Alkali-free liquid setting accelerator

A technology of quick-setting agent and liquid, which is applied in shaft lining, tunnel lining, underground chamber, etc. It can solve the problems of loss of mechanical properties, concrete cracking, etc., and achieves no irritating smell, no alkali metal ions, good storage stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

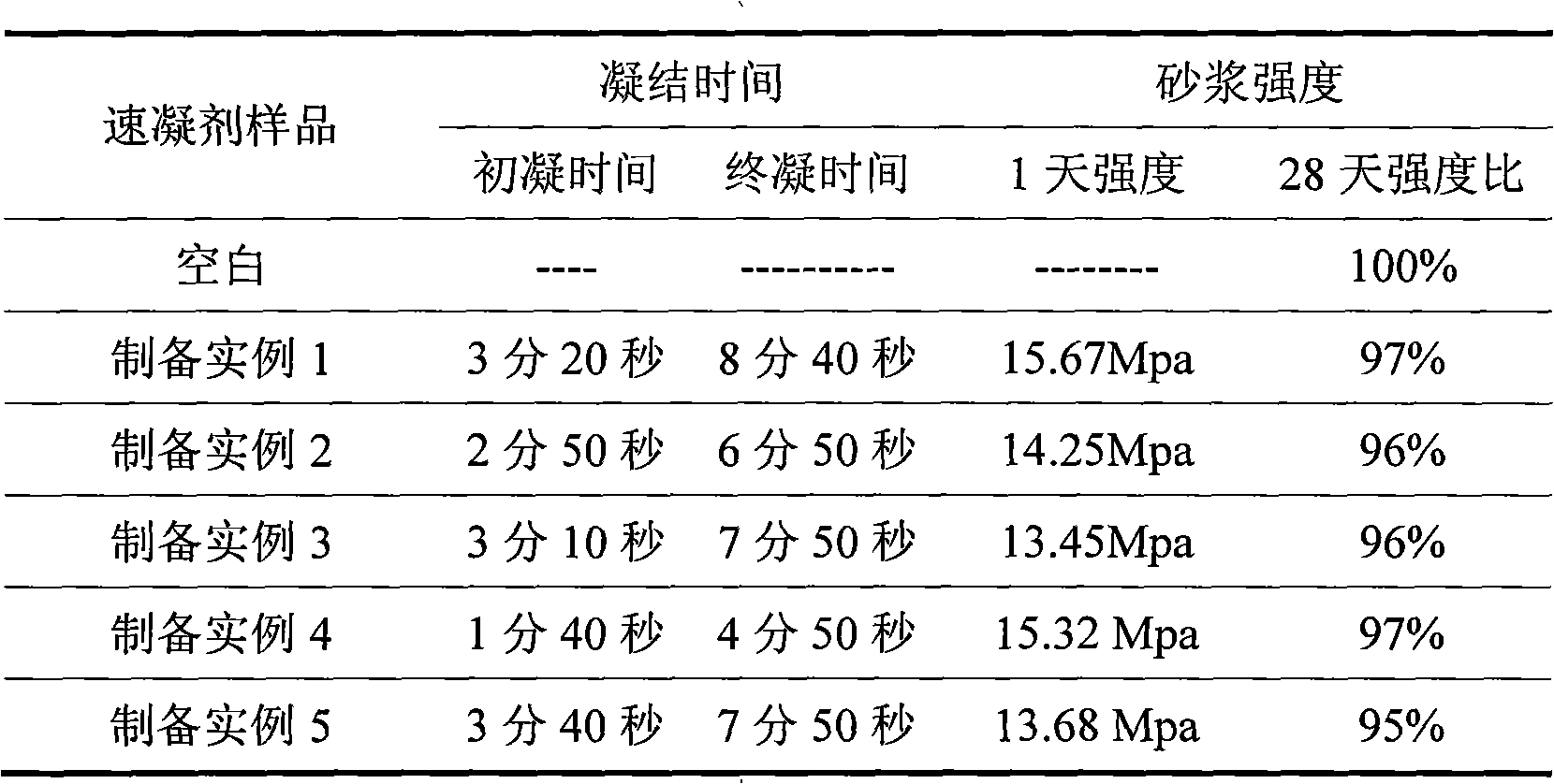

Examples

preparation Embodiment 1

[0024] Prepare raw materials according to the following weight ratio (%):

[0025] Amorphous aluminum hydroxide 15

[0026] Formic acid 10

[0027] Oxalic acid 8

[0028] Phosphoric acid (85%) 5

[0029] Diethanolamine 5

[0030] Polyether defoamer 0.1

[0031] water 56.9

[0032] Dissolve the hydroxycarboxylic acid in water first and stir rapidly, then add aluminum hydroxide at a temperature of 75°C and keep it warm for 45 minutes, after the solution is clarified, add diethanolamine, phosphoric acid and defoamer in sequence, and cool to room temperature to obtain Sulfate-free, alkali-free liquid accelerator.

preparation Embodiment 2

[0034] Prepare materials according to the following weight ratio (%)

[0035] Amorphous aluminum hydroxide 20

[0036] Formic acid 15

[0037] Acetic acid 5

[0038] Oxalic acid 20

[0039] Phosphoric acid (98%) 1

[0040] Polyether defoamer 0.01

[0041] Diethanolamine 0.5

[0042] water 38.49

[0043] The preparation method of the above-mentioned liquid quick-setting agent for shotcrete is specifically:

[0044] Add aluminum hydroxide to part of the water to form a suspension, dissolve the mixture of hydroxycarboxylic acids in water to form a mixed solution of carboxylic acids, then add the mixed solution of carboxylic acids to the aluminum hydroxide suspension at a temperature of 90°C and keep it warm for 1.5 hours. After clarification, add diethanolamine, phosphoric acid and defoamer in sequence, and cool to normal temperature to obtain sulfate-free and alkali-free liquid accelerator.

preparation Embodiment 3

[0046] Prepare materials according to the following weight ratio (%)

[0047] Amorphous aluminum hydroxide 30

[0048] Formic acid 10

[0049] Maleic acid 20

[0050]Phosphoric acid (85%) 1

[0051] Triethanolamine 2

[0052] Silane defoamer 0.05

[0053] water 36.95

[0054] The preparation method of the above-mentioned liquid quick-setting agent for shotcrete is specifically:

[0055] First add aluminum hydroxide to water and stir quickly to form a suspension, then add hydroxycarboxylic acid at a temperature of 120°C and keep it warm for 2.5 hours. After the solution is clarified, add triethanolamine, phosphoric acid and defoamer in sequence, and cool to At normal temperature, the sulfate-free and alkali-free liquid quick-setting agent is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com