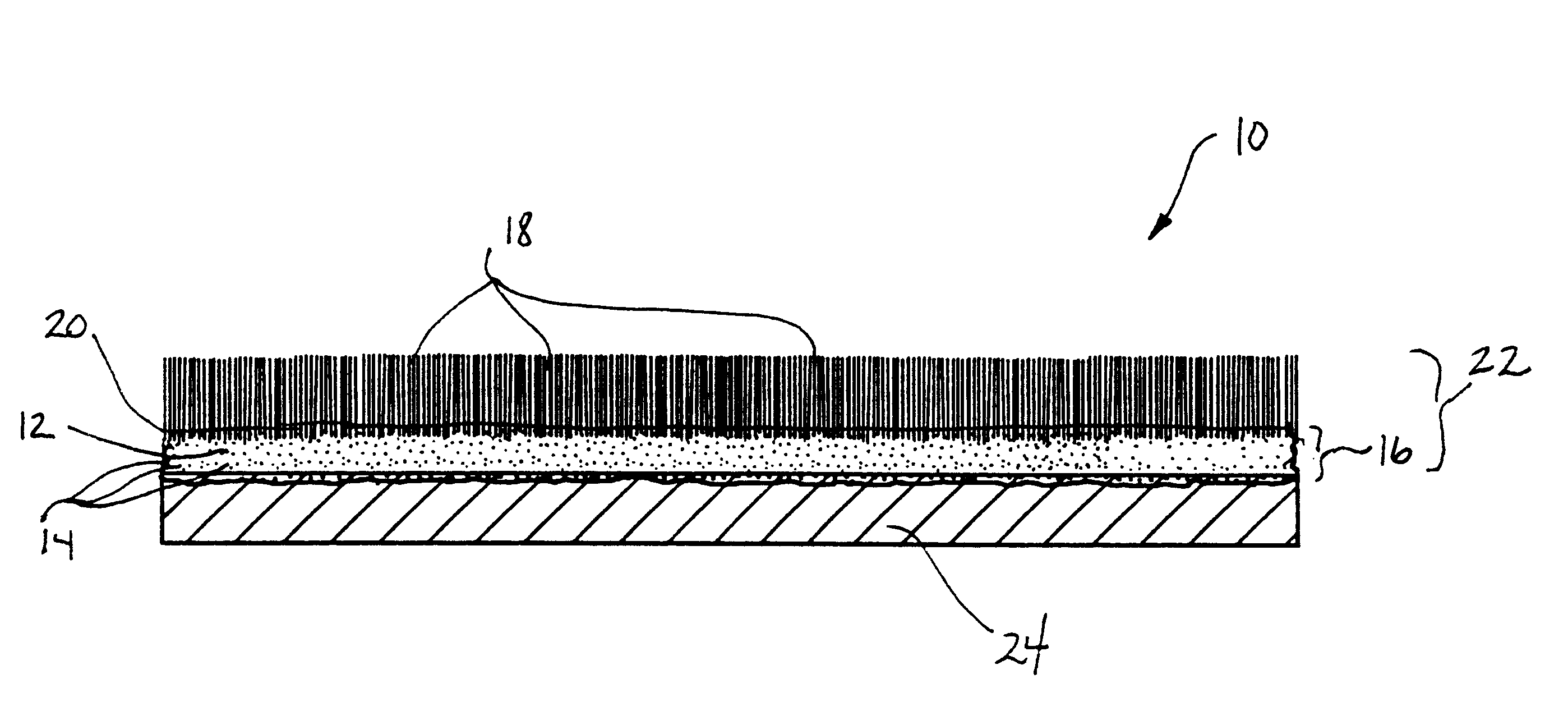

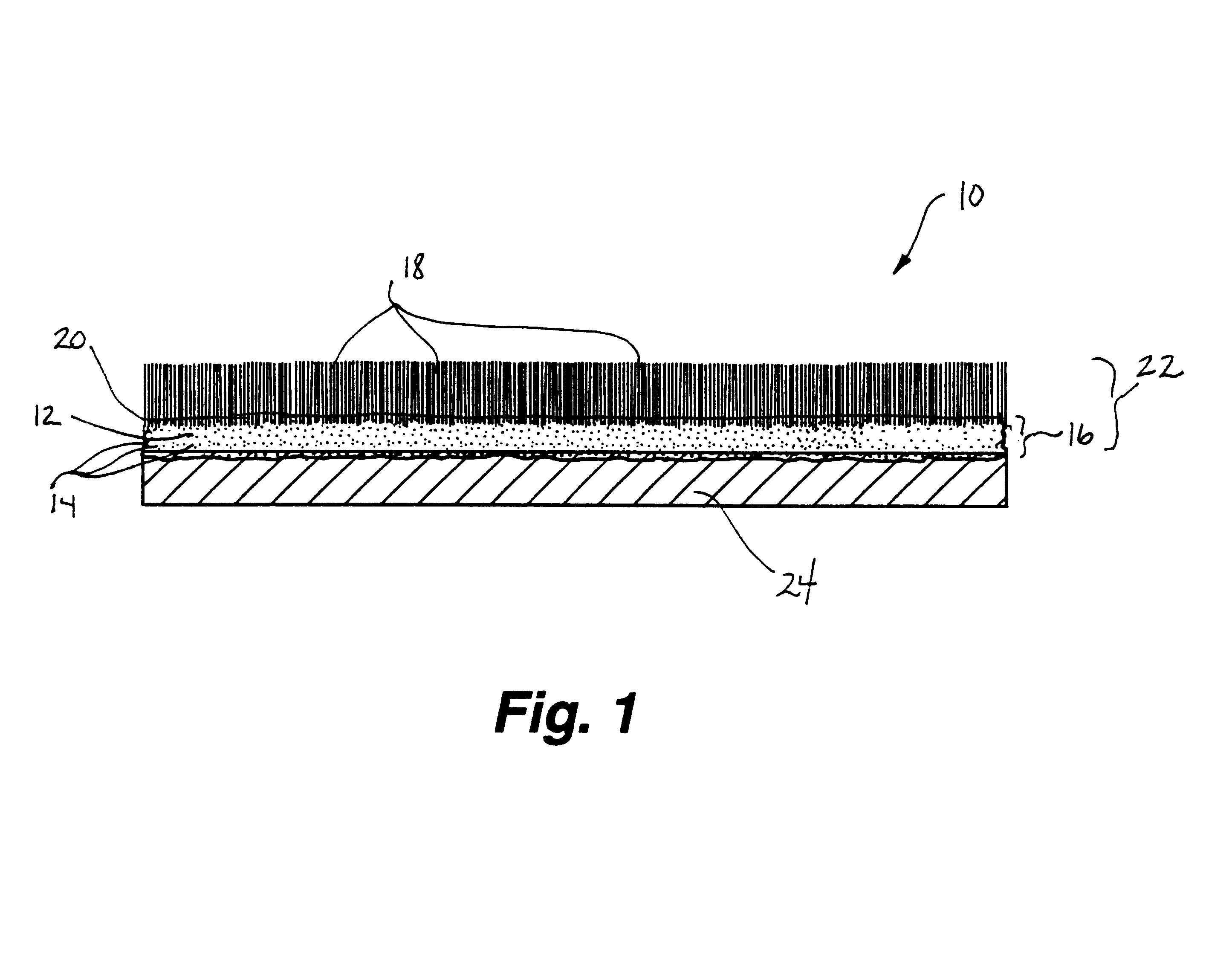

Fabric coating composition containing energy absorbing phase change material

InactiveUS6207738B1Solve the lack of densityReduce and eliminate heat transferHeat storage plantsFibre treatmentMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric.

Owner:OUTLAST TECH LLC

Fabric coating containing energy absorbing phase change material and method of manufacturing same

InactiveUS6514362B1Evenly dispersedEqually distributedDecorative surface effectsHeat storage plantsMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric. In an alternative embodiment, an extensible fabric is coated with an extensible binder containing microencapsulated phase change material to form an extensible, coated fabric. The coated fabric is optionally flocked. The coated fabrics are manufactured using transfer techniques.

Owner:OUTLAST TECH LLC

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

Multifunctional high-efficiency thermal insulation insulating mold paint

The invention relates to a multifunctional high-efficiency heat-preservation heat-insulation coating material. The compositions in percentage by weight of the coating material are: 10 to 20 percent of water, 0.1 to 0.2 percent of multifunctional auxiliary agent, 0.1 to 0.2 percent of wetting agent, 0.5 to 0.8 percent of dispersing agent, 0.3 to 0.5 percent of antifoam agent, 1.5 to 3.0 percent of propylene glycol, 16 to 20 percent of rutile-type titanium pigment, 3 to 5 percent of mica powder, 6 to 8 percent of hollow glass microballoon, 3 to 5 percent of infrared powder, 3 to 4 percent of fire retardant, 35 to 40 percent of elastic acrylic acid emulsion, 3 to 5 percent of opaque polymer, 0.5 to 0.8 percent of film-forming auxiliary agent, 0.2 to 0.3 percent of bactericide and preservative and 0.3 to 0.6 percent of thickening agent. The multifunctional high-efficiency heat-preservation heat-insulation coating material is of aqueous monocomponent and does no harm to human body and the environment so as to be an environment-friendly product; meanwhile, the coating material also has excellent waterproof and fire-retardation functions, convenient and quick construction, excellent adhesion strength, outstanding crack resistance, infrequent pollution and service life as long as 15 years; moreover, during practical use, the coating material can effectively reduce solar heat accumulated in a house by approximately 8 to 15 DEG C, and can greatly reduce energy consumption.

Owner:董善刚

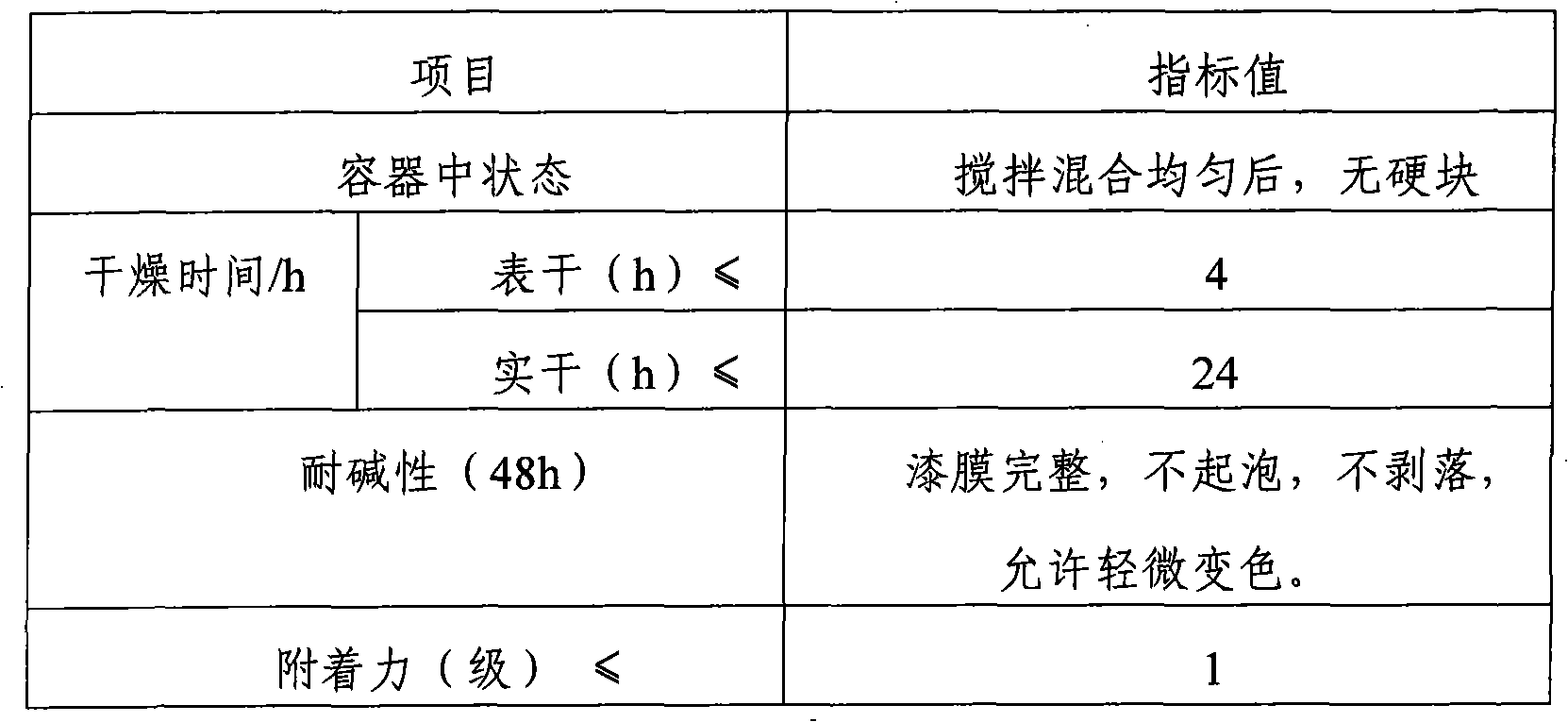

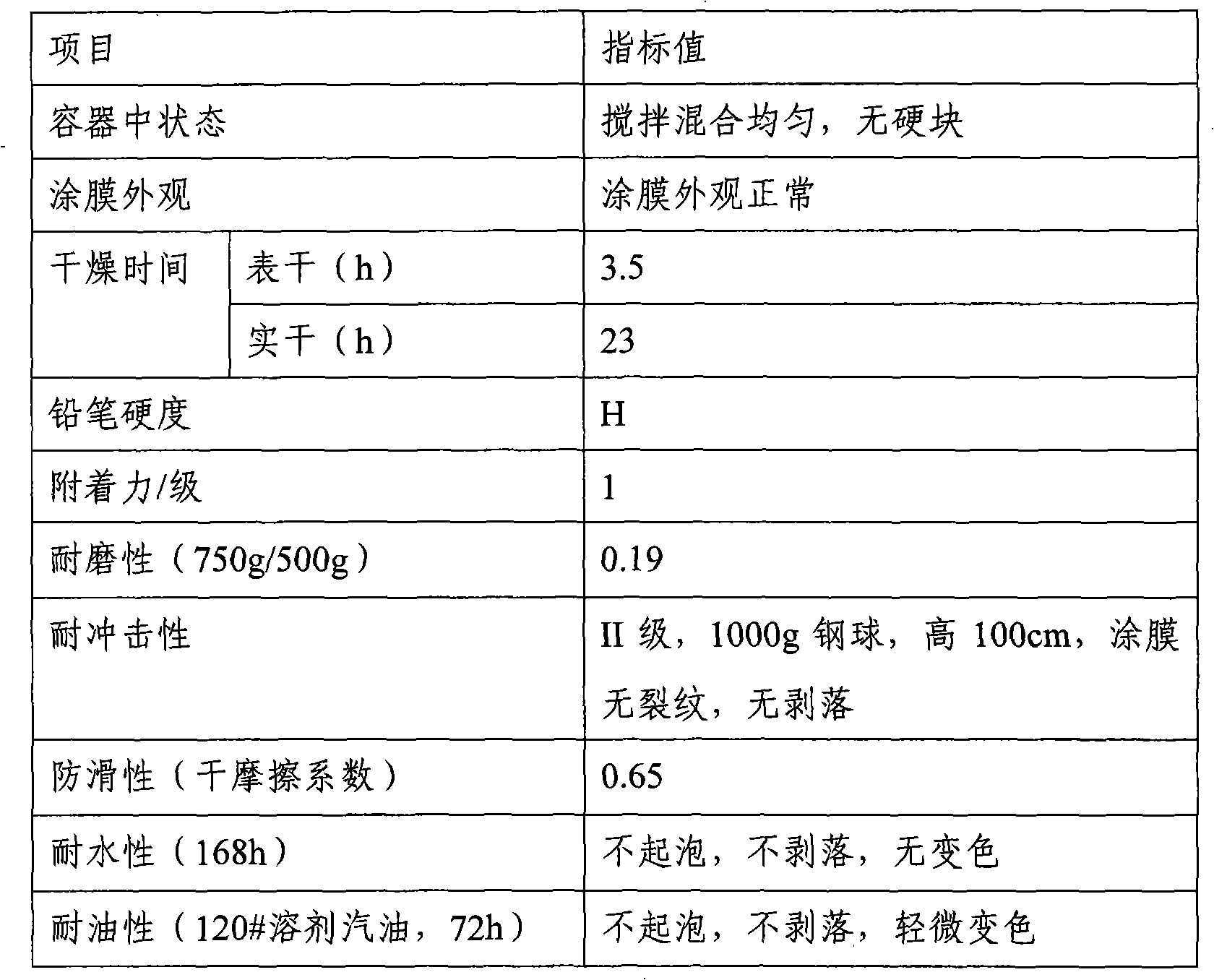

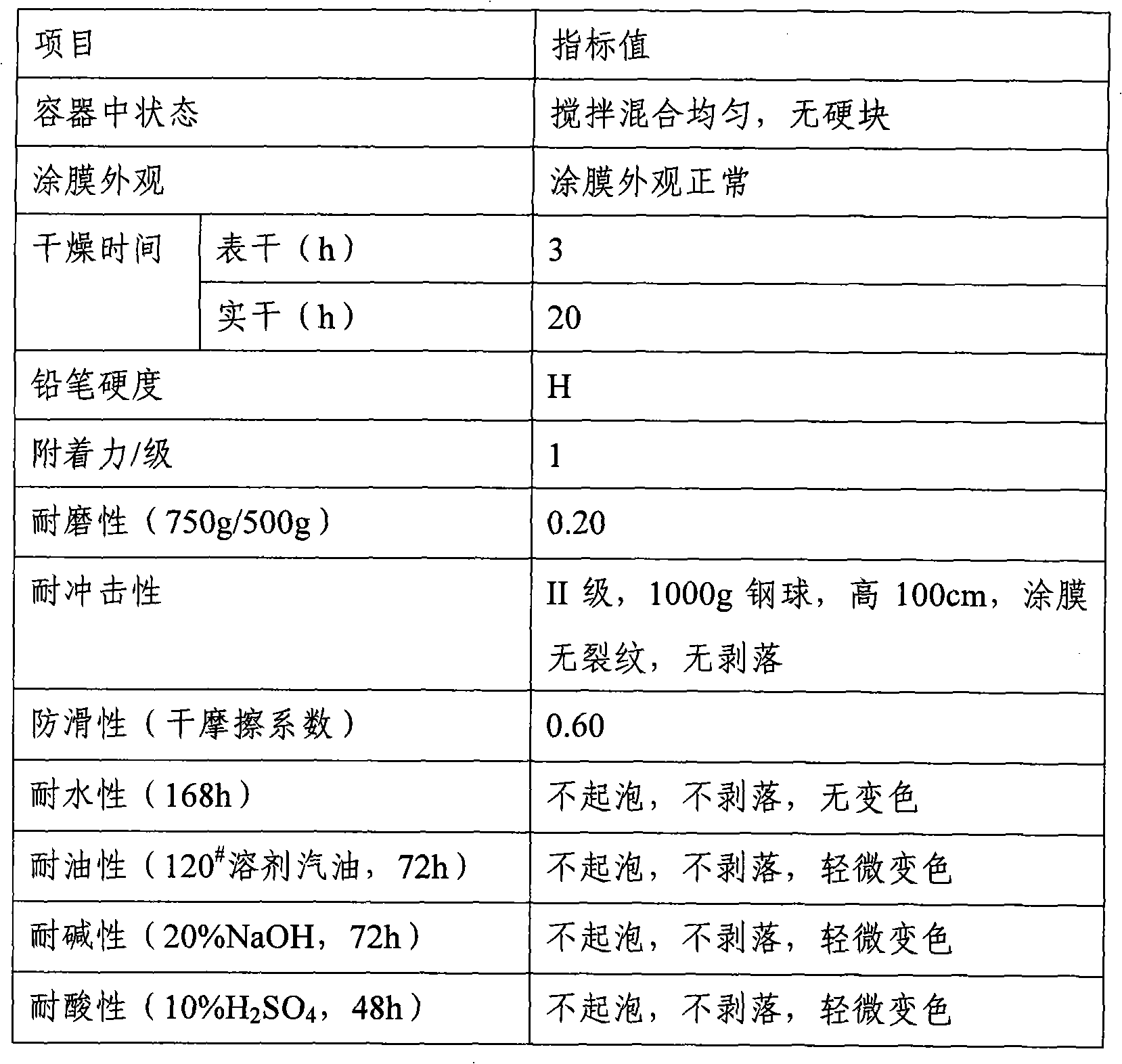

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

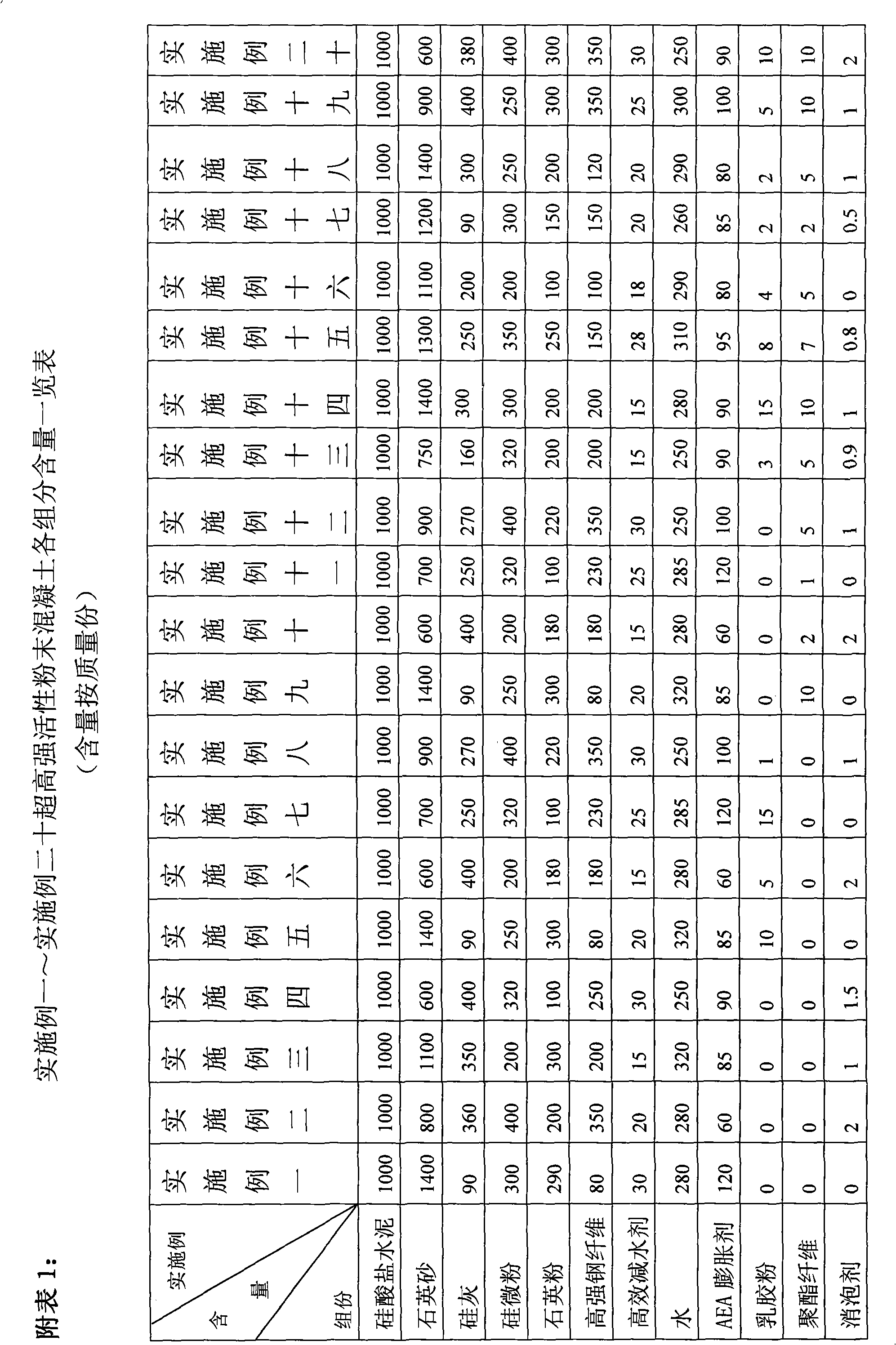

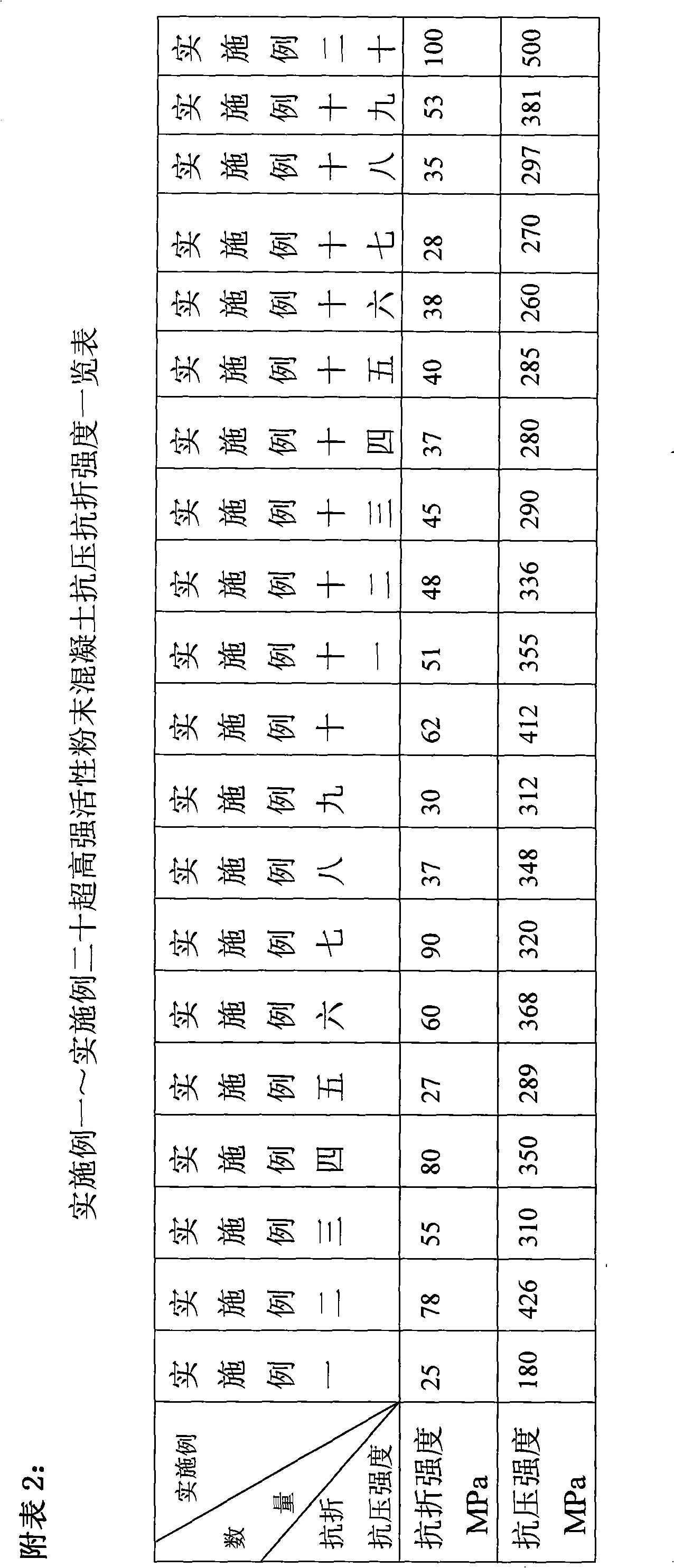

Ultrahigh-strength active powder concrete and preparation method thereof

An ultrahigh-strength active powder concrete is a mixture prepared by mixing the following materials according to weight portion: 1000 portions of Portland cement, 600-1400 portions of quartz sand, 90-400 portions of siliceous dust, 200-400 portions of silicon powder, 100-300 portions of quartz powder, 80-350 portions of high-strength steel fiber, 15-30 portions of high-efficiency water reducing agent, 250-320 portions of water, 60-120 portions of AEA expanding agents, 0-15 portions of latex powder, 0-10 portions of polyester fiber and 0-2 portions of antifoam agents. The preparation method comprises the following steps: preparing the materials according to the weight proportion, firstly mixing water, cement, quartz sand, siliceous dust, silicon powder, quartz powder, AEA expanding agents, high-efficiency water reducing agent, latex powder, polyester fiber, and antifoam agents into pasty state; then adding high-strength steel fiber, and mixing for 4-6 minutes. The prepared active powder concrete has super-high compressive and bending strengths, high mechanical property and high durability.

Owner:LIUZHOU OVM MASCH CO LTD

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

Novel aqueous insulation paint

InactiveCN101205436AHigh thermal resistanceLarge thermal resistanceFireproof paintsAntifouling/underwater paintsEmulsionThermal insulation

The invention relates to a water thermal-insulation paint used in constructions, comprising the following raw materials: ceramic hollow micro bead, emulsion, latent solvent, filler, pigment, wetting agent, dispersing agent, thickening agent, antifoam agent, germicide and water. The ceramic hollow micro bead, which is added in the paint, can form a paper-thin enclosed hollow cavity layer when coated on the surface of a building, thereby effectively preventing thermal conduction and thermal radiation.

Owner:北京世纪百成装饰工程有限公司

Phosphorus-free water-based metal cleaning agent

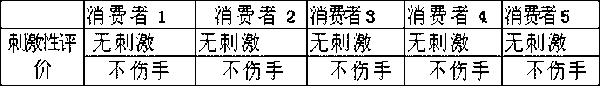

The invention relates to a phosphorus-free metal cleaning agent comprising the components of, by weight, 2-20% of a cleaning aid, 1-20% of a surfactant, 1-10% of a chelating agent, 1-20% of an emulsifier, 1-10% of an antirust agent, 0.2-4% of a copper alloy corrosion inhibitor, 1-10% of a penetration agent, 1-6% of a solubilizing agent, 0.1-0.6% of a defoaming agent, and balance of water. The cleaning agent provided by the invention has excellent cleaning capacity, long rust proof period, low foam, long service life, and the like. The cleaning agent is suitable for ferrous metal and non-ferrous metal processing industries. The agent has the advantages of no volatilization, no irritation, no toxic or harmful substance such as nitrite, no damage to health, and no environment pollution.

Owner:SHENYANG PARKERIZING

Candlewax compositions with improved scent-throw

InactiveUS7588607B1Improve release of aromaPromote escapeSolid fuelsCapillary burnersPolymer scienceEngineering

A candlewax composition having improved scent-throw, and candles made from the composition, are provided. The candlewax composition includes at least a wax component and an antifoam agent. An effective amount of a scenting agent can be separately added by a candlemaker.

Owner:CAP DANIEL S

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Sunless tanning emulsions with disappearing color indicator

InactiveUS6261541B1Improve visualizationLight colorCosmetic preparationsToilet preparationsFlavorEmulsion

A colored, sunless tanning emulsion is disclosed which employs a water-soluble dye or a blend of water-soluble dyes whose color substantially disappears when the sunless tanning emulsion dries after it is spread on the skin and / or is rubbed out. The coloration in the sunless tanning emulsion enables the user to apply the emulsion more evenly to the skin, giving a smooth, uniform tan over the skin surface The colored, sunless tanning emulsion comprises:a) at least one water-soluble dye that imparts a color other than white to the sunless tanning emulsion, such that when the emulsion dries after it is spread on the skin and / or is rubbed out, the color substantially disappears;b) at least one sunless tanner;c) at least one emulsifier; andd) sufficient water to form the colored emulsion; and optionally,e) one or more emollients, humectants, dry-feel modifiers, antimicrobial preservatives, thickening agents, antifoaming agents, antioxidants, chelating agents, sunscreen actives and fragrances as well as any other class of materials whose presence may be cosmetically, efficaciously or otherwise desirable.

Owner:MSD CONSUMER CARE INC

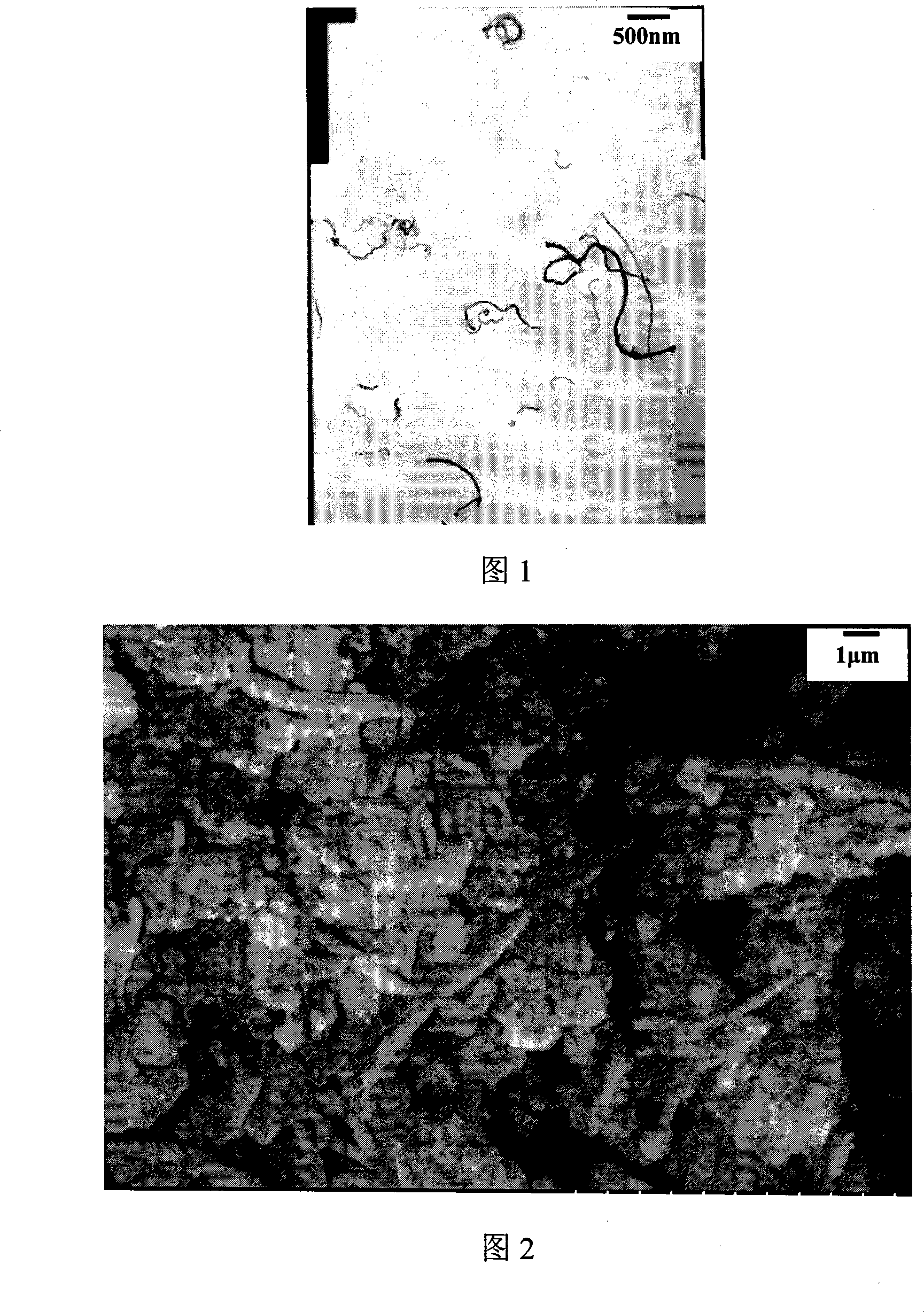

Carbon nano-tube enhanced cement-base composite material and preparation method thereof

InactiveCN101239800AResolve aggregationSolve the problem of tanglesSolid waste managementCarbon nanotubeMetal fibers

The present invention provides a carbon nano-tube reinforcing cement-based composite material and the preparing method thereof, which relates to an inorganic non-metal fiber-reinforced cement-based composite material and the preparing method thereof. The invention settles the problem that the carbon nano-tube is hard to uniformly dispersed in the cement substrate, and the carbon nano-tube reinforcing cement-based composite material of the invention is mainly composed of carbon nano-tube, dispersing agent, thickening stabilizing agent, cement blending material, superplasticiser, antifoaming agent and cement; the method of the invention comprises the following steps: slowly injecting the continuous phase mixed liquid of the thickening stabilizing agent into the carbon nano-tube disperse phase mixed liquid; adding the cement mixing material, mixing to uniform, heating and ultrasonic agitating, then vacuum discharging the bubble; then adding into the mixed liquid of the superplasticiser and the water for mixing to uniform, further eliminating the bubble with the antifoam agent; at last adding cement for mixing to uniform, adding the slurry into the oil mould and jolt ramming for molding; mode removing and standard maintaining to the prescribed lifetime. The carbon nano-tube in the product prepared by the method of the invention is uniformly dispersed in the cement substrate. The mechanical property and conductivity of the product is increased for several times.

Owner:HARBIN INST OF TECH

Environment-friendly type aqueous aluminum foil protecting agent and preparation thereof

InactiveCN101407655ALow VOC contentReduce manufacturing costPolyurea/polyurethane coatingsPolyamide coatingsGeneral purposeOrganosolv

The invention relates to an environmental-friendly waterborne aluminum foil protective agent and a prepration method thereof, wherein, the protective agent comprises the following components according to the formula by weight: 45 percent to 70 percent main resin; 0 percent to 20 percent assisted resin; 10 percent to 50 percent water; 0 percent to 35 percent cosolvent; 0 percent to 0.5 percent film-forming auxiliary agent; 0 percent to 0.5 percent leveling agent; 0 percent to 0.5 percent defoamer; 0 percent to 2 percent anti-abrasion agent; and 0 percent to 0.5 percent pH regulator. Compared with the prior art, the environmental-friendly waterborne aluminum foil protective agent and the prepration method have the advantages: (1) the aluminum foil protective agent contains no organic solvent which is harmful to human body and has very low content of VOC, and water and ethanol are used for dilution during the using process, thereby being non-toxic and low in production cost; (2) the aluminum foil protective agent has good adhesion, good transparency, high smoothness and high thermal resistance performance; (3) the aluminum foil protective agent belongs to the general purpose products, and the range of application is broad; and (4) the production process is reasonable, the operation is simple and the production efficiency is high.

Owner:SHANGHAI WEIKAI CHEM

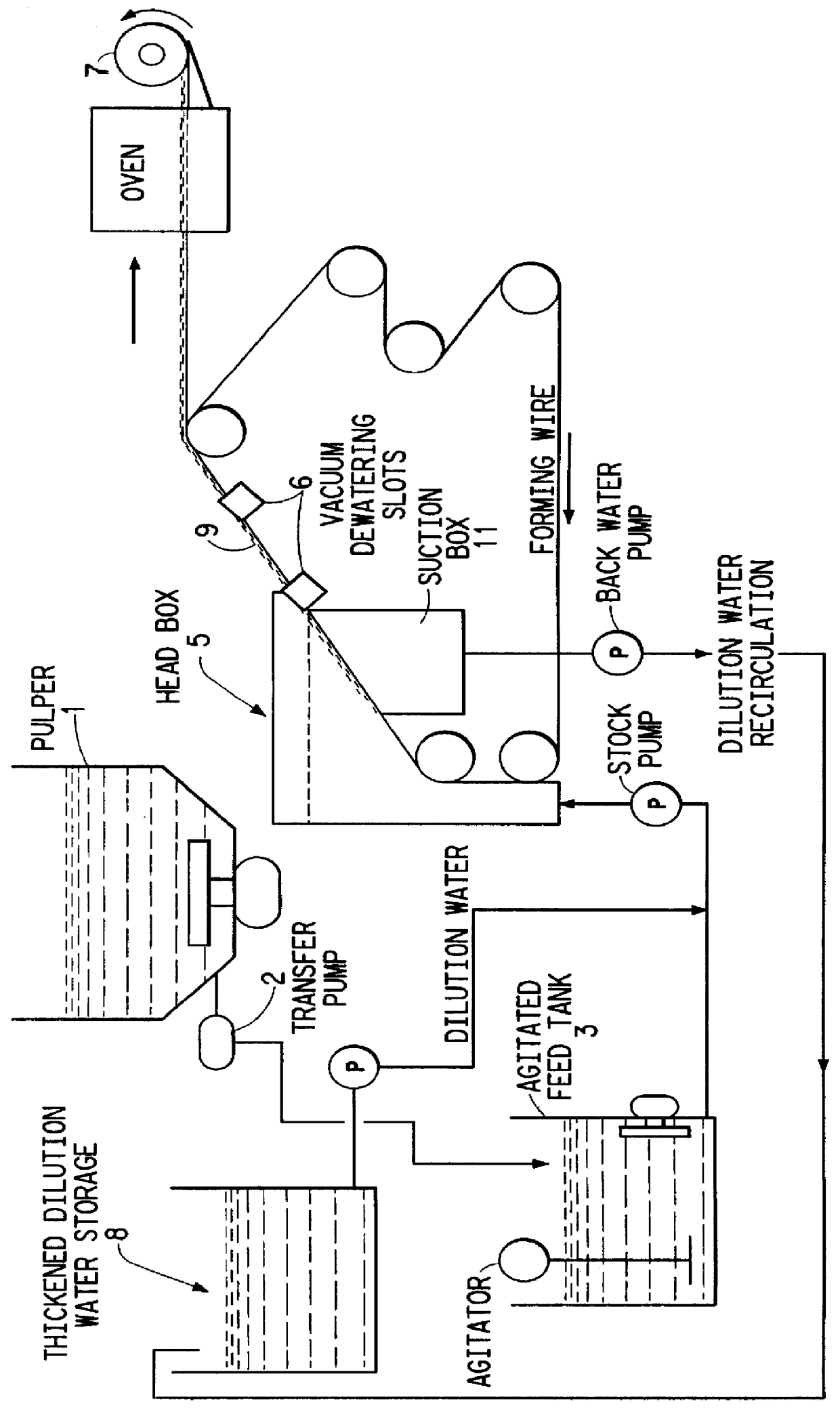

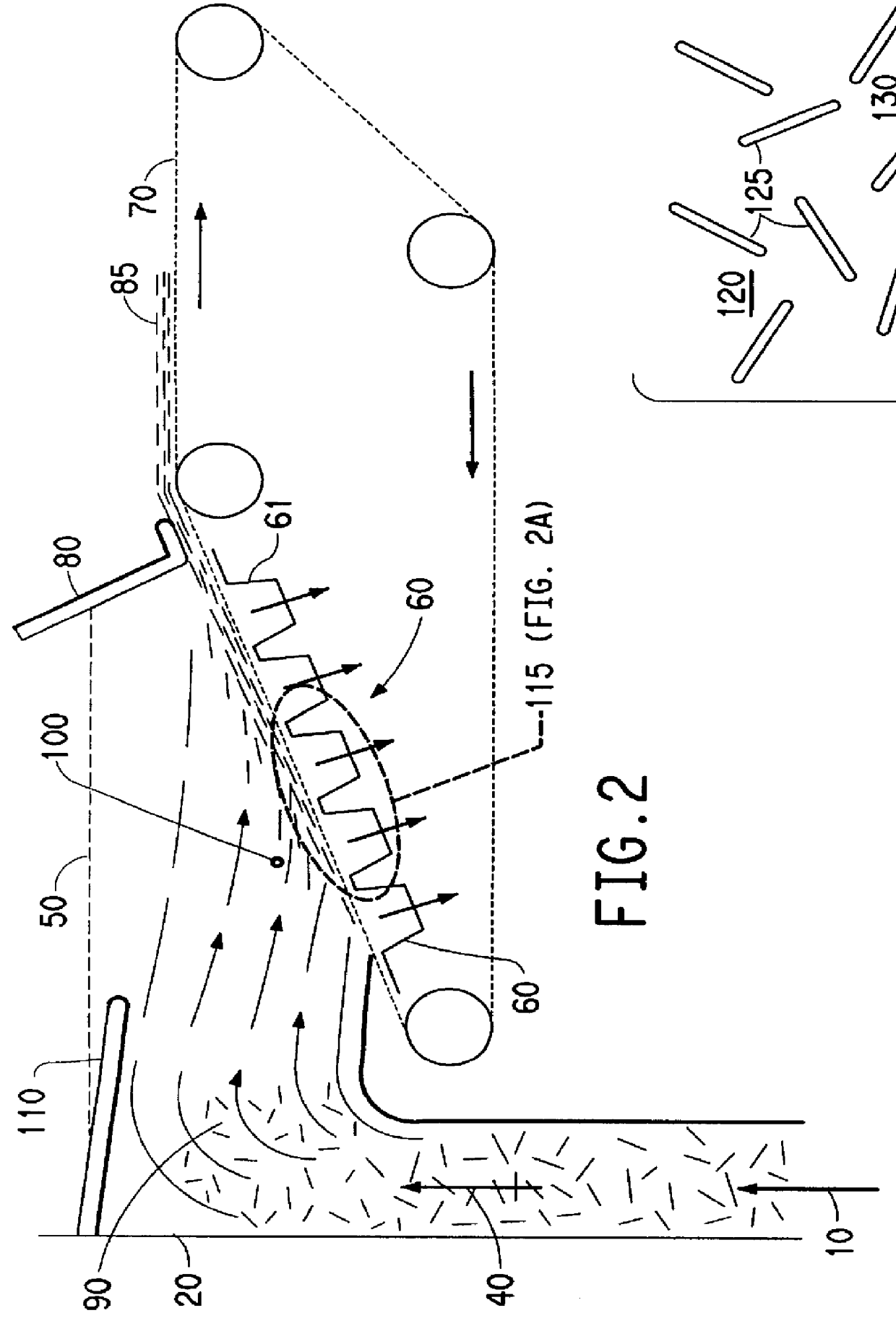

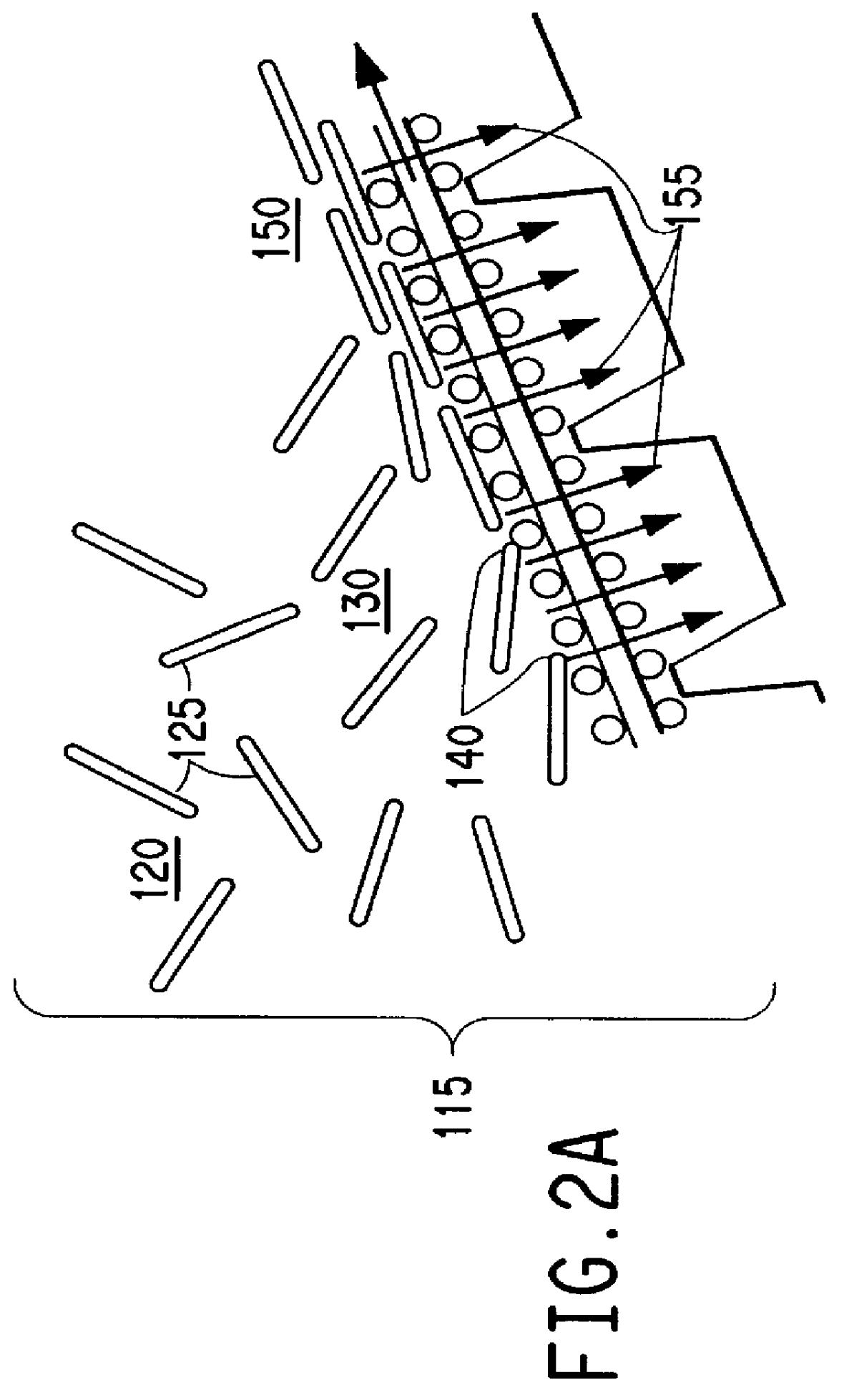

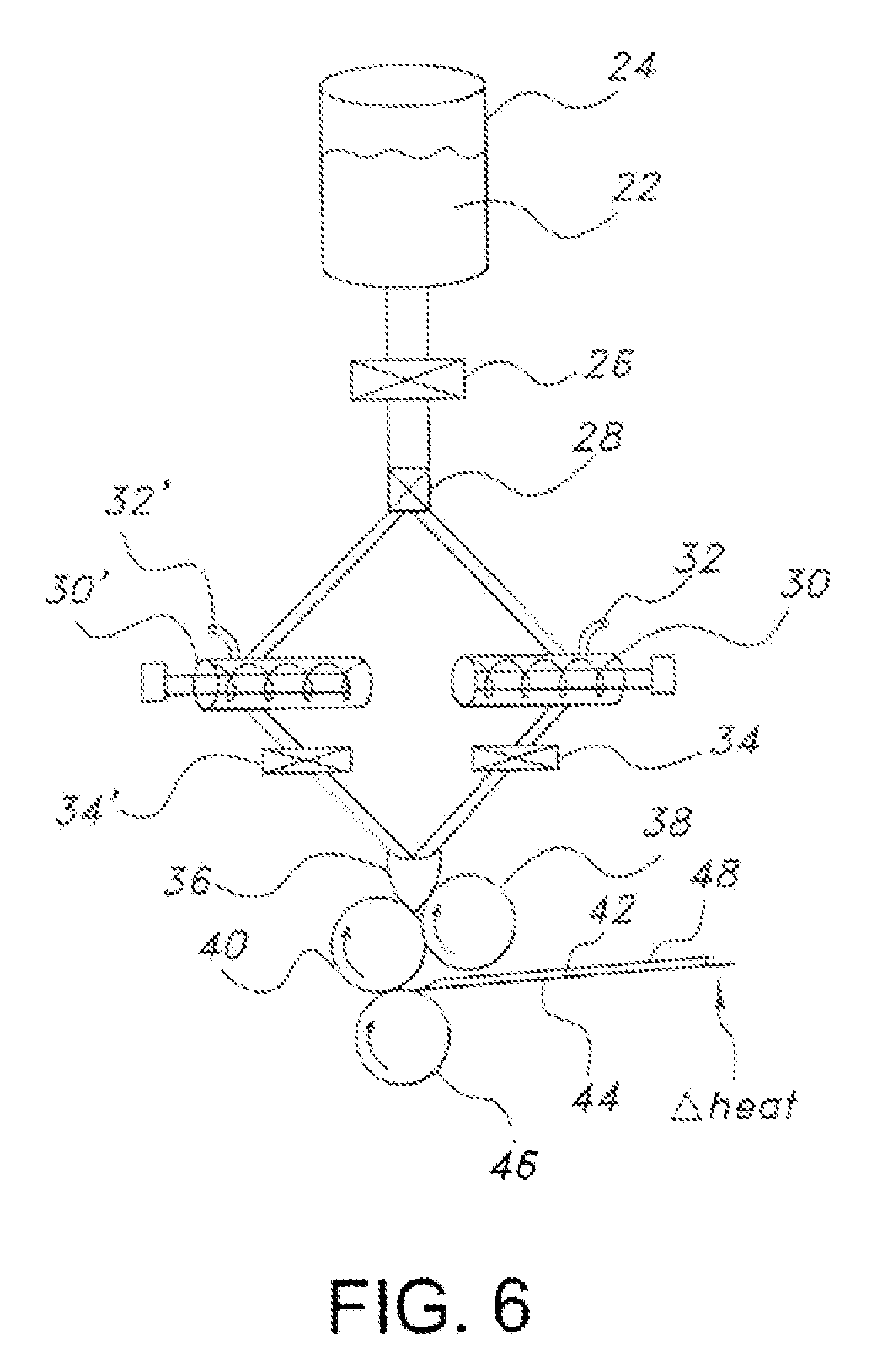

Wetlay process for manufacture of highly-oriented fibrous mats

A mat containing highly machine direction oriented (90% or greater), discontinuous reinforcement fibers, is produced on inclined wire or rotary paper making machinery. Fibers are first uniformly dispersed in an aqueous medium containing thickeners and wetting agents. In one embodiment, antifoaming agents are also added to prevent floating fibers which entangle and reduce orientation. Thermoplastic fibers or particles may also be included. Stock is brought into an open headbox in a flow pattern which allows the fibers to decelerate before approaching the porous suction belt (wire). As the fibers approach the suction belt, the fibers begin to turn and align in the streamline so as to present one end toward the suction wire. The leading ends of the fibers are gripped by the moving belt which drags the fibers out of the dispersion stock in a straight line. The porous mat produced may be dried and bonded through hot air, heat and / or pressure, or chemical binders. Stacks of such mats may be compressed partially to produce porous structures, or fully to produce

Owner:VIRGINIA TECH FOUND

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

Edible Water-Soluble Film Containing a Foam Reducing Flavoring Agent

ActiveUS20080075825A1Uniform appearanceEasy to solvePharmaceutical delivery mechanismPharmaceutical non-active ingredientsWater solublePolymer chemistry

An edible water-soluble film is provided. The film includes at least one water-soluble polymer, and a foam reducing flavoring agent, wherein the film is free of added anti-foaming or defoaming agents.

Owner:AQUESTIVE THERAPEUTICS INC

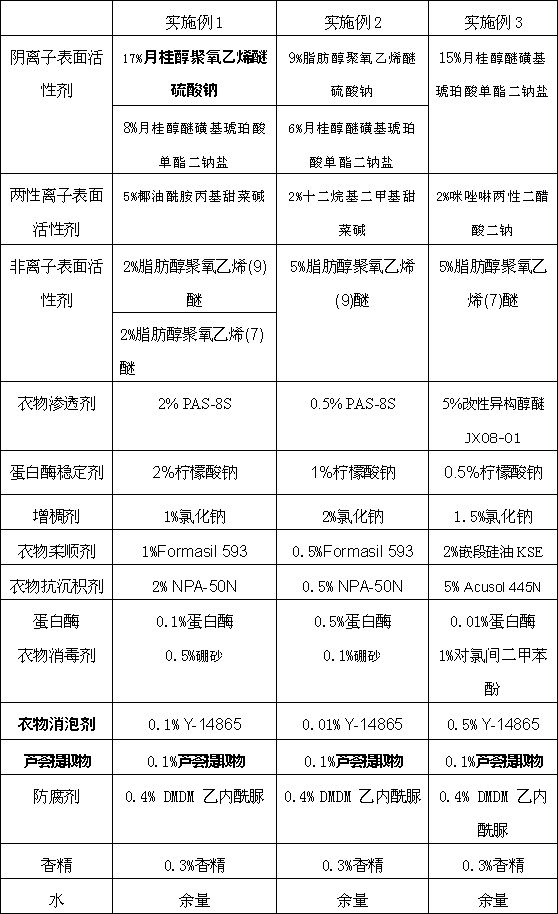

Cleaning and protecting integrated infant laundry detergent

ActiveCN102703249AImprove performanceAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsActive agentMedicine

The invention relates to a household cleaning product, in particular to a cleaning and protecting integrated infant laundry detergent. The cleaning and protecting integrated infant laundry detergent is characterized in that the laundry detergent comprises the following components in weight percentage: 15-20 percent of anionic surfactant, 3-6 percent of non-ionic surfactant, 2-5 percent of amphoteric ionic surfactant, 0.5-5 percent of clothing penetrant, 0.5-2 percent of protease stabilizer, 0.5-2 percent of thickener, 0.5-2 percent of protease stabilizer, 0.1-1 percent of clothing disinfectant, 0.3-2 percent of clothing softener, 0.01-0.5 percent of clothing antifoaming agent, 0.01-0.5 percent of aloe extract, 0.01-0.5 percent of protease, 0.01-0.5 percent of preservative, 0.1-0.5 percent of essence and the balance of water. According to the cleaning and protecting integrated infant laundry detergent disclosed by the invention, the surfactants with excellent performances and mild properties are compounded with the aloe plant extract and the special clothing softener and disinfectant are added, so that the functions of cleaning, protecting and conditioning clothing are realized; and the unique clothing penetrant and hydrolysis protease can be used for deeply removing dirt on infant clothing and decomposing milk on the clothing.

Owner:OPAL COSMETICS HUIZHOU

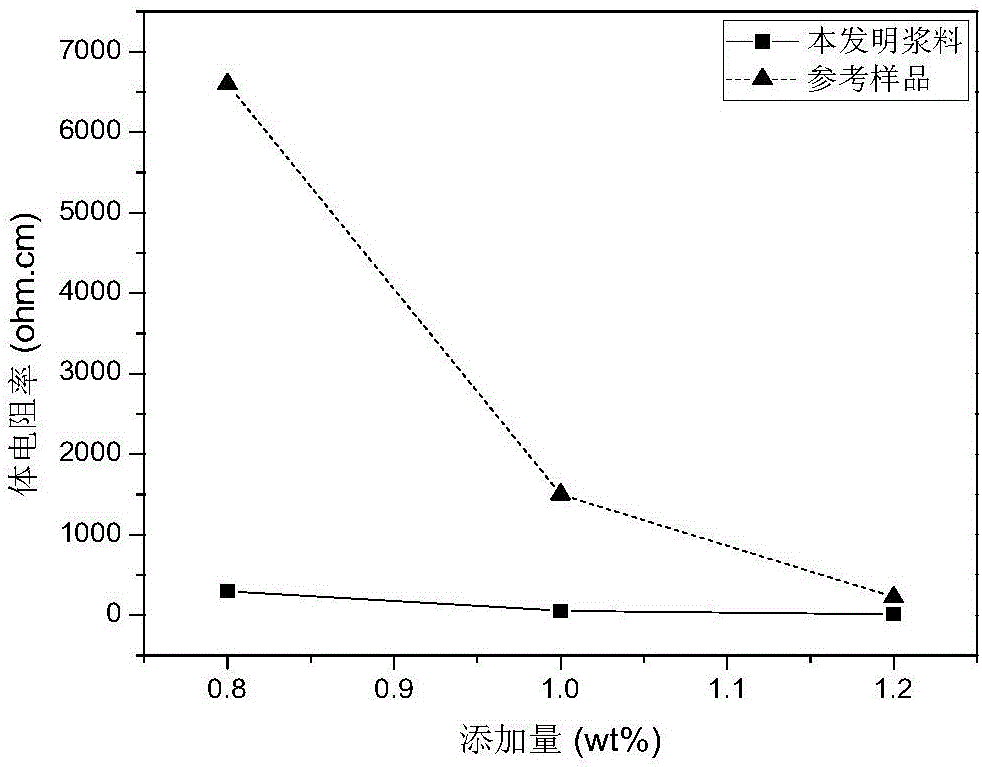

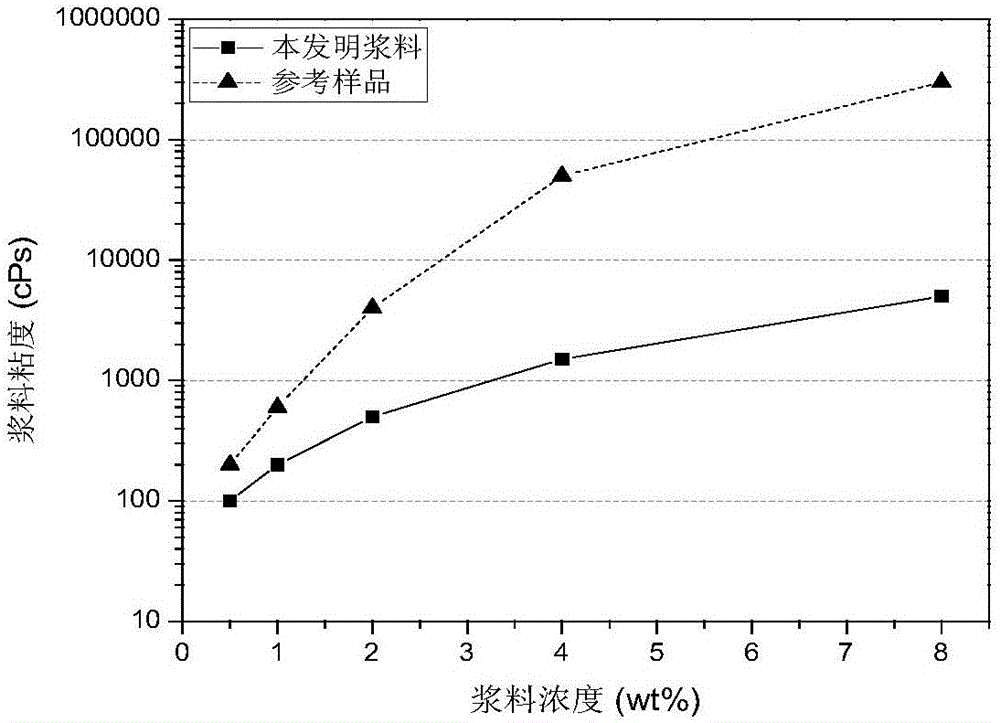

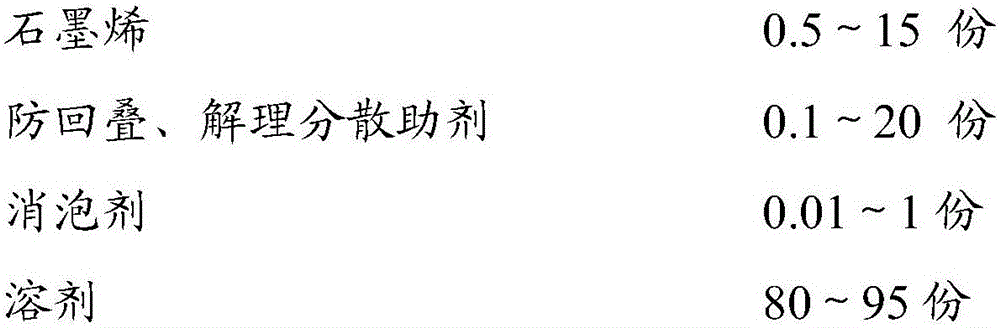

High-concentration and high-purity graphene slurry and preparation method and application thereof

InactiveCN105895870AAchieve high concentration cleavageLow viscosityCell electrodesSecondary cellsHigh concentrationPhysical chemistry

The invention belongs to the technical field of new materials, and particularly relates to high-concentration and high-purity highly pre-dispersed graphene slurry and a preparation method and an application of thereof. The graphene slurry is prepared from the following raw materials in parts by weight: 0.5-15 parts of graphene, 0.1-20 parts of an anti-fold cleavage dispersing agent, 0.01-1 part of a defoamer and 80-95 parts of a solvent; the graphene slurry is prepared through high-energy cleavage and dispersion; the viscosity of the prepared graphene slurry is smaller than 10,000cPs; and the metal impurity content in the slurry is smaller than 100ppm. High-concentration cleavage and folding prevention can be achieved; and the graphene slurry has the properties of extremely high purity and low viscosity, is very easy to be dispersed for the second time, and is suitable for an automatic feeding system.

Owner:SUPERCDONGGUAN TECH

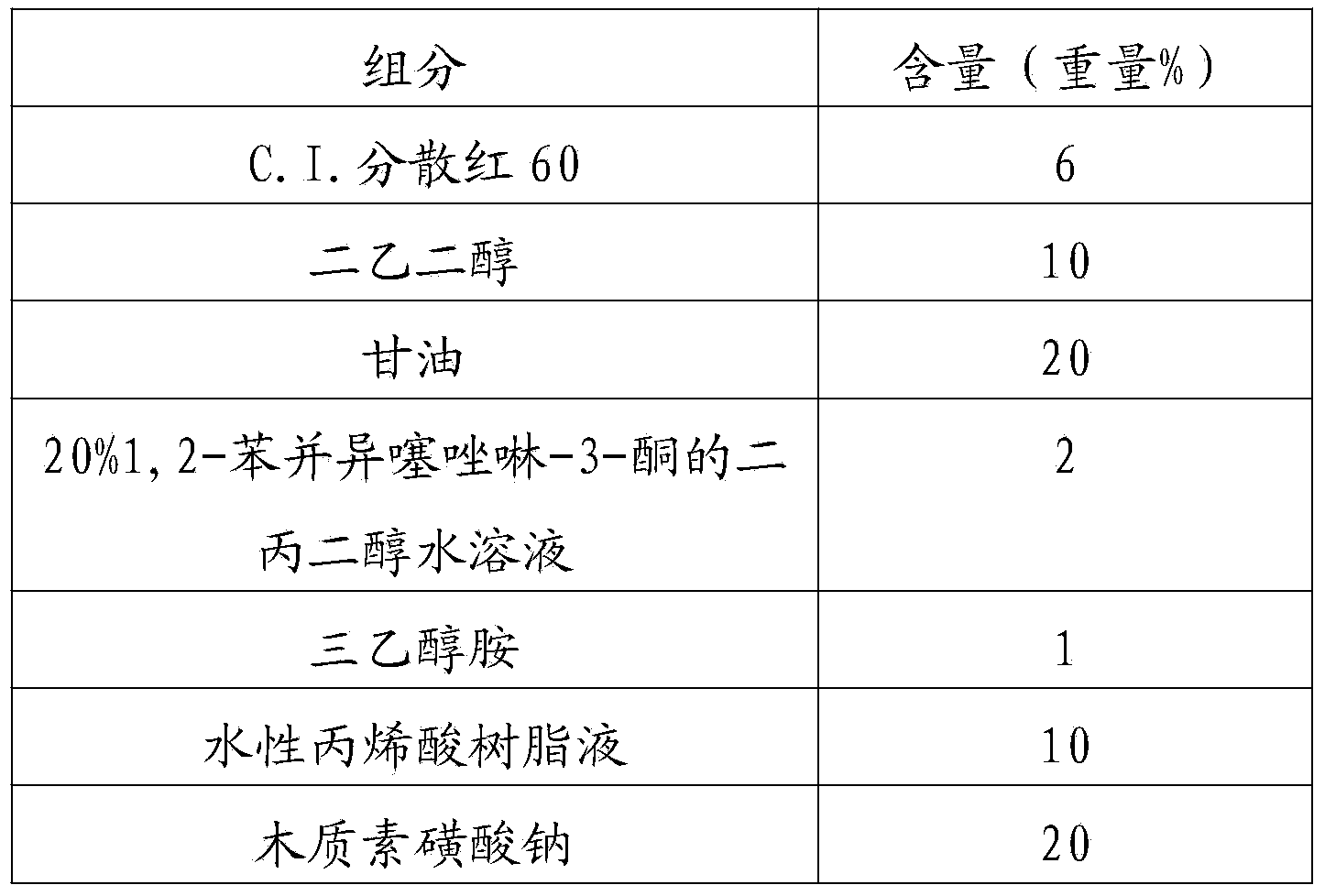

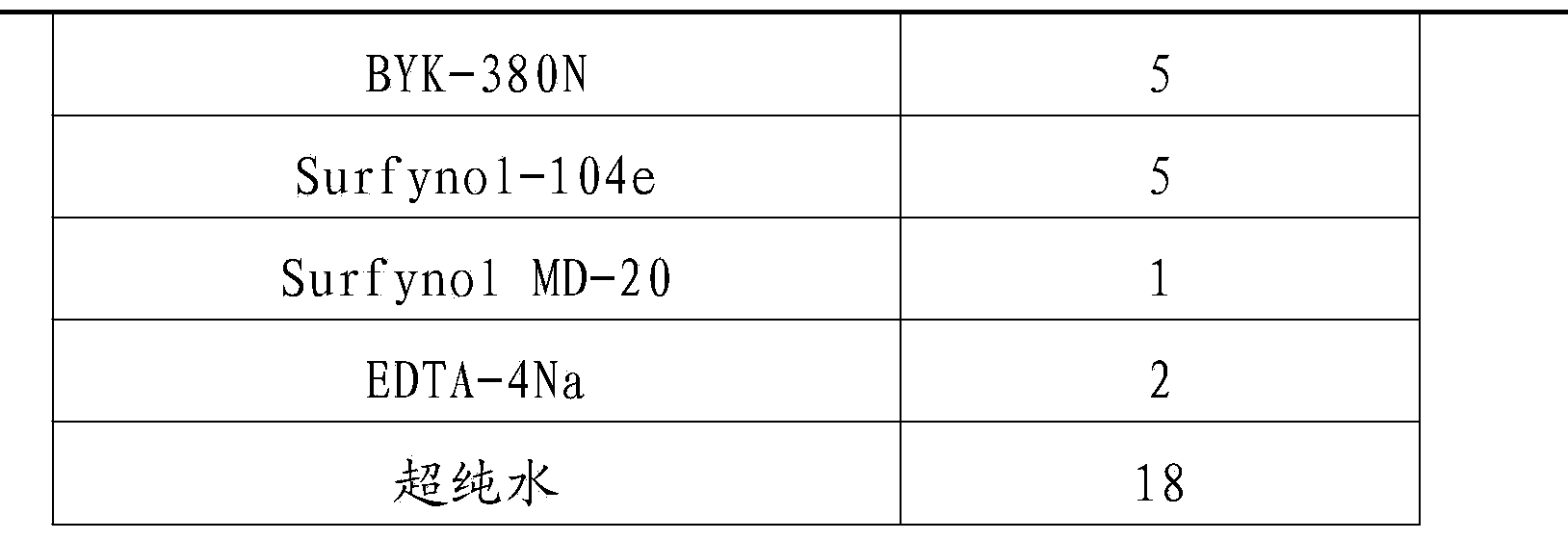

Sublimation ink-jetting ink used for industrial nozzle and manufacturing method thereof

The invention relates to an ink-jetting ink, in particular to a sublimation ink-jetting ink used for an industrial nozzle and a manufacturing method thereof. The sublimation ink-jetting ink comprises, by weight, 1-6% of disperse dyes, 10-14% of wetting agents, 5-20% of viscosity adjusting agents, 0.1-2% of bactericides, 0.01-1% of pH buffering agent, 1-10% of liquid resin, 0.1-40% of disperse agents, 0.01-5% of antifoaming agents, 0.1-5% of surface active agents, 0.01-2% of metal ion chelating agents and 10-80% of purified water. The manufacturing method of the sublimation ink-jetting ink used for the industrial nozzle includes color paste manufacturing and finished product manufacturing. The sublimation ink-jetting ink used for the industrial nozzle is simple in manufacturing method, smooth in ink jetting, free of blocking the nozzle, good in dispersion stability, free of going bad or denaturing even if being stored for a long time and low in cost, and diameters of dispersed ink points are even.

Owner:山东力美喷墨科技有限公司

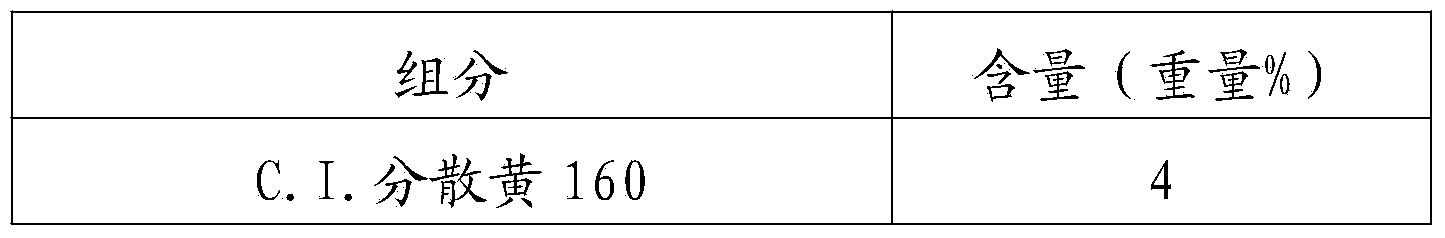

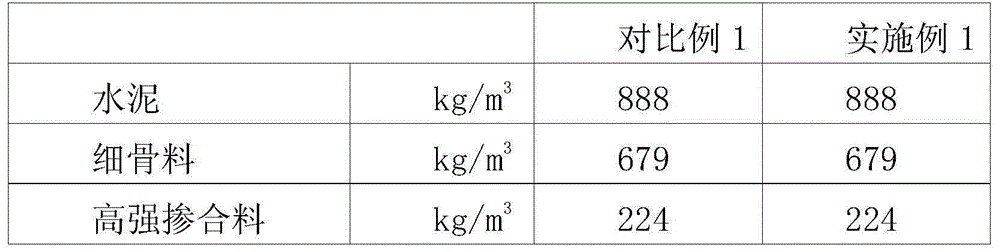

Wear-resistant, antiknock and radiation-resistant concrete and preparation method thereof

The invention discloses wear-resistant, antiknock and radiation-resistant concrete and a preparation method thereof. Each cubic meter of the concrete comprises 600-1600kg of cement, 400-1400kg of fine aggregate, 30-560kg of a high-strength admixture, 250-1800kg of functional aggregate, 3-500kg of high tensile strength fibers, 0.4-45kg of organic fibers, 0.6-43.2kg of a water reducer (based on solid content), 0.06-43kg of an antifoaming agent, 6-129kg of an expanding agent and 100-430kg of water. The wear-resistant, antiknock and radiation-resistant concrete has high wear resistance, instant high temperature explosion resistance, high knock resistance, high toughness and radiation resistance.

Owner:CHINA BUILDING MATERIALS ACAD

Modified urea-formaldehyde resin adhesive and production method thereof

ActiveCN103450832AHigh viscosityViscosity increases relatively gentlyNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePhosphoric acid

The invention provides a modified urea-formaldehyde resin adhesive low in formaldehyde residue and a production method thereof. The modified urea-formaldehyde resin adhesive is characterized by being prepared from the following raw materials in parts by weight: 100 parts of modified urea-formaldehyde resin, 20-25 parts of reinforcing agent and 0.1-0.2 part of defoamer, wherein the reinforcing agent is any one or a composition of several of white carbon black, titanium dioxide, calcium carbonate and kaolin having the particle size greater than 300 meshes; the defoamer is polydimethylsiloxane or tributyl phosphate. The formaldehyde residue of the modified urea-formaldehyde resin adhesive provided by the invention is less than 0.1 mg / L; the modified urea-formaldehyde resin adhesive is used as an adhesive for an artificial board; as the modified urea-formaldehyde resin adhesive is low in release amount of formaldehyde, the health of customers is protected.

Owner:广西横州丽冠环保材料有限公司

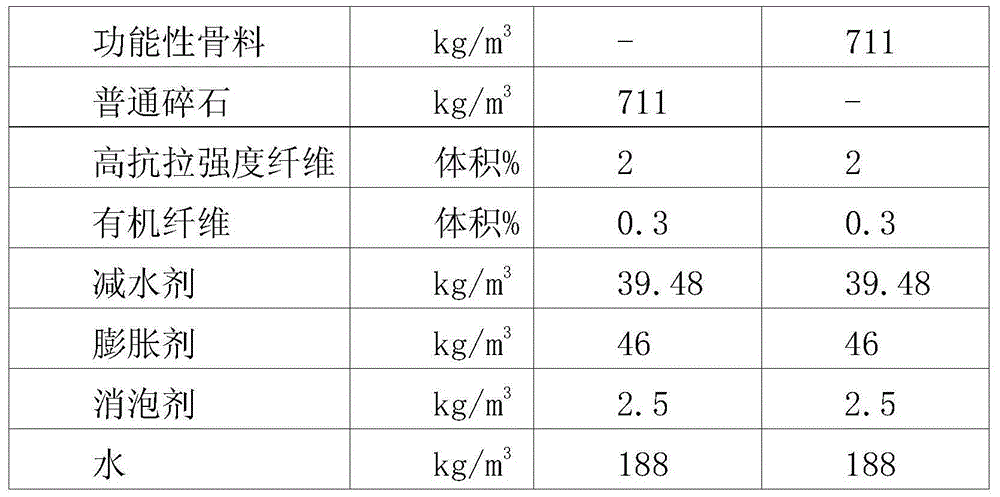

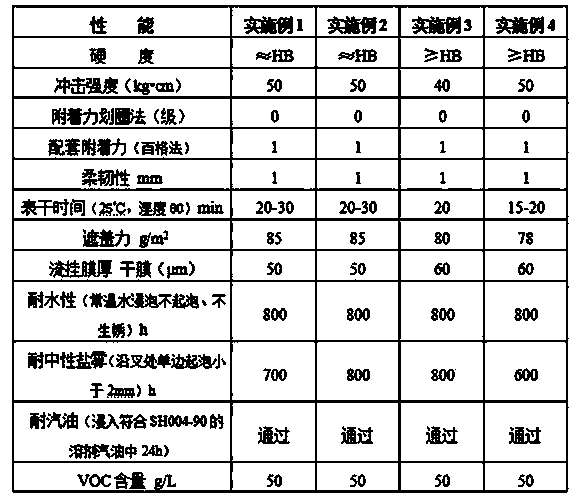

Room-temperature-curable aqueous anticorrosion primer used for coating external surface of construction crane and preparation method of primer

ActiveCN103436136AIntensity rises fastShort construction intervalAnti-corrosive paintsPolyurea/polyurethane coatingsAntifoam agentCorrosion resistant

The invention discloses a room-temperature-curable aqueous anticorrosion primer used for coating the external surface of a construction crane. The primer comprises the following components by weight: 35-45% of an aqueous resin, 5-8% of a curing agent, 1-3% of a dispersant, 5-12% of an antirust pigment, 20-35% of a pigment filling material, 1-2% of an anti-settling agent, 0.5-1% of a wetting agent, 0.5-1% of a thixotropic agent, 0.5-1% of an antifoaming agent, 0.1-0.8% of a flash etching inhibitor, 0.1-0.8% of a mildew inhibitor, 1-3% of a film-forming auxiliary agent and 10-20% of deionized water. The invention also discloses a preparation method of the aqueous anticorrosion primer. The aqueous anticorrosion primer has a room-temperature-curable paint film, is energy-saving and environment friendly, and can satisfy safe production requirements of enterprises; the primer is high in solidity, low in viscosity, convenient for construction; and the coating of the primer has good corrosion resistance and water proofness, and the comprehensive properties of the coating reach performance indexes of same-type oiliness products.

Owner:GUANGZHOU KINTE IND +1

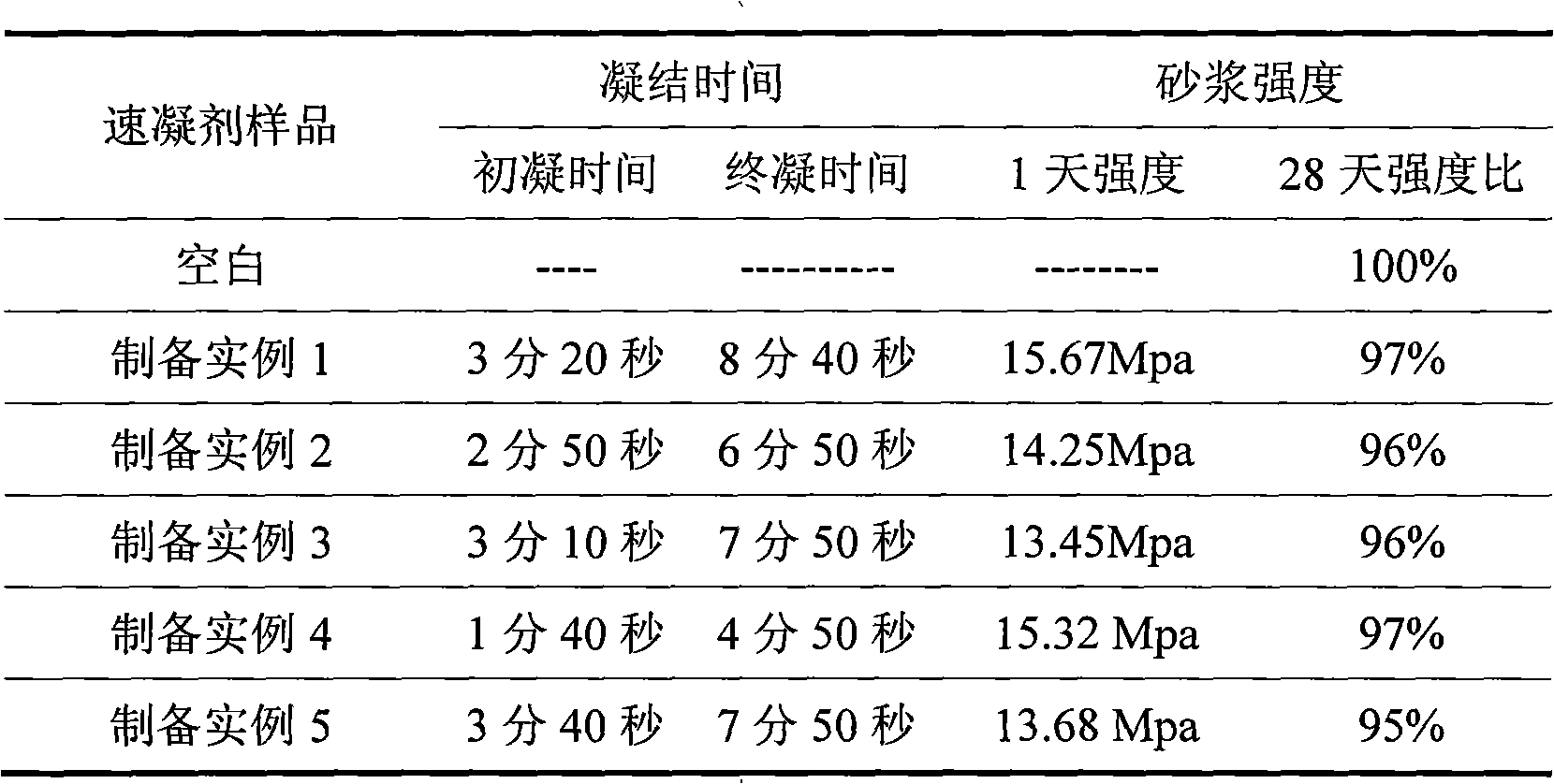

Alkali-free liquid setting accelerator

ActiveCN101648785ANo lossNo irritating smellUnderground chambersBuilding material handlingO-Phosphoric AcidSulfate radicals

The invention discloses an alkali-free liquid setting accelerator which is prepared from the following components by weight percent: 18-40% of hydroxycarboxylic acid, 1-5% of phosphoric acid, 15-30% of aluminium hydroxide, 0-5% of alkylol amine, 0.01-0.2% of defoaming agent and the balance water. The alkali-free liquid setting accelerator of invention does not contain alkali metal ions, sulfate ions and other corrosive materials, is safe to use and has no bad effect on the durability of sprayed concrete, thus being capable to be used in the construction of sprayed concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

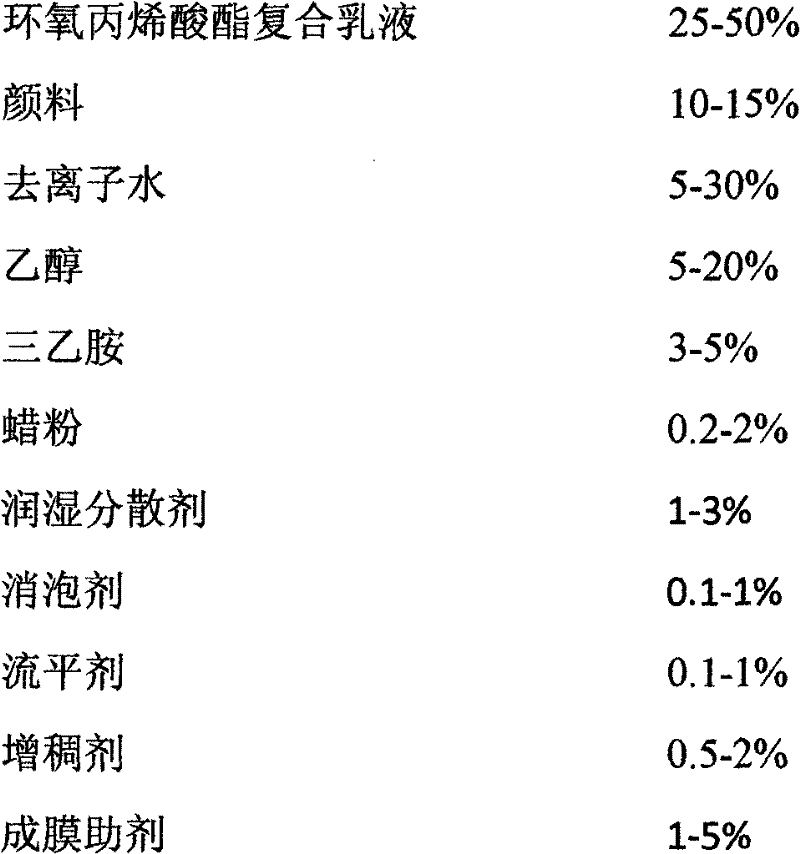

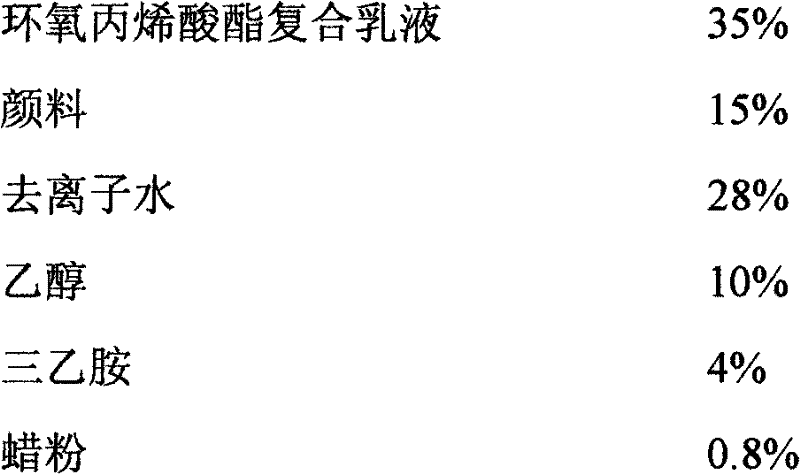

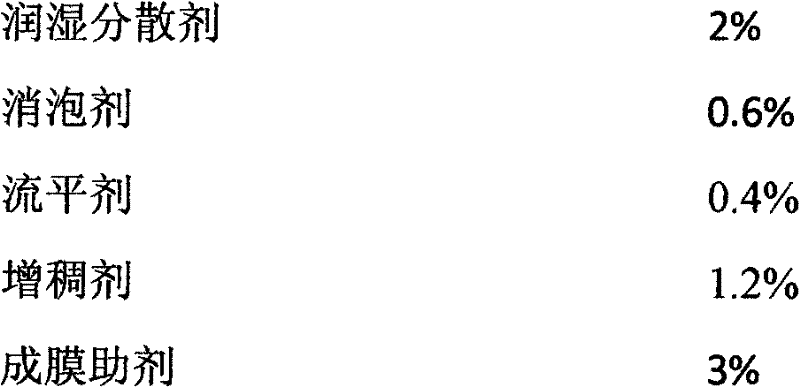

Environment-friendly type water-based intaglio ink used for package printing and preparation method thereof

The invention relates to a water-based ink and a preparation method thereof, especially to an environment-friendly type water-based intaglio ink used for package printing and a preparation method thereof. The ink is prepared by mixing epoxy acrylate composite emulsion, pigments, deionized water, ethanol, triethylamine, wax powder, a wetting dispersant, an anti-foaming agent, a levelling agent, a thickening agent and a film forming auxiliary agent according to a certain mass ratio, wherein, the epoxy acrylate composite emulsion is prepared by modifying acrylate emulsion with an epoxy resin and allowing the epoxy resin and acrylate to organically bind together, has the advantages of good adhesion, thermostability, good chemically-resistant properties and the like and has a certain application value when used as a binder for a water-based ink. The water-based intaglio ink in the invention is applicable to package printing in the field of flexible package which mainly relates to packaging of tobacco, liquor, foodstuffs, beverage, medicines, daily chemical articles and the like; the ink is nontoxic, non-combustible and non-explosible, has no pungent smell, accords with environmental protection requirements, and has a very promising prospect.

Owner:哈尔滨大东方新材料科技股份有限公司

Preparation for general defoaming agent and its application

InactiveCN101053706AGood defoamingGood anti-foam performanceTransportation and packagingMixingDefoaming AgentsMetal

The invention discloses a general anorganosilicon antifoaming agent compound and preparation thereof, comprising 20-90% by weight of organic hydrocarbons material, 0.5-10% by weight of main antifoaming material, 1-15% by weight of antifoaming synergist and 1-10% by weight of emulsifying agent. The preparation method is: (1) mixing half of organic hydrocarbons material with main antifoaming material, rising the temperature to 80-120 degree C and keeping for 0.5-3h to make sure the main antifoaming material to be dispersed completely; (2) adding the rest of the organic hydrocarbons material and the antifoaming synergist to said mixture in turns, and keeping the temperature at 60-90 degree C for 0.5-2.0h to make sure to be mixed thoroughly; (3) dropping the temperature below 50 degree C, adding the emulsifying agent and mixing blend even. The anorganosilicon antifoaming agent compound substantially improves the defoaming properties of the antifoaming agent based on adding high molecular antifoaming synergist, has the advantage of good stability, little recruitment and good security, and is used in the process of papermaking and coating, circuit board developing and metal cleaning of the paper industry.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

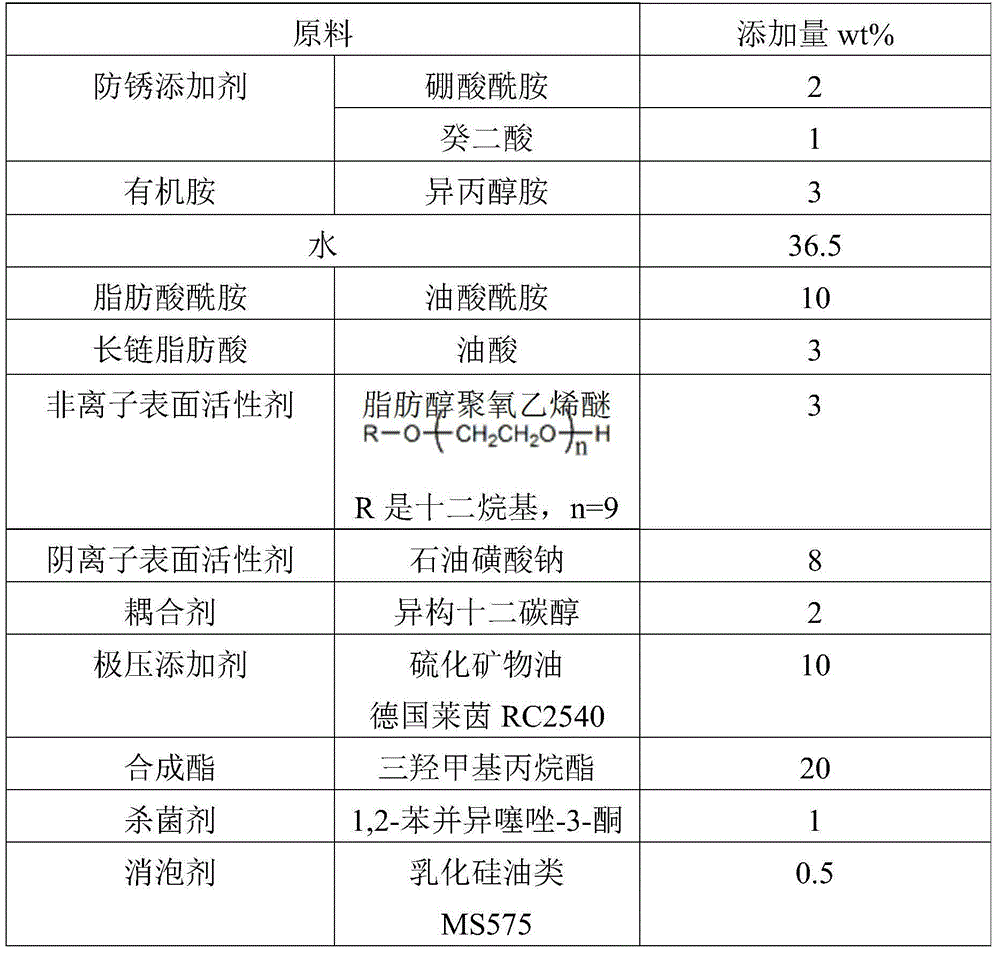

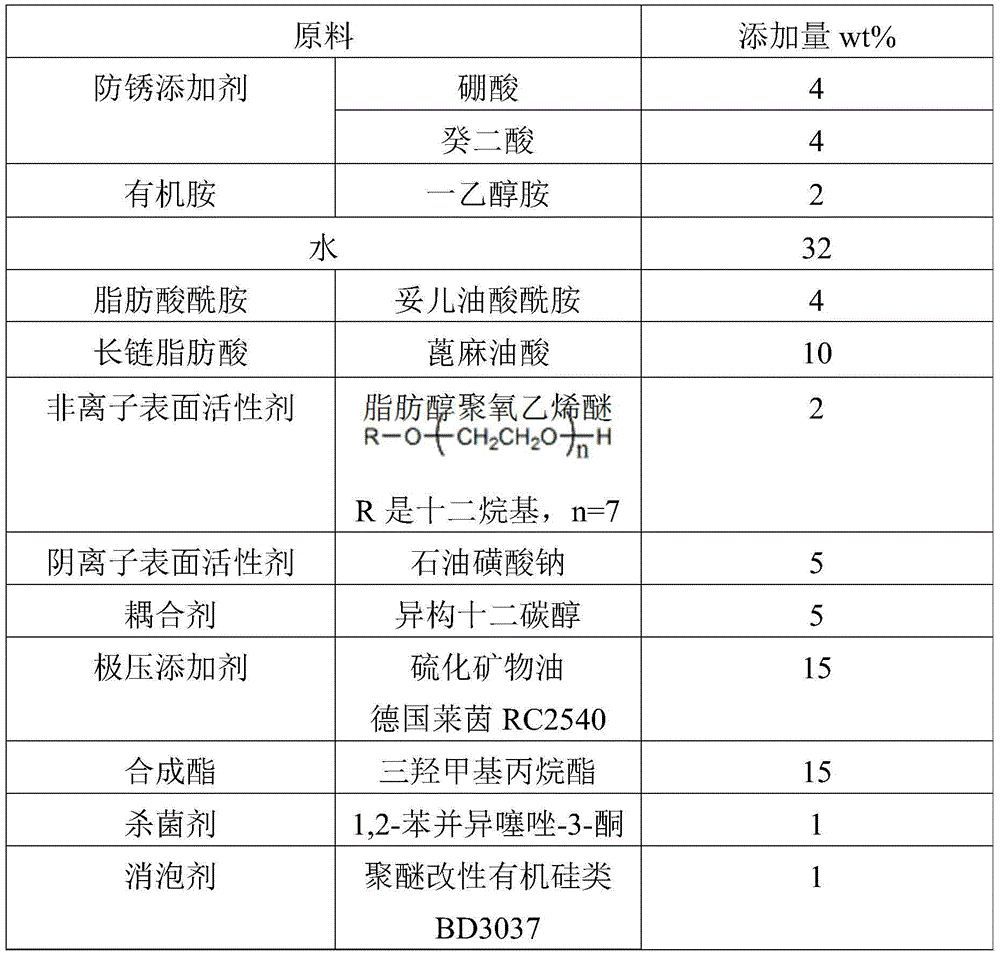

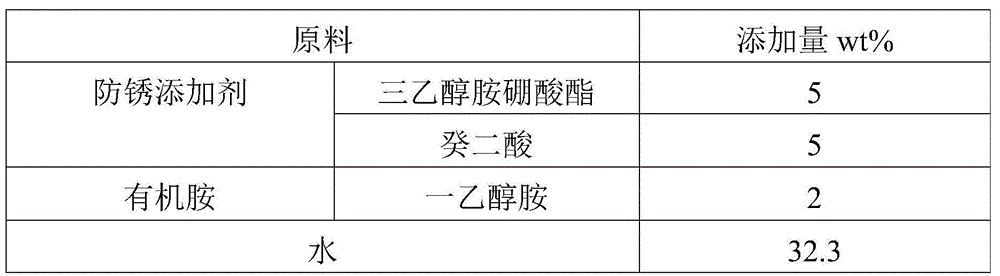

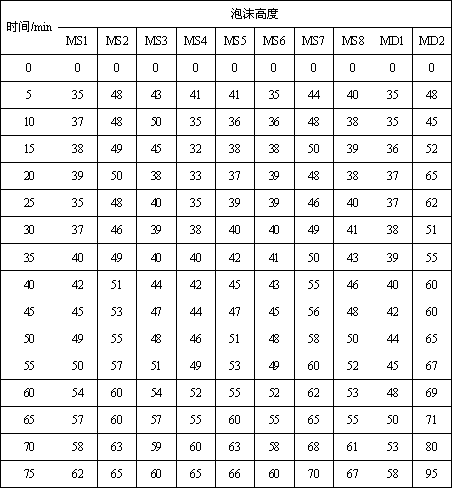

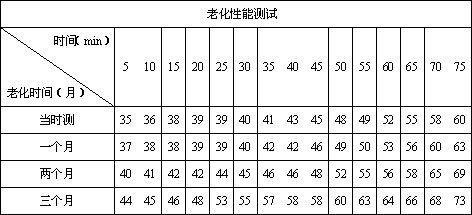

Water-based cutting fluid for vermicular cast iron processing, and dilution solution thereof

ActiveCN104877749AImprove the lubrication effectImprove cooling effectLubricant compositionWater basedNitro compound

The present invention discloses a water-based cutting fluid for vermicular cast iron processing, and a dilution solution thereof. The water based cutting fluid comprises 3-10% of an anti-rust additive, 4-10% of fatty acid amide, 2-3% of organic amine, 3-10% of long-chain fatty acid, 2-5% of fatty alcohol polyoxyethylene ether, 5-8% of petroleum sodium sulfonate, 1-5% of a coupling agent, 10-15% of an extreme pressure additive, 15-20% of a synthetic ester, 1-2% of a sterilization agent, 0.5-1.0% of an anti-forming agent, and 32-45% of water, wherein the anti-rust additive is a boric acid anti-rust additive and dicarboxylic acid, and the coupling agent is a fatty alcohol and / or aliphatic ether. The water-based cutting fluid of the present invention has characteristics of good lubrication performance, good cooling performance, good anti-rust property, no chlorine, diamine, nitrite and other nitro compounds, no environmental pollution, no irritating odor, easy cutting, easy powder settlement, and effective cutter service life prolonging.

Owner:上海德润宝特种润滑剂有限公司

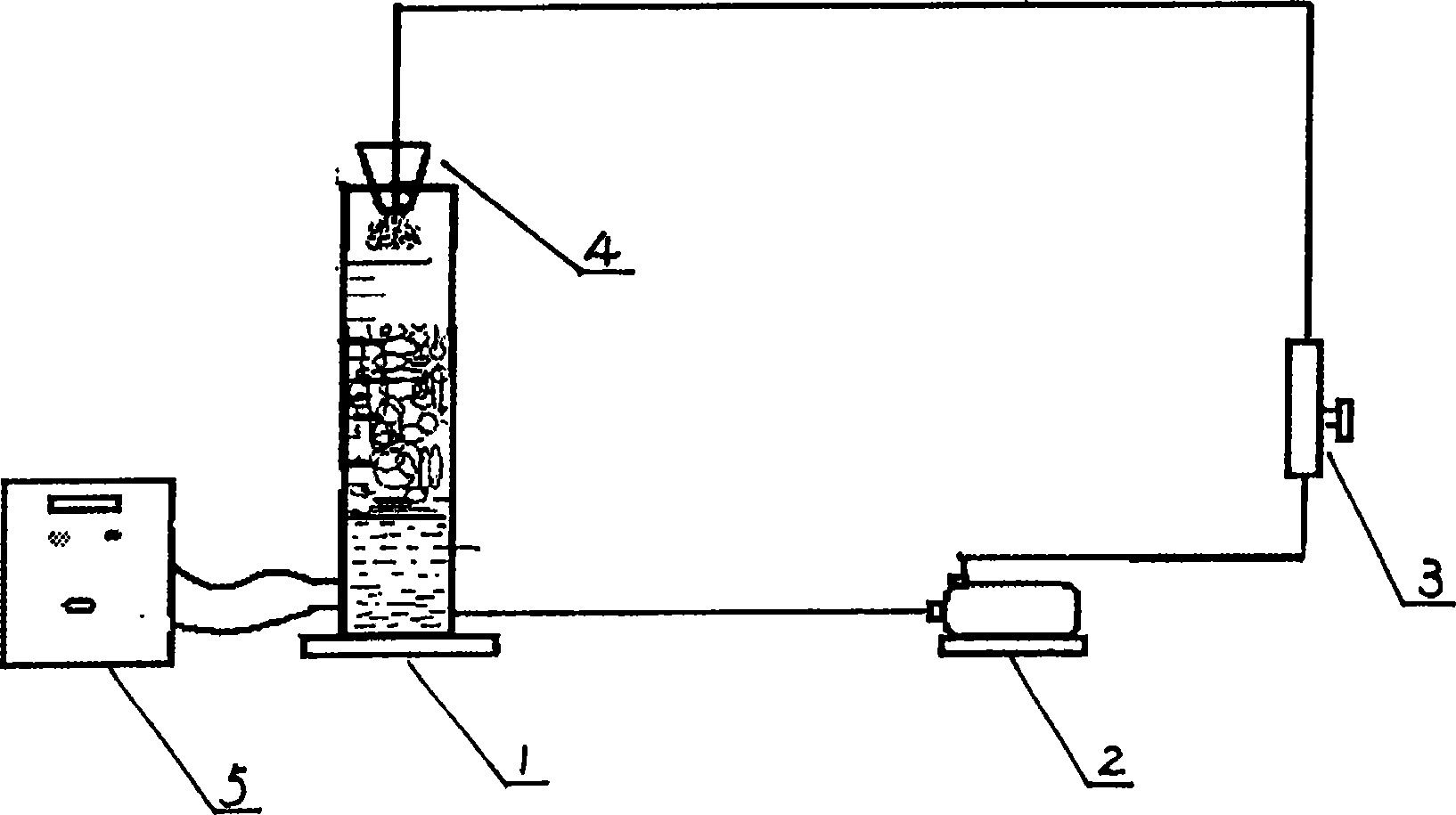

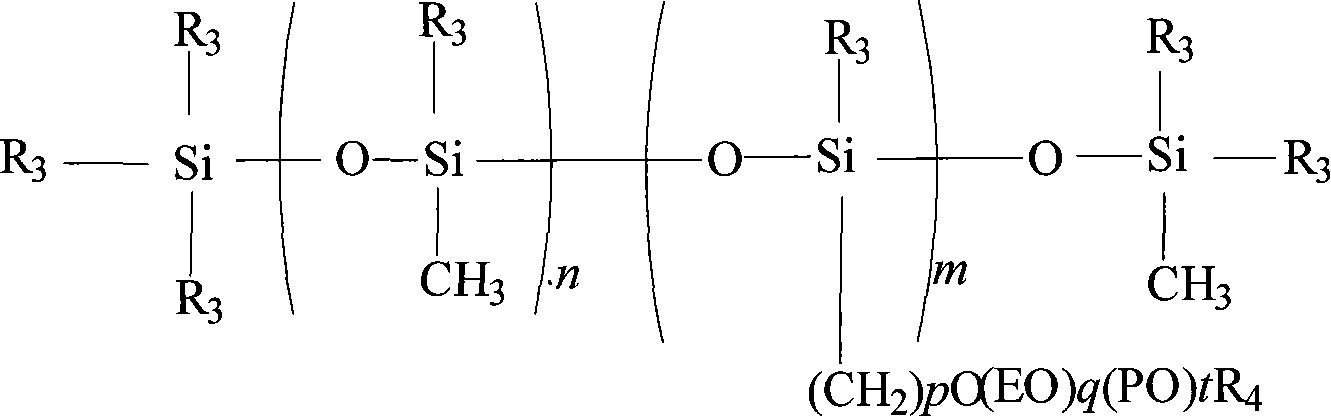

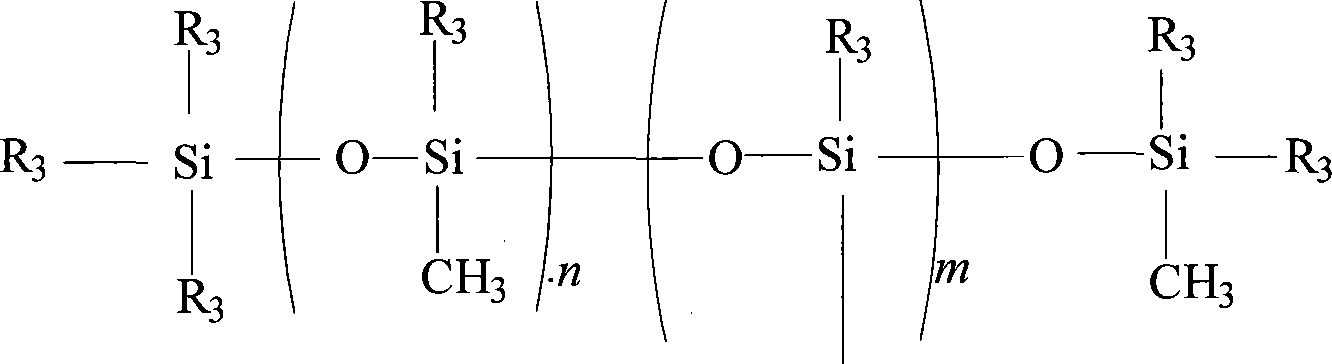

Foam inhibitor and preparation method thereof

The present invention relates to a foam inhibitor and a preparation method thereof. The preparation method comprises that hydrogen-containing polyorganosiloxane, an unsaturated polyether and alpha-olefin are subjected to a polymerization reaction under an acid catalyst effect through active groups such as -H and CH2=CH- to obtain alkyl-unsaturated polyether co-modified polyorganosiloxane, and then hydrophobic particles and an organosilicon resin are added to carry out a mixing treatment to obtain the foam inhibitor, wherein the foam inhibitor is used for preparing an emulsion type antifoaming agent, and a foam elimination and inhibition effect in a liquid detergent is significant while clarity of the liquid detergent is not affected.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Weather-resistant and fire-proof nanometer coating for expanding ultrathin steel structure and production thereof

The invention relates to the process of an inflatable ultrathin steel structural weather-fire resisting nanopaint. It is composed of acrylic resin:16-25; amine resin:5-8; epoxy modified high polymer: 5-8; nano-compound fire retardant:3-6; superfine compound fire retardant: 35-45; intensify spun glass: 4-7; smoke abatementer:2-4; chlorinated paraffin:2-4; rutile titanium white:3-5; elasticizer:2-4; antifoam agent:0.3-0.6; flow promoter:0.3-0.6; mixing solvent:15-20. The above mixture is lapped to 60um of diameter and we can get the product. The product has the good resistance of the fire, water, oil and salt.

Owner:中科纳米涂料技术(苏州)有限公司

Aluminum alloy semisynthesis cutting liquid and preparation method thereof

ActiveCN102925269AResistant to corruption and odorWill not corrodeLubricant compositionActive agentSurface-active agents

The invention discloses aluminum alloy semisynthesis cutting liquid and a preparation method thereof. The aluminum alloy semisynthesis cutting liquid is composed by weight of 12%-20% of mineral oil, 9%-15% of surfactant, 8%-12% of antirust agent, 1%-2% of aluminum corrosion inhibitor, 3%-7% of lubricant, 8%-12% of extreme pressure agent, 0.5%-1% of defoamer, 0.5%-1% of fungicide and the balance, water. The preparation method includes sequentially adding the surfactant, the antirust agent, the aluminum corrosion inhibitor, the lubricant, the extreme pressure agent, the defoamer, the fungicide and the water into the mineral oil and evenly stirring and mixing the mixture to obtain the aluminum alloy semisynthesis. The aluminum alloy semisynthesis cutting liquid has excellent performance on aluminum corrosion inhibition performance, corrosion resistance, lubricant performance, anti-rust performance, defoaming performance, use period and the like.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com