PCC (Large Diameter Pipe Pile by using Cast-in-place Concrete) energy pile and manufacturing method thereof

An energy pile and pile bottom technology, which is applied in the field of civil engineering, can solve the problems of inability to repair, damage, and small pile side surface area, and achieve the effects of convenient repair and maintenance, high energy transmission efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

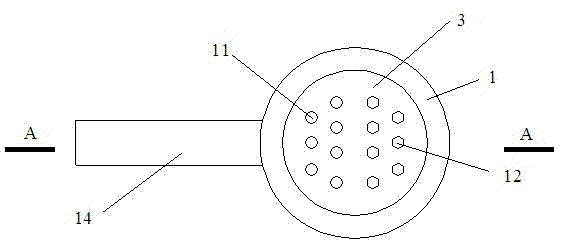

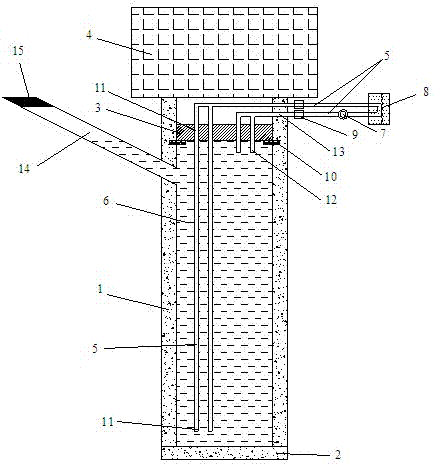

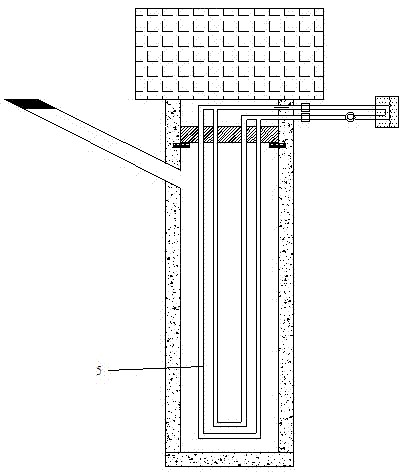

[0048] like Figure 1~Figure 4 As shown, a PCC energy pile is composed of PCC pile (1), heat transfer liquid (6), cover plate (3), bottom plate (2), heat pipe (5), heat collector (8), inspection channel ( 14) and other parts, PCC pile (1) pile bottom is completely closed with reinforced concrete to form the bottom plate (2); reinforced concrete cover plate (3) is set on the top of PCC pile; multiple holes are set on the cover plate (3), respectively Connect with the heat conduction pipe (5) of the water inlet hole (11) and the heat conduction pipe (5) of the water outlet hole (12); the cavity of the pipe pile is filled with heat conduction liquid (6); the heat conduction pipe (5) passes through the cover plate ( 3) The hole on the top goes deep into the heat-conducting liquid (6) in the cavity of the PCC pile (1); the heat-conducting pipe (5) is connected with the heat collector (8), and forms a circulation together with the cavity of the PCC pile (1) aisle. An inspection pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com